Patents

Literature

294results about How to "Particle size adjustable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Spherical carriers for olefin polymerization catalyst and preparation method

ActiveCN102040683ANarrow particle size distributionParticles in good shapeParticle-size distributionPhotochemistry

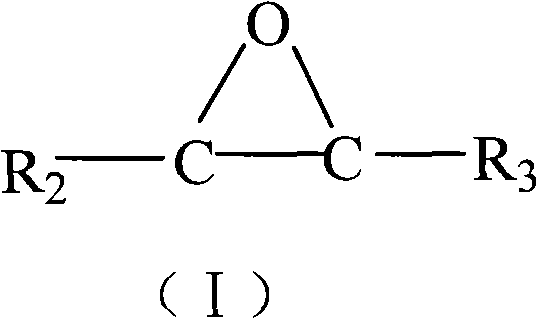

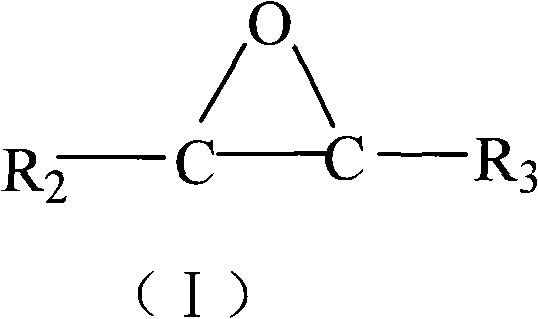

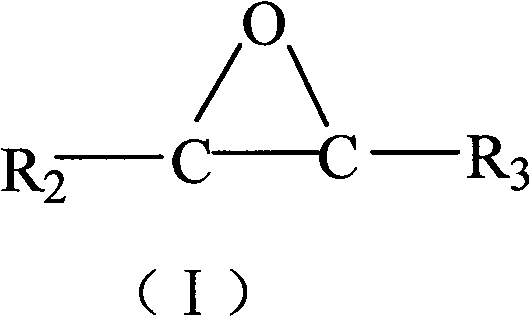

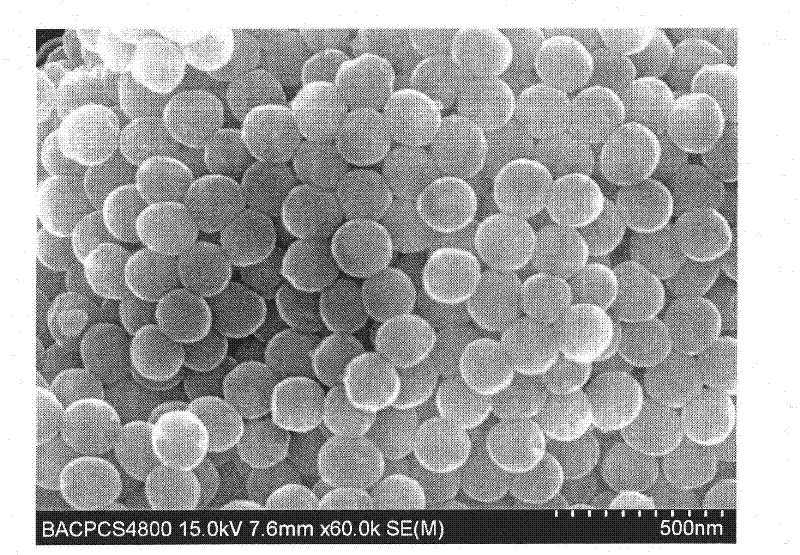

The invention relates to spherical carriers for an olefin polymerization catalyst and a preparation method. Each spherical carrier comprises reaction products of the following components: (1) magnesium halide which is shown as the general formula MgX2, (2) alcohol compounds which are shown as the general formula ROH, and (3) ethylene oxide compounds which are shown as the general formula (I), wherein in the general formula (I), R2 and R3 are alkyls with a C1-C5 straight chain or branched chain; and hydrogen on the alkyls can be randomly substituted by a halogen atom. The spherical carriers have good particle shapes, adjustable particle sizes and narrow particle size distribution, and the preparation method is simple.

Owner:CHINA PETROLEUM & CHEM CORP +1

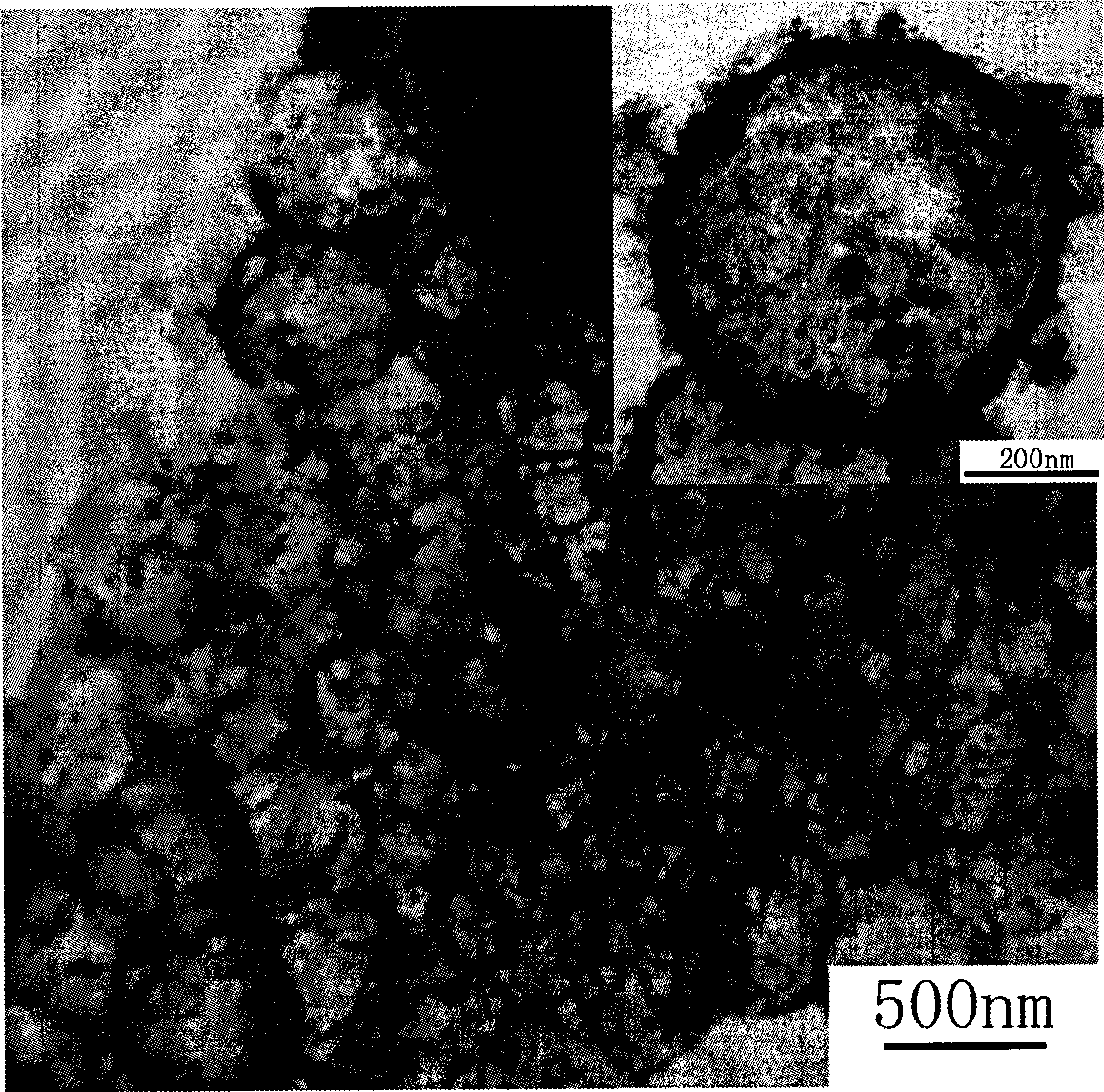

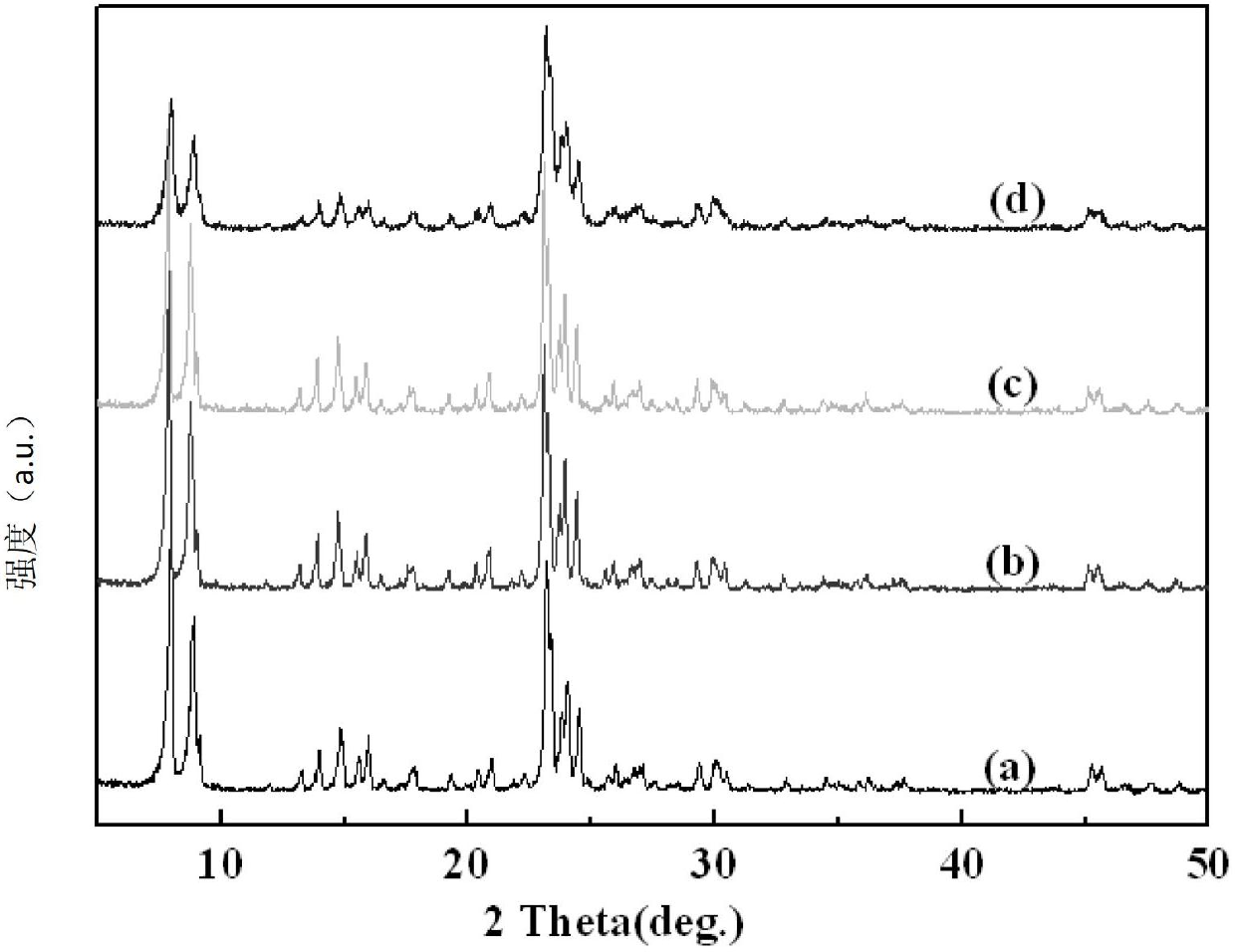

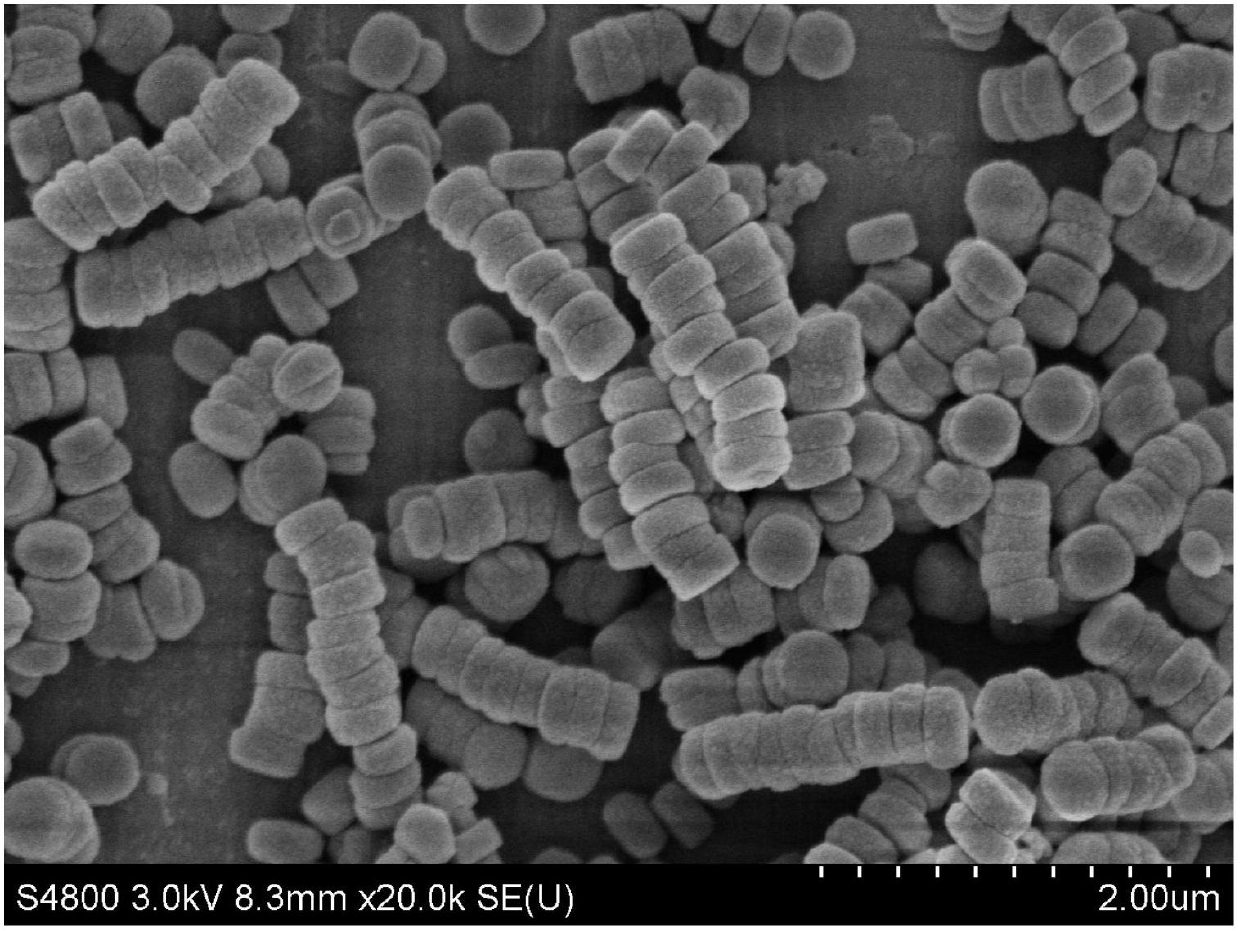

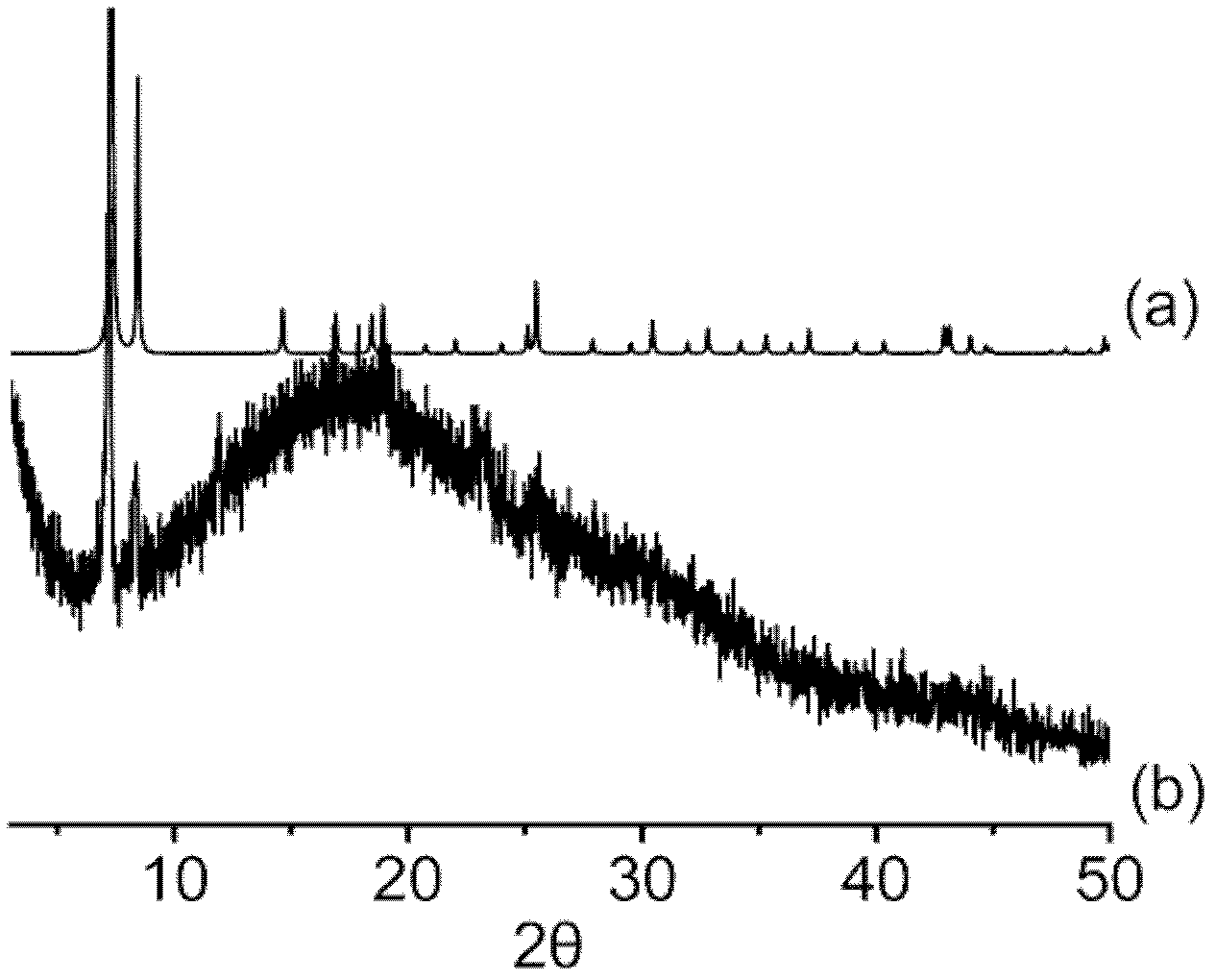

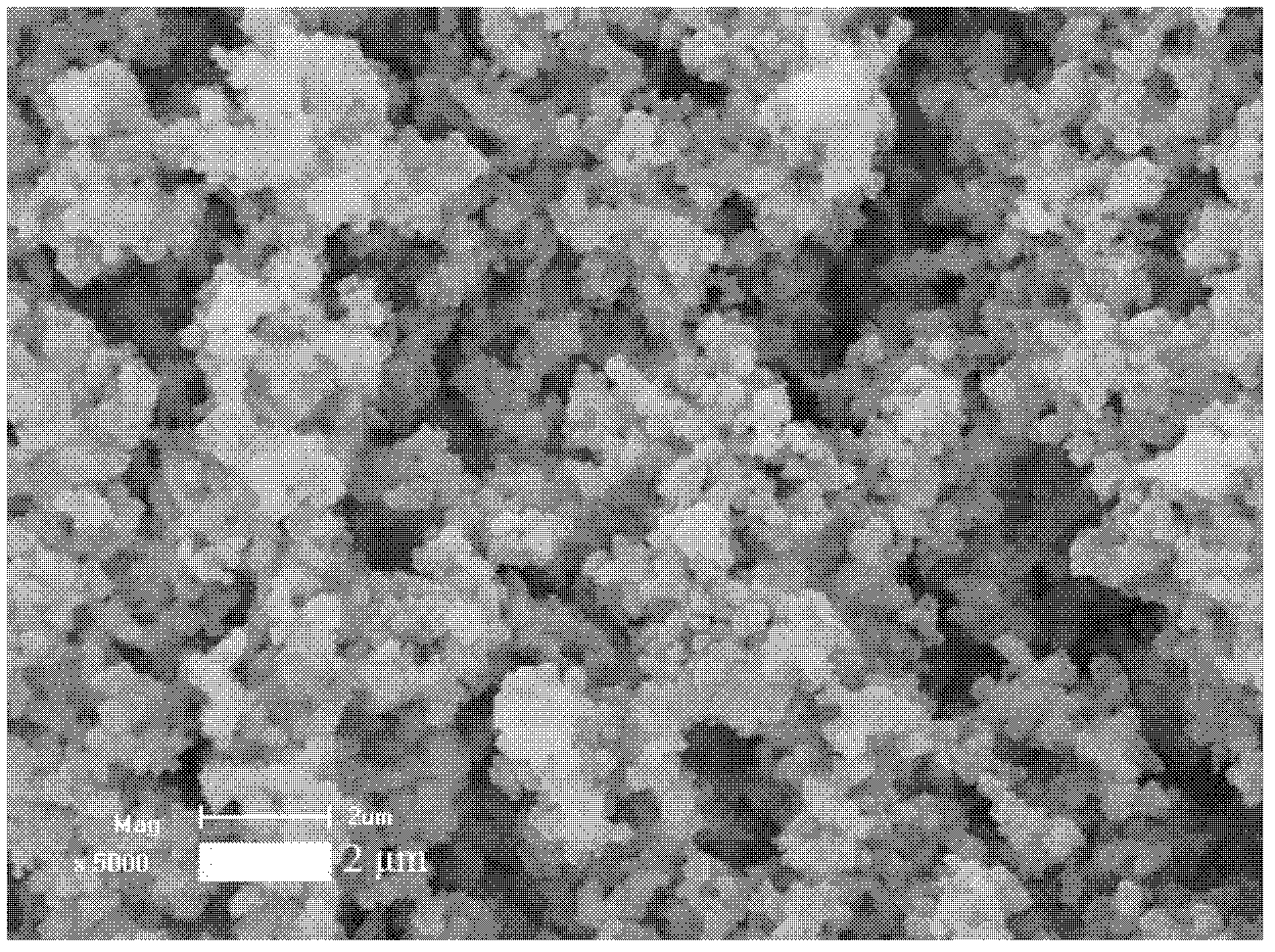

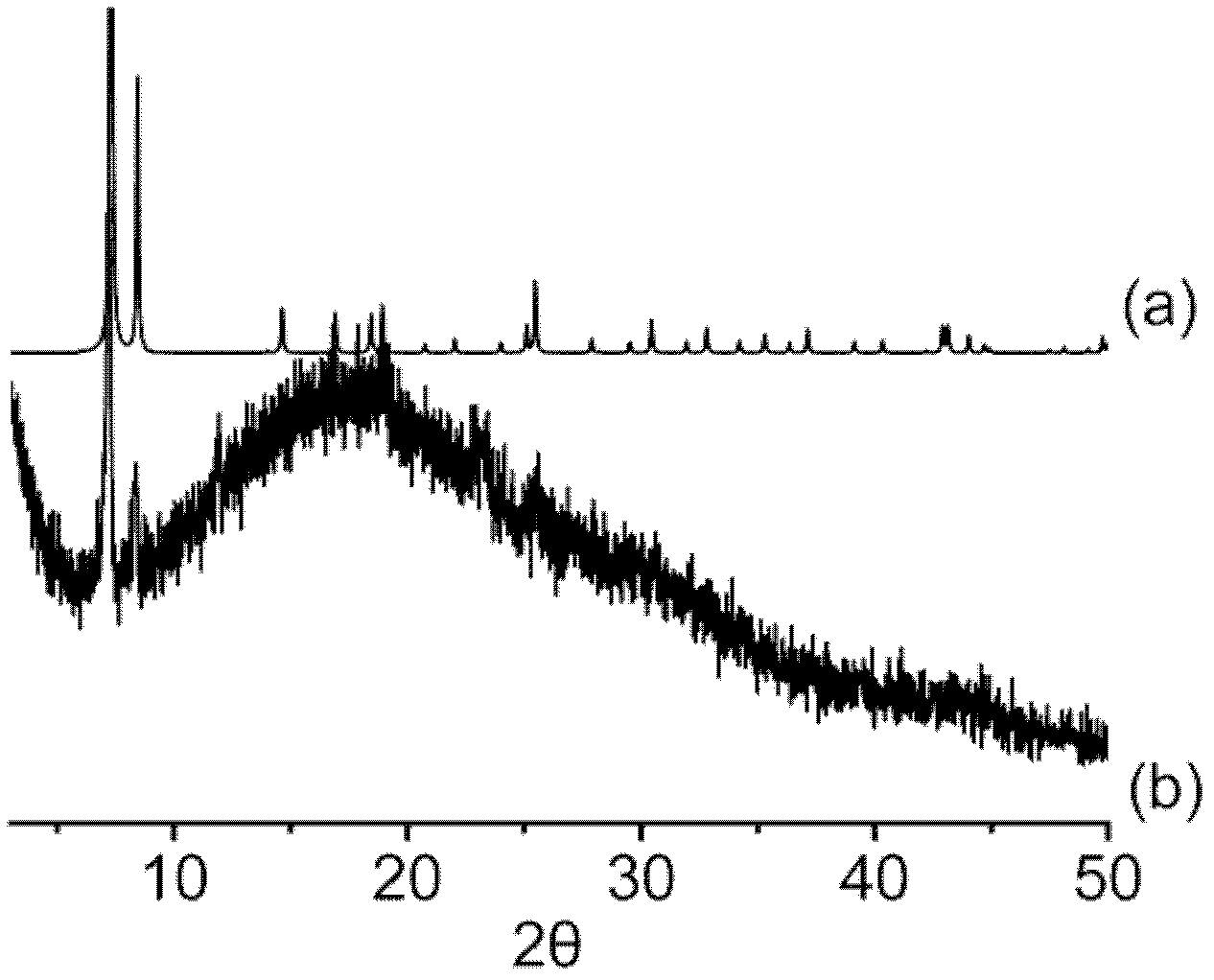

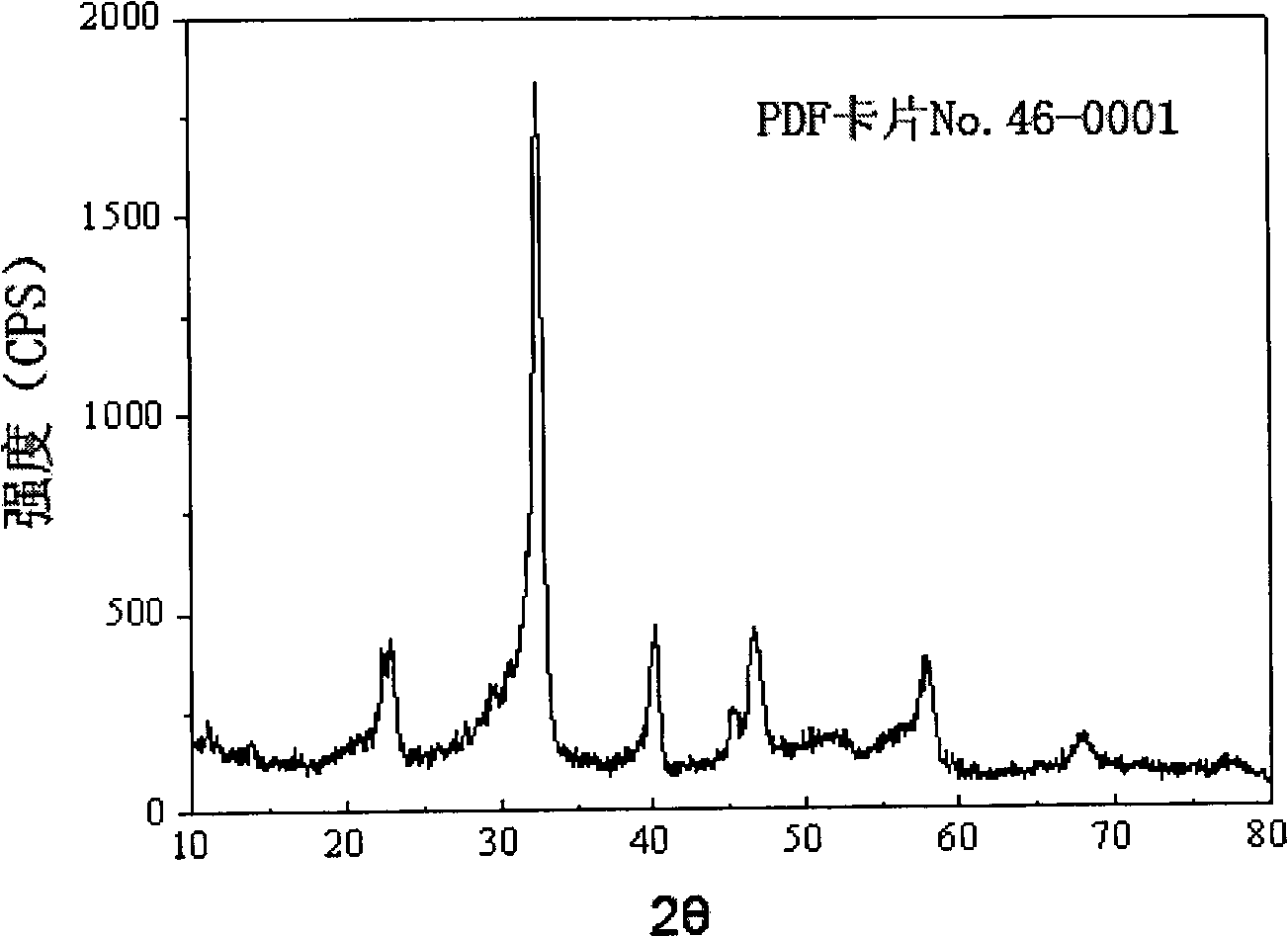

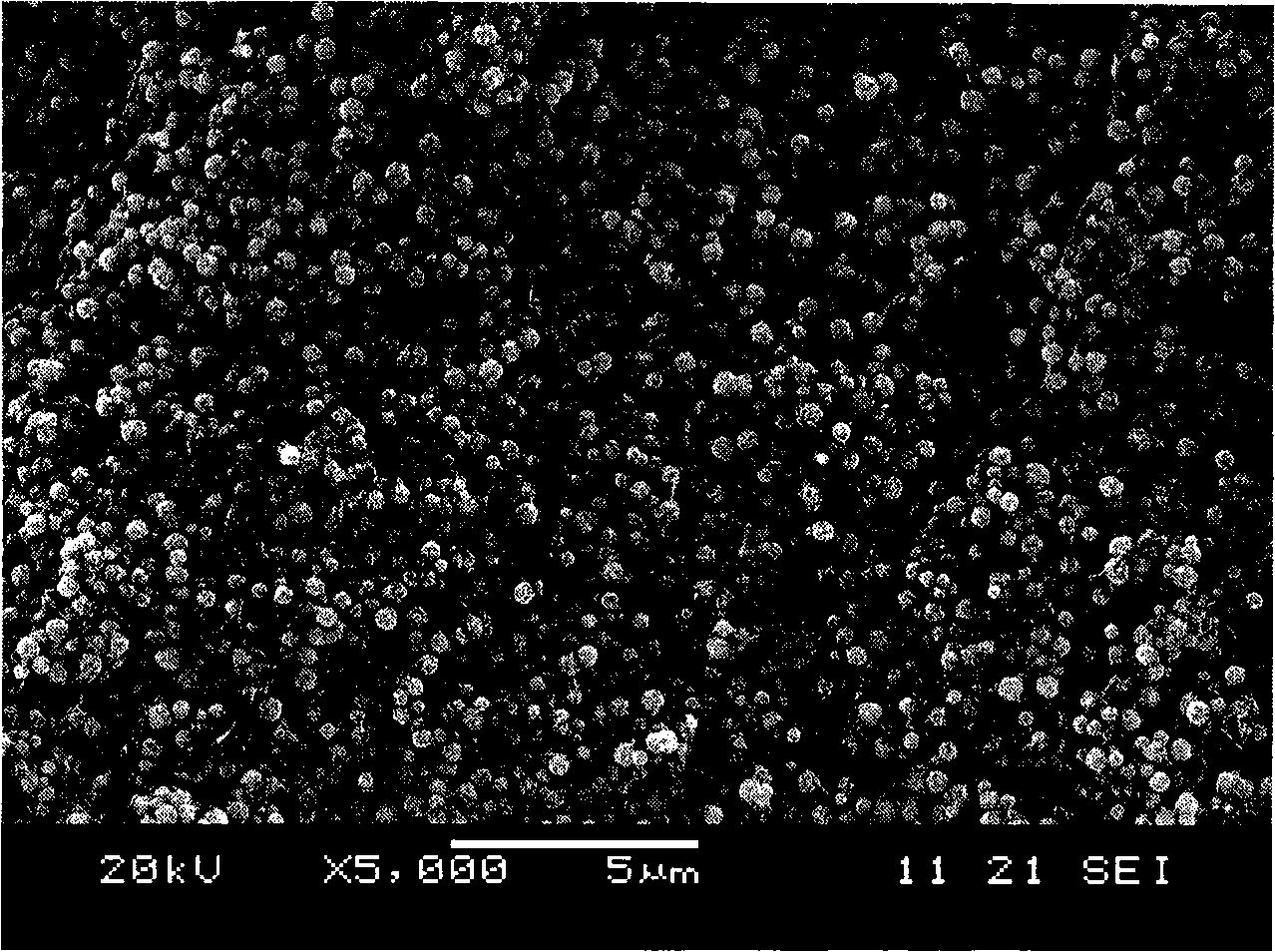

Layered double hydroxide and preparation method thereof

InactiveCN101665233AParticle size controlRegular layered structureOxide/hydroxide preparationIndividual molecule manipulationDivalent metal ionsCrystallinity

The invention relates to a layered double hydroxide and a preparation method thereof, belonging to the technical field of metal hydroxide preparation. A chemical formula of the layered double hydroxide is as follows: (M1(1-x)M2x(OH)2)(A<n->)x / n), wherein x is larger than or equal to 0.2 and smaller than or equal to 0.33; M1 represents any one or more of divalent metal ions including Mg<2+>, Zn<2+>, Ni<2+>, Co<2+>, Ca<2+>, Cu<2+>, Fe<2+> and Mn<2+>; M2 represents any one or two of trivalent metal ions including Fe<3+> and Al<3+>; A<n-> represents any one of interlayer anions including CO3<2->,NO3<->, Cl<-> and SO4<2->; and the grain size ranges from 12 nm to 80 nm. The invention has the advantages that the preparation method is a direct method for preparing the layered double hydroxide with high crystallinity, layered structure regularity, wide application range and adjustable particle size. The preparation method comprises the following steps: obtaining highly dispersed metal nanoparticle sol by utilizing the action of colloid mill axial shear force and the sodium borohydride reducibility, and then performing slow oxydrolysis in a hydrothermal system, and the like to generate thenano layered double hydroxide with layered structure regularity and adjustable particle size. The method has the advantages of wide application range, low cost, simple operation and environmental protection.

Owner:BEIJING UNIV OF CHEM TECH

Method for preparing spherical carbon material

The invention relates to a method for preparing spherical porous carbon, wherein the spherical porous carbon is obtained through the following steps of taking commercialized spherical polyvinylidene fluoride (PVDF) resin as a raw material, carrying out defluorination stabilization at a low temperature below 150 DEG C, carrying out carbonization at high temperature, and activating. The commercial production of the spherical PVDF resin is realized, the particle diameter of the spherical PVDF resin is controllable, and the method for preparing the spherical porous carbon has the advantages that the method is simple, the degree of sphericity of a carbon sphere is good, the particle diameter is uniform, the size of the particle diameter is easy to regulate and control, and the like. The particle diameter of the spherical porous carbon is adjustable between 5 nm and 50 microns, the specific surface area is 50-3000 m<2> / g, and thus, the spherical porous carbon can be used for an electrode material of a super capacitor, an electrode material of a lithium ion battery, an electrode material of a capacitance-method desalination equipment, blood purification, a catalyst carrier, water treatment, gas purification, solvent recovery and the like.

Owner:NO 63971 TROOPS PLA

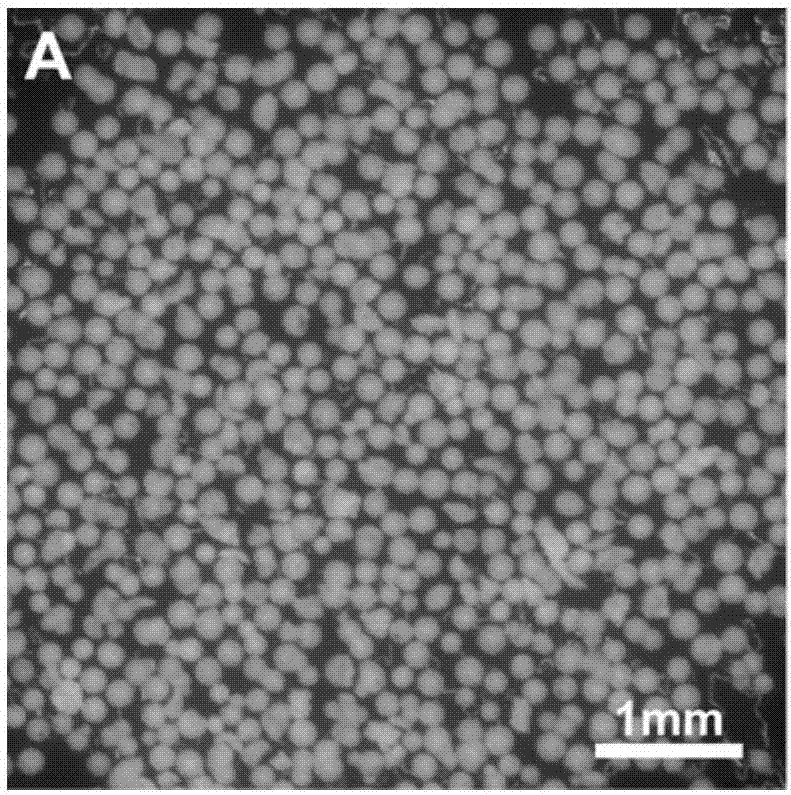

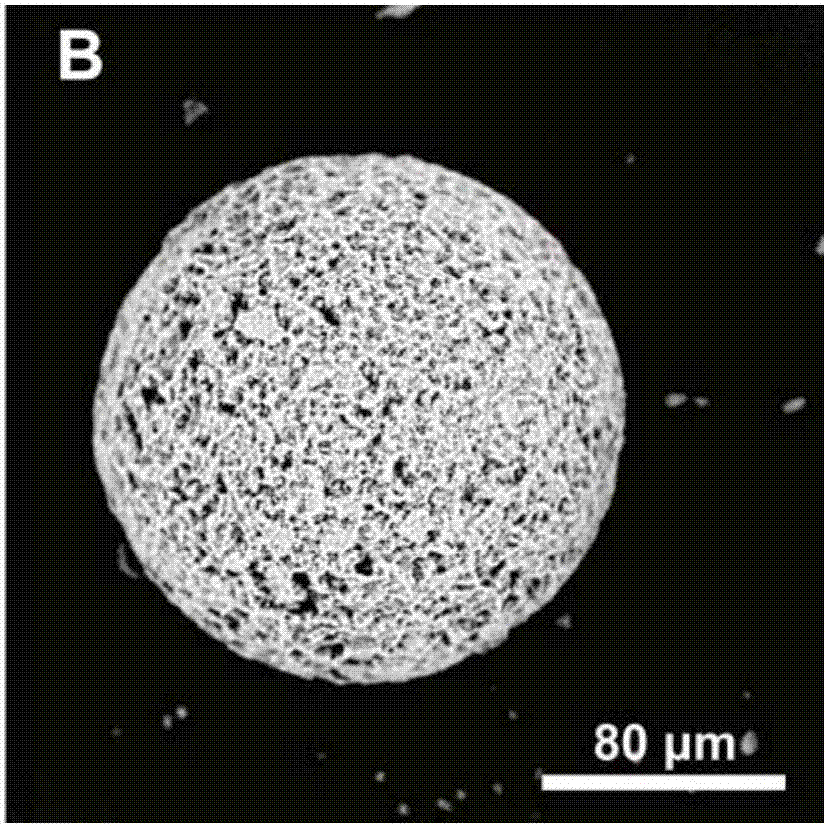

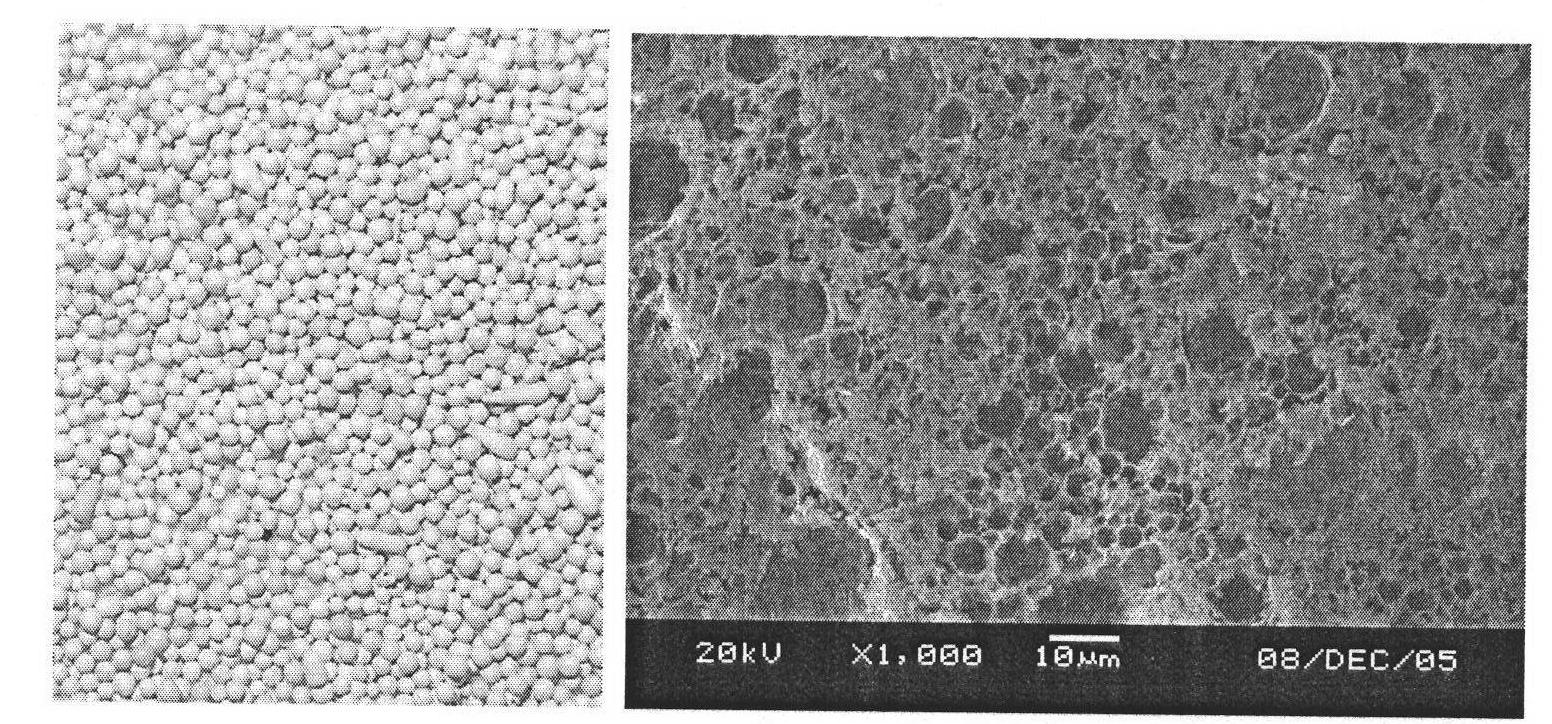

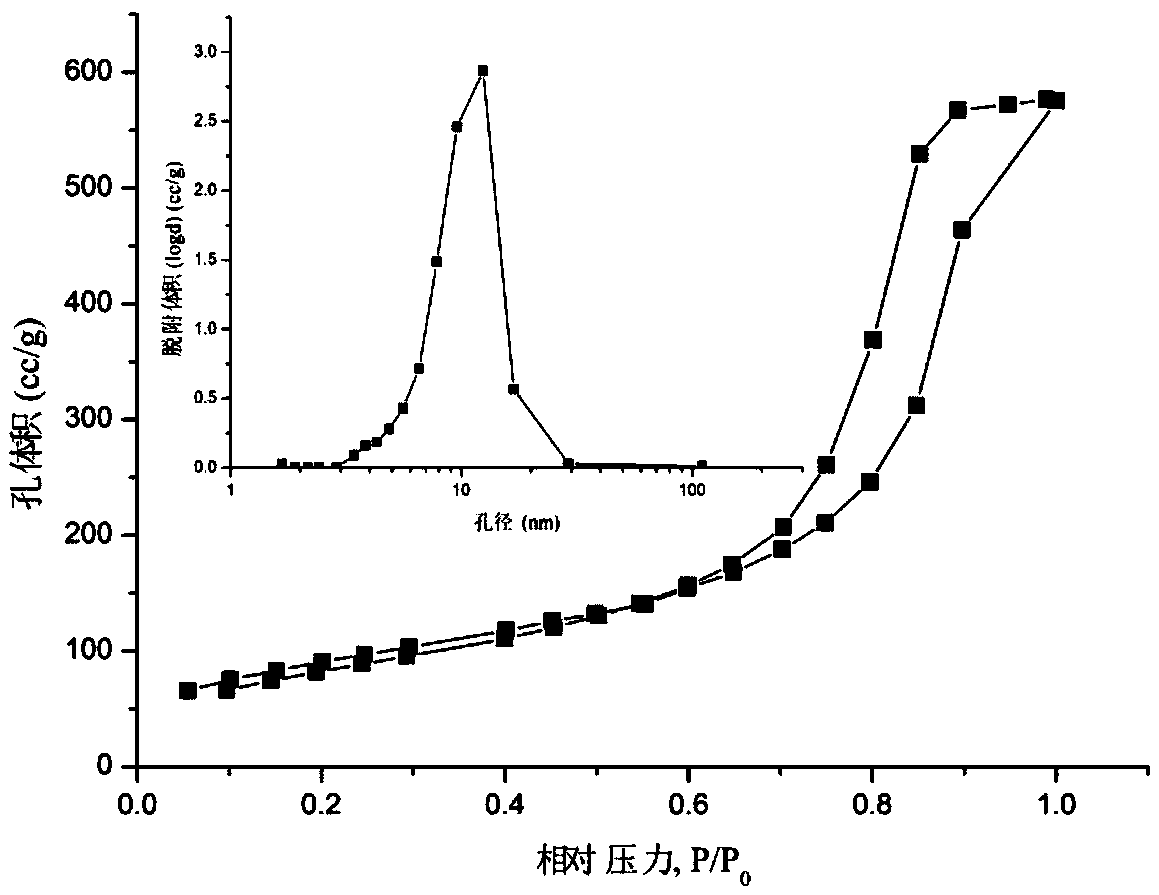

Preparation method and application of porous geological polymer microspheres

ActiveCN107973559AHigh Microsphere EfficiencyParticle size adjustableOther chemical processesRadioactive contaminantsMicrosphereSorbent

The invention discloses a preparation method of porous geological polymer microspheres. The porous geological polymer microspheres are prepared by a dispersion suspension solidification method. Compared with the prior art, low-temperature curing and one-shot molding granulation are realized without requirements of high-temperature calcination and curing and addition of other auxiliaries; and at the same time, large-scale use of solid wastes is realized, and raw materials are widely available, cost is low, process is simple, and the whole process is non-toxic and pollution-free; in addition, the preparation efficiency is high with a ball-forming degree exceeding 90%; the size of the particles can be adjusted, and the pore size distribution is uniform; the pore volume is large, and can be regulated, and a specific surface area of the microspheres reaches 110m2 / g, thus, the porous geological polymer microspheres can be directly used for packed columns for column separation. Experiments show that the porous geological polymer microspheres have a good adsorption effect on heavy metals, and can be used as adsorbents for heavy metals, and have a broad application prospect in the aspect ofremoving heavy metals and radioactive elements in water.

Owner:GUANGXI UNIV

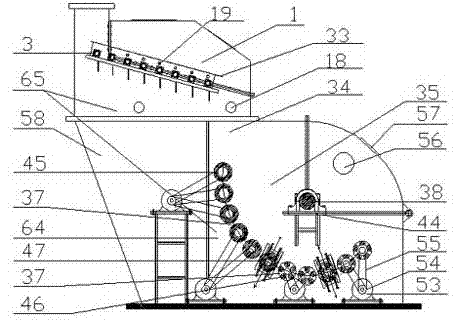

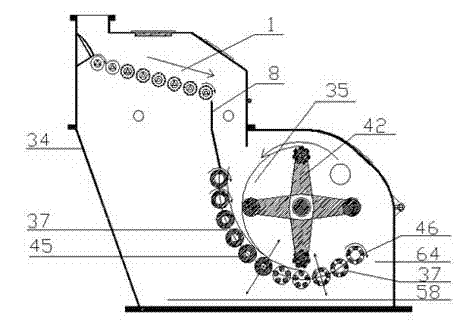

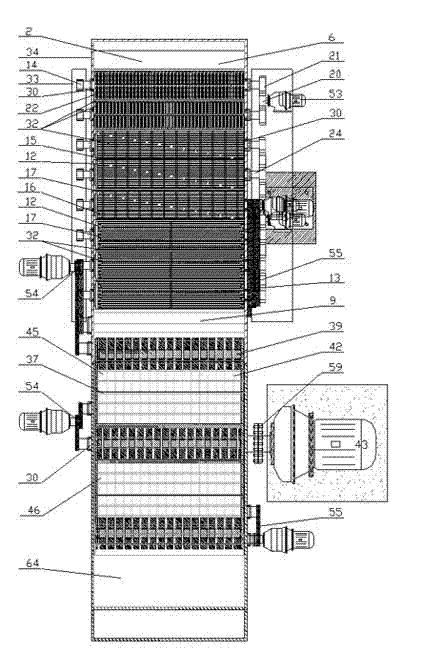

Sieving and crushing integrated machine

ActiveCN102896019AStrong impact resistanceReduces impact and wearSievingScreeningSystem structureProcess engineering

The invention discloses a sieving and crushing integrated machine. The sieving and crushing integrated machine comprises a machine housing, a sieving and distributing machine (1) arranged at an upper part of the machine housing, and a sieving and crushing machine (35) arranged at a lower part of the machine housing, wherein the sieving and distributing machine (1) comprises a charge hole (2), an arc-shaped distributing plate (6), an iron remover (11), a transmission device, a flange type sieve shaft (4) and a filter sieve shaft (5); the sieving and crushing machine (35) comprises a main rotor, an arc-shaped counterattack sieve roller set, a particle size adjusting device and a transmission device; and a charge hole (36) of the sieving and crushing machine is positioned below a discharge hole (9) of the sieving and distributing machine. The sieving and crushing integrated machine has the following creative effects: the original two-stage crushing and one-stage sieving mode is changed to be a one-stage sieving and one-stage crushing mode, so that a system structure is simplified; problems of material adhesion and blockage, high iron content, low sieving and crushing efficiency, high power consumption, non-uniform ring hammer wear, unadjustable particle size, high difficulty in overhauling and replacement of spare parts, inconvenience in operation and the like are solved; and the sieving and crushing integrated machine is a major innovation of sieving and crushing equipment technology.

Owner:SICHUAN ZHONGMENG ELECTRIC POWER EQUIP MFG CO LTD

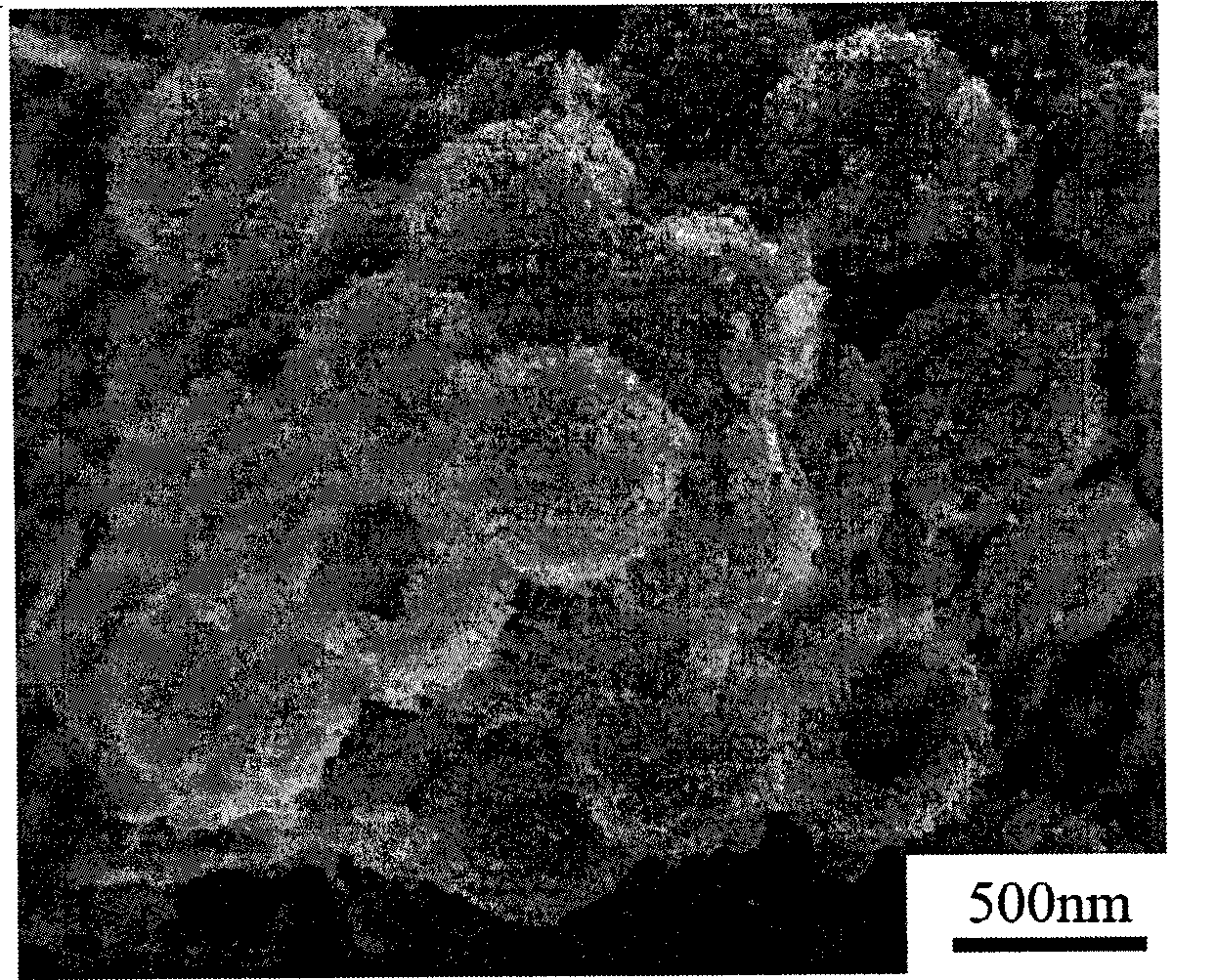

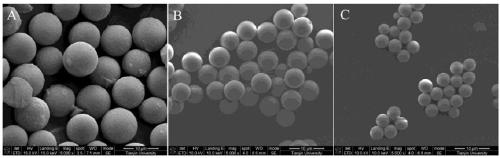

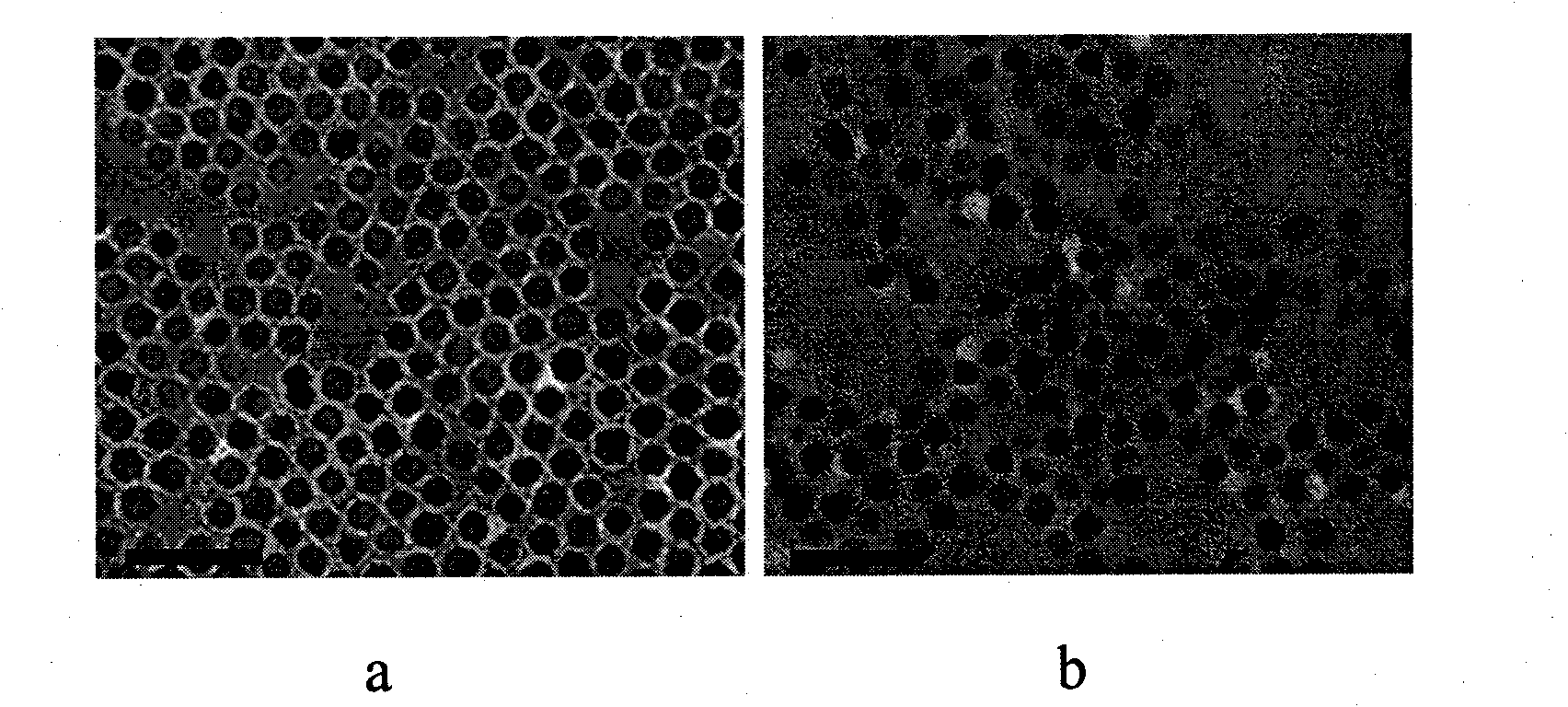

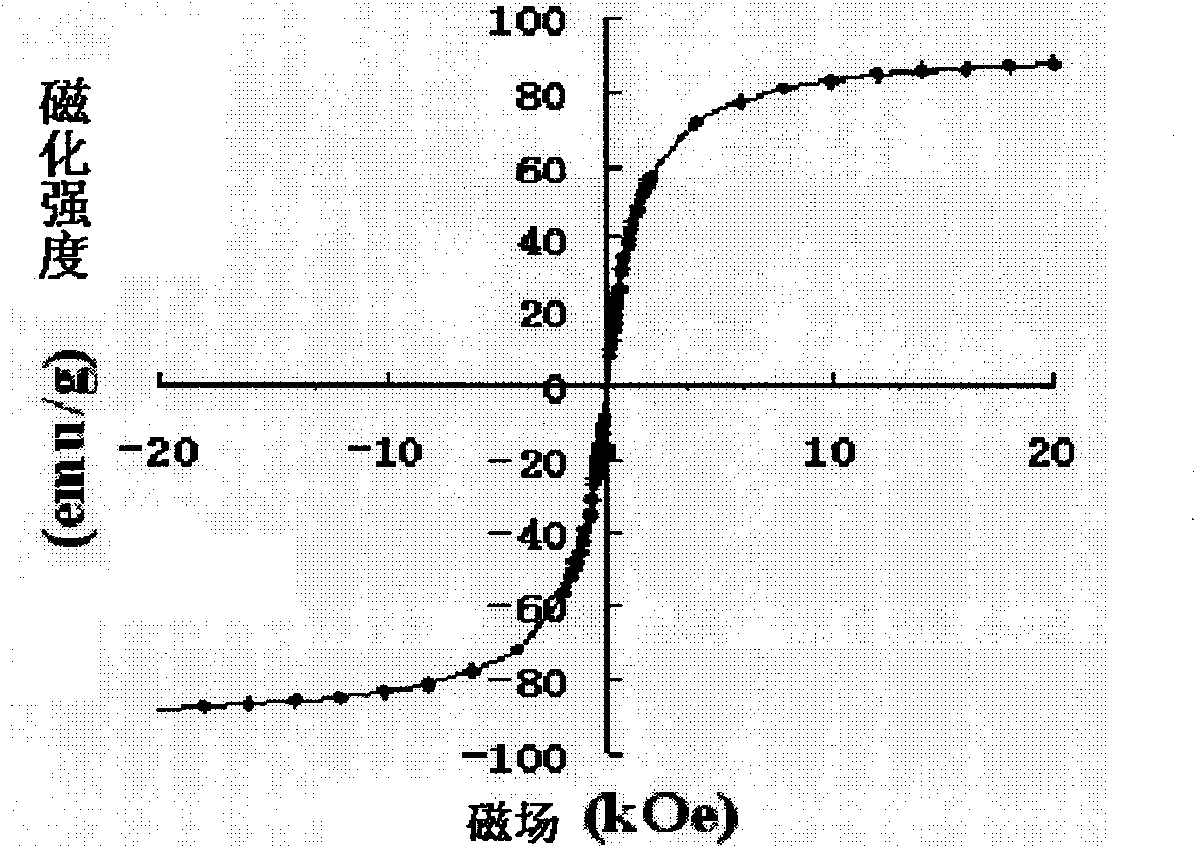

Magnetic titanium dioxide hollow ball and preparation method thereof

InactiveCN101428220AParticle size adjustableShell thickness controllableMetal/metal-oxides/metal-hydroxide catalystsTitanium tetrachloridePhoto catalysis

The invention provides a magnetic titanium dioxide hollow sphere and a preparation method thereof, which belong to the technical field of magnetic nanomaterials. The magnetic TiO2 hollow sphere is characterized by the monodisperse property, contains magnetic cobalt ferrite and anatase TiO2 with the photocatalytic activity, and has the following formula: TiO2 / CoFe2O4. The magnetic TiO2 hollow sphere is prepared by the template method. The magnetic component is spinel ferrite prepared by the co-precipitation method. The TiO2 precursor is titanium tetrachloride. The magnetic TiO2 hollow sphere has the advantages that the magnetic material has the characteristics of light weight and large specific surface area, has photocatalytic property, can decompose organic dyes, and is enriched and recovered by an applied magnetic field. Furthermore, the preparation method adopts inexpensive titanium tetrachloride as the TiO2 precursor and adopts water as a reaction medium, and has the advantages of easy operation, easy promotion, good economic benefit and environmental protection. Additionally, the particle size and the shell thickness of the magnetic TiO2 hollow sphere are adjustable and controllable, and can meet various needs in practical application. The magnetic TiO2 hollow sphere has good application prospects in the fields of photo-catalysis, photocells, gas sensors and the like.

Owner:BEIJING UNIV OF CHEM TECH

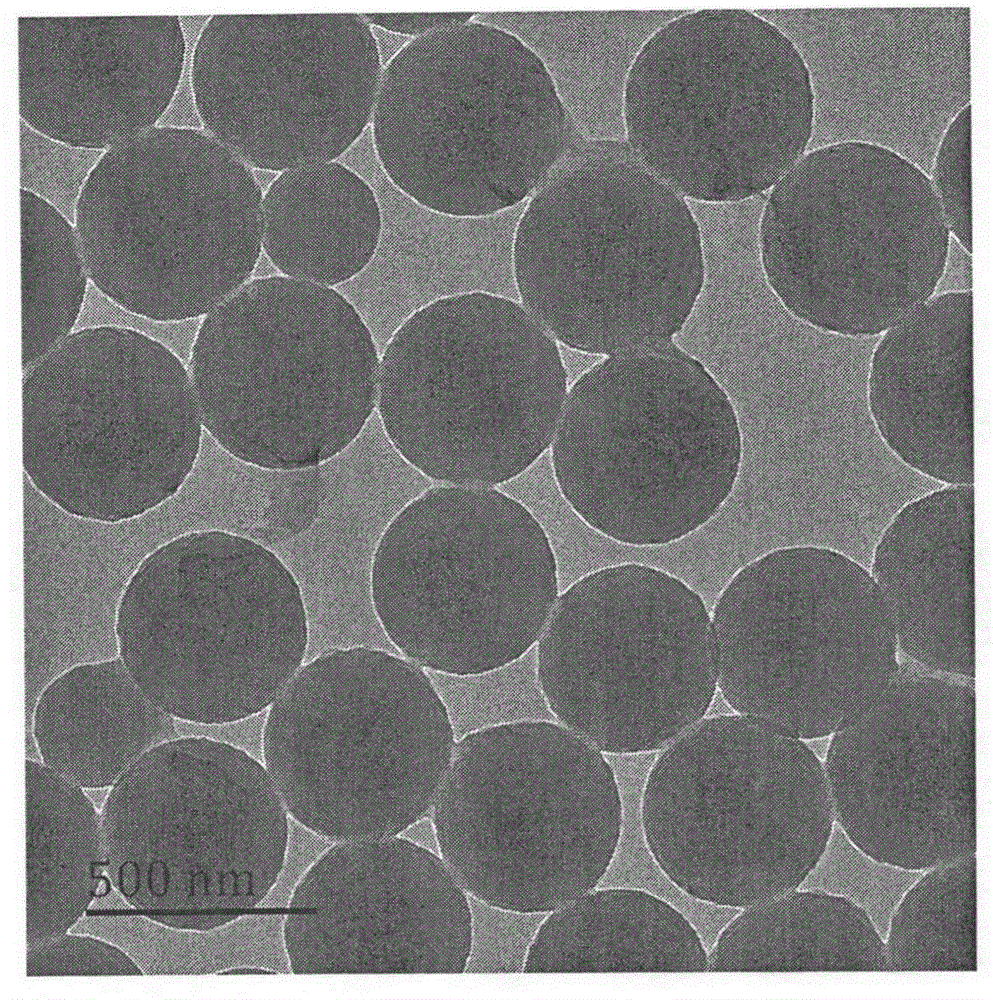

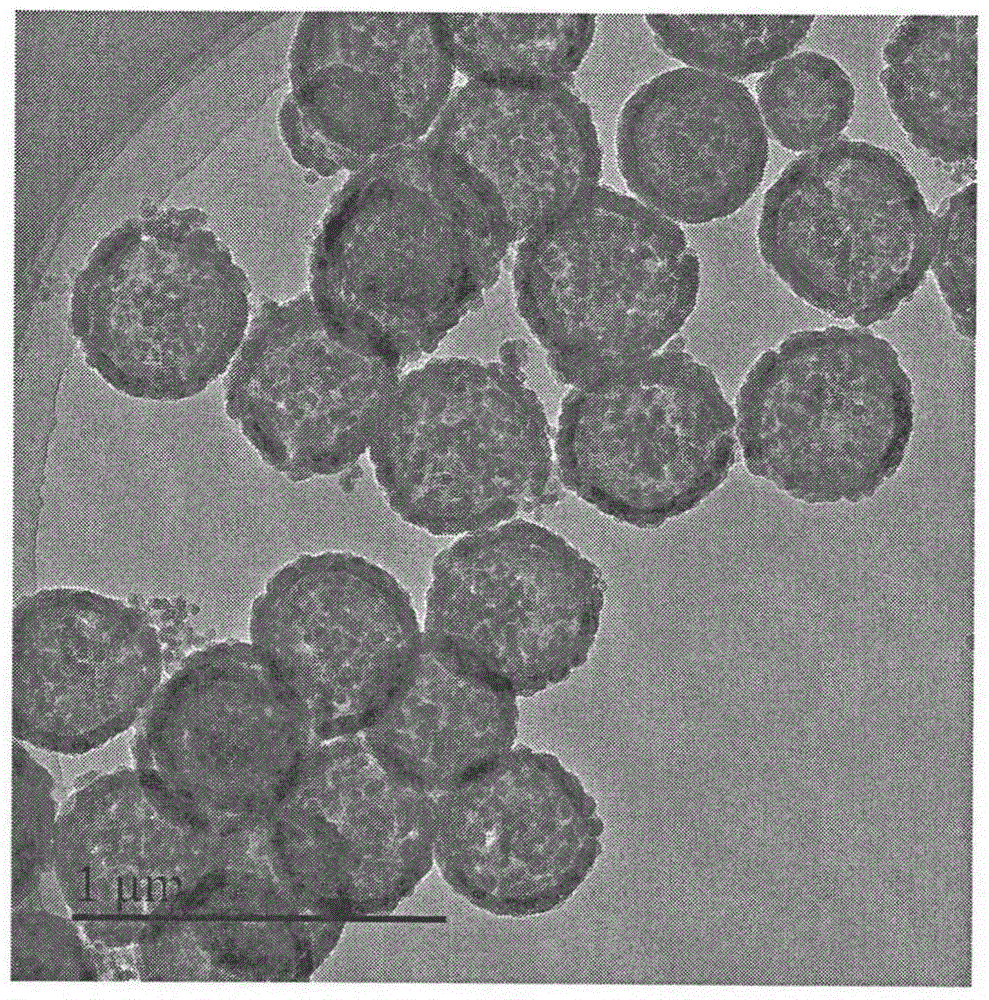

Mesoporous silica nano hollow sphere and preparation method thereof

InactiveCN104445214ALow priceEasy to operateMaterial nanotechnologySilicaBiocompatibility TestingMesoporous silica

The invention provides a mesoporous silica nano hollow sphere and a preparation method thereof. The mesoporous silica nano hollow sphere is characterized by comprising a spherical shell in which a cavity is formed; the spherical shell is formed by aggregating mesoporous silica nano particles with the grain size being 5-50nm, and amino is contained on the inner and outer surfaces of the spherical shell. The novel mesoporous silica nano hollow sphere prepared in the invention is rich in amino on the surface and has the characteristics of being great in specific surface area, good in biocompatibility, high in stability, great in drug loading capacity and the like.

Owner:DONGHUA UNIV

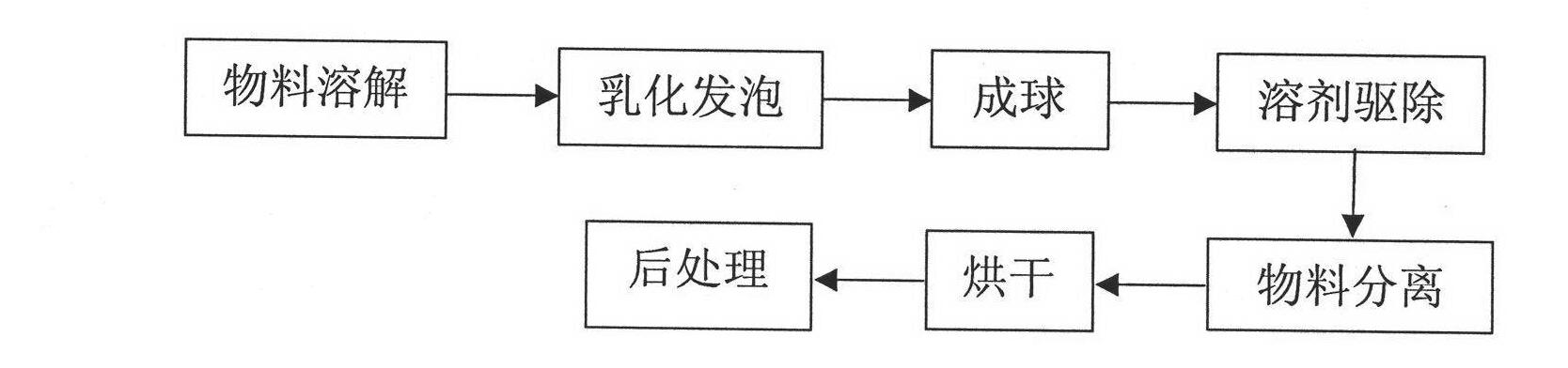

Microporous smokeless firework explosive and preparation method thereof

ActiveCN101844954AImprove securityReduce generationNitrocellulose explosive compositionsCelluloseNon solvent

The invention discloses microporous smokeless firework explosive and a preparation method thereof. The preparation method comprises the following steps of: dissolving scrapped military smokeless explosive containing nitrated cellulose into a solvent to form macromolecular sol, emulsifying and foaming the sol to form paint emulsion, dispersing the paint emulsion into a non-solvent medium under stirring action to form balls, then driving the solvent, separating the materials, and drying the materials to obtain explosive particles with microporous structures on the inner part for emitting and dissecting fireworks. The smokeless firework explosive has high fire transfer rate and adjustable stacking density and particle size because of a large amount of microporous structures on the inner part, the appearance of the microporous smokeless firework explosive is approximately spherical or oblate, the particle size is controllable, the stacking density is 0.05 to 0.4 g / cm<3>, and the aperture of the inner part is 0.01 to 500 microns in variety.

Owner:NANJING UNIV OF SCI & TECH

Method for preparing polymer fluorescent microsphere

InactiveCN103275700AReduce dosageReduce volumeLuminescent compositionsMicroballoon preparationPolymer dissolutionPolymer science

The invention relates to a method for preparing a polymer fluorescent microsphere. The method comprises the following steps of: 1, preparing polymer fluorescent microsphere liquid drops, namely dissolving a first polymer into a solvent, adding a fluorescent material into the solvent, magnetically and uniformly stirring the fluorescent material and the first polymer in the solvent to prepare a non-continuous phase, respectively putting the non-continuous phase and a continuous phase into injectors connected with a non-continuous phase inlet and a continuous phase inlet of a microfluid device, adjusting the flowing speeds of the two phases of solutions through a trace sample injection pump, so as to obtain the fluorescent microsphere liquid drops, and at a microfluid outlet, collecting the fluorescent microsphere liquid drops into a fluorescent microsphere receiving device; and 2, preparing the polymer fluorescent microsphere, namely drying the fluorescent microsphere liquid drops until the solvent is completely volatilized, then washing the fluorescent microsphere liquid drops by a washer, and cleaning the continuous phase of solution to finally obtain the polymer fluorescent microsphere. Equipment used by the method is simple and convenient to operate; the particle size of the microsphere can be adjusted by adjusting the flowing speeds of the continuous phase and the non-continuous phase; and the uniformity of the particle sizes of the prepared microspheres is high.

Owner:NANJING UNIV OF TECH

Water-based zinc stearate dispersion liquid and preparation method thereof

ActiveCN102102312ASignificant progressSimple methodNon-fibrous pulp additionCoatingsWater basedFoaming agent

The invention relates to a water-based zinc stearate dispersion liquid, the main component of which is zinc stearate, and a preparation method thereof. The dispersion liquid is mainly used as a coating lubricating agent for papermaking, a sensitizing agent for heat-sensitive paper, and a functional auxiliary agent for water-based paint. The dispersion liquid is prepared from the zinc stearate, emulsifier A, emulsifier B, auxiliary agent, dispersing agent, de-foaming agent, bactericide and water. The method for preparing the dispersion liquid comprises the following steps: adding the zinc stearate, emulsifier A, emulsifier B, auxiliary agent, dispersing agent, de-foaming agent, bactericide and water into a high-pressure reactor according to a certain proportion, sealing the reactor, heating to 140-180 DEG C, stirring for 1 hour at constant temperature, quickly cooling to room temperature, thereby obtaining the target product. The method is simple and convenient, the process is reasonable, and the prepared water-based zinc stearate dispersion liquid has the advantages of low cost, small grain size, high solid content, small viscosity and high efficiency.

Owner:DONGGUAN CHNV TECH CO LTD

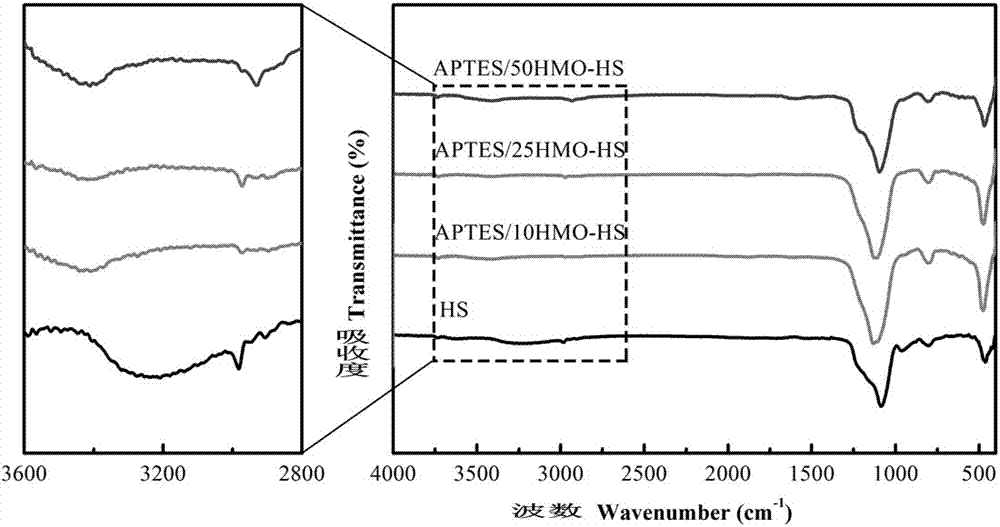

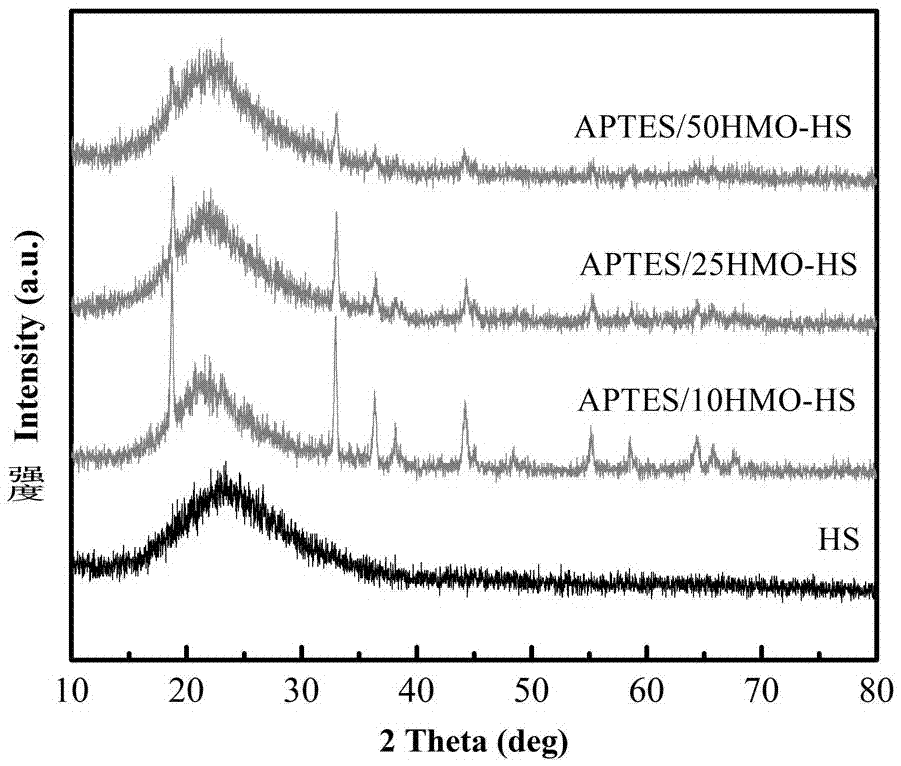

Preparation method and application of modified hollow mesoporous silicon sphere adsorbent

InactiveCN106902781ALarge specific surface areaGood monodispersityOther chemical processesWater contaminantsDispersityMicro nano

The invention belongs to the technical field of material preparation and separation, and relates to preparation of lithium / rubidium ion adsorbing materials, in particular to a preparation method and application of a modified hollow mesoporous silicon sphere adsorbent. Hollow mesoporous silicon spheres (HSs) are synthesized, a manganese-based lithium ion sieve (HMO) is supported on the surface of the hollow mesoporous silicon spheres (HS), and finally, 3-aminopropyltriethoxysilane (APTES) is modified to form the modified hollow mesoporous silicon sphere adsorbent. Synthetic process steps are simple, the prepared micro-nano hollow mesoporous silicon spheres have the advantages of large specific surface area, modifiable surface hydroxyl, good mono-dispersity, good particle size and duct size adjustability and the like, the surface of the micro-nano hollow mesoporous silicon spheres with a high specific surface is modified, and the adsorbing capacity of the materials is greatly improved. The manganese-based lithium ion sieve and the APTES are compounded with the micro-nano hollow mesoporous silicon spheres to obtain the modified hollow mesoporous silicon sphere adsorbent with unique physical and chemical properties, and lithium / rubidium ions can be efficiently adsorbed and separated in a high-selectivity manner.

Owner:JIANGSU UNIV

Surface modified particle diameter mixed silver powder and preparation method thereof

The invention provides surface modified particle diameter mixed silver powder and a preparation method thereof. The preparation method comprises the following steps of: adding an alcoholic solution containing 0.3-3.0mol / L of silver nitrate aqueous solution, a pH modifier and an alcohol or ester surface modifier into a reducing solution containing hydrazine monohydrate or ascorbic acid in a parallel flow mode; under a high-shear stirring action, reacting for 20-100min in a stainless steel reaction kettle; regulating reaction temperature to be 20-50DEG C and the pH value to be 1-14 to select a control range; reducing precipitated silver powder in one step; synchronously carrying out surface treatment on silver powder surface, wherein the silver powder is quickly precipitated because the surface of the silver powder is non-hydrophilic, and solid and liquid are extremely easy to separate; washing with deionized water; drying at 50-80DEG C; and smashing and screening to obtain the surface modified silver powder. The preparation method of the silver powder is characterized in that the particle diameter can be adjustably changed between the nanometer / micron scale and the micron / micron scale. The silver powder obtained with the preparation method has the advantages of good silver powder dispersibility, high tap density, good filling property and good affinity solubility with an organic carrier, is extremely easy to disperse in slurry to form silver paste with high solid content, and is especially suitable for pouring in holes and for solar cell silver paste.

Owner:ZHEJIANG GUANGDA ELECTRONICS TECH

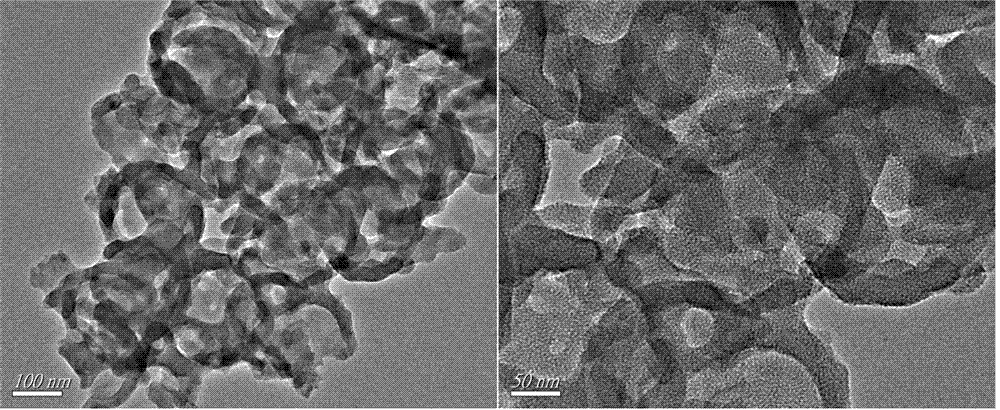

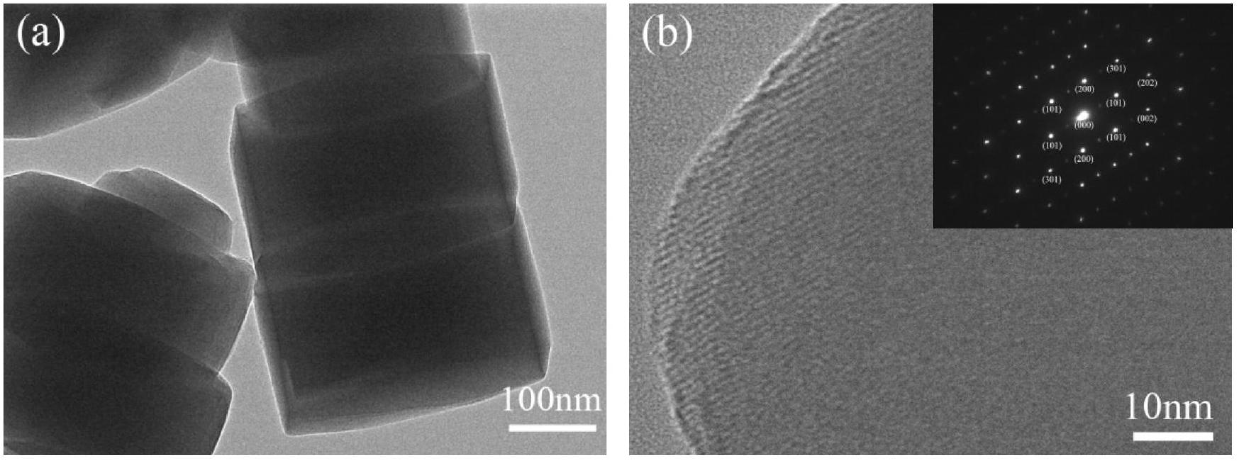

Nanometer ZSM-5 molecular sieve catalyst with high silica-alumina ratio and preparation method thereof

InactiveCN102671693AExtend your lifeHigh catalytic activityMolecular sieve catalystsHydrocarbonsMolecular sieveSilanes

The invention relates to the field of materials and catalysts, and provides a nanometer ZSM-5 molecular sieve catalyst with a high silica-alumina ratio. The nanometer ZSM-5 molecular sieve catalyst has an appropriate nano particle size and a high silica-alumina ratio, wherein the nano particle size is in the range of 0.1nm to 500nm; the molar ratio of SiO2 to Al2O3 is not less than 30; and micropores 0.5-2nm in diameter are arranged in a molecular sieve. An organic template method is adopted; organosilane is directly added into an original solution of the molecular sieve and silane is grafted onto a ZSM-5 molecular sieve seed crystal under the conditions of condensation and backflow; and a product is roasted to remove an organic template and the organosilane. By adopting the invention, synthetic steps are simplified, the synthetic method is simple, the cost is low and the application prospect is wide.

Owner:SHANGHAI NORMAL UNIVERSITY

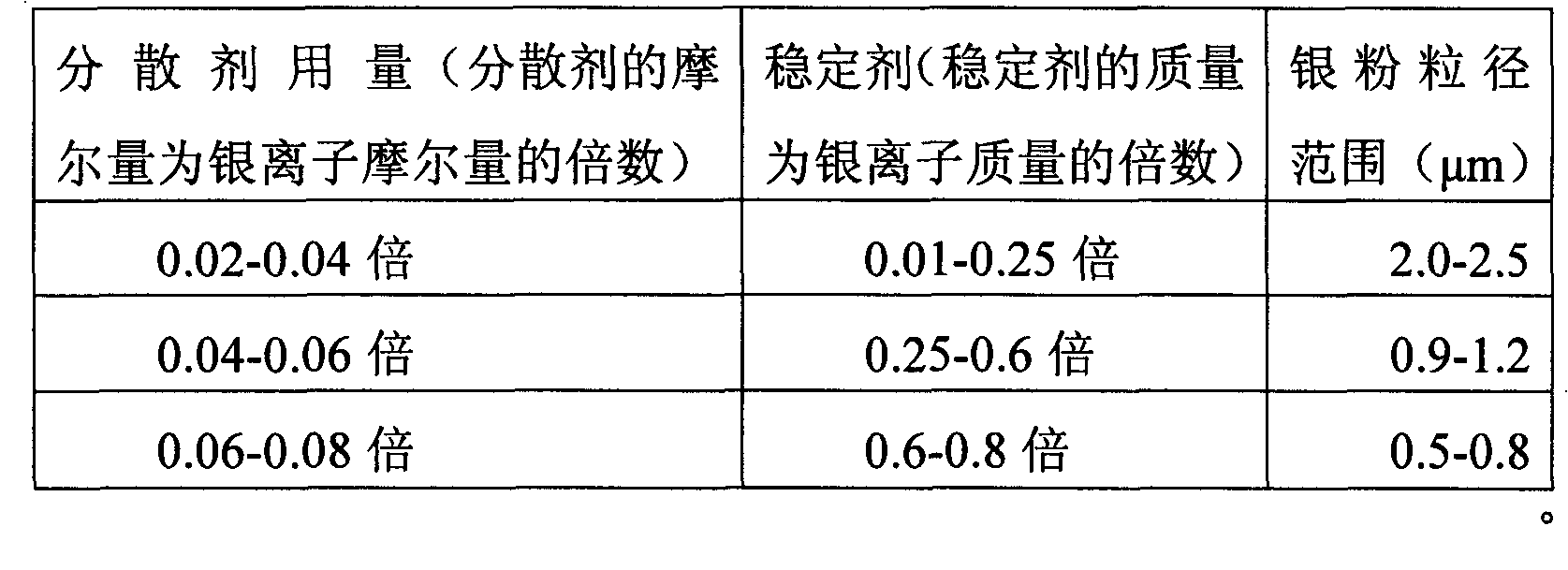

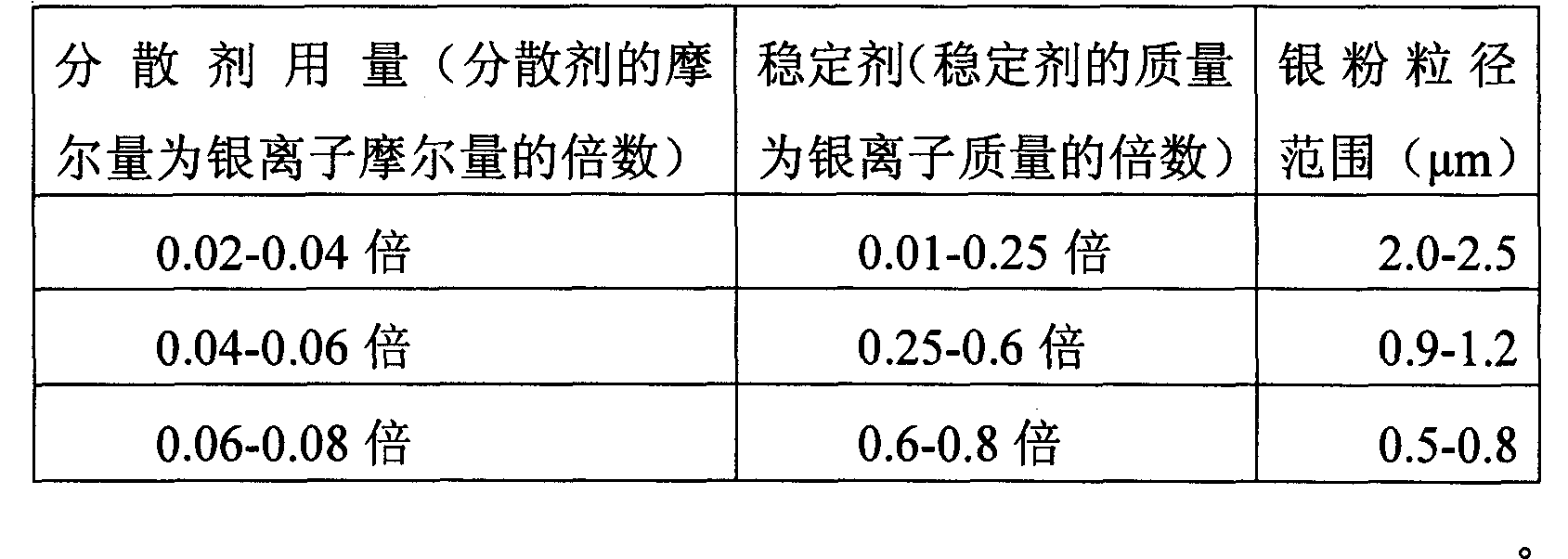

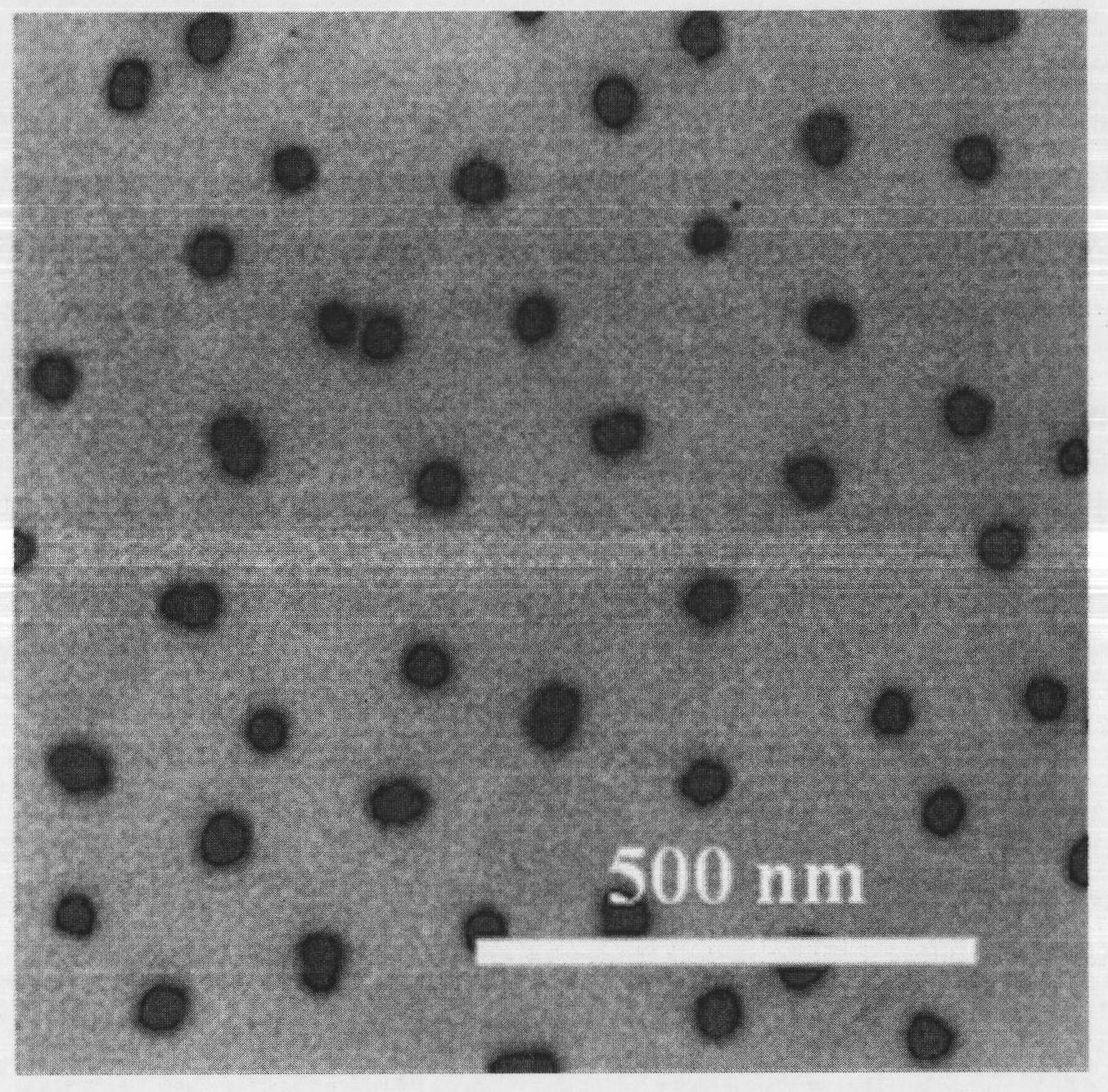

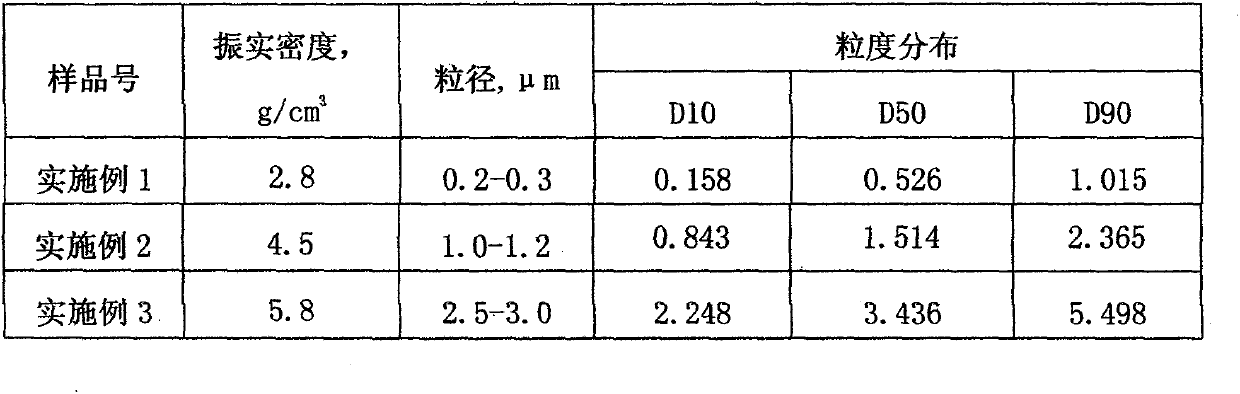

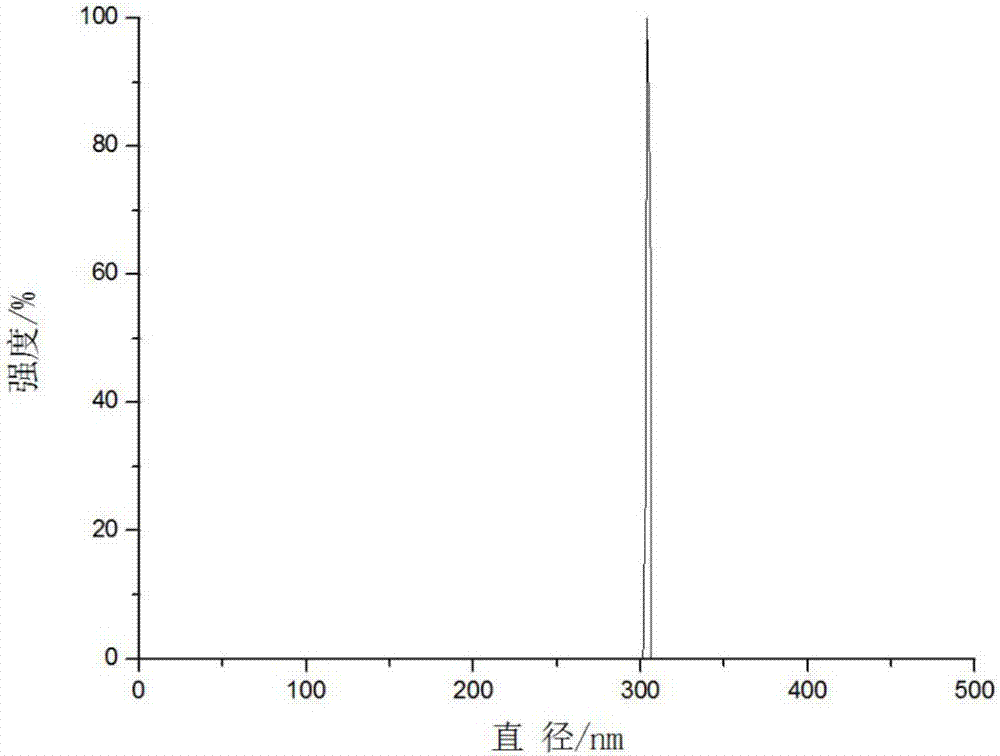

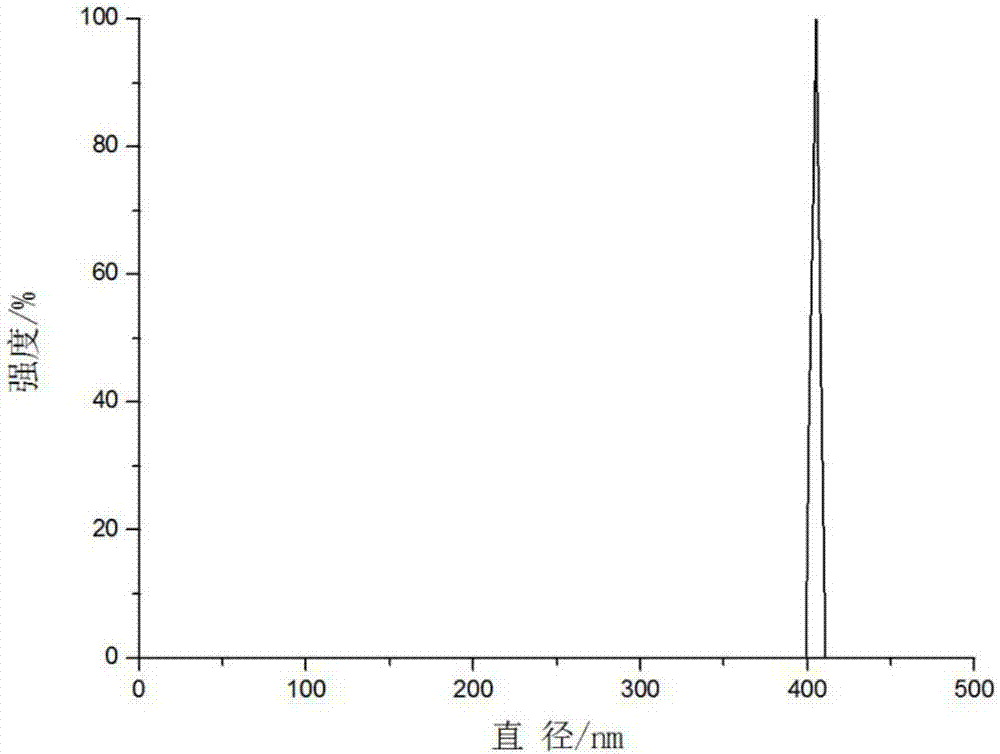

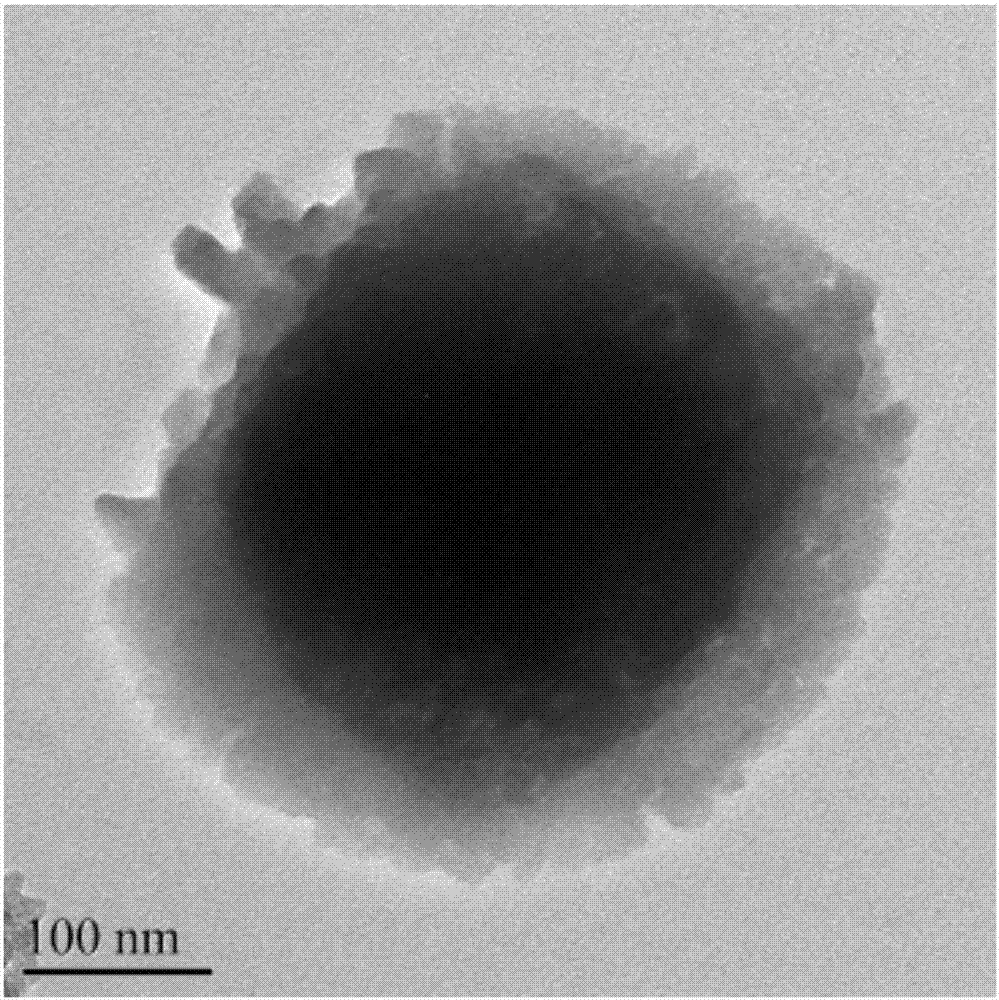

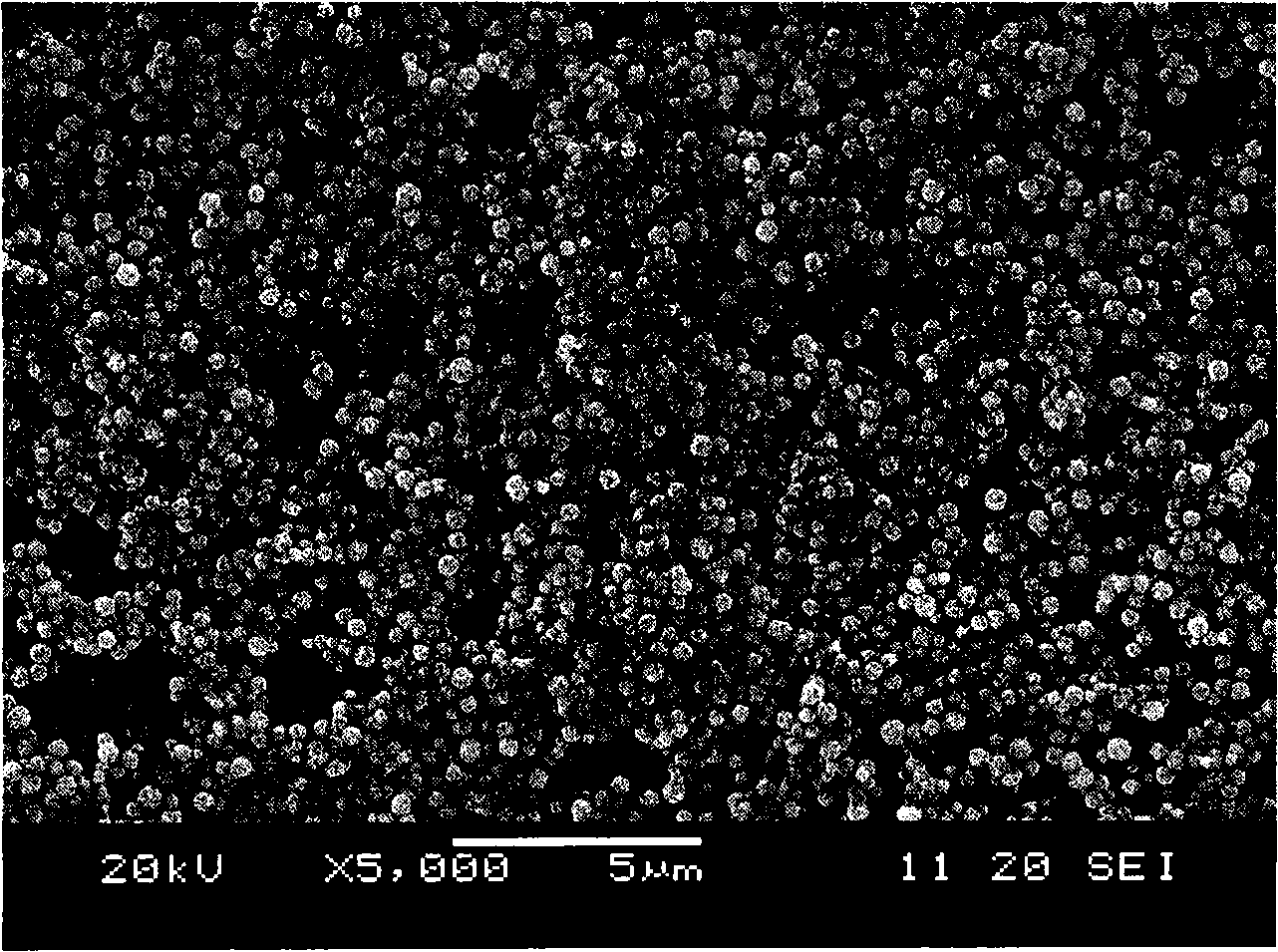

Preparation method of mono-dispersed highly crystalline silver powder with adjustable particle size

InactiveCN102554265AParticle size adjustableNarrow particle size dispersionVolumetric Mass DensitySalt solution

The invention relates to a preparation method of mono-dispersed highly crystalline silver powder with adjustable particle size. The preparation method comprises uniformly mixing an acidic silver salt solution and a mixed reducing solution containing a reducing agent, a dispersing agent and a stabilizing agent, precipitating, washing and drying to obtain the mono-dispersed highly crystalline silver powder with adjustable particle size, wherein the particle size of the silver powder can be adjusted by adjusting the amount of the dispersing agent and the stabilizing agent. In comparison with the prior art, the silver powder has an adjustable particle size, and D50 of the silver powder can be controlled to a range close to 0.5 mum, 1.0 mum, and 2.5 mum. Meanwhile, the silver powder has the advantages of narrow particle size distribution range, high tap density, high particle sphericity, smooth surface, and small specific surface area, and is easy for large-scale production.

Owner:SHANGHAI JIAO TONG UNIV +1

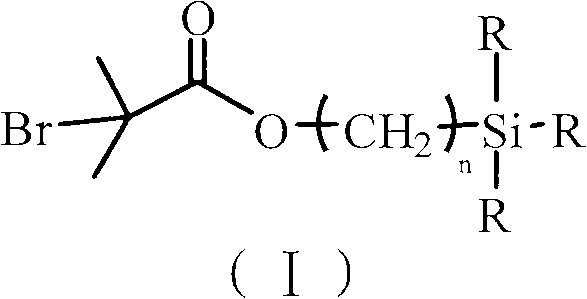

Method for preparing SiO2-poly(dimethylaminoethyl methacrylate) (PDMAEMA) nanoparticles having core-shell structure

ActiveCN101891867AParticle size adjustableNarrow particle size distributionGraft reactionSio2 nanoparticle

The invention relates to the field of nano technology and discloses a method for preparing SiO2-PDMAEMA nanoparticles having a core-shell structure. The method comprises the following steps of: selecting 2-bromideisobutyryl bromide with a higher initiation activity or a compound represented by a formula (I) as an initiator by using an atom-transfer radical-polymerization method; and during reaction, mixing CuX2 serving as a passivator, a ligand, SiO2 nanoparticles modified by the initiator, a solvent and diethylaminoethyl methacrylate at first and then adding CuX to perform a grafting reaction to obtain the SiO2-PDMAEMA nanoparticles with the core-shell structure. Experiments show that: the prepared SiO2-PDMAEMA nanoparticles have the advantages of controllable particle size, narrow particle size distribution and controllable molecular weight of the polymer PDMAEMA grafted on the surface of SiO2. Moreover, the preparation method provided by the invention has the characteristics of mild reaction conditions, convenience, feasibility and short preparation period and is easy for mass production.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

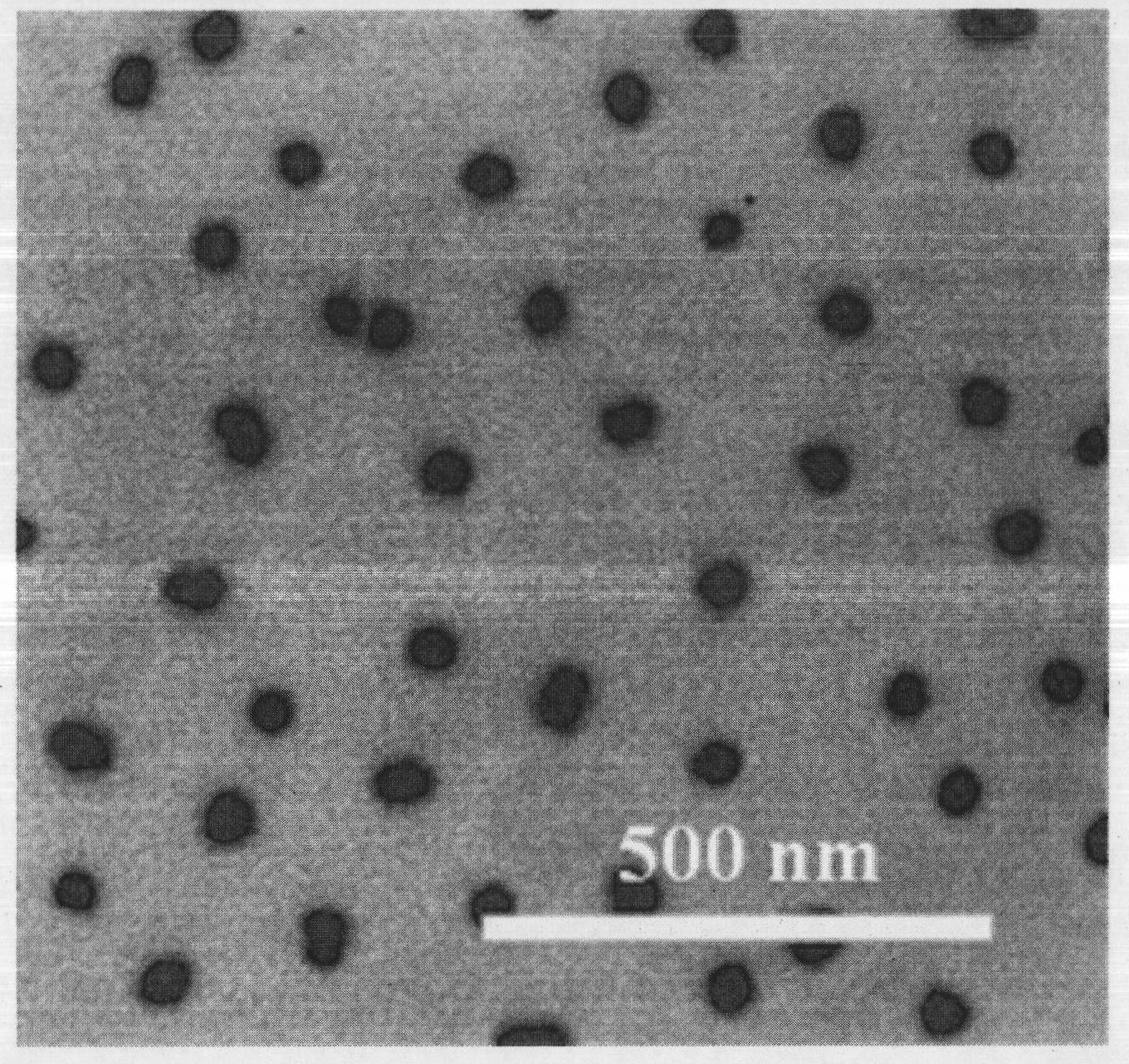

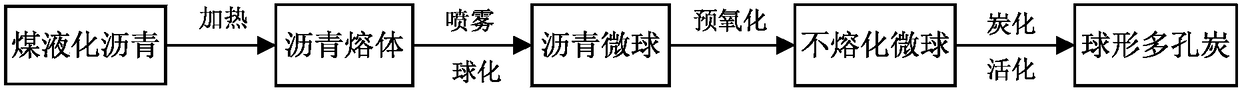

Spherical porous carbon and preparation method thereof

The invention provides a spherical porous carbon and a preparation method thereof. The preparation method comprises the following steps of: carrying out heating treatment on the coal liquefied asphaltto obtain an asphalt melt; carrying out spraying and drying treatment on the asphalt melt to obtain an asphalt microsphere, carrying out pre-oxidation on the asphalt microsphere to obtain a non-melted asphalt microsphere; carbonizing and activating the non-melted asphalt microsphere to obtain spherical porous carbon. The method prepares spherical porous carbon by using coal liquefied asphalt as araw material, high-value utilization of the asphaltene in the coal liquefaction oil slag can be carried out, and the characteristics of high aromatic degree, high carbon content, easy polymerizationor cross-linking are fully utilized. Furthermore, the preparation method of the spherical porous carbon has the advantages of simple steps, strong continuous operability, high sphere-forming rate, high sphericity and adjustable micro-sphere particle diameters.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

Method for synthesizing silicon dioxide hollow sphere with mesoporous channel controlled by dodecyl sulfonic acid sodium salt

InactiveCN101143724AFacilitate internal and external transmissionIncrease storage capacitySilicon oxidesCeramicwareMesoporous materialSilicon dioxide

The invention belongs to an inorganic mesoporous material area, in particular to a preparation method of a controllable silica hollow sphere material in a certain diameter range. The anionic surfactant sodium dodecyl sulfonate (SDS) controls the synthesis of spherical wall, which is provided with mesoporous channels and narrow distribution of diameter. The invention uses block copolymer and sodium dodecyl sulfonate as mixing template; with the addition of silicon source, the sol is formed after mixing; under the acid condition, through the agitating and aging treatment, after hydrothermal process, filtering and drying, the template is calcined to obtain silica hollow sphere with the mesoporous channel. Through changing the content of SDS, the synthesis of different size of silica hollow spheres with the mesoporous channel can be controlled. The invention has a simple process and a low cost; the mesoporous shell thickness and the pore diameter of the prepared silica hollow sphere with the mesoporous channel can be controlled in a large range; the invention is beneficial to the internal and external transmission of guest molecules; the invention also improves the reserves of guest molecules, which realizes the controlled release effectively.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method for preparing silver powder in continuous mode

A method for preparing silver powder in a continuous mode is characterized by comprising the following steps that (a) a silver solution is prepared, namely silver nitrate, pH adjusting agents, complexing agents and dispersing agents are dissolved in deionized water to form a water solution with the silver ion concentration of 0.3-3.0 mol / L; (b) reducing agents and pH adjusting agents are dissolved in deionized water to form a reducing solution; (c) a and b liquid reaction temperature, the pH value, flow and an injection included angle are adjusted, and meanwhile liquid flows into a pipeline reactor for mixing reaction; and (d) discharging silver powder suspension liquid passes through solid-liquid separating equipment, silver powder is filtered and separated, deionized water is used for washing, 30-60 DEG C drying is carried out, screening is carried out, and ultra-thin silver powder is obtained. Silver powder products prepared with the method are stable in performance, high in dispersity, even in particle size distribution and capable of meeting the application requirements of various electronic pastes.

Owner:ZHEJIANG GUANGDA ELECTRONICS TECH

Method for preparing polysiloxane-acrylate/styrene copolymers with large particle sizes and core-shell structures

The invention discloses a method for preparing polysiloxane-acrylate / styrene copolymers with large particle sizes and core-shell structures. The method includes adding polyacrylate agglomerating agents into polysiloxane-butyl acrylate emulsion and carrying out agglomeration to obtain polysiloxane-acrylate core emulsion; regulating the temperature of the polysiloxane-acrylate core emulsion until the temperature of the polysiloxane-acrylate core emulsion ranges from 60 DEG C to 80 DEG C, adding inorganic peroxide initiators and sodium carbonate into the polysiloxane-acrylate core emulsion to obtain mixtures, regulating pH (potential of hydrogen) values of the mixtures, adding methyl methacrylate and styrene into the mixtures and carrying out reaction to obtain polysiloxane-acrylate / styrene copolymer emulsion with core-shell structures; adding water into the polysiloxane-acrylate / styrene copolymer emulsion, diluting the polysiloxane-acrylate / styrene copolymer emulsion, allowing the solid content to range from 15% to 19% under the control, adding inorganic salt aqueous solution into the polysiloxane-acrylate / styrene copolymer emulsion to obtain mixtures, stirring the mixtures at the room temperature, ageing the mixtures, carrying out re-cooling, centrifugal separation and washing on the mixtures and drying obtained precipitates. The method has the advantages that particles of polysiloxane-acrylate / styrene copolymer products prepared by the aid of the method have obvious core-shell structures, the average particle sizes range from 400 nm to 600 nm, and obvious low-temperature toughening effects can be realized for polycarbonate for engineering plastics.

Owner:广州广化塑料管道有限公司

Method for preparing liquid chromatography monolithic column based on metal-organic frameworks

ActiveCN102631796ALarger than the areaImprove thermal stabilitySolid sorbent liquid separationFoaming agentIn situ polymerization

A method for preparing a liquid chromatography monolithic column based on metal-organic frameworks. The porous MOFs (metal-organic frameworks) and organic polymer monolithic materials are used as separation media, and the stainless steel liquid chromatography monolithic column is prepared by means of in-situ polymerization. Firstly, the MOFs are prepared by means of self-assembly reaction of different metal centers and organic ligands, activated at a certain temperature and ultrasonically dispersed in solvents to obtain suspending liquid of the MOFs. Secondly, the suspending liquid is added into precursor solution, and the doped monolithic column is prepared by means of thermal-initiation polymerization. Thirdly, pore-foaming agents in the MOFs monolithic column are flushed at a high flow rate by a liquid high-pressure pump, and then the liquid chromatography monolithic column can be prepared. The method has the advantages that the superiority of double separation of the MOFs and the monolithic column is integrated, the shortcomings of large backpressure, high consumption of the separation media, complicated filling and the like of a traditional packed column are overcome, the types of the MOFs serving as separation media are expanded, and large-scale popularization and application are facilitated.

Owner:NANKAI UNIV

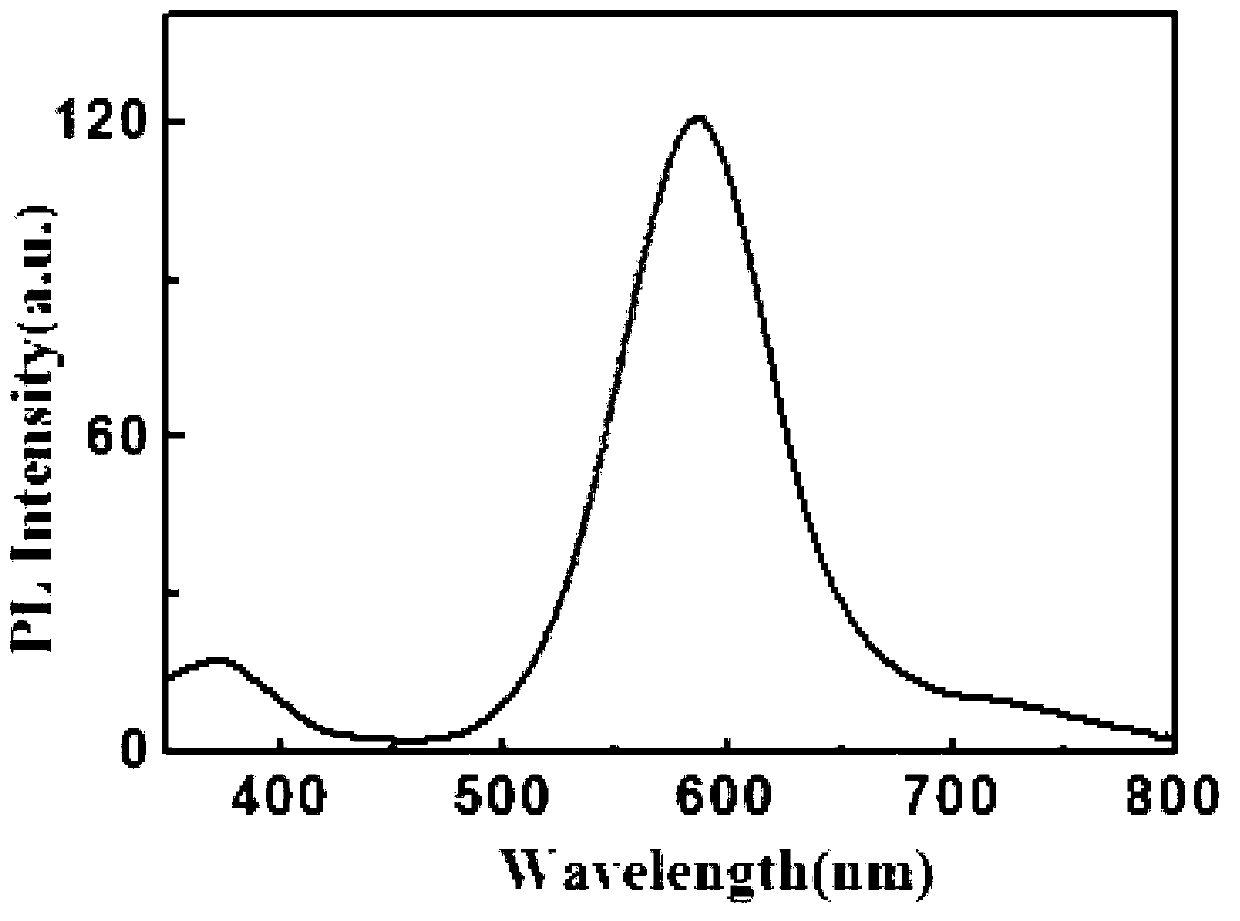

Method of preparing nano-level sphere cerium activated yttrium aluminum garnet phosphor powder

InactiveCN101077974AGood dispersionComplete crystal formLuminescent compositionsLuminous intensityPhosphor

The present invention belongs to the field of composite RE oxide as light emitting material, and is process of preparing nanometer level spherical Ce activated YAG phosphor. The process includes the reaction between the transparent oil phase emulsion comprising oil phase material, surfactant and co-surfactant and the aqueous phase liquid comprising reactant solution or precipitant solution in the volume ratio of 1 to (0.1-1) in the micro emulsion drop serving in W / O micro emulsion system as the nanometer micro reactor to obtain the precipitate, washing the precipitate, suction filtering, drying and calcining to obtain nanometer level spherical YAG:Ce phosphor with high dispersivity. The process is simple, low in power consumption, environment friendly, low in cost and suitable for industrial production, and the YAG:Ce phosphor has high luminous intensity and light emitting efficiency.

Owner:TSINGHUA UNIV

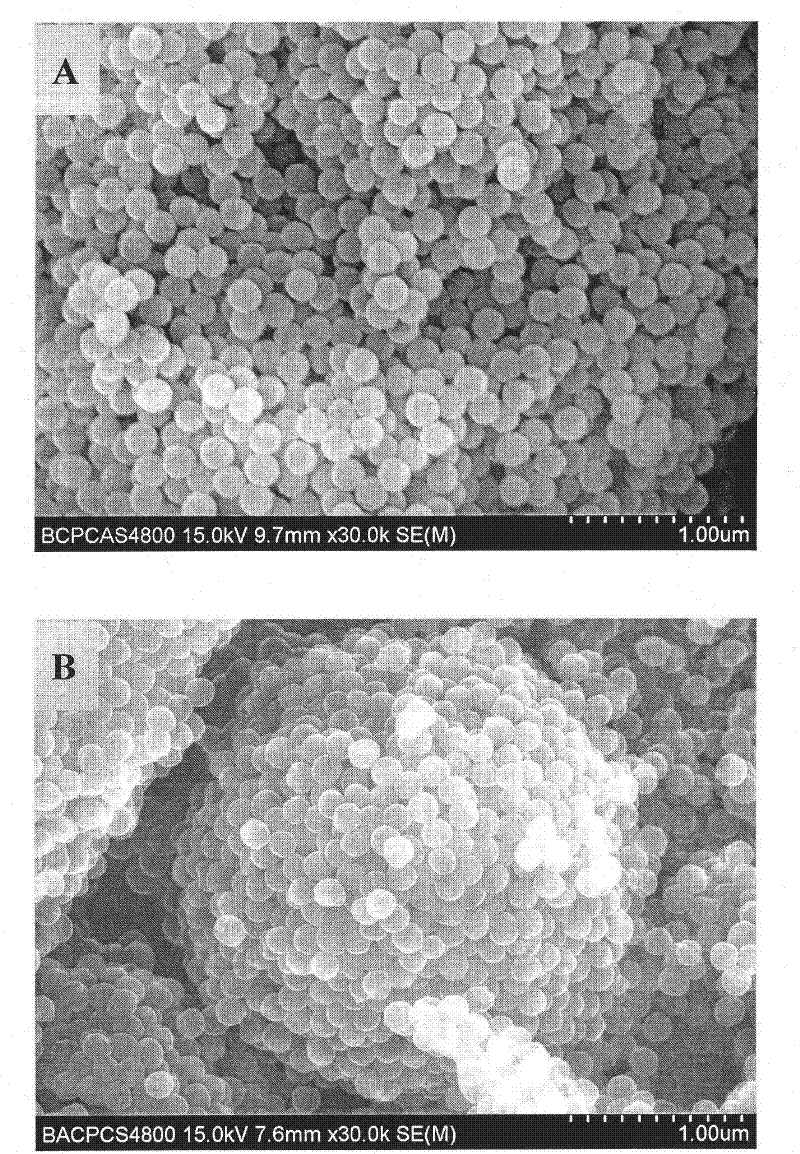

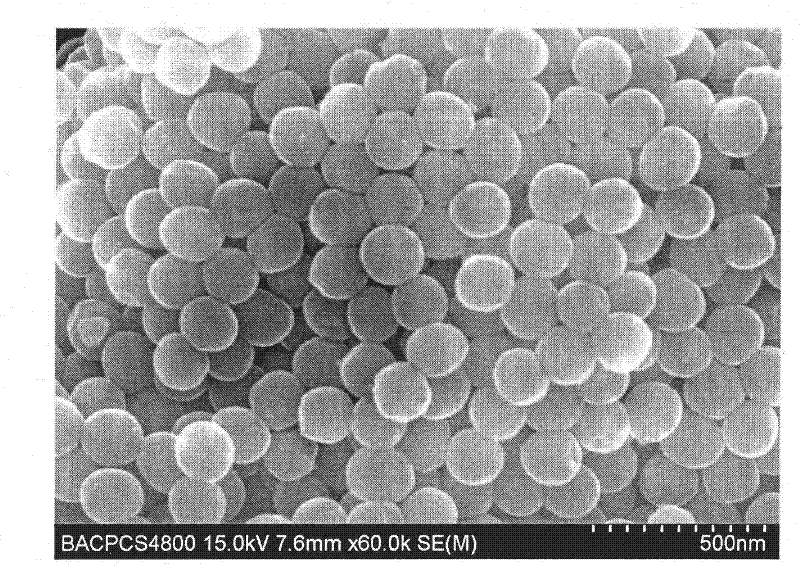

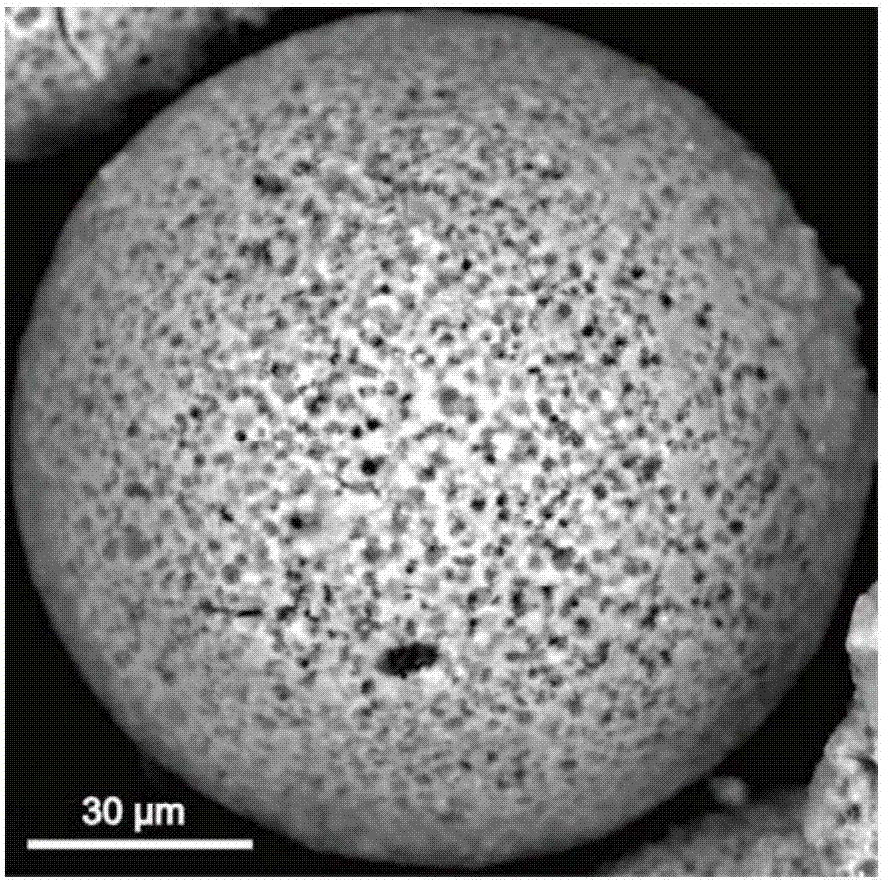

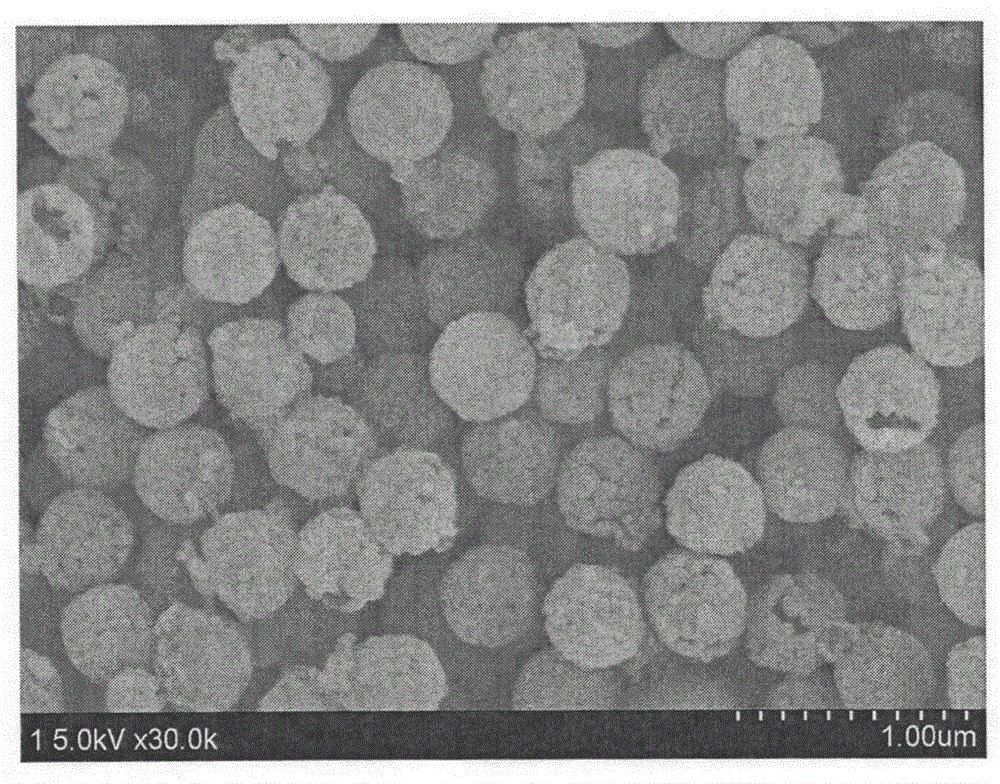

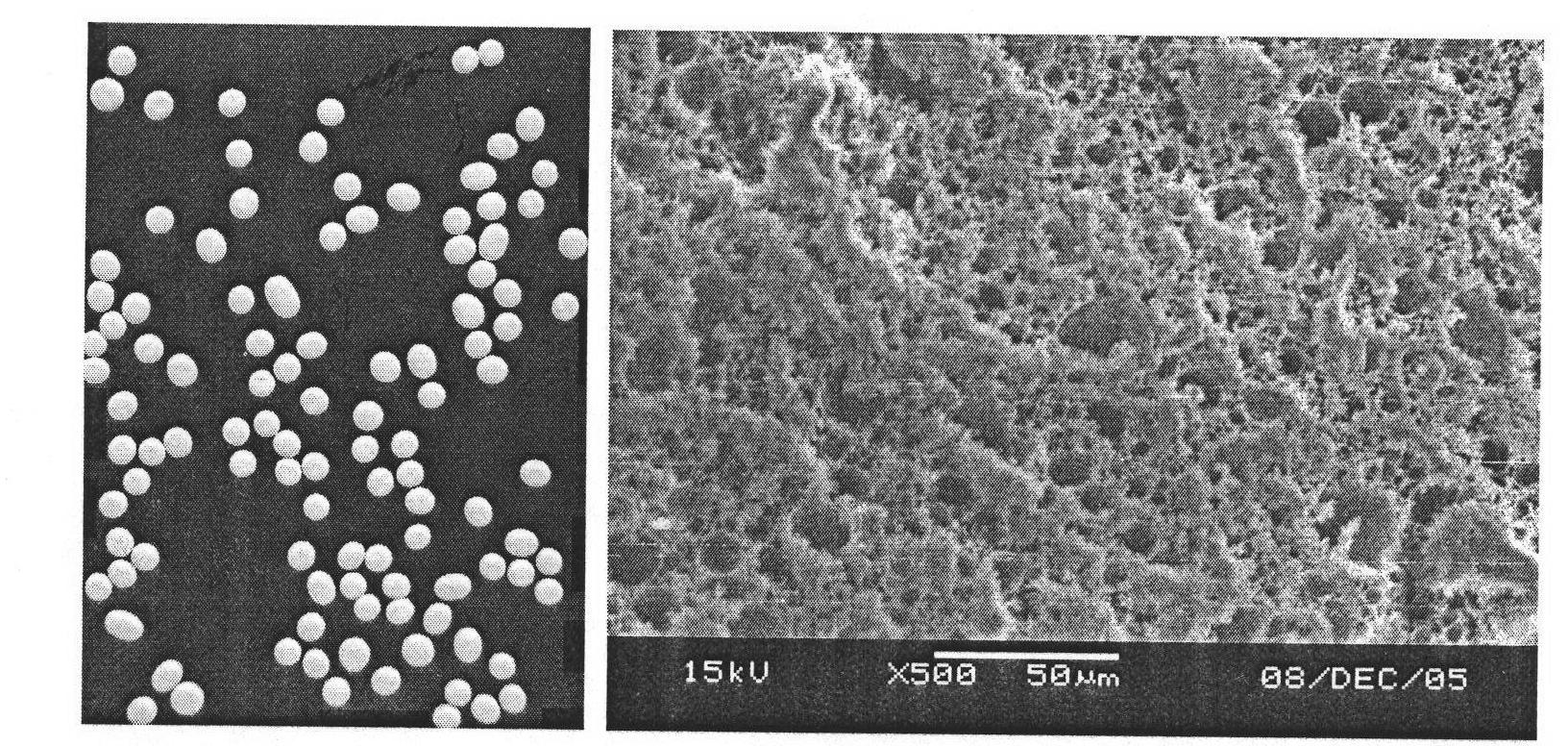

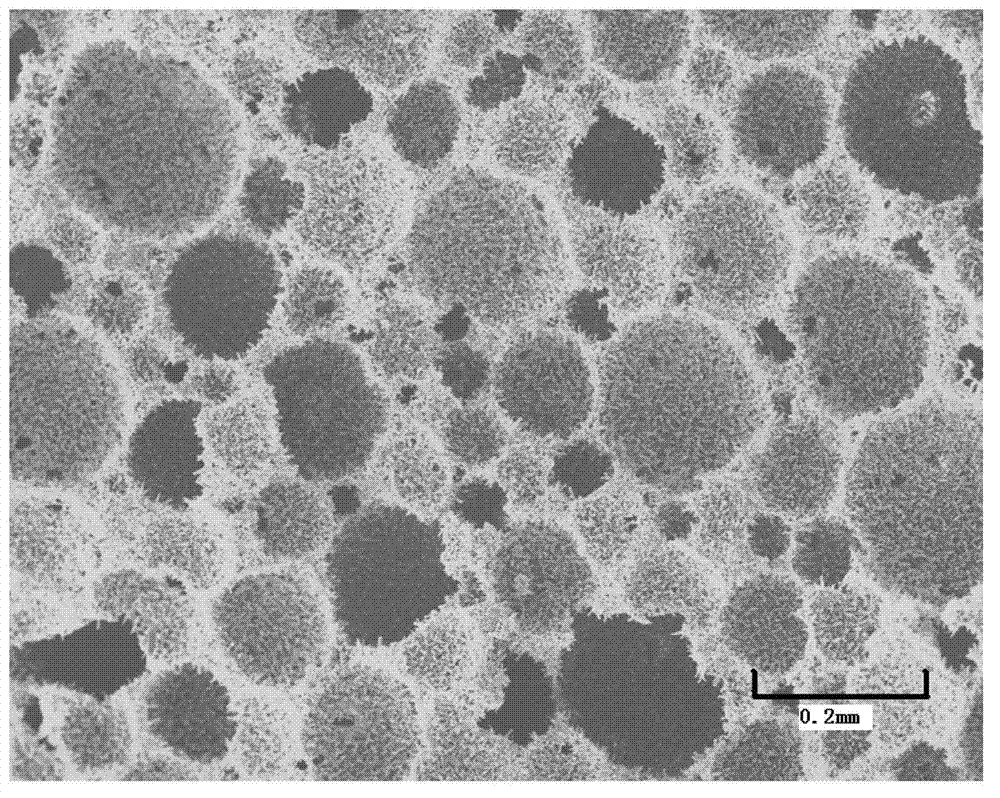

Micron-sized monodispersed porous silica microsphere and preparation method thereof

ActiveCN109399648ASimple preparation processRound shapeMaterial nanotechnologySilicaOrganic componentMicrosphere

The invention discloses a preparation method of a micron-sized monodispersed porous silica microsphere. A novel porous polysilsesquioxane microsphere is taken as a template, direct calcinations is conducted for removing organic components, and thus a monodispersed porous silica microsphere material with the controllable particle size and hole diameter. The invention further discloses the micron-sized monodispersed porous silica microsphere prepared through the preparation method, the particle size of the silica microsphere is 3-10 [mu]m, the pore volume is 0.3-0.9 cm<3> / g, the specific surface area is 100-400 m<2> / g, and the hole diameter is 3-100 nm. Compared with a traditional process, the preparation method is simple, the economical effect is achieved, graded screening is not needed, and the prepared porous silica microsphere is round and normal in shape and uniform in particle size distribution, has a mesoporous structure, can be directly applied to high performance liquid chromatography stationary phases, and can also be applied to the fields such as catalytic carriers, coating and cosmetic additives.

Owner:TIANJIN UNIV

Low temperature synthesis of ultra-fine ZnO-SiO2 microwave dielectric ceramic powder by sol-gel method

The invention discloses a preparation method of sol-gel to synthesize the ultrafine microwave dielectric ceramic powder of ZnO-SiO2 in the low temperature, which comprises the steps that: the zinc salt and the tetraethyl orthosilicate are respectively dissolved in the anhydrous ethanol to form the ethanol solution of zinc salt and the ethanol solution of tetraethyl orthosilicate; the two solutions are stirred and mixed with the mole ratio of Zn to Si being 2 : 1, then proper anhydrous ethanol is added to control the density of the zinc salt in the mixed solution within a range of 0.5 to 1 mol / l; deionized water is added to promote hydrolytic polymerization; at least one of nitric acid and acrylic acid is added dropwise to adjust the pH value; proper dispersing agent is added to overcome the powder agglomeration; and the gel is obtained after even stirring, sealing and standing of the obtained solution, and then the obtained gel is dried and calcined to obtain the ultrafine microwave dielectric ceramic powder of ZnO-SiO2. The preparation method has the advantages that the ultrafine powder with an adjustable particle size of 80 to 200 nm can be calcined and synthesized under the low temperature condition of 800 to 850 DEG C; and the powder has good microwave property after sintering.

Owner:ZHEJIANG UNIV

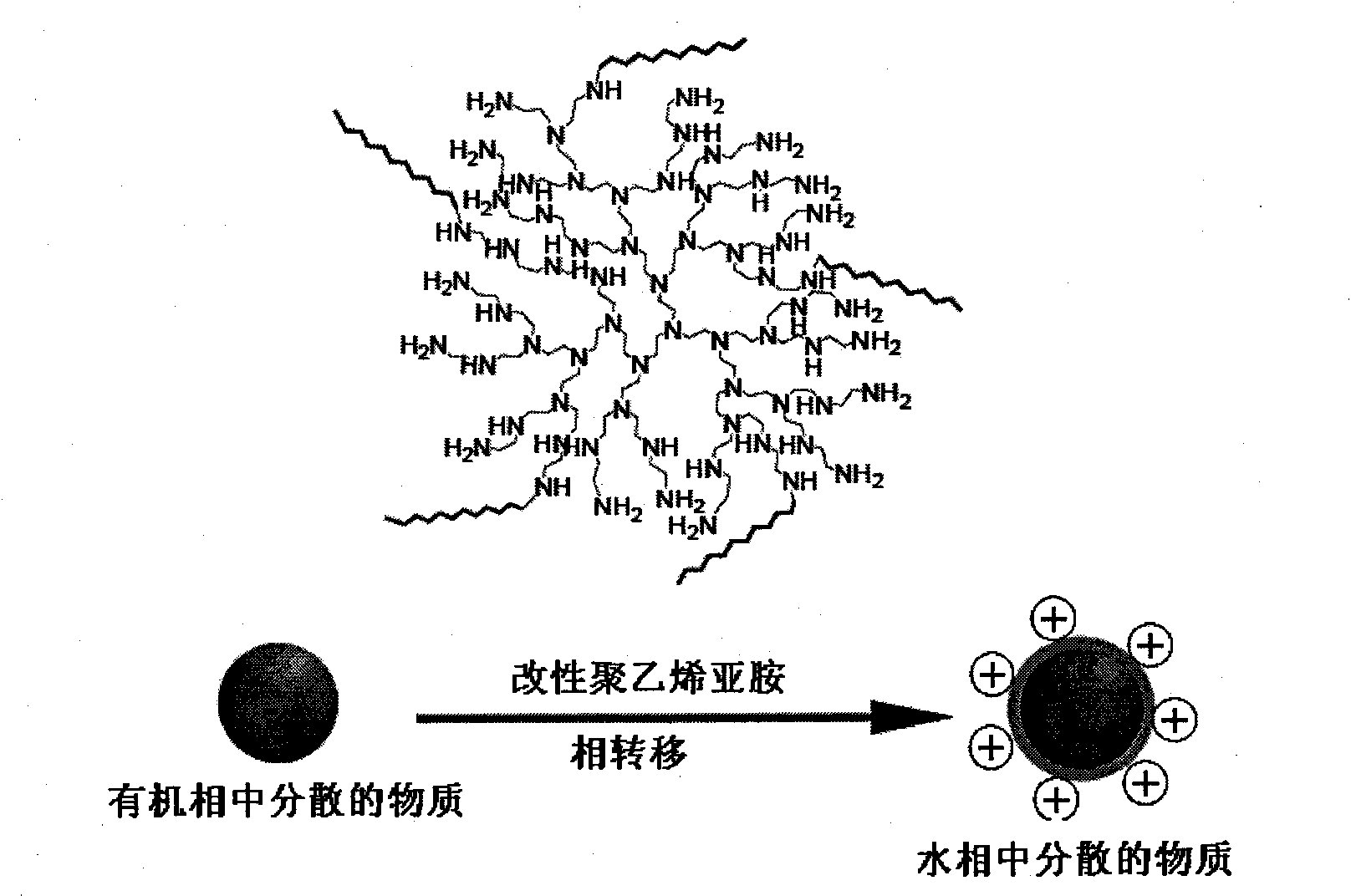

Preparation method of multifunctional nanometer composite particle constructed by modified polymine

ActiveCN101928458APhysical properties do not changeParticle size adjustableTissue culturePharmaceutical non-active ingredientsPhase conversionMolecular imaging

The invention discloses a preparation method of a multifunctional nanometer composite particle constructed by modified polymine, which is characterized by converting the organic phase of a nanometer crystalloid synthesized by an organic phase to a water phase. In the phase conversion process, the agglomeration of a large quantity of particles are not required to occur so as not to cause precipitation in a pure water solvent or a buffer water solvent, and the controllability of dispersion degree needs to be realized according to different uses; the nanometer particles subjected to phase conversion are decorated by adding different surface groups according to application conditions to meet the necessary function and characteristic requirement; and the nanometer crystalloid is covered by themodified polymine to keep the original physical characteristic and have the excellent dispersion performance in the water phase. The nanometer composite particle can carry hydrophobic nanometer crystalloid and medicines to be applied to molecular imaging and medicine delivery, and can be used as a gene carrier to be applied to gene transfection; meanwhile, gold ion or silver ion in the water solution is reduced by utilizing amino on the modified polymine in the nanometer composite particle to realize in-situ crystalloid growth so as to construct a multifunctional molecular developing probe.

Owner:SICHUAN UNIV

Aqueous zinc stearate dispersion liquid and preparation method thereof

ActiveCN103266534AHigh speed stirringSmall particle sizeNon-fibrous pulp additionCoatingsPreservativeZinc

The invention discloses an aqueous zinc stearate dispersion liquid. The aqueous zinc stearate dispersion liquid is prepared from the following components by weight: 35 to 45% of zinc stearate, 4 to 10% of an emulsifier, 1 to 4% of a dispersant, 0.1 to 0.5% of a defoaming agent, 0.1 to 0.3% of an antiseptic and 40.2 to 59.8% of water, wherein the content of the above-mentioned components sums to 100%. The invention further discloses a preparation method for the aqueous zinc stearate dispersion liquid. The aqueous zinc stearate dispersion liquid provided by the invention has the advantages of a small particle size, high solid content, small viscosity, good stability, no toxicity, environment friendliness and an ideal lubrication effect. The preparation method for the aqueous zinc stearate dispersion liquid is simple, easy to operate and beneficial for industrialized application and enables production cost to be reduced.

Owner:肇庆市至立自动化科技有限公司

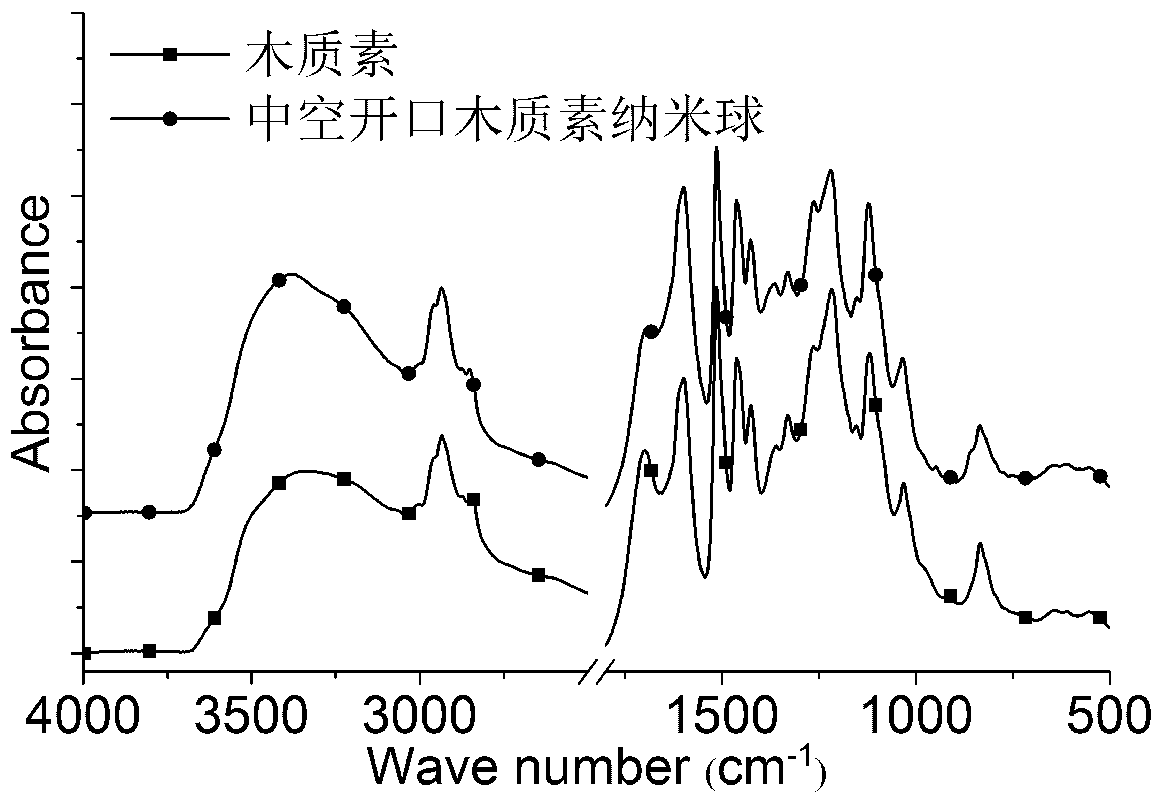

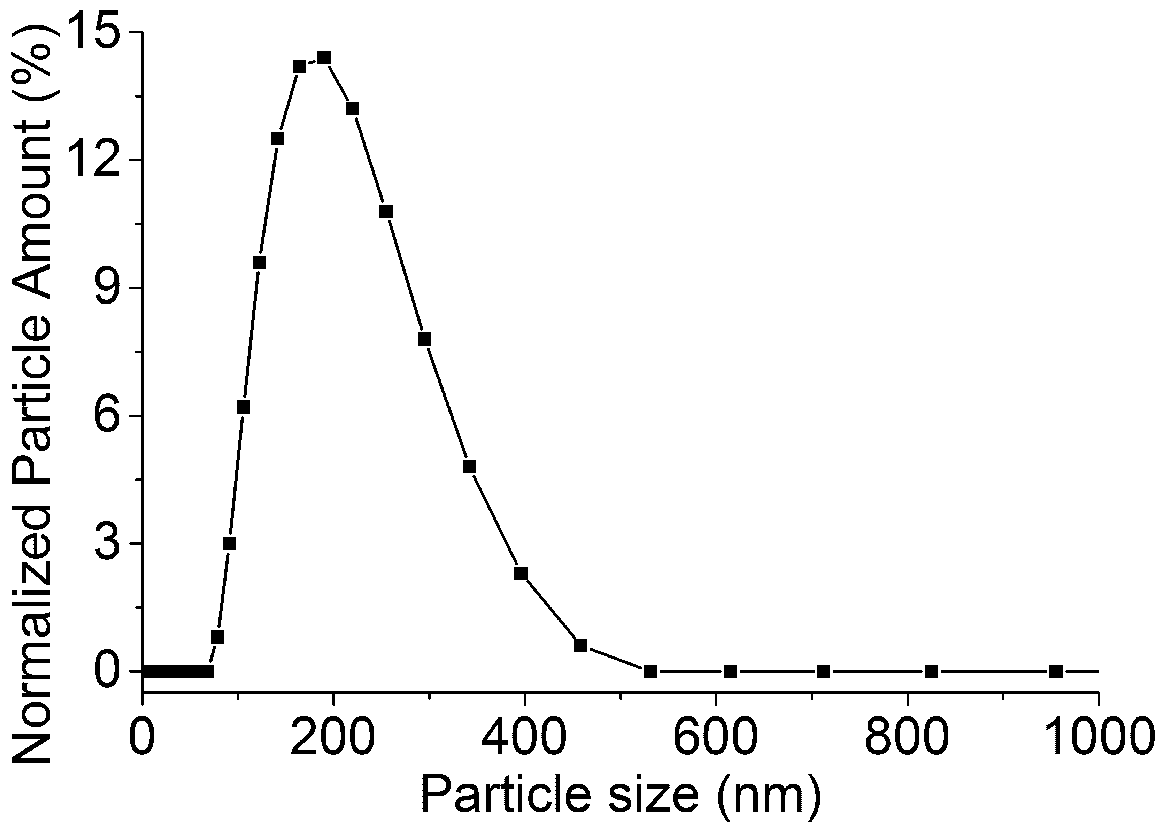

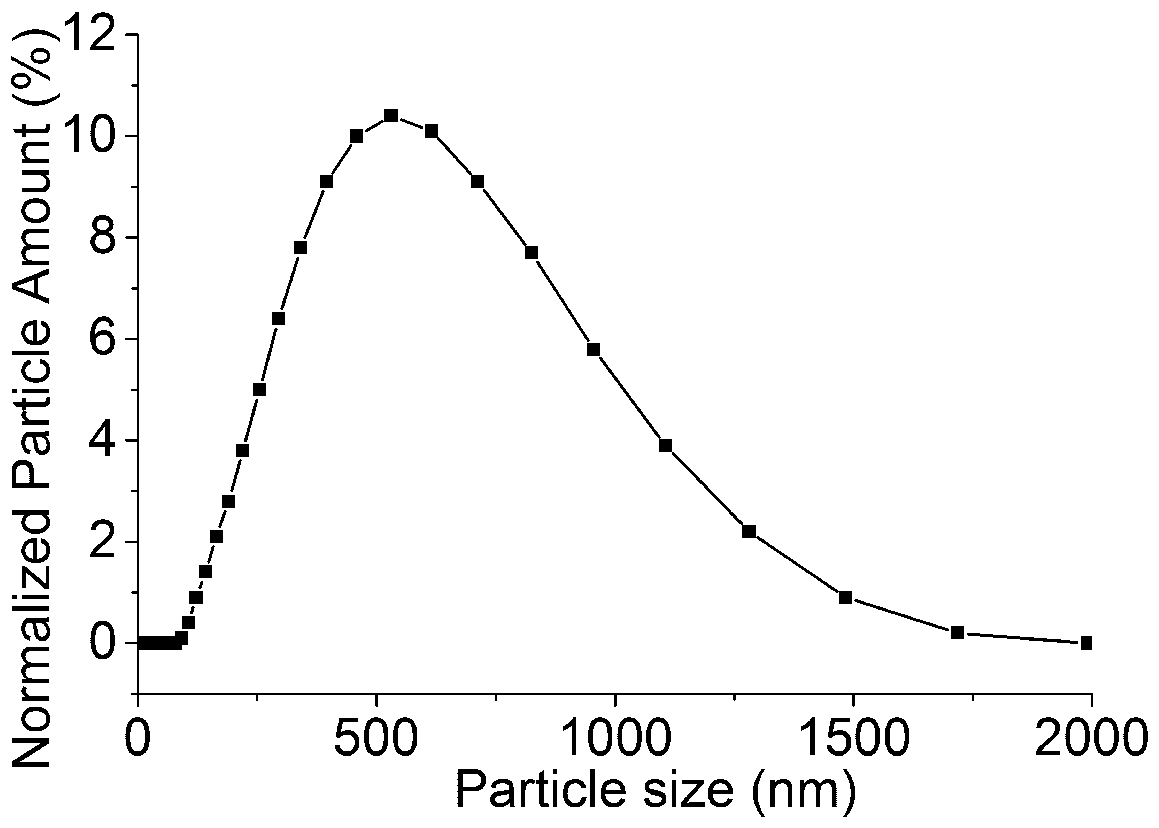

Hollow open lignin nano-sphere and preparation method thereof

PendingCN107774204AParticle size adjustableEasy to prepareMicroballoon preparationMicrocapsule preparationOrganic solventFreeze-drying

The invention discloses a preparation method of a hollow open lignin nano-sphere. The preparation method comprises the following steps: 1, adding a proper amount of lignin raw materials into an organic solvent to dissolve; 2, under proper stirring speed, adding deionized water into an organic solution dropwise at proper speed, or adding an organic solution, in which lignin is dissolved, into deionized water at proper speed, and slowly forming a hollow open nano-sphere; 3, transferring suspension liquid into a dialysis bag to perform dialysis and removing the residual organic solvent; and 4, freeze-drying the suspension liquid after dialysis to finally obtain the hollow open lignin nano-sphere with the grain size of 50 to 600 nm. The prepared hollow open lignin nano-sphere can serve as a medicine carrier.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

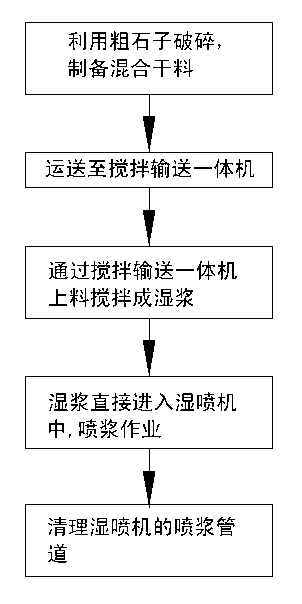

Coal mine wet method guniting process

InactiveCN103244148AContinuously adjustable particle size distributionRegular shapeUnderground chambersTunnel liningFiberDry mixing

The invention provides a coal mine wet method guniting process and belongs to the technical field of coal mine wet method guniting. The coal mine wet method guniting process comprises the following steps of 1.1 manufacturing mixed dry materials, namely performing dry mixing of a sand and stone mixed material, cement, coal ash, a water reducing agent, fiber and an accelerator to form the mixed dry materials; 1.2 performing dry material transportation, namely transporting the mixed dry materials to a guniting working face under a coal mine; 1.3 manufacturing wet slurry, namely pouring the mixed dry materials into a stirring, conveying and guniting integrated machine and simultaneously adding water to perform stirring to form evenly-mixed wet slurry; 1.4 performing guniting operation, namely utilizing a plunger type wet spraying machine (11) to perform continuous and quick guniting operation to the working face needing guniting; and 1.5 cleaning a pipeline, namely cleaning the guniting pipeline of the plunger type wet spraying machine (11), keeping the pipeline to be clean and preventing blockage. By means of the coal mine wet method guniting process, dry mixing, conveying, stirring, guniting and other processes are tightly combined integrally, the processes are compact, manpower is saved, the efficiency is improved, guniting materials are even and consistent in proportion, and the guniting effect is remarkable.

Owner:ZIBO MINING GRP

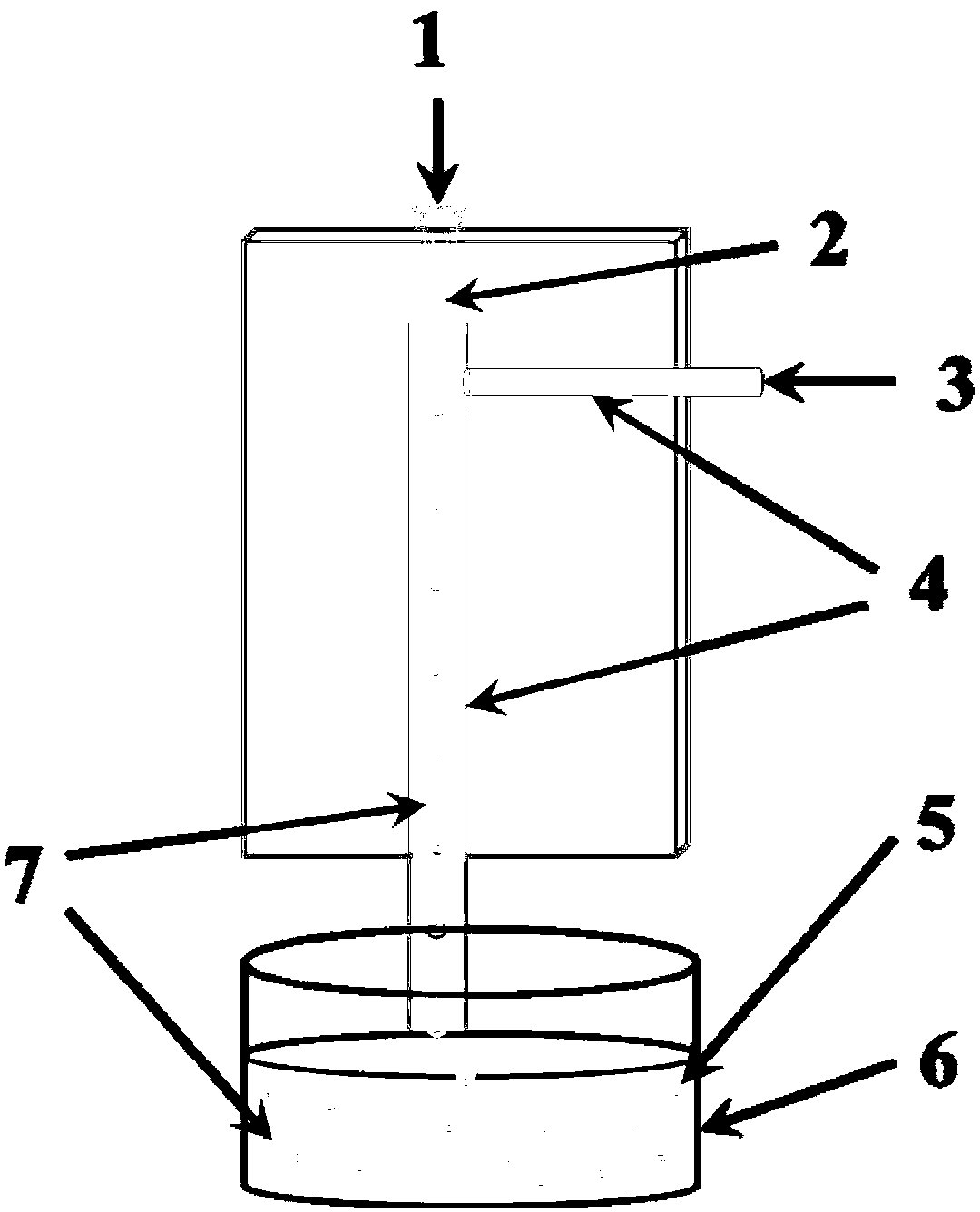

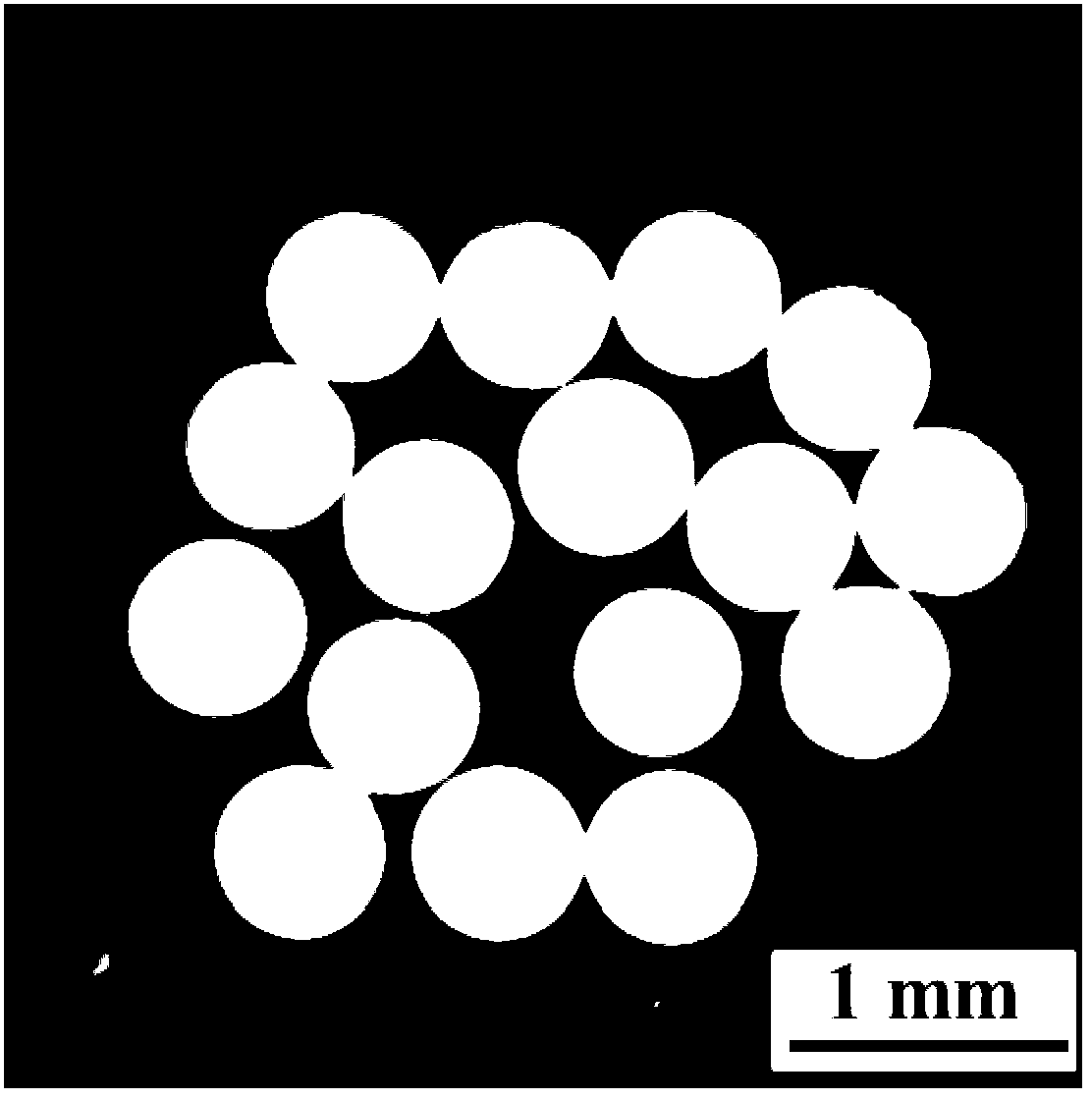

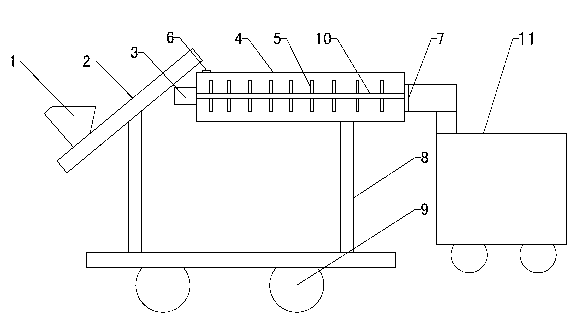

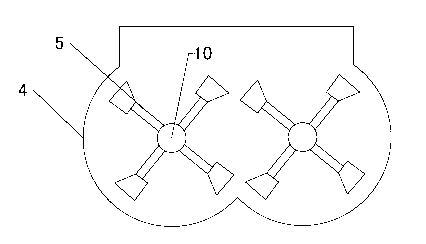

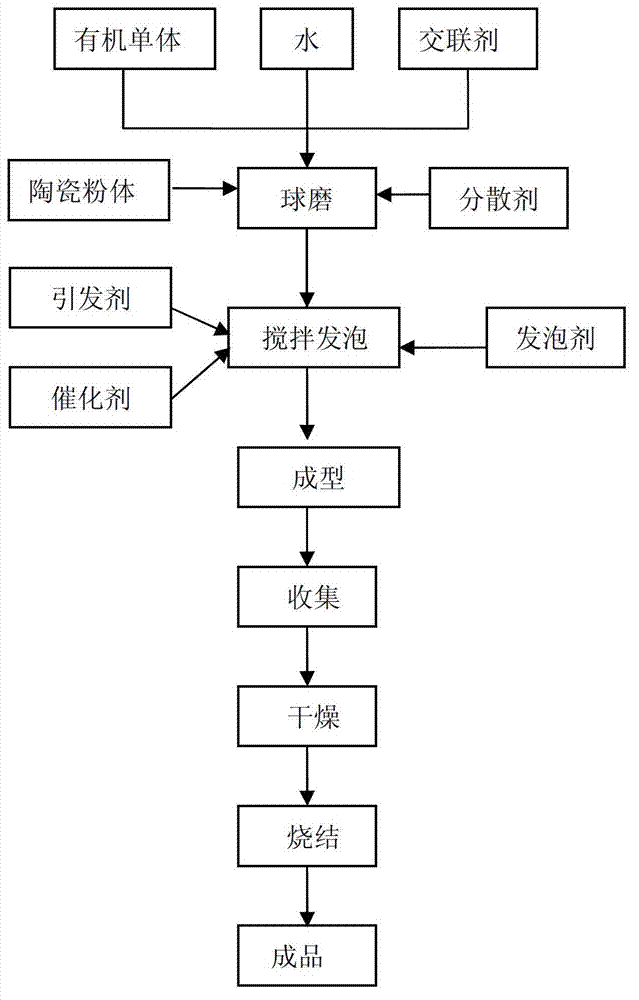

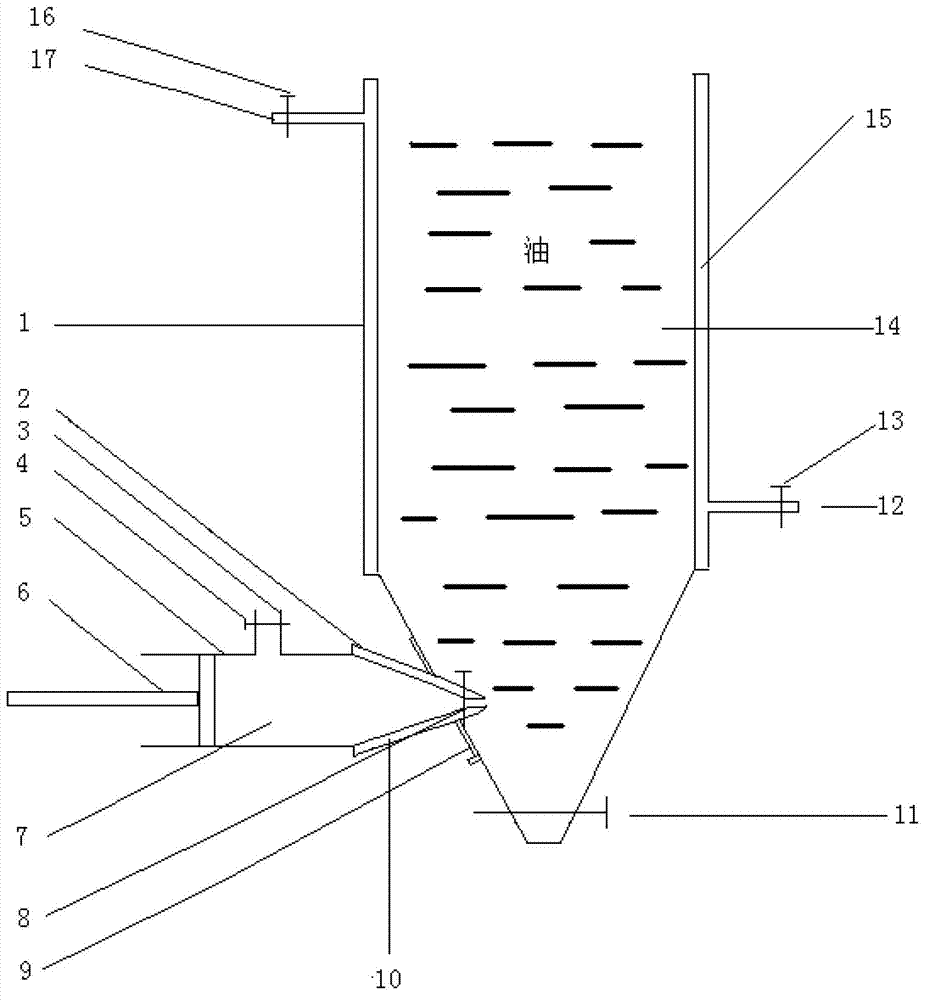

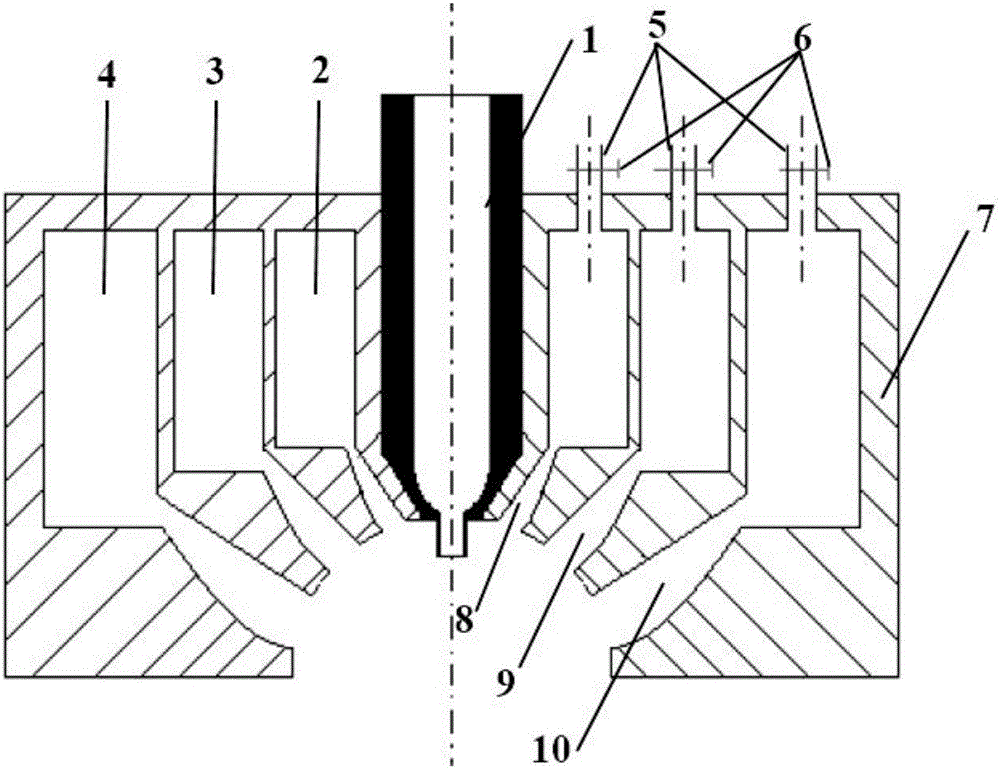

Method and device for preparing porous ceramic micro beads

The invention discloses a method and a device for preparing porous ceramic micro beads. The method comprises the following steps of: mixing an organic monomer and a crosslinking agent with water according to a certain proportion for dissolving, adding ceramic powder and a dispersing agent into a solution, and performing ball milling to obtain a ceramic suspension with high solid phase content and low viscosity; adding a foaming agent, an initiator and a catalyst into the suspension for stirring to obtain water-based stable foam ceramic slurry; and continuously injecting the water-base slurry into an oily medium of a certain temperature by using the device for preparing the porous ceramic micro beads to form foam slurry spheres, floating and curing into porous ceramic micro bead blanks in the oily medium, collecting, cleaning, drying and sintering to obtain a porous ceramic micro bead product. The invention further discloses a device for preparing the porous ceramic micro beads. The device comprises a micro bead forming tower and an injection gun, and can be used for realizing continuous automatic injection and generation of spheres. The device has universality, and can be used for realizing large-scale continuous production of porous ceramic micro beads which are of different systems and are 0.3-4.0 millimeters in diameter.

Owner:TSINGHUA UNIV

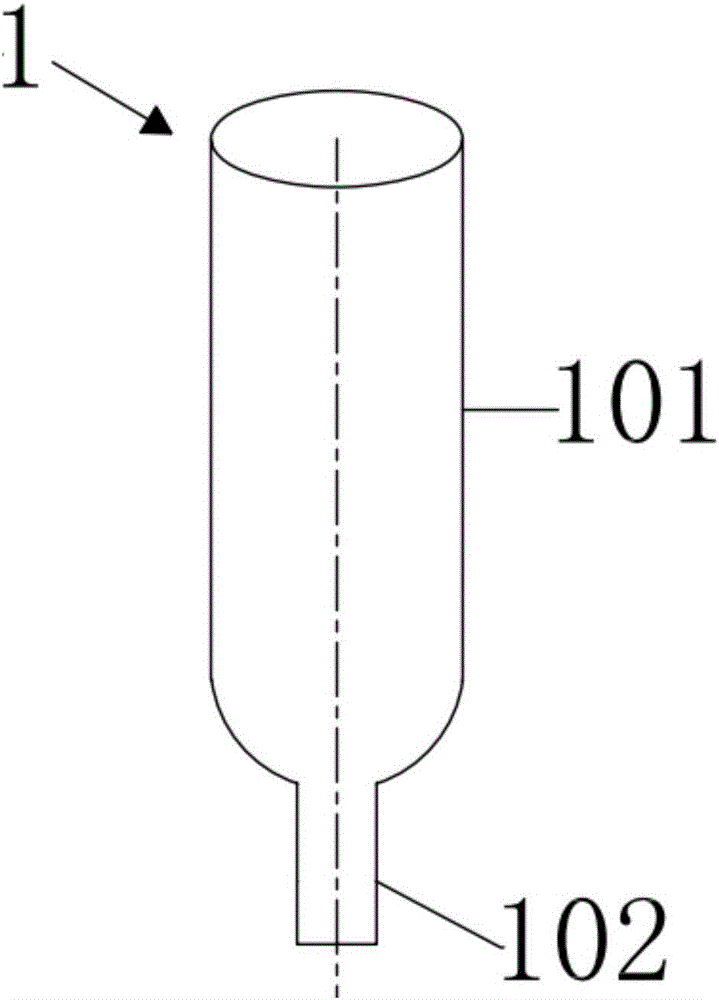

Atomizing nozzle and method for producing powder

The invention relates to an atomizing nozzle for producing 3D printing powder. The atomizing nozzle comprises a nozzle body, wherein a flow guide pipe is arranged in the center of the nozzle body; a first annular atomizing chamber, a second annular atomizing chamber and a third annular atomizing chamber are arranged around a center line of the flow guide pipe in the nozzle body from inside to outside; air feeding tubes are arranged on the first annular atomizing chamber, the second annular atomizing chamber and the third annular atomizing chamber; the first annular atomizing chamber, the second annular atomizing chamber and the third annular atomizing chamber are correspondingly connected with a first injecting chamber, a second injecting chamber and a second injecting chamber; the area of air inlets of the injecting chambers is less than that of air outlets of the injecting chambers; the annular atomizing chambers and the injecting chambers form Laval tubes; the distance from the air inlets of the injecting chamber to the center line of the flow guide pipe sequentially increases from inside to outside. The atomizing nozzle is high in production efficiency; the powder is high in degree of sphericity; the particle size of a product is adjustable; a powder product with a certain particle size distribution can be produced as requirement, so that the workload of after-treatment in powder production can be decreased.

Owner:航天科工(长沙)新材料研究院有限公司

Method for synthesizing Bi0.5Na0.5TiO3 spheroidal particles by microwave hydrothermal method

The invention relates to a method for synthesizing Bi0.5Na0.5TiO3 spheroidal particles by a microwave hydrothermal method. The method for synthesizing Bi0.5Na0.5TiO3 spheroidal particles comprises the following concrete steps: firstly, preparing bismuth nitrate solution; then, dripping titanium-containing compound solution into the bismuth nitrate solution to form uniform mixed solution; gradually dripping NaOH water-solubility solution into the uniform mixed solution and controlling the molar concentration of the OH<-> of the mixed solution between 1M and 5M; carrying out heating reaction for the mixing solution in a microwave heating way and controlling the temperature of the heating reaction between 140 DEG C and 190 DEG C and the reaction time of the heating reaction between 2 hours and 6 hours; and obtaining the Bi0.5Na0.5TiO3 spheroidal particles by filtering, washing to be neutral and drying after the heating reaction is finished. The production method has simple process, uses no organic solvent or organic reactant, has short reaction time and is suitable for industrialized production. The particle size distribution of the synthesized Bi0.5Na0.5TiO3 spheroidal particles is narrow, thus the invention meets the requirement of high reliability, multifunction and micromation proposed for electronic ceramic components.

Owner:NANJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com