Method for preparing liquid chromatography monolithic column based on metal-organic frameworks

A metal-organic framework and liquid chromatography technology, which is applied in the field of polymer material preparation and chromatography application, can solve the problems of inappropriate reversed-phase system, poor reproducibility, time-consuming and labor-intensive, etc. Good stability and permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

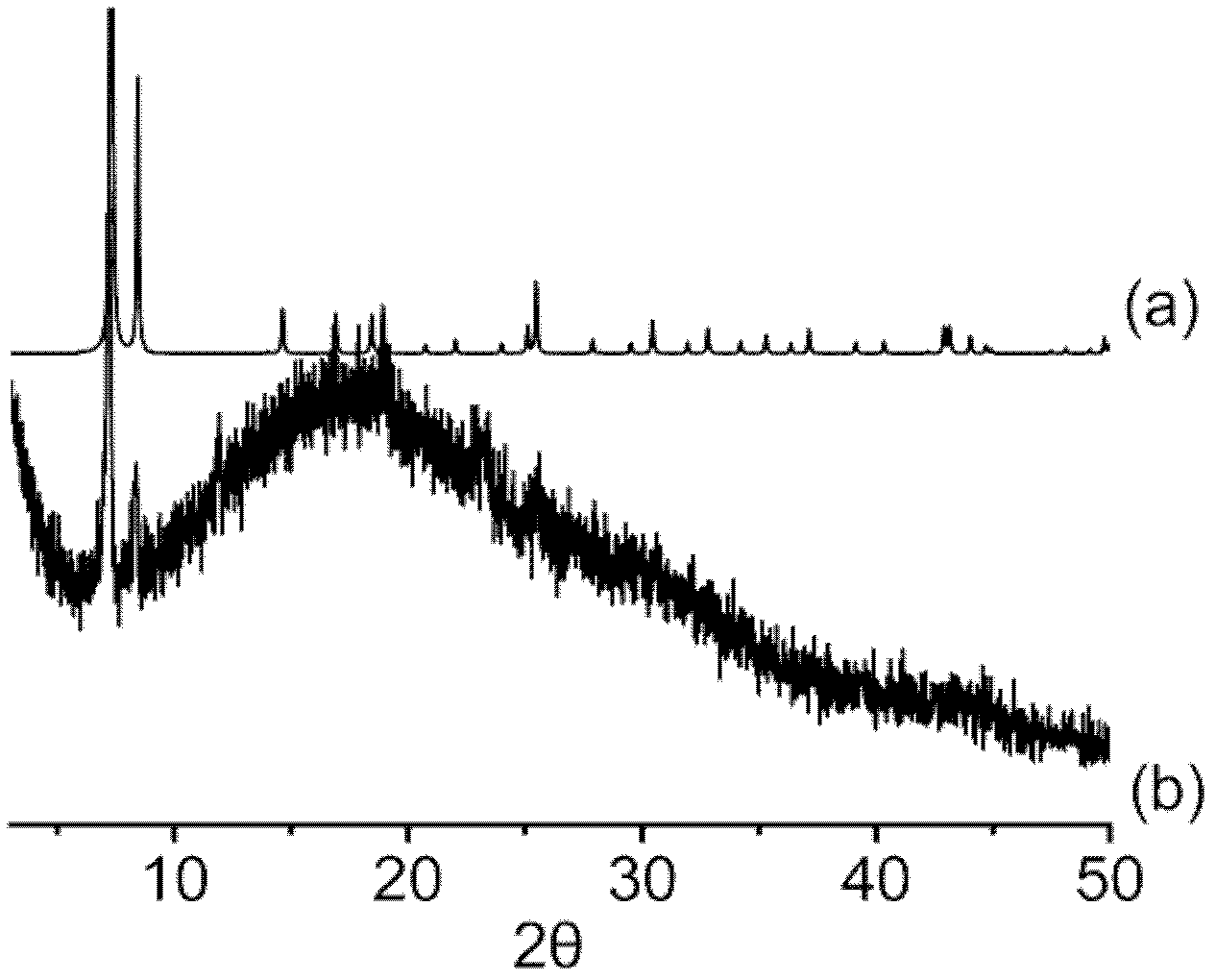

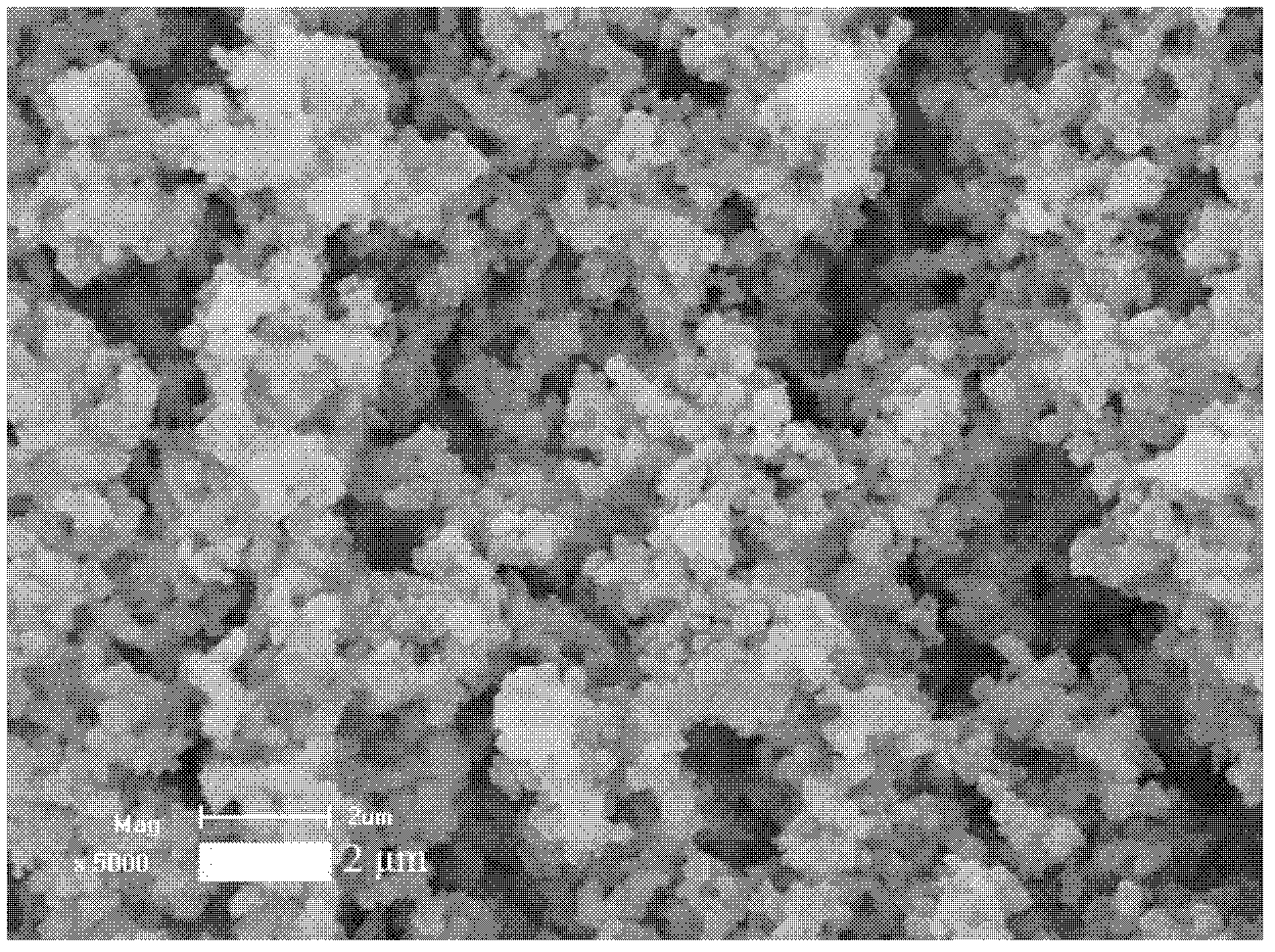

Embodiment 1

[0027] A method for preparing a liquid chromatography monolithic column based on a metal organic framework material includes the following steps:

[0028] 1) Preparation of stainless steel column tube:

[0029] The stainless steel column tube and column cap are soaked in ethanol, ultrasonically cleaned for 30 minutes, and then air-dried at room temperature; take two pieces of about 2cm silica gel tube, heat to soften them, and put them into the two ends of the column tube while they are softened. Fix the silicone tube and the column tube with the membrane, mark the filling direction, and seal the bottom of the column tube with tape to prepare for the filling of the whole column mixture;

[0030] 2) Preparation of MOFs suspension:

[0031] Add 2mmol of chromium nitrate nonahydrate, 2mmol of terephthalic acid, 2mmol of 40% hydrofluoric acid aqueous solution, 9.6mL of water to the reaction kettle, stir it evenly, seal it, and heat it in a blast drying oven at 220℃. After hours, the reac...

Embodiment 2

[0039] A method for preparing a liquid chromatography monolithic column based on a metal organic framework material includes the following steps:

[0040] 1) Same as Example 1;

[0041] 2) Preparation of MOFs suspension:

[0042] Add 1mmol of aluminum chloride hexahydrate, 1.67mmol of 2-aminoterephthalic acid, 15mL of N,N-dimethylformamide to the reaction kettle in sequence, stir well and seal, and heat in a 130℃ blast drying oven for 3 day. After the reaction kettle was cooled, it was centrifuged to obtain a light yellow solid, which was washed three times with N,N-dimethylformamide and once with ethanol. The obtained solid was vacuum dried at 150°C for 12 hours. Disperse 50 mg of the solid powder in 5 mL of N,N-dimethylformamide, and ultrasonically obtain a uniform MOFs suspension;

[0043] 3) Same as Example 1;

[0044] 4) Same as Example 1;

[0045] 5) Same as Example 1.

Embodiment 3

[0047] A method for preparing a liquid chromatography monolithic column based on a metal organic framework material includes the following steps:

[0048] 1) Same as Example 1;

[0049] 2) Preparation of MOFs suspension:

[0050] Add 5mmol of iron powder, 3.35mmol of trimesic acid, 10mmol of 40% hydrofluoric acid aqueous solution, 3mmol of 65% concentrated nitric acid, 25mL of water to the reaction kettle in turn, stir well, seal, and place at 150℃ for air drying Heat in the box for 12 hours. After the reaction kettle is cooled, it is washed with water and centrifuged to obtain a light orange solid. The solid was soaked in hot water at 80°C for 5 hours, and then soaked in hot ethanol at 60°C for 3 hours until the filtrate was colorless to obtain a purified MOF material. The obtained solid was vacuum dried at 150°C for 12 hours, and 50 mg of the solid powder was taken Disperse in 5mL N,N-dimethylformamide and ultrasonically obtain a uniform MOFs suspension;

[0051] 3) Same as Exampl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com