Patents

Literature

587results about "Preparation by OH group elimination" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Synthesis of liquid fuels and chemicals from oxygenated hydrocarbons

ActiveUS20080216391A1Organic compound preparationHydrocarbon from oxygen organic compoundsFuranLiquid fuel

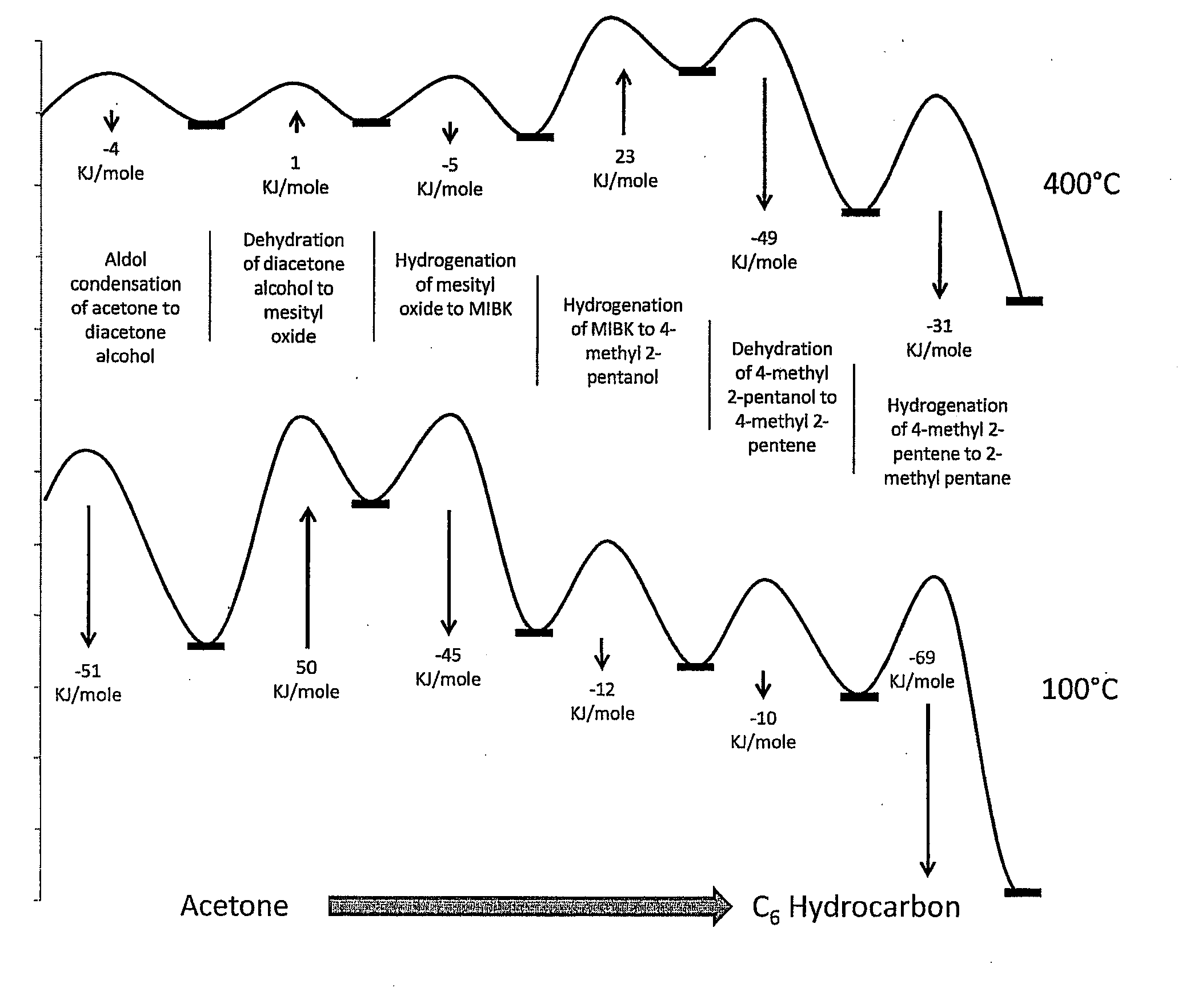

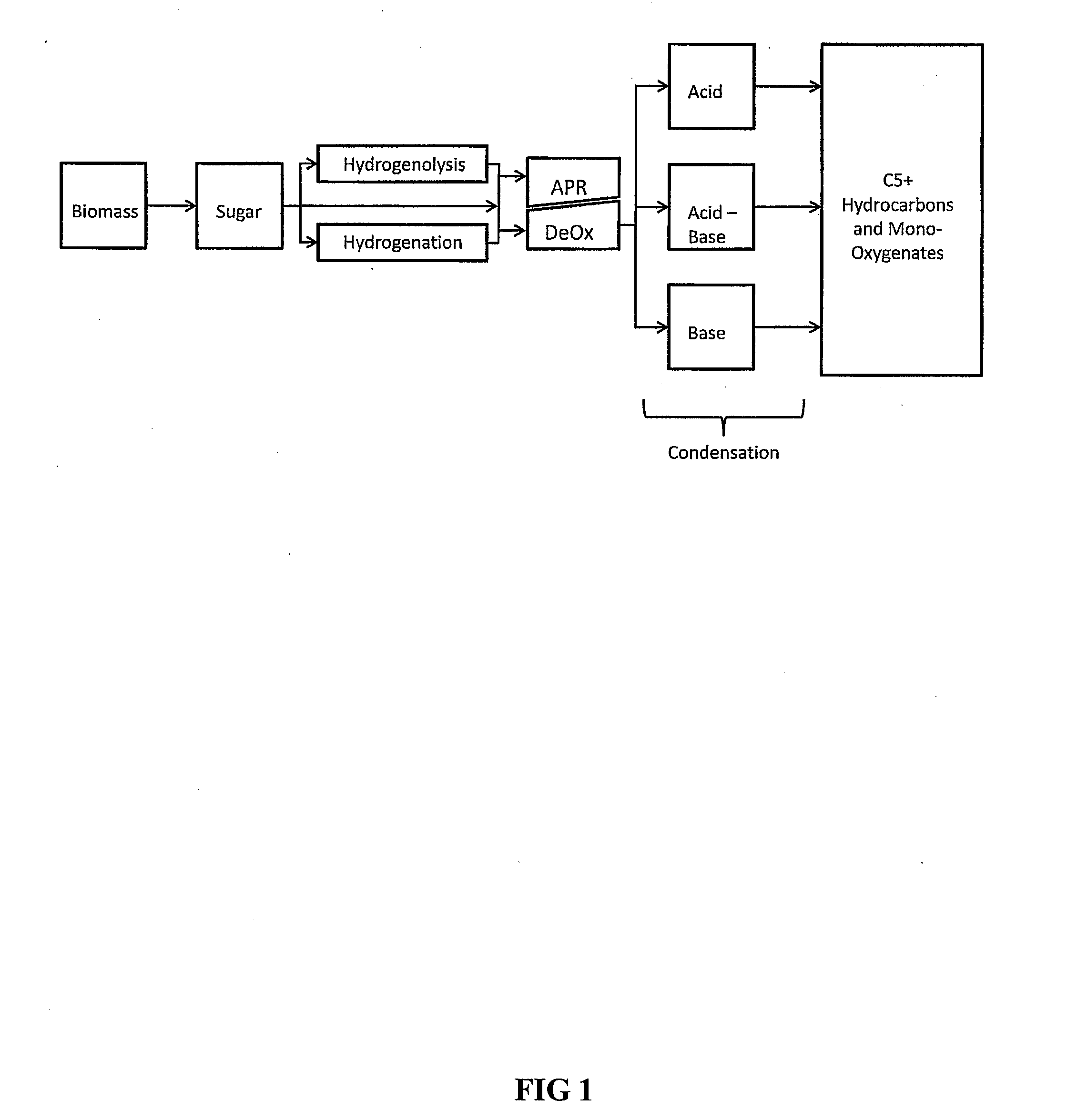

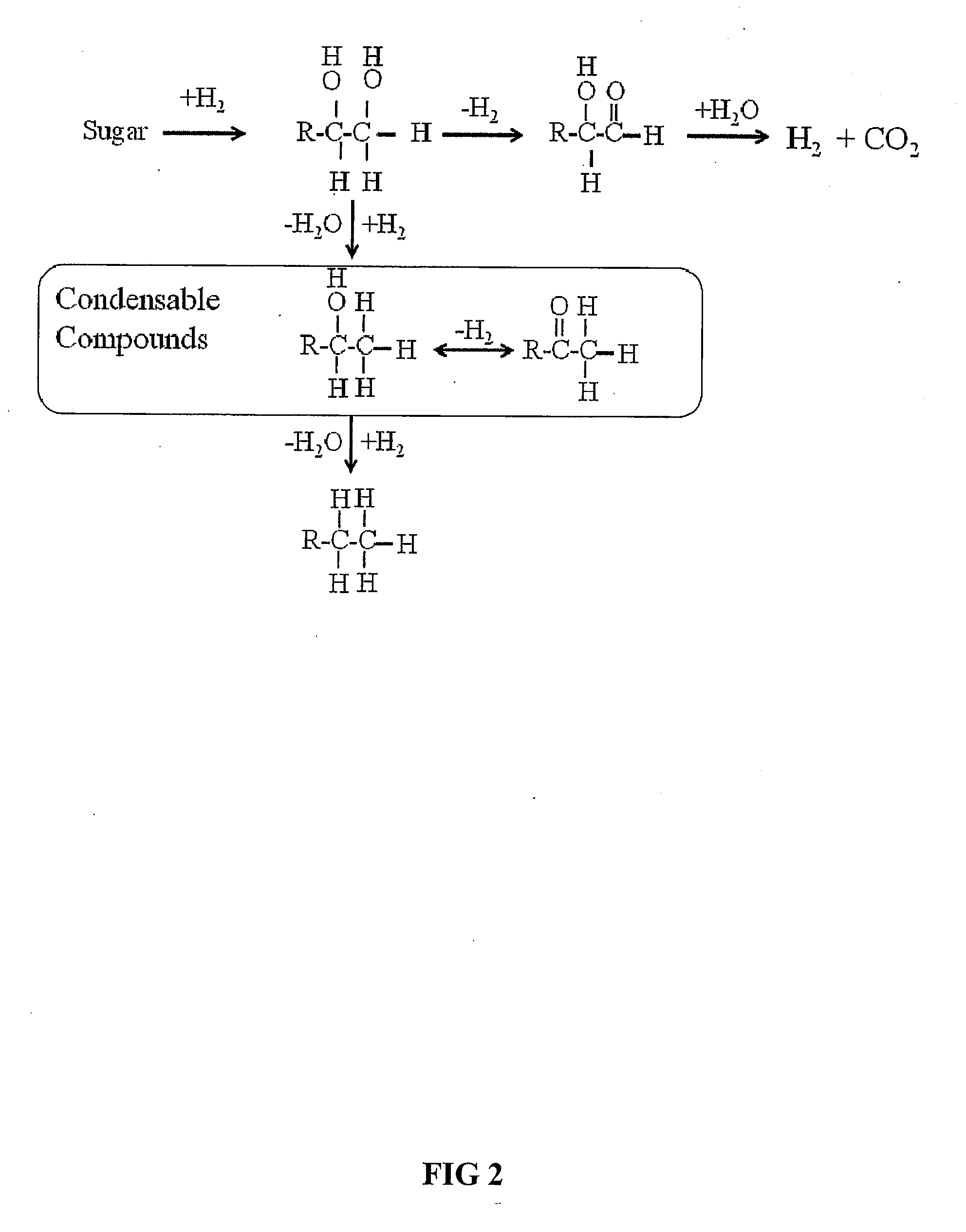

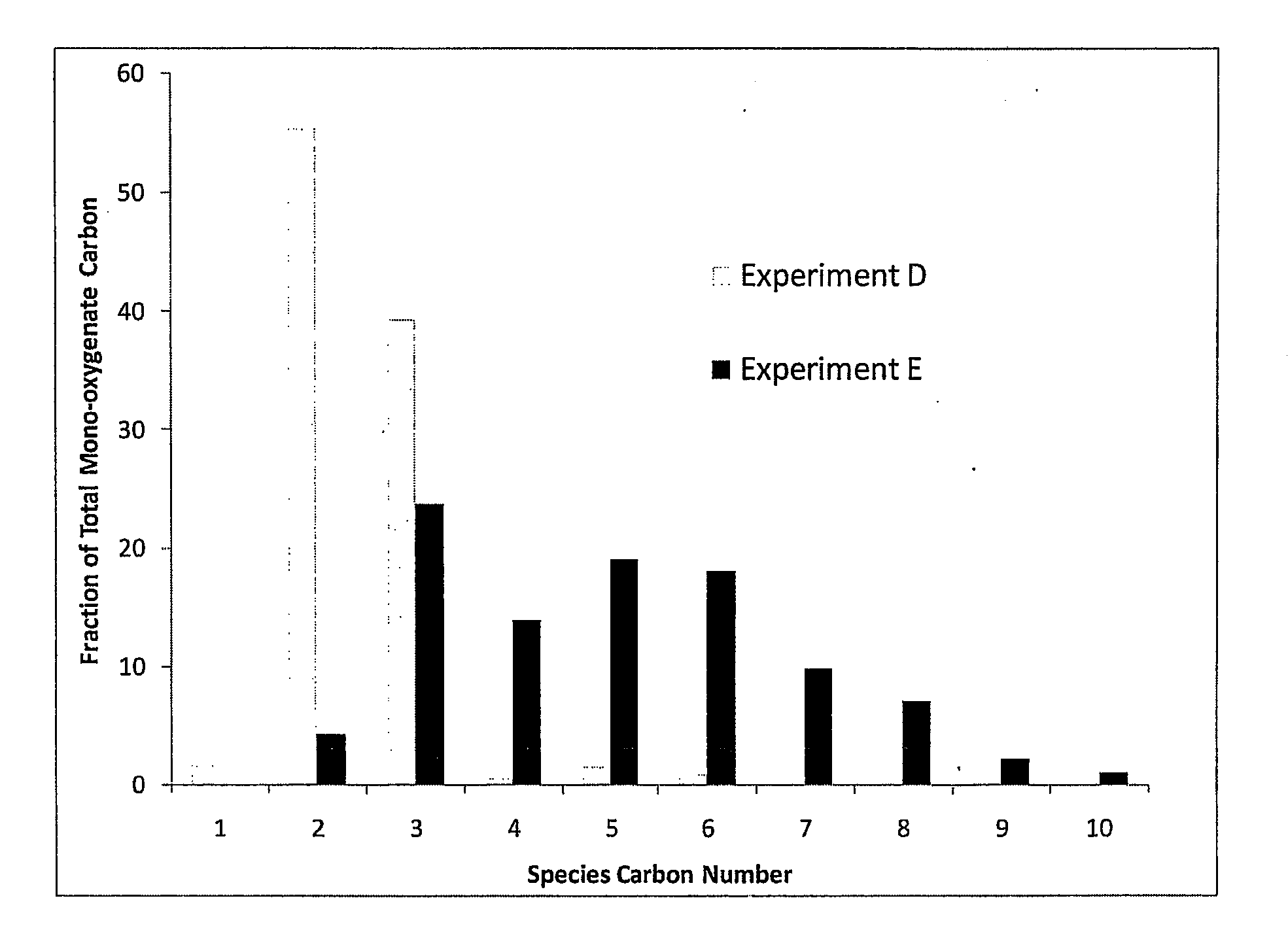

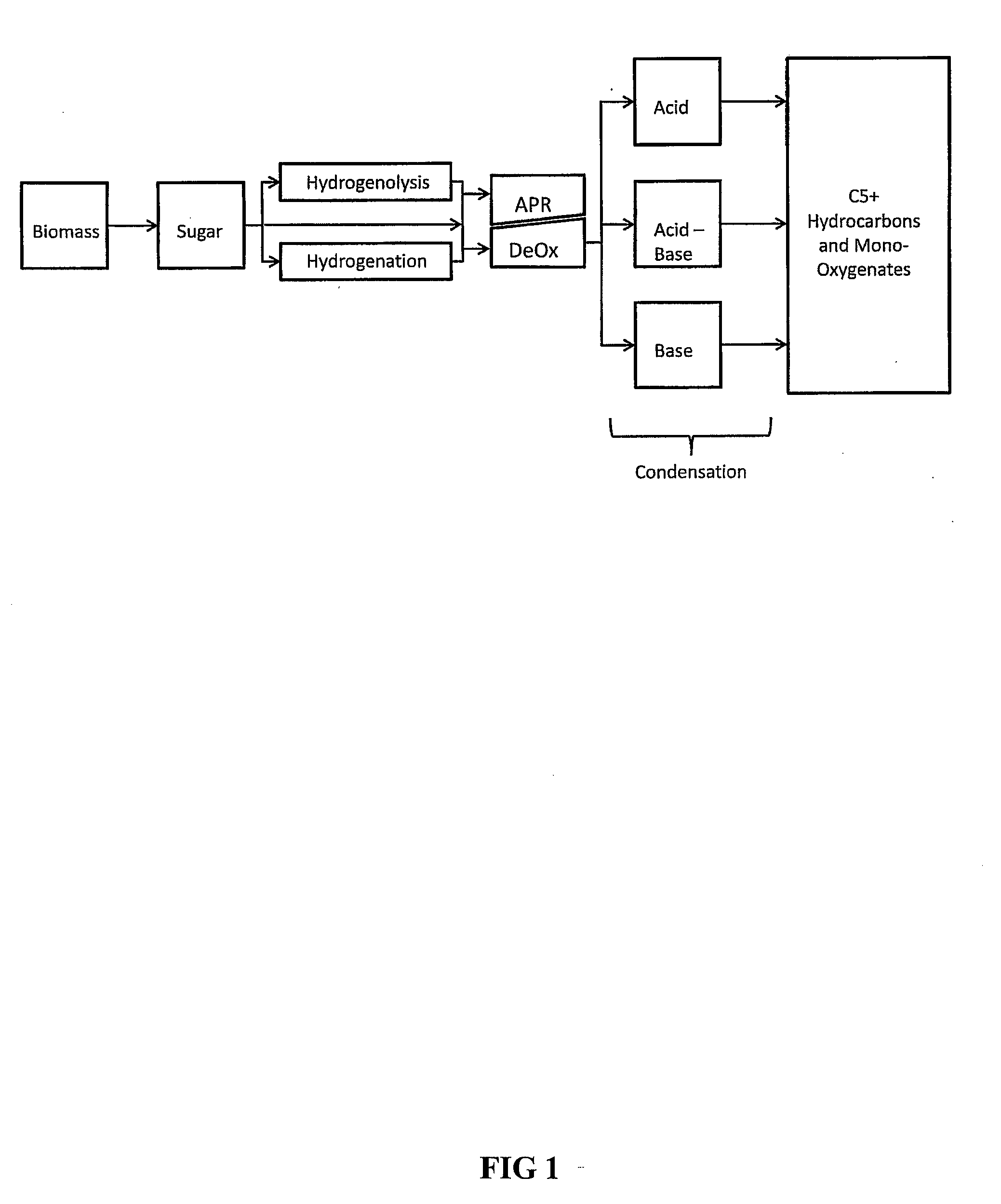

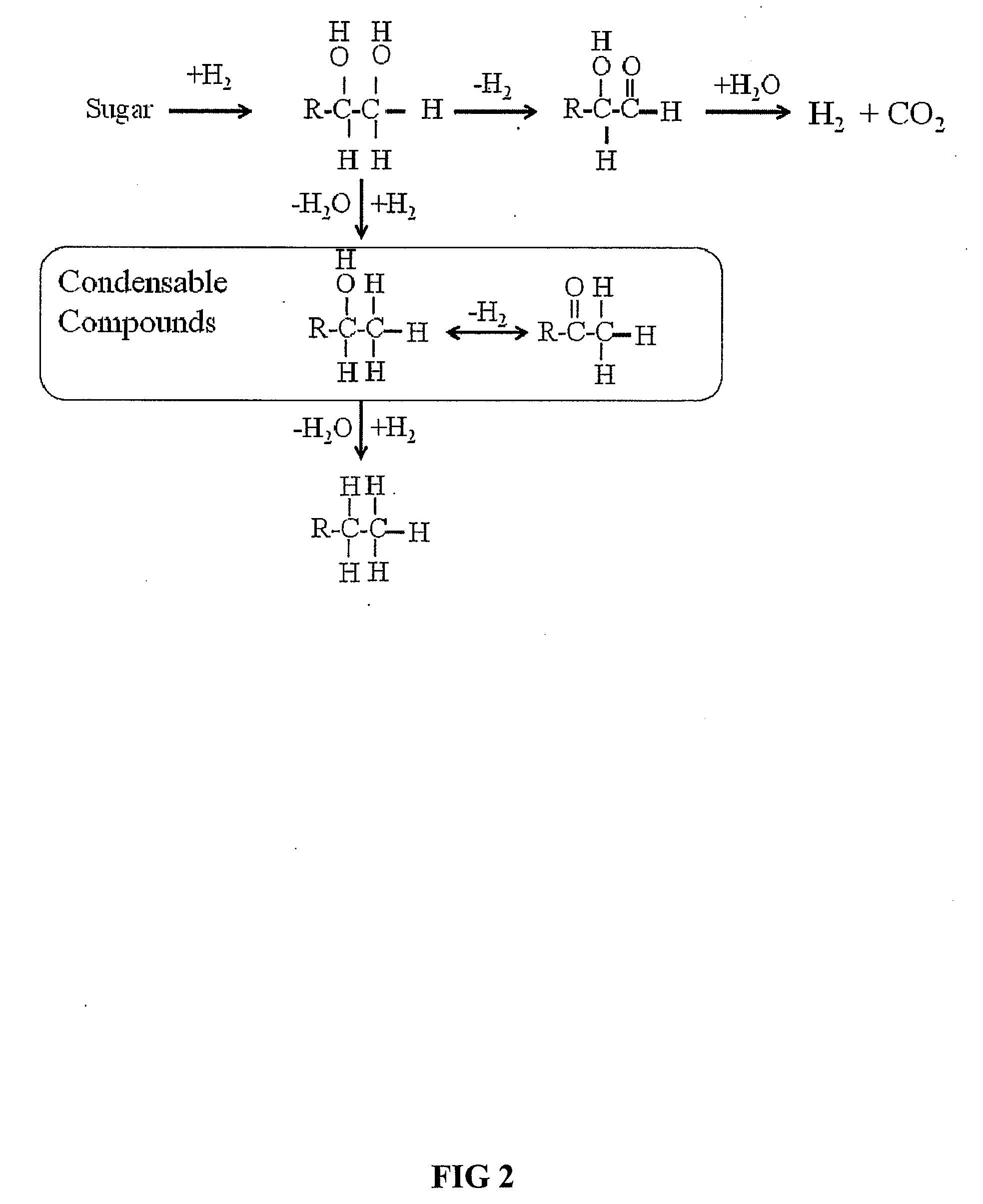

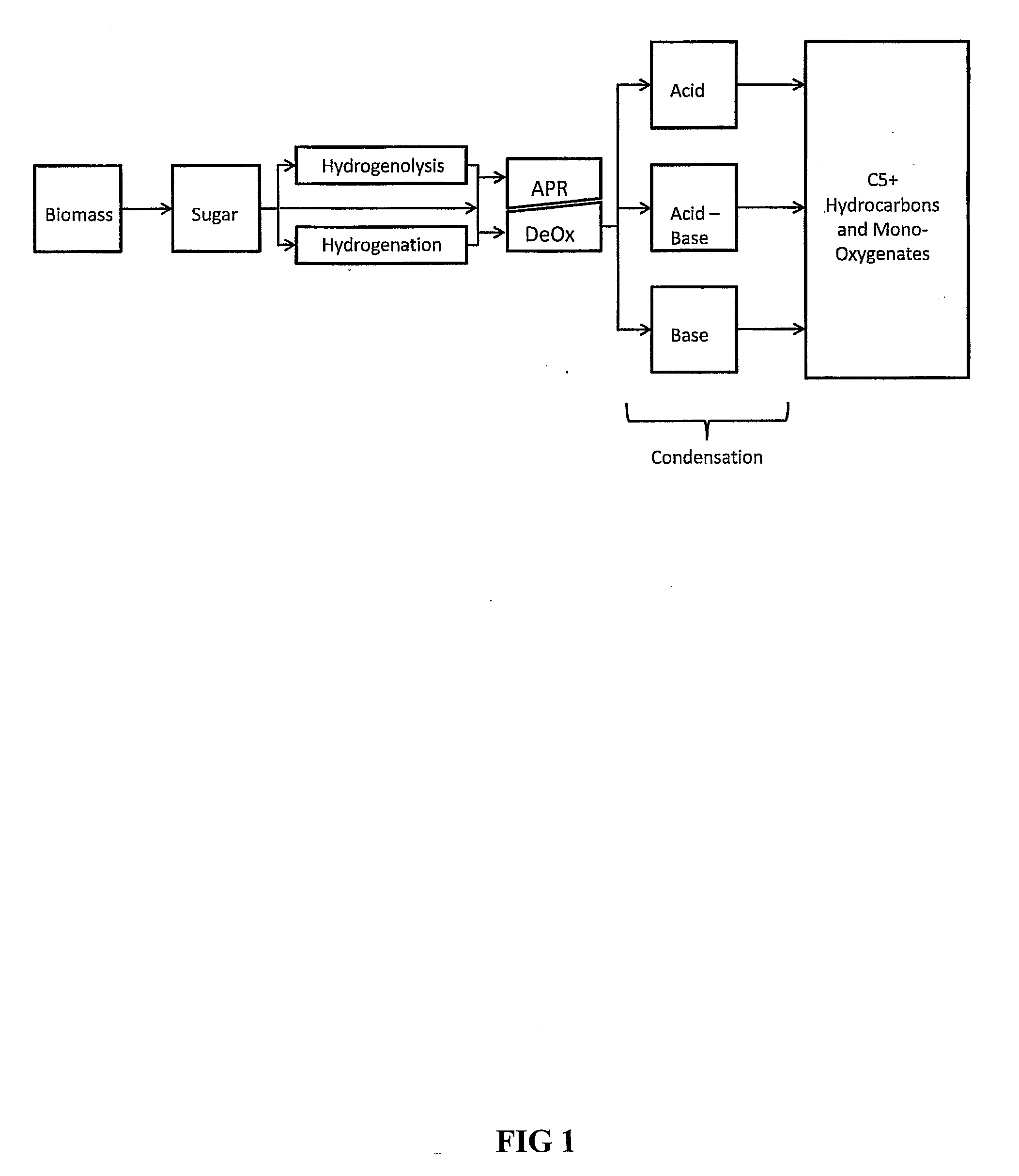

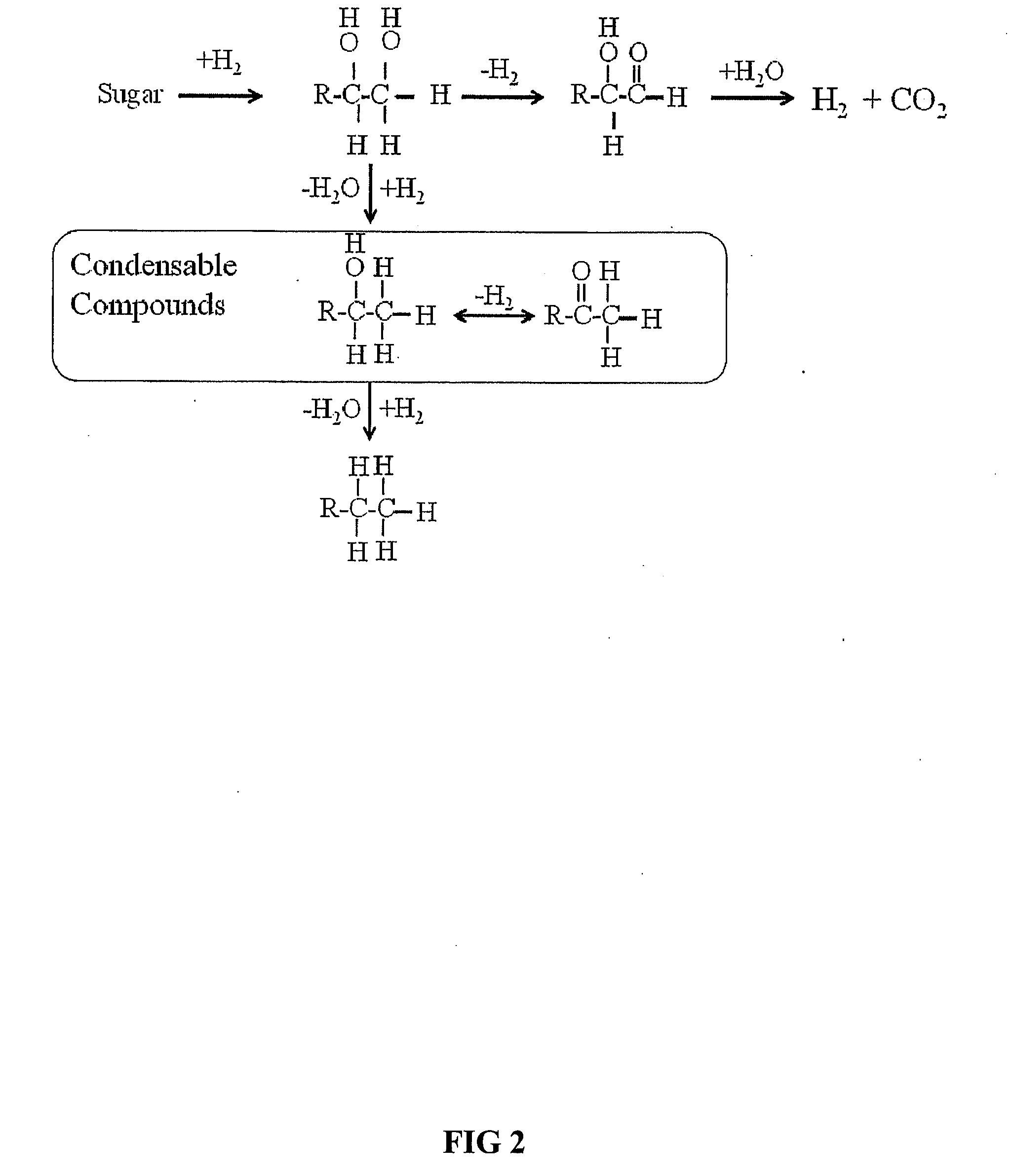

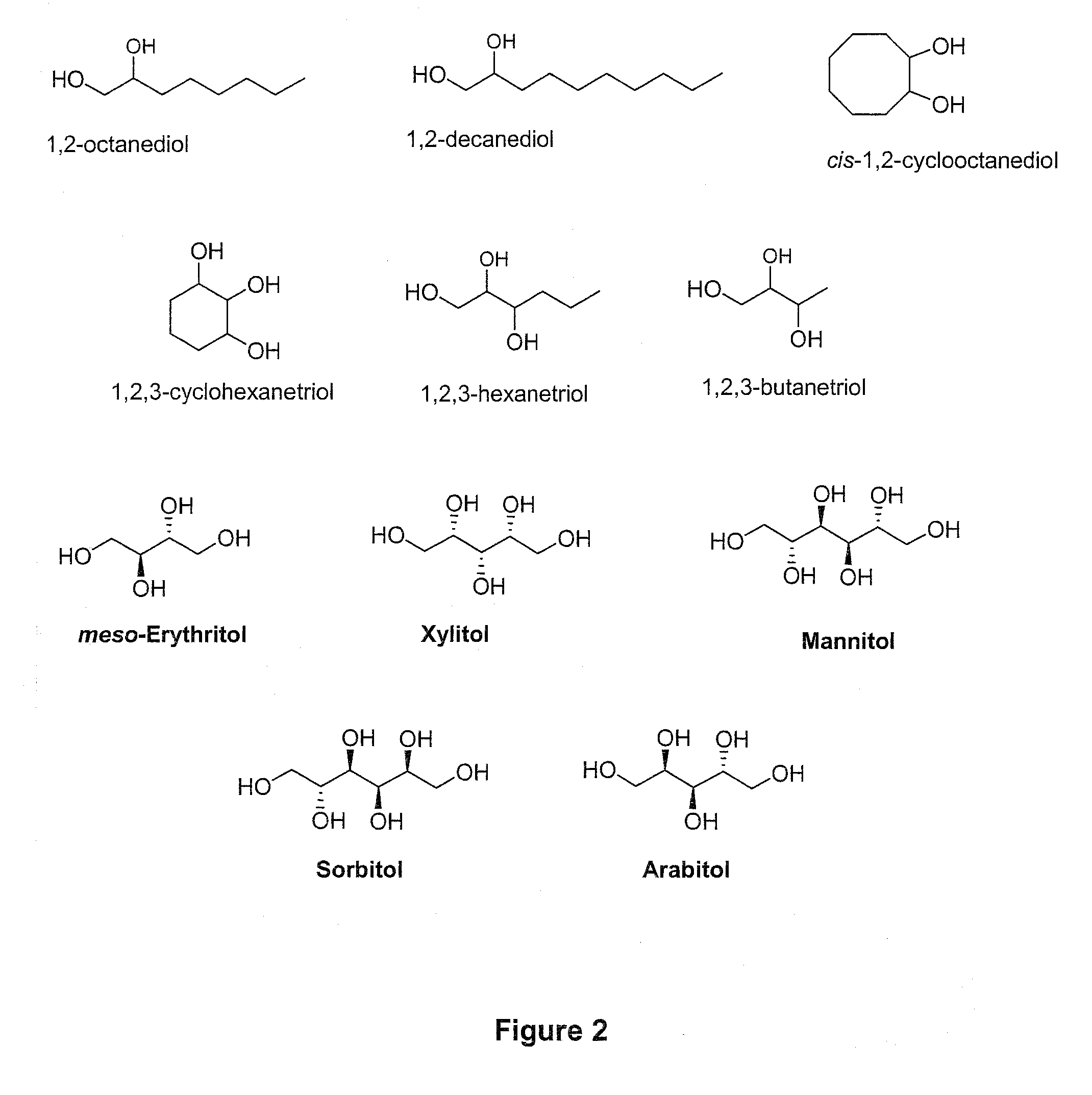

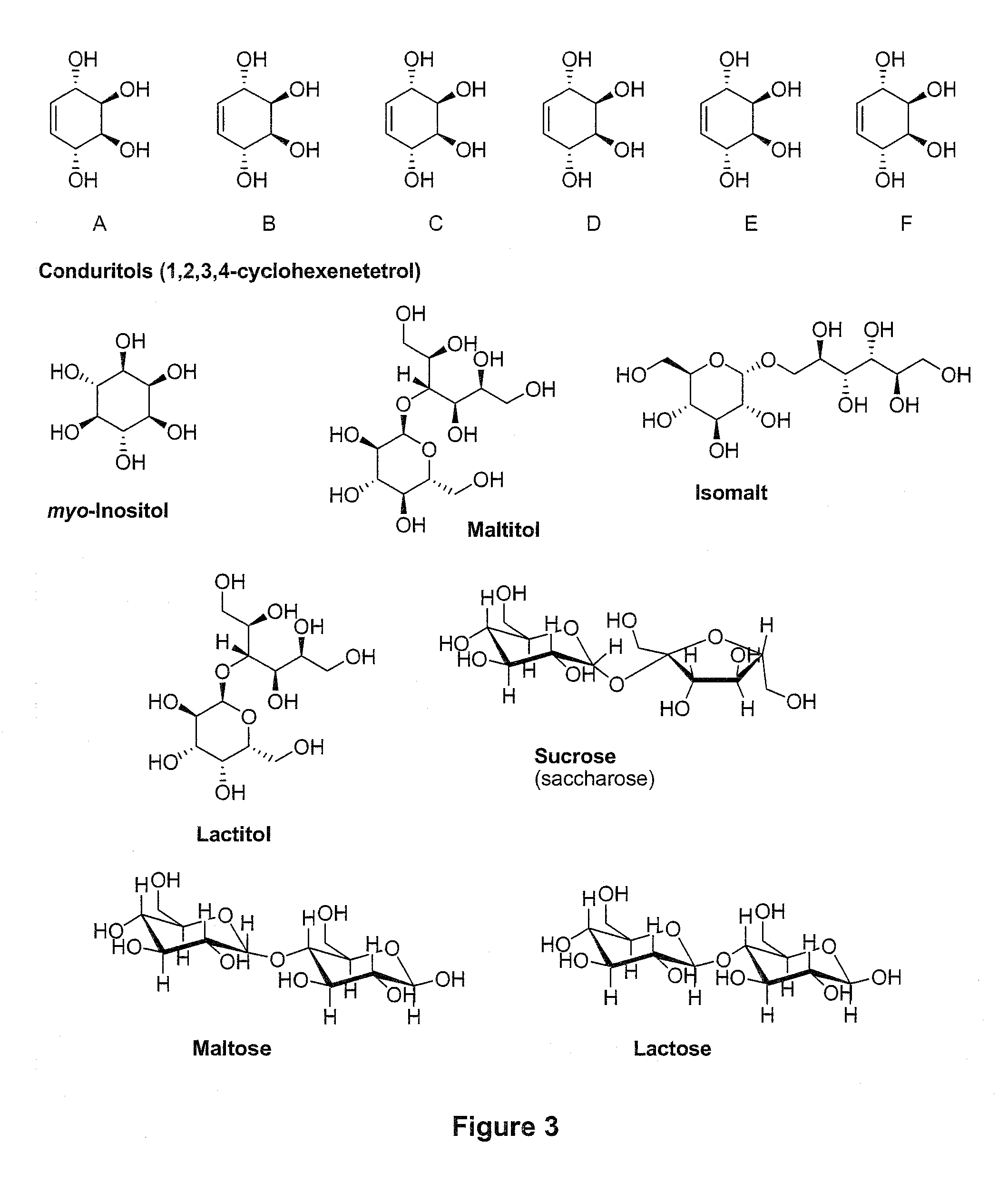

Processes and reactor systems are provided for the conversion of oxygenated hydrocarbons to hydrocarbons, ketones and alcohols useful as liquid fuels, such as gasoline, jet fuel or diesel fuel, and industrial chemicals. The process involves the conversion of mono-oxygenated hydrocarbons, such as alcohols, ketones, aldehydes, furans, carboxylic acids, diols, triols, and / or other polyols, to C4+ hydrocarbons, alcohols and / or ketones, by condensation. The oxygenated hydrocarbons may originate from any source, but are preferably derived from biomass.

Owner:VIRENT

Synthesis of liquid fuels and chemicals from oxygenated hydrocarbons

ActiveUS20080300435A1Oxygen-containing compound preparationLiquid hydrocarbon mixture productionFuranLiquid fuel

Processes and reactor systems are provided for the conversion of oxygenated hydrocarbons to hydrocarbons, ketones and alcohols useful as liquid fuels, such as gasoline, jet fuel or diesel fuel, and industrial chemicals. The process involves the conversion of mono-oxygenated hydrocarbons, such as alcohols, ketones, aldehydes, furans, carboxylic acids, diols, triols, and / or other polyols, to C4+ hydrocarbons, alcohols and / or ketones, by condensation. The oxygenated hydrocarbons may originate from any source, but are preferably derived from biomass.

Owner:VIRENT

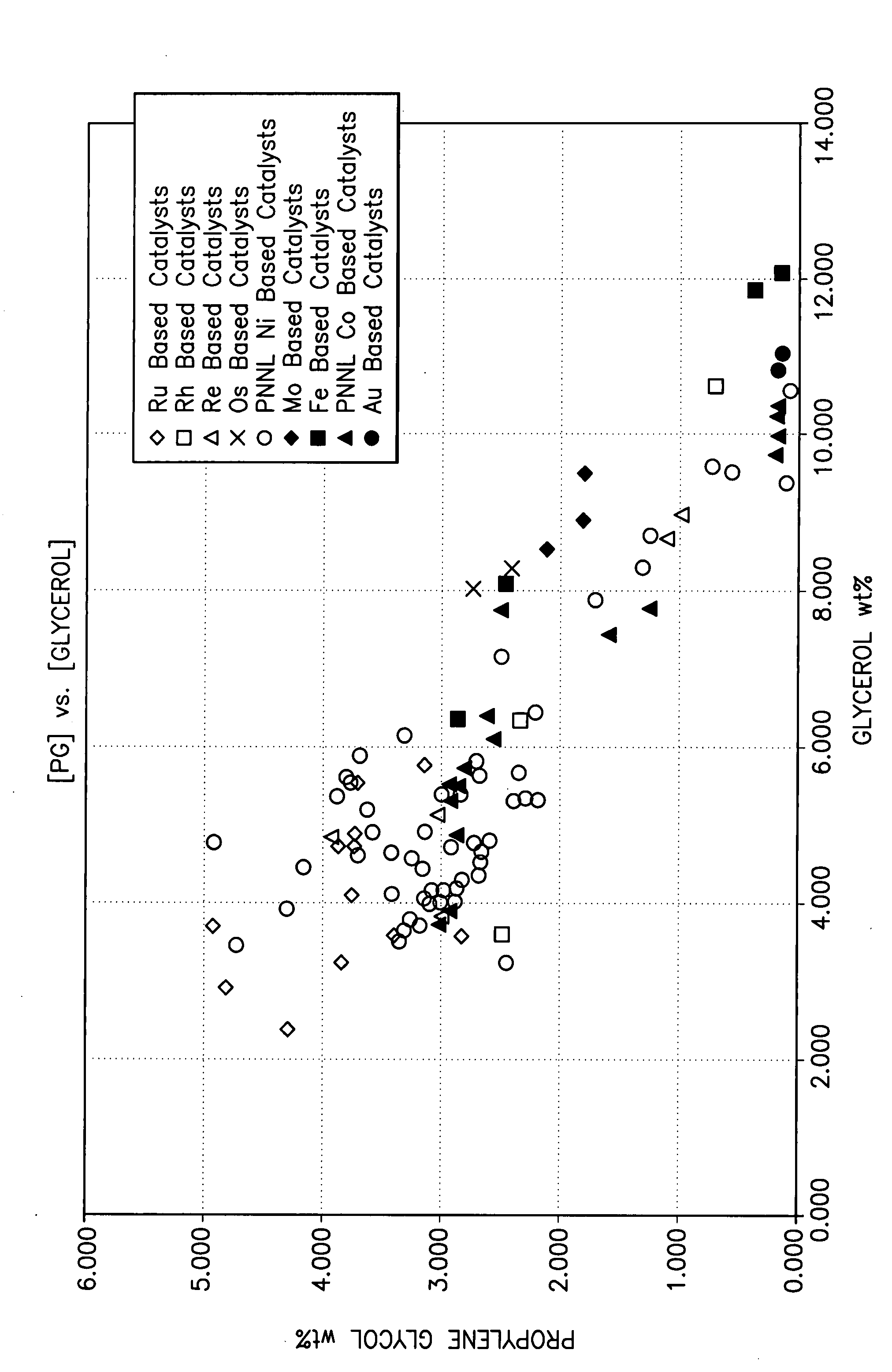

Hydrogenolysis of 6-carbon sugars and other organic compounds

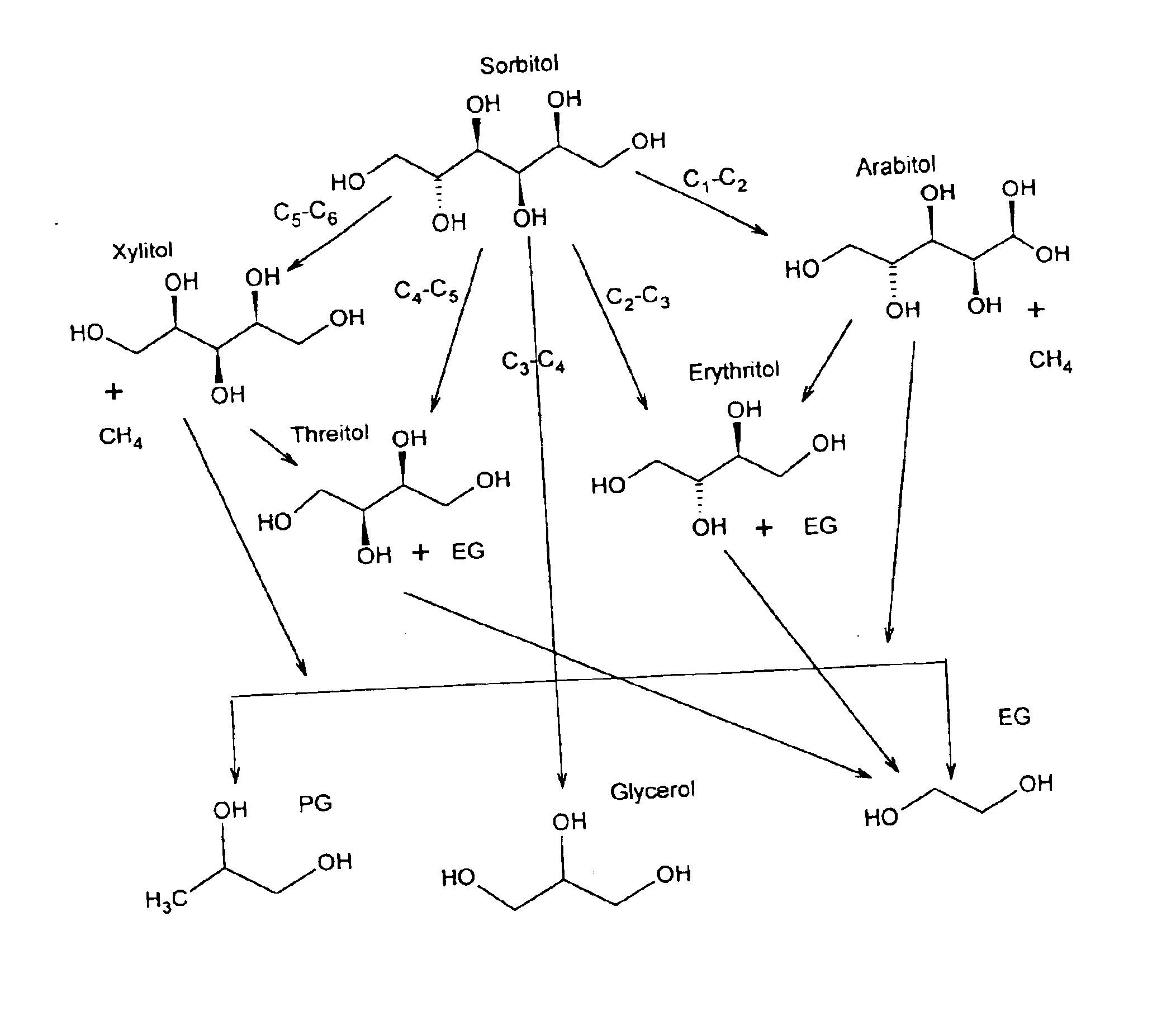

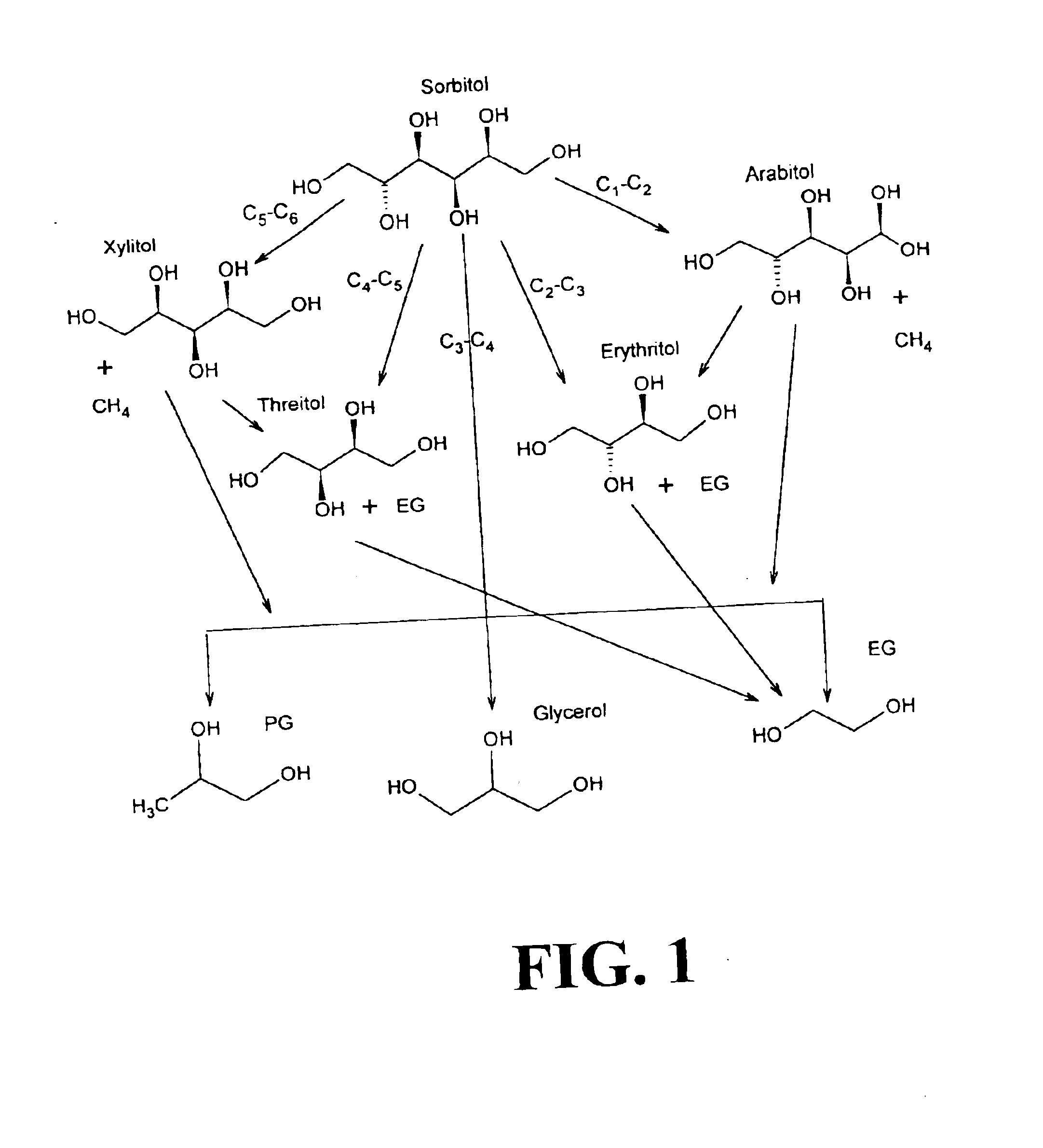

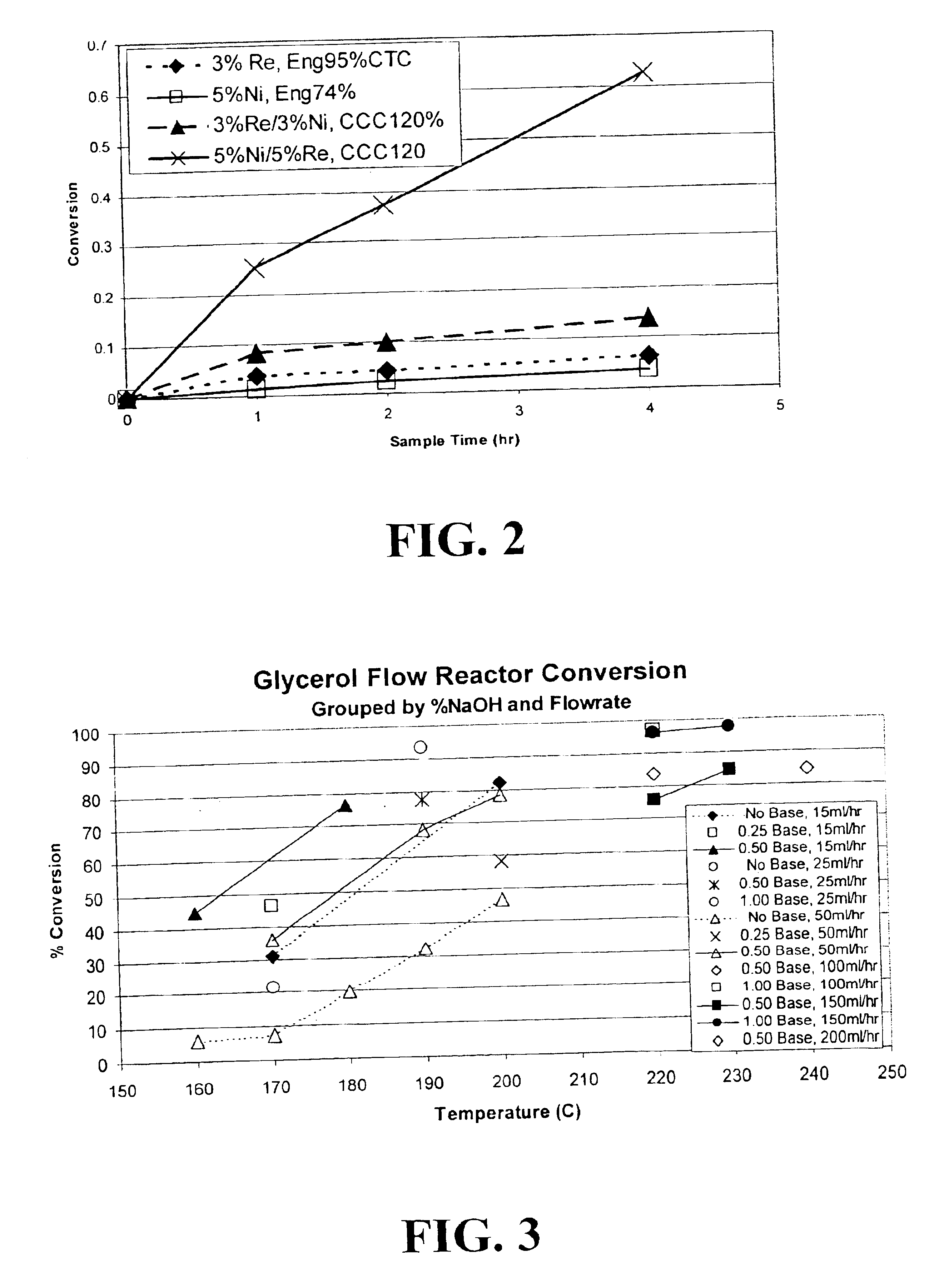

InactiveUS6841085B2High selectivityHigh activityBiocideHydroxy compound active ingredientsHydrogenAlcohol sugars

Methods for hydrogenolysis are described which use a Re-containing multimetallic catalyst for hydrogenolysis of both C—O and C—C bonds. Methods and compositions for reactions of hydrogen over a Re-containing catalyst with compositions containing a 6-carbon sugar, sugar alcohol, or glycerol are described. It has been surprisingly discovered that reaction with hydrogen over a Re-containing multimetallic catalyst resulted in superior conversion and selectivity to desired products such as propylene glycol.

Owner:MICHIGAN STATE UNIV +1

Synthesis of liqiud fuels and chemicals from oxygenated hydrocarbons

ActiveUS20080300434A1Oxygen-containing compound preparationHydrocarbon purification/separationFuranCarboxylic acid

Processes and reactor systems are provided for the conversion of oxygenated hydrocarbons to hydrocarbons, ketones and alcohols useful as liquid fuels, such as gasoline, jet fuel or diesel fuel, and industrial chemicals. The process involves the conversion of mono-oxygenated hydrocarbons, such as alcohols, ketones, aldehydes, furans, carboxylic acids, diols, triols, and / or other polyols, to C4+ hydrocarbons, alcohols and / or ketones, by condensation. The oxygenated hydrocarbons may originate from any source, but are preferably derived from biomass.

Owner:VIRENT

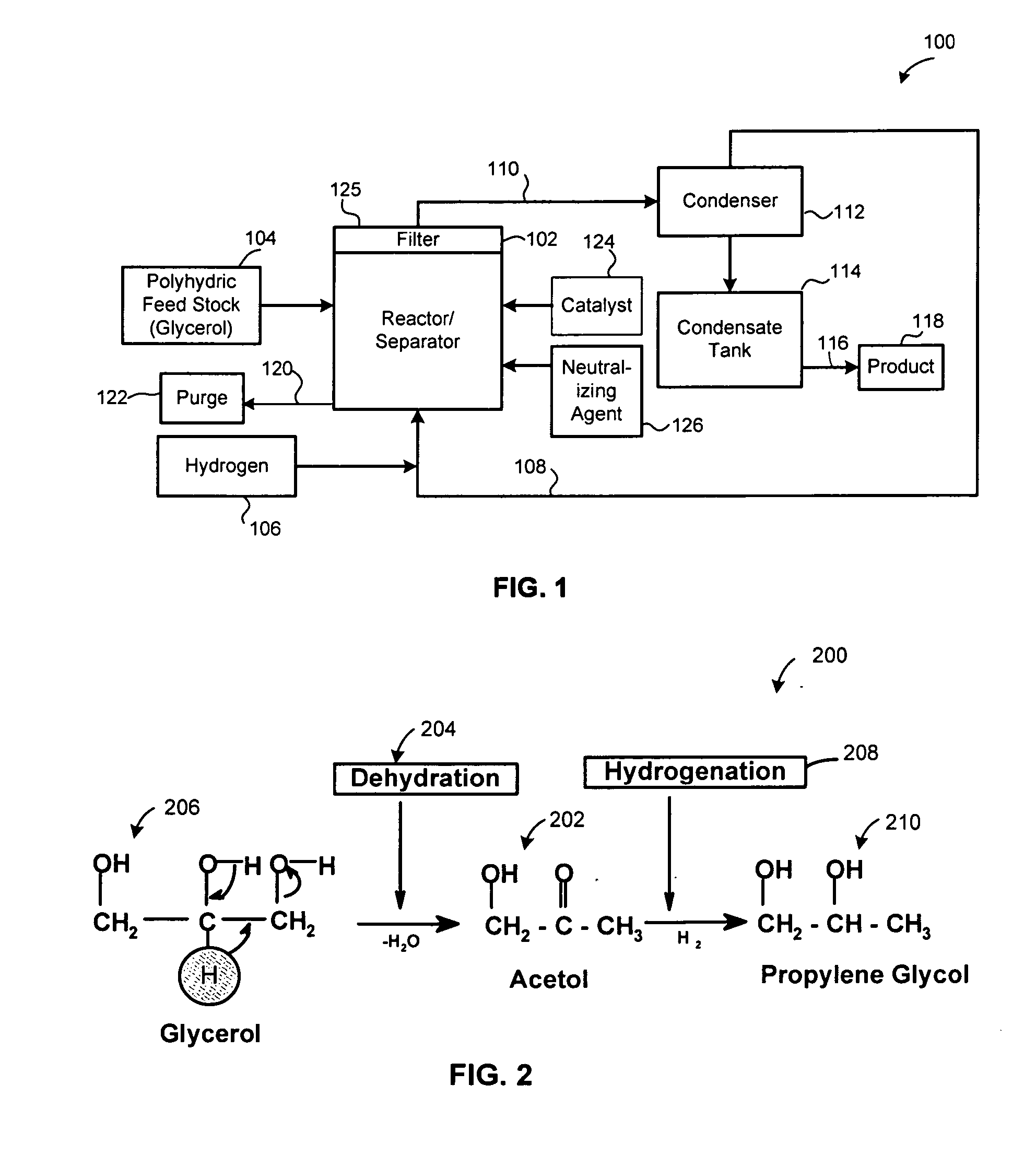

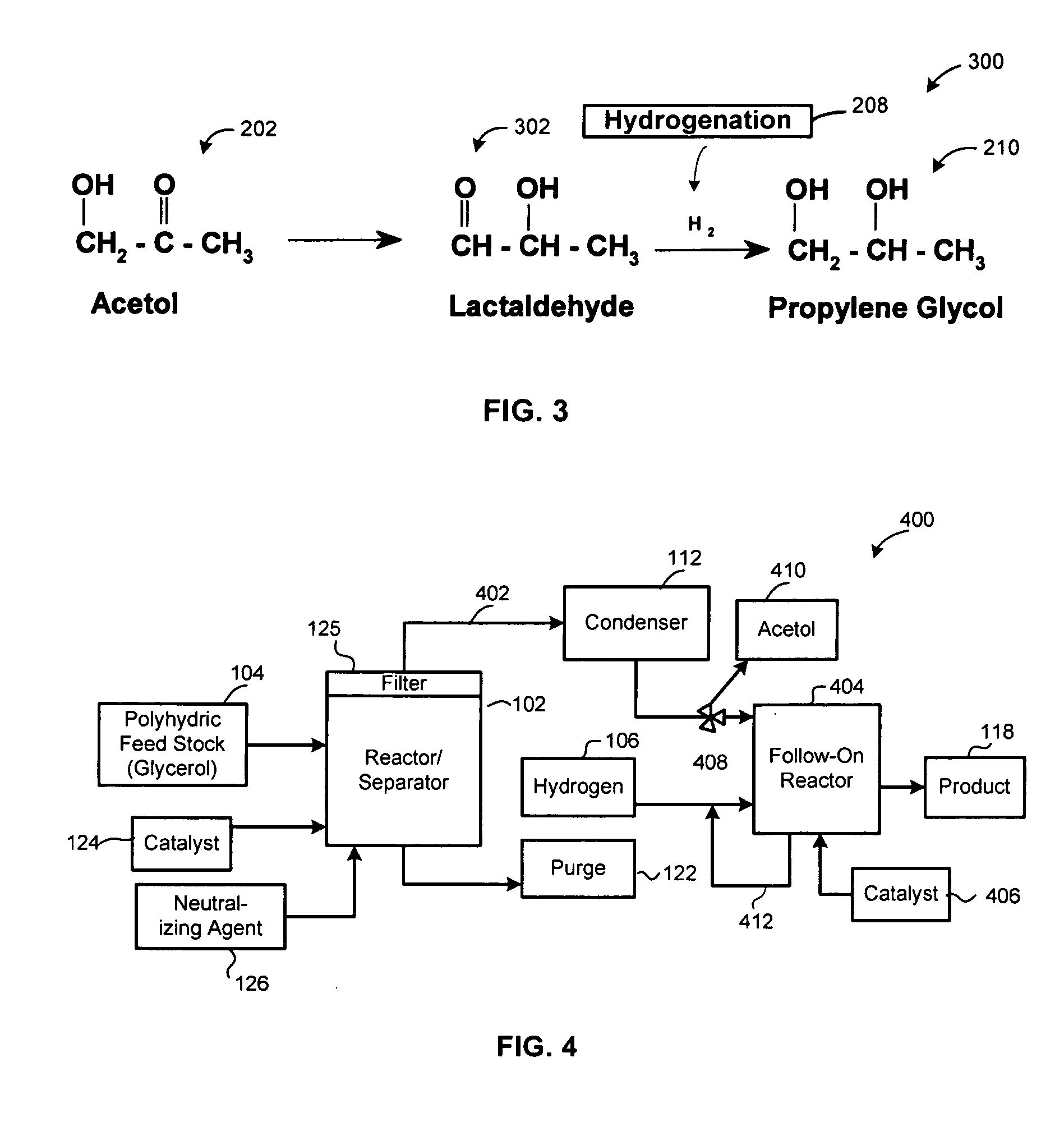

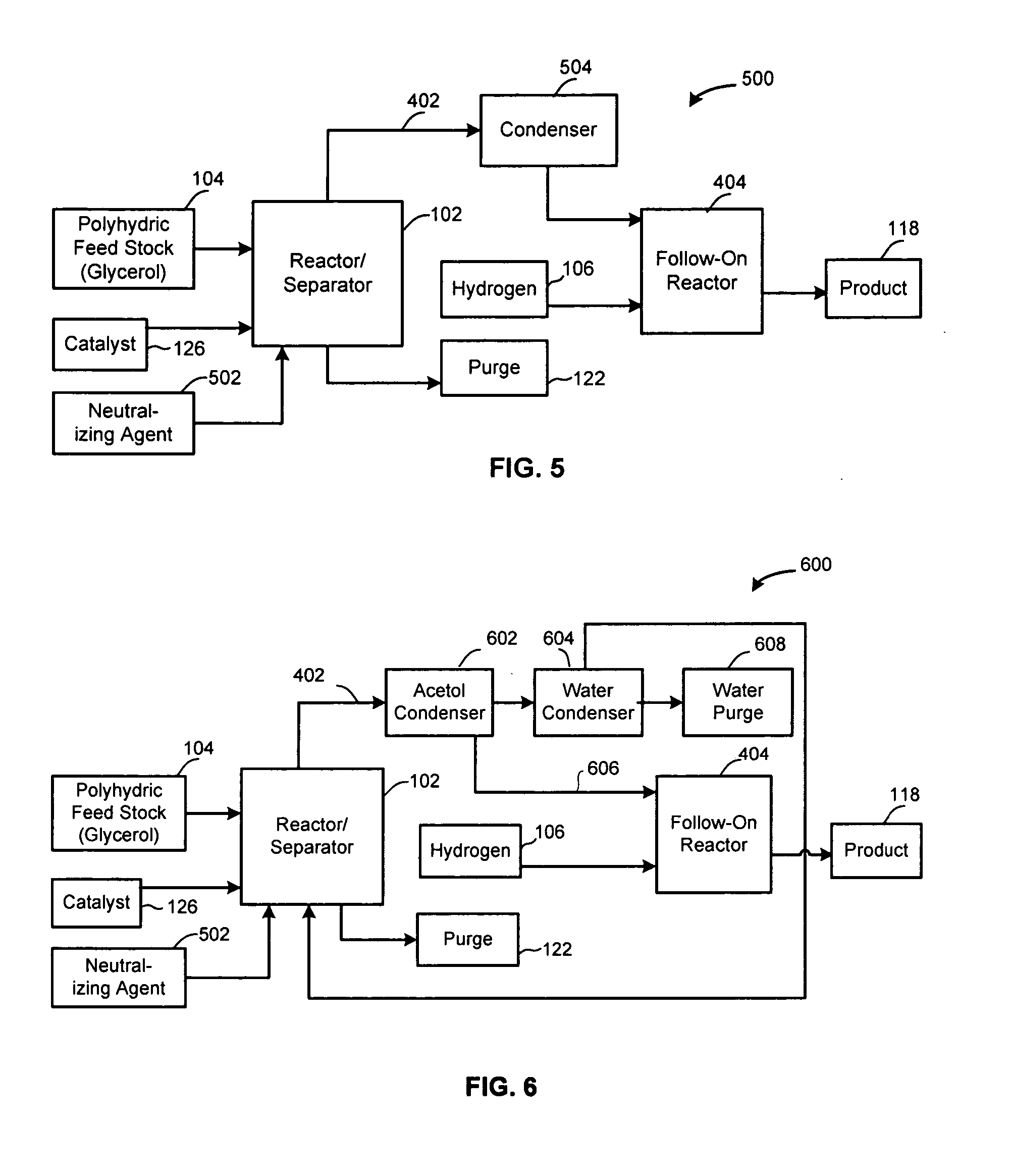

Method of producing lower alcohols from glycerol

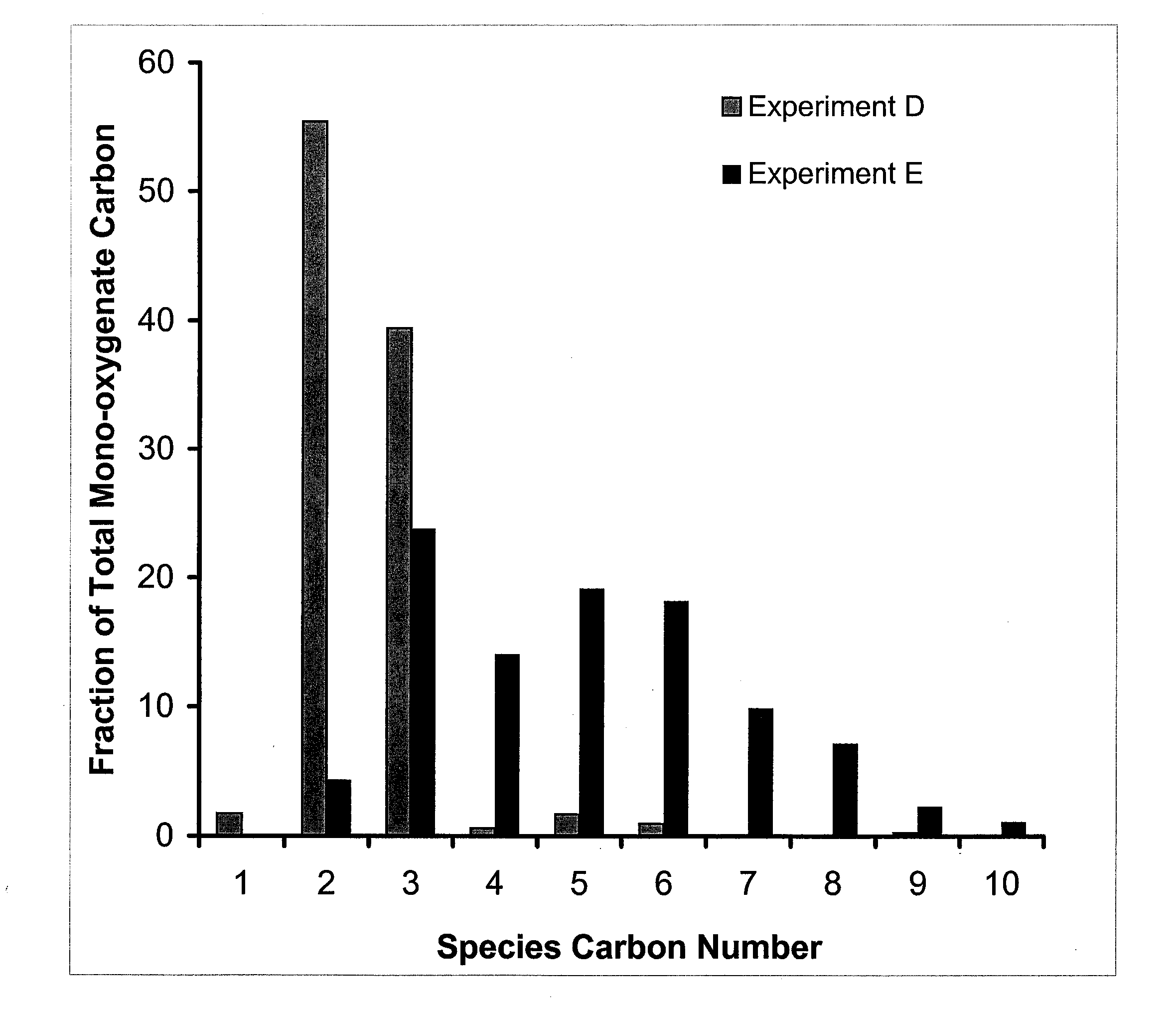

ActiveUS20050244312A1High selectivityOrganic compound preparationOxygen compounds preparation by reductionAlcoholBoiling point

A reactive-separation process converts glycerin into lower alcohols, having boiling points less than 200° C., at high yields. Conversion of natural glycerin to propylene glycol through an acetol intermediate is achieved at temperatures from 150° to 250° C. at a pressure ranging from 1 and 25 bar. The preferred applications of the propylene glycol are as an antifreeze, deicing compound, or anti-icing compound. The preferred catalyst for this process in a copper-chromium powder.

Owner:RENEWABLE ALTERNATIVES LLC +1

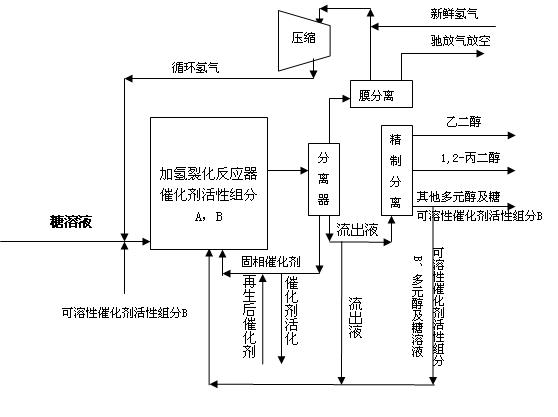

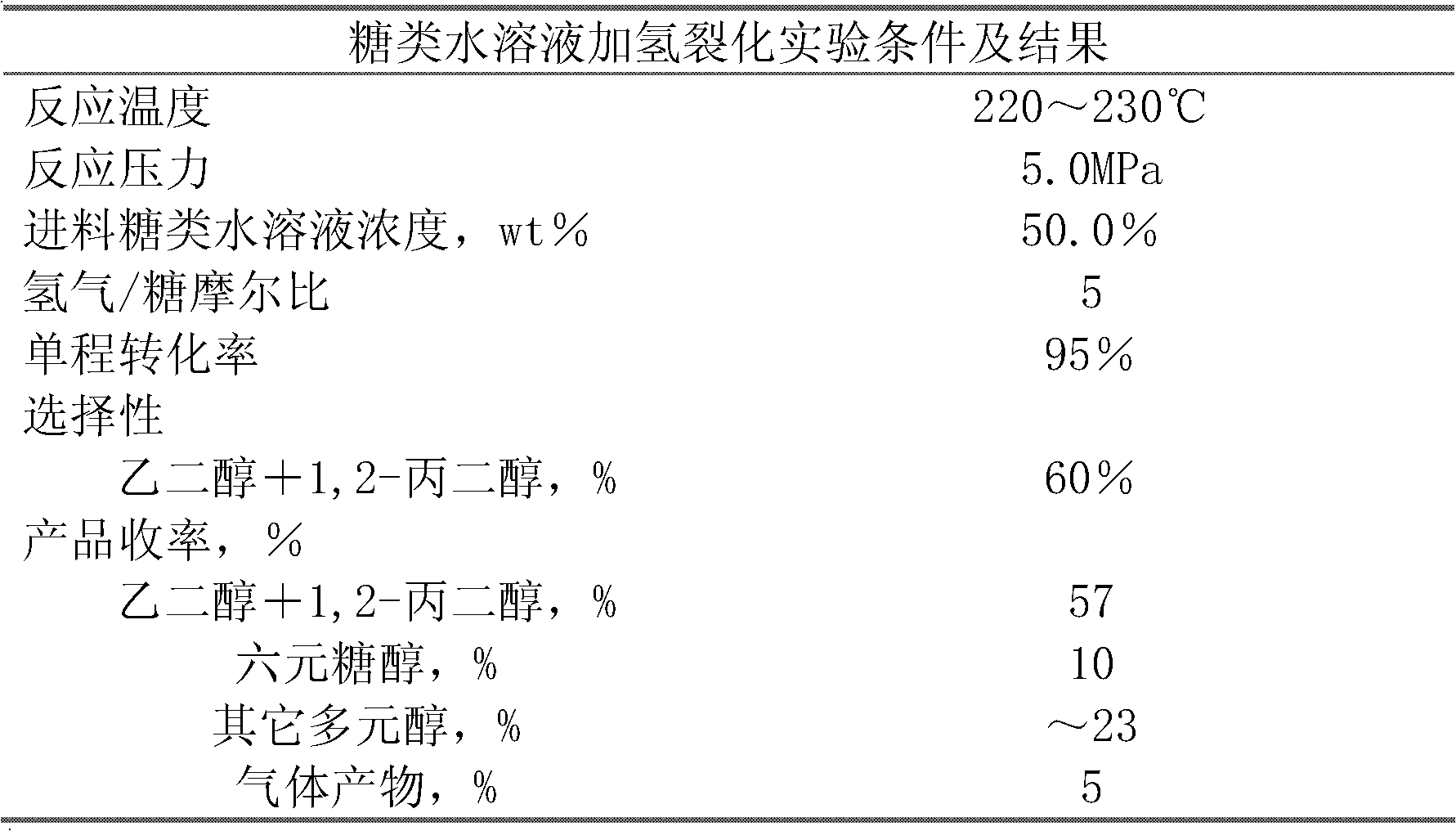

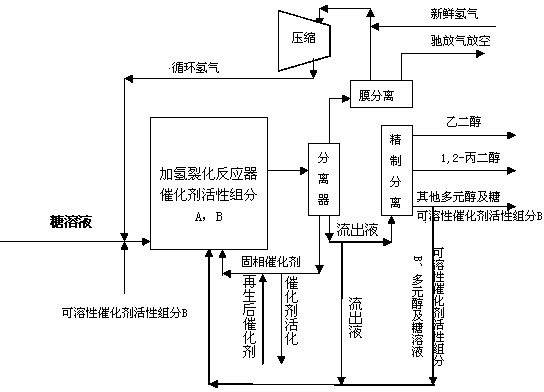

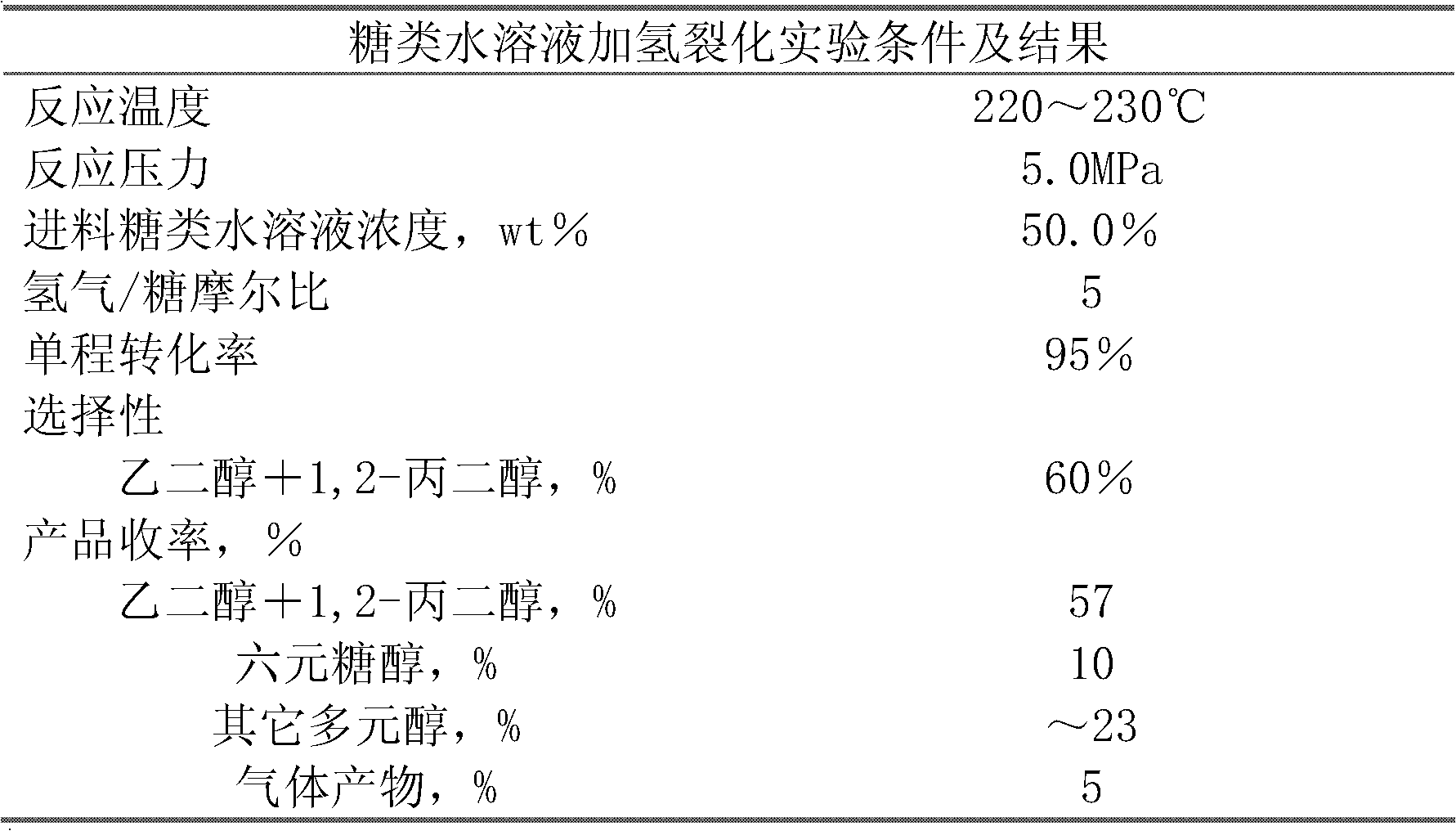

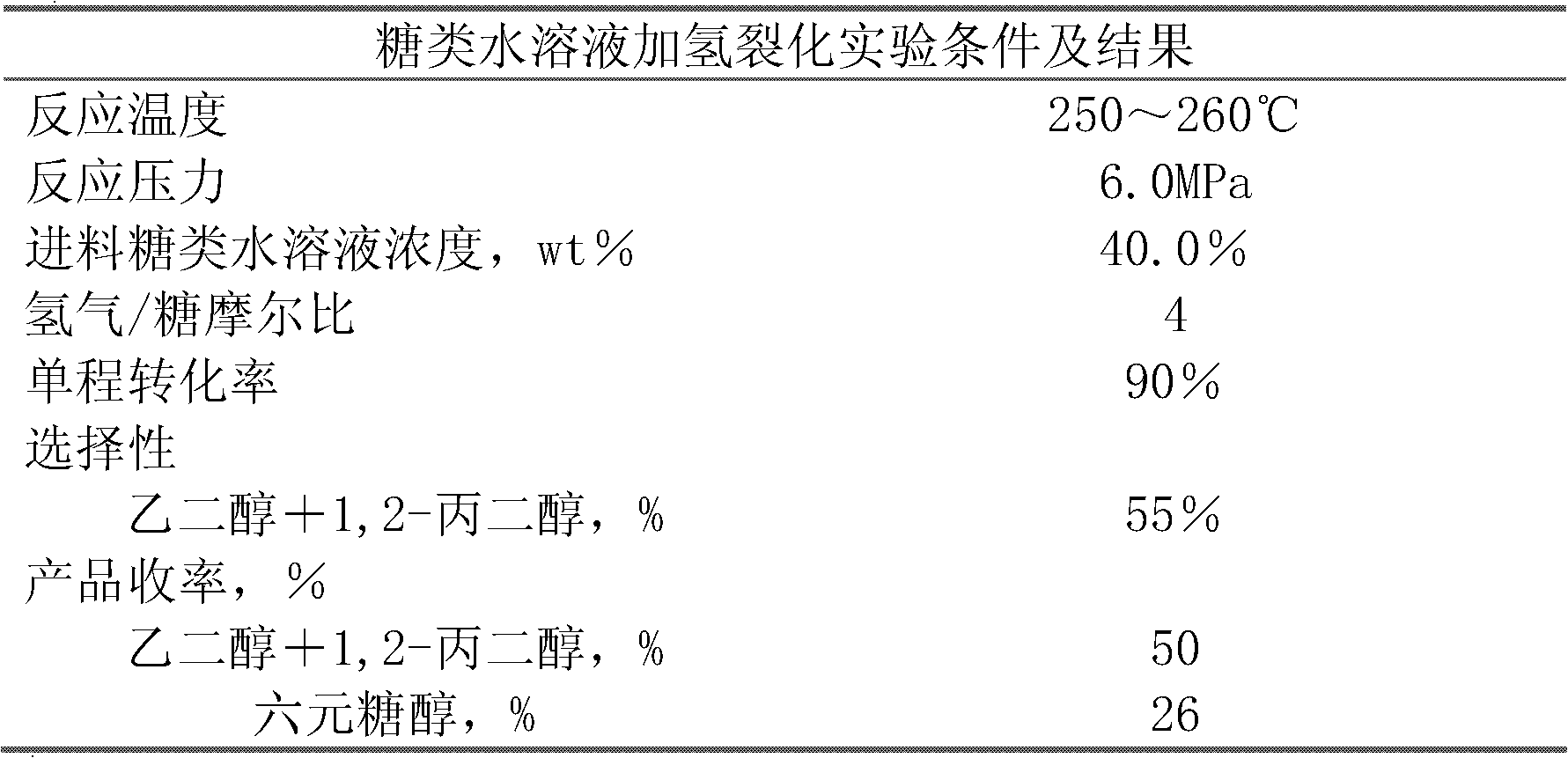

Method for producing ethylene glycol and 1,2-propylene glycol through continuous hydrocrackin of sugars

ActiveCN102643165ARealize continuous inputReduce consumptionOrganic compound preparationPreparation by OH group eliminationGas phaseOligosaccharide

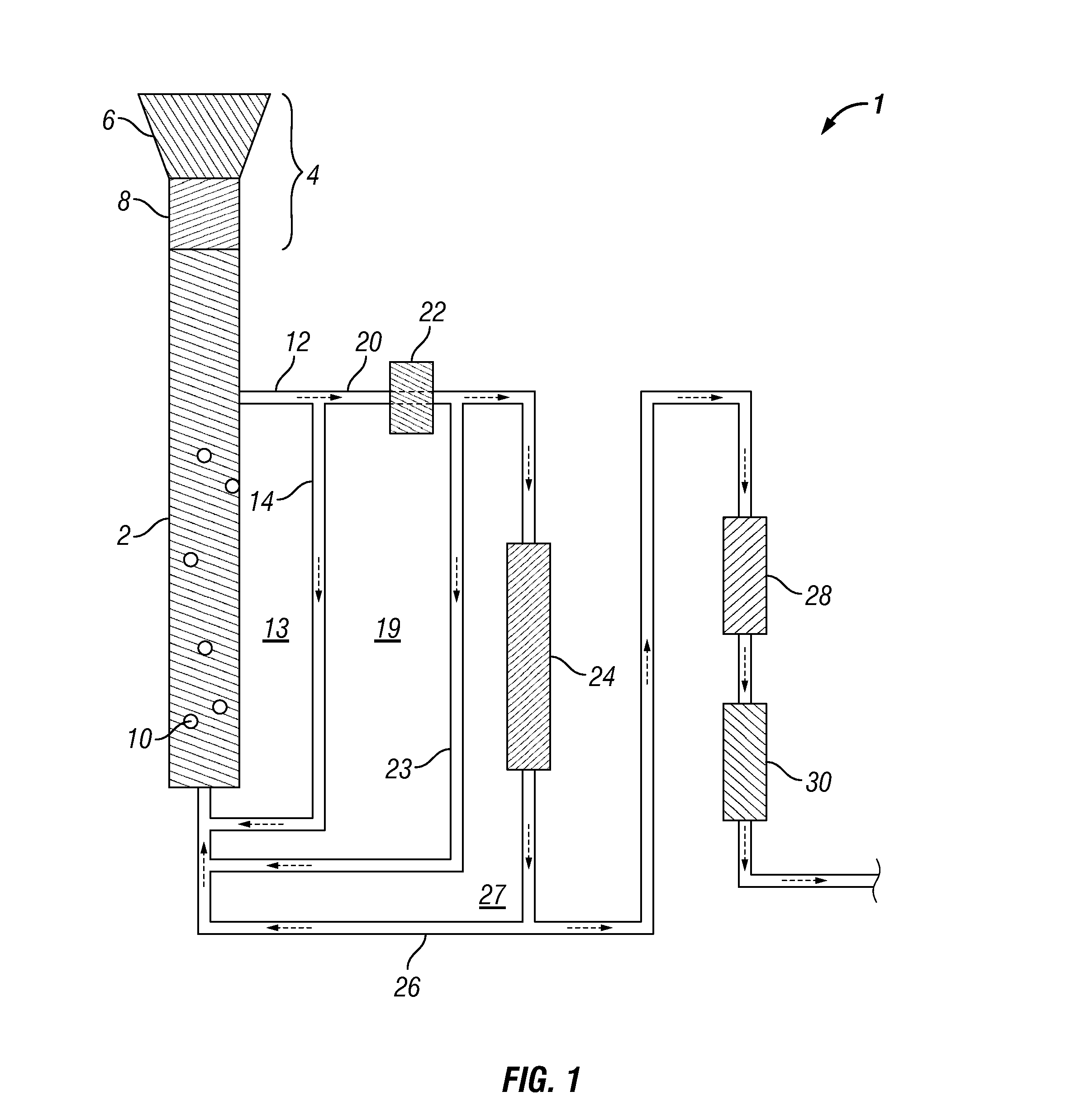

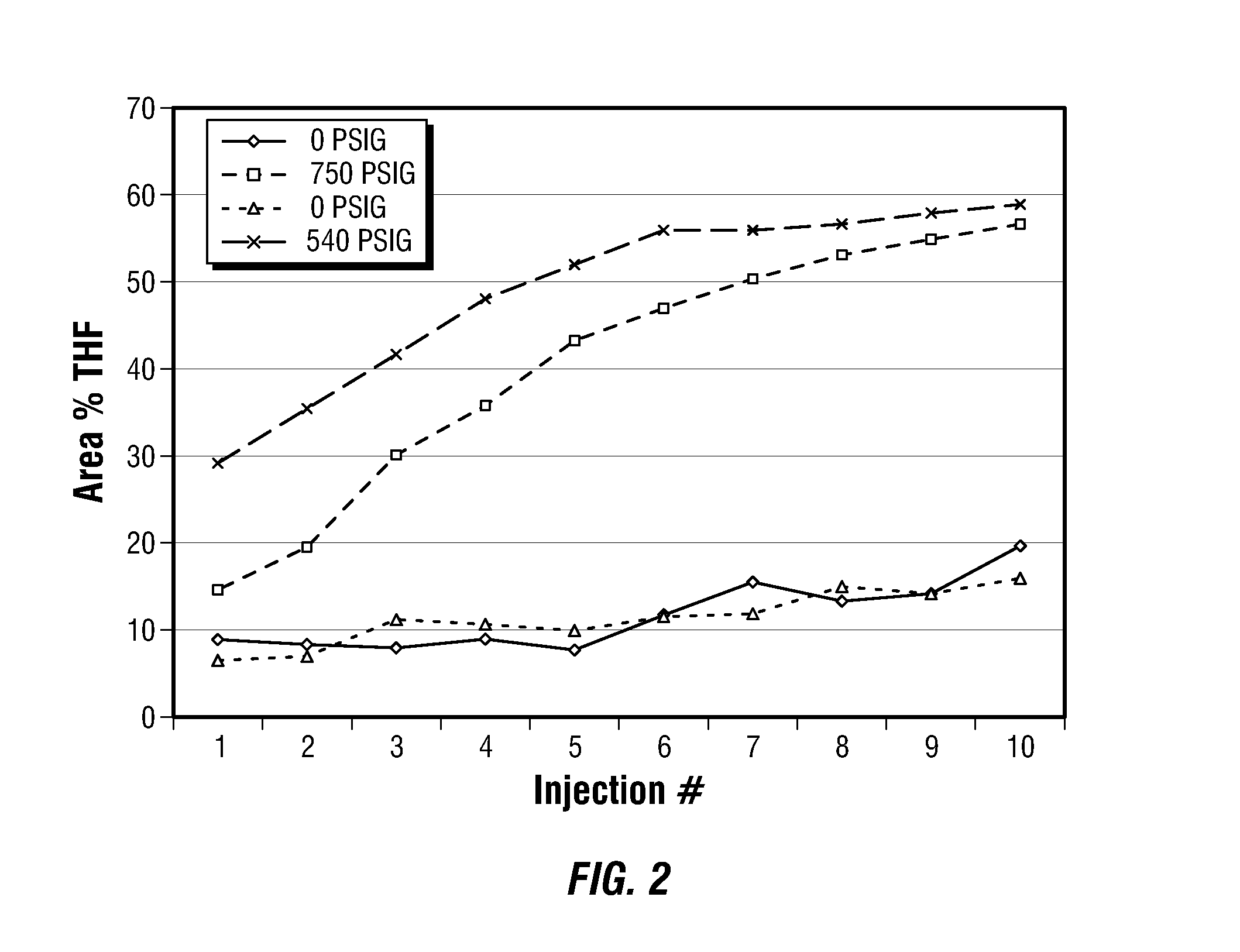

The invention relates to a continuous reaction process flow for producing ethylene glycol and 1, 2-propylene glycol through continuous hydrocrackin of sugars and provides a method for producing the ethylene glycol and the 1,2-propylene glycol through continuous hydrocrackin of sugars. In the process flow, sugars (comprising one or more than two of sugar, glucose, fructose, xylose, soluble xylo-oligosaccharide and starch) are hydrocracked in the presence of a catalyst in a reactor and the hydrocracked product enters a separating system. Hydrogen gas in a gas phase is recycled by separating and recovering; a liquid phase product partially reflows to the reactor and other liquid phase products are refined and separated to form the ethylene glycol, the propylene glycol and other polyhydric alcohols; and concentrated soluble catalyst components in the refined and separated residual component liquid phase are partially returned to the reactor.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

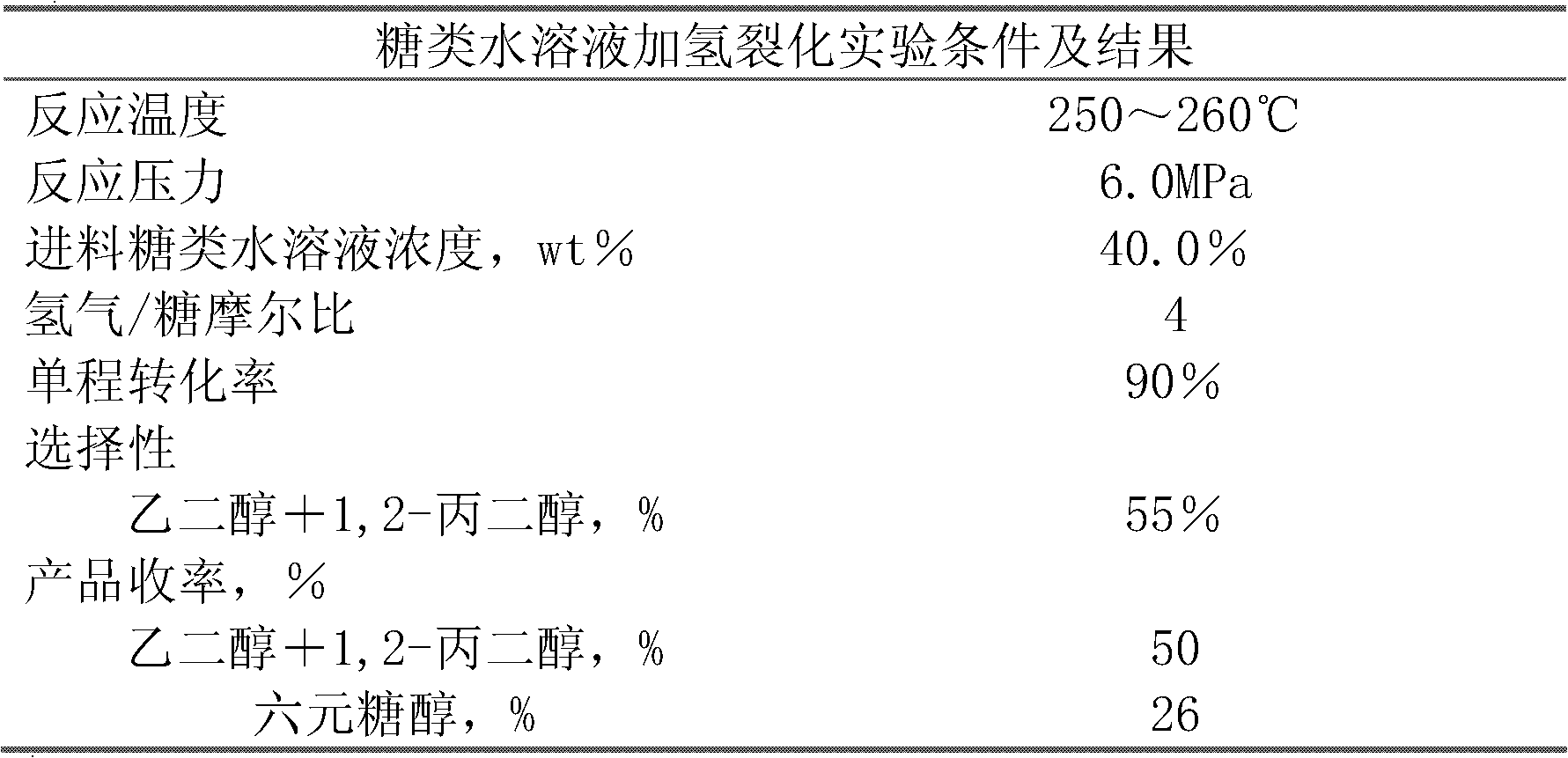

Method and Systems for Procesing Lignin During Hydrothermal Digestion of Cellulosic Biomass Solids While Producing a Monohydric Alcohol Feed

InactiveUS20140121418A1Low viscosityOrganic compound preparationOxygen compounds preparation by reductionCelluloseAlcohol

Digestion of cellulosic biomass solids may be complicated by release of lignin therefrom. Methods for digesting cellulosic biomass solids may comprise: providing cellulosic biomass solids in the presence of a digestion solvent, molecular hydrogen, and a slurry catalyst capable of activating molecular hydrogen; at least partially converting the cellulosic biomass solids into a phenolics liquid phase comprising lignin, an aqueous phase comprising a glycol derived from the cellulosic biomass solids, and an optional light organics phase; wherein at least a portion of the slurry catalyst accumulates in the phenolics liquid phase as it forms; combining the glycol with the phenolics liquid phase, thereby forming a combined phase; and heating the combined phase in the presence of molecular hydrogen; wherein heating the combined phase reduces the viscosity of the phenolics liquid phase and transforms at least a portion of the glycol into a monohydric alcohol.

Owner:SHELL OIL CO

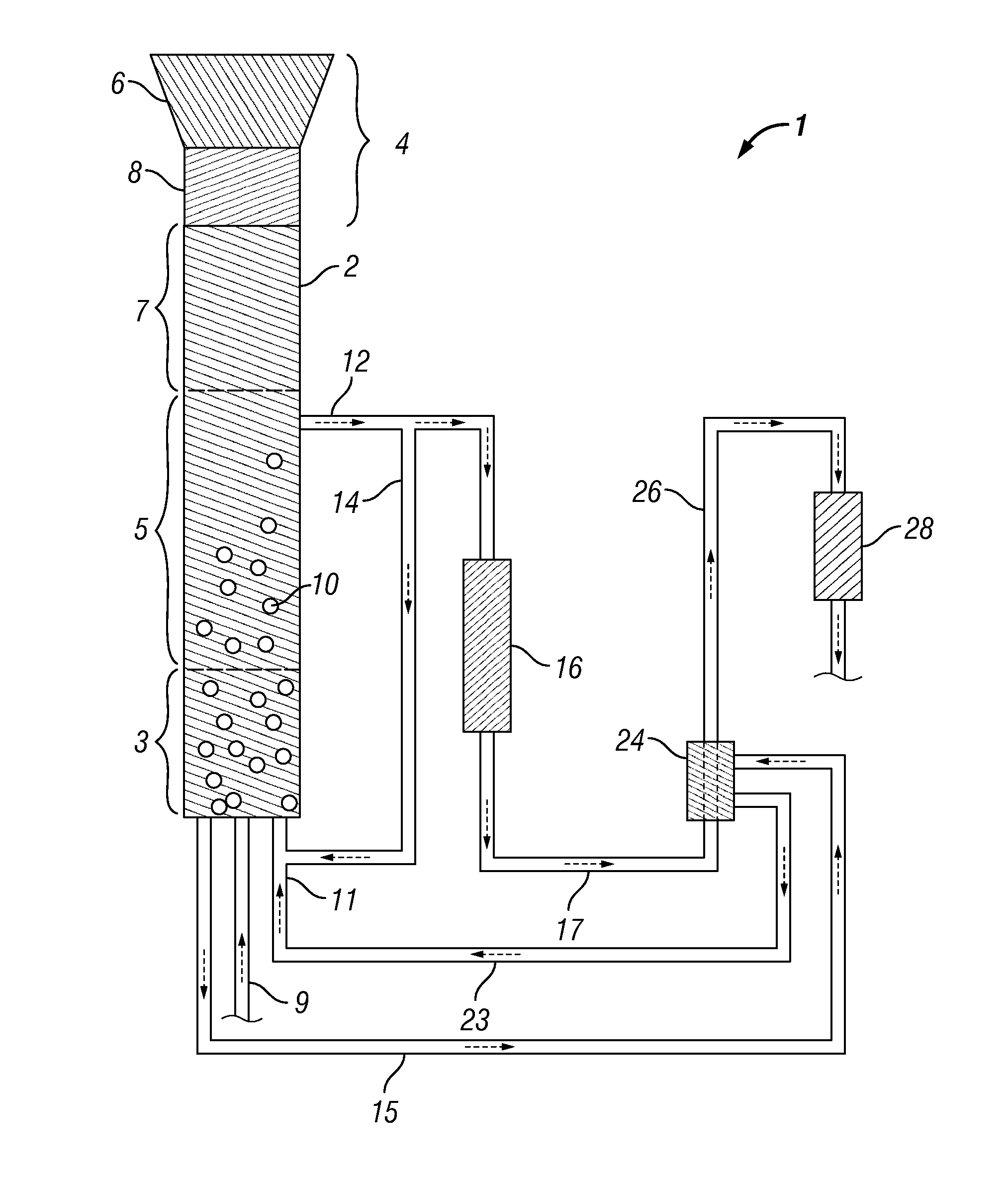

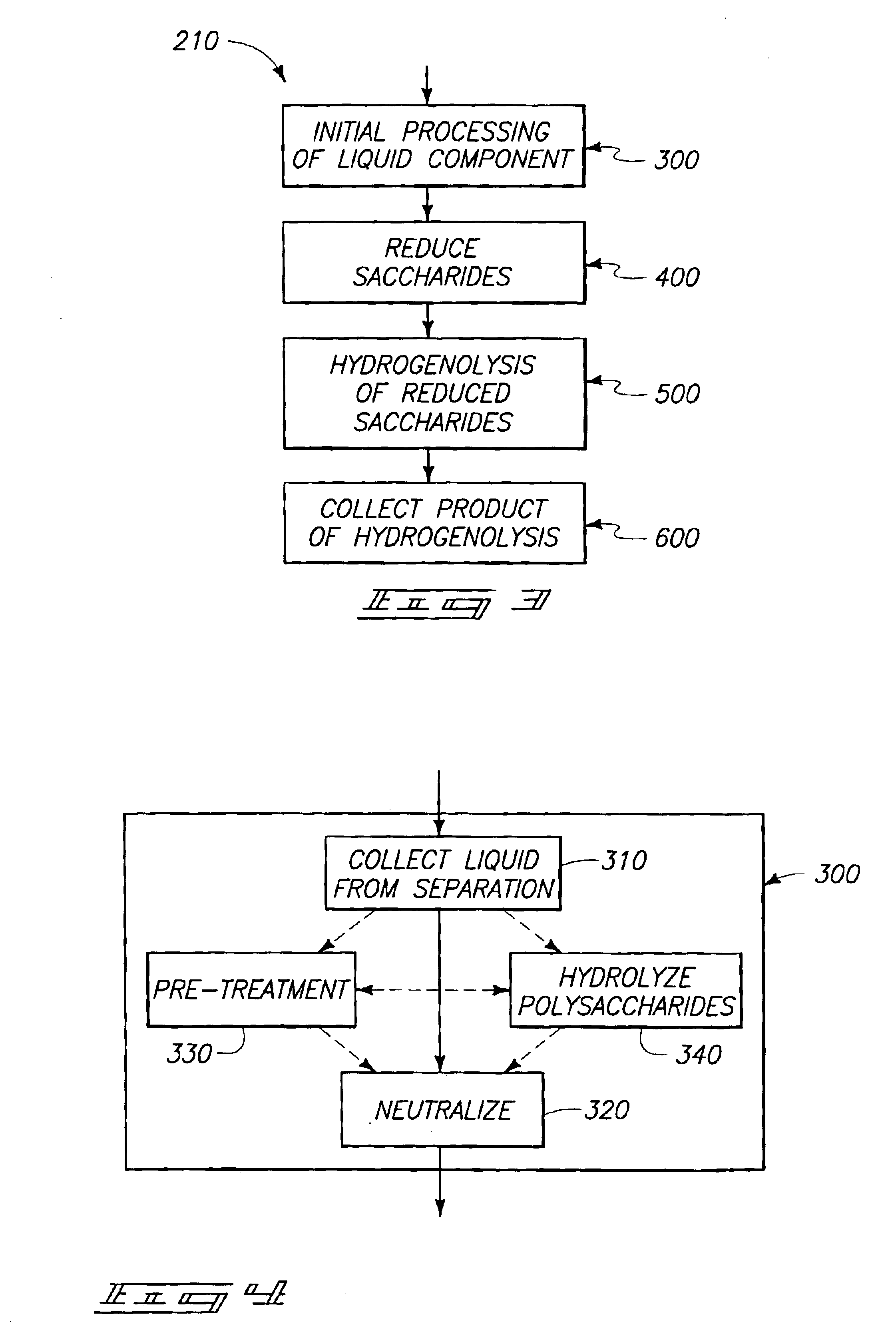

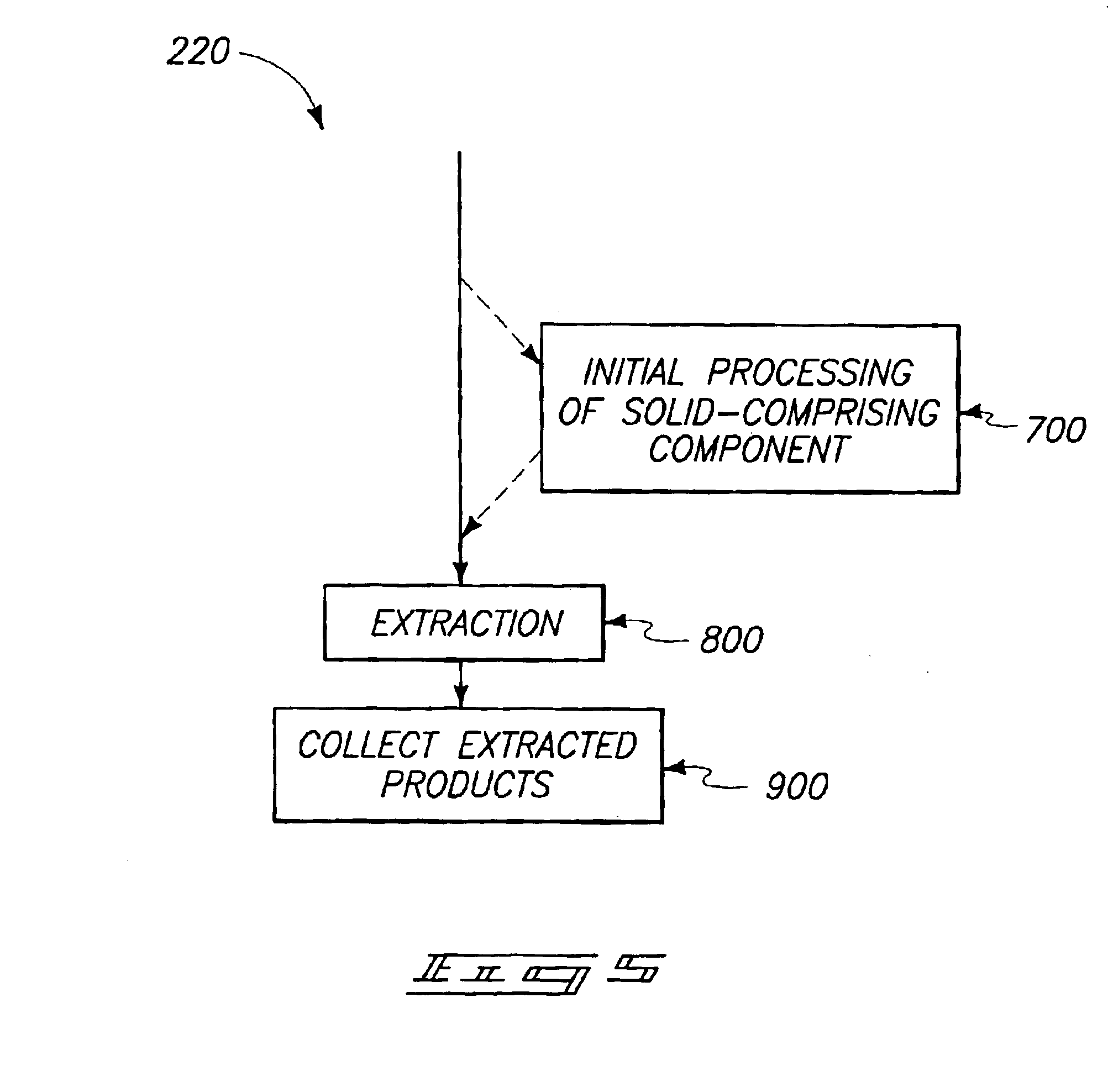

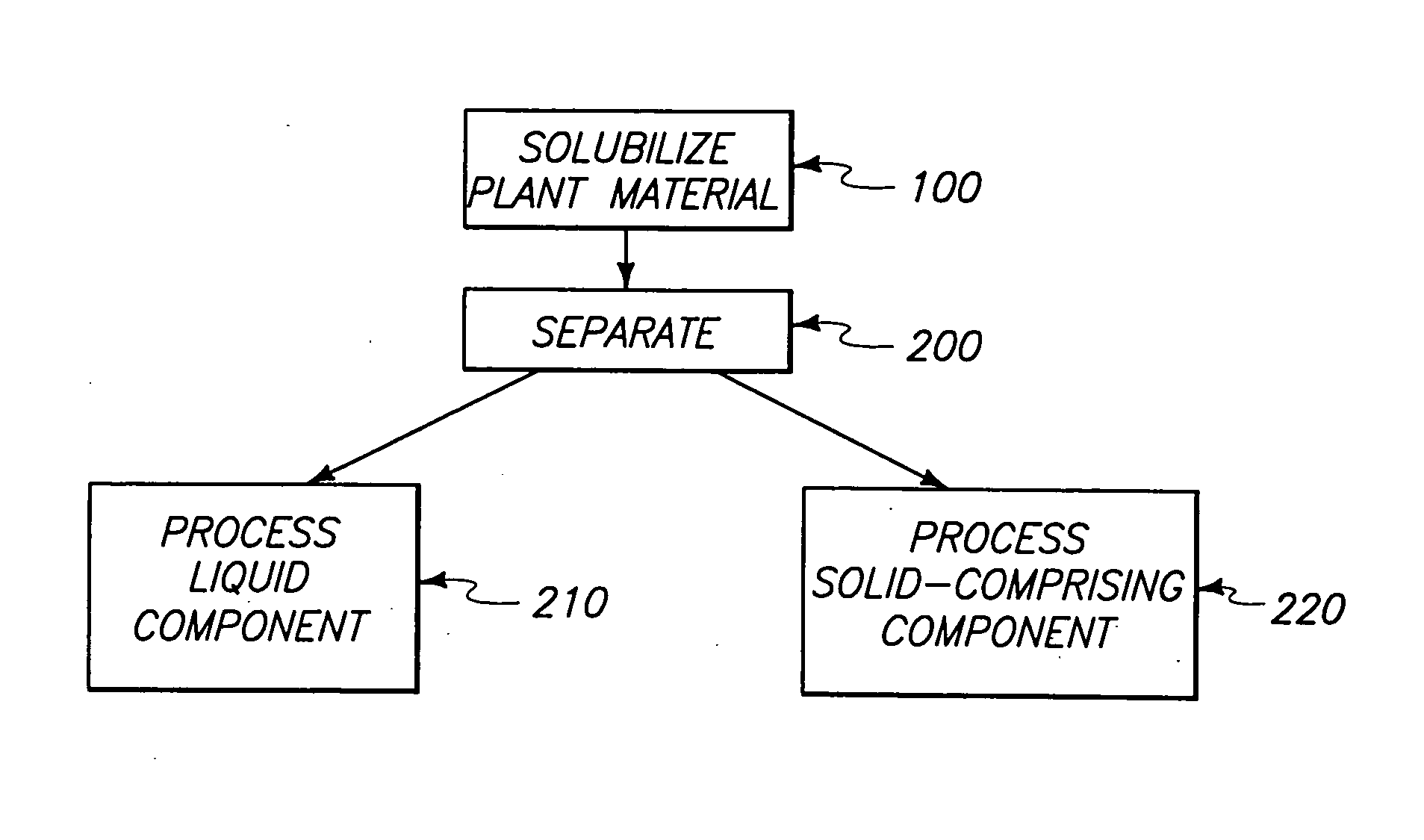

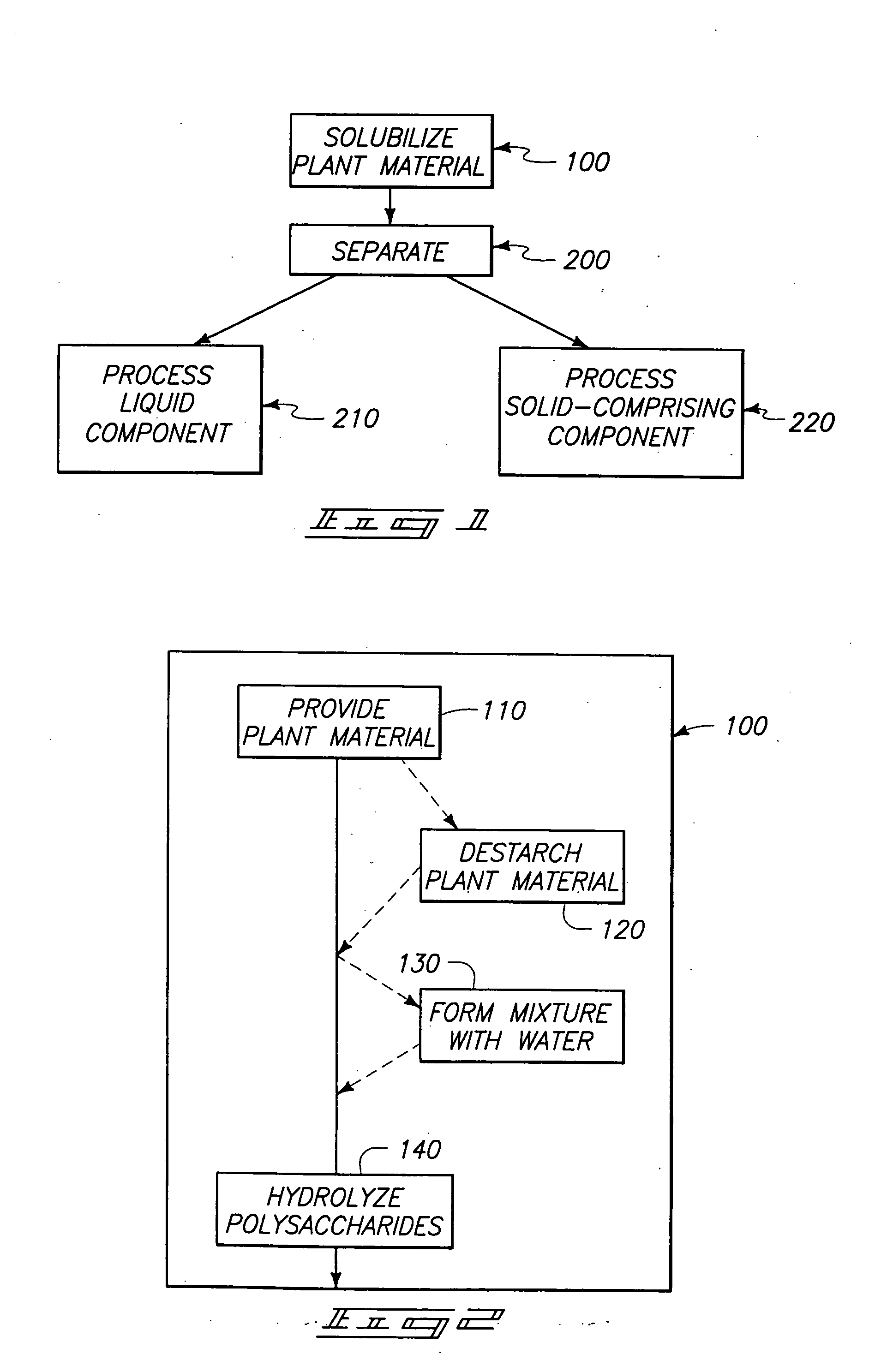

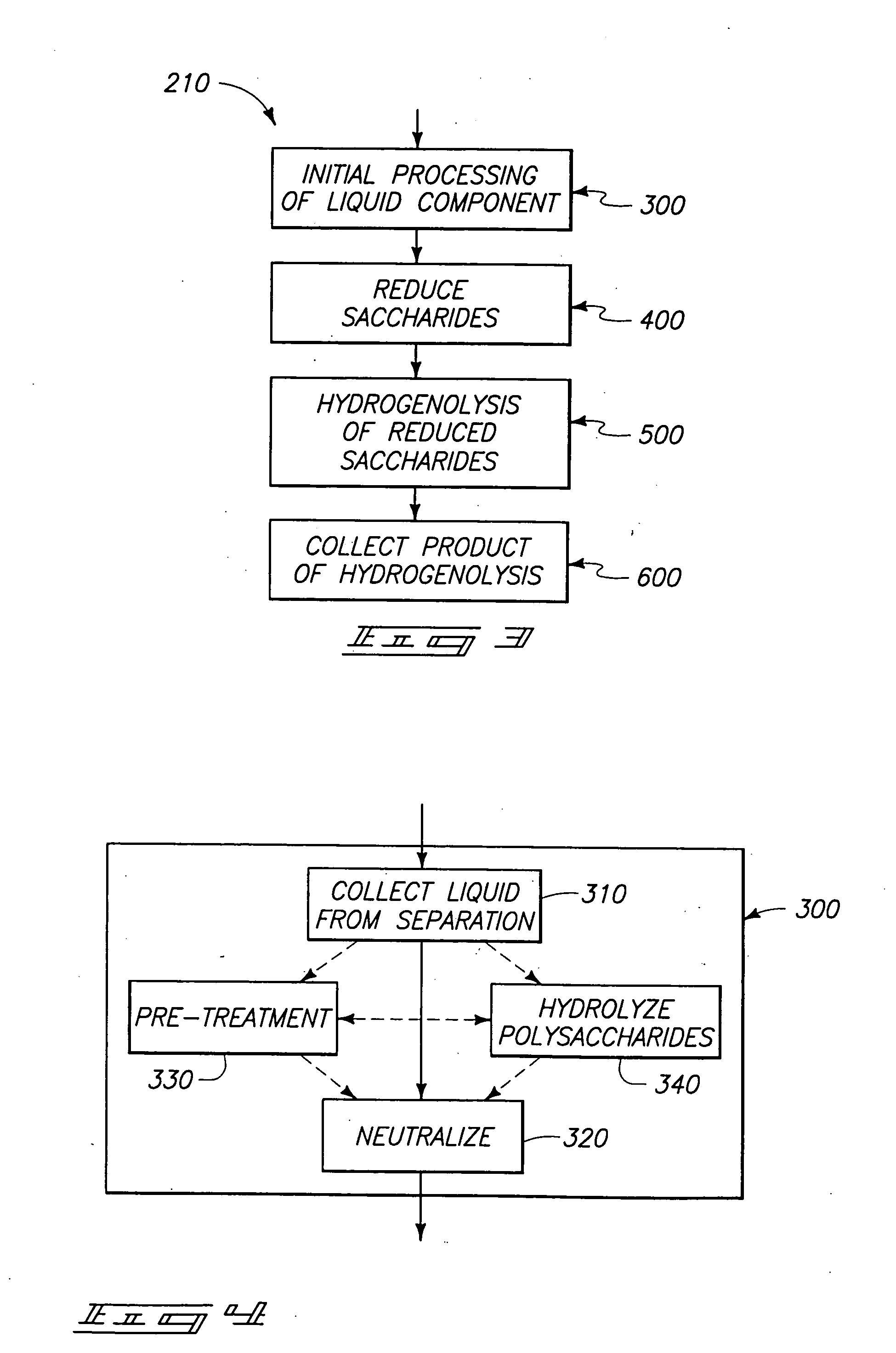

Methods of producing compounds from plant material

The invention includes methods of processing plant material by adding water to form a mixture, heating the mixture, and separating a liquid component from a solid-comprising component. At least one of the liquid component and the solid-comprising component undergoes additional processing. Processing of the solid-comprising component produces oils, and processing of the liquid component produces one or more of glycerol, ethylene glycol, lactic acid and propylene glycol. The invention includes a process of forming glycerol, ethylene glycol, lactic acid and propylene glycol from plant matter by adding water, heating and filtering the plant matter. The filtrate containing starch, starch fragments, hemicellulose and fragments of hemicellulose is treated to form linear poly-alcohols which are then cleaved to produce one or more of glycerol, ethylene glycol, lactic acid and propylene glycol. The invention also includes a method of producing free and / or complexed sterols and stanols from plant material.

Owner:BATTELLE MEMORIAL INST +1

Multi-metal reduction catalysts and methods of producing reduction catalysts

InactiveUS20090088317A1Catalyst activation/preparationPreparation by OH group eliminationMetalChemistry

A reduction catalyst having a first metal component comprising one of Co, Os, Fe, Re, Rh and Ru. The first metal component is present in the catalyst at from 0.5 percent to 20 percent, by weight. A second metal component differing from the first metal component present in the catalyst with the second metal component being selected from the group consisting of Fe, Mn, Ru, Os, Rh, Ir, Ni, Pd, Pt, Ag, Au, Zn, Co, Re, Cu, Pb, Cr, W, Mo, Sn, Nb, Cd, Te, V, Bi, Ga and Na. A hydrogenation catalyst comprising one or both of Ni and Co and one or more elements selected from the group consisting of Mn, Fe, Ag, Au, Mo and Rh.

Owner:BATTELLE MEMORIAL INST

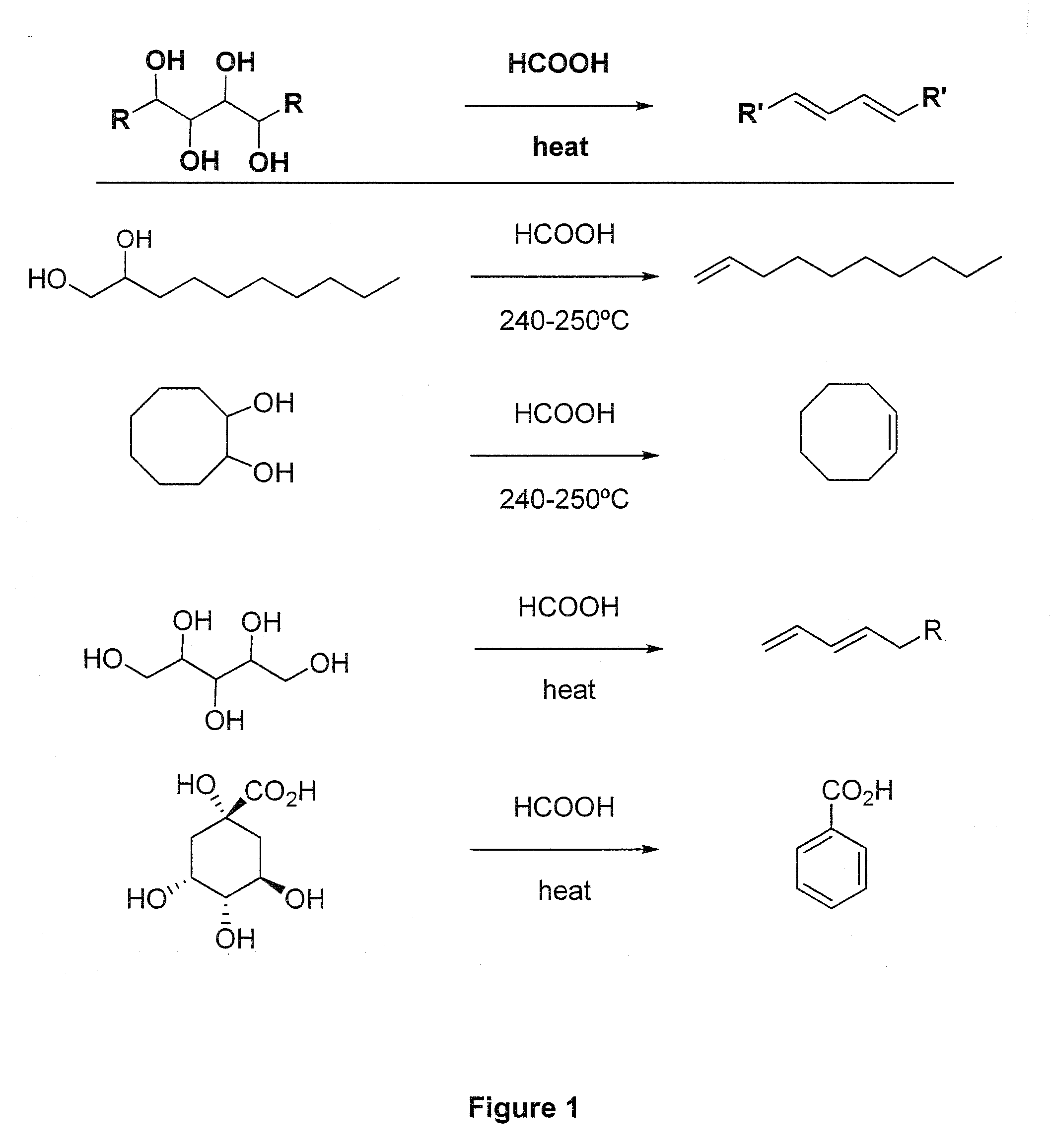

Method of Converting a Polyol to an Olefin

ActiveUS20090287004A1High purityHigh yieldOxygen-containing compound preparationOrganic compound preparationPolyolCarboxylic acid

A method of preparing an olefin comprising: reacting a polyol in the presence of a carboxylic acid, such that an olefin is produced by the deoxygenation of the polyol. The reacting step can comprise (a) providing a composition comprising the polyol, (b) heating the composition, and (c) introducing the carboxylic acid to the composition wherein the introducing step occurs prior to, at the same time as, or subsequent to the heating step. In one embodiment, the polyol is glycerol, the carboxylic acid is formic acid, and the olefin is allyl alcohol, which is produced at a yield of about 80% or greater.

Owner:RGT UNIV OF CALIFORNIA

Methods for conversion of a glycol reaction product obtained from hydrothermal digestion of cellulosic biomass solids into a dried monohydric alcohol feed

InactiveUS20140128639A1Easy to adaptOrganic compound preparationLiquid hydrocarbon mixture productionCelluloseHydrogen

Hydrothermal digestion of cellulosic biomass solids may produce a glycol reaction product for subsequent processing. Methods for digesting cellulosic biomass solids to form and process a glycol reaction product may comprise: providing cellulosic biomass solids and a slurry catalyst in a hydrothermal digestion unit, the slurry catalyst being capable of activating molecular hydrogen; heating the cellulosic biomass solids in the hydrothermal digestion unit in the presence of the slurry catalyst, a digestion solvent, and molecular hydrogen, thereby forming a liquor phase comprising soluble carbohydrates; performing a first catalytic reduction reaction on the soluble carbohydrates within the hydrothermal digestion unit, thereby at least partially converting the soluble carbohydrates into a reaction product comprising a glycol; at least partially drying the reaction product, thereby forming a dried reaction product comprising a dried glycol; and at least partially converting the dried glycol into a monohydric alcohol external to the hydrothermal digestion unit.

Owner:SHELL OIL CO

High carbon polyol hydrocracking catalyst and preparing process and application thereof

InactiveCN101199930ALarge specific surface areaEasy to makeOrganic compound preparationCatalyst activation/preparationChemical synthesisPtru catalyst

The invention discloses a novel longevity-type catalyst with high activity and selectivity of high alcohol hydrogenation and chemical stability and physical stability under reacting condition, the preparation method and the application. The catalyst of the invention adopts metal as the catalyst framework, so that the hydrothermal stability and alkali tolerance of the catalyst are high. The catalyst can be prepared by the melting method, the machine-alloying method and the chemical synthesis method. The invention can be used for high alcohol hydrogenation, in particular for the preparation of hydrogenation low-carbon polyatomic alcohol by using regenerated material as D-sorbitol which is made from corn.

Owner:马波

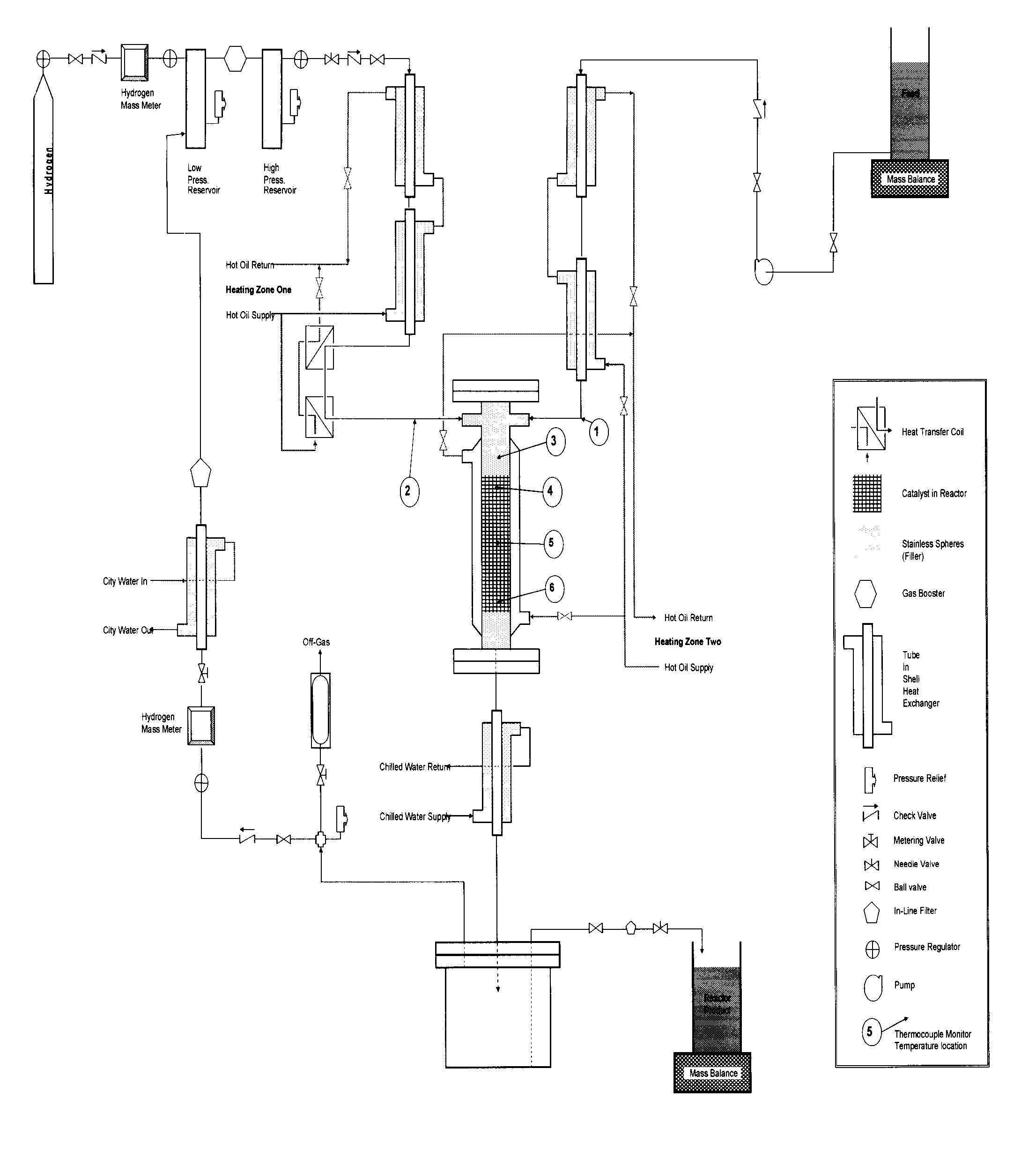

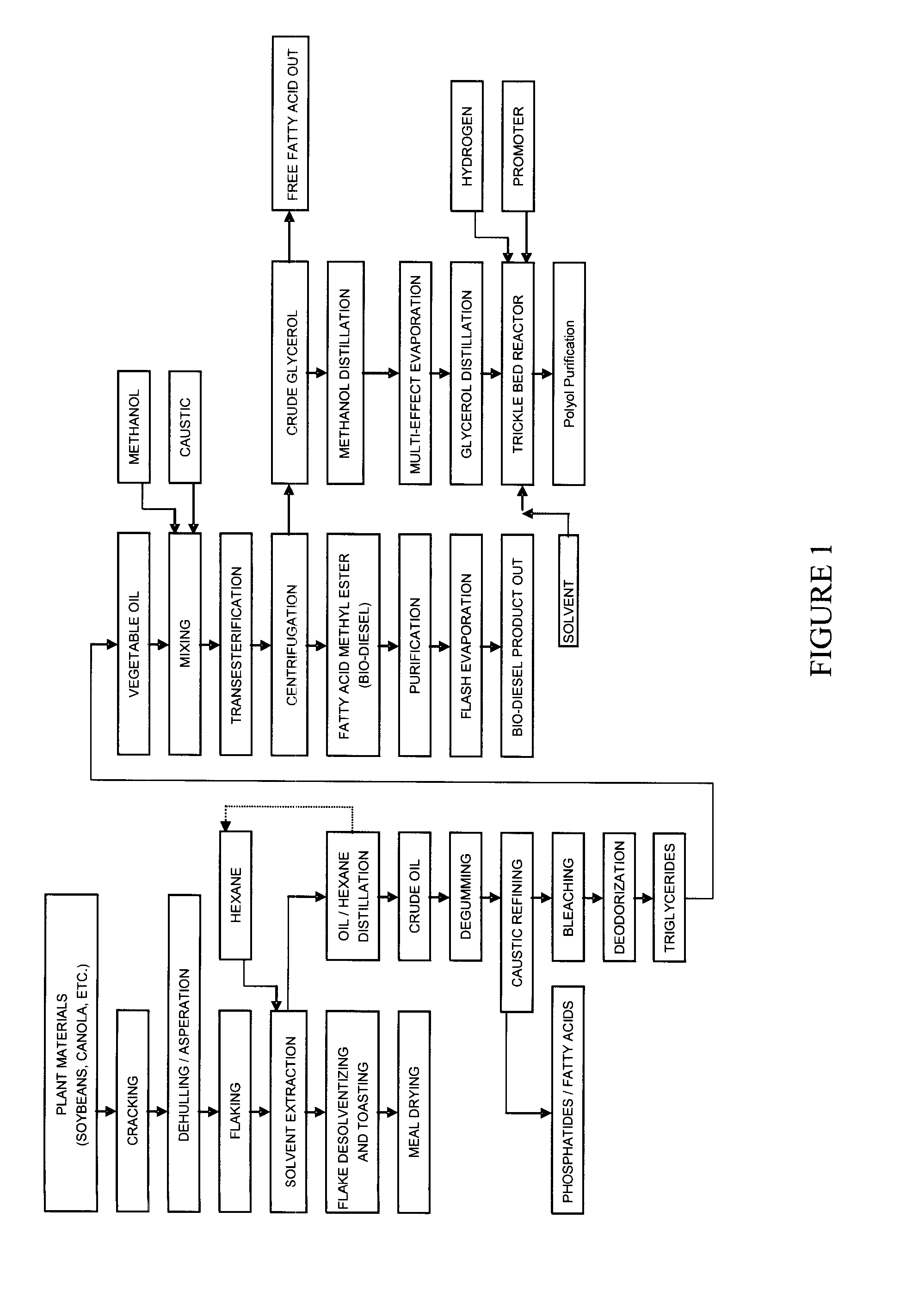

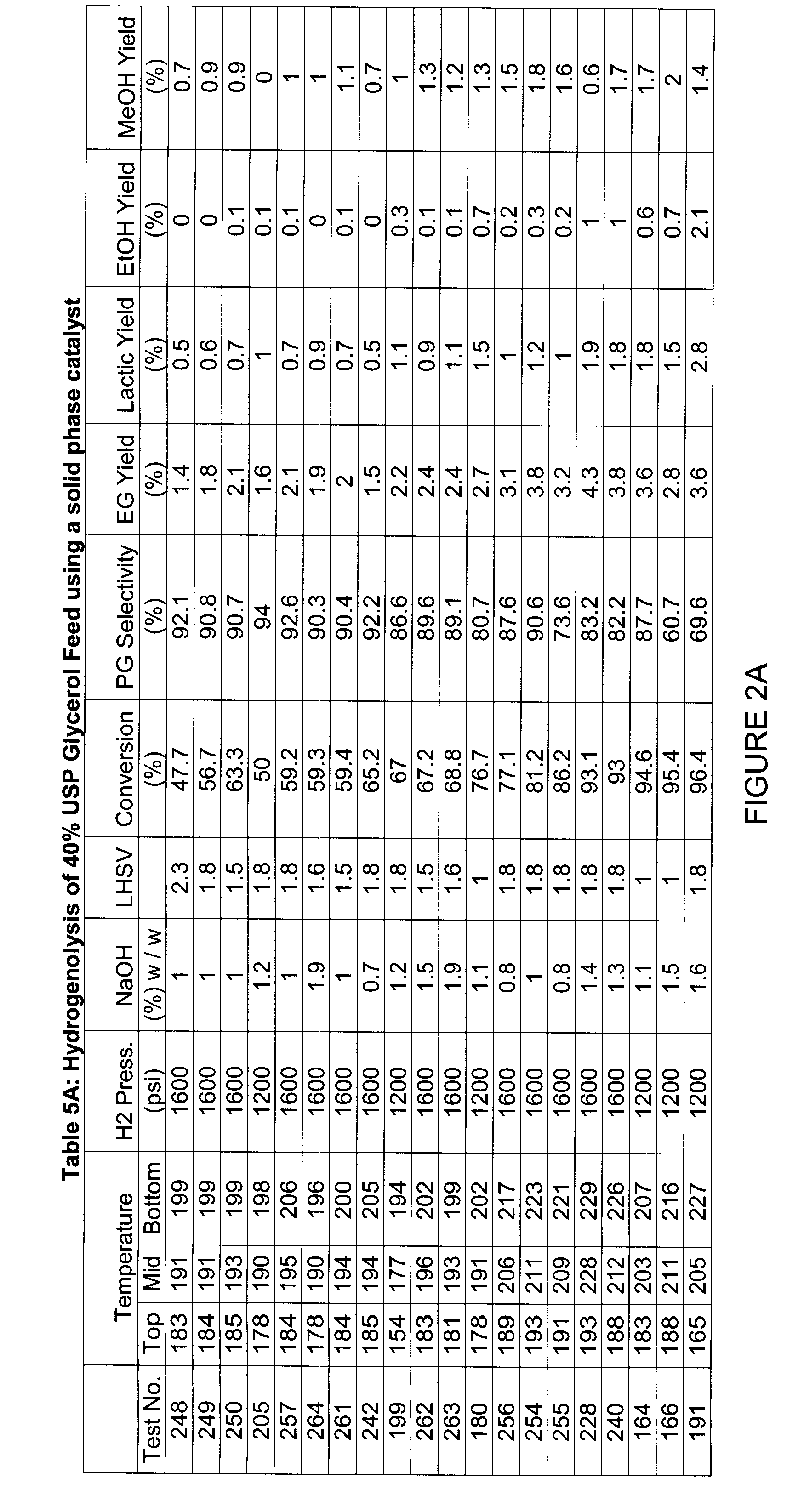

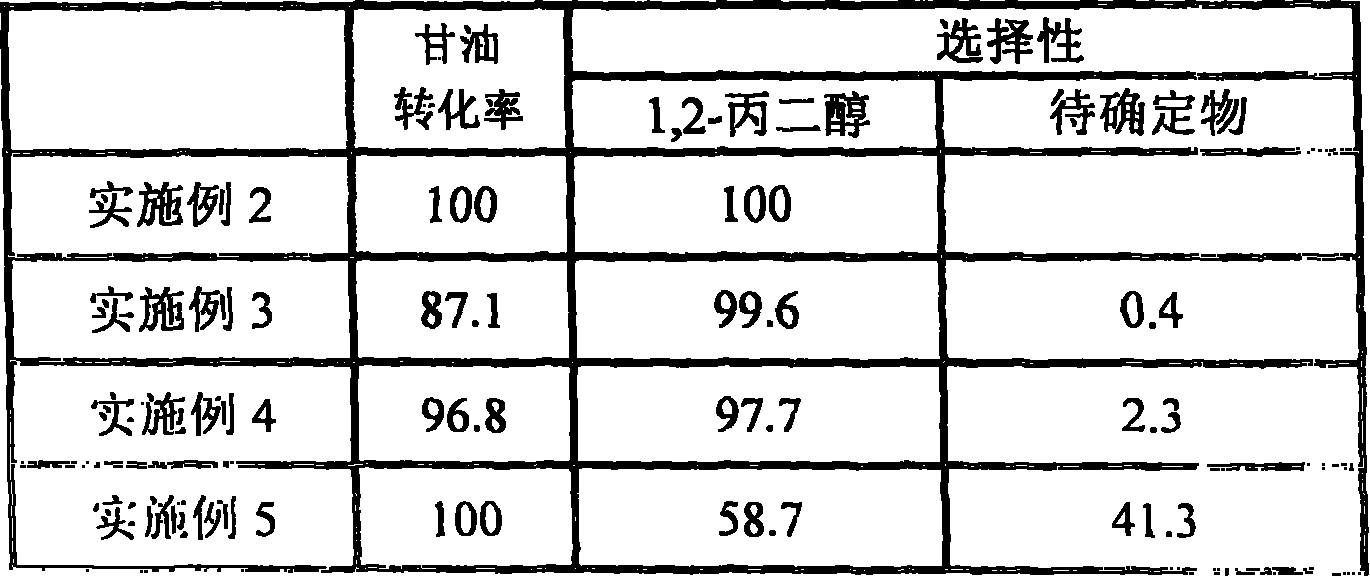

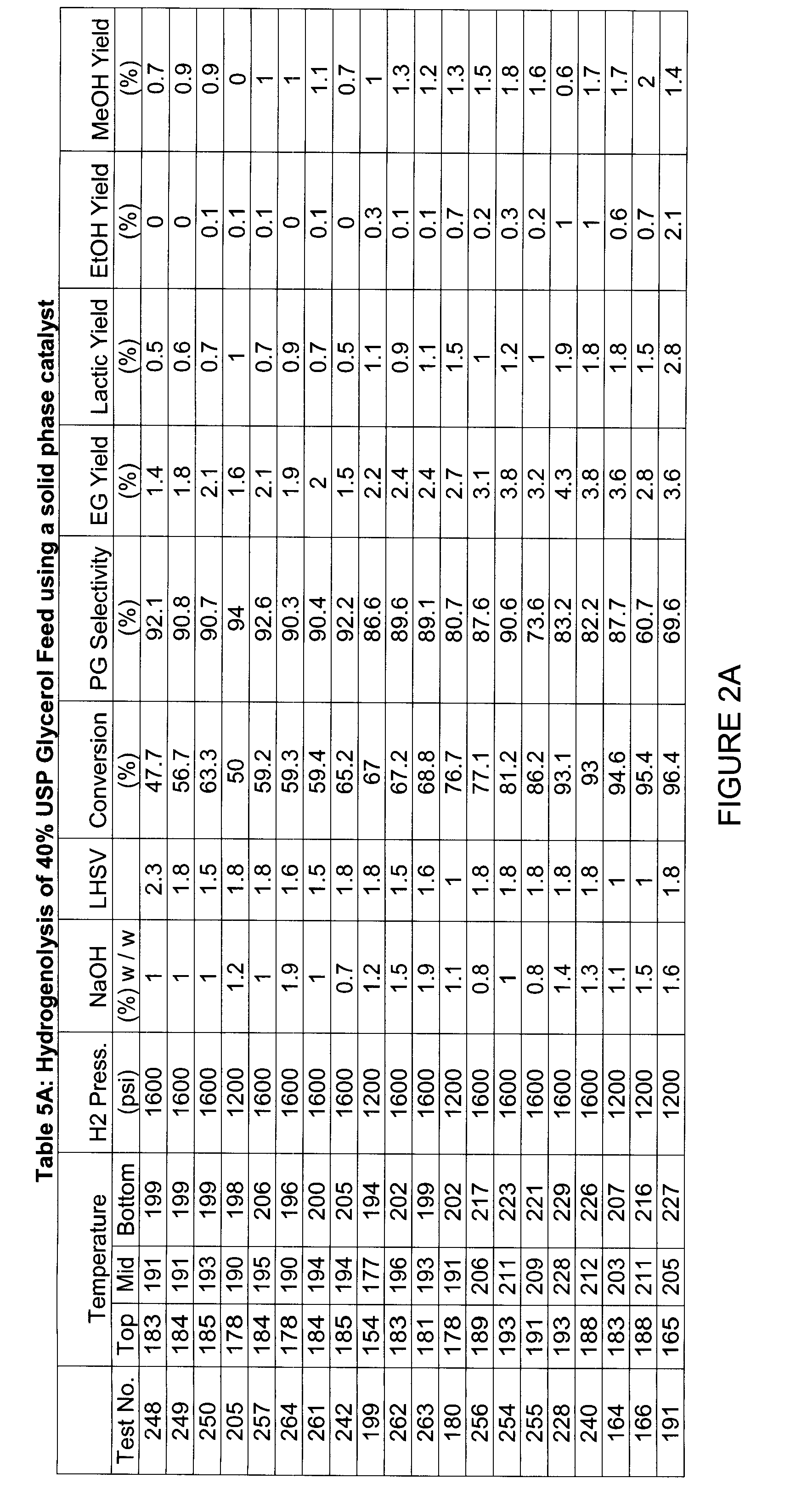

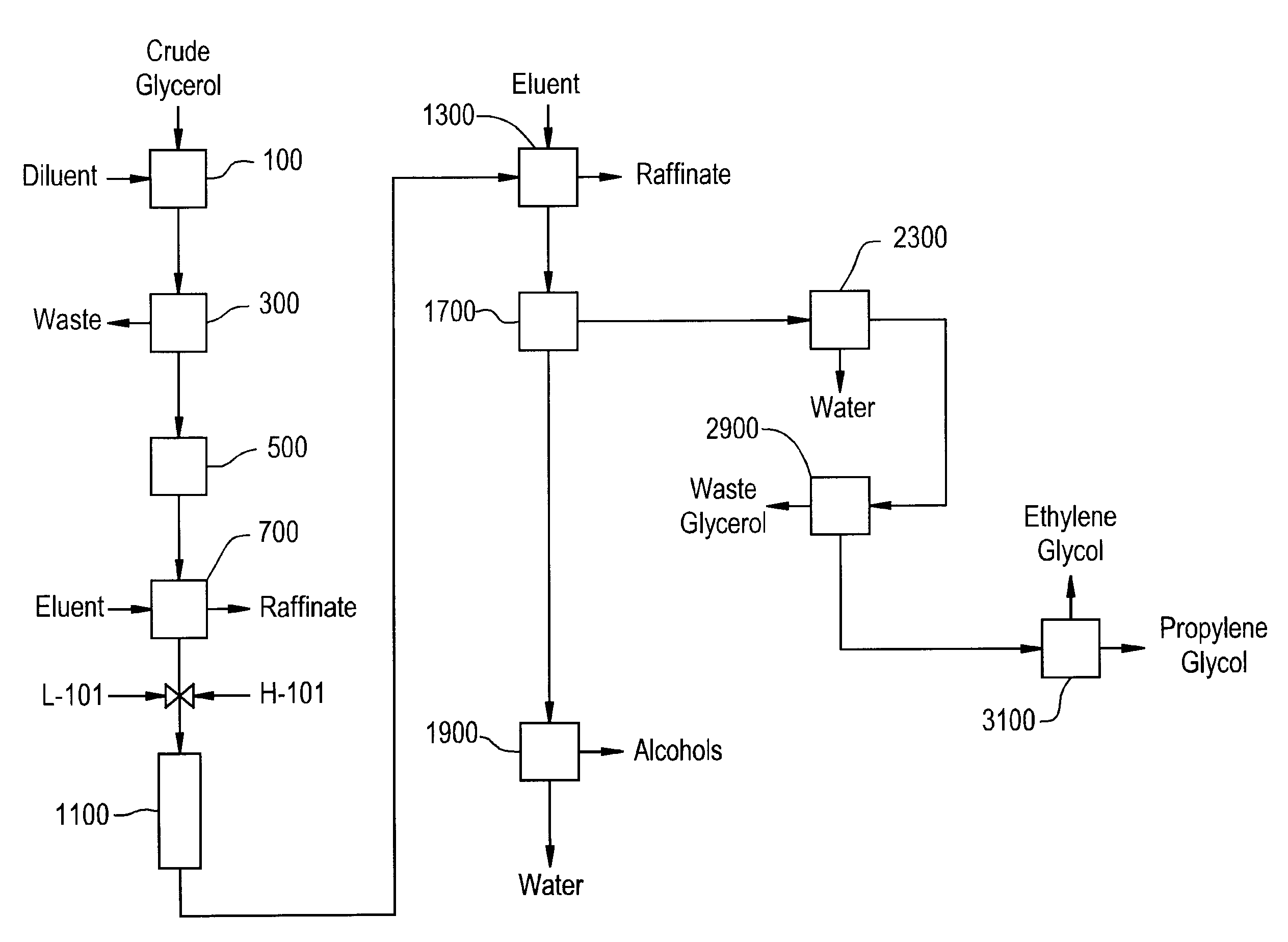

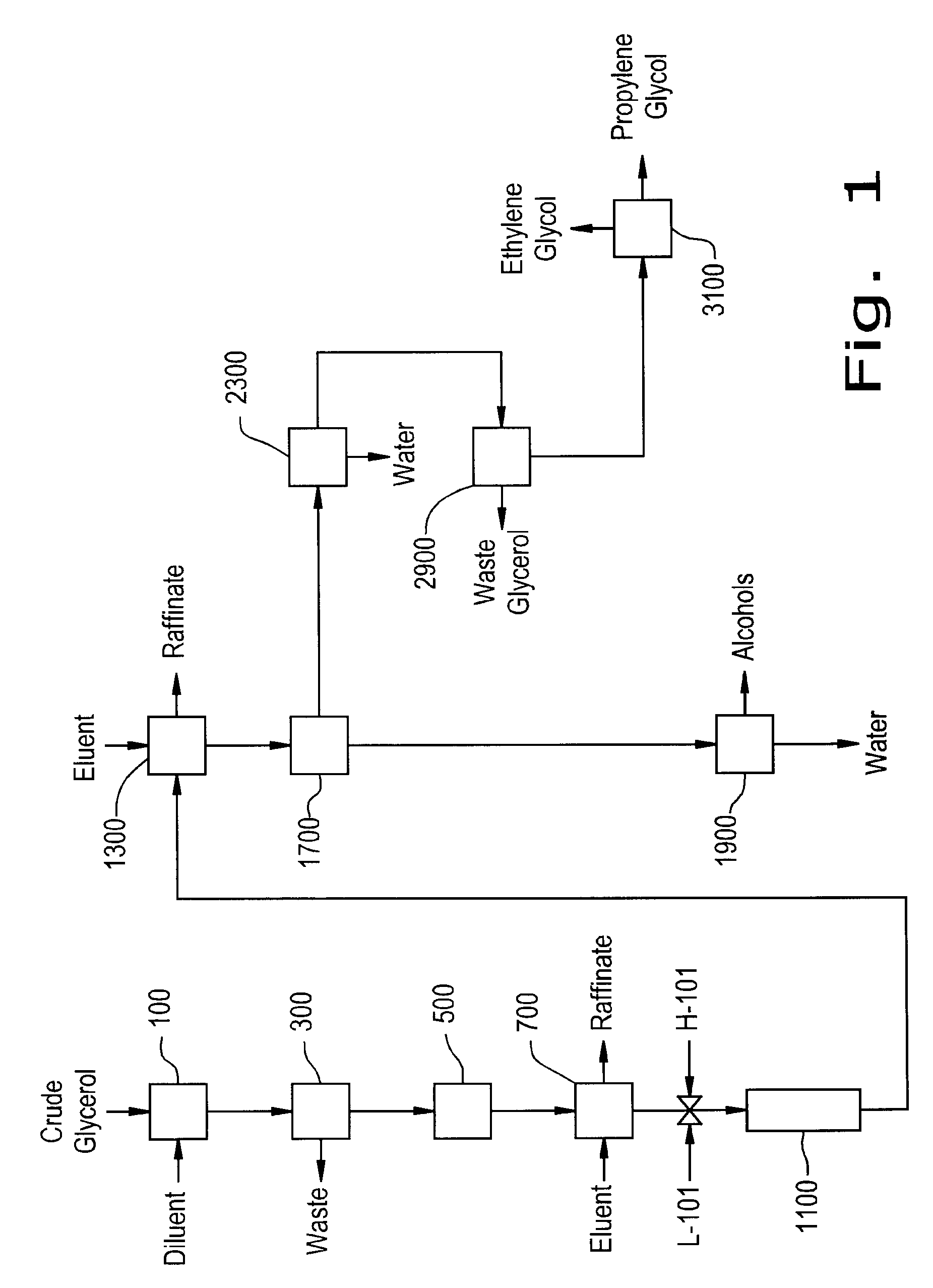

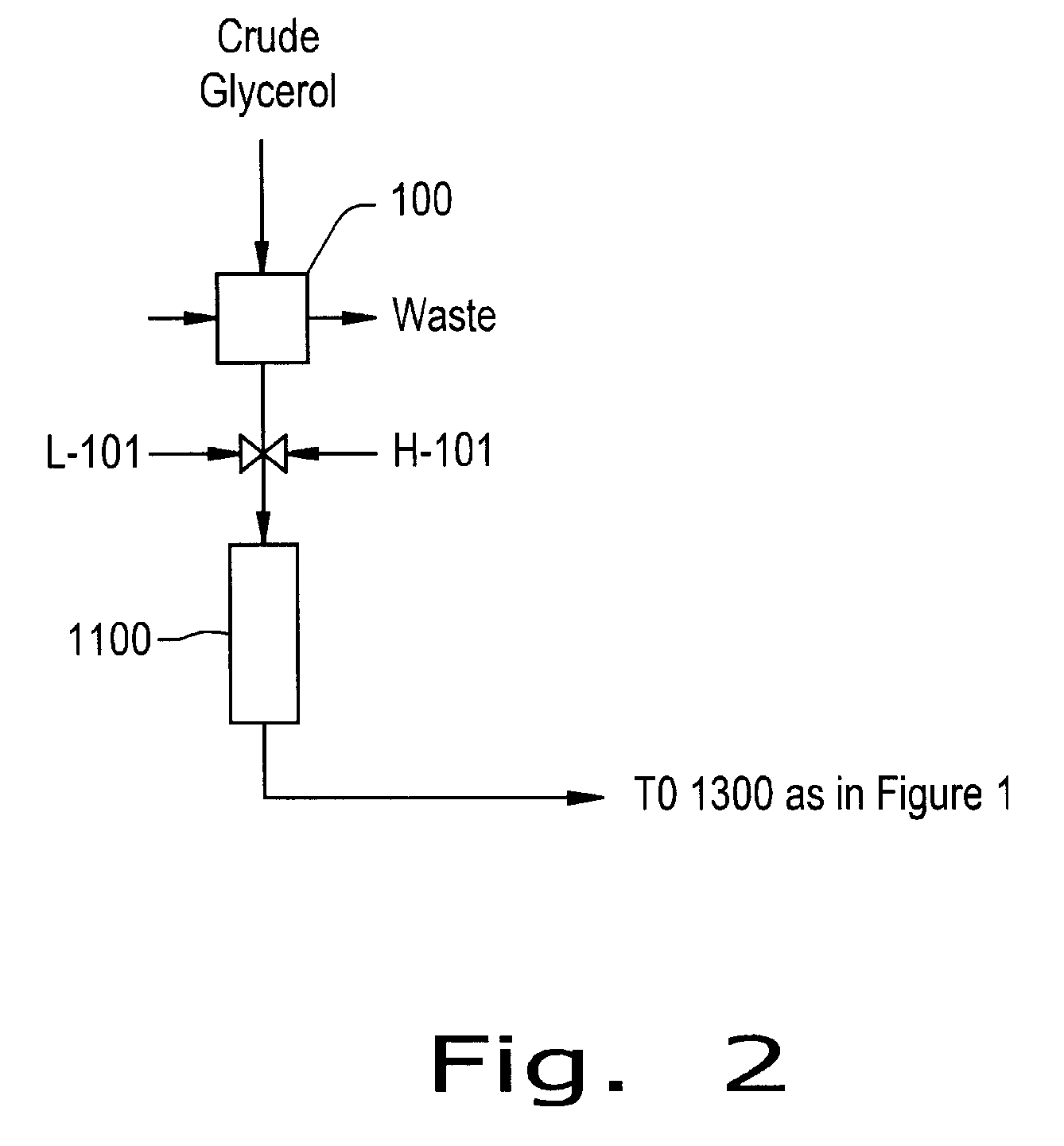

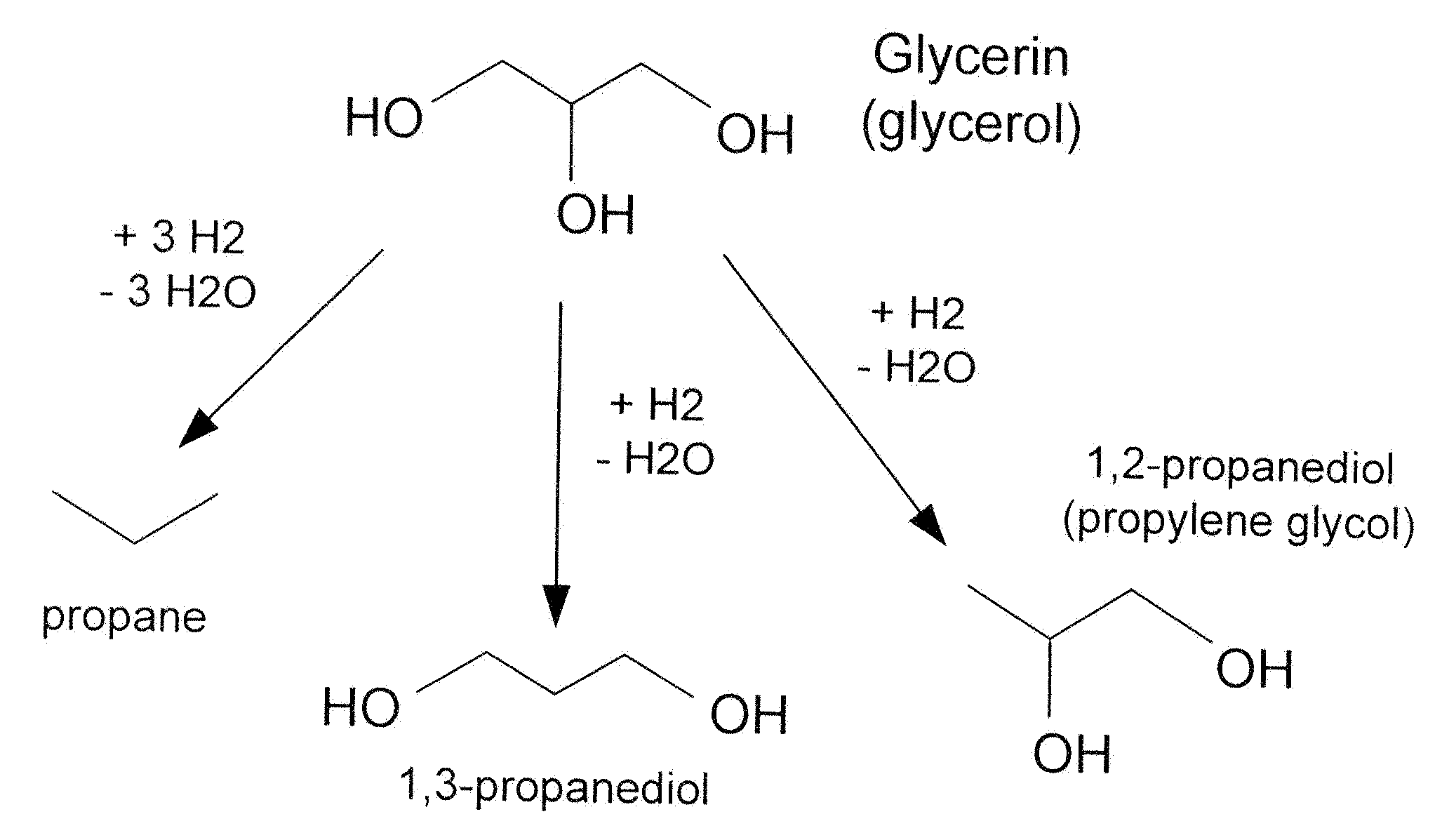

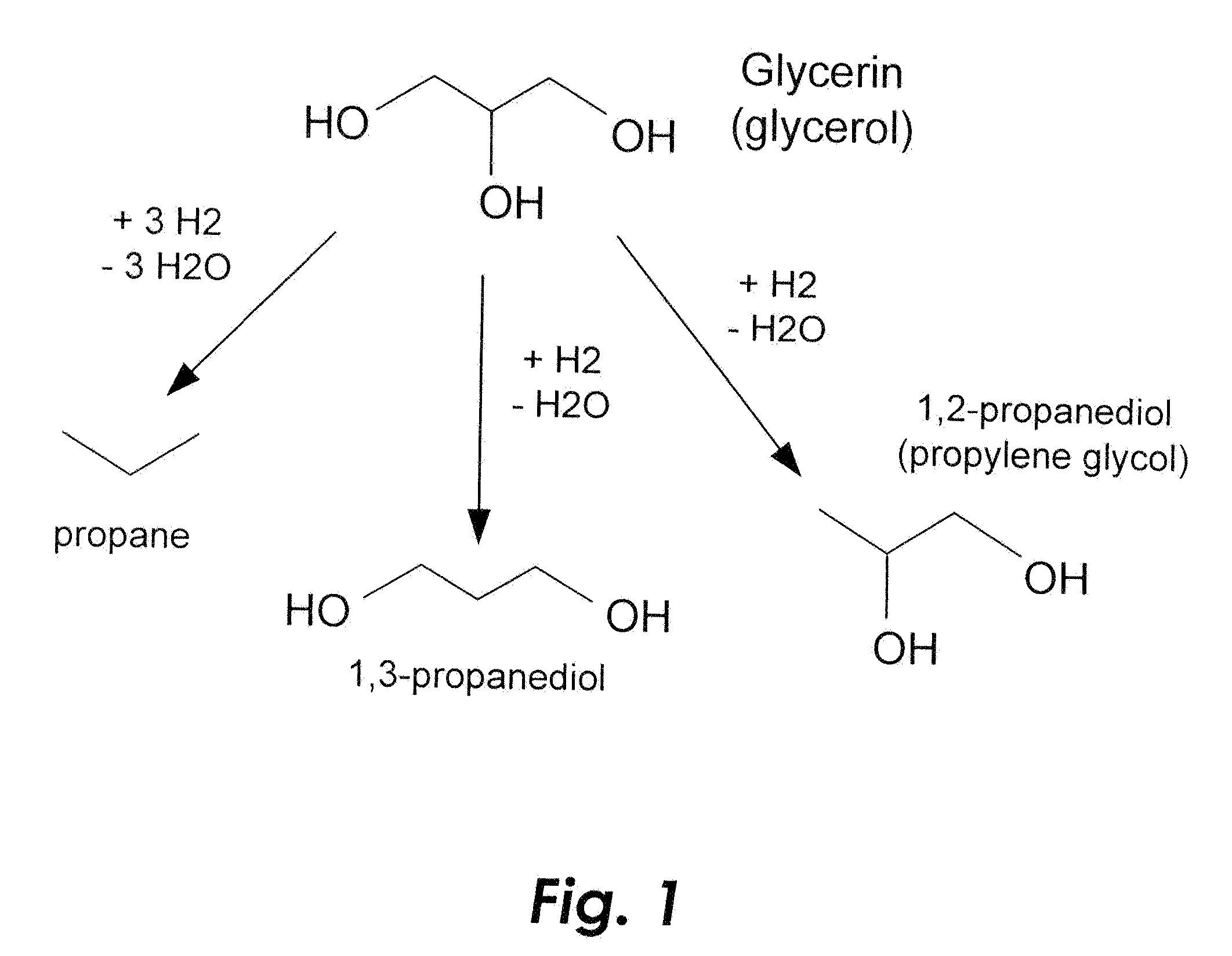

Hydrogenolysis of Glycerol and Products Produced Therefrom

ActiveUS20080228014A1Organic compound preparationPreparation by OH group eliminationGlycerolRadiochemistry

Owner:ARCHER DANIELS MIDLAND CO

Method for producing 1-propylene glycol with glycerol hydrogenation

InactiveCN101195557ASimple compositionImprove conversion ratePreparation by OH group eliminationMetal/metal-oxides/metal-hydroxide catalystsAlcoholReaction temperature

The invention discloses a method for preparing 1, 2-propylene glycol reaction hydrogenated by glycerol, which adopts CuO-SiO2 as catalyst, one or two of carbinol and water as reaction solvent. The glycerol is hydrogenated to prepare 1, 2-propylene glycol under the operation condition of reaction temperature of 140-200 DEG C and reaction pressure of 4.0-10.0 Mpa. The inventive catalyst adopts normal preparation procedure and the catalyst composition is simple and doesn't contain chromium metal. The alcohol-water mixed solvent system realizes high conversion rate of the reaction.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Hydrogenolysis of Glycerol and Products Produced Therefrom

Owner:ARCHER DANIELS MIDLAND CO

Preparation of Derivative of Polyhydric Alcohols

A method for converting a polyhydric alcohol into propylene glycol and butanediols is disclosed. Also disclosed are methods for converting polyhydric alcohols into three-carbon products and four-carbon products. Also disclosed are methods for maximizing conversion of polyhydric alcohols and minimizing formation of reaction products that are difficult to remove from the desired product. In other embodiments, methods are described to optimize use of reactants, including hydrogen, in hydrogenolysis of polyhydric alcohols.

Owner:ARCHER DANIELS MIDLAND CO

Flexible glycerol conversion process

ActiveUS20090054701A1Oxygen-containing compound preparationOrganic compound preparationBiodieselHydrogen

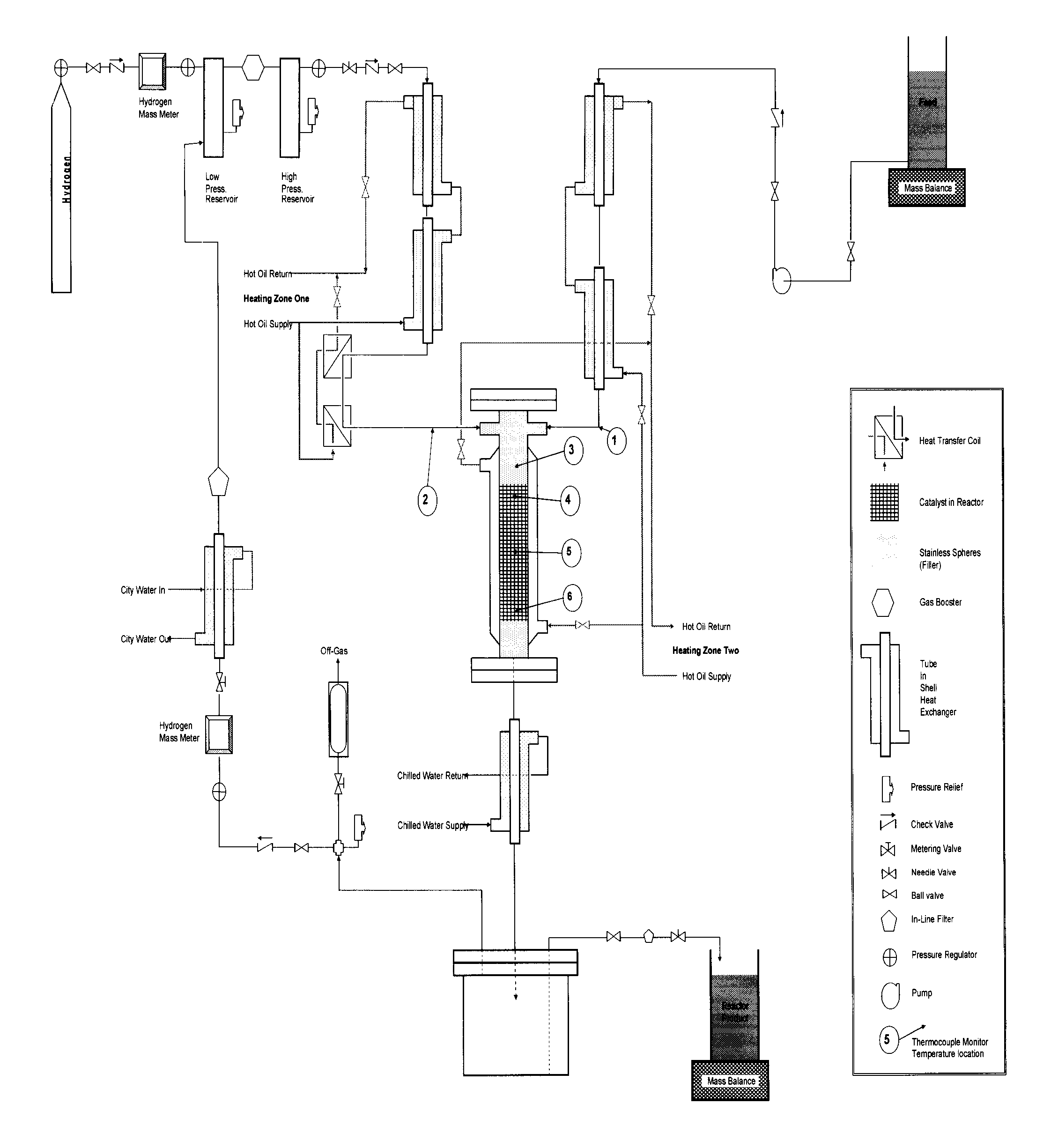

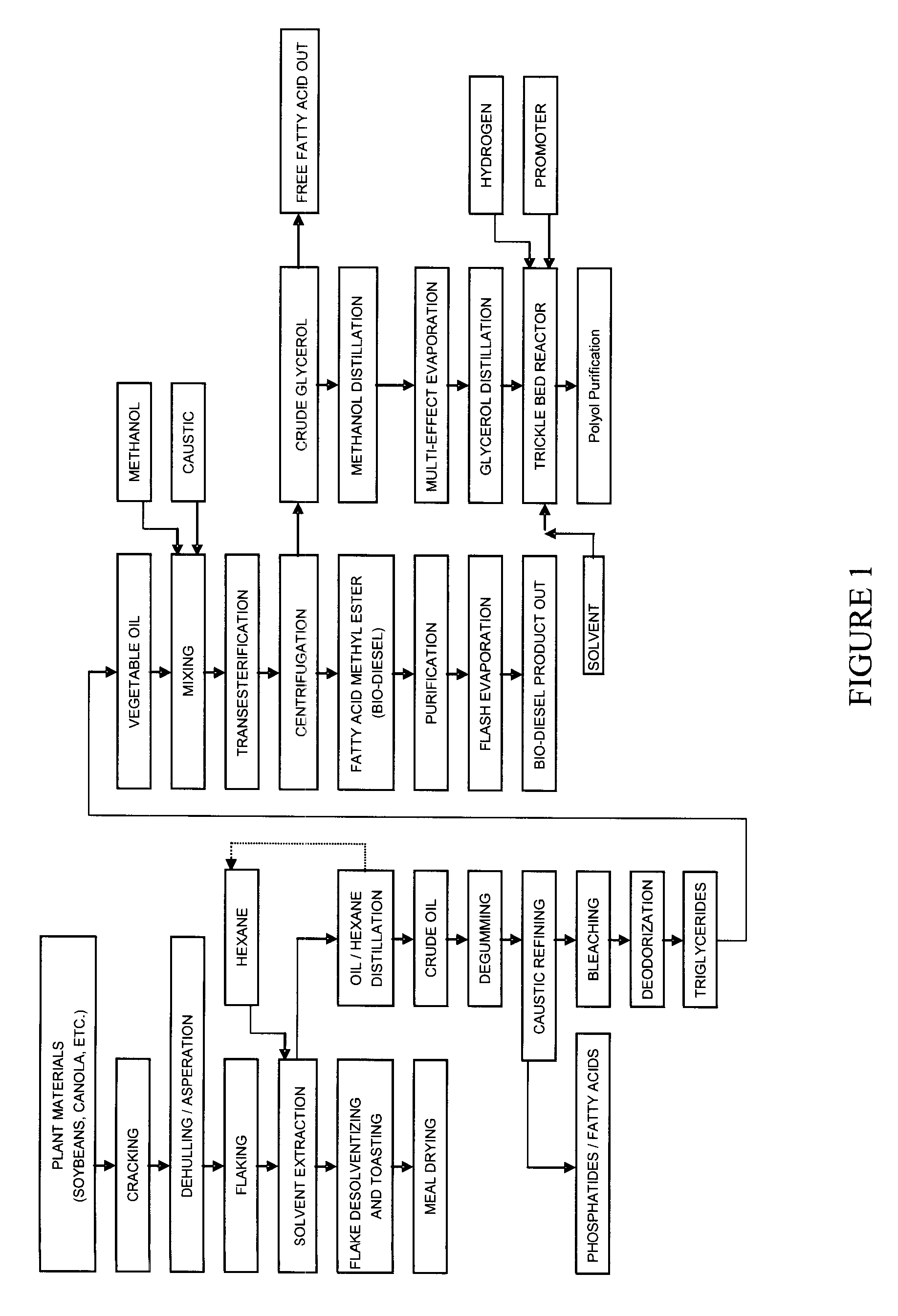

The present invention relates to a process for converting byproducts of the manufacture of biodiesel into industrially useful oxygenated products of greater commercial value. The process includes a trickle bed reactor in which a glycerol-rich feedstock is reacted with hydrogen in the presence of a nickel-tungsten catalyst under typical refining condition of high temperature and pressure, yielding propane synfuel or propanediols.

Owner:REG SYNTHETIC FUELS LLC

Method of continuously preparing 1,2-dihydroxypropane by glycerin catalytic hydrogenation

The invention discloses a making method of 1, 2-propanediol under mild condition, which is characterized by the following: adopting copper, zinc and manganese and or aluminium catalyst; aerating glycerin and hydrogen continuously from the top of reactor; hydrogenating glycerin at 200-250 deg.c under 2.5-5Mpa; outputting and collecting reacting product from the bottom of reactor continuously; separating gas; returning to recycle; setting the weight rate of metal element of catalyst at 16-48:24-48:0.15-4:0-8.

Owner:NANJING TECH UNIV

Process for the production of anhydrosugar alcohols

InactiveUS6849748B2High yieldOxygen-containing compound preparationSugar derivativesOrganic solventAlcohol

A process is provided for the preparation of anhydrosugar alcohols. The process involves heating a sugar alcohol or a monoanhydrosugar alcohol starting material in the presence of an acid catalyst, and subsequent purification of the anhydrosugar alcohol. Very high purities are achieved, without the use of organic solvents in the process.

Owner:ARCHER DANIELS MIDLAND CO

High-efficiency hydrogenation catalyst and method for preparing same

ActiveCN102764656AHigh catalytic activityLong catalyst lifeOrganic compound preparationCarboxylic acid esters preparationPtru catalystManganese

The invention discloses a high-efficiency hydrogenation catalyst and a method for preparing the high-efficiency hydrogenation catalyst. The high-efficiency hydrogenation catalyst comprises the following components by weight: 5-30% of active metal, 0-20% of auxiliary metal and 40-85% of carrier. The active metal is copper or copper oxide; the auxiliary metal is the composition of one or more than two of the sodium, aluminum, nickel, zinc, cobalt, manganese, cerium, lanthanum and strontium; and the carrier the silicon dioxide of silica sol or the aluminum oxide of pseudo-boehmite or aluminum salt. The high-efficiency hydrogenation catalyst is prepared by adopting the impregnation or precipitation method, and the urea is used as the precipitating agent. Compared with the prior art, the catalyst prepared under the condition that the content of the active metal and the auxiliary metal is low has high catalytic activity and long life. In addition, the catalyst has low preparation and production cost and can be universally used for preparing methyl glycolate, ethylene glycol and ethanol by catalytic hydrogenation and preparing 1,2-glycol from glycerin by hydrogenation.

Owner:久泰能源(鄂尔多斯)有限公司

Catalyst for preparing 1, 2-trimethylene glycol by glycerol hydrogenoiysis and preparation thereof

InactiveCN101214440AIncrease conversion rate per passHigh activityPreparation by OH group eliminationMetal/metal-oxides/metal-hydroxide catalystsRare-earth elementGlycerol

The invention relates to a catalyst of a 1, 2-propanediol prepared by hydrogenolysis of glycerine. The catalyst is a compound oxide, and contains cuprocide (weight fraction) 25 percent to 60 percent, zinc oxide 35 percent to 70 percent, aluminum oxide (weight fraction) 0 percent to 10 percent and at least one or a plurality of rare-earth oxides 0.5 percent to 10 percent of rare earth elements, such as Y, La, Ce, Pr, Nd, Sm, Eu, Gd, Tb, Dy, etc. The catalyst is used in continuous hydrogenolysis reaction of glycerine, in which the conversion rate of the glycerine is high, the selectivity of the 1, 2-propanediol is high and the activity of the catalyst is very stable. The invention also provides the preparation method of the catalyst and application of the catalyst in preparation of 1, 2-propanediol by hydrogenolysis reaction of glycerine.

Owner:NANJING UNIV OF TECH

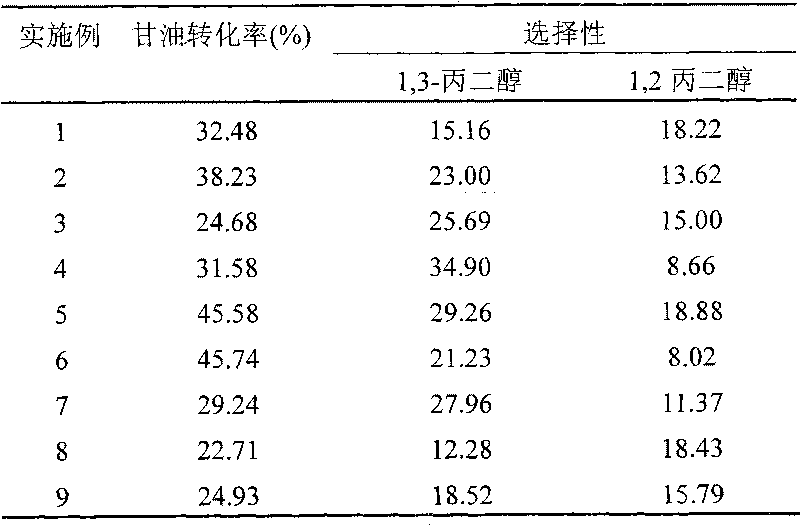

Method for preparing 1,3-propylene glycol by directly hydrogenizing glycerol

ActiveCN101723801AHigh selectivityImprove conversion ratePreparation by OH group eliminationMetal/metal-oxides/metal-hydroxide catalystsHydrogen pressureReaction temperature

The invention relates to a method for preparing 1,3-propylene glycol by directly hydrogenizing glycerol. A reaction system comprises glycerol, hydrogen, catalyzer and two or more of dissolvants. In the reaction system, the weight ratio of the dissolvants to the glycerol is 0.2-9.8:1, and the weight ratio of the catalyzer to the glycerol is 0.2-2:1; the reaction conditions are shown as follows: the reaction temperature is 80-300 DEC G, the hydrogen pressure is 0.1-18.0MPa, and the contact time of the glycerol and the catalyzer in the reaction process is 0.3-50h; the catalyzer contains a carrier and active components carried on the carrier, wherein the carrier is ZrO2, SiO2-Al2O3 or Al2O3, and the active components are one or more of Ru, Pt, Pd and Rh. The invention can obviously increase the selectivity of generating 1,3-propylene glycol by hydrogenizing glycerol or increase the percent conversion of glycerol and reduce the generation of the byproduct of 1,2-propylene.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

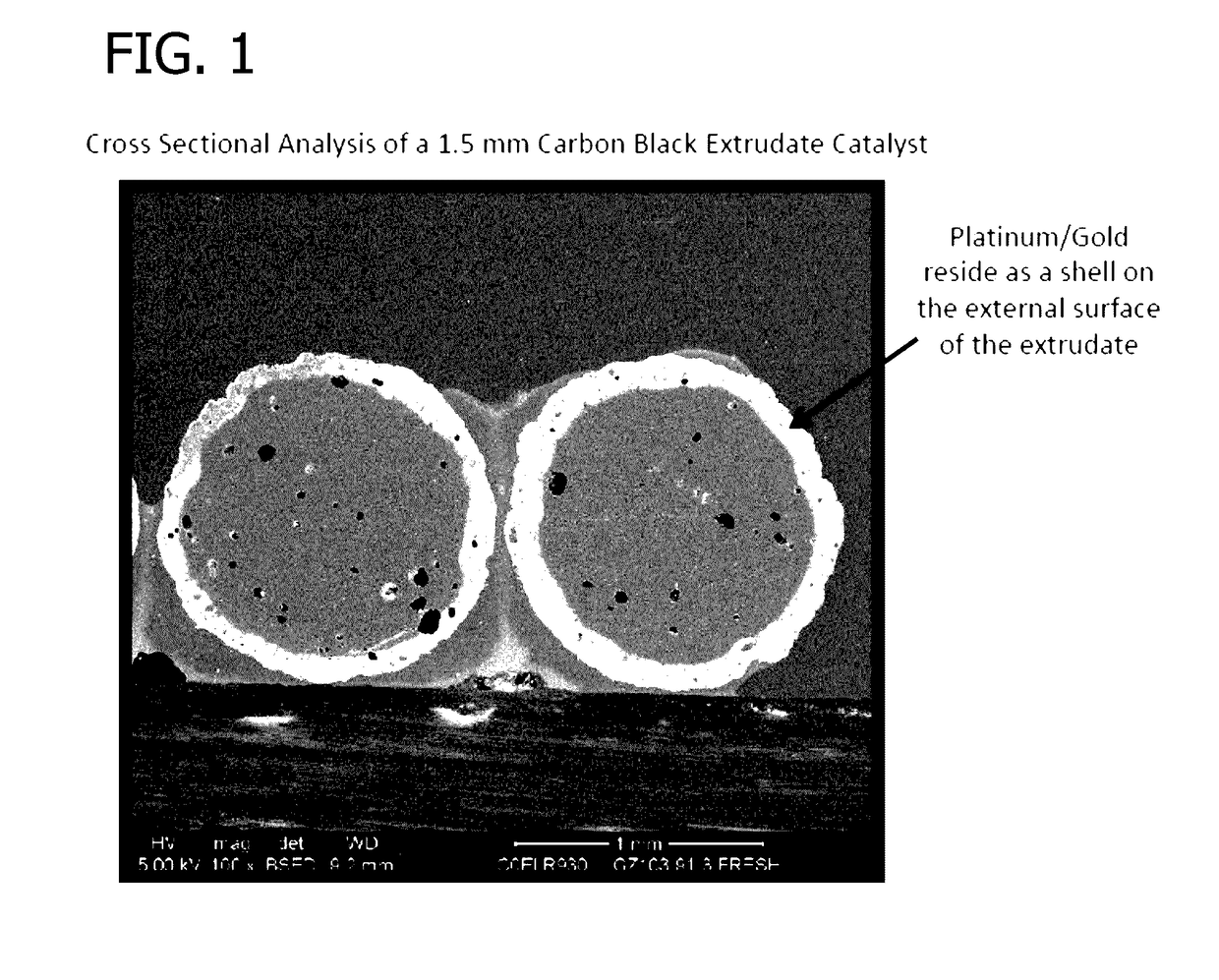

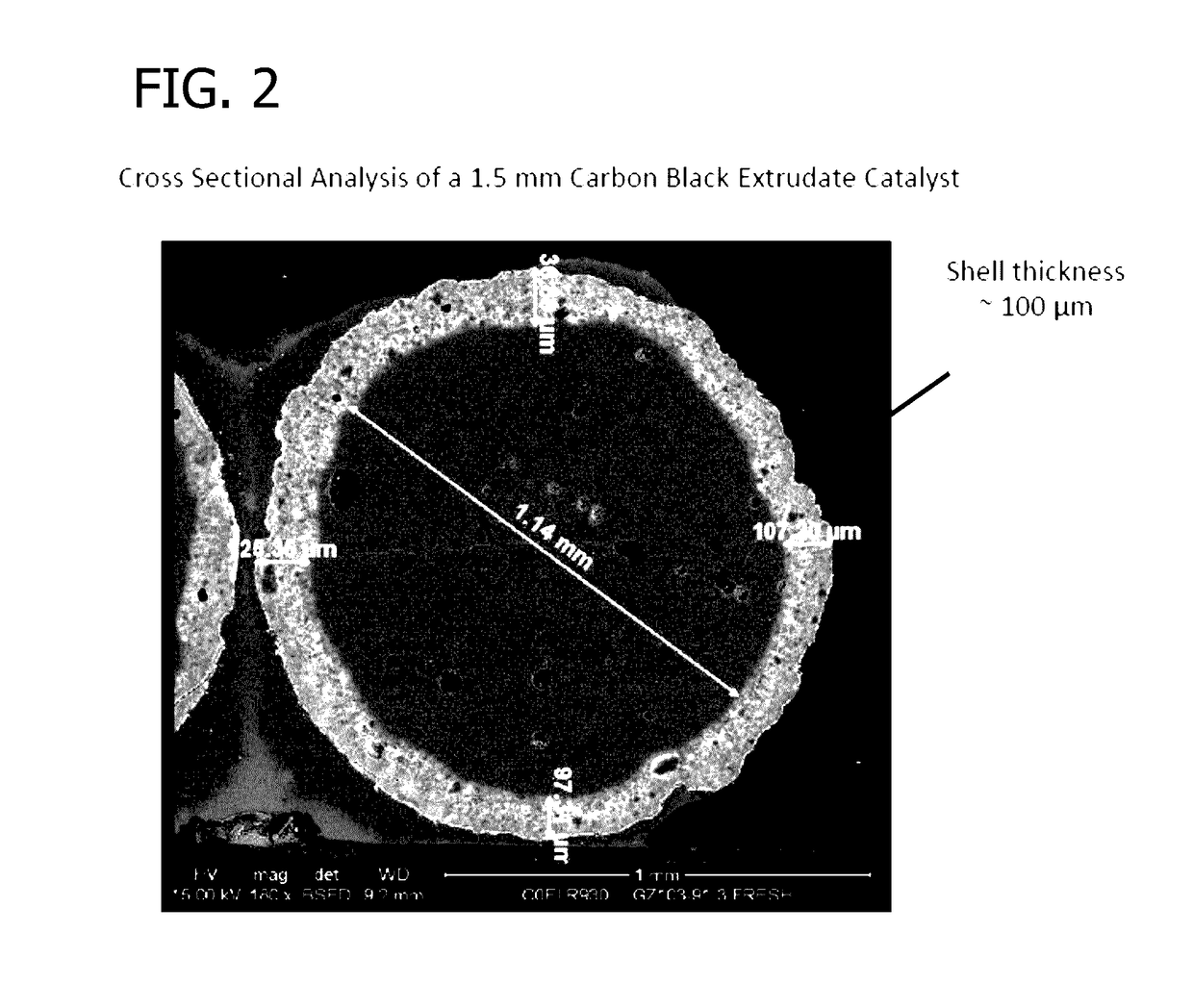

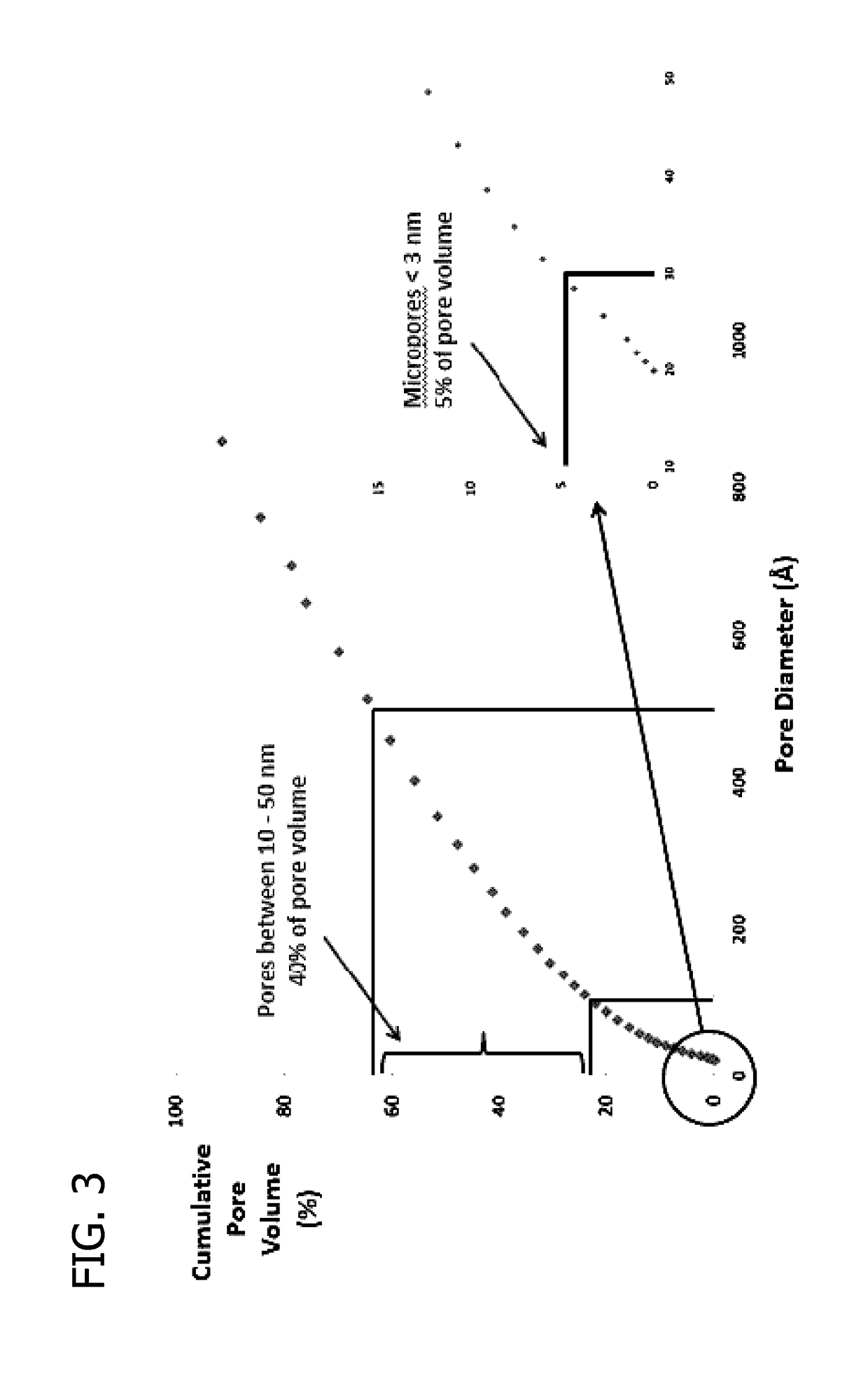

Porous shaped carbon products

ActiveUS20170120219A1Improve wettabilityPigmenting treatmentOrganic compound preparationPorous carbonSorbent

Shaped porous carbon products and processes for preparing these products are provided. The shaped porous carbon products can be used, for example, as catalyst supports and adsorbents. Catalyst compositions including these shaped porous carbon products, processes of preparing the catalyst compositions, and various processes of using the shaped porous carbon products and catalyst compositions are also provided.

Owner:ARCHER DANIELS MIDLAND CO

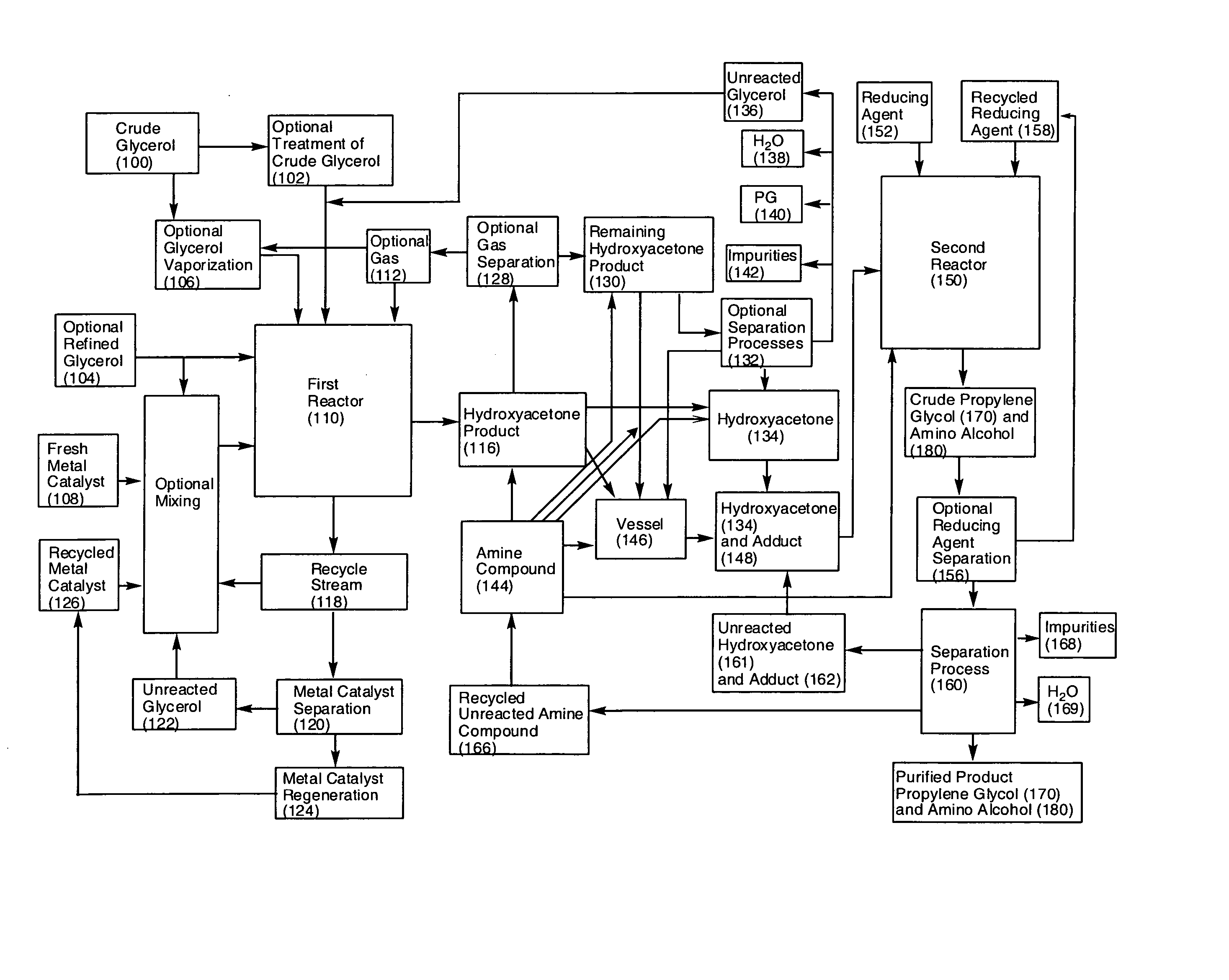

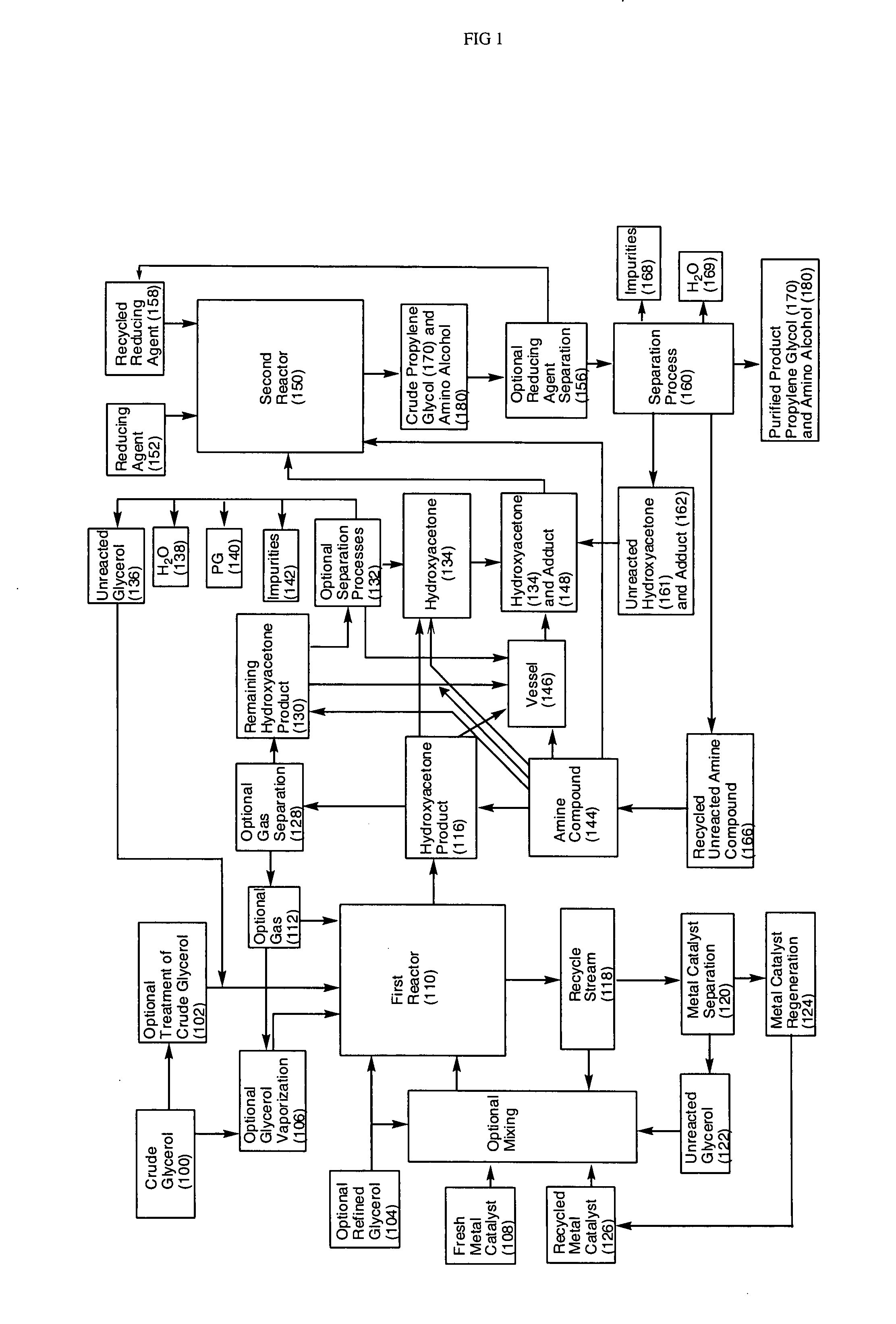

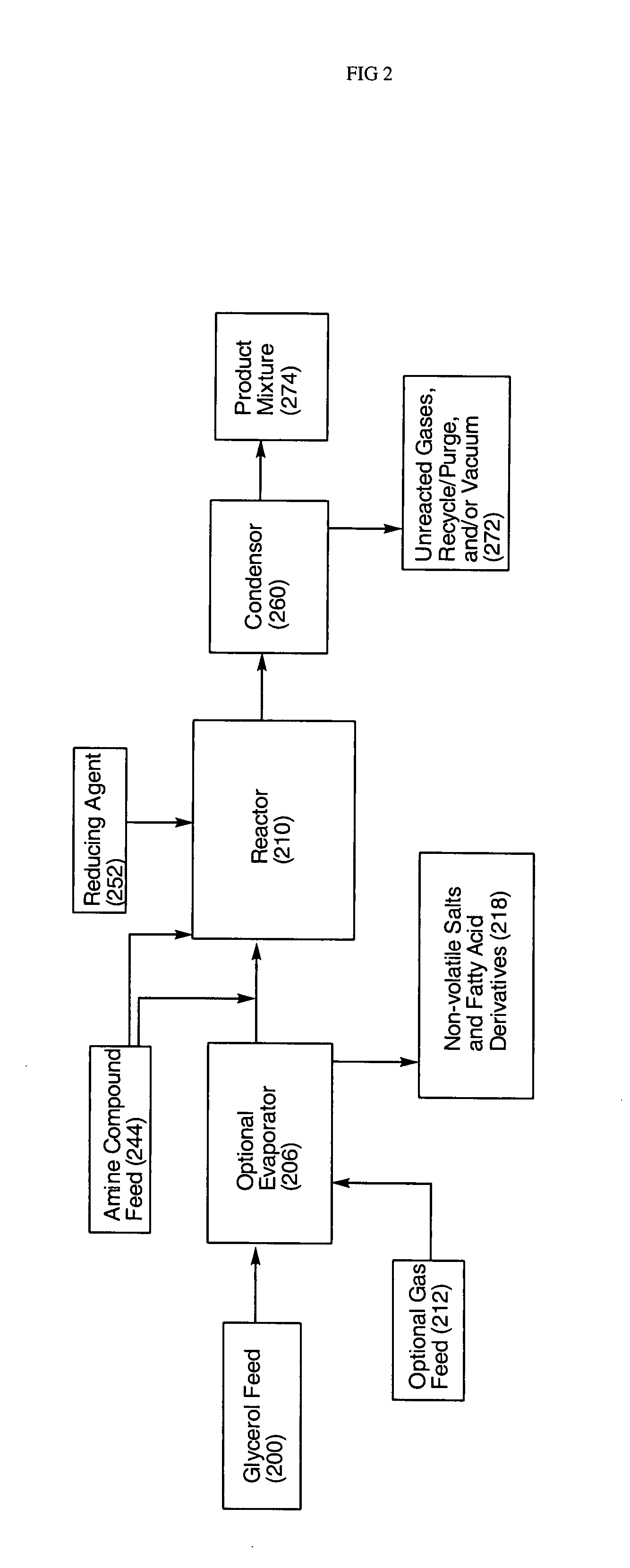

Process for the conversion of glycerol to propylene glycol and amino alcohols

ActiveUS20070287865A1Oxygen-containing compound preparationOrganic compound preparationGlycerolAlcohol products

Processes for the conversion of glycerol to a product mixture of an amino alcohol product and propylene glycol are disclosed. Glycerol is converted to hydroxyacetone and the hydroxyacetone is reduced with a reducing agent or reacted with an amine compound to give an adduct which is reduced using the reducing agent to obtain a product mixture of propylene glycol and an amino alcohol product.

Owner:THE PROCTER & GAMBLE COMPANY

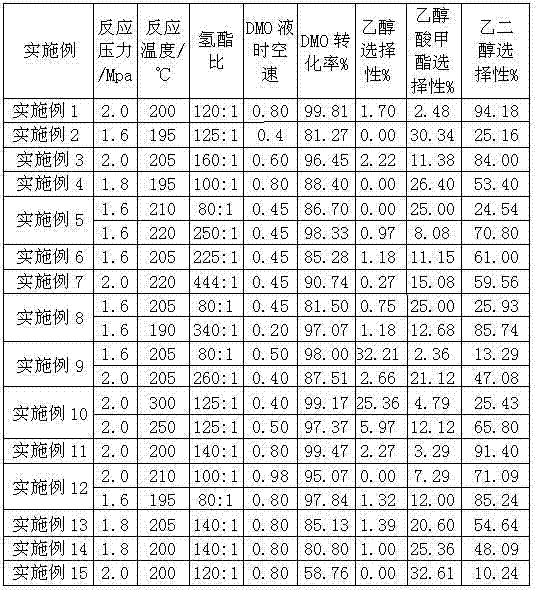

Method for producing ethylene glycol and 1,2-propylene glycol through continuous hydrocrackin of sugars

ActiveCN102643165BRealize continuous inputReduce consumptionOrganic compound preparationPreparation by OH group eliminationSucroseGas phase

The invention relates to a continuous reaction process for producing ethylene glycol and 1,2-propanediol by catalytic hydrocracking sugar conversion, and provides a method for producing ethylene glycol and 1,2-propanediol by continuous hydrogenation cracking sugar conversion. During this process, sugars (including one or more of sucrose, glucose, fructose, xylose, soluble xylooligosaccharides, and starch) are hydrocracked by catalysts in the reactor and then enter the separation system. The hydrogen in the gas phase is separated and recovered for recycling; part of the liquid phase product is returned to the reactor, and the rest of the liquid phase product is refined to separate ethylene glycol, propylene glycol, and other polyols; it exists in the remaining heavy components after refining and separation. Concentrate in the liquid phase The soluble catalyst components are partially recycled back to the reactor.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Process for producing hydrogenolysis products of polyhydric alcohols

ActiveUS8188321B2Good choiceHigh yieldOxygen-containing compound preparationMolecular sieve catalystsAlcoholPolyol

The present invention relates to a process for producing hydrogenolysis products of polyhydric alcohols with a good selectivity and a high yield, as well as hydrogenolysis catalysts used in the production process. The present invention provides (1) a process for producing a hydrogenolysis product of a polyhydric alcohol which includes the step of reacting the polyhydric alcohol with hydrogen in the presence of a catalyst containing a copper component, wherein the catalyst is a catalyst (A) containing the copper component, an iron component and an aluminum component, or a catalyst (B) containing the copper component and a silicon component; and (2) a hydrogenolysis catalyst for polyhydric alcohols which includes a copper component, an iron component and an aluminum component, and (3) a hydrogenolysis catalyst for polyhydric alcohols which includes a copper component and a silicon component.

Owner:KAO CORP

Methods of producing compounds from plant materials

The invention includes methods of processing plant material by adding water to form a mixture, heating the mixture, and separating a liquid component from a solid-comprising component. At least one of the liquid component and the solid-comprising component undergoes additional processing. Processing of the solid-comprising component produces oils, and processing of the liquid component produces one or more of glycerol, ethylene glycol, lactic acid and propylene glycol. The invention includes a process of forming glycerol, ethylene glycol, lactic acid and propylene glycol from plant matter by adding water, heating and filtering the plant matter. The filtrate containing starch, starch fragments, hemicellulose and fragments of hemicellulose is treated to form linear poly-alcohols which are then cleaved to produce one or more of glycerol, ethylene glycol, lactic acid and propylene glycol. The invention also includes a method of producing free and / or complexed sterols and stanols from plant material.

Owner:BATTELLE MEMORIAL INST

Method for preparing 1,2-dihydroxypropane by glycerine hydrogenation

ActiveCN101085719AHigh activityGood choicePreparation by OH group eliminationPreparation by oxygen reductionHydrogenBiodiesel

The invention provides a method for preparing 1, 2- methyl glycol through glycerin hydrogenation. The glycerin, diluted glycerin or side product coarse glycerin of biodiesel mixes with hydrogen gas or hydrogen gas- containing gas, and reacts under catalyst action to produce 1, 2- methyl glycol. The conversion rate is high.

Owner:SHANGHAI HUAYI NEW MATERIAL

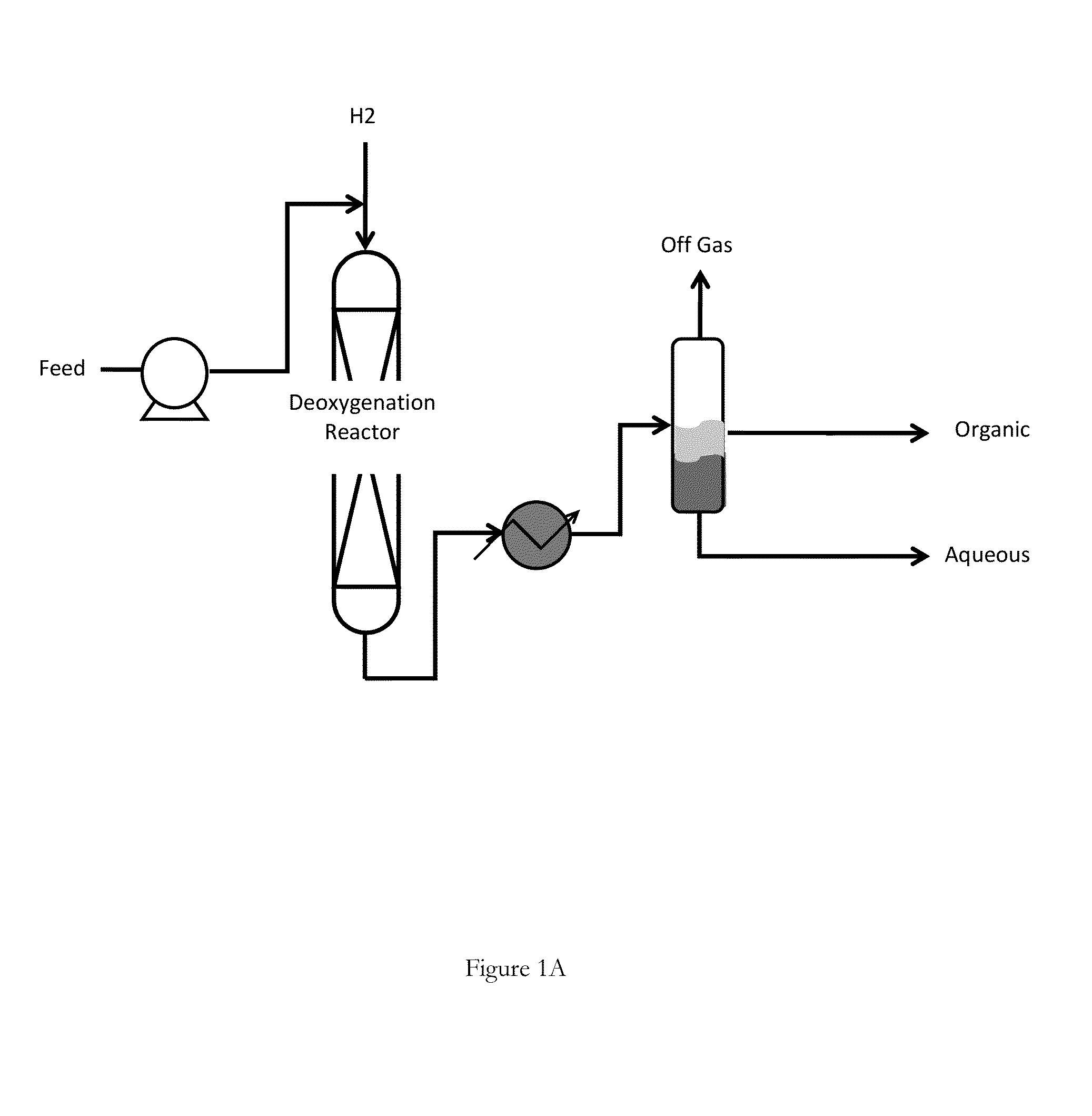

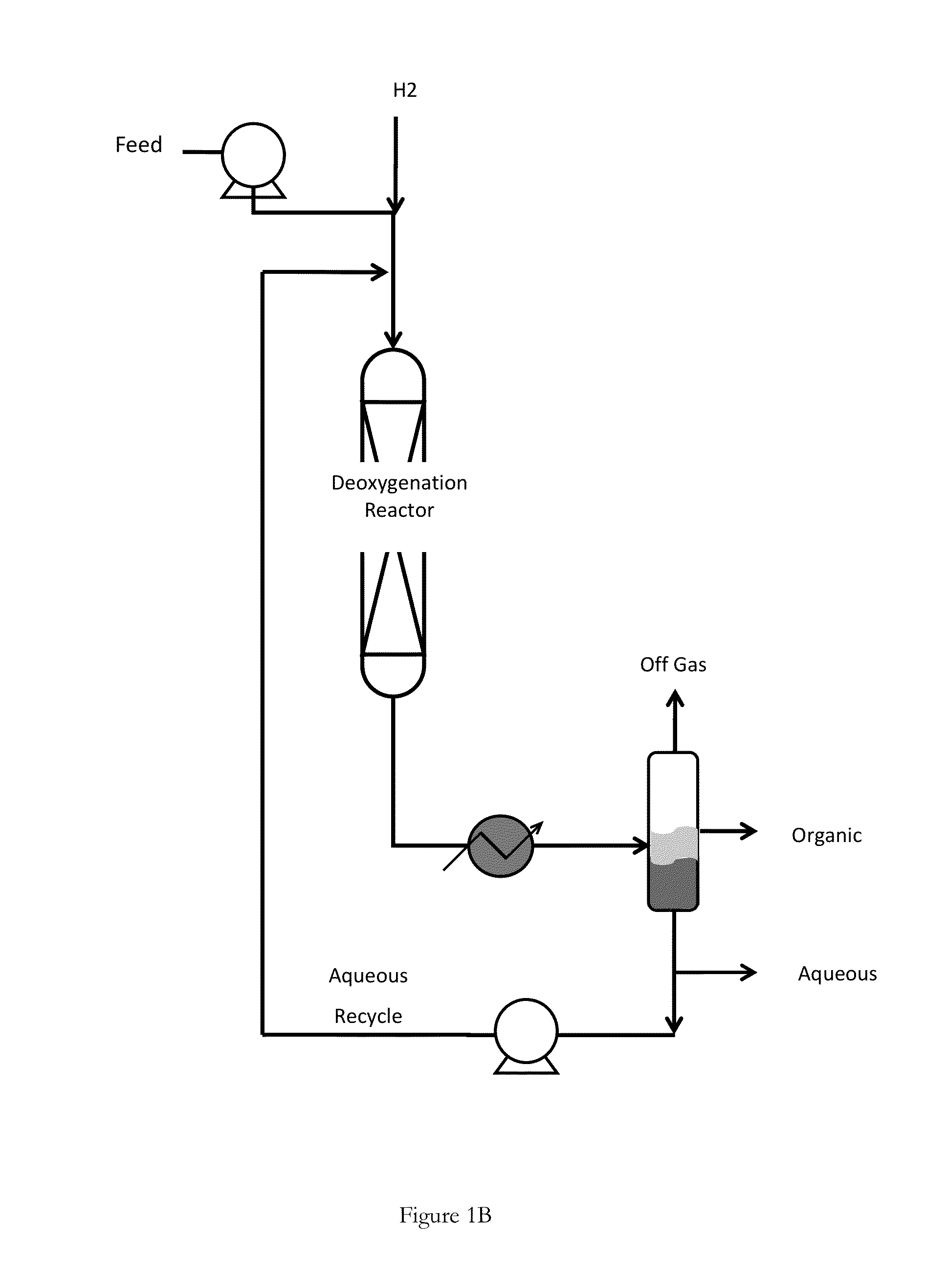

Processes for Converting Biomass-Derived Feedstocks to Chemicals and Liquid Fuels

ActiveUS20140273118A1Preparation by OH group eliminationLiquid hydrocarbon mixture productionHydrogenHydrolysate

The present invention provides processes, methods, and systems for converting biomass-derived feedstocks to liquid fuels and chemicals. The method generally includes the reaction of a hydrolysate from a biomass deconstruction process with hydrogen and a catalyst to produce a reaction product comprising one of more oxygenated compounds. The process also includes reacting the reaction product with a condensation catalyst to produce C4+ compounds useful as fuels and chemicals.

Owner:VIRENT

Catalyst for preparing 1,2-propylene glycol by glycerol hydrogenation and use thereof

ActiveCN101239315AEfficient preparationPreparation by OH group eliminationMetal/metal-oxides/metal-hydroxide catalystsCelsius DegreeHydrogen pressure

The present invention provides a catalyst for preparing 1, 2-trimethylene glycol using glycerol and hydrogen, and its application. The catalyst precursors are prepared by coprecipitation method or immersion method, the constitute of non-oxygen element is Cu-Zr-A, A is one selected from titanium, tungsten or molybdenum, Cu is 4-40% by weight percentage composition of the catalyst precursors, A / Zr ratio is 0.1-10; the catalyst being reduction activation in hydrogen stream under 200-450 Celsius before being used. The catalyst shows excellent catalyzing effect in the preparing course of the 1, 2-trimethylene glycol using glycerol and hydrogen, and lower hydrogen pressure, reacting temperature, high selectivity and life.

Owner:SHANGHAI HUAYI NEW MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com