Method for producing 1-propylene glycol with glycerol hydrogenation

A technology for the preparation of hydrogen and propylene glycol, which is applied to the hydrogenation of glycerol to prepare 1, which can solve the problems of environmental pollution, low selectivity and conversion rate, and achieve the effect of simple catalyst composition, high selectivity and high conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Add 30 grams of copper nitrate and 200 ml of water into the reactor, and stir the solution at 30°C. Titrate with 15% sodium hydroxide and stop when pH=8-9. Solution A was formed.

[0023] Mix solution A with 44ml of silica sol containing 40% silica, heat up to 80°C, age for 4 hours; filter; dry at 120°C for 16 hours, and bake at 400°C for 4 hours. Get CuO(30%wt) / SiO 2 (70%wt) hydrogenation catalyst. The above-mentioned catalyst is crushed into small particles, sieved, and set aside.

Embodiment 2

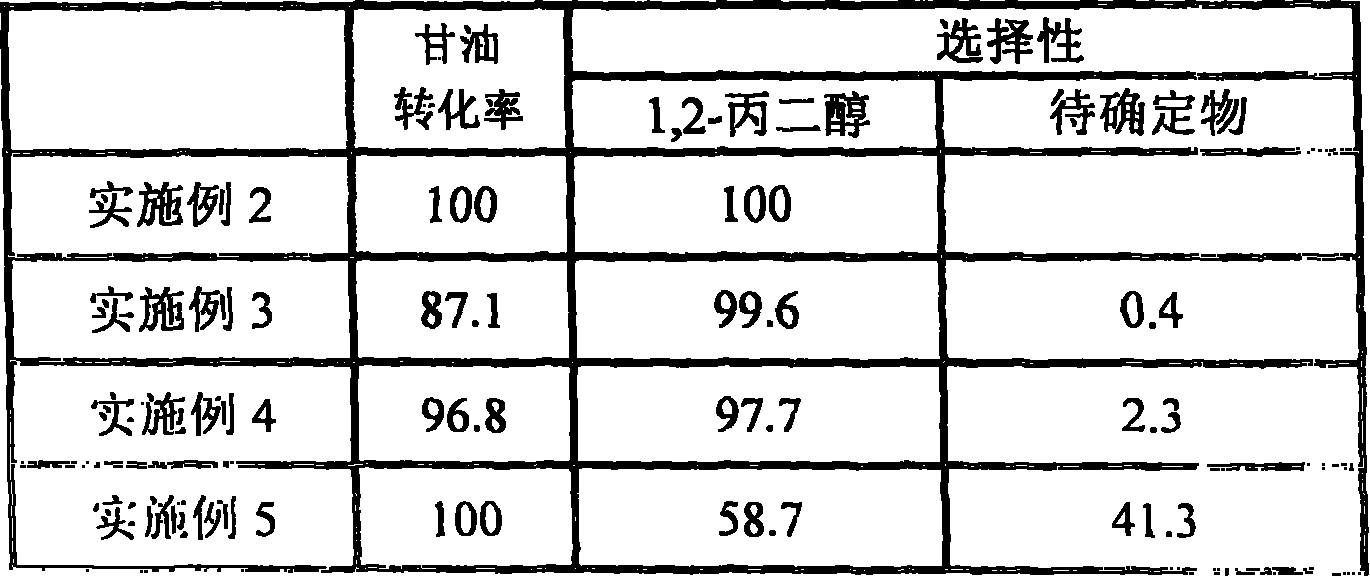

[0025] Hydrogen reduction of the above catalyst particles, 5% glycerin methanol solution. A tank reaction was adopted, and the hydrogenation reaction was carried out at 150° C. and 6.5 MPa for 12 hours. The catalyst was isolated and sampled for gas chromatographic analysis. The results are shown in Table 1.

Embodiment 3

[0027] The above catalyst particles were reduced with hydrogen, 20% glycerol in methanol. A tank reaction was adopted, and the hydrogenation reaction was carried out at 150° C. and 6.5 MPa for 12 hours. The catalyst was isolated and sampled for gas chromatographic analysis. The results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com