Method for preparing 1,3-propylene glycol by directly hydrogenizing glycerol

A technology of propylene glycol and glycerol, applied in chemical instruments and methods, preparation of hydroxyl elimination, metal/metal oxide/metal hydroxide catalyst, etc., can solve the problems of low selectivity, low production efficiency, low economy, etc. The effect of increasing conversion rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

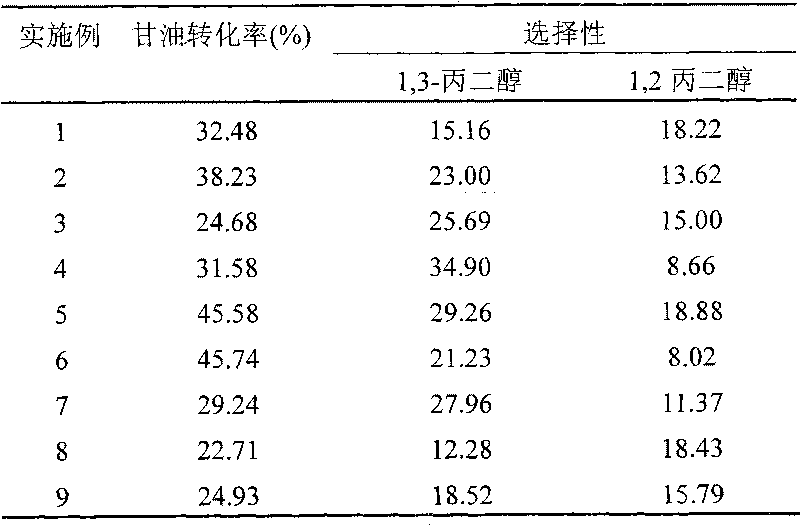

Examples

Embodiment 1

[0022] The catalyst used is Pt / WO 3 / ZrO 2 . Catalyst weight composition is: Pt%=2%, WO 3 %=20%, the rest is carrier ZrO 2 . Carrier ZrO 2 It is prepared by precipitation method, and the catalyst active component Pt and auxiliary agent WO are prepared by conventional impregnation method. 3 Loaded on the prepared carrier ZrO 2 superior. The catalyst is activated by hydrogen before the reaction. The activation conditions are: temperature 400°C, hydrogen pressure 0.1MPa, hydrogen space velocity 1000h - , The activation time is 2h. A slurry bed reactor is selected, the solvent is 1,3-dimethyl-2-imidazolidinone, the weight ratio of the solvent to glycerin in the reaction system is 9:1, and the weight ratio of the catalyst to glycerol is 1:1. The reaction temperature is 170°C, the hydrogen pressure is 5.5Mpa, and the reaction time is 4h.

Embodiment 2

[0024] The solvent used is ethanol, and other conditions are the same as in Example 1.

Embodiment 3

[0026] The solvent used is water, and other conditions are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com