Method for producing ethylene glycol and 1,2-propylene glycol through continuous hydrocrackin of sugars

A technology for hydrocracking and ethylene glycol, applied in 1, can solve the problems of time-consuming, inconvenient operation, waste of energy and materials, etc., and achieve the effects of reducing production costs, facilitating take-out and saving use costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

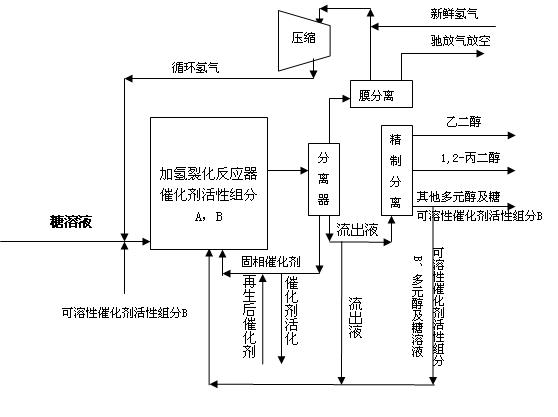

Method used

Image

Examples

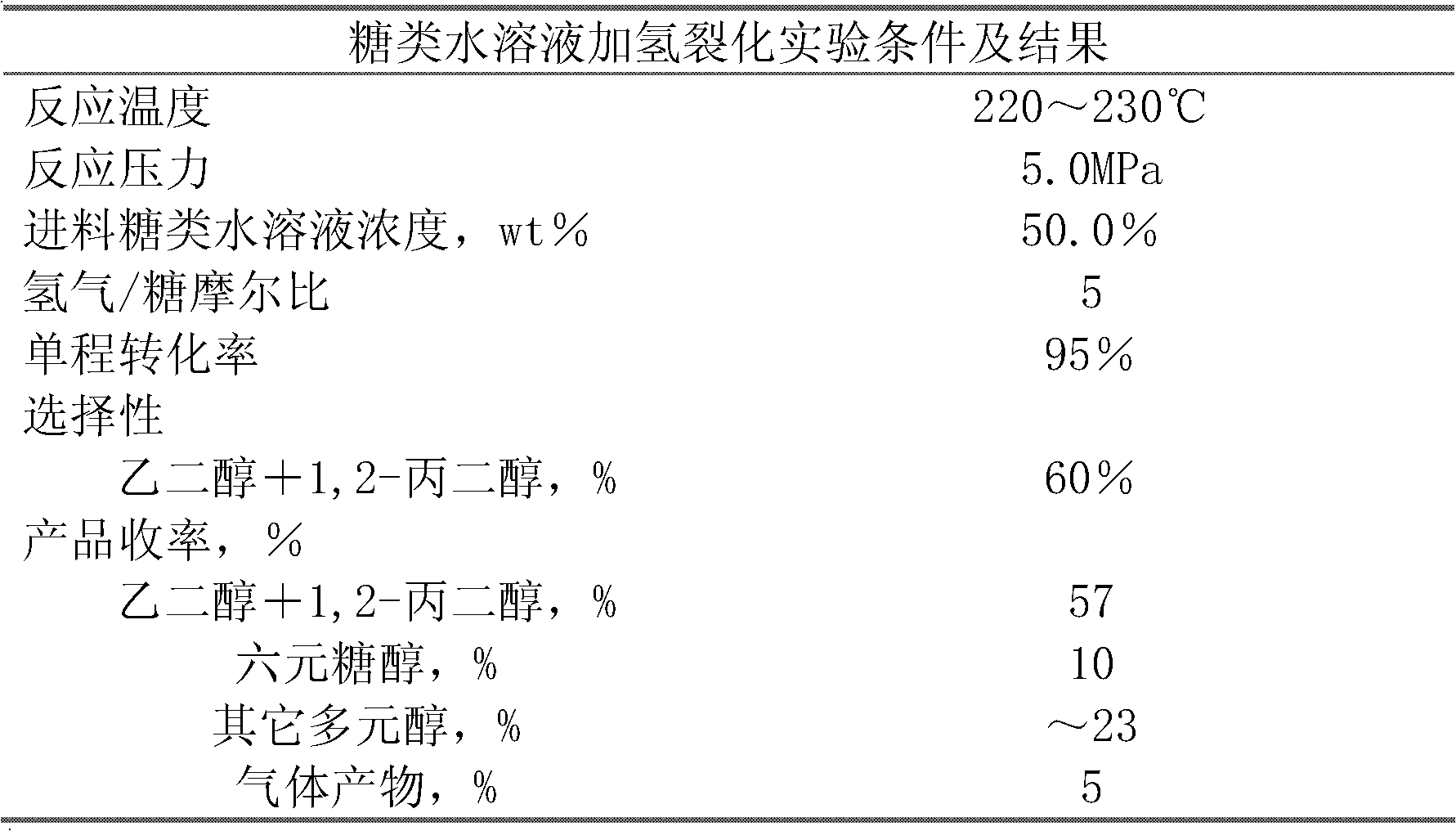

Embodiment 1

[0031] The glucose of 50wt% and the ammonium metatungstate 0.1wt% (in terms of metal tungsten weight) aqueous solution of 50wt% enter hydrogenation reactor by high-pressure pump, are filled with the Ru / AC of slurry state and tungstic acid catalyst (ruthenium The weight ratio of tungsten to tungsten is 1:10, water is used as solvent to immerse the catalyst at the beginning of the reaction), the weight ratio of sugar raw material to catalyst (the sum of the weight of ruthenium and tungsten elements) is between 450:1 and 460:1, and the volume is empty Speed is 2 to 3. The temperature of the reactor is 220-230° C., and the hydrogen pressure is 5 MPa. Hydrogen enters from the bottom of the reactor and stirs the catalyst slurry. The reaction solution enters the reactor and is discharged from the upper outlet of the reactor after being reacted, accompanied by 1wt% solid catalyst (Ru / AC), part of hydrogen and gas products. The reactor effluent then enters a separator to separate g...

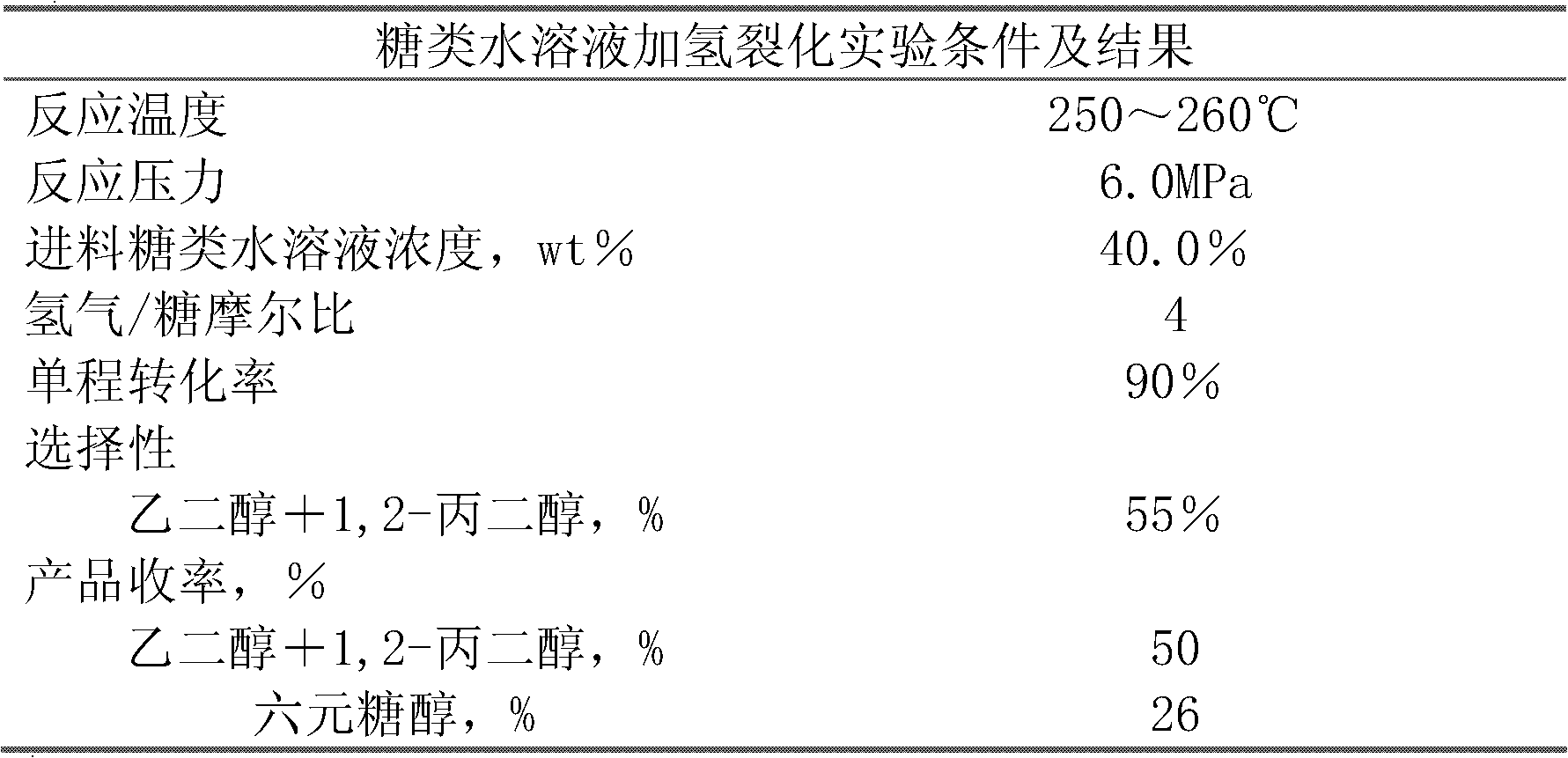

Embodiment 2

[0040] The glucose of 40wt% and the ammonium metatungstate 0.05wt% (in terms of metal tungsten weight) aqueous solution of 40wt% enter hydrogenation reactor by high-pressure pump, the Ru / AC of slurry state and tungstic acid catalyst (ruthenium The weight ratio of tungsten to tungsten is 1:5, water is used as solvent to immerse the catalyst at the beginning of the reaction), the weight ratio of sugar raw material to catalyst (the sum of the weight of ruthenium and tungsten elements) is between 800:1 and 750:1, and the volume is empty The speed is 10 to 20. The temperature of the reactor is 250-260° C., and the hydrogen pressure is 6 MPa. Hydrogen enters from the bottom of the reactor and stirs the catalyst slurry. The reaction liquid enters the reactor and is discharged from the upper outlet of the reactor after being reacted, accompanied by some hydrogen and gas products. Then the reactor effluent enters the separator to separate the gas and liquid parts.

[0041] The gas p...

Embodiment 3

[0049] The glucose of 60wt% and the ammonium metatungstate 0.2wt% (in terms of metal tungsten weight) aqueous solution of 60wt% enter hydrogenation reactor by high-pressure pump, the Ru / AC and tungstic acid catalyst (ruthenium of ruthenium) of slurry state are packed in the reactor The weight ratio to tungsten is 1:1, the catalyst is immersed in water as solvent at the beginning of the reaction), the weight ratio of sugar raw material to catalyst (the sum of the weight of ruthenium and tungsten elements) is 150:1, and the volume space velocity is 70 to 80. The temperature of the reactor is 240-250° C., and the hydrogen pressure is 10 MPa. Hydrogen enters from the bottom of the reactor and stirs the catalyst slurry. The reaction liquid enters the reactor and is discharged from the upper outlet of the reactor after being reacted, accompanied by a part (0.5-2wt%) of solid catalyst (Ru / AC), part of hydrogen and gas products. The reactor effluent then enters a separator to separat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com