A method and device for treating printing and dyeing wastewater by fenton oxidation using iron filings as an iron source

A printing and dyeing wastewater, oxidation treatment technology, applied in the direction of oxidation water/sewage treatment, chemical instruments and methods, special compound water treatment, etc., can solve the problems of a large amount of iron sludge, secondary pollution, unfavorable wastewater continuous treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

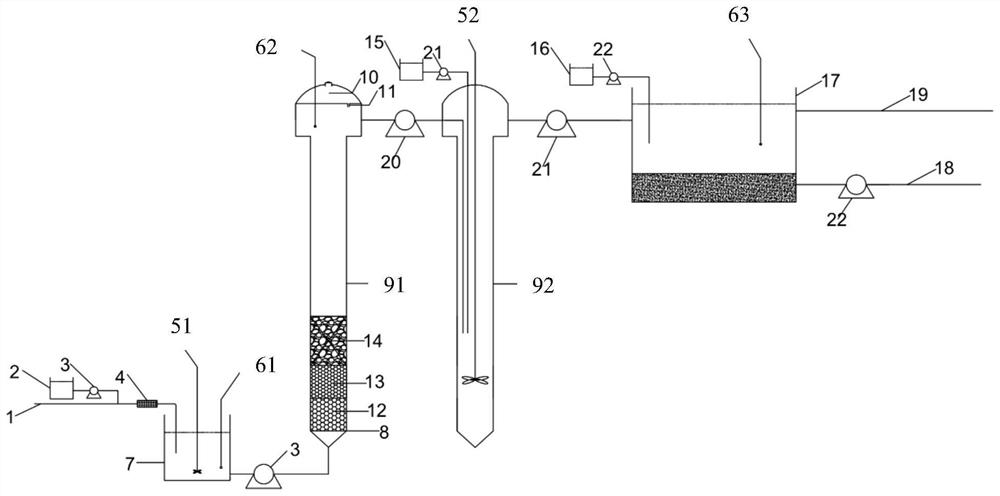

[0070] Example 1, Fenton oxidation treatment of printing and dyeing wastewater using iron filings as an iron source

[0071] like figure 1 Shown is a schematic structural view of the device for the Fenton oxidation treatment of printing and dyeing wastewater using iron filings as the iron source in the present invention.

[0072] The design parameters of each component are as follows: the water inlet pipe a 1 is made of 304 stainless steel (anti-acid); the acid medicine tank 2 is made of phenolic resin-lined steel, and the design size is Φ20×20cm; the water pump a 3 is made of CN-7M (alloy 20) Type water pump, the pipeline where the water pump a 3 is located is made of 304 stainless steel; the size of the pH adjustment pool 7 is 50×50×50cm, and it is made of carbon steel for corrosion protection; Fe 2+ The main material of the dissolution tower 91 adopts glass fiber reinforced plastics (FRP), and the tower body is divided into 3 parts. The lower part of the tower is H=100cm, ...

Embodiment 2

[0075] experimental method:

[0076] The waste water enters through the water inlet pipe 1. Start the centrifugal pump to extract the H in the acid medicine tank 2 2 SO 4 , enter the pH adjustment pool through the pipeline mixer 4, open the stirring paddle 5, and adjust the H in real time according to the pH detector 6 2 SO 4 The amount of input is to ensure that the pH of the wastewater is stable as early as 2±0.2. The wastewater in the regulating tank enters the Fe through the centrifugal pump 2+ Stripping tower 9, at this moment, the H produced 2 Enter the air storage tank 10 through the air duct 11, and the contact time between the waste water and the iron filings filling layer depends on the experimental conditions. mixed Fe 2+ The waste water enters the Fenton reaction tower 9 through a centrifugal pump, from the H 2 o 2 Add H to the medicine tank 2 o 2 solution, and the stirring paddle 5 is turned on, and the residence time is determined through experiments a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com