Patents

Literature

144results about How to "Enables continuous processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Deep treatment process of oily wastewater

ActiveCN102060350ASolving Deep Processing ChallengesImplement deep processingFatty/oily/floating substances removal devicesCombustible gas purificationActivated carbonSorbent

The invention relates to a deep treatment process of oily wastewater, which is characterized in that an absorption system and a regeneration system are provided in the process, wherein the absorption system is formed by a series of absorption tower groups with columns in series used for realizing parallel operation, the absorption tower groups are used for alternately performing deep treatment on oily yielding water with a low concentration of 30-50 mg / L of a traditional process, the absorption operation is carried out at normal temperature, the oil content in the yielding water is controlled to be lower than 1 mg / L through the treatment of a group of the absorption towers with columns in series, and an absorbing agent is made of modified fly ash, activated carbon and an expanded graphite absorbing material; when the yielding water in a group of the absorption towers exceeds a treatment requirement, the group of the absorption towers is switched to a biological regeneration system, and other absorption tower groups are simultaneously switched to the absorption system for continuous absorption; and saturated absorption towers are used for performing in-situ regeneration on the saturated absorbing agent by utilizing degradation ability of high temperature-resistant and efficient petroleum hydrocarbon for degrading bacteria.

Owner:CHINA NAT OFFSHORE OIL CORP +2

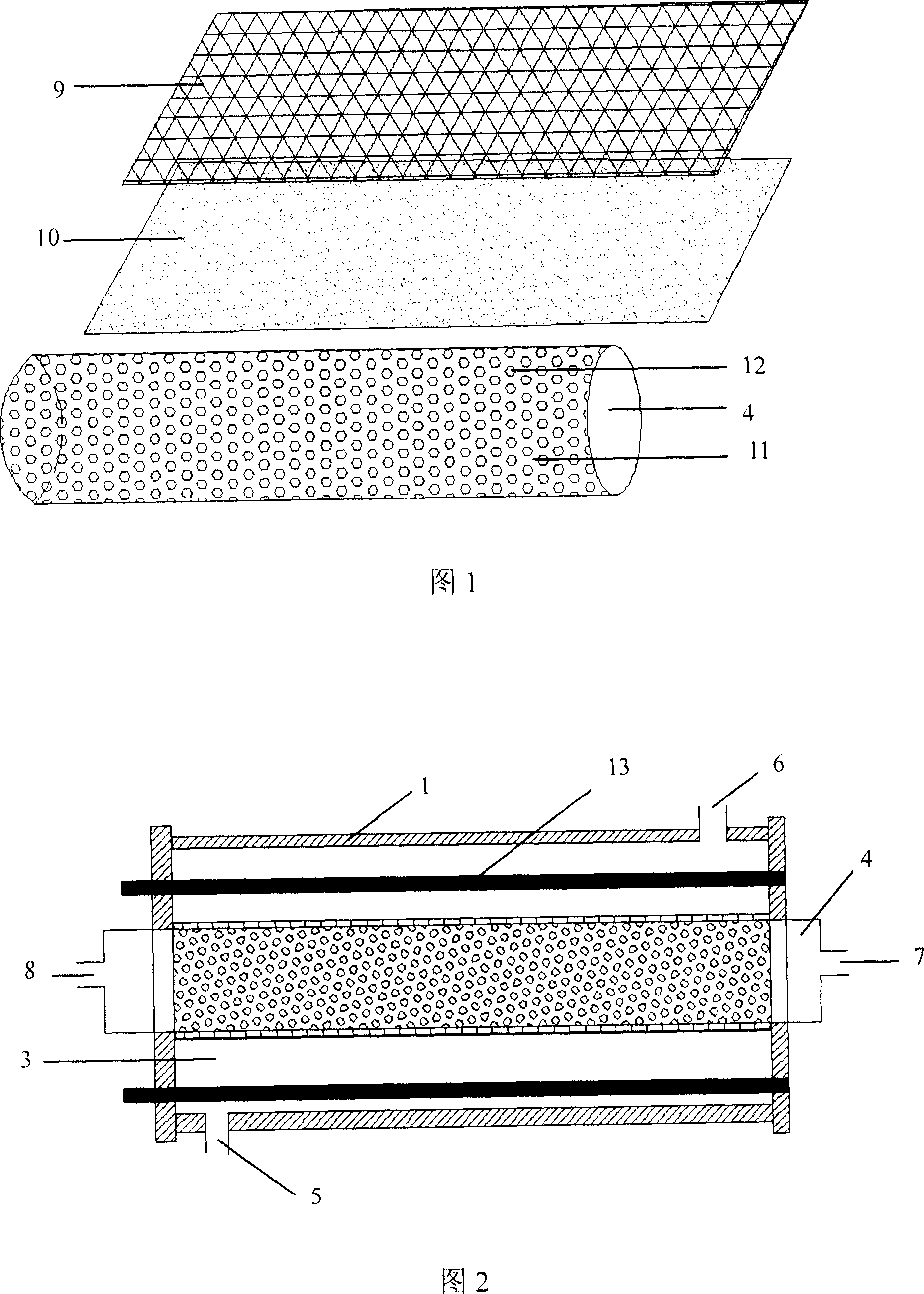

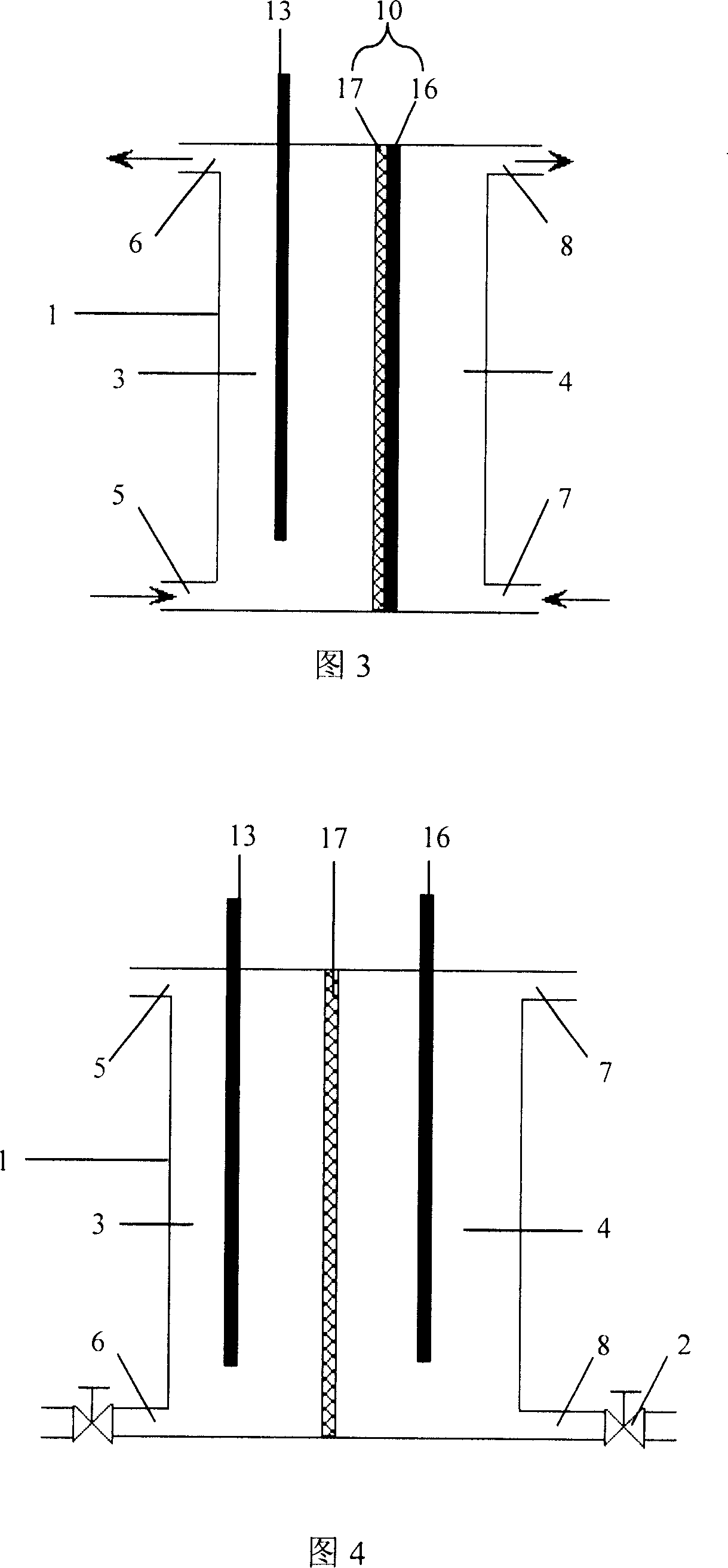

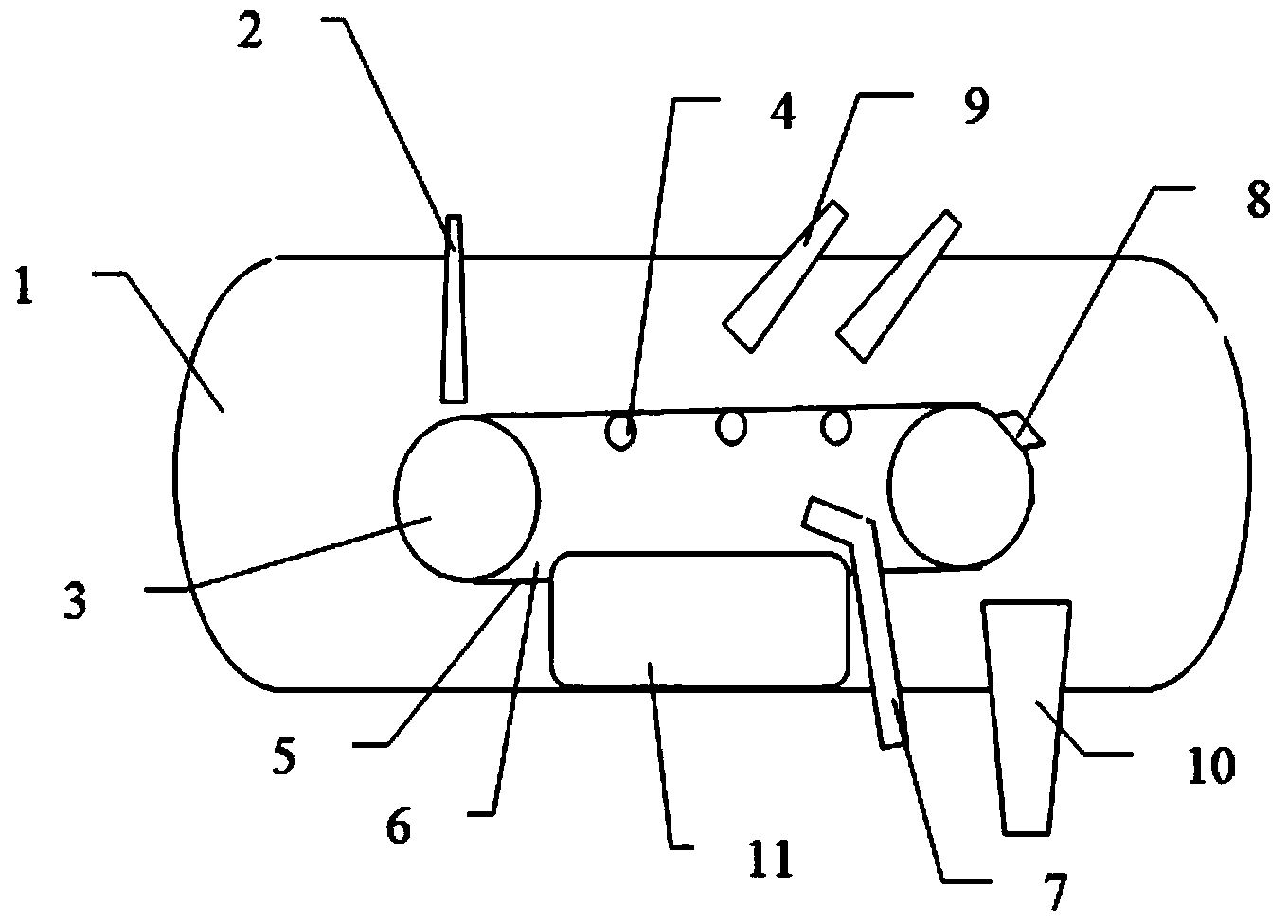

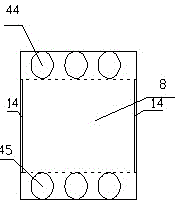

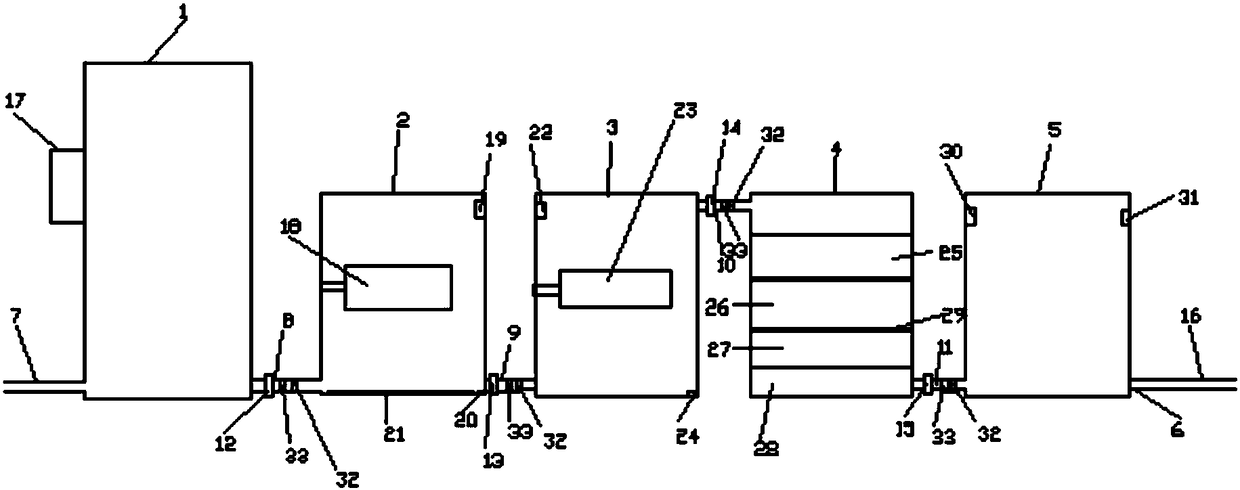

Microbiological fuel cell device and battery and use and water treatment system

InactiveCN101118973AIncrease reaction rateImprove migration efficiencyBiochemical fuel cellsBiological water/sewage treatmentEngineeringWater treatment system

A microorganism fuel cell device comprises an outer cover(1) of the fuel cell, an anode chamber(3), an anode(13), a cathode chamber(4), a cathode(16) and a septum(17). Wherein, the anode(13) is positioned inside the anode chamber(3); the septum(17) is positioned between the anode chamber(30) and the cathode chamber(4). The cathode(16) is a slice-shaped cathode, one surface of the slice-shaped cathode and one surface of septum(17) are jointed to form a septum cathode component(10); the surface of slice-shaped cathode not jointing with the septum(17) is positioned at one side of the cathode chamber(4). As the disclosed microorganism fuel cell device forms the septum cathode component by jointing the slice-shaped cathode with the septum, the invention further improves the moving efficiency of the media and also speeds up the cathode reaction, so that the overall reacting speed of the microorganism fuel cell for the device is greatly improved. Therefore, the invention can realize the large scaled successive disposal of the waste water.

Owner:BYD CO LTD

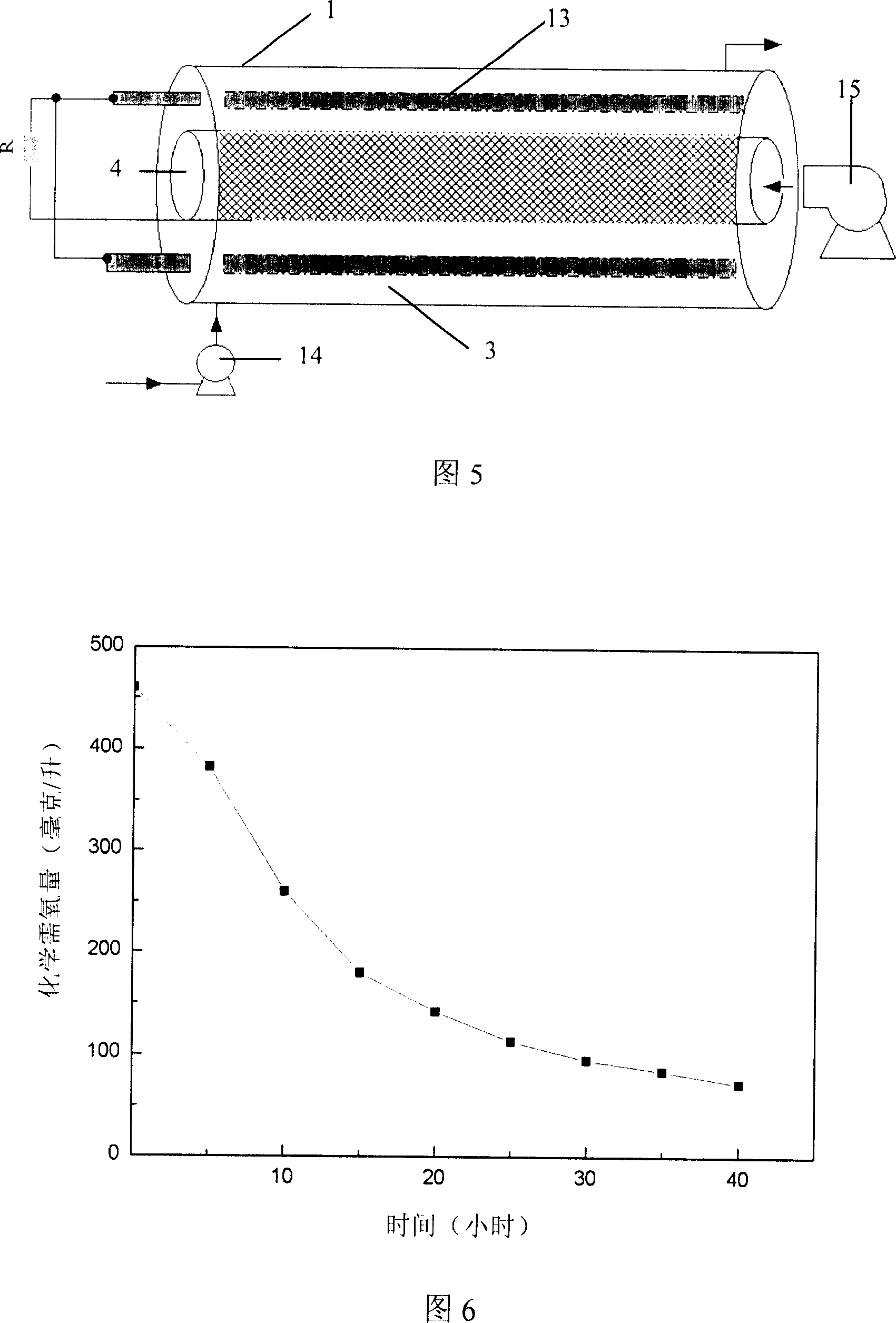

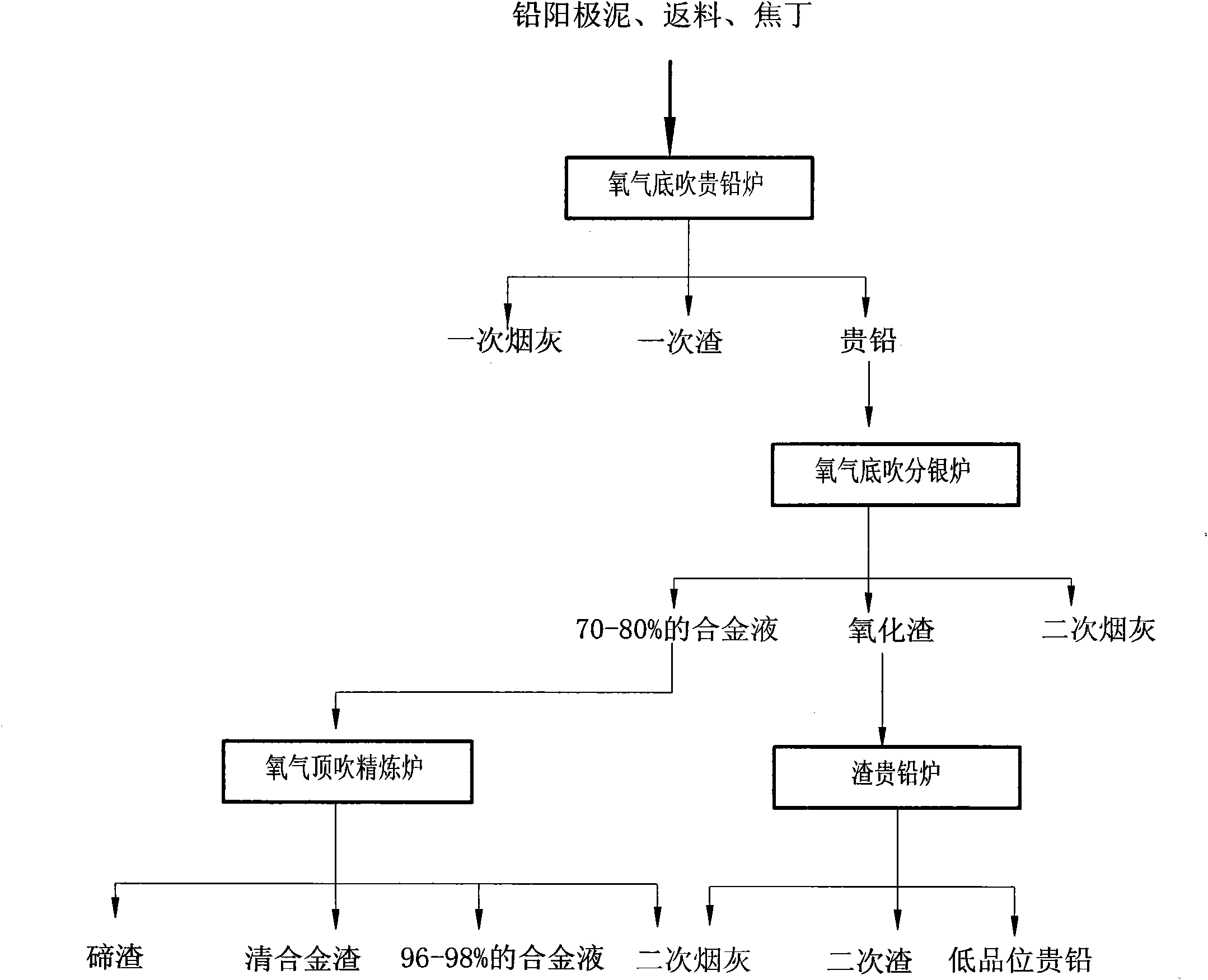

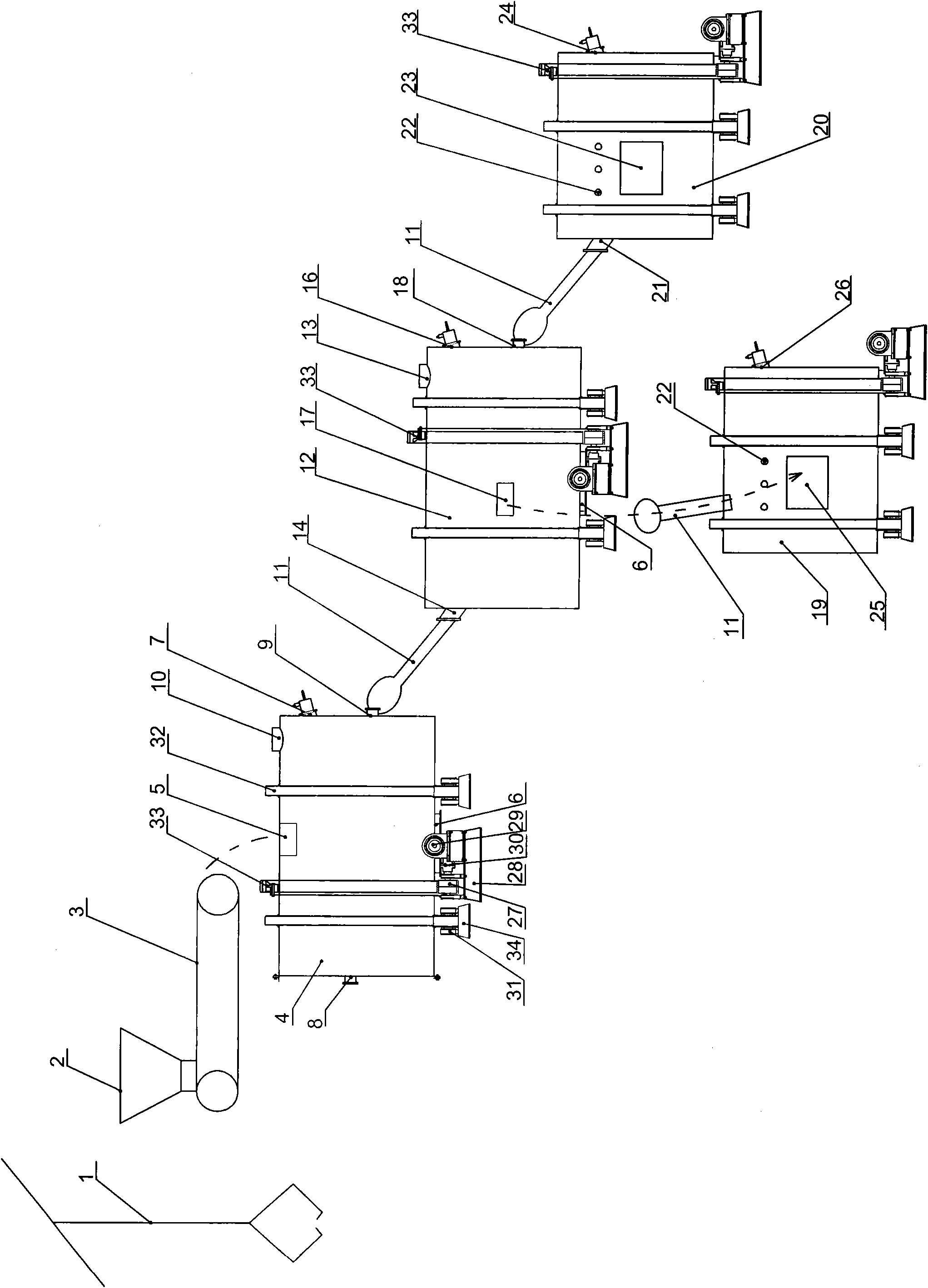

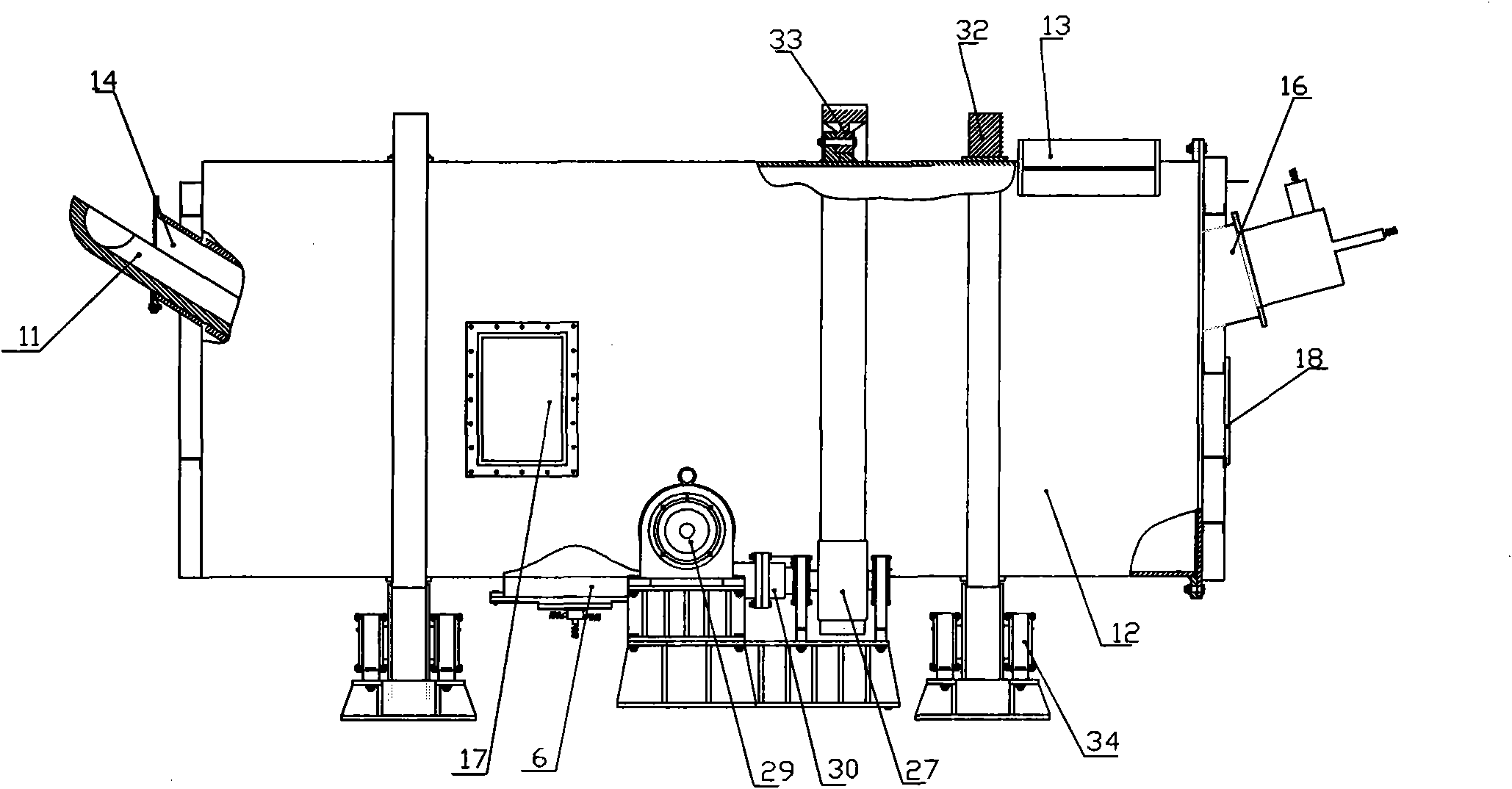

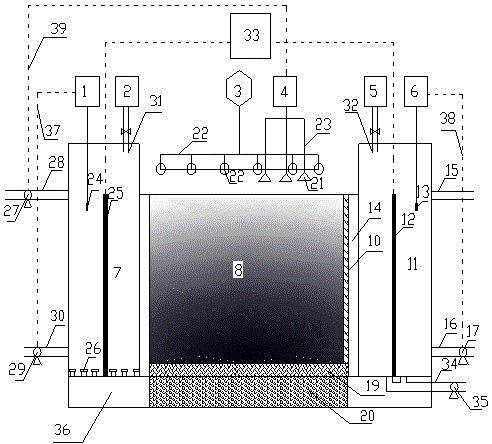

Method and device for continuously treating lead anode slime

ActiveCN101892388AEnables continuous processingShort processing cycleProcess efficiency improvementMelting tankSmelting process

The invention relates to a method and device for continuously treating lead anode slime by bath smelting. The method comprises the following steps: proportionally adding lead anode slime, recycled materials and nut coke as charging materials into an oxygen bottom blowing bullion lead furnace for smelting to generate bullion lead of which the bullion grade is 25-50%, primary slag and primary soot; adding the bullion lead into an oxygen bottom blowing silver-smelting furnace to react to generate oxidizing slag, secondary soot and alloy liquid of which the bullion grade reaches 70-80%; introducing the alloy liquid into an oxygen top blowing refining furnace to react to generate tellurium slag, clear alloy slag, secondary soot and alloy liquid of which the bullion grade reaches 96-98%; and discharging the oxidizing slag, then enabling the oxidizing slag to enter a slag bullion lead furnace, and adding the nut coke to react to generate low-grade bullion lead, secondary slag and secondary soot, wherein the low-grade bullion lead is returned for proportioning. The invention realizes the continuous treatment of the anode slime, strengthens the smelting process, improves the direct recovery rate of the bullion, lowers the production cost, reduces the environmental pollution, and shortens the treatment period of the anode slime.

Owner:JIYUAN YUGUANG NONFERROUS METALLURGY DESIGN & RES INST CO LTD

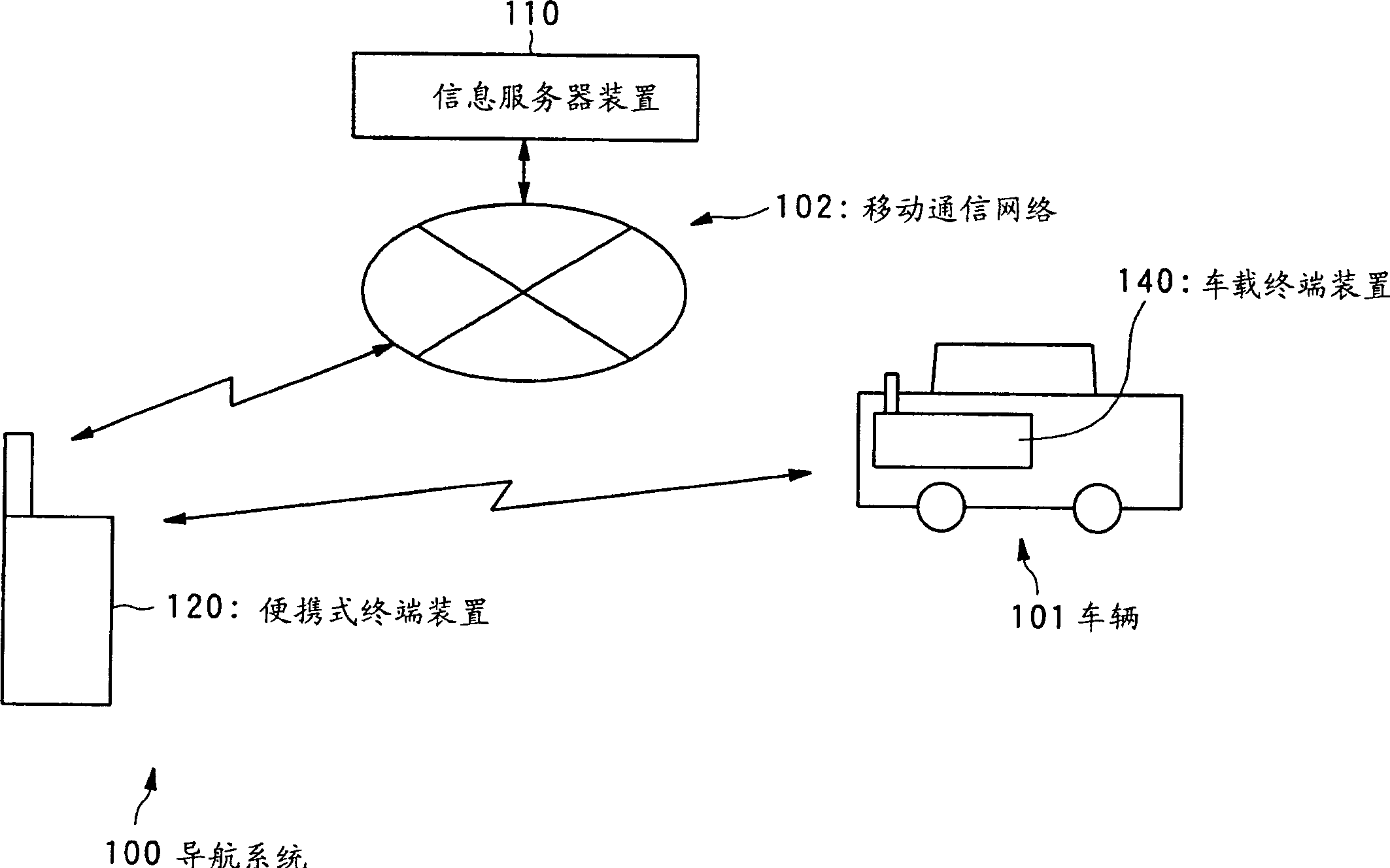

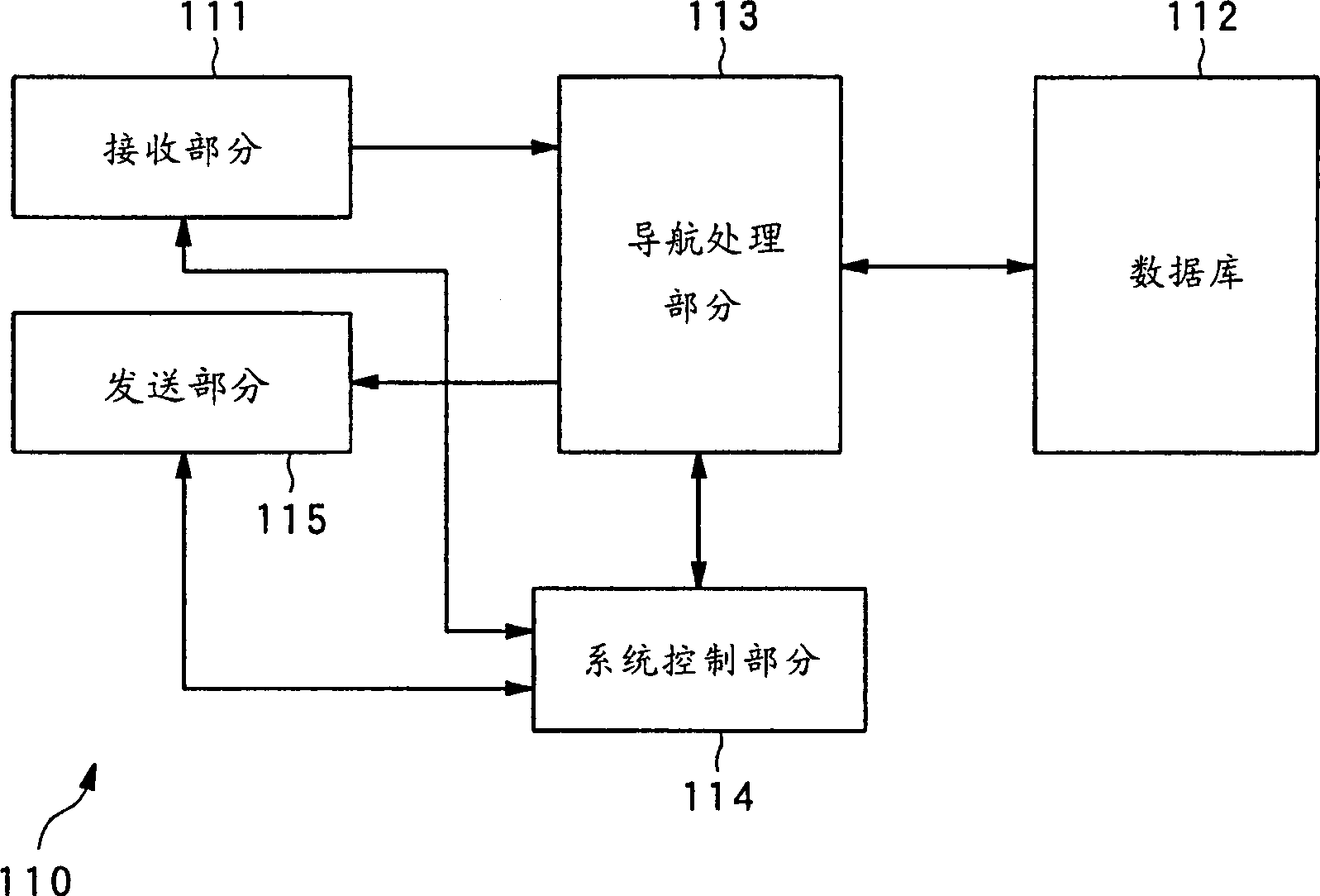

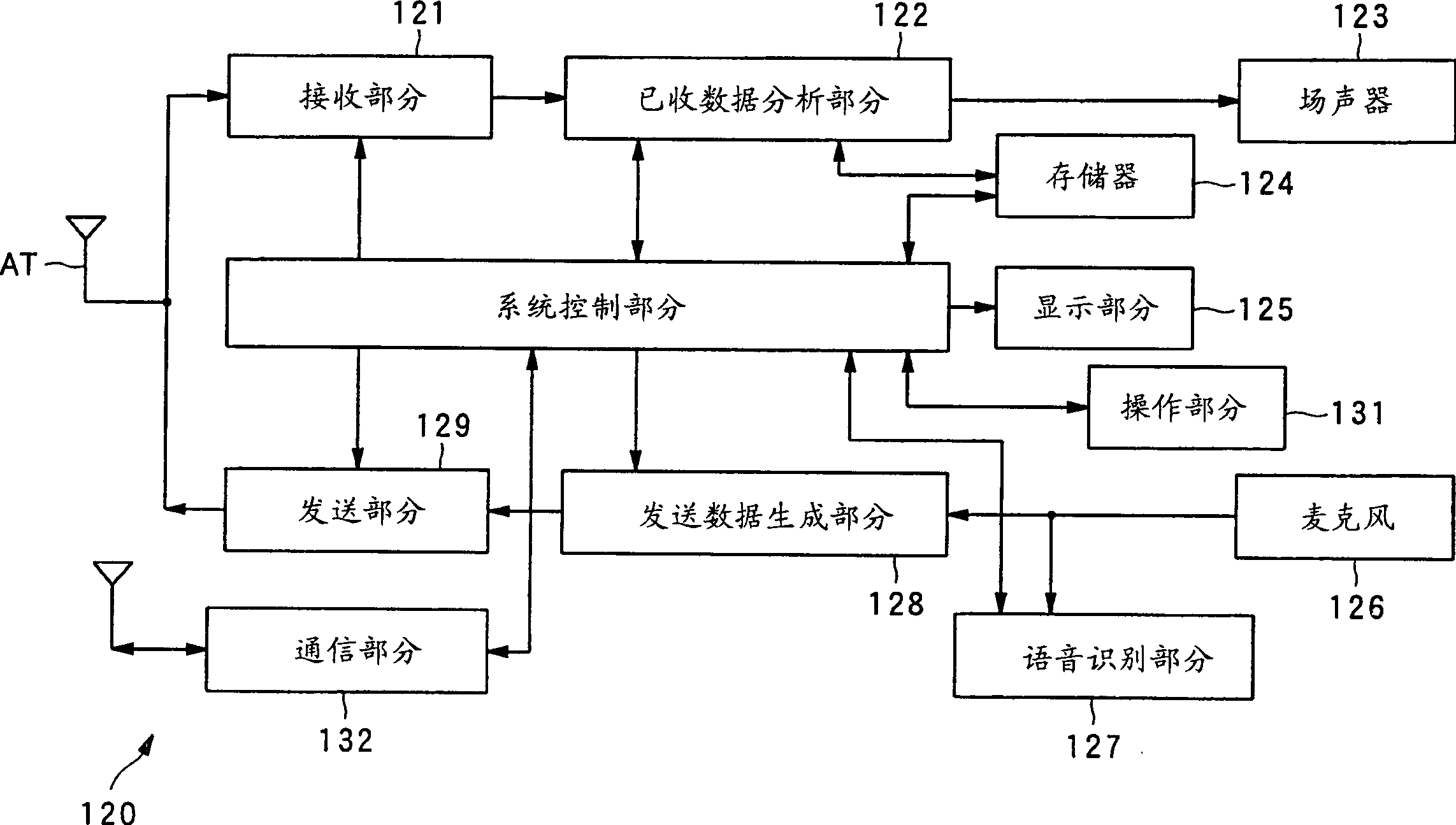

Navigation system, movable navigation device, communication navigation device and its method

InactiveCN1409087ASimple forwardingEnables continuous processingInstruments for road network navigationArrangements for variable traffic instructionsIn vehicleEngineering

The navigation system includes an information server apparatus, a terminal apparatus for conducting navigation processing while conducting communication with the information server apparatus, and a vehicle navigation apparatus mounted on a vehicle to conduct navigation processing independently of the information server apparatus. During execution of the navigation processing in the terminal apparatus, detection is effected to determine whether the vehicle navigation apparatus is started. Upon detecting that the vehicle navigation apparatus has been started, information for the navigation processing conducted until then is transferred to the vehicle navigation apparatus. The vehicle navigation apparatus conducts navigation processing by using the transferred information.

Owner:PIONEER CORP

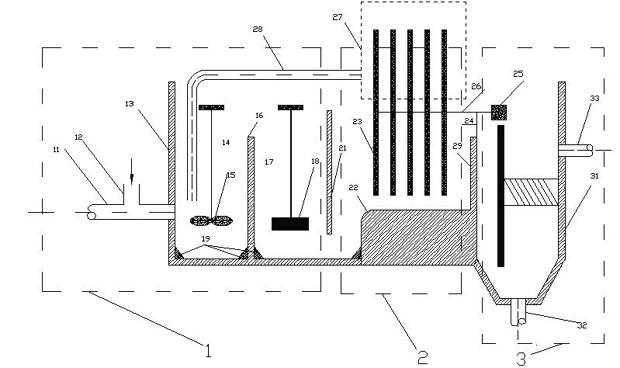

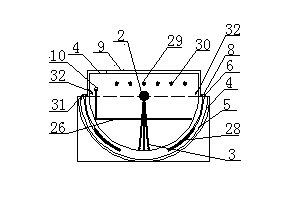

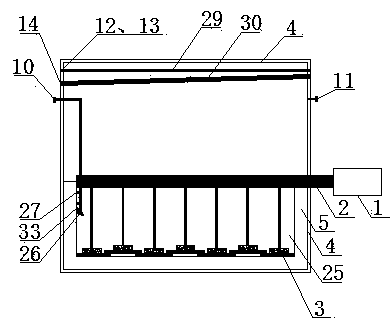

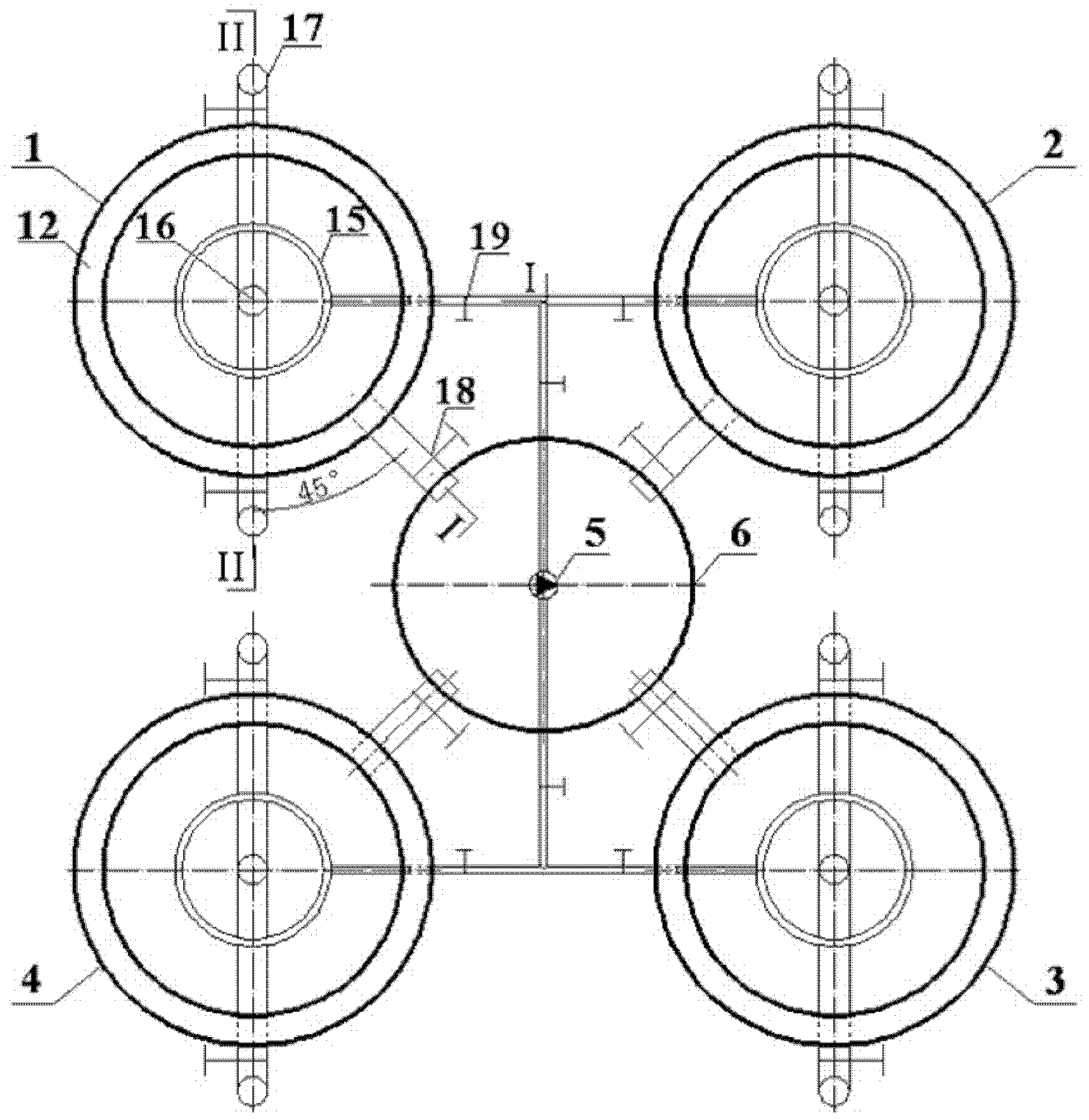

Magnetic flocculation reactor

InactiveCN101948198AEnables continuous processingIncrease contact areaWater/sewage treatment by magnetic/electric fieldsMultistage water/sewage treatmentFlocculationWater quality

The invention discloses a magnetic flocculation processor for overflow sewage, belonging to the technical field of overflow sewage treatment equipment. In the invention, overflow sewage is purified by taking advantages of the double flocculation actions of a rapid stirring area and a slow stirring to enable a magnetic seed composite flocculating agent to absorb suspended matters in overflow sewage to form a magnetic flocculated constituent, rapidly absorbing the magnetic flocculated constituent by a magnetic disc in water through a magnetic separation device, leading the overflow sewage to pass through a mud scraper and a screw conveyer to realize magnetic seed separation and recycling, and then leading the overflow sewage to pass through a sedimentation area. The invention integrates flocculation, magnetic separation, sedimentation and magnetic seed recycling into a whole, and can adapt to the characteristic of great change in water quantity and water quality of the overflow sewage and achieve the purposes of rapid reaction and good treatment effect.

Owner:JIANGSU UNIV

Compact kitchen waste aerobic fermentation equipment

ActiveCN103992148ACompact structureImprove internal space utilizationClimate change adaptationOrganic fertilisersWater bathsThermal insulation

The invention provides compact kitchen waste aerobic fermentation equipment, which is composed of a reaction chamber with a stirrer, a cooling water circulating and condensate water collecting system, an air heating ventilation system having the function of deodorizing, a water bath heating and thermal insulation system, and an intelligent control system with a remote supervisor; a travel switch is arranged in the reaction chamber and used for changing the stirring direction of a motor; a heater and a temperature sensor are arranged in a water bath cavity; heat is supplied to the reaction chamber in time according to reaction requirements; a thermal insulation interlayer is outside the water bath cavity and used for insulating the chamber; the air heating ventilation system is capable of ensuring enough oxygen concentration in the reaction chamber in the treatment process; the cooling water circulating and condensate water collecting system is capable of condensing and guiding out water vapour in the reaction chamber in time; a tail gas deodorizing system is capable of preventing secondary pollution to the environment by malodorous gas in the reaction chamber; and the equipment is controlled to operate by a PLC (Programmable Logic Controller) intelligent control system. The compact kitchen waste aerobic fermentation equipment disclosed by the invention is simple in structure, high in space utilization rate, low in operation energy consumption and good in processing effect.

Owner:INST OF URBAN ENVIRONMENT CHINESE ACAD OF SCI

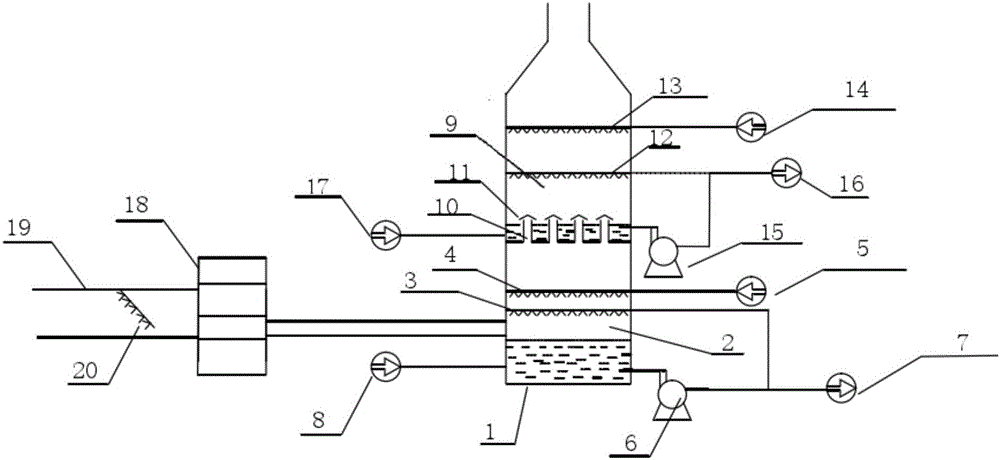

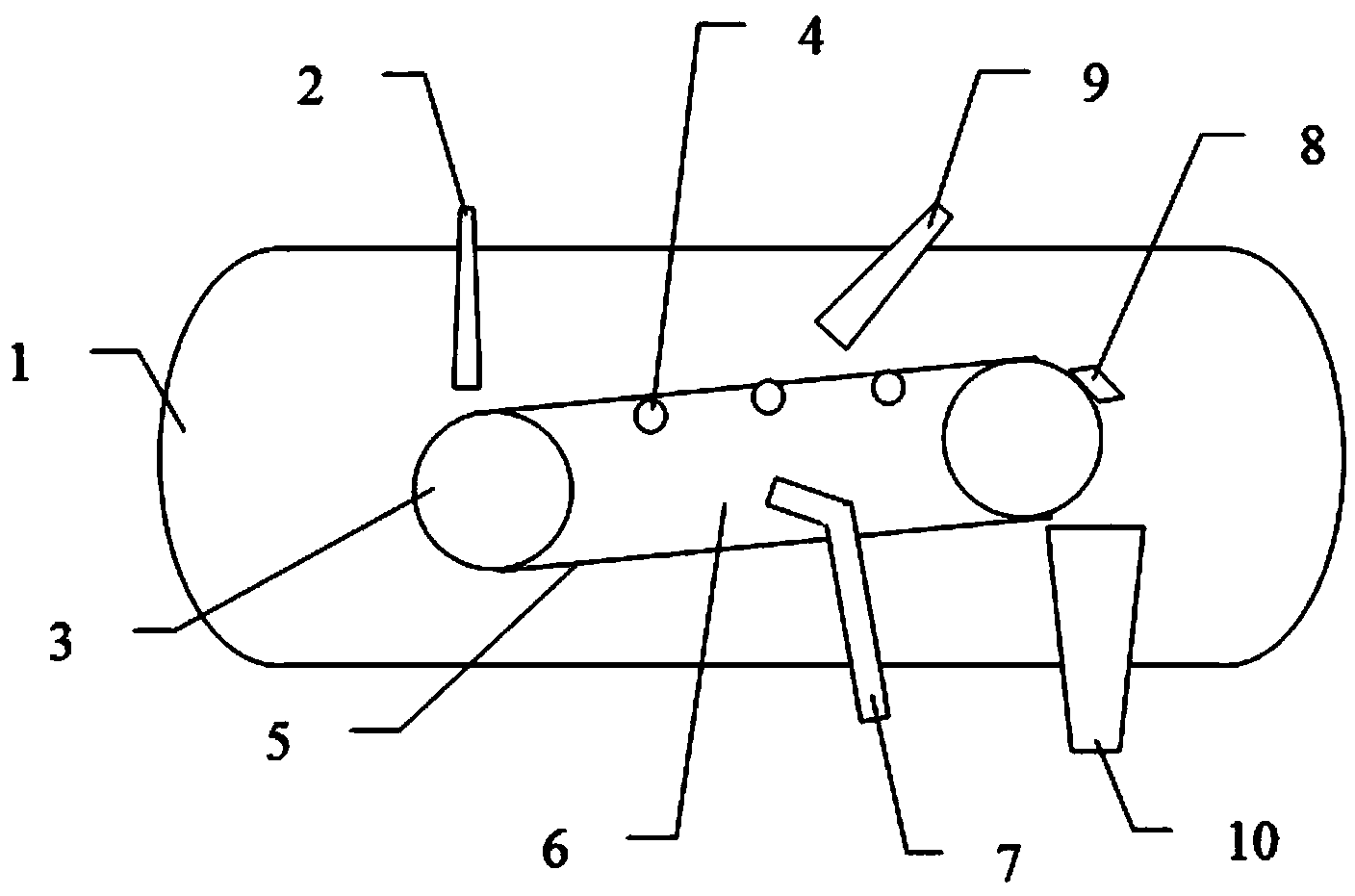

Ammonia oxidizing denitration process and reaction apparatus

InactiveCN105854547AEliminate emission pollutionAchieve recyclingGas treatmentDispersed particle separationHigh absorptionFlue gas

The present invention provides an ammonia oxidizing denitration process for flue gas denitration treatment. Ozone oxidation, hydrogen peroxide oxidation and ammonia absorption are orderly and organically combined, in order to achieve efficient flue gas denitration treatment. The treatment process has low energy consumption, low operating costs and high absorption rate, is able to recycle nitrogen resources, and does not produce secondary pollution caused by the escape of ammonia. At the same time, the present invention also provides an ammonia oxidizing denitrification reaction apparatus, which is beneficial for the flue gas continuous treatment, and improves the processing efficiency.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

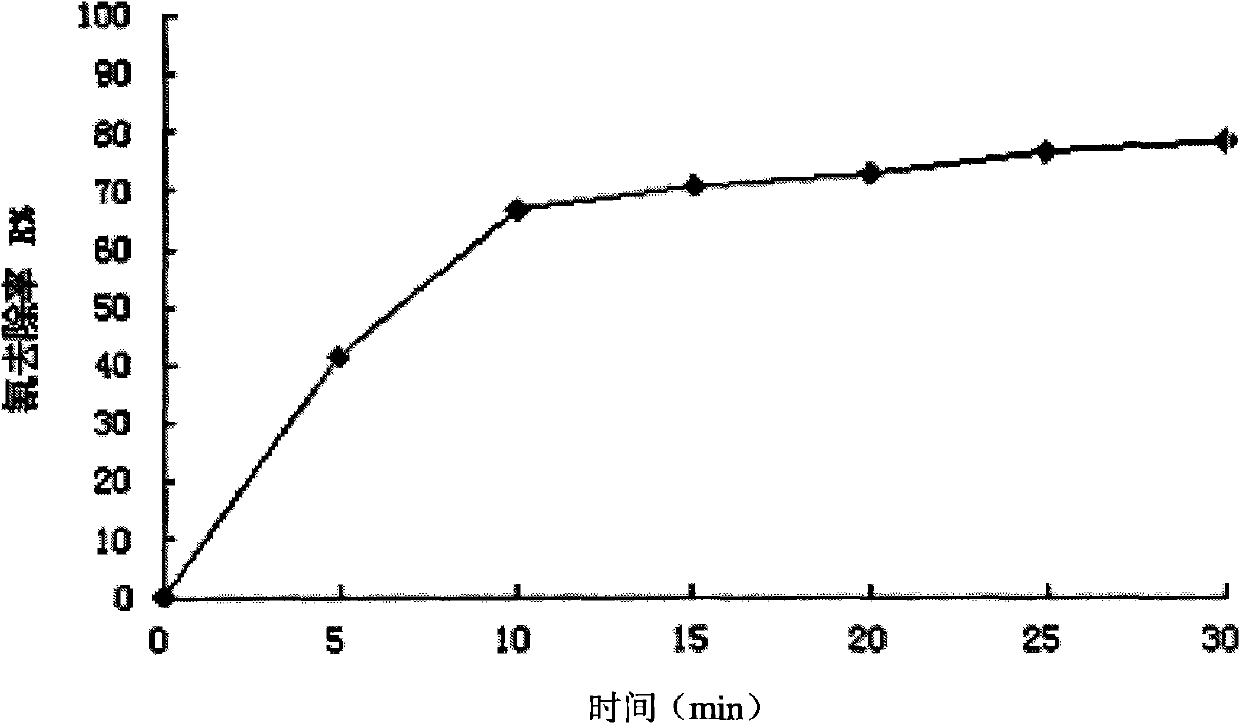

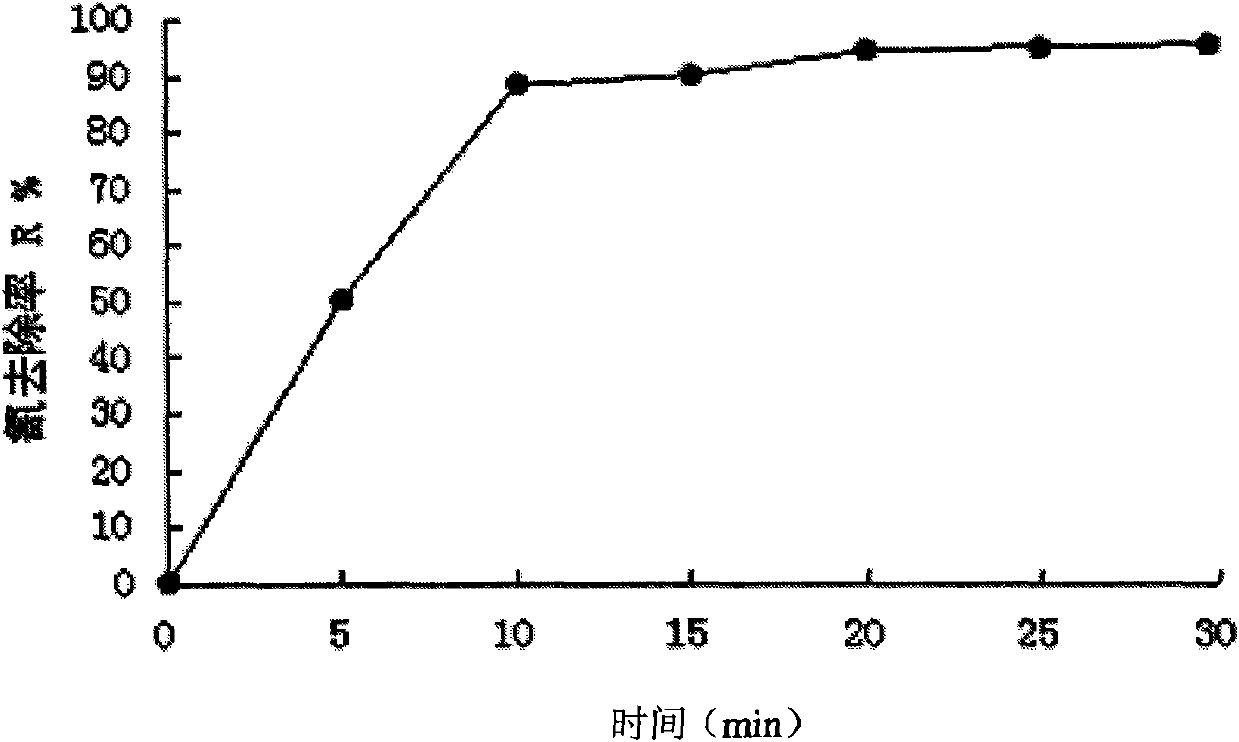

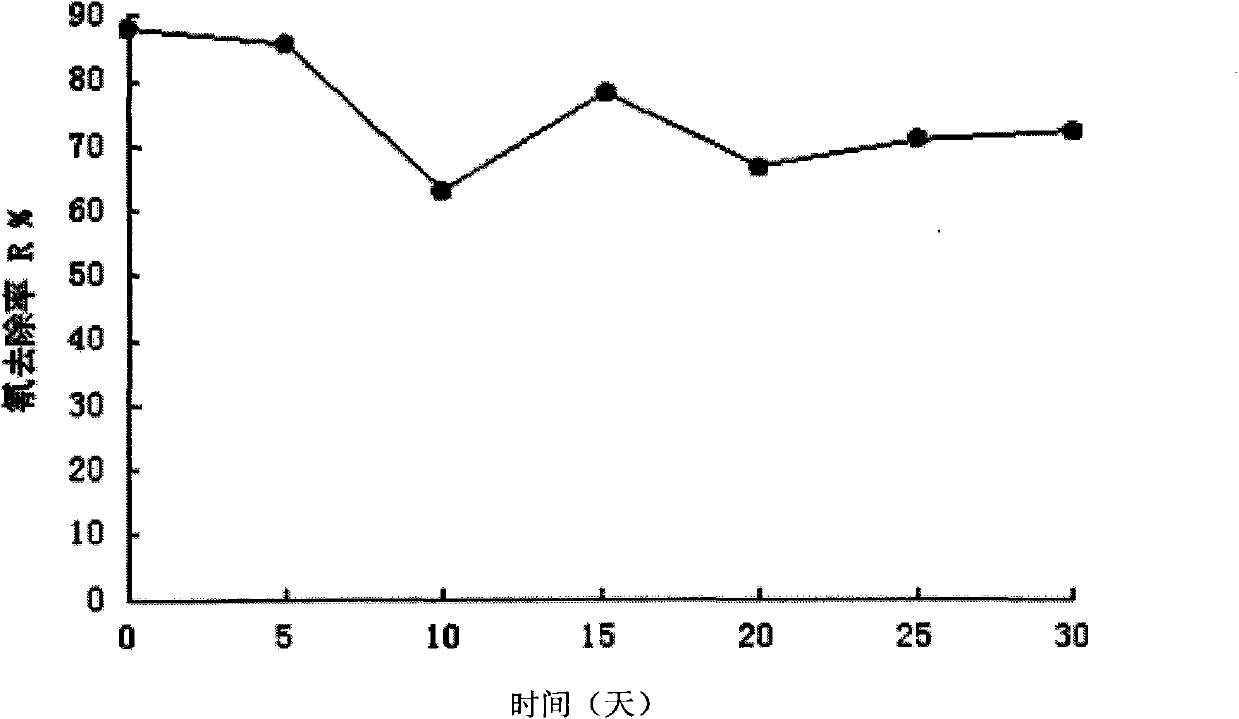

Electrocatalysis particle for treating cyanide-containing waste water and method for treating cyanide-containing waste water

ActiveCN102001737ALow cost of preparationHigh mechanical strengthWater contaminantsWater/sewage treatment by oxidationActivated carbonCo-processing

The invention relates to an electrocatalysis particle for treating cyanide-containing waste water and a method for treating cyanide-containing waste water, belonging to the field of water treatment. The electrocatalysis particle comprises the following components in mass percentage: 40-44% of activated carbon, 14-19% of bonding agent, 13-16% of iron oxides, 22-25% of copper oxides, 4-7% of magnesium oxides, 1-1.5% of zinc oxides, 0.5-1% of zirconium oxides and 0.5-1% of cerium oxides. The electrocatalysis particle provided by the invention has low preparation cost and high mechanical strength, and the treatment efficiency of the electrocatalysis particle on cyanide-containing waste water is greatly improved as compared with the traditional catalysis particle. In the invention, the electrocatalysis particle is placed in an electrocatalysis device capable of recycling and cleaning the particle, the new electrocatalysis particle and a waste water treatment device capable of cleaning the electrocatalysis particle in place are organically combined to treat cyanide-containing waste water, and the best cooperative treatment effect is obtained by organically combining various treatment parameters. When the concentration of total cyanide is lower than 200 mg / L, the removal rate of cyanide-containing pollutants is greater than 60% by using the method of the invention, the power consumption for treating each ton of waste water is generally 1500-2000 W, and the operating cost is lower than 2.3 RMB. The invention has the advantages of investment saving, low energy consumption, low maintenance expense, fewer sludge amount, no secondary pollution and broad application prospect.

Owner:SUN YAT SEN UNIV

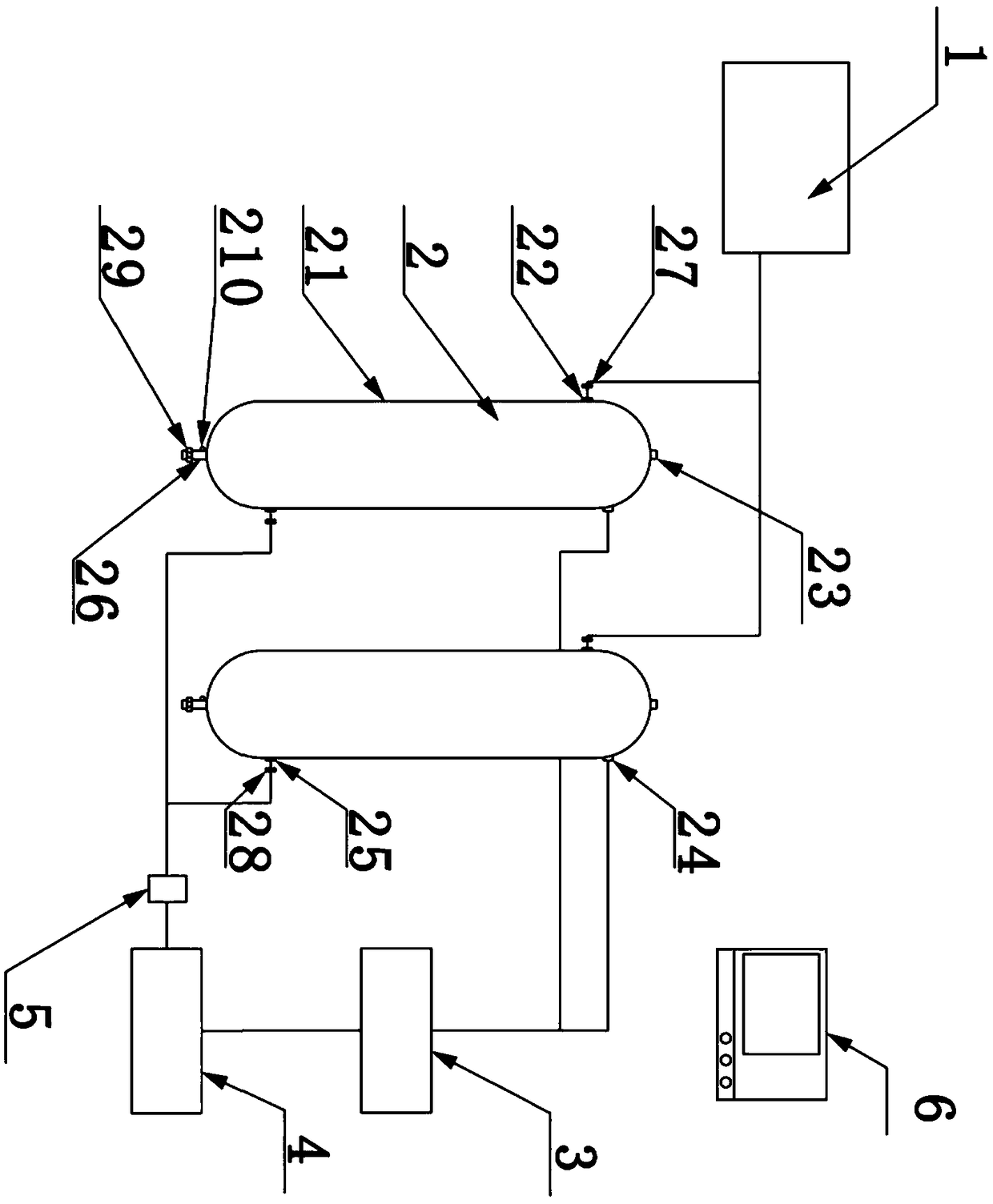

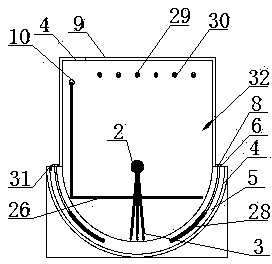

Ammonia-nitrogen wastewater treatment system and ammonia-nitrogen wastewater treatment method

InactiveCN108751325AHigh selectivityEnables continuous processingWater contaminantsCombustible gas purificationAmmoniacal nitrogenWater treatment system

The invention discloses an ammonia-nitrogen wastewater treatment system and an ammonia-nitrogen wastewater treatment method. The treatment system comprises an ammonia-nitrogen wastewater storage tank,an adsorption column group, a sodium chloride solution collection box, an electrolytic bath and a control terminal, wherein the adsorption column group comprises two adsorption columns arranged in parallel; each adsorption column comprises a housing; inlets / outlets for allowing ammonia-nitrogen wastewater and regenerated liquid to flow in / out are formed in each housing; each housing is connectedwith the ammonia-nitrogen wastewater storage tank and the electrolytic bath through pipelines provided with solenoid valves; the electrolytic bath is communicated with the sodium chloride solution collection box; a gas discharging outlet for discharging gas is formed in the top of each housing; and the solenoid valves are electrically connected with the control terminal. When the ammonia-nitrogenwastewater is treated, the control terminal controls the solenoid valves to be switched on or off, so that the two adsorption columns alternately performs adsorption and regeneration processes, so that the wastewater treatment efficiency is greatly improved. The ammonia-nitrogen wastewater treatment system can achieve the purposes of low treatment cost and high efficiency.

Owner:CHENGDU EN SHAIN TECH INC +1

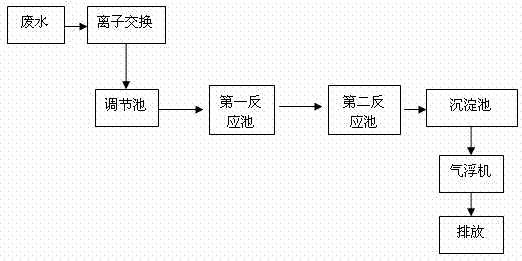

Method for processing waste water generated by extracting copper oxide from acidic corrosion waste fluid

ActiveCN102583819AReduce processing costsSave human effortWater/sewage treatment by ion-exchangeMultistage water/sewage treatmentEnvironmental chemistryPolyacrylamide

The invention discloses a method for processing waste water generated by extracting copper oxide from acidic corrosion waste fluid. The processing method comprises the following steps of: (1) extracting the copper oxide from the acidic corrosion waste fluid through strong alkaline solution, and generating waste water; (2) adopting cationic resin to carry out initial treatment; (3) adding sodium hypochlorite to remove ammonia nitrogen; (4) conveying to a first reaction pond, adding aluminium polychlorid to remove heavy metal ions, then conveying to a second reaction pond, and adding polyacrylamide to carry out sedimentation; and (5) in a settling pond, setting and layering suspending matters in waste water, conveying clear water on an upper layer into an air floating machine to remove the suspending matters, and discharging. According to the processing method, not only can the content of copper ions and ammonia nitrogen in the waste water can be reduced, but also COD (Chemical Oxygen Demand) can be greatly reduced, the processing effect for waste water with low COD content is good, and continuous processing of waste water generated by extracting the copper oxide from the acidic corrosion waste fluid can be realized.

Owner:GUANGZHOU KECHENG ENVIRONMENTAL PROTECTION TECH

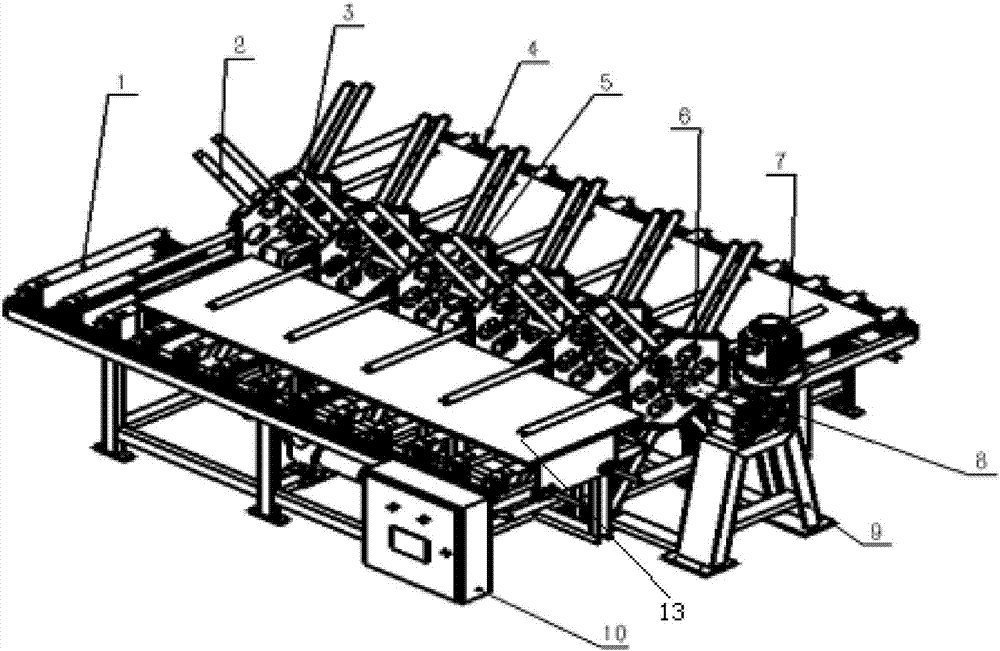

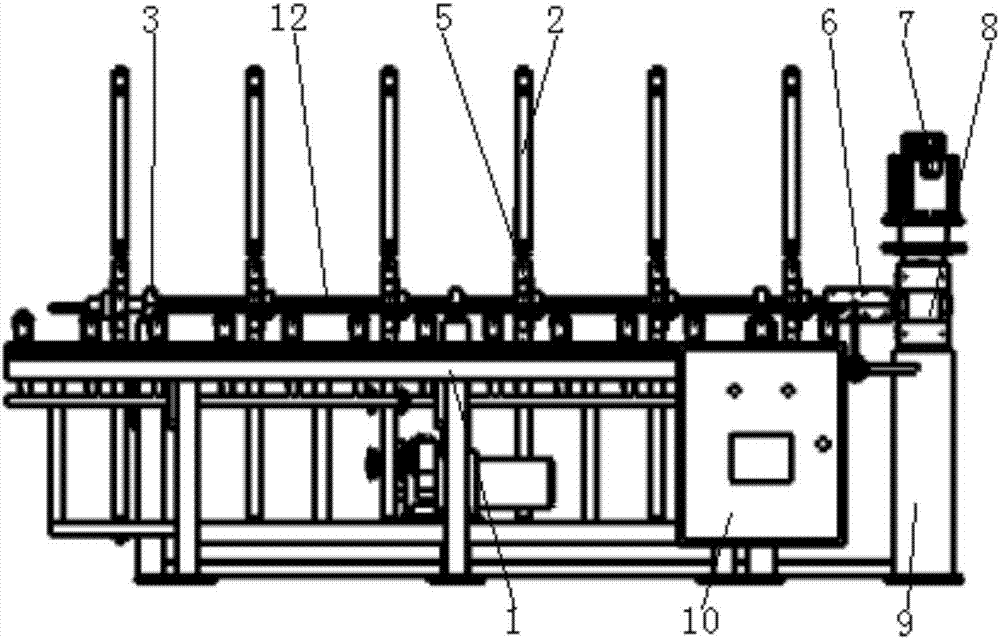

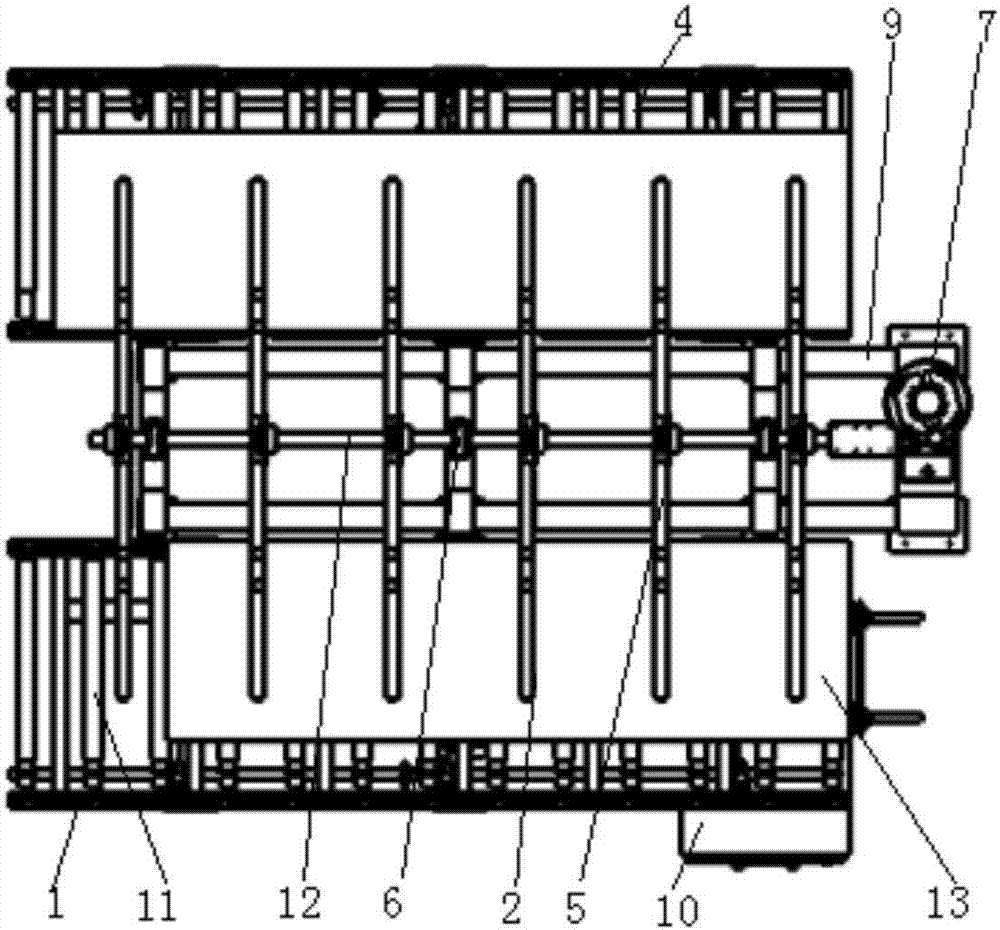

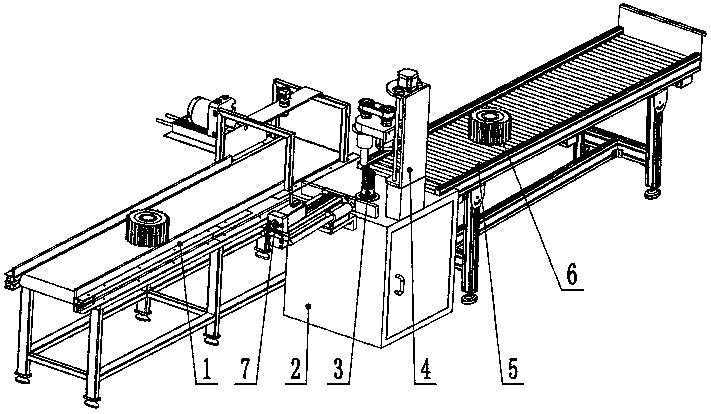

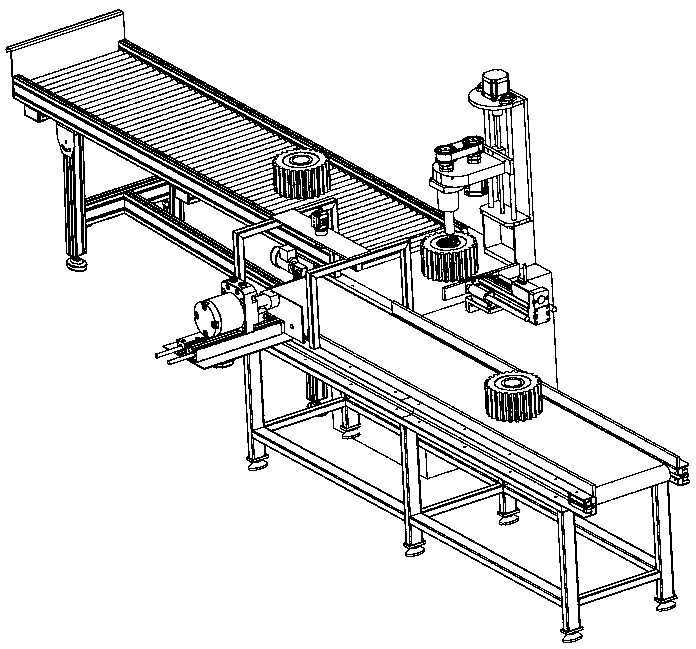

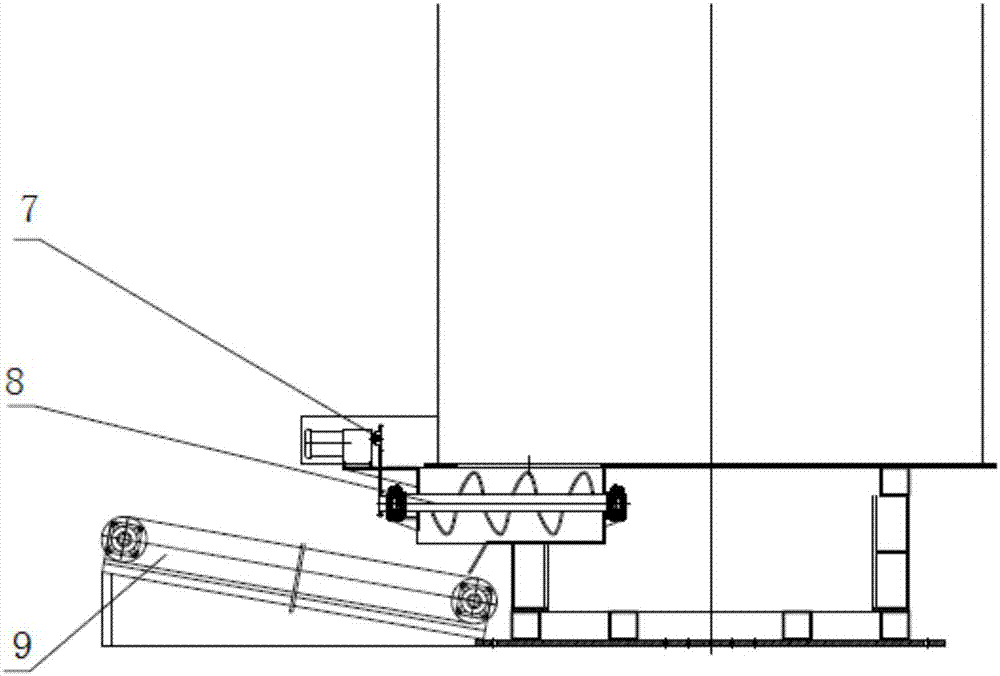

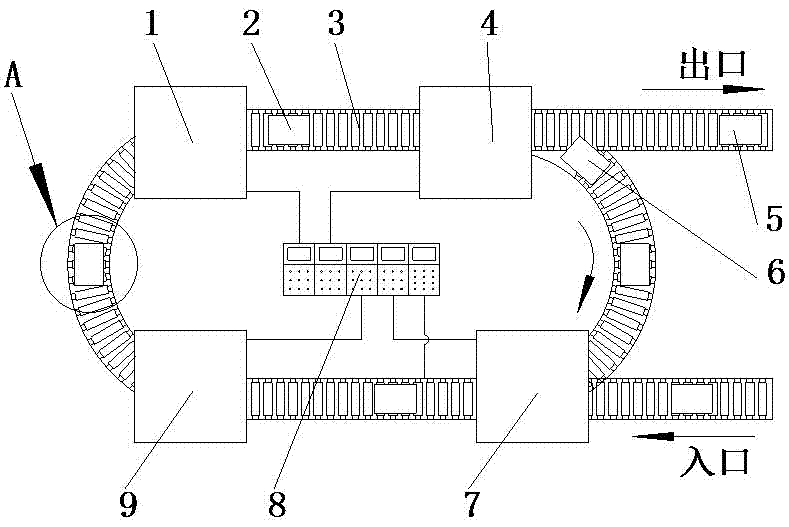

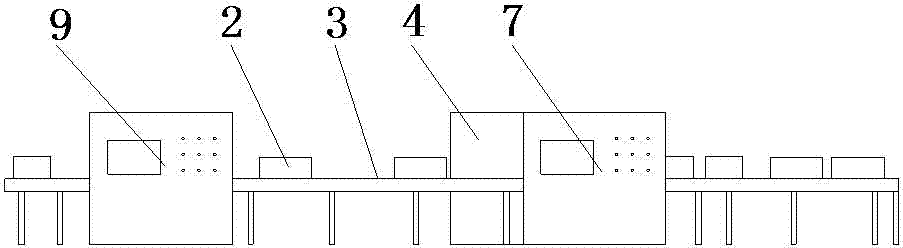

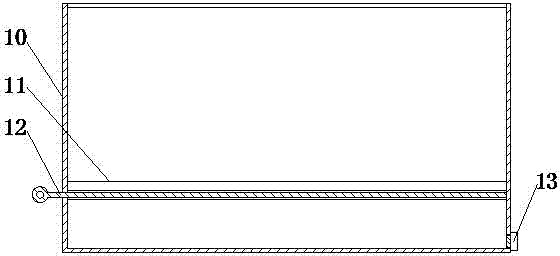

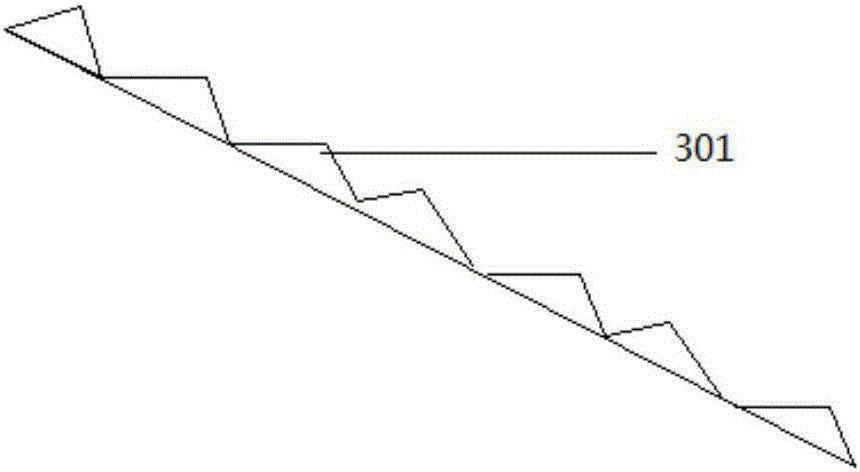

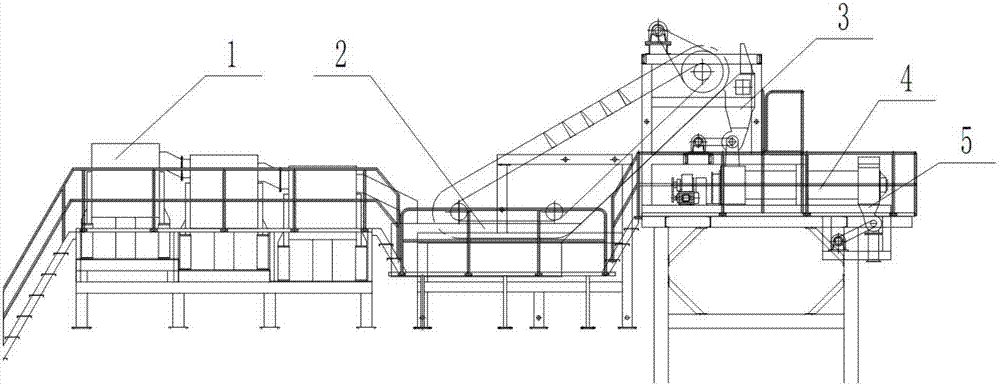

Plate overturning machine and plate overturning method

PendingCN107416484AEnables continuous processingInhibit sheddingConveyorsConveyor partsCouplingControl engineering

The invention discloses a plate overturning machine. The plate overturning machine comprises a frame, and a feed conveyor and a discharge conveyor symmetrically arranged on two sides of the frame; conveying rollers are uniformly distributed on the feed conveyor and the discharge conveyor; driving devices for driving the conveying rollers to rotate are respectively arranged below the feed conveyor and the discharge conveyor; the frame is provided with a servo motor and a matched speed reducer; a rotating shaft is arranged above the frame; the speed reducer drives the rotating shaft to rotate through a coupling; at least two mounting plates are arranged on the rotating shaft; parallel forks for clamping plates are arranged on the mounting plates; and when the mounting plates are rotated along with the rotating shaft, the parallel forks can clamp the plates to overturn from the feed conveyor onto the discharge conveyor. The plate overturning machine can be used for improving the defect of manual overturning of the plates in traditional processing equipment.

Owner:QUANYOU FURNITURE

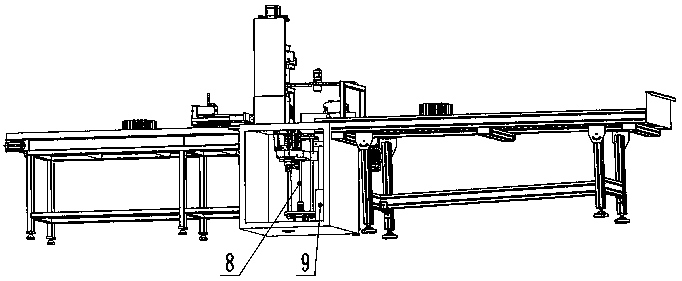

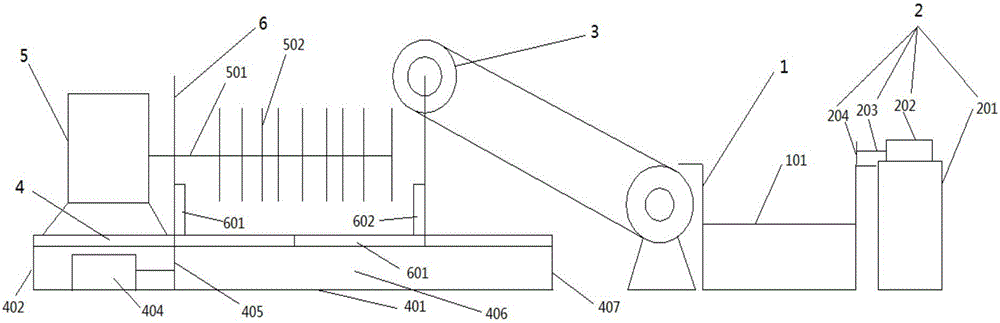

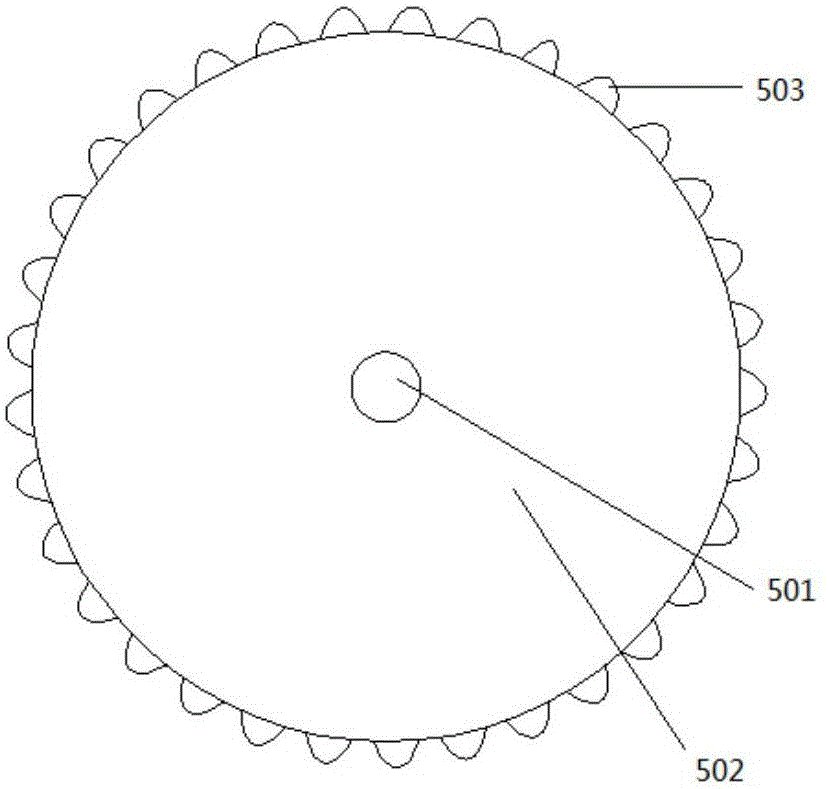

Gear finish machining grinding positioning mechanism

ActiveCN111112758AEnables continuous processingAccurately monitor real-time locationBelt grinding machinesGrinding feed controlGear wheelEngineering

The invention discloses a gear finish machining grinding positioning mechanism, which comprises a feeding device, a fixed workbench, an adjustable positioning device, a grinder, a discharging roller bed, a workpiece gear, a discharging and pushing device, a lifting mechanism and a hydraulic station. The box type workbench is fixedly installed on the ground, and the box body of the workbench is provided with a set of lifting mechanism and hydraulic system; the adjustable positioning device is fixedly installed on a lifting sliding seat of the lifting mechanism, can move up and down in the central hole of the upper table of the fixed workbench with movement of the sliding seat, and is used for machining and positioning of gears; the grinder is fixedly installed on the upper face of the workbench, and a set of pushing device used for moving out finished products is further arranged on the side face of the workbench; and workblank of the workpiece gear is transmitted to the fixed workbenchthrough the feeding device, and then a finished product is transported to a next station through the discharging roller bed after being processed through positioning of the adjustable positioning device. The mechanism is arranged in line, degree of automation is high, positioning is precise and reliable, the processing quality can be effectively guaranteed, and the production efficiency is improved.

Owner:浙江陆鑫门控设备有限公司

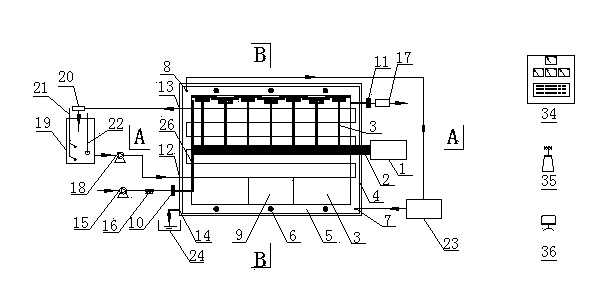

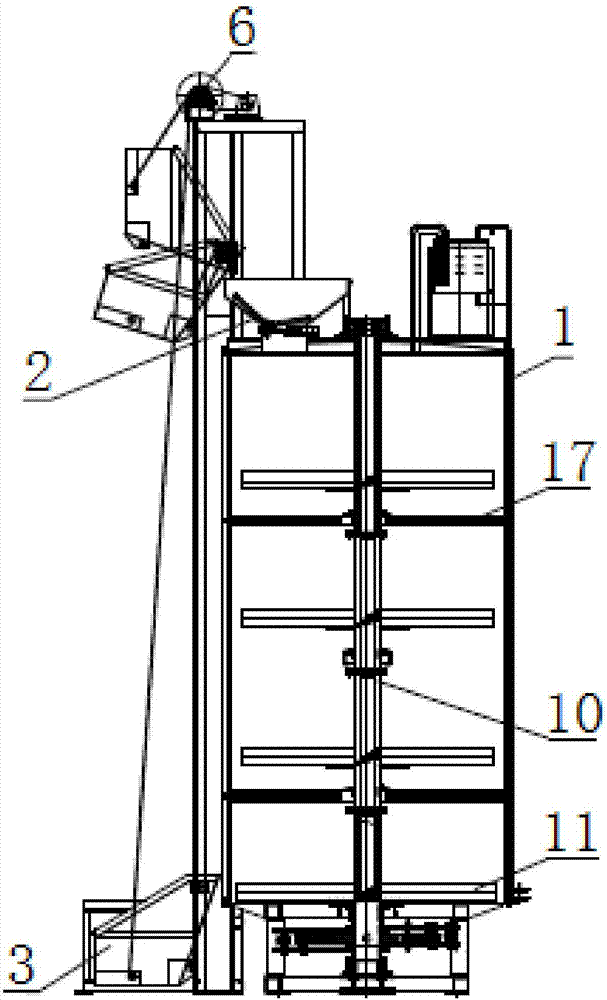

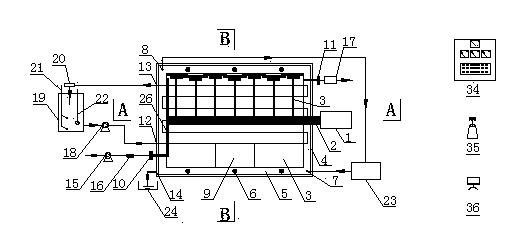

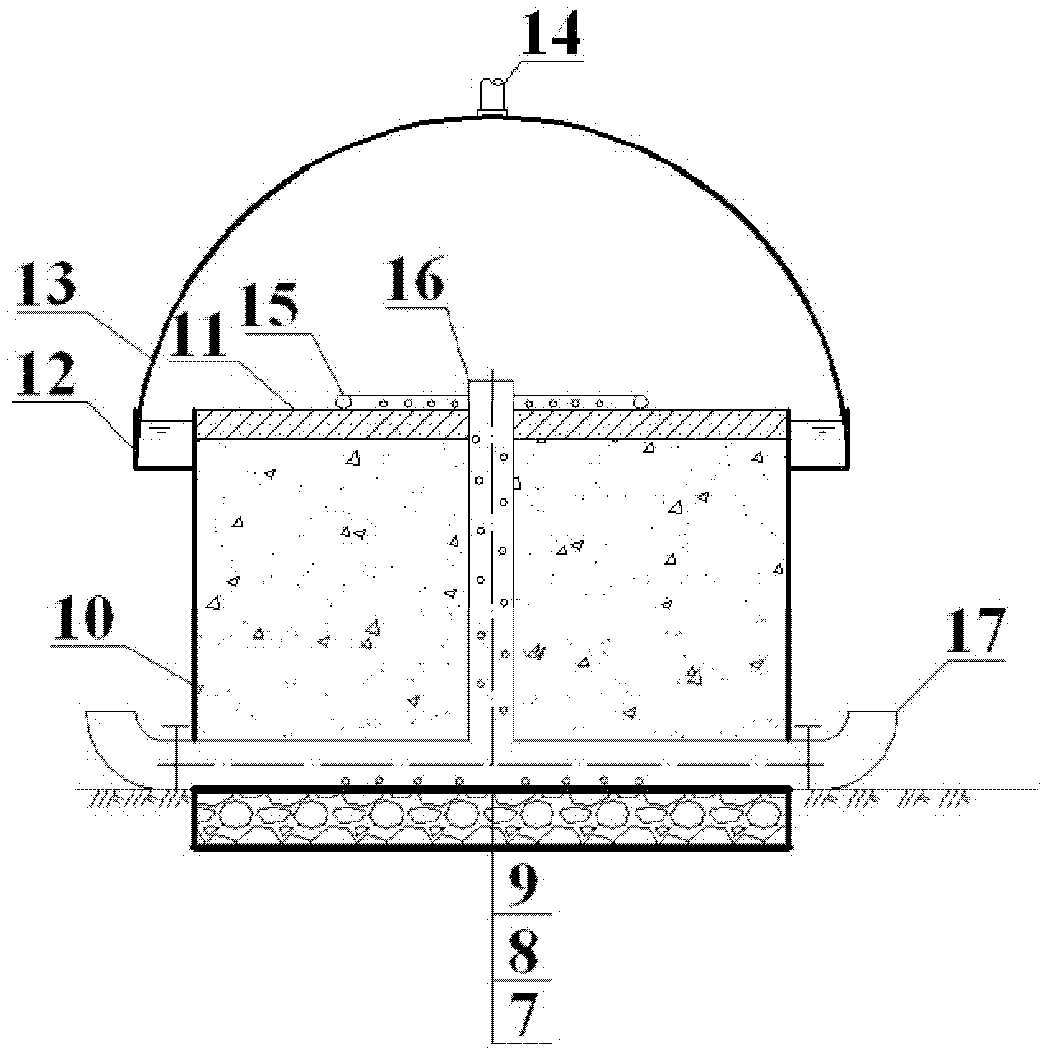

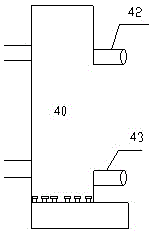

Composting reactor system capable of achieving intelligent layered aeration

PendingCN107473788AEnables continuous processingRealize automatic monitoringBio-organic fraction processingOrganic fertiliser apparatusReactor systemAeration system

The invention discloses a composting reactor system capable of achieving intelligent layered aeration. The composting reactor system capable of achieving the intelligent layered aeration comprises a tank, a feeding system, a discharging system, a stirring system, an aerating system and a control part, wherein a plurality of supporting beams with different heights are arranged inside the tank; the aerating system comprises aerating pipelines, gas concentration sensors, a gas supply manifold and valves; the aerating pipelines are arranged on first side surfaces of the supporting beams and are provided with a plurality of aerating holes; the gas concentration sensors are arranged on second side surfaces of the supporting beams and are used for detecting the concentration of predetermined gas at the heights of the supporting beams inside the tank; the gas supply manifold is communicated with each aerating pipeline and supplies gas; each valve is arranged inside each aerating pipeline, is positioned at a connecting end of each aerating pipeline and the gas supply manifold, and can be opened and closed under the control of the control part. When the gas concentration sensor arranged on the supporting beam detects that the concentration of the predetermined gas is lower than or higher than a predetermined value, the valve in the aerating pipeline arranged on the same supporting beam is opened under the control of the control part so as to aerate the tank through the aerating holes.

Owner:江苏中科纽克生态科技有限公司

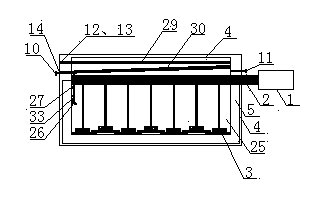

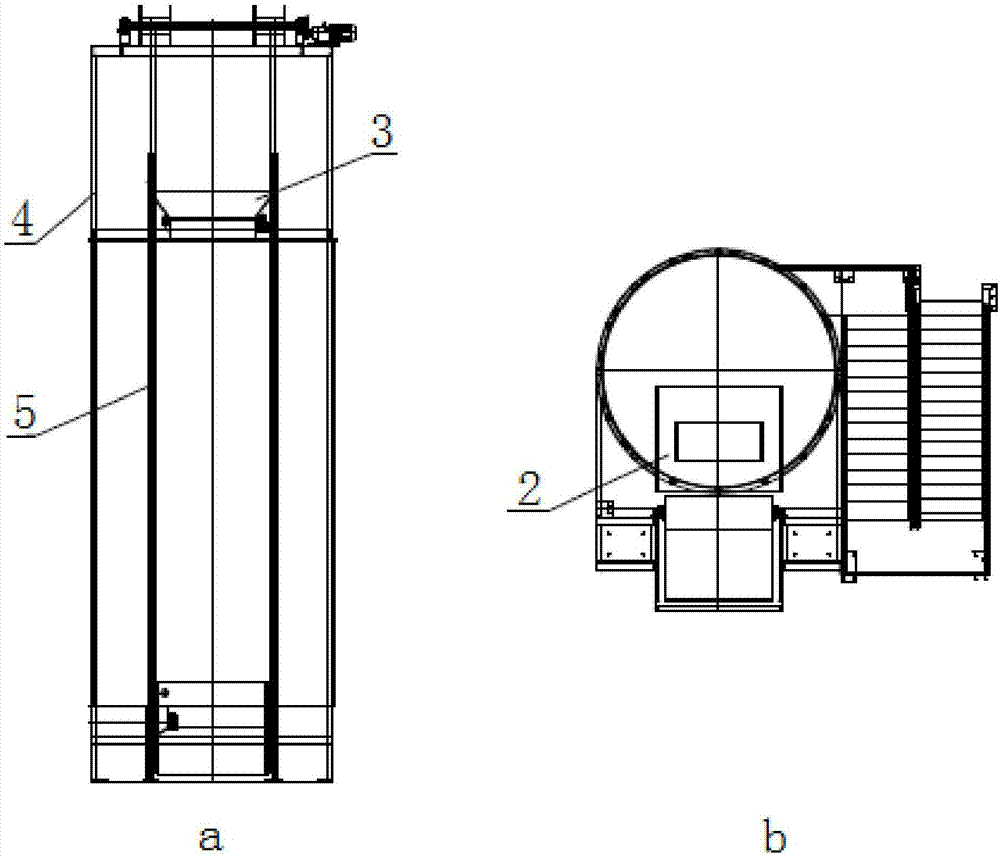

Kitchen waste aerobic fermentation equipment with capability of rapid drying

ActiveCN104003767AEnables continuous processingStable moisture contentClimate change adaptationOrganic fertilisersWater bathsThermal insulation

The invention provides kitchen waste aerobic fermentation equipment with the capability of rapid drying. The kitchen waste aerobic fermentation equipment comprises a reaction cavity with the function of mixing, a cooling water circulation and condensate water collection system, an air heating and ventilation system with the function of deodorization, a water bath heating and thermal insulation system and an intelligent control system with the function of remote monitoring, wherein a temperature / humidity sensor and an oxygen concentration sensor are installed in the reaction cavity and used for monitoring the temperature, the humidity and the oxygen concentration in the reaction cavity; a heater and a temperature sensor are installed in a water bath cavity and can be used for providing heat to the reaction cavity timely, a thermal insulation interlayer is arranged outside the water bath cavity and used for preserving the heat of the water bath cavity; the air heating and ventilation system can be used for ensuring the oxygen concentration in the reaction cavity in the treating process; the cooling water circulation and condensate water collection system can be used for educing water vapor in the reaction cavity timely; a tail gas deodorization system can be used for preventing secondary environmental pollution due to the gas; and the equipment is controlled to run by a PLC (Programmable Logic Controller) intelligent control system. The kitchen waste aerobic fermentation equipment has a simple structure, is low in the running energy consumption and is good in the treating efficiency.

Owner:INST OF URBAN ENVIRONMENT CHINESE ACAD OF SCI

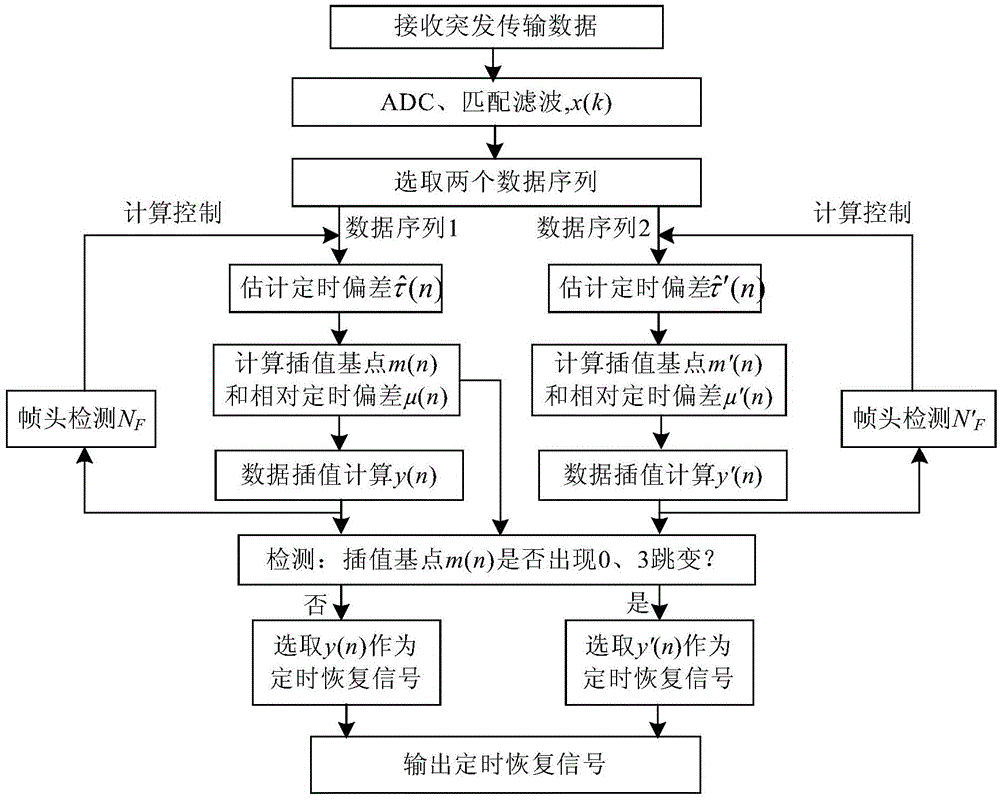

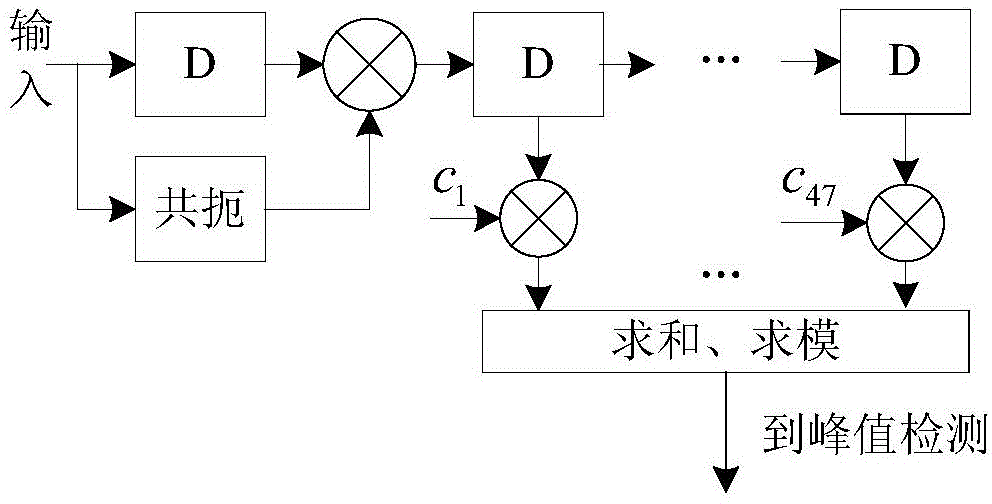

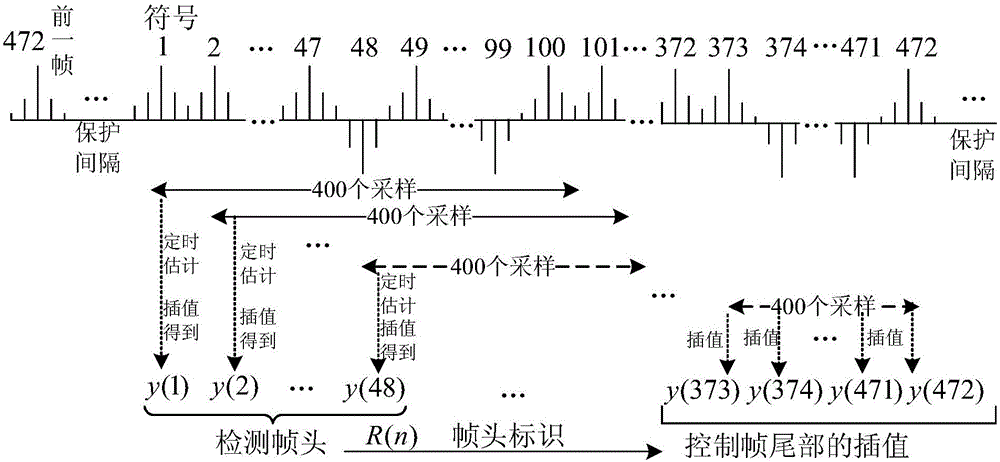

Feed-forward timing recovery method suitable for satellite communication burst transmission system

ActiveCN104135360AResume continuousAccurate recoveryBaseband system detailsRadio transmissionRecovery methodTime deviation

The invention relates to a feed-forward timing recovery method suitable for a satellite communication burst transmission system. According to the method, timing deviation estimation is realized on the basis of a sliding accumulation method, so that the estimation accuracy can be increased, the calculated amount of timing deviation estimation is effectively reduced, and continuous processing of burst transmission data is realized. In the method, calculation is performed by adopting signal amplitude and a frame header is detected by adopting cross-correlation operation, so that the influence of signal frequency deviation on the timing deviation estimation can be avoided, namely, the signal frequency deviation does not need to be estimated. The feed-forward timing recovery method can be applied under the condition of severe channel environment, and is easy for engineering realization. The sampling clock period of a digital receiver is set to be a quarter of a symbol period, and the working frequency of the receiver is low.

Owner:BEIJING RES INST OF TELEMETRY +1

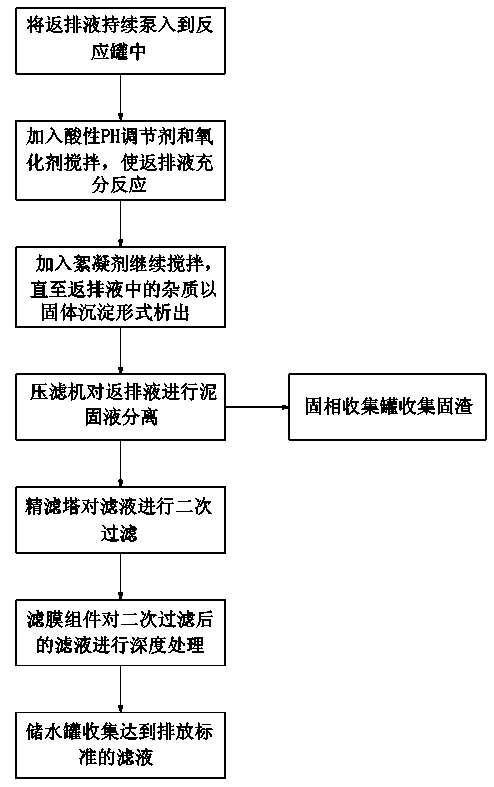

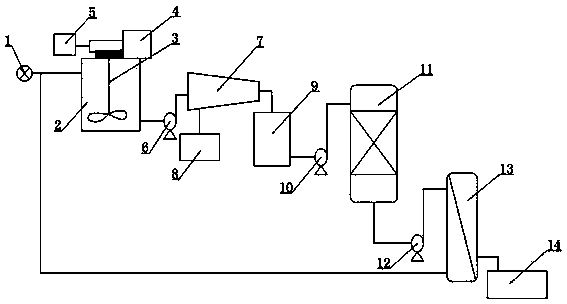

Fracturing flow-back fluid treatment system and treatment technology

ActiveCN104261592AHigh recycling valueAvoid risk of leakageWaste water treatment from quariesTreatment involving filtrationWater storage tankFilter press

The invention discloses a fracturing flow-back fluid treatment system and a treatment technology and aims to solve the problems that the existing fracturing flow-back fluid treatment technology pollutes the environment, waste the resources and is high in fracturing construction cost. The fracturing flow-back fluid treatment system comprises a flow-back fluid reaction device, a first screw pump, a press filter, a filtrate fine filter, a third screw pump, a filter membrane assembly and a water storage tank, which are sequentially connected, and a solid phase collecting tank connected with the press filter. The fracturing flow-back fluid treatment system is reasonable in structure, simple in process and convenient to operate, and can greatly reduce environment pollution, improve the recycling utilization value of fracturing flow-back fluid and reduce treatment cost and later fracturing construction cost, thereby having high application value.

Owner:SICHUAN WELDON CHEM

Preparation technology of pectin in sunflower disk and used continuous microwave system device

The invention discloses a preparation technology of pectin in a sunflower disk. The preparation technology of the pectin in the sunflower disk includes: using a smashing machine to evenly smash the sunflower disk, and using a 60 mesh screen to screen sunflower disk powder; destroying enzyme of the screened sunflower disk powder in boiling water for 3min, using 400 mesh gauze to remove filter liquor by filtering the sunflower disk powder, and preserving temperature of filter residues for 30min after using water at 75 degree centigrade to wash the filter residues; filtering the filter residues, adding distilled water into the filter residues according to a material-water ratio of 1:25, and adding hydrochloric acid to adjust PH (potential of hydrogen) value into 2; using a continuous microwave auxiliary extraction device to extract material liquid, and performing secondary extraction on the filter residues; filtering the material liquid, using diluted ammonia water to adjust PH value of the material liquid into a value about 3.5, using 95% ethyl alcohol to deposit the pectin, drying the pectin until the pectin is constant in weight under 50 degree centigrade, and thereby obtaining the final pectin.

Owner:XINJIANG RUIYUANFENG TRADE

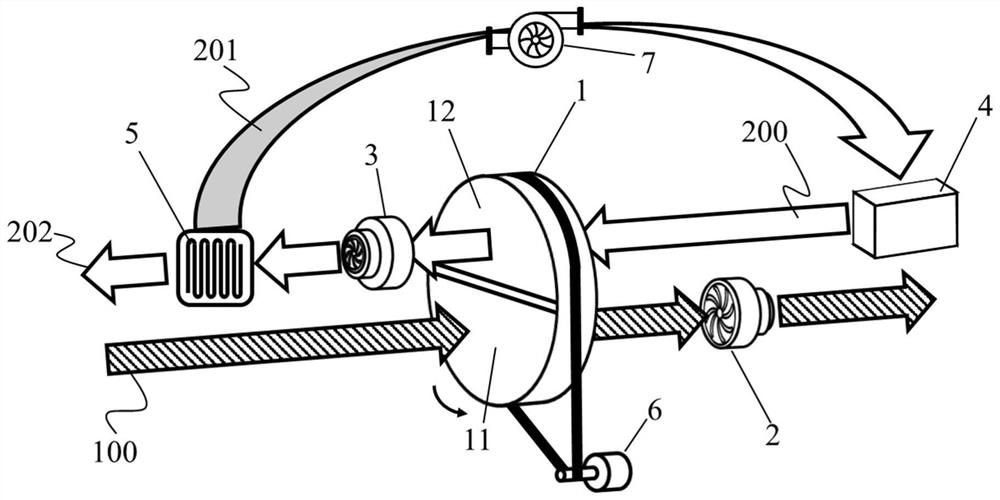

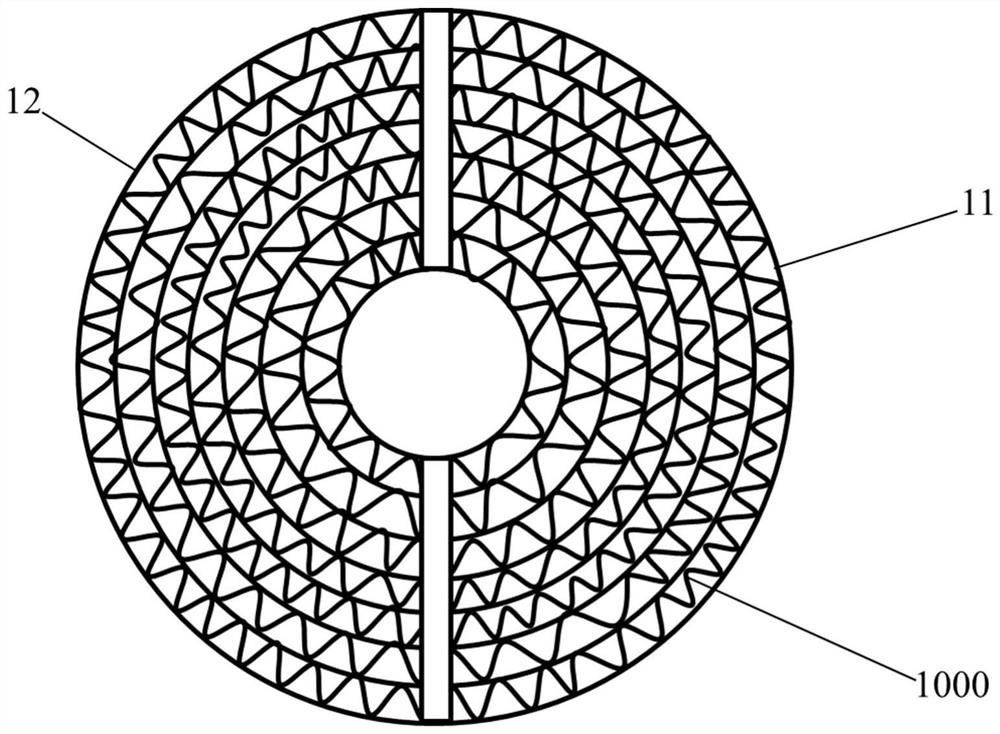

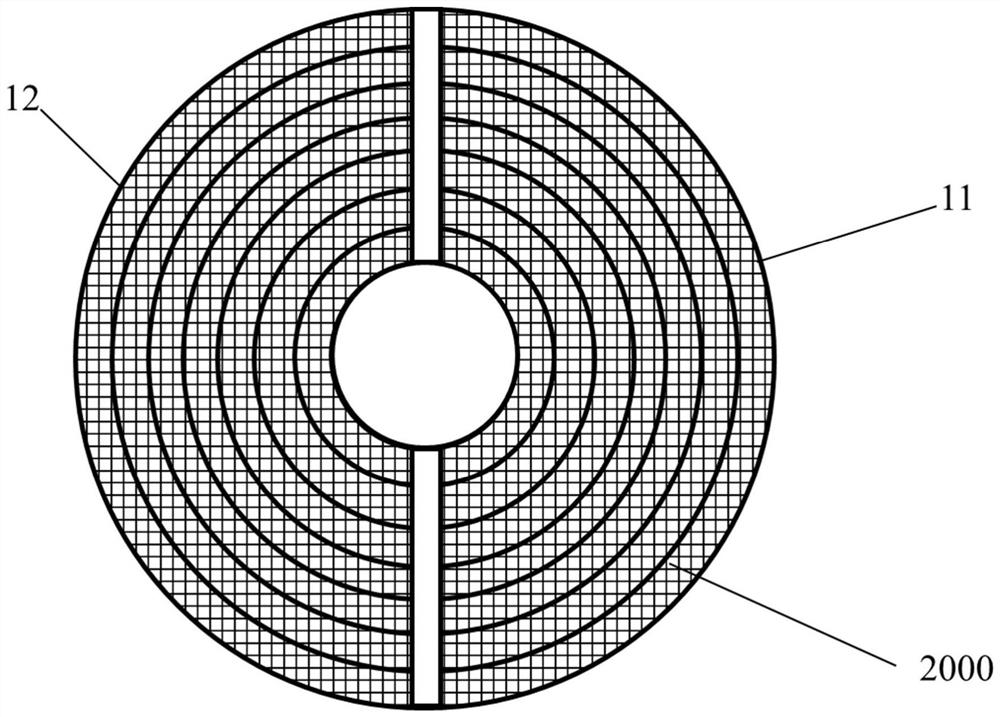

Rapid temperature swing adsorption rotating wheel type direct air carbon dioxide trapping system and method

PendingCN112169537AIncrease flexibilitySmall air pressure dropProductsGas treatmentPhysicsCondensed water

The invention discloses a rapid temperature swing adsorption rotating wheel type direct air carbon dioxide trapping system. The rapid temperature swing adsorption rotating wheel type direct air carbondioxide trapping system comprises a rotating wheel, an adsorption flow path and a regeneration flow path, wherein the regeneration gas flows in the regeneration flow path in a second direction opposite to the first direction, the regeneration gas is water vapor generated by heating of the water vapor generator, the heated regeneration gas flows through a regeneration area of the rotating wheel and then enters the condenser to be condensed, liquid obtained through condensation is condensate water, the condensate water flows into the water vapor generator through a condensation pipeline, and the gas obtained by condensation separation is the collected carbon dioxide gas. In addition, the invention further discloses a rapid temperature swing adsorption rotating wheel type direct air carbon dioxide trapping method. According to the invention, direct and rapid trapping of carbon dioxide in air is realized, and the adsorbent is regenerated by using negative pressure steam so that the energyconsumption of the system is effectively reduced.

Owner:SHANGHAI JIAO TONG UNIV

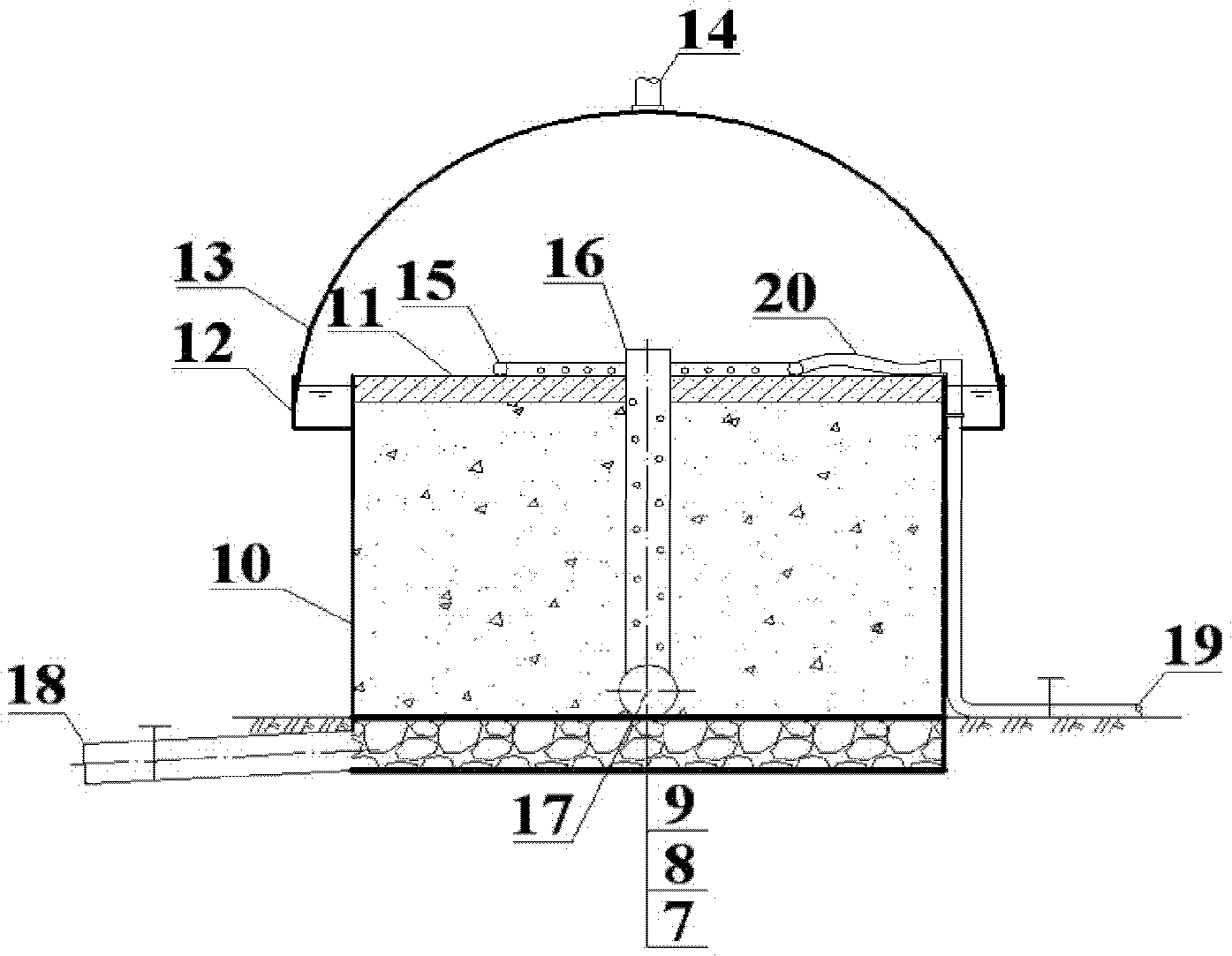

Household garbage bioreactor and aerobic-anaerobic-semi-aerobic circulation treatment method

The invention discloses a bioreactor, which comprises a reactor, a horizontal perforation ventilation pipe, a vertical perforation ventilation pipe, a percolate adjusting tank, a percolate discharge guide pipe, a water seal tank and an air collection cover. The horizontal ventilation pipe is installed at the bottom end inside the reactor, and two ends of the horizontal ventilation pipe are both communicated with the external. One end of the vertical ventilation pipe is communicated with the horizontal ventilation pipe, and the other end of the vertical ventilation pipe is communicated with the external. A submersible sewage pump is arranged in the percolate adjusting tank, a water outlet of the submersible sewage pump is communicated with a water distributor through a percolate recharge pipe, and the water distributor is arranged at the top of the reactor. One end of the percolate discharge guide pipe is communicated with the bottom of the reactor, the other end of the percolate discharge guide pipe is communicated with the percolate adjusting tank, and an outlet of the percolate discharge guide pipe is located above the highest water line of the percolate adjusting tank. The percolate discharge guide pipe, the percolate recharge pipe and the horizontal ventilation pipe are respectively provided with a switch valve. The water seal tank is arranged at the upper end of the reactor, and air collection cover is installed on the water seal tank and covers the opening end at the top of the reactor, and an air discharge port is arranged on the air collection cover. An aerobic-anaerobic-semi-aerobic circulation treatment method of household garbage is further disclosed.

Owner:BIOGAS SCI RES INST MIN OF AGRI +1

Efficient filtering device for roll steel sludge treatment

ActiveCN104096405AQuick filterEfficient and continuous filtrationMoving filtering element filtersSludge

The invention discloses an efficient filtering device for roll steel sludge treatment, which comprises a sealed pressurizing bin and a filtering chamber, wherein the sealed pressurizing bin is a sealed hollow tank body; the filtering chamber is arranged inside the sealed pressurizing bin; the filtering chamber comprises a driving wheel and a filtering belt; the filtering belt winds the periphery of the driving wheel to form a filtering delivery mechanism; the driving wheel is connected with a vibrating pump, and is driven by the vibrating pump to vibrate; besides, a cleaning device used for cleaning the filtering belt is fixed in a cleaning tank at the bottom of the sealed pressurizing bin; air blowing pipes are further arranged inside the sealed pressurizing bin; the open ends of the air blowing pipes are flat, and the widths of the open ends correspond to the width of the filtering belt, and the opening directions of the air blowing pipes are opposite to the transmission direction of the filtering belt.

Owner:TANGSHAN YANSHAN IRON & STEEL CO LTD

Device of leaching and electrokinetically remediating chromium slag stacking place by nanometer zero-valent iron and nickel

ActiveCN106424107AReal-time monitoring of changing valuesImprove the efficiency of electrolytic repairContaminated soil reclamationProcess efficiency improvementElectrokinetic remediationSlag

The invention discloses a device of leaching and electrokinetically remediating a chromium slag stacking place by nanometer zero-valent iron and nickel. The device comprises an electrokinetic remediation device and a leaching system; the electrokinetic remediation device is arranged on the upper end surface of a soil chamber between a cathode chamber and an anode chamber and is provided with eluent nozzles of the leaching system to carry out spraying on the soil chamber through the eluent nozzles, thus automatic continuous remediation of heavy metal contaminated soil is realized. According to the device, by utilizing the electrokinetics and a nanometer zero-valent iron-nickel double metal eluent to commonly remediate the soil, the remediation time of the soil is effectively shortened, and the remediation efficiency of the soil is improved.

Owner:TAIYUAN UNIV OF TECH

High-pressure filtering device used for steel rolling sludge treatment

InactiveCN104096403AReduce lossExtend the life cycleMoving filtering element filtersDrive wheelSludge

The invention discloses a high-pressure filtering device used for steel rolling sludge treatment. The high-pressure filtering device comprises a sealed pressurizing chamber and a filtering compartment, the sealed pressurizing chamber is an enclosed hollow tank, a gas inlet pipe and a feeding pipe are arranged on the outer wall of the sealed pressurizing chamber, the filtering compartment is arranged inside the sealed pressurizing chamber and comprises driving wheels, transmission rollers and a filtering strip, the driving wheels are arranged at two ends of the filtering compartment, the transmission rollers are arranged between the driving wheels, the filtering strip winds the peripheries of the driving wheels and the transmission rollers to form a filtering transmission mechanism, the filtering compartment and the sealed pressurizing chamber are divided into two independent enclosed spaces by the filtering strip, a filtrate outlet pipe is arranged on the side face of the filtering compartment, and the filtering compartment comprises a scraping plate which is a V-shaped plate and is used for scraping intercepting objects on the filtering strip.

Owner:梁均全

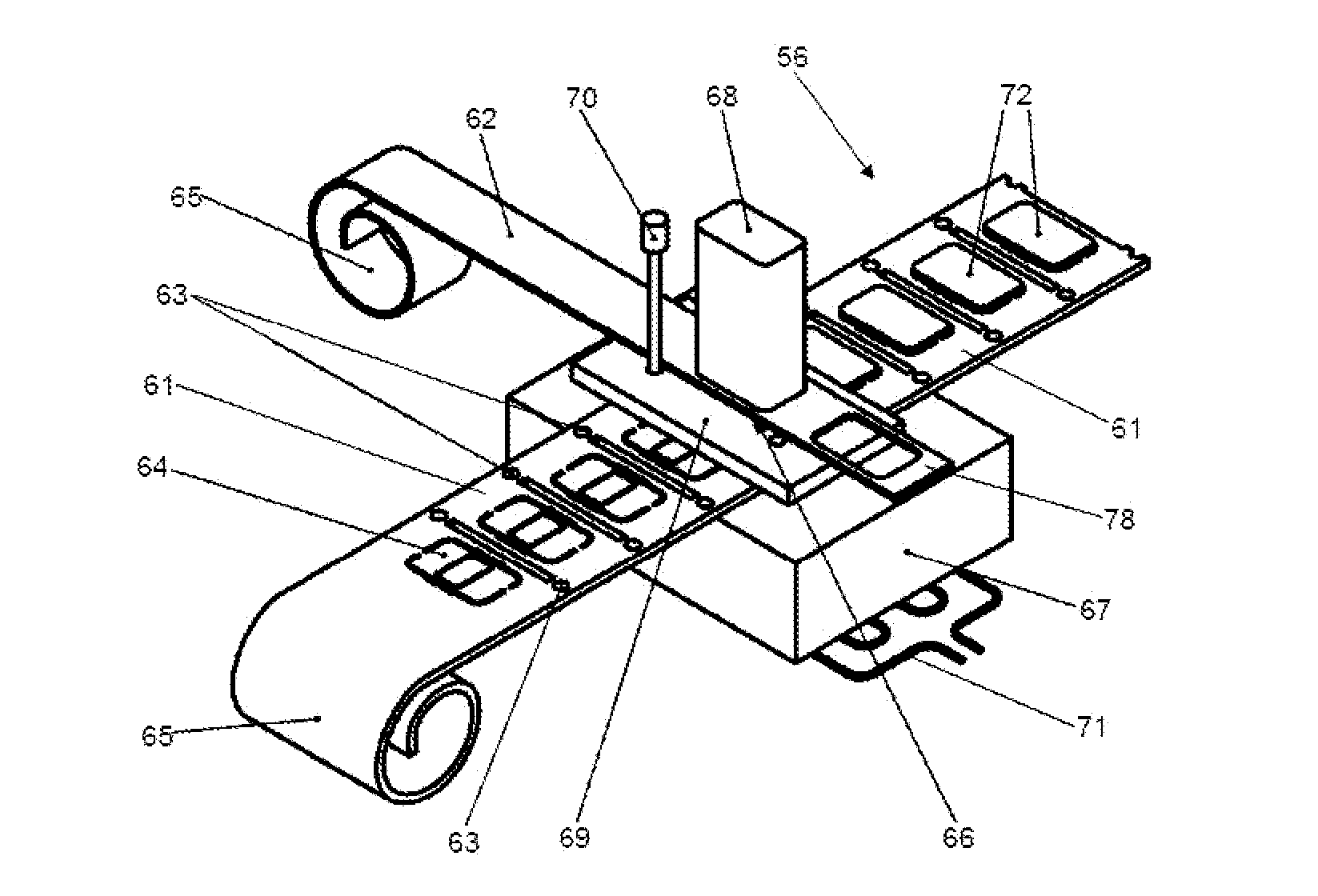

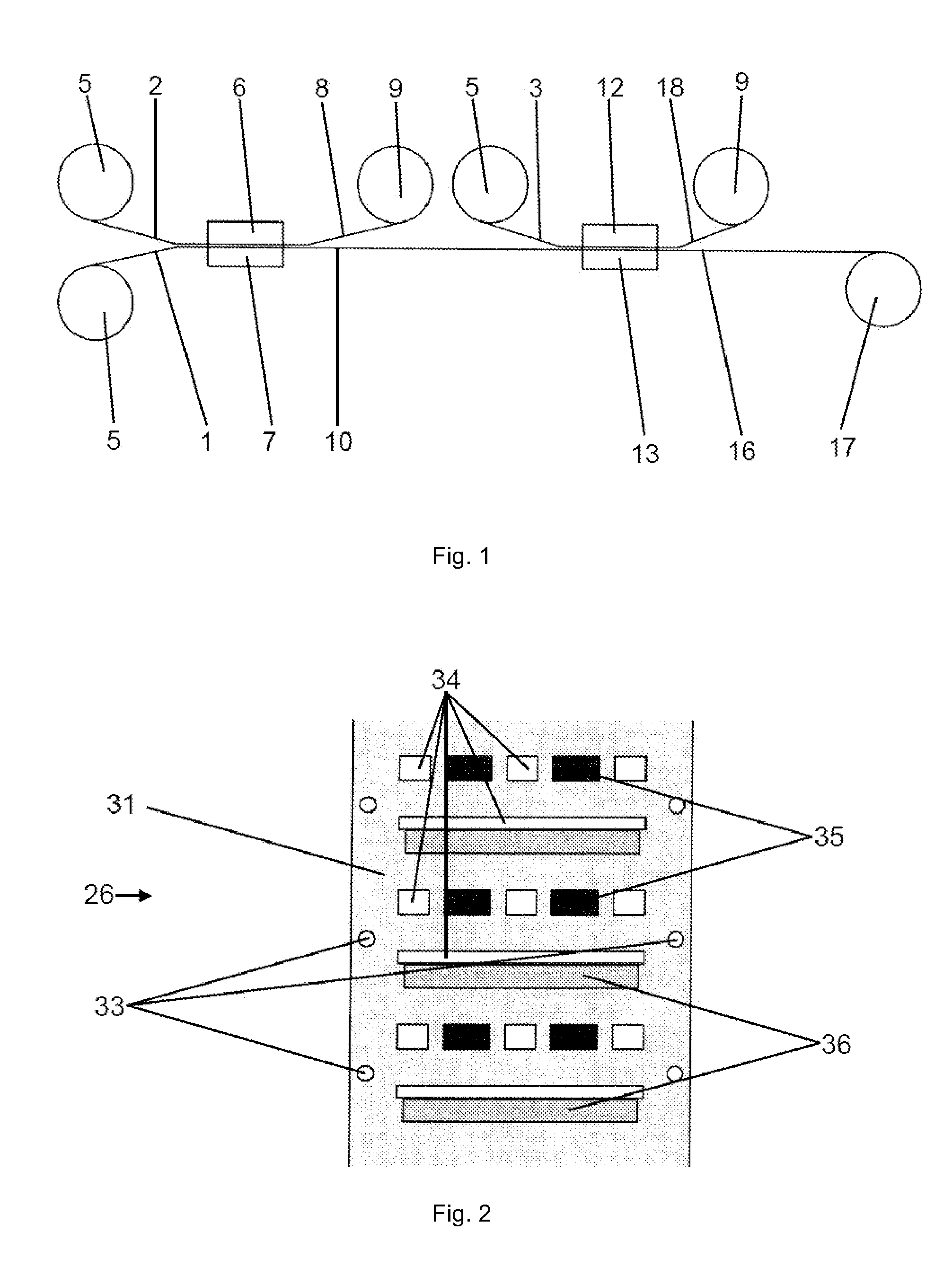

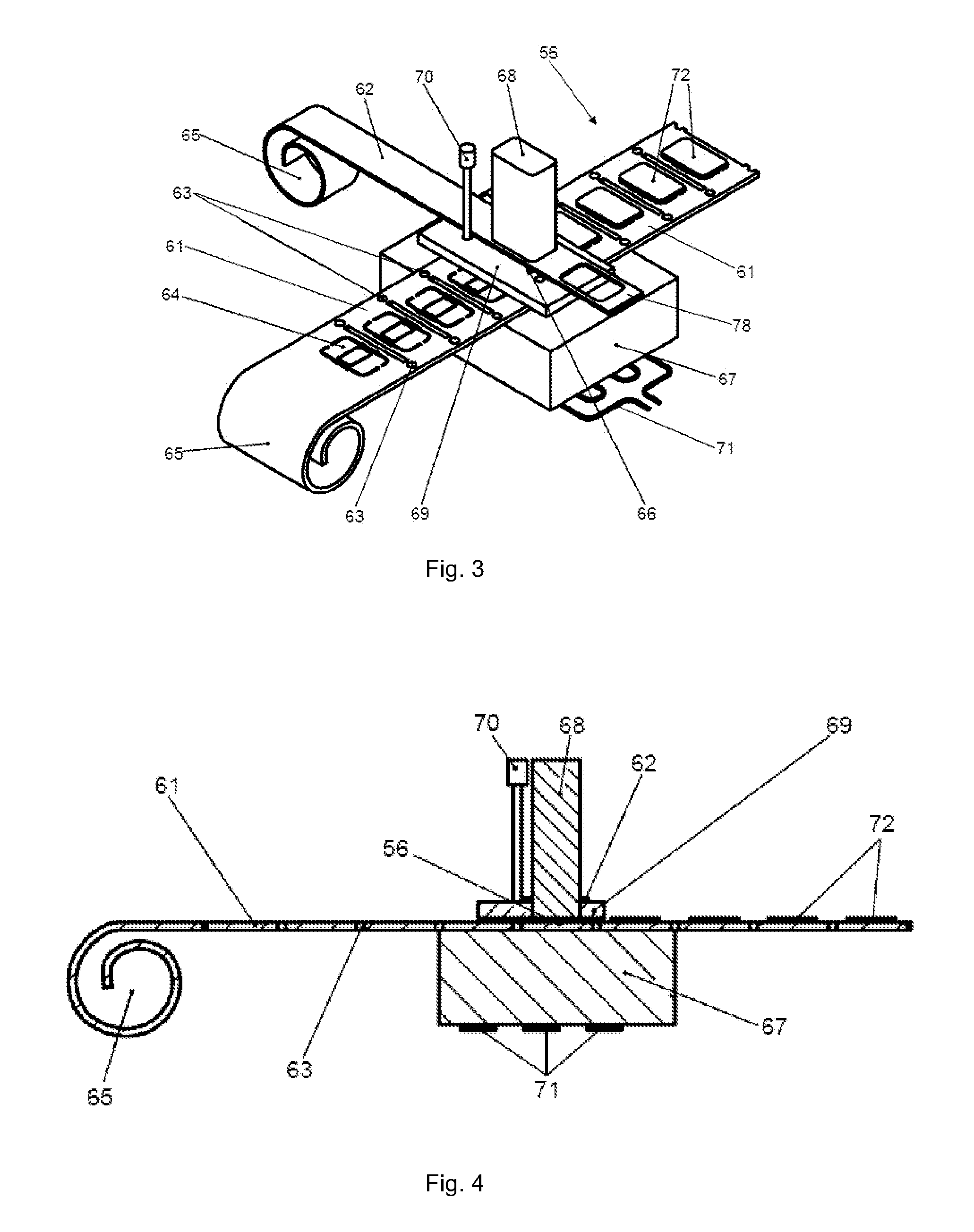

Method for partial lamination of flexible substrates

InactiveUS20130316122A1Simple processPrecise positioningLamination ancillary operationsOrnamental structuresEngineering

Owner:HERAEUS PRECIOUS METALS GMBH & CO KG

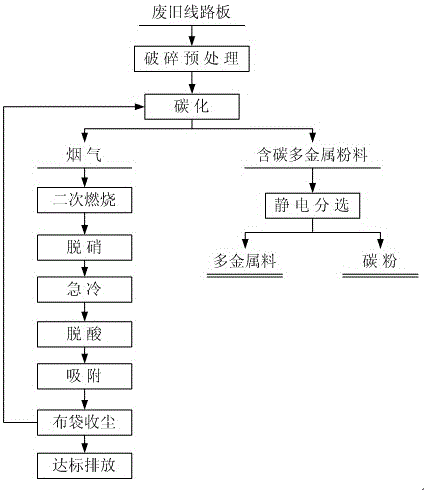

Resourceful treatment method for waste circuit board

ActiveCN105728434AImprove energy efficiencyEnables continuous processingSolid waste disposalTransportation and packagingHalogenCombustion

The invention discloses a resourceful treatment method for a waste circuit board. The resourceful treatment method comprises the process steps: carrying out crushing pretreatment of the waste circuit board, carbonization treatment of the waste circuit board, selective separation of carrying out flows including carbon-containing polymetallic materials, secondary combustion of flue gas, denitrification of the flue gas, rapid solidification treatment of the flue gas, deacidification treatment of the flue gas, adsorption treatment of the flue gas and collection and treatment of the flue gas; and finally respectively recovering a metal mixture and carbon powder, which are supplied for subsequent recycling. The resourceful treatment method has the following advantages that harms of dioxins and halogen substances can be fundamentally put an end, so that the environmental protection index is increased, and sanitary production of resource recycling the waste circuit board is realized; compared with other circuit board methods, the resourceful treatment method can fully utilize the heat energy of organic components in the waste circuit board, and the energy utilization ratio of the waste circuit board is increased; and metal and nonmetal in the waste circuit board are effectively separated from each other, regeneration recycling of resources is realized without secondary pollution, and the environmental, social and economic benefits are remarkable.

Owner:HUNAN JIANG YE MECHANICAL & ELECTRICAL TECH CO LTD

Disposable degradable paper cup and preparation method thereof

ActiveCN106579958AImprove performanceImprove stabilityAntifouling/underwater paintsChemical industryFiberPullulan

The invention discloses a disposable degradable paper cup. The disposable degradable paper cup comprises a degradable paper cup body and an inner film coated on the inner surface of the degradable paper cup body. The degradable paper cup body comprises following raw material including tapioca, citrus fibers, algae fibers, peach gums, trehalose, pullulan polysaccharide, polyvinyl alcohol, methyl cellulose, carrots, onions, cabbages, licorice, ebony, citrus peels, gardenias and officinal magnolia barks. The inner film comprises following raw material including polyhydroxy fatty acid esters, lotus leaf powder, locust bean gums, protamines and mustard powder. The invention provides a preparation method of the disposable degradable paper cup. The disposable degradable paper cup has the advantage that: degradability of the paper cup is effectively improved.

Owner:安徽双羽新材料包装有限公司

Wastewater treatment device and wastewater treatment technology

PendingCN108218117AIntelligent processingEasy and fast handlingMultistage water/sewage treatmentWater/sewage treatment by neutralisationFlocculationWater storage tank

The invention discloses a wastewater treatment device and a wastewater treatment technology. The wastewater treatment device comprises a water storage tank, a microbial water purification tank, a flocculation tank, an adsorption tank, an acid-base adjustment tank, a filter membrane, a water inlet pipe, 4 water pump and connecting pipe assemblies, four water pumps, a water outlet pipe and an intelligent controller, wherein the water storage tank, the microbial water purification tank, the flocculation tank, the adsorption tank and the acid-base adjustment tank are orderly connected through thewater pump and connecting pipe assemblies. Through reasonable matching and order adjustment of components such as the water storage tank, the microbial water purification tank, the flocculation tank,the adsorption tank, the acid-base adjustment tank, the filter membrane and the like, the wastewater treatment device has high treatment effect, low wastewater treatment cost and high treatment stability and treatment capacity.

Owner:广州市绿潮环保工程有限公司

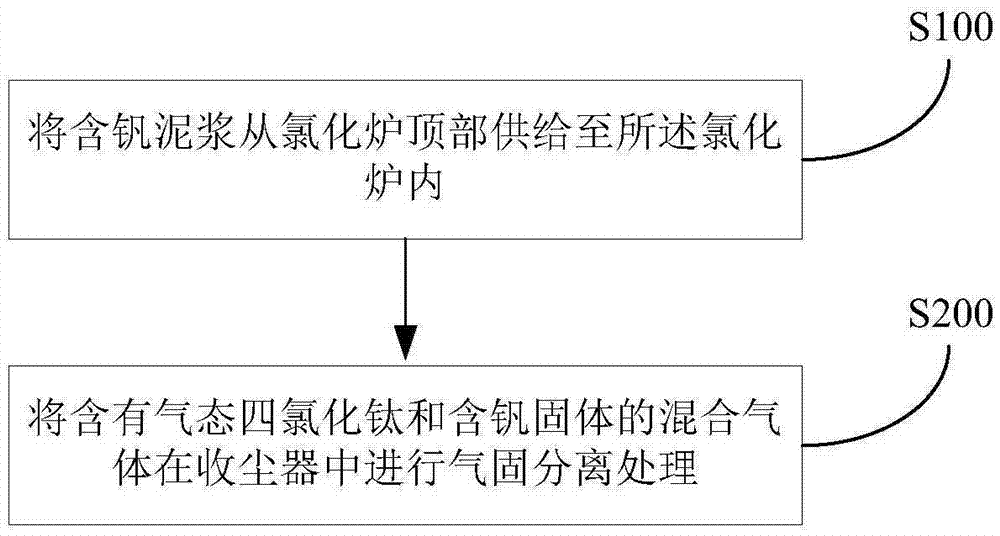

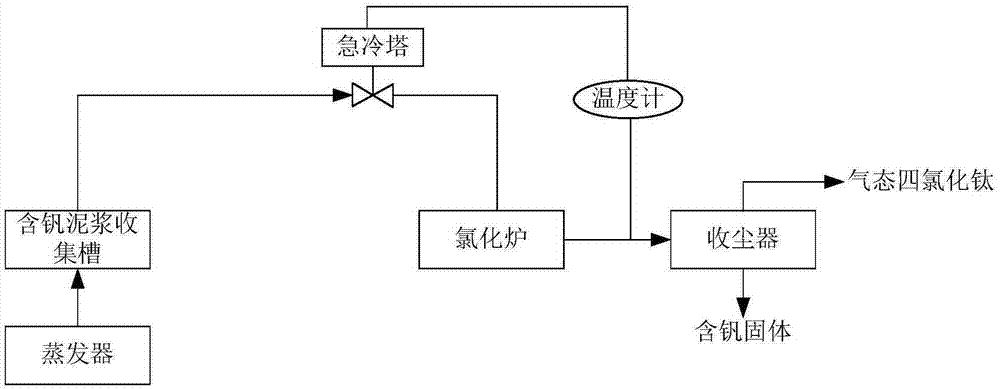

Vanadium-containing mud slurry treatment method

The present invention discloses a vanadium-containing mud slurry treatment method, wherein the vanadium-containing mud slurry contains titanium tetrachloride. The vanadium-containing mud slurry treatment method comprises: (1) supplying a vanadium-containing mud slurry into a chlorination furnace from the top portion of the chlorination furnace to make the vanadium-containing mud slurry contact the hot flue gas generated in the chlorination furnace to obtain mixing gas containing gas-state titanium tetrachloride and a vanadium-containing solid; and (2) carrying out gas-solid separation treatment on the mixing gas containing the gas-state titanium tetrachloride and the vanadium-containing solid in a dust collector so as to respectively obtain the titanium tetrachloride and the vanadium-containing solid. With the vanadium-containing mud slurry treatment method of the present invention, the continuous treatment on the vanadium-containing mud slurry can be achieved, and the separation efficiency of the titanium tetrachloride and the vanadium-containing solid in the vanadium-containing mud slurry is high so as to completely recover the titanium tetrachloride.

Owner:YUNNAN METALLURGICAL XINLI TITANIUM IND CO LTD

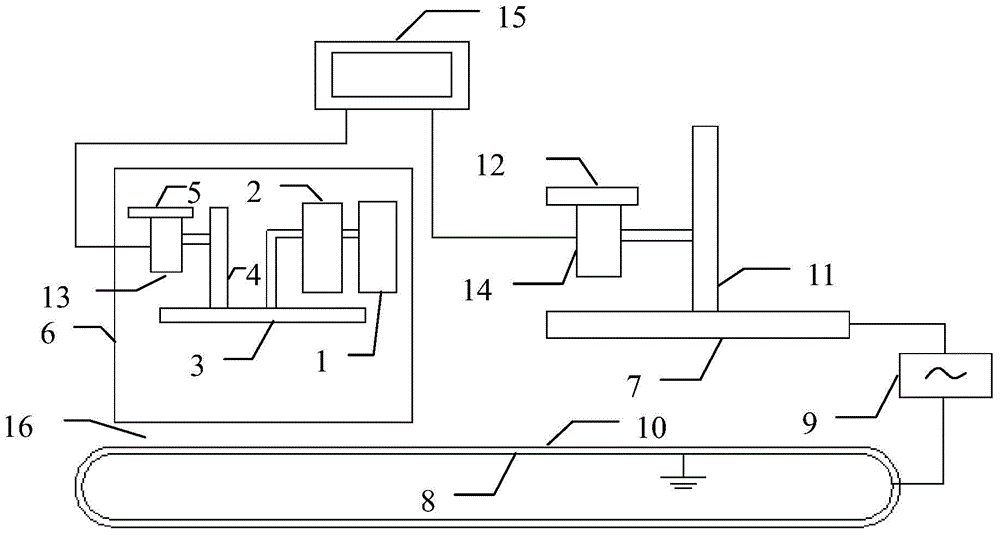

Continuous deacidifying system

InactiveCN105019305AAvoid deformationPrevent discolorationOld paper after-treatmentEngineeringRadio frequency

The invention provides a continuous deacidifying system. The system comprises a deacidification agent atomizing device which comprises a deacidification agent tank, an atomization generating mechanism and a sprinkler for applying a deacidification agent to a to-be-deacidified sample; a radio frequency discharge device which comprises a discharge electrode, a grounding electrode and a matched circuit, wherein the grounding electrode is made from a flexible material and is wound as a conveyor belt for bearing the to-be-deacidified sample; and a driving device for driving the discharge electrode and the sprinkler so as to change the position relative to the conveyor belt. The continuous deacidifying system for treating samples at normal temperature and normal pressure is safe to use and free of pollution to external environment, is simple in structure and convenient to use, is short in treatment time, thorough in deacidification and difficult to return acid, effectively prevents the sample from being deformed and discolored, and can be used for realizing continuous treatment of the to-be-deacidified sample and is suitable for industrialized large-scaled application.

Owner:ZHEJIANG UNIV

System for recycling PVA (Polyvinyl Alcohol) slurry from printing and dyeing wastewater and desizing wastewater

InactiveCN102887577AEnables continuous processingImprove biodegradabilityFibre treatmentMultistage water/sewage treatmentChemical oxygen demandPolyvinyl alcohol

The invention discloses a system for recycling PVA (Polyvinyl Alcohol) slurry from printing and dyeing wastewater and desizing wastewater. The system is characterized by comprising a reaction device, a solid-liquid separation device, a feed grinding device, a dehydration device and a discharge grinding device. The desizing wastewater is reacted and coagulated in a flocculent form in the reaction device, subjected to solid-liquid separation by the solid-liquid separation device, grinded by the feed grinding device, dehydrated and pressed into blocks by the dehydration device, and grinded by the discharge grinding device, so that the recycling of PVA is completed. The system disclosed by the invention adopts a chemical coagulation method, and recycles the PVA from the desizing wastewater through the units, such as a reaction unit, a solid-liquid separation unit, a grinding unit and a dehydration unit. The system has the capabilities of realizing the continuous treatment of the desizing wastewater, achieving a PVA recovery rate of 85-90% from the desizing wastewater, reducing COD (chemical oxygen demand) in the wastewater, largely lowering the loads of wastewater treatment facilities, effectively improving the biodegradability of the wastewater, and benefiting for the treatment of textile wastewater as well as the printing and dyeing wastewater.

Owner:JIANGSU REDFLAG PRINTING & DYEING MACHINERY

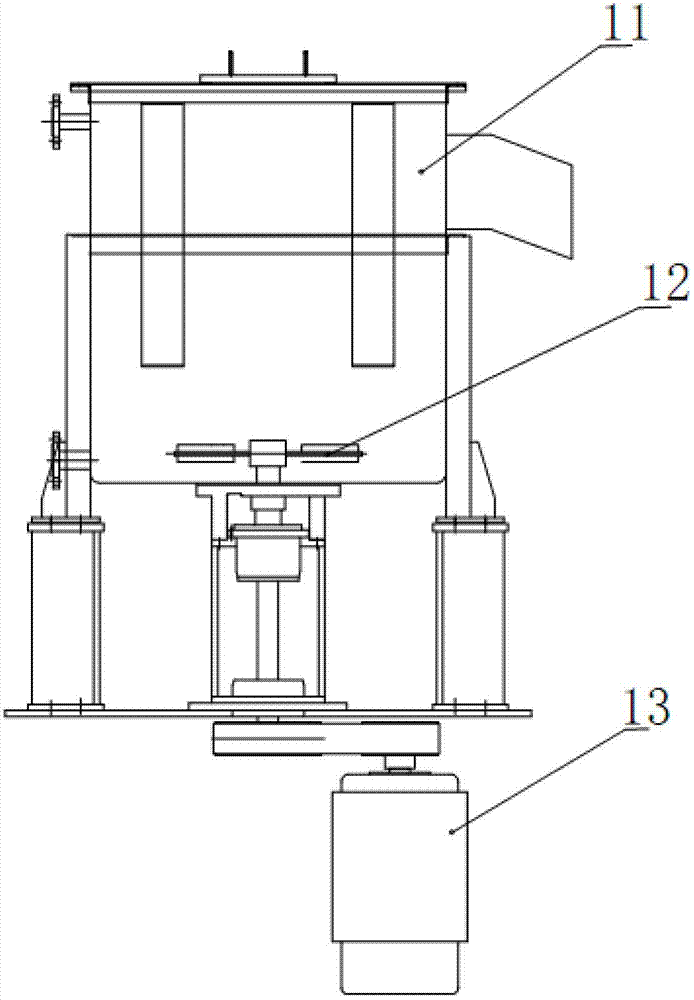

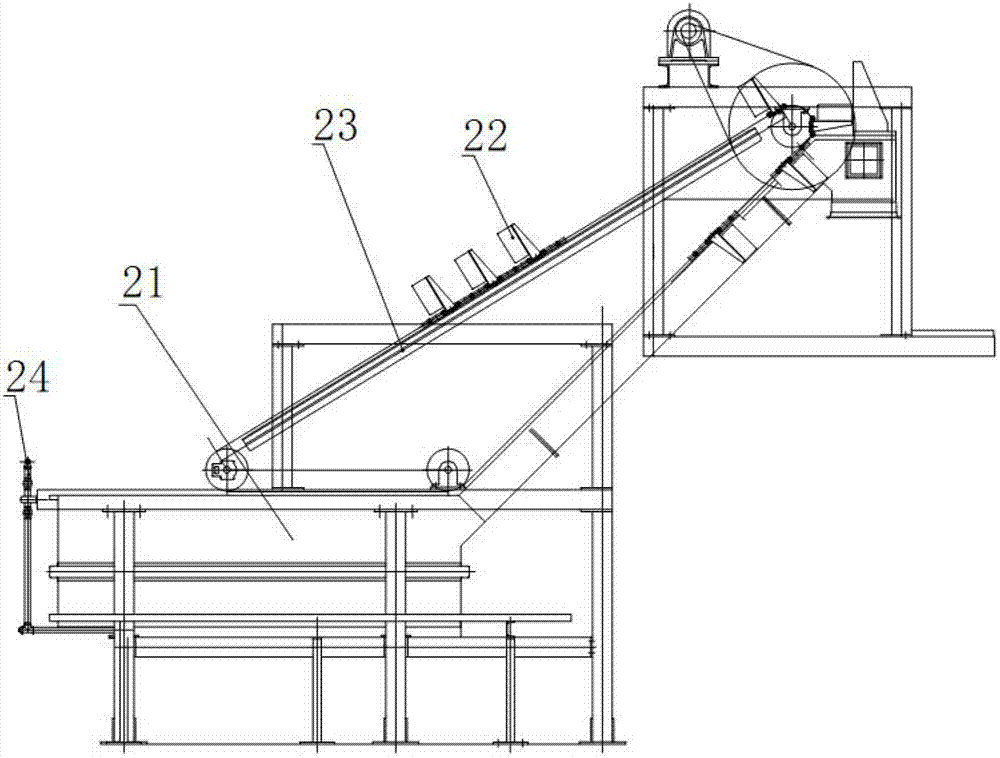

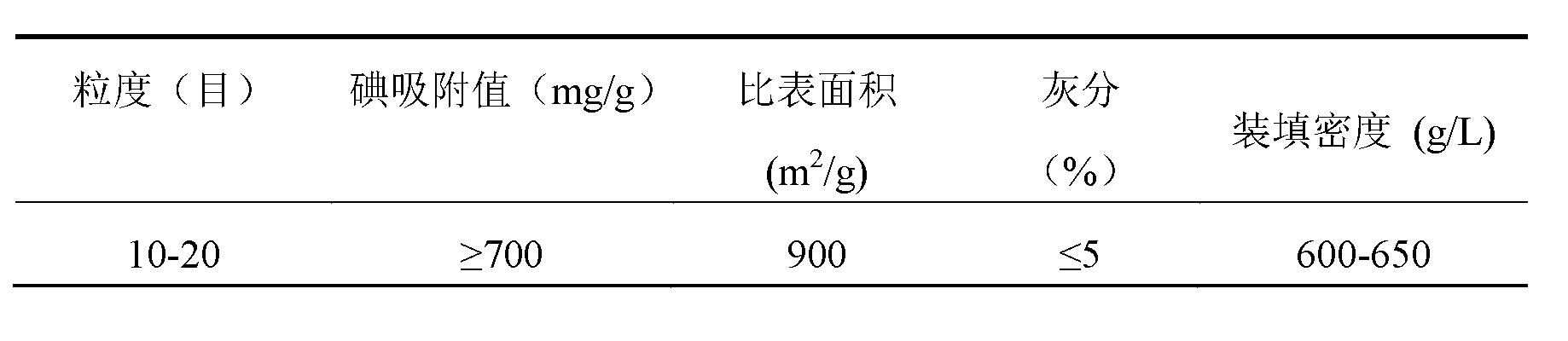

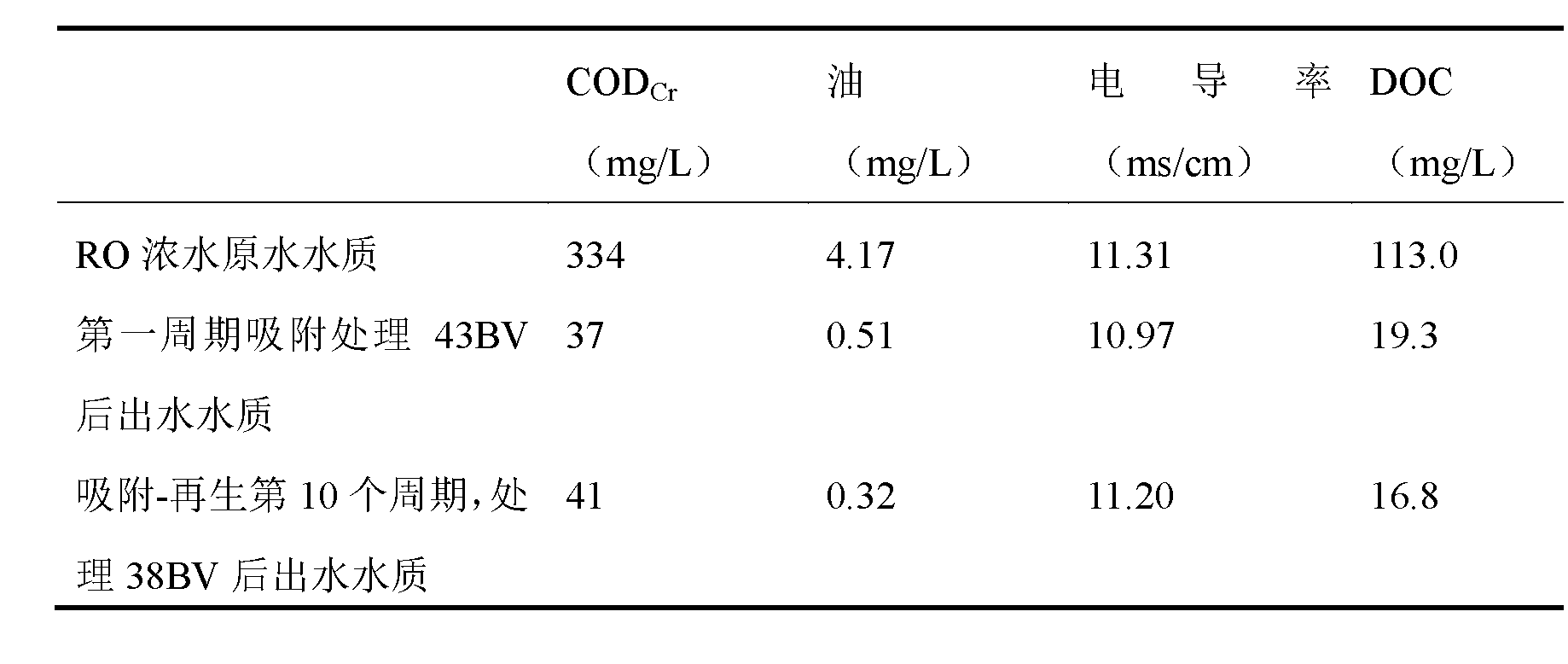

Method for reverse osmosis concentrated water by adsorption-regeneration circular treatment

ActiveCN103214056ARealize automatic controlLess investmentWater/sewage treatment by sorptionAfter treatmentChemical oxygen demand

The invention discloses a method for reverse osmosis concentrated water by adsorption-regeneration circular treatment, belonging to the field of advanced wastewater treatment. An adsorption-regeneration combination treatment process is adopted, the advanced treatment problem of reverse osmosis concentrated water is solved, the COD (Chemical Oxygen Demand) of inlet water is 150-300mg / L, the COD of the outlet water is less than or equal to 50mg / L after treatment. According to the combination process, adsorption treatment is adopted as the main, an electrochemistry regeneration manner is adopted to recover the adsorption capacity on a saturation adsorption material, the adsorption-regeneration combination treatment process is realized, and the treatment cost of the reverse osmosis concentrated water is greatly reduced.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com