Patents

Literature

62results about How to "Avoid loading and unloading" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Deep treatment process of oily wastewater

ActiveCN102060350ASolving Deep Processing ChallengesImplement deep processingFatty/oily/floating substances removal devicesCombustible gas purificationActivated carbonSorbent

The invention relates to a deep treatment process of oily wastewater, which is characterized in that an absorption system and a regeneration system are provided in the process, wherein the absorption system is formed by a series of absorption tower groups with columns in series used for realizing parallel operation, the absorption tower groups are used for alternately performing deep treatment on oily yielding water with a low concentration of 30-50 mg / L of a traditional process, the absorption operation is carried out at normal temperature, the oil content in the yielding water is controlled to be lower than 1 mg / L through the treatment of a group of the absorption towers with columns in series, and an absorbing agent is made of modified fly ash, activated carbon and an expanded graphite absorbing material; when the yielding water in a group of the absorption towers exceeds a treatment requirement, the group of the absorption towers is switched to a biological regeneration system, and other absorption tower groups are simultaneously switched to the absorption system for continuous absorption; and saturated absorption towers are used for performing in-situ regeneration on the saturated absorbing agent by utilizing degradation ability of high temperature-resistant and efficient petroleum hydrocarbon for degrading bacteria.

Owner:CHINA NAT OFFSHORE OIL CORP +2

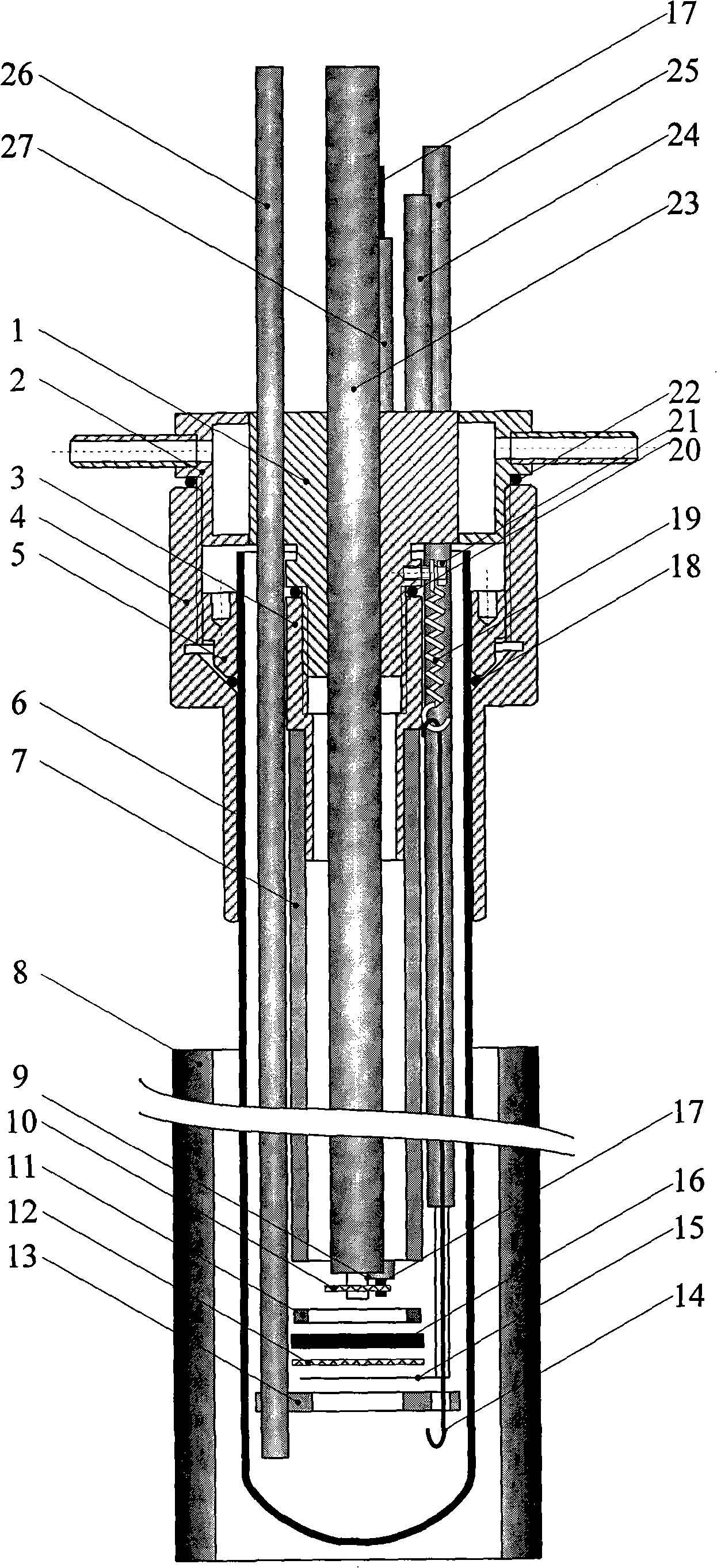

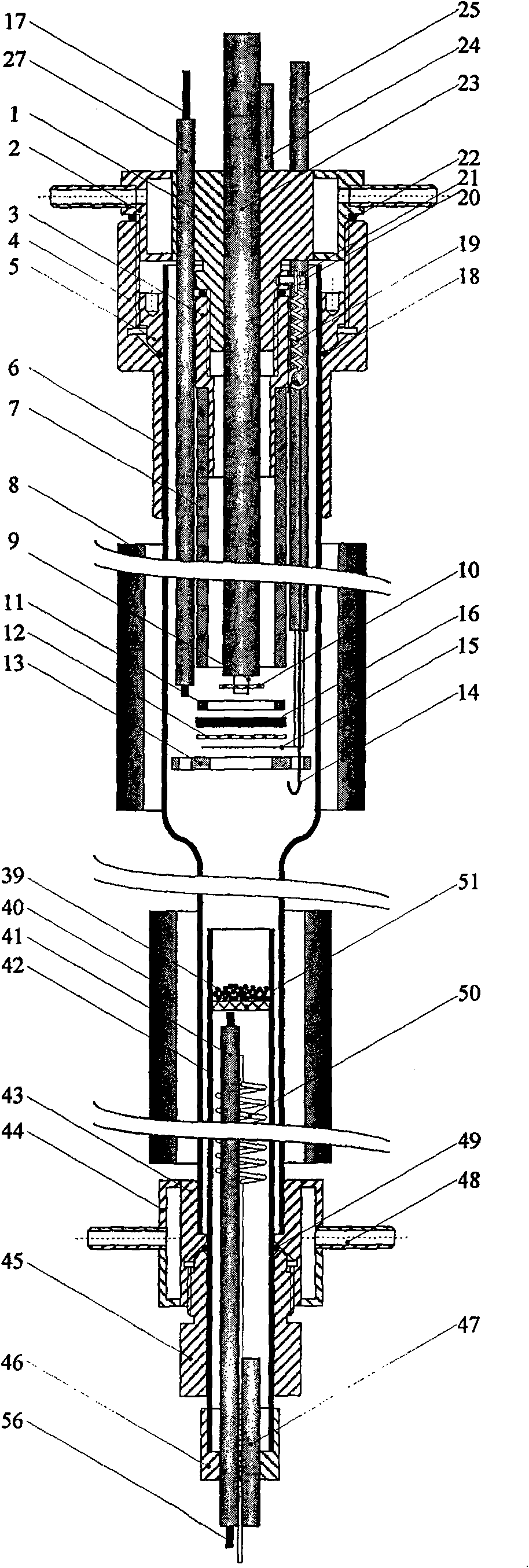

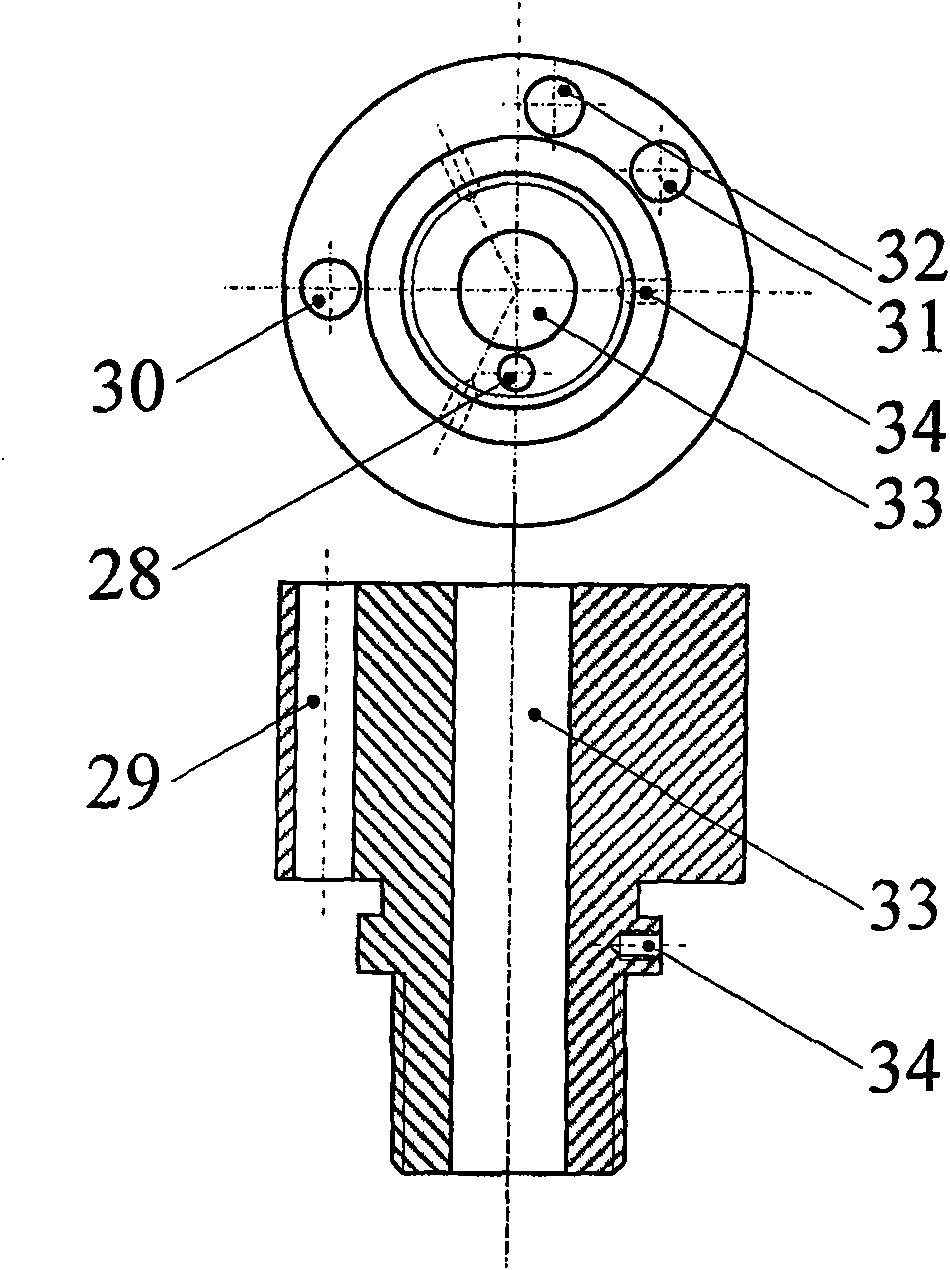

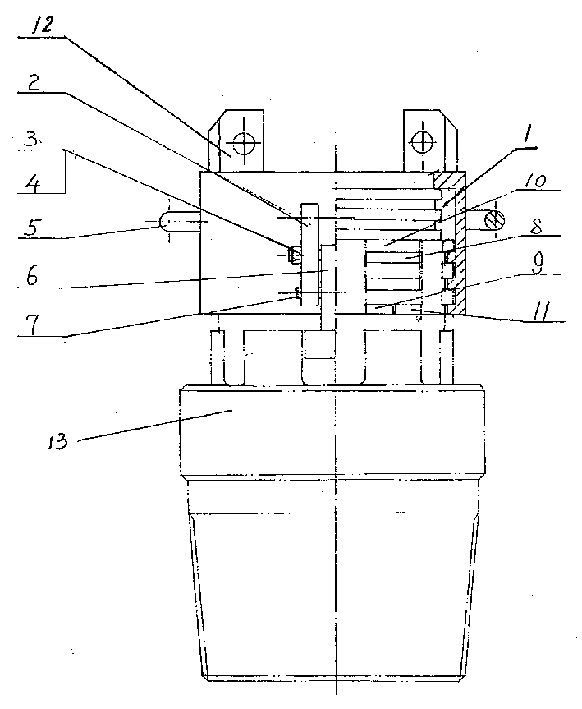

Direct carbon fuel cell reaction device

ActiveCN101345315AImprove performanceSolve adding waterFuel cell auxillariesSolid electrolyte fuel cellsFuel cellsEngineering

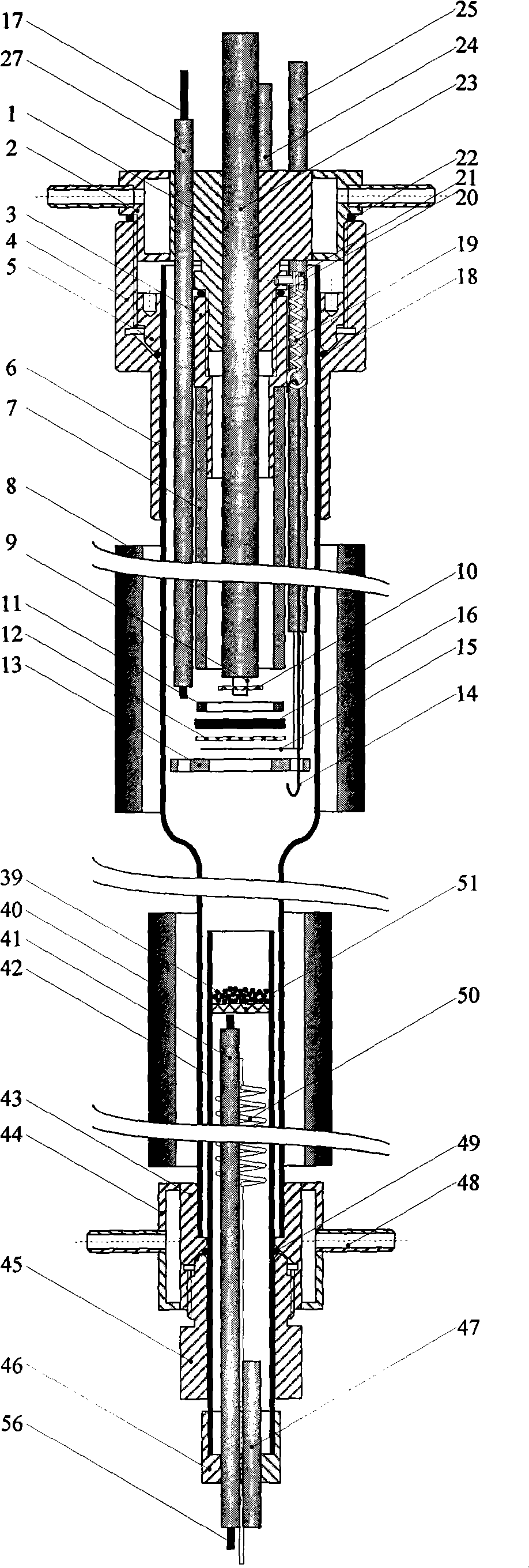

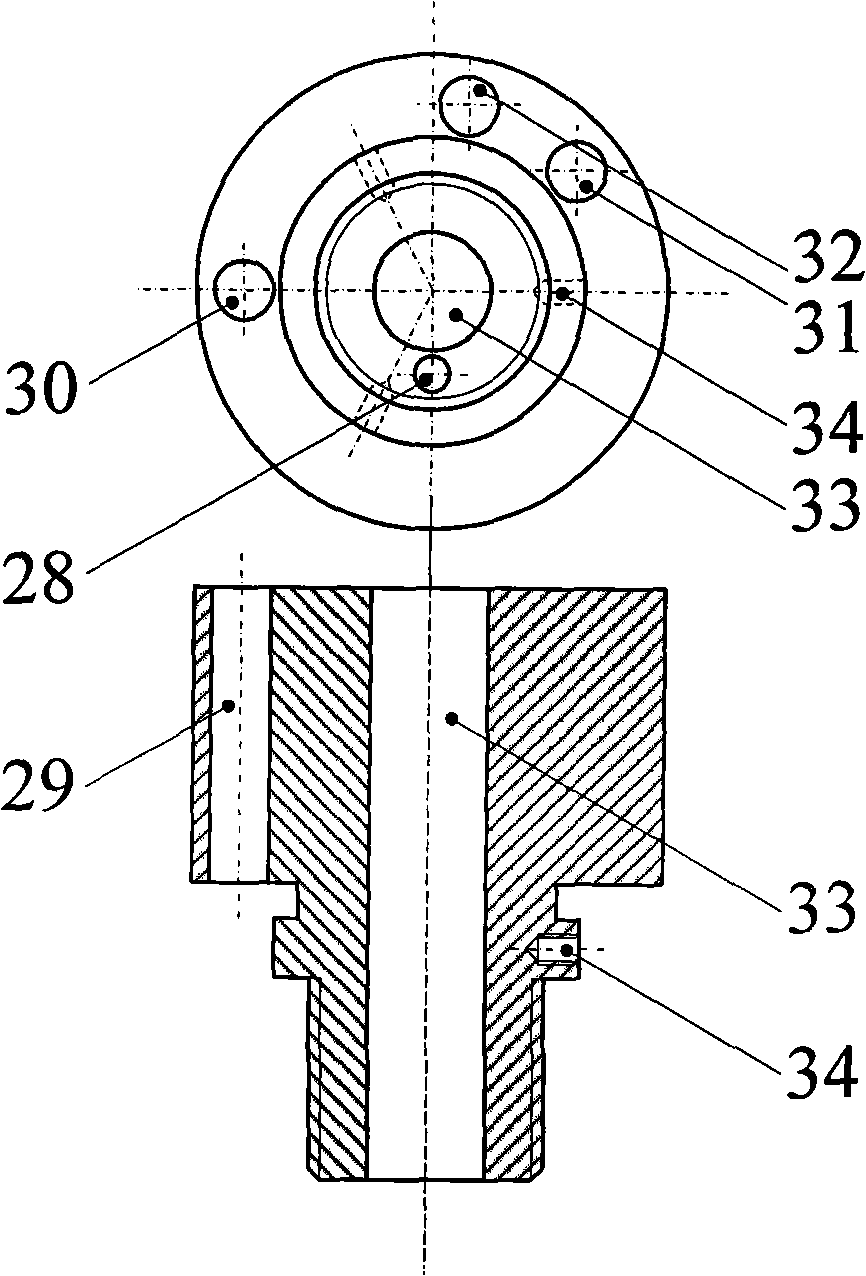

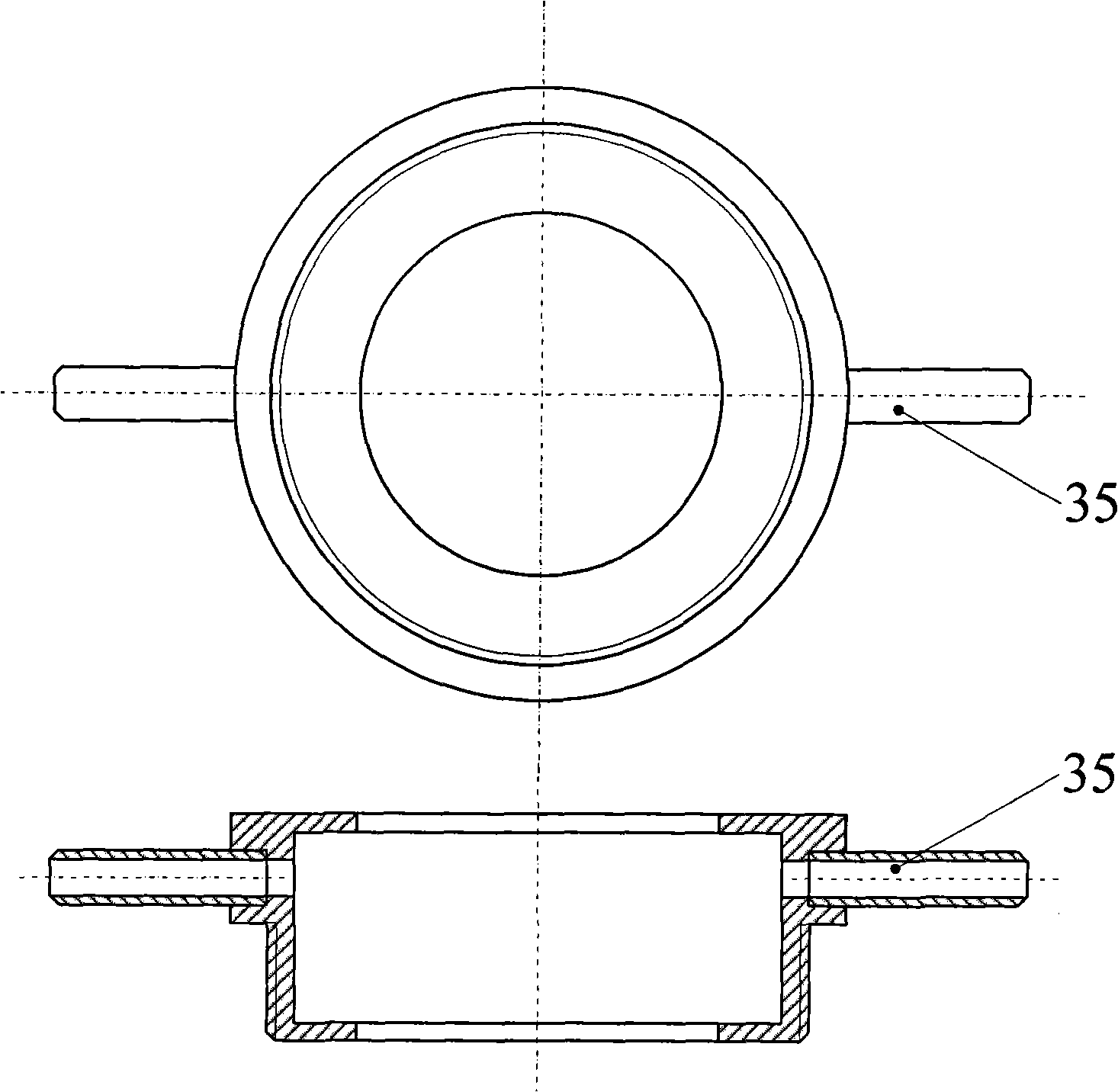

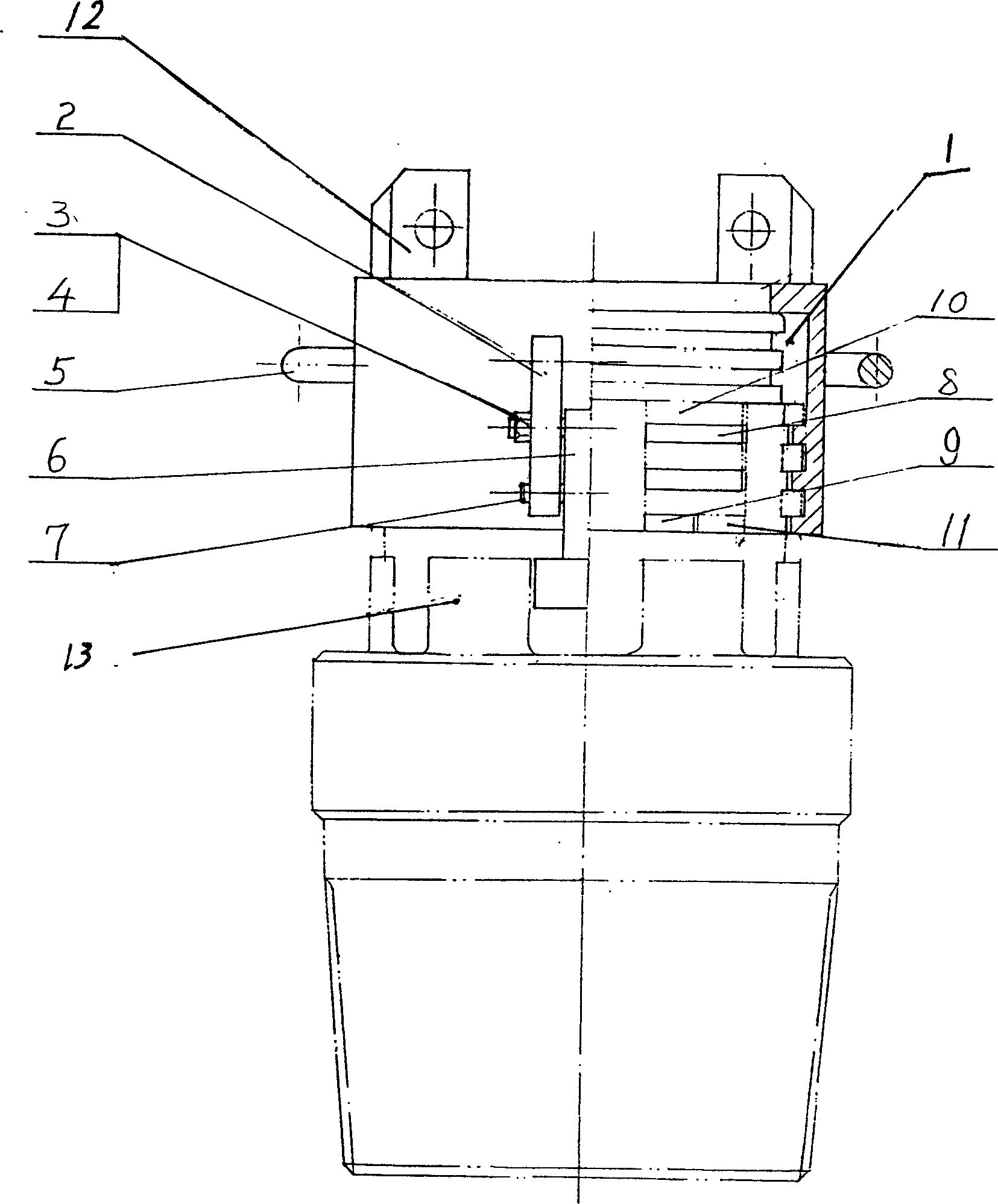

The invention provides a direct carbon fuel battery reaction device, belonging to the field of direct carbon fuel battery technique. An upper base (1) of the reaction device is coaxially arranged into a water cooling sleeve (2); the connection of the upper base and the water cooling sleeve is welded and sealed to form a water cooling chamber; an anode current collecting Pt net (12) is used for collecting current from the anode of a button-typed solid oxide fuel battery (16); two ends of an anode current collecting Pt wire (15) are respectively used as an reference electrode and a testing electrode; the temperature measuring point of a temperature measuring thermal-couple (17) and the button-typed solid oxide fuel battery (16) keep in the same height; the bottom of an anode chamber pipe (6) is inserted into the upper hole of a lower base (43); the lower surface of a quartz sand sintering plate (42) is provided with a carbon fuel thermal-couple (56); all pipes and sealing heads (46) are hermetically connected with each other. The direct carbon fuel battery reaction device of the invention solves the problem of water adding of anode chamber and the arranging of carbon fuel, realizes that the temperatures required by the running of fuel battery and the reacting of the carbon fuel are respectively controlled, avoids complex disassembly / assembly process and personnel scald, prevents the sealing invalidity and reduces the cost.

Owner:TSINGHUA UNIV

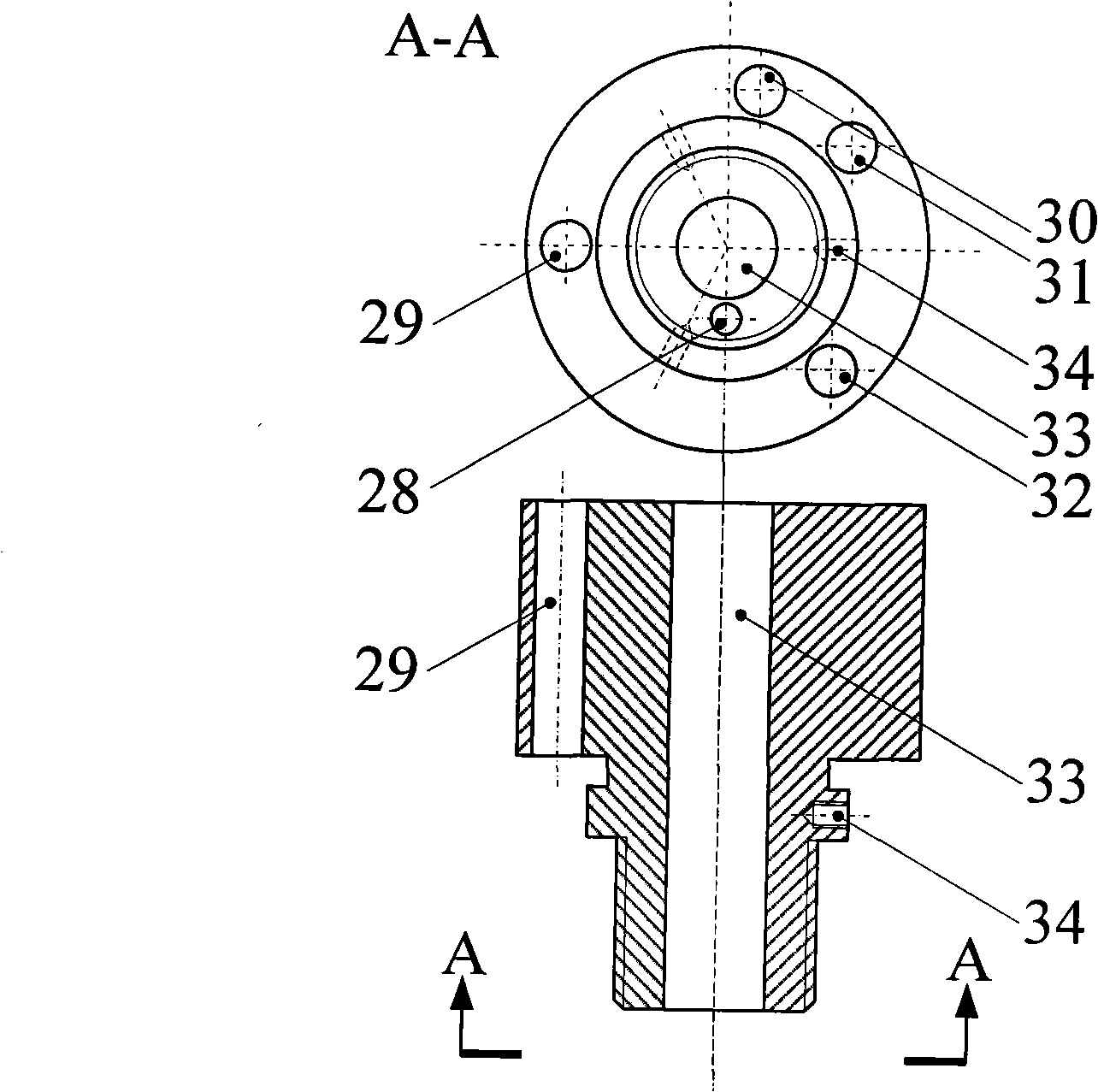

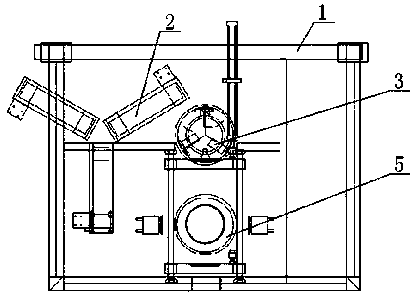

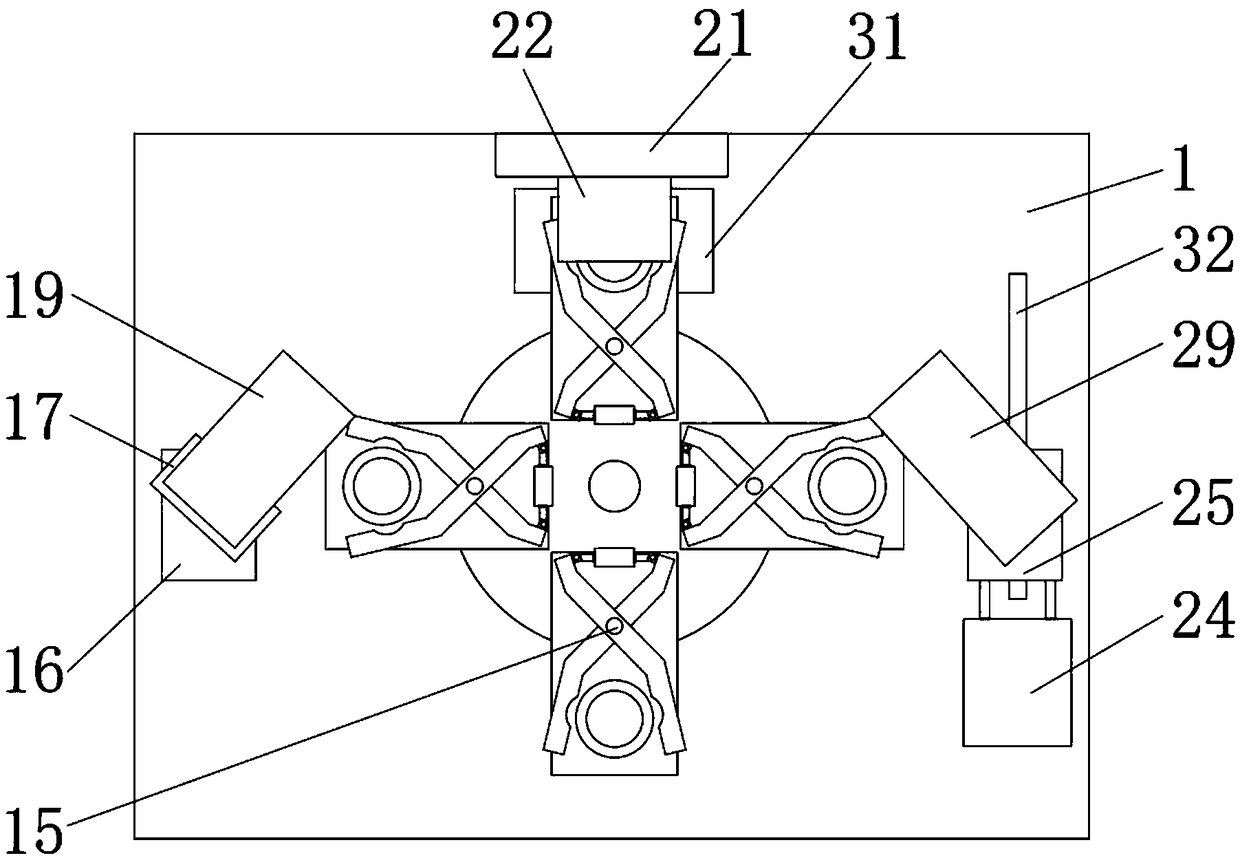

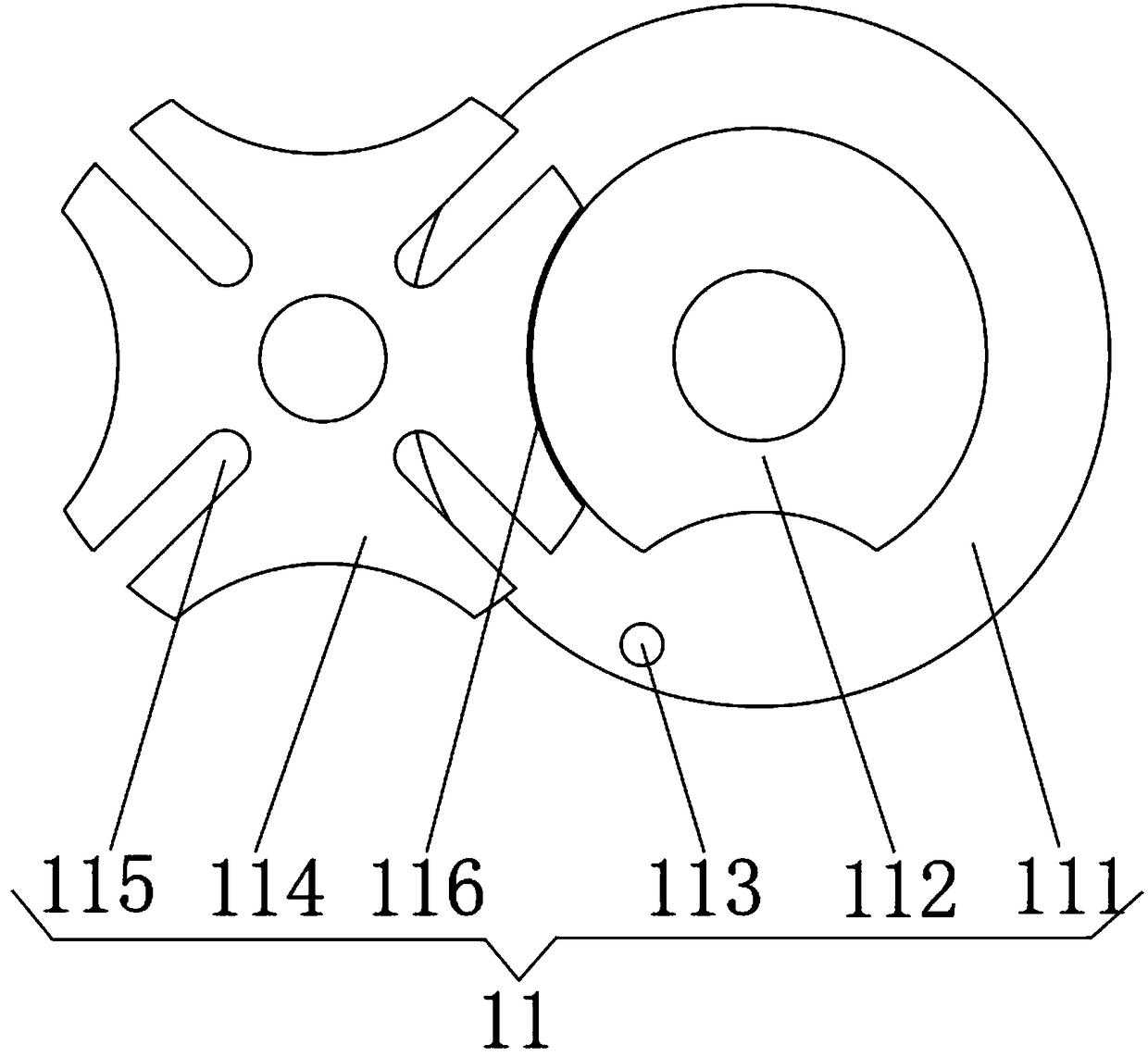

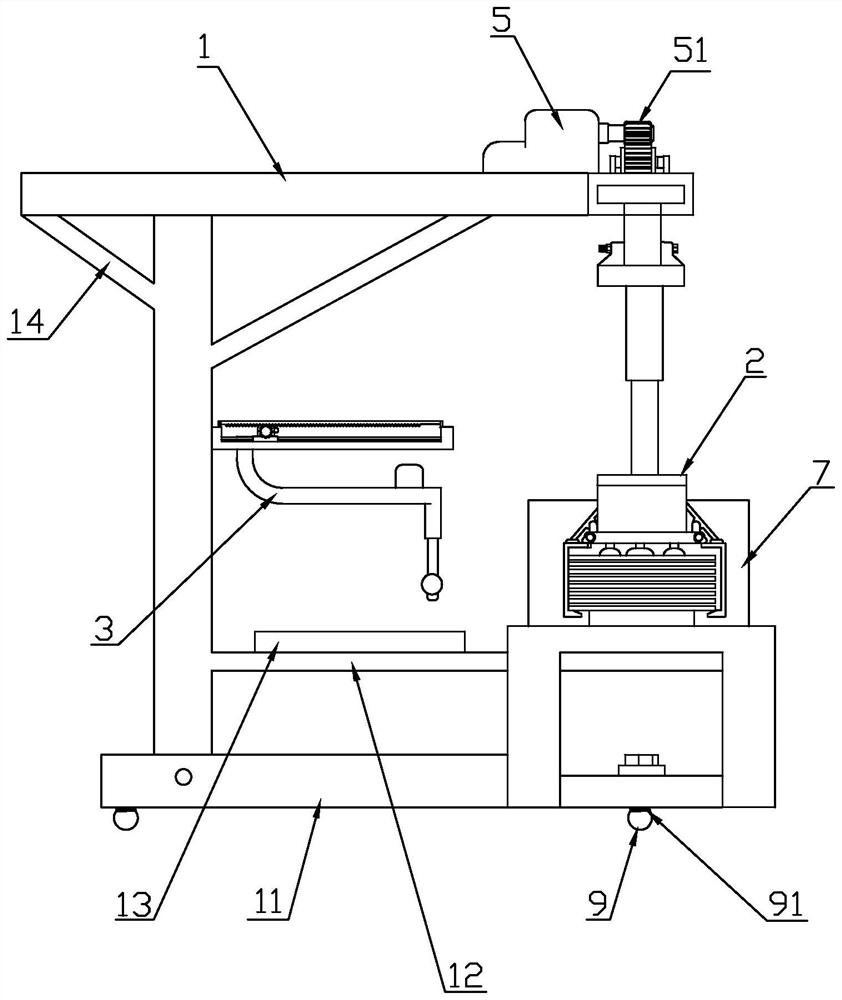

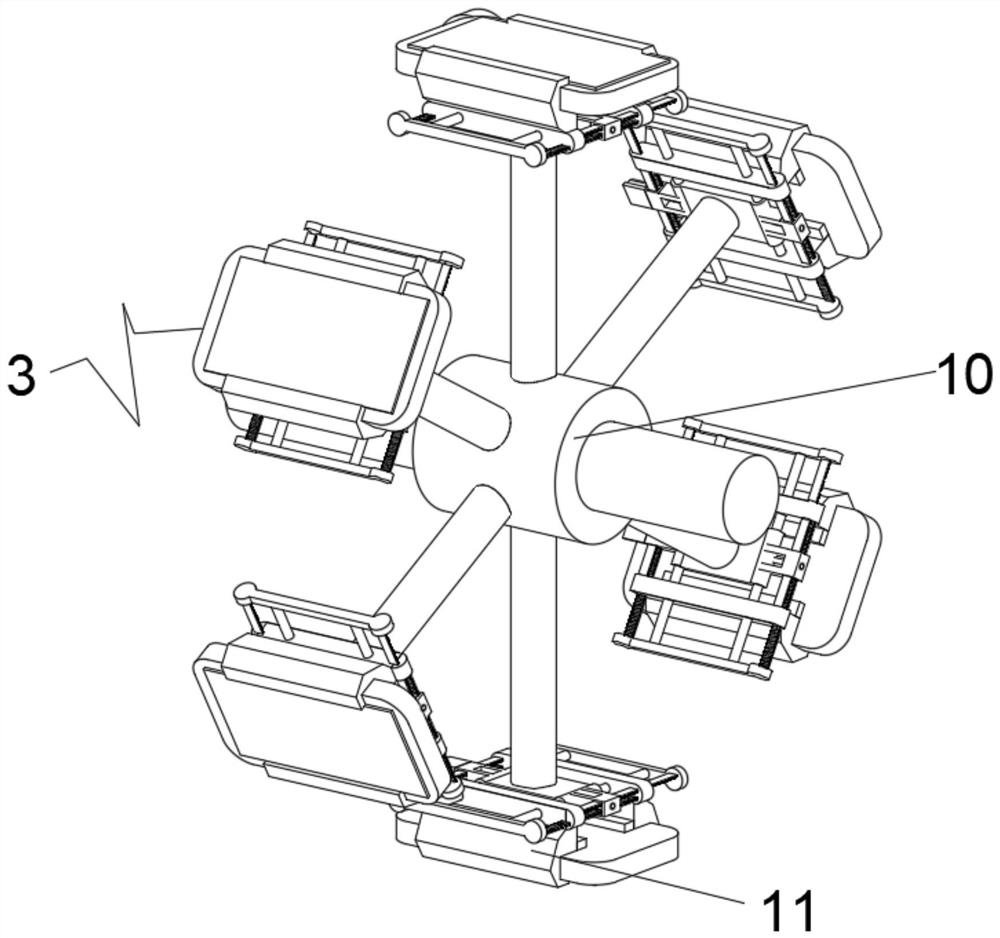

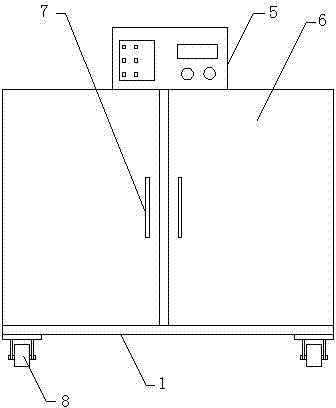

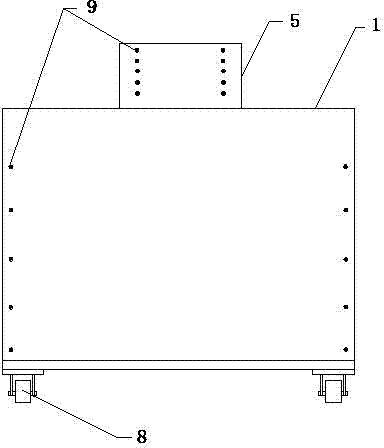

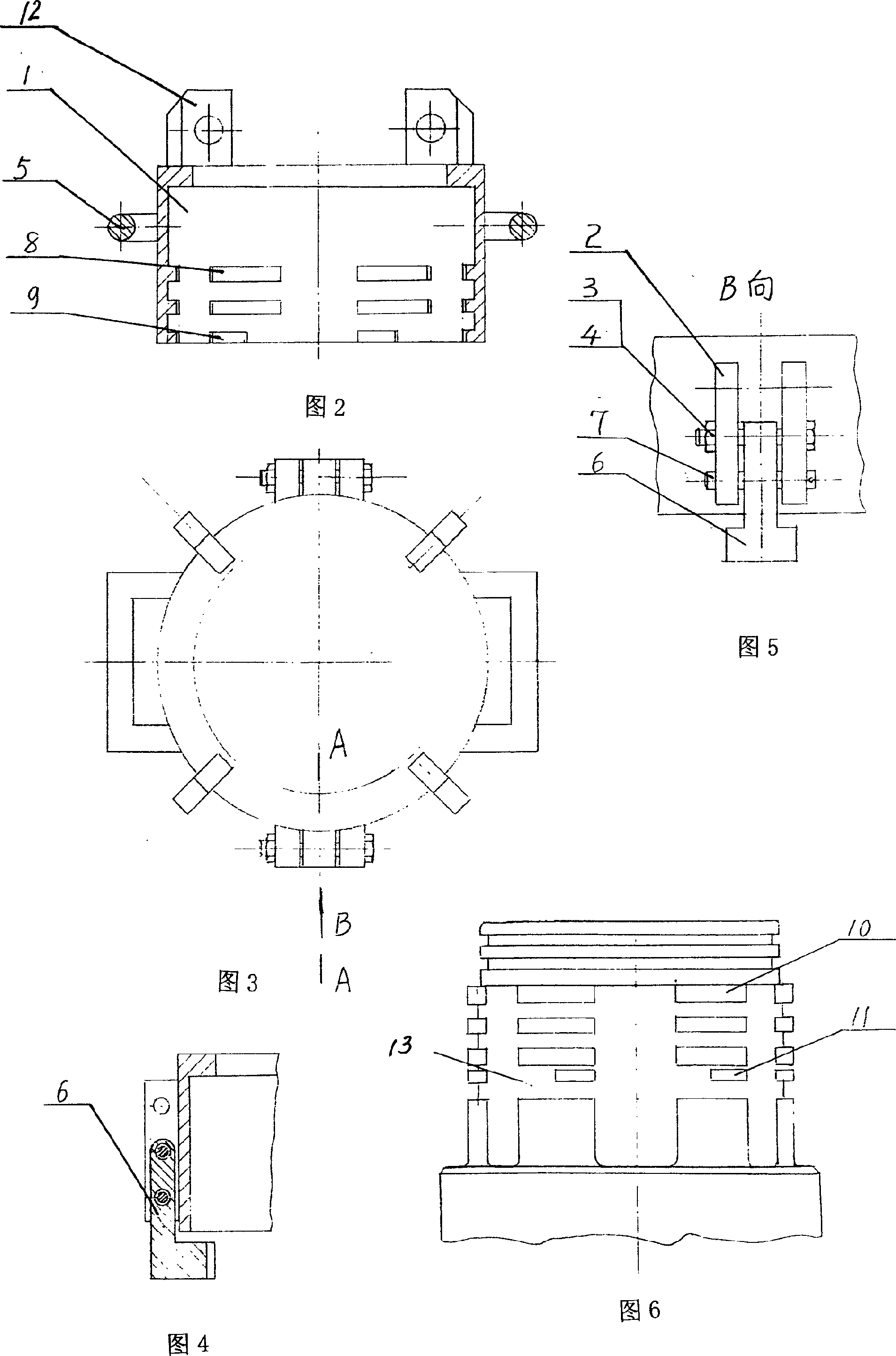

Flange end face machining device

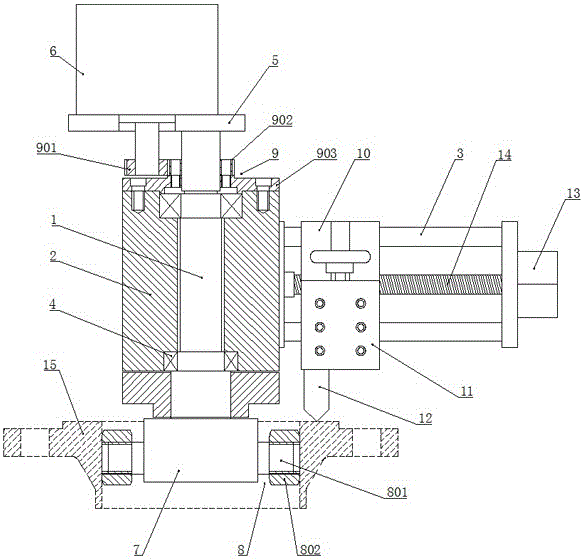

InactiveCN106392102AAvoid loading and unloadingReasonable designFeeding apparatusLarge fixed membersBall screw driveDrive motor

The invention discloses a flange end face machining device for solving the problem that an existing flange takes a long time for assembly, disassembly and maintenance and is high in construction cost. The flange end face machining device comprises a fixing shaft, a rotating sleeve and parallel guide rails, and is characterized in that the rotating sleeve is rotationally arranged on the fixing shaft through a rotary supporting part; a driving motor is mounted on one end of the fixing shaft through a fixing frame; a fixing seat is coaxially arranged on the other end of the fixing shaft; a plurality of fixing parts are symmetrically and uniformly distributed in the radial direction and on the circumferential surface of the fixing seat; an output shaft of the driving motor is used for driving the rotating sleeve to rotate by virtue of a transmission part; the parallel guide rails are horizontally fixed on the rotating sleeve; a cutting knife holder is arranged on the parallel guide rails in a sliding manner; a cutting knife rest is longitudinally arranged on the cutting knife holder in a sliding manner; a knife is assembled on the cutting knife rest; the cutting knife rest is used for driving the knife to implement longitudinal feeding on the cutting knife holder; a feeding motor arranged at the end parts of the parallel guide rails is used for driving the cutting knife holder to move horizontally by virtue of a ball screw. The flange end face machining device disclosed by the invention is capable of preventing assembly and disassembly of a flange, convenient to operate and use and low in construction cost.

Owner:丁乐冲

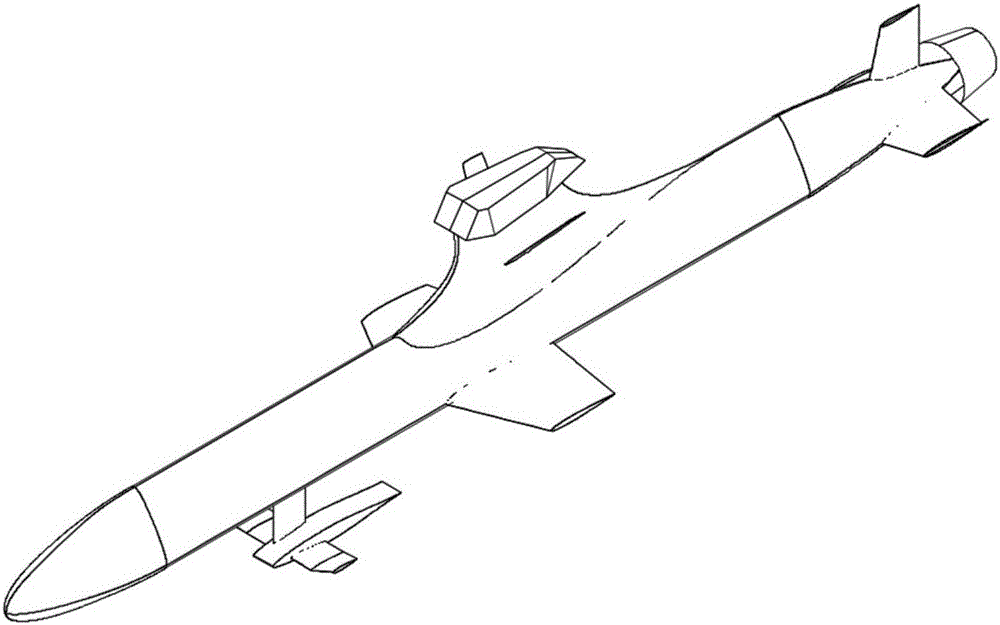

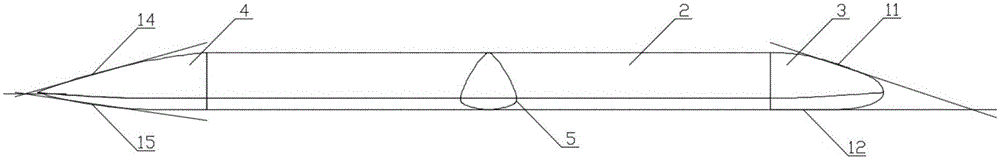

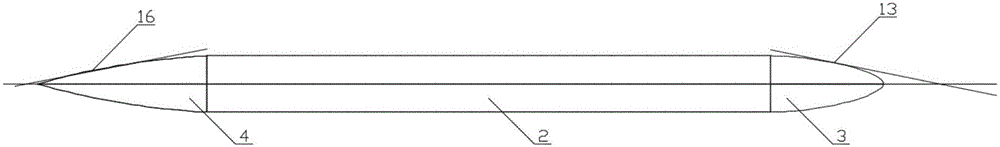

Triangular-section power draft-increase ballast-free semi-submersible conveying ship

ActiveCN105836079AReduce wavesImprove seakeepingUnderwater vesselsUnderwater equipmentControl systemStern

The invention provides a triangular-section power draft-increase ballast-free semi-submersible conveying ship. The ship comprises a main ship body, a power draft-increase system and a control system. The main ship body comprises an upright rounded-triangular-cross-section parallel body, a flow inflow section and a flow removal section, the upright rounded-triangular-cross-section parallel body is designed in an optimized mode to adapt to underwater near-surface sailing, the flow inflow section and the flow removal section downward incline to a blunt bow and a conical stern respectively. The power draft-increase system is a multi-wing combined system, comprises board side fixed negative lift horizontal wings, a controllable main lift adjusting wing combined appendage and stern lift adjusting horizontal wings, and is used for adjusting vertical force of the ship body under various loading conditions to achieve the optimal semi-submersible draft. The control system comprises a variable wing type section forward-leaning upright column, an inward-leaning light invisible upper construction part, shallowly submerged piercing hydrofoils and a stern controllable vertical wing, and is used for controlling the course and stability of the ship body. The ship is novel in type and high in subsequent expansion performance, is a tool for navy land battle force hiding, quick delivery and emergency transport of special civil materials in a route, and has certain research and application value in military and civil fields.

Owner:HARBIN ENG UNIV

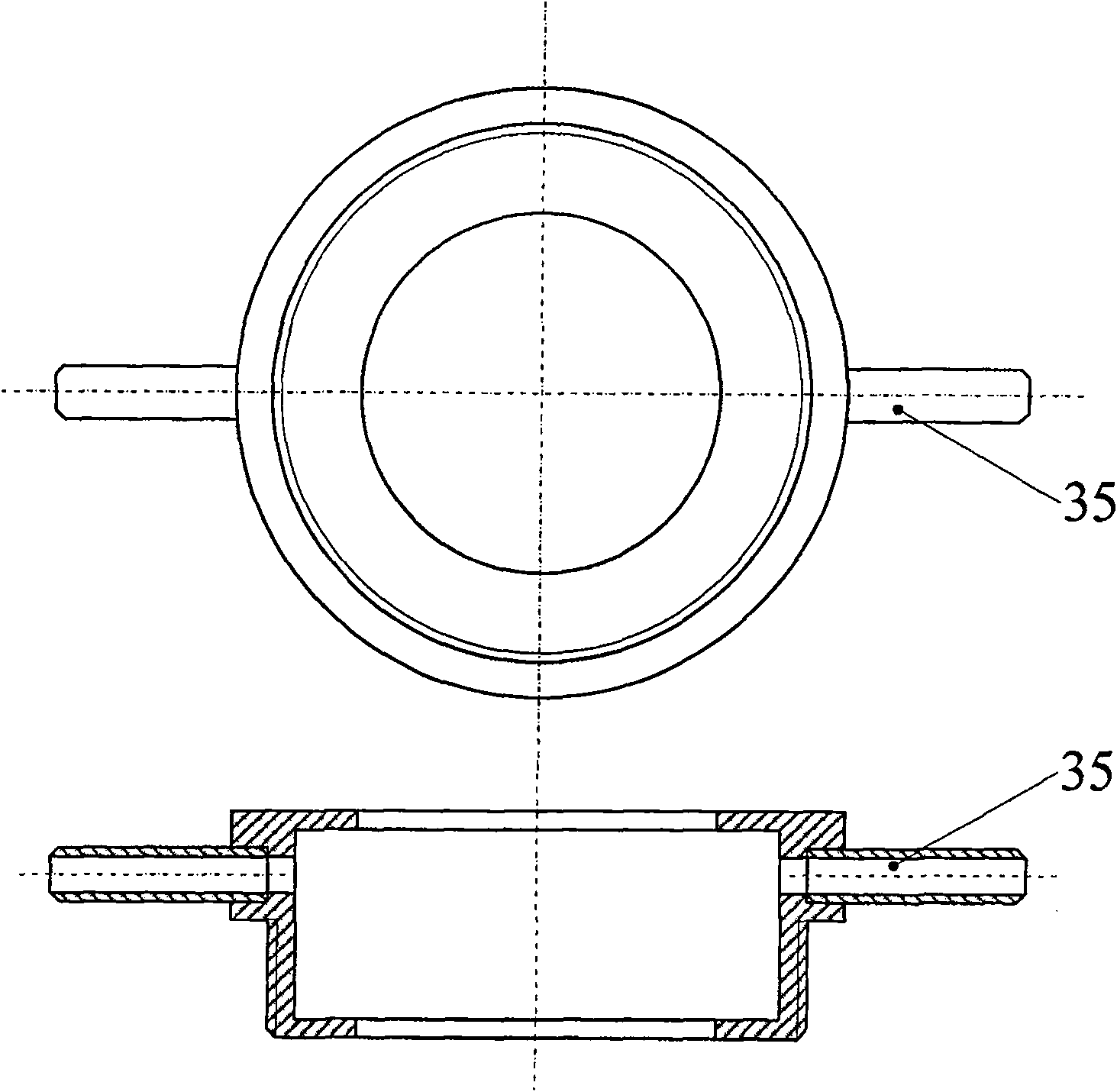

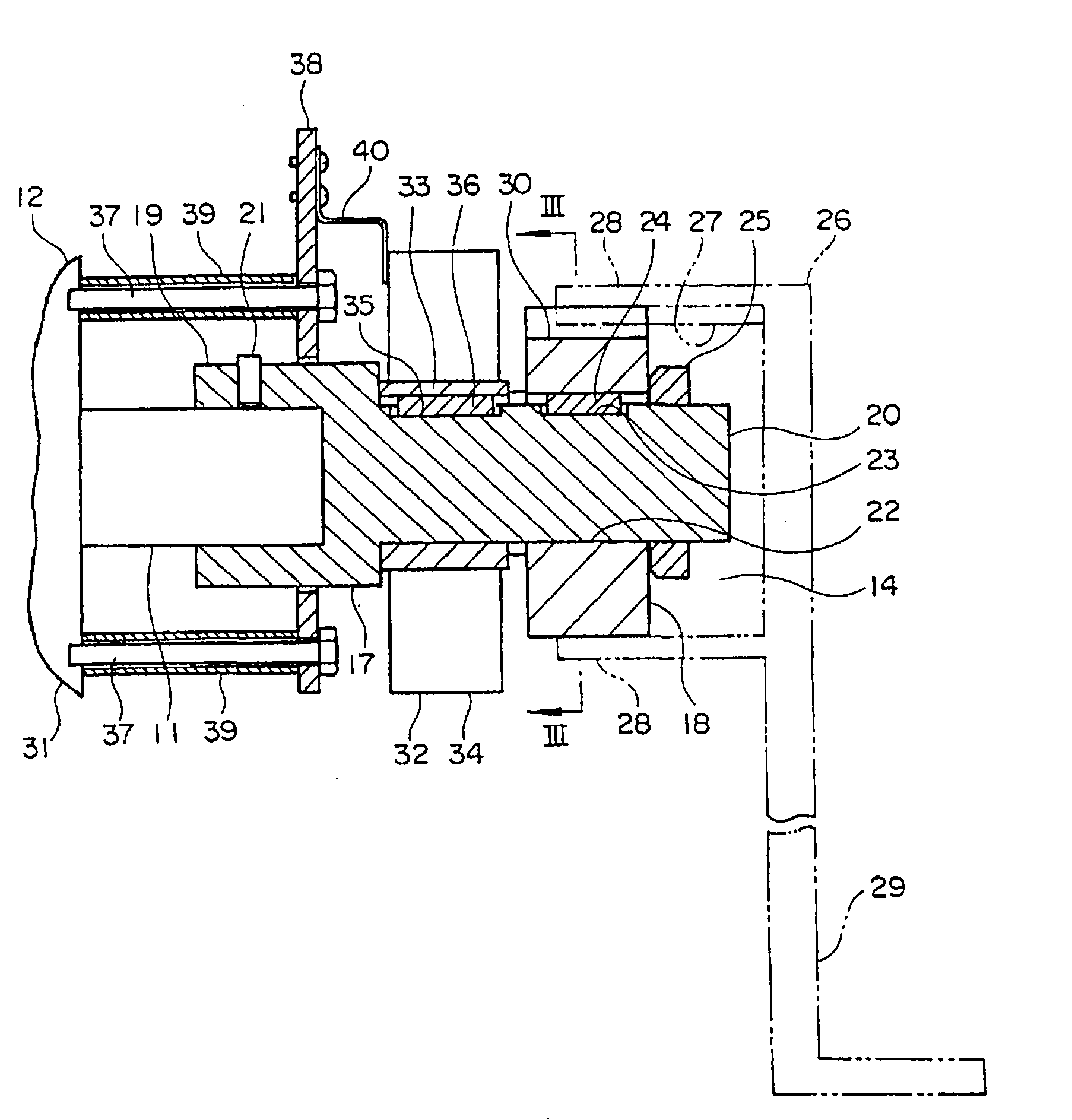

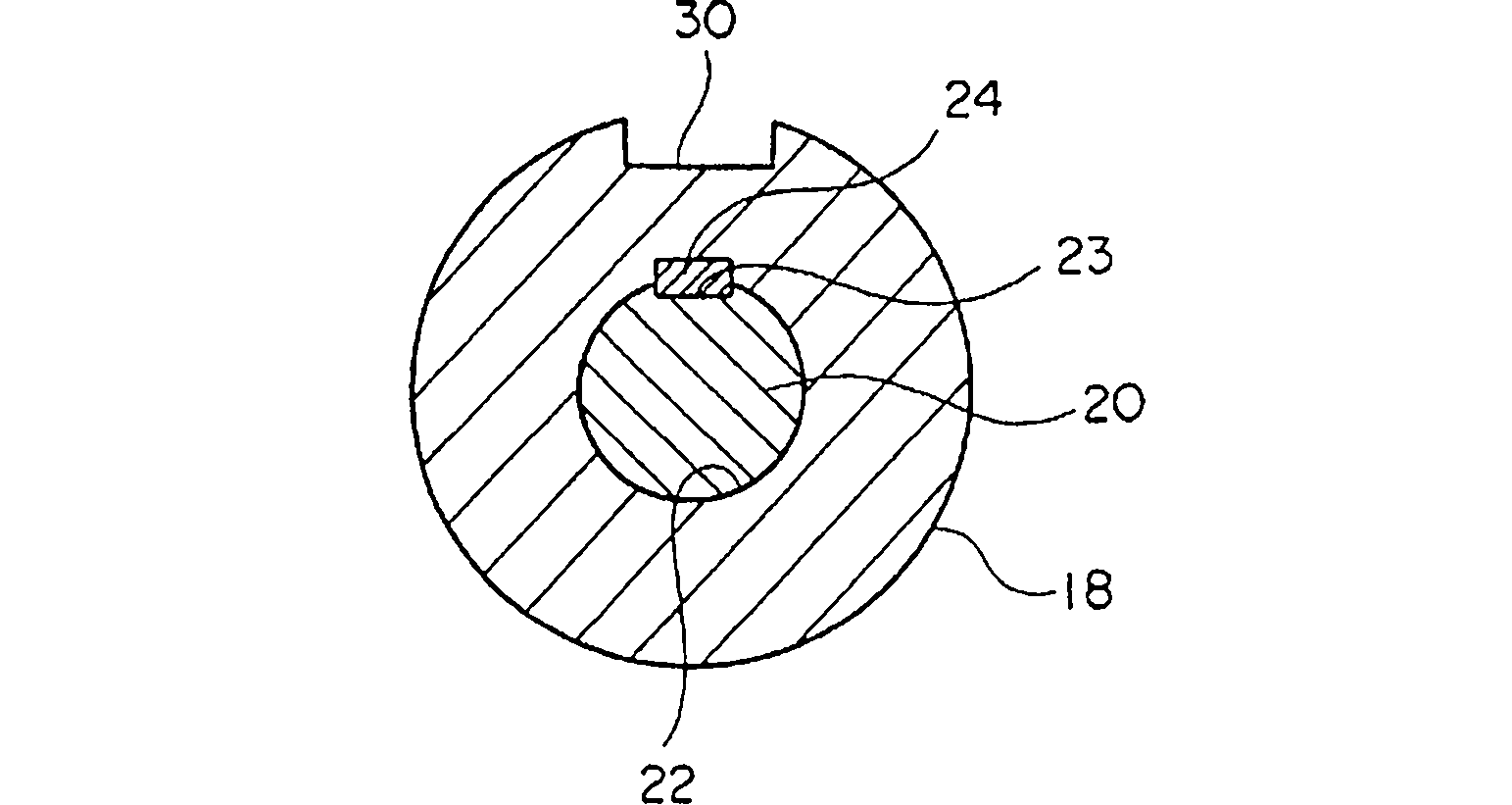

Button solid-oxide fuel battery reaction device

ActiveCN101345316AAvoid burnsReduce volumeFuel cell auxillariesCell component detailsRubber ringFuel cells

The invention provides a button-typed solid oxide fuel battery reaction device, belonging to the field of solid oxide fuel battery technique. The reaction device comprises a base (1), an O-shaped rubber ring I (18), etc.; a water cooling sleeve (2) is connected with a cooled water conduit (35); an internal sleeve (3) is connected with the base (1); a tensioning nickel-cadmium wire (4) passes through a tensioning hole (38) and hooks a pressing ceramic sheet (13); two ends of a cathode current collecting Pt wire (9) respectively pass through a cathode current collecting Pt net (10) and a cathode gas inlet pipe (23); the cathode current collecting Pt net (10) collects the current at the cathode of the button-typed solid oxide fuel battery; two ends of the cathode current collecting Pt (9) are respectively a reference electrode and a testing electrode; all pipes are hermetically connected with the base (1); an anode chamber is arranged in a pipe-typed heating electric furnace (8). The button-typed solid oxide fuel battery reaction device of the invention avoids complex disassembly / assembly process, has reasonable structure, prevents the sealing invalidity, avoids personnel scald, is beneficial for shortening the reaction device, and reduces the cost.

Owner:TSINGHUA UNIV

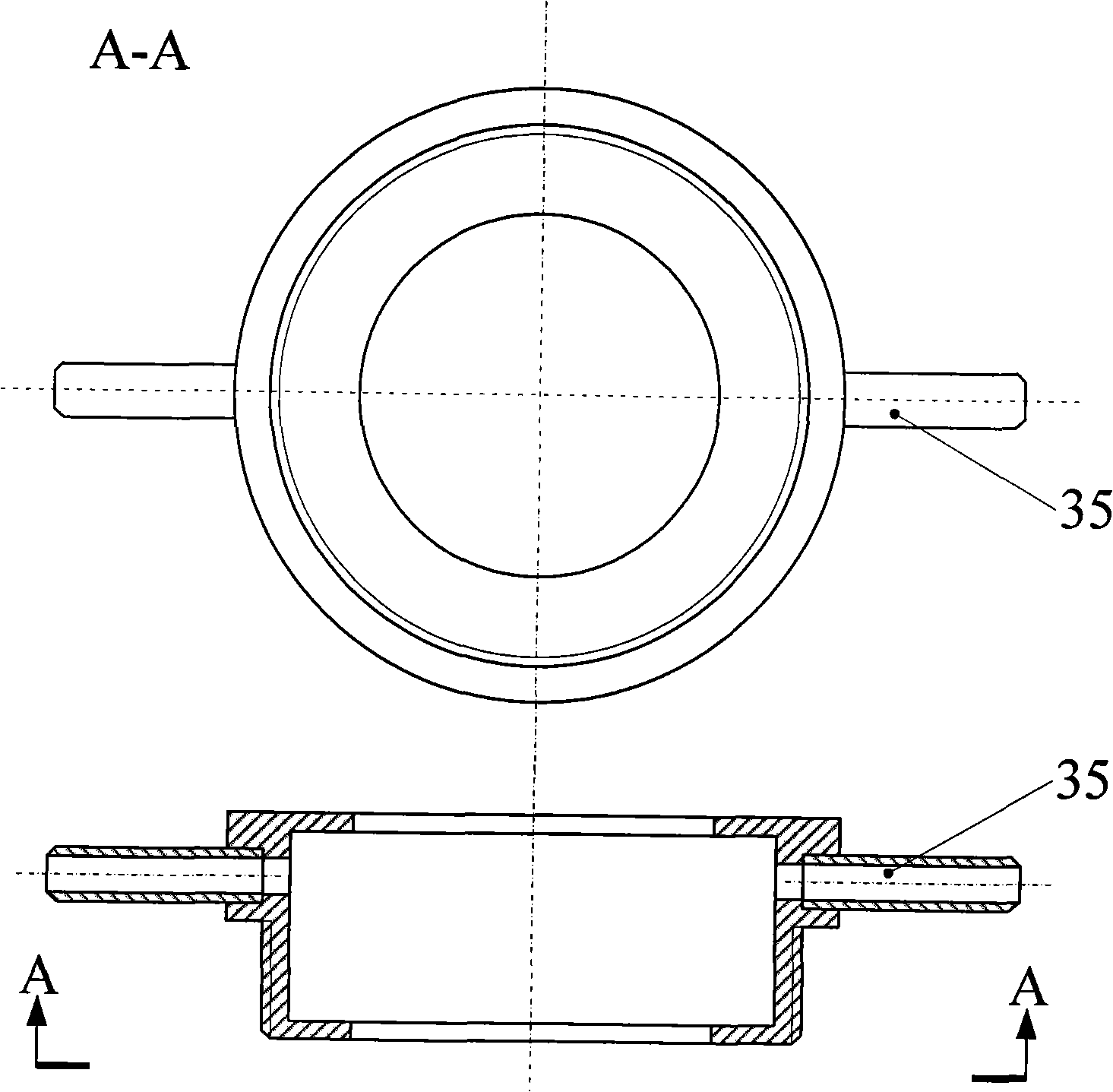

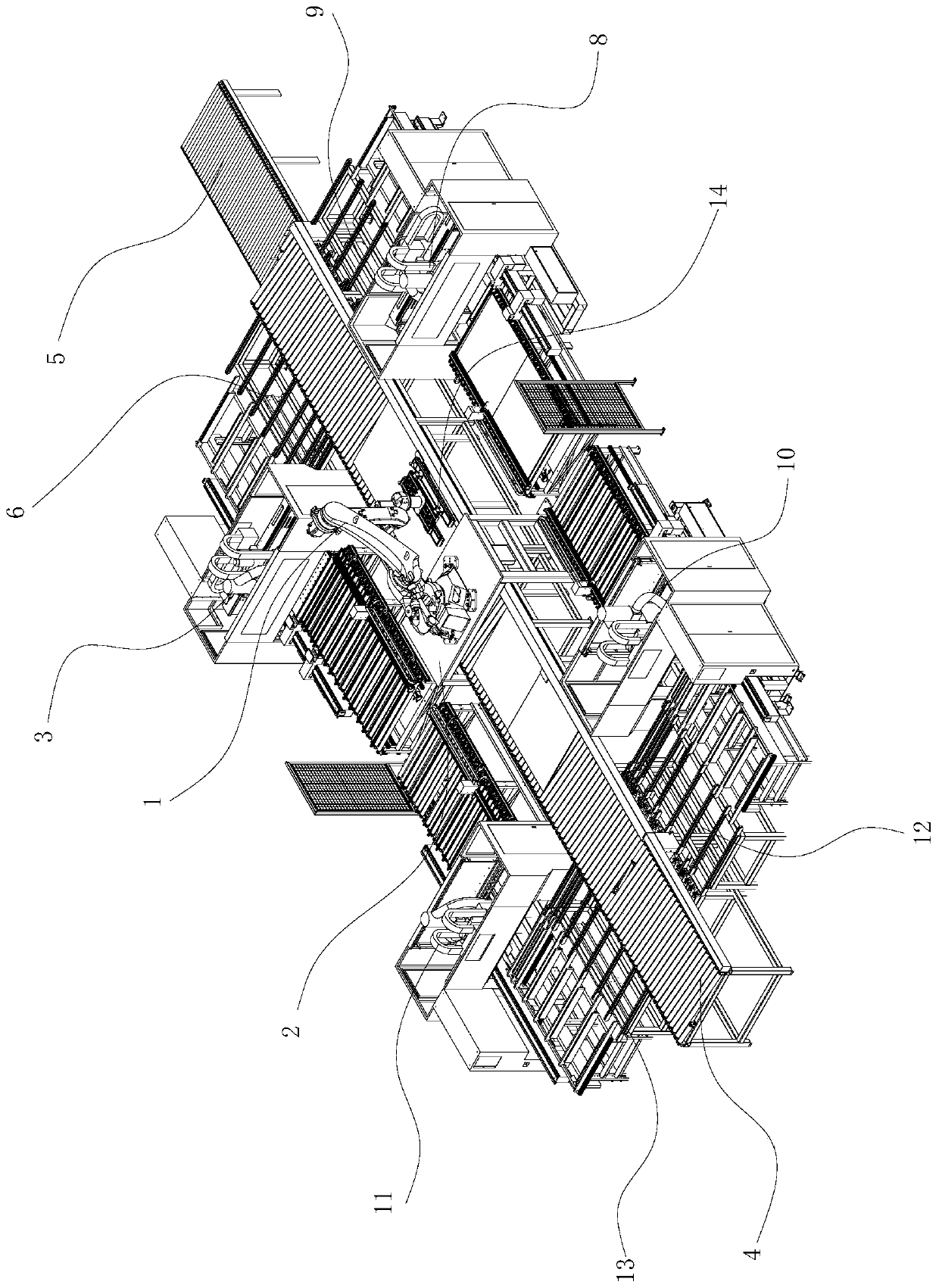

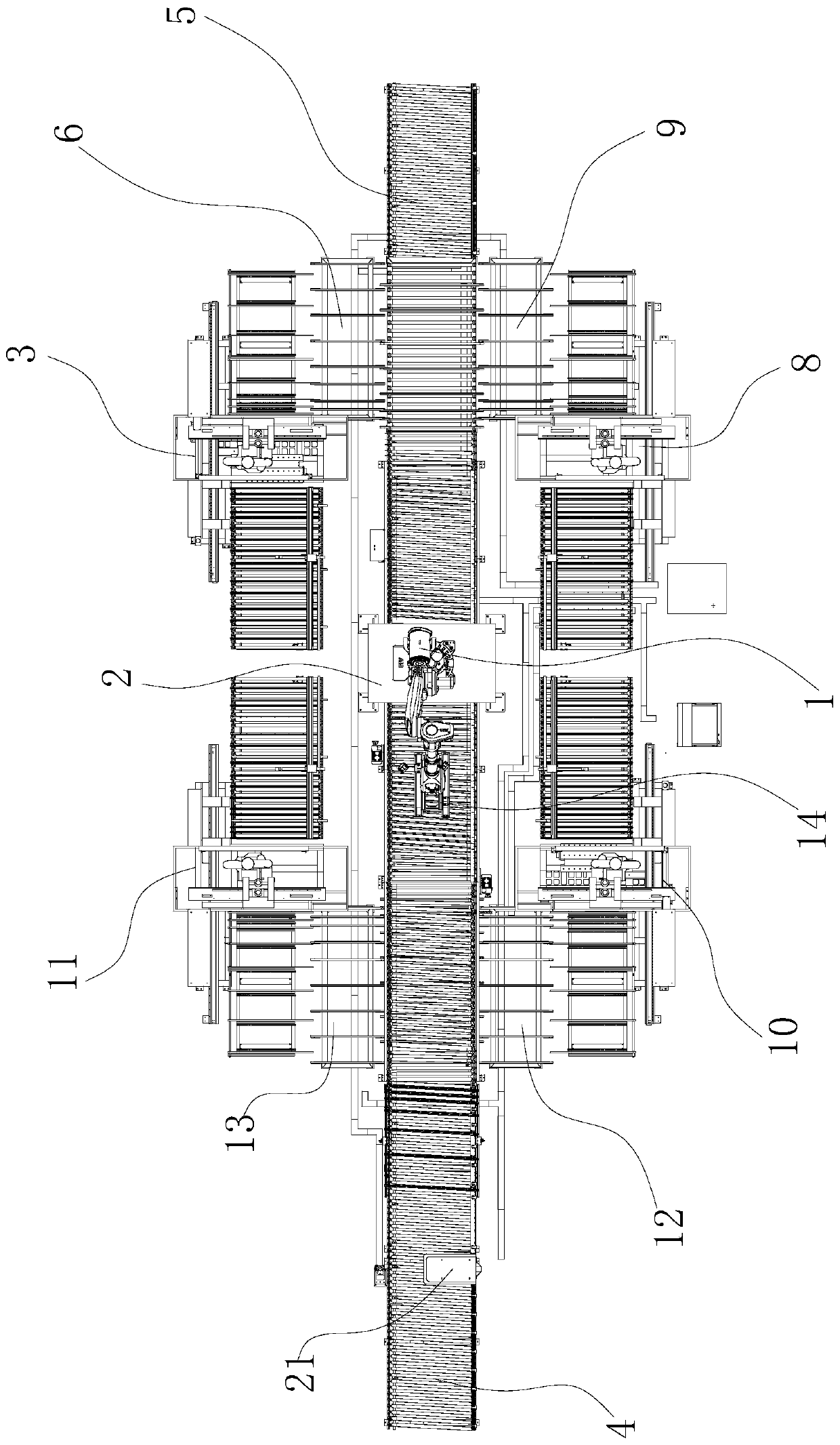

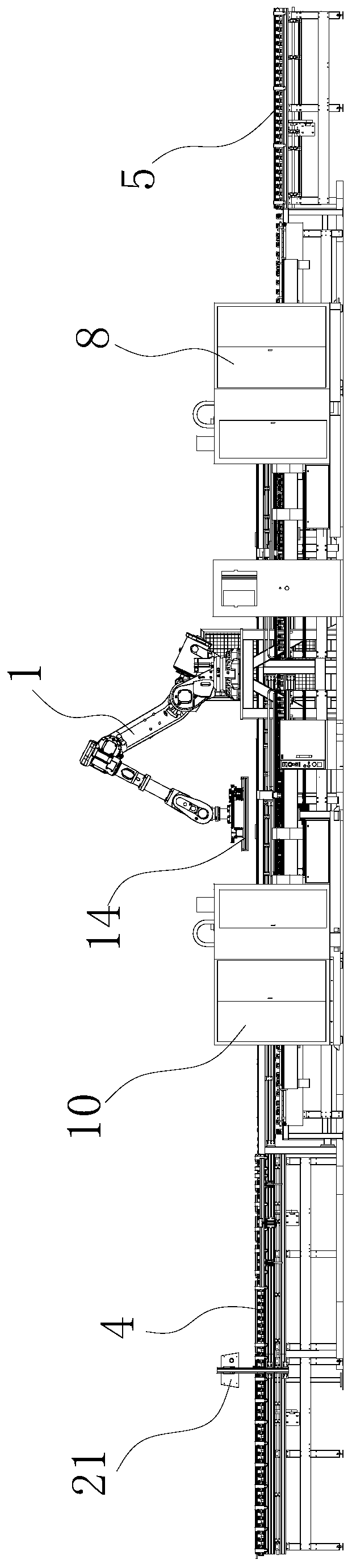

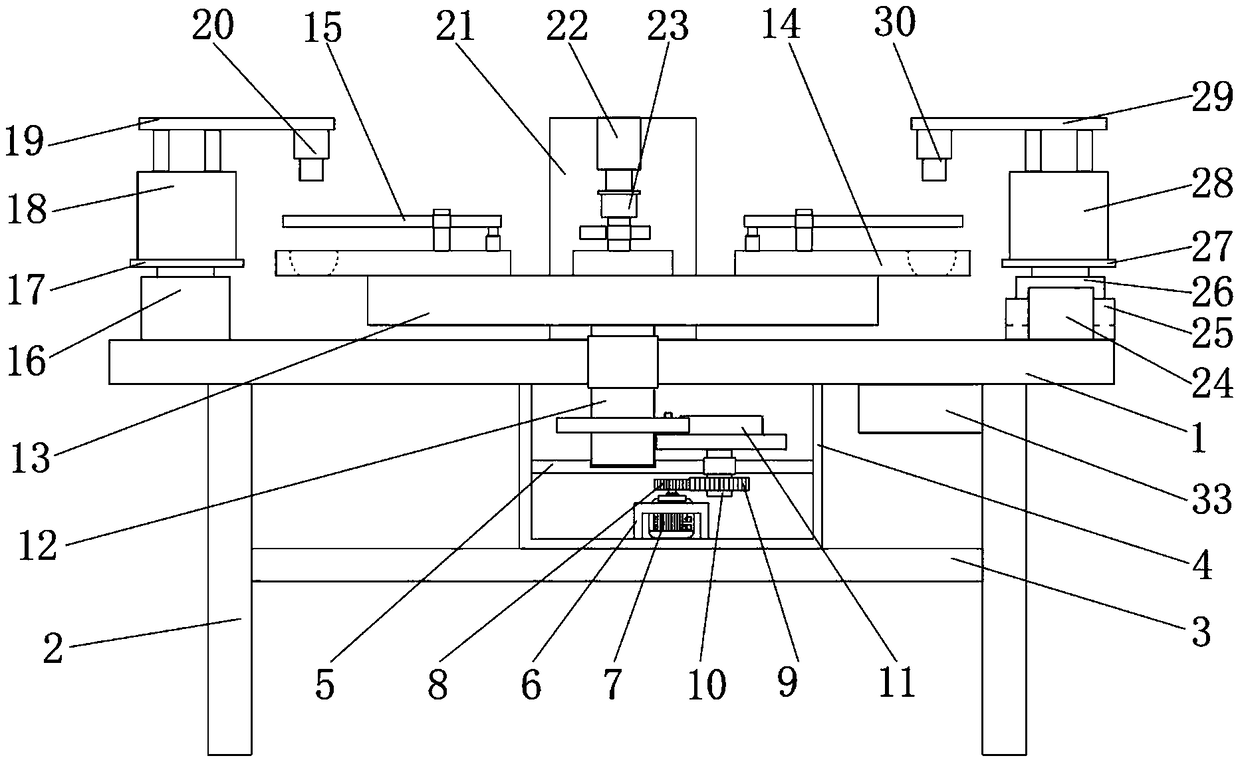

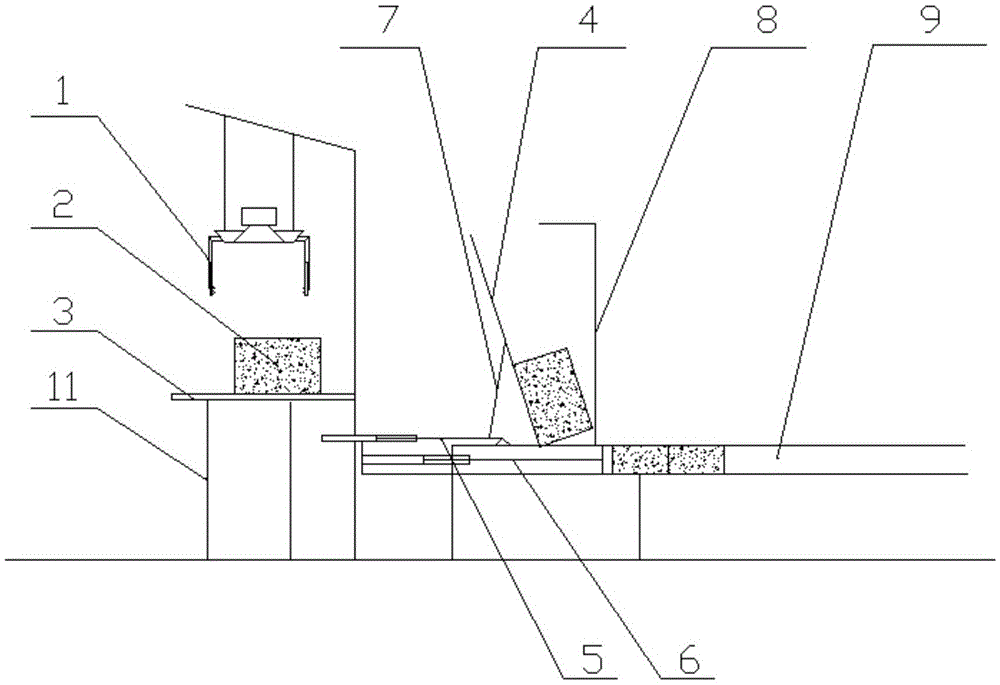

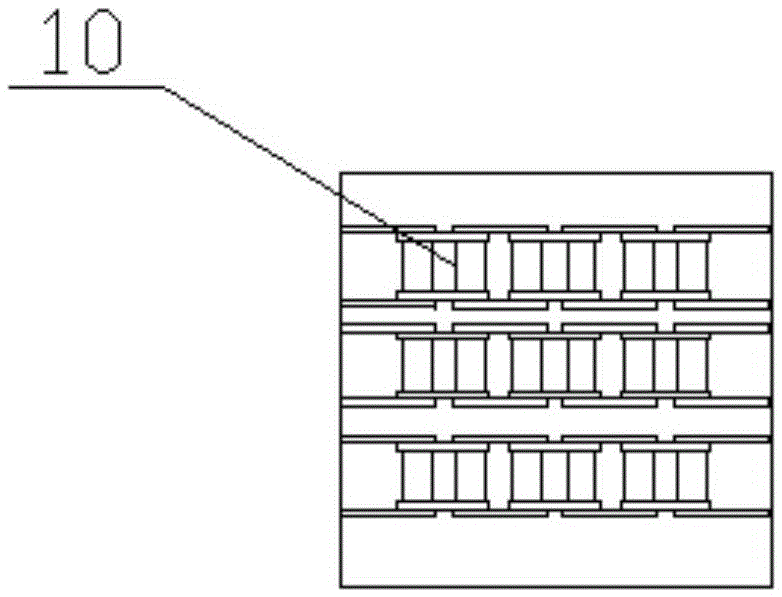

Numerical control drilling machine system used for plate

PendingCN110451198AAvoid artificialAvoid manual loading and unloading of the first CNC drilling machineDrilling machinesMetal working apparatusNumerical controlFixed frame

The invention provides a numerical control drilling machine system used for a plate. The system comprises a mechanical arm, a fixed frame, a first numerical control drilling machine, a first conveyingdevice and a second conveying device; the mechanical arm is fixedly connected to the fixed frame, the first conveying device penetrates through the fixed frame, the first conveying device is locatedbelow the mechanical arm, the feeding end of the first numerical control drilling machine is located on the first side of the fixed frame, the free end of the mechanical arm can clamp the plate from the first conveying device and convey the plate to the feeding end of the first numerical control drilling machine, and the discharging end of the first numerical control drilling machine is connectedwith the second conveying device. According to the numerical control drilling machine system used for the plate, manual loading and unloading are not needed, manual cost is reduced, production efficiency is improved, and meanwhile, the occupied area of the equipment can be reduced.

Owner:广州赛志系统科技有限公司

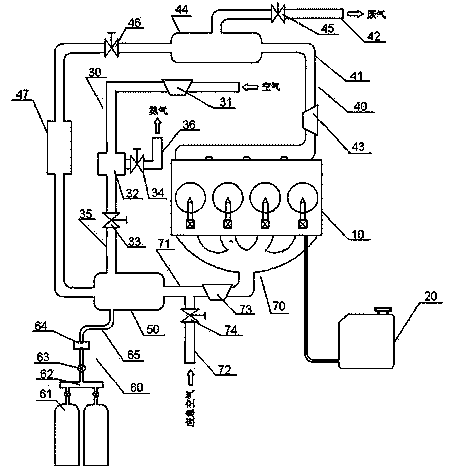

Internal combustion engine nitrogen oxide emission control system and control method thereof

ActiveCN103925125ALow running costAvoid loading and unloadingNon-fuel substance addition to fuelMachines/enginesExternal combustion engineSeparation technology

The invention discloses an internal combustion engine nitrogen oxide emission control system and a control method of the internal combustion engine nitrogen oxide emission control system. The control system comprises an internal combustion engine, a fuel tank, an oxygen generation assembly, an exhaust gas recycling assembly, an inlet gas mixing chamber, a standby gas filling device and a gas inlet assembly, wherein the oxygen generation assembly, the exhaust gas recycling assembly and the gas inlet assembly are communicated with the inlet gas mixing chamber, the gas inlet assembly is communicated with the internal combustion engine, and the internal combustion engine is communicated with the exhaust gas recycling assembly and the fuel tank. According to the control system and the control method of the control system, a large amount of nitrogen in inlet gas of the internal combustion engine is filtered out based on the molecular film separation technology, so that nitrogen oxides generated after combustion in a cylinder are substantially reduced and the purpose of reducing nitrogen oxide emission of the internal combustion engine is achieved finally. The consumption of a large amount of ammonium hydroxide or urea and expensive catalysts is not needed, and therefore operating cost is low. The usage problems of difficulty in loading, unloading and storage of ammonium hydroxide and catalysts, poor safety and the like are solved. The control system is small in size and does not occupy a large space, and therefore difficulty in modification of traffic means like ships is reduced.

Owner:尚和(上海)海洋工程设备有限公司

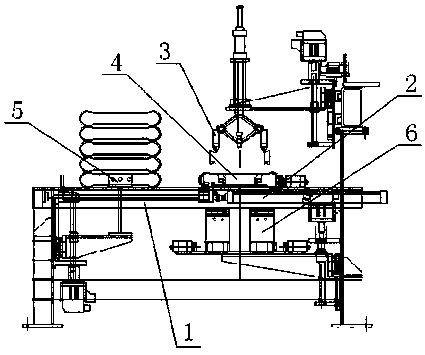

Automatic assembling machine for tire plastic clamping plate

InactiveCN108382845AAvoid loading and unloadingNot receive deformationConveyorsConveyor partsManipulatorEngineering

The invention discloses an automatic assembling machine for a tire plastic clamping plate. The automatic assembling machine comprises a machine frame, the frame is sequentially and horizontally provided with a clamping plate conveying mechanism, a clamping plate grabbing mechanism, a tire fetching mechanism and a tire waiting and releasing mechanism. The clamping plate conveying mechanism is provided with a clamping plate feeding device, and the clamping plate grabbing mechanism is provided with a clamping plate material taking device and a clamping plate grabbing mechanic arm capable of horizontally and radially stretching. The tire fetching mechanism is provided with a tire fetching mechanic arm, the tire waiting mechanism sends tires to the lower end of the tire fetching mechanism, anda corresponding tire sub-port expanding mechanism is further arranged at the lower end of the clamping plate grabbing mechanism. The automatic assembling machine mainly prevents the tires from deformation, breakage and destruction when the tires are piled up, carried and squeezed by external force during loading and unloading, the assembly quality is consistent, the control is fine, the operationis smooth and flexible, the site is neat and orderly, and the labor cost and labor intensity of people can be reduced at the same time.

Owner:ZHEJIANG JUQI MACHINERY SCI & TECH

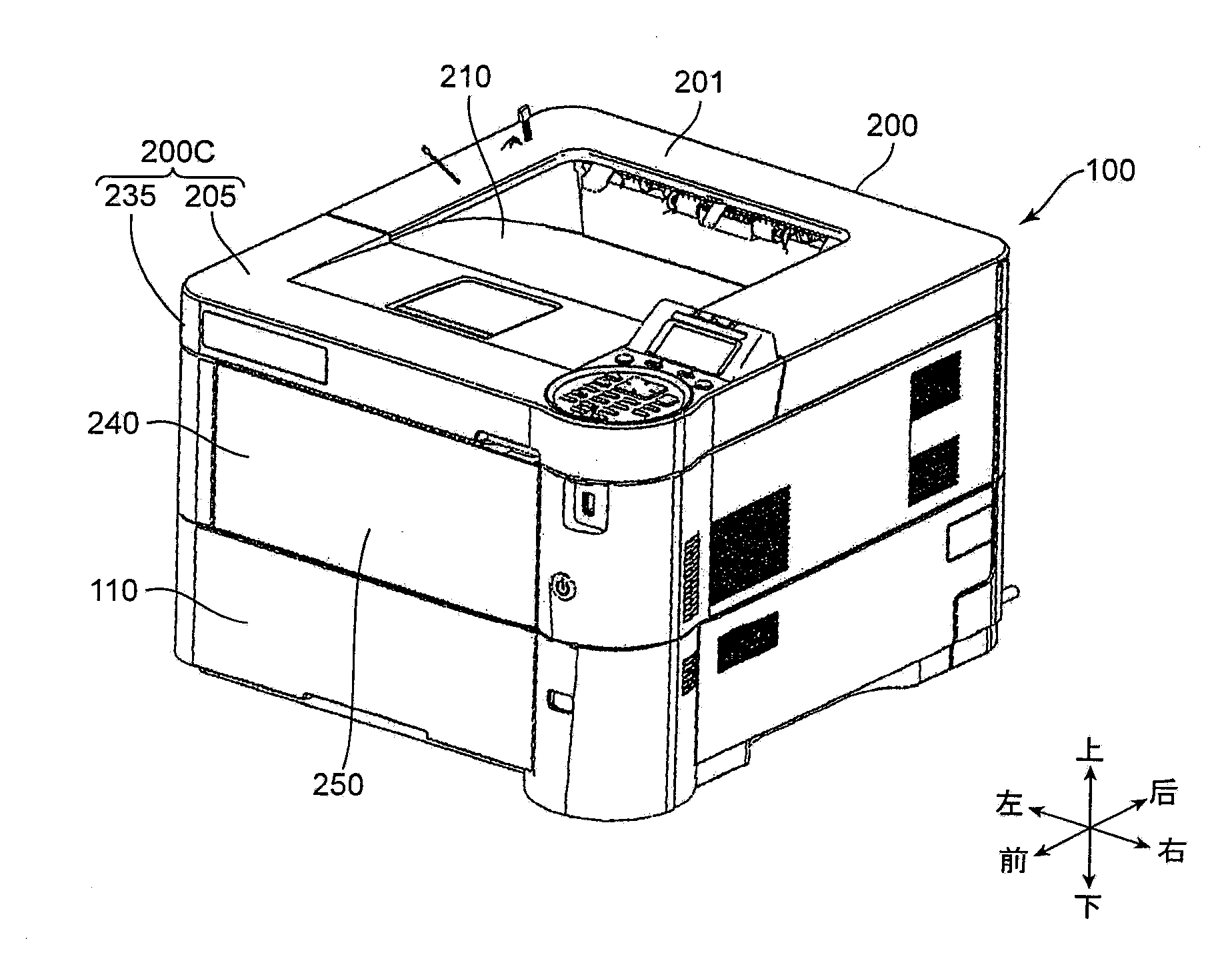

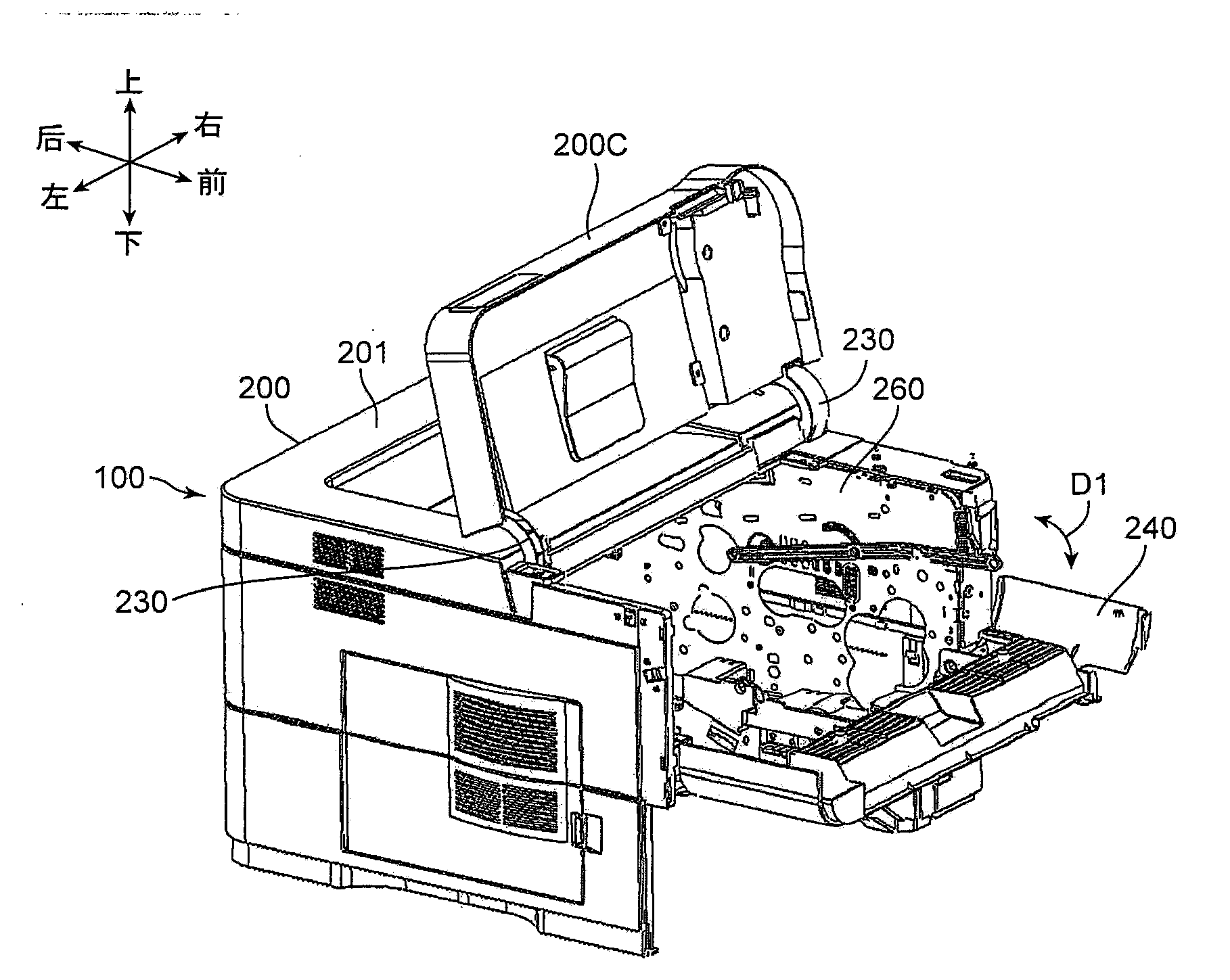

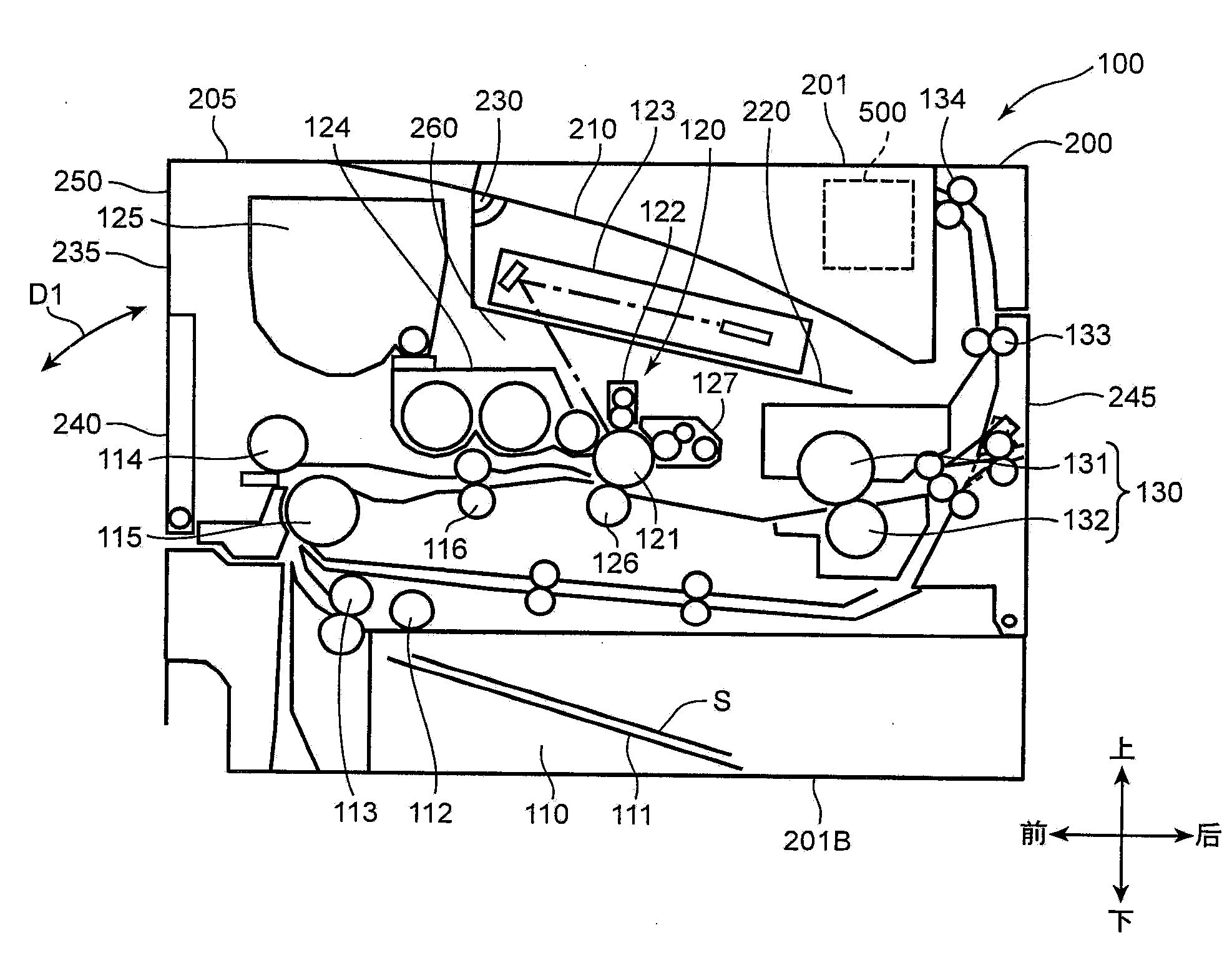

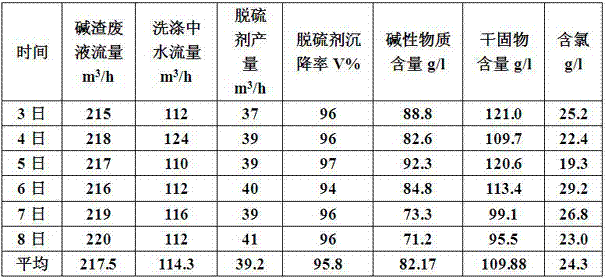

Image forming apparatus

An image forming apparatus has a casing, an opening / closing cover, an exposure device, an image forming unit, an airflow generator, a cooling air path, and a partition member. The partition member is disposed between the exposure device and the image forming unit, and is configured to change a state thereof between a first state and a second state. The first state is such that the partition member constitutes part of the cooling air path when the opening / closing cover is in a closed state. The second state is such that the image forming unit is allowed to be dismounted from an inner space of the casing, while passing between the exposure device and the image forming unit when the opening / closing cover is in an opened state.

Owner:KYOCERA DOCUMENT SOLUTIONS INC

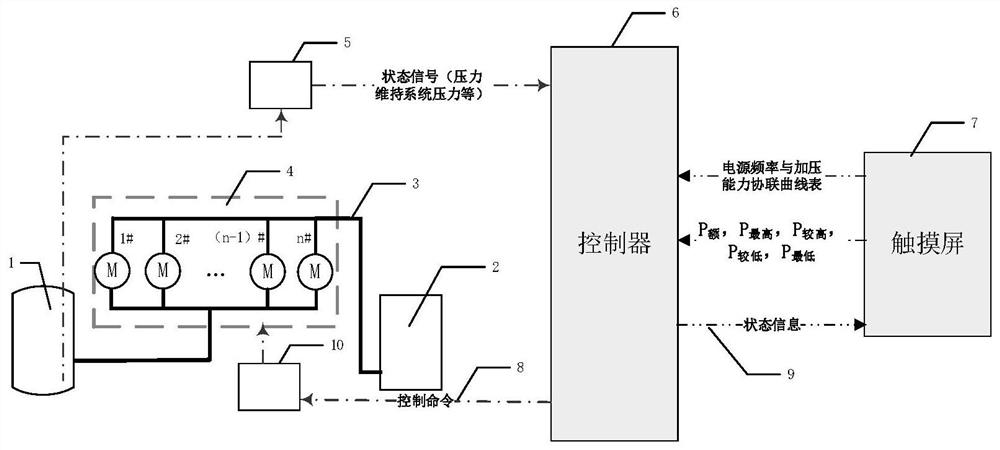

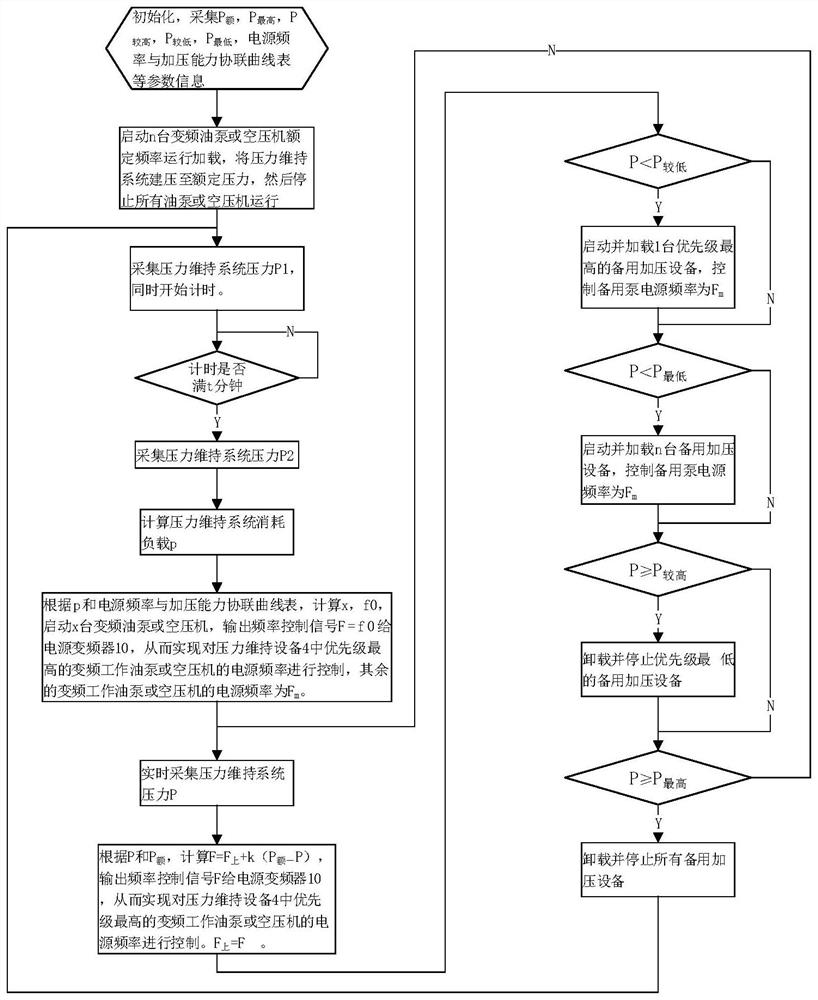

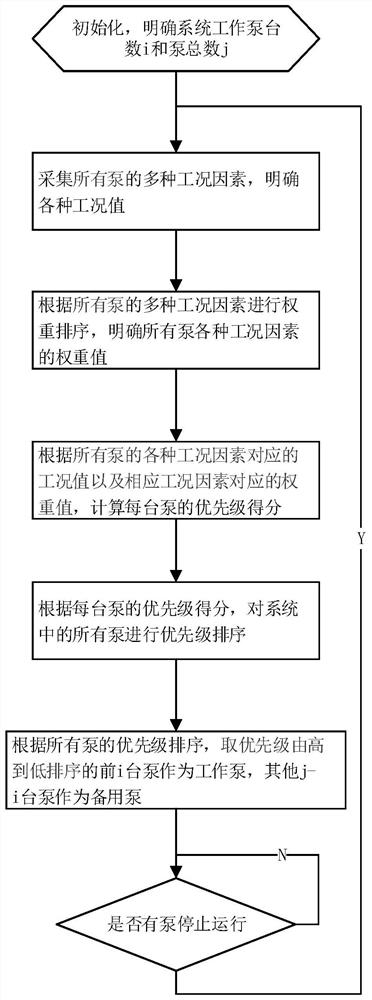

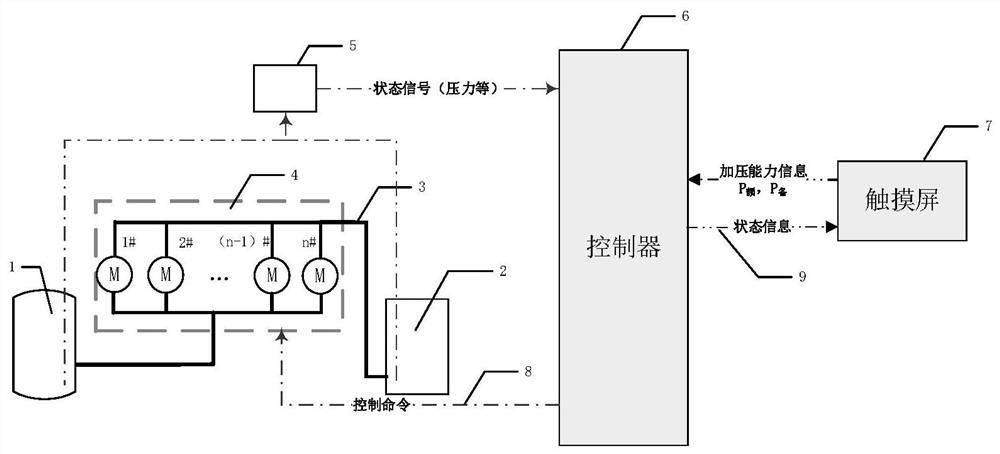

Pressure maintaining system adopting variable-frequency pressure maintaining equipment and self-adaptive control method

ActiveCN112783224AExtend your lifeReduce wear consumptionFluid pressure control using electric meansInteraction deviceMaintaining equipment

The invention discloses a pressure maintaining system adopting variable-frequency pressure maintaining equipment and a self-adaptive control method. The system comprises a pressure container, a non-pressure container and pressure maintaining equipment; and the pressure container is connected with the non-pressure container through pressure maintaining equipment. The pressure container is provided with a sensor. The sensor and the pressure maintaining equipment are both connected with a controller, and the controller is connected with a man-machine interaction device. The invention aims to solve problems that the consumption load is not matched with the output power of the pressure maintaining equipment, the pressure maintaining equipment is frequently started, stopped or loaded and unloaded, the abrasion consumption of equipment original parts is aggravated, the service life of the pressure maintaining equipment is influenced, energy loss is caused, and the system energy efficiency and economy are influenced.

Owner:CHINA YANGTZE POWER

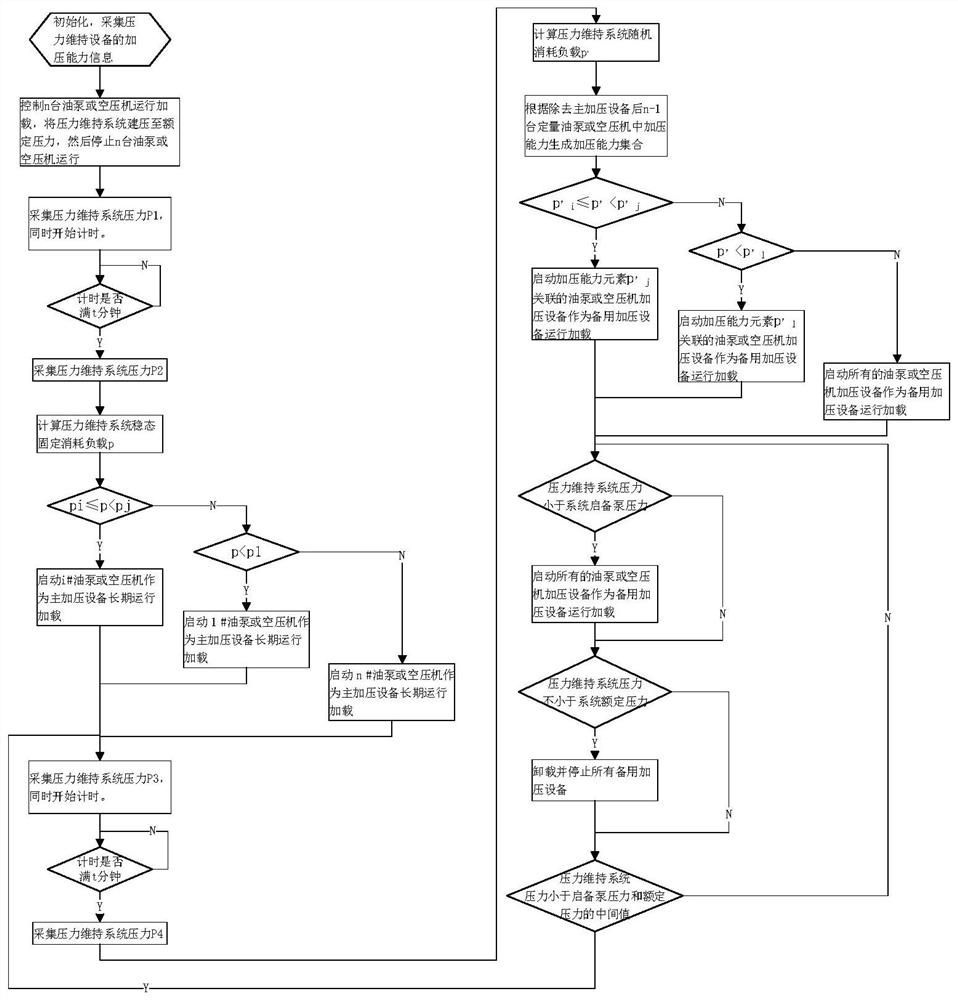

Self-adaptive control method of pressure maintaining system

ActiveCN112731982AWide adaptabilityAvoid loading and unloadingFluid pressure control using electric meansControl systemSystem pressure

The invention relates to a self-adaptive control method of a pressure maintaining system, the related control system comprises a plurality of fixed-frequency oil pumps or air compressors with different models and specifications as pressure maintaining equipment, the system also comprises a pressure container and a non-pressure container, and the pressure container is connected with the non-pressure container through the pressure maintaining equipment. The pressure container is provided with a first sensor, and the non-pressure container is provided with a second sensor. The first sensor, the second sensor and the pressure maintaining device are connected with the controller, and the controller is connected with a man-machine interaction device. According to the invention, the problem that the random consumption load with a long change period of the pressure maintaining system is not matched with the output power of the pressure maintaining equipment, that is, the pressure maintaining equipment is frequently started, stopped or loaded and unloaded due to the fact that the speed of random consumption reduction with a long change period of the system pressure is not matched with the pressurizing capacity of the pressure maintaining equipment, then abrasion consumption of original parts of equipment is increased, the service life of pressure maintaining equipment is affected, energy loss is caused, and system energy efficiency and economy are affected can be solved.

Owner:CHINA YANGTZE POWER

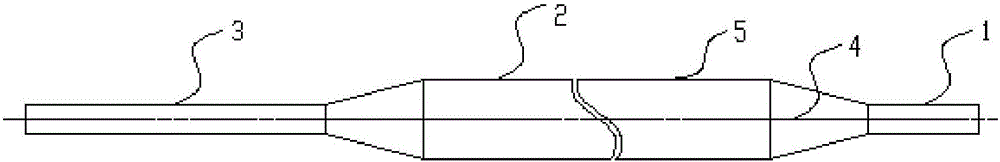

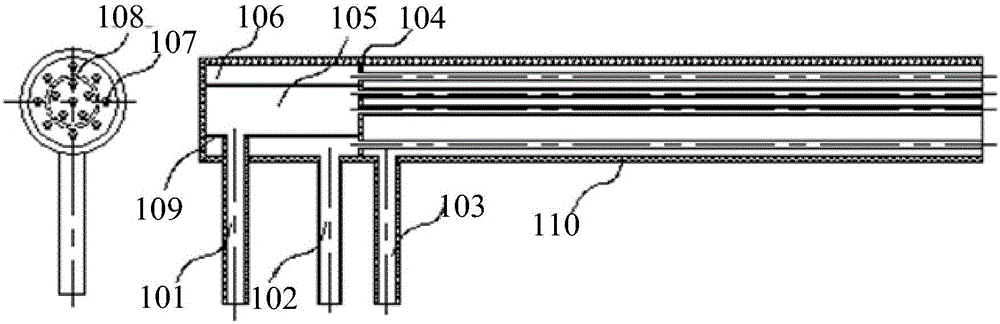

Wire drawing pretreatment device and method of optical fiber preform

InactiveCN105084753AAvoid loading and unloadingReduce complexityGlass making apparatusPre treatmentHydrogen supply

The invention discloses a wire drawing pretreatment device and method of an optical fiber preform. The device comprises at least one blowtorch, wherein the blowtorch comprises a first oxygen pipeline of which a first end is communicated with a first oxygen supply component, a second oxygen pipeline of which a first end is communicated with a second oxygen supply component, and a hydrogen pipeline of which a first end is communicated with a hydrogen supply component; and a second end of the first oxygen pipeline, a second end of the second oxygen pipeline and a second end of the hydrogen pipeline are respectively positioned on the sprayer of the blowtorch. The device and method disclosed by the invention can complete the whole wire drawing pretreatment process on the premise of performing one clamping process on the optical fiber preform, thereby lowering the wire drawing pretreatment complexity and enhancing the work efficiency.

Owner:ZHEJIANG FUTONG OPTICAL FIBER TECH

Detecting device for energy-saving lamp production line

ActiveCN108447752AImplement automatic loop detectionAvoid detectionManufacture testing/measurementsProduction linePulp and paper industry

The invention discloses a detecting device for an energy-saving lamp production line. The detecting device comprises a bottom plate. One side of the top of the bottom plate is fixedly connected with afirst rotating cylinder. The working end of the first rotating cylinder is fixedly connected with a first cylinder through the first connecting plate. The working end of the first cylinder is fixedlyconnected with a first clamping device through a second connecting plate. One side of the top of the bottom plate is fixedly connected with a third cylinder through a mounting plate. A fourth cylinder is fixedly connected to a side of the top of the bottom plate. The working end of the fourth cylinder is fixedly connected with a sliding block. A second rotating cylinder is fixedly connected to the top of the sliding block. The working end of the second rotating cylinder is fixedly connected with a fifth cylinder through a third connecting plate. The working end of the fifth cylinder is fixedly connected to a second clamping device through a fourth connecting plate. A photosensitive sensor is fixedly connected to the top of the bottom plate. The present invention relates to the technical field of detection. The detecting device for the energy-saving lamp production line solves low detection efficiency and reduces labor intensity.

Owner:安徽智时代软件服务有限公司

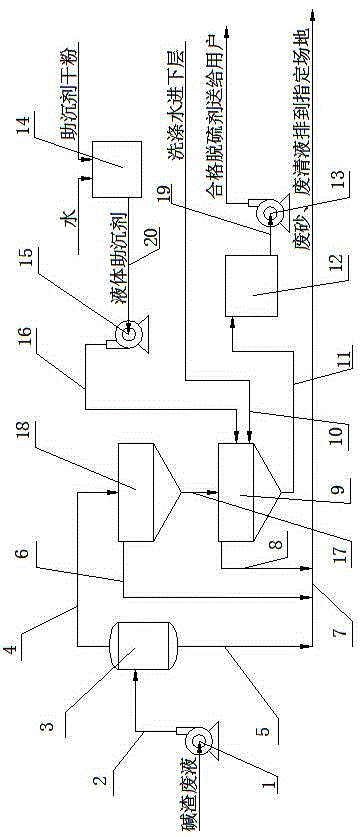

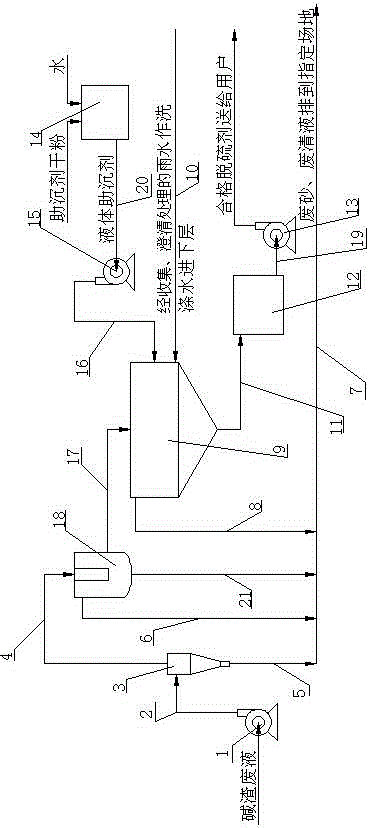

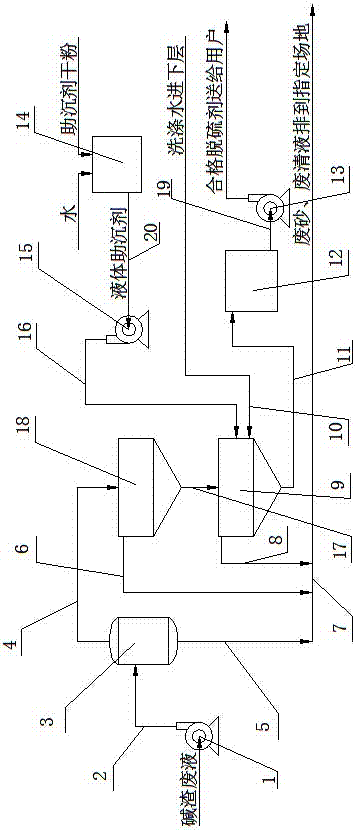

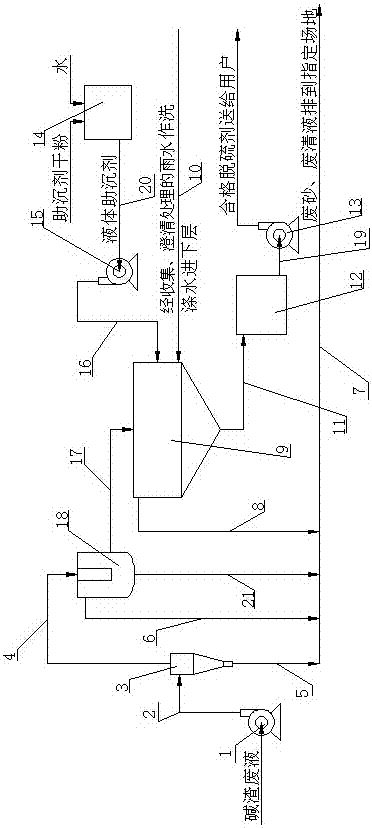

Preparation device and method for alkali residue liquid desulfurizing agent

ActiveCN104857831AAvoid loading and unloadingBlock deliveryDispersed particle separationFlue gasProcess engineering

The invention relates to a preparation device and method for a desulfurizing agent, in particular to a preparation device and method for an alkali residue liquid desulfurizing agent. The preparation device comprises an alkali residue conveying pump, wherein the alkali residue conveying pump is connected with a sand removal device through a first pipeline; the top end of the sand removal device is connected with a thickener through a second pipeline; the upper part of the thickener is connected with a main collection pipeline through a first overflow pipeline; the thickener is connected with a chlorine reducing bucket through a fifth pipeline; an assistant preparation tank is connected with a middle layer of the chlorine reducing bucket; a washing water pipeline is connected with a lower layer of the chlorine reducing bucket; the bottom of the chlorine reducing bucket is connected with a finished product buffer bucket through a sixth pipeline; an upper layer of the chlorine reducing bucket is connected with the main collection pipeline through a second overflow pipeline. The preparation method comprises the following steps: performing gravitational sand settling, thickening and settling and chlorine reduction by washing, performing settling and thickening, discharging the liquid desulfurizing agent from the bottom of the chlorine reducing bucket, and enabling the liquid desulfurizing agent to enter the buffer bucket for storage. Compared with the prior art, the application of high-energy equipment such as a pressure filter, a centrifuge and the like is avoided, mechanical solid-liquid separation of waste alkali residue liquid is avoided, and the flue gas desulfurization effect is effectively improved.

Owner:TANGSHAN SANYOU CHEM IND

Raw material conveying device used for straw combustion

InactiveCN105546568AReduce scatterAvoid cloggingLump/pulverulent fuel feeder/distributionAutomatic controlCombustion

The invention provides a raw material conveying device used for straw combustion. The raw material conveying device used for straw combustion comprises a straw bundling machine, an automatic straw bundle grab bucket crane, a horizontal straw conveying belt, a rotary straw conveying belt, a horizontal cutting knife and a feeding bin. The straw bundling machine is located at the front end of the automatic straw bundle grab bucket crane. The automatic straw bundle grab bucket crane is located above the horizontal straw conveying belt. The tail end of the horizontal straw conveying belt is seamlessly connected with the rotary straw conveying belt. The lower portion of the rotary straw conveying belt is connected with the horizontal cutting knife through a plurality of hydraulic rods. A reciprocating piston push rod is arranged on the lower portion of the horizontal cutting knife. A vertical baffle is arranged above an inlet of the feeding bin. The horizontal cutting knife, the horizontal straw conveying belt, the rotary straw conveying belt and the reciprocating piston push rod are all connected with a hydraulic device controller. The raw material conveying device is simple in structure, automatic control is achieved, operation is stable, and energy consumption of equipment is low; straw can be remotely conveyed for combustion.

Owner:JIANGSU UNIV

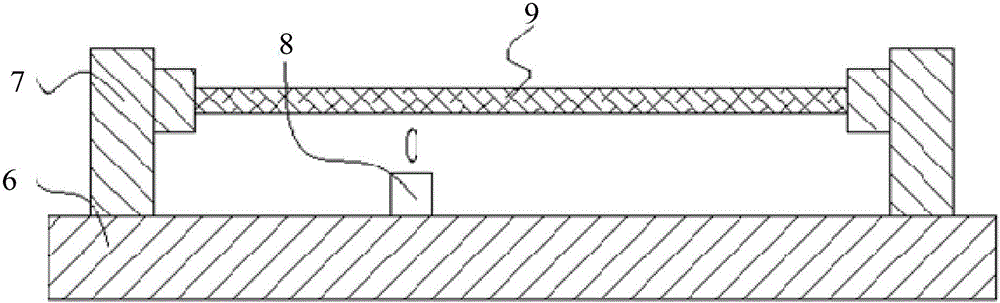

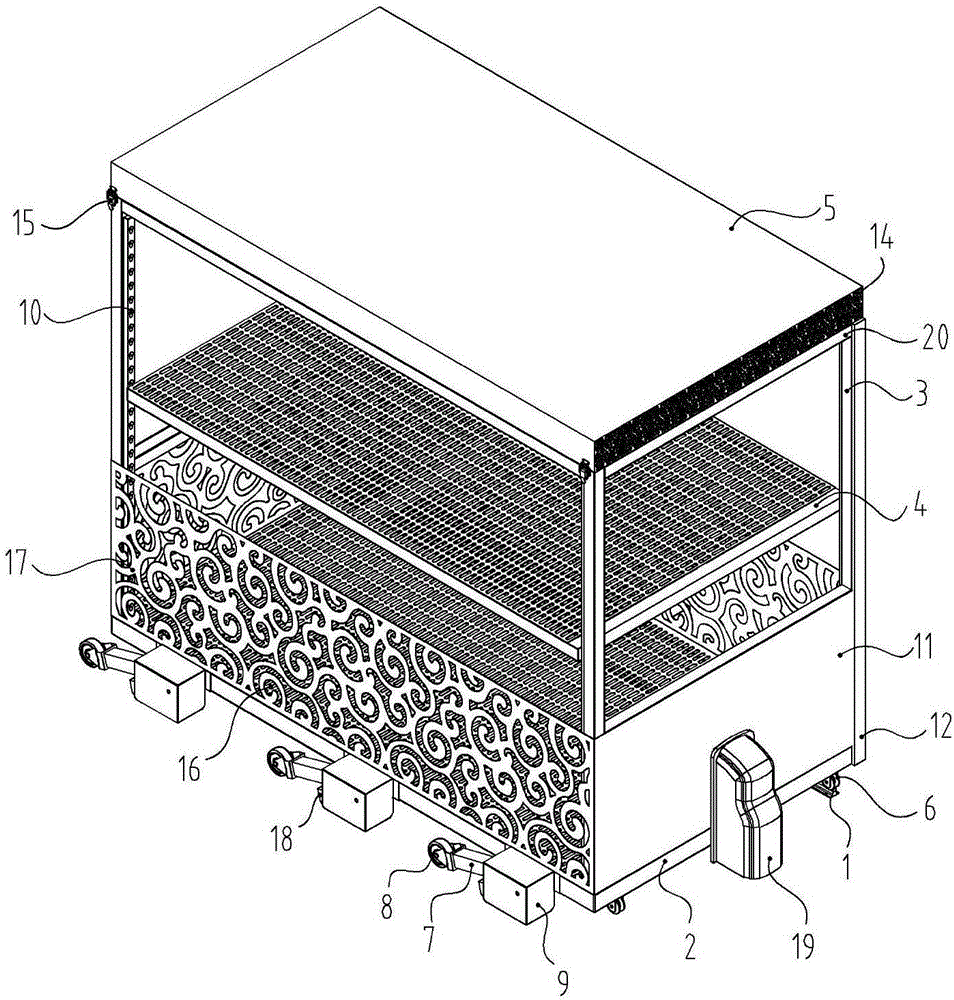

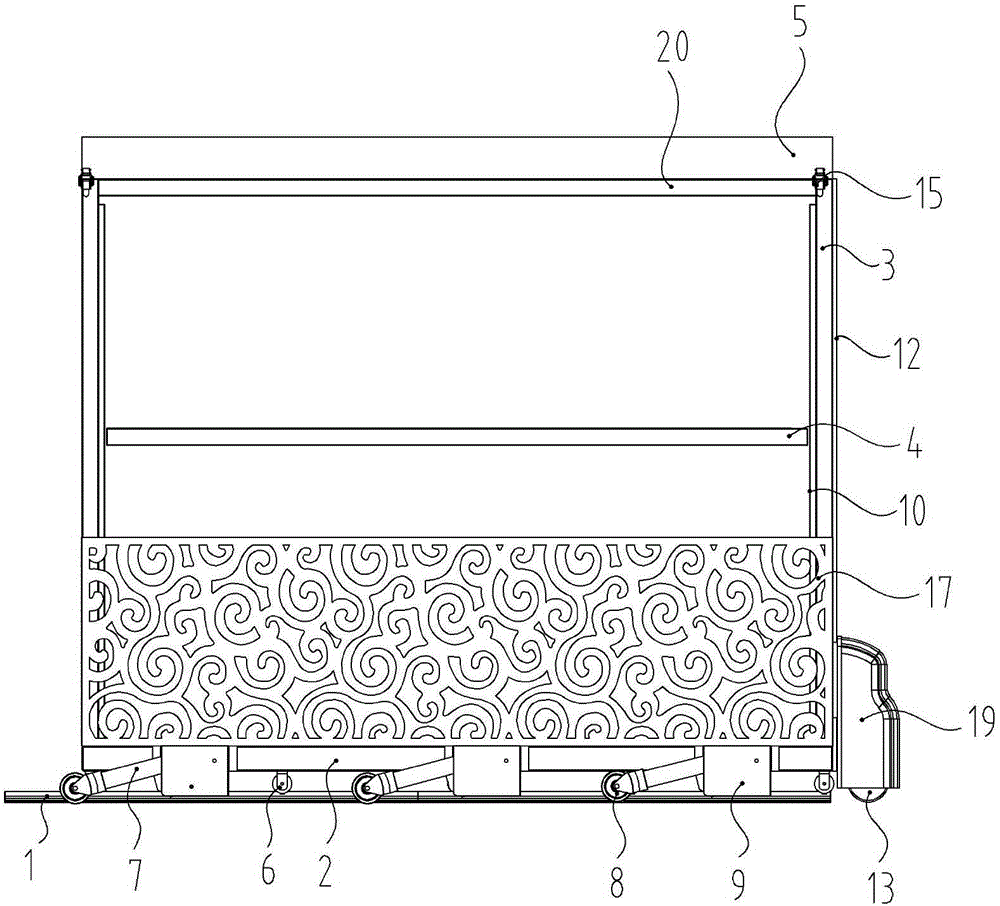

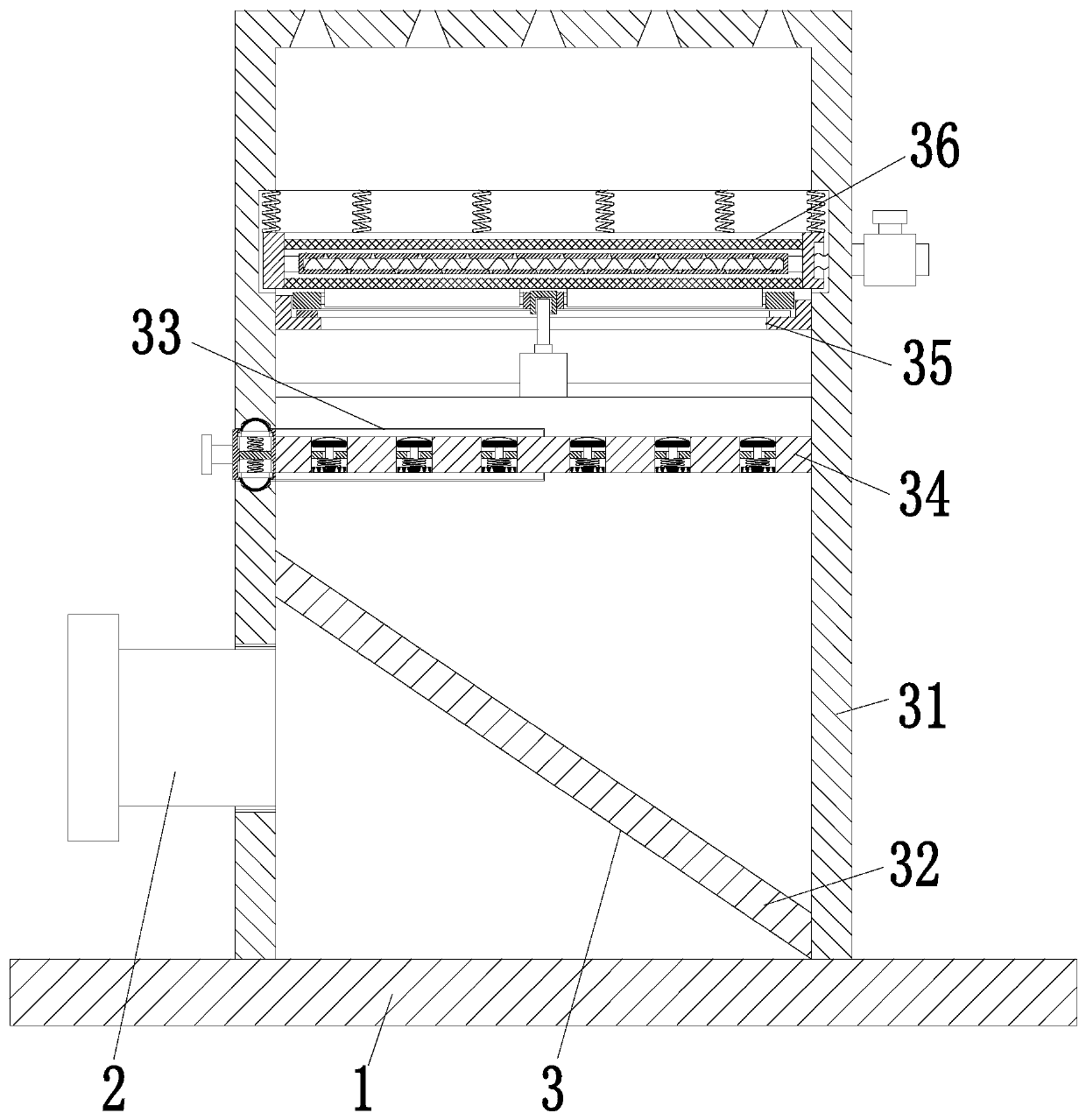

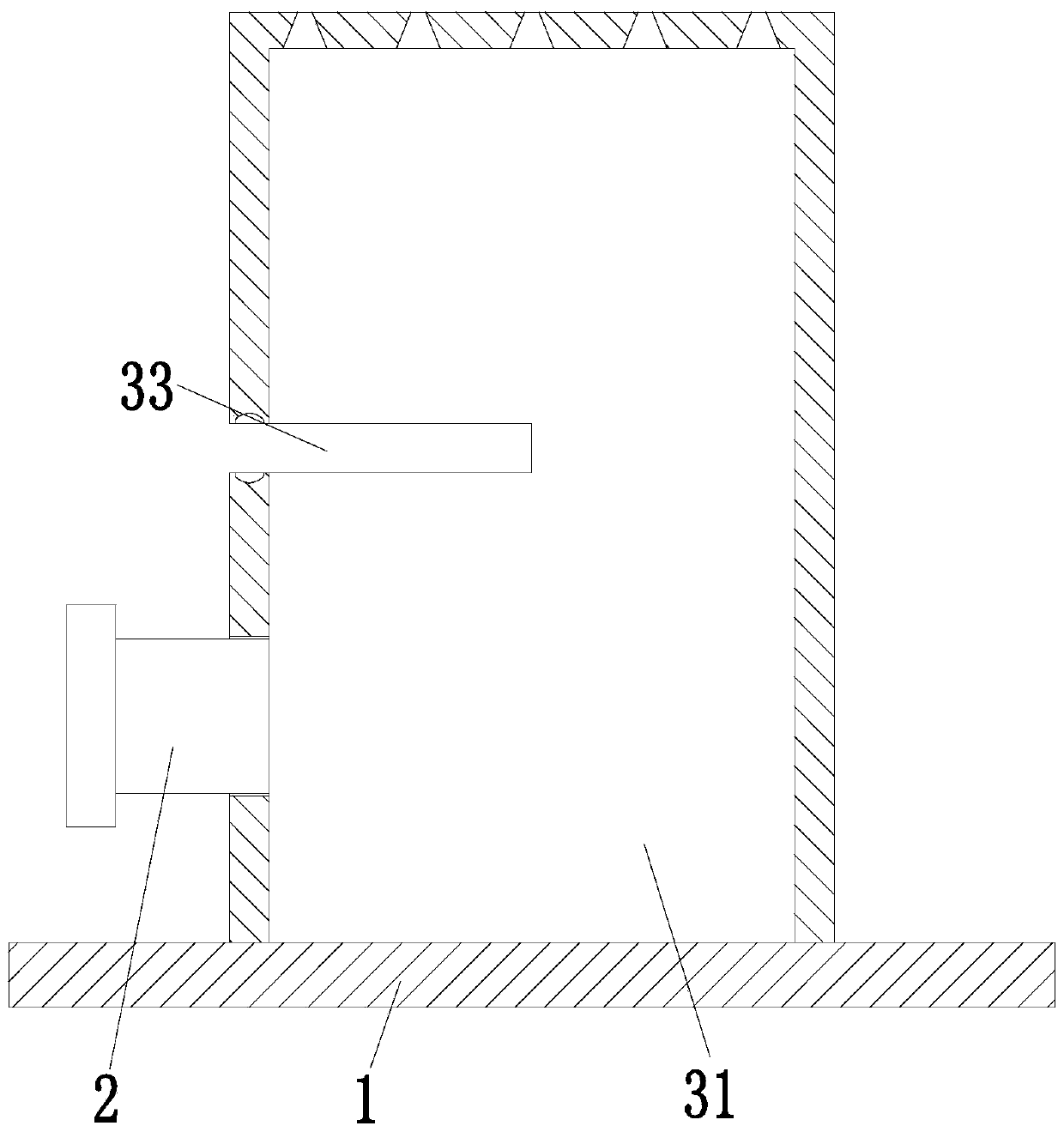

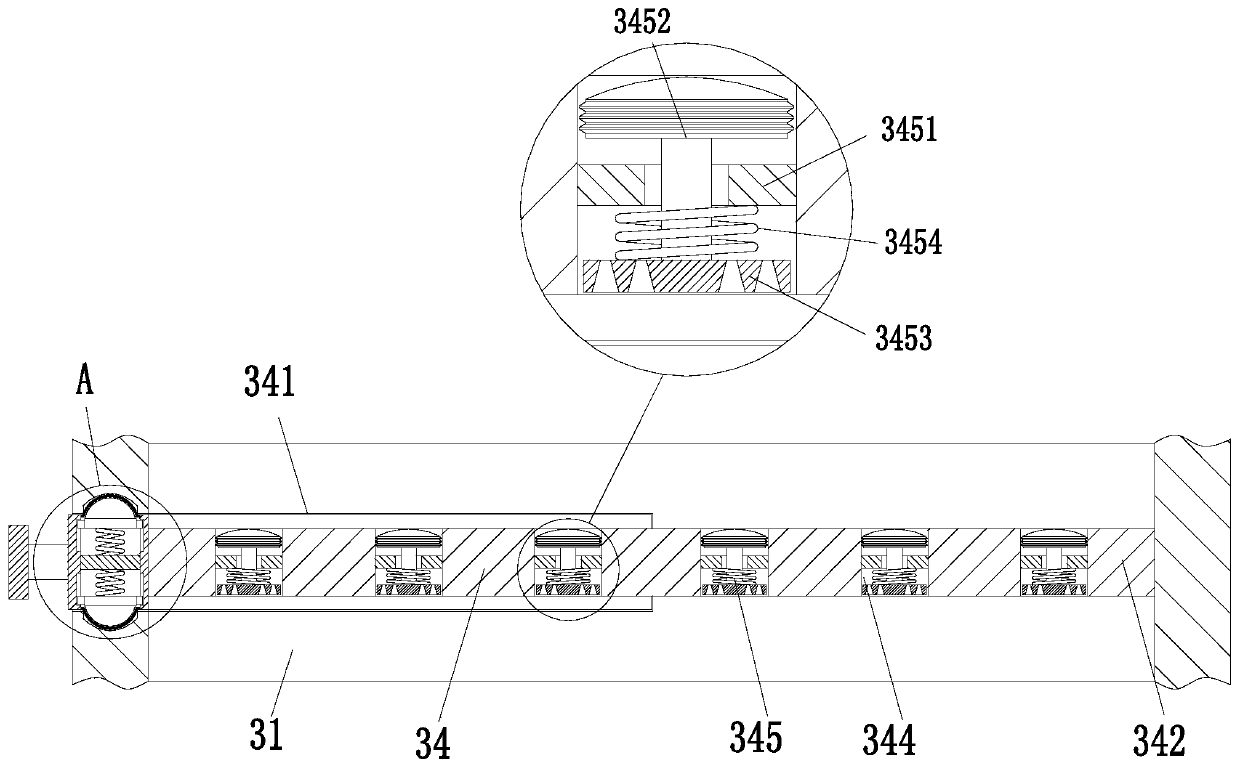

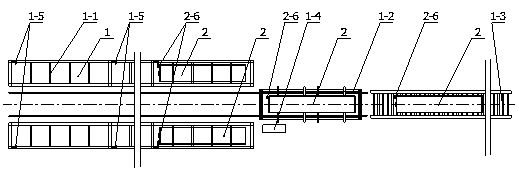

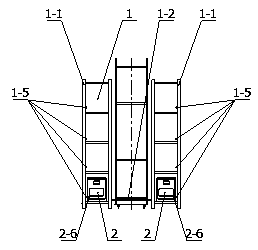

Cultural relic fumigating conveying system

ActiveCN106729855AAvoid loading and unloadingAvoid wear and tearLavatory sanitoryChemicalsDisinfectantEngineering

The invention discloses a cultural relic fumigating conveying system. The cultural relic fumigating conveying system comprises a rectilinear rail and a trolley, wherein the trolley comprises a trolley underframe; a first walking mechanism and a plurality of second walking mechanisms are arranged on the bottom surface of the trolley underframe; the first walking mechanism is matched with the rectilinear rail; upright trolley columns are arranged at the four top corners of the top surface of the trolley underframe respectively; a supporting frame is fixed together to the tops of the four upright trolley columns; a partition board is mounted on the four upright trolley columns; a disinfectant uniformizing box communicated with an air inlet of a disinfector is fixed above the supporting frame. Through the arrangement of the trolley in the disinfector, on one hand, cultural relic fetching and storing operation is more convenient, and damage to cultural relics and serious damage caused by a residual disinfectant to the body of a worker are avoided; on the other hand, through the trolley, uniform distribution of the disinfectant in a disinfecting cabin is achieved so as to ensure a good cultural relic disinfecting effect, the cultural relics can be safely and orderly placed on the trolley, and the space utilization of the disinfecting cabin is maximized while the safety of the cultural relics is ensured.

Owner:CHONGQING SHENGGUANGDIAN ZHILIAN ELECTRONICS CO LTD

Recycled plastic waste gas treatment equipment and waste gas treatment process

InactiveCN111195455AAvoid frequent replacementAvoid loading and unloadingGas treatmentDispersed particle filtrationActivated carbonProcess engineering

The invention relates to recycled plastic waste gas treatment equipment and a waste gas treatment process. The equipment comprises a bottom plate, a gas inlet frame and a gas treatment device, whereinthe gas treatment device is installed at the upper end of the bottom plate, the gas treatment device is of a cylindrical structure, a gas inlet is formed in the lower end of the left side of the gastreatment device, and the gas inlet frame is installed on the gas inlet. The problems that when existing equipment is used for treating plastic waste gas, activated carbon is generally used for filtering and purifying gas, however, the activated carbon is frequently replaced during use, the processes of loading, unloading, transporting, replacing and the like are added, the gas purification treatment efficiency is affected, and when existing equipment treats plastic waste gas, impurities in the waste gas usually easily block through holes in a filter pad, impurities in the filter pad can not be quickly cleaned, and the gas filtering effect is affected are solved.

Owner:陈妹儿

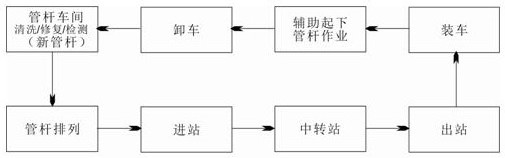

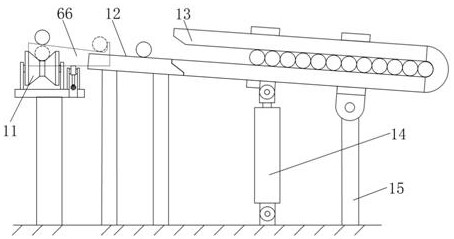

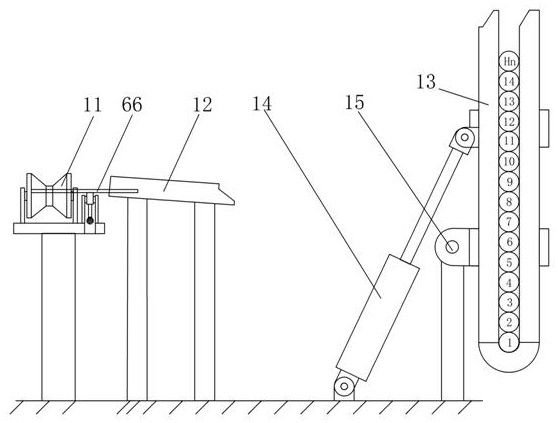

Oil pipe and sucker rod turnover system and method

ActiveCN113982510AHigh degree of automationNo need for manual relocationDrilling rodsLoading/unloadingOil fieldEngineering

The invention relates to the technical field of oil field downhole operation, and particularly discloses an oil pipe and sucker rod turnover system and method.The oil pipe and sucker rod turnover system comprises a pipe arranging unit, a transfer station storage unit, an in-out station conveying unit and a loading conveying unit. The pipe arranging unit comprises a roller way; an inclined material frame is arranged on one side of the roller way; one side of the material frame is provided with a displacement pipe arranging device used for vertically arranging pipe rods; the bottom of the displacement pipe arranging device is provided with a displacement cylinder used for driving the displacement pipe arranging device to rotate; the displacement pipe arranging device is of a U-shaped structure, and the opening end of the displacement pipe arranging device is movably connected with one end of the material frame. In the whole turnover process, the pipe rods do not fall to the ground, the simple, reliable and durable mine field mechanical properties are achieved, the safety and environmental protection requirements can be met, light single-row pipe rows serve as the basis in all links, assistance of other equipment such as hoisting is not needed, manual carrying and row moving are not needed, and the management level and efficiency are improved.

Owner:东营恒基石油科技有限公司

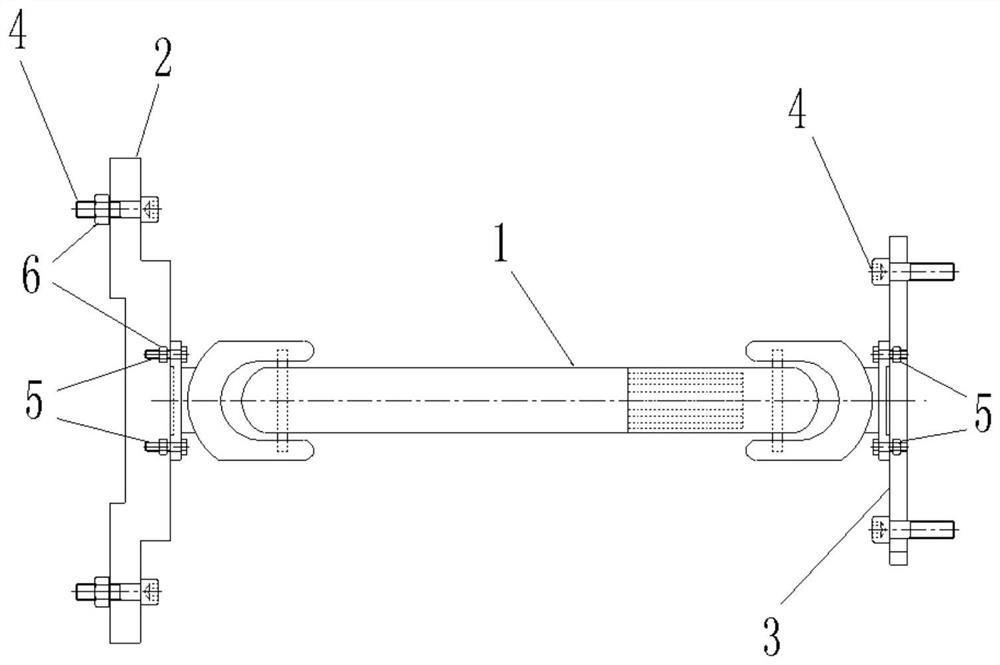

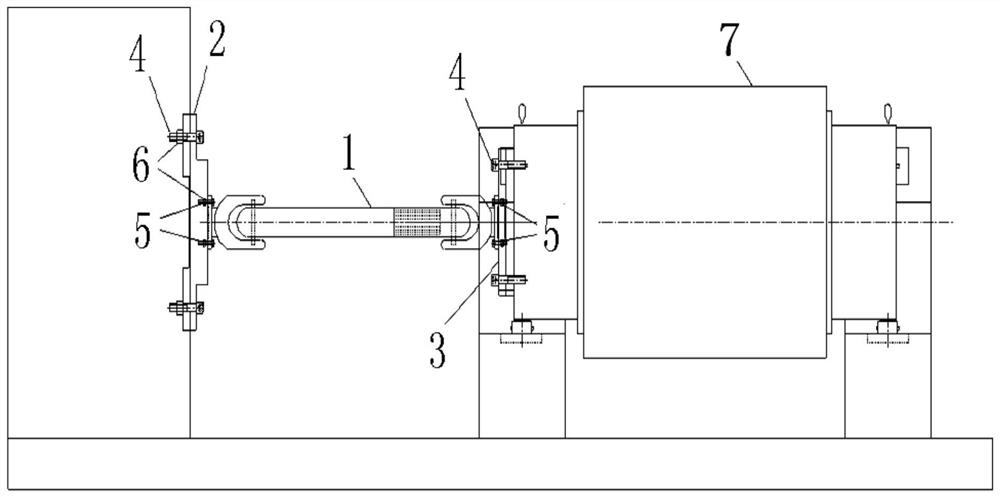

Universal transmission tool for processing crosshead pin of marine diesel engine

PendingCN113997198AWide versatilitySave special toolingGrinding drivesGrinding work supportsEngineeringDiesel engine

The invention provides a universal transmission tool for processing a crosshead pin of a marine diesel engine. The universal transmission tool is installed on a machine tool and is characterized by comprising a universal transmission rod, a chuck connecting plate and a universal transmission plate, wherein the chuck connecting plate is fixedly connected to the machine tool through an inner hexagon screw and a nut, the universal transmission plate is fixedly connected to the end surface of a crosshead pin through an inner hexagon screw and a nut, one end of the universal transmission rod is fixedly connected with the chuck connecting plate through a bolt and a nut, the other end of the universal transmission rod is fixedly connected with the universal transmission plate through a bolt and a nut, and the machine tool drives the crosshead pin to rotate through the chuck connecting plate, the universal transmission rod and the universal transmission plate in sequence. According to the invention, the universality and the mounting efficiency of the tool are greatly improved, the labor intensity is effectively reduced while the process cost is reduced, the machining quality is improved, and the tool has the advantages of being easy and convenient to operate on site and safe and reliable in performance and is also suitable for machining of various large shaft parts.

Owner:CSSC MES DIESEL

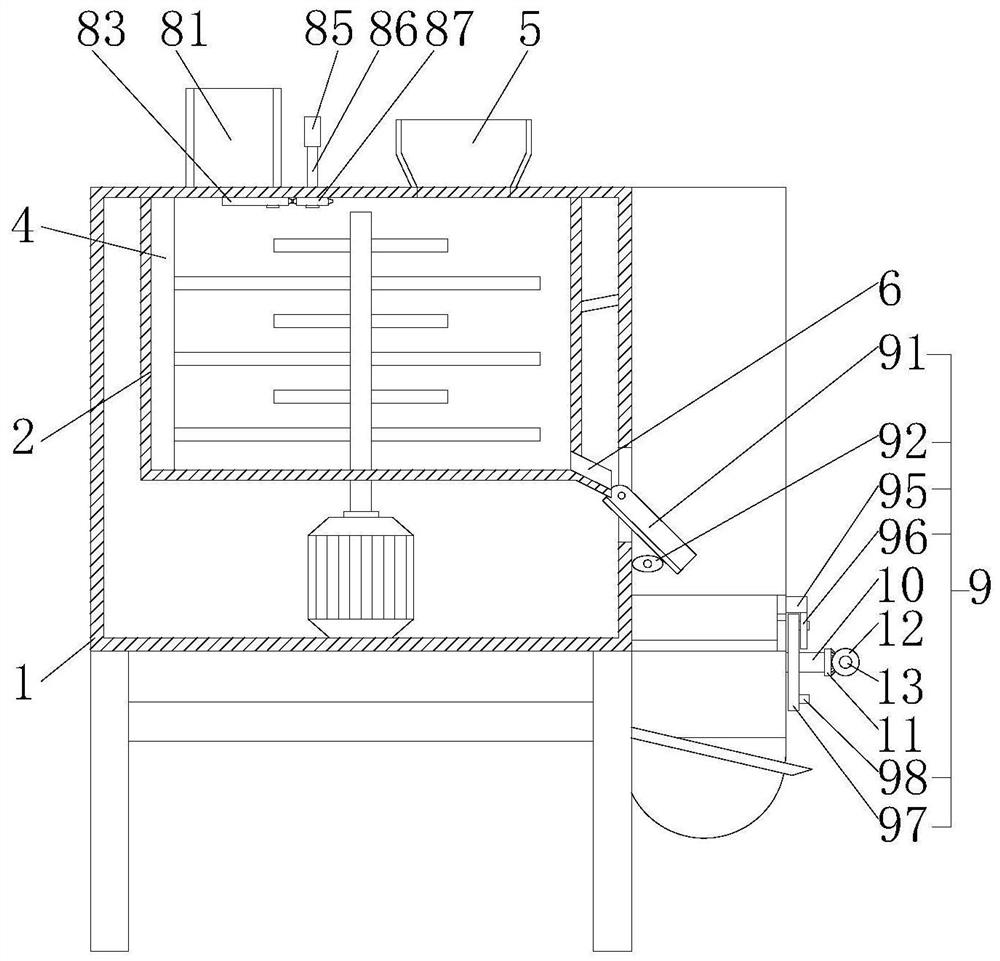

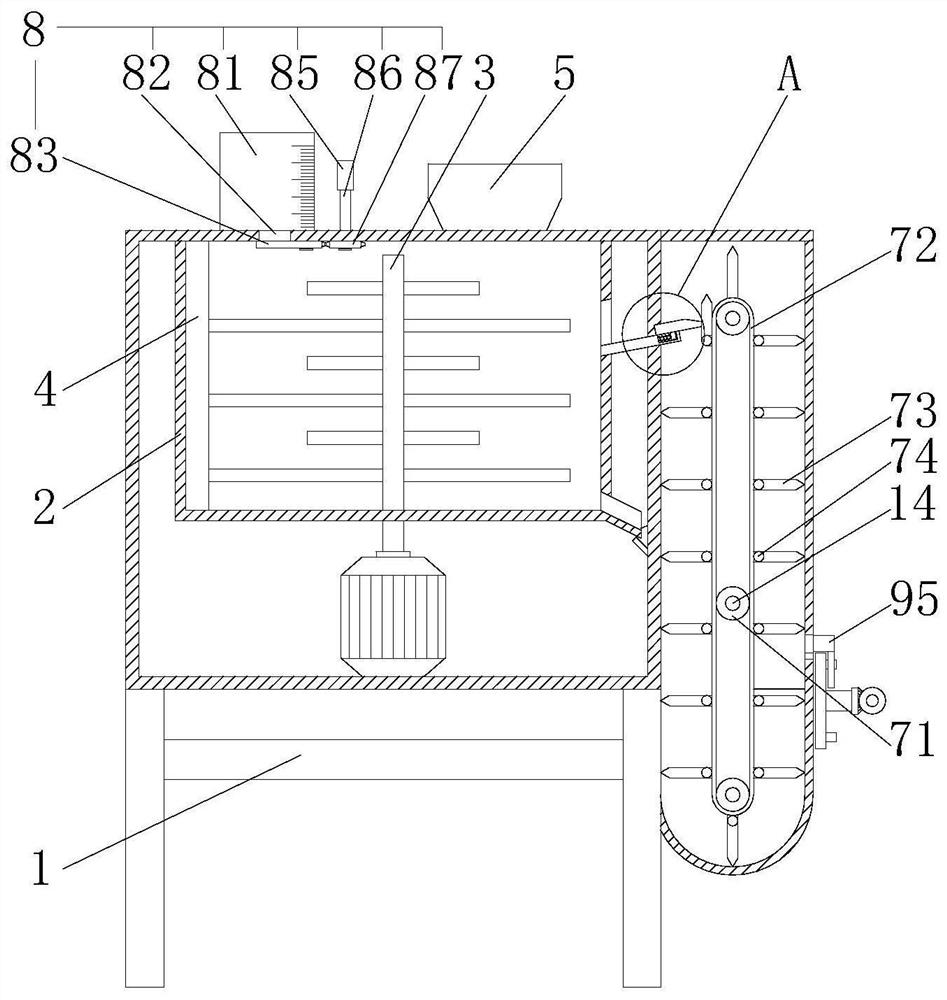

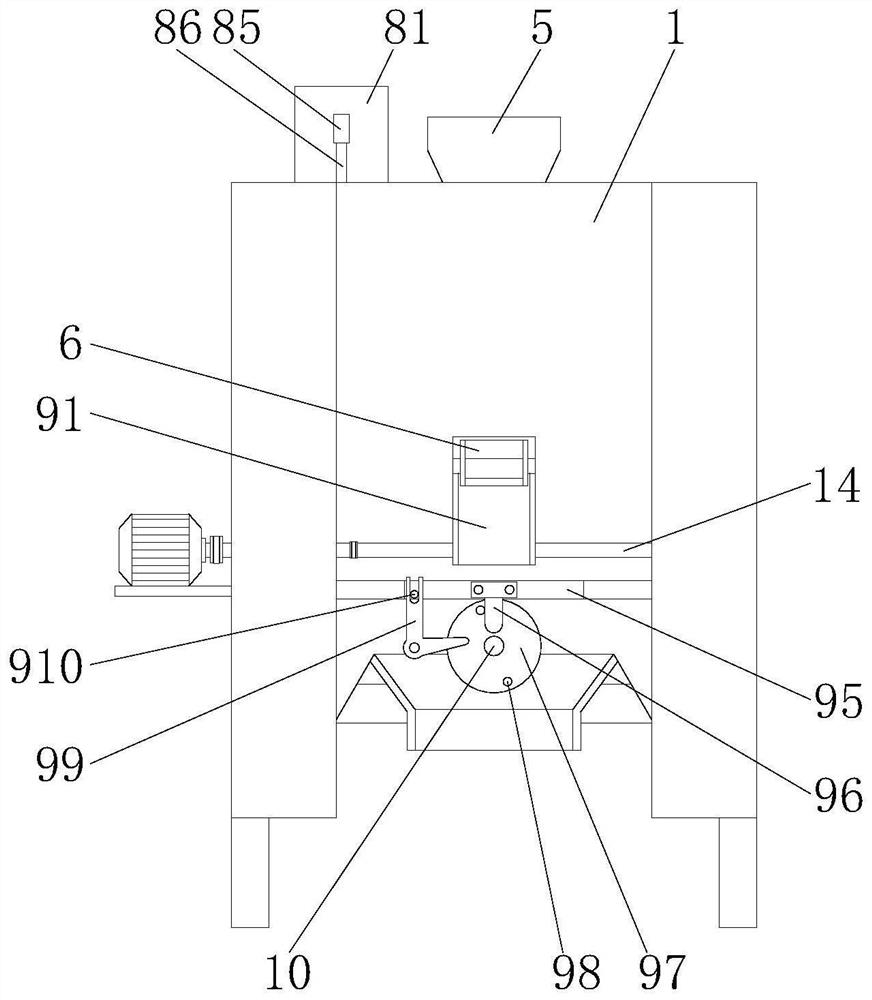

Modified asphalt rubber milling equipment

ActiveCN113231148AEasy to operateRubber mill thoroughlySolid waste managementHollow article cleaningAsphaltManufacturing engineering

The invention discloses modified asphalt rubber milling equipment. The equipment comprises an equipment body, a rubber milling cavity, a rubber milling rod and a feeding port, the rubber milling cavity is formed inside the equipment body, the rubber milling rod is installed inside the rubber milling cavity, a scraper blade is fixedly installed at one end, close to the inner wall of the rubber milling cavity, of the rubber milling rod, the feeding port is formed in the top of the rubber milling cavity, a discharging port is formed in one side of the rubber milling cavity, one side, close to the discharging port, of the rubber milling cavity is connected with a conveying mechanism, a quantifying mechanism is arranged on the top of the equipment body, and a screening mechanism is arranged on one side, close to the discharging port, of the equipment body. By arranging the screening mechanism and the conveying mechanism, modified asphalt with large particles can be screened, qualified modified asphalt can be collected, the modified asphalt with the large particles can be conveyed into the interior of the rubber milling cavity again under the action of the conveying mechanism to be subjected to rubber milling treatment, it is avoided that raw materials are manually fed and discharged many times, the operation time is saved, and machining efficiency and machining quality are improved.

Owner:日照公路材料有限公司

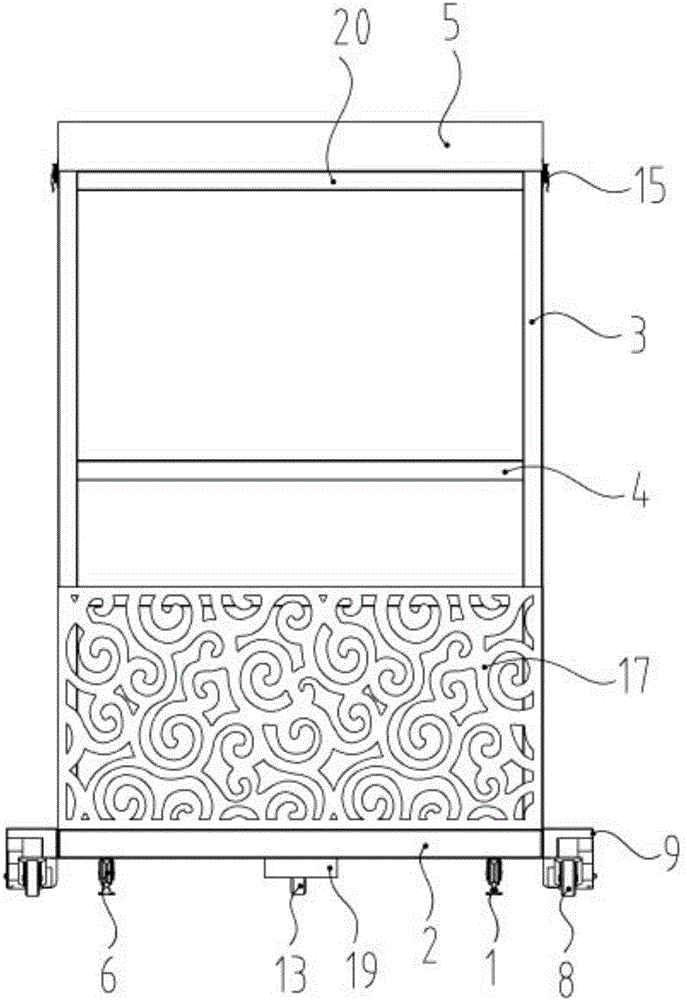

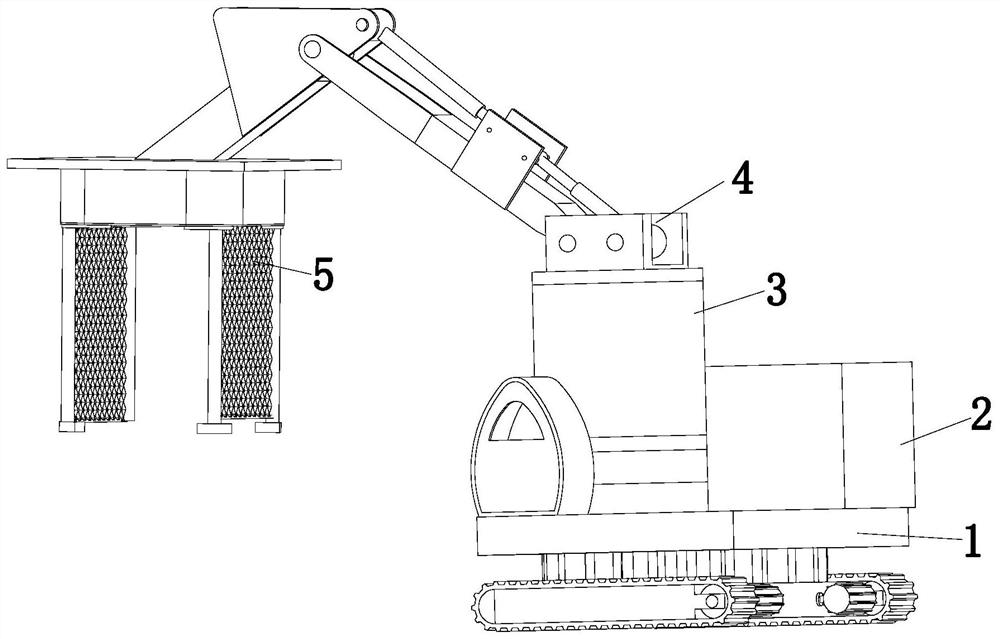

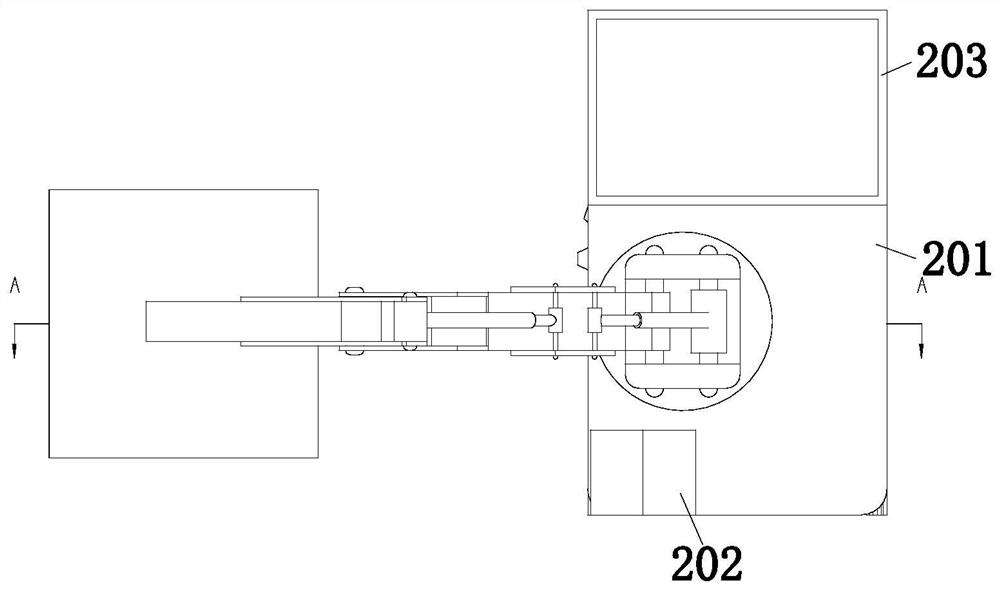

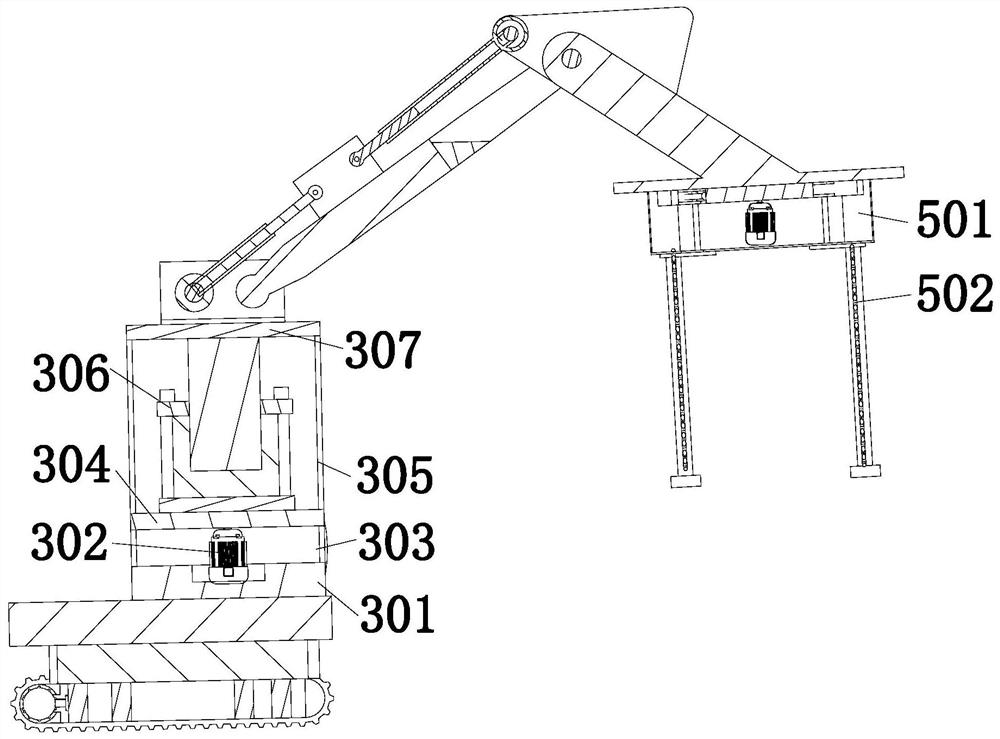

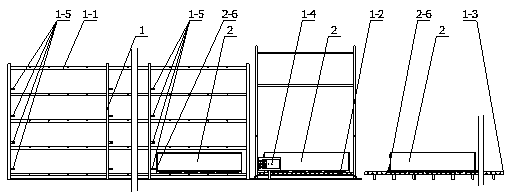

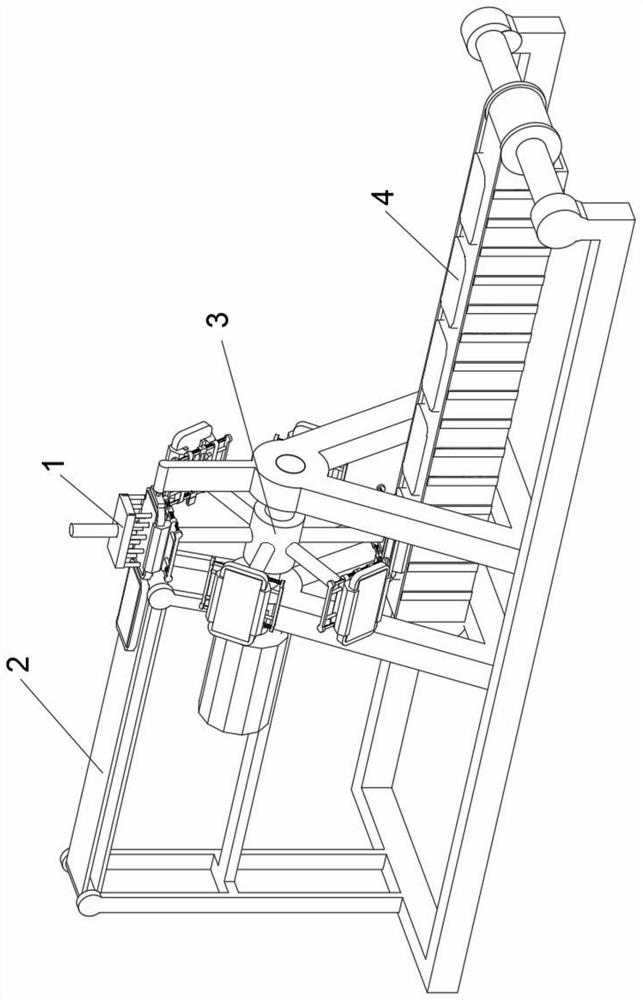

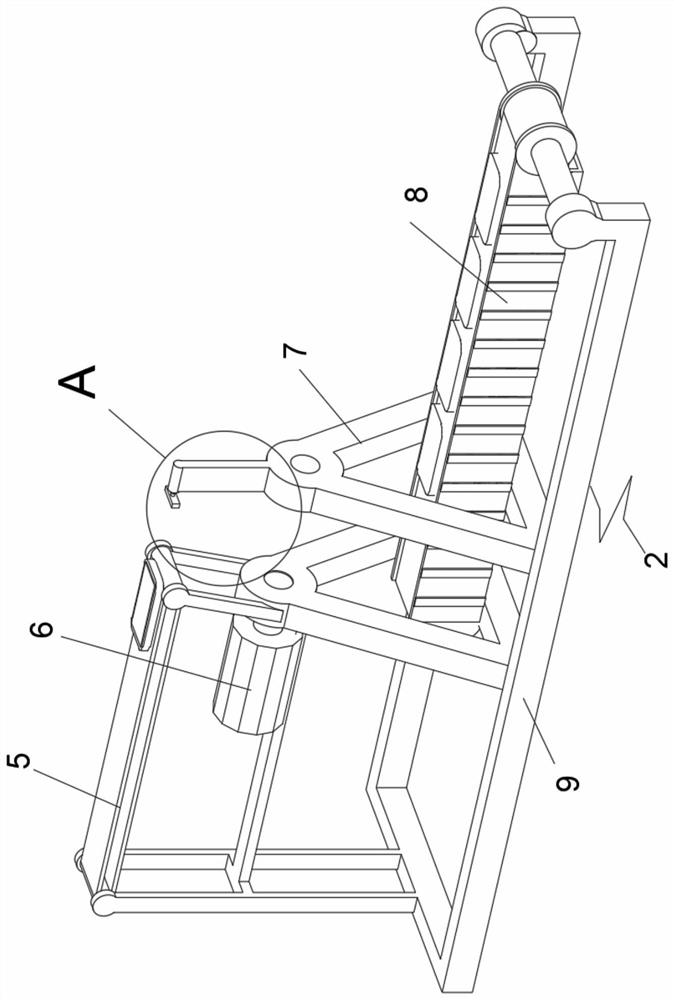

Brick loading and unloading machine for building

InactiveCN111606038AProtection against delays in transitTransport perfectDischarging arrangementConveyor partsBrickArchitectural engineering

The invention belongs to the technical field of brick loading and unloading machines, and relates to a brick loading and unloading machine for a building. The brick loading and unloading machine for the building comprises a moving mechanism, a bearing mechanism, a driving mechanism, a mechanical arm and a grabbing mechanism, wherein the moving mechanism is arranged on the ground, the bearing mechanism is arranged at the top of the moving mechanism, and the bearing mechanism is connected with the moving mechanism; and the driving mechanism is arranged at the top of the bearing mechanism, the driving mechanism is fixedly connected with the bearing mechanism, the mechanical arm is arranged at the top of the driving mechanism, the bottom of the mechanical arm is fixedly connected with the topof the driving mechanism, and the grabbing mechanism is arranged on the mechanical arm and connected with the mechanical arm. The brick loading and unloading machine for the building can solve the problems that bricks in a construction site need to be transported in different places, the adaptability is poor, and the labor force of workers is wasted.

Owner:高飞

Cold transportation method and cold transportation equipment

PendingCN109502220ABreak the time limitGuaranteed refrigeration qualityLarge containersTank wagonsAutomatic controlRefrigeration temperature

The invention discloses a cold transportation method and cold transportation equipment, and aims to provide the cold transportation method and the cold transportation equipment which are low in use cost. The cold transportation method comprises the following steps that cargos needing refrigerated transportation are put into a box body with a heat preservation and heat insulation function, the boxbody is provided with the functions that internal temperature can be controlled automatically, suitability for shipping and automobile transportation is achieved, stacking is feasible and working through connection with an external power supply can be realized, meanwhile, the box body can be used for setting the refrigeration temperature according to the refrigerated storage requirements of articles, and refrigeration power is provided by an internal power supply during the transportation process; the box body loaded with the cargos can be automatically stacked and stored at constant temperature through a three-dimensional library with a charging function in the turnover process; and power supply of the box body is stopped when the box body is in the three-dimensional library, power supplyis conducted by the three-dimensional library. According to the cold transportation method and the cold transportation equipment, the refrigerated storage quality of the cargos in the whole transferring process can be ensured.

Owner:YUNNAN KUNMING SHIPBUILDING DESIGN & RESEARCH INSTITUTE

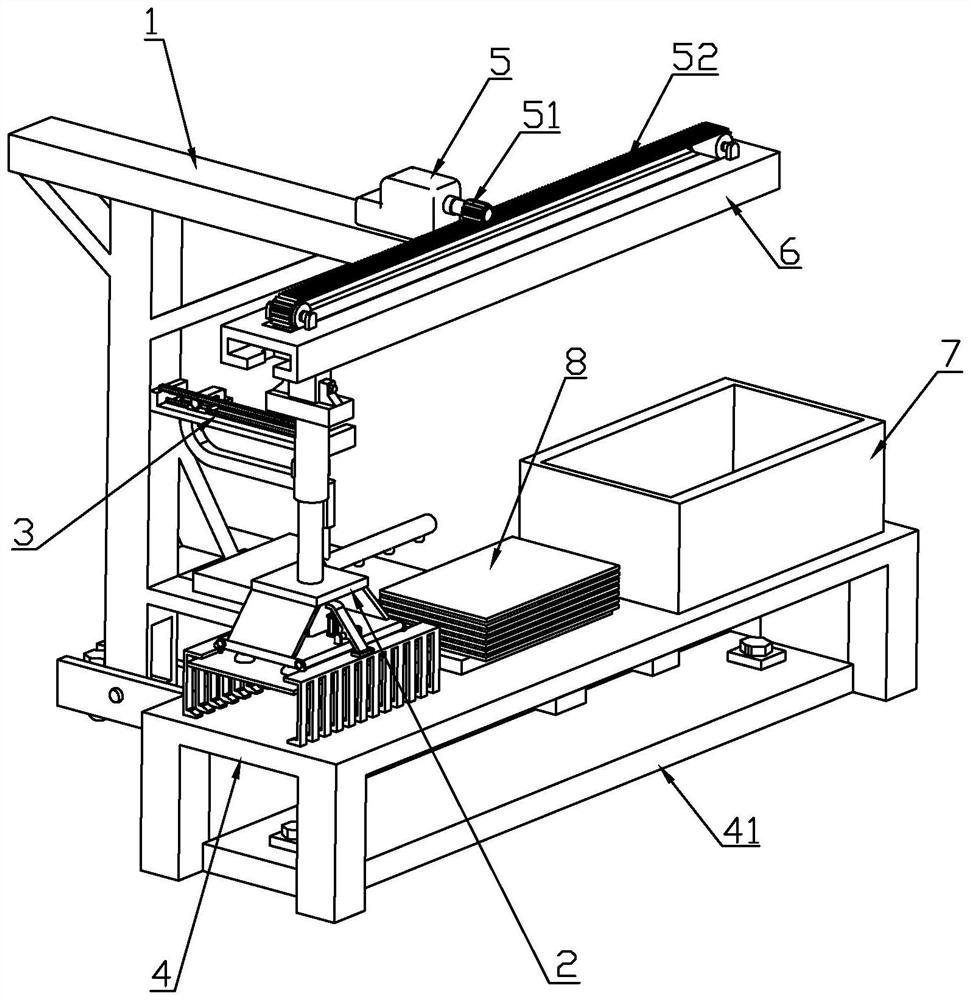

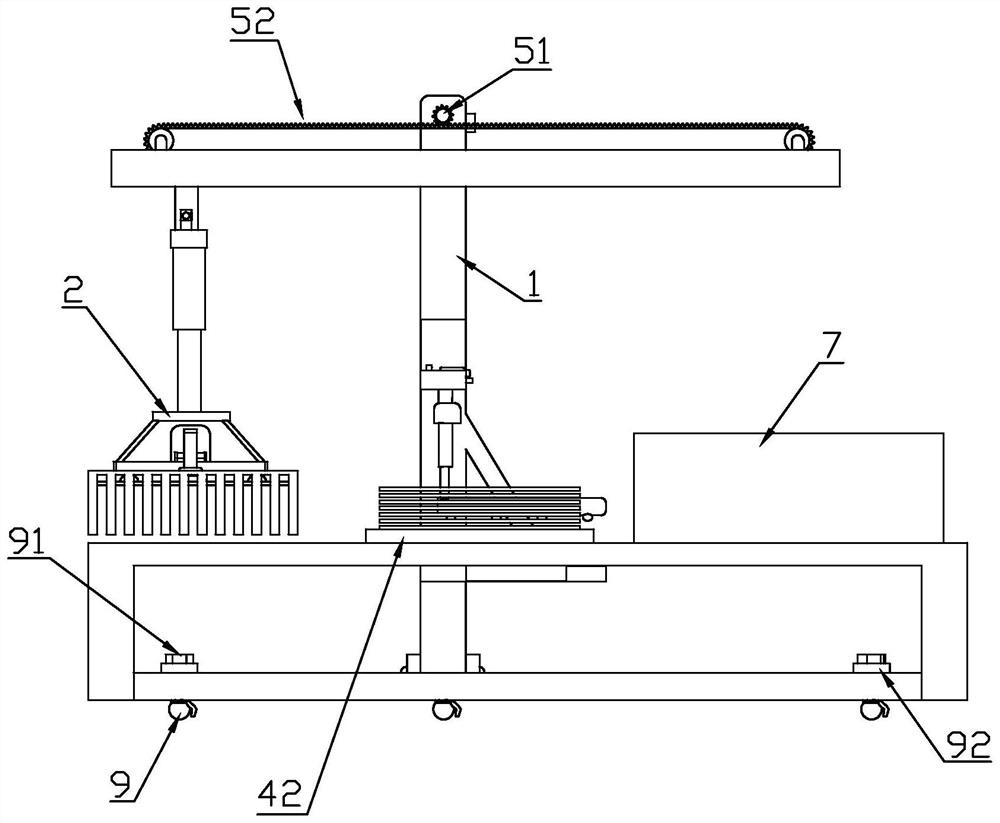

Boxing equipment for engineering construction glass

PendingCN113415461AAvoid loading and unloadingGuaranteed continuous stabilityPackaging automatic controlShock-sensitive articlesConstruction engineeringSupport plane

The invention discloses boxing equipment for engineering construction glass. The equipment comprises a support frame, a grabbing mechanism, a gasket conveying mechanism and a support table, the support table is arranged at one side of the support frame, the grabbing mechanism is arranged at the top side of the support table, the gasket conveying mechanism is arranged at one side of the grabbing mechanism, and the gasket conveying mechanism is fixedly connected to one side of the support frame. A T-shaped groove plate is slidably connected to the top of the grabbing mechanism, the grabbing mechanism is slidably connected to the inner side of the T-shaped groove plate, an outer tooth conveying belt is arranged at the top side of the T-shaped groove plate, a servo motor II is arranged at one side of the outer tooth conveying belt, and a tooth roller connected with the outer tooth conveying belt in a meshed manner is arranged at the output end of the servo motor II. A glass storage box is mounted at the top side of one end of the support table, and a placement table is arranged at one side of the glass storage box and arranged at one side of the gasket conveying mechanism. The boxing equipment is reasonable in structure, and automatic glass boxing is achieved.

Owner:孙波涛

Function testing device for electronic product

InactiveCN112798891AEasy to disengageEasy to holdElectrical testingMeasurement instrument housingTest efficiencyFunctional testing

Owner:EASTERN LIAONING UNIV

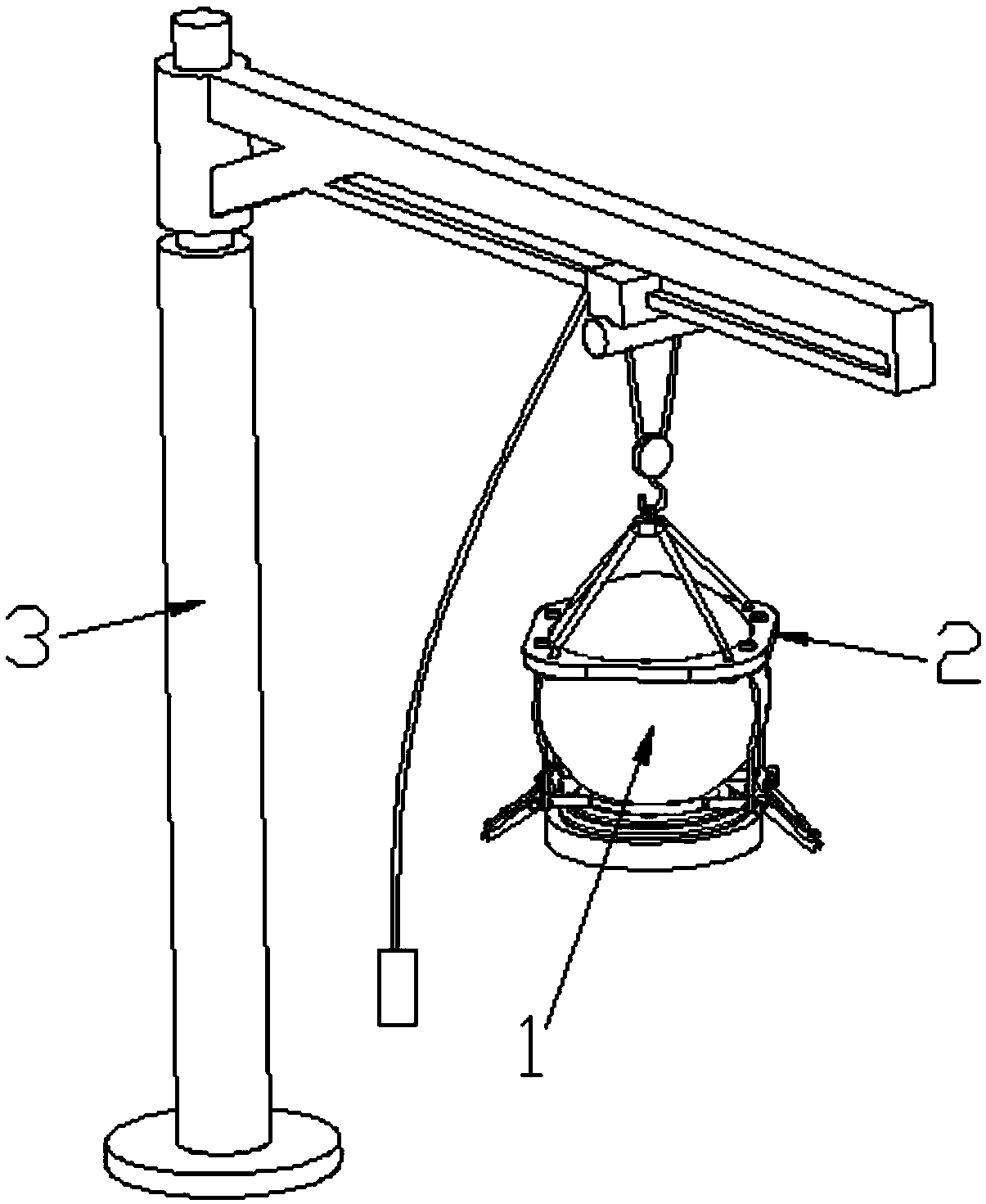

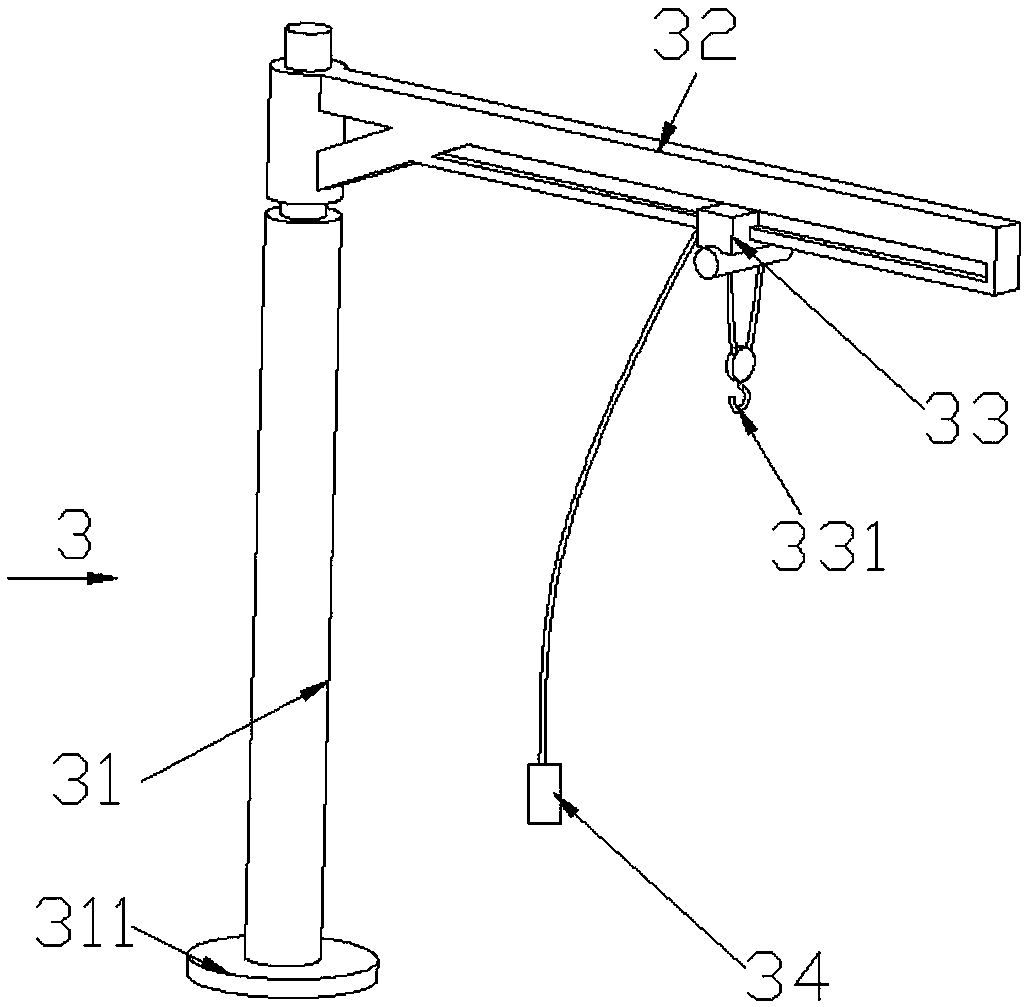

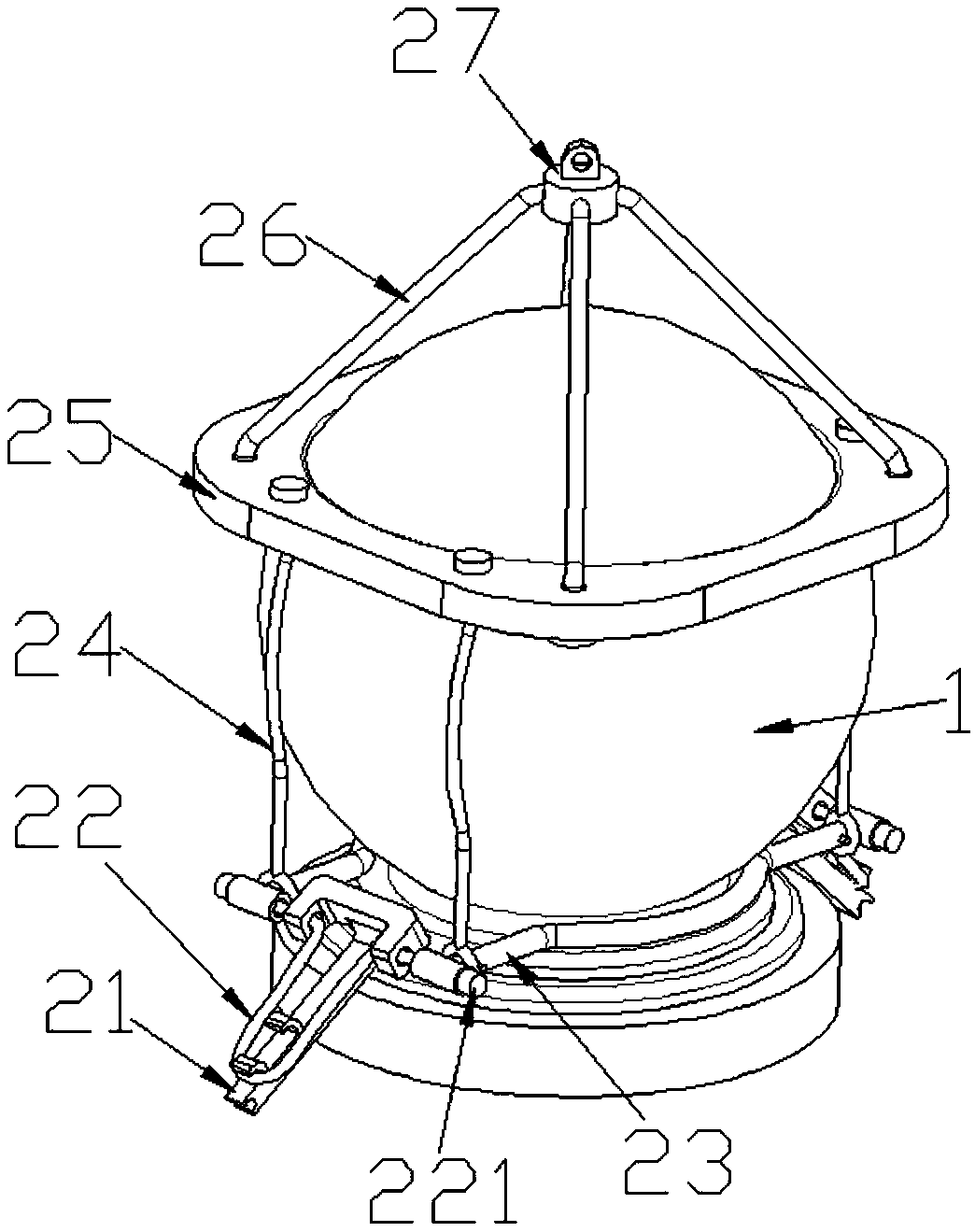

Vehicle-warding-off stone block hoisting device

InactiveCN108715405AAvoid loading and unloadingAvoid damageLoad-engaging elementsCranesEngineeringCantilever

The invention relates to a vehicle-warding-off stone block hoisting device. The vehicle-warding-off stone block hoisting device comprises a stone block. The vehicle-warding-off stone block hoisting device is characterized in that the device further comprises a clamping mechanism and a cantilever crane; the clamping mechanism comprises a rope taking-up mechanism; the rope taking-up mechanism comprises a U-shaped plate and a wire supporting rod; first wire penetration holes are formed in a lug plate pair of the U-shaped plate in a penetrating manner; and the wire support rod is arranged betweenside edges of the U-shaped plate and provided with wire scraping hooks. By means of the vehicle-warding-off stone block hoisting device, the vehicle-warding-off stone block does not need to be carriedmanually to be loaded and unloaded, and labor intensity is lowered; and in addition, the vehicle-warding-off stone block hoisting device can maintain the vertical state when the vehicle-warding-off stone block is loaded and unloaded, and the problem that edges and corners of the stone block are collided, so that the stone block is damaged is avoided.

Owner:HUZHOU ZHONGCHEN CONSTR

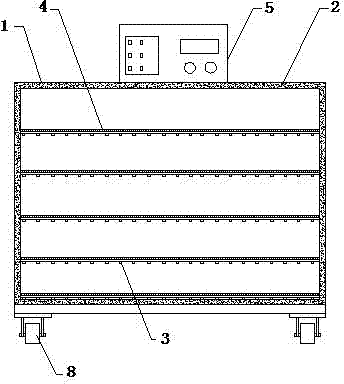

Drying equipment for ceramic processing and production

ActiveCN103712423AAvoid complicated loading and unloadingAvoid loading and unloadingDrying chambers/containersDrying machines with local agitationElectronic control systemHeat conducting

The invention discloses drying equipment for ceramic processing and production. The drying equipment comprises a container. Two side walls, top and bottom of the container are paved with liners. A plurality of layers of parallel heat conducting plates are arranged inside the container sequentially from bottom to top, two ends of each layer of heat conducting plates are respectively fixed on the two side walls inside the container, and the bottom of each layer of heat conducting plate is connected to an electric heating element; the electric heating elements are operated under control of an electronic control system; preferably, a layer of thin aluminum alloy mesh belt is paved on each layer of the heat conducting plates. The drying equipment has the advantages that heating effect is fine, efficiency is high, heating is uniform, service life of the container is long, automation degree is high, labor force can be reduced, working intensity is reduced, cost is lowered, operation is simple, environment protection is achieved, and pollution is prevented.

Owner:朱莉娟

Direct carbon fuel cell reaction device

ActiveCN100595959CImprove performanceAchieve coolingFuel cell auxillariesSolid electrolyte fuel cellsFuel cellsEngineering

The invention provides a direct carbon fuel battery reaction device, belonging to the field of direct carbon fuel battery technique. An upper base (1) of the reaction device is coaxially arranged intoa water cooling sleeve (2); the connection of the upper base and the water cooling sleeve is welded and sealed to form a water cooling chamber; an anode current collecting Pt net (12) is used for collecting current from the anode of a button-typed solid oxide fuel battery (16); two ends of an anode current collecting Pt wire (15) are respectively used as an reference electrode and a testing electrode; the temperature measuring point of a temperature measuring thermal-couple (17) and the button-typed solid oxide fuel battery (16) keep in the same height; the bottom of an anode chamber pipe (6)is inserted into the upper hole of a lower base (43); the lower surface of a quartz sand sintering plate (42) is provided with a carbon fuel thermal-couple (56); all pipes and sealing heads (46) arehermetically connected with each other. The direct carbon fuel battery reaction device of the invention solves the problem of water adding of anode chamber and the arranging of carbon fuel, realizes that the temperatures required by the running of fuel battery and the reacting of the carbon fuel are respectively controlled, avoids complex disassembly / assembly process and personnel scald, preventsthe sealing invalidity and reduces the cost.

Owner:TSINGHUA UNIV

Transporting and handling implement for rapid adapter or joint in cementing-head apparatus

InactiveCN1570345AReduce labor intensityAvoid handlingBorehole/well accessoriesRelative motionUltimate tensile strength

This invention involves to in the mining petroleum and the natural gas process uses cement head in the installment fast attachment or connects the body the transporting and the handling tool, its characteristic lies in: Unexpectedly is separated in the transporting and handling tool in on establishes 2 or connects the tooth block to 5 rows with cement head the installment fast attachment which the body the long tooth block is more corresponding than and mounts, in the terminal which mutually connects separately is equipped with the limit the spacing half tooth block which corresponds to the identical direction rotation, symmetrically installs the card and the fast attachment or the connection body scoop channel L clip outside the tool after the wall on.

Owner:王继兰 +1

Alkali slag liquid desulfurizer preparation device and method

ActiveCN104857831BAvoid loading and unloadingBlock deliveryDispersed particle separationLiquid wasteThick line

The invention relates to a device and method for preparing a desulfurizing agent, in particular to a device and a method for preparing an alkali slag liquid desulfurizing agent. Including the alkali slag conveying pump, the alkali slag conveying pump is connected to the desanding device through the first pipeline, the top of the desandering device is connected to the thickener through the second pipeline, and the upper part of the thickener is connected to the collector through the first overflow pipeline. The main pipeline is connected, the thickener is connected to the chlorine reduction tank through the fifth pipeline; the auxiliary agent tank is connected to the middle layer of the chlorine reduction tank, the washing water pipeline is connected to the lower layer of the chlorine reduction tank, and the bottom of the chlorine reduction tank is connected to the finished buffer tank through the sixth Pipeline connection; the upper layer of the chlorine reduction tank is connected with the general collection pipeline through the second overflow pipeline. The preparation method is: gravity sand settling, thick sedimentation, washing and dechlorination, and sedimentation after thickening. The liquid desulfurizer is discharged from the bottom of the chlorine desulfurization tank and stored in a buffer tank. Compared with the existing technology: the application of high energy consumption equipment such as filter presses and centrifuges is avoided, the mechanical solid-liquid separation of alkali slag waste liquid is avoided, and the flue gas desulfurization effect is effectively improved.

Owner:TANGSHAN SANYOU CHEM IND

Elevator

ActiveCN1993287BAvoid loading and unloadingContainers for flexible articlesPackaging cigaretteRotational axisControl engineering

A hoisting machine for an elevator includes a motor having a motor body and a rotary shaft rotatable with respect to the motor body and a boss, which is a handle fit / removal member and is fixed to the rotary shaft. Amanually operated handle for manually rotating the rotary shaft can be removably fitted on the boss. The boss is provided with a rotation prevention portion for preventing, when the manually operated handle is fixed to the boss, the manually operated handle from rotating with respect to the boss in a rotational direction of the rotary shaft.

Owner:MITSUBISHI ELECTRIC CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com