Elevator

A technology of elevators and electric motors, which is applied in the direction of elevators, lifts, packaged items in buildings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

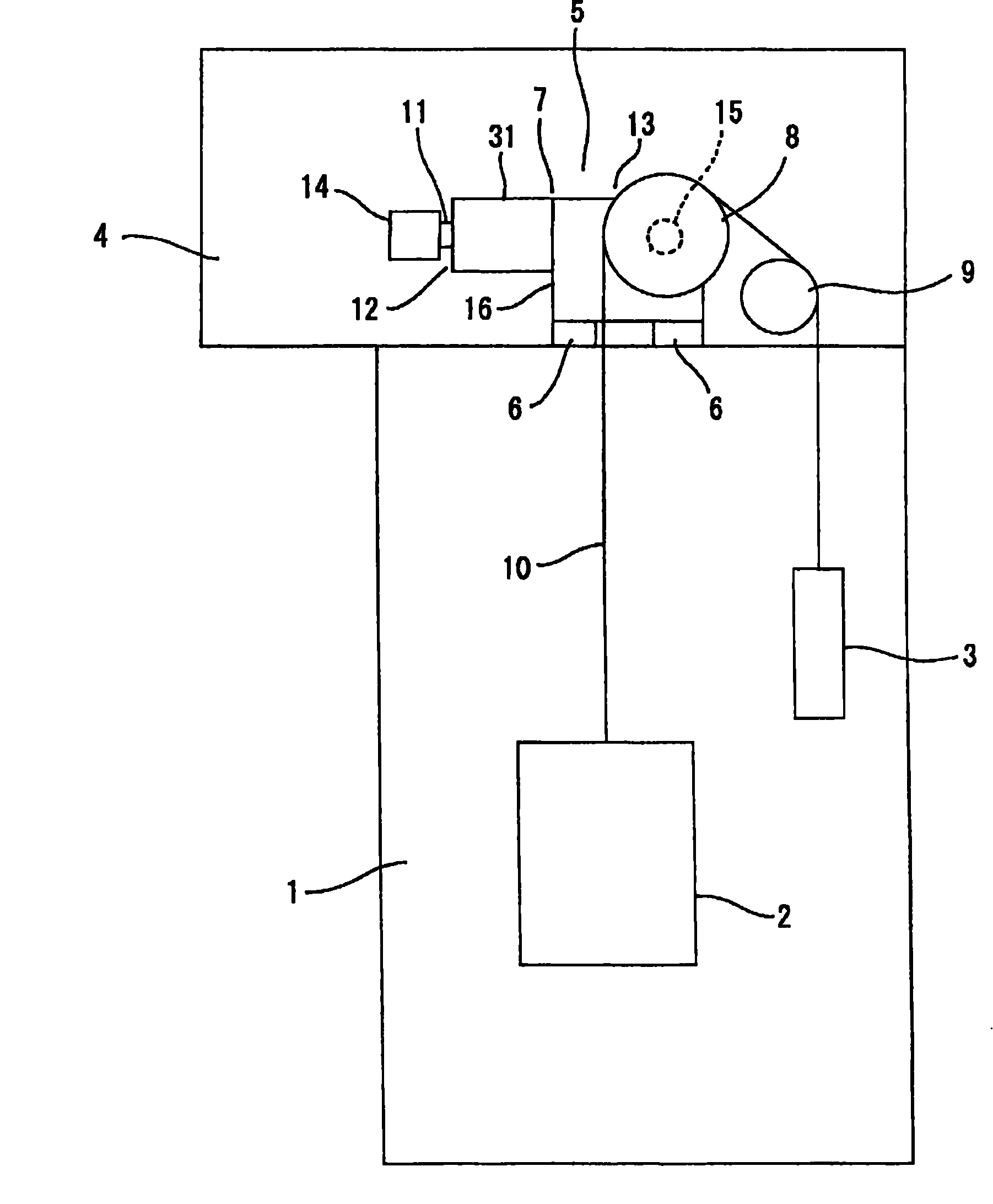

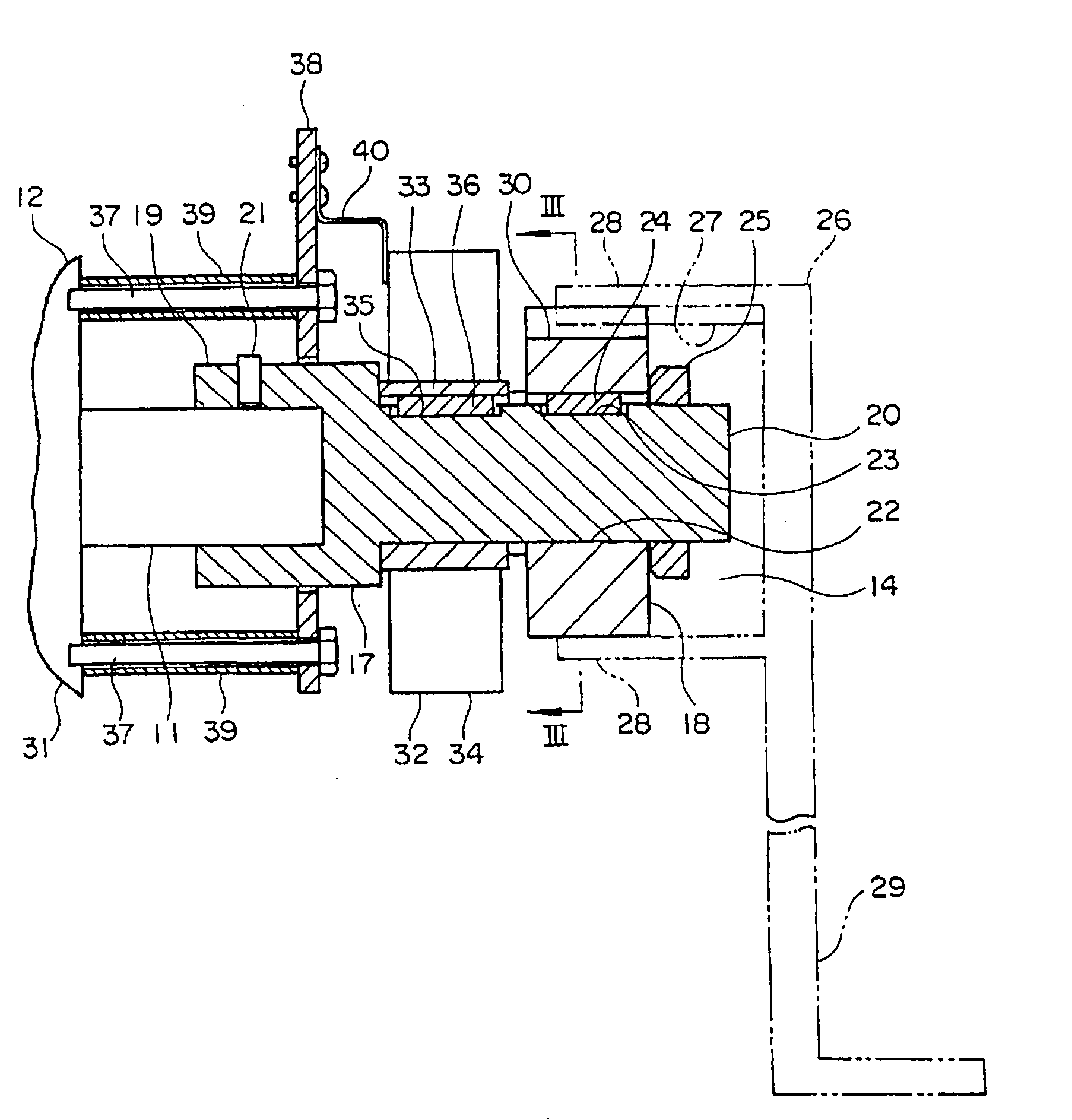

[0016] figure 1 It is a block diagram showing the elevator according to Embodiment 1 of the present invention. In the drawing, a car 2 and a counterweight 3 are provided in a hoistway 1 so that they can be raised and lowered. A machine room 4 is provided on the top of the hoistway 1 . In the machine room 4, a traction machine 5 is installed as a driving device. This traction machine 5 generates a driving force for raising and lowering the car 2 and the counterweight 3. The traction machine 5 is supported by a support member provided in the machine room 4. 6 on.

[0017] The hoisting machine 5 has a hoisting machine main body (drive device main body) 7 and a drive sheave 8 rotated by the hoisting machine main body 7 . In addition, a deflector sheave 9 arranged at a distance from the driving sheave 8 is provided in the machine room 4 .

[0018] A plurality of main ropes 10 are hung around the driving sheave 8 and the deflecting pulley 9 . The car 2 and the counterweight 3 ...

Embodiment approach 2

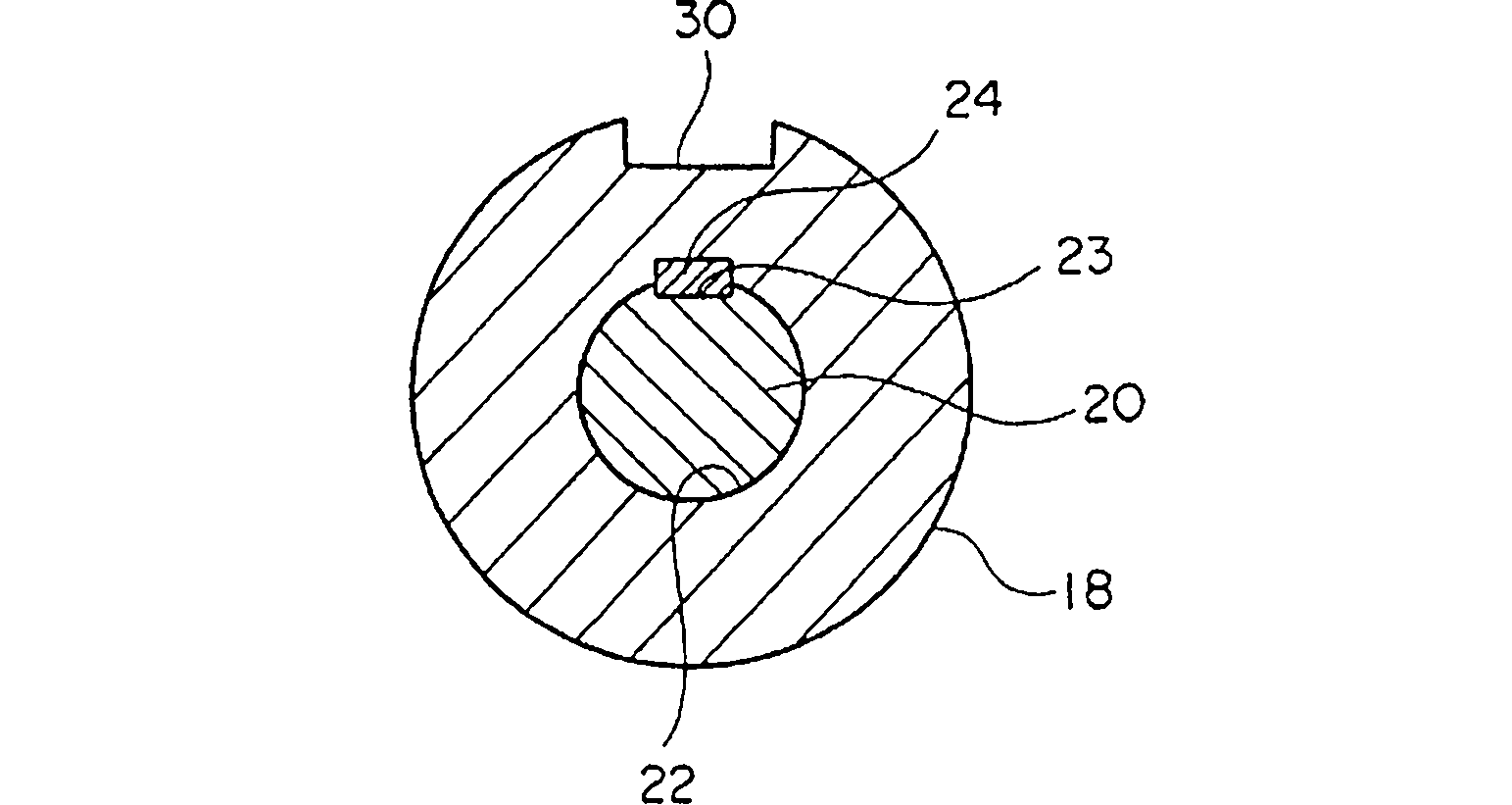

[0036] In the above example, one groove portion 30 is provided on the outer peripheral portion of the hub 18 as the anti-rotation portion, but a pair of groove portions arranged at symmetrical positions with respect to the axis of the motor shaft 11 may be provided as a pair of anti-rotation portions. on the outer periphery of the hub 18.

[0037] which is, Figure 4 It is a cross-sectional view of main parts showing a hoisting machine of an elevator according to Embodiment 2 of the present invention. also, Figure 4 is the same as in Embodiment 1 image 3 Corresponding sectional view. In the drawing, a pair of grooves (rotation stoppers) 41 arranged at symmetrical positions with respect to the axis of the motor shaft 11 are provided on the outer peripheral portion of the hub 18 . The cross-sectional shape of each groove part 41 is the same shape. Thus, the shape of the outer peripheral portion of the hub 18 is symmetrical with respect to the axis of the motor shaft 11 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com