Transporting and handling implement for rapid adapter or joint in cementing-head apparatus

A technology of loading and unloading tools and connectors, which is applied in the direction of wellbore/well parts, earthwork drilling, etc., can solve the problems of heavy weight, high labor intensity, unsafety, etc., and achieve the effect of avoiding equipment and personal accidents and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

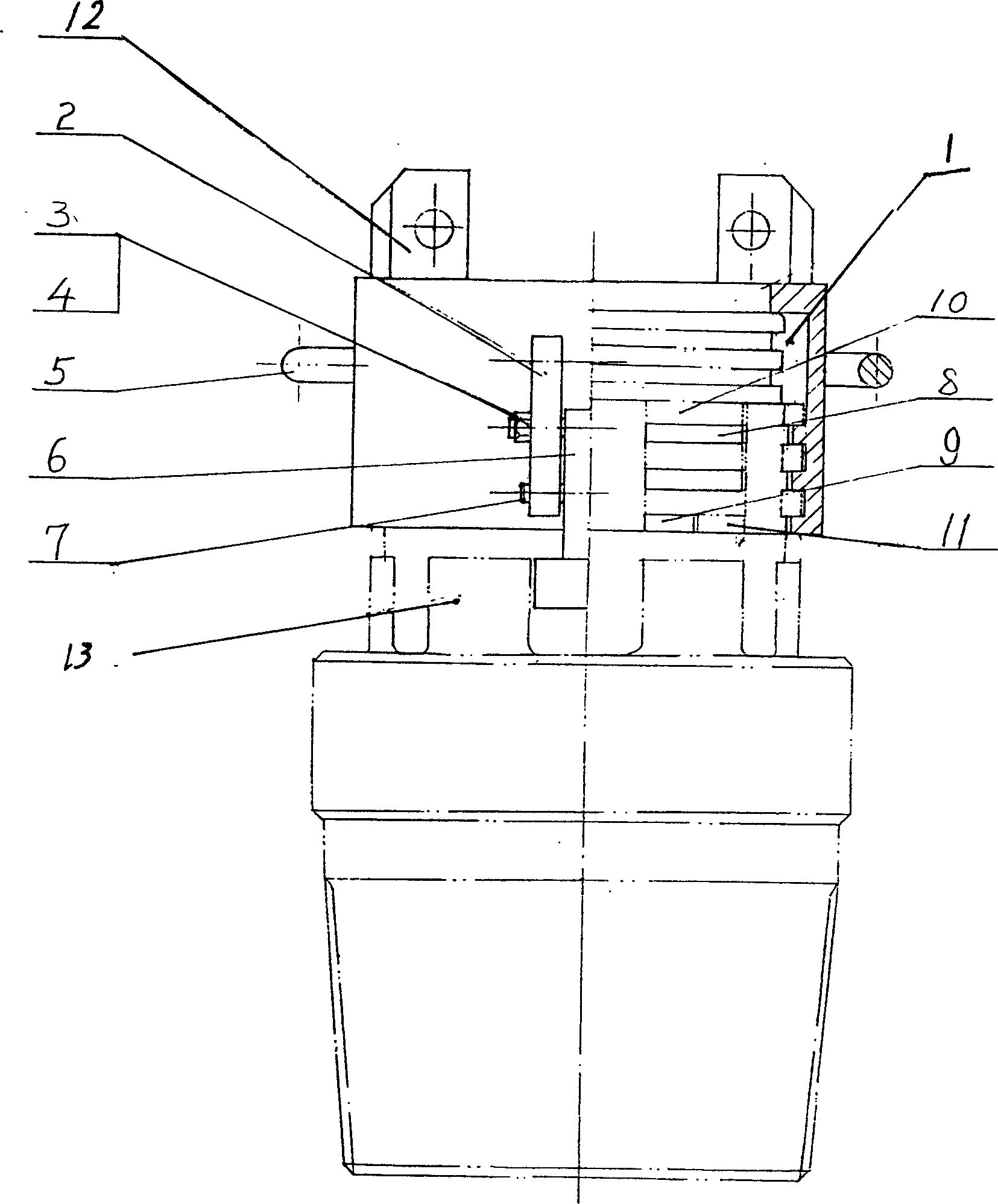

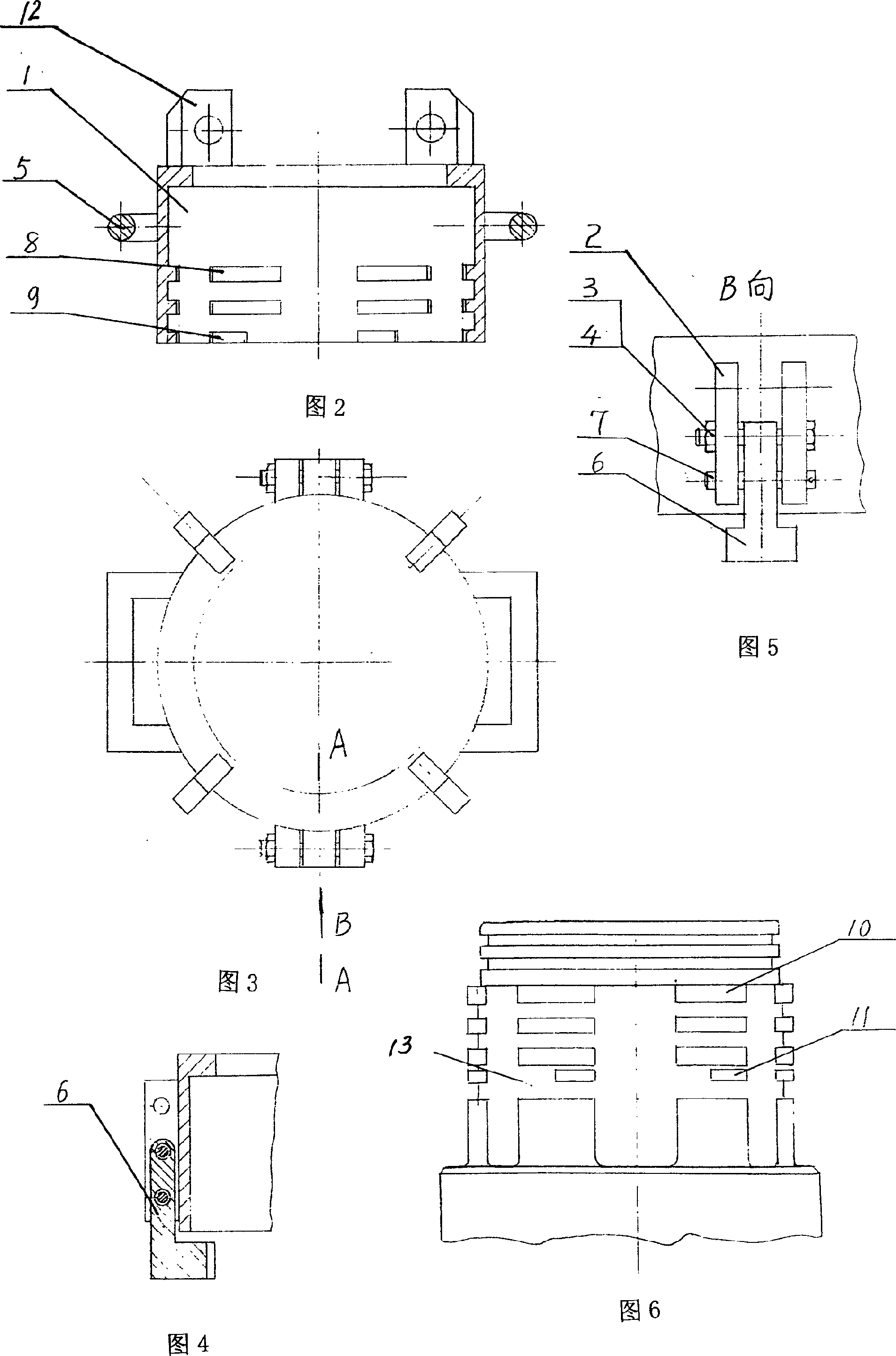

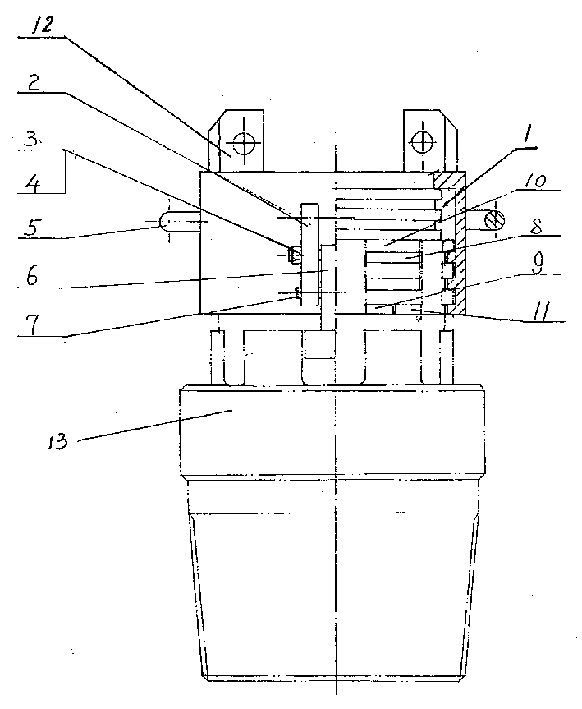

[0014] The structure and effect according to the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0015] See figure 1 As shown in -6, on the inner diameter wall of the tool 1, the tooth blocks 8 and 10 for load-bearing corresponding to the quick connector or the connecting body 13 are processed and inlaid. The corresponding restriction tool and the quick joint or the connecting body rotate the half blocks 9 and 11 in the same direction, that is, when the half block on the tool conflicts with the corresponding half block 11 on the quick joint or the connecting body , which limits the rotation of the tool and the quick connector or the connecting body in the same direction. In order to prevent the tool from rotating in the opposite direction with the quick connector or connecting body, two clamps 6 are respectively installed on the symmetrical lifting lug 2 outside the tool through bolts 3, nuts 4 and pins 7, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com