Patents

Literature

369results about How to "Avoid handling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

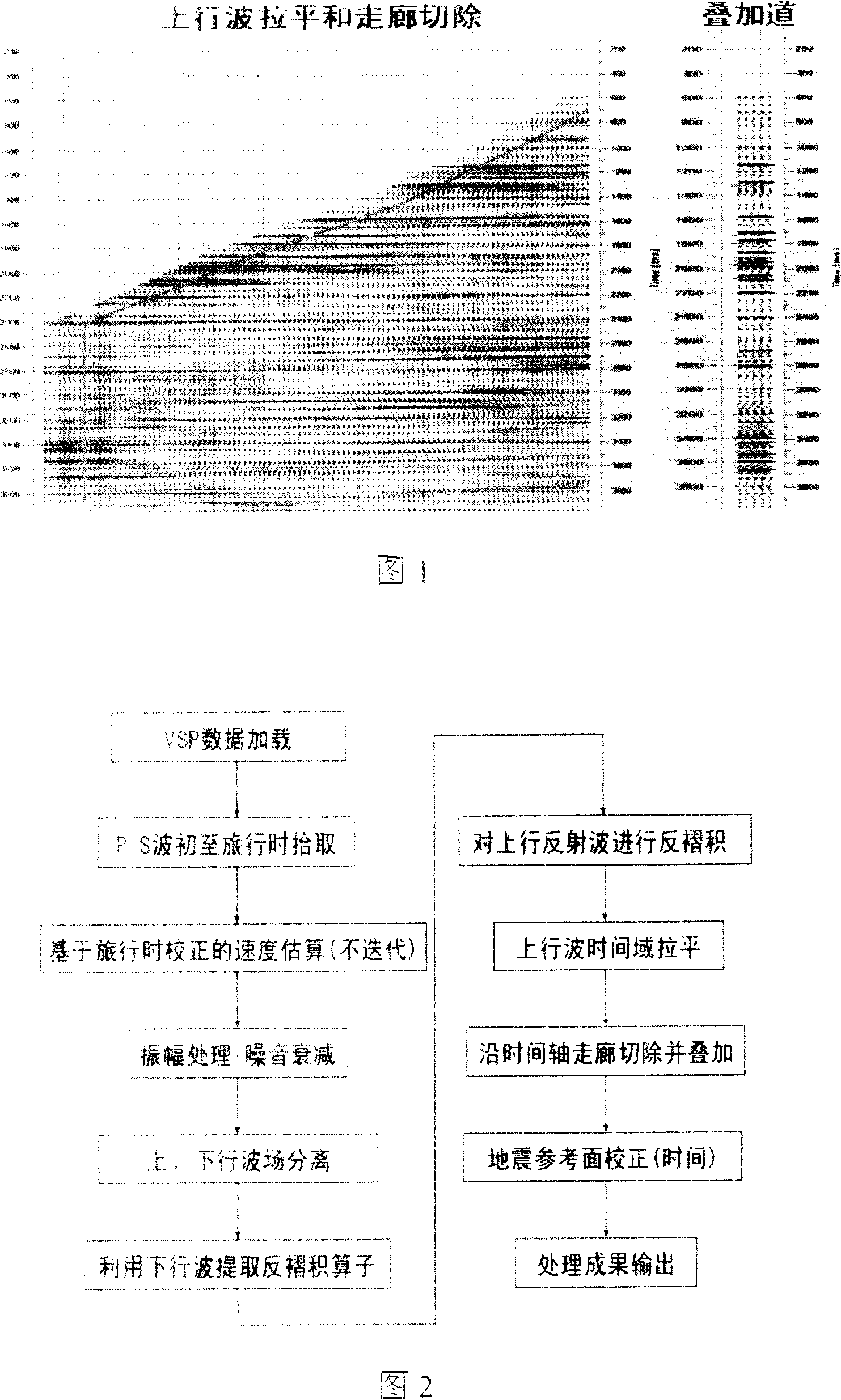

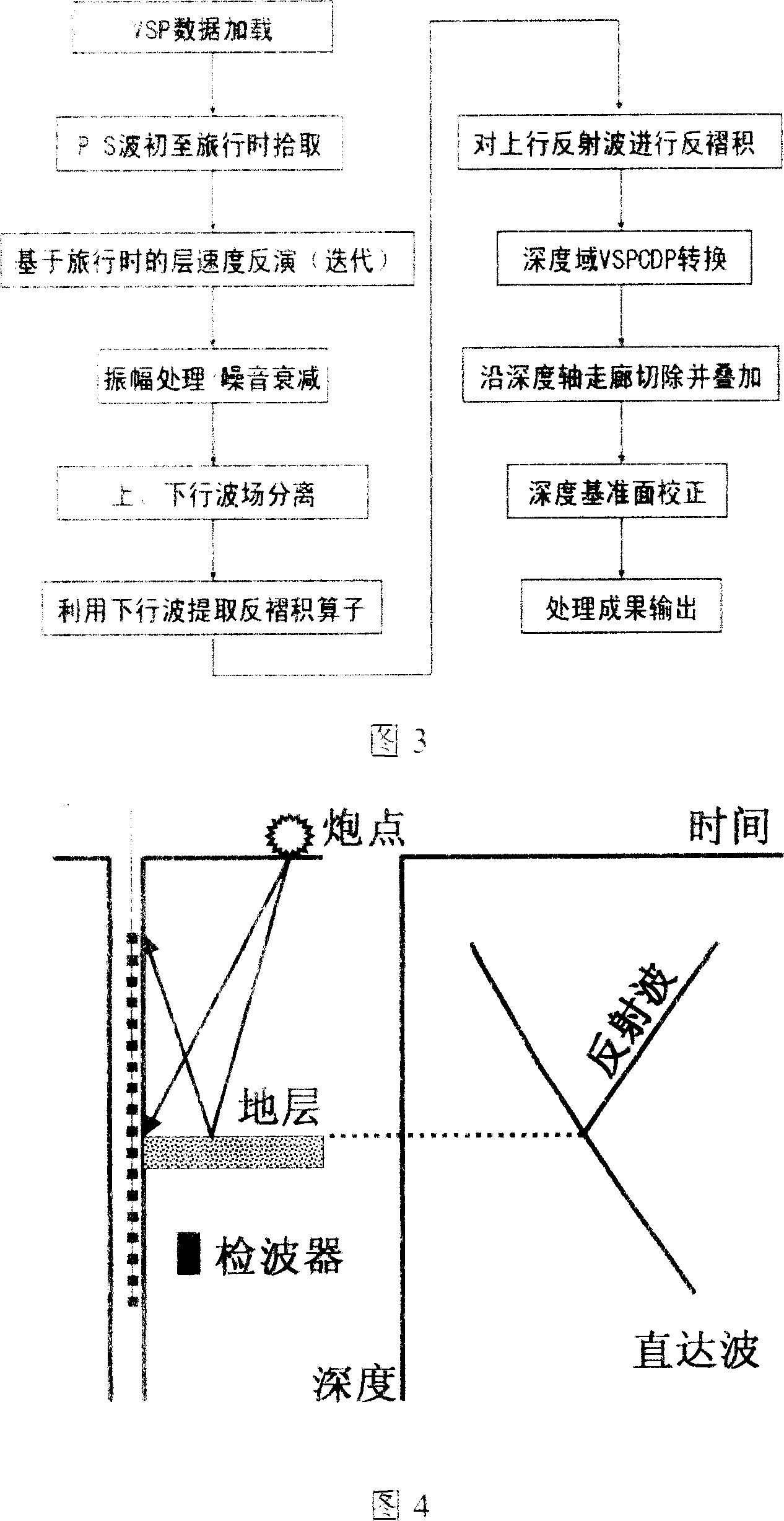

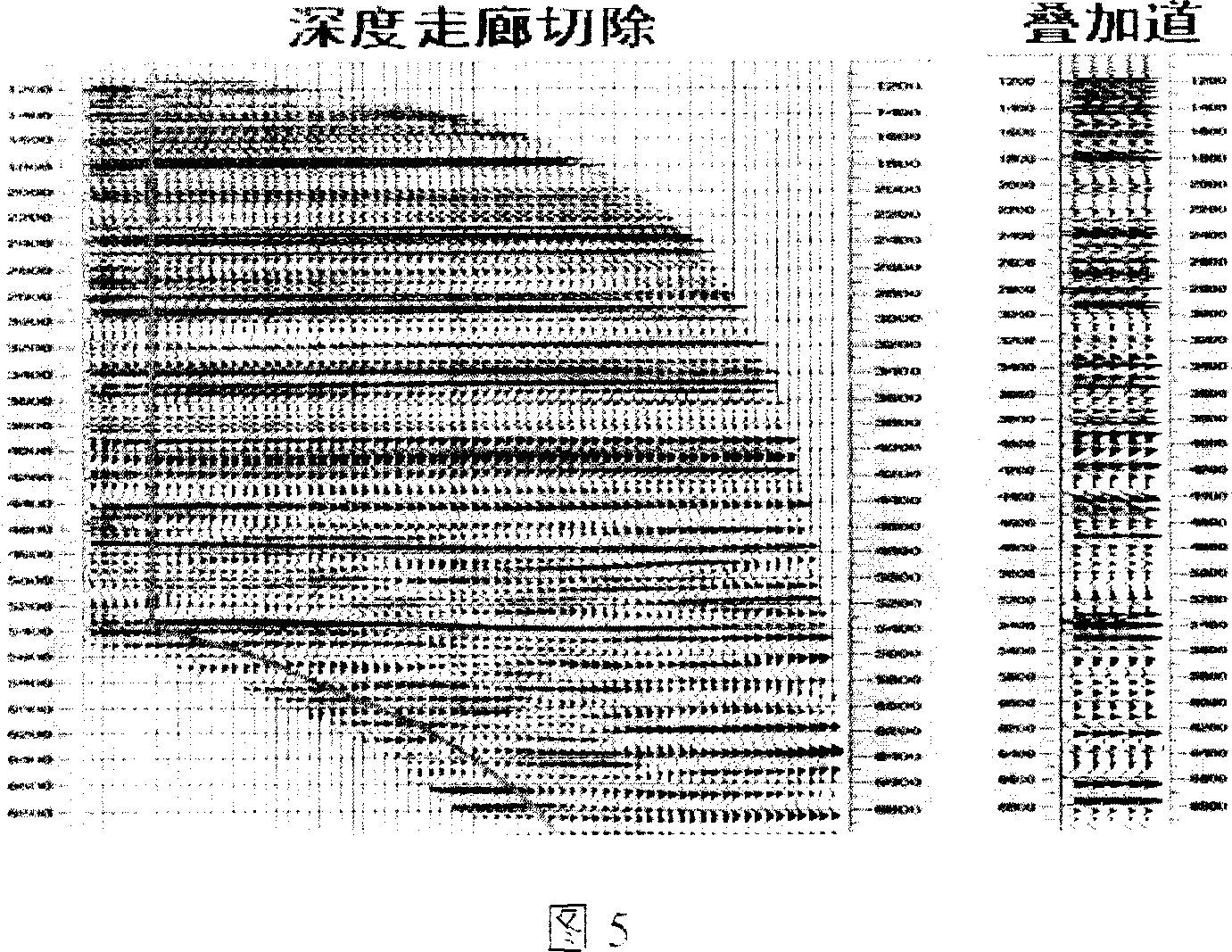

Zero hypocentral distance vertical seismic section compressional-shear wave data depth field corridor stacked section processing method

Geophysical exploration for oil wells, the source from the vertical seismic profile aspect wave data stack depth domain Corridor profile approach is the use of in situ collection of well spacing VSP data, which will all receive points drilling depth of information and hierarchical data with the depth of information, the use of direct wave VSP data travel through and optimization algorithms are highly accurate anti-layer velocity model, the direct wave to the beginning of the reflected wave in the vicinity of the depth and precision homing imaging, further in-depth domain Corridor section and with the superposition of alternative conventional method leveled in the time domain, with corridors and the superposition method, the results can be superimposed for direct comparison with the drilling and seismic data stratified layer identification. More intuitive, but also made full use of VSP data in the depth of information, make geological formation of the earthquake response and drilling, logging data in depth domain direct contrast, a more intuitive geological layer and the relationship between seismic horizon, thereby enabling layer of identification and calibration more reliable.

Owner:BGP OF CHINA NAT GASOLINEEUM CORP

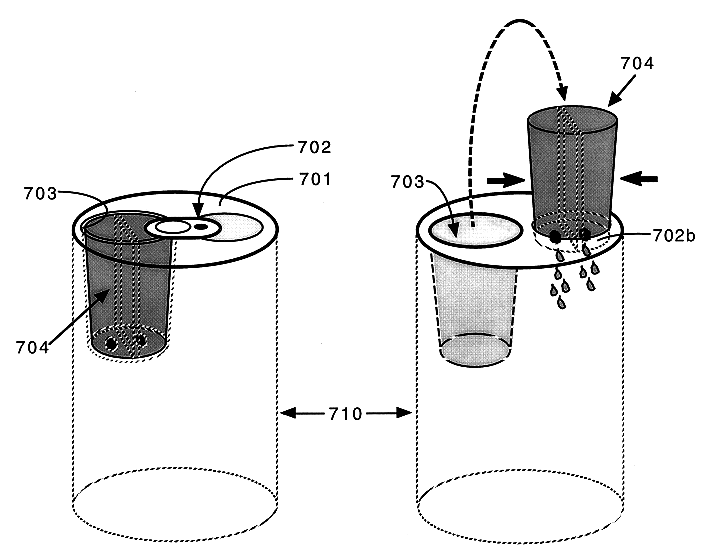

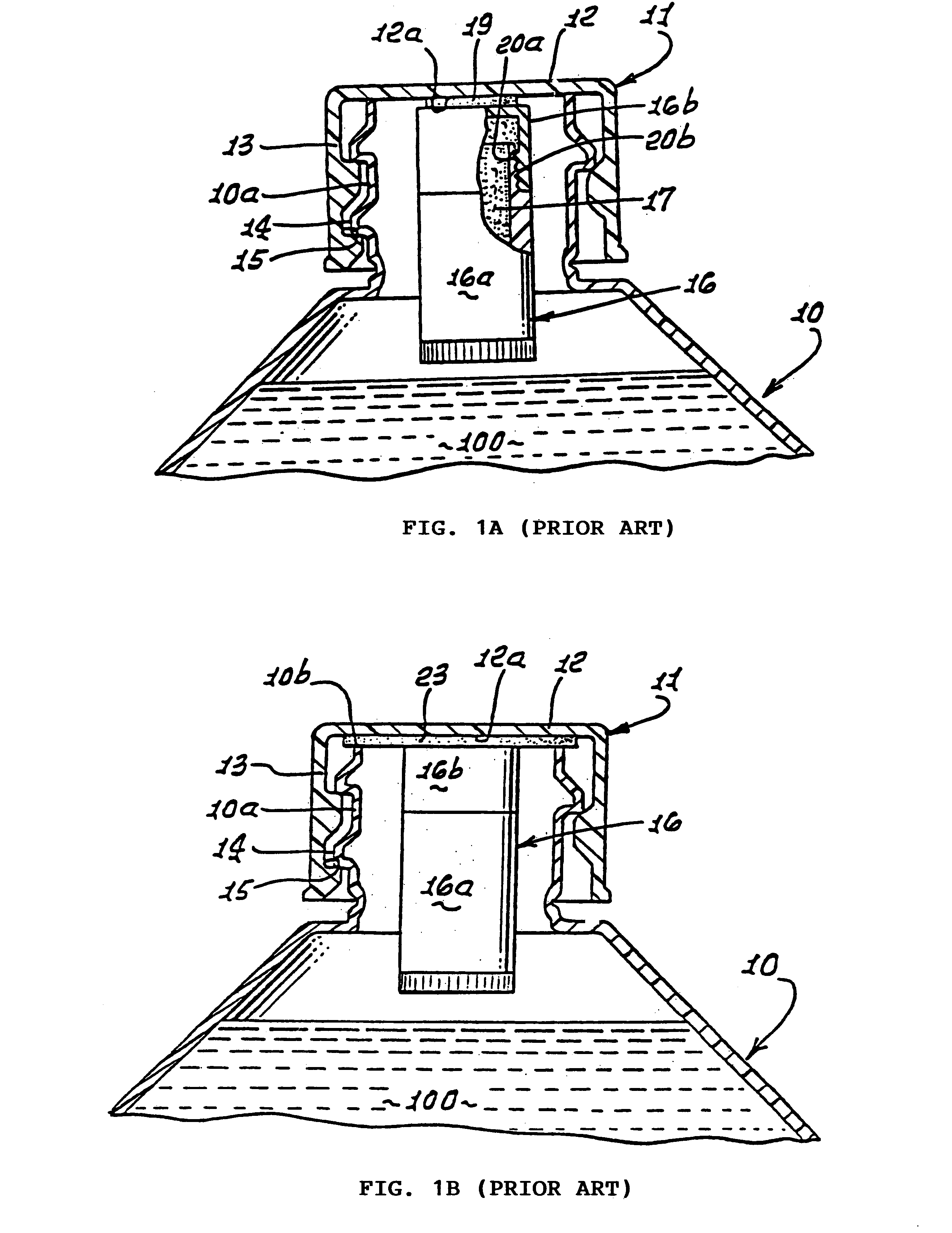

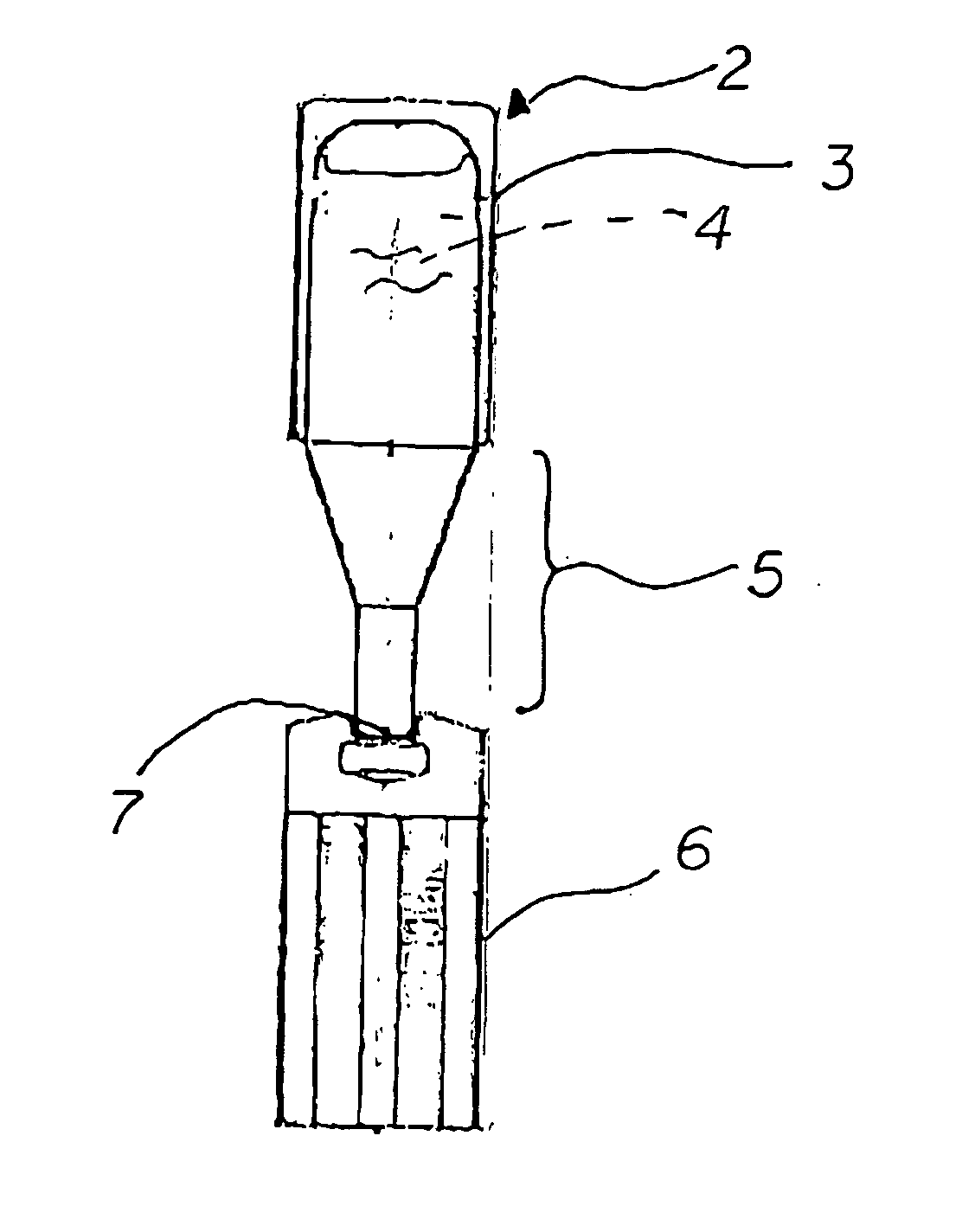

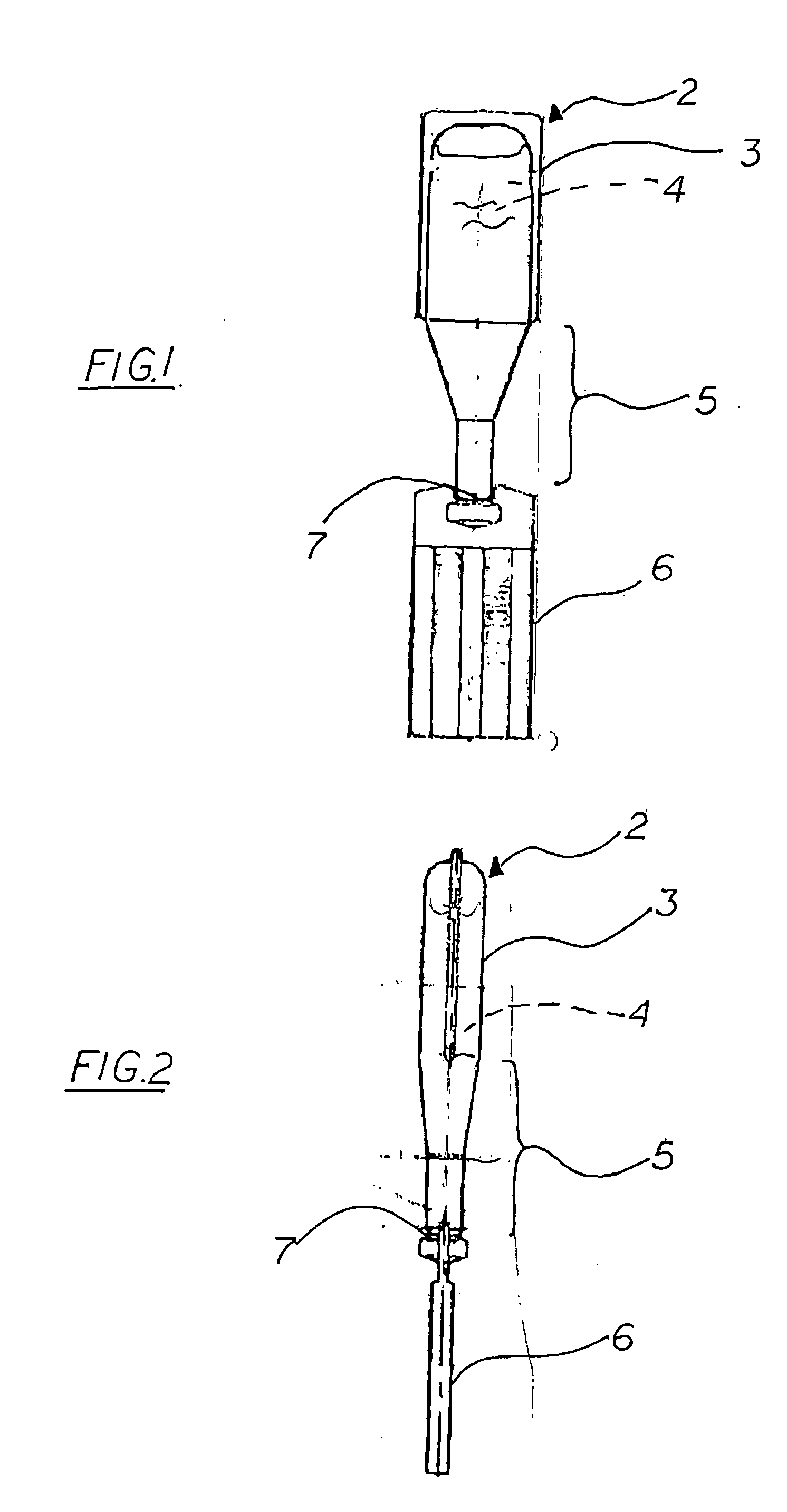

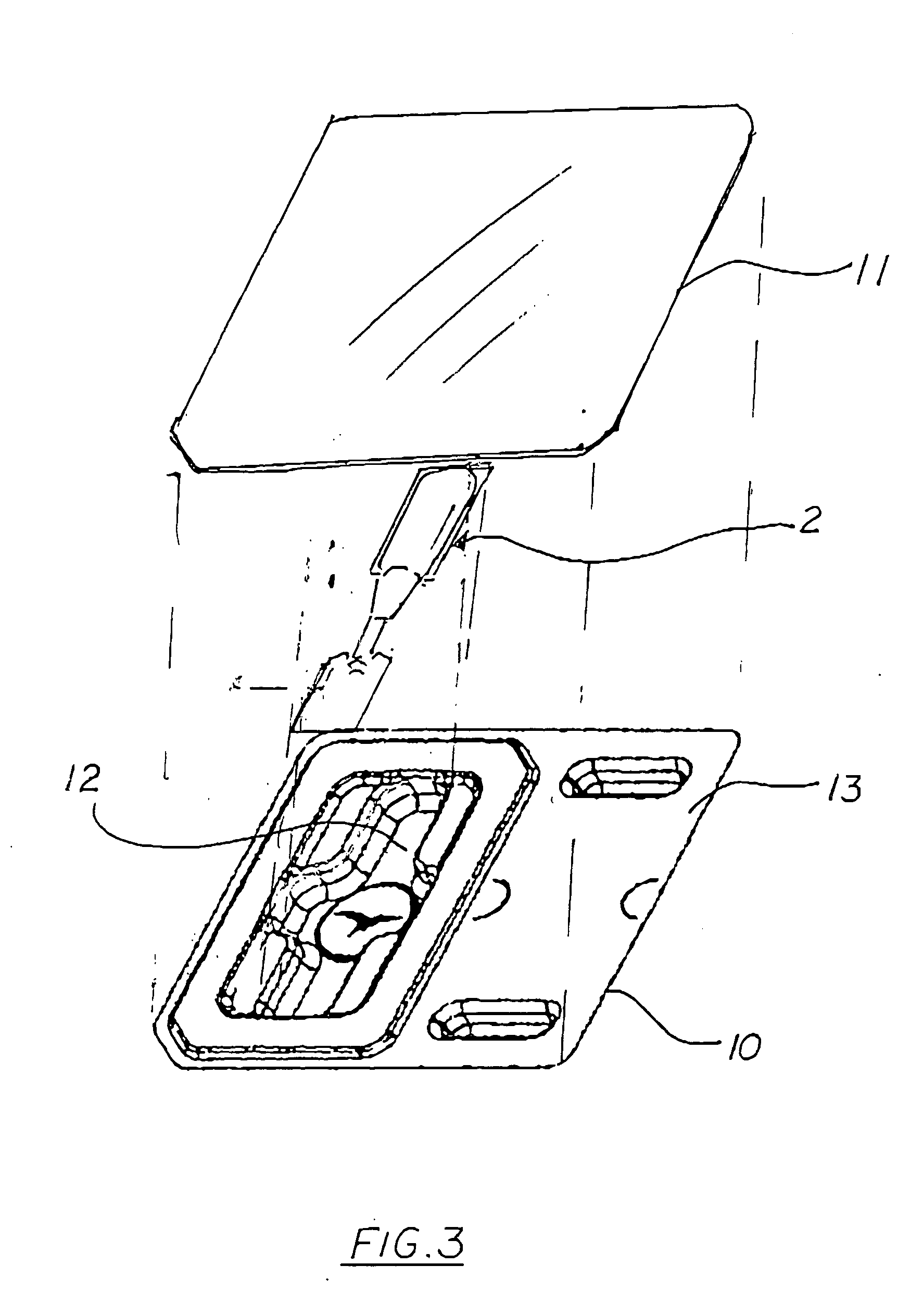

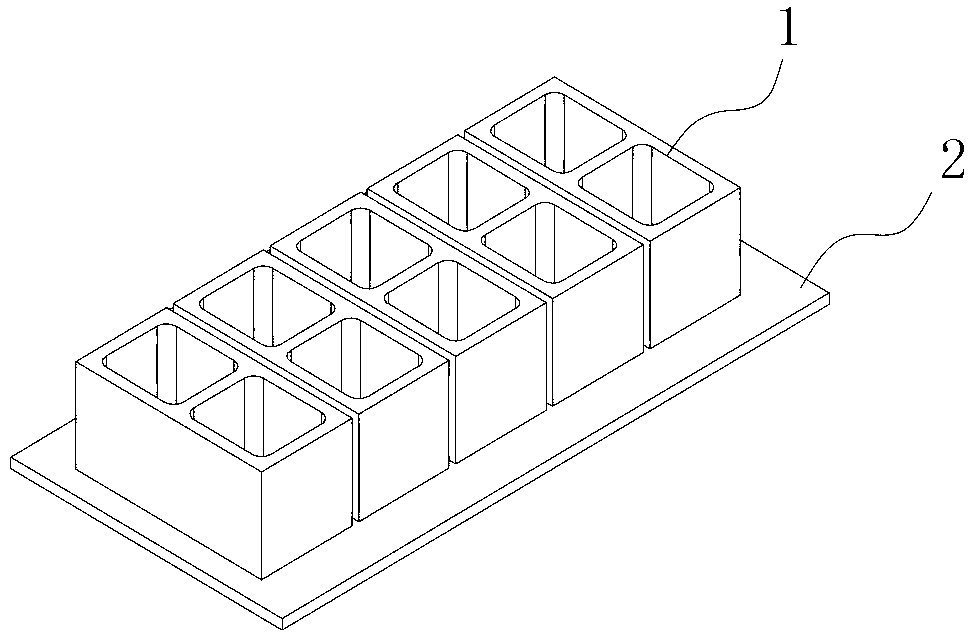

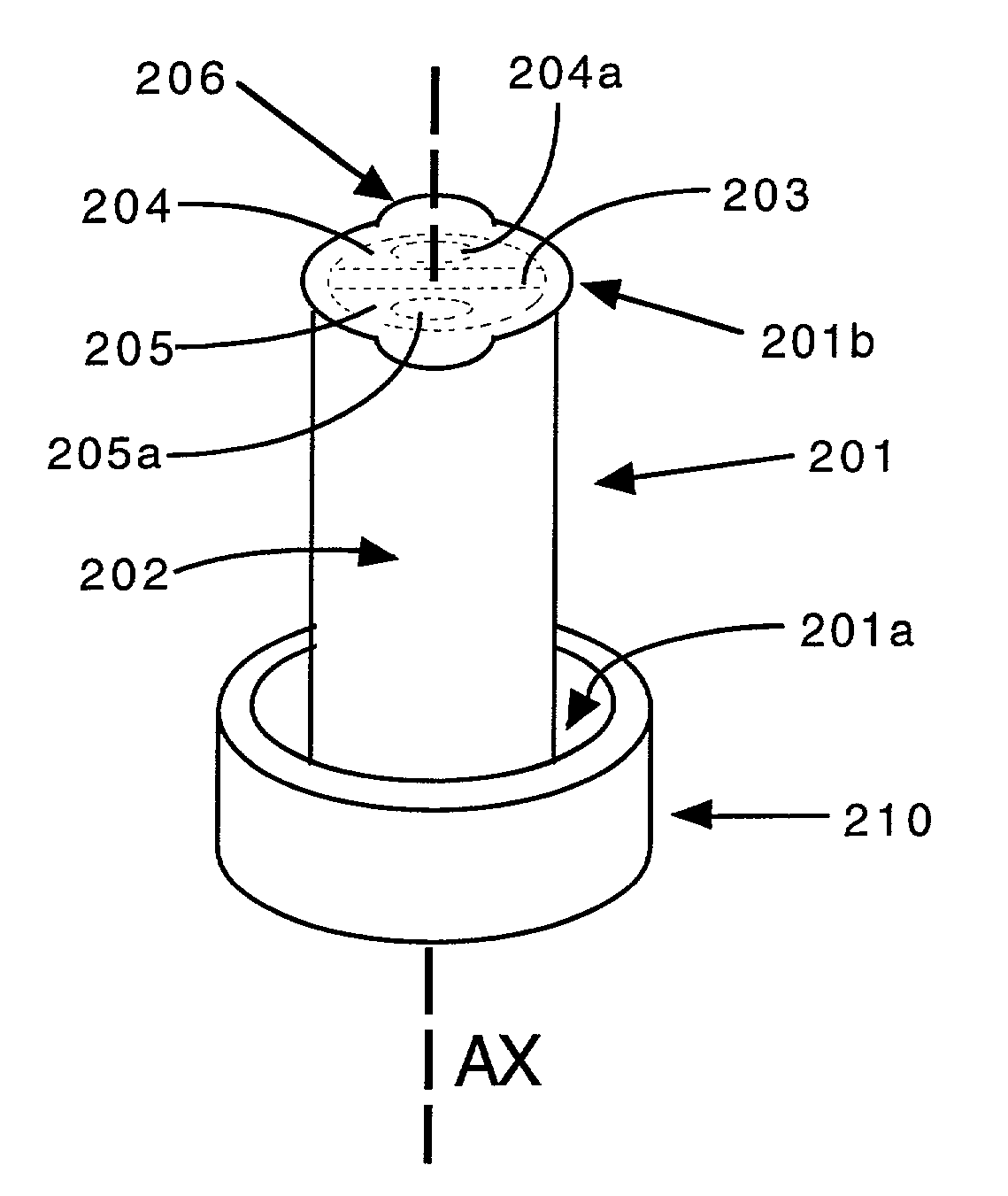

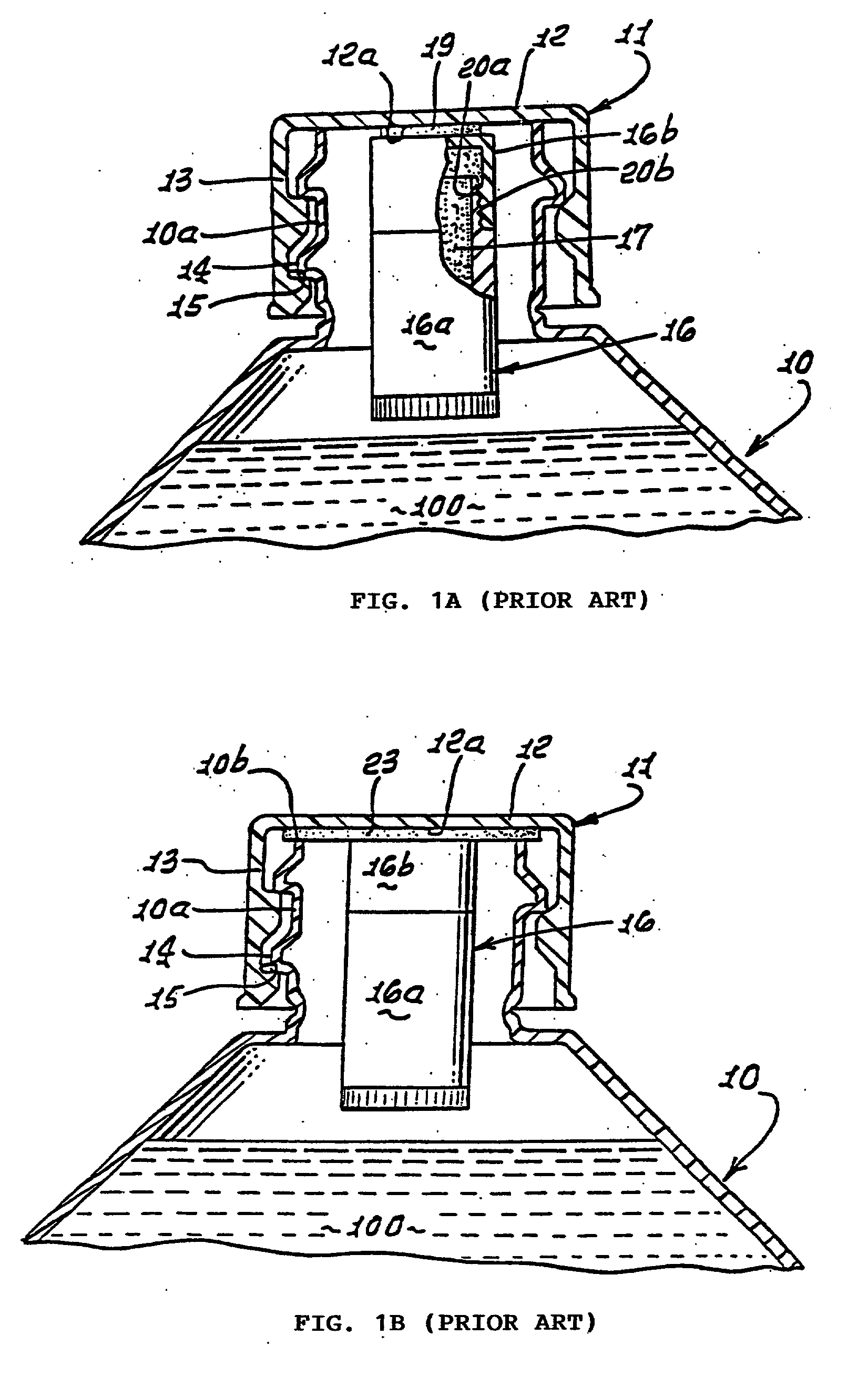

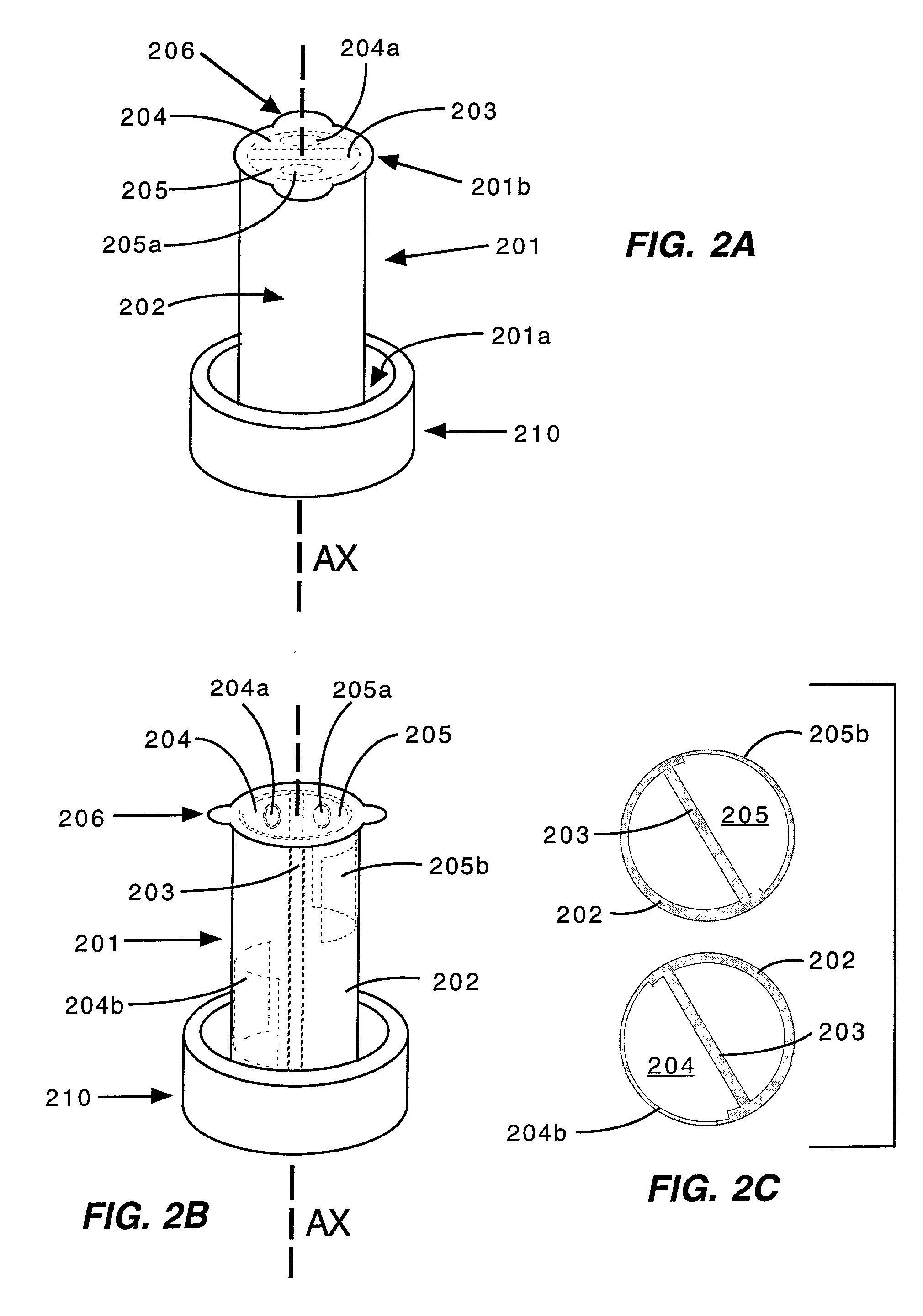

Device for maintaining separate ingredients in liquid food products

InactiveUS6263923B1Reduce manufacturing costEasy to useCapsLiquid fillingAdditive ingredientScrew thread

A device for maintaining ingredients separately within a container, of the type having a removable container cap applied on a neck with a central opening, has a sub-container body mounted in the container neck which is formed with a proximate end having screw threads which can be engaged with internal screw threads in the container neck for holding them securely together to allow the ingredients to be shaken out of the sub-container body and mixed with fluid in the container. The sub-container body can have inner divider walls forming multiple compartments with respective orifices for dispensing ingredients selectively from the compartments. The sub-container body may be sealed to the underside of the cap with a sealing film, or seated on the neck rim and held by the cap. In one version, the proximate end of the sub-container body has a protruding shape with inclined walls for guiding it into the neck opening. In other versions, the sub-container body is formed integrally with the container cap, or is formed as an annular ring shape carried between inner and outer flanges of the cap. These improved devices allow viscous or powdered ingredients to be mixed by shaking with fluid in the container without risk of spilling or splashing outside the container.

Owner:CASTILLO JAMES A

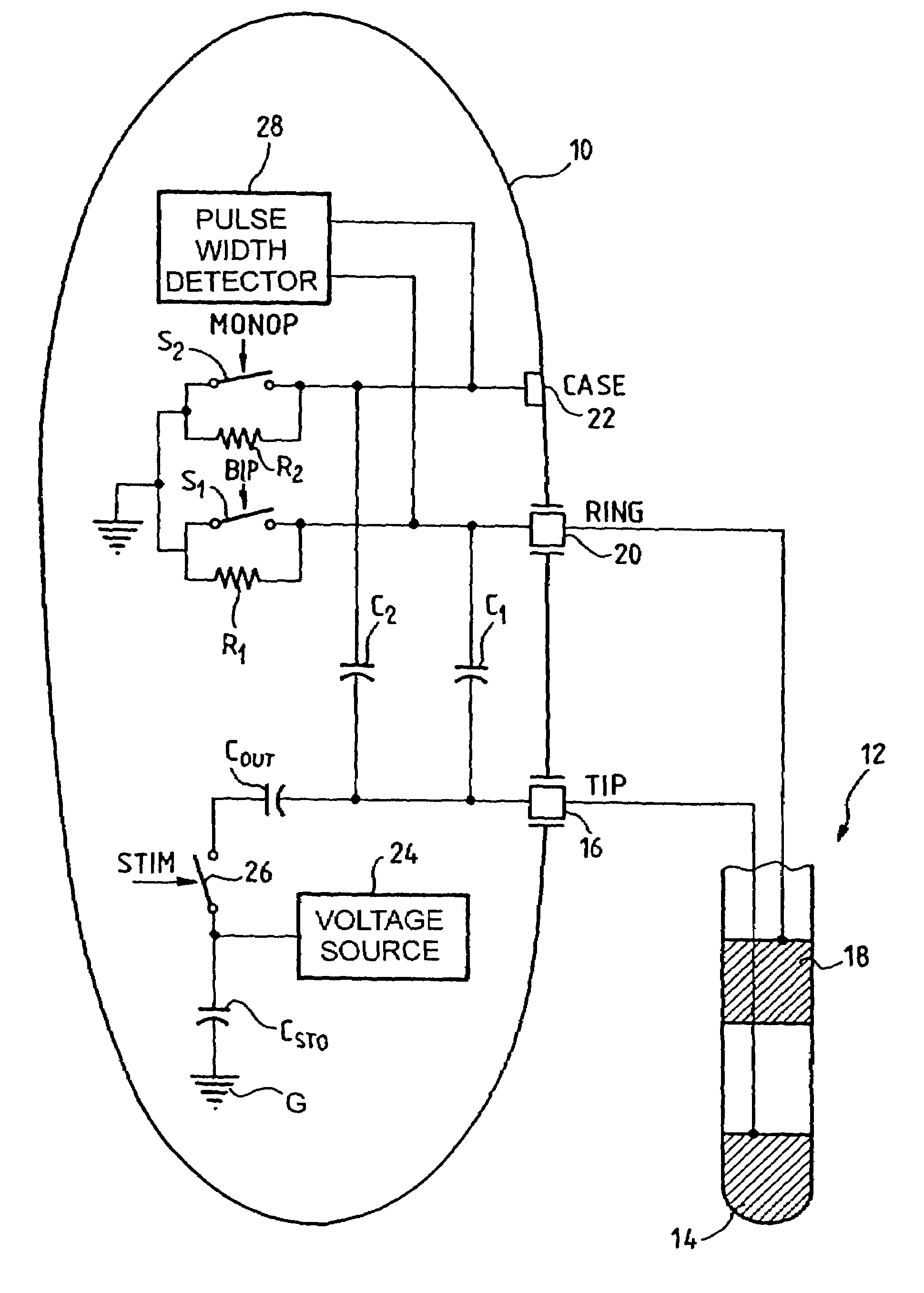

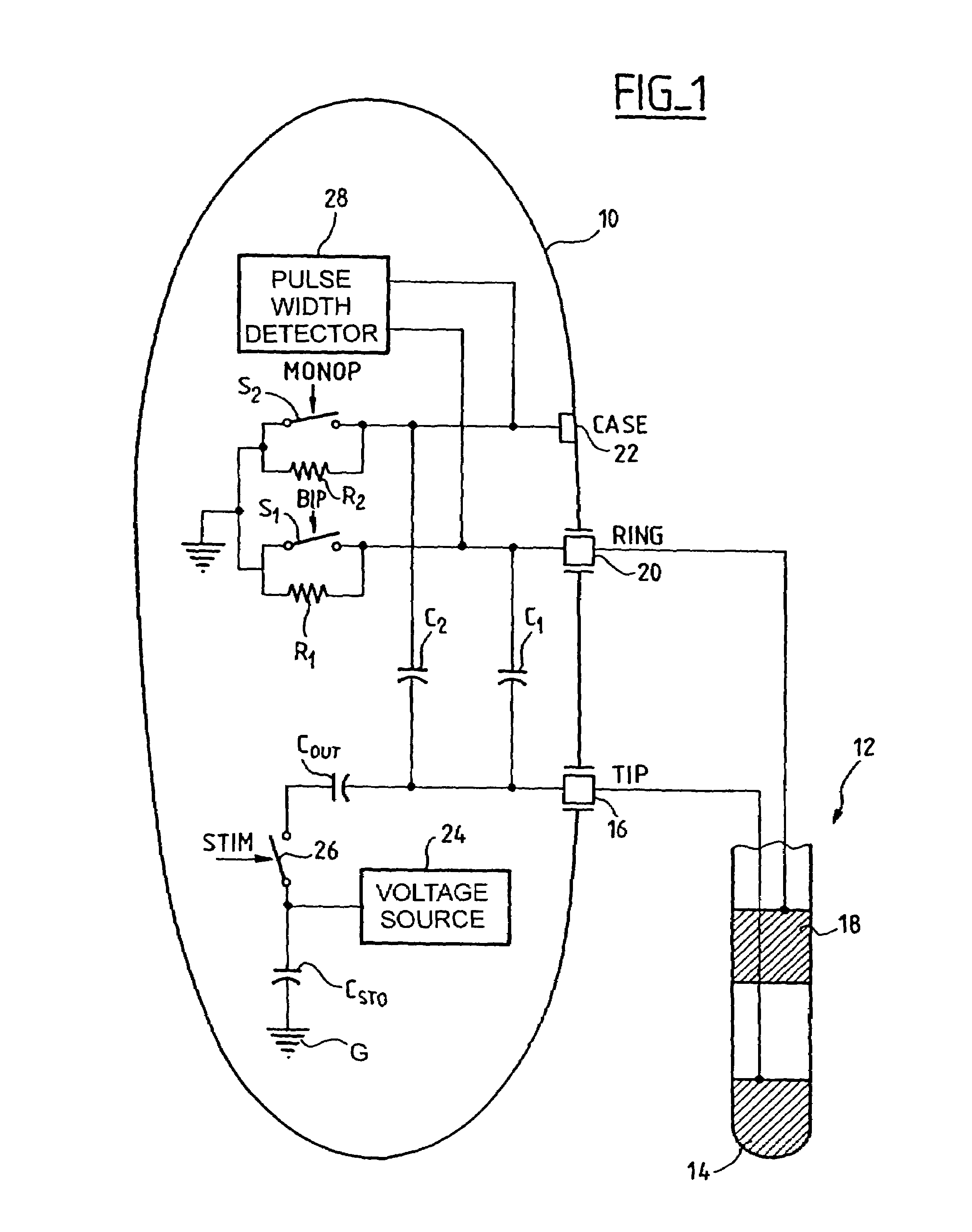

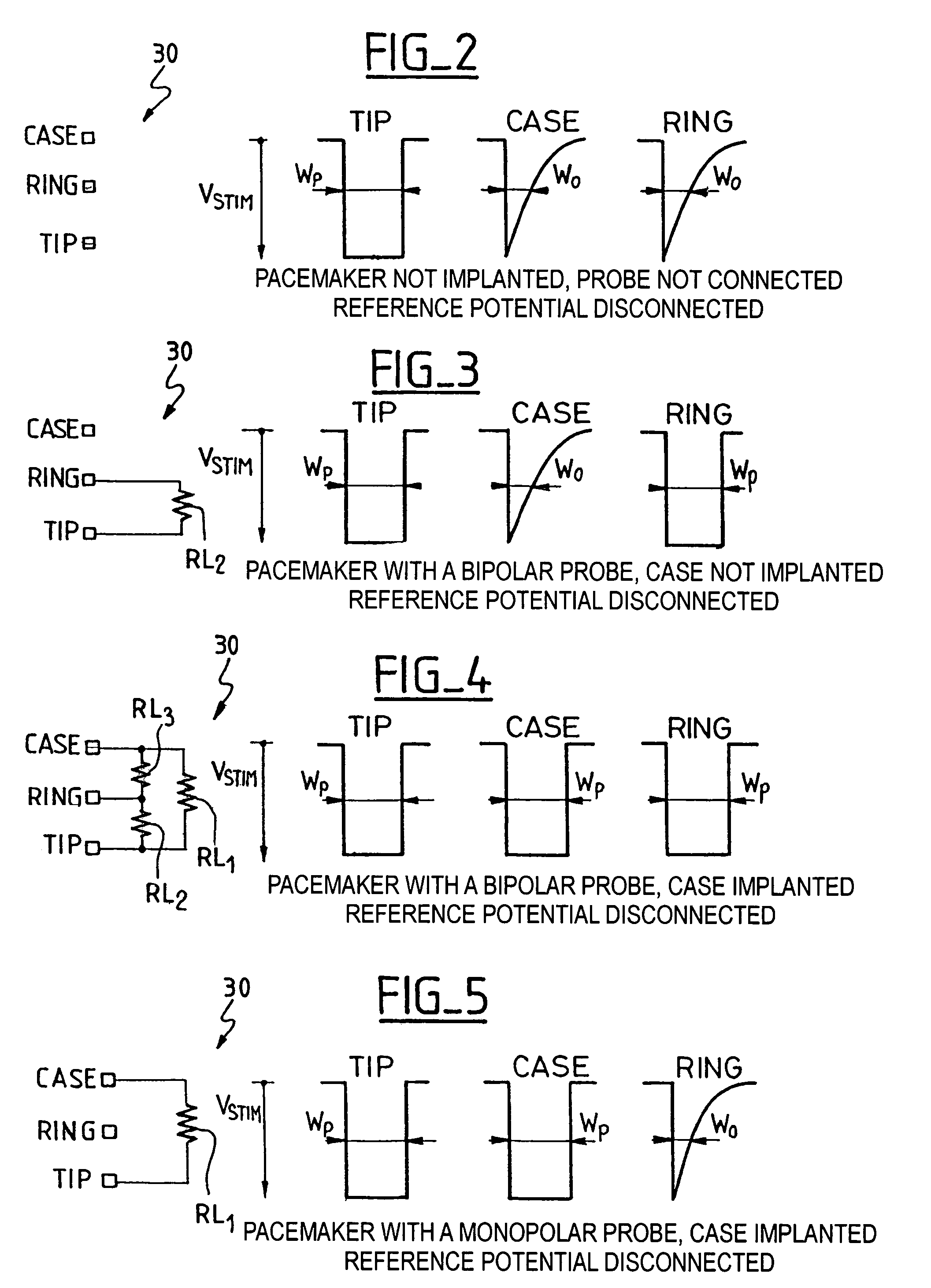

Determining the presence and type of probe associated with an active implantable medical device, in particular a cardiac pacemaker

ActiveUS7113827B2Increase energy levelAvoid handlingElectrotherapyDiagnosticsCardiac pacemaker electrodeCardiac pacemaker

Determining the presence and type of a probe associated with an active implantatable medical device, in particular a cardiac pacemaker and devices having similar pacemaker functionality. This device includes circuits for producing monopolar or bipolar stimulation pulses, selectively with or without disconnection of a connection (S1, S2) to a reference potential, and a circuit for sensing a pulse signal produced by the variation of potential induced on one and / or the other of terminals (RING, TIP) and / or on the metallic case (CASE) in response to an application of stimulation pulses. The device operates to analyze a characteristic of the shape (28), in particular the pulse width, and to deliver an indicator representative of the presence or the absence of a probe. The device also can selectively modify at least one operating parameter of the device according to the delivered indicator.

Owner:SORIN CRM

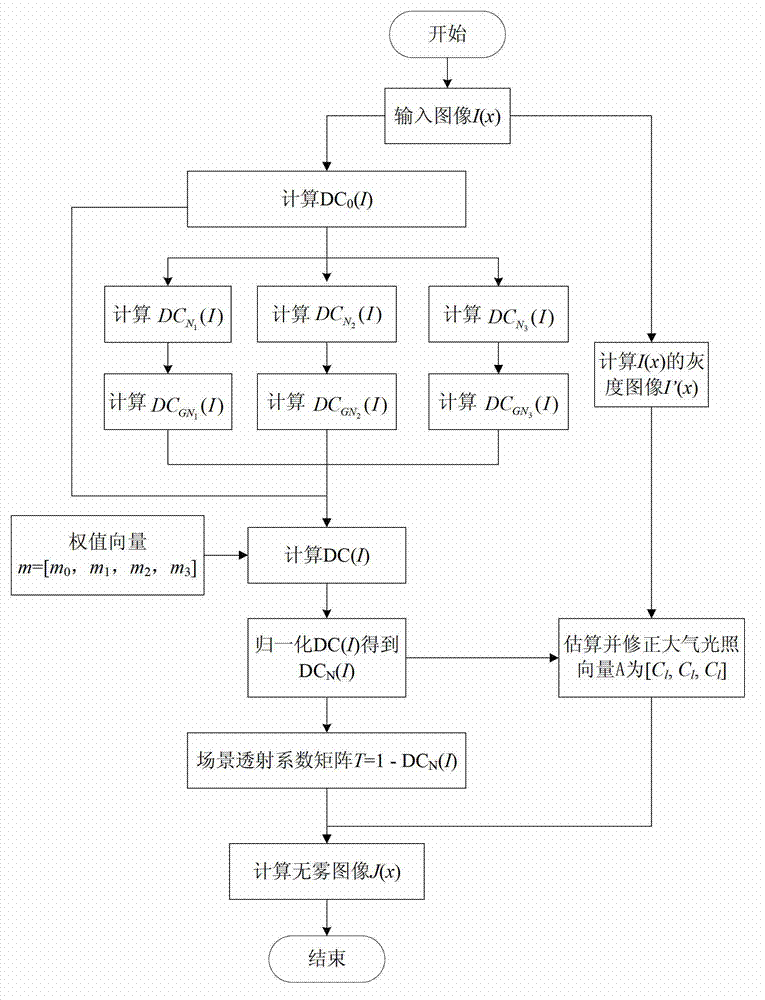

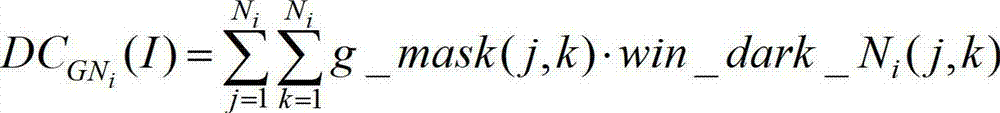

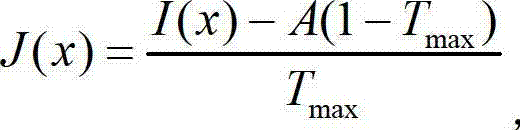

Image defogging method based on dark channel information

ActiveCN102968772AReduce computational complexityAvoid handlingImage enhancementPattern recognitionTransmission coefficient

The invention discloses an image defogging method based on dark channel information, belonging to the technical field of image treatment and computer vision. The method disclosed by the invention comprises the following steps of: calculating the minimum value of each pixel of each color channel of an input image via a minimum value filter; then calculating dark channel counting values of the image under different scale parameters and carrying out Gaussian smoothing filter on the dark channel counting value corresponding to each scale parameter; distributing different weight values to the filtered dark channel counting values according to different scale parameters; and carrying out weighted optimization on the dark channel counting values and calculating a transmission coefficient of the scene so that the defogging of the image is realized. The application of the invention can avoid complex soft matting optimization steps and computing complexity of the defogging; the image with high quality can be obtained after the defogging; and the requirement on real-time treatment application can be met.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

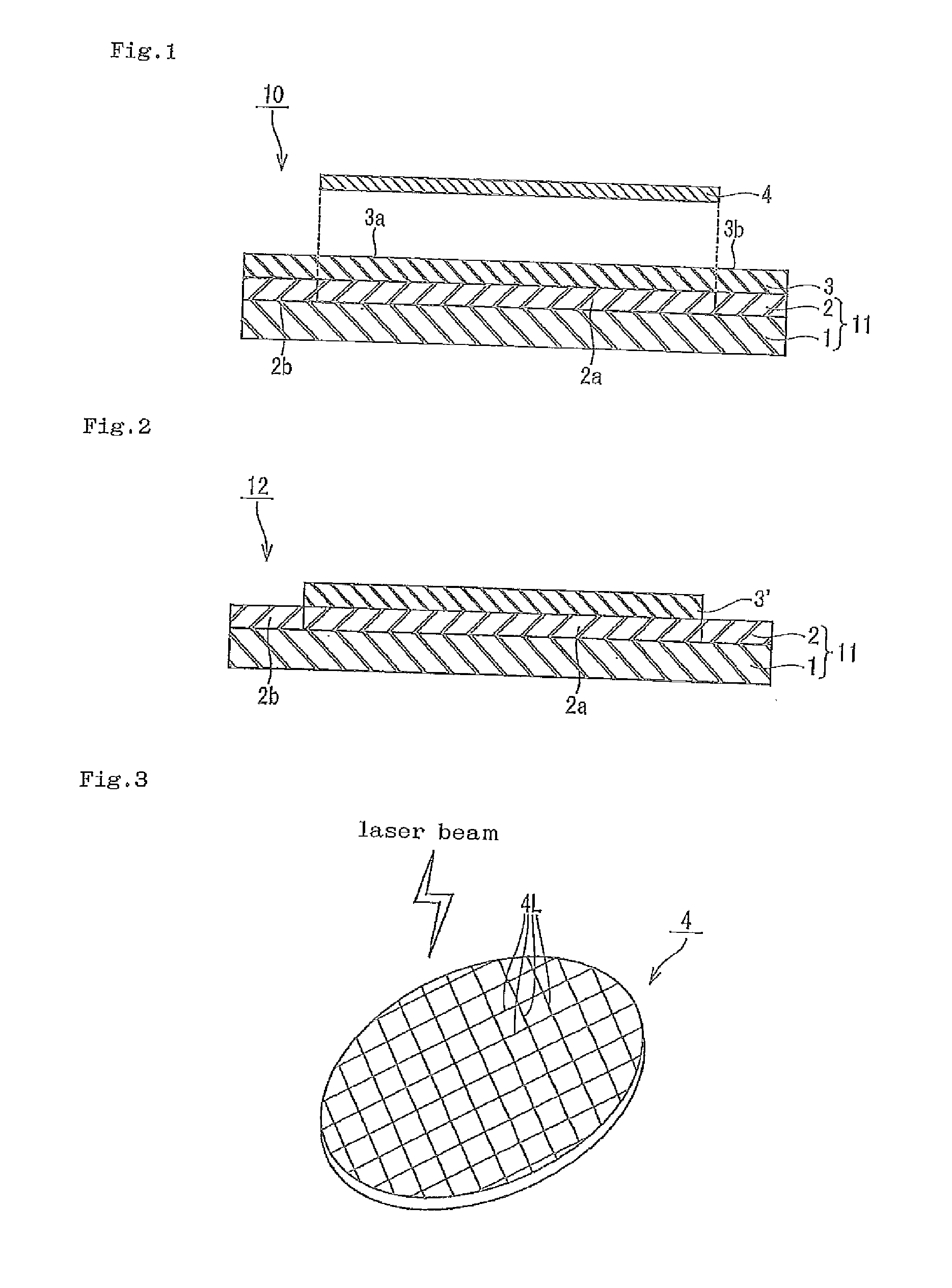

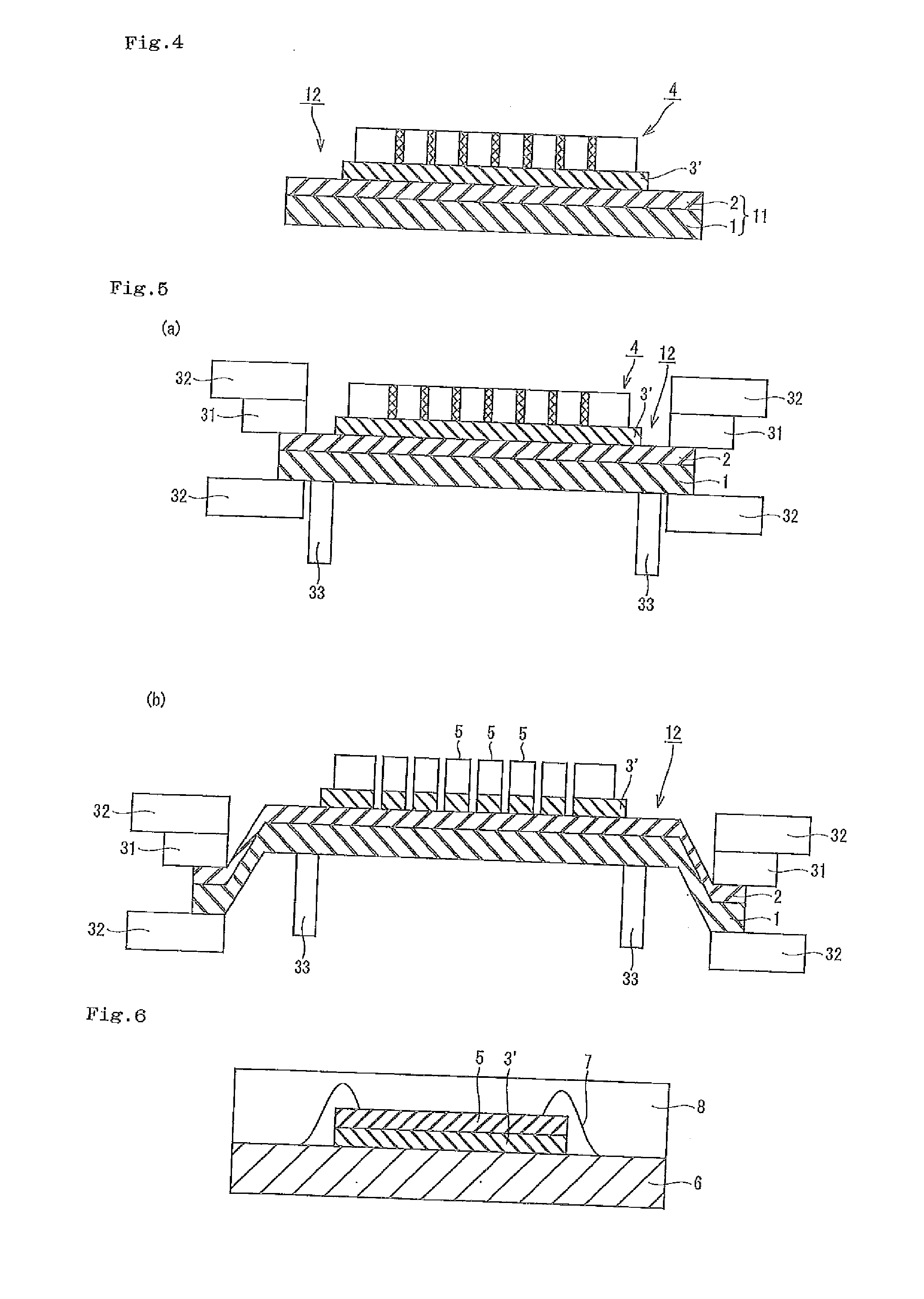

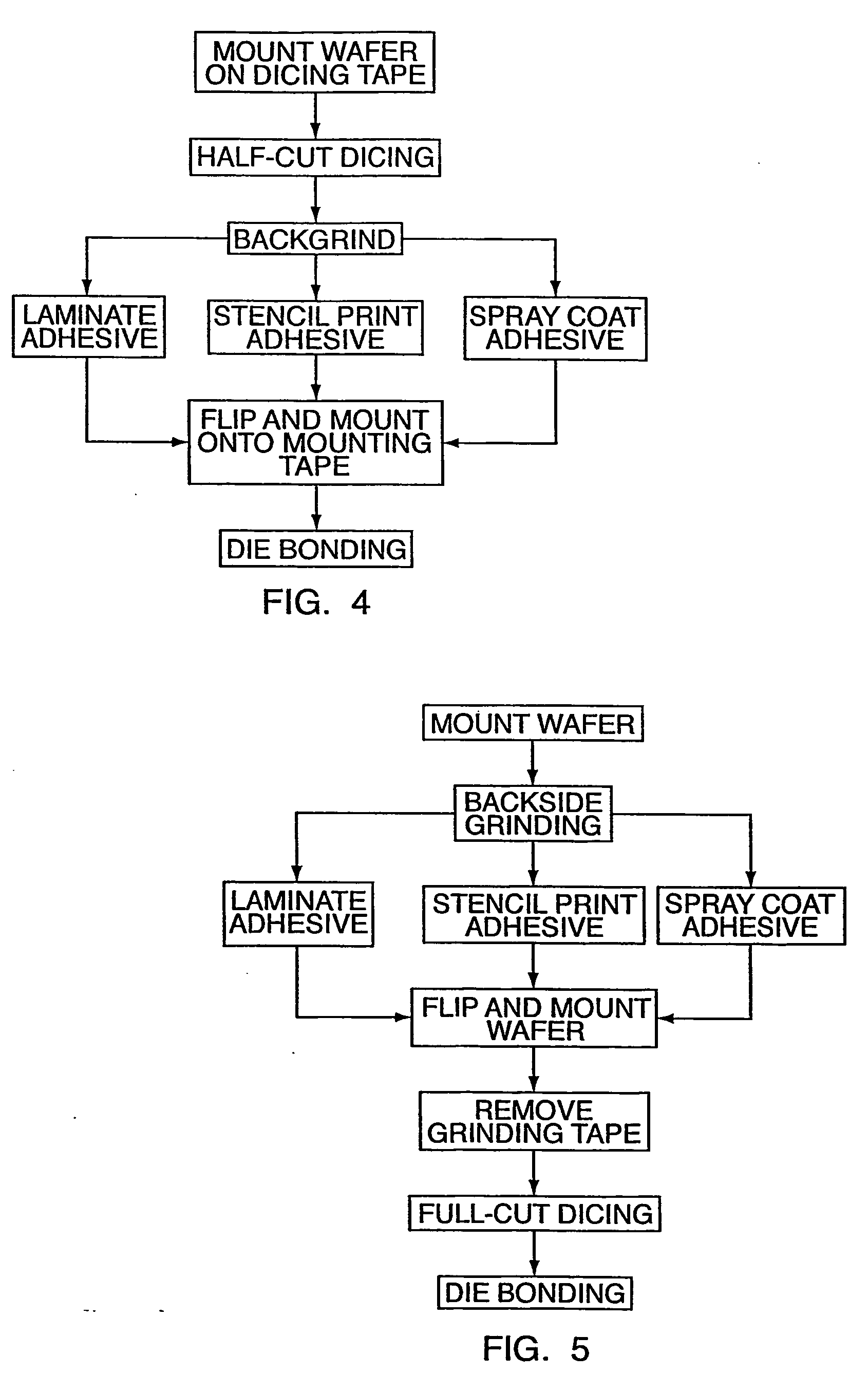

Dicing die bond film

InactiveUS20120061805A1Good tackinessImprove workabilitySemiconductor/solid-state device detailsSolid-state devicesDie bondingPolymer chemistry

The present invention provides a dicing die bond film in which peeling electrification hardly occurs and which has good tackiness and workability. The dicing die bond film of the present invention is a dicing die bond film including a dicing film and a thermosetting type die bond film provided thereon, wherein the thermosetting type die bond film contains conductive particles, the volume resistivity of the thermosetting type die bond film is 1×10−6 Ω·cm or more and 1×10−3 Ω·cm or less, and the tensile storage modulus of the thermosetting type die bond film at −20° C. before thermal curing is 0.1 to 10 GPa.

Owner:NITTO DENKO CORP

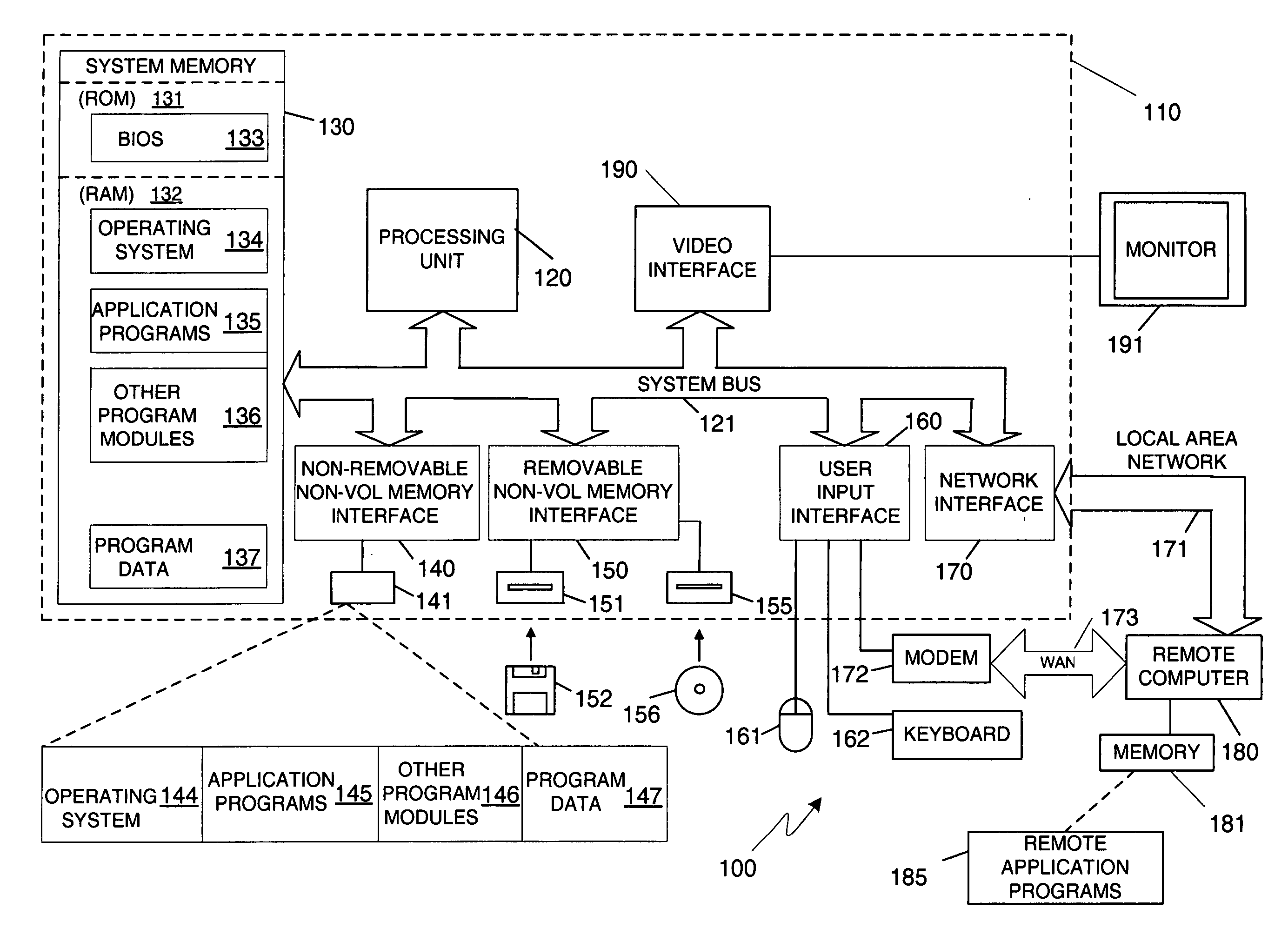

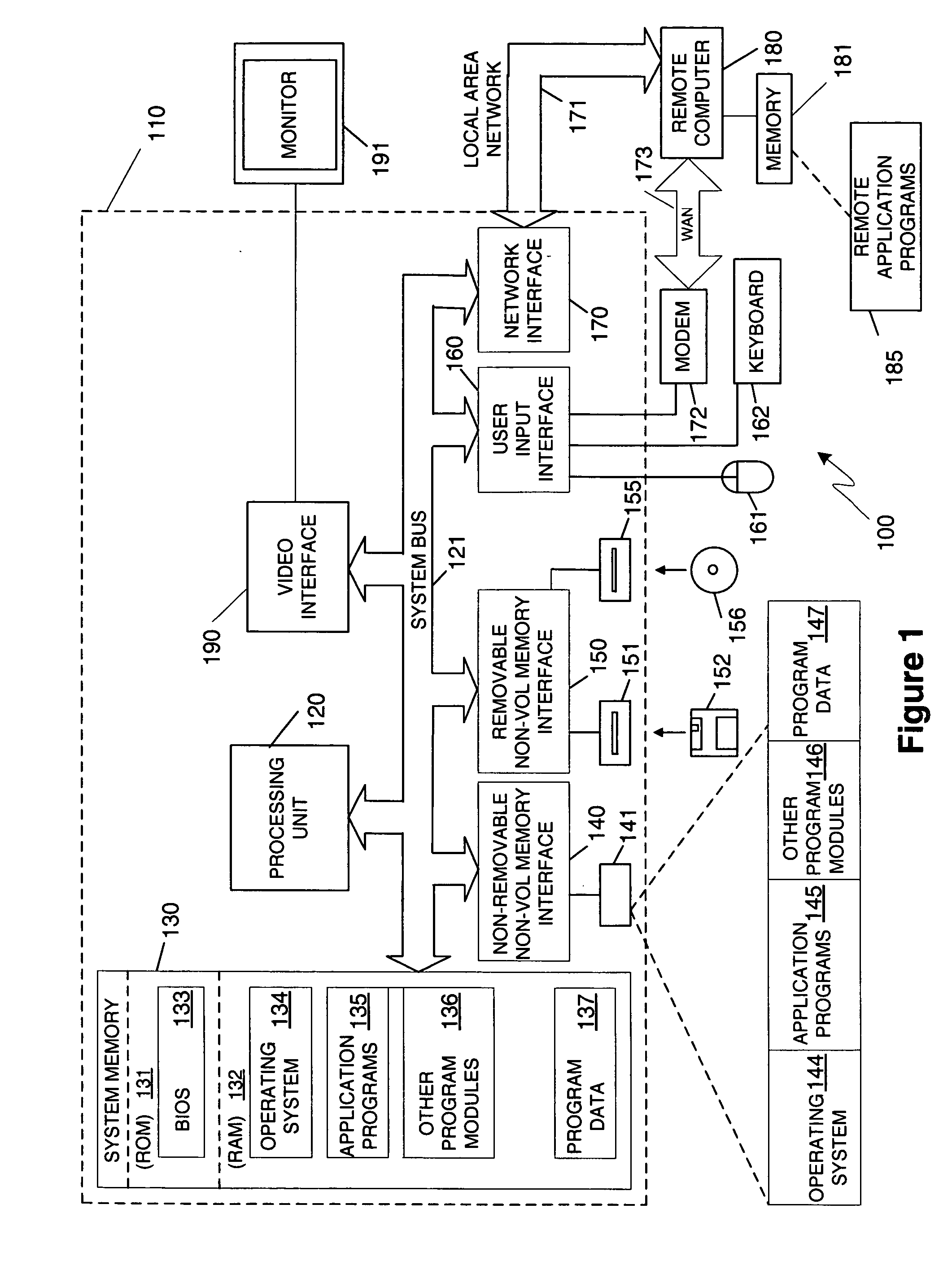

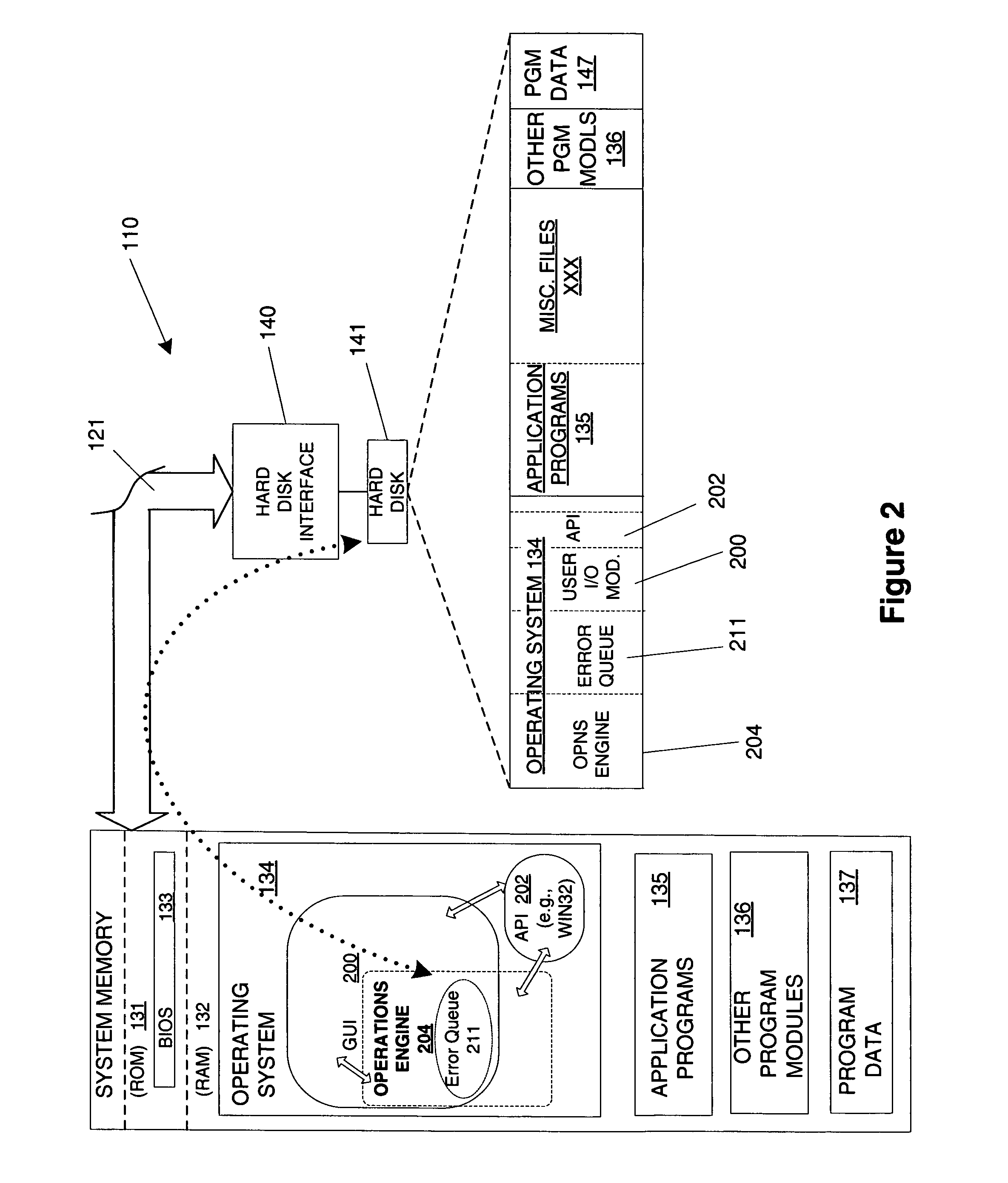

File handling for naming conflicts

ActiveUS20060271602A1Avoid operationImproper operationDigital data processing detailsFile/folder operationsNaming collisionDatabase

A file operations engine is provided that manages many user interactions with their files via a computer system. The operation engine may provide a user with the option to keep both files that have a file name conflict. It may further permit the user to rename a file involved with a file name conflict. The operations engine may also automatically rename one of the files of a file name conflict by appending a character to a root of the filename. The character may include the lowest integer available for the root in a destination for the files. The operations engine may provide the option to keep both files as part of a pre-calculation of potential errors for a requested operation. The operations engine may place file name conflicts in an error queue and permit the user to select an option to keep both files after the conflict is encountered.

Owner:MICROSOFT TECH LICENSING LLC

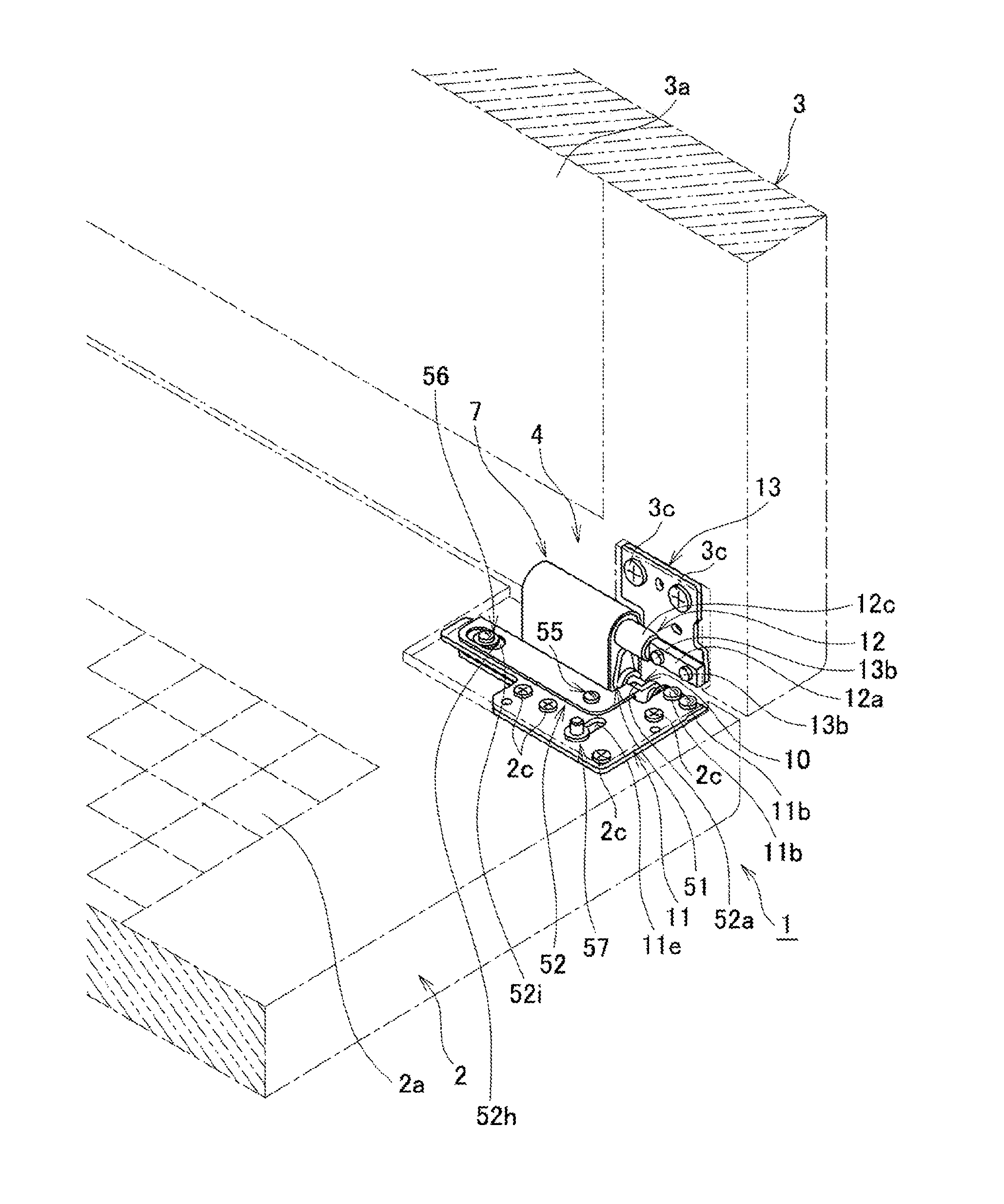

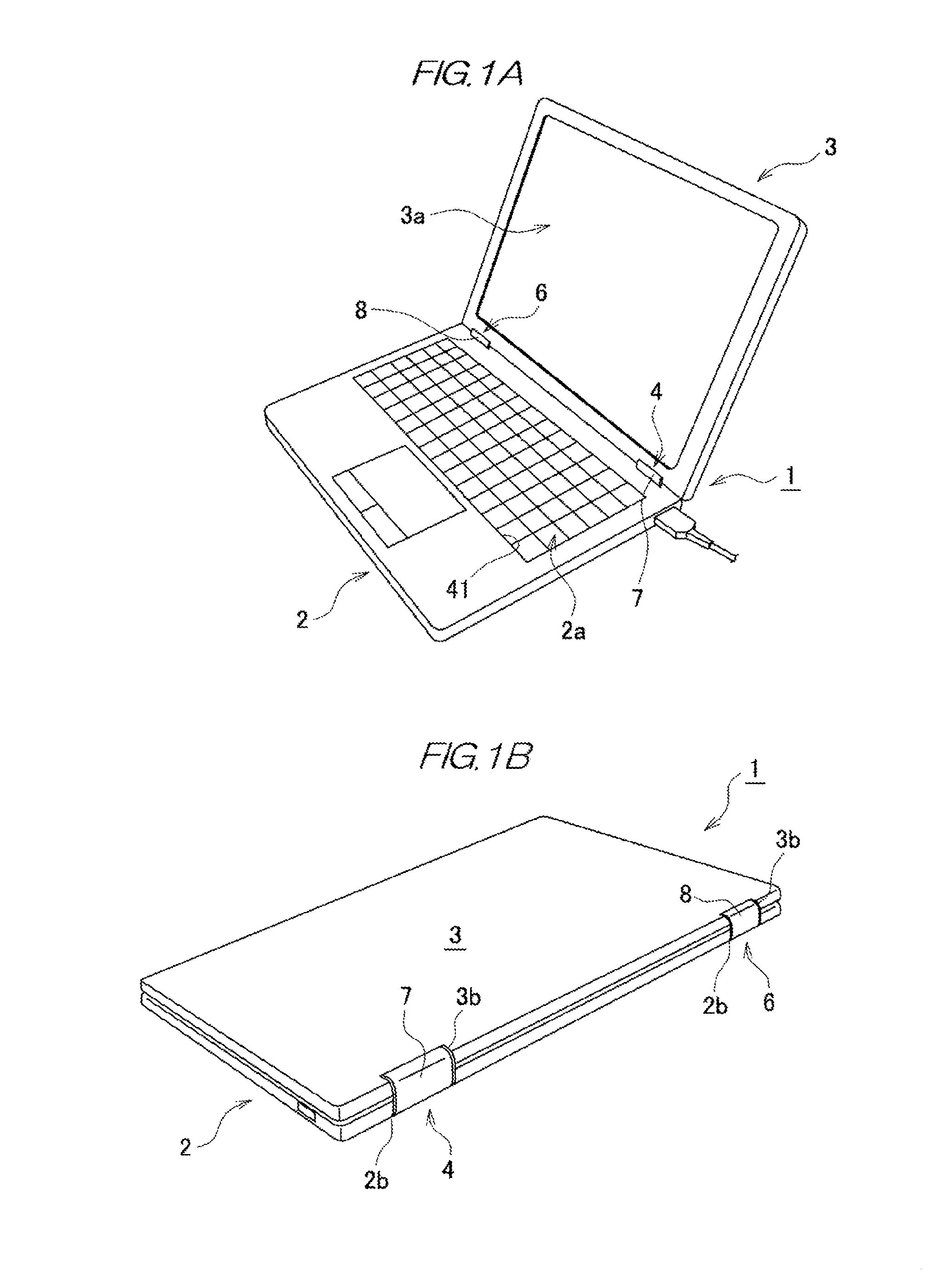

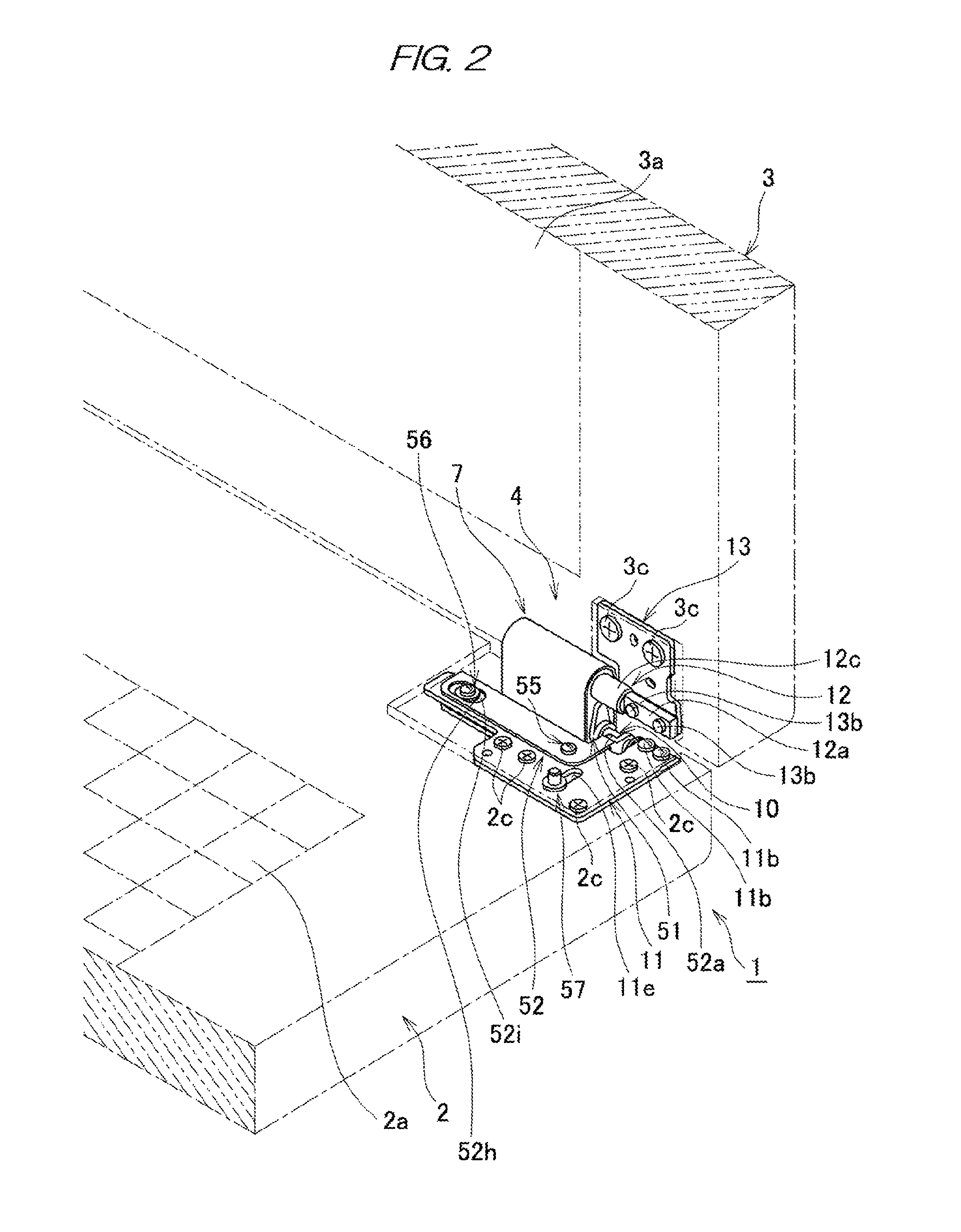

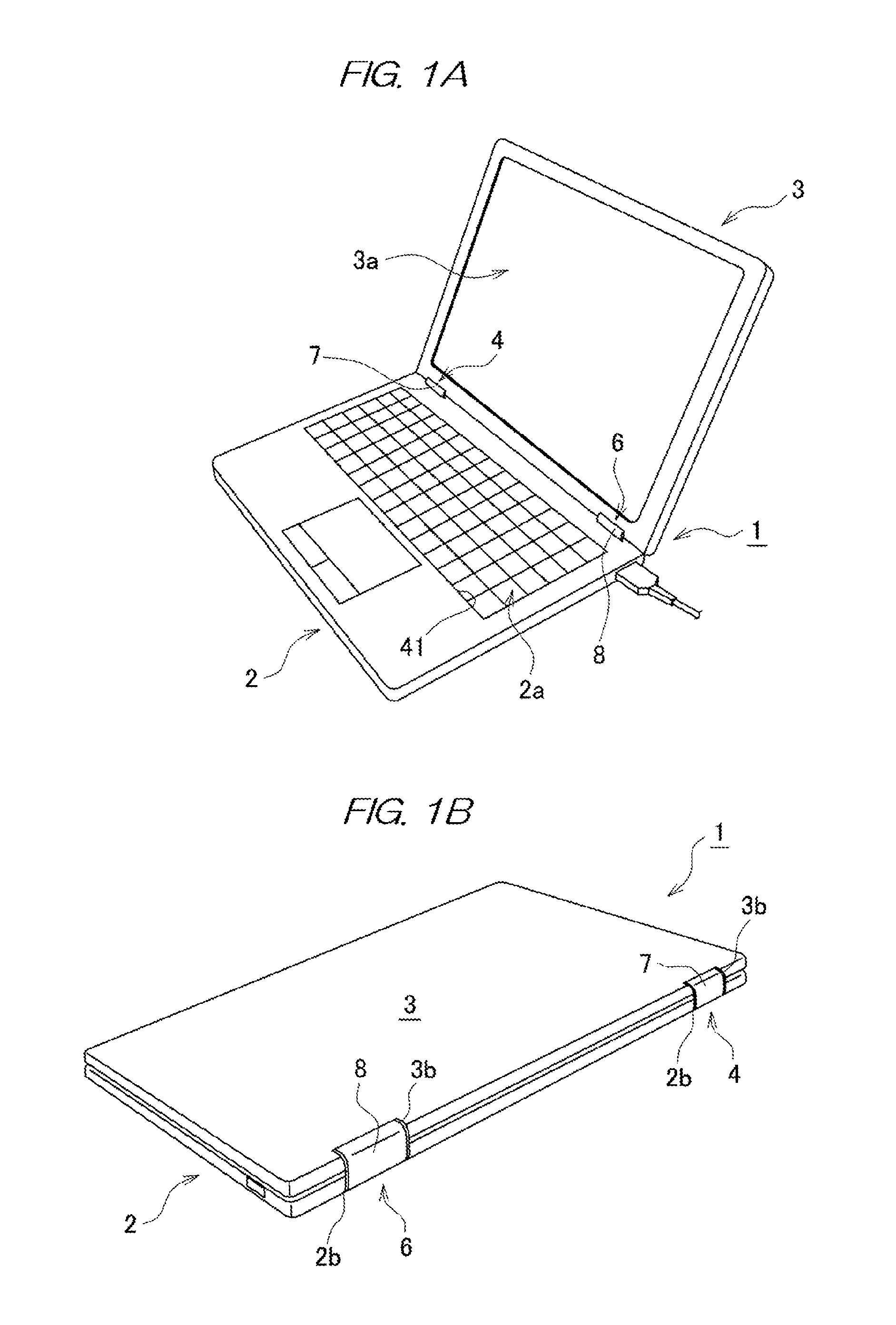

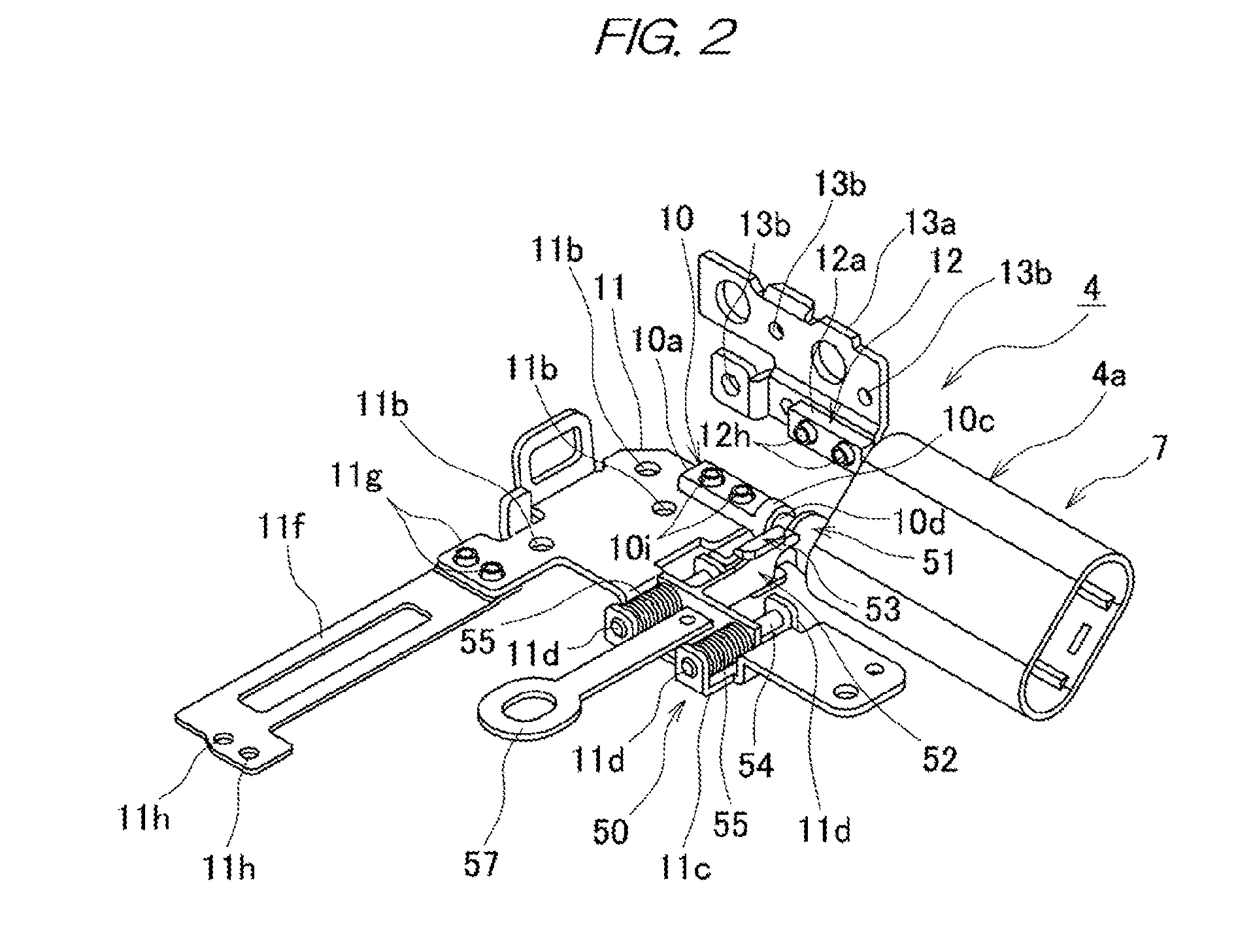

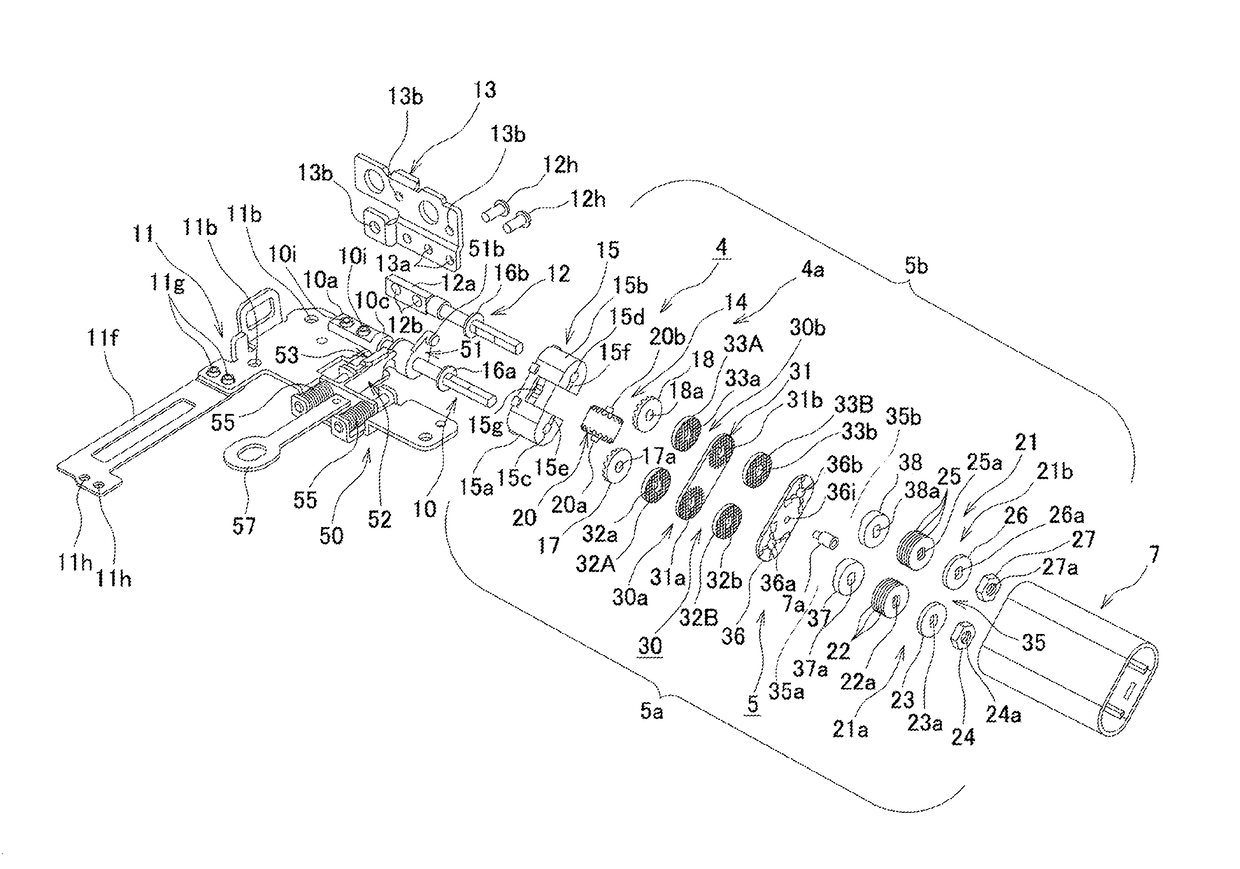

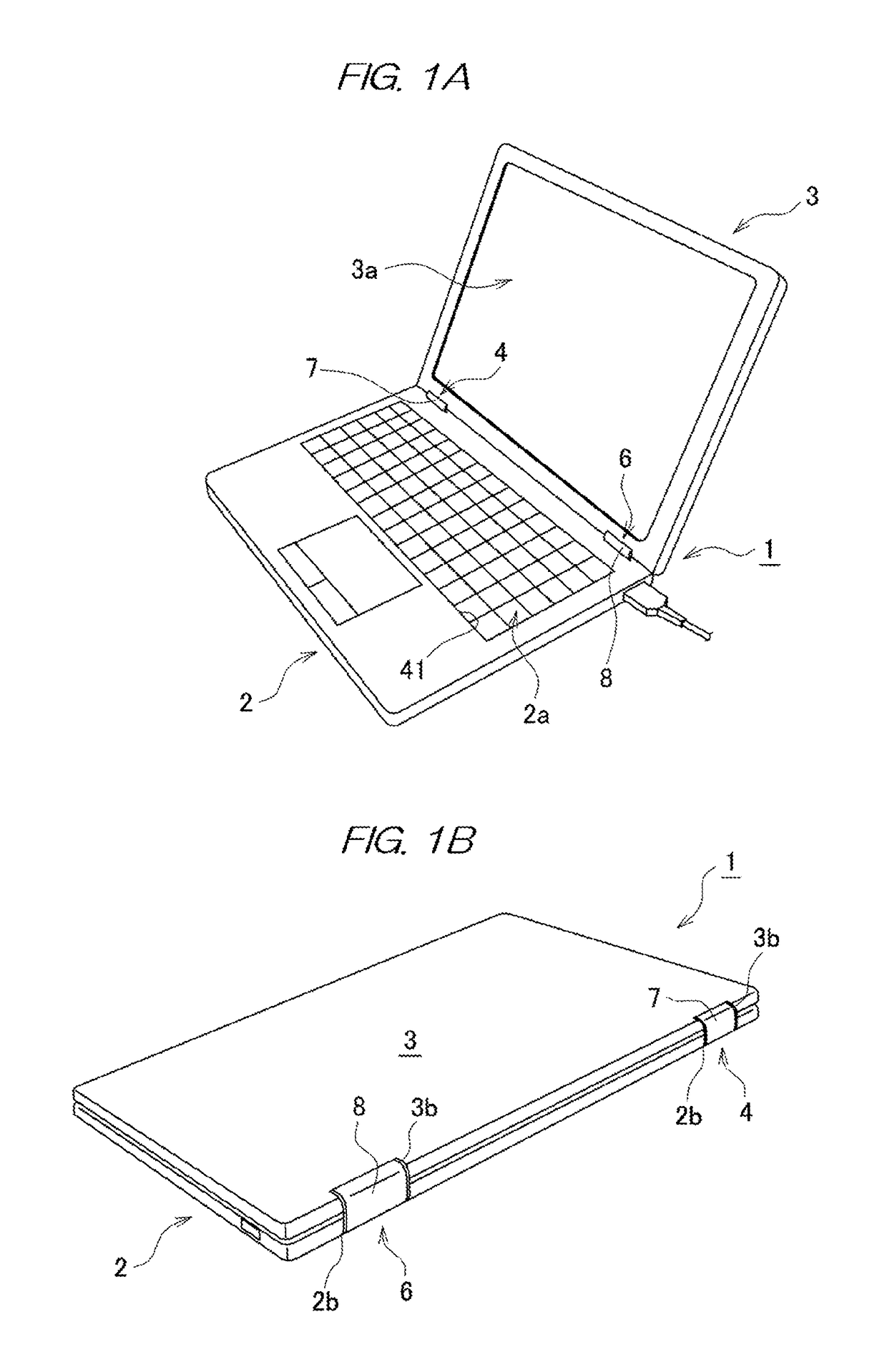

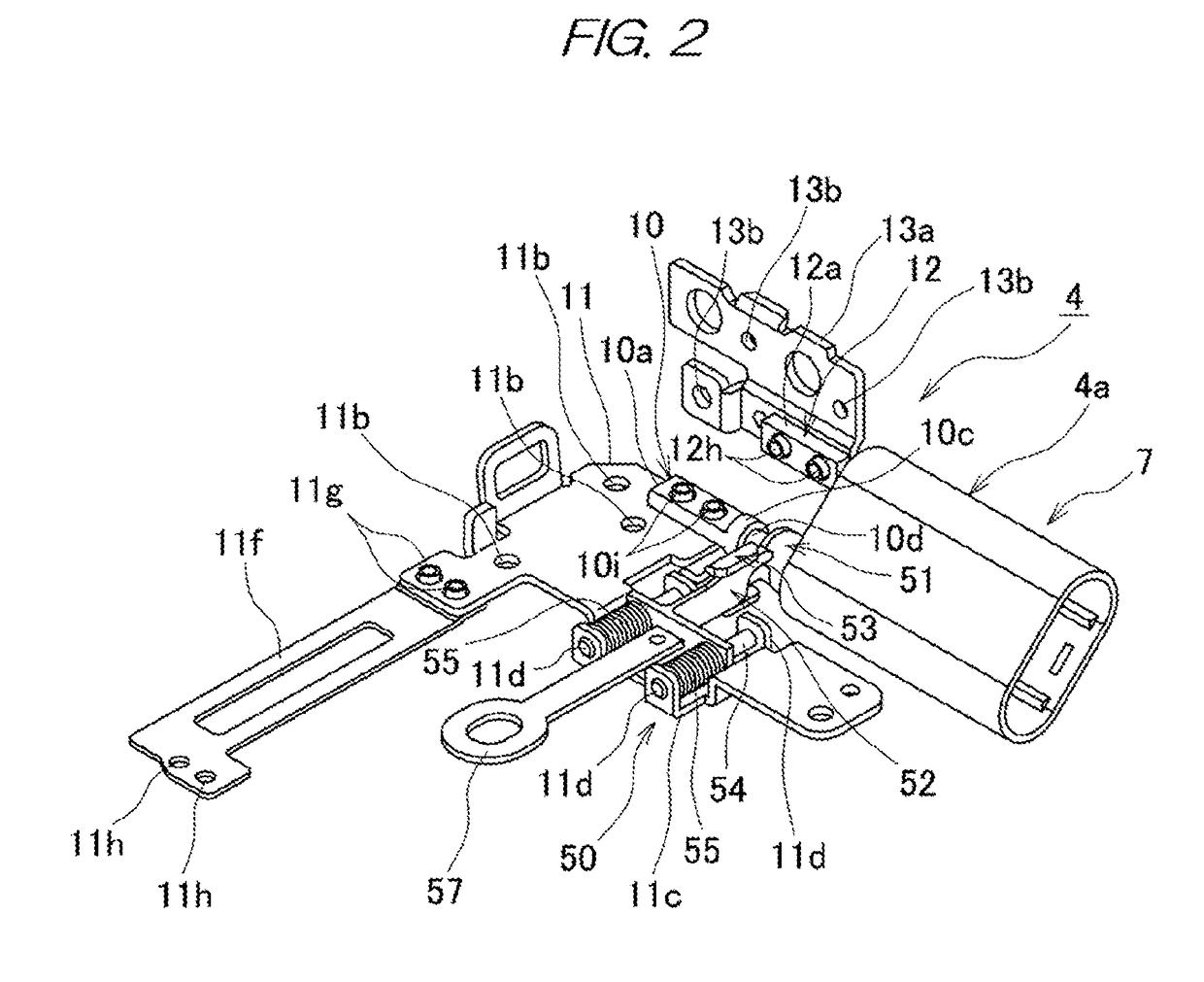

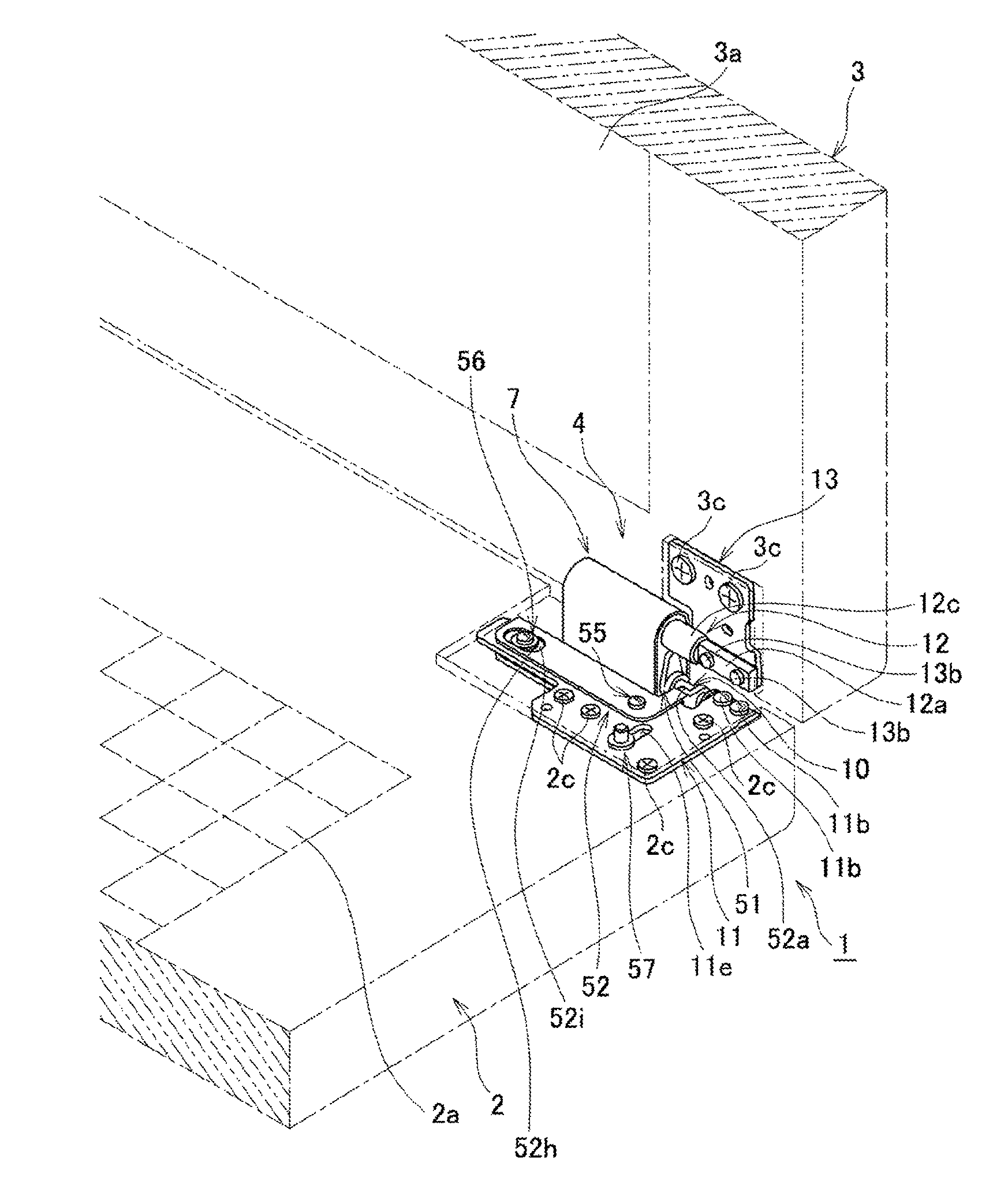

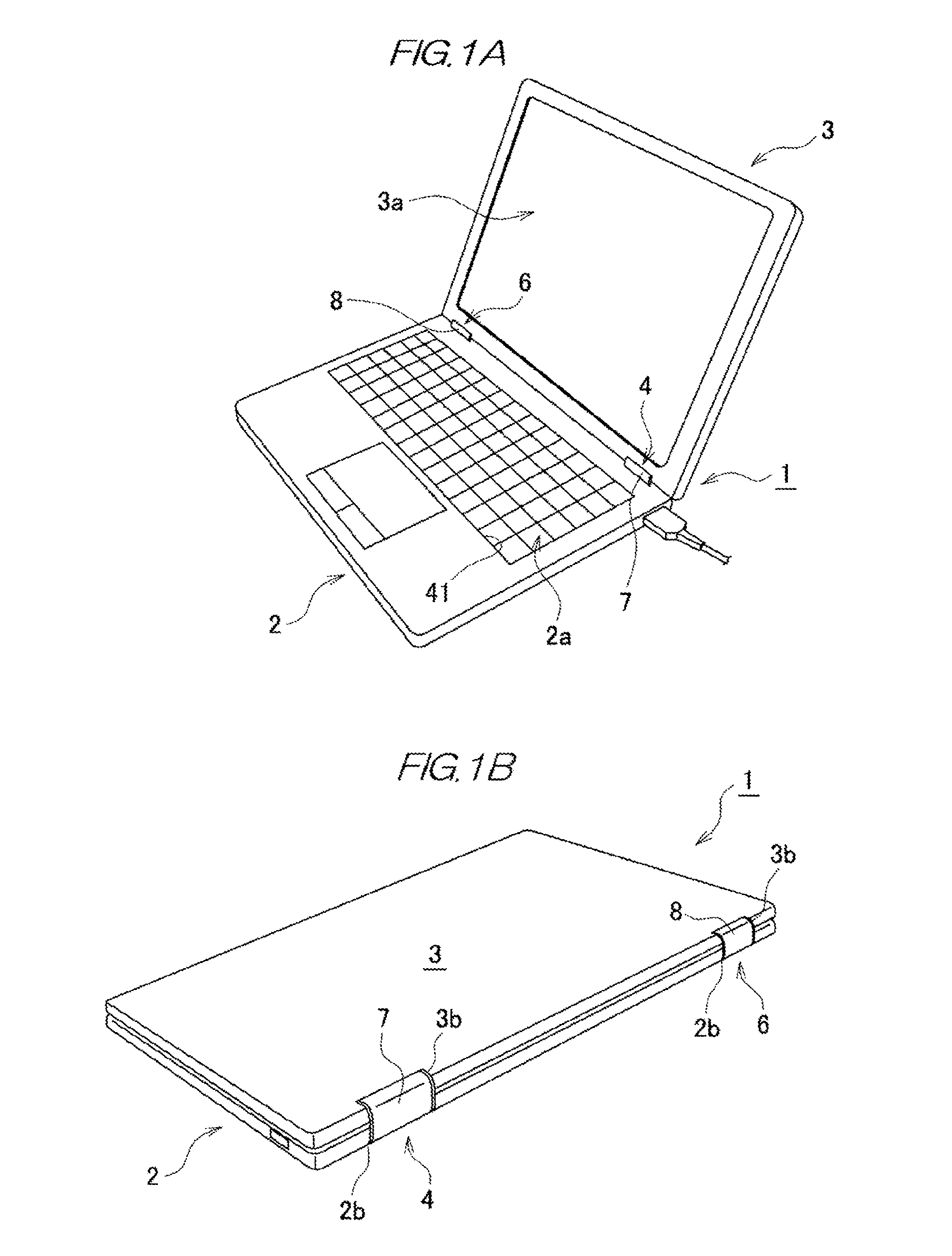

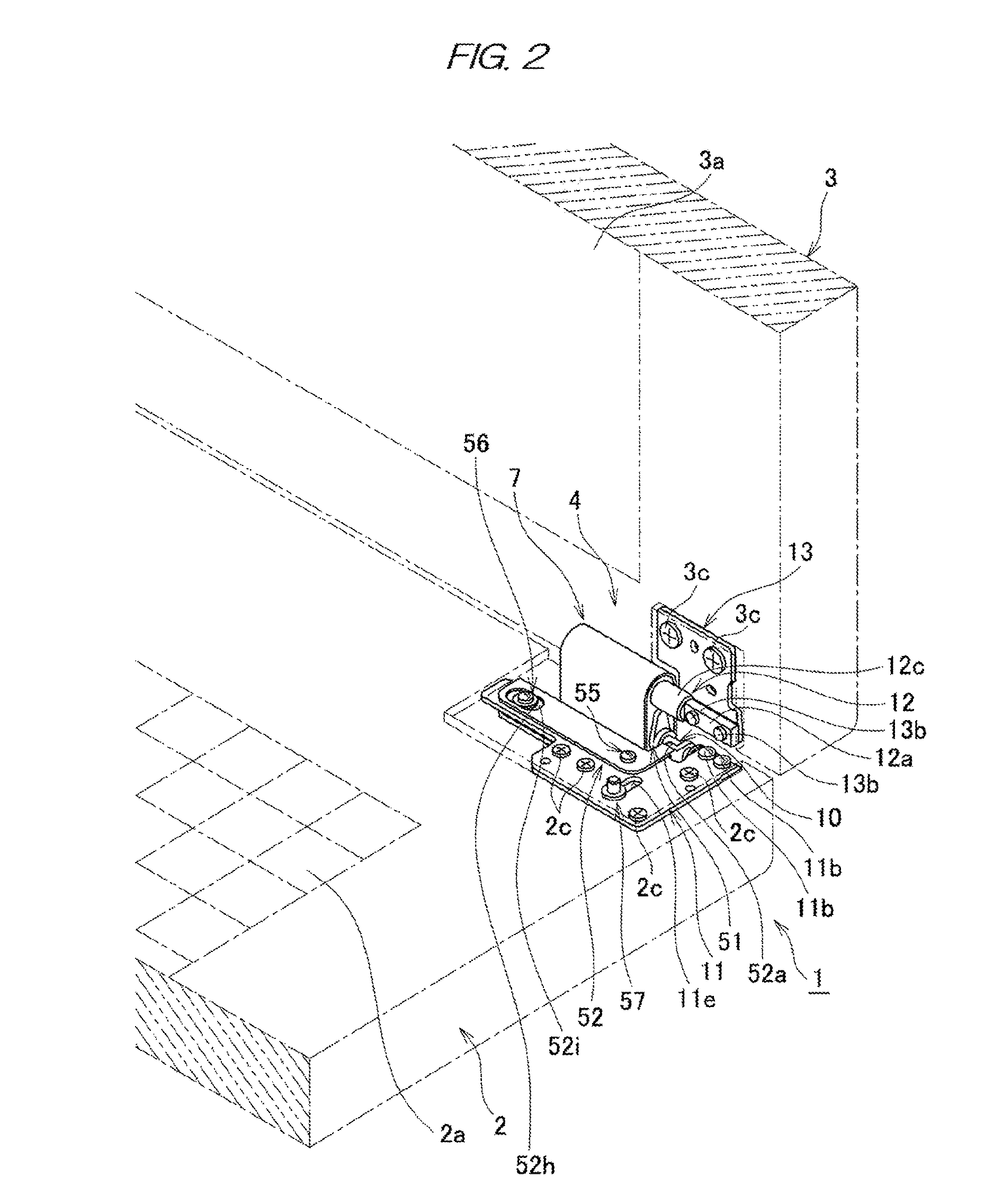

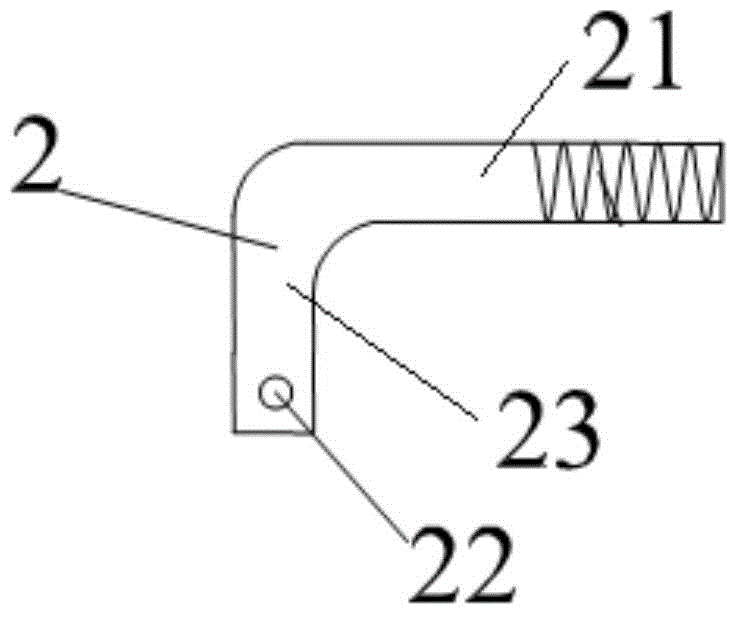

Biaxial hinge and electronic device using the same

ActiveUS20160201367A1Hinder handling and operationEnhance operabilityWing fastenersDetails for portable computersDual axisHinge angle

A biaxial hinge which allows a first casing having a keyboard and a second casing having a display to open and close 360 degrees relative to each other. The biaxial hinge ensures that the keyboard, rubber feet, and other parts can sink relative to the first casing. The biaxial hinge includes a biaxial hinge portion and an actuating mechanism. The biaxial hinge portion includes a rotation controlling unit. The actuating mechanism includes a fixed cam part, a slide cam part facing the fixed cam part, and a link part.

Owner:KEM HONGKONG

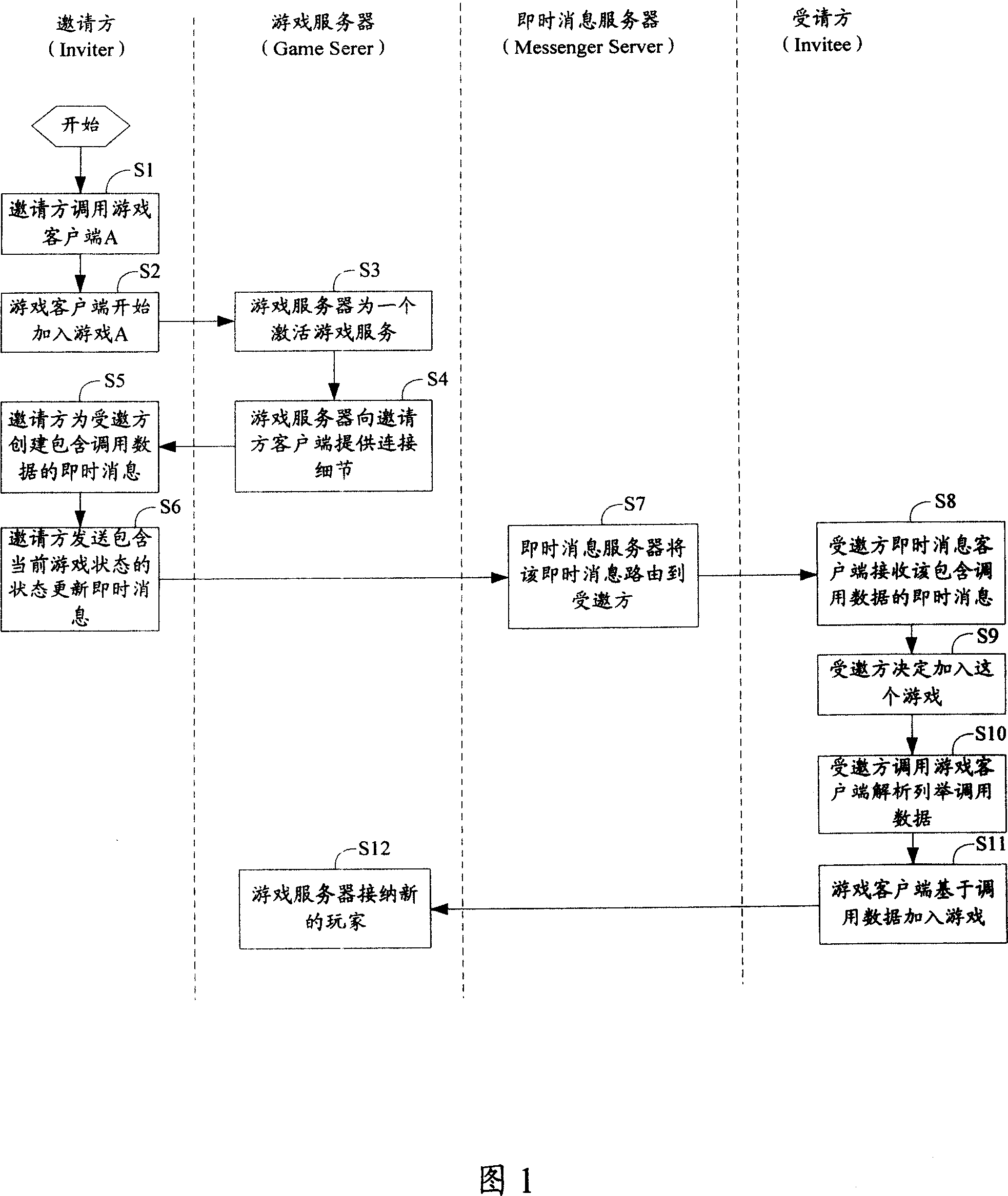

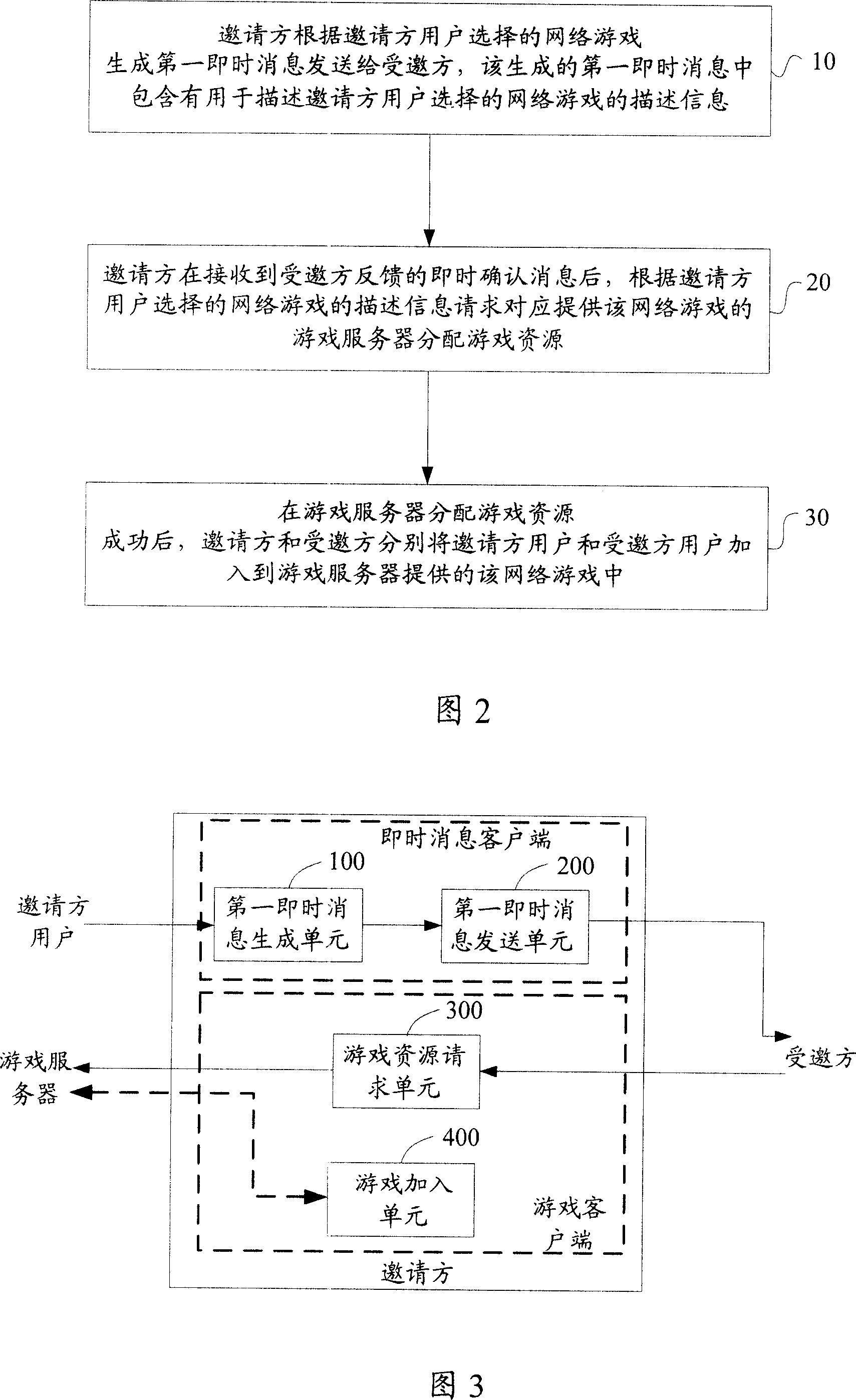

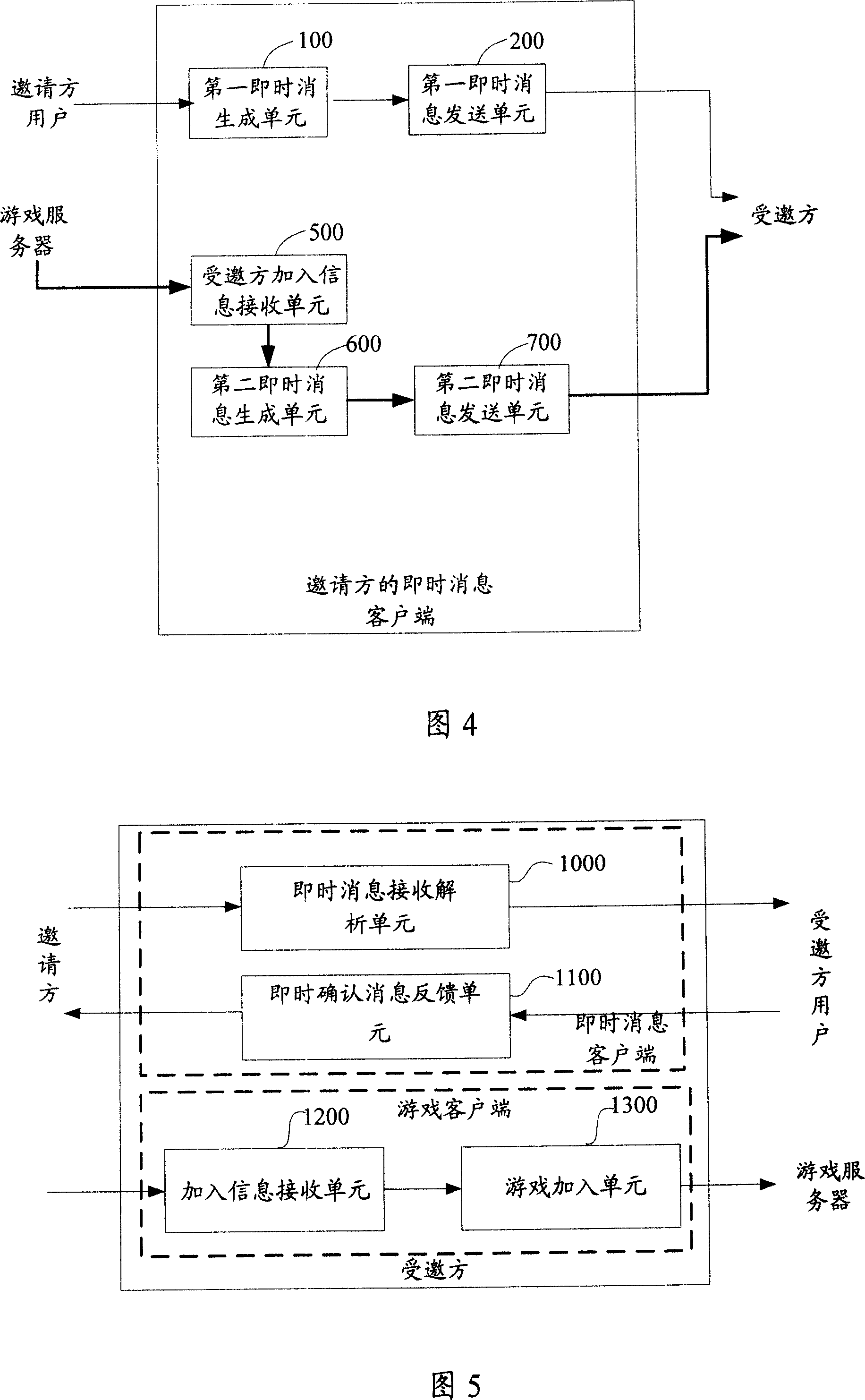

Method and user's set for inviting instant communication user into network game

ActiveCN101155044AAvoid handlingConserve operational processing resourcesSpecial service provision for substationGame serverMultimedia

The invention discloses a method of inviting the instant communication user into network game. The inviting part generates a first instant information to the invited part based on network game selected by the inviting part, wherein the said first instant information comprises descriptor for describing the network game selected by the inviting part. After the inviting part receives the instant confirmation message of agreement of the invited part to enter, the game server of the network game is provided to distribute the game resource based on the request of descriptor for describing the network game selected by the inviting part. After the said game server successfully distributes the game resource, the inviting part and the invited part respectively add the user of the inviting part and the user of the invited part into the network game provided by the said game server. The invention can prevent the inviting part from performing the needless operation on adding the user of the inviting part into the network game and save the transfer processing resource of instant information server.

Owner:TENCENT TECH (SHENZHEN) CO LTD

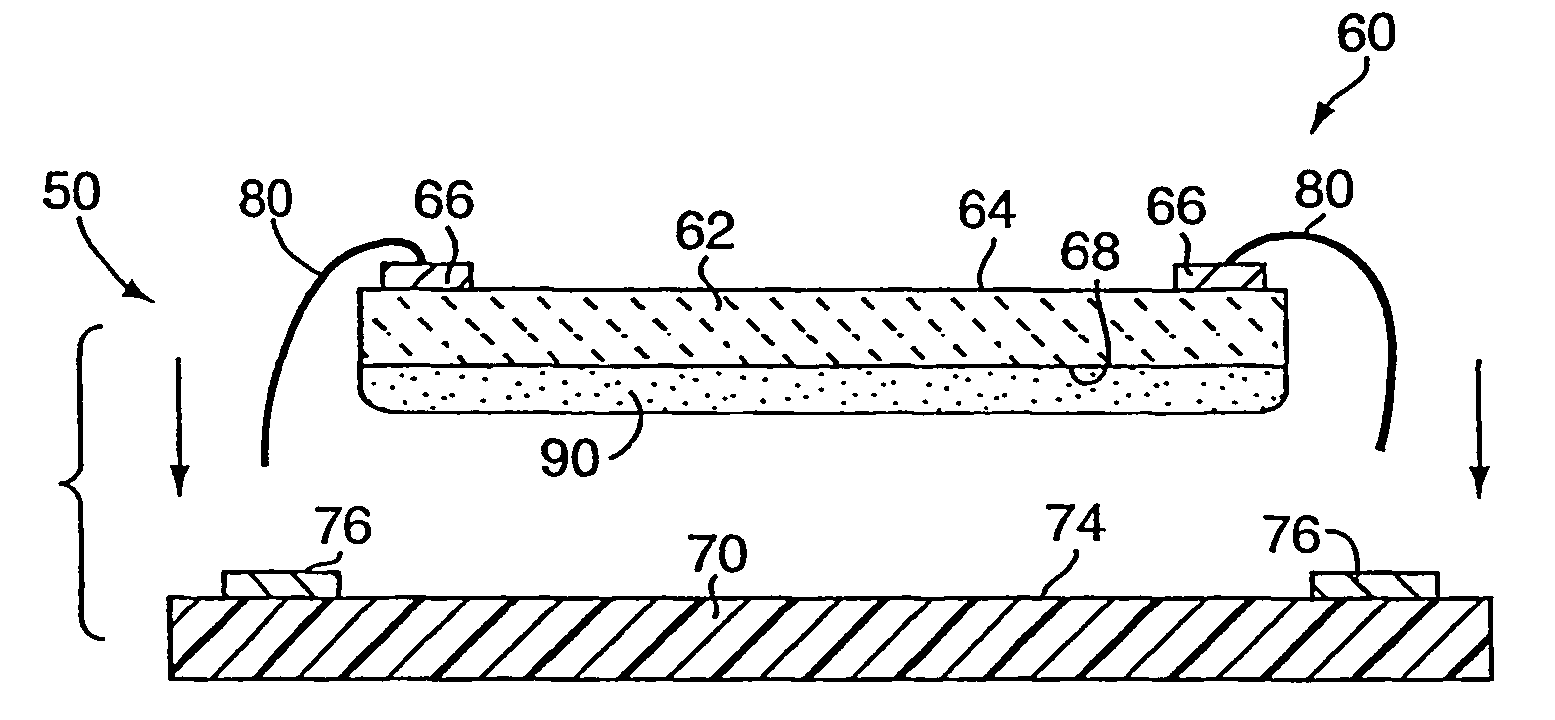

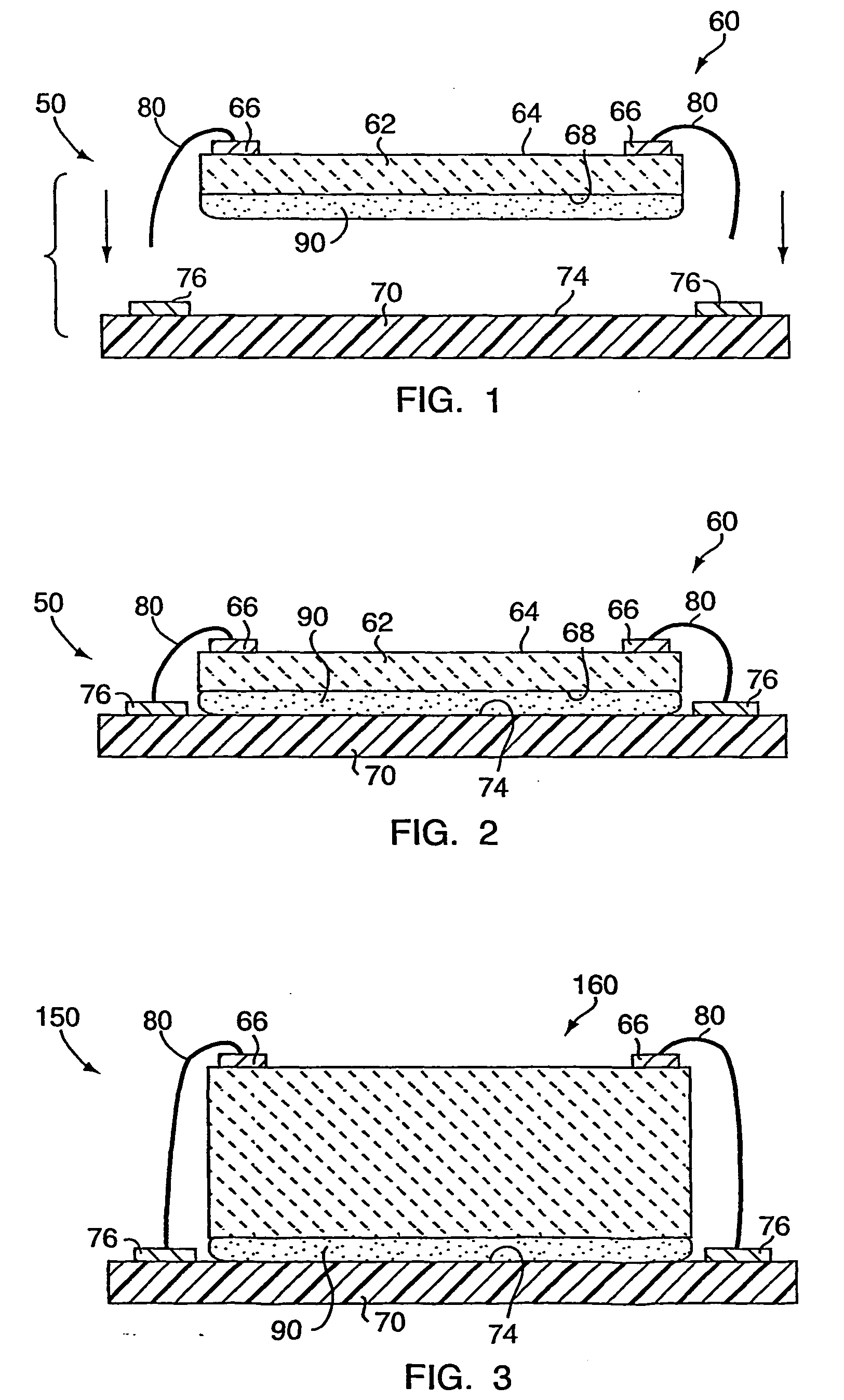

Interlayer dielectric and pre-applied die attach adhesive materials

InactiveUS20050008832A1Avoidance of dispensingAvoid handlingNon-macromolecular adhesive additivesSemiconductor/solid-state device detailsSemiconductor chipMicroelectronic circuits

The present invention relates to interlayer dielectric materials and pre-applied die attach adhesives, more specifically pre-applied die attach adhesives (such as wafer and other substrate-applied die attach adhesives), methods of applying the interlayer dielectric materials onto substrates to prepare low K dielectric semiconductor chips, methods of applying the pre-applied die attach adhesives onto wafer and other substrate surfaces, and assemblies prepared therewith for connecting microelectronic circuitry.

Owner:HENKEL CORP

Biaxial Hinge and Terminal Device Using the Same

ActiveUS20160102487A1Avoid handlingReduce stepsDetails for portable computersPin hingesTerminal equipmentEngineering

In order to provide a biaxial hinge and terminal device which ensure that a first and a second casings can open and close 360 degrees relative to each other, as well as enable a keyboard portion and rubber feet to sink relative to the upper surface of the first casing, from a predetermined opening / closing angle, the biaxial hinge comprises a biaxial hinge portion and an actuating mechanism for actuating operating mechanism(s) working on keyboard and rubber feet. Further, the actuating mechanism comprises a cam part moving in association with the movement of the biaxial hinge portion and together with opening / closing operations of the first and the second casings, and a slide part of which an end contacts with the cam part. The slide part is further provided on the attaching plate attached to the first and the second hinge shafts so as to start moving from a predetermined opening / closing angle.

Owner:KEM HONGKONG

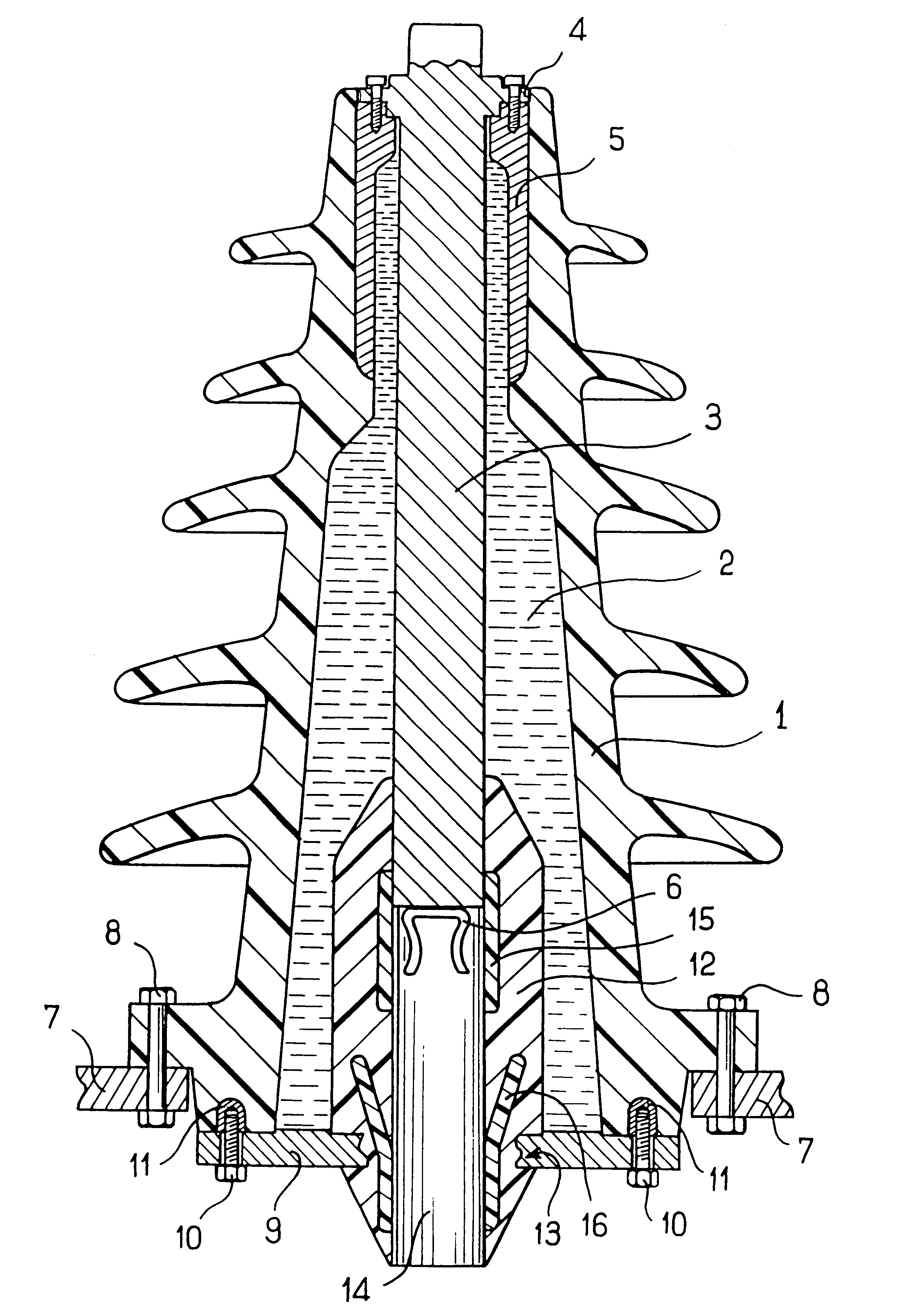

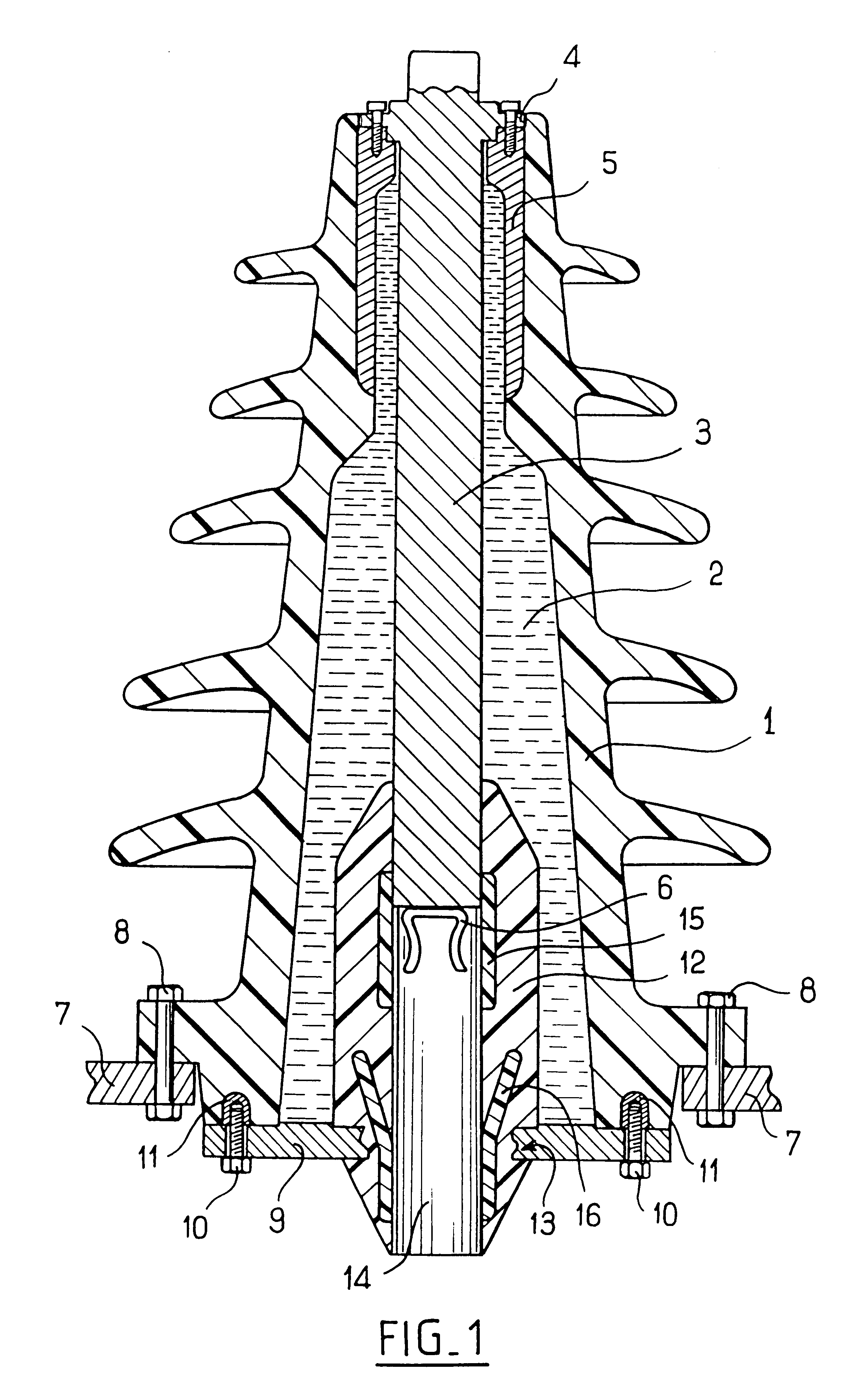

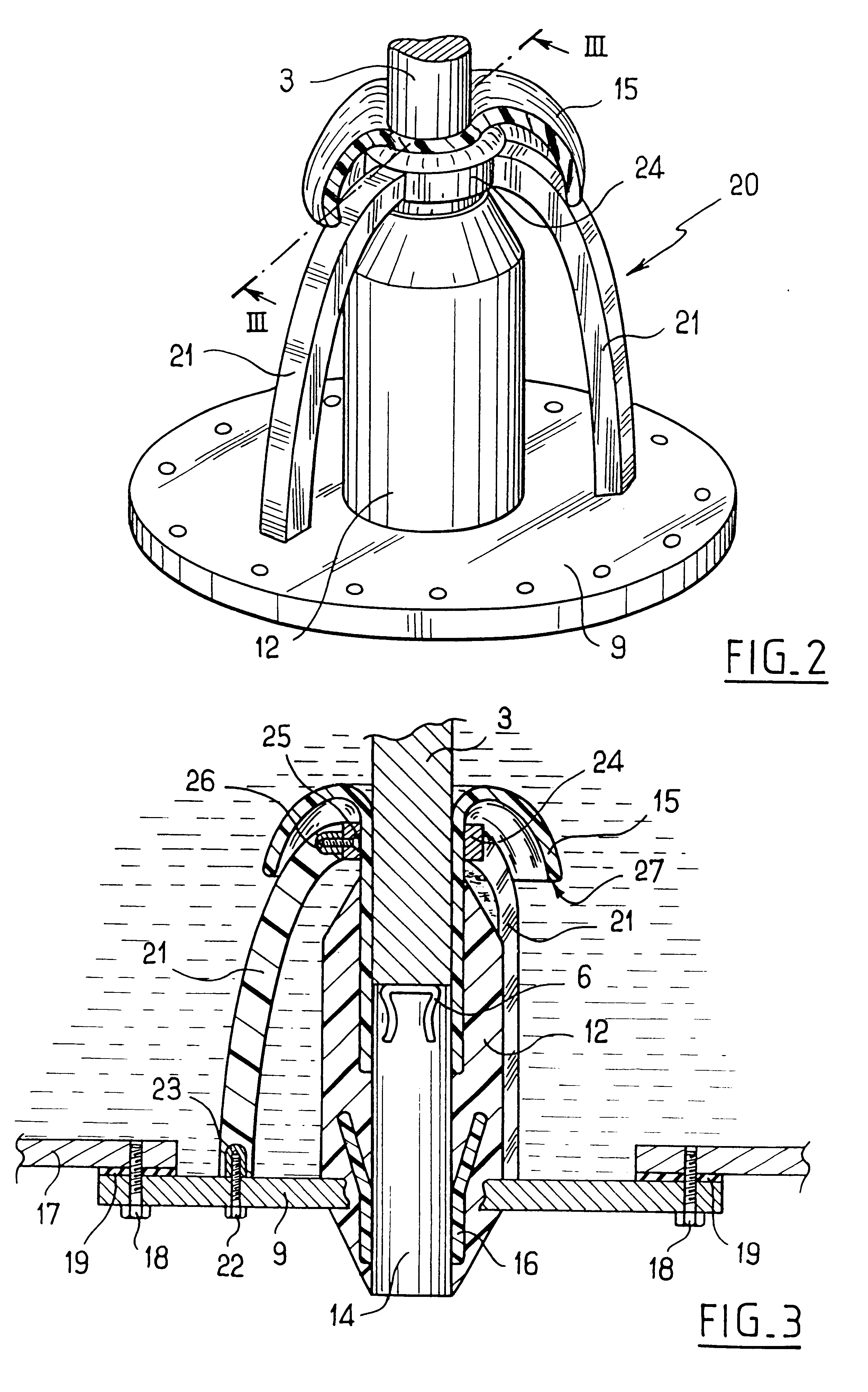

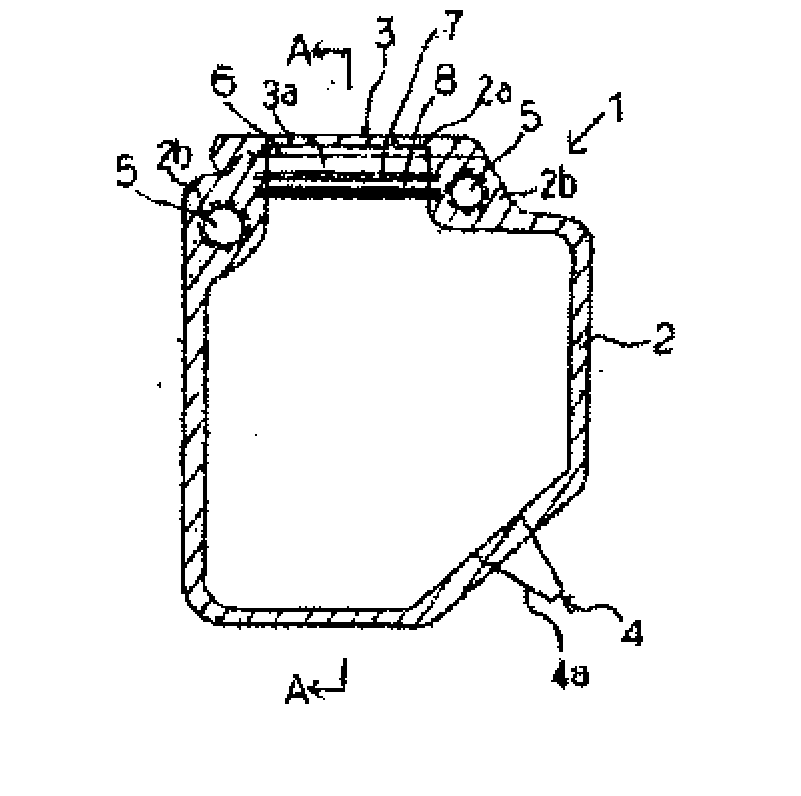

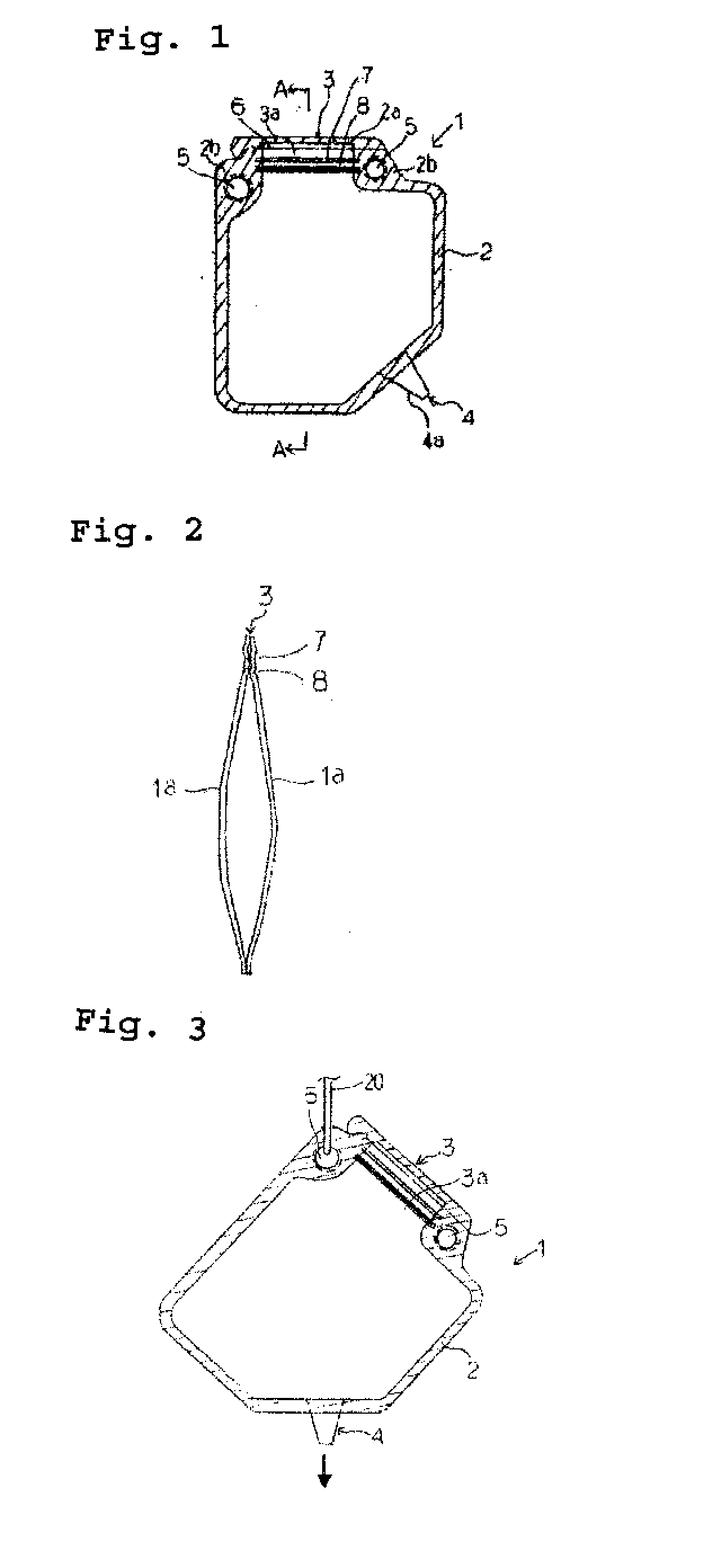

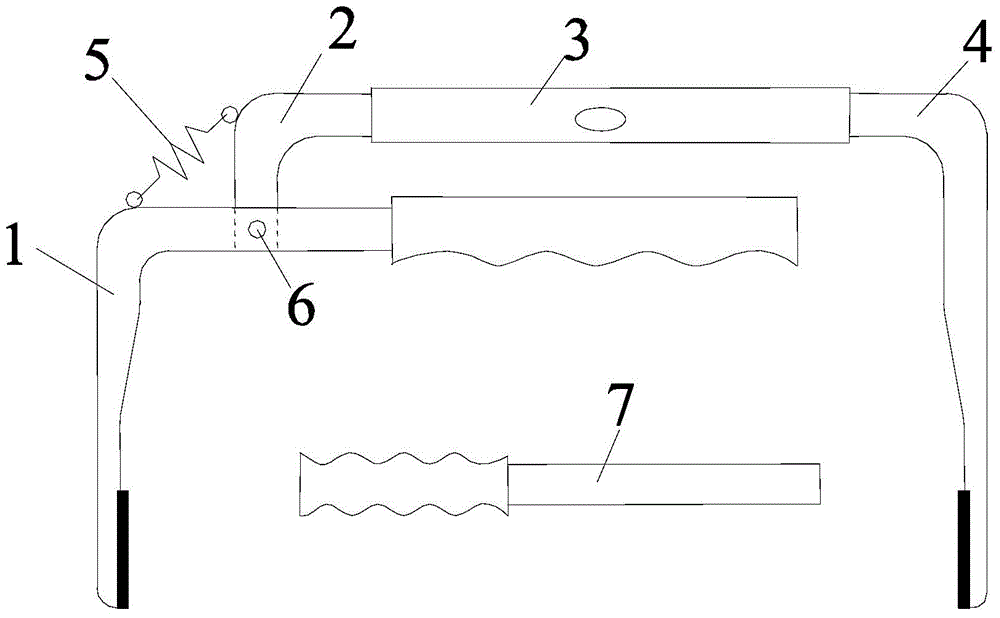

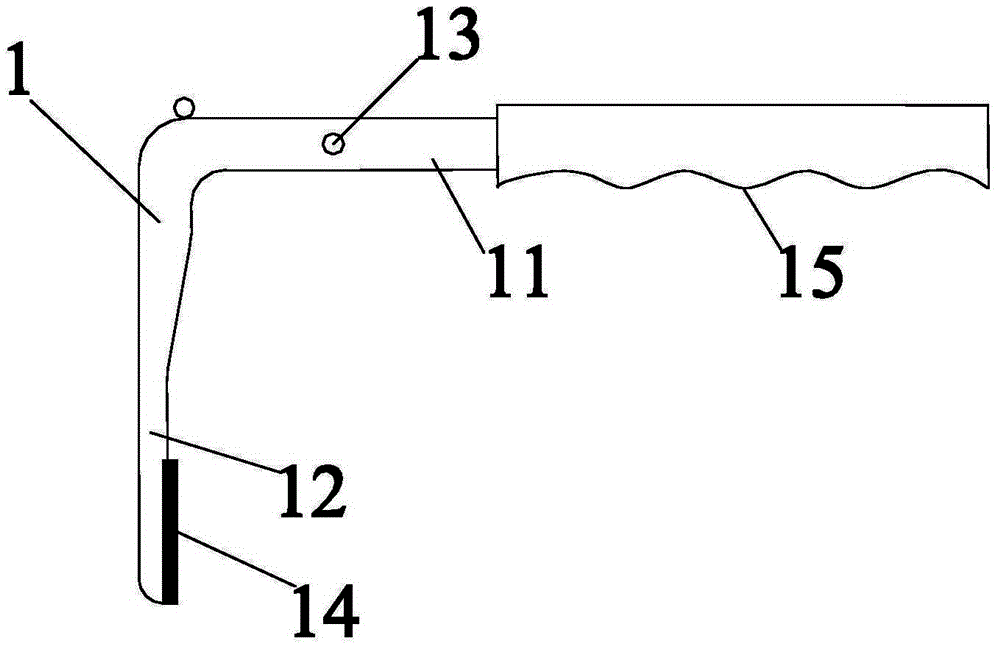

Fluid-insulated electrical link device

InactiveUS6309235B1Minimised electrical stressReduce processingCouplings bases/casesInsulatorsEngineeringInternal connection

The electrical link device comprises an enclosure (1, 9) containing a fluid insulator (2), a conductive link bar (3) disposed inside the enclosure and having one end fixed in leakproof manner to an insulating elastomer sleeve (12) that passes through the wall of the enclosure in leakproof manner, the link bar (3) being connected inside the enclosure to a pluggable connection member (6) surrounded by a conductive screen (15), the elastomer sleeve (12) also including a conductive deflector (16) flush with the inside surface of the insulating sleeve at a distance from the conductive screen (15).

Owner:SILEC CABLE

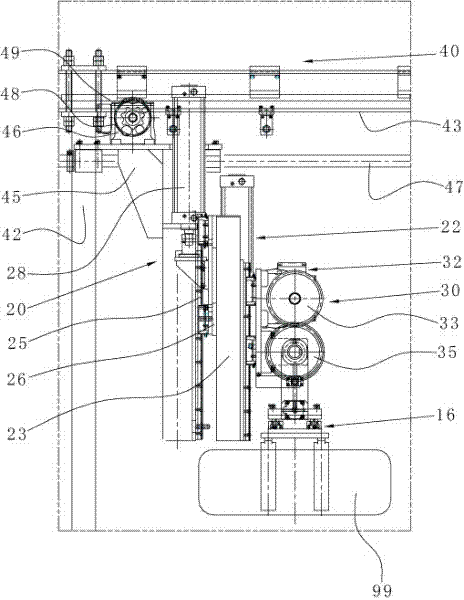

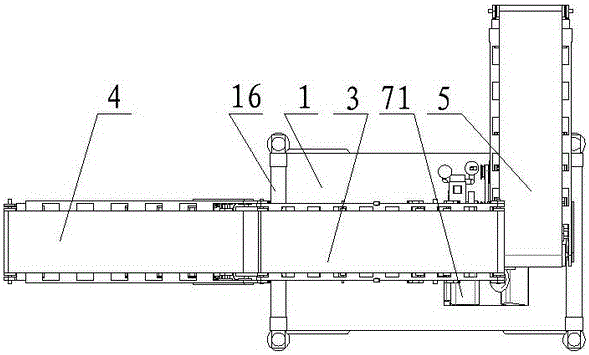

Full-automatic rubber ointment painting and coating equipment and technique

InactiveCN101293236AMeet production requirementsReduce manufacturing costLiquid surface applicatorsCoatingsProduction lineAgricultural engineering

The invention discloses a full automatic adhesive plaster coating device and a technique thereof; the device is the improvement of a common roll coater, a thickness gauge is installed on a first worktable, the first worktable is connected with a first servomotor by a connecting block, a first nut and a first screw rod, and the thickness gauge extends into a cooling box through a square hole at the lower part of the cooling box. The technique includes cloth feeding, cloth coating, rolling up process and the process for detecting the thickness of a coating; the process for detecting the thickness of a coating can detect the thickness of the coating coated on the upper surface of cloth through a coating thickness automatic testing device and change the clearance between a coating roll and a scraper by adjusting the height at one side or two sides of the coating roll, thus the coating thickness can reach a set value. By integrating a plurality of processes into one production line, the invention can avoid the transfer of semi-finished products among different workshops, improve working efficiency, dynamically and automatically control the coating thickness to ensure the coating thickness to meet production requirement; however, people do not need to thicken the coating on purpose for worrying about that the coating thickness can not meet the requirement, thus saving the production cost.

Owner:SOUTH CHINA UNIV OF TECH +1

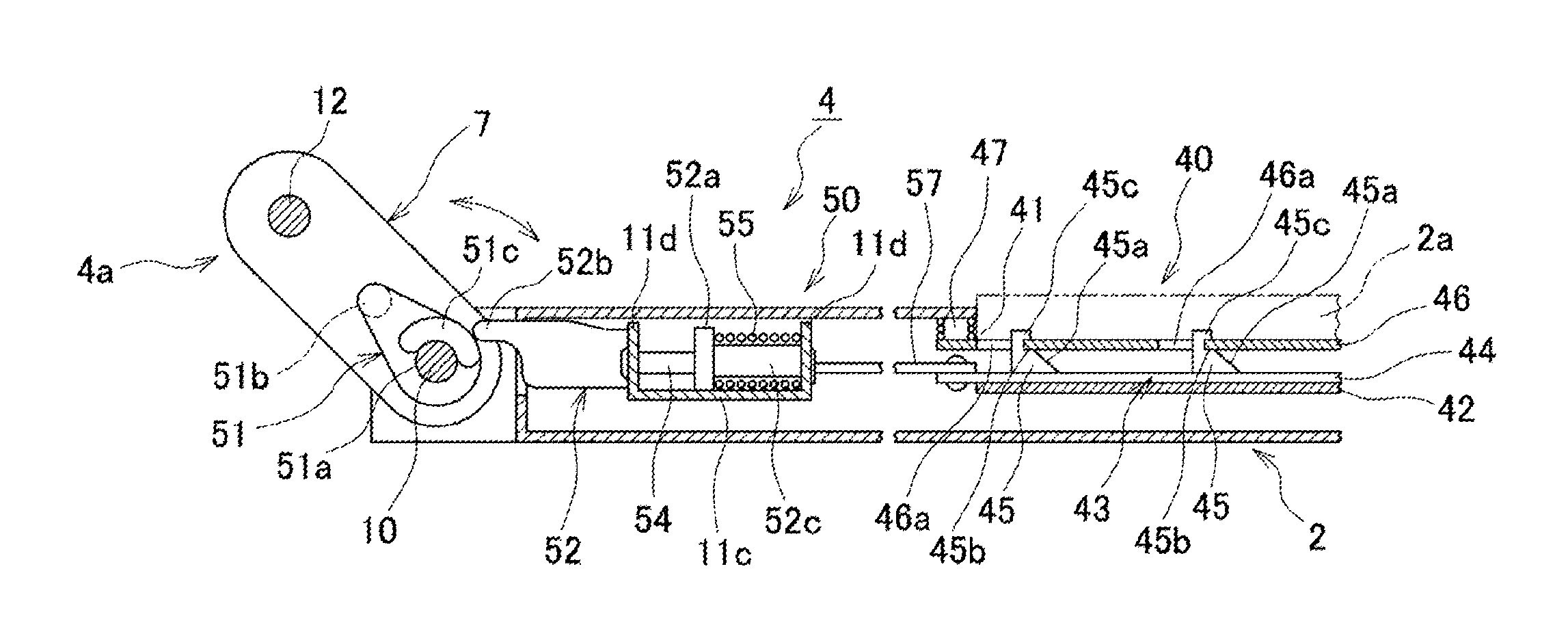

Biaxial hinge and terminal device using the same

ActiveUS9714533B2Avoid handlingReduce stepsDetails for portable computersPin hingesTerminal equipmentCam

In order to provide a biaxial hinge and terminal device which ensure that a first and a second casings can open and close 360 degrees relative to each other, as well as enable a keyboard portion and rubber feet to sink relative to the upper surface of the first casing, from a predetermined opening / closing angle, the biaxial hinge comprises a biaxial hinge portion and an actuating mechanism for actuating operating mechanism(s) working on keyboard and rubber feet. Further, the actuating mechanism comprises a cam part moving in association with the movement of the biaxial hinge portion and together with opening / closing operations of the first and the second casings, and a slide part of which an end contacts with the cam part. The slide part is further provided on the attaching plate attached to the first and the second hinge shafts so as to start moving from a predetermined opening / closing angle.

Owner:KEM HONGKONG

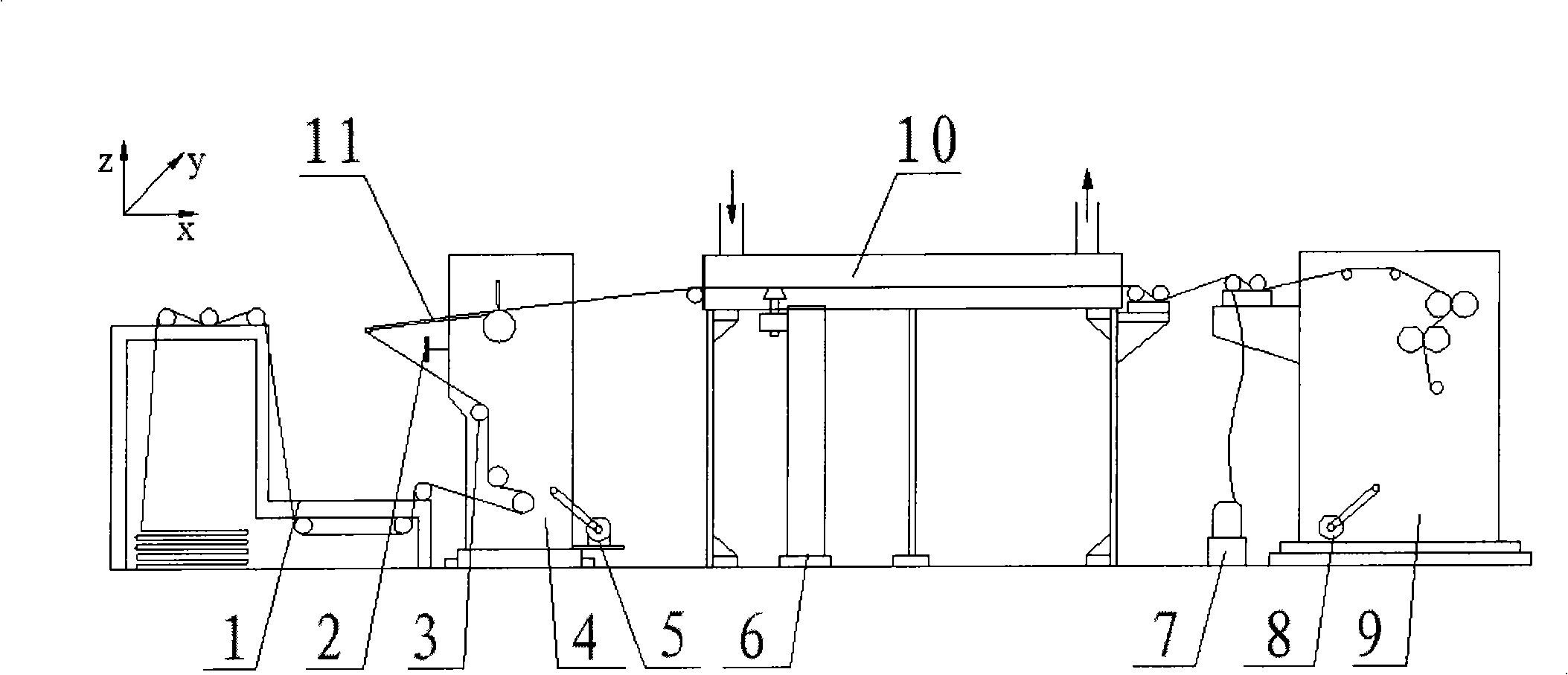

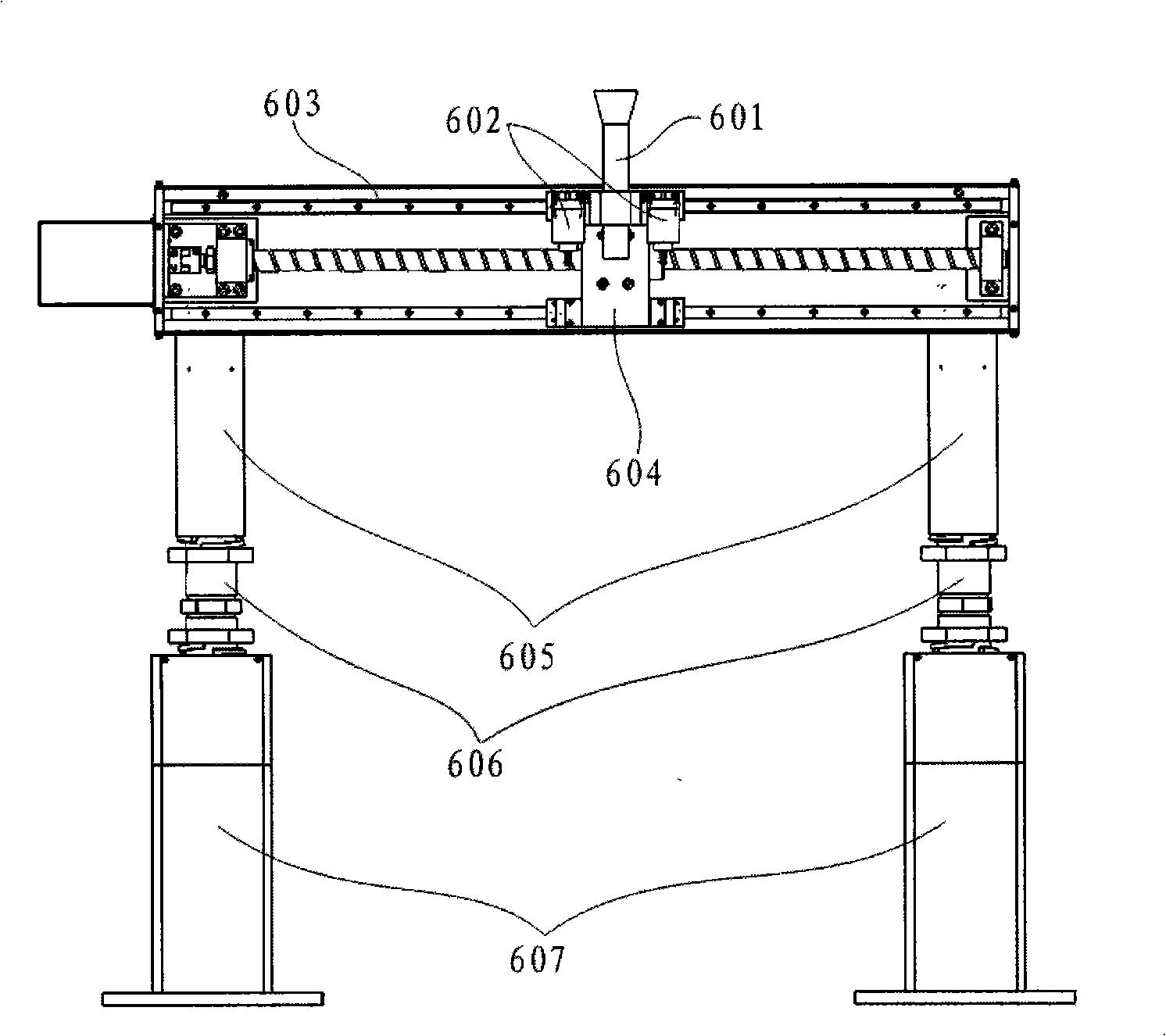

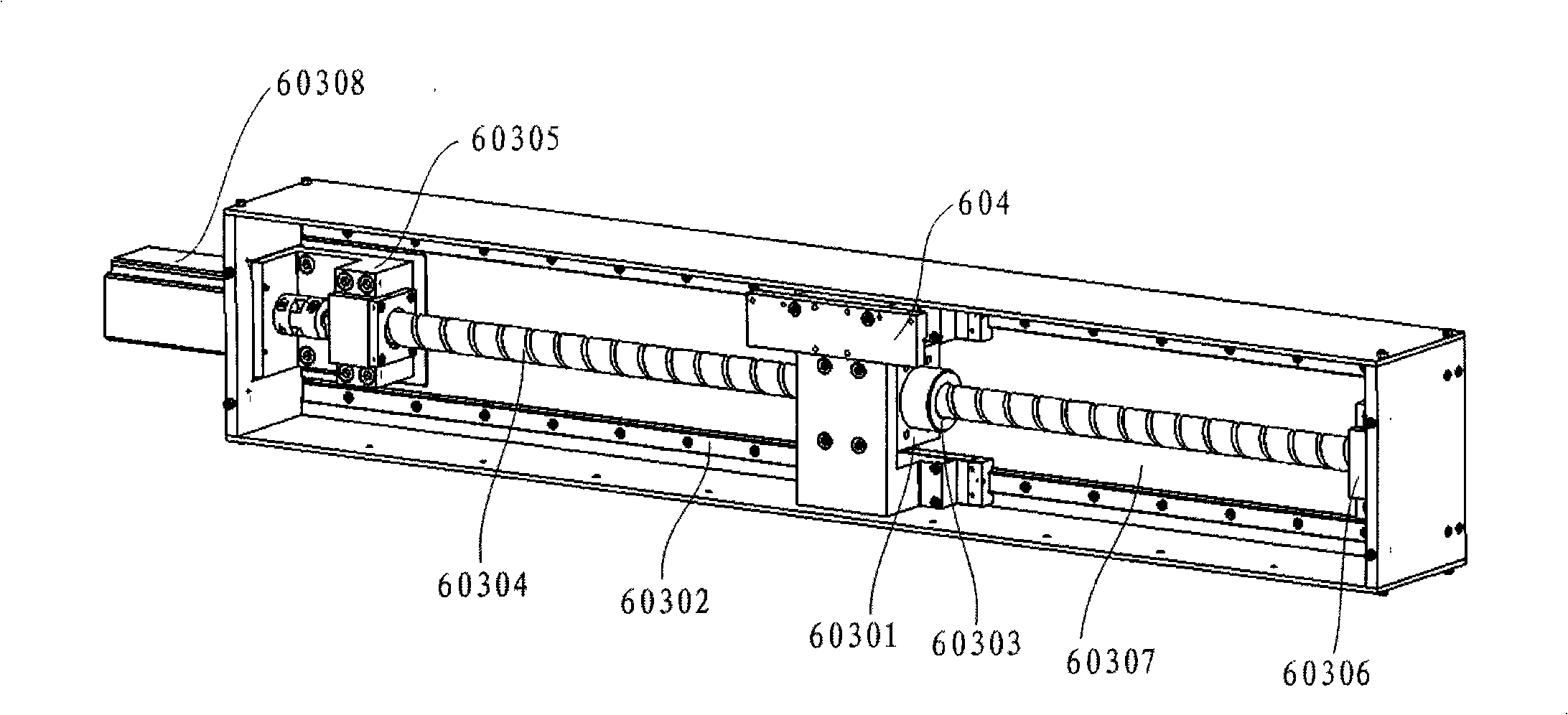

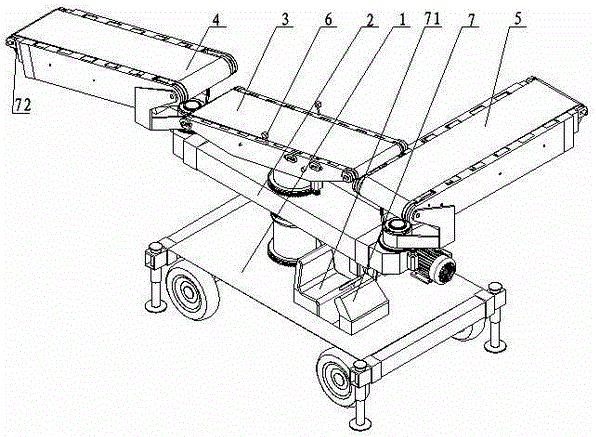

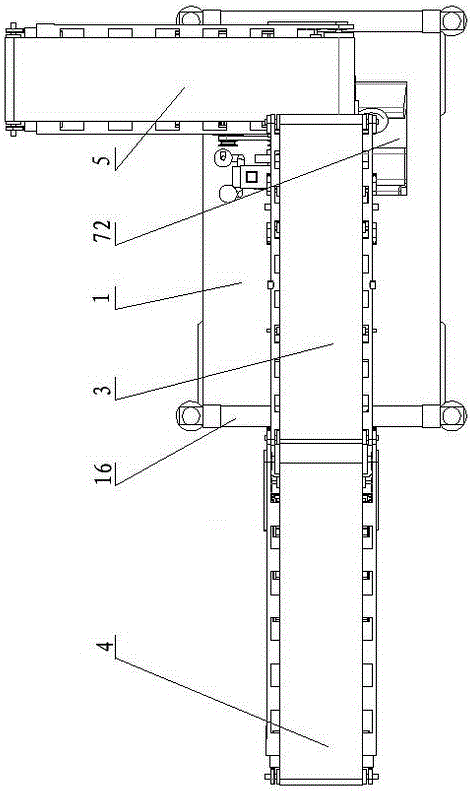

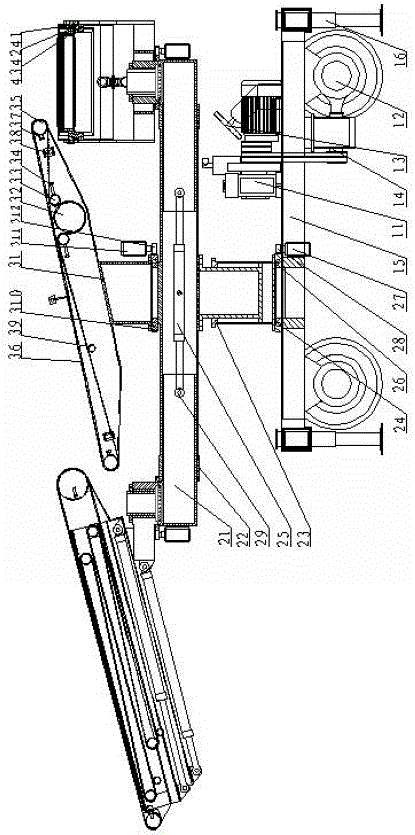

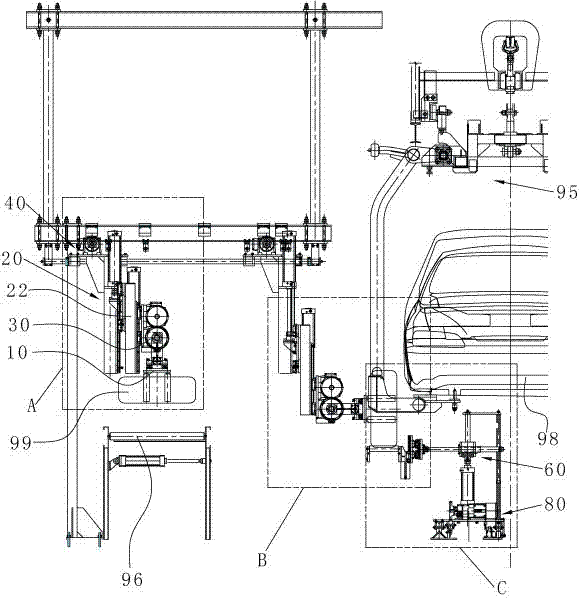

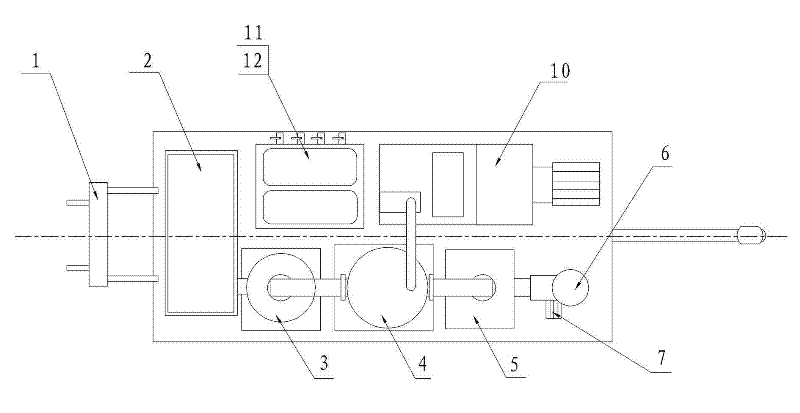

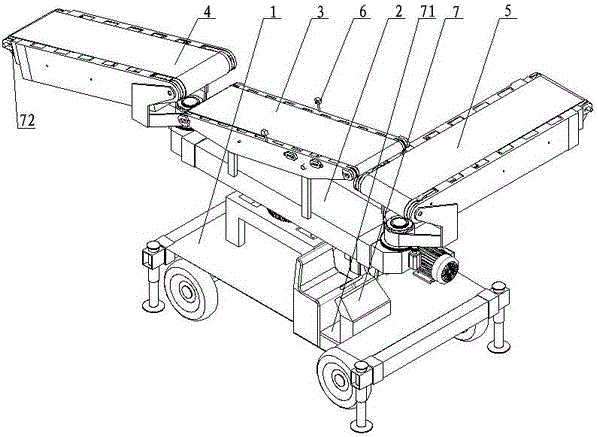

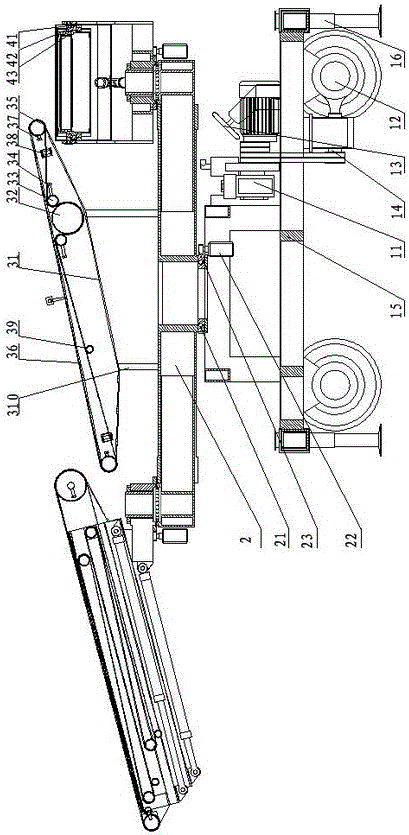

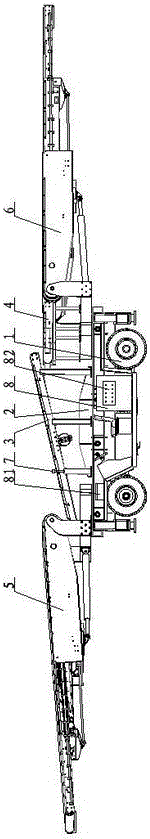

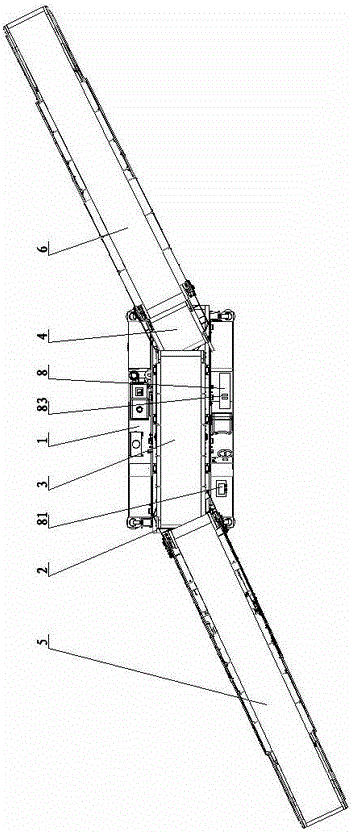

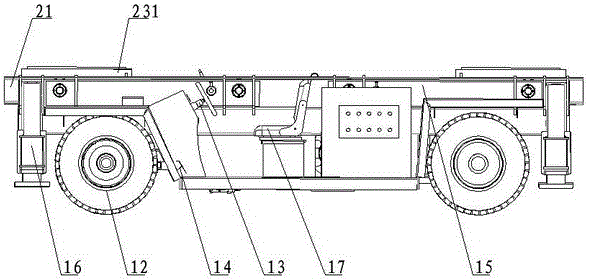

A derricking direction-changeable telescopic belt conveying bidirectional loader-unloader

InactiveCN106608551AAdjustable working heightRealize orientationConveyorsRollersControl systemStatistical analysis

The invention provides a derricking direction-changeable telescopic belt conveying bidirectional loader-unloader and relates to the field of logistics transportation cargo loading and unloading mechanical equipment. The derricking direction-changeable telescopic belt conveying bidirectional loader-unloader comprises a vehicle having bearing and walking functions, a telescopic cross arm having lifting, telescoping and swinging functions, a middle transition conveyor which has a swinging function and is capable of inclined conveying, a first belt conveyor and a second belt conveyor having derricking, swinging and telescoping functions, a metering device having metering, displaying, storing and printing functions, and an operating control system used for complete machine operation of the loader-unloader. The derricking direction-changeable telescopic belt conveying bidirectional loader-unloader has the advantages of simple structure, reliable work, convenient and rapid movement and transfer, and wide operating scope; the derricking direction-changeable telescopic belt conveying bidirectional loader-unloader can reduce manually-assisted carrying, reduce workload, shorten operating time, increase loading and unloading working efficiency, reduce the cost of loading and unloading carrying, improve working environment and work conditions, guarantee economical, rapid, convenient and safe loading and unloading and transportation, allow change of the direction of logistics conveying, and realize forward and reverse loading and unloading, automatic metering statistical analysis, and loading and unloading quantity / weight recording, displaying and storing.

Owner:襄阳忠良工程机械有限责任公司

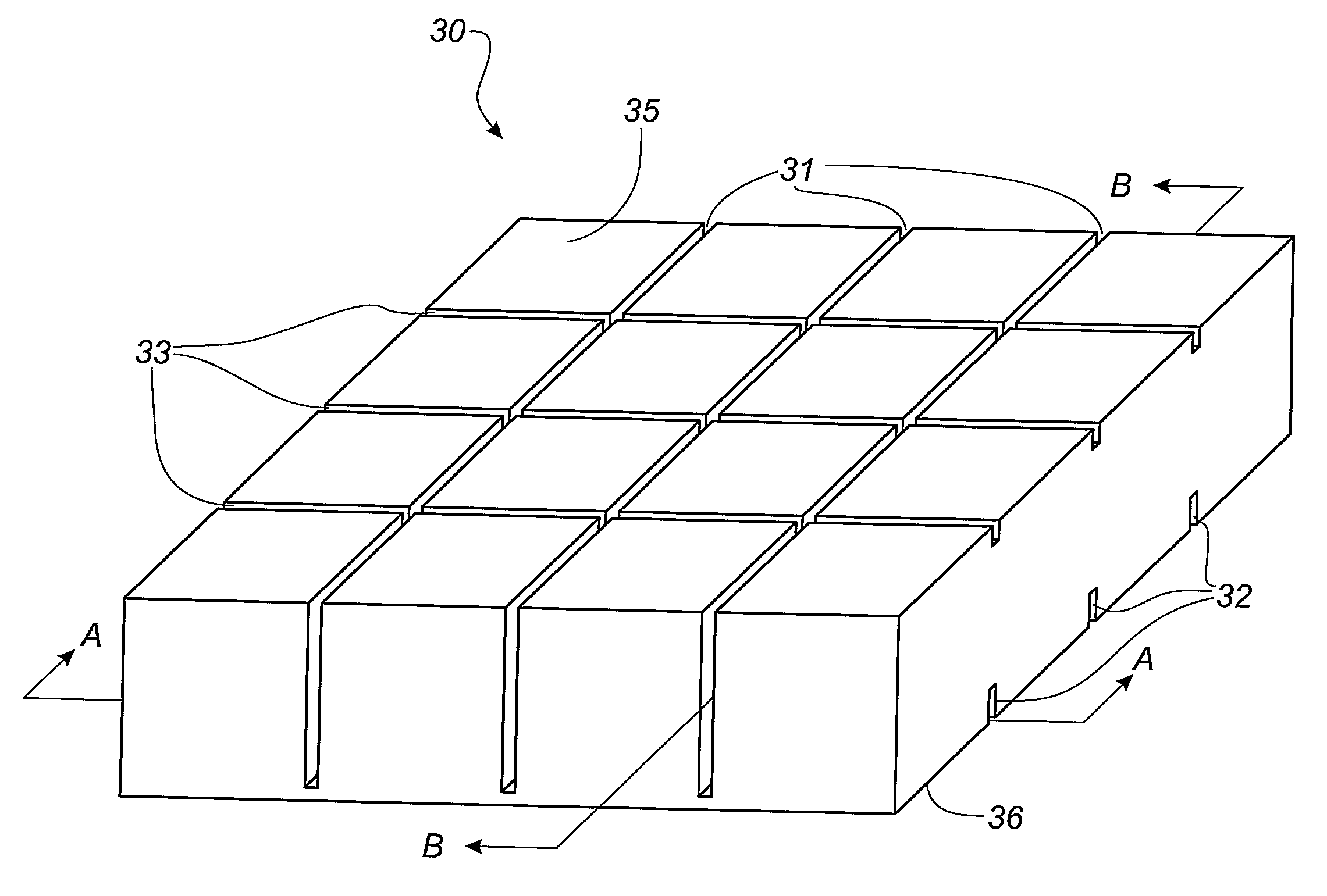

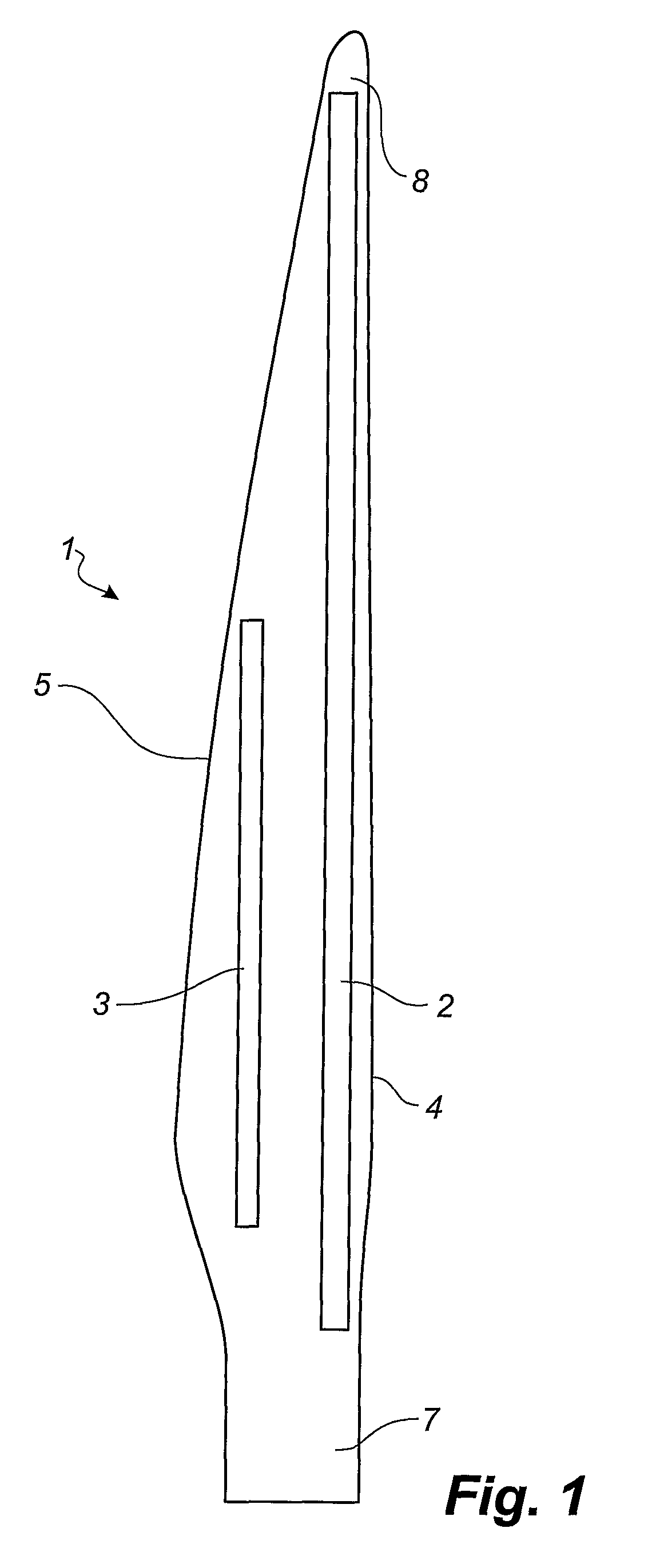

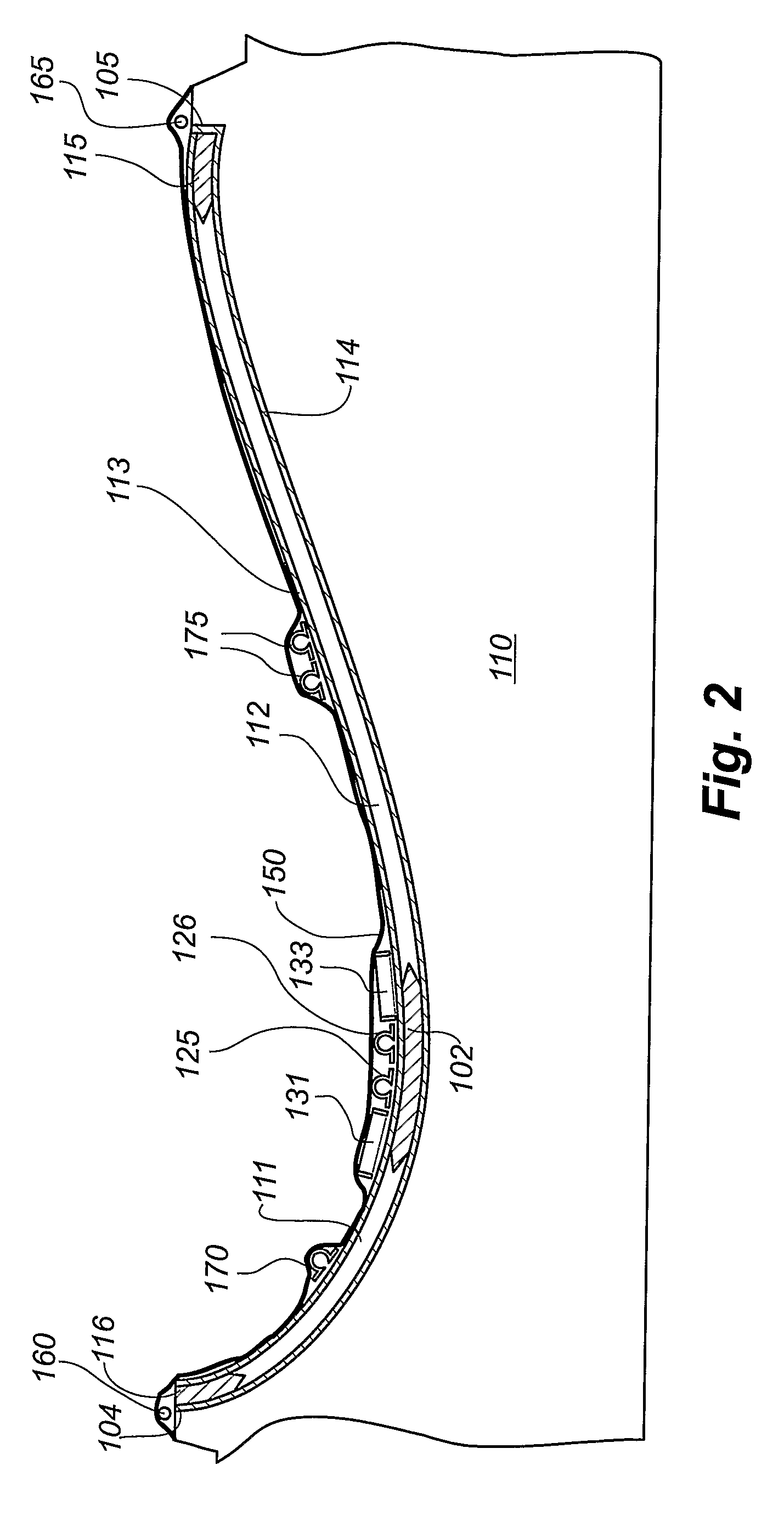

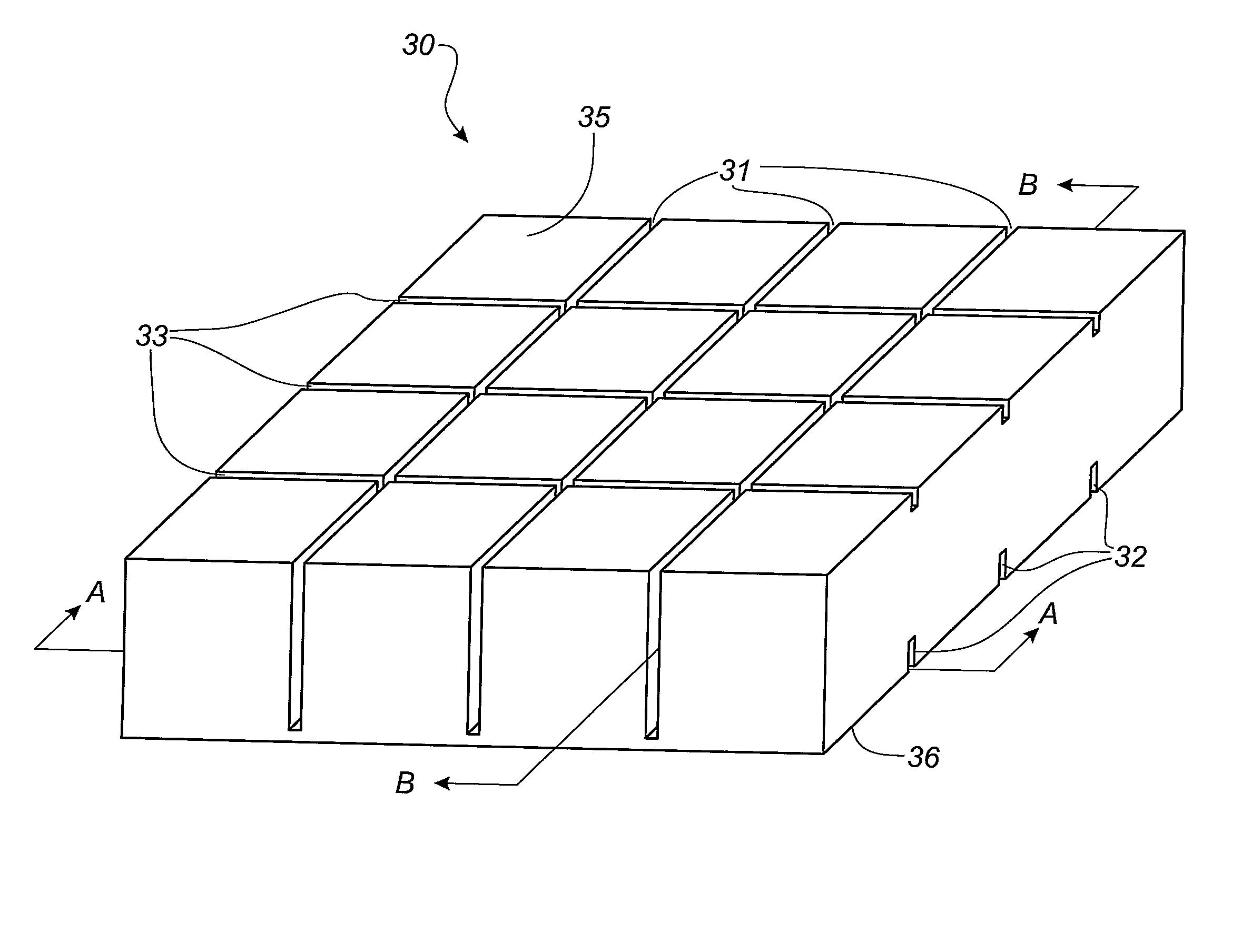

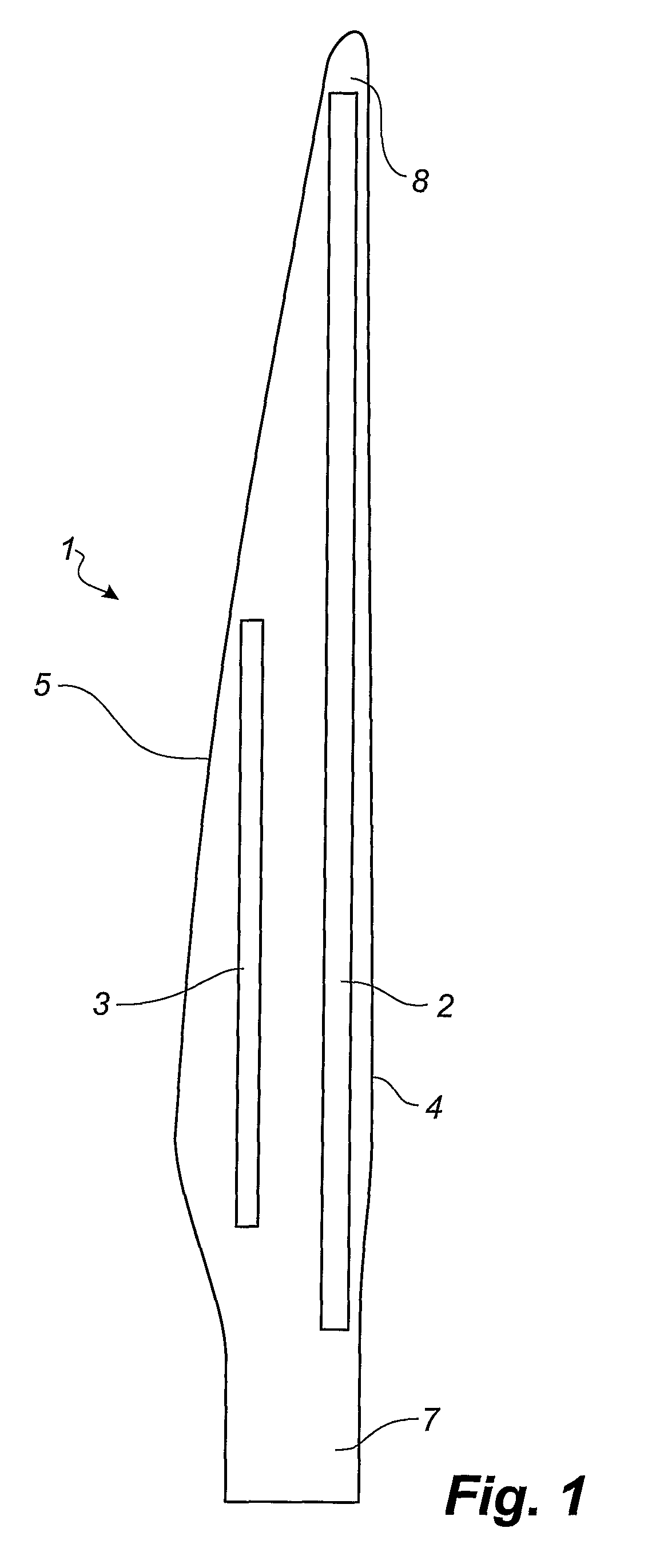

Method of Using a Formable Core Block for a Resin Impregnation Process

ActiveUS20100189973A1Easy to disassembleAvoid handlingFinal product manufactureMovable spraying apparatusResin dispensingEngineering

A use of a core block for an impregnation process as well as a composite structure comprising such a core block is described. The core block has a first surface and a second surface, and a number of first grooves is formed in the first surface of the core. Furthermore, a number of second grooves is formed in the second surface of the core. The first grooves have a first height (h1) and a bottom, and the first grooves and the second grooves are part of a resin distribution network formed in the core block. The distance (t) between the bottom of the first grooves and the second surface of the core block is of such a size that the core block is flexible along the first grooves. Additionally, the sum of the first height and the second height is larger than the thickness of the core block, and at least one of the first grooves in the first surface of the core block crosses at least one of the second grooves in the second surface of the core block.

Owner:LM GLASSFIBER

Biaxial hinge and electronic device using the same

ActiveUS9540855B2Simple structureAvoid handlingDetails for portable computersPin hingesDisplay deviceCam

A biaxial hinge which allows a first casing having a keyboard and a second casing having a display to open and close 360 degrees relative to each other. The biaxial hinge ensures that the keyboard, rubber feet, and other parts can sink relative to the first casing. The biaxial hinge includes a biaxial hinge portion and an actuating mechanism. The biaxial hinge portion includes a rotation controlling unit. The actuating mechanism includes a fixed cam part, a slide cam part facing the fixed cam part, and a link part.

Owner:KEM HONGKONG

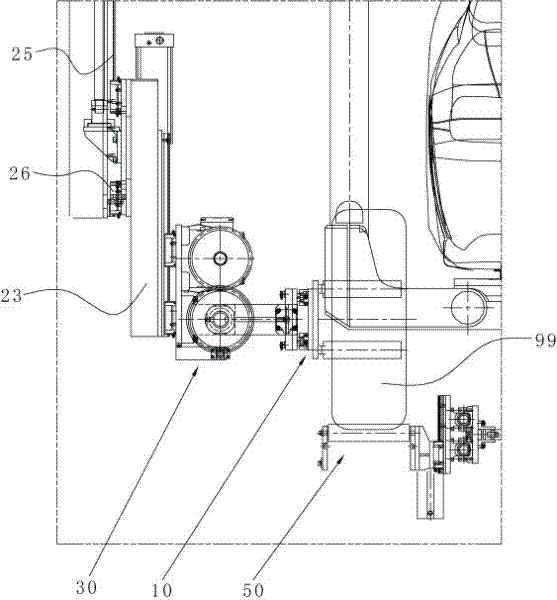

Automatic tire-supplying system

The invention discloses an automatic tire-supplying system, which is used for automatically transferring tires on a tire conveying raceway to side edges of wheel hubs at an assembly line. The automatic tire-supplying system comprises a clamping device, a lifting and turnover device and a line-shifting device which are sequentially connected, a vehicle-side supporting bracket, a three-way aligning device used for adjusting the position of the vehicle-side supporting bracket, and a following device used for supporting the three-way aligning device to synchronously move along with a vehicle body at the assembly line, wherein the vehicle-side supporting bracket, the three-way aligning device and the following device are sequentially connected and arranged at the lower side part of the assembly line; and a pre-inflated tire is clamped through the clamping device, is then lifted and overturned into a vertical state, is conveyed to the side of the moving trajectory of a wheel hub through the line-shifting device and is placed at the vehicle-side supporting bracket, then the position of the tire is adjusted under the control of the three-way aligning device, and the tire is aligned with the wheel hub and synchronously moves with the vehicle body. According to the automatic tire-supplying system disclosed by the invention, automatic carrying, conveying and aligning of machinery are realized, the assembly of the tire can be completed without manual carrying, conveying and aligning, the labor intensity is reduced, and the automation level is improved.

Owner:GUANGQI HONDA +1

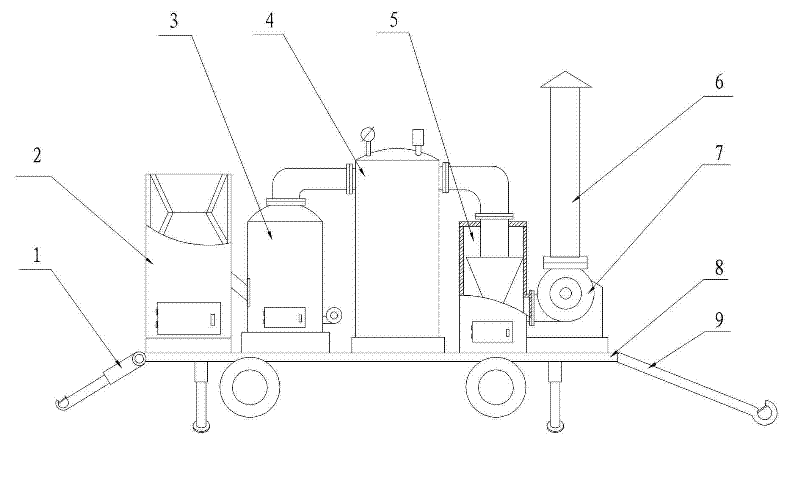

Mobile waste disposal plant

InactiveCN102247975ASolve processing problemsEasy to cleanSolid waste disposalVehicle fittings for liftingRefuse DisposalsWaste disposal

The invention discloses a mobile waste disposal plant. The invention is characterized in that a waste disposal system is integrated in one trailer platform. The platform is freely towed and moved to any place requiring waste disposal by a motor vehicle or other powered vehicles. The mobile waste disposal plant comprises a hoisting mechanism, a waste sorting mechanism, a waste incinerator, a waste heat boiler, a dust remover, a centrifugal fan, a chimney, a turbo-generator unit, a power distribution cabinet and an energy storage water tank. While the domestic waste is incinerated, the generated energy is stored for heating water or boiling drinking water; besides, the generated electric energy is directly used or supplied to municipal power grids.

Owner:FUJIAN NANPING JIAHE BOILER MFG

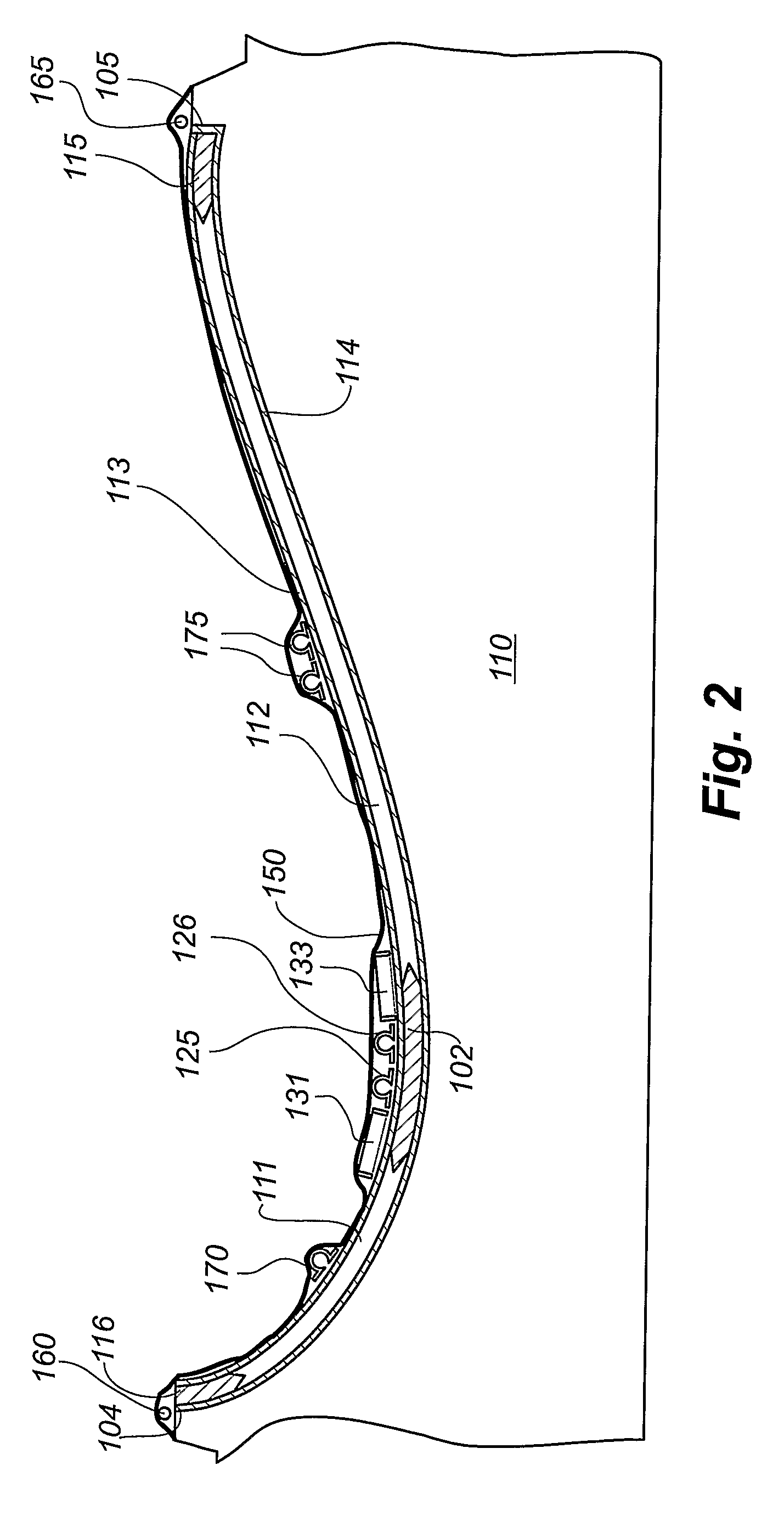

Ophthalmic surgery preparation system and method

InactiveUS20050267423A1Avoid repeated handlingAvoids storage conditionPackage sterilisationMedical applicatorsSTERILE FIELDSurgical preparation

The invention described herein is a sterile, disposable ophthalmic surgery preparation system and technique that can be introduced directly into the sterile field of surgical preparation without significantly compromising sterile conditions. Both the antimicrobial solution and the container holding the solution can be presented into the sterile field in sterile condition. The antimicrobial solution and container are dimensioned and proportioned for single patient or single procedure usage. The invention includes a sterile, disposable ophthalmic surgery preparation system comprising: a sealed, rupturable flexible container structured as a dropper; the container being filled with a liquid antimicrobial composition formulated for ophthalmic application; wherein the container and composition are proportioned for single application use. The invention further provides a surgical kit and method of preparing a patient for ophthalmic surgery.

Owner:JOHNSON RUSS +4

Solar polyurethane thermal insulation material

Owner:SHANDONG LINUO PARADIGMA

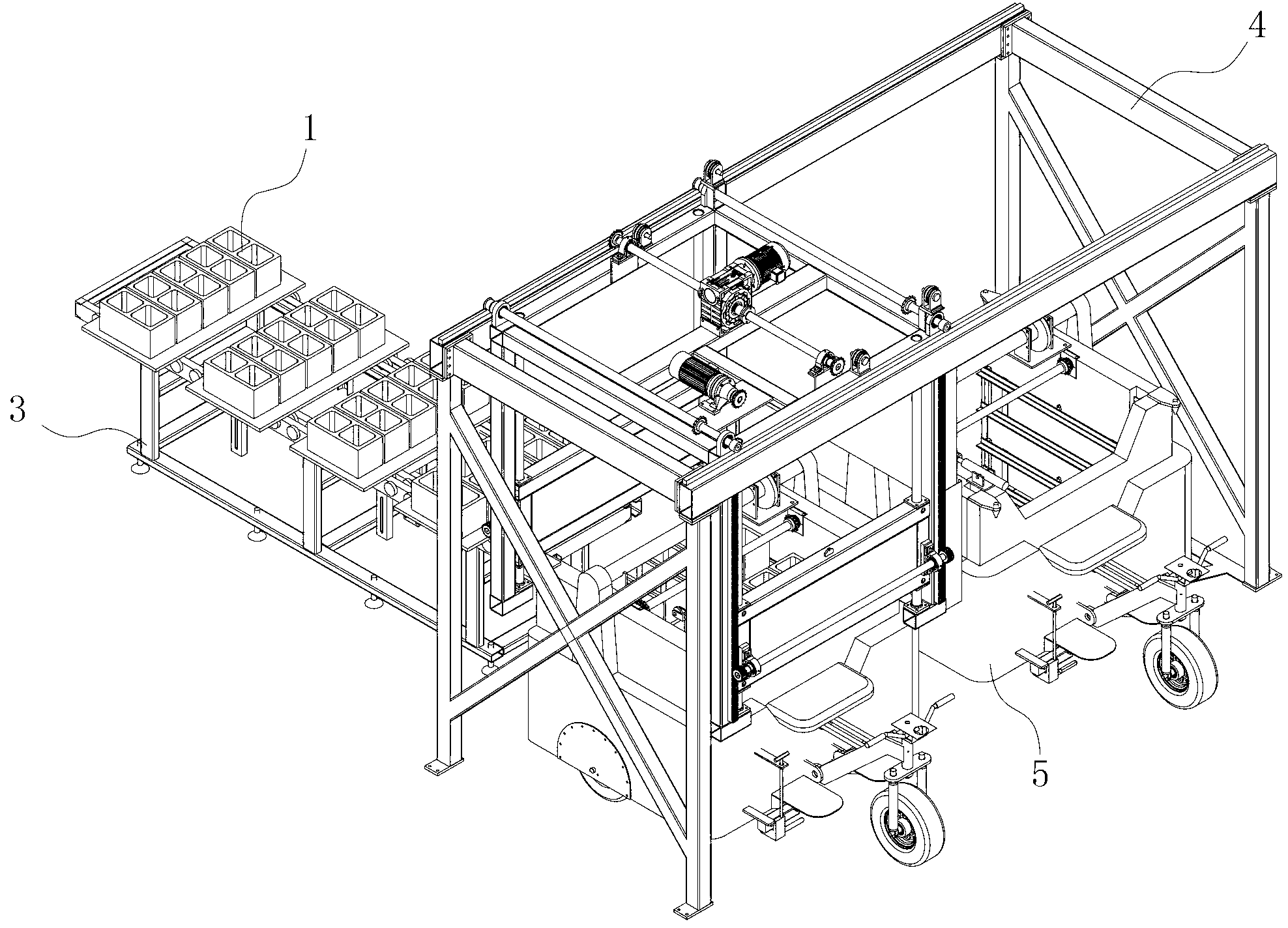

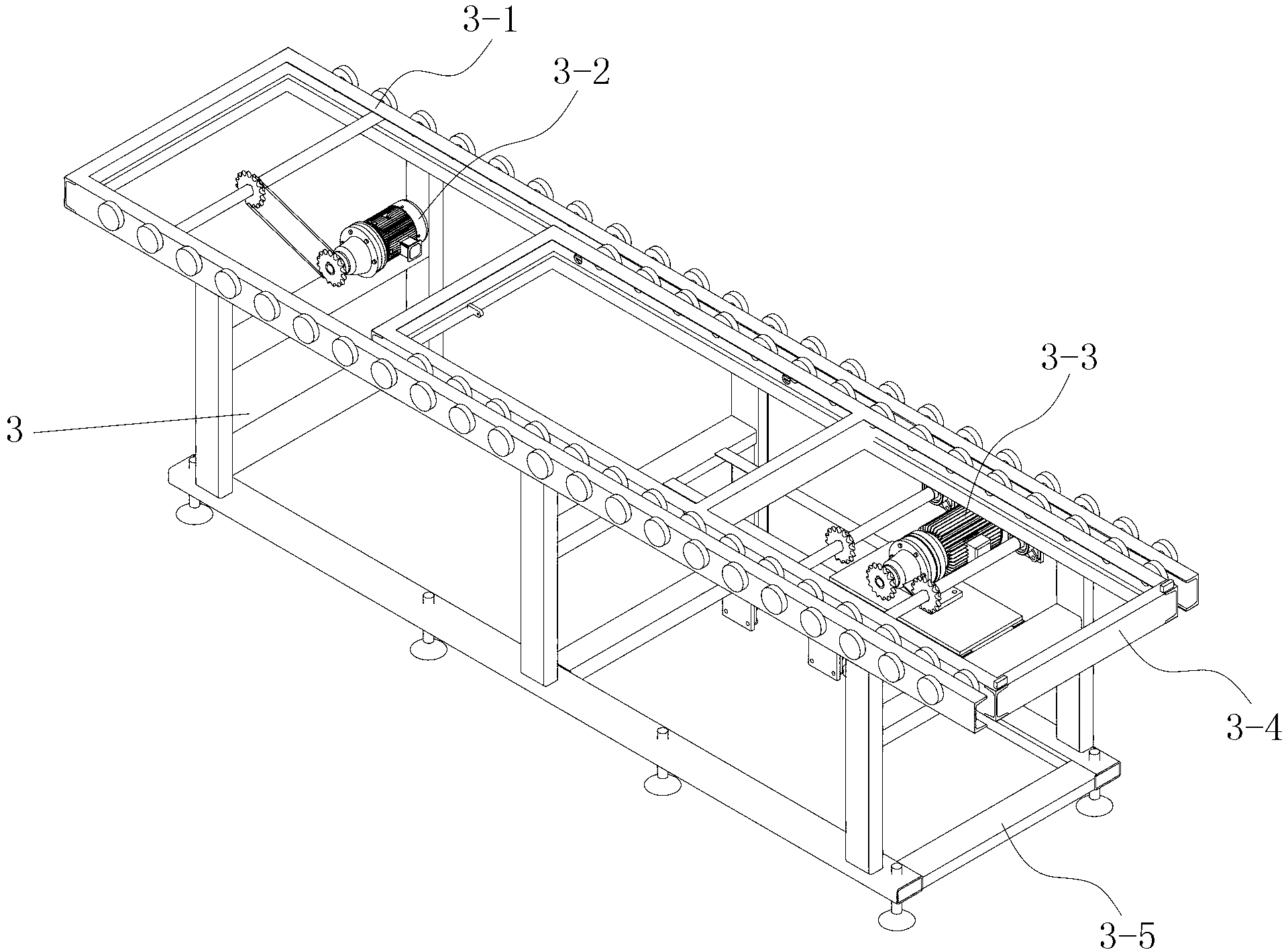

Brick discharging system of automatic production line of brick making machine

ActiveCN103171049AHigh degree of automationReduce personal injury incidentsCeramic shaping plantsProduction lineBrick

The invention belongs to the technical field of brick making machine equipment, and particularly relates to a brick discharging system of an automatic production line of a brick making machine used for baking-free brick production. The brick discharging system of the automatic production line of the brick making machine comprises a conveyor rack, a loading rack and a conveying vehicle, wherein the conveyor rack is connected with a discharging part of the automatic production line of the brick making machine in a butted mode, the conveyor rack is used for sending materials to the feeding rack, the feeding rack is arranged in front of the conveyor rack and is used for lifting the conveying vehicle and matching with the conveyor rack to place the materials on the conveying vehicle layer by layer, the conveying vehicle is located below the feeding rack and is used for receiving materials fed by the feeding rack, and the conveying vehicle is driven manually to a baking-free brick maintenance place after material feeding. The brick discharging system of the automatic production line of the brick making machine can replaces an existing manual carrying mode, is high in automation degree, has no harm to products, and is high in safety.

Owner:TIANJIN JIANFENG HYDRAULIC MACHINERY

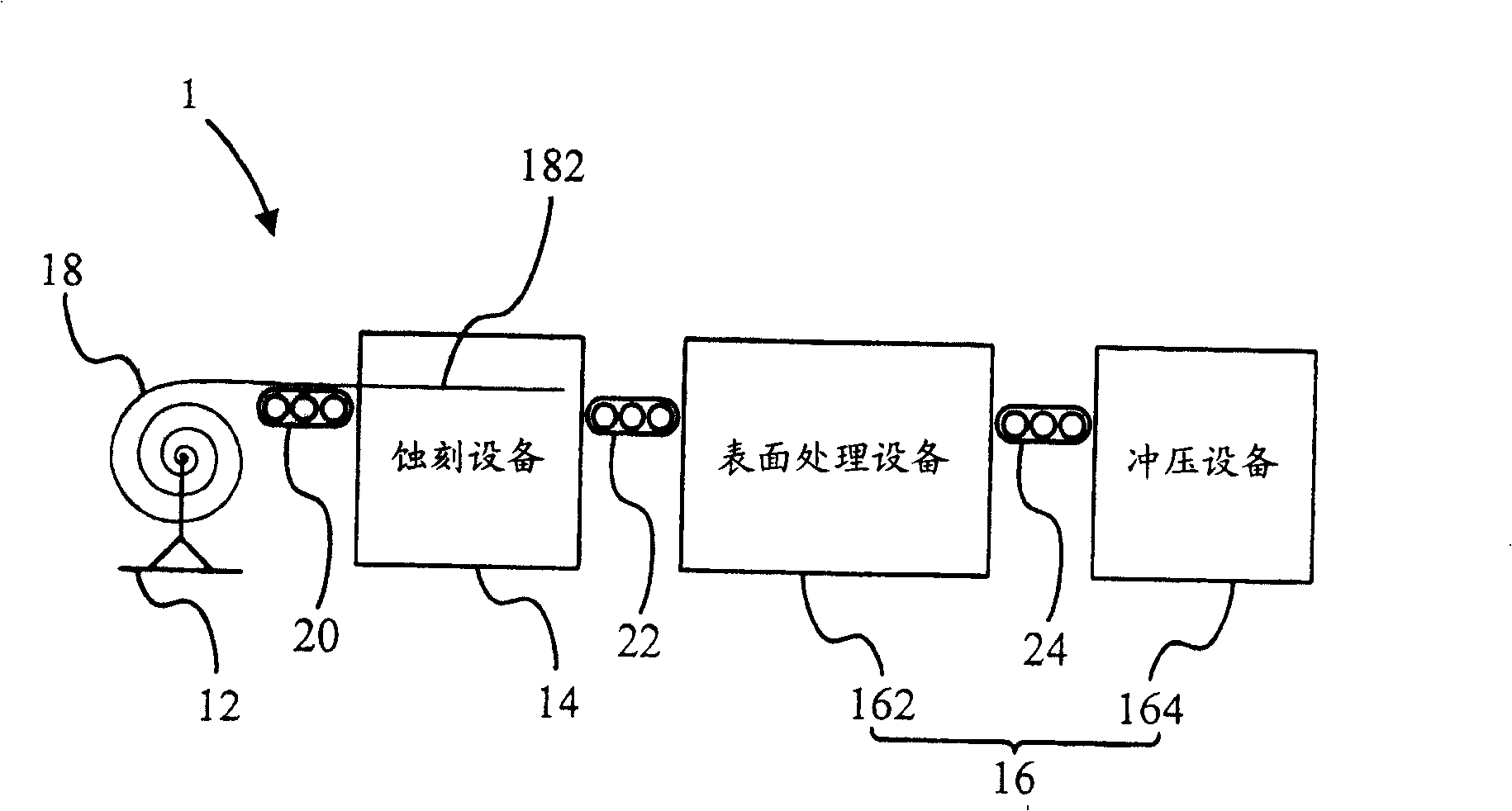

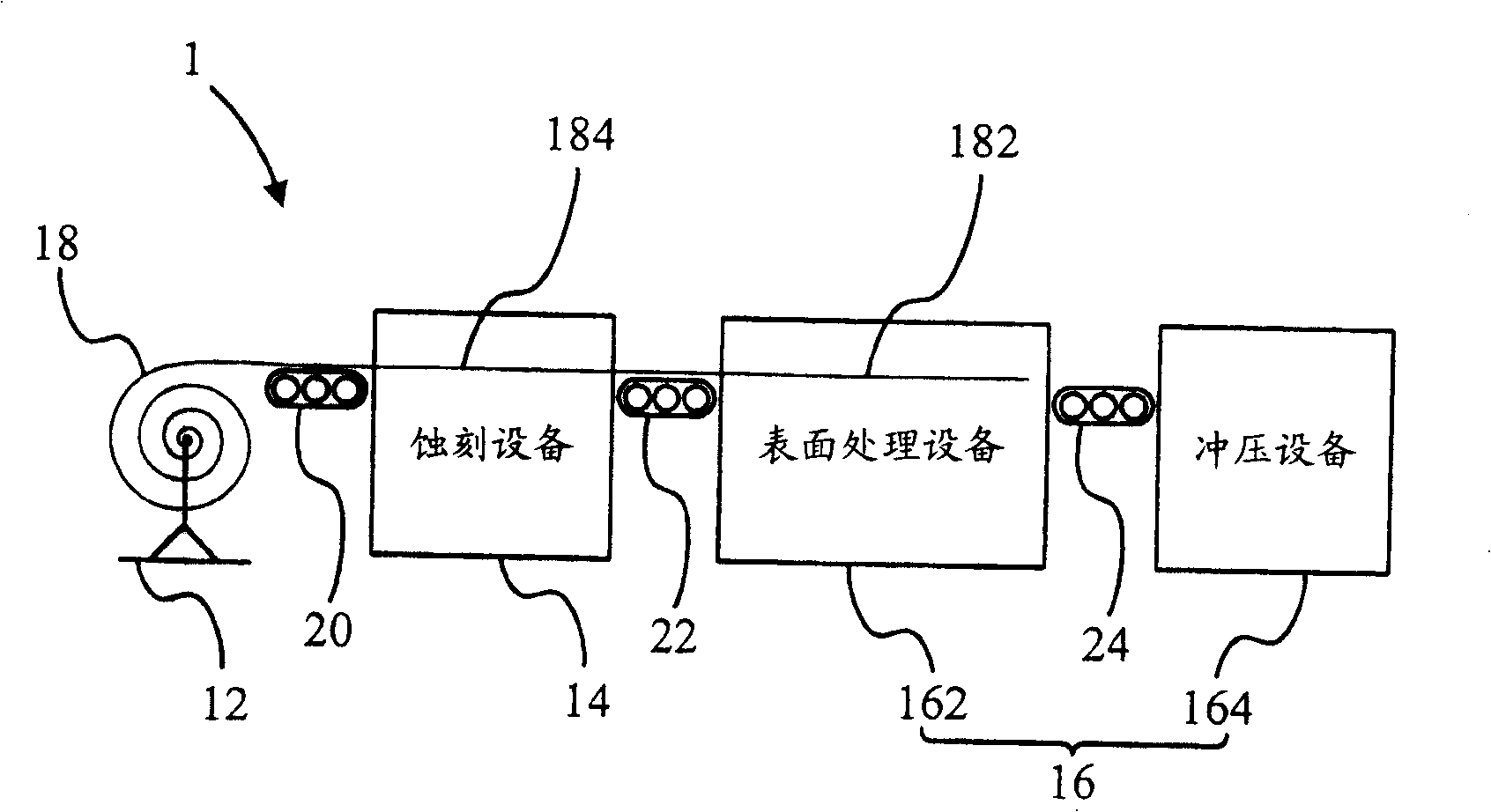

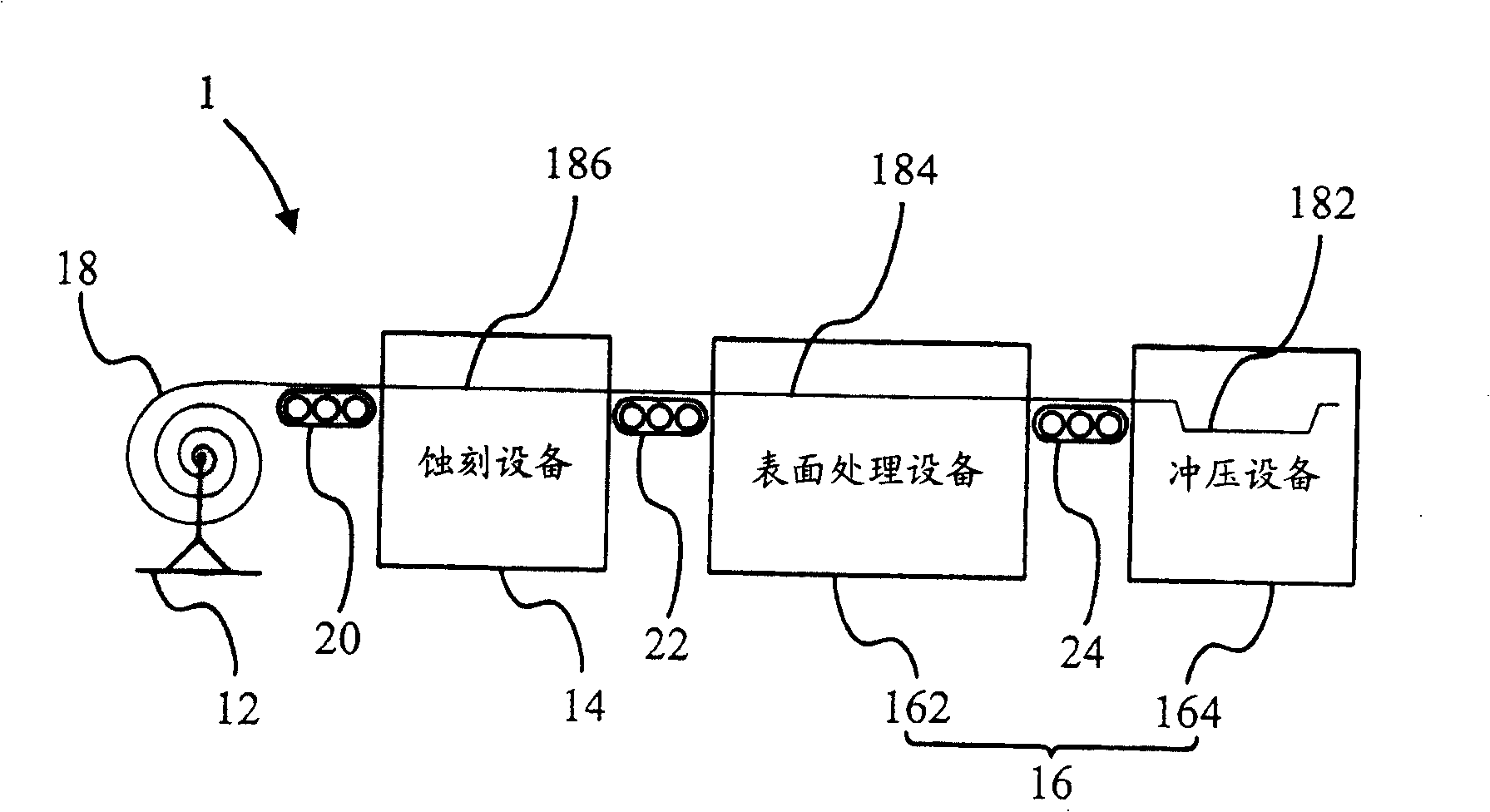

Method and system for manufacturing metal case

InactiveCN101247706AAvoid handlingReduce variablesTelevision system detailsMetal casingsMetalSurface processing

The invention provides method for manufacturing metal casing, which includes steps as follows: (a) stocking a roll of metal plate; (b) extruding a part of metal plate from the roll of metal plate in proper sequence; (c) etching a plurality of holes on the part of metal plate; and (d) forming the part of metal plate to generate metal casing. Step (d) also includes: applying surface process to the part of metal plate; and punch forming the part of metal plate to generate metal casing. Therein, surface process step and punch forming step can be exchanged. The invention also provides a system for manufacturing metal casing, which includes feeder equipment, etching equipment and forming equipment. Metal casing can be manufactured continuously by using the method, and semifinished product management problem in traditional production process can be avoided.

Owner:MARKETECH INT

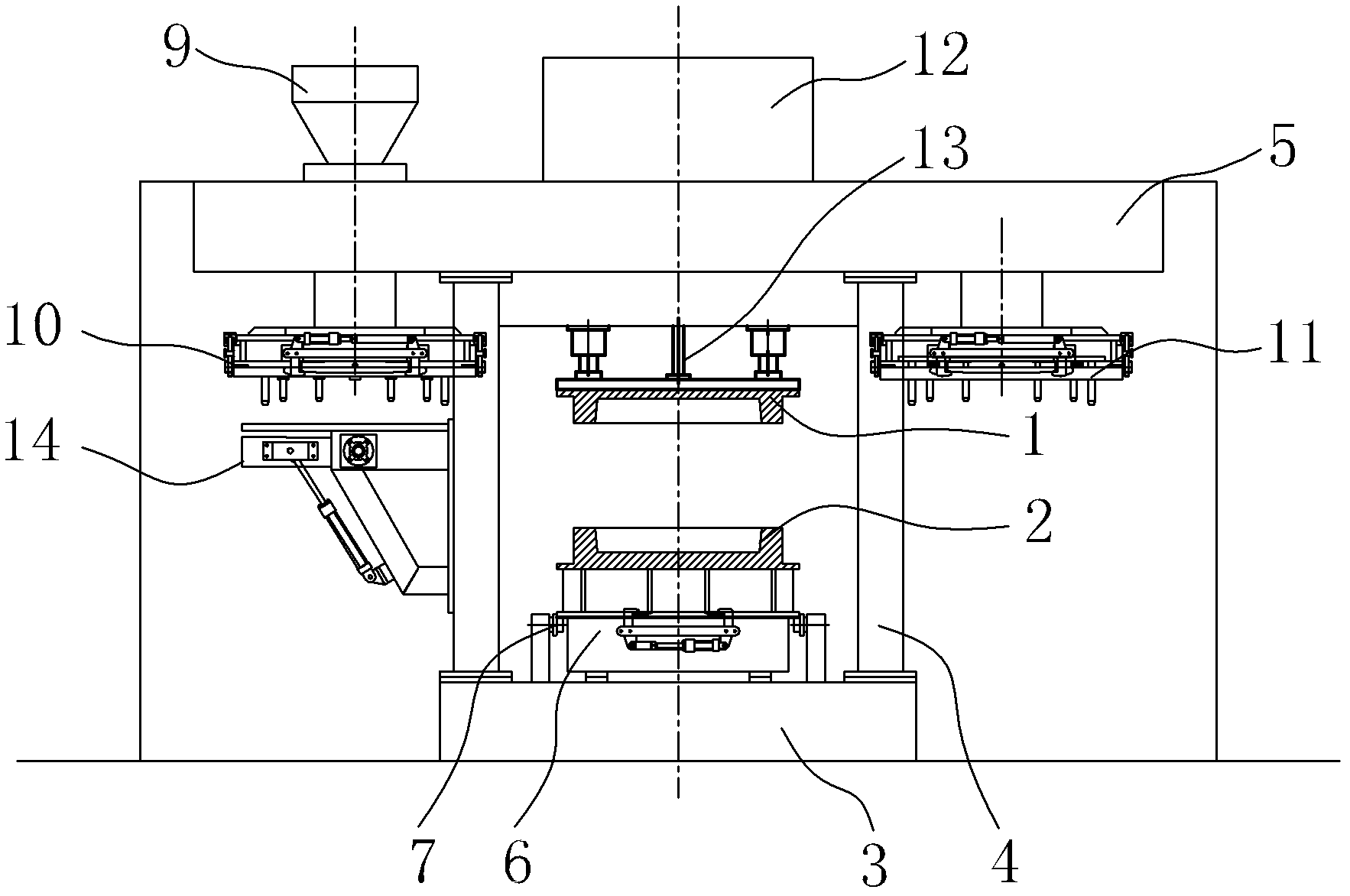

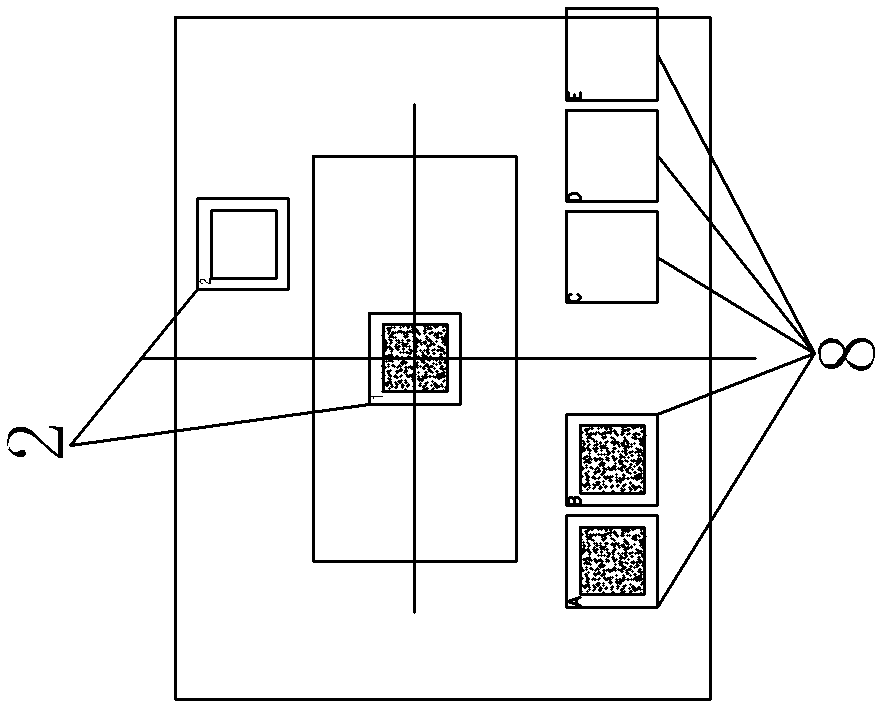

On-line core making technology and device

ActiveCN102626772AGuaranteed dimensional accuracyHigh dimensional accuracyFoundry mouldsMoulding machinesEngineeringDimensional precision

The present invention relates to an on-line core making technology. The technology comprises steps of: carrying out sand shooting and curing at a core making position in an upper die and a lower die to form a sand core; removing the sand core from the lower die, leaving the sand core in the upper die and removing the lower die from the core making position; moving a pallet into the core making position, removing the sand core from the upper die and putting the sand core on the pallet; and moving the pallet out of the core making position. An on-line core making device comprises a frame, an upper die, a lower die and a sand shooting air blowing component. The lower die is movably arranged on the frame, and the frame can be movably provided with a plurality of pallets; during core making, the lower die is below the upper die; and during core connection, the pallet is located under the lower die. The invention solves a problem of moving a molded sand core from a core box to the pallet and ensures size precision of the molded sand core and the stability of the sand core, so as to improve size precision, performance and quality of the final casting, simplify system configuration, cancel a handling process from the core box to the pallet achieved by a robot and a spreader or an artificial sling and improve the reliability of the system.

Owner:SUZHOU MINGZHI TECH

Spout member and packaging bag utilizing same

InactiveUS20110293202A1Excellent handle property and hygiene management performanceCut operationCapsClosure capsEngineeringInternal pressure

It is aimed to provide a spout member and a packaging bag using the spout member which have excellent handling property and hygiene management performance at the time of supplying water or the like from the outside before and during use such as administration of water and medicine, in which a closure means for freely opening and closing an aperture formed by cutting off parts of peripheral portions of sealed film pieces is protected from a contained content at the time of storage or transportation and which have excellent protecting property even when an inner pressure acts in the packaging bag, excellent contamination preventing property until a spout is opened and excellent contamination preventing property and handling property after opening.In a packaging bag formed by sealing peripheral portions of a plurality of film pieces and including an inlet portion and a spout portion at the peripheral portions, the inlet portion is opened as an inlet port by cutting off parts of the peripheral portions of the sealed film pieces to form an aperture by an unsealed portion, at least two holes are formed at the opposite sides of a part which becomes the inlet port at the peripheral portions near the inlet portion, and the holes serve as a suspension means for enabling the packaging bag to be suspended and a finger holding means. An operable and closable closure means including first and second members engageable with each other is formed by bonding an upper part of a first base member including the first member and an upper part of a second base member including the second member respectively to inner sides of the film pieces forming the aperture and facing each other, and a bottom end portion of one base member is formed to be longer than that of the other base member and bonded to the other film piece opposite thereto by an easily peelable seal, thereby forming an easily peelable portion which is peeled open to open the aperture at the time of opening. A spout member is provided with a spout portion including a base portion and a cylindrical portion projecting from the base portion, a sealing portion for sealing a tip portion of the cylindrical portion via a tearable weakened portion, and a cap portion. The weakened portion is torn by turning the cap portion to separate the sealing portion and the cap portion from the spout portion and simultaneously open the tip portion of the cylindrical portion, thereby forming a spout. The cap portion is shaped to cover the entire cylindrical portion, and the cap portion and the spout portion include a locking mechanism capable of locking the cap portion to the spout portion.

Owner:MORINAGA MILK IND CO LTD +1

Device for maintaining separate ingredients in liquid food products

InactiveUS20020011277A1Reduce manufacturing costEfficient use ofCapsLiquid fillingAdditive ingredientEngineering

A device for maintaining ingredients separately within a container, of the type having a removable container cap applied on a neck with a central opening, has a sub-container body mounted in the container neck which is formed with a proximate end having screw threads which can be engaged with internal screw threads in the container neck for holding them securely together to allow the ingredients to be shaken out of the sub-container body and mixed with fluid in the container. The sub-container body can have inner divider walls forming multiple compartments with respective orifices for dispensing ingredients selectively from the compartments. The sub-container body may be sealed to the underside of the cap with a sealing film, or seated on the neck rim and held by the cap. In one version, the proximate end of the sub-container body has a protruding shape with inclined walls for guiding it into the neck opening. In other versions, the sub-container body is formed integrally with the container cap, or is formed as an annular ring shape carried between inner and outer flanges of the cap. These improved devices allow viscous or powdered ingredients to be mixed by shaking with fluid in the container without risk of spilling or splashing outside the container.

Owner:CASTILLO JAMES A

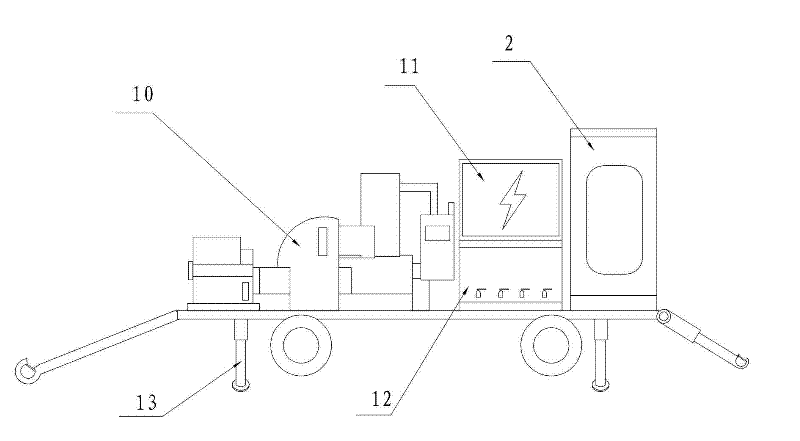

Telescopic belt conveying two-way loading/unloading machine

The invention discloses a telescopic belt conveying two-way loading / unloading machine, and relates to the field of logistics transportation goods loading / unloading mechanical equipment. The telescopic belt conveying two-way loading / unloading machine consists of a vehicle with bearing and walking functions, a rotating arm with a swing rotating function, a middle transition conveyor capable of aslant conveying, a belt conveyor 1 with amplitude change, swing rotating and extension functions, a belt conveyor 2, a metering device with metering, displaying, storage and printing functions, and an operation control system for operating the whole loading / unloading machine. The telescopic belt conveying two-way loading / unloading machine is simple in structure, reliable in work, convenient and fast in movement and transfer and wide in operation range, can reduce manual auxiliary carrying, relieves the labor intensity, shortens the operation time, improves the loading / unloading efficiency, reduces the loading / unloading carrying cost, improves the working environment and labor conditions, guarantees economical, fast, convenient and safe loading / unloading transportation, can change the logistics conveying direction, realizes forward / reverse two-way loading / unloading, and can automatically meter, count and record the loading / unloading number and weight for displaying and storage.

Owner:襄阳忠良工程机械有限责任公司

Moving belt type conveying loading and unloading machine

InactiveCN106629136AReduce wasteReduce investmentConveyorsSupporting framesWorking environmentEngineering

The invention discloses a moving belt type conveying loading and unloading machine and relates to the field of logistic transporting cargo loading, unloading and carrying equipment. The moving belt type conveying loading and unloading machine comprises a bearing vehicle, a sliding trolley, a middle conveyor, a transition conveyor, a feeding conveyor, a discharging conveyor, a metering device and an operation control system of the moving belt type conveying loading and unloading machine. The sliding trolley is arranged on the bearing vehicle. The two ends of the sliding trolley are symmetrically installed on the feeding conveyor and the discharging conveyor. The middle conveyor is installed at the middle portion of the sliding trolley. The metering device is installed on the middle conveyor. The transition conveyor is fixed to a bracket of the discharging conveyor. The moving belt type conveying loading and unloading machine is simple in structure and reliable in work, moving and field transferring are convenient and fast, the work range is large, manual auxiliary carrying can be reduced, the labor intensity is lowered, the work time is shortened, the loading and unloading work efficiency is improved, the loading and unloading carrying cost is reduced, the work environment and labor conditions are improved, it is ensured that loading and unloading transporting is economic, fast, convenient and safe, the logistic conveying direction can be changed, positive and negative bidirectional loading and unloading are achieved, and the loading and unloading number and weight are automatically metered, counted and recorded and are displayed and stored.

Owner:襄阳忠良工程机械有限责任公司

Method of using a formable core block for a resin impregnation process

ActiveUS8440120B2Avoid handlingAvoid layeringFinal product manufactureMovable spraying apparatusResin dispensingEngineering

A use of a core block for an impregnation process as well as a composite structure comprising such a core block is described. The core block has a first surface and a second surface, and a number of first grooves is formed in the first surface of the core. Furthermore, a number of second grooves is formed in the second surface of the core. The first grooves have a first height (h1) and a bottom, and the first grooves and the second grooves are part of a resin distribution network formed in the core block. The distance (t) between the bottom of the first grooves and the second surface of the core block is of such a size that the core block is flexible along the first grooves. Additionally, the sum of the first height and the second height is larger than the thickness of the core block, and at least one of the first grooves in the first surface of the core block crosses at least one of the second grooves in the second surface of the core block.

Owner:LM GLASSFIBER

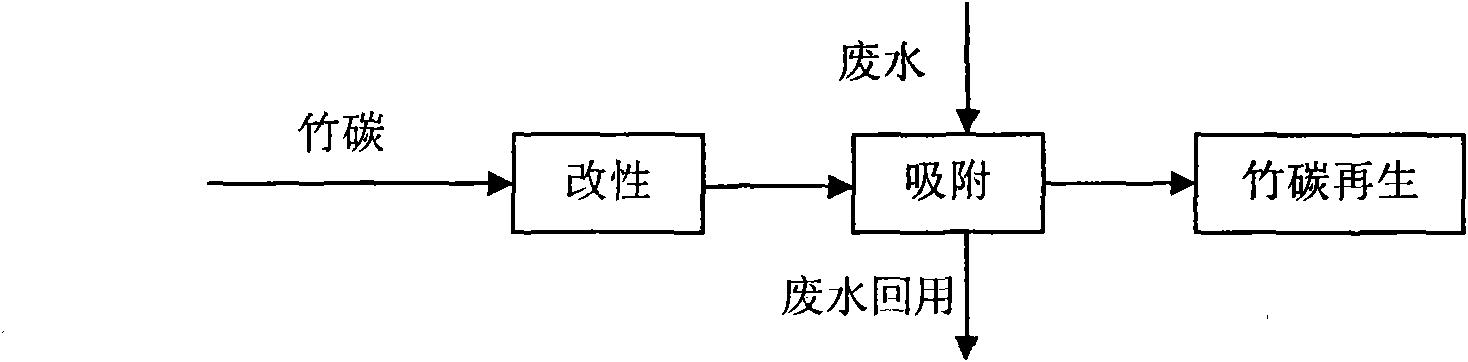

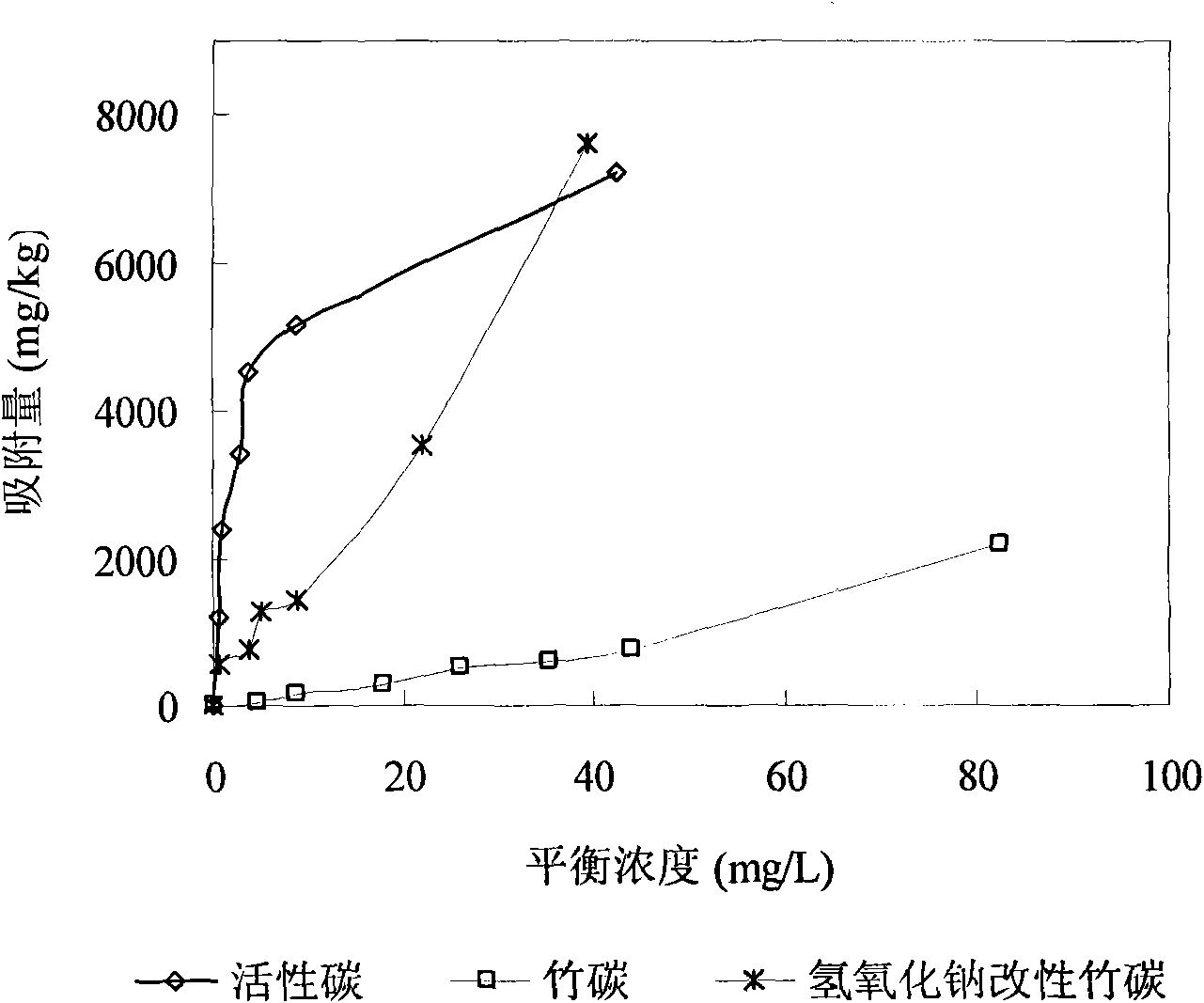

Method for adsorbing, recycling and disposing wastewater

InactiveCN101555045AAvoid handlingAchieve regenerationOther chemical processesCombustible gas purificationNitro compoundFenton reagent

The invention discloses a method for adsorbing, recycling and disposing a wastewater, which is suitable for disposing water body polluted by difficultly degraded organics (nitro compounds, halogenated organics, etc.) and comprises the following steps of: (1) crushing block-shaped bamboo charcoal into powders (10-1000 meshes) and washing the powders by water to remove impurities; (2) soaking the pre-disposed bamboo charcoal powders with concentrated nitric acid (10-70%) or concentrated sodium hydroxide (10-40%) and washing the solution by water to neutral; (3) using the modified bamboo charcoal to adsorb the released wastewater meeting the standard and recycling the released water; and (4) oxidating the bamboo charcoal with saturated adsorption by Fenton reagent (the mixing aqueous solution of H2O2 and Fe, wherein the concentration of the H2O2 solution is 0.1-5%, the molar concentration ratio of H2O2 and Fe is 10:1-50:1 and the pH is 2-6) or ClO2 aqueous solution (0.5-5%), and recovering the adsorbing performance of the bamboo charcoal. The method has the advantages of low energy consumption, being friendly to environment, good disposal effect, convenient operation, etc.

Owner:HUAZHONG UNIV OF SCI & TECH

Two-way extending assembly brick clamp for shale-sintered thermal-insulating blocks

The invention discloses a two-way extending assembly brick clamp for shale-sintered thermal-insulating blocks. The two-way extending assembly brick clamp comprises a boosting clamping bar, a positive thread clamping bar, a sleeve and a negative thread clamping bar. All of the boosting clamping bar, the positive thread clamping bar and the negative thread clamping bar are L-shaped bars. The boosting clamping bar comprises a first brick clamp and a hand lever perpendicular to the first brick clamp, and the middle of the hand lever is provided with a round hole. The positive thread clamping bar comprises a clamping-bar connecting rod and a sleeve connecting screw rod perpendicular to the clamping-bar connecting rod; a round hole is formed at the tail end of the clamping-bar connecting rod which is connected onto the hand lever of the boosting clamping bar through a rotating shaft. The negative thread clamping bar comprises a screw rod and a second brick clamp perpendicular to the screw rod. One end of the sleeve is connected with the positive thread clamping bar while the other end of the sleeve is connected with the negative thread clamping bar. A clamping space is formed between the first brick clamp and the second brick clamp and used for allowing the clamped blocks to be disposed therein. By the brick clamp, the problem that the shale-sintered thermal-insulating blocks of different types cannot be carried with a single fixed-size brick clamp due to different sizes is solved, and block carrying and masonry construction are enabled to be more convenient.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com