Patents

Literature

40results about How to "Realize Orientation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

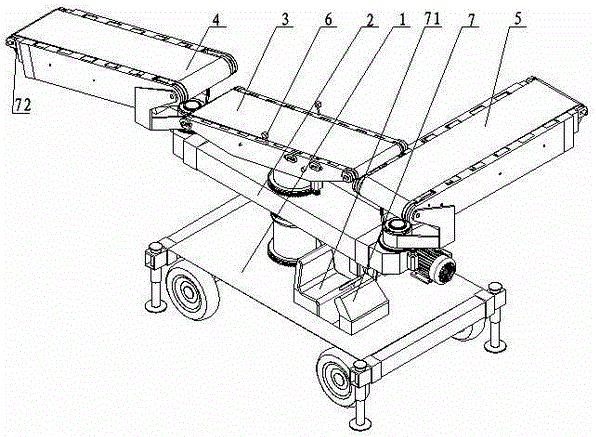

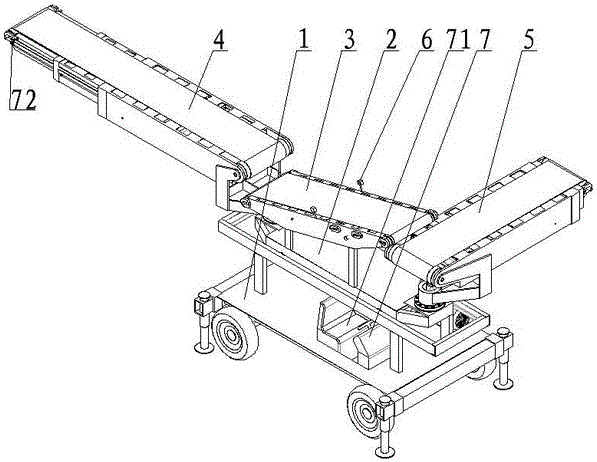

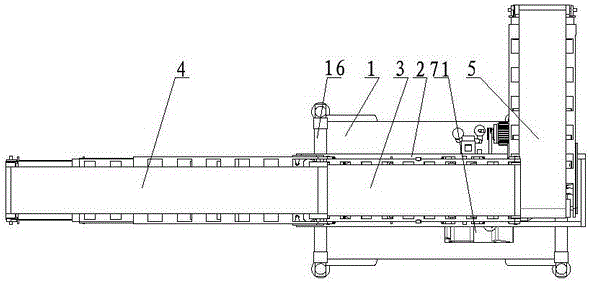

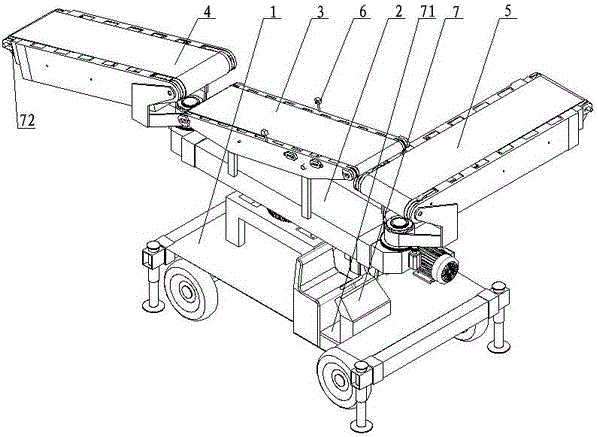

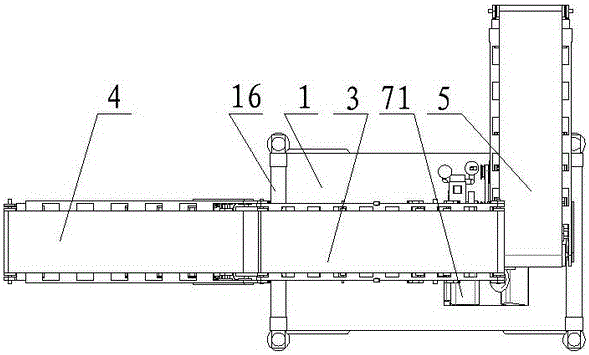

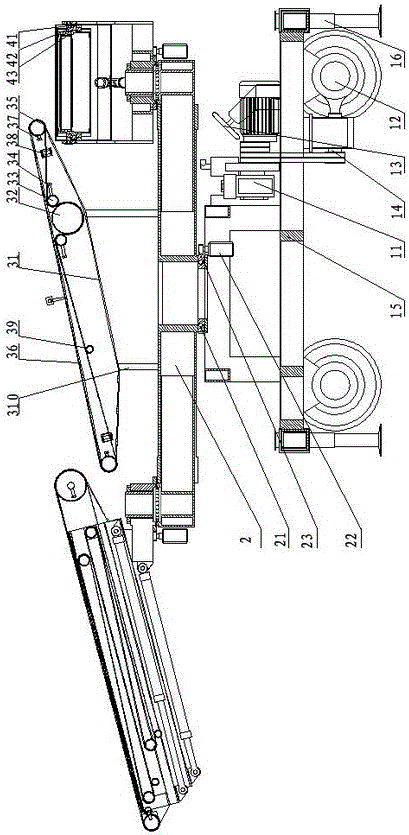

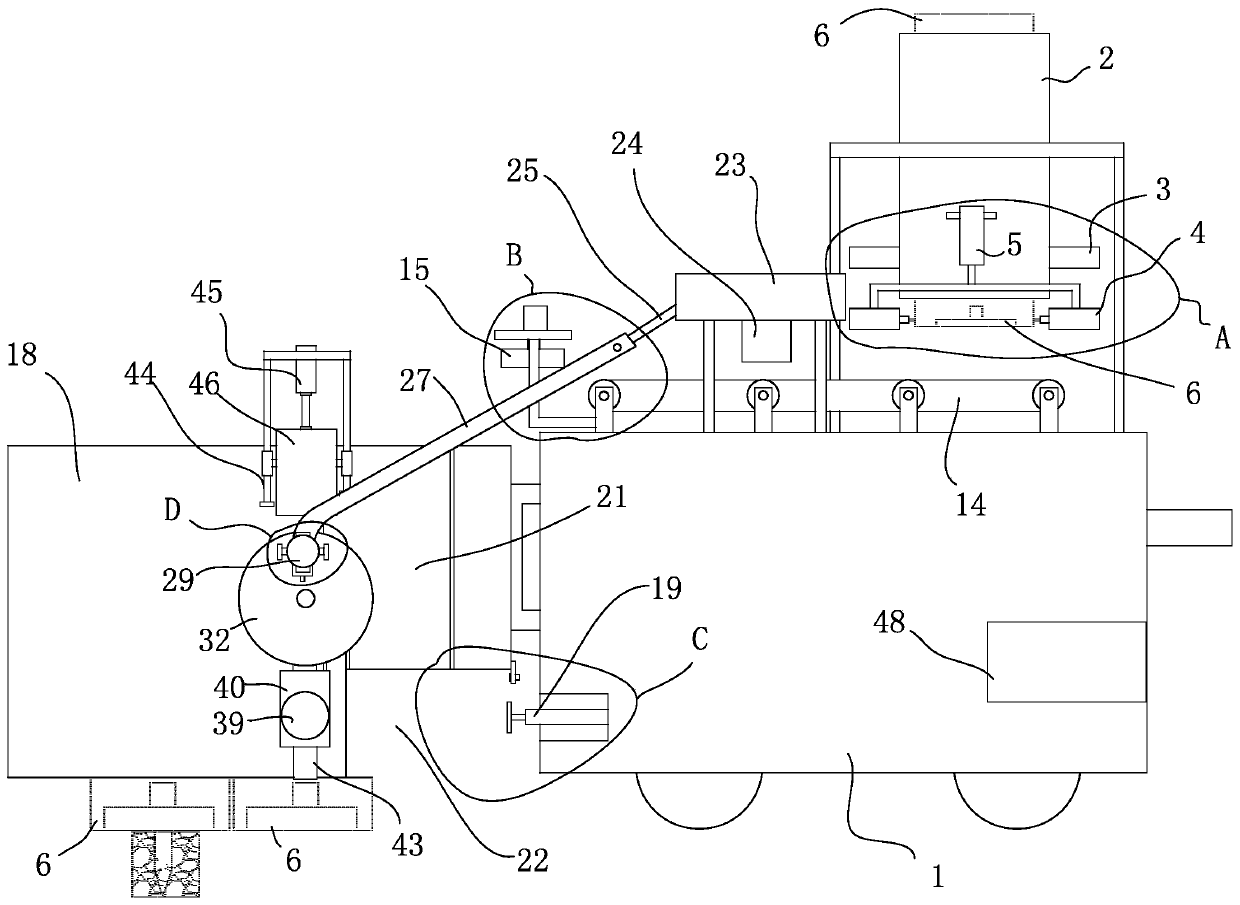

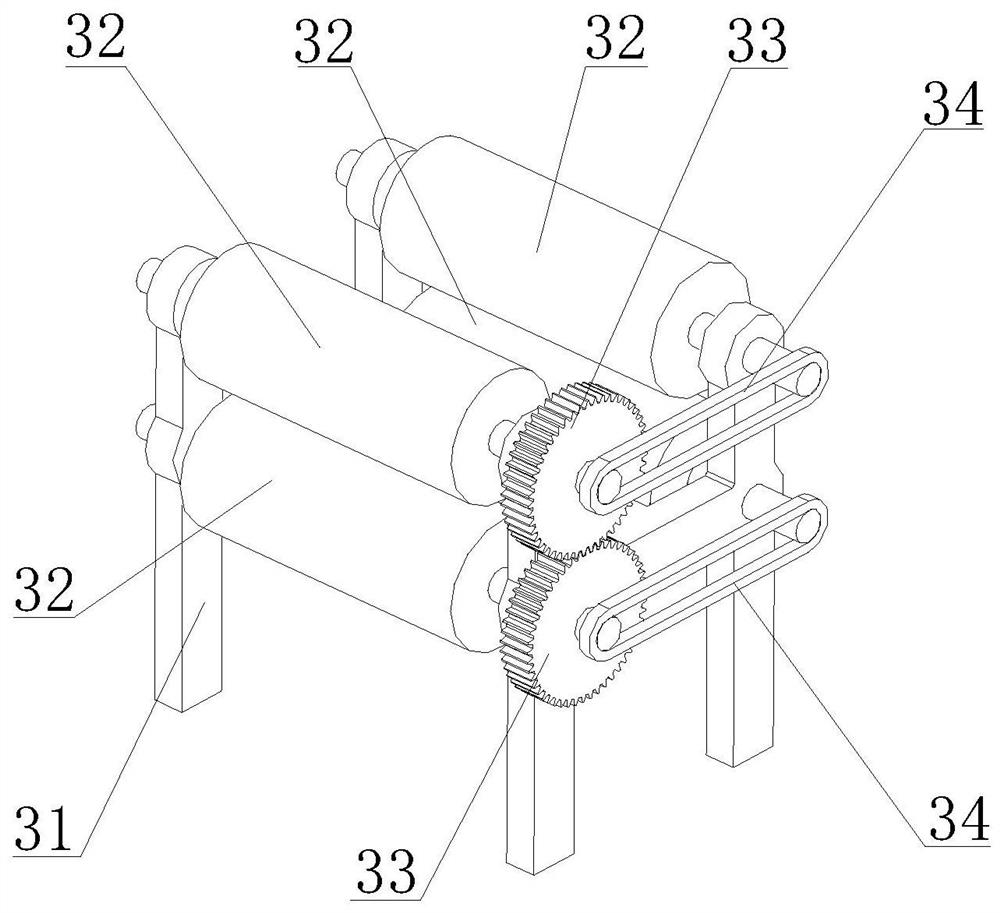

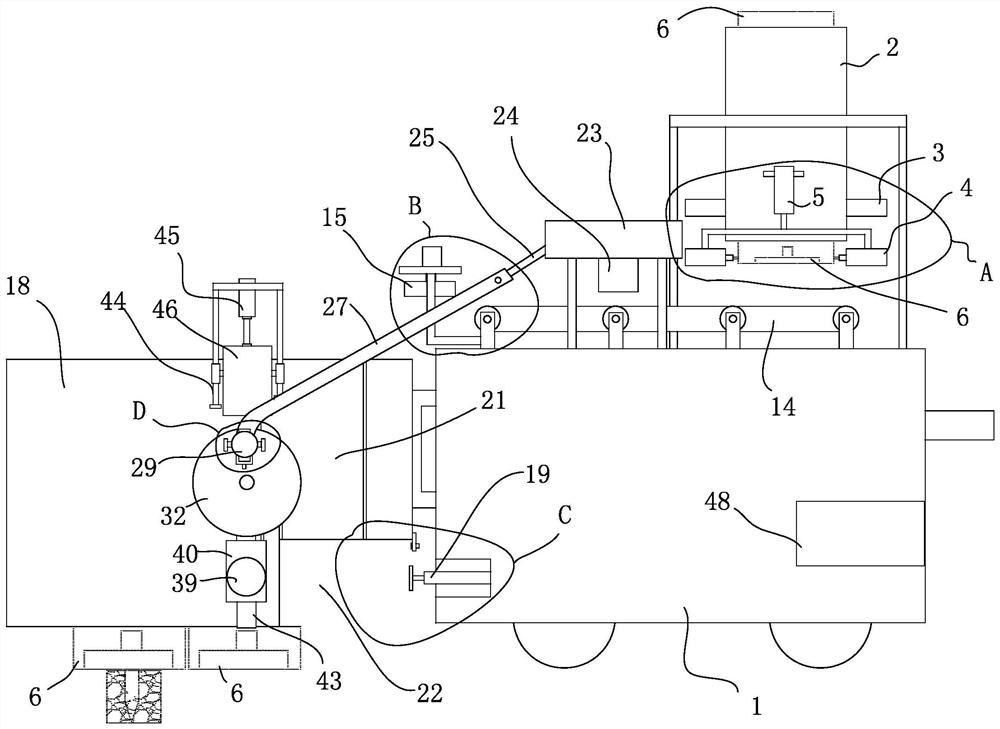

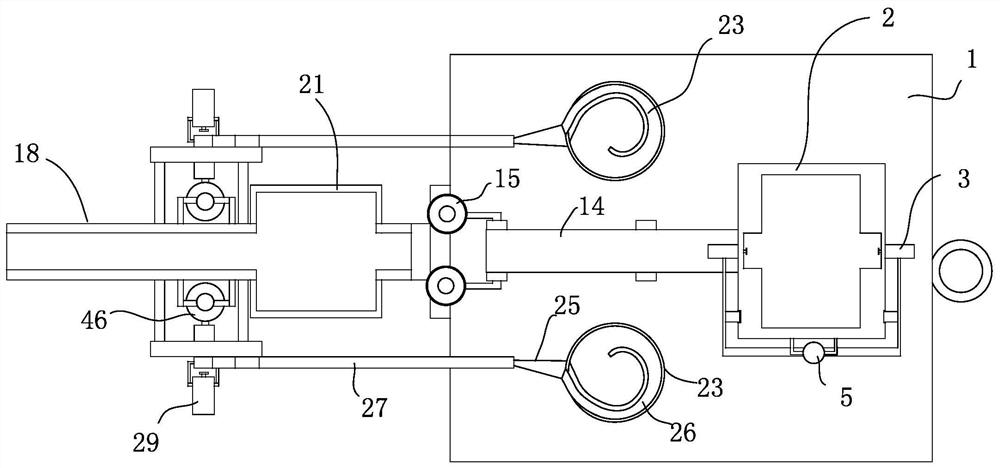

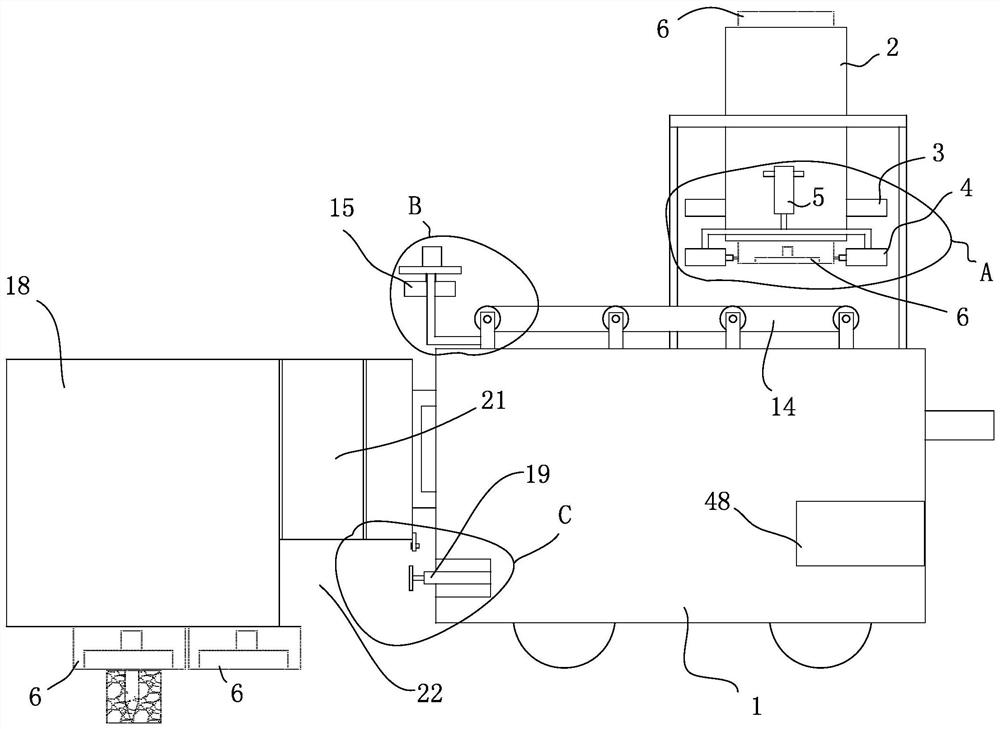

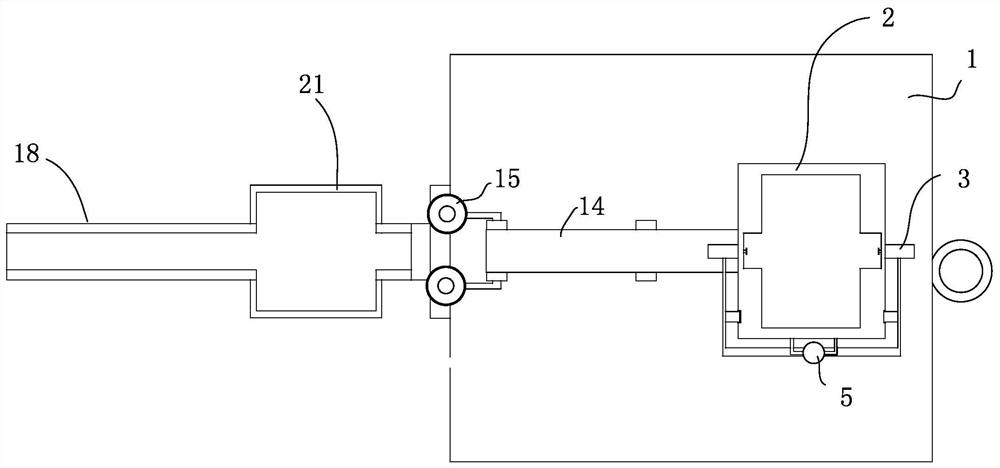

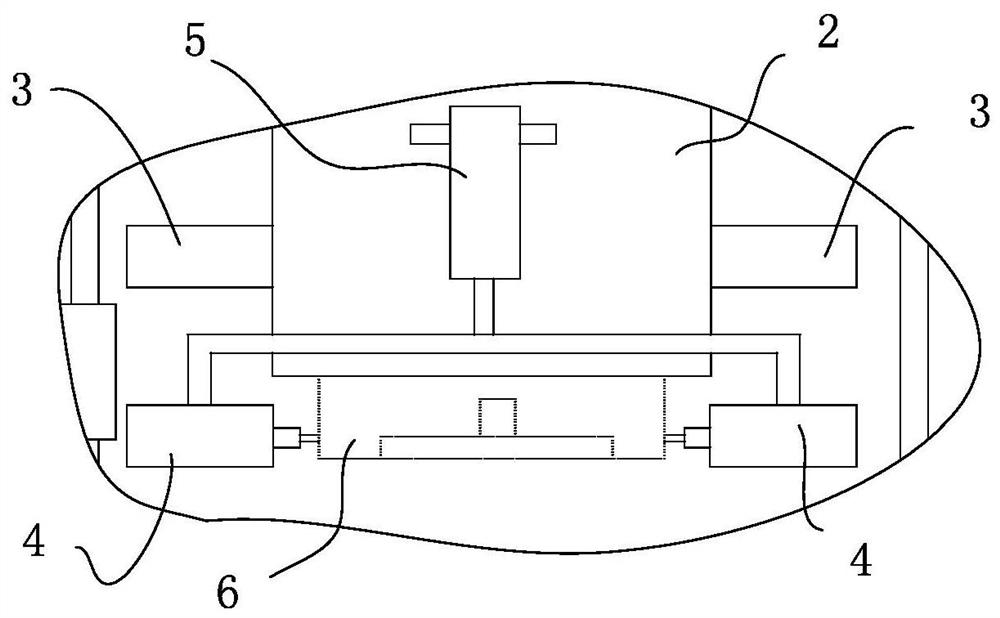

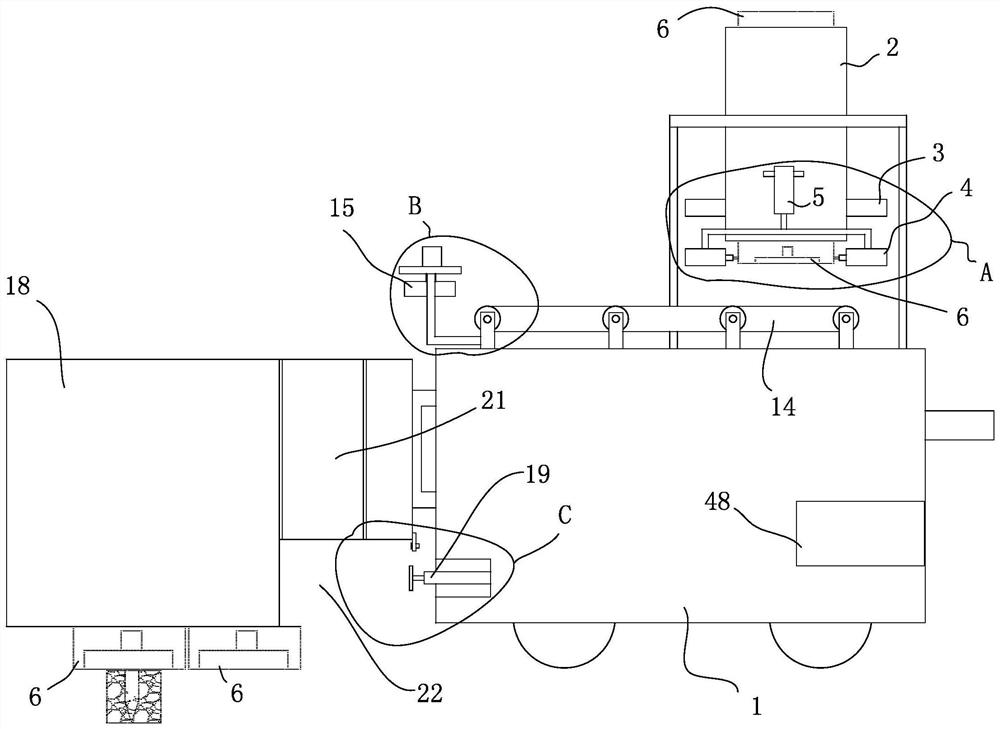

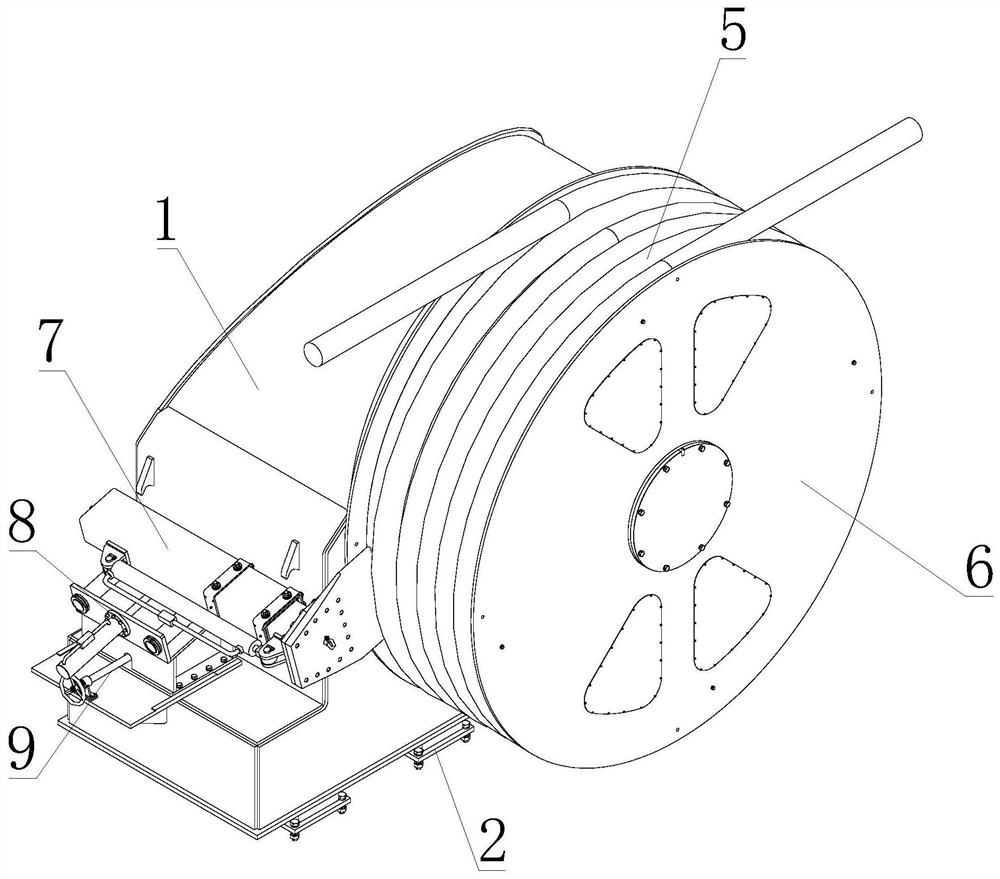

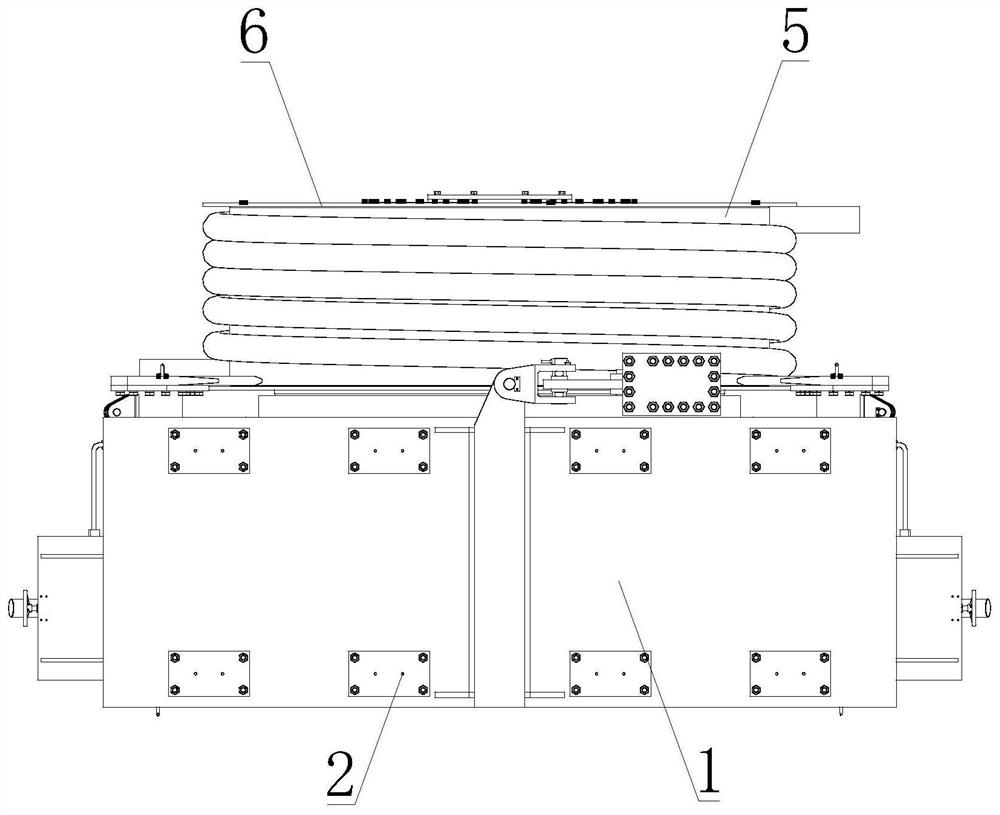

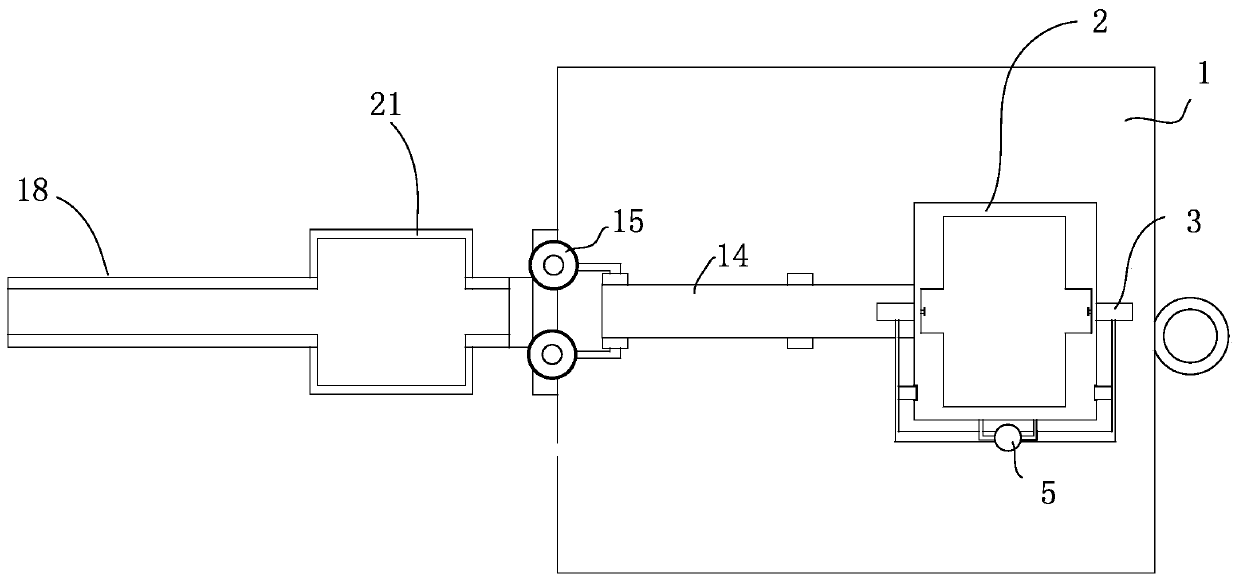

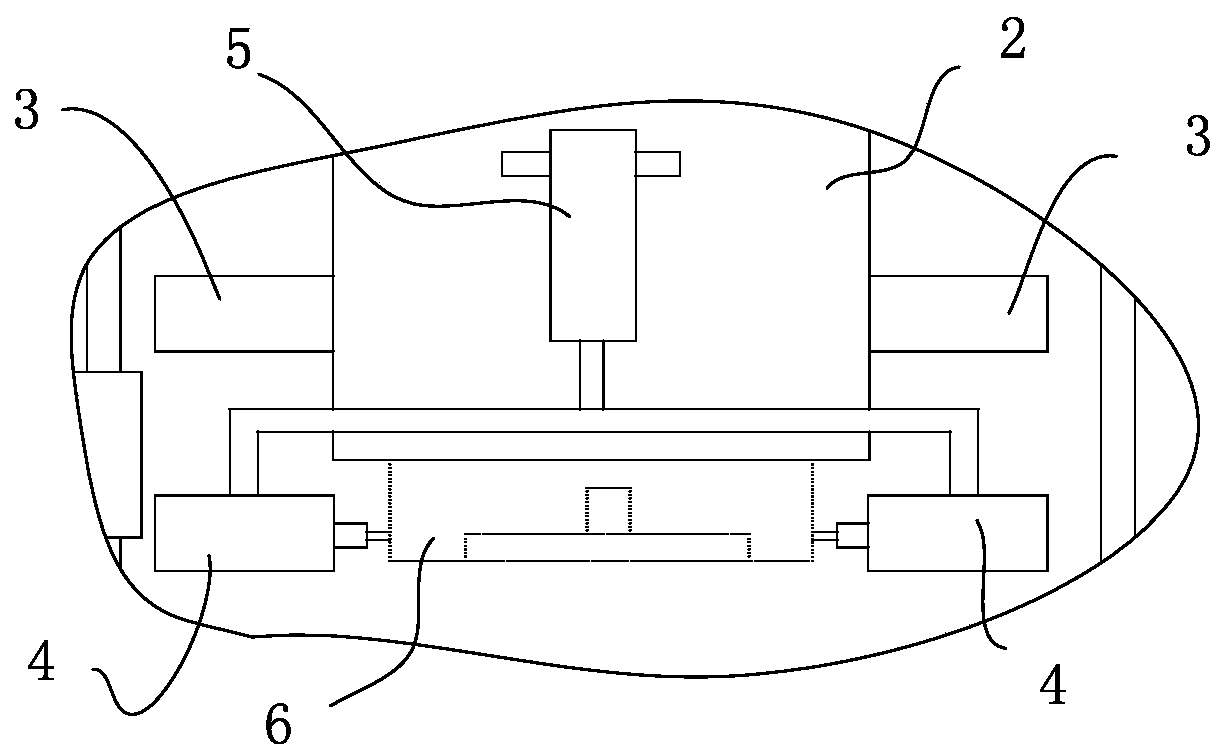

A derricking direction-changeable telescopic belt conveying bidirectional loader-unloader

InactiveCN106608551AAdjustable working heightRealize orientationConveyorsRollersControl systemStatistical analysis

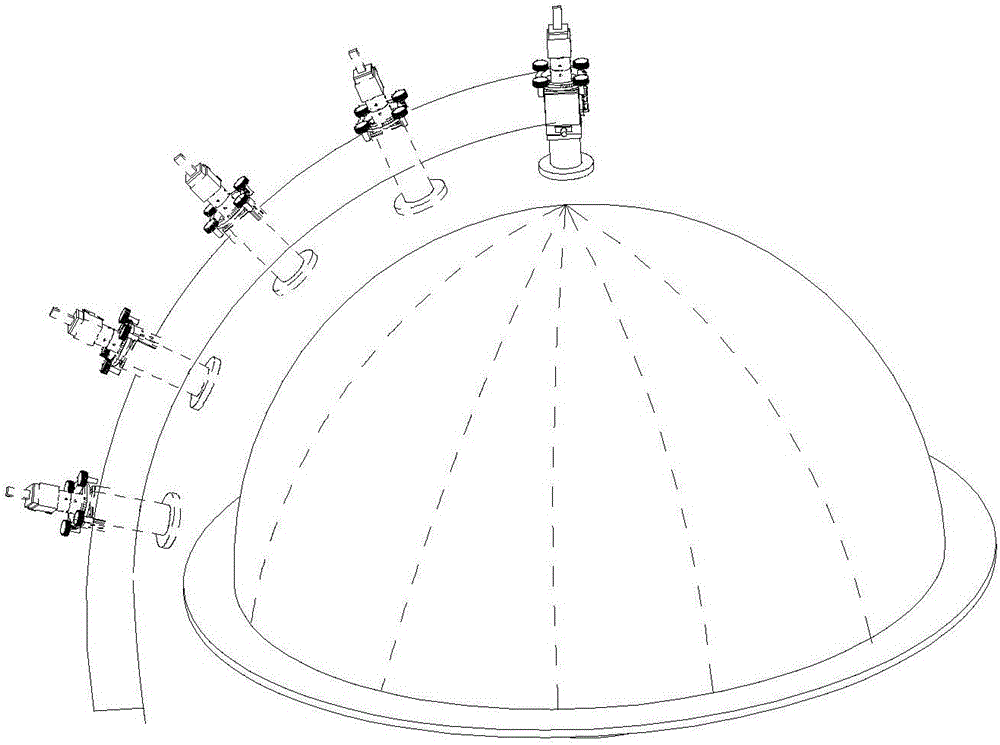

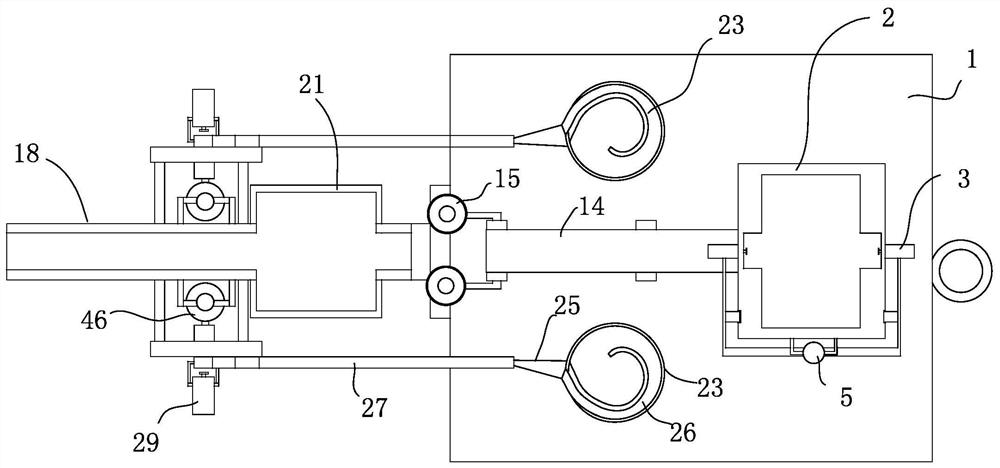

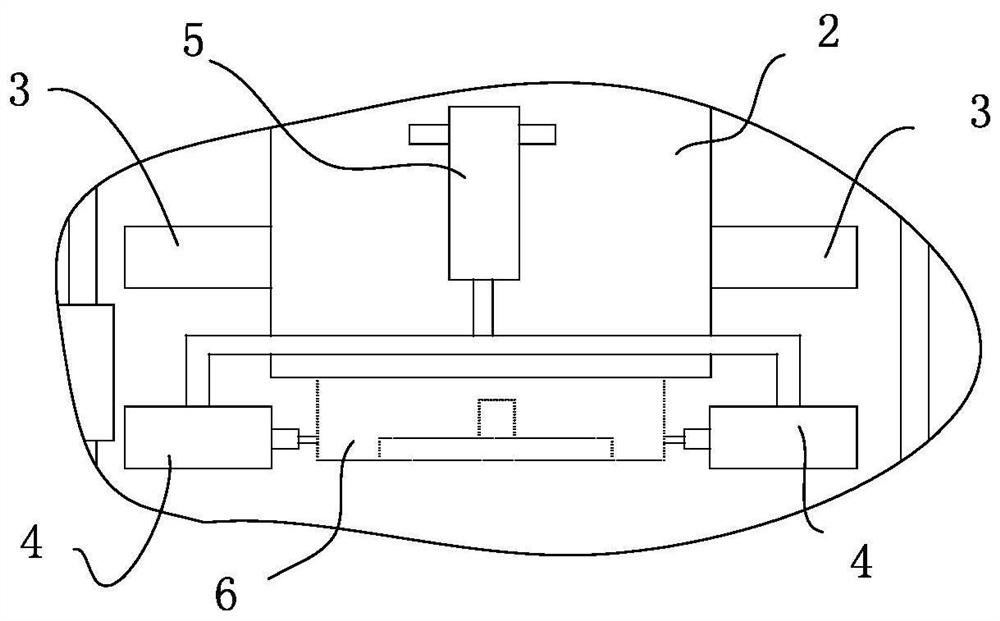

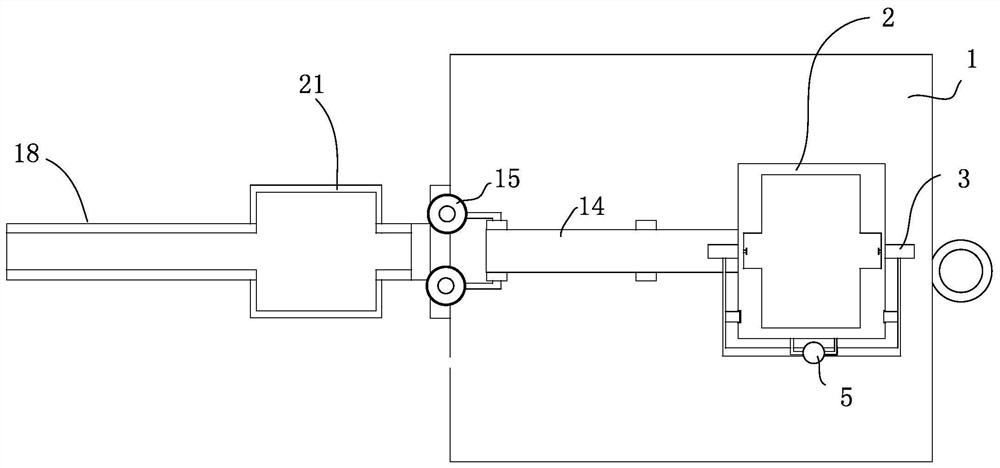

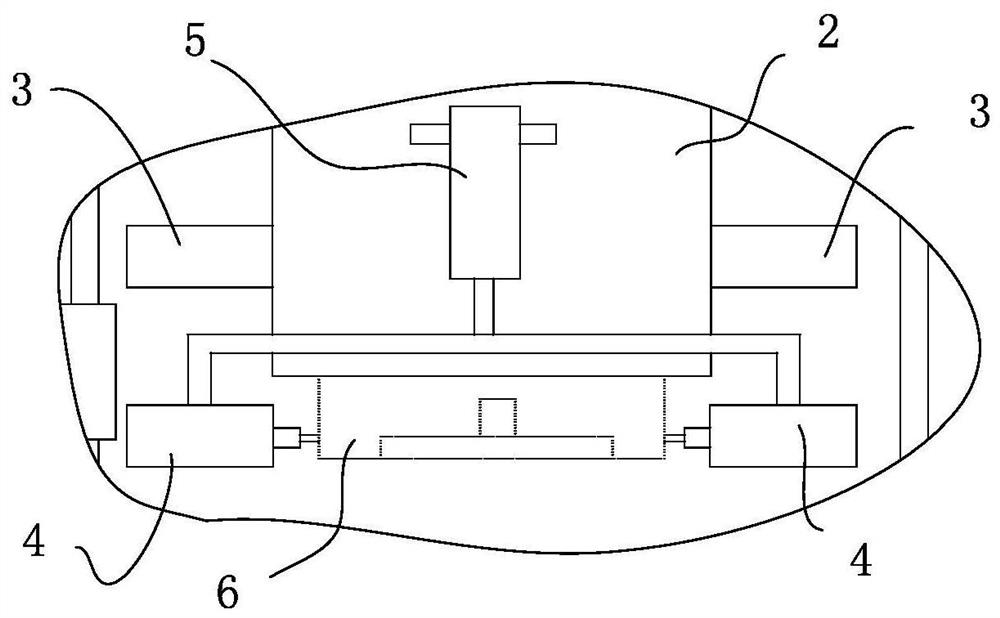

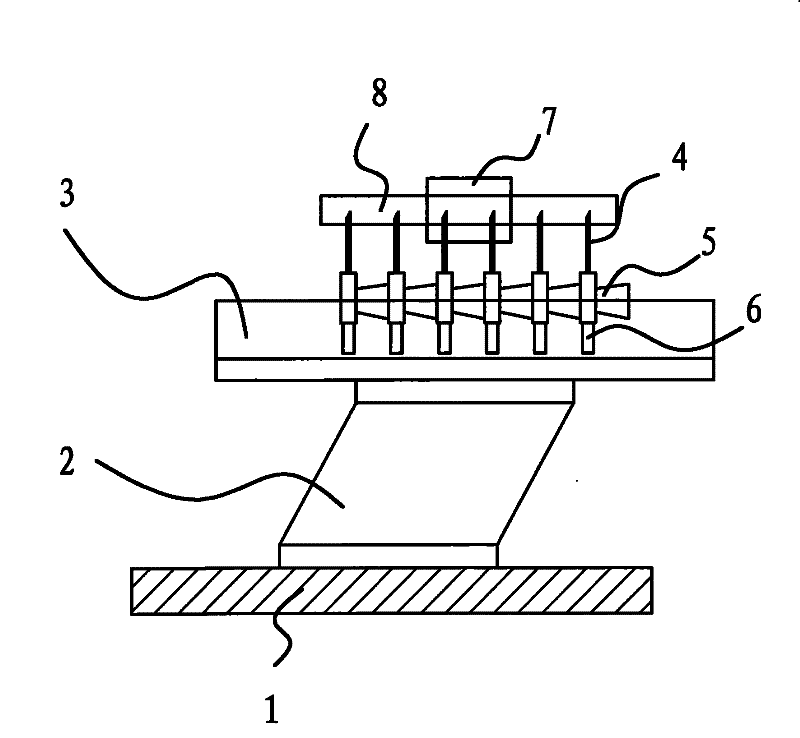

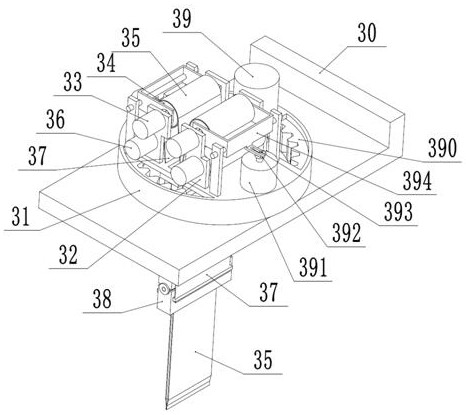

The invention provides a derricking direction-changeable telescopic belt conveying bidirectional loader-unloader and relates to the field of logistics transportation cargo loading and unloading mechanical equipment. The derricking direction-changeable telescopic belt conveying bidirectional loader-unloader comprises a vehicle having bearing and walking functions, a telescopic cross arm having lifting, telescoping and swinging functions, a middle transition conveyor which has a swinging function and is capable of inclined conveying, a first belt conveyor and a second belt conveyor having derricking, swinging and telescoping functions, a metering device having metering, displaying, storing and printing functions, and an operating control system used for complete machine operation of the loader-unloader. The derricking direction-changeable telescopic belt conveying bidirectional loader-unloader has the advantages of simple structure, reliable work, convenient and rapid movement and transfer, and wide operating scope; the derricking direction-changeable telescopic belt conveying bidirectional loader-unloader can reduce manually-assisted carrying, reduce workload, shorten operating time, increase loading and unloading working efficiency, reduce the cost of loading and unloading carrying, improve working environment and work conditions, guarantee economical, rapid, convenient and safe loading and unloading and transportation, allow change of the direction of logistics conveying, and realize forward and reverse loading and unloading, automatic metering statistical analysis, and loading and unloading quantity / weight recording, displaying and storing.

Owner:襄阳忠良工程机械有限责任公司

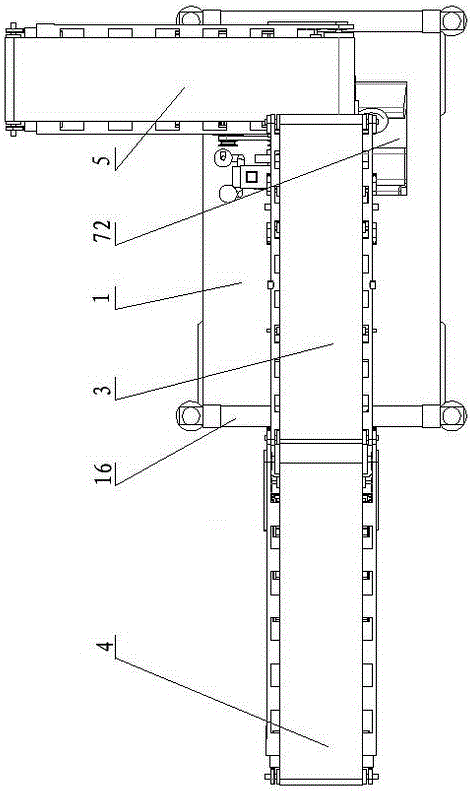

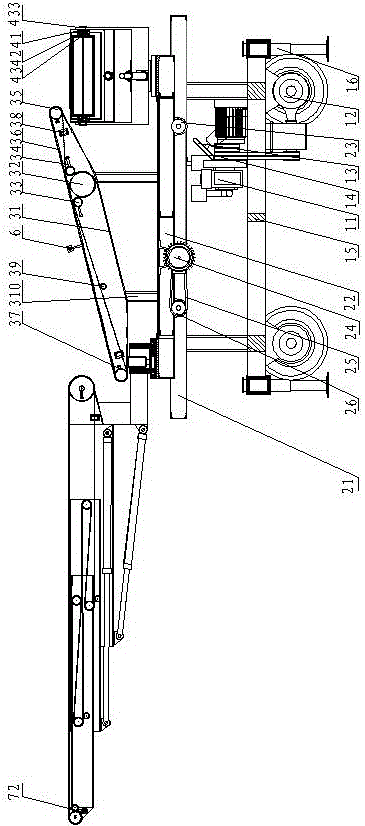

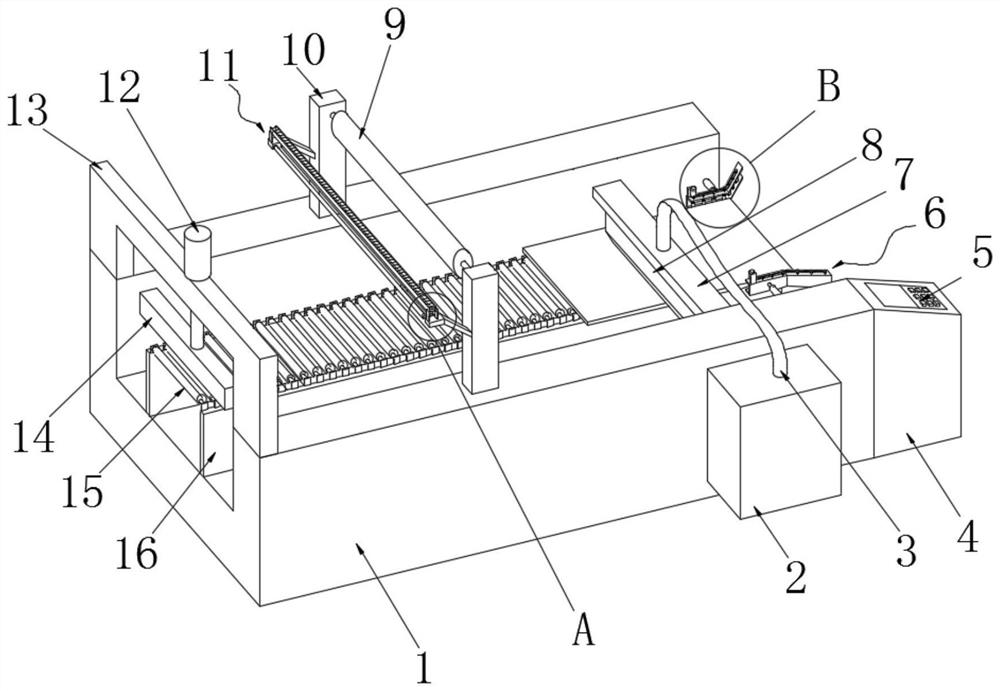

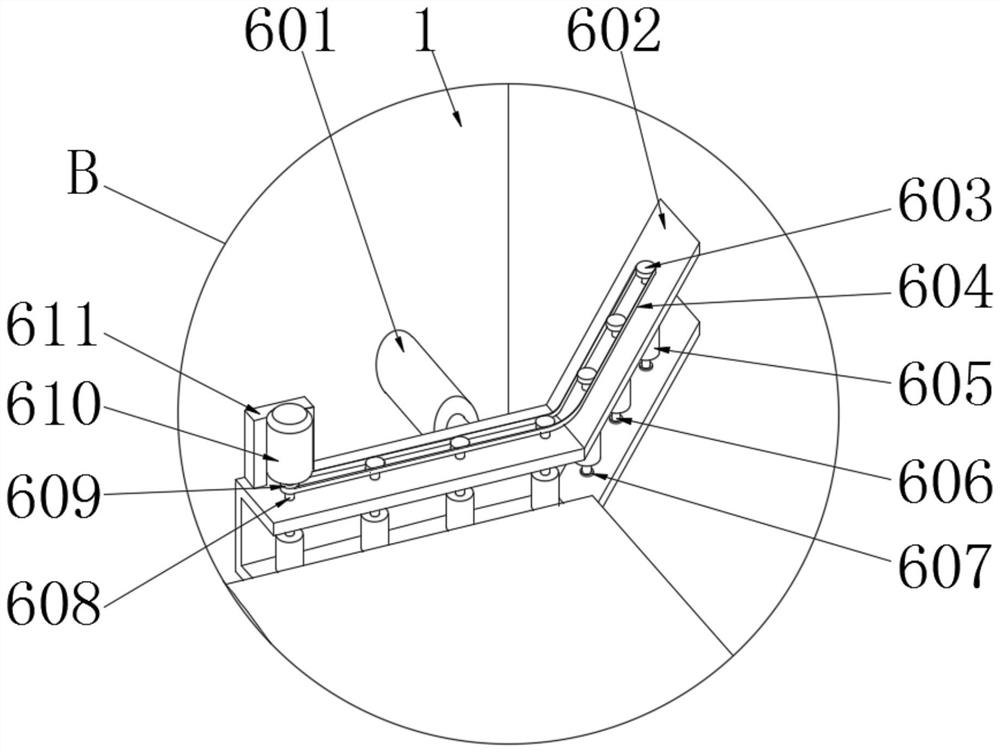

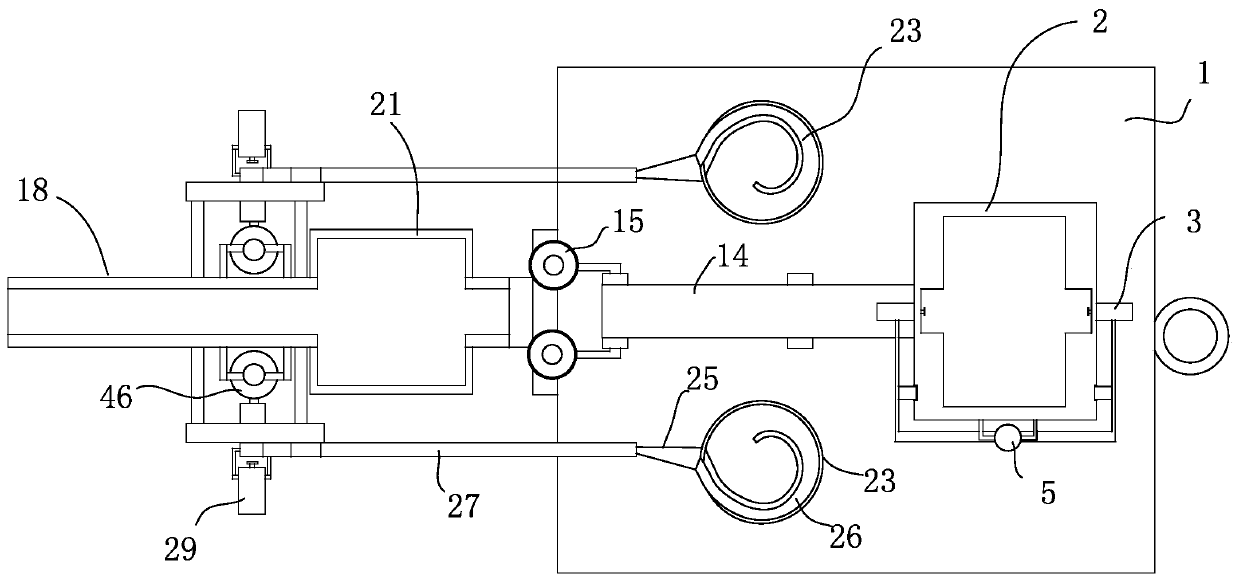

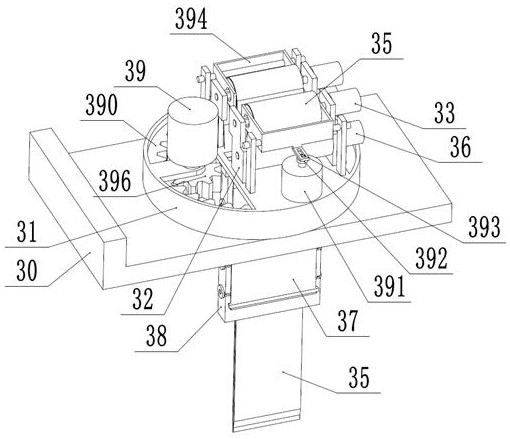

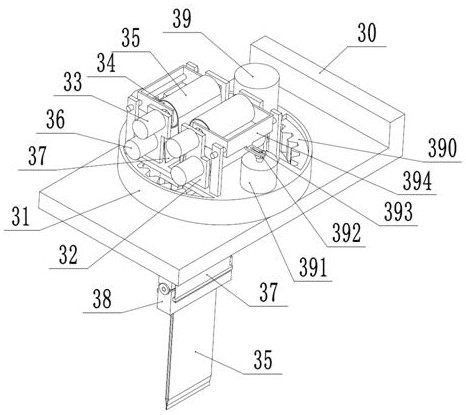

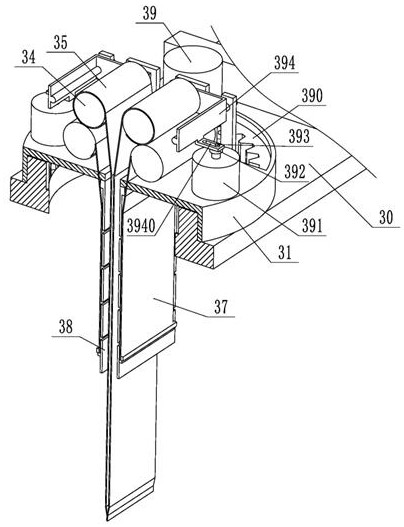

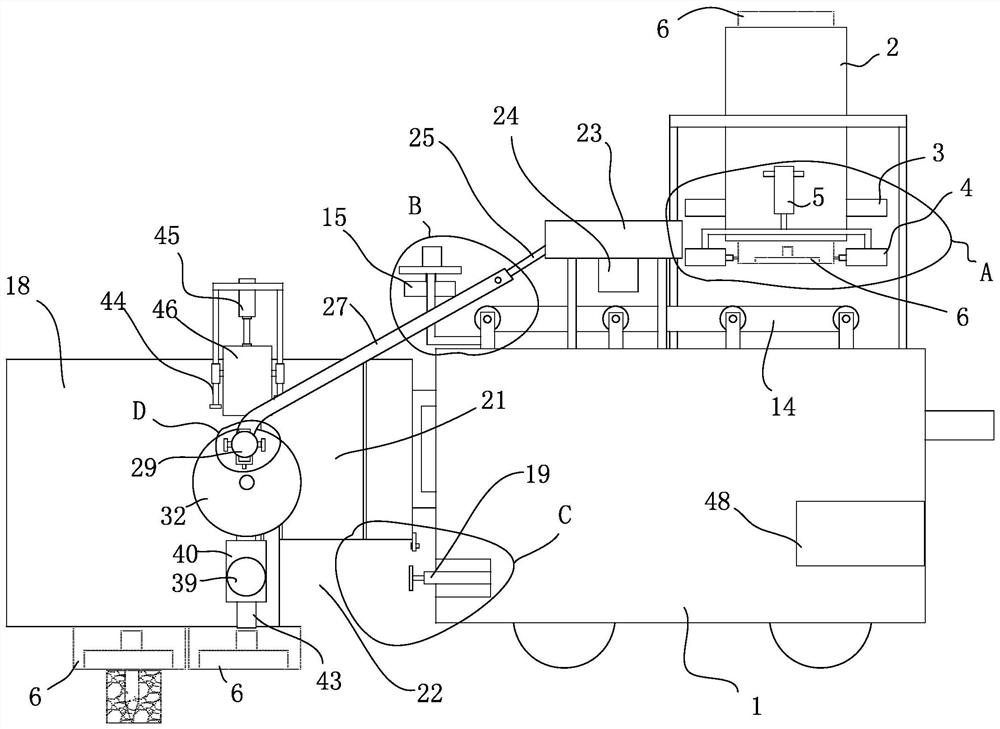

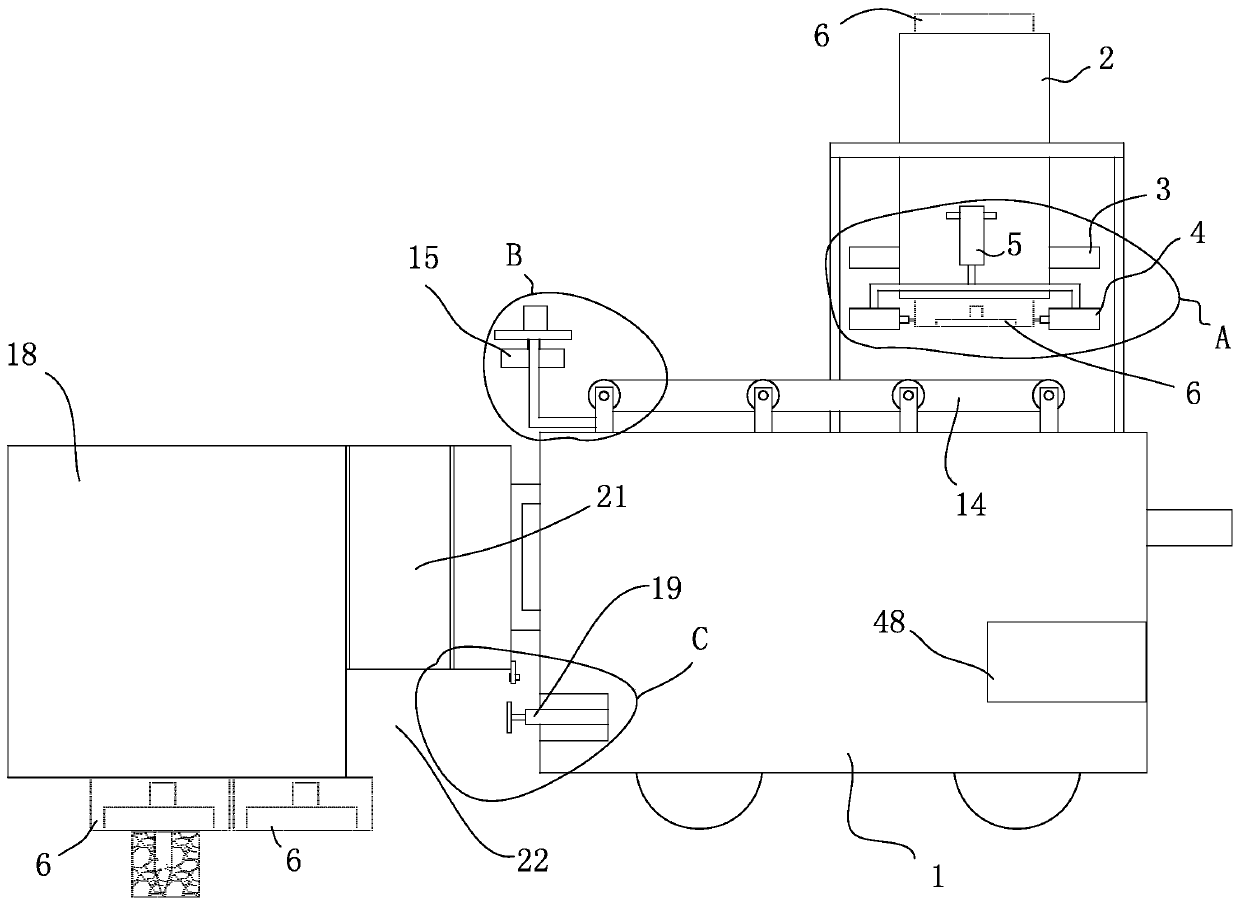

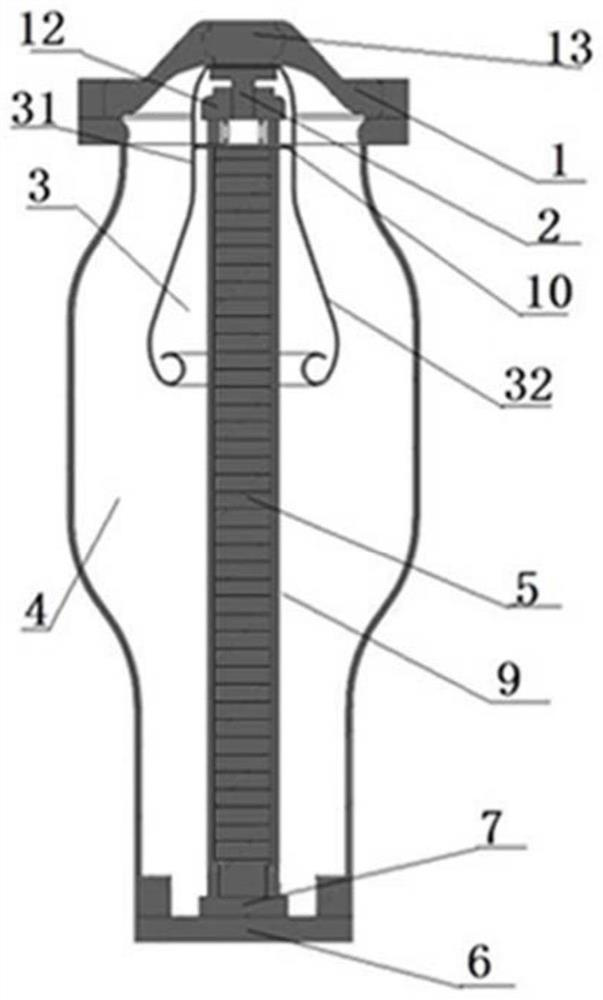

Amplitude-variable extensible belt turning conveying bidirectional loading-unloading machine

InactiveCN106629092AAdjustable workAdjustable postureConveyorsRollersWorking environmentMechanical equipment

The invention discloses an amplitude-variable extensible belt turning conveying bidirectional loading-unloading machine and relates to the field of logistics transportation cargo loading-unloading mechanical equipment. The loading-unloading machine is composed of a vehicle, a sliding platform, a middle transition conveyor, a first belt conveyor, a second belt conveyor, a metering device and an operation control system, wherein the vehicle has bearing and walking functions, the sliding platform has a sliding function, the middle transition conveyor is capable of achieving inclined conveying, the first belt conveyor and the second belt conveyor have amplitude changing, swing rotation and extending functions, the metering device has metering, display, storage and printing functions, and the operation control system is used for operation of the whole loading-unloading machine. According to the amplitude-variable extensible belt turning conveying bidirectional loading-unloading machine, the structure is simple, work is reliable, movement and place transfer are convenient and fast, the operation range is large, manual auxiliary carrying can be reduced, the labor intensity is lowered, operation time is shortened, the loading-unloading work efficiency is improved, the loading-unloading carrying cost is reduced, the working environment and labor conditions are improved, it is ensured that loading-unloading transportation is economical, fast, convenient and safe, the logistics transportation direction can be changed, forward and reverse bidirectional loading and unloading are achieved, and the loading-unloading number and weight can be automatically counted, recorded, displayed and stored.

Owner:襄阳忠良工程机械有限责任公司

Double-spiral-arm type luneberg lens antenna

PendingCN106785444AGuaranteed centripetalIncrease travel distanceAntennas earthing switches associationDouble supportPhysics

Owner:NO 54 INST OF CHINA ELECTRONICS SCI & TECH GRP

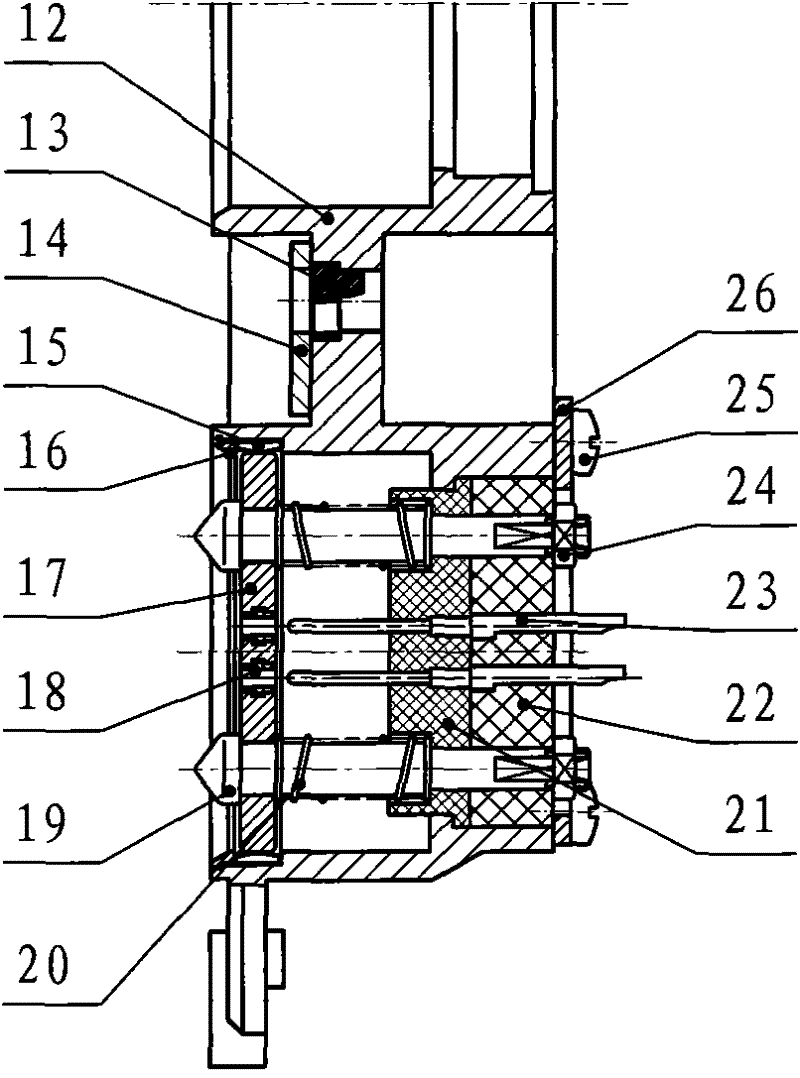

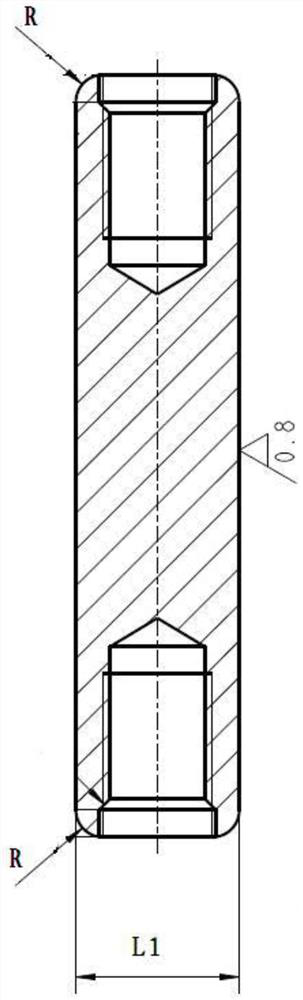

Cabinet-type electric connector

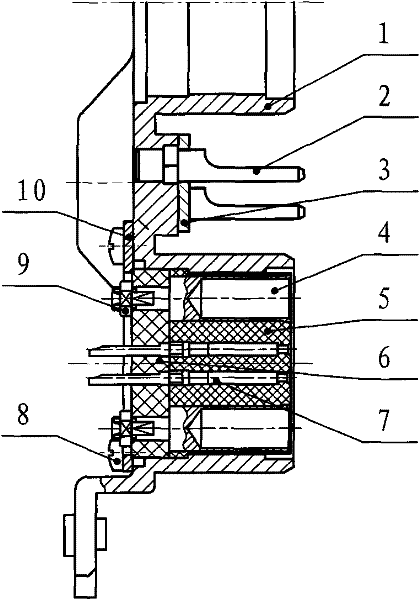

ActiveCN101714727AMeet the needs of the applicationWith electromagnetic shielding functionCoupling protective earth/shielding arrangementsElectricityEngineering

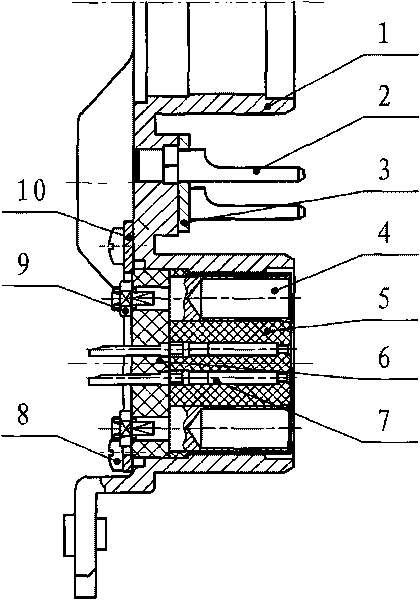

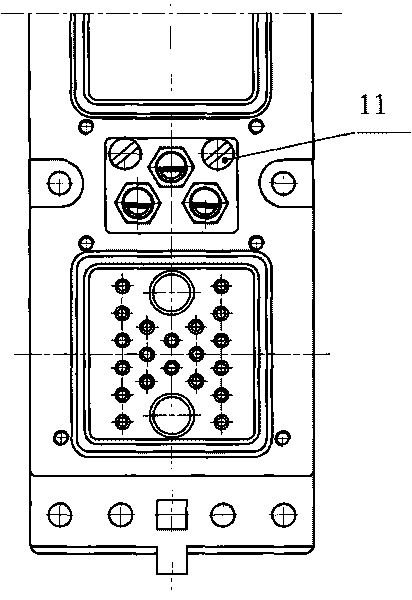

A cabinet-type electric connector consists of a plug and a socket; the plug and a shell of the socket are provided with a plurality of cavities for mounting a plurality of corresponding functional modules; and the abutting end of each functional module is provided with a mobile electromagnetic shielding device and a guide positioning device, wherein the mobile electromagnetic shielding device consists of a shielding plate, an elastic shielding reed, an insulating sleeve and a spring. By using a matching form of the mobile shielding plate and the elastic shielding reed, the electromagnetic shielding function after the connector is plugged and separated is well implemented; meanwhile, the arranged guide positioning device can well implement guiding and positioning when the plug is plugged in the socket so as to realize automatic alignment of the connector; and the cabinet-type electric connector has higher mounting error compensation capability, meets the requirements of cabinet-type application occasions, and has stronger practicability.

Owner:GUIZHOU SPACE APPLIANCE CO LTD

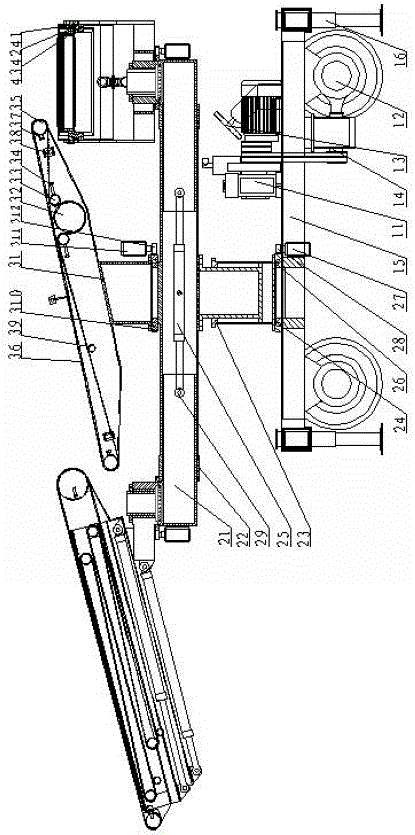

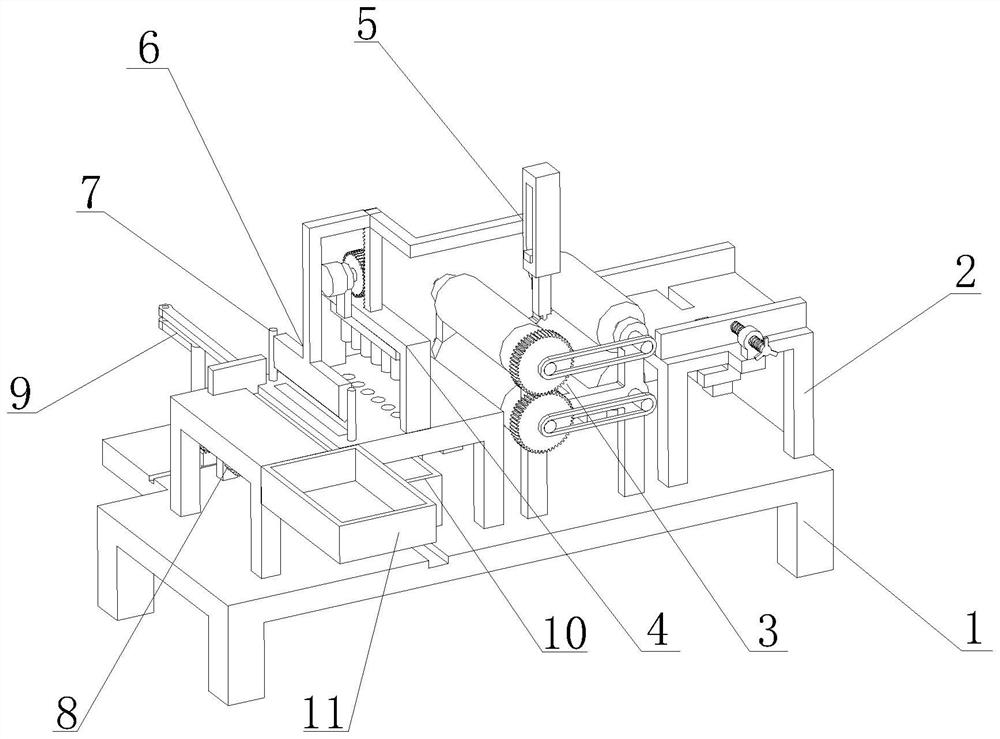

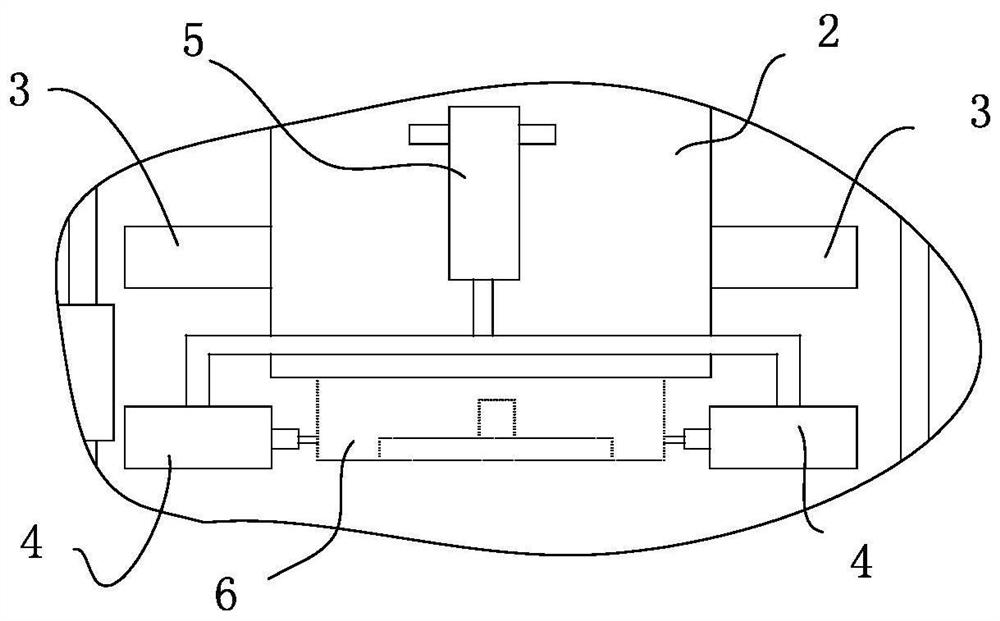

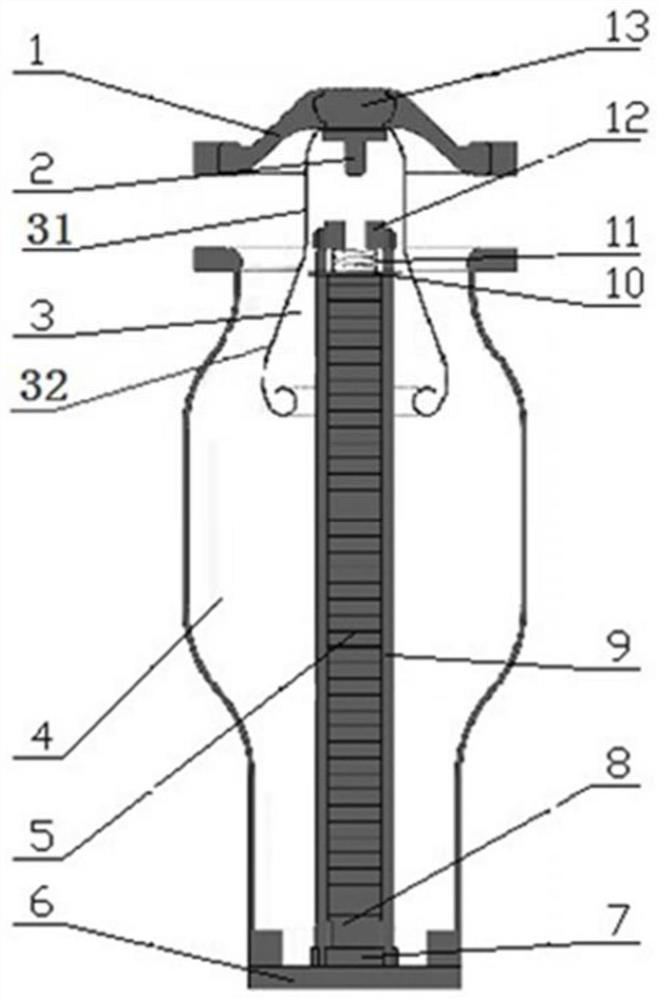

Telescopic belt conveying two-way loading/unloading machine

The invention discloses a telescopic belt conveying two-way loading / unloading machine, and relates to the field of logistics transportation goods loading / unloading mechanical equipment. The telescopic belt conveying two-way loading / unloading machine consists of a vehicle with bearing and walking functions, a rotating arm with a swing rotating function, a middle transition conveyor capable of aslant conveying, a belt conveyor 1 with amplitude change, swing rotating and extension functions, a belt conveyor 2, a metering device with metering, displaying, storage and printing functions, and an operation control system for operating the whole loading / unloading machine. The telescopic belt conveying two-way loading / unloading machine is simple in structure, reliable in work, convenient and fast in movement and transfer and wide in operation range, can reduce manual auxiliary carrying, relieves the labor intensity, shortens the operation time, improves the loading / unloading efficiency, reduces the loading / unloading carrying cost, improves the working environment and labor conditions, guarantees economical, fast, convenient and safe loading / unloading transportation, can change the logistics conveying direction, realizes forward / reverse two-way loading / unloading, and can automatically meter, count and record the loading / unloading number and weight for displaying and storage.

Owner:襄阳忠良工程机械有限责任公司

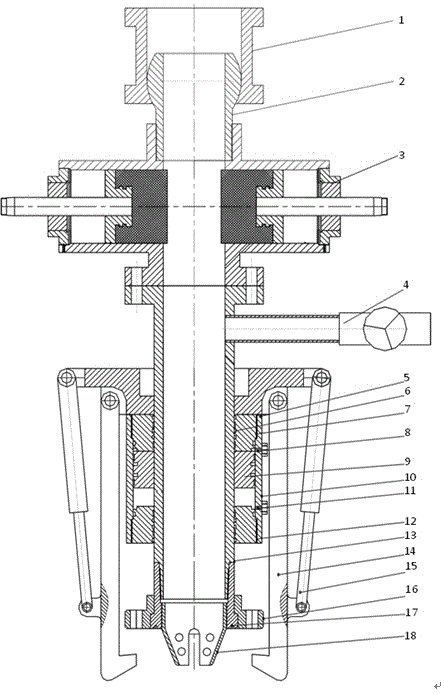

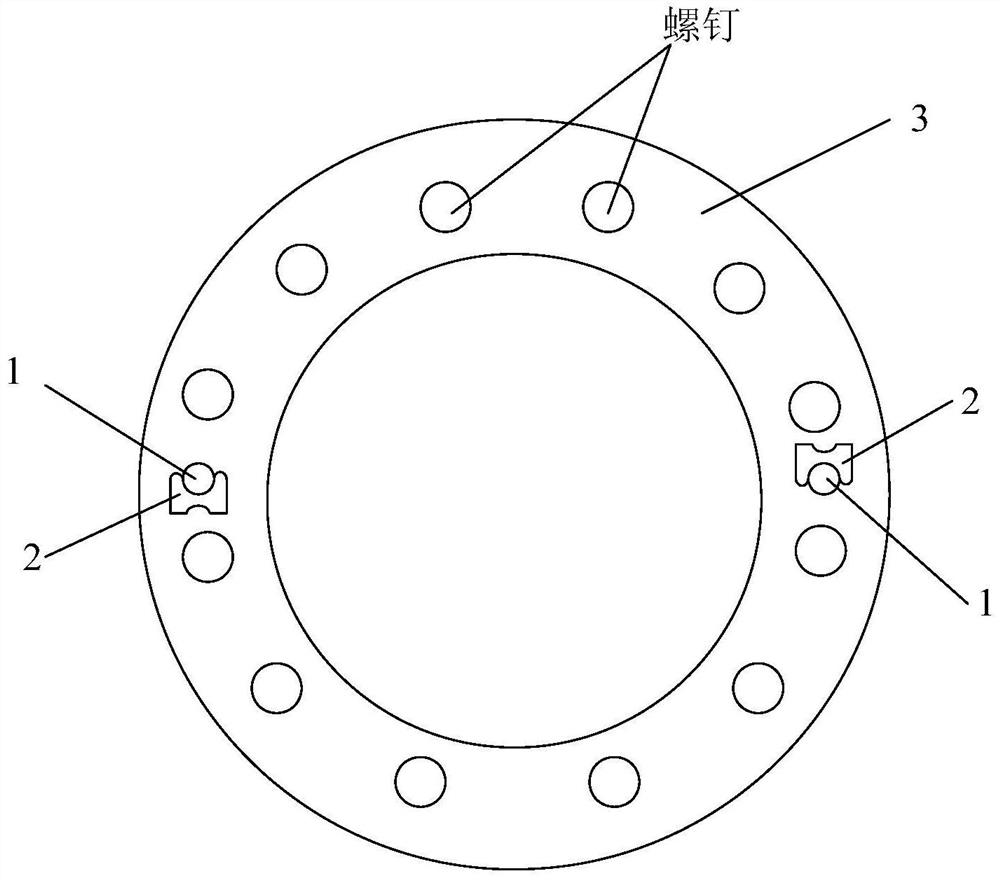

Hydraulic self-locking quick-mounting blowout prevention device and method

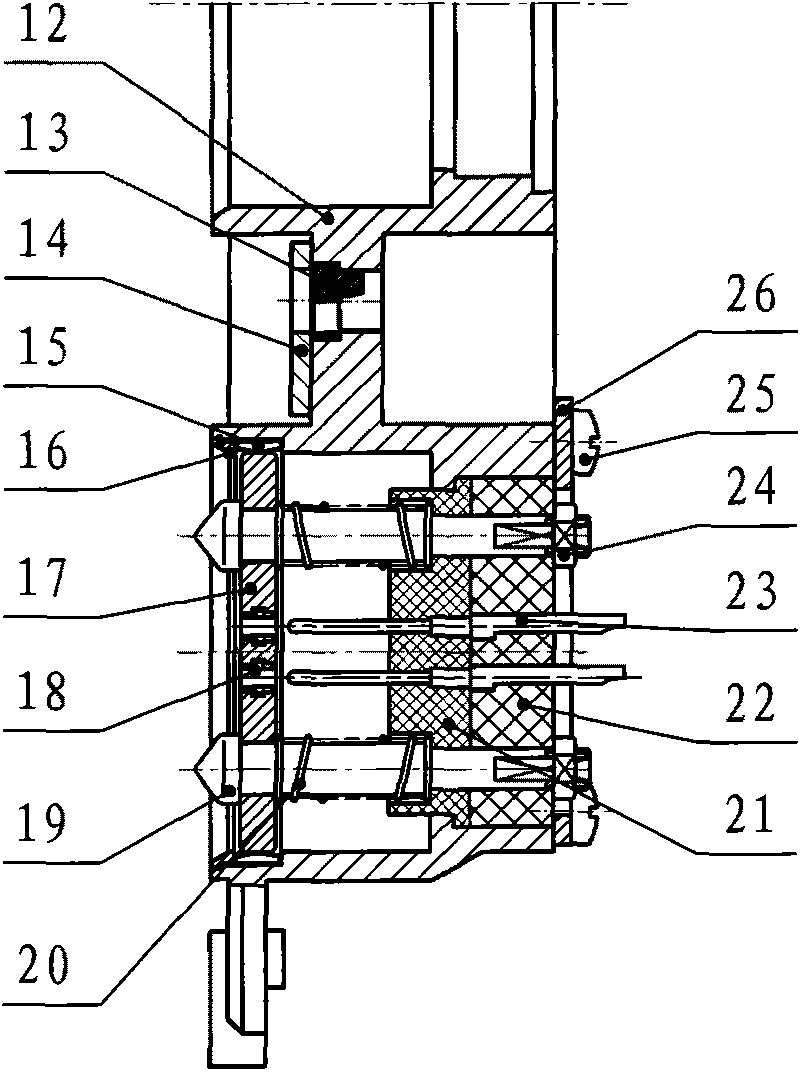

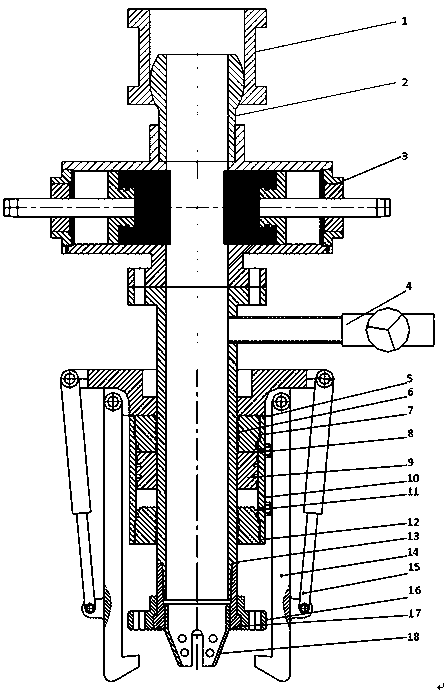

ActiveCN105089542ASolve the non-parallelSolve alignment problemsSealing/packingLocking mechanismSelf locking

The invention discloses a hydraulic self-locking quick-mounting blowout prevention device and method, wherein the blowout prevention device comprises a blowout preventer assembly, a central tube and a blowout prevention tube; the central tube is connected with the lower end of the blowout preventer assembly, the blowout prevention tube is branched from the central tube, and an upper flange plate is connected with the lower end of the central tube and correspondingly cooperates a wellhead lower flange plate. The blowout prevention device further comprises a space rotation fine-adjustment control mechanism and a hydraulic self-locking mechanism, wherein the space rotation fine-adjustment control mechanism is connected with the upper end of the blowout preventer assembly; the hydraulic self-locking mechanism sleeves the outer side of the central tube and hooks upwards and locks the wellhead lower flange plate, so that bolt-free quick clamping connection between the upper flange plate and the wellhead lower flange plate is achieved. According to the hydraulic self-locking quick-mounting blowout prevention device and method, no person is required to stand on a wellhead to mount a blowout preventer, and a blowout prevention device for the wellhead is quickly mounted by utilizing a mechanical manner, so as to win time for preventing blowout of an oil / gas production well.

Owner:CHINA PETROLEUM & CHEM CORP +1

Motor wiring welding joint protection part and wiring method of winding lead and power supply wire

ActiveCN104852499AImprove solid reliabilityImprove product qualityWindingsManufacturing dynamo-electric machinesEngineeringConductor Coil

The invention is applicable to the field of motors, and discloses a motor wiring welding joint protection part and a wiring method of a winding lead and a power supply wire. The motor wiring welding joint protection part comprises an insulating body, wherein an inner cavity into which a wiring welding joint of the winding lead and the power supply wire is stuffed and located is formed in the insulating body; the insulating body comprises an inserting part which can be clamped and inserted into a winding groove of an iron core, and a clamping part which is arranged at one end of the inserting part in a convex manner and is clamped outside the winding groove; the inserting part comprises a bottom plate far away from the clamping part, and a plurality of side plates which are arranged in an annular manner in the circumferential direction and is connected between the bottom plate and the clamping part; positioning convex plates which can be clamped and inserted between an insulating frame and the tooth boot of the iron core are arranged on two opposite edges which extend in opposite direction, of one side plate in the convex manner. Due to the novel motor wiring welding joint protection part, the wiring welding joint of the winding lead and the power supply wire can be protected, the wiring efficiency of the winding lead and the power supply wire can be improved, the protection reliability of the wiring welding joint is improved, and the production efficiency and the production quality of a motor can be improved.

Owner:WELLING WUHU MOTOR MFG

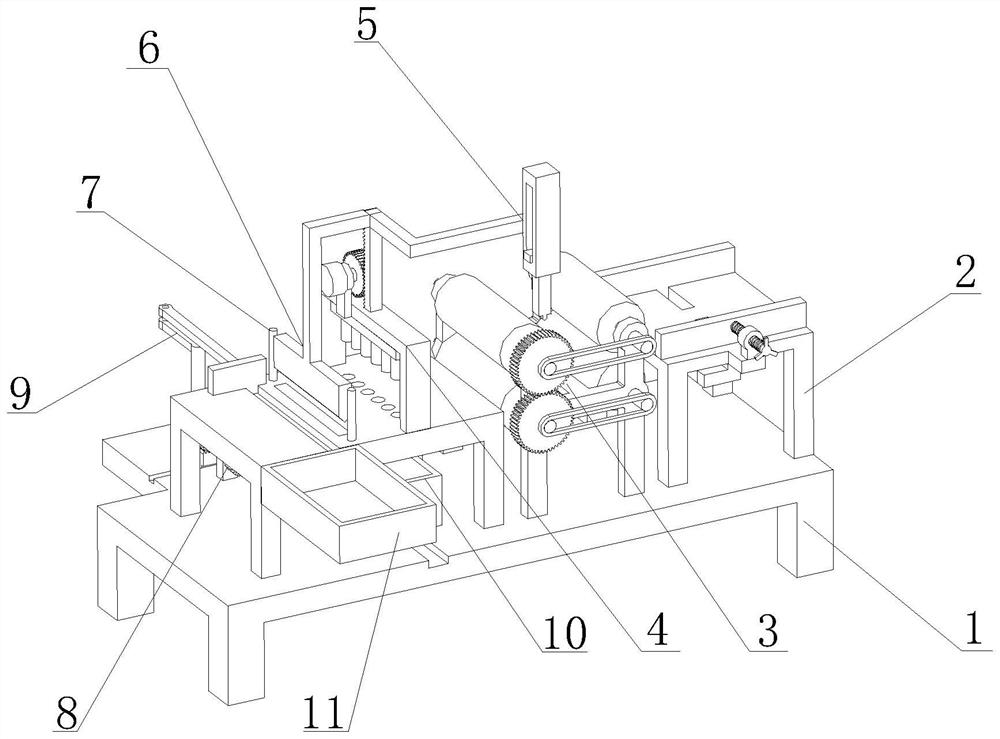

Automatic processing equipment and method for color steel film-coated plate

PendingCN113334900AGuaranteed accuracyImprove practicalityLamination ancillary operationsLaminationFilm-coated tabletSurface film

The invention discloses automatic processing equipment for a color steel film-coated plate, which comprises a film coating machine main body, a dust suction box, a dust suction pipe, an electric control box, a control panel, a positioning guide mechanism, a splitter plate, a dust suction cover, a first roller, a support arm, a dust removal mechanism, a first hydraulic telescopic rod, a portal frame, a film pressure head, a conveying roller, a mounting plate, an exhaust fan and a cloth bag, through the arrangement of the guide mechanism, positioning and guiding of color steel plates of different sizes are achieved, the accuracy of the conveying position of the color steel plates is guaranteed, the practicability of the equipment is improved. The equipment is simple in structure and low in manufacturing cost, automatic film coating machining is achieved, the automation degree of the equipment is improved, and the labor cost is reduced. The dust on the surface film is cleaned through a dust removal mechanism, and the surface of the color steel plate is subjected to suction dust removal through the exhaust fan, so that the dust on the surface film and the color steel plate is reduced, and the bonding firmness of the surface film and the color steel plate is improved.

Owner:山东沃丰新材料有限公司

Method for installing and constructing building workpiece

ActiveCN110748235AAchieve placementRealize transmissionFencingArchitectural engineeringBuilding construction

The invention aims to provide a method for installing and constructing a building workpiece. The technical problem of installing a partition guard plate base during a building construction process issolved. The method for installing and constructing the building workpiece includes the following steps of S1 guard plate base acquisition, S2 guard plate base transportation, S3 guard plate base positioning and S4 guard plate base fixing.

Owner:江西省连城建筑工程有限公司

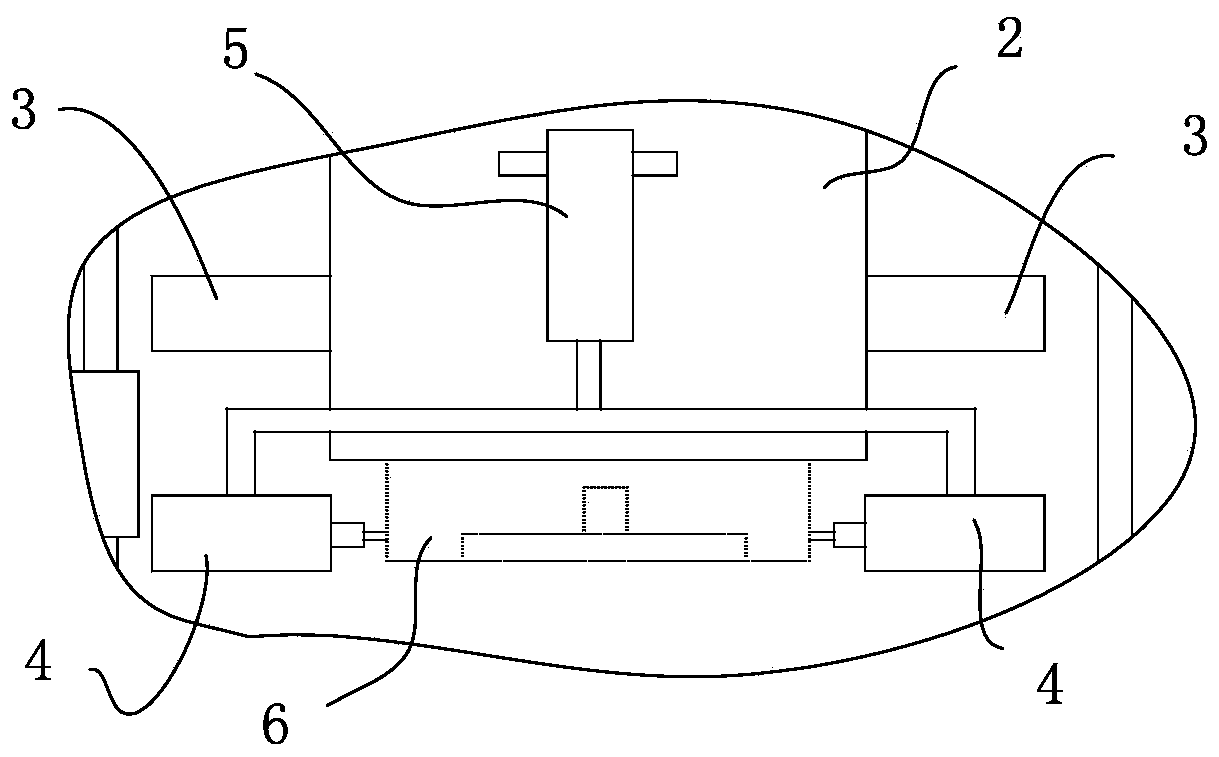

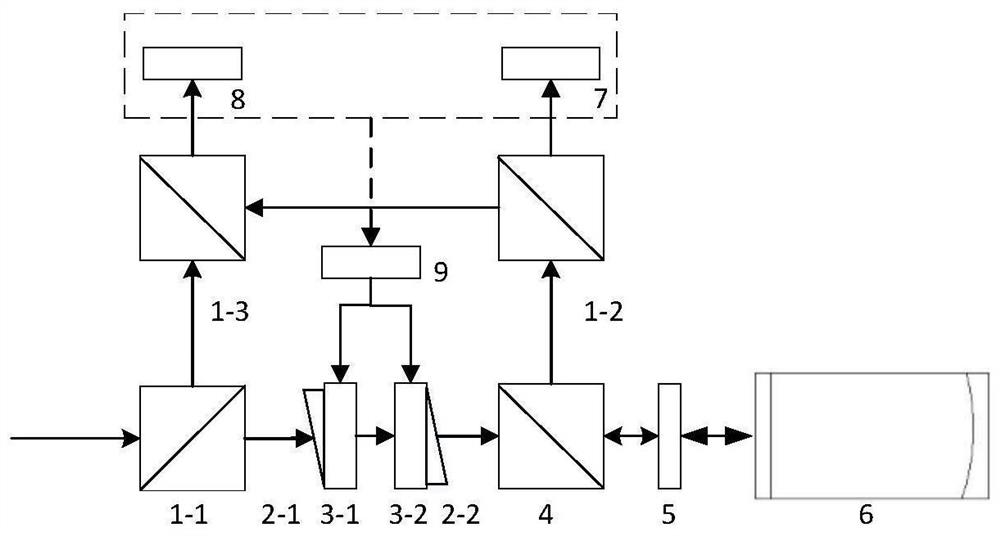

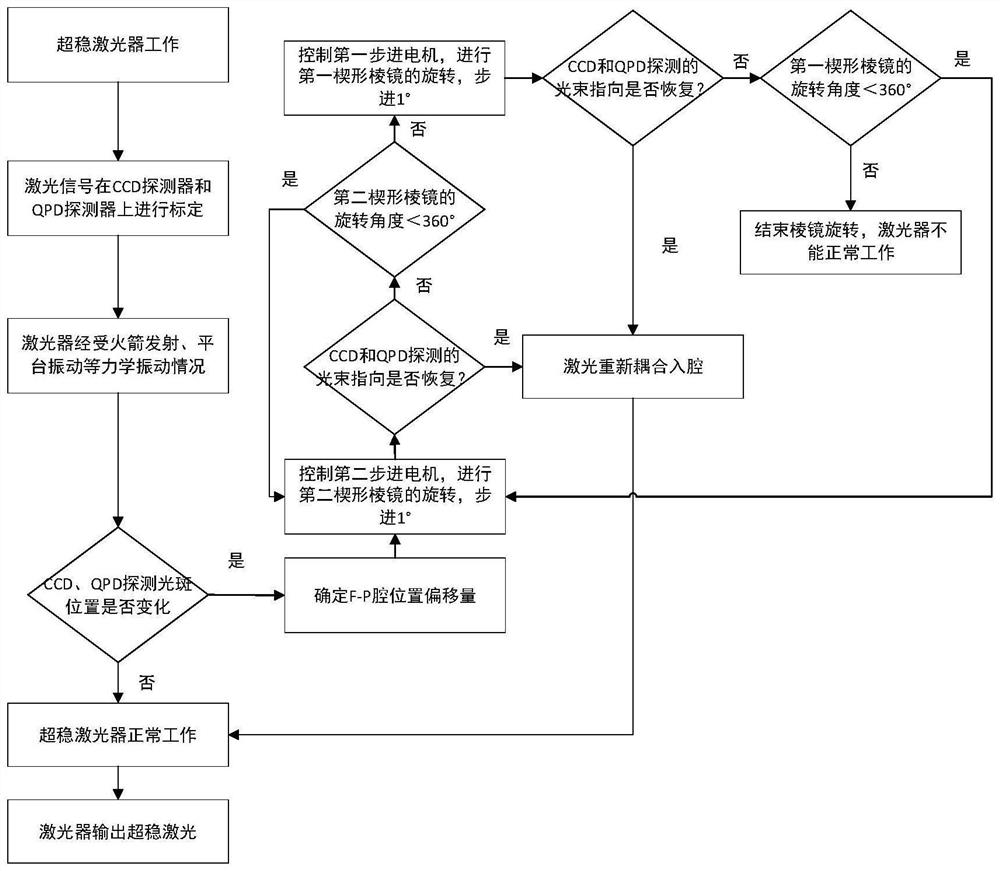

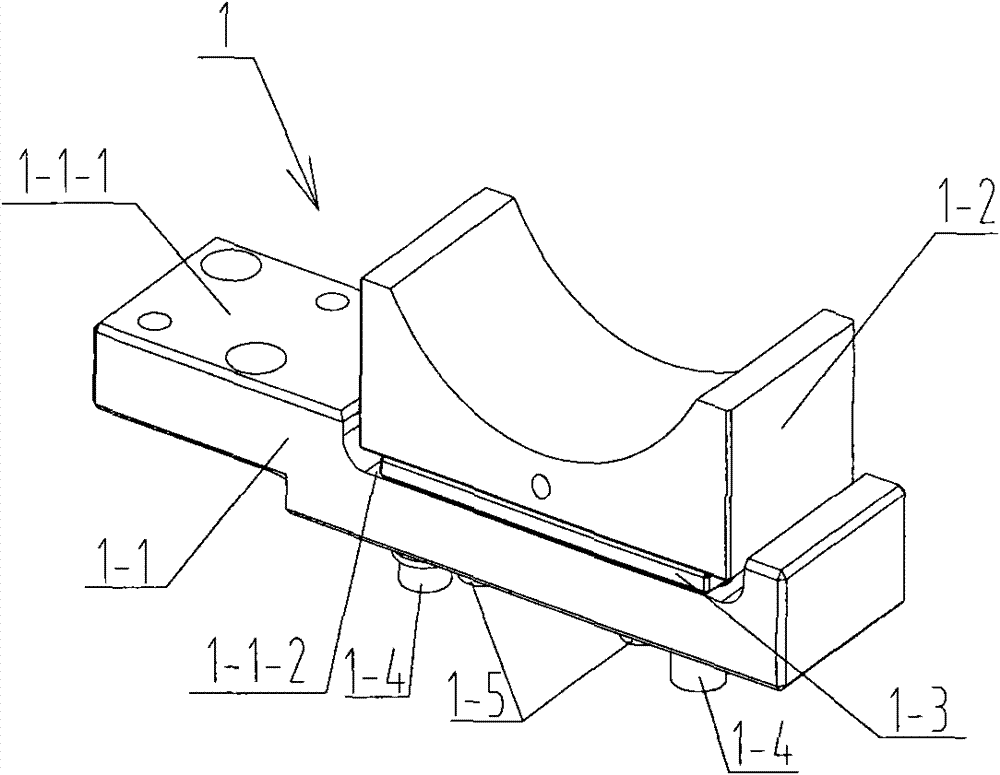

Ultra-stable laser device laser self-adaptive coupling cavity-entering matching system and method

ActiveCN113991415AFor fine tuningAchieving Active CompensationLaser detailsImage analysisPhotovoltaic detectorsLight spot

The invention provides an ultra-stable laser device laser self-adaptive coupling cavity-entering matching system and method, and the method comprises the steps: the precise measurement of light beam pointing is achieved through a charge coupling element light spot mass center detection technology and a four-quadrant photoelectric detector phase detection technology, and the offset of an F-P cavity is obtained; besides, a wedge-shaped prism pair is adjusted through a stepping motor to achieve precise adjustment of a laser light path, precise measurement of light beam pointing and precise adjustment of the light path form a closed loop, and active compensation of F-P cavity position deviation is achieved. According to the laser self-adaptive coupling in-cavity matching system and method for the ultra-stable laser, the structure is simple, adjustment and correction are automatic, the in-cavity matching precision is high, and the system and method have wide application prospects in the fields of ultra-stable lasers in space application and optical communication.

Owner:HANGZHOU INST FOR ADVANCED STUDY UCAS

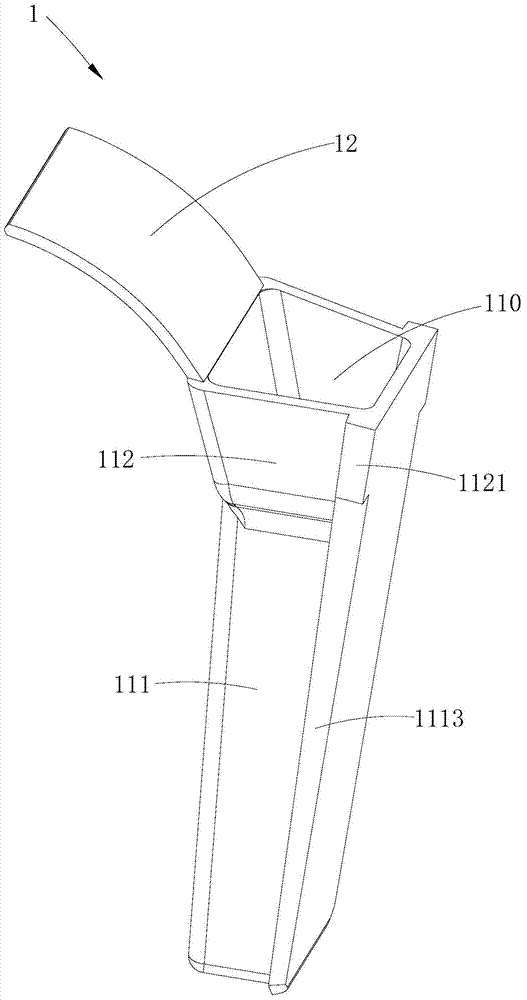

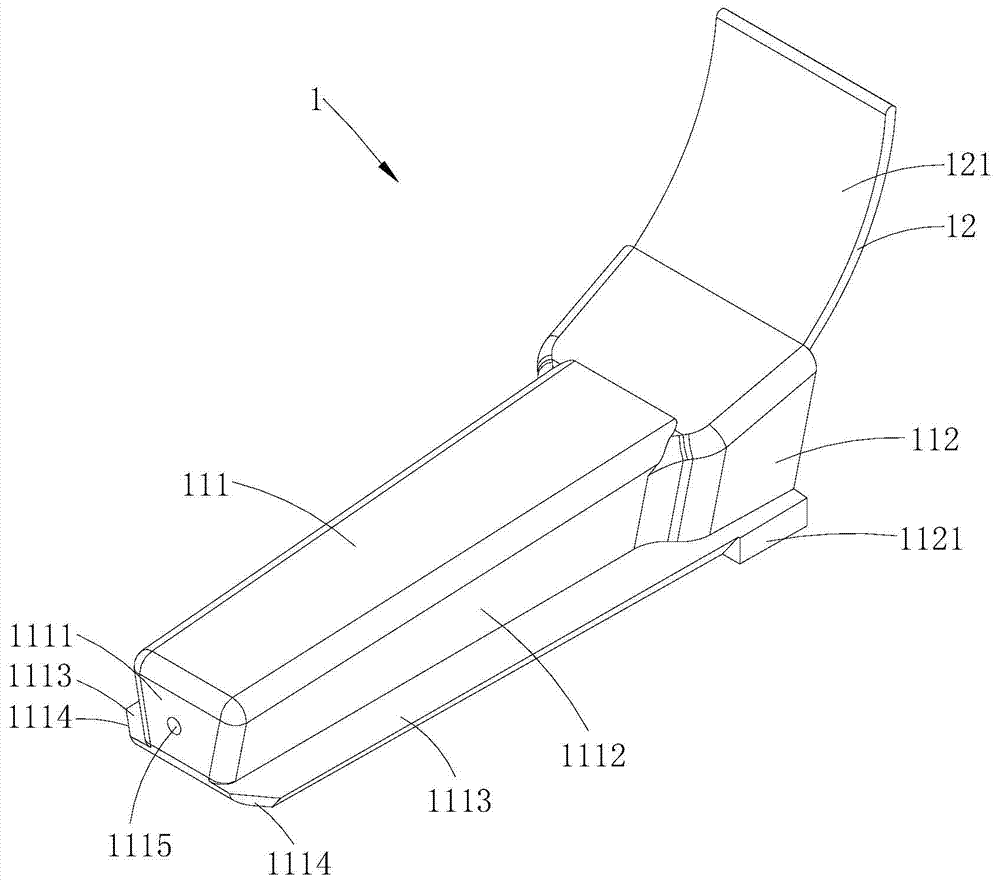

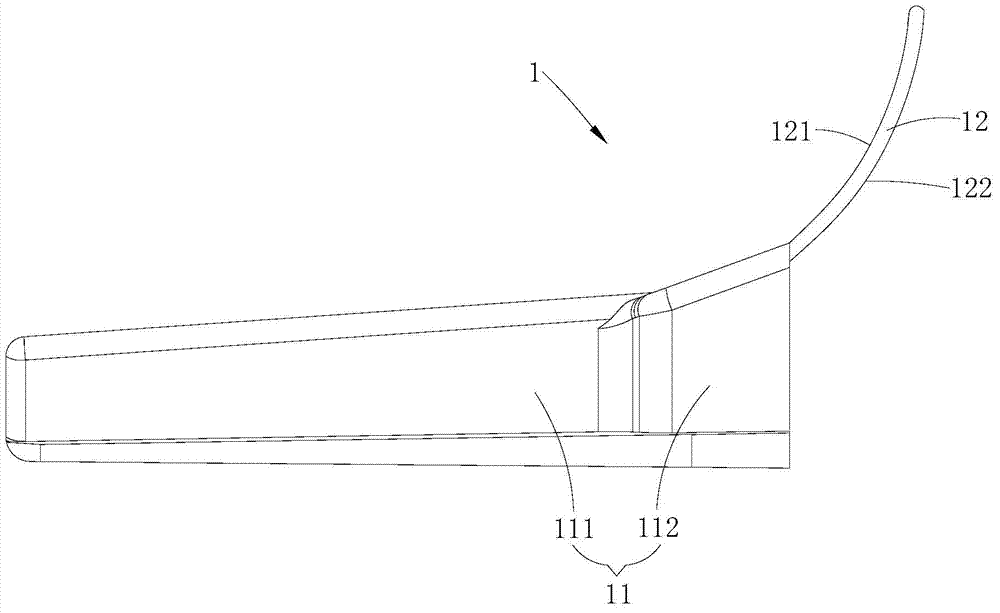

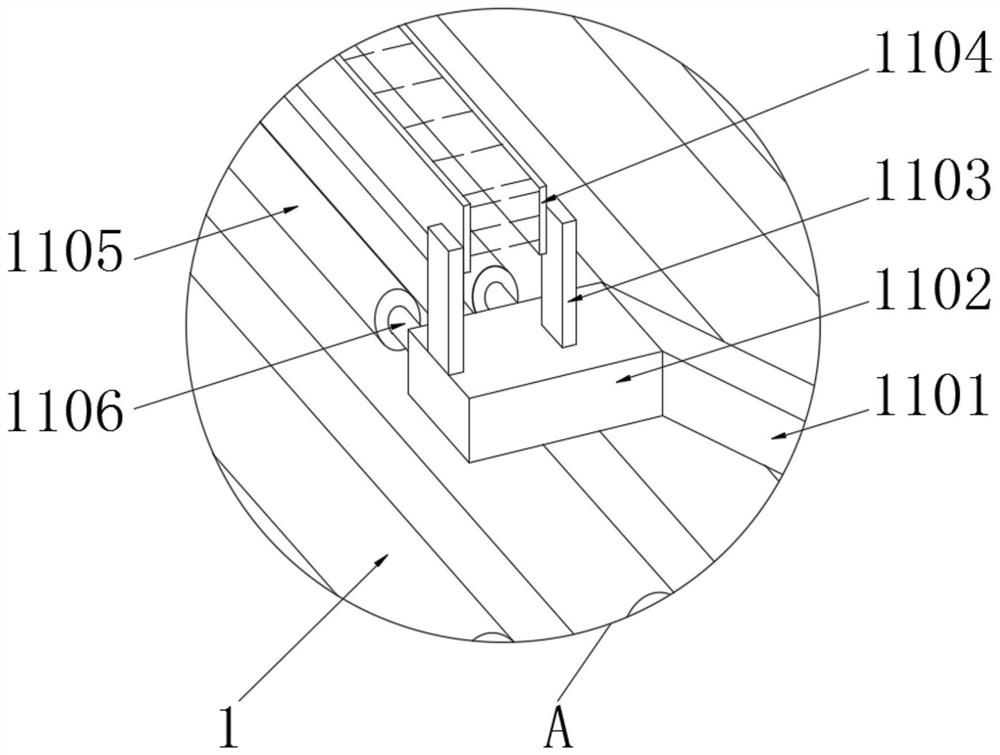

Loading guiding mechanism for injection mold

Owner:QINGDAO HAIER MOLDS

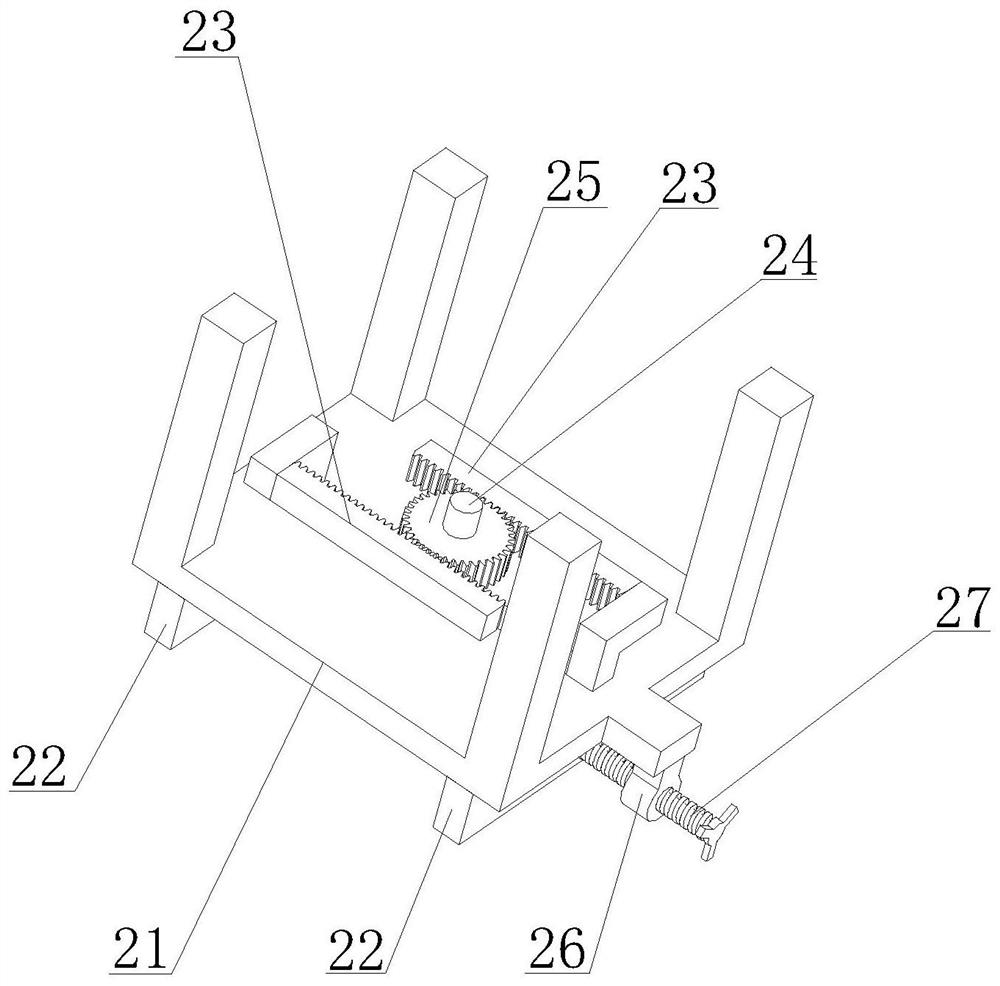

Automatic production line for comprehensively utilizing button leftover materials

ActiveCN113681642AAvoid repeated extensionsRealize orientationMetal working apparatusProcess engineeringIndustrial engineering

The invention discloses an automatic production line for comprehensively utilizing button leftover materials, and belongs to the field of button production. The automatic production line for comprehensively utilizing the button leftover materials comprises a conveying mechanism, a punching mechanism, a lifting mechanism, a locking mechanism, a punching mechanism, a triggering mechanism and a pushing mechanism. A cutter is arranged in the downstream direction of the punching mechanism to cut off the punched leftover materials, and the situation that the leftover materials are too large and consequently difficult to collect is prevented; the locking mechanism is arranged on one side of the punching mechanism, so that when the punching mechanism conducts punching action, the locking mechanism limits the conveying action of the conveying mechanism, and the punching effect is guaranteed; the cutter and the punching mechanism are designed in a linkage mode, so that stable proceeding of the cutting-off action is guaranteed; and the pushing mechanism is arranged on a supporting frame, and a buffering mechanism and the triggering mechanism are arranged to control the pushing time of the pushing mechanism, so that interference between the pushing mechanism and a plate is avoided.

Owner:嘉兴赵氏钮扣股份有限公司

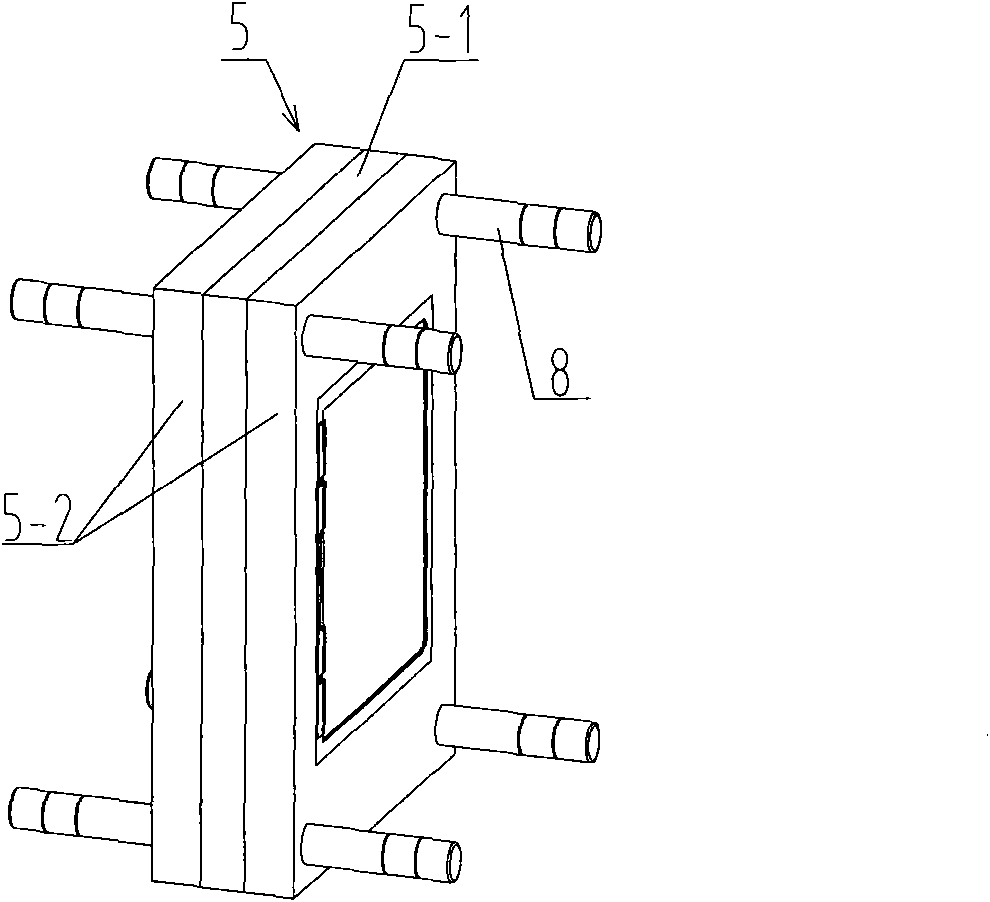

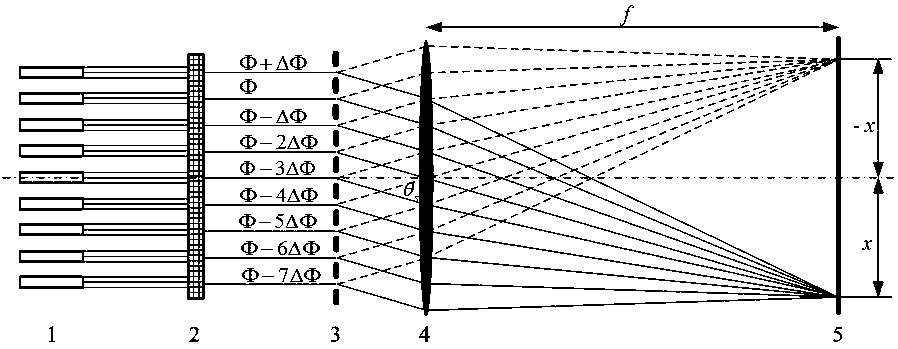

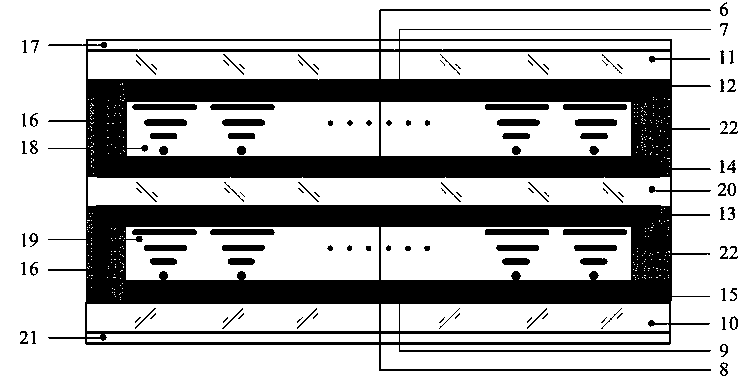

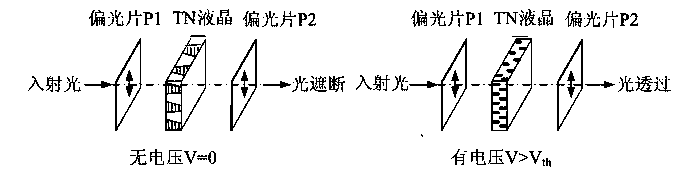

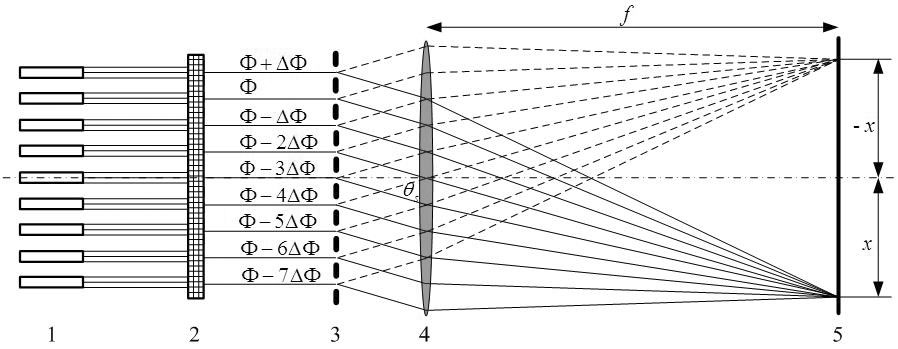

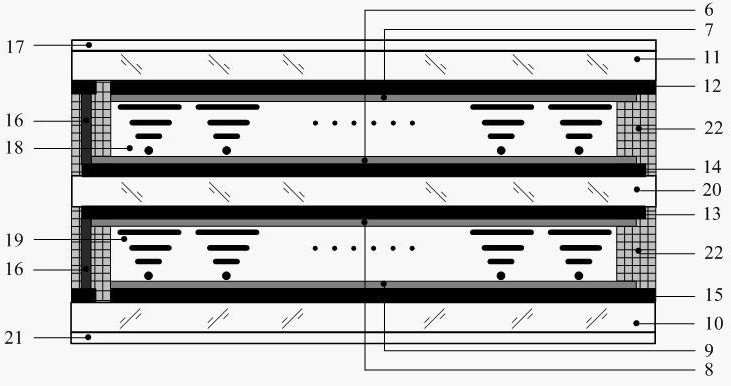

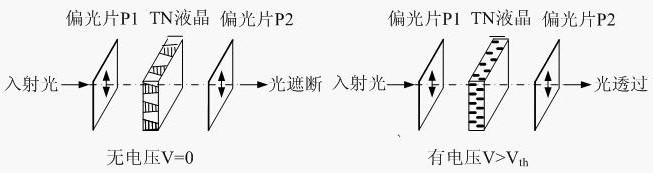

Liquid crystal optical switch for optical phased array scanning

InactiveCN109239993ARealize orientationRealize tilt scanStatic indicating devicesNon-linear opticsGratingLaser array

The invention discloses a liquid crystal optical switch for optical phased array scanning, and an assembly manufacturing method. The switch is composed of a first layer of liquid crystal panel and a second layer of liquid crystal panel which are arranged in an up-down manner; a first directional thin film, a row scanning electrode, an upper layer glass plate and an upper polarizer are sequentiallyarranged on the upper surface of the first layer of the liquid crystal panel in parallel; a second directional thin film, a row signal electrode and a middle glass plate are sequentially arranged onthe lower surface of the first layer of the liquid crystal panel in parallel; a third directional thin film and a column scanning electrode are sequentially arranged on the upper surface of the secondlayer of the liquid crystal panel in parallel; and a fourth directional thin film, a column signal electrode, a lower layer glass plate and a lower polarizer are sequentially arranged on the lower surface of the second layer of the liquid crystal panel in parallel. Double layers of structures are made into an optical switch plane array with independent controllable units; through the on / off control of a unit switch, the phase modulation is carried out on light beams passing through the unit switch; the plane array is matched with a grating array and a scanning drive circuit to form a laser array scanning device with an optical phased array function; and the orientation and pitching scanning and the depth focusing can be realized.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

Cleaning mechanism

ActiveCN111804675AEnable mobilityAchieve rotationHollow article cleaningWindow cleanersElectric machineStructural engineering

The invention discloses a cleaning mechanism. The cleaning mechanism comprises a mounting base, a rotary driving assembly, a rotary disc, a support, a first winding assembly, a second winding assembly, a vibration driving assembly, a flexible layer and a joint assembly, wherein the first winding assembly comprises a first motor, a first winding drum and a first steel sheet; and the second windingassembly comprises a second motor, a second winding drum and a second steel sheet. The cleaning mechanism is used for cleaning garbage in narrow gaps, the efficiency of cleaning the garbage in the narrow gaps is improved, and time and labor are saved.

Owner:湖南汉坤实业有限公司

An intelligent building construction guard plate base installation device

ActiveCN110748230BAchieve placementRealize transmissionFencingControl systemArchitectural engineering

The invention discloses an intelligent guard plate base mounting device for building construction. The device comprises a control system, a travelling base plate, a guard plate base placement system,a guard plate base conveying system, a guard plate base guiding system, a bolt conveying system and a bolt fastening system; the travelling base plate is used for allowing other functional componentsto be arranged; the guard plate base placement system is used for containing and placing a plurality of guard plate bases in a stacked mode and sequentially placing the guard plate bases on the guardplate base conveying system, the guard plate base conveying system is used for sequentially conveying the guard plate bases to the guard plate base guiding system, and the guard plate base guiding system is used for guiding the guard plate bases to move to a specified road surface mounting position; and the bolt conveying system is used for sequentially moving fastening bolts to the position in which the guard plate bases are mounted, and the bolt fastening system is used for fixing the guard plate bases to the ground through the fastening bolts in a screw connection mode.

Owner:SHENZHEN MUNICIPAL ENG

An automatic production line for comprehensive utilization of button scraps

ActiveCN113681642BAvoid hard to collectRealize OrientationMetal working apparatusProduction linePunching

The invention discloses an automatic production line for comprehensive utilization of button scraps, which belongs to the field of button production; an automated production line for comprehensive utilization of button scraps includes a transmission mechanism, a punching mechanism, a lifting mechanism, a locking mechanism, a punching mechanism, The trigger mechanism and the pushing mechanism; by setting a cutter in the downstream direction of the punching mechanism, the scraps after punching are cut off to prevent the scraps from being too large and difficult to collect; by setting a locking mechanism on one side of the punching mechanism, to Realize that when the punching mechanism performs the punching action, the locking mechanism restricts the transmission action of the transmission mechanism to ensure the punching effect; through the linkage design of the cutter and the punching mechanism, the stability of the cutting action is ensured; through the supporting frame The pusher mechanism is set on the top, and the timing of the pusher mechanism is controlled by setting the buffer mechanism and the trigger mechanism, so as to avoid the interference between the pusher mechanism and the plate.

Owner:嘉兴赵氏钮扣股份有限公司

A construction method for installing a construction workpiece

ActiveCN110748235BAchieve placementRealize transmissionFencingConstruction engineeringArchitectural engineering

The invention aims to provide a method for installing and constructing a building workpiece. The technical problem of installing a partition guard plate base during a building construction process issolved. The method for installing and constructing the building workpiece includes the following steps of S1 guard plate base acquisition, S2 guard plate base transportation, S3 guard plate base positioning and S4 guard plate base fixing.

Owner:江西省连城建筑工程有限公司

A guide type construction workpiece conveying device

Owner:安徽贵宏建工集团有限公司

A method for intelligent transportation and positioning of construction workpieces

InactiveCN110759046BAchieve placementRealize transmissionFencingSupporting framesCard holderMechanical engineering

The purpose of the present invention is to provide an intelligent conveying and positioning method for building workpieces, which is used to solve the technical problem of conveying and placing the base of the partition guard plate during the building construction process. A method for using an intelligent conveying and positioning method for construction workpieces, comprising the following steps: obtaining the base of the S1 guard plate, elongating the upper cut-off oil cylinder, and using the upper cut-off plate on the power output end of the upper cut-off oil cylinder to align the penultimate guard plate base below The clamping ends; the lower clamping cylinder is extended, and the lower clamping plate on the power output end of the lower clamping cylinder is used to clamp the lowermost guard plate base; the lower clamping cylinder is elongated, and the lowermost guard plate base is clamped at the bottom Driven by the oil cylinder, it moves downwards, and after detaching from the upper guard base, it falls on the above guard base conveying system; S2 guard base conveys, and the guard base moves to the guard under the drive of the belt conveying mechanism Inside the base guide system; S3 guard base positioning.

Owner:SHANDONG SANJIAN CONSTR ENG MANAGEMENT +1

A liquid crystal light switch for optical phased array scanning

InactiveCN109239993BRealize orientationRealize tilt scanStatic indicating devicesNon-linear opticsGratingLaser array

The invention discloses a liquid crystal optical switch for optical phased array scanning, and an assembly manufacturing method. The switch is composed of a first layer of liquid crystal panel and a second layer of liquid crystal panel which are arranged in an up-down manner; a first directional thin film, a row scanning electrode, an upper layer glass plate and an upper polarizer are sequentiallyarranged on the upper surface of the first layer of the liquid crystal panel in parallel; a second directional thin film, a row signal electrode and a middle glass plate are sequentially arranged onthe lower surface of the first layer of the liquid crystal panel in parallel; a third directional thin film and a column scanning electrode are sequentially arranged on the upper surface of the secondlayer of the liquid crystal panel in parallel; and a fourth directional thin film, a column signal electrode, a lower layer glass plate and a lower polarizer are sequentially arranged on the lower surface of the second layer of the liquid crystal panel in parallel. Double layers of structures are made into an optical switch plane array with independent controllable units; through the on / off control of a unit switch, the phase modulation is carried out on light beams passing through the unit switch; the plane array is matched with a grating array and a scanning drive circuit to form a laser array scanning device with an optical phased array function; and the orientation and pitching scanning and the depth focusing can be realized.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

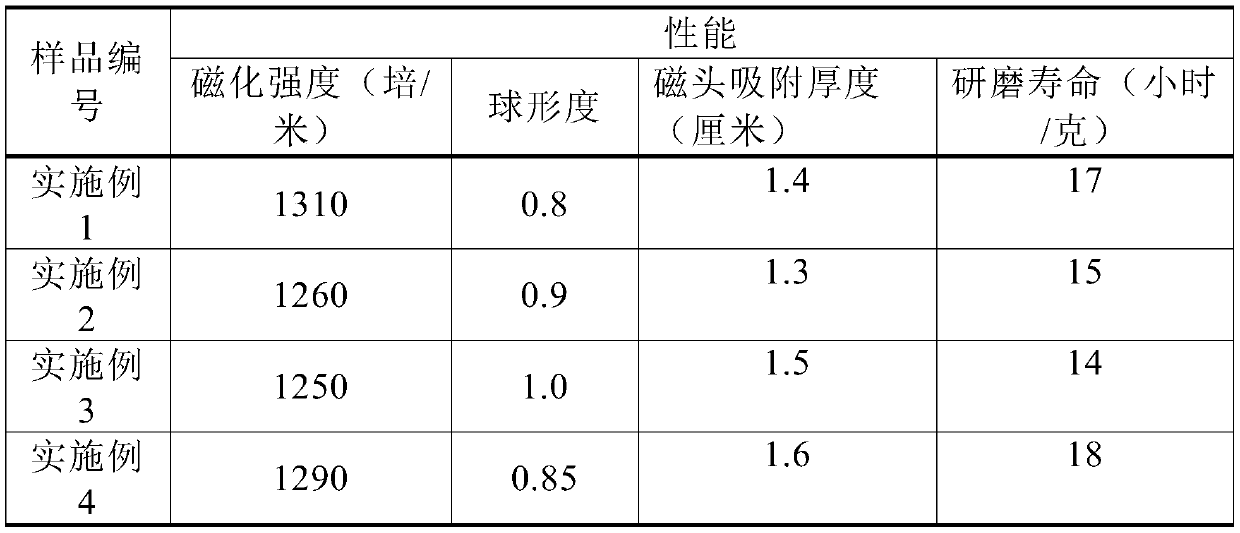

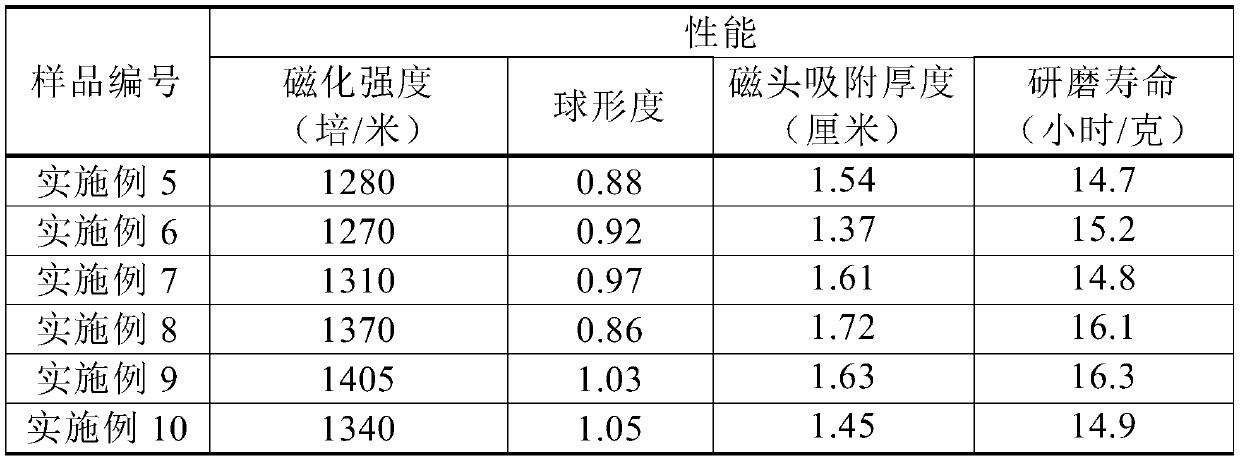

Preparation method of nano cutting element iron-based magnetic fine polishing powder

ActiveCN110508803BGood for chemical adhesionIncrease bezel forceTransportation and packagingMetal-working apparatusHoneycombCold air

The invention discloses a preparation method of nanometer cutting element iron-based magnetic fine throwing powder. First, the atomized iron powder is impacted into a honeycomb micro-involute mold at a high speed by using cold air-driven impact technology, and the mold is vibrated at the same time, and then the obtained double involute The open-line dent iron powder, nano-zirconia powder and dispersant are put into the ammonium hydrogen phosphate solution, and the nano-powder is evenly arranged on the dent of the iron-based powder by a water-bath heat collecting and stirring device, and then filtered, washed, dried, and finally The nano zirconium dioxide is adhered to the iron-based powder for quenching treatment, and finally the nano-cutting element iron-based magnetic fine polishing powder is obtained. This method has high control precision of cutting element array, strong process stability and repeatability, and can realize high performance and long life of iron-based magnetic fine polishing powder.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

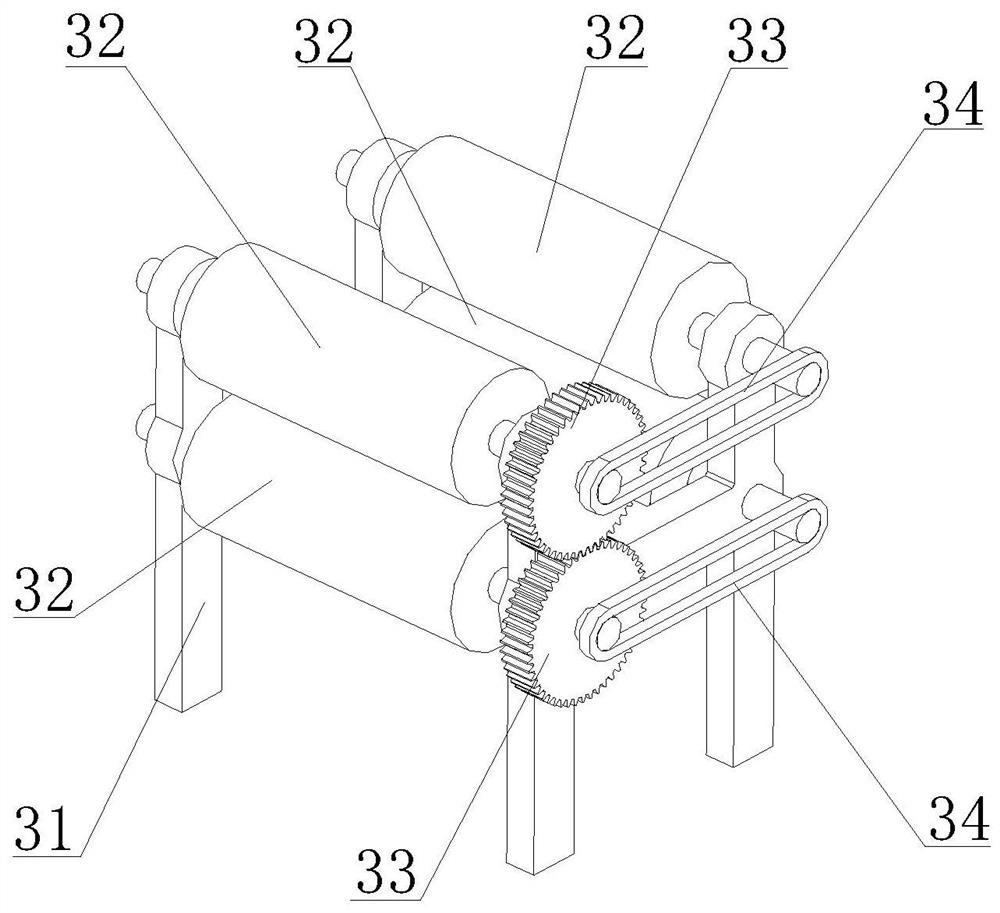

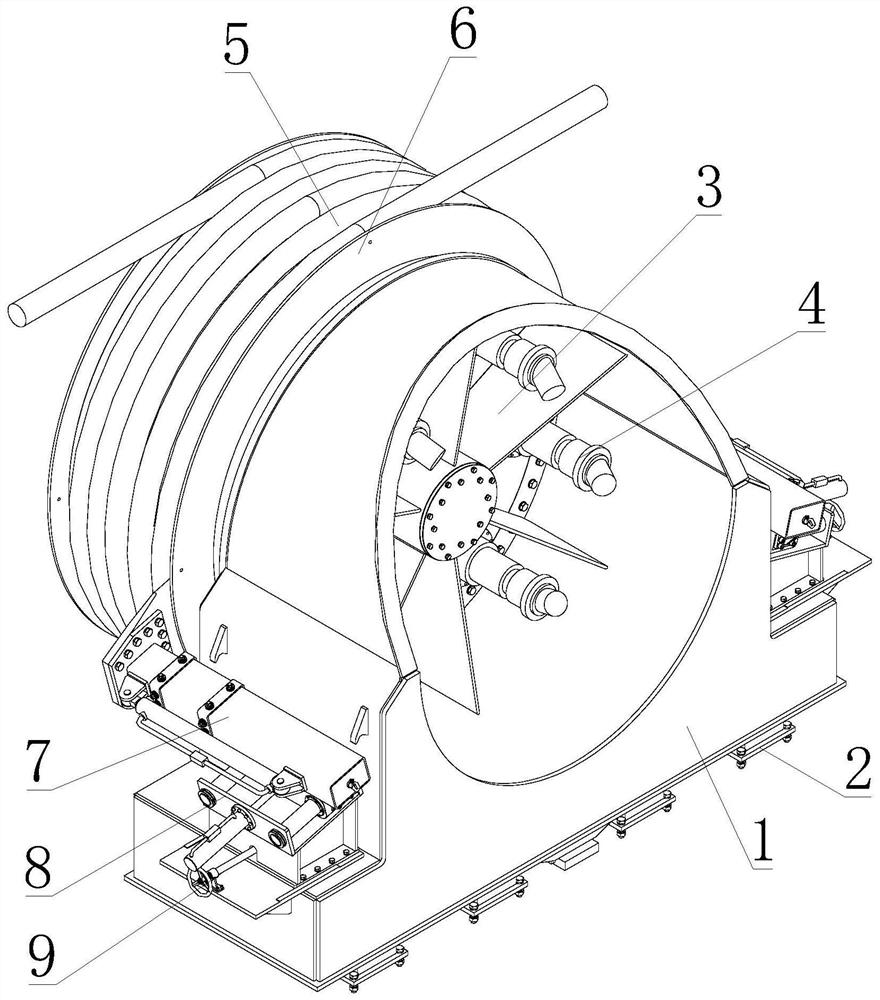

A cable traction method for a drum tractor

The invention discloses a cable traction method for a drum-type traction machine. The traction method specifically includes the following steps: Step 1: Drive the driving gear to rotate through the operation of the hydraulic motor, and the meshing transmission of the driving gear drives the transmission internal gear and the traction wheel to rotate. By setting traction baffles on both sides of the traction wheel, the cable traction can be limited; Step 2: During the rotation of the traction wheel, the speed measuring gear rotates with the transmission internal teeth, and the speed measuring gear is realized by connecting with the external encoder The speed of the rotation of the traction wheel is measured, so as to obtain the data of how much the cable is retracted, and the lubricating wheel is connected to the external lubricating oil system, and the lubricating wheel is added to the lubricating wheel; the first cylinder of the present invention drives the connecting rod in the fixed Slip on the sleeve, push the cable row knife to move, guide and locate the cables on the traction wheel, and prevent the cables from being stacked and misplaced.

Owner:HEFEI SMARTER TECH GROUP CORP

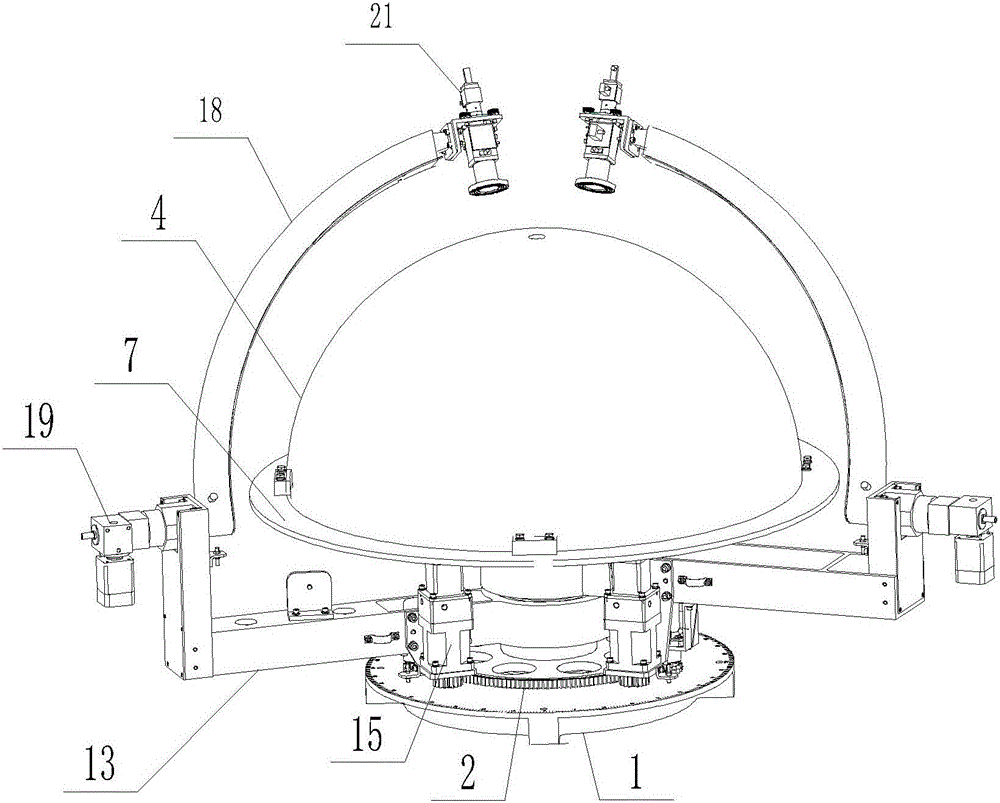

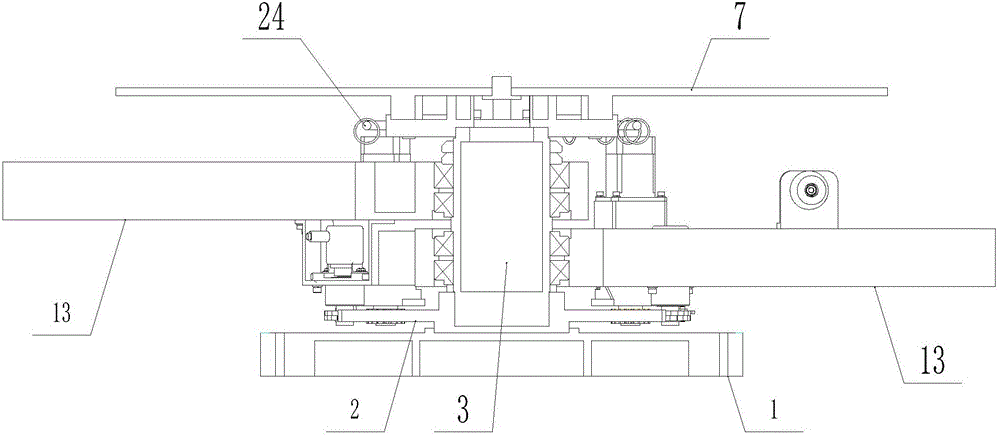

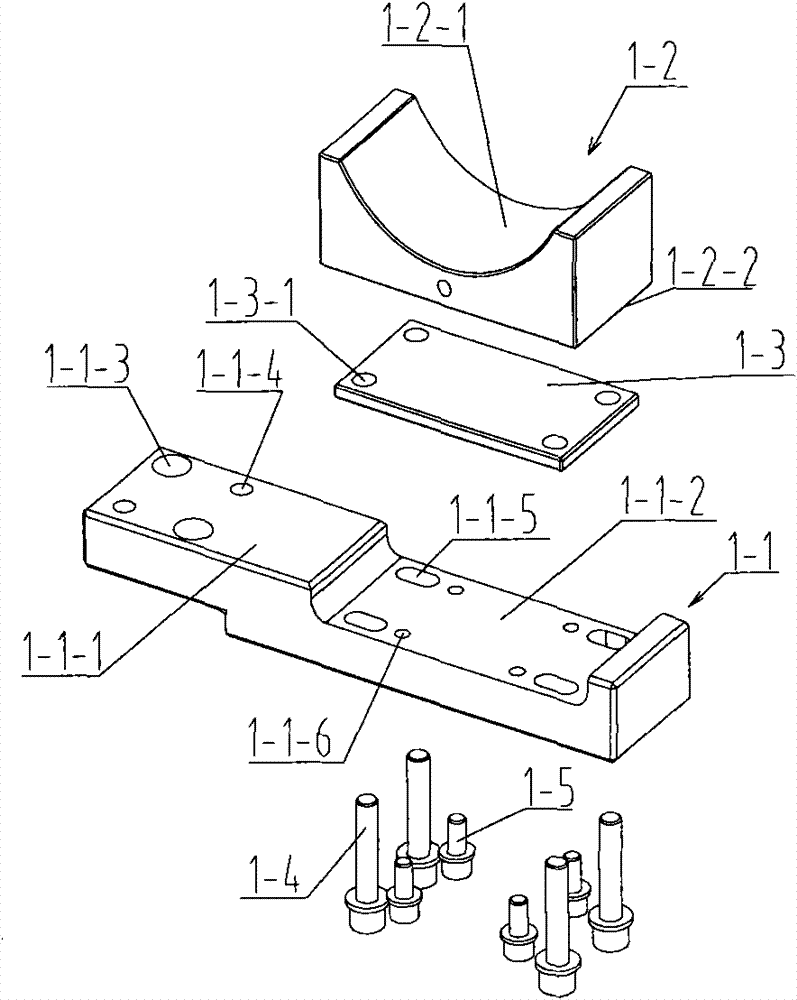

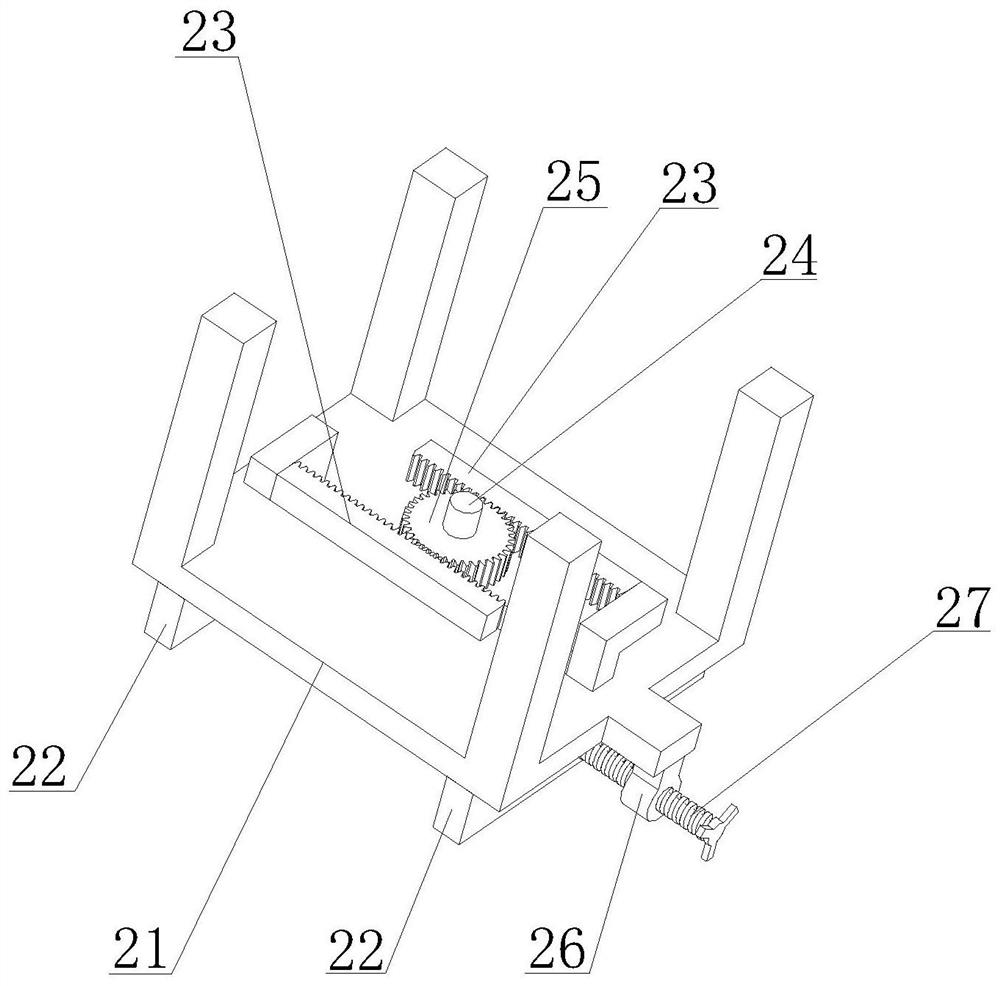

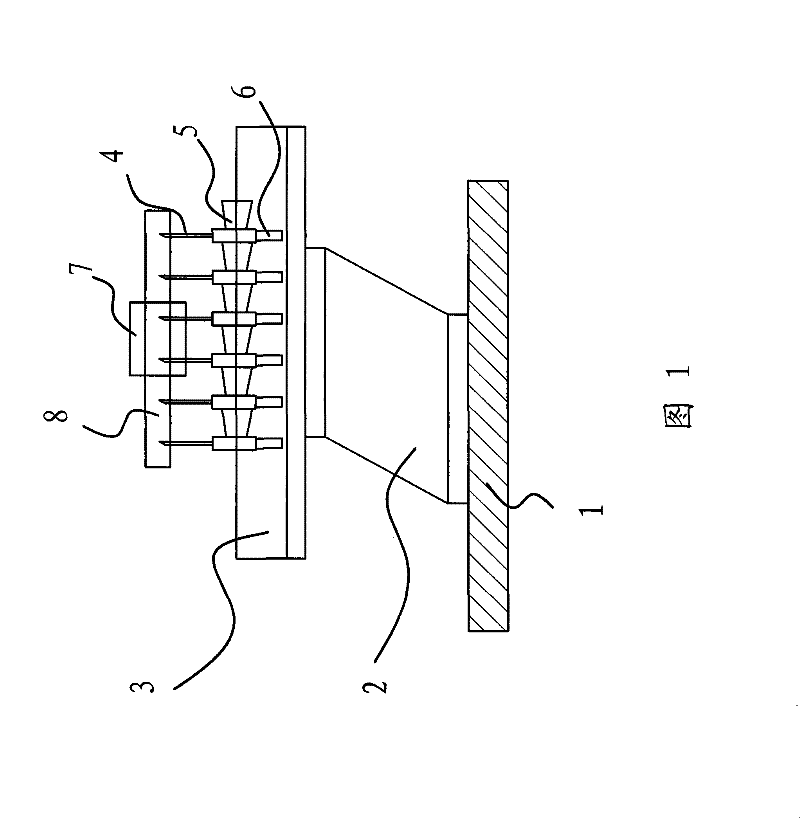

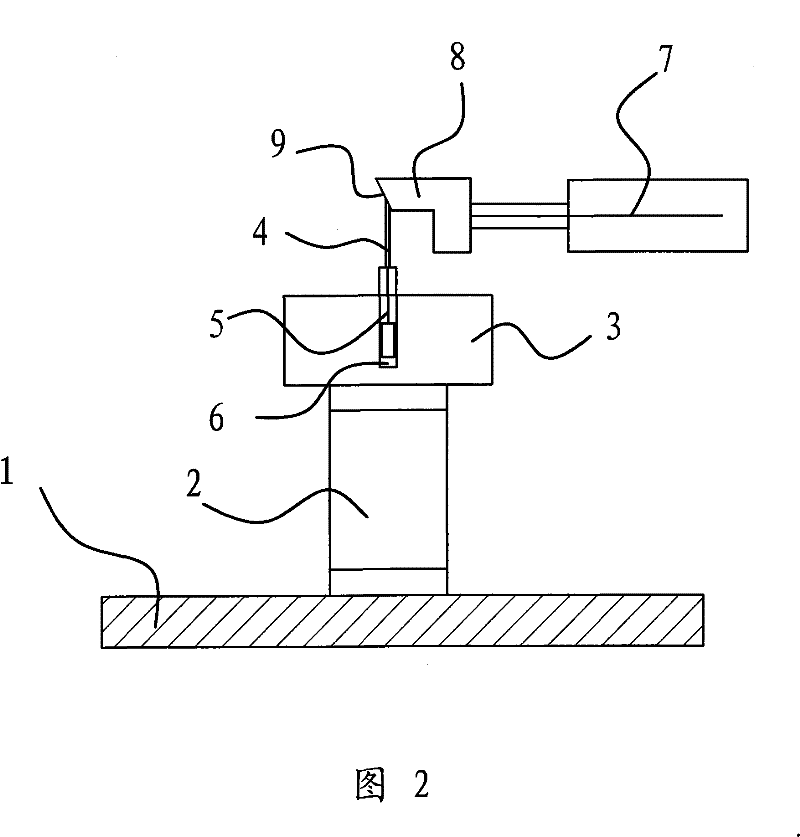

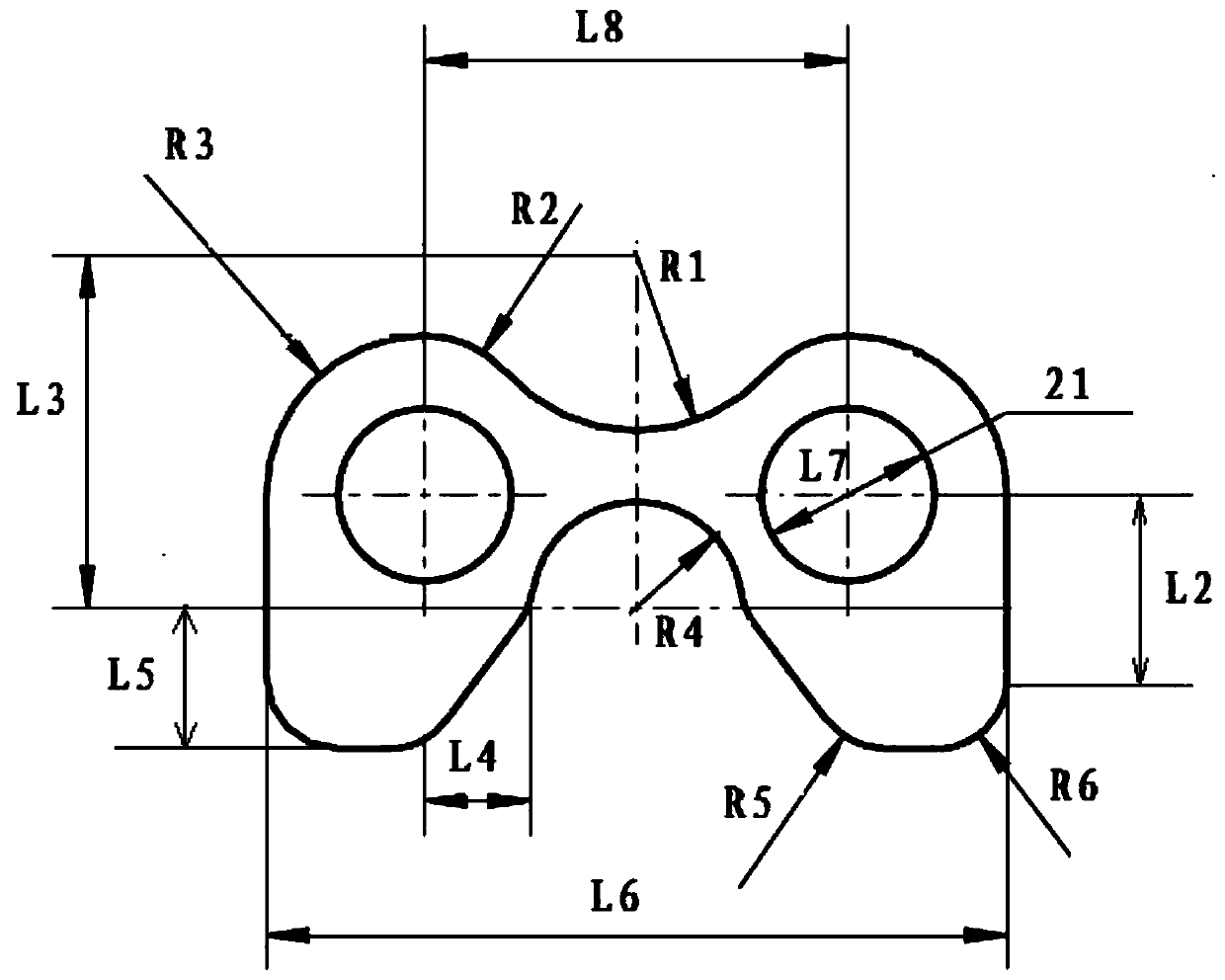

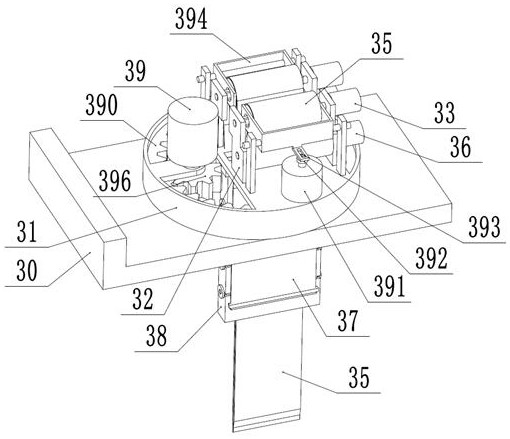

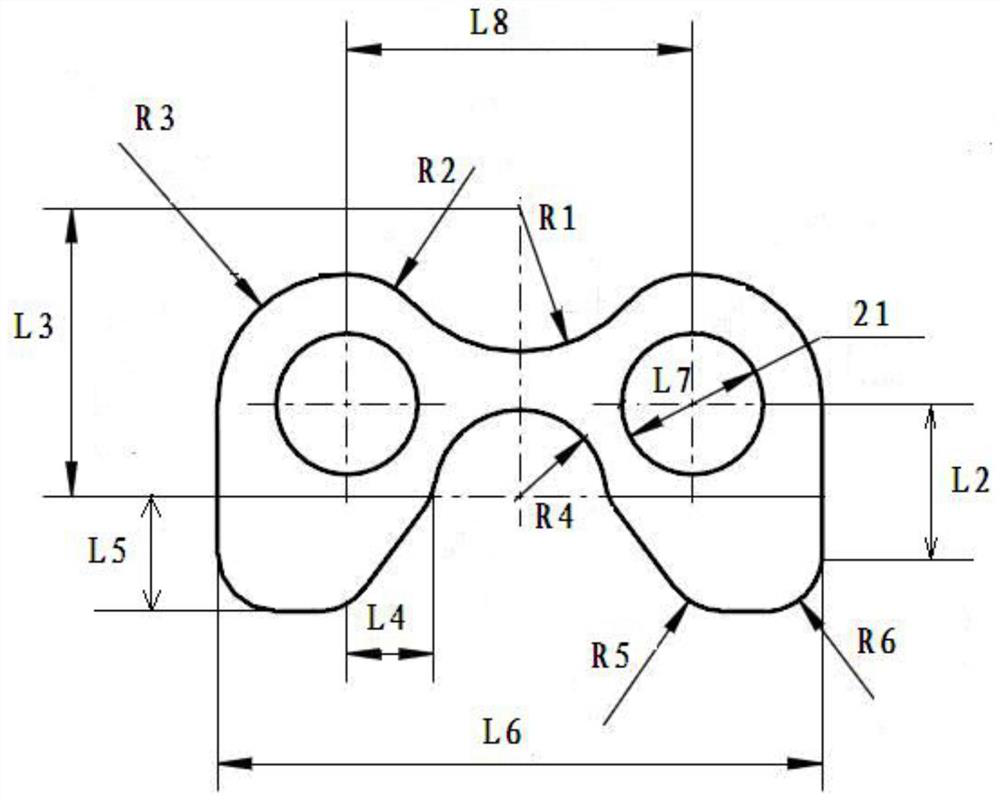

Medical device for aligning active-face of needle-tube

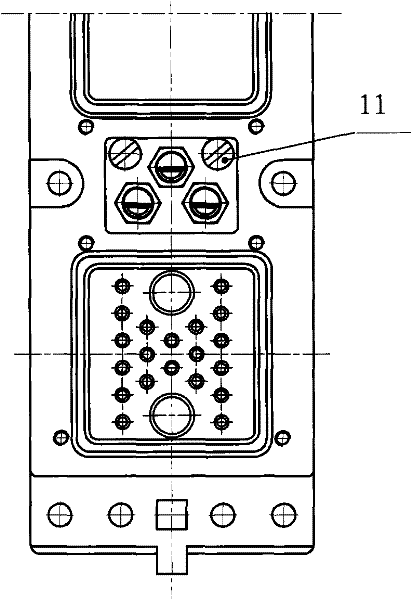

ActiveCN101336838BSimple structureRapid positioningSurgical needlesInfusion needlesMedical deviceBiomedical engineering

The present invention provides a medical needle blade face aligning apparatus, pertains to medical machine technology field. The invention resolves technical problems that poor positioning of needle tube blade angle, low production efficiency etc. of prior medical needle blade face aligning apparatus. The medical needle blade face aligning apparatus comprises a base and a vibrator arranged on thebase, a positioning base is fixed on the vibrator, a plurality of grooves capable of placing medical needle blades are arranged on the positioning base, a profiling mechanism capable of positioning all blade faces of the needle tube inserted into the medical needle blade on the positioning base in a same direction is arranged on the base. The invention has advantages of simple structure, quick and accurate positioning, improved product quality and reduced production cost.

Owner:MAIDER MEDICAL IND EQUIP

Hydraulic self-locking quick installation blowout preventer and method

ActiveCN105089542BRealize automatic positioning and guidanceQuick installationSealing/packingLocking mechanismSelf locking

The invention discloses a hydraulic self-locking quick-mounting blowout prevention device and method, wherein the blowout prevention device comprises a blowout preventer assembly, a central tube and a blowout prevention tube; the central tube is connected with the lower end of the blowout preventer assembly, the blowout prevention tube is branched from the central tube, and an upper flange plate is connected with the lower end of the central tube and correspondingly cooperates a wellhead lower flange plate. The blowout prevention device further comprises a space rotation fine-adjustment control mechanism and a hydraulic self-locking mechanism, wherein the space rotation fine-adjustment control mechanism is connected with the upper end of the blowout preventer assembly; the hydraulic self-locking mechanism sleeves the outer side of the central tube and hooks upwards and locks the wellhead lower flange plate, so that bolt-free quick clamping connection between the upper flange plate and the wellhead lower flange plate is achieved. According to the hydraulic self-locking quick-mounting blowout prevention device and method, no person is required to stand on a wellhead to mount a blowout preventer, and a blowout prevention device for the wellhead is quickly mounted by utilizing a mechanical manner, so as to win time for preventing blowout of an oil / gas production well.

Owner:CHINA PETROLEUM & CHEM CORP +1

Cabinet-type electric connector

ActiveCN101714727BRealize electromagnetic shielding functionRealize automatic alignmentCoupling protective earth/shielding arrangementsElectrical connectionEngineering

A cabinet-type electric connector consists of a plug and a socket; the plug and a shell of the socket are provided with a plurality of cavities for mounting a plurality of corresponding functional modules; and the abutting end of each functional module is provided with a mobile electromagnetic shielding device and a guide positioning device, wherein the mobile electromagnetic shielding device consists of a shielding plate, an elastic shielding reed, an insulating sleeve and a spring. By using a matching form of the mobile shielding plate and the elastic shielding reed, the electromagnetic shielding function after the connector is plugged and separated is well implemented; meanwhile, the arranged guide positioning device can well implement guiding and positioning when the plug is plugged in the socket so as to realize automatic alignment of the connector; and the cabinet-type electric connector has higher mounting error compensation capability, meets the requirements of cabinet-type application occasions, and has stronger practicability.

Owner:GUIZHOU SPACE APPLIANCE CO LTD

Guiding type building workpiece conveying device

ActiveCN110803488AAchieve placementRealize transmissionFencingSupporting framesControl systemArchitectural engineering

The invention aims to provide a guide type construction workpiece conveying device. The device is used for solving the technical problem of conveying and placing of a partition guard plate base in theconstruction process. The device comprises a control system, a walking chassis guard plate base placing system, a guard plate base conveying system and a guard plate base guiding system. A walking chassis is used for installing other functional components; the guard plate base placing system is used for stacking and accommodating a plurality of guard plate bases, and successively placing the guard plate bases on the guard plate base conveying system; the guard plate base conveying system is used for successively conveying the guard plate bases to the guard plate base guiding system; the guardplate base guide system is used for guiding and moving the guard plate bases to designated road surface installation positions.

Owner:安徽贵宏建工集团有限公司

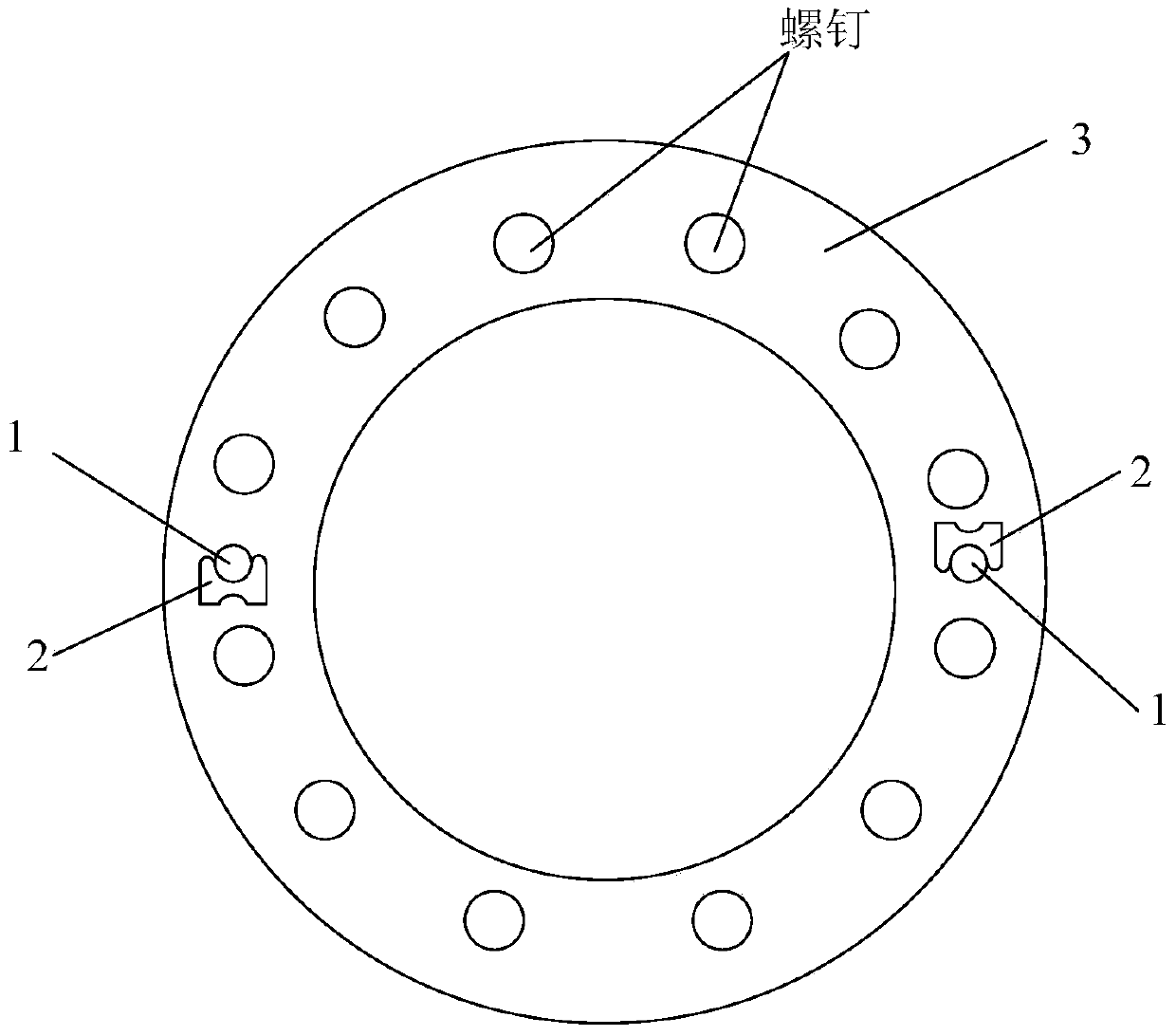

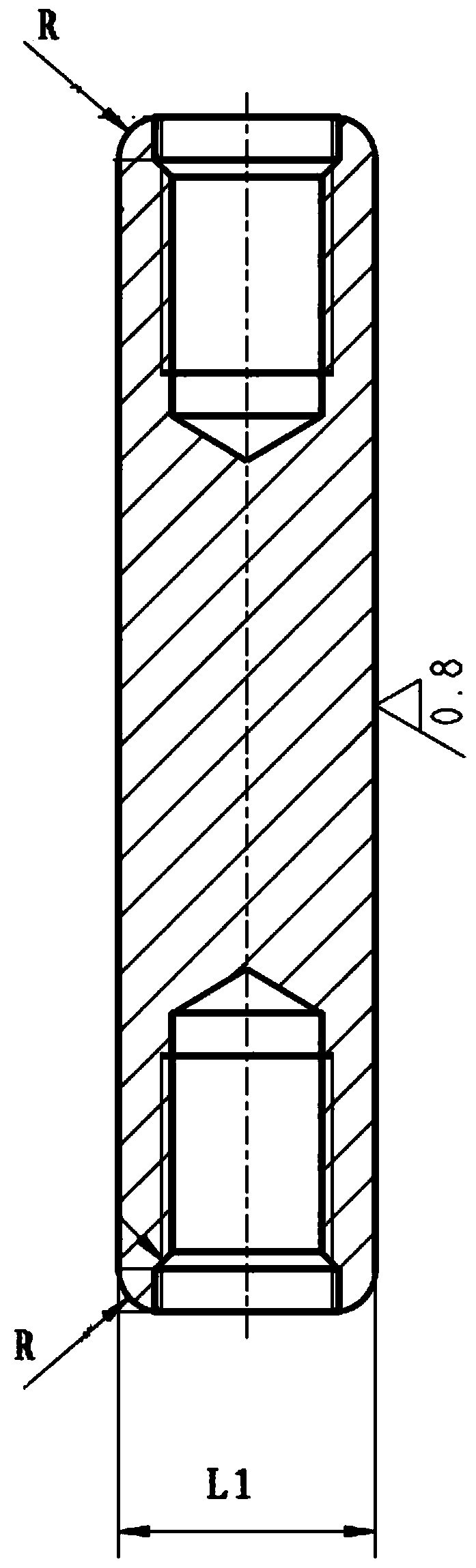

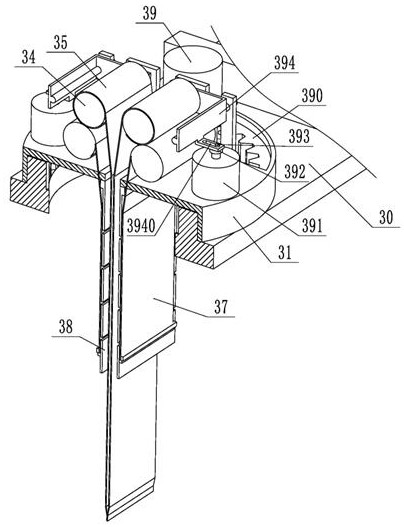

Spacing device for disassembling spatially large-bearing product

ActiveCN110816893ADoes not affect functionStable disassemblyCosmonautic vehiclesCosmonautic partsCircular discStructural engineering

The invention relates to a spacing device for disassembling a spatially large-bearing product, and belongs to the field of the in orbit disassembling design of the large-bearing product. The spacing device comprises a cabin flange plate, two positioning pins and two spacing blocks, wherein the cabin flange plate is of a disk-shaped structure; two positioning pins are symmetrically arranged on theinstallation surface of the cabin flange plate; the two spacing blocks are independently correspondingly cooperated with the two positioning pins; the spacing and the fixing of the cabin flange plateare realized; the two spacing blocks are in 180-degree distribution; when an outer cabin rises to an outer space, under a vacuum environment, screws between the cabin flange plate and the outer cabinare disassembled; under the spacing cooperation of the positioning pins and the spacing blocks, the circumferential spacing of the cabin flange plate is realized; and 12 screws are disassembled in sequence. According to the function requirements of an out-cabin product, the problem that the in-orbit disassembling and spacing design of the out-cabin product large-bearing product can be solved.

Owner:SHANGHAI INST OF SPACE POWER SOURCES

a cleaning mechanism

ActiveCN111804675BEnable mobilityAchieve rotationHollow article cleaningWindow cleanersElectric machineEngineering

Owner:湖南汉坤实业有限公司

Large space to carry the limit device for product disassembly

ActiveCN110816893BDoes not affect functionStable disassemblyCosmonautic vehiclesCosmonautic partsCircular discFlange

The invention relates to a limiting device for the disassembly of a product with a large space and belongs to the field of on-rail disassembly design for a product with a large load; it includes a cabin flange, two positioning pins and two limit blocks; wherein, the cabin flange is a circular Disc-shaped structure; 2 positioning pins are arranged symmetrically on the mounting surface of the cabin flange; The blocks are distributed at 180°; when the outer cabin rises into space, remove the screws between the flange of the cabin and the outer cabin in a vacuum environment; Circumferential limit of the flange of the cabin; remove 12 screws in sequence; this invention solves the problem of on-orbit disassembly and limit design of products with large loads outside the cabin according to the functional requirements of the outboard product.

Owner:SHANGHAI INST OF SPACE POWER SOURCES

A kind of metal oxide arrester for gis

ActiveCN109524186BSimple structureImprove shielding effectResistor housing/enclosing/embeddingOvervoltage protection resistorsThermodynamicsMetal oxide surge arrester

Owner:HENAN PINGGAO ELECTRIC +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com