Patents

Literature

39results about How to "For fine tuning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

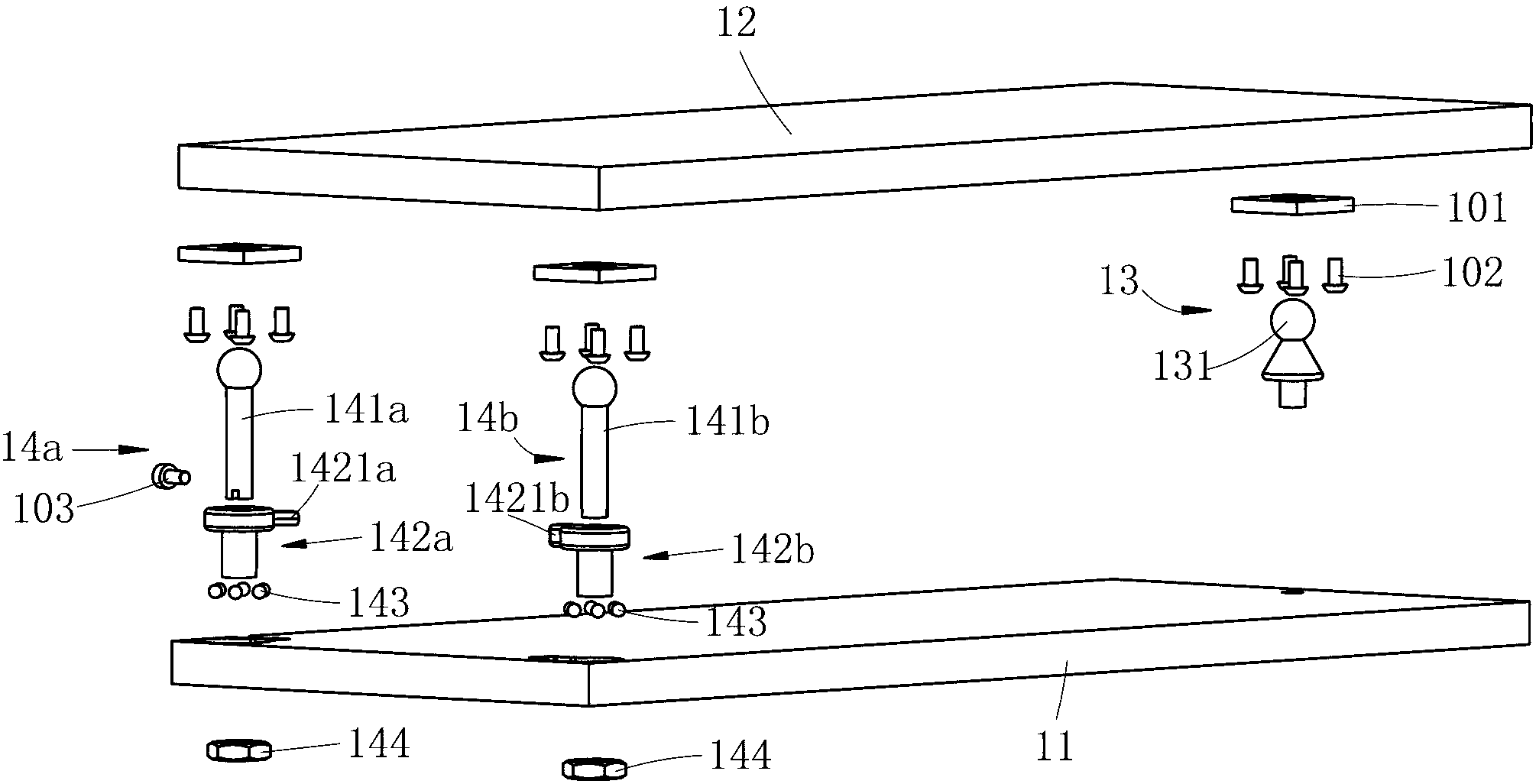

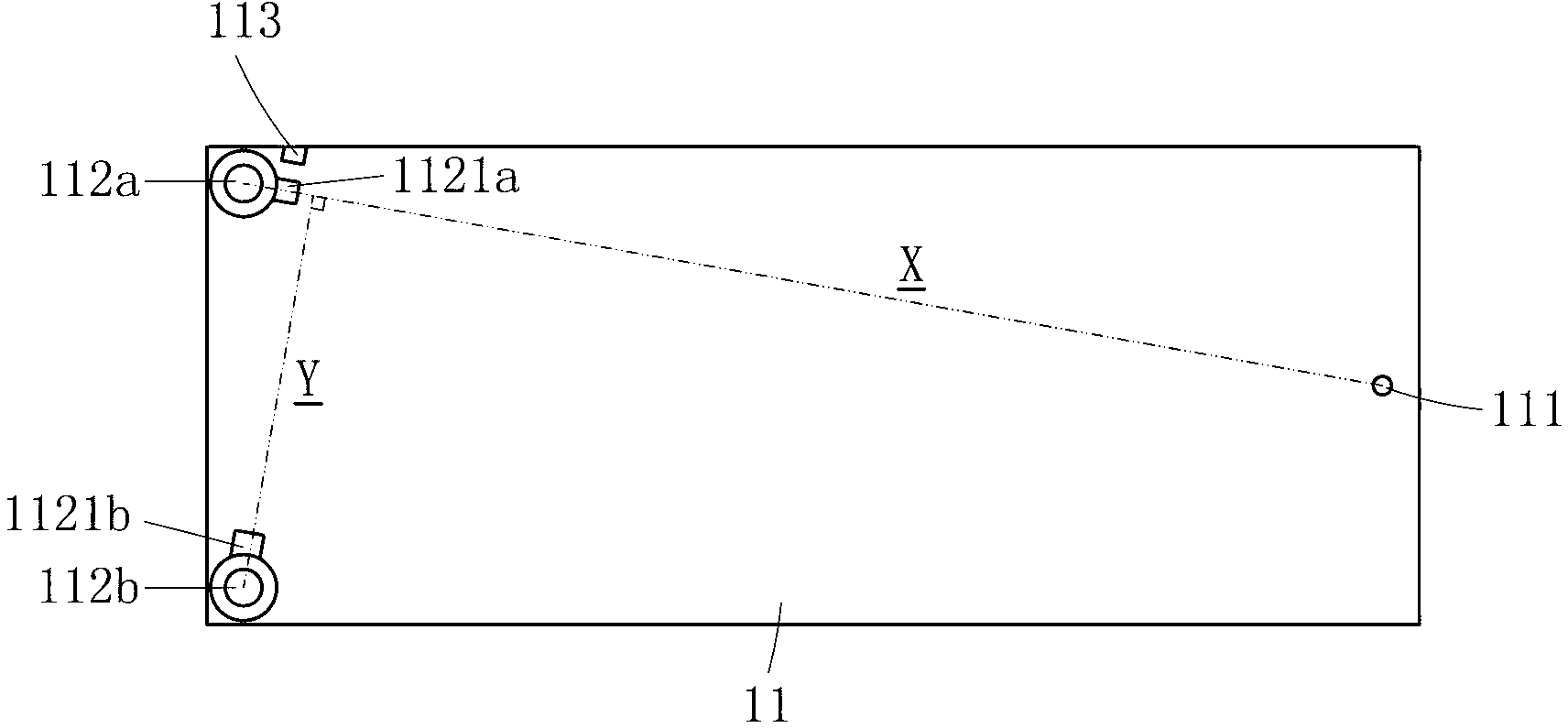

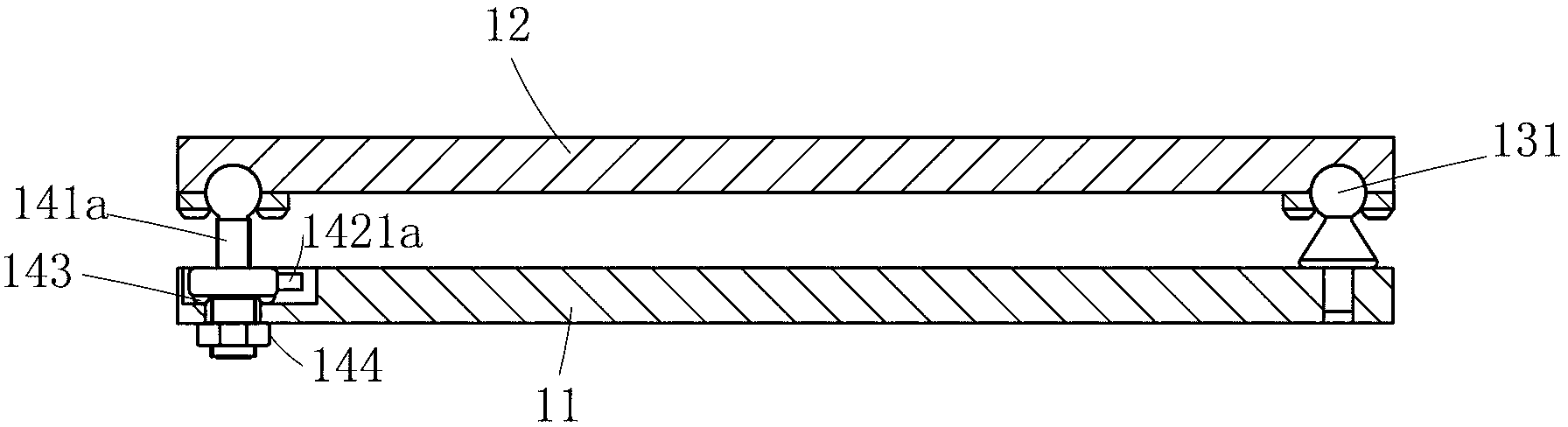

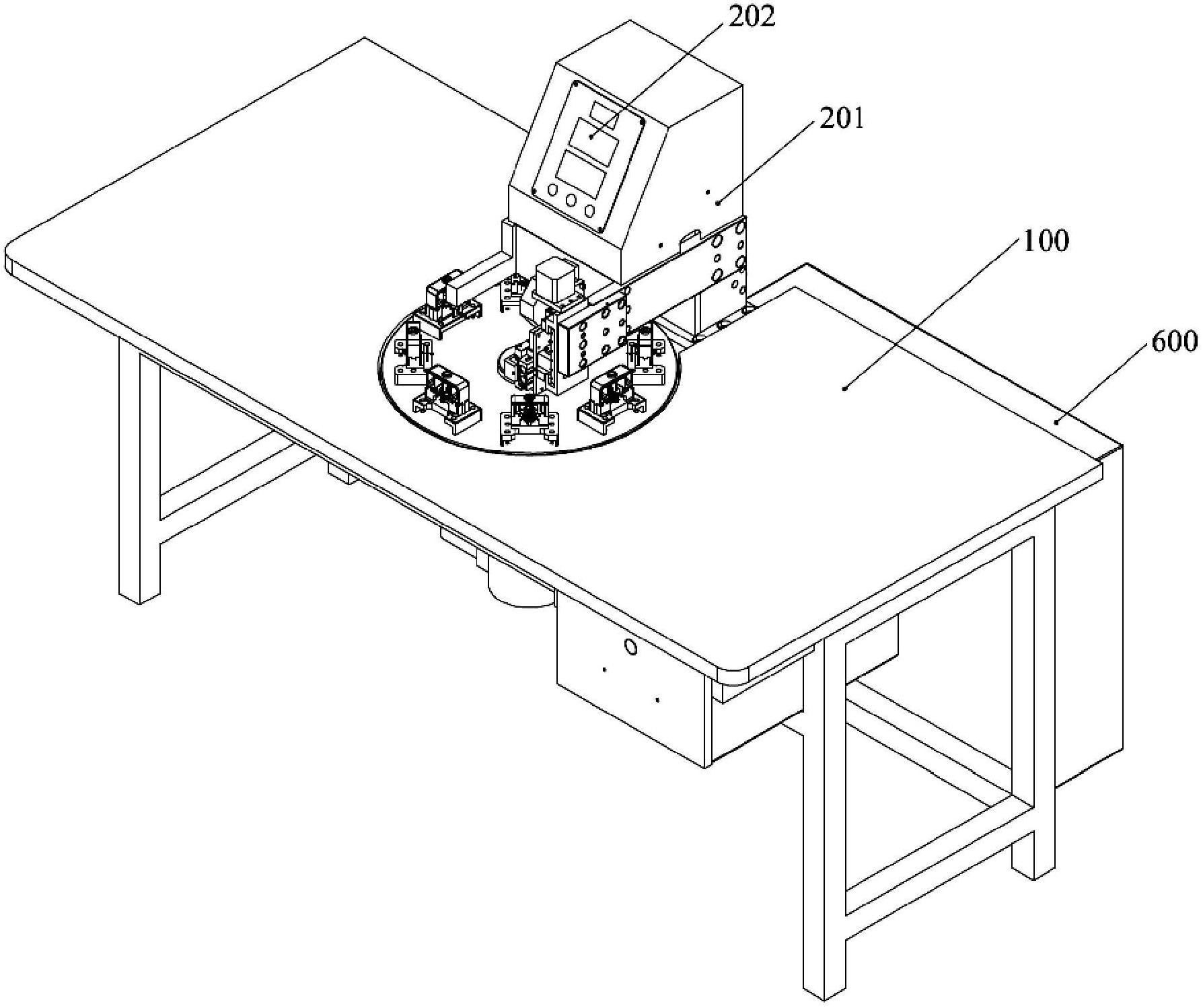

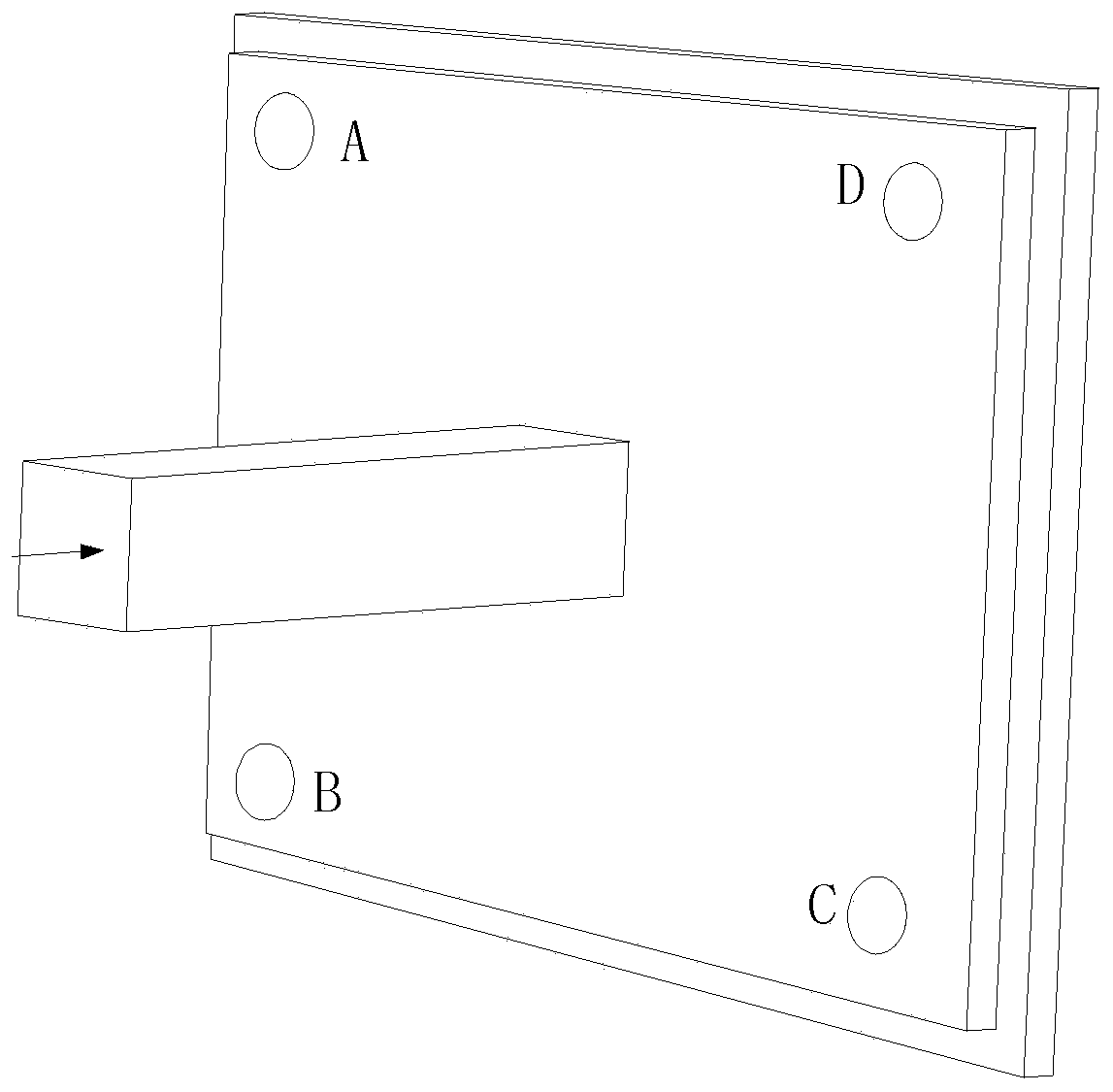

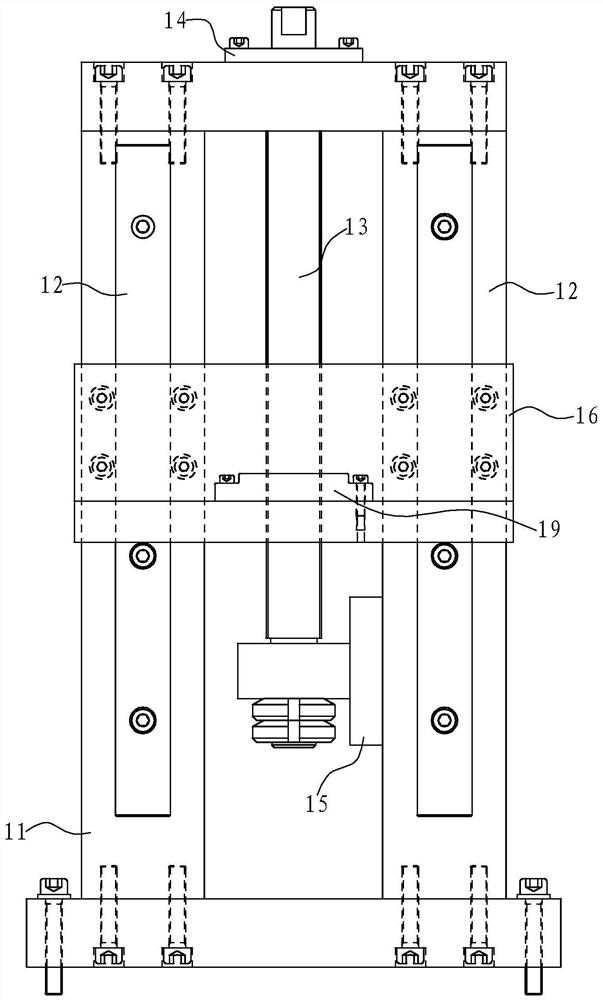

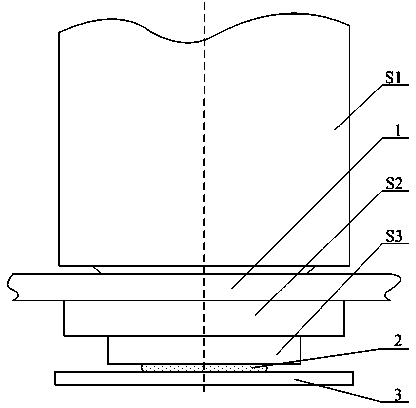

Plane trimming device and laser marking machine using plane trimming device

The invention discloses a plane trimming device and a laser marking machine using the plane trimming device, and relates to the technical field of plane adjusting equipment of precision machinery. The plane trimming device comprises an adjusting plate and a fixing plate, wherein the fixing plate and the adjusting plate are vertically connected together by three groups of support assemblies, the three groups of support assemblies are arranged in a triangle way, one of three groups of support assemblies is fixed support assemblies, and the other two groups of support assemblies are adjusting support assemblies. The plane trimming device has the advantages that the structure is simple, and the cost is low; a principle of using three points not in a common line to form a plane is utilized, so the precise adjusting of the parallel degree or the inclination degree between the two planes is realized, and easiness, convenience and easy implementation are realized; and the plane trimming device is applied to the laser marking machine, and on the premise of slight increase of the cost, the marking precision and the marking quality are greatly improved, and further the price-performance ratio of a product and the market competitiveness are improved.

Owner:WEIFANG LOKOMO PRECISION IND

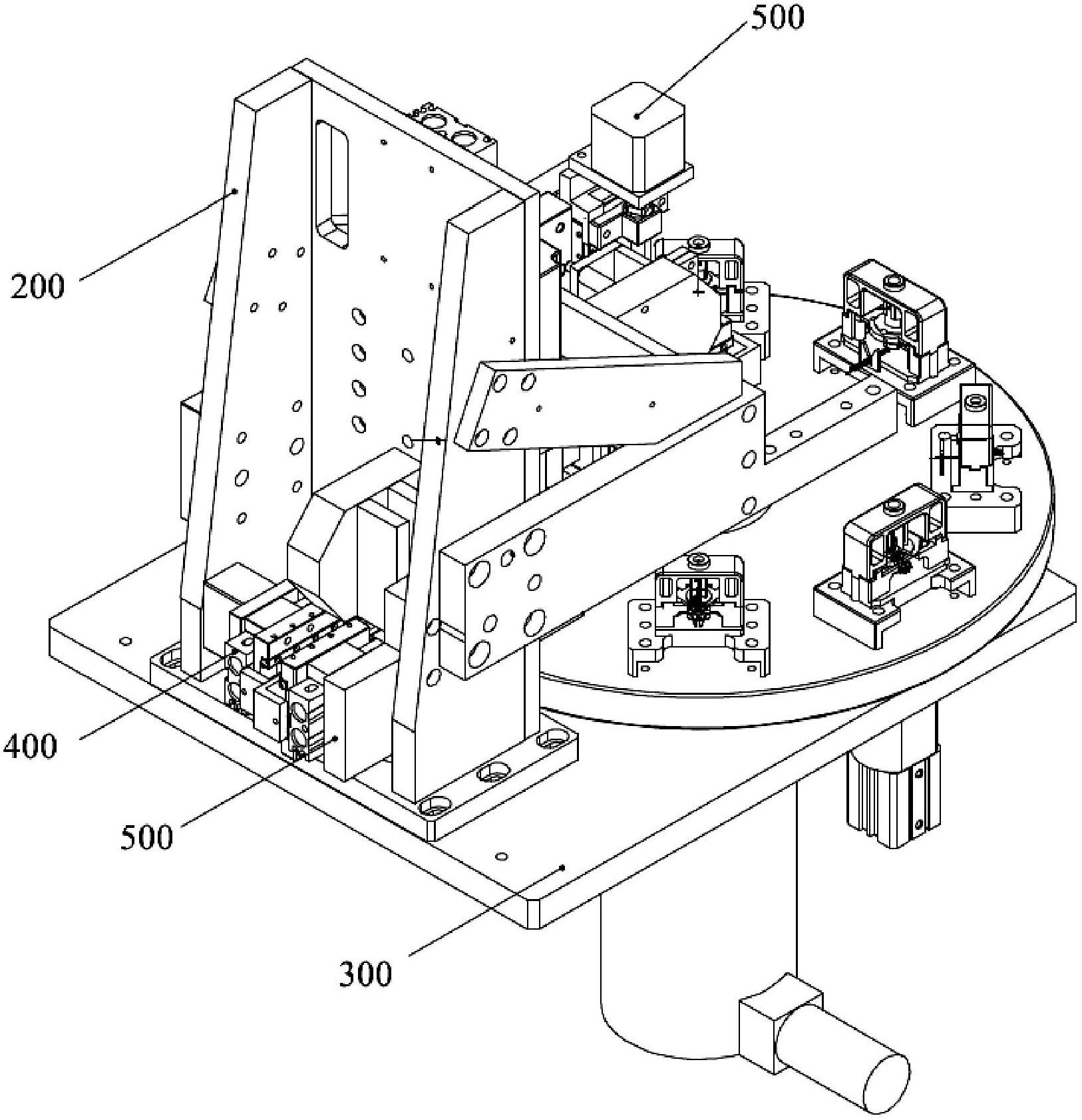

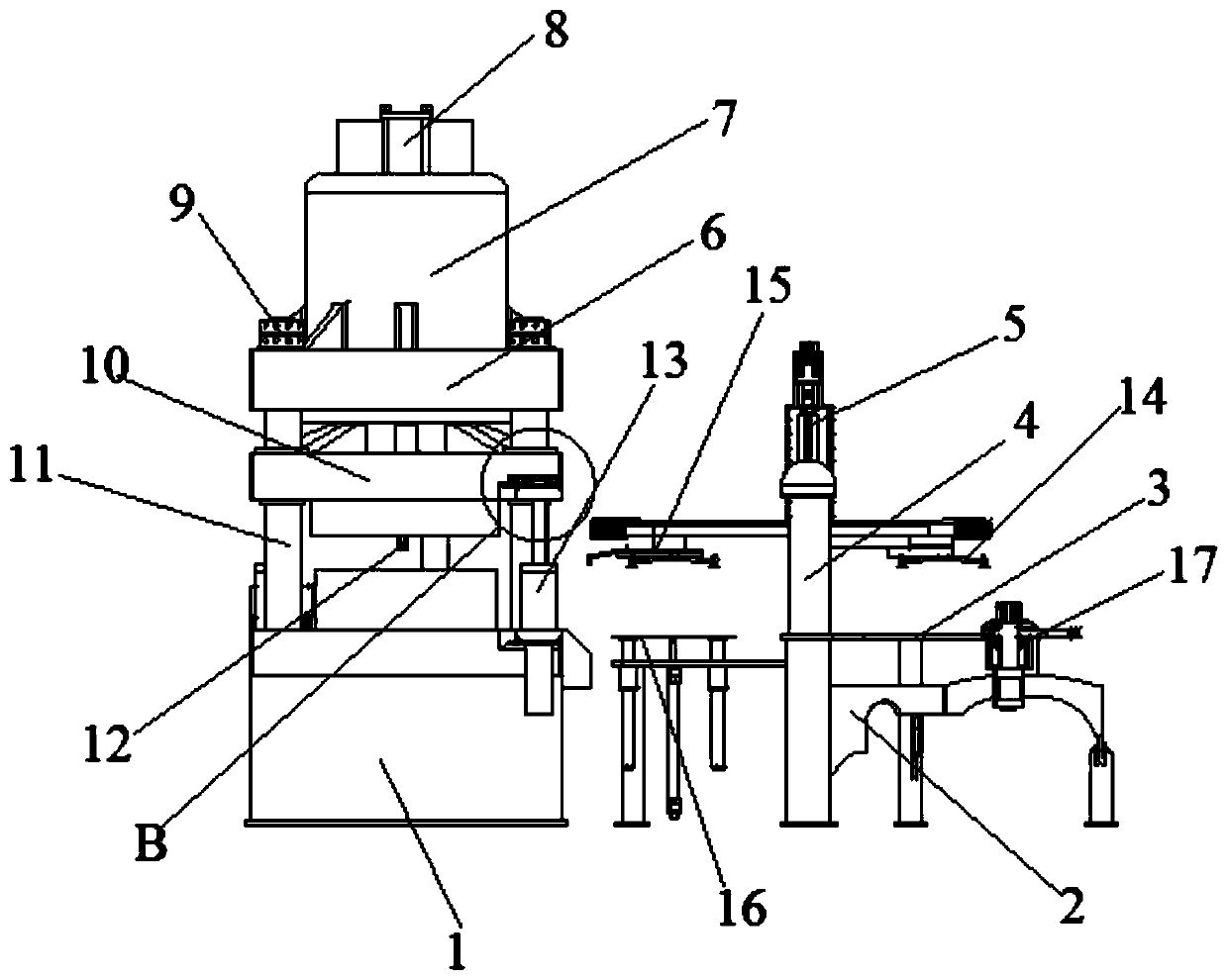

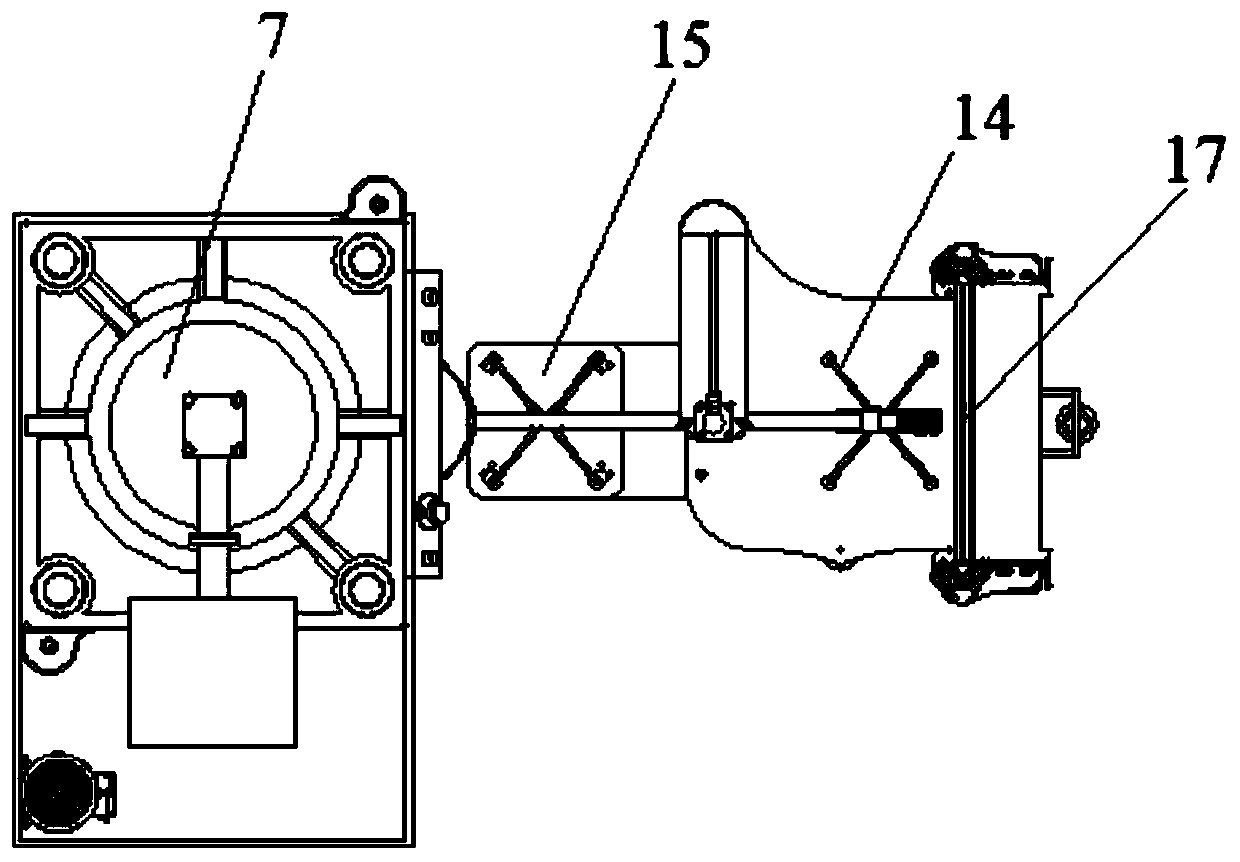

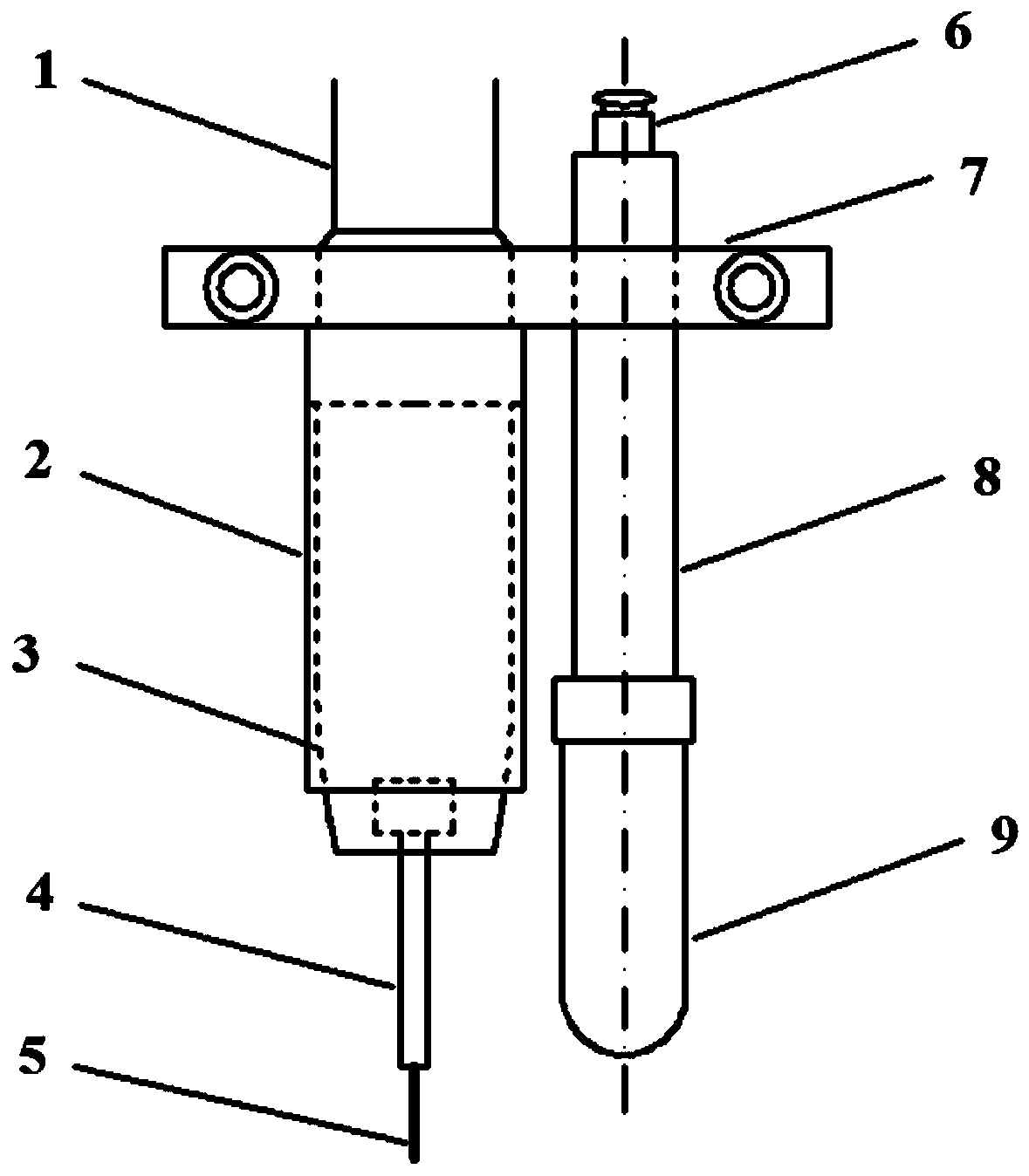

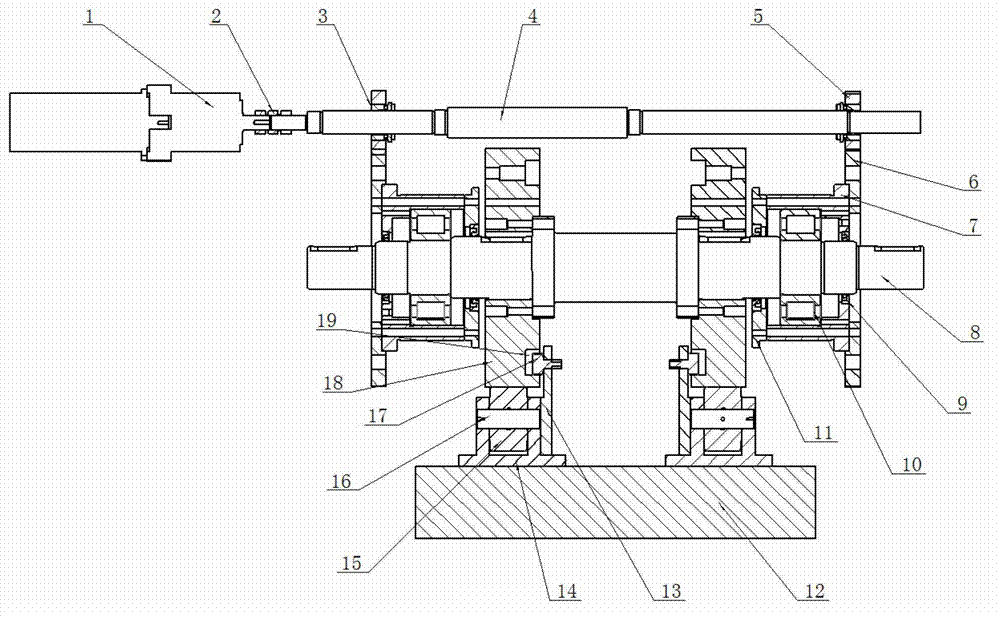

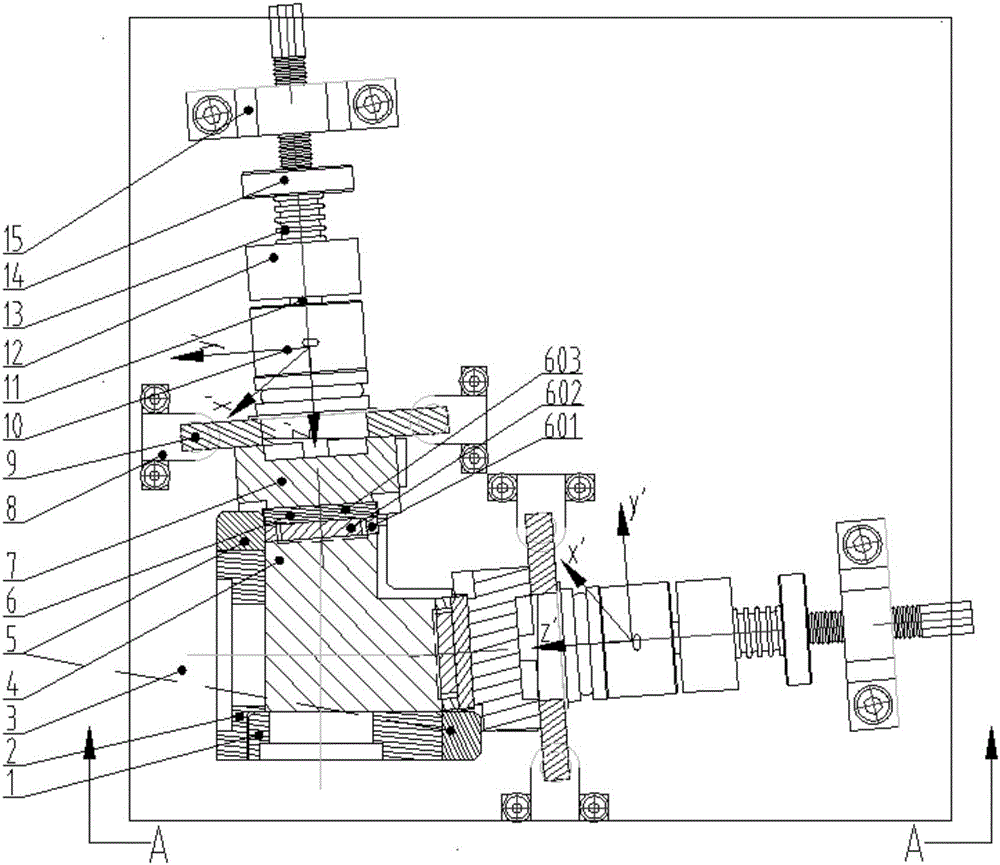

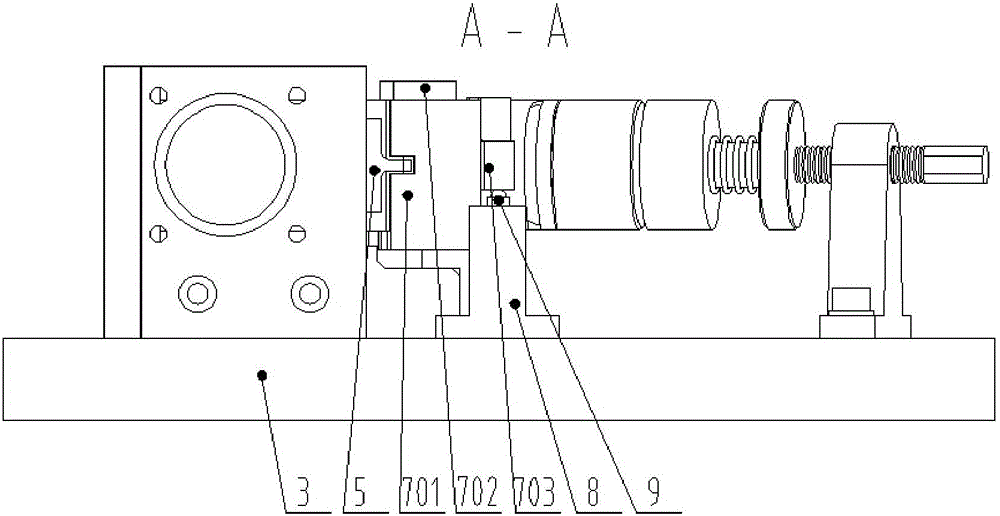

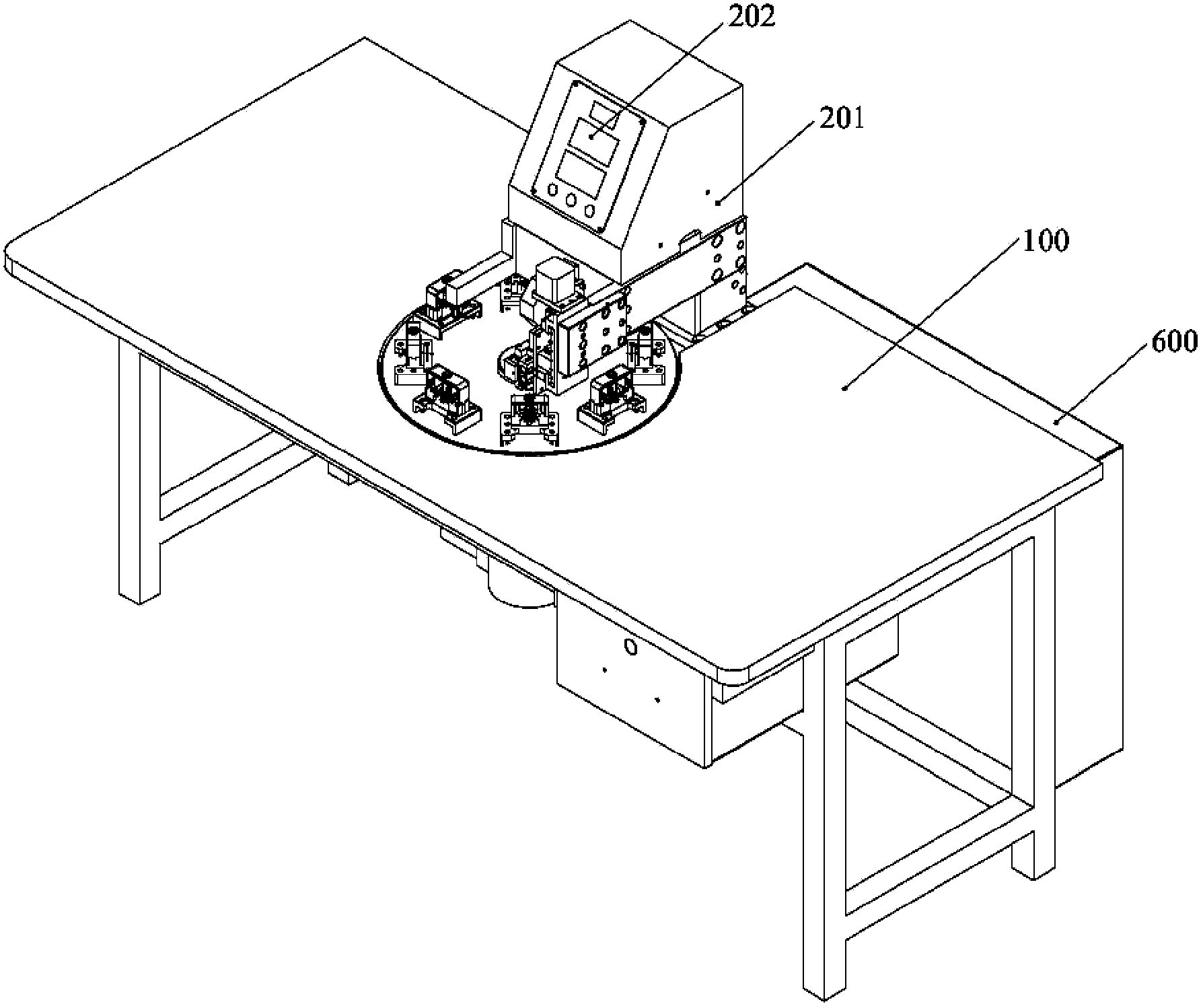

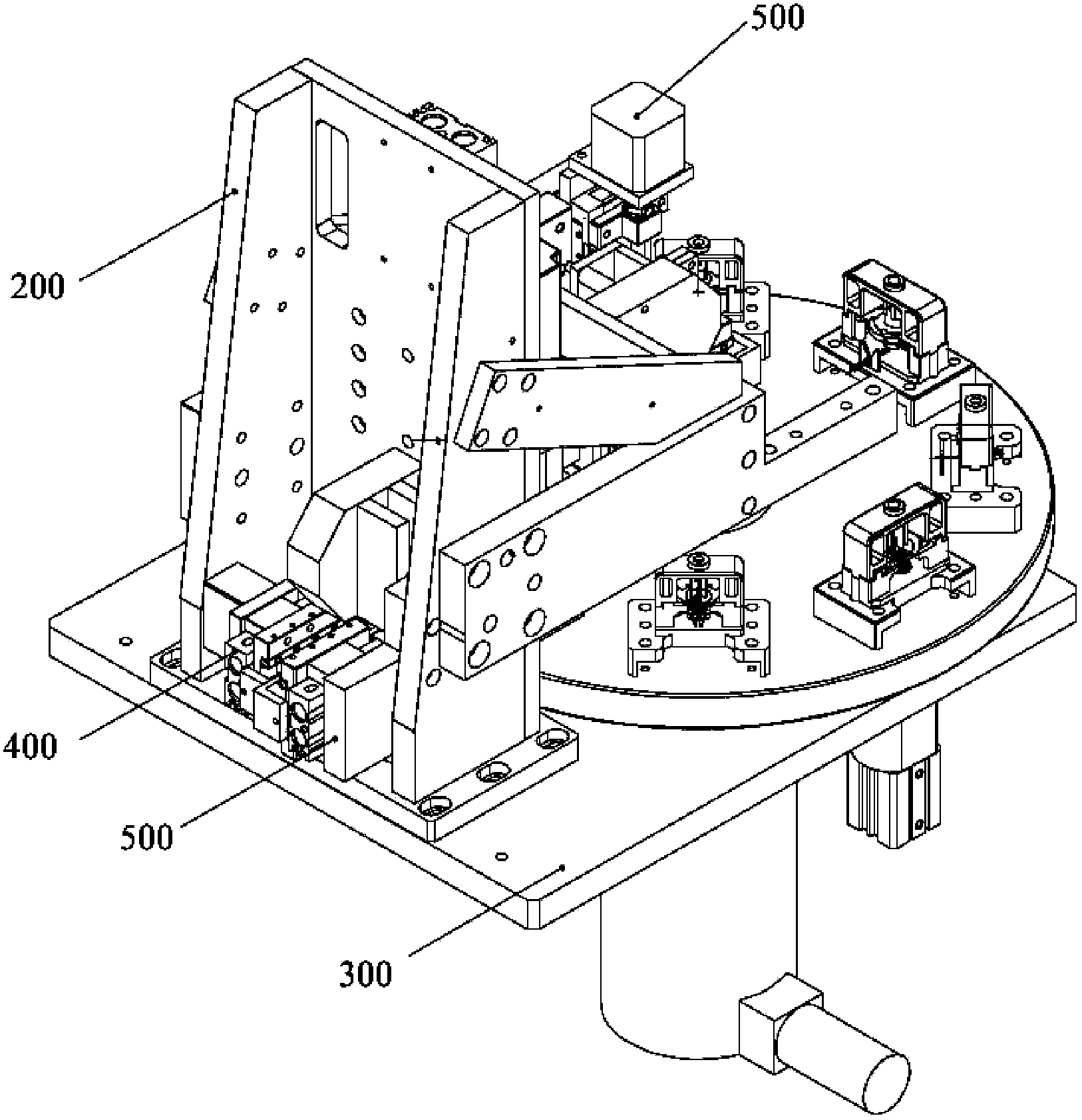

Automatic accurate adjustment system for instrument movement clearance

The invention discloses an automatic accurate adjustment system for an instrument movement clearance. The automatic accurate adjustment system comprises a work table, a handpiece module, an engine base module, a shifting module, a laser displacement sensor module and a controller. The handpiece module comprises a cutter head and a cutter head drive mechanism; the shifting module comprises a shifting plate and a shifting plate drive mechanism; the laser displacement sensor module comprises a probe, a laser displacement sensor and a probe drive mechanism; the signal output end of the laser displacement sensor is connected with the controller; and the control ends of drive elements in the cutter head drive mechanism, the shifting plate drive mechanism and the probe drive mechanism are connected with the controller. A clearance between a lower bearing and a shaft tip in a measurement mechanism of an electrical measuring instrument to be adjusted is detected by using the shifting plate, the probe and the laser displacement sensor, an adjustment quantity is output by using the controller according to a detection signal, and axial displacement is generated by driving the lower bearing through the cutter head, so that the accurate adjustment of the clearance between the lower bearing and the shaft tip is realized. The automatic accurate adjustment system is short in machining period, low in cost and high in efficiency; and moreover, the batch uniformity and the stability of the accuracy can be improved.

Owner:SHANGHAI COMPLEE INSTR

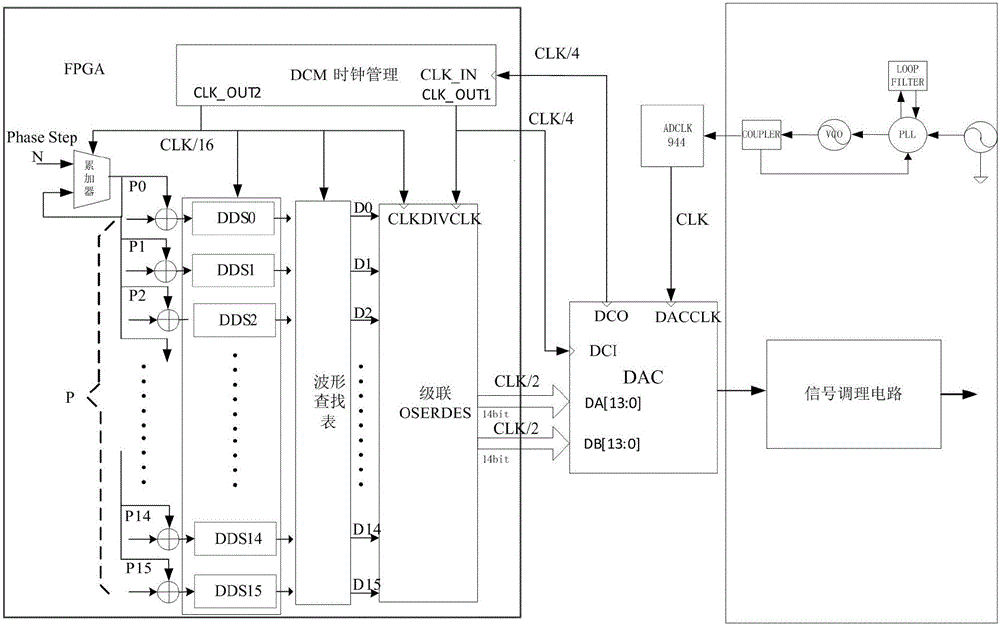

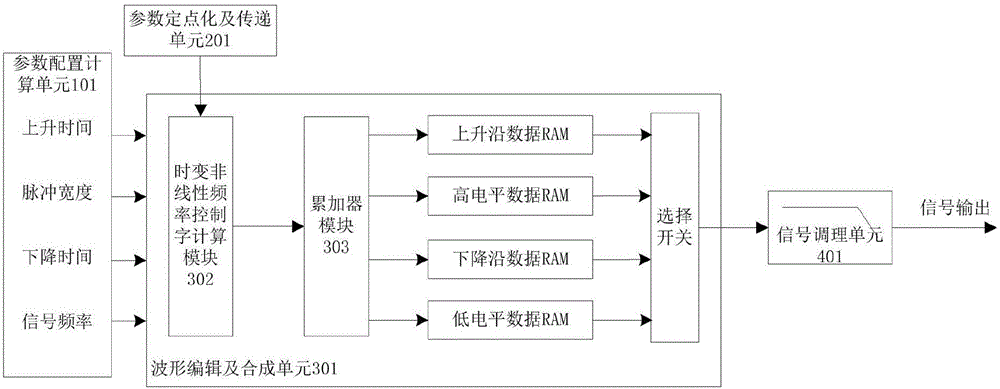

Multichannel random waveform editing device and method

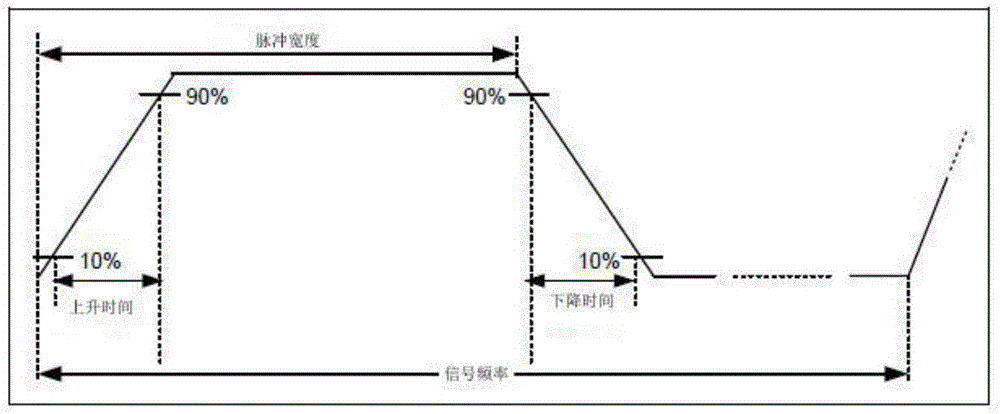

InactiveCN106774628AEliminate errorsSolve the problem of low resolution of pulse width adjustmentDigital function generatorsImage resolutionSignal conditioning

The invention relates to the technical field of tests, in particular to a multichannel random waveform editing device. The multichannel random waveform editing device comprises a DDS frequency synthesis channel arranged in a multichannel parallel mode, each channel of the DDS frequency combining channel comprises a parameter configuration calculation unit, a parameter fixed-point and transfer unit, a waveform editing synthesis unit and a signal conditioning unit. A wireless technology is adopted, a waveform sequence is edited on a PC terminal, parameter calculation is conducted in the DSP, parallel transmission and waveform control are conducted on an FPGA, occurrence of multiple regular and irregular waveform signals can be achieved, an improved type DDS technology is adopted, the frequency and pulse width error are drastically eliminated, and the problem that the existing DDS technology that the pulse width adjusting resolution is not high is solved.

Owner:THE 41ST INST OF CHINA ELECTRONICS TECH GRP

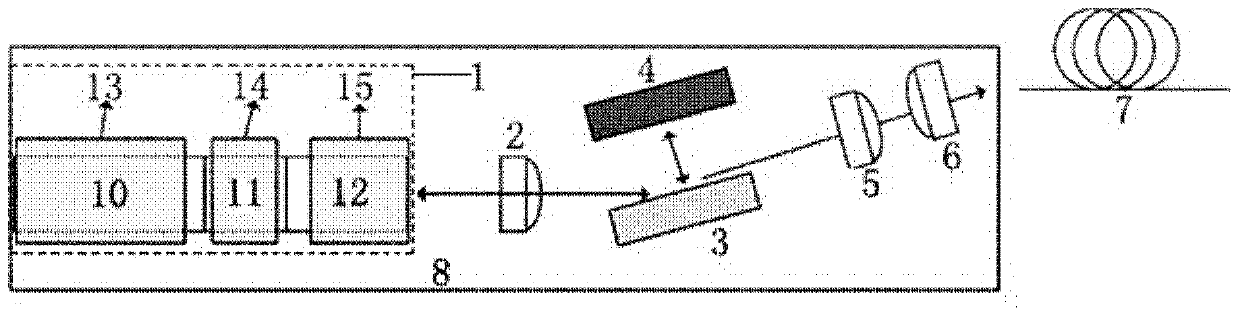

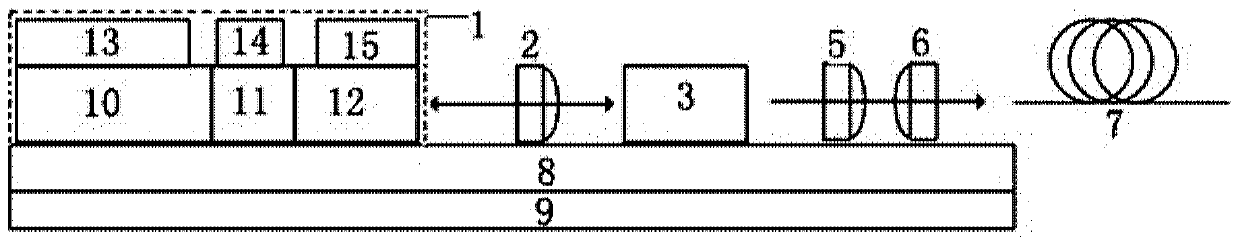

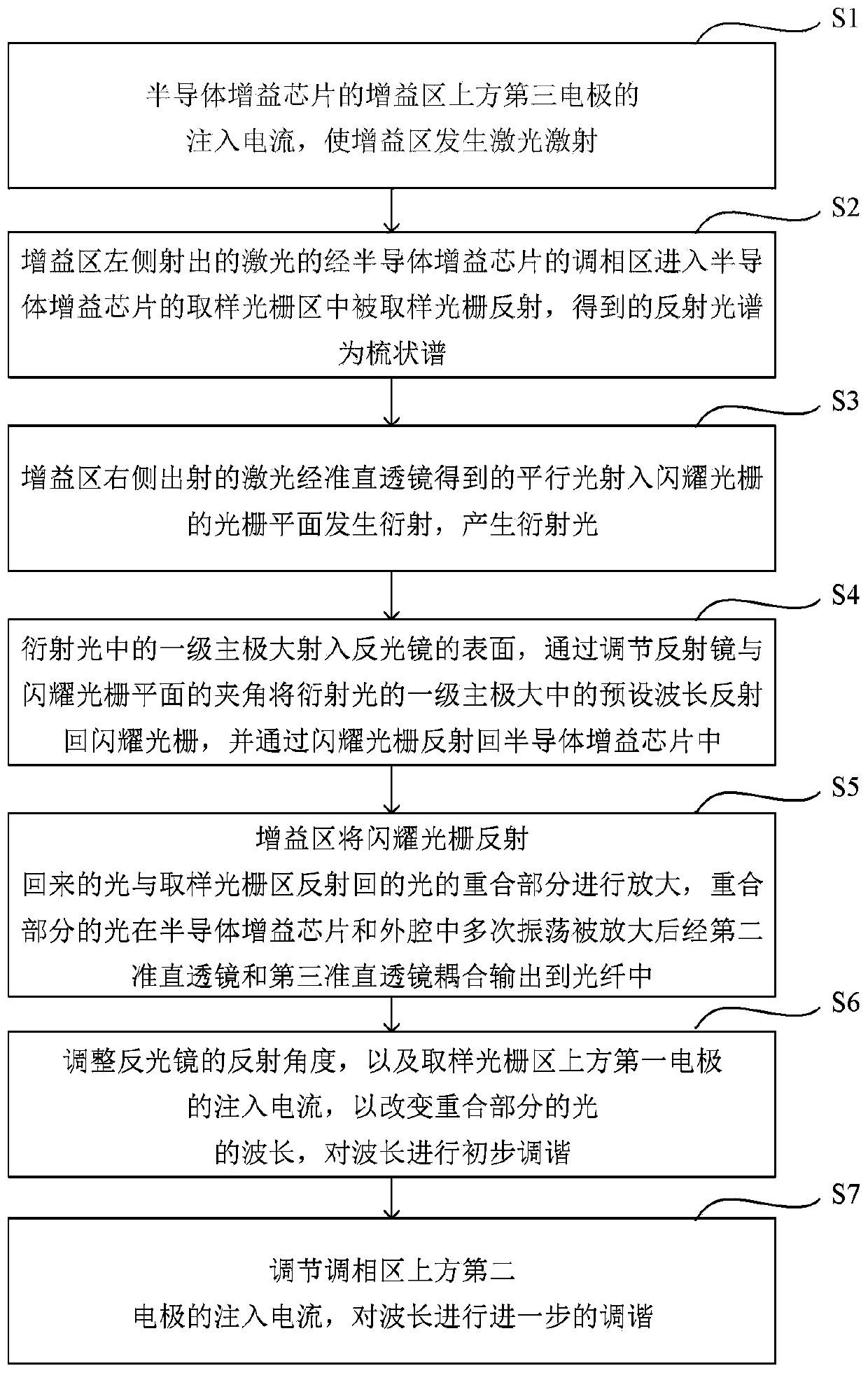

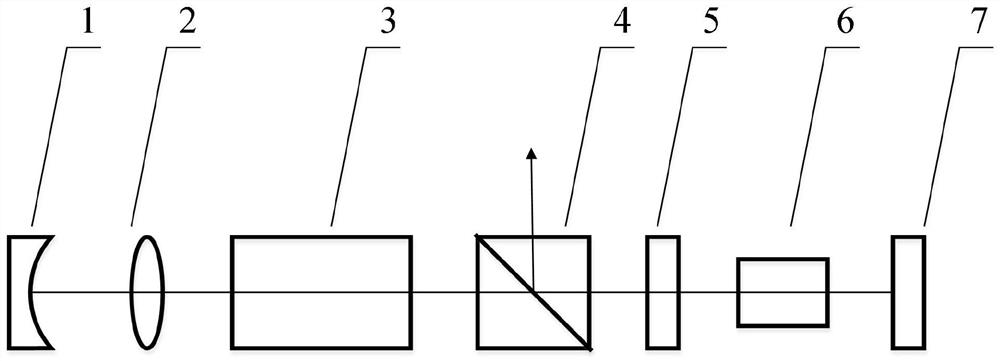

External cavity tunable laser and wavelength tuning method

InactiveCN110112652AQuick tuneFor fine tuningLaser detailsLaser optical resonator constructionGratingBlazed grating

The invention provides an external cavity tunable laser and a wavelength tuning method, and belongs to the technical field of lasers. The external cavity tunable laser comprises a semiconductor gain chip, a first collimating lens, a blazed grating and a reflector opposite to the blazed grating, wherein the semiconductor gain chip, the first collimating lens and the blazed grating are located on the same optical axis, and an included angle larger than 0 exists between the grating plane of the blazed grating and the optical axis. The semiconductor gain chip sequentially comprises a sampling grating region, a phase modulation region, a gain region, and a first electrode, a second electrode and a third electrode which respectively cover the sampling grating region, the phase modulation regionand the gain region from left to right. The blazed grating and the reflector are fixed on an electric or manual control mechanical structure. According to the invention, the large-range, rapid and fine tuning of the wavelength by the laser is realized, and the output wavelength can be narrowed.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

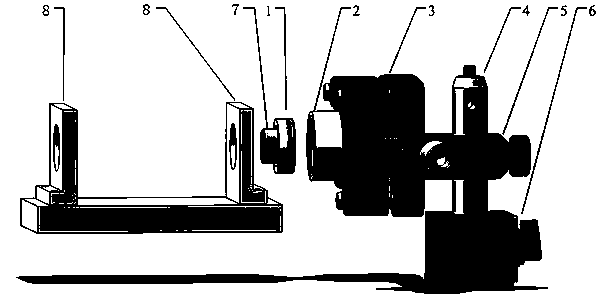

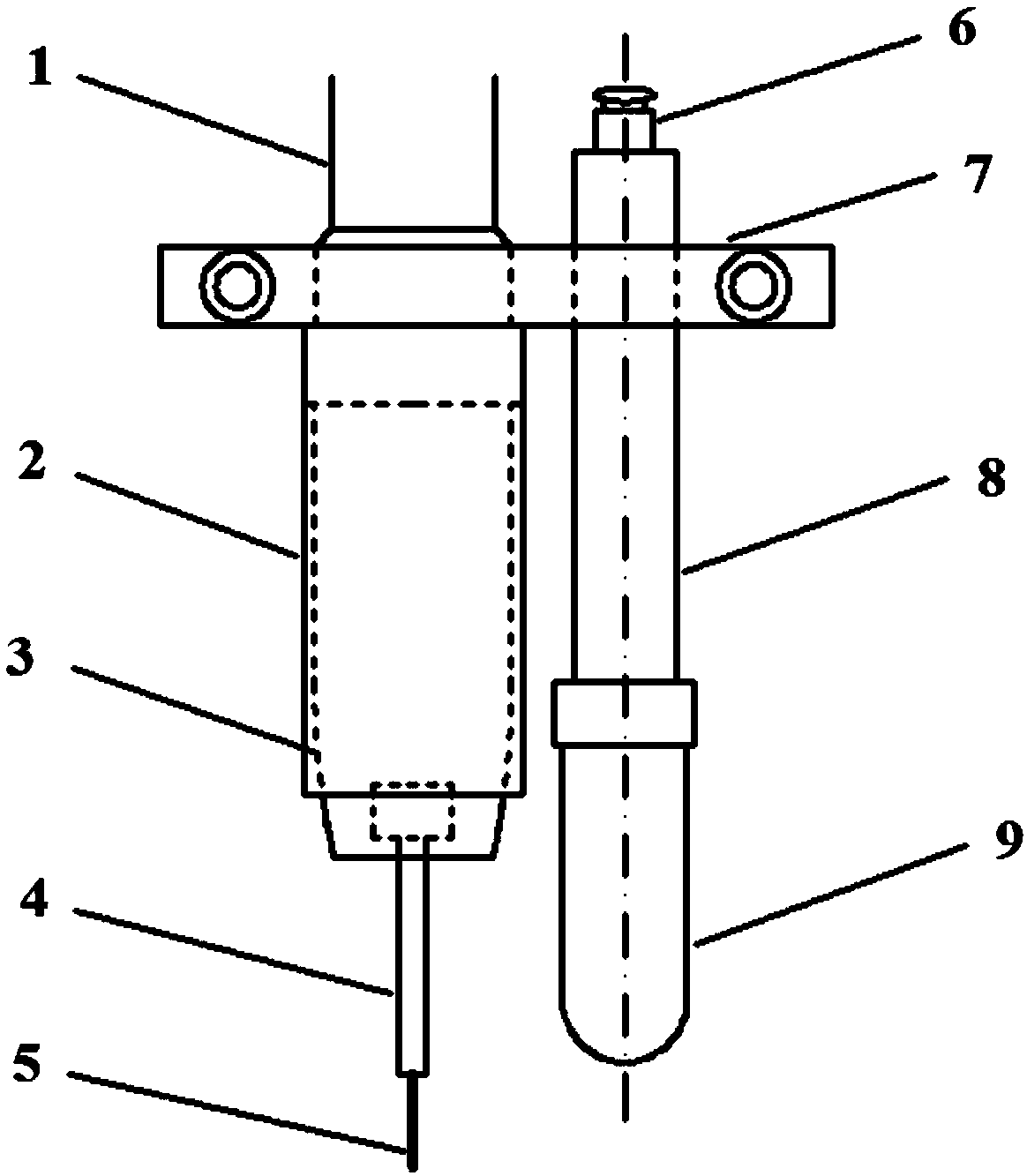

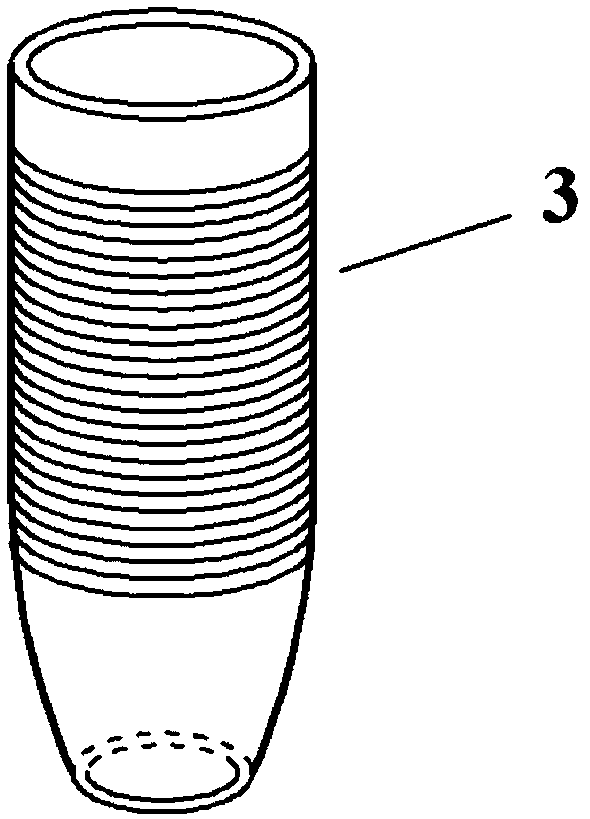

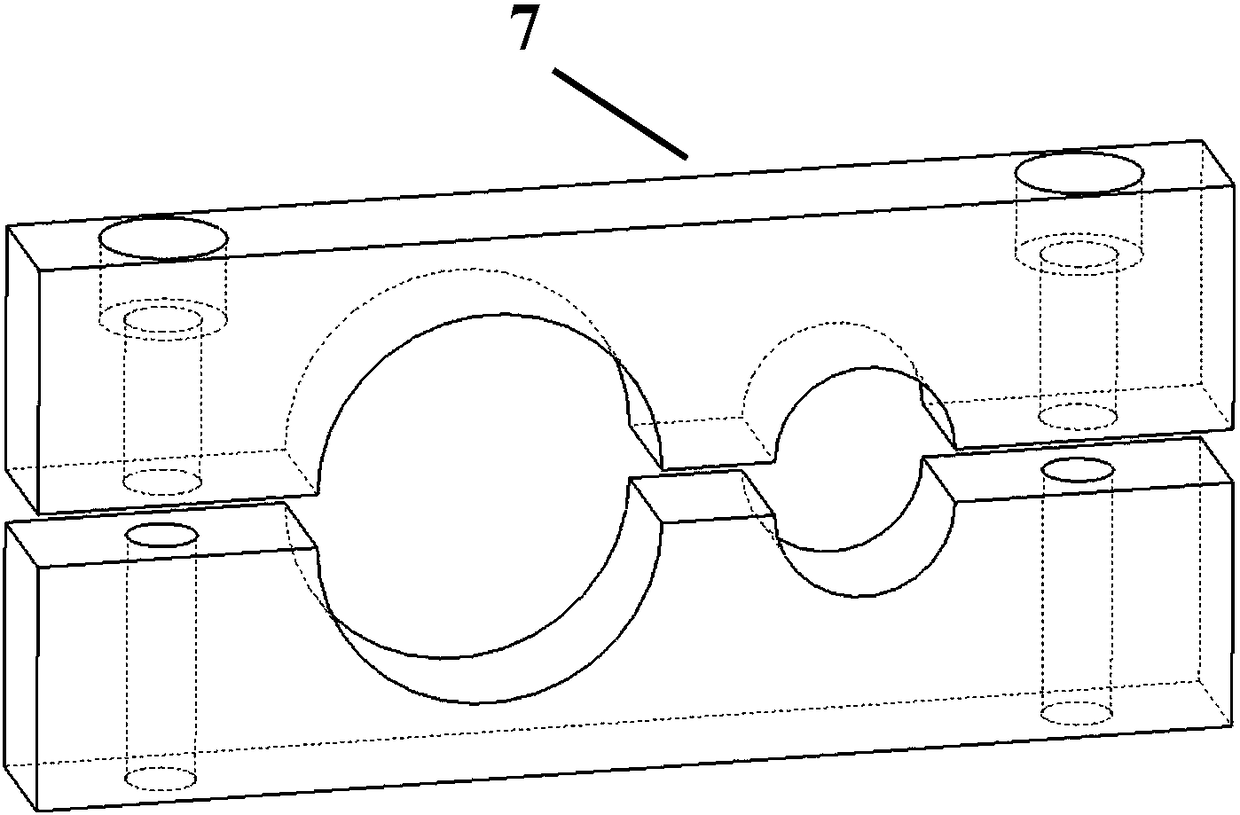

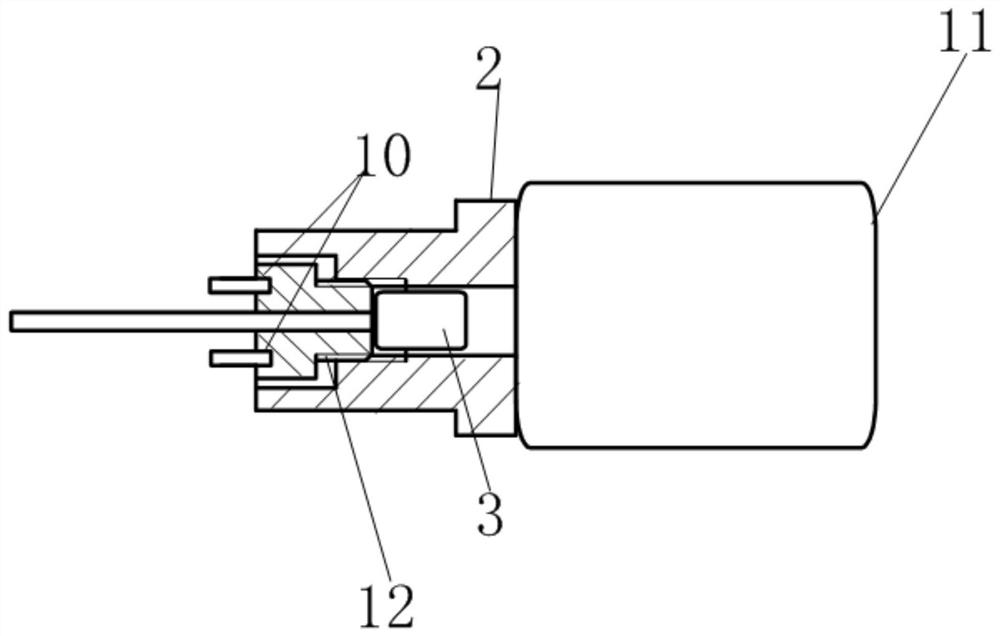

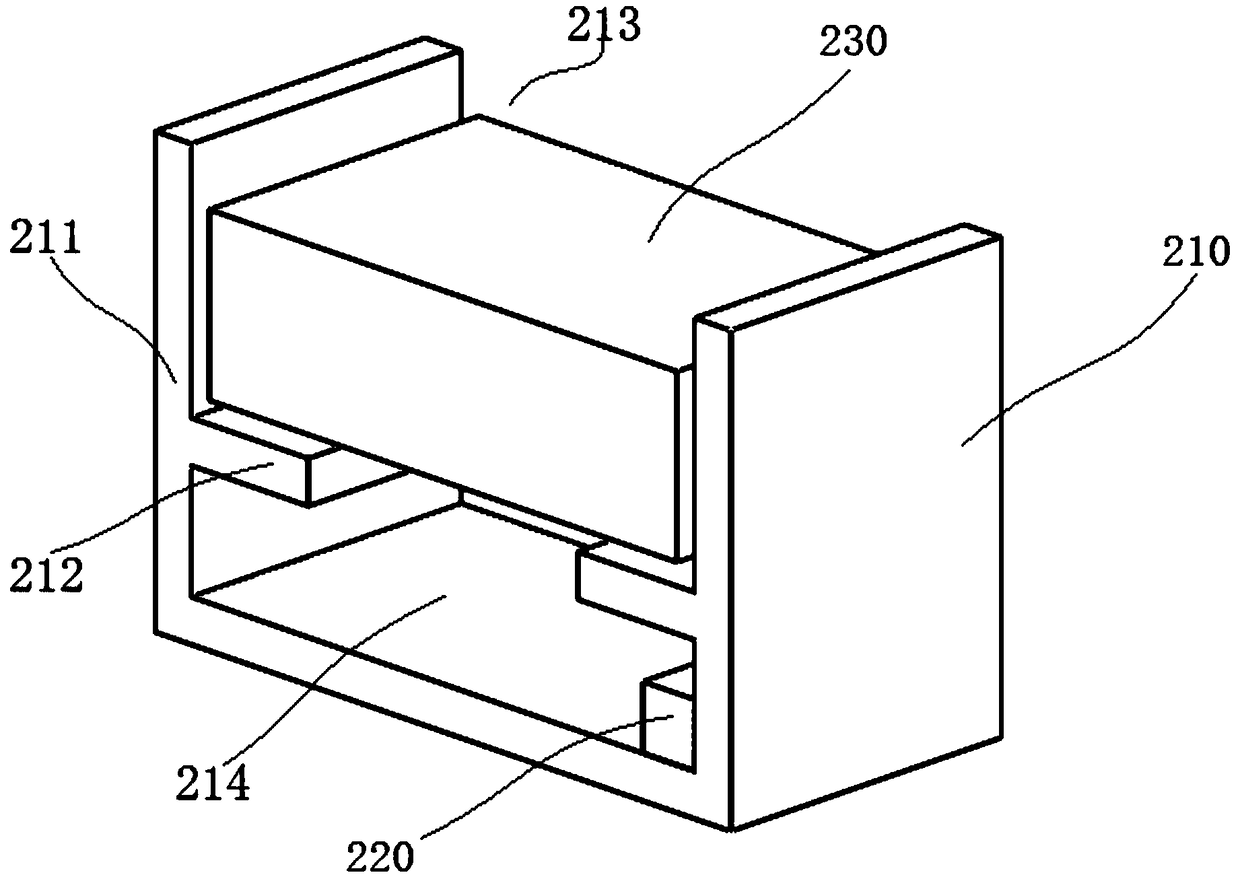

Auxiliary device and method for accurately adjusting and fixing engineering laser resonant cavity lens

InactiveCN108471041ASolve the problem of difficult fine adjustmentFor fine tuningLaser detailsOptical elementsResonant cavityEngineering

The invention discloses an auxiliary device and method for accurately adjusting and fixing an engineering laser resonant cavity lens. The auxiliary device comprises a structural piece, a sleeve, an adjustment rack, a connection rod, an universal rod rack and a magnetic seat, wherein one end of the sleeve is in threaded connection with the structural piece, the other end of the sleeve is fixedly arranged on the adjustment rack, the adjustment rack is fixedly arranged on the universal rod rack, the universal rod rack sleeves the connection rod, and a lower end of the connection rod is fixedly arranged on the magnetic seat. The lens is cured and pasted onto the structural piece by ultraviolet glue, the accurate angle adjustment of the resonant cavity lens is achieved by the auxiliary device,so that optimal laser output is achieved; and finally, the auxiliary structural piece and a laser resonant cavity rack to be debugged are cured and pasted by the ultraviolet glue, the auxiliary deviceis removed, and the adjustment and fixing of the lens are completed. By the auxiliary device, the problem of difficulty in accurate adjustment of the laser resonant cavity lens is solved, and accurate adjustment and high stability of the resonant cavity lens are achieved.

Owner:HARBIN INST OF TECH

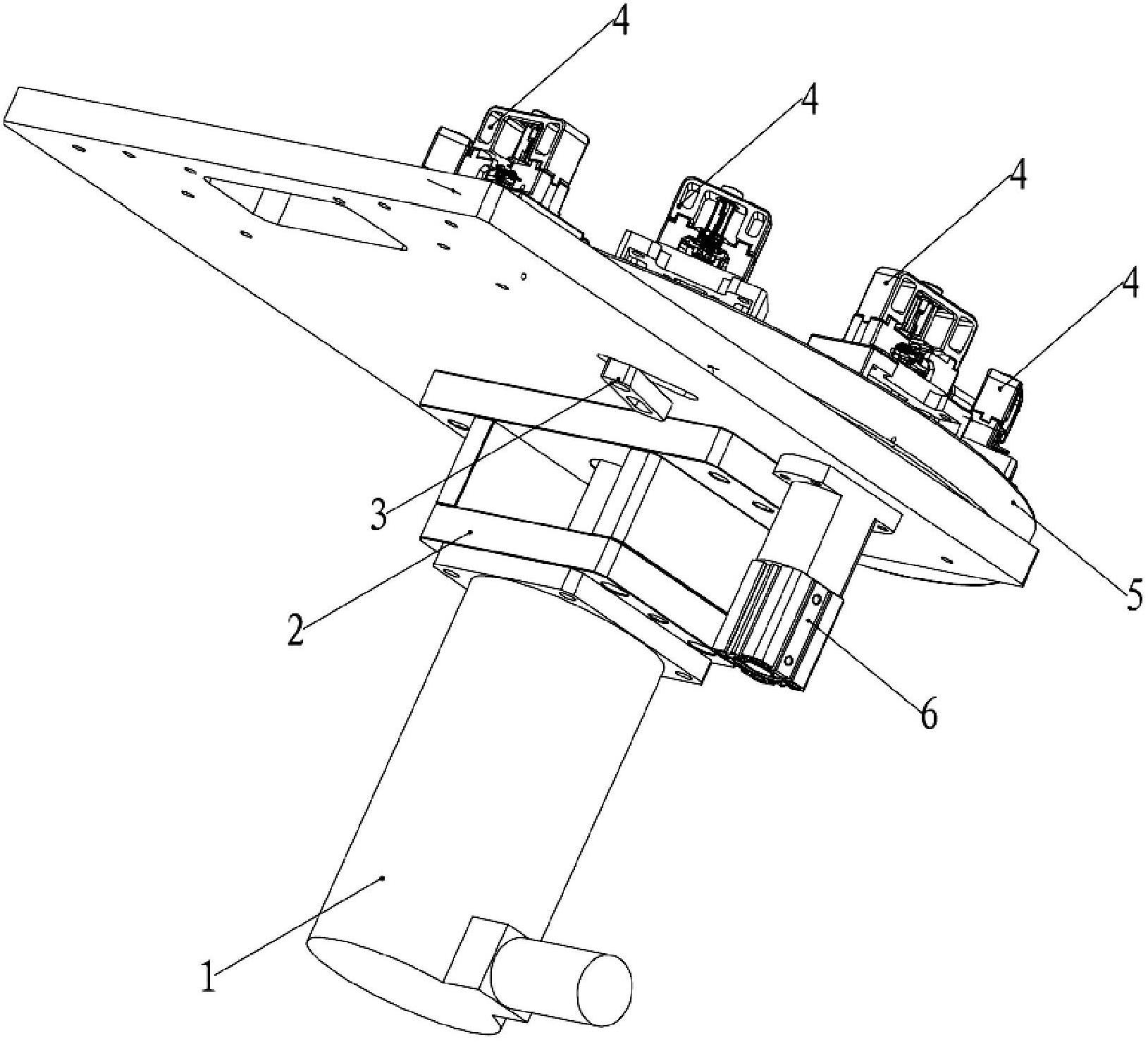

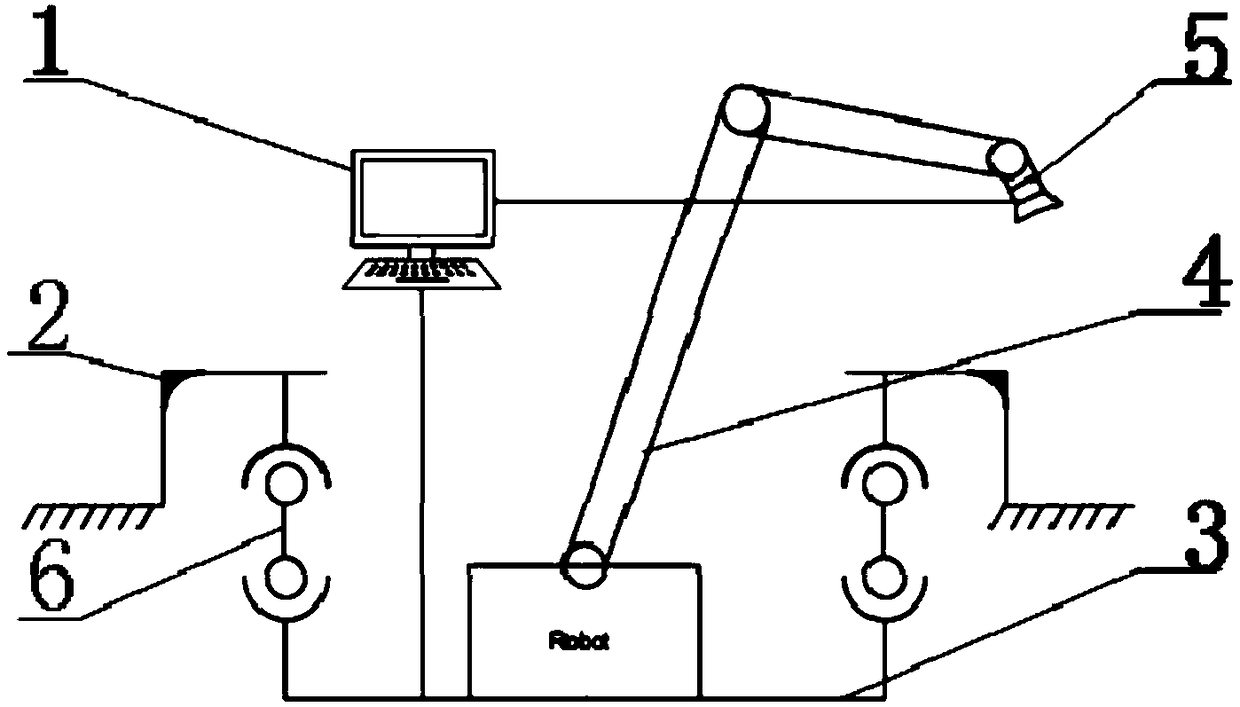

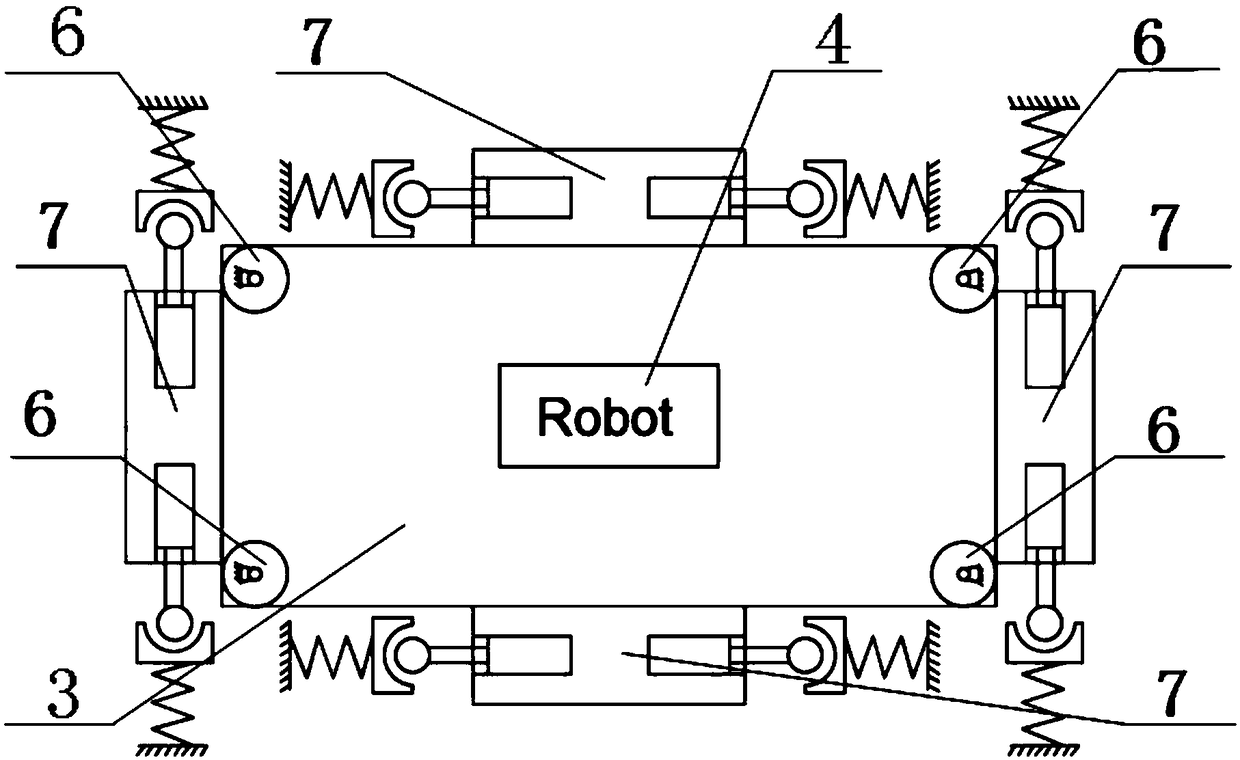

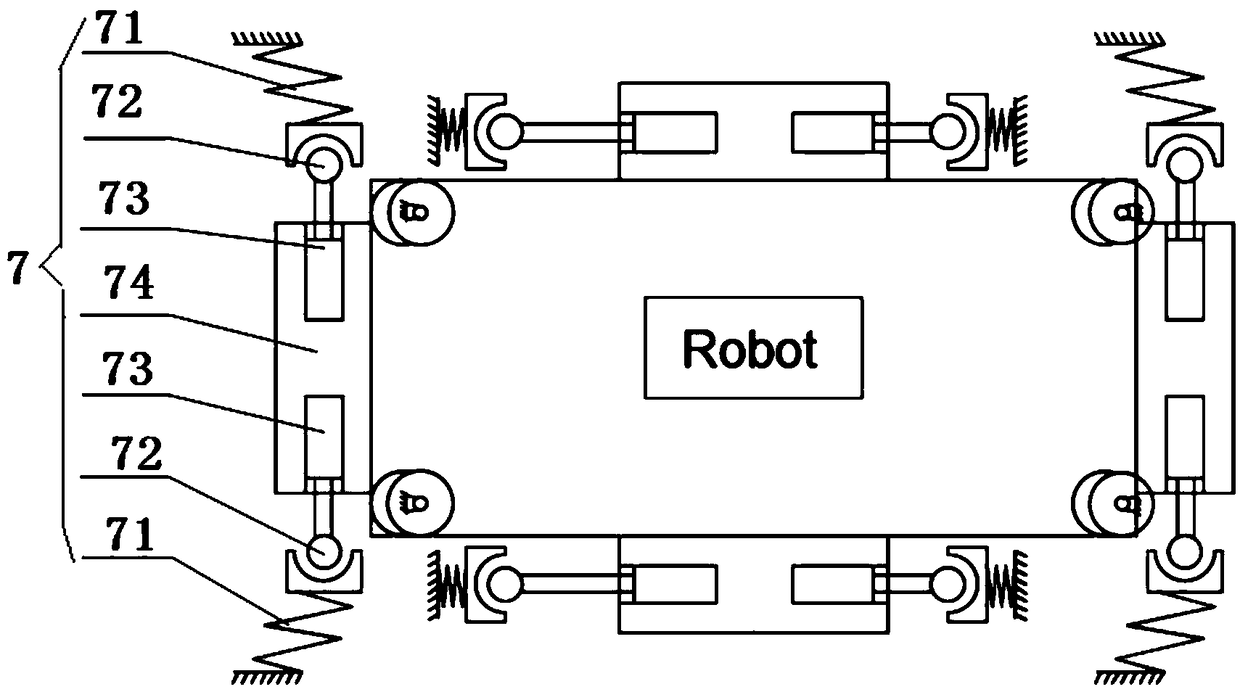

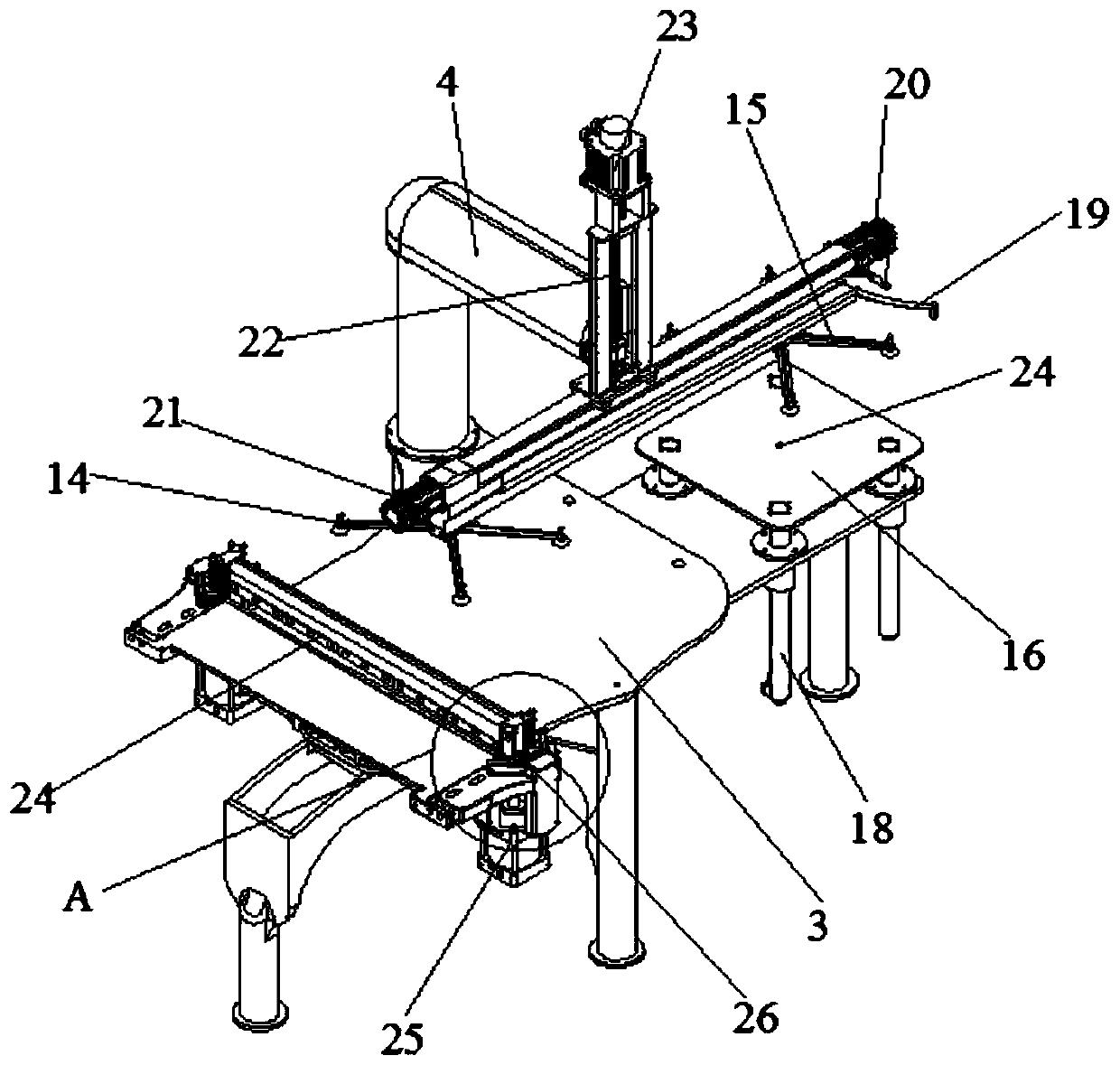

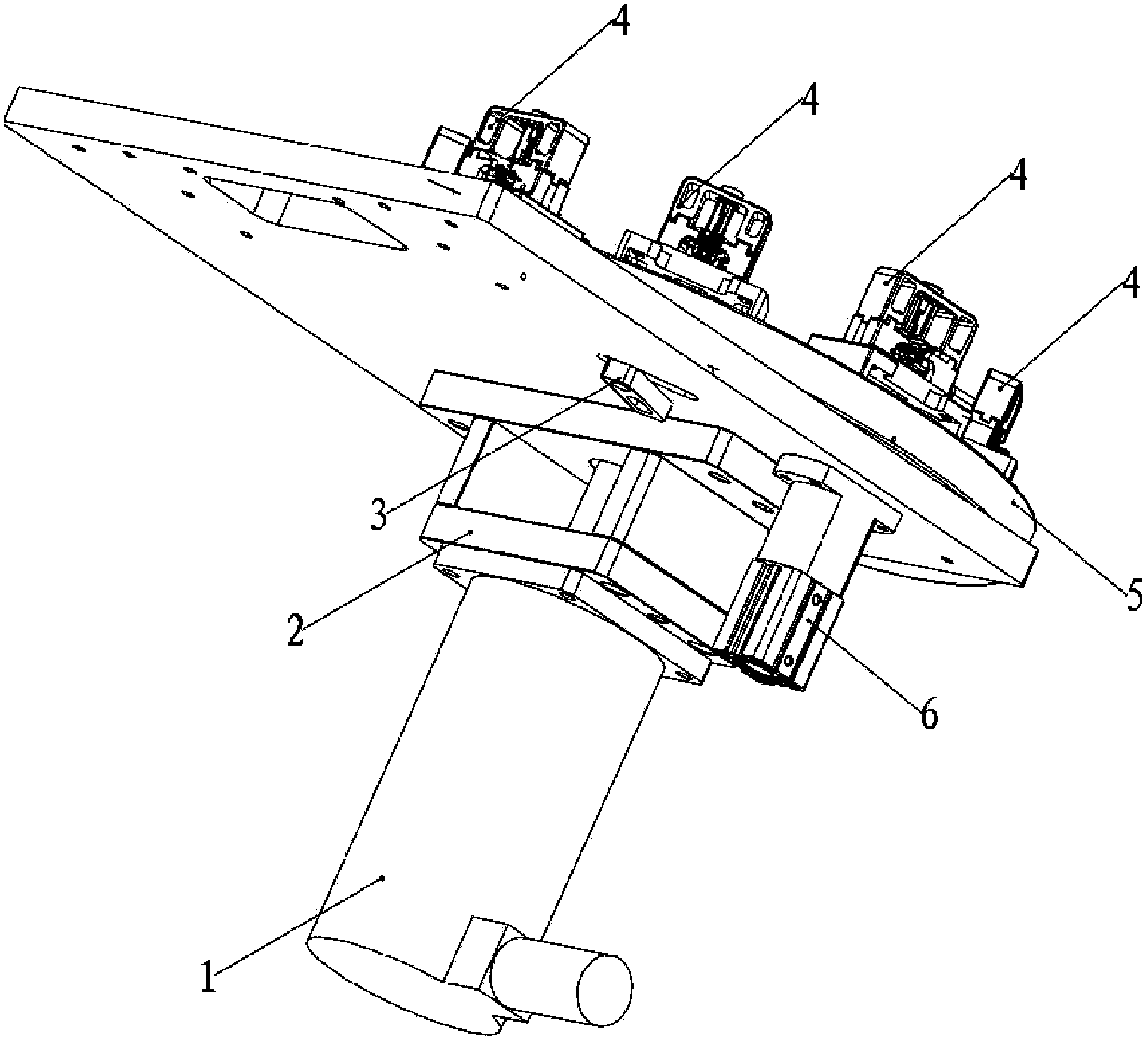

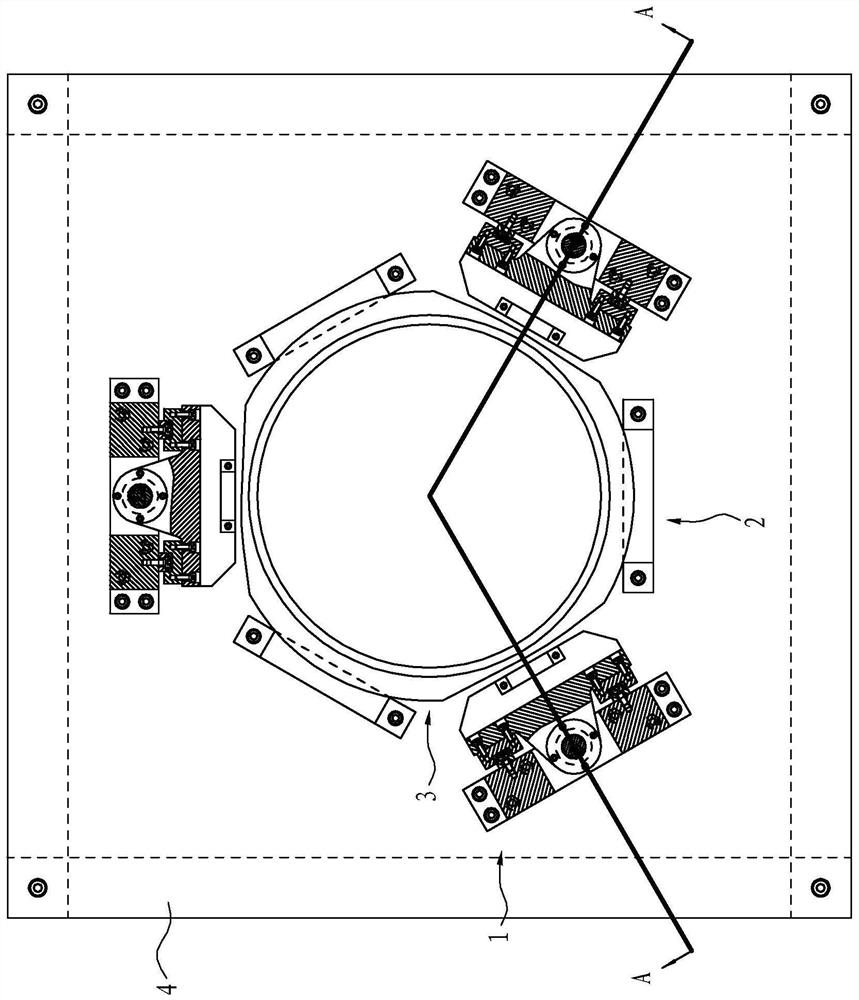

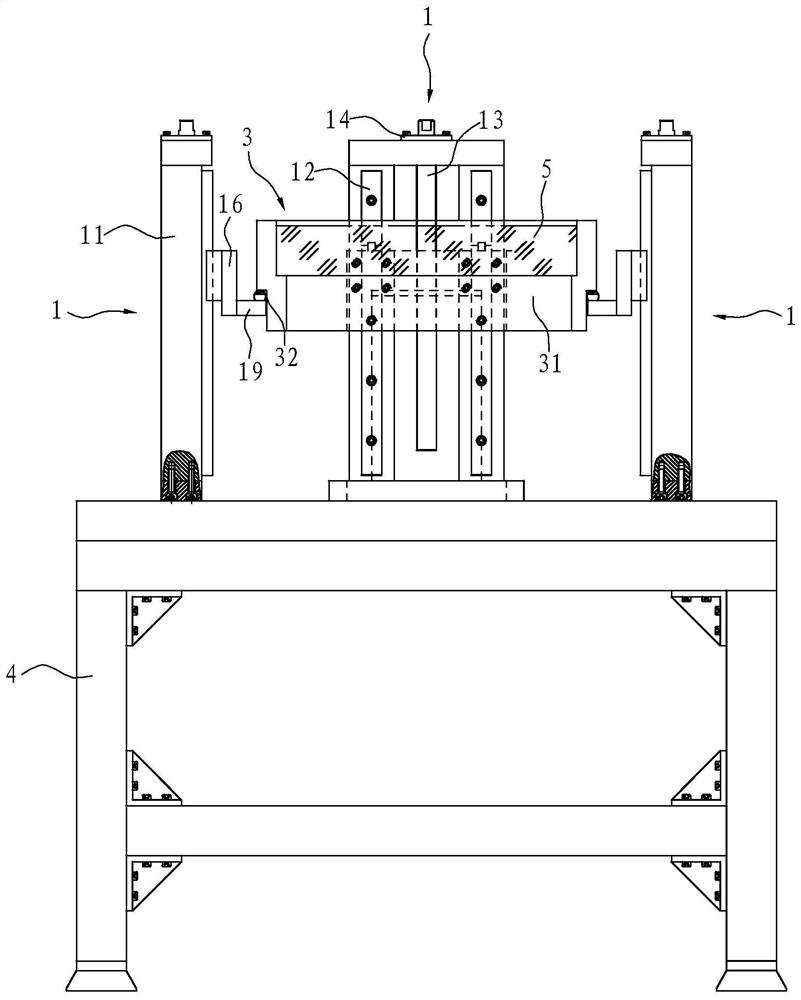

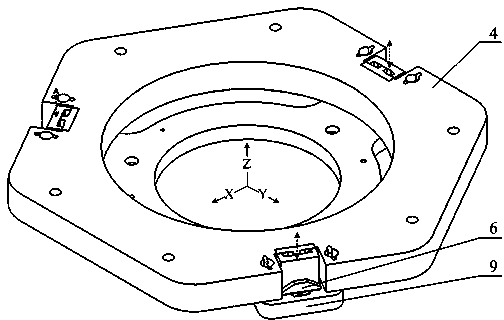

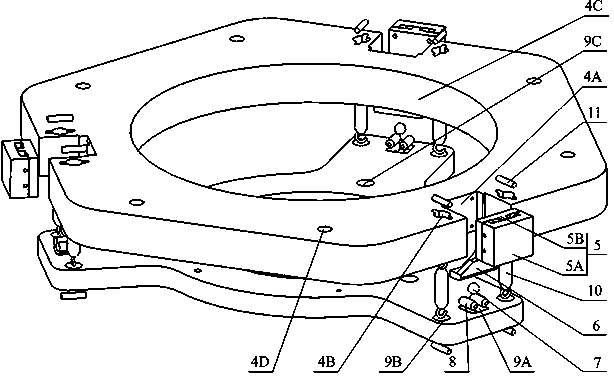

Driving flexible floating platform capable of fine adjustment and method

ActiveCN109176473AFor fine tuningHigh adjustment accuracyProgramme-controlled manipulatorRotational degrees of freedomEngineering

The invention discloses a driving flexible floating platform capable of fine adjustment. The floating platform comprises a computer, a base, a floating platform body, a robot, a torque sensor, a plurality of movable connecting pieces and a plurality of flexible fine adjustment modules; and the floating platform is movably connected on the base in a manner of two translational degrees of freedom inhorizontal direction and one rotational degree of freedom, the two ends of the movable connecting pieces are connected with the floating platform and the base respectively, the robot is fixed on thefloating platform, the torque sensor is fixed at the tail end of the robot and is connected with the computer, the plurality of flexible fine adjustment modules are adjustably arranged on the periphery of the floating platform, the two ends of the flexible fine adjustment modules are connected with the base and the floating platform respectively, and the computer is connected with the plurality offlexible fine adjustment modules. The invention further discloses a method to adopt the platform. The floating platform and the method has the beneficial effects that the precise adjustment of the robot in the horizontal direction and in the moving operation can be well realized, the adjustment precision is high, the automation degree is high, the safety is high, and the application range is wide.

Owner:合肥哈工图南智控机器人有限公司

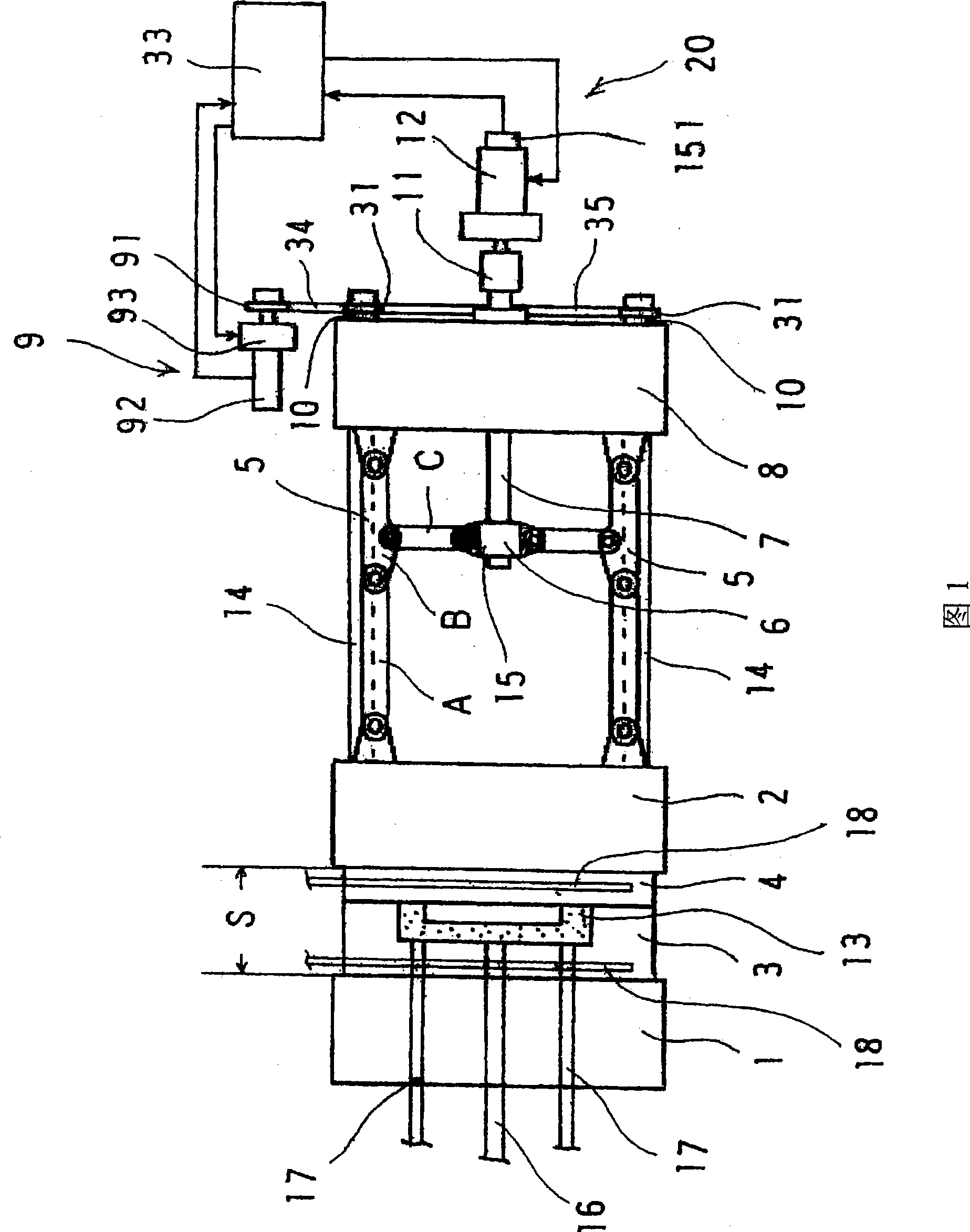

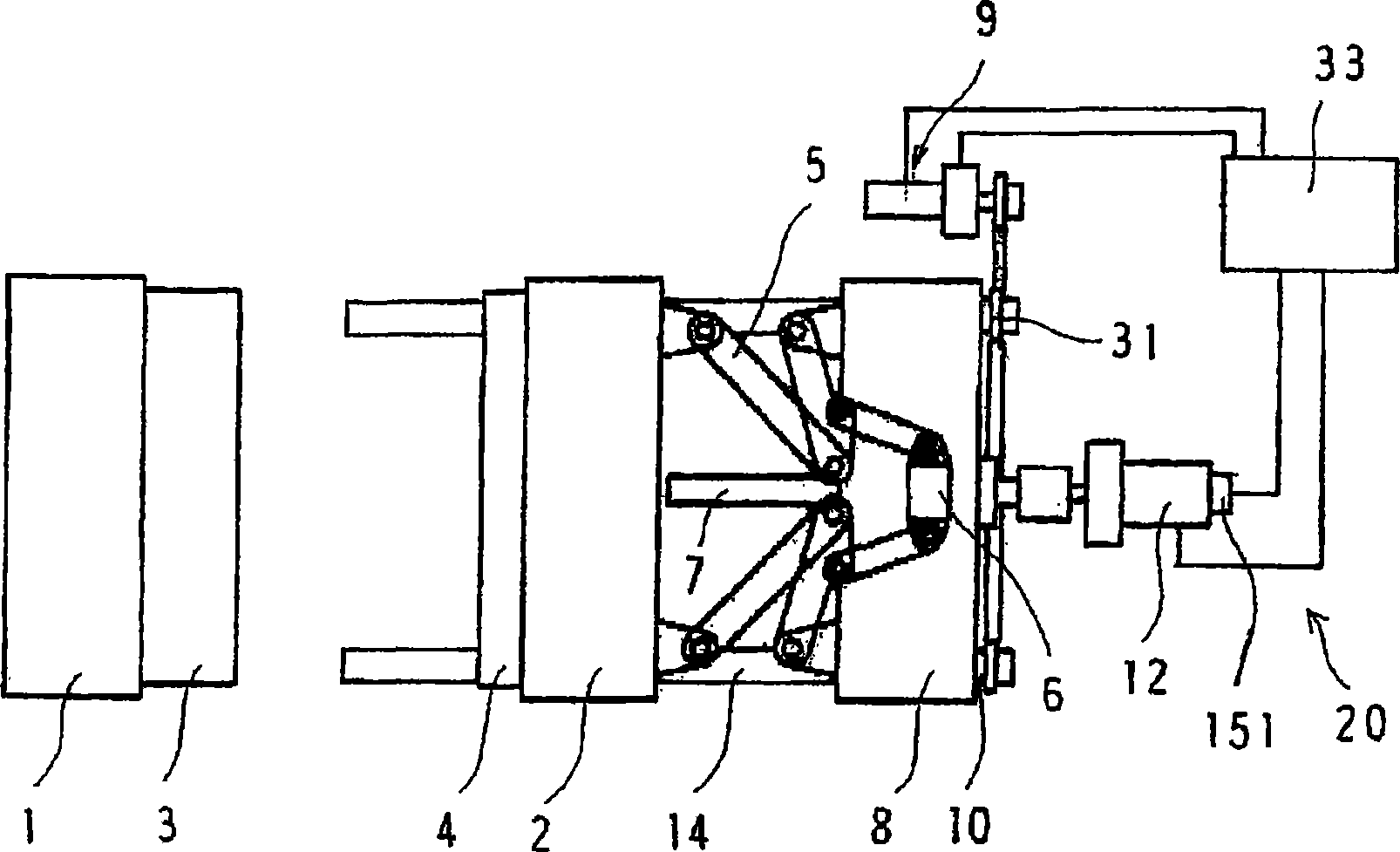

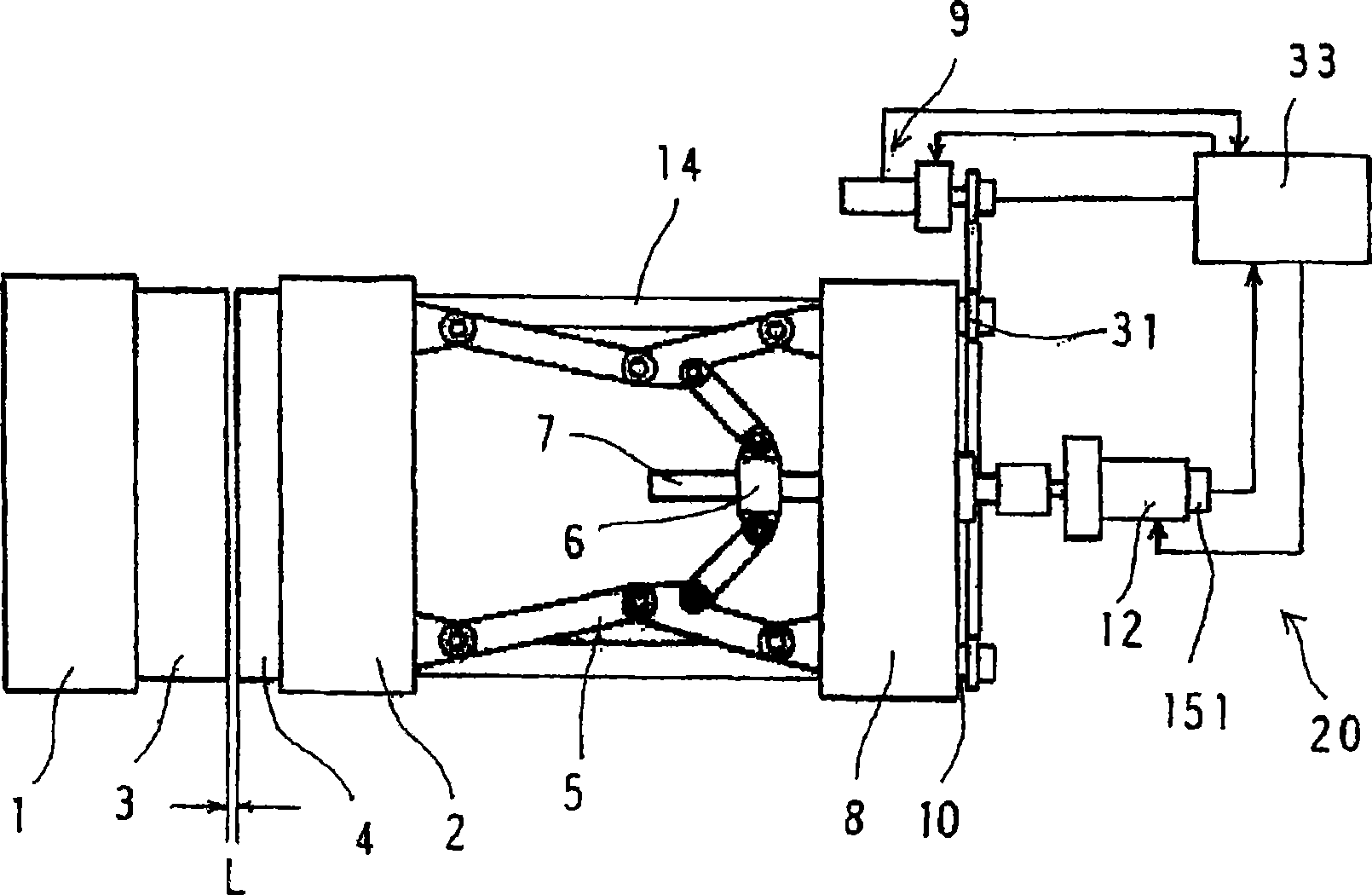

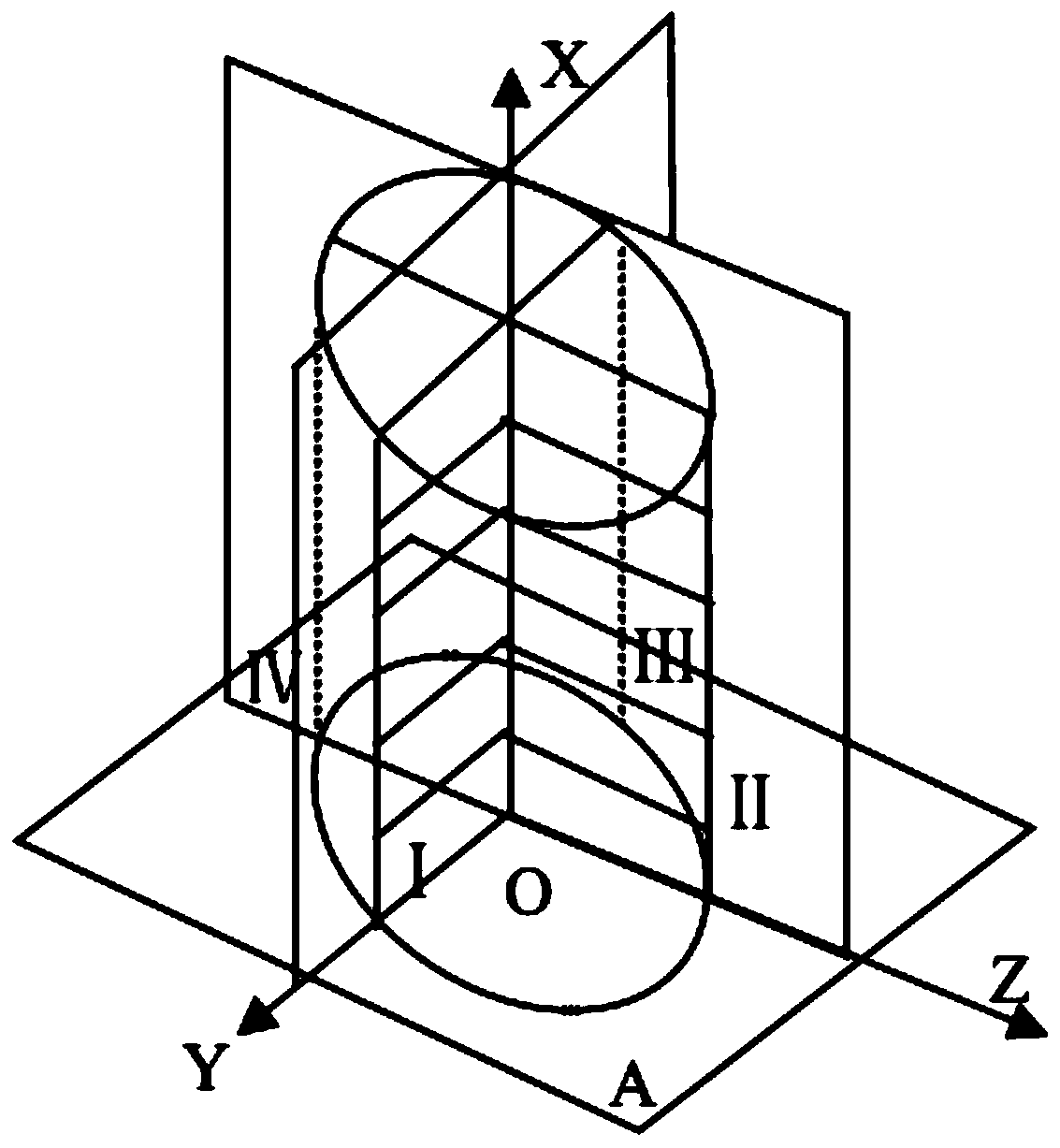

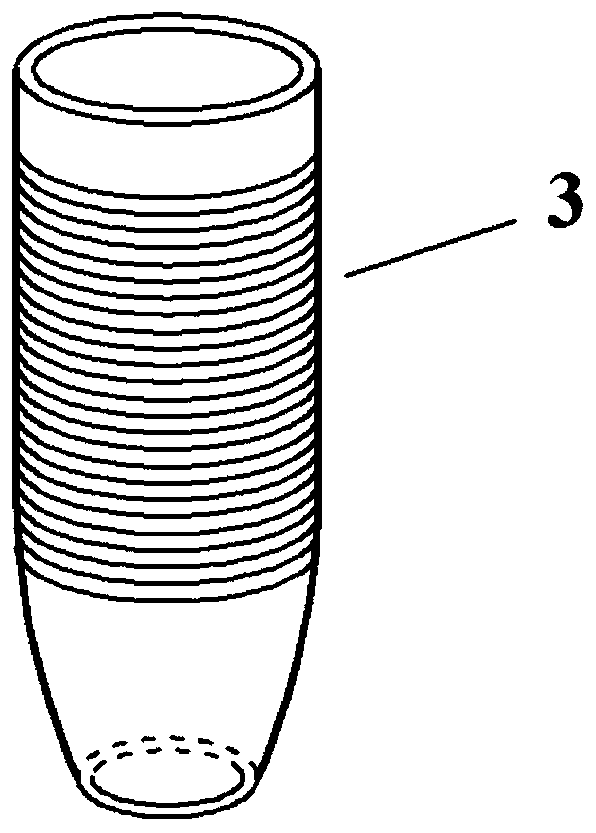

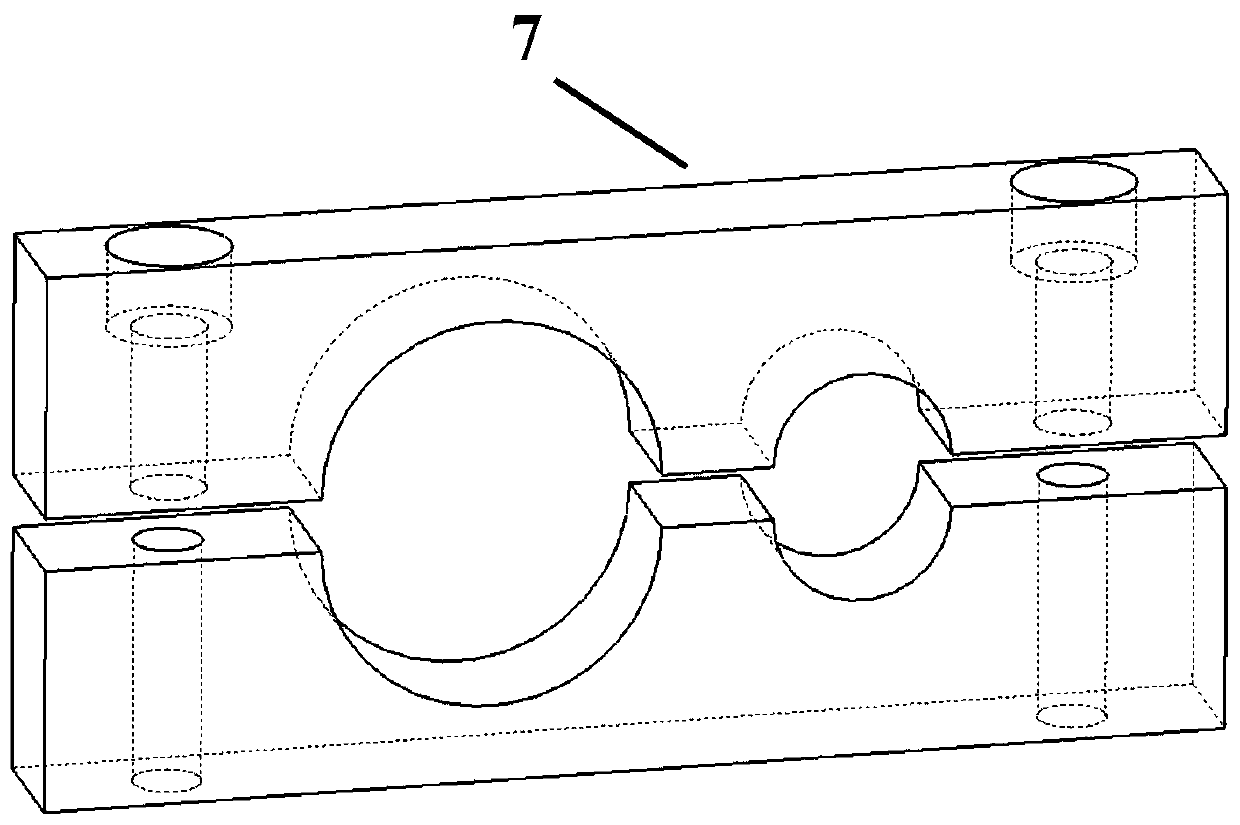

Foamed resin molding machine and method of operating the same

A die opening and closing device for a movable die plate 2 and a fixed die plate 1 includes a toggle link 5 disposed between the movable die plate 2 and a die tightening housing 8, a cross head 6 for flexing the toggle link 5, and a motor-driven ball screw 7 penetrating through the die tightening housing 8 and inserted into the cross head 6, and this die opening and closing device is provided with die thickness adjusting means 9 for adjusting the die thickness S when the die is tightened by extension of the toggle link 5, and ball screw rotation control means 20 for controlling constant the cracking gap, and a foamed resin molding machine is presented, together with its operating method.

Owner:DAISEN IND CO LTD

Precise adjustment method of satellite-borne instrument equipment

PendingCN111046584AOvercome the lack of practicalityReduce labor intensityDesign optimisation/simulationComplex mathematical operationsEngineeringSatellite

The invention discloses a precision adjustment method of satellite-borne instrument equipment, and relates to the technical field of satellite assembly adjustment. The invention aims to solve the problem of low adjustment precision caused by incomplete consideration factors in the existing satellite final assembly process. According to the numerical values of an actual measurement matrix and a designed measurement matrix, the actual measurement global coordinates and the designed global coordinates of the gaskets are obtained, then a gasket adjustment equation is established, a constraint equation of a gasket plane is established according to the number of gaskets to form an overdetermined equation set and solve to obtain a gasket adjustment amount numerical value, and finally the gasket by utilizing the adjustment amount is adjusted.

Owner:HARBIN INST OF TECH

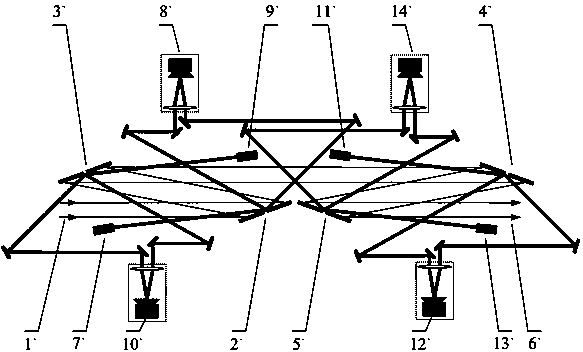

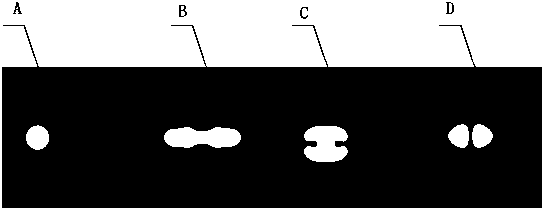

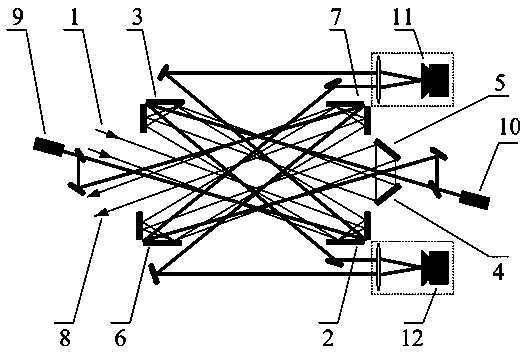

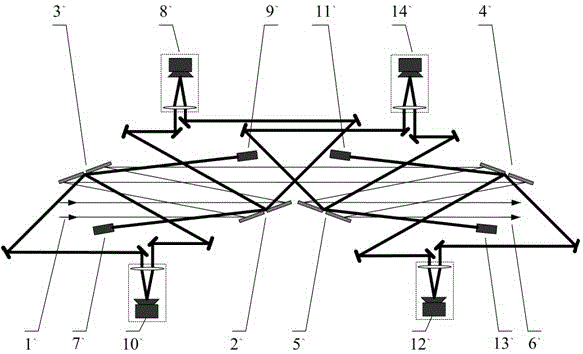

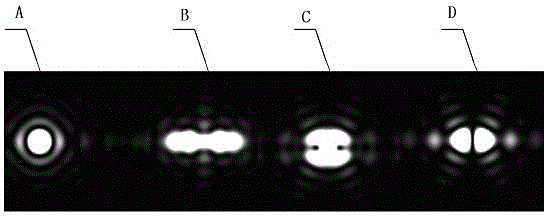

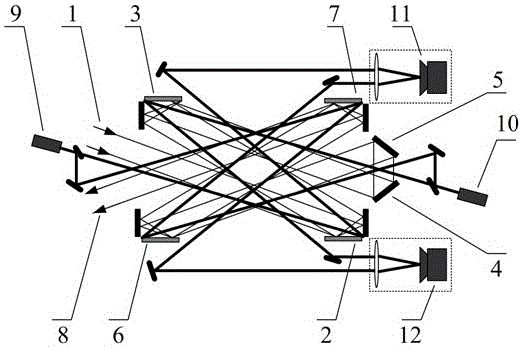

Foldable objective image stitching grating pulse compressor and stitching status diagnosis system

ActiveCN103365029AIncrease the equivalent rasterSave spaceDiffraction gratingsMountingsImage stitchingLight source

The invention relates to a foldable objective image stitching grating pulse compressor and a stitching status diagnosis system. The foldable objective image stitching grating pulse compressor comprises four groups of stitching gratings and two foldable reflectors, wherein the first groups of stitching gratings and the second group of stitching gratings are parallel, the third group of stitching gratings and the fourth group of stitching gratings are parallel, and two pairs of parallel stitching gratings are symmetrically distributed up and down. The stitching status diagnosis system comprises two monitoring light sources and two observation devices, wherein each monitoring light source emits one beam of light, which is divided into two monitoring light beams, and four monitoring light beams are respectively received by the corresponding observation devices after passing through four stitching positions and form diffractive focal spots. The size of the compressor is reduced, the stitching deviation of the stitching gratings is reduced and the stitching status diagnosis system is simplified.

Owner:中国工程物理研究院上海激光等离子体研究所

Friction stir welding device for 2219 aluminum alloy panel

InactiveCN111375885ASpeed up the flowRealize automatic conveying and feedingWelding/cutting auxillary devicesAuxillary welding devicesFriction stir weldingAluminium alloy

The invention discloses a friction stir welding device for a 2219 aluminum alloy panel. A friction stir welding mechanism of the friction stir welding device comprises a friction stir welding head. During friction stir welding, the friction stir welding head rotates at a high speed, the slight up-down vibration arrangement can be achieved, the slight vibration amplitude is smaller than 15% of thewelding thickness and larger than 5% of the welding thickness, accordingly, by utilization of the slight vibration, plastic metal at various positions of the welding position can evenly flow, and in addition, by means of the friction stir welding device, automatic sectional material conveying and feeding can be achieved; and meanwhile, precise adjustment on the height position of sectional materials can be achieved, it is guaranteed that the sectional materials are welded at the correct matched position, the reliability and stability of the welding position are guaranteed, and the friction stir welding quality is improved.

Owner:GUILIN UNIV OF AEROSPACE TECH

Narrow gap laser-electric arc hybrid welding gas shielding device and adjusting method

ActiveCN108067736AImprove protectionImprove cooling effectLaser beam welding apparatusSpray nozzleEngineering

The invention discloses a narrow gap laser-electric arc hybrid welding gas shielding device and an adjusting method. The device comprises a main spraying nozzle assembly and a back-mounted auxiliary gas flat spraying nozzle assembly; the main spraying nozzle assembly comprises a main spraying nozzle outer barrel and a main spraying nozzle inner barrel, the main spraying nozzle outer barrel is of abullet-shaped spraying nozzle structure, and the front end is provided with a conic shape with a smooth convergence curve; and the back-mounted auxiliary gas flat spraying nozzle assembly comprises agas guide pipe quick insertion, a clamping block, an auxiliary gas connecting rod and a back-mounted auxiliary gas flat spraying nozzle. In the adjustment process, the main spraying nozzle inner barrel can move up and down in the welding gun axis direction, the back-mounted auxiliary gas flat spraying nozzle assembly can be adjusted to move up and down in the direction parallel to the welding gunaxis direction by releasing the clamping block, and stretchable adjustment of the distance between the main spraying nozzle and the workpiece surface and the distance between the back-mounted auxiliary gas flat spraying nozzle and the notch bottom is finally achieved in the multi-layer welding process. The narrow gap laser-electric arc hybrid welding gas shielding device is compact in structure,convenient to adjust and high in reliability, the hybrid welding adjusting efficiency can be obviously improved, and high-quality welding of large-thickness materials is achieved.

Owner:HUAZHONG UNIV OF SCI & TECH

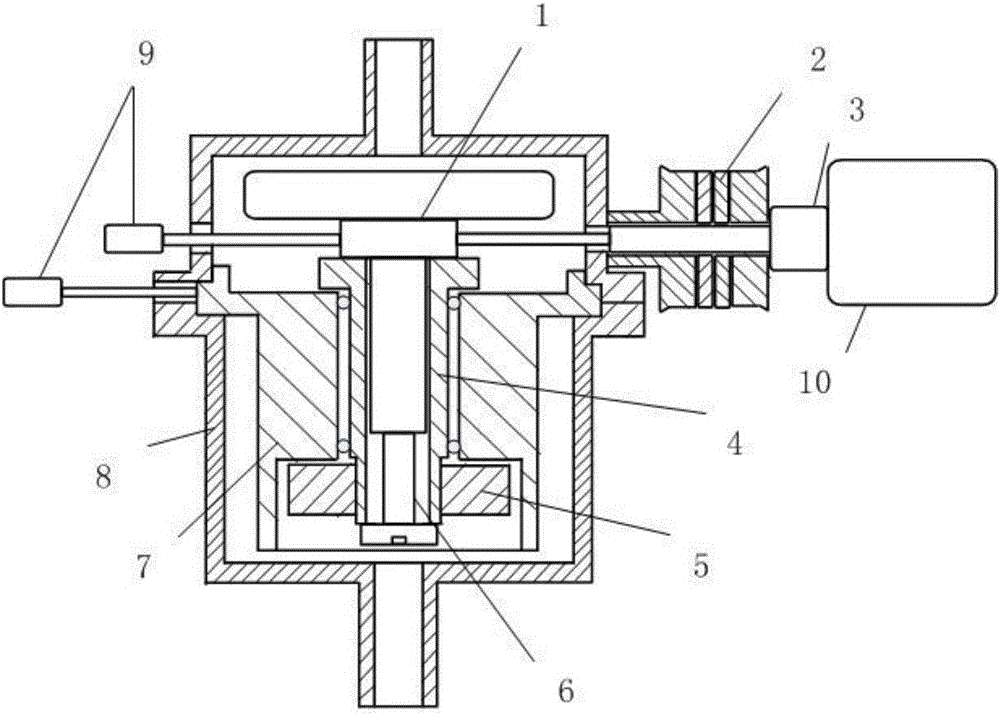

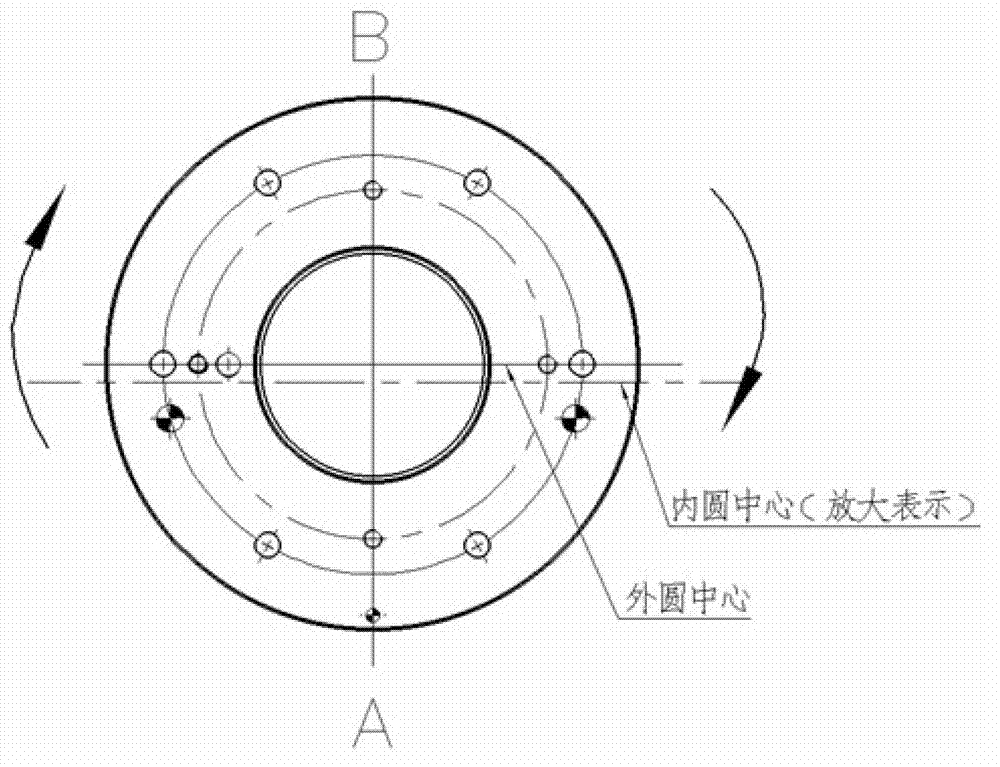

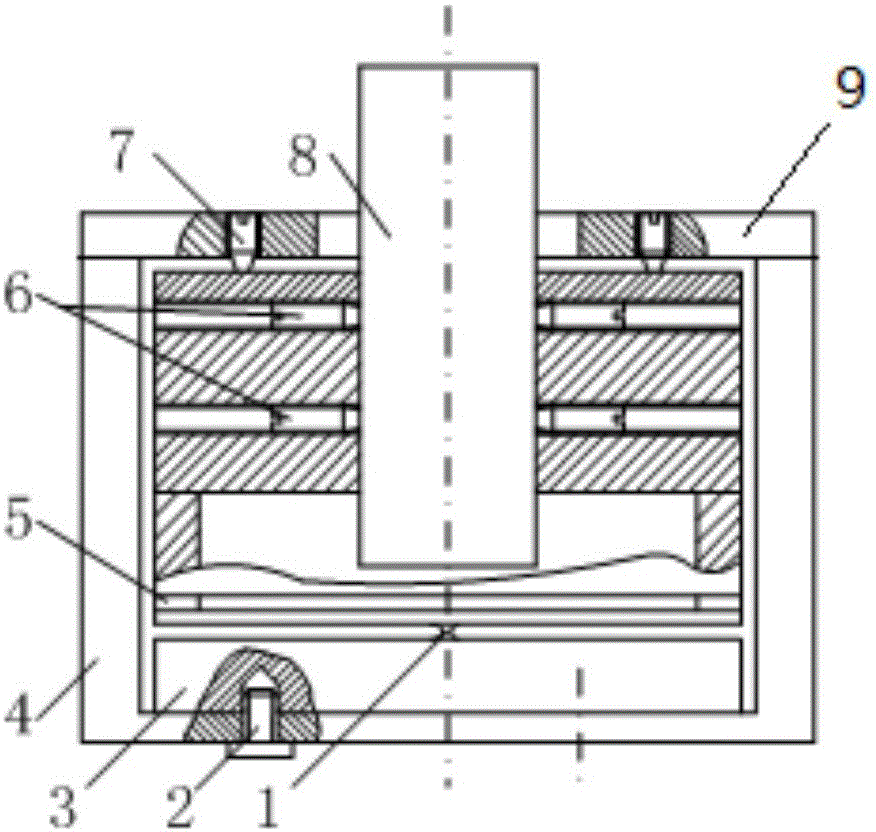

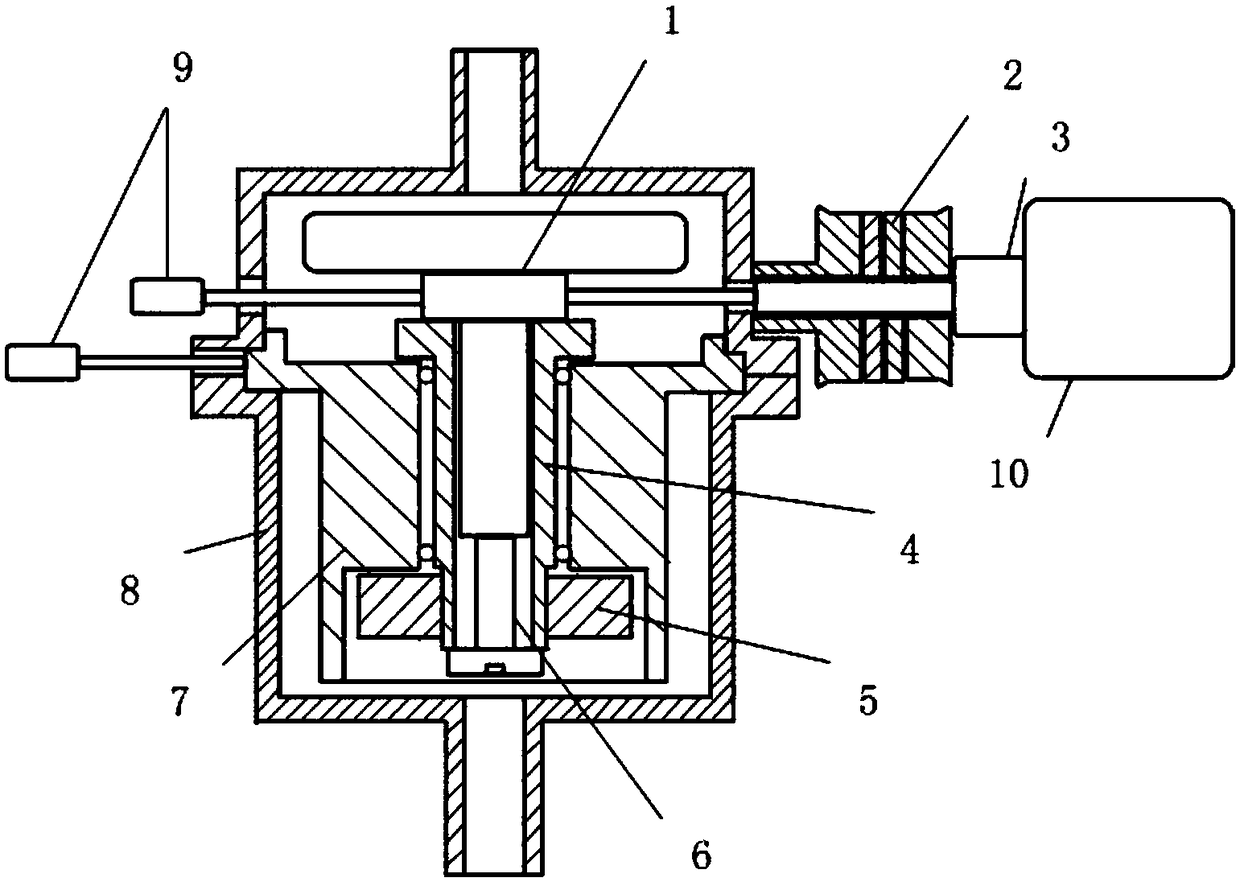

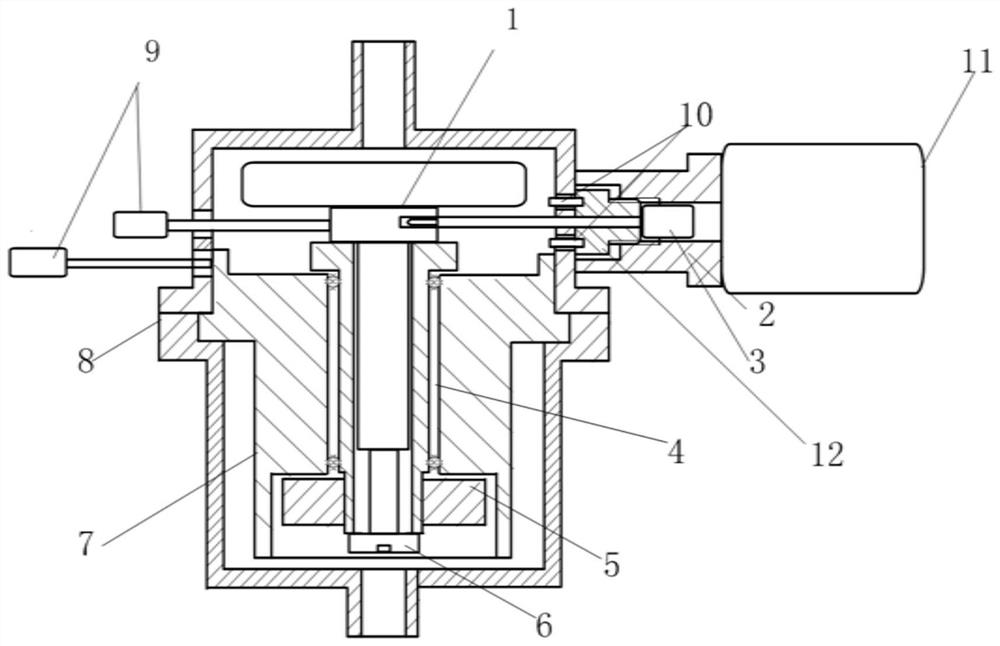

Gyro rotor mass center position accurate adjustment device and method based on ultrasonic antifriction effect

ActiveCN106370349AReduce frictionPrecise Adjustment of Gyro Rotor's Centroid Position Based on Ultrasonic Antifriction EffectStatic/dynamic balance measurementGyroscopeThrough transmission

The invention discloses a gyro rotor mass center position accurate adjustment device and method based on an ultrasonic antifriction effect, and belongs to the field of small displacement adjustment of precision machinery. An ultrasonic transducer is added between an adjusting screw and a gyro clamp; in the adjusting process, the ultrasonic transducer transmits ultrasonic vibration to the adjusting screw; and at the moment, the adjusting screw has already been screwed into a rotor adjusting screw hole, so that the ultrasonic vibration can be transmitted to a gyro rotor through transmission of the adjusting screw to realize ultrasonic vibration between rotor contact surfaces. Transverse vibration between the contact surfaces can reach the ultrasonic antifriction effect, and besides, through axial rotation of the adjusting screw, accurate adjustment of gyro rotor mass center position can be realized under the condition of smaller friction force. The device and method can effectively reduce the friction force between the rotor and bearing contact surfaces, thereby reducing creeping phenomenon and improving adjusting precision and efficiency; and the device and method can be widely applied to the small displacement accurate adjustment process.

Owner:DALIAN UNIV OF TECH

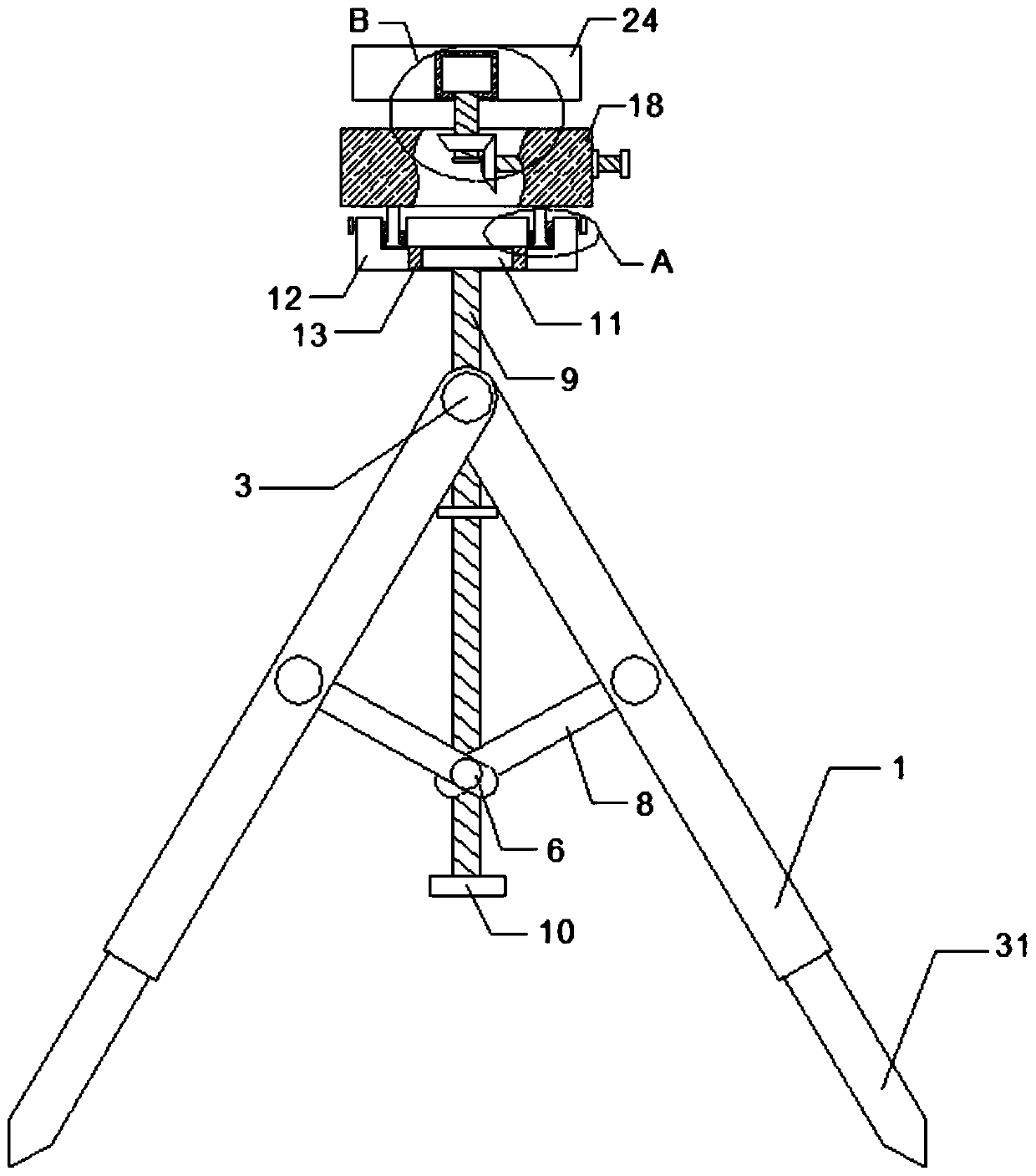

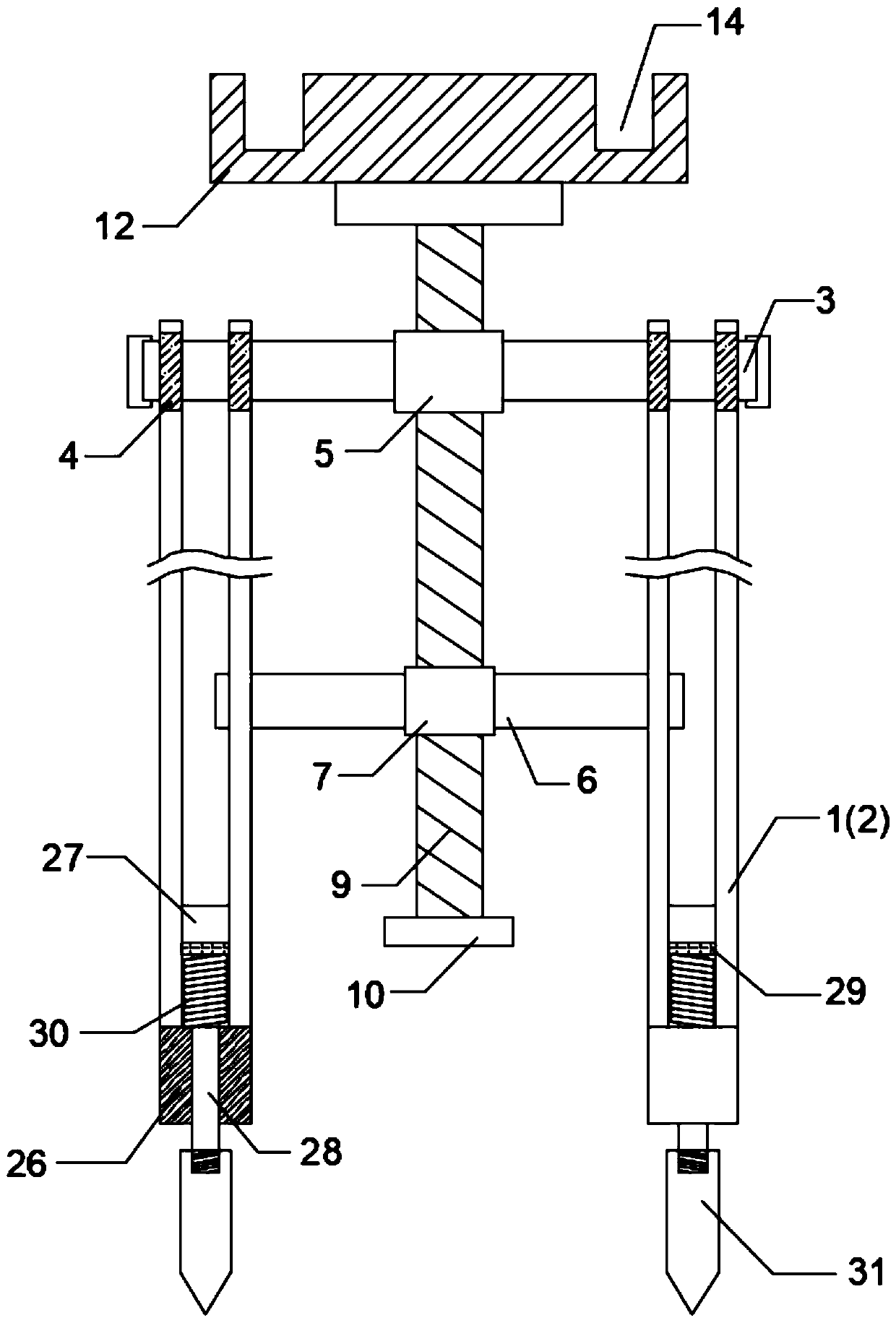

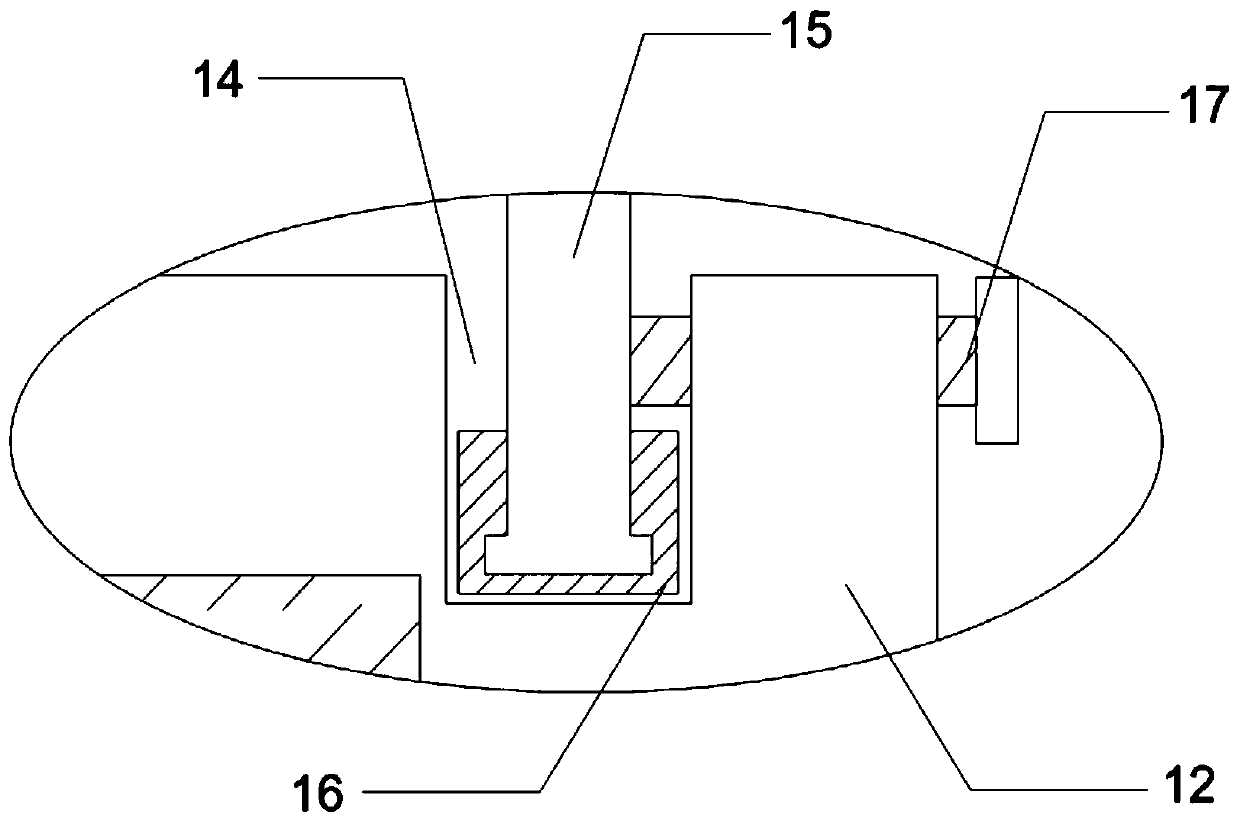

A stable and precisely regulated auxiliary device for surveying and mapping instruments

The invention discloses a stable and precise control surveying instrument auxiliary device. The auxiliary device comprises two primary supports, two secondary supports and a primary connecting rod; the two primary supports and the upper ends of the two secondary supports are symmetrically provided with through cavities; the two primary supports and the two secondary supports are rotationally connected with the two ends of the primary connecting rod correspondingly; and a primary threaded pipe is fixedly sleeved with the middle end of the primary connecting rod. By stretching and contracting the supports, the height of a rotary plate base is adjusted in a large range through a screw, a rotary plate is driven by a sliding rail and a sliding groove to rotate circumferentially with the rotaryplate base as a fulcrum, clamping and fixing are achieved, thus, angle adjustment is met, and by rotating a driving screw, a roller screw moves up and down through gear transmission, so that the height of a mounting seat is precisely adjusted, and through threaded connection of ground gripping cones at the lower ends of the supports and spring shock absorption, the overall stability of the surveying instrument auxiliary device is ensured.

Owner:江西省第九地质勘察规划有限公司

A narrow gap laser-arc hybrid welding gas protection device and its adjustment method

ActiveCN108067736BImprove protectionImprove cooling effectLaser beam welding apparatusSpray nozzleEngineering

The invention discloses a narrow gap laser-electric arc hybrid welding gas shielding device and an adjusting method. The device comprises a main spraying nozzle assembly and a back-mounted auxiliary gas flat spraying nozzle assembly; the main spraying nozzle assembly comprises a main spraying nozzle outer barrel and a main spraying nozzle inner barrel, the main spraying nozzle outer barrel is of abullet-shaped spraying nozzle structure, and the front end is provided with a conic shape with a smooth convergence curve; and the back-mounted auxiliary gas flat spraying nozzle assembly comprises agas guide pipe quick insertion, a clamping block, an auxiliary gas connecting rod and a back-mounted auxiliary gas flat spraying nozzle. In the adjustment process, the main spraying nozzle inner barrel can move up and down in the welding gun axis direction, the back-mounted auxiliary gas flat spraying nozzle assembly can be adjusted to move up and down in the direction parallel to the welding gunaxis direction by releasing the clamping block, and stretchable adjustment of the distance between the main spraying nozzle and the workpiece surface and the distance between the back-mounted auxiliary gas flat spraying nozzle and the notch bottom is finally achieved in the multi-layer welding process. The narrow gap laser-electric arc hybrid welding gas shielding device is compact in structure,convenient to adjust and high in reliability, the hybrid welding adjusting efficiency can be obviously improved, and high-quality welding of large-thickness materials is achieved.

Owner:HUAZHONG UNIV OF SCI & TECH

Precise stroke adjusting device

The invention discloses a precise stroke adjusting device. The precise stroke adjusting device comprises a pinion shaft system, an upper shaft system and a roller sliding block system, wherein the pinion shaft system comprises a servo motor and a pinion shaft which are connected with each other; a pinion is fixed on the pinion shaft; the upper shaft system comprises an upper shaft; a cam is fixed on the upper shaft; the upper shaft is provided with an eccentric bushing by a bearing; a large gear is fixed at the eccentric bushing; the large gear and the pinion are meshed; the end face of the cam is provided with an annular tank; the roller sliding block system comprises an upper mold sliding block; a roller support is fixed on the upper mold sliding block; a sheave support is fixed on the roller bracket; the roller bracket is provided with a roller; the sheave support is provided with a cam follower; the outer edge of the cam and the outer edge of the roller are meshed; and the cam follower and the annular tank are meshed. During the transmission process of the large gear and the pinion, the eccentric bushing performs a rotating motion following with the large gear; the upper mold sliding block is driven by the upper shaft, the cam and the follower to move up and down, so that the precise adjustment of the stroke of a forming machine is achieved.

Owner:BEIJING RES INST OF MECHANICAL&ELECTRICAL TECH

Heterodyne spectrometer grating gluing assembling structure and assembling method

PendingCN106017684AMeet glue curingFor fine tuningRadiation pyrometryInterferometric spectrometryEngineeringHeterodyne

The invention discloses a heterodyne spectrometer grating gluing assembling structure and an assembling method. The assembling structure comprises a support base plate, imaging switching plates, collimation switching plates and an L-shaped to-be-glued interference assembly, wherein the upper end and the lower end of the support base plate are each provided with an imaging switching plate to form a vertical surface, the left end and the right end of the support base plate are each provided with a collimation switching plate to form a horizontal surface, the vertical surface and the horizontal surface form a three-vertical-surface reference assembly, and the L-shaped to-be-glued interference assembly is placed on the three-vertical-surface reference assembly. According to the invention, the angle and the tower difference precision of the to-be-glued interference assembly are transmitted and carried on by use of a two-dimensional positioning mechanism, and functions of primary limiting, repeated positioning and high-precision phase error adjustment of grating assemblies are realized by use of a rotation adjustment mechanism and an optical member block. The operation is convenient, the resilience is high, solidification areas are uniform, and the assembling effect of interferogram phase errors can be monitored in real time.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Structure for freely adjusting direction of optical axis of laser

InactiveCN106410600AFor fine tuningIncrease elasticityLaser detailsSemiconductor laser structural detailsOptical axisEngineering

The invention relates to the technical field of engineering measurement and more particularly to a structure for freely adjusting the direction of the optical axis of a laser. The adjusting mechanism comprises a base, a flexible hinge structure, an upper cover, and a plurality of adjusting screws. The flexible hinge structure is fixed inside the base; the upper end of the base is fixed to the upper cover; the laser is fixed in a circular hole in the center of the flexible hinge; the adjusting screws pass through the upper cover to be abutted against the upper part of the flexible hinge structure. The laser is a semiconductor laser with a diameter of 20mm and a wavelength of 650nm. The base material is 6061-T6 aluminum alloy. The flexible hinge is made of spring steel material and quenched, and has good flexibility. The semiconductor laser is fixed to the flexible adjustment mechanism by being locked in the radial direction by locking screws, and the precision adjustment of the laser optical axis can be realized by adjusting the four adjusting screws arranged orthogonally on the upper end face of the base in the hinge direction.

Owner:BEIJING AEROSPACE INST FOR METROLOGY & MEASUREMENT TECH +1

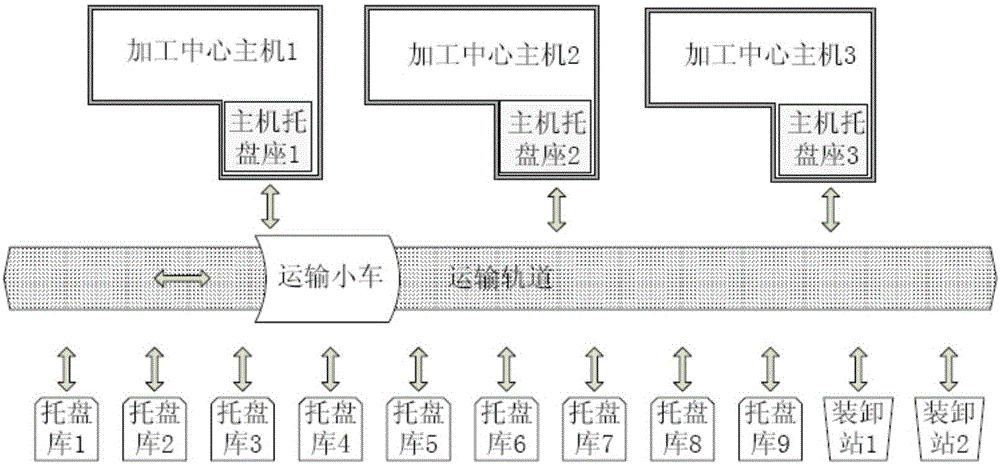

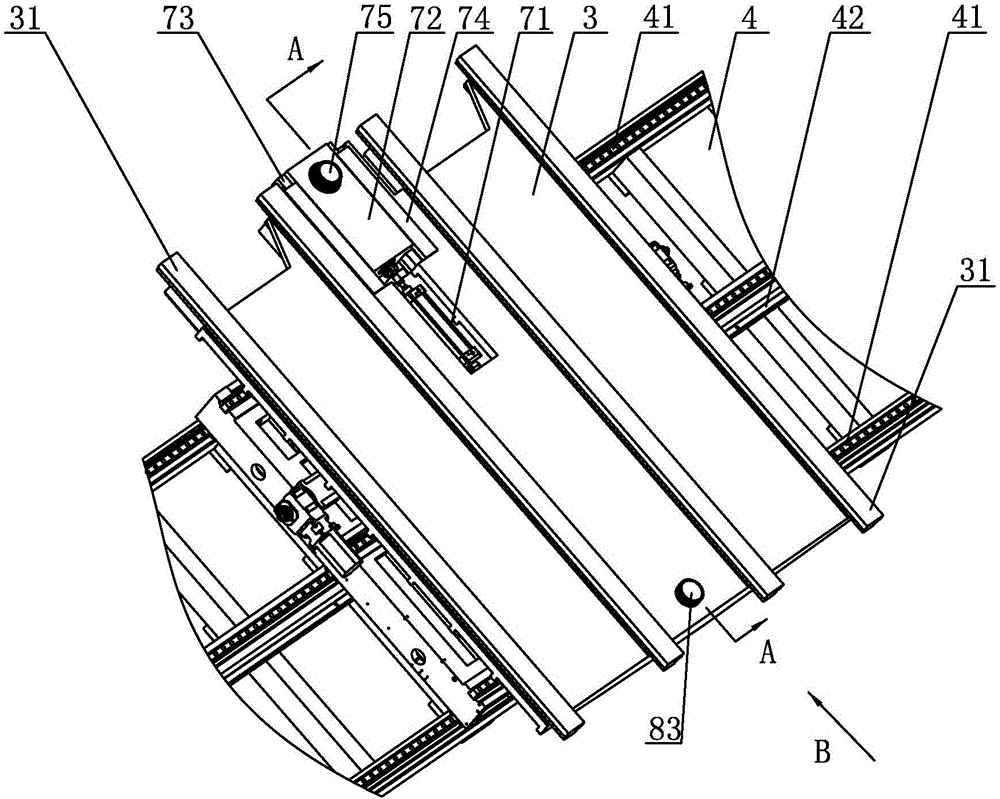

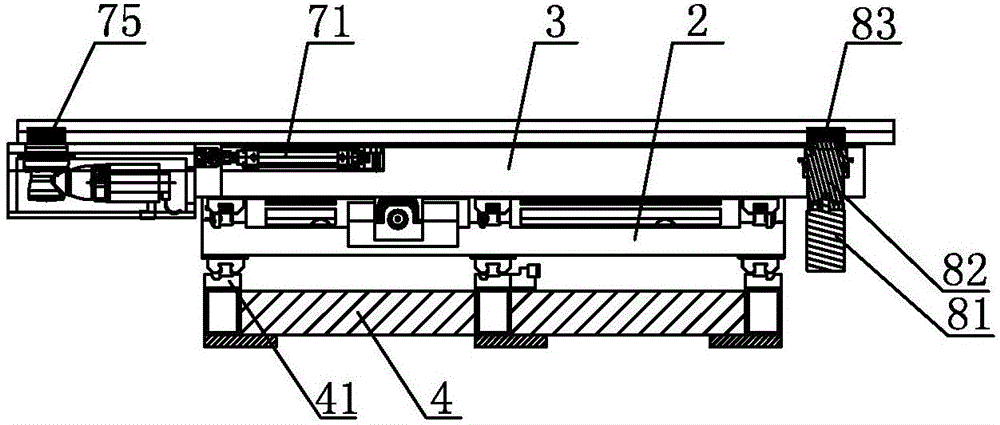

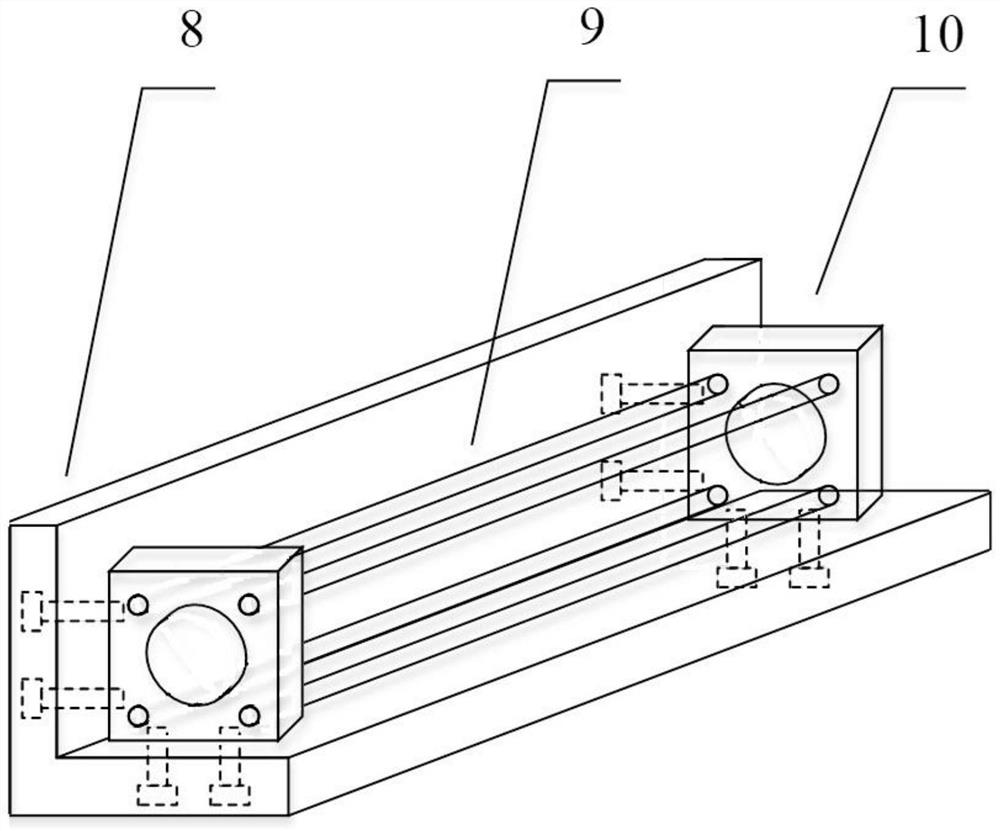

Transporting trolley for gantry multi-tray exchange system

ActiveCN106271841AContinuous actionSmooth movementMetal working apparatusEngineeringMechanical engineering

The invention discloses a transporting trolley for a gantry multi-tray exchange system. A support, a first oblique sliding base and a second oblique sliding base of the transporting trolley are integrally arranged on a transporting track, and the movement of the transporting trolley along a first linear rail on the transporting track is achieved through engagement of a first drive gear and a first rack. Compared with a manner that a traditional double-exchange workbench gantry machining center exchanges workbenches through an oil cylinder and a chain transmission system, the gear and rack transmission manner of the transporting trolley is continuous and stable in action, the transmission precision and reliability are greatly improved, precision retentivity is good, and the workbench transmission precision can be ensured; meanwhile, the problem that after the traditional chain transmission system is used for a long term, a chain is stretched, and consequently precision is lowered can be effectively solved; and the transporting trolley is adjustable in height, and stable and smooth exchange of the workbenches between a machining center main machine and the transporting trolley or between the transporting trolley and a tray warehouse or an unloading and loading station can be achieved.

Owner:NINGBO HAITIAN PRECISION MASCH CO LTD

Device and method for precise adjustment of gyro rotor mass center position based on ultrasonic anti-friction effect

ActiveCN106370349BReduce frictionFor fine tuningStatic/dynamic balance measurementGyroscopeThrough transmission

The invention discloses a gyro rotor mass center position accurate adjustment device and method based on an ultrasonic antifriction effect, and belongs to the field of small displacement adjustment of precision machinery. An ultrasonic transducer is added between an adjusting screw and a gyro clamp; in the adjusting process, the ultrasonic transducer transmits ultrasonic vibration to the adjusting screw; and at the moment, the adjusting screw has already been screwed into a rotor adjusting screw hole, so that the ultrasonic vibration can be transmitted to a gyro rotor through transmission of the adjusting screw to realize ultrasonic vibration between rotor contact surfaces. Transverse vibration between the contact surfaces can reach the ultrasonic antifriction effect, and besides, through axial rotation of the adjusting screw, accurate adjustment of gyro rotor mass center position can be realized under the condition of smaller friction force. The device and method can effectively reduce the friction force between the rotor and bearing contact surfaces, thereby reducing creeping phenomenon and improving adjusting precision and efficiency; and the device and method can be widely applied to the small displacement accurate adjustment process.

Owner:DALIAN UNIV OF TECH

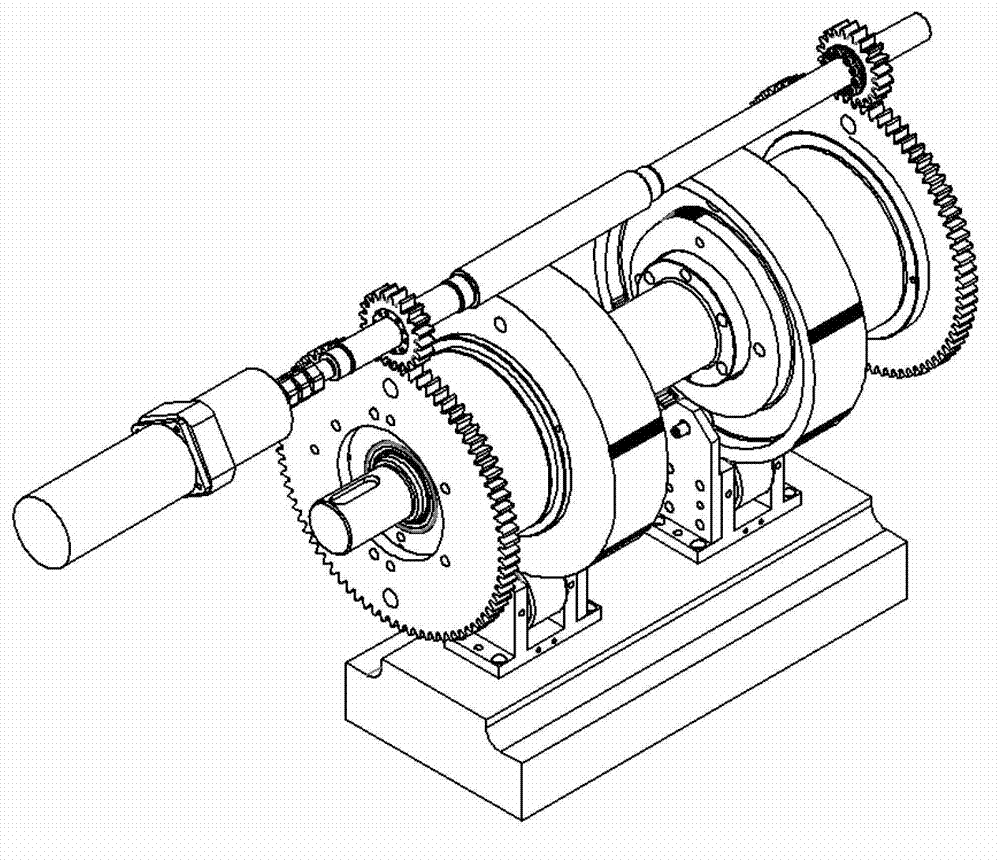

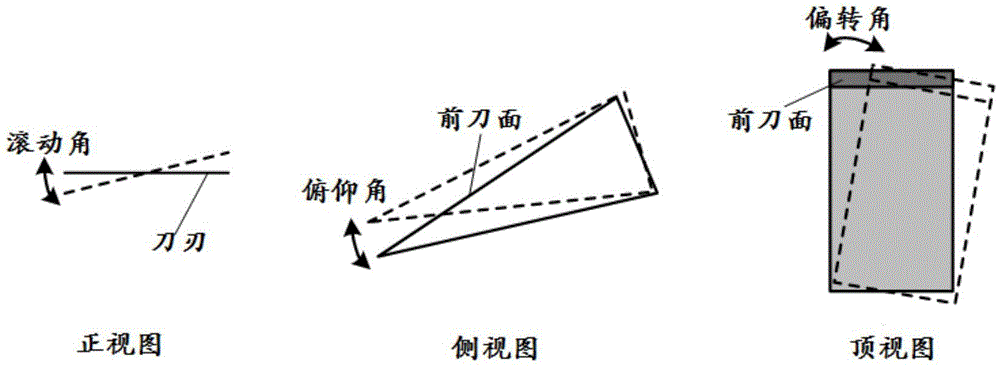

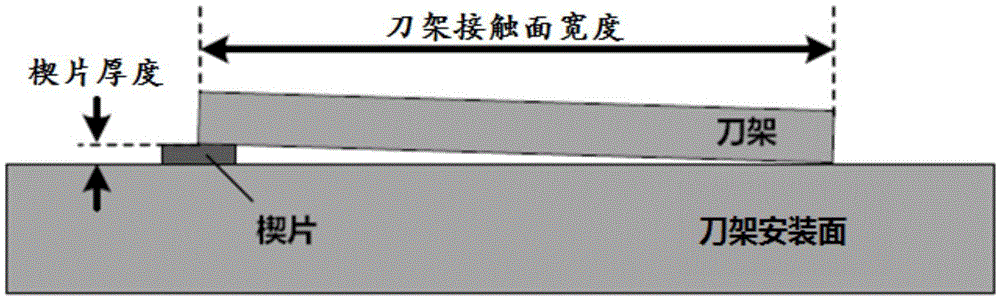

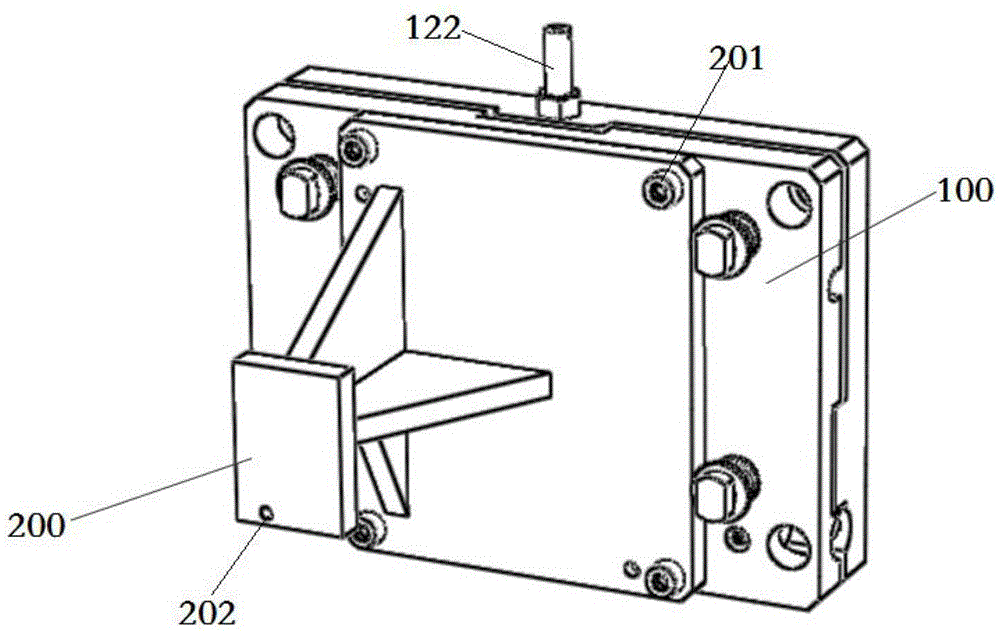

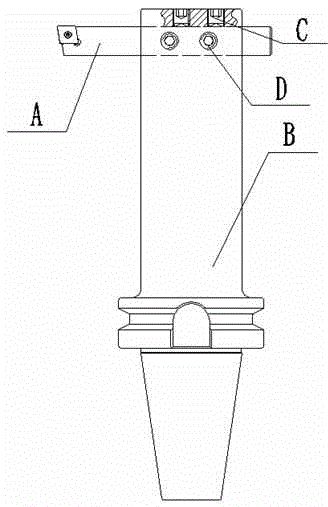

A precision adjustment device for tool rolling angle

ActiveCN104626255BFor fine tuningSolve the problem of continuous regulationMetal working apparatusEngineeringMechanical engineering

The invention discloses a precise adjustment device for the tool rolling angle. The technical problem that in the prior art, when wedge pieces are adopted for adjusting the rolling angle of a tool bit, because the thickness of the wedge pieces is fixed, the rolling angle can not be continuously adjusted is solved. The precise adjustment device for the tool rolling angle comprises a tool adjustment support and a tool installing frame, wherein a threaded rod is arranged on the tool adjustment support, and the tool installing frame is fixed to the tool adjustment support and used for installing the tool bit. The rolling angle of the tool bit can be adjusted through rotating the threaded rod.

Owner:WUHAN OE BIO CO LTD

Anti-interference and high-stability cavity dumping laser and mounting method thereof

InactiveCN112563871AImprove stabilityEfficient outputOptical resonator shape and constructionResonant cavityAnti jamming

The invention discloses an anti-interference and high-stability cavity dumping laser and a mounting method thereof, and belongs to the technical field of lasers. A cavity plate which is fixed througha connecting rod and provided with a through hole is arranged on an L-shaped plate, and a plano-concave mirror, a convex lens, an LD side pump module, a polarization cube, a quarter-wave plate, a Pockels cell and the plane mirror are arranged in a light path propagation direction; the plano-concave mirror and the plane mirror are arranged in the through hole; the convex lens, the LD side pump module, the polarization cube, the quarter-wave plate and the Pockels cell are arranged on the L-shaped plate; and the curvature radius of the plano-concave lens, the focal length of the convex lens and the distance between the plano-concave lens and the convex lens are equal. According to the invention, insensitivity of the laser to the detuning of a resonant cavity is improved, the precise adjustment of the resonant cavity can be realized, the high stability of the laser is ensured, the output optimization of the laser is ensured, and the anti-interference capability of the laser is improved.

Owner:HARBIN INST OF TECH

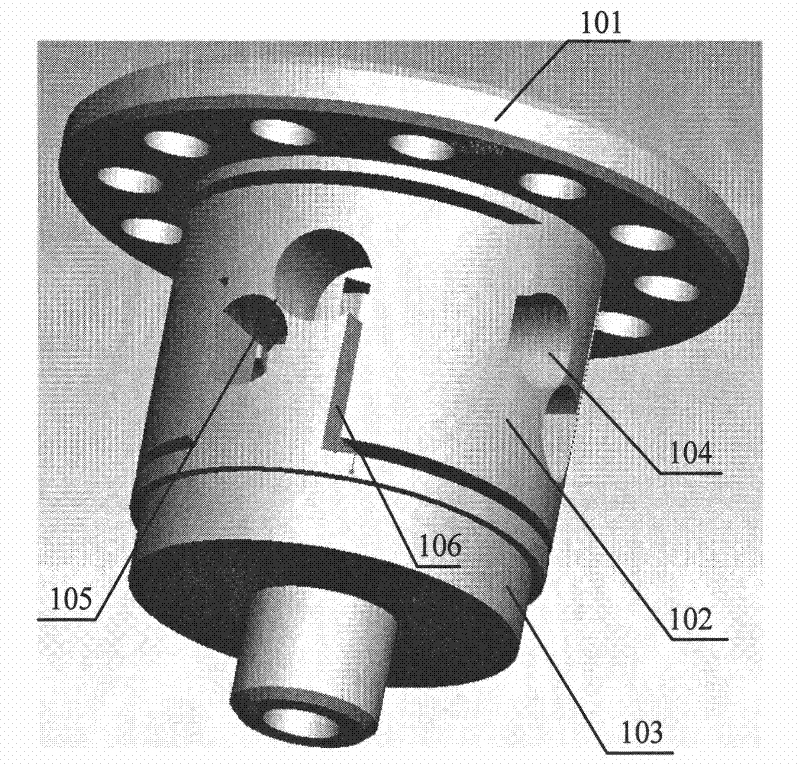

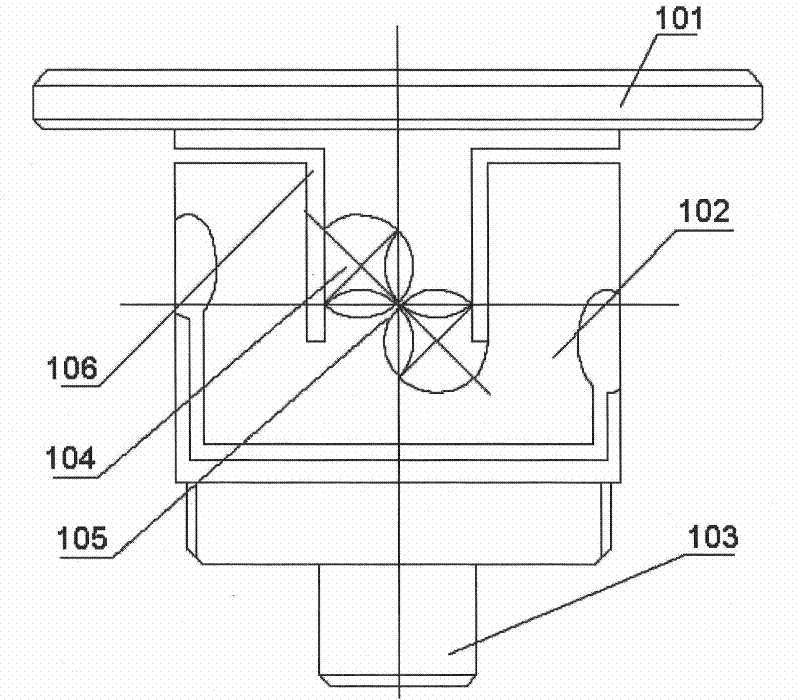

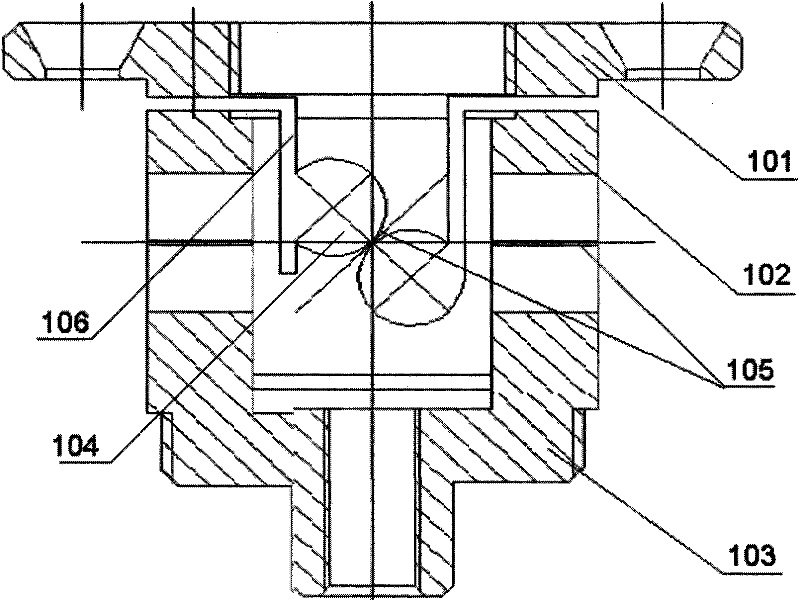

Small-sized integral type flexible joint and minitype high-speed dynamic tuned gyroscope

The invention relates to a small-sized integral type flexible joint and a minitype high-speed dynamic tuned gyroscope. The small-sized integral type flexible joint is made of an elastic material, has small volume and simple structure, prevents a welding link of an inner flexible joint and an outer flexible joint and enhances the processing precision of the flexible joint. The minitype high-speed dynamic tuned gyroscope formed by the small-sized integral type flexible joint is in a dumbbell type symmetrical structure, one end of the minitype high-speed dynamic tuned gyroscope is a gyroscope rotation part, the other end of the same is a driving motor part, the gyroscope rotation part is connected with the driving motor part by the small-sized integral type flexible joint, thereby reducing the volume of the dynamic tuned gyroscope and enhancing resistance of the gyroscope against mechanical environment and improving the measuring precision of the gyroscope.

Owner:BEIJING INST OF AEROSPACE CONTROL DEVICES

Automatic accurate adjustment system for instrument movement clearance

ActiveCN102689171BFor fine tuningReduce mistakesMetal working apparatusAxial displacementElectricity

Owner:SHANGHAI COMPLEE INSTR

Device and method for precise adjustment of centroid position of gyro rotor for solving wear debris pollution

ActiveCN108168778BImprove pass rateAdjust the centroid positionStatic/dynamic balance measurementLinear motionGyroscope

Owner:DALIAN UNIV OF TECH

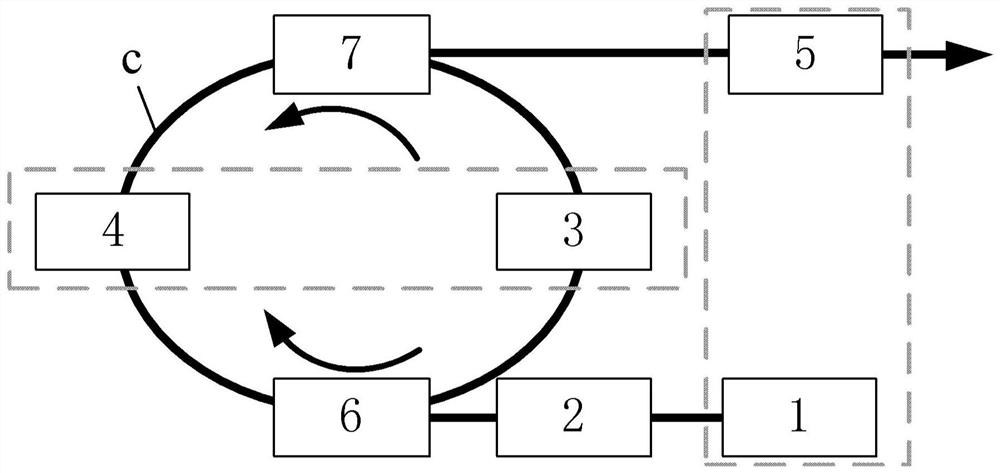

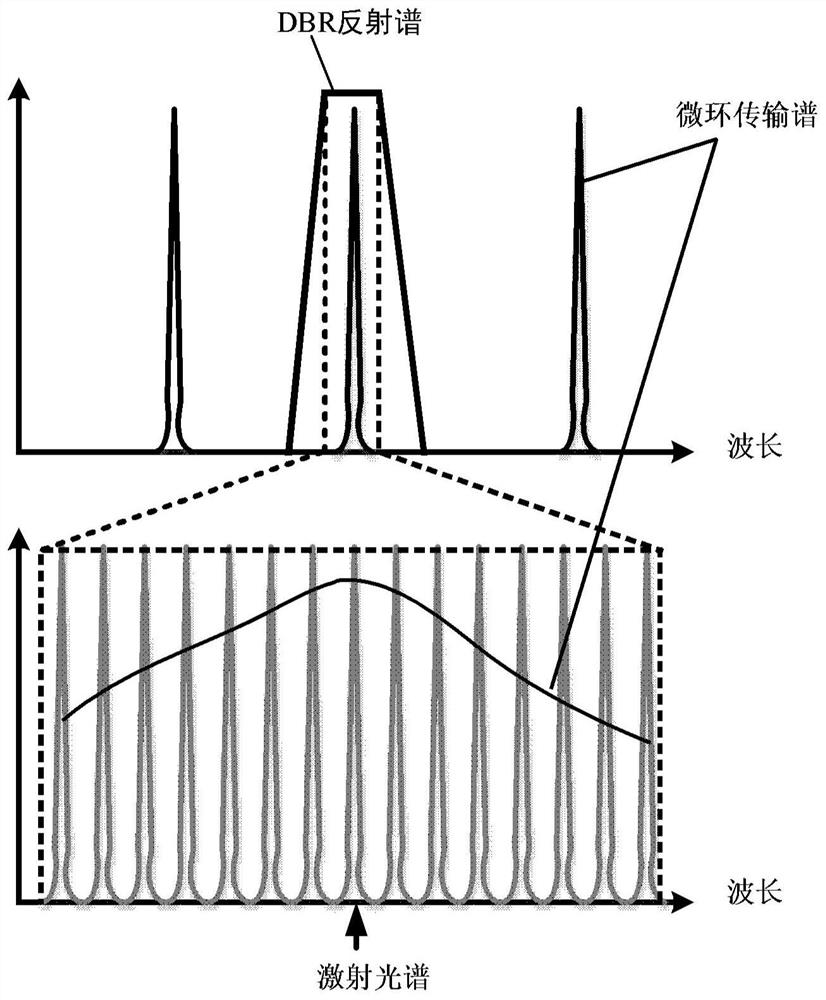

Tuned Laser Chip

ActiveCN112366517BFor fine tuningOptimizing the side mode suppression ratioLaser detailsLaser optical resonator constructionGratingEngineering

A tuned laser chip, comprising: a backward grating region (1), a first gain region (2), a microring resonator (c) and a forward grating region (5); the microring resonator (c) includes The second gain area (3), the first multi-mode interference waveguide (6), the phase modulation area (4) and the second multi-mode interference waveguide (7) which are ring-connected in sequence; the backward grating area (1) is connected to The first gain region (2), the first gain region (2) is connected to the first multimode interference waveguide (6), and the forward grating region (5) is connected to the second multimode An interference waveguide (7); wherein, the backward grating area (1) and the forward grating area (5) form a Bragg reflection resonant cavity, and the second gain area (3) and the phase modulation area (4 ) form a gain resonator. The laser chip can realize fine tuning and wide-range tuning of the L-band spectrum and avoid mode hopping.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

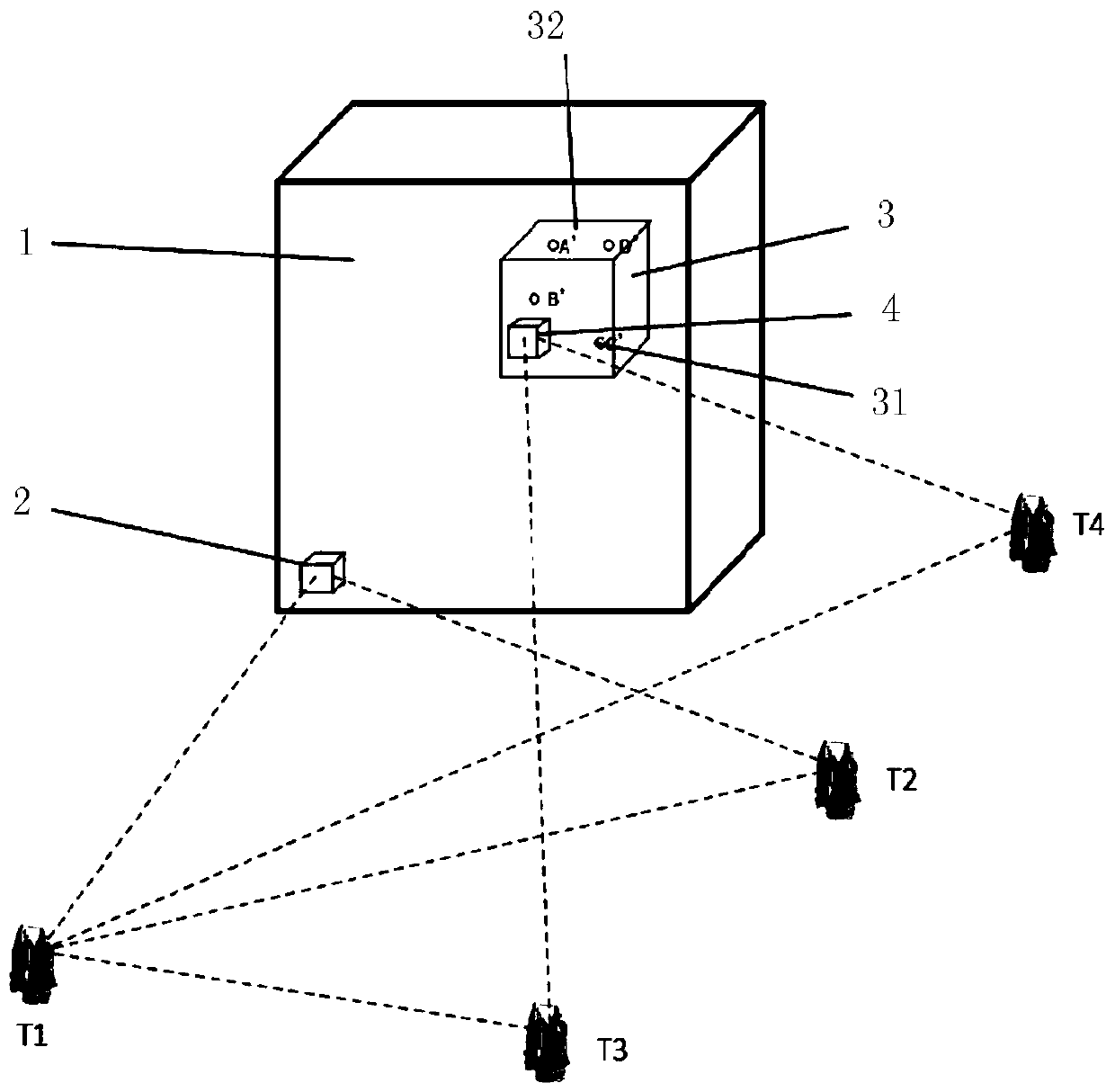

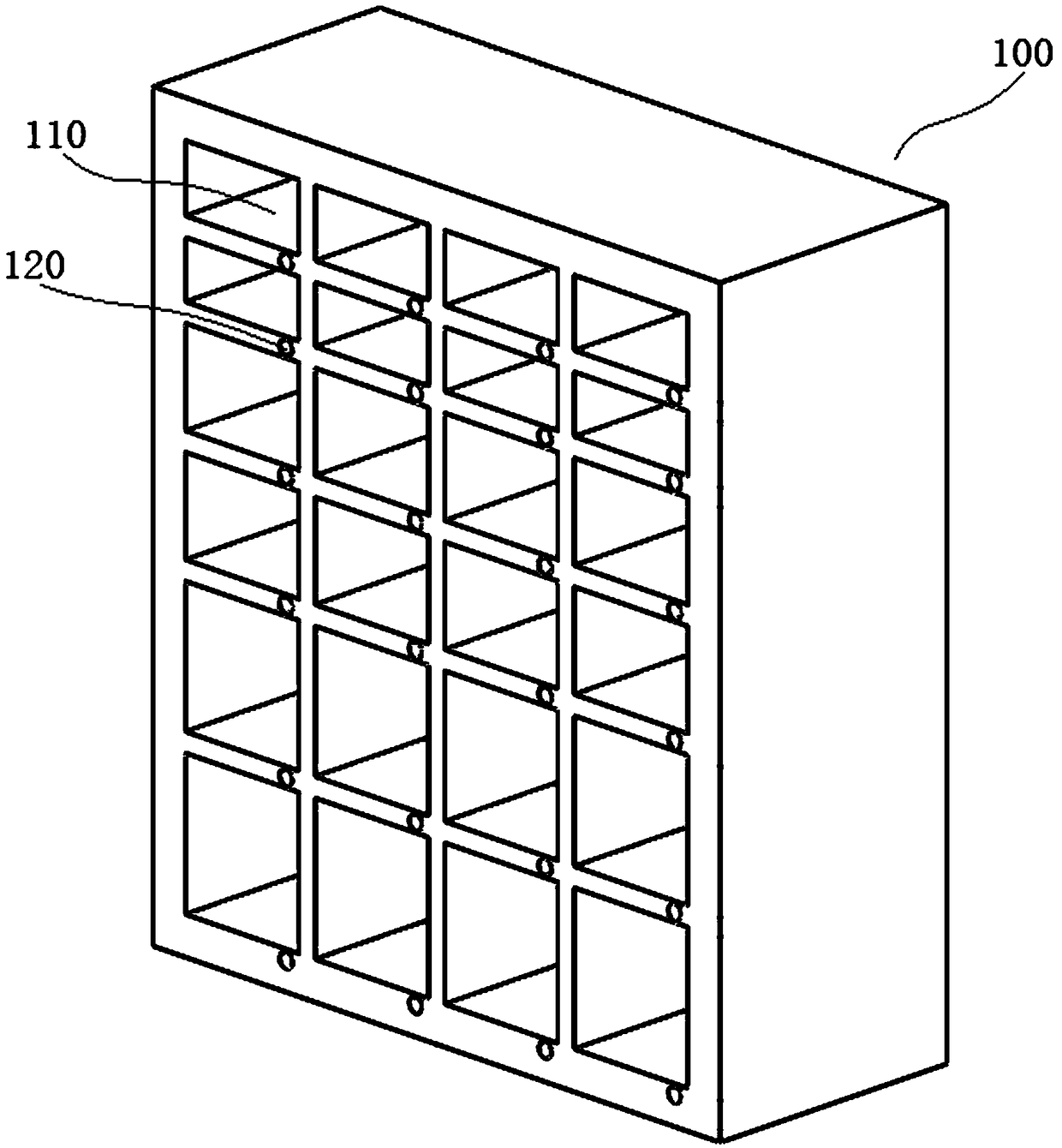

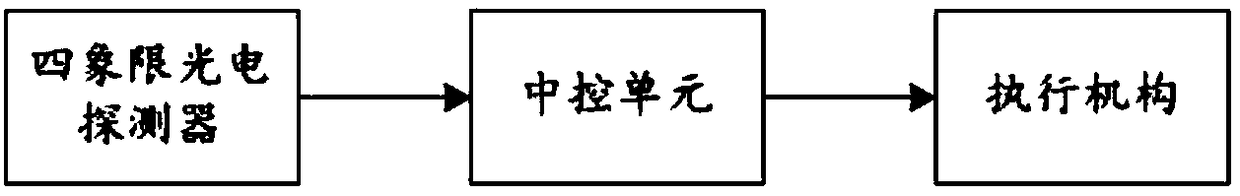

Self-calibration system used for full-automatic safe deposit box and method thereof

The invention relates to the technical field of safe deposit boxes, in particular to a self-calibration system used for a full-automatic safe deposit box and a method thereof. The self-calibration system comprises a light source device arranged below any one safe deposit box storage groove of a safe deposit box storage frame and a four-quadrant photoelectric detector arranged on a grabbing mechanism; the four-quadrant photoelectric detector corresponds to the light source device in position, the four-quadrant photoelectric detector is used for detecting real-time position data of the light source device and uploads the data to a central control unit, the central control unit is used for comparing the real-time position data with the reference position data, and fine adjustment of the grabbing mechanism is controlled through an execution mechanism until the real-time position data and the reference position data are the same. The self-calibration method is achieved based on the self-calibration system. Automatic calibration of opposite positions between the grabbing mechanism and the grabbing target is achieved.

Owner:安徽中科智链信息科技有限公司

A vertical interferometer standard mirror clamping device and method for surface shape detection of optical components

ActiveCN109581609BReduce vibrationGuaranteed horizontal accuracyUsing optical meansMountingsClip deviceOptics

The invention relates to a vertical interferometer standard mirror clamping device and method for optical element surface shape detection. The vertical interferometer standard mirror clamping device includes a leveling mechanism, an auxiliary support and a tray for placing the standard mirror , the number of the leveling mechanism is at least three, and is evenly distributed along the circumferential direction of the tray, each of the leveling mechanisms includes a drive system and a support block for supporting the tray, and the drive system can drive the support block along the Moving in the height direction, the lowest value of the height that the support block can reach is recorded as H min , the highest value is recorded as H max , the auxiliary support includes a bracket and a buffer pad installed on the bracket, the buffer pad is used to support the pallet, and its height is denoted as h, H min 、H max The relationship with h satisfies: H min <h<H max . Compared with the prior art, the present invention has the advantage that the levelness of the standard mirror can be precisely adjusted.

Owner:CHINA WEAPON SCI ACADEMY NINGBO BRANCH

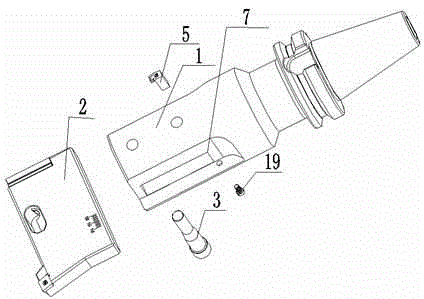

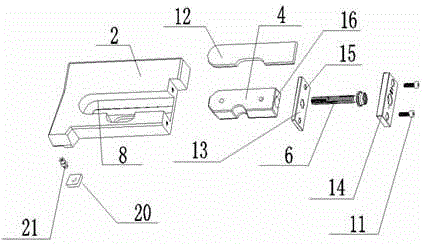

An adjustable single-edged boring tool

ActiveCN103394719BEfficient compressionThe installation position is not restrictedTurning toolsCircular coneEngineering

The invention relates to a novel adjustable single-blade boring cutter structurally comprising a holder, a boring cutter plate, a pin, a slider, a vernier and a fine-turning transmission nut. The novel adjustable single-blade boring cutter is characterized in that a rectangular hole matching with the boring cutter plate is formed in the holder, the boring cutter plate is disposed in the rectangular hole of the holder, a goose-tail groove is formed in the boring cutter plate, the slider precisely slides into the goose-tail groove, the pin is provided with a conical surface, the slider is provided with a conical hole matching with the conical surface of the pin, and the fine-turning transmission nut is fixed in the boring cutter plate through two bolts. Compared with the existing single-blade boring cutter, the novel adjustable single-blade boring cutter is simple in structure, good in compacting effect of a boring cutter, space saving, and capable of coarse turning and fine turning, and meanwhile, fast installation for front boring and back boring can be realized.

Owner:成都成林数控刀具股份有限公司

A folded object image splicing grating pulse compressor and splicing state diagnosis system

ActiveCN103365029BReduce footprint sizeSimple structureDiffraction gratingsMountingsGratingLight beam

The invention relates to a folded object-image splicing grating pulse compressor and a splicing state diagnosis system. The folded object-image splicing grating pulse compressor includes four sets of splicing gratings and two folding mirrors. Among the four sets of splicing gratings The first group of mosaic gratings is parallel to the second group of mosaic gratings, the third group of mosaic gratings is parallel to the fourth group of mosaic gratings, and the two pairs of parallel mosaic gratings are symmetrically distributed up and down; the splicing state diagnosis system includes two monitoring light sources and two observation devices , each monitoring light source emits a light beam and is divided into two monitoring beams, and the four monitoring beams respectively pass through four splicing positions and are received by corresponding observation devices to form diffractive light focal spots. The compressor and diagnosis system of the invention reduce the volume of the compressor, reduce the splicing deviation of the spliced grating, and simplify the splicing state diagnosis system.

Owner:中国工程物理研究院上海激光等离子体研究所

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com