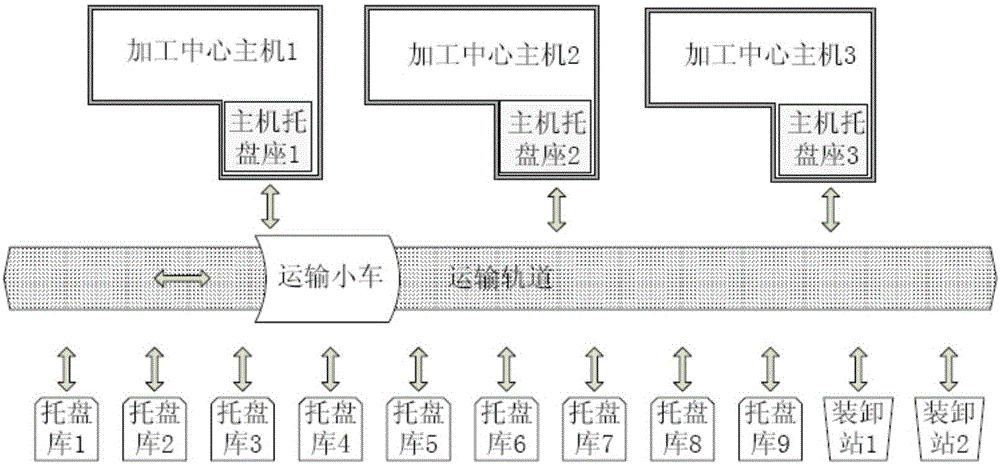

Transporting trolley for gantry multi-tray exchange system

A pallet exchange and transport trolley technology, which is applied in metal processing and other directions, can solve problems such as difficulty in assembly, achieve good accuracy retention, ensure accuracy, and avoid the effect of reducing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

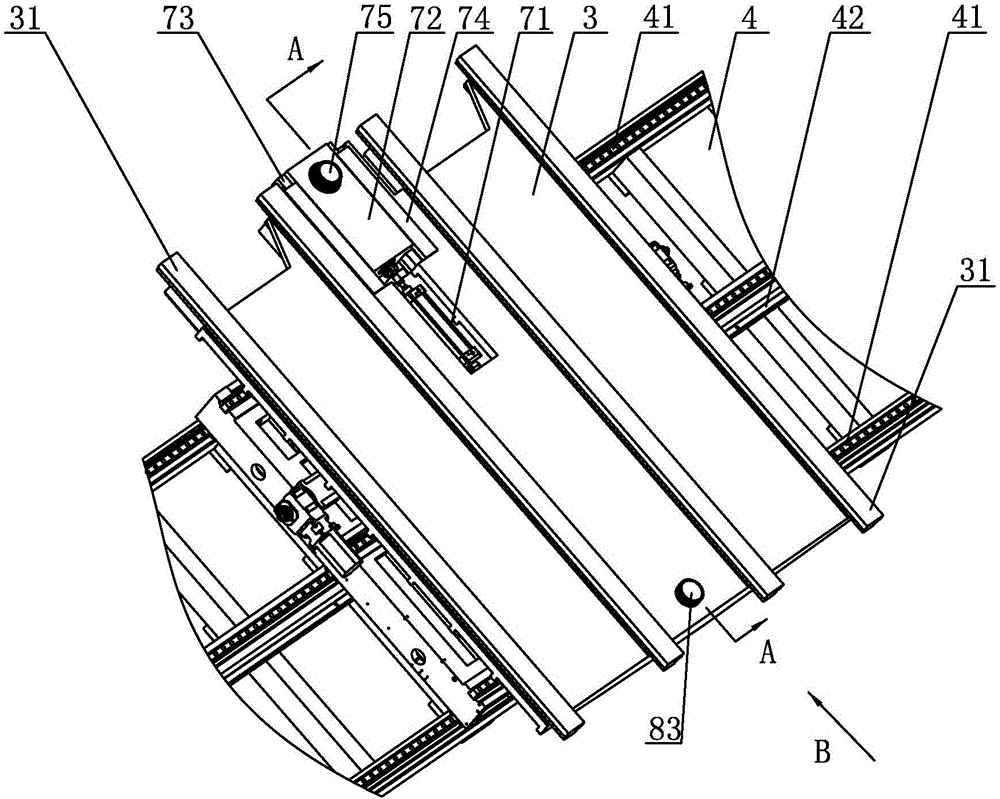

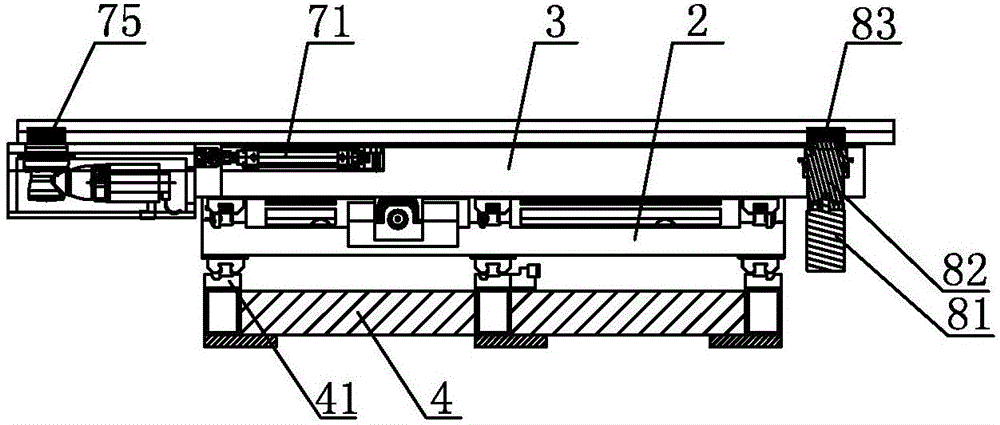

[0028] The transport trolley for the gantry multi-pallet exchange system of embodiment 1, as shown in the figure, includes a support 3, a first inclined slide seat 1, a second inclined slide seat 2 and a transport track 4, and the transport track 4 is equipped with The first line rail 41 and the first rack 42 arranged in the direction, the first inclined sliding seat 1 and the second inclined sliding seat 2 are installed on the first line rail 41 through the first slider 43 and the second sliding block 44 respectively, The first gear drive mechanism is installed on the first inclined slide seat 1, the output end of the first gear drive mechanism is connected with the first drive gear 51, the first drive gear 51 is meshed with the first rack 42, the first inclined slide seat The top of 1 is inclined from top to bottom. The top of the first inclined slide seat 1 is equipped with a first screw drive mechanism 11 and a second line rail 12. The first screw drive mechanism 11 include...

Embodiment 2

[0029] The transport trolley for the gantry multi-pallet exchange system of embodiment 2, as shown in the figure, includes a support 3, a first inclined slide seat 1, a second inclined slide seat 2 and a transport track 4, and the transport track 4 is equipped with The first line rail 41 and the first rack 42 arranged in the direction, the first inclined sliding seat 1 and the second inclined sliding seat 2 are installed on the first line rail 41 through the first slider 43 and the second sliding block 44 respectively, The first gear drive mechanism is installed on the first inclined slide seat 1, and the first gear drive mechanism includes two gear drive units installed on the first drive box 54, and the first drive box 54 is installed on the first inclined slide seat 1 , each gear drive unit includes a first servo motor 52 and a first reducer 53, the first drive gear 51 is installed on the output end of the first servo motor 52 through the first reducer 53, and the first driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com