Patents

Literature

35results about How to "Ensure accuracy and consistency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

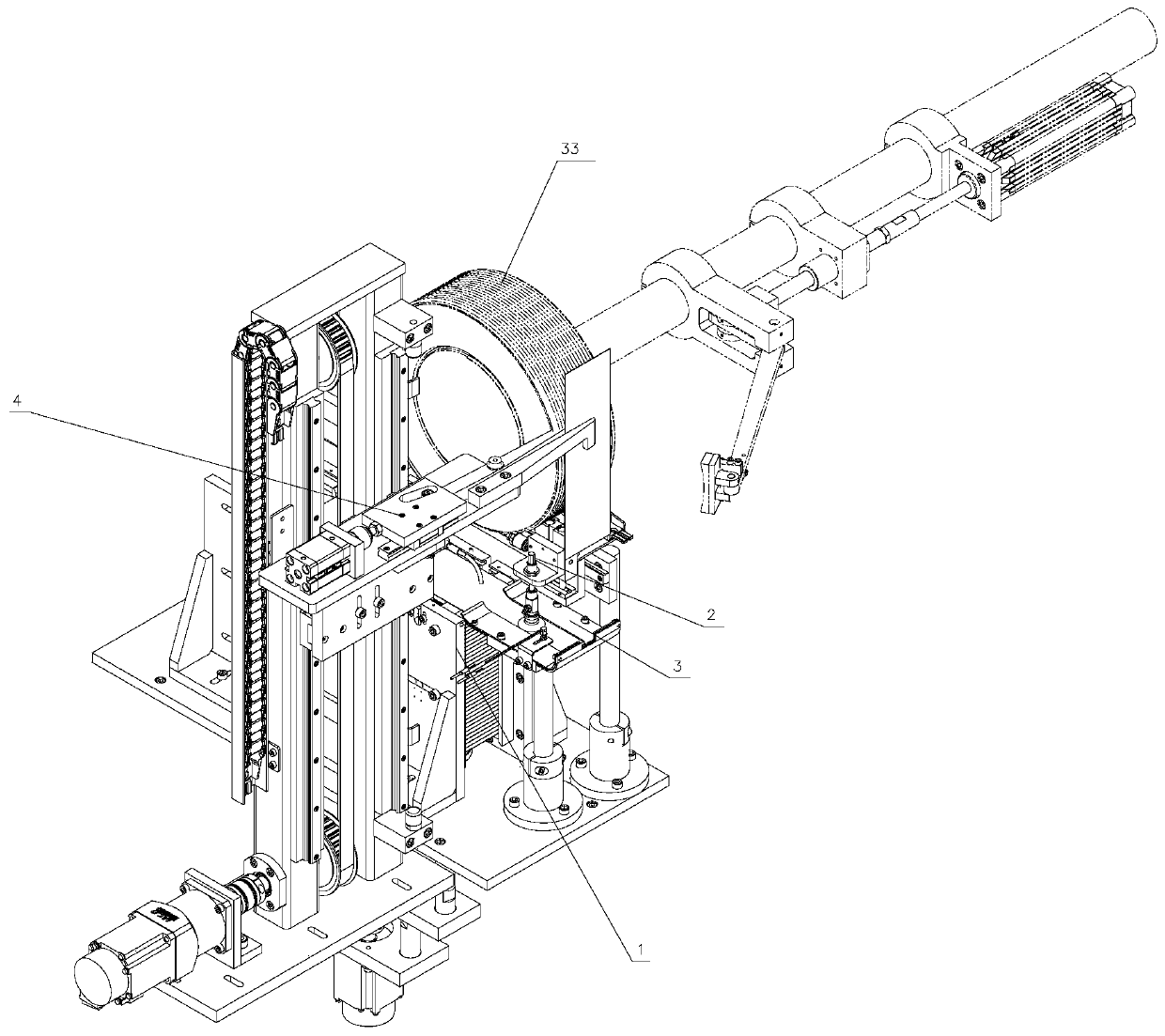

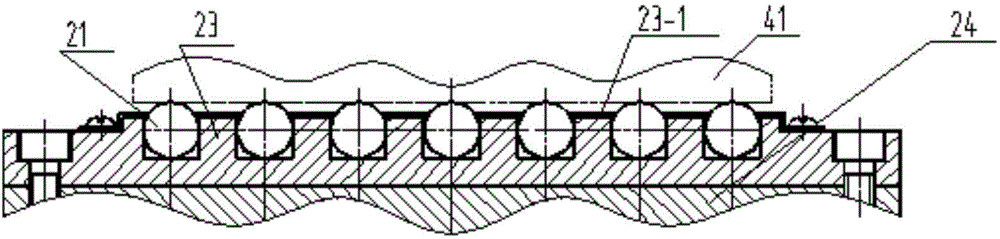

Frication stir welding flexibility tool for subway vehicle side wall

ActiveCN105033448AImprove versatilitySmall footprintWelding/cutting auxillary devicesAuxillary welding devicesShaped beamStructural engineering

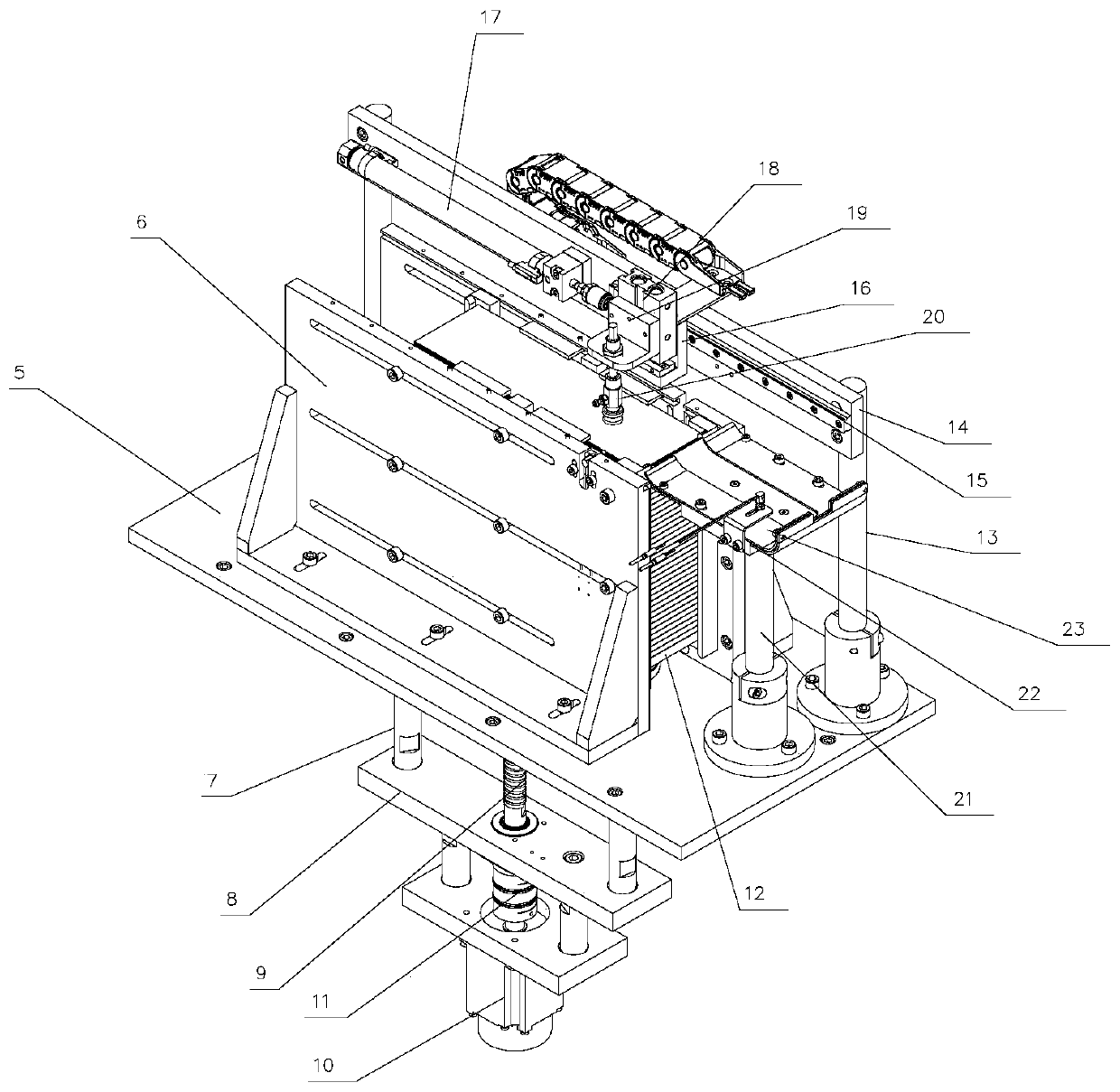

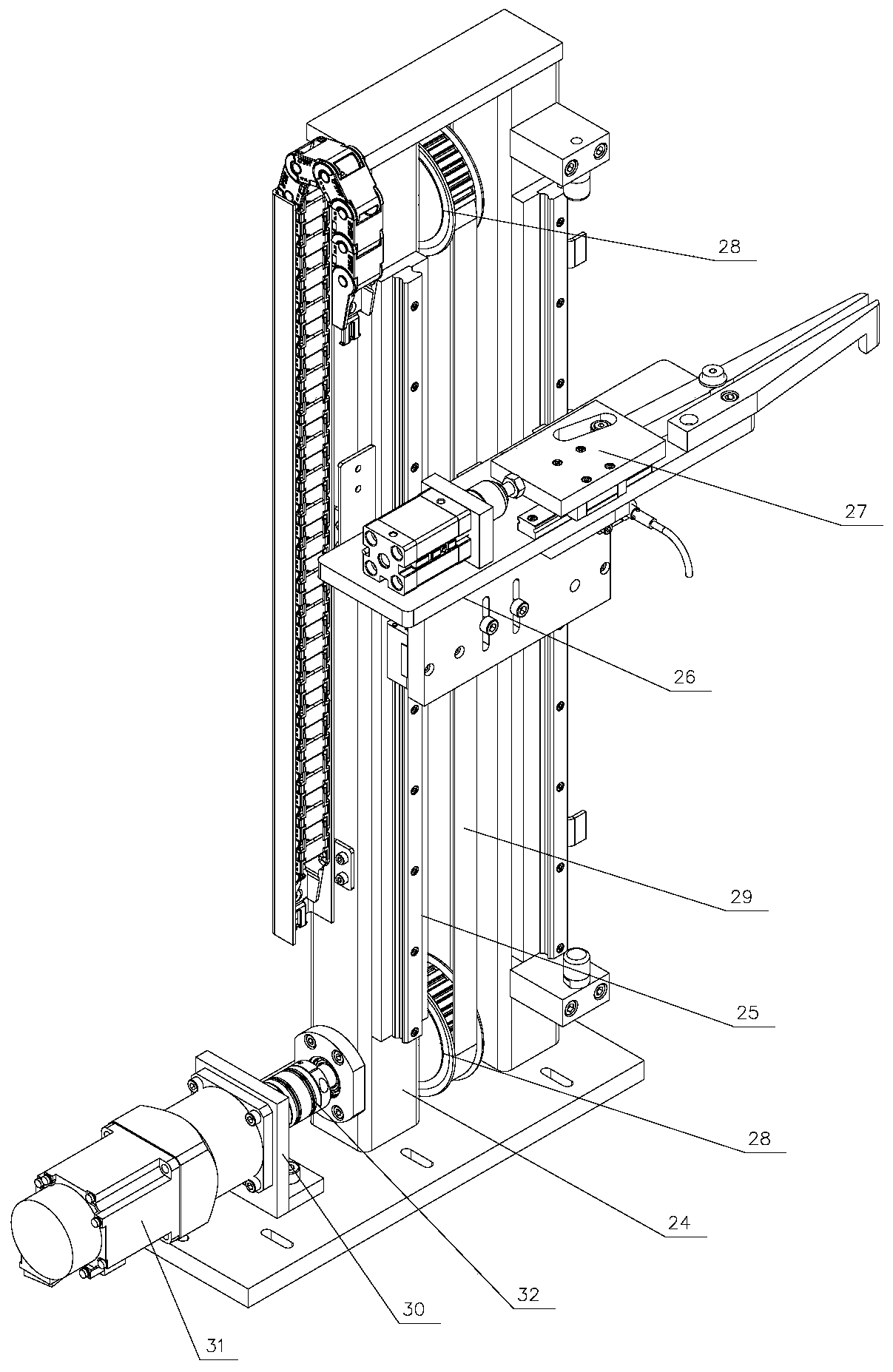

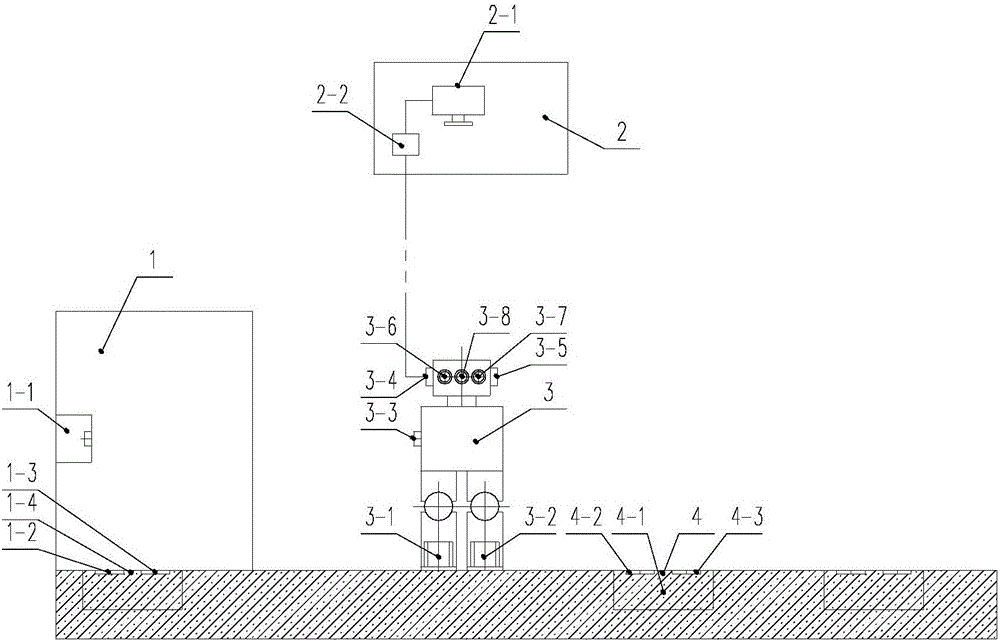

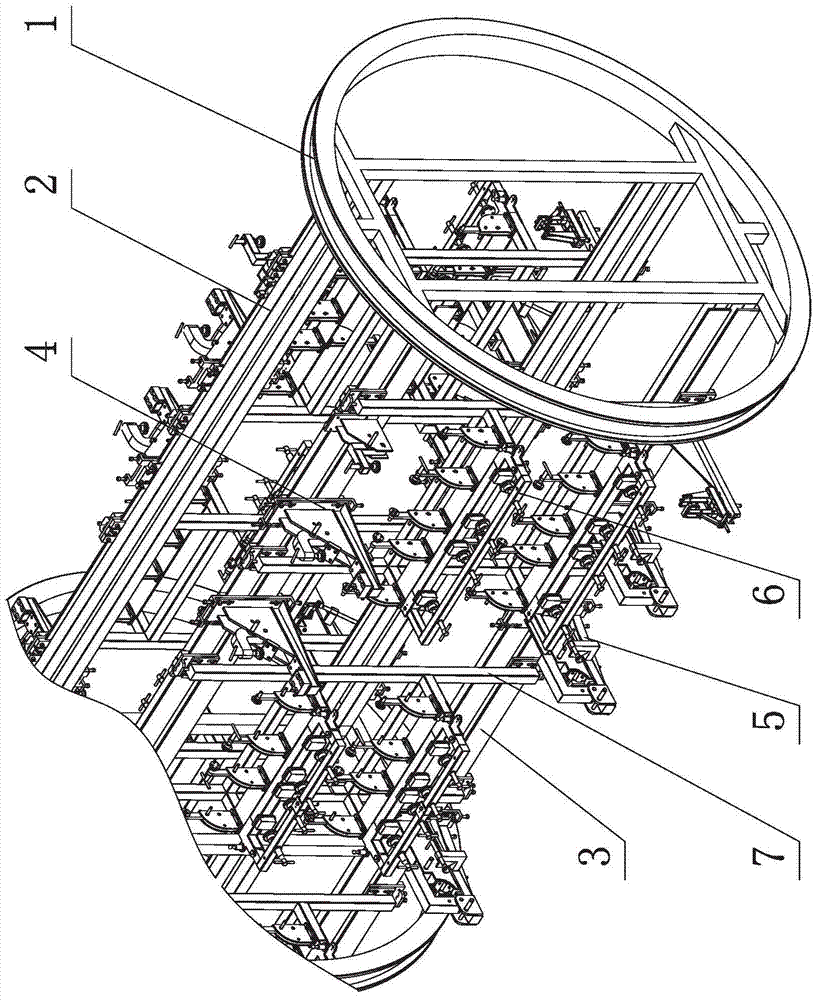

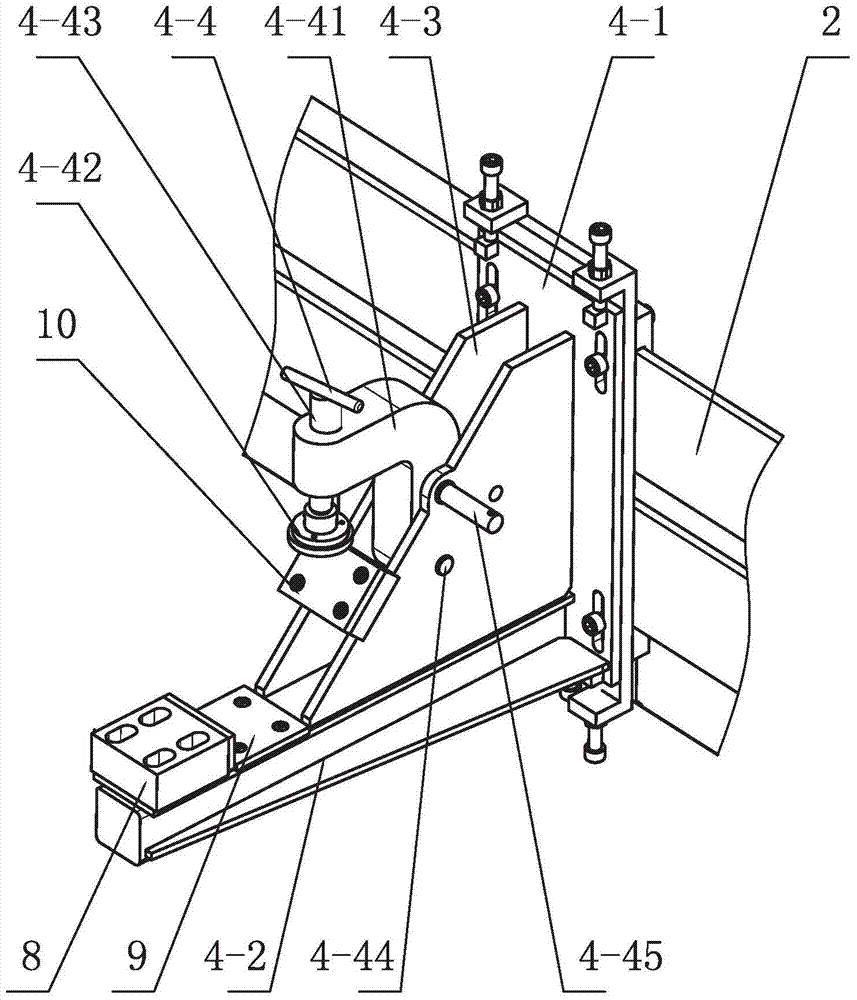

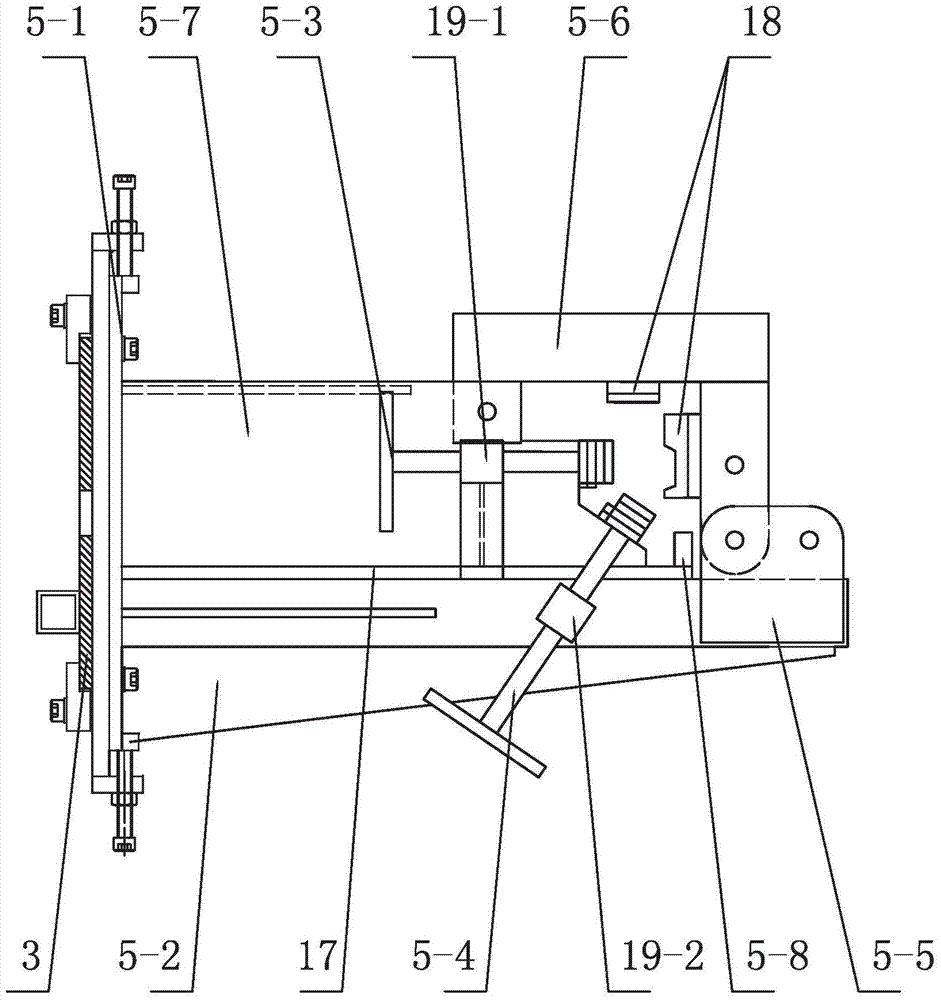

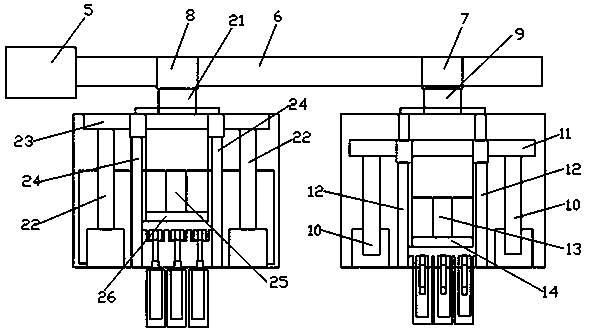

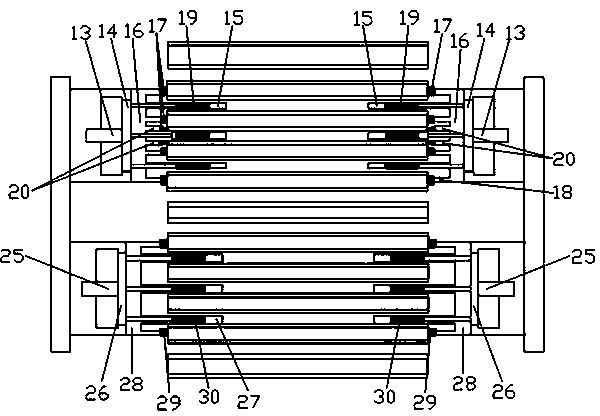

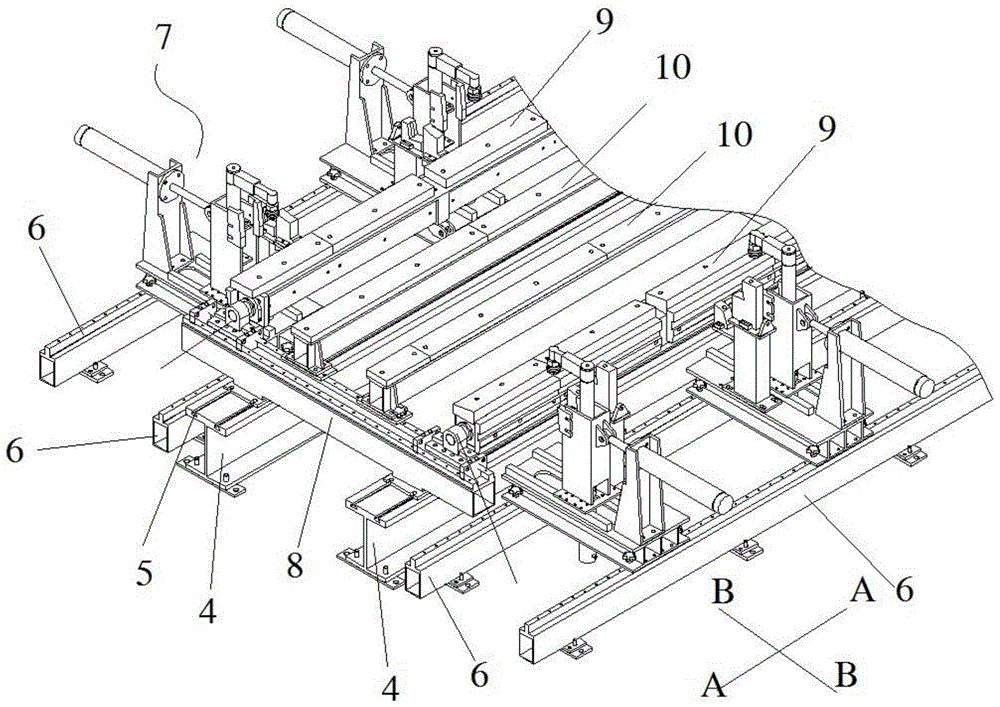

The invention discloses a frication stir welding flexibility tool for a subway vehicle side wall. The frication stir welding flexibility tool comprises a pair of I-shaped beam bases, four square steel bases symmetrically arranged on the two sides of the I-shaped beam bases respectively, multiple locating and clamping mechanisms installed on the square steel bases in a sliding manner, multiple beams installed on the I-shaped beam bases in a sliding manner and a turnover mechanism. Every two adjacent beams are connected with a pair of rotary welding joint supporting strips and a pair of fixed welding joint supporting strips in a sliding manner. The tool is suitable for frication stir welding of the subway vehicle side wall; common features of existing and following projects are fully considered, the universality of the tool is improved; high cost for a newly-made tool is saved; the preparation cycle of tools for new projects is greatly shortened; the space and the position occupied by the tool are saved; the project production tool switching time spent in the multi-project combined production process is shortened; the accuracy and uniformity of the tool are guaranteed; and the capacity is improved. The tool is good in reliability, simple in structure, high in efficiency and suitable for practical application.

Owner:NANJING ZHONGCHE PUZHEN URBAN RAIL VEHICLE CO LTD

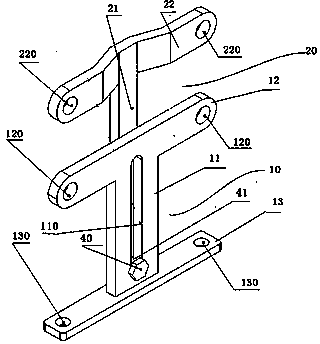

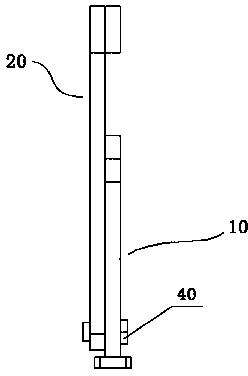

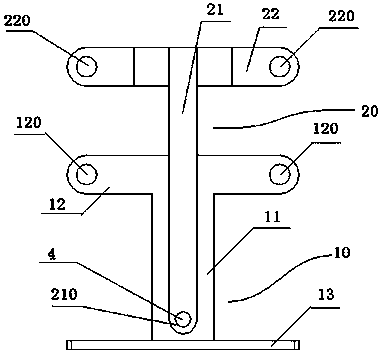

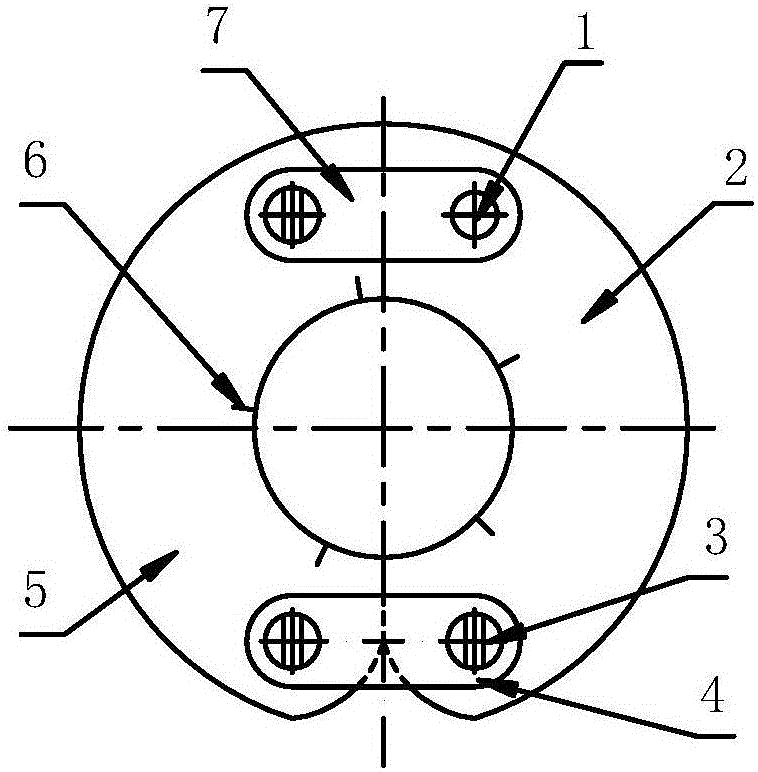

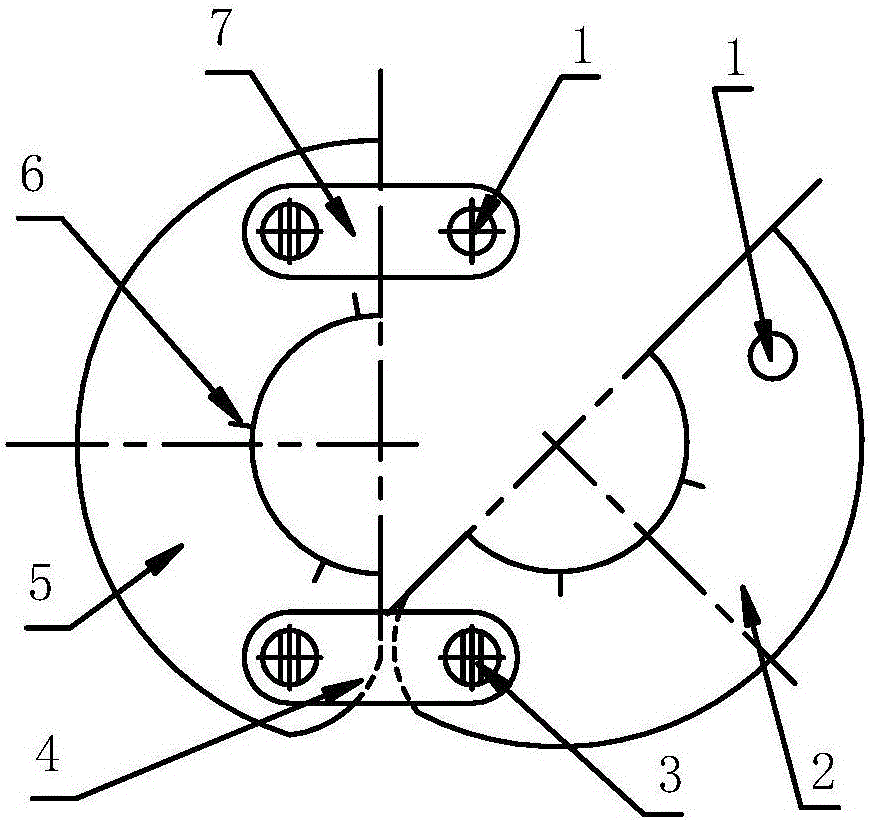

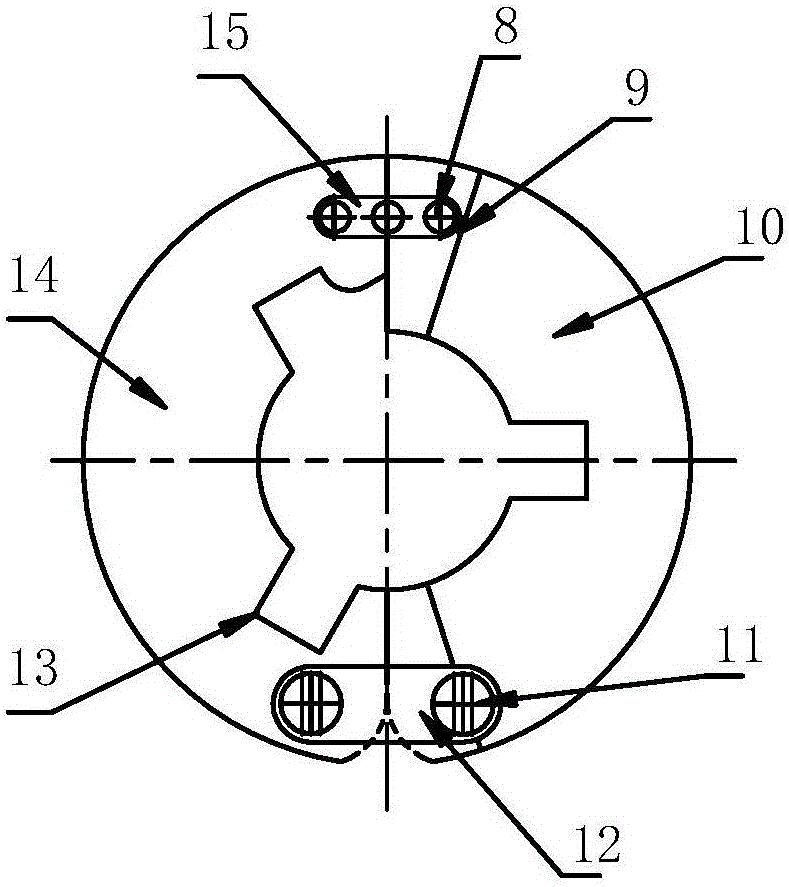

Fixing device for braking calipers needing to be tested through liquid measurement rack

ActiveCN103921231AEnsure accuracy and consistencyGuaranteed accuracyMachine part testingWork holdersEngineeringCalipers

The invention discloses a fixing device for braking calipers needing to be tested through a liquid measurement rack. The fixing device can guarantee the accuracy. A lower frame (10) of the fixing device is of an H shape as a whole and comprises a vertical connecting portion (11), a lower transverse clamping portion (12) and a base (13), wherein the lower clamping portion is connected with the upper end and the lower end of the connecting portion. The connecting portion is provided with a longitudinal slot (110). The two ends of the lower clamping portion are provided with installation holes (120) used for installing the braking calipers. An upper frame (20) of the fixing device is of a T shape as a whole and comprises a vertical supporting portion (21) and an upper transverse clamping portion (22) connected with the upper end of the supporting portion. The two ends of the upper clamping portion are provided with matching installation holes (220) corresponding to the installation holes, used for installing the braking calipers, in the two ends of the lower clamping portion. The lower end of the supporting portion is connected with the longitudinal slot in the connecting portion of the lower frame, can relatively rotate relative to the lower frame and can move vertically. The matching installation holes in the two ends of the upper clamping portion and the installation holes in the two ends of the lower clamping portion correspond vertically and are located in the same plane.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

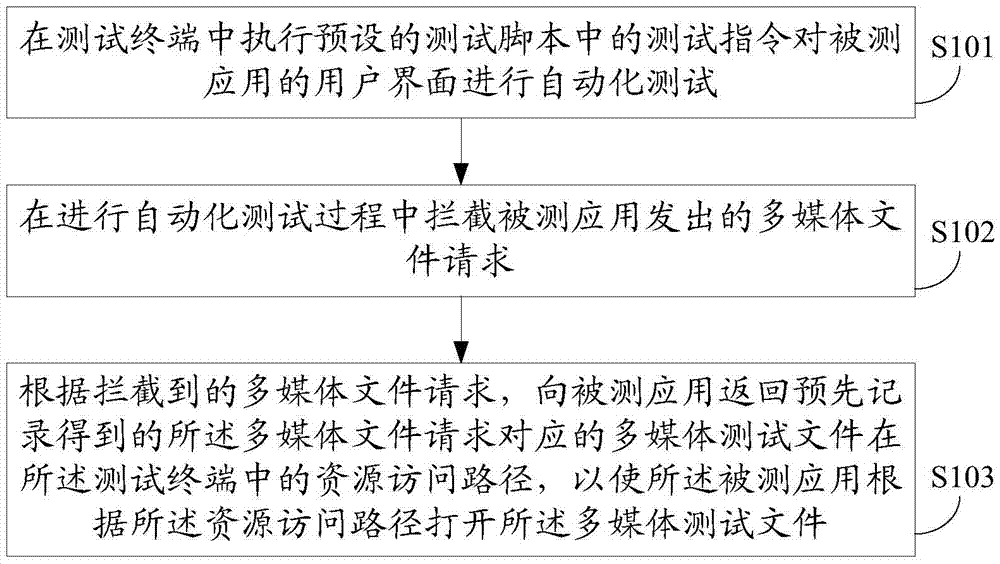

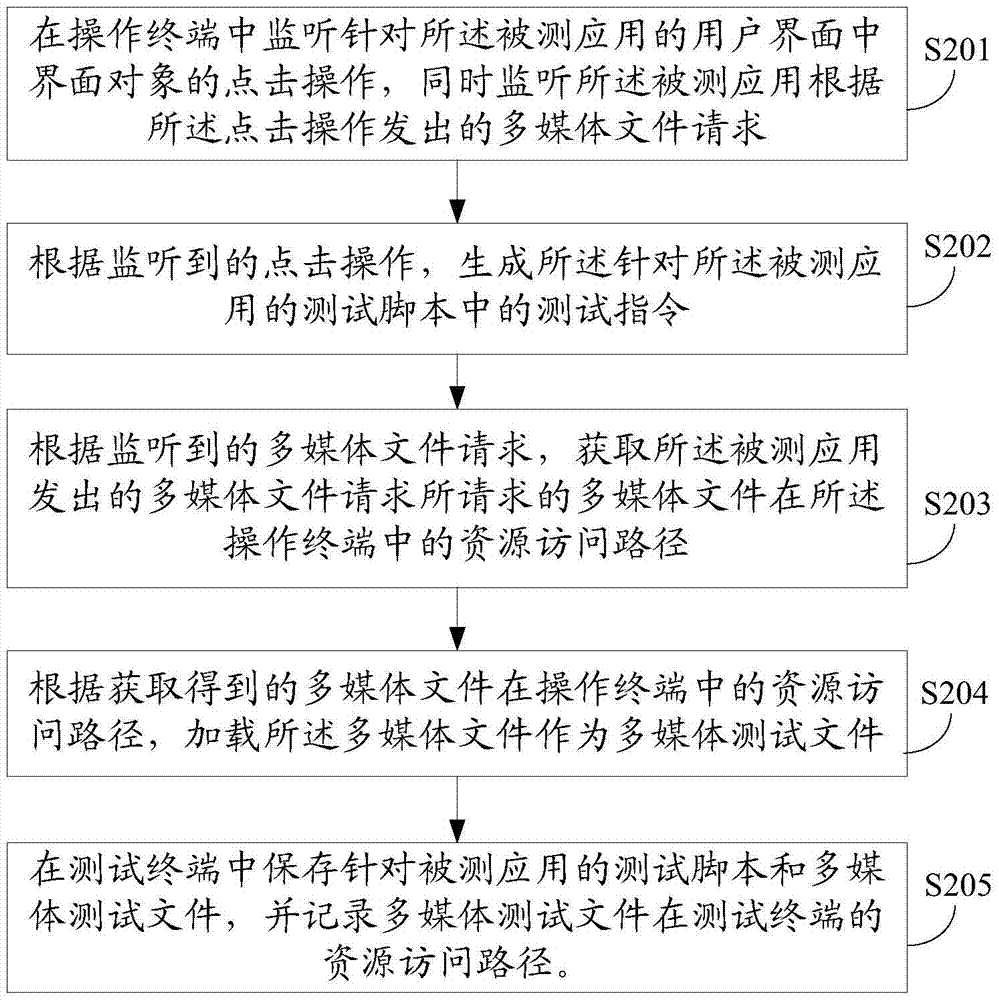

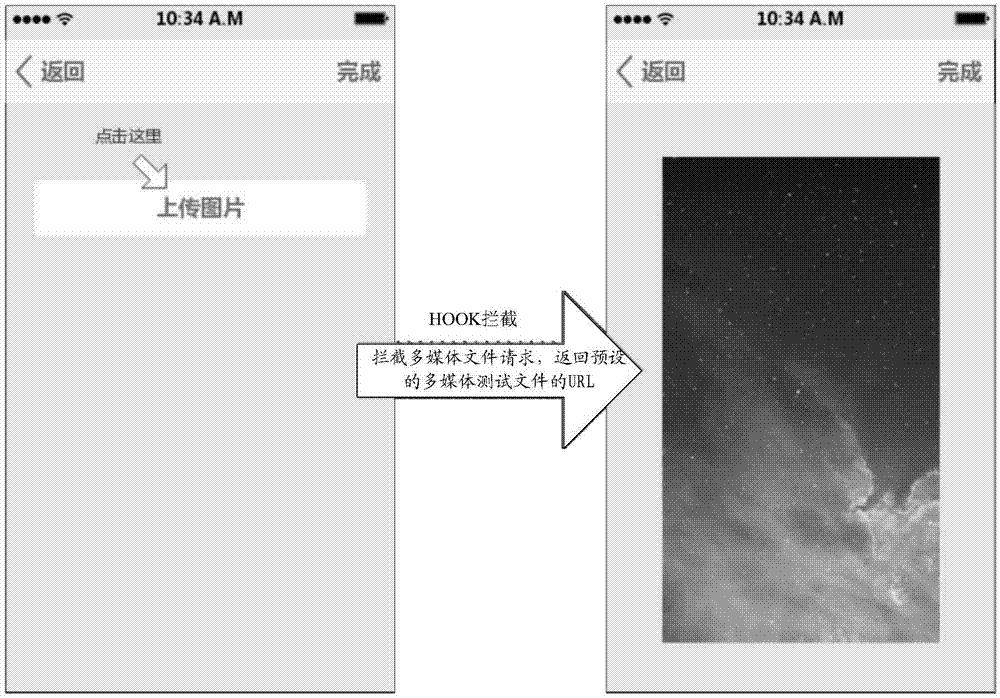

Method and device for testing user interface

ActiveCN107102937AEnsure accuracy and consistencyGuaranteed accuracySoftware testing/debuggingZoomUser interface

One embodiment of the invention discloses a method for testing a user interface comprising following steps: executing a test instruction in a preset script in a test terminal for automatically testing a user interface of a tested application; intercepting multimedia file requests sent by the tested application during the automatic test; according to the intercepted multimedia file requests, returning a resource access path of the multimedia test file in the tested terminal corresponding to the multimedia file requests obtained in a prior record to the tested application so that the tested application opens the multimedia test file according to the resource access path of the multimedia test file. One embodiment of the invention also discloses a device for testing user interfaces. By means of the method and device of the invention, the accuracy and consistency of user interface testing can be guaranteed.

Owner:TENCENT TECH (SHENZHEN) CO LTD

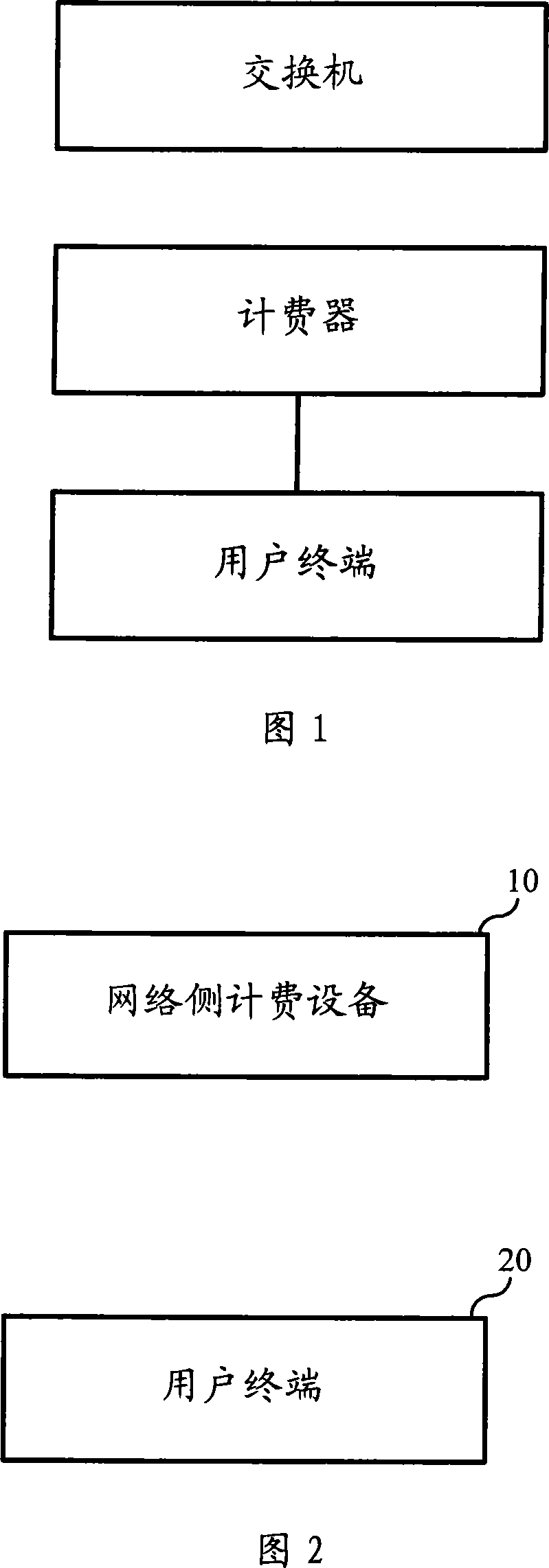

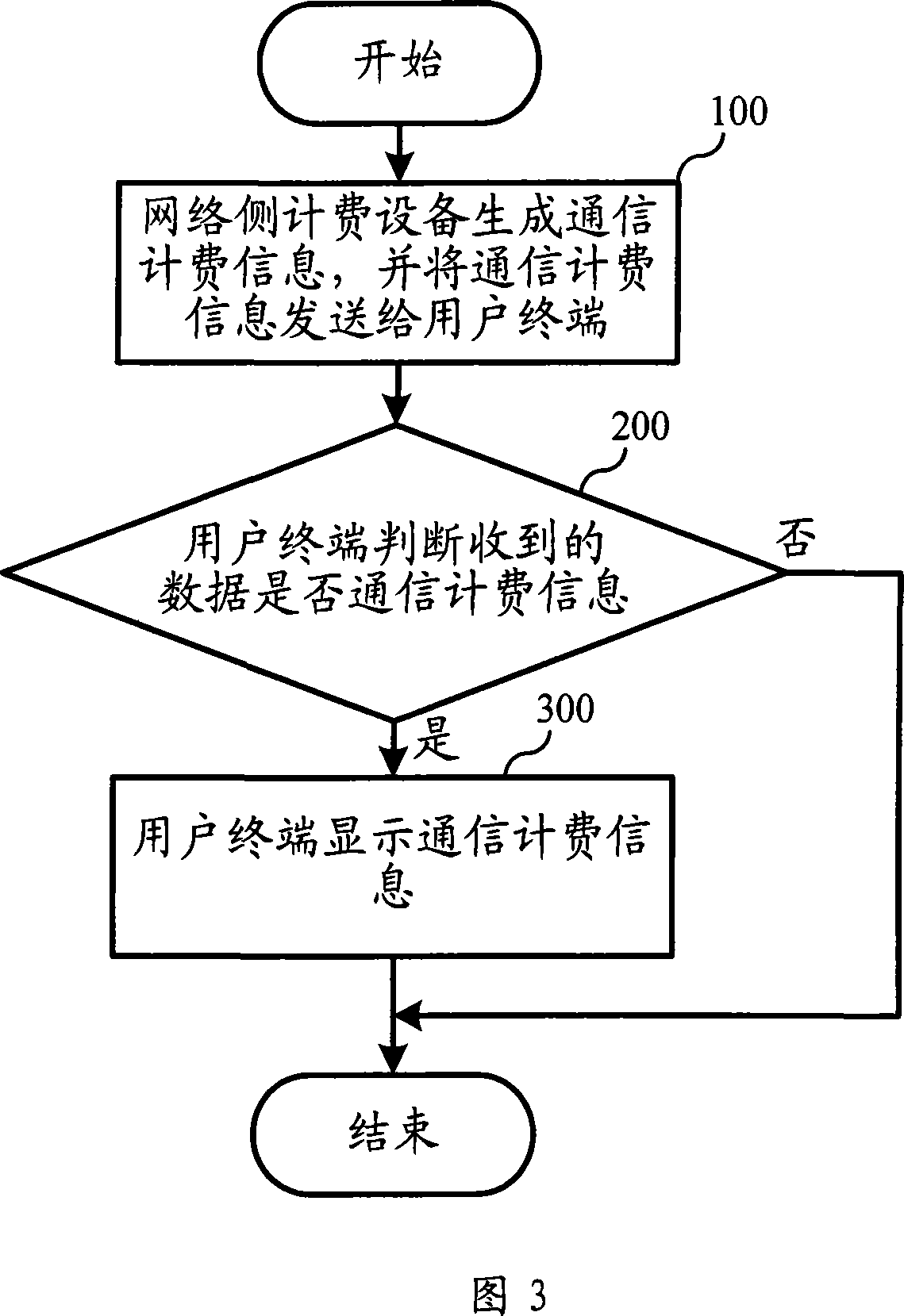

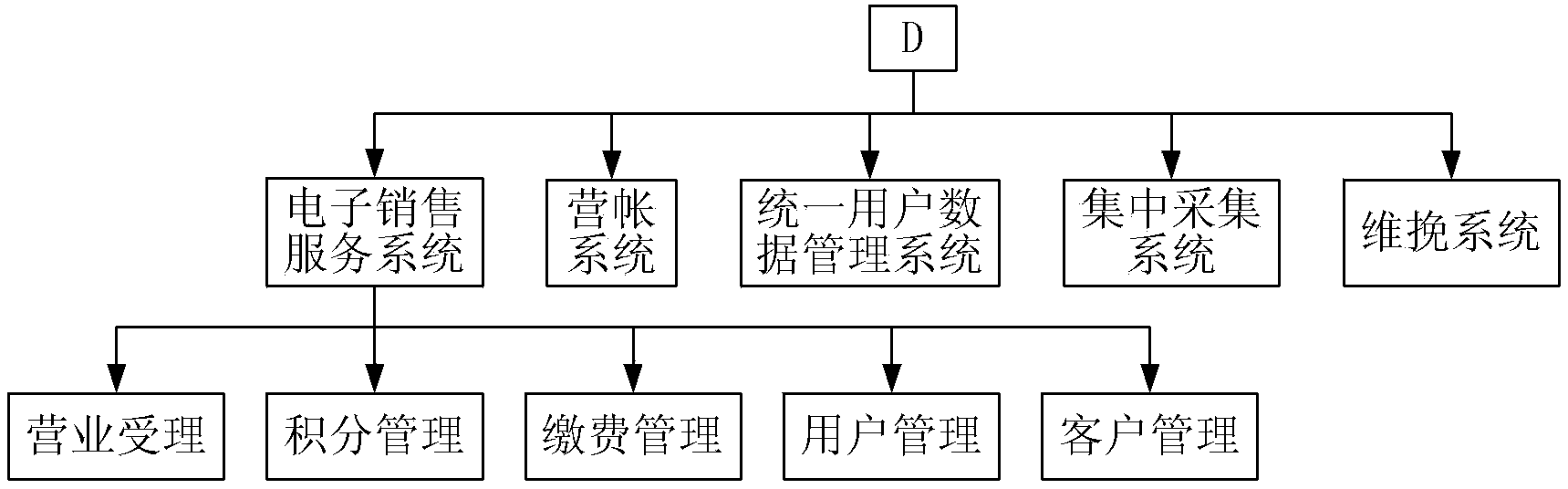

A communication charging information feedback method and the corresponding system

InactiveCN101217609AEnsure accuracy and consistencyReduce communication costsSpecial service for subscribersRadio/inductive link selection arrangementsTelecommunicationsWarning tone

Owner:HUAWEI TECH CO LTD

Automatic electric coil label placement device

PendingCN109896092AContinuous actionEnsure accuracy and consistencyLabelling machinesElectric machineryEngineering

The invention belongs to the technical field of electric machinery, and particularly relates to an automatic electric coil label placement device. The automatic electric coil label placement device iscomposed of a label storage box, a movable label sucking head, a label separating and guiding groove and a lifting label clamping assembly. Labels are horizontally put in the label storage box, the label sucking head downwards extends to suck the horizontally put labels and forwards moves, the labels pass through the guiding groove and are changed to be vertically arranged along the guiding groove, a pneumatic label clamping head clamps the labels to upwards move, the labels are put on the side face of a coil, and the label placement task is automatically completed. According to the automaticelectric coil label device, sucking to placement of the labels is automatically completed, movement is continuous and reliable, the automatic electric coil label device can take the place of manual work, the accuracy and the consistency of the put labels can be effectively guaranteed, the labor intensity of manpower can be greatly reduced, and the production efficiency is improved. The automaticelectric coil label device is compact in design and safe and reasonable in transmission and can completely meet requirements of the production process.

Owner:WUXI HENGTAI CABLE MACHINERY MFG

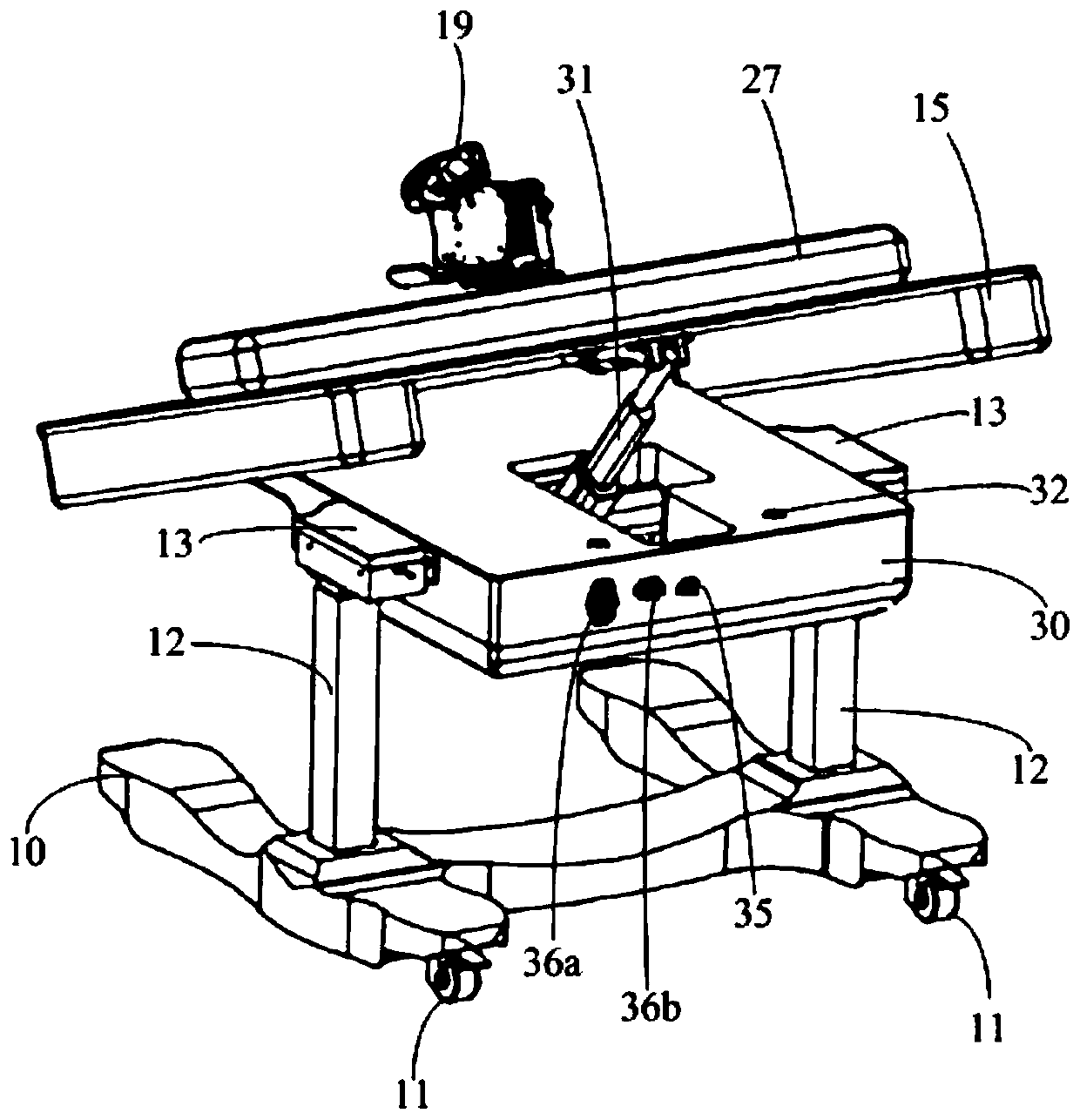

Upper limb rehabilitation training robot

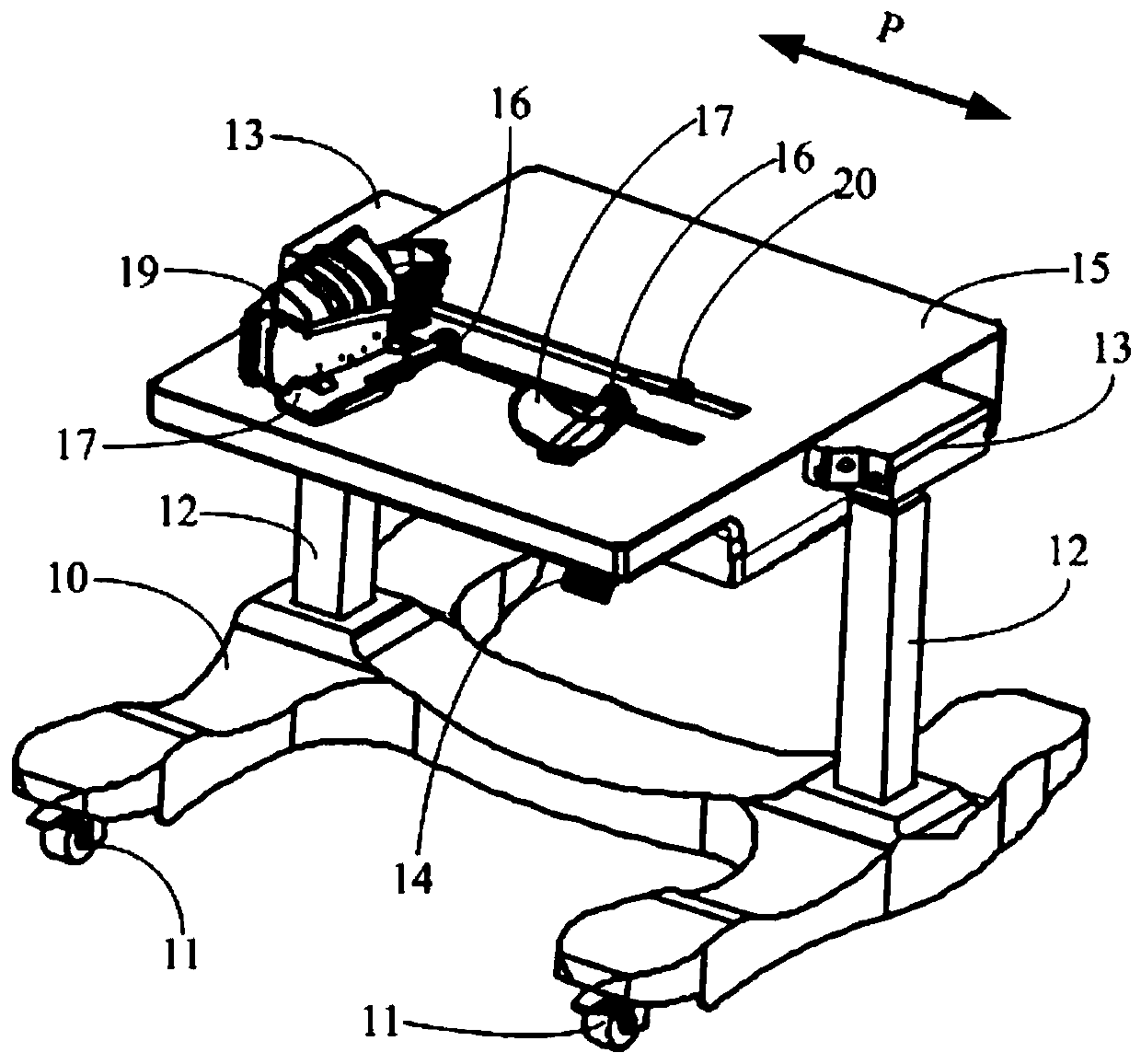

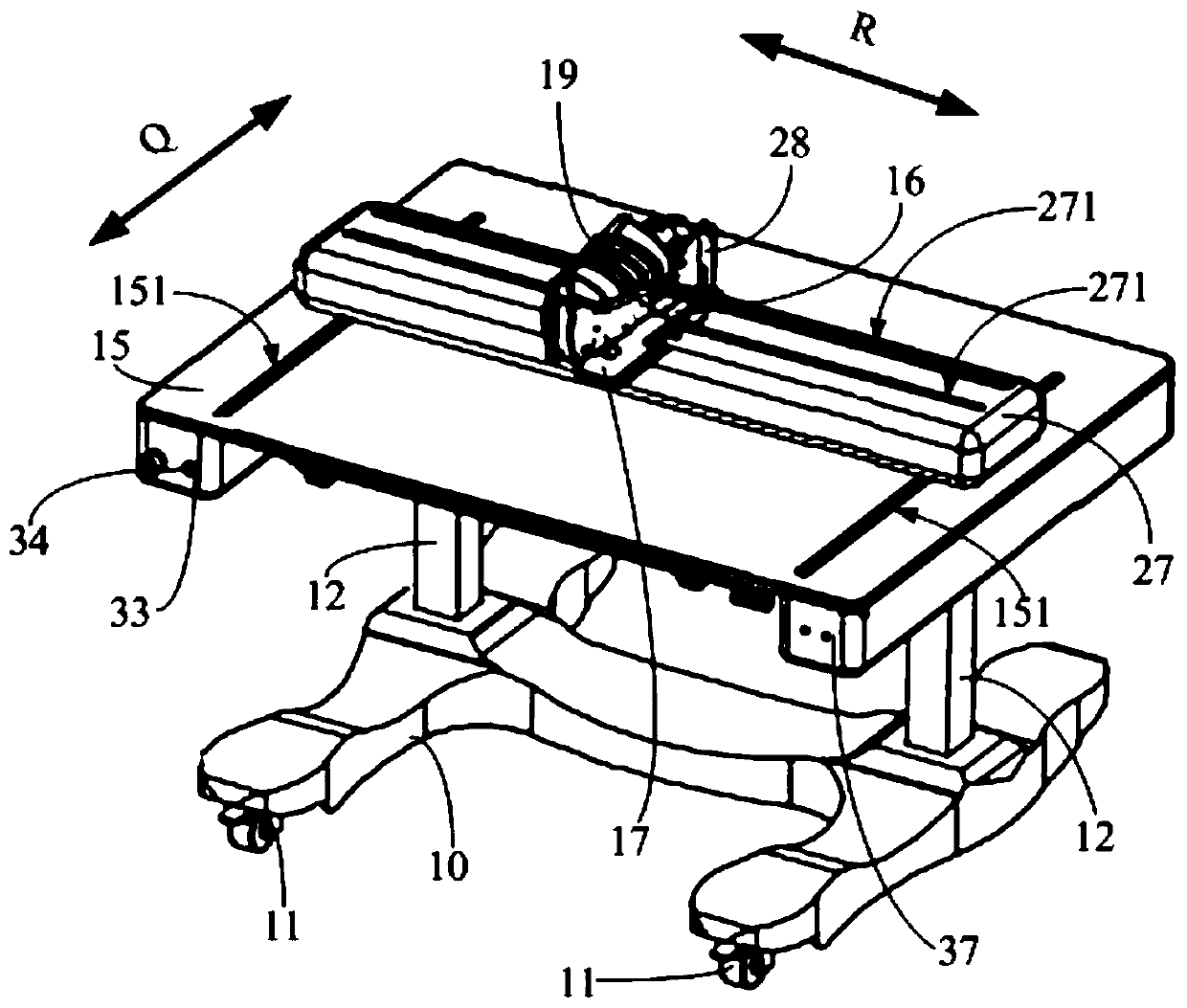

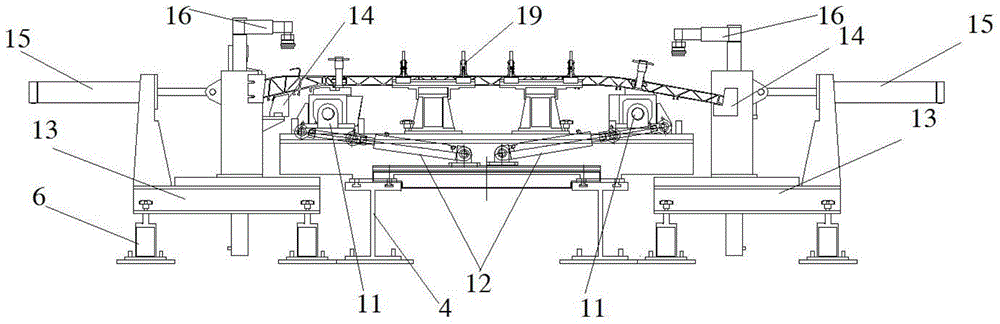

ActiveCN110384602AReduce labor intensityEnsure accuracy and consistencyChiropractic devicesRocker armUpper limb rehabilitation

The application relates to the technical field of rehabilitation equipment, in particular to an upper limb rehabilitation training robot. The upper limb rehabilitation training robot can comprise a base, a lifting device and a training device, wherein the lifting device comprises a lifting module and an operation table; one end of the lifting module is connected with the base, and the other end ofthe lifting module is connected with the operation table; the lifting module is used for driving the operation table to perform lifting movement; the training device comprises a training module and one or more bearing structures; the training module is mounted on the operation table, and is used for training an upper limb; each bearing structure comprises a bearing part for bearing the upper limband a rocker arm which is rotatably mounted on the operation table; an assembling hole is formed in the bottom of each bearing part; and a locking pin is arranged on each rocker arm, and can be in inserting and drawing movement relative to the assembling hole to realize the assembling and disassembling process of each bearing part and the corresponding rocker arm. The upper limb rehabilitation training robot disclosed by the invention can be used for performing systematic rehabilitation training on upper limbs of a patient, and favorable rehabilitation training effects are achieved.

Owner:上海术理智能科技有限公司

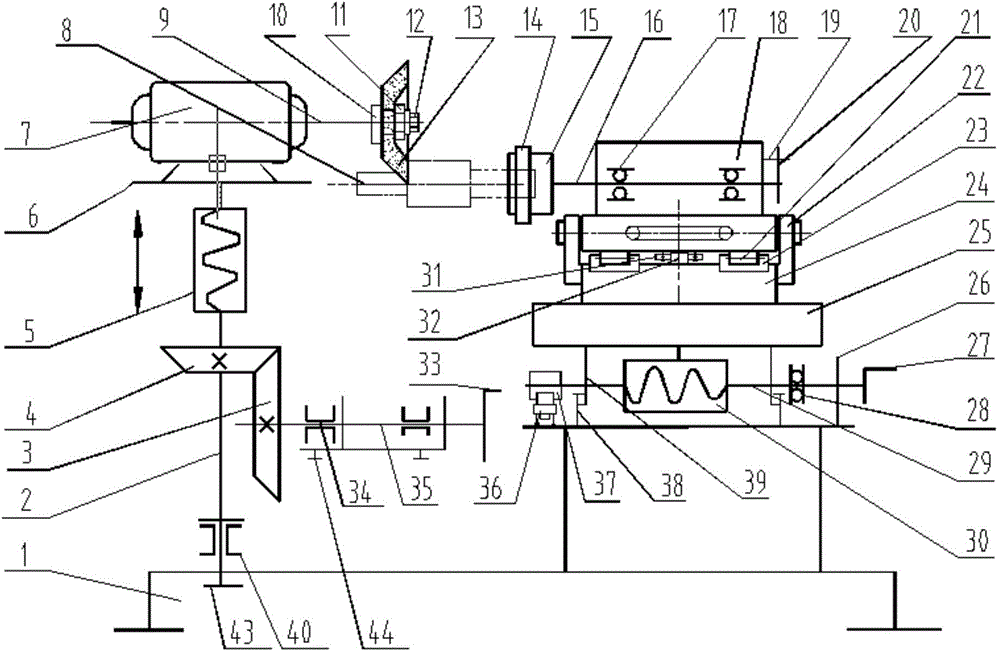

Device for polishing rear angle of combined drill bit cutter

InactiveCN104416424AEnsure accuracy and consistencyImprove grinding efficiencyDrilling toolsPush and pullEngineering

The utility model relates to a combined drill tool orthogonal clearance coping device, in particular to a tool orthogonal clearance coping device and belongs to the field of coping. The combined drill tool orthogonal clearance coping device comprises a motor and a shaft, wherein the shaft is fixedly installed on an engine base through a bearing, one end of the shaft is provided with an elastic clamping sleeve and a fastening nut, the other end of the shaft is fixedly provided with a dividing plate, the dividing plate is provided with a dividing hole, the engine base is provided with a pin positioning hole enabling a pin to be inserted, and the output shaft of the motor is provided with a grinding wheel. The combined drill tool orthogonal clearance coping device is provided with a tracked horizontal moving function and a directional vertical push-and-pull coping manual function, can realize the coping of a tool moving along the X, Y, Z axes, enables the gear grinding dividing function and the clamping tool to be serialized, and is suitable for combined drill tool orthogonal clearance coping different in diameters. The clamping sleeve is convenient to exchange, and the problems that the manual coping is low in passing percent and reusing rate, and general equipment is low in coping efficiency and high in cost are solved.

Owner:INNER MONGOLIA NORTH HEAVY INDS GROUP

Robot power station inspection system and method

ActiveCN106556428AEnsure accuracy and consistencyBroad application prospectsMeasurement devicesPosition/course control in two dimensionsPower stationDecibel

The invention discloses a robot power station inspection system and method. The system comprises a robot base station, a main control room, an inspection robot and inspection points. According to the robot power station inspection system, the inspection robot can enter an inspection point area according to a satellite navigation and positioning system, and then an image recognition system installed on the left and right feet of the inspection robot is used to carry out image recognition on inspection positioning points buried in the ground in advance, leads the left and right feet of the inspection robot to completely match the left and right positioning points so as to achieve secondary precise positioning of the inspection robot. Relevant data is acquired by a temperature detector, a decibel detector and a camera installed on the inspection robot, and then is transmitted to a master control computer through a signal remote switch to be analyzed and processed by the master control computer. The image recognition system can lead the inspection robot to realize the secondary precise positioning so that the robot power station inspection system and method fully guarantee the accuracy and consistency of the relevant data collected by the inspection robot, and are wide in application prospect.

Owner:HOHAI UNIV CHANGZHOU

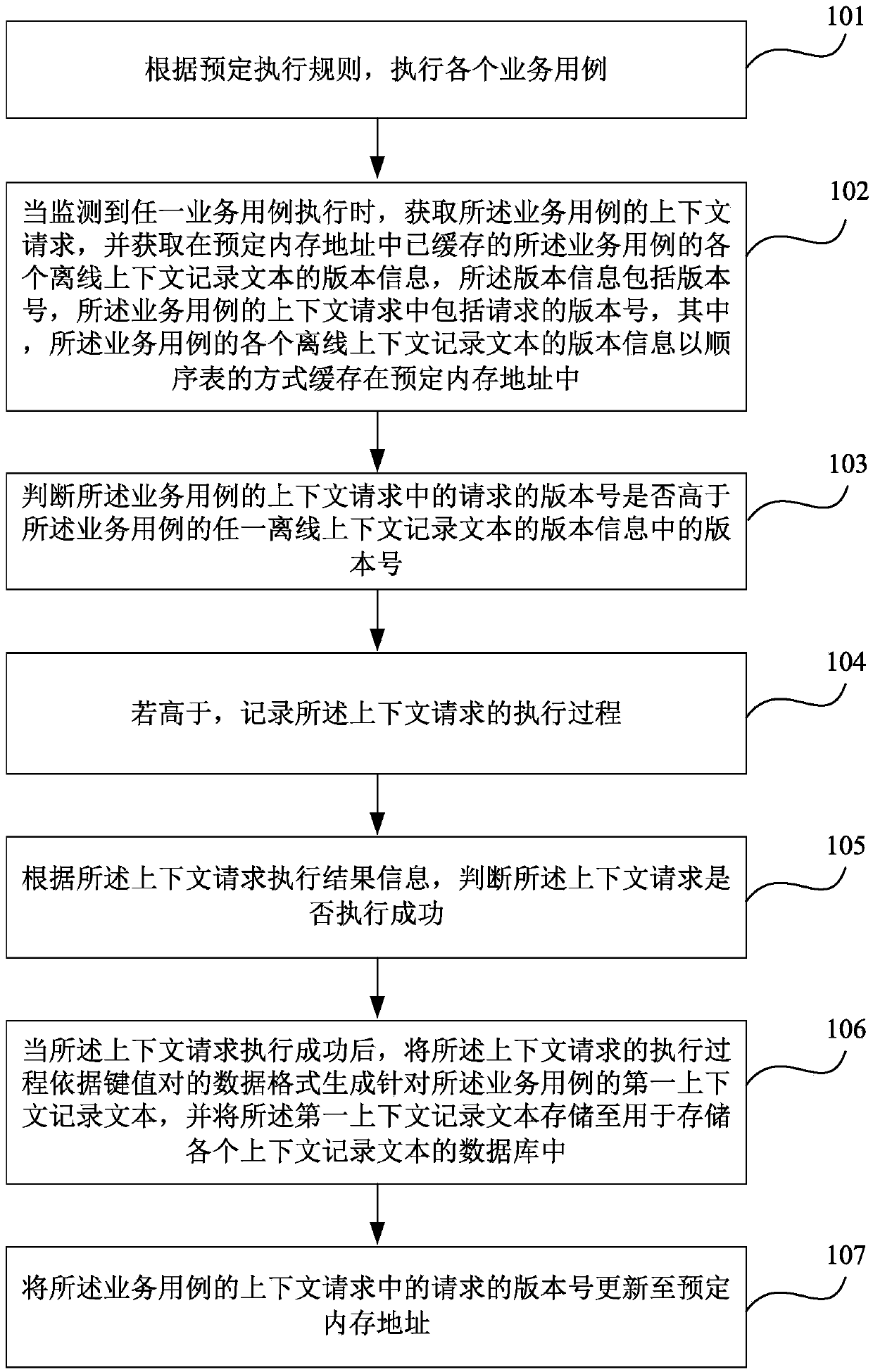

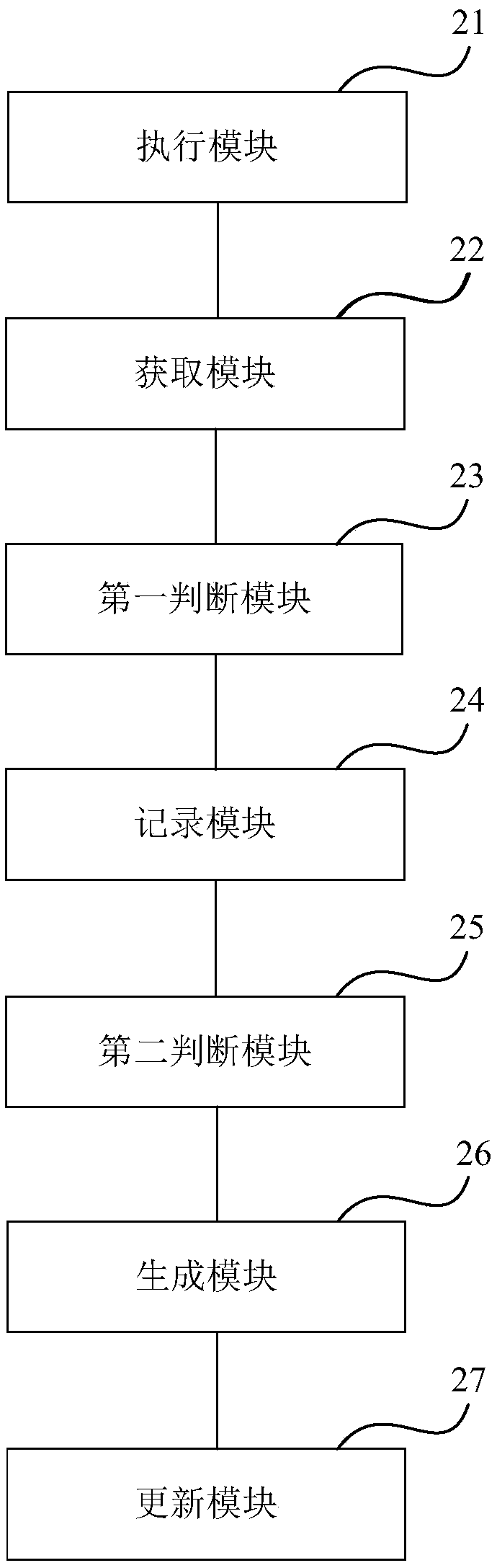

A method and a device for recording a context request execution process

ActiveCN109582685AEnsure accuracy and consistencyGuaranteed real-timeDatabase updatingSpecial data processing applicationsData formatMemory address

The embodiment of the invention provides a method and device for recording a context request execution process, and the method comprises the steps: obtaining a context request of a service case, and obtaining version information of each offline context record text of the service case cached in a predetermined memory address; Judging whether the version number of the request in the context requestof the service case is higher than the version number in the version information of any offline context record text of the service case or not; If yes, recording an execution process of the context request; After the context request is successfully executed, generating a first context record text for the service case from an execution process of the context request according to a data format of akey value pair; And updating the version number of the request in the context request of the service case to a predetermined memory address. According to the method and the device, accurate and efficient service change can be realized through the text generated by the context without depending on manual maintenance of manpower.

Owner:武芮

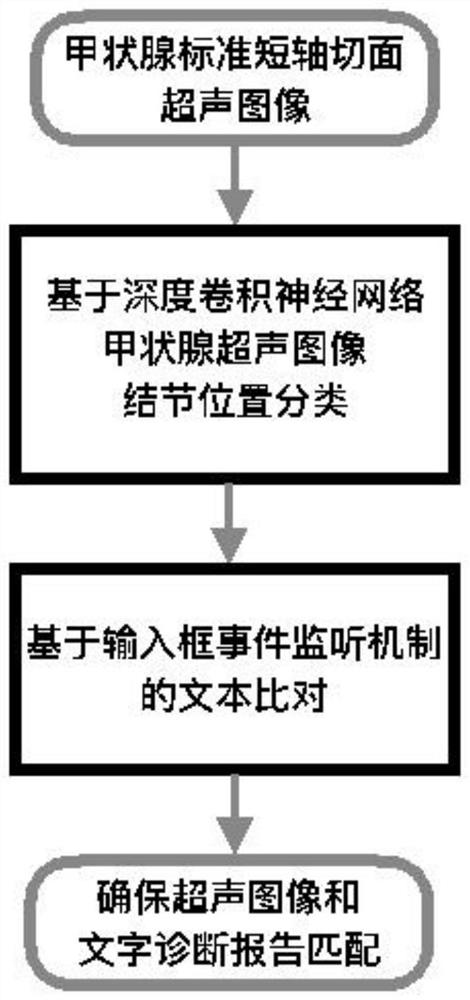

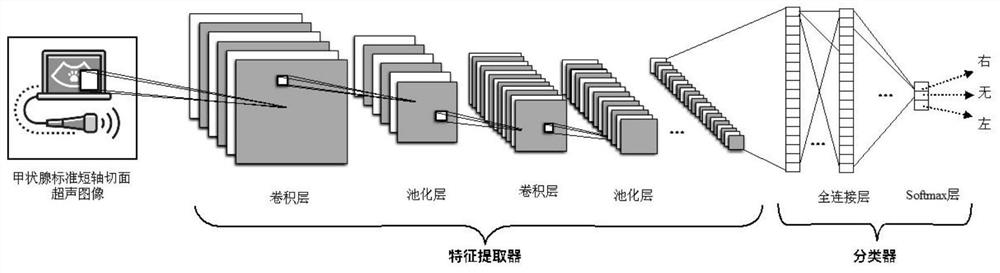

AI-based thyroid nodule left and right leaf positioning and ultrasonic report error correction method

ActiveCN111652837AAvoid mistreatmentEnsure accuracy and consistencyImage enhancementImage analysisNuclear medicineUltrasound image

The invention relates to an AI-based thyroid nodule left and right leaf positioning and ultrasonic report error correction method, and the method comprises the following steps: building a deep convolution neural network, extracting the features of a thyroid standard short-axis section ultrasonic image through the deep convolution neural network, and carrying out the classification; and based on aninput box event monitoring mechanism, comparing the classification result with keywords in the ultrasonic report, and if the classification result is inconsistent with the keywords in the ultrasonicreport, giving a prompt. According to the invention, the phenomenon that left and right focuses are reversed due to manual errors is effectively avoided, so that the consistency and accuracy of text reports and pictures are ensured, and adverse medical accidents are reduced.

Owner:SHANGHAI CHANGZHENG HOSPITAL

Finished piece positioning method for grinding die of automobile outer cover panel

InactiveCN102343516AEnsure accuracy and consistencyAvoid surface defectsPositioning apparatusMetal-working holdersEngineeringWaste material

The invention relates to a finished piece positioning method for a grinding die of an automobile outer cover panel, transition process holes are adopted in the grinding die of the automobile outer cover panel, and the method is implemented through the following steps: 1) punching two transition process holes on the non-A type surface of a finished piece after grinding stably, wherein the positions of the transition process holes are arranged in the non-exposed area of the finished piece and are not arranged in the waste material area of the next process step; 2) punching at least two positioning process holes on the A type surface of the finished piece after utilizing the transition holes on the non-A type surface for grinding, wherein the panel punched with the transition process holes can not be trimmed off when the positioning process holes are punched; and 3) adopting the processing process holes for grinding in all the following process steps, wherein the punching of the transition process holes and the positioning process holes adopts special pins for the positioning process holes, and the position precision is + / -0.1mm. The finished piece positioning method has the advantages that by adopting the processing method adopting the transition process holes in the grinding die of the automobile outer cover panel, the consistency and accuracy of the grinding reference of the outer panel can be ensured, and the defects in the surface quality of the outer panel caused by the process holes of the grinding die can be simultaneously avoided.

Owner:TIANJIN MOTOR DIES

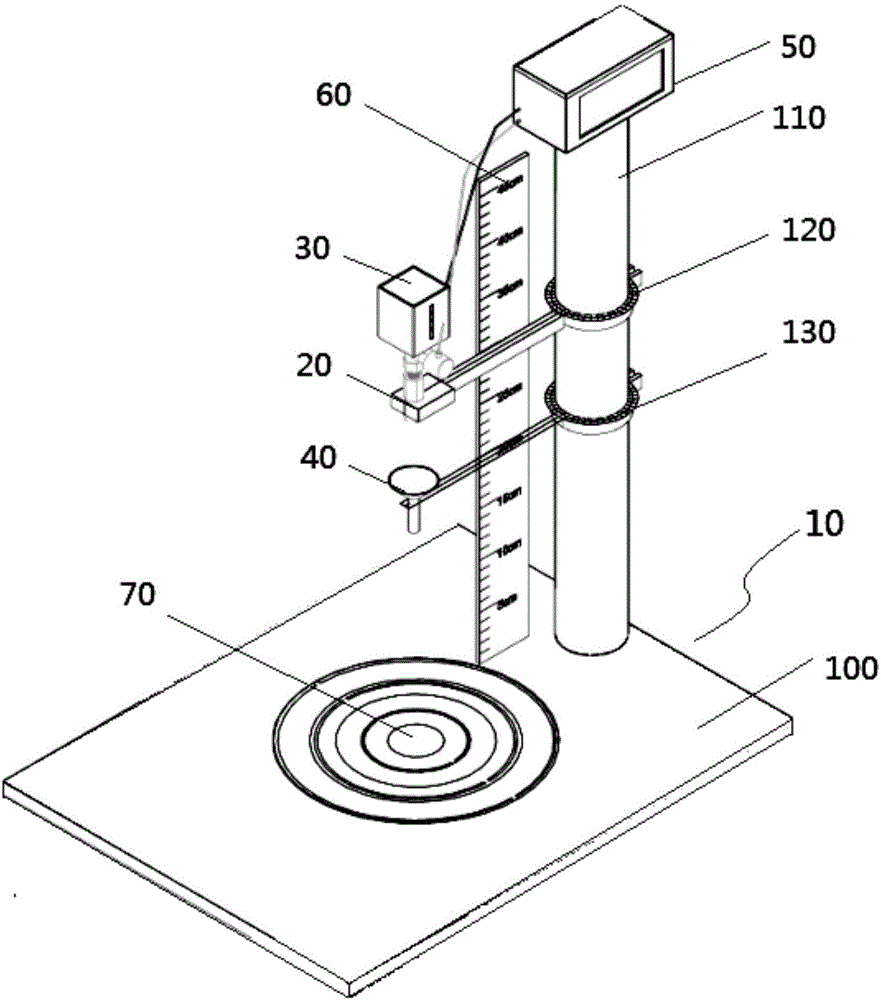

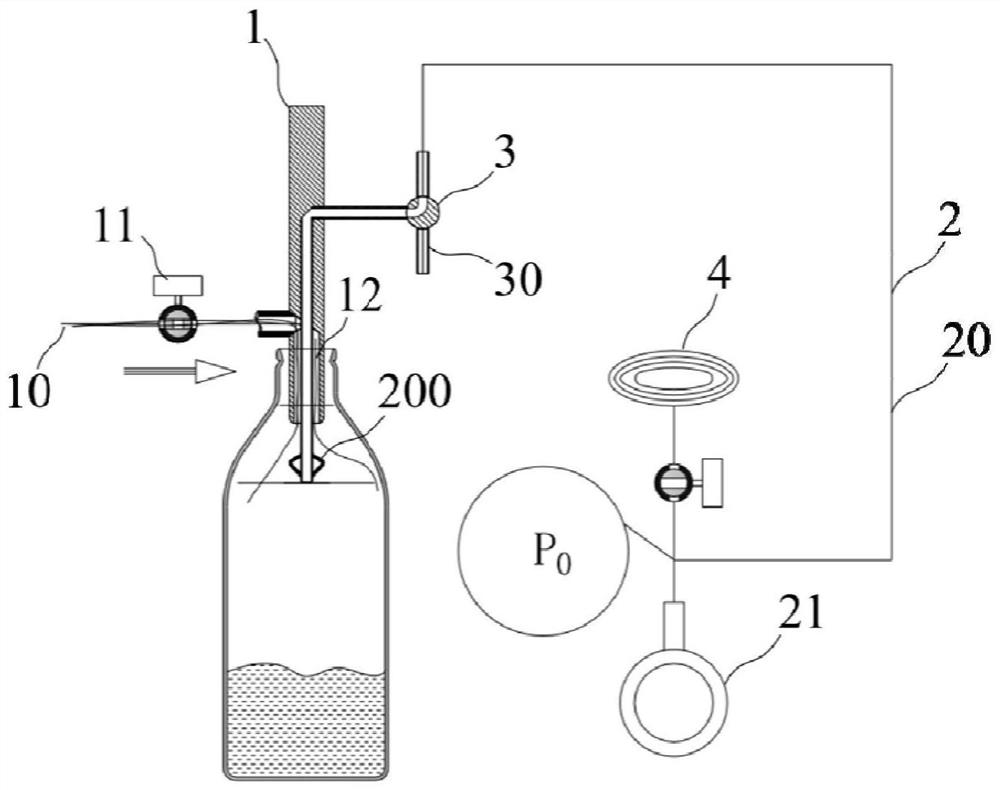

Water spray test device

ActiveCN106770966AEnsure accuracy and consistencyGuaranteed accuracyFlow control using electric meansStructural/machines measurementEngineeringStreamflow

The invention discloses a water spray test device. The device comprises a supporting platform, a container, a control valve, a funnel and a controller, wherein the supporting platform comprises a platform base, a vertical column arranged on the platform base, and a plurality of clamps on the vertical column; the funnel is clamped by a first clamp positioned at the lower part of the vertical column; the funnel is vertically laid; the container is clamped by a second clamp positioned at the upper part of the vertical column; a blended solution is accommodated in the container; the control valve is further arranged on the container; the control valve is connected with the controller; the opening vertical projection of the control valve falls into the maximum external diameter of the funnel; a plurality of circular holes homocentric with the funnel are formed in the platform base. The device guarantees the veracity and consistency of test results through the concentricity of the control valve, the funnel and the hole circles of the supporting platform and through the control on concentration, flow and time.

Owner:CQC INTIME TESTING TECH CO LTD

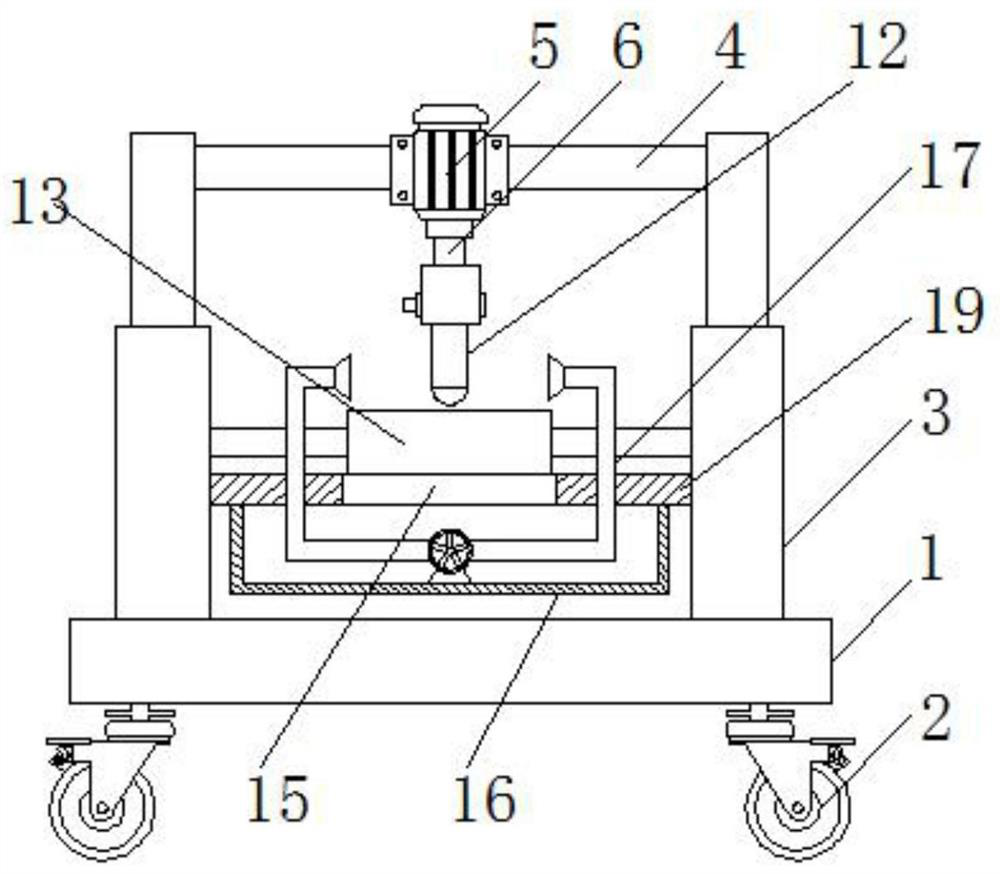

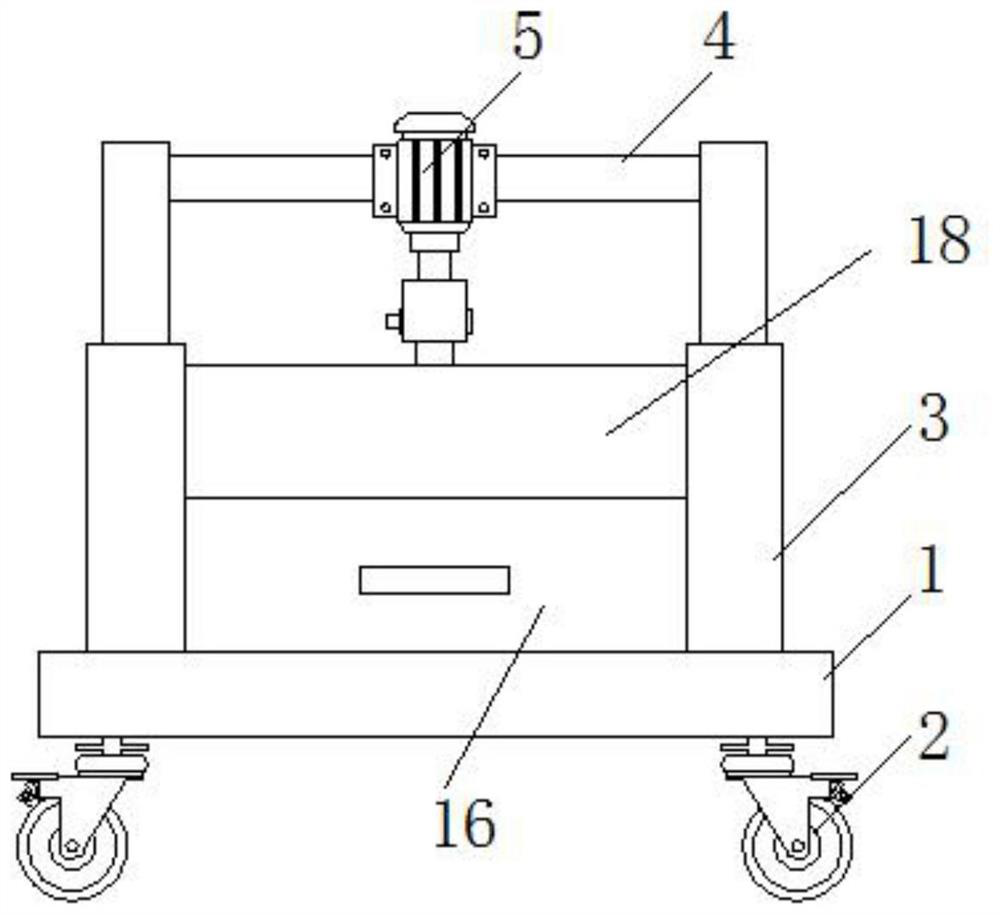

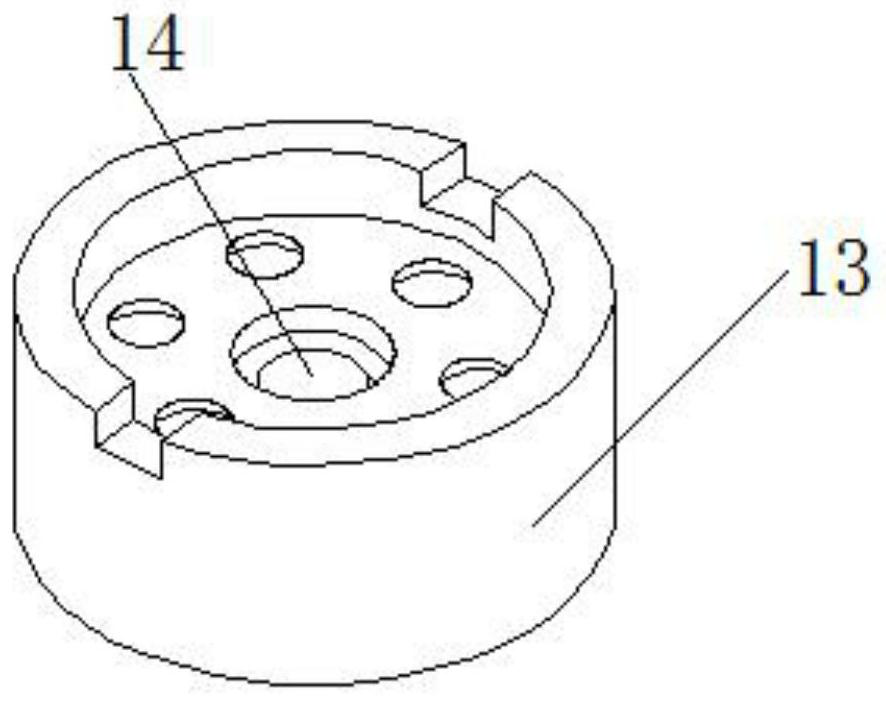

Punching device for flange production

InactiveCN112570552AEnsure accuracy and consistencyImprove processing efficiency and product qualityPerforating toolsMetal-working feeding devicesElectric machineryStructural engineering

The invention discloses a punching device for flange production. The punching device for flange production comprises a base, a telescopic rod, a clamping block, a flange die and a placing table, wherein a movable wheel is connected below the base, the telescopic rod is fixedly connected above the base, a motor is arranged on the supporting rod, a connecting rod is fixedly connected below the motor, a mounting seat is fixedly connected to the bottom of the connecting rod, a drain hole is formed below the flange die, an aggregate box is arranged below the drain hole, and dust collectors are arranged on the left and right sides of the aggregate box. The punching device for flange production is provided with a flange die and a punching slot. In the using process, a flange can be placed in theflange die for being fixedly arranged through the flange die, such that a punch punches the corresponding punching slot correspondingly, the punching accuracy and consistence of the flange disc are ensured, and the processing efficiency and the product quality of flange punching are improved effectively.

Owner:苏州拓达精密机械有限公司

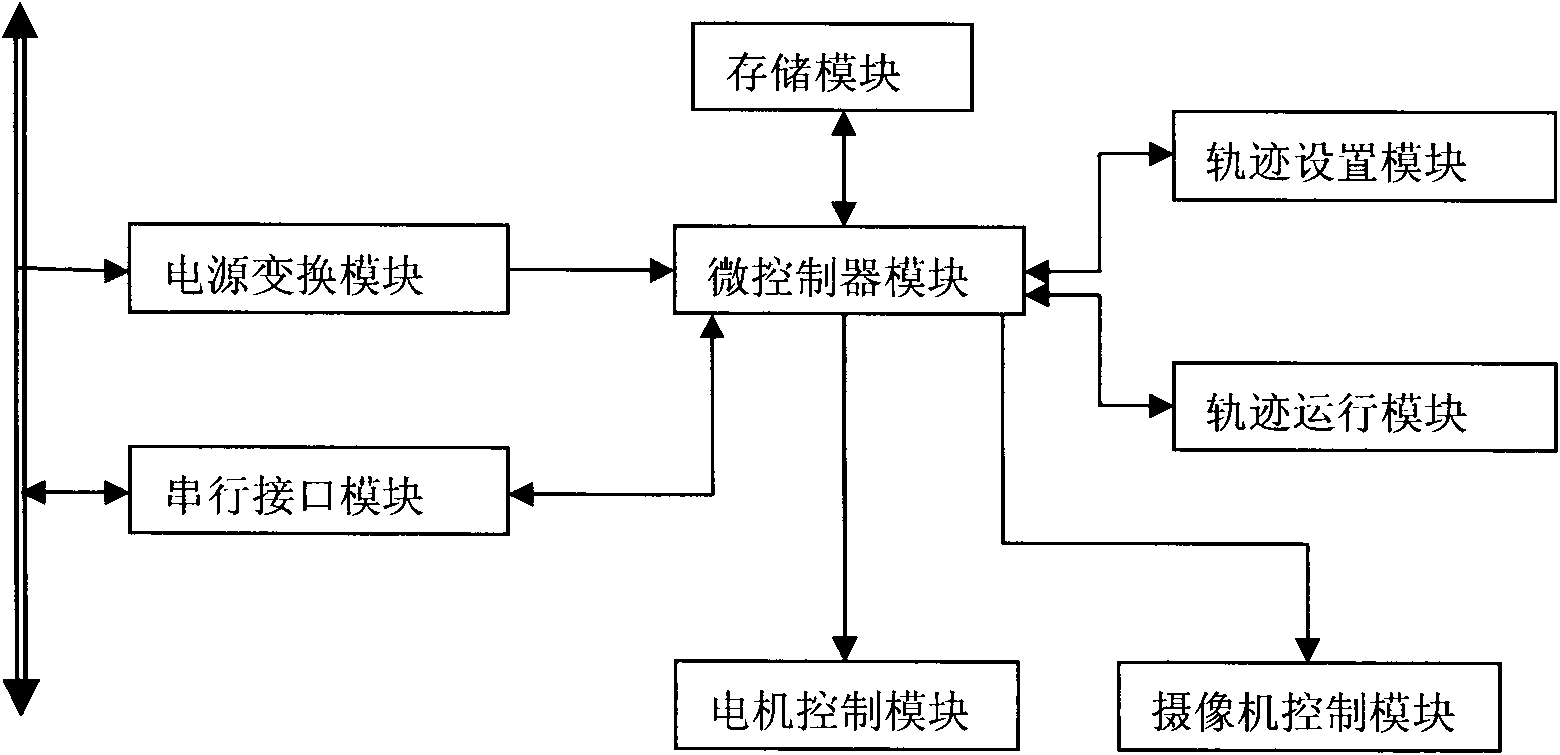

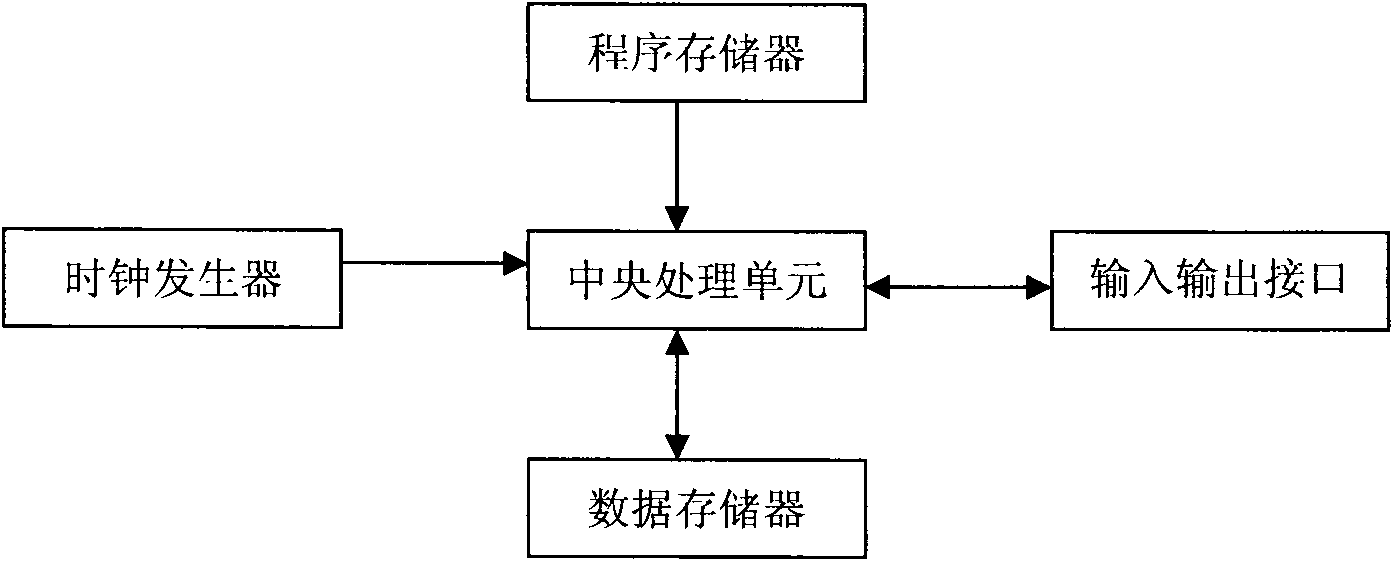

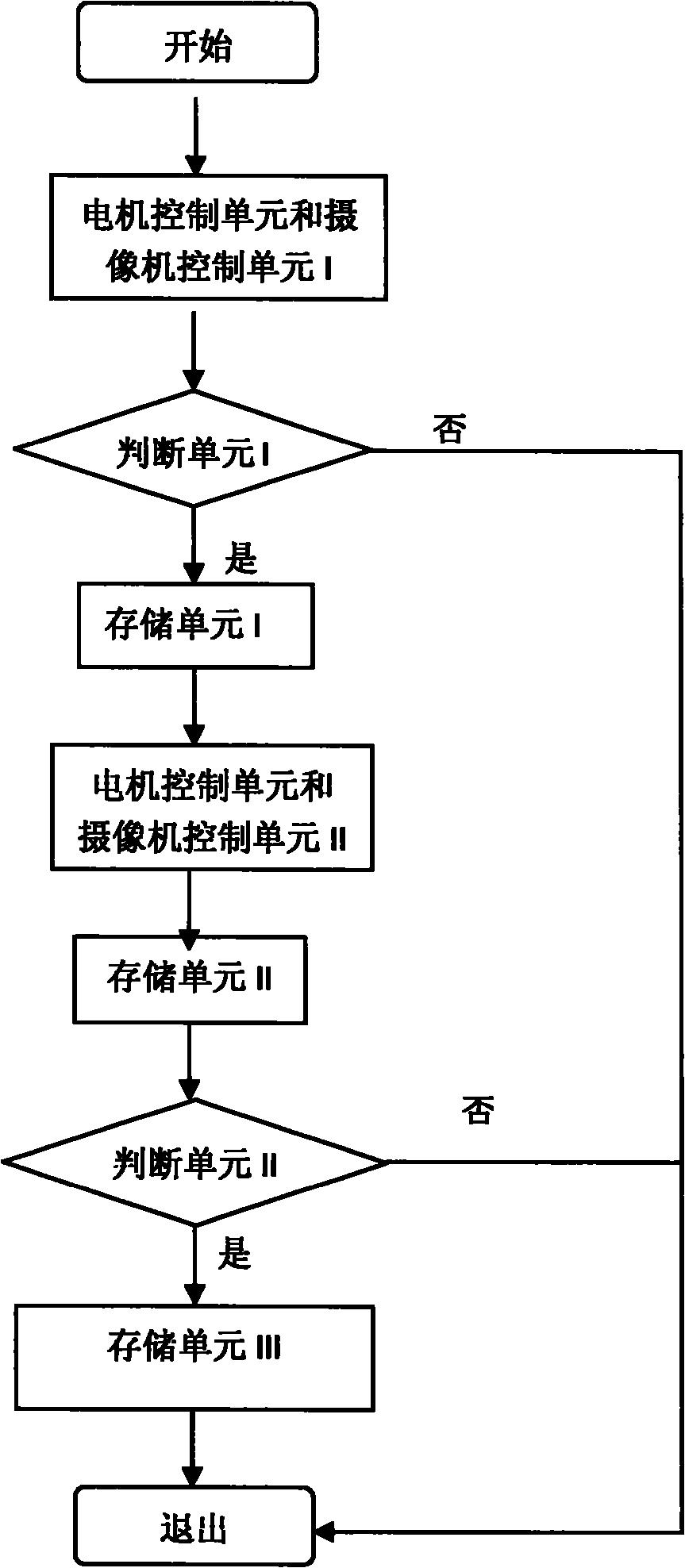

High-speed ball track control method and high-speed ball track control device

InactiveCN102486651AEnsure accuracy and consistencySave storage spacePosition/direction controlControl theoryRecording duration

The invention relates to an intelligent high-speed ball track control method and a high-speed ball track control device. The high-speed ball track control method comprises the following steps that: actions and action time of a motor and a camera are recorded, and when two adjacent received orders are identical when a track is set, the action time is accumulated; and when two adjacent orders are different from each other, the recorded order is accumulated, and the order quantity is also accumulated. Compared with the prior art, the high-speed ball track control method and the device can guarantee the track recording accuracy and continuity, so the storage space of the record time can be saved, the orders of the track record can be increased, and the record time can be prolonged.

Owner:TIANJIN WORLD DIGITAL VIDEO

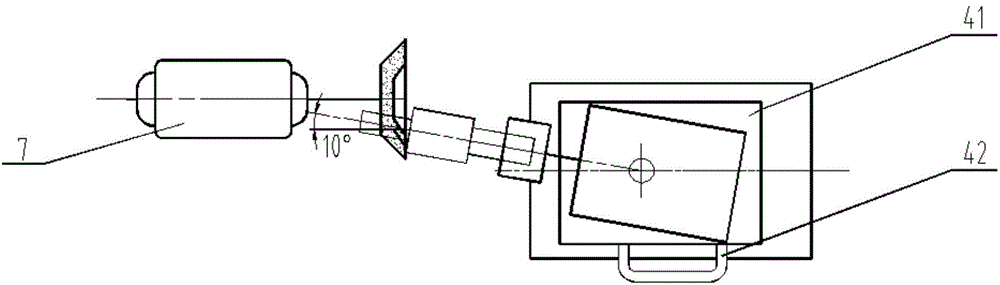

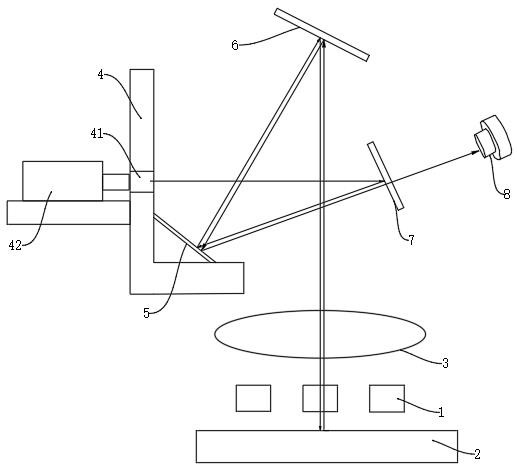

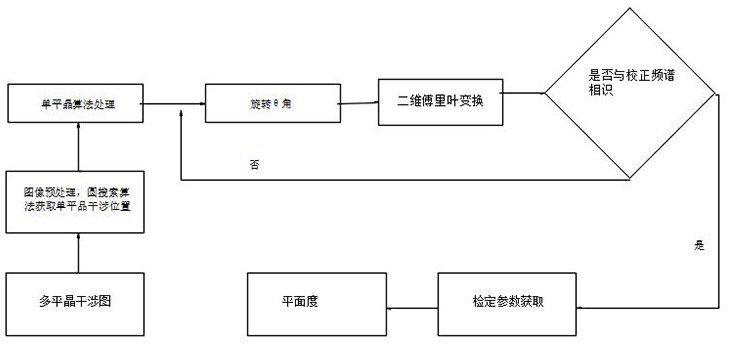

Planar optical flat calibrating device and calibrating method

The invention discloses a planar optical flat calibrating device and method. The planar optical flat calibrating device comprises a detected optical flat, a standard optical flat is arranged at the bottom of the detected optical flat, a collimator objective is arranged at the top of the detected optical flat, a baffle is arranged on the upper left portion of the collimator objective, a small hole is formed in the baffle, and optical fiber laser is arranged on the side face of the baffle. A first reflector is arranged on the right side of the baffle, a second reflector is arranged right above the collimator objective, a spectroscope is arranged in front of the laser of the fiber laser, and a CCD camera is arranged on the right side of the spectroscope; according to the invention, a plane equal-thickness interference method is adopted, the interference pattern of the detected optical flat and the standard optical flat is acquired through the camera, and a planeness algorithm established by itself is adopted, so that the detection of the detected optical flat is completed, the planeness of a plurality of detected optical flat can be detected in parallel, and the detection efficiency is improved.

Owner:深圳众庭联合科技有限公司

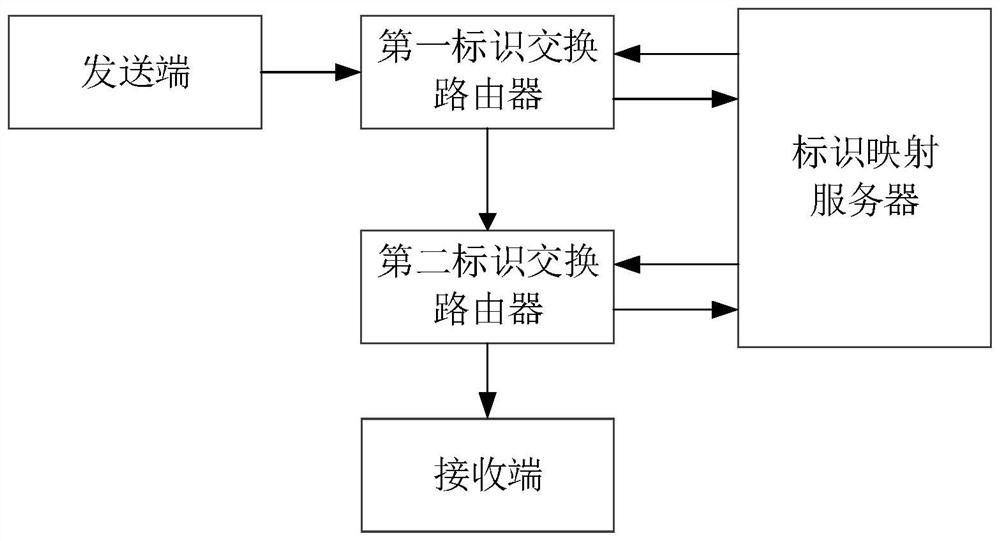

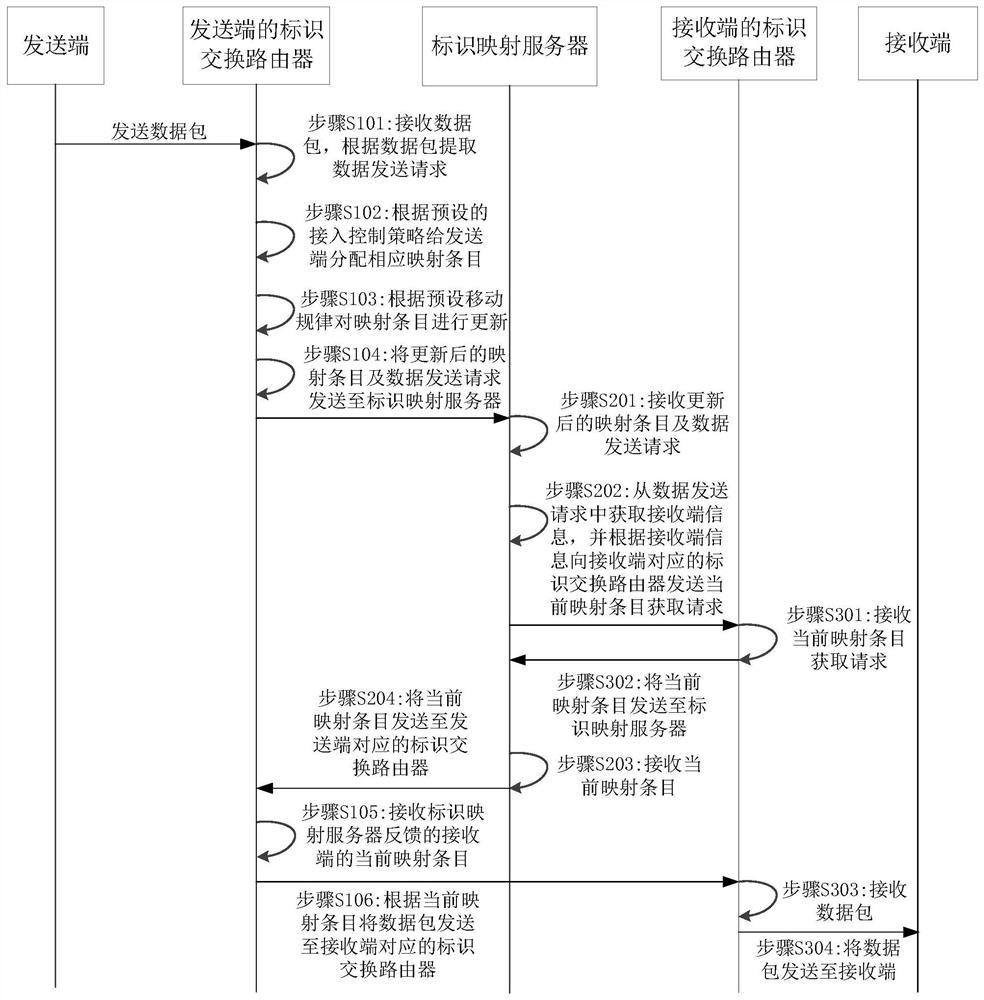

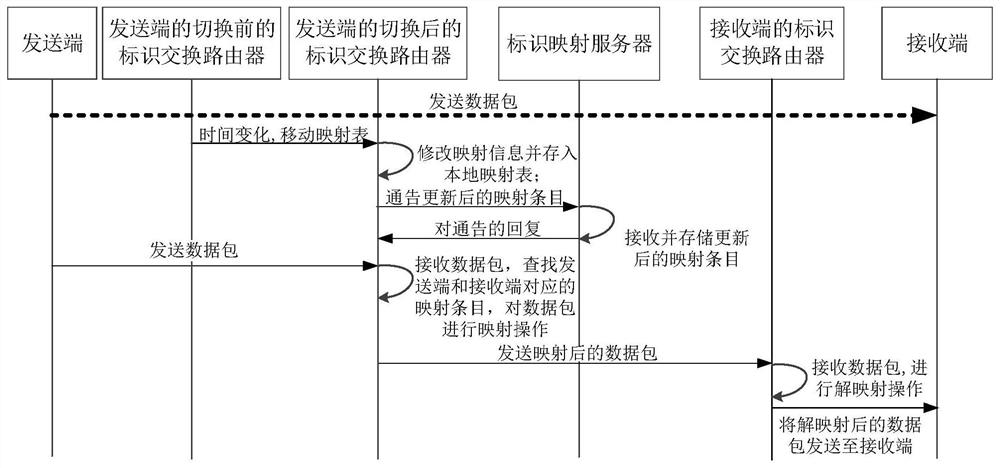

Communication method, device and system applied to satellite network

ActiveCN112055391AAddress poor mobility supportEnsure accuracy and consistencyNetwork topologiesTelecommunicationsRouter

The invention provides a communication method, a device and a system applied to a satellite network. The method comprises the following steps: receiving a data packet sent by a sending end; allocatinga corresponding mapping entry to the sending end according to a preset access control strategy; updating the mapping entry according to a preset movement rule; extracting a data sending request according to the data packet sent by the sending end; sending the updated mapping entry and the data sending request to an identifier mapping server; receiving a current mapping entry of the receiving endfed back by the identification mapping server; and sending the data packet to an identifier switching router corresponding to the receiving end according to the current mapping entry. According to themethod, the mapping entry is updated and the data packet is mapped through the corresponding identifier switching router, so that the terminal can always use the original IP to establish logical communication connection, and in the inter-satellite mobile switching process of the user terminal, the original established logical communication connection is not interrupted due to the change of the routing identifier. And the transmission accuracy and consistency are ensured.

Owner:BEIJING JIAOTONG UNIV +1

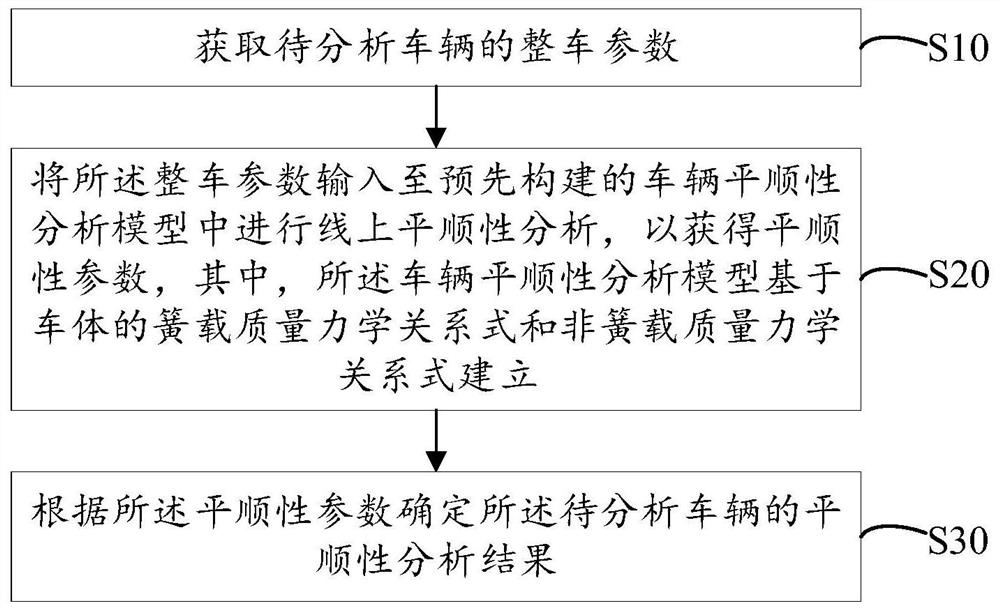

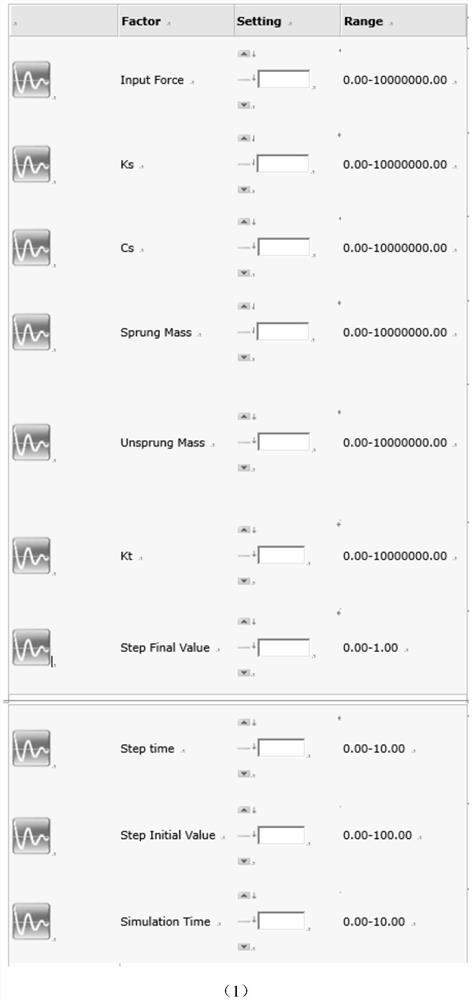

Vehicle smoothness analysis method, device and apparatus and storage medium

PendingCN113887070AHigh penetration rateImprove completenessGeometric CADDesign optimisation/simulationSprung massControl theory

The invention relates to the technical field of vehicles, and discloses a vehicle smoothness analysis method, device and apparatus and a storage medium, and the method comprises the steps: obtaining the whole vehicle parameters of a to-be-analyzed vehicle; inputting the whole vehicle parameters into a pre-constructed vehicle smoothness analysis model for online smoothness analysis so as to obtain smoothness parameters, wherein the vehicle smoothness analysis model is established based on a sprung mass mechanical relational expression and an unsprung mass mechanical relational expression of a vehicle body; and determining a ride comfort analysis result of the to-be-analyzed vehicle according to the ride comfort parameters. The vehicle smoothness analysis result of the to-be-analyzed vehicle can be quickly obtained only by inputting the whole vehicle parameters of the to-be-analyzed vehicle into the vehicle smoothness analysis model for online smoothness analysis, so that the vehicle smoothness analysis speed is increased, the vehicle smoothness analysis is conveniently and quickly performed. And the popularity rate and the intelligent degree of vehicle smoothness analysis are also improved.

Owner:ZHEJIANG GEELY HOLDING (GROUP) CO LTD +2

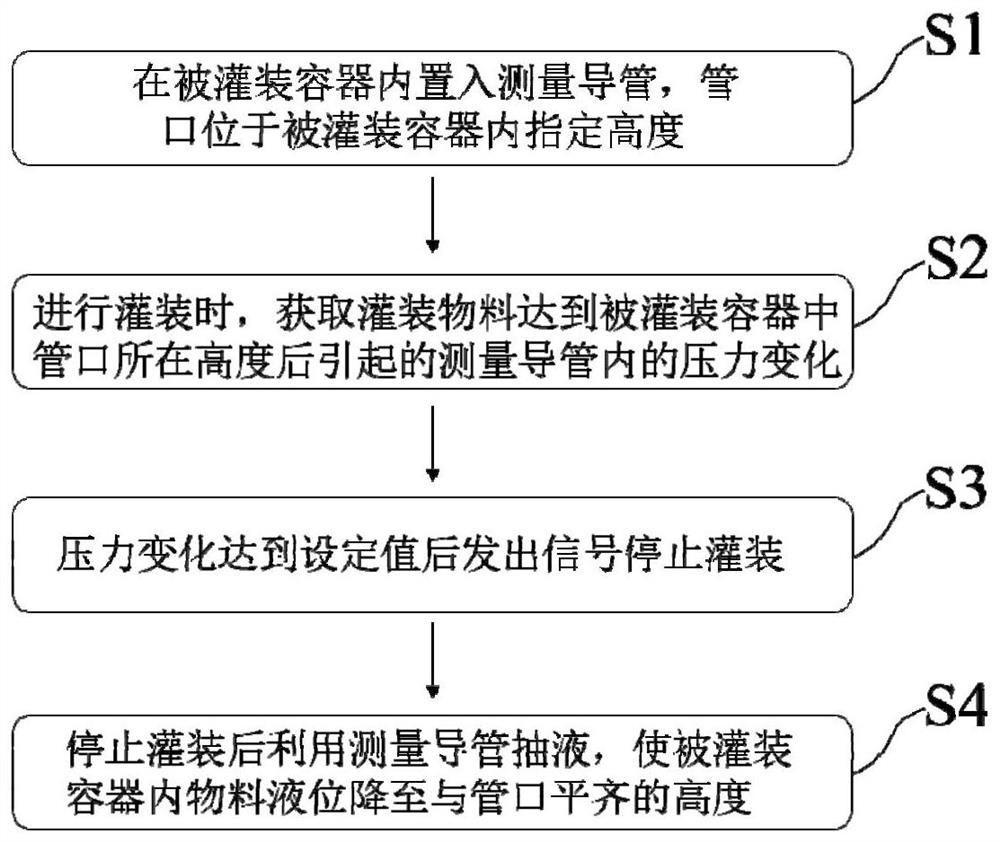

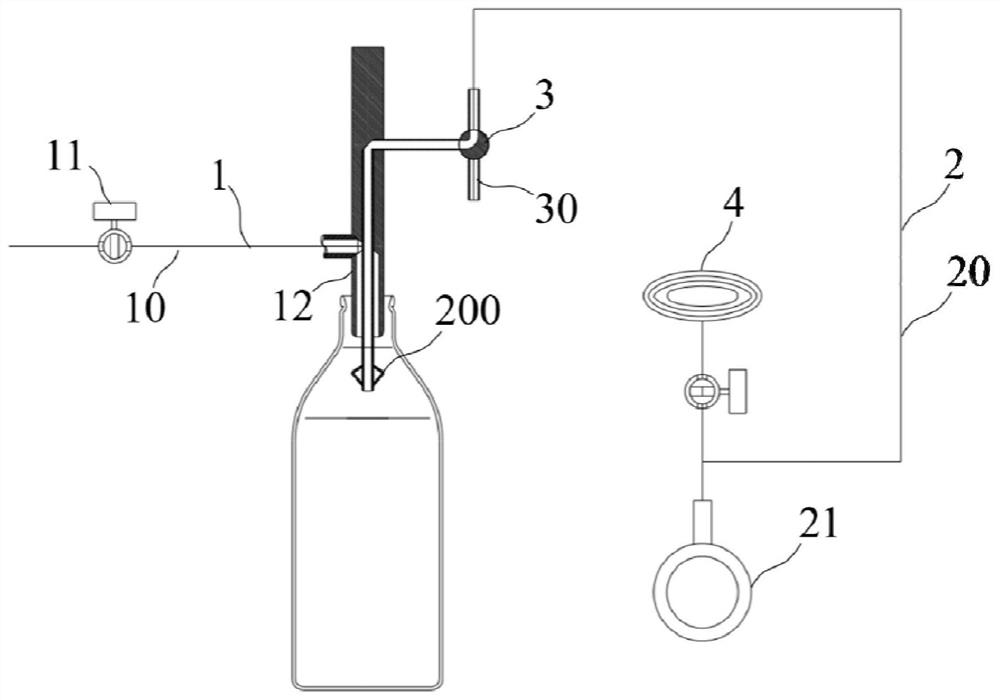

A non-contact liquid filling method for controlling liquid level

ActiveCN110979772BEnsure consistencyReduce height errorPackaging automatic controlLiquid materialLiquid stateEngineering

The invention discloses a non-contact liquid filling method for controlling liquid level, which belongs to the technical field of filling. It includes the following steps: S1, inserting a measuring conduit into the container to be filled, and the nozzle is located at a specified height in the container to be filled; S2, during filling, obtaining the temperature caused by the filling liquid material reaching the specified height of the container to be filled Measure the pressure change in the conduit; S3, send a signal to stop filling after the pressure change reaches the set value; S4, use the measuring conduit to pump liquid after stopping filling, so that the liquid level of the liquid material in the filled container drops to the level of the nozzle Qi height. Through the method of the present invention, when filling liquid materials, when the liquid level in the container to be filled rises to the point where the measuring conduit extends into the nozzle, the pressure in the measuring conduit will change, thereby triggering a signal to control the filling. The filling action ensures that the liquid levels of the filled liquid materials in all containers are consistent, achieving the effect of accurately controlling the filling liquid level.

Owner:安徽沛愉包装科技有限公司

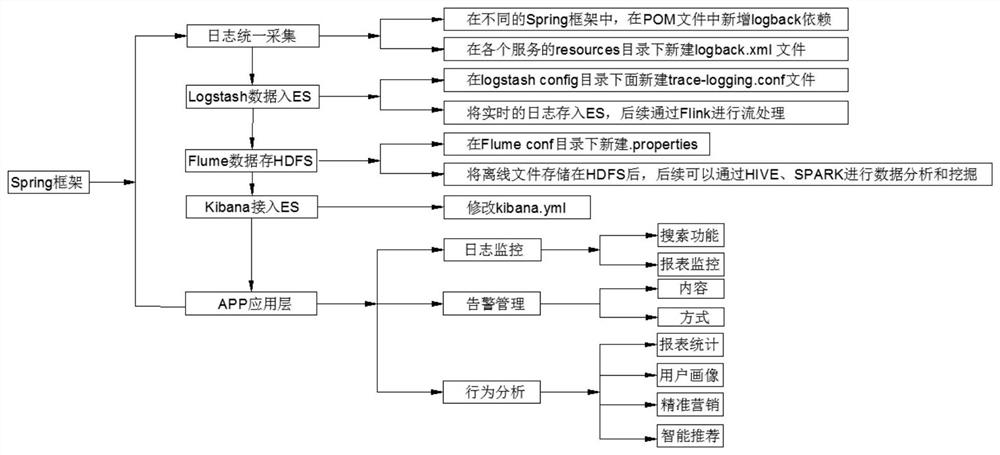

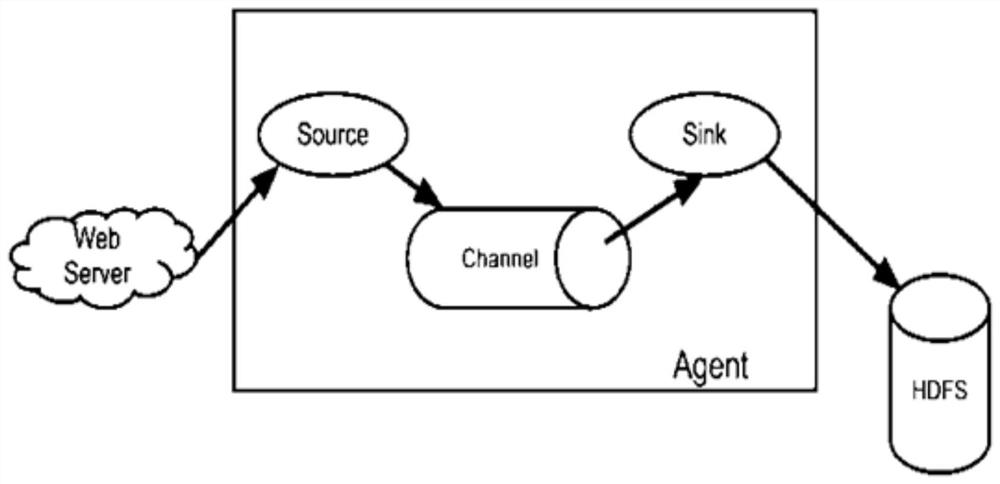

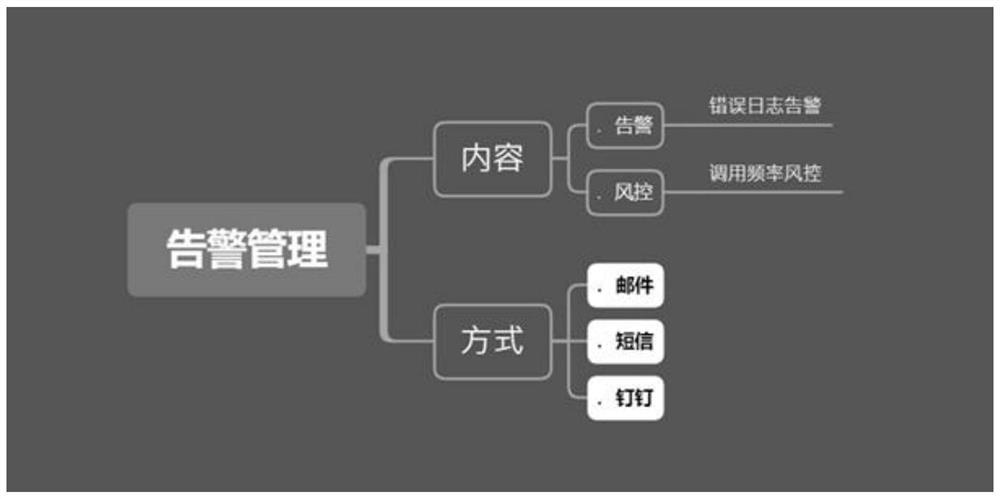

Big data log analysis method and system based on Spring framework

PendingCN113282557AEnsure accuracy and consistencyGuaranteed accuracySpecial data processing applicationsFile system typesDirectoryEngineering

The invention discloses a big data log analysis method and system based on Spring frameworks, and belongs to the technical field of information security, and the method comprises the following steps: uniformly collecting logs, in different Spring frameworks, newly adding logback dependency in a POM file, and meanwhile, newly establishing a logback.xml file under a resource directory of each service. According to the invention, a unified management platform is provided for internal WEB services of different Spring frameworks; the data is analyzed and mined from offline and real-time dimensions, so that the accuracy and consistency of the data are ensured; and the functions of searching time, service names, log levels and keywords are provided, so that development, operation and maintenance personnel can quickly position the production environment.

Owner:联通(江苏)产业互联网有限公司

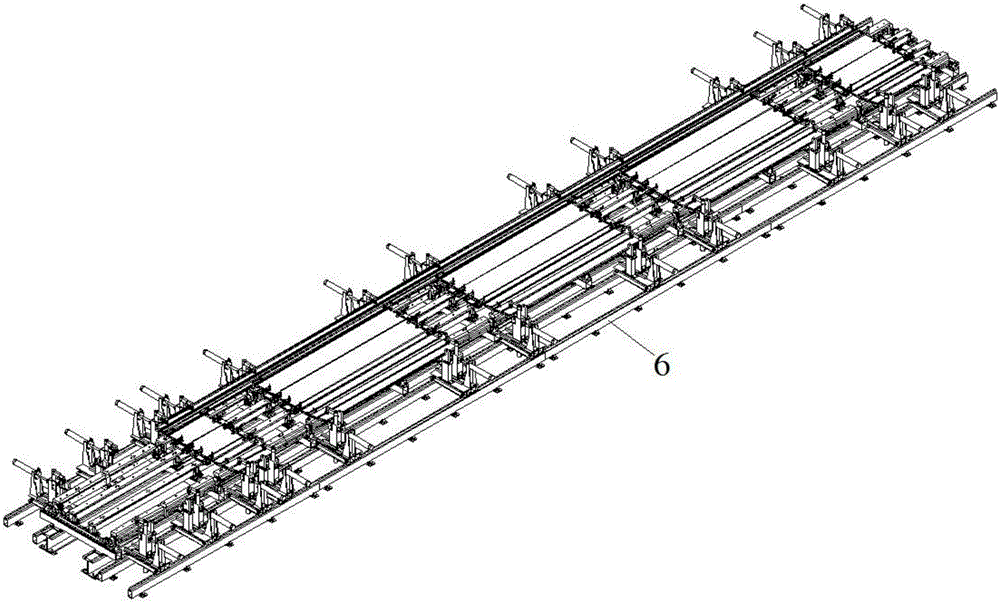

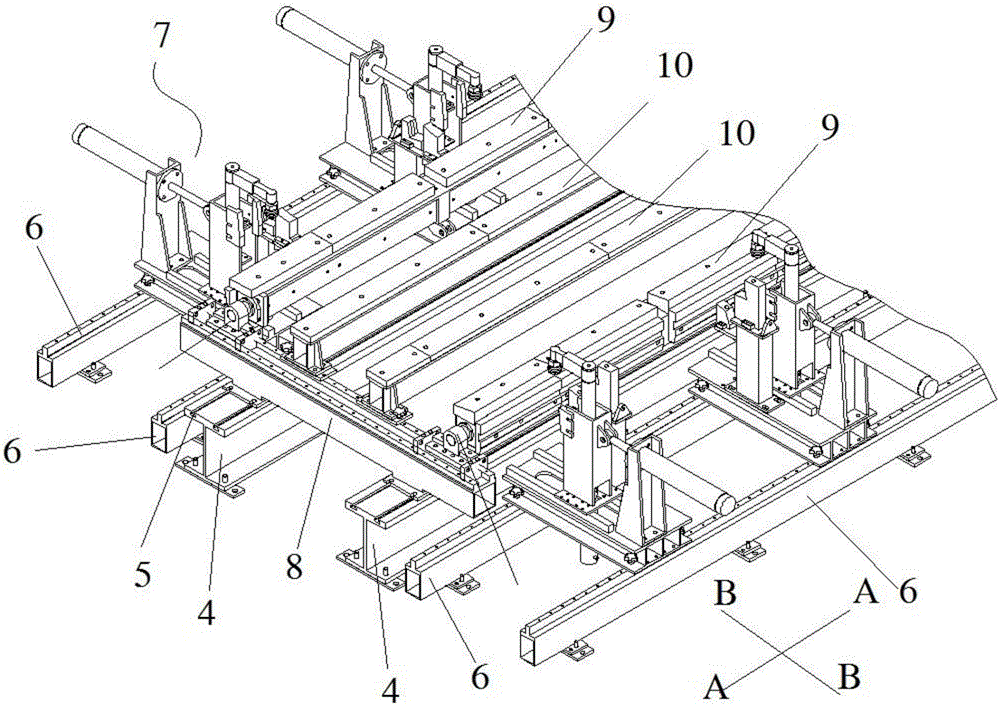

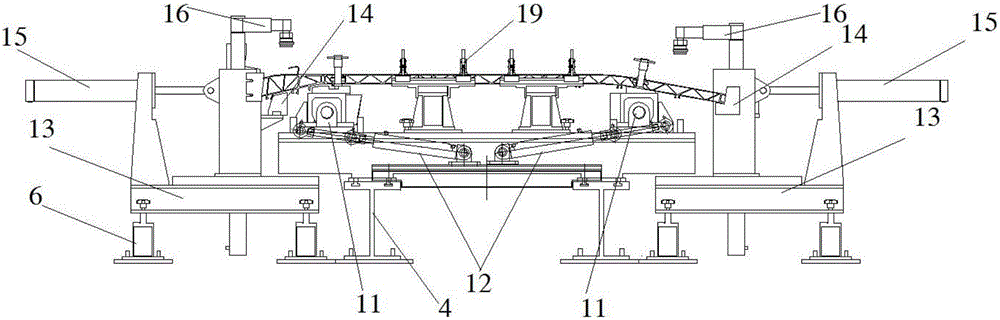

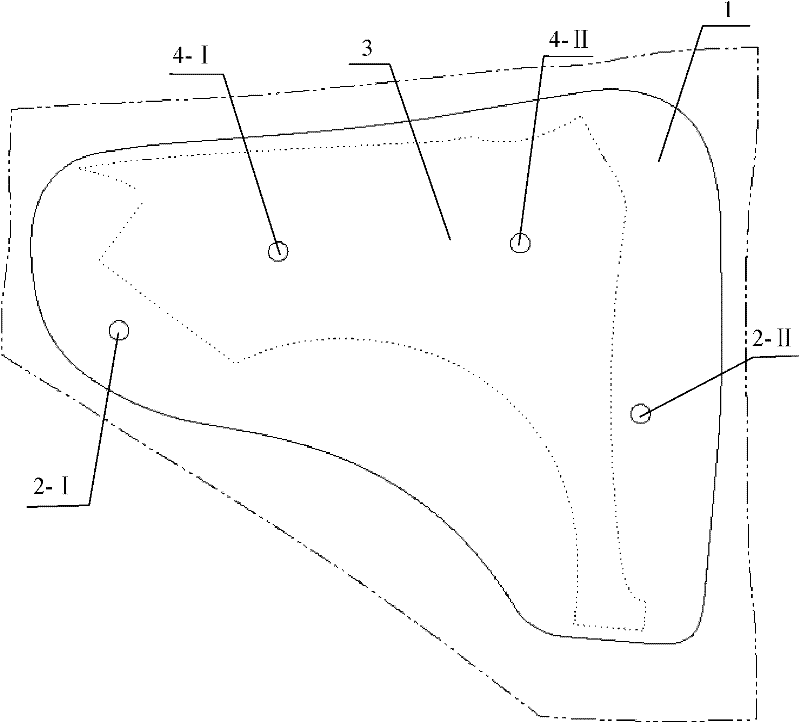

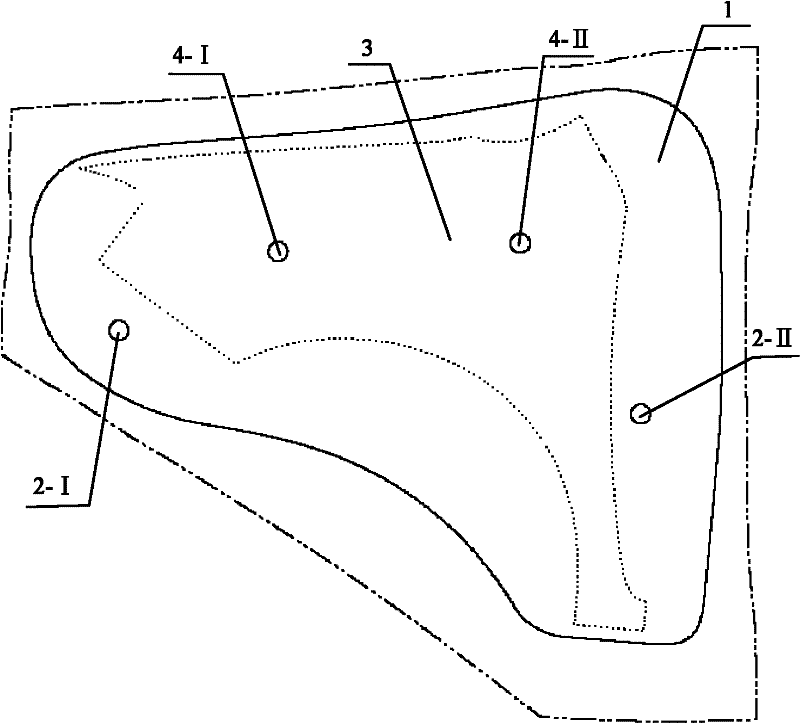

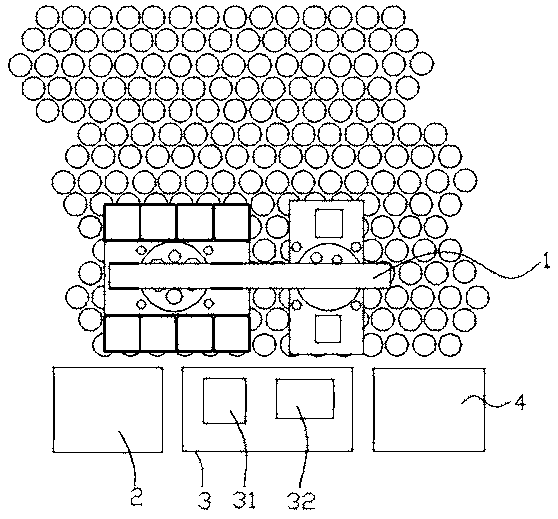

Aluminum alloy riveted subway vehicle side wall general assembly welding flexible chemical equipment

ActiveCN104907753BEnsure accuracy and consistencyGuaranteed flexibilityWelding/cutting auxillary devicesAuxillary welding devicesCompound (substance)Structural engineering

Owner:NANJING ZHONGCHE PUZHEN URBAN RAIL VEHICLE CO LTD

Automatic crawling helium leakage detection system for heat-exchanging tube and caulk weld in heat exchanger tube plate

PendingCN109540406ASimple structureEnsure accuracy and consistencyDetection of fluid at leakage pointProgrammable logic controllerHuman power

The invention relates to an automatic crawling helium leakage detection system for a heat-exchanging tube and a caulk weld in a heat exchanger tube plate. The automatic crawl helium leakage detectionsystem comprises a movable sealing front end device, a PLC (Programmable Logic Controller) front end control unit, a vacuum leakage detection device and an industrial control computer, wherein one endof the movable sealing front end device is electrically connected with the PLC front end control unit; the other end of the movable sealing front end device is electrically connected with the vacuumleakage detection device and the industrial control computer respectively; and the movable sealing front end device comprises a first motor, a slide plate, a first slide block, an integral detection assembly, a second slide block and a branch detection assembly. The automatic crawling helium leakage detection system for the heat-exchanging tube and the caulk weld in the heat exchanger tube plate has the advantages of simple structure, capability of keeping detection consistency and accuracy, higher integral working efficiency, saving of manpower and material resources and higher integral detection efficiency, and can be conveniently popularized and used.

Owner:广州灵帕机电科技有限公司

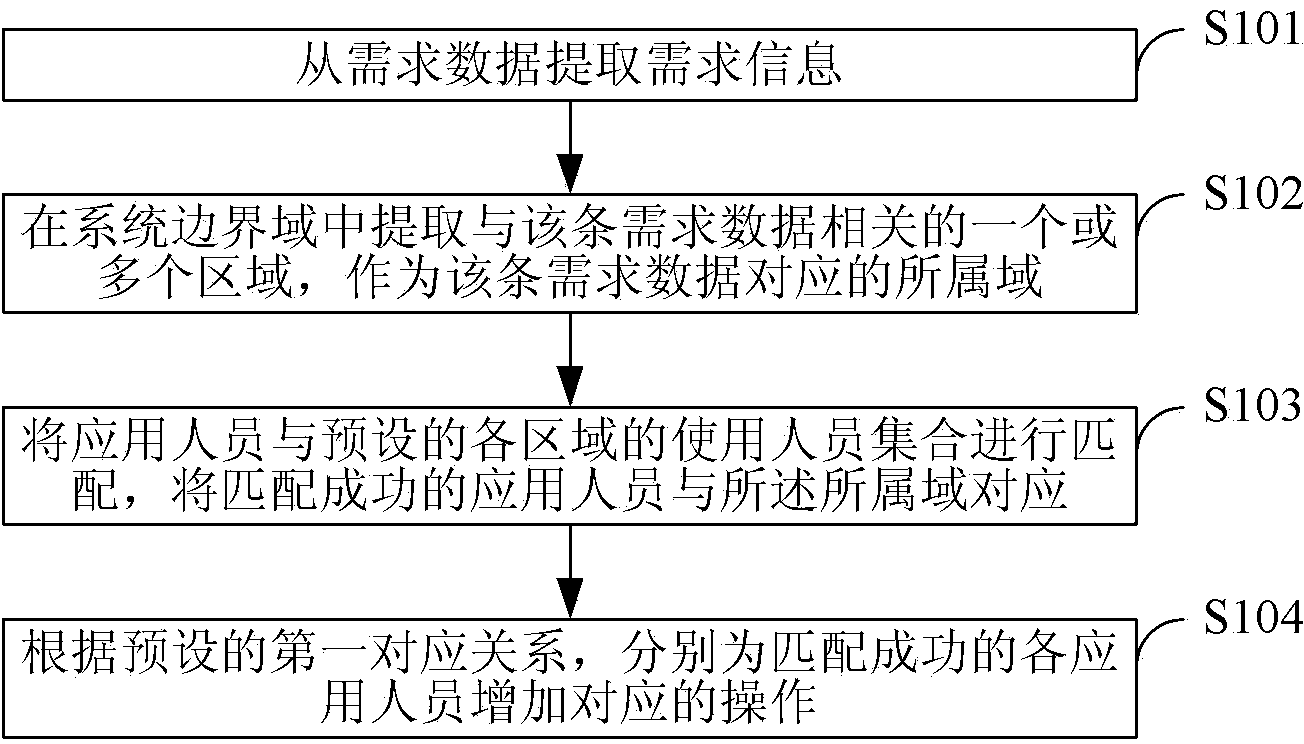

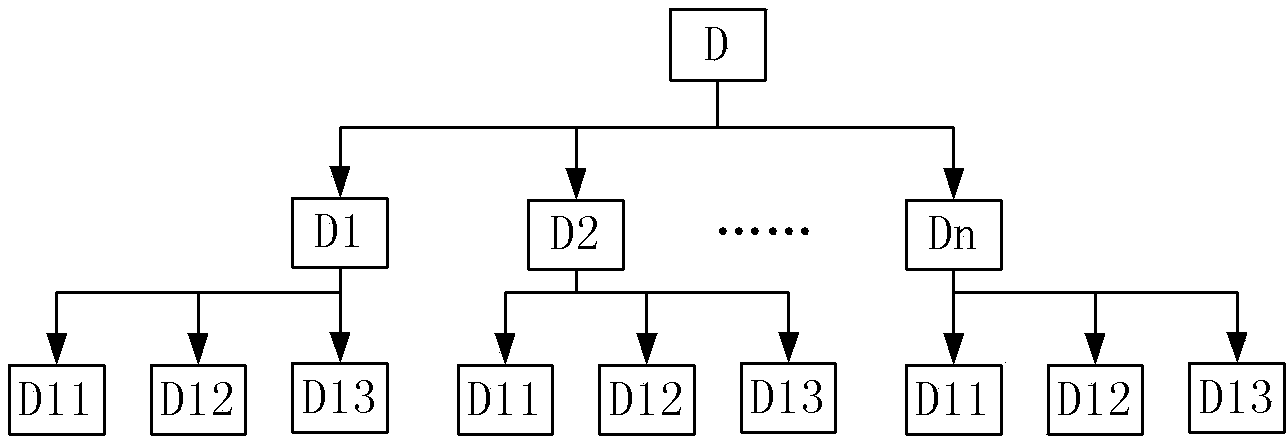

Demand data decomposition method and system

ActiveCN103530368AImprove efficiencyEnsure accuracy and consistencySpecial data processing applicationsData decompositionDecomposition

The invention provides a demand data decomposition method and system. The method comprises the following steps: demand information is extracted from demand data to be decomposed, wherein the demand information comprises a demand identification and a user; according to the demand identification, one or more areas relevant to the demand data are extracted from a preset system boundary region and recorded as belonging areas corresponding to the demand data; the user is matched with preset user sets of all the belonging areas respectively, and successfully matched users are recorded as users of the corresponding belonging areas; according to a preset first corresponding relation, operations corresponding to the demand data are added for the users of all the belonging areas respectively. By means of the demand data decomposition method and system, the demand data can be decomposed automatically and efficiently, and accuracy and consistency of decomposition are guaranteed.

Owner:CHINA UNITED NETWORK COMM GRP CO LTD +1

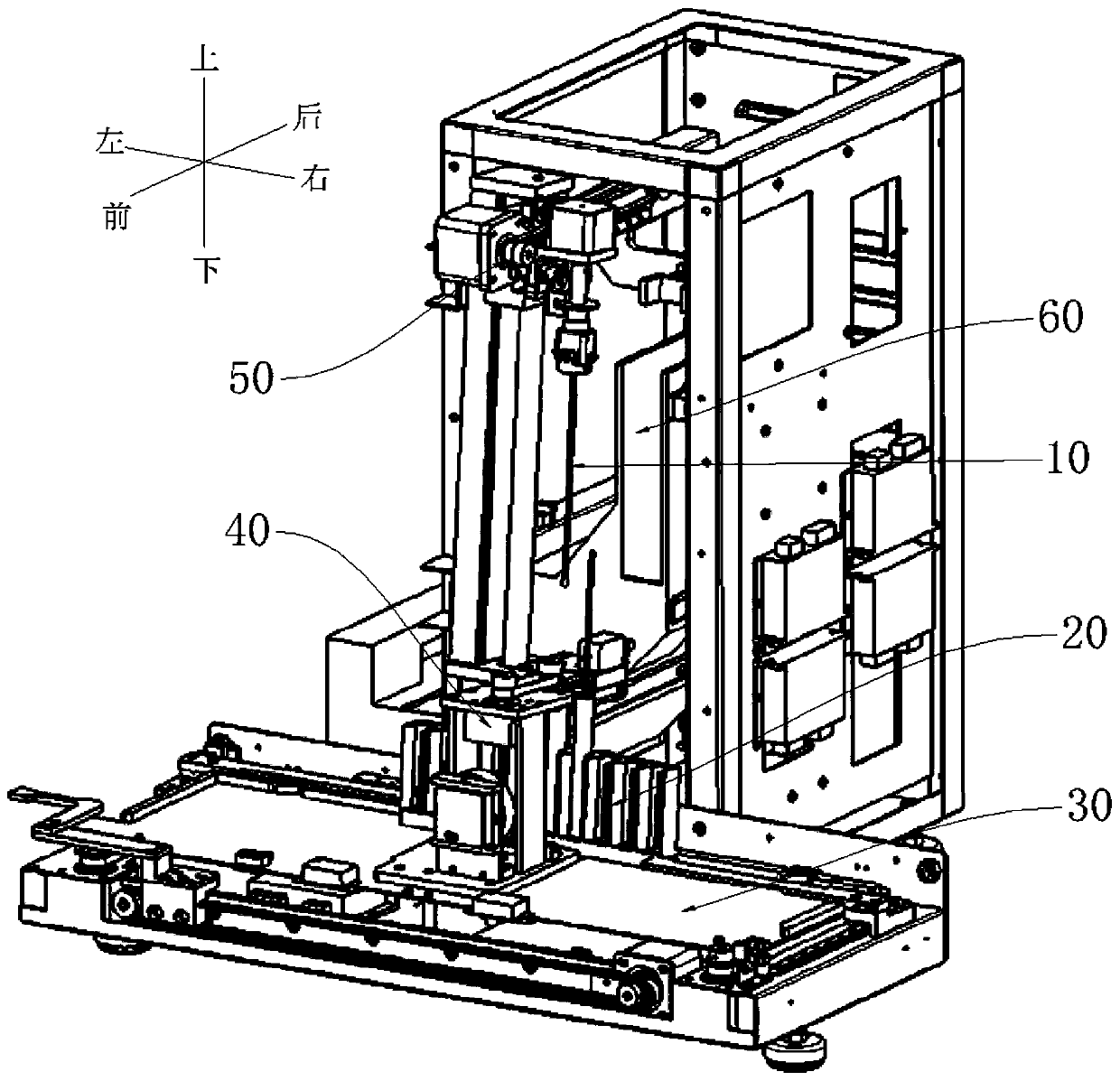

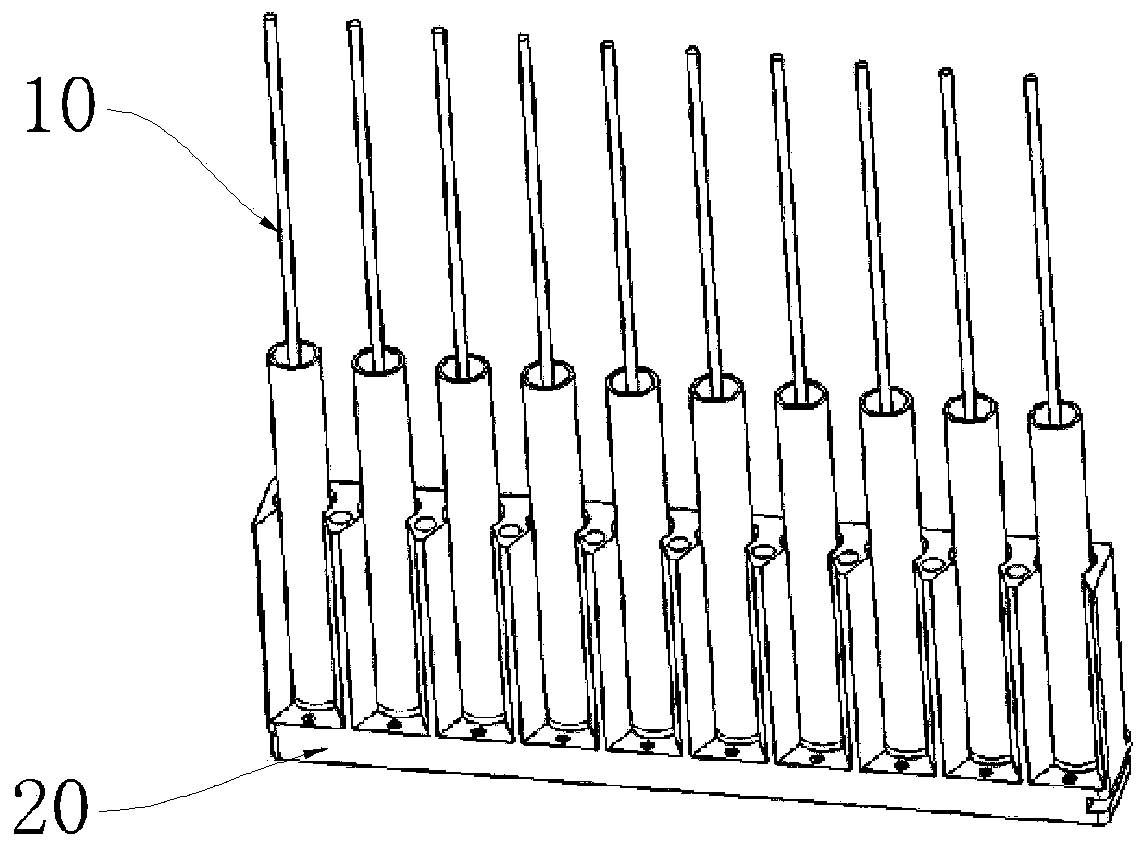

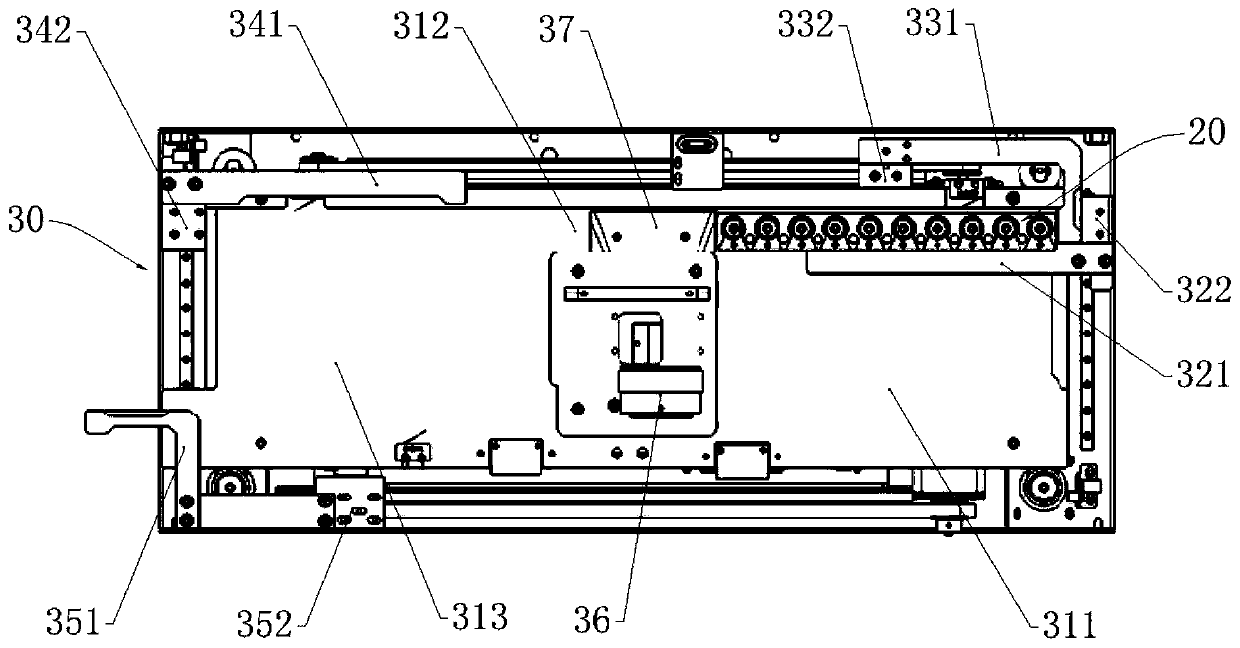

Equipment for pretreating samples collected by sampling rods

PendingCN111596079AHigh degree of automationEnsure accuracy and consistencyMaterial analysisNuclear energy generationTest tubeWaste material

The invention discloses equipment for pretreating samples collected by sampling rods. The equipment comprises a test tube rack, a tube arranging system, a dilution system, a uniform mixing system anda waste collection system; the tube arranging system comprises a tube arranging platform and a conveying device, the tube arranging platform comprises a right side feeding area and a middle pretreatment area, and the conveying device can sequentially convey a plurality of test tubes to a designated area for pretreatment; the dilution system can inject a diluent into test tubes to be pretreated; the uniform mixing system comprises a clamping device and a driving device, the clamping device can clamp the sampling rods in the test tubes to be pretreated, and the driving device can drive the clamping device to rotate and move. According to the equipment for pretreating the samples collected by the sampling rods, the sampling rods collecting the samples can be pretreated, the automation degreeis high, consistency and accuracy of operation can be guaranteed when the large-batch sampling rods are pretreated, and meanwhile the risk that medical workers are infected can be reduced.

Owner:重庆天海医疗设备有限公司

Team calendar processing method and system, electronic equipment and storage medium

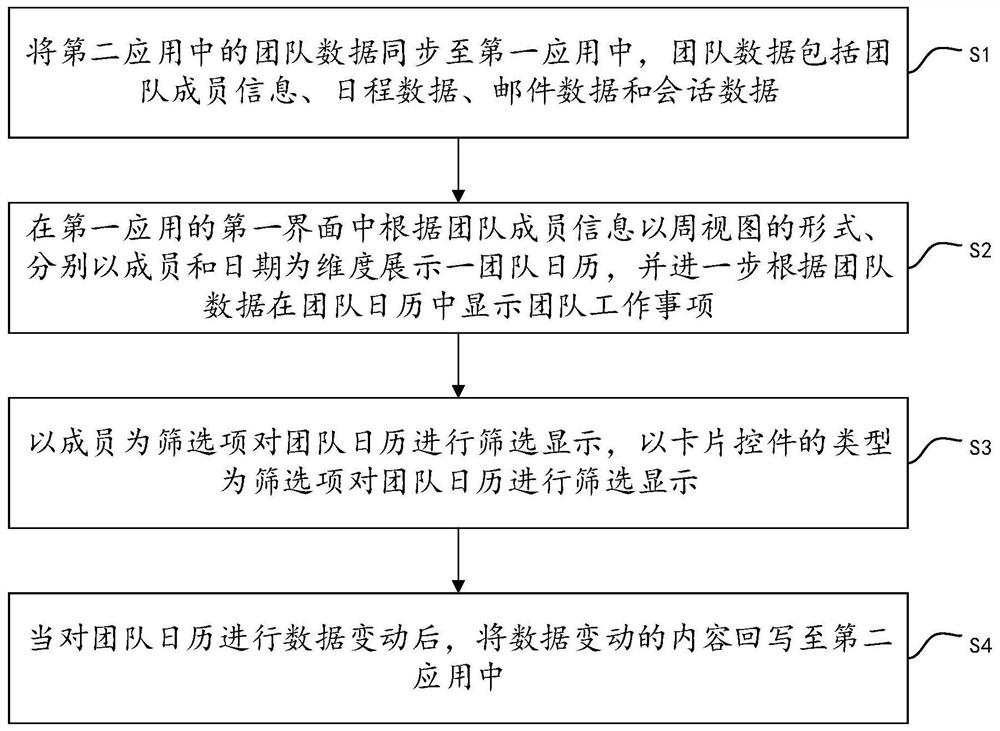

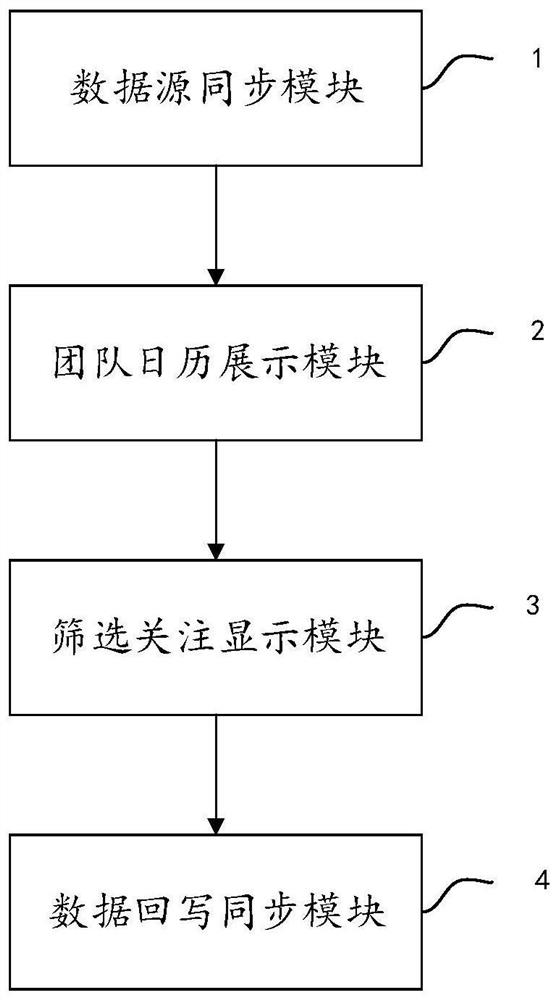

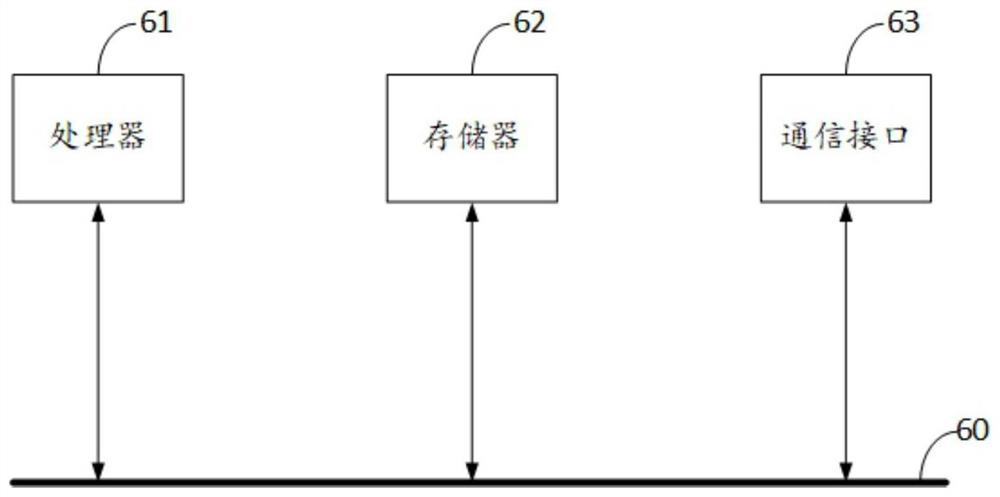

PendingCN113793133AEnsure accuracy and consistencyImprove efficiencyOffice automationExecution for user interfacesEngineeringData pack

The invention provides a team calendar processing method and system, electronic equipment and a storage medium, and the technical scheme of the method comprises the steps: synchronizing team data in a second application to a first application, the team data comprising team member information, schedule data, mail data and session data; in a first interface of the first application, displaying a team calendar by taking members and dates as dimensions according to the team member information in a panoramic view form, and further displaying team work items in the team calendar according to the team data; and after data change is carried out on the team calendar, writing back the content of the data change into the second application. The problem that the existing calendar processing technology lacks attention to teams and customers is solved.

Owner:BEIJING XUEZHITU NETWORK TECH

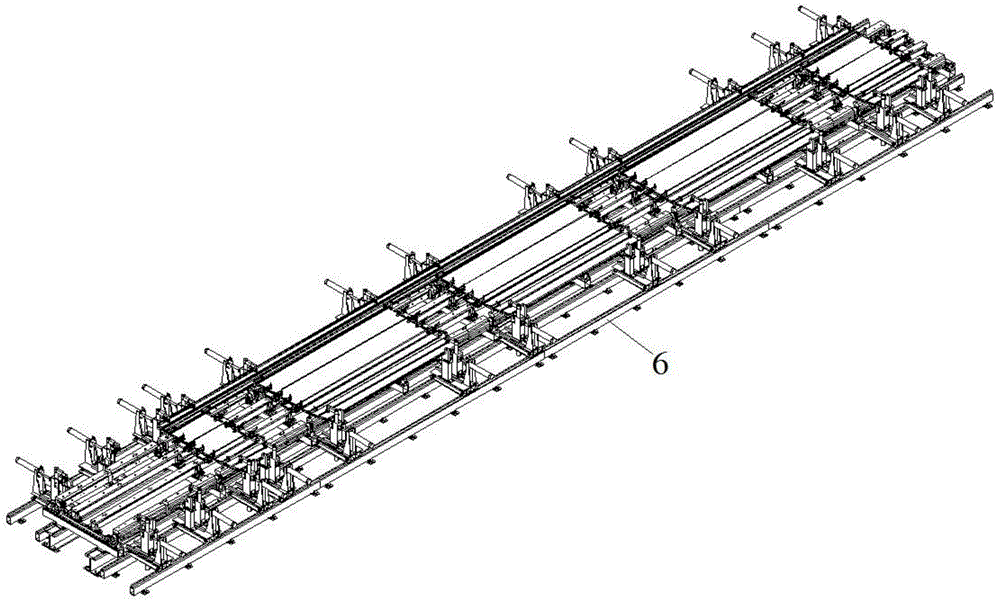

Flexible chemical equipment for friction stir welding of side walls of subway vehicles

ActiveCN105033448BImprove versatilitySmall footprintWelding/cutting auxillary devicesAuxillary welding devicesShaped beamEngineering

The invention discloses a frication stir welding flexibility tool for a subway vehicle side wall. The frication stir welding flexibility tool comprises a pair of I-shaped beam bases, four square steel bases symmetrically arranged on the two sides of the I-shaped beam bases respectively, multiple locating and clamping mechanisms installed on the square steel bases in a sliding manner, multiple beams installed on the I-shaped beam bases in a sliding manner and a turnover mechanism. Every two adjacent beams are connected with a pair of rotary welding joint supporting strips and a pair of fixed welding joint supporting strips in a sliding manner. The tool is suitable for frication stir welding of the subway vehicle side wall; common features of existing and following projects are fully considered, the universality of the tool is improved; high cost for a newly-made tool is saved; the preparation cycle of tools for new projects is greatly shortened; the space and the position occupied by the tool are saved; the project production tool switching time spent in the multi-project combined production process is shortened; the accuracy and uniformity of the tool are guaranteed; and the capacity is improved. The tool is good in reliability, simple in structure, high in efficiency and suitable for practical application.

Owner:NANJING ZHONGCHE PUZHEN URBAN RAIL VEHICLE CO LTD

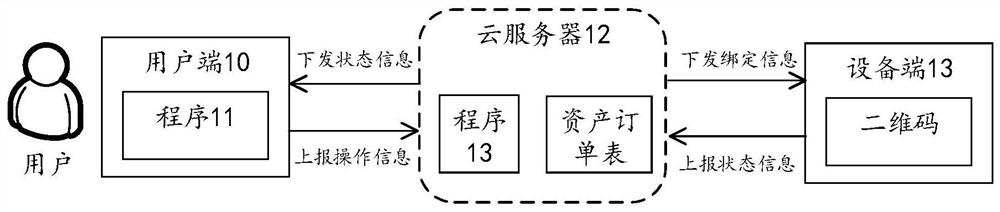

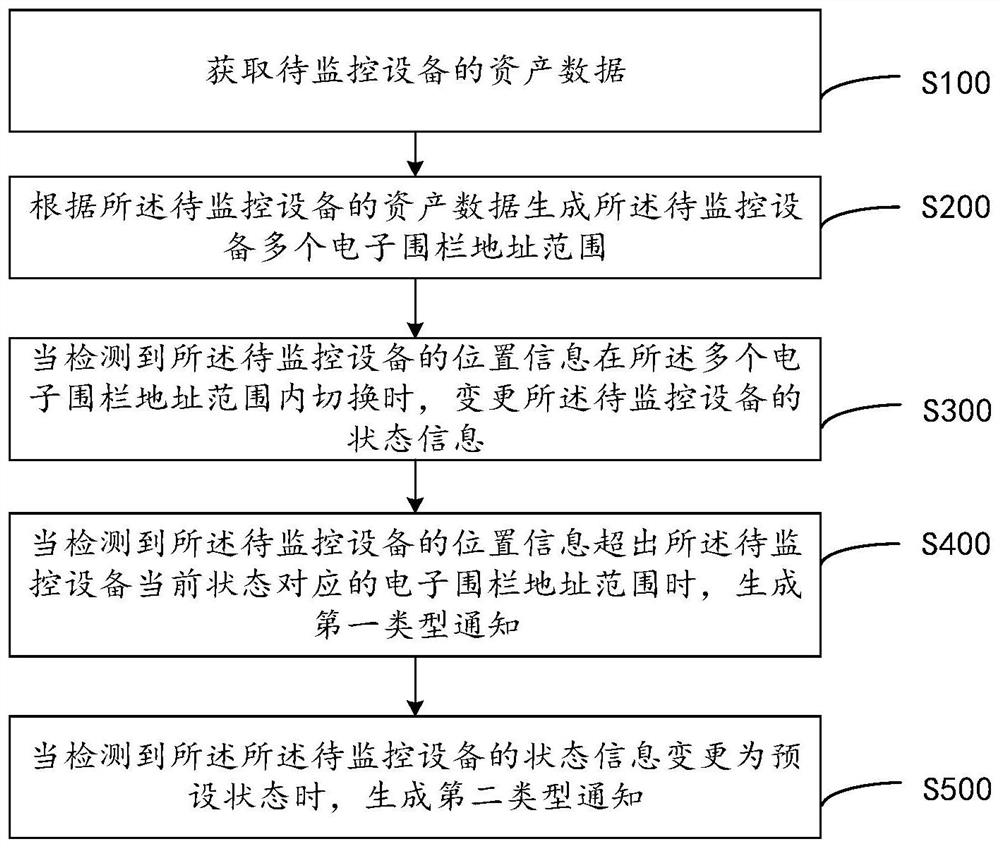

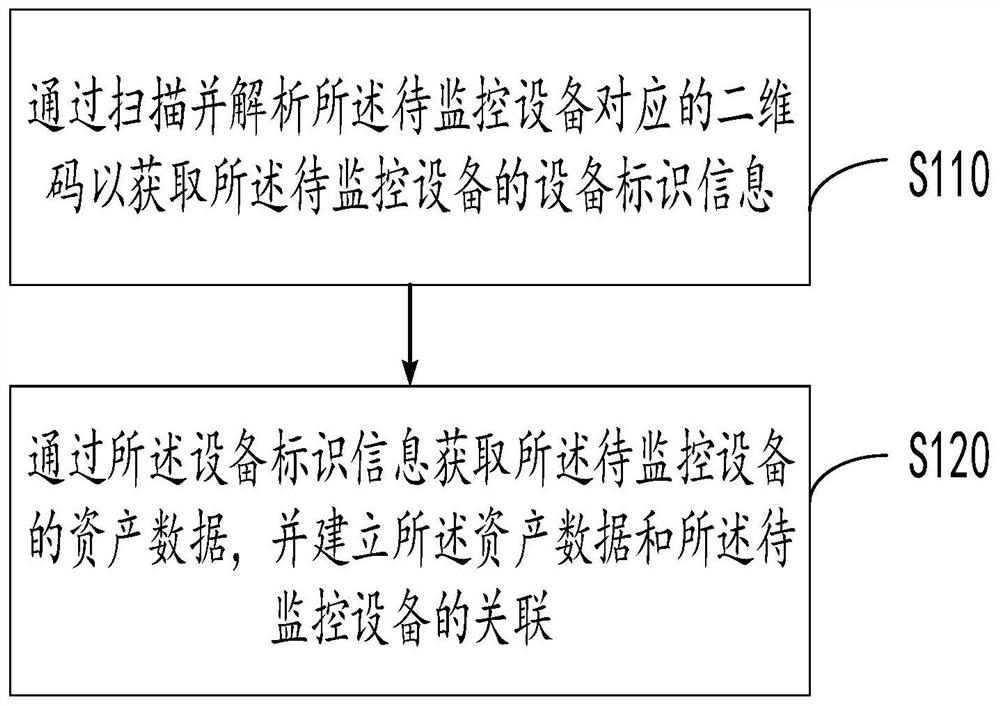

Equipment asset monitoring method and device, computer equipment and storage medium

PendingCN111882013AEnsure accuracy and consistencyGuaranteed accuracyFinanceText processingComputer equipmentSmart community

The invention discloses an equipment asset monitoring method and device, computer equipment and a storage medium, and the method comprises the steps: generating a plurality of electronic fence addressranges of to-be-monitored equipment according to the asset data of the to-be-monitored equipment, wherein the plurality of electronic fence address ranges correspond to a plurality of pieces of stateinformation of the to-be-monitored equipment; and when it is detected that the position information of the to-be-monitored device is switched in the multiple electronic fence address ranges, changingthe state information of the to-be-monitored device, and when it is detected that the position information of the to-be-monitored device exceeds the electronic fence address range corresponding to the current state information of the to-be-monitored device, generating a notification early warning. Accuracy and consistency of asset equipment state information can be ensured, monitoring requirements of multi-process states of equipment assets can be met, and the method can be applied to smart government affairs, smart city management, smart communities, smart security and protection, smart logistics, smart medical treatment, smart education, smart environmental protection and smart traffic scenes, so that construction of smart cities is promoted.

Owner:PING AN INT FINANCIAL LEASING CO LTD

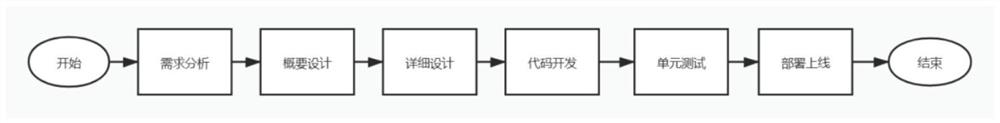

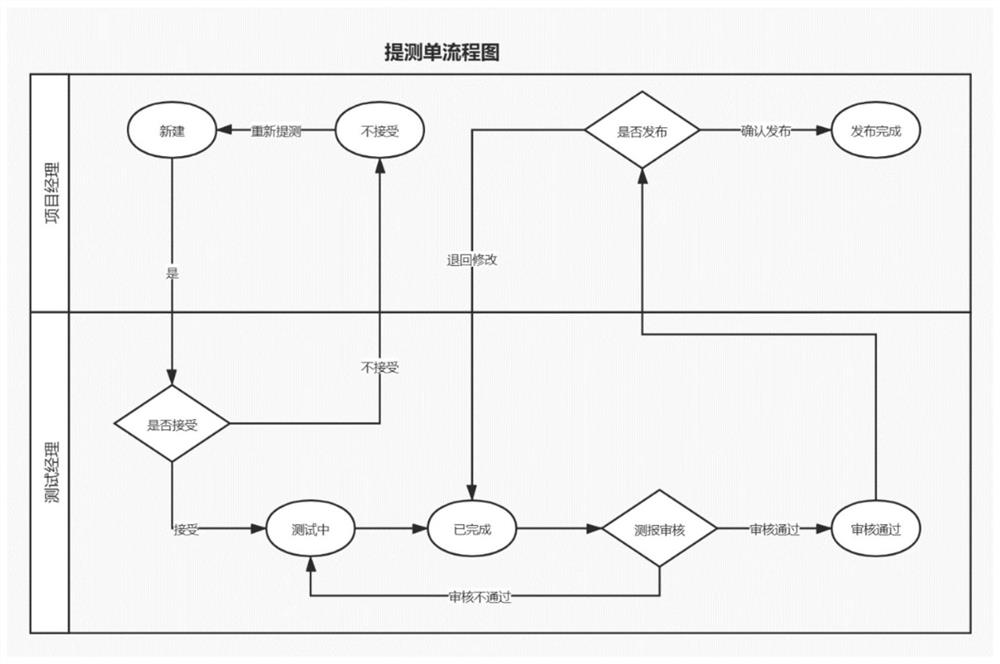

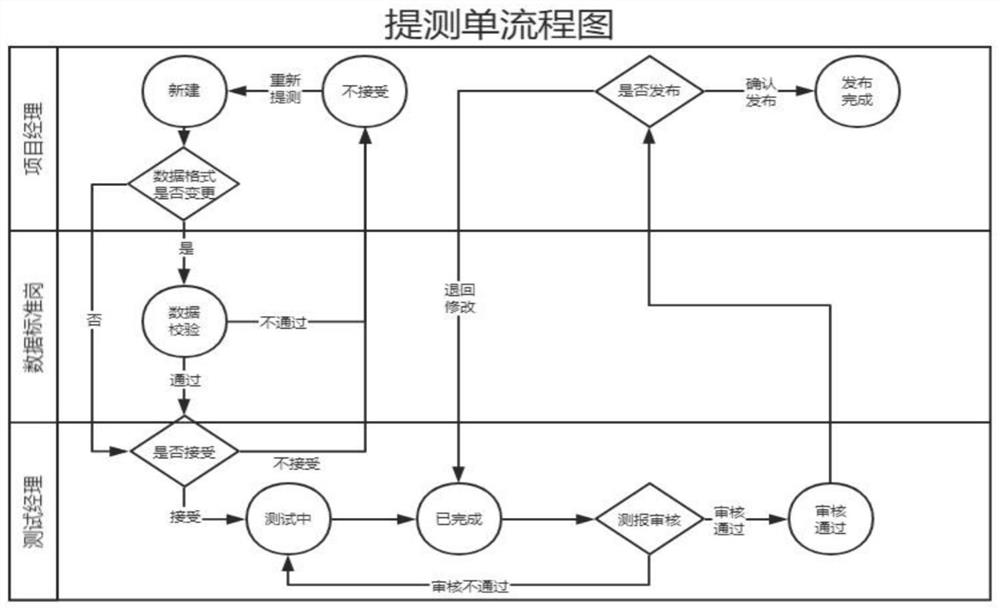

Full-life-cycle management and control method for improving data standard falling rate

PendingCN112905329AImprove data interaction efficiencyEnsure accuracy and consistencyDatabase updatingProgram initiation/switchingProject managerData criteria

The invention discloses a full-life-cycle management and control method for improving a data standard falling rate, belongs to the field of data management, and solves the problems of non-ideal data standard execution and data standard work quantification. According to the method, a data standard post is added between two nodes of a project manager post and a test manager post, and is used for checking whether metadata changes related to the project meet data standards or not in the event. The method is used for realizing full-life-cycle management and control for improving the data standard falling rate.

Owner:武汉众邦银行股份有限公司

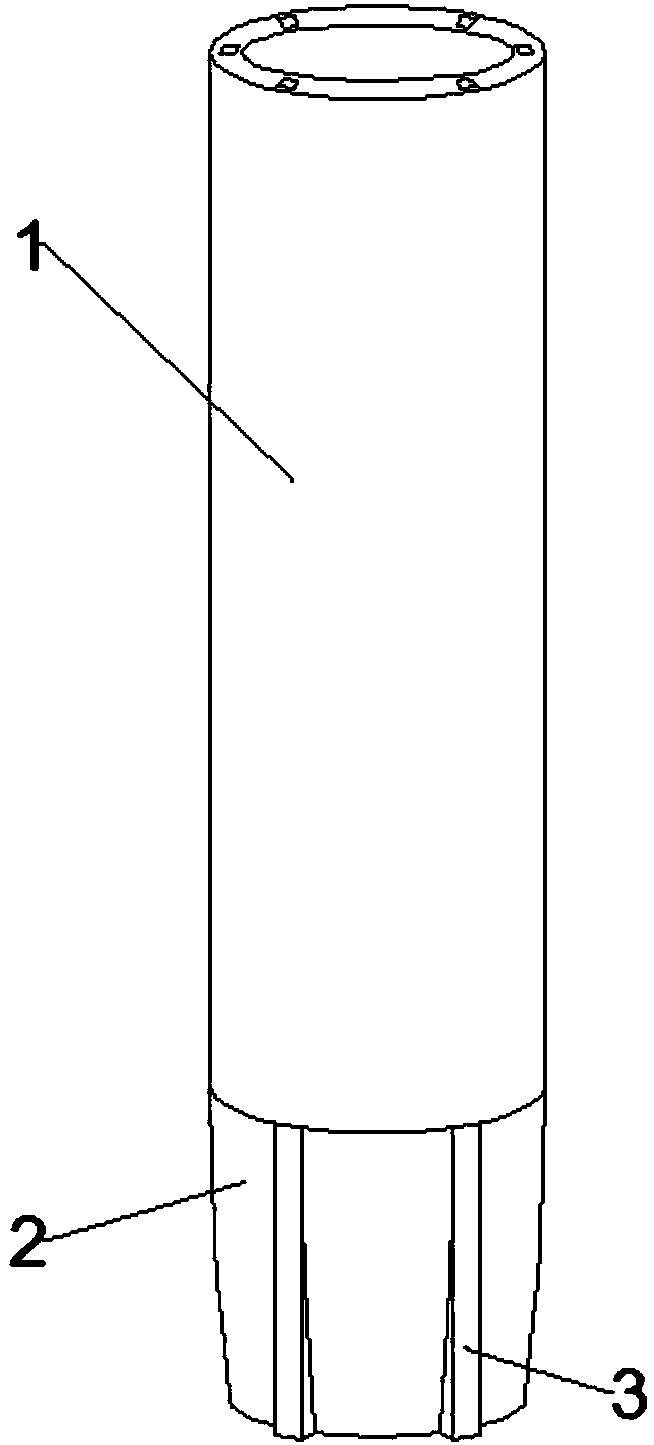

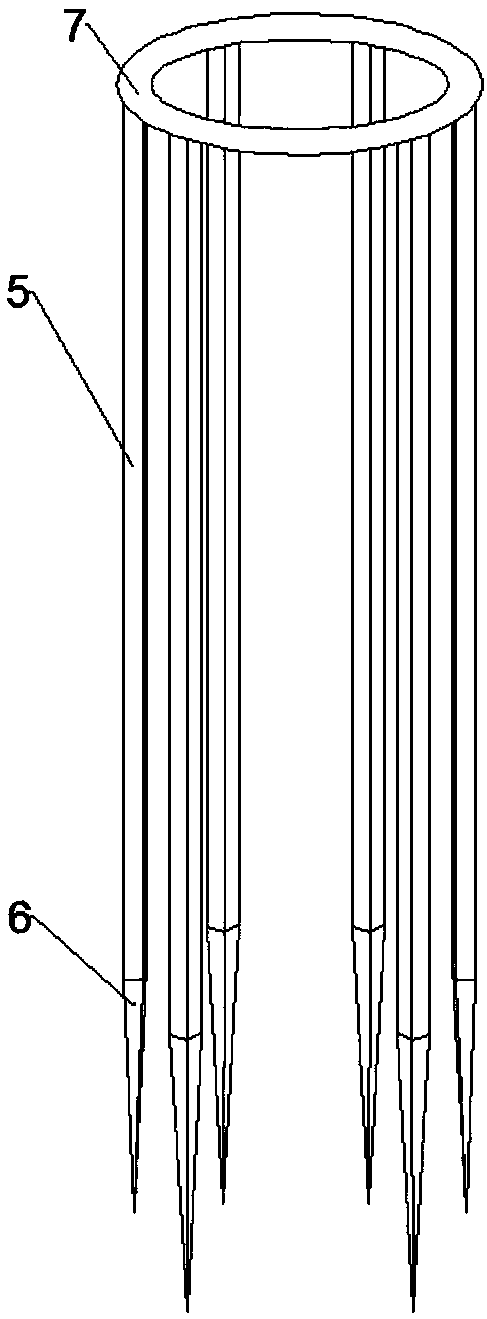

Soil sample collection tool

The invention discloses a soil sample collection tool. The soil sample collection tool comprises a sampling tube, a soil boring assembly, a first cylinder, and a soil cutting assembly, wherein the sampling tube is formed by coaxially splicing an upper portion and a lower portion, the outer circumferential surface of the lower portion of the sampling tube is uniformly provided with six ribbed blocks at interval along the circumferential direction, six first through holes are arranged in the wall of the sampling tube from top to bottom along the straight line, an upper opening of the first through hole is positioned on the upper end surface of the upper portion of the sampling tube, a lower opening of the first through hole is positioned on the lower end surface of the ribbed block, and thelower openings of the six first through holes are respectively correspondingly arranged in the six ribbed blocks; the soil boring assembly comprises six spines and an annular end plate connecting thesix spines; the first cylinder is detachably connected to the upper end of the sampling tube by virtue of threads so as to abut against the annular end plate; and the soil cutting assembly comprises asecond regular quadrangular column and a second regular quadrangular cone. By adopting the soil sample collection tool, the accuracy for sampling the soil at a predetermined depth can be ensured, andthe completeness and effectiveness of an obtained soil sample can be kept.

Owner:中国林业科学研究院热带林业实验中心

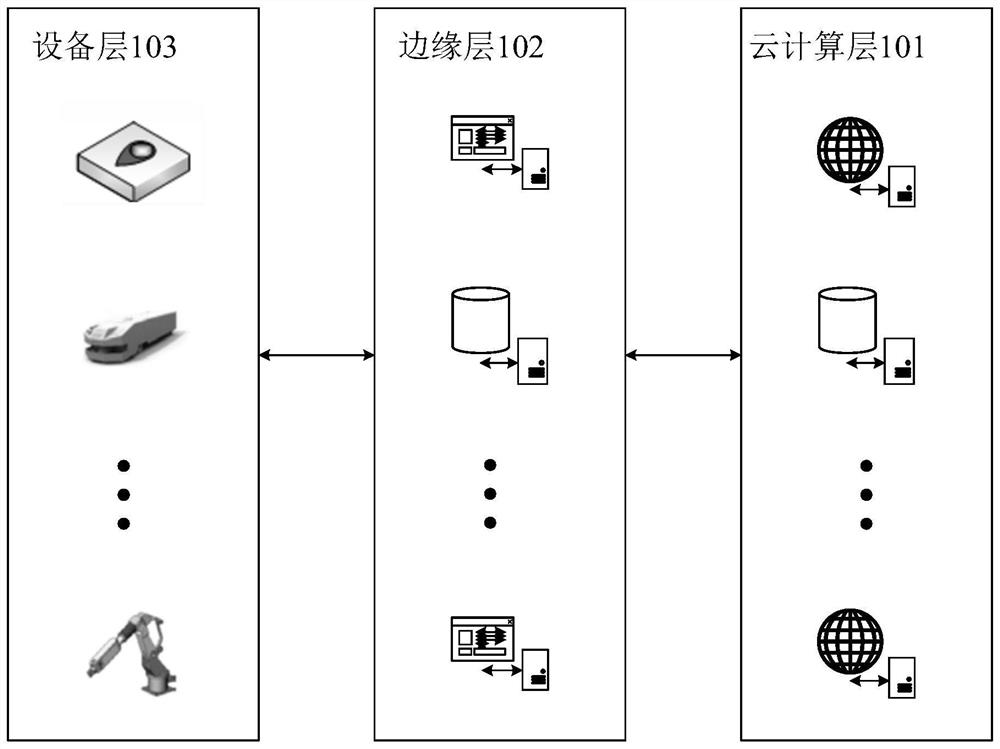

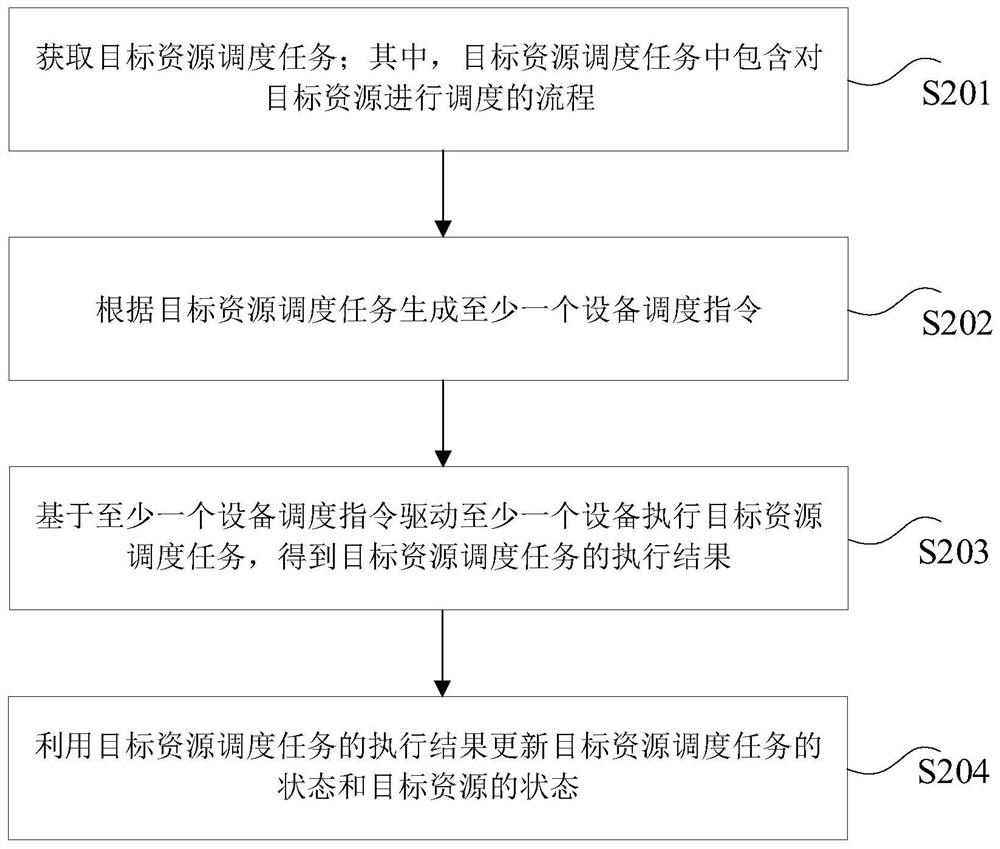

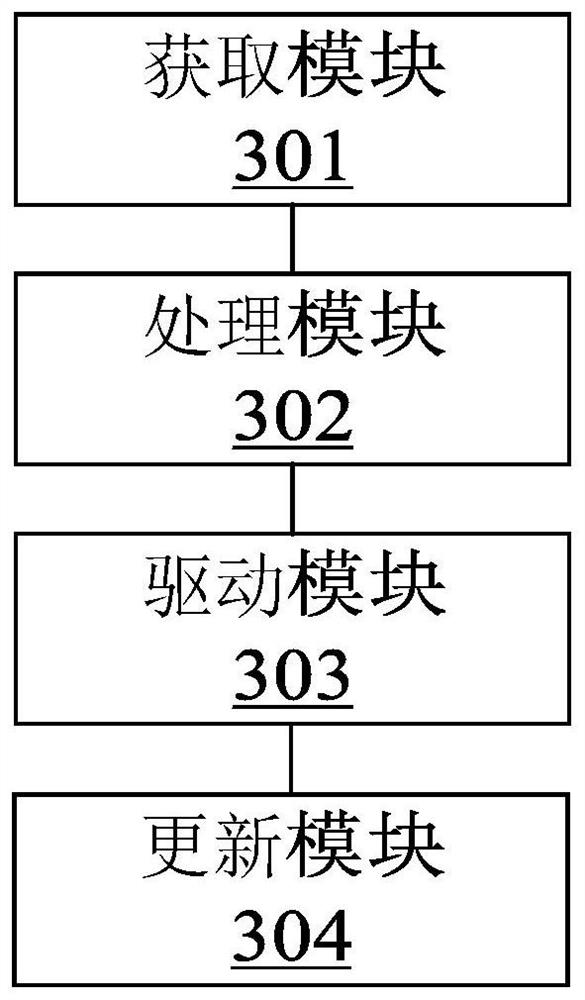

Resource management system, method and device

PendingCN112084039AEnsure accuracy and consistencyReduce the chance of errorProgram initiation/switchingResource allocationCloud computingResource Management System

The embodiment of the invention provides a resource management system, method and device. The system comprises a cloud computing layer which is used for transmitting a generated target resource scheduling task to an edge layer, and updating the state of the target resource scheduling task and the state of a target resource through the execution result of the target resource scheduling task comprising a process of scheduling a target resource, an edge layer used for generating at least one equipment scheduling instruction according to the target resource scheduling task, and a device layer usedfor driving at least one device to execute the target resource scheduling task based on the at least one device scheduling instruction, and sending an obtained execution result of the target resourcescheduling task to the cloud computing layer. In the embodiment of the invention, the target resource scheduling instruction can be timely and efficiently responded and accurately executed by utilizing the equipment, so that the problems that errors are easy to occur and the operation efficiency is low due to manual resource scheduling are effectively solved.

Owner:CHINA CONSTRUCTION BANK

Installation tool for helical strakes in marine riser vortex-induced vibration restraining test

ActiveCN104985556APrecise positioningEnsure accuracy and consistencyMetal-working hand toolsEngineeringHelix

The invention discloses an installation tool for helical strakes in a marine riser vortex-induced vibration restraining test. The installation tool comprises helical line marking and locating rings and helical line adhesion locating rings, wherein the helical line marking and locating rings and the helical line adhesion locating rings are each formed by hooping and connecting two half rings. Multiple radial locating lines are distributed circumferentially from the inner edges of the helical line marking and locating rings at equal intervals. The number of the radial locating lines is the same as the number of the helical line marking and locating rings fixed to each thread pitch on a bare pipe in the helical line marking process. Multiple helical strake locating grooves are formed circumferentially in the inner surfaces of the helical line adhesion locating rings at equal intervals. The number of the helical strake locating grooves is the same as that of the helical strakes. The end face of each adhesion locating ring is provided with an adhesion locating ring locating line. By the adoption of the installation tool, the position marking work of the helical lines is simplified, it is conveniently guaranteed that the thread pitch of the helical strakes is accurate, a continuous helical line is located among marking points, and the helical strakes are convenient to install.

Owner:TIANJIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com