Automatic electric coil label placement device

An electric coil and label technology is applied in the field of automatic placement of electric coil label devices, which can solve the problems of difficulty in guaranteeing product quality, difficulty in improving production efficiency, and missing labels, so as to ensure accuracy and consistency, reduce labor intensity, and improve The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

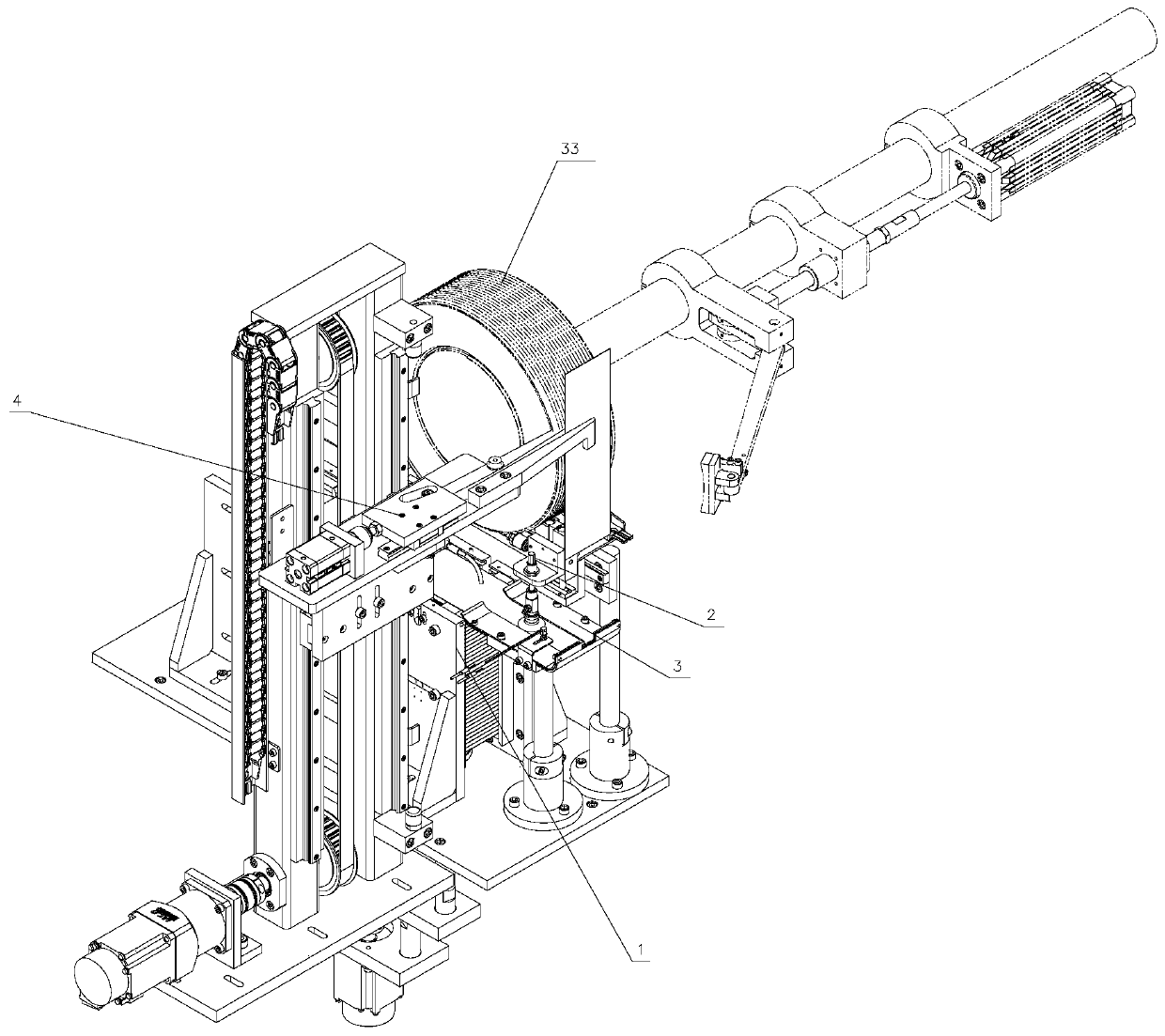

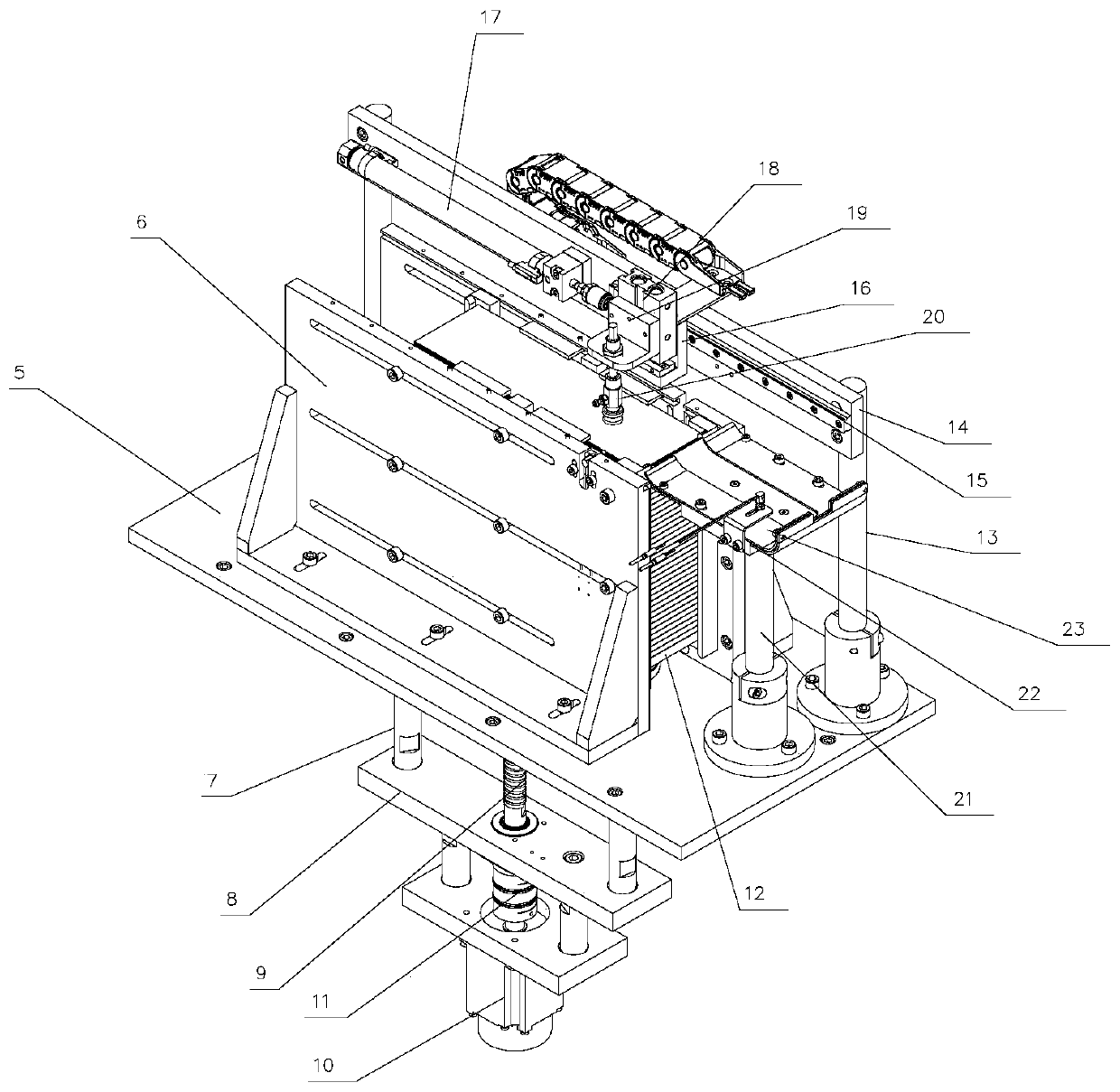

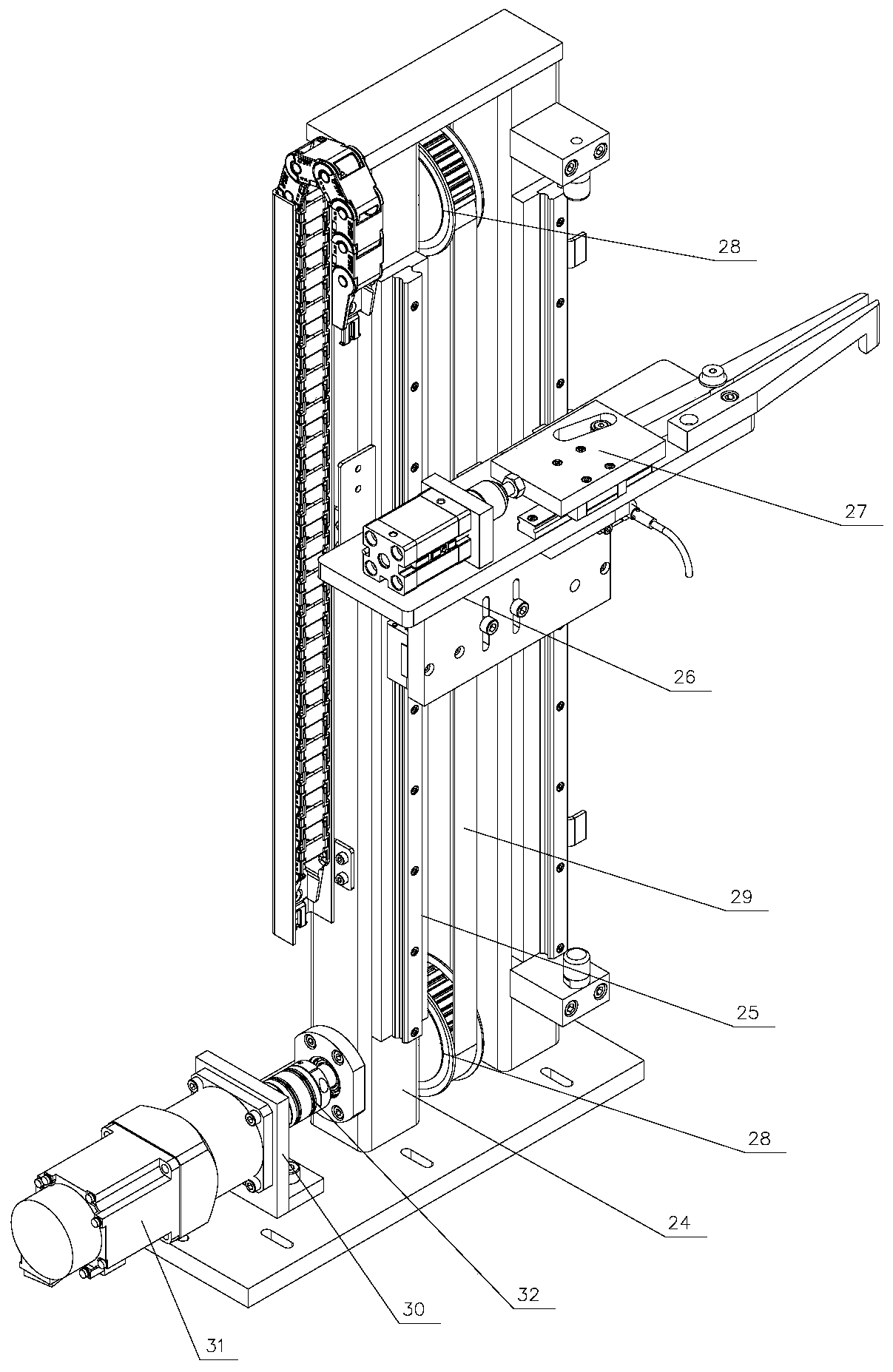

[0011] The technical solution of the present invention will be clearly and completely described below in conjunction with the accompanying drawings. The device for automatically placing electric coil labels in the present invention is composed of a label storage box 1, a movable label suction head 2, a label separation and guide groove 3 and a liftable label clamping assembly 4. The standard storage box 1 is composed of a fixed base plate 5, a surrounding plate 6, a fixed column 7, a fixed plate 8, a ball screw 9, a servo motor 10, a shaft coupling 11 and a lifting base plate 12, and the surrounding plate 6 is fixed on the fixed base plate 5. The fixed column 7 is fixed under the fixed bottom plate 5, the fixed plate 8 is installed on the lower end of the fixed column 7, the servo motor 10 is fixed on the fixed plate 8 through the connecting plate, and the shaft head of the servo motor 10 is connected with the ball screw through the coupling 11. 9 is connected, and the top of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com