Patents

Literature

141results about How to "Clamp fastening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

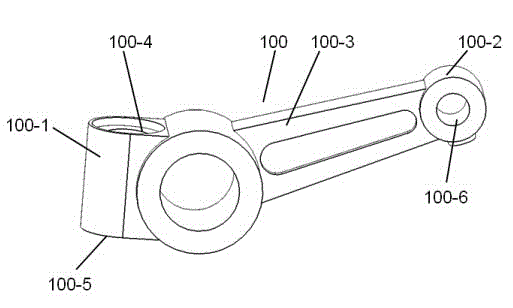

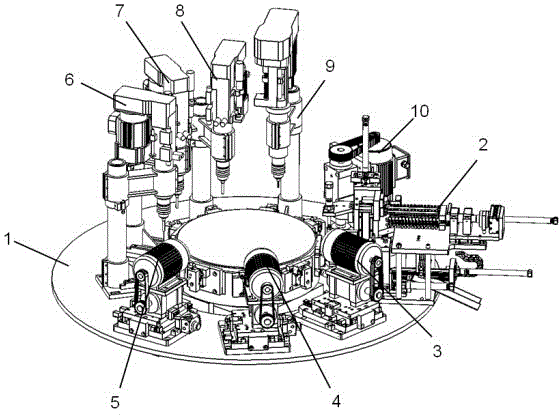

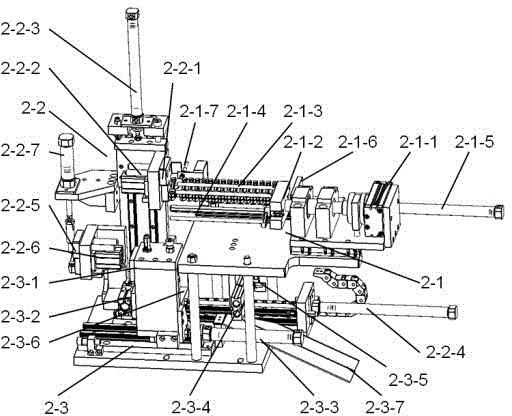

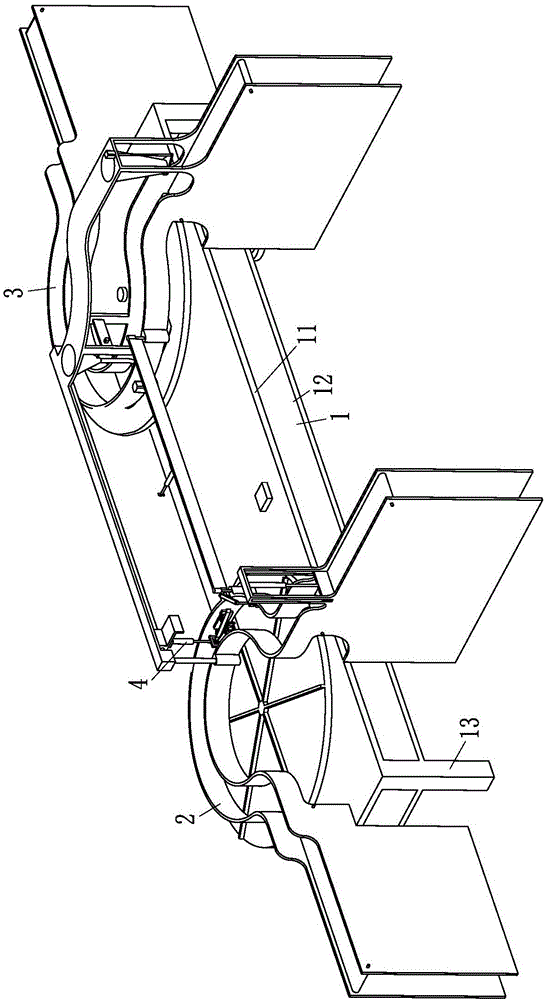

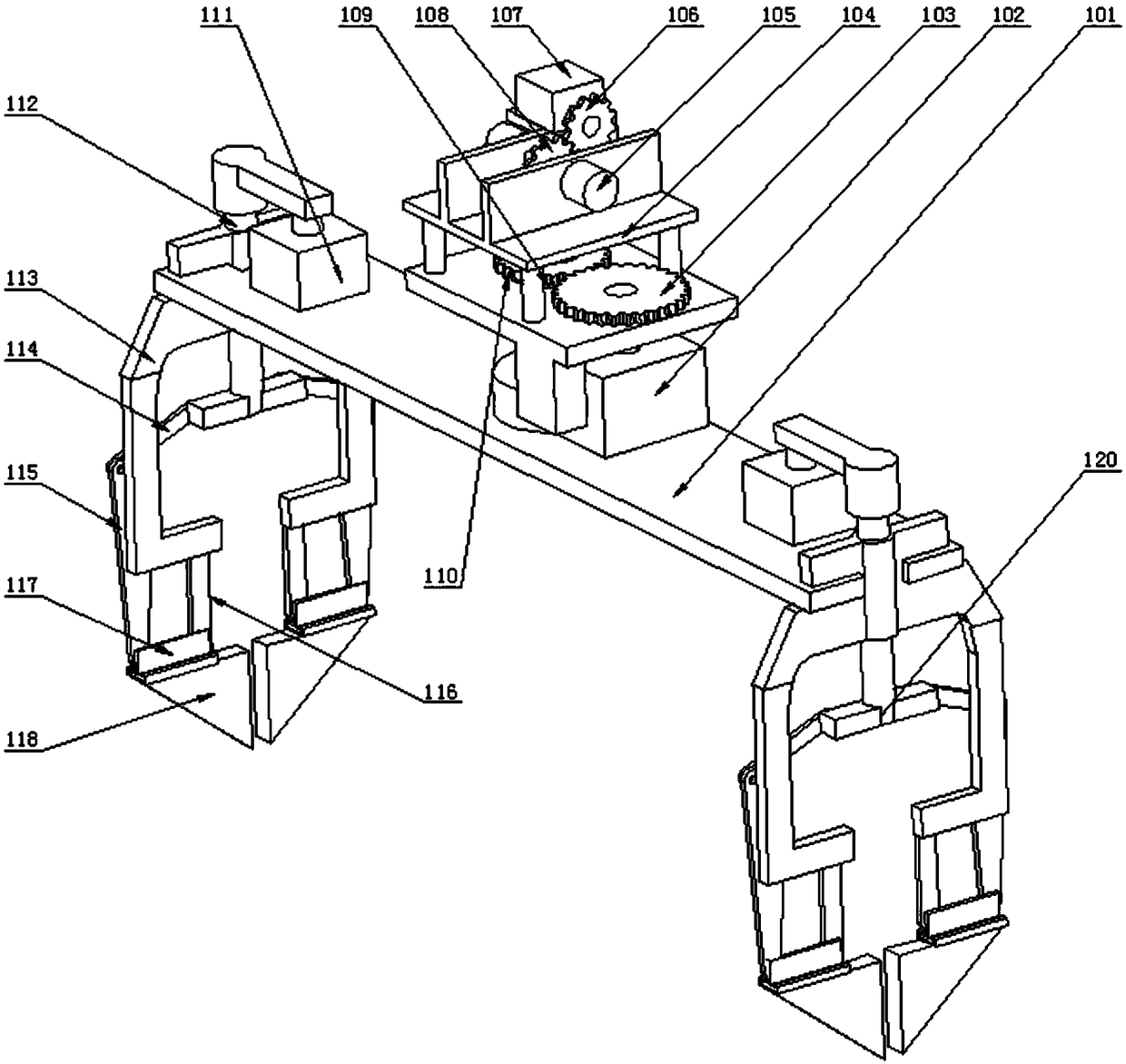

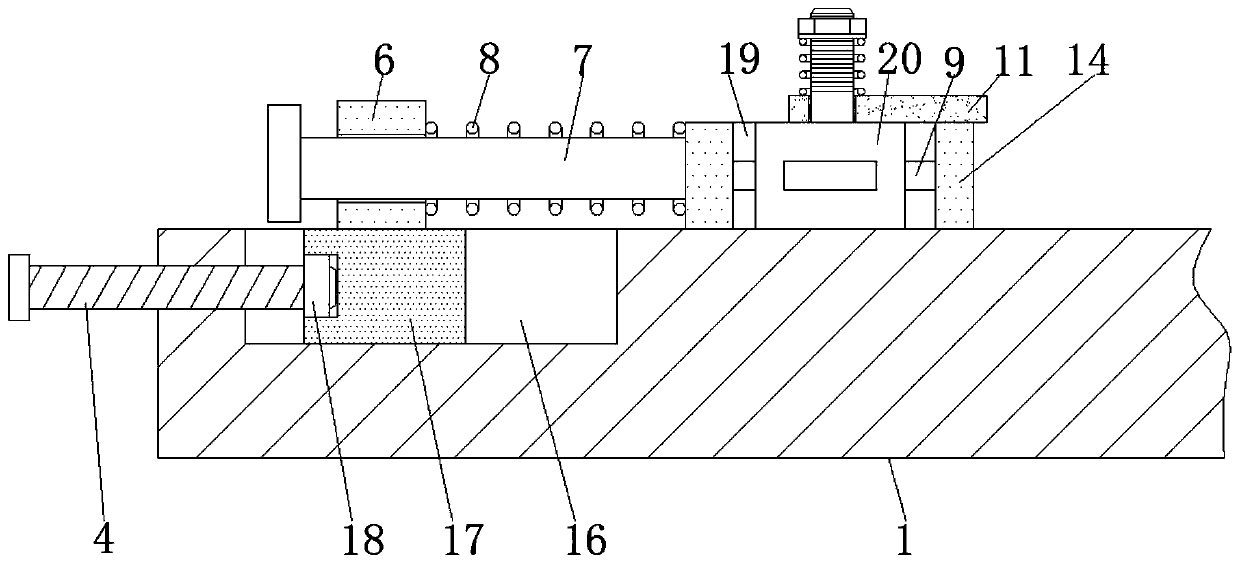

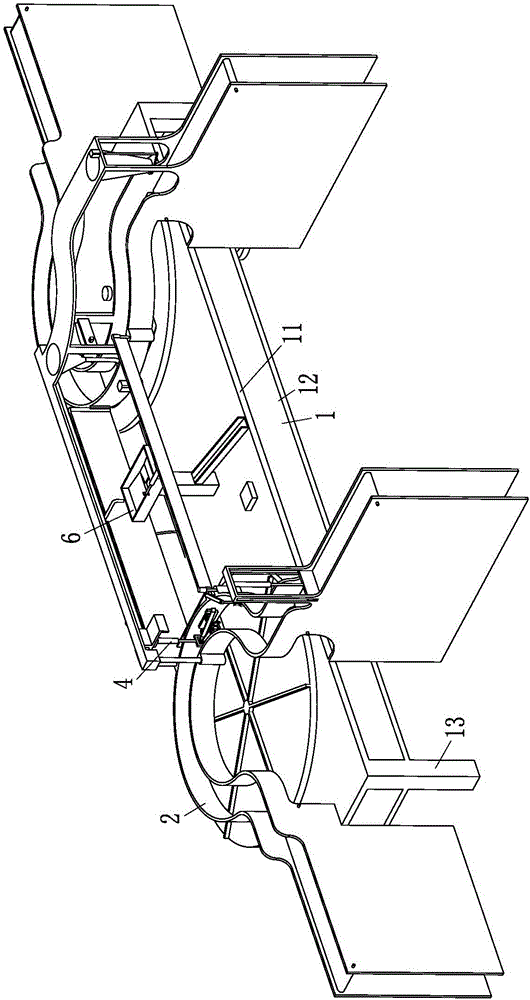

Automatic machining device for curved needle crank of sewing machine and machining method of automatic machining device

InactiveCN104858659ACompact structureSmall sizeOther manufacturing equipments/toolsEngineeringSewing machine

The invention discloses an automatic machining device for a curved needle crank of a sewing machine. The automatic machining device comprises a rotating disc workbench, wherein the rotating disc workbench is provided with an automatic feeding and discharging module, a small head end point hole module, a small head end drilling module, a small head end hole expanding module, a large head end reaming module, a first large head end drilling module, a second large head end drilling module, a taping module and a large head end sawing module in the circumferential direction. The automatic machining device integrates feeding and discharging, one station is formed, the structure is compact, the dimension of whole equipment can be reduced, and the working efficiency is higher. The invention further discloses an automatic machining method for the curved needle crank of the sewing machine.

Owner:RES INST OF ZHEJIANG UNIV TAIZHOU

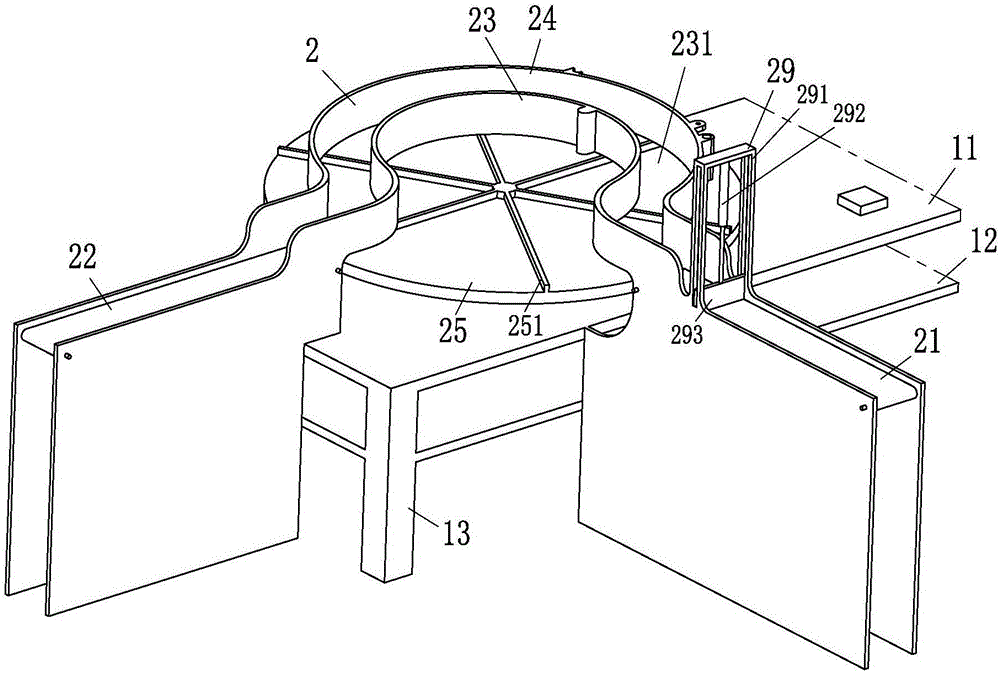

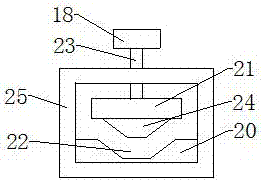

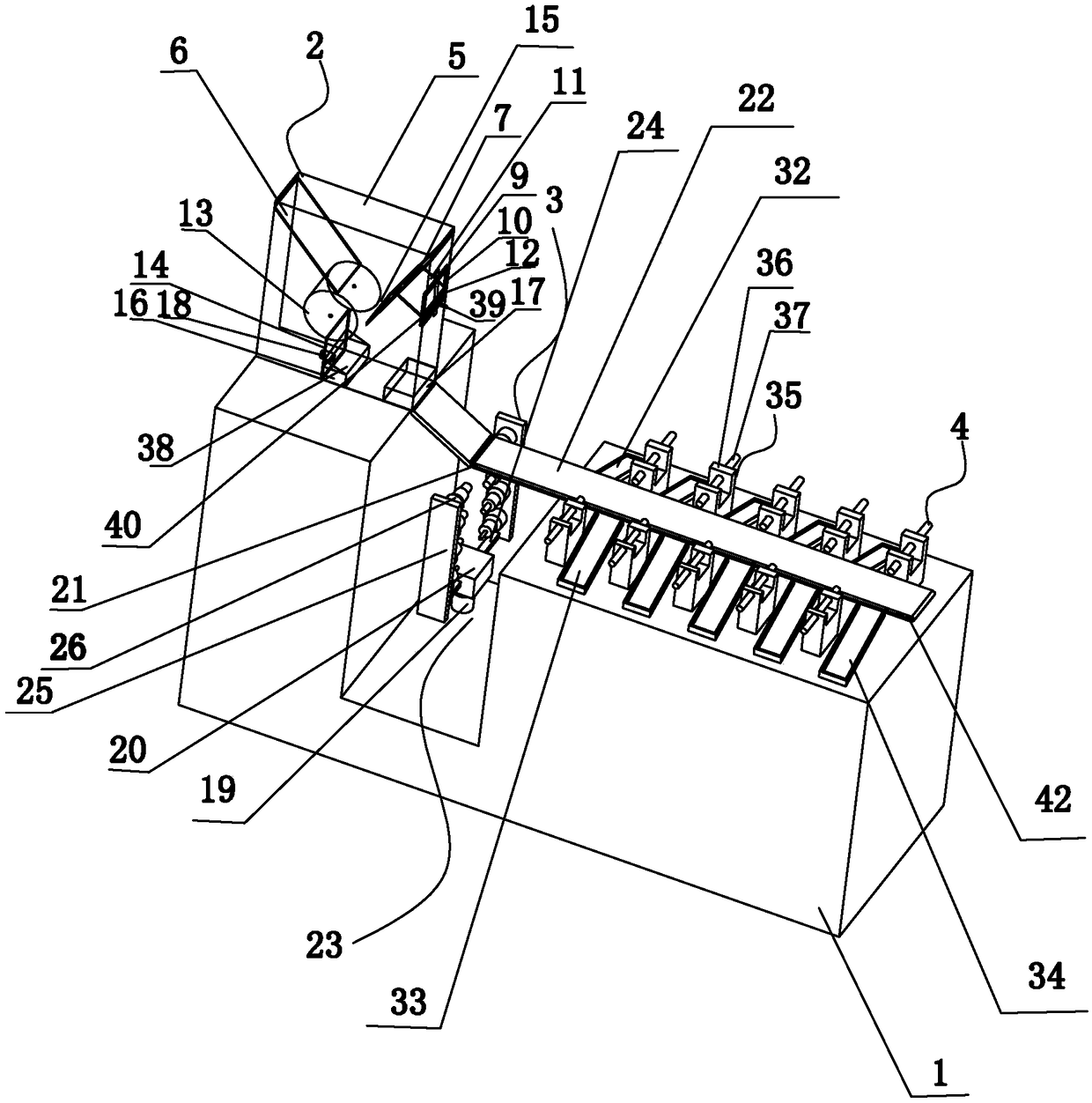

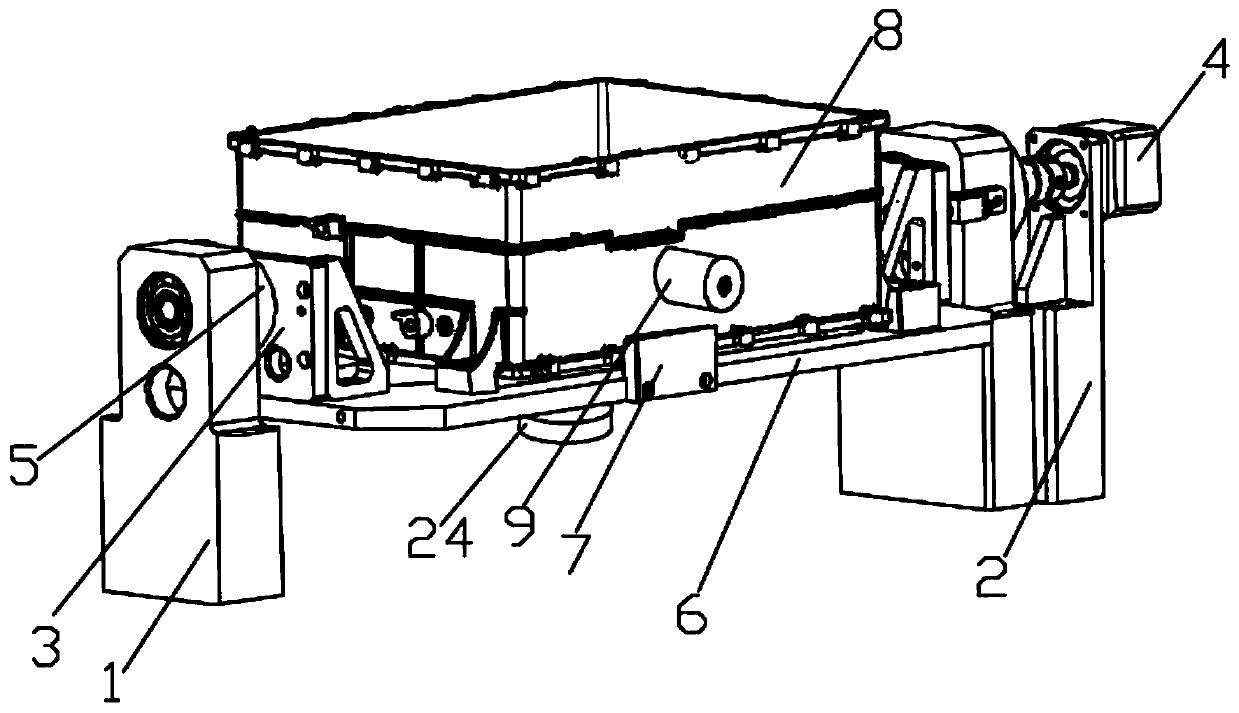

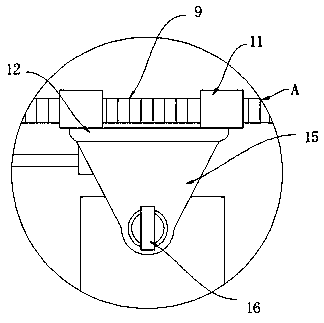

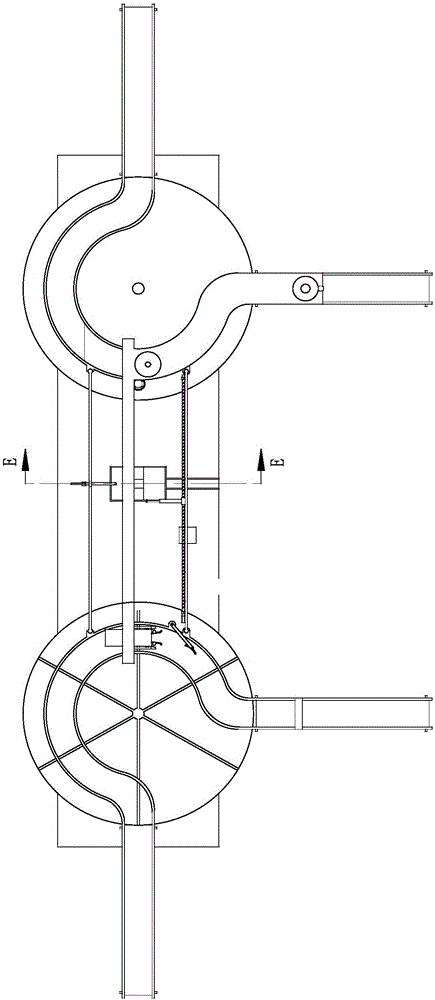

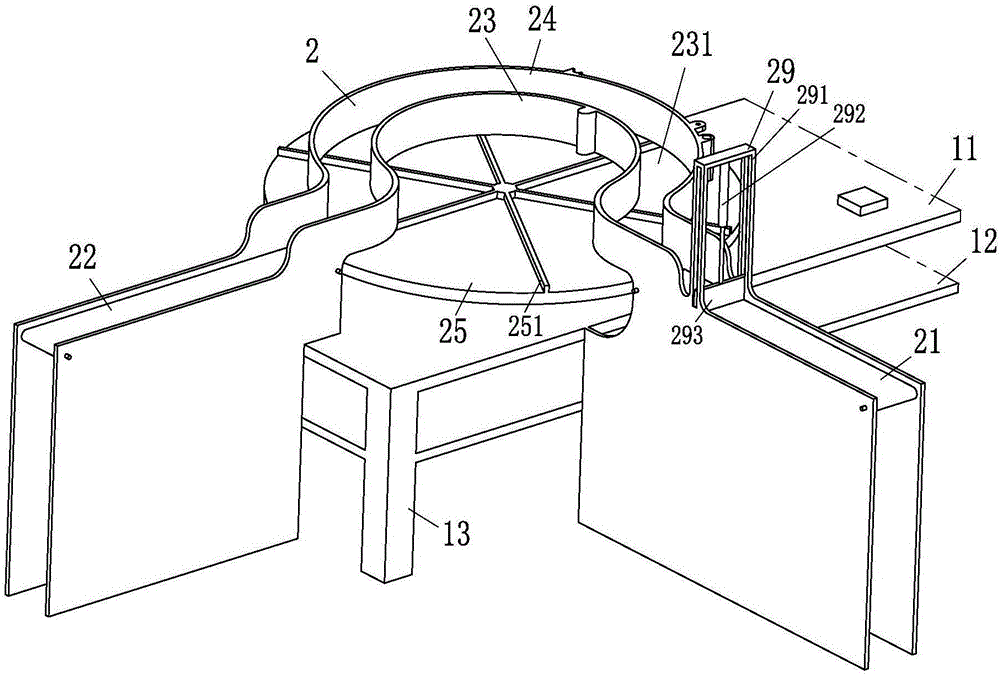

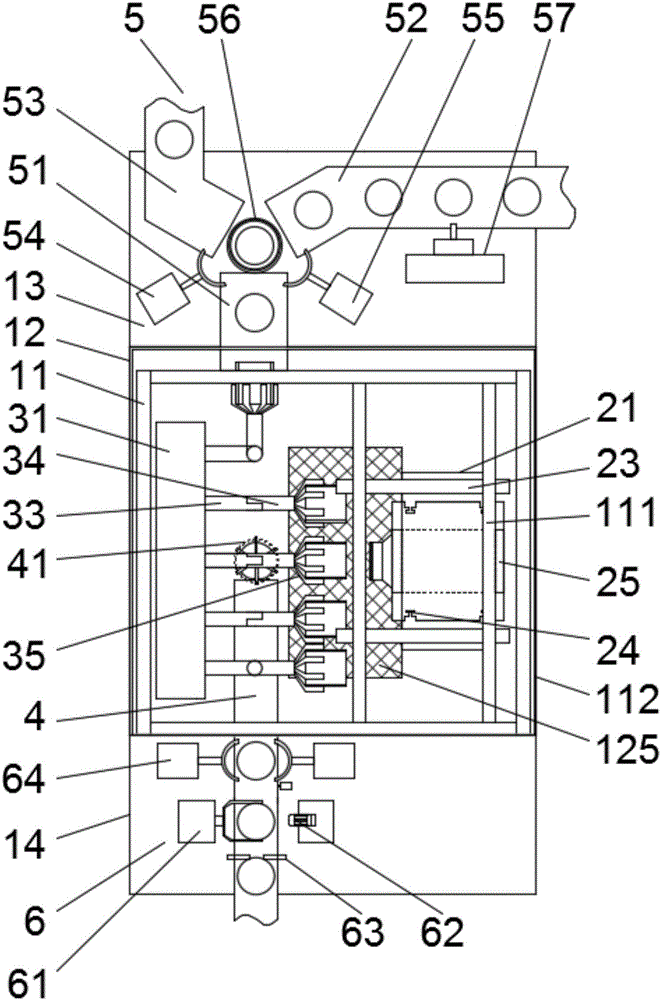

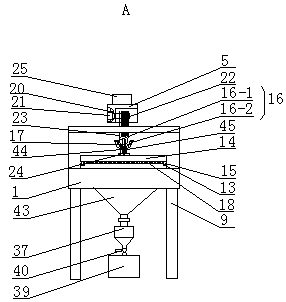

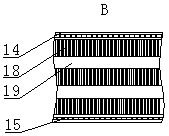

Pot changing robot for succulent plants

ActiveCN106508477AAchieve interval exerciseClamp fasteningCultivating equipmentsFlower-pot fillingIntegrated operationsAgricultural engineering

The invention relates to the field of agricultural machinery, in particular to a pot changing robot for succulent plants. The pot changing robot comprises a rack, a plant conveying device, a pot loading device and a pot separating device, the plant conveying device comprises a first belt conveyor, a second belt conveyor, a plant-conveying inner ring plate, a plant-conveying outer ring plate, a plant-conveying rotating disc, a plant-conveying rotating shaft, a grooved wheel mechanism a plant-conveying motor and a pot blocking device, the pot loading device comprises a third belt conveyor, a fourth belt conveyor, a pot-loading inner ring plate, a pot-loading outer ring plate, a pot-loading rotating disc, a pot-loading rotating shaft, a pot-loading motor and a soil adding device, and the pot separating device comprises a pot separating body, a pot fixing device and a plant conveying device. The pot changing robot can make the succulent plants to automatically break away from old pots and automatically convey the succulent plants to the pot loading device and can realize automatic adding of ceramite and soil to new pots and automatic pot loading of the succulent plants, and the whole process realizes integrated operation, so that working efficiency is improved.

Owner:ANHUI HUATENG AGRI TECH CO LTD

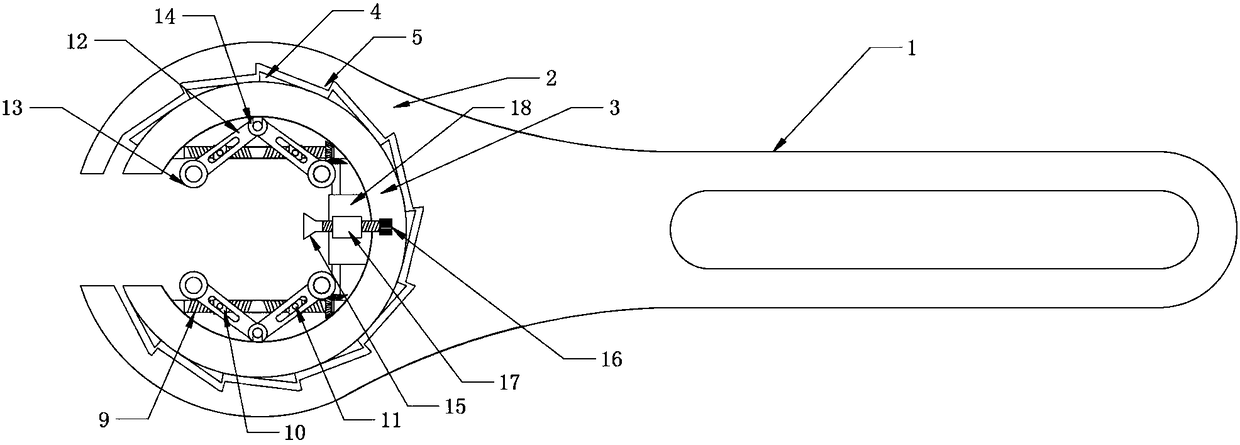

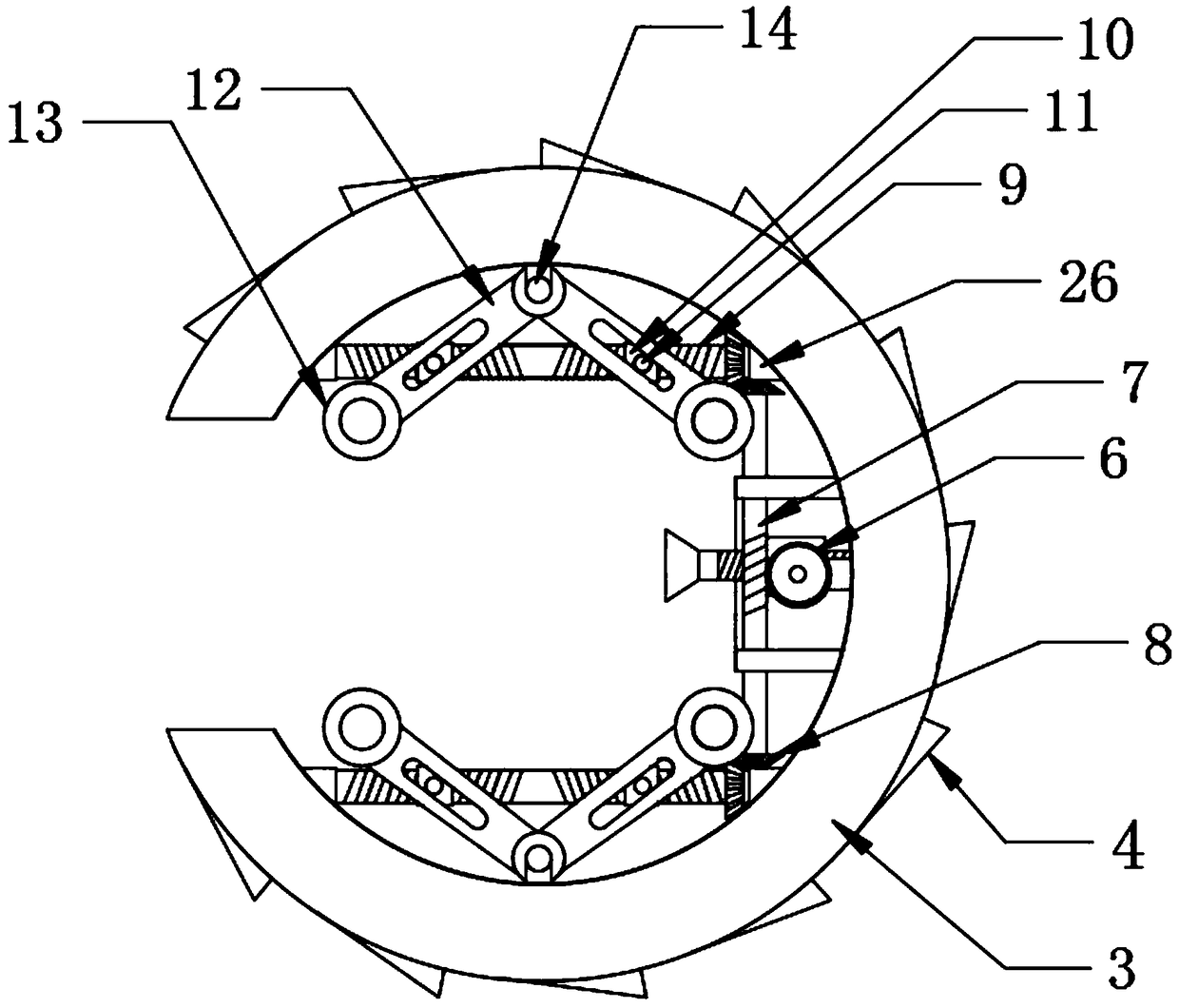

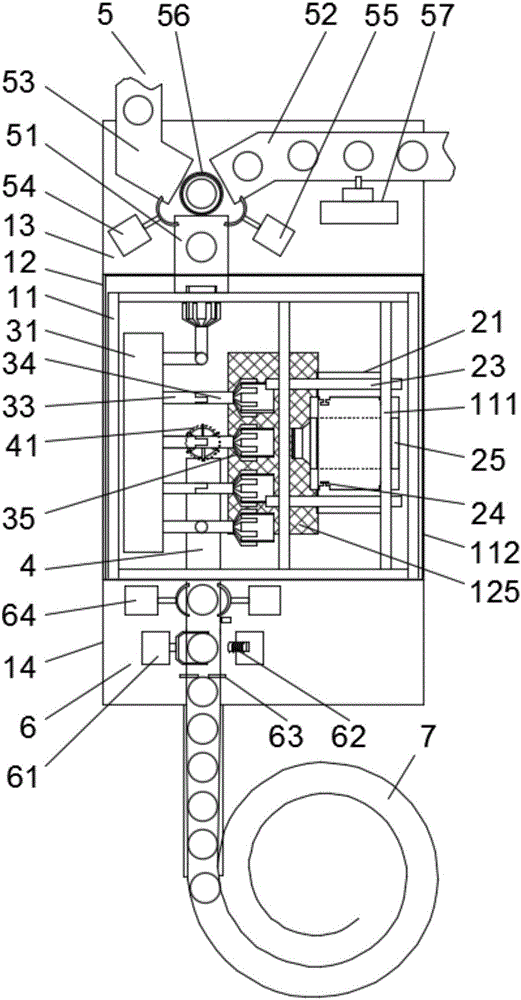

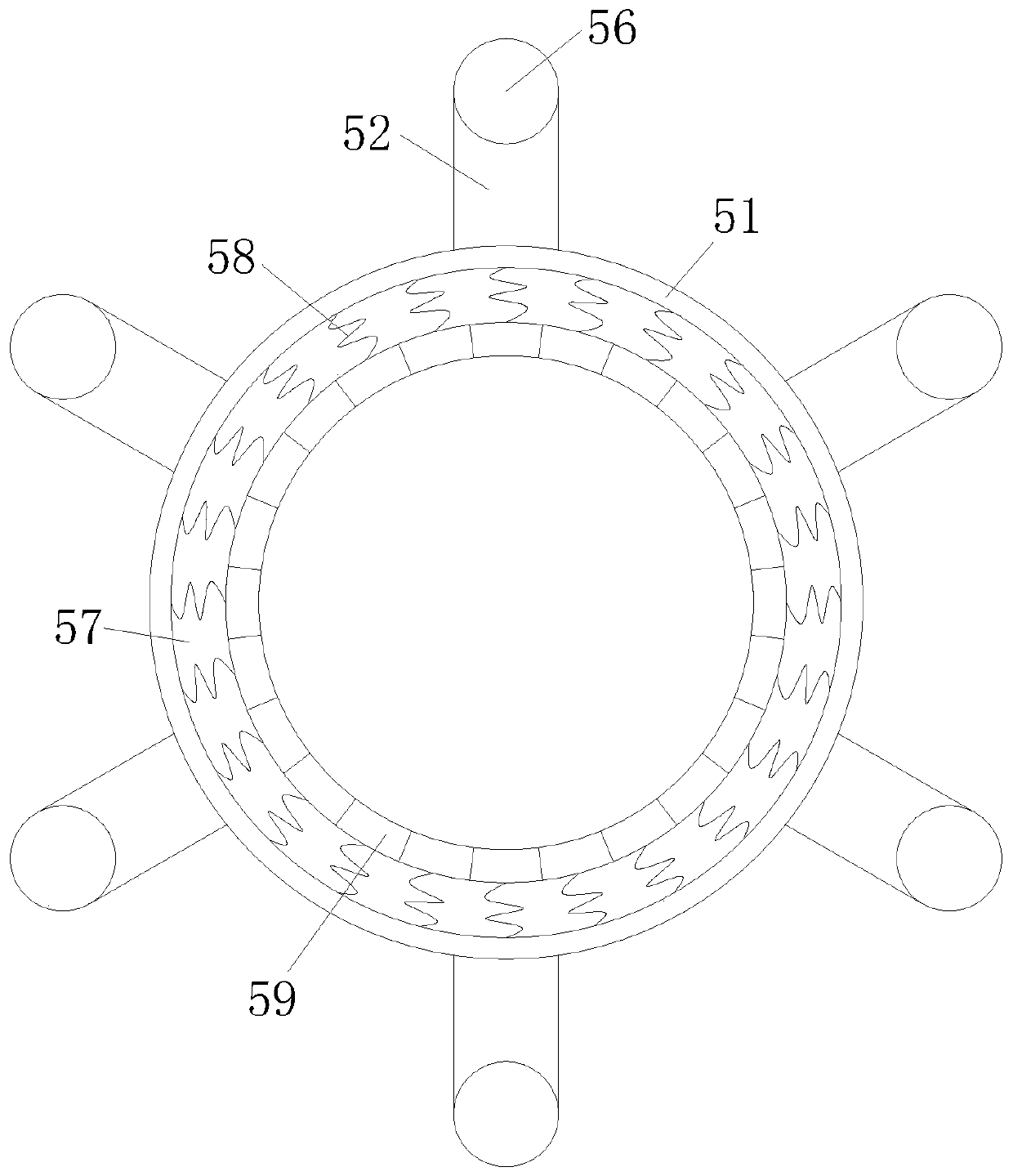

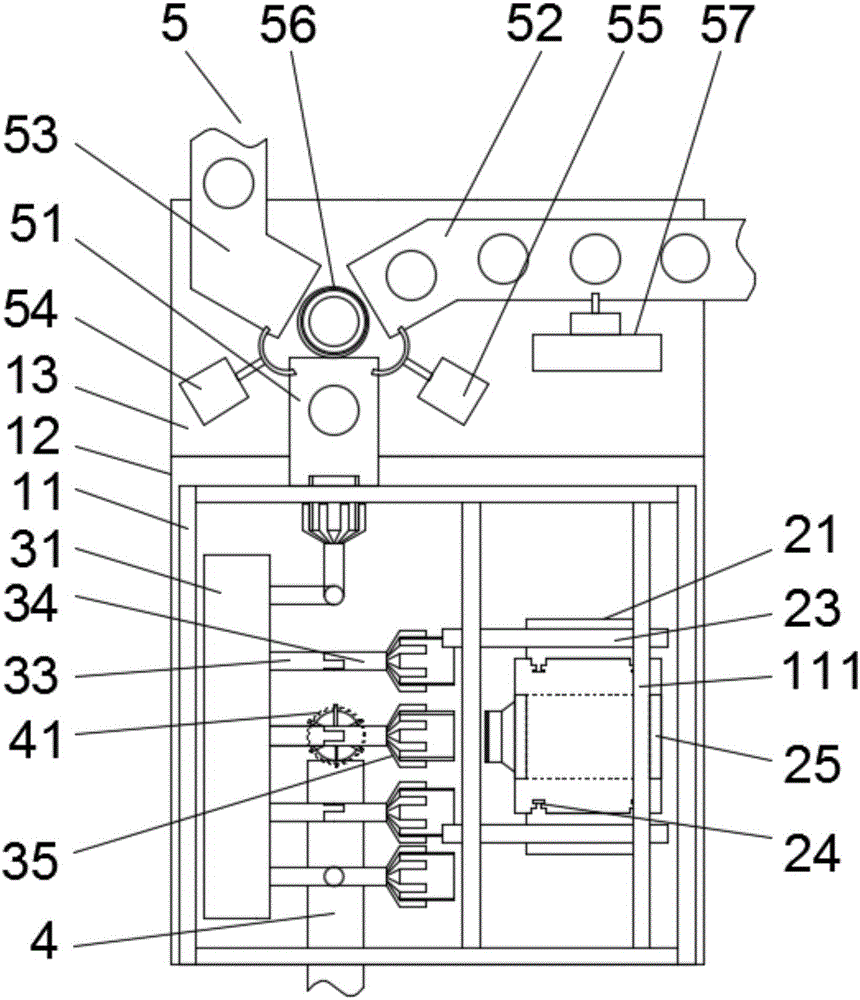

Ratchet cable stripper

PendingCN108512142AImplement peelingImprove efficiencyApparatus for removing/armouring cablesIntermittent motionEngineering

The invention provides a ratchet cable stripper, which comprises a handle, a ratchet and pawl mechanism arranged at one end of the handle, a clamp assembly which is arranged in the ratchet and pawl mechanism and is used for clamping a cable, and a tool bit assembly for scraping the cable skin, wherein the ratchet and pawl mechanism comprises a circular columnar handle head part, a circular columnar ratchet arranged on the inner wall of the handle head part in a sleeving manner, multiple straight triangular teeth arranged on the outer wall of the ratchet in a uniform spacing manner along the circumferential direction of the ratchet, and a pawl part which is arranged on the inner wall of the handle head part and is matched with the straight triangular teeth. The ratchet cable stripper provided by the invention has the beneficial effects that: the tool bit assembly and the clamp assembly are driven to rotate around a cable by use of the unidirectional intermittent motion characteristic ofthe ratchet and pawl mechanism, so as to scrap the cable skin; and furthermore, the handle can swing back and forth within a certain angle range on one side of the cable instead of rotating around the cable, so that the labor is saved, and the efficiency is high.

Owner:WUHAN JIANGXIA DISTRICT POWER SUPPLY CO STATE GRID HUBEI ELECTRIC POWER CO +2

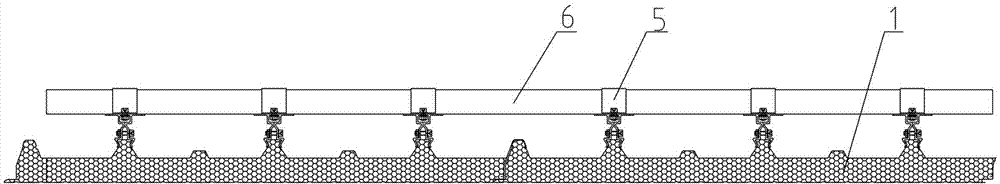

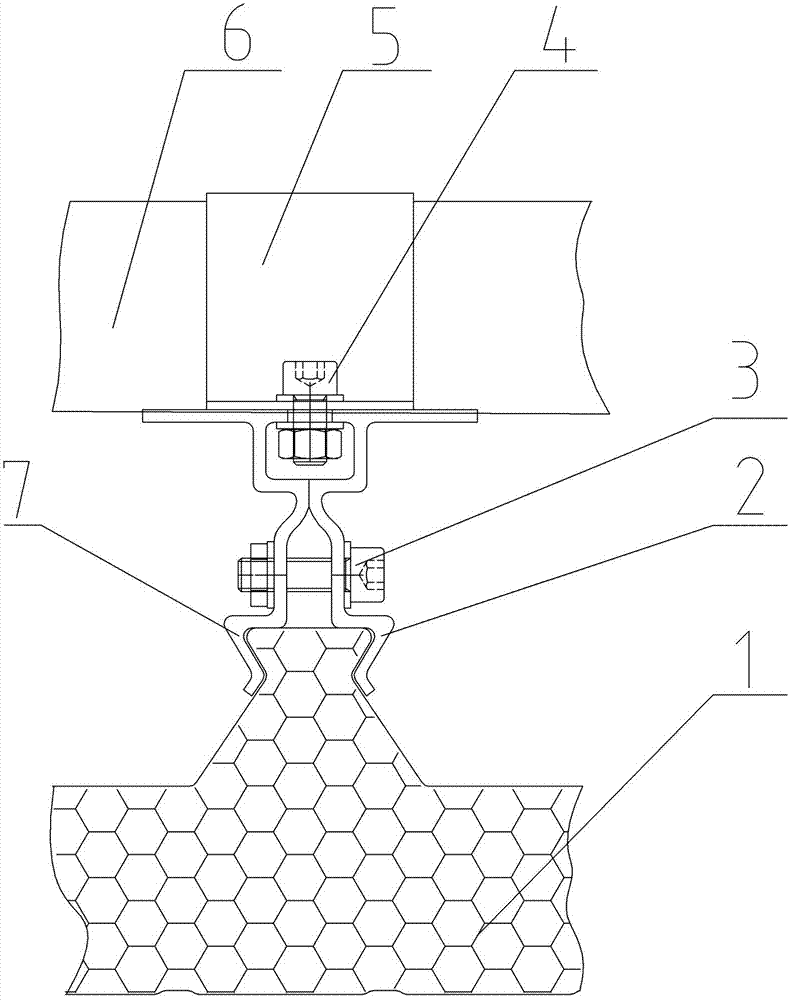

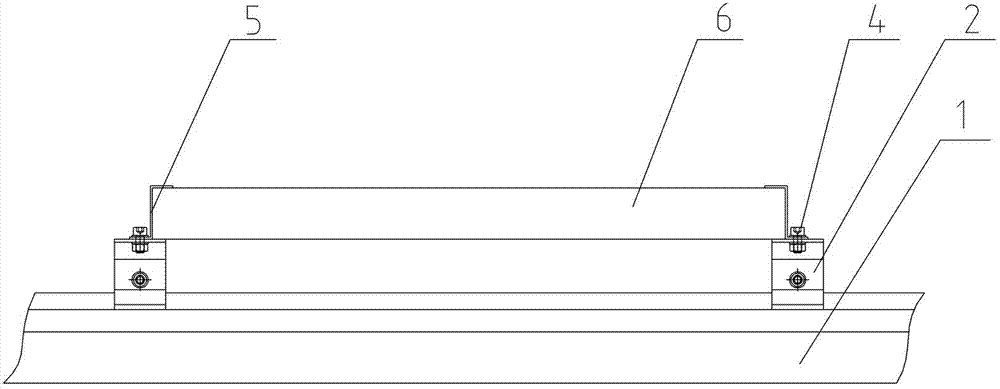

Photovoltaic roof adapting fixture and photovoltaic roof structure with same

ActiveCN103243874AEasy to operateNot easy to losePhotovoltaic supportsRoof covering using slabs/sheetsEngineeringMechanical engineering

The invention relates to a photovoltaic roof adapting fixture and a photovoltaic roof structure with the same. The photovoltaic roof adapting fixture comprises left clamp arms and right clamp arms. Each of the left and right clamp arms is provided with a clamping end used for clamping a roof rib. The upper ends of the left and right clamp arms are hinged so that the left and right clamp arms open and close in a swinging manner, or integrated so that the left and right clamp arms open and close elastically. The upper ends of the left and right clamp arms are integrated or connected by hinging, the left and right clamp arms can be locked conveniently during installation by lifting up the hinged or integrated parts of the upper ends and pushing the clamping ends to two sides of each roof rib with no need for repeatedly regulating lock bolt holes, and loss is resisted during transportation. A roof board is made of a metal-surface polyurethane composite board, the metal-surface polyurethane composite board has the functions of energy saving and heat insulation, and accordingly energy consumption of building systems is reduced greatly. The roof ribs are in inverted trapezoidal structures, so that clamping is firmer and facilities such as solar panels are effectively prevented from damage caused by connection failure.

Owner:HENAN TIANFON ENERGY SAVING PANEL SCI & TECH

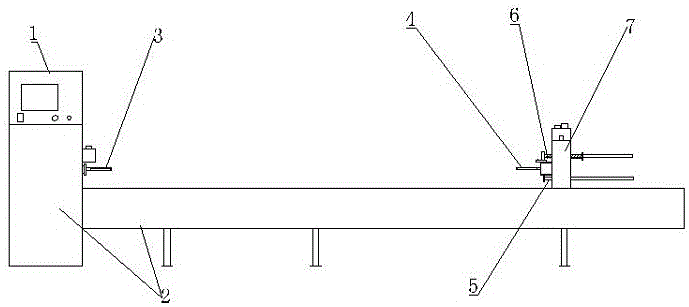

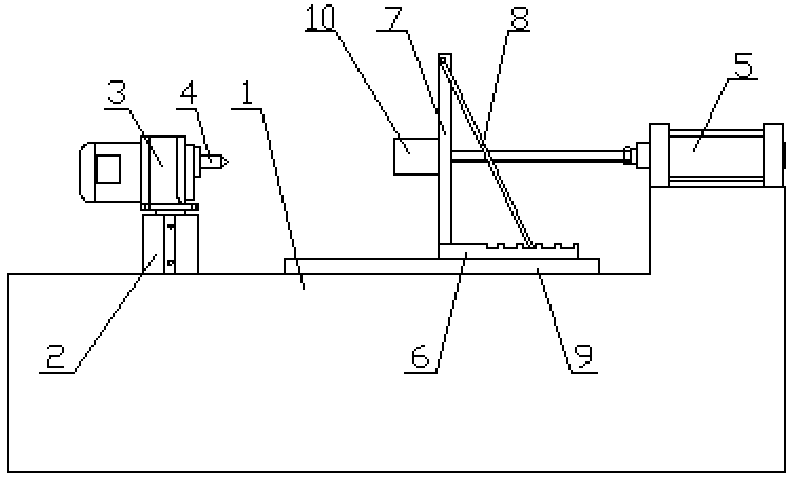

Stranding machine

The invention discloses a stranding machine comprising a rack and a control box. A left clamping mechanism and a right clamping mechanism are arranged at the rack; the left clamping mechanism includes a left clamping block and a motor that drives the left clamping block to rotate; and the right clamping mechanism consists of a moving frame, a right clamping block, a clamping block adjustment cylinder and a clamping block buffer rod. The moving frame slides at the rack left and right; the clamping block buffer rod is arranged above the right clamping block and a buffer spring sleeves the clamping block buffer rod; the front end of the clamping block buffer rod is connected with the right clamping block and the middle part is connected with the moving frame; the clamping block adjustment cylinder is arranged below the right clamping block; a telescopic rod of the clamping block adjustment cylinder is connected with the right clamping block; a cylinder body is connected to the moving frame; and the motor, the moving frame, the right clamping block, and the clamping block adjustment cylinder are connected with the control box electrically. The stranding machine has advantages of good clamping effect and low maintenance cost.

Owner:柳州天海盟立电器有限公司

Rebar cutting device for building construction

The invention discloses a rebar cutting device for building construction. The rebar cutting device comprises a base, supporting vertical columns, a supporting cross beam, a driving motor, a rotating rod, a protective hood, a cutting knife, a collecting tank, a first clamping mechanism and a second clamping mechanism, wherein the protective hood is fixedly mounted on the lower surface of the middle of the supporting cross beam; the cutting knife is arranged inside the protective hood; feeding channels are symmetrically formed in two side plates of the protective hood; the collecting tank is arranged on the upper surface of the middle of the base; the first clamping mechanism is fixedly erected at the top end of a No.1 electric telescopic rod; and the second clamping mechanism is fixedly erected at the top end of a No.2 electric telescopic rod. The rebar cutting device disclosed by the invention is simple in structure, reasonable in design and convenient to use; the firm rebar clamping effect is achieved and the rebar cutting operation is facilitated; scraps are easy to collect in the cutting process; and the safety and the practicability are high.

Owner:朱发平

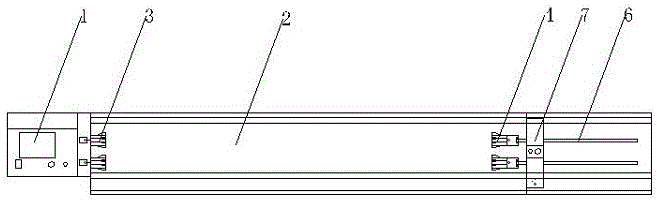

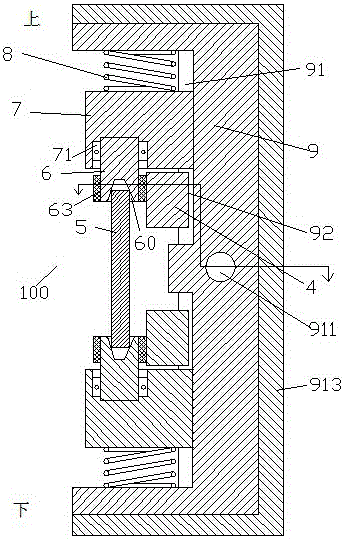

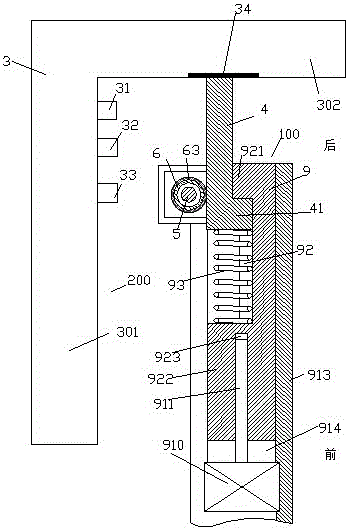

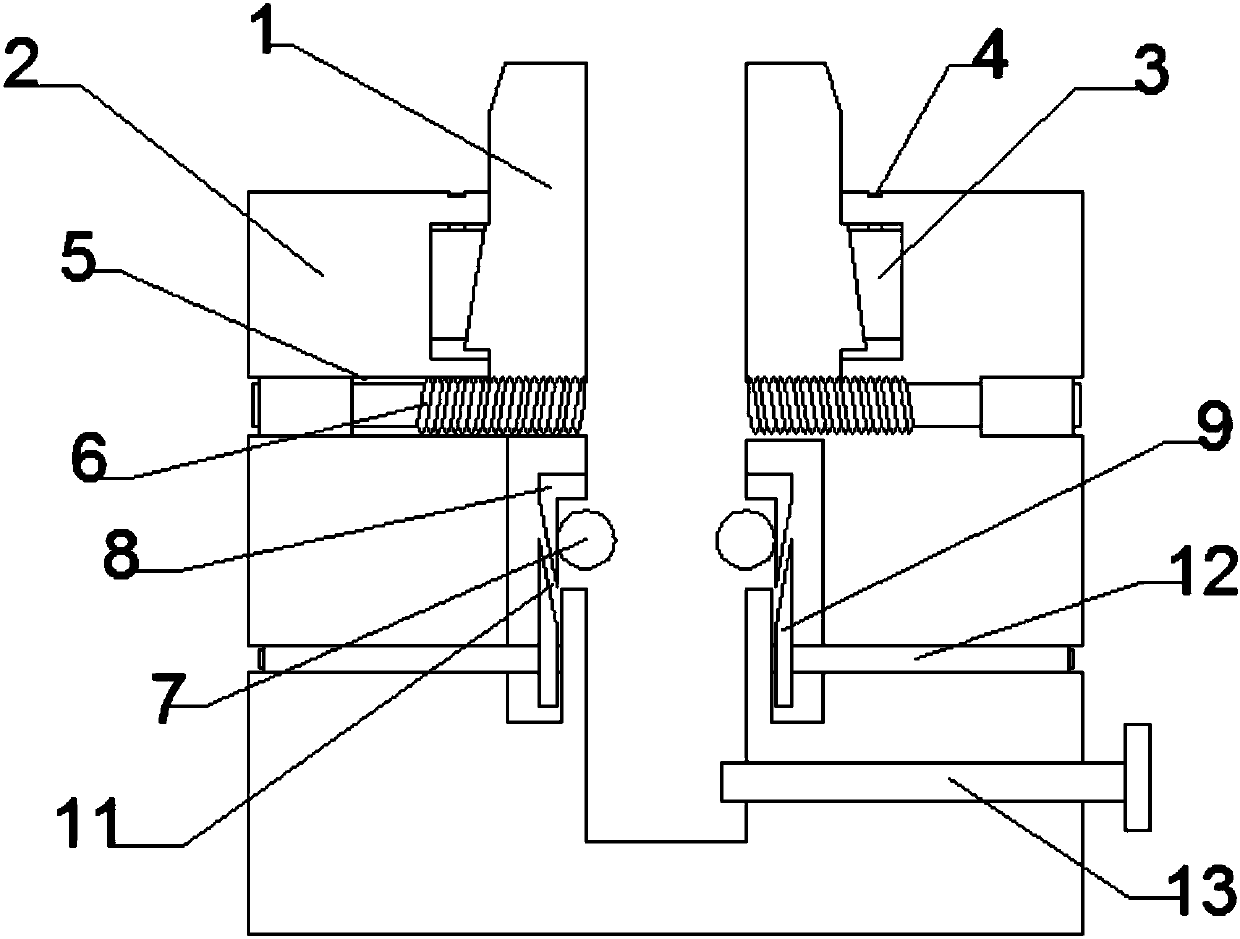

Intelligent detection device for shaft part and using method of intelligent detection device

InactiveCN105806945AEasy loadingEasy to uninstallAnalysing solids using sonic/ultrasonic/infrasonic wavesOptically investigating flaws/contaminationEngineeringMechanical engineering

The invention discloses an intelligent detection device for a shaft part and a using method of the intelligent detection device.The device comprises a fixture part and a detection part, the fixture part comprises a sliding seat of which the front end is provided with a mobile motor, a sliding groove is formed in the sliding seat, a base is slidably installed in the sliding groove and provided with a front-end limiting portion and a back-end limiting portion, a threaded hole is formed in the front-end limiting portion, a threaded rod is installed in the mobile motor, and the threaded rod is installed in the threaded hole in a matched mode; the base is provided with two sliding clamp blocks which can slide in two vertical slideways vertically and symmetrically arranged in the base, the two sliding clamp blocks are oppositely arranged, and each sliding clamp block is rotatably provided with a clamping part through a bearing, wherein the outer side end face of the clamping part is provided with a conical concave portion for performing clamping; the shaft part between the clamping parts of the two sliding clamp blocks is clamped with the help of the pushing and pressing force of the elastic clamping parts which abut against the base to enable the two sliding clamp blocks to obliquely press each other towards each other.

Owner:温岭市锦鹏日用品有限公司

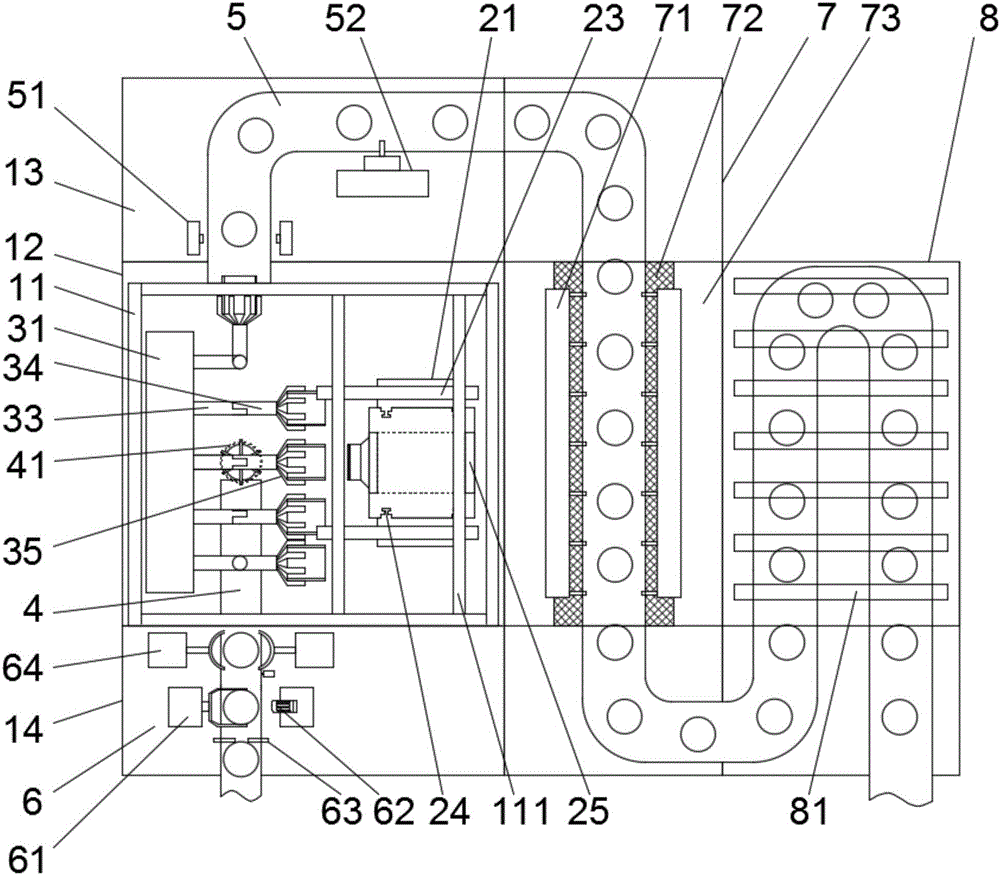

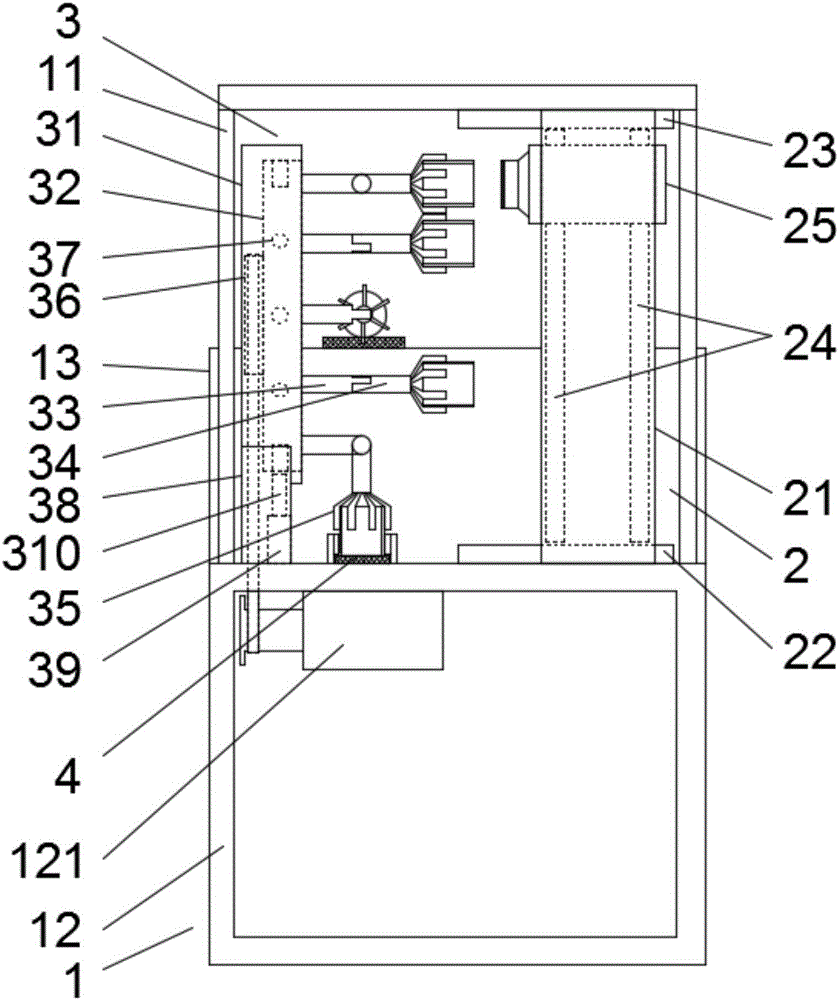

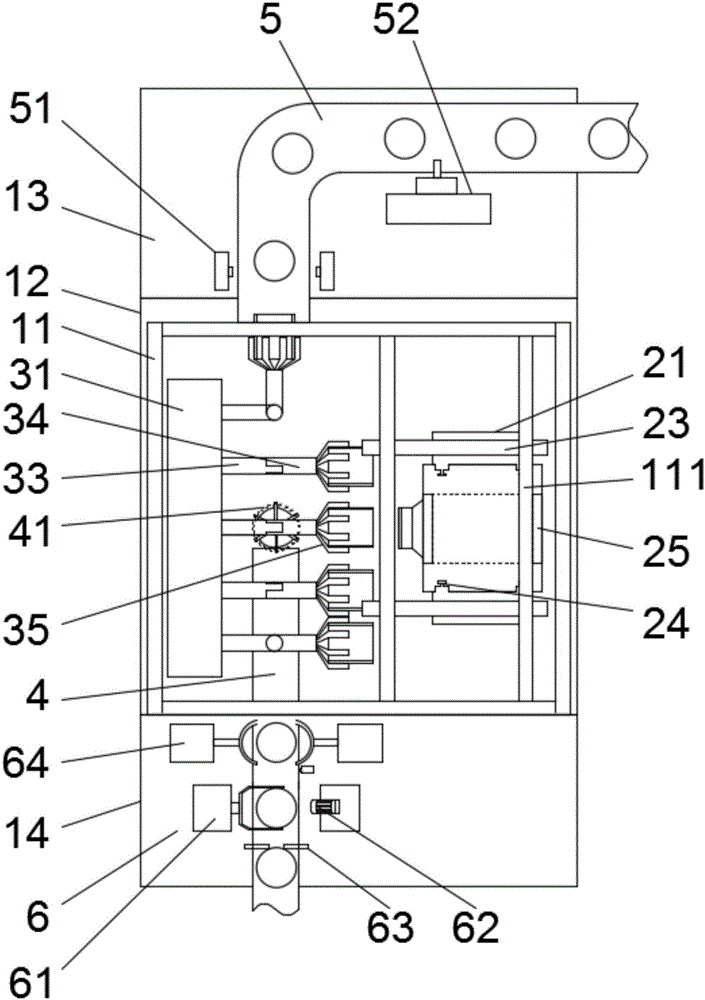

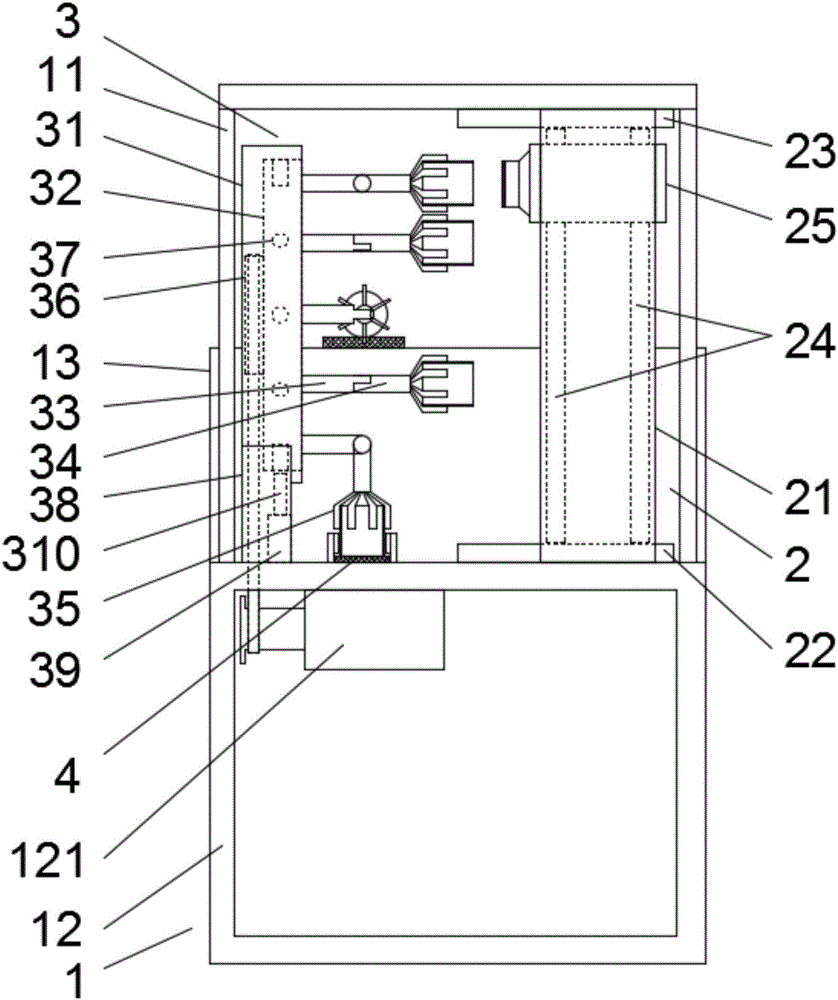

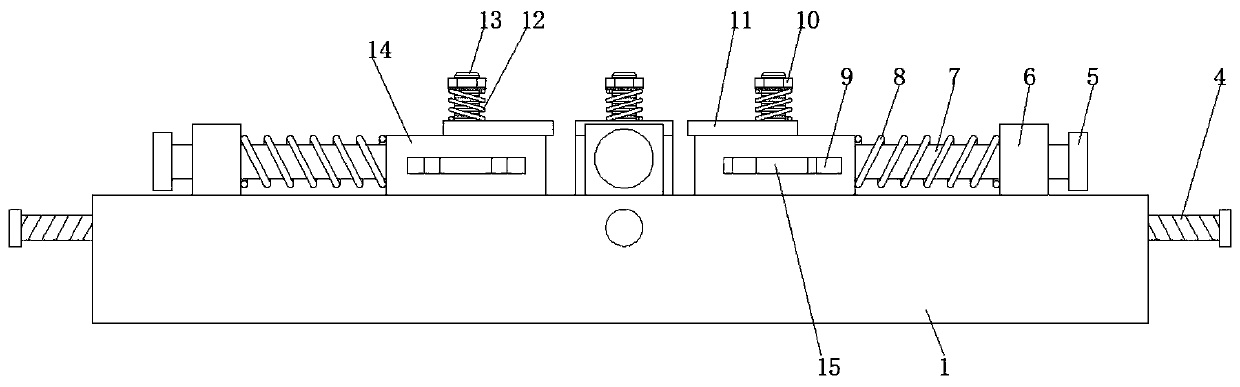

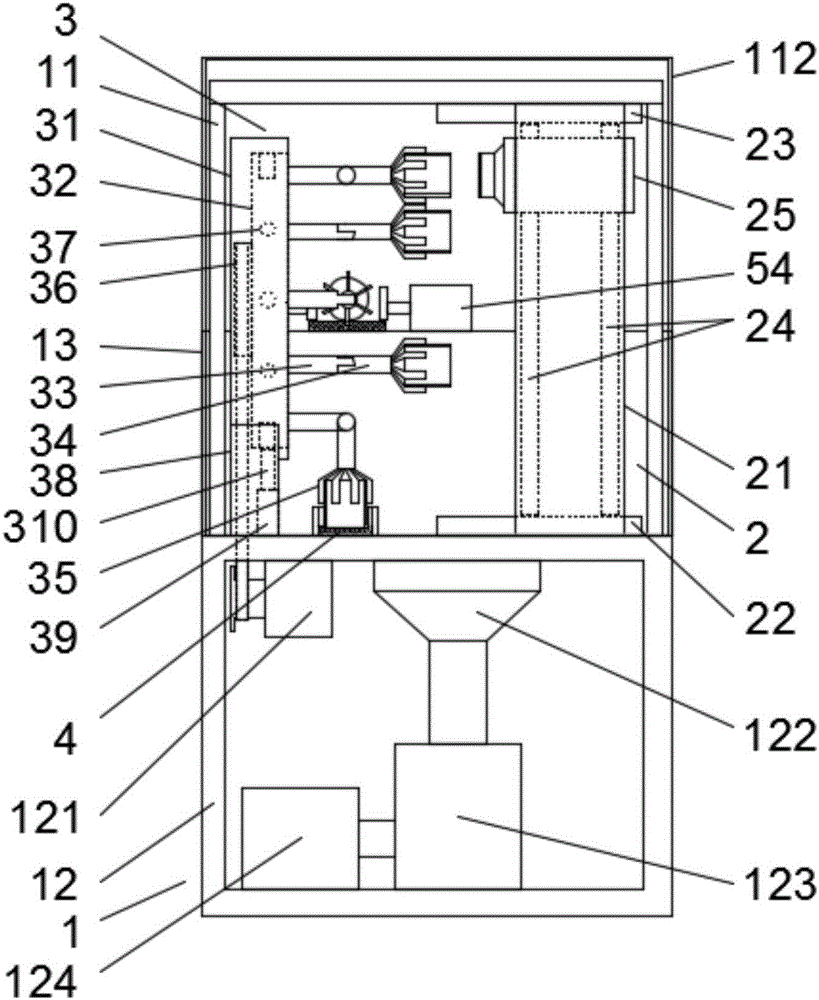

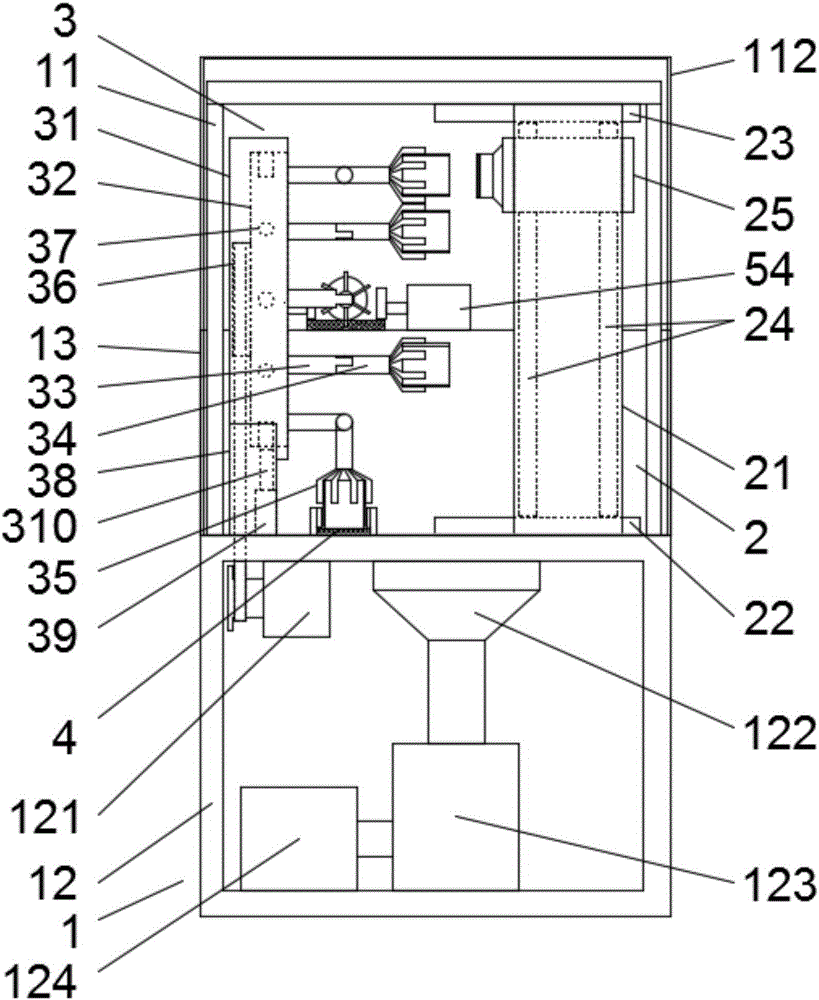

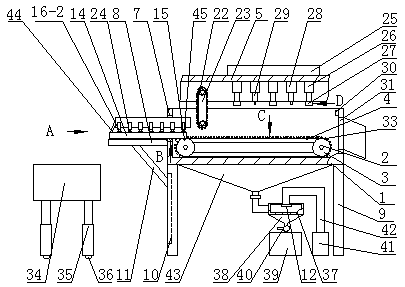

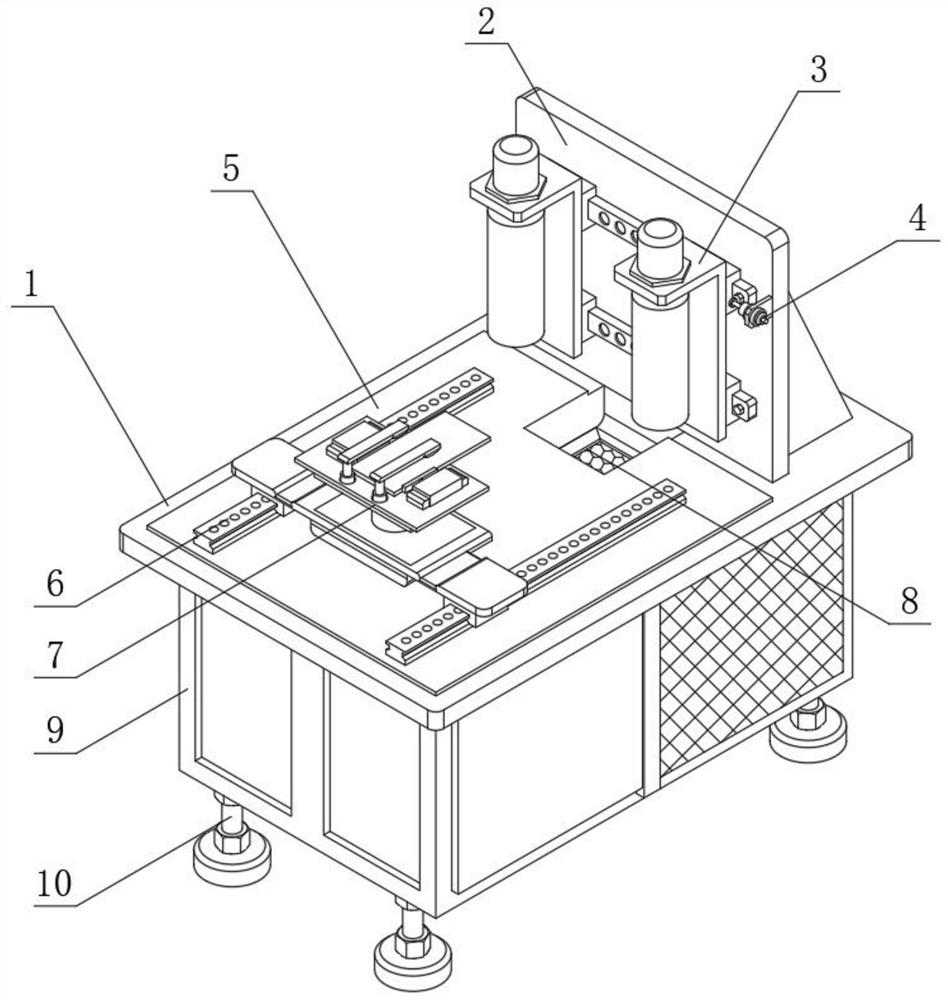

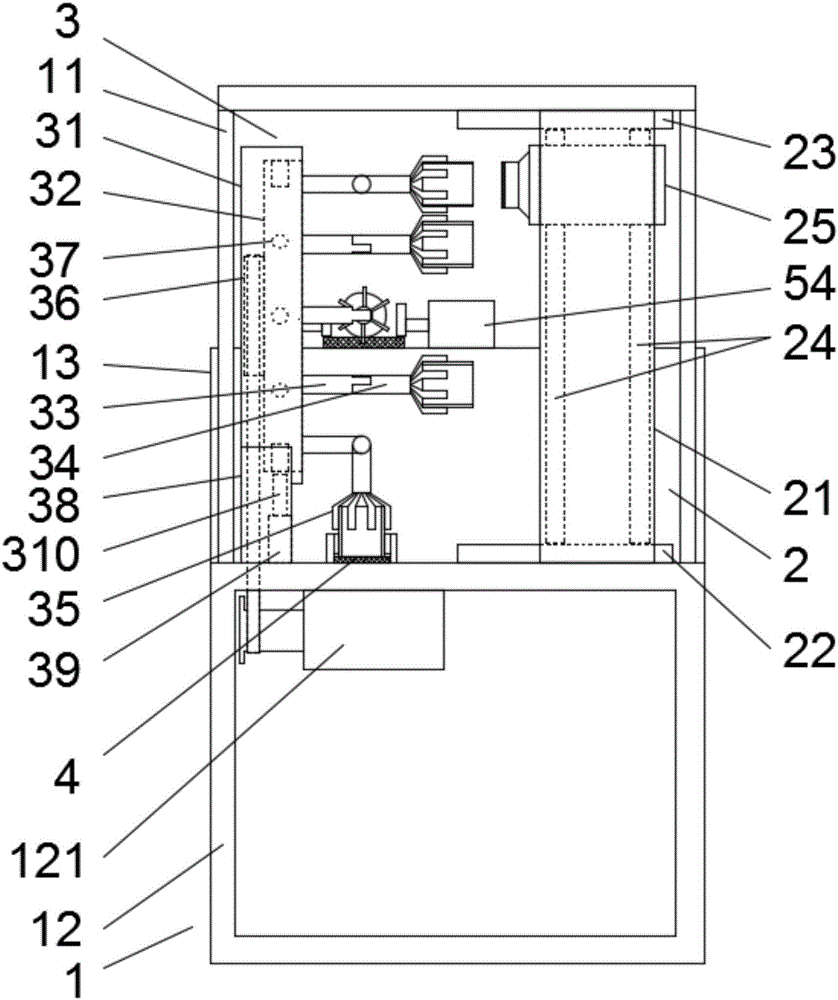

Assembly line type automatic grinding machine

ActiveCN106217204AContinuous actionClamp fasteningGrinding carriagesGrinding feed controlEngineeringAssembly line

The invention relates to an assembly line type automatic grinding machine. The assembly line type automatic grinding machine comprises a rack, wherein the rack comprises a lower rack and a grinding machine upper rack; a grinding device and a rotary disc type clamping device are arranged in the grinding machine upper rack; the lower rack is provided with a rotary disc driving motor; a feeding conveyor belt is arranged on the rack; a discharging platform is further arranged on the rack, and a discharging conveyor belt is arranged on the discharging platform; the bottom end of the feeding conveyor belt is further provided with a feeding CCD detection device; the discharging conveyor belt is provided with a counting sensor, and a laser marking device is arranged at the outlet part of the discharging conveyor belt; the rack is provided with a feeding platform; an adjusting device and a vibrating plate are arranged on the feeding platform; the adjusting device sequentially comprises a feeding baffle, a rotating cylinder and an aligning device in a conveying direction; an azimuth detection device is further arranged near the rotating cylinder; and the right side of the rack is further provided with a sprinkling chamber and a drying chamber. The assembly line type automatic grinding machine continuously acts, automatically carries out clamping and fastening, is short in time consumption, is accurate in locating and ensures workpiece machining quality.

Owner:MAANSHAN YASHIDA INTELLIGENT TECH CO LTD

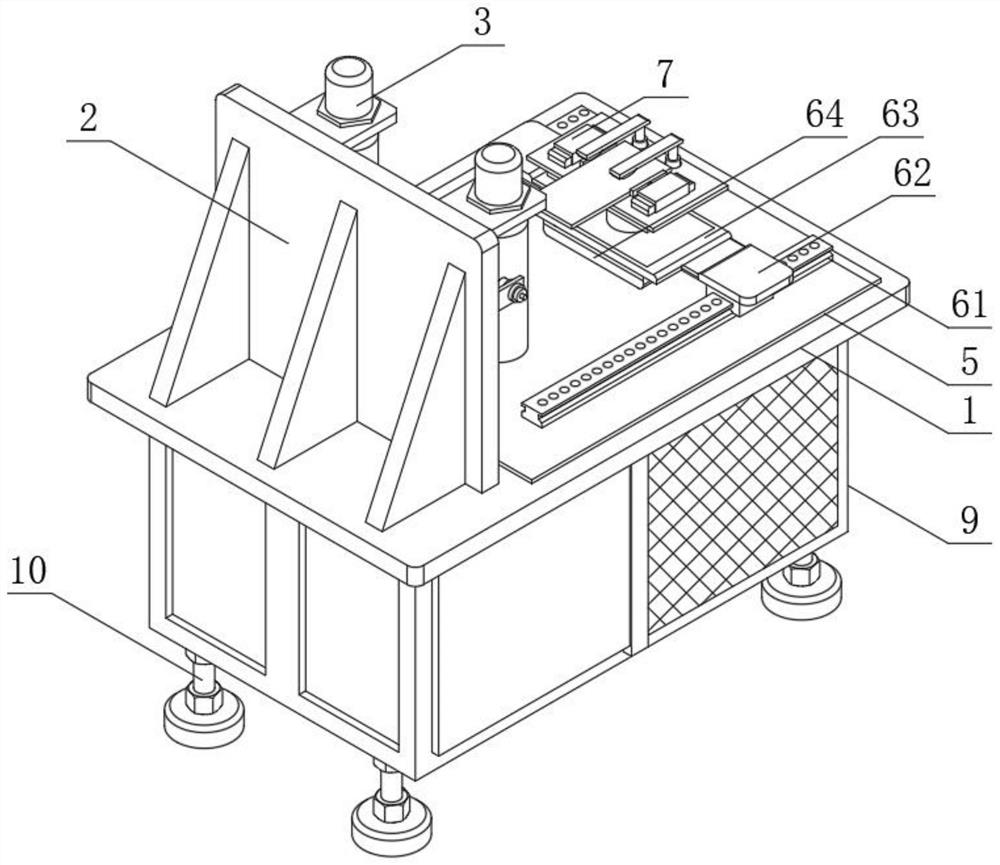

Integrated precise adjustment grinder

ActiveCN106166703AContinuous actionClamp fasteningGrinding carriagesGrinding feed controlEngineeringDirection detection

The invention relates to an integrated precise adjustment grinder which comprises a frame. The frame comprises a lower frame and an upper grinder frame, a grinding device and a rotating disk type clamping device are arranged in the upper grinder frame, a rotating disk driving motor is arranged on the lower frame, a feed conveying belt and a discharge platform are arranged on the frame, an L-shaped discharge conveying belt is arranged on the discharge platform, a feed CCD (charge coupled device) detection device is arranged at the tail end of the feed conveying belt, a counting sensor is arranged at an inlet of the discharge conveying belt, a laser labeler is arranged at an outlet of the discharge conveying belt, the frame is provided with a feed platform, an adjustment device and a vibration disk are arranged on the feed platform, the adjustment device sequentially comprises a feed baffle plate, a turnover cylinder and a righting device along the conveying direction, and a direction detection device is arranged near the turnover cylinder. The integrated precise adjustment grinder is continuous in action, firm and automatic in clamping, short in clamping time and precise in positioning, and workpiece machining quality is ensured.

Owner:宿迁海通科技有限公司

Multifunctional kelp clamp and kelp cleaning device

The invention discloses a multifunctional kelp clamp and a kelp cleaning device. The multifunctional clamp comprises a fixing plate, a first motor, a second gear, a clamp fixing block, a roller, a first gear, a second motor, a fourth gear, a first bearing, a first gear, a first rotating shaft and clamping assemblies; the two sides of the fixing plate are each provided with one clamping assembly; each clamping assembly comprises an air cylinder, a push rod, a support, a first connecting rod, a second connecting rod, a third connecting rod, a connecting rod block and a clamp head, the tops of the two sides of the fixing plate are each provided with a cylinder through a bolt, a push rod is arranged at the outer side of each cylinder, the two sides of the bottom of the push rod are each provided with a first connecting rod through a screw, the bottoms of the two sides of the fixing plate are each provided with a support through a bolt. The multifunctional clamp is simple in structure and convenient to operate, in the kelp cleaning process, clamping is firm, disengagement is not likely to be caused, the two faces of kelp can be cleaned, the cleaning effect is good, and the kelp cleaningefficiency is greatly improved.

Owner:台州市黄岩五星车业有限公司

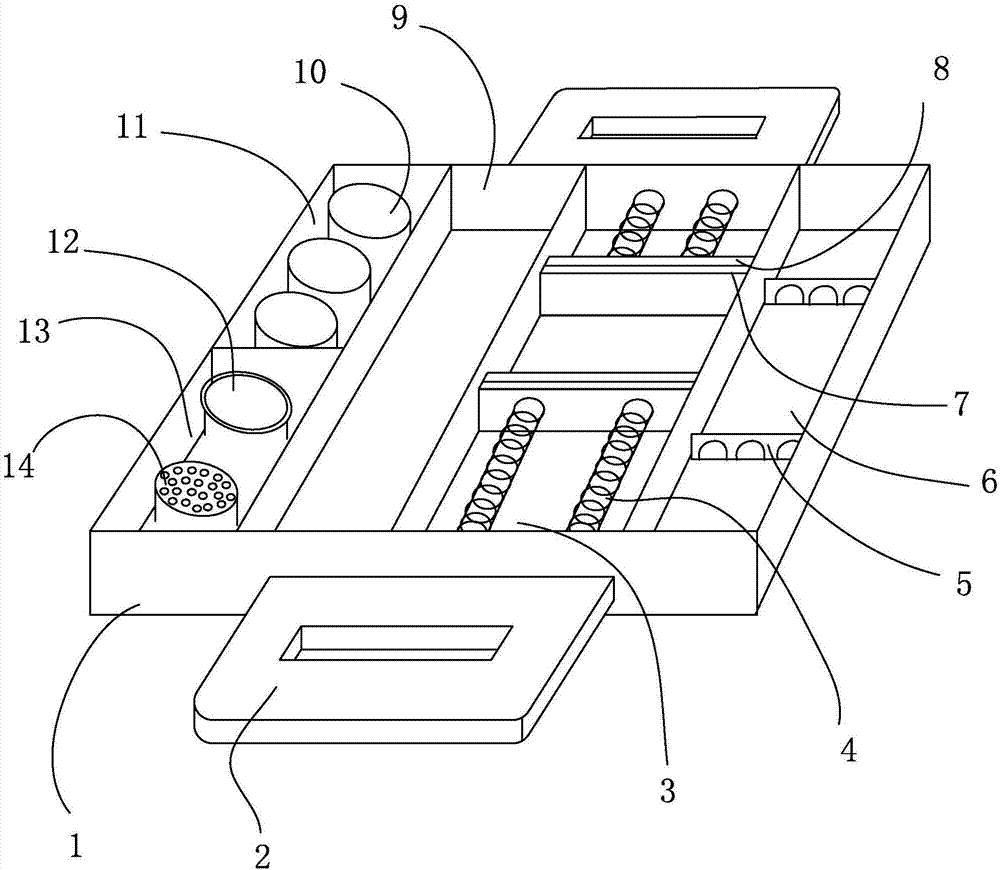

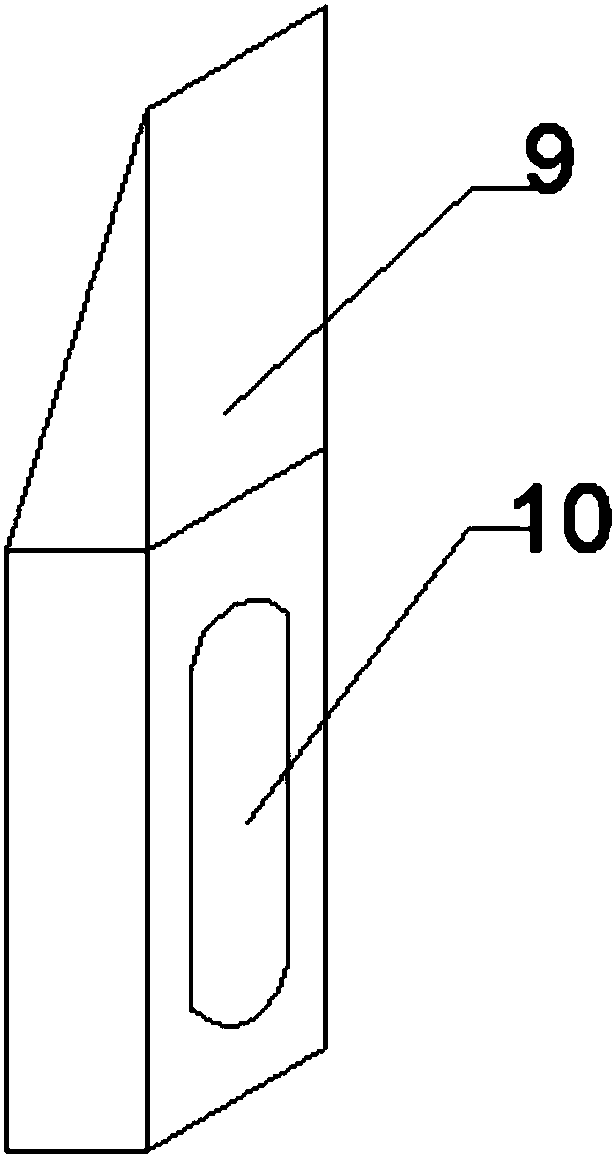

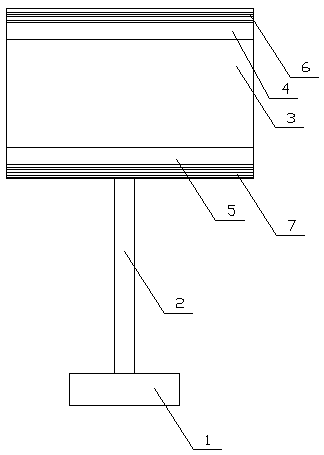

Medical tray

PendingCN107049513ASimple and reasonable structureEasy to useSurgical furnitureNursing accommodationPhysicsEngineering

The invention discloses a medical tray which comprises a tray body. The bottom of the tray body is a square plate, and vertical plates used for blocking at the edges of the square plate are arranged on the periphery of the square plate; handles are arranged on the two sides of the tray body, each handle is shaped like a plate provided with a long through hole which is big enough to allow a finger to pass through, and the handle areas between the long through holes and the handle outer side edges can be held by the palms; the tray body is provided with a partition plate which divides the interior of the tray body to form a rectangular clamping area, two clamping plates parallel to the short side edges of the clamping area are arranged in the clamping area, clamping springs are arranged between the clamping plates and short side edges of the clamping area, and a buffer plate made from flexible materials is arranged on the clamping surface of each clamping plate. The medical tray is simple and reasonable in structure, secondary pollution of internal equipment can be avoided while the medical tray is held by the hand conveniently, contained objects can be fastened and clamped, and use is convenient.

Owner:GUILIN MEDICAL UNIVERSITY

Battery core sorting machine

The invention discloses a battery core sorting machine. The battery core sorting machine comprises a rack, a material feeding module, a test module and a sorting module, wherein the material feeding module comprises a material feeding bin, the material feeding bin is internally provided with a first material guide plate, a second material guide plate and a sliding groove, the sliding groove is provided with a through hole, the second material guide plate is provided with a support plate, and the support plate is provided with a sliding rod; the lower portion of the first material guide plate is provided with a material passing rotating wheel, the lower portion of the material passing rotating wheel is provided with a first baffle, a material passing passage just capable of containing one battery core to pass through is formed between the material passing rotating wheel and the second material guide plate, the material feeding bin is internally provided with a material conveying pushingblock and a material outlet passage, and the first baffle is provided with a driving motor; and the test module comprises a lifting air cylinder, the lifting air cylinder is provided with a fixed block, a conveying platform is arranged above the fixed block and is provided with a conveying belt, and the fixed block is provided with a test mechanism with a plurality of test units of different sizes. The battery core sorting machine is simple in structure, simple and convenient to operate and adaptable to use for battery cores of various sizes and specifications.

Owner:江西尚立动力科技有限公司

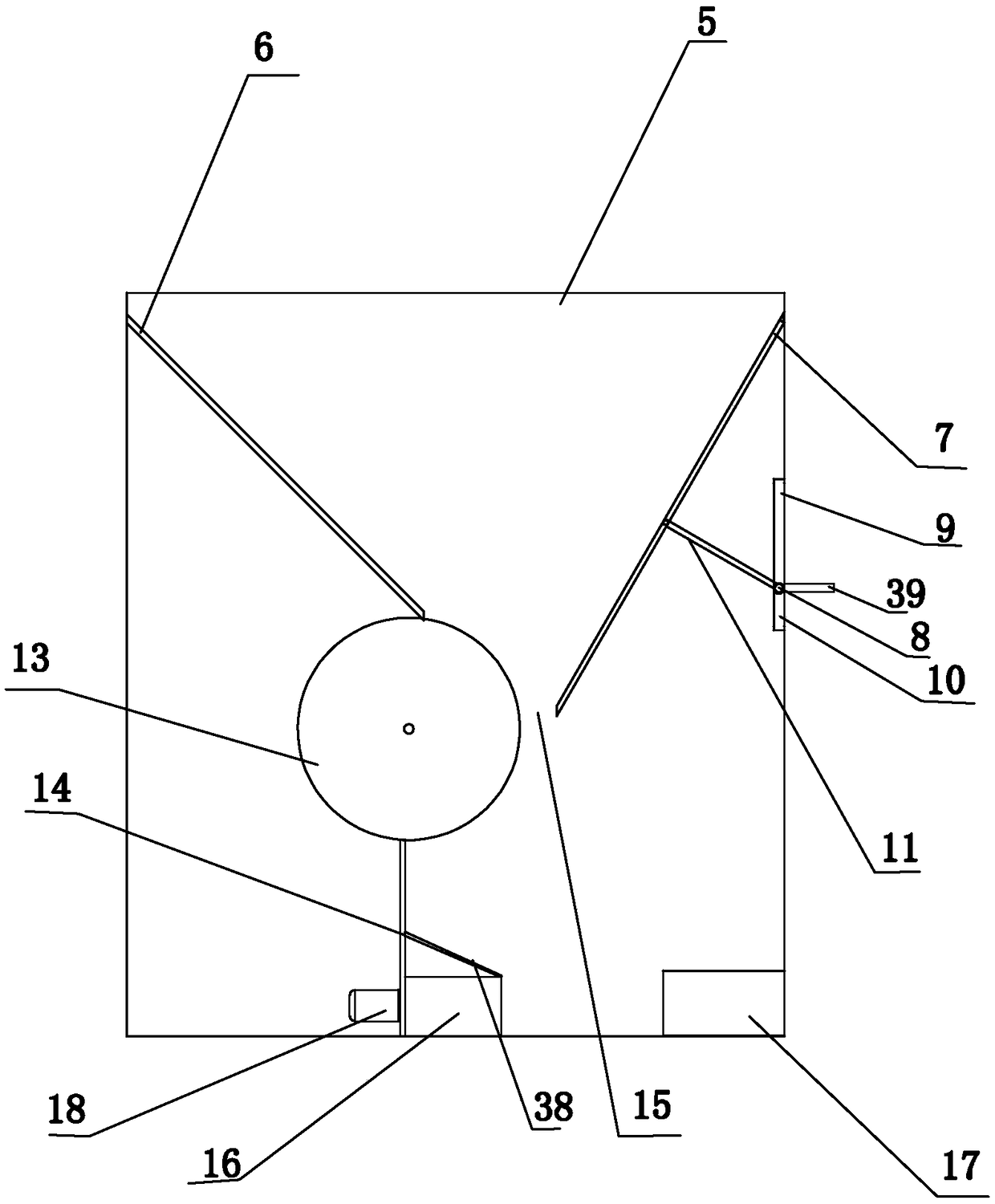

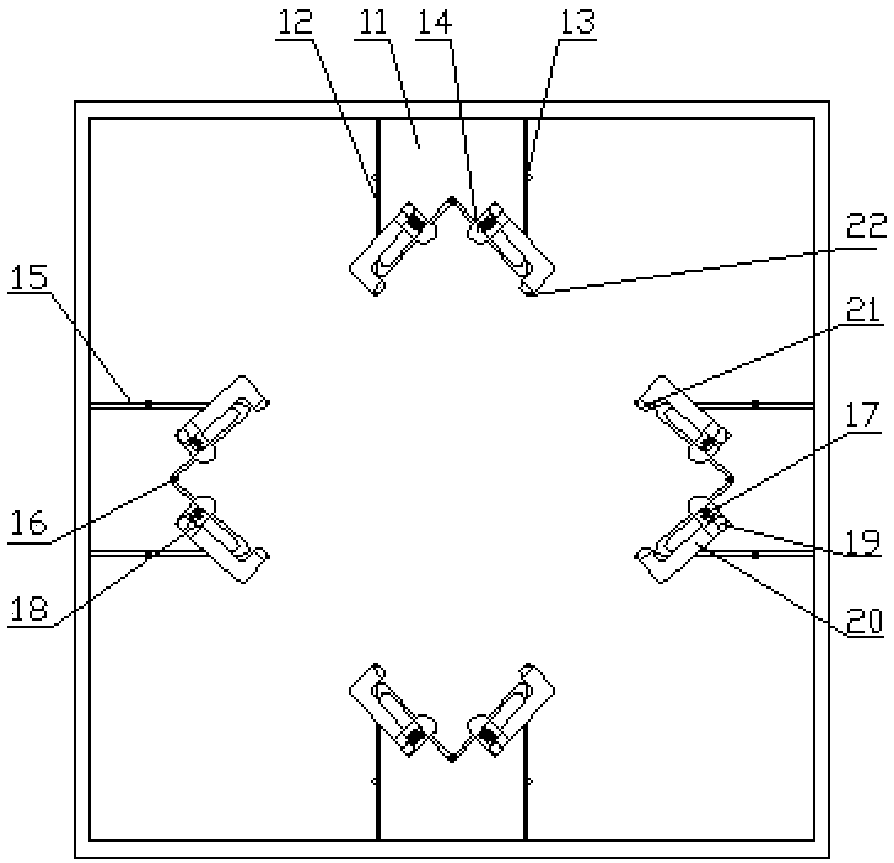

Bracket fixing device for glue dispensing machine

InactiveCN111068988AClamp fasteningAvoid disassemblyLiquid surface applicatorsCoatingsEngineeringScrew thread

The invention discloses a bracket fixing device for a glue dispensing machine. The bracket fixing device comprises a workbench. Four clamping mechanisms are distributed on the upper surface of the workbench in an annular array at the center of the workbench. Each clamping mechanism comprises a vertical block and a push block sliding on the upper surface of the workbench. A pull rod is arranged atone end of each push block. Each pull rod is sleeved with a clamping spring. Each pull rod penetrates through one side of the corresponding vertical block and extends to the other side of the corresponding vertical block and is connected with a limiting disc. Sliding grooves are formed in the upper surface of the workbench. Screw holes communicated with the sliding grooves are formed in the side face of the workbench. The interiors of the screw holes are in threaded connection with threaded rods. According to the bracket fixing device for the glue dispensing machine, a workpiece is fixedly clamped through the four clamping mechanisms, assembling and disassembling of bolts are avoided, and the working efficiency is improved; and in order to adapt to clamping of workpieces of different sizes, the clamping springs are matched with the pull rods at the push blocks, and clamping of the workpieces is tighter through the elastic action of the clamping springs.

Owner:安徽徽合台智能科技有限公司

Tool clamp for bionic bait

ActiveCN110314789AThe lifting process is linearHigh economical availabilitySpraying apparatusEngineeringMechanical engineering

The invention discloses a tool clamp for bionic baits. The tool clamp comprises two symmetrically-arranged bearing plates, wherein bearings on the surfaces of the bearing plates are rotationally connected with bosses, one ends, far away from the bearing plates, of the two bosses are rotationally connected with right-angle frames, the two right-angle frames are fixedly arranged on the two sides ofthe length direction of the upper end surface of a supporting plate respectively. According to the tool clamp, the bottom of the bionic baits is fixed through positioning holes, a screw rod is used for being matched with a lifting plate to rotate, and the two sides are guided through a sliding groove, so that the lifting process of the lifting plate is more linear, the lifting plate drives the relative position of the bionic bait and clamping arms to be adjusted, and the technical problem that the bionic bait with different lengths cannot be effectively fixed in the prior art is solved; and avertical plate is pulled by the output end of a telescopic air cylinder through a piston rod, the vertical plates move in the direction of sliding rods on the two sides, and soft rubber pads on arc-shaped clamping blocks clamp the bionic baits, so that the technical problems that in the prior art, the multiple bionic baits cannot be clamped and the clamping effect is poor are solved.

Owner:安徽宏飞钓具有限公司

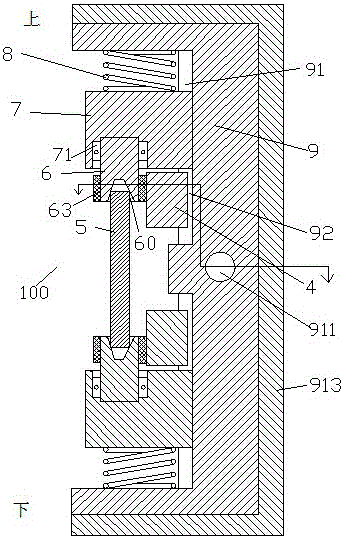

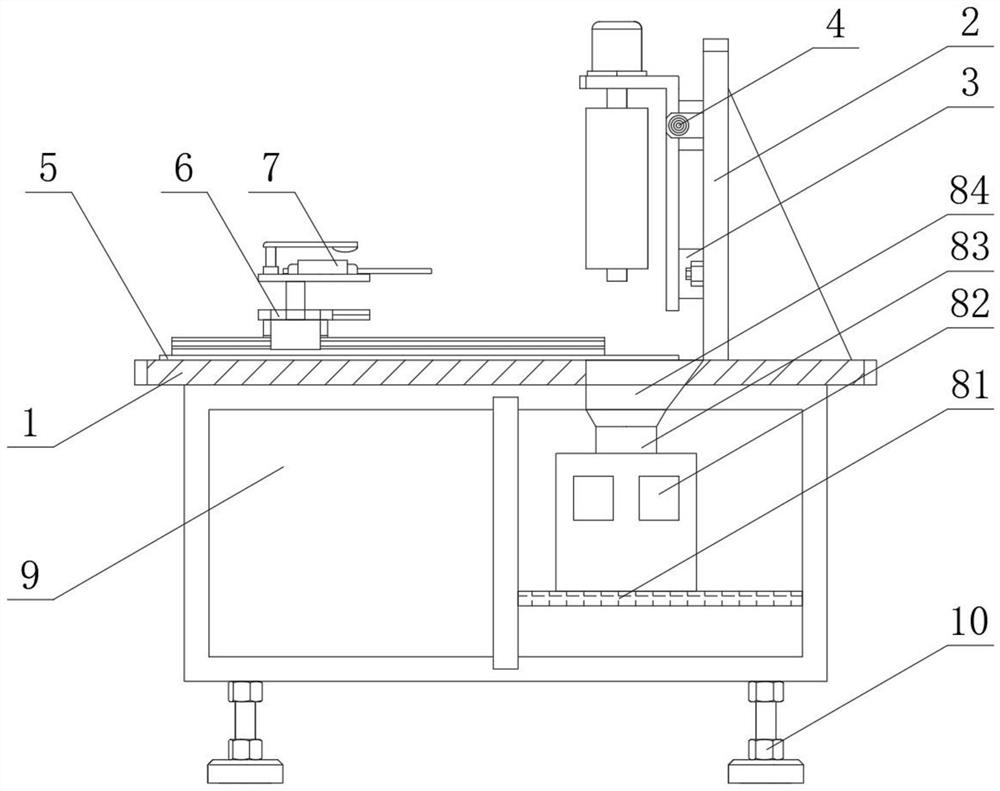

Drilling machining device

ActiveCN107671323AClamp fasteningIncrease the clamping areaPositioning apparatusMetal-working holdersManufacturing technologyFixed frame

The invention discloses a drilling machining device and relates to the technical field of motor part machining and manufacturing. The drilling machining device comprises a worktable. A motor and a thrust air cylinder are arranged on the worktable. A drill bit is arranged on the motor. A driving device is arranged on the thrust air cylinder. The driving device comprises a rotating plate, a base anda supporting frame. The rotating plate is rotationally connected with the base. A groove is formed in the base. The supporting frame and the rotating plate are rotationally connected. The rotating plate is provided with a clamping box, and the clamping box is provided with clamping devices. Each clamping device comprises a fixing frame and a clamping head, wherein the clamping head is provided with a connecting spring, a protrusion, a sliding groove and a pipeline hole, the protrusion is provided with a compression spring, the compression spring is connected with a compression plate, the compression plate is provided with a first air bag which is connected with a connecting pipeline, the connecting pipeline is provided with a second air bag, the second air bag is provided with an air inlet hole, and the air inlet hole is provided with an air inlet stopper. By the adoption of the technical scheme, the problem that an existing drilling device cannot conduct drilling on workpieces with irregular shapes, and the drilling machining device can be used for drilling machining of workpieces with all shapes.

Owner:NANTONG GUANFENG CASTING

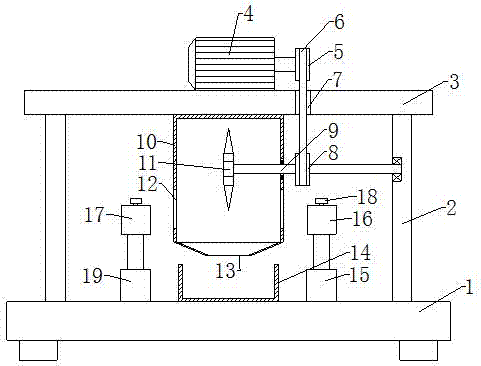

Vibration forming platform for casting mold

ActiveCN111496230AClamp fasteningQuality improvementFoundry mouldsFoundry coresAir springEngineering

The invention discloses a vibration forming platform for a casting mold. The platform comprises a platform base. A vibration box is arranged on the upper surface of the platform base, the vibration box is internally filled with a sand-water mixed solution, a plurality of air springs and supporting springs are fixedly connected between the vibration box and the platform base, the bottom end of theouter surface of the vibration box is fixedly connected to a tension spring, and the bottom of the tension spring is fixedly connected to the platform base. According to the vibration forming platformfor the casting mold, by arranging the inner wall of the vibration box and a plurality of vibrators on the inner bottom wall, a mold immersed into the sand-water mixed solution receives a vibration force transferred by the sand-water mixed solution as a medium all around, so that vibration is more thorough and air bubbles in the mold can collide and are discharged from a sprue gate of the mold. By arranging a heating sheet, the sand-water mixed solution in the mold is heated to prevent molten iron in the mold from being cooled quickly, so that the surface of a cooled and formed casting is smoother, and the casting quality is improved.

Owner:安徽省安工机械制造有限公司

Automatic detection grinding machine capable of adjusting feeding and collecting dust

ActiveCN106217183AGuarantee processing qualityContinuous actionGrinding carriagesGrinding feed controlGlass coverEngineering

The invention relates to an automatic detection grinding machine capable of adjusting feeding and collecting dust. The automatic detection grinding machine capable of adjusting feeding and collecting dust comprises a rack, wherein the rack comprises a lower rack and a grinding machine upper rack; the grinding machine upper rack is provided with a glass cover shell, a grinding device, a rotary disc type clamping device and a dust collector; the lower rack is provided with a rotary disc driving motor; a feeding conveyor belt is arranged on the rack; a discharging platform is arranged on the rack, a Y-shaped discharging conveyor belt is arranged on the discharging platform, a discharging CCD detection device is arranged at the crossed point, and the discharging conveyor belt is provided with a laser marking device; the feeding conveyor belt is provided with a feeding CCD detection device; the rack is provided with a feeding platform; an adjusting device and a vibrating plate are arranged on the feeding platform; the adjusting device sequentially comprises a feeding baffle, a rotating cylinder and an aligning device in a conveying direction; and an azimuth detection device is further arranged near the rotating cylinder. The automatic detection grinding machine capable of adjusting feeding and collecting dust continuously acts, automatically carries out clamping and fastening, is short in time consumption, is accurate in locating and ensures workpiece machining quality.

Owner:MAANSHAN YASHIDA INTELLIGENT TECH CO LTD

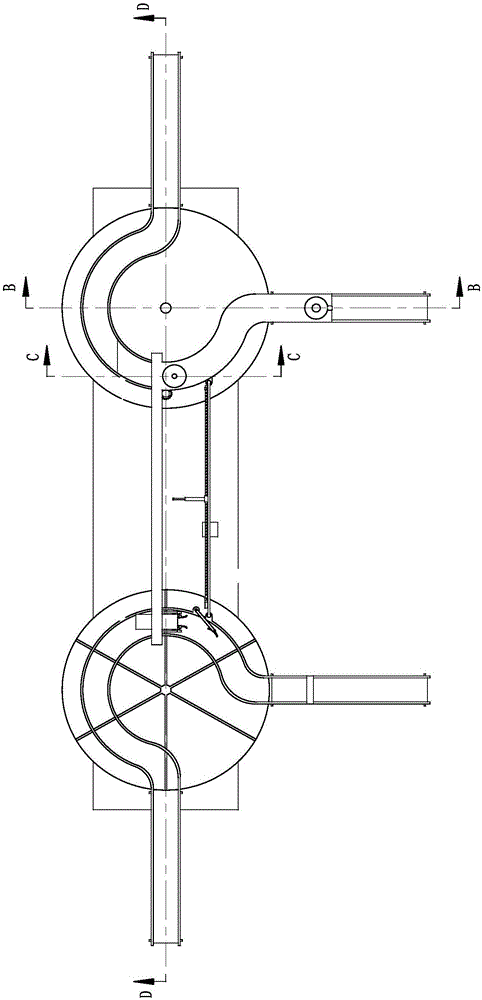

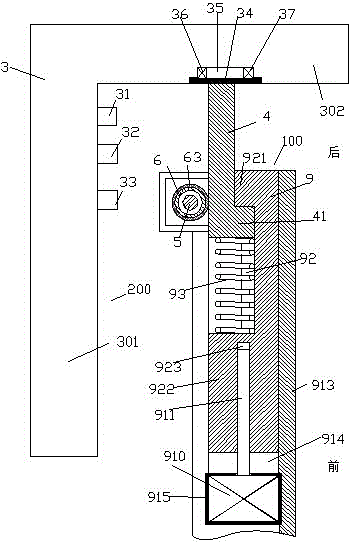

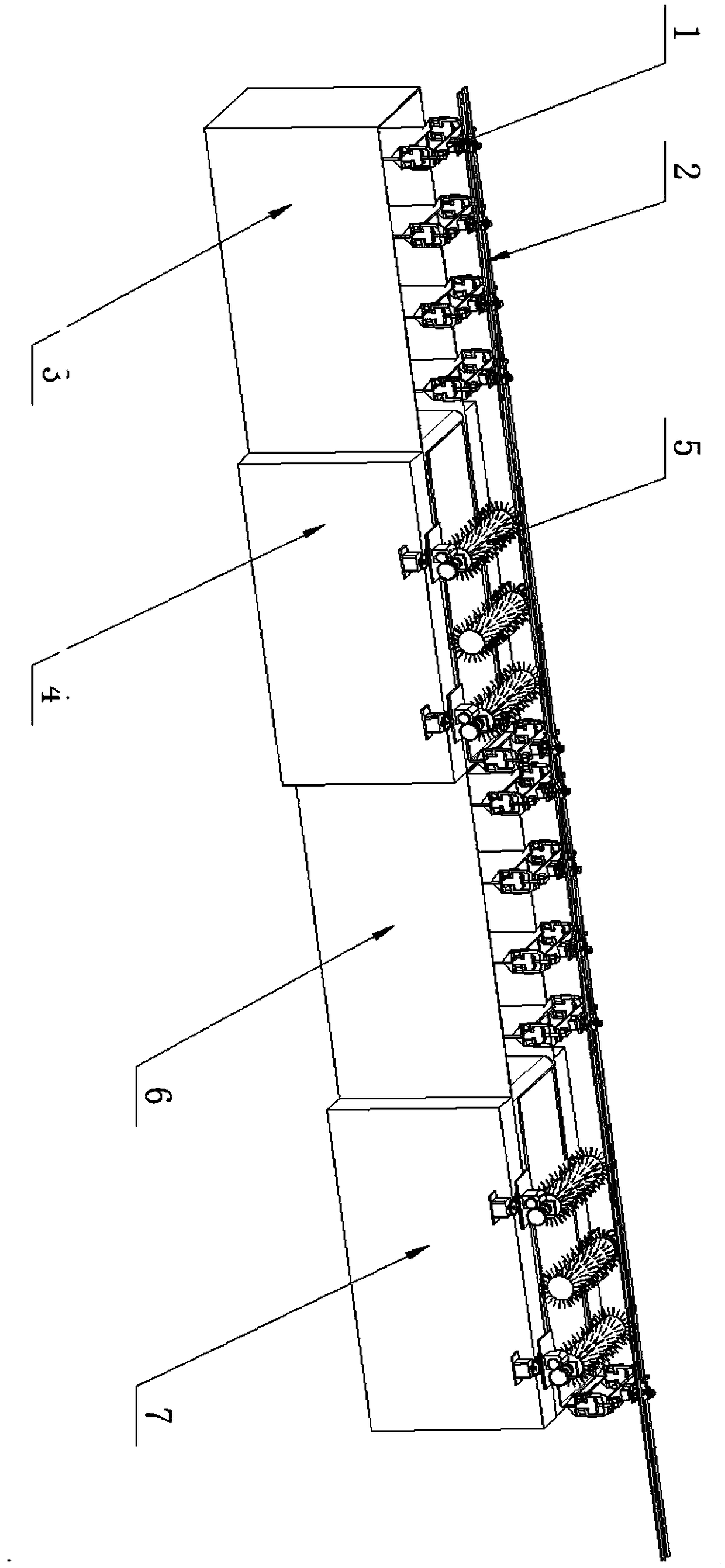

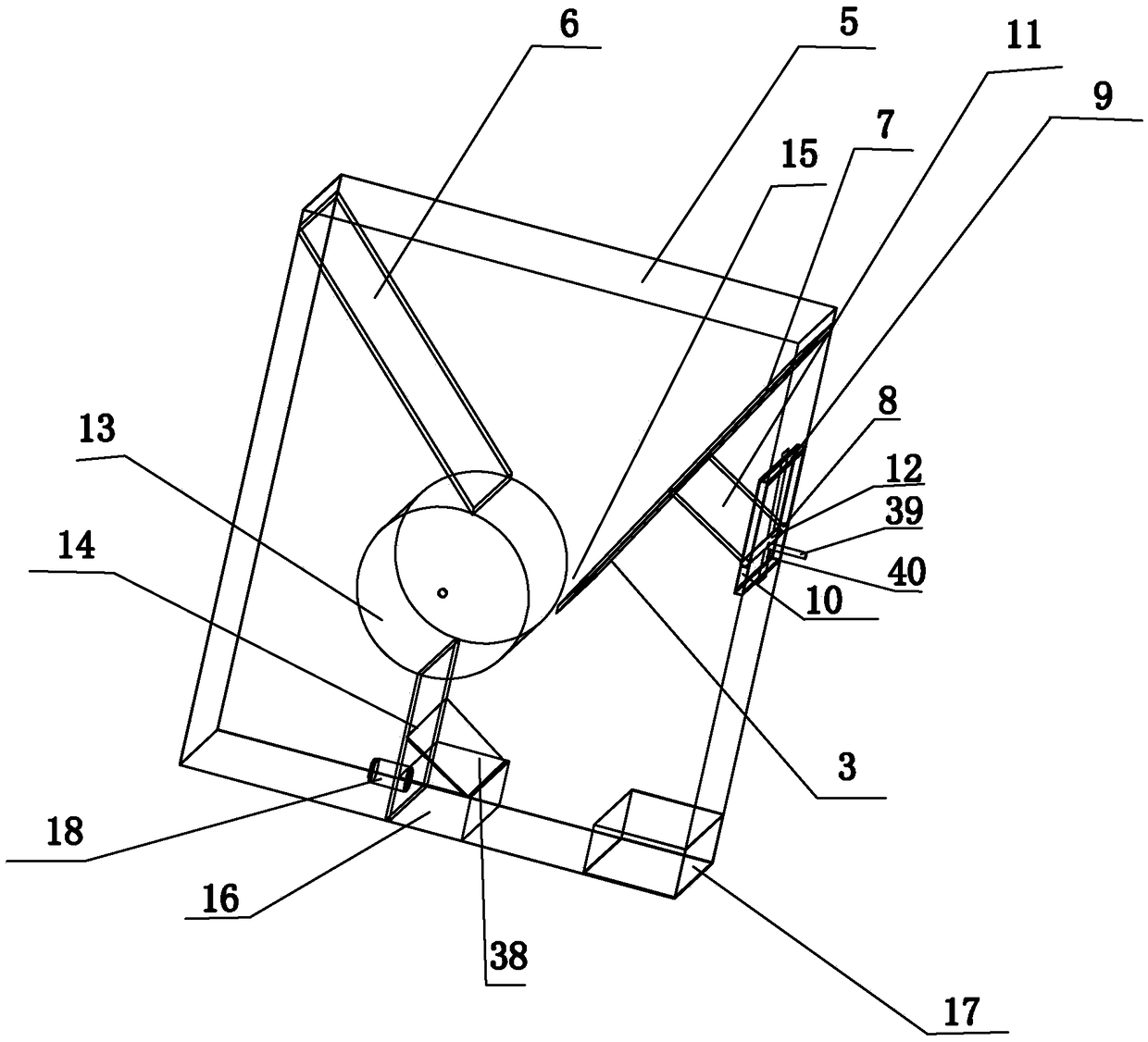

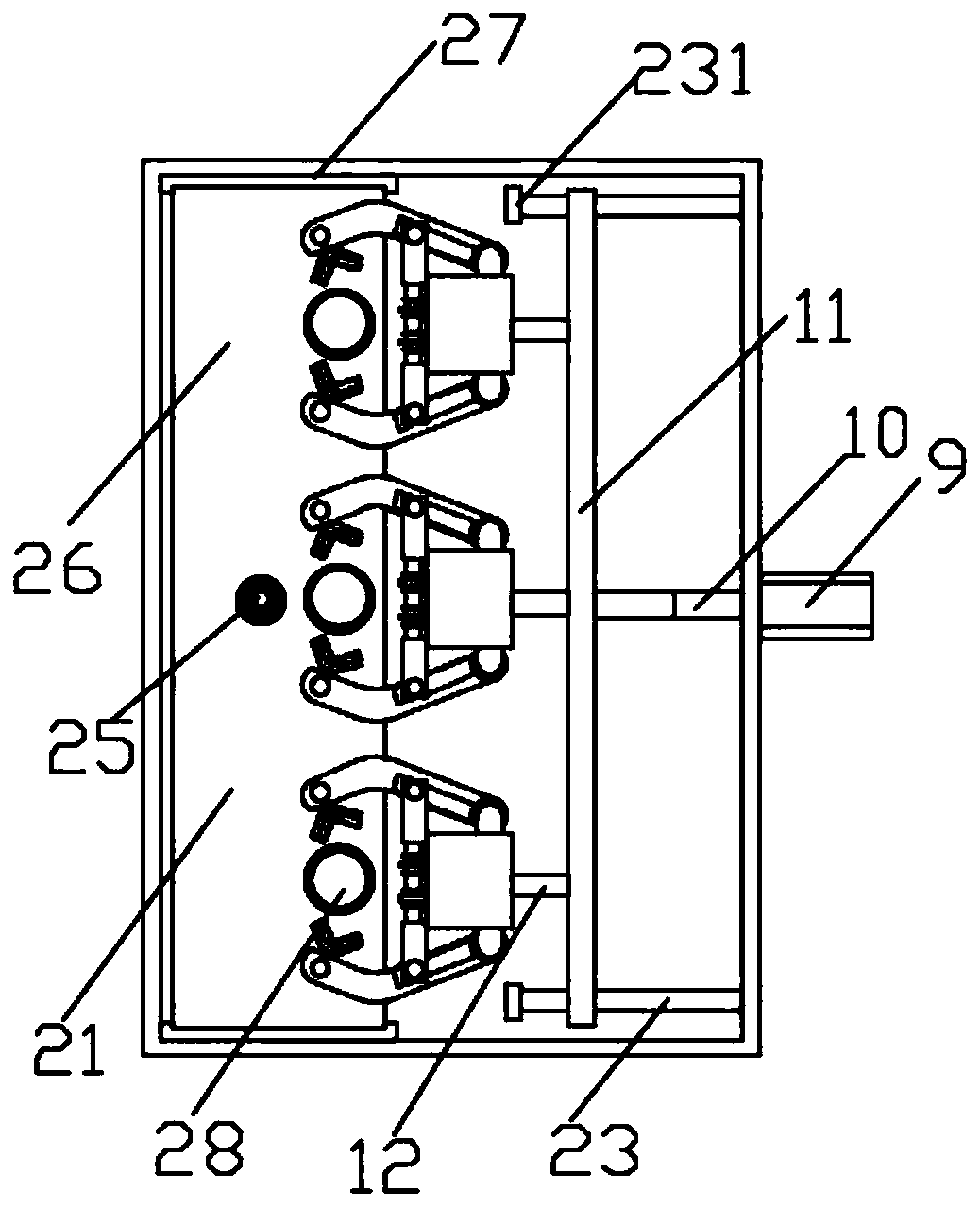

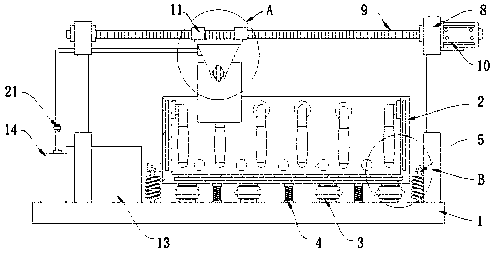

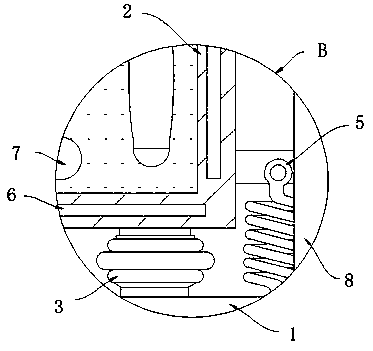

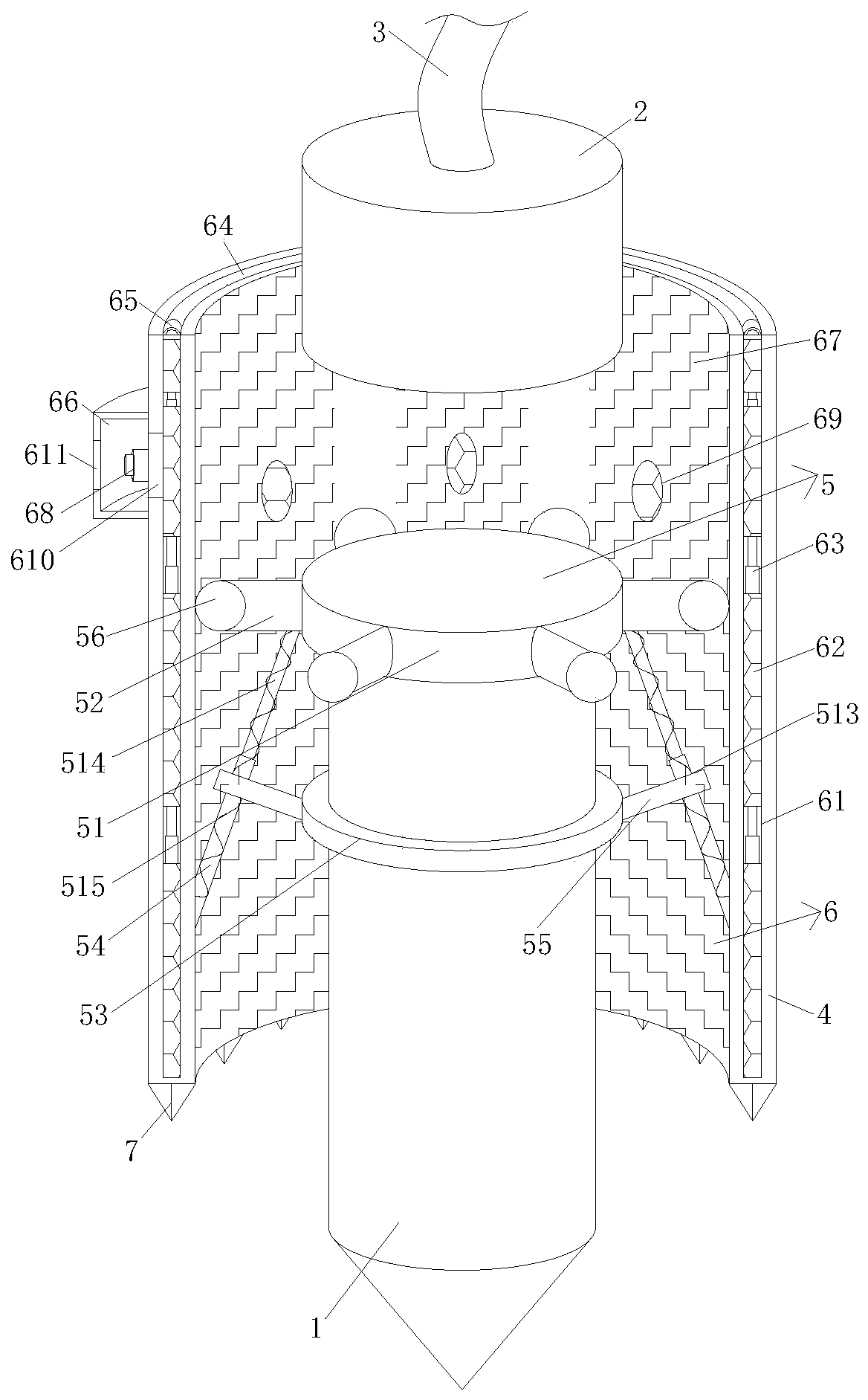

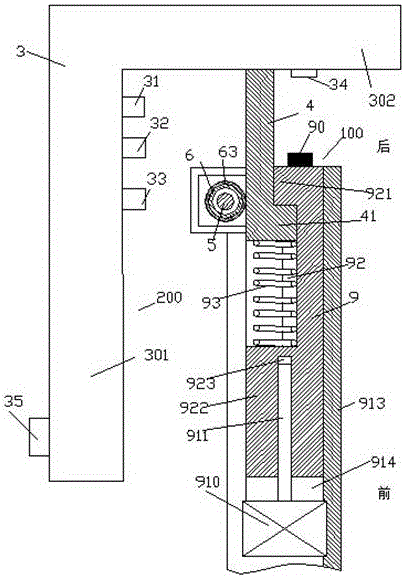

Gardening succulent plant pot dividing and root dipping integrated machine

ActiveCN106538258AAchieve interval exerciseClamp fasteningHorticulture methodsConveyor partsStops deviceEngineering

The invention relates to the field of agricultural machinery, in particular to a gardening succulent plant pot dividing and root dipping integrated machine which comprises a frame, a plant conveying device, a pot dividing device and a root dipping device. The frame comprises a top support plate, a middle support plate and four support legs, the plant conveying device comprises a first belt conveyor, a second belt conveyor, a plant conveying inner ring plate, a plant conveying outer ring plate, a plant conveying turntable, a plant conveying rotation shaft, a grooved wheel mechanism, a plant conveying motor and a pot stopping device, and the pot dividing device comprises a pot dividing body, a pot fixing device and a plant transferring device, and the root dipping device comprises a liquid transport hard pipe, a liquid transport flexible pipe, a liquid collection tank, a liquid baffle plate, a liquid baffle cylinder and a root dipping support plate. Succulent plants can be automatically separated from an old pot, and roots of the succulent plants are automatically dipped in sterilization water. Compared with a traditional succulent plant pot replacing step, manual operation is saved, working efficiency is improved, and the integrated machine is high in practicability.

Owner:新昌县博衍智能科技有限公司

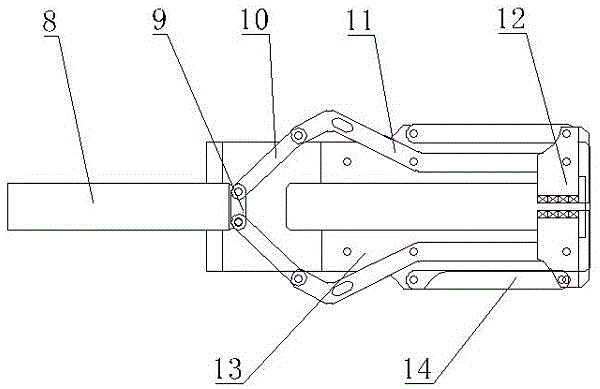

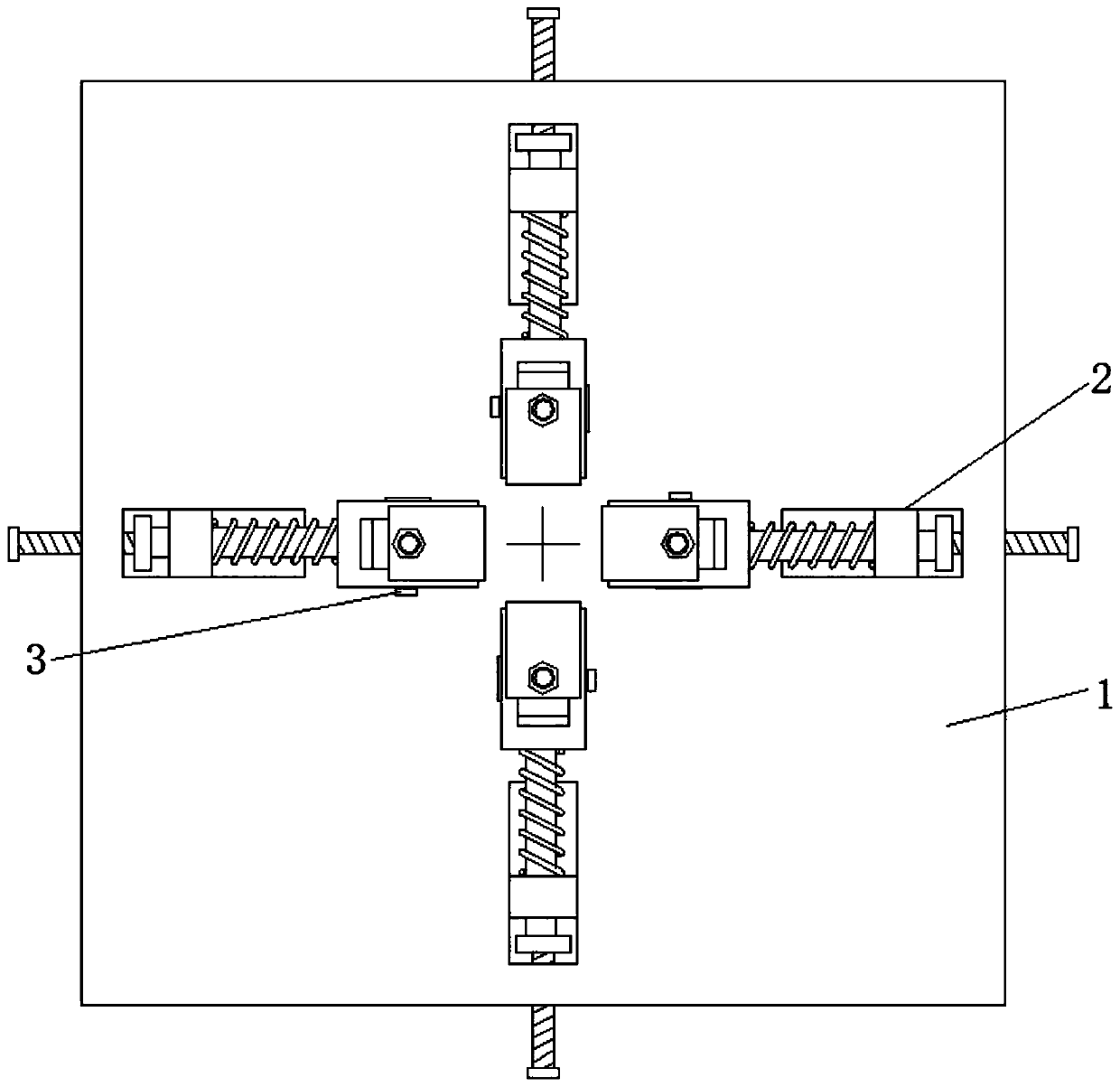

Shaft part detection device provided with contact sensor and using method thereof

InactiveCN105698866AEasy loadingEasy to uninstallMaterial analysis using sonic/ultrasonic/infrasonic wavesMaterial analysis using wave/particle radiationElastic componentEngineering

The invention discloses a shaft part detection device provided with contact sensor and a using method thereof. The device comprises a clamp component and a detection component, wherein the clamp component comprises a sliding seat whose front end is provided with a mobile motor; a sliding groove is arranged in the sliding seat; a base is arranged in a sliding mode in the sliding groove; the base is provided with a front-end limiting part and a rear-end limiting part; a threaded hole is arranged in the front-end limiting part; a screw rod is arranged in the mobile motor; the screw rod and the threaded hole are matched and arranged; two sliding clamping blocks which can slide in two vertically symmetrically-arranged vertical sliding ways respectively are arranged on the base; the two sliding clamping blocks are oppositely arranged, and each is provided with a clamping component whose outer end surface is provided with a clamping-used conical recess in a rotary mode via a bearing, and with the help of a pushing and pressing force of a clamping elastic component abutting against the base to enable the two sliding clamping blocks to press bias facing each other, and the shaft part between the clamping components of the two sliding clamping blocks is clamped.

Owner:温岭市锦鹏日用品有限公司

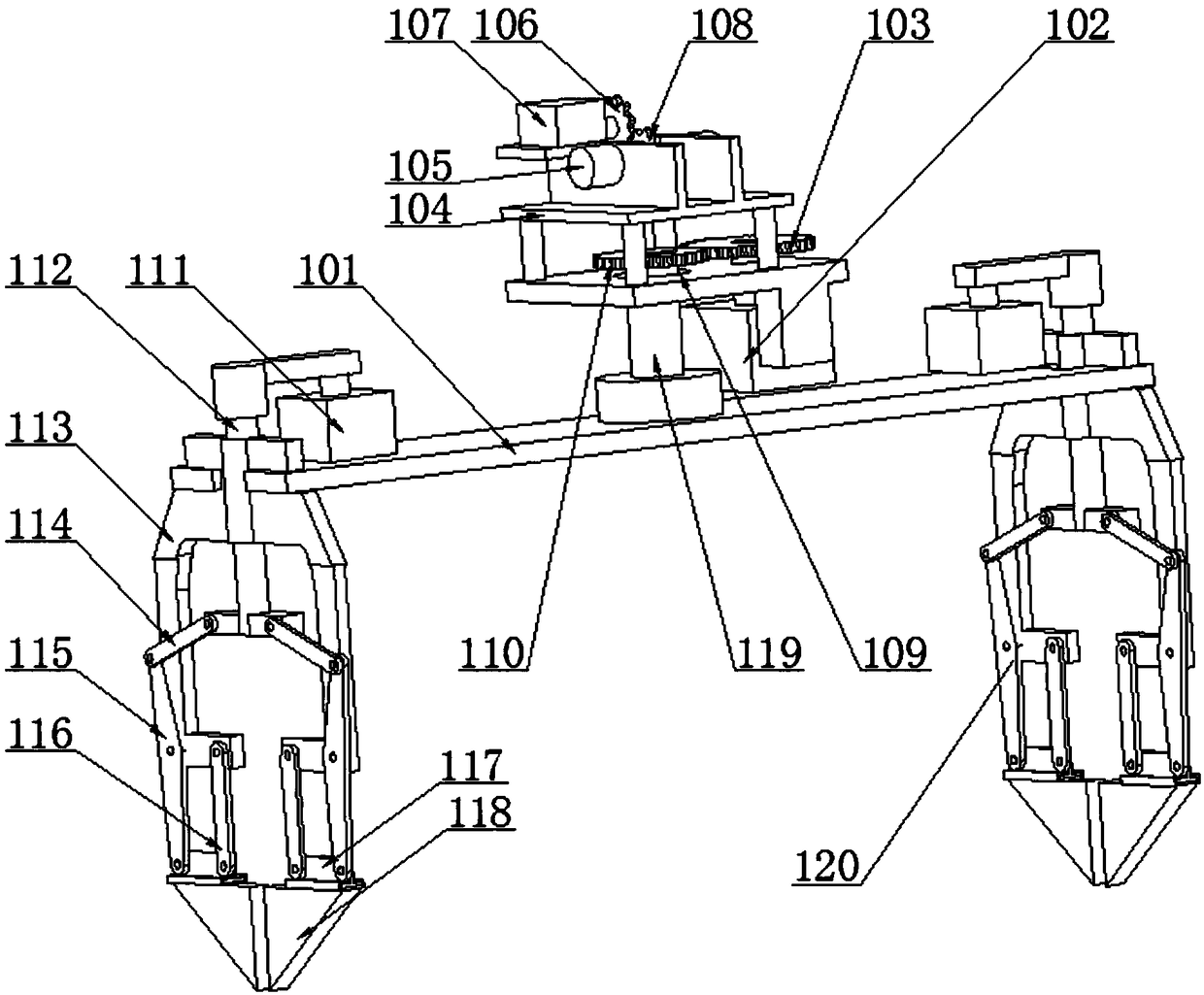

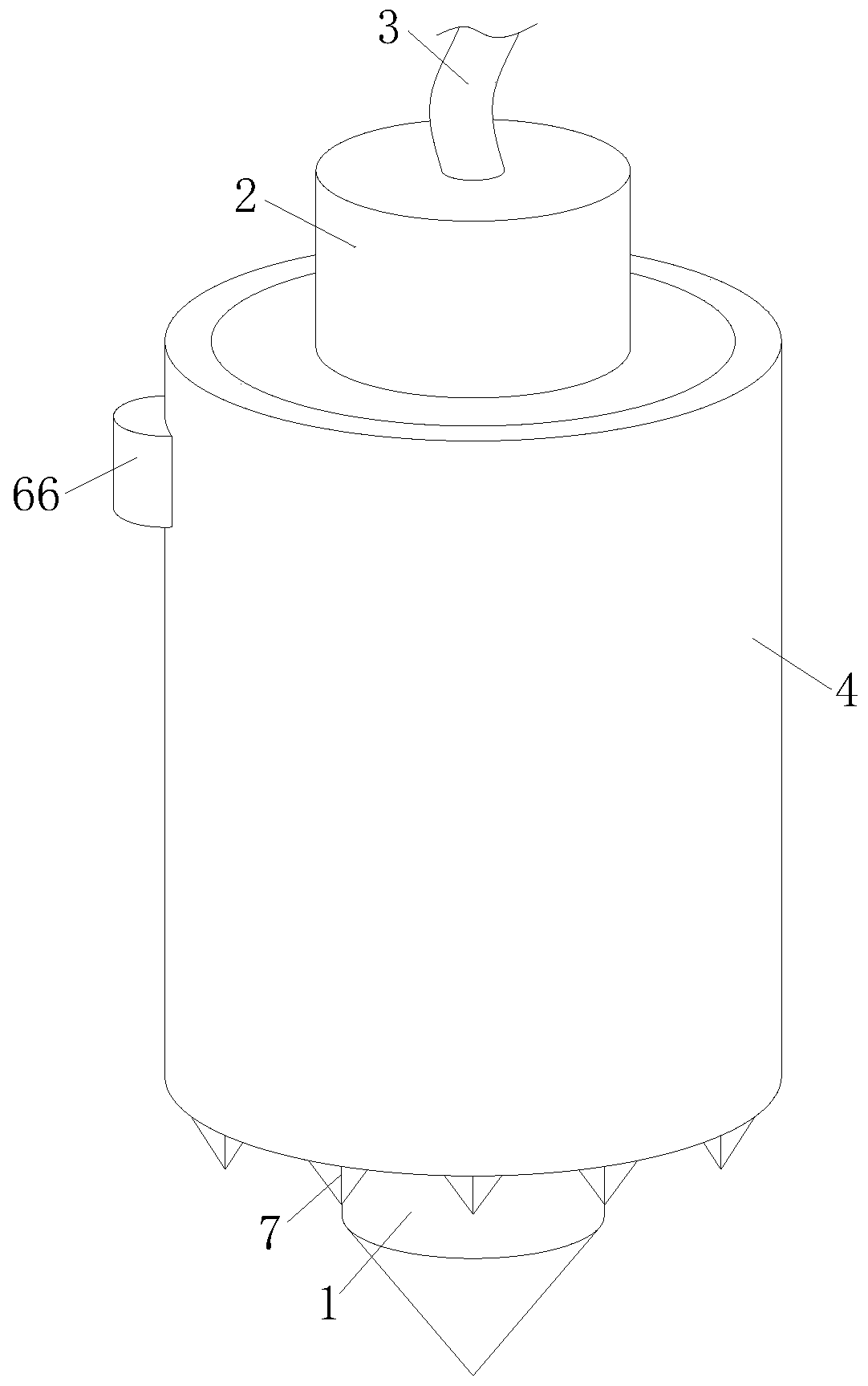

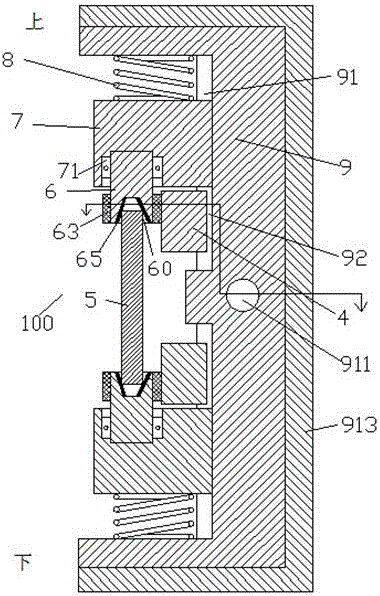

Energy-saving and environmentally friendly high-accuracy pile driver for building construction

ActiveCN111456003AReduce noiseAvoid skewBulkheads/pilesEnvironmentally friendlyEnvironmental geology

The invention provides an energy-saving and environmentally friendly high-accuracy pile driver for building construction. The energy-saving and environmentally friendly high-accuracy pile driver for building construction comprises a ground pile, a hammer dropping hammer head, a connecting hinge, a surrounding cylinder, an accuracy control mechanism and a noise reduction and dust removal mechanism,wherein the ground pile is used for being driven underground; the hammer dropping hammer head is used for beating the ground pile to enable the ground pile to penetrate underground; the connecting hinge is used for connecting the hammer dropping hammer head with a hoisting device; the surrounding cylinder is used for surrounding the pile driving area; the accuracy control mechanism is used for limiting the ground pile and is convenient for high-accuracy driving of the ground pile; and the noise reduction and dust removal mechanism is used for reducing noises and removing dust. The invention relates to the field of buildings. According to the energy-saving and environmentally friendly high-accuracy pile driver for building construction, by analyzing the pile driving technology, the designis simple, the force of the hammer head can be more sufficiently developed to the ground pile by means of outside force, and therefore, the efficiency is greatly enhanced, more energy is saved, the noise can be reduced, the dust can also be removed, and the energy-saving and environmentally friendly high-accuracy pile driver for building construction is more environmentally friendly; and therefore, the problems that a common pile driver is hard to get outside force to realize a supporting effect during using due to large impact force of the hammer head and the ground pile is easy to be inclined to cause pile driving failure due to different underground soil force bearing capabilities are effectively solved.

Owner:上海通核建筑科技有限公司

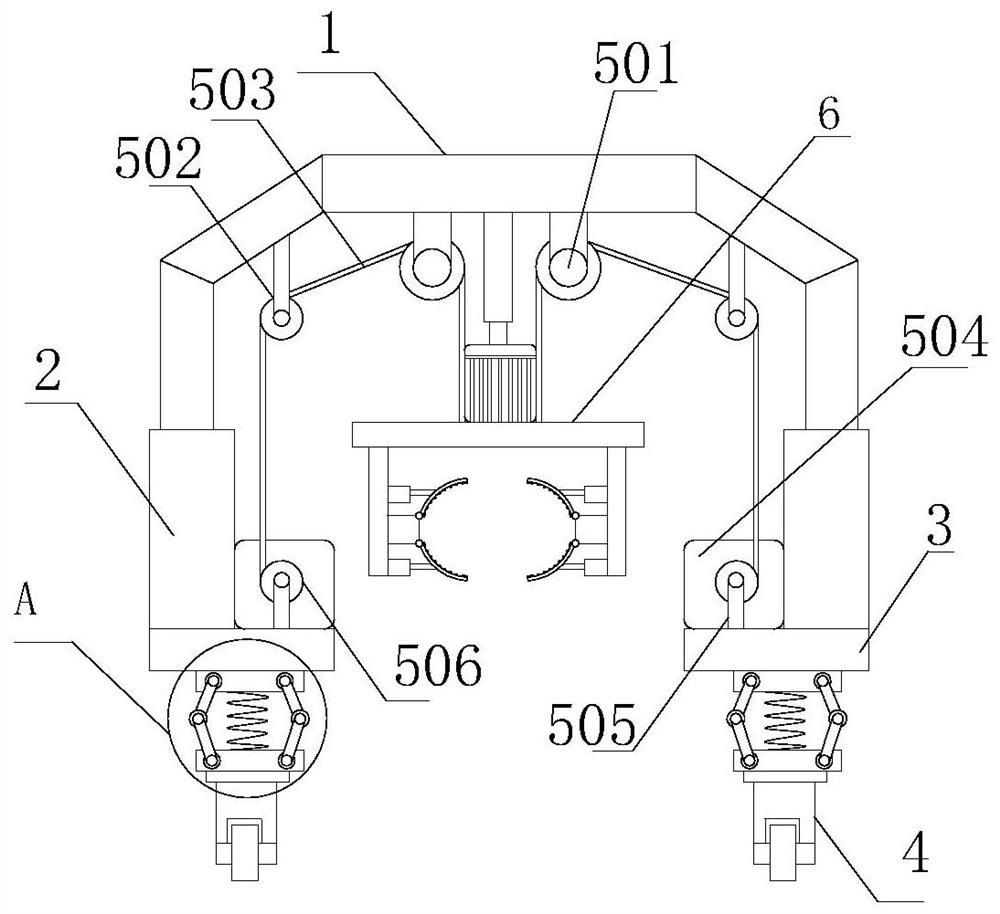

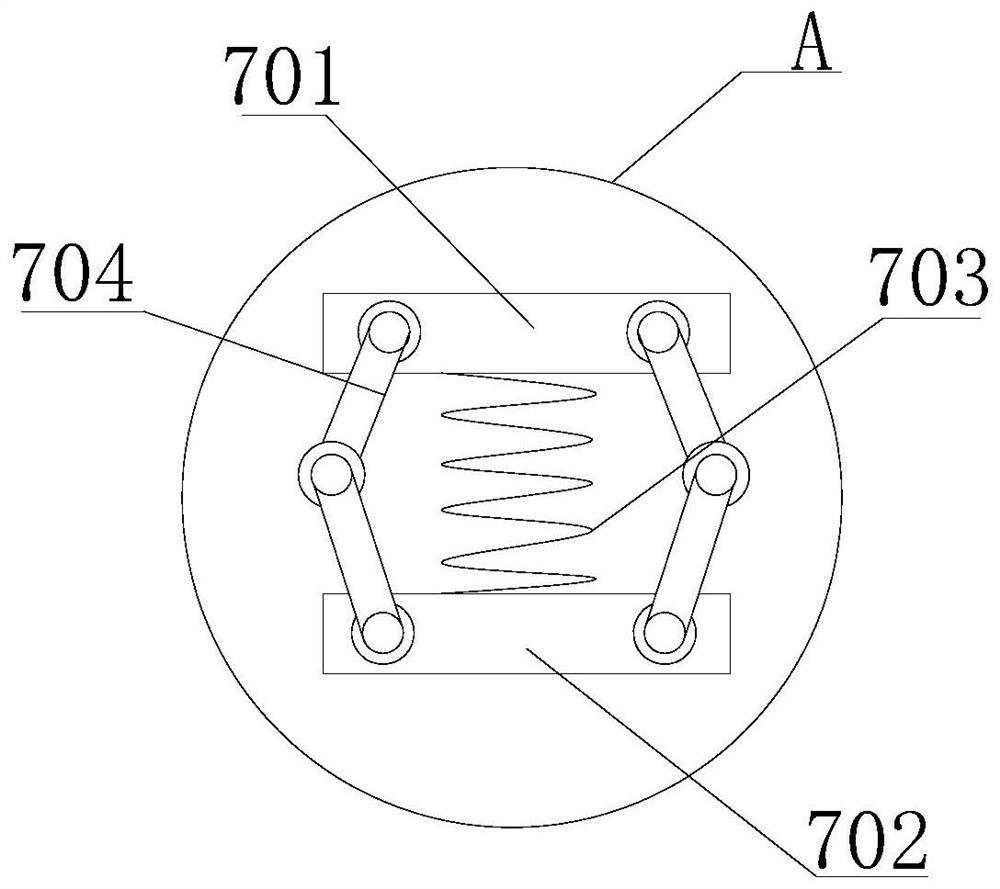

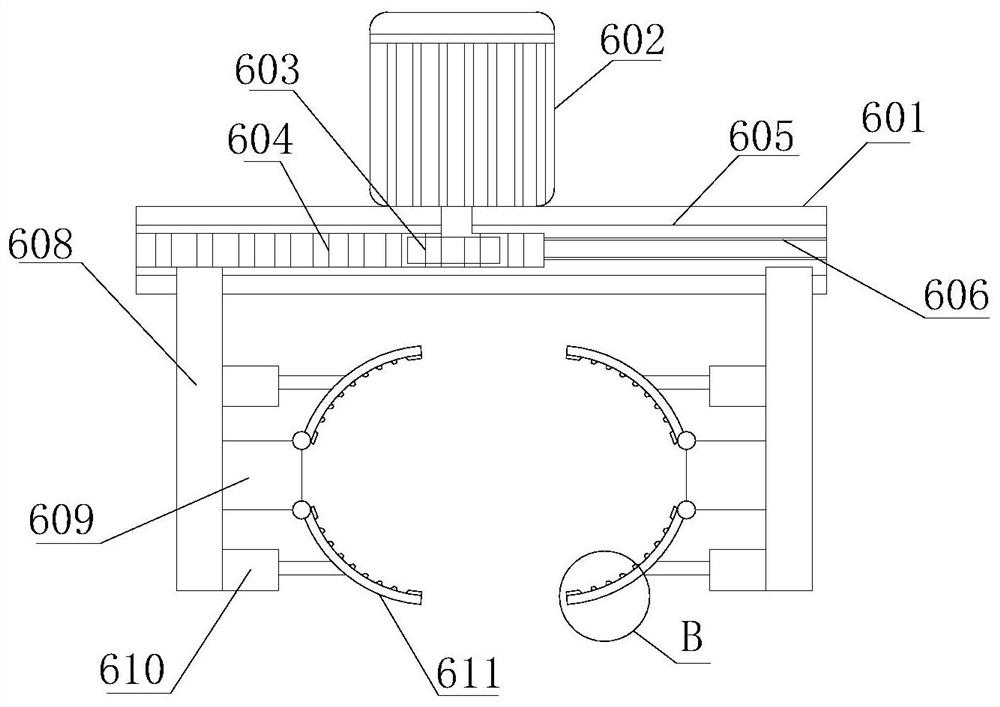

Carrying device for tubular pile

InactiveCN112158723ASave handling timeFast and accurate position improvementBase supporting structuresBraking devices for hoisting equipmentsArchitectural engineeringElectric machinery

The invention relates to the technical field of mechanical equipment, and discloses a carrying device for a tubular pile. The carrying device for the tubular pile comprises a main support, the bottomof the main support is fixedly connected with hydraulic lifting columns, and the bottoms of the hydraulic lifting columns are fixedly connected with bottom plates. By arranging lifting devices and cooperating with the hydraulic lifting columns, multiple sections of adjustment of different heights can be carried out when the tubular pile is carried, and use is more flexible and convenient; after the tubular pile is clamped, motors on the left side and the right side rotate synchronously, the motor on the left side rotates anticlockwise, the motor on the right side rotates clockwise to drive spools to rotate, steel wire ropes on the left side and the right side are wound, and clamping devices at the other ends of the steel wire ropes are driven to ascend slowly to finely adjust the height ofthe clamped tubular pile; and the position of the tubular pile can be conveniently and accurately placed when the tubular pile is manufactured and used, the main support is rapidly and accurately lifted in cooperation with the hydraulic lifting columns, and the carrying time of the tubular pile is greatly shortened.

Owner:浙江意力管业科技有限公司

Steady shaft part detection device and using method thereof

InactiveCN105675282AEasy loadingEasy to uninstallMachine part testingAnalysing solids using sonic/ultrasonic/infrasonic wavesElastic componentEngineering

The invention discloses a steady shaft part detection device and a using method thereof. The steady shaft part detection device comprises a clamp component and a detection component, wherein the clamp component comprises a sliding base provided with a mobile motor at the front end, a sliding groove is formed in the sliding base, a pedestal is installed in the sliding groove in a slidable manner, the pedestal is provided with a front end limiting part and a rear end limiting part, a threaded hole is formed in the front end limiting part, a screw rod is installed in the mobile motor, the screw rod is matched with the threaded hole in installation, two sliding clamp blocks are installed on the pedestal, the two sliding clamp blocks can slide in two vertical slideways which are symmetrically arranged up and down in the pedestal, the two sliding clamp blocks are oppositely arranged and each is provided with a clamping component in a rotatable manner through a bearing, and a conical recess for clamping is formed in the outer side end surface of each clamping part. According to the steady shaft part detection device, a shaft part positioned between the clamping components of the two sliding clamp blocks is clamped with the aid of a pushing force of a clamping elastic component which is pressed against the pedestal so that the two sliding clamp blocks are biased toward each other.

Owner:骆伟法

Adjustable sorting detecting grinding machine

ActiveCN106181682AContinuous actionClamp fasteningGrinding carriagesGrinding drivesGlass coverDrive motor

The invention relates to an adjustable sorting detecting grinding machine. The adjustable sorting detecting grinding machine comprises a frame, wherein the frame comprises a lower frame and a grinding machine upper frame; a glass cover shell, a grinding device, a rotating plate type clamping device and a dust removal device are arranged on the grinding machine upper frame; a rotating plate driving motor is arranged on the lower frame; the frame is provided with a feeding conveying belt and a discharging platform; the discharging platform is provided with a Y-shaped discharging conveying belt; a discharging CCD detector is arranged at a junction; the discharging conveying belt is provided with a laser marking device; the feeding conveying belt is provided with a feeding CCD detecting device; the frame is provided with a feeding platform; an adjusting device is arranged on the feeding platform; the adjusting device successively comprises a feeding baffle, an overturning cylinder and a correction device in the conveying direction; and a direction detecting device is further arranged nearby the overturning cylinder. The adjustable sorting detecting grinding machine is continuous in action and clamps fixedly, automatic clamping can be implemented, consumed time is short, positioning is accurate, and machining quality of workpieces is guaranteed.

Owner:宿迁海通科技有限公司

Fixture for hole drilling bit

InactiveCN107671563AReasonable designExtended service lifePositioning apparatusMetal-working holdersSet screwEngineering

The invention discloses a fixture for a hole drilling bit. The fixture comprises a chuck, a sleeve, a fastening slide block, a fastening bolt, a through groove, a rotating rod, a fixed steel ball, a steel ball pus block, a movable block, a screw hole, a butting groove, a fixed screw rod and a positioning screw rod. The fixture has the following beneficial effects: layers of antioxidant films are coated on the outer sides of the chuck and the sleeve for preventing oxidization and rusting of the surfaces of the chuck and the sleeve, so that the service life of the fixture is prolonged; the positioning screw rod is rotated for fixing a drill bit placed in the fixture, so that the drill bit is primarily fixed without falling; the fixed screw rod is rotated to driven the movable block to move up and down, so that the fixed drill bit is positioned and prevented from aslant installing; the rotating rod pushes the chuck to clamp the drill bit placed in the fixture, so that the structure of thefixture is simplified, and operators are convenient to install and disassemble; and the fastening slide block enables clamping of the chuck to be tighter under the effect of the fastening bolt, so that the looseness condition cannot be generated after long-time use, and the use stability is good.

Owner:常州山迪智能科技有限公司

Timber cutting device for furniture production

ActiveCN108032372APrevent rollingPrevent disengagementChain sawsBark-zones/chip/dust/waste removalFixed frameEngineering

The invention discloses a timber cutting device for furniture production. The device comprises a supporting body, the upper portion of the supporting body is provided with a fixing frame, the supporting body is internally provided with two first rotating shafts, the two first rotating shafts are located on the left side and the right side of the supporting body correspondingly, the upper portionsof the two first rotating shafts are provided with rotating wheels correspondingly, and the rotating wheels are connected through a conveying belt. A supporting plate and the cut timber can slide outof a discharging port, two first through grooves are formed in the upper portion of the conveying belt, a second through groove is formed in the upper portion of the supporting plate, and the saw dustcan pass through the first rectangular grooves and the second rectangular groove to fall into a dust discharging box and then is discharged out.

Owner:温州市莫道文化创意有限公司

Chamfering device for processing positive and negative pole pieces of lithium battery

InactiveCN112123084AEasy to fixStable supportEdge grinding machinesGrinding carriagesPole pieceMechanical engineering

The invention discloses a chamfering device for processing positive and negative pole pieces of a lithium battery. The device comprises a rack, a chamfering back plate, a processing assembly, limitingassemblies, a workbench, an adjusting assembly, a mounting assembly, a cleaning assembly, an equipment box and a supporting base, and is characterized in that the rack is fixedly mounted in the center of the top end surface of the equipment box through bolts; the chamfering back plate is fixedly installed at one side of the top end face of the rack through bolts, the processing assembly is arranged at one side of the end face of the chamfering back plate, the limiting assemblies are arranged at the tops of the front side and the rear side of the chamfering back plate, and the workbench is fixedly installed at the other side of the top end face of the rack through bolts; and the adjusting assembly is fixedly installed on the end face of the top of the workbench. The chamfering device for processing the positive and negative pole pieces of the lithium battery is firm in support; a workpiece is easy to install and firm in clamping, the battery pole pieces can be chamfered during working,the chamfering effect is good, and the chamfering size is adjustable; and meanwhile, chippings generated by chamfering can be cleaned conveniently.

Owner:宋庆忠

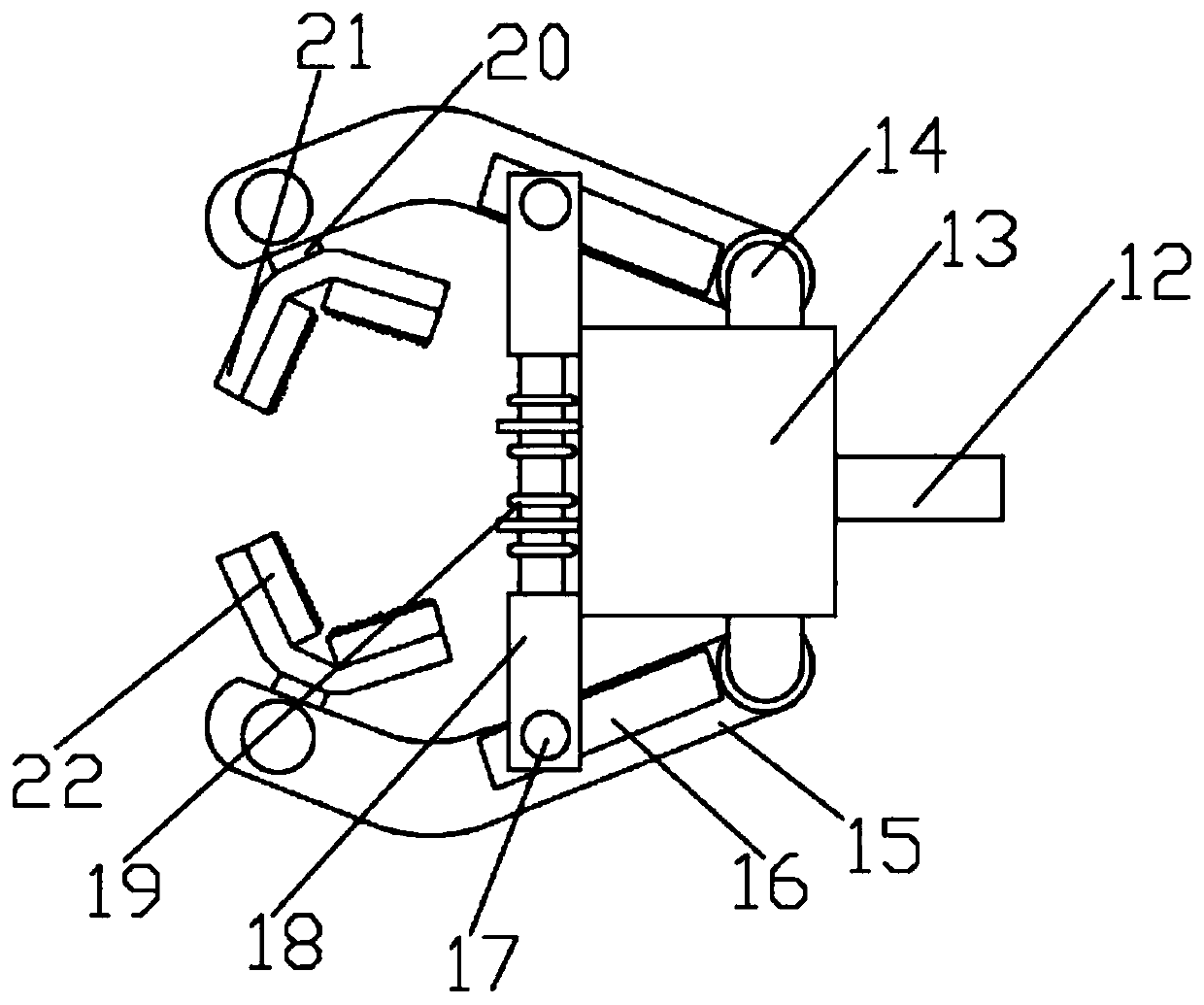

Dual-detection integrated grinding machine

ActiveCN106217237AGuarantee processing qualityContinuous actionGrinding carriagesGrinding feed controlEngineeringGrinding wheel

The invention relates to a dual-detection integrated grinding machine. The dual-detection integrated grinding machine comprises a rack, wherein the rack comprises a lower rack and a grinding machine upper rack; a grinding device and a turntable type clamping device are arranged in the grinding machine upper rack; the grinding device comprises a fixed frame, a lower X-axial sliding rail, an upper X-axial sliding rail, Y-axial sliding rails and a grinding wheel device; the turntable type clamping device comprises a turntable shell, a clamping turntable, fixed arms, bent arms, clamping claws, a transmission gear, a turntable supporting frame and a locating cylinder; the lower rack is provided with a turntable driving motor; a material entering conveying belt is arranged on the rack; a material discharging platform is further arranged on the rack; a Y-shaped material discharging conveying belt is arranged on the material discharging platform, and a material discharging CCD detection device is arranged at the position of an intersection; a laser labeling device is arranged at the tail end of the material discharging conveying belt; and a material entering CCD detection device is further arranged at the tail end of the material entering conveying belt. The dual-detection integrated grinding machine operates continuously, clamps workpieces firmly, realizes automatic clamping, is short in operation time and accurate in location, and guarantees the machining quality of the workpieces.

Owner:MAANSHAN YASHIDA INTELLIGENT TECH CO LTD

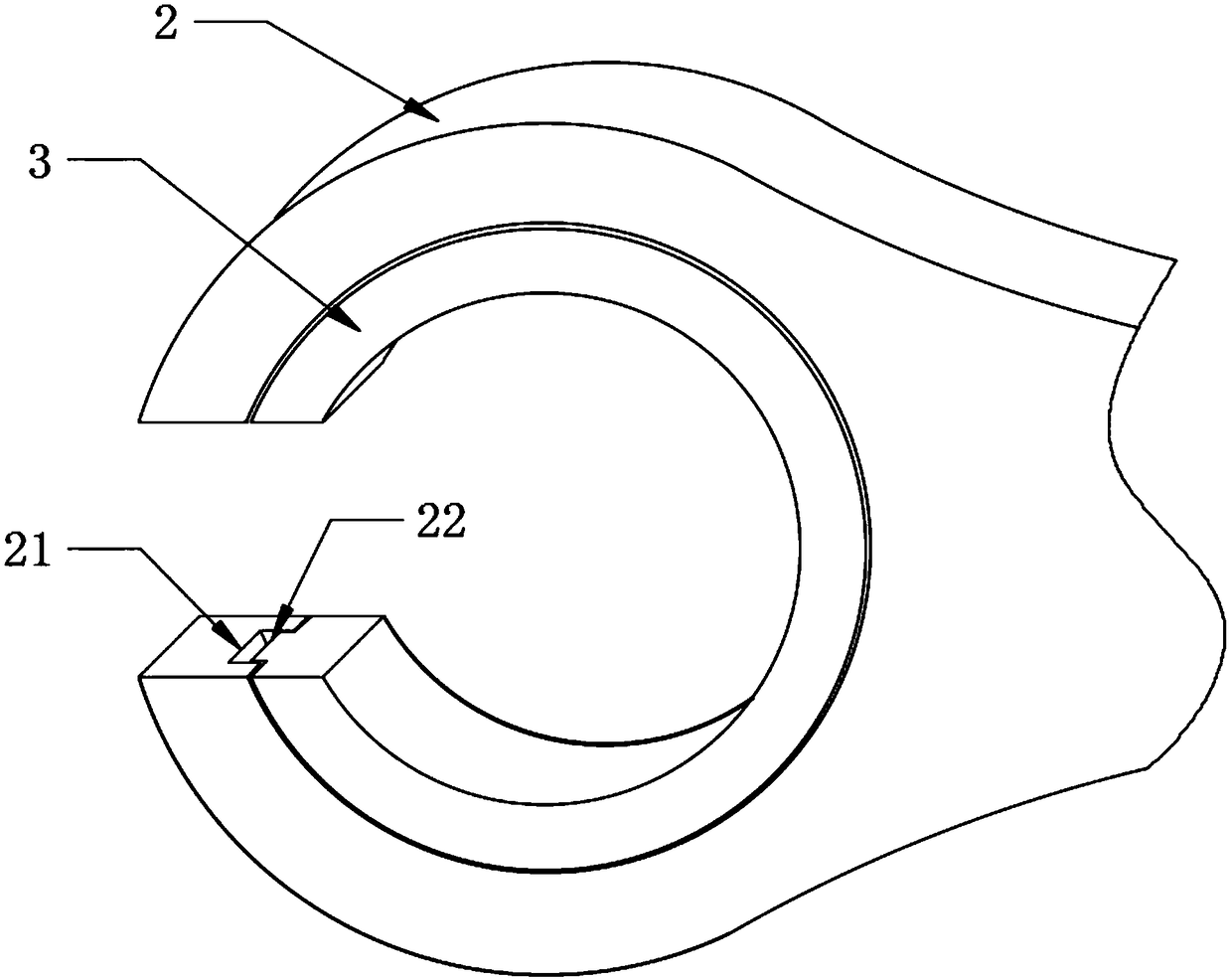

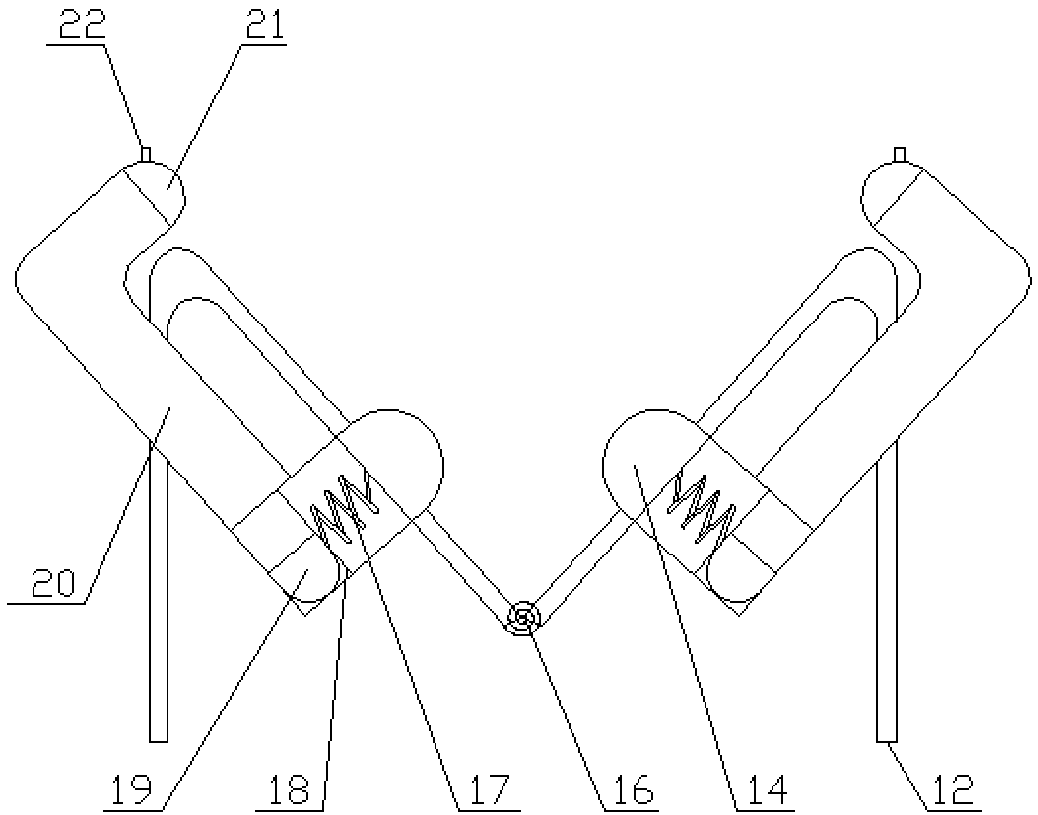

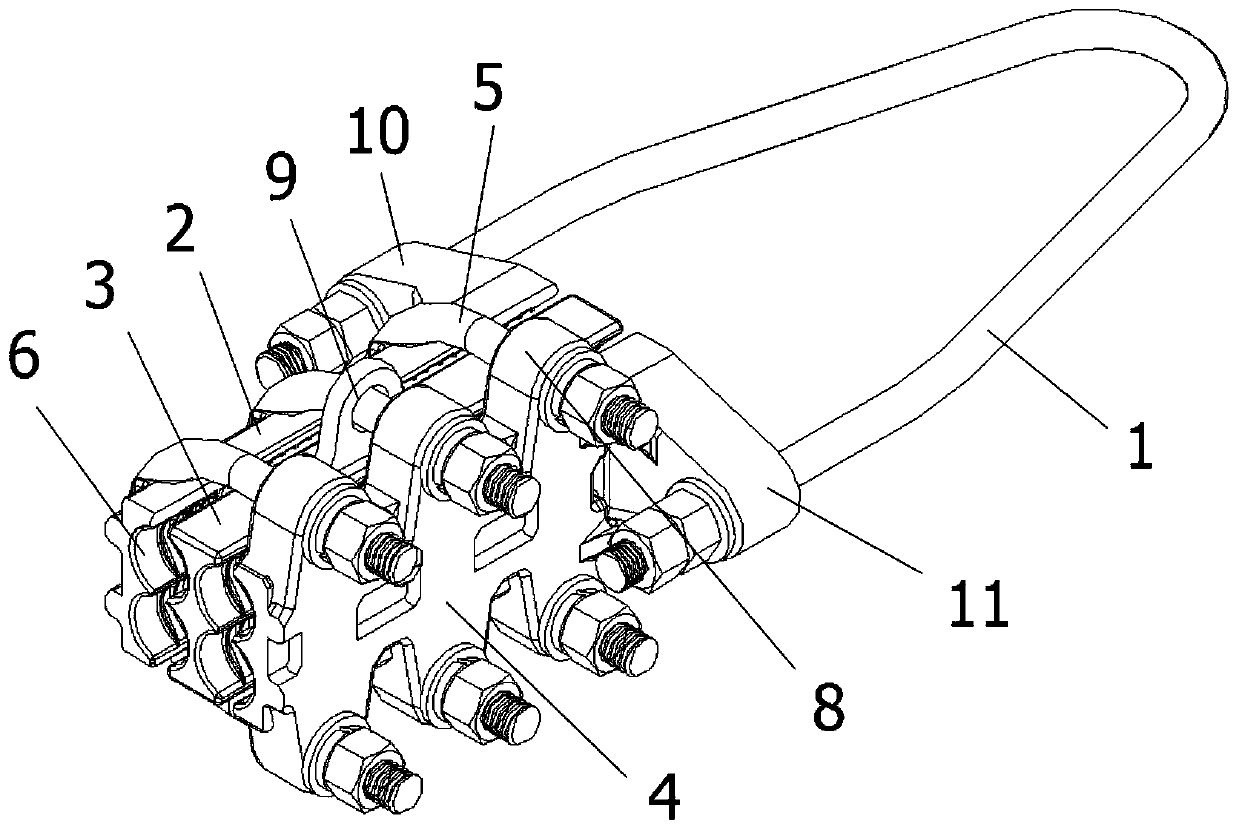

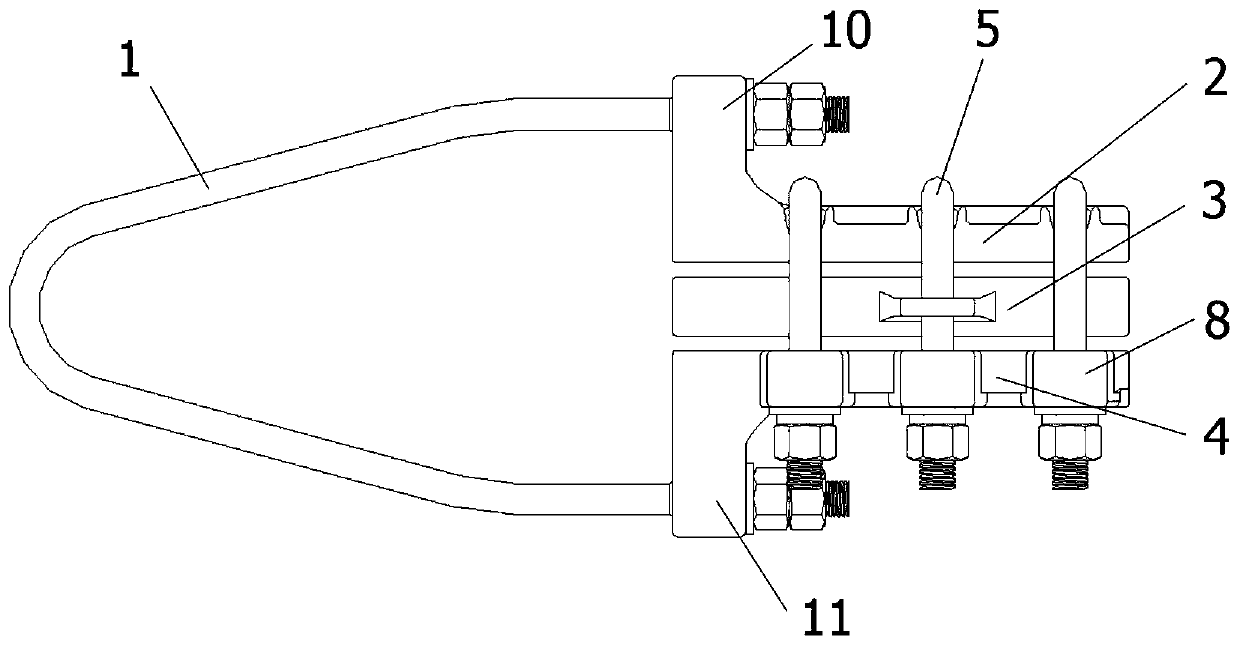

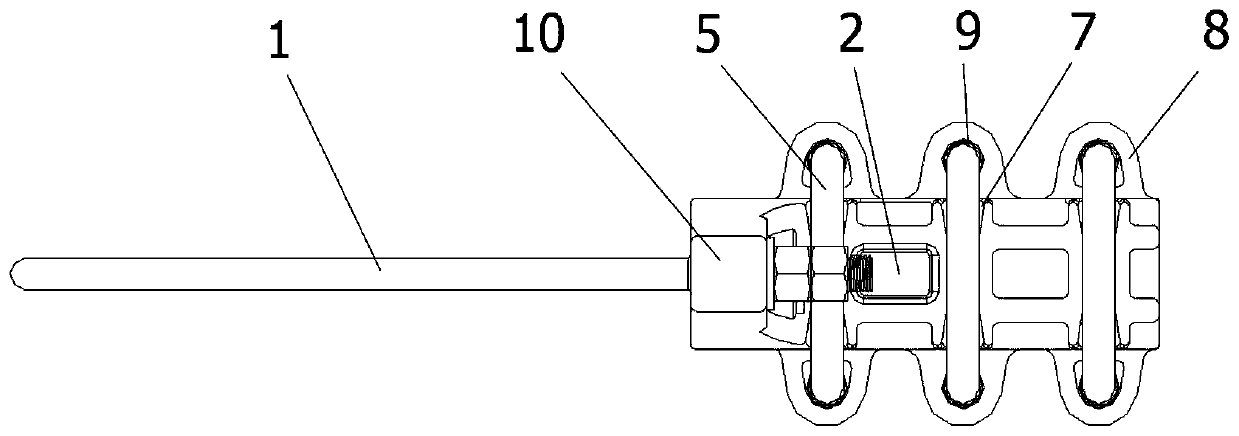

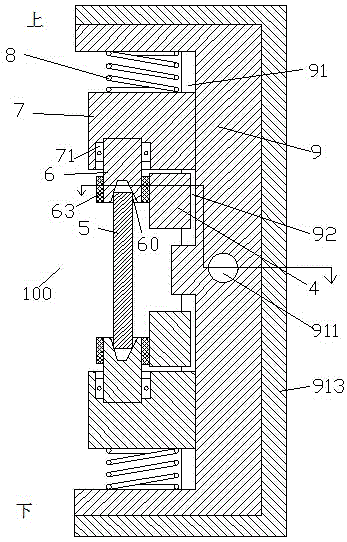

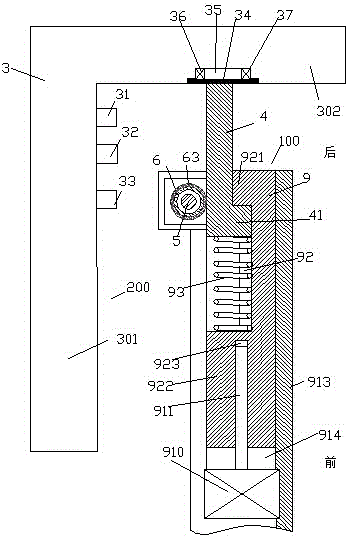

cable strain relief

ActiveCN107276003BClamp fasteningEffective clampingSuspension arrangements for electric cablesWhole bodyBiomedical engineering

The invention provides a cable tension clamp which comprises a wire clamp body and a pull piece connected to the wire clamp body. The wire clamp body comprises a clamping device which comprises at least two layers of clamping mechanisms, and a fastening structure which removably encircles and fastens a whole body formed by the clamping device and the cable and applies an action force of clamping the cable to the clamping mechanism, wherein at least one cable is clamped between two adjacent layers of clamping mechanisms. The fastening structure can removably encircle and fasten the whole body formed by the clamping device and the cable, in this way, the force of the fastening structure applied to the clamping device is dispersed to the peripheral wall of the clamping device, the clamp looseness of the cable caused by the tilt of two sides of the clamping device under the opposite force of the cable to the two sides of the clamping devices for a long time is prevented, thus the clamping device can maintain the effective and firm clamping of the cable under long-term use.

Owner:YONGGU GRP

Intelligent device for detecting shaft part and use method of intelligent device

PendingCN105598882AEasy loadingEasy to uninstallMachine part testingWork holdersScrew threadThreaded rod

The invention discloses an intelligent device for detecting a shaft part and a use method of the intelligent device. The intelligent device comprises a clamp part and a detecting part. The clamp part comprises a slide base with a movable motor at the front end. A slide groove is formed in the slide base. A base is installed in the slide groove in a slidable mode. A front end limiting part and a rear end limiting part are arranged on the base. A threaded hole is formed in the front end limiting part. A threaded rod is installed in the movable motor and matched with the threaded hole. Two slide clamping blocks which can slide in two vertically-symmetrical vertical slide ways respectively are arranged on the base. The two slide clamping blocks are oppositely arranged, and a clamping part with a clamping cone concave part on the outer side end face is installed on each slide clamping block through a bearing in a rotating mode. With the aid of the pushing and pressing force of a clamping elastic part which abuts against the base and then presses the two slide clamping blocks towards each other, the shaft part between the clamping parts of the two slide clamping blocks is clamped.

Owner:温岭市锦鹏日用品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com