Steady shaft part detection device and using method thereof

A technology of shaft parts and detection devices, which is applied in the field of parts detection, can solve problems such as increased detection costs, increased equipment costs, and comprehensive detection of difficult products, and achieves the effect of simple operation and reliable use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

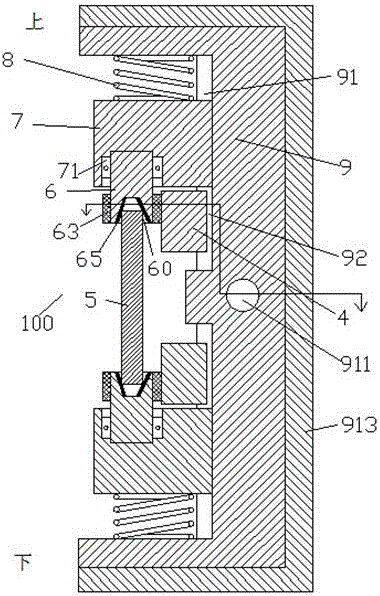

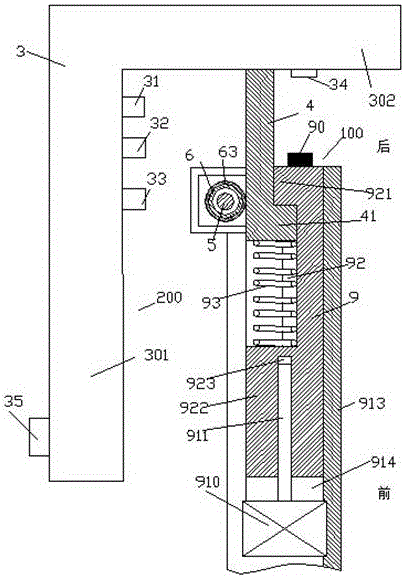

[0010] Combine below Figure 1-2 The present invention will be described in detail.

[0011] A stable detection device for shaft parts according to an embodiment includes a fixture part 100 and a detection part 200, the fixture part 100 includes a sliding seat 913 with a moving motor 910 installed at the front end, and a sliding seat 913 is provided in the sliding seat 913. Slot 914, the base 9 is slidably installed in the sliding groove 914, the base 9 is provided with a front-end limiting portion 922 and a rear-end limiting portion 921, and the front-end limiting portion 922 is provided with a threaded hole 923, a screw 911 is installed in the mobile motor 910, the screw 911 is installed in cooperation with the threaded hole 923, and the base 9 is installed with two vertical slides 91 that can be arranged symmetrically up and down. Two sliding clamping blocks 7 that slide, the two sliding clamping blocks 7 are arranged oppositely and each is rotatably installed with a clamp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com