Drilling machining device

A technology of processing device and driving device, which is used in positioning devices, boring/drilling, metal processing equipment, etc., can solve the problems of drilling and processing of workpieces of different shapes, etc., to increase the clamping area and achieve diversification , the effect of expanding the clamping area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below by means of specific embodiments:

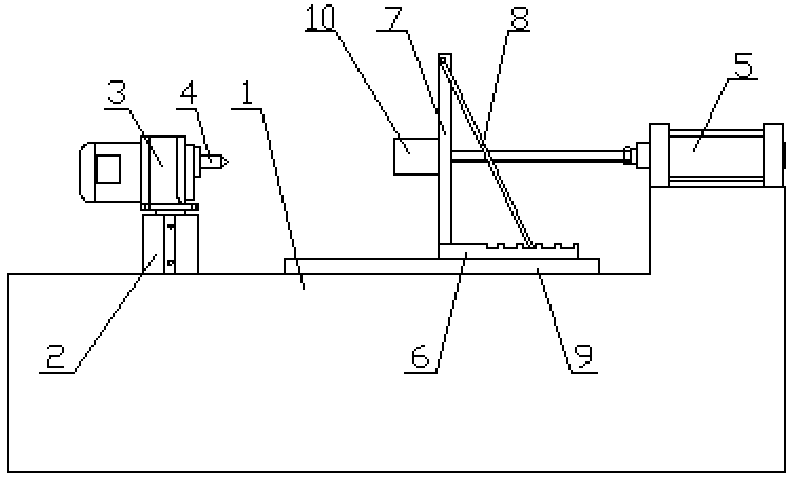

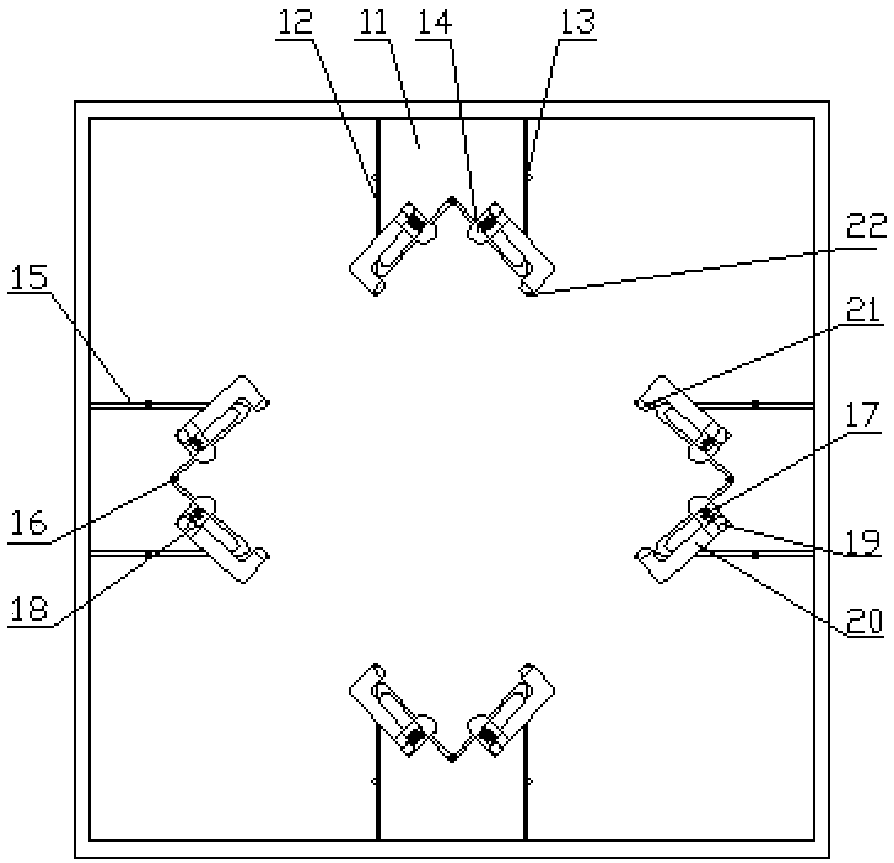

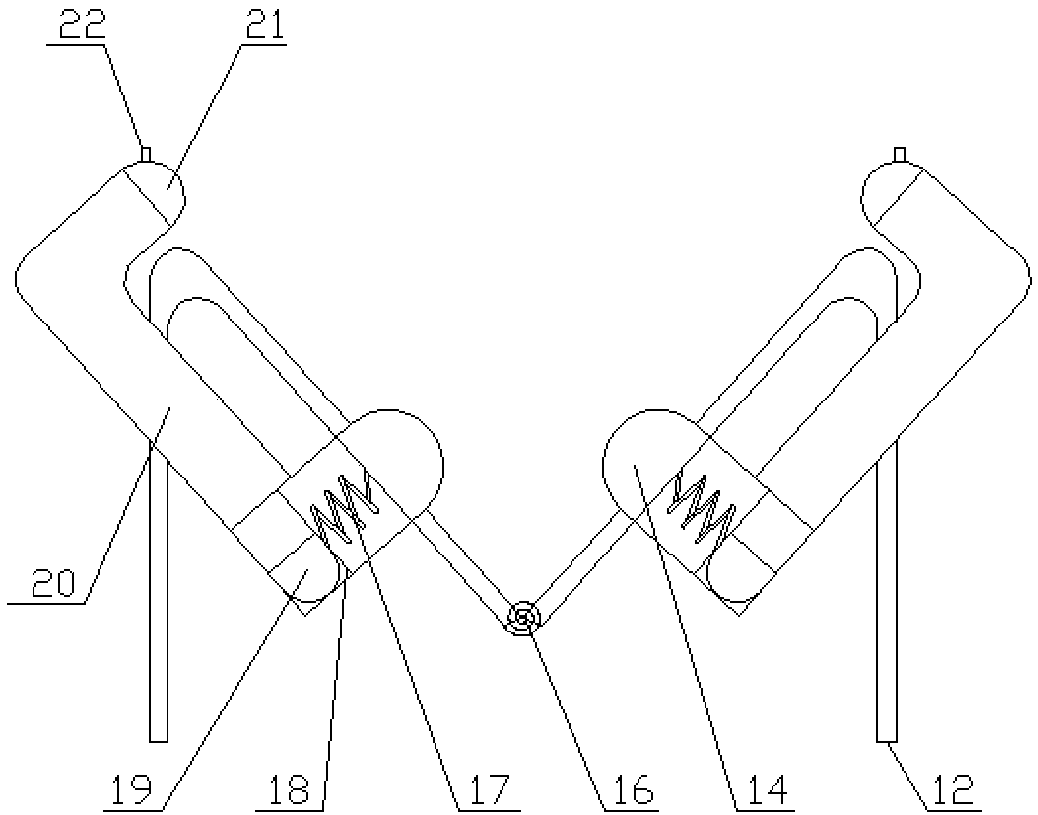

[0015] The reference signs in the drawings of the description include: workbench 1, lifting cylinder 2, motor 3, drill bit 4, thrust cylinder 5, base 6, rotating plate 7, support frame 8, slide rail 9, clamping box 10, clip Holder 11, clamping head 12, hinge 13, protrusion 14, fixed frame 15, connection spring 16, compression spring 17, compression plate 18, first air bag 19, connecting pipe 20, second air bag 21, air intake plug 22 .

[0016] The embodiment is basically as attached figure 1 and 2 Shown: the basic scheme of the present invention is as follows: drilling device, comprises workbench 1, and the left side on workbench 1 is provided with motor 3, and the right side on workbench 1 is provided with thrust cylinder 5, between motor 3 and work A lifting cylinder 2 is arranged between the platforms 1, and the lifting cylinder 2 can realize the lifting of the moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com