Patents

Literature

45results about How to "Strong blessing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

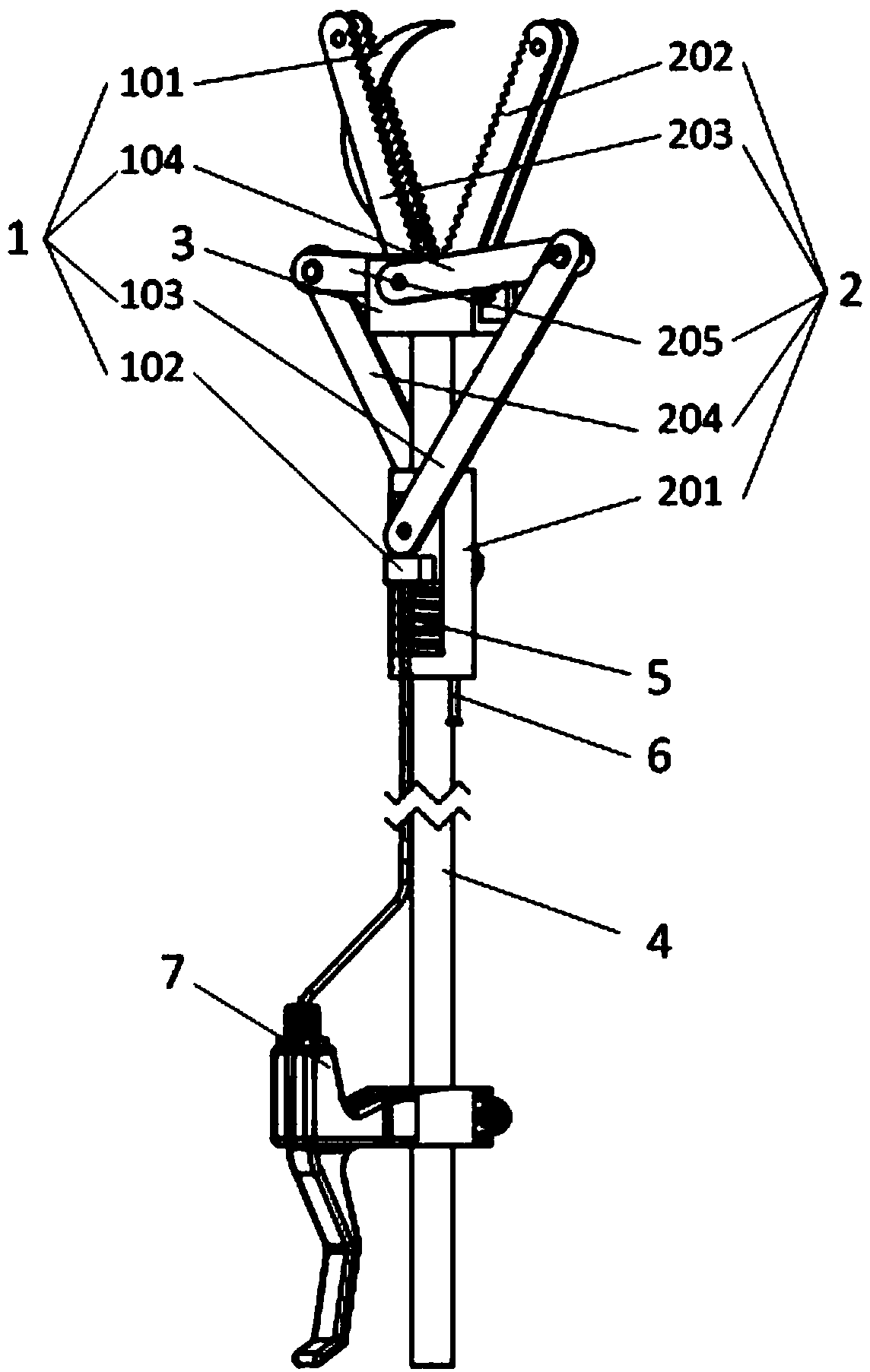

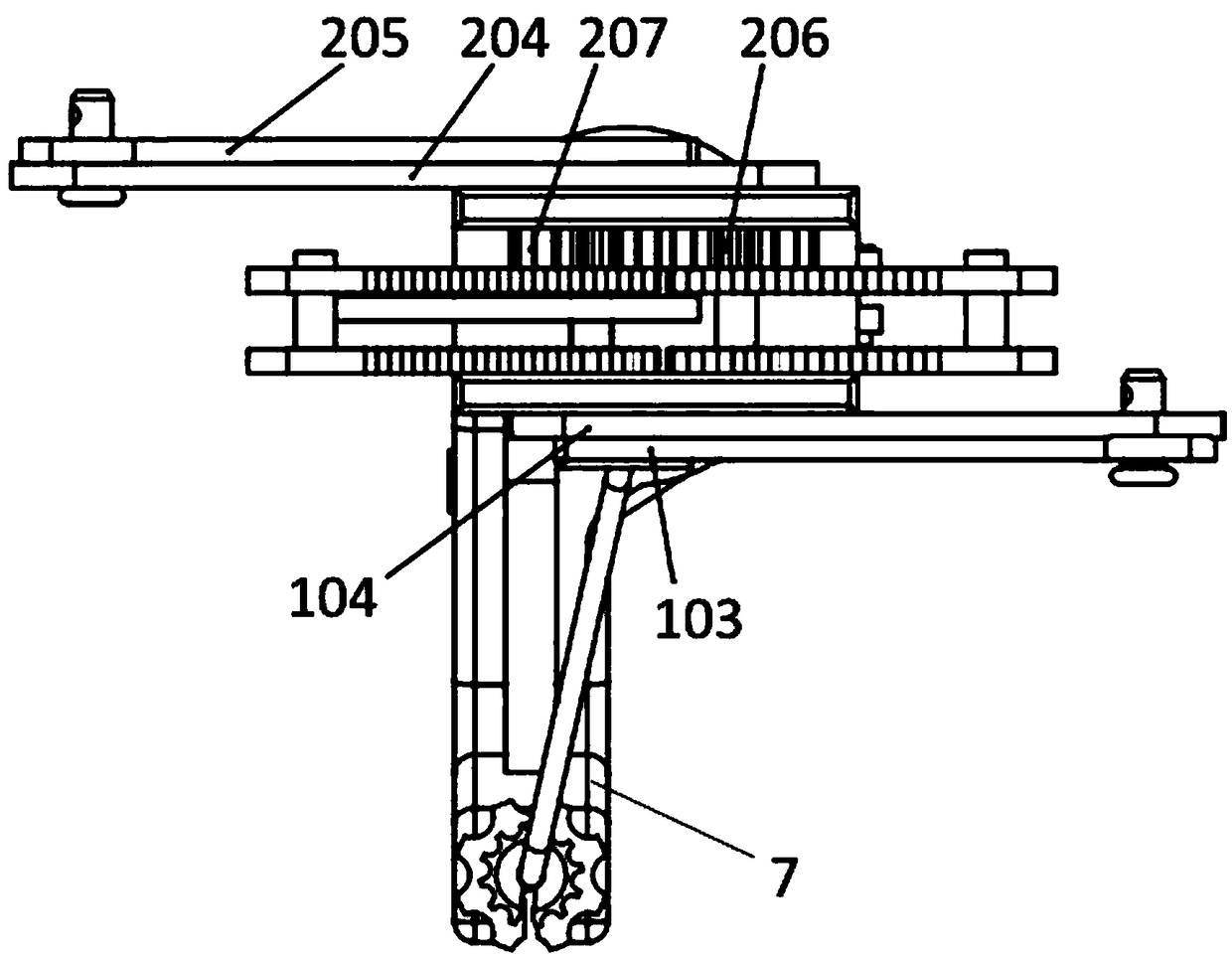

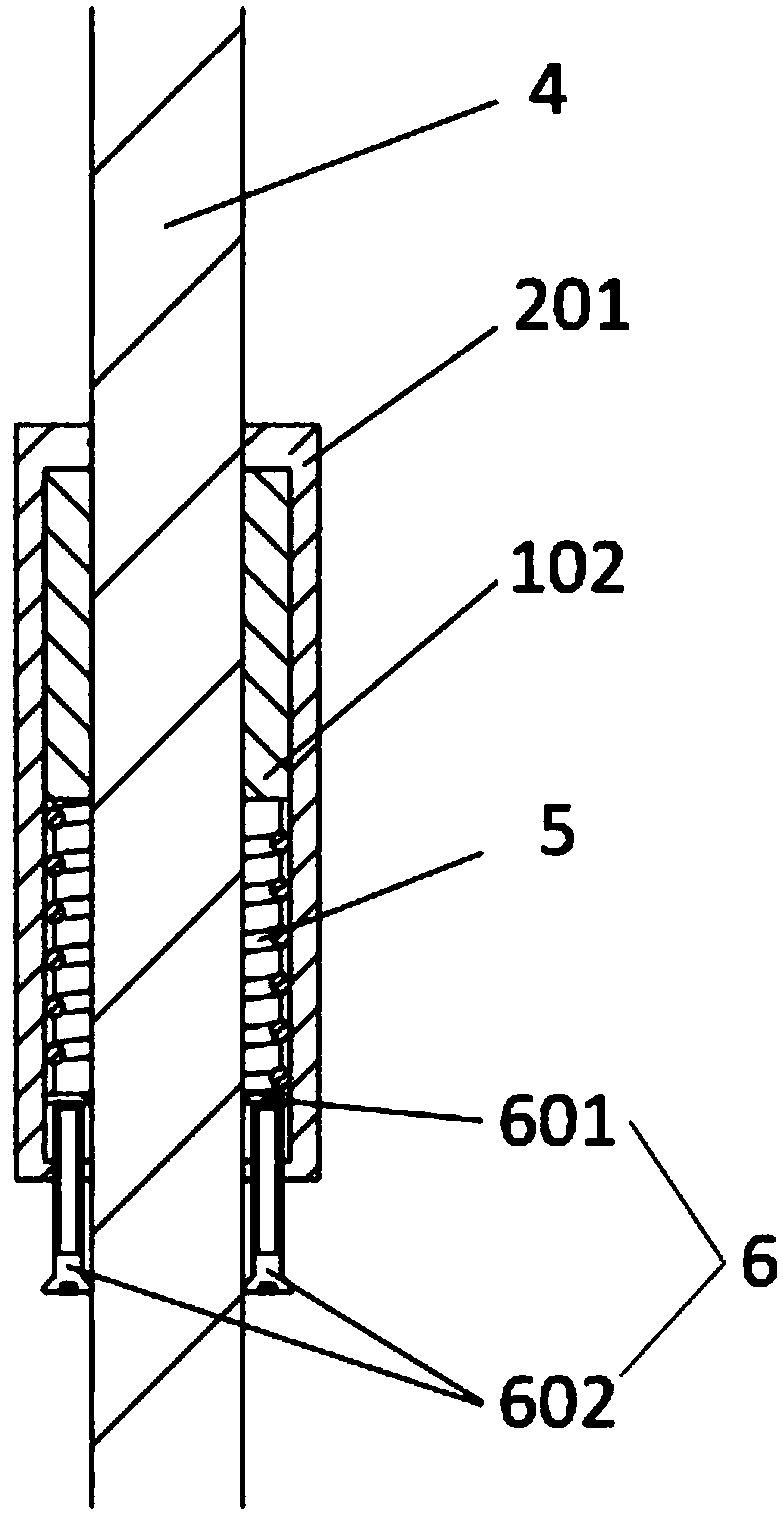

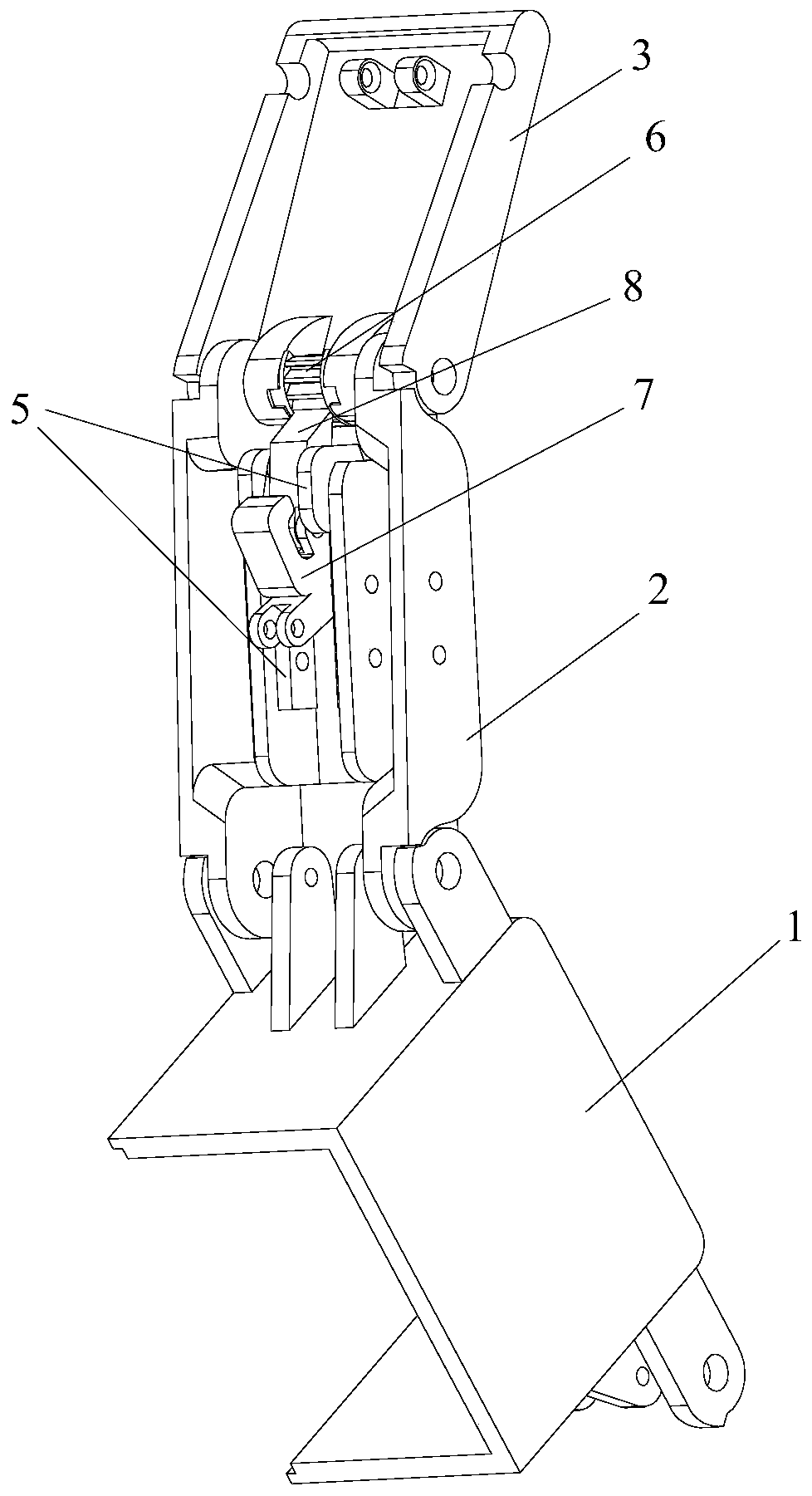

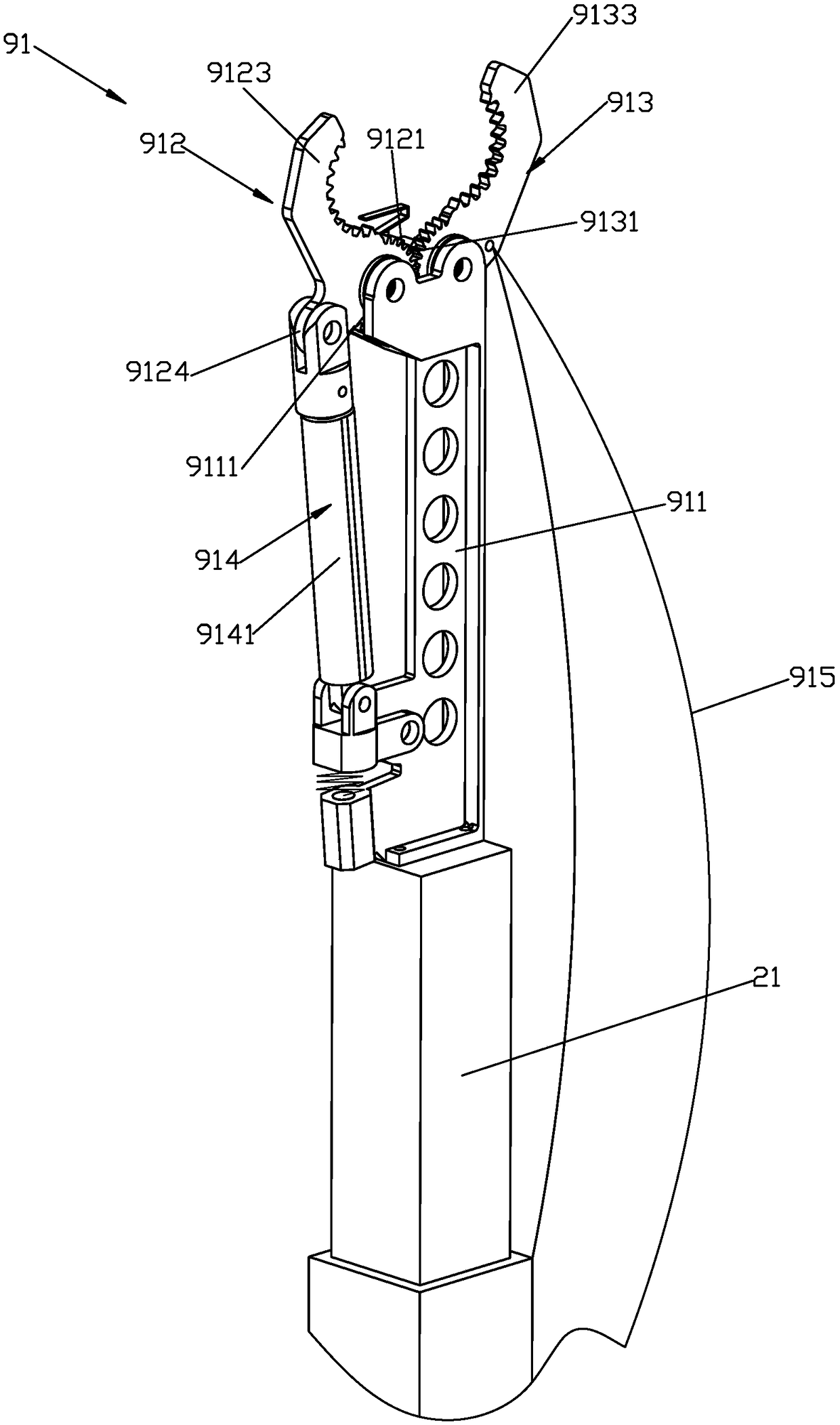

Fruit picking device

ActiveCN108207325AStrong blessingRenewable energy machinesPicking devicesElastic componentEngineering

The invention discloses a fruit picking device which comprises a shearing mechanism, a clamping mechanism, a frame, a supporting rod, an elastic component and an adjusting component. The clamping mechanism is rotatably arranged on the frame, a shearing cutter of the shearing mechanism is rotatably connected with the clamping mechanism, the frame is fixed at the top end of the supporting rod, an inner slider of the shearing mechanism is embedded into an outer slider of the clamping mechanism, the elastic component is arranged on the supporting rod in a sleeving manner, the inner slider is abutted into a cavity of the top of the outer slider, the outer slider is slidably arranged on the supporting rod, and the adjusting component is arranged at the bottom of the outer slider and used for adjusting the pre-compressed quantity of the elastic component. According to the fruit picking device, a compression spring of the inner slider is drawn downwards in the shearing process of fruit branches after the fruit branches are fixed and applies downward pressure to the outer slider, so that the outer slider continues to move downwards to drive the clamping mechanism to continue to apply largerclamping force to the fruit branches, and the fruit branches are smoothly sheared.

Owner:GUANGDONG UNIV OF TECH

Drilling machining device

ActiveCN107671323AClamp fasteningIncrease the clamping areaPositioning apparatusMetal-working holdersManufacturing technologyFixed frame

The invention discloses a drilling machining device and relates to the technical field of motor part machining and manufacturing. The drilling machining device comprises a worktable. A motor and a thrust air cylinder are arranged on the worktable. A drill bit is arranged on the motor. A driving device is arranged on the thrust air cylinder. The driving device comprises a rotating plate, a base anda supporting frame. The rotating plate is rotationally connected with the base. A groove is formed in the base. The supporting frame and the rotating plate are rotationally connected. The rotating plate is provided with a clamping box, and the clamping box is provided with clamping devices. Each clamping device comprises a fixing frame and a clamping head, wherein the clamping head is provided with a connecting spring, a protrusion, a sliding groove and a pipeline hole, the protrusion is provided with a compression spring, the compression spring is connected with a compression plate, the compression plate is provided with a first air bag which is connected with a connecting pipeline, the connecting pipeline is provided with a second air bag, the second air bag is provided with an air inlet hole, and the air inlet hole is provided with an air inlet stopper. By the adoption of the technical scheme, the problem that an existing drilling device cannot conduct drilling on workpieces with irregular shapes, and the drilling machining device can be used for drilling machining of workpieces with all shapes.

Owner:NANTONG GUANFENG CASTING

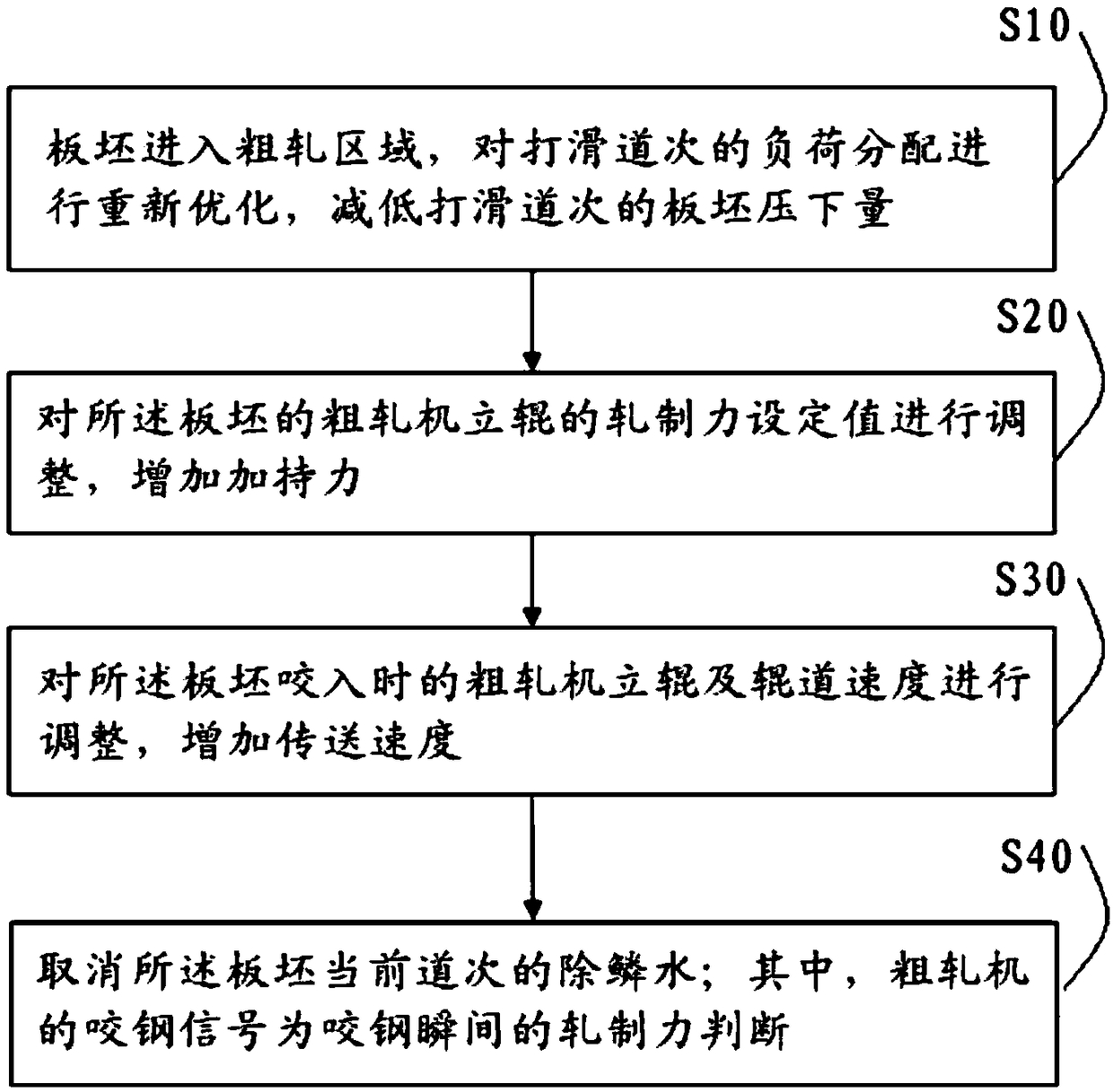

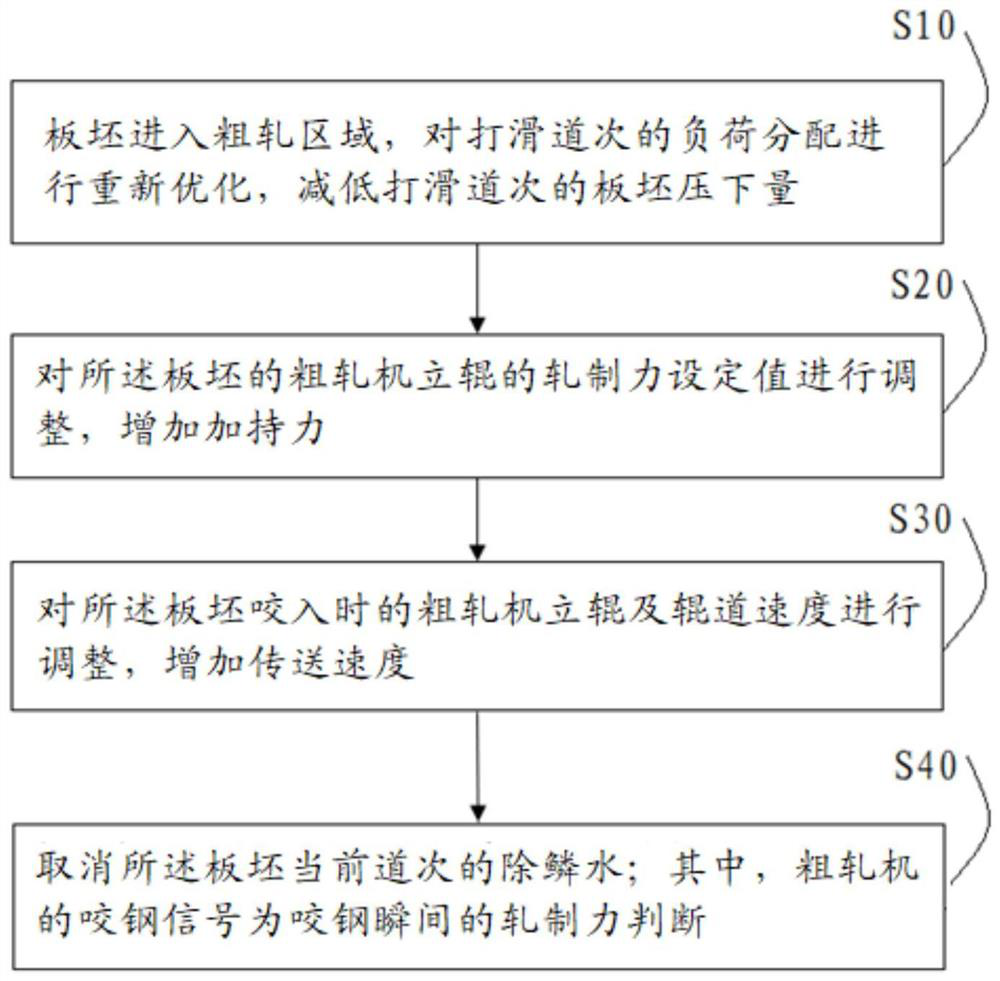

Control method of hot rolling roughing mill

ActiveCN108838212ASmall amount of depressionAdjustable speedRoll mill control devicesMetal rolling arrangementsStrip millEngineering

The invention discloses a control method of a hot rolling roughing mill. The method comprises the steps that a board blank enters a rough rolling area, load distribution of a slip pass is optimized again, and the board blank rolling reduction of the slip pass is reduced; the set value of rolling force of a roughing mill vertical roll of the board blank is adjusted, and the holding force is increased; the speed of the roughing mill vertical roll and a roller way when the board blank is gripped is adjusted, and the conveying speed is increased; and descaling water of the current pass of the board blank is eliminated, wherein the steel gripping signal of the roughing mill is judgment of rolling force at the moment of steel gripping. The technical problem that due to the slip phenomenon of a board blank in a roughing mill in the prior art, the board blank cannot be normally gripped, and accordingly normal production rhythm is affected is solved. The technical effect that rapid response isachieved when the board blank slides while being gripped in the roughing mill, the production accidents of board blank abandoning and rollback are avoided, and the production efficiency is improved are achieved.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

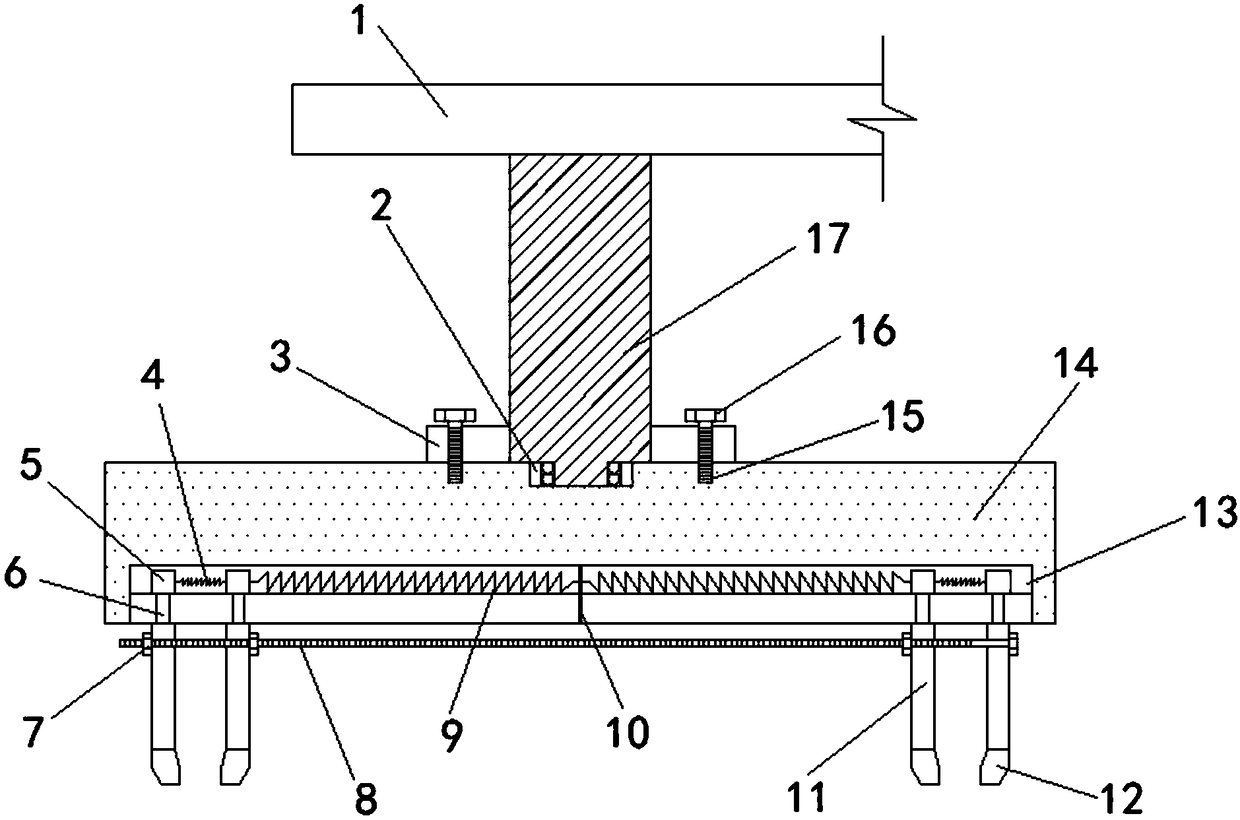

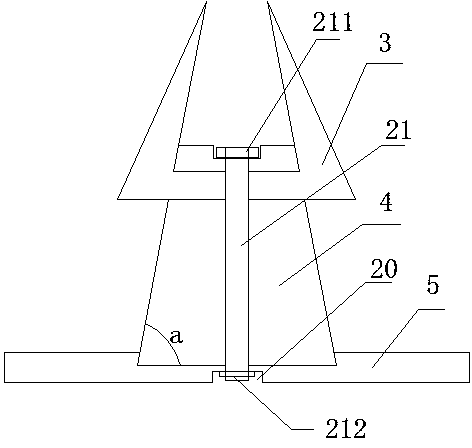

Anti-capsizing support of bridge

InactiveCN106087717AHigh sensitivityStrong blessingBridge structural detailsScrew threadFriction force

The invention discloses an anti-capsizing support of a bridge. The anti-capsizing support of the bridge comprises a first plate, a second plate and a third plate, wherein the first plate, the second plate and the third plate are arranged in parallel from top to bottom. Clamping grooves are formed in the two sides of a second insertion plate vertically. Each clamping groove communicates with a channel through a square hole between the clamping groove and the channel. A movable brake pad is placed in each clamping groove. A tie piece is arranged in the channel. Wedges are arranged on the two sides of the tie piece at intervals and face the same direction, and each wedge makes contact with the movable brake pad in the corresponding position. A threaded hole is formed in the end of the tie piece, and a tension bolt is installed in the threaded hole for tensioning connection. The anti-capsizing support of a bridge is of a pure mechanical structure, and long-term maintenance-free operation can be achieved; and in addition, main friction force happens to friction plates between the insertion plates, the automobile brake pads are used as the friction plates and are free of maintenance in the whole life, and the friction force of the brake pads can be adjusted conveniently through the tension bolt.

Owner:孙新迪 +11

Device and method for regulating warping of glass plate

ActiveCN106242250AGuaranteed uptimeEliminate warpingGlass forming apparatusArchitectural engineeringOverflow downdraw method

The invention discloses a device and method for regulating warping of a glass plate. The device comprises overflow down-drawing forming equipment. Glass plate cutting equipment is arranged at the rear end of the overflow down-drawing forming equipment, and a traction roller is arranged between the overflow down-drawing forming equipment and the glass plate cutting equipment. The holding force of the traction roller to a glass plate is increased, in an overflow down-drawing method, the clamping force of the traction roller is greatly affected by friction force between the surface of a boss and the glass plate, the friction coefficient of the surface of the boss is increased, friction force is increased, therefore, the glass plate runs stably through the method of increasing the clamping force, and warping badness caused by back-and-forth running of the glass plate is eliminated.

Owner:RAINBOW (HEFEI) LIQUID CRYSTAL GLASS CO LTD

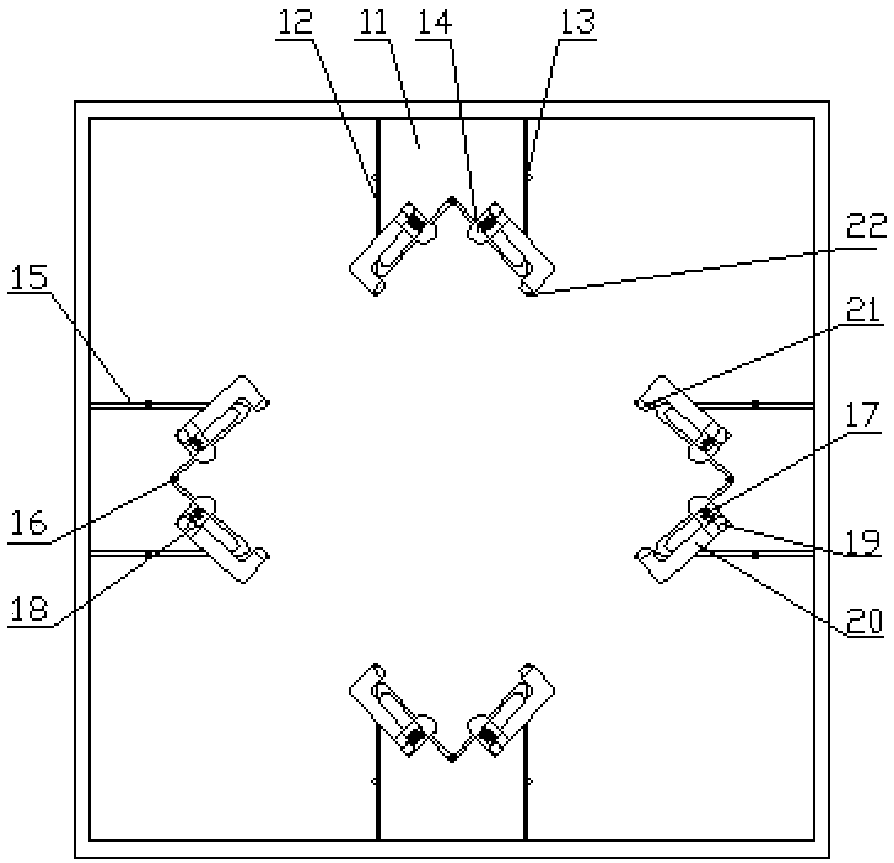

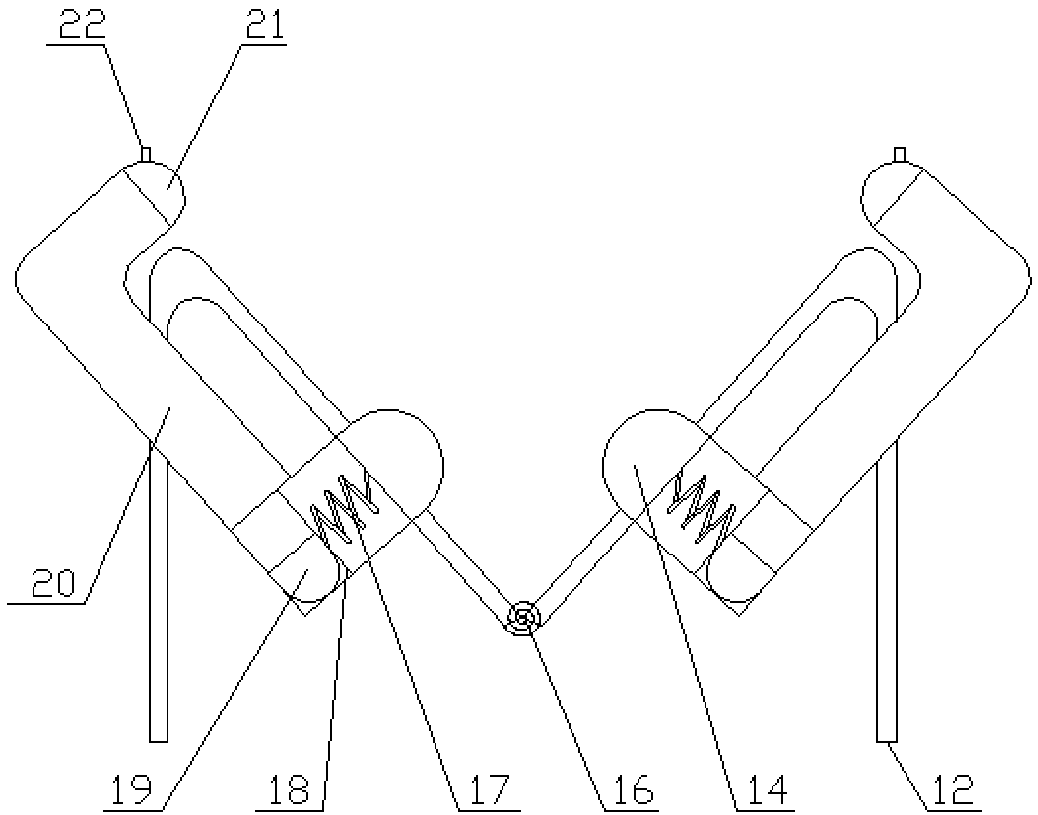

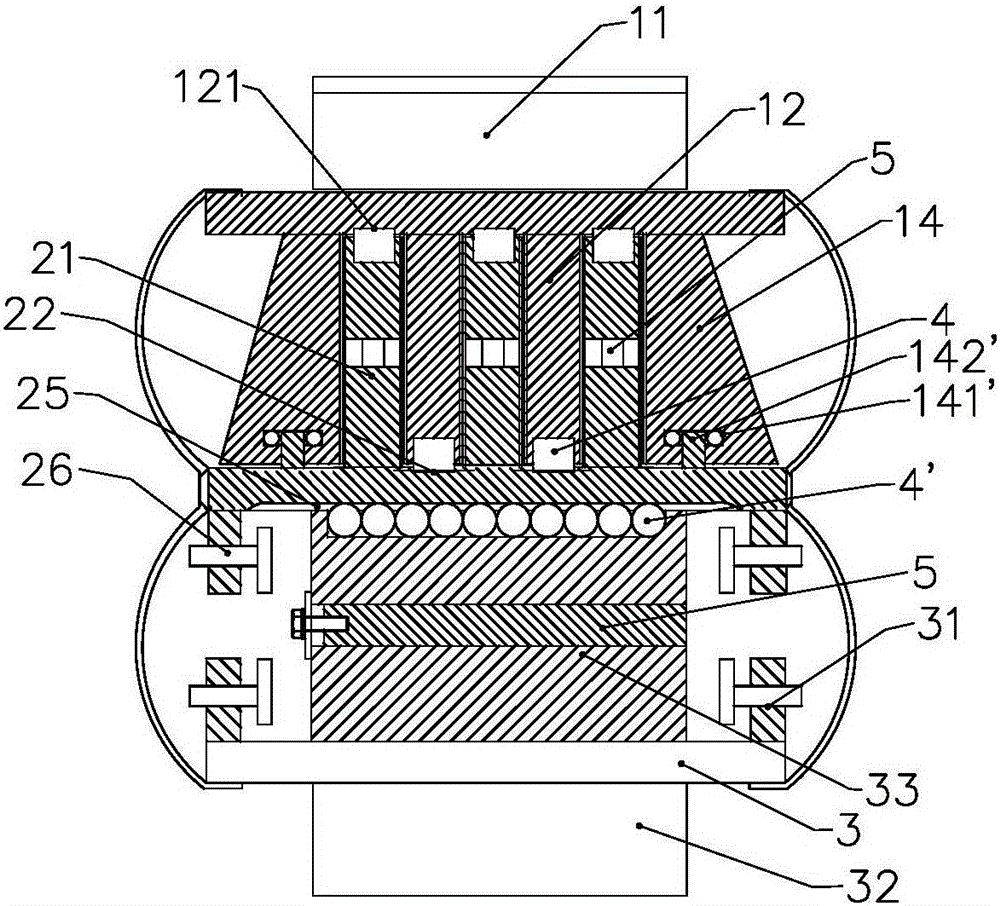

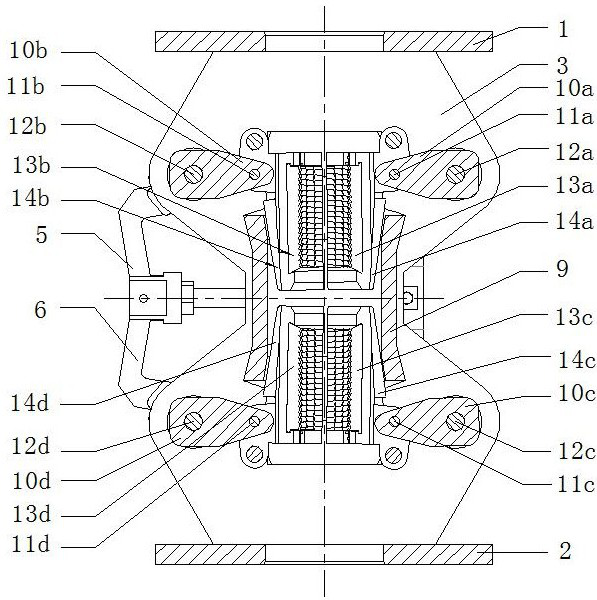

Centering clamping device of hydraulic forging machine

InactiveCN102632180AGood flexibilityImprove synchronicityForging/hammering/pressing machinesRobotic armEngineering

The invention discloses a centering clamping device of a hydraulic forging machine, which is characterized by comprising mechanical arms which are symmetrically arranged, wherein the upper ends of the mechanical arms are sleeved on spline shafts and the spline shafts are arranged on a fixed support; the fixed support is fixedly connected with a slide block of a hydraulic machine; an oil cylinder is arranged between the middle part of each mechanical arm and the slide block of the hydraulic machine; the lower end of each mechanical arm is provided with a mechanical claw; and each mechanical claw is provided with a clamping wheel. The fixed support is fixed on the slide block of the hydraulic machine and moves along the movement of the slide block; the slide block drives the device to move to a work piece; and the oil cylinders are used for driving the mechanical arms to push the work piece to move towards the center and clamp the work piece. In order to increase the synchronism, a synchronous gear is additionally arranged. In order to increase the flexibility of the mechanical arms, the mechanical claws and the clamping wheels are additionally arranged at the tail ends of the mechanical arms; and in order to increase a clamping force, a friction groove is machined on a clamping hydraulic wheel.

Owner:南通市腾达锻压机床厂

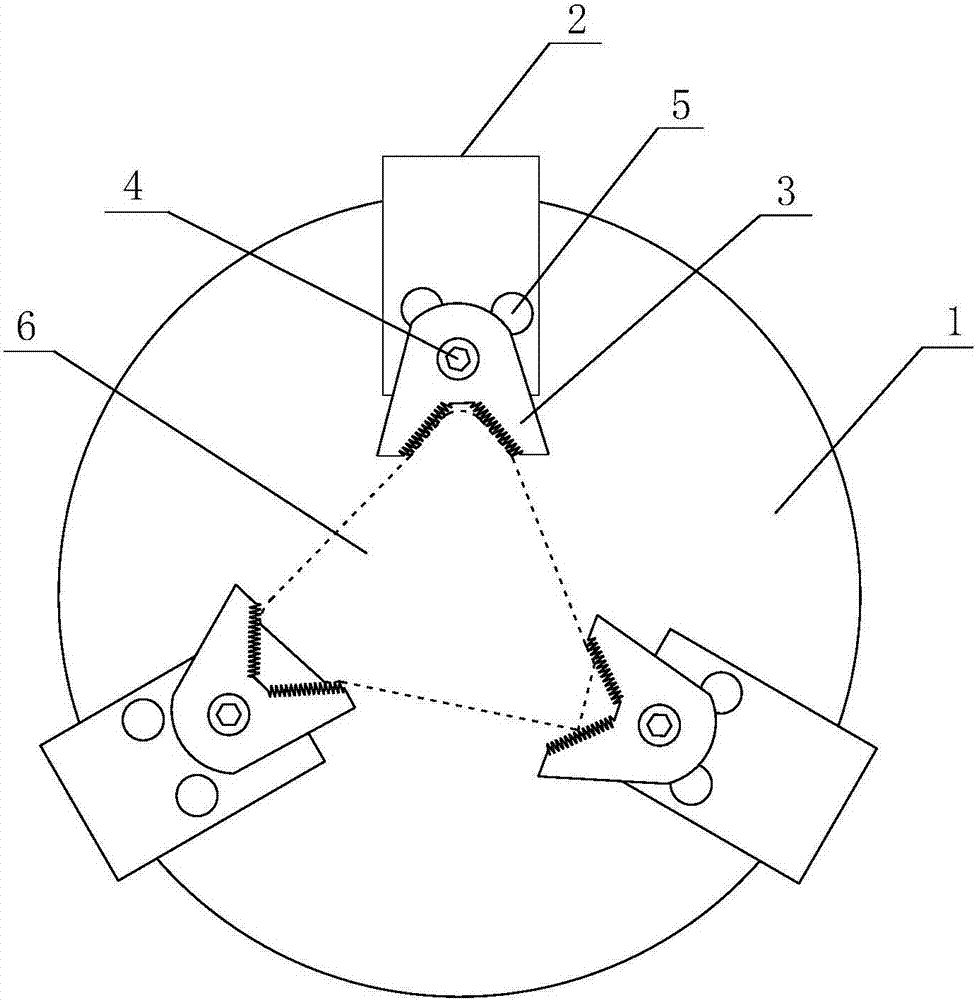

Chuck suitable for irregular part

The invention relates to the technical field of machining, in particular to a chuck suitable for an irregular part. The chuck comprises a chuck body and a plurality of claws located on the chuck body. Clamping jaws are arranged on the claws correspondingly. The clamping jaws are in a V shape and are connected with the claws through locking bolts. Connecting holes are formed in the clamping jaws. Thread holes matched with the connecting holes are formed in the claws. The locking bolts penetrate through the connecting holes to be connected with the thread holes. By adjusting the angles of the clamping jaws on the claws, the irregular part can be firmly clamped on the chuck, so that the machining quality is guaranteed. Insections or elastic spacers are arranged on the clamping jaws, so that the surface of the part is protected against damage while the clamping force is increased. The chuck suitable for the irregular part is simple in structure, convenient to mount and low in cost.

Owner:CHENGDU XINGYU PRECISION CASTING

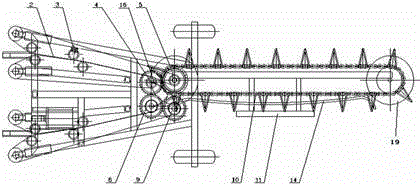

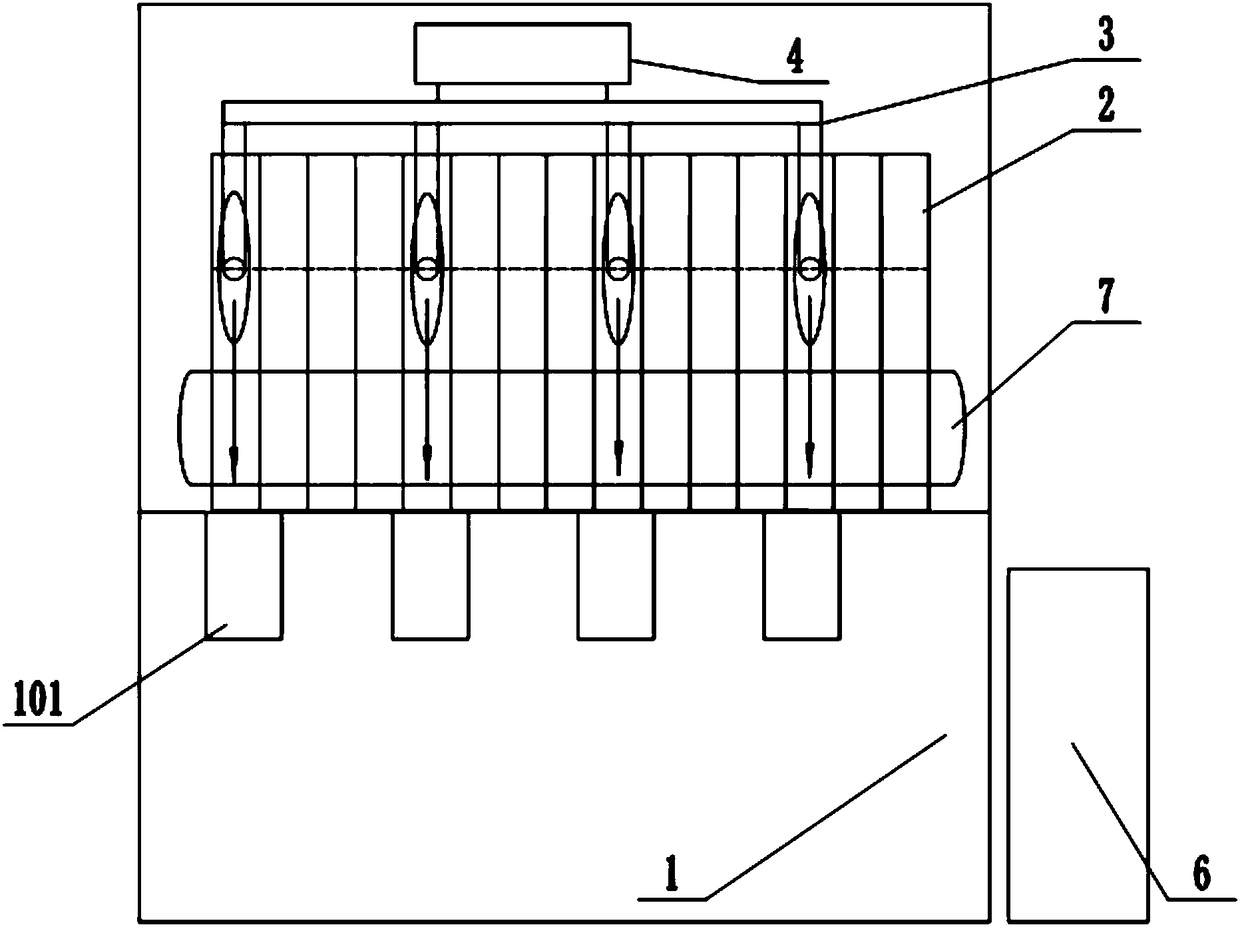

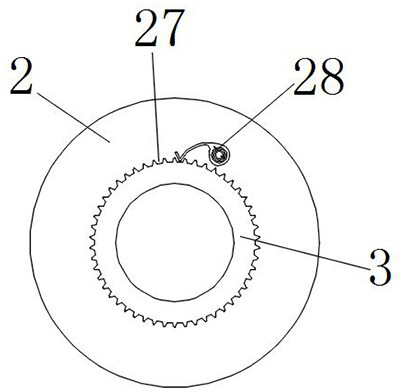

A peanut harvester

InactiveCN106804195AEasy to recycleReduce white pollutionDigger harvestersAgricultural engineeringSprocket

The invention discloses a peanut harvester, which comprises a frame, a support frame, the rear part of the frame is connected with the front part of the support frame, the middle part of the frame is provided with walking wheels, the front part of the frame is provided with a gearbox, and the The front end is provided with a passive pulley, the input shaft of the gearbox is connected with the rear output shaft of the tractor, the output shaft of the gearbox is provided with an output sprocket, the output sprocket and the passive sprocket are connected by a chain, and the passive sprocket is set on the transmission shaft , there is also a driving gear on the transmission shaft, a driven gear in the middle of the frame, a driving pulley on the connecting shaft, and a driven sprocket II on the connecting shaft; the support frame is equipped with a laying device, and the driven chain Wheel I is connected with driven sprocket II by laying chain. Harvesting saves labor and effort, and has high efficiency. When harvesting peanuts, the plastic film is not cut or broken, which facilitates the subsequent recycling of the plastic film and reduces white pollution.

Owner:青岛沃德农业科技有限公司

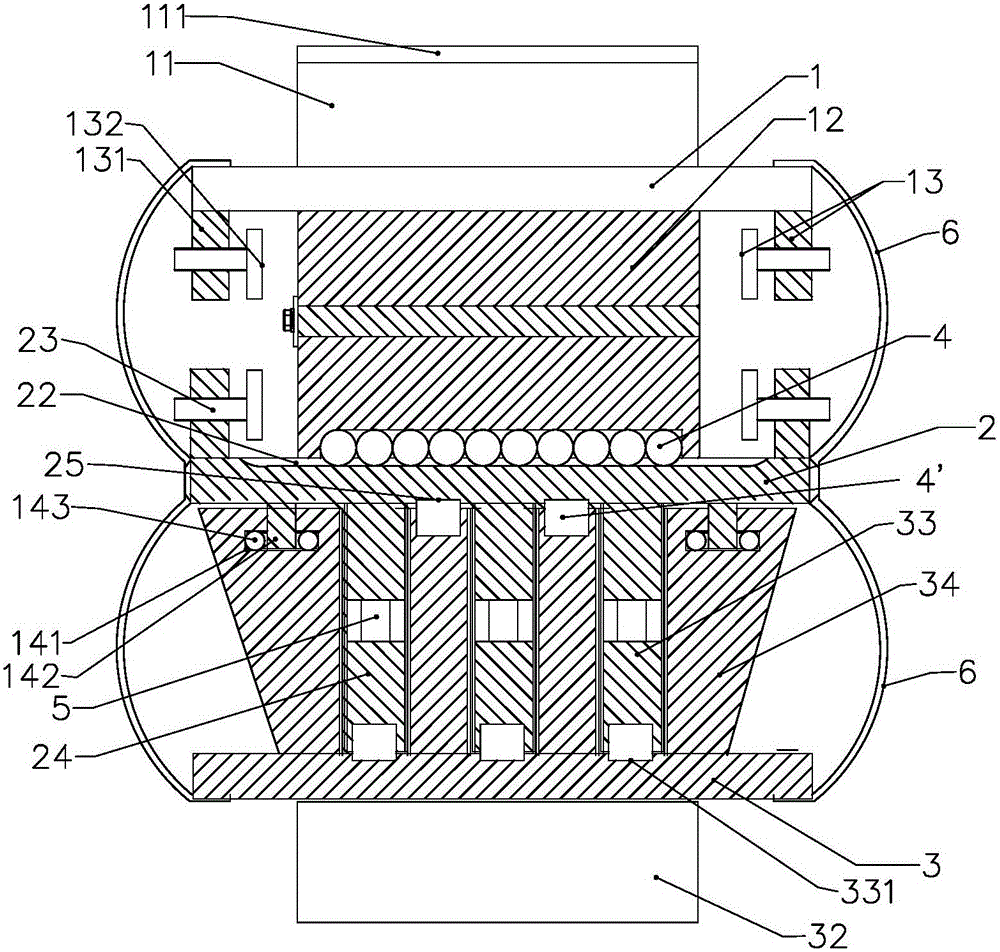

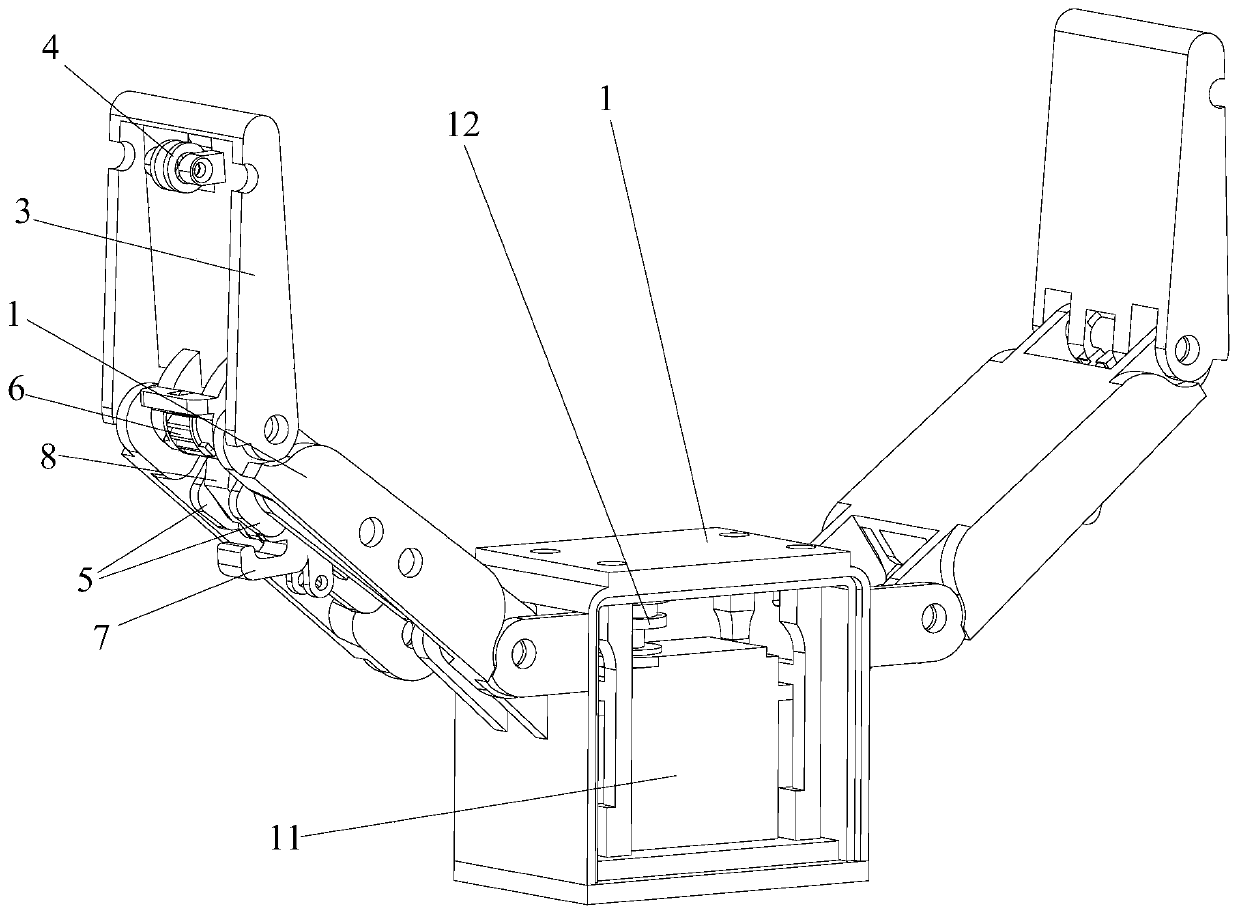

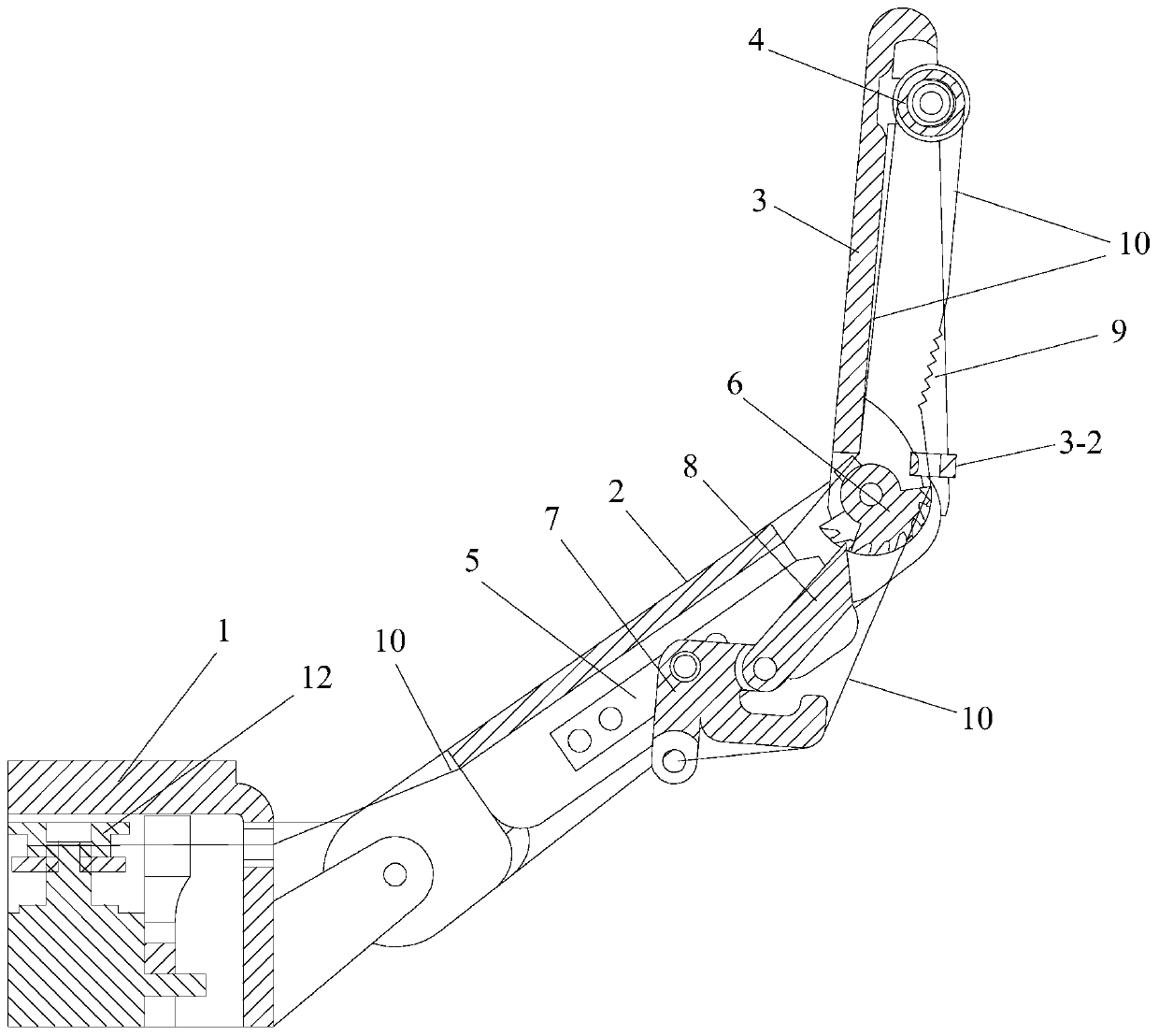

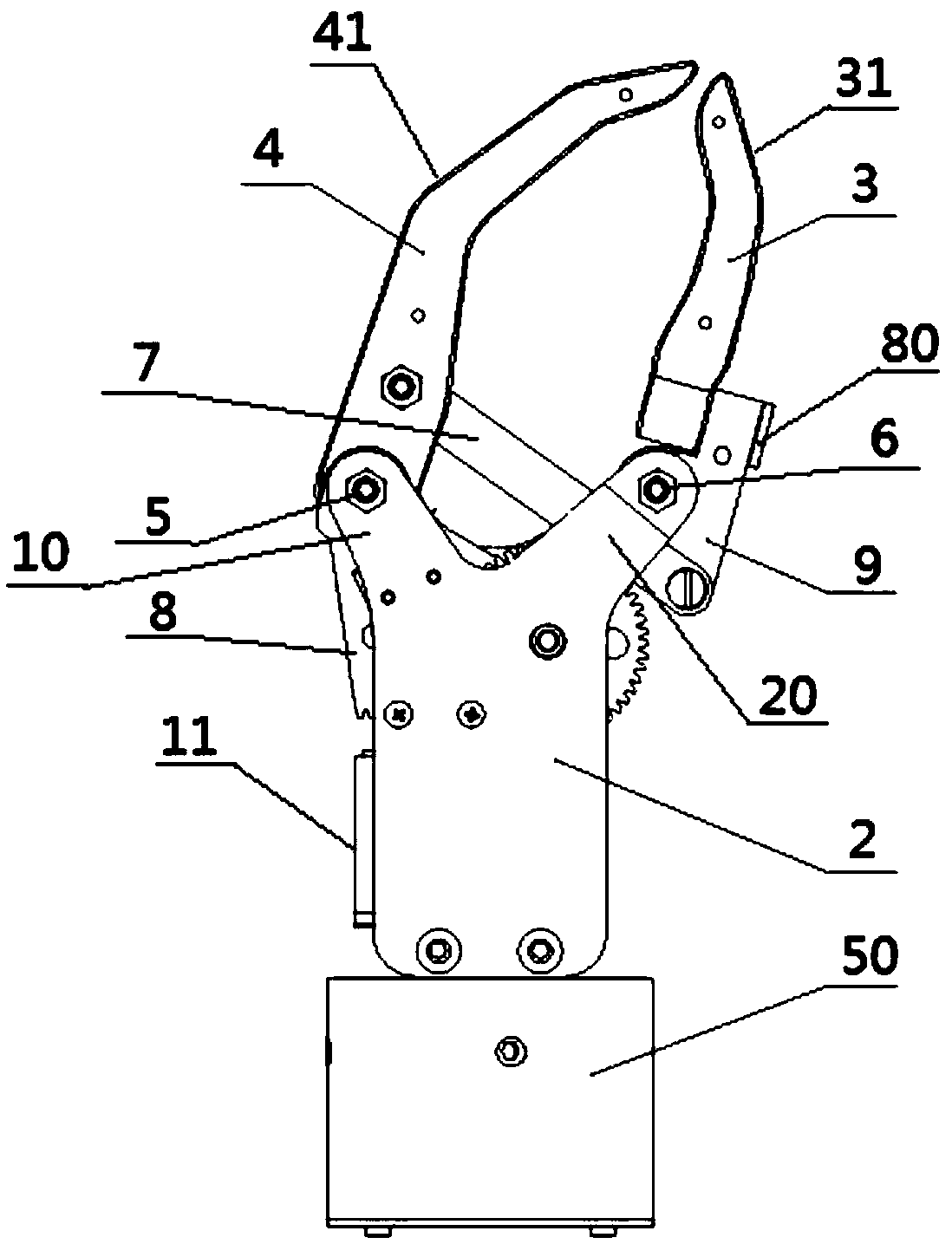

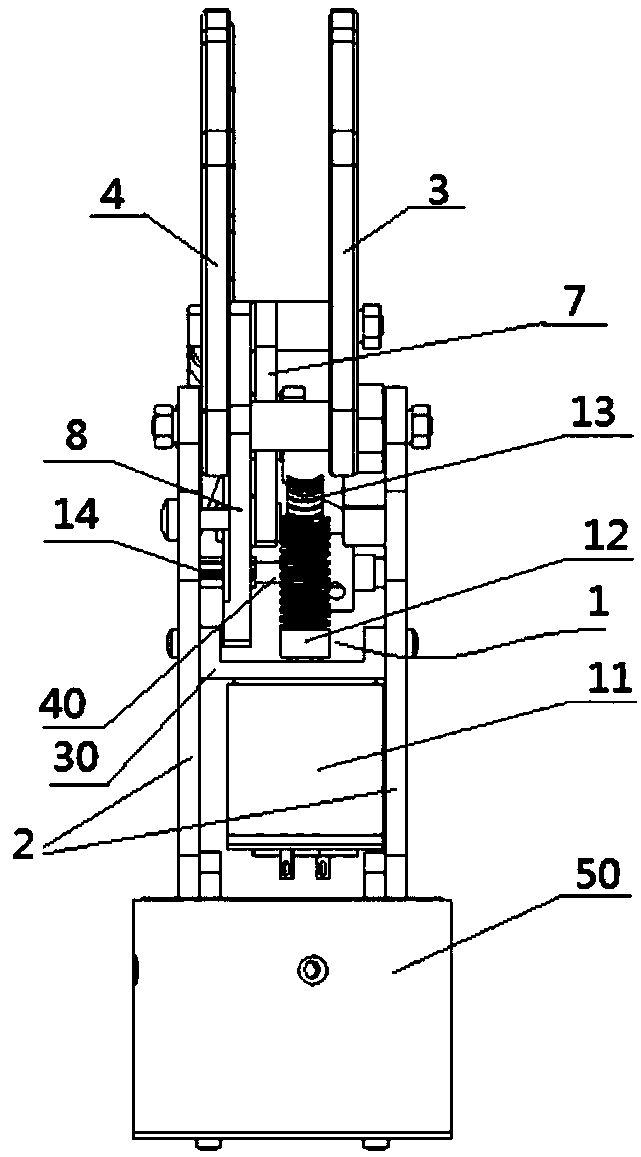

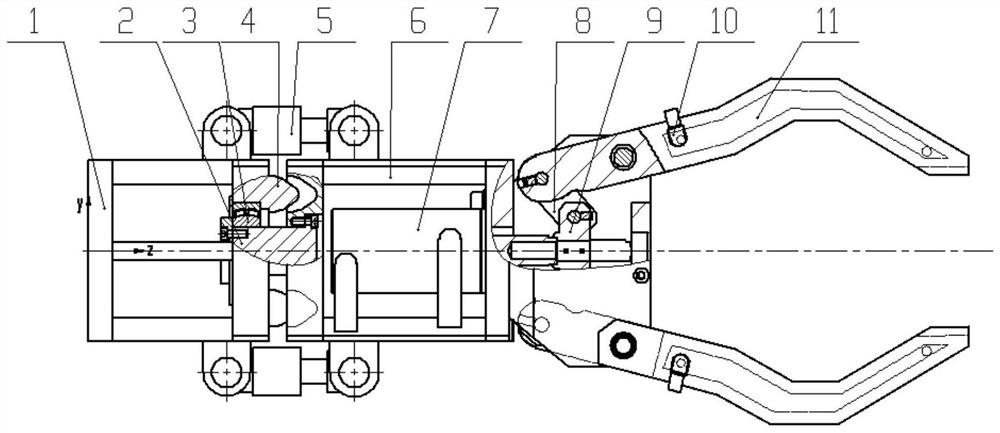

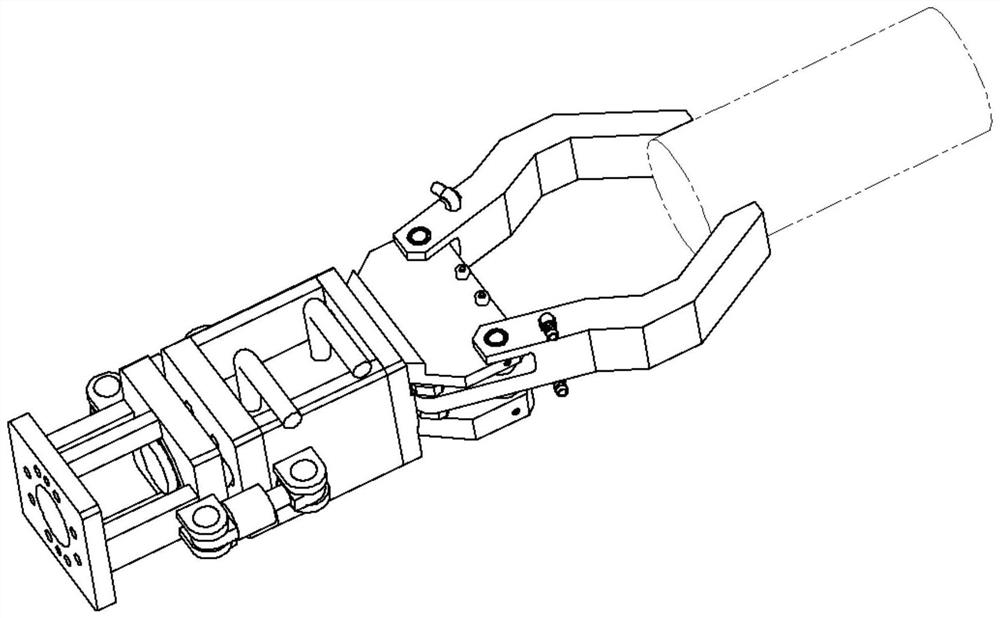

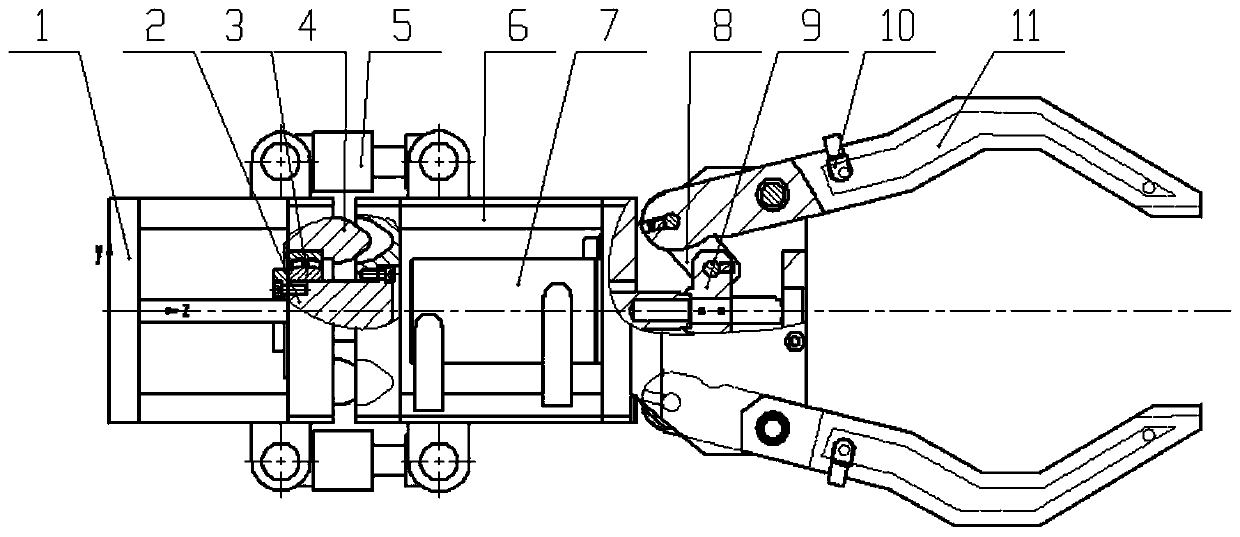

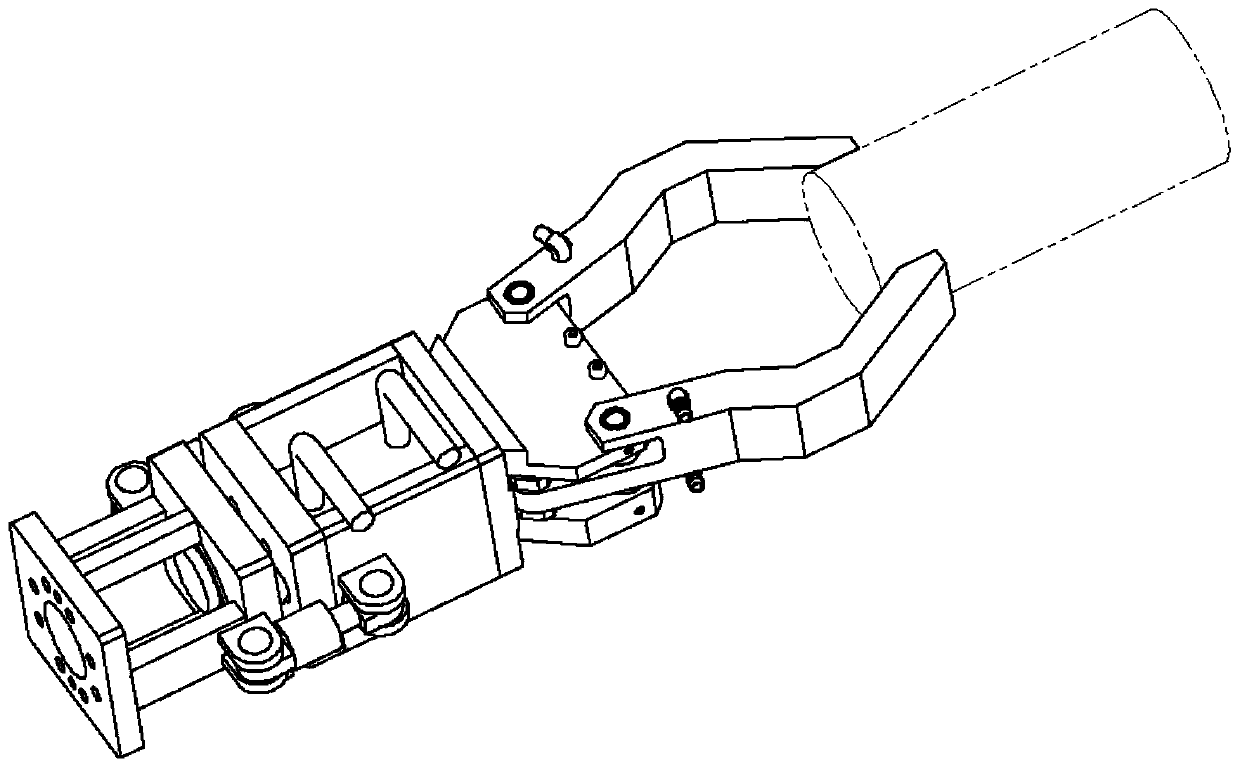

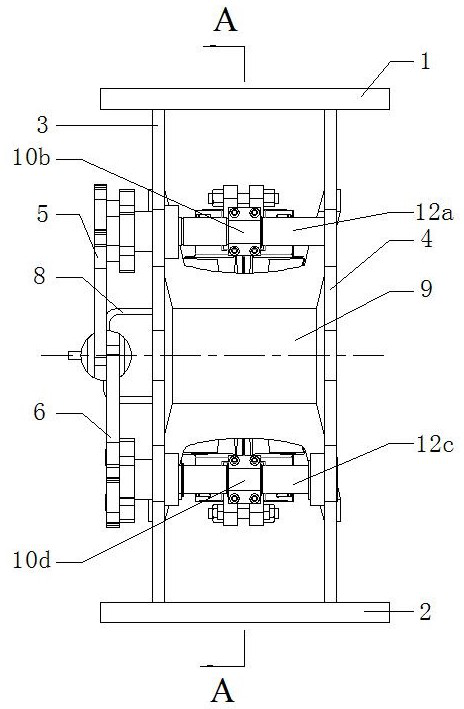

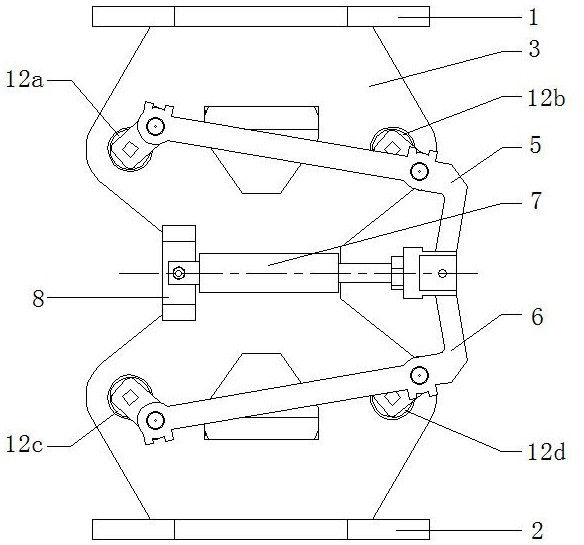

Manipulator capable of enhancing clamping force

ActiveCN111015713AStrong blessingIncrease clamping forceGripping headsManipulatorClassical mechanics

The invention provides a manipulator capable of enhancing clamping force. The manipulator comprises two clamping arms, a base and a driving part. The two clamping arms are arranged in a mirror symmetry mode and are each connected with the base and the driving part. The driving part drives the two clamping arms to move so as to realize clamping or opening movement; the driving part is arranged in the base, and is connected with a rope and used as a starting end of the rope; each clamping arm comprises a root finger component, a tail finger component and a locking transmission mechanism, whereinthe root finger component and the tail finger component are hinged with the base, the locking transmission mechanism is used for transmitting the clamping or opening movement of the clamping arm andlocking the clamping state of the clamping arm, the locking transmission mechanism is arranged on the root finger part and connected with the tail finger part, and the tail finger part is hinged withthe root finger part and is provided with a pulley; and the rope starts from the driving part, sequentially passes through the base, the root finger parts and the tail finger parts, and passes aroundthe pulleys to be connected with the locking transmission mechanisms. The manipulator has higher clamping force when clamping an object, so that the clamping stability is improved.

Owner:FOSHAN UNIVERSITY

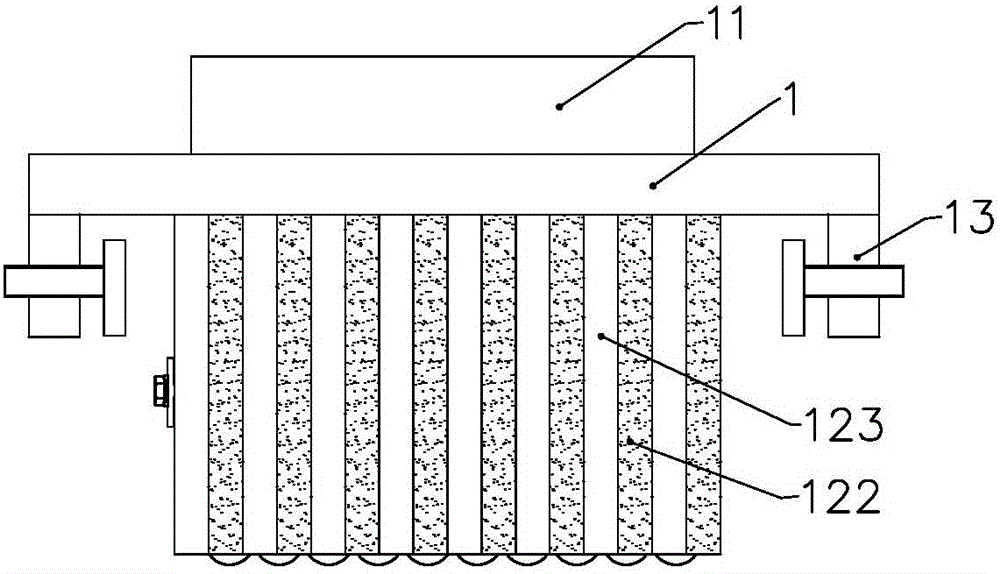

Metal pipe cutting device

ActiveCN108098040AFixed issue where it wouldn't cut to the bottom of the standAvoid damageTube shearing machinesPositioning apparatusEngineeringMechanical engineering

The invention relates to a cutting machine, in particular to a metal pipe cutting device which comprises a cutting base. The cutting base is provided with a plurality of grooves in uniform distribution and further provided with a plurality of sheets which are closely attached and orderly arrayed, and the sheets are in slide connection with the cutting base and provided with openings. One end of each opening is symmetrically provided with two clamping blocks, one end of each clamping block is connected with a connecting rod, the other end of each connecting rod is connected with the corresponding sheet, an elastic part sleeves each connecting rod, and cutters are arranged at intervals at the other ends of the openings. Inner upper ends of the sheets are partially provided with the cutters,lower ends of the sheets are provided with the clamping blocks for clamping metal pipes, the sheets with the cutters move downwards to allow the cutters in the sheets to cut the metal pipes into corresponding sections in a moving process, the sheets with the cutters can be stored in the grooves, and equipment damages in cutting are avoided. The problem of equipment damages in a cutting process inthe prior art is solved.

Owner:宁波隆锐机械制造有限公司

Tensile stress detection device for safety production of steel wire

PendingCN112924290AGuaranteed stabilityIncrease internal pressureMaterial strength using tensile/compressive forcesTension stressManufacturing engineering

The invention discloses a tensile stress detection device for safety production of a steel wire. The tensile stress detection device comprises a rack, a third gear and a fixed channel, wherein the outer side of the rack is connected with a motor, one end of the motor is provided with a supporting column, the supporting column is located in the rack, the outer side of the supporting column is provided with a first gear, a second gear is connected to one side of the first gear, the two ends of the second gear are connected with the rack, a fixing column is connected to the interior of the connecting frame, a first clamping plate is arranged at the lower end of the fixing column, a fixing cap is connected to the side face of the interior of the fixed channel, and a supporting rod is arranged at the upper end of the interior of the fixed channel. According to the tensile stress detection device for the safety production of the steel wire, when the device is used, the internal pressure of the fixed channel is increased, so that the supporting rod and the push rod are pushed to move upwards, and when the push rod moves upwards, a pushing force is generated on the steel wire, so that the deformation force of the steel wire is detected.

Owner:王琦

Fixing device for stretcher stretching

PendingCN110115661AExtended driving distanceExpand the scope of detectionDiagnosticsAmbulance serviceEngineeringMedical treatment

The invention discloses a fixing device for stretcher stretching. By arranging a stretcher locking structure on a main slideway, when the stretcher is locked by the stretcher locking structure, part of the stretcher stretches out of the main slideway toward the detection device, in this way, the driving distance of the main slideway is prolonged in disguise, then the detection range of the position of the main slideway is prolonged, the wounded located on the stretcher can be inspected to the maximum range, and doctors can determine the injury position and injury degree of the wounded within ashort time; meanwhile, the doctors can establish the correct medical care means within a short time, the wounded is protected to the maximum extend, and the phenomenon that due to the fact that the injury position and the injury degree cannot be determined in time, the wounded cannot be treated in time is reduced.

Owner:上海大骋医疗科技有限公司

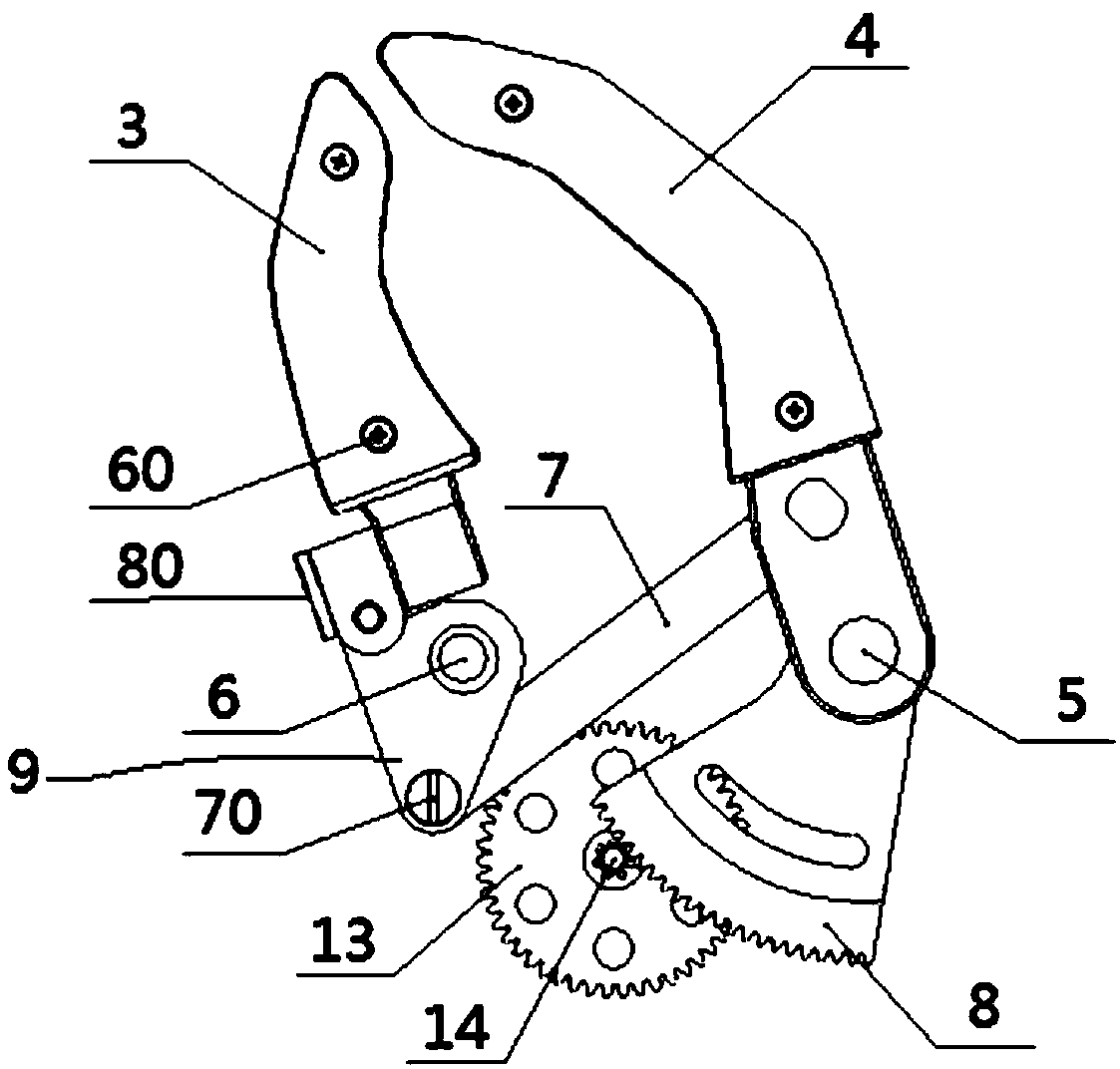

Linkage-type prosthetic hand

PendingCN109330751ARealize opening and closingSimple structureArtificial handsEngineeringProsthetic hand

The invention discloses a linkage-type prosthetic hand. The prosthetic hand comprises a gear driving device, two supporting plates, a thumb and a finger pinched with the thumb; the finger is in relative rotational connection with the two supporting plates through a first rotating shaft disposed between the two supporting plates, the thumb is in relative rotational connection with the two supporting plates through a second rotating shaft disposed between the two supporting plates, and a connecting rod is disposed between the thumb and the finger; a driving gear is disposed at the lower end of the thumb or the finger, and the gear driving device is in driving connection with the driving gear; the gear driving device drives the driving gear to rotate, and the driving gear drives the finger orthe thumb to rotate around the corresponding first rotating shaft or the corresponding second rotating shaft, so that the other end of the connecting rod drives the thumb or the finger to rotate around the corresponding second rotating shaft or the corresponding first rotating shaft in the opposite direction. The finger and the thumb are connected and disconnected under the joint action of the gear driving device and the connecting rod, the structure is simple, and adoption of a cumbersome structure of a reversing gear is avoided.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI +1

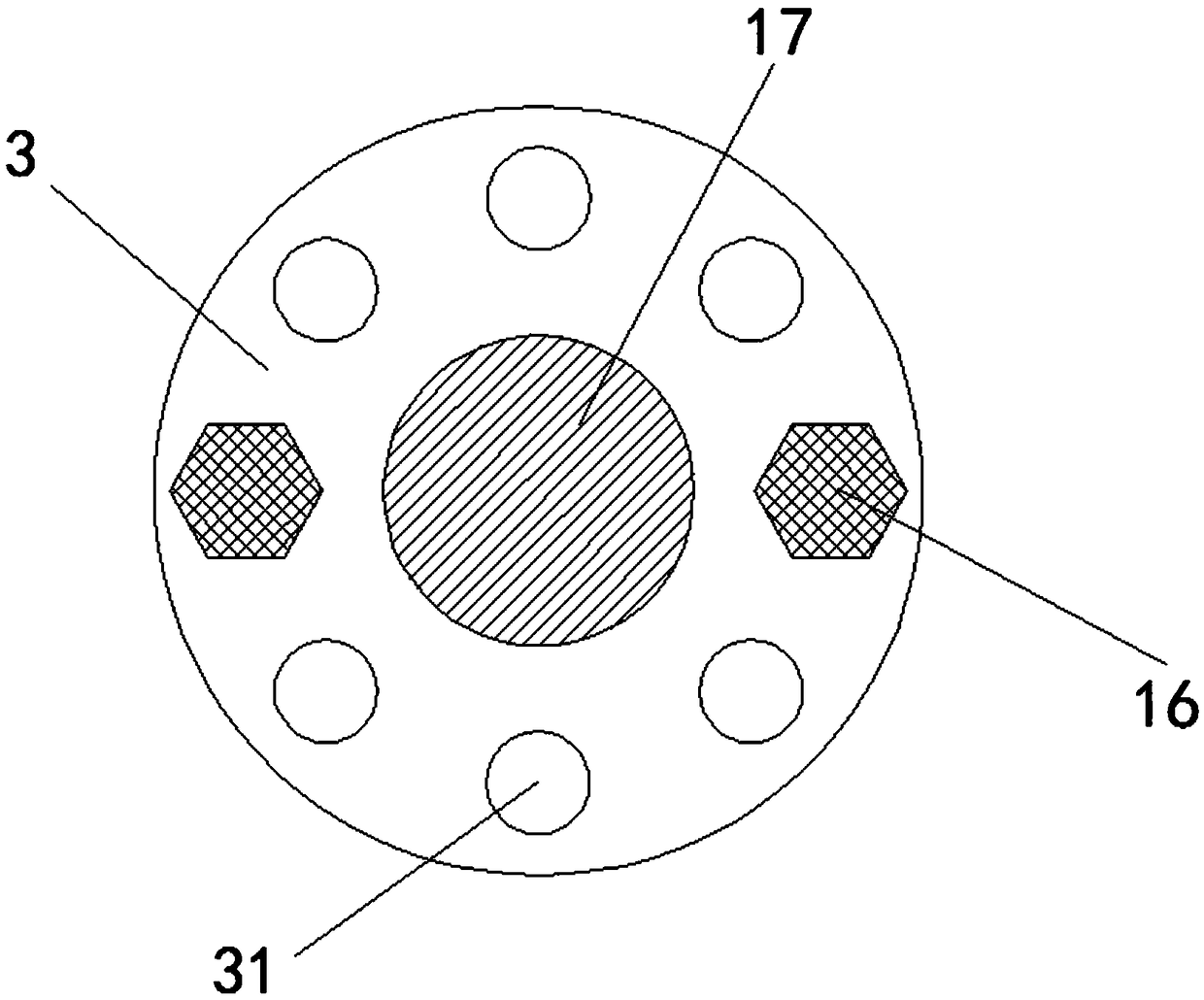

Novel die cutting machine fixture

InactiveCN108247747AImprove applicabilitySimple and efficient operationMetal working apparatusFlangeLarge size

The invention relates to a novel die cutting machine fixture. The novel die cutting machine fixture comprises a pressure bearing plate, an adjustable flange plate, clamping plates, clamping heads, a fixture main body and a connecting rod; the vertical connecting rod is fixed below the pressure bearing plate; the adjustable flange plate sleeves the lower end of the connecting rod; four clamping plates capable of moving in chutes are arranged below the fixture main body; gaps between the clamping plates are adjusted through springs and nuts on screw rods; outer side clamping areas connected by first springs can be used for clamping such mold plates as cutters with smaller widths, and a middle clamping area connected by second springs can be used for clamping such mold plates as gold stampingmold plates and belled mold plates with larger sizes, so that the applicability of the device is widened, the condition of replacing the fixture at the same time when molds are replaced is prevented,the operation is more convenient, and a lot of manpower and working time are saved; and meanwhile, the two outer side clamping areas can be singly used, and the other one is for future use or can beused at the same time for cutting such materials as paper with equal gaps, so that the working efficiency is improved.

Owner:孙柳英

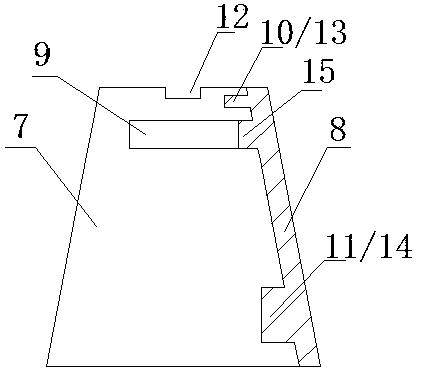

A flexible jaw for continuous high temperature forging

ActiveCN110722087BAvoid direct impactAccurate captureForging/hammering/pressing machinesHandling devicesCompliant mechanismMechanical engineering

The invention belongs to the field of forging devices, particularly relates to a flexible clamping jaw for continuous high-temperature forging. The flexible clamping jaw for continuous high-temperature forging comprises an installation flange, an installation frame, a clamping jaw oil cylinder, clamping jaw bodies and a flexible mechanism. The installation flange and the installation frame achieveflexible connection or rigid connection through the flexible mechanism. When flexible connection is conducted, the clamping jaw bodies can move and rotate along the z axis and rotate along the x axisand the y axis. The clamping jaw oil cylinder is installed on the installation frame. A piston rod of the clamping jaw oil cylinder is rotationally connected with the clamping jaw bodies through a connection rod mechanism. The clamping jaw bodies are hinged to the installation frame. Cooling water channels are arranged on the clamping jaw bodies. The overall flexible clamping jaw can achieve switch between flexibility and rigidity, avoids direct influence of a vibration environment on a robot and an end executor, improves the stability of the end executor and the robot and prolongs the service lives of the end executor and the robot; the position of the clamping jaw can be accurately located; the cooling water circularly flows to cool the clamping jaw, the forging clamping jaw is kept ata low temperature, and continuous work of the clamping jaw is guaranteed.

Owner:JARI AUTOMATION CO LTD CHINA

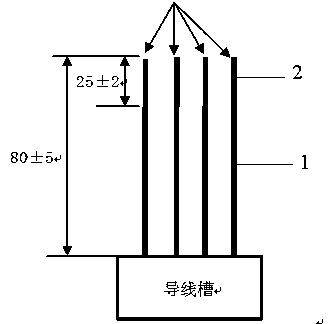

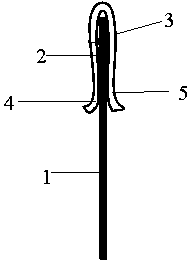

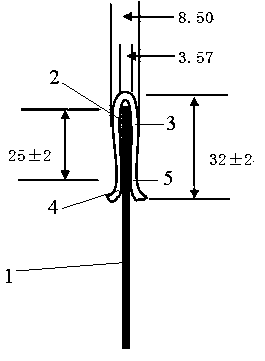

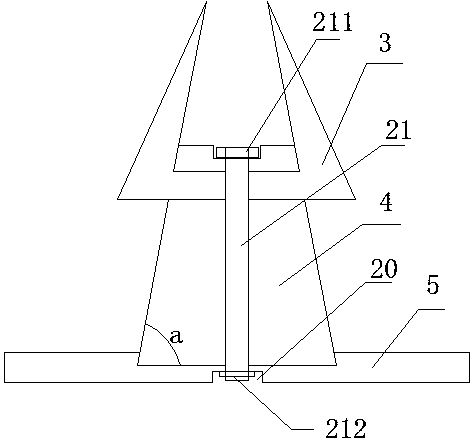

Pin for illuminating bus duct plug box

ActiveCN104242194AThe process is simple and convenientSave raw materialsBus-bar installationEngineering

The invention relates to a pin for an illuminating bus duct plug box. The pin comprises an elastic part, a supporting column and a base. An elastic base of the elastic part is fixed in an elastic part clamping groove of the supporting column in a clamping mode, and the supporting column is fixed in a supporting column clamping groove of the base in a clamping mode. The elastic part, the supporting columns and the base are fixed into a whole through bolts. The pin for the illuminating bus duct plug box is simple in structure, good in stability, firm in plugging, safer and more reliable. Meanwhile, cost is further lowered.

Owner:JIANGSU SHILIN ELECTRIC EQUIP

Manipulator

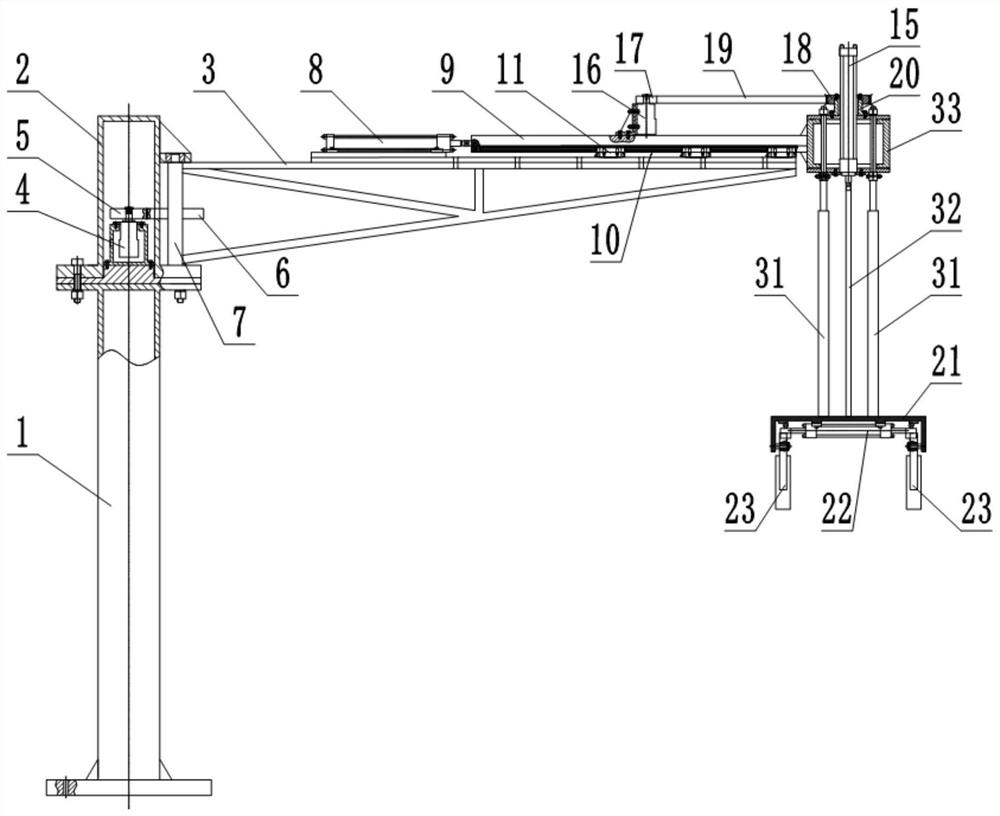

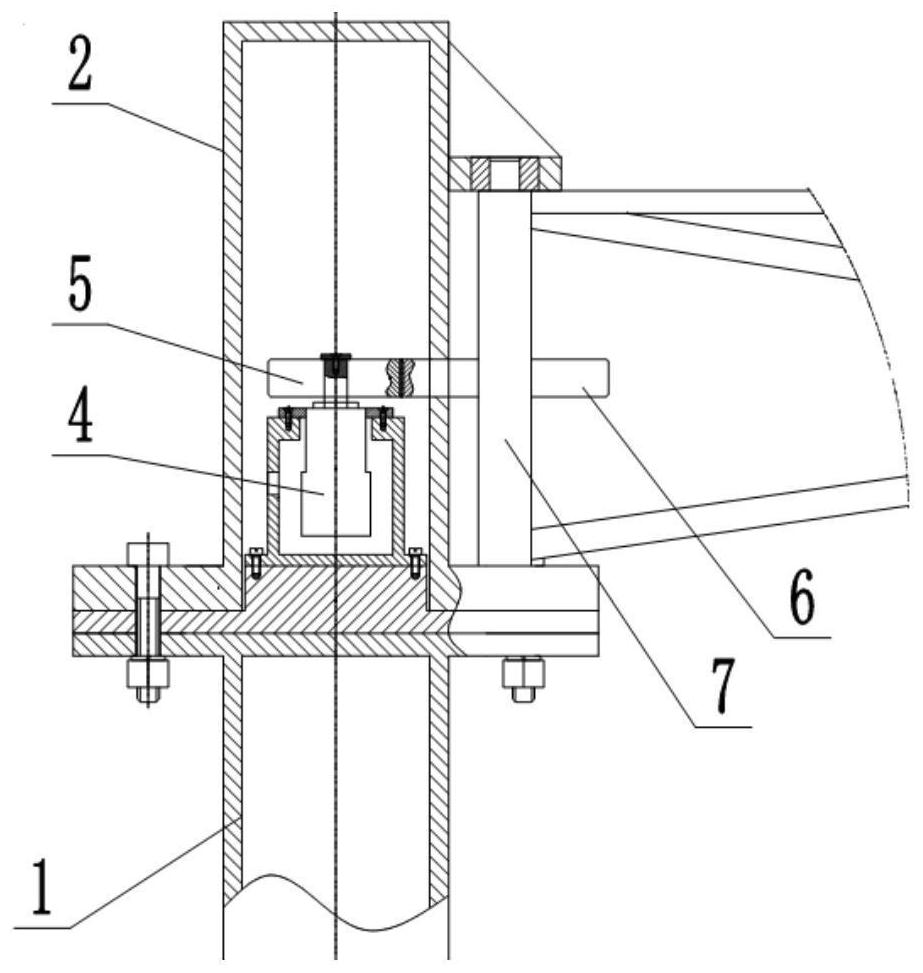

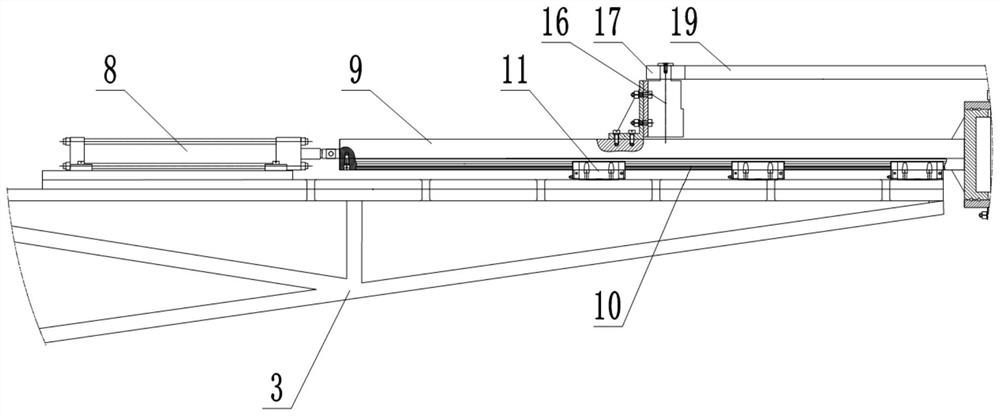

ActiveCN111606035AAchieve four degrees of freedomSimple structureGripping headsArmsClassical mechanicsEngineering

The invention discloses a manipulator which comprises a substrate, a transverse arm, a second driving mechanism, a vertical arm and a clamping device, wherein the transverse arm is rotatably connectedto the substrate and is driven by the first driving mechanism to rotate horizontally relative to the substrate; the second driving mechanism is arranged on the transverse arm; the vertical arm is rotatably connected to the second driving mechanism and is driven by the second driving mechanism to move linearly, the vertical arm is driven by a third driving mechanism to rotate, and the vertical armcomprises a fourth driving mechanism; and the clamping device is arranged on the fourth driving mechanism, is driven by the fourth driving mechanism to lift, and is used for clamping a workpiece. Themanipulator has four degrees of freedom, can complete complex carrying work and is simple in structure and easy to maintain.

Owner:浙江中光新能源科技有限公司

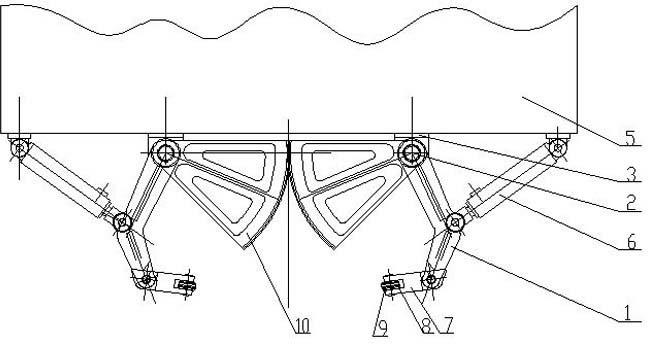

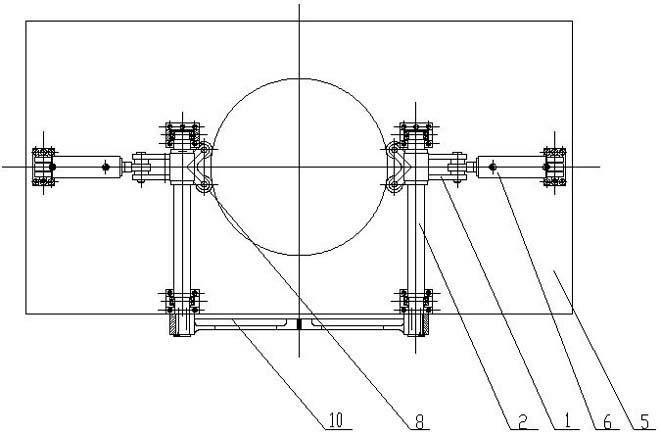

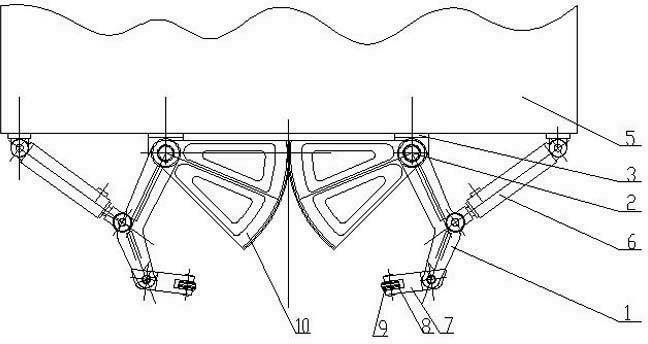

Flexible clamping jaw for continuous high-temperature forging

ActiveCN110722087AAvoid direct impactAccurate captureForging/hammering/pressing machinesHandling devicesCompliant mechanismWater circulation

The invention belongs to the field of forging devices, particularly relates to a flexible clamping jaw for continuous high-temperature forging. The flexible clamping jaw for continuous high-temperature forging comprises an installation flange, an installation frame, a clamping jaw oil cylinder, clamping jaw bodies and a flexible mechanism. The installation flange and the installation frame achieveflexible connection or rigid connection through the flexible mechanism. When flexible connection is conducted, the clamping jaw bodies can move and rotate along the z axis and rotate along the x axisand the y axis. The clamping jaw oil cylinder is installed on the installation frame. A piston rod of the clamping jaw oil cylinder is rotationally connected with the clamping jaw bodies through a connection rod mechanism. The clamping jaw bodies are hinged to the installation frame. Cooling water channels are arranged on the clamping jaw bodies. The overall flexible clamping jaw can achieve switch between flexibility and rigidity, avoids direct influence of a vibration environment on a robot and an end executor, improves the stability of the end executor and the robot and prolongs the service lives of the end executor and the robot; the position of the clamping jaw can be accurately located; the cooling water circularly flows to cool the clamping jaw, the forging clamping jaw is kept ata low temperature, and continuous work of the clamping jaw is guaranteed.

Owner:JARI AUTOMATION CO LTD CHINA

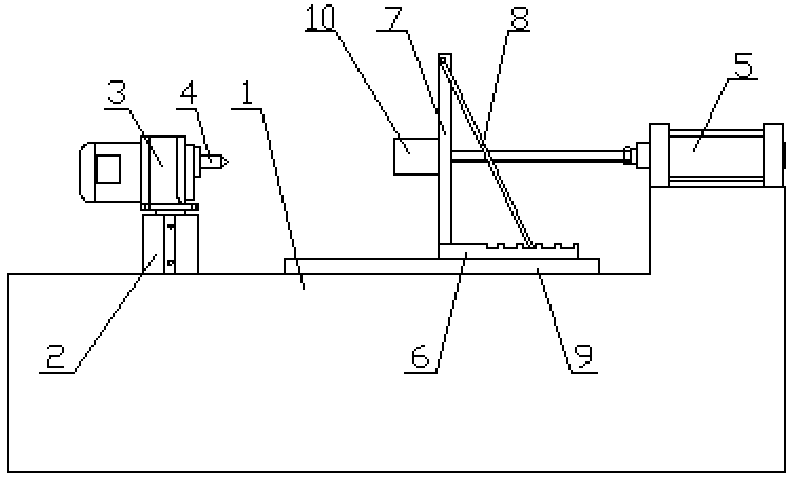

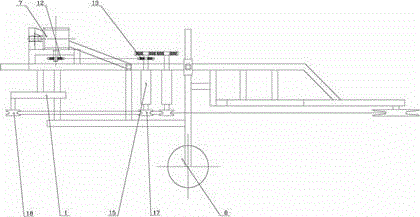

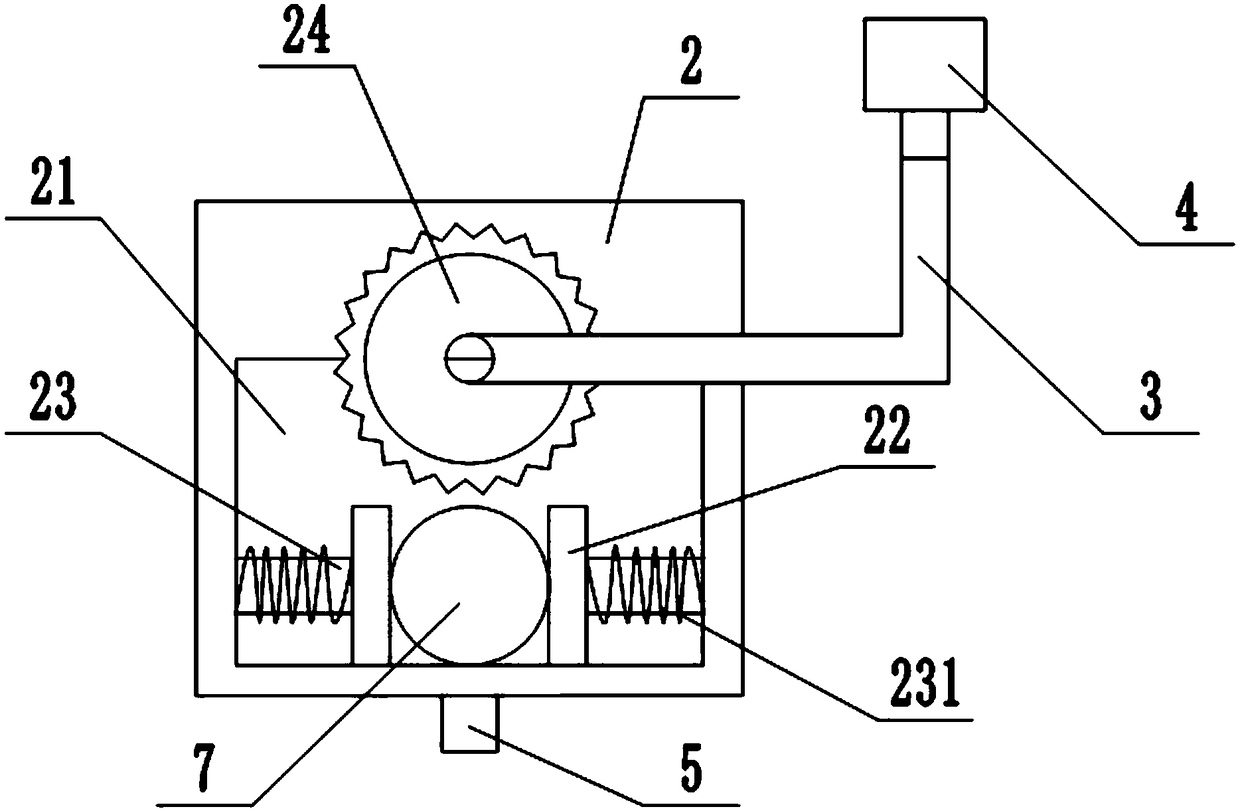

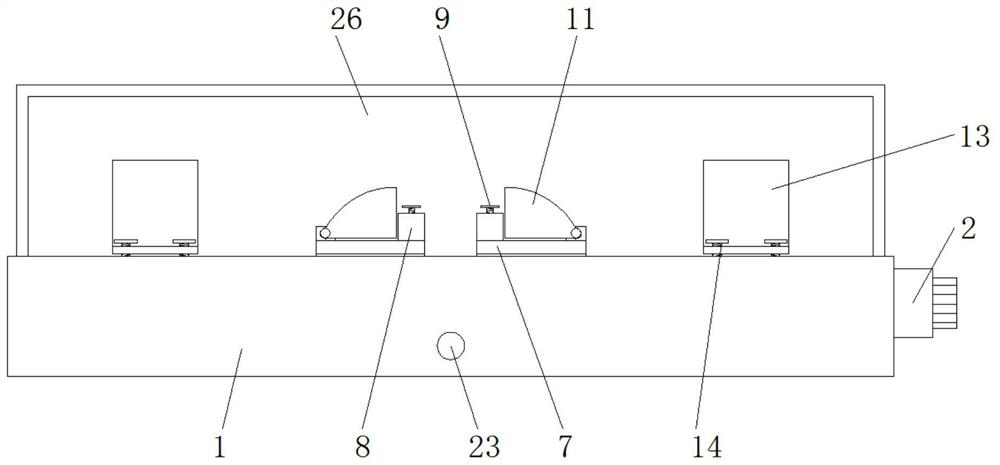

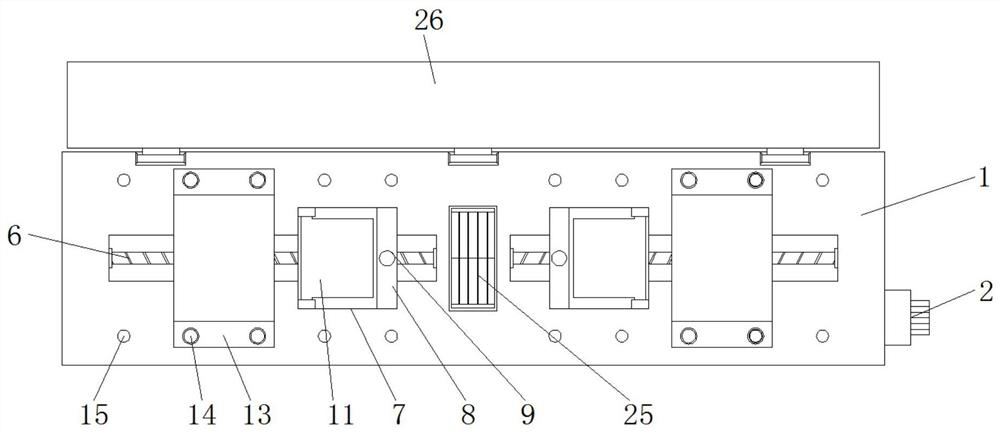

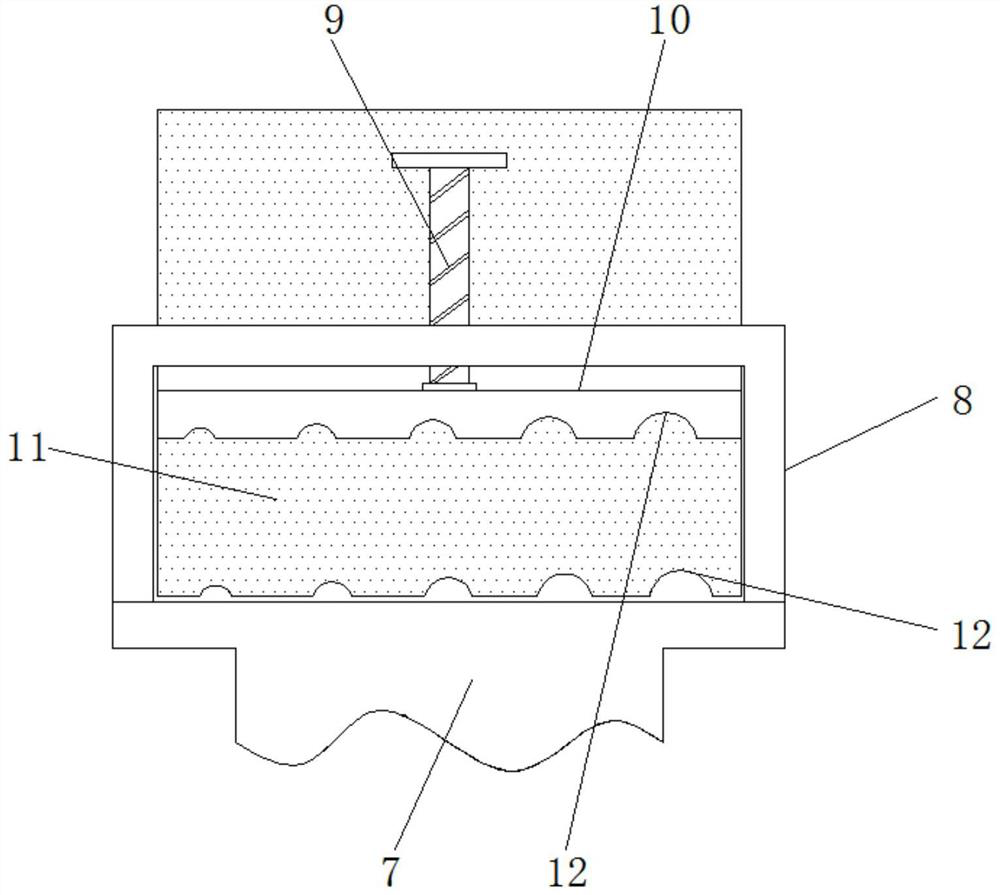

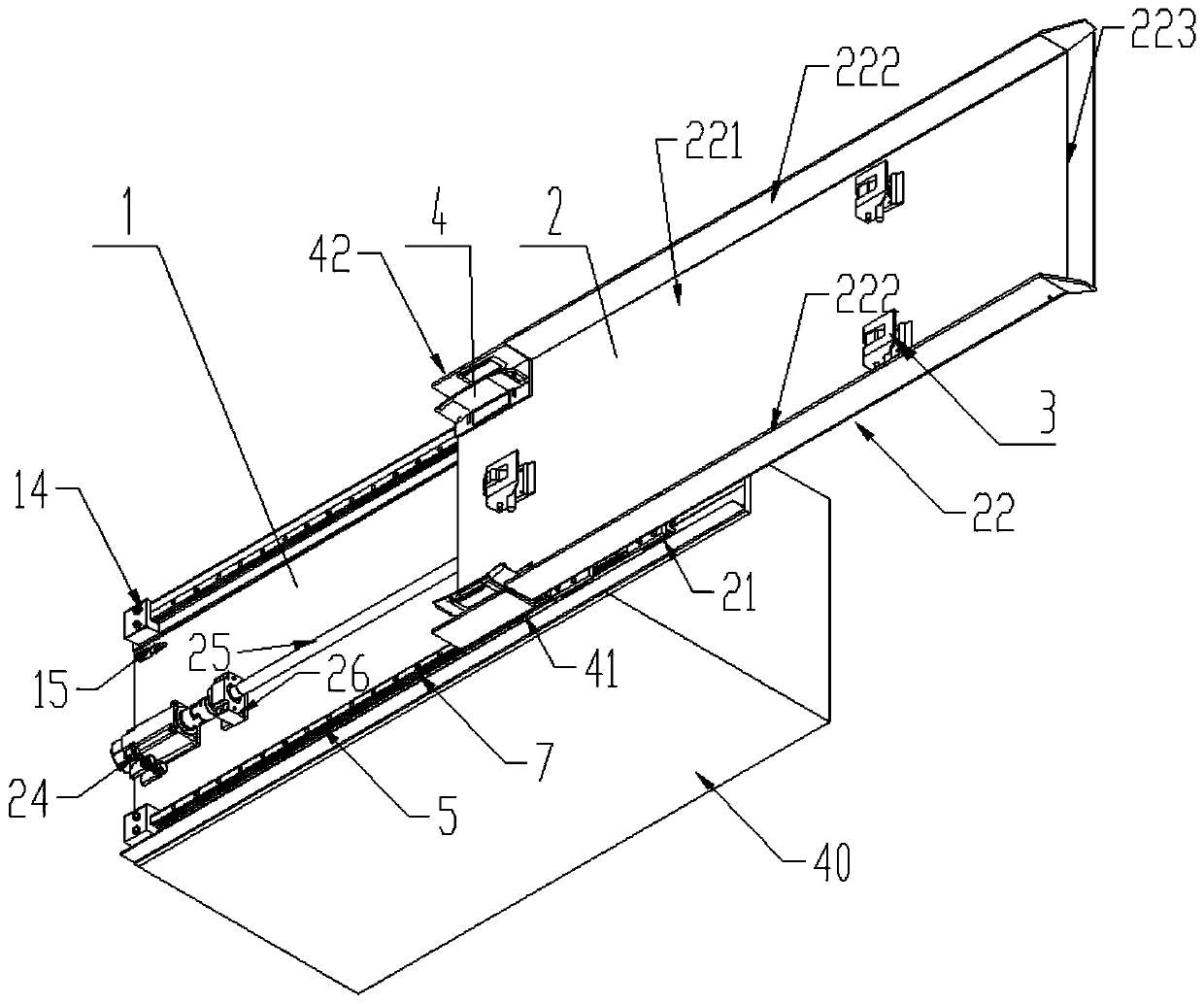

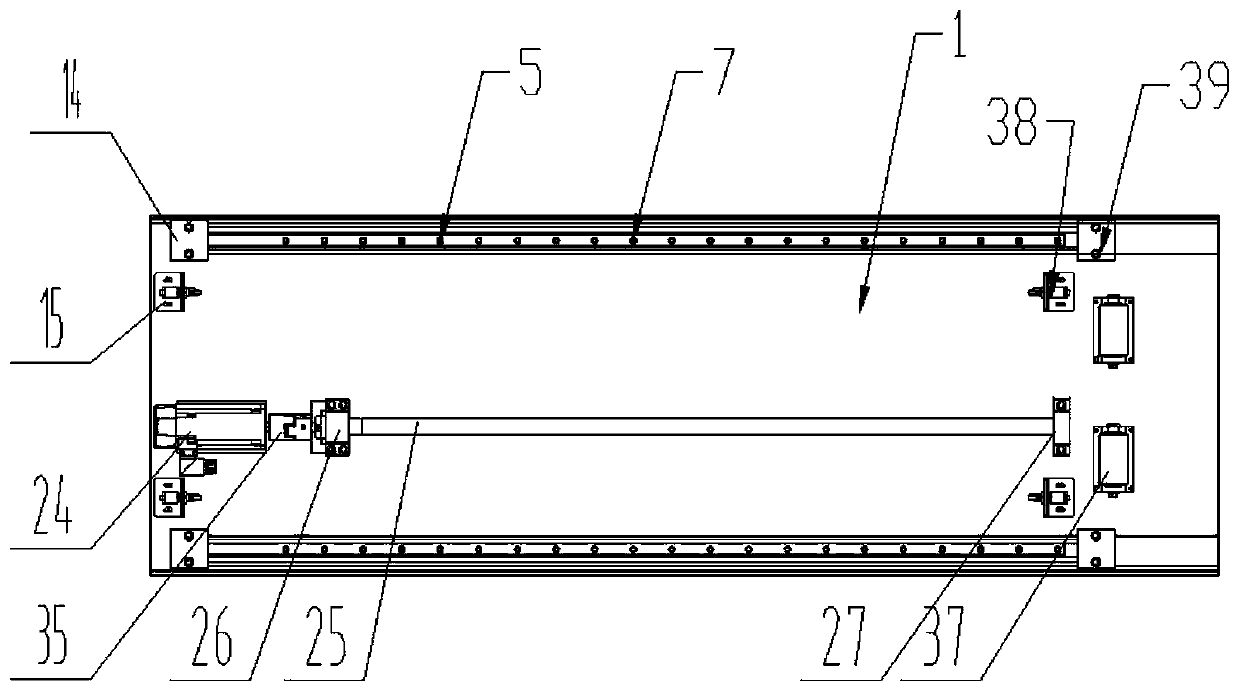

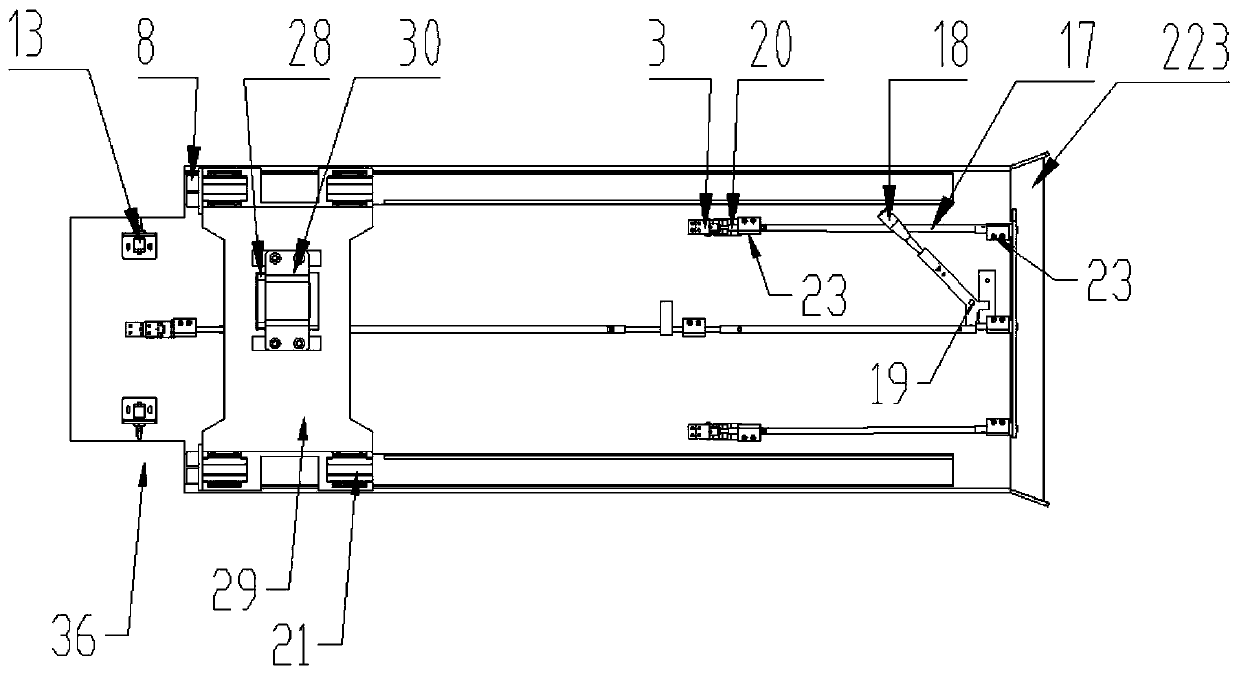

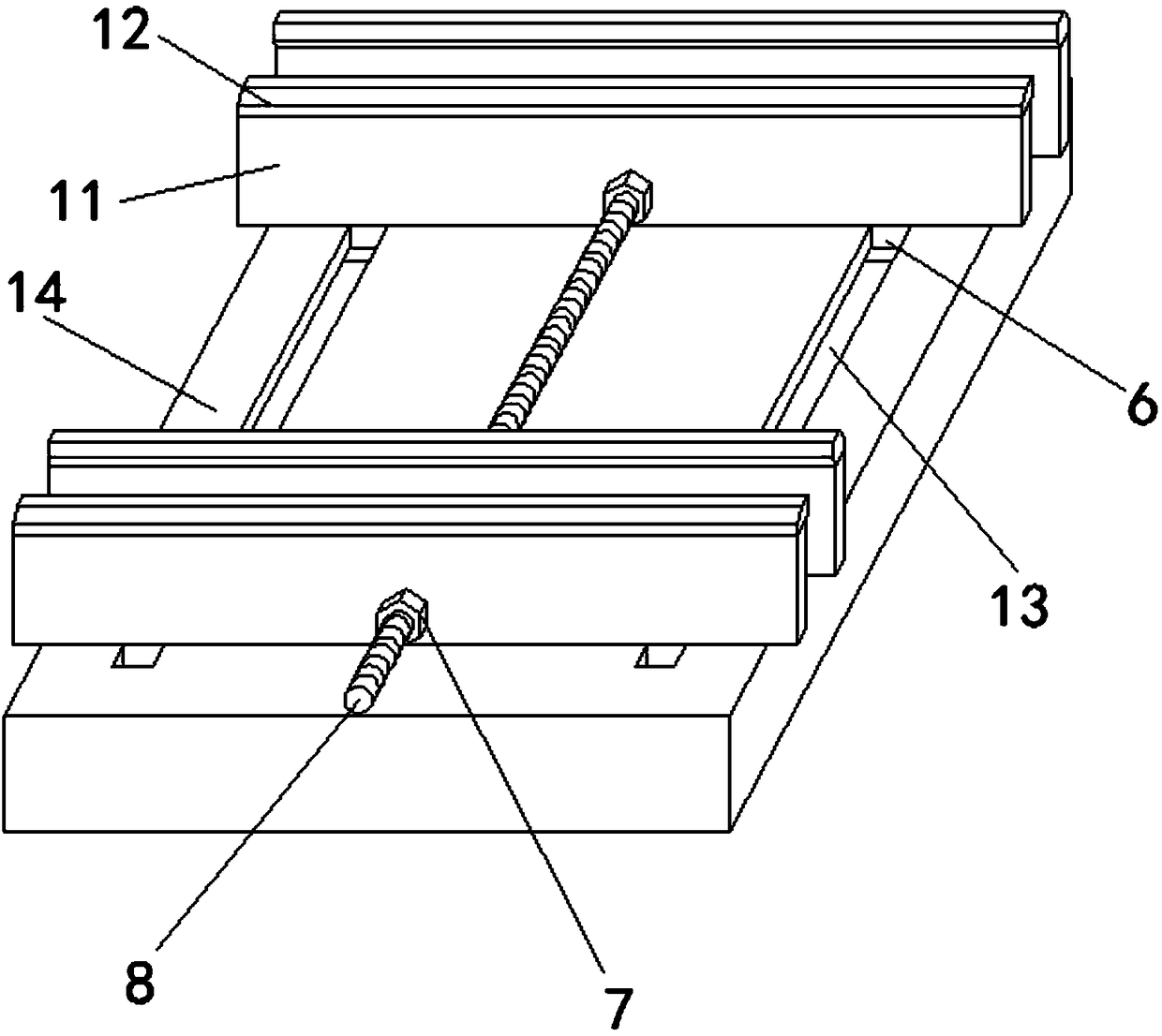

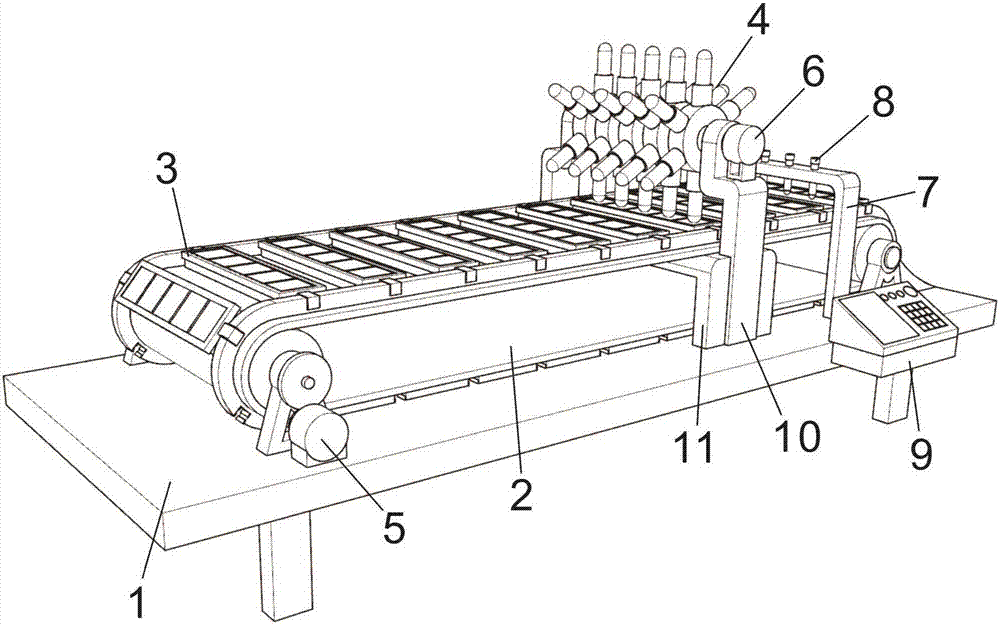

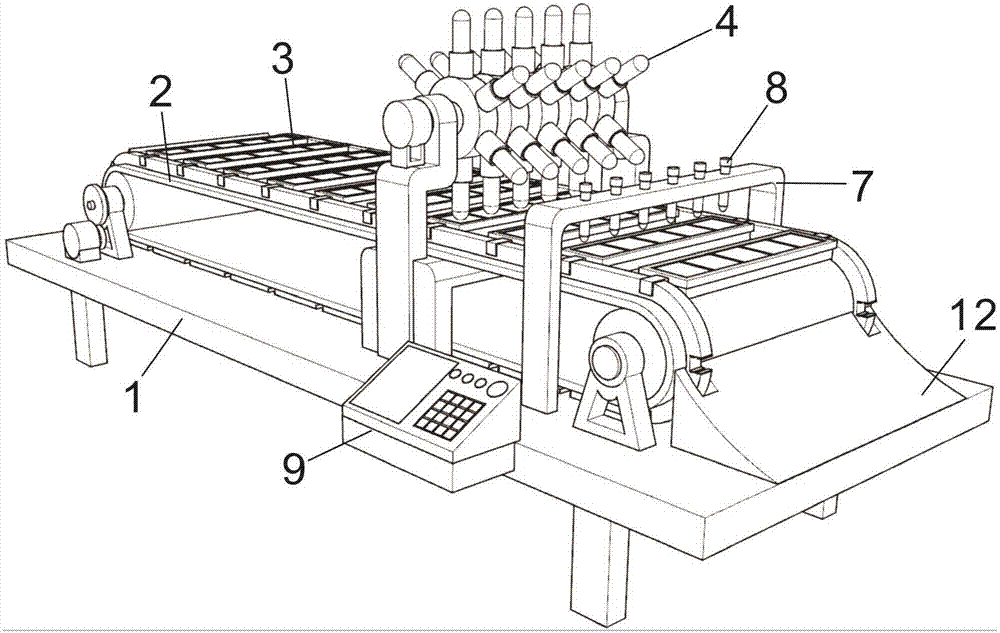

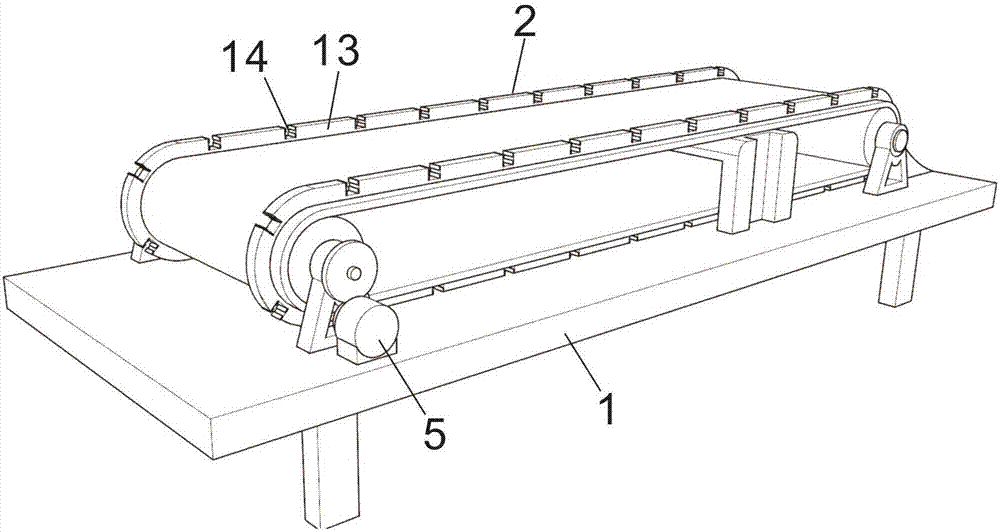

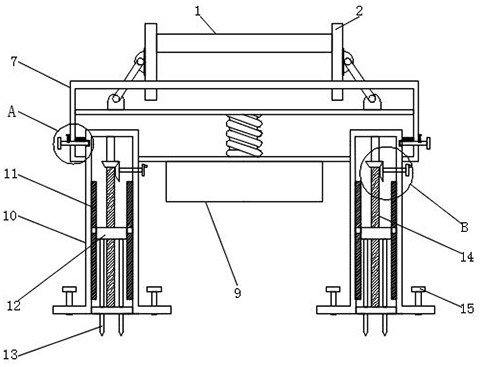

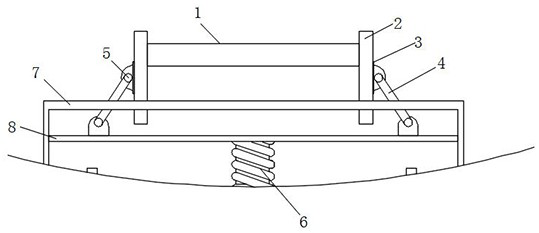

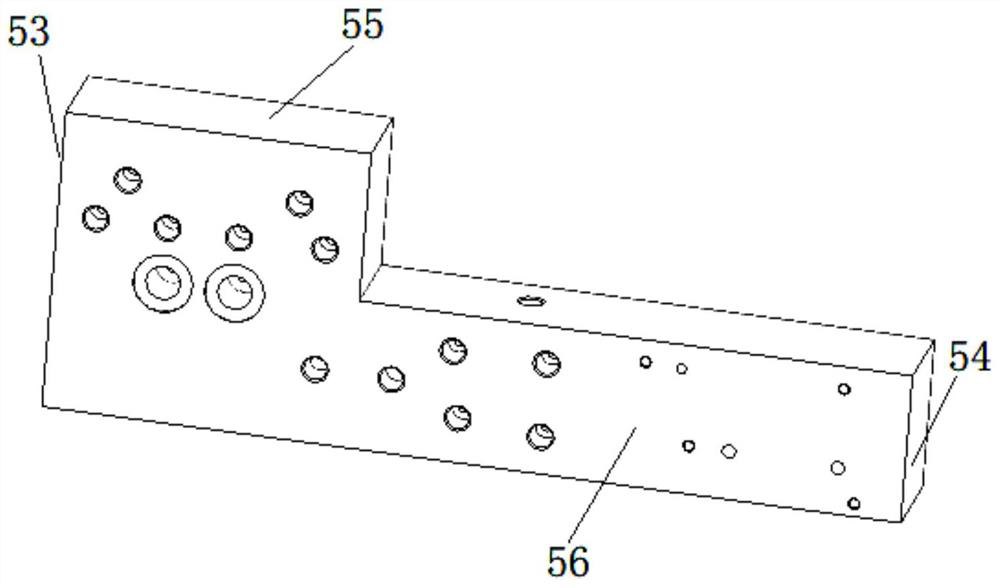

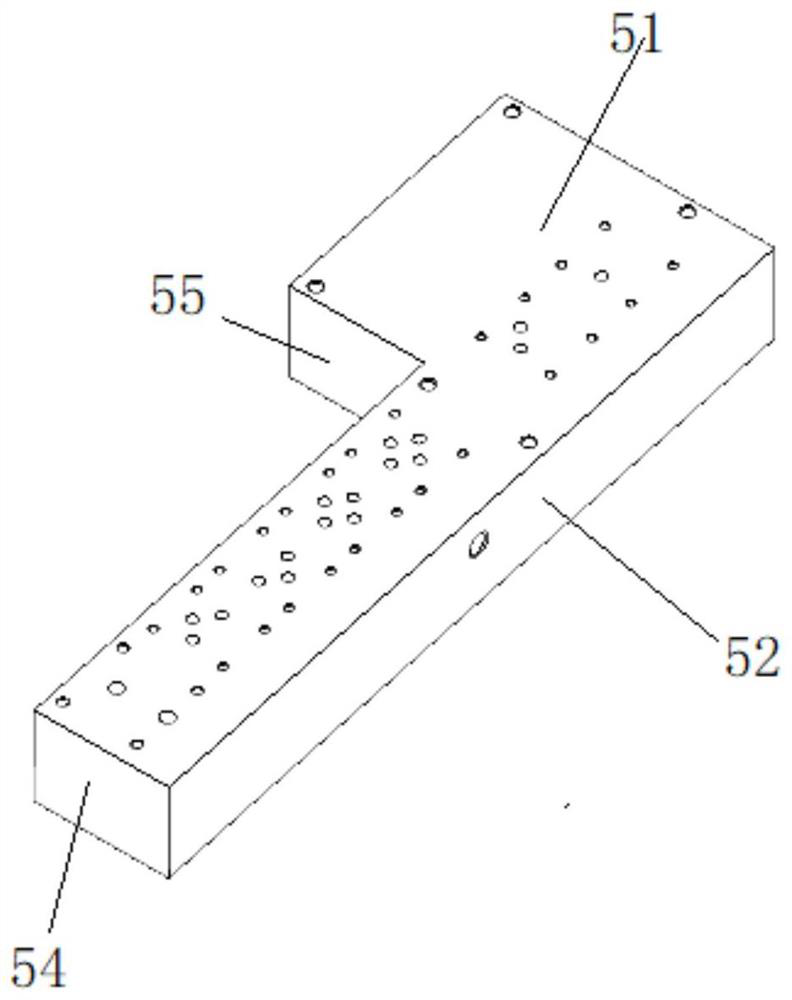

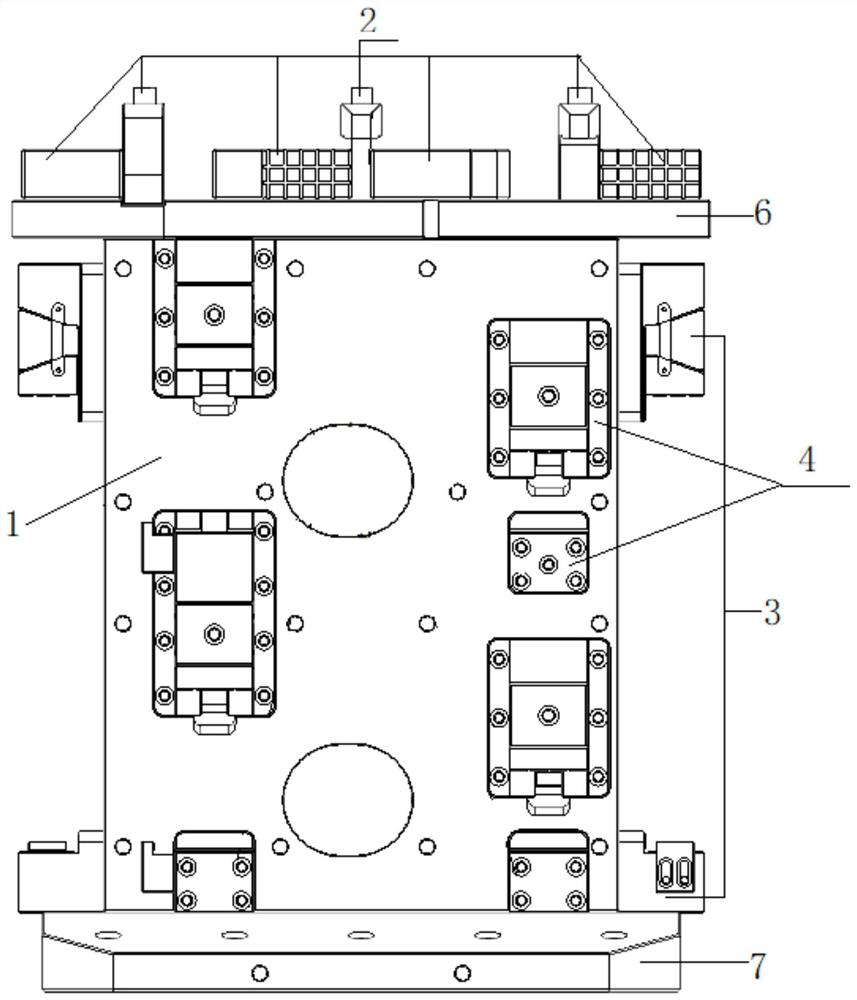

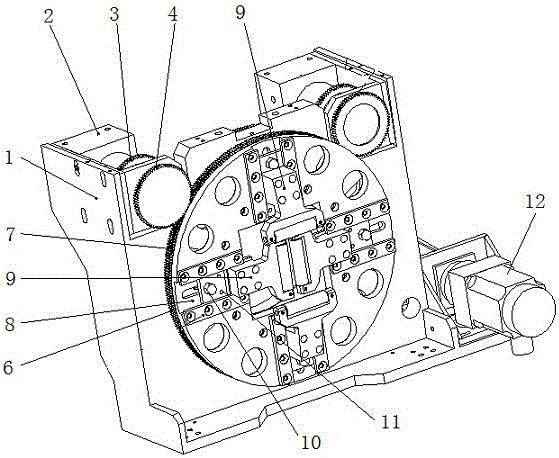

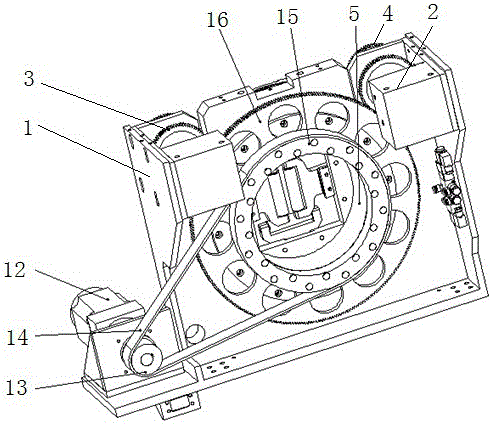

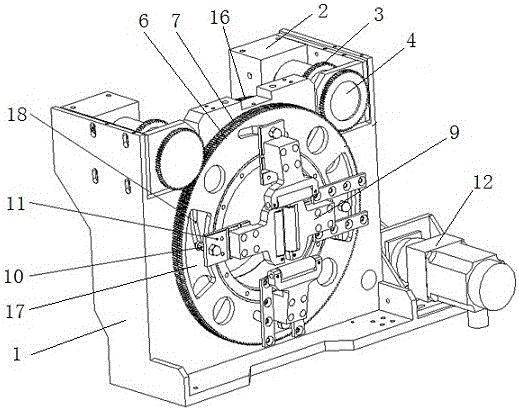

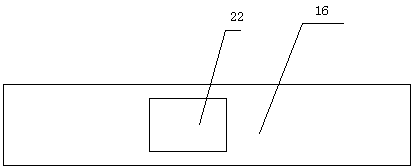

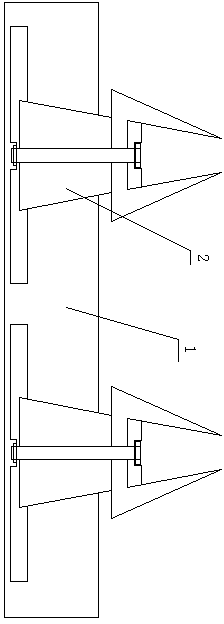

Full-automatic jointed board test tool device

PendingCN107356790AEasy to chooseContinuous testingPrinted circuit testingMeasurement instrument housingMarking outMaster station

The invention relates to a full-automatic jointed board test tool device comprising a table board 1, a driving belt 2, a jointed board tool 3, a rolling test device 4, a driving belt driving device 5, a rolling test device driving device 6, a marking device fixed frame 7, a marking device 8, a master station 9, a support 10, and an unloading bench 12. The driving belt 2 is installed on the table board 1 and is driven by the driving belt driving device 5; the jointed board tool 3 is installed on the driving belt 2; the master station 9 is installed on the table board 1; the rolling test device 4 is arranged above the driving belt 2 and is installed on the support 10 fixed on the table board 1; the rolling test device 4 is driven by the rolling test device driving device 6; and the marking device 8 is installed at the rear of the rolling test device 4 by the marking device fixed frame 7. With the device provided by the invention, a plurality of jointed boards are tested simultaneously; continuous testing is realized; the efficiency of jointed board testing is increased; and the device can be operated only by one person, so that the labor is saved.

Owner:杭州敏坤电子科技有限公司

Solar conversion collector and conversion method thereof

ActiveCN112511077AImprove stabilityAvoid lostPhotovoltaic supportsSolar heating energyEngineeringEarth surface

The invention relates to the technical field of photovoltaics, in particular to a solar conversion collector and a conversion method thereof. The solar conversion collector comprises a frame and a collector body, the frame is of a square hollow structure, two sets of openings are formed in the lower end of the frame, supporting frames are installed at the positions of the openings and are of a cylindrical hollow structure, one end of each supporting frame is arranged in the frame, the other end of each supporting frame is arranged at the lower end of the frame, a through hole is formed in theside edge of the frame, a fixing rod is inserted into the through hole in a penetrating mode, a groove is formed in the side edge of the end, arranged in the frame, of each supporting frame, the fixing rod penetrates through the frame to be clamped with the grooves in the supporting frames, and a baffle is fixedly connected to the position, between the inner wall of the frame and the supporting frames, of the fixing rod. According to the invention, grips installed on the side edges of the supporting frames rotate to drive a threaded rod to rotate, so that a sliding block moves downwards, and on the basis that the supporting frames are installed on the earth surface, puncture legs penetrate through the earth surface to be fixed again.

Owner:海口昌鑫投资合伙企业(有限合伙)

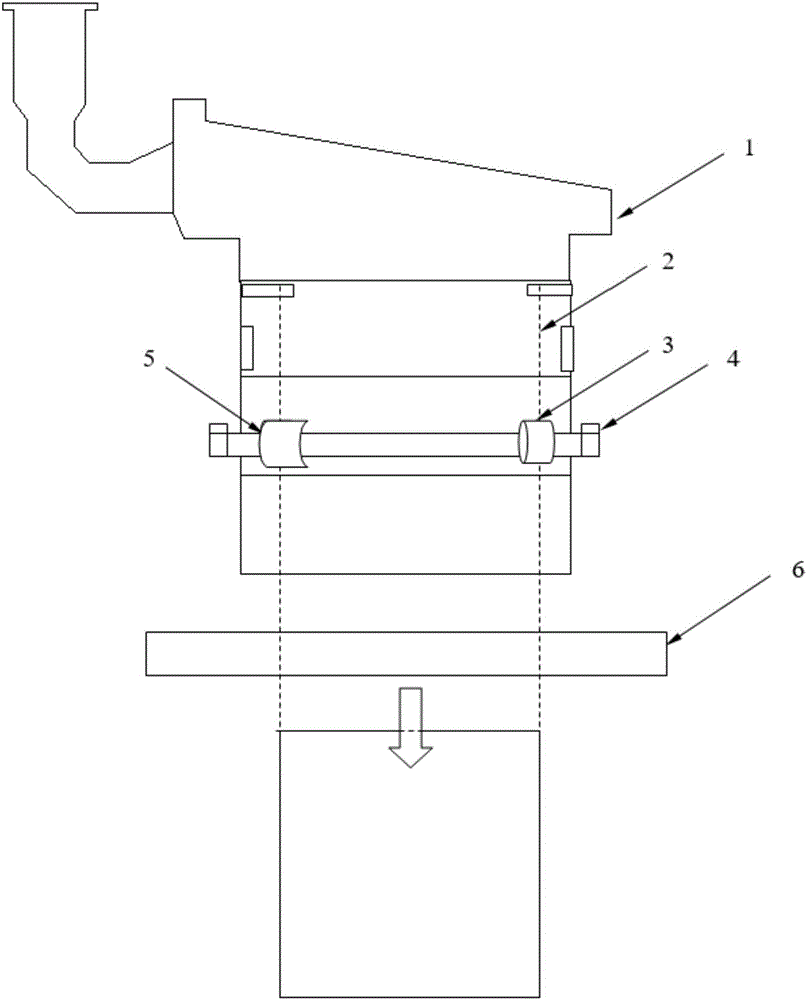

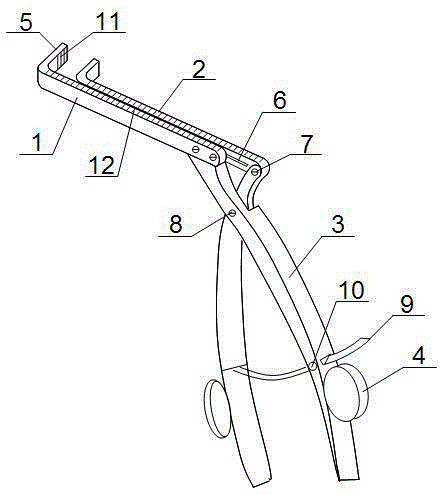

Operating forceps

The invention discloses a surgical forceps, which comprises a first forceps arm and a second forceps arm. The front ends of the first forceps arm and the second forceps arm are respectively provided with mutually clamping forceps heads. The bottom of the end is respectively connected with the two handles by bolts, and the two handles are connected through the cross rotation of the rotating shaft. There is a ring on the two handles which is easy to grasp. A projection freely sliding in the groove is provided, a stop lock is provided between the two handles, and a buckle for fixing the stop lock is provided on one handle. The invention is suitable for operations at various positions, has strong holding force, adjustable clamping width, wide application range, and is worthy of popularization.

Owner:郭艾芳

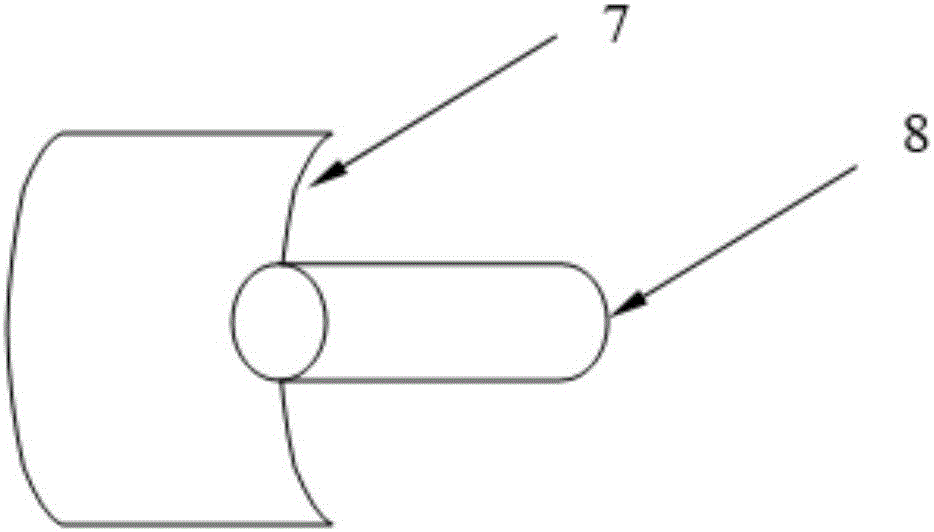

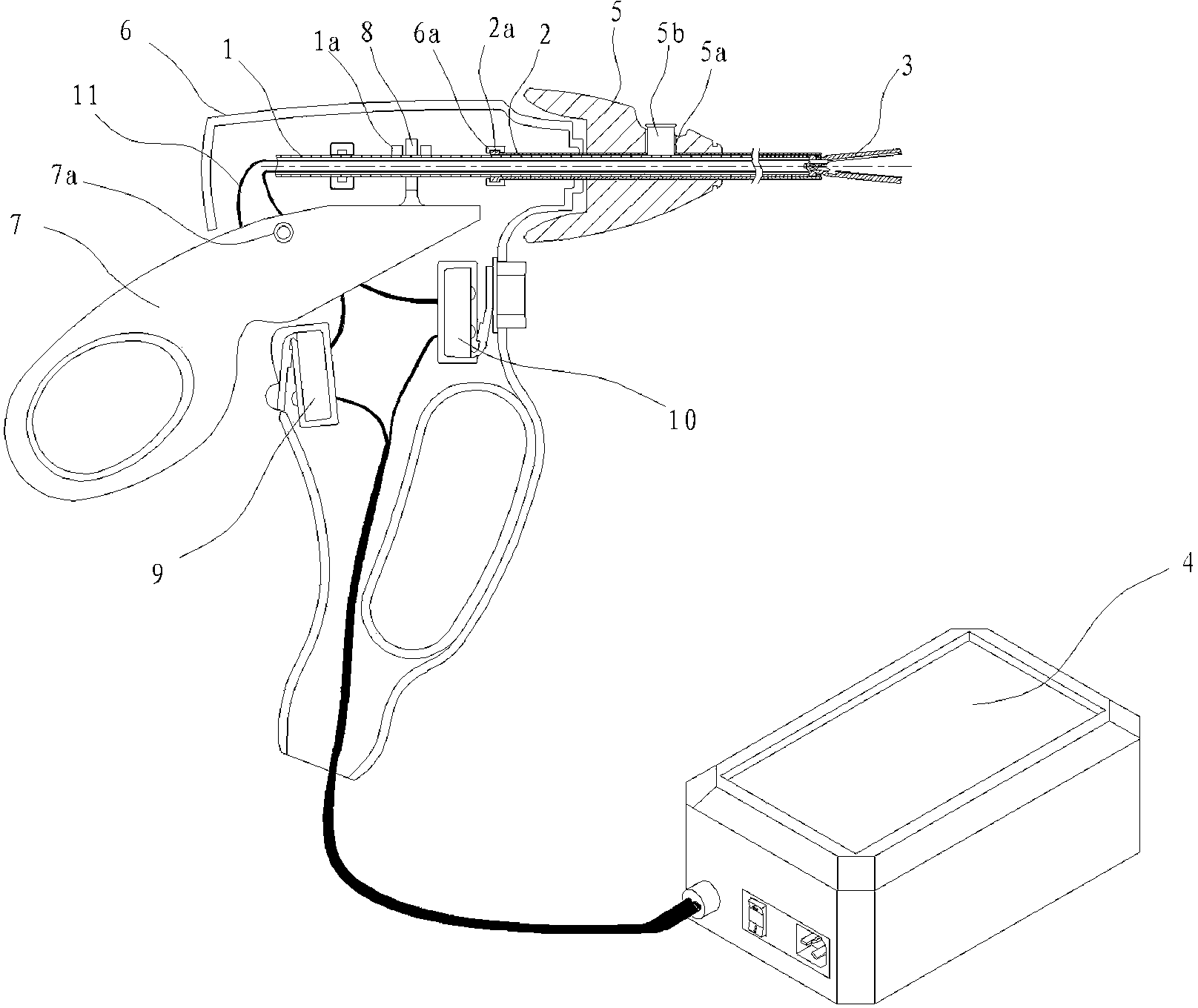

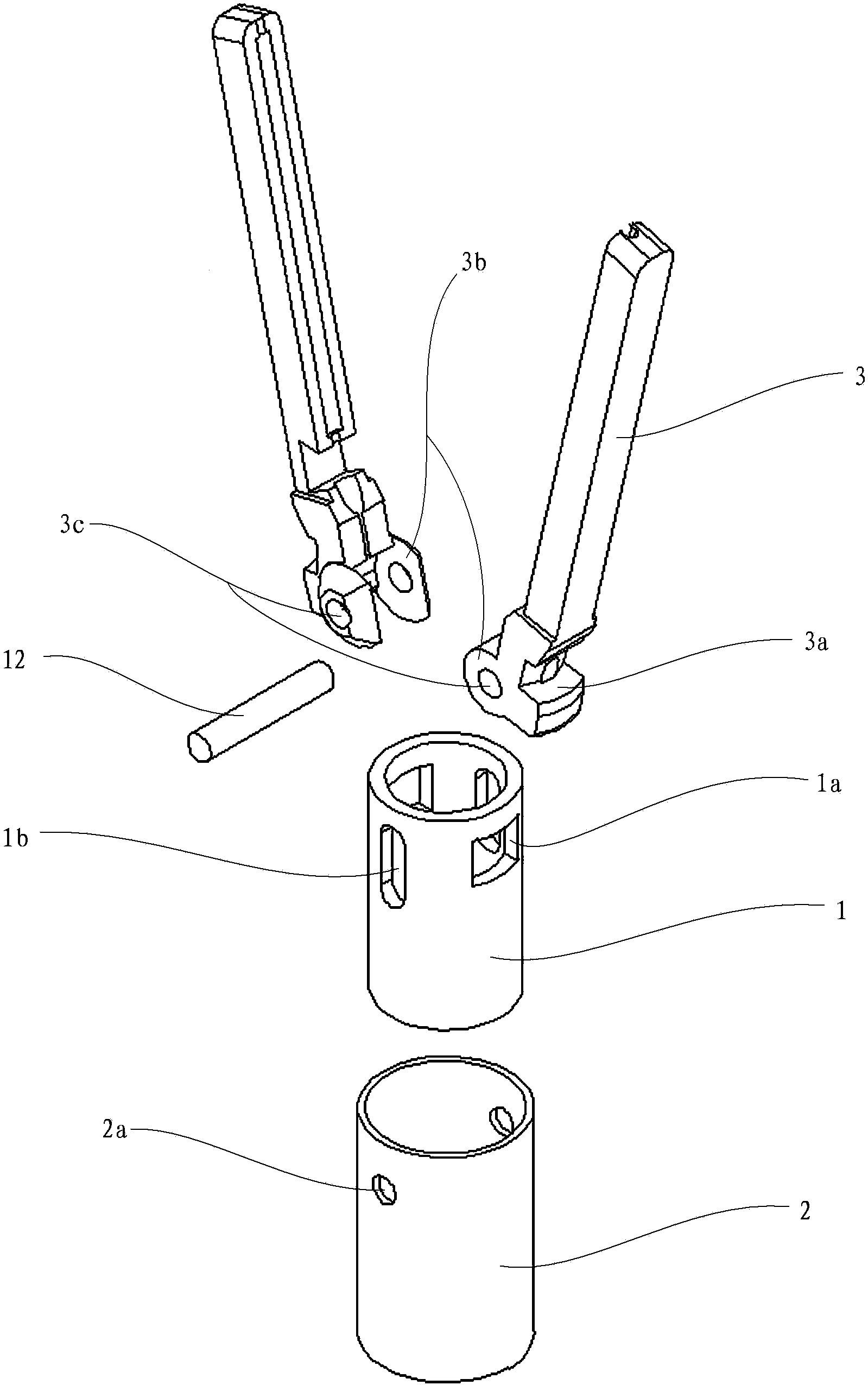

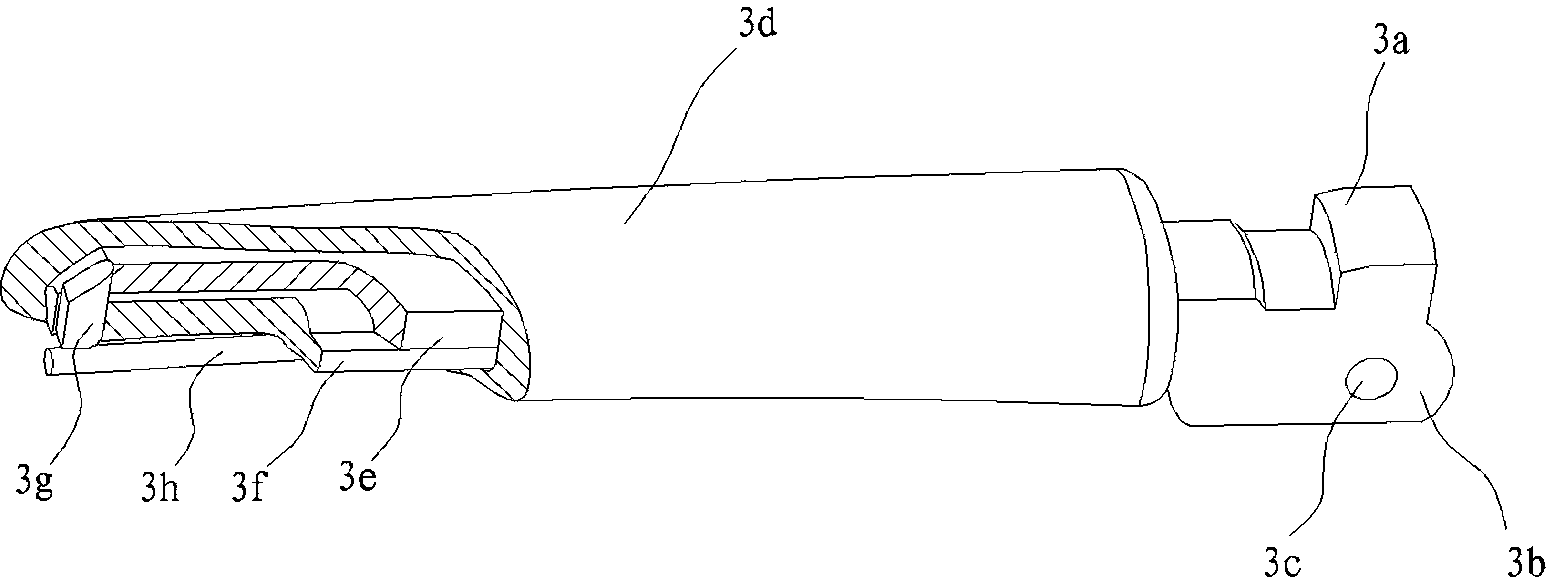

Thermosetting cutting knife

The invention relates to a thermosetting cutting knife which comprises a housing (6), wherein both a wrench (7) and a supporting tube (1) are connected to the interior of the housing (6); the front end of the supporting tube (1) is matched and connected with gripper jaws (3) matched mutually; the thermosetting cutting knife is characterized in that the supporting tube (1) is sleeved with a section of outer tube (2); the supporting tube (1) and the outer tube (2) are connected with two gripper jaws (3) matched mutually; the wrench (7) is connected with the supporting tube (1) through a shift fork (8); the gripper jaws (3) are connected with an electronic control box (4) through guide lines (11). The thermosetting cutting knife has the advantages that the thermosetting cutting knife is convenient to operate, larger and stable clamping force can be provided for the gripper jaws, the guide lines are adopted for electric conduction, so that the phenomenon of partial electric resistance increase is eliminated, and meanwhile, the gripper jaws provided by the invention are heated uniformly.

Owner:ANHUI AOFO MEDICAL EQUIP TECH

Special clamp suitable for L-shaped valve body machining and machining method

ActiveCN112108899AAvoid replacementSimple and fast operationWork clamping meansPositioning apparatusMachiningEngineering

The invention discloses a special clamp suitable for L-shaped valve body machining and a machining method. The special clamp comprises a main body, and a first clamping assembly, a second clamping assembly and a third clamping assembly are arranged on the main body; the first clamping assembly positions the second back face, the second bottom face and the second left side face of an L-shaped valvebody; the second clamping assembly positions the second left side face and the second right side face of the L-shaped valve body; and the third clamping assembly positions the second top face and thesecond bottom face. According to the clamp, the problem that a clamp needs to be frequently replaced when the L-shaped valve body is machined is solved.

Owner:HANDAN HENGGONG METALLURGICAL MACHINERY CO LTD

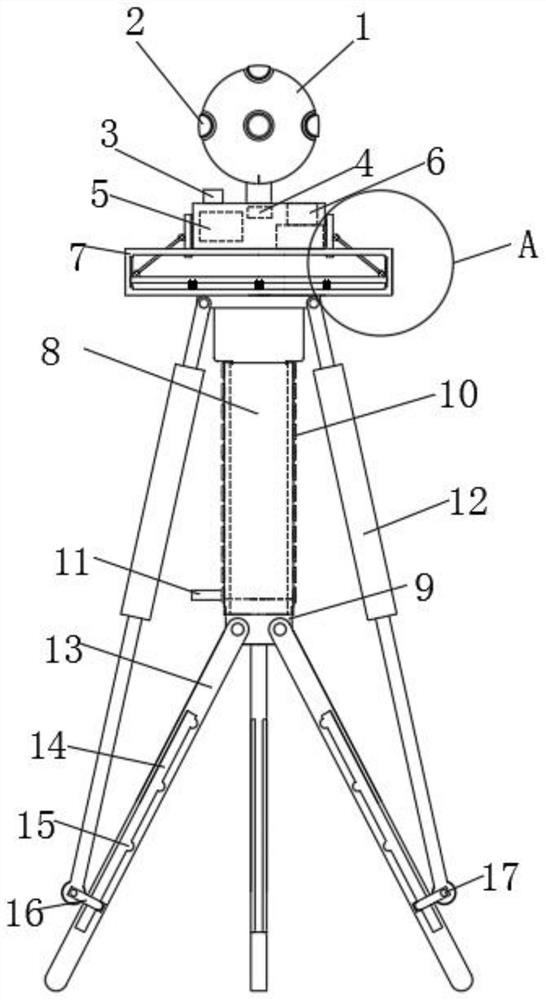

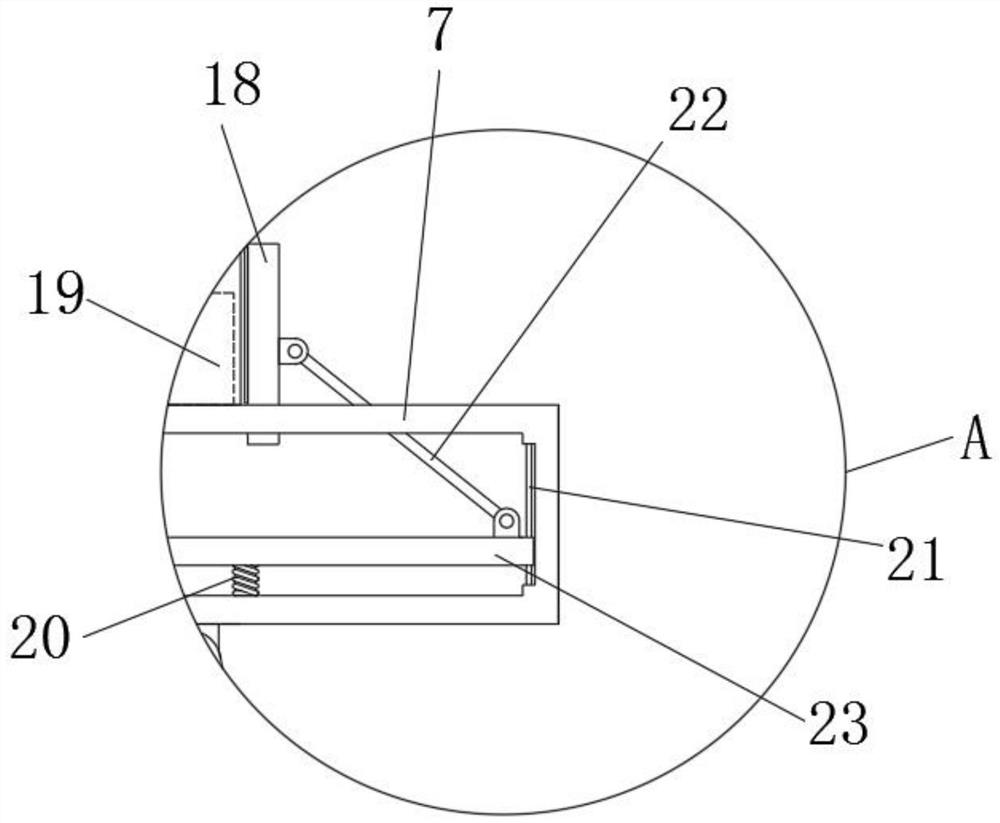

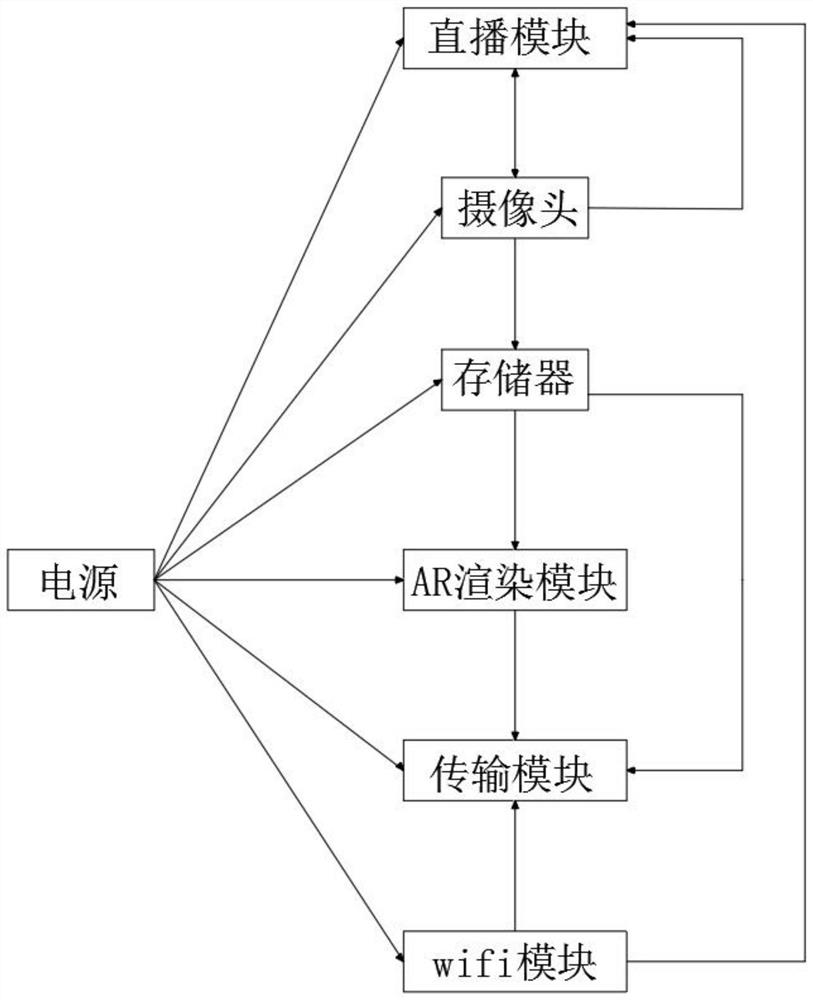

A panoramic vr video collection, transmission and rebroadcasting device and method

ActiveCN112702578BLive broadcastRealize support and fixationTelevision system detailsColor television detailsClassical mechanicsControl theory

The present invention relates to the technical field of panoramic VR, and discloses a panoramic VR video collection, transmission and rebroadcasting device and method. A frame is installed at the lower end of the panoramic VR collector. Slider, the two ends of the two groups of sliders are fixedly connected to the upper and lower ends of the inner wall of the frame, a slide plate is slidably connected between the two groups of sliders, and the slider is connected to one end of the push rod close to the position of the slide rod, and the push rod The other end is placed on the outside of the frame to rotate and connect the clamping block. The top block of the frame is provided with an opening, and the clamping block is slidably connected to the buckle at the top of the frame. The two sets of clamping blocks are symmetrical to each other. spring. The device and method for collecting, transmitting and rebroadcasting panoramic VR video captures the surrounding scenery through a panoramic collector. Cameras are installed around and at the top of the panoramic collector to achieve 360-degree shooting without dead angles.

Owner:河北优盈信息技术有限公司

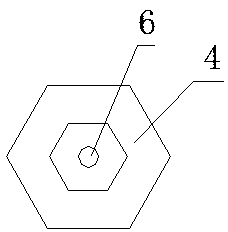

A pneumatic chuck

ActiveCN105269213BAchieve diversificationFast clamping speedWelding/cutting auxillary devicesAuxillary welding devicesLaser cuttingEngineering

Owner:JINAN JINQIANG LASER CNC EQUIP

Insulation cover for wires at empty meter position of metering box

InactiveCN104181347AEasy to installEasy to operateMeasurement instrument housingEngineeringMetering mode

The invention discloses an insulation cover for wires at an empty meter position of a metering box. The insulation cover is Omega-shaped and comprises a cover body and a clamping part, wherein the cover body is arranged on an exposed wire portion in a sleeved mode, and the clamping part is tightly contacted with an insulated wire portion. An opening at the bottom part of the clamping part expands outward, and the diameter of the inner side of a clamping position of the clamping part is less than the diameter of the inner side of the cover body. An opening at the clamping position of the clamping part is narrow, and the internal part of the cover body is wide, thereby being capable of clamping the wire, and being convenient to install. The insulation cover disclosed by the invention can be arranged on the exposed wire quickly in a sleeved mode, is simple to operate, reliable in operation and attractive in overall appearance, and improves the safety performance of the metering box.

Owner:STATE GRID CORP OF CHINA +1

Tubular column two-way coupling integrated self-adaptive traveling slip

InactiveCN111911098ASolve the topSolve the falling problemDrilling rodsDrilling casingsDrive shaftClassical mechanics

The invention discloses a tubular column two-way coupling integrated self-adaptive traveling slip. Specifically, the self-adaptive traveling slip comprises a shell, an upper slip assembly and a lowerslip assembly, and through the matched connection action of the upper and lower slip assemblies and a rotating shaft and the matched connection action of a transmission shaft and the rotating shaft, compared with a single traveling slip or a separated upper and lower slip set, the two-way traveling slip is larger in clamping force on a pipe string and higher in reliability; and the technical problems that in the prior art, a traveling slip set is complex in structure and tedious in operation, and misoperation possibly occurs to cause incorrect limitation of the direction of a tubular column are solved.

Owner:SICHUAN SHENGNUO OIL & GAS ENG TECH SERVICE CO LTD

Illuminating bus duct system

ActiveCN104241918AImprove conductivityThe process is simple and convenientCoupling device detailsBus-bar installationSoftware engineering

The invention relates to an illuminating bus duct system which comprises a bus duct and a plug box fixed on the bus duct. The plug box comprises a box body, and a plurality of pins are arranged in the box body. Each pin comprises an elastic part, a supporting column and a base, an elastic base of each elastic part is fixed in an elastic part clamping groove of the corresponding supporting column in a clamping mode, and each supporting column is fixed in a supporting column clamping groove of the corresponding base in a clamping mode. The elastic parts, the supporting columns and the bases are fixed into a whole through bolts. The illuminating bus duct system is simple in structure, good in stability, safer and more reliable. Meanwhile, the cost is further lowered.

Owner:JIANGSU SHILIN ELECTRIC EQUIP

A control method for a hot rolling roughing mill

ActiveCN108838212BSmall amount of depressionAdjustable speedRoll mill control devicesMetal rolling arrangementsLoad distributionRapid response

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

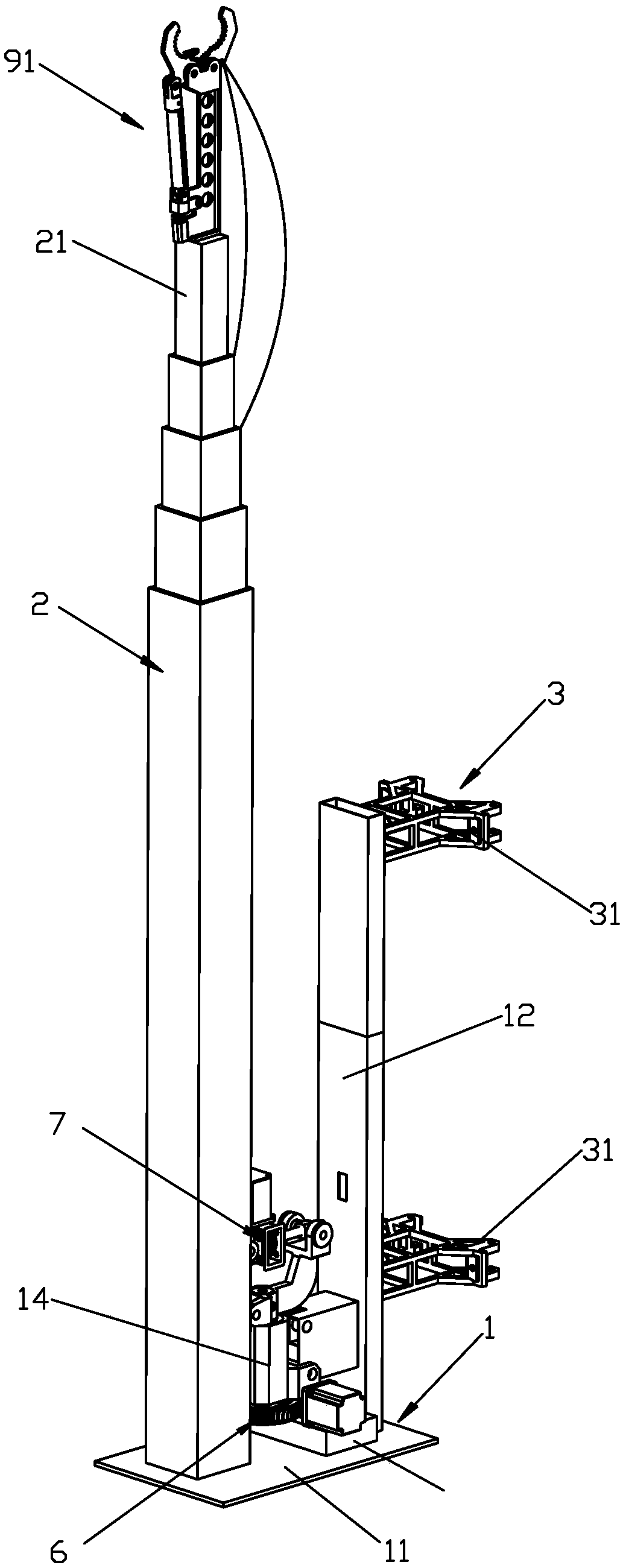

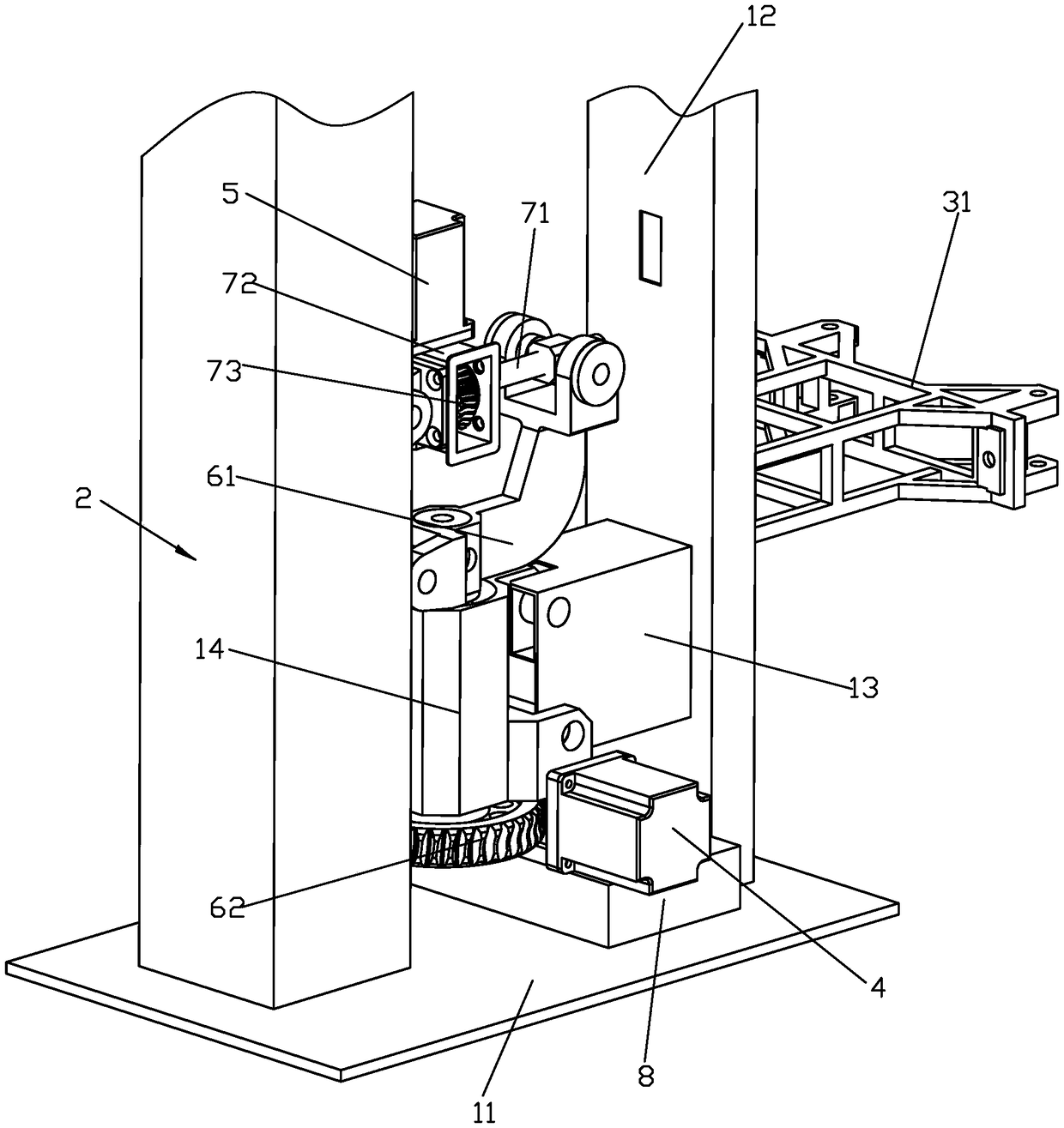

Multi-functional live maintenance device

ActiveCN106887803BReduce outage timeReduce the risk of working at heightsSwitchgearEconomic benefitsHorizontal axis

The invention discloses a multifunctional live overhauling device which comprises a stand, a lifting mechanism, a fixed mechanism, a rotation motor, a pitching motor, a rotation regulation mechanism and a pitching regulation mechanism, wherein the fixed mechanism is fixedly arranged on the stand, and is detachably and fixedly mounted on a transformer substation equipment stand; the rotation regulation mechanism comprises a rotating seat, the rotating axis of the rotating seat and the lifting mechanism is the horizontal axis X, and the rotation motor is in transmission connection with the rotating seat to drive the rotating seat to rotate along the vertical axis and further drive the lifting mechanism to rotate along the vertical axis; the pitching motor is in transmission connection with the pitching regulation mechanism, and the pitching regulation mechanism is connected with the rotating seat and the lifting mechanism to control pitching regulation of the lifting mechanism relative to the horizontal axis X through the pitching motor; an insulating rod is arranged at the uppermost end of the lifting mechanism, and multiple sets of functional devices are additionally assembled, and are all provided with connecting structures which can be detachably connected to the insulating rod. The multifunctional live overhauling device has the advantages that live operation can be carried out, the power outage time of equipment can be reduced, economic benefits can be improved, and aloft work risks can be reduced.

Owner:STATE GRID PUTIAN ELECTRIC POWER SUPPLY +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com