Patents

Literature

361results about How to "Fast clamping speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

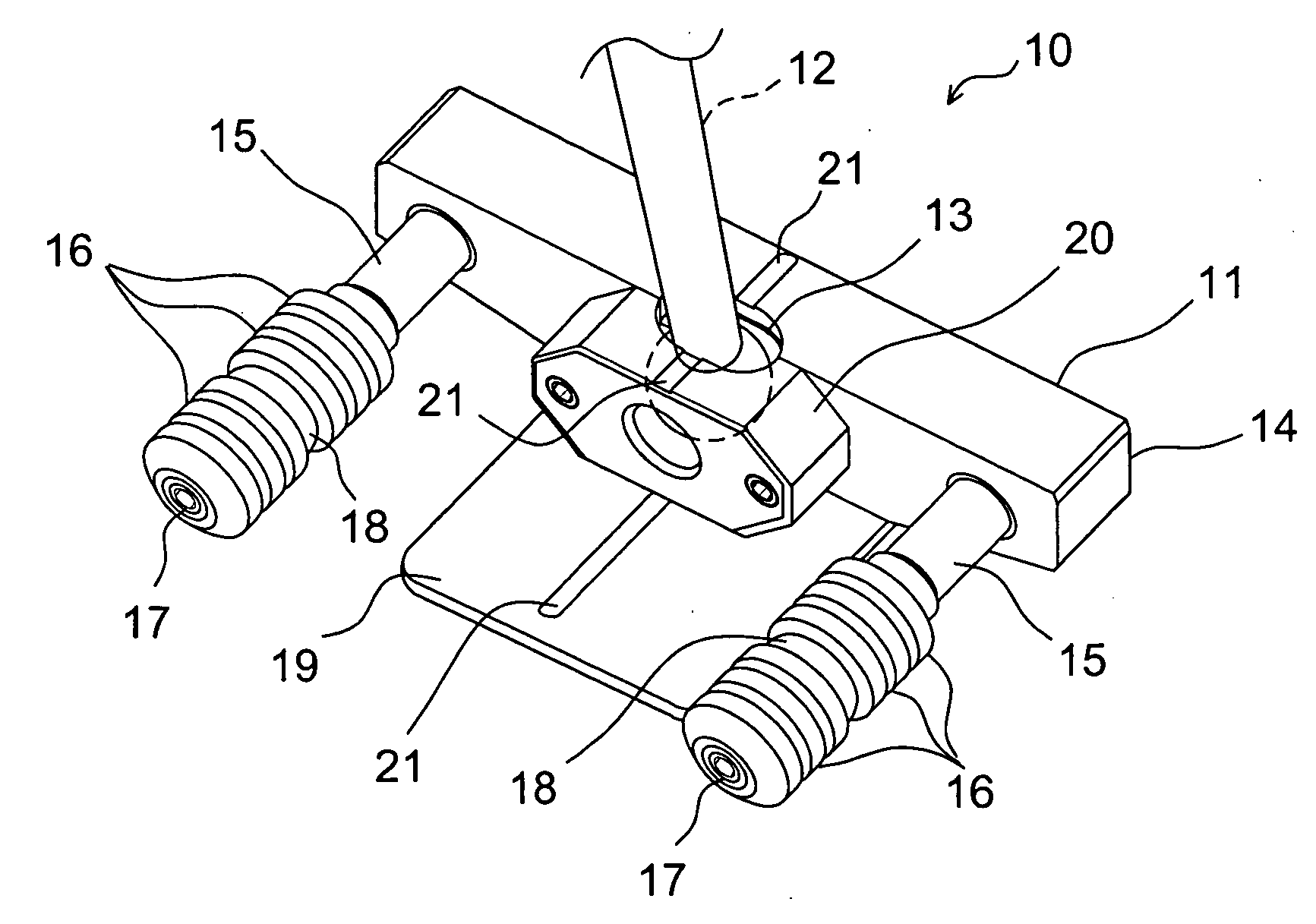

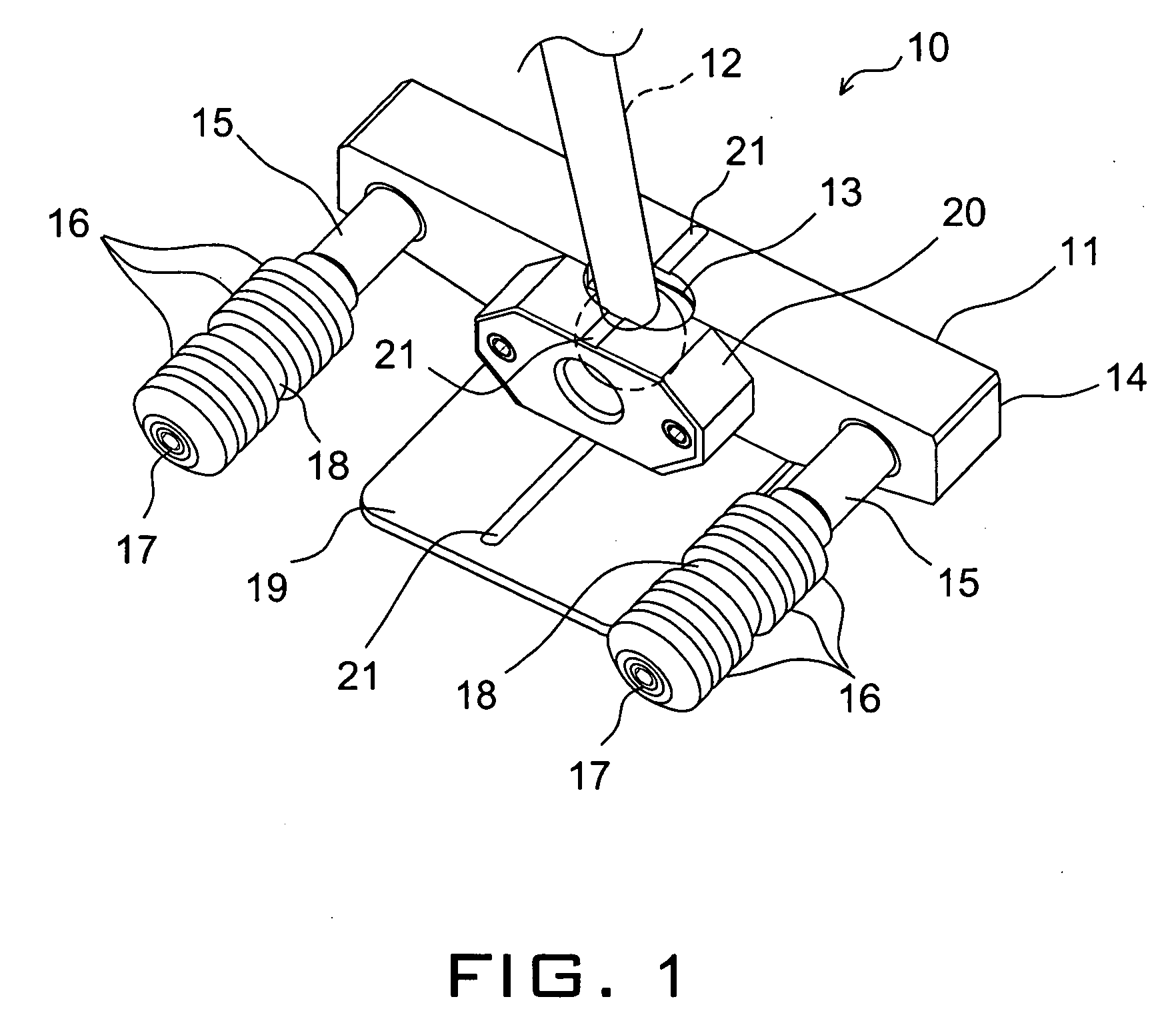

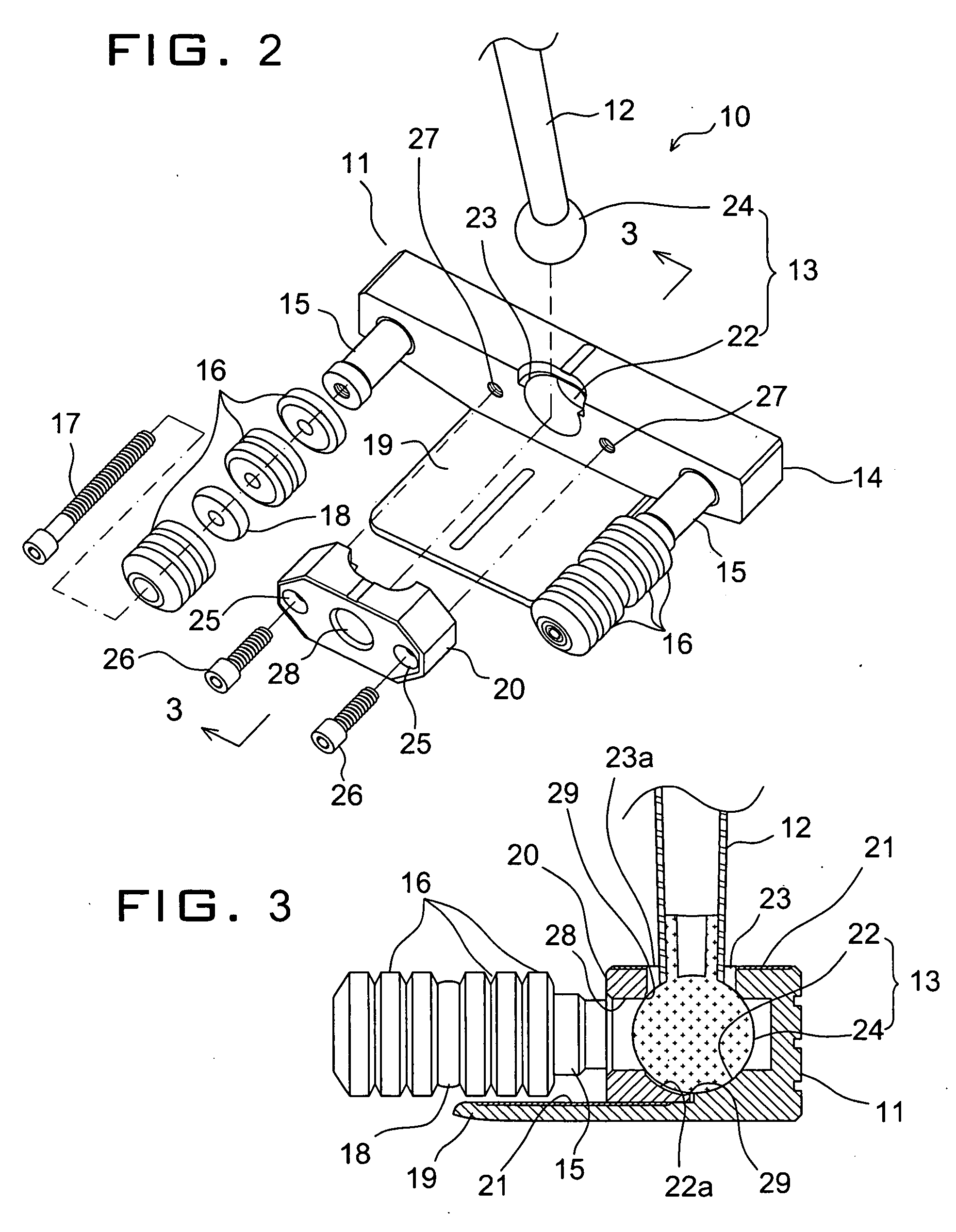

Adjustable putter

InactiveUS20070298904A1Fast clamping speedIncrease forceGolf clubsStringed racketsEngineeringGolf Ball

A golf putter comprises latitudinally elongated head having a generally rectangular hitting face against a golf ball. The head has an integral center plate extending longitudinally and rearward from the hitting face at its bottom. The center plate has a visible centerline for aiming at the ball. A ball joint for angularly fixing a shaft to the head includes a frictional sphere attached to the bottom end of the shaft. A truncated spherical socket is formed by a middle section of the head and a clamp member screw fastened to the head, whereby the shaft is locked in a truncated spherical interior wall at an adjusted angle to the head. Two swappable posts extend from the opposite side of the hitting face of the head near its latitudinal edges, each post having a centrally threaded bore and being threadedly attached to the head so that it may be replaced by a body of varying weight for plugging a void created by the threading of the post.

Owner:DYNAFLEX INT

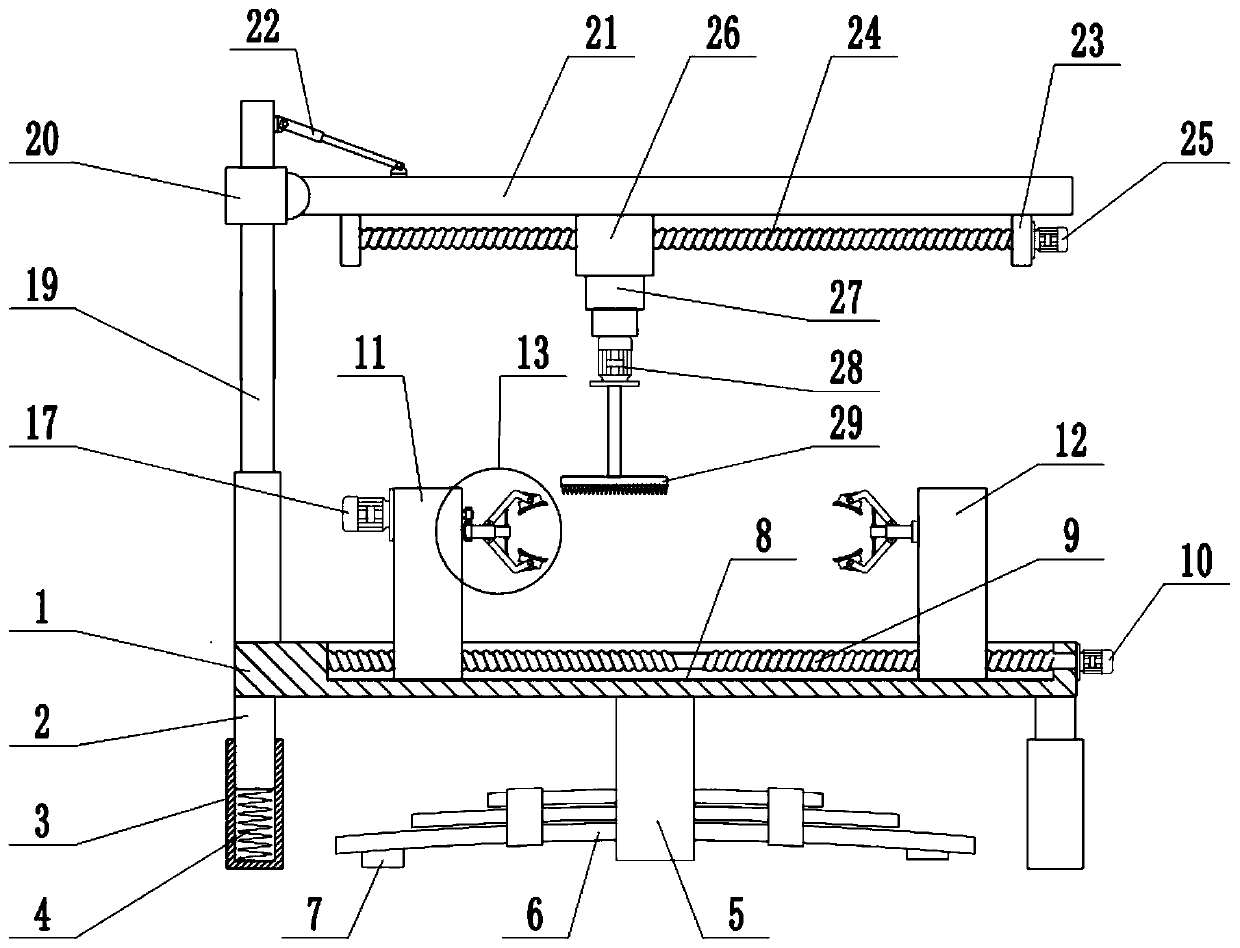

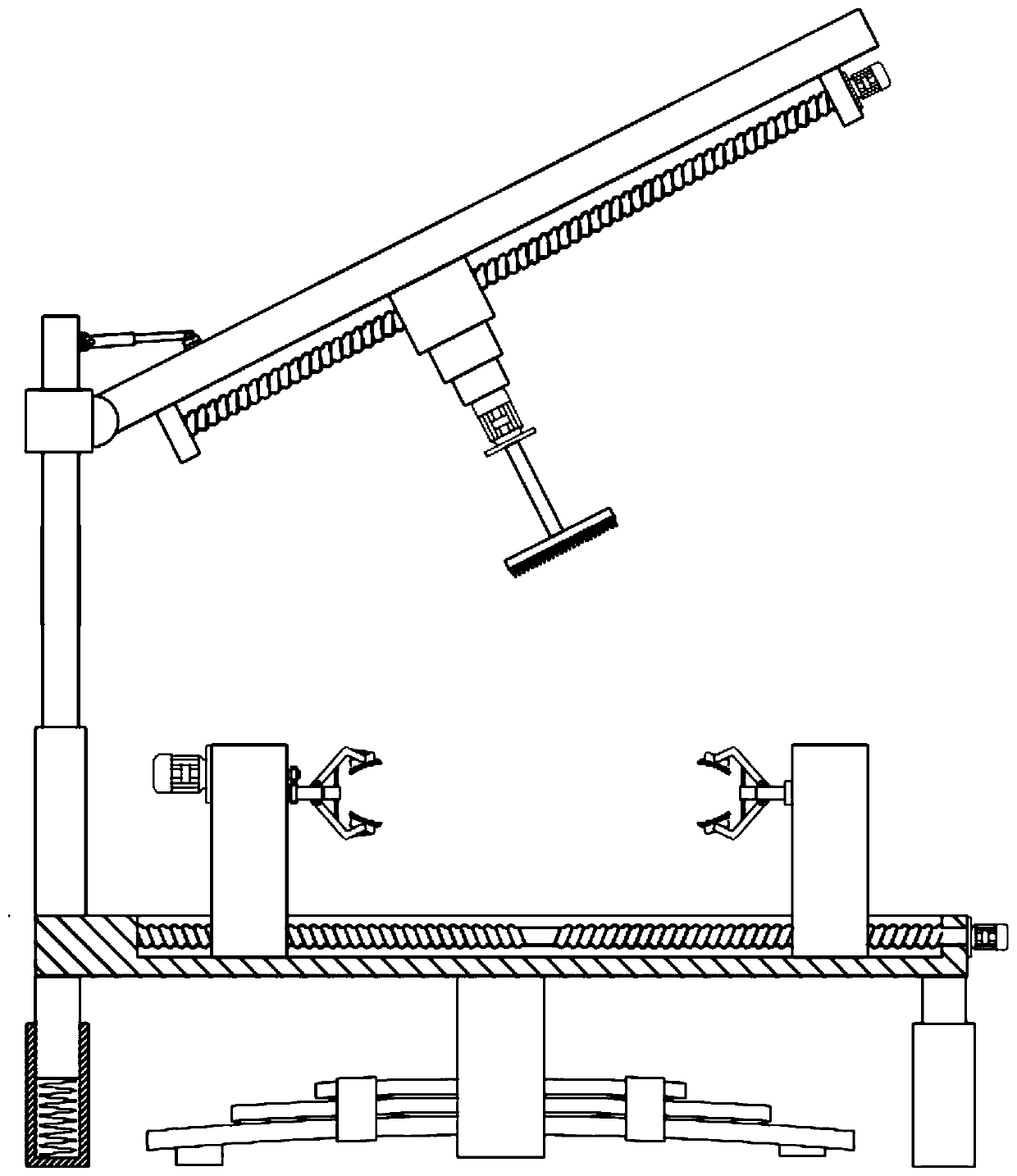

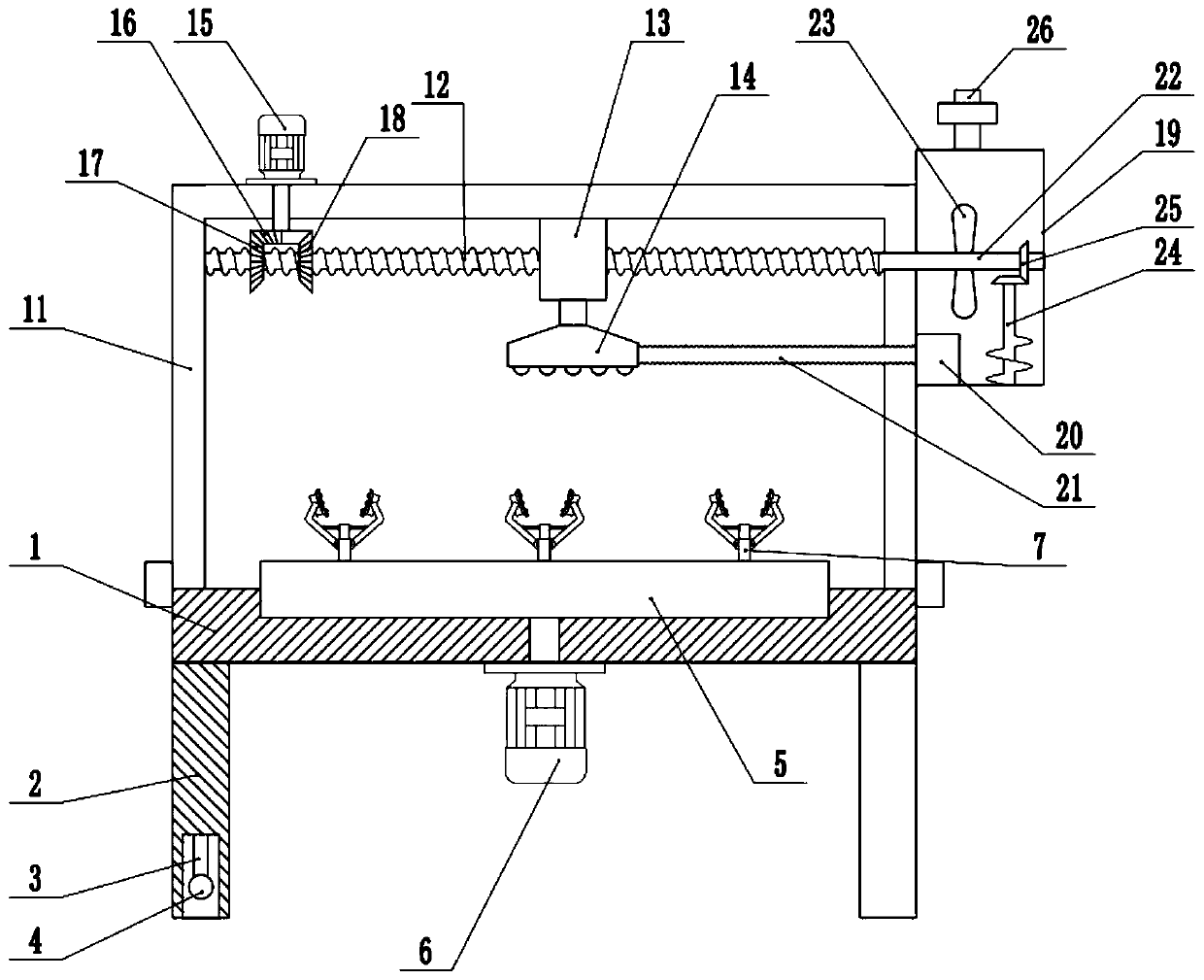

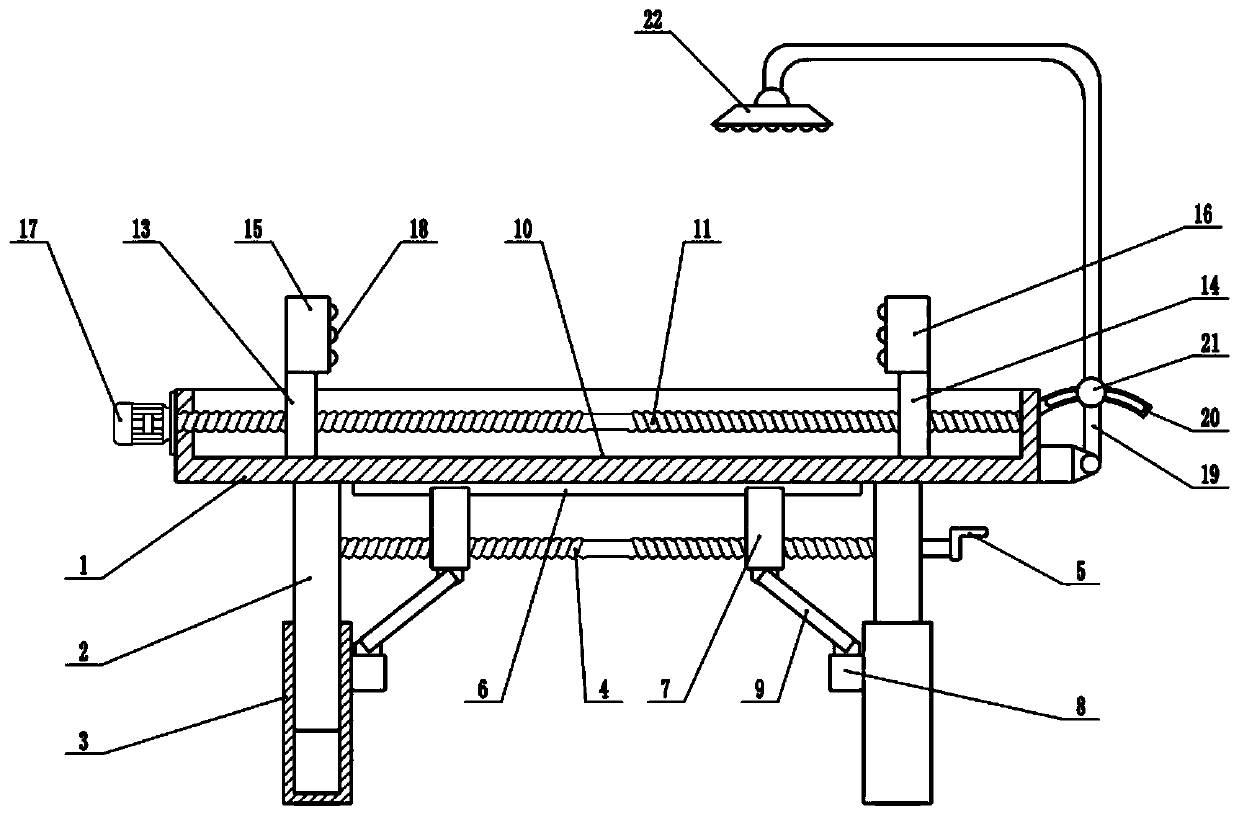

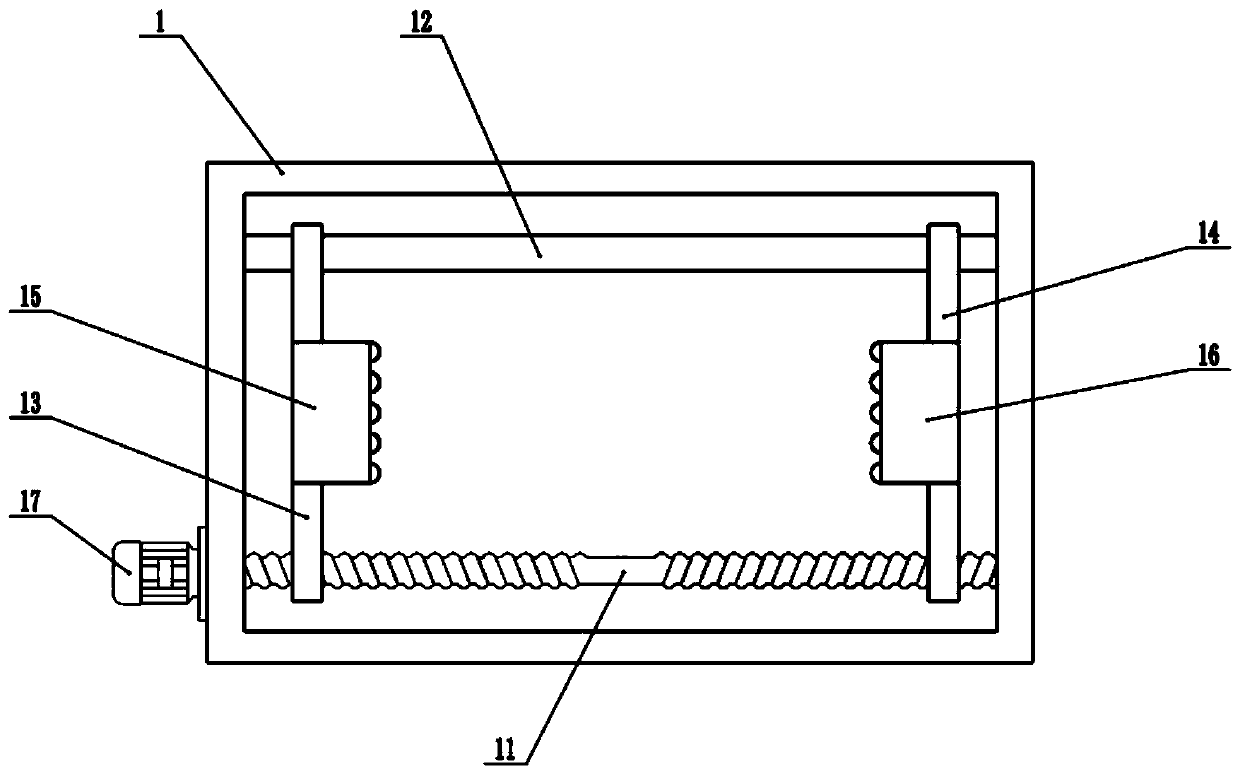

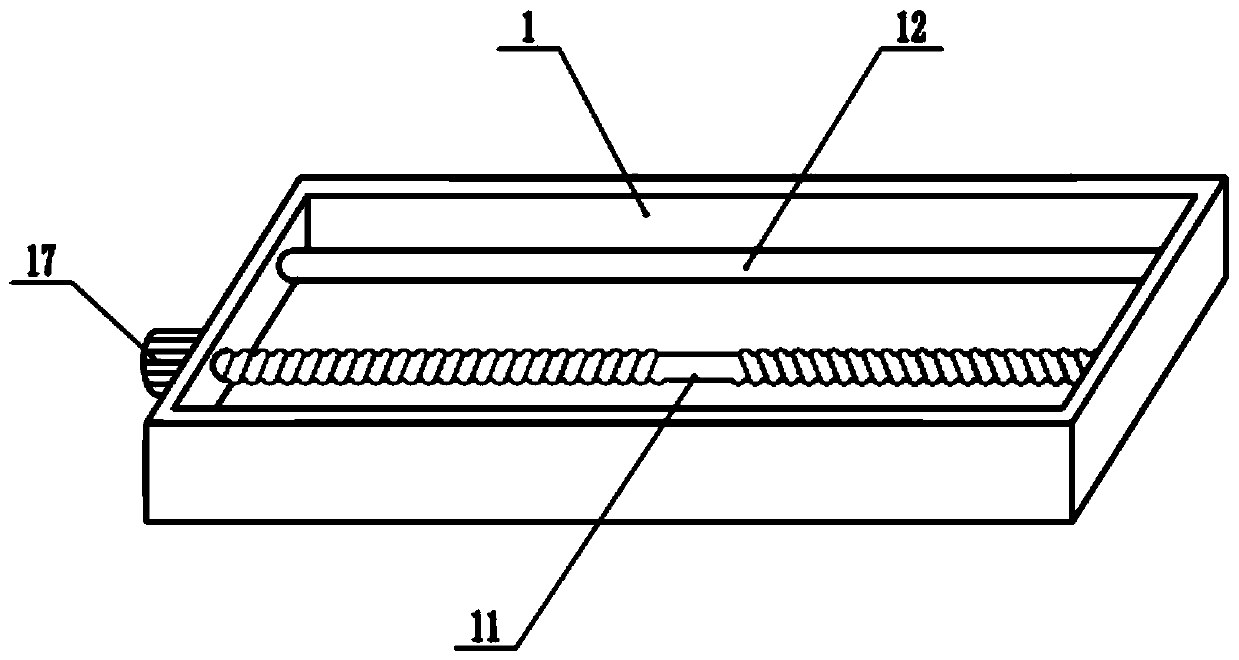

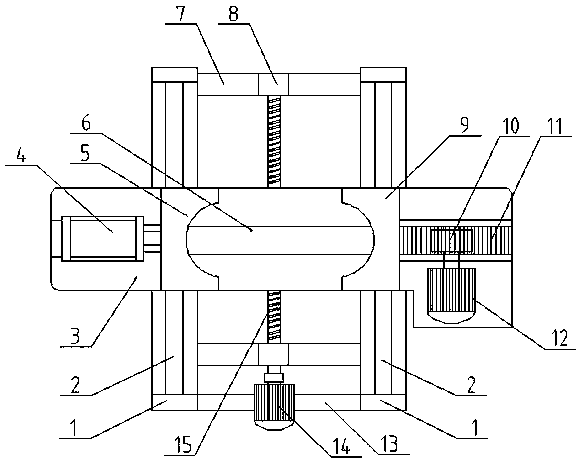

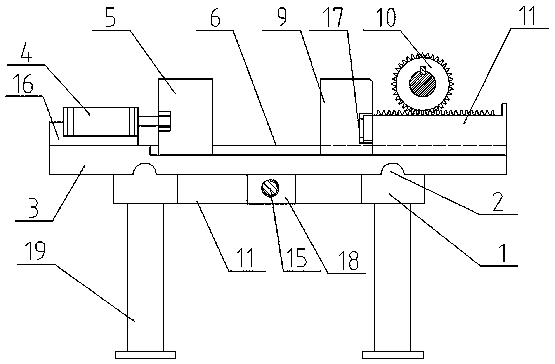

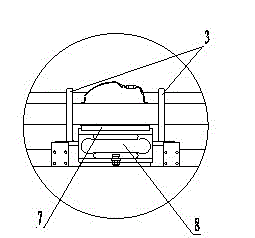

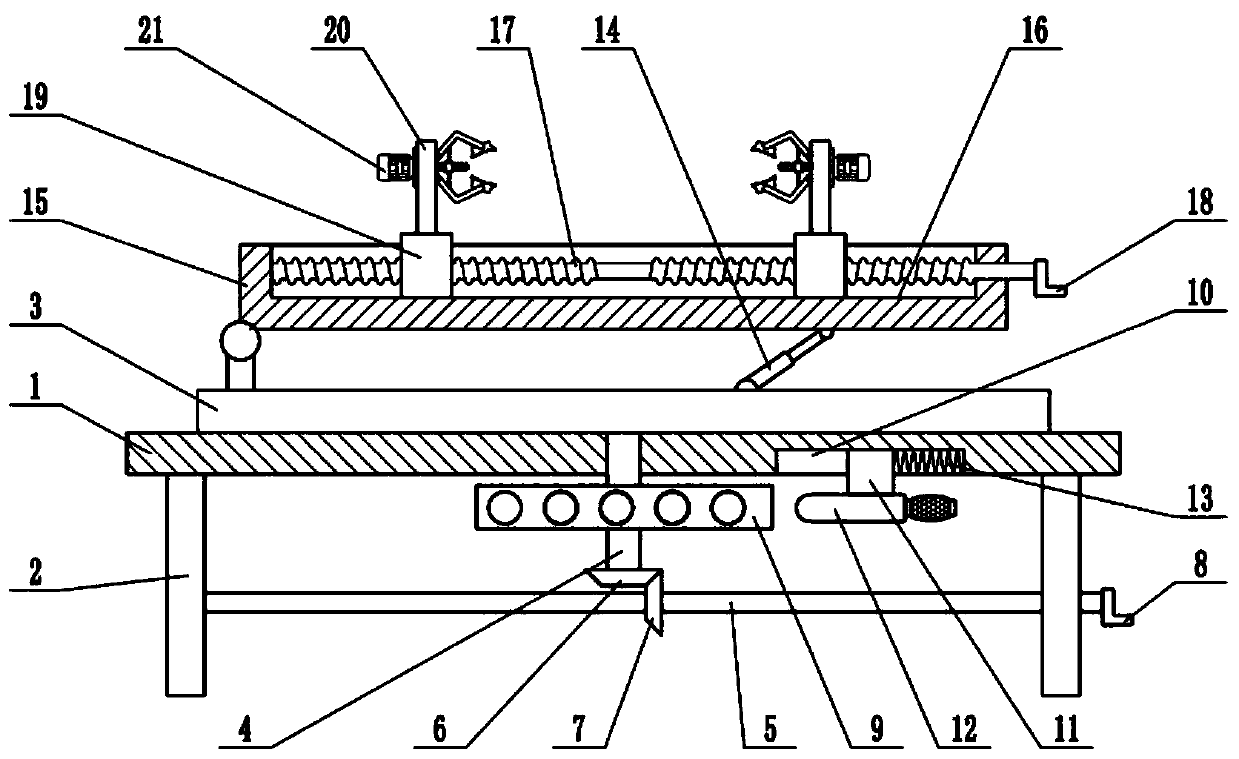

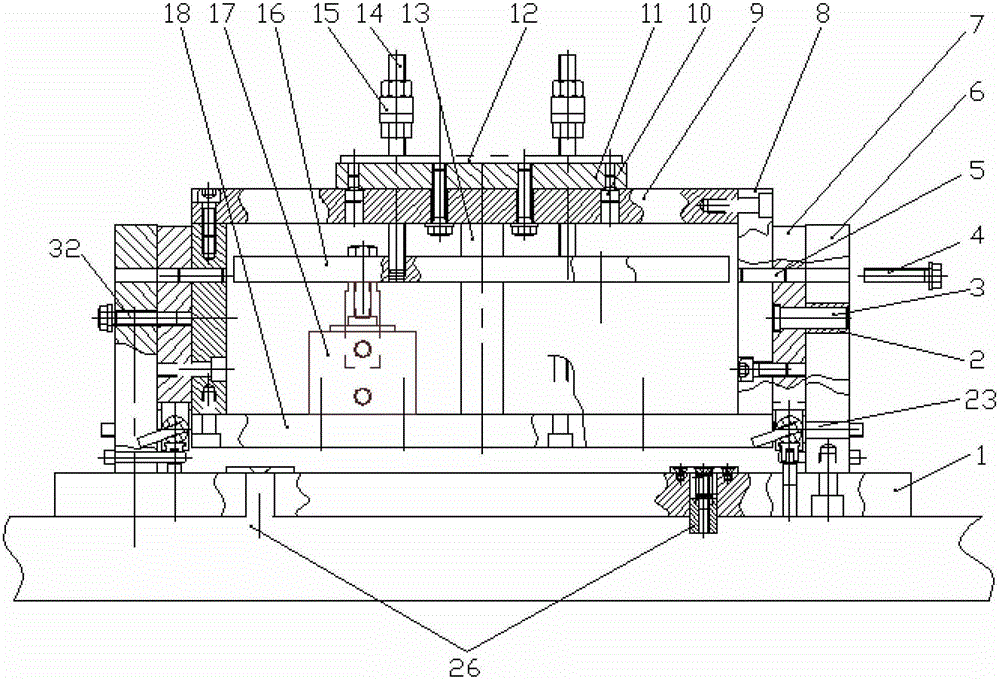

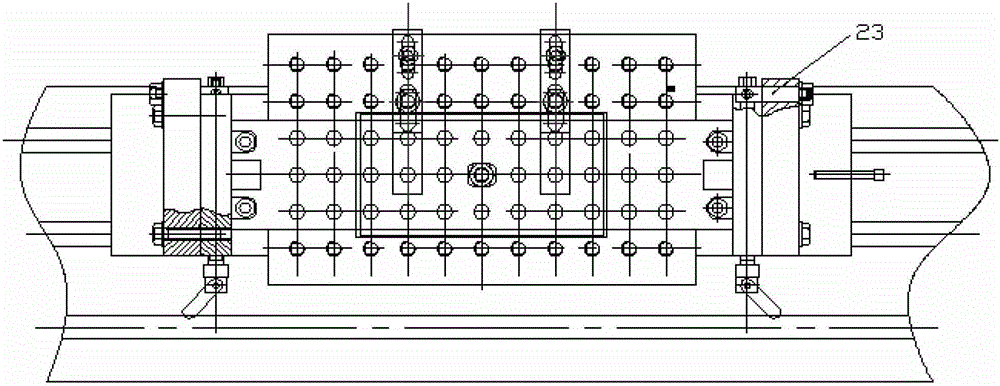

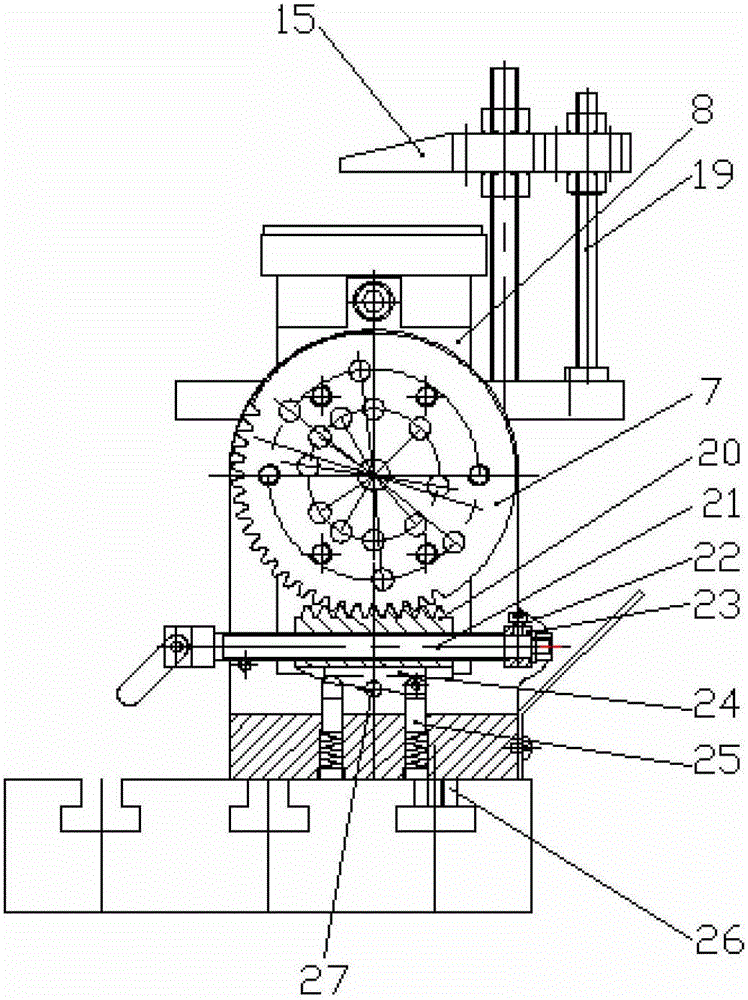

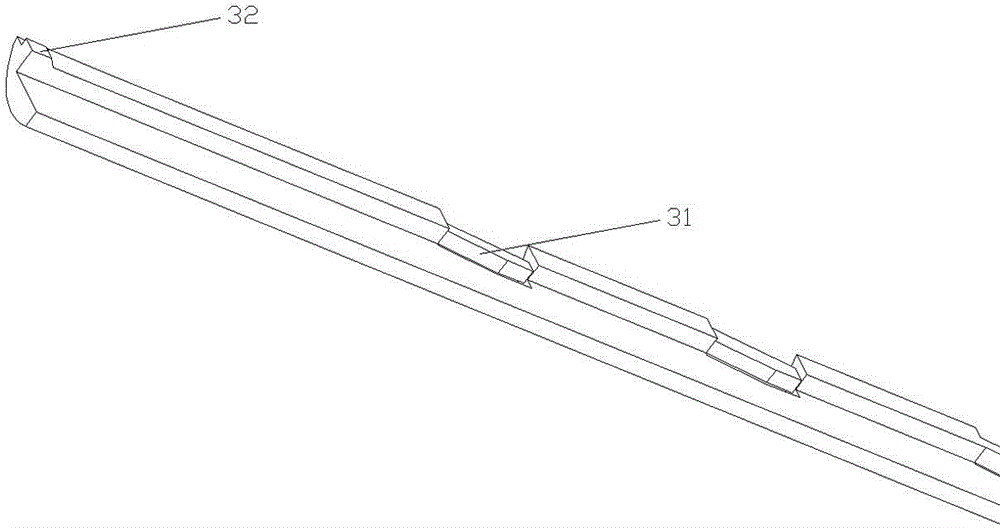

Overturning grinding rust removal device for metal plate

InactiveCN110142678AFast clamping speedEasy to remove rustGrinding carriagesGrinding drivesEngineeringMechanical engineering

The invention relates to the field of metal processing equipment, and more specifically relates to an overturning grinding rust removal device for a metal plate. The overturning grinding rust removaldevice for the metal plate comprises a workbench, a left clamping block, a right clamping block and a rust removal brush plate, wherein a slide groove is formed in the upper surface of the workbench;a bidirectional screw rod is installed in the slide groove; the left clamping block and the right clamping block sleeve the bidirectional screw rod; a second telescoping mechanism is fixedly connectedto the upper surface of the workbench; a lifting block sleeves a stretching end of the second telescoping mechanism; an installation plate is hinged to the sidewall of the lifting block; a displacement screw rod is arranged below the installation plate; a movable block sleeves the middle part of the displacement screw rod; a fourth telescoping mechanism is fixedly connected to the lower surface of the movable block; and a rust removal motor is fixedly connected to the lower end of the fourth telescoping mechanism. The metal plate is clamped by virtue of the clamping plate to keep fixed, and high clamping speed is achieved; in a rust removal process, the rust removal brush plate moves to left and right, so that a rust removal range is expanded; and through arrangement for a rotary motor, rust removal can be conveniently carried out on the front surface and the back surface of the metal plate.

Owner:蒋艳红

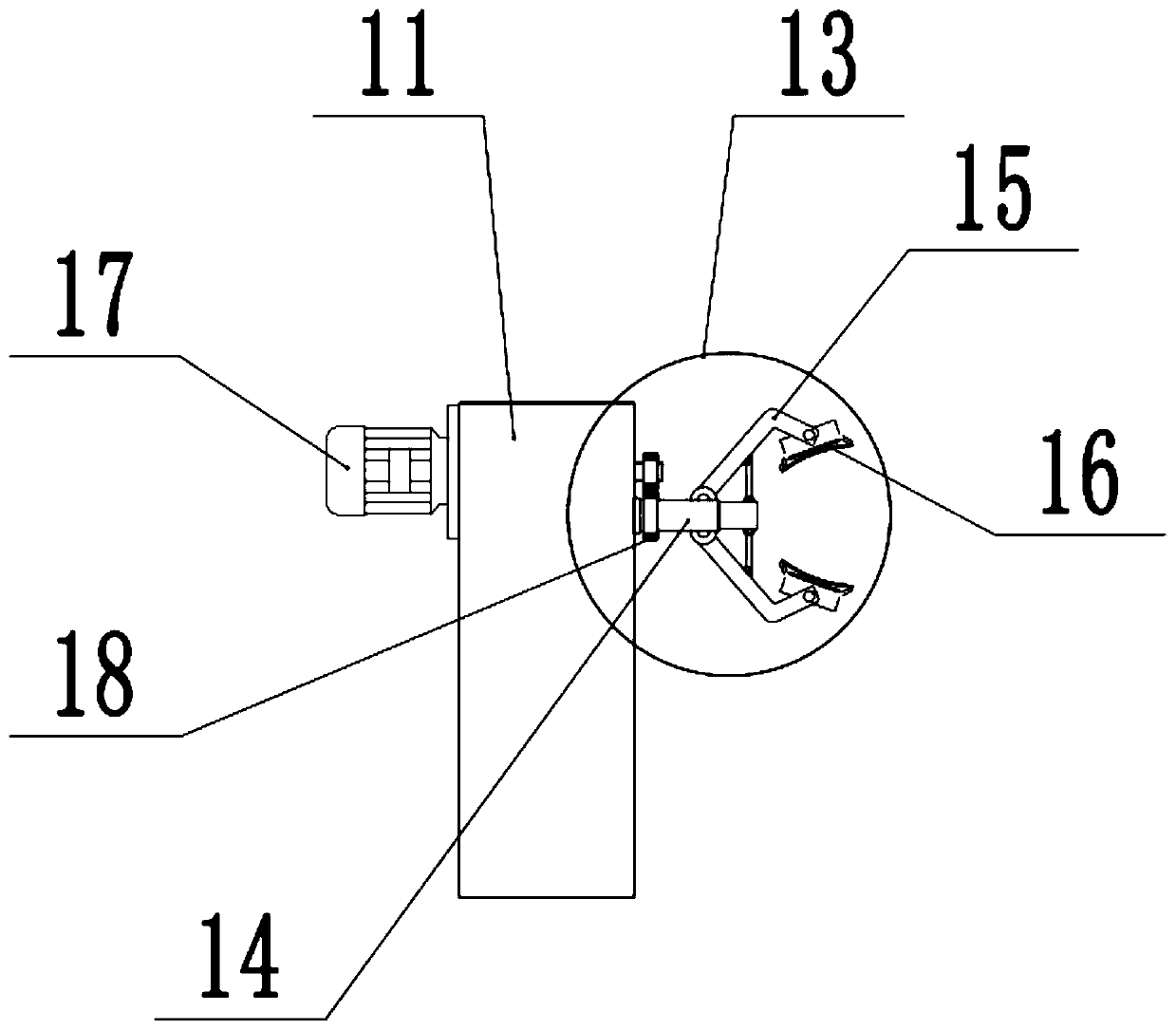

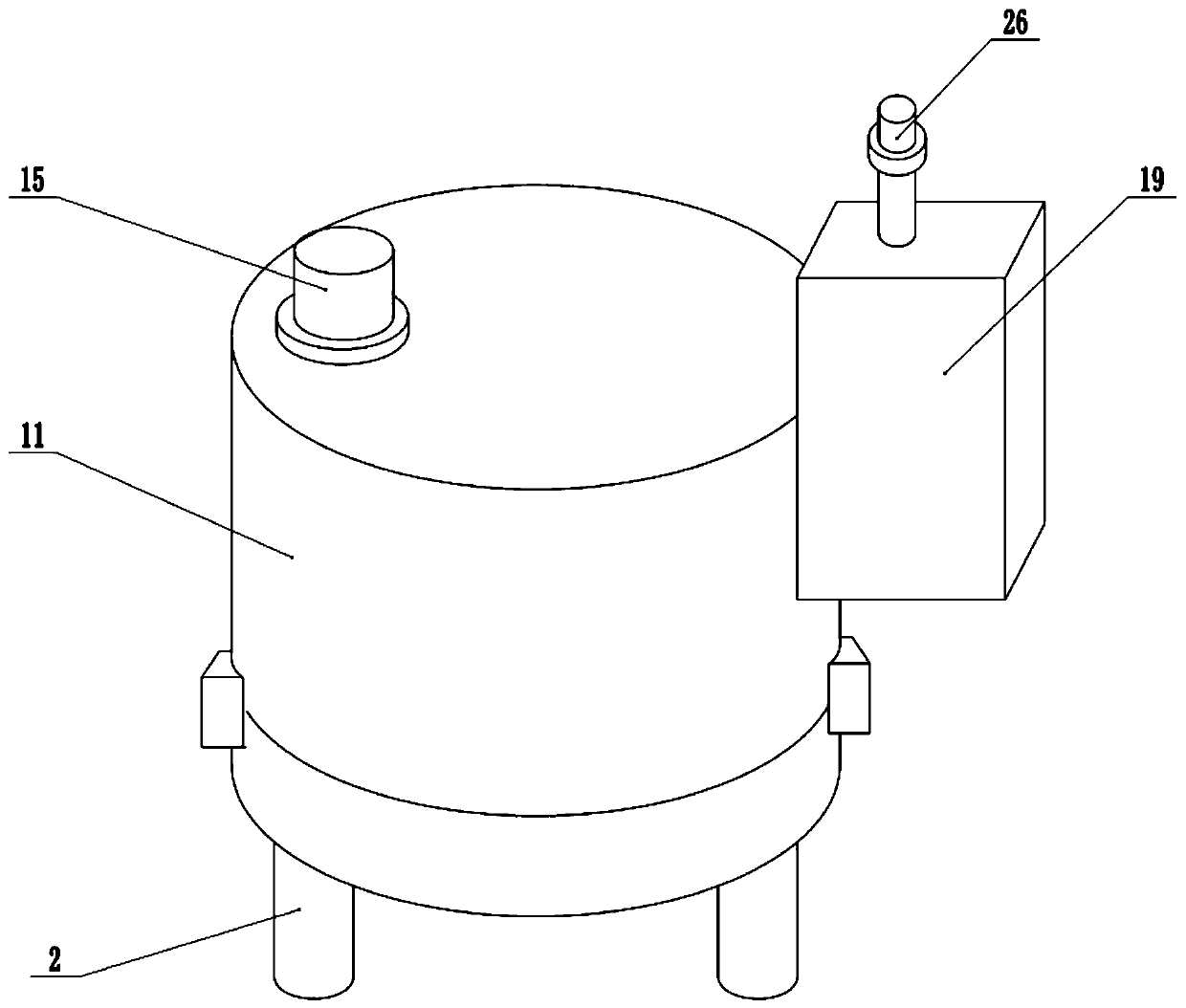

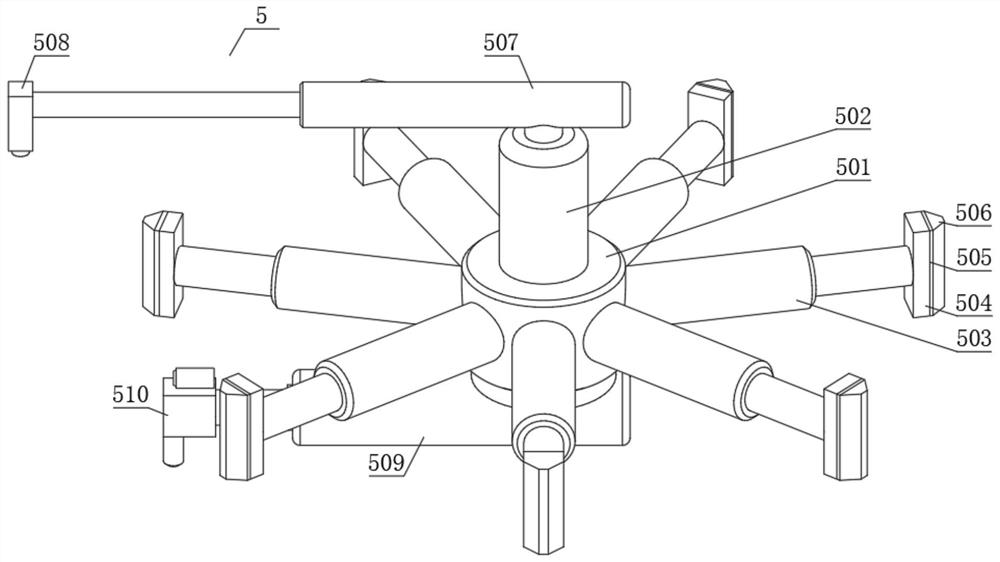

Oil drum rust removal device convenient to clamp

InactiveCN107855903AShorten the timeFast clamping speedGrinding carriagesGrinding machinesEngineeringThreaded rod

The invention discloses an oil drum rust removal device convenient to clamp. The device comprises a base, supporting legs, a rotary workbench, a clamping block, rust removal rods and rust removal balls. The rotary workbench is arranged above the base, the lower surface of the rotary workbench is fixedly connected with a rotary shaft, the lower surface of the base is fixedly connected with a motor,a supporting column is fixedly connected to the left end of the base, a top plate is fixedly connected to the top of the supporting column, a telescopic mechanism is fixedly connected to the lower surface of the top plate, a sleeve is fixedly connected to the lower end of the telescopic mechanism, a threaded rod is arranged in the sleeve and sleeved with a sleeve ring, and the rust removal rods are hinged to the left side and the right side of the sleeve ring. The clamping block is used for clamping an oil drum, the clamping speed is high, working efficiency is greatly improved, and time of workers is saved; the rust removal rods are adjusted to enable the rust removal balls to be in abutting connection with the inner wall of the oil drum so as to adapt to oil drums with different inner diameters, and the using range of the device is enlarged; and in the rust removal process, the rust removal balls are used for removing rust on the inner wall of the oil drum, and the rust removal efficiency is high.

Owner:邱杨舒

Rotary small-size paint spraying chamber convenient to move

The invention relates to the field of machining equipment, in particular to a rotary small-size paint spraying chamber convenient to move. The rotary small-size paint spraying chamber comprises a workbench, a spray head, a storage box and a paint pump; the upper surface of the workbench is rotationally connected with a rotary disc; a plurality of clamping mechanisms are distributed on the upper surface of the rotary disc; a shell is detachably installed on the upper surface of the workbench, a screw rod is arranged in the shell, and the middle of the screw rod is sleeved with a slide block; areciprocating motor is fixedly connected to the upper surface of the shell, and the spray head is fixedly connected to the lower surface of the slide block; the outer side wall of the workbench is fixedly connected with the storage box, paint is poured into the storage box through an injection pipe, and the storage box is internally provided with the paint pump and a stirring mechanism; a to-be-machined workpiece is clamped through a clamping mechanism, the clamping speed is high, and the working efficiency is improved; and in the paint spraying process, the spray head does reciprocating motion, meanwhile, the to-be-machined workpiece is driven to rotate through the rotary disc, the paint is sprayed more uniformly, and the paint is stirred by stirring blades and prevented from settling.

Owner:马单智

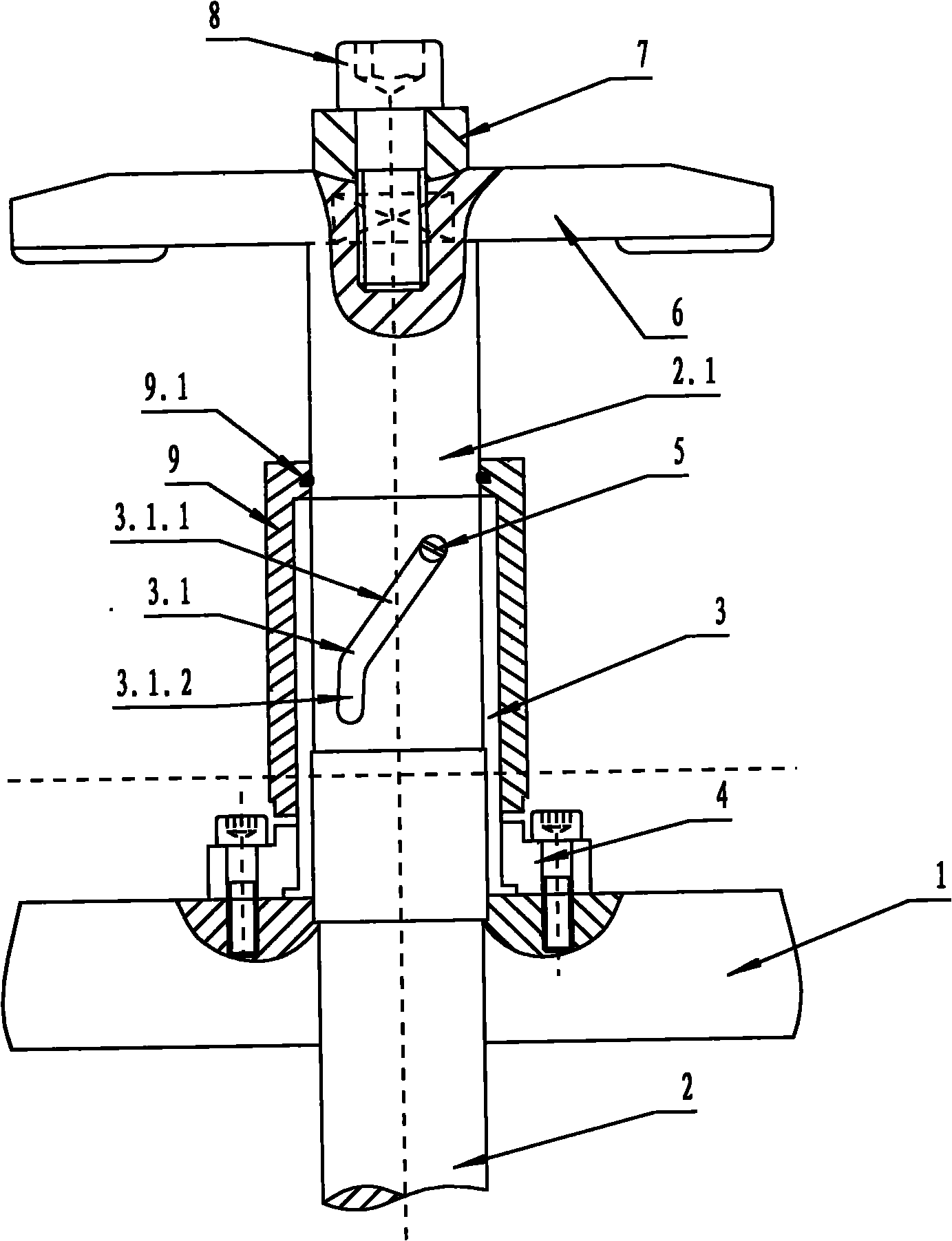

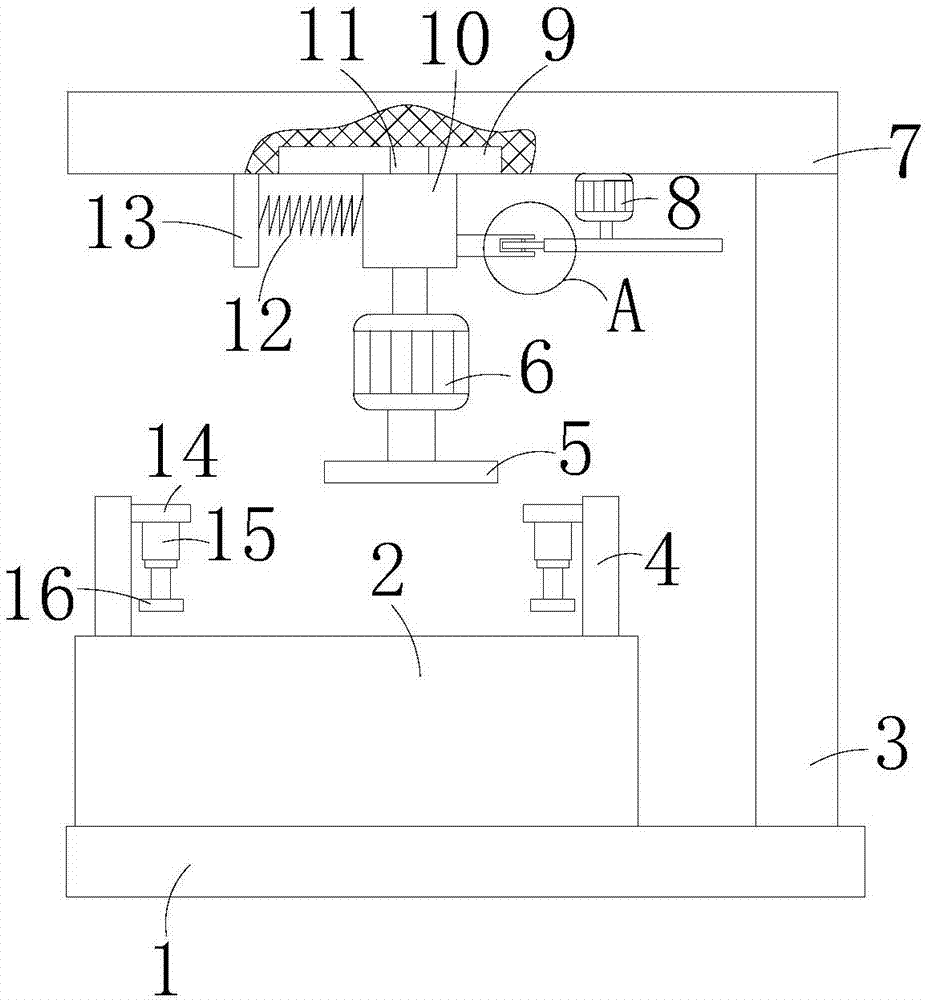

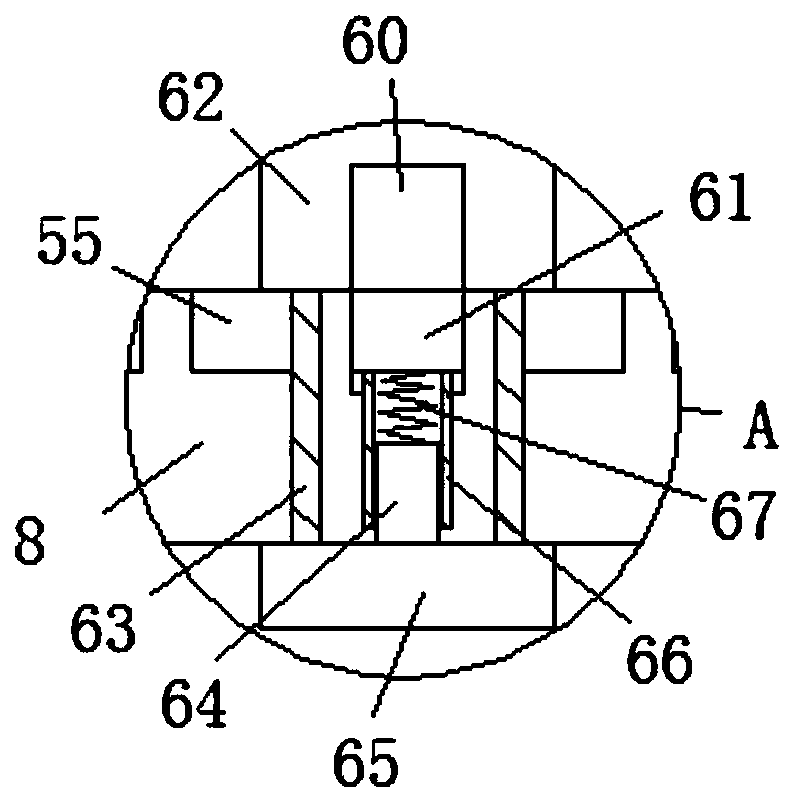

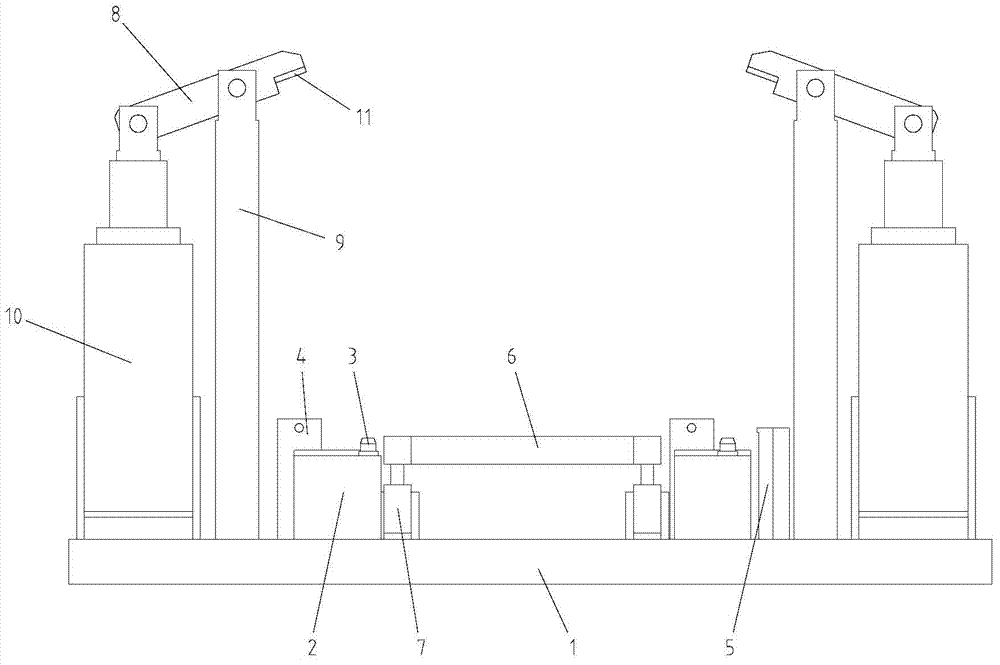

Workpiece-pressing jig

InactiveCN101829970AFast clamping speedGuaranteed flatnessWork holdersPositioning apparatusEngineeringMechanical engineering

The invention discloses a workpiece-pressing jig. The jig comprises a jig table (1), an air cylinder (2) and a pressure plate (6). The jig is characterized in that the jig also comprises a guide sleeve (3), a fixing seat (4), a guide pin (5) and a pressure plate locking device, wherein the guide sleeve (3) is arranged on the cylinder shaft (2.1) of the air cylinder (2), the fixing seat (4) is used to fix the guide sleeve (3) on the jig table (1); the guide sleeve (3) comprises a guide groove (3.1), the guide groove (3.1) comprises a spiral groove part (3.1.1) and a straight-flute part (3.1.2); the guide pin (5) penetrates through the guide groove (3.1) to be fixed on the cylinder shaft (2.1); and the pressure plate (6) is locked on the end of the cylinder shaft (2.1) by the pressure plate locking device. By using the workpiece-pressing jig, the pressure plate fixed on the cylinder shaft can lean to one side so that the workpiece on the jig table can have larger space in vertical direction, the operation can be convenient and the clamping rate can be greatly improved.

Owner:宁海县海裕铝业有限公司

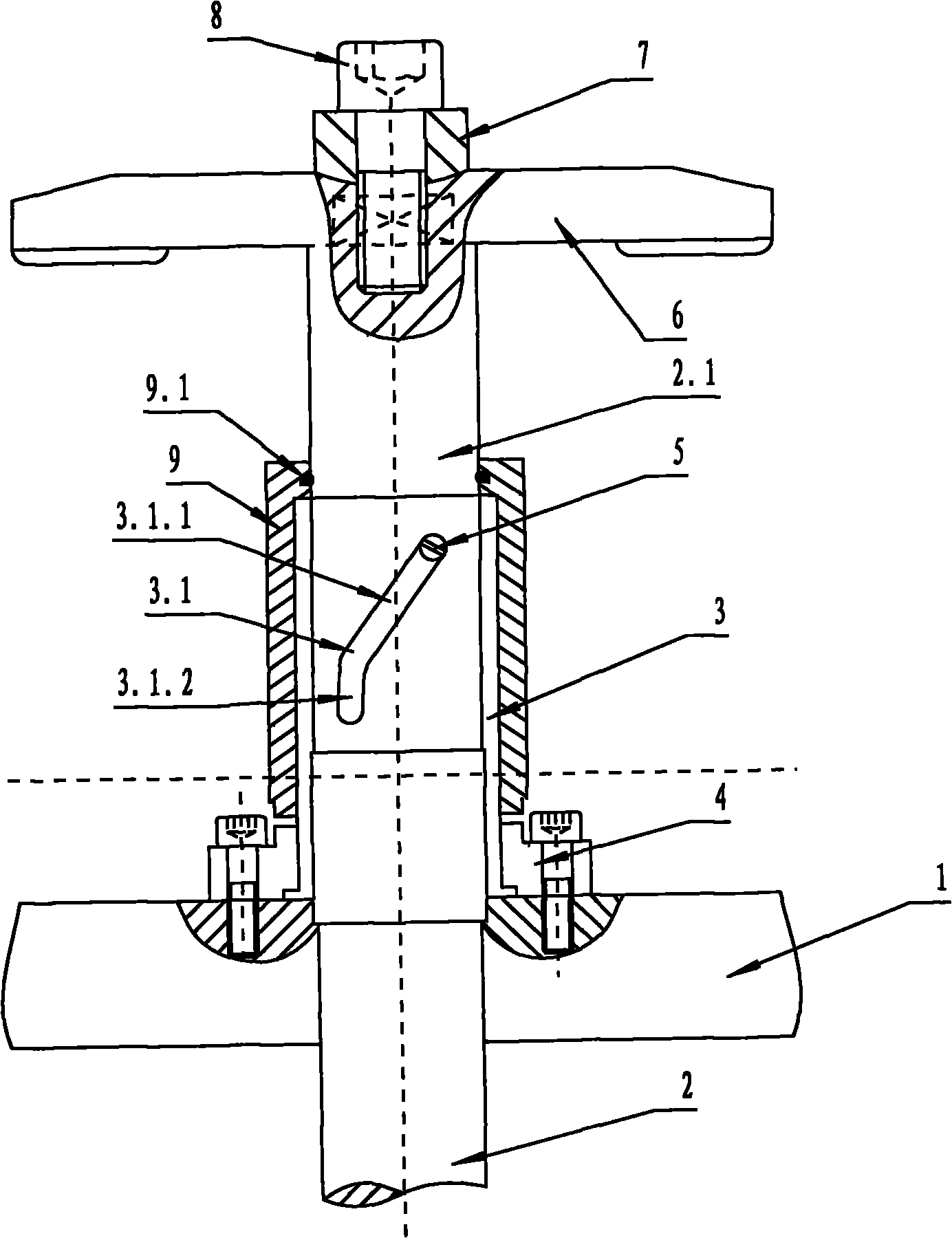

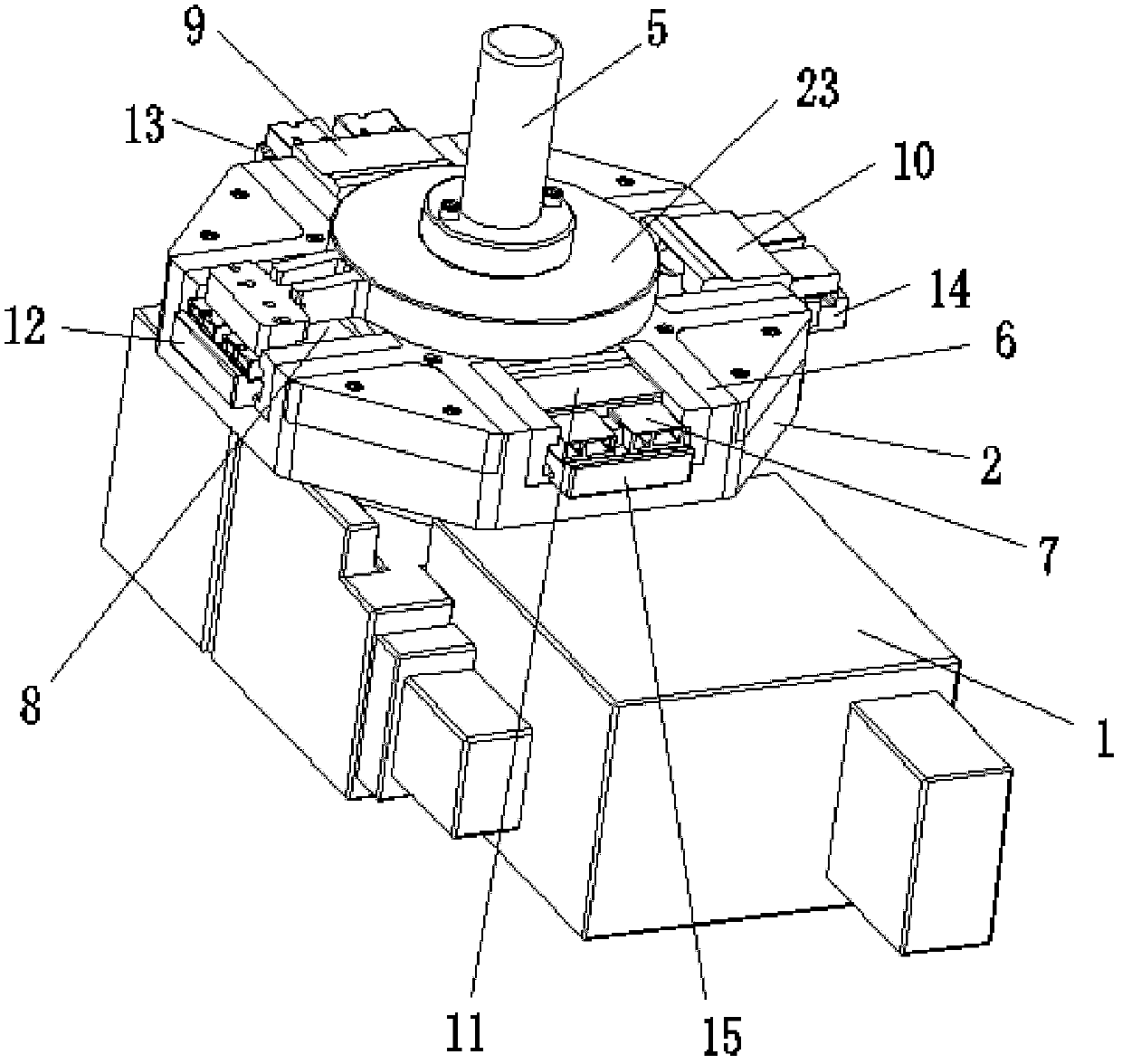

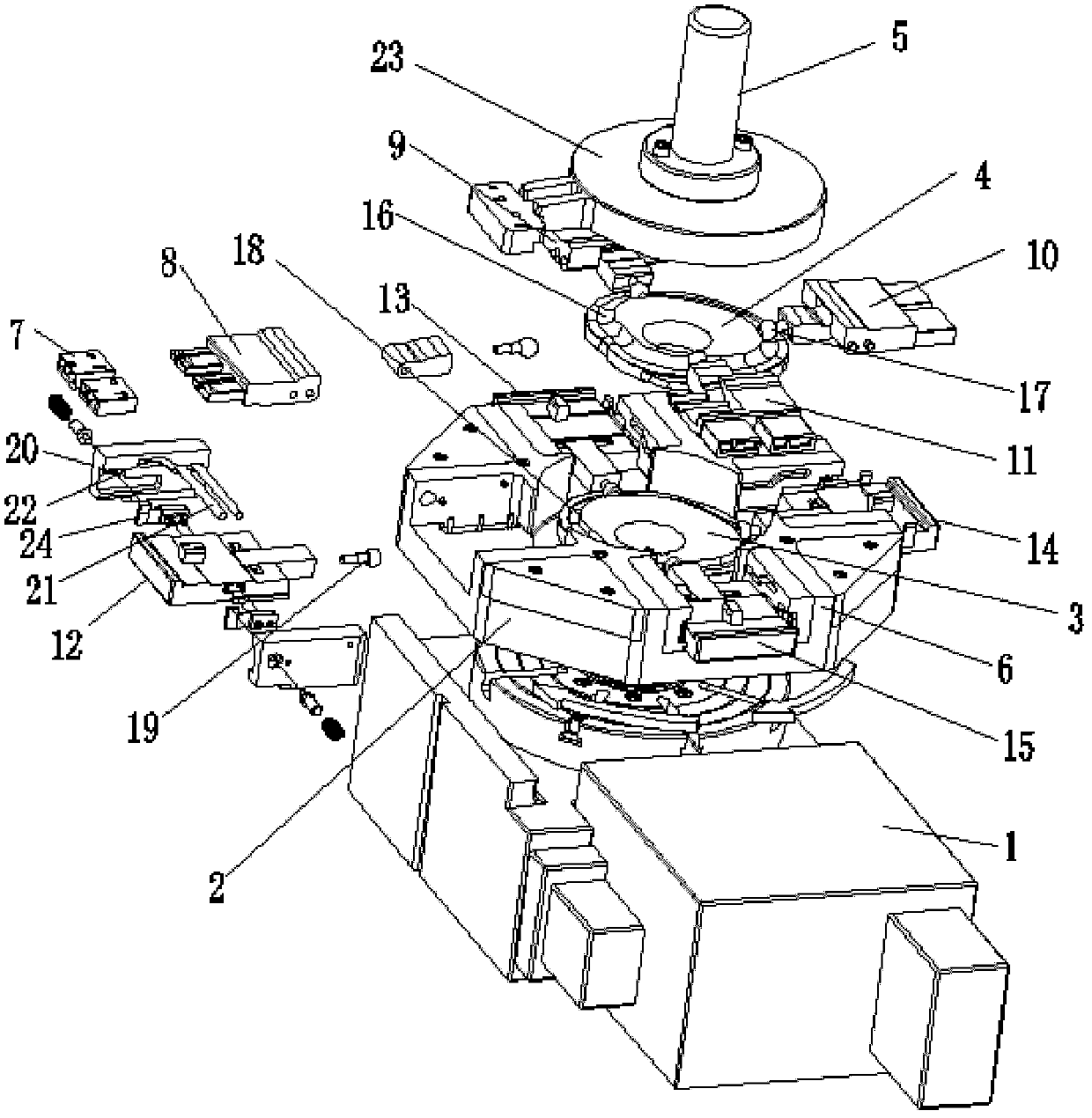

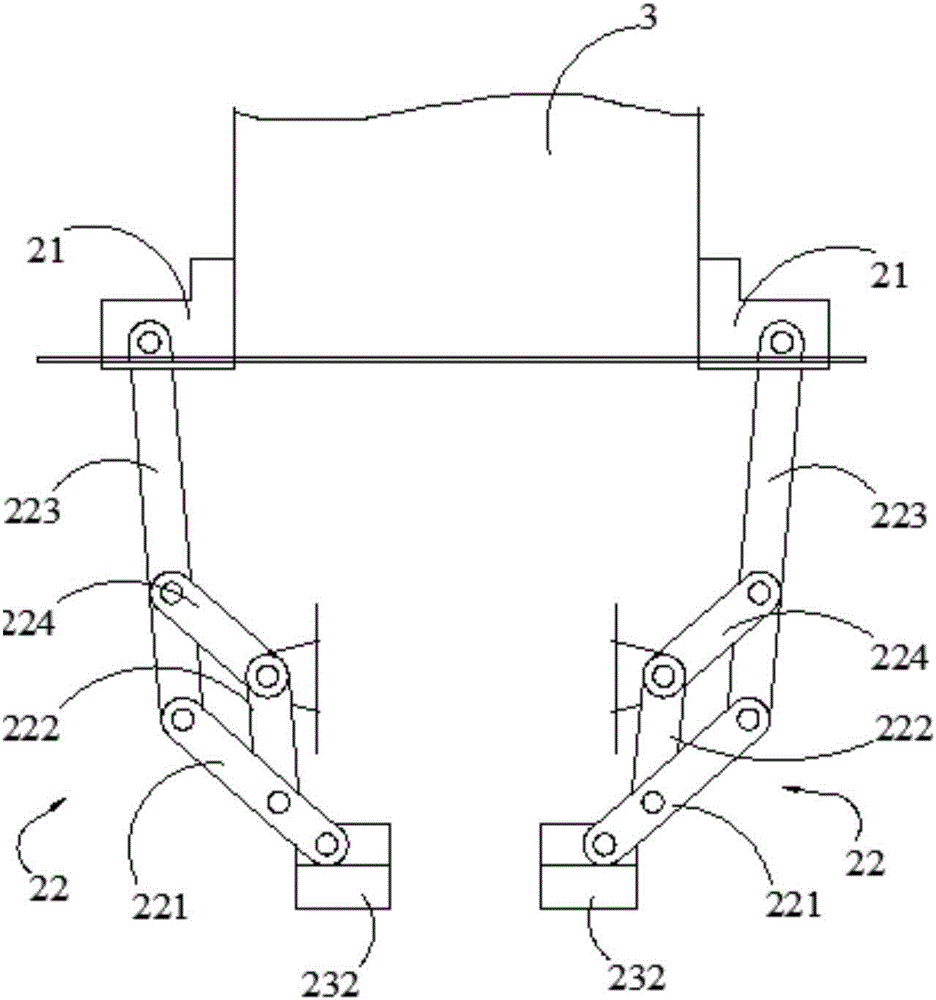

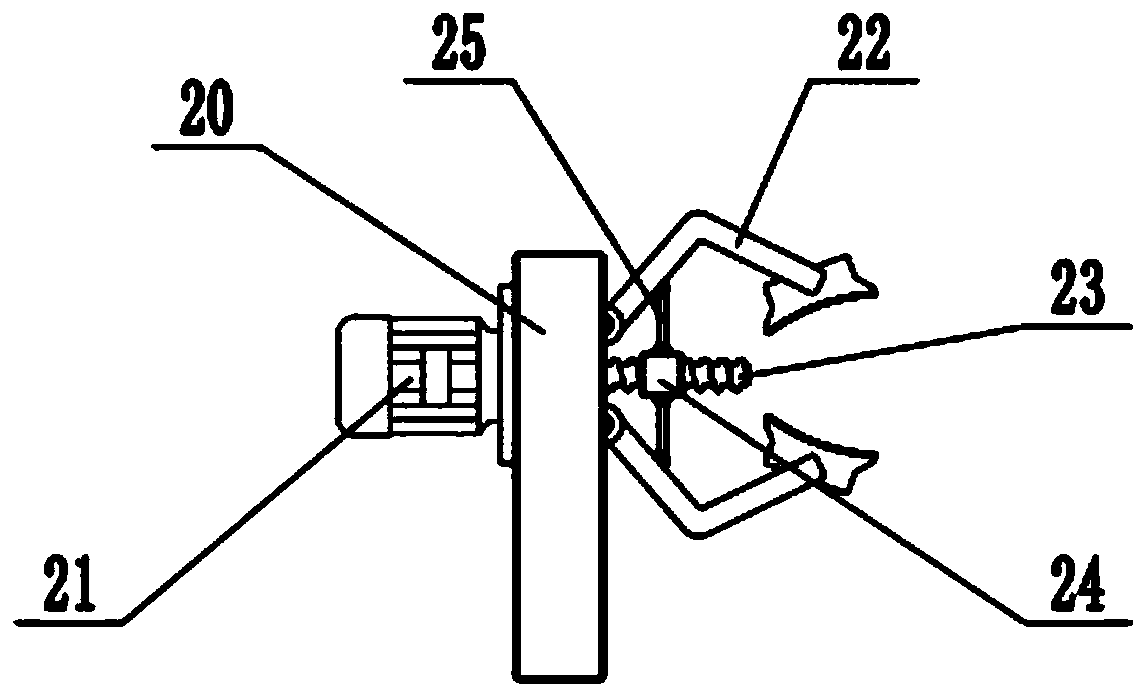

Robot electric gripper

InactiveCN104209953AClamping force controlFast clamping speedProgramme-controlled manipulatorGripping headsGrip forceEngineering

The invention provides a robot electric gripper, which comprises a flange base, wherein the middle part of interior of the flange base is provided with a worm, the two sides of the worm are provided with one pair of fan-shaped worm wheels which are engaged with the worm and rotate in the same direction, the axes of the pair of fan-shaped worm wheels are respectively and fixedly connected with a crank connecting rod, the lower end of each crank connecting rod is hinged to a hand claw, the pair of fan-shaped worm wheels are fixedly arranged in a box body, the interior of the box body is hinged to curved rods which are parallel with the crank connecting rods, the lower end of each curved rod is connected with each hand claw, and the crank connecting rods, the curved rods and the hand claws form a parallel double-crank mechanism. The gripper has the advantages that a brushless direct current flat motor is used for driving, so the gripping force, gripping speed and position can be more flexibly and conveniently controlled; by designing the gripping method of fitting the worm wheels and the worm, the parallel double-crank mechanism is adopted, and the hand claws are always parallel in the gripping process; meanwhile the strength of the gripping mechanism is improved, the impact load in the gripping process is little, the transmission is stable, and the noise is low.

Owner:FUZHOU UNIV

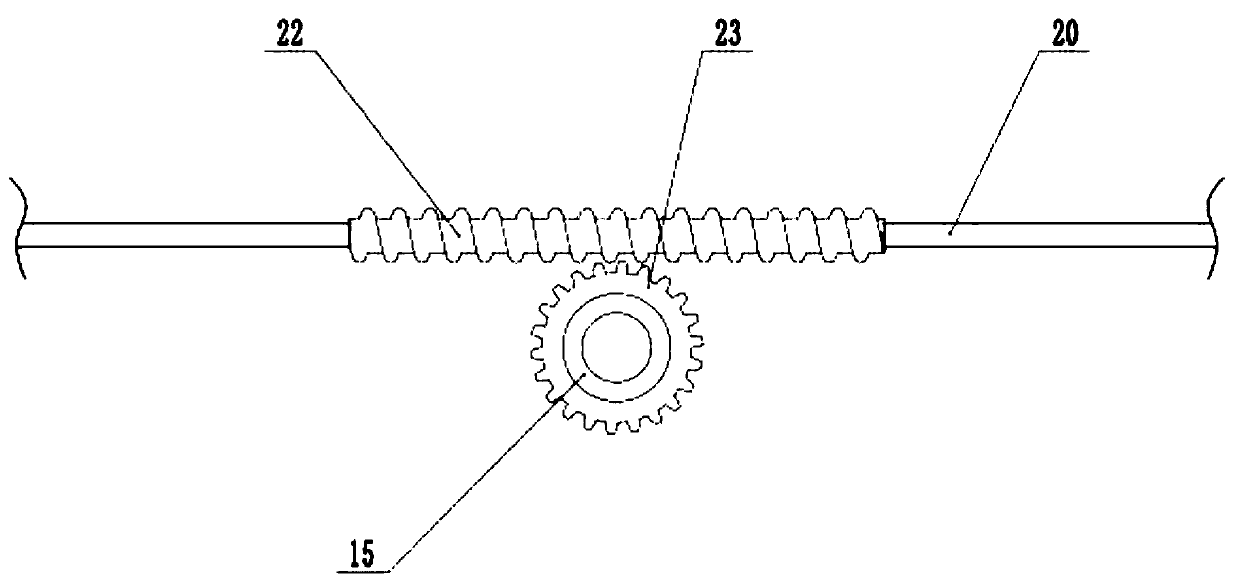

Fast clamping mechanism of machine tool

InactiveCN103433777AReduce processing auxiliary timeFast clamping speedPositioning apparatusMetal-working holdersControl engineeringProcess engineering

The invention discloses a fast clamping mechanism of a machine tool, and belongs to the field of machine tool clamps. The fast clamping mechanism comprises a sliding rail, an adjusting screw rod, a movable block and a clamping block, wherein the upper end of the sliding rail is clamped on the concave edge of the lower end of the movable block, the lower end of the clamping block is pressed on a concave edge of the upper end of the movable block, and the adjusting screw rod is meshed with the movable block. The fast clamping mechanism solves the problems that an existing machine tool clamping mechanism is long in clamping face moving time, large in labor intensity and low in work efficiency, and has the advantages of being simple in structure, reasonable in design and easy to manufacture.

Owner:WUXI YICHEN MOLD TECH

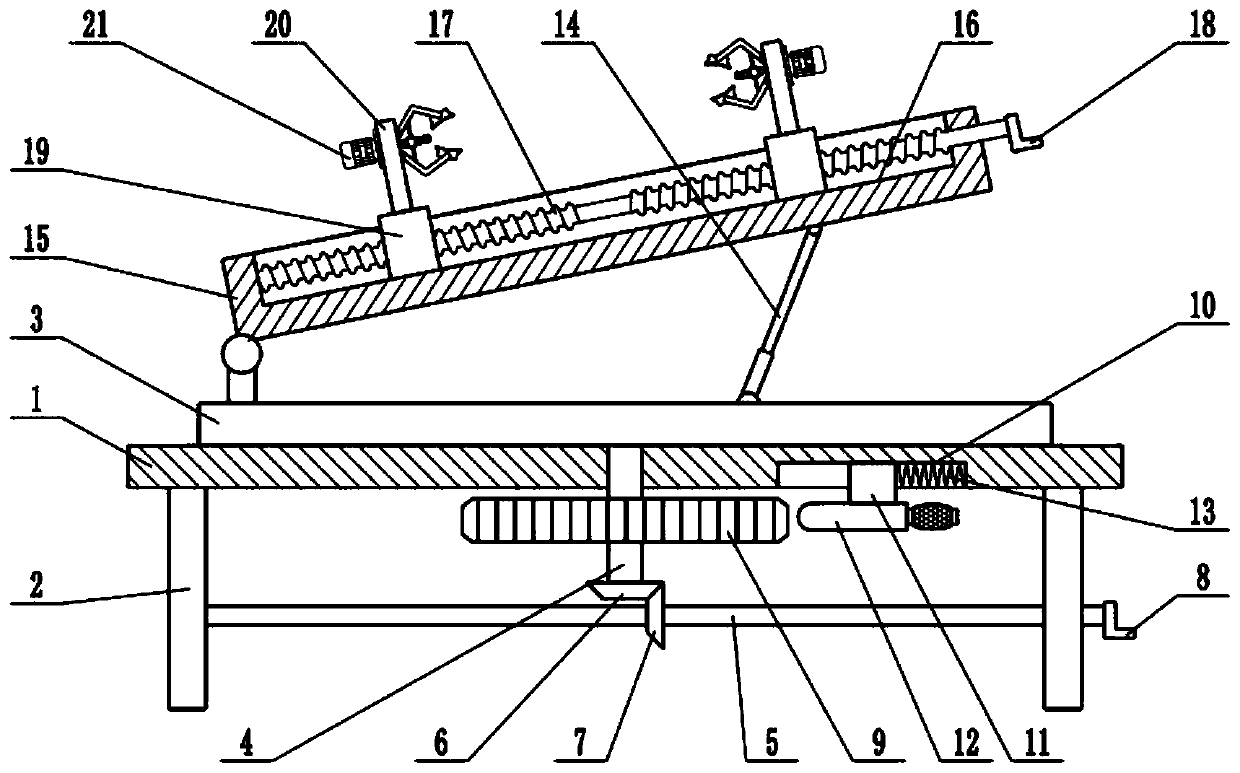

Clamping workbench for electric push rod machining

InactiveCN110549271ASolve the speed problemSolve the adjustmentLighting elementsWork holdersMachine partsMachining

The invention relates to the field of machining equipment, in particular to a clamping workbench for electric push rod machining. The clamping workbench comprises a rack, a movable plate, a left movable plate, a right movable plate, a left clamping block and a right clamping block, wherein the lower surface of the rack is fixedly connected with the movable plate; a sliding groove is formed in theupper surface of the rack, the sliding groove is internally provided with a second bidirectional screw rod, and the two ends of the second bidirectional screw rod are provided with the left movable plate and the right movable plate in a sleeved mode correspondingly; the left clamping block is arranged at the top of the left movable plate, and the right clamping block is arranged at the top of theright movable plate; and the side wall of the rack is further provided with an illuminating mechanism, and a height adjusting mechanism is arranged below the rack. An electric push rod part to be machined is placed between the left clamping block and the right clamping block, the left clamping block and the right clamping block are used for clamping the to-be-machined part, and the clamping speedis high; and the angle-adjustable illuminating mechanism is arranged so that the illumination angle can be adjusted according to actual requirements, and the height adjusting mechanism is arranged sothat the height of the rack can be adjusted according to actual machining requirements.

Owner:徐州天泓传动设备有限公司

Metal tube antirust paint internal and external synchronous spraying equipment

The invention relates to the field of machining equipment, in particular to metal tube antirust paint internal and external synchronous spraying equipment which comprises a working table, a rotary table, a fixed frame, a liquid storing box and a spraying disc, wherein a lifting plate is arranged below the working table; a first motor is fixedly connected with the lower surface of the lifting plate; the shaft extending end of the first motor is fixedly connected with a rotary shaft; the rotary table is fixedly connected with the top end of the rotary shaft; the fixed frame is fixedly connectedwith the upper surface of the working table; a first hollow rotary shaft is mounted on the top of the fixed frame; a spraying pipe is distributed on the first hollow rotary shaft; a rotary communicating joint is mounted at the top end of the first hollow rotary shaft; a second hollow rotary shaft is mounted on the side wall of the fixed frame; and the spraying disc is mounted at the end, towards ametal tube, of the second hollow rotary shaft. An arc shaped clamping plate is utilized to clamp the side wall of the metal tube to keep the metal tube stable, the clamping speed is high and the efficiency is high; and a booster pump is utilized to convey antirust paint to the spraying pipe and the spraying disc to simultaneously carry out paint spraying on the internal and external walls of themetal tube.

Owner:TONGLING QUNLI MACHINERY

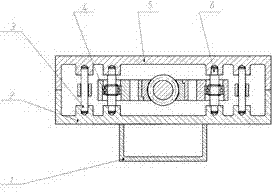

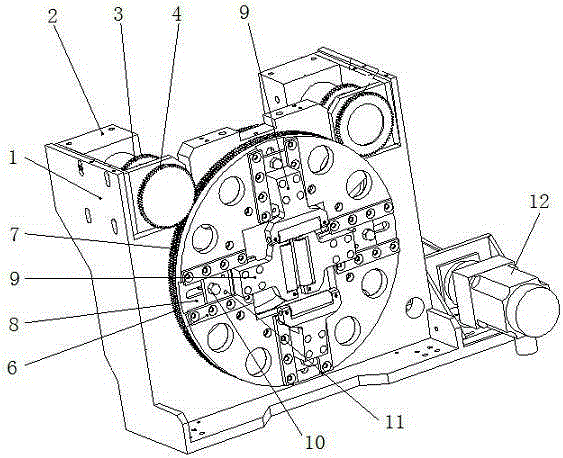

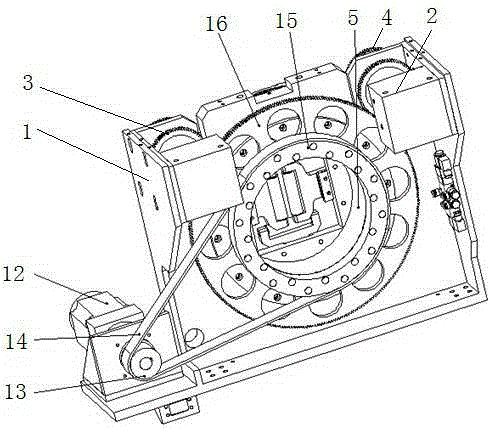

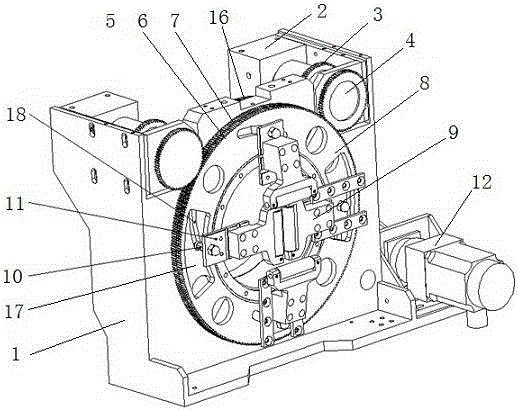

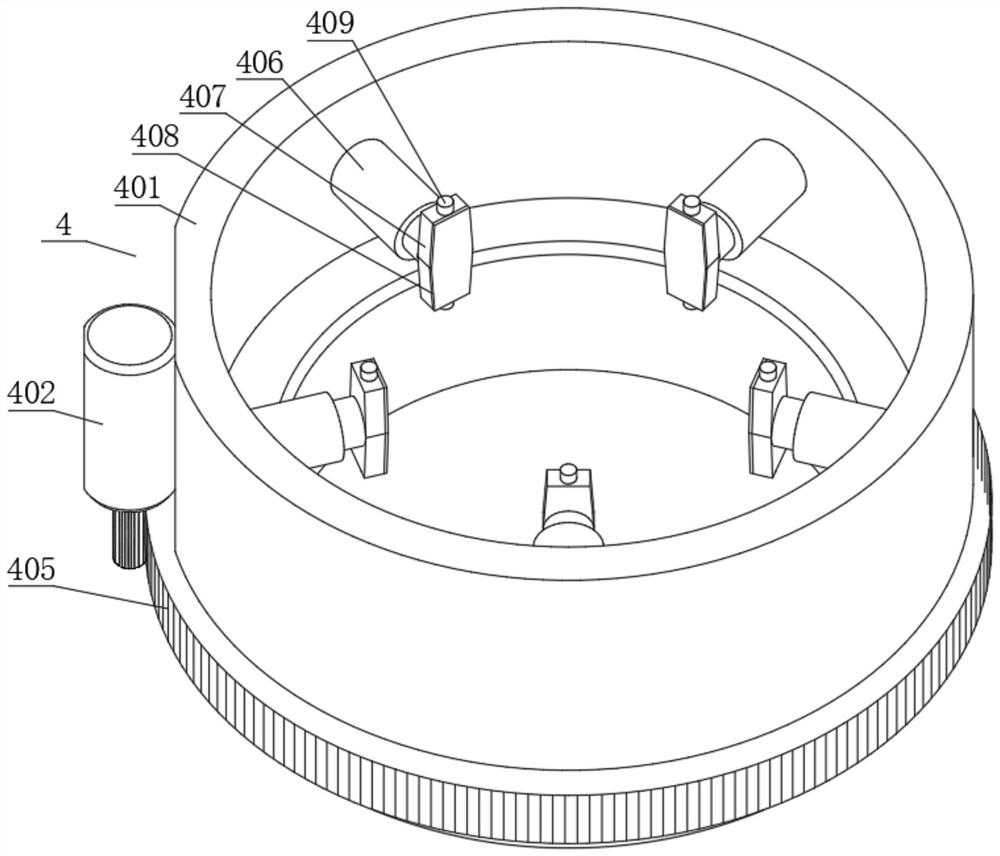

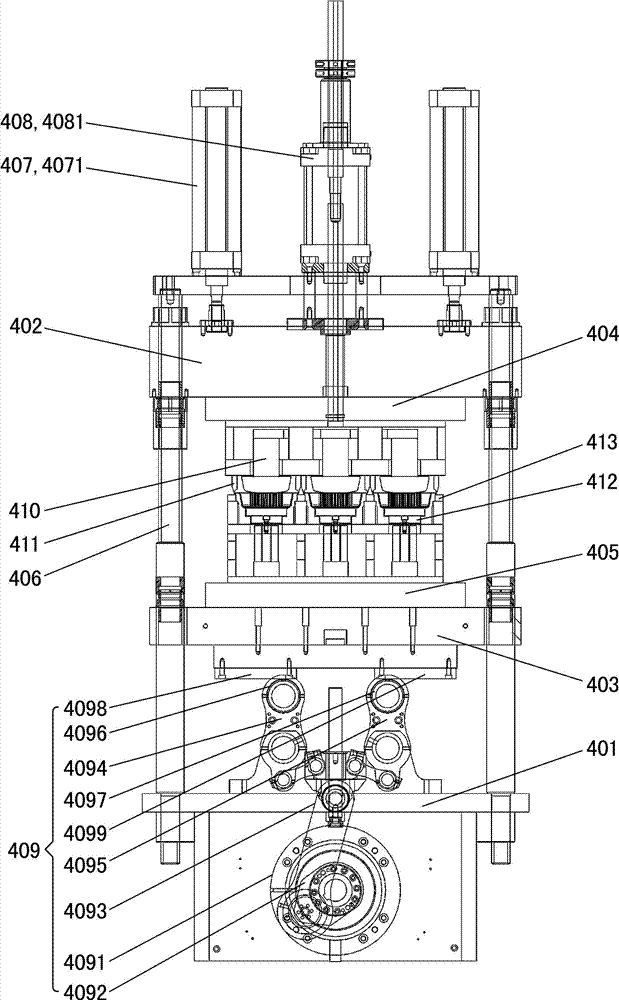

Multi-station automatic fixture rotating system

ActiveCN103302546AFast clamping speedFully automaticMetal-working feeding devicesMetal working apparatusNumerical controlEngineering

The invention discloses a multi-station automatic fixture rotating system, which comprises a power mechanism, a rotating disk, a lower cam, an upper cam and a cylinder, wherein the rotating disk is correspondingly provided with four station areas used for product assembly, product assembly in place, product deep processing and product taking out; the four stations are correspondingly provided with four product fixtures and processing trays; and the power mechanism, the upper cam and the lower cam together drive the four stations to act so as to realize quick feeding, positioning, fixing, locked processing and taking. During use, the multi-station automatic fixture rotating system is arranged on a working table of a computer numerical control (CNC) machining center, can realize full-automatic and unattended production by matching feeding and taking mechanical arms, has the advantages of high clamping speed, accurate positioning and uninterrupted production, and has high production efficiency.

Owner:瑞鼎机电科技(昆山)有限公司

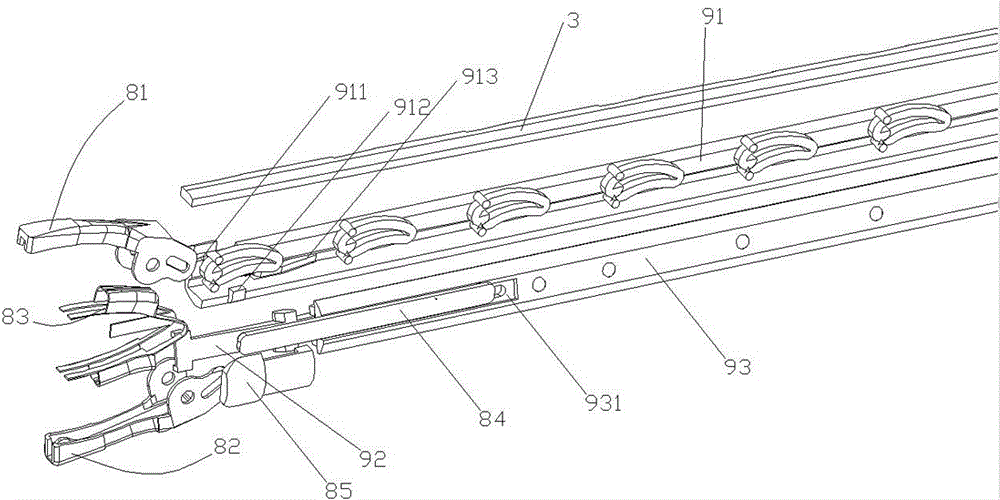

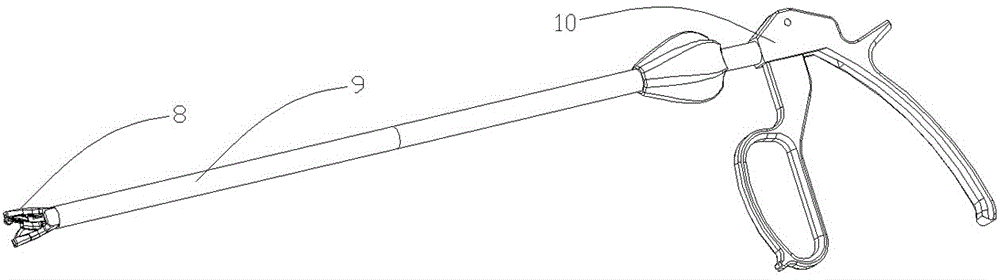

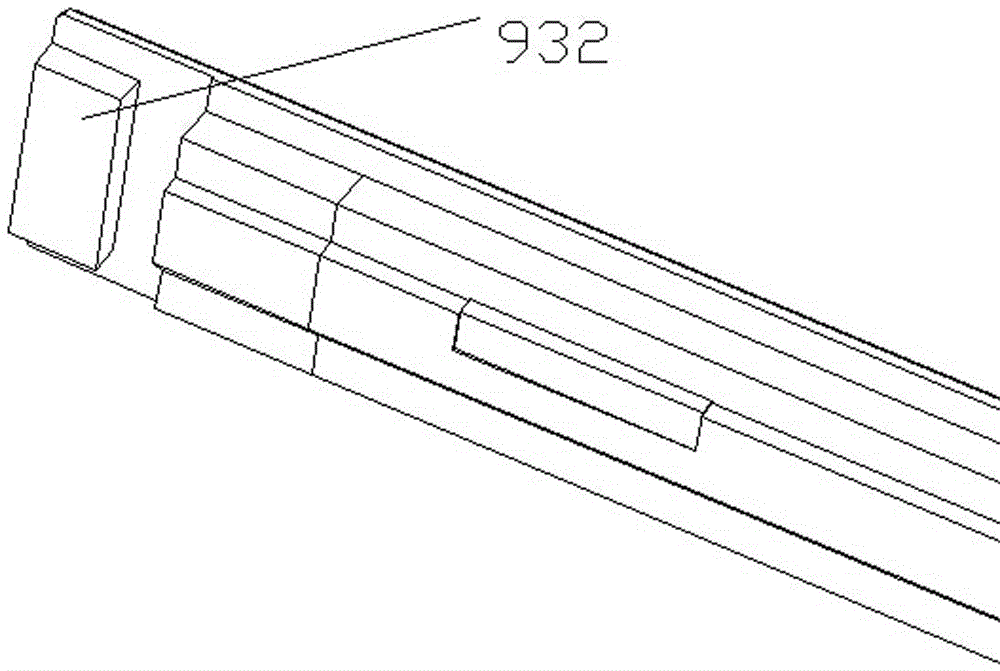

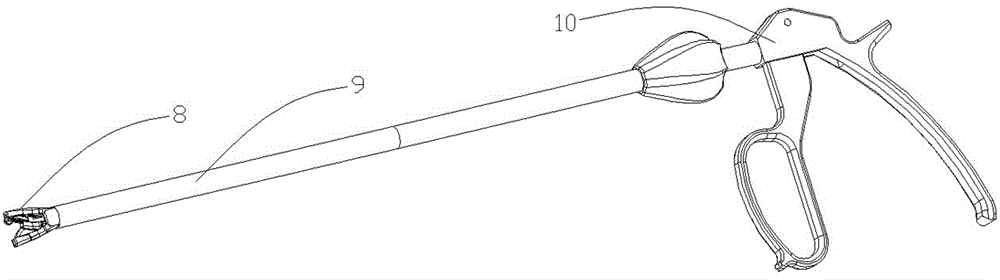

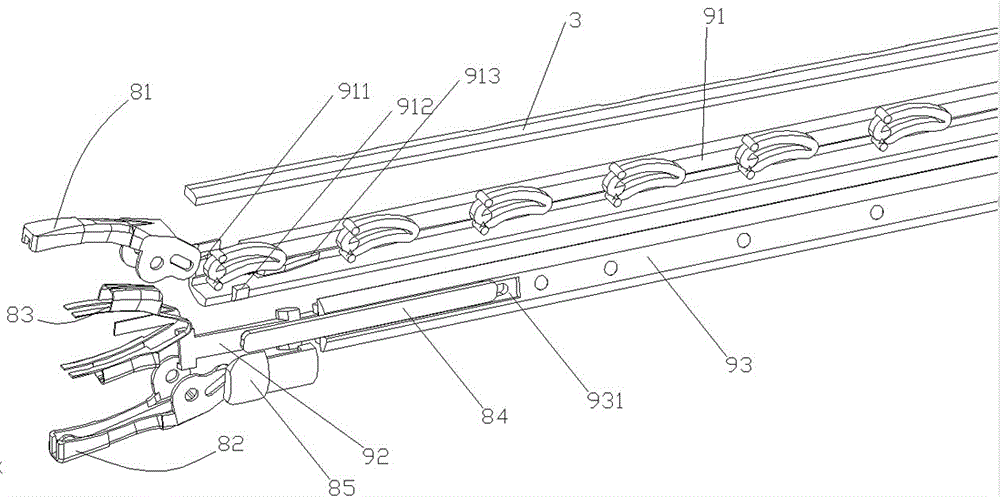

Hemostatic clip applier capable of continuously serving

InactiveCN106037866AShorten the timeImprove the effect of surgeryWound clampsContinuous usePower apparatus

The invention discloses a hemostatic clip applier capable of continuously serving, and belongs to the field of medical articles, aiming at solving the problems of an existing hemostatic clip applier which is slow to take effects, easy to cause accidents and poor in hemostatic clip fastening performance. The hemostatic clip applier comprises a clip head, a clip pipe which is connected to the clip head and a power device which is connected to the clip pipe, wherein the clip pipe comprises a cartridge holder, a clamping plate pushing device, a right side plate as well as a sleeve which sleeves the cartridge holder, the clamping plate pushing device and the right side plate; a passage, in which the hemostatic clip can advance, is surrounded by the cartridge holder, the clamping plate pushing device and the right side plate; a locating groove is formed in the cartridge holder; a pushing device for pushing the hemostatic clip to advance is arranged on the clamping plate pushing device; and the power device comprises a tail pipe.

Owner:CHENGDU IDING IND PROD DESIGN

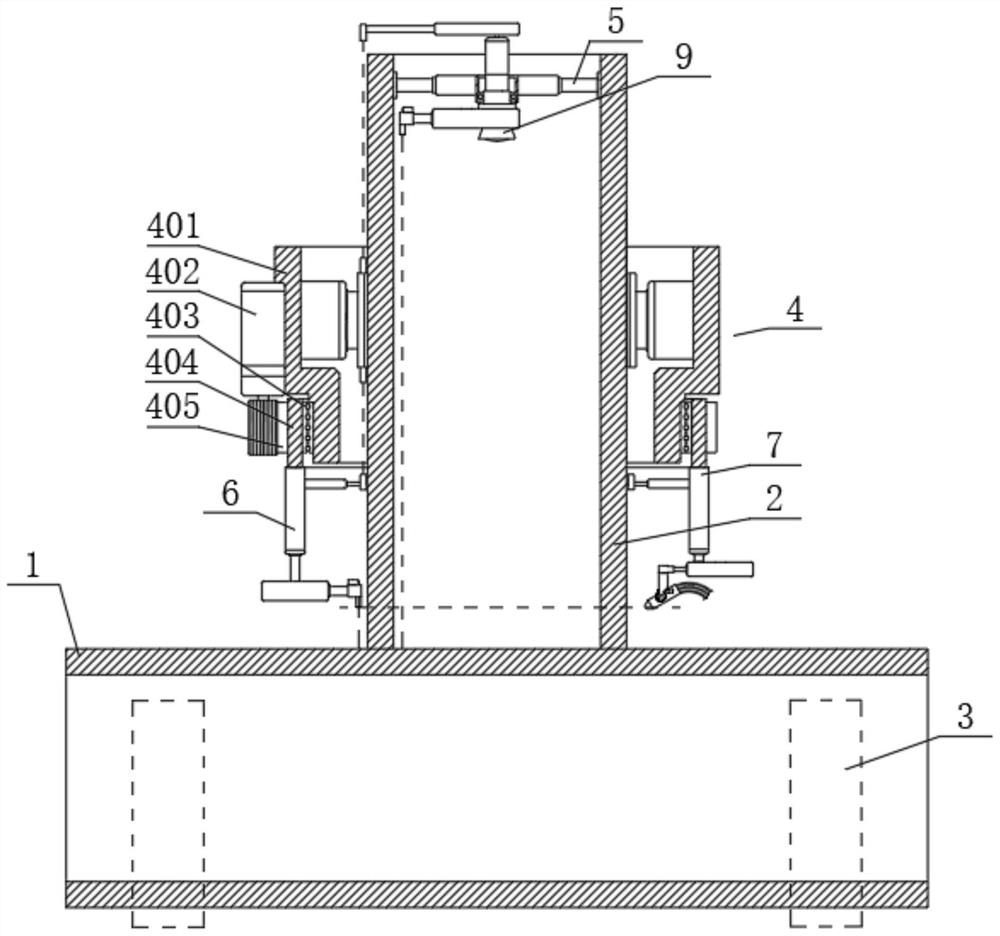

Automatic machining clamp with multi-directional adjustment function

InactiveCN108972082ASimple structureGuaranteed uptimeWork clamping meansMeasurement/indication equipmentsEngineeringMachining

The invention provides an automatic machining clamp with a multi-directional adjustment function, and belongs to the field of machining equipment. The automatic machining clamp comprises a first bracket, a second bracket, an air cylinder, a first clamping block, a second clamping block, a first motor, a second motor, a lead screw and supporting legs; and the supporting legs are arranged on the lower portion of the first bracket, the second motor is arranged in the middle of the first bracket, the second motor is fixedly connected with the lead screw, the second bracket is arranged on the upperportion of the first bracket, the first clamping block and the second clamping block are mounted on the second bracket, the air cylinder is arranged on the left side of the second bracket, the air cylinder is fixedly connected with the first clamping block, and the first motor is arranged on the right side of the second bracket. The automatic machining clamp is simple in structure, stable in operation and easy to maintain; workpieces are automatically clamped, the clamping speed is high, and the efficiency of workpiece mounting is high; the workpiece mounting position can be adjusted in the multiple directions, machining and positioning are facilitated, and the production efficiency is improved; and the multiple clamping blocks are arranged, and thus the automatic machining clamp is applied to clamping of the workpieces with different shapes, and is high in applicability and convenient to use.

Owner:DONGGUAN KAILEDI NUMERICAL CONTROL SCI & TECH CO LTD

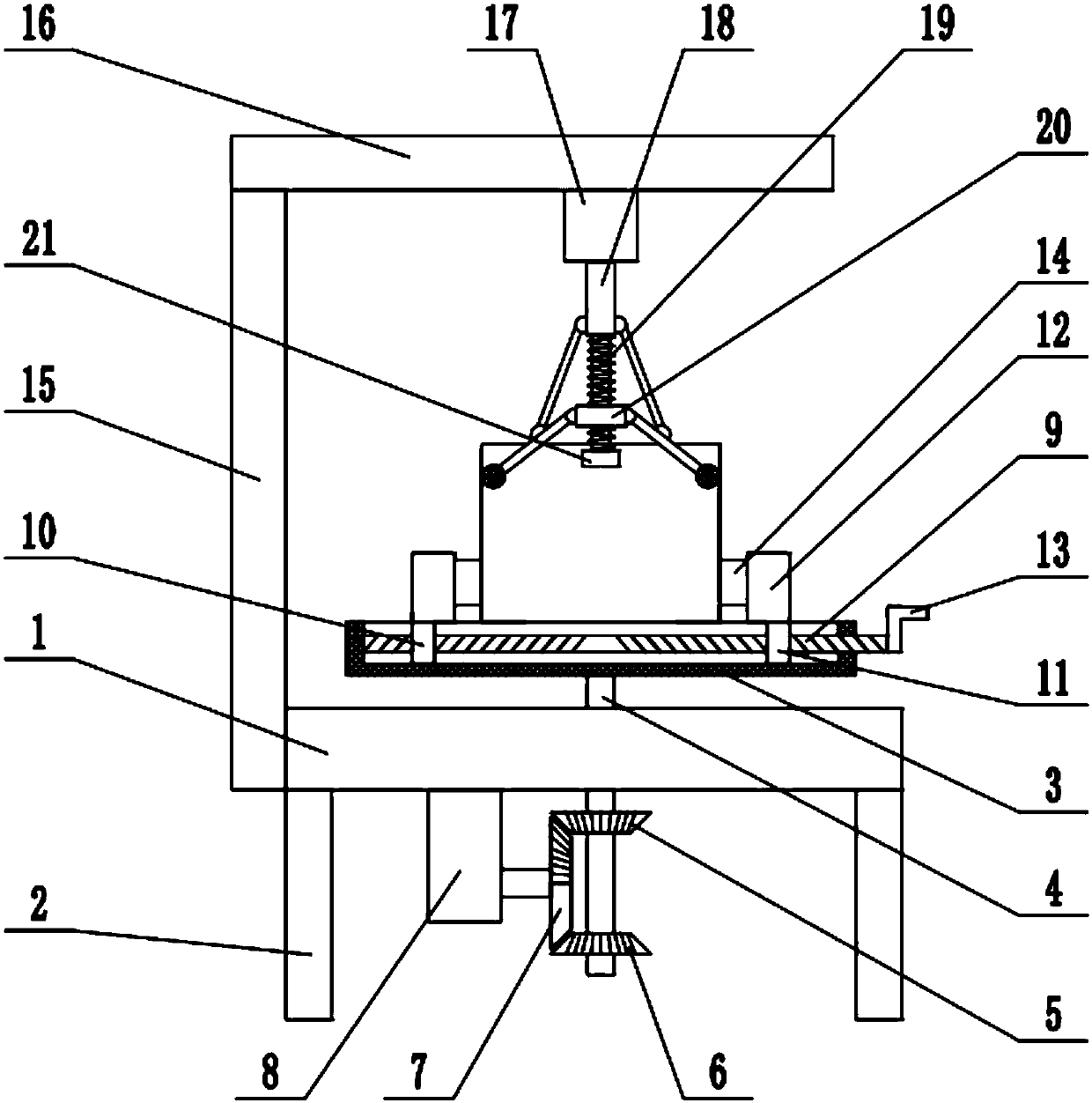

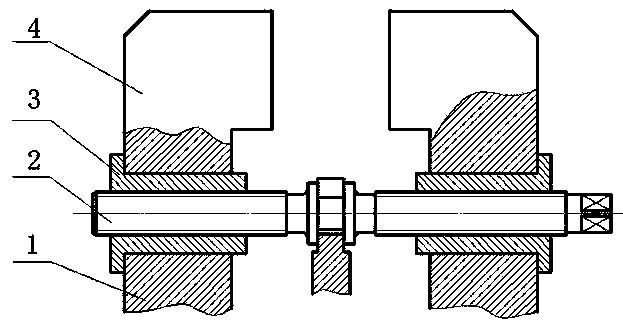

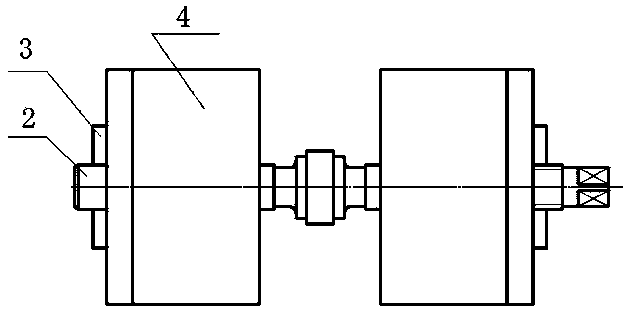

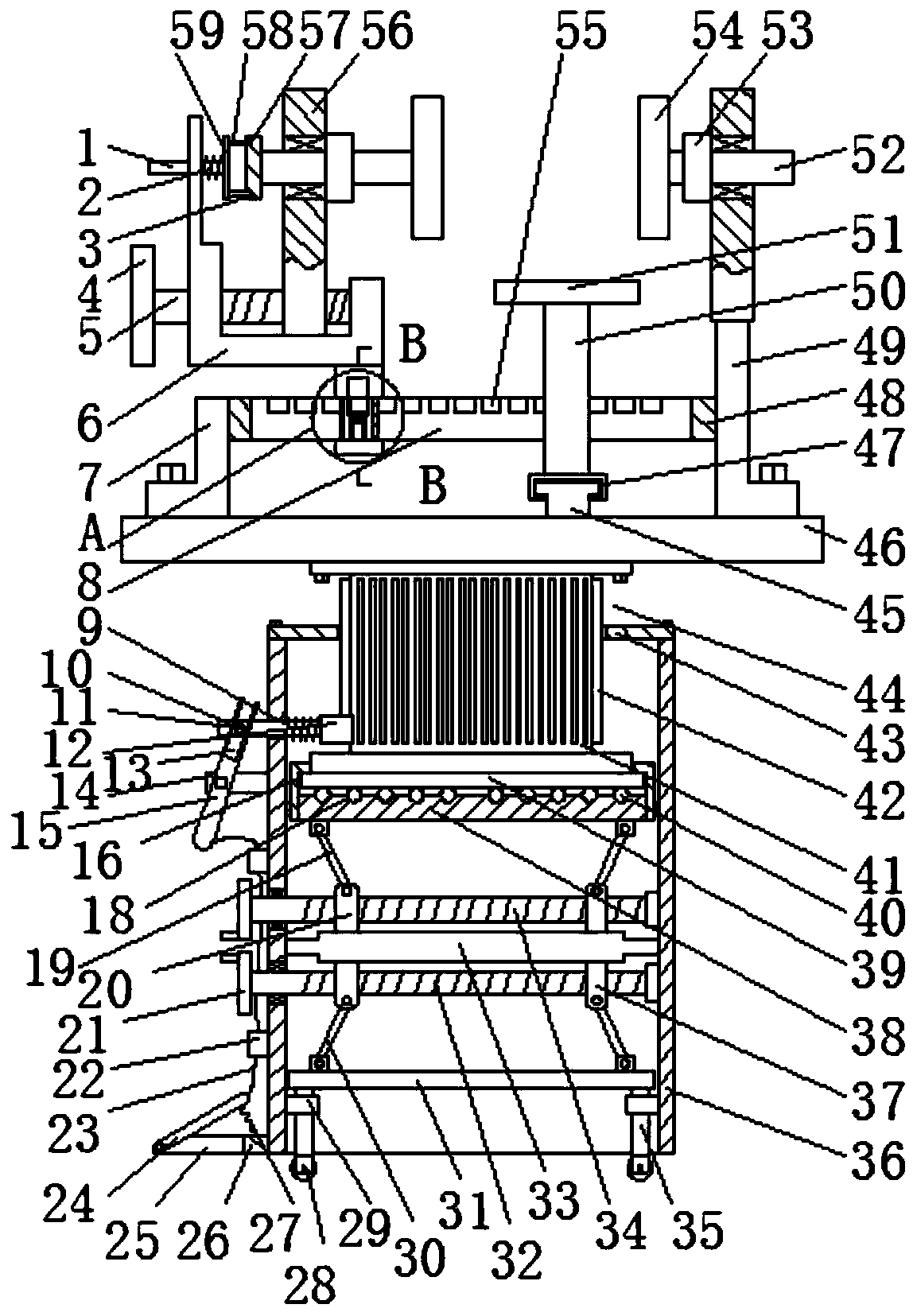

Ceramic ball surface quality detection device

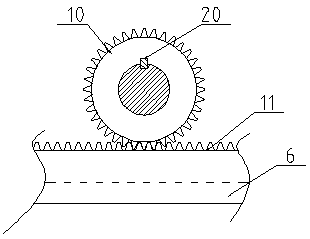

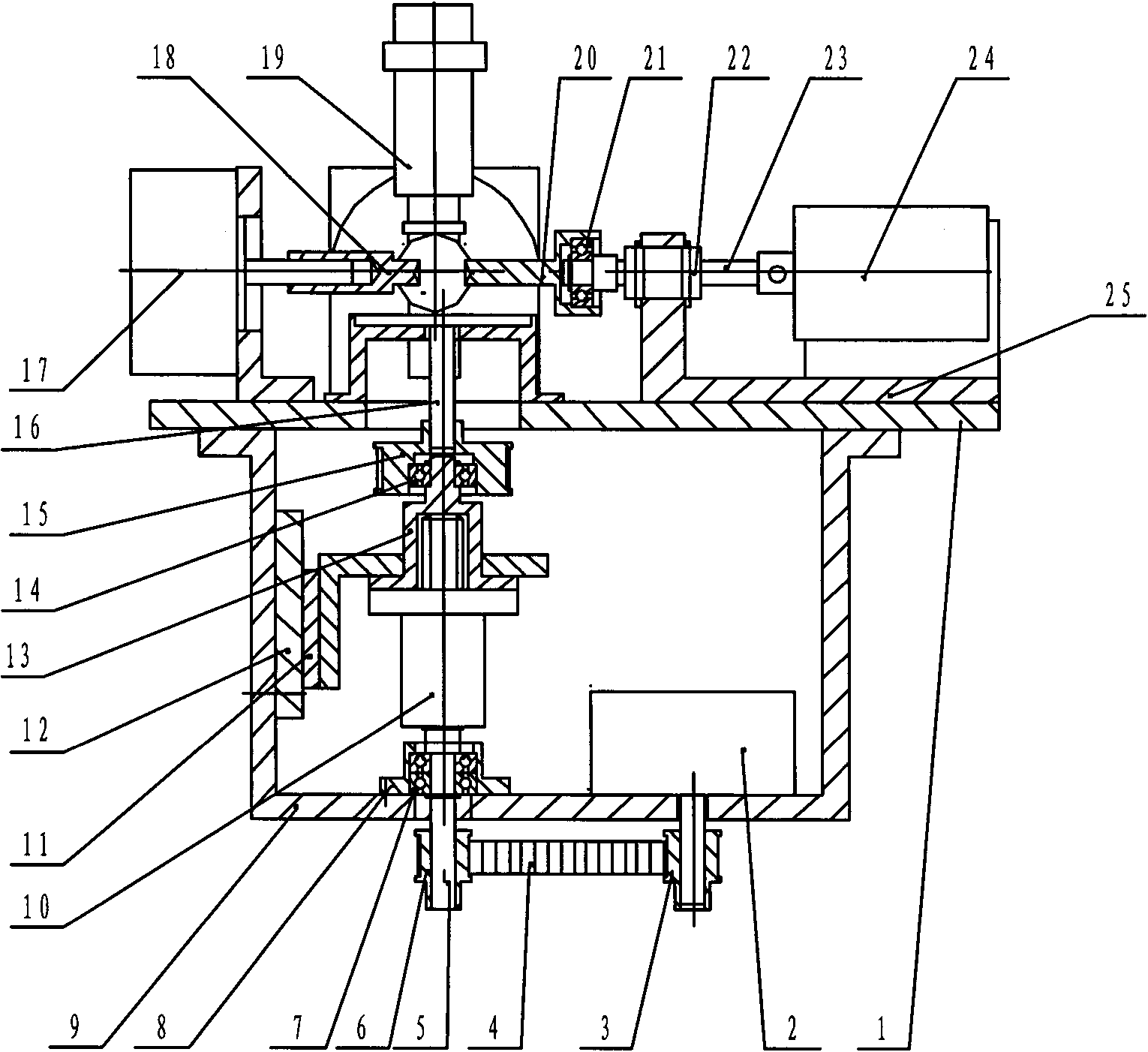

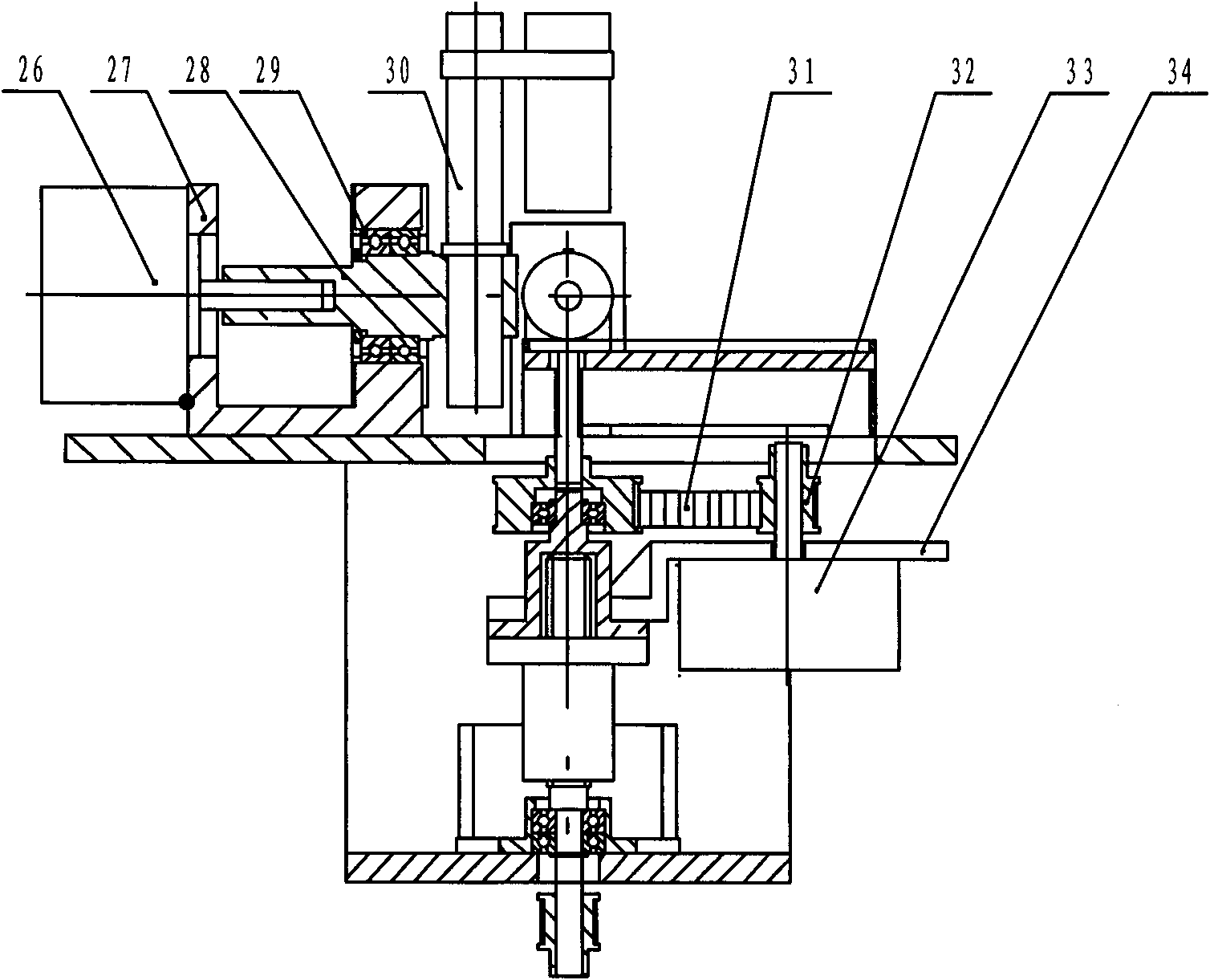

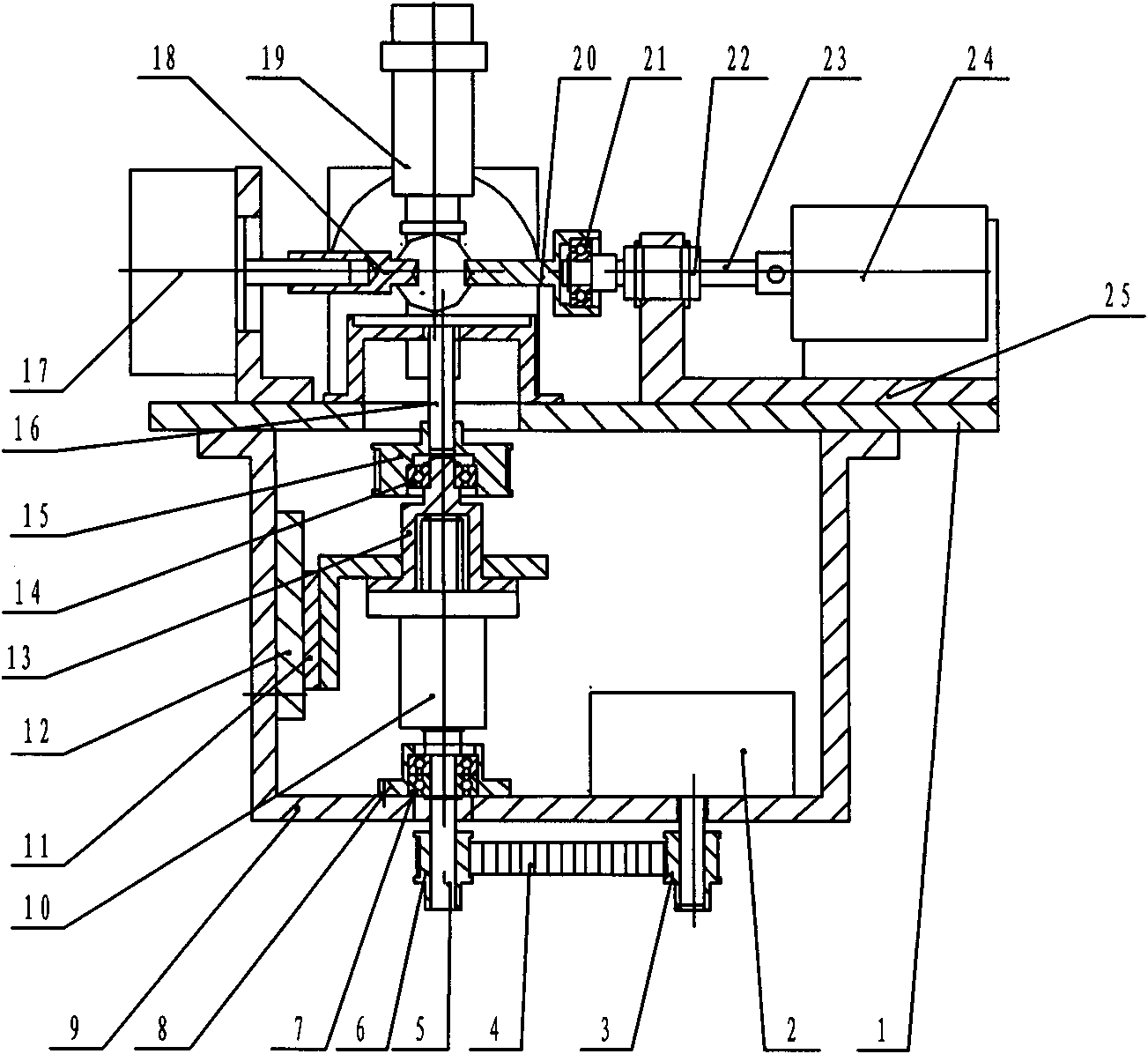

InactiveCN101915768ARealize detectionFast clamping speedMaterial analysis by optical meansStands/trestlesEngineeringMechanical engineering

The invention relates to a ceramic ball surface quality detection device, comprising a rack (1), a clamping assembly, a ball lifting assembly, a ball vertically rotating assembly, a ball horizontally rotating assembly and a microscope swinging assembly; wherein the clamping assembly, the ball lifting assembly, the ball vertically rotating assembly and the ball horizontally rotating assembly are respectively arranged on the rack (1); the claming assembly and the ball vertically rotating assembly are horizontally arranged on the horizontal platform surface of the rack (1), the ball horizontally rotating assembly and the ball lifting assembly are arranged below the horizontal platform surface of the rack (1), and the microscope swinging assembly is arranged above the horizontal platform surface of the rack (1). The invention can realize detection on ball by virtue of parallel spherical zone expansion method or spiral spherical zone expansion method, an electromagnet is adopted for clamping, so as to improve clamping speed, and detection speed is improved.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

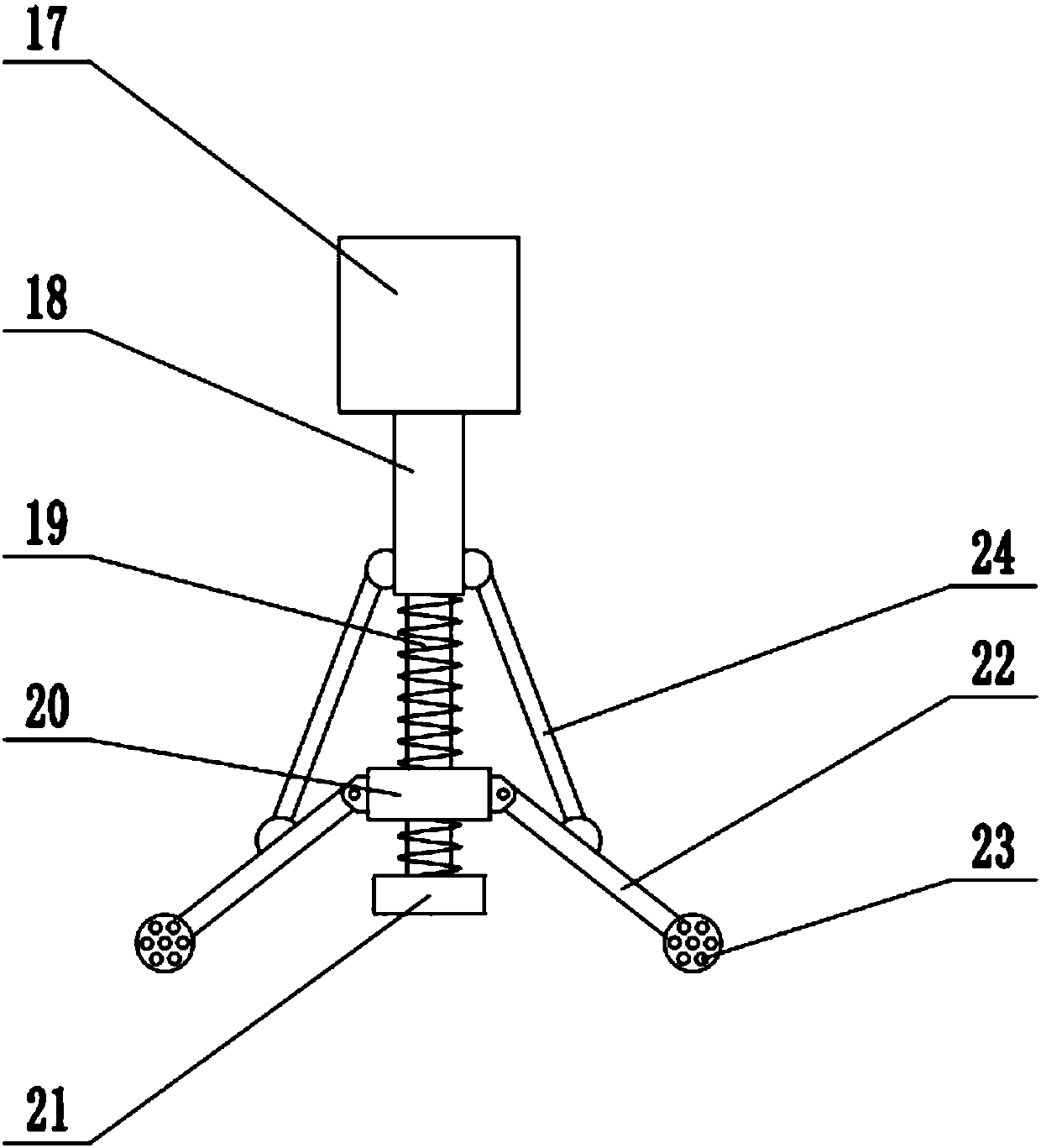

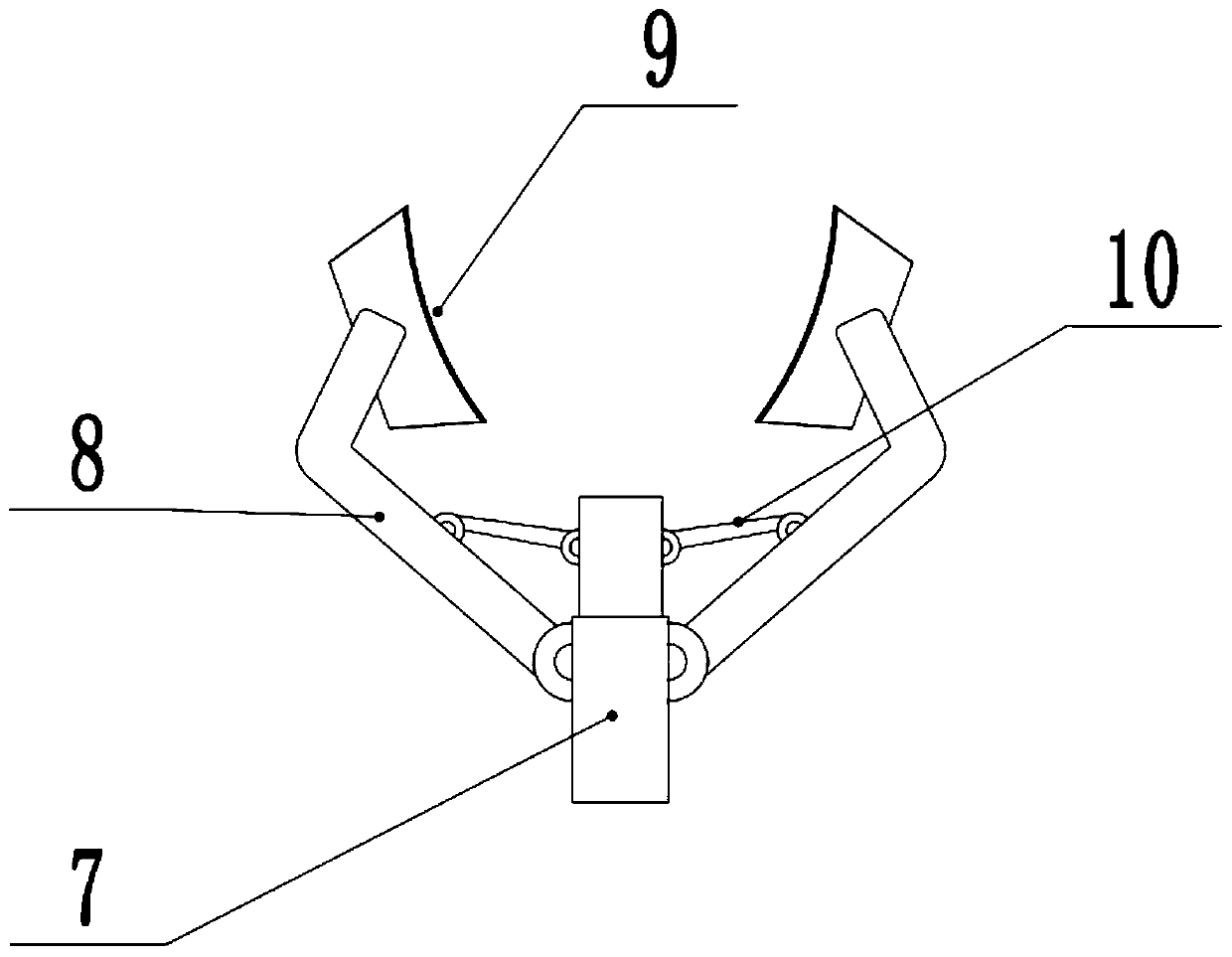

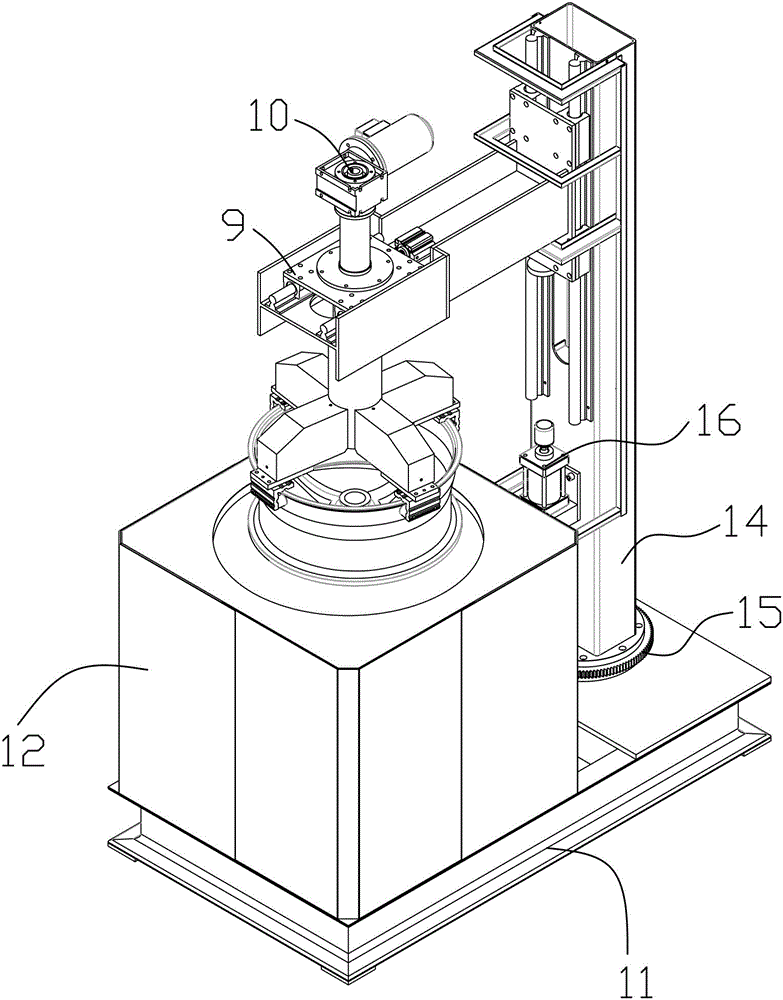

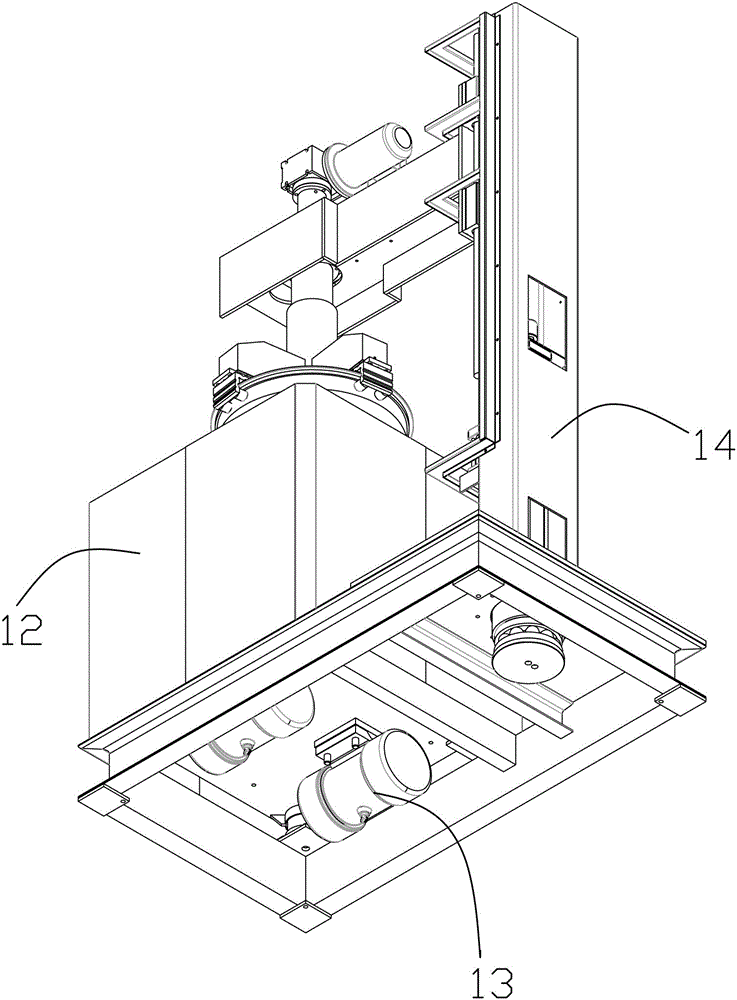

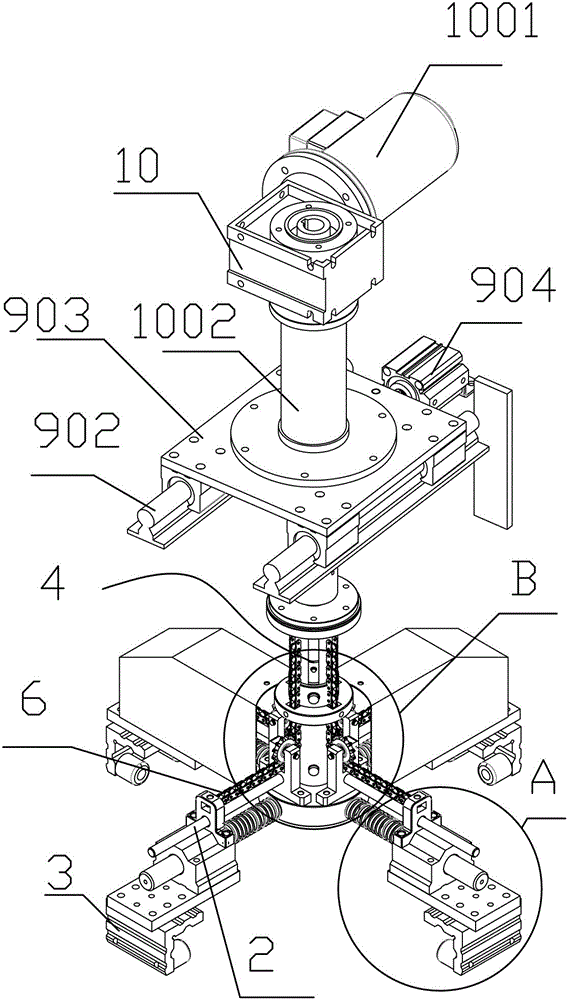

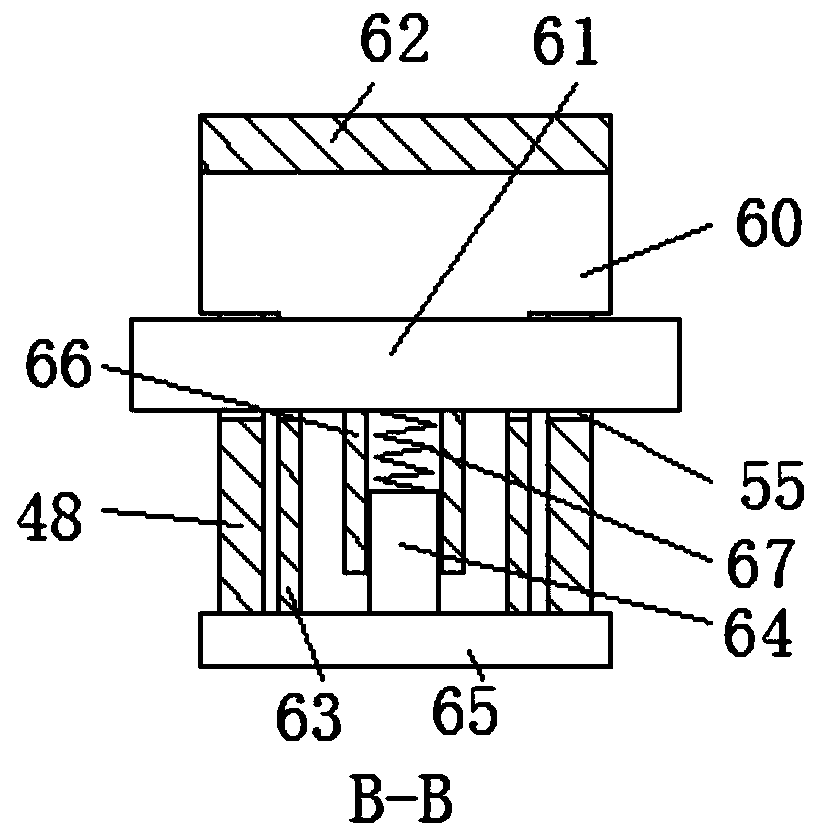

Vibration grinding polishing machine

InactiveCN104690634AFast clamping speedGood effectEdge grinding machinesPolishing machinesEngineeringMechanical engineering

The invention relates to a vibration grinding polishing machine. The vibration grinding polishing machine comprises a supporting base, wherein a polishing barrel, a vibrating motor, a rotating arm and a rotating driving portion are arranged on the supporting base; the polishing barrel is driven to vibrate by the vibrating motor; the rotating driving portion is used for driving the rotating arm to rotate; the rotating arm is provided with a transverse moving device, a vertical driving portion, a clamping jaw device and a rotating device; the vertical driving portion is used for driving the transverse moving device to move vertically; the clamping jaw device is arranged on the transverse moving device; and the rotating device is used for driving the clamping jaw device to rotate. The vibration grinding polishing machine is suitable for polished objects with various specifications; the capturing stability is high; and the polishing effect and the polishing efficiency on the fixed polished objects are high.

Owner:黄尚进

Polishing device for machining for automobile accessories

InactiveCN107498409ASolve the problem of poor grinding effect and uneven grindingImprove grinding effectGrinding drivesGrinding work supportsEngineeringPulley

The invention discloses a polishing device for machining for automobile accessories. The polishing device for machining for the automobile accessories comprises a workbench, wherein a placement plate is fixedly connected to the left side of the top of the workbench; a press plate is arranged at the top of the placement plate; a vertical column is fixedly connected to the right side of the top of the workbench; a cross plate is fixedly connected to the top of the vertical column; a second motor is fixedly connected to the right side of the bottom of the cross plate; and a cam is fixedly connected to the output end of the second motor. According to the polishing device for machining for the automobile accessories, the problems of poor polishing effect and non-uniform polishing in most of the existing polishing devices for automobile accessories are solved through the matching use of a polishing wheel, a first motor, the cross plate, the second motor, a first cylinder, a spring, a fixed plate, the cam, a support rod and a pulley; and the polishing device for machining for the automobile accessories has the advantages of being good in polishing effect and uniform in polishing, and the working efficiency of workers is increased, so that the next procedure can be normally carried out.

Owner:长兴运达汽车配件有限公司

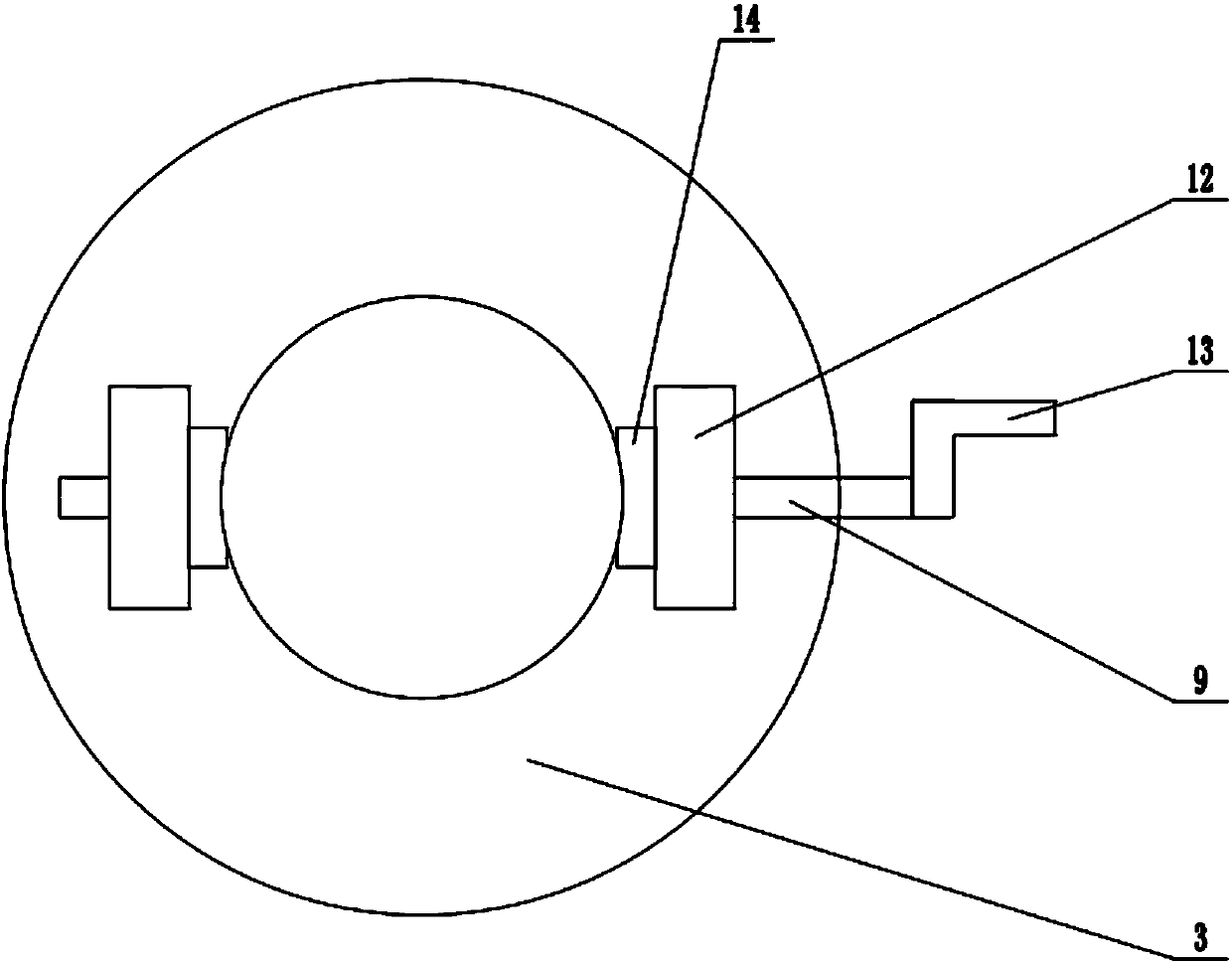

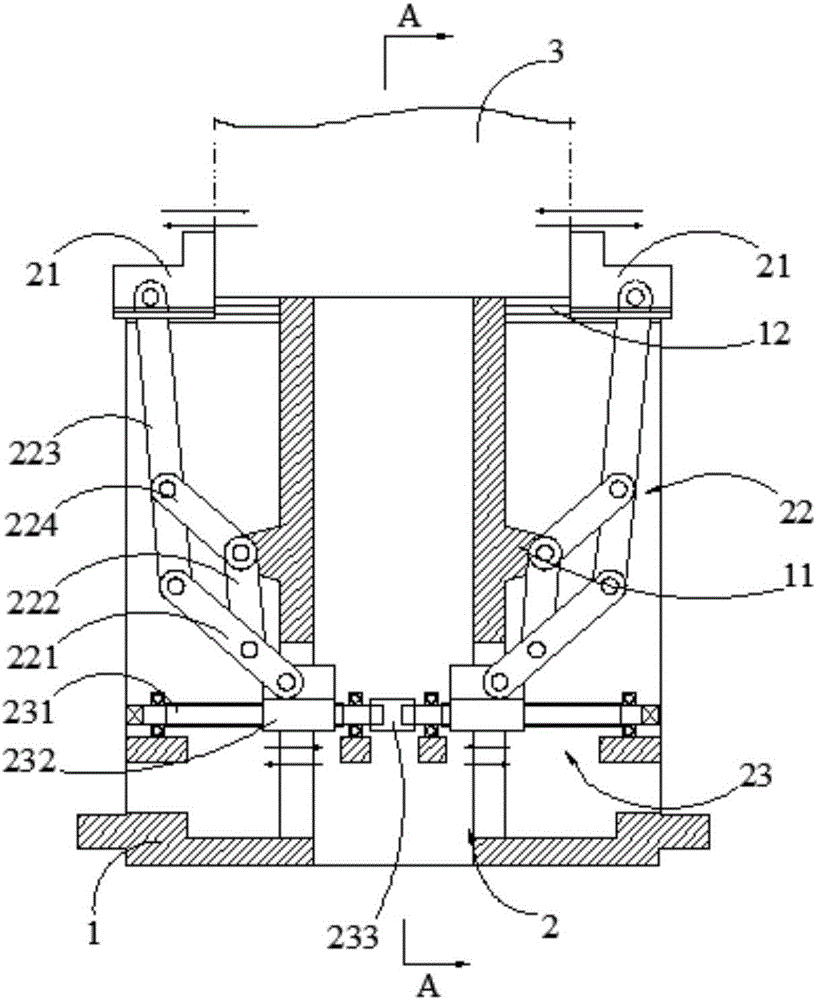

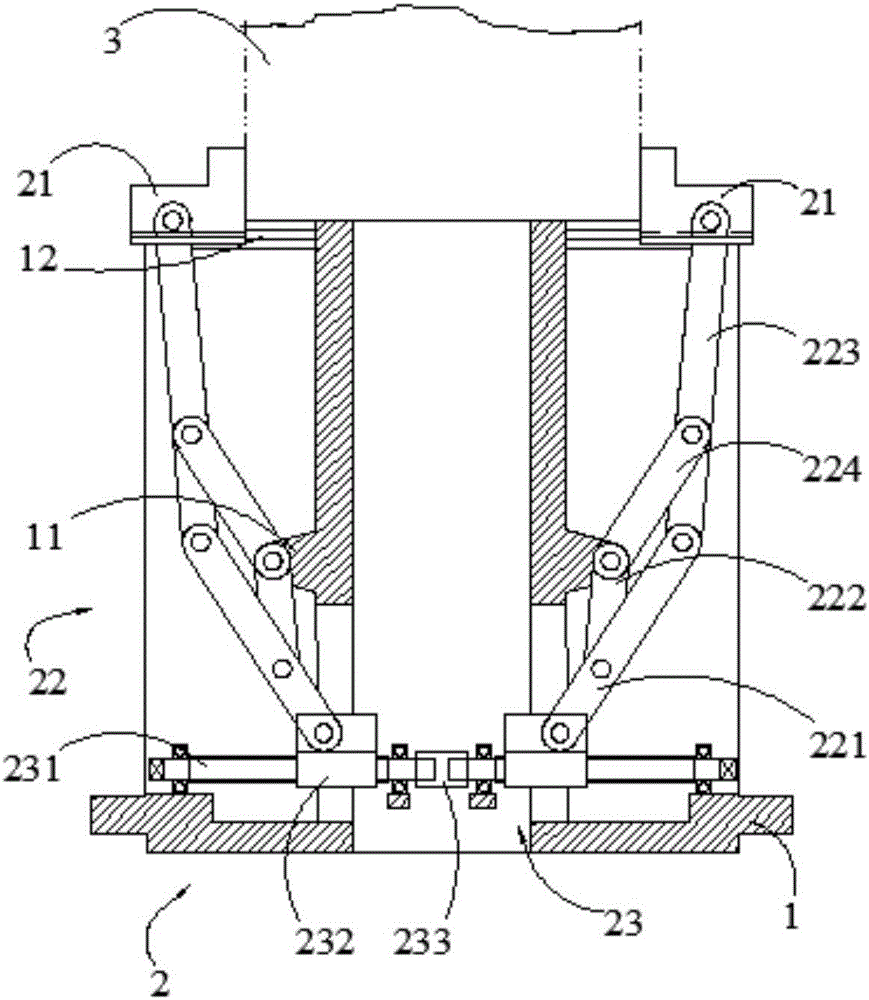

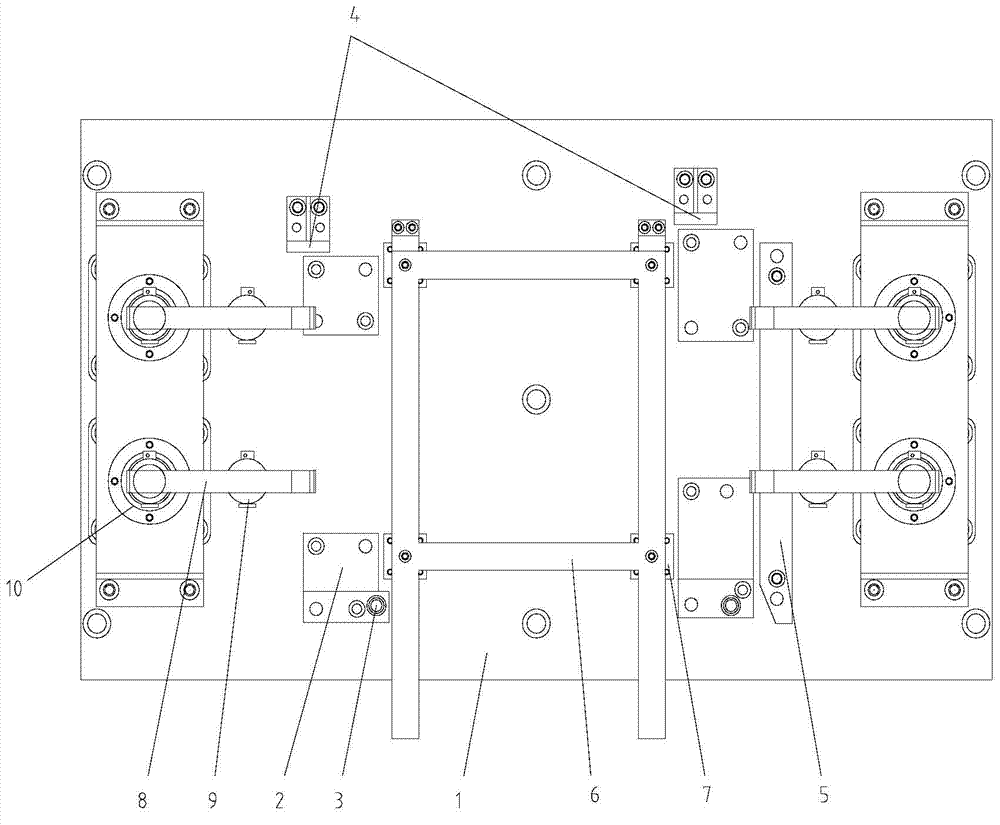

Four-claw automatic centering chuck and machine tool

ActiveCN106583945AAchieve clampingLarge clamping strokeChucksLaser beam welding apparatusEngineeringMachine tool

The invention relates to machine tool clamping and provides a four-claw automatic centering chuck. The four-claw automatic centering chuck comprises a machine base and two two-claw clamping mechanisms, wherein each two-claw clamping mechanism comprises two clamping claws, two transmission assemblies and a driving part; each transmission assembly comprises a driving rod, a driving connecting rod, a clamping connecting rod and a clamping rod which are hinged sequentially to form a parallelogram; and a hinged point between the driving connecting rod and the clamping connecting rod is hinged on the machine base and is positioned on or near a connecting straight line between a first elongating end and a second elongating end. The invention also provides a machine tool comprising the chuck. The four clamping claws can be shrunk towards the middle part under the action of the driving part to realize workpice clamping, and the speed and the precision are high; furthermore, a parallel four-rod mechanism formed by the driving rod, the driving connecting rod, the clamping rod and the clamping connecting rod performs transmission between the clamping claws and the driving part, the four clamping claws can be shrunk towards the circle center in pairs to realize workpiece clamping, and the clamping speed, the clamping precision and the clamping force are high.

Owner:WUHAN GUANYOU TECH CO LTD

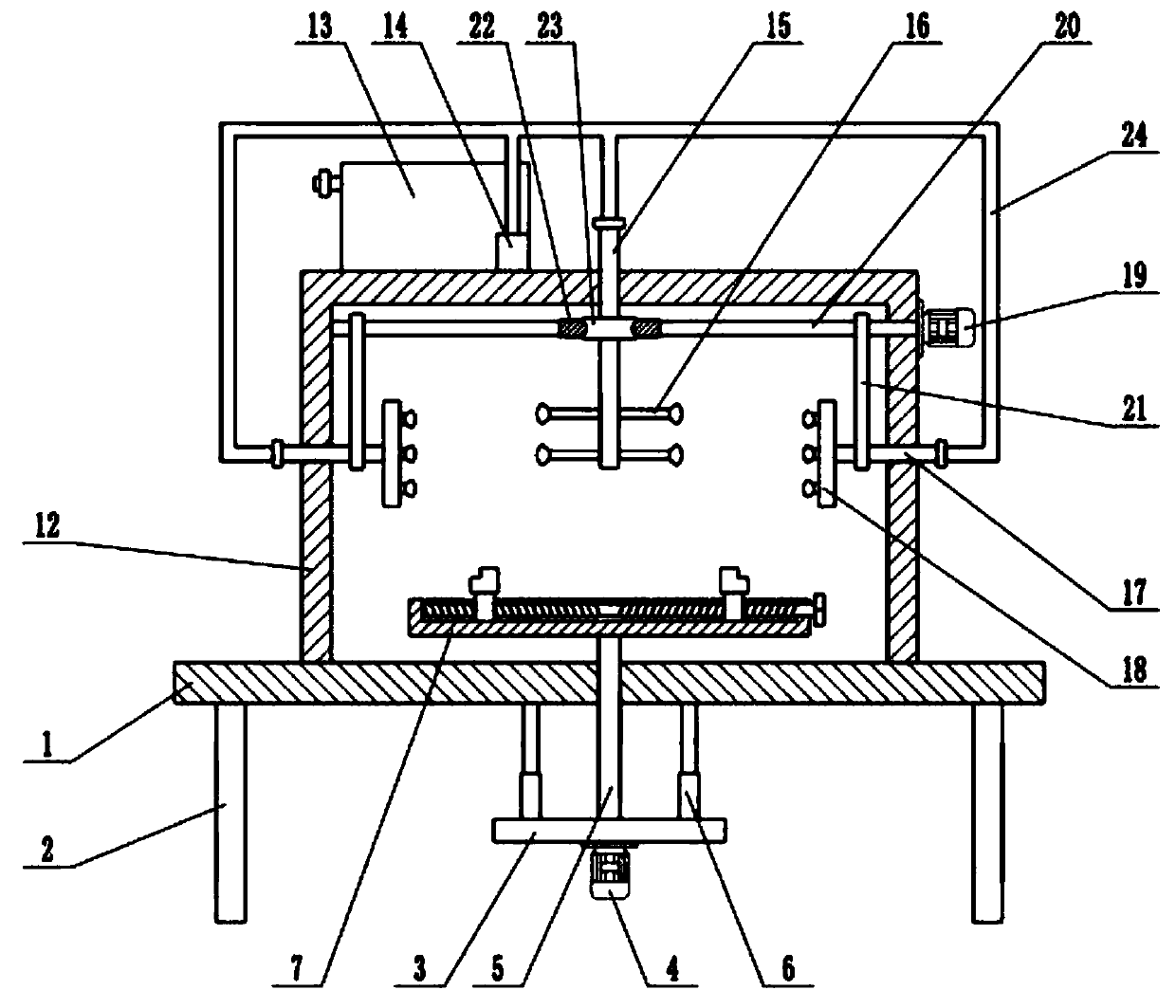

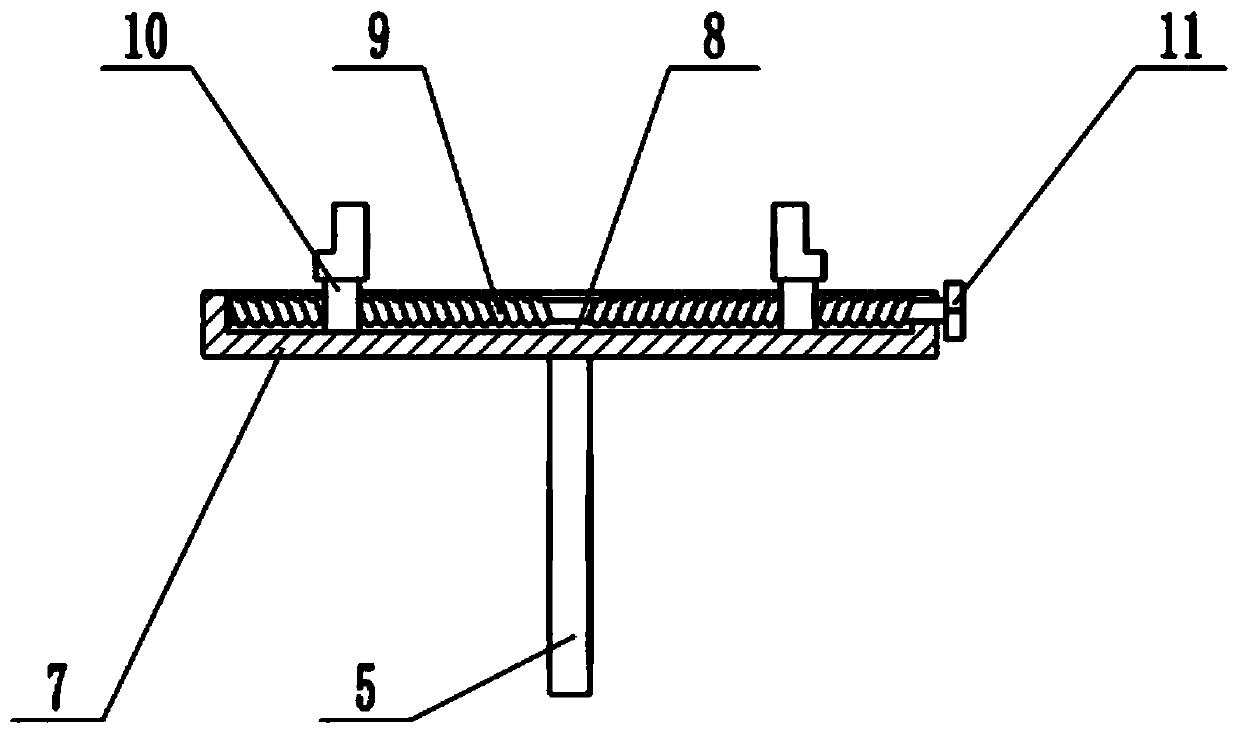

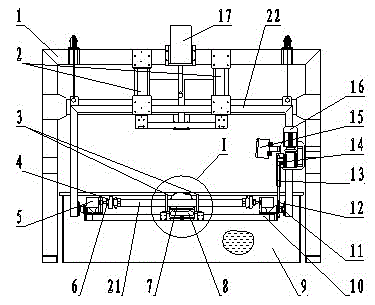

Equipment for evaluating sealing property of automobile rear axle housing

ActiveCN102944367AReduce weightSmooth rotationDetection of fluid at leakage pointPurchasingLeft–right symmetry

The invention discloses equipment for evaluating the sealing property of an automobile rear axle housing, and the equipment is applied to solve the problems in the prior art that the existing tools for evaluating the sealing property of automobile rear axle housings are low in work efficiency. The equipment comprises a tool support, a workbench, an elevating mechanism, a rotating mechanism, a sealing and clamping mechanism, a water tank and a control box. The equipment is characterized in that the workbench is provided with a frame structure, a force guide rod is arranged between a front cross beam and a rear cross beam of the workbench, axle housing limiting blocks are arranged on the rear cross beam in a way of left-right symmetry, rear cross beam reinforcing plates are arranged in the mounting positions of the axle housing limiting blocks, and the rear cross beam reinforcing plates are wrapped on the outer side wall of the rear cross beam. The equipment has the characteristics of reliable performance, strong practicability and convenience in operation, and can greatly increase the production efficiency and reduce the purchasing cost.

Owner:精诚工科汽车系统有限公司

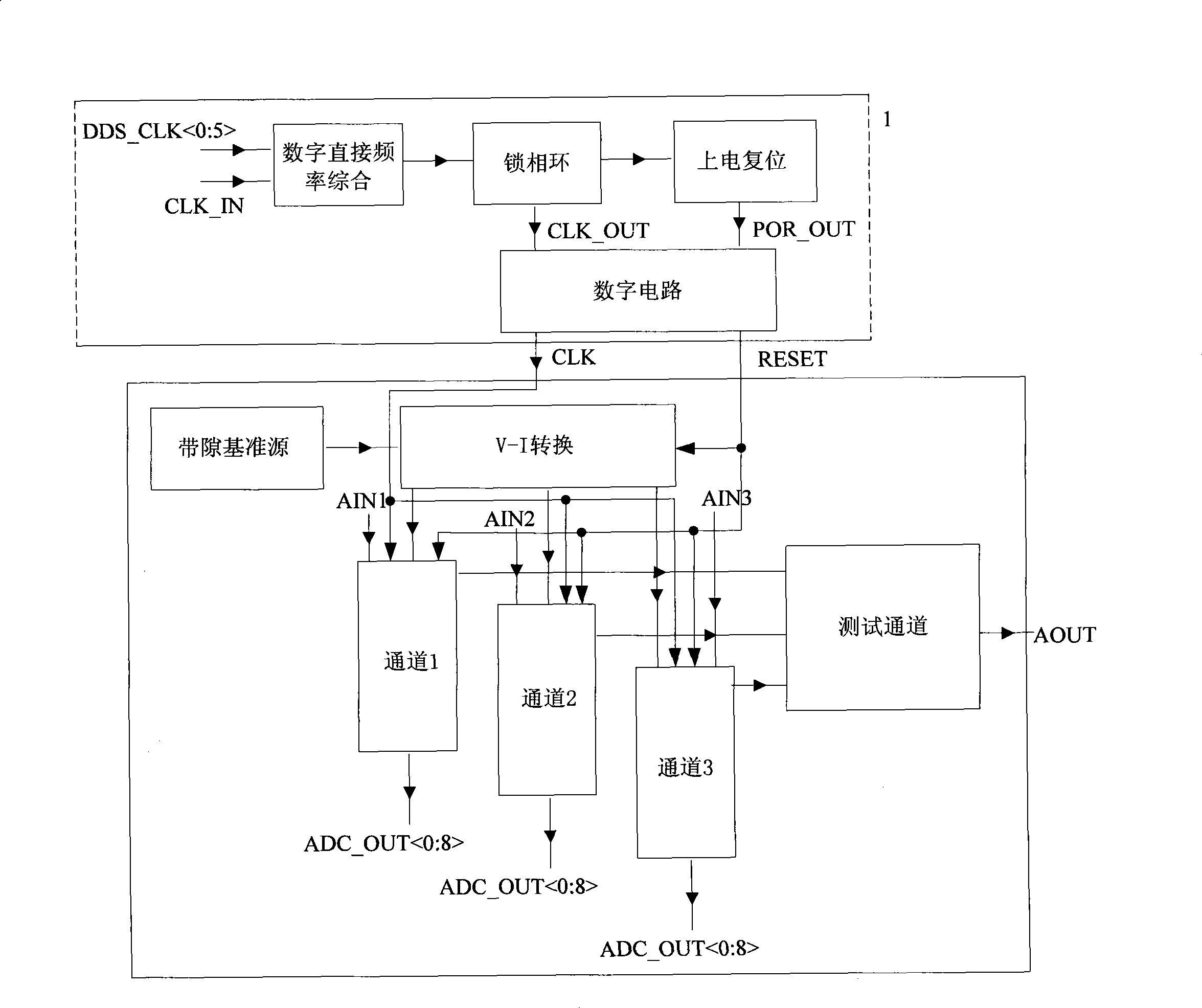

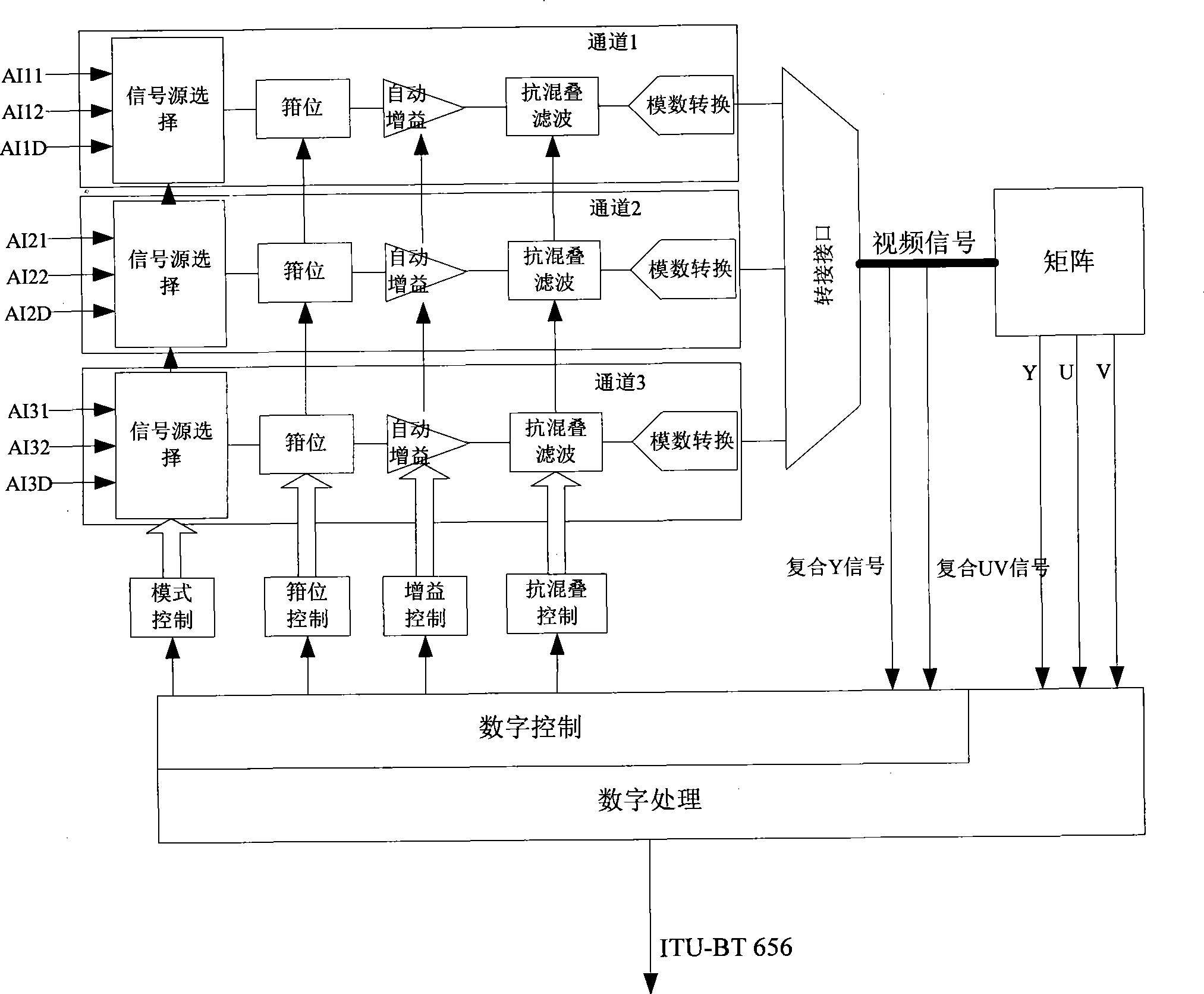

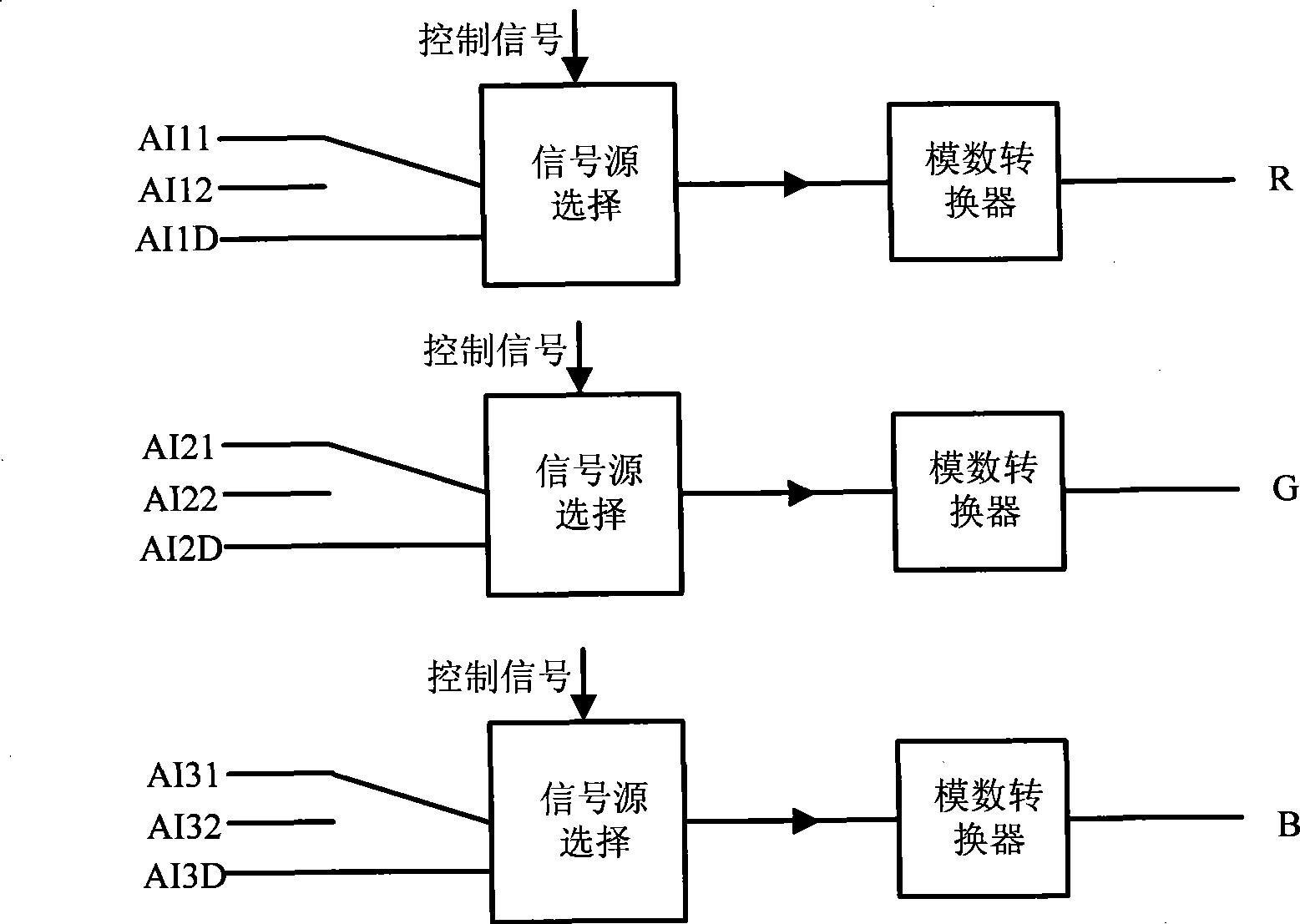

Video input decoding chip

InactiveCN101420611AReduce noise interferenceStable Clock FrequencyTelevision system detailsColor television detailsPower-on resetCapacitance

The invention relates to a video input decoder chip which comprises a digital direct frequency synthesizing module, a phase lock loop module, a power on reset module, a digital circuit module, a bandgap reference module, a V-I conversion module, a test end selection module and three signal processing channels, i.e. channel 1, channel 2 and channel 3, wherein, the channels comprise a signal source selection module, a clamp module, an automatic gain control module, an anti-alias filter and an analog-to-digital conversion module. The chip can process CVBS, Y / C and RGB signals, has strong noise suppression capability, generates a reference voltage and a clock interiorly, realizes the high integration degree, needs no external decoupling capacitor, greatly reduces the system area and the complexity degree and improves the signal processing efficiency.

Owner:CHENGDU CORPRO TECH CO LTD

Working table for stone machining

InactiveCN110405965AFast clamping speedImprove efficiencyWorking accessoriesGrinding work supportsMachining processEngineering

The invention relates to the field of stone machining equipment, and more particularly relates to a working table for stone machining. The working table comprises a table top, a movable plate, clamping blocks and clamping plates, wherein the lower surface of the table top is fixedly connected to supporting plates; the upper surface of the table top is rotatably connected to a rotary table; the lower surface of the rotary table is fixedly connected to a rotating shaft; a transmission shaft is arranged below the rotating shaft; a positioning plate is arranged on the rotating shaft in a sleevingmanner; the movable plate is arranged above the rotary table; a sliding chute is formed in the upper surface of the movable plate; a bidirectional lead screw is arranged inside the sliding chute; theclamping blocks are arranged on the bidirectional lead screw in a sleeving manner; the upper surfaces of the clamping blocks are fixedly connected to the clamping plates; clamping mechanisms are arranged on the clamping plates; stone to be machined is put between the two clamping plates; the two ends of the stone are clamped by using the clamping mechanisms, so that the stone is fixed, the clamping speed is fast, and the efficiency is high; the inclination of the stone can be adjusted in the machining process according to the actual machining requirements, and meanwhile the rotary table can beconveniently rotated so as to adjust the machining position of the stone.

Owner:刘志成

Clamping device for bench worker with omnibearing rotation function

The invention relates to the technical field of machineries, in particular to a clamping device for a bench worker with an omnibearing rotation function. The clamping device for the bench worker withthe omnibearing rotation function comprises a shell, a third threaded rod is rotatably mounted in the middle of the inner side of the shell, a lifting column is mounted on the upper surface of a second limiting plate, a pedal is rotatably mounted in a mounting groove, a push groove connected with a push head is formed in one end of a rotating rod, and a limiting device is jointly mounted between aU-shaped plate and a left side rotary shaft. Compared with the prior art, according to the clamping device for the bench worker with the omnibearing rotation function, omnibearing rotation of a workpiece can be realized only by requiring clamping the workpiece at a time, various positions of the workpiece are presented in front of people, the working efficiency can be greatly improved, and the labor strength of operating personnel is reduced; meanwhile, the clamping speed of the workpiece is high, using is convenient, and safety and reliability are achieved; and the height of the clamping device can be adjusted and can meet the operating personnel with different heights for use, the clamping device can be further conveniently moved and placed, and the convenience of using is greatly improved.

Owner:JILIN TEACHERS INST OF ENG & TECH

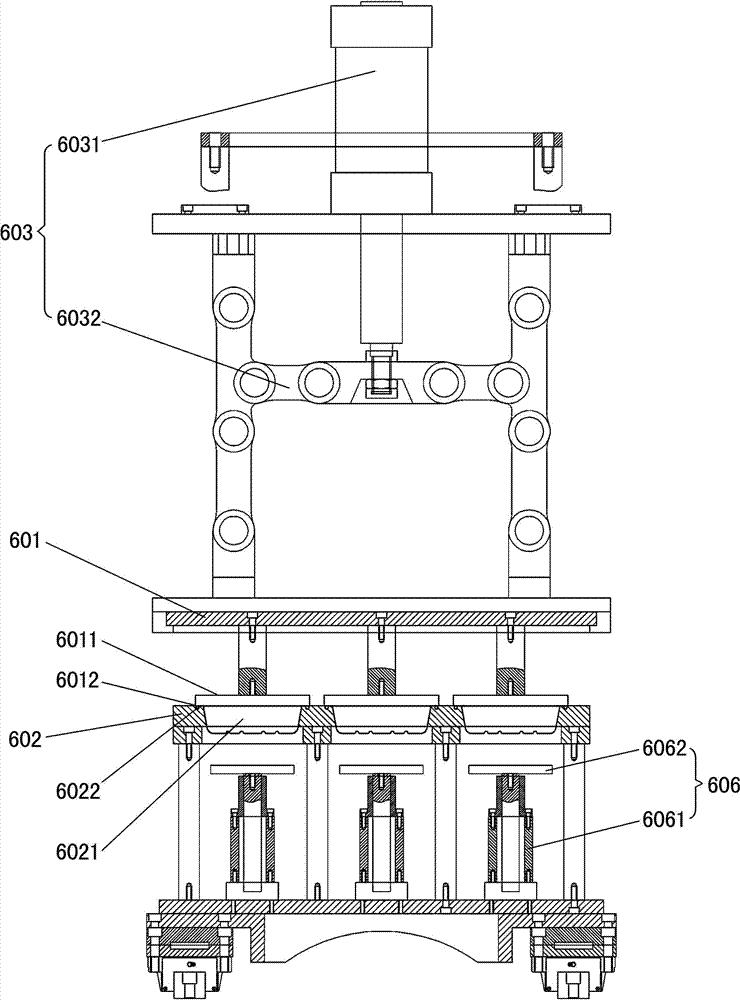

Double formwork quick injection molding machine

The double-formwork quick injection molding machine includes frame, injection molding unit, oil path, control mechanism, mold closing cylinder, mold locking cylinder, pushing-out mechanism, moving formwork and fixed formwork. There are oil hole in the mold locking piston in the mold locking cylinder and corresponding blocking pin in the back end cap of the mold locking cylinder for blocking the oil hole during mold locking operation. The present invention is stable, smooth, reliable, small and saving in power.

Owner:蔡桂森

Rapid-positioning and pneumatic-compressing universal fixture capable of slightly adjusting inclination angle

ActiveCN103143967ARapid positioningQuick compressionPositioning apparatusMetal-working holdersBody angleEngineering

The invention discloses a rapid-positioning and pneumatic-compressing universal fixture capable of slightly adjustable inclination angle, which comprises a bracket mounted on a workbench, wherein a box body is rotationally connected with the bracket; a flat fixture is fixed on a top plate of the box body and used for mounting a workpiece; the box body is provided with a pneumatic compressing mechanism for compressing the workpiece; and a box body angle adjustment device is arranged between the box body and the bracket. The universal fixture can rapidly position and press the workpiece when medium and small parts are machined; the inclination angle of the fixture can be adjusted; and the universal fixture has the advantages of good universality, high positioning accuracy, good self-locking property, and the like.

Owner:钱汝玉

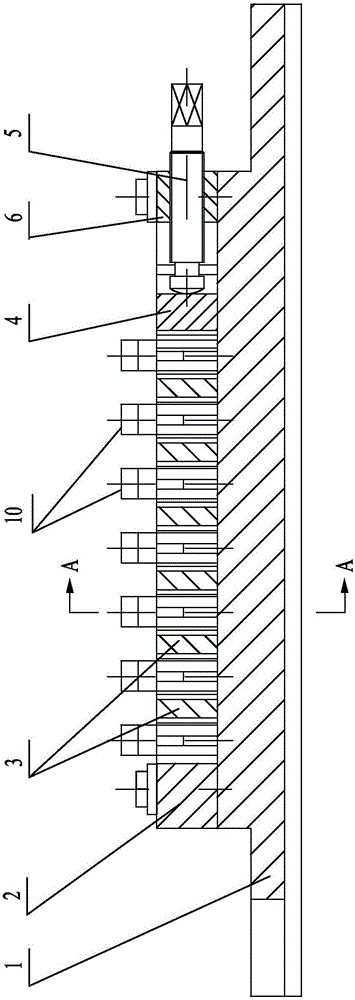

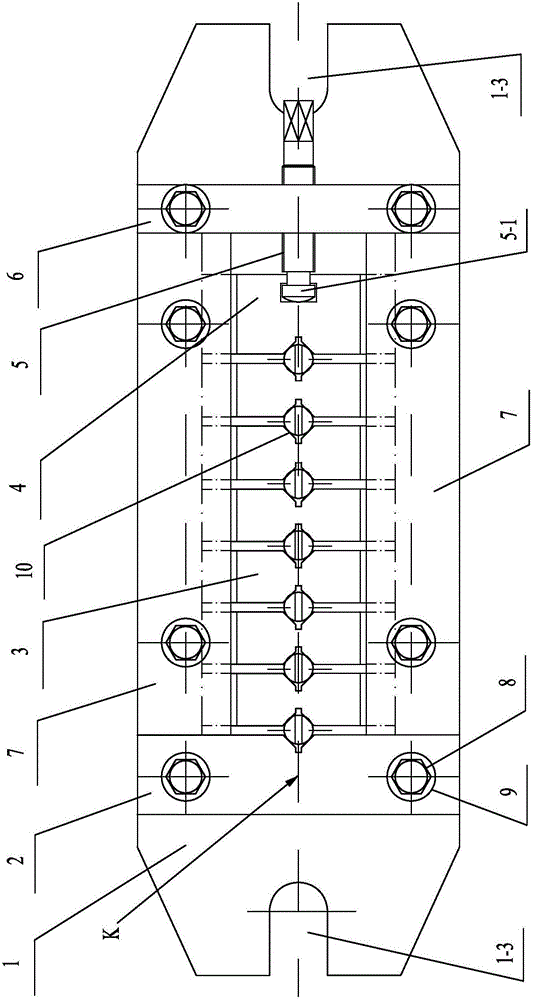

Hemostatic clip packaging box

InactiveCN106037947AShorten the timeImprove the effect of surgerySurgical furnitureWound clampsMedical treatmentHemostatics

The invention discloses a hemostatic clip packaging box, and belongs to the field of medical articles, aiming at solving the problem of an existing packaging box that the performance of a hemostatic clip is easy to decline. The packaging box comprises a box body which is formed by fastening a left cover plate and a right cover plate, wherein the box body is provided with a conveying passage in a length direction of the box body and a compression passage which is perpendicular to the conveying passage; a cartridge holder is arranged in the conveying passage; two ends of the conveying passage are an output end and an input end; a sliding cover, by which the hemostatic clip is compressed to a compressed state from stretching state, is matched with the compression passage in a sliding mode; a pushing-pulling device is matched with the cartridge holder; and the cartridge holder, under force exerted by the pushing-pulling device, is moved from the output end.

Owner:CHENGDU IDING IND PROD DESIGN

Clamp special for groove milling of end faces of shaft parts

InactiveCN105710675AMeet the requirements of mass productionGuaranteed accuracyPositioning apparatusMetal-working holdersEngineeringMechanical engineering

The invention discloses a clamp special for groove milling of end faces of shaft parts, and relates to a clamp. The clamp solves the problems that during groove milling of the end faces of existing shaft parts, only one shaft part can be clamped each time, and the production efficiency is low. According to the clamp, a positioning block and a baffle are arranged on the two sides of two rectangular bosses in the length direction, the opposite side faces of the positioning block and the baffle are each provided with a first V-shaped groove in the height directions of the positioning block and the baffle, and the two sides of each inversed-T-shaped sliding block are each provided with a second V-shaped groove in the height direction of the inversed-T-shaped sliding block; one side of each inversed-T-shaped sliding block is provided with a third V-shaped groove in the height direction of the inversed-T-shaped sliding block, and the sizes of the first V-shaped grooves, the second V-shaped grooves and the third V-shaped grooves are matched with the outer diameter of the to-be-machined shaft parts; and ejection screws penetrate center screw holes to be rotationally connected with inversed-T-shaped clamping blocks, and the multiple inversed-T-shaped sliding blocks and the inversed-T-shaped clamping blocks can slide in zones between two pressing plates and a clamp body. The clamp is used for groove milling of the end faces of the shaft parts.

Owner:HARBIN JIANCHENG GRP

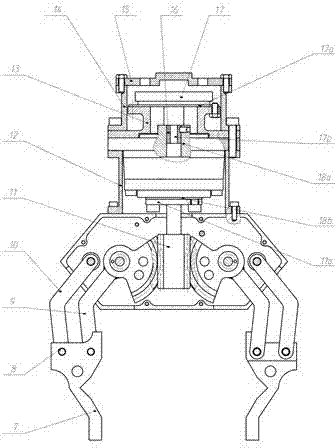

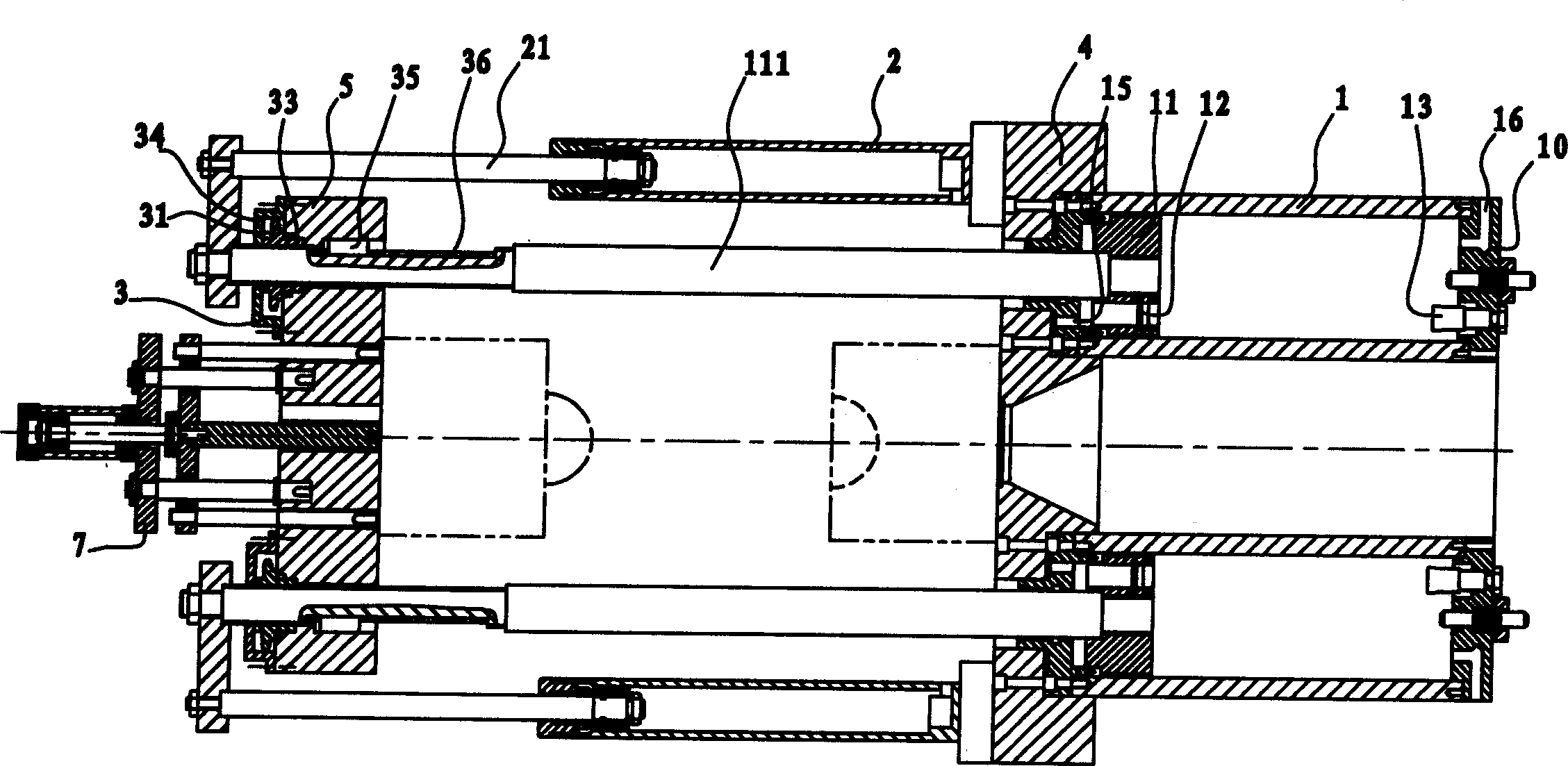

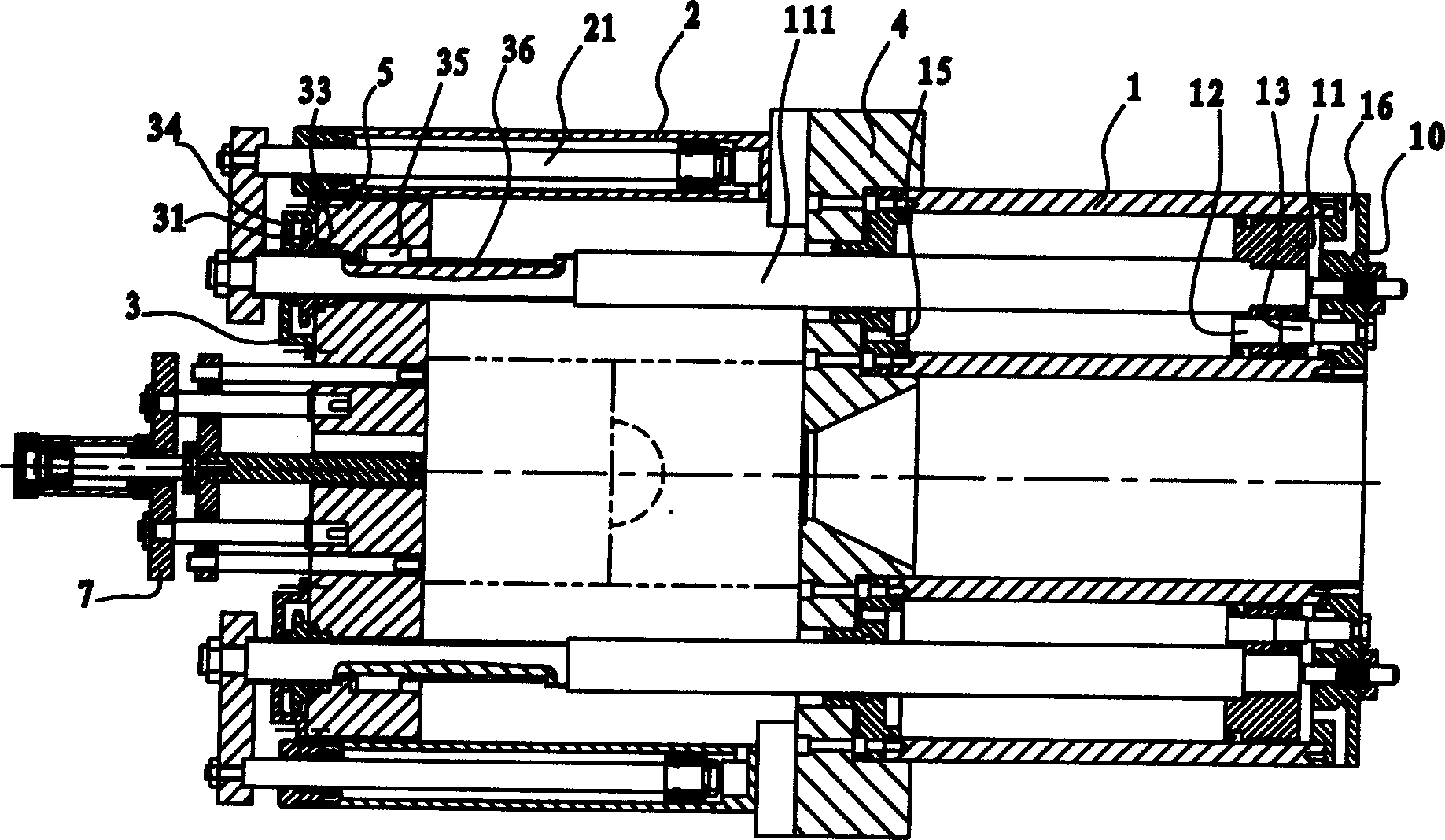

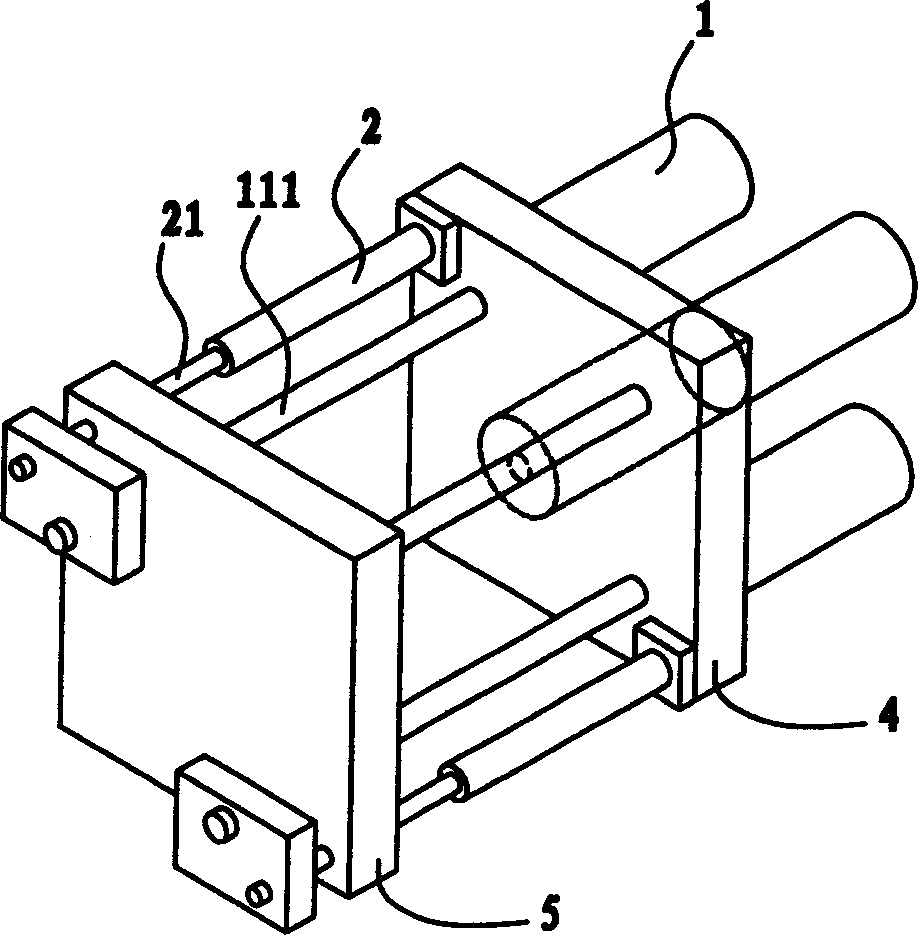

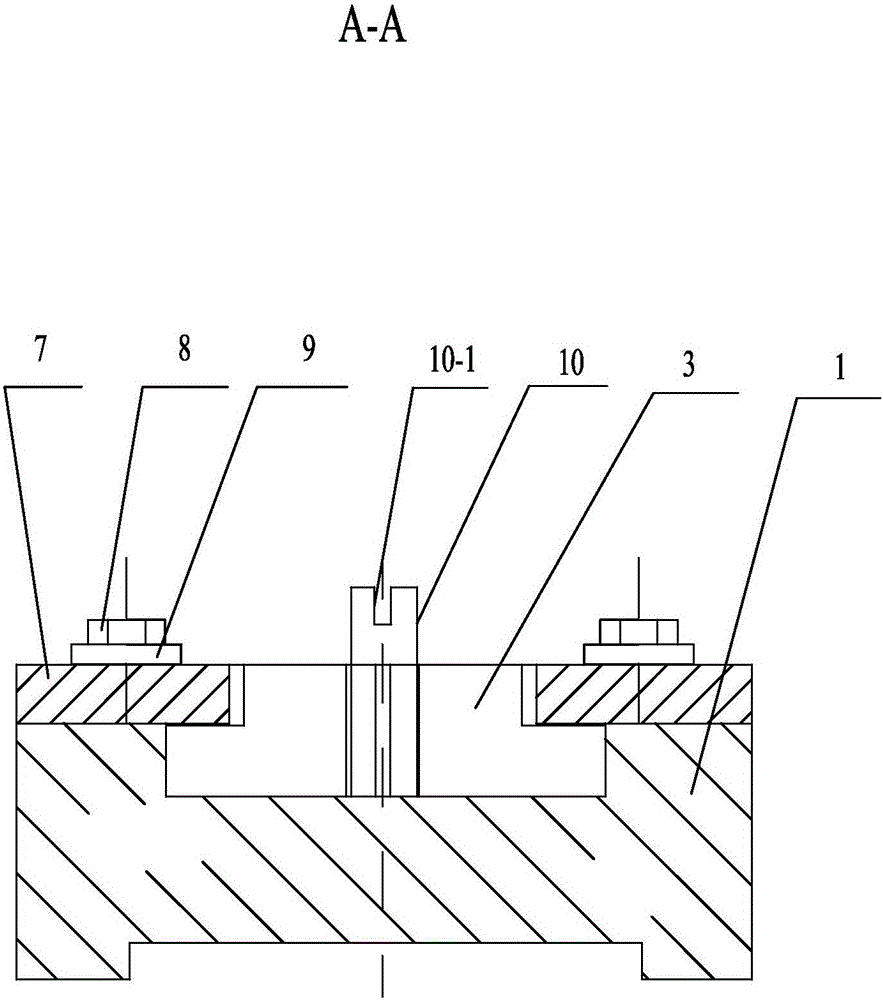

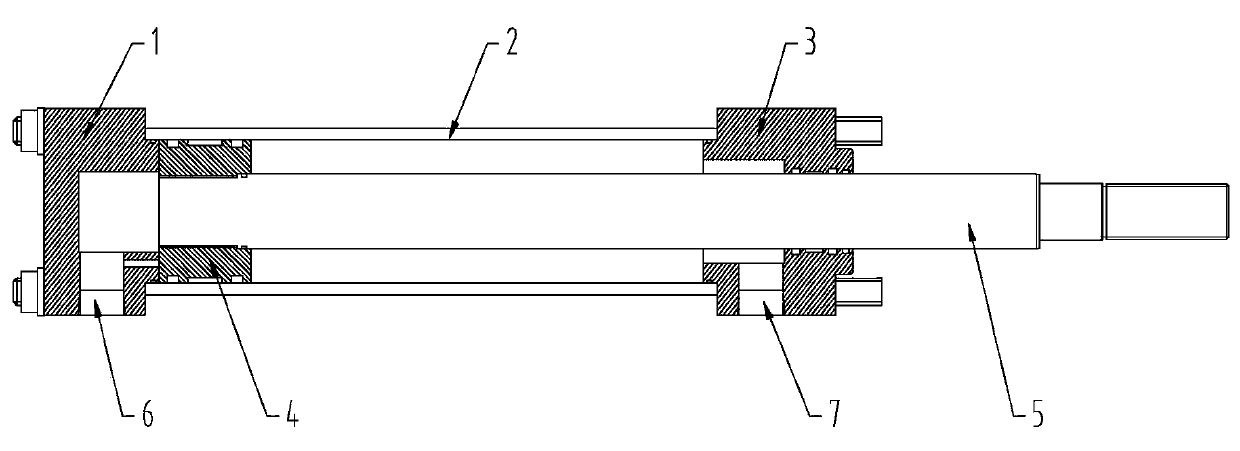

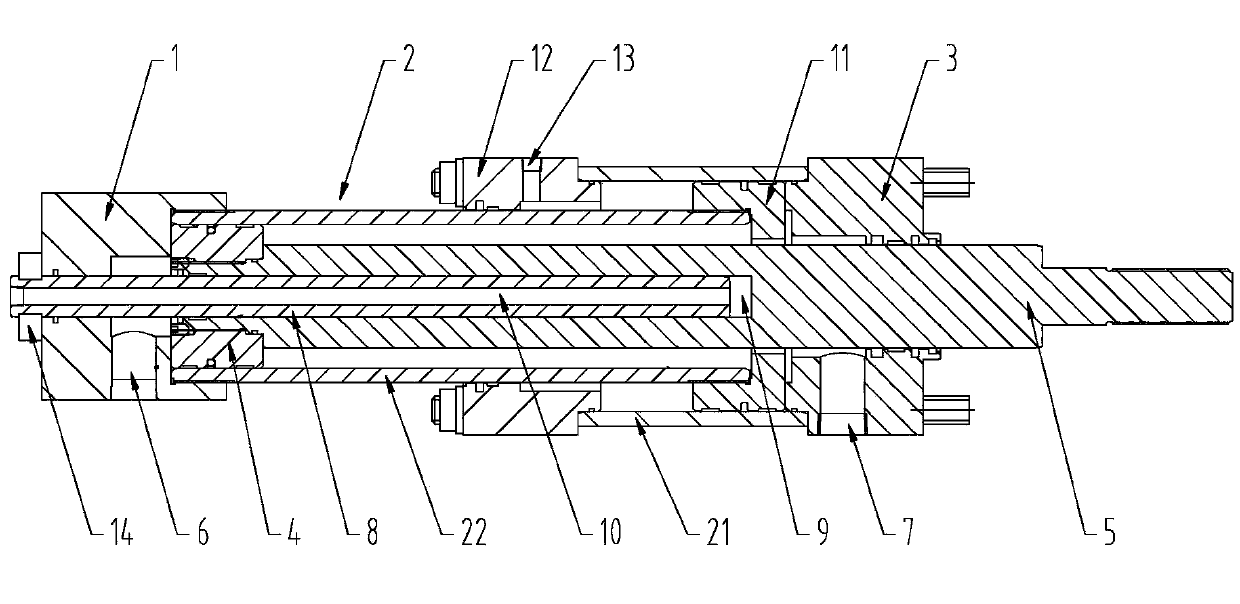

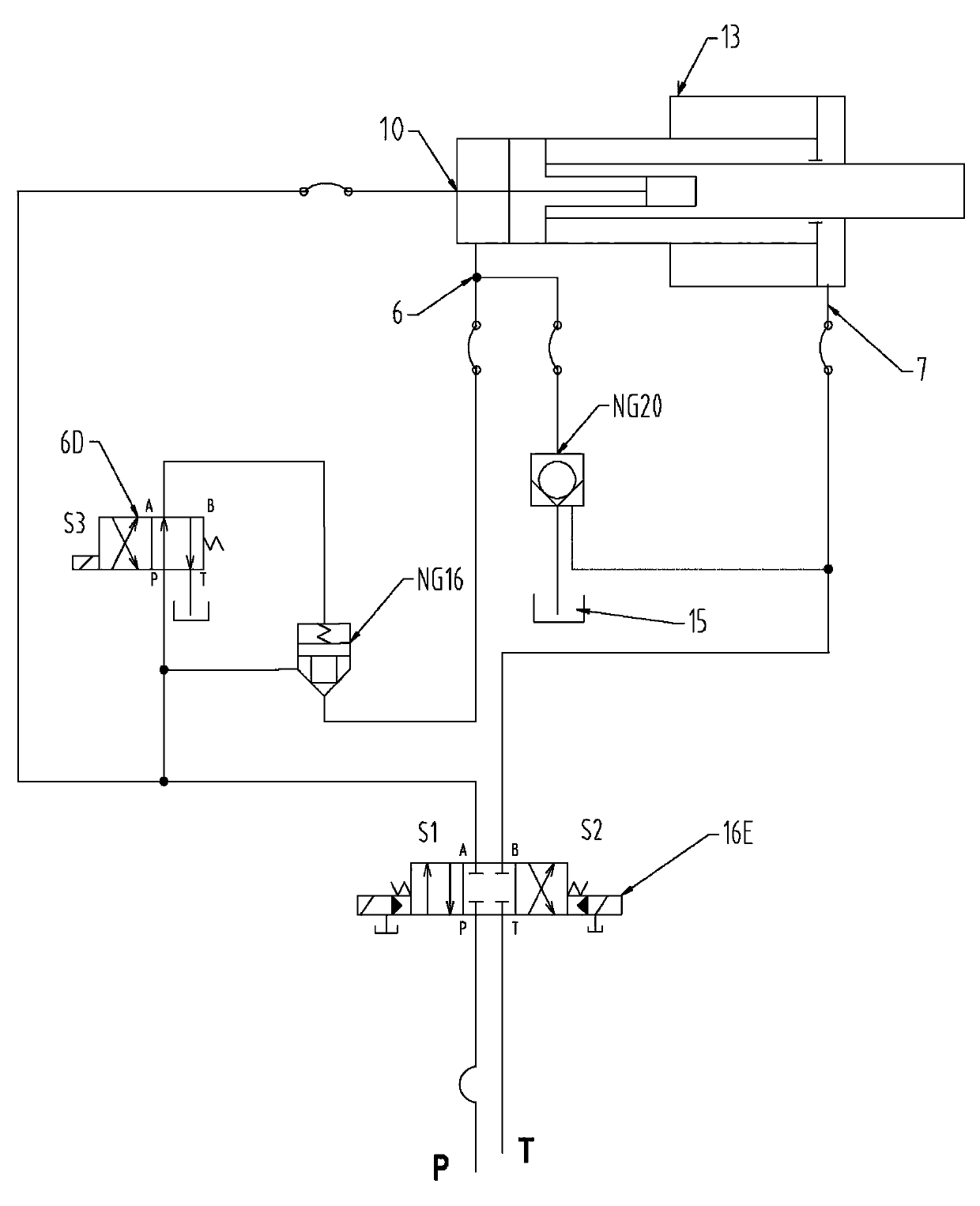

Fast die closingoil cylinder used for high-speed die-casting machine

InactiveCN104196813AFast clamping speedHigh speedFluid-pressure actuatorsPiston rodsDie castingEngineering

The invention discloses a fast die closing oil cylinder used for a high-speed die-casting machine. The fast die closing oil cylinder comprises a die closing cylinder rear cover (1), a die closing cylinder barrel (2), a die closing cylinder front cover (3), a die closing cylinder piston (4), a die closing cylinder piston rod (5), an oil supply hole (6) and an oil return hole (7), wherein the die closing cylinder piston rod (5) is internally provided with a cavity (9) used for a fast piston rod (8) to insert, the fast piston rod (8) is internally provided with a through hole (10) arranged along the axial direction, and the other end of the fast piston rod (8) sequentially penetrates through the die closing cylinder piston (4) and the die closing cylinder rear cover (1) so as to enable the through hole (10) to be communicated with a main oil path of a hydraulic system, so that the hydraulic system can push the die closing cylinder piston rod (5) to move forward by supplying oil into the cavity (9) through the through hole (10). The fast piston rod is arranged in the die closing cylinder piston rod, so that the die closing speed is improved by more than 60 percent, and meanwhile, the die opening speed is improved by increasing the diameter of the die closing cylinder piston rod.

Owner:江苏佳晨华科机械技术研究院有限公司

Pneumatic type chuck

ActiveCN105269213AAchieve diversificationFast clamping speedWelding/cutting auxillary devicesAuxillary welding devicesPneumatic motorEngineering

The invention relates to the field of laser cutting and particularly discloses a pneumatic type chuck which comprises a machine base. Two pneumatic motors are arranged on the machine base, and each pneumatic motor is provided with a motor braking disk and a motor locking disk; a rotating shaft sleeve is arranged in the center of the machine base, a braking disk and a driven belt wheel are fixedly arranged on the rotating shaft sleeve, and the braking disk are in meshed connection with the two motor braking disks; the rotating shaft sleeve is sleeved by an inner locking disk, an outer locking disk and a rotating disk, the inner locking disk is in meshed connection with one motor locking disk, and the outer locking disk is in meshed connection with the other motor locking disk; and four claws are evenly distributed on the rotating disk, the inner locking disk controls two opposite claws, and the outer locking disk controls the other two claws. According to the pneumatic type chuck, the function diversity is achieved. Furthermore, the pneumatic type chuck is quick in clamping speed, high in clamping accuracy and strong in clamping ability, the producing cost is reduced, and the working efficiency is improved.

Owner:JINAN JINQIANG LASER CNC EQUIP

Intersecting line welding seam welding equipment and method

ActiveCN113909766AImprove accuracyReduce mistakesWelding/cutting auxillary devicesAuxillary welding devicesLap jointEngineering

The invention discloses intersecting line welding seam welding equipment, comprising a main pipe and a branch pipe. The end of the branch pipe is in lap joint with the side wall of the main pipe. The intersecting line welding seam welding equipment further comprises a clamping table; the main pipe is fixed through the clamping table; the middle of the outer side wall of the branch pipe is sleeved with a fixed rotating mechanism; the outer side wall of the fixed rotating mechanism is fixedly connected with the upper portion of the clamping table; and the inner wall of the branch pipe is fixedly connected with an inner rotation measuring mechanism. By arranging a first distance measuring assembly and a second distance measuring assembly, intersecting line data with small errors can be obtained through calculation; when the measuring, cutting and welding procedures are carried out, a fixed rotating mechanism does not need to be disassembled and assembled, intersecting line data measuring, branch pipe cutting and welding are all completed on the same equipment, a welding starting point does not need to be manually positioned, and the relative position of the fixing sleeve of the fixed swing mechanism and the branch pipe is always unchanged, so that the running track of cutting and welding can completely coincide with intersecting line data, and the precision after welding is improved.

Owner:INNER MONGOLIA UNIV OF TECH

Quick clamping fixture for rough boring of engine cylinder block

InactiveCN104493580AFast clamping speedCompress bigPositioning apparatusMetal-working holdersCushionEngineering

The invention discloses a quick clamping fixture for rough boring of an engine cylinder block. The quick clamping fixture comprises a fixture body, a left lever type oil cylinder pressing device and a right lever type oil cylinder pressing device are arranged at two ends of the fixture body, four supporting cushions are arranged on the fixture body, two of the supporting cushions are provided with positioning pins, and a front suspension face rough positioning block and a right end face rough positioning plate are arranged on the fixture body. The quick clamping fixture further comprises a workpiece holder and a lifting oil cylinder, and the lifting oil cylinder is arranged on the fixture body and used for lifting the workpiece holder. When a workpiece is mounted, the workpiece holder is lifted up, the workpiece is placed on the workpiece holder, an operator can push the workpiece, the front suspension face rough positioning block and the right end face rough positioning plate along the workpiece holder to realize rough positioning of the workpiece, and then the workpiece holder descends to enable the positioning pins to be quickly and accurately inserted into positioning holes of the workpiece. Quickness and convenience in workpiece mounting are achieved, the workpiece can be lifted up by the aid of the workpiece holder after machining is finished and can be quickly separated from the positioning pins, and convenience in taking of the workpiece and high production efficiency are achieved.

Owner:重庆光荣摩托车配件有限公司

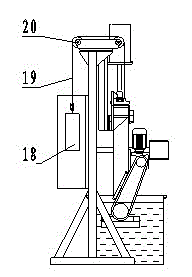

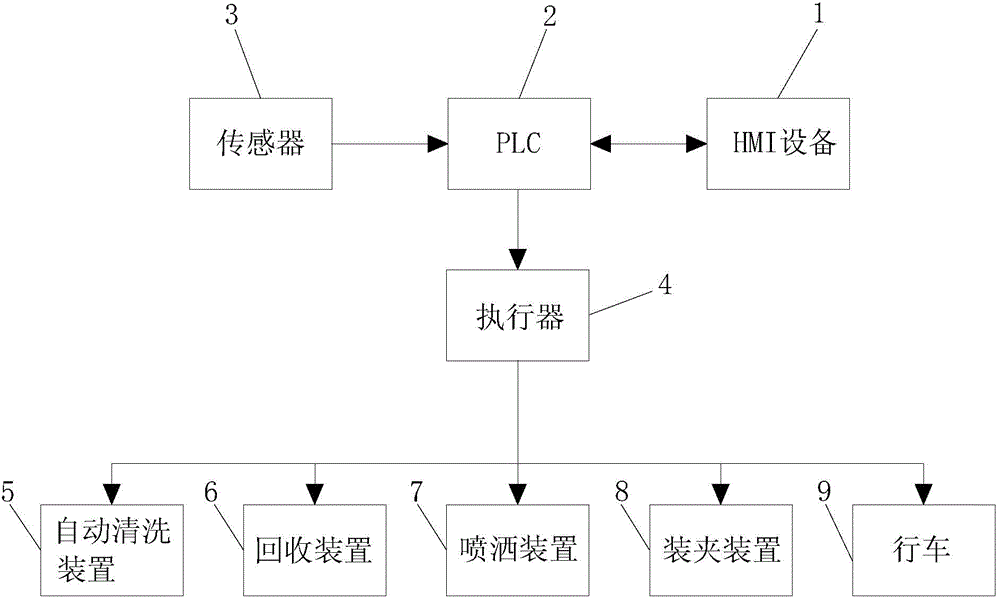

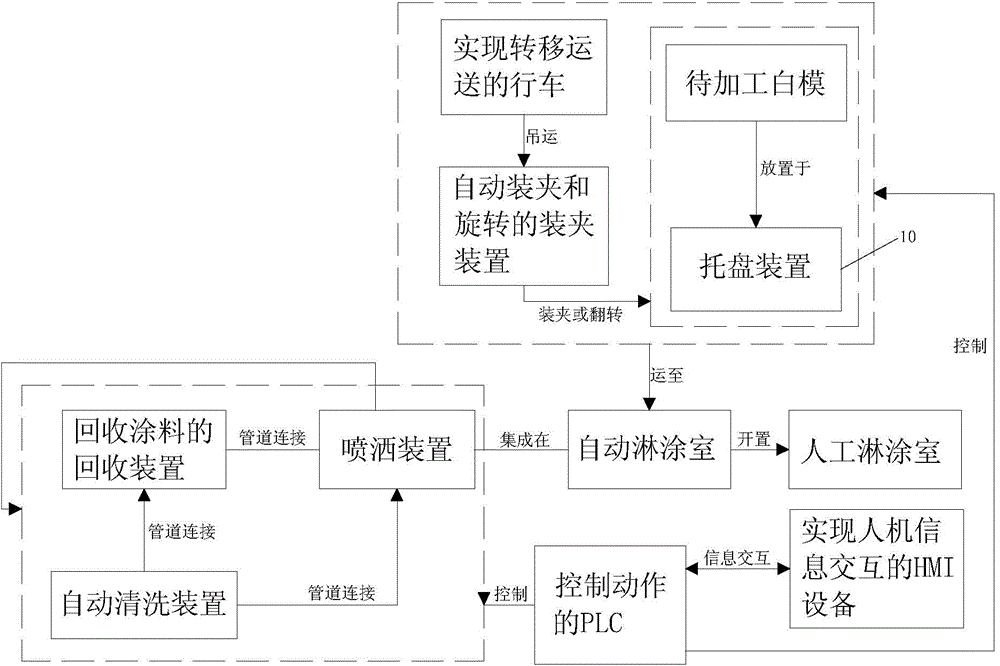

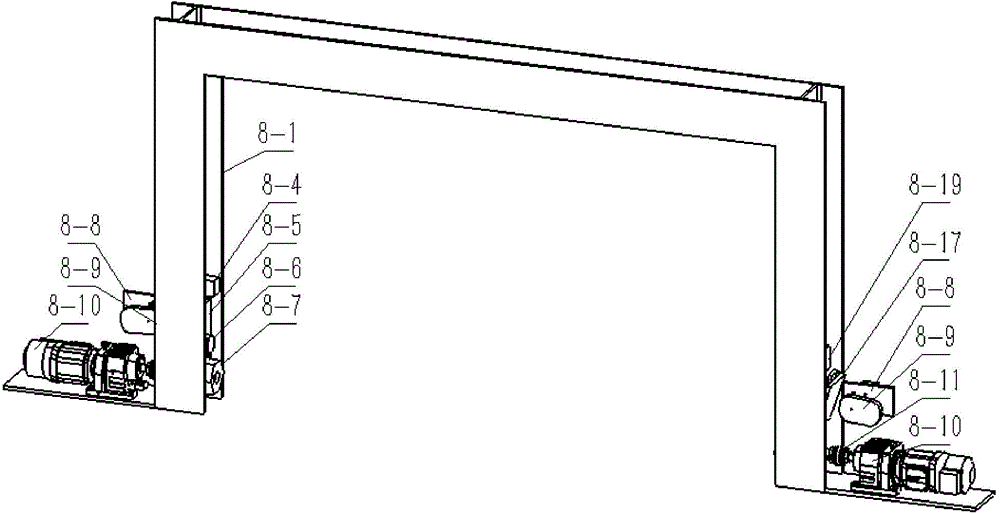

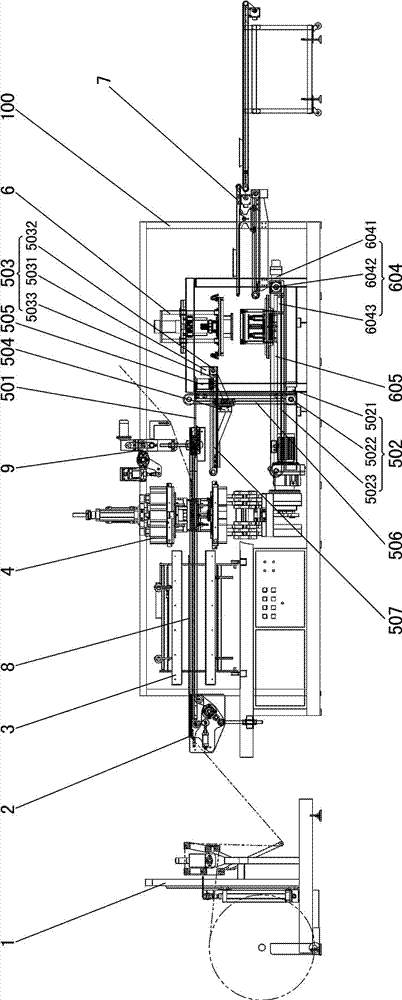

Automatic curtain-coating system for lost foam casting

ActiveCN104588250AHigh degree of automationImprove efficiencyLiquid surface applicatorsLiquid spraying apparatusDevice formControl system

The invention relates to an automatic curtain-coating system for lost foam casting. The system comprises a control system, a curtain-coating-recovery-cleaning system, a clamping device, a pallet device and a traveling crane, wherein the curtain-coating-recovery-cleaning system is formed by integrating an automatic cleaning device, a recovery device and a spraying device through a pipeline and a reversing valve; the automatic cleaning device, the recovery device, the spraying device, the clamping device and the traveling crane are connected with the control system through cables; the curtain-coating-recovery-cleaning system is distributed in the conveying direction of the traveling crane; the clamping device is connected to the traveling crane through a steel cable; the pallet device is connected with the clamping device; the recovery device and the spraying device form curtain-coating equipment. The system has the advantages of high automation degree, high efficiency, low production cost and the like, safety in a production process can be improved, curtain-coating quality can be ensured, manpower is saved, and working efficiency is improved.

Owner:WUHU ANPU ROBOT IND TECH RES INST

Full-automatic plastic sucking and punching former

The invention relates to a full-automatic plastic sucking and punching former which comprises an unreeling device, a sheet feeding device, a heating device, a forming device, a finished product withdrawal device, a caterpillar track device and a caterpillar track adjustment device, wherein the unreeling device, the sheet feeding device, the heating device, the forming device and the finished product withdrawal device are arranged on a rack in sequence; and the caterpillar track device and the caterpillar track adjustment device are arranged on the heating device and the forming device and connected with the sheet feeding device. The full-automatic plastic sucking and punching former is characterized by further comprising a cup switching device and a cup flanging device, wherein the cup switching device and the cup flanging device are arranged on the rack between the forming device and the finished product withdrawal device in sequence. By independently driving an upper template, the problem of excessive impact force during die spotting is solved, so that the punching shearing speed is increased; a cutter device which is provided with a ring-shaped cutter and a cutter baffle is arranged, so that the problem of adhering materials on the blade is solved and then the forming and punching shearing of PP (Propene Polymer) materials can be carried out at the same time; and the cup switching device and the cup flanging device are arranged, so that the full-automatic thermal forming production of the PP materials is realized, the production efficiency is improved and the flanged edge has better quality and more beautiful appearance.

Owner:广东金兴机械股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com