Clamp special for groove milling of end faces of shaft parts

A technology for shaft parts and special fixtures, which is applied in the direction of metal processing machinery parts, clamping, manufacturing tools, etc., can solve the problems of low production efficiency and only one piece of clamping, and achieve short processing cycle, ensure precision, and install Clip speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

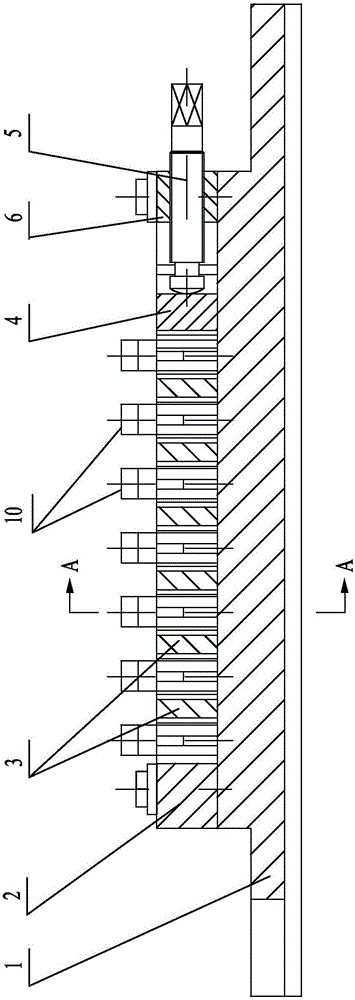

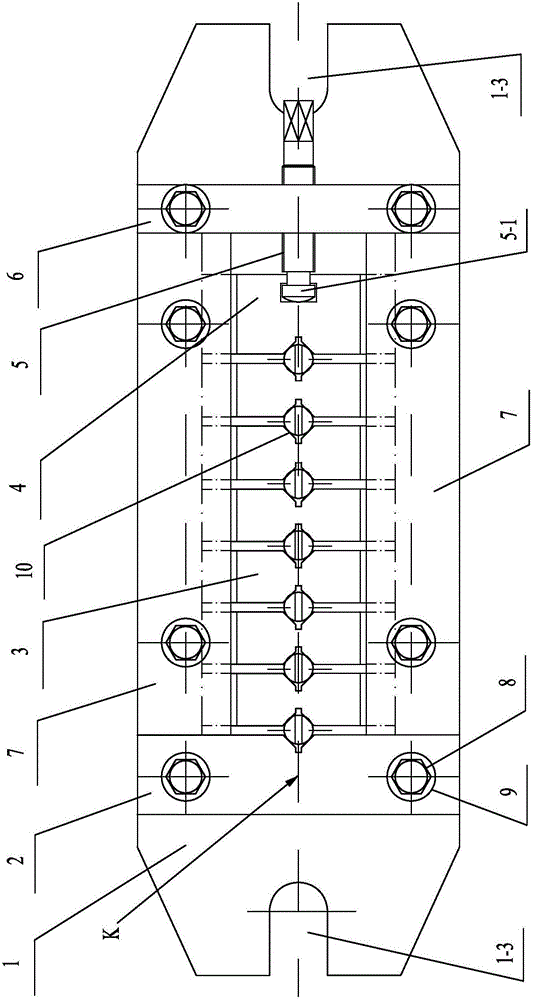

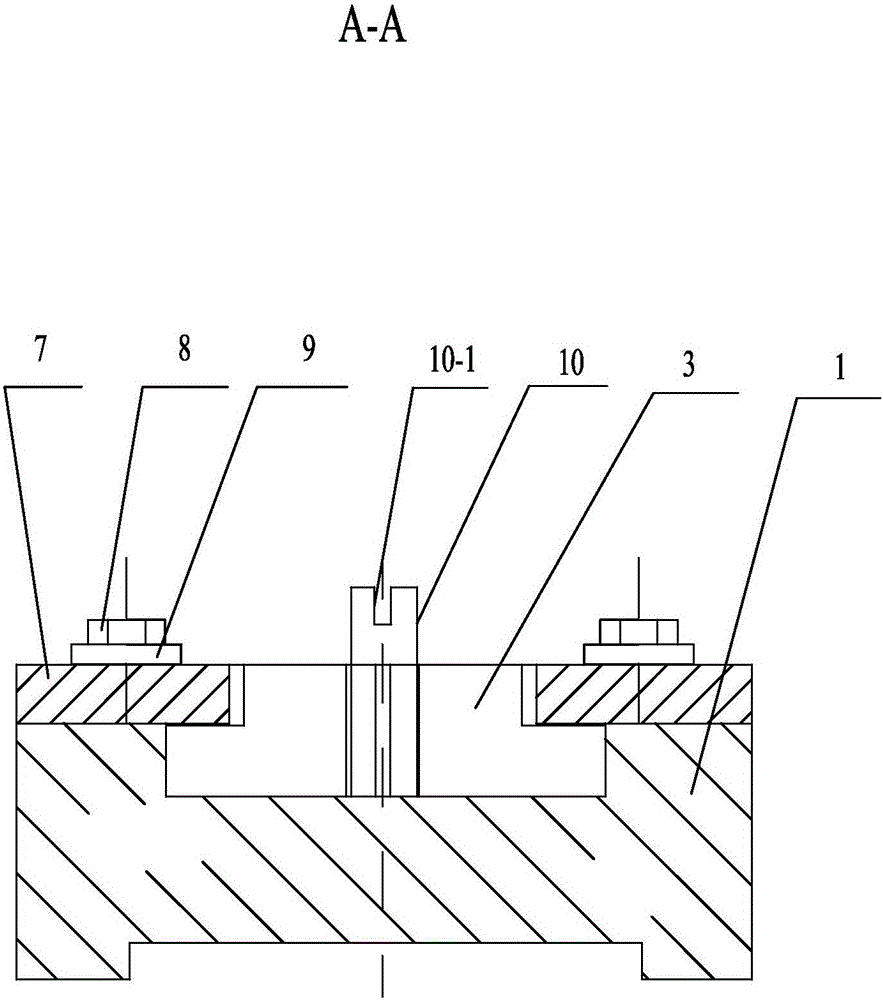

[0021] Specific implementation mode one: combine Figure 1 to Figure 11 Describe this embodiment, the special fixture for end face milling of shaft parts in this embodiment includes a clamp body 1, a positioning block 2, an inverted T-shaped clamping block 4, a jacking screw 5, a baffle plate 6, two pressure plates 7 and a plurality of Inverted T-shaped slider 3, the clamp body 1 includes a base 1-1 and two rectangular bosses 1-2, the two rectangular bosses 1-2 are arranged facing each other and fixed to the upper surface of the base 1-1, and the positioning block 2 and baffle plate 6 are respectively arranged on the both sides of the length direction of two rectangular bosses 1-2, the bottom surface of positioning block 2 and baffle plate 6 are all fixedly connected with base 1-1, the side of positioning block 2 and baffle plate 6 The plate surface of the positioning block 2 is close to the corresponding side faces of the two rectangular bosses 1-2, and the side face opposite...

specific Embodiment approach 2

[0022] Specific implementation mode two: combination figure 2 , Figure 8 and Figure 10 The present embodiment will be described. The longitudinal sections of the plurality of inverted T-shaped sliders 3 in this embodiment are the same in size and shape as the longitudinal sections of the inverted T-shaped clamping block 4 . Such a design can make the inverted T-shaped clamping block 4 fully contact with the inverted T-shaped slider 3, making the clamping more stable. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0023] Specific implementation mode three: combination figure 2 Referring to this embodiment, the central sections of the first V-shaped groove 2-1, the plurality of second V-shaped grooves 3-3 and the third V-shaped groove 4-3 in this embodiment are all located in the first plane K. Such a design can ensure that the shaft parts 10 to be processed are located in the same row, which is convenient for slot milling. Other components and connections are the same as those in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com