Open pipe tellurium cadmium mercury epitaxial material heat treatment method

A heat treatment method and epitaxial material technology, applied in the field of P-type heat treatment of open-tube mercury cadmium telluride epitaxial materials, can solve the degradation of PN junction performance, the large dispersion of carrier concentration of P-type materials, and the inability to large-scale and large-scale Material heat treatment and other issues to achieve the effect of maintaining surface integrity and excellent surface morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] 1) Production of graphite box

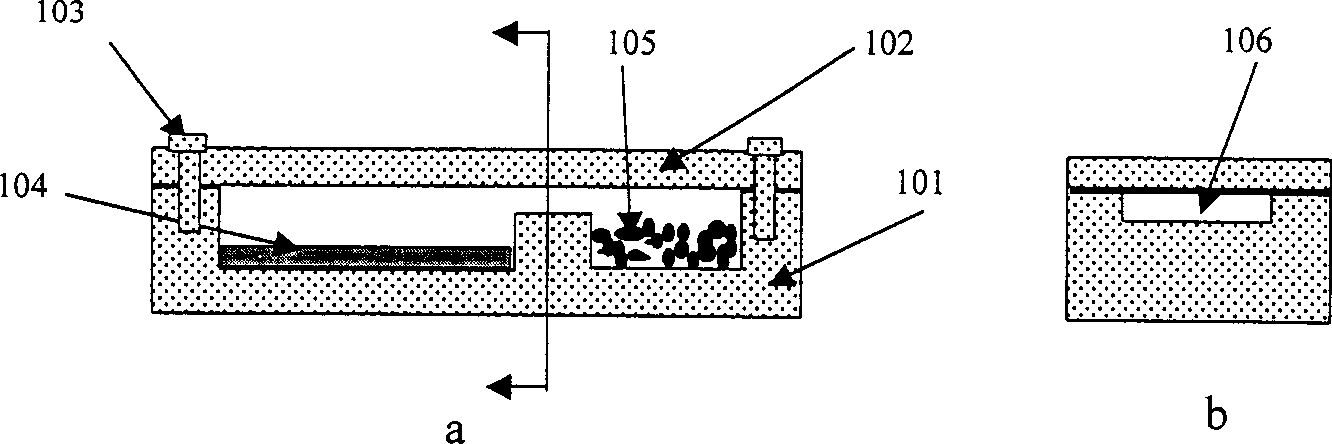

[0020] The present invention utilizes the characteristics of high purity, high density and easy processing of today's graphite materials. The graphite box 1 is composed of a graphite box body 101 and a graphite lid 102. The structure is as follows: figure 1 shown. There are two cavities in the graphite box, and a groove 106 in the middle connects the two cavities. One cavity is a cavity 104 for placing epitaxial materials, and its depth is slightly larger than the thickness of the sample. The other cavity is for placing HgTe powder. body 105, the depth of which is determined according to the amount of HgTe powder required to be placed, and on the side where the graphite box body and the graphite box cover are in contact, the two surfaces are polished brightly with a polishing paper with a particle size of less than 1 micron, so that they can be polished when they are in contact with each other. The sealing effect is better played, and th...

Embodiment 2

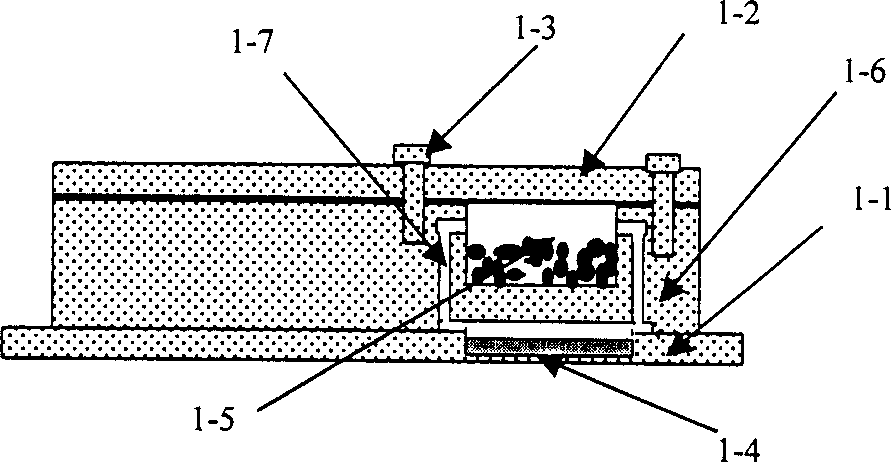

[0035] In this embodiment, the heat treatment method proposed by the present invention is implemented by using the graphite boat used in the improved push boat liquid phase epitaxy. The structure of the graphite boat is shown in figure 2 , 1-1 is the graphite boat body, 1-2 is the graphite boat cover, 1-3 is the graphite screw, 1-4 is the epitaxial material cavity, 1-5 is the HgTe powder cavity, 1-6 is the graphite slider , 1-7 are through holes. When the growth of the liquid phase epitaxy material ends, add the HgTe powder into the powder cavity 1-5, or before the growth of the epitaxial material, add the HgTe powder into the powder cavity 1-5, after the growth of the epitaxial material, by pulling The slider 1-6 makes the cavity 1-5 for placing the HgTe powder communicate with the cavity 1-4 for placing the epitaxial material through the through hole 1-7, so that the epitaxial material can be heat-treated together with the graphite boat without taking it out, thereby The c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com