Patents

Literature

31results about How to "Guaranteed Surface Integrity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

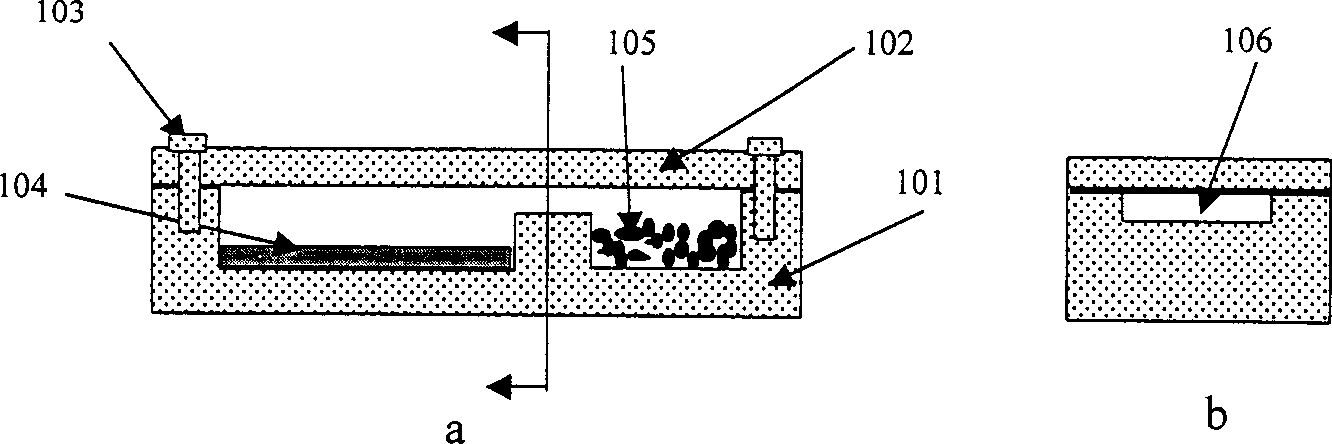

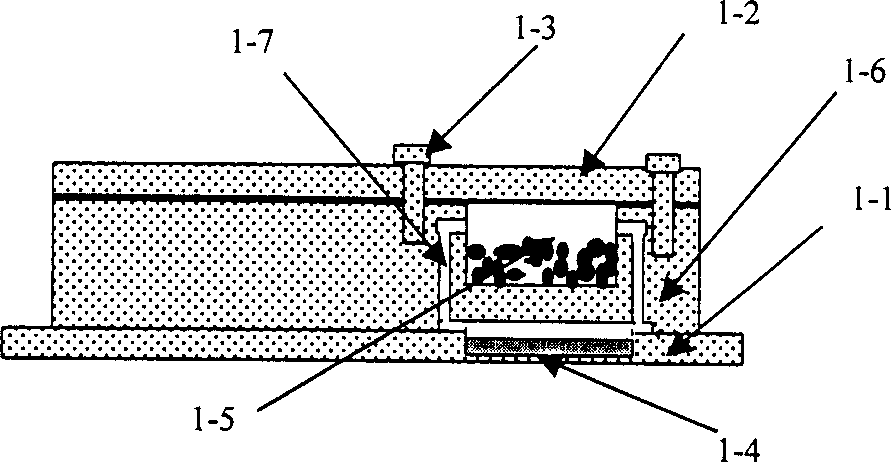

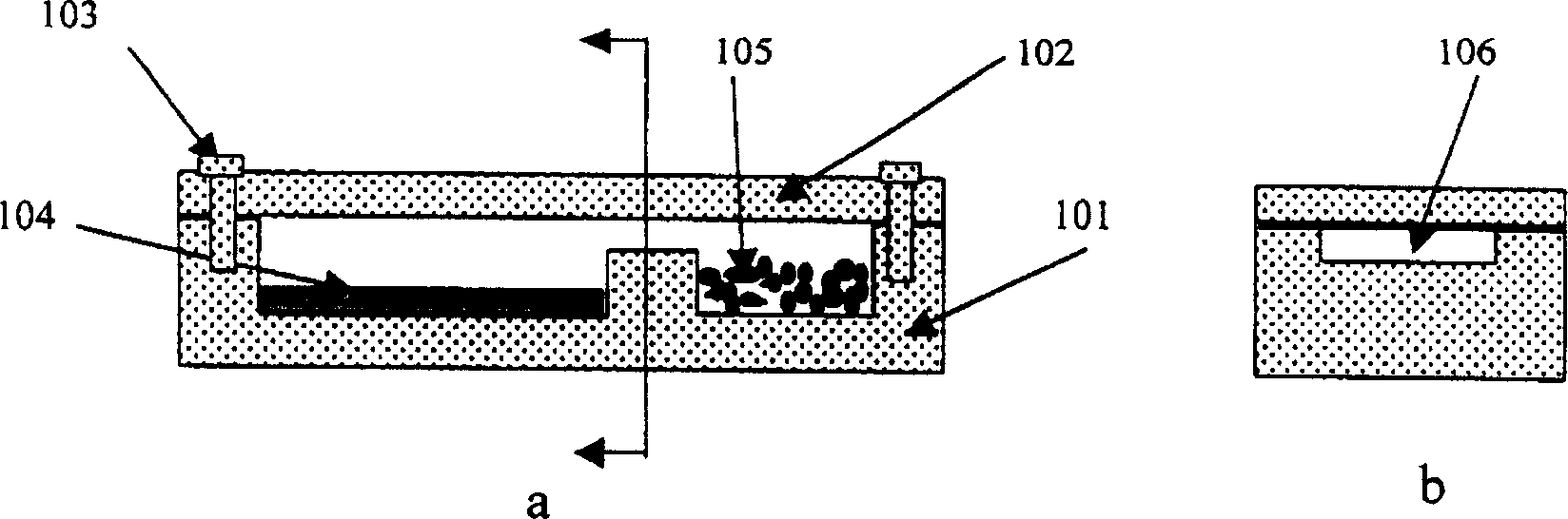

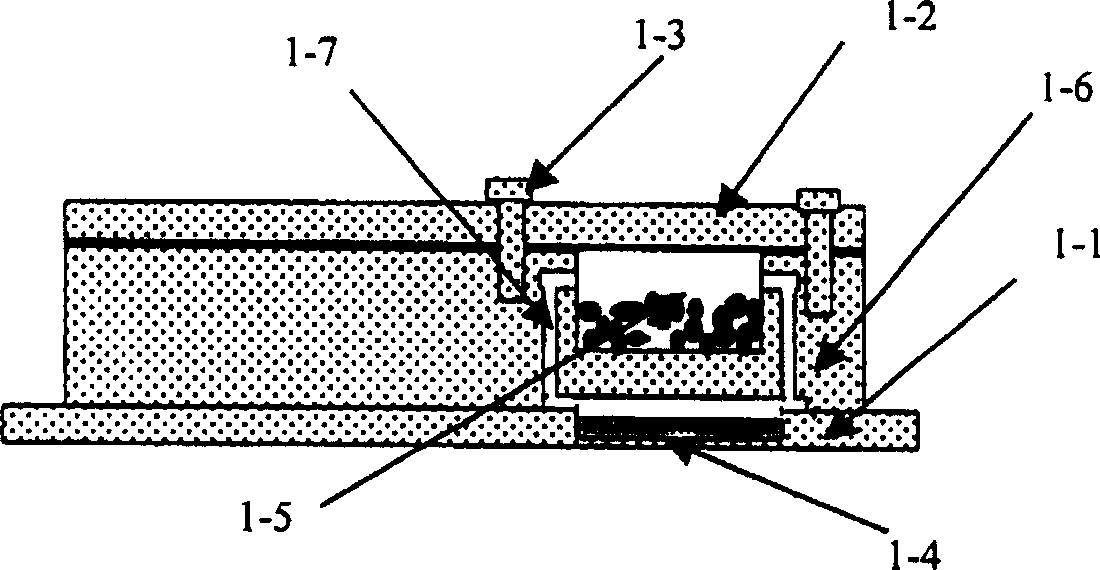

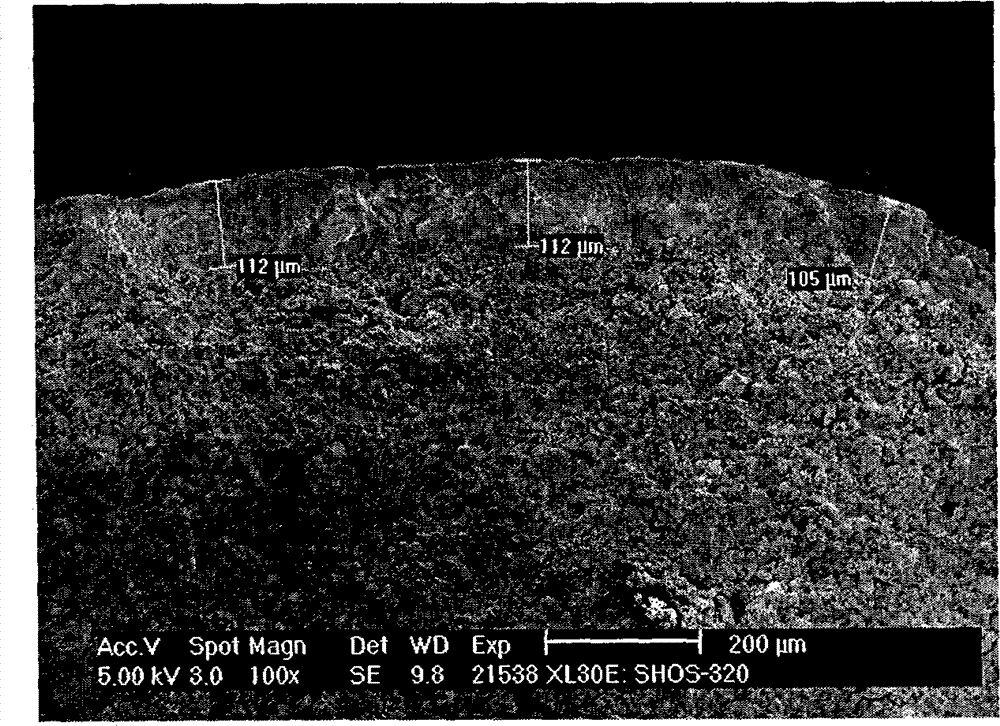

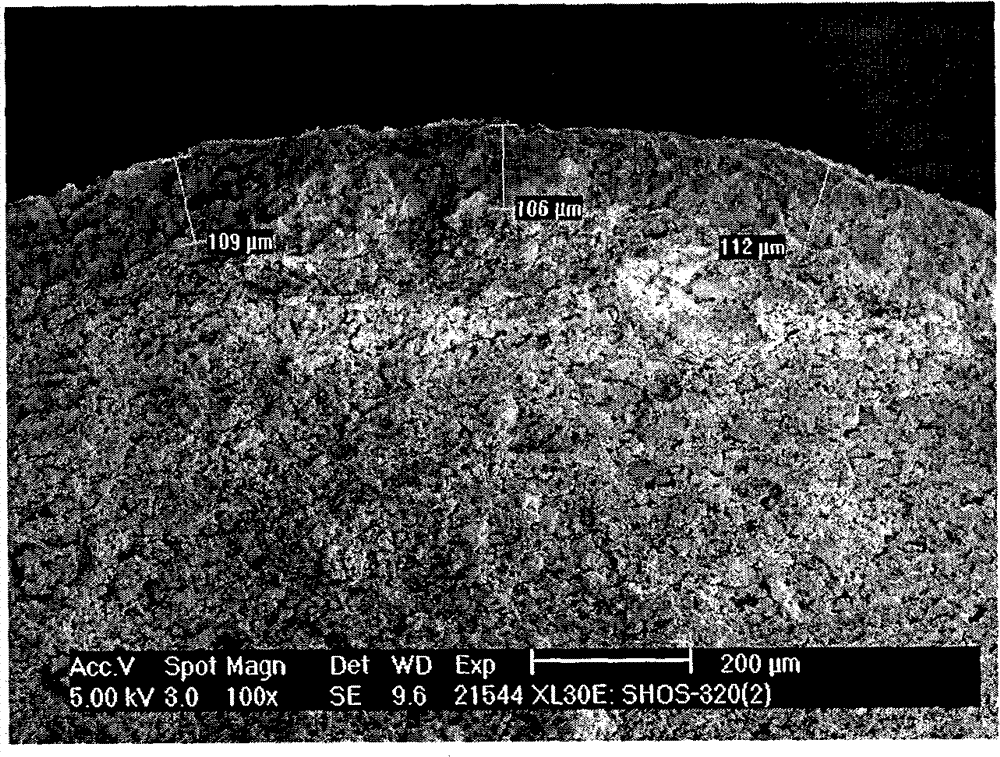

Open pipe tellurium cadmium mercury epitaxial material heat treatment method

InactiveCN1354287AMaintain surface integrityGood surface morphologyAfter-treatment detailsSemiconductor/solid-state device manufacturingDislocationBatch production

The present invention discloses an open tube HgTe source Te-Cd-Hg epitaxial material heat treatment method. The stable mercury steam pressure required for heat treatment is provided by adopting graphite box structure. Said graphite box also can be implemented by utilizing improved liquid-phase epitaxial graphite boat, and its open tube process provides a way for batch production of the part. The success rate of using said process to make hole conduction heat treatment can be up to 100%. The hole density of the material of 77K temp. can be arbitrarily regulated in the range of 5X10 to the power 15 to 5X10 to the power 16 cm (-3). At the same time, the dislocation of material surface in the course of heat treatment does not produce increment effect, and the material composition and appearance form can be better retained.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

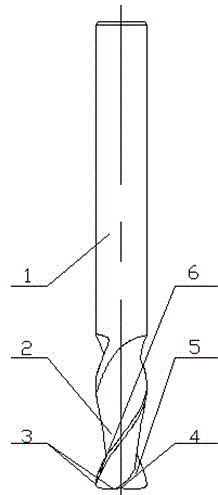

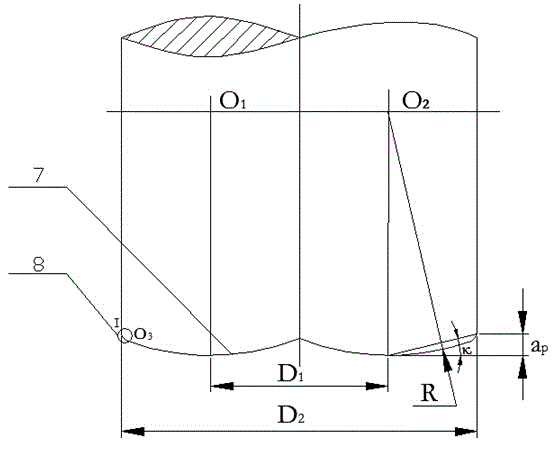

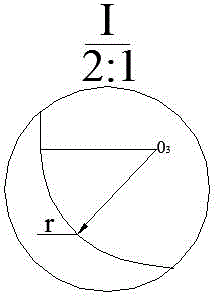

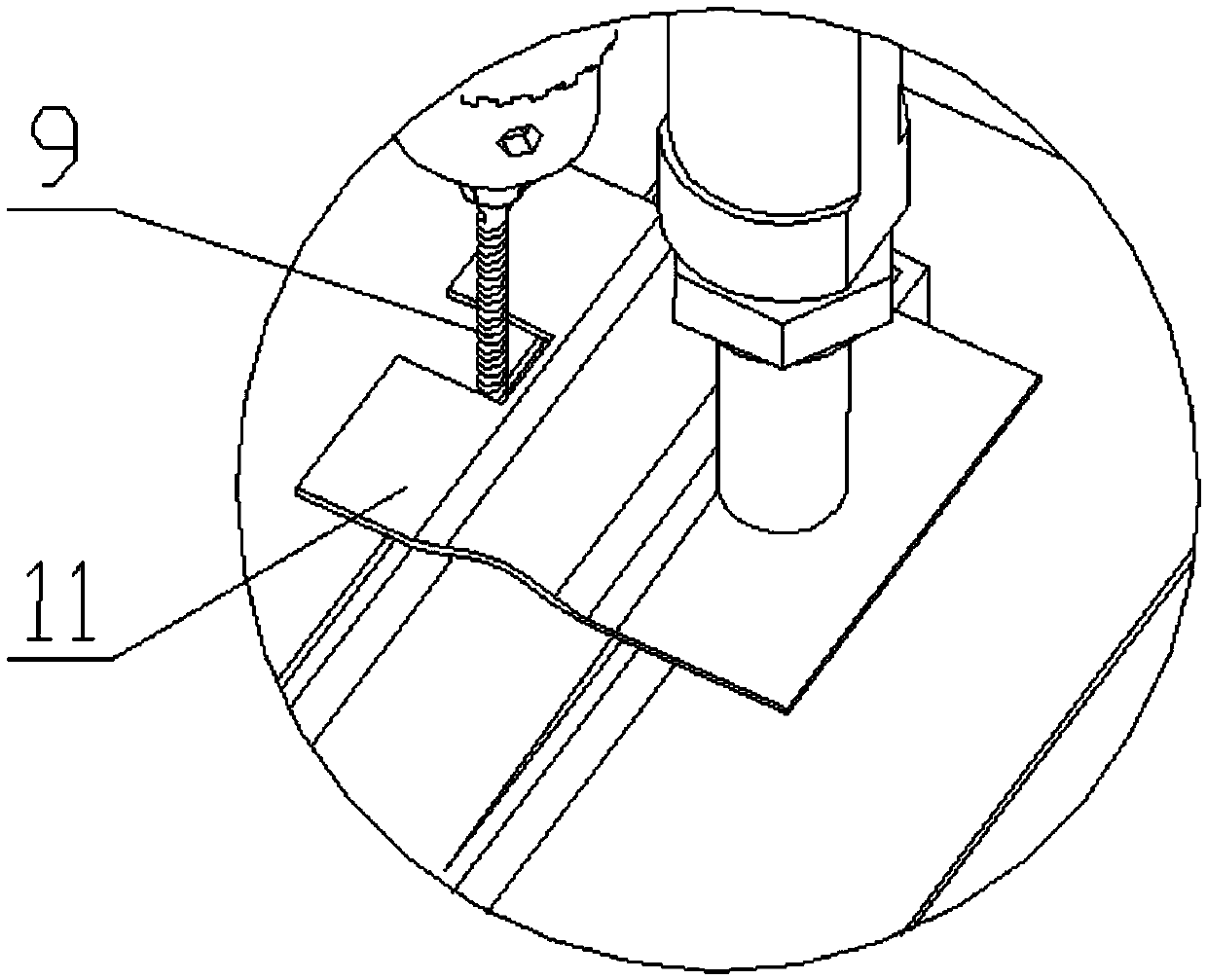

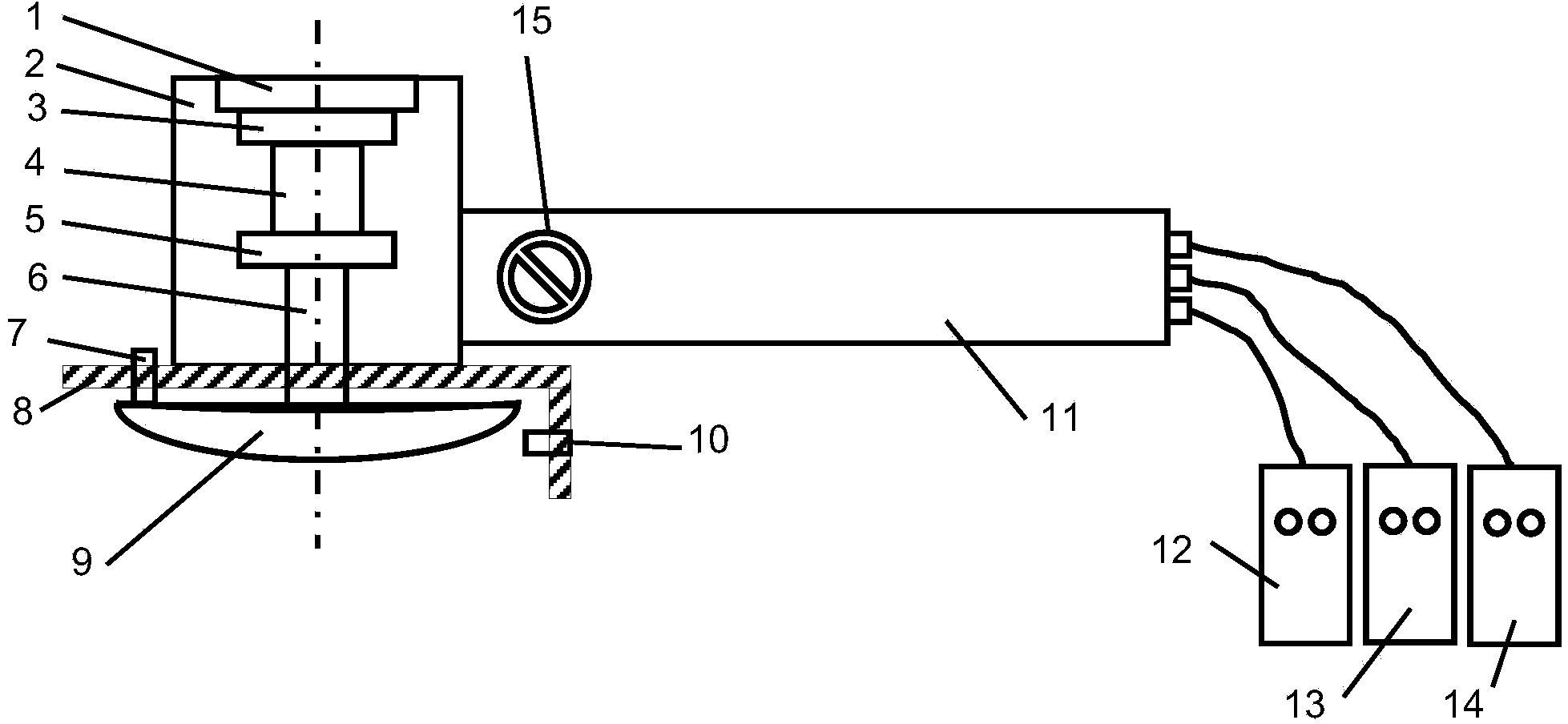

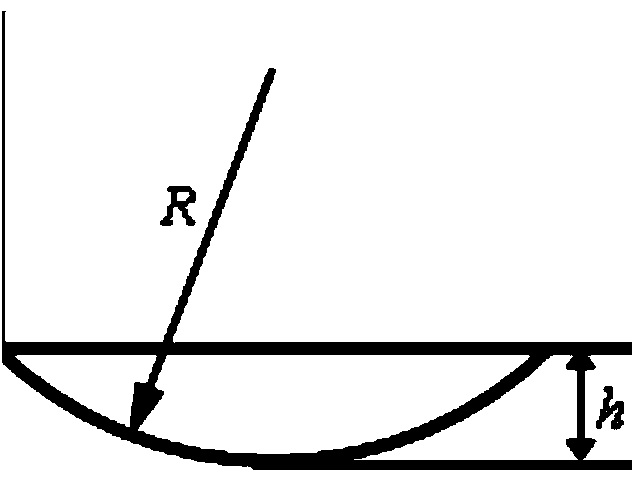

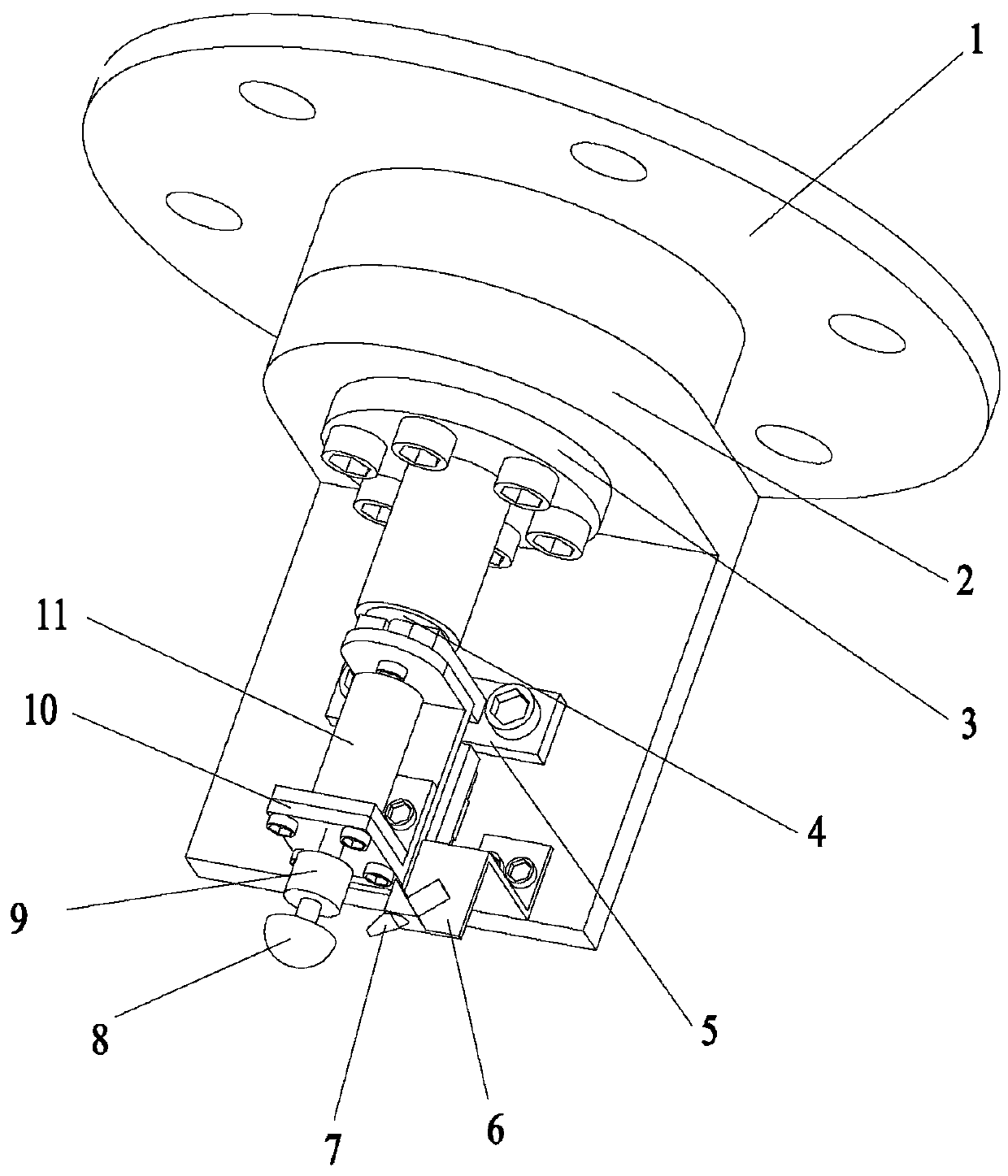

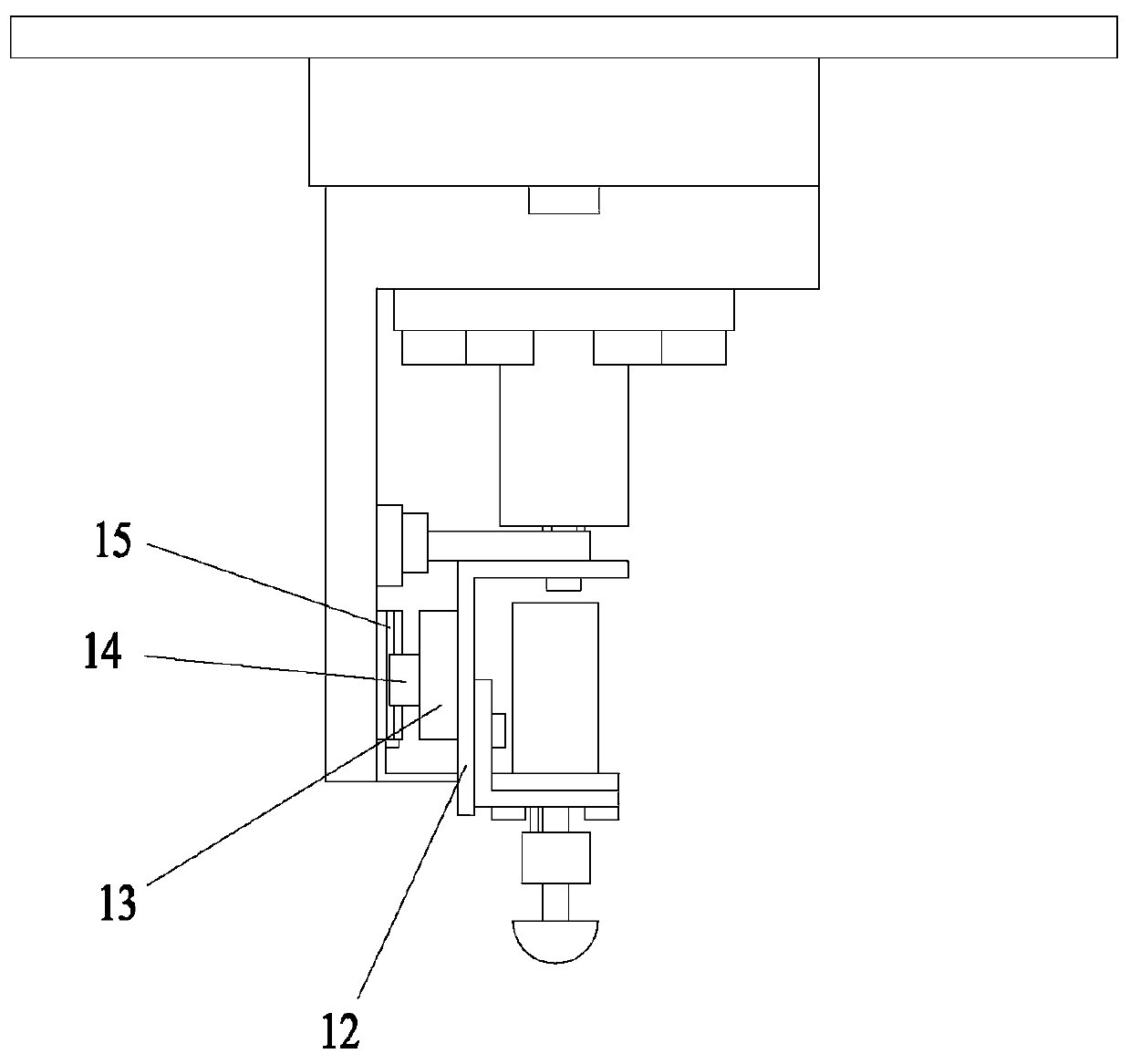

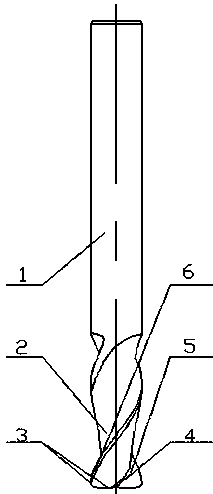

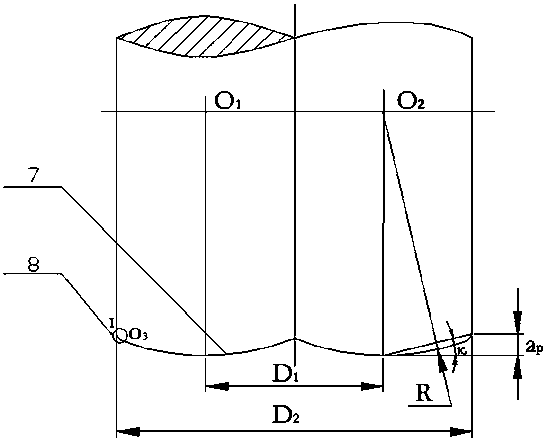

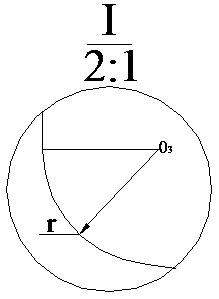

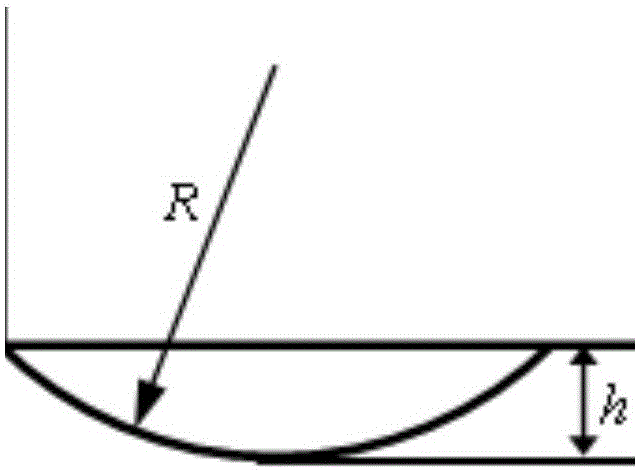

Double-arc large feed ring mill cutter and preparation process and monitor method thereof

InactiveCN104959666AHigh removal rateReduce cutting forceMilling cuttersGrinding feed controlMilling cutterCutting force

The present invention relates to a preparation process and a monitor method of a double-arc large feed ring mill cutter. Currently, ring mill cutter having curved surface high adaptability is widely used in aerospace, automotive and other mold curved surface semi-finishing field, but in order to achieve better cutting performance, improvement of milling efficiency by breakthroughs in the aspects of cutting feed, cutting forces and the like has certain difficulty, on the other hand, grinding process affects processing efficiency, tool life and surface integrity of a workpiece, meanwhile the method for effectively verifying the accuracy of the grinding is worth of considering. The double-arc large feed ring mill cutter comprises a ring mill cutter handle (1), the front end of the ring mill cutter handle is successively connected with a spiral cutter groove (2), a double-arc large feed cutting edge (3), and an end tooth chip pocket (4), the double-arc large feed cutting edge comprises a main-arc cutting edge (7) and a sub-arc cutting edge (8). The double-arc large feed ring mill cutter is used for milling die steel, at the same time, a reference opinion for the preparation process and the monitor method of the mill cutter is provided.

Owner:HARBIN UNIV OF SCI & TECH

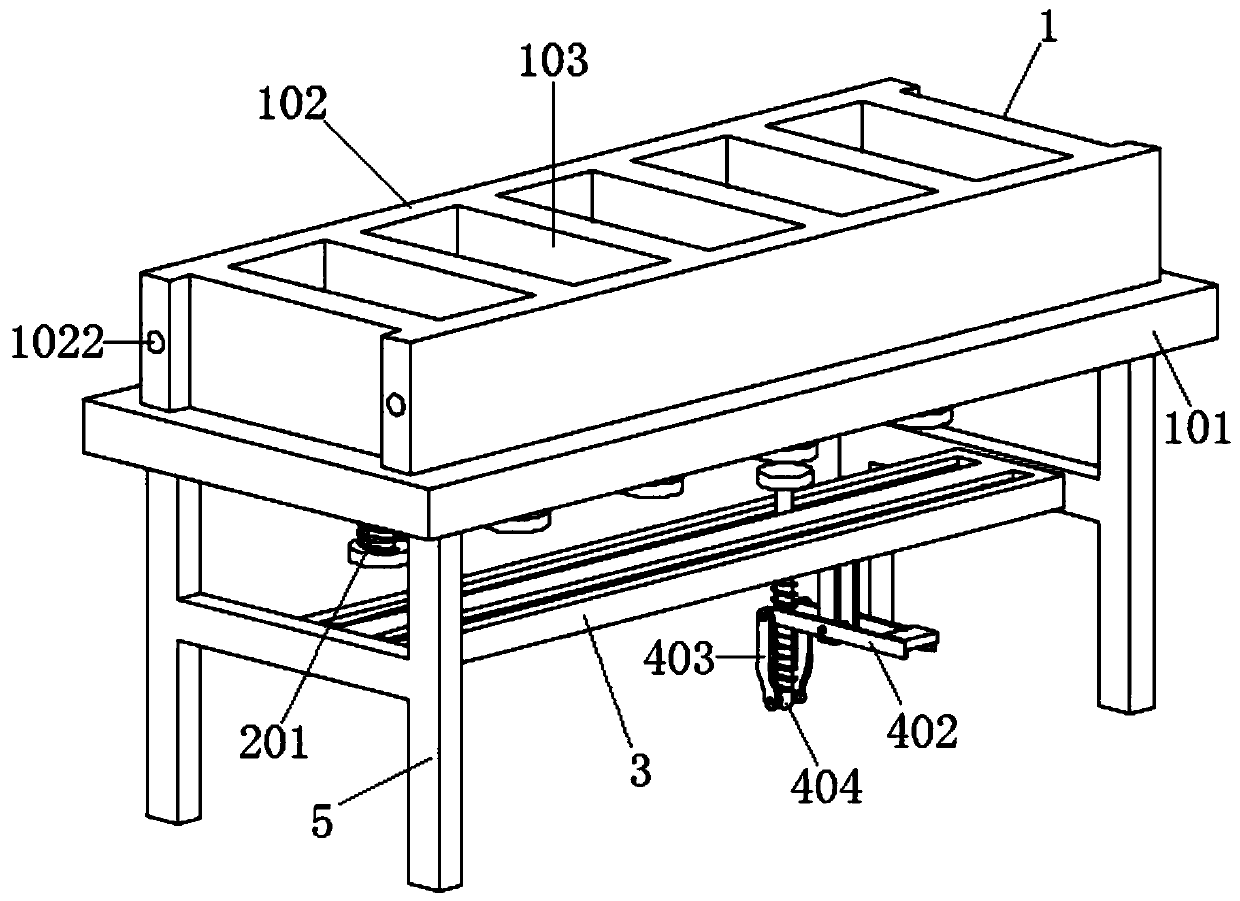

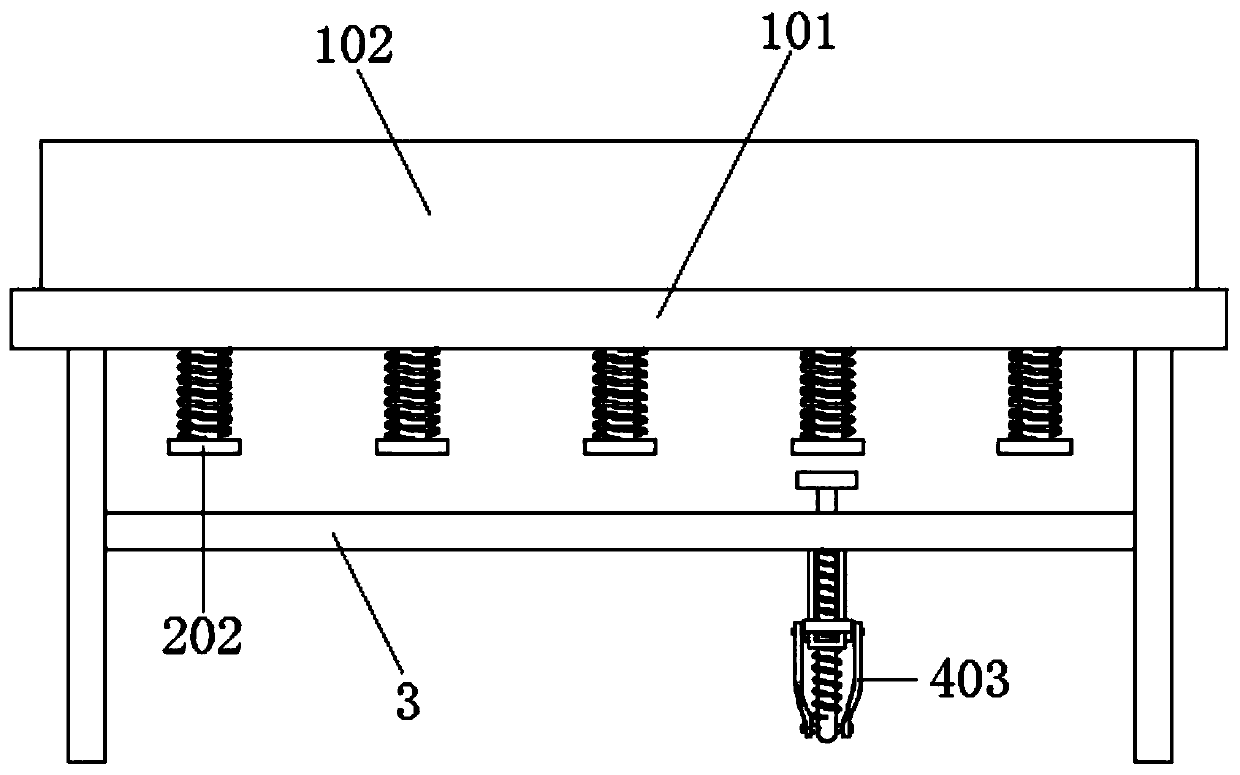

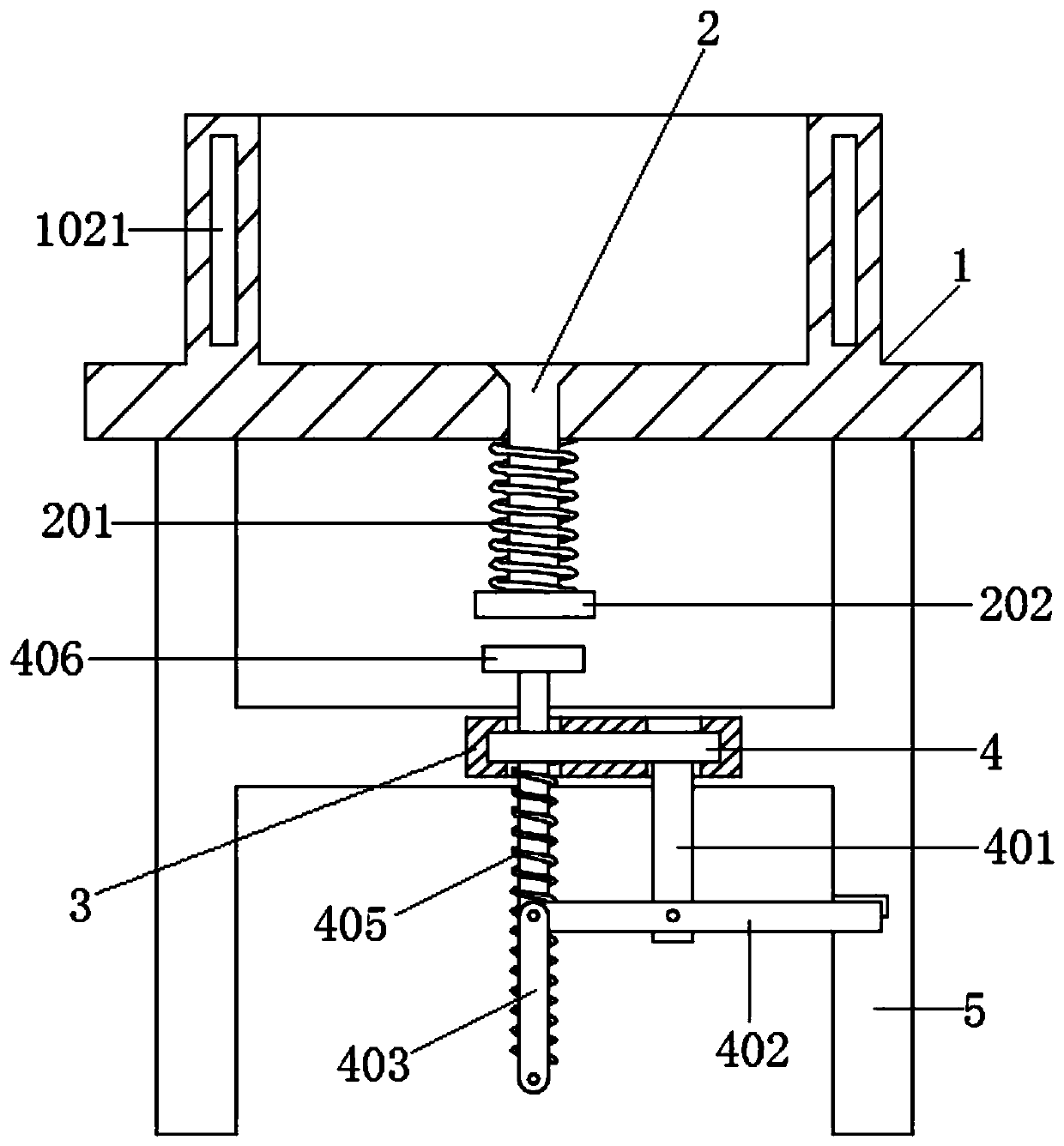

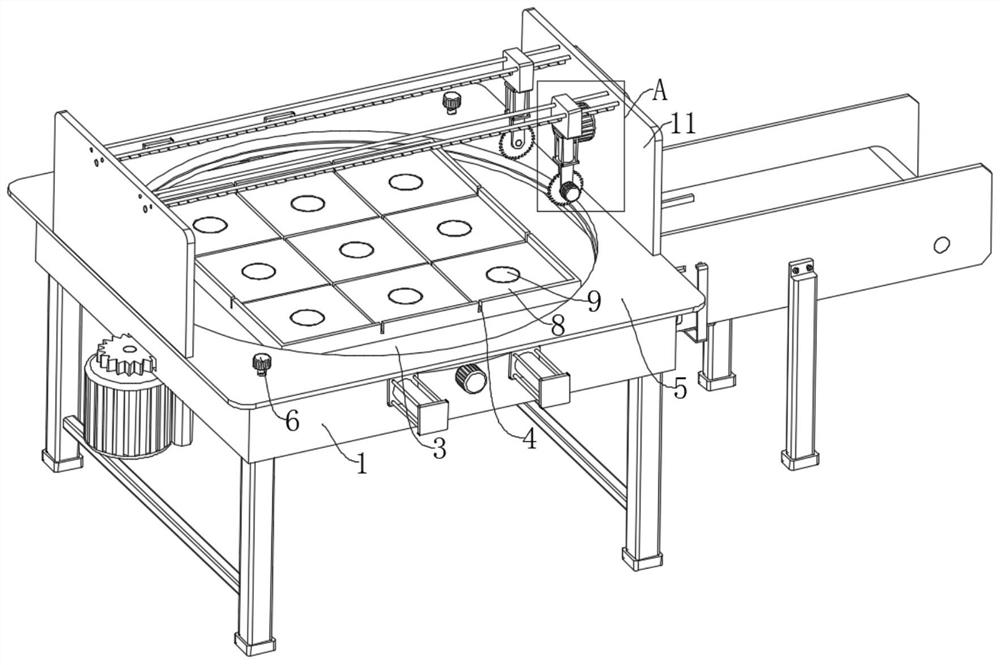

Building cement brick molding device

InactiveCN110561599AShorten cooling molding timeGuaranteed production efficiencyDischarging arrangementMould auxillary partsBrickSlide plate

The invention discloses a building cement brick molding device, and relates to the technical field of building equipment. The building cement brick molding device comprises a molding box, wherein themolding box comprises a base plate and side supporting plates, wherein division plates are fixed to the upper surface of the base plate side by side; a molding groove is formed between the two adjacent division plates and the two side supporting plates; through holes are formed in the upper surface of the base plate side by side; the interiors of the through holes are matched with a guide rod in asliding manner; a guide plate is arranged below the molding box; a sliding plate is arranged on the guide plate; a U-shaped frame is fixed to the lower surface of the sliding plate; one end of the U-shaped frame is rotatably connected to a brake rod; one end of the brake rod is rotatably connected to a driven rod; one end of the driven rod is rotatably connected to a power rod; and one end of thepower rod penetrates through one surface of the guide plate and extends to the upward side of the guide plate. By arranging the molding box with a constant temperature cavity and using the sliding plate to adjust the position of the power rod, the building cement brick molding device realizes the work of taking out a plurality of cement bricks, and has a relatively high market promotion value.

Owner:界首市天瓴建筑工程有限公司

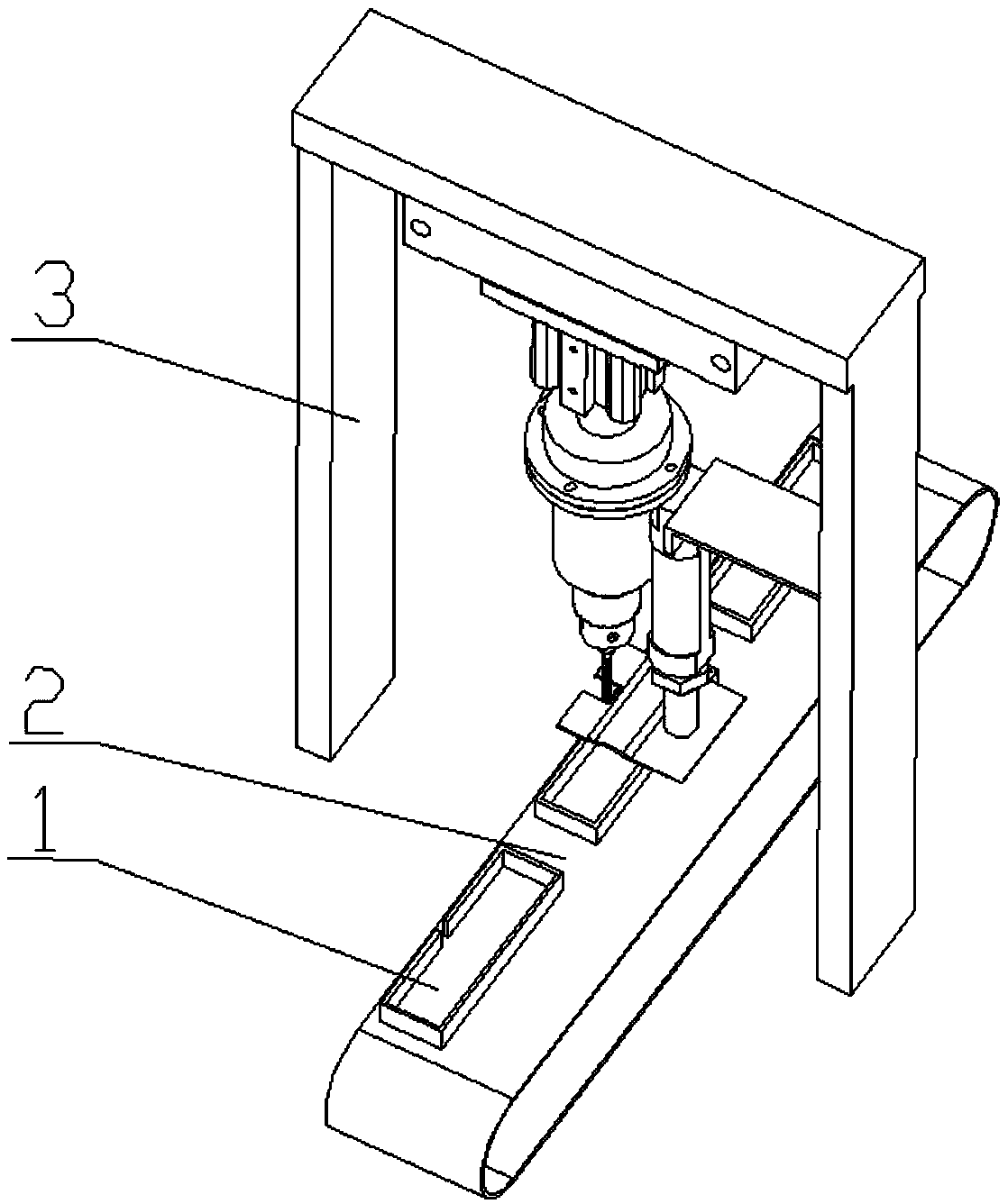

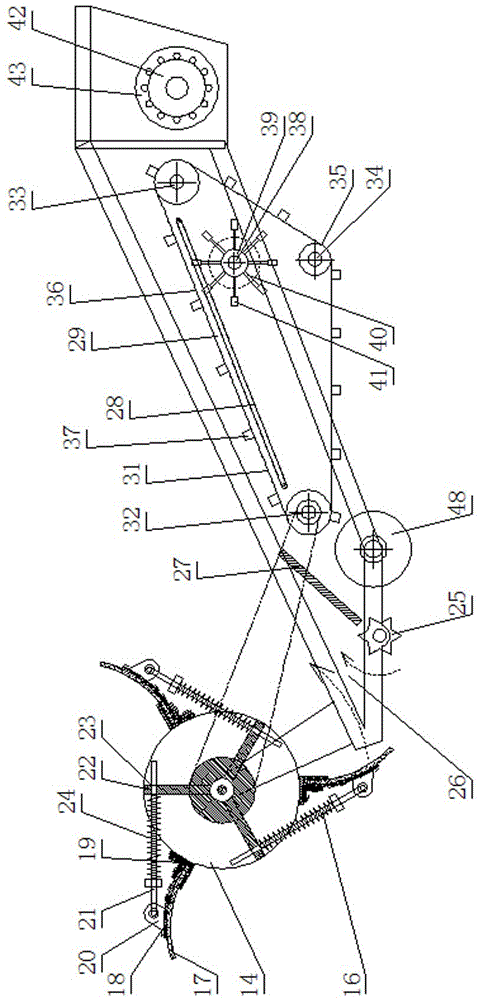

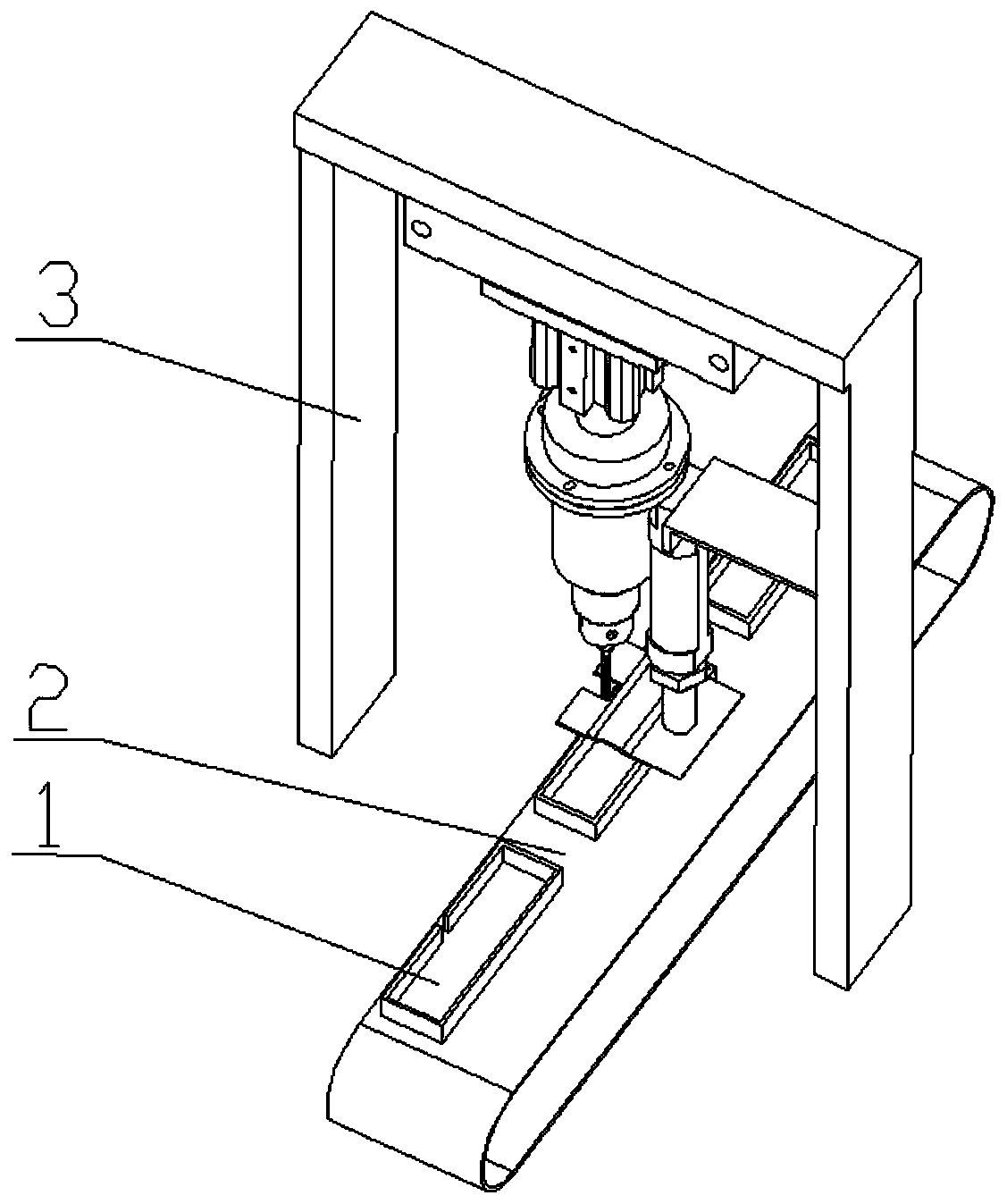

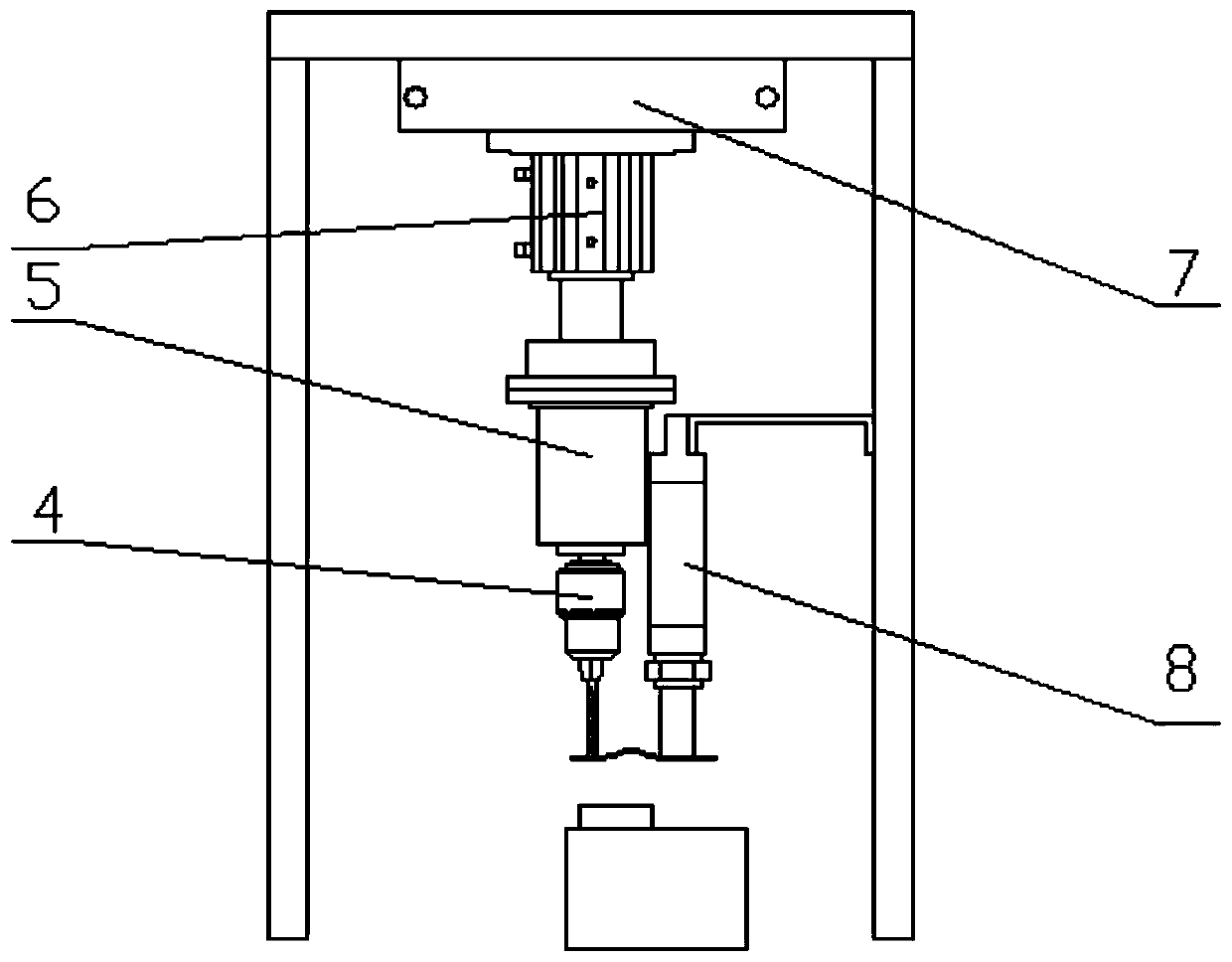

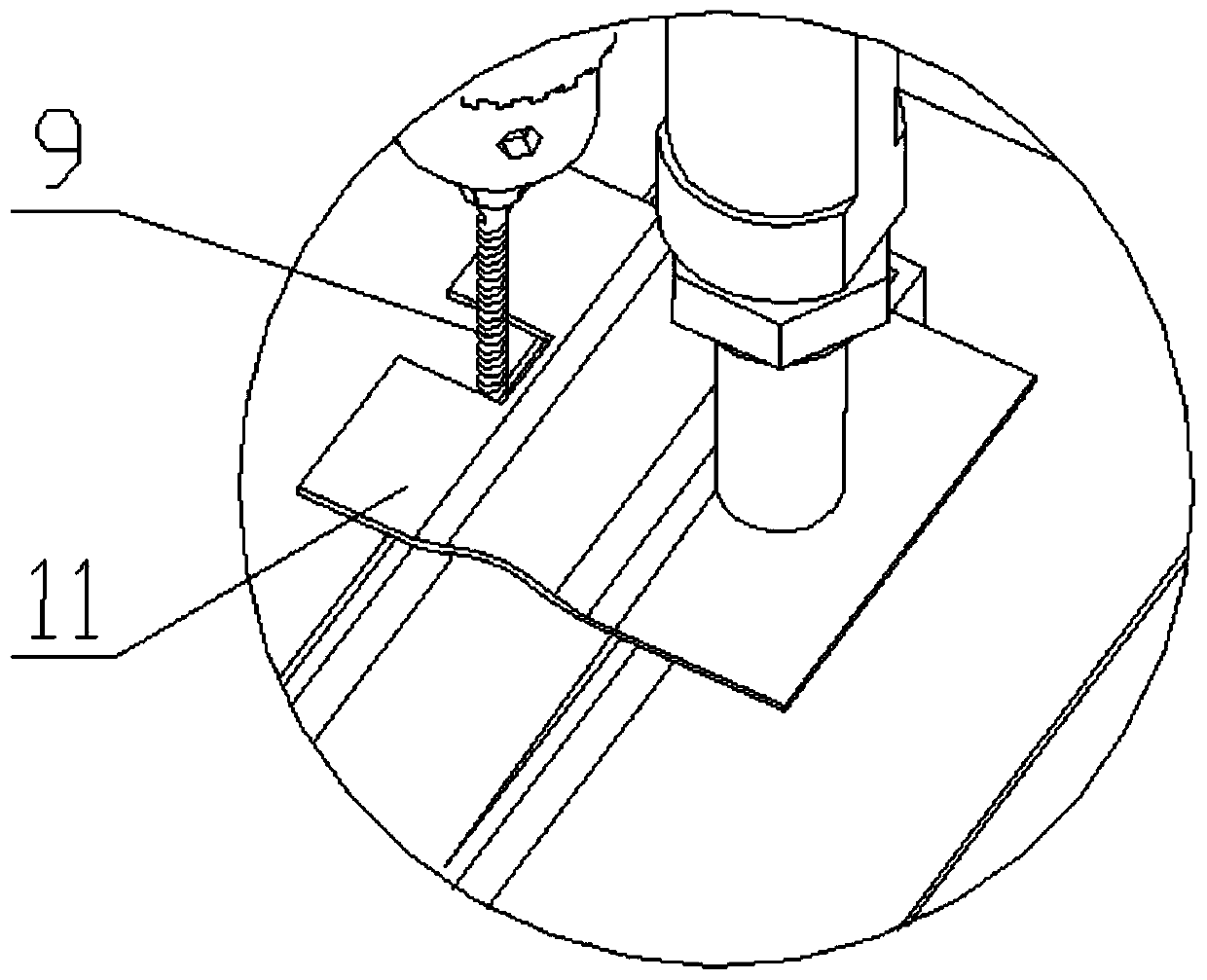

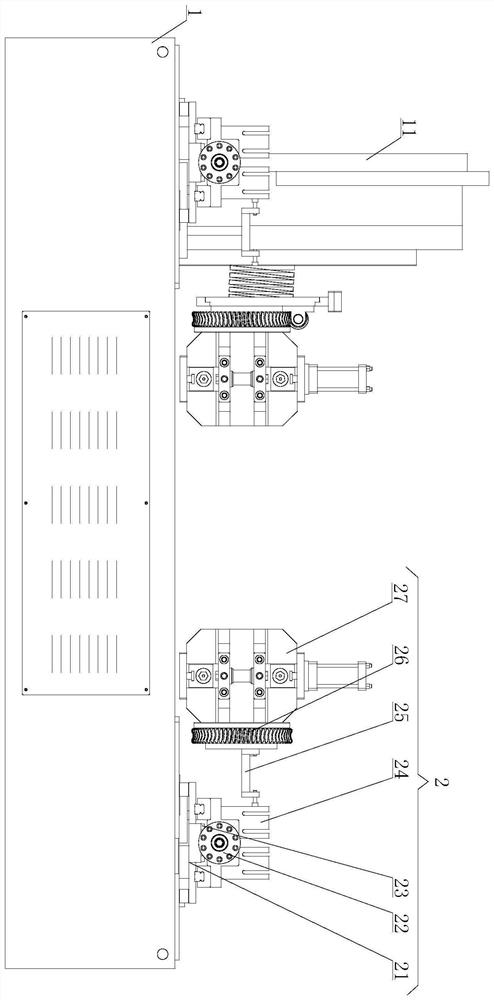

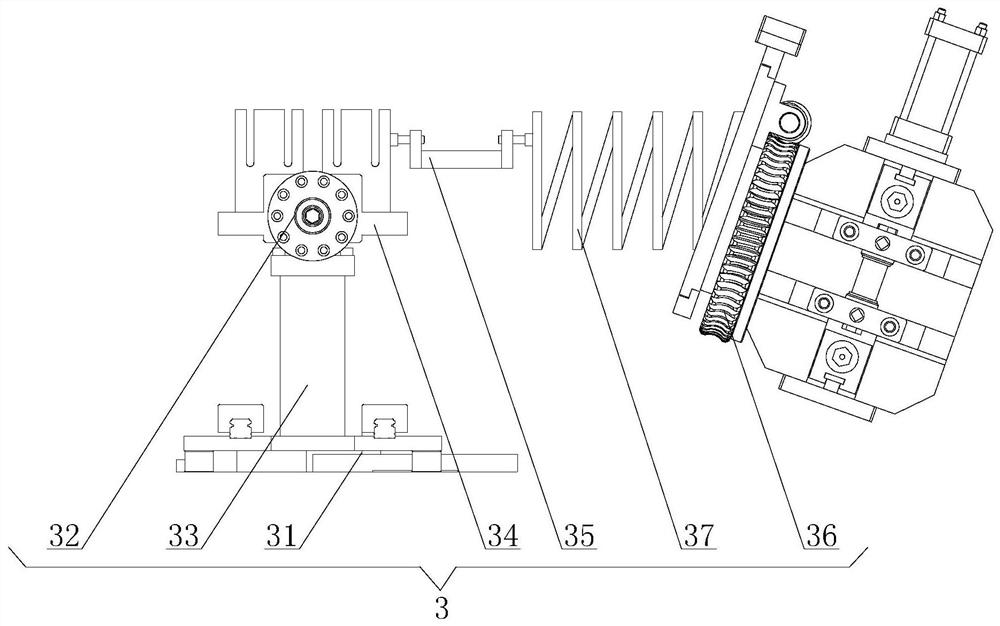

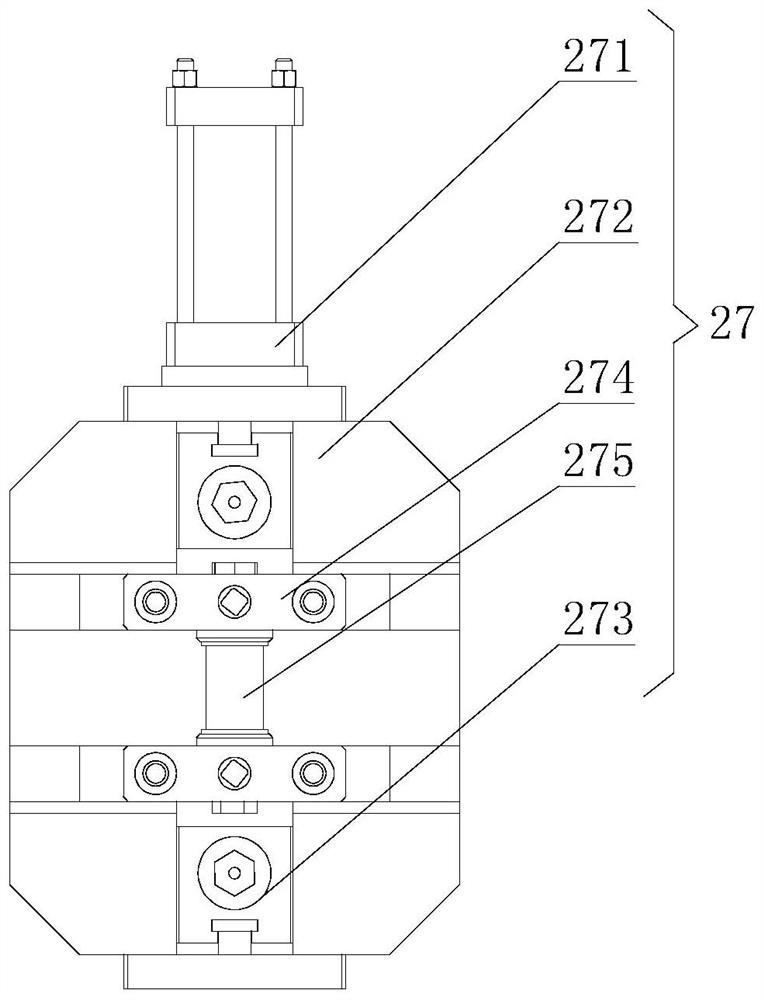

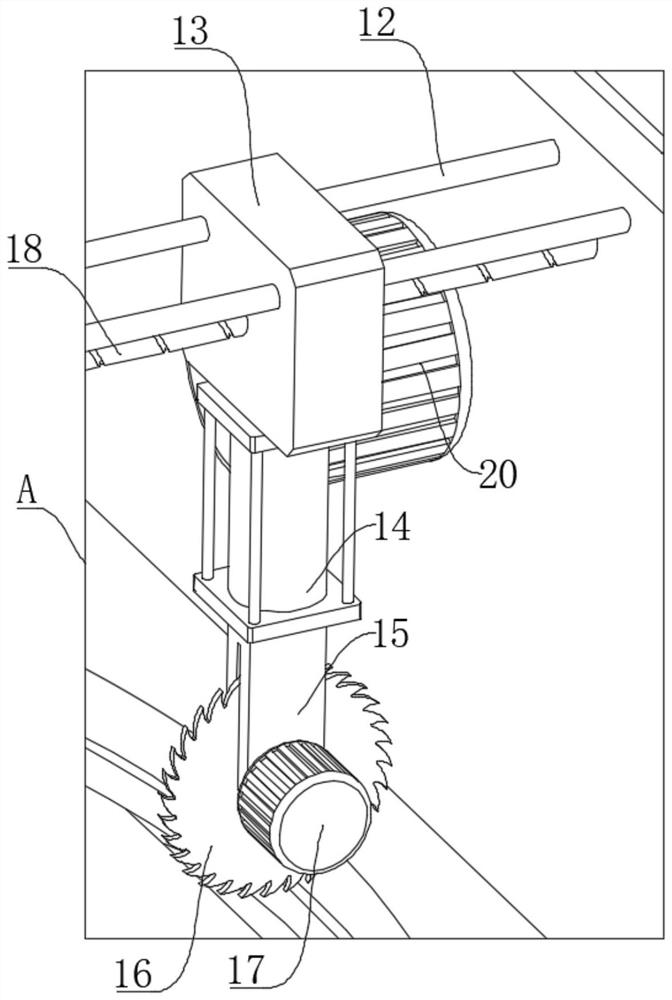

Shrimp digestive tract removing device and method

The invention belongs to the field of machine designs and relates to a shrimp digestive tract removing device and method. The removing device comprises a conveyor belt system, a shrimp compression system and a cutter system, wherein the conveyor belt system is located below the whole device; after shrimps are removed to a target position, the shrimps are compressed through the shrimp compression system; and meanwhile, shrimp digestive tracts are removed through the cutter system. The shrimp digestive tract removing device is simple in structure and convenient to use; the removal efficiency ishigh and a condition that the shrimp digestive tracts are broken is avoided and the effectiveness of removing the shrimp digestive tracts is ensured; and the surface integrity and the beautiful degreeof shrimp bodies can be ensured and unnecessary wastes of shrimp meat are avoided.

Owner:DALIAN UNIV OF TECH

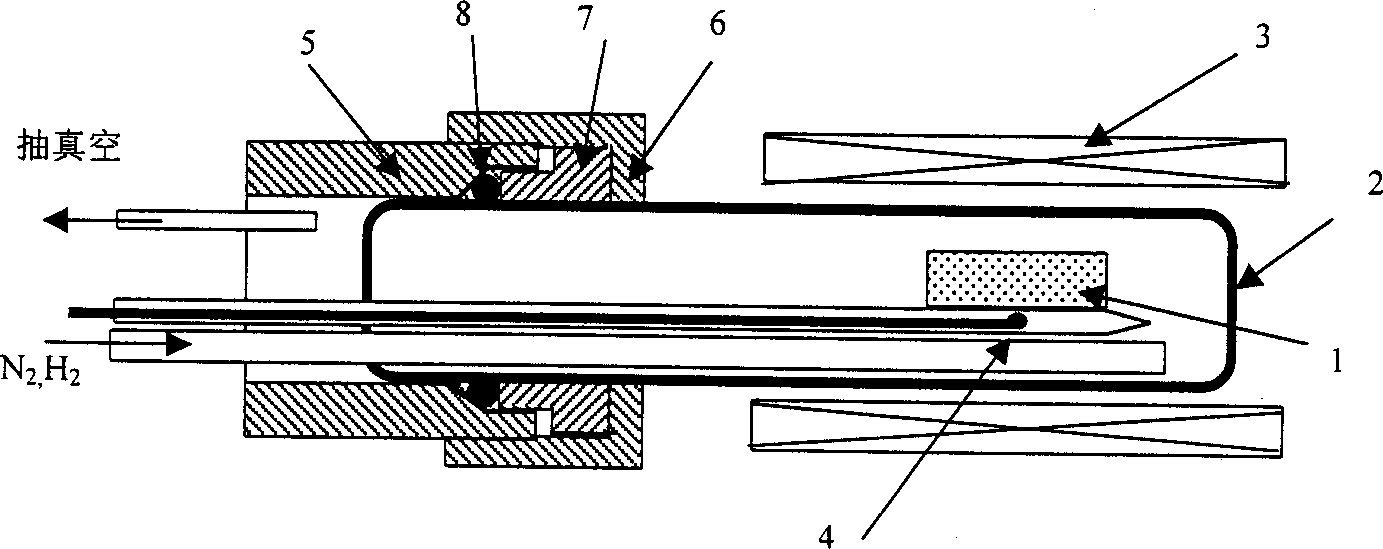

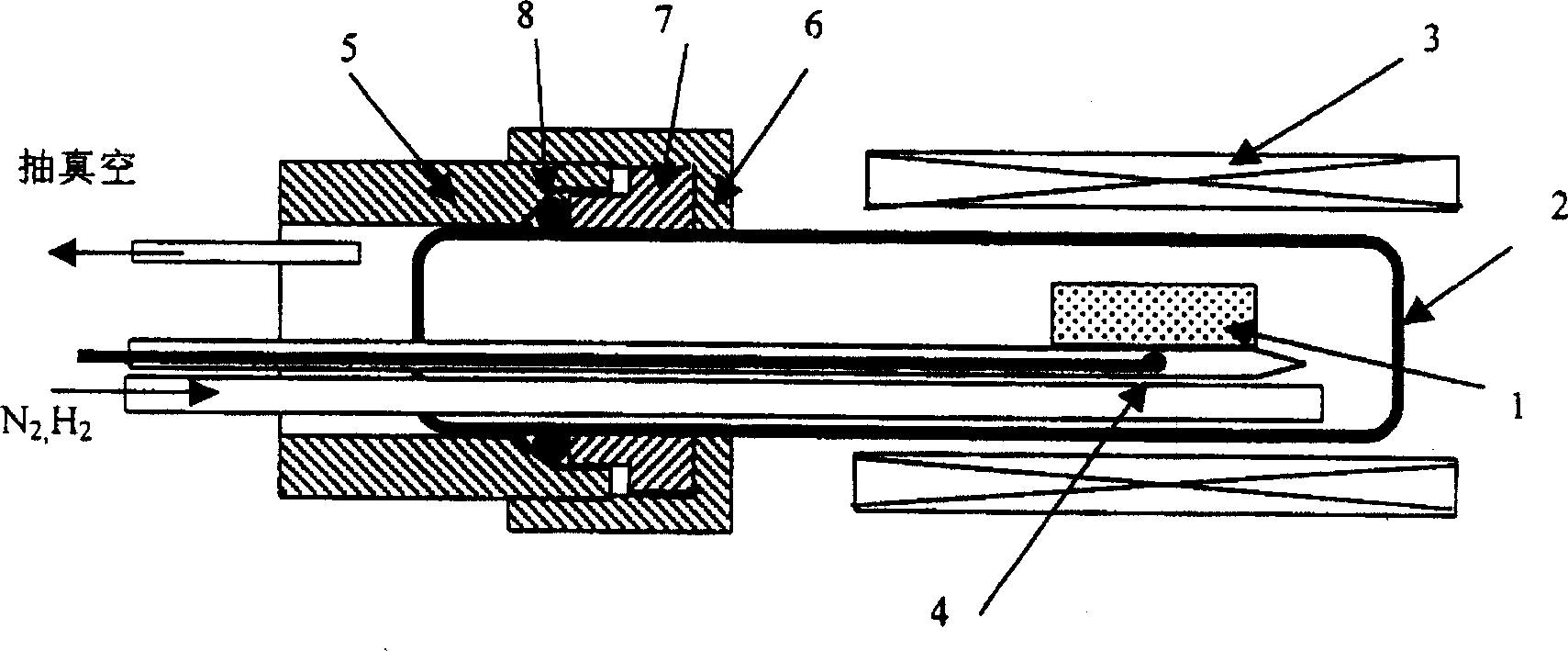

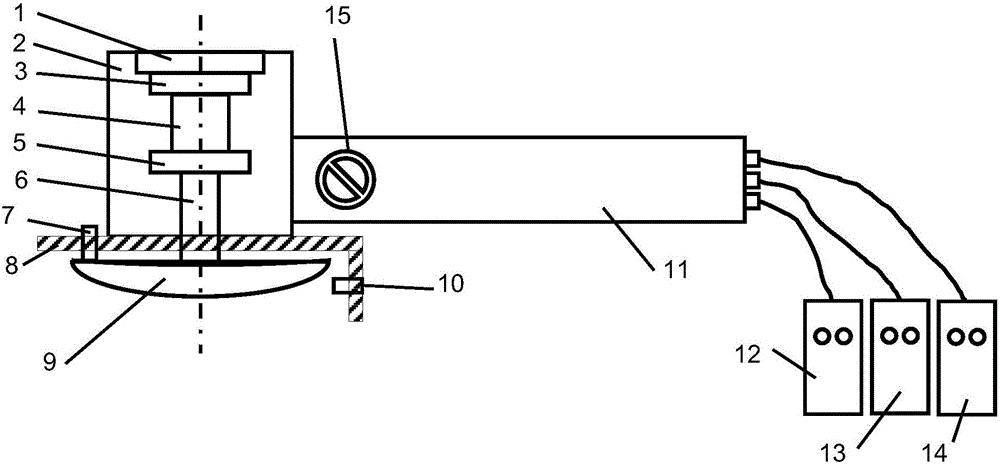

Handheld high-speed electric arc machining equipment and method

InactiveCN103752989ACompact structureReduce weightOther manufacturing equipments/toolsWelding/cutting media/materialsUltrasonic generatorElectric arc

The invention discloses handheld high-speed electric arc machining equipment and method, and belongs to the field of non-traditional machining equipment. The handheld high-speed electric arc machining equipment comprises a shell, a motor, a coupler, a spindle, a connection flange, an amplitude transformer, a protection cover, an electric brush, a conductive grinding wheel, a handle, an ultrasonic generator and an electric arc machining control power supply. The motor drives the spindle to rotate via the coupler. The amplitude transformer penetrates through the lower end of the shell and is fixedly connected with the conductive grinding wheel in an insulation manner. The spindle drives the amplitude transformer to rotate via the connection flange. Amplitude and vibrating frequency of the amplitude transformer are adjusted via the ultrasonic generator. The conductive grinding wheel is connected with a cathode of the electric arc machining control power supply via the electric brush. Three machining modes including high-speed electric arc machining, ultrasonic vibrating and grinding are combined, and by means of combining the machining modes, and a material removal rate of the handheld high-speed electric arc machining equipment can reach 6-8 times of that of normal electrosparking, and even more than 10 times for parts of materials, so that the handheld high-speed electric arc machining equipment is quite applicable to onsite repairing and machining for surface fatigue layers of parts of large and non-movable waste machines.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

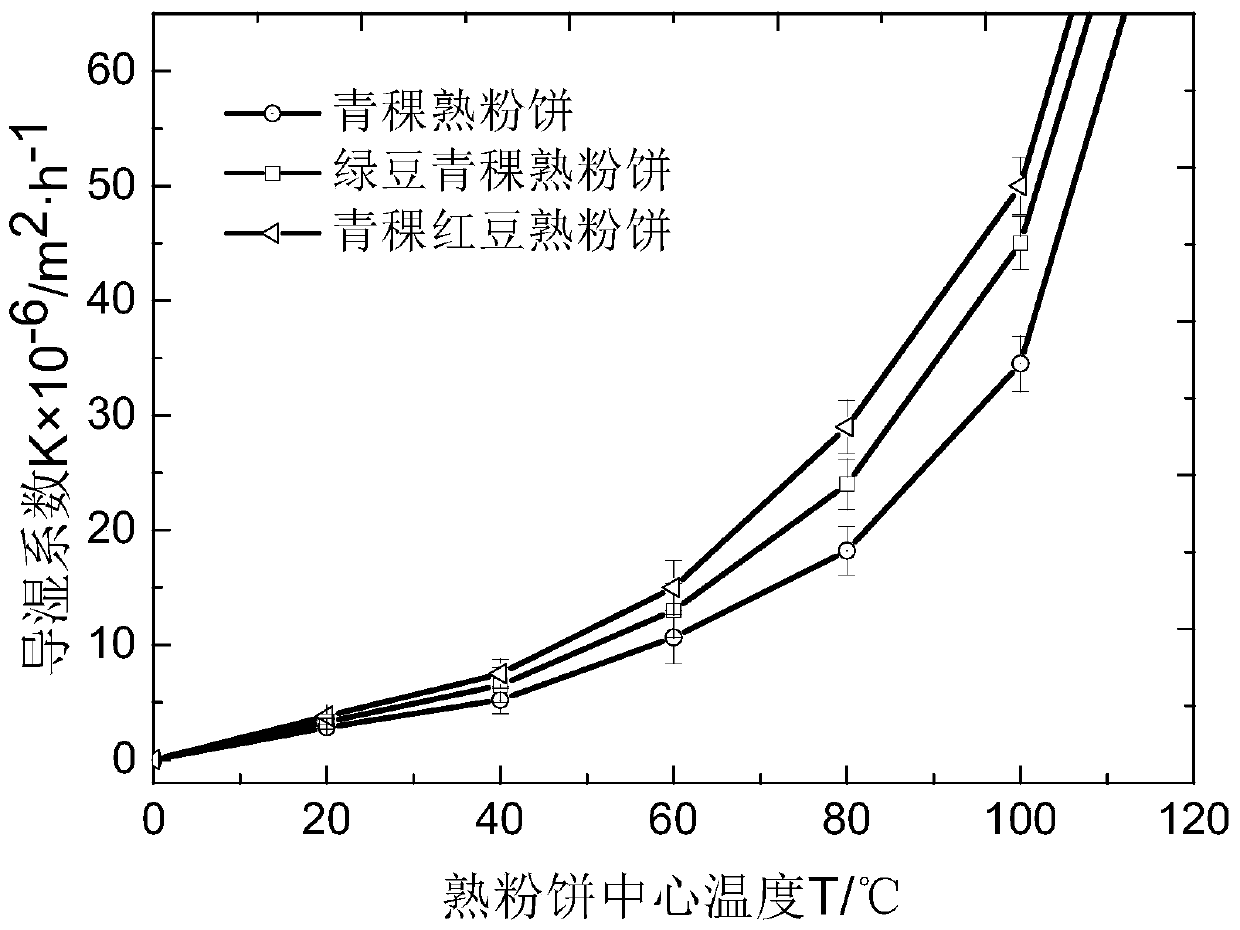

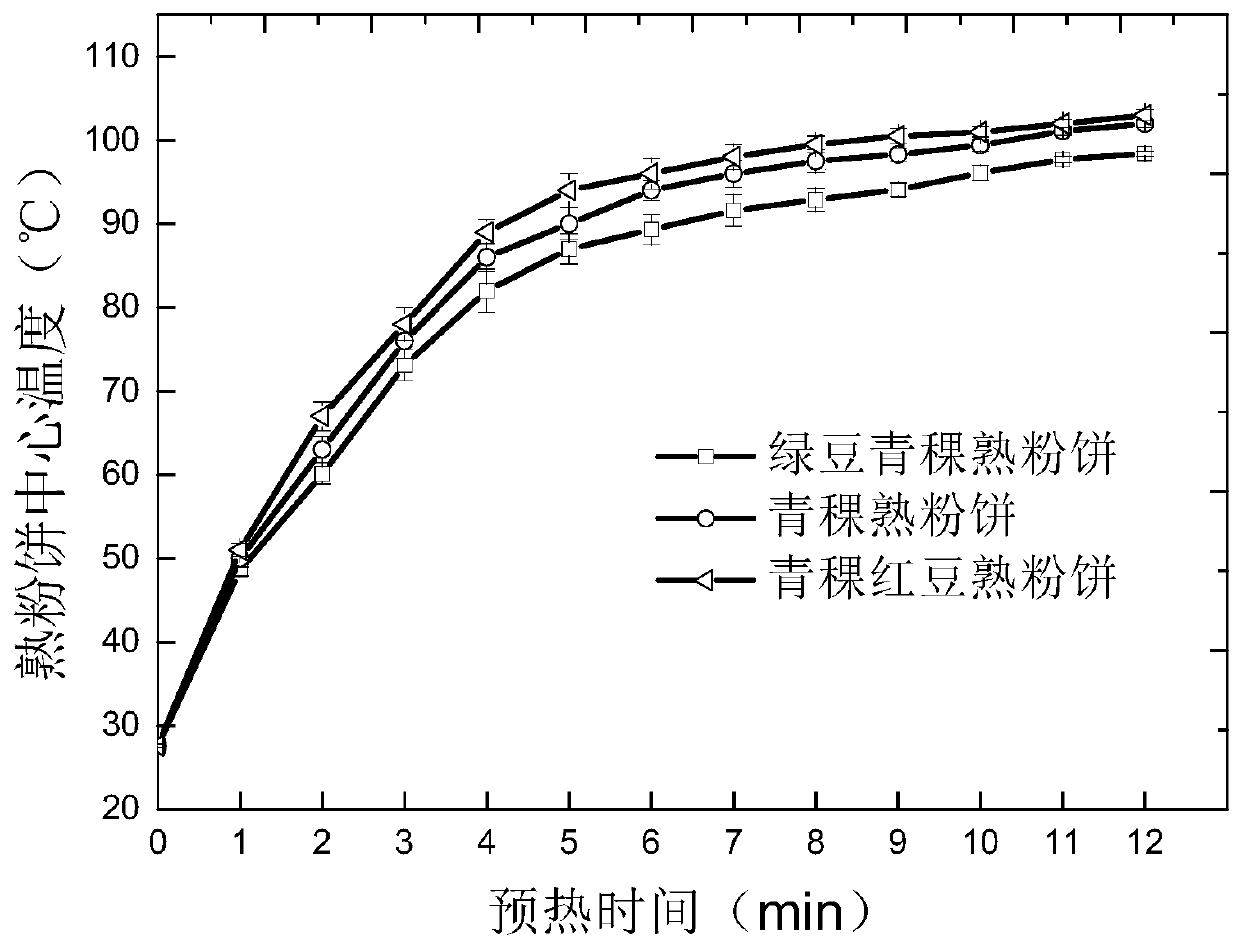

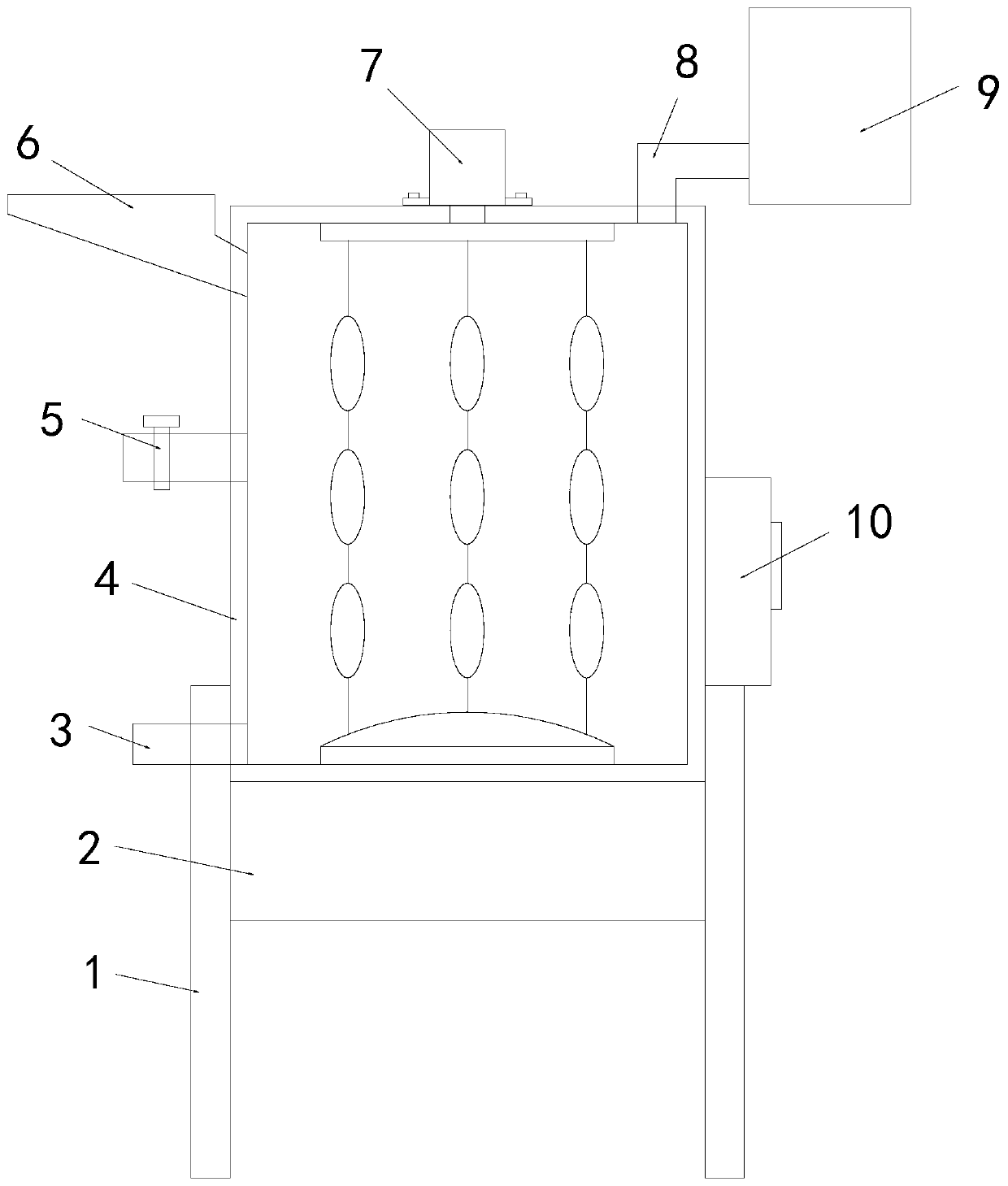

Rapid baking method and device for cooked puff cake

ActiveCN109769882AIncrease ambient humidityCrispy texture propertiesBaking ovenBaking processesIcing sugarCooking & baking

The invention discloses a rapid baking method for a cooked puff cake. The method comprises the following steps that 1, one or more cooked flour materials are taken, all cooked flour materials are mixed to be uniform to obtain a mixed flour material for use; 2, sugar, water and grease are taken to be mixed and stirred to be uniform to obtain a paste mixture for use; 3, the mixed flour material in step 1 is added into the paste mixture obtained in step 2, and stirring and press molding are performed to obtain the molded cooked puff cake; 4, the cooked puff cake obtained in step 3 is subjected toconstant wetness preheating, and the preheating time is 8-10 min; low and medium temperature hot-blast air baking is performed on the cooked puff cake, and the low and medium temperature baking timeis 25-30 min. A rapid baking device for the cooked puff cake comprises a constant wetness preheating assembly, a hot-blast-air baking assembly, a central processing unit and a displayer; the constantwetness preheating assembly comprises a constant wetness preheater body, a front end conveying mechanism, a water storage mechanism and the like. The method has the advantages that the machining timeis short, energy consumption is low, and the made product is crispy in structure. The invention belongs to the technical field of puff cake production.

Owner:SOUTH CHINA UNIV OF TECH

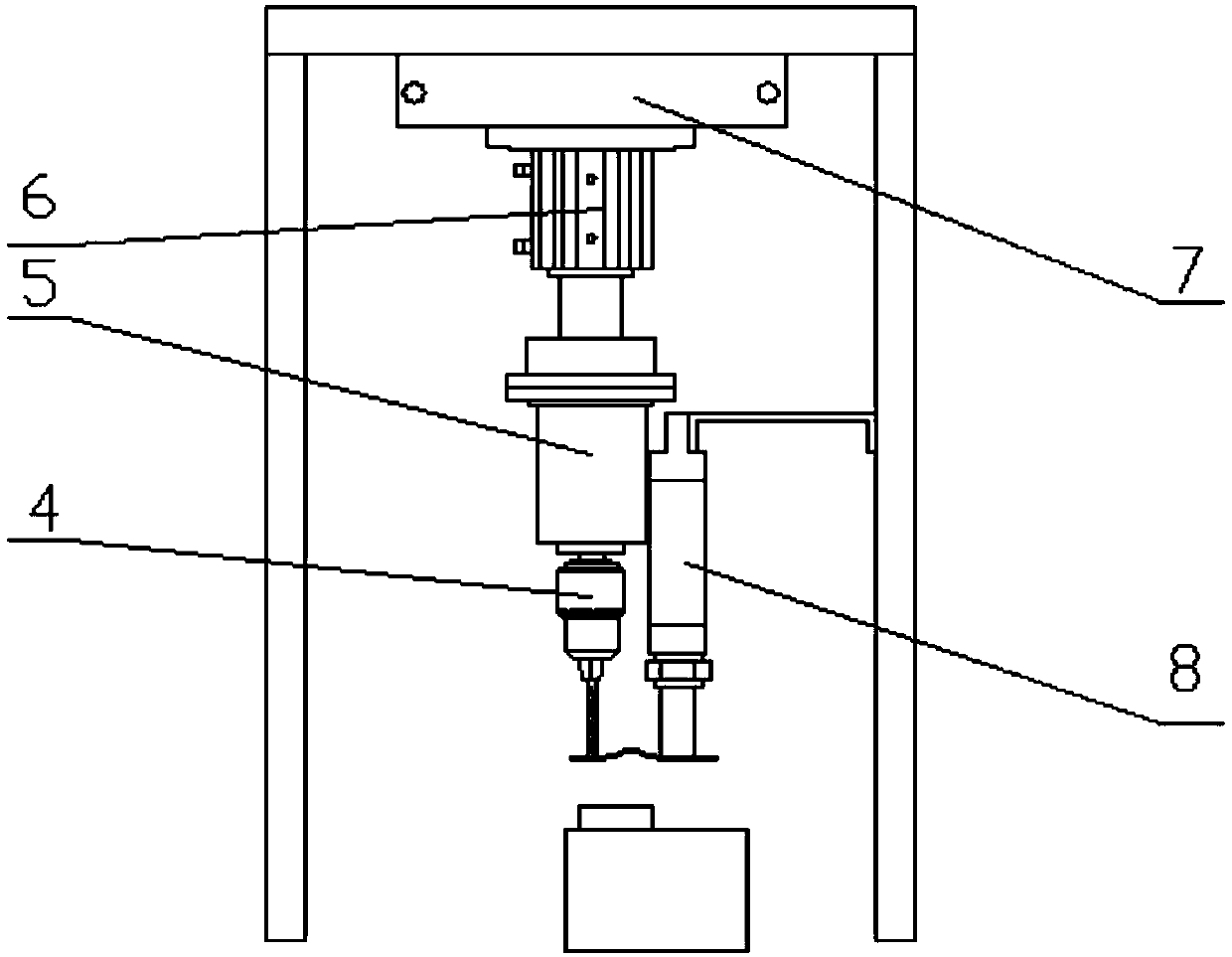

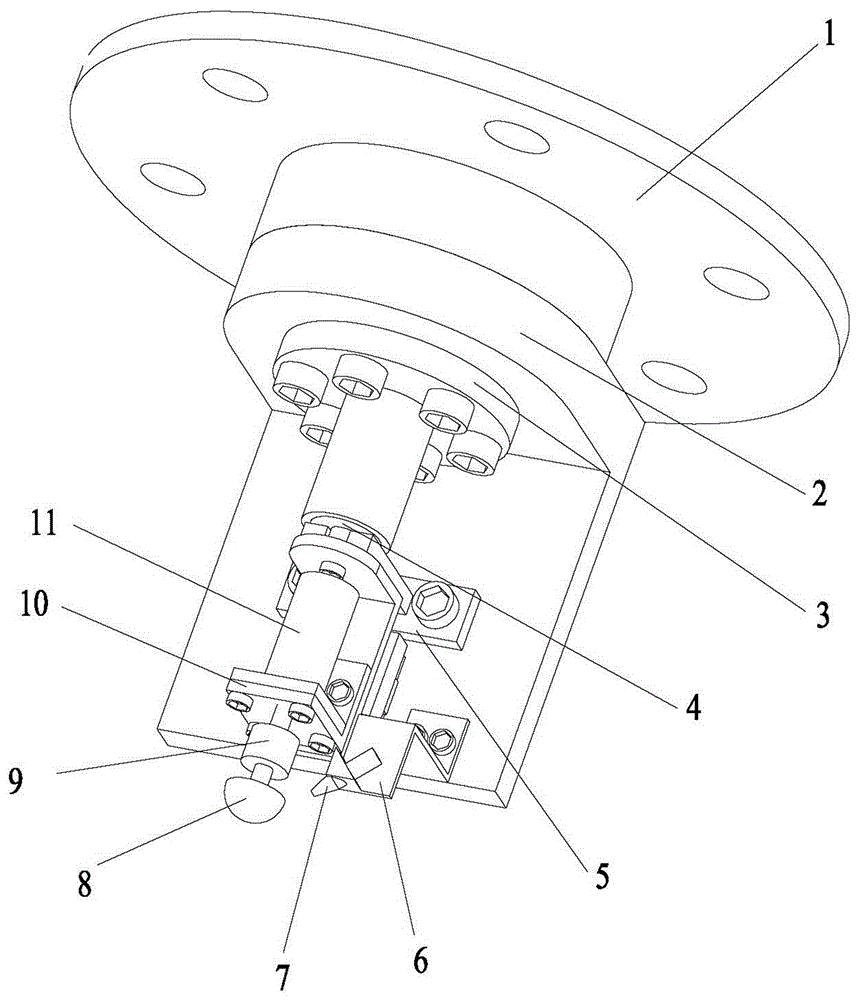

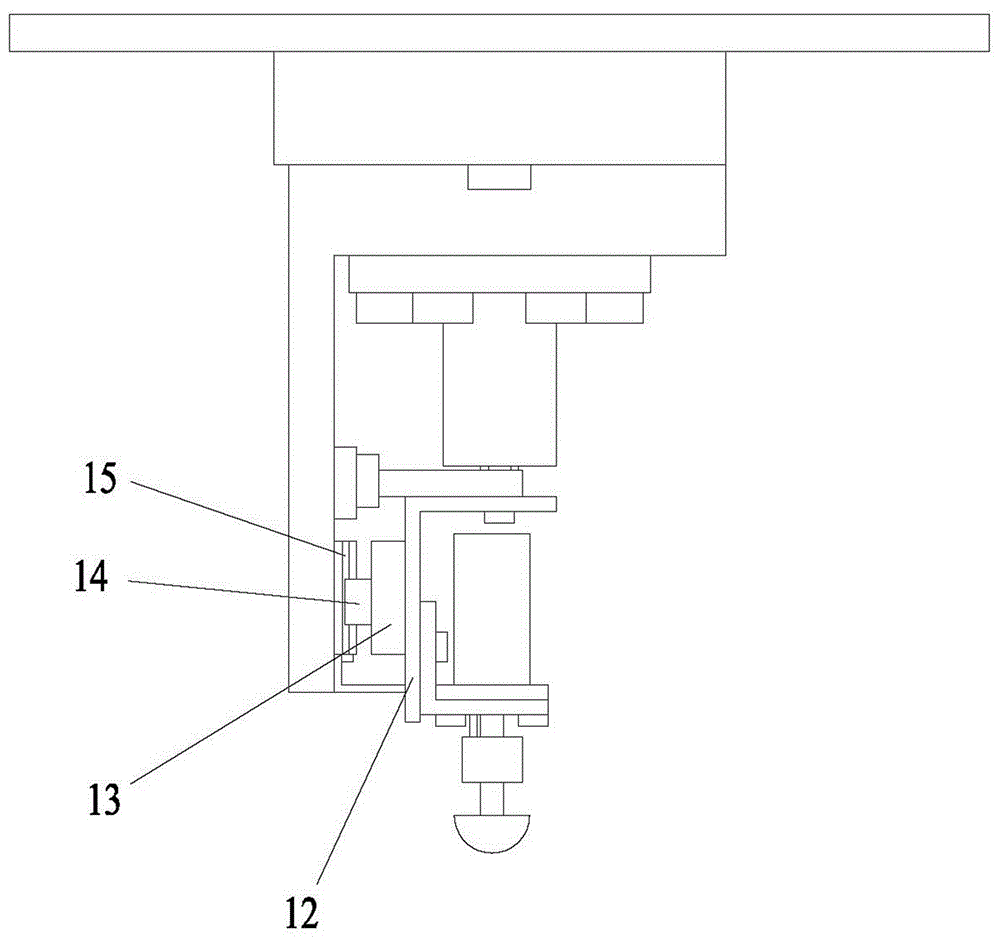

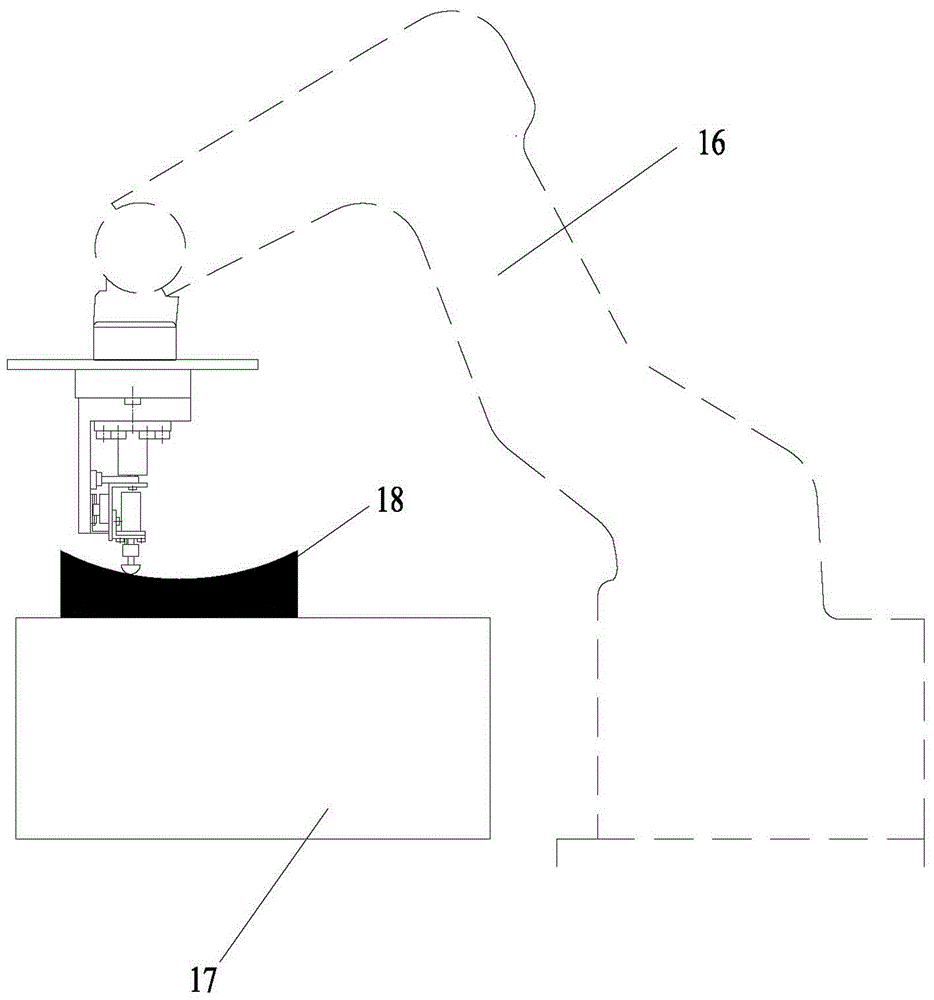

Mechanical hammering flattening device

ActiveCN105964779AImprove processing efficiencyImprove surface integrityShaping toolsNumerical controlFree form

The invention relates to a mechanical hammering flattening device which is installed on a numerically-controlled machine tool or a robot. The mechanical hammering flattening device is characterized by comprising a machine frame, a piezoelectric ceramic actuator, a supporting frame, a motor, a hammering head and an air gun, wherein the piezoelectric ceramic actuator, the supporting frame, the motor, the hammering head and the air gun are arranged on the machine frame. The supporting frame is slidably arranged on the machine frame according to a preset track, an inner shaft of the piezoelectric ceramic actuator is fixedly connected with the supporting frame, the motor is fixedly arranged on the supporting frame, a motor output shaft is in transmission connection with the hammering head, and the air gun is arranged on the side of the motor output shaft and connected with an external connection power source. An air outlet of the air gun is aligned with an acting point of the hammering head on a workpiece. The mechanical hammering flattening device is used for processing the plane or free-form surface workpiece, and not only is high in processing efficiency, but also can improve workpiece surface hardness.

Owner:XIAMEN UNIV OF TECH

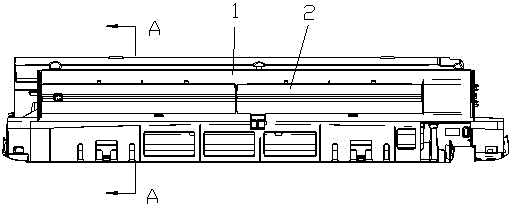

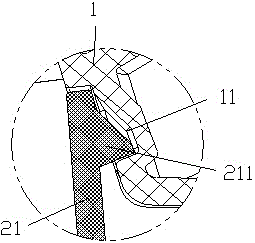

Air outlet structure of air conditioner, mounting method and air conditioner

InactiveCN106322708AEasy to fixGuaranteed Surface IntegrityAir-flow control membersEngineeringSurface integrity

The invention provides an air outlet structure of an air conditioner, a mounting method and the air conditioner. The air outlet structure of the air conditioner comprises a base and a guide plate fixed to the base in a clamped mode. The guide plate comprises a first guide part and a second guide part, and the first guide part and the second guide part are arranged at a certain angle. At least two first buckle assemblies are arranged between the base and the first guide part, and at least two second buckle assemblies are arranged between the base and the second guide part. According to the air outlet structure of the air conditioner, the first guide part and the second guide part which are arranged at a certain angle are fixed to the base in the clamped mode, so that the clamping stress direction of the first buckle assemblies is different from the clamping stress direction of the second buckle assemblies, force from different directions can be borne after combination, and the firmness after fixing is improved; in addition, fixation between the base and the guide plate with screws is omitted, and the assembling efficiency is improved; and furthermore, the first buckle assemblies and the second buckle assemblies are all of a hidden buckle structural form, so that surface integrity of the appearance surface is guaranteed, and the strength of structural components can be improved.

Owner:HISENSE (GUANGDONG) AIR CONDITIONER

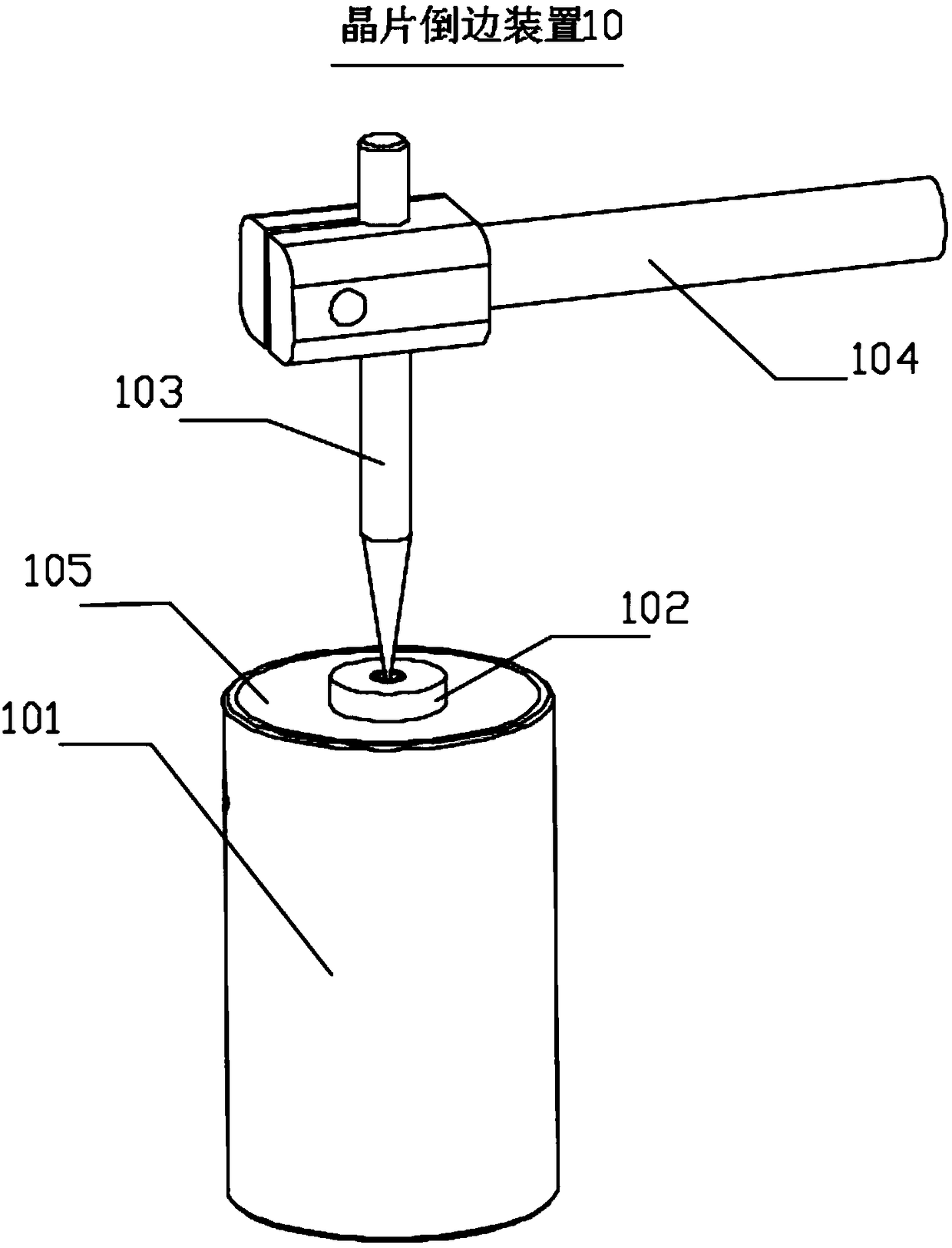

Wafer edge reversing device and edge reversing method

PendingCN109176217AAchieve relative motionGuaranteed Surface IntegrityEdge grinding machinesGrinding work supportsSurface roughnessMaterials science

The invention discloses a wafer edge reversing device and an edge reversing method. The device comprises a mold reversing cylinder, a buckling part, a thimble and a bracket; the mold reversing cylinder can be rotated, and the top is of a bowl-shaped mold reversing structure; the buckling part is arranged on the inclined surface of the mold reversing structure; wafers for mold reversing are fixedlyplaced in the buckling part; one end of a point of the thimble is tightly contacted with the surface, far from the mold reversing structure, of the buckling part, and the other end is fixedly connected with the bracket; grinding sand liquid is poured in the mold reversing structure; and the grinding sand liquid can be filled in gaps between the wafers and the mold reversing structure. The devicecan guarantee the surface completeness of reversed edges of the wafers, reduces the edge collapse phenomenon and the surface roughness, and improves the product yield.

Owner:CHENGDU TIMEMAKER CRYSTAL TECH

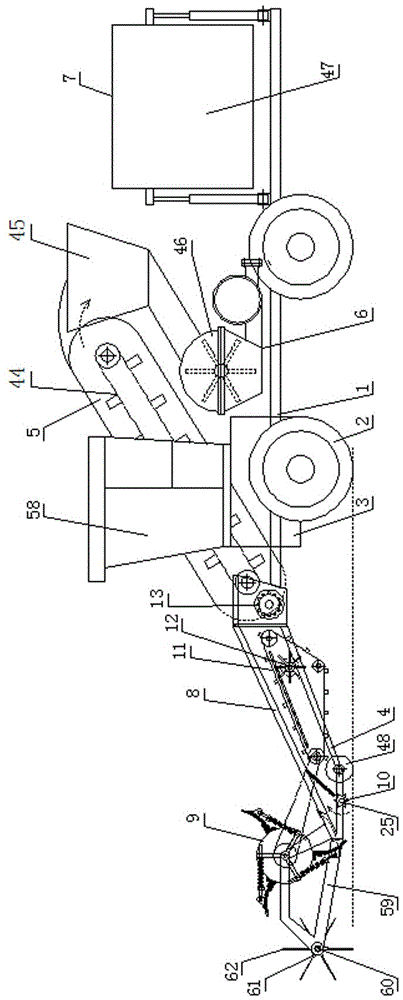

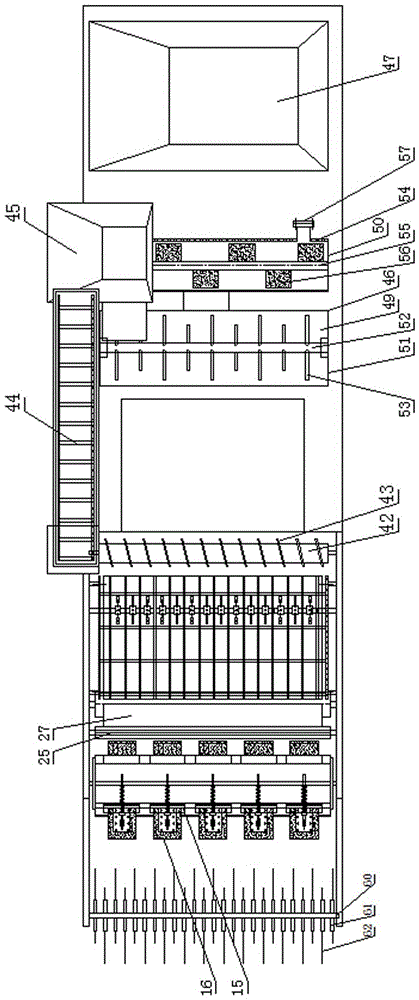

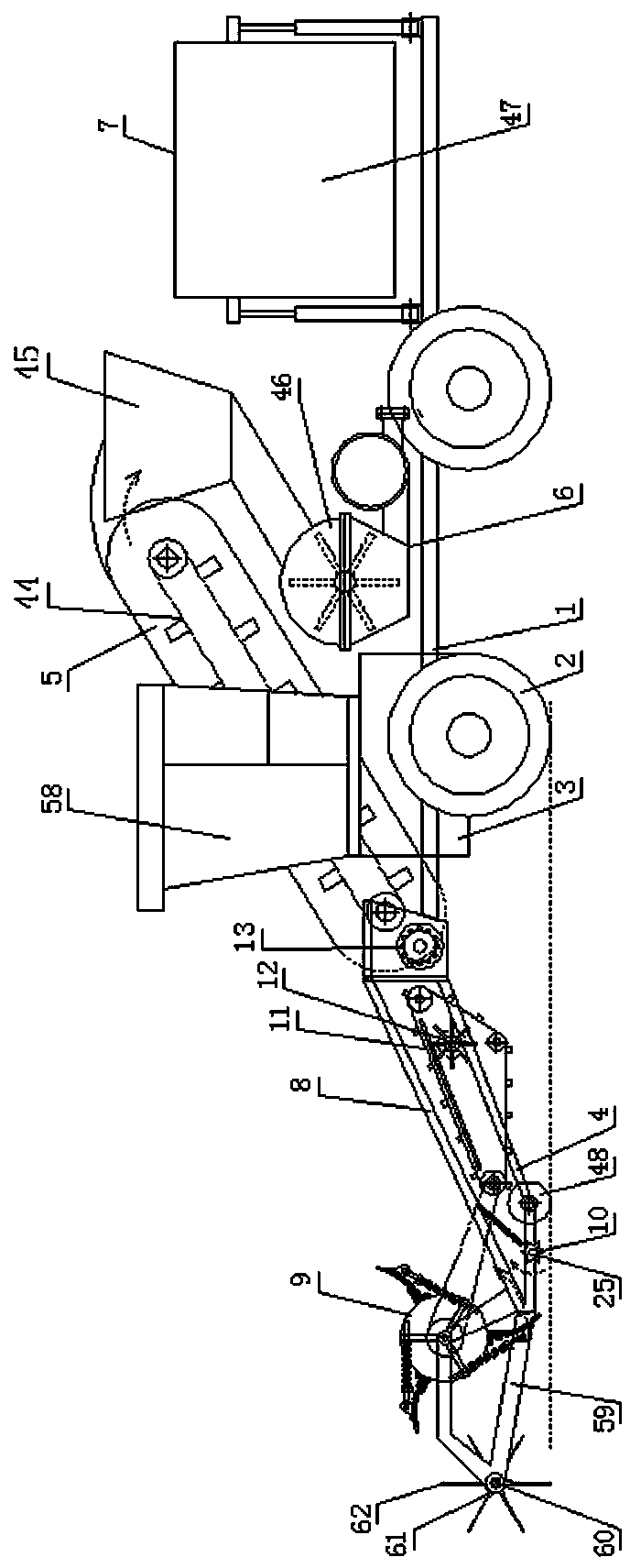

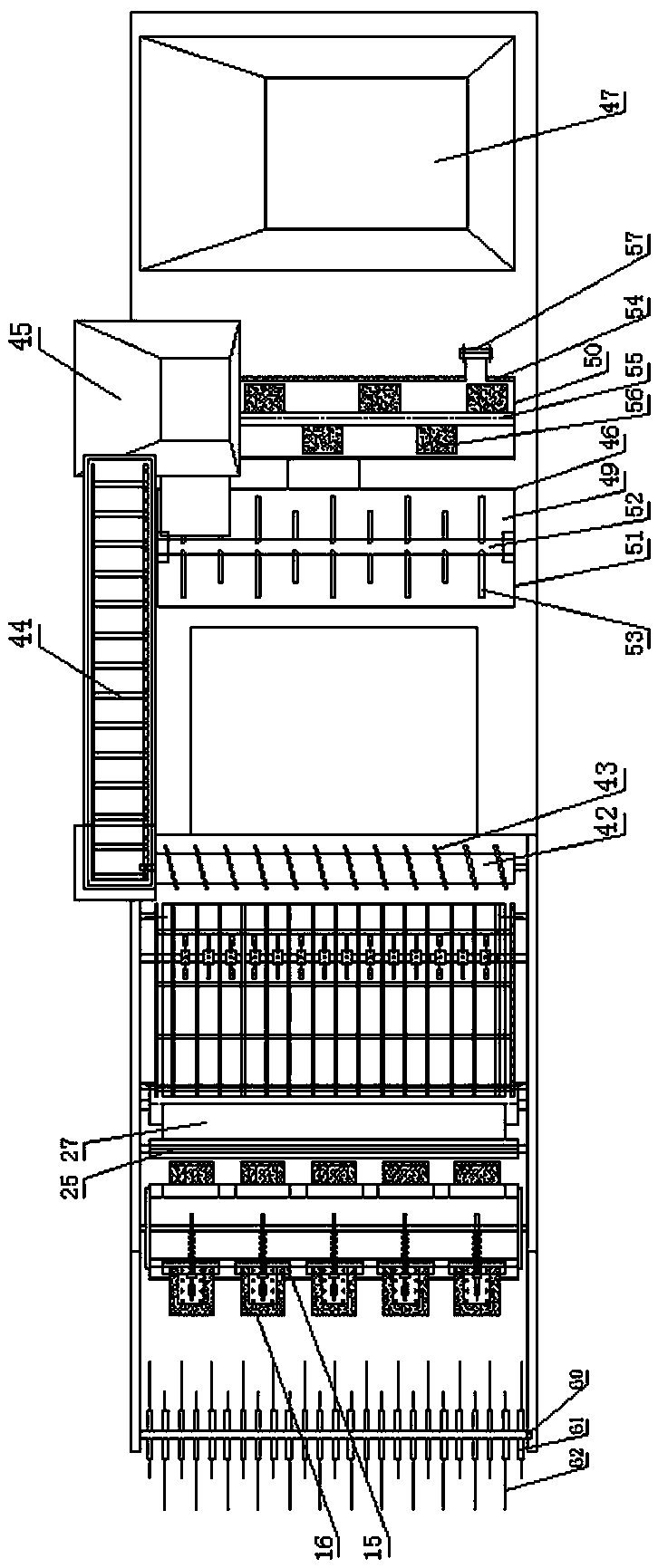

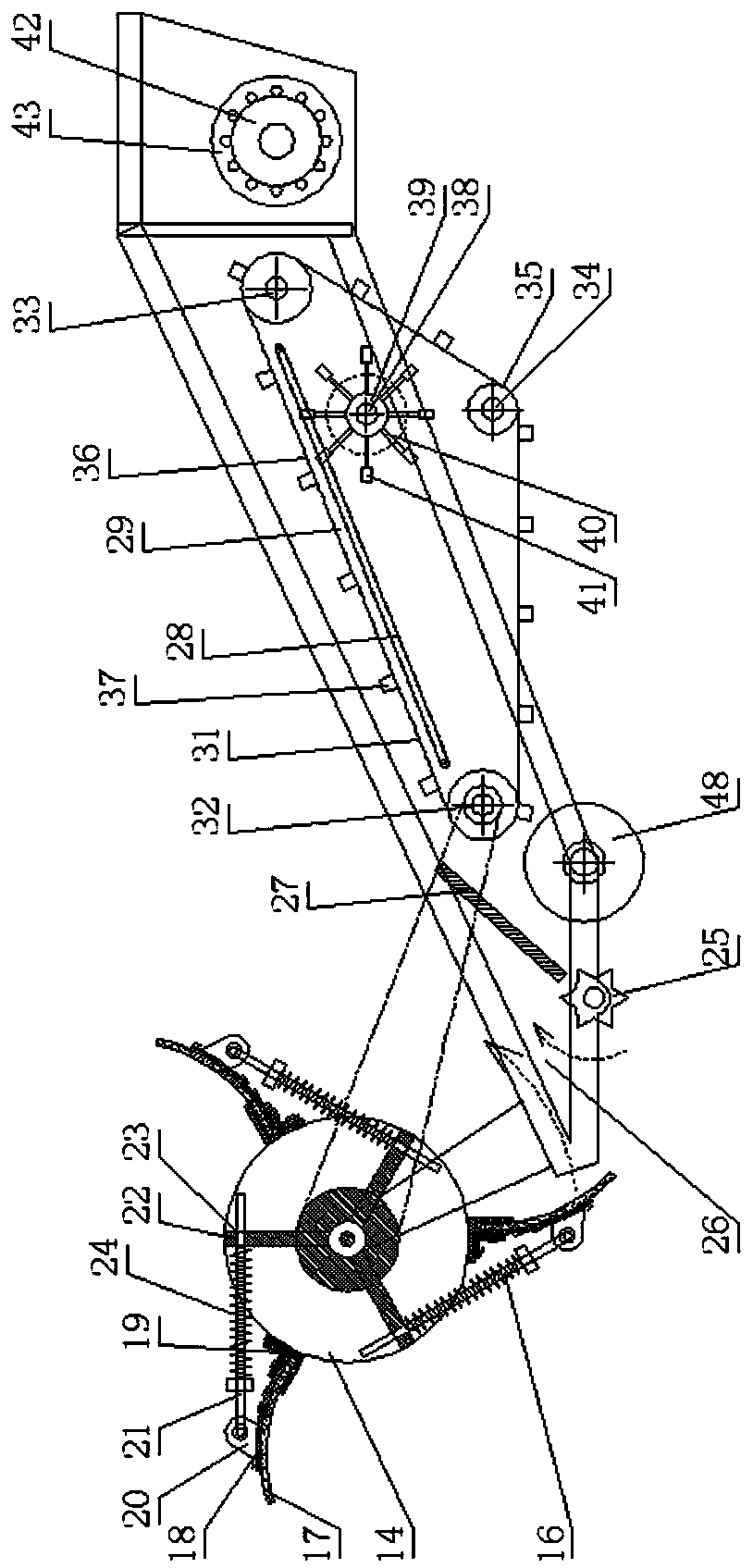

Self-propelled type melon-striking and seed-extracting harvester

ActiveCN106358575AAvoid breakingGuaranteed Surface IntegrityMowersThreshersVehicle frameAgricultural engineering

The invention provides a self-propelled type melon-striking and seed-extracting harvester and belongs to the technical field of agricultural machinery. The self-propelled type melon-striking and seed-extracting harvester structurally comprises a vehicle frame, wheels, a power mechanism, a plough platform, a hoisting mechanism, a melon-striking and seed-extracting mechanism and a storage mechanism, wherein the plough platform comprises a plough platform frame, a melon-pulling mechanism, an auxiliary melon-pulling mechanism, a melon conveying mechanism, a seedling mechanism and a horizontal spiral conveying mechanism; the structure of the melon-pulling mechanism is as follows: a rolling roller is horizontally erected at the front end of the plough platform frame, horizontal melon-pulling sets which are rotated forward and arrayed in rows are arranged on the roller surface of the rolling roller in the manner of embracing the roller surface of the rolling roller, and three to ten melon-pulling units are horizontally arrayed in rows and formed into the horizontal melon-pulling sets; a melon-pulling channel is formed between the adjacent hexagonal rolling shaft and rolling roller; and the seedling mechanism is arranged on the plough platform frame under the rear end of a longitudinal screen frame. The self-propelled type melon-striking and seed-extracting harvester utilizes the synergistic effect of all mechanisms to harvest melons, strike the melons and extract seeds in turn; upstream and downstream structures are compactly jointed with each other; and the harvesting is free from error, high in error-tolerant rate and stable.

Owner:DEZHOU CHUNMING AGRI MACHINERY

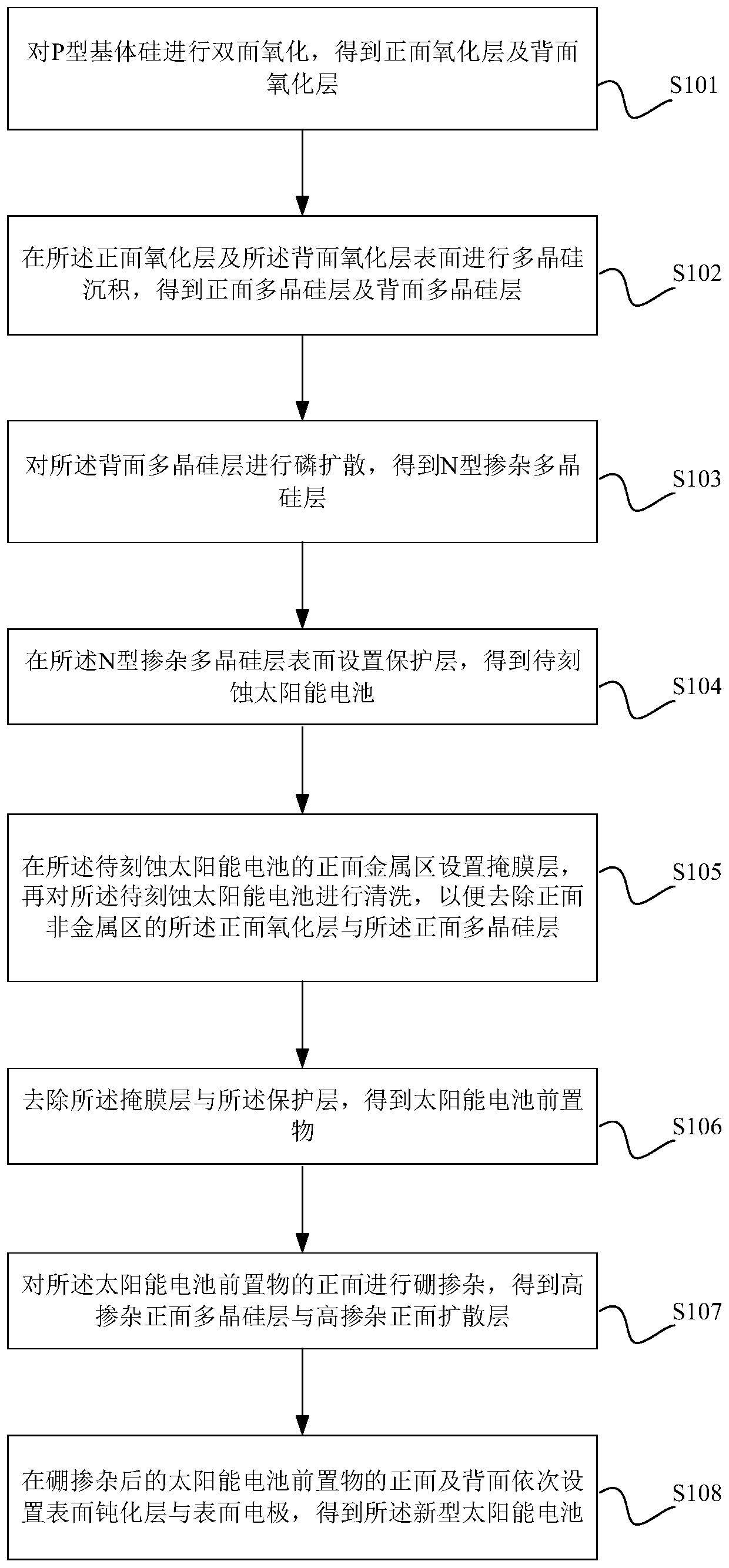

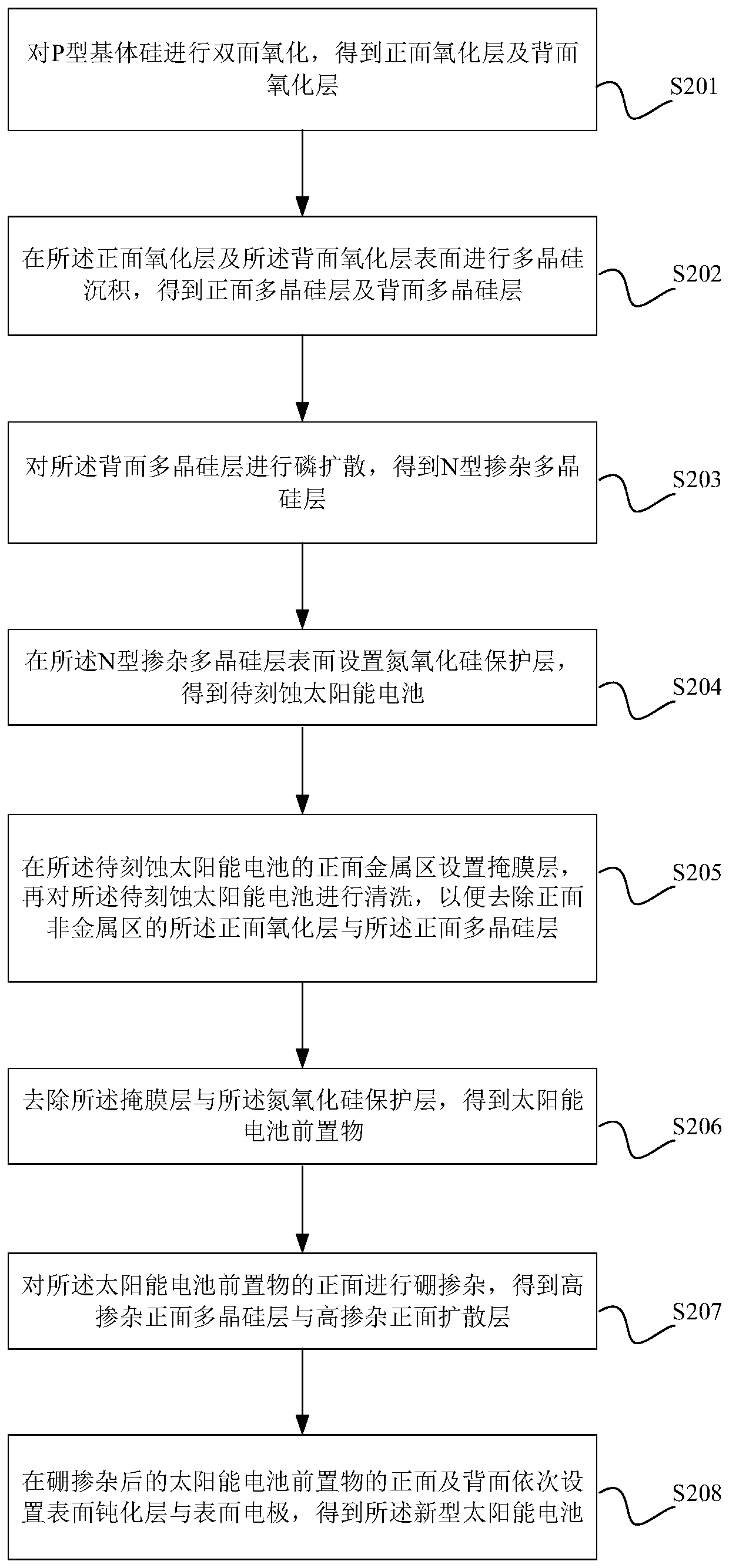

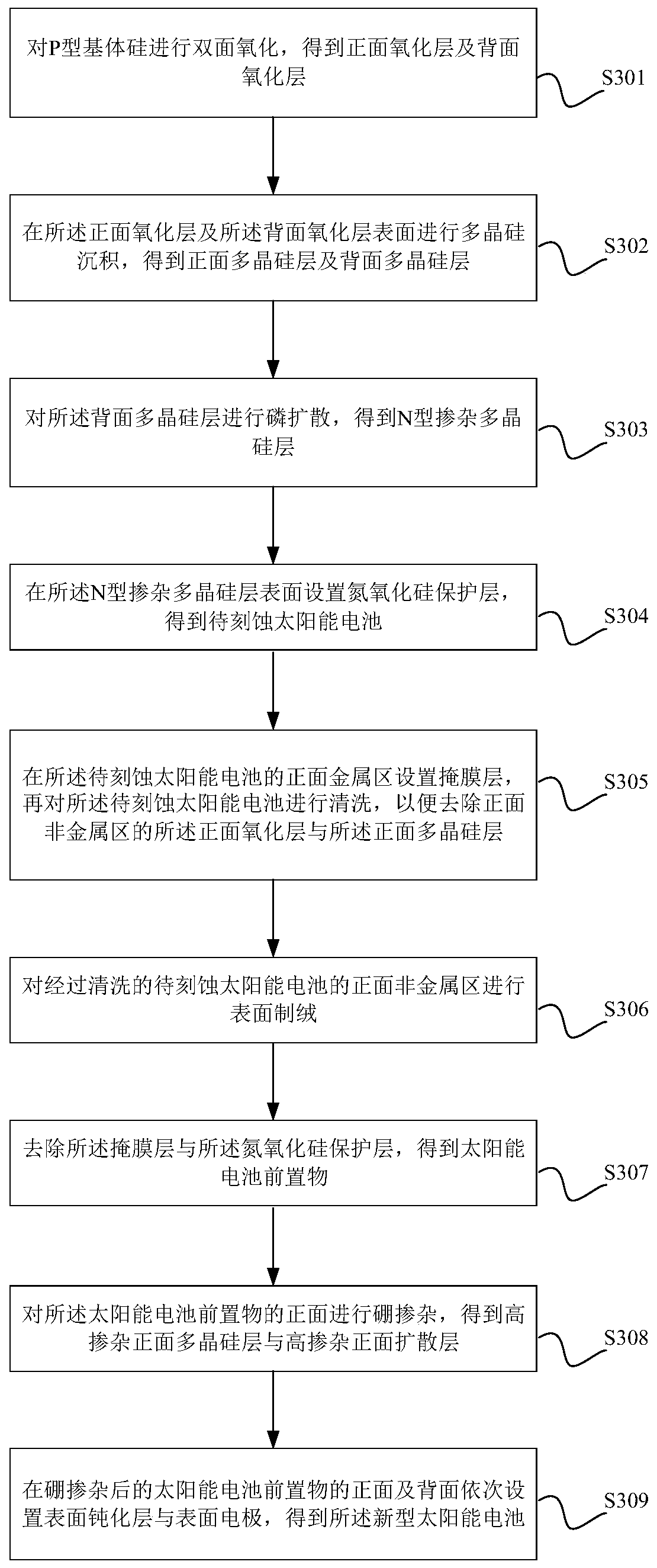

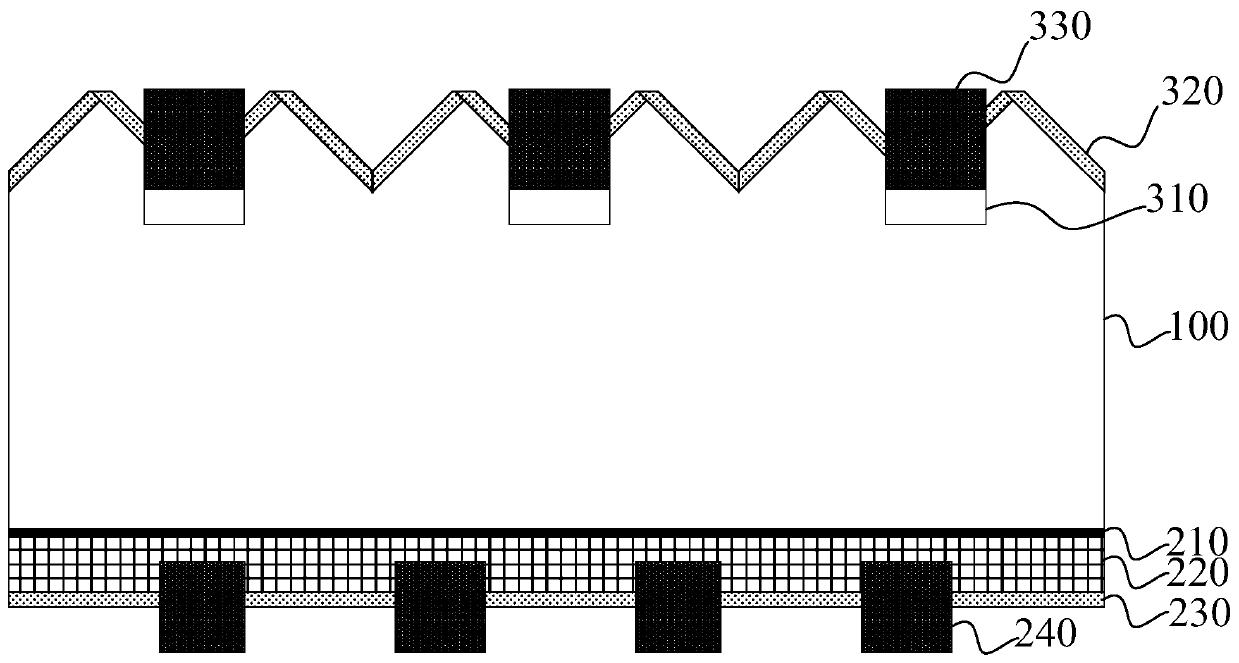

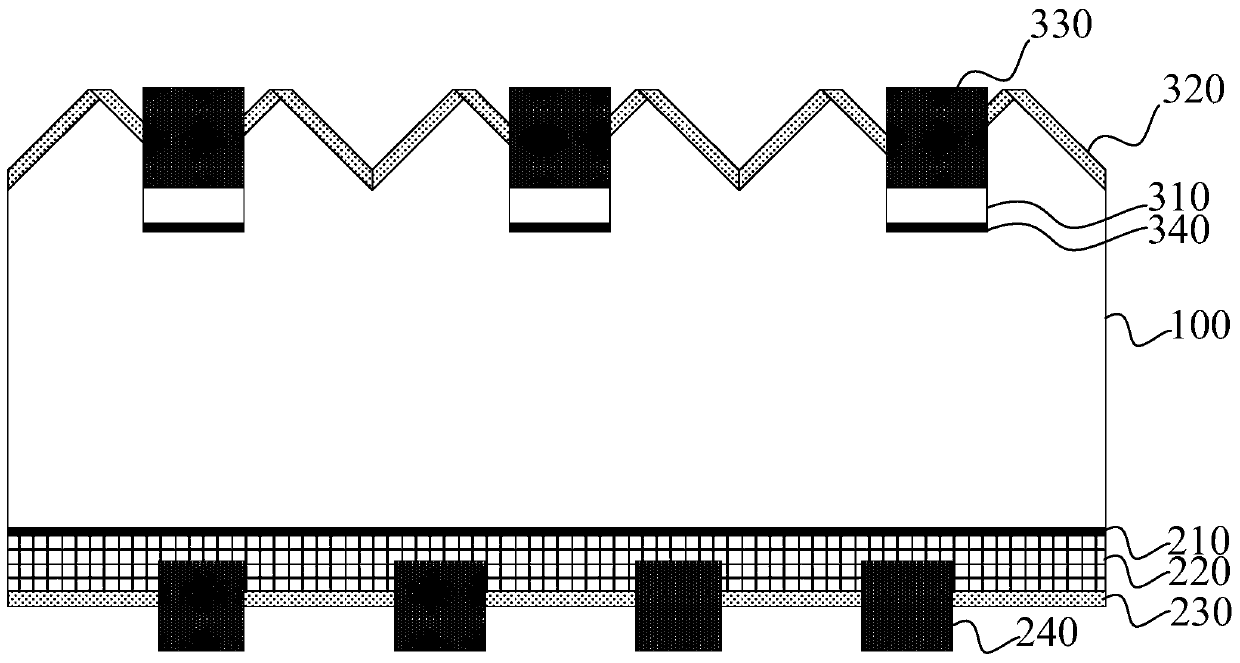

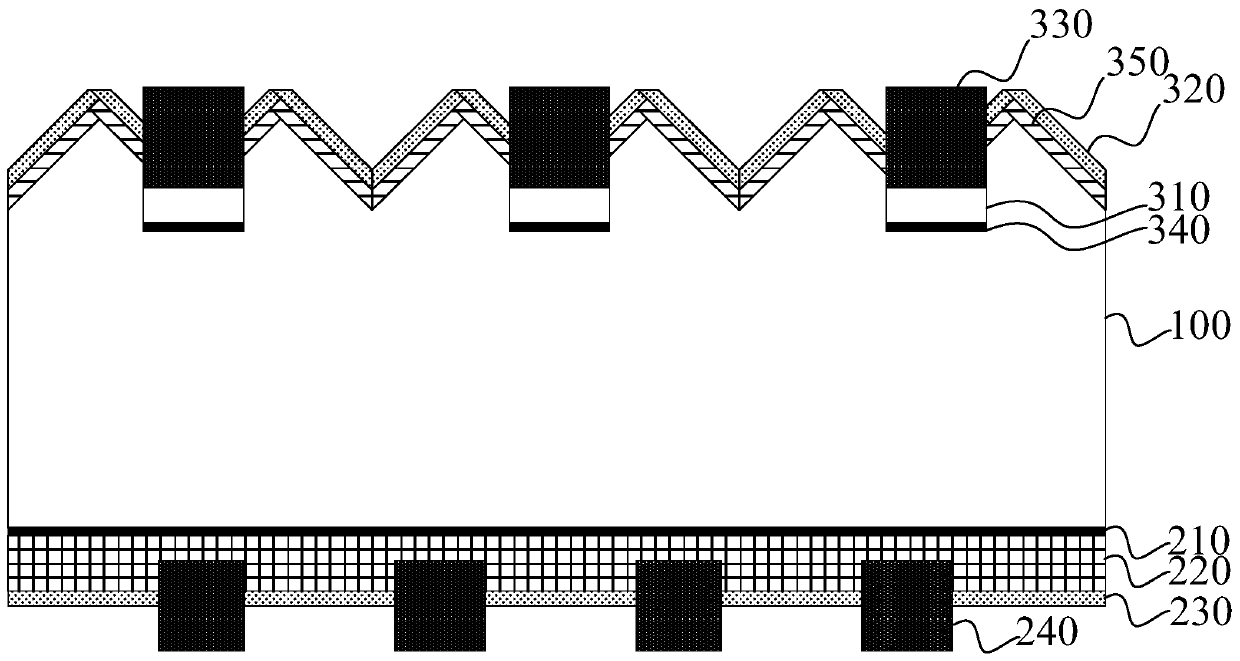

Novel solar cell and preparation method thereof

InactiveCN111584685ASimple production processIncrease productivityFinal product manufacturePhotovoltaic energy generationBattery cellMaterials science

The invention discloses a preparation method of a novel solar cell, and the method comprises the steps: carrying out the double-side oxidation of P-type substrate silicon, and then carrying out the polycrystalline silicon deposition to obtain a front polycrystalline silicon layer and a back polycrystalline silicon layer; performing phosphorus diffusion on the back polycrystalline silicon layer toobtain an N-type doped polycrystalline silicon layer; arranging a protective layer on the surface of the N-type doped polycrystalline silicon layer to obtain a solar cell to be etched; removing a front oxide layer and the front polycrystalline silicon layer in a front non-metal region; removing a mask layer and the protective layer to obtain a solar cell front object; carrying out boron doping onthe front surface of the solar cell front object; and sequentially arranging a surface passivation layer and a surface electrode on the front surface and the back surface of the boron-doped solar cellfront object to obtain the novel solar cell. According to the invention, the production process of the solar cell is simplified, the emitter damage and non-uniformity are reduced, and the cell efficiency is improved. The invention also provides the novel solar cell with the above advantages.

Owner:上饶捷泰新能源科技有限公司

Graphite multi-polarization fine purifier and graphite multi-polarization fine purification method

InactiveCN112624105AWon't wear outGuaranteed Surface IntegrityCarbon compoundsPurification methodsMagnetic poles

Owner:童志超

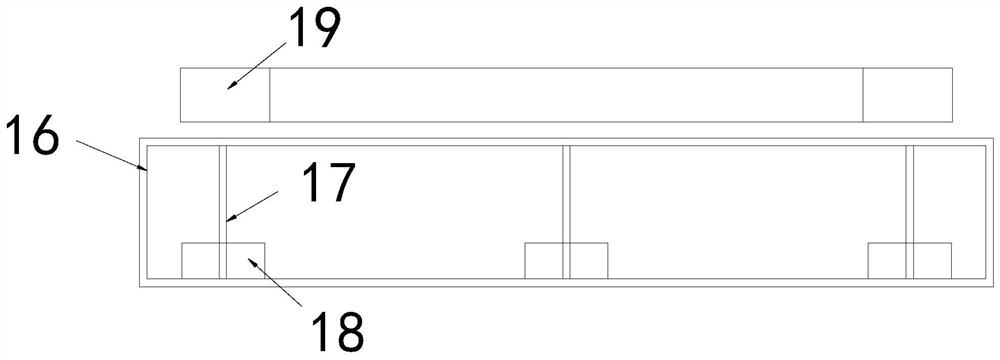

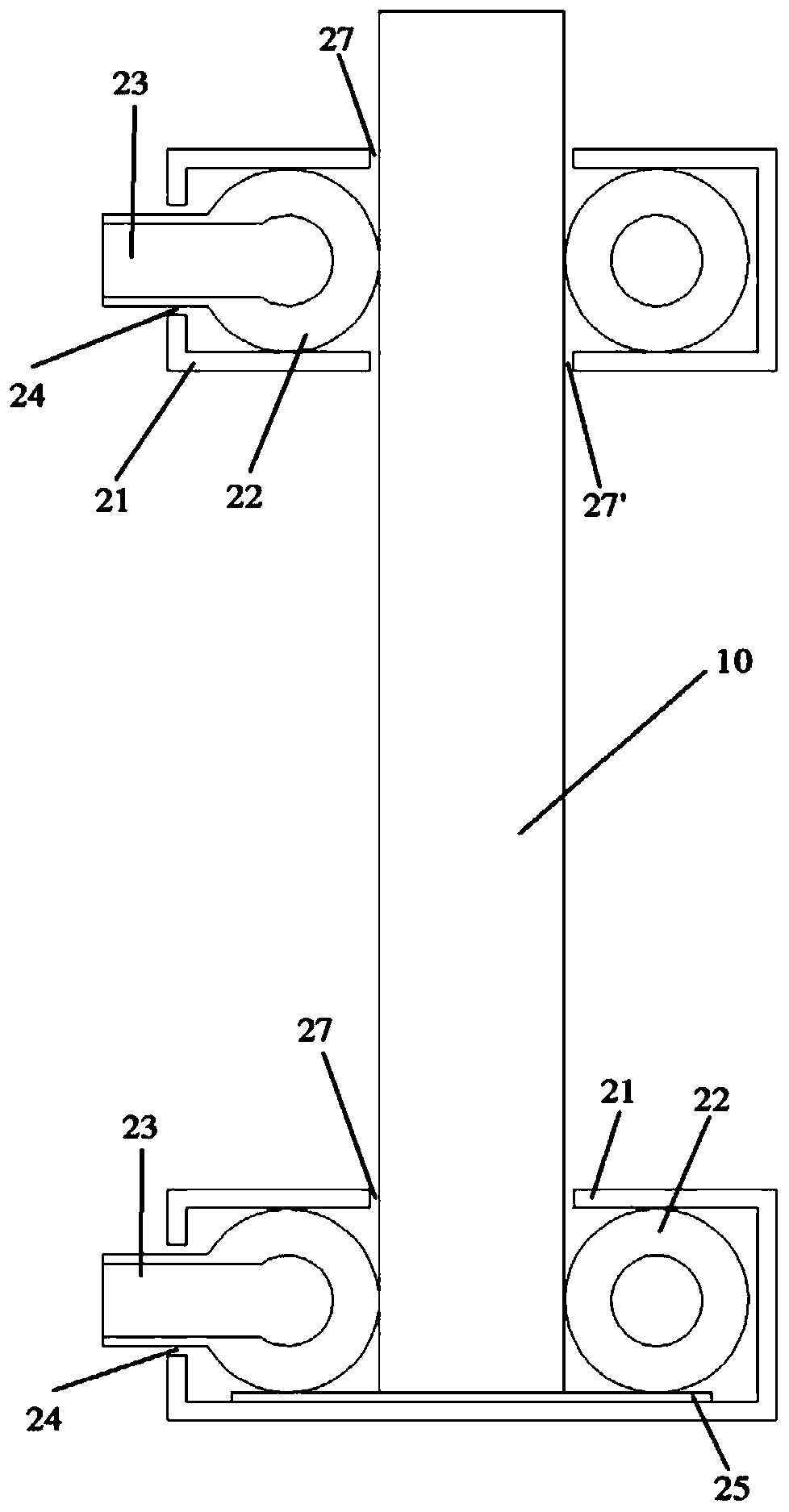

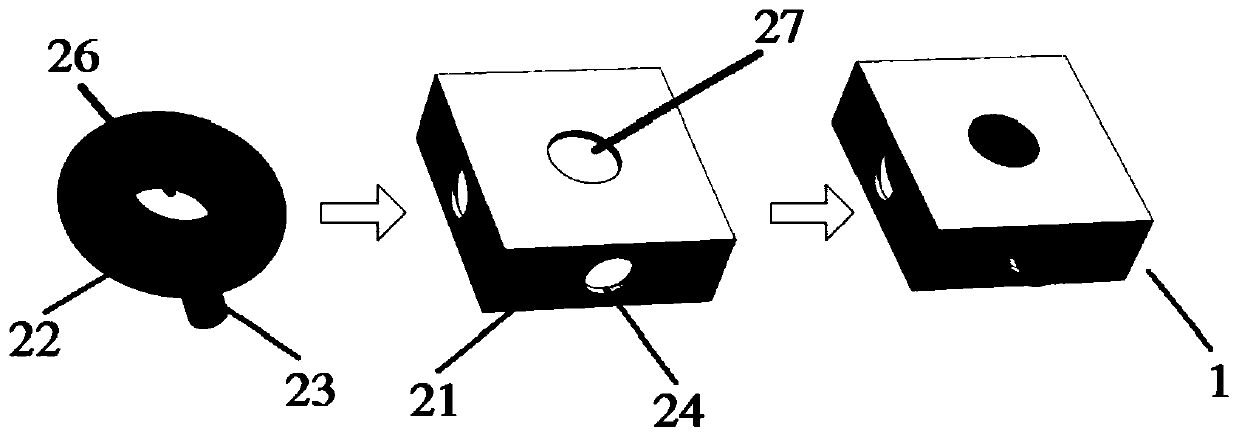

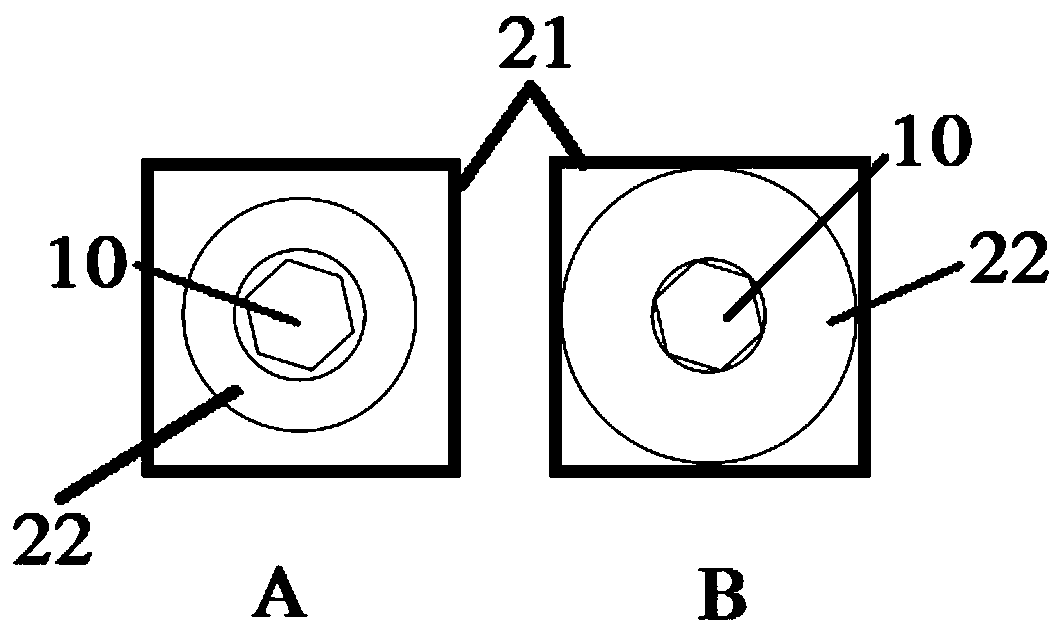

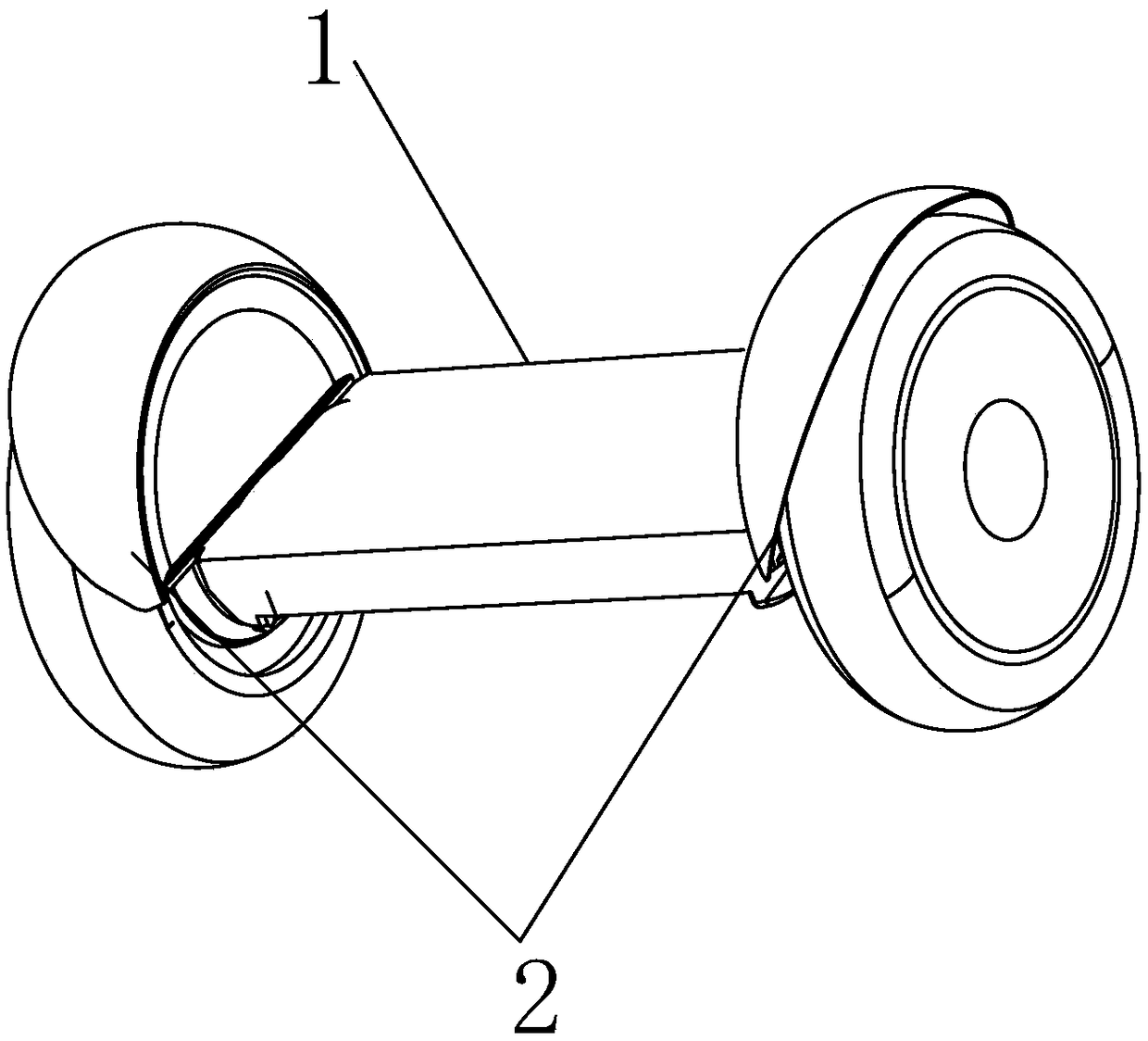

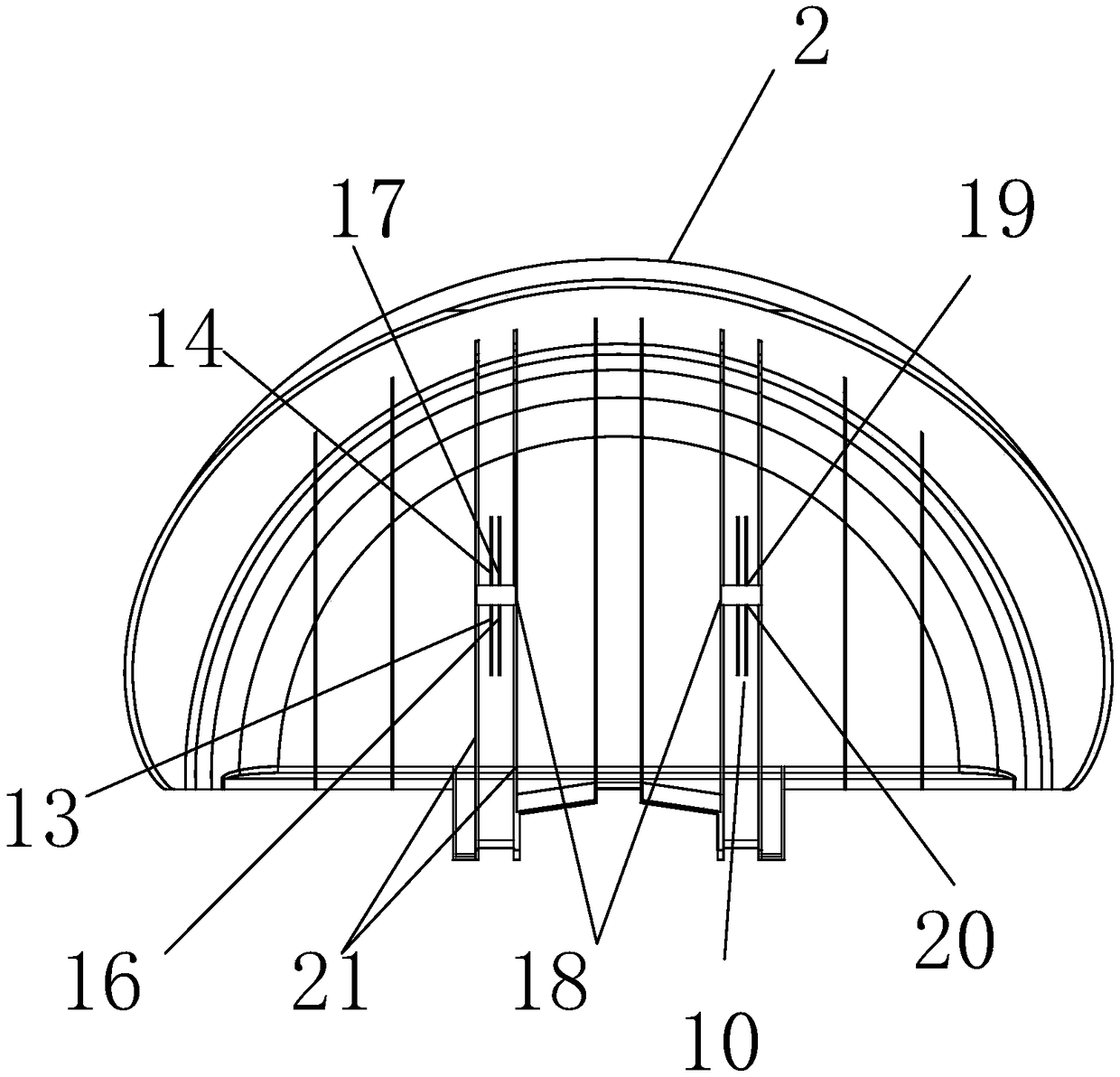

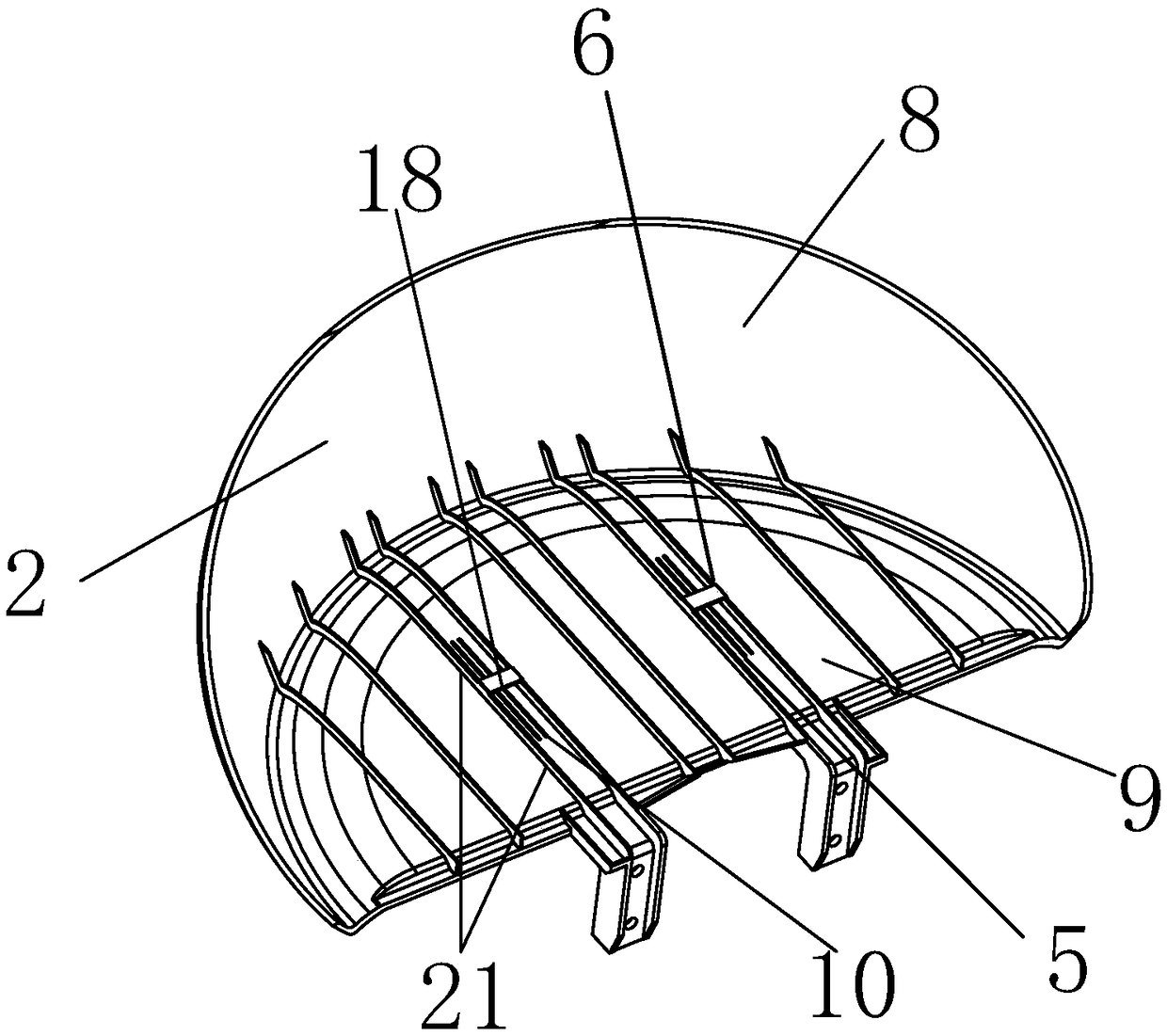

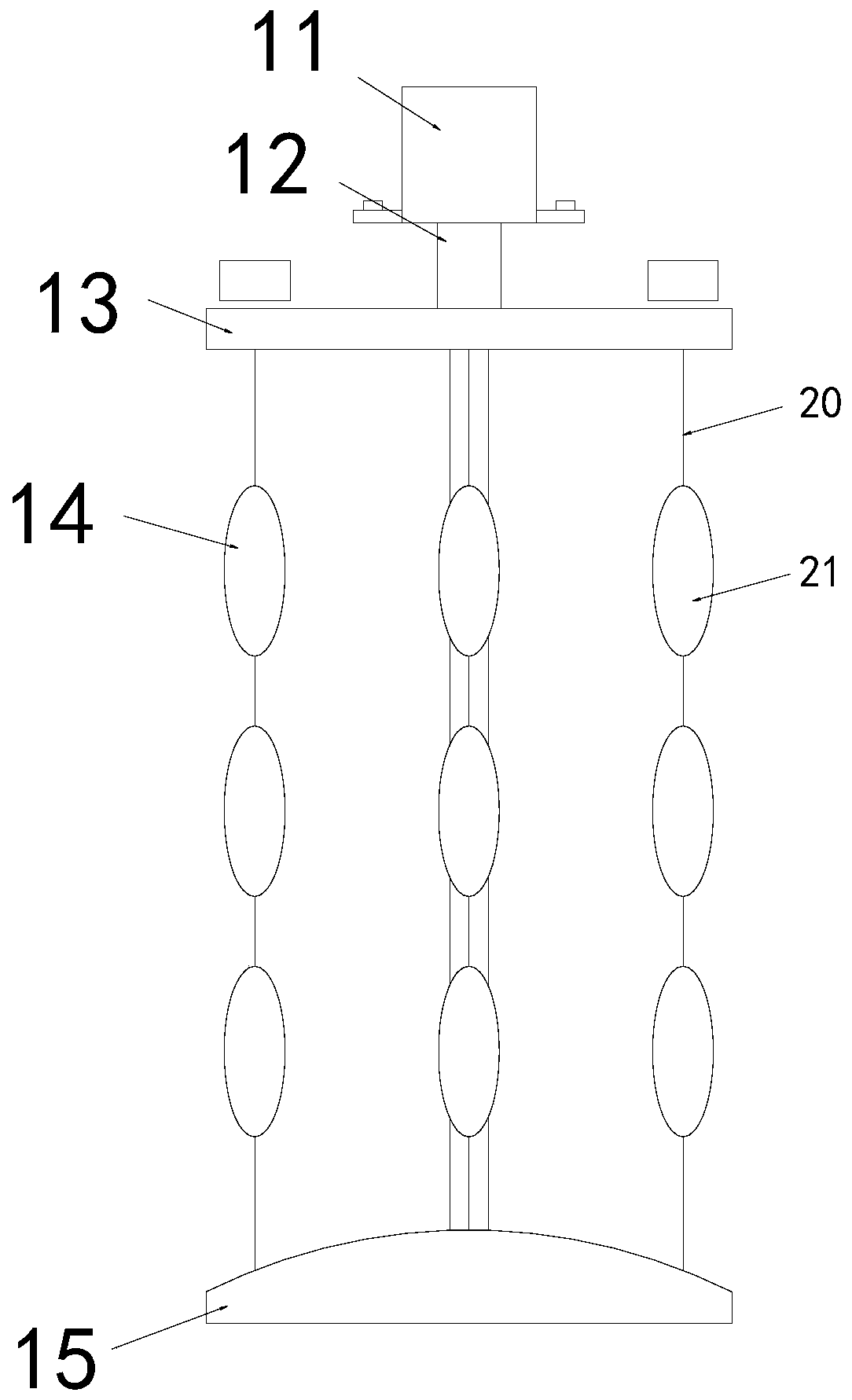

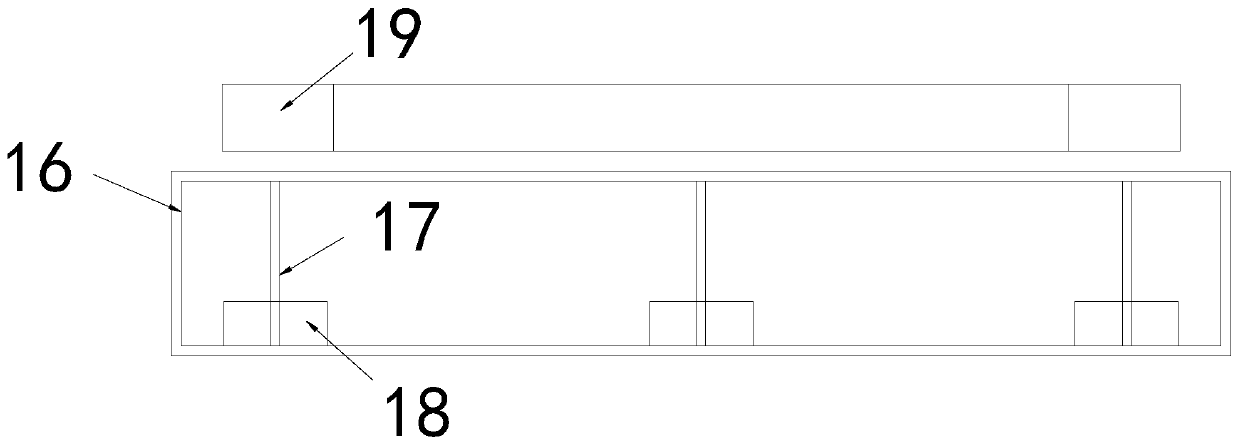

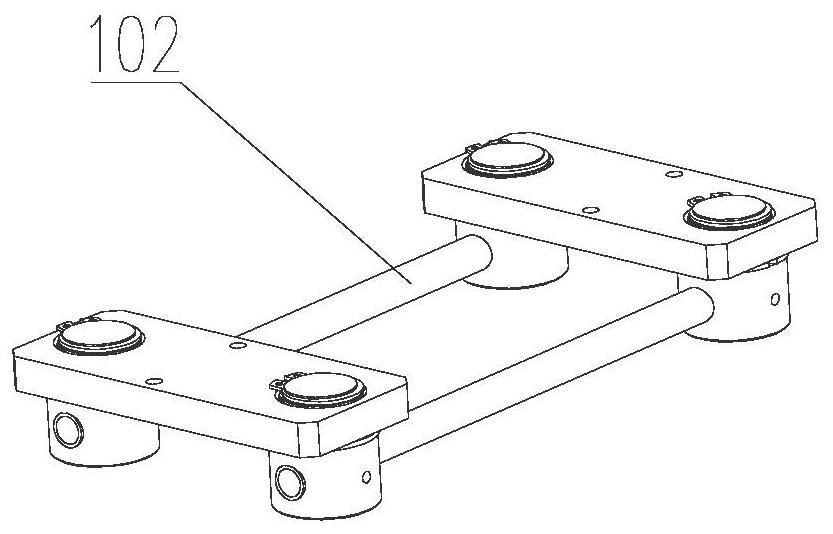

Flexible automatic wire connection device and method

PendingCN110451258AAvoid frictional contactGuaranteed surface integrity and dimensional accuracyConveyor partsSurface integrityEngineering

The invention discloses a flexible automatic wire connection device and method. The flexible automatic wire connection device comprises a supporting stand column, rotary plate-shaped flexible gripperassemblies perpendicular to the axial direction of the supporting stand column are symmetrically arranged at the upper end and the lower end of the supporting stand column; a turning table is arrangedat the bottom of the supporting stand column; and the flexible gripper assemblies are provided with a plurality of flexible grippers for flexible wire connection of semiconductor material filaments.According to the flexible automatic wire connection device, the flexible wire connection of the optical fiber class semiconductor material filaments is realized, the flexible automatic wire connectiondevice can be used for holding and connecting high-grade optical fiber class filaments, and can also be used for holding and connecting other high-grade hard material filaments; and the flexible automatic wire connection device protects the surfaces and the cross sections of the filaments to the greatest extent in the process of wire connection, each flexible gripping unit is connected to only one filament at one time, friction contact between the filaments is avoided, and thus the surface integrity and the dimension accuracy of the filaments in the wire connection process are ensured.

Owner:BEIJING TRIUMPH INT ENG

Self-propelled melon seed harvester

ActiveCN106358575BAvoid breakingGuaranteed Surface IntegrityMowersThreshersVehicle frameAgricultural engineering

The invention provides a self-propelled type melon-striking and seed-extracting harvester and belongs to the technical field of agricultural machinery. The self-propelled type melon-striking and seed-extracting harvester structurally comprises a vehicle frame, wheels, a power mechanism, a plough platform, a hoisting mechanism, a melon-striking and seed-extracting mechanism and a storage mechanism, wherein the plough platform comprises a plough platform frame, a melon-pulling mechanism, an auxiliary melon-pulling mechanism, a melon conveying mechanism, a seedling mechanism and a horizontal spiral conveying mechanism; the structure of the melon-pulling mechanism is as follows: a rolling roller is horizontally erected at the front end of the plough platform frame, horizontal melon-pulling sets which are rotated forward and arrayed in rows are arranged on the roller surface of the rolling roller in the manner of embracing the roller surface of the rolling roller, and three to ten melon-pulling units are horizontally arrayed in rows and formed into the horizontal melon-pulling sets; a melon-pulling channel is formed between the adjacent hexagonal rolling shaft and rolling roller; and the seedling mechanism is arranged on the plough platform frame under the rear end of a longitudinal screen frame. The self-propelled type melon-striking and seed-extracting harvester utilizes the synergistic effect of all mechanisms to harvest melons, strike the melons and extract seeds in turn; upstream and downstream structures are compactly jointed with each other; and the harvesting is free from error, high in error-tolerant rate and stable.

Owner:DEZHOU CHUNMING AGRI MACHINERY

Open pipe tellurium cadmium mercury epitaxial material heat treatment method

InactiveCN1133761CGuaranteed Surface IntegrityGood surface morphologyAfter-treatment detailsSemiconductor/solid-state device manufacturingSteam pressureTe element

The present invention discloses an open tube HgTe source Te-Cd-Hg epitaxial material heat treatment method. The stable mercury steam pressure required for heat treatment is provided by adopting graphite box structure. Said graphite box also can be implemented by utilizing improved liquid-phase epitaxial graphite boat, and its open tube process provides a way for batch production of the part. The success rate of using said process to make hole conduction heat treatment can be up to 100%. The hole density of the material of 77K temp. can be arbitrarily regulated in the range of 5X10 to the power 15 to 5X10 to the power 16 cm (-3). At the same time, the dislocation of material surface in the course of heat treatment does not produce increment effect, and the material composition and appearance form can be better retained.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

Efficient P-type solar cell and photovoltaic module

InactiveCN111584650AImprove efficiencyAvoid damagePhotovoltaic energy generationSemiconductor devicesSolar cellBattery cell

The invention discloses an efficient P-type solar cell. The efficient P-type solar cell comprises a light-facing surface epitaxial layer, P-type substrate silicon and a backlight surface epitaxial layer, wherein the light-facing surface epitaxial layer comprises a front passivation layer arranged in a non-metal region on the surface of the P-type substrate silicon, a highly doped polycrystalline silicon layer arranged in a metal region on the surface of the P-type substrate silicon, and a front surface electrode arranged on the surface of the highly doped polycrystalline silicon layer, whereinthe highly-doped polycrystalline silicon layer is a P-type semiconductor layer, and the doping concentration is higher than that of the P-type substrate silicon; the backlight surface epitaxial layercomprises a back tunneling oxide layer arranged on the surface of the P-type substrate silicon, an N-type doped layer arranged on the surface of the back tunneling oxide layer, a back surface electrode arranged on a metal region on the surface of the N-type doped layer, and a back surface passivation layer arranged on a non-metal region on the surface of the N-type doped layer. According to the invention, the surface passivation of the solar cell and the surface integrity of an emitter are both achieved. The invention also provides a photovoltaic module with the above advantages.

Owner:上饶捷泰新能源科技有限公司

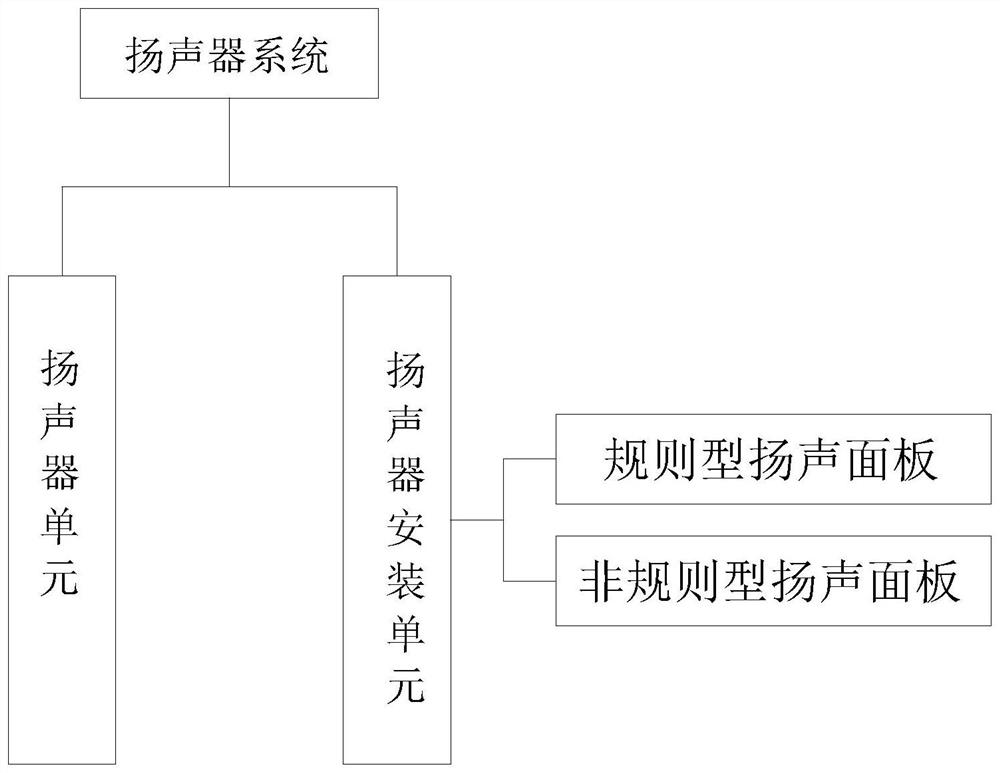

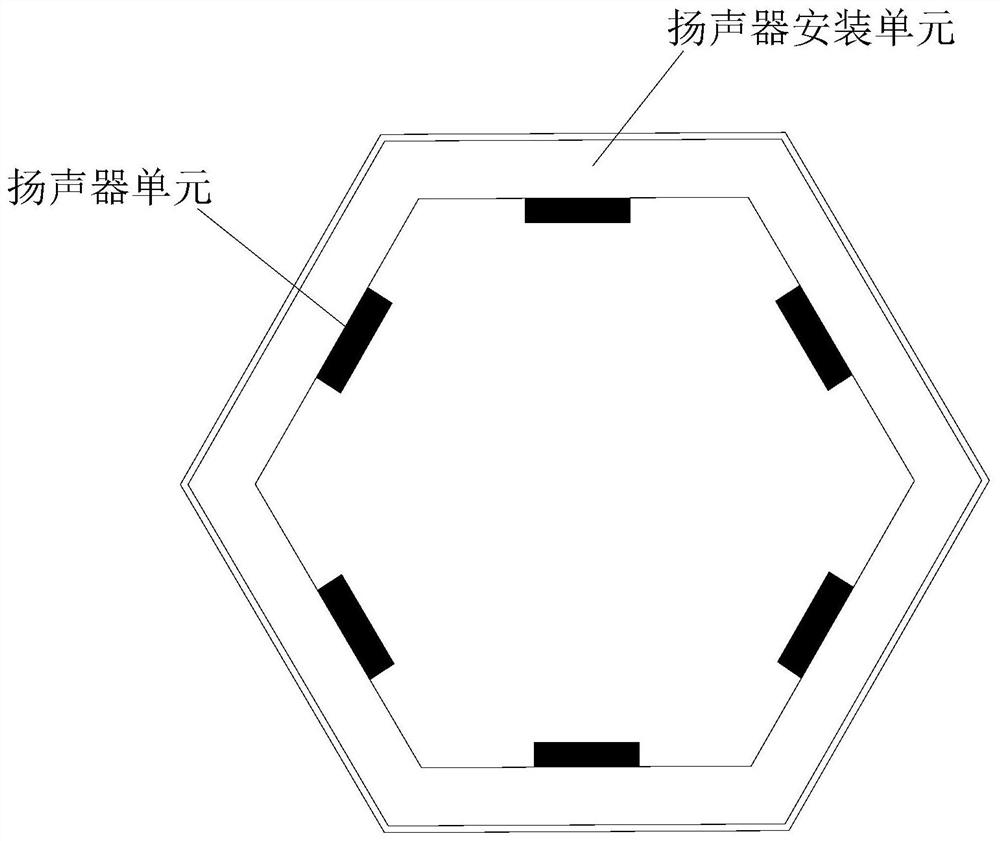

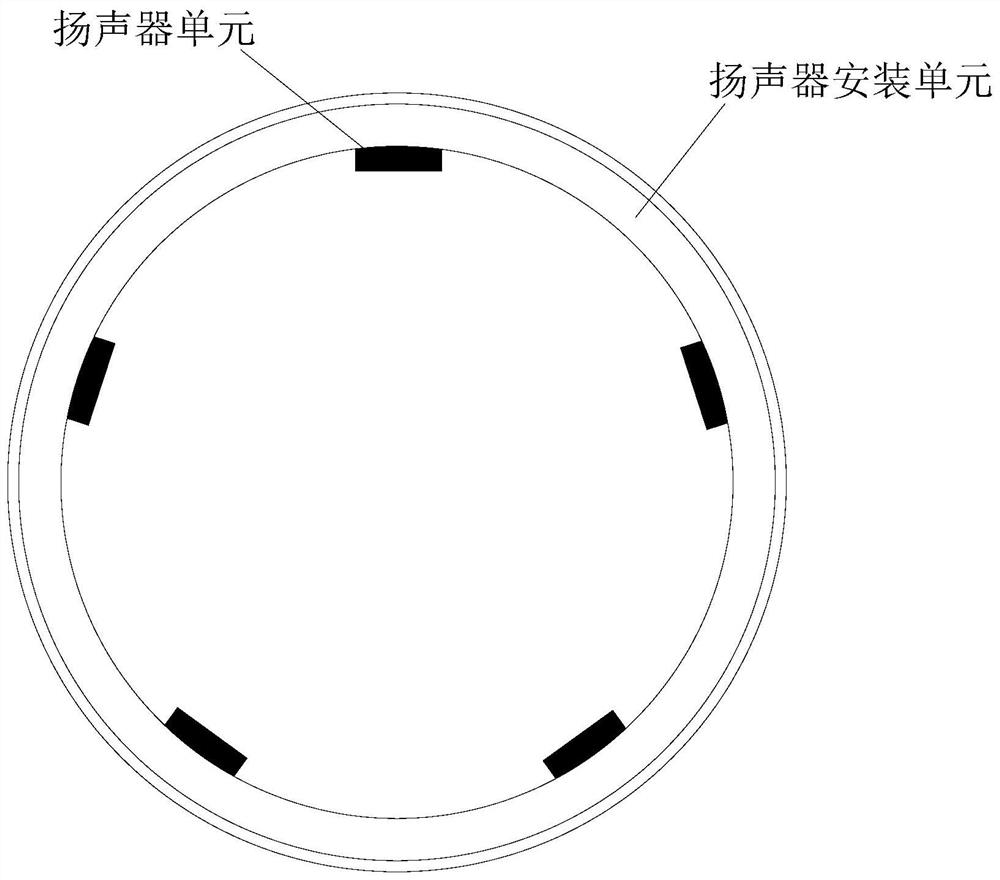

Supporting structure and speaker system of a speaker unit

ActiveCN110996199BImprove adaptabilityLighten playback loadFrequency/directions obtaining arrangementsLoudspeaker spatial/constructional arrangementsEngineeringLoudspeaker

Owner:安徽井利电子有限公司

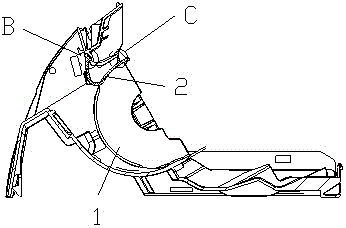

Scooter mud guard and scooter

InactiveCN108820090AGuaranteed Surface IntegrityFit tightlyMotorcyclesMud-guardsMetal stripsEngineering

The invention discloses a scooter mud guard and a scooter. The scooter comprises a scooter body, the scooter body comprises the mud guard and metal strips, the metal strips are fixed on the mud guard;the mud guard comprises a mud guard body, supporting structures and fixing structures, and the supporting structures and the fixing structures are all arranged on the mud guard body; each metal stripis arranged between the corresponding supporting structure and fixing structure, the supporting structures support the metal strips, the fixing structures fix the metal strips, and the metal strips are fixed on the mud guard through squeezing of the supporting structures and fixing structures. Therefore, holes are not needed to be formed in the mud guard, thereby effectively ensuring the completion of the surface of the mud guard, in addition, the metal strips closely fit the mud guard and are fixed to the mud guard through the supporting structures and the fixing structures, thereby ensuringclose fitting among the mud guard and the metal strips.

Owner:深圳市百汇新健康管理有限公司

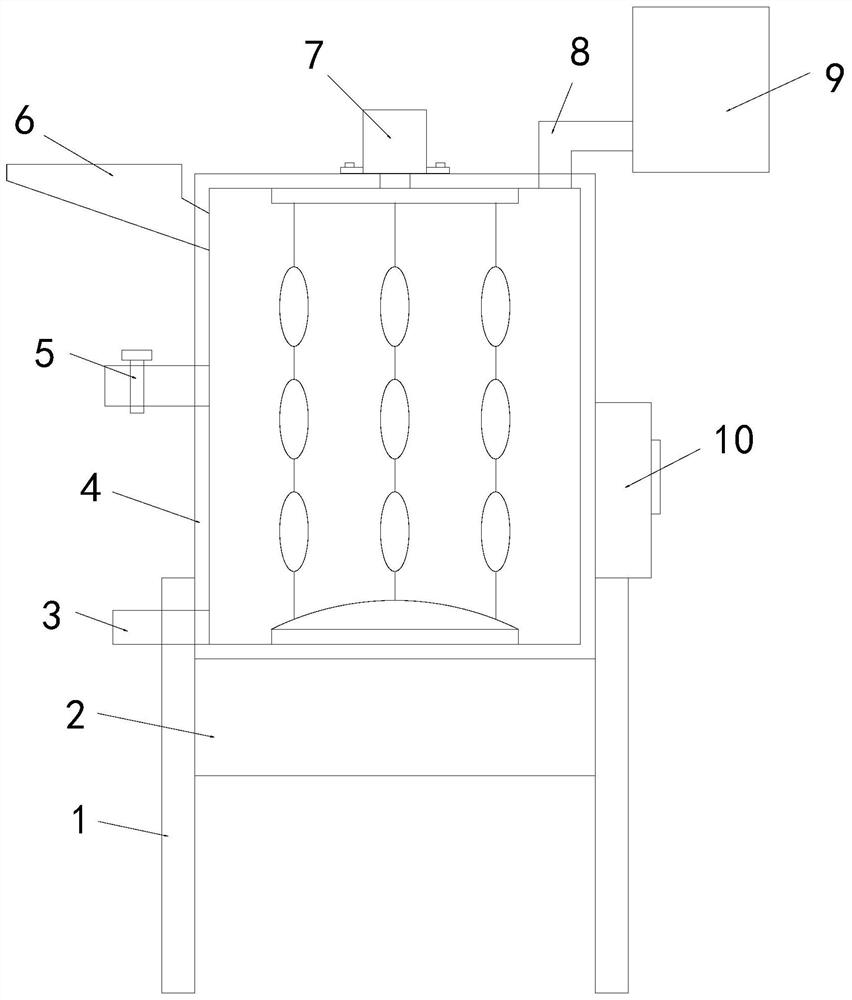

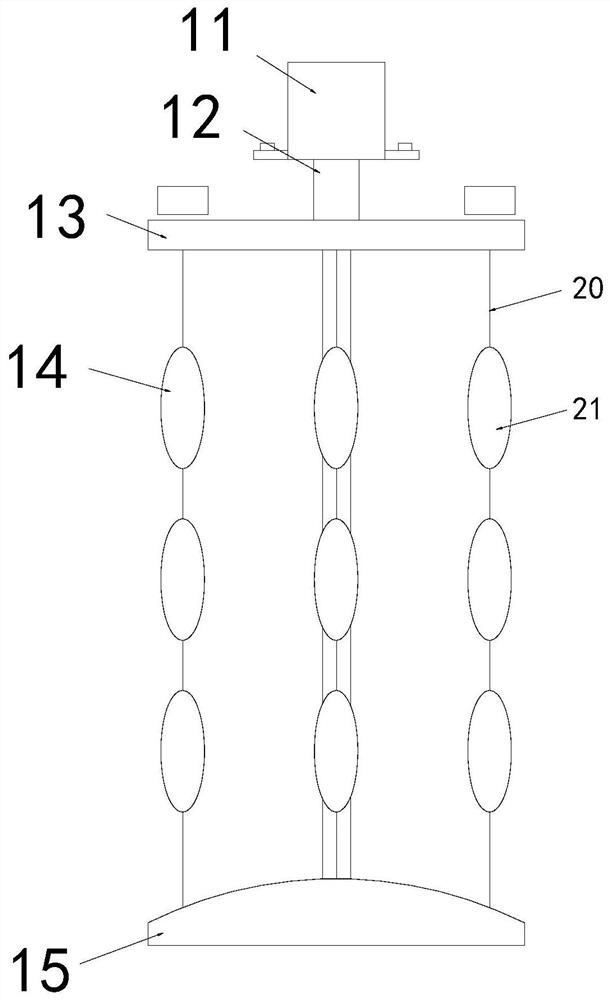

Novel spherical graphite multi-polarity fine purification machine

ActiveCN110697701AWon't wear outGuaranteed Surface IntegrityCarbon compoundsProcess engineeringWater pipe

The invention discloses a novel spherical graphite multi-polarity fine purification machine which structurally includes a bracket, a drying box, a water outlet valve, a purification box, a steam valve, a feeding port, a stirring device, a water pipe, a water box and a control box. The bracket is welded to the bottom of the purification box, the water outlet valve is connected to the bottom side surface of the purification box, the water box is arranged above the purification box and communicates with the top of the purification box through a water pipe, the feeding port is formed in the side surface of the top of the purification box, and the steam valve is arranged on the side surface of the purification box; the control box is installed on outside the purification box, the drying box isconnected to the bottom of the purification box, and the stirring device is installed inside the purification box; and the stirring device is electrically connected with the control box. The novel spherical graphite multi-polarity fine purification machine has the beneficial effects that a rotating strip composed of a pull ring and an airbag replaces a stirring blade, due to the elasticity of theairbag can buffer when colliding with graphite occurs, abrasion on the graphite surface is avoided, the surface integrity of the graphite is ensured, the rotating strip continuously move up and down through the action of magnetic poles, stirring is more comprehensive, and the stirring effectiveness is improved.

Owner:萝北县云山石墨新材料有限公司

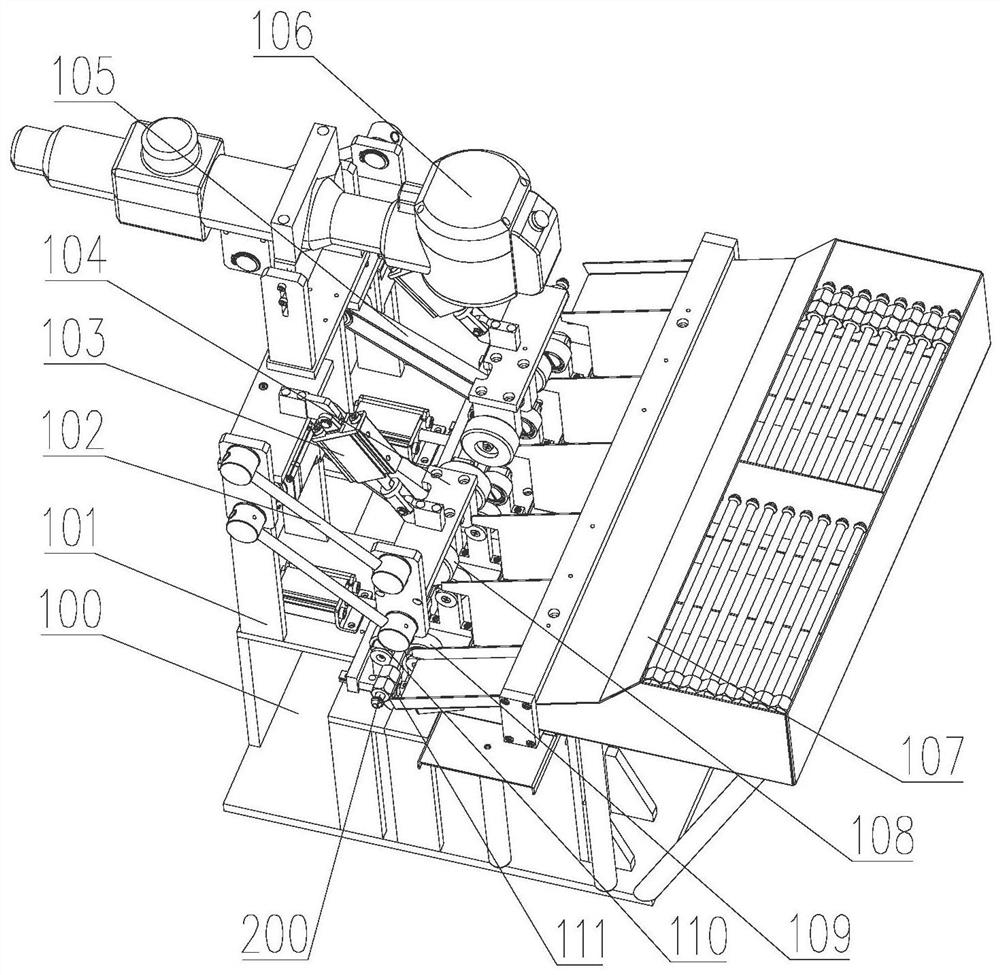

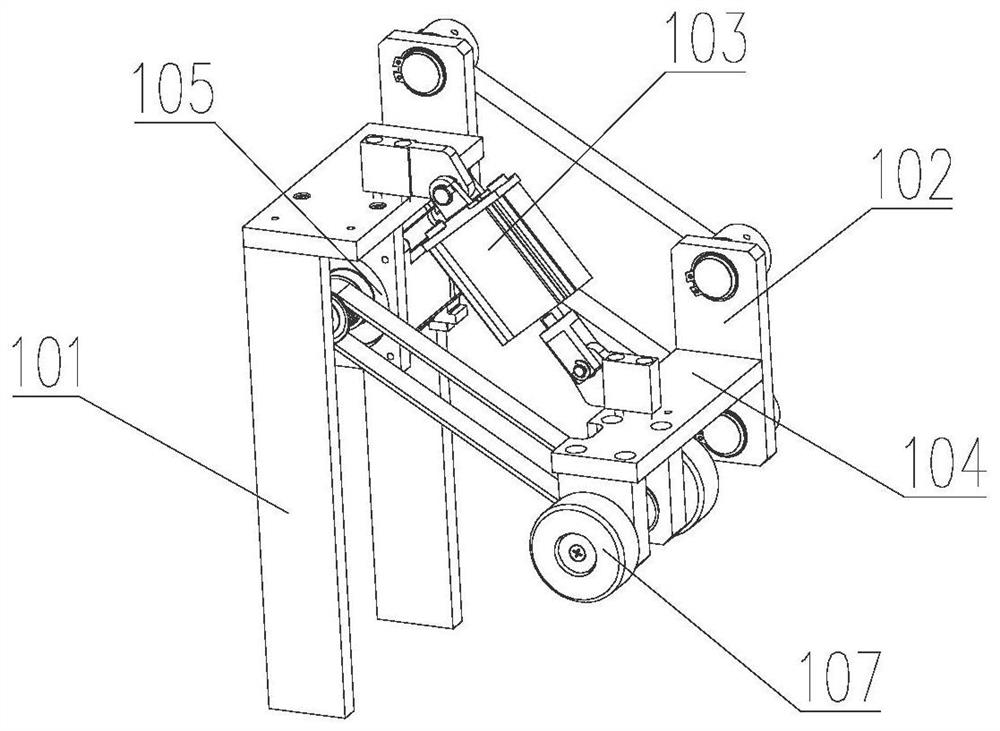

A roller pressing driving mechanism and a laser cleaning machine

ActiveCN112474615BAvoid destructionGuaranteed Surface IntegrityConveyorsRollersMachineSurface integrity

The invention discloses a roller-driven compacting mechanism and a laser cleaning machine, wherein the roller-driven compacting mechanism proposed by the present invention mainly uses rollers to support and rotate a cylindrical workpiece set in a rolling installation position, and then drives it through a driving structure. The roller rotates and the friction drives the workpiece to rotate, so that the rotation and positioning of the workpiece can be realized by means of rotation and compression, which can avoid damage to the workpiece and ensure the surface integrity of the workpiece while effectively positioning the rotating workpiece. The laser cleaning machine realizes the non-destructive positioning and rotation of the workpiece by setting the roller pressing drive mechanism, which can ensure the surface integrity of the workpiece while cleaning the workpiece efficiently, and can also facilitate the rapid replacement of the workpiece by rotating the swing structure, which is conducive to further Improve cleaning efficiency and reduce labor intensity of technicians.

Owner:深圳水滴激光科技有限公司

Device and method for removing shrimp line

The invention belongs to the field of machine designs and relates to a shrimp digestive tract removing device and method. The removing device comprises a conveyor belt system, a shrimp compression system and a cutter system, wherein the conveyor belt system is located below the whole device; after shrimps are removed to a target position, the shrimps are compressed through the shrimp compression system; and meanwhile, shrimp digestive tracts are removed through the cutter system. The shrimp digestive tract removing device is simple in structure and convenient to use; the removal efficiency ishigh and a condition that the shrimp digestive tracts are broken is avoided and the effectiveness of removing the shrimp digestive tracts is ensured; and the surface integrity and the beautiful degreeof shrimp bodies can be ensured and unnecessary wastes of shrimp meat are avoided.

Owner:DALIAN UNIV OF TECH

Suction cup clamping device

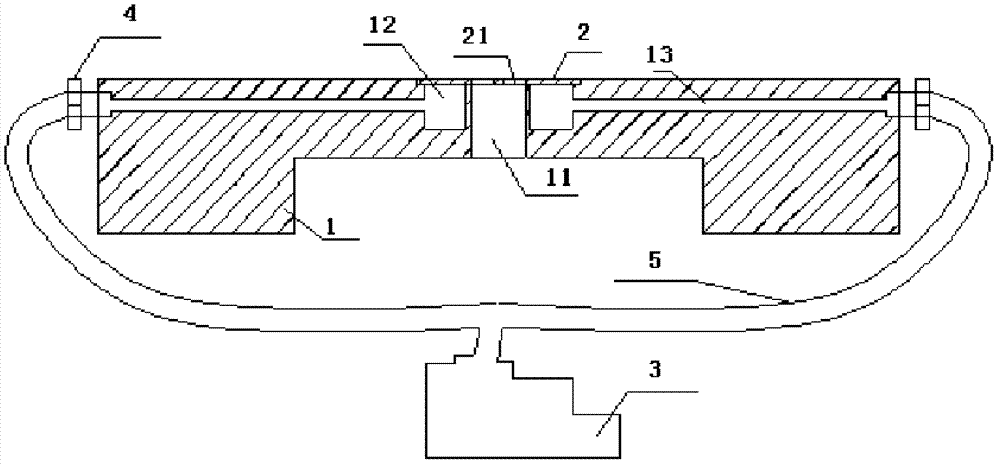

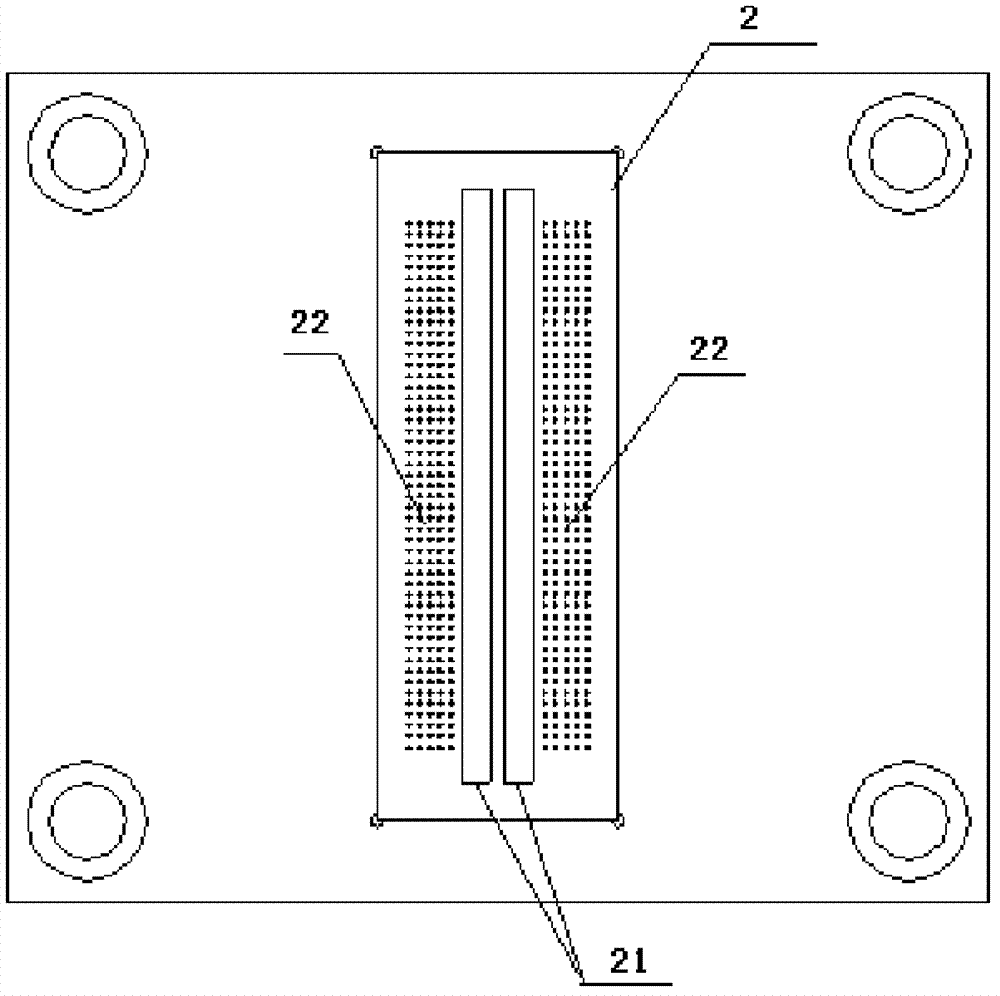

InactiveCN102528300BAvoid deformationAvoid damageLaser beam welding apparatusLaser lightFilm material

A sucker-type clamping device comprises a clamping body, an adsorption panel and a gas suction device. An elongated laser light outlet is arranged on the clamping body in a through manner, an elongated grooved cavity is arranged near the laser light outlet along the length direction, and the clamping body is further provided with a gas guide channel communicated with the cavity. The adsorption panel is arranged on the upper surface of the clamping body and covers the laser light outlet and the cavity of the clamping body, a suction hole array consisting of a plurality of small through holes is arranged on a portion of the adsorption panel corresponding to the cavity, and an elongated opening is formed on a portion of the adsorption panel corresponding to the laser light outlet. The gas suction device is connected with the gas guide channel through a gas pipe, and gas in the cavity and the gas guide channel can be sucked out. According to the structure, a film material can be neatly placed on the adsorption panel in a clinging manner, deformation of the film material is avoided, and machining precision and machining efficiency are improved.

Owner:BEIJING UNIV OF TECH

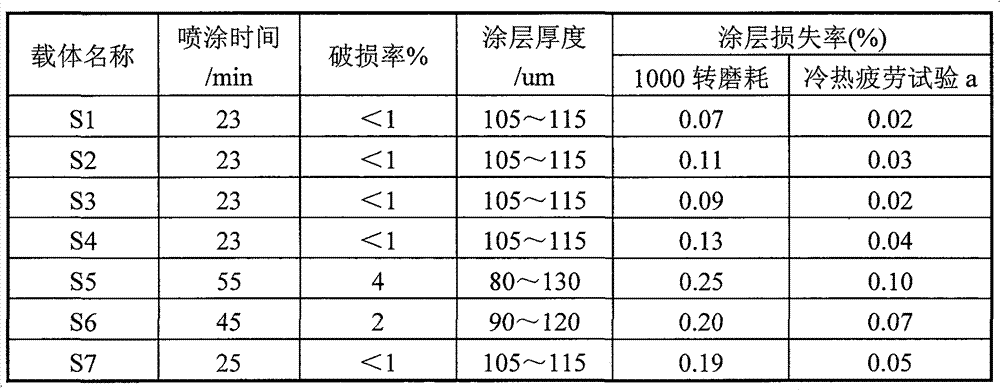

Spraying preparation method of layered composite oxide carrier

ActiveCN102189006BGuaranteed Surface IntegrityGuaranteed uniformityCatalyst carriersCatalyst activation/preparationChemical industrySlurry

The invention relates to a spraying preparation method of a layered composite oxide carrier, which mainly solves the shortcomings that the spraying and drying cannot be uniformly and continuously performed at the same time, the coating spraying and drying are not uniform and consequently the coating quality and production efficiency are low. The invention solves the problems preferably by adopting a technical method which feeds the required core carrier into the inner cavity of a circular spraying device with compressed gas in a suspension manner, sprays the coating oxide slurry containing a binder on the surface of the core with a spray gun in the inner cavity to obtain a precursor I of the layered composite carrier, collects the precursor I and circularly sprays or directly dries and roasts the precursor to obtain the layered composite oxide carrier. The method can be widely applied to the industrial production for preparing the layered composite carrier in the chemical industry.

Owner:CHINA PETROLEUM & CHEM CORP +1

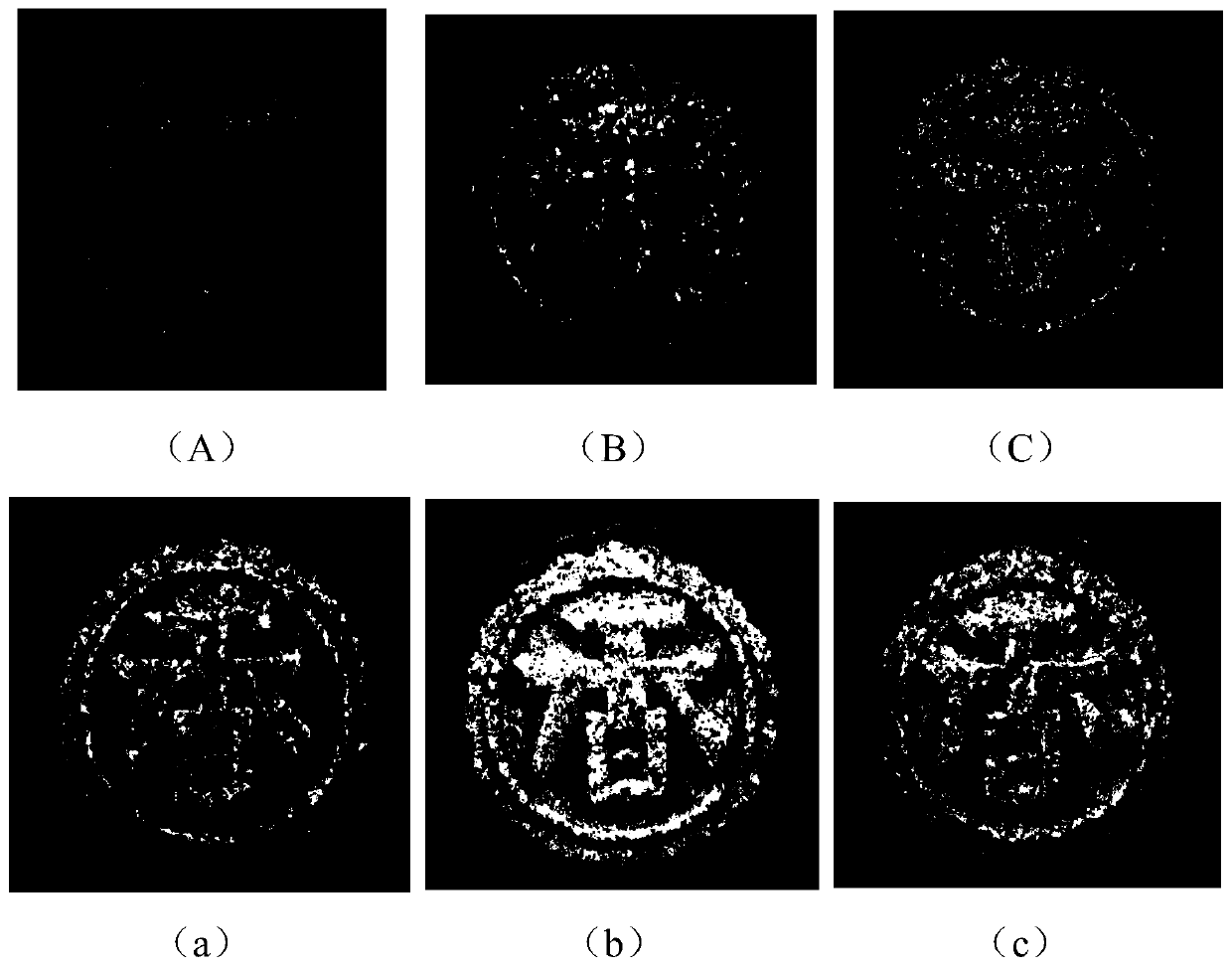

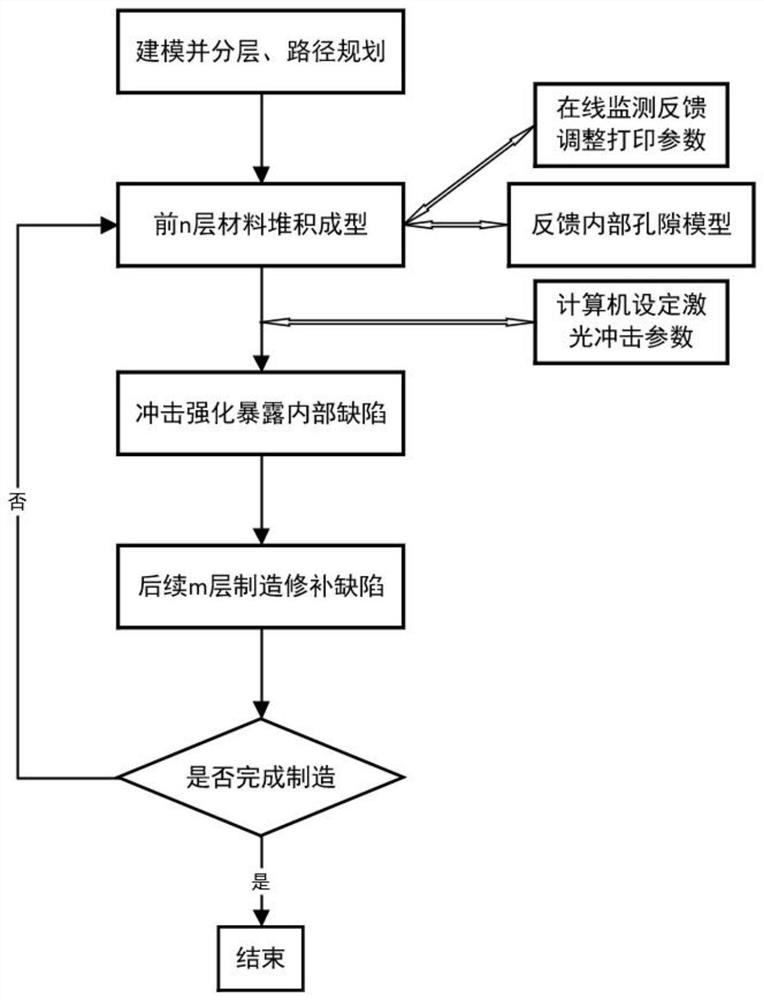

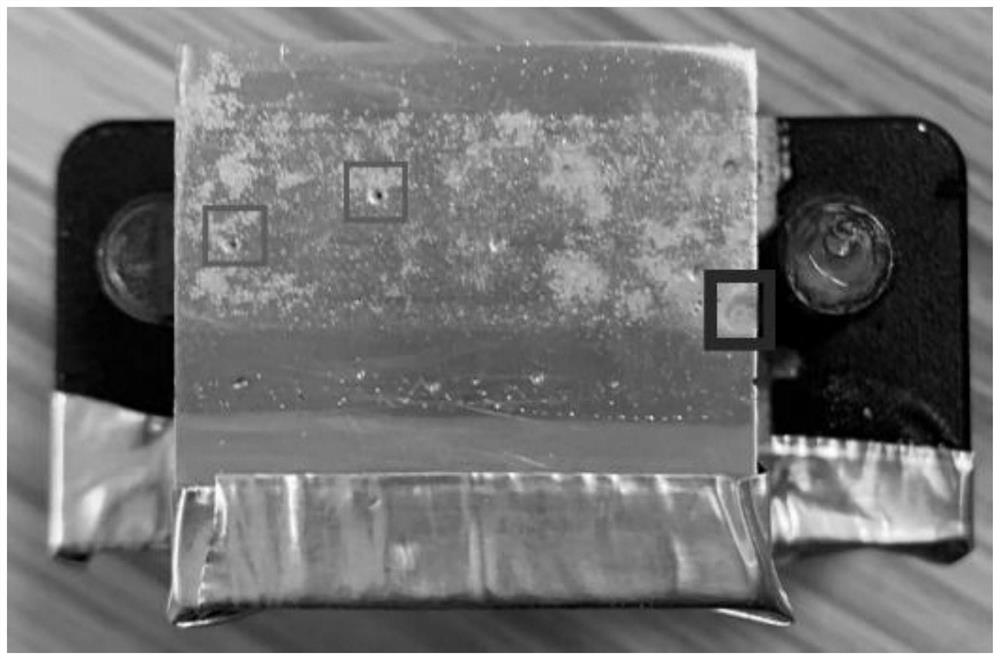

A Method for Removing Pore Defects in Metal Additive Manufacturing Components Based on Online Monitoring

ActiveCN111036911BEnsure Structural IntegrityGuaranteed Surface IntegrityAdditive manufacturing apparatusIncreasing energy efficiencyPore distributionControl system

A method for removing pore defects in metal additive manufacturing components based on online monitoring, including a set of DED metal additive manufacturing systems, a set of online monitoring systems for real-time monitoring of pore defect positions during the additive manufacturing process, and a set for performing defect detection. The repaired laser shock peening system and the central control system that coordinates the additive manufacturing process, the online monitoring process, and the laser shock peening process. The central control system controls the utilization of the laser shock peening system based on the pore distribution model obtained by the online monitoring system The high-energy pulsed laser performs interlayer 3D impact strengthening on the additive manufacturing sample. For the pore defect, the thin layer of metal above the defect is first crushed, and then the DED metal additive manufacturing system controls the feeding in the subsequent forming process to eliminate it. ; For cracks whose length direction is parallel to the manufacturing direction, the central control system closes the cracks by applying residual compressive stress, and the invention can remove the defects after detection.

Owner:XI AN JIAOTONG UNIV

Movable adjusting device for straightener

PendingCN112935016AImprove adaptabilityGuaranteed Surface IntegrityShaping toolsControl theoryMechanical engineering

The invention discloses a movable adjusting device for a straightener. The movable adjusting device for a straightener comprises a straightener base, a fixed straightening assembly and a movable straightening assembly, wherein the two ends of a material are arranged on the inner side of a clamp plate; a longitudinal position of the clamp plate is adjusted by an air cylinder; because of arrangement of the buffering cylinder, buffering is provided for movement of the clamp plate, so that damage and scratches of the surface of the straightening material can be prevented because the movement of the clamp plate is moved too fast, the surface completeness of the material in a straightening process is ensured, and the stability of the device is improved; the height of the fixed straightening assembly is adjusted through a lifting rod A, so that mounting requirements of different height can be met, and thus, the practicability is higher; and the movable straightening assembly can realize change of a horizontal distance between the fixed straightening assembly and the movable straightening assembly through horizontal shrinkage of a shrinkage frame, so that a straightening or extension process can be completely carried out. According to the device, the height adjusting device can be additionally arranged based on a conventional straightener, so that the adaptability of the straightener is improved, working requirements of operating personnel with different height can be met, the site adaptability is improved, and the practicability is improved.

Owner:倪清

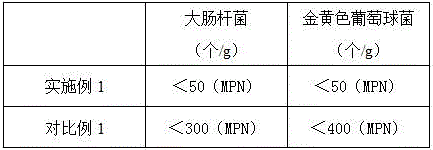

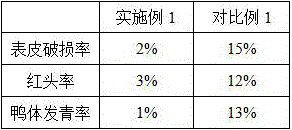

Processing method of duck body

InactiveCN105558866AExtend freshnessGuaranteed Surface IntegrityFood scienceSucroseSurface integrity

The invention belongs to the field of food processing, and particularly relates to a processing method of a duck body. The method is realized through the following steps of washing a meat duck without duck feather and internal organs, putting the washed duck into a treating fluid, and soaking, wherein the treating liquid is prepared by 2 parts of citric acid, 8 parts of fructus crataegi, 8 parts of bamboo leaves, 1 part of sucrose fatty acid ester, 2 parts of sodium chloride, water and yellow wine; then wiping and packaging. The duck body prepared by the invention is long in preservation time; the meat duck is pre-soaked by the treating fluid, so that extravasated blood and the like remained in the meat duck can be quickly cleaned, overcompression is avoided, the surface integrity of the meat duck is maintained, and the processed duck body is good in condition.

Owner:DANGSHAN SHENGFENG FOOD CO LTD

A mechanical hammer leveling device

ActiveCN105964779BImprove processing efficiencyImprove surface integrityShaping toolsNumerical controlFree form

Owner:XIAMEN UNIV OF TECH

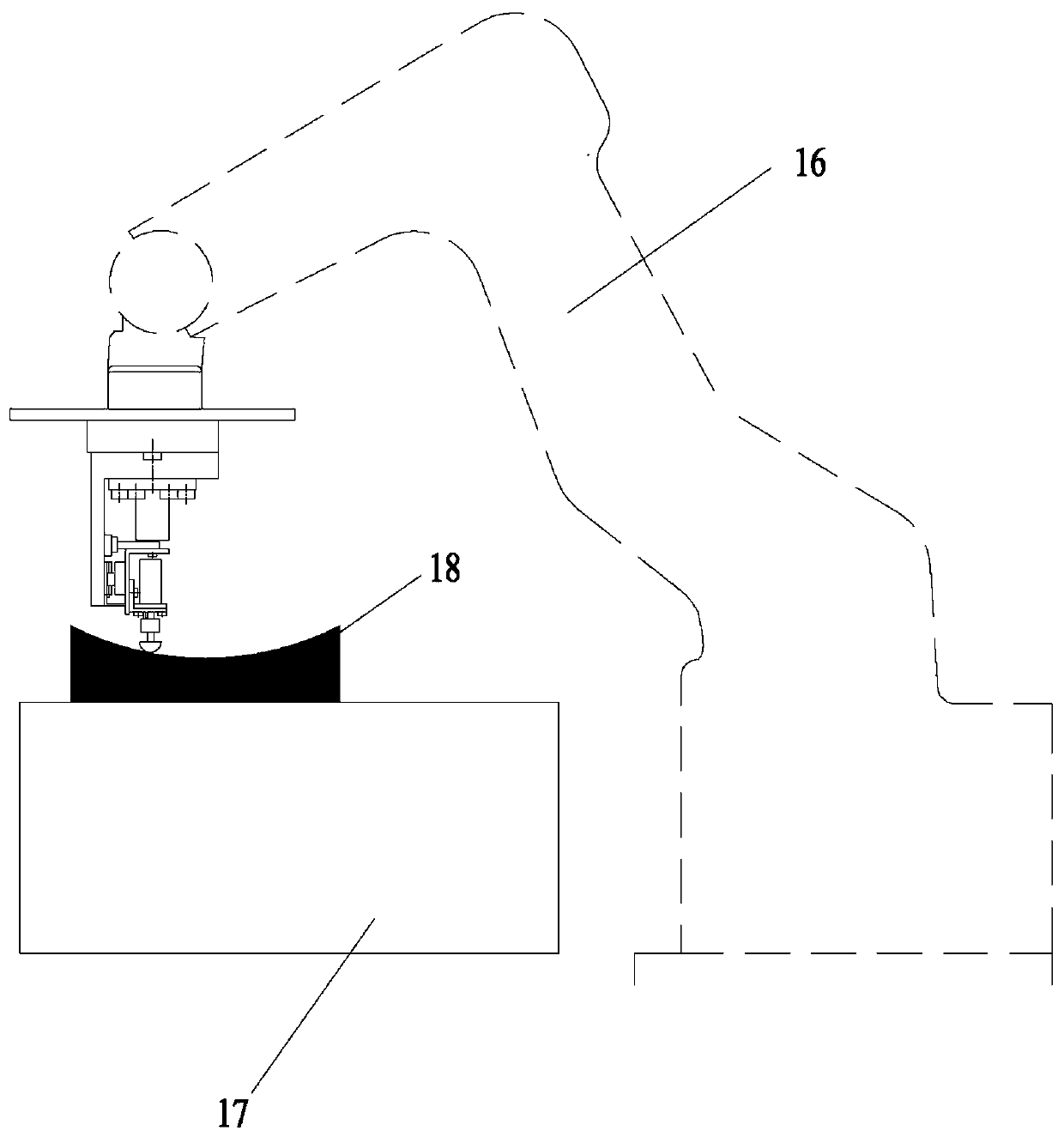

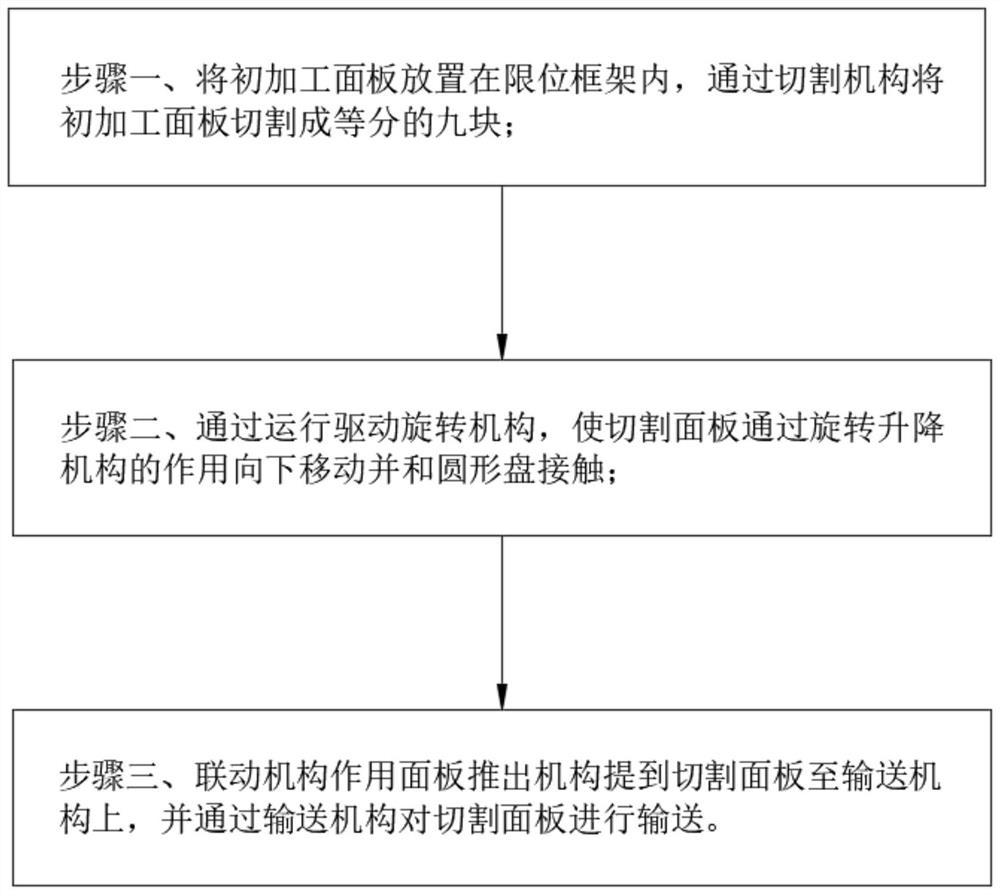

Panel machining equipment for low-smoke furnace and machining technology of panel machining equipment

PendingCN114474430AGuaranteed Surface IntegritySafe and stable processingWorking accessoriesStone-like material working toolsMachining processMechanical engineering

The invention relates to the technical field of panel machining, in particular to low-smoke furnace panel machining equipment and a machining process thereof.The low-smoke furnace panel machining equipment comprises a machining table, a containing groove is formed in the top of the machining table, the top of the containing groove is connected with a limiting frame through a vertical lifting mechanism, and two cutting grooves are formed in each of the four edges of the top of the limiting frame; according to the panel cutting device, the linkage mechanism acts on the panel pushing-out mechanism, a cutting panel is pushed to the conveying mechanism from the interior of the containing groove, in the process that the panel pushing-out mechanism pushes the cutting panel, the panel pushing-out mechanism pushes the cutting panel, the panel pushing-out mechanism pushes the cutting panel, and the panel pushing-out mechanism pushes the cutting panel to the conveying mechanism. The conveying mechanism conveys the cut panels in sequence through the action of the linkage mechanism, the primarily-machined panels are cut through a series of operation steps, the cut panels are conveyed in sequence, mutual stacking and squeezing generated in the moving process are reduced, it is guaranteed that the surfaces of the cut panels are complete, and stability and safety of panel machining are facilitated.

Owner:潘红星

Double-arc high-feed annular milling cutter and its preparation process and detection method

InactiveCN104959666BHigh removal rateReduce cutting forceMilling cuttersGrinding feed controlMilling cutterEngineering

The present invention relates to a preparation process and a monitor method of a double-arc large feed ring mill cutter. Currently, ring mill cutter having curved surface high adaptability is widely used in aerospace, automotive and other mold curved surface semi-finishing field, but in order to achieve better cutting performance, improvement of milling efficiency by breakthroughs in the aspects of cutting feed, cutting forces and the like has certain difficulty, on the other hand, grinding process affects processing efficiency, tool life and surface integrity of a workpiece, meanwhile the method for effectively verifying the accuracy of the grinding is worth of considering. The double-arc large feed ring mill cutter comprises a ring mill cutter handle (1), the front end of the ring mill cutter handle is successively connected with a spiral cutter groove (2), a double-arc large feed cutting edge (3), and an end tooth chip pocket (4), the double-arc large feed cutting edge comprises a main-arc cutting edge (7) and a sub-arc cutting edge (8). The double-arc large feed ring mill cutter is used for milling die steel, at the same time, a reference opinion for the preparation process and the monitor method of the mill cutter is provided.

Owner:HARBIN UNIV OF SCI & TECH

A hand-held high-speed electric arc processing equipment and method

InactiveCN103752989BCompact structureReduce weightOther manufacturing equipments/toolsWelding/cutting media/materialsMaterial removalTransformer

The invention discloses handheld high-speed electric arc machining equipment and method, and belongs to the field of non-traditional machining equipment. The handheld high-speed electric arc machining equipment comprises a shell, a motor, a coupler, a spindle, a connection flange, an amplitude transformer, a protection cover, an electric brush, a conductive grinding wheel, a handle, an ultrasonic generator and an electric arc machining control power supply. The motor drives the spindle to rotate via the coupler. The amplitude transformer penetrates through the lower end of the shell and is fixedly connected with the conductive grinding wheel in an insulation manner. The spindle drives the amplitude transformer to rotate via the connection flange. Amplitude and vibrating frequency of the amplitude transformer are adjusted via the ultrasonic generator. The conductive grinding wheel is connected with a cathode of the electric arc machining control power supply via the electric brush. Three machining modes including high-speed electric arc machining, ultrasonic vibrating and grinding are combined, and by means of combining the machining modes, and a material removal rate of the handheld high-speed electric arc machining equipment can reach 6-8 times of that of normal electrosparking, and even more than 10 times for parts of materials, so that the handheld high-speed electric arc machining equipment is quite applicable to onsite repairing and machining for surface fatigue layers of parts of large and non-movable waste machines.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com