Novel solar cell and preparation method thereof

A solar cell, a new type of technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of emitter damage and complex production process, and achieve the effect of improving production efficiency, reducing process complexity, and simplifying production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

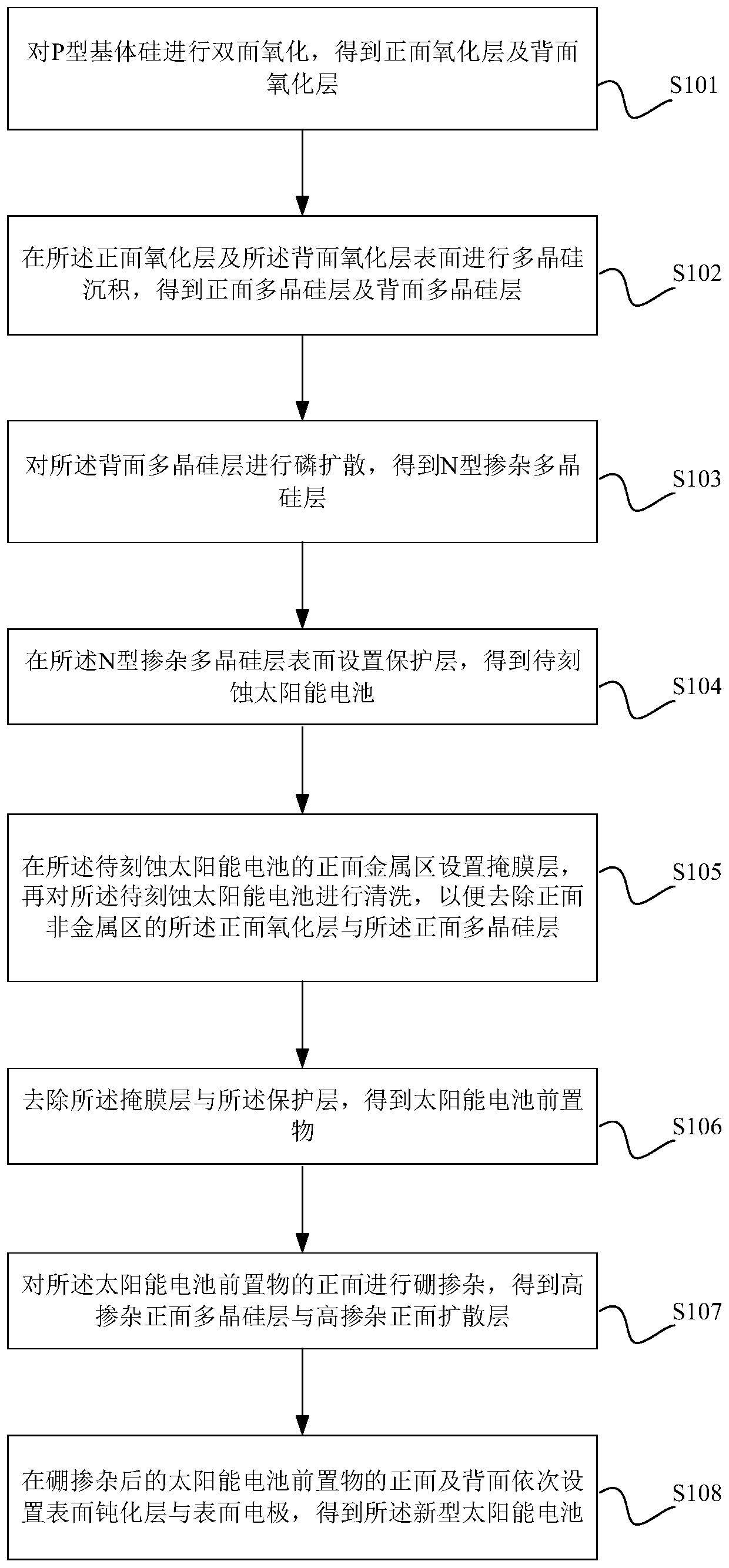

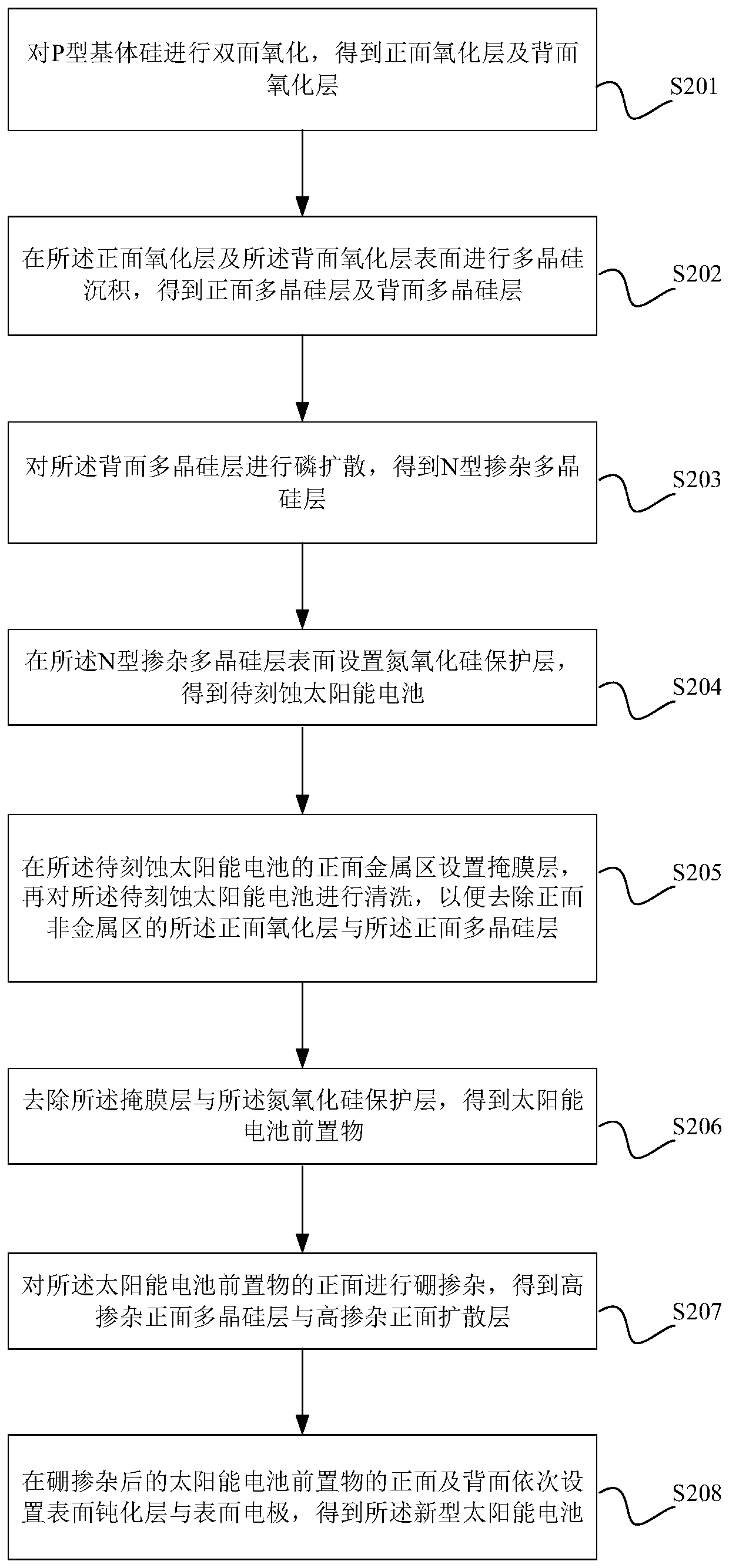

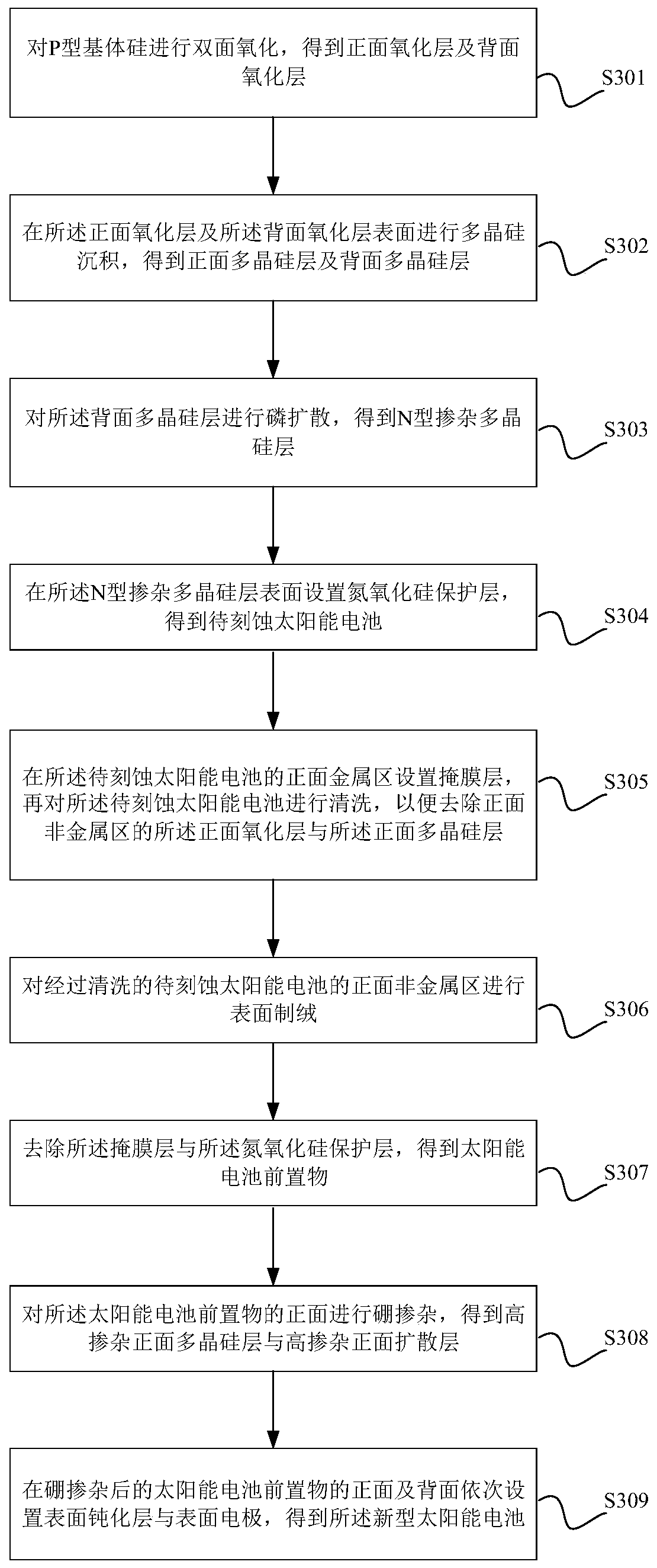

[0035] The core of the present invention is to provide a method for preparing a novel solar cell, and a schematic flow diagram of a specific embodiment thereof is as follows: figure 1 As shown, it is referred to as the specific embodiment one, including:

[0036] S101 : performing double-sided oxidation on the P-type base silicon to obtain a front-side oxide layer and a back-side oxide layer.

[0037] Before the double-sided oxidation of the P-type base silicon, the surface of the P-type base silicon can also be polished and cleaned to remove the surface damage layer of the P-type silicon base. The reflectivity of the polished silicon wafer is controlled at 30 %-40%, and further, the surface polishing is alkali polishing.

[0038] The thickness of the front oxide layer and the back oxide layer is in the range of 1.5-2.5 nanometers.

[0039] S102: Perform polysilicon deposition on the surface of the front oxide layer and the backside oxide layer to obtain a front polysilicon ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com