Double-arc high-feed annular milling cutter and its preparation process and detection method

A circular milling cutter and double-arc technology, which is applied in the control of workpiece feed movement, milling cutter, milling machine equipment, etc., can solve the problems of residual step surface, limited feed rate, large cutting force, etc., and achieve reduction Cutting force, good cutting performance and tool life, and the effect of improving grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

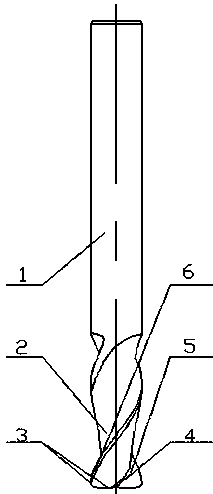

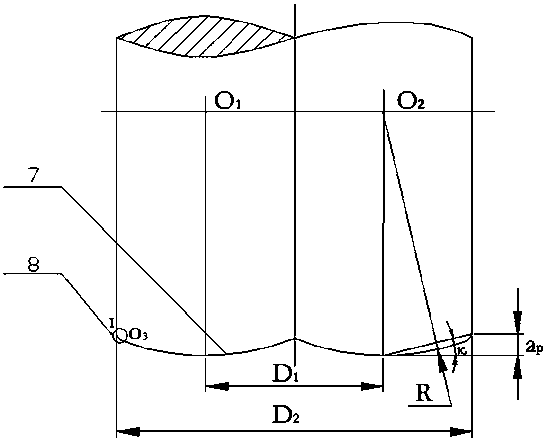

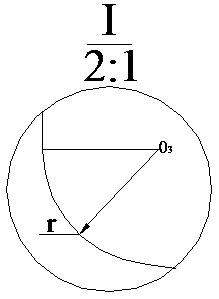

[0030] A double-arc high-feed annular milling cutter, which consists of: an annular milling cutter shank 1, the front end of the annular milling cutter shank is sequentially connected with a spiral sipe 2, a double-arc high-feed cutting edge 3, and an end tooth The chip pocket 4 is connected, and the double-arc high-feed cutting edge has a double-arc high-feed cutting edge rake face 5 and a double-arc high-feed cutting edge flank 6, and the double-arc The high-feed cutting edge includes a main arc cutting edge 7 and a sub-arc cutting edge 8 .

Embodiment 2

[0032] According to the double-arc high-feed annular milling cutter described in embodiment 1, the described knife handle is a cylindrical knife handle with strong rigidity and a diameter of 20mm, which is used for semi-finishing, and the material is hard alloy. Milling hardened die steel.

Embodiment 3

[0034] According to the double-arc high-feed ring milling cutter described in Embodiment 1, the double-arc high-feed cutting edge has certain advantages in terms of milling characteristics. By controlling the radian of the main arc cutting edge and the sub-arc cutting edge to control the cutting main deflection angle, the cutting angle of milling is small, thin chips are formed during the cutting process, and the feed rate is increased, thereby improving the metal removal rate. When the main arc cutting edge has a concave arc cutting edge structure to participate in the cutting of the concave curved surface, the remaining step area is reduced to zero, ensuring the uniformity of the cutting residue height in semi-finishing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com