Patents

Literature

806results about How to "Reduce cutting force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

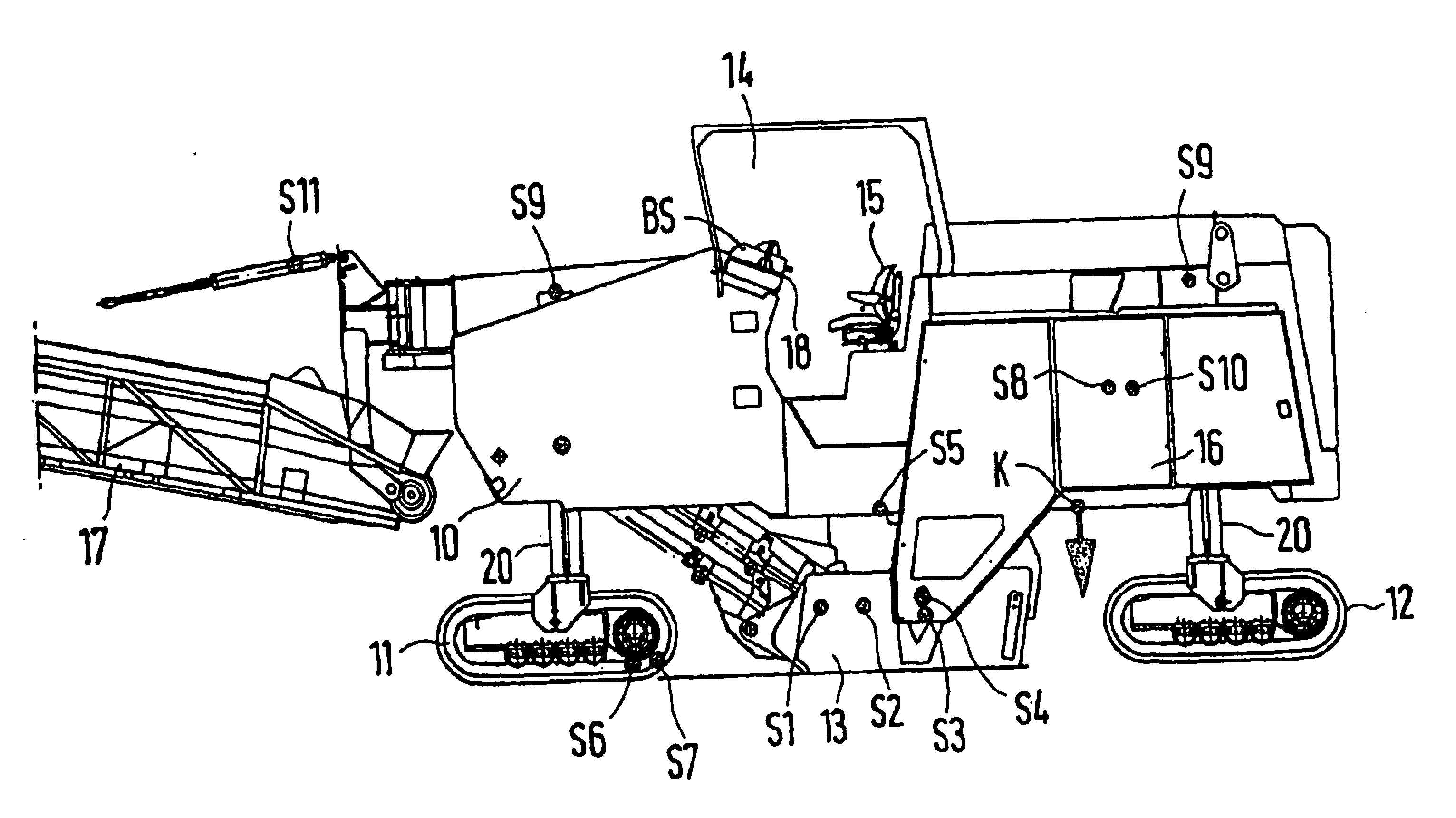

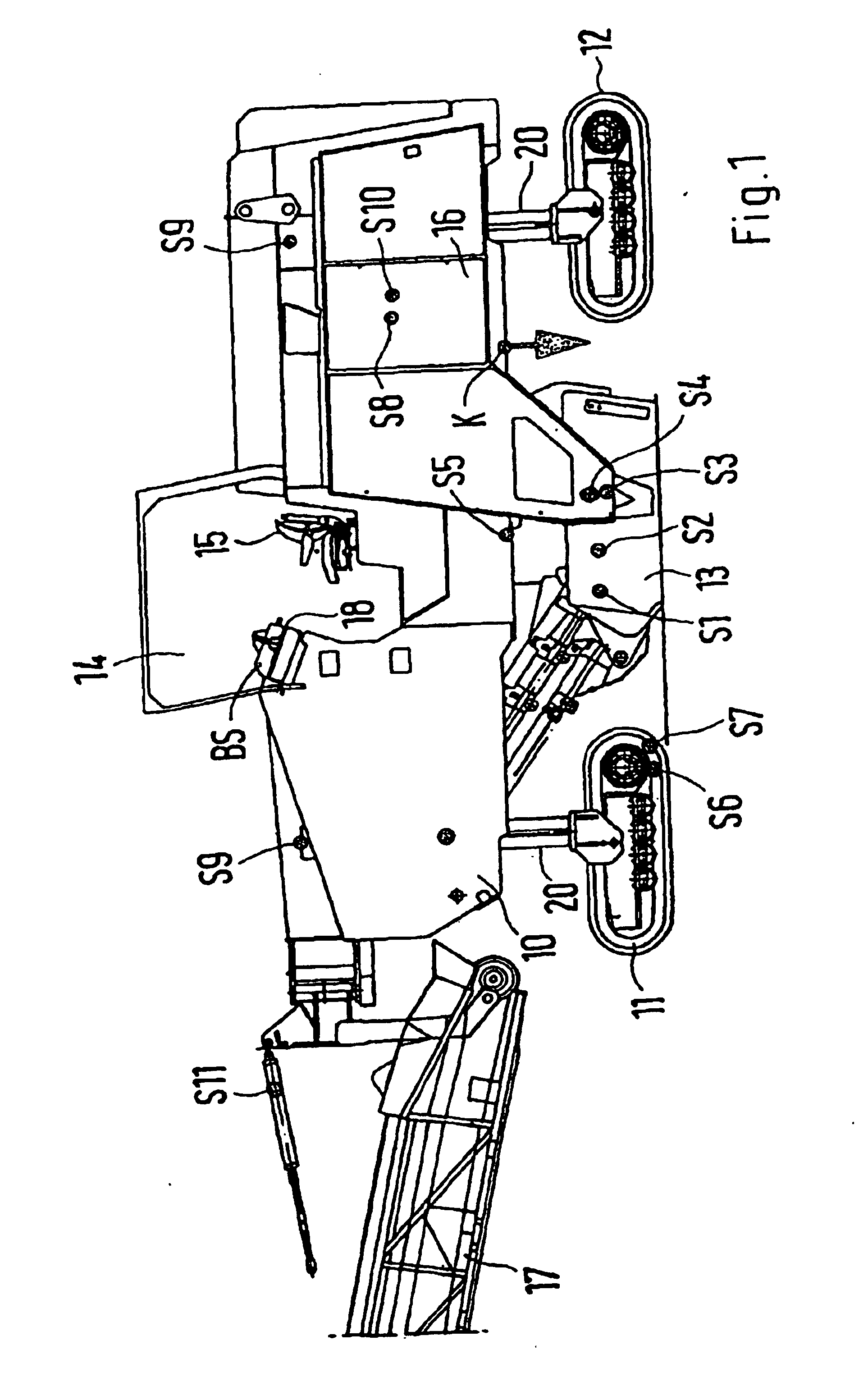

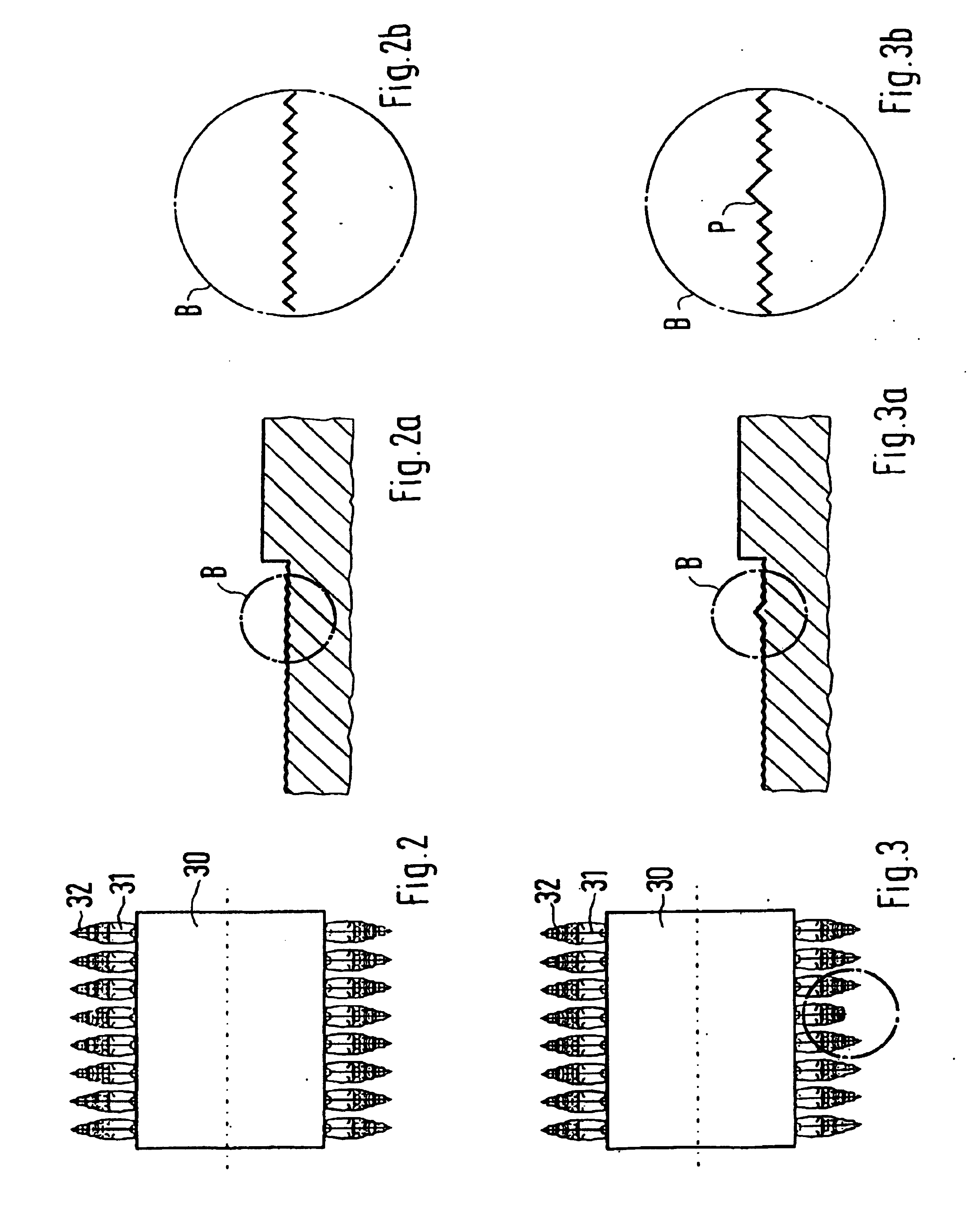

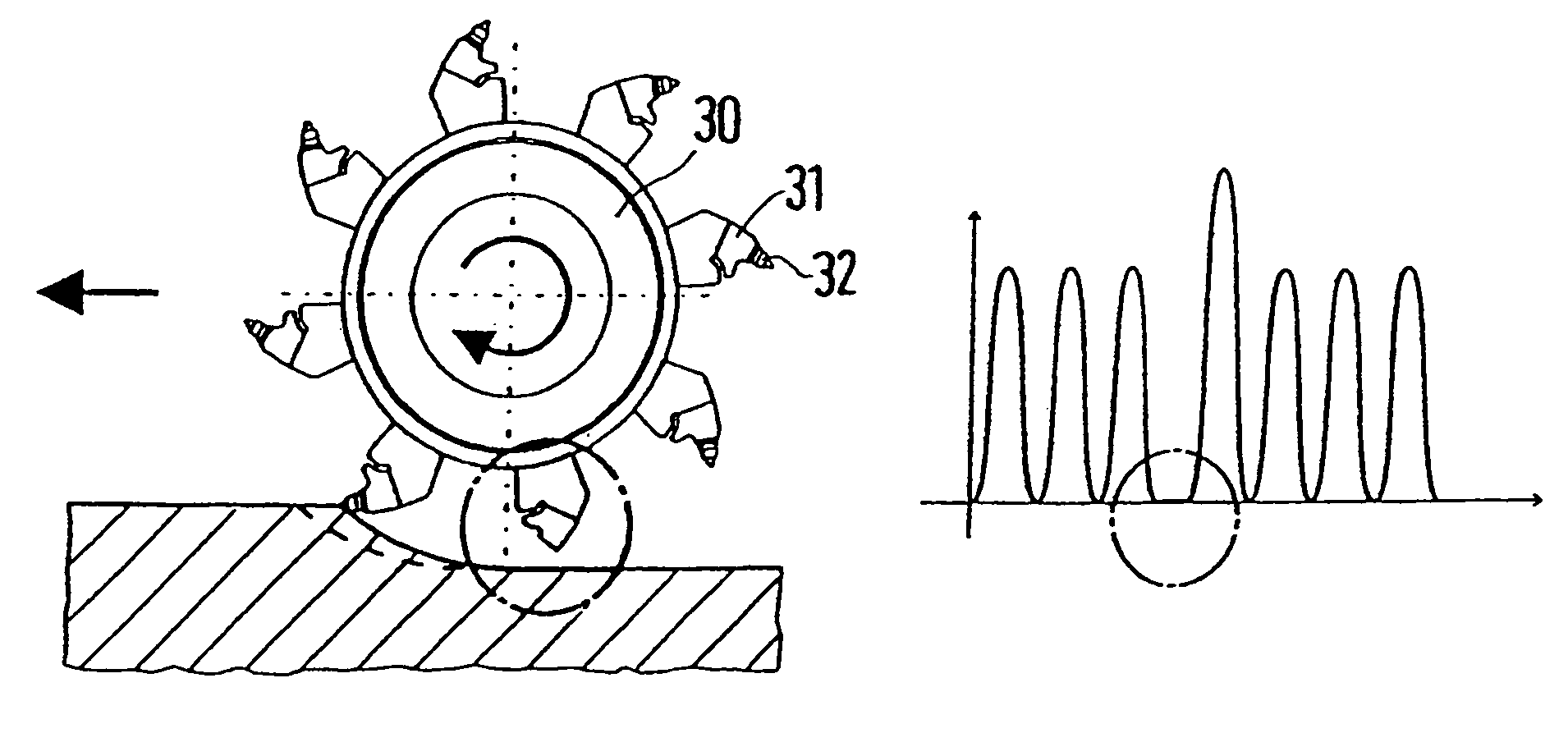

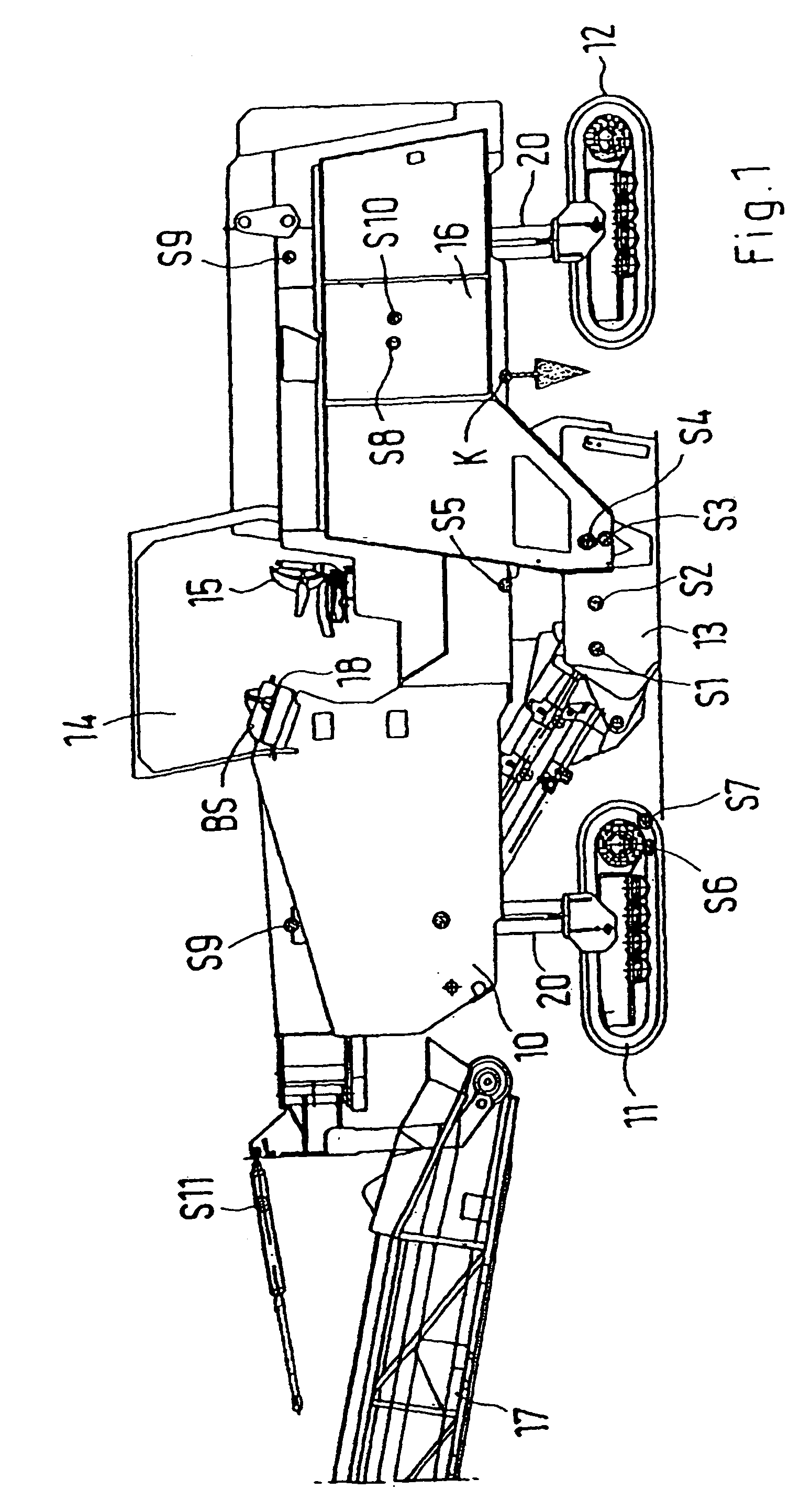

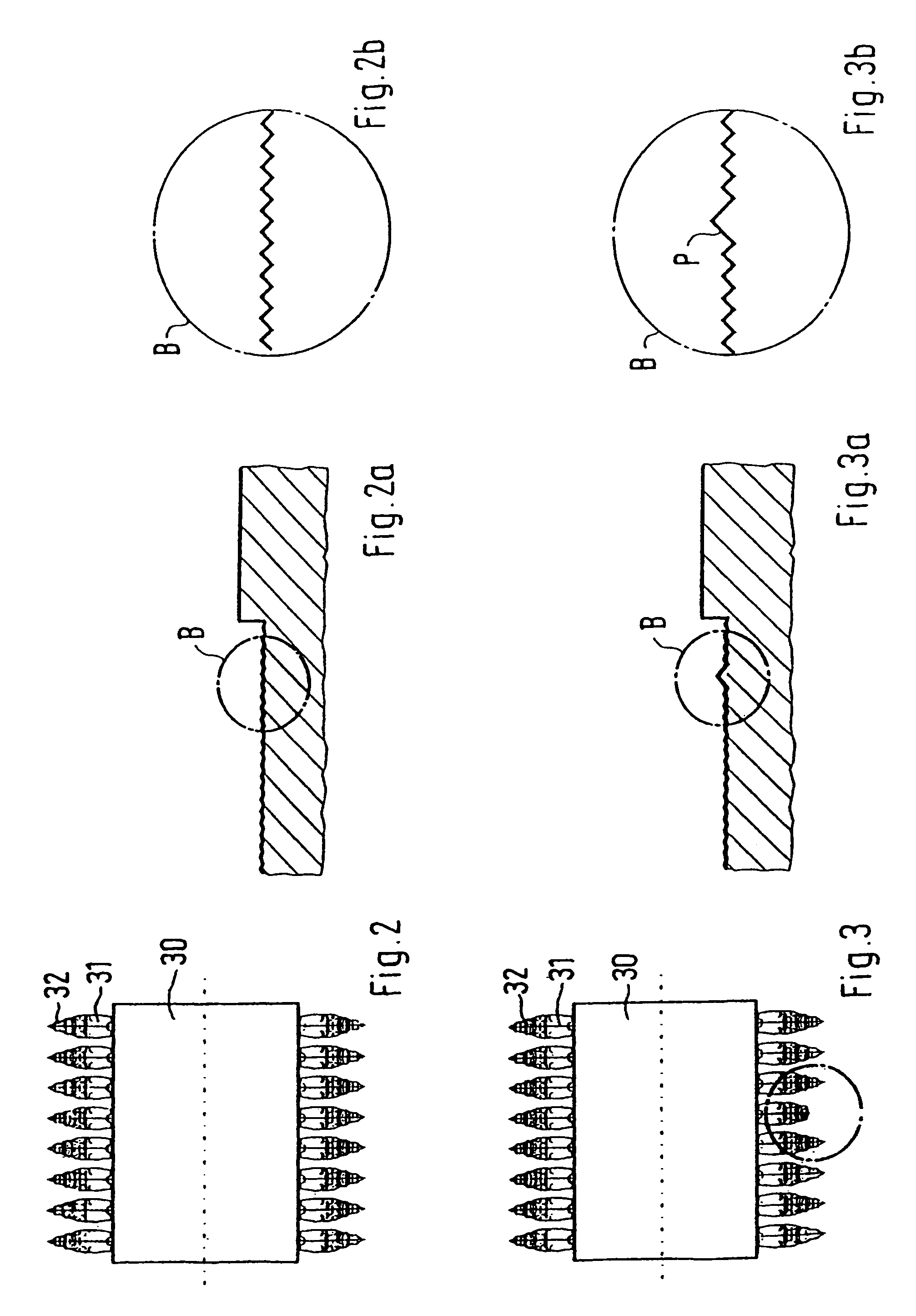

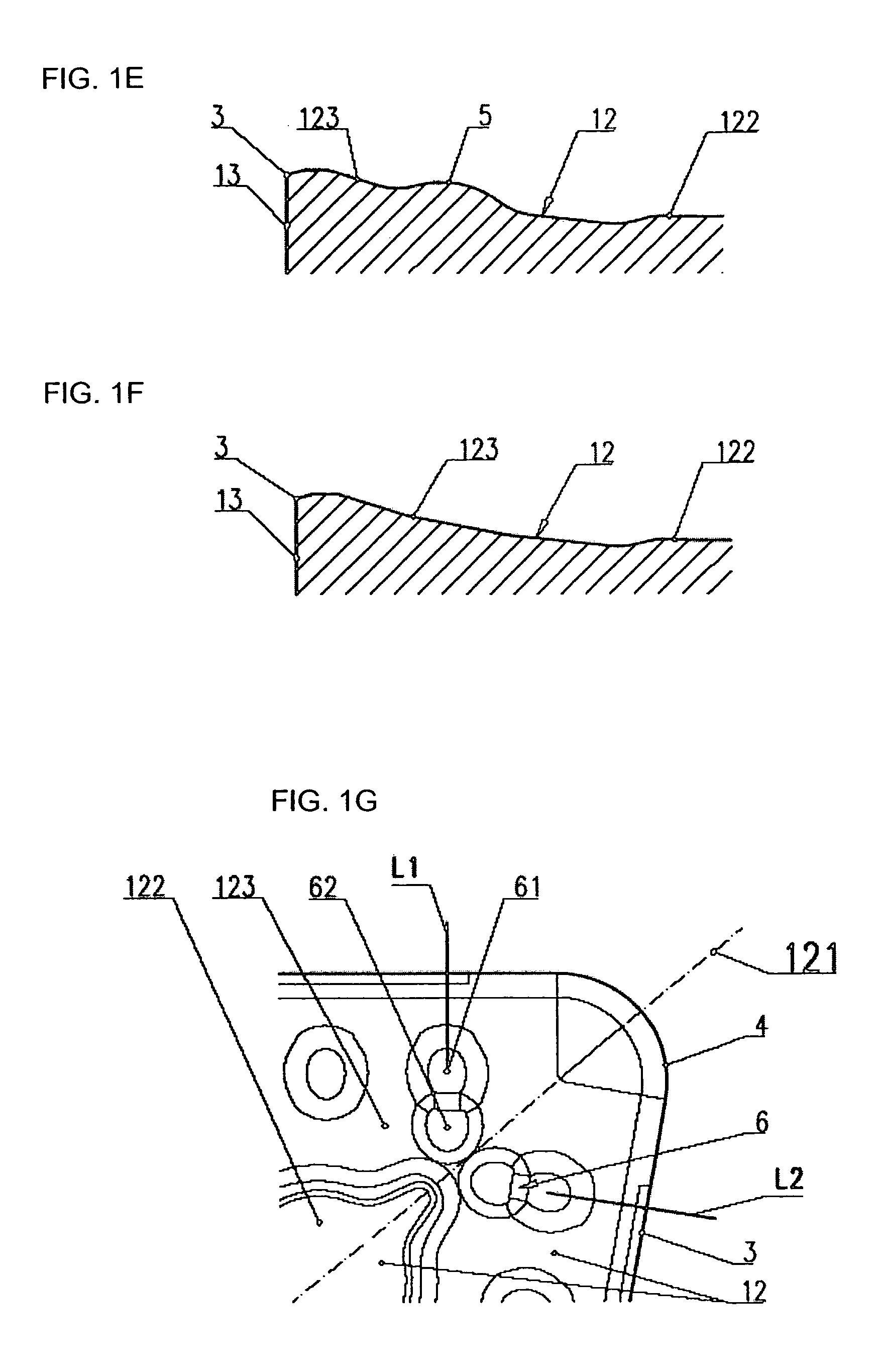

Road milling machine with optimized operation

ActiveUS20050207841A1Reduce the burden onReduce cutting forceMetal sawing devicesSlitting machinesElectrical and Electronics engineeringChisel

A road milling machine having a milling roller with a plurality of chisels. A signal receiving unit is assigned to a machine component which is directly or indirectly involved in the milling process or to another machine component. The signal receiving unit detects an operating condition of the machine component and is connected to a signal emitting unit. An optical detecting device may be assigned to the road milling machine, whereby operations are made easier and the milling pattern is optimized.

Owner:WIRTGEN GMBH

Road milling machine with optimized operation

InactiveUS7422391B2Reduce the burden onReduce cutting forceSlitting machinesWorking accessoriesChiselEngineering

A road milling machine having a milling roller with a plurality of chisels. A signal receiving unit is assigned to a machine component which is directly or indirectly involved in the milling process or to another machine component. The signal receiving unit detects an operating condition of the machine component and is connected to a signal emitting unit. An optical detecting device may be assigned to the road milling machine, whereby operations are made easier and the milling pattern is optimized.

Owner:WIRTGEN GMBH

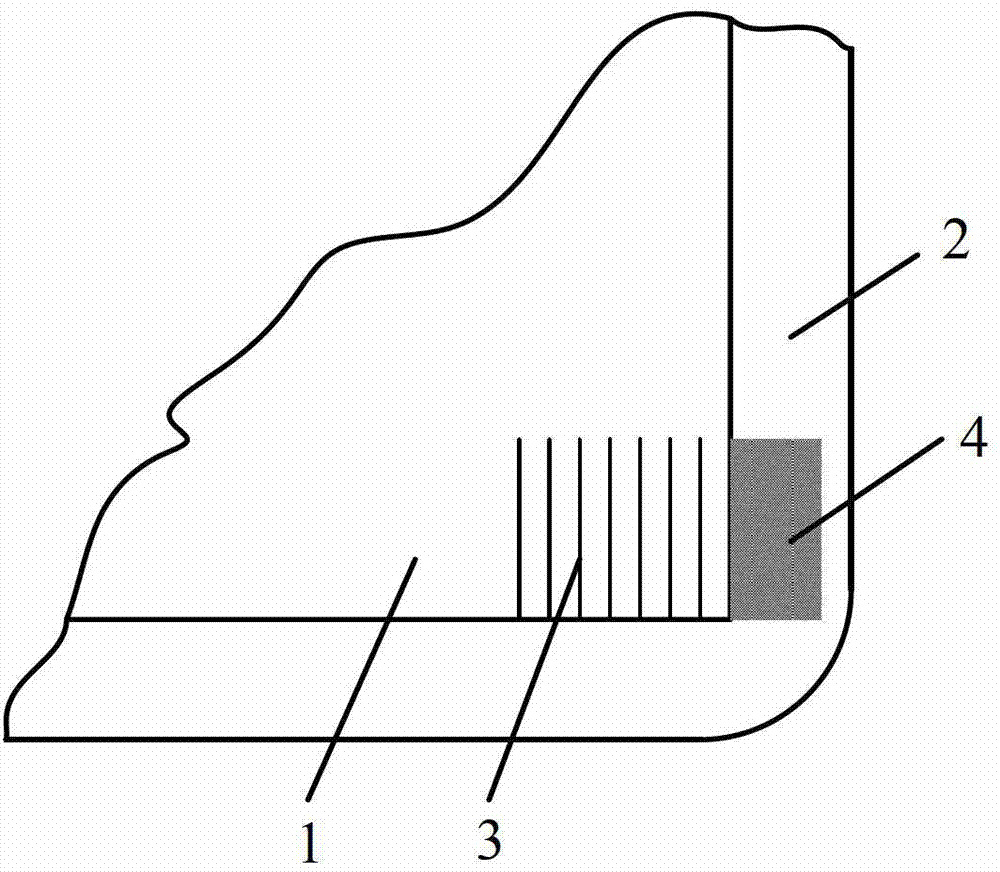

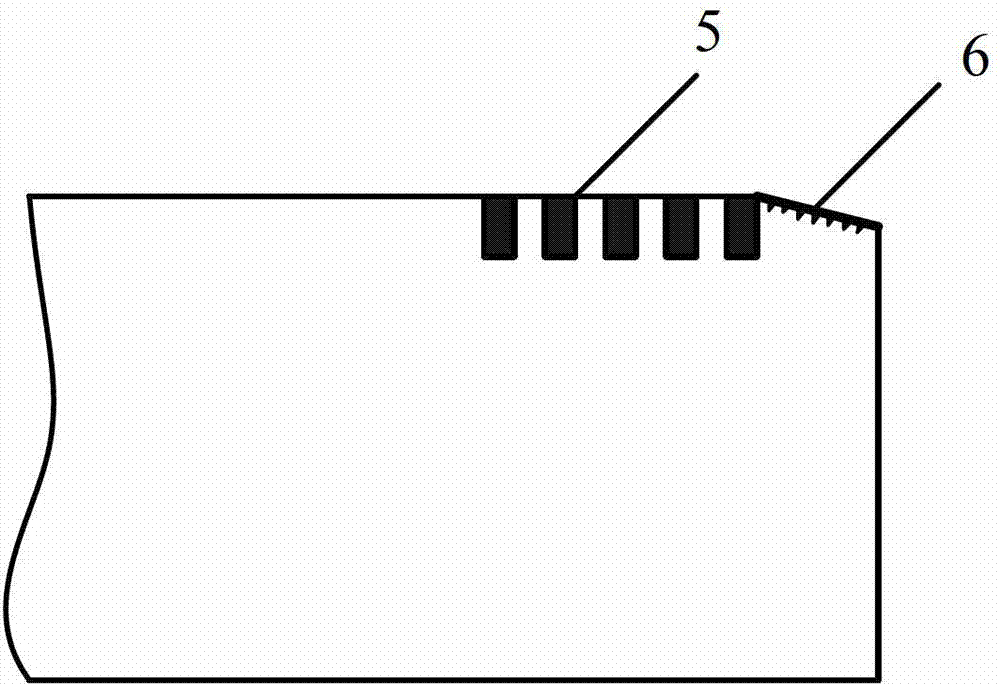

Plane wing titanium alloy thin-wall web efficient numerical control machining technology

A plane wing titanium alloy thin-wall web efficient numerical control machining technology comprises the following steps that (1) blanking is carried out; (2) web outer contour machining is carried out, and an ear piece for locating is machined; (3) a web is clamped, and a cavity on the front face of the web is machined; (4) a web side wall is machined; (5) web quick converting is carried out, and a cavity on the back face of the web is machined; (6) the locating ear piece is removed by milling; and (7) quality testing is carried out. The rigidity of a machining technology system is improved, unstressed machining is achieved, by optimized design of a feed track, the stability of a machining process is improved, machining speed is increased, titanium alloy shallow cutting large feeding milling technology parameters are used, heat deforming during machining is lowered, rectifying processes are omitted, the metal removing rate is improved by 30%-50%, finally, machining efficiency is obviously improved, the clamping time of workpieces is obviously shortened through a quick-reloading technology, the repeated locating accuracy of clamping is guaranteed, and accordingly numerically-controlled machine tool machining efficiency is greatly improved.

Owner:HUANGHE S & T COLLEGE

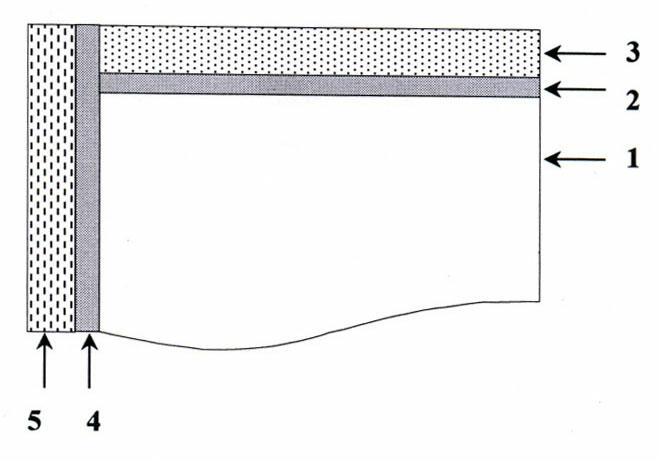

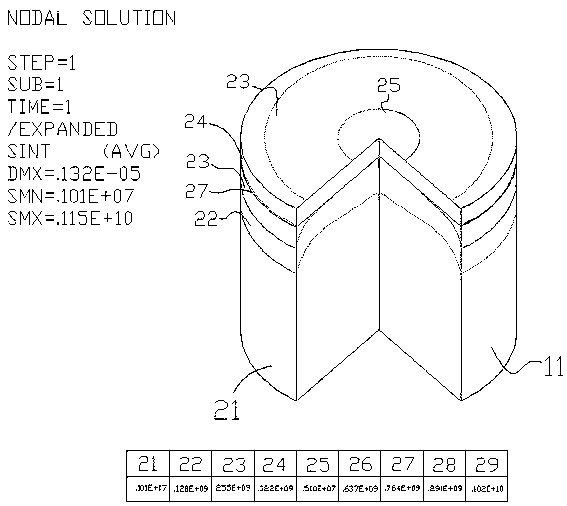

Self-lubricating composite soft coating cutter and manufacture method thereof

ActiveCN1927579ARealize self-lubricating functionSelf-lubricating function preventsLayered productsVacuum evaporation coatingManufacturing technologyMiddle frequency

The invention relates to a self-lubricant composite soft coat blade, and relative production. Wherein, said blade uses the MoS2 / Zr / Ti composite coat blade made from middle-frequency magnetic-control multi-arc plating method; the surface of blade is MoS2 layer, between which can base there are Ti, MoS2 / Zr / Ti, and MoS2 / Zr transition layer; when using said blade to cut, the surface of blade can form continuous lubricant layer, to realize self-lubricant function; since the solid lubricant has low shearing strength, the solid lubricant layer will be transferred to the surface of work piece, to form transfer film and the friction in the cutting process will generate inside the solid lubricant layer, to reduce friction, reduce shearing force and reduce shearing temperature.

Owner:ZHEJIANG DEWEI CEMENTED CARBIDE MFG CO LTD

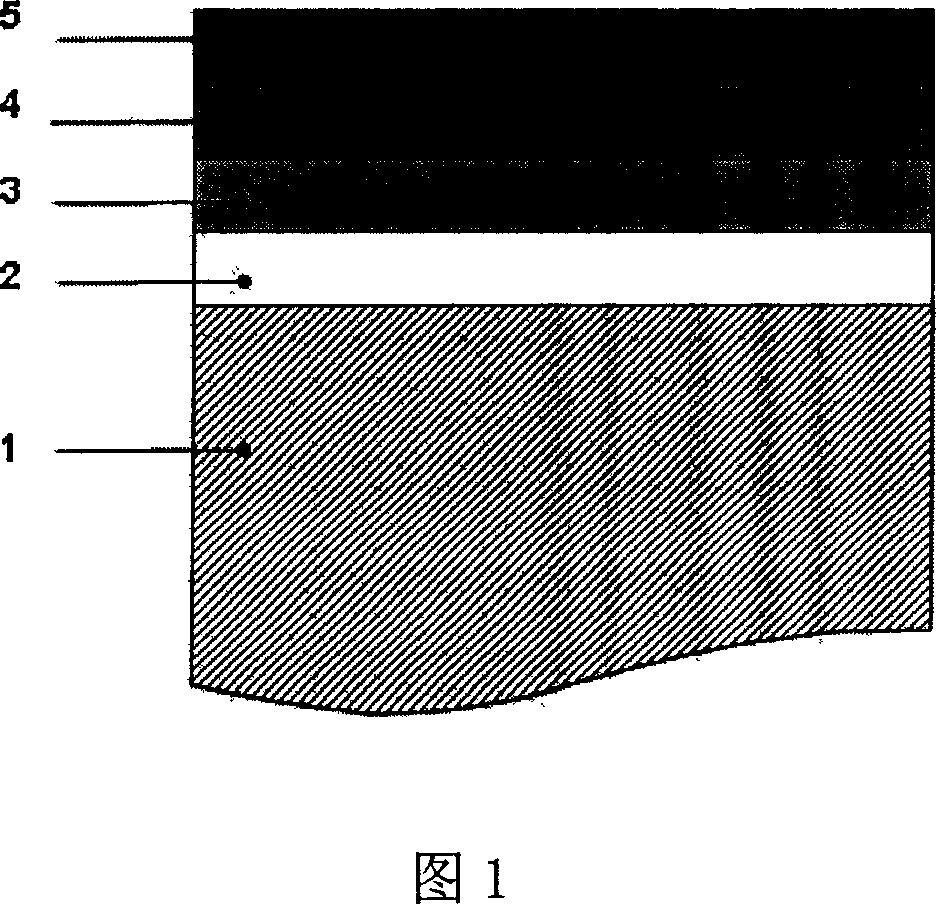

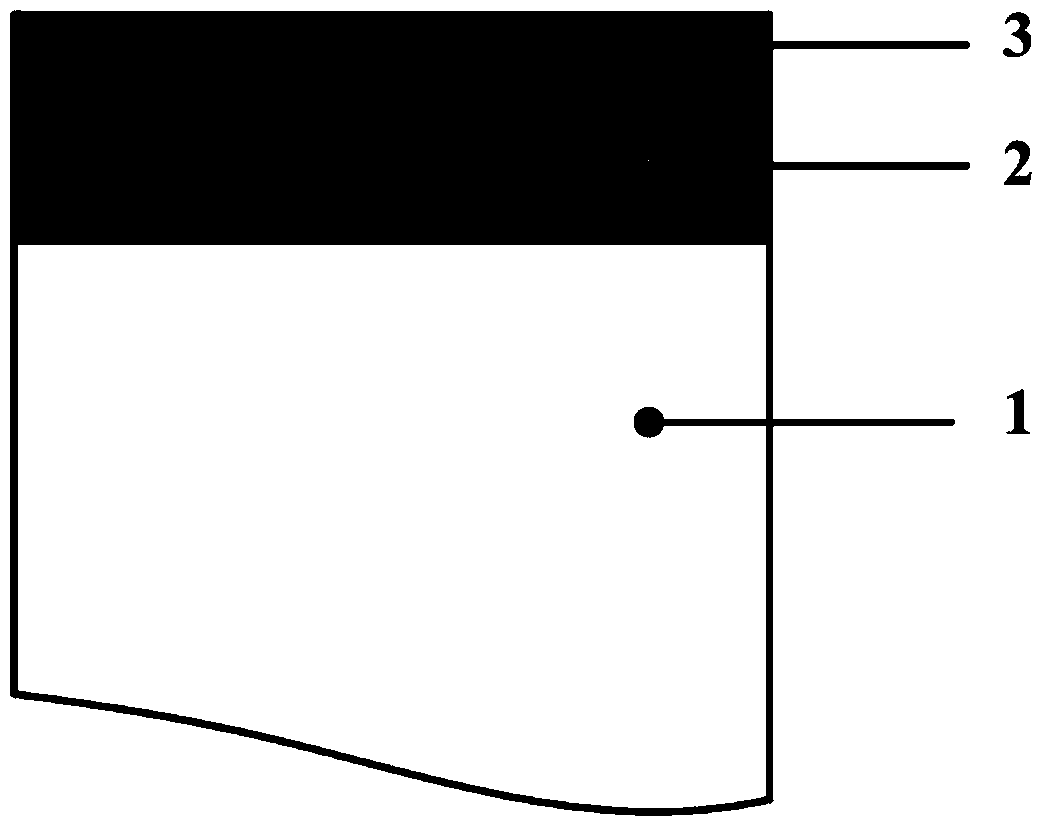

Machining method of thin-wall honeycomb core material curve machining molded surface

ActiveCN106903357AImprove milling efficiencyImprove machining accuracy and surface qualityWorkpiecesMilling equipment detailsThin walledHoneycomb

The invention discloses a machining method of a thin-wall honeycomb core material curve machining molded surface, and aims to provide a honeycomb machining method with high milling efficiency and capable of prolonging the life of a special honeycomb combined milling tool. The machining method is realized through the following technical scheme: when a double sided tape fixing state at the earlier stage of honeycomb machining is good, the special honeycomb combined milling tool with a conical disc return milling tool is changed for cutting; the rotating direction of the special honeycomb combined milling tool is changed; the conical disc return milling tool for feeding by a wedged angle of 30-45 degrees through high-speed rotation is used for cutting roughing; according to an anticlockwise tool rotating mode in the tool rotating direction, the downward pressure is applied to a honeycomb thin-edge area (1) through anticlockwise rotation; the part, easy to be pulled and damaged, of the thinnest honeycomb edge of the honeycomb bottom cutting profile is firstly machined; and after the honeycomb thin-edge area (1) of a NOMEX honeycomb part blank is machined, the sequential gradient machining is performed in (2-6) thickness direction of the thick-edge area cutting profile layer by layer, and the other parts are machined.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

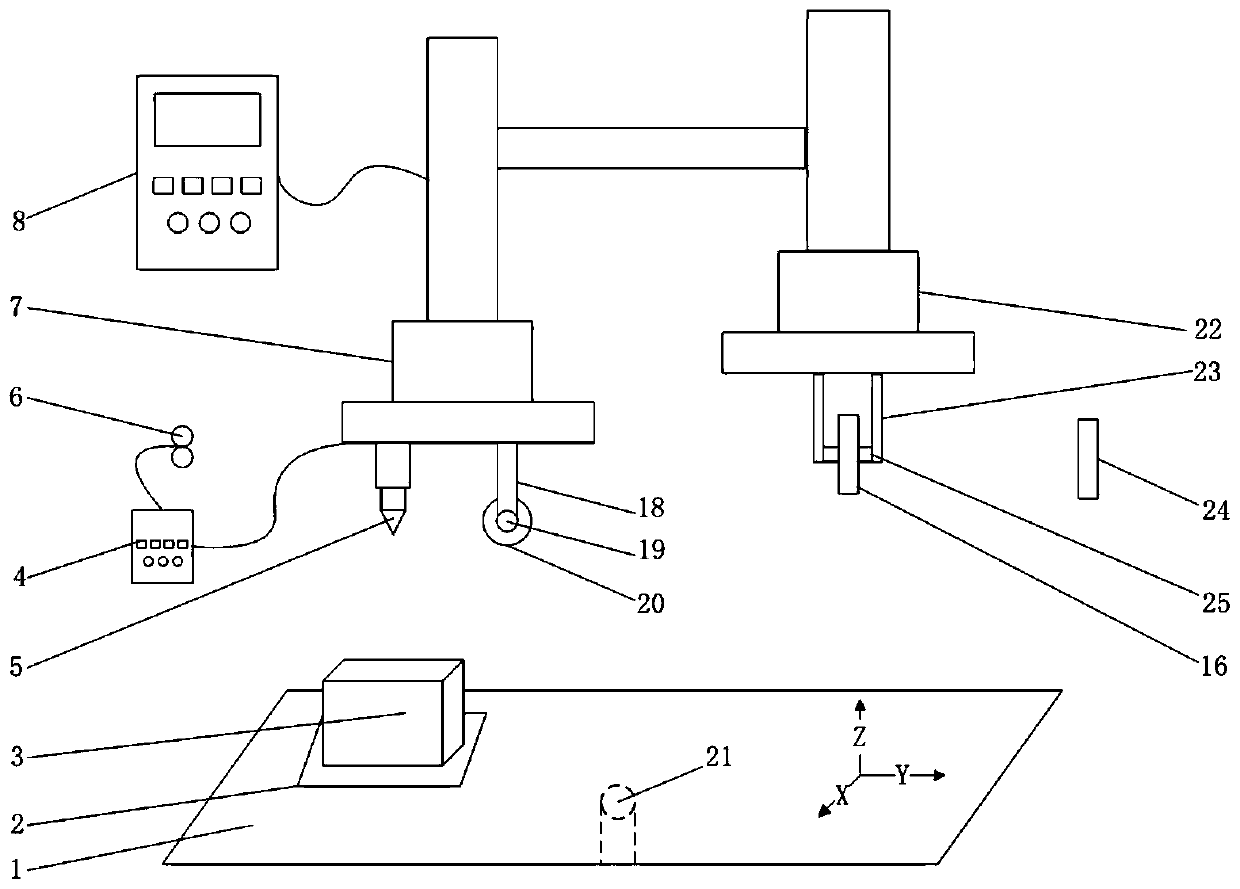

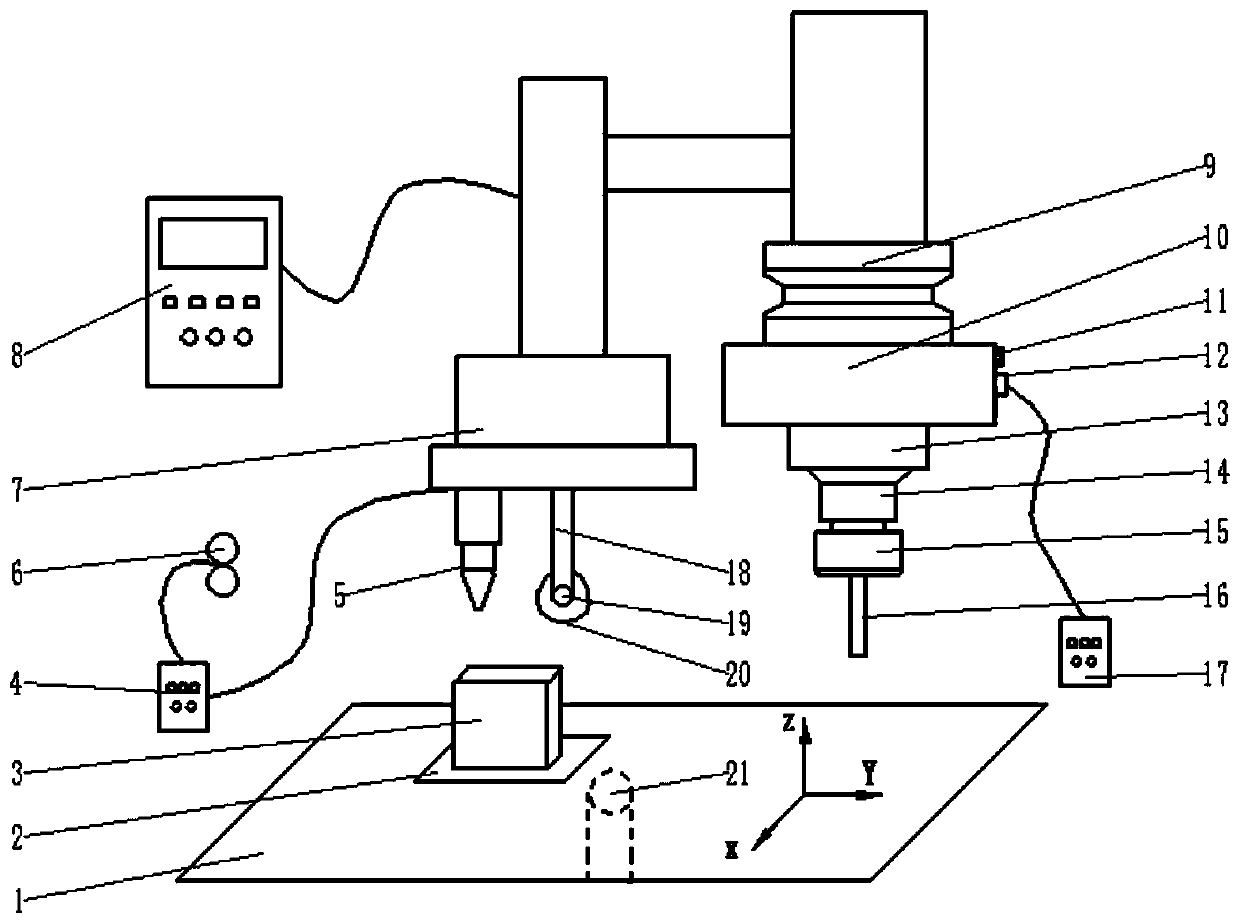

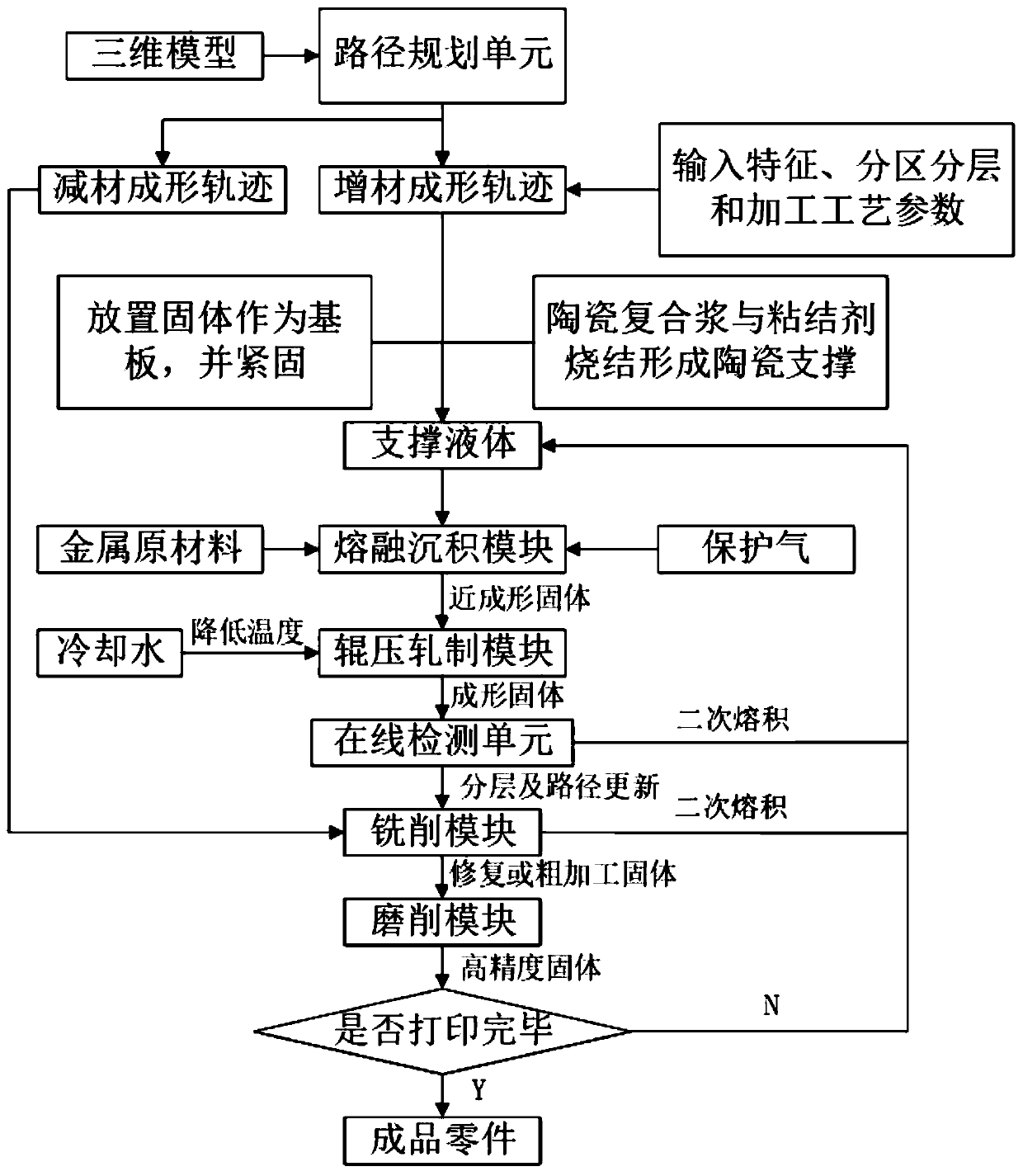

Metal part manufacturing system and method adopting micro-casting-forging and milling-grinding in-situ composite

InactiveCN110076566AImprove tissue mechanical propertiesImprove processing efficiencyAdditive manufacturing apparatusOther manufacturing equipments/toolsEngineeringManufacturing systems

The invention belongs to the field of metal part manufacturing, and particularly discloses a metal part manufacturing system and method adopting the micro-casting-forging and milling-grinding in-situcomposite. The system involves a micro-casting-forging module, a milling module, a five-axis linkage workbench and a control device, wherein the micro-casting-forging module is connected with the milling module and comprises a fusion deposition sub-module and a roller-pressing rolling sub-module, the five-axis linkage workbench is positioned below the micro-casting-forging module and the milling module, and is used for containing metal parts to be formed, and the control device is connected with the fusion deposition sub-module, the roller-pressing rolling sub-module, the milling module and the five-axis linkage workbench. According to the system and method, micro-casting-forging and a milling process are composited to process and manufacture the metal parts, so that the problems that whenthe metal parts are made through the additive manufacturing, the structure is not uniform, the deformation is serious, the residual stress is large, the structure performance is poor, and the surfacequality is poor are solved, and the system and method is especially suitable for processing a high-performance complicated special-shaped element.

Owner:HUAZHONG UNIV OF SCI & TECH

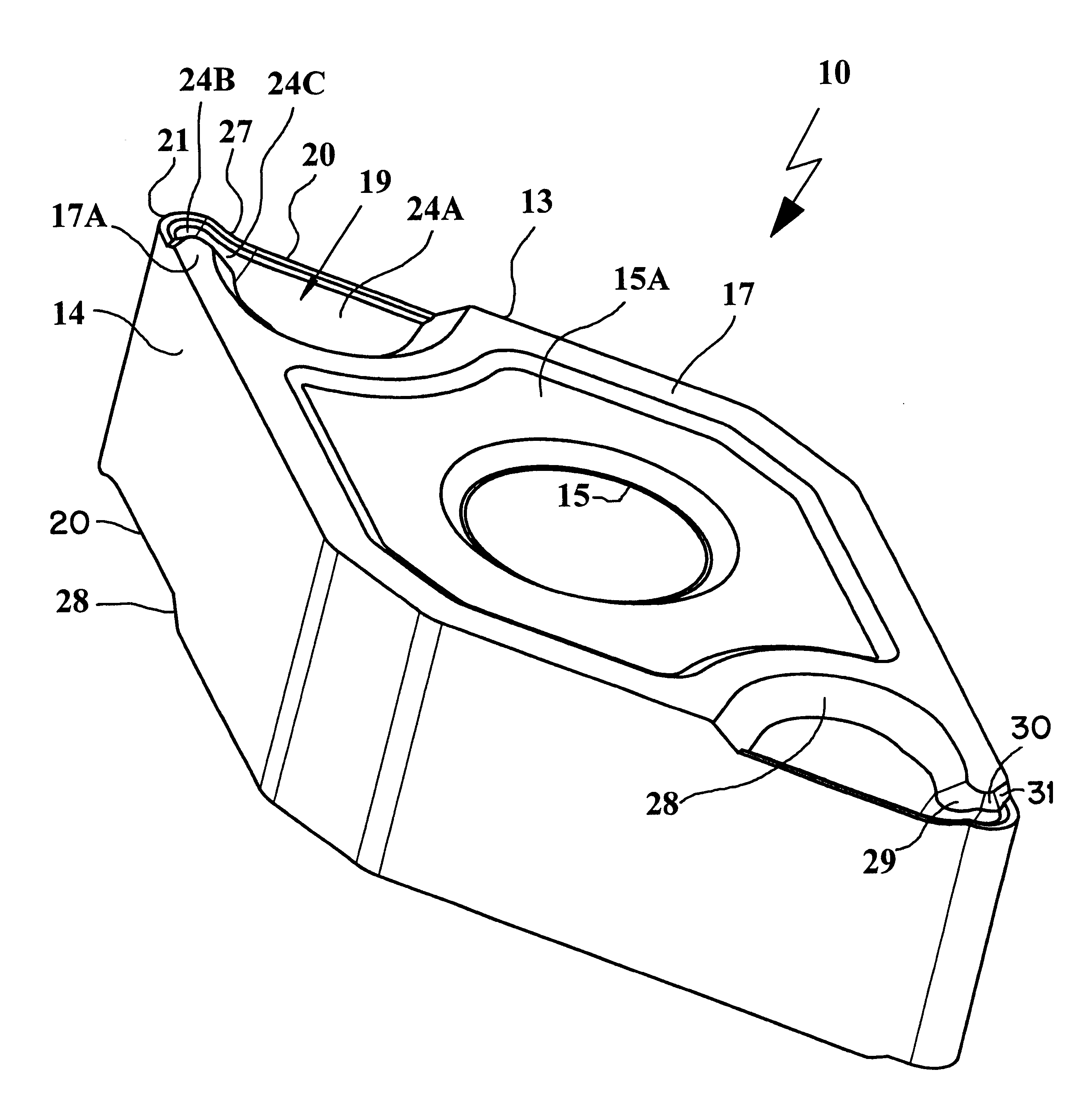

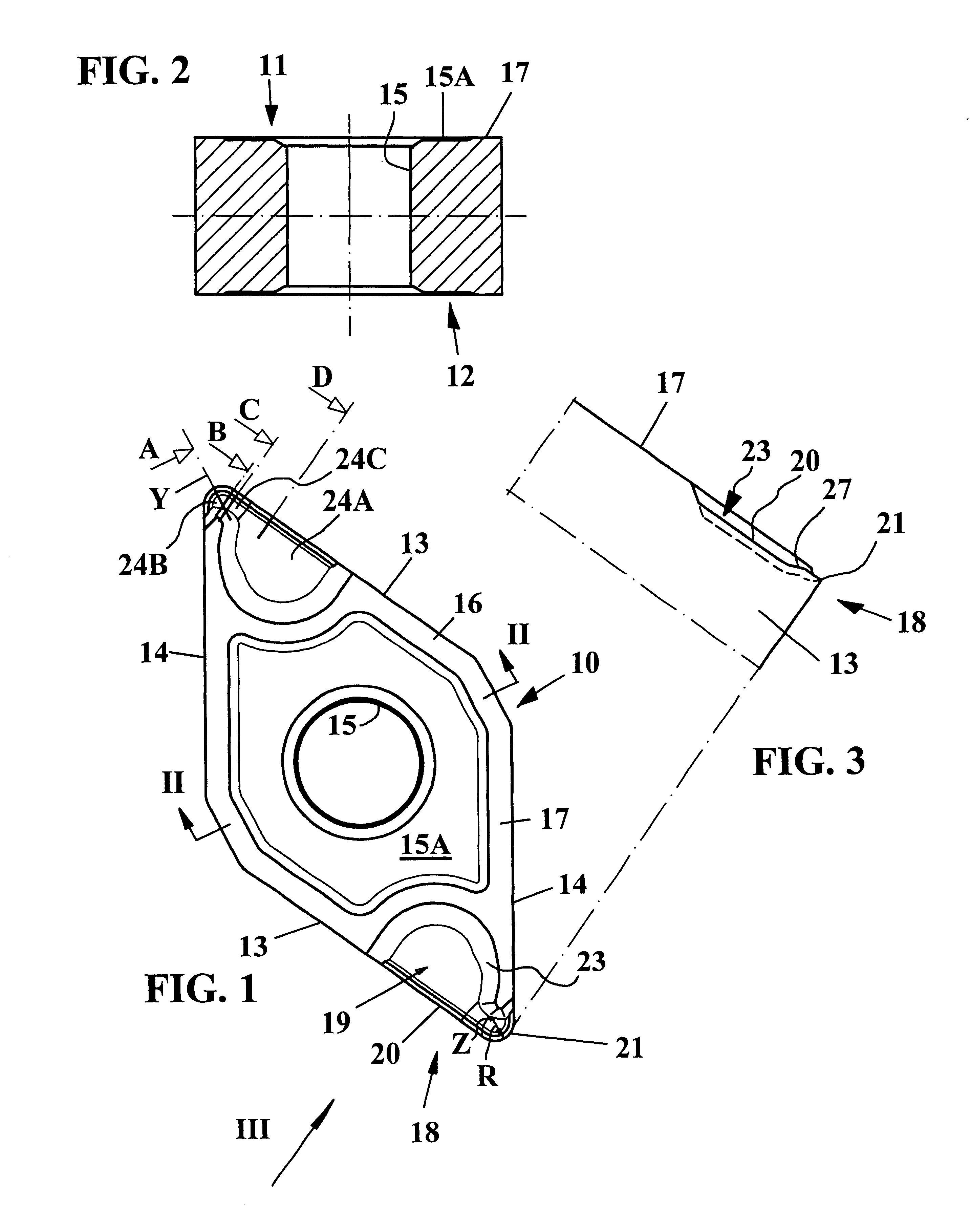

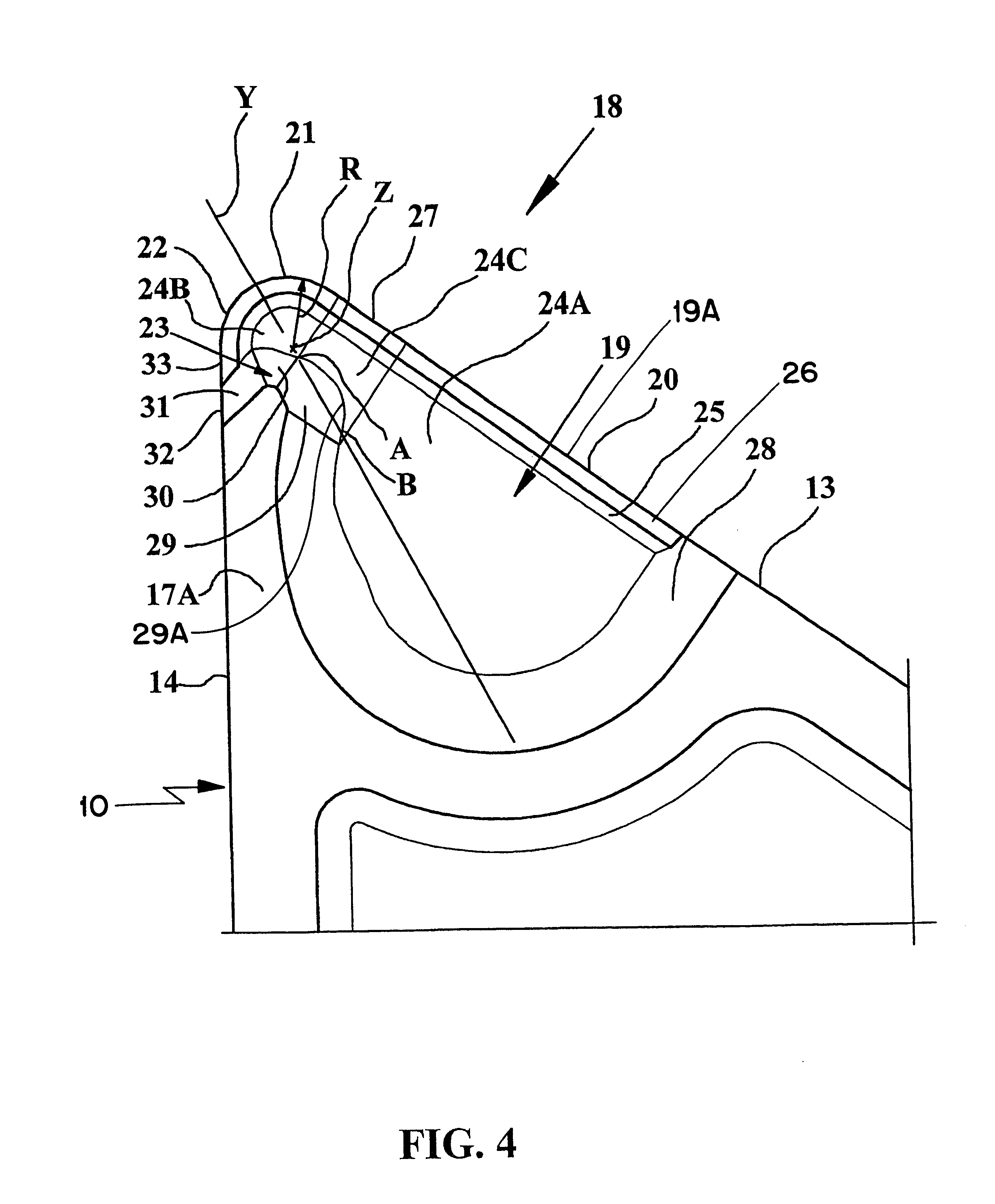

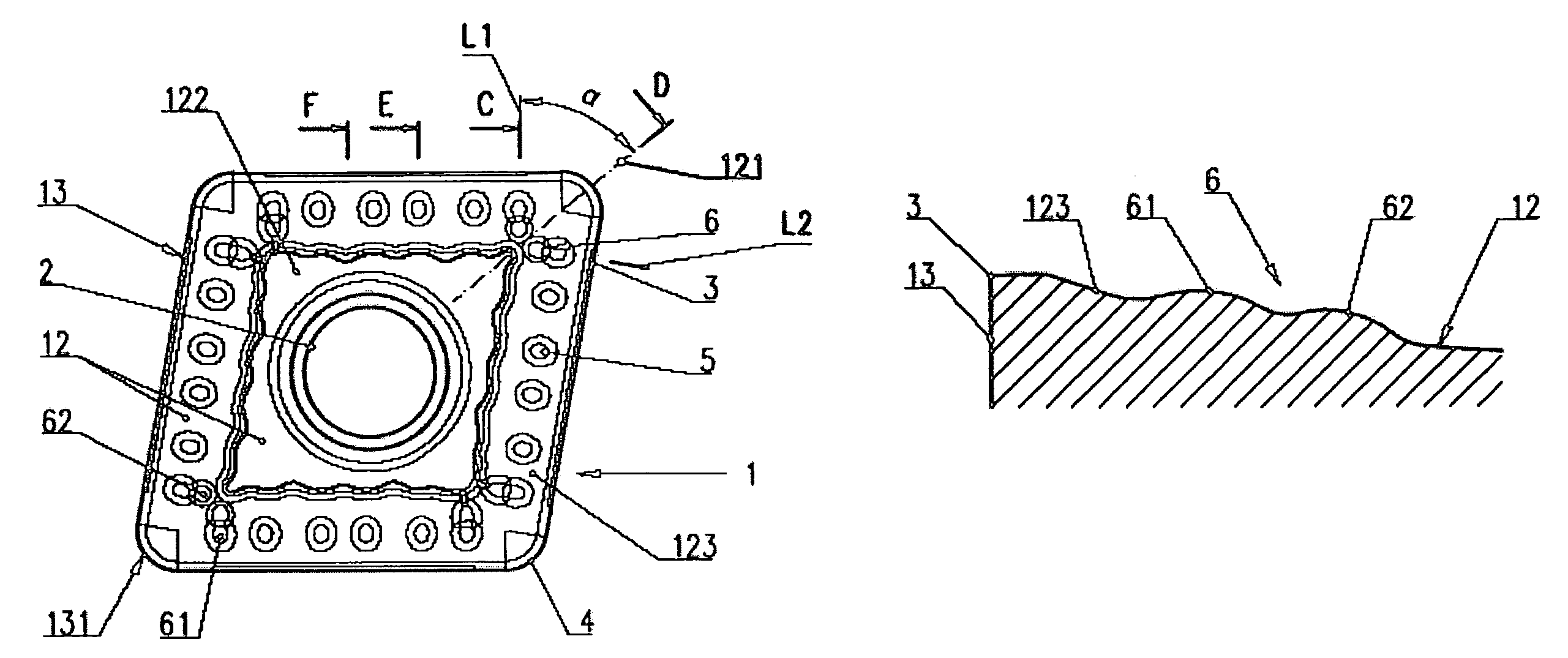

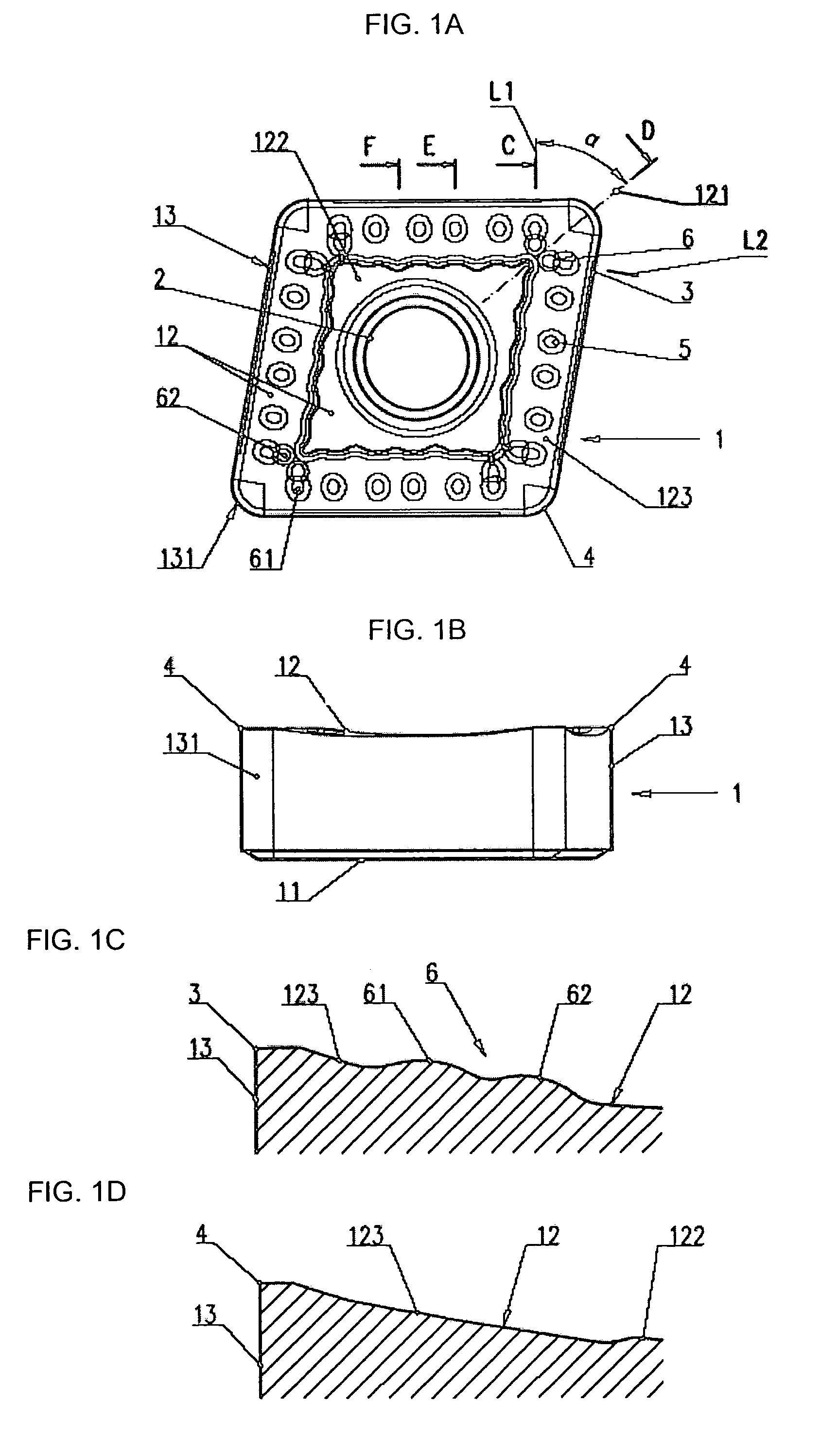

Cutting insert having a chip former

InactiveUS6241430B1Not to damageReduce cutting forceTurning toolsShaping cuttersLeading edgeWear resistant

A turning insert, preferably for internal machining, includes a polygonal body of hard wear resistant material, which has an upper surface and a lower surface provided in separate substantially parallel planes and a number of side surfaces each interconnecting the upper and lower surfaces. A first side surface is a leading edge surface, and a second side surface is a trailing edge surface during machining. At least one chip former is provided. At least one rounded cutting corner having cutting edges is formed at an intersection of the two side surfaces. The cutting corner defines a bisector plane. The chip former is asymmetrically arranged relative to the bisector plane. The chip former has a surface that is provided in the plane of the upper surface. The surface is provided at substantially one side of the bisector plane and the convex portion of the chip former has a lower edge intersected by the bisector plane at least twice.

Owner:SECO TOOLS AB

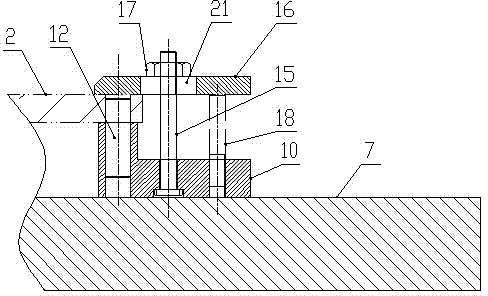

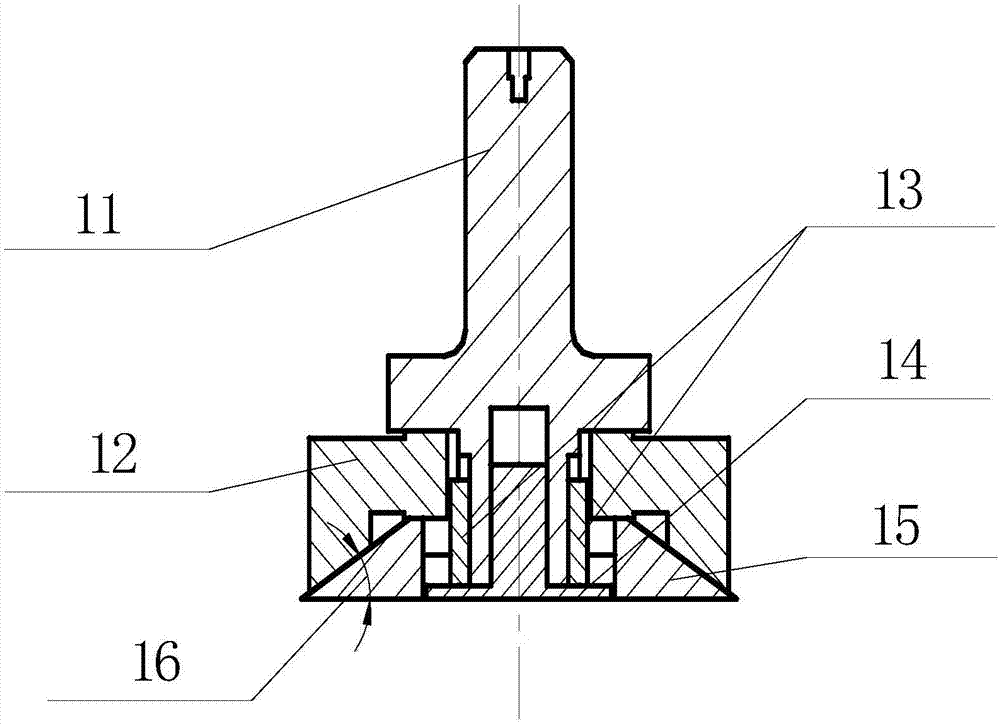

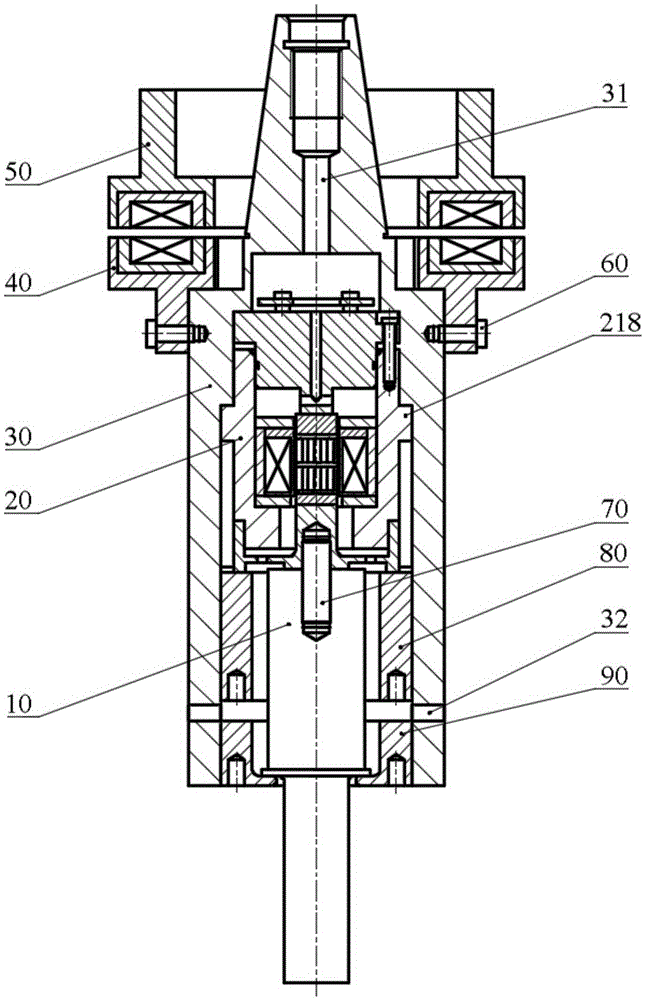

Giant magnetostrictive rotary ultrasonic vibration knife handle

ActiveCN105397920AHigh magnetostriction coefficientIncrease output powerMechanical vibrations separationStone-like material working toolsTransducerAir cooling system

The invention relates to a giant magnetostrictive rotary ultrasonic vibration knife handle and belongs to the technical field of ultrasonic precise special machining. The knife handle comprises an amplitude-change pole, a giant magnetostrictive ultrasonic transducer, a hollow knife handle body, an auxiliary side component, a primary side component and a threaded pressing block, wherein the giant magnetostrictive ultrasonic transducer is connected with the amplitude-change pole through a threaded rod and installed in a cavity in the lower portion of the knife handle body; an ultrasonic vibrator formed by connecting the giant magnetostrictive ultrasonic transducer with the amplitude-change pole makes contact with the inner wall of the knife handle body, the lower end of the giant magnetostrictive ultrasonic transducer is tightly pressed onto the knife handle body through the threaded pressing block, and the threaded pressing block is connected with the knife handle body through threads; the lower end of the amplitude-change pole is tightly pressed through the threaded pressing block, and the threaded pressing block is connected with the knife handle body; the lower end of the auxiliary side component is fixed to the knife handle body through a screw, and the primary side component is fixed to the end face of a machine tool spindle. According to the giant magnetostrictive rotary ultrasonic vibration knife handle, the problem of heating of the transducer is effectively solved by means of a giant magnetostrictive material of a slice structure and an air cooling system. By the adoption of the knife handle, the machining efficiency can be improved. In addition, the knife handle can be suitable for any knife handle connection standards.

Owner:TSINGHUA UNIV

Aluminum alloy semisynthesis cutting liquid and preparation method thereof

ActiveCN102925269AResistant to corruption and odorWill not corrodeLubricant compositionActive agentSurface-active agents

The invention discloses aluminum alloy semisynthesis cutting liquid and a preparation method thereof. The aluminum alloy semisynthesis cutting liquid is composed by weight of 12%-20% of mineral oil, 9%-15% of surfactant, 8%-12% of antirust agent, 1%-2% of aluminum corrosion inhibitor, 3%-7% of lubricant, 8%-12% of extreme pressure agent, 0.5%-1% of defoamer, 0.5%-1% of fungicide and the balance, water. The preparation method includes sequentially adding the surfactant, the antirust agent, the aluminum corrosion inhibitor, the lubricant, the extreme pressure agent, the defoamer, the fungicide and the water into the mineral oil and evenly stirring and mixing the mixture to obtain the aluminum alloy semisynthesis. The aluminum alloy semisynthesis cutting liquid has excellent performance on aluminum corrosion inhibition performance, corrosion resistance, lubricant performance, anti-rust performance, defoaming performance, use period and the like.

Owner:SHANGHAI INST OF TECH

Precision numerical control milling method for thin-wall parts

InactiveCN101602122AReduce stiffnessGuaranteed machining accuracyMilling equipment detailsNumerical controlEngineering

The invention discloses a precision numerical control milling method for thin-wall parts, and provides a processing method for reducing the milling deformation of the thin-wall parts and improving processing precision and surface quality. When a thin-wall part is finished by fine processing through end milling, the machining allowances of the side wall and a web plate are larger than those of the prior process, and are between 2 and 5mm respectively; when the side wall is processed, the axial depth ap is between 0.2 and 0.8mm, and the radial cutting width is 60 to 80 percent of the diameter of a cutting tool; and when the web plate is processed, the axial depth ap is between 2 and 5mm, and the radial cutting width ae is 10 to 20 percent of the diameter of the cutting tool. The processing method effectively slows down the reduction of the self-rigidity of workpieces and control the cutting force in the thin-wall direction when the processing efficiency is ensured, thereby effectively reducing and controlling the processing deformation of the thin-wall parts, and ensuring the processing precision and surface quality of the parts.

Owner:TIANJIN UNIV OF COMMERCE

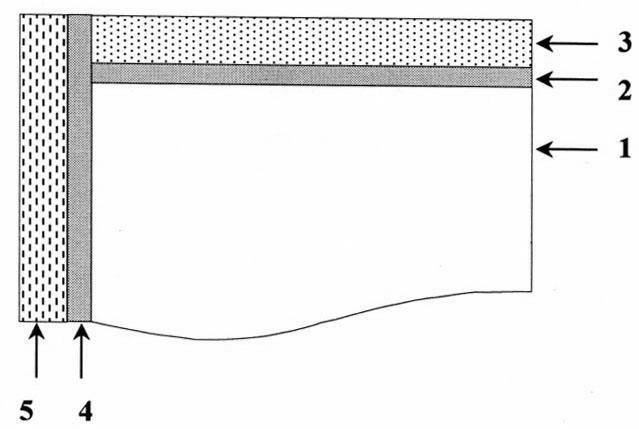

Preparation method for laser cladding soft and hard composite coating self-lubricating cutter

InactiveCN103522652AImprove toughnessHigh surface hardnessMetallic material coating processesMetal layered productsNano al2o3Hardness

The invention belongs to the field of machinery cutting cutter manufacturing, and relates to a preparation method for a laser cladding soft and hard composite coating self-lubricating cutter. A rake face coating of the cutter is a multi-layer structure. Firstly, a hard coating of nano Al2O3 ceramic or an ultrafine cemented carbide, etc. is clad on the rake face of the cutter by utilization of a CO2 laser synchronous feeding manner, and then a self-lubricating soft coating is clad by utilization of nickel-covered MoS2 powder or nickel-covered WS2 powder. The cutter has characteristics of good toughness, high hardness, a self-lubrication function, and the like. During a drying cutting process, the hard coating bears loads and the rake face self-lubricating soft coating has low shearing strength, thus reducing friction between the cutter and chips, reducing the cutting temperature and the cutting force, and therefore cutter abrasion is reduced. The cutter can be widely used for dry cutting and cutting machining of difficult-to-machine materials.

Owner:SHANDONG UNIV

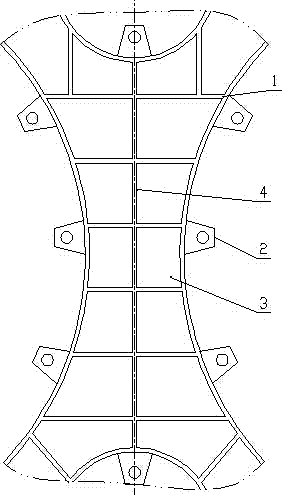

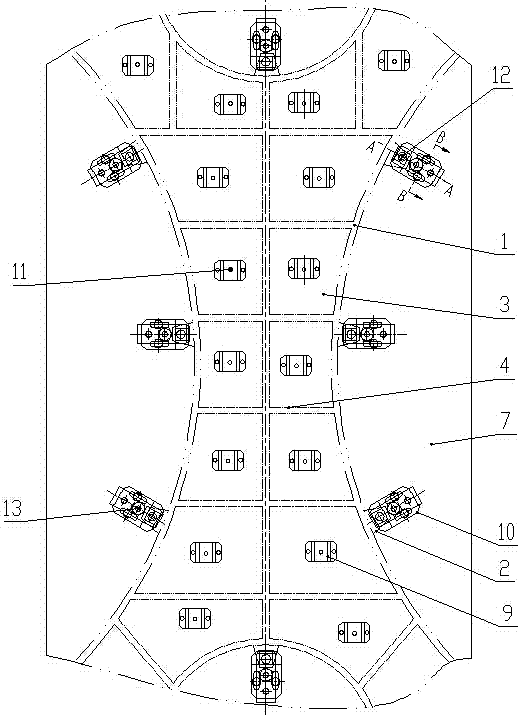

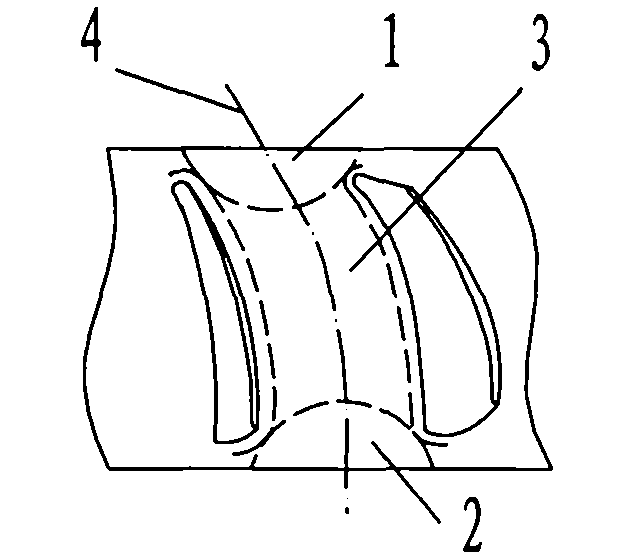

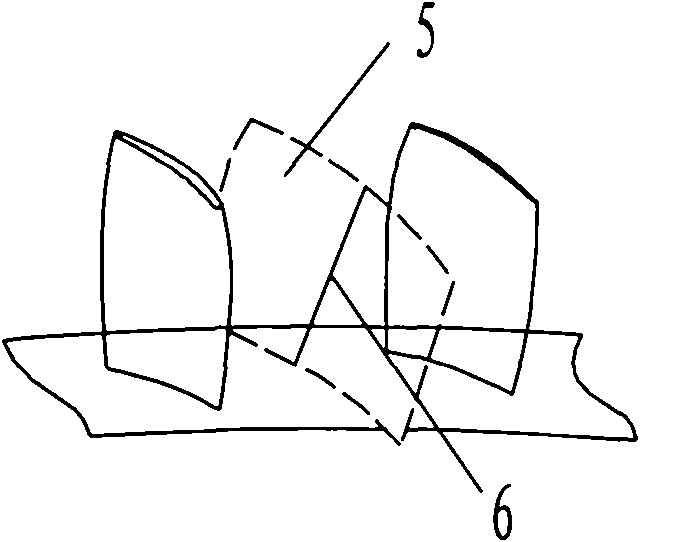

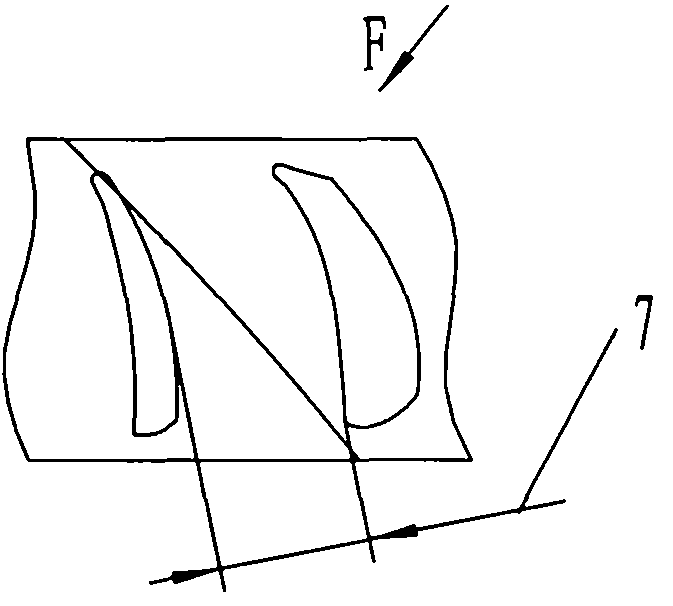

Method for composite machining of blisk flow passage

InactiveCN101966604AImprove rigidityImprove processing stabilityMilling equipment detailsNumerical controlBoundary contour

The invention belongs to the technical field of aircraft engines, and discloses a method for the composite machining of a blisk flow passage. The method is a numerical control machining method of selecting the adaptive machining strategy based on regional characteristics. The method comprises the following steps of: (1) dividing a machining region; and (2) selecting the adaptive numerical control machining strategy based on the regional characteristics. In the method, a rough slotting numerical control machining method of combining milling, drilling milling and slotting milling of a cycloid is adopted, so that a medial cambered surface is approximate to a curved surface of a blade profile, and the boundary contour and the optimal cutter-axis vector of a rough machining region in a channel are determined. The method has the advantages that the machining method of region division and cutting-in changing enhances the rigidity and machining stability of blades; a process method of combining the milling and slotting milling of the cycloid improves the durability of cutters and the removal rate of materials; and the vibration phenomenon in the rough machining process is prevented effectively, the cutting force is reduced, the movement space of the cutters is expanded farthest, and the machining efficiency is improved.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Micro-nano composite texture self-lubricating ceramic tool and manufacture method thereof

InactiveCN103028746AExtended service lifeReduce frictionTurning toolsLaser processingManufacturing technology

The invention belongs to the technical field of manufacture of mechanical cutting tools, and in particular relates to a micro-nano composite texture self-lubricating ceramic tool and a manufacture method thereof. According to the micro-nano composite texture self-lubricating ceramic tool, a micron level texture is processed on a front cutter surface by adopting a laser processing technology, a nano level texture is processed on a negative chamfered edge, a solid lubricating agent is filled in the micron level texture and the nano level texture respectively, during chip dry cutting, the dual functions of the micro-nano composite texture and the solid lubricating agent can realize that the friction is reduced and the cutting force and the cutting temperature are reduced, and thus the purposes of preventing adhesion, reducing friction and abrasion and prolonging the service life of the tool can be achieved. The micro-nano composite texture self-lubricating ceramic tool can be widely applied to high-speed dry cutting and cutting of difficult-to-machine materials, can overcome the environment pollution caused by cutting solution, realizes clean production, and is reduced in cost.

Owner:SHANDONG UNIV

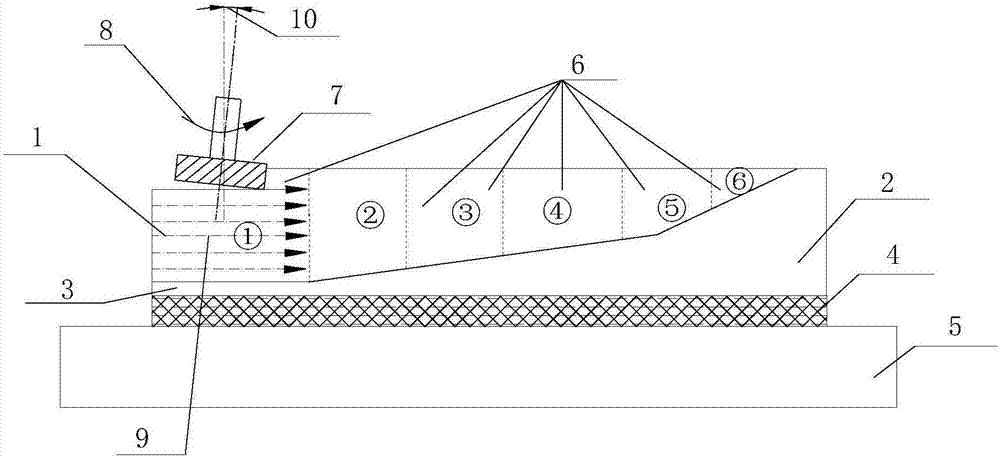

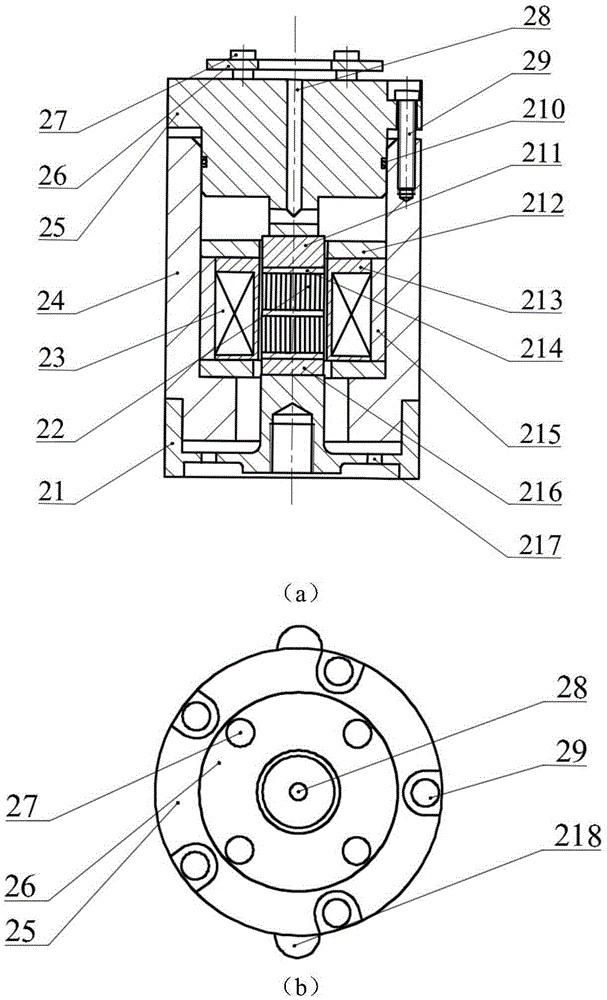

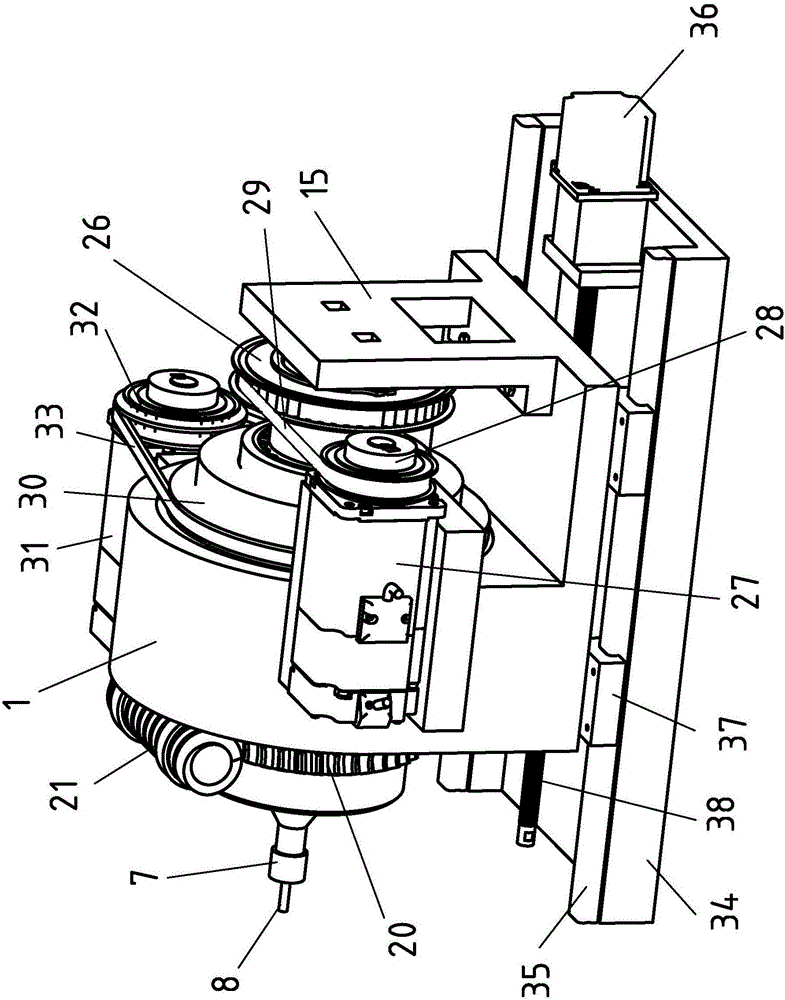

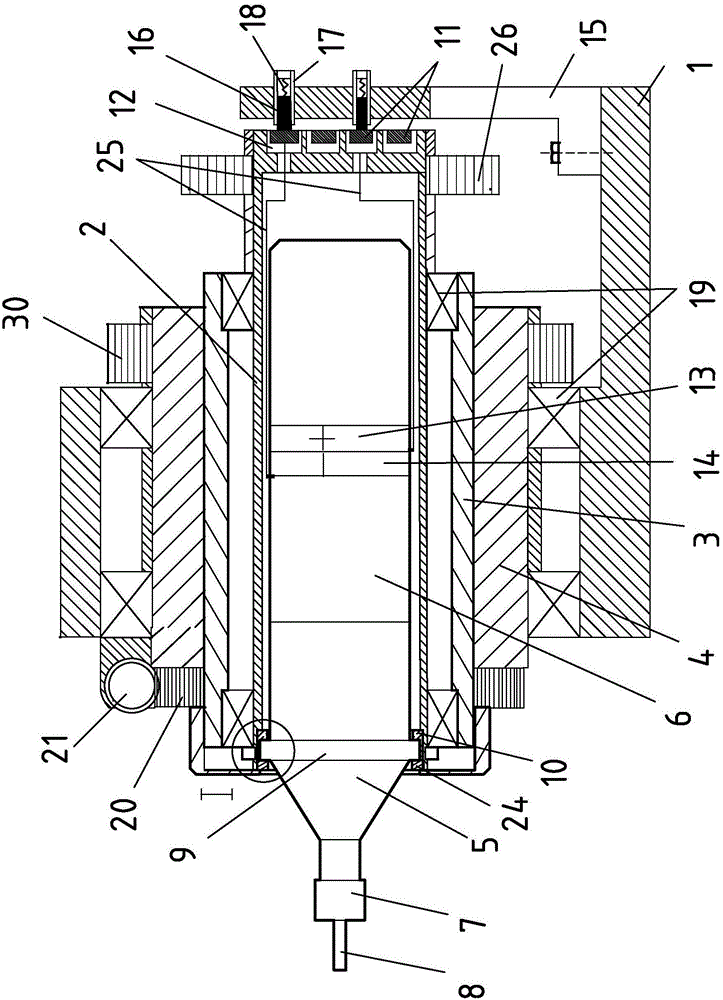

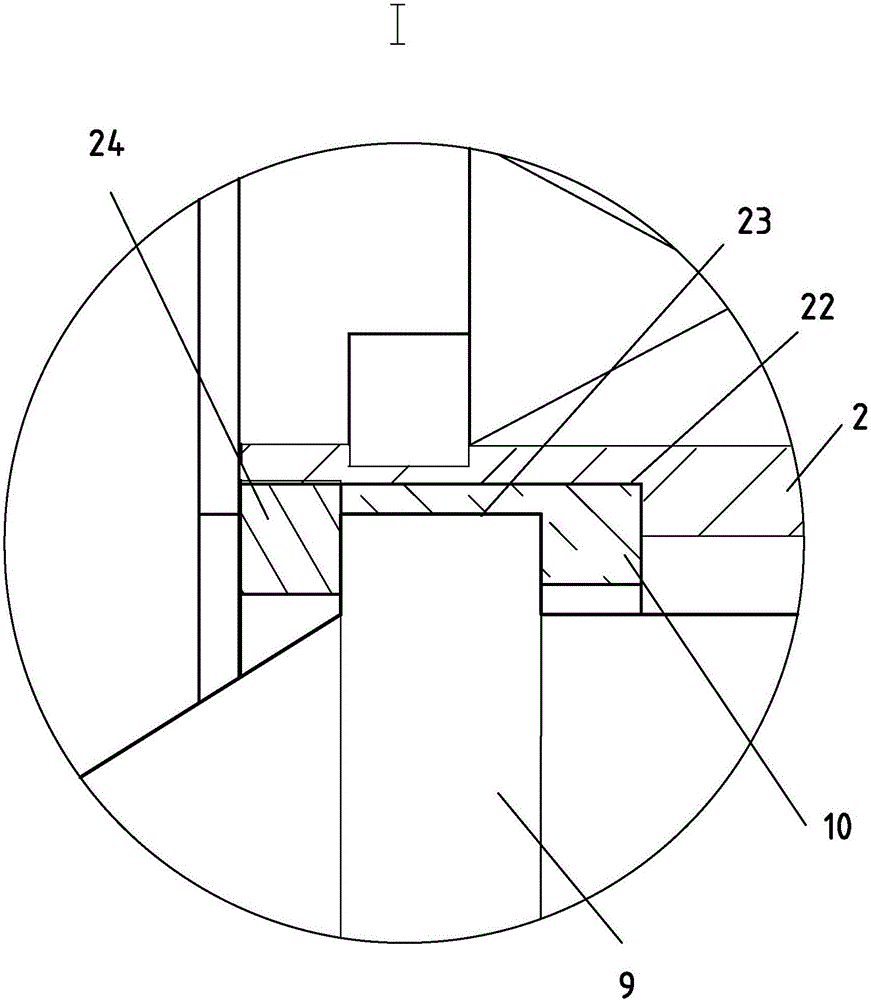

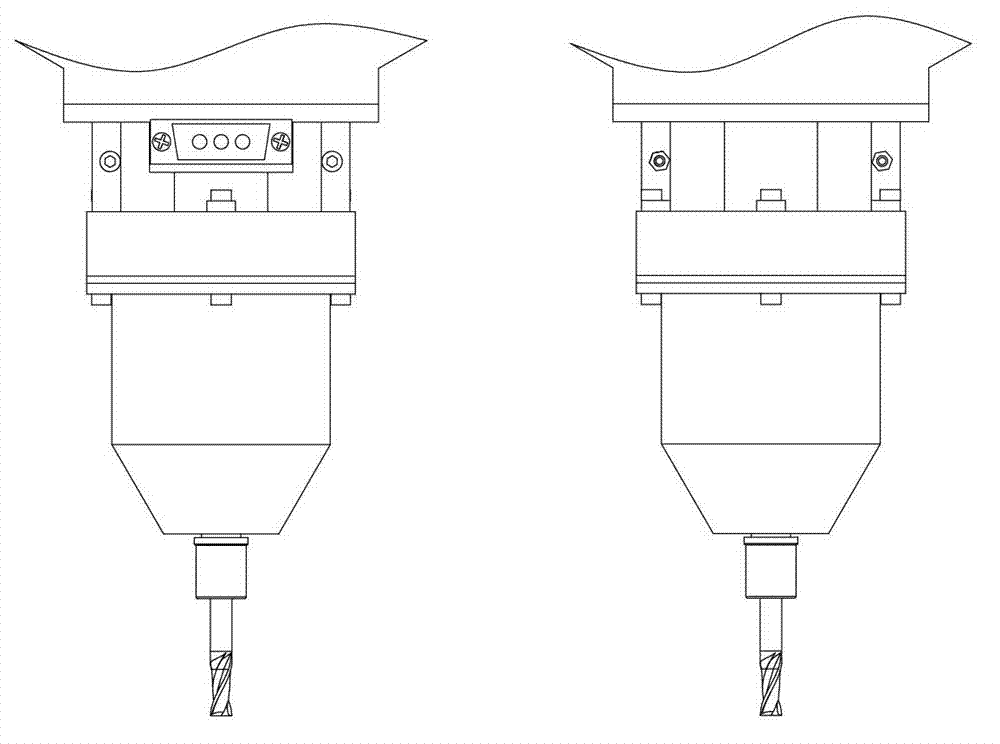

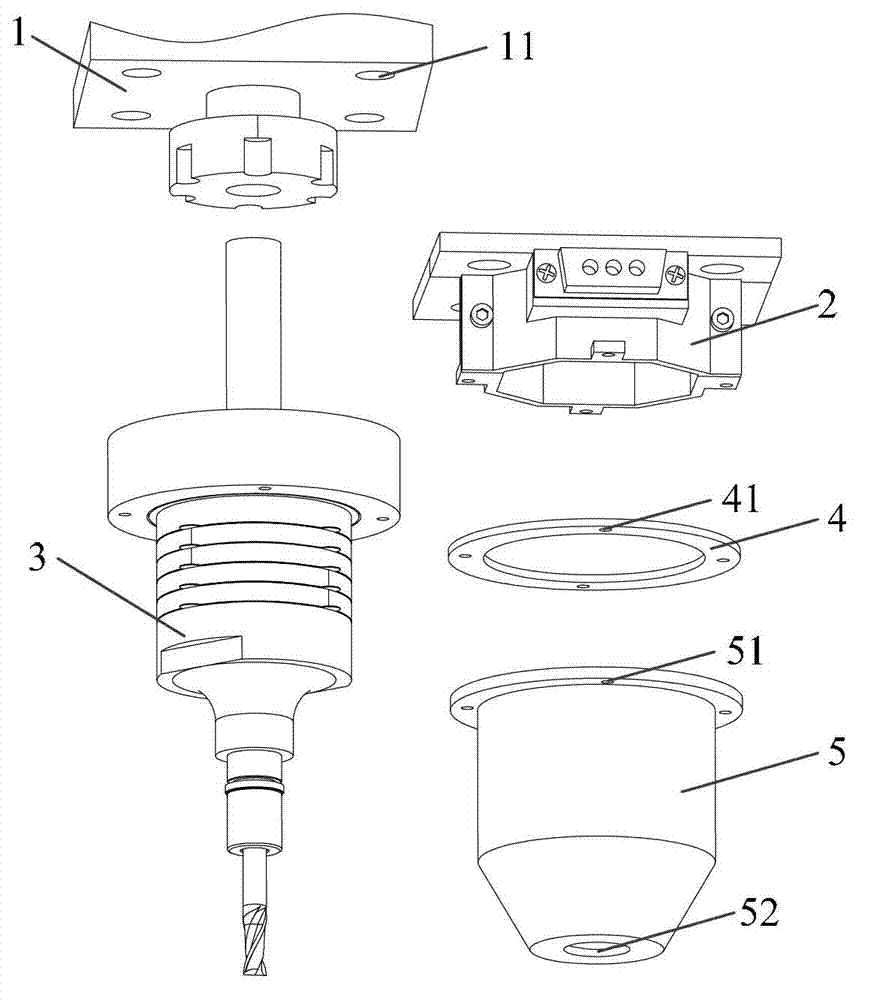

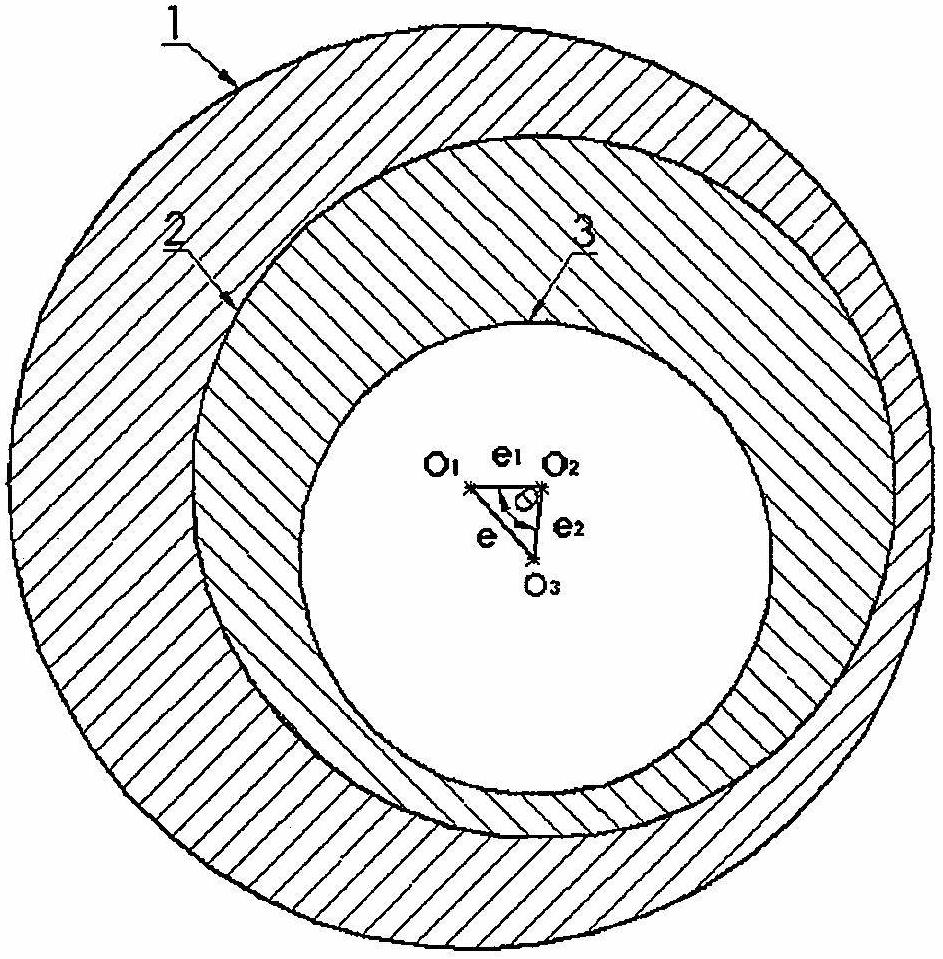

Ultrasonic helical hole milling device and machining method

ActiveCN106077774AImprove hole qualityReduce cutting forceRevolution surface grinding machinesMilling equipment detailsMilling cutterTransducer

The invention discloses an ultrasonic helical hole milling device which comprises a spindle support, an ultrasonic sleeve, an inner eccentric sleeve, an outer eccentric sleeve, an amplitude-change pole and a transducer located in the ultrasonic sleeve. The amplitude-change pole is connected with a hole forming tool through a spring chuck, and the hole forming tool is a milling cutter or a grinding wheel. The amplitude-change pole is connected with the transducer through an annular flange which is connected with the inner wall of the ultrasonic sleeve through an annular force sensor used for measuring axial and radial force borne by the annular flange. The ultrasonic helical hole milling device further comprises a helical hole-milling rotation driving device connected with the ultrasonic sleeve, a helical hole-milling revolution driving device connected with the outer eccentric sleeve and a feeding system for driving the spindle support to conduct feeding along the axis of the amplitude-change pole. The invention further discloses a machining method for conducting ultrasonic helical hole milling through the ultrasonic helical hole milling device. The ultrasonic helical hole milling device and the machining method have the advantages that the hole forming quality is high, hole forming quality consistency is good, and machining stability is good.

Owner:DALIAN UNIV OF TECH

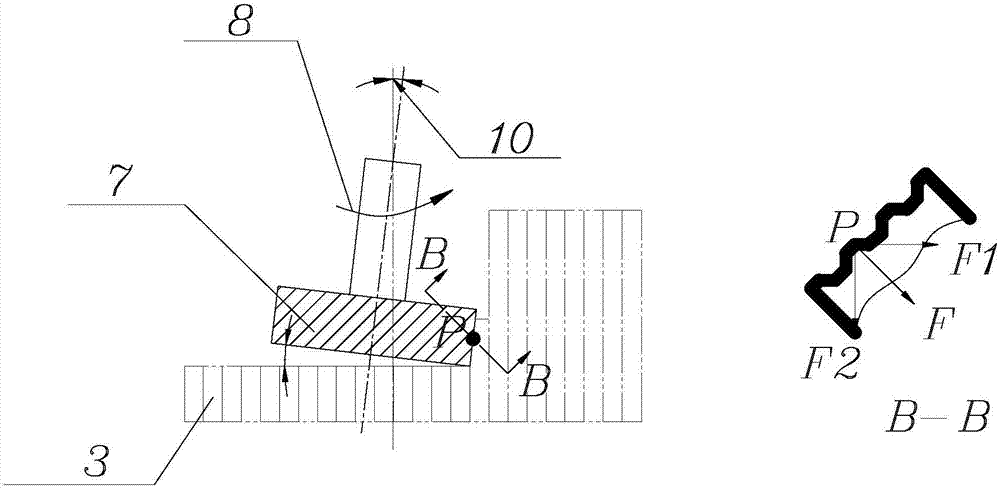

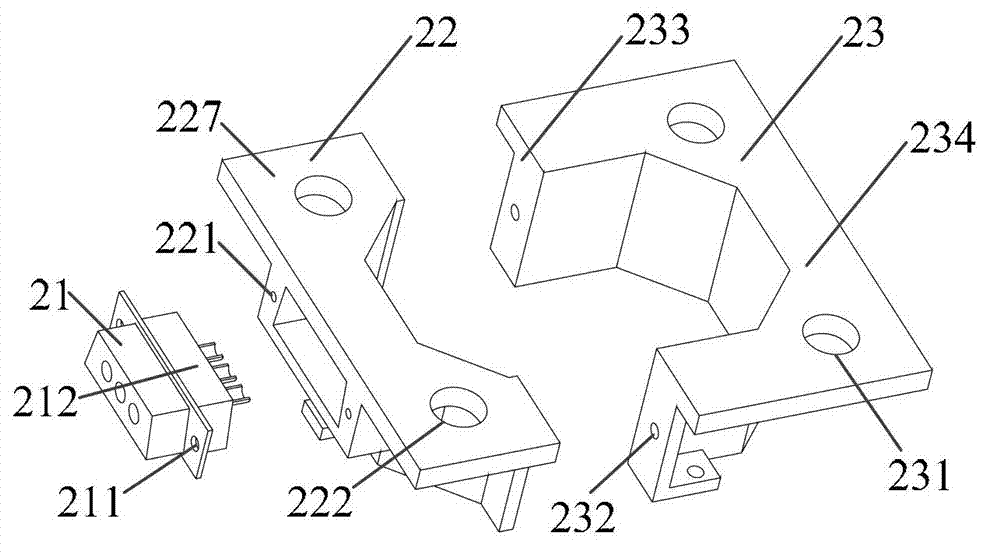

Ultrasound ellipse vibration milling knife handle device

ActiveCN103157593AAvoid rotation errorEasy tool changeMilling cuttersMechanical vibrations separationEllipseTitanium alloy

An ultrasound ellipse vibration milling knife handle device comprises a power supply box, an ultrasound ellipse vibration milling knife handle, a sealing ring and a protective cover. The upper end surface of the power supply box is connected with the lower plane of a cutter disk of a tool through bolts, a small circular shaft of the ultrasound ellipse vibration milling knife handle is connected with the cutting disk through a spring collet, the upper end surface of a large cylinder is connected with the lower end surface of the power supply box in a screw mode, the sealing ring is arranged on the lower end surface of the large cylinder, and the sealing ring is connected with the protective cover through bolts. The ultrasound ellipse vibration milling knife handle device can be flexibly connected with a traditional processing center in a butted mode, high frequency ultrasound ellipse vibration milling is achieved, and the effects of titanium alloy and composite material milling with high accuracy and high efficiency are achieved. The ultrasound ellipse vibration milling knife handle device has a wide application prospect in the technical field of ultrasound vibration processing devices.

Owner:BEIHANG UNIV

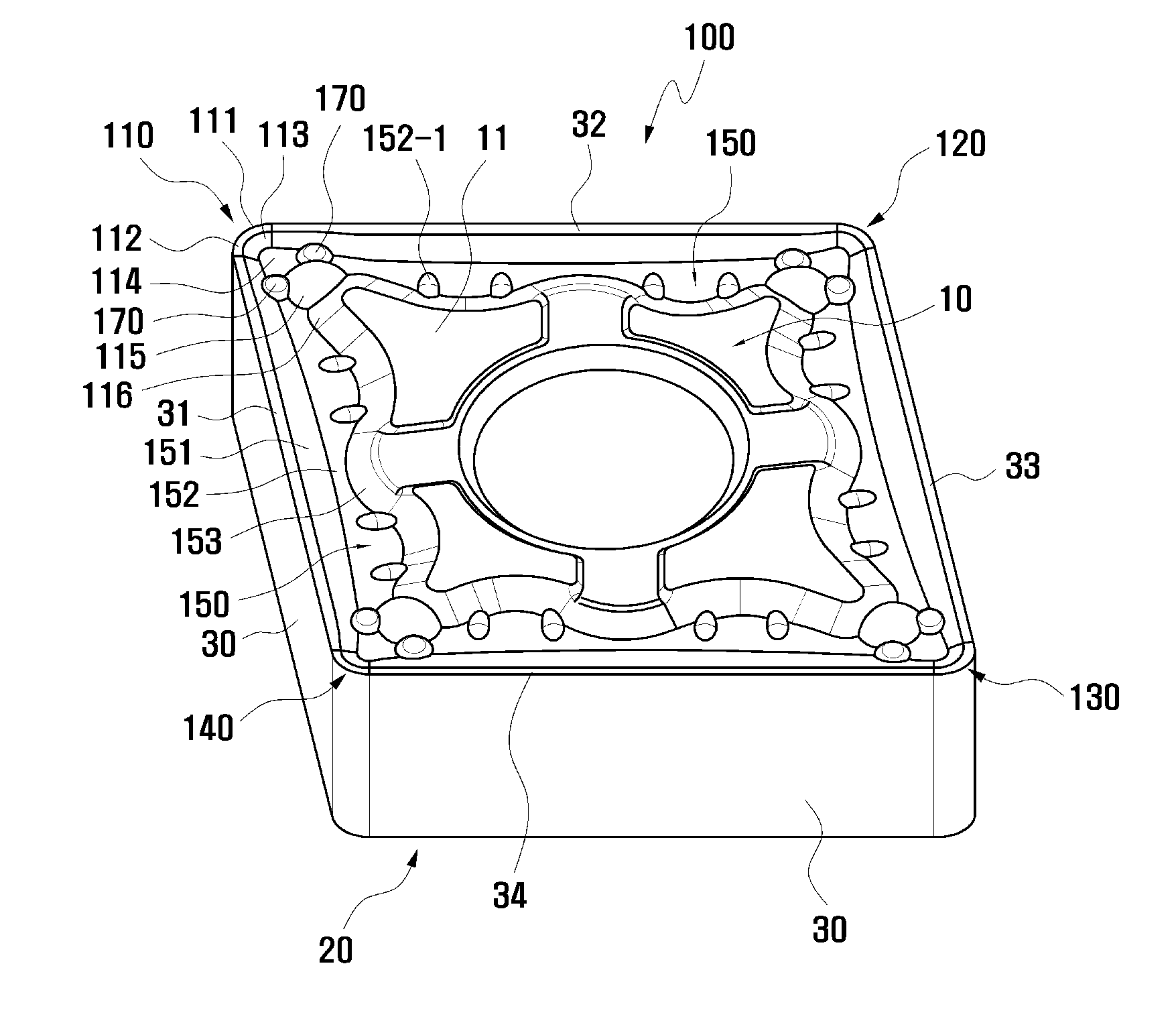

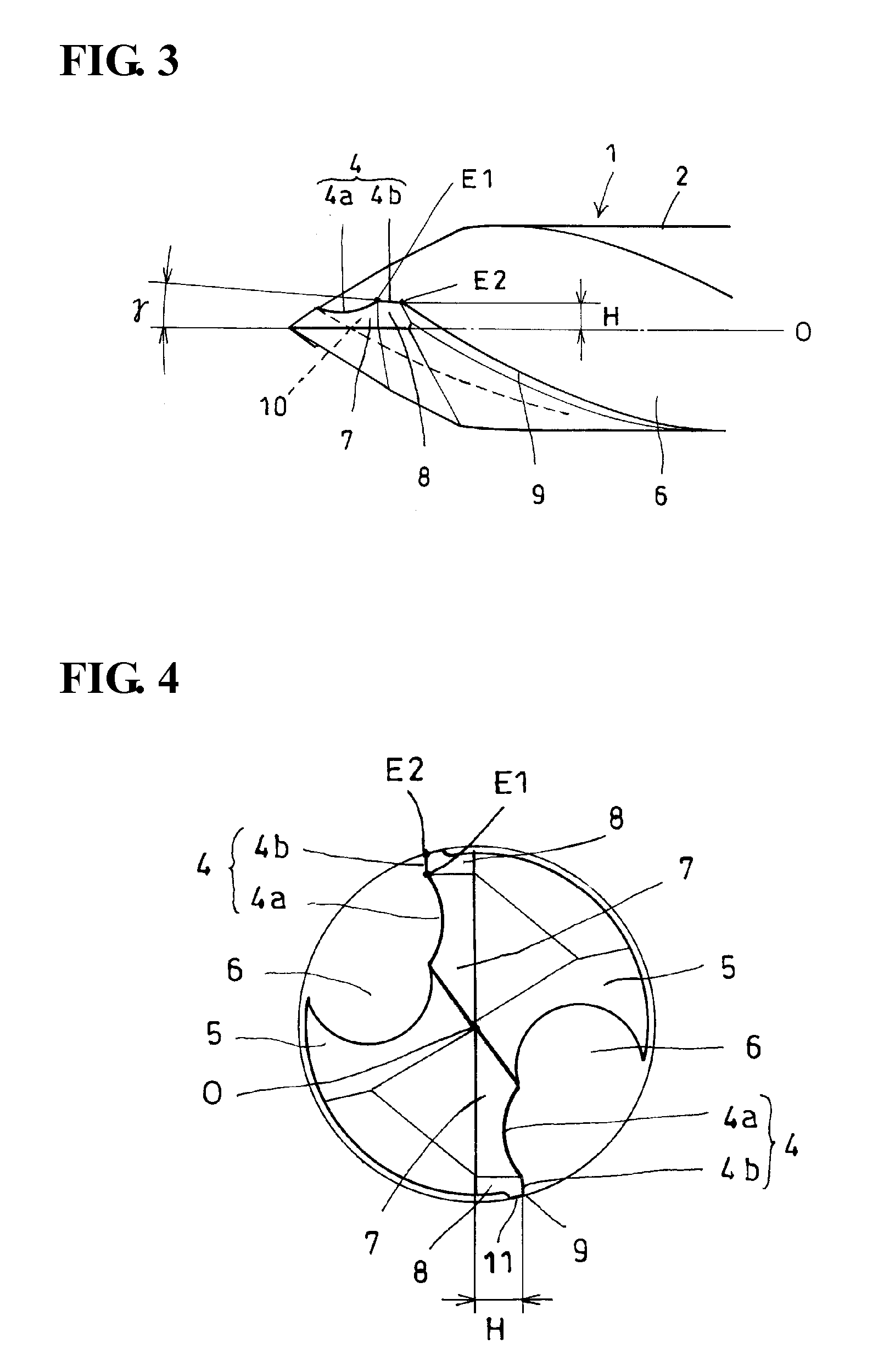

Cutting insert

An indexable cutting insert for chip removal machining, the insert having a polygonal body having opposed lower and upper faces that are mutually interconnected by peripheral faces meeting at rounded corners, which are formed symmetrically with respect to upper face bisectors. The upper face includes a mid portion, which is positioned inside of a chip face. Intersections of the chip face and the peripheral face forming major cutting edges and corner cutting edges. The chip face comprises a row of protrusions. A pair of oblong corner protrusions are provided at each corner area of the chip face. The pair is located symmetrically with respect to an associated bisector of the upper face. Each oblong corner protrusion has a longitudinal axis and at least two peak areas. The peak areas are positioned in line, essentially on the longitudinal axis of each oblong corner protrusion.

Owner:PRAMET TOOLS

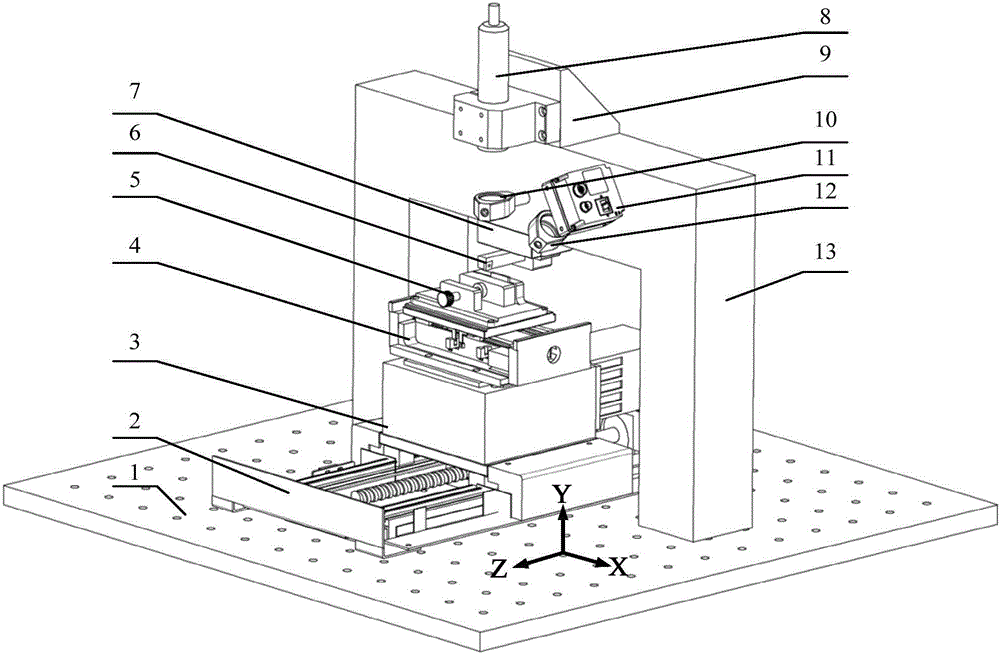

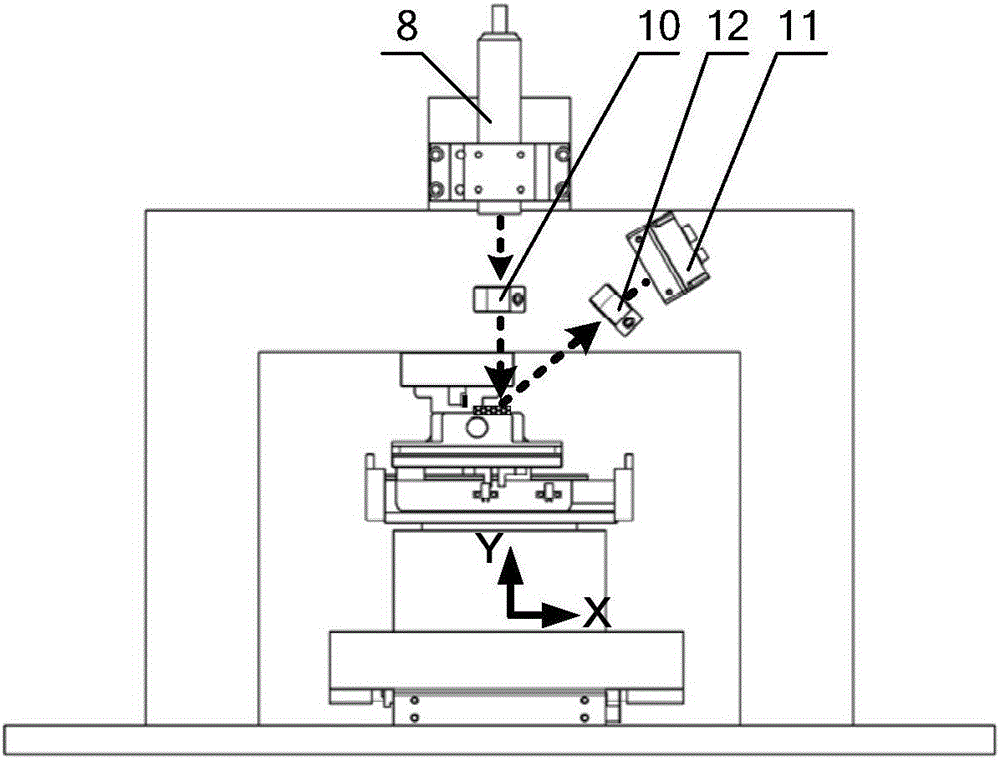

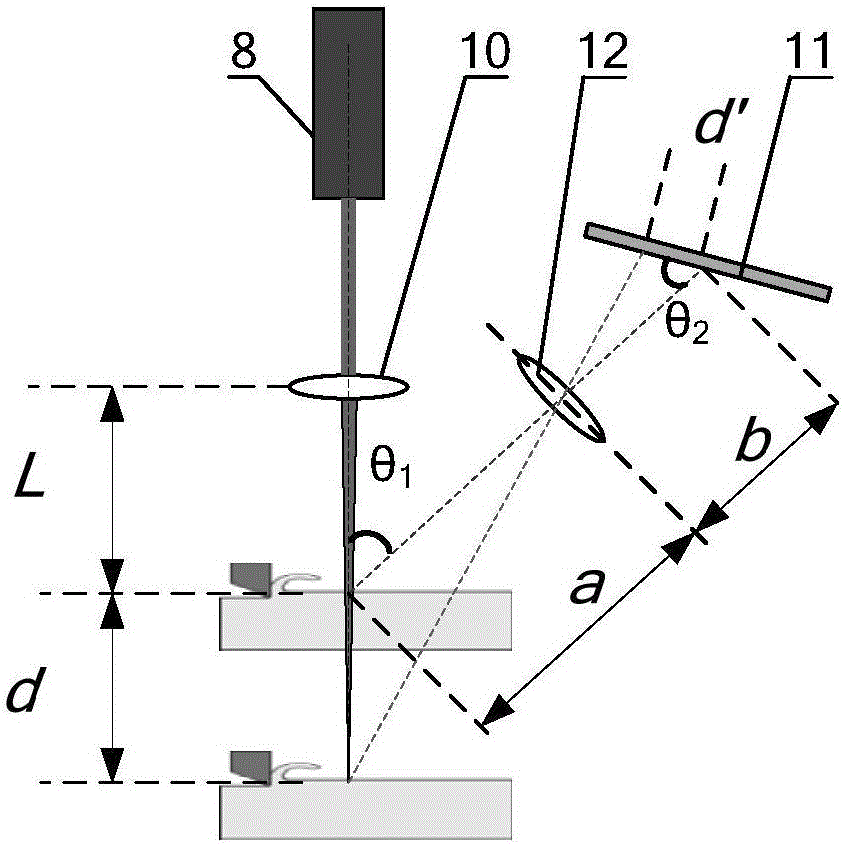

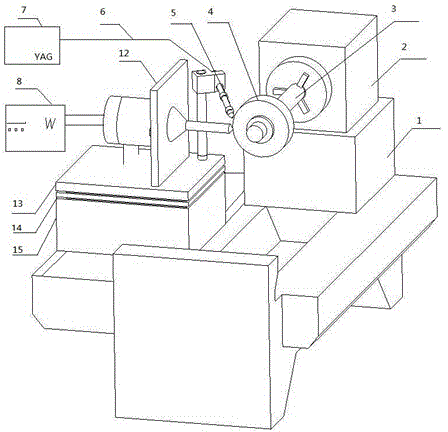

Laser-assisted orthogonal micro-cutting device and method having automatic laser focus following function

ActiveCN106312567AIncreased durabilityExtend your lifeOther manufacturing equipments/toolsLaser beam welding apparatusMachined surfaceLight beam

The invention discloses a laser-assisted orthogonal micro-cutting device and method having an automatic laser focus following function, belongs to the technical field of machining equipment and aims to solve the problem that height changes of to-be-machined surfaces cannot be monitored in real time in laser-assisted micro-cutting processes in the prior art. A motion unit and a laser-assisted machining unit of the device are mounted on a shock-absorbing platform; an optical automatic following unit is arranged on the laser-assisted machining unit and comprises a lens A, a lens B and a linear array charge coupled device (CCD) sensor; laser emitted by a laser light source of the laser-assisted machining unit irradiates a to-be-machined surface via the lens A, and a laser beam reflected by the to-be-machined surface is focused on the linear array CCD sensor via the lens B; and the to-be-machined surface is mounted on the motion unit, and a computer control unit adjusts displacement of the to-be-machined surface in the direction X, the direction Y and the direction Z in real time by the aid of the motion unit according to the laser action range fed back by the linear array CCD sensor.

Owner:CHANGCHUN UNIV OF SCI & TECH

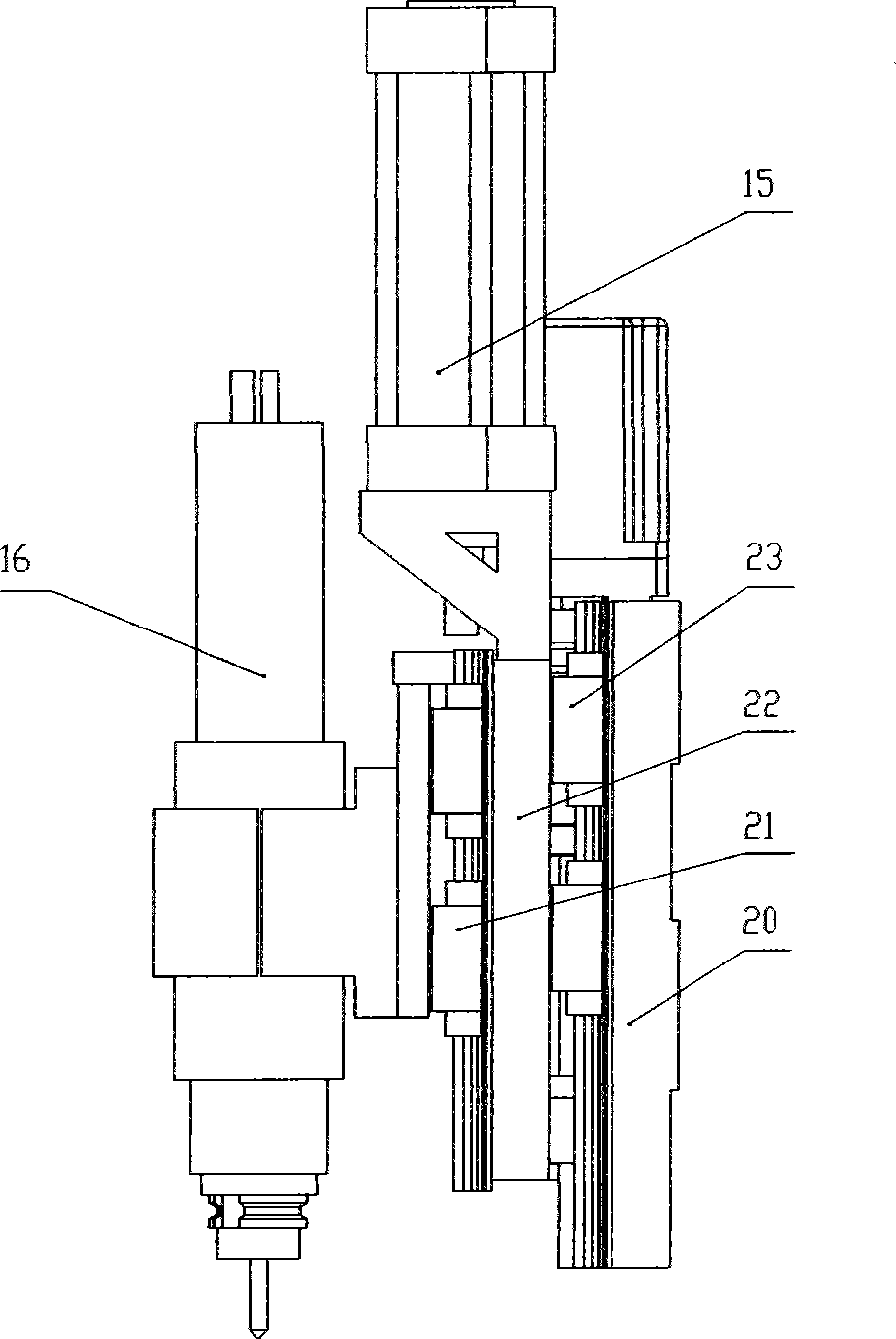

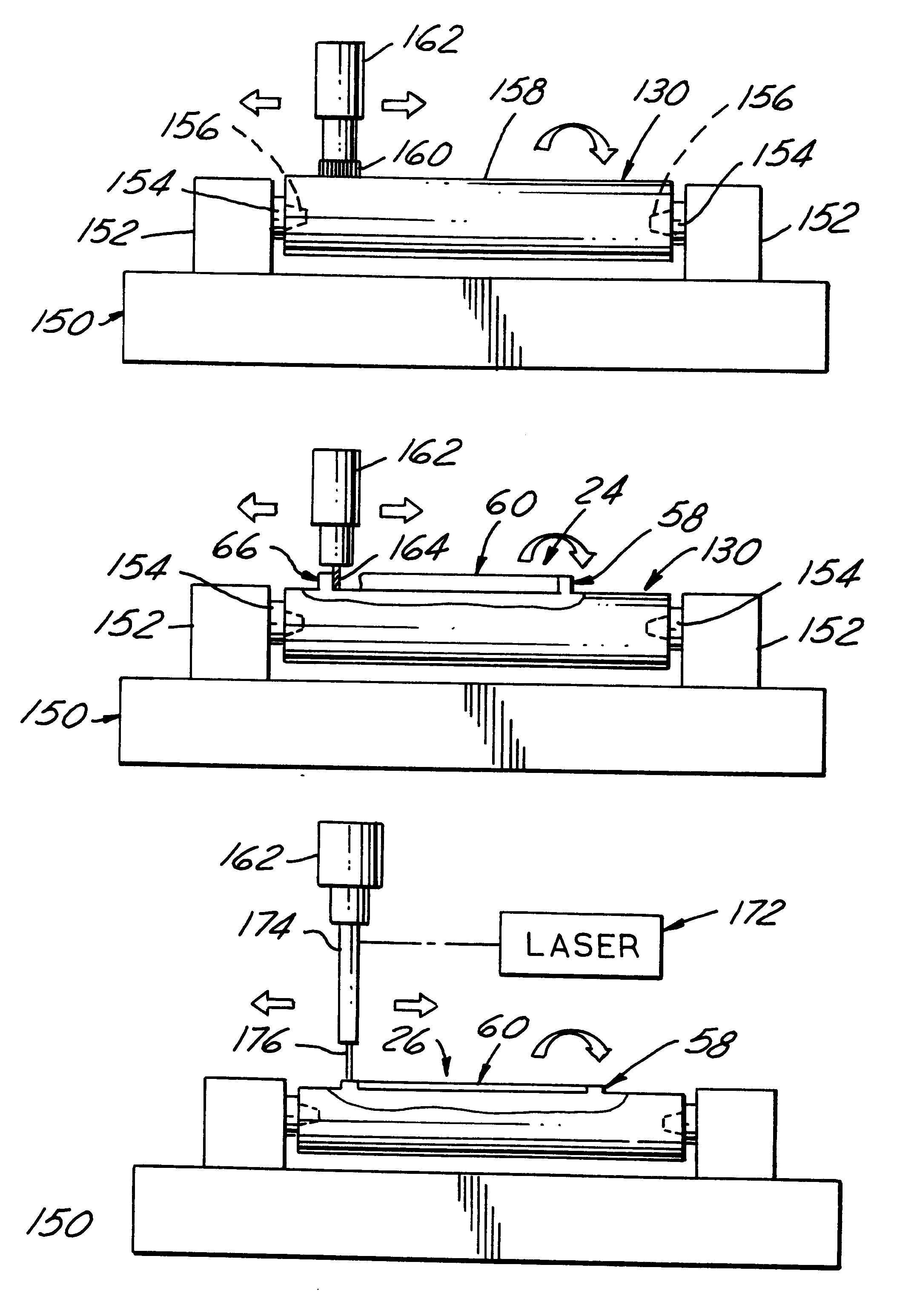

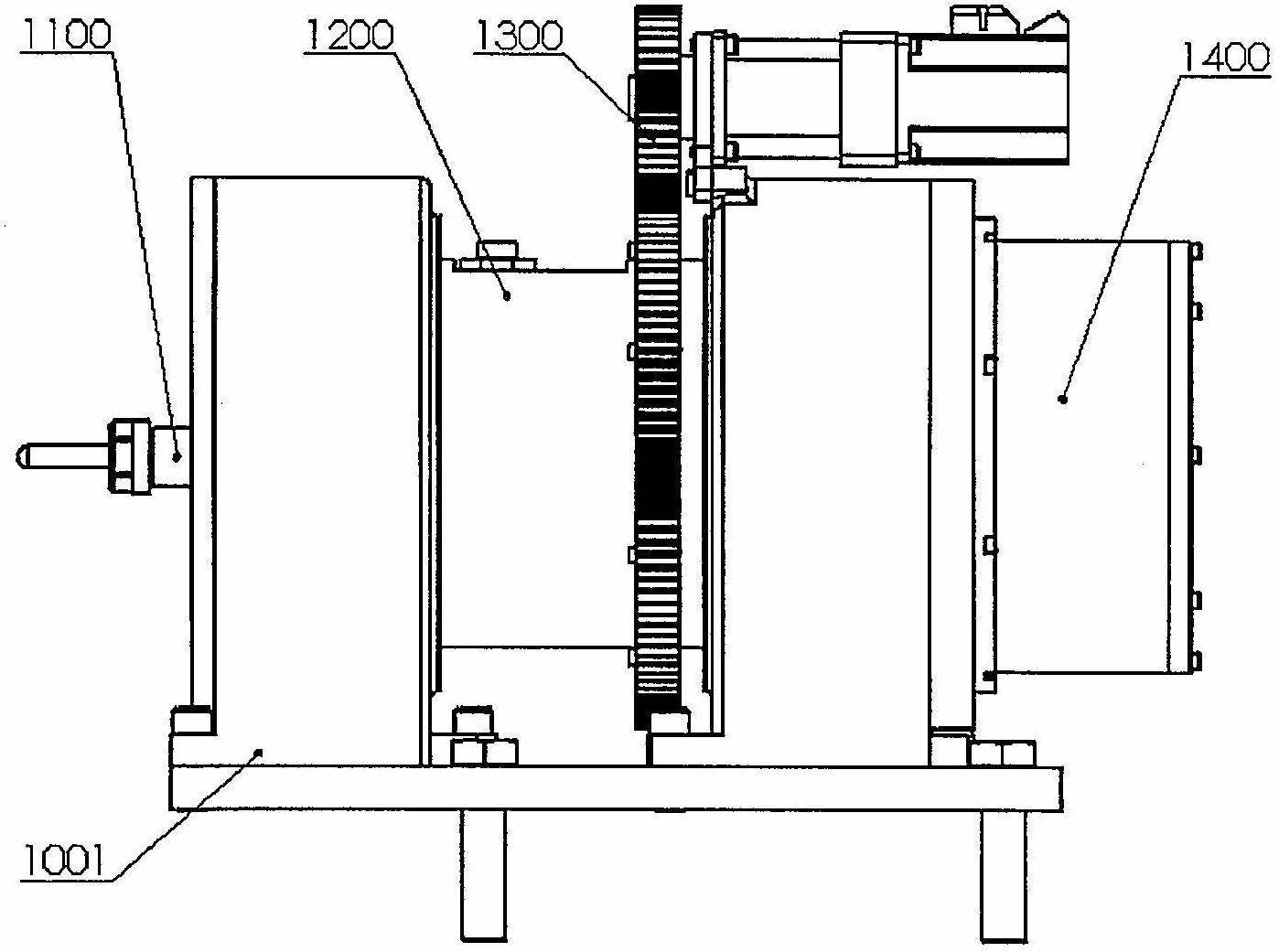

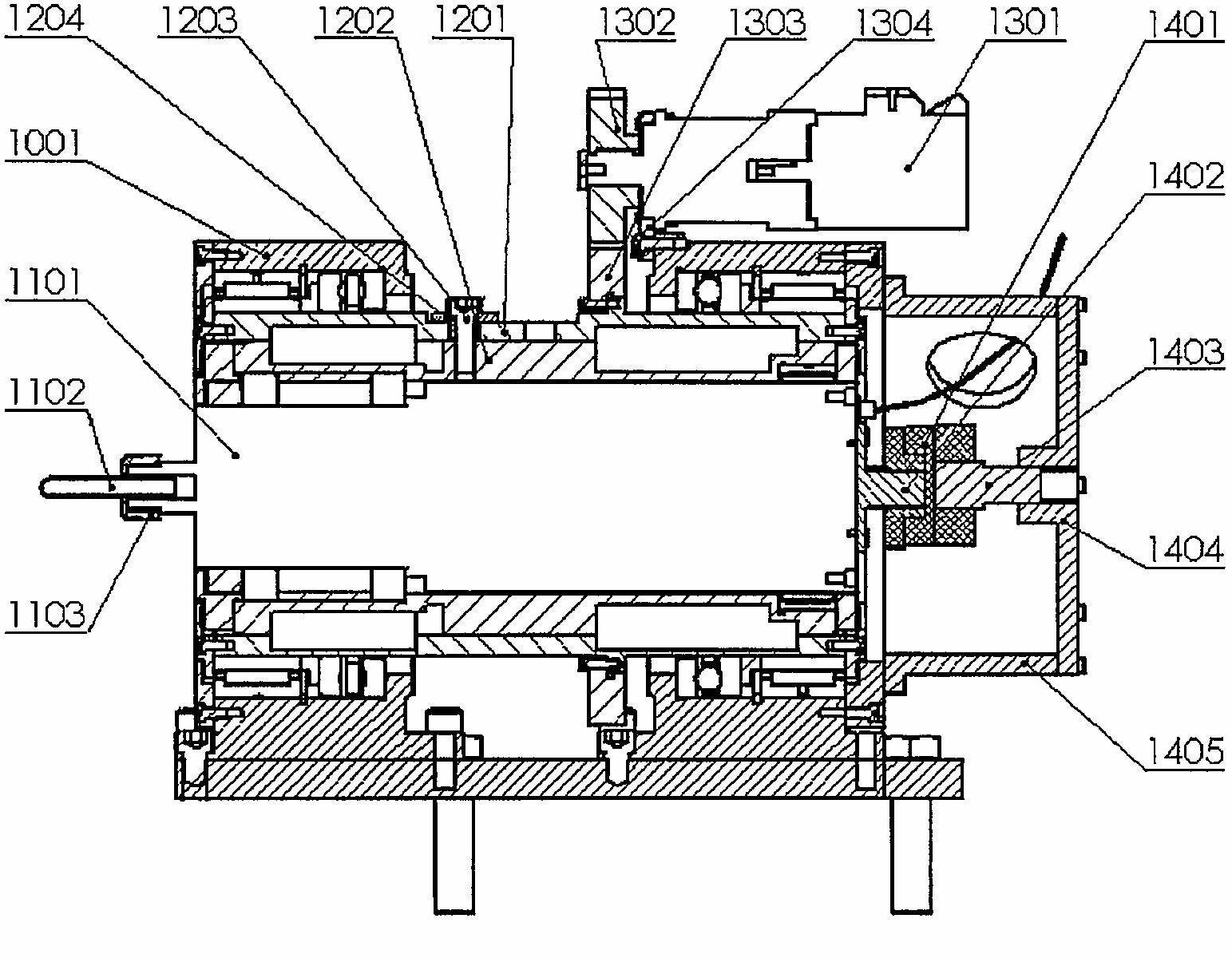

Helical milling device and method

InactiveCN101786180ASimple structureReduce weightFeeding apparatusMilling equipment detailsEngineeringRadial deviation

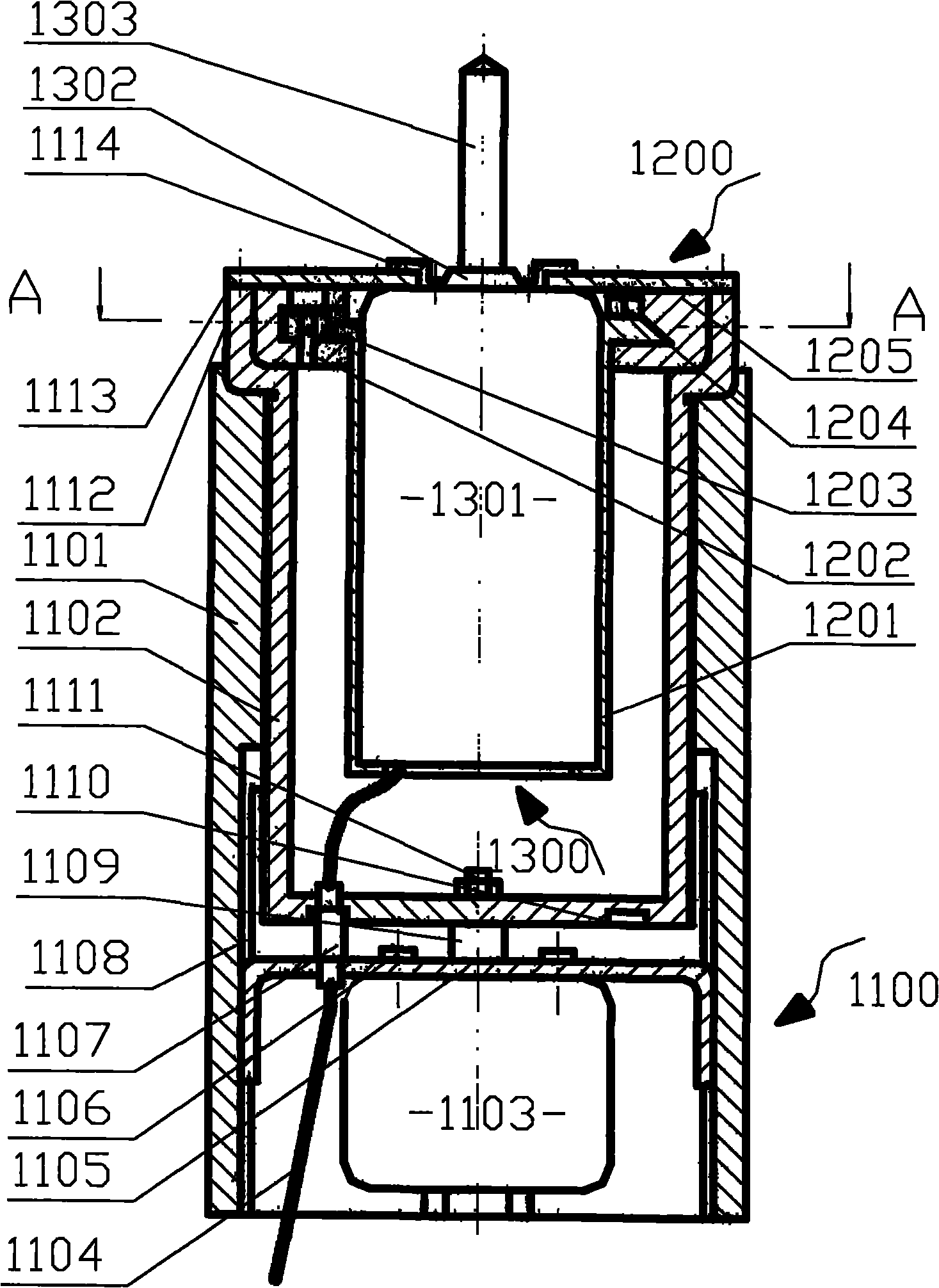

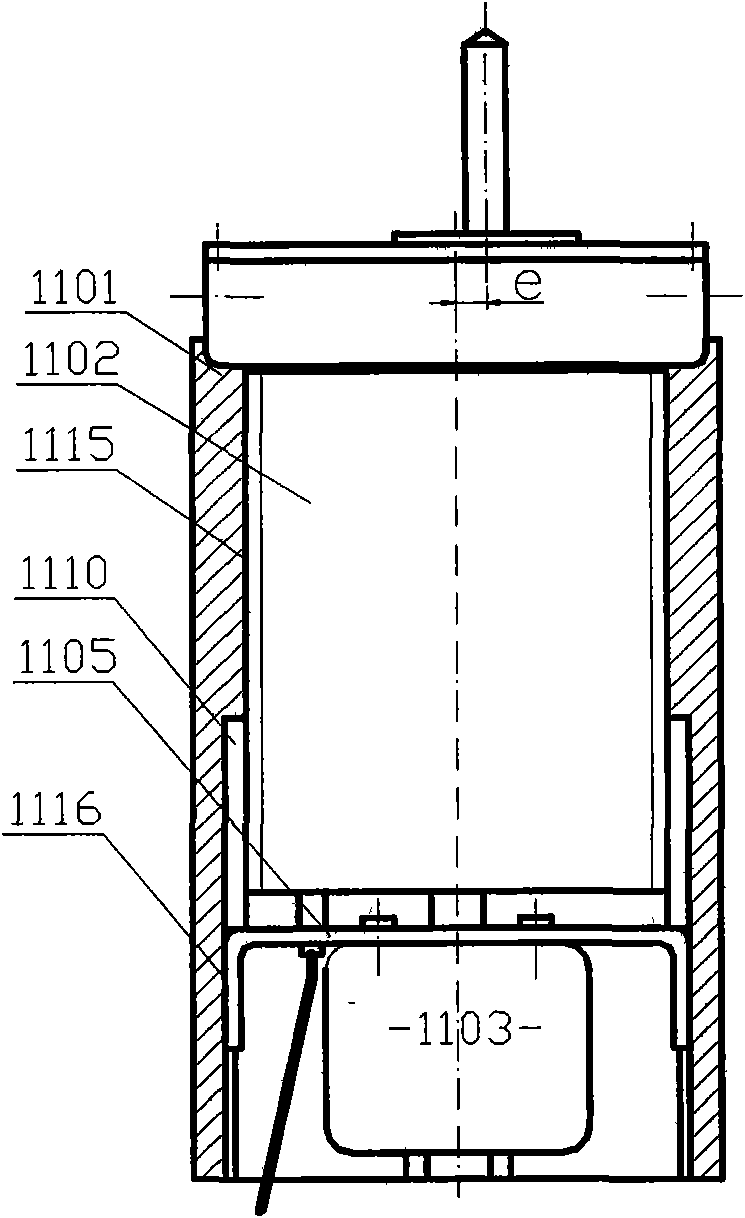

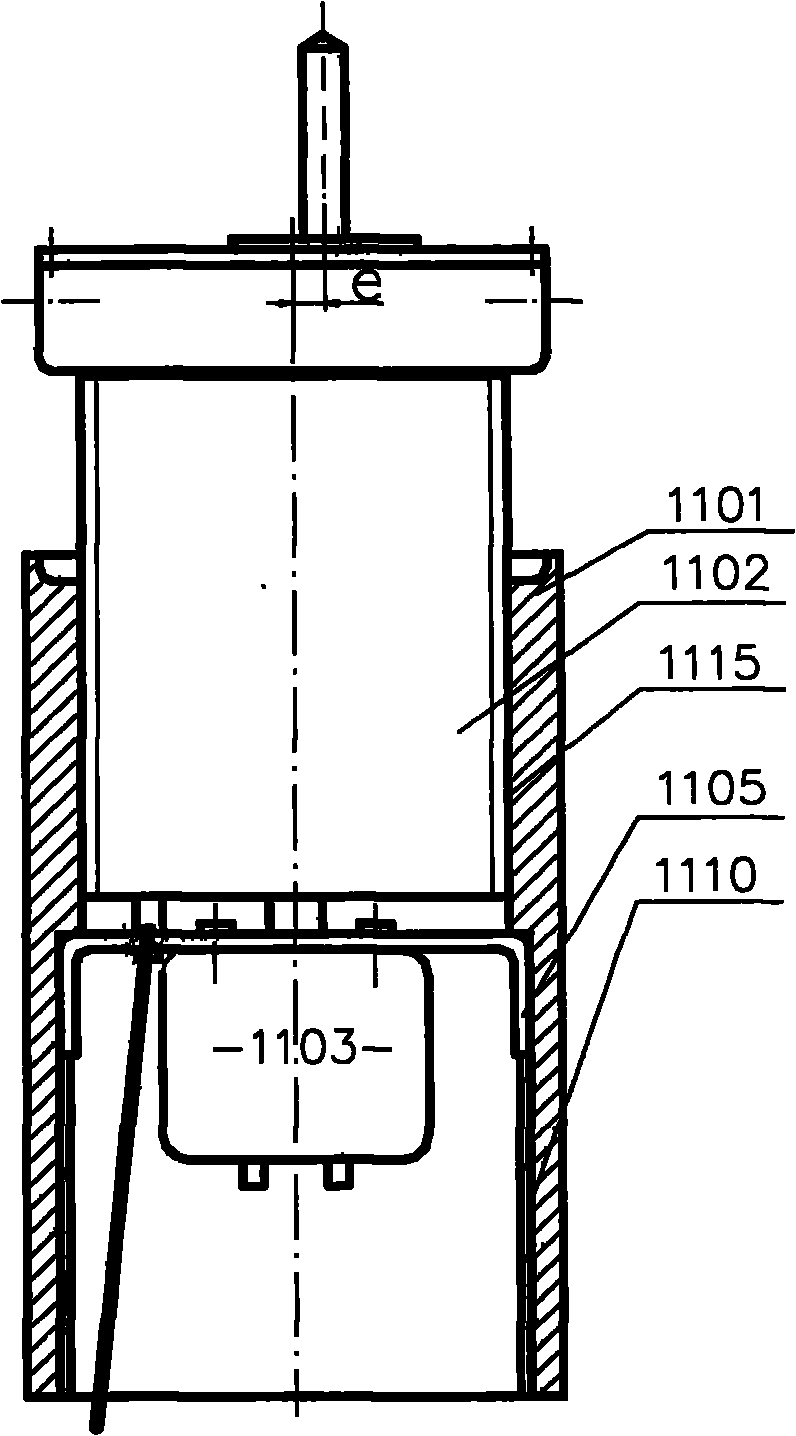

The invention relates to a helical milling device and a helical milling method, and belongs to the technical field of machining. The device mainly comprises a helical feed mechanism (1100) used for realizing the axial feeding and revolution of a cutter (1303), a radial deviation mechanism (1200) used for adjusting the revolution radius of the cutter (1303) relative to axes of pores and a rotation mechanism (1300) used for driving the cutter to rotate. The device and the method of the invention can greatly improve the manufacturing quality and machining efficiency of complex pore series on surfaces of large-scale workpieces.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

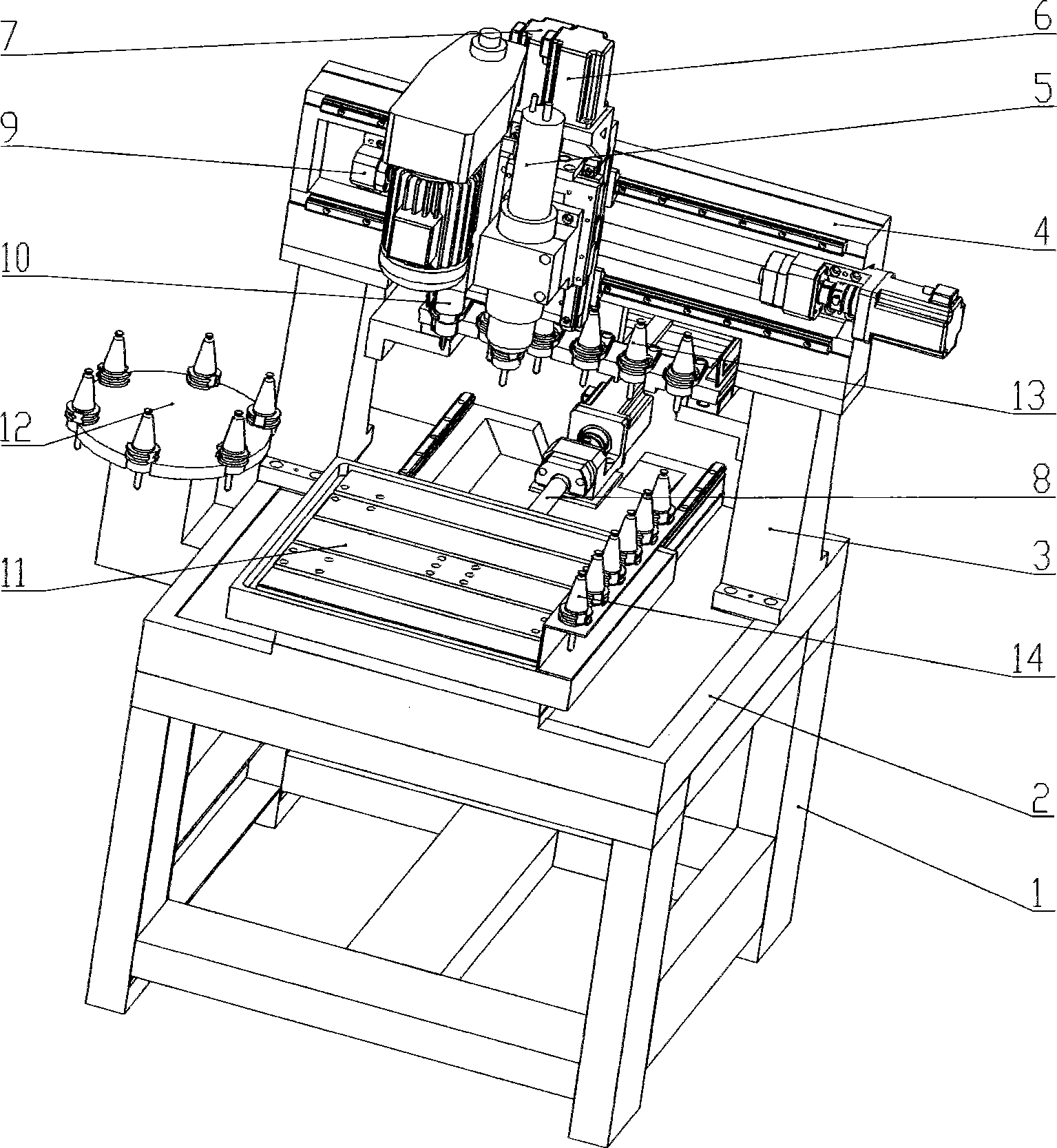

Small-sized gantry double-main shaft numerical control machine for drilling, milling and tapping

InactiveCN101502932AIncrease feed rateHigh positioning accuracyOther manufacturing equipments/toolsPositioning apparatusElectricityNumerical control

The invention relates to a small gantry dual-spindle drilling milling tapping numerical control machine. The small two-axis gantry drilling tapping digital control machine essentially solves the technical problem of providing a drilling milling tapping machine with low cost and high efficiency for the light metal hardware processing of the communication and the consumption electronic industry, and the machine has the advantages of simple structure and stable and reliable operation. The technical proposals for solving this problem is as follows: a frame structure support welded with channel steel, a diamond-shaped rib square structure soleplate and a gantry beam are adopted; a sliding plate of the beam is equipped with dual spindles, and the dual spindles are respectively a high-speed drilling milling head spindle and a high-speed tapping head spindle. The drilling milling head spindle uses a high-speed knife replaceable electric spindle; the tapping head spindle uses a self-invented mechanical tapping spindle able to carry out the screw distance selection automatically. The drilling milling head spindle can install the tool magazine on the rear, left and right positions of the machine; the tool magazine uses row-type tool magazine, inverted bamboo hat style tool magazine or row-type tool magazine and the arbitrary combination methods of inverted bamboo hat tool magazine.

Owner:深圳市康铖机械设备有限公司

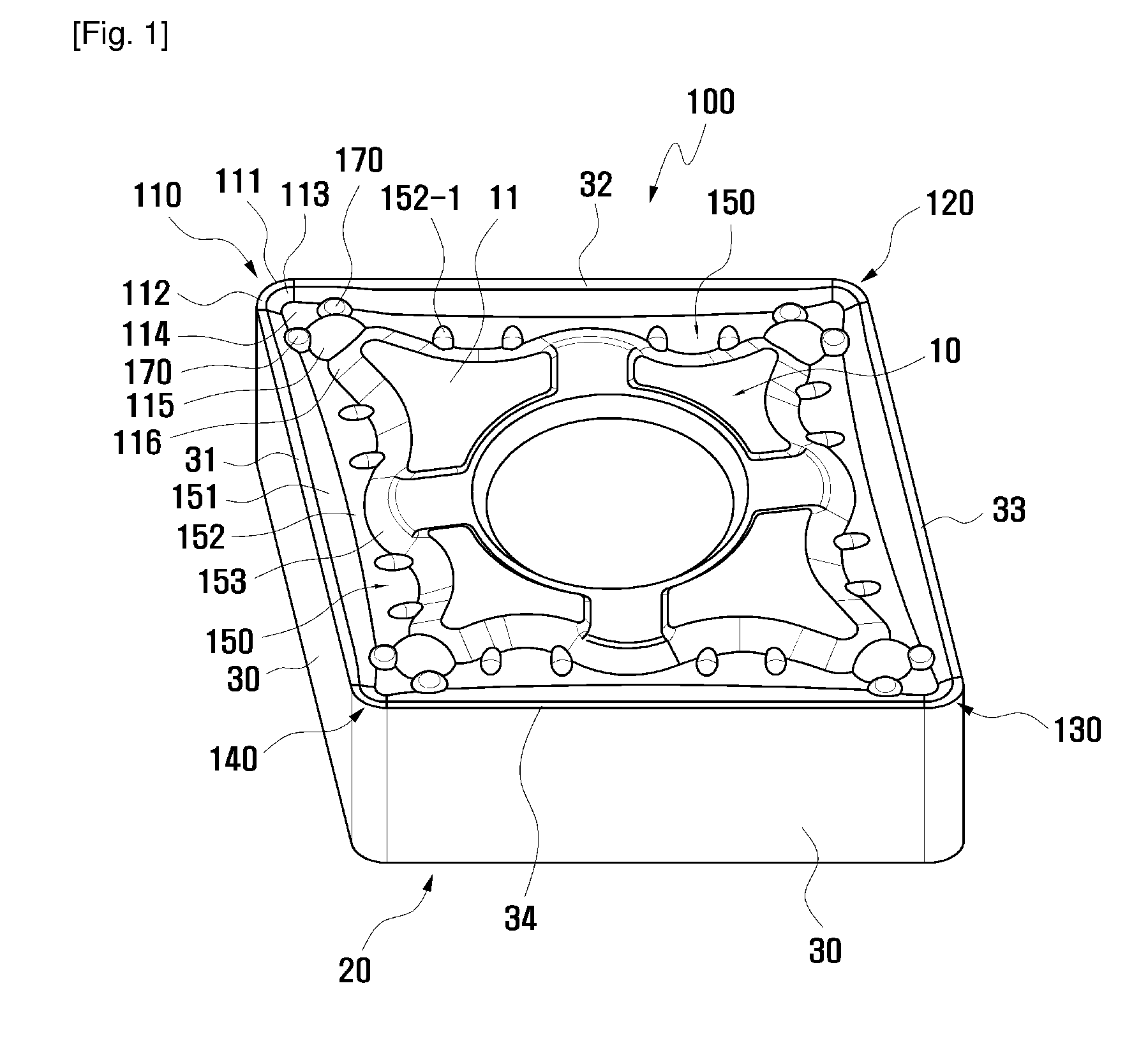

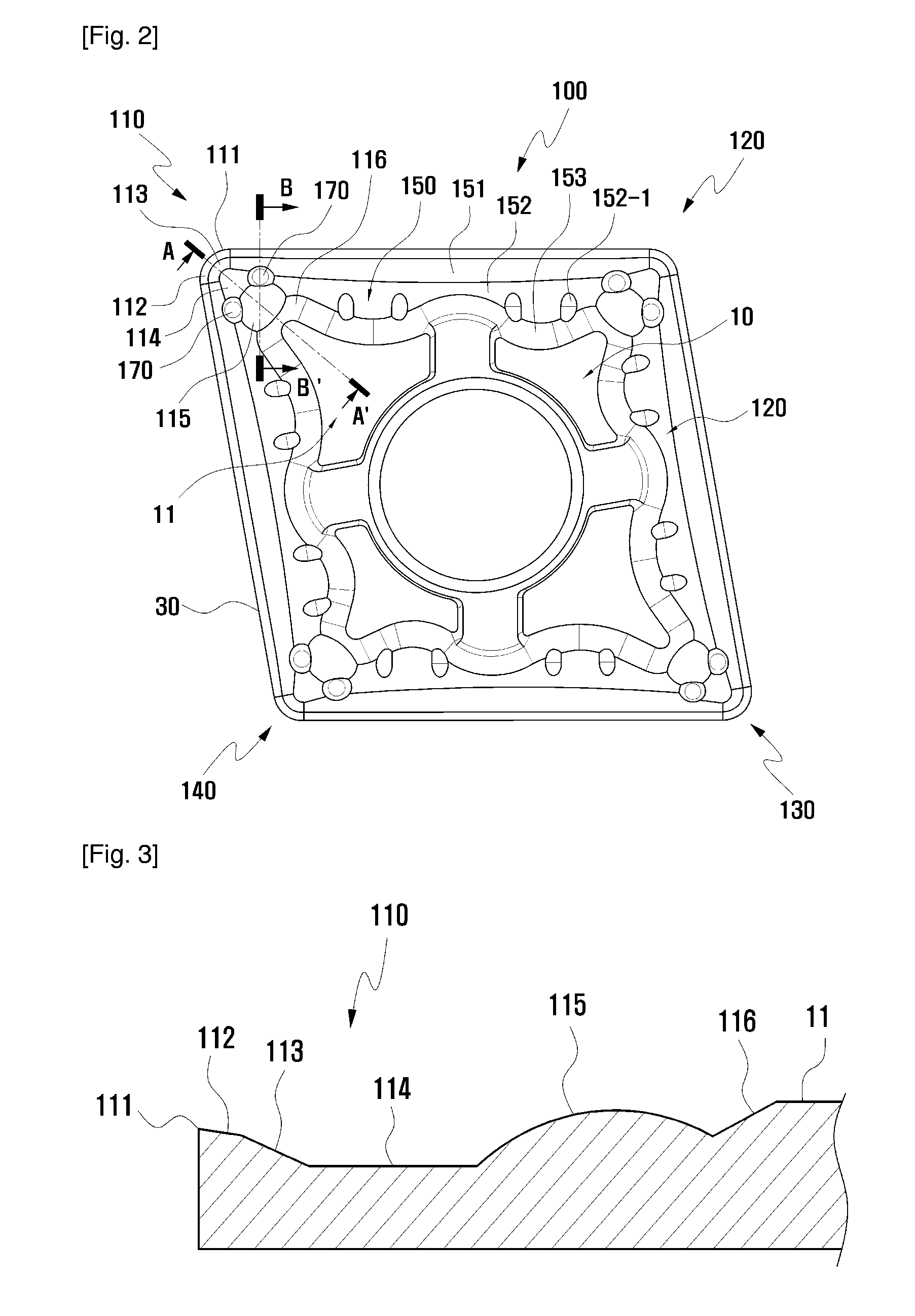

Cutting Insert with Protrusions Formed at Corner Area Thereof

InactiveUS20110070039A1Reduce cutting forceLittle strengthCutting insertsTurning toolsEngineeringMechanical engineering

A cutting insert has an upper surface, a lower surface, a plurality of side surfaces connecting the upper surface and the lower surface and a central hole formed at a central portion thereof. The cutting insert has a flat seating surface formed on a highest level of the upper surface, a plurality of side cutting edge portions formed at intersections of the upper surface and the side surfaces, and a corner cutting edge portion formed at an intersection of two adjacent side cutting edge portions and having a cutting edge formed at a front end thereof. A land portion, a downward inclined surface, a corner bottom surface, a first protrusion, an upward inclined surface and the seating surface are formed on the corner cutting edge portion sequentially along a diagonal line directed from the cutting edge to the central hole. A pair of second protrusions are formed and disposed symmetrically on both sides of the diagonal line so that the corner bottom surface is surrounded by the downward inclined surface, the first protrusion, and the second protrusions, and the corner bottom surface has the smallest height and the seating surface has the largest height along the diagonal line.

Owner:TAEGUTEC

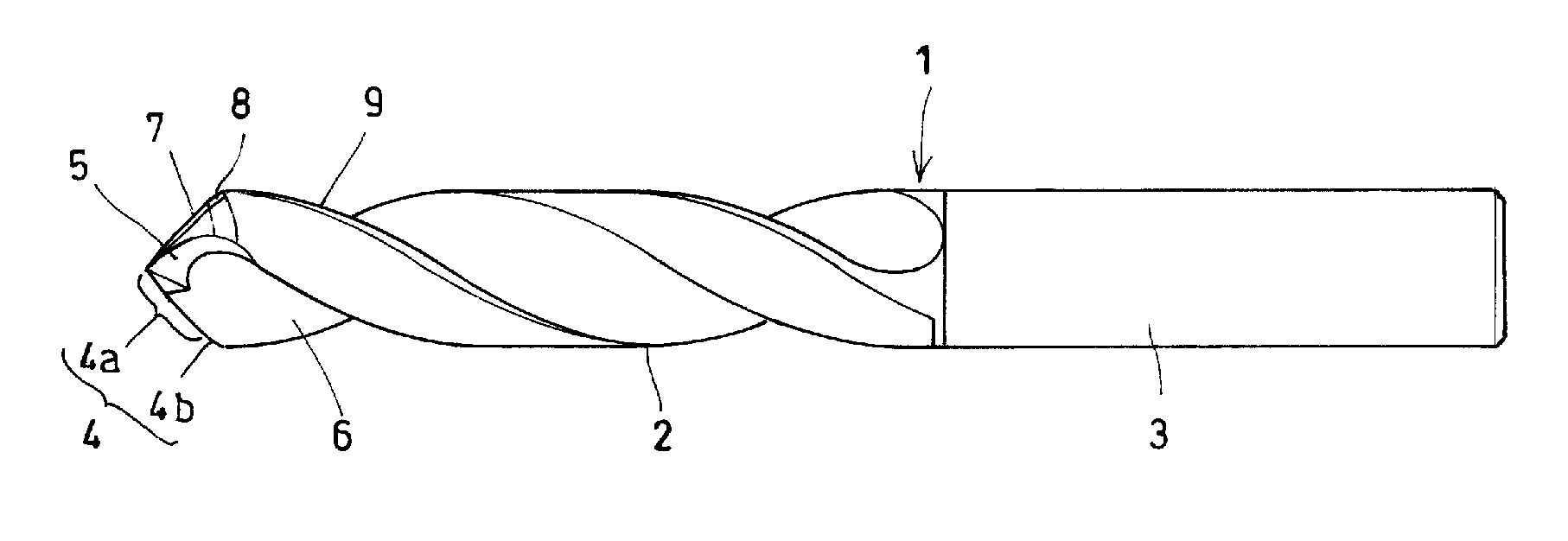

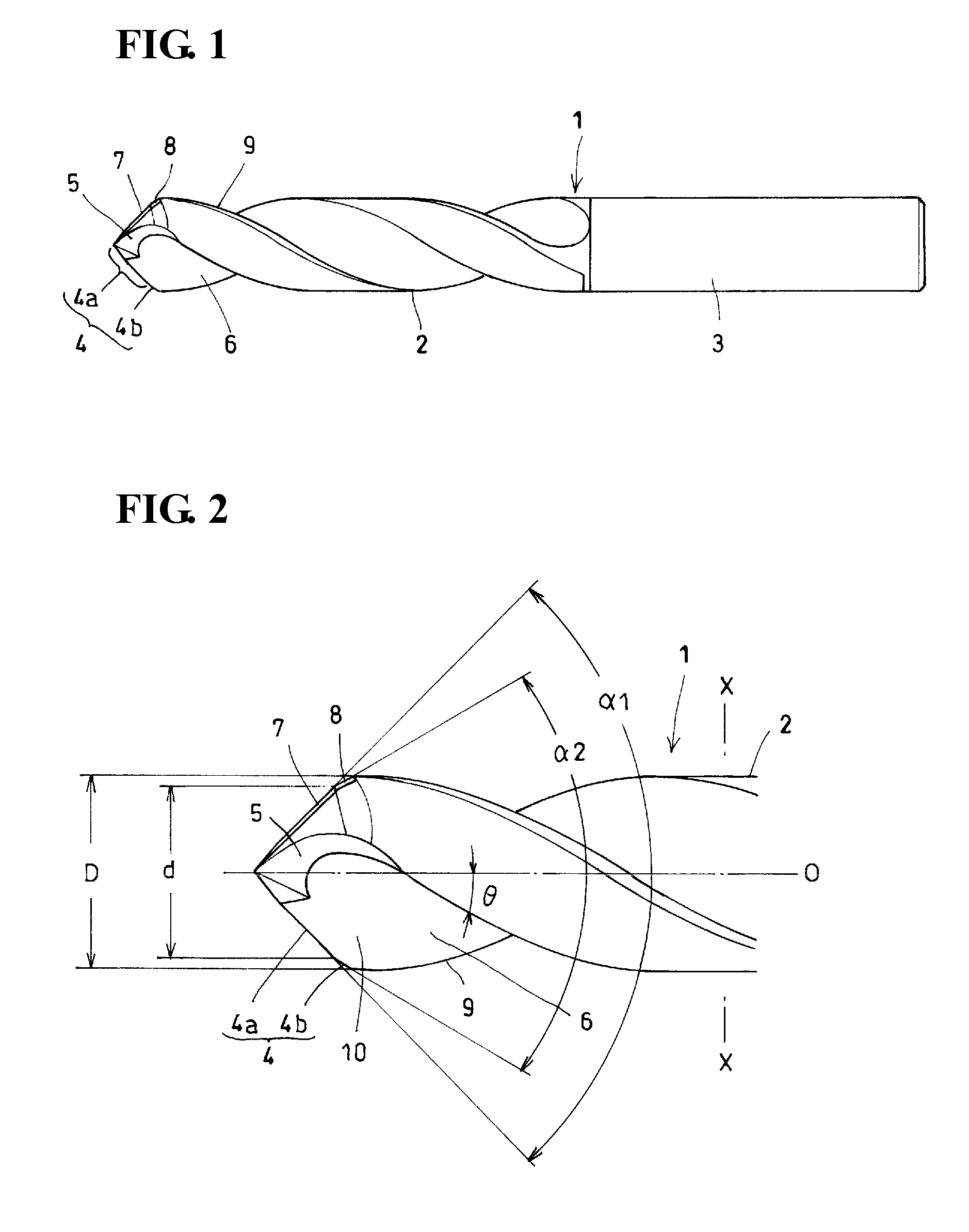

Twist drill

InactiveUS20110081215A1High quality drillingSmall liftWood turning toolsTransportation and packagingFluteLeading edge

Provided is a double-angle twist drill that increases the quality of drilling without increasing the amount of manufacturing work or the like. A secondary cutting edge 4b is substantially parallel to the rotation axis O of the drill, and at least a rake face 10 of the secondary cutting edge is included in the flute face of a helical flute 6. A part of the flute face of the helical flute that is located along a leading edge 9 is convexly curved with respect to the normal direction of rotation of the drill, so that the secondary cutting edge 4b having a small skew angle with respect to the rotation axis can be formed as a ridge at which the flute face intersects a second flank face.

Owner:SUMITOMO ELECTRIC HARDMETAL CORP

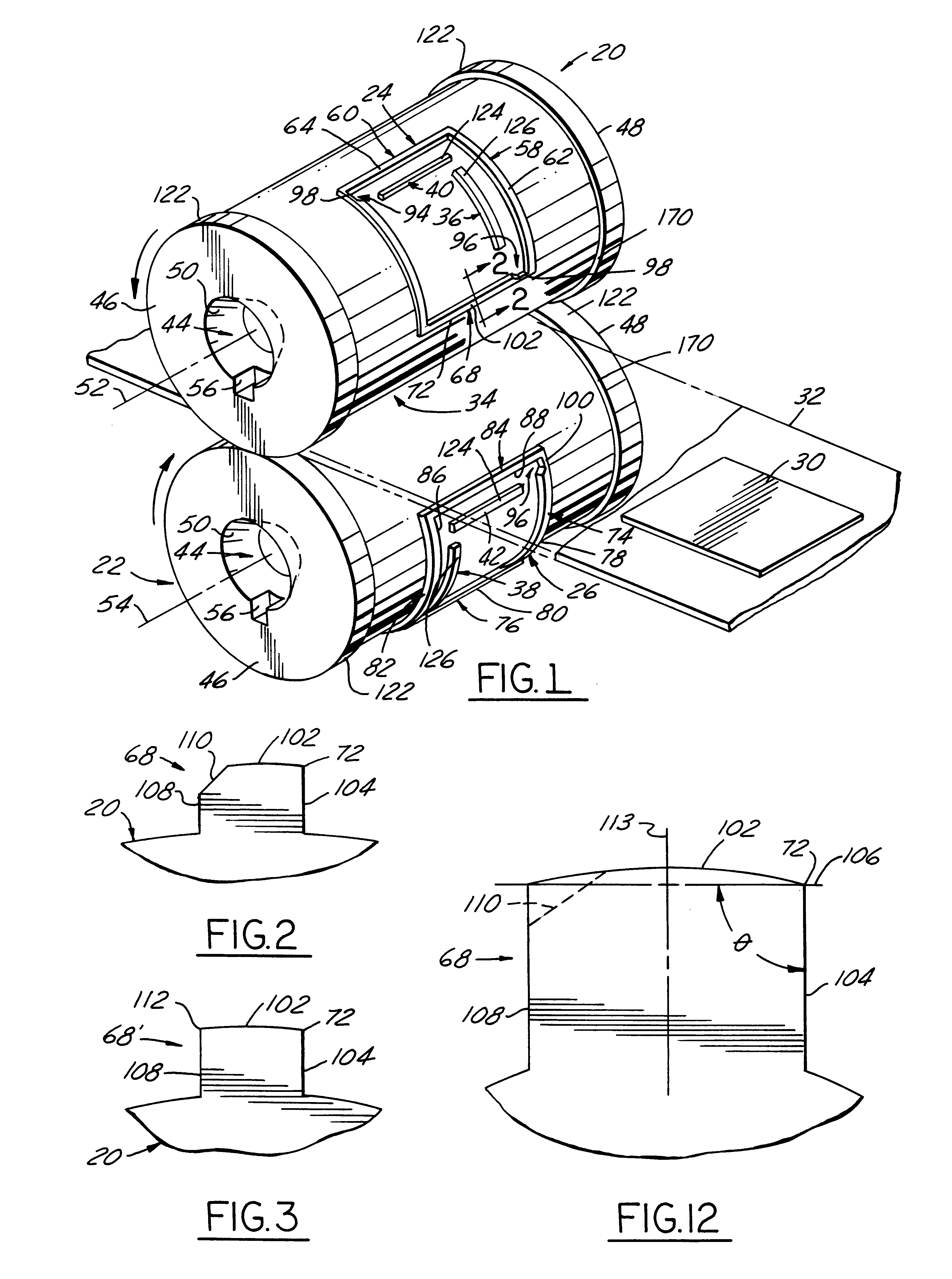

Method of making rotary cutting dies

InactiveUSRE37366E1Accurate locationExtended service lifeCutting toolsMetal rolling stand detailsEngineeringKnife blades

A method of making a pair of rotary die cylinders with lands having coacting cutting edges which cut blanks from a web of material passing through the nip of the rotating dies. In cross section each land has an outer face and a pair of spaced apart side faces which are parallel to each other and perpendicular to the chord of the outer face to provide a clean cut and facilitate release of the cut blank from the cutting blades as it emerges from the nip of the dies. The die cylinders are journalled for rotation by recesses with frusto conical locating surfaces in their opposed ends. Each die cylinder is made by machining the recesses in the opposed ends of a generally cylindrical workpiece of tool steel and then utilizing the recesses to locate and orient the workpiece relative to a cutting tool to produce a cylindrical surface on the workpiece concentric with the axis of the recesses and then to machine away portions of the periphery of the cylindrical surface to form the cutting blade lands thereon. After machining is completed the cutting blade lands may be hardened by heat treating utilizing a laser beam directed onto the lands to heat them at an elevated temperature so that upon quenching they are hardened without any substantial hardening and resulting distortion of the core or body of the workpiece.

Owner:BERNAL

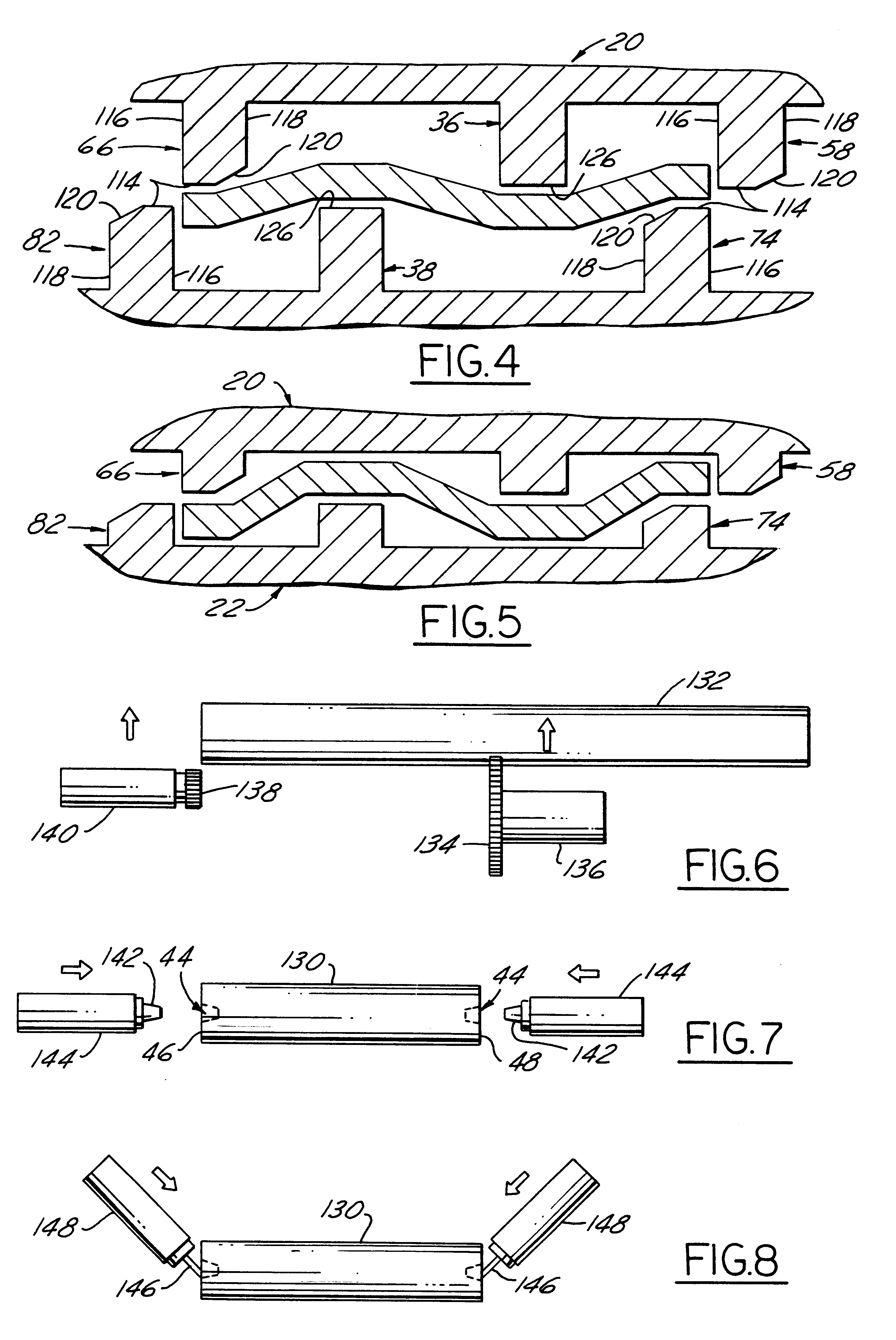

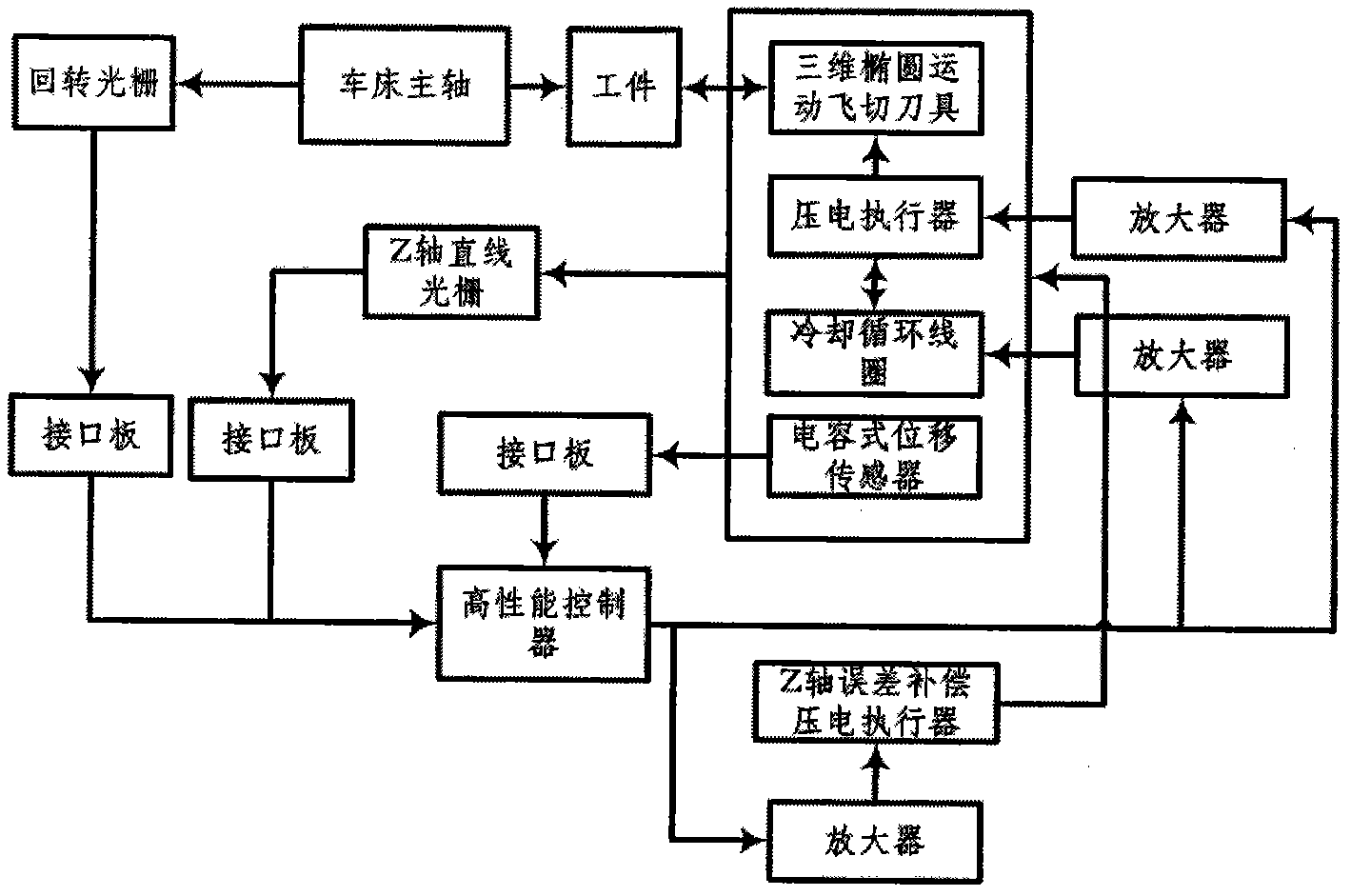

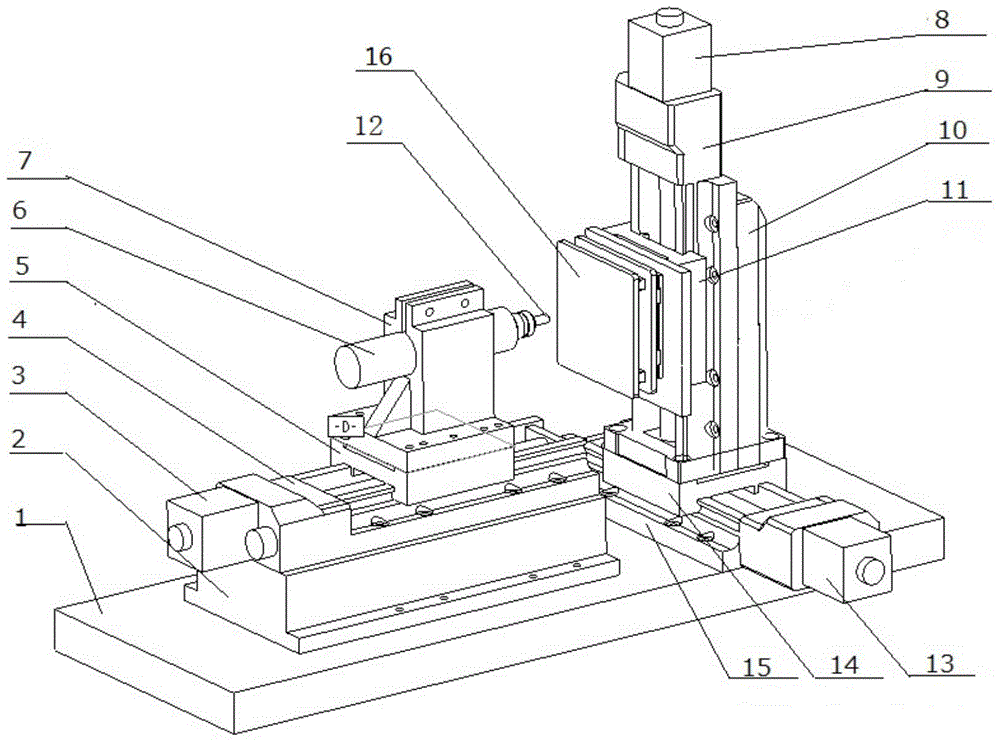

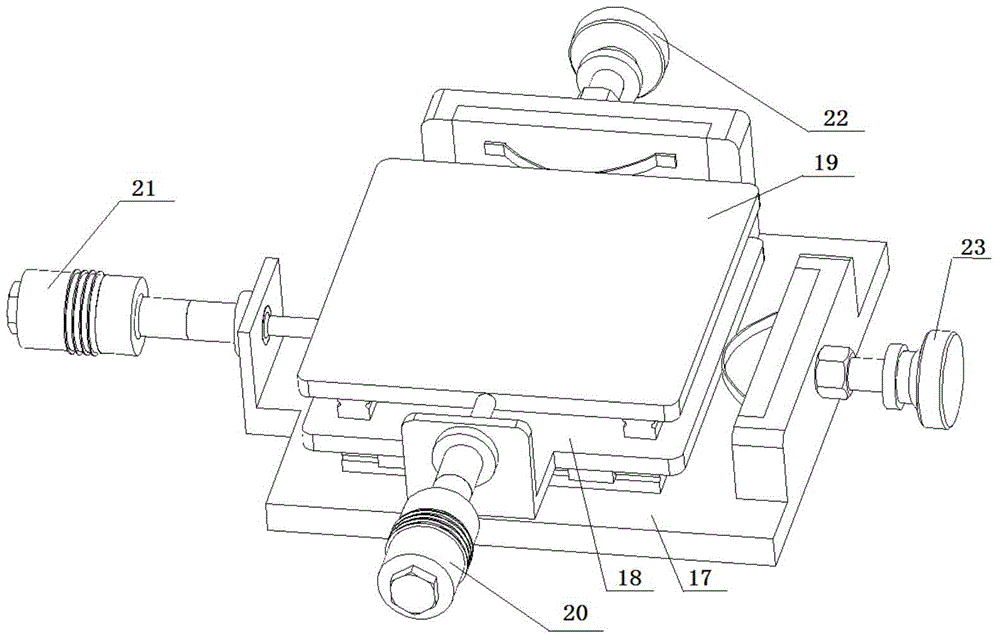

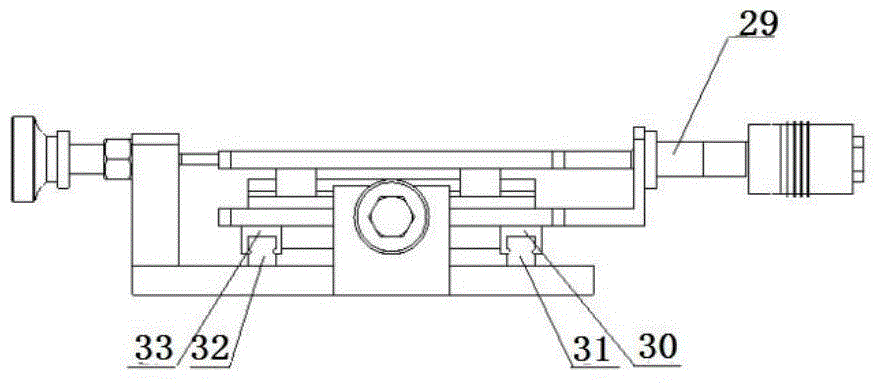

Non-resonant three-dimensional elliptical diamond fly-cutting optical free curved surface method and special device

The invention discloses a non-resonant three-dimensional elliptical diamond fly-cutting optical free curved surface method and a special device, belonging to the field of cutting technology of free curved surface of hard-processing materials. In the invention, a non-resonant driving mode is used to enable a diamond cutter to generate medium-high frequency or ultrahigh frequency three-dimensional elliptical movement in order to form high-speed or ultrahigh-speed diamond fly-cutting main movement; a cutter edge motion track is projected as reciprocating rectilinear movement on an x-z plane and is respectively projected as elliptical movement on an x-y plane and a y-z plane; the optical free curved surface is created on the basis of the combination of the movements of three-dimensional elliptical diamond fly cutting, X-axis feeding, Z-axis reciprocating feeding, worepiece rotary feeding, and the like. The invention also discloses a diamond cutter three-dimensional elliptical movement track generating device which are directly driven by four piezoelectric stacks, the three-dimensional elliptical movement parameters can be independently controlled, which is beneficial to the obtaining of optimal cutting performance, and the follow-up control of the three-dimensional elliptical movement avoids distortion in a real cutting process.

Owner:CHANGCHUN UNIV OF TECH

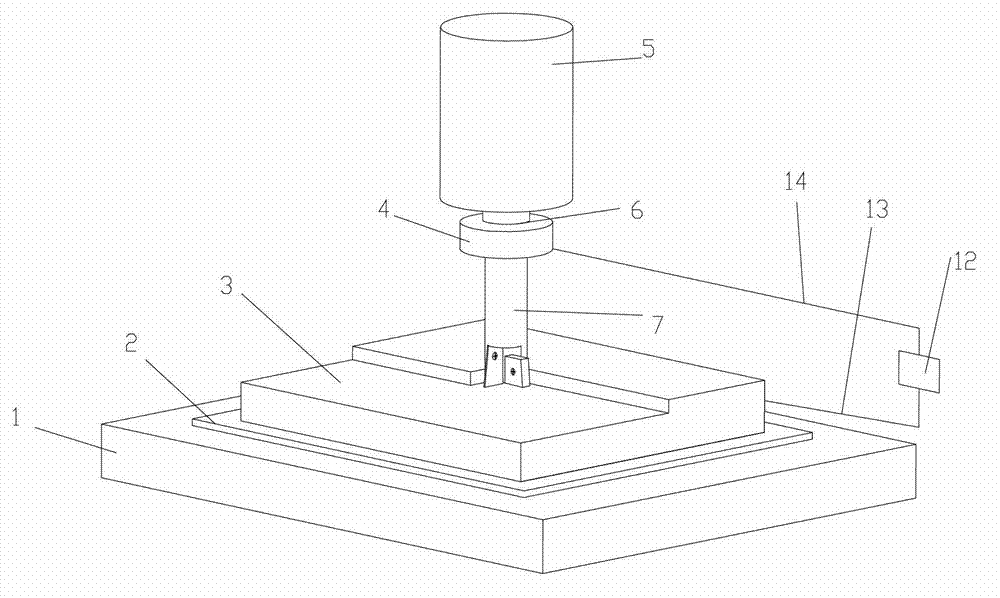

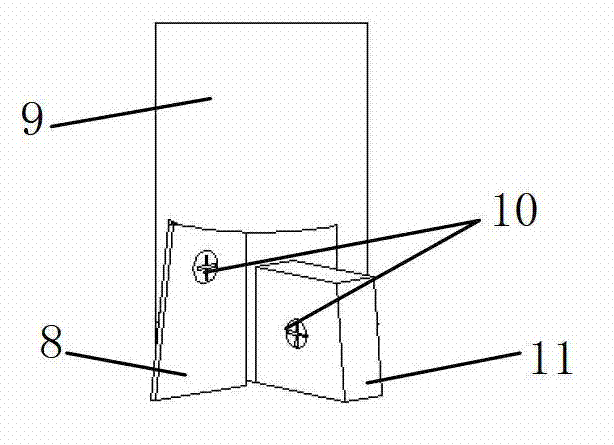

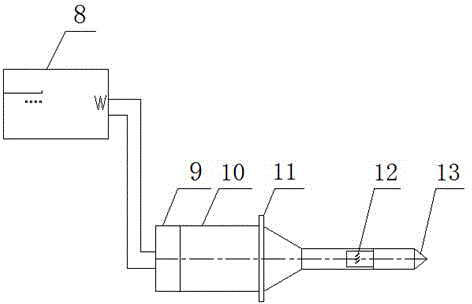

Supersonic-vibration-assisted micro-milling system

InactiveCN104625172AAchieve high precision machiningRealize processingWorkpiecesMilling machinesMilling cutterUltrasonic vibration

The invention discloses a supersonic-vibration-assisted micro-milling system, comprising a horizontally arranged base, as well as an X-direction sliding way, a Y-direction slide way and a Z-direction slide way which are arranged on the base. Each of the X-direction sliding way, the Y-direction slide way and the Z-direction slide way is provided with a guide rail, a sliding block, a motor and a screw driven by the motor, wherein the sliding block and the motor are arranged on the guide rail, the screw is supported by the guide rail, the sliding block is in threaded connected with the screw. A cushion block is arranged under the guide rail of the X-direction sliding way and is fixed on the base; the sliding block of the X-direction slide way is provided with an electric main shaft arranged along the X direction and the output end of the electric main shaft is provided with a micro milling cutter. The guide rail of the Y-direction slide way is fixed on the base. The guide rail of the Z-direction slide way is fixedly connected with a stand column and the guide rail of the Z-direction slide way and the stand column are both fixedly connected with the sliding block of the Y-direction slide way; and a supersonic vibration platform is mounted on the sliding block of the Z-direction slide way. The supersonic-vibration-assisted micro-milling system can be used for precisely processing a complicated part under a high rotation speed condition and milling a crisp and hard material.

Owner:TIANJIN UNIV

Milling and electrosparking combined machining method

The invention discloses a milling and electrosparking combined machining method, and relates to a mechanical cutting method. An indexable milling tool is chosen, the blade of the indexable milling tool is a non-conducting blade, or arranges an insulating layer on an electrically conductive blade, the insulating layer enables the blade to be insulated with a toolbar, and then one of the blades is replaced with an electrically conductive metal sheet. A bearing matched with the toolbar of the indexable milling tool is chosen to be sleeved on the toolbar, an insulating sleeve is sleeved at the upper end of the toolbar, and then the upper end of the toolbar is clamped on the main shaft of a milling machine, a workpiece is clamped on the workbench of the milling machine, an insulating plate is arranged under the bottom face of the workpiece, two wires are respectively connected with two electrodes of a power supply, one of the wires is pressed on the bottom face of the workpiece, and the other wire is wound on the wall of the bearing outer ring. The rotatable milling tool and the workpiece are enabled to form a return circuit, and are insulated with the milling machine. And after powered on, the milling machine can be run to carry out milling. The electric sparks are used for auxiliary milling, the loss of the milling tool can be greatly reduced, milling efficiency is obviously improved, and the loss of the electrodes does not influence the milling precision of parts.

Owner:XIAMEN UNIV

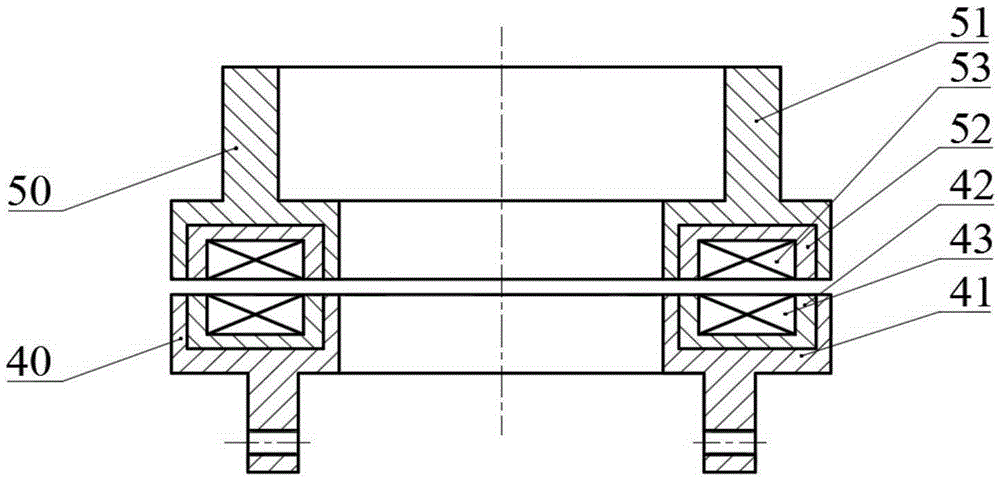

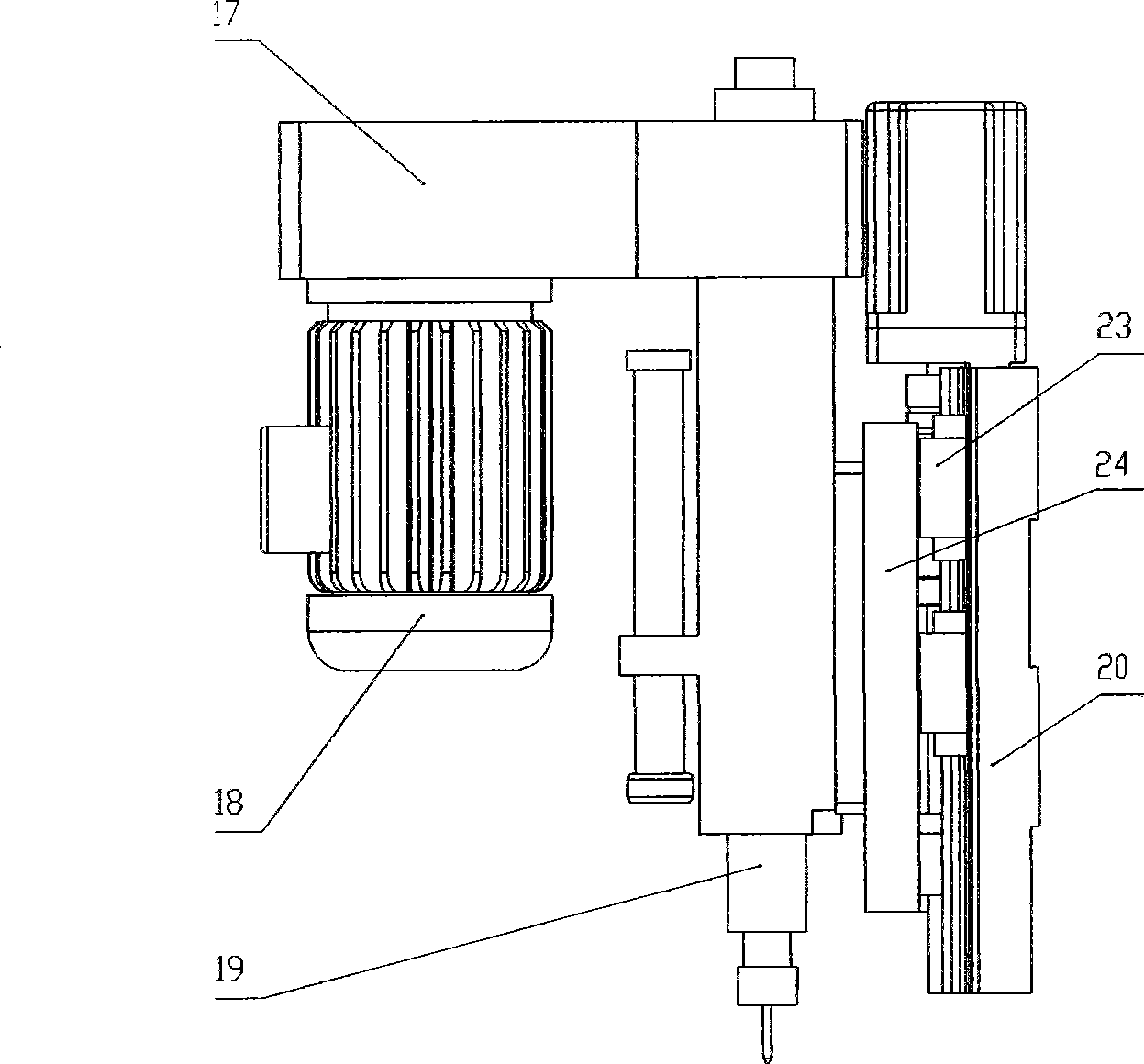

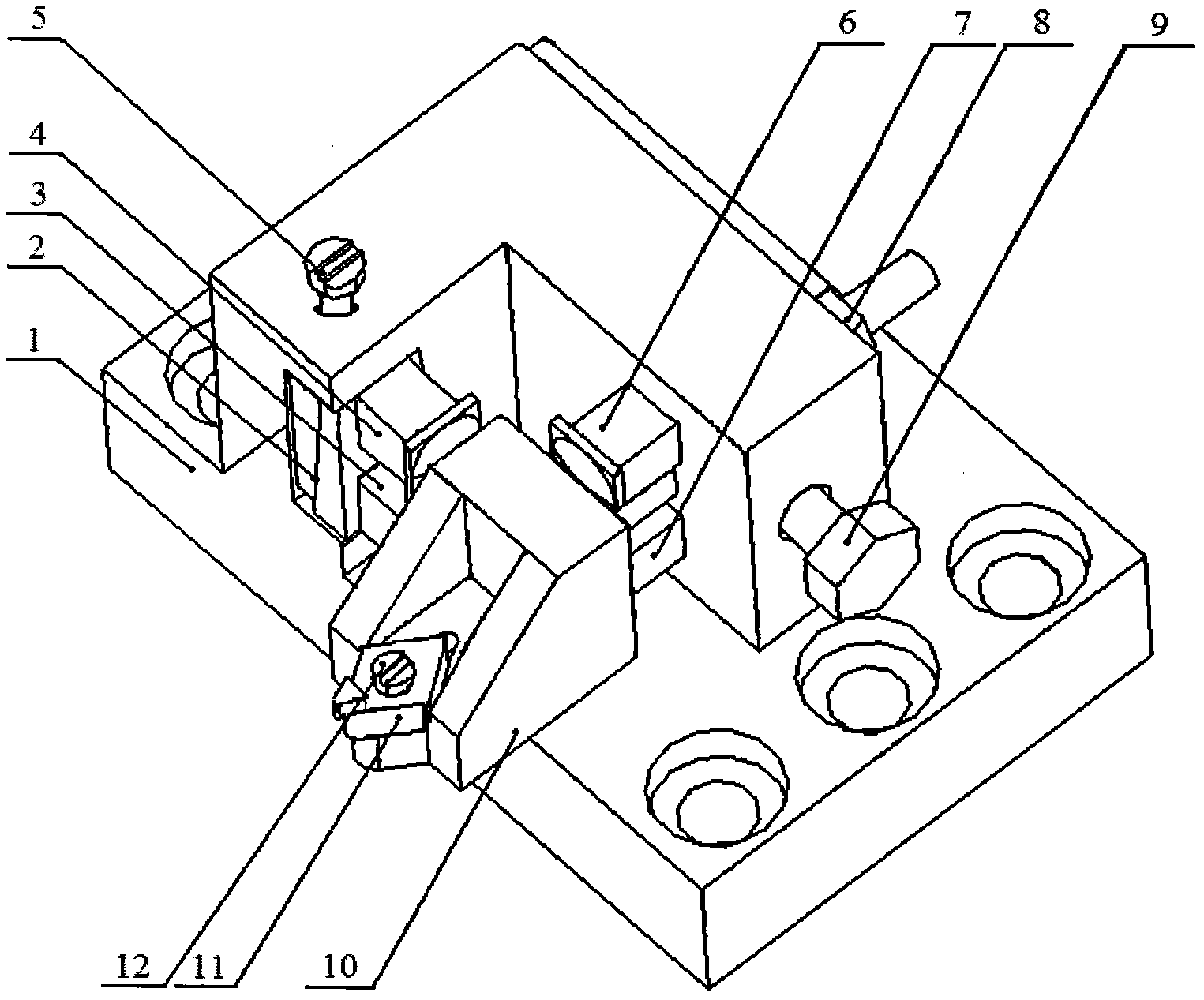

Hole helical milling device

ActiveCN102689040AImprove hole making efficiencyReduce processing costsMilling machinesNumerical controlMilling cutter

The invention provides a hole helical milling device, which comprises a frame, a main shaft system, a deviation regulating mechanism, a revolution system and an anti-winding mechanism. The main shaft system includes an electric main shaft and a milling cutter fixed to the free end of the electric main shaft, and the electric main shaft drives the miller cutter to rotate. The deviation regulating mechanism includes an inner cylinder and an outer cylinder, the inner cylinder surrounds the electric main shaft, the outer cylinder surrounds the inner cylinder, the inner circle and the outer circle of the outer cylinder are eccentrically arranged, and the inner circle and the outer circle of the inner cylinder are eccentrically arranged. The revolution system includes a driving motor, a pinion and a bull gear, the driving motor drives the pinion to drive the bull gear so as to realize revolution of the main shaft system, and an eccentric distance exists between the axial line of rotation of the milling cutter and the axial line of the revolution of the main shaft system. The device disclosed by the invention can be mounted on a mechanical arm, realizes accurate positioning of hole center and axial milling feeding by CNC (computer numerical control) during hole formation, is suitable for work occasions where a large number of series hole-diameter hole structures are rapidly manufactured.

Owner:SHANGHAI AIRCRAFT MFG +1

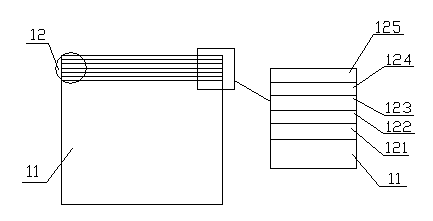

Ti-TiN & Ti-MoS2/Ti double-cutting-surface coated cutting tool and preparation process thereof

ActiveCN102161106AImprove performanceReduce coefficient of frictionVacuum evaporation coatingSputtering coatingHardnessTransition layer

The invention relates to a Ti-TiN & Ti-MoS2 / Ti double-cutting-surface coated cutting tool and a preparation process thereof. The front surface of the cutting tool is an MoS2 / Ti lubricating coating and a Ti front cutting tool surface transition layer is arranged between the MoS2 / Ti lubricating coating and a cutting tool substrate. The rear surface of the cutting tool is a TiN coating with high hardness and a Ti rear cutting tool surface transition layer is arranged between the TiN coating with high hardness and the cutting tool substrate. The preparation process comprises the steps of pre-processing, ion cleaning, depositing the Ti transition layer on the front cutting tool surface, depositing the MoS2 / Ti coating on the front cutting tool surface, sampling, refitting a furnace, ion cleaning, depositing the Ti transition layer on the rear cutting tool surface, depositing the TiN coating on the rear cutting tool surface and post-processing. Advantages of a Ti-TiN coated cutting tool withhigh hardness and a Ti-MoS2 / Ti lubricating coated cutting tool are combined in the present invention of the double-cutting-surface coated cutting tool which has both high hardness and low friction coefficient, so that performance of the coated cutting tool is substantially improved. The preparation process enables the Ti-TiN & Ti-MoS2 / Ti coated cutting tool to be produced conveniently. It is easyto grasp the process and the production process is stable and reliable.

Owner:SHANTUI CONSTR MASCH CO LTD

Ultrasonic laser composite dressing device for superabrasive grinding wheel

InactiveCN104440559AEasy outflowReduce wearAbrasive surface conditioning devicesLaser transmitterCutting force

The invention discloses an ultrasonic laser composite dressing device for a superabrasive grinding wheel. The ultrasonic laser composite dressing device is mainly formed by an ultrasonic vibration dressing system, a laser transmitting system and a lathe bed. A laser transmitter transmits energy to a laser focusing head with a focusing head fixing and adjusting device through optical fibers, laser beams are focused during work to heat the rotating grinding wheel in front of a dressing point at proper energy density for proper heating time, an ultrasonic generator transmits an ultrasonic frequency signal to an ultrasonic transducer, the ultrasonic frequency signal is converted into mechanical vibration through the transducer to be transmitted to an amplitude-change pole, waves, generating longitudinal vibration, of the amplitude-change pole will be decomposed at the position, where a diamond slot is formed, of the small end, the vibration type involves longitudinal vibration and bending vibration, composite elliptical ultrasonic vibration is formed at the point of a diamond dressing stylus for dressing, and after the dressing stylus completely disengages from the grinding wheel, the dressing stylus will be moved to the position where dressing is started for the next time and starts dressing for the next round. In the dressing process, under the recombination action of ultrasonic vibration and laser auxiliary heating, removal of partial materials of the grinding wheel is changed from brittle removal into plastic removal, cutting force is reduced, abrasion to the dressing stylus is reduced, and the dressing efficiency and dressing result are improved.

Owner:HENAN POLYTECHNIC UNIV

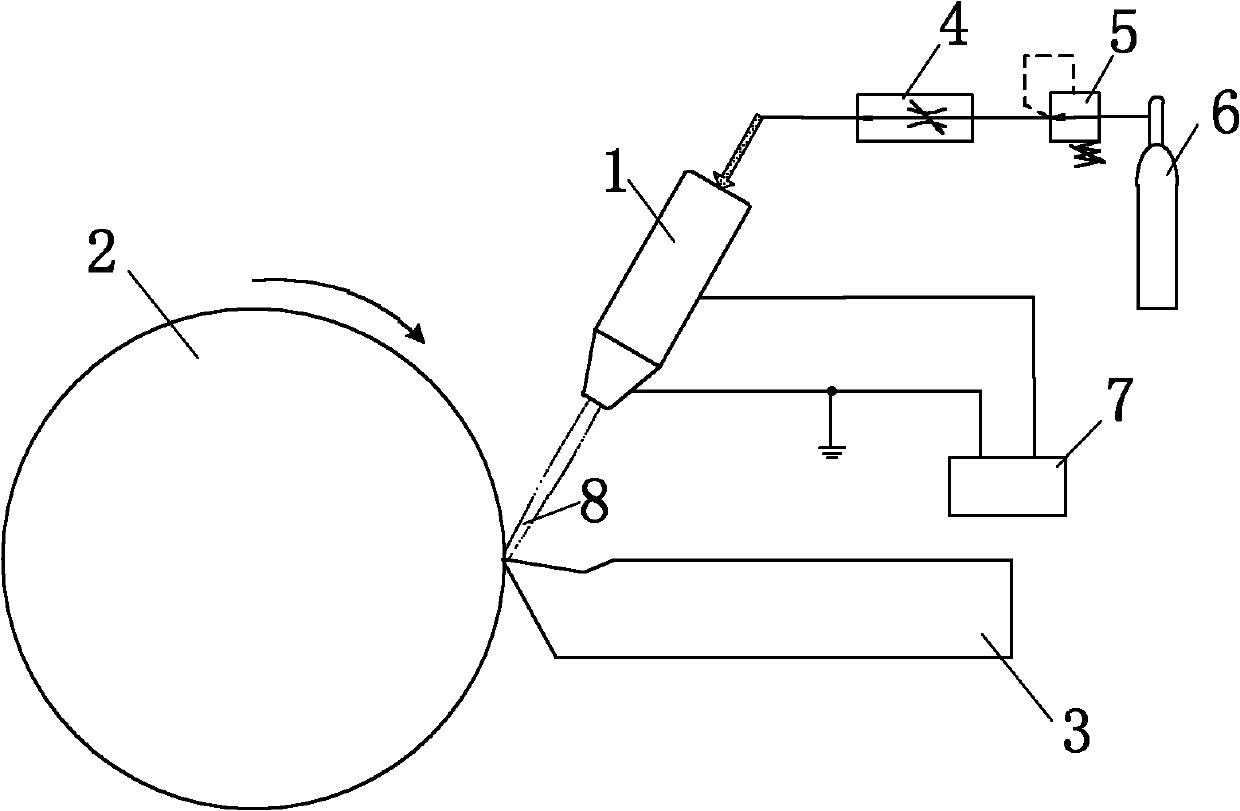

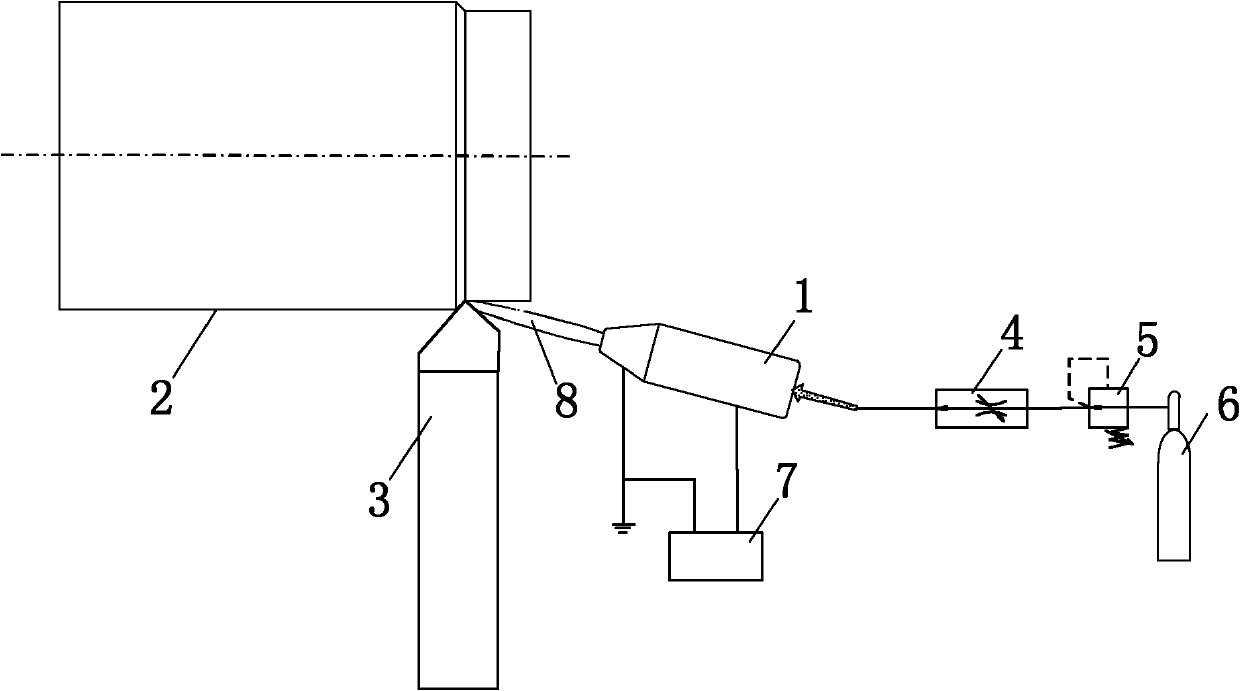

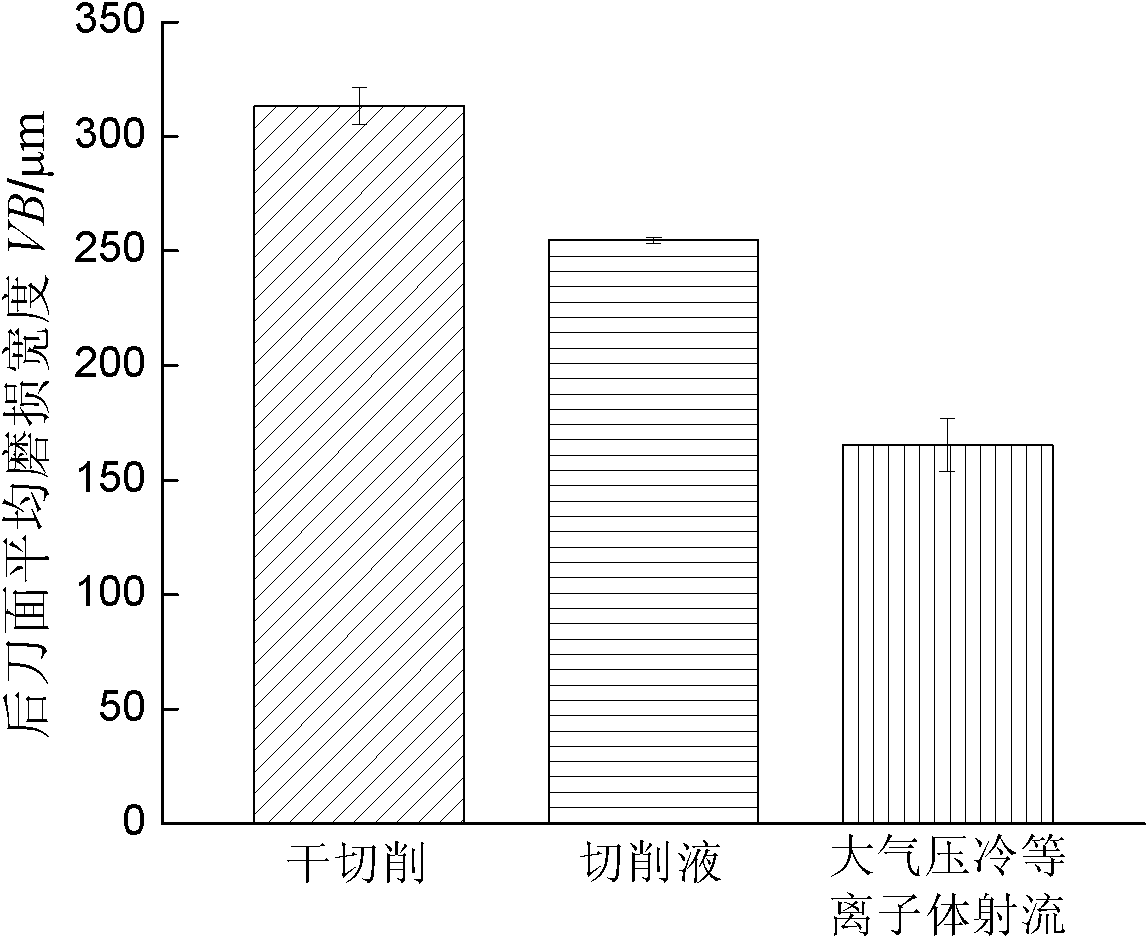

Atmospheric cold plasma jet auxiliary cutting method

ActiveCN102601677AReduce plastic deformation resistanceExtend your lifeMaintainance and safety accessoriesPlasma jetCooling effect

The invention provides an atmospheric cold plasma jet auxiliary cutting method. Cold plasma jet generated under atmospheric pressure is used as a lubricating cooling medium during material cutting. Working gas enters a cold plasma jet generator from a working gas source via a pressure reducing valve and an adjustable flow meter, the flow of the working gas and output voltage of a high-voltage power source are adjusted so that uniform cold plasma jet is sprayed out from a nozzle outlet of the cold plasma jet generator, the temperature of the jet is the room temperature or is slightly higher than the room temperature, and a tool and workpiece interface and a tool and chip interface are always soak in the cold plasma jet during cutting by means of adjusting a spraying angle. Plasma can be generated in a dielectric barrier discharge mode, a suspension electrode discharge mode or a bare electrode discharge mode. The atmospheric cold plasma jet auxiliary cutting method is an environment-friendly cutting method, an excellent lubricating and cooling effects for various metal and nonmetal materials can be realized during cutting, accordingly, cutting force is reduced, the service life of a tool is prolonged, and the quality of the surface of a workpiece is enhanced.

Owner:DALIAN UNIV OF TECH

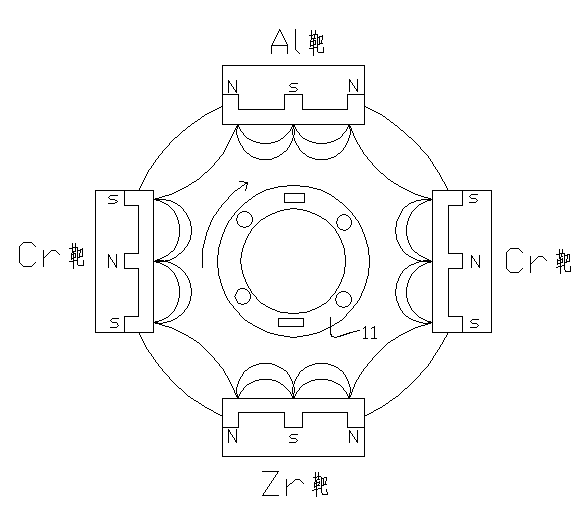

A1ZrCrN composite dual-gradient coating cutting tool and preparation method thereof

ActiveCN103132019AReduce residual thermal stressHigh bonding strengthVacuum evaporation coatingSputtering coatingIon platingComposite coating

The invention relates to an A1ZrCrN composite dual-gradient coating cutting tool and a preparation method thereof. The composite dual-gradient coating cutting tool is prepared by a nonequilibrium closed field magnetron sputtering ion plating manner; and a Cr transition layer, a gradient CrN transition layer, a gradient A1ZrCrN transition layer and an A1ZrCrN layer are sequentially arranged on the coating cutting tool from inside to outside along the a vertical matrix surface direction, so that transition between coatings is smoother, residual thermal stress among all coatings can be obviously lowered in use of the coating cutting tool, and the coating quality of the cutting tool is greatly improved.

Owner:成都史特迪新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com