Ti-TiN & Ti-MoS2/Ti double-cutting-surface coated cutting tool and preparation process thereof

A ti-tin&ti-mos2, cutting tool technology, applied in the field of mechanical manufacturing metal cutting tools, to achieve the effect of reducing friction, low friction coefficient, and easy to master the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

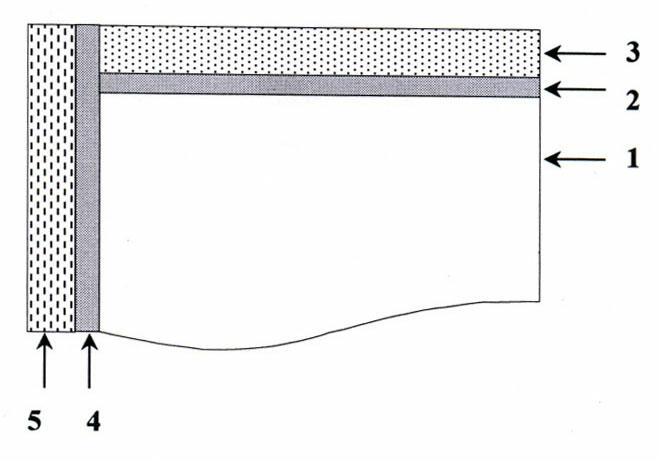

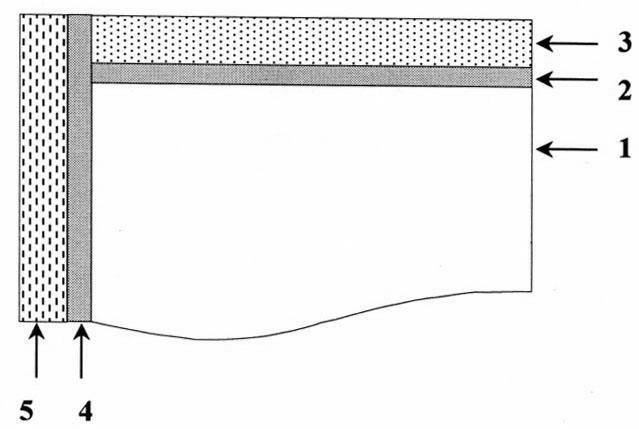

[0020] Referring to the attached drawings, the tool is an ordinary milling insert, the material of the tool base 1 is cemented carbide YT15; the coating materials are: Ti-TiN and Ti-MoS 2 / Ti, the surface of the tool rake face is MoS 2 / Ti Lubrication Coating 3, MoS 2 There is a Ti rake face transition layer 2 between the Ti lubricating coating 3 and the tool base 1; the tool flank surface is a TiN high-hardness coating 5, and there is a Ti flank between the TiN high-hardness coating 5 and the tool base 1 Surface transition layer 4.

[0021] The deposition method is: arc ion plating deposition of Ti transition layer and intermediate frequency magnetron sputtering MoS on the rake face 2 And arc ion plating Ti composite deposition MoS 2 / Ti lubricating coating; the flank surface is arc ion plating deposited Ti transition layer and TiN high hardness coating, and the preparation process steps are as follows:

[0022] Pre-treatment: Polish the surface of the carbide YT15 tool b...

Embodiment 2

[0032] Referring to the attached drawings, the tool is an ordinary welding turning tool, and the base material of the tool is high-speed steel W 18 Cr 4 V, the coating materials are Ti-TiN and Ti-MoS 2 / Ti; the surface of the tool rake face is MoS 2 / Ti Lubrication Coating 3, MoS 2 There is a Ti rake face transition layer 2 between the Ti lubricating coating 3 and the tool base 1; the tool flank surface is a TiN high-hardness coating 5, and there is a Ti flank between the TiN high-hardness coating 5 and the tool base 1 Surface transition layer 4.

[0033] The deposition method is: arc ion plating deposition of Ti transition layer and intermediate frequency magnetron sputtering MoS on the rake face 2 And arc ion plating Ti composite deposition MoS 2 / Ti lubricating coating; the flank surface is arc ion plating deposited Ti transition layer and TiN high hardness coating, and the preparation process steps are as follows:

[0034] Pretreatment: High-speed steel W 18 Cr 4 T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com