Milling and electrosparking combined machining method

A compound machining and EDM technology, applied in the field of mechanical cutting, can solve problems such as low efficiency, easy peeling, and influence on machining accuracy, and achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

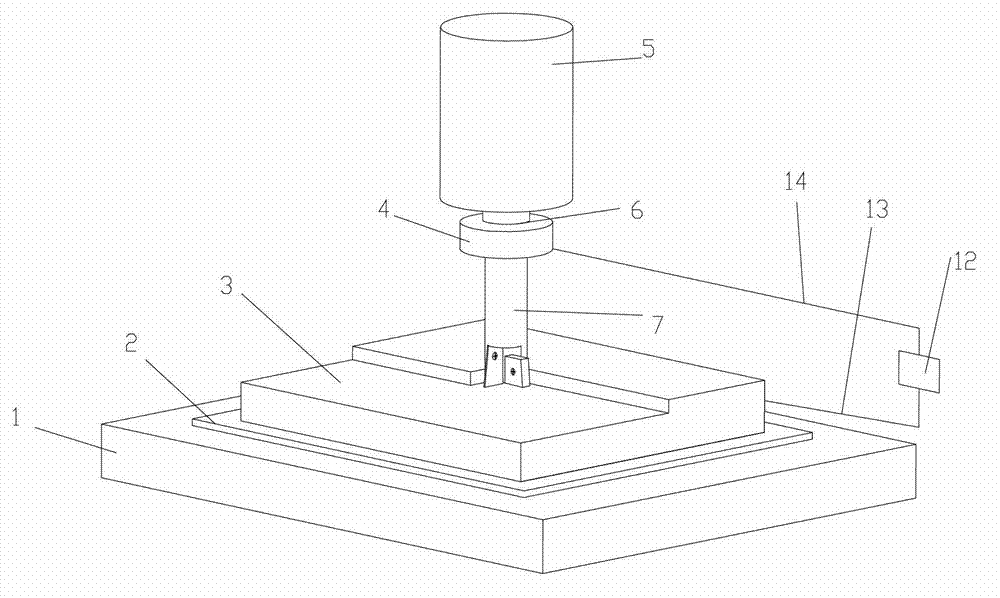

[0019] see figure 1 with 2 , a milling and electric discharge compound machining method described in the embodiment of the present invention, comprising the following steps:

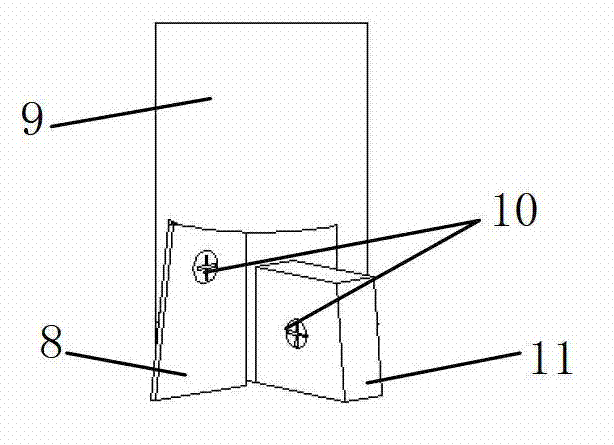

[0020] 1. Select an indexable milling cutter 7 with 2 teeth, the blade 11 is a non-conductive cubic boron nitride (CBN) blade, and then replace one of the blades with a copper sheet 8, the blade 11 and the copper sheet 8 are all fixed on the cutter bar 9 by fastening screw 10.

[0021] 2. Select one of the lightest series ball bearings 4 matched with the indexable milling cutter bar, which is used to conduct electricity to the rotating indexable milling cutter 7, and set the ball bearing 4 on the tool bar 9. The upper end is put on the insulating sleeve 6, and then the upper end of the tool bar with the insulating cover 6 is clamped on the milling machine main shaft 5, and the insulating cover 6 is used to insulate the tool bar 9 from the milling machine main shaft 5.

[0022] 3. Clamp the workpiece 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com