Patents

Literature

133results about How to "Small slope" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

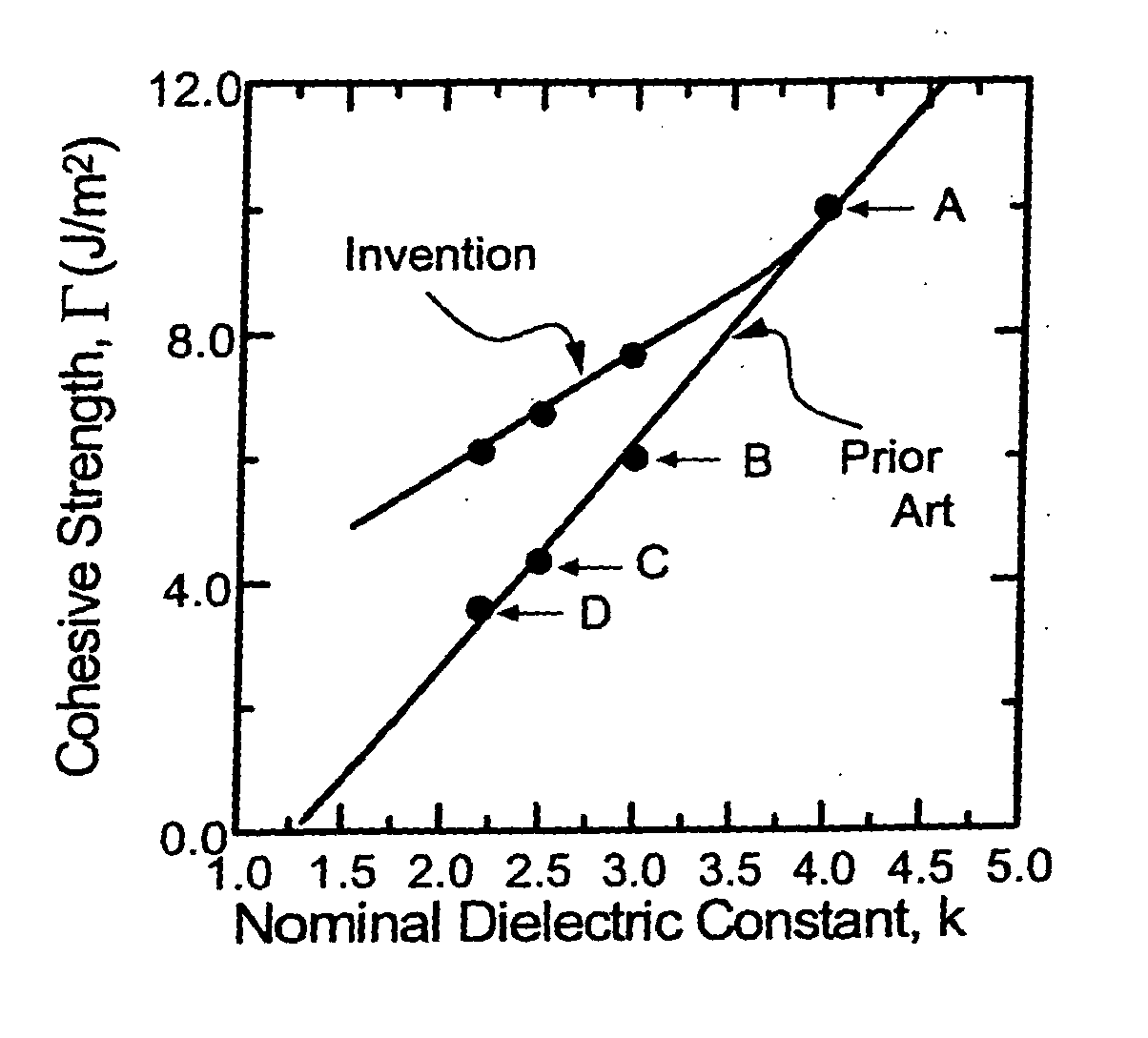

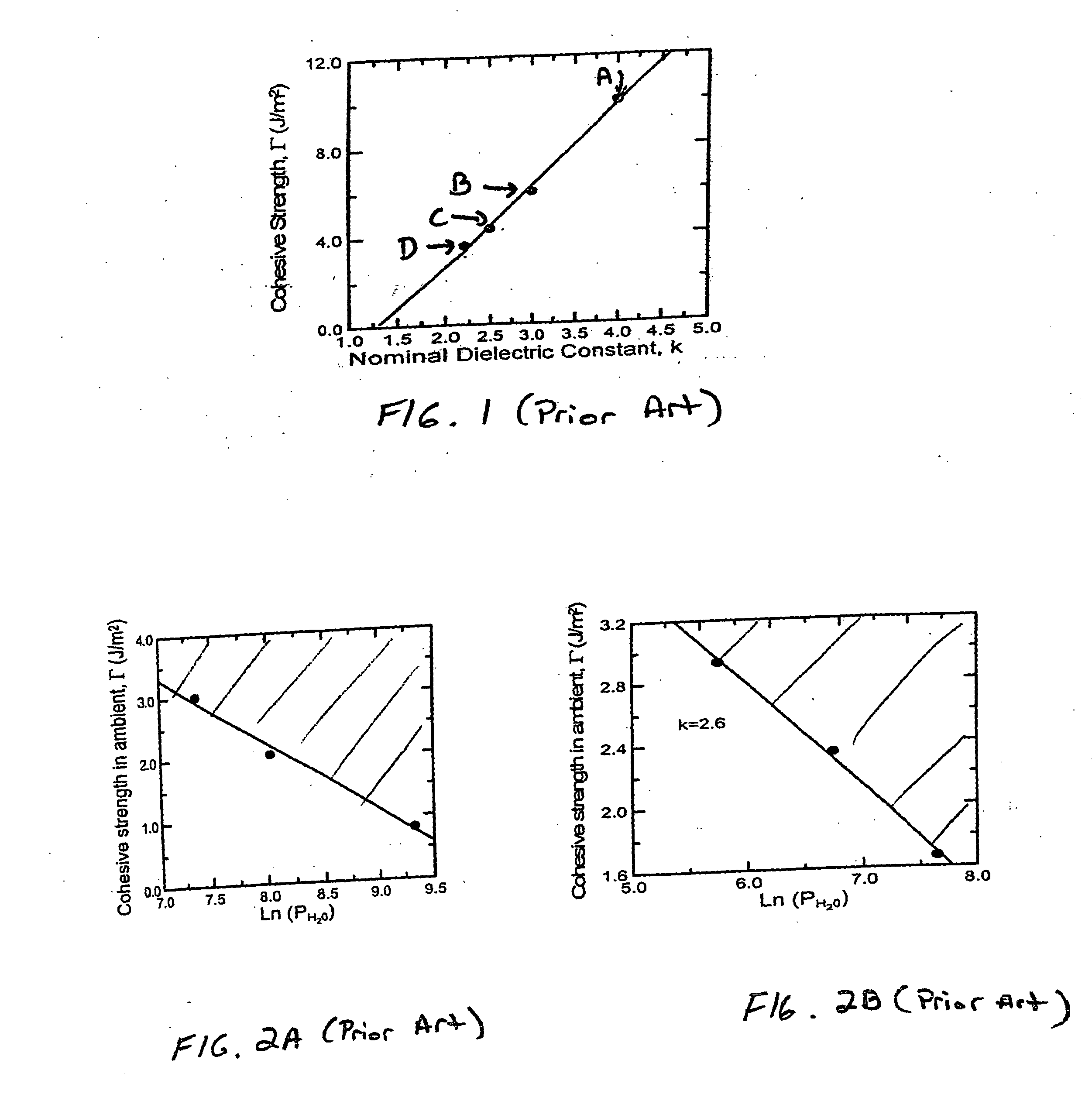

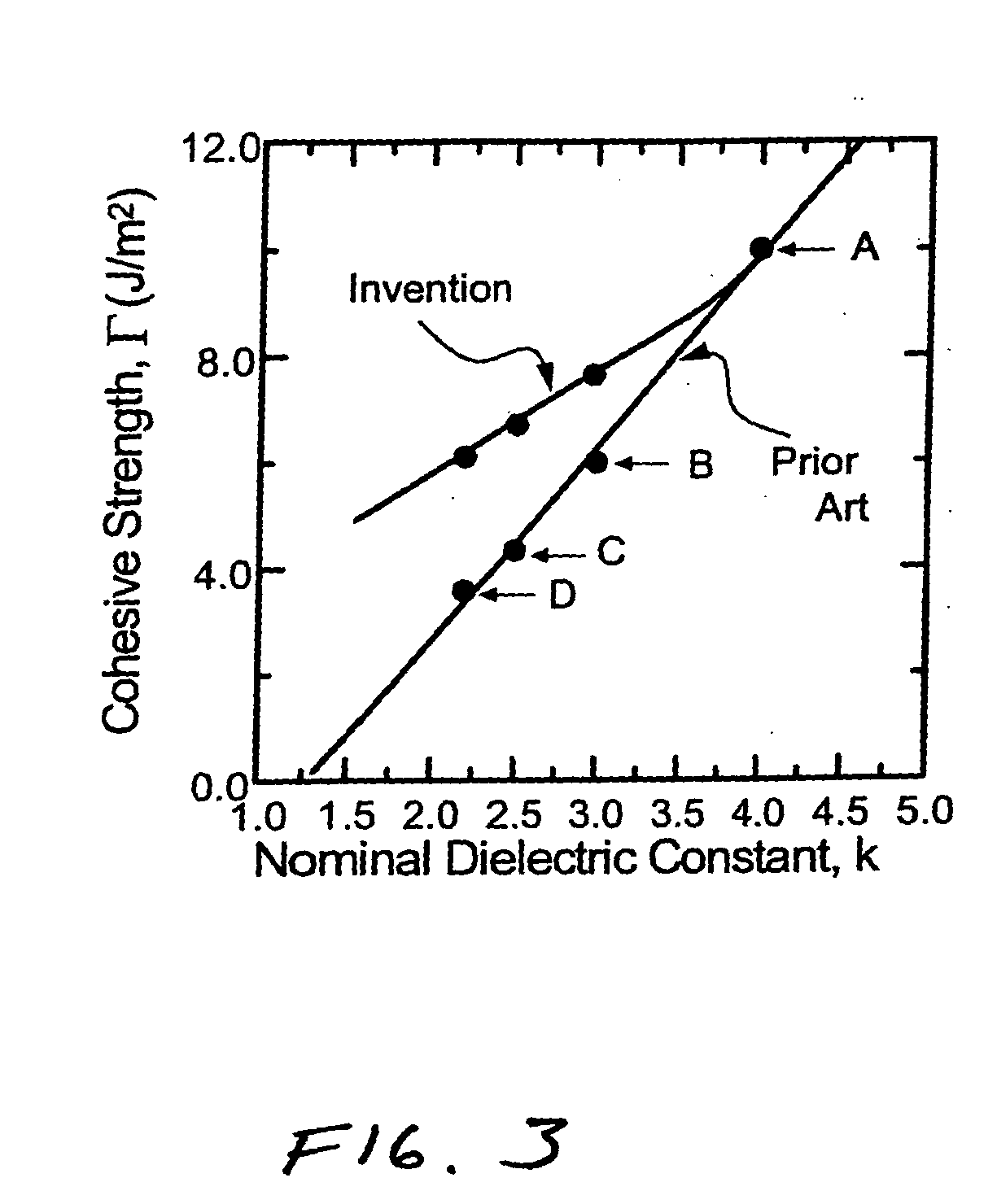

SiCOH dielectric material with improved toughness and improved Si-C bonding, semiconductor device containing the same, and method to make the same

InactiveUS20060165891A1Small slopeDelayed slopeMolten spray coatingPretreated surfacesElectronic structureDevice material

A low-k dielectric material with increased cohesive strength for use in electronic structures including interconnect and sensing structures is provided that includes atoms of Si, C, O, and H in which a fraction of the C atoms are bonded as Si—CH3 functional groups, and another fraction of the C atoms are bonded as Si—R—Si, wherein R is phenyl, —[CH2]n— where n is greater than or equal to 1, HC═CH, C≡CH2, C≡C or a [S]n linkage, where n is a defined above.

Owner:INTEL CORP

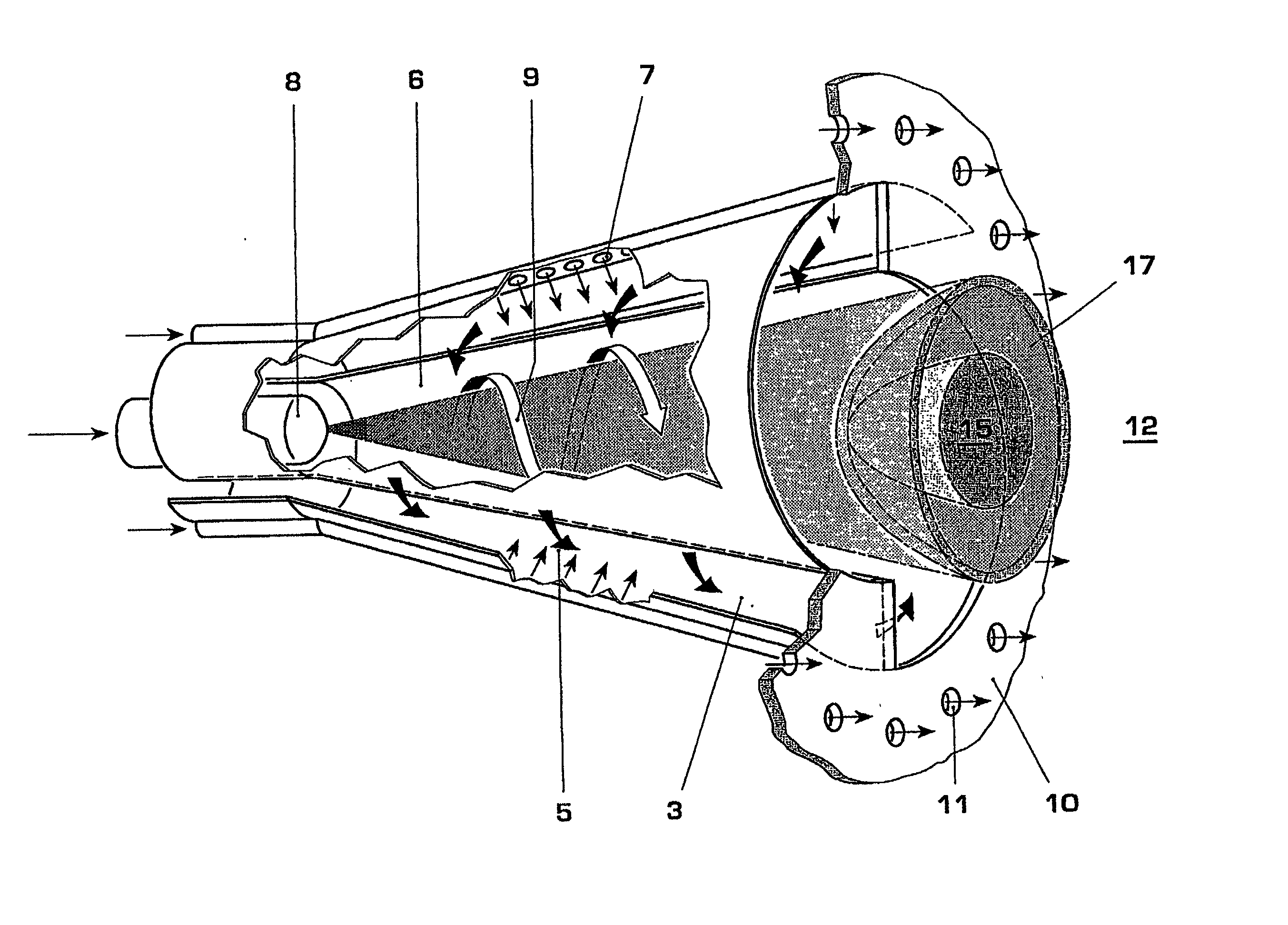

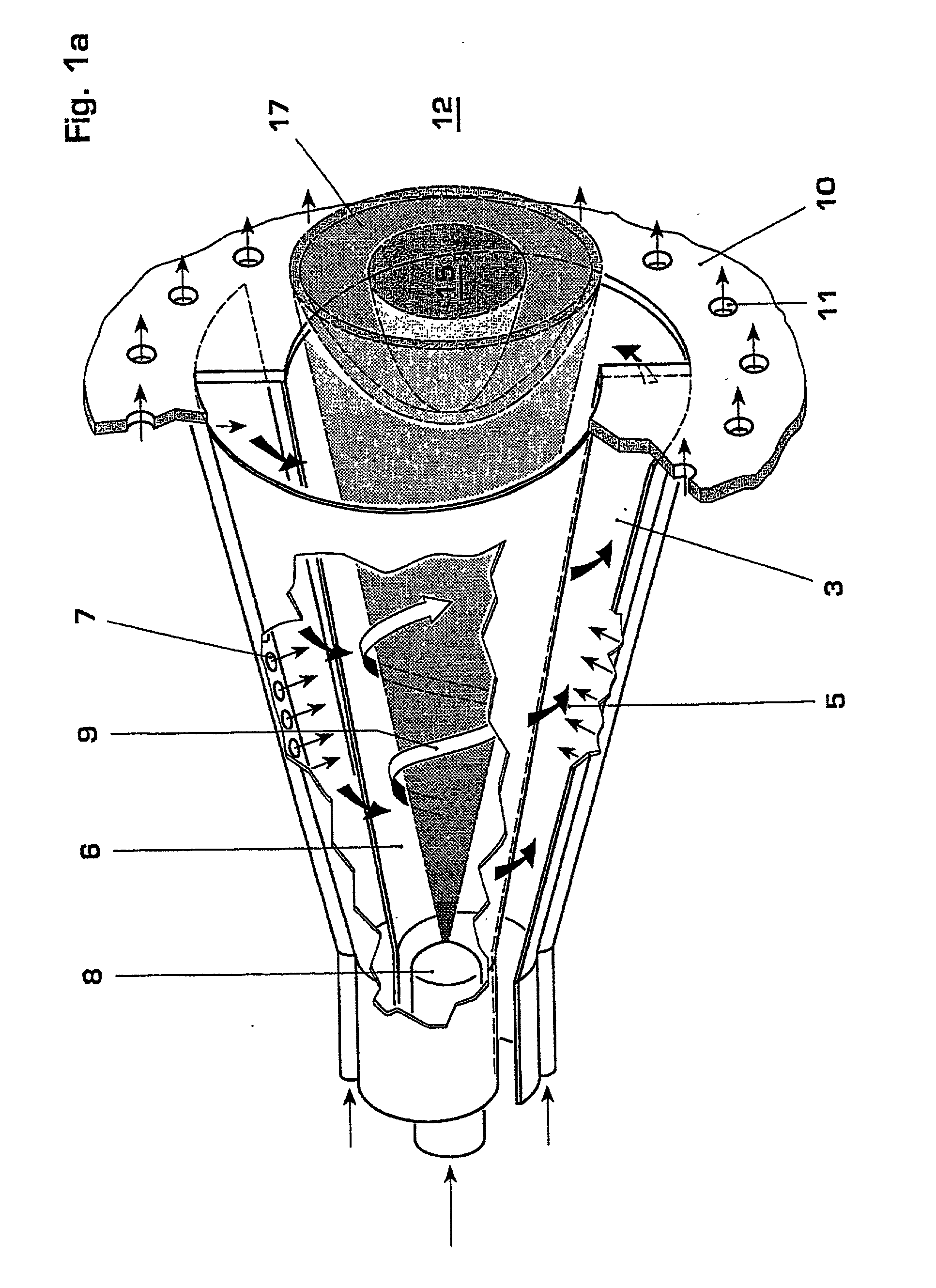

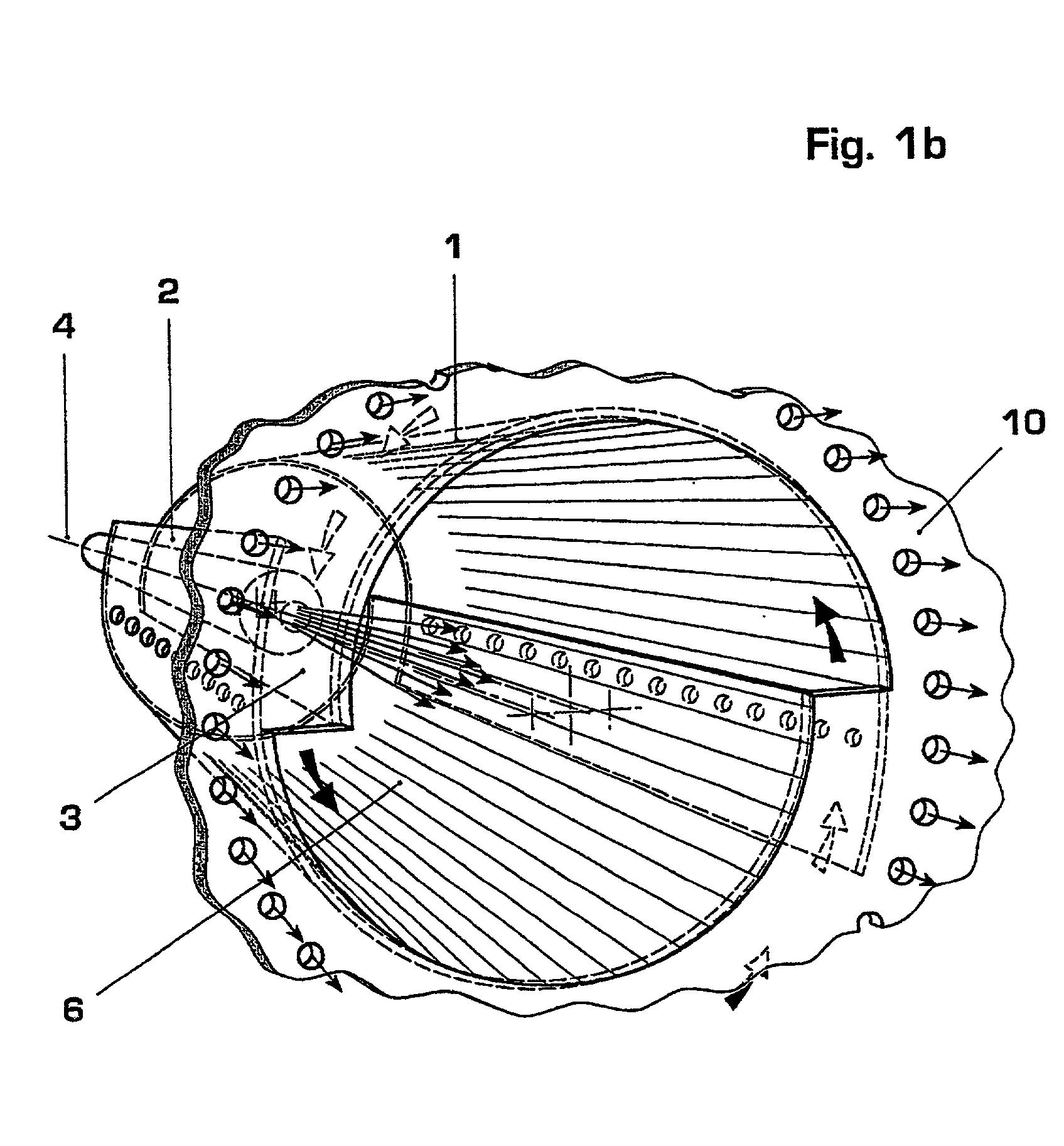

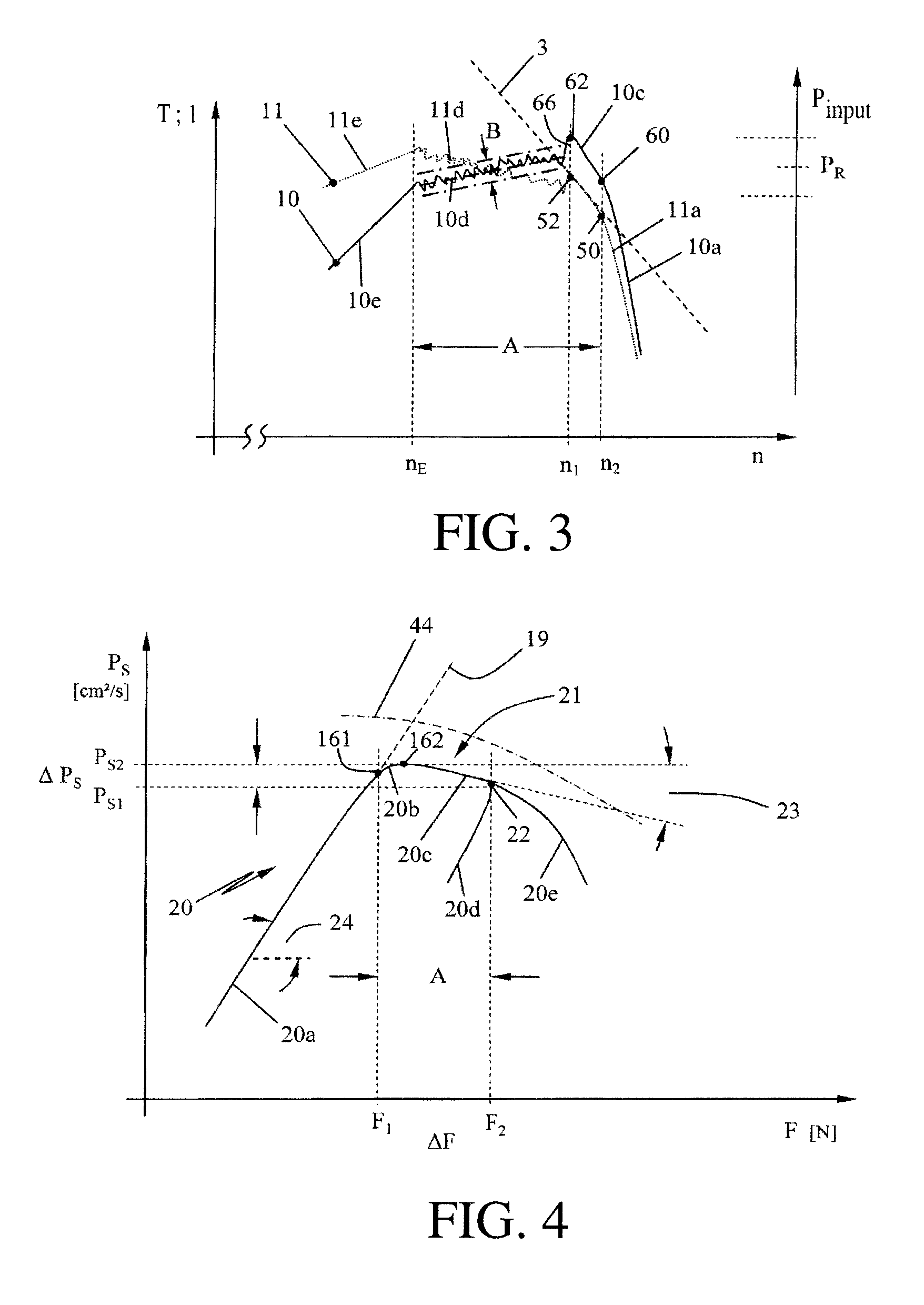

Method for increasing the fluid-mechanical stability of a premix burner as well as a premix burner for performing the method

InactiveUS20020026796A1Broad of delay timeSmall slopeBurner safety arrangementsTurbine/propulsion fuel supply systemsCombustorMechanical stability

The subject of the invention is a method as well as an apparatus for suppressing flow vortices within a turbo power machine with a premix burner, into which fuel and air are introduced for mixing, which then leave the burner downstream along its burner axis in the form of a fuel / air mixture through a burner outlet and flow into a combustor located downstream from the burner in the flow direction of the fuel / air mixture. The invention is based on the basic idea of-for the fluid-mechanical stabilization of a premix burner, into which at least one combustion air stream (5) is fed tangentially into a burner chamber (6) and is mixed with an injected gaseous and / or liquid fuel (7;8) while forming a swirl flow (9) oriented coaxially to the burner axis and induces a reverse flow zone (15) at a change in the cross-section on a burner mouth (14), that is used during the operation of the burner to stabilize the flame-increasingly, radially deforming the swirl flow (9) within the burner chamber (6) in the direction of the burner mouth (14) and let it enter the combustor (12) in a non-rotation-symmetrical flow cross-section, whereby this deformation is created by reducing the free flow cross-section (18) of the burner chamber (6). The fuel / air mixture flows into the combustor with a non-rotation-symmetrical flow cross-section.

Owner:ANSALDO ENERGIA SWITZERLAND AG

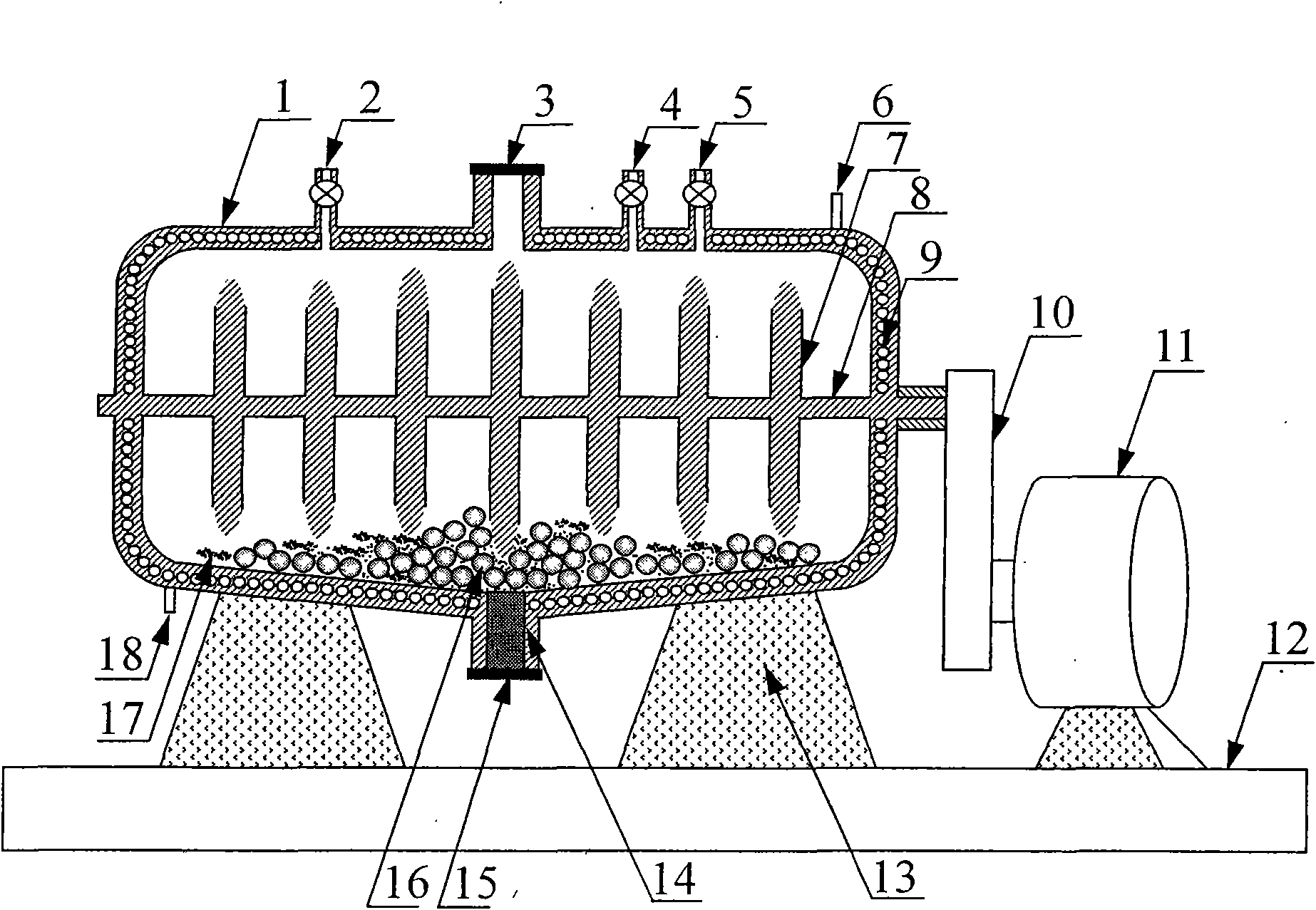

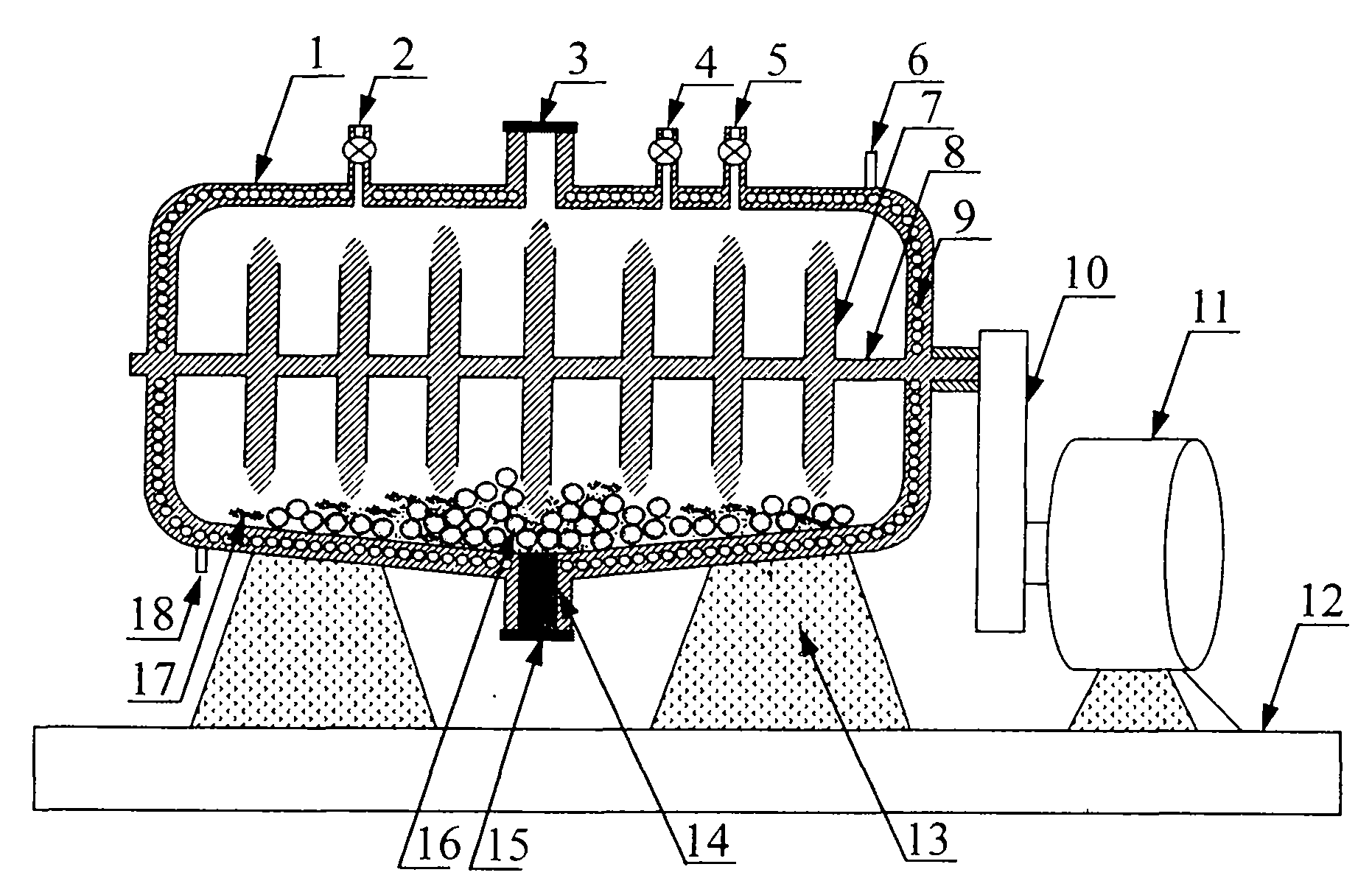

Ball grinder available for solid state reaction of powder

InactiveCN101823013AImprove mechanical energyMeeting the Energy Requirements of Solid-State Chemical ReactionsGrain treatmentsChemical reactionHigh energy

The invention relates to a ball grinder available for the solid state reaction of powder, which mainly comprises a ball grinding cylinder, an electromotor, a driving device, a grinding ball and a material inlet and outlet, wherein the horizontal type ball grinding cylinder is fixedly supported on a bracket; a jar is internally provided with the girding ball; the center of the ball grinding cylinder is provided with a rotatable main shaft; the main shaft is driven by the electromotor through the driving device to rotate; the main shaft is provided with a blade, wherein the rotating speed of the blade is 300-2000 r / min; the mechanical energy is transmitted to the grinding ball through the beating of the blade, so that the grinding ball can irregularly move with high speed; the bottom of theball grinding cylinder is in the shape of gradient with 0-30 degrees from the two ends to the center; the jar body of the ball grinding cylinder is provided with a cooling sleeve and an inlet and an outlet of cooling medium; and the jar body of the ball grinding cylinder is provided with an air exhausting opening and an air inlet. The ball grinder can lead the grinding ball to generate higher mechanical energy to provide high energy for inducing the solid state reaction among materials, thereby smashing, grinding and dispersing the materials and directly reacting to generate nanometer composite oxide.

Owner:BEIJING UNIV OF CHEM TECH

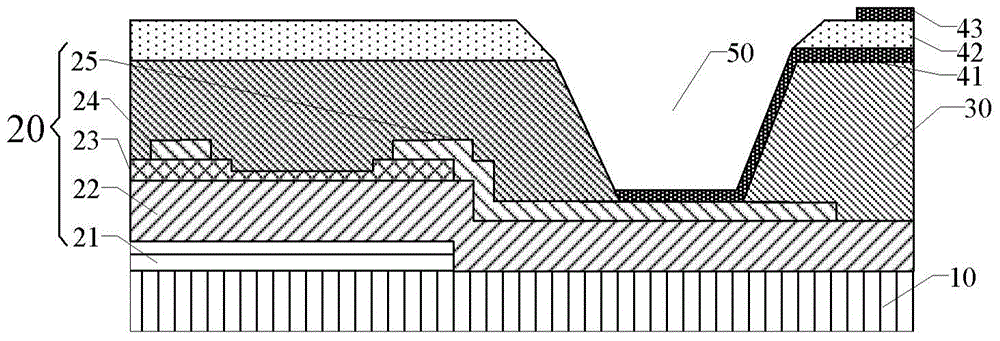

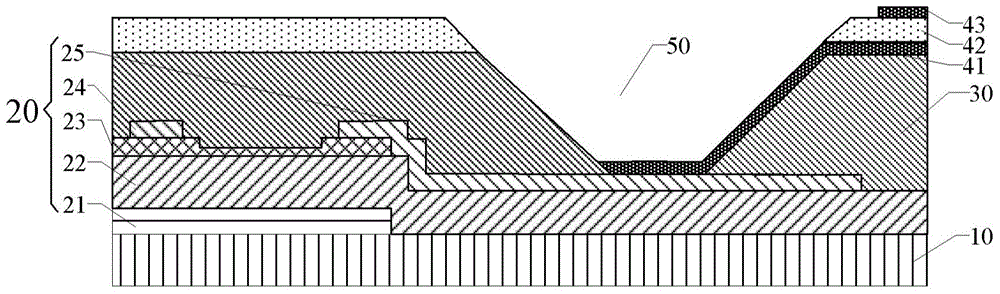

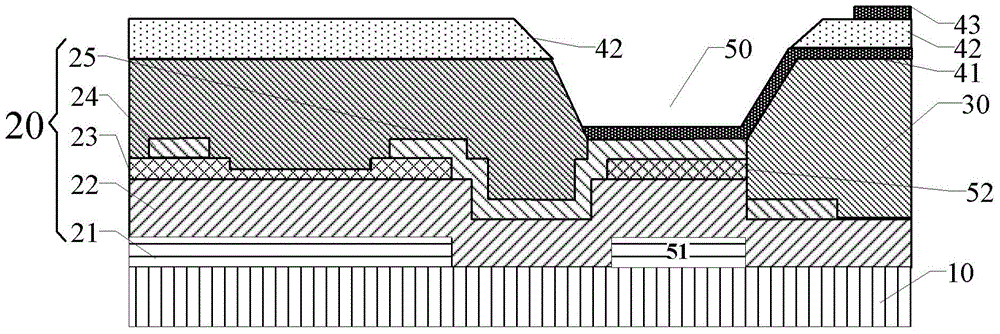

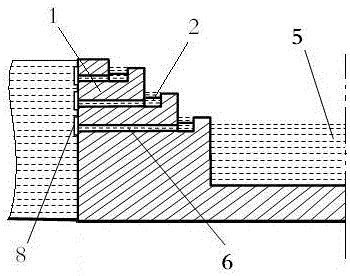

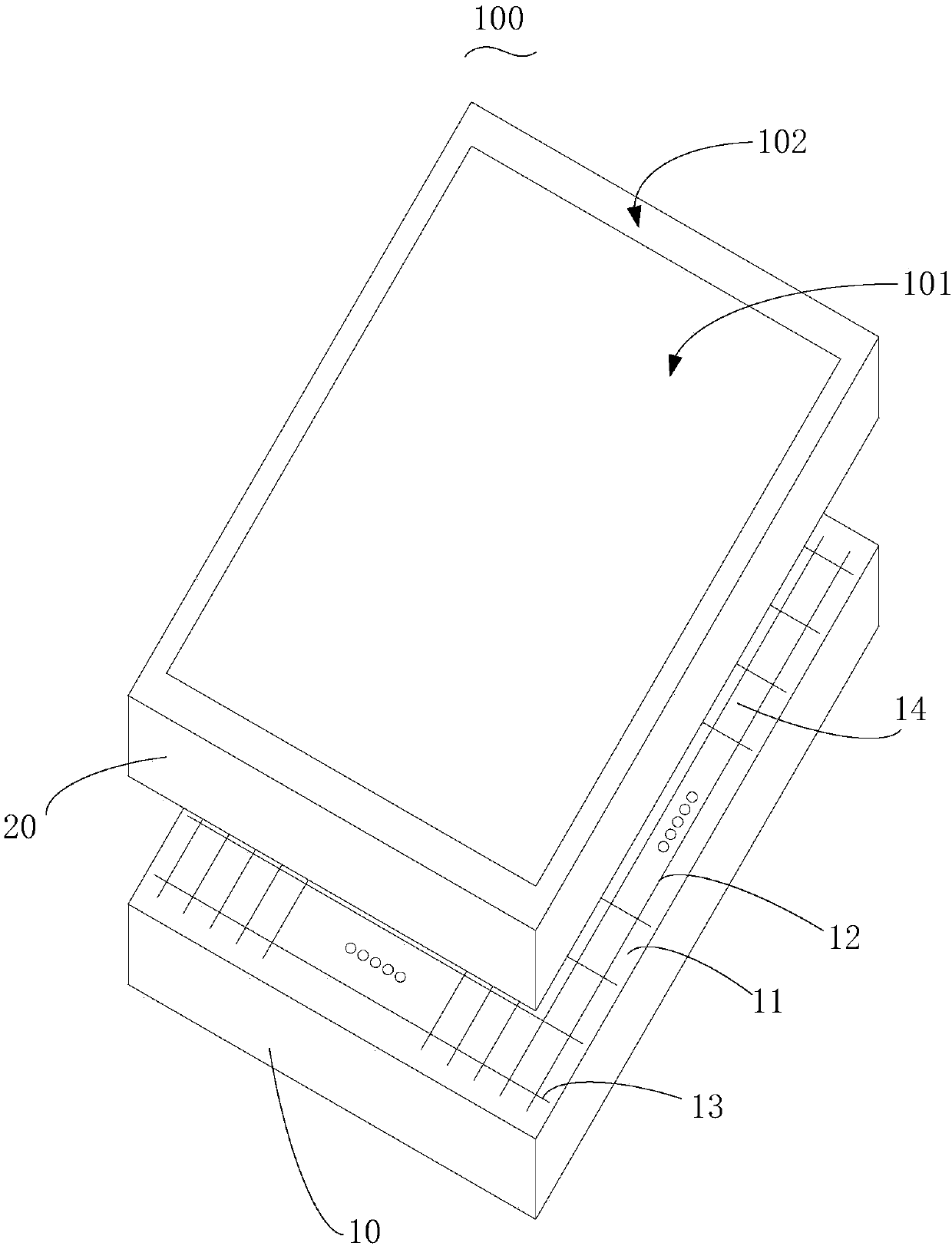

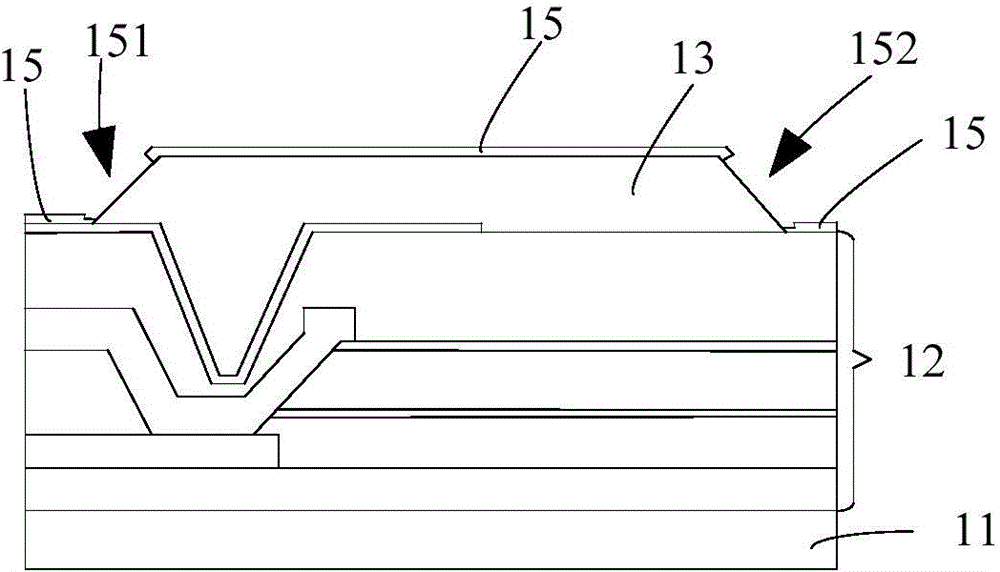

Pixel unit, preparation method thereof, array substrate and display device

InactiveCN104867939AReduced risk of breakageReduce the slope of the viaSolid-state devicesSemiconductor/solid-state device manufacturingOrganic filmDisplay device

The invention provides a pixel unit, a preparation method thereof, an array substrate and a display device. The pixel unit comprises a thin film transistor, an insulating layer, a pixel electrode and a first heightening layer and / or a second heightening layer, wherein the insulating layer is formed on the thin film transistor, a preset position of the insulating layer forms a via hole so as to expose a drain electrode of the thin film transistor below; the pixel electrode is formed on the insulating layer and electrically connected with the drain electrode of the thin film transistor at the via hole; and the first heightening layer and / or the second heightening layer are / is formed below the via hole so as to heighten the via hole. According to the invention, the slope of the via hole is reduced through additionally arranging the heightening layers at the bottom part of the organic film via hole. Meanwhile, the heightening layers can be formed by a gate metal layer and / or an active layer which are / is not etched in the technological process, thereby not increasing any production cost or processing difficulty.

Owner:HEFEI BOE OPTOELECTRONIC TECH CO LTD +1

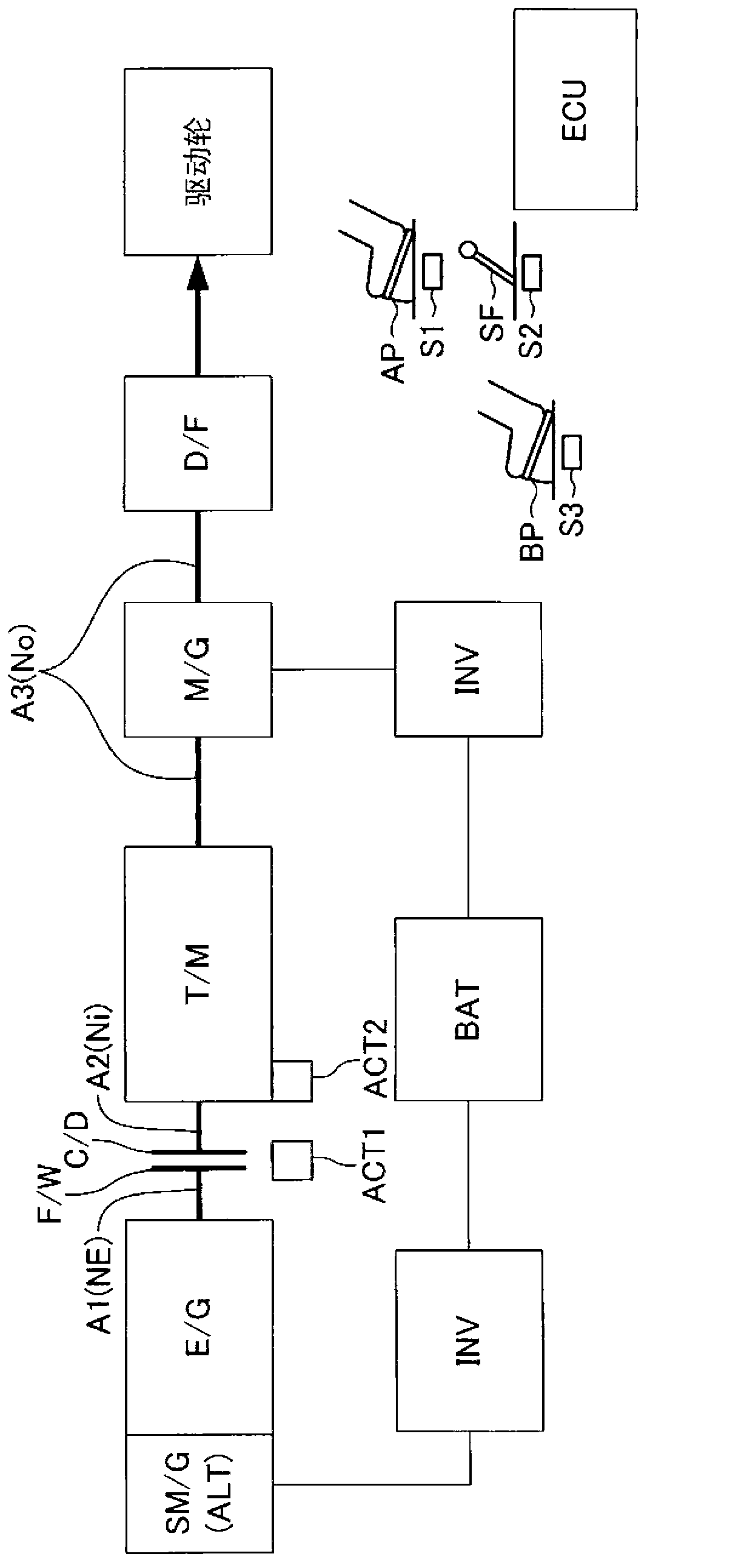

Vehicle power transmission control device

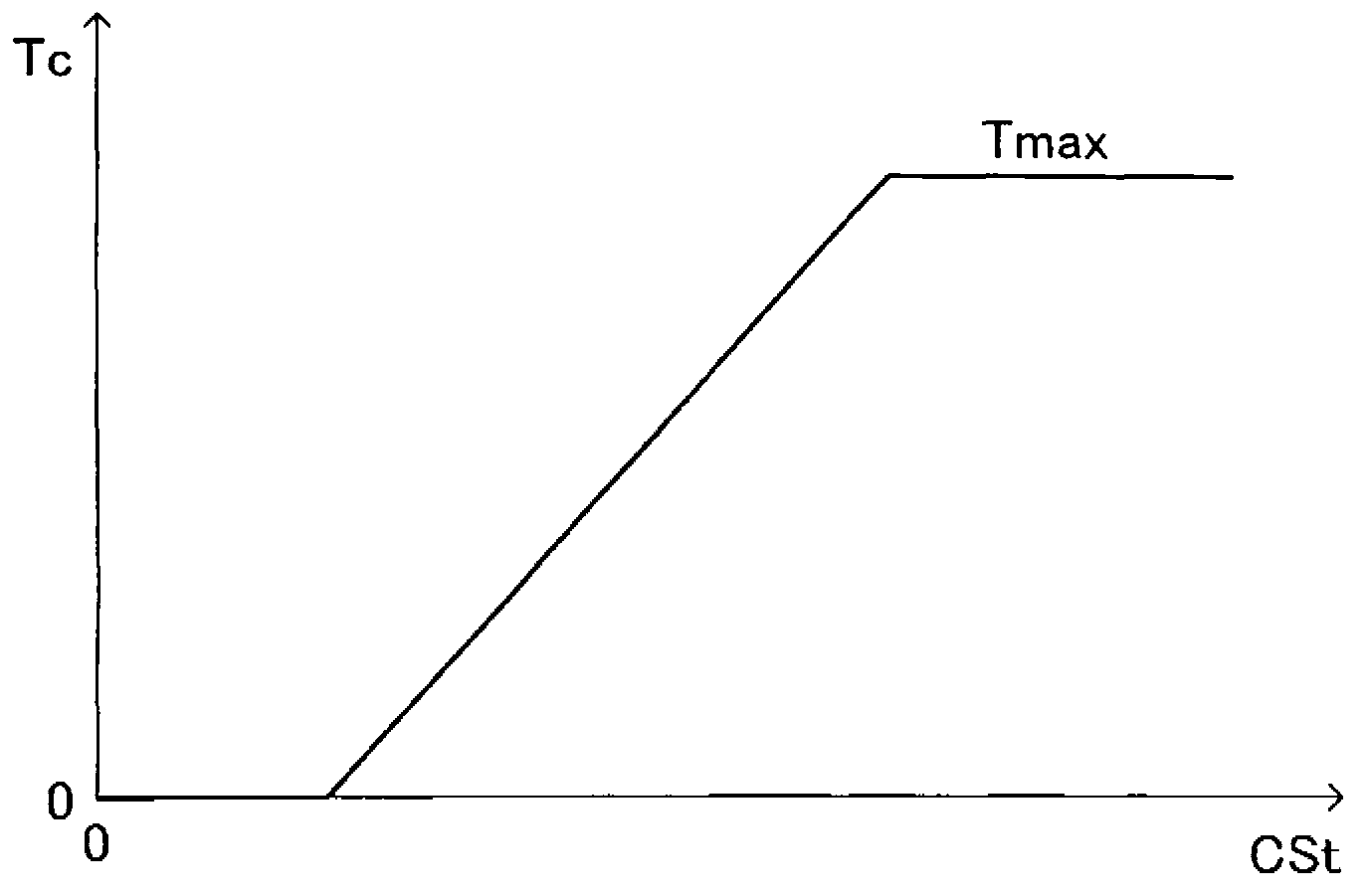

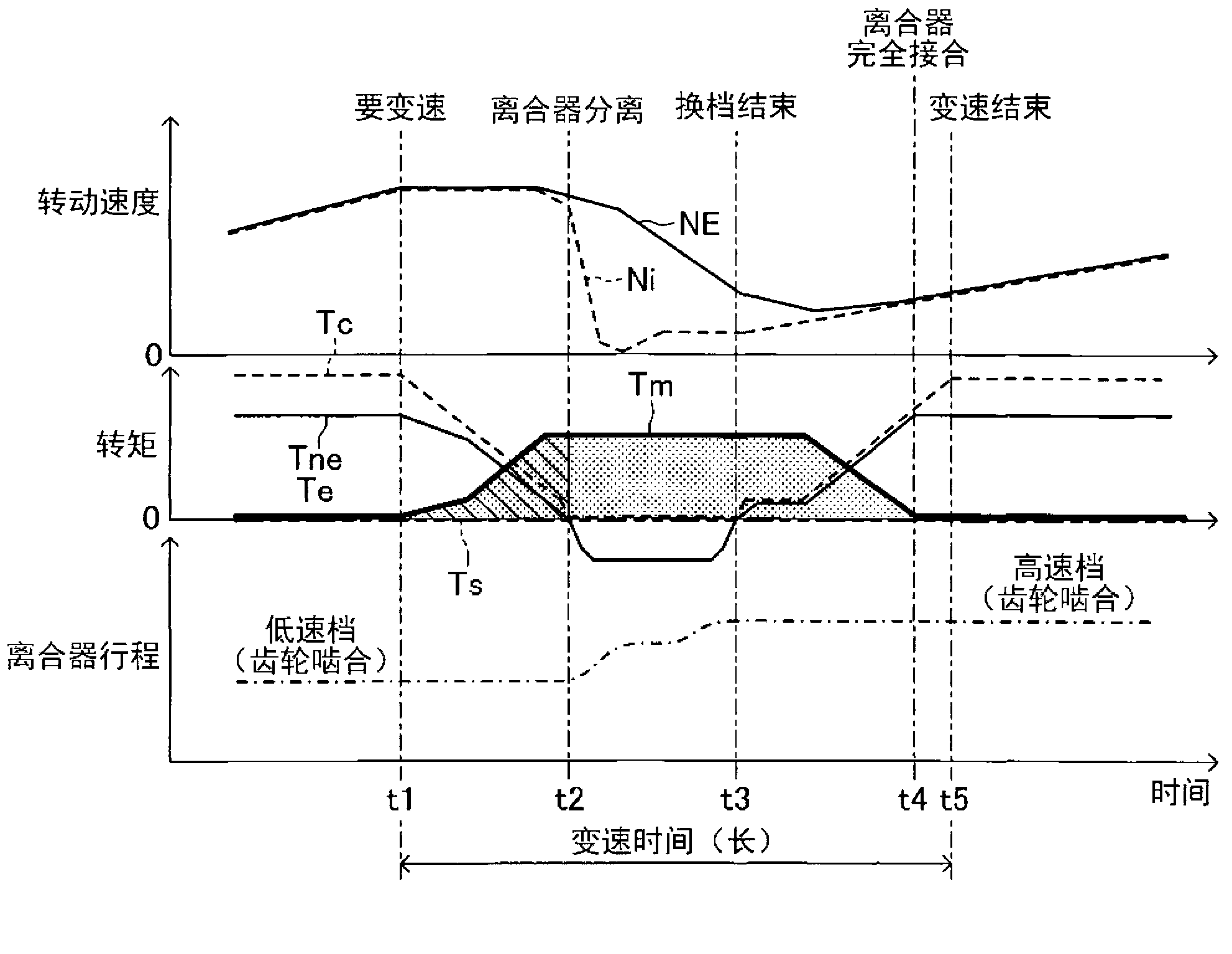

InactiveCN103140365AReduce drive torqueSuppression of slippageGearing controlEngine controllersDrive wheelExternal combustion engine

A state in which a vehicle travels while an internal combustion engine drive torque (Te) is transmitted to a driving wheel wherein, Te and a clutch torque Tc are reduced and an electric motor torque (Tm) is increased based on the fact that a shift up condition has been established (t1). Thereafter, based on the fact that Tc is zero (t2), Tc is maintained at zero, and while maintaining a state in which Tm is transmitted to the driving wheel, a shift up operation is performed (t2 - t3). Then, based on the fact that the shift up operation is complete (t3), Te and Tc are increased and Tm is reduced (T3 - T5). After the shift up condition has been established, during the time until Tc becomes zero, the load torque (Ts) of a generator rotatably driven by the power shaft of the internal combustion engine is generated. In a hybrid vehicle equipped with an AMT, the power consumption accorded to the electric motor drive when shifting up while using the assist for the electric motor torque can be reduced.

Owner:AISIN AI CO LTD +1

Hot-rolled thin gauge strip steel coiling method

ActiveCN107199246AGuaranteed uptimeSmall slopeRoll mill control devicesMetal rolling arrangementsStrip steelMetallurgical industry

The invention discloses a hot-rolled thin gauge strip steel coiling method and relates to the technical field of the metallurgical industry. The method comprises the steps that when strip steel is in a finishing rolling unit, the strip steel operates at a first speed; the head of the strip steel exits from the finishing rolling unit and enters a runout table, and the strip steel operates at the first speed; the runout table and a pinch roll of a coiling machine operate at a second speed; the head of the strip steel enters the coiling machine to build tension, and the strip steel operates in an accelerated mode; when the tail of the strip steel reaches a first preset rack of the finishing rolling unit, the strip steel operates in a decelerated mode until the tail of the strip steel exits from the finishing rolling unit, and the speed of the runout table and the pinch roll is the same as the speed of the strip steel; and the tail of the strip steel exits from the finishing rolling unit, the strip steel operates at a third speed, and the runout table and the pinch roll operate at a fourth speed. By adoption of the hot-rolled thin gauge strip steel coiling method, the thin gauge strip steel coiling quality can be improved.

Owner:HEBEI IRON AND STEEL

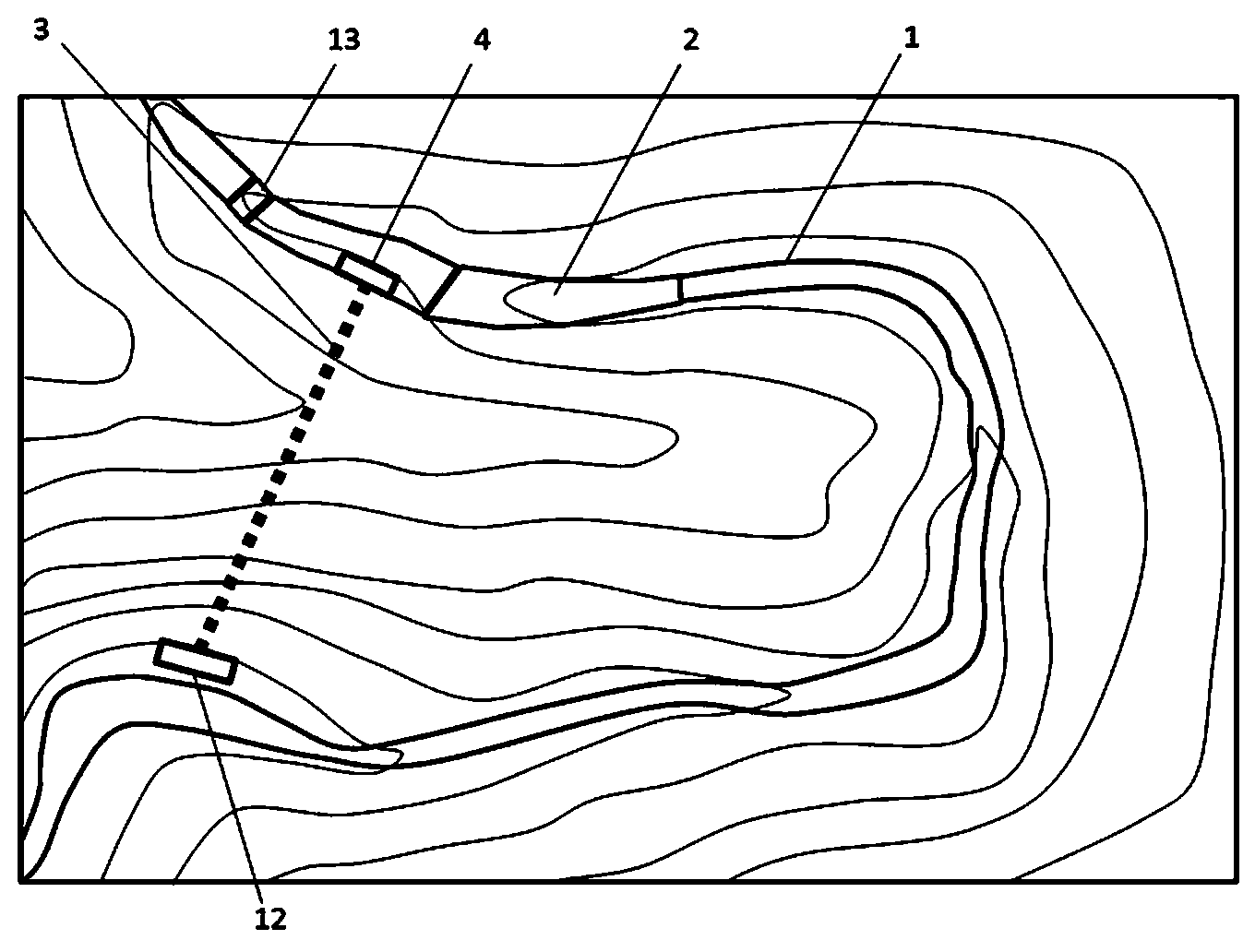

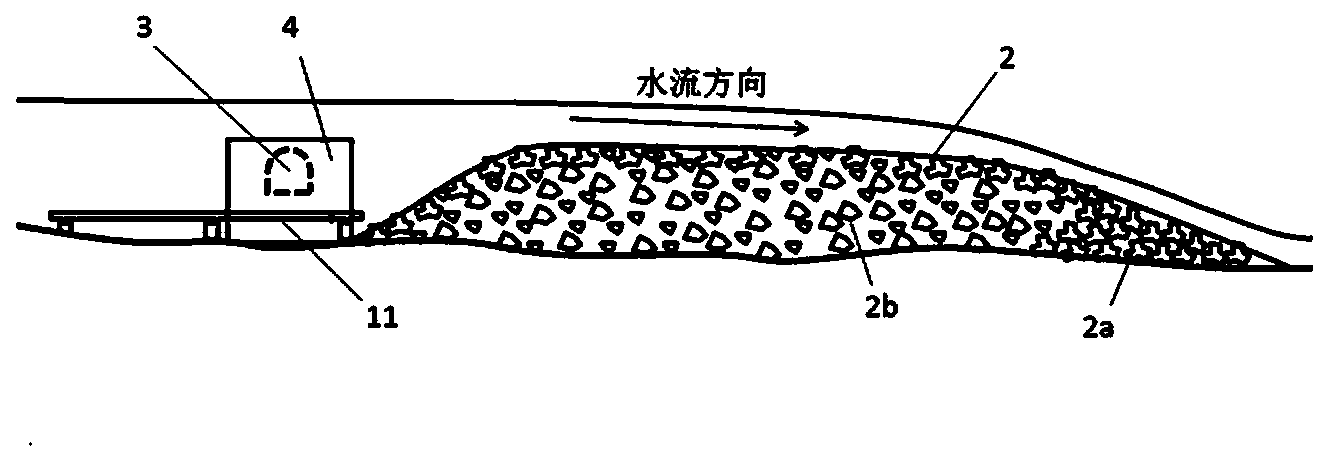

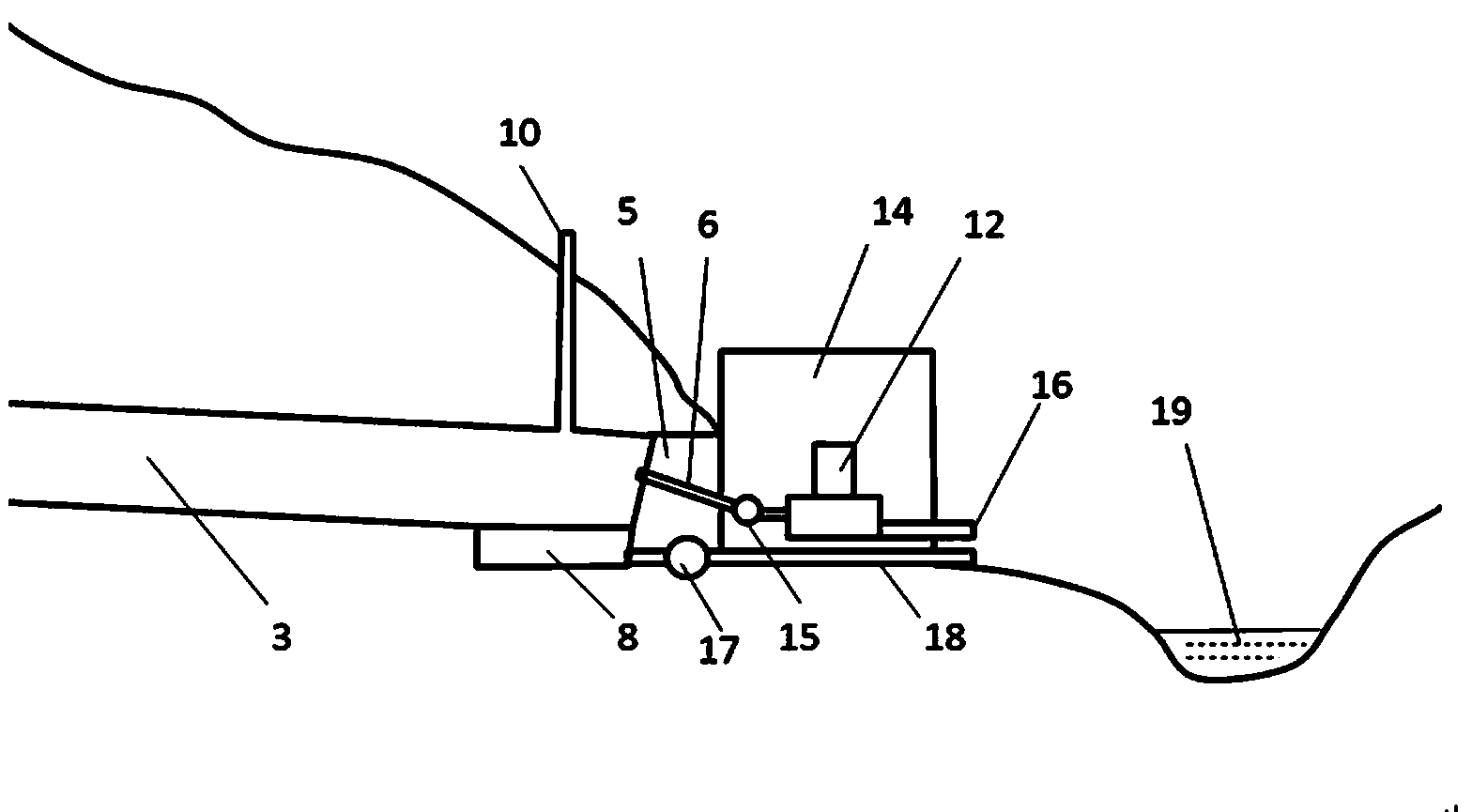

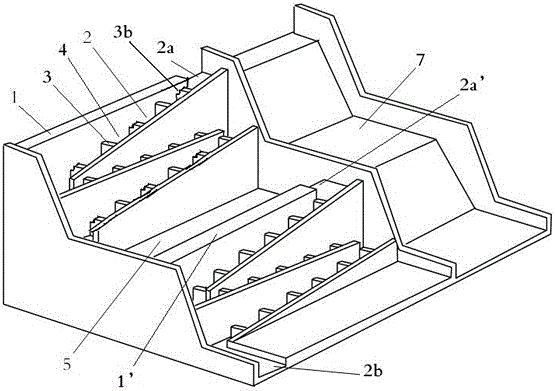

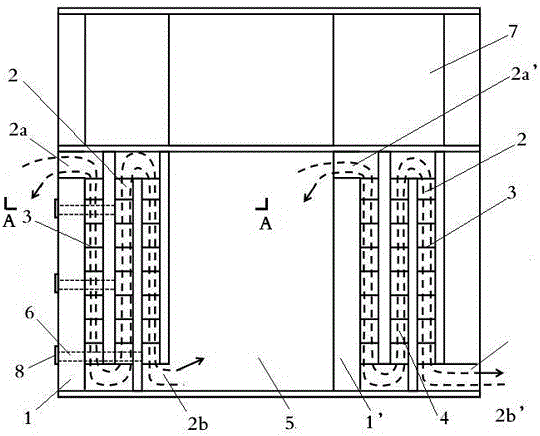

Low overflow dam cave depot type hydropower station

InactiveCN103510493AAvoid cut-offAvoid destructionWater-power plantsHydro energy generationWater turbineWater diversion

The invention relates to a low overflow dam cave depot type hydropower station. An low overflow dam is built at the upstream position of a river with an arc-shaped way; a water diversion tunnel cave depot of which the water diversion amount reaches or exceeds the annual average runoff of the river is built between the upstream position and the downstream position of the arc-shaped way of the river; the water inlet of the cave depot is positioned at the upstream position of the low overflow dam; a submerged front pool of which the top is lower than the body of the low overflow is built, or a channel of which the diameter is greater than that of the opening of the cave depot is built at the front end of the water inlet of the cave depot for water diversion from the cave depot, and a gate is built on the channel; a blocking wall body and a longitudinal water diversion pipeline are arranged at the water outlet tail end of the cave depot; the longitudinal water diversion pipeline is arranged in the blocking wall and used for connecting the cave depot with a water-turbine generator set outside the cave depot; the low overflow dam refers to that the dam body can be partially percolated by river water, part of the river water can overflow the top of the low overflow damp to flow downstreams in the high water period, and part of the river water seeps from the dam body and flows towards a dam body at the downstream position. The low overflow dam cave depot type hydropower station does not need to cut off the river, can be built on a river with a small or even very small head drop, further increases the utilization ratio of hydropower resources, and is low in construction difficulty.

Owner:贵州道轮水电科技开发有限公司

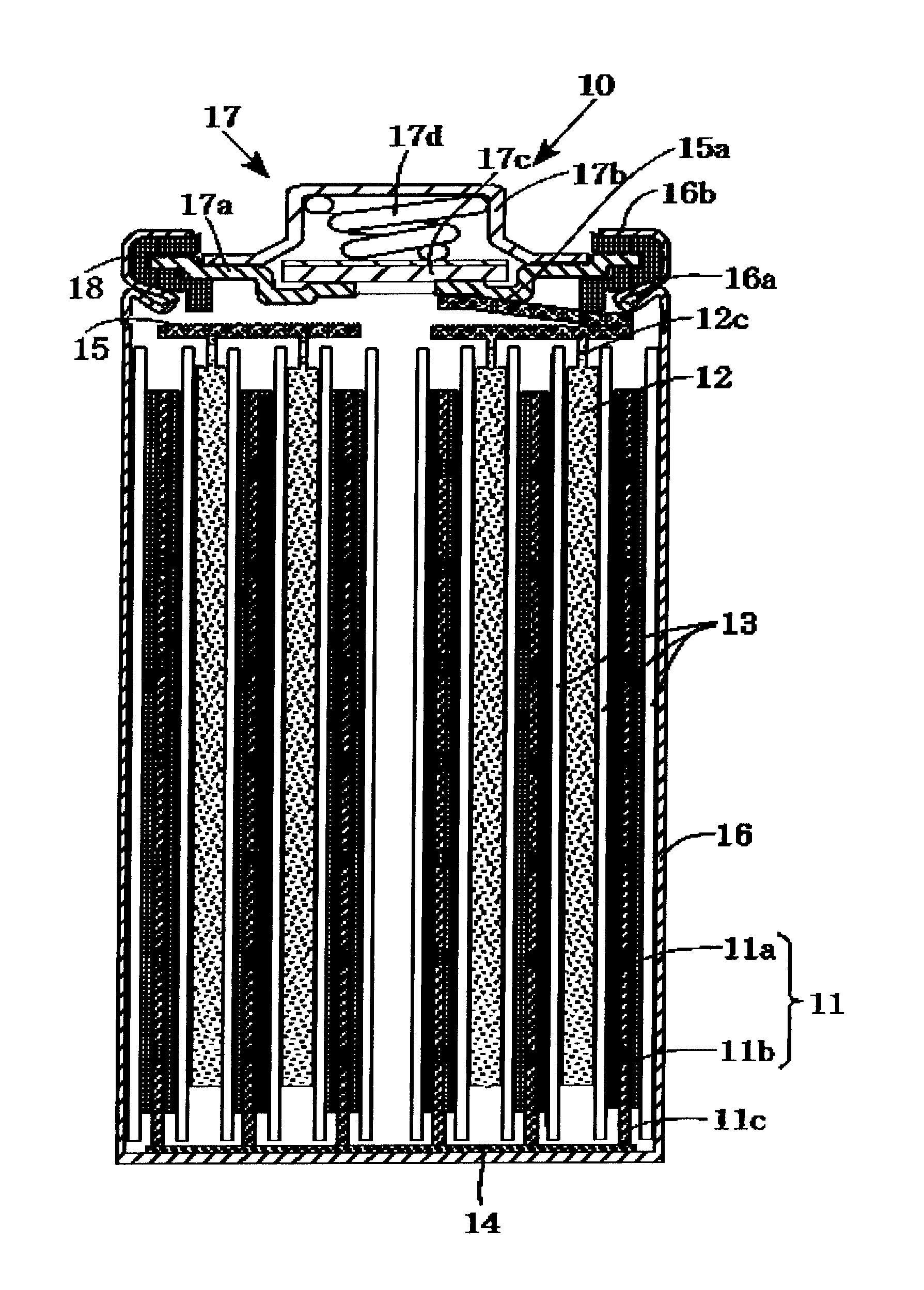

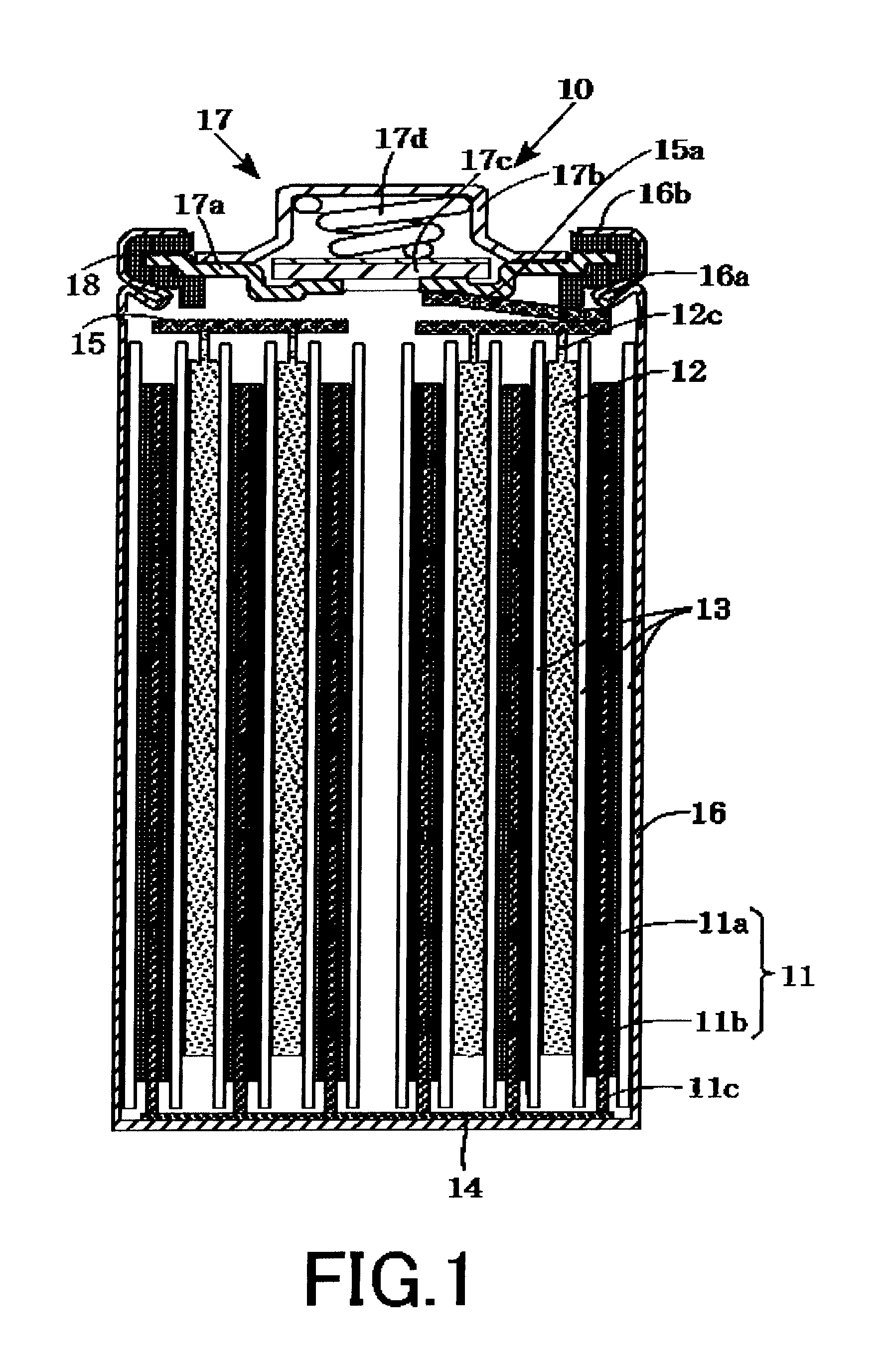

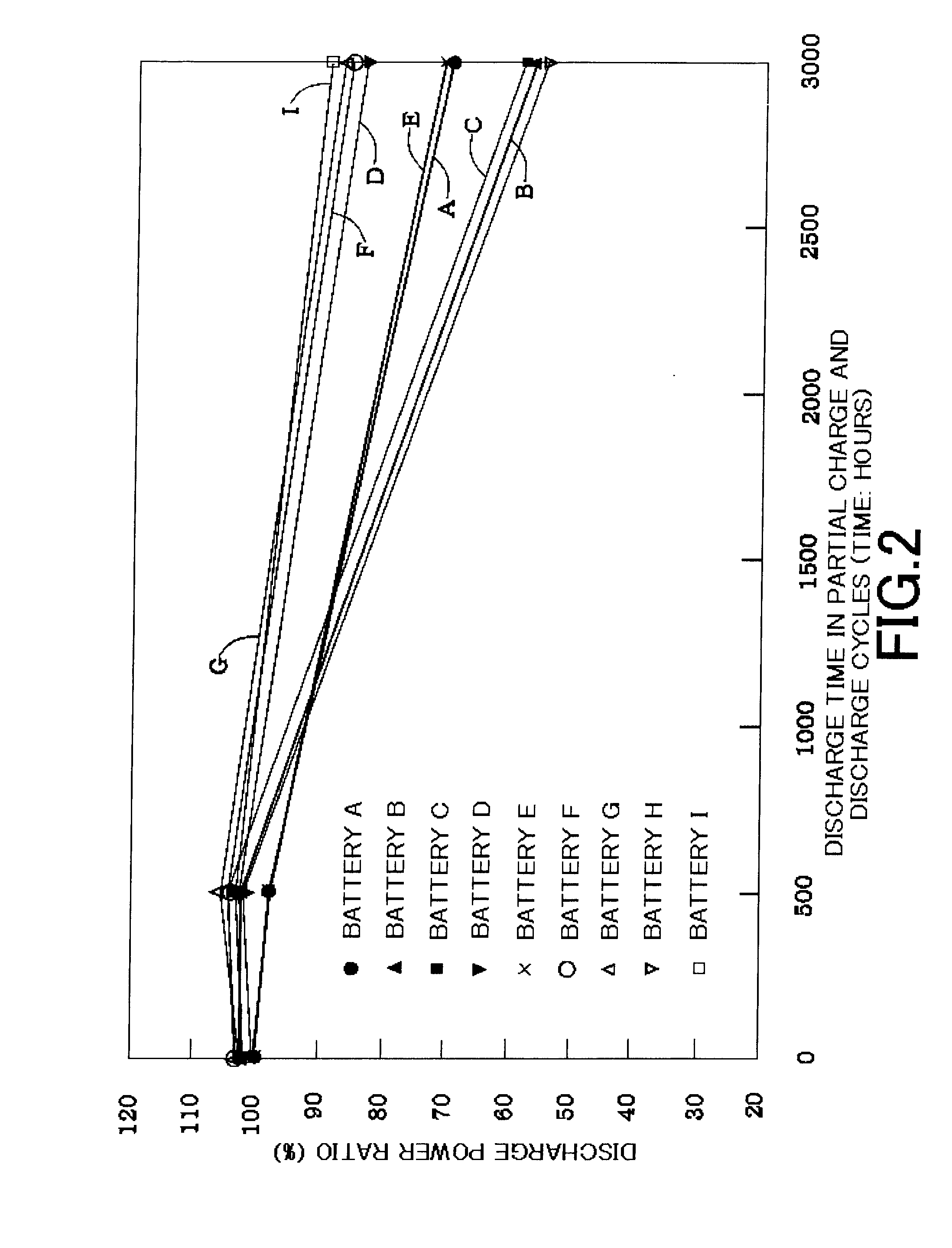

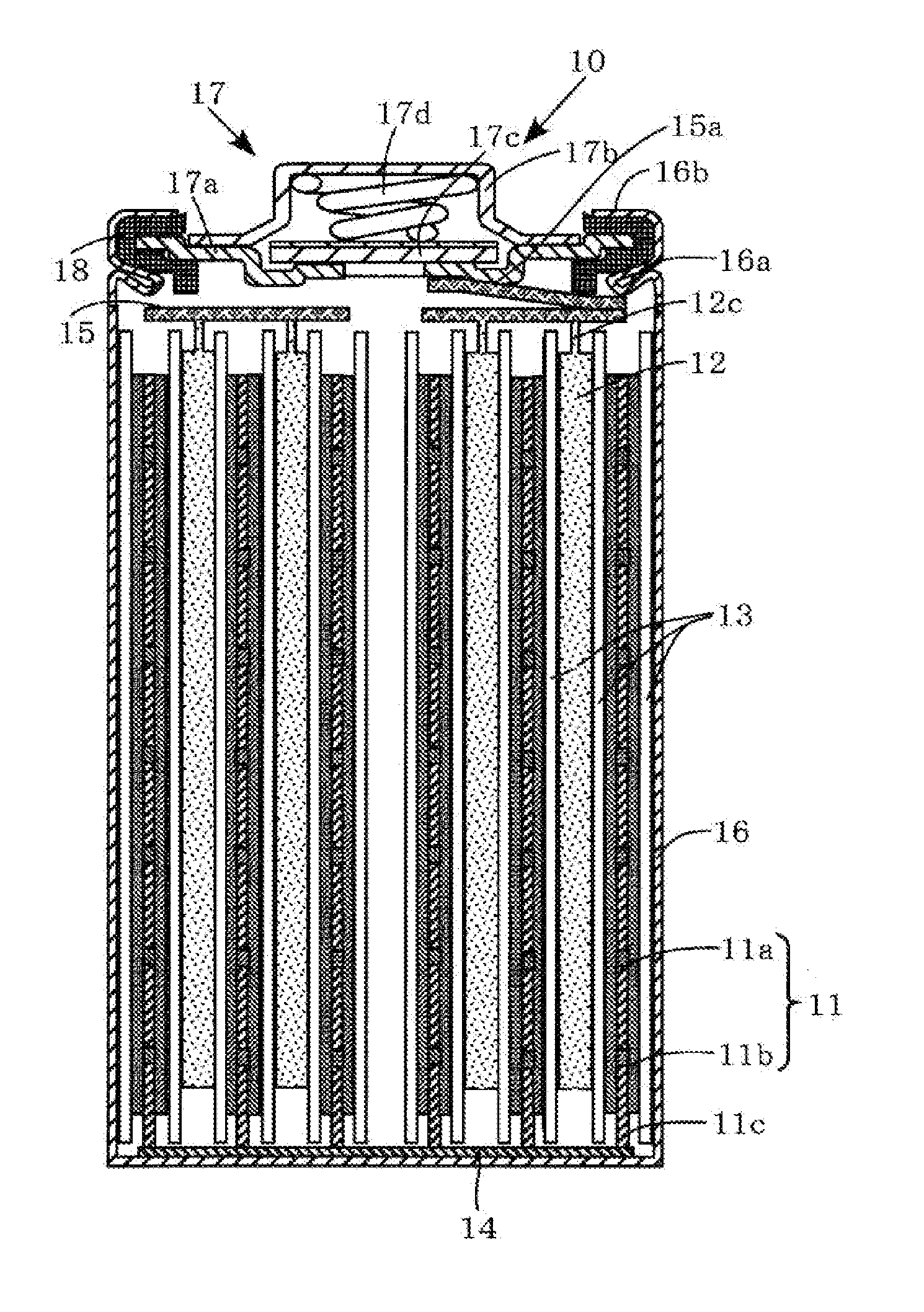

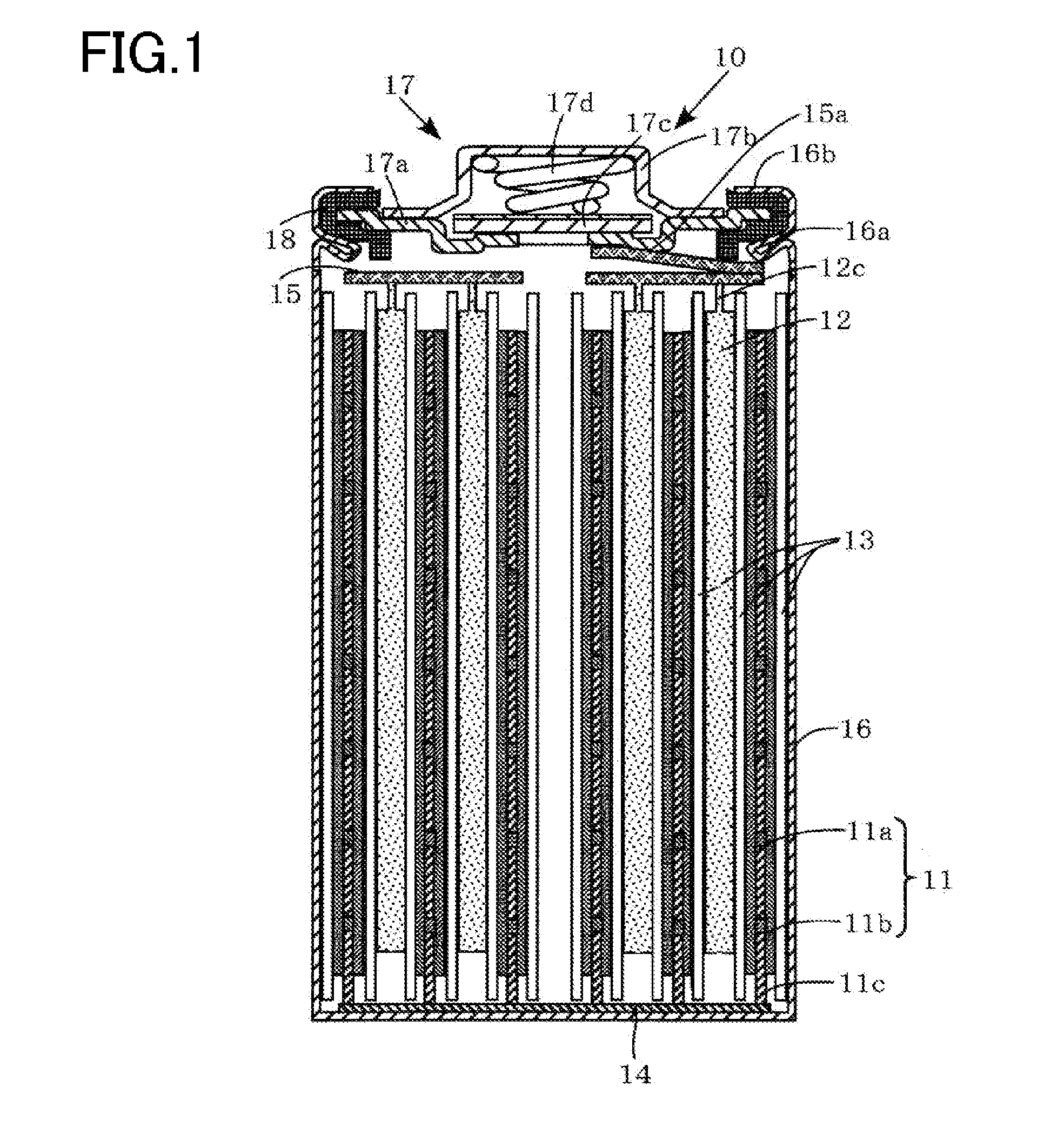

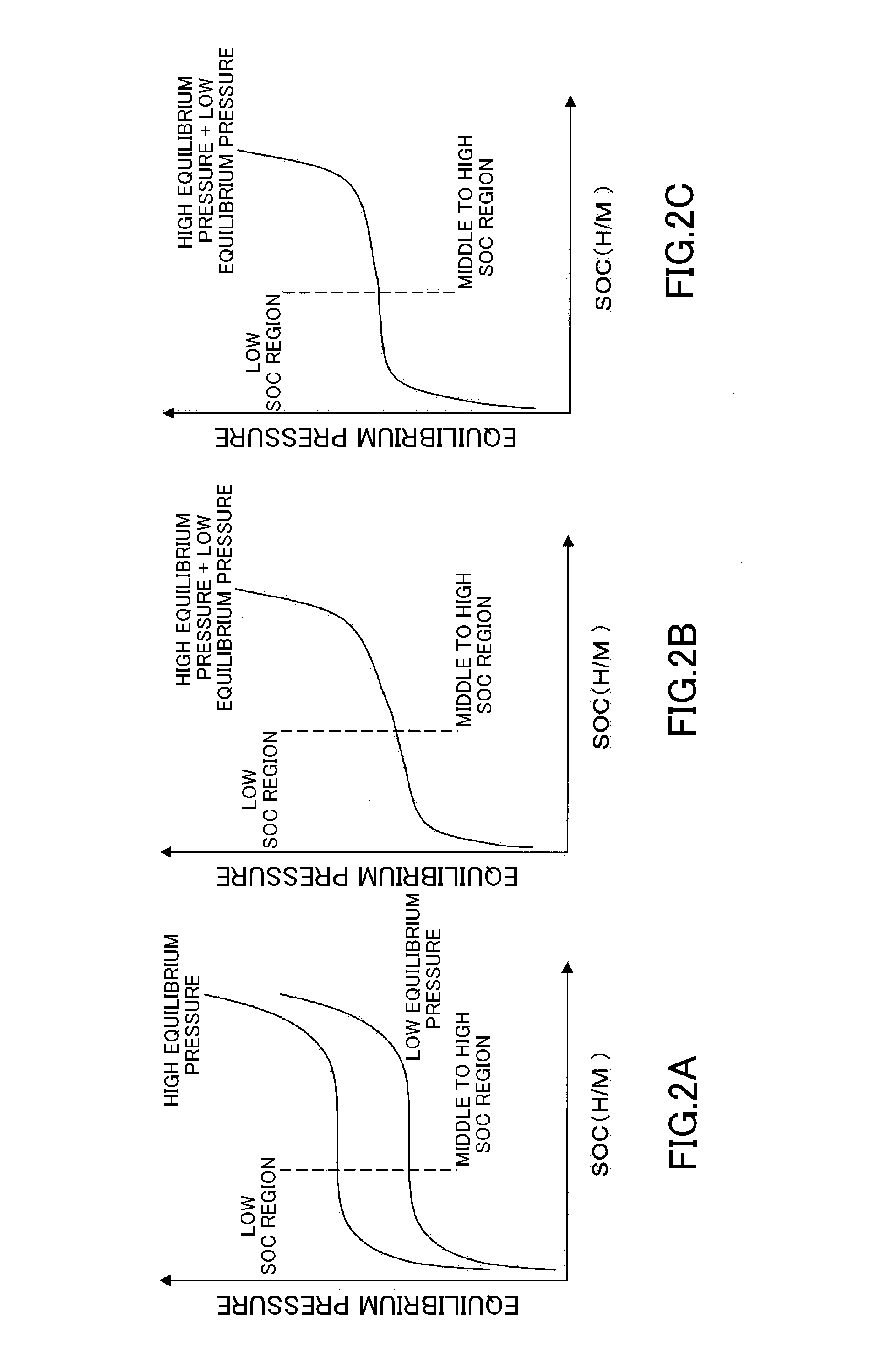

Hydrogen storage alloy for alkaline storage battery, and alkaline storage battery and alkaline storage battery system each including negative electrode having the alloy

ActiveUS20110229755A1Improve output powerIncrease output powerHydrogenMultiple metal hydridesRare-earth elementSurface layer

To provide a hydrogen storage alloy for an alkaline storage battery that improves output power by pulverization of the alloy in the initial stage of partial charge and discharge cycles and that maintains its surface condition to improve the amount of lifetime work (Wh), and an alkaline storage battery and battery system. A hydrogen storage alloy for an alkaline storage battery includes a composition expressed by LaxReyMg1-x-yNin-m-vAlmTv (Re; rare earth element(s) including Y; T: Co, Mn, Zn; 0.17≦x≦0.64, 3.5≦n≦3.8, 0.06≦m≦0.22, v≧0), and a main phase of an A5B19 type crystal structure. A ratio of X / Y of the concentration ratio X of Al to Ni in a surface layer and the concentration ratio Y of Al to Ni in a bulk layer is 0.36≦X / Y≦0.85. An alkaline storage battery includes the hydrogen storage alloy in its negative electrode. An alkaline storage battery system performs partial charge and discharge control.

Owner:SANYO ELECTRIC CO LTD

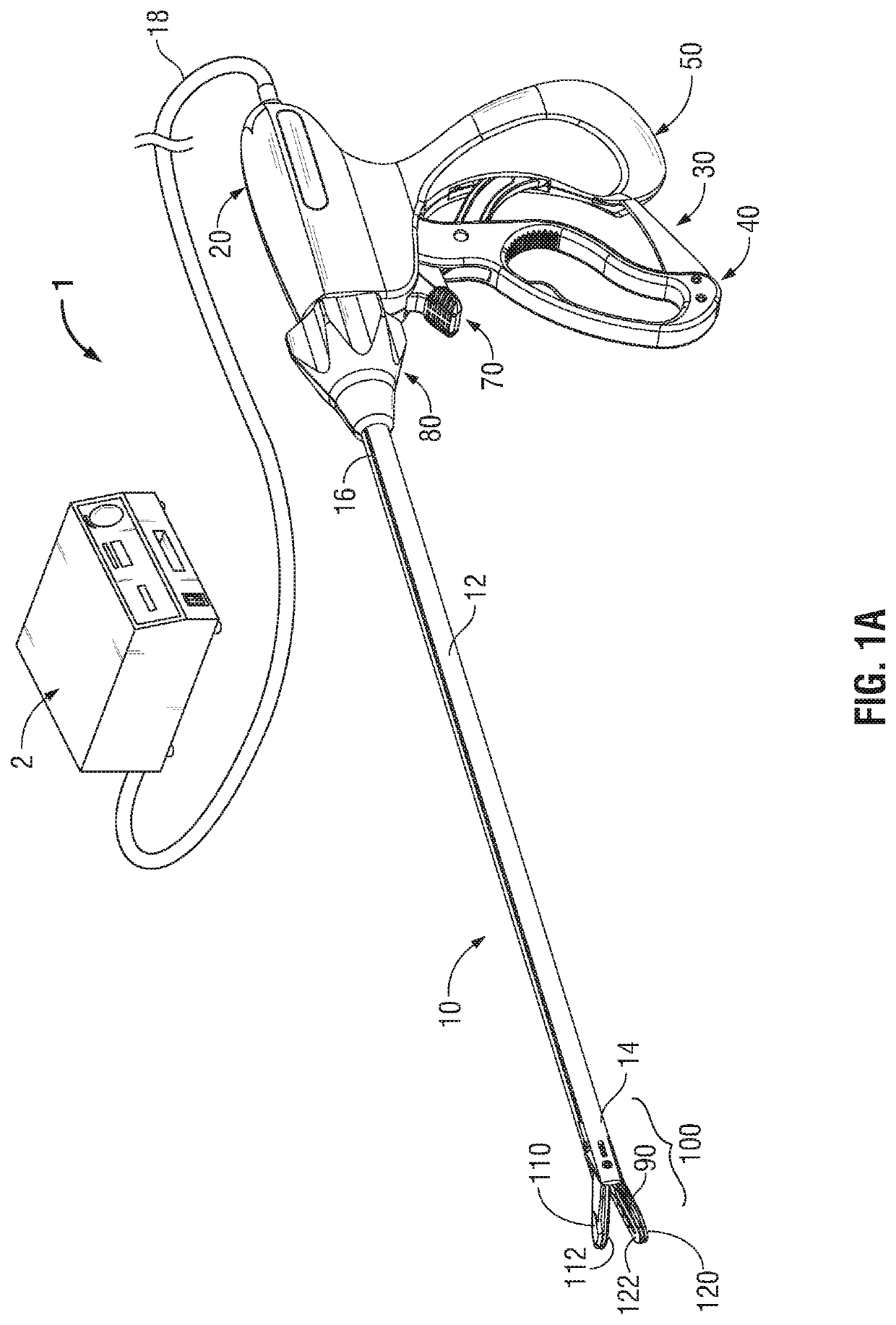

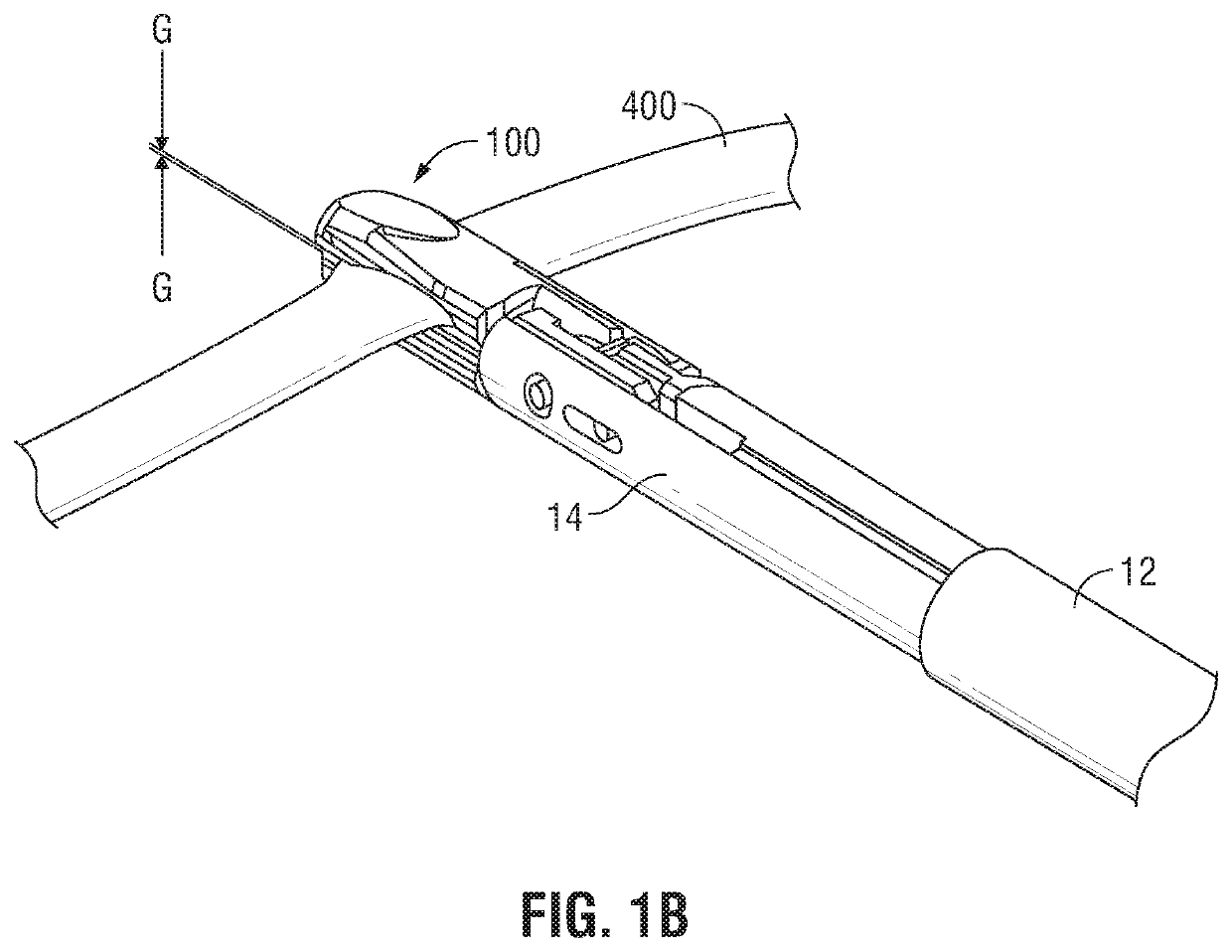

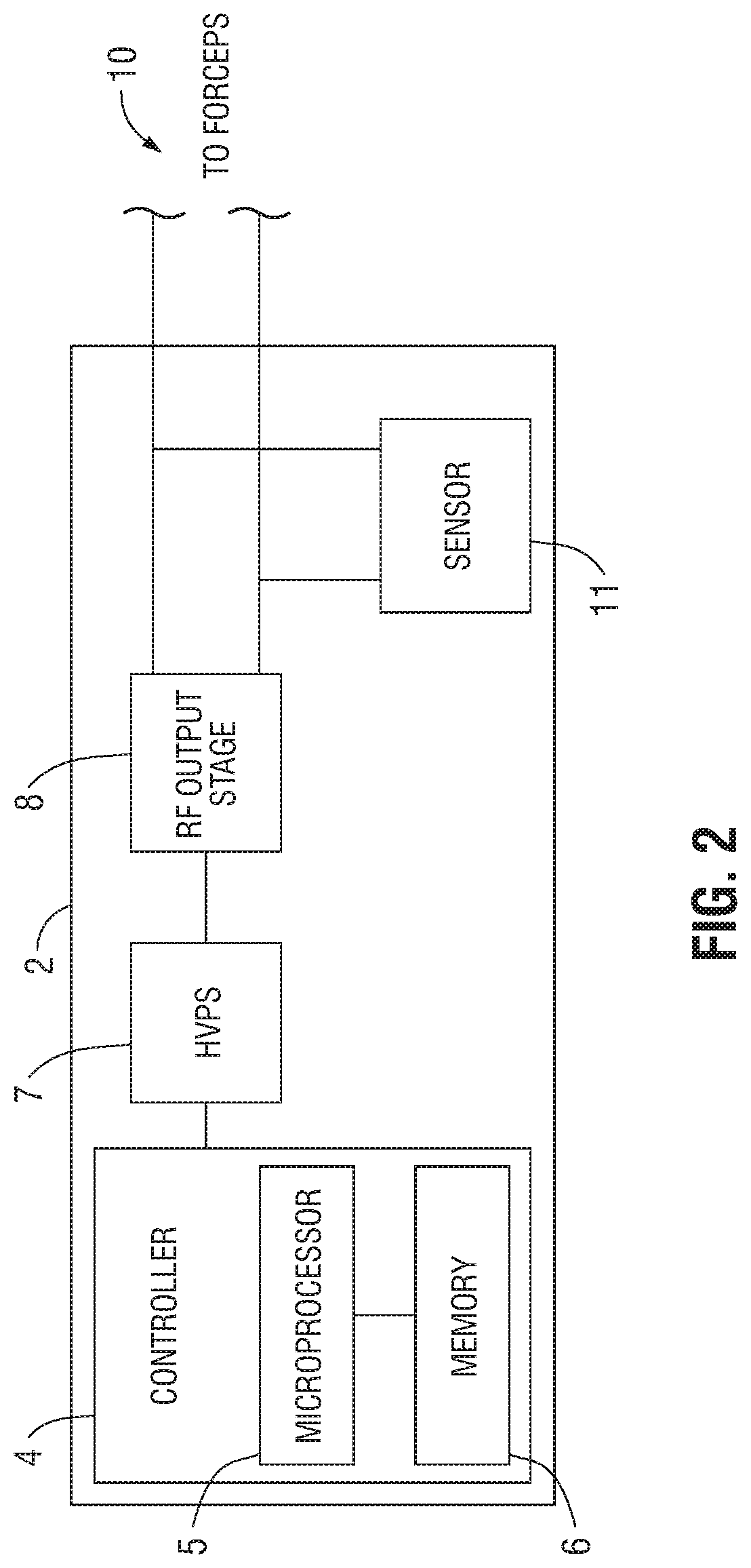

Systems and methods for controlling power in an electrosurgical generator

ActiveUS10617463B2Short durationLarge slopeSurgical instruments for heatingSurgical forcepsControl powerControl engineering

The electrosurgical systems and corresponding methods of the present disclosure involve an electrosurgical generator, sensing circuitry, and a controller. The electrosurgical generator includes a radio frequency (RF) output stage that supplies power to tissue. The sensing circuitry measures impedance of tissue. The controller controls the power supplied from the RF output stage to track a nonlinear power curve until the power supplied from the RF output stage has reached a predetermined peak power of the nonlinear power curve. The controller further determines whether a tissue reaction has occurred based on impedance measured by the sensing circuitry and controls the power supplied from the RF output stage during a cooling phase if the controller determines that a tissue reaction has occurred. The controller may further control the power supplied from the RF output stage to track a linear power curve.

Owner:TYCO HEALTHCARE GRP LP

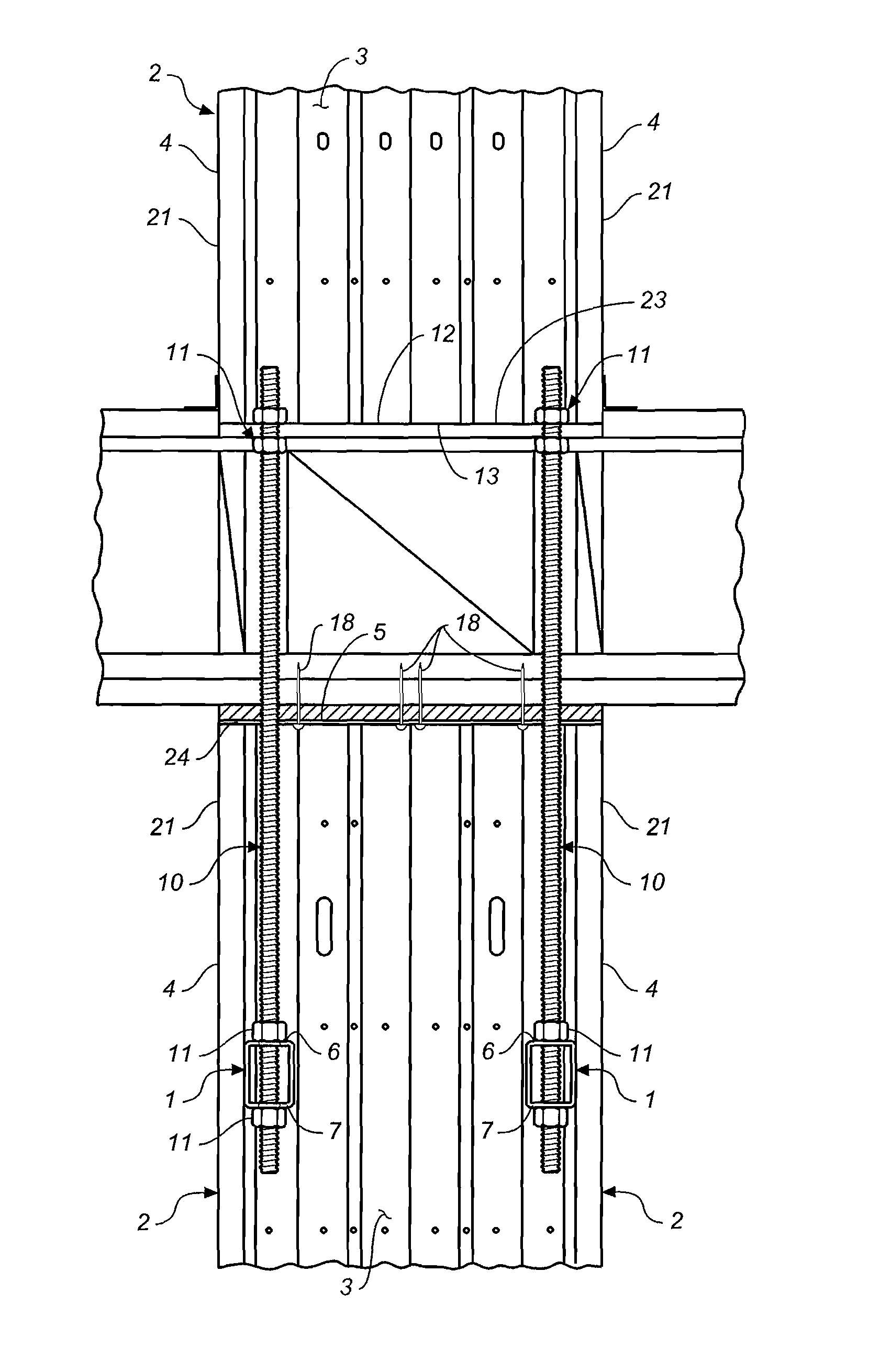

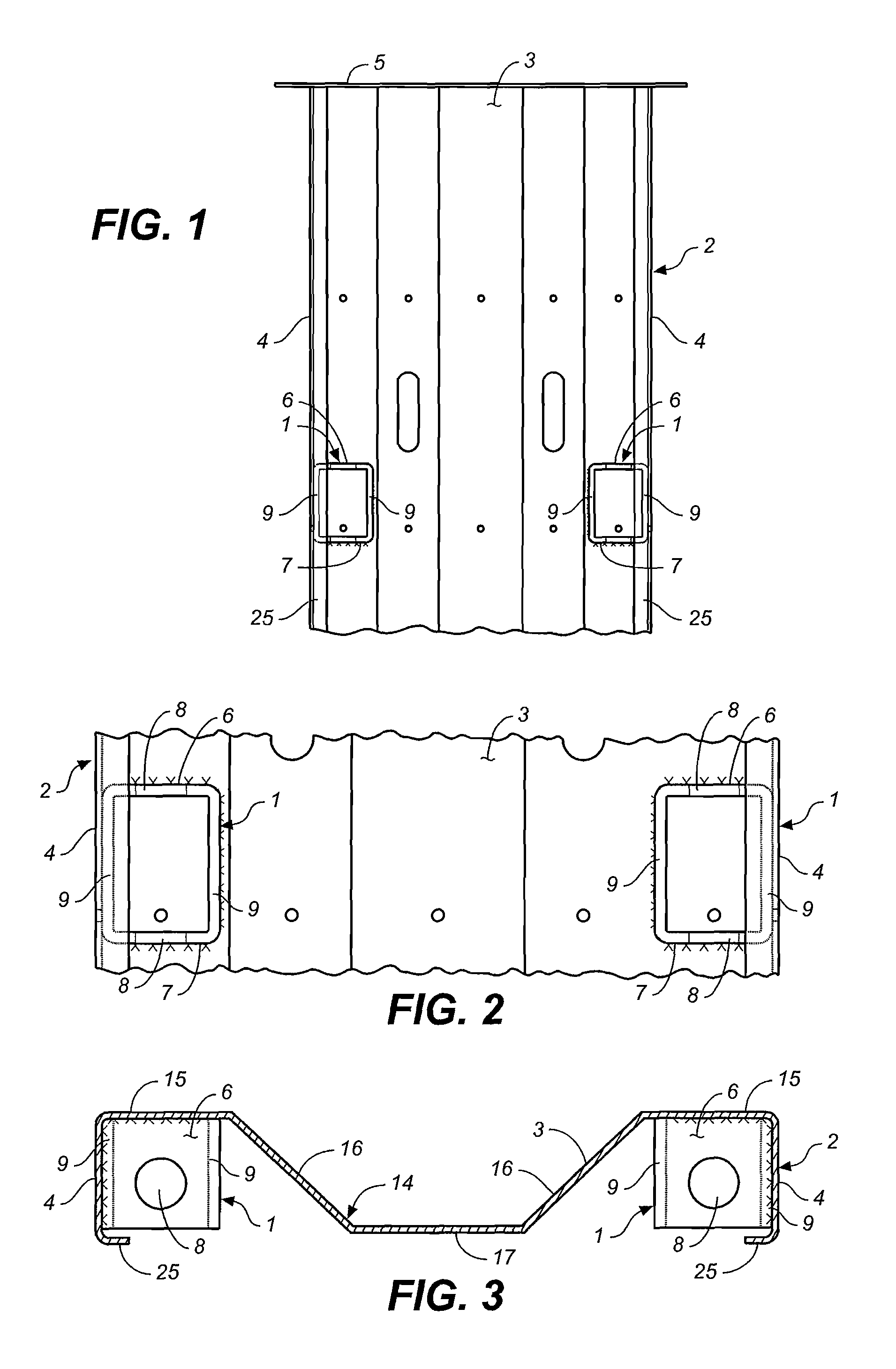

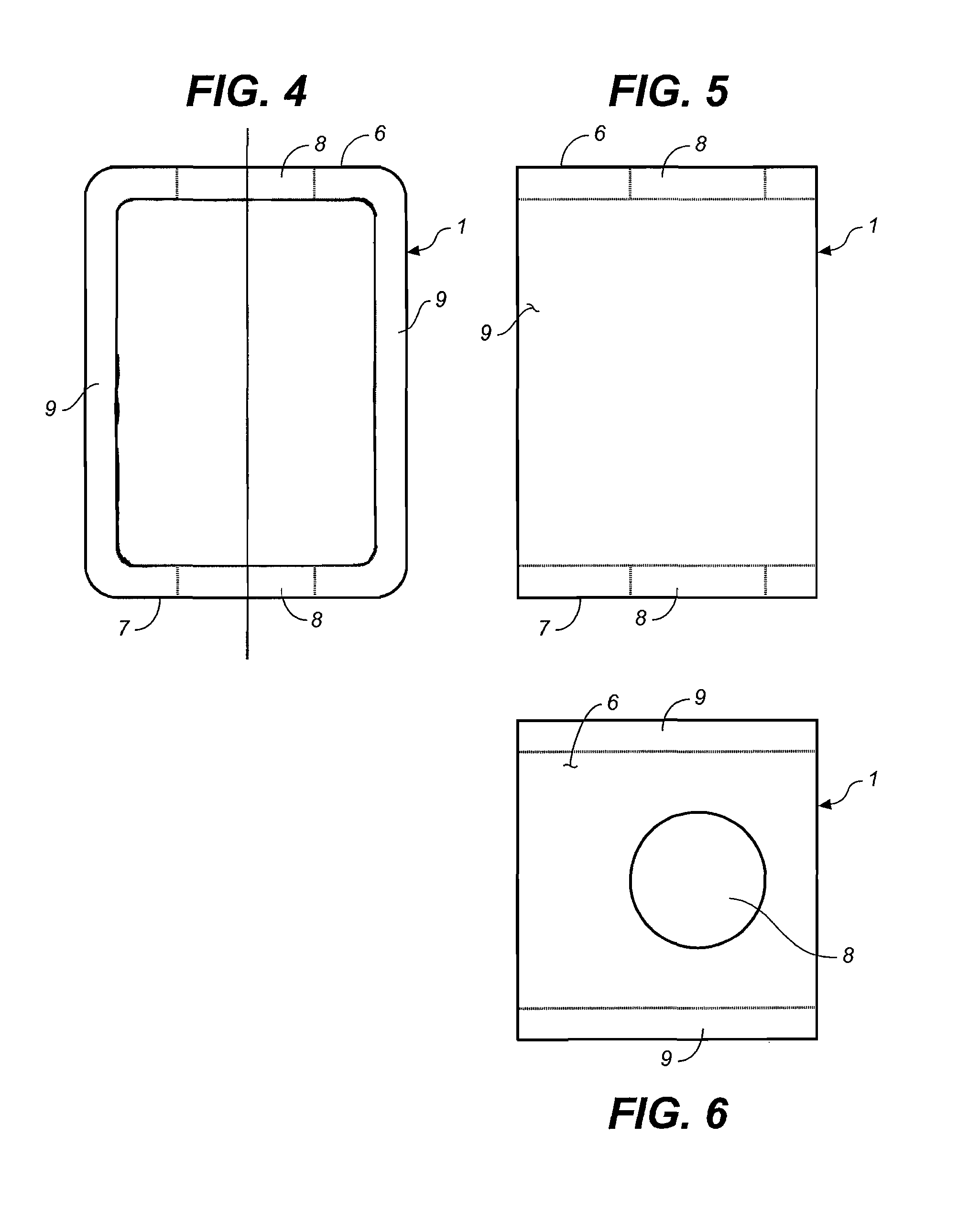

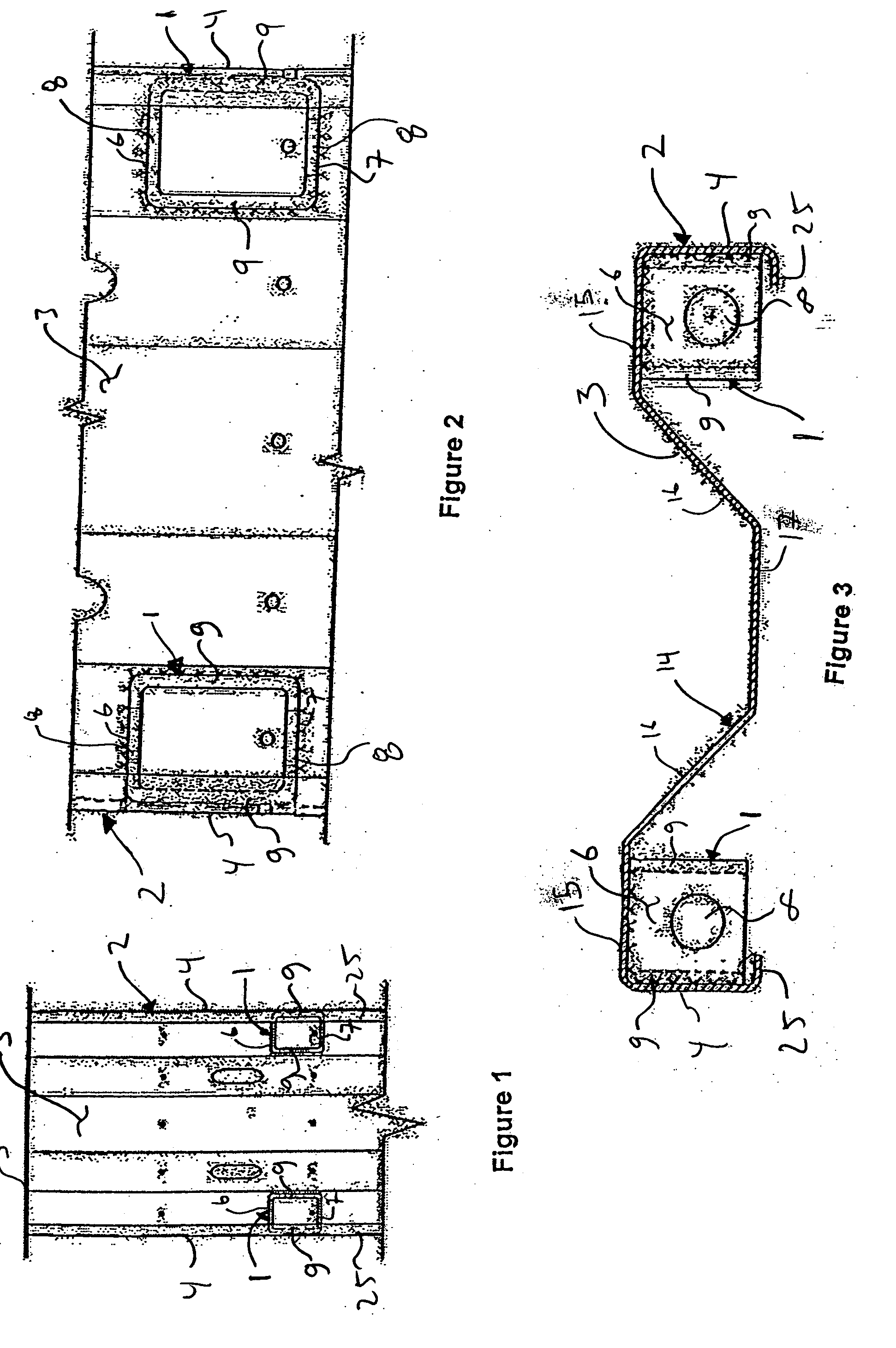

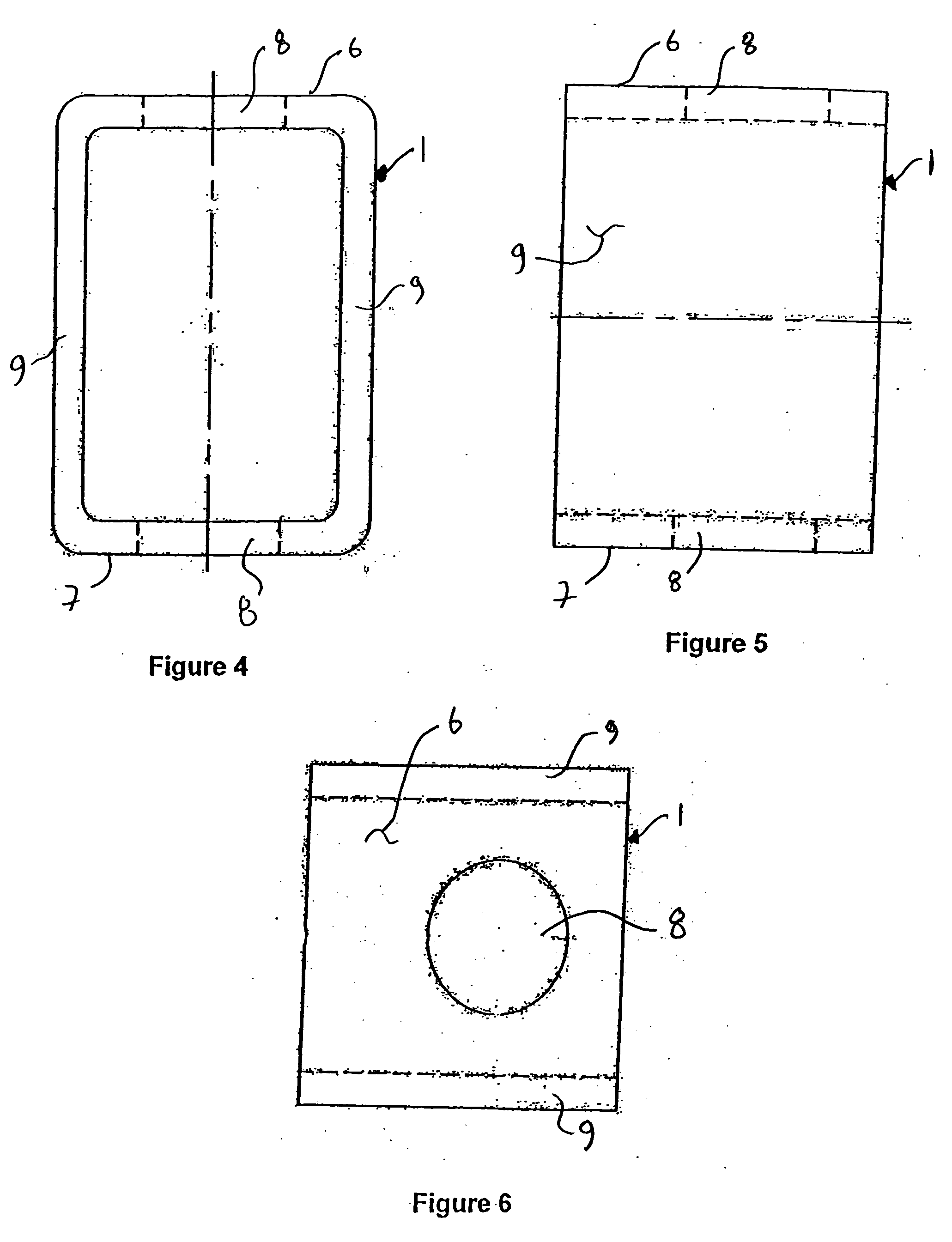

Continuity tie for prefabricated shearwalls

ActiveUS8689518B2Increases cross-sectional area and ductilityImprove the immunityBuilding roofsFoundation engineeringEngineeringMechanical engineering

A continuity tie is provided for connecting a prefabricated shearwall to a structural member above the prefabricated shearwall. In the preferred embodiment, the continuity tie is a steel tube with aligned openings for receiving a threaded rod therethrough. The tube is welded to the shearwall. A pair of tubes are preferably attached. Nuts attach the threaded rod to the tube. The threaded rod attaches to a structural member above the tube.

Owner:SIMPSON STRONG TIE

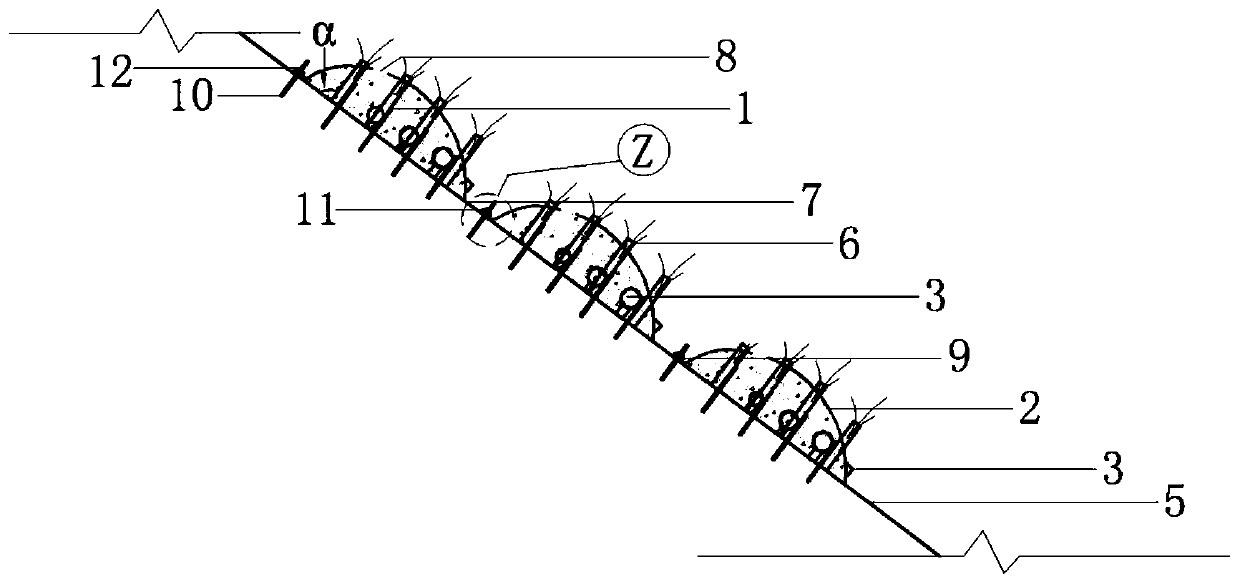

Ecological dam with fish migration channel

InactiveCN106087906AMaintain the ecological environmentIncrease the lengthBarrages/weirsClimate change adaptationAquatic animalFishery

The invention discloses an ecological dam with a fish migration channel. According to the ecological dam with the fish migration channel, a dam body (1) is a trapezoidal dam body or a triangular dam body with a cross section which is wide in bottom and narrow in top in an overall shape, and the zigzag ditch-type fish migration channel (2) which gradually ascends in a Z-shape is arranged on a backwater surface corresponding to one side of a reservoir area, of the dam body; stepped partitions (3) are arranged in the fish migration channel, and partition the fish migration channel into a string of migration pools (4) which gradually ascend, so as to form the stepped fish migration channel. The ecological dam with the fish migration channel, which is disclosed by the invention, is unlimited by terrain in construction, easy to build, and low in cost; and the firmness of the dam body can be enhanced, and fishes in a river can be smoothly migrated, thus the living environment of aquatic animals is prevented from heavy destroy.

Owner:罗富强

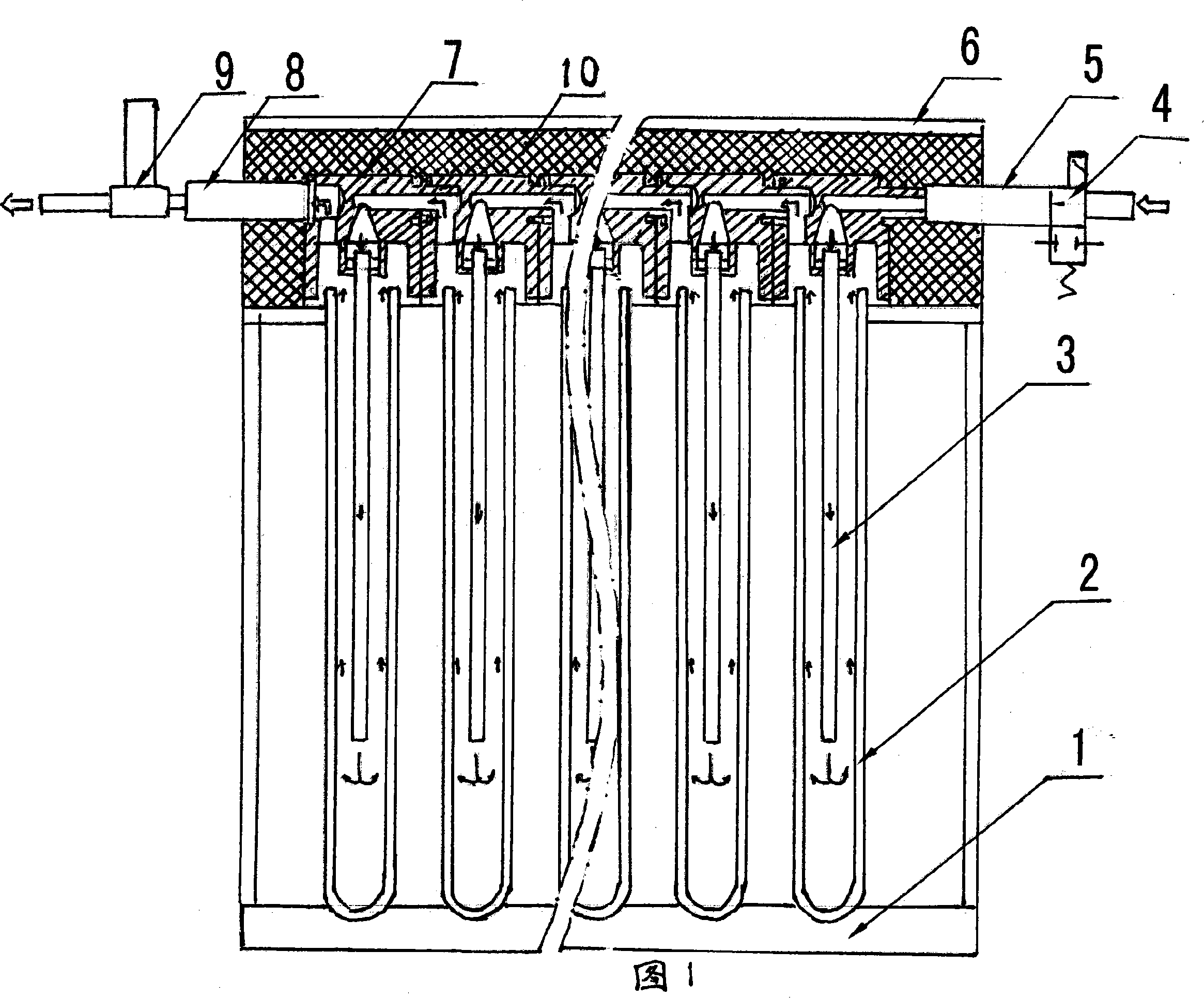

Instantaneously heated type solar water heater

InactiveCN101140109AImprove fermentation effectHeating fastSolar heat devicesSolar thermal energy generationSolar waterEngineering

The invention relates to an instantaneous solar water heater which comprises a solar heat collecting pipe and a member bracket, wherein a plurality of solar heat collecting pipes are arranged on the member bracket, the interior of an integral pipe is lined with an insulating layer, the integral pipe is provided with an SU-shaped series device, the SU-shaped series device is provided with an S-shaped channel and a U-shaped opening, the solar heat collecting pipe is inserted in the U-shaped opening of the SU-shaped series device, the solar heat collecting pipe is provided with an internal flow pipe, the internal flow pipe is inserted in the S-shaped channel of SU-shaped series device, the head end of the SU-shaped series device is connected with the tail end of the SU-shaped series device, the head end of the first SU-shaped series device is connected with a water inlet interface, and the tail end of the last SU-shaped series device is connected with a water outlet interface. The invention has the advantages of the rapid heating, the installation not limited by a field and the wide purpose.

Owner:赵日启

Ecological renovating technical method for suburban hardened revetments

ActiveCN103190273ADehardeningPromote root growthHorticultureEnvironmental resource managementRoot growth

The invention relates to a method for ecological renovation of suburban hardened revetments. The method includes: removing a hardened structure of a suburban revetment and eliminating the gradient to facilitate rooting and growing of plants and water and soil conservation; laying ecological soil and fixing the soil by a preserving trough to prevent collapse and water and soil loss of the revetment; and arranging reasonable plants to beautify the revetment and purify water. The suburban hardened revetment is ecologically renovated by taking measures like de-hardening, gradient elimination, ecological soil laying and fixing, beautifying and purifying plant arranging and the like to the revetment. On the basis of combining existing ecological restoration and reconstruction of the hardened revetment, aiming at characteristics of the suburban hardened revetment, water and soil linking is realized by removing the hardened structure, and gradient elimination of the revetment provides a condition for plant rooting and is beneficial to prevention of water and soil loss. Reasonable greening, beautifying and water-purifying plants are arranged, so that ecological renovation of the hardened revetment is realized.

Owner:NANJING INST OF GEOGRAPHY & LIMNOLOGY

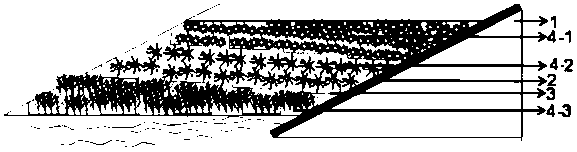

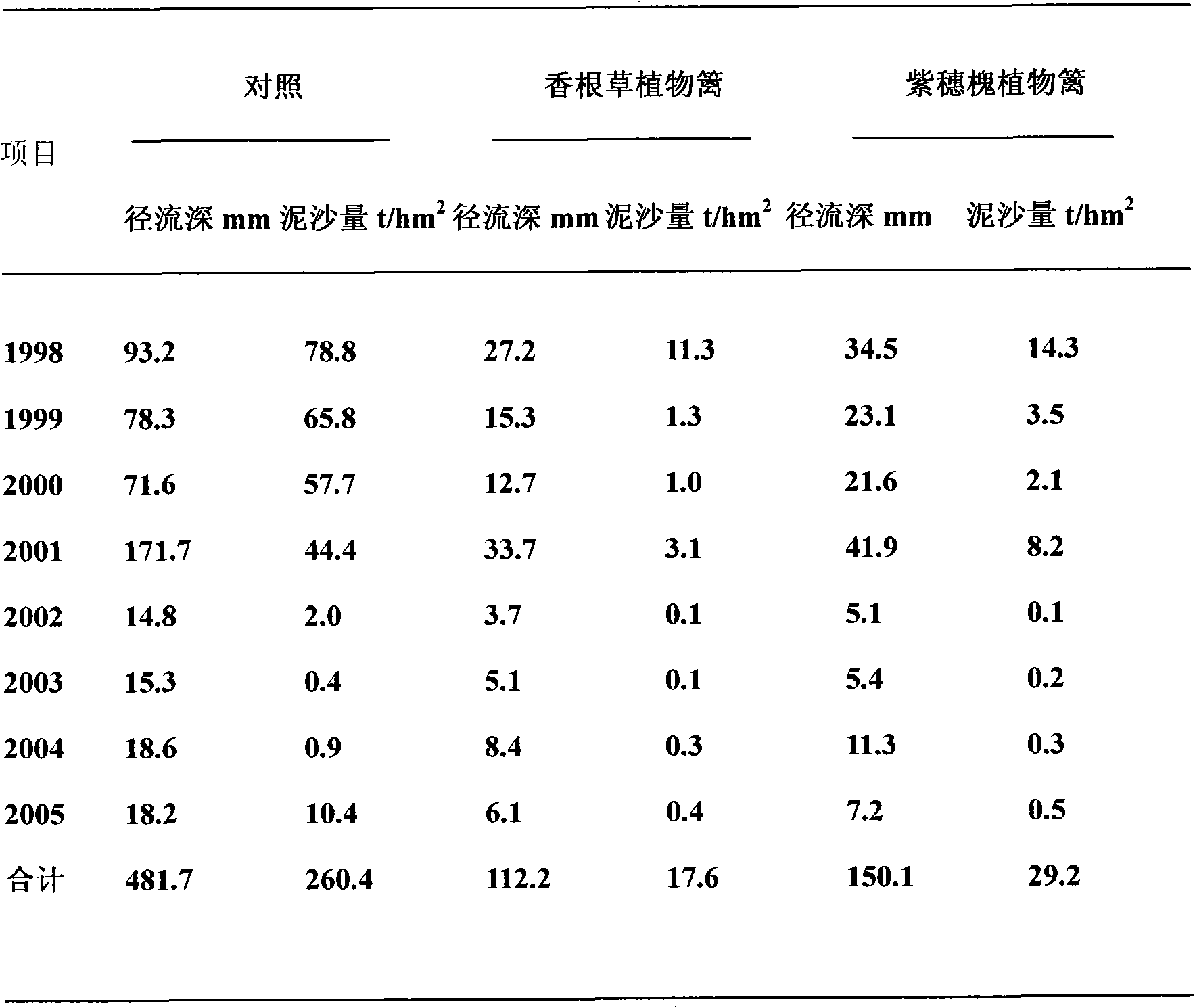

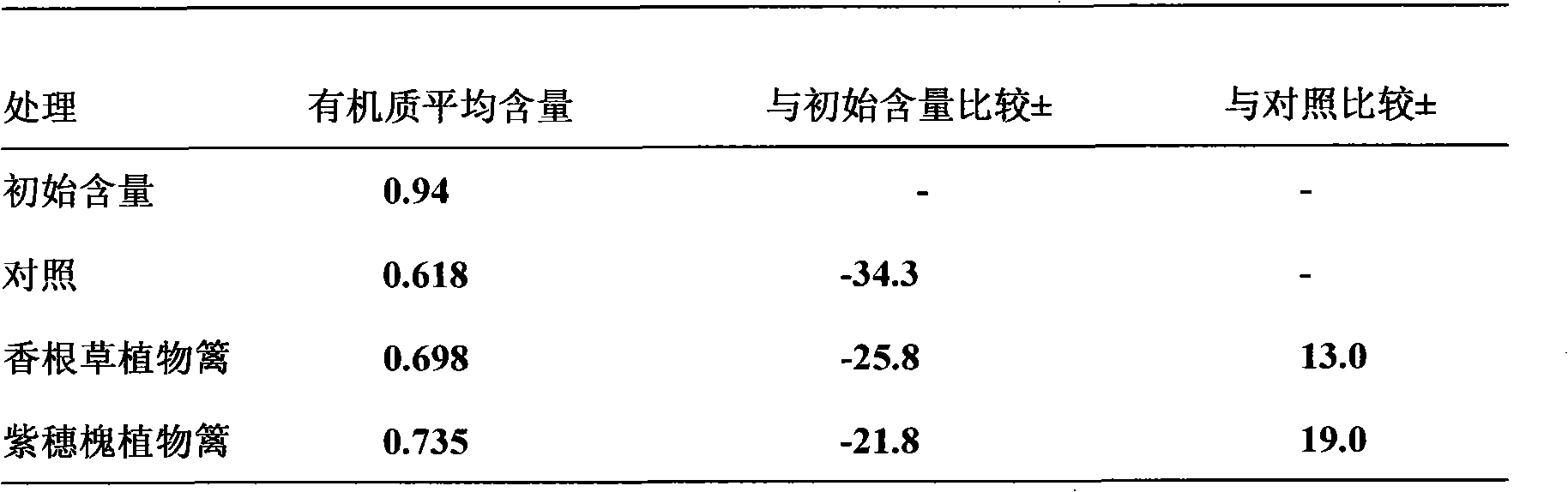

Forage hedgerow soil conservation planting technology

The invention discloses a forage hedgerow soil conservation planting technology, comprising the following steps of: tillage and land preparation, seeding and seedling, and plantation. The technology has the following advantages that: the forage hedgerow can prominently reduce sediment loss amount and runoff and has good effect of fast controlling water and soil loss; the forage hedgerow promotes value-cost ratio of energy of the entire system and becomes an effective measure to enhance the agricultural efficiency in hilly areas; bean forage hedgerow can offer excellent shelter to ground spider so as to enrich the diversity of spiders in farmland. The technology not only focuses on ecological and social benefits, but can also create economical benefit, in addition, the technology realizes sustainable agricultural development on dry hillside fields, effectually controls water and soil loss of dry hillside farmlands, enriches soil fertility, enhances grain yield and can also produce a certain amount of high-grade forage to further guarantee the supply of partial feed for the development of animal husbandry in agricultural regions.

Owner:INST OF SOIL FERTILIZER SICHUAN ACAD OF AGRI SCI

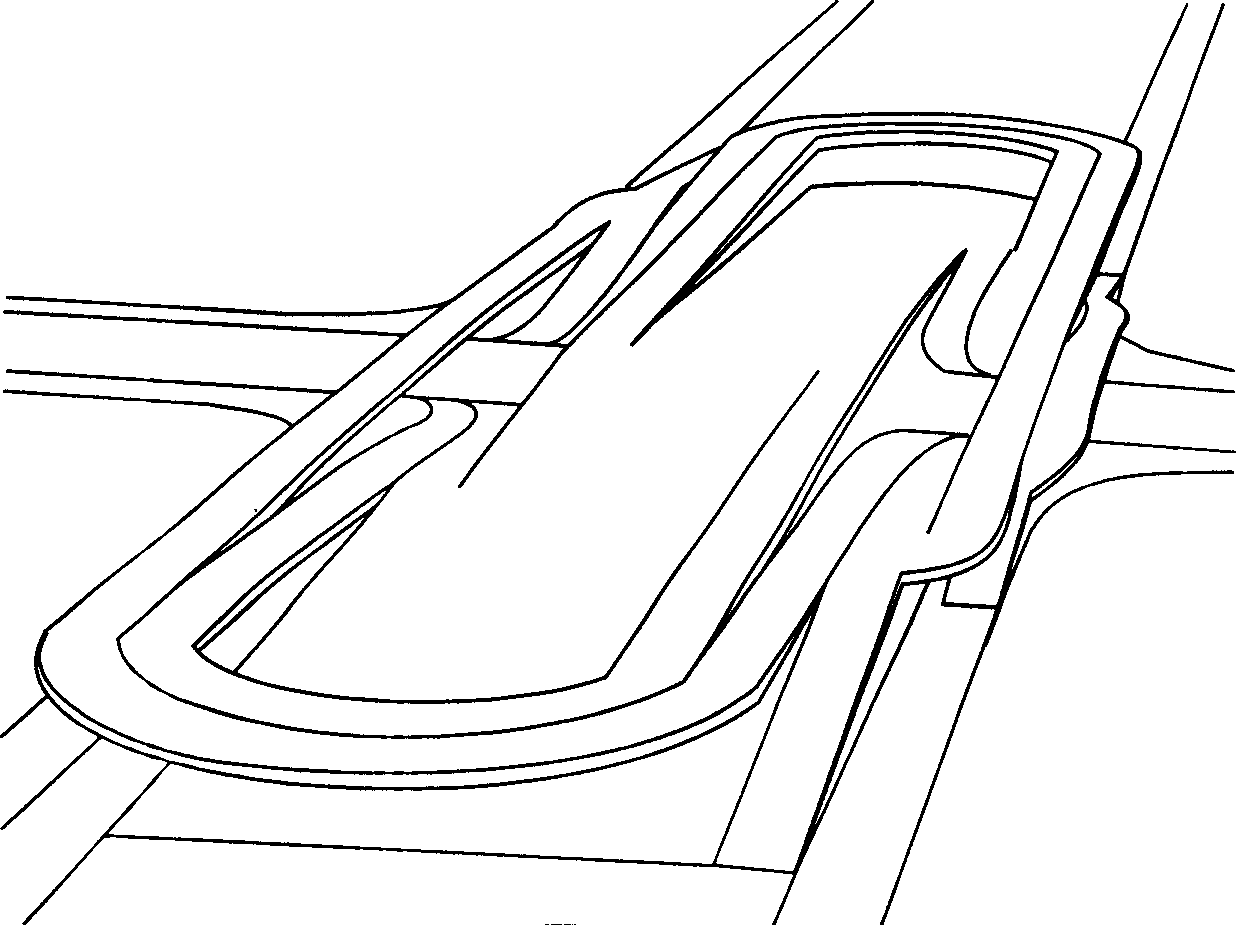

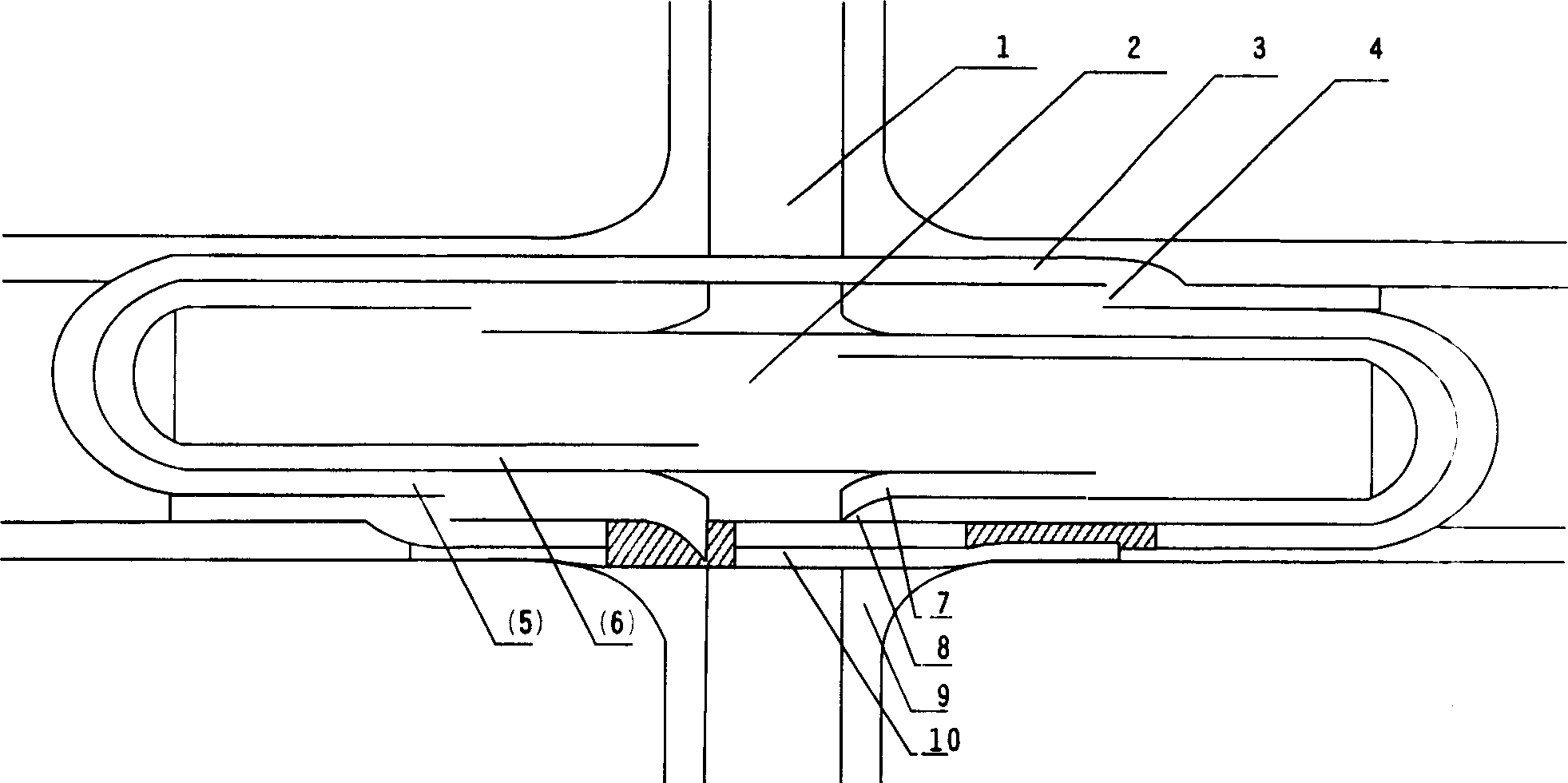

Single-line full mutual passage one layer overpass

The invention relates a fly-over bridge. It is utilized the original one load surface of the cross road as longitudinal vehicle straight-going lane, and added an arc high crossover to use as transversal straight-going passageway. Another two sets of U type ramp is formed arc high crossover to realize left and right turning. Both of them are set at its inner side to realize left turning. The inner side arc small crossover can realize right turning, and longitudinal walker cross. The transversal can be realized by pedestrian overpass. Thus the single layer road way realizes many functions, such as all sides vehicle not cross each other, machine non separation, and so on. It can solve traffic jam, increase driving speed and reduce energy consumption.

Owner:徐志力 +1

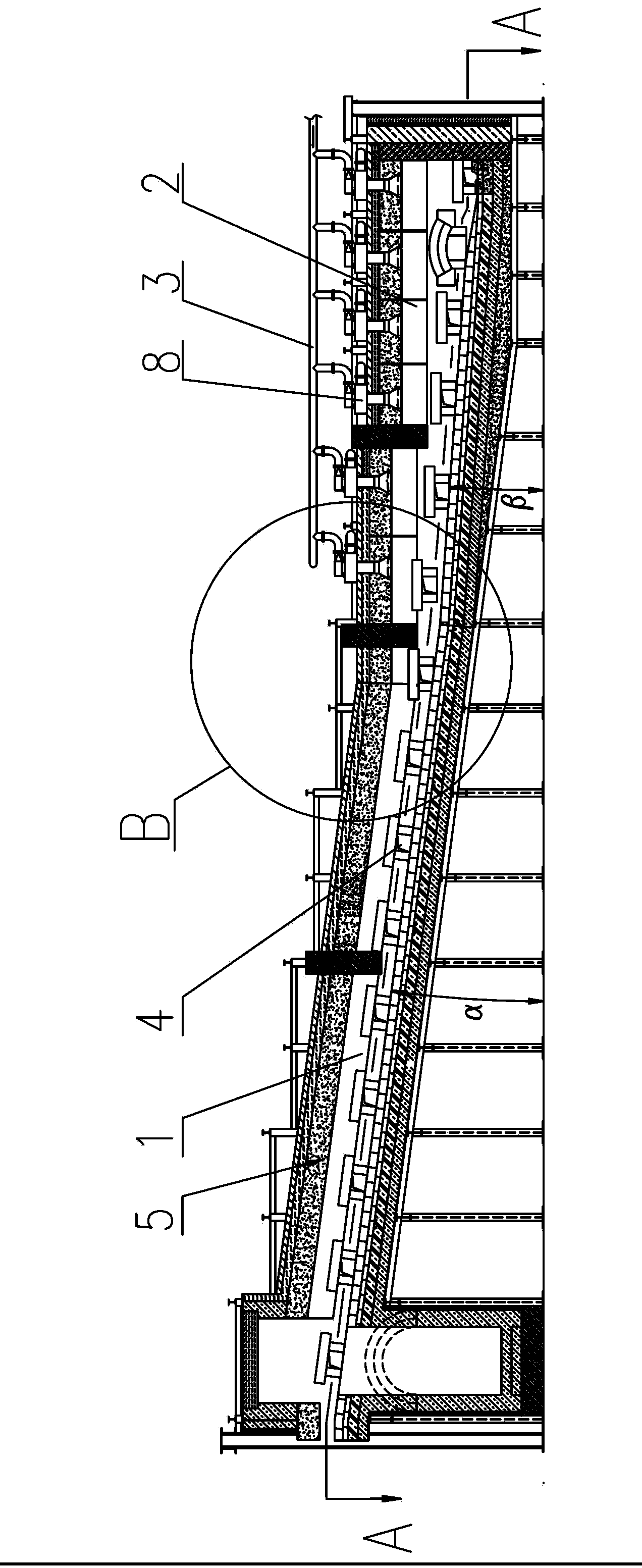

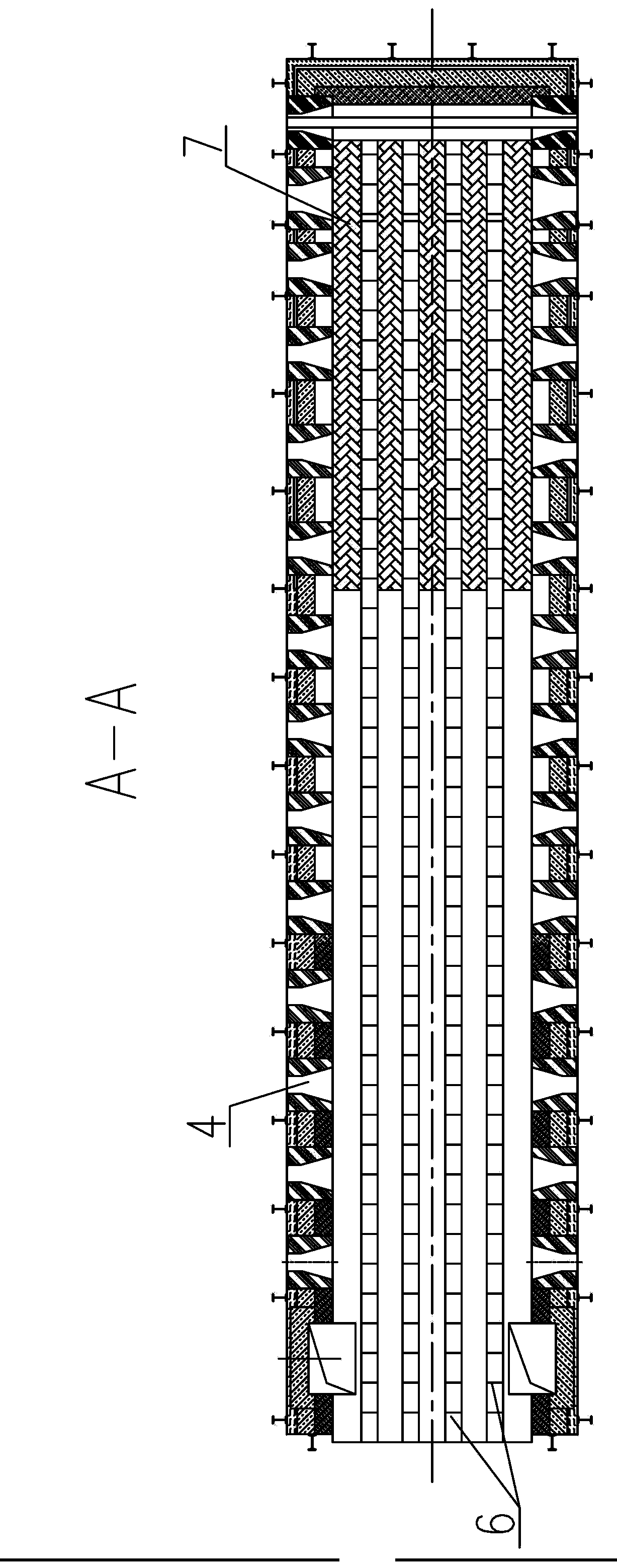

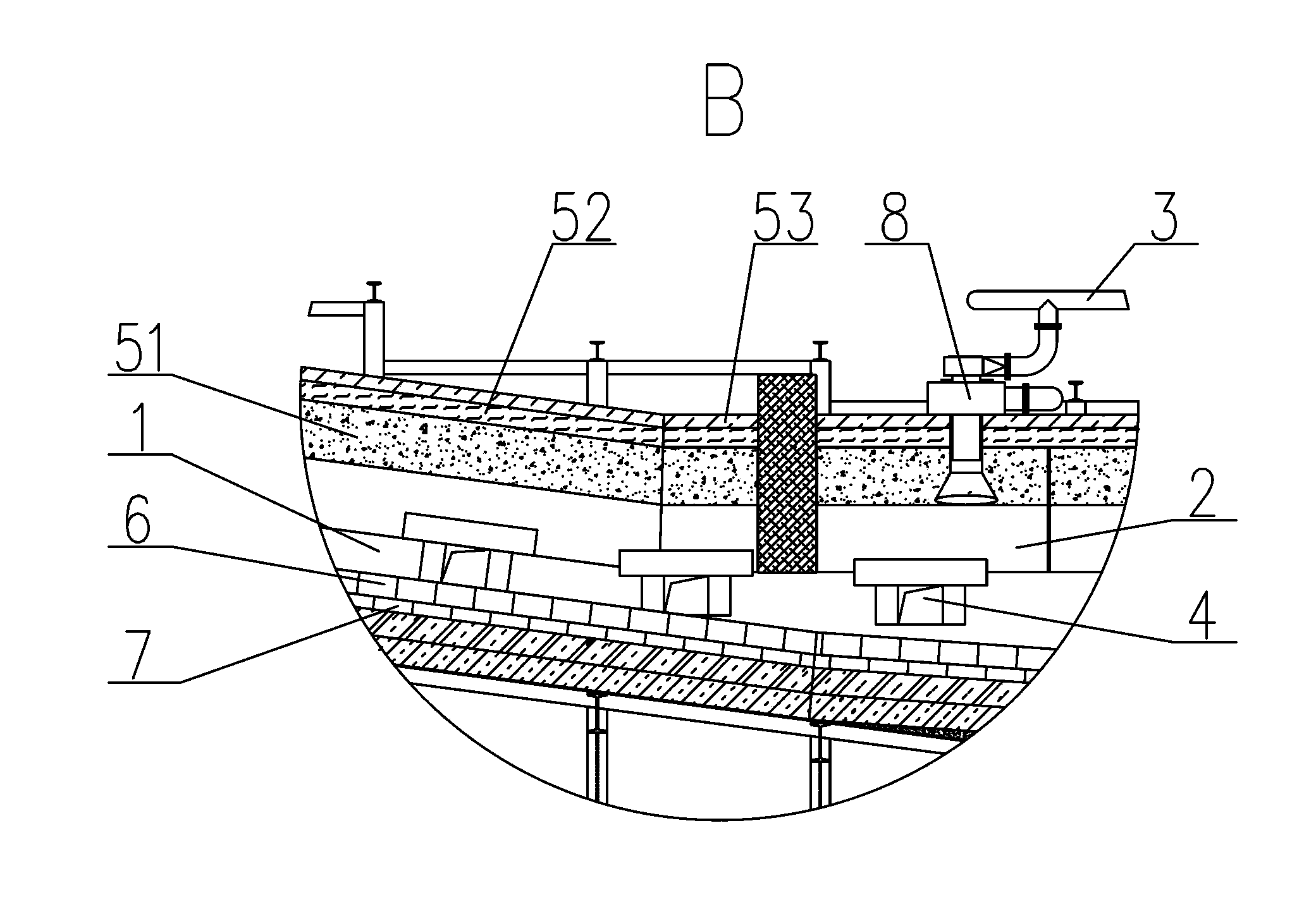

Energy-saving inclined-bottom heating furnace

InactiveCN103388072AHigh calorific valueLow priceFurnace typesHeat treatment furnacesBrickHeating time

The invention relates to an energy-saving inclined-bottom heating furnace. The furnace has a hearth. A preheating channel and a heating channel inclined downwards are sequentially arranged in the hearth from an inlet port. The heating channel communicates with a natural gas pipe used for providing fuel. The slope alpha of the preheating channel is 8 DEG, and the slope beta of the heating channel is 4-6 DEG. A plurality of trumpet-shaped material poking ports with larger ports facing inwards are arranged on both side walls of the hearth. According to the invention, the natural gas pipe is adopted, and a fuel generation device is not needed, such that cost is low; natural gas has high cost performance; hearth slope is small, such that heating time is long, and energy-saving and consumption-reducing effects are provided; with the material poking ports, energy can be saved, consumption can be reduced, and operation condition can be improved; heat loss at furnace top can be reduced, and service life can be prolonged; with a slide rail and a surface brick layer, furnace bottom wear resistance can be enhanced, and service life can be prolonged; certain gap exists between the furnace bottom and a billet bottom, such that billet treatment effect of the hearth can be improved; and with burner nozzles connected in parallel, heating quality can be improved, management is convenient, and safety is high.

Owner:JIANGSU WUJIN STAINLESS STEEL PIPE GRP

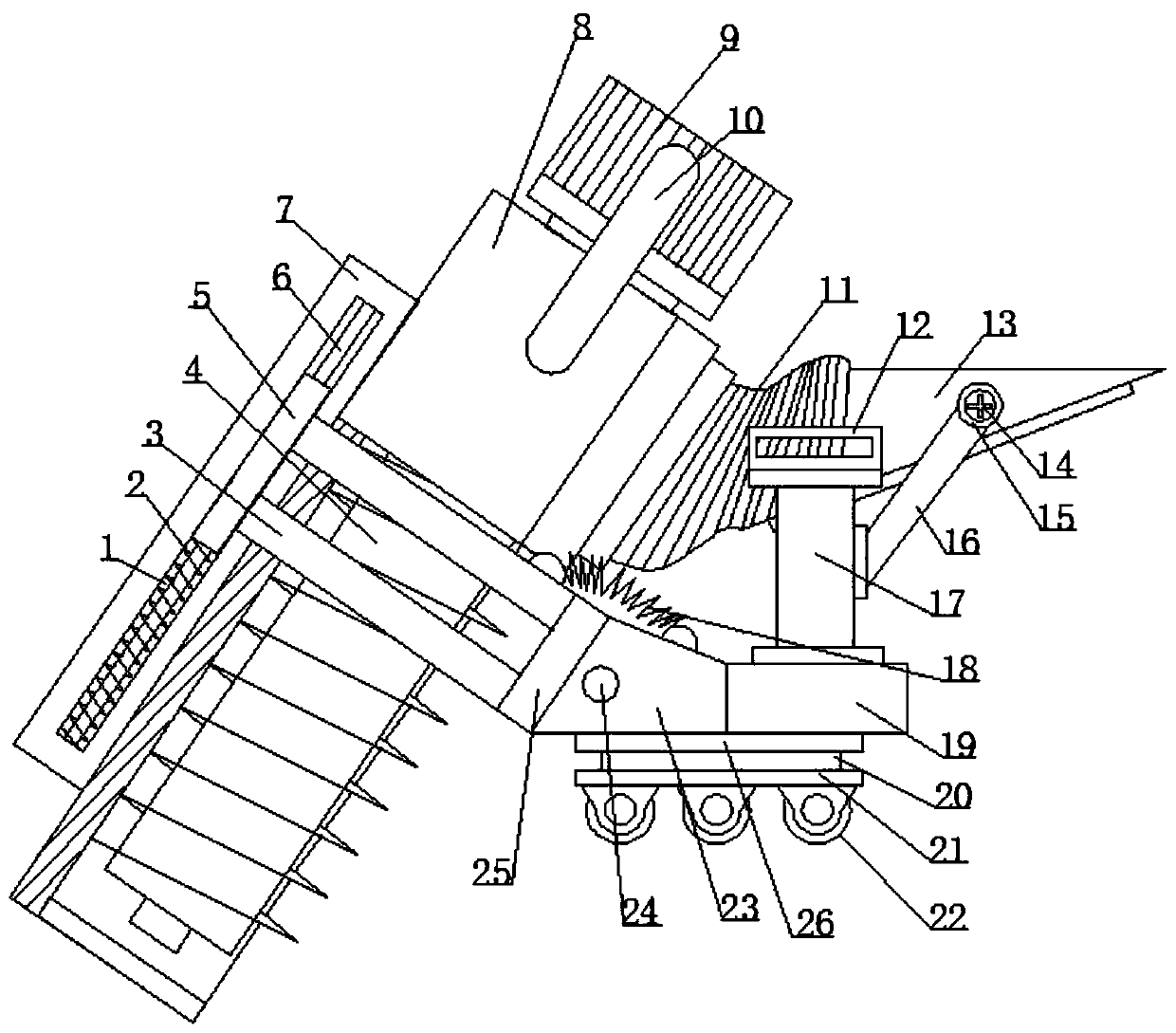

Novel rotor type concrete injection unit

PendingCN109356617AConvenient feedingFeeding opening increasedUnderground chambersTunnel liningEngineeringSmall unit

The invention discloses a novel rotor type concrete injection unit, and belongs to the field of anchoring and shotcreting support such as mine well lanes, railway (highway) tunnels and subways. The novel rotor type concrete injection unit comprises a chassis machine frame, walking wheels installed on the lower part of the chassis machine frame, a concrete injection machine body, an automatic setting accelerator adding mechanism, a dust removing device, a feeding device and a hydraulic tensioning device. Connecting bolts are installed at the left and right ends of the chassis machine frame, andthe chassis machine frame is provided with the dust removing device, a lower support rod, the feeding device, the automatic setting accelerator adding mechanism, an upper support rod, an injection machine body support frame, the hydraulic tensioning device and the concrete injection machine body from left to right in sequence. The novel rotor type concrete injection unit has the beneficial effects that the dust removal efficiency is high, tiny fine dust with the particle diameter larger than 5 microns can collected, and the dust removal efficiency can reach more than 99%; the novel rotor typeconcrete injection unit is flexible to use, can be arranged directly indoors and placed in small units near equipment; and the structure is relatively simple, the operation is relatively stable, theinitial investment is less, and the maintenance is convenient.

Owner:徐州大屯工贸实业有限公司

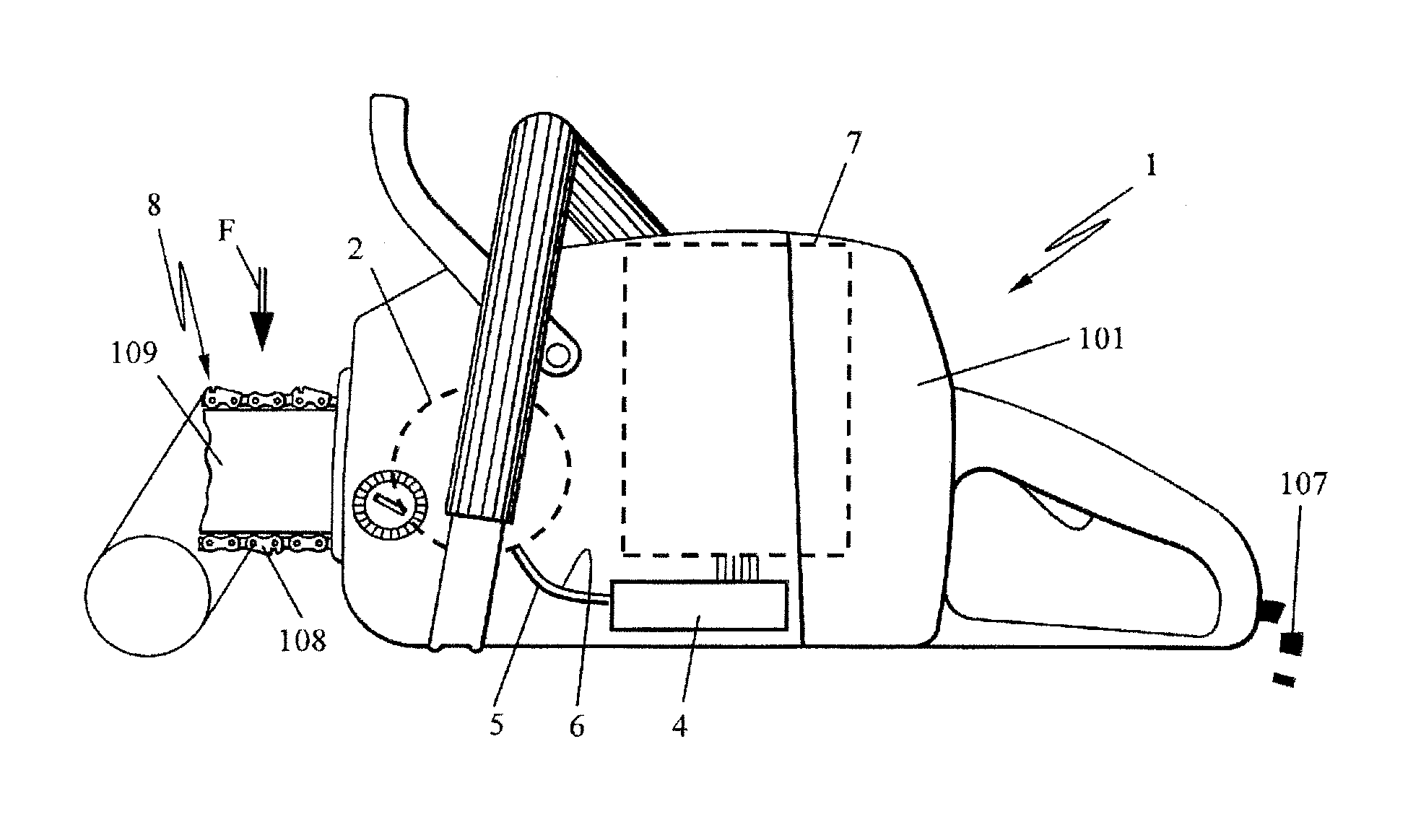

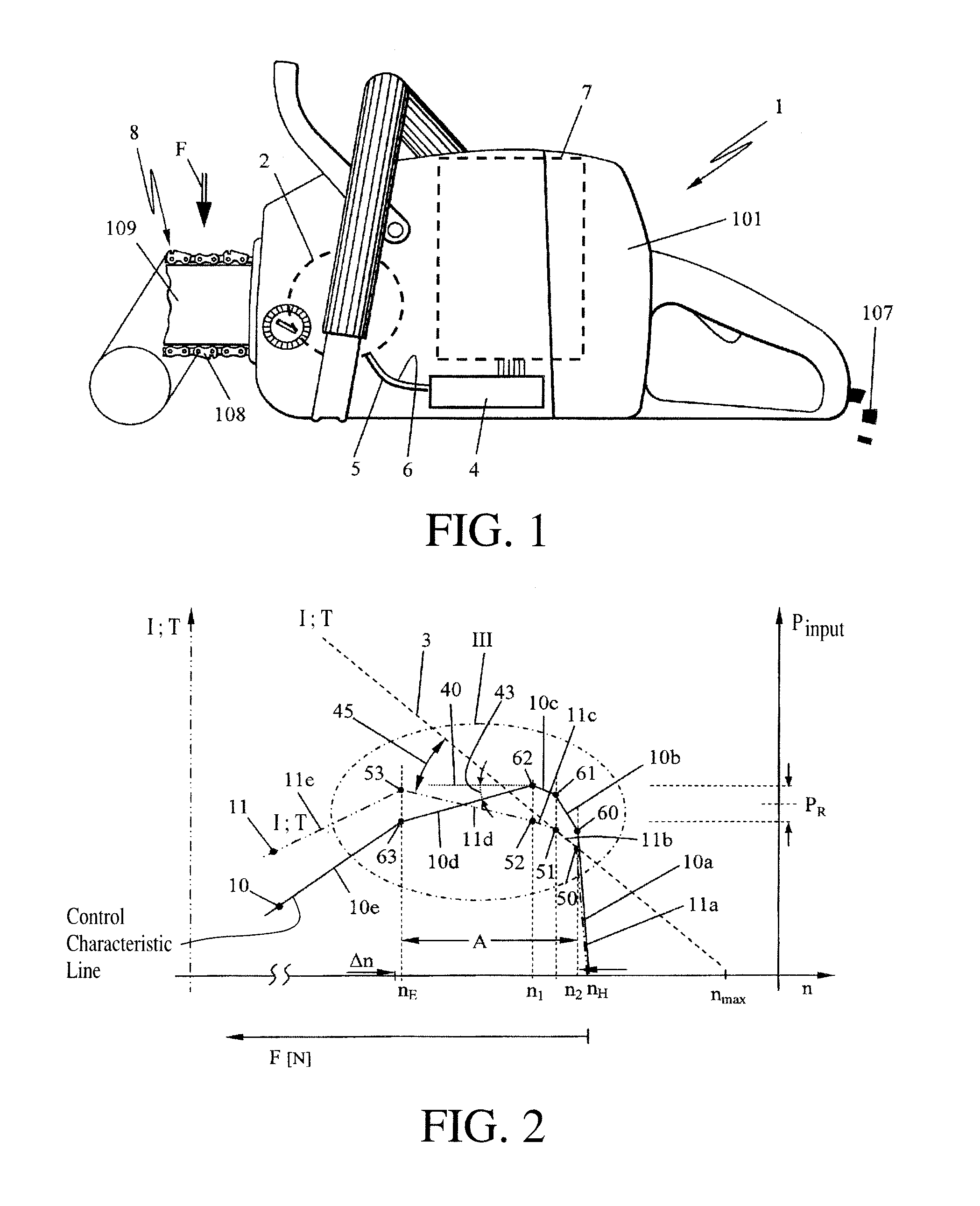

Work apparatus having an electric drive motor

ActiveUS8723453B2Improve efficiencyGood to optimal efficiencyDC motor speed/torque controlSynchronous motors startersElectricityOperating point

An electric chain saw has an electric drive motor defining a motor-specific characteristic line of the drawn-in current as a function of the rotational speed of the motor. A control unit controls the current flowing through the drive motor below an engaging rotational speed to values below the motor-specific characteristic line. In order to generate an operating point the operator can feel in a working region in a predetermined rotational speed band, a control characteristic line of the electric input power of the electric drive motor as a function of the rotational speed is provided above the engaging rotational speed. The control characteristic line is adapted to reduce the electric input power within the rotational speed band to an approximately even mean power so as to cause the torque of the drive motor to increase within the rotational speed band with falling rotational speed.

Owner:ANDREAS STIHL AG & CO KG

Hydrogen-absorbing alloy for alkaline storage battery and method for manufacturing the same

ActiveUS20100323243A1Improve power characteristicsImprove output power stabilityFinal product manufactureSecondary cellsRare-earth elementChemical measurement

A hydrogen-absorbing alloy for an alkaline storage battery with high power characteristics and excellent output power stability and a method for manufacturing the same are provided. The hydrogen-absorbing alloy for an alkaline storage battery of the invention is represented by ABn (A: LaxReyMg1-x-y, B: Nin-zTz, Re: at least one element selected from rare earth elements including Y (other than La), T: at least one element selected from Co, Mn, Zn, and Al, and z>0) and has a stoichiometric ratio n of 3.5 to 3.8, a ratio of La to Re (x / y) of 3.5 or less, at least an A5B19 type structure, and an average C axis length α of crystal lattice of 30 to 41 Å.

Owner:SANYO ELECTRIC CO LTD

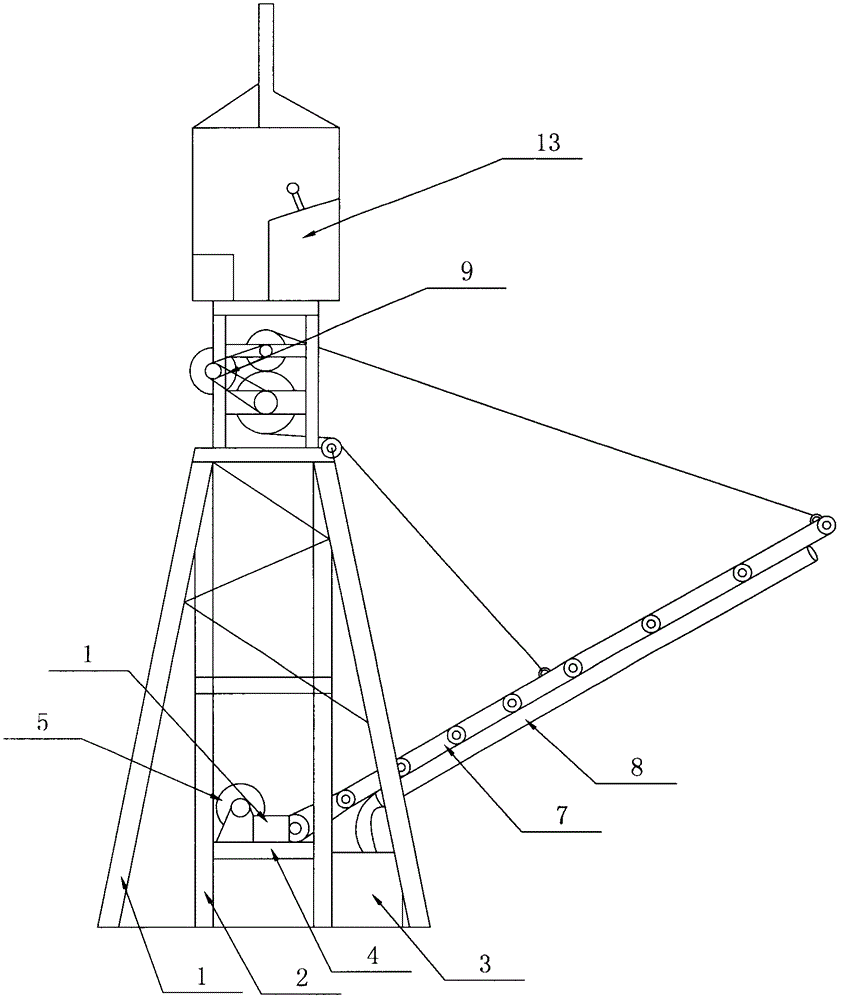

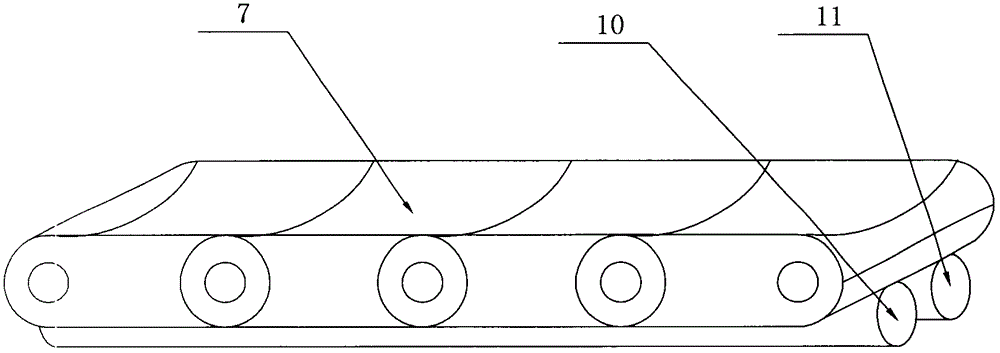

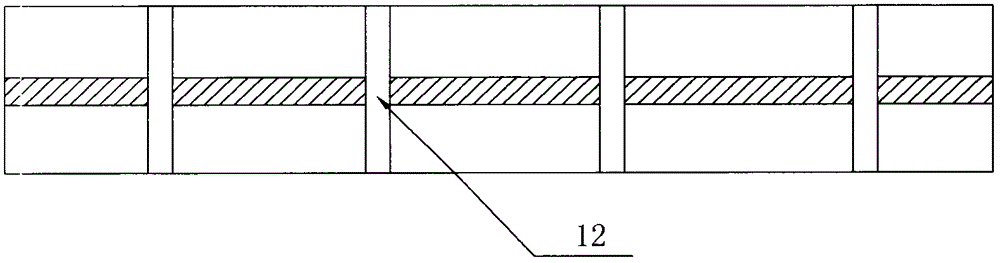

Material conveying control table for ship

InactiveCN104444450AIngenious designFunction increaseLoading/unloadingSuspension bridge typesDrive motor

The invention provides a material conveying control table for a ship, and relates to the technical field of ship material conveying equipment. Uplink and downlink rails are arranged in the middle of a profiled steel structure support A, the upper ends of the uplink and downlink rails are fixedly connected with the profiled steel structure support A, a lifting platform is clamped in the uplink and downlink rails, a drive motor is arranged on one side of the upper end of the lifting platform and connected with a conveying belt through a speed reducer, the conveying belt is connected to the front end of the lifting platform, a conveying pipe is arranged at the lower end of the conveying belt, the lower end of the conveying pipe is connected with a powder and liquid conveying pump, the powder and liquid conveying pump is arranged on one side of the uplink and downlink rails, a steel wire rope control roller is arranged at the top end of the profiled steel structure support A and connected to the middle and the top end of the conveying belt, and a control command set is arranged at the upper end of a steel wire rope control roller support. The material conveying control table is ingenious in design, the suspension bridge type structural design is adopted, liquid, powder and large-particle material conveying equipment is integrated at the bottom, and the cost of the equipment is saved.

Owner:镇江船舶电器有限责任公司

Continuity tie for prefabricated shearwalls

ActiveUS20100229495A1Increases cross-sectional area and ductilityImprove the immunityFoundation engineeringBuilding reinforcementsEngineeringMechanical engineering

A continuity tie is provided for connecting a prefabricated shearwall to a structural member above the prefabricated shearwall. In the preferred embodiment, the continuity tie is a steel tube with aligned openings for receiving a threaded rod therethrough. The tube is welded to the shearwall. A pair of tubes are preferably attached. Nuts attach the threaded rod to the tube. The threaded rod attaches to a structural member above the tube.

Owner:SIMPSON STRONG TIE

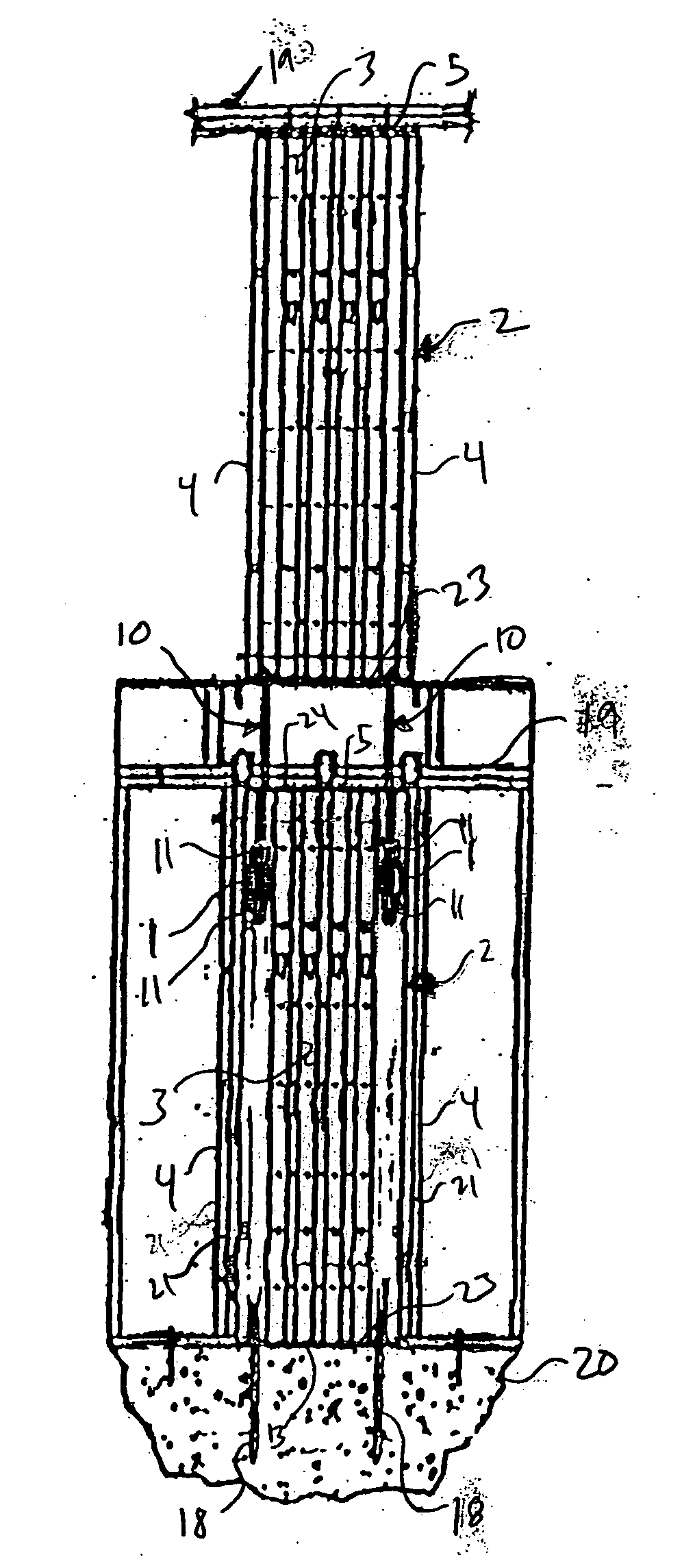

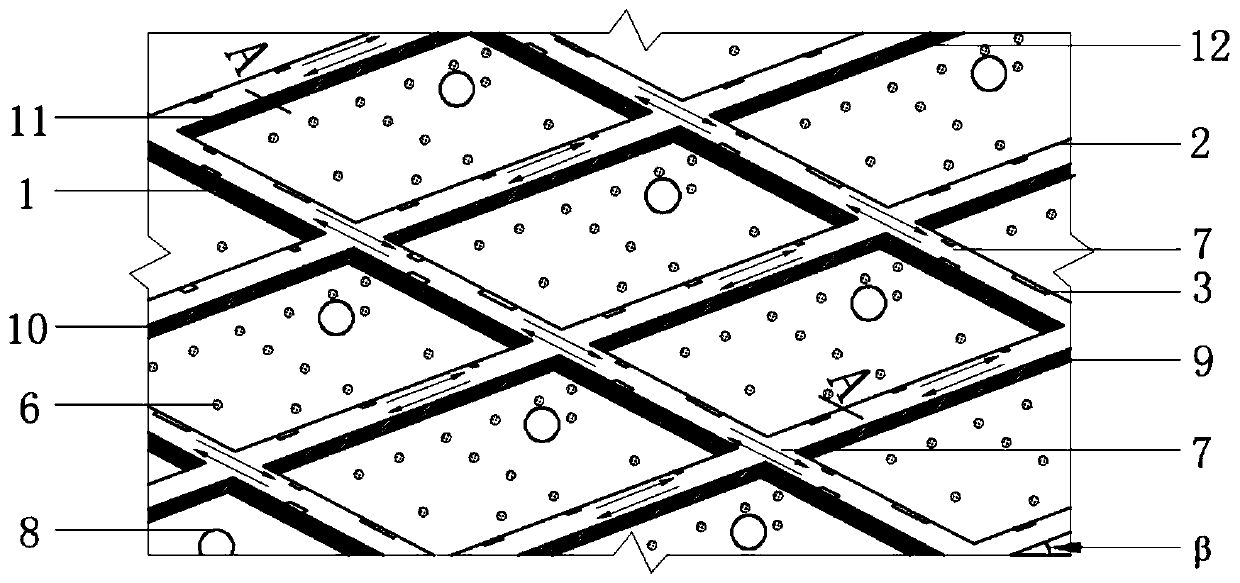

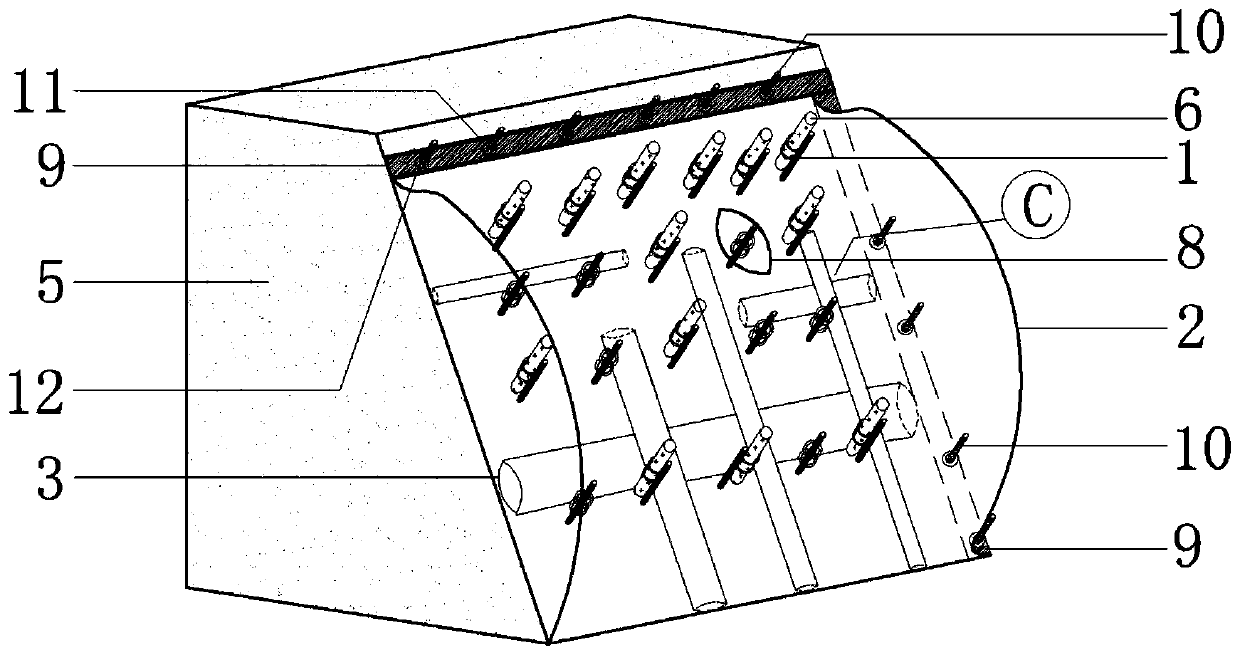

Porous mold bag concrete ecological bank protection structure and construction method thereof

ActiveCN110106830AAvoid protectionSolve the problem of greeningClimate change adaptationCoastlines protectionVegetationTerrain

The invention discloses a porous mold bag concrete ecological bank protection structure and a construction method thereof. The porous mold bag concrete ecological bank protection structure mainly comprises concrete fins, bamboo pipes and anchor rods; the concrete fins are made of mold bag self-compacting concrete, and a certain angle is formed between the length direction of the concrete fins andthe slope surface contour line; valleys parallel to the length direction and the width direction of the concrete fins correspondingly are reserved between the concrete fins; and one ends of the anchorrods are inserted in a side slope, and the other ends of the anchor rods are fixed to the nest bamboo pipe and the vegetation bamboo pipe and buried in the concrete fins. The porous mold bag concreteecological bank protection structure can adapt to the complex terrain, is high in construction efficiency and can be applied to rocky water banks or hydro-fluctuation belts, nests are provided for wild animals while the water banks or the hydro-fluctuation belts are effectively protected, and the growing environment is provided for plants.

Owner:HUBEI UNIV OF TECH

Ecological slope protection and trimming mechanism capable of achieving gradient regulation in case of flood

PendingCN110374153AAdjustable inclinationEasy to drillMechanical machines/dredgersCoastlines protectionCoil springWater flow

The invention aims to solve the problem that the gradient of existing ecological slope protection is hard to regulate, and discloses an ecological slope protection and trimming mechanism capable of achieving gradient regulation in case of flood. The ecological slope protection and trimming mechanism comprises a guide slot, a first spiral spring, ejector rods, a screw conveyor, a sliding plate, a guide rod, a guide frame, a cover body, a motor, a locating rod, a universal pipe, a handle, a discharging hood, fastening screws, a locating ring, an oblique rod, a support rod, a second spiral spring, a connecting plate, a screw rod, a baseplate, universal wheels, a guide plate, a rotating shaft, a rotating plate and a support plate. According to the ecological slope protection and trimming mechanism, reverse thinking is adopted; through reduction of the gradient of ecological slope protection, on one hand, water level can be reduced, and on the other hand, the volume of a channel is furtherincreased; impact force of water flow on the slope protection is reduced, and meanwhile drilled soil is stacked on the top side of the slope protection; flood prevention is further achieved, and the ecological slope protection and trimming mechanism is rational in design and easy to operate, and meets the requirements of ecological slope protection field.

Owner:HEILONGJIANG UNIV

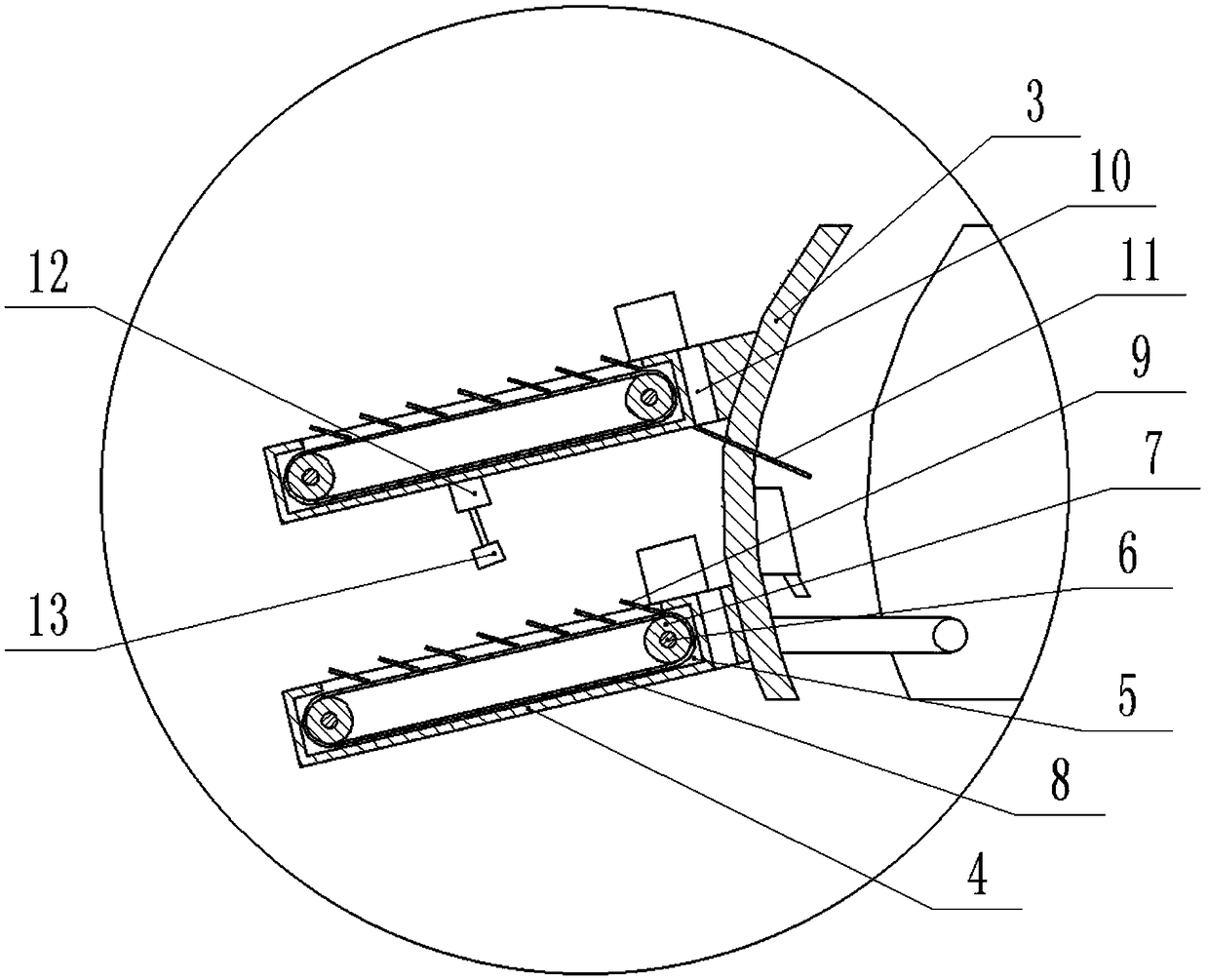

Mechanized planting method of saccharum officinarum in hilly and mountainous regions

PendingCN109699428ASmall slopePromote harmonious developmentSugarcane cultivationClimate change adaptationLand preparationSaccharum officinarum

The invention provides a mechanized planting method of saccharum officinarum in hilly and mountainous regions. The mechanized planting method comprises the following steps of land preparation, varietyselection, ditching and harvesting. The mechanized planting method of the saccharum officinarum in hilly and mountainous regions has the advantages that the large-scale, intensive, standardized, mechanized and simplified production of saccharum officinarum in the hilly and mountainous regions is achieved, the labor cost is reduced, the soil fertility and utilization rate are improved, the simplified and mechanized production of saccharum officinarum in the hilly and mountainous regions is promoted, and the saccharum officinarum planting earnings of saccharum officinarum farmers are increased.

Owner:SUGARCANE RES INST OF YUNNAN ACADEMY OF AGRI SCI

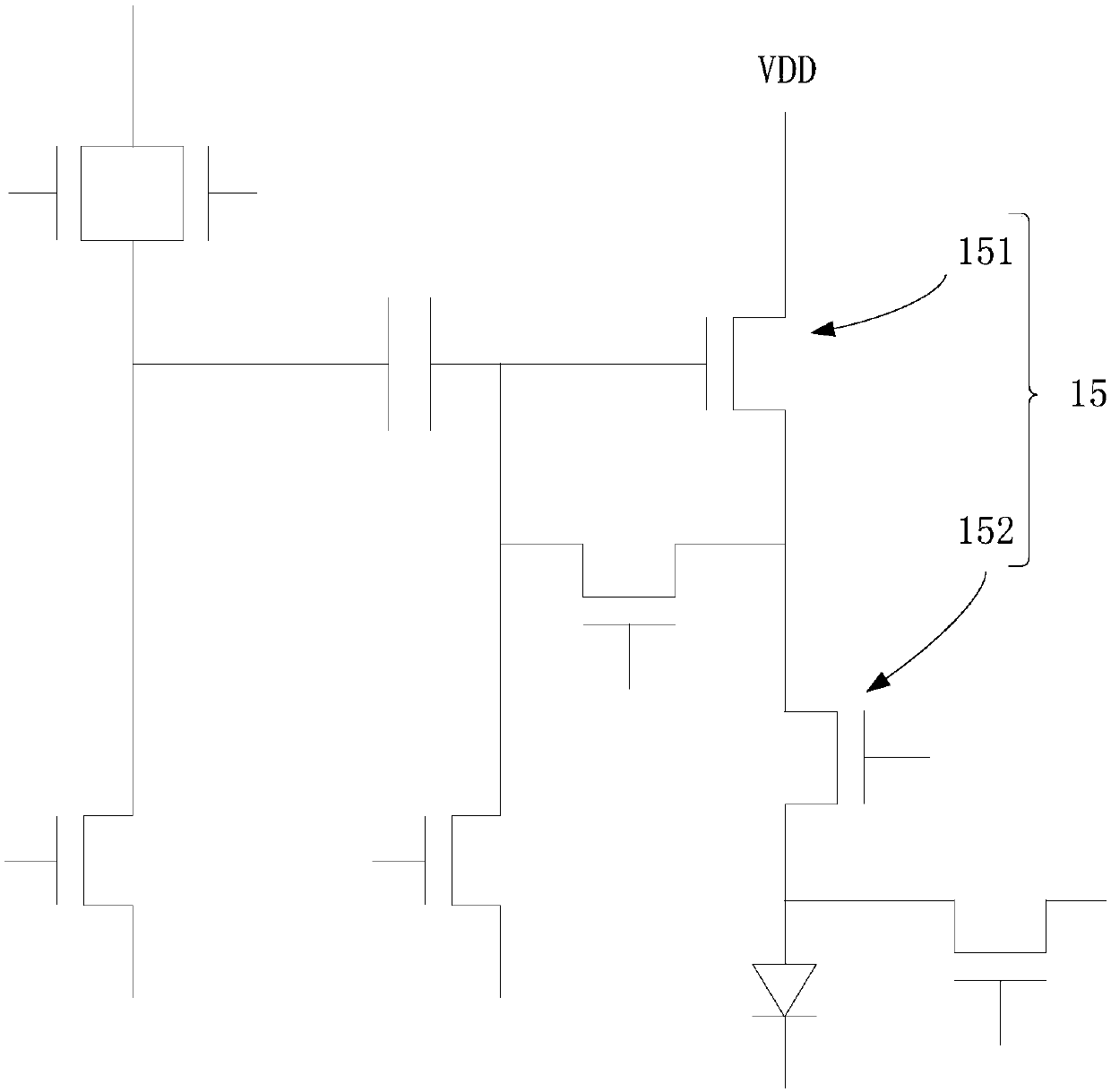

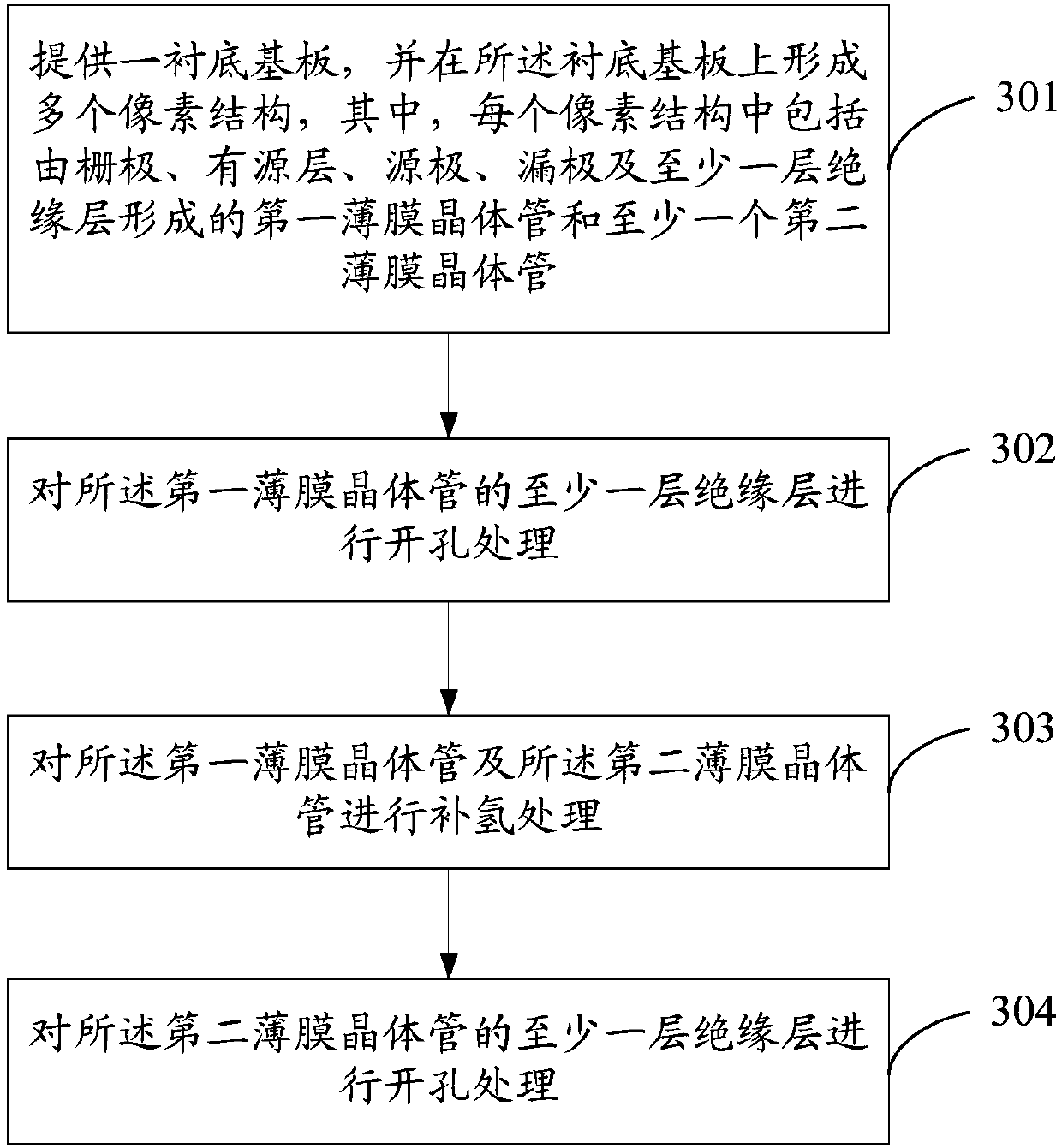

Manufacturing method of array substrate, array substrate and display device

ActiveCN109994510ALight evenlyWeaken the effect of hydrogen replenishmentSolid-state devicesSemiconductor devicesCapacitanceHydrogen

Embodiments of the invention provide a manufacturing method of an array substrate, the array substrate and a display device. The manufacturing method is characterized by firstly opening a hole on a first thin film transistor, then simultaneously performing hydrogen supplement processing for the first thin film transistor and a second thin film transistor, and opening a hole on the second thin filmtransistor, so that the first thin film transistor and the second thin film transistor can be repaired and compensated to different degrees through the hydrogen supplement processing respectively, wherein, because the hole is opened on the first thin film transistor firstly, the hydrogen supplementing effect of the first thin film transistor is weakened, in this way, the gradient of a current-voltage curve of the first thin film transistor can be properly reduced, a current difference caused by a threshold voltage difference is reduced, and electron mobility of the second thin film transistoris increased as much as possible, the charging electric quantity of a capacitor within the rated time is increased, the current difference between circuits is reduced, therefore, the display device can emit light uniformly, the occurrence probability of Mura is reduced, and the Mura effect is reduced.

Owner:BOE TECH GRP CO LTD +1

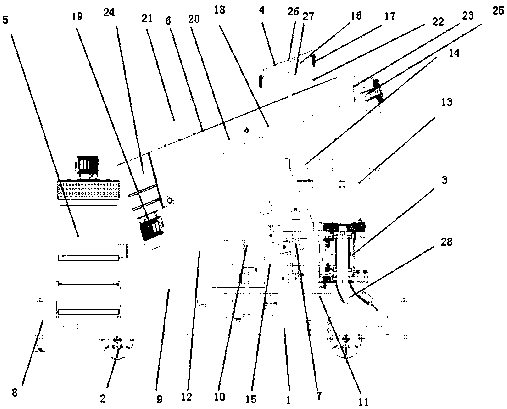

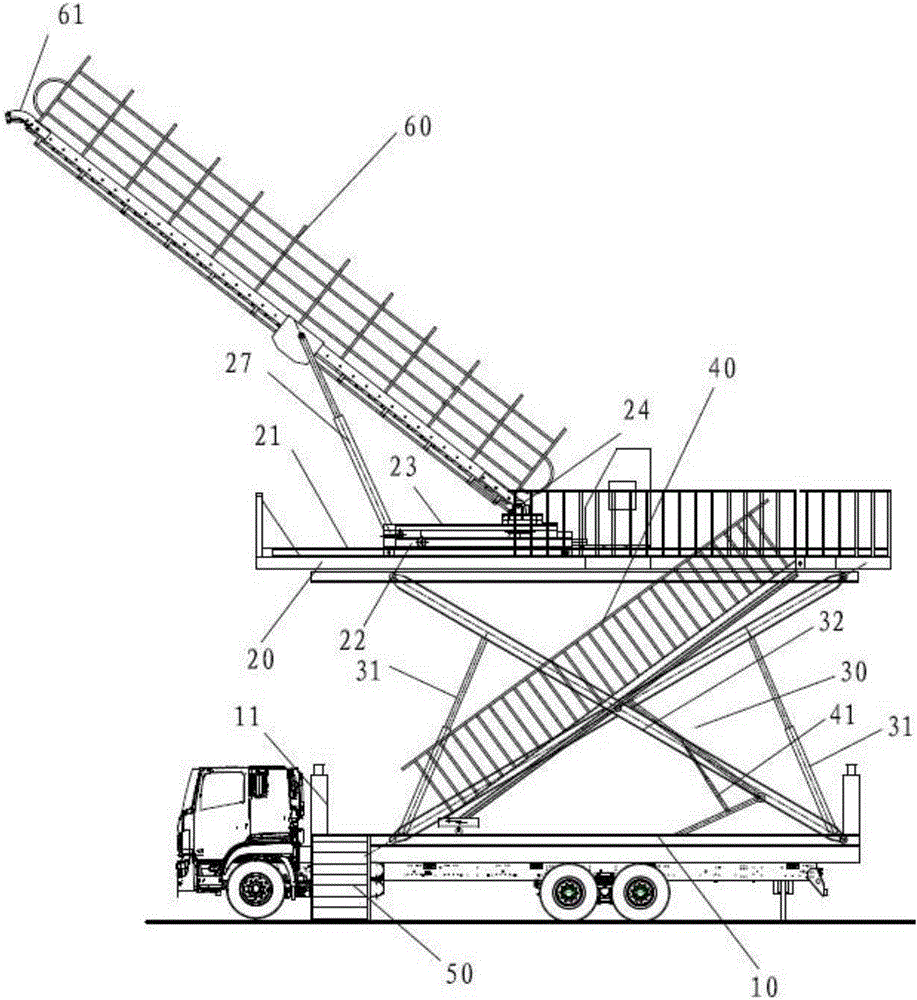

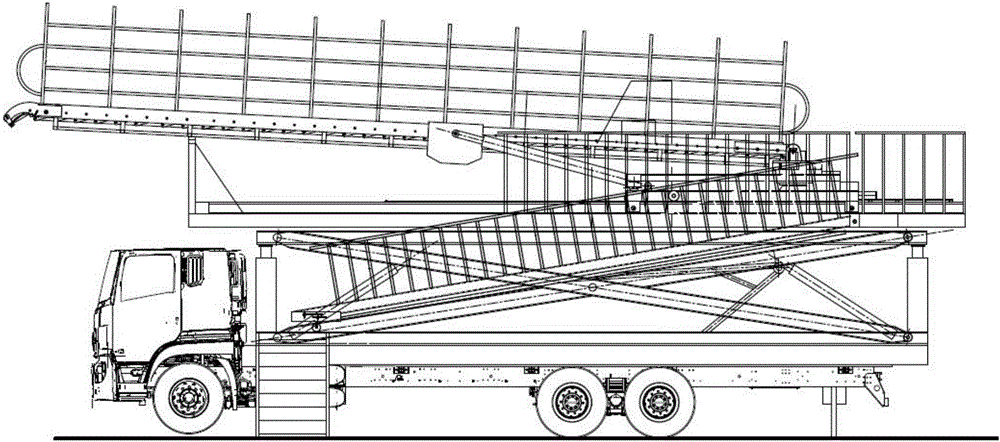

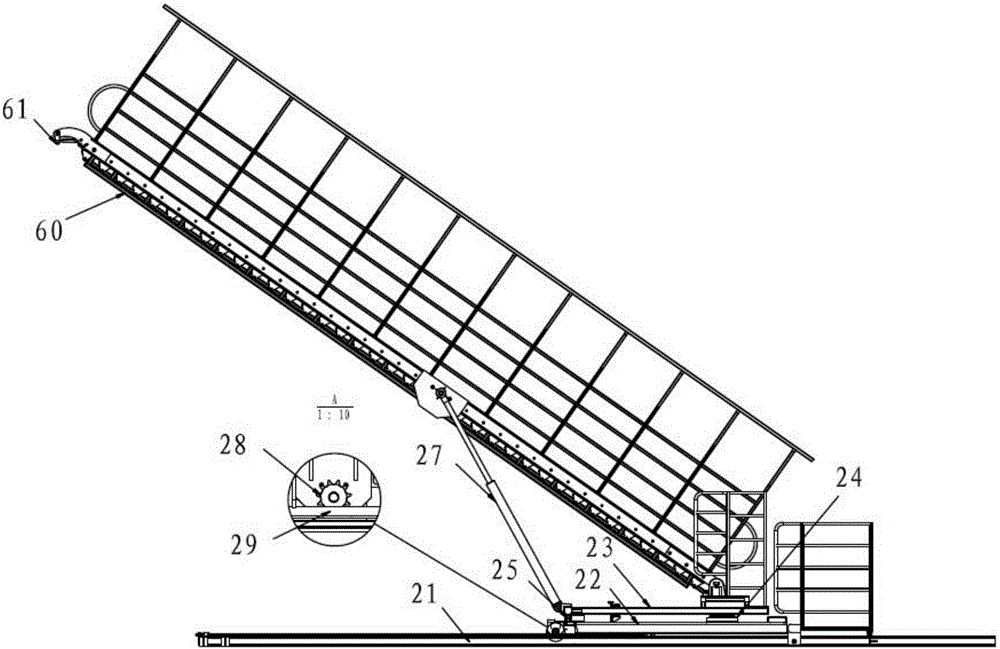

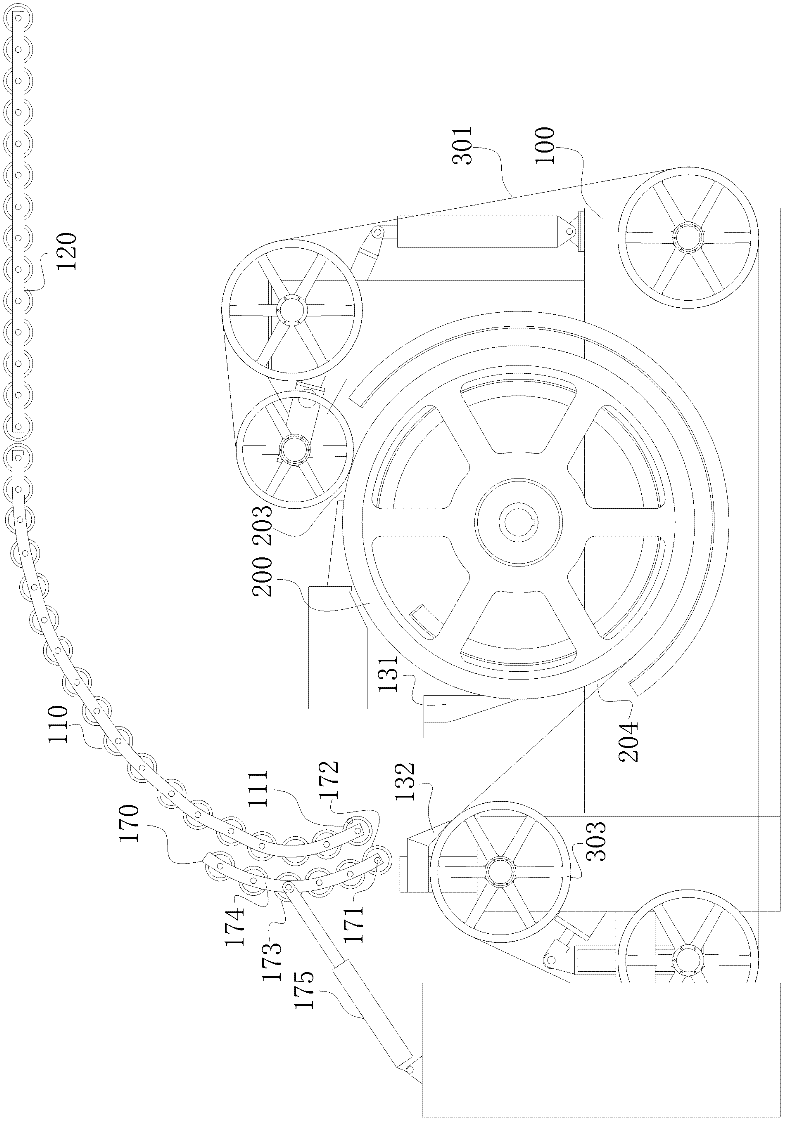

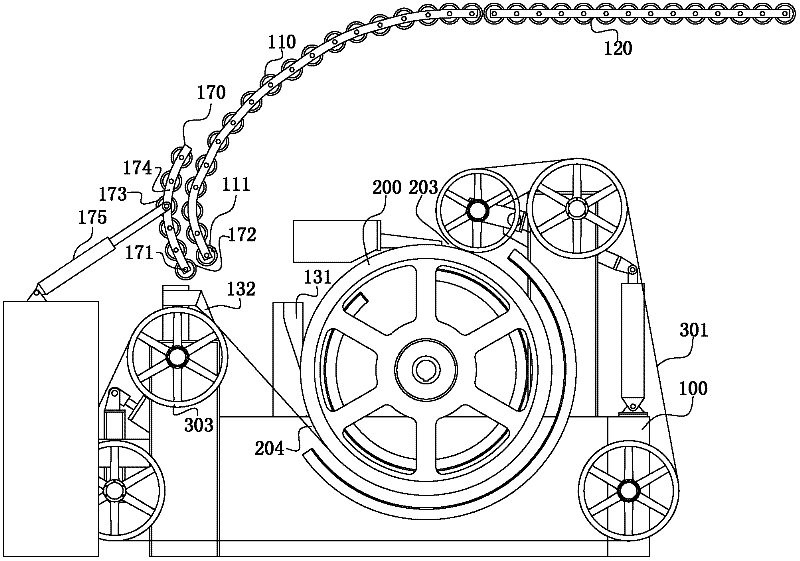

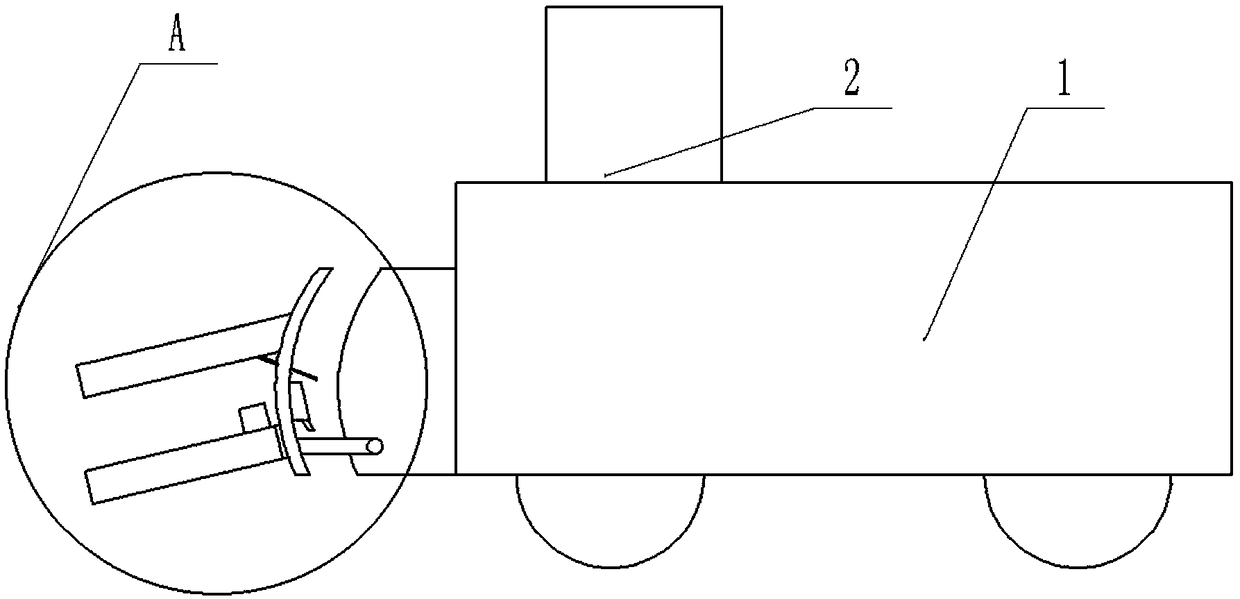

Embarking equipment

InactiveCN106089017ASmall slopeSimple and compact structureLifting framesLaddersMarine engineeringChassis

The invention discloses embarking equipment. A lifting mechanism is arranged between a lifting platform and a motor vehicle chassis, and the height of the lifting mechanism can be adjusted. An intermediate ladder is arranged between the lifting platform and the chassis, and passengers get on and off a ship through an overturned ladder, the intermediate ladder, the lifting platform and an accommodation ladder. The lifting mechanism adopts a scissor-type lifting mechanism to drive the lifting platform to be adjusted vertically, the take-over height range is larger, and the demand for ro-ro passenger ship take-over in the larger range is met; and meanwhile, the gradient of the accommodation ladder is reduced, so that the ship is safer and more comfortable. Double pitch oil cylinders symmetrically arranged on the two sides are adopted, the pitch smoothness is improved, and safety of the passengers during embarking and disembarking is ensured.

Owner:VATAPLE MACHINERY KUNSHAN

Steel belt wheel type continuous casting machine with casting blank conveying mechanism for continuous casting lead belt

The invention relates to a continuous casting equipment for a nonferrous alloy, providing a steel belt wheel type continuous casting machine with a casting blank conveying mechanism for a continuous casting lead belt. A longitudinal plane which passes through the axial direction of a crystallizing wheel is used for dividing the crystallizing wheel into a first zone and a second zone; a pouring gate is positioned on the upper part of the first zone; a throwing hole is positioned on the lower part of the second zone; a casting blank support mechanism which is fixed on a rack and is aslant downwards extended from the outer side of the second zone to be above the throwing hole is arranged; the higher end of an approach bridge is positioned above the crystallizing wheel; the lower end of the approach bridge is positioned above one end of the casting blank support mechanism, which is far away from the crystallizing wheel; one end of a conveying roller bed is positioned above the crystallizing wheel and is connected with one higher end of the approach bridge; and the other end of the conveying roller bed is positioned on the outer side of the first zone of the crystallizing wheel. The phenomenon that the lead belt between the throwing hole and the conveying roller bed deforms even is broken under the action of dead load can be avoided by adding the casting blank support mechanism, lowering the gradient of the approach bridge and providing support for the throwing hole and the approach bridge. The steel belt wheel type continuous casting machine is suitable for producing lead belts, especially lead belts with large cross sections.

Owner:SICHUAN HUASHEN NEW ENERGY EQUIP

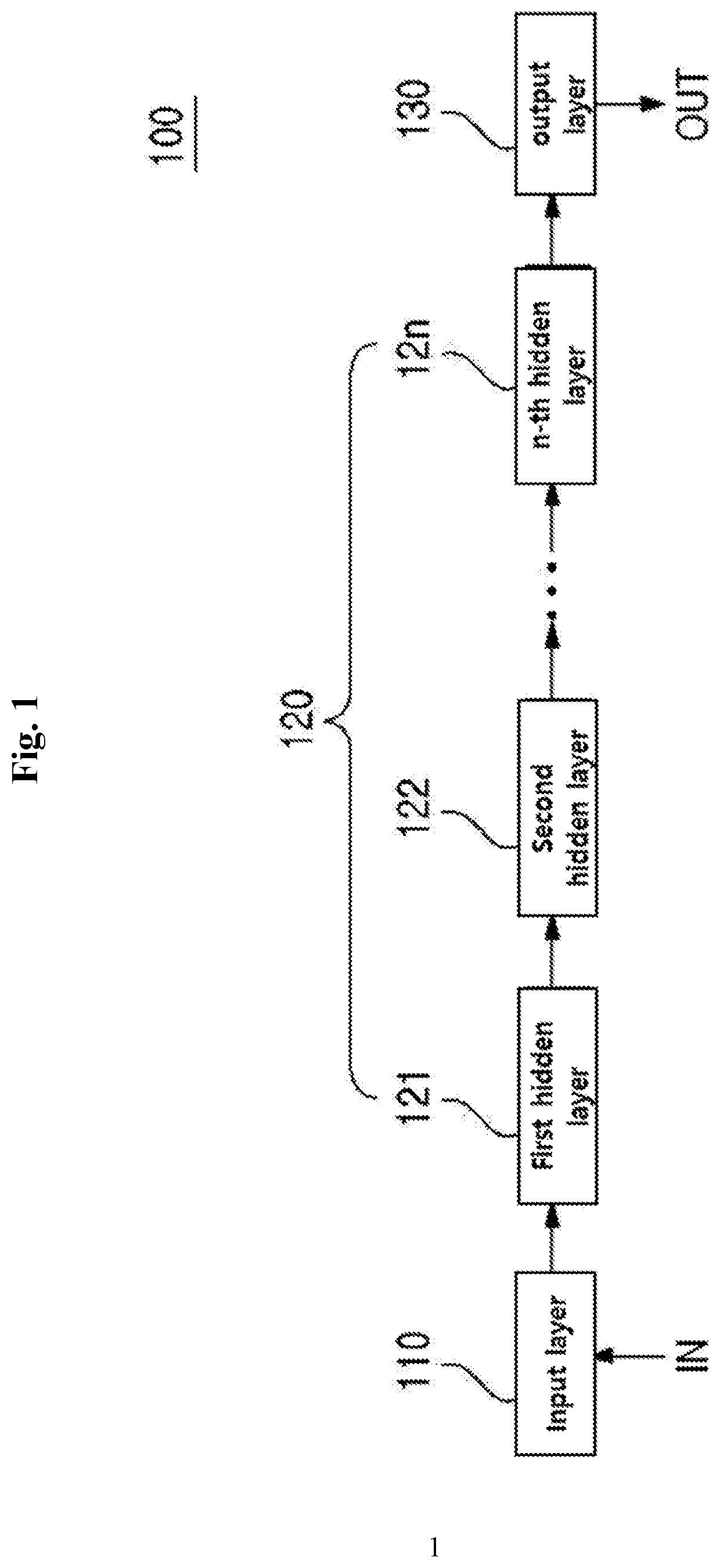

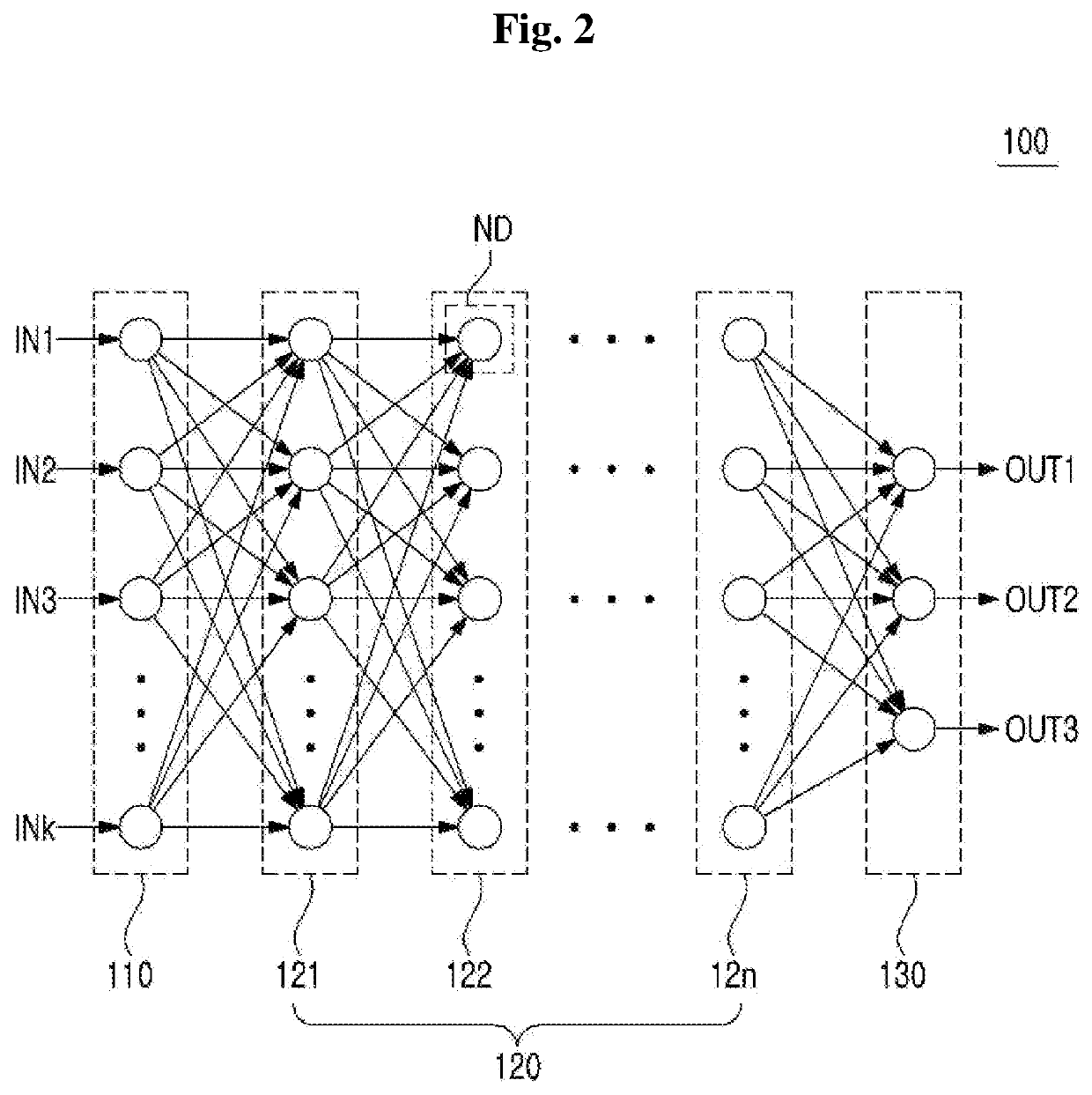

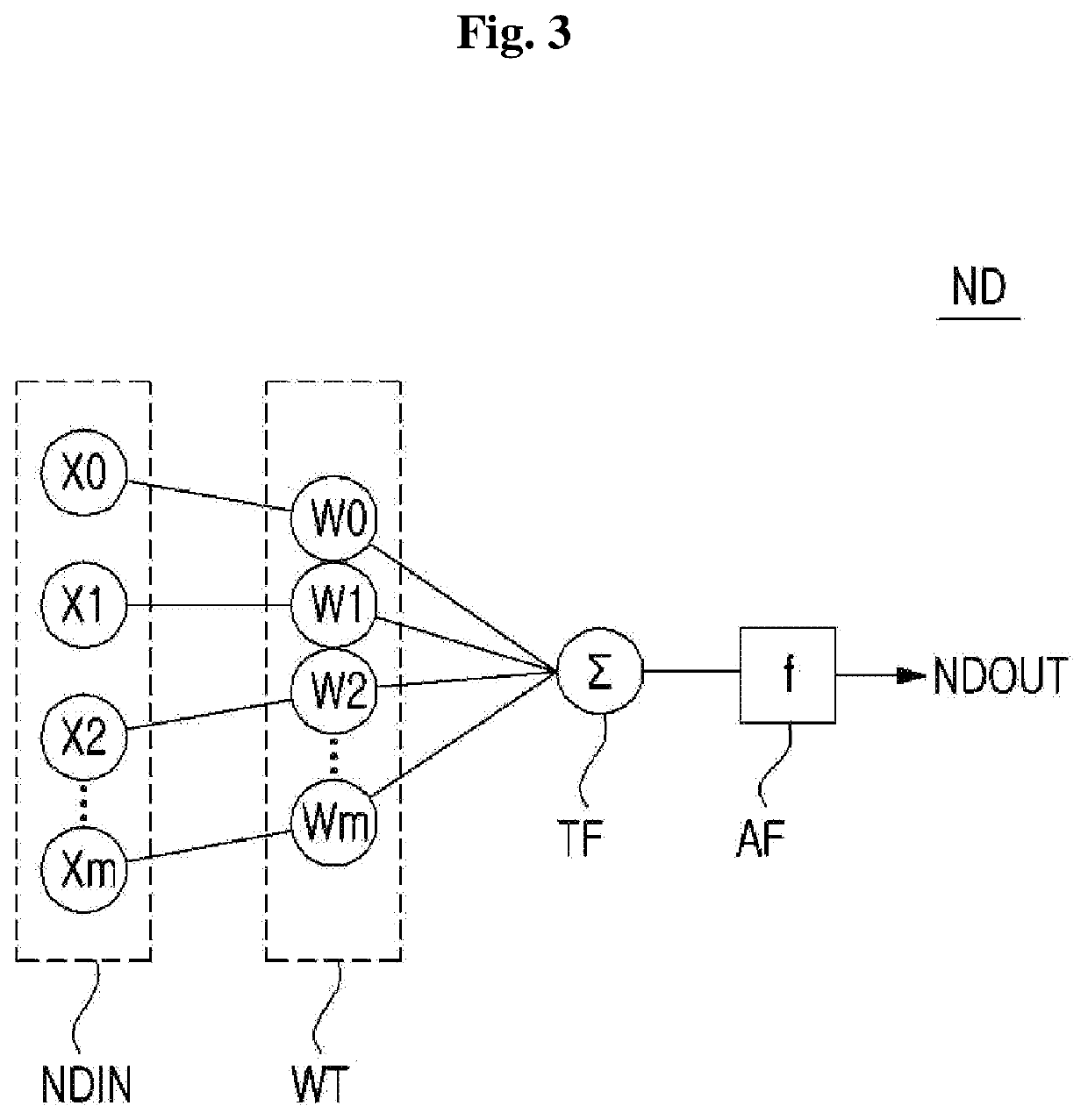

Artificial neural network system using a piecewise linear rectifier unit for compensating component defects

ActiveUS20200034714A1Small slopeConvenient distanceCharacter and pattern recognitionDesign optimisation/simulationHidden layerActivation function

An artificial neural network system of the present invention can include an input layer that receives input data; an output layer that outputs output data corresponding to the input data; and a hidden layer group including a multiple number of hidden layers that are positioned between the input layer and the output layer and are connected by connection weights, with the connection weights updated based on a difference between the output data and prediction data corresponding to the input data, where each of the hidden layers can include a hidden node that includes an activation function, which can output 0 if the input value is negative and can determine the output value based on linear functions having different slopes according to the range of the input value if the input value is positive, and the linear functions can have smaller slopes for greater distances from the origin point.

Owner:UNIV IND COOP GRP OF KYUNG HEE UNIV

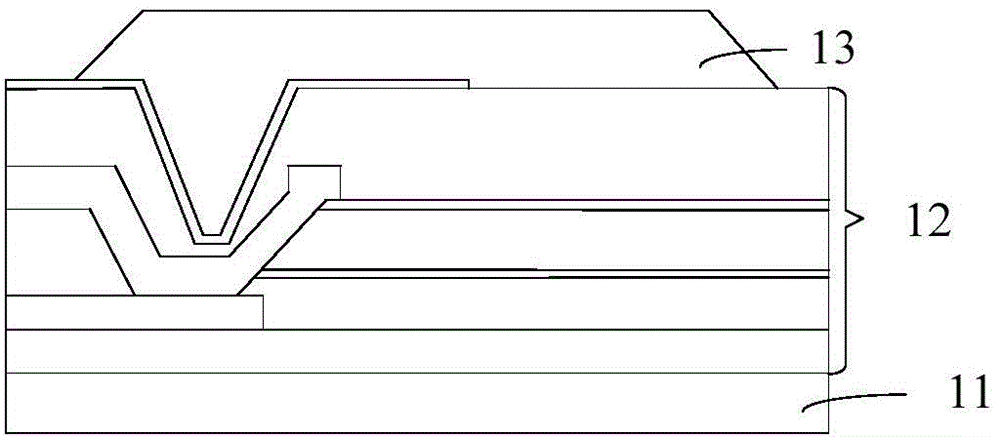

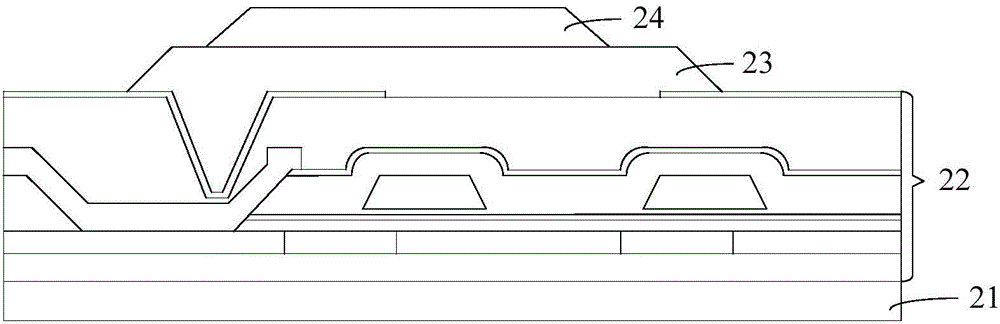

AMOLED structure and manufacturing method thereof

InactiveCN104091896ASolve the problem of fracture phenomenonAvoid breakingSolid-state devicesSemiconductor/solid-state device manufacturingComputer science

The invention provides an AMOLED structure and a manufacturing method of the AMOLED structure, and the AMOLED structure is used for solving the problem of cracking of an OLED films. The AMOLED structure comprises a TFT circuit layer, a pixel layer on the TFT circuit layer, and an OLED layer on the pixel layer; the pixel layer comprises a first pixel layer and a second pixel layer; the first pixel layer is arranged on the TFT circuit layer, and first slopes are formed on the two sides of the first pixel layer; the second pixel layer is arranged on the first pixel layer, and second slopes are formed on the two sides of the second pixel layer; the OLED layer wraps the TFT circuit layer, the first pixel layer and the second pixel layer. By the adoption of the structure, the problem of cracking of the OLED film can be effectively solved.

Owner:EVERDISPLAY OPTRONICS (SHANGHAI) CO LTD

Remediation method for making land in hilly and mountainous areas suitable for mechanization

The invention belongs to the technical field of land, and specifically discloses a remediation method for making the land in hilly and mountainous areas suitable for mechanization. The method includesthe following steps: measuring the slope; dividing a land into horizontal fields, gentle slope fields, steep slope fields and terrace fields according to the slope; cleaning gravels, and removing field ridges and ditches; building passages; carrying out field layout, and setting the length and width of fields according to the different properties of fields; digging pits and turning the soil; andfertilizing. The purpose of the invention is to provide a remediation method which makes the land in hilly and mountainous areas adapt to large and medium-sized mechanized planting.

Owner:CHONGQING AGRI MECHANIZATION TECH PROMOTION GENERAL STATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com