Patents

Literature

39results about How to "Low environmental sensitivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

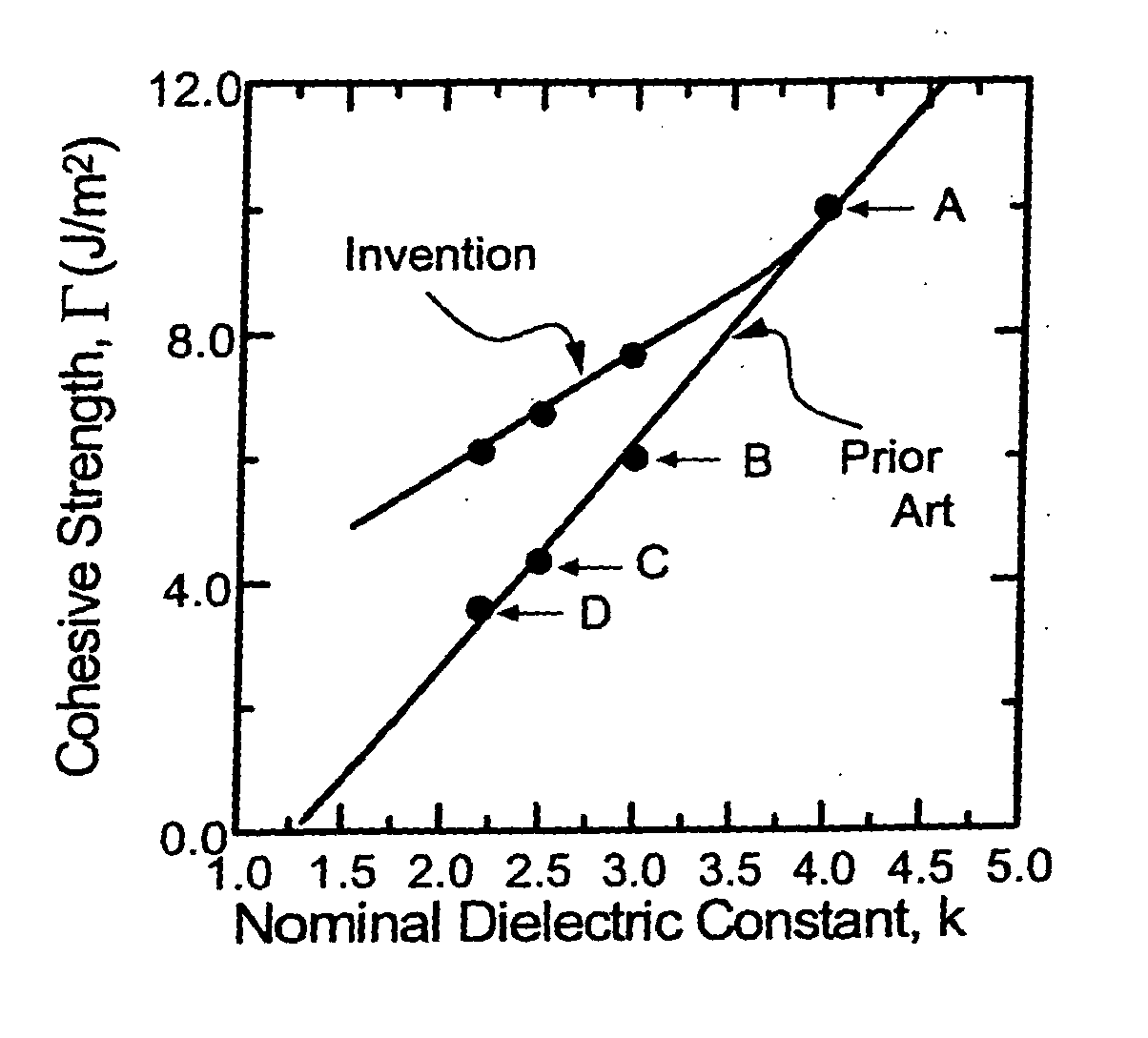

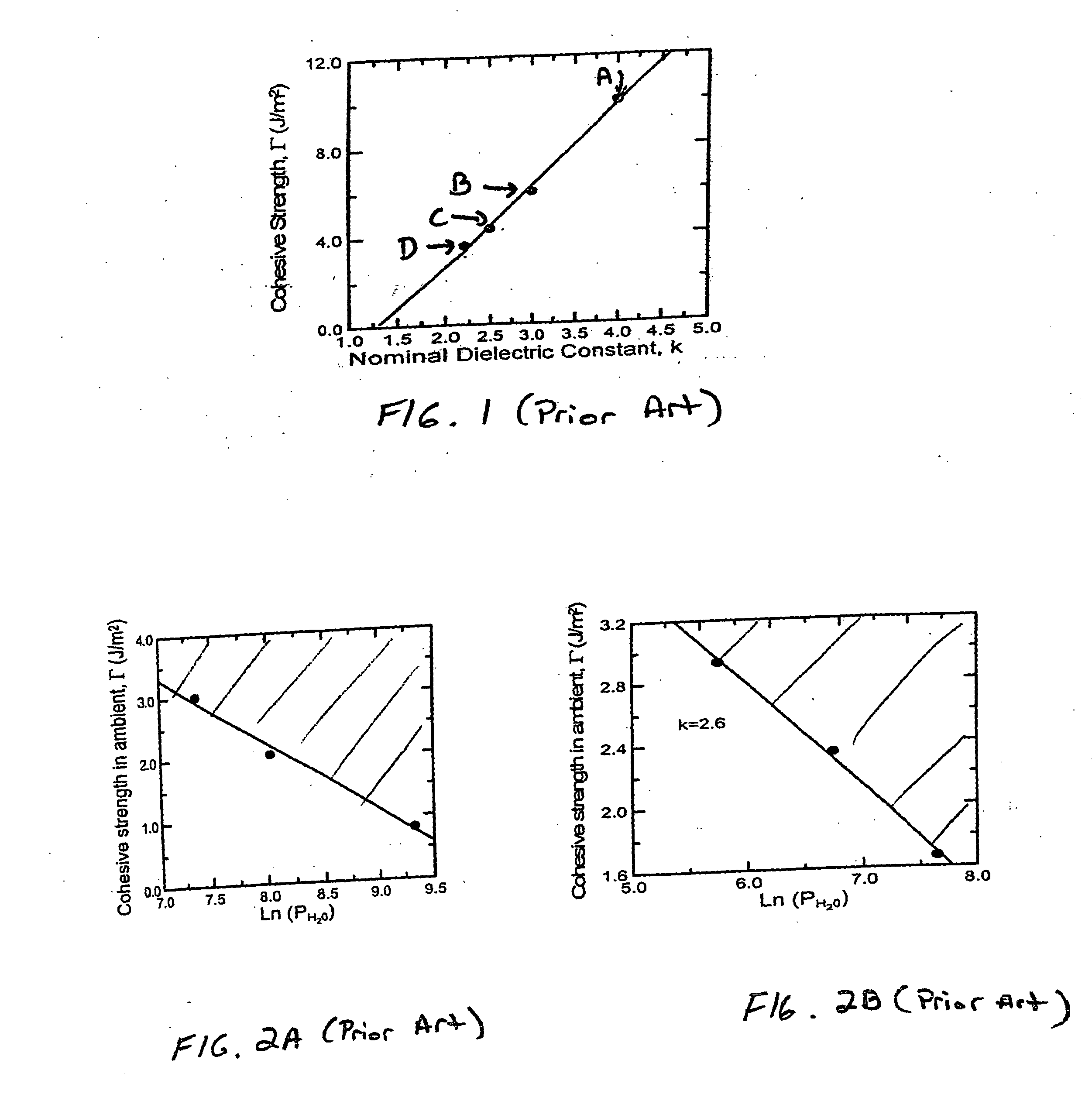

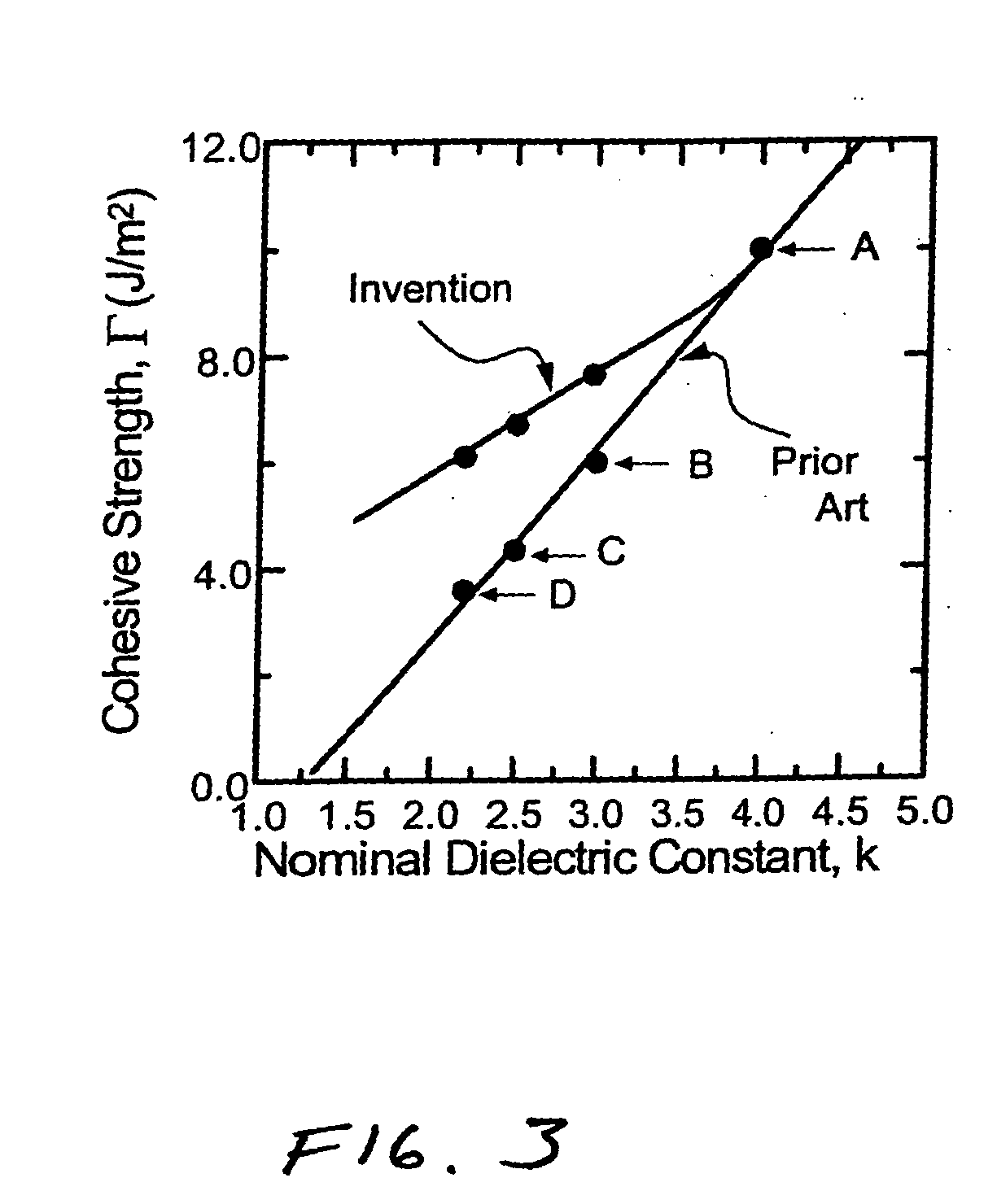

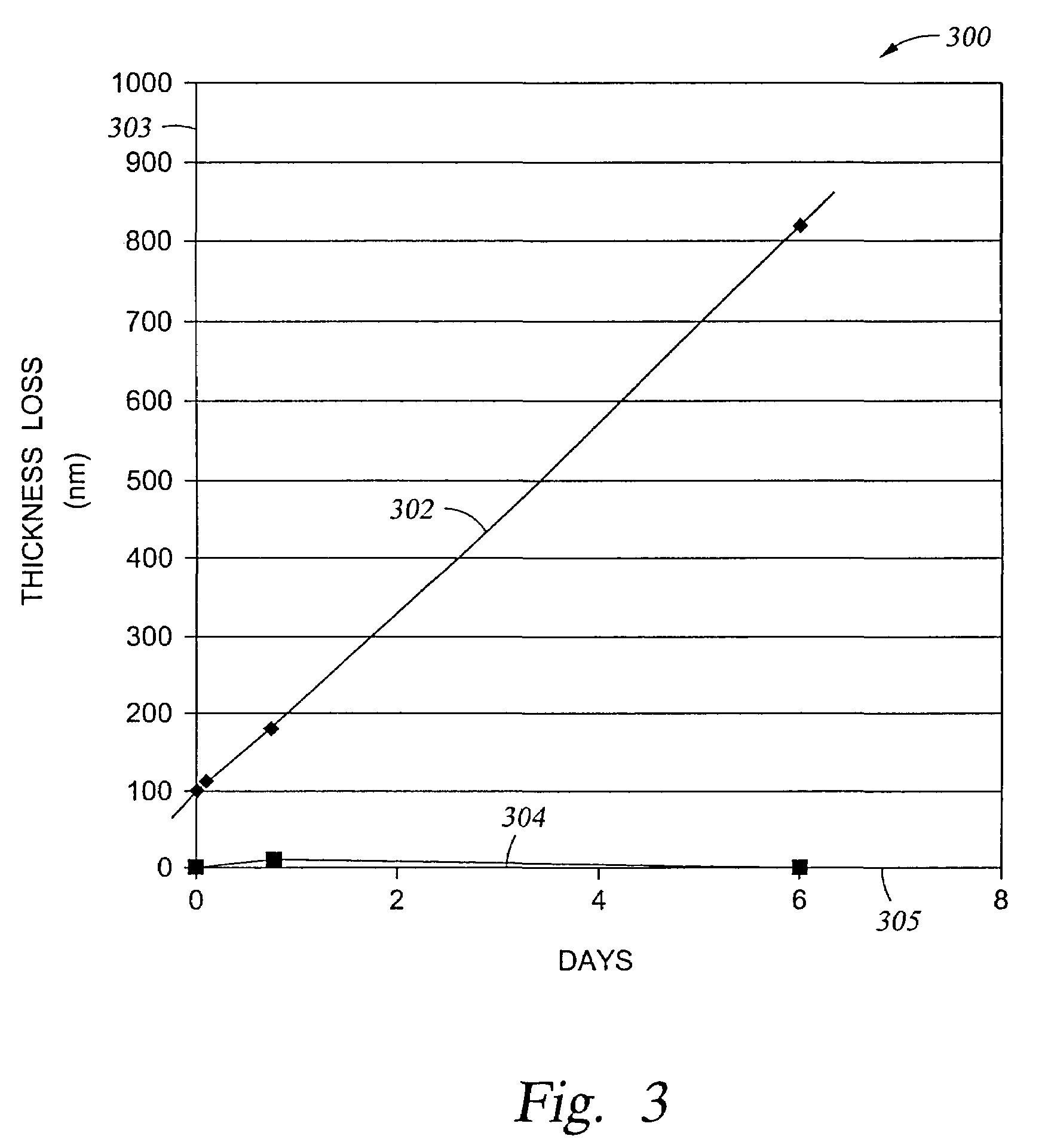

SiCOH dielectric material with improved toughness and improved Si-C bonding, semiconductor device containing the same, and method to make the same

InactiveUS20060165891A1Small slopeDelayed slopeMolten spray coatingPretreated surfacesElectronic structureDevice material

A low-k dielectric material with increased cohesive strength for use in electronic structures including interconnect and sensing structures is provided that includes atoms of Si, C, O, and H in which a fraction of the C atoms are bonded as Si—CH3 functional groups, and another fraction of the C atoms are bonded as Si—R—Si, wherein R is phenyl, —[CH2]n— where n is greater than or equal to 1, HC═CH, C≡CH2, C≡C or a [S]n linkage, where n is a defined above.

Owner:INTEL CORP

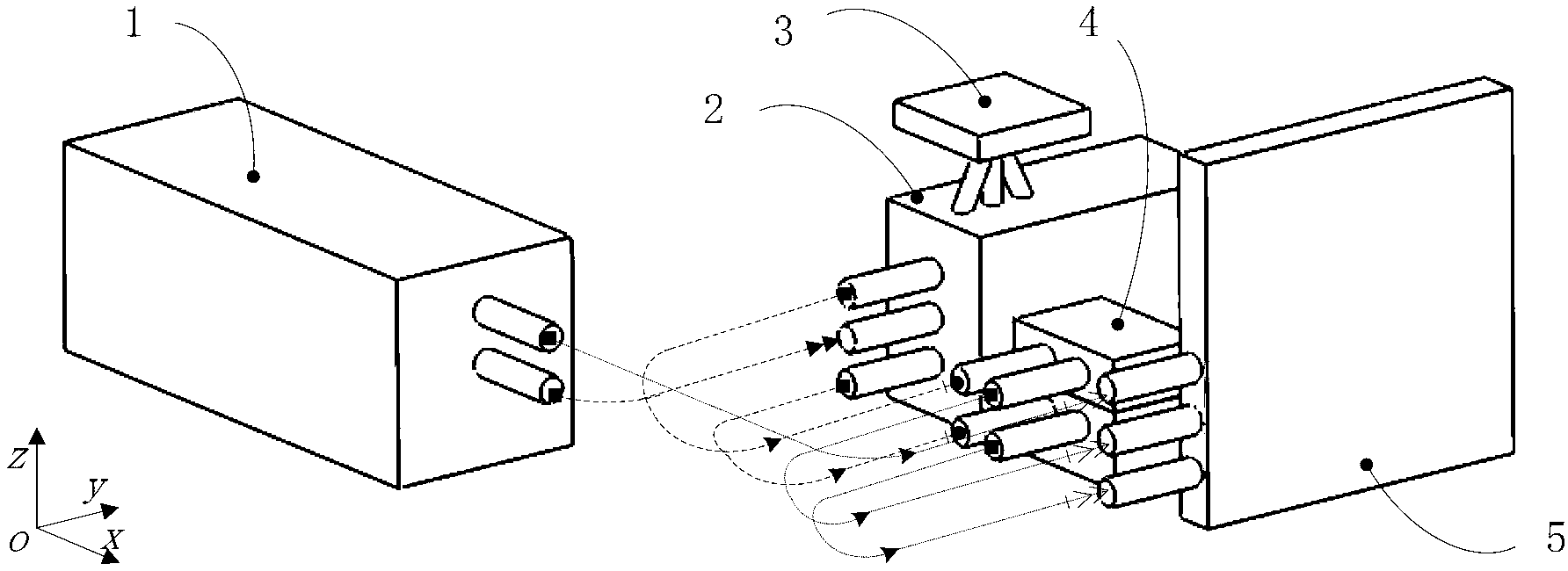

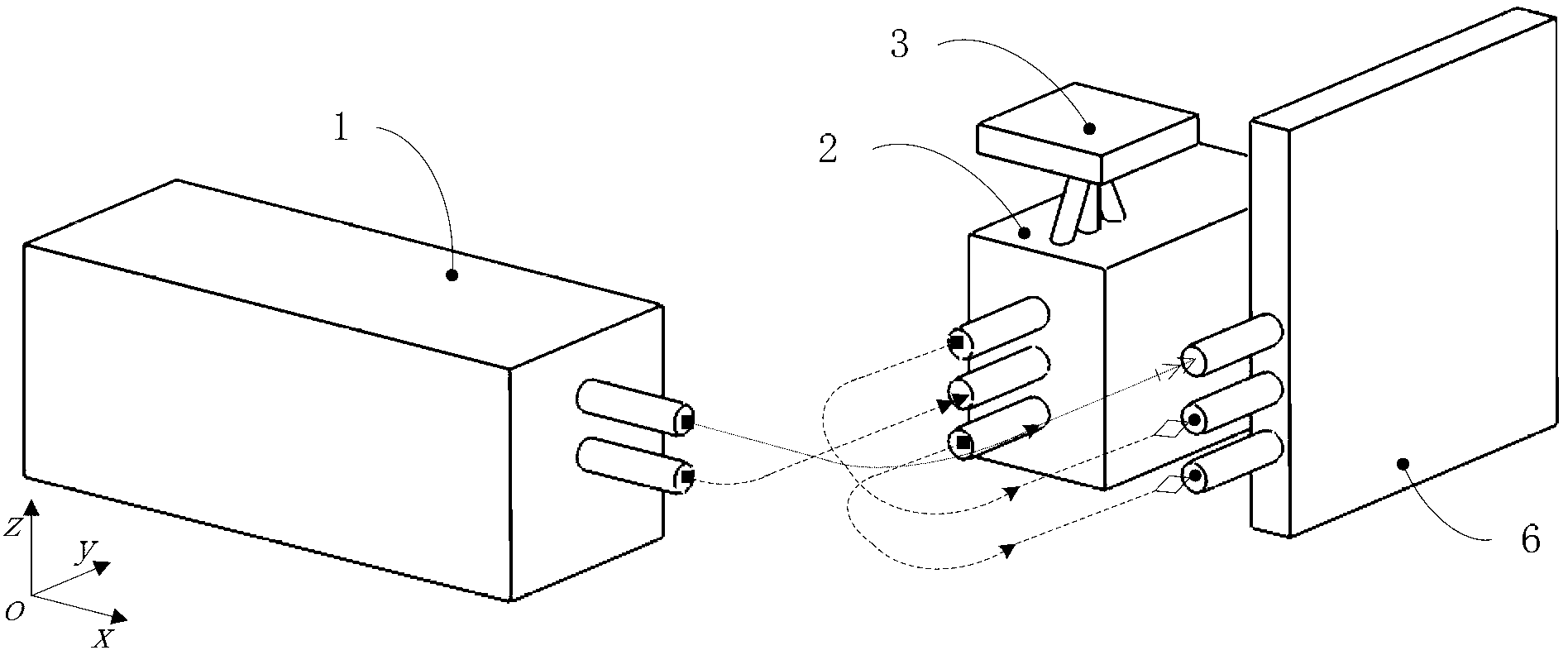

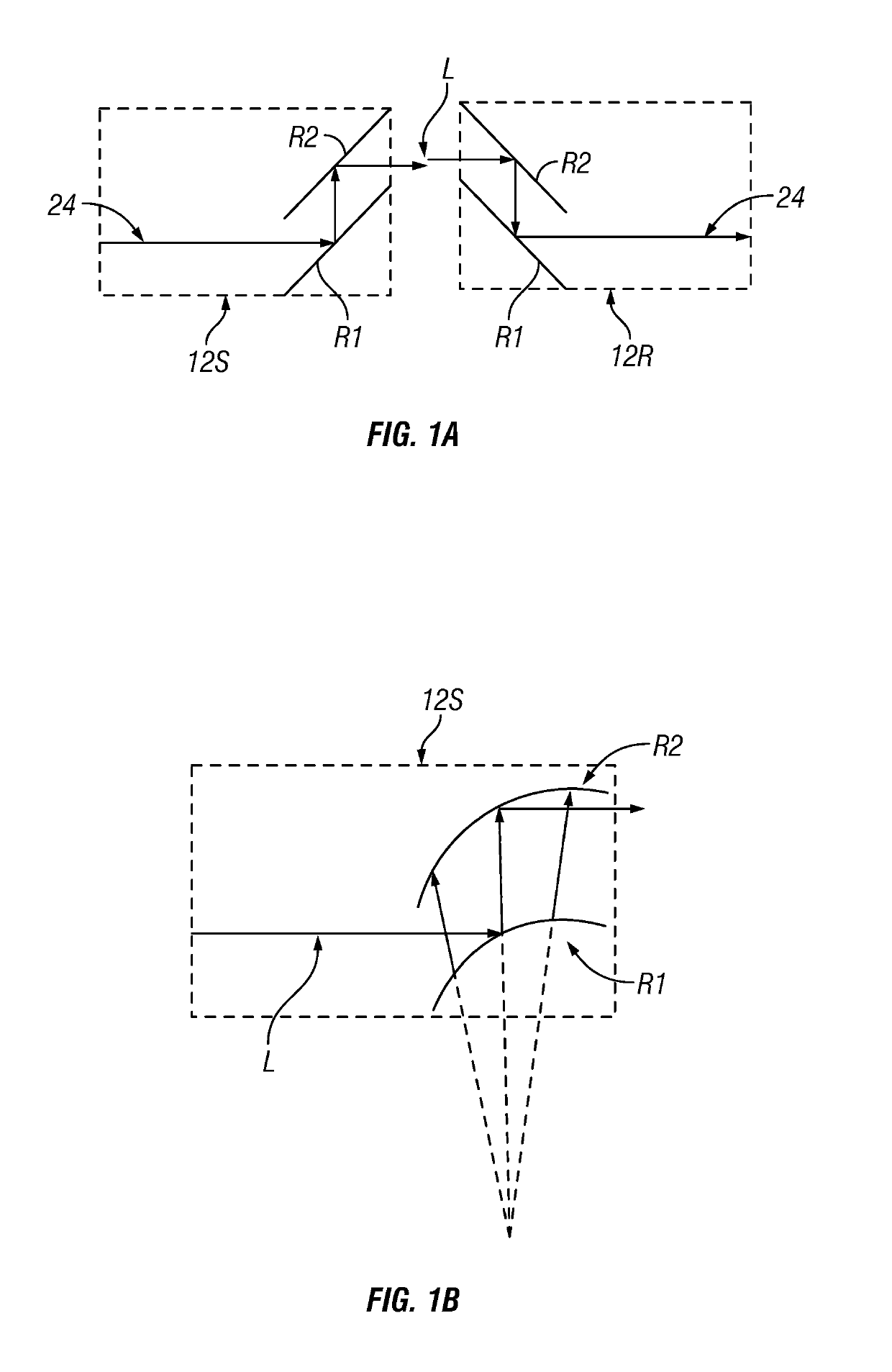

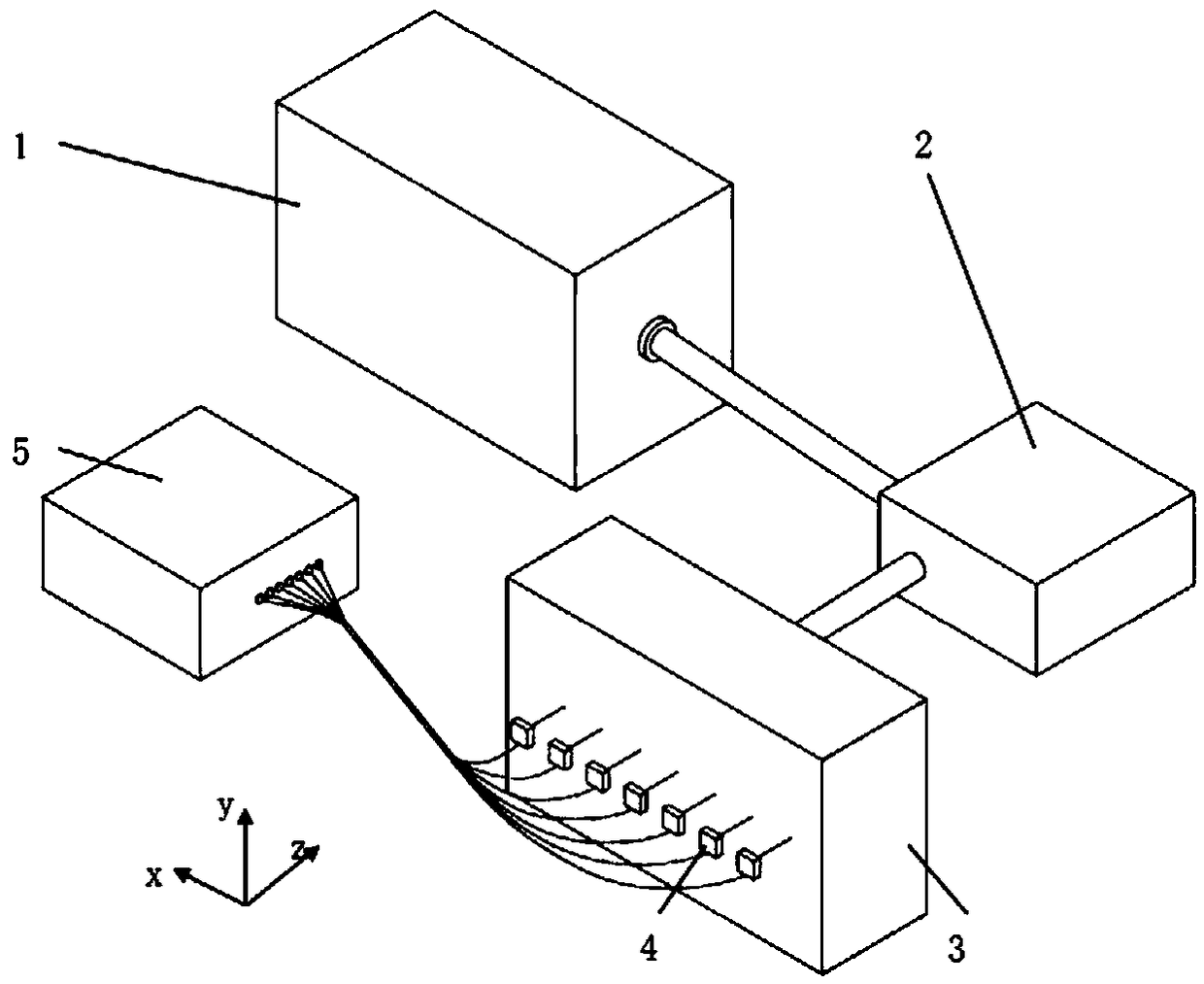

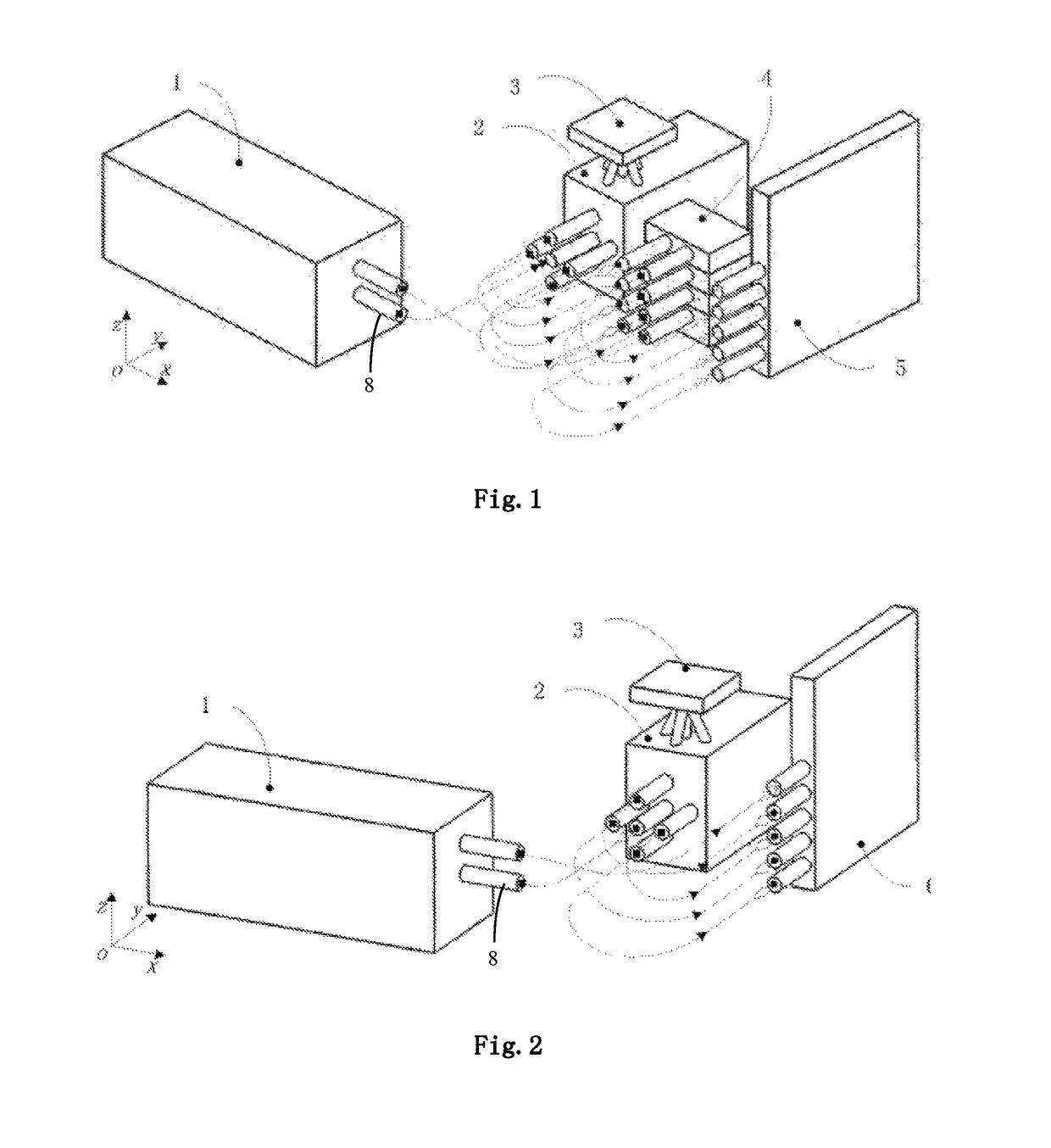

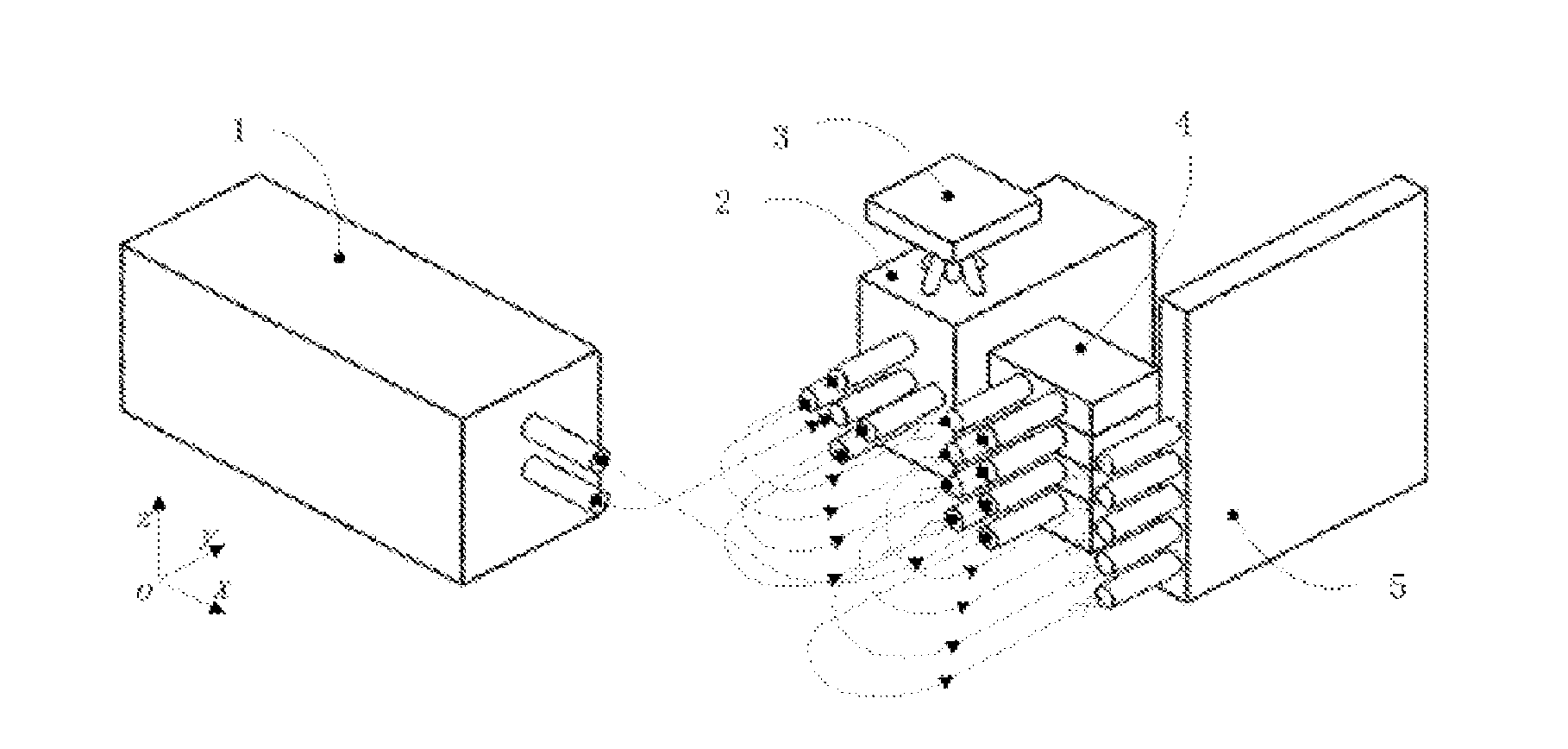

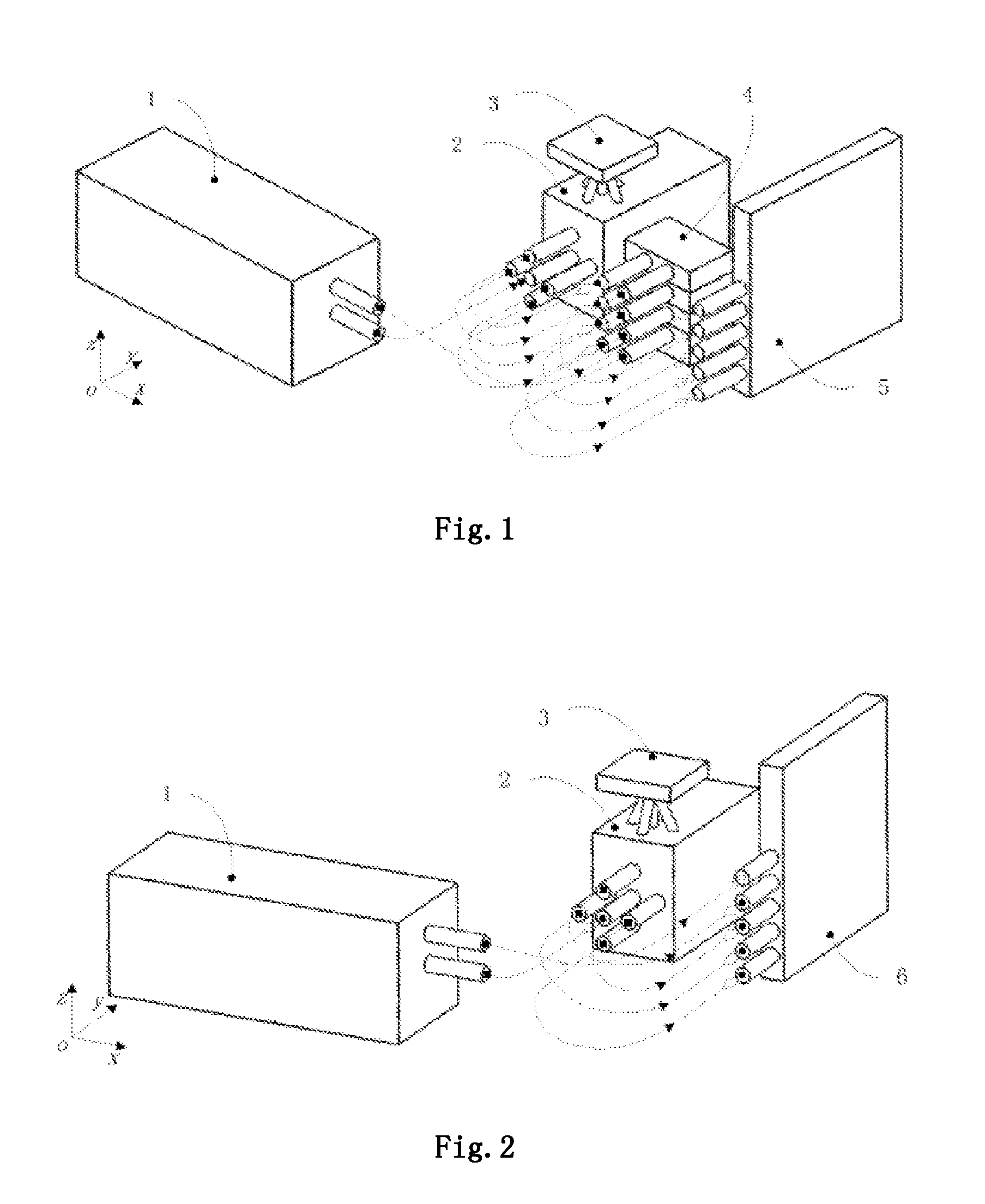

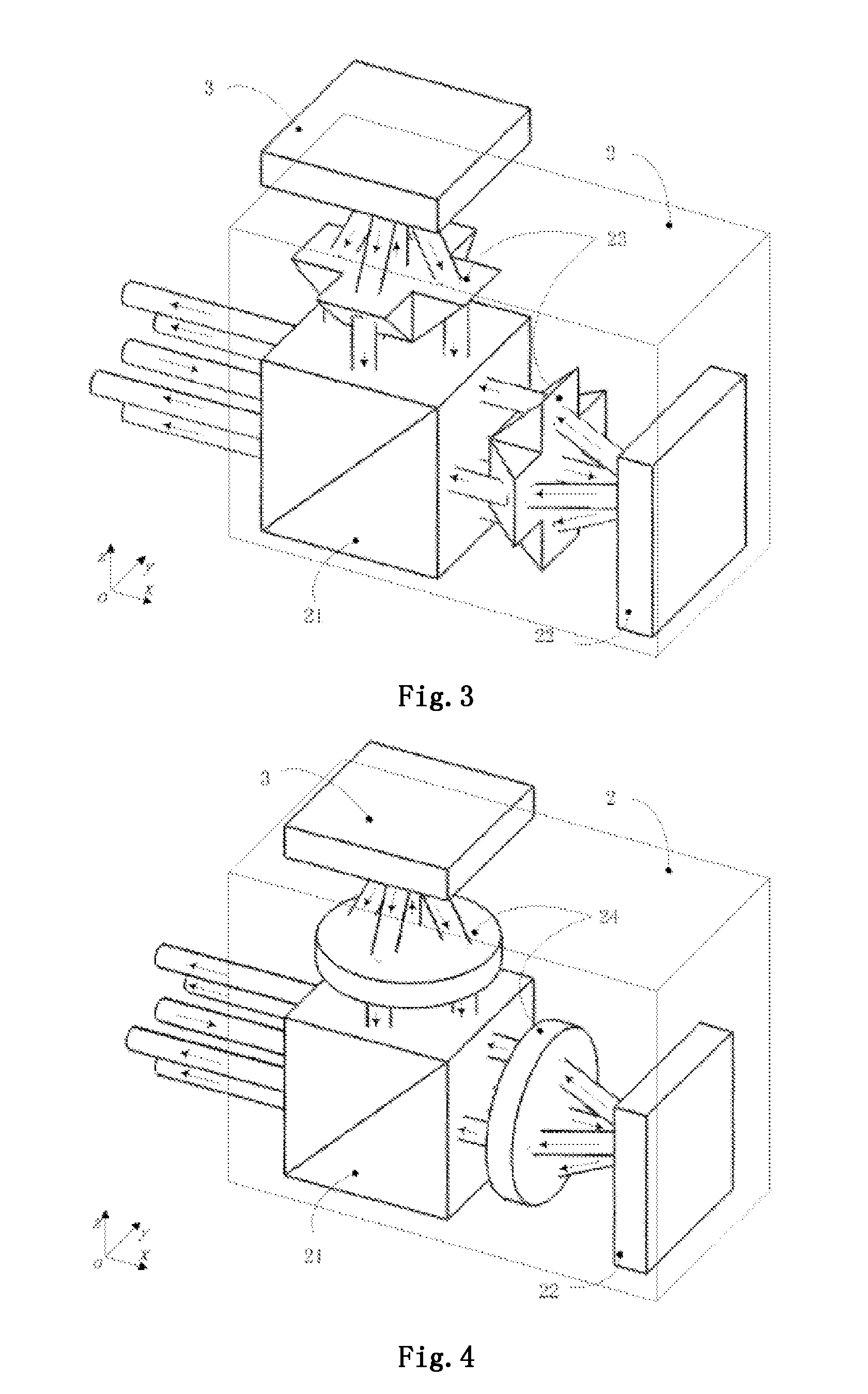

Two-DOF (degree of freedom) heterodyne grating interferometer displacement measurement system

ActiveCN103307986AMeasuring light path is shortLow environmental sensitivityInterferometersUsing optical meansGratingBeam splitter

A two-DOF (degree of freedom) heterodyne grating interferometer displacement measurement system comprises a two-frequency laser, a grating interferometer, a measuring grating, a receiver, and an electronic signal processing part. The grating interferometer comprises a polarizing beam splitter, a reference grating and a refraction element. The measurement system measures displacement according to optical grating diffraction, optical Doppler Effect and optical beat frequency principle. A two-frequency laser beam emitted by the two-frequency laser enter the grating interferometer and the measuring grating before two light signals are output to the receiver, and the signals are sent to the electronic signal processing part. When the grating interferometer is in two-DOF linear relative motion with the measuring grating, the system can output two linear displacements. The measurement system allows for sub-nano or higher resolution and precision, and can measure two linear displacements simultaneously. The measurement system has the advantages of insensitivity to environment, high measurement precision, small size, light weight and the like, and after the measurement system is used as a lithography machine ultra-precision workpiece bench position measurement system, comprehensive performances of a workpiece bench can be improved.

Owner:TSINGHUA UNIV +1

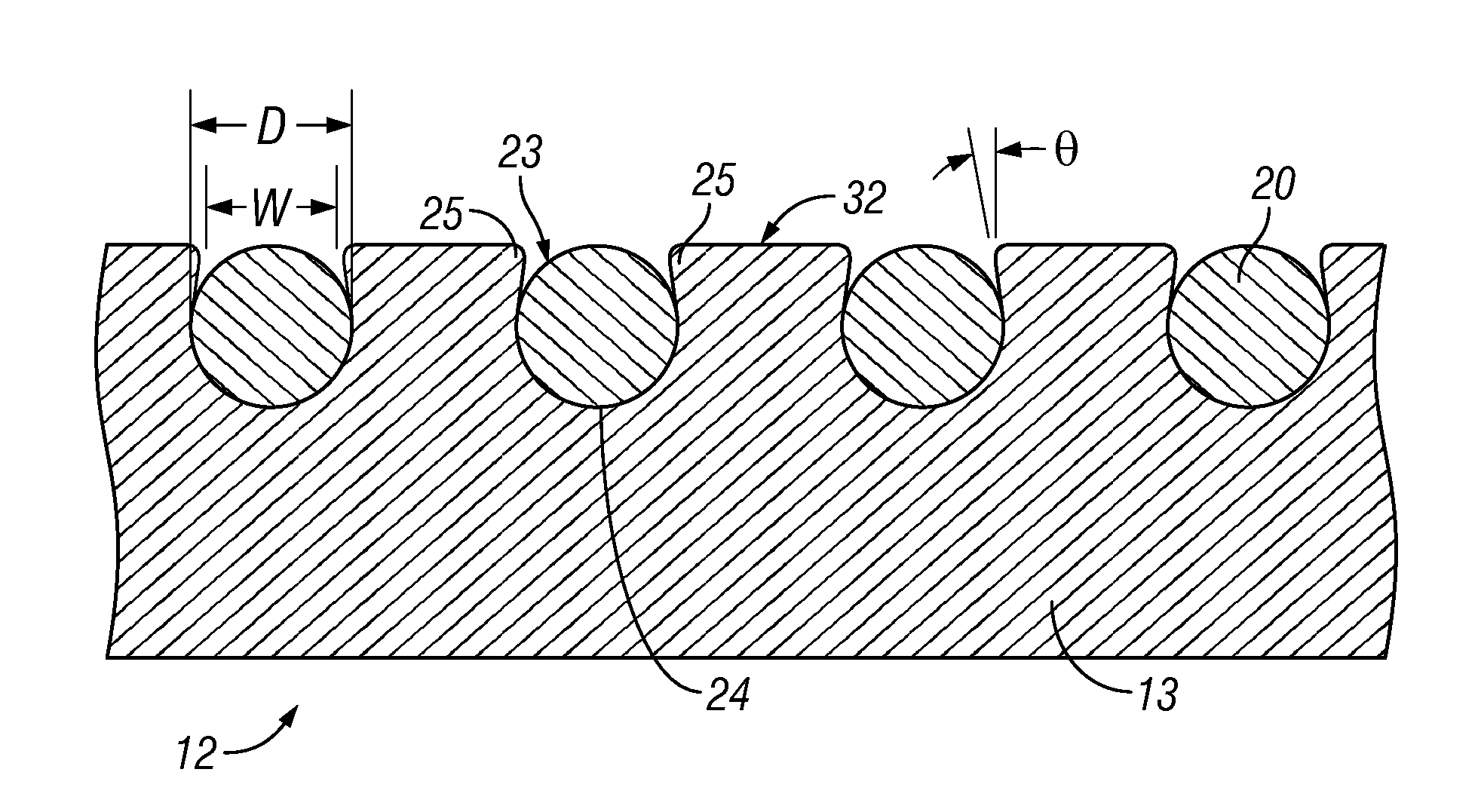

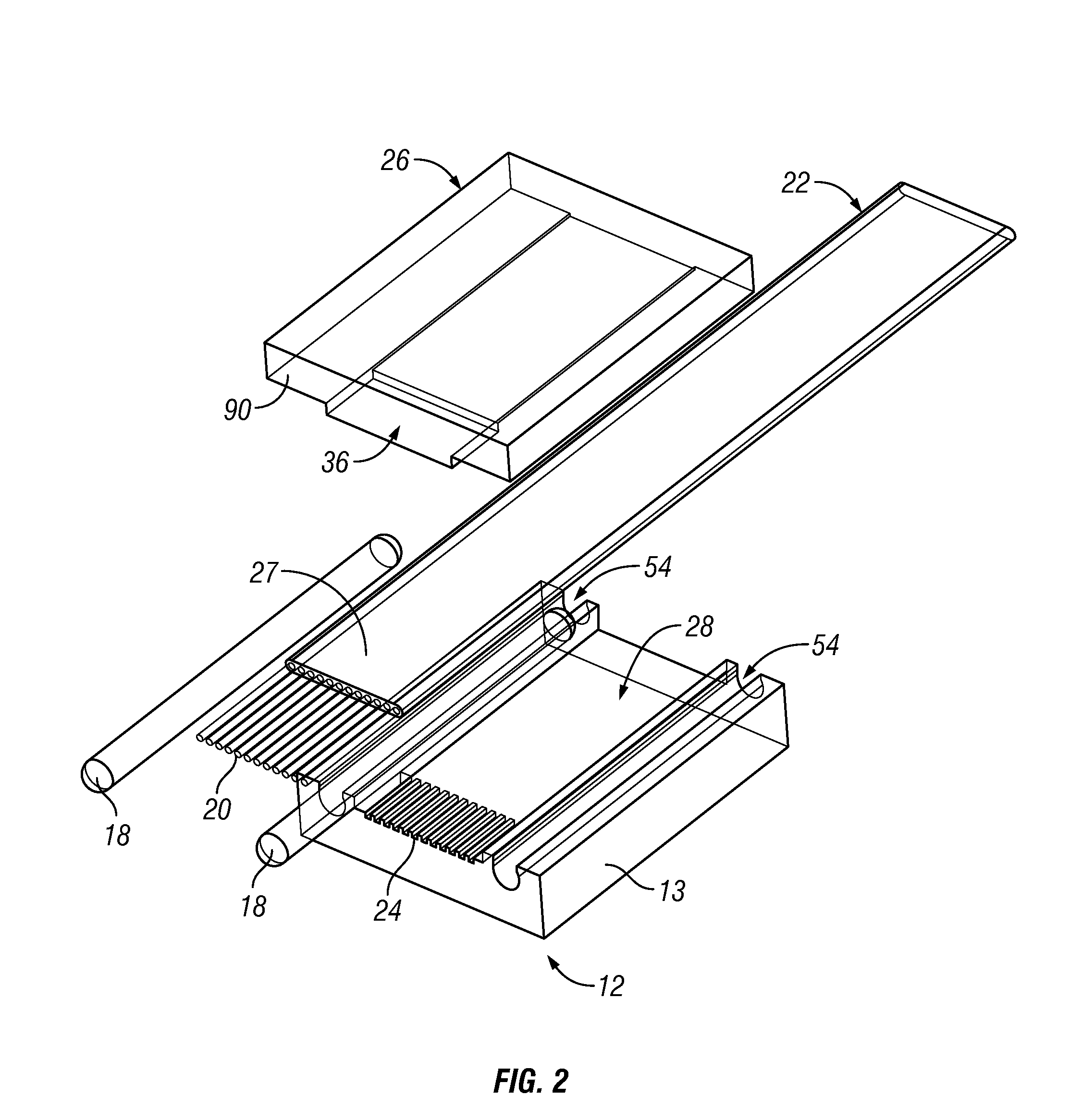

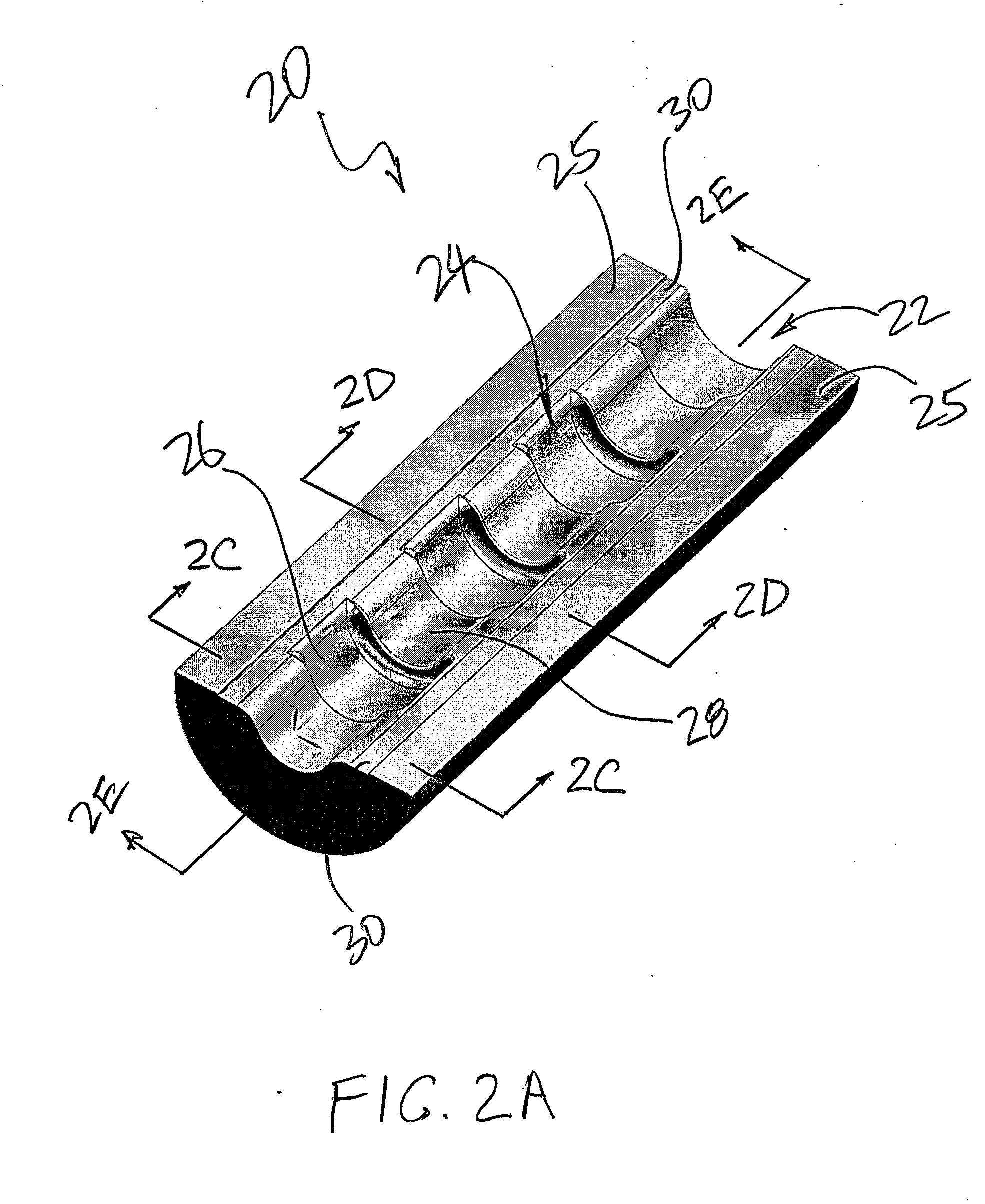

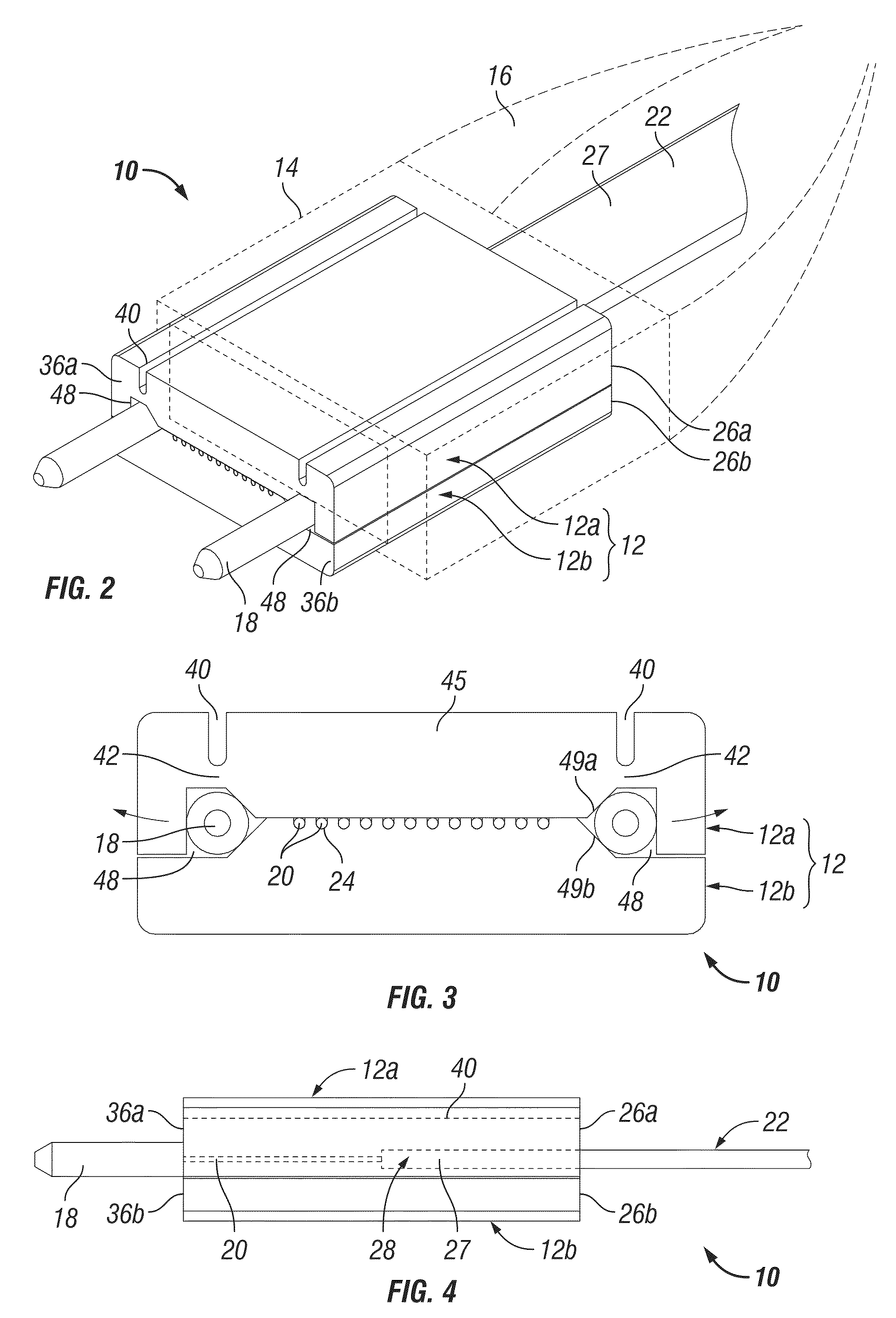

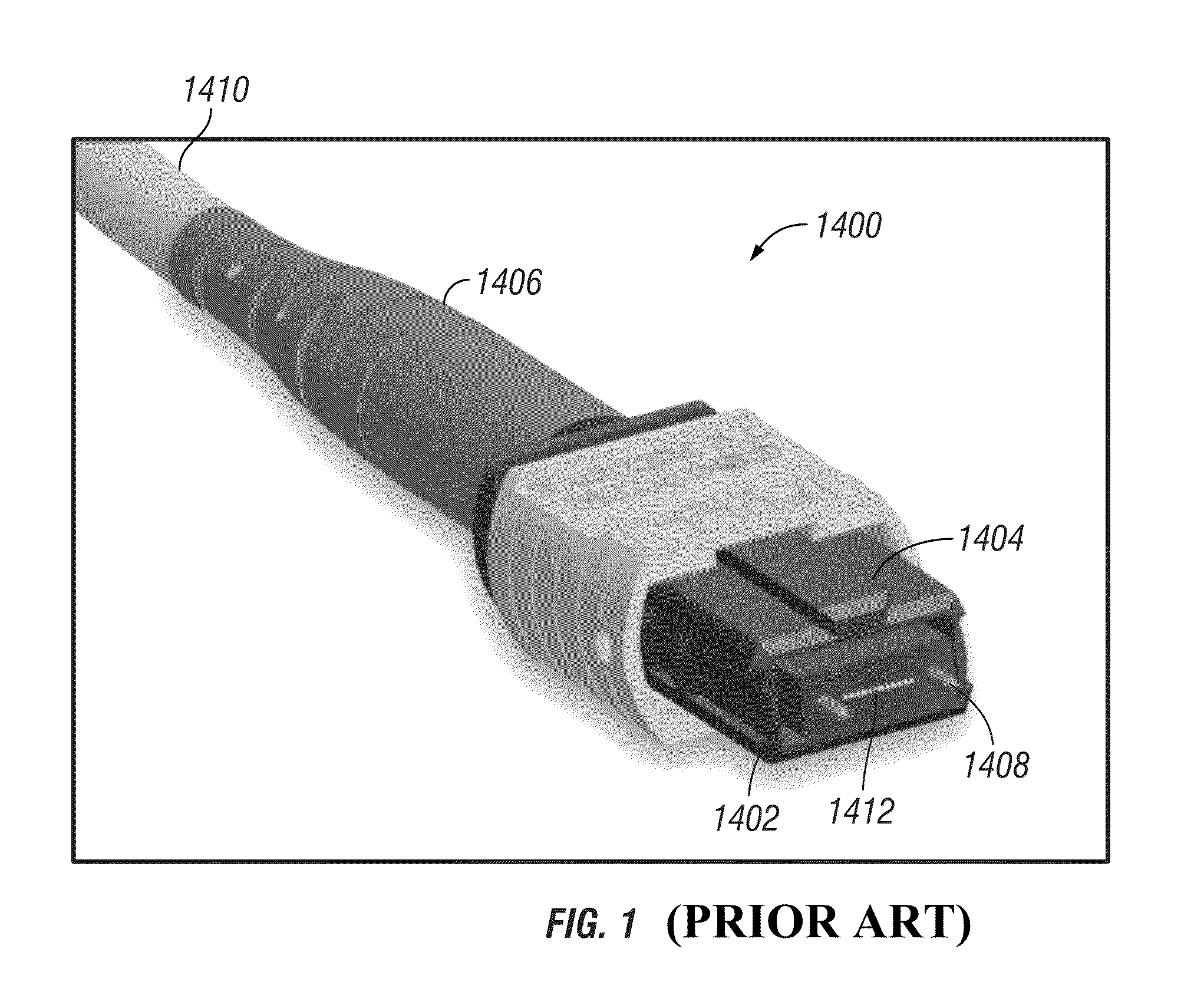

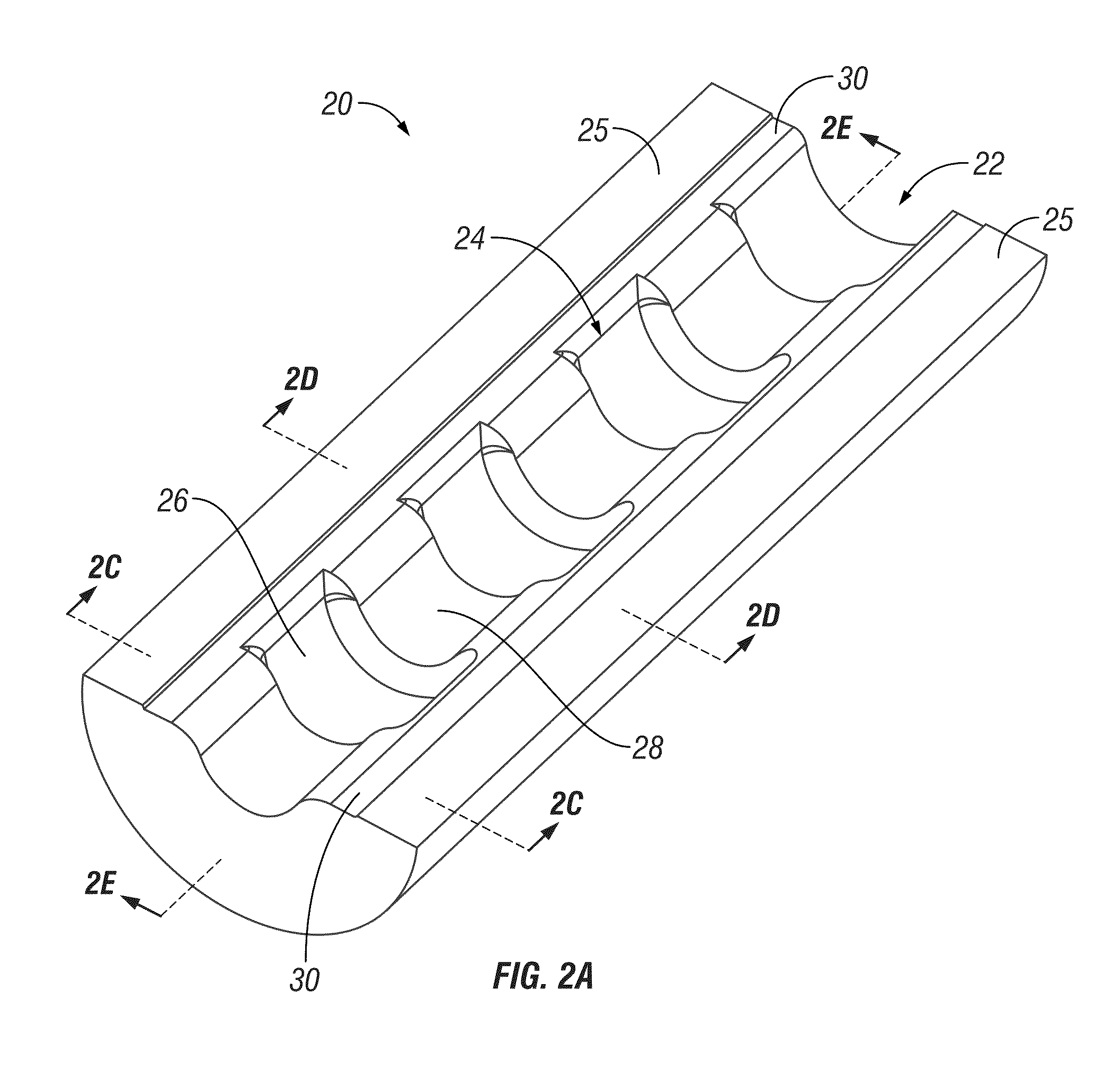

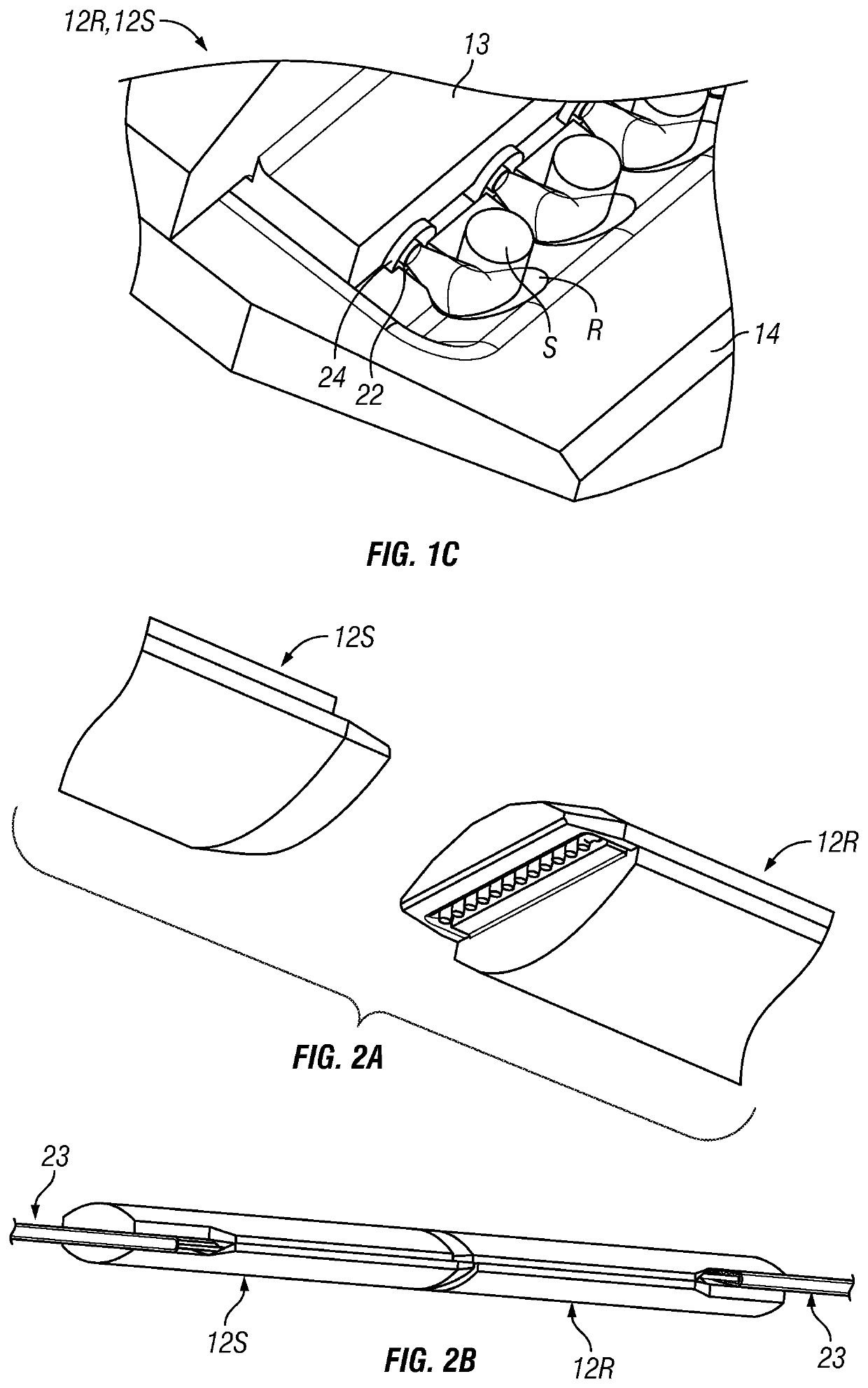

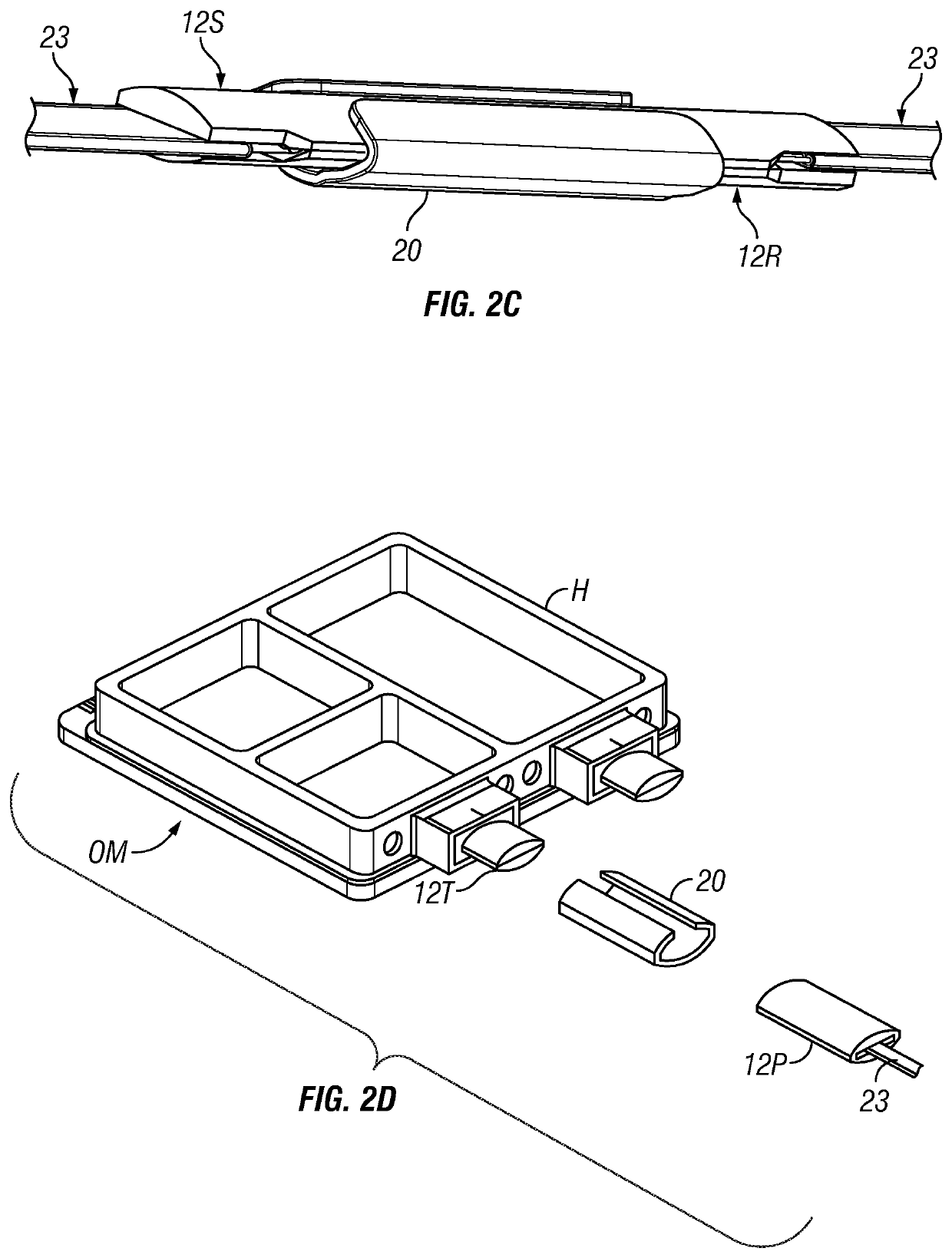

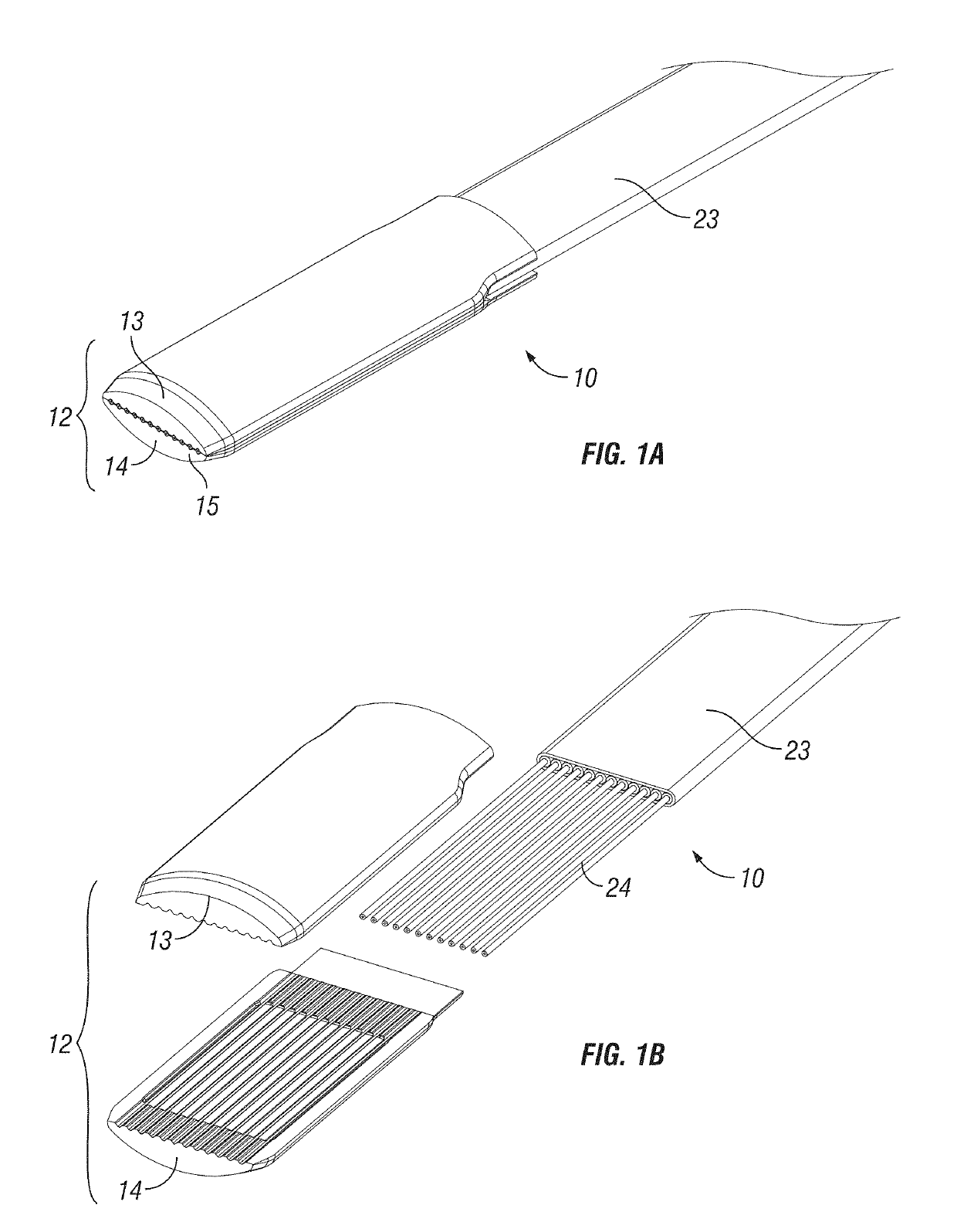

Optical fiber connector ferrule having open fiber clamping grooves

A ferrule for an optical fiber connector having open fiber clamping grooves. The ferrule has a body having a plurality of open grooves for clamping the terminating end sections of optical fibers. At least a section of the longitudinal opening of the groove is provided with opposing lips to provide a clamping effect. The width of the longitudinal opening defined between the lips along at least a section of the grooves is narrower than the diameter of the optical fibers to create a tight fit. The grooves and the width of the longitudinal groove openings are shaped and sized to retain the fibers without any clearance to allow for movement of the fiber relative to the groove. Similar grooves may be provided in the ferrule body for alignment guide pins. The grooves are precision formed by high throughput processes, such as stamping and extrusion.

Owner:SENKO ADVANCED COMPONENTS

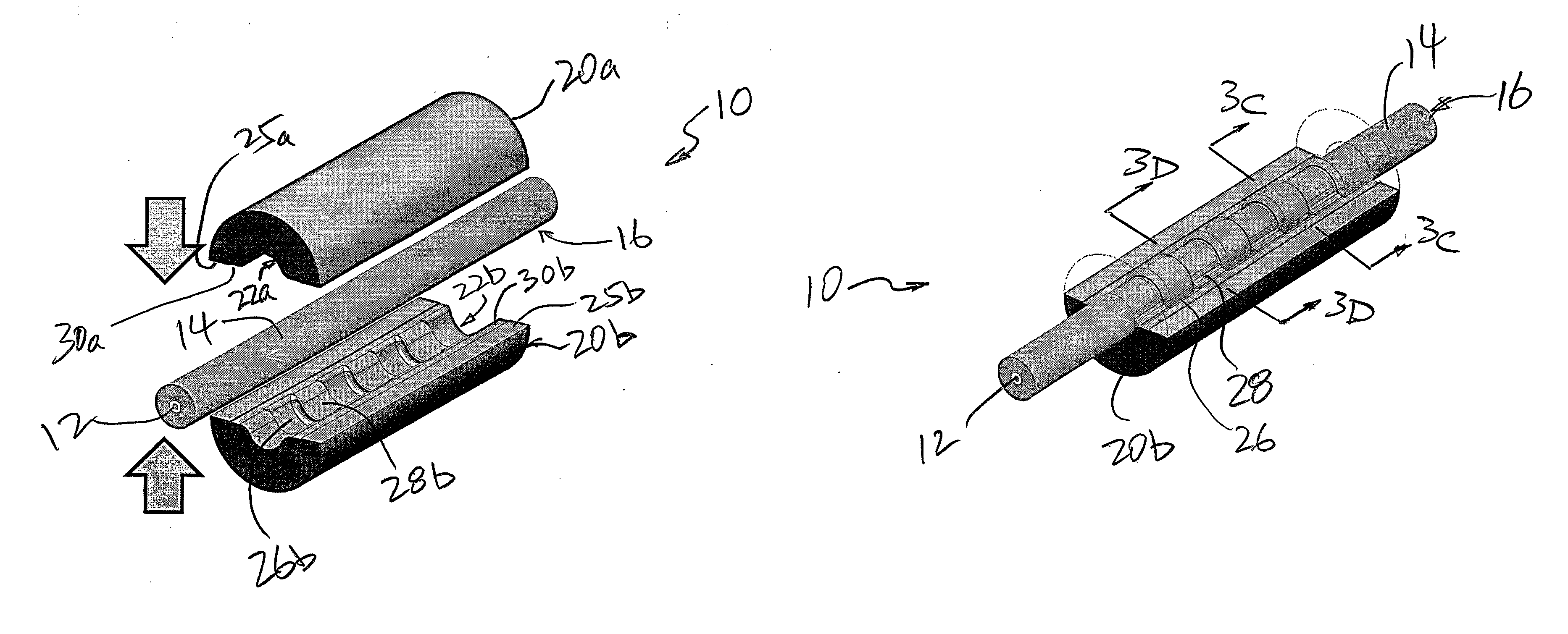

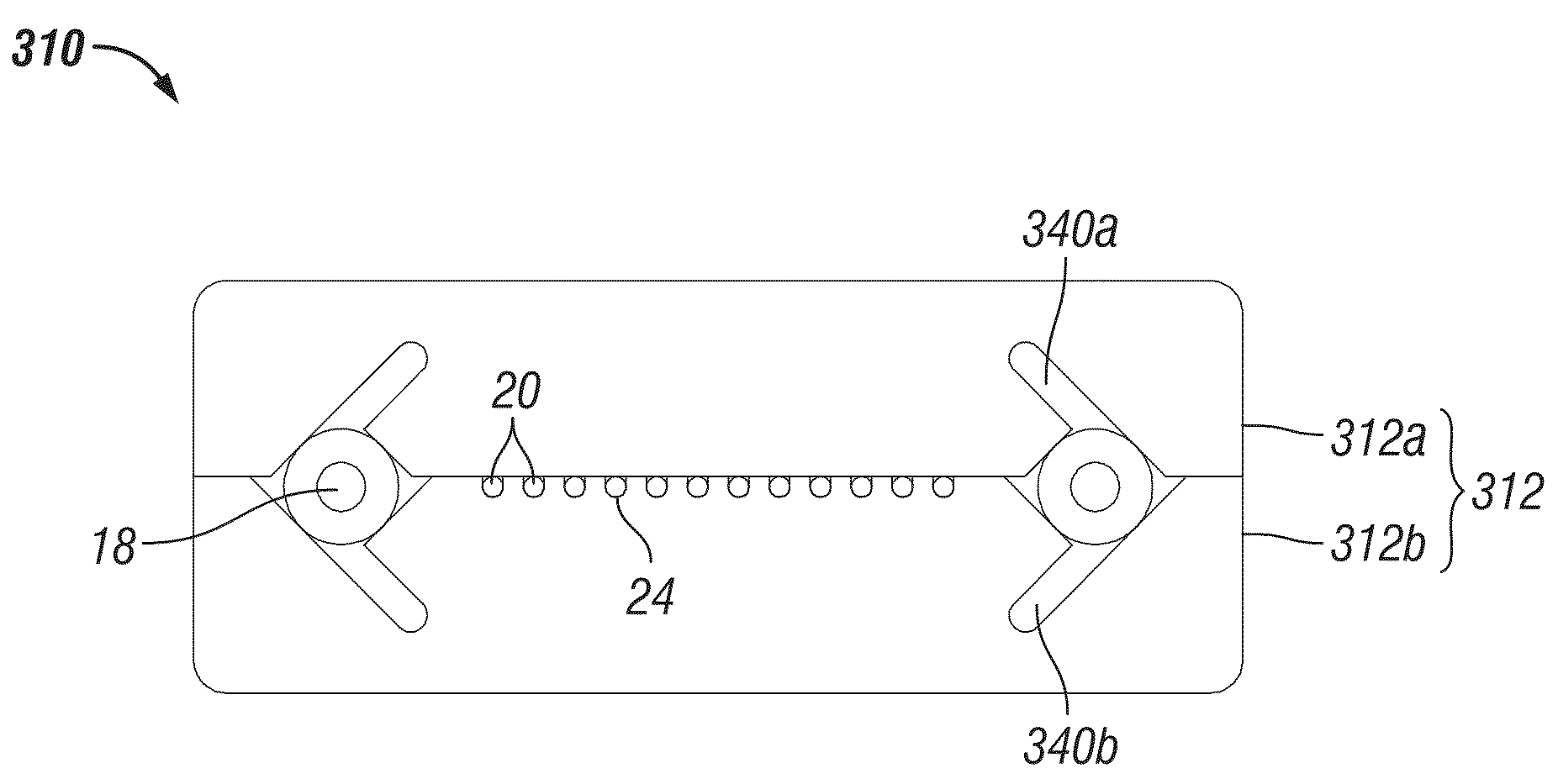

Castellated optical fiber cable retention structure

InactiveUS20130121656A1Improve reliabilityLow environmental sensitivityCoupling light guidesFibre mechanical structuresFiberSoft materials

A cable retention structure defining a castellated fiber cable clamping surface. The castellated surface has a series of alternating small and large cavities distributed along the axial direction. The small cavities are sized such that when the castellated surface is pressed against the buffer jacket exterior of the fiber cable, the small cavities will be able to clamp the fiber cable jacket within its full dimensional tolerance range. The large cavities are sized to provide sufficient clearance to accommodate the relatively soft material of the cable jacket which cannot be accommodated by the small cavities. The cable jacket is securely held by the retention structure to prevent slipping. Accordingly, fiber cables having buffer jackets with large dimensional variations can still be securely retained by the castellated retention structure in accordance with the present invention.

Owner:SENKO ADVANCED COMPONENTS

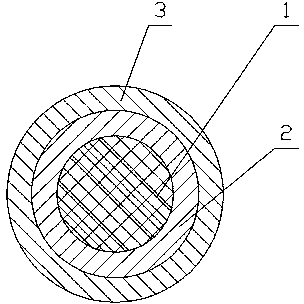

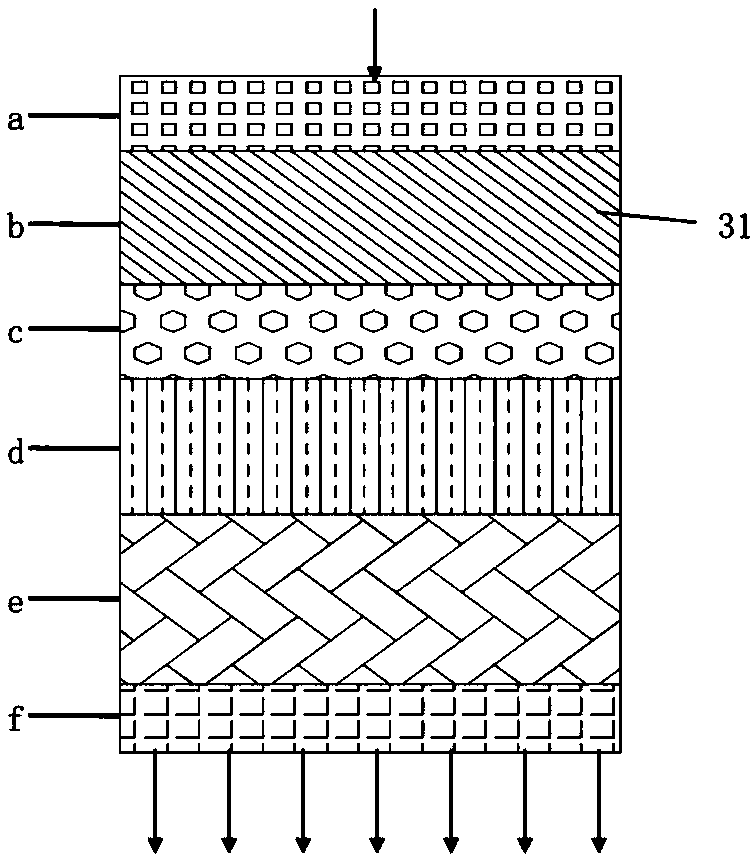

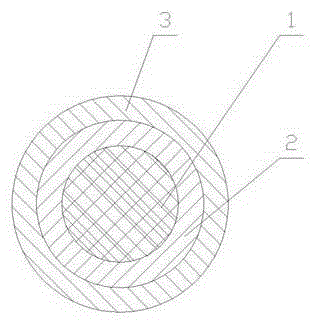

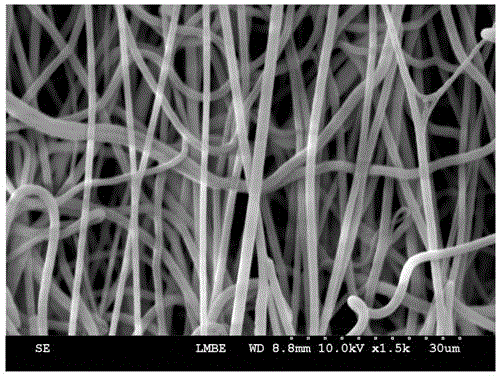

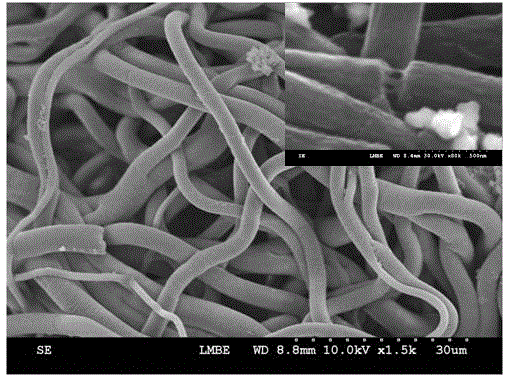

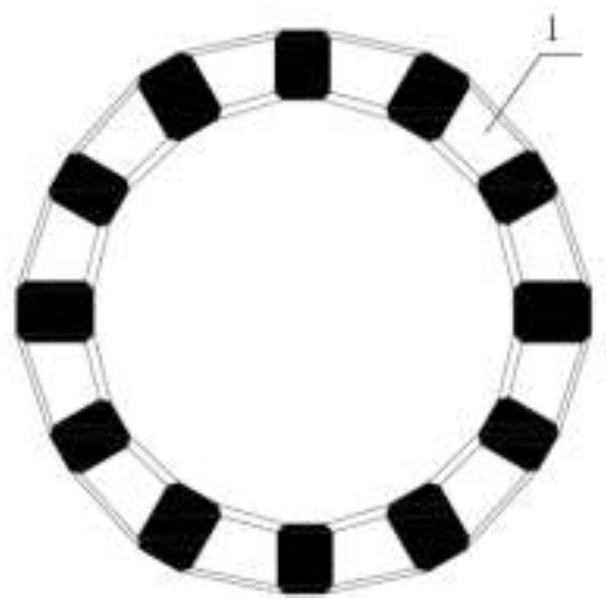

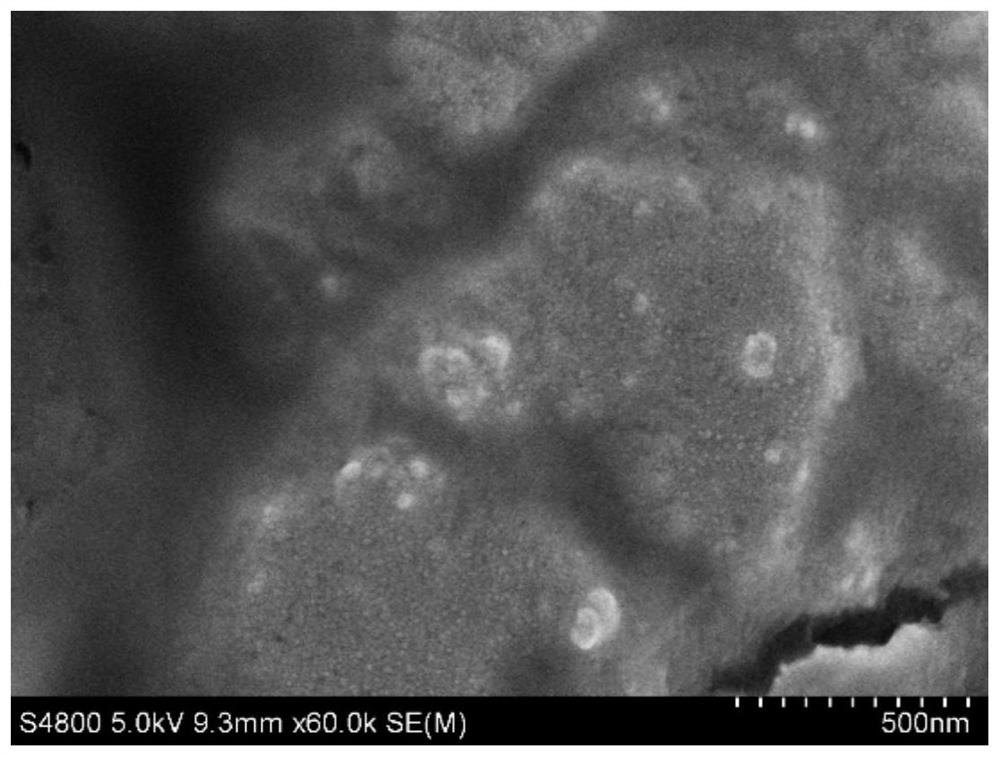

Coaxial three-layer high-activity bio-enzyme-embedded electrostatic spinning nano-fiber membrane and preparation method thereof

InactiveCN103668485AIncrease the amount of enzyme immobilizedPromote full accessFilament/thread formingNon-woven fabricsMembrane configurationReusability

The invention discloses a coaxial three-layer high-activity bio-enzyme-embedded electrostatic spinning nano-fiber membrane and a preparation method thereof. The coaxial three-way electrostatic spinning technology is used to allow bio-enzyme to be embedded into the sandwich layer of slow release activating agent and porous polymer so as to form the porous nano-fiber membrane. The nano-fiber membrane of a sandwich structure sequentially comprises a slow release activating agent layer (1), an immobilized bio-enzyme layer (2) and a porous polymer layer (3) from inside to outside. By building the structure with communicating ducts, immobilization amount of enzyme is increased, sufficient contact of the enzyme and a substrate is promoted, mass transfer resistance between the enzyme and the substrate is lowered, catalytic efficiency and reusability of the enzyme are increased effectively, environmental sensitivity of the bio-enzyme is lowered, and lasting stability of the bio-enzyme when being applied in complex environments is increased.

Owner:DALIAN OCEAN UNIV +1

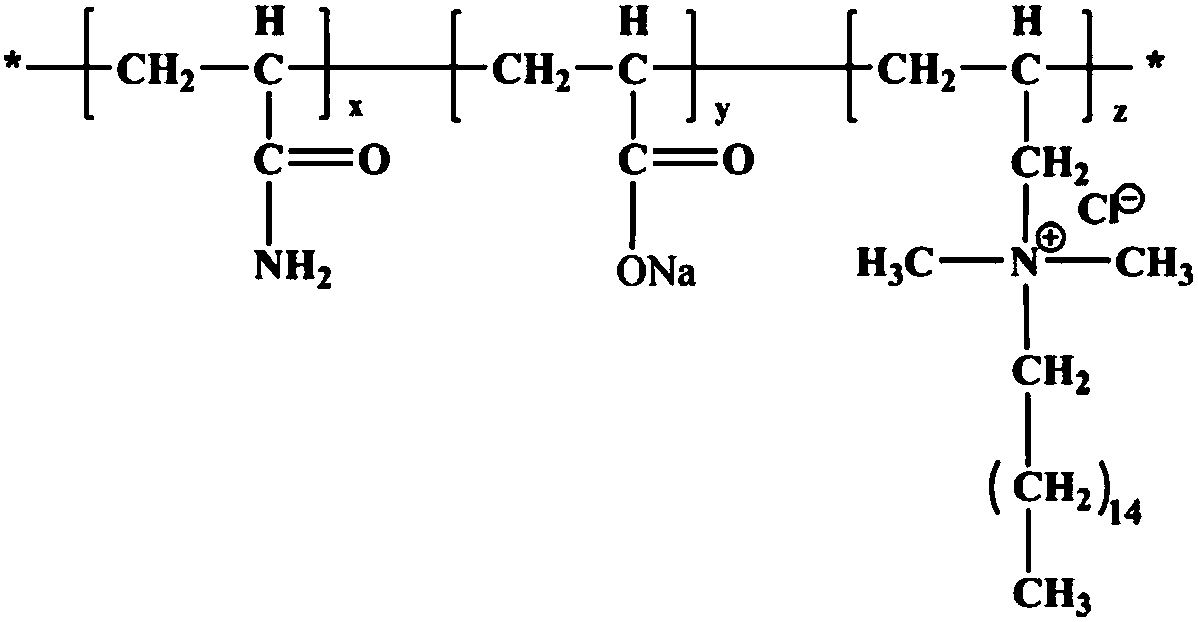

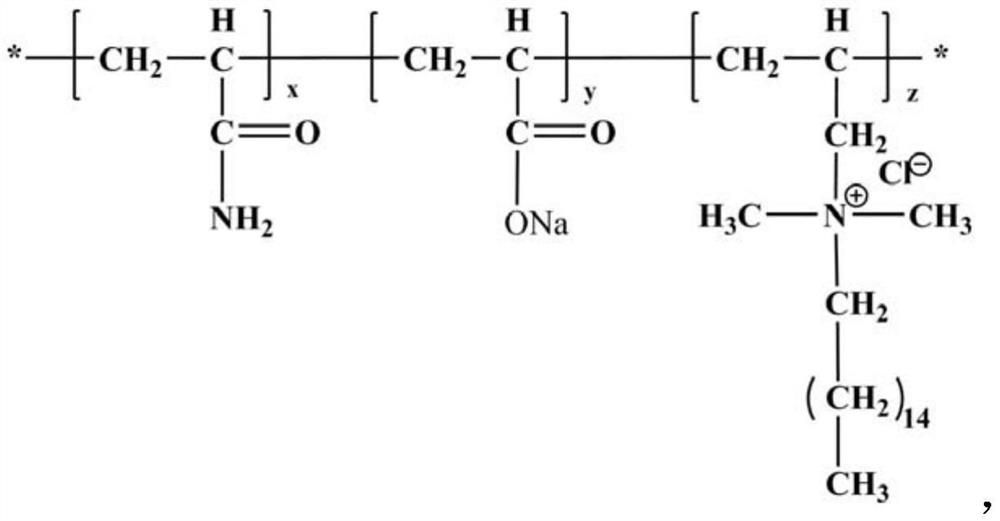

Profile adjusting and water plugging agent and application, profile adjusting and water plugging system and preparation method and application thereof

ActiveCN108587585AIncrease forceImprove long-term stabilityDrilling compositionUltimate tensile strengthPolyacrylamide

The invention provides a profile adjusting and water plugging agent and application, a profile adjusting and water plugging system and preparation method and an application thereof, and relates to thetechnical field of oilfield development. The profile adjusting and water plugging agent comprises, by weight, the following raw materials: 5-30 parts of inorganic nano-particles, 2-10 parts of amphiphilic polymer, 2-10 parts of activator and 1-10 parts of cross-linking agent; the profile adjusting and water plugging system comprises profile adjusting and water plugging agent and water; the technical problem of limited application range of the existing polyacrylamide gel water plugging system under the condition of high temperature and high salt is relieved, so that the long-term stability andthe plugging strength of the generated water plugging gel are obviously improved, and the environmental sensitivity is obviously reduced, so that the system has a wide application prospect in the development of high-temperature and high-salt oil reservoirs.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

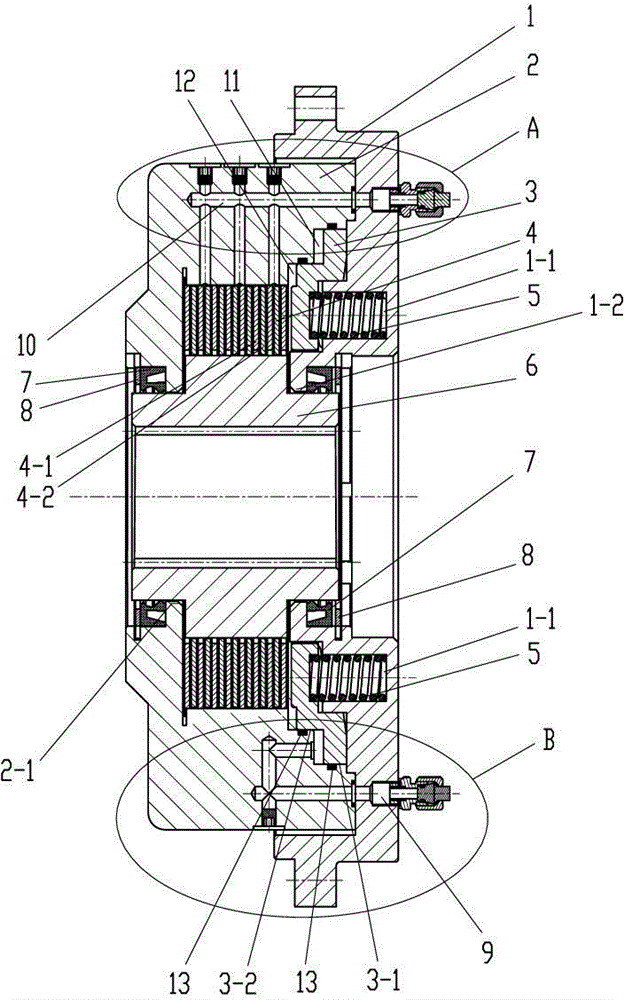

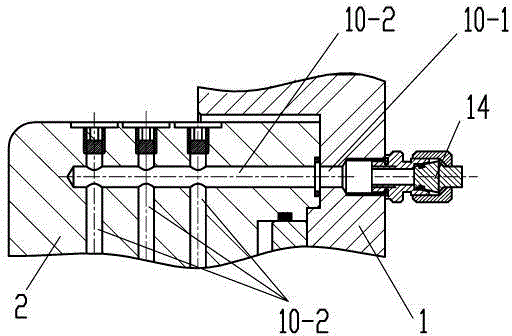

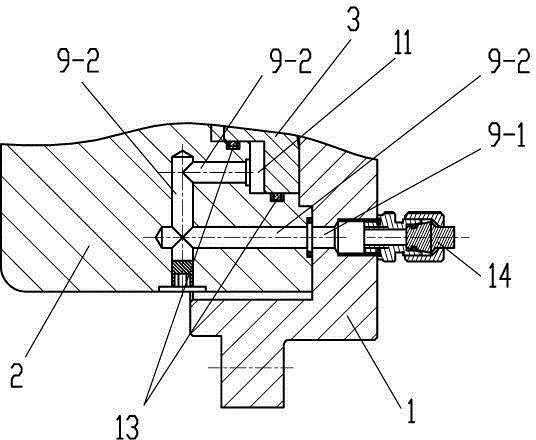

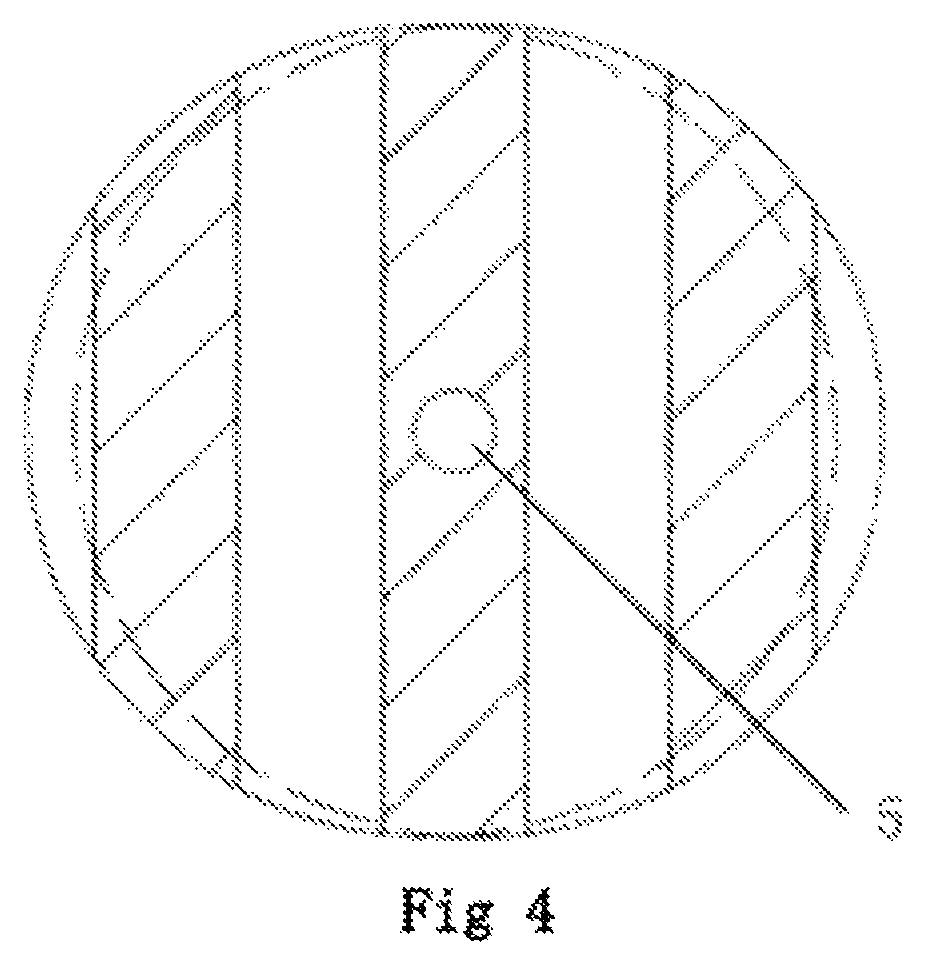

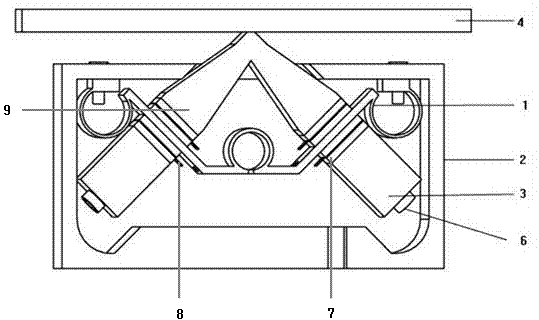

Wet multi-disc parking brake

InactiveCN103912613ALow environmental sensitivitySafe and reliable performanceFluid actuated brakesBrake actuating mechanismsPistonPiston cylinder

The invention discloses a wet multi-disc parking brake which comprises a brake cover, a brake shell, a piston, a friction pair, a spring, a spline shaft, a sealing element and a retainer ring. The piston is mounted in a piston cylinder encircled by the brake cover and the brake shell, the piston cylinder comprises a first cylinder hole with a large diameter and a second cylinder hole with a small diameter, the piston is provided with a first sliding surface with a large diameter and a second sliding surface with a small diameter, the first sliding surface is in slide fit with the wall of the first cylinder hole, the second sliding surface is in slide fit with the wall of the second cylinder hole, the spring on the brake cover is butted to the back of the piston, the friction pair comprises friction discs and dual discs, is arranged on the outer periphery of the spline shaft and is positioned on a side of the front surface of the piston, the friction discs and the dual discs are axially alternately arranged, the brake shell is meshed with the friction discs via internal spline, the dual discs are meshed with the spline shaft via internal splines, and a high-pressure oil circuit and a lubricating oil circuit are arranged in a tank. The wet multi-disc parking brake has the advantages that the wet multi-disc parking brake is small in radial size, and dry friction among the friction discs and the dual discs can be prevented.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

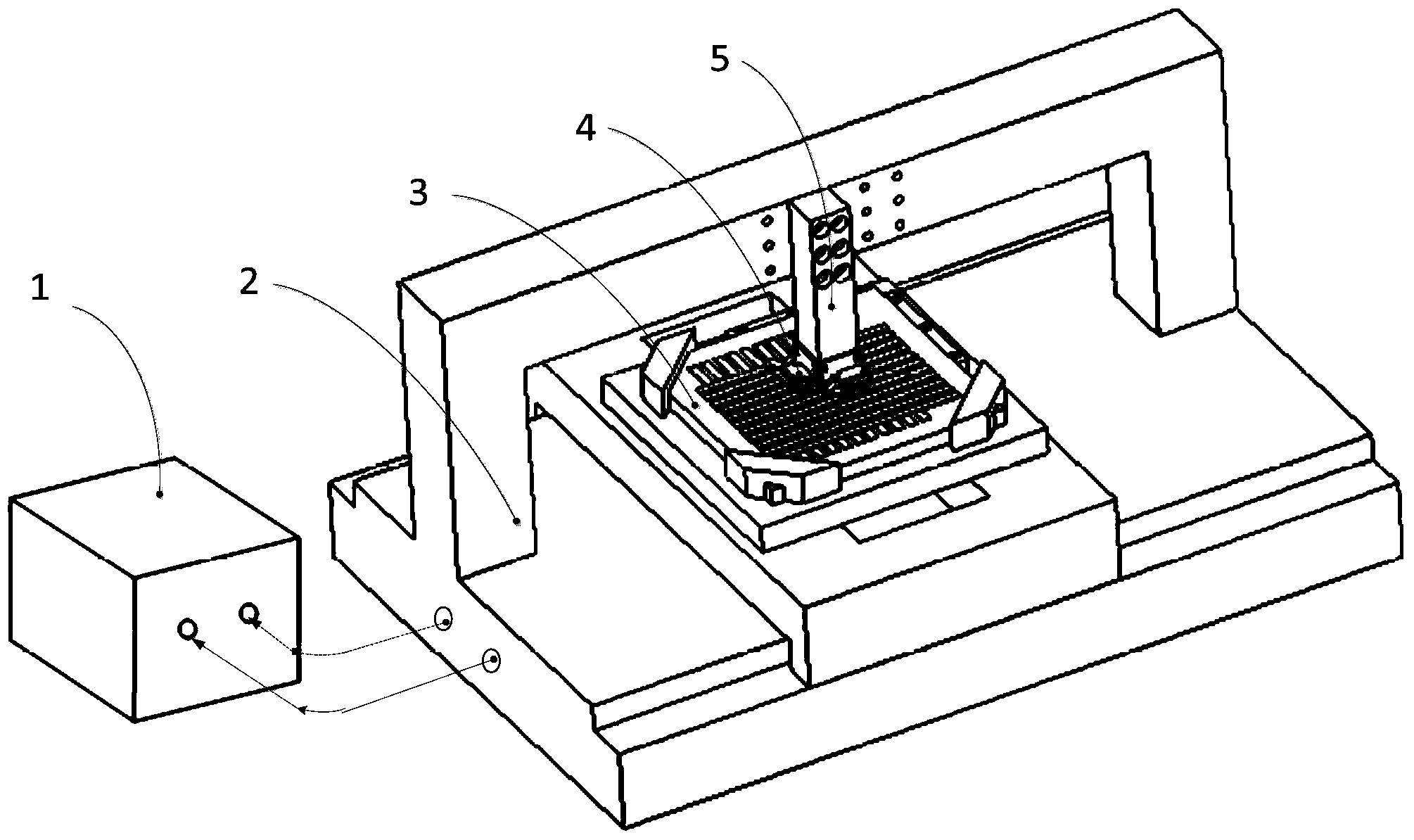

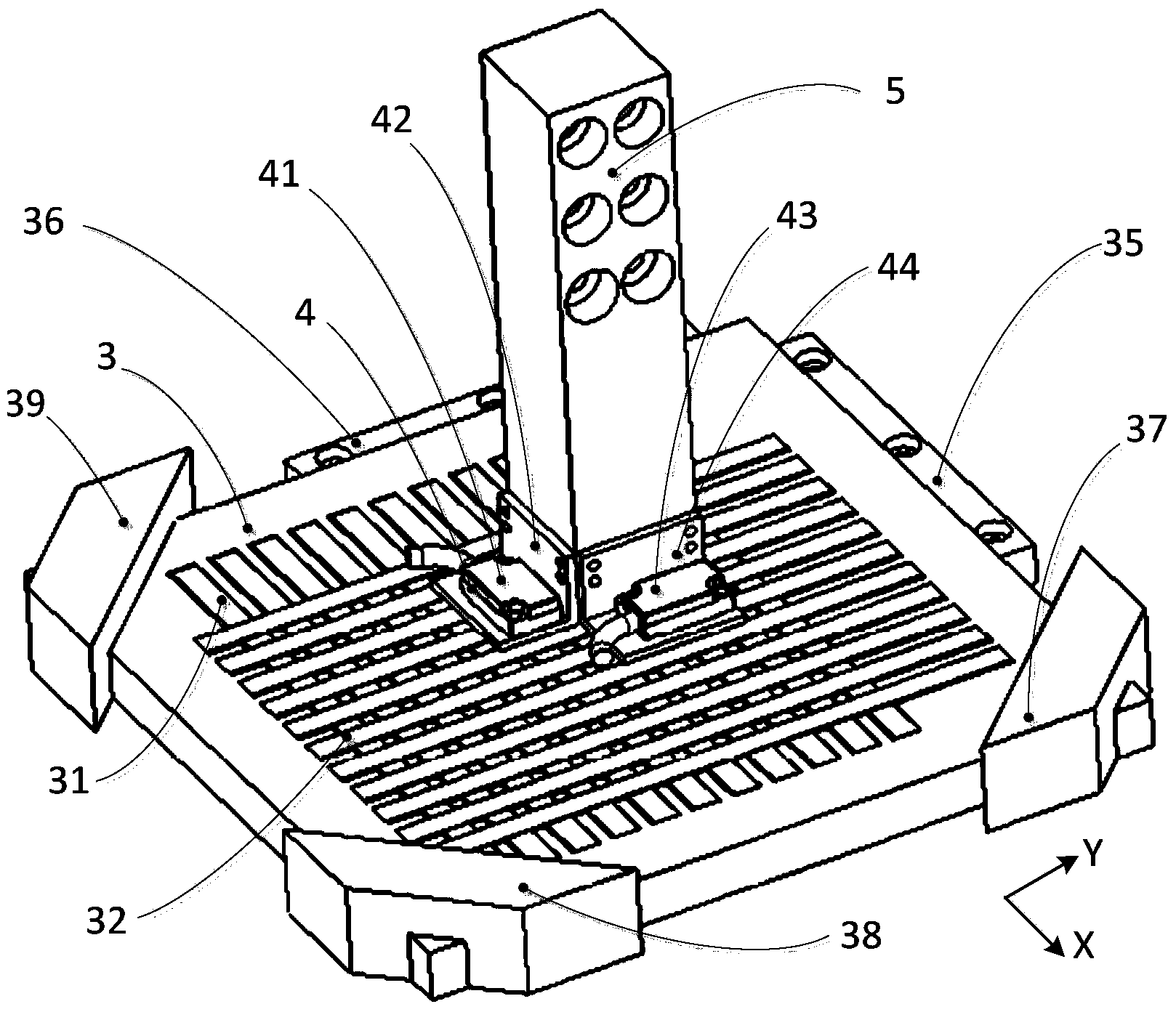

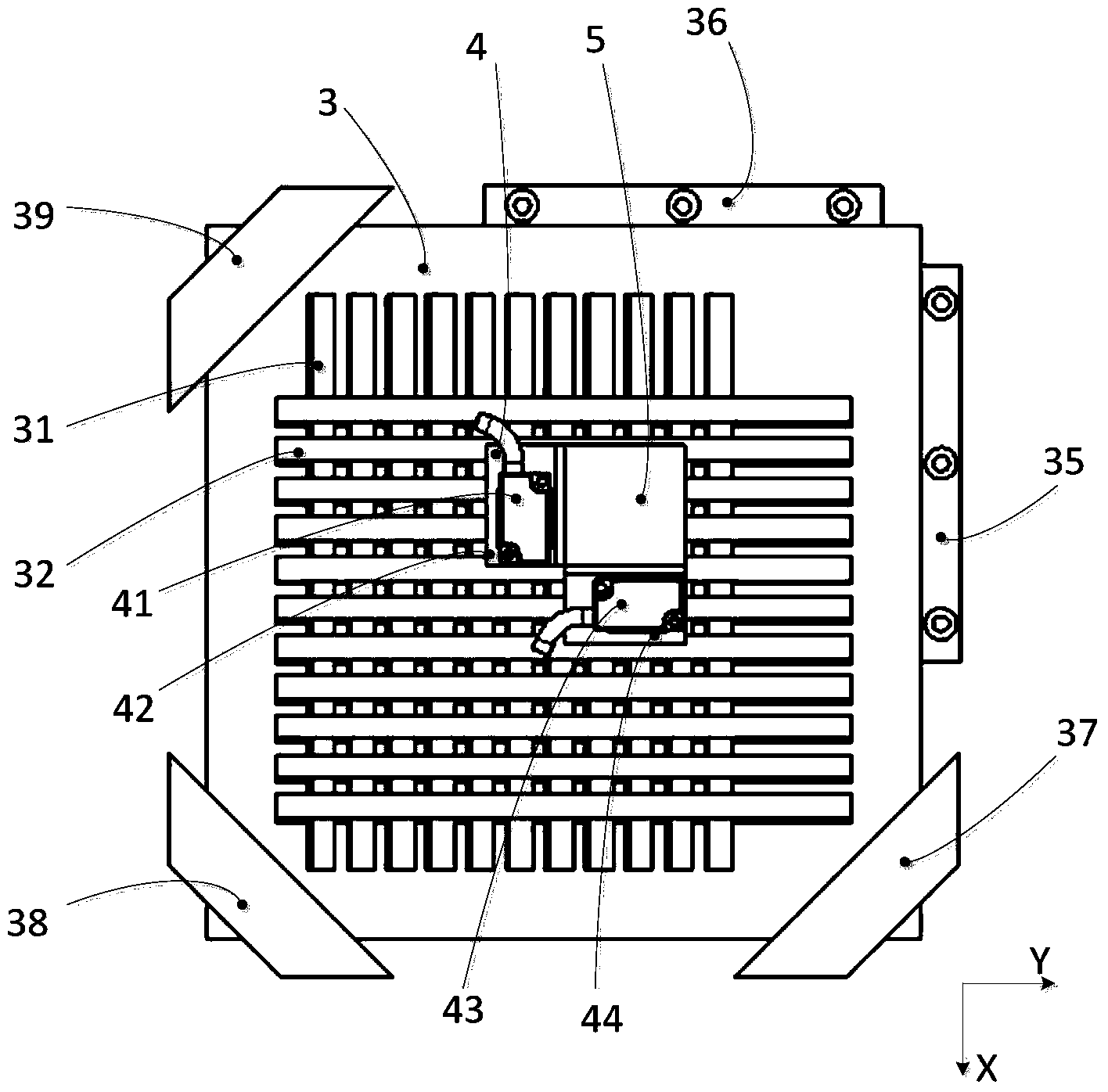

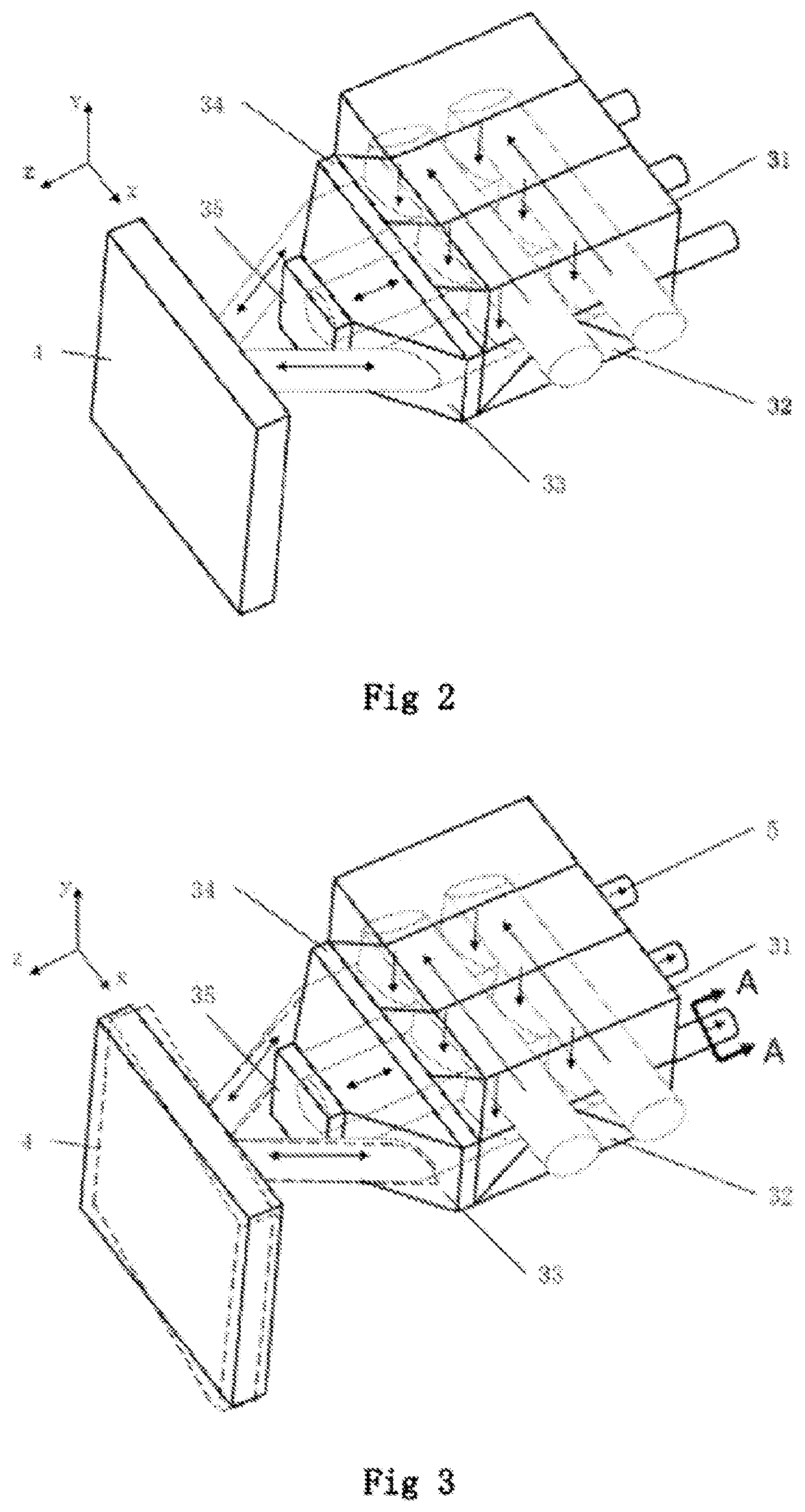

Two-dimension self-calibration gauge point detection alignment system

ActiveCN104019744AMature detection technologySimplified Detection TechnologyUsing optical meansGratingSignal on

A two-dimension self-calibration gauge point detection alignment system comprises a zero signal reader, a two-dimension workbench, a grating ruler auxiliary calibration plate, a reading head detection part and a measuring reference frame. The grating ruler auxiliary calibration plate comprises grating rulers with zero gauge points in the X direction and in the Y direction. The reading head detection part comprises a grating ruler reading head and a mounting support. The alignment system achieves gauge point alignment based on a grating ruler detection alignment principle and a zero signal detection principle. The reading head detects zero gauge point signals on the grating ruler auxiliary calibration plate to transmit the signals to the zero signal reader, meanwhile, the two-dimension workbench records the position coordinates of the two-dimension workbench and transmits the signals to the zero signal reader, and the position coordinates of the zero gauge points are obtained. The two-dimension self-calibration gauge point detection alignment system can be applied to the two-dimension self-calibration technology, and nanoscale resolution and alignment precision are achieved. Signal reading time delay is small, and the two-dimension self-calibration gauge point detection alignment system can be applied to workbench dynamic and high-speed calibration. The entire structure is relatively simple, the performance is high, and the two-dimension self-calibration gauge point detection alignment system is not sensitive to environments.

Owner:TSINGHUA UNIV +1

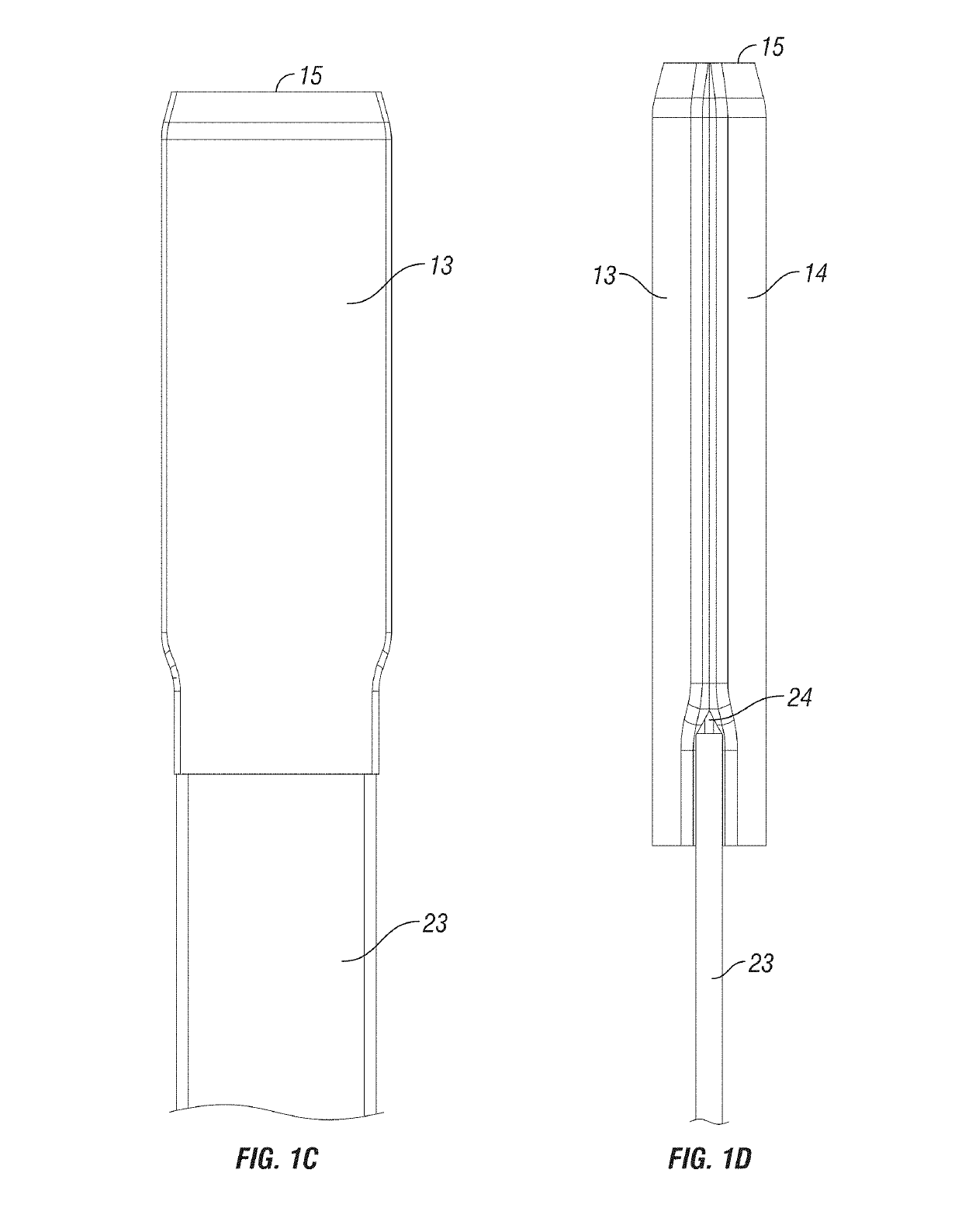

Ferrule for optical fiber connector having a compliant structure for clamping alignment pins

ActiveUS9279942B2Low insertion lossReduce usageCoupling light guidesEngineeringOptical fiber connector

A compliant structure clamps the alignment pins to accurately and precisely locate the alignment pins. The compliant structure supports the alignment pins with no clearance. The compliant structure is defined by at least a flexure in the form of a cantilevered structure extending at a side of the ferrule. The cantilevered structure, with or without a complementary support structure, defines a space in which an alignment pin can be supported. The flexure may be defined by one or more slots provided on the body of the ferrule to facilitate bending of the extended cantilevered structure. In another embodiment, the ferrule comprises a ferrule insert having grooves for supporting optical fibers, and a ferrule frame that supports the ferrule insert and alignment pins. The compliant structure is provided on the frame. In a further embodiment, the ferrule insert is provided with optical fiber grooves at its perimeter.

Owner:SENKO ADVANCED COMPONENTS

Castellated optical fiber cable retention structure

InactiveUS9091833B2Improve reliabilityLow environmental sensitivityCoupling light guidesFibre mechanical structuresFiberEngineering

A cable retention structure defining a castellated fiber cable clamping surface. The castellated surface has a series of alternating small and large cavities distributed along the axial direction. The small cavities are sized such that when the castellated surface is pressed against the buffer jacket exterior of the fiber cable, the small cavities will be able to clamp the fiber cable jacket within its full dimensional tolerance range. The large cavities are sized to provide sufficient clearance to accommodate the relatively soft material of the cable jacket which cannot be accommodated by the small cavities. The cable jacket is securely held by the retention structure to prevent slipping. Accordingly, fiber cables having buffer jackets with large dimensional variations can still be securely retained by the castellated retention structure in accordance with the present invention.

Owner:SENKO ADVANCED COMPONENTS

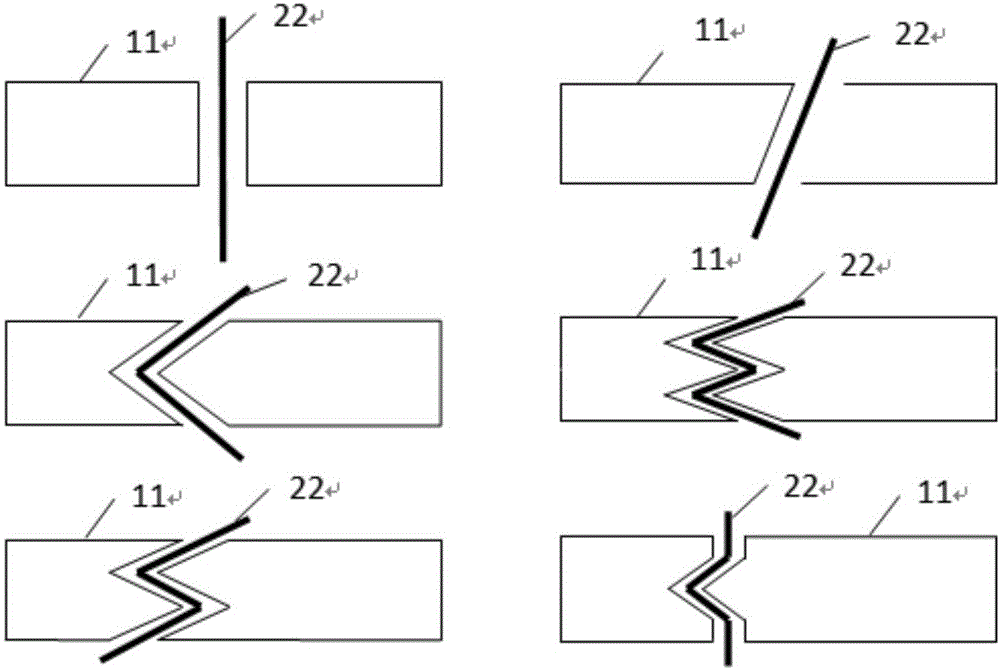

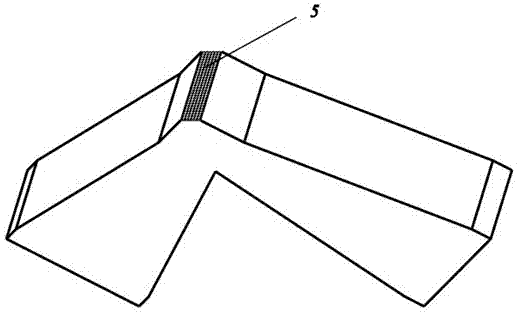

Thermoplastic composite material joint connecting method

InactiveCN105729791ALow environmental sensitivityStructural weight gain is smallLap jointThermoplastic composites

A method for connecting joints of thermoplastic composite materials, which includes pretreating the joint parts of thermoplastic composite materials; fixing the thermoplastic composite materials on a fixture in a way that the joint parts are opposite or overlapping; clamping carbon fiber unidirectional tapes or fabrics on the thermoplastic composite materials Between the joints, leave some carbon fiber unidirectional tape or fabric outside the joints, apply conductive glue and clamp it on the conductive clip of the heating equipment, turn on the DC power supply of the heating equipment, until the joints are welded together to form a joint ; Steps such as trimming the shape of the joint. Effects of the present invention: the joint structure made has less influence on the in-plane performance of thermoplastic composite materials, lowers environmental sensitivity, less weight gain to the structure, less change in shape, and can improve the bonding effect between joints of thermoplastic composite materials , so that the mechanical properties and reliability of the thermoplastic composite joint structure can be improved, and the practical risk of the thermoplastic composite joint structure can be reduced.

Owner:CIVIL AVIATION UNIV OF CHINA

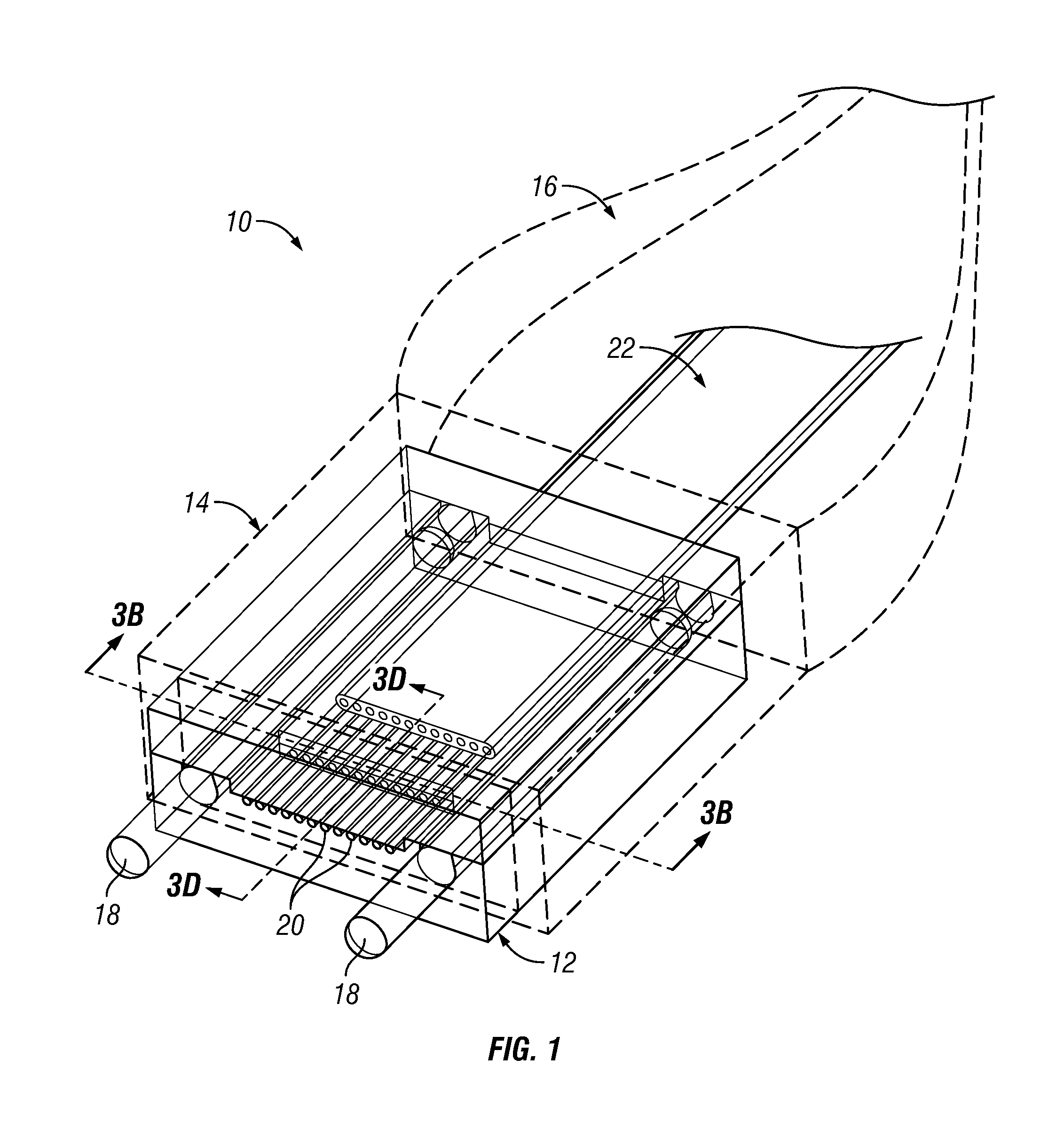

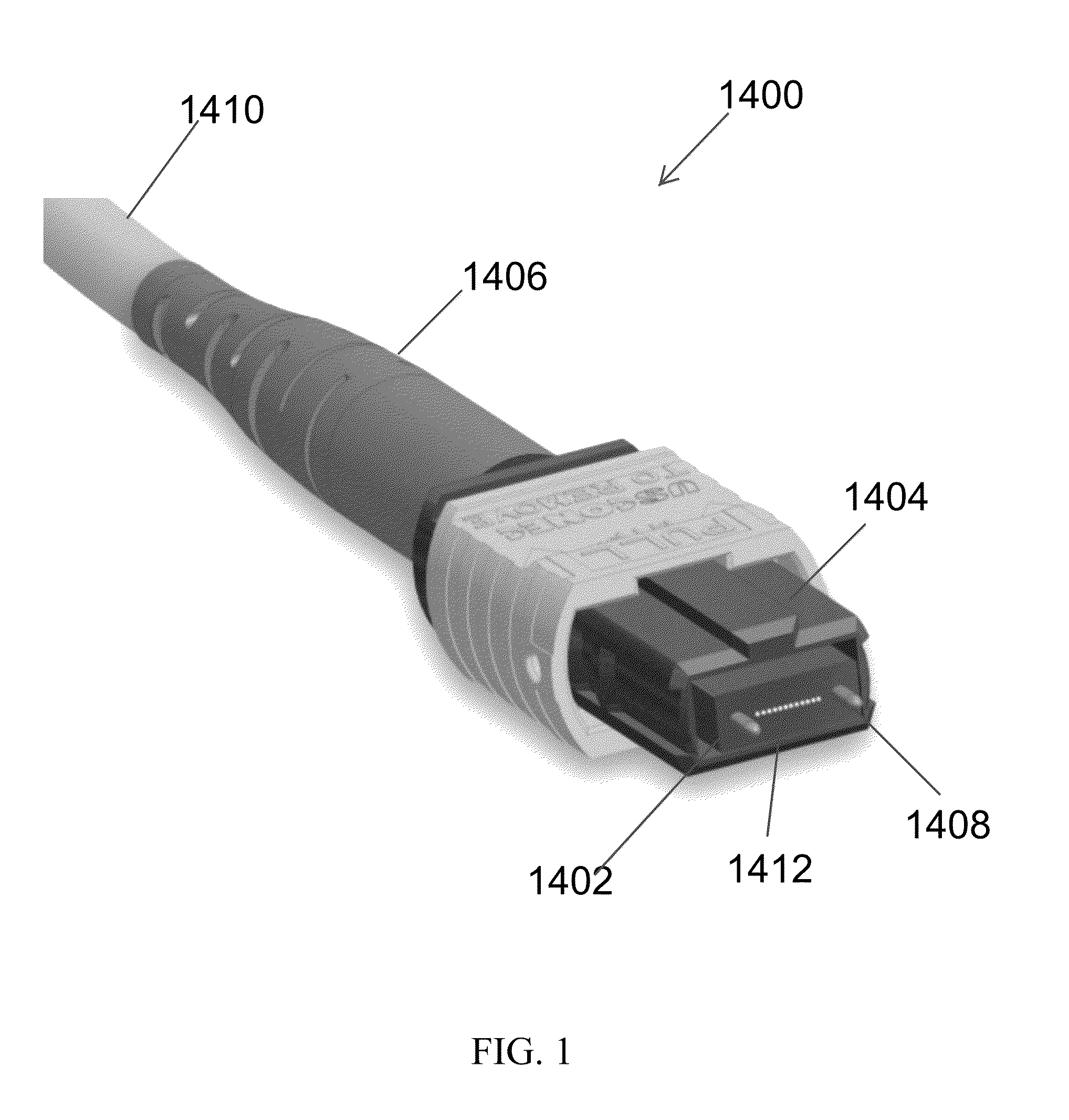

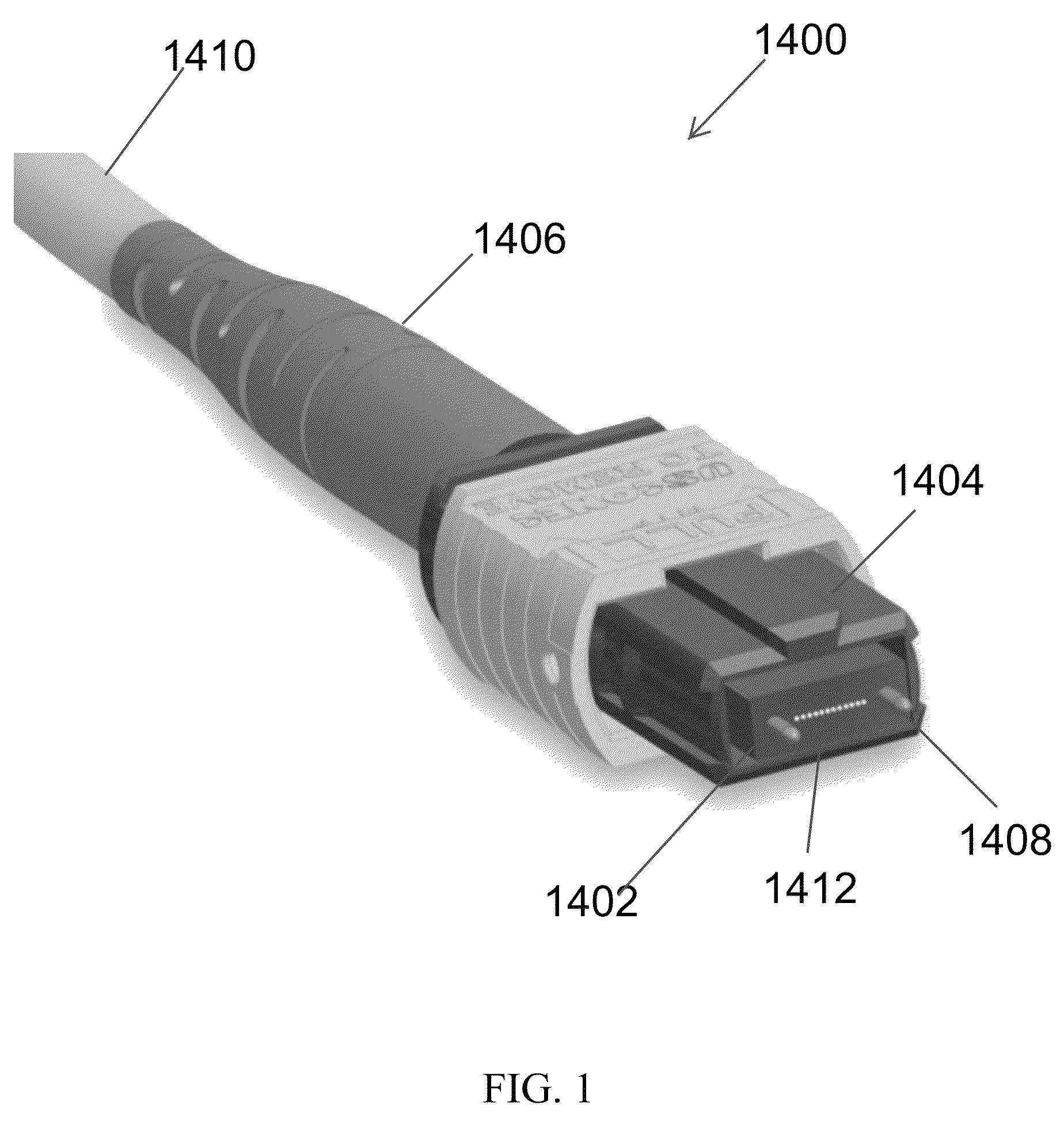

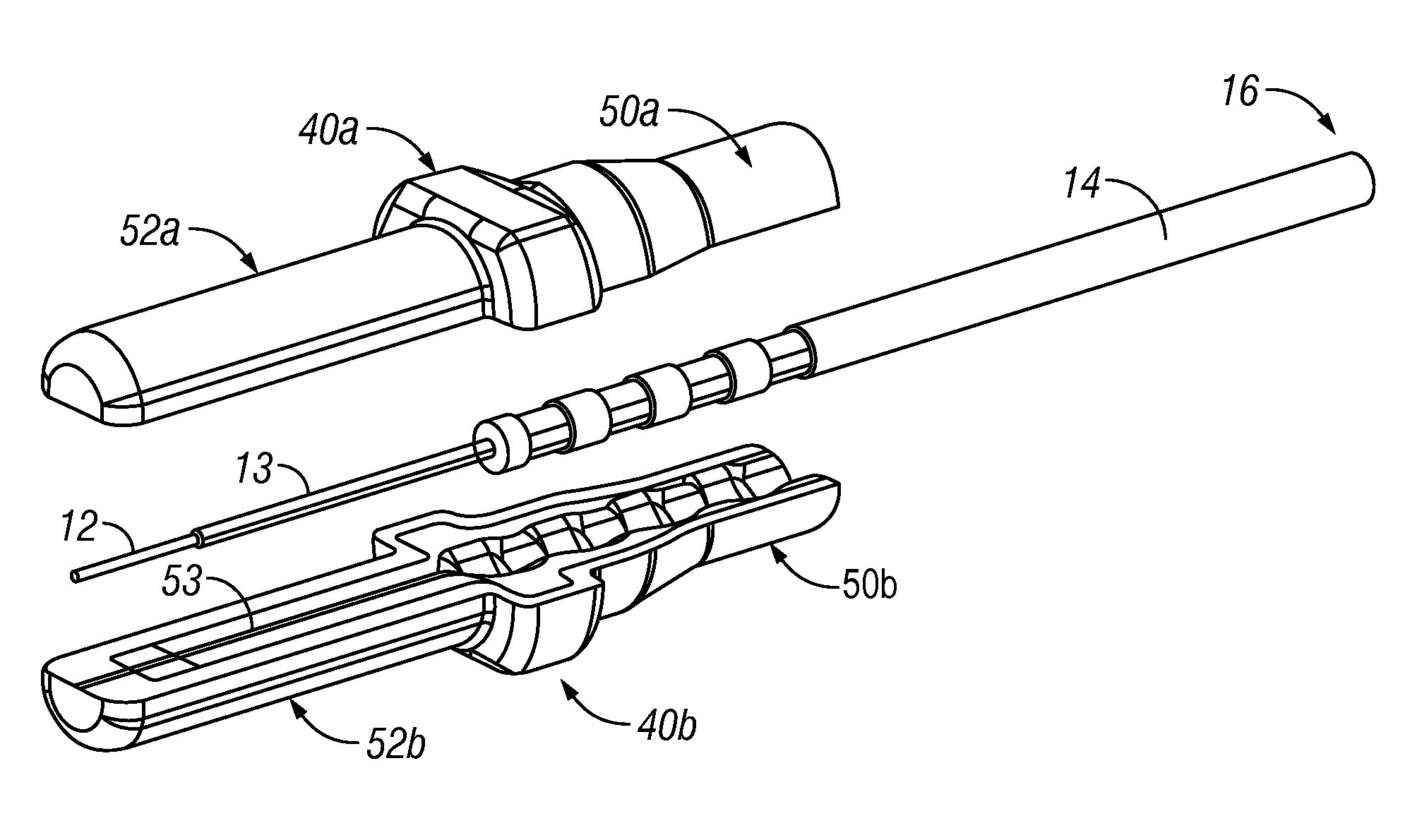

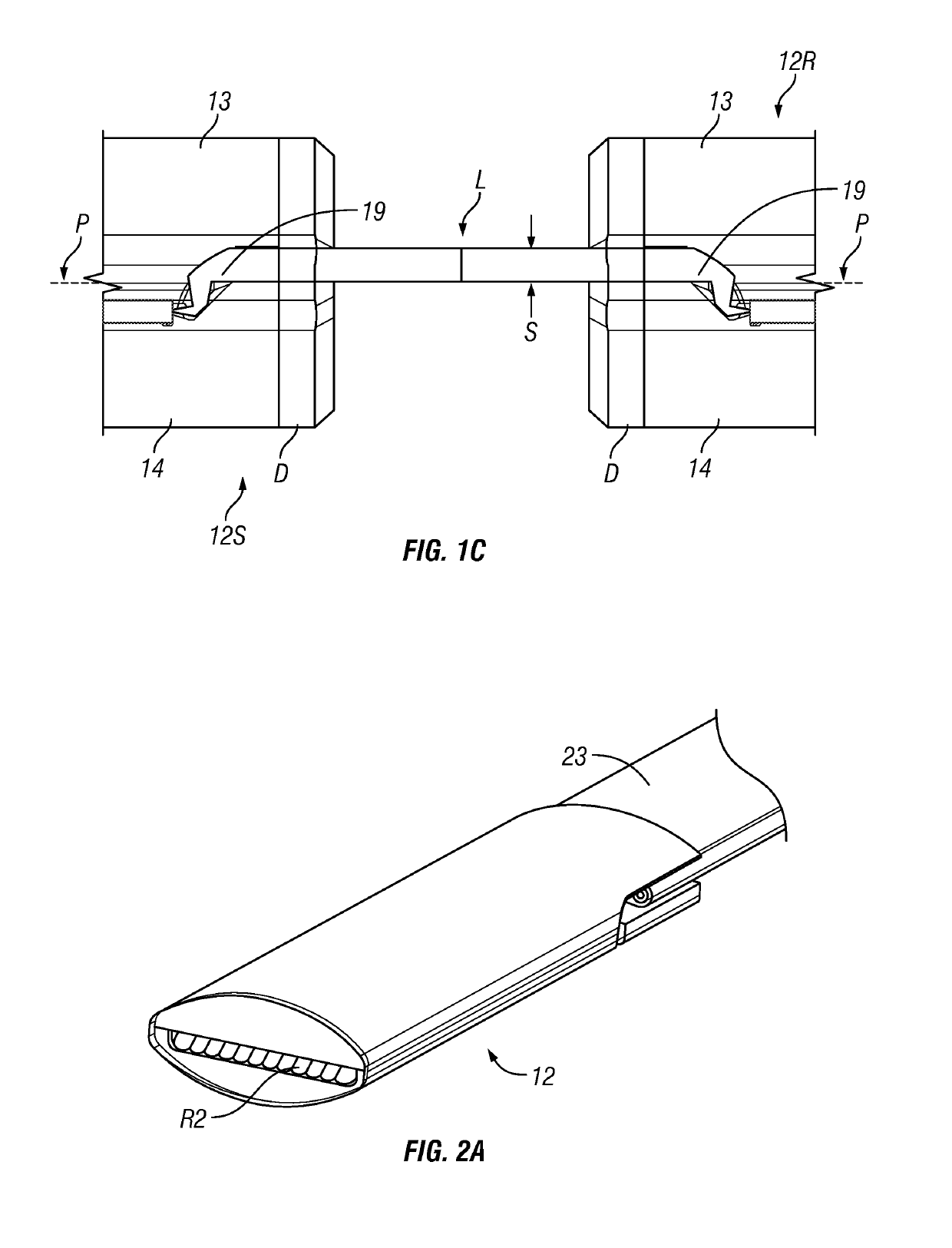

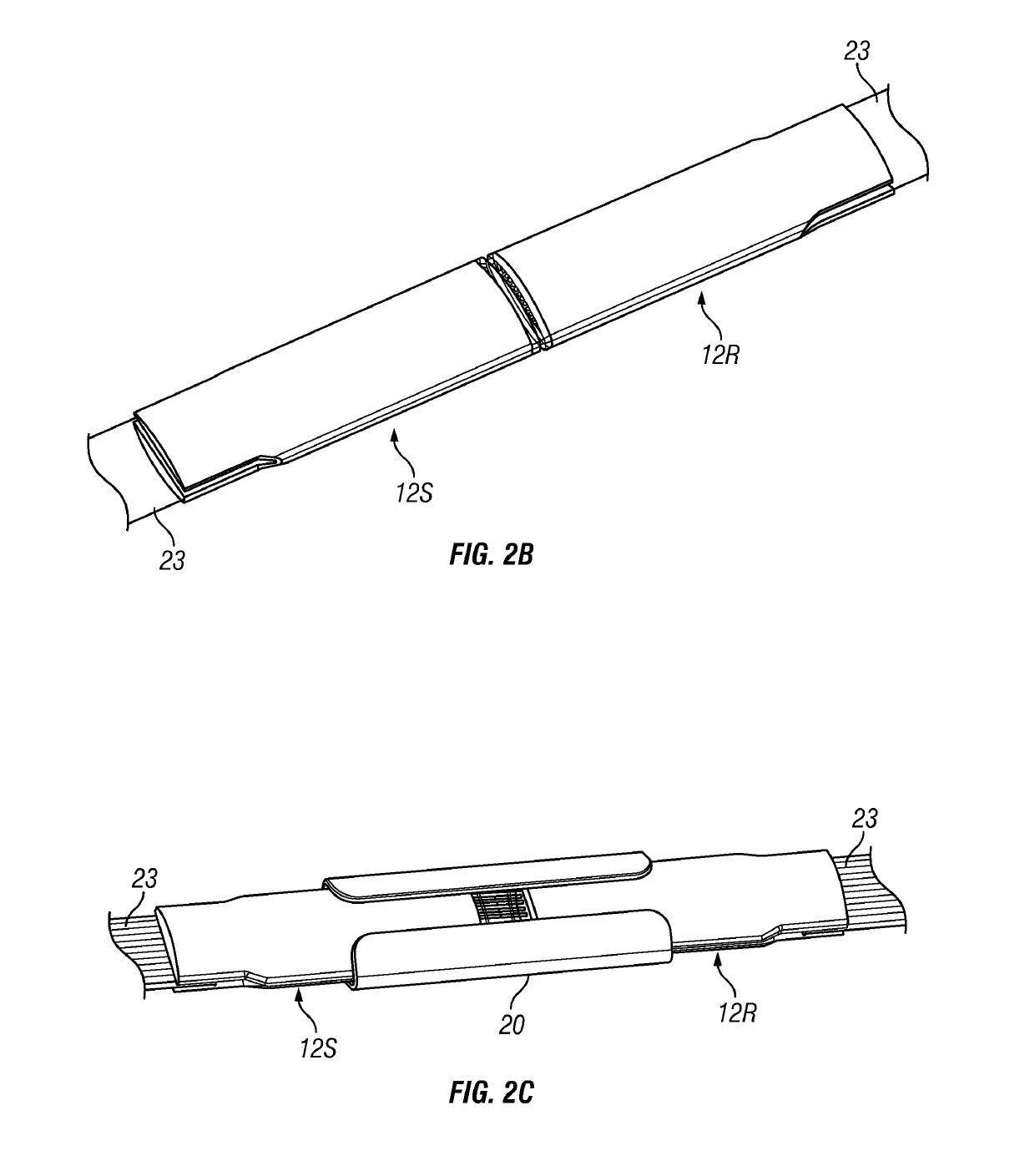

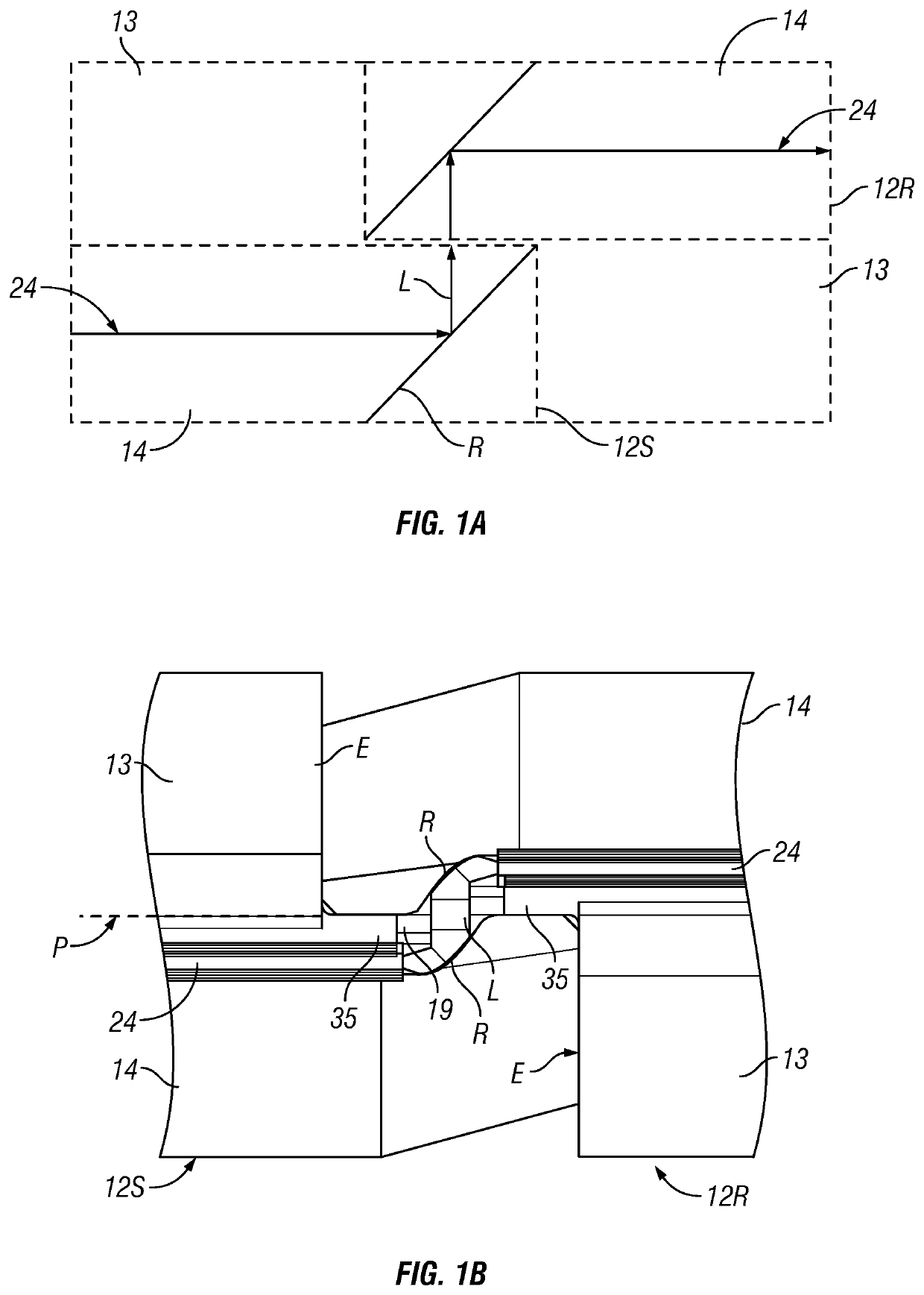

Optical fiber connector ferrule assembly having dual reflective surfaces for beam expansion and expanded beam connector incorporating same

ActiveUS10241275B2Reduce insertionEasy to useCoupling light guidesFibre mechanical structuresLight beamOptical fiber connector

An expanded beam ferrule includes a first ferrule halve having first reflective surfaces and a second ferrule halve having second reflective surfaces, which together retain optical fibers. The pair of reflective surfaces output collimated light parallel to the mid-plane of the ferrule. An external sleeve aligns the external surface of two similar ferrules, with corresponding second reflective surfaces of the ferrules facing each other. Output light from an optical fiber held in one ferrule is bent twice by the pair of reflective surfaces, with beam divergence after the first bent, and collimation after the second bent. The collimated light is transmitted to the facing second reflective surface in a facing second ferrule aligned by the sleeve, which is subject to optical reshaping in reverse to that undertaken in the first ferrule, so as to converge and focus light to input to the optical fiber held in the other ferrule.

Owner:SENKO ADVANCED COMPONENTS

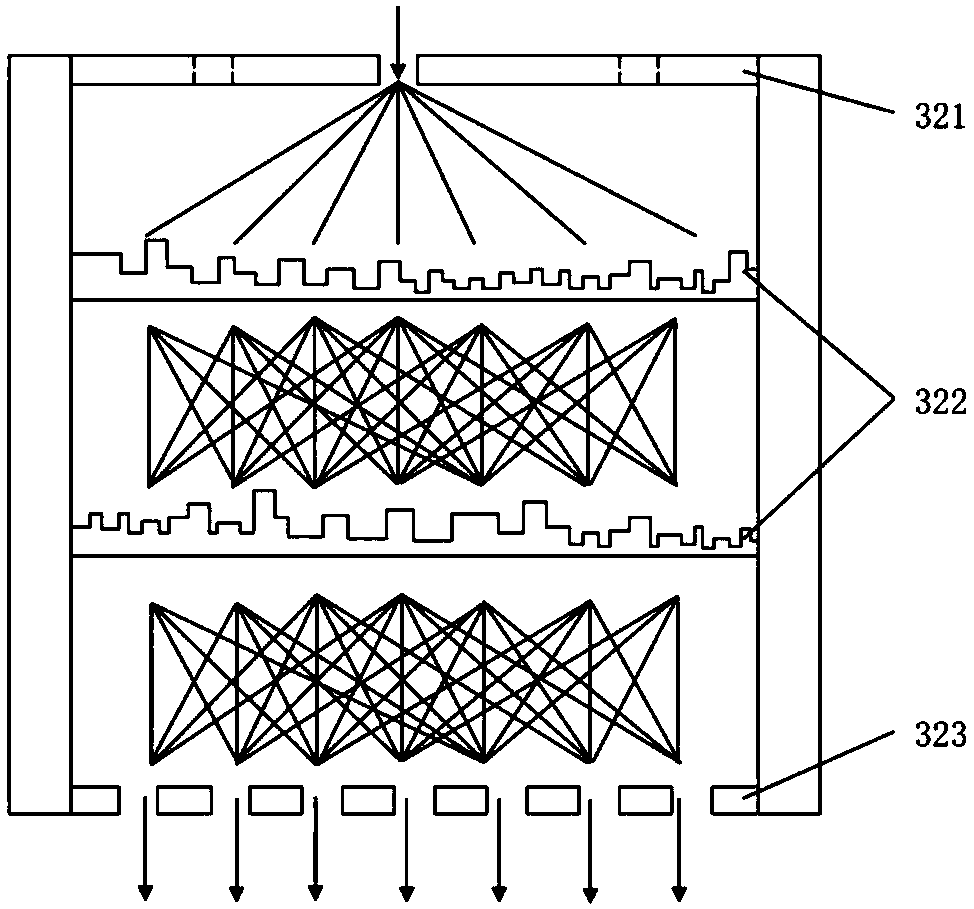

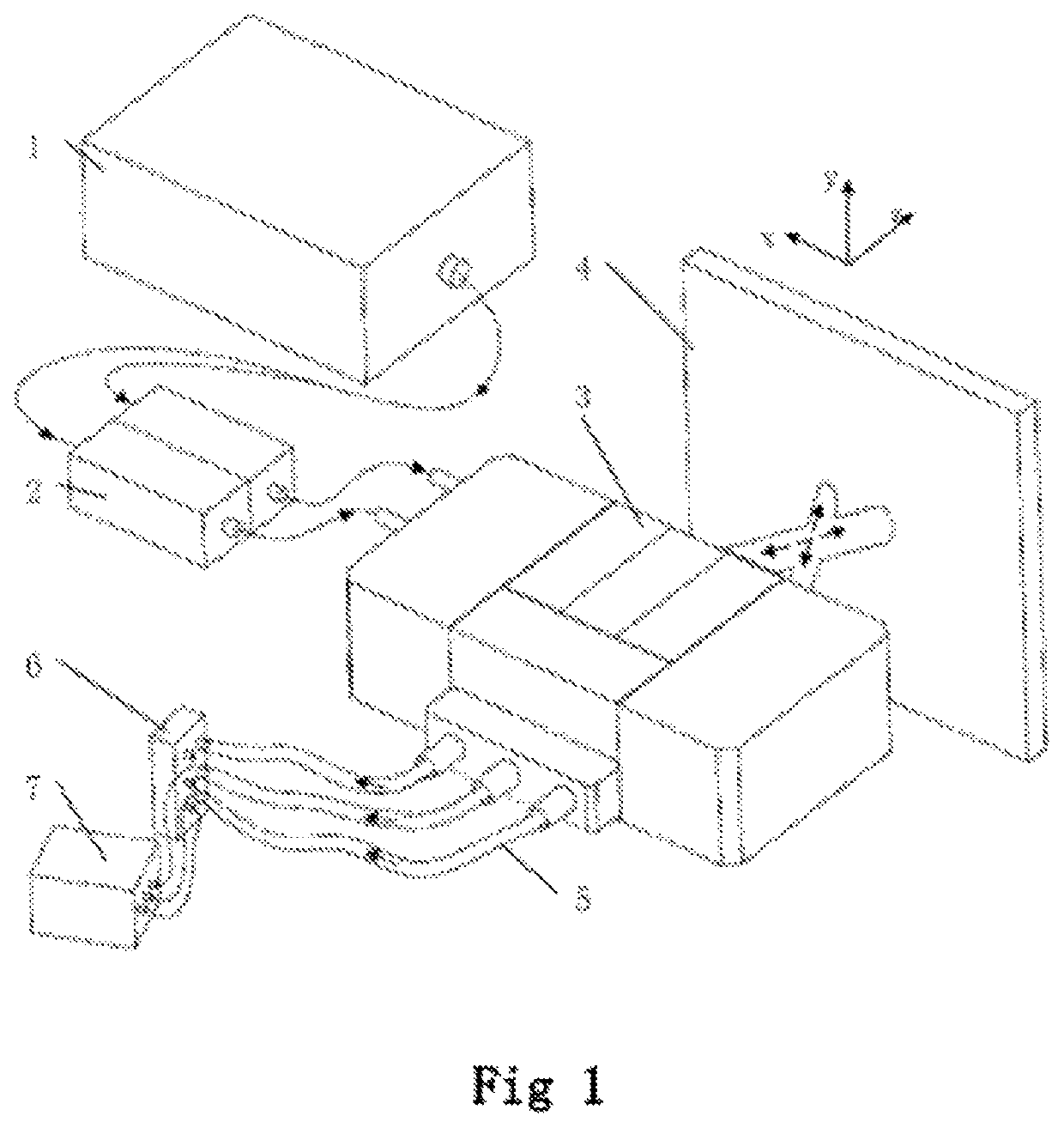

Ultra-precise displacement measuring system based on optical neural network

ActiveCN109211122AReduce volumeHighly integratedUsing optical meansPhysical realisationDetector arrayMulti degree of freedom

The invention discloses an ultra-precise displacement measuring system based on an optical neural network. The system comprises a light source, an optical displacement measuring device, an optical neural network, a detector array and a signal processing device. When a target object moves, the system takes a measurement optical signal output by the optical displacement measuring device as a signalinput, the signal is received by the detector array after being processed by the optical neural network, and finally the signal is converted into displacement information of the target object throughthe signal processing device. The invention further discloses an ultra-precise displacement measuring method based on the optical neural network. The optical neural network is used for processing themeasurement optical signal, so that the displacement of the target object can be directly measured; the phase discrimination process of the electronic signal is not needed; the response speed is extremely high; the size can be zoomed; the energy utilization rate is high; and the system is suitable for ultra-precise measurement occasions with high speed and high dynamic performance requirements. According to the system, the multi-degree-of-freedom pose measurement of the target object also can be realized by increasing the number of input measurement optical signals and the number of detector arrays.

Owner:TSINGHUA UNIV +1

Nickel-based alloy with high grain-boundary strength and preparation method thereof

The invention relates to a nickel-based alloy with high grain-boundary strength and a preparation method thereof. The nickel-based alloy consists of the chemical components in percentage by weight; 20-25 percent of chromium, 0.2-0.7 percent of copper, 0.01-0.2 percent of carbon, 8.0-10.0 percent of molybdenum, 10-15 percent of cobalt, 0.5-1.5 percent of aluminum, 0.2-0.6 percent of titanium, 0.01-0.02 percent of boron, 0.01-0.03 percent of tungsten, 0.01-0.3 percent of tantalum, 0.02-0.06 percent of rare earth and the balance of nickel and other unavoidable trace impurity elements. The preparation method for the nickel-based alloy with high grain-boundary strength comprises the following steps of (1) preparing raw materials: preparing a proper amount of Incone1617 main material and a small amount of Re, B, Ta and W for component adjustment; and (2) feeding the materials for smelting: putting the materials Cr, Mo, Ta and W which have high smelting points to the bottom of a crucible, then adding the Incone1617 furnace material, sequentially adding the rest of the raw materials, covering the materials with a slag removal agent, and smelting the materials in a vacuum smelting furnace. By the adding of B, Ta and the rare earth elements, the nickel-based alloy is low in environment sensitivity and can achieve effects of purifying the grain boundary and effectively improving the grain-boundary bonding strength.

Owner:CHANGZHOU UNIV

Optical fiber connector ferrule assembly having single reflective surface for beam expansion and expanded beam connector incorporating same

An expanded beam ferrule includes a first ferrule halve having reflective surfaces and a second ferrule halve, which together retain optical fibers. The reflective surfaces output light perpendicular to the mid-plane of the ferrule. A sleeve aligns the external surface of two similar ferrules, with the reflective surfaces of the respective ferrules facing each other. Output light from an optical fiber held in the first ferrule is bent and collimated by a reflective surface, transmitted to the facing reflective surface in a second ferrule aligned by the sleeve, which bends the light to input to the optical fiber held in the second ferrule. The ferrule components and / or sleeve are precision formed by high throughput metal stamping. The ferrule is incorporated in an optical fiber connector.

Owner:SENKO ADVANCED COMPONENTS

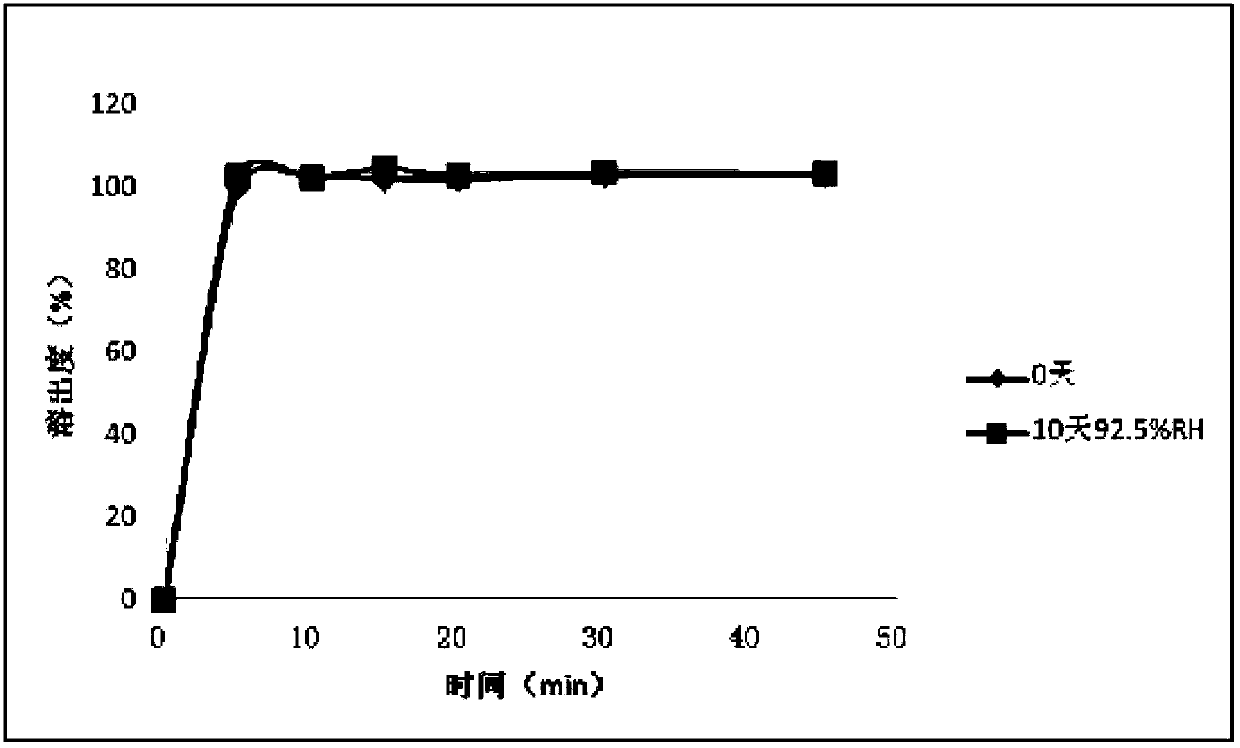

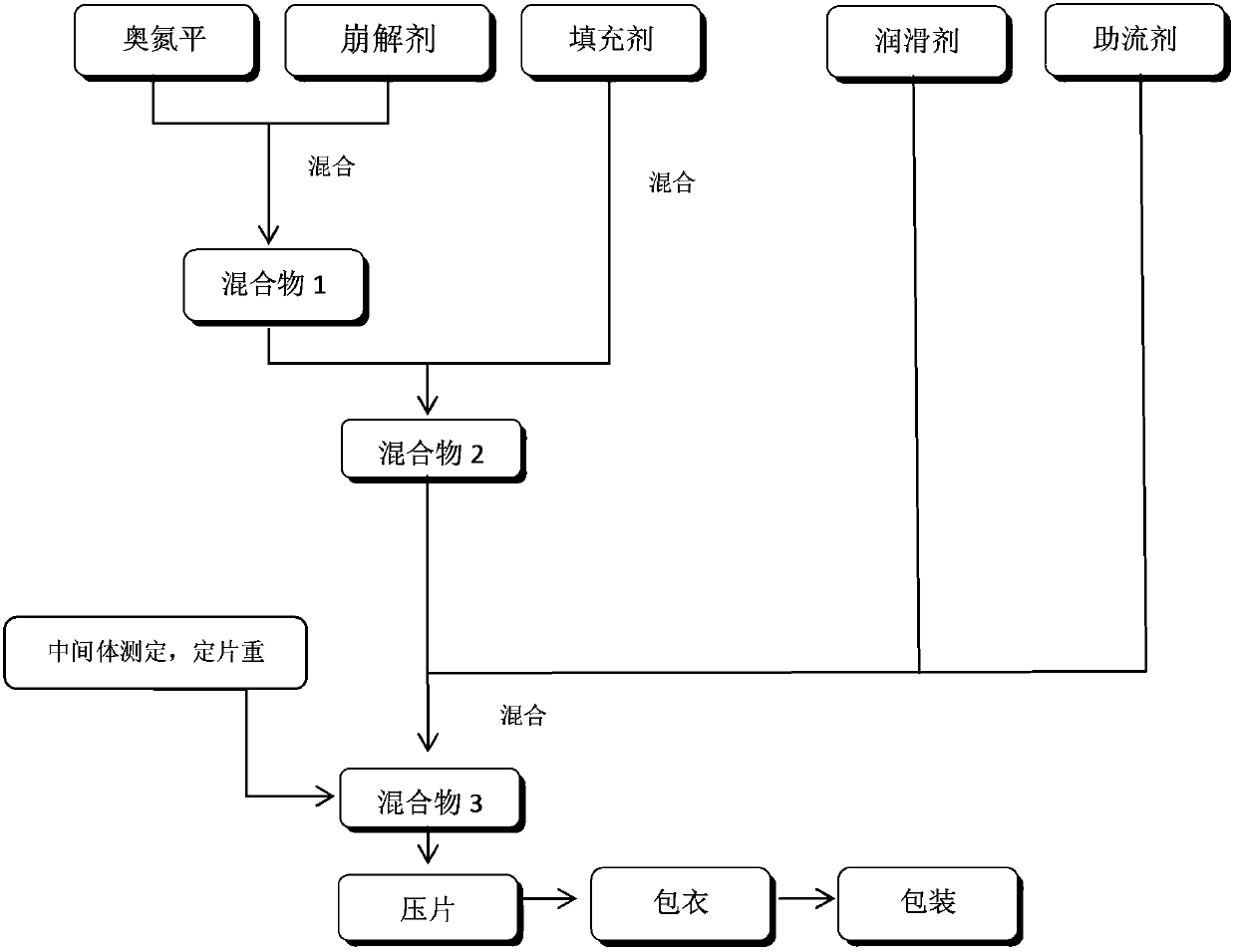

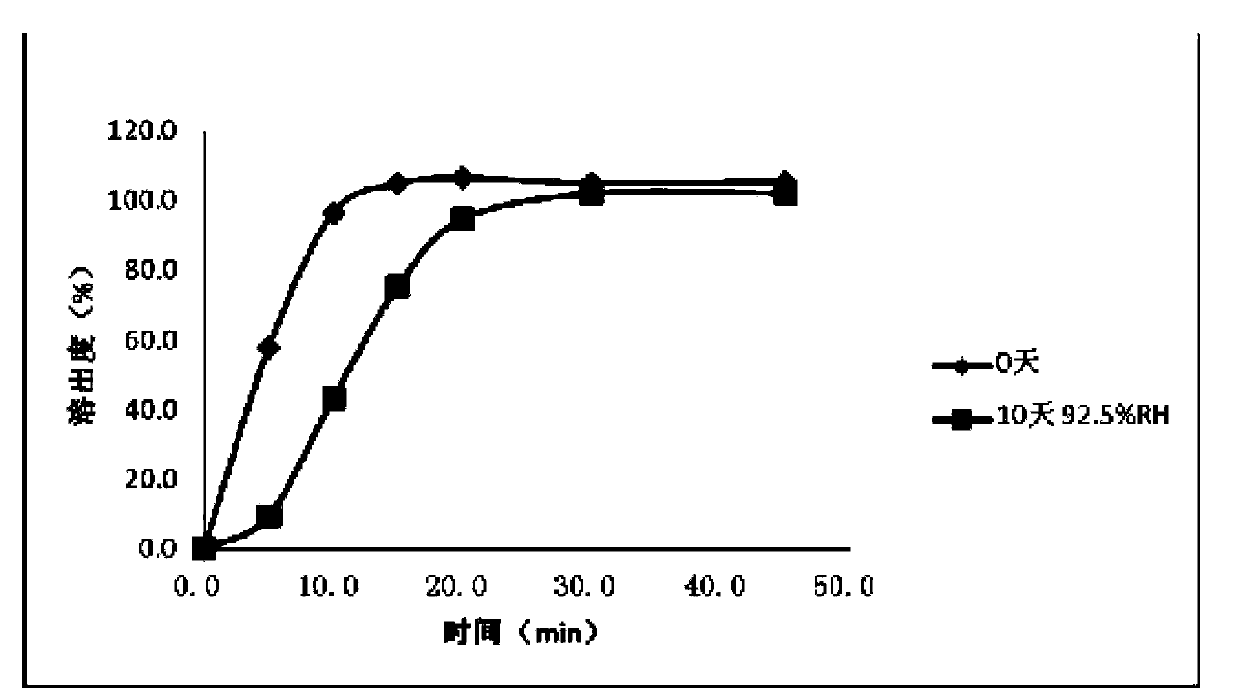

Pharmaceutical composition containing olanzapine and preparation method thereof

ActiveCN103919782AQuality assuranceGuaranteed stabilityOrganic active ingredientsNervous disorderSocial benefitsMedicine

The invention belongs to the medical technical field, and particularly provides a pharmaceutical composition containing olanzapine. A preparing way is a direct tabletting process method, and auxiliary materials suitable for olanzapine stability and compatibility are selected through testing; olanzapine tablets obtained through the process preparing way have good quality stability and have the content uniformity and other oral preparation related quality items all according with requirements. The process has the advantages of good reproducibility, strong operability, low process cost, relatively good clinical use value and relatively good social benefits. The oral preparation provided by the invention is used for treating schizophrenia.

Owner:TIANJIN INSTITUTE OF PHARMA RESEARCH

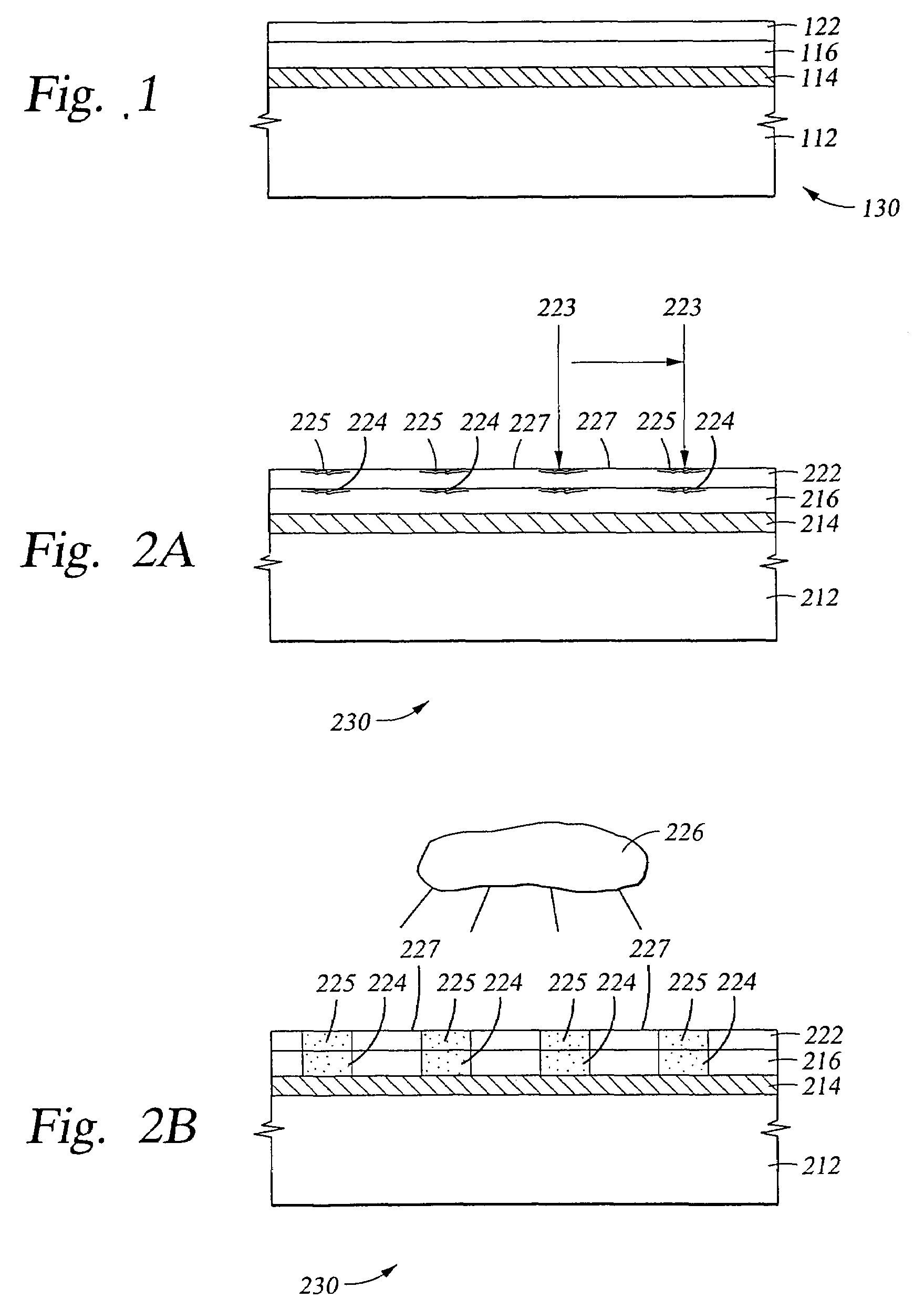

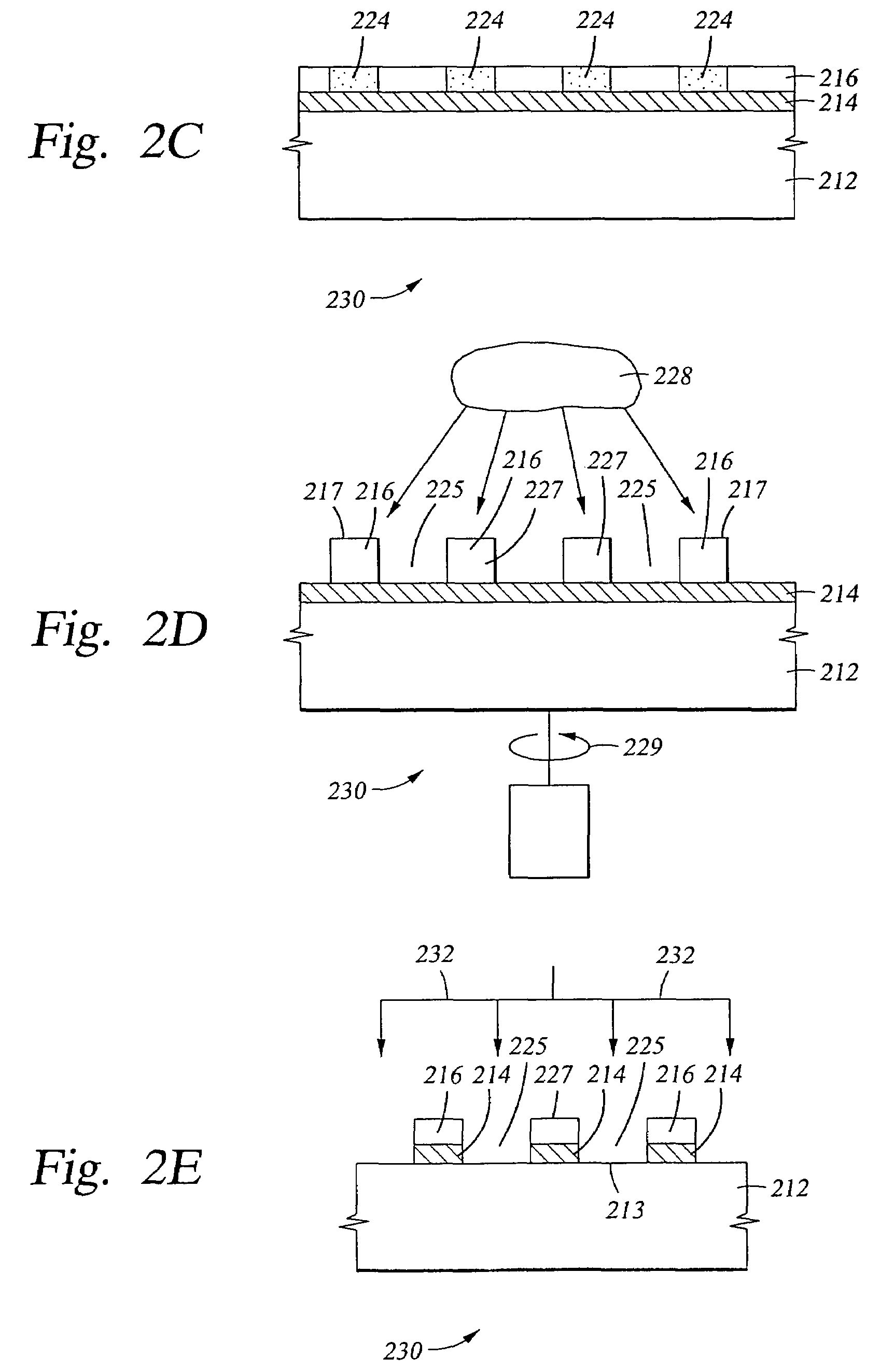

Method of increasing the shelf life of a photomask substrate

InactiveUS7135256B2Reduce sensitivityKeep shelf lifeElectric discharge tubesPhotosensitive materialsResistDirect writing

Owner:APPLIED MATERIALS INC

Optical fiber connector ferrule having curved external alignment surface

ActiveUS10359575B1Low insertion lossEasy alignmentCoupling light guidesOptical fiber connectorBiomedical engineering

A ferrule for an optical fiber connector has an external surface for alignment with a complementary surface of an alignment sleeve (i.e., the inside surface of a generally cylindrical or tubular sleeve). The external surface of the ferrule is generally cylindrical, having a sectional contact surface profile that is generally oval in shape. More specifically, a plurality of points of contact between the ferrule and the sleeve are defined along a curve in cross-section, wherein the center of curvature at each of the contact points along this contact point curve (i.e., the curve containing contact points that contribute to alignment) does not lie in the plane of the axis of the array of optical fibers.

Owner:SENKO ADVANCED COMPONENTS

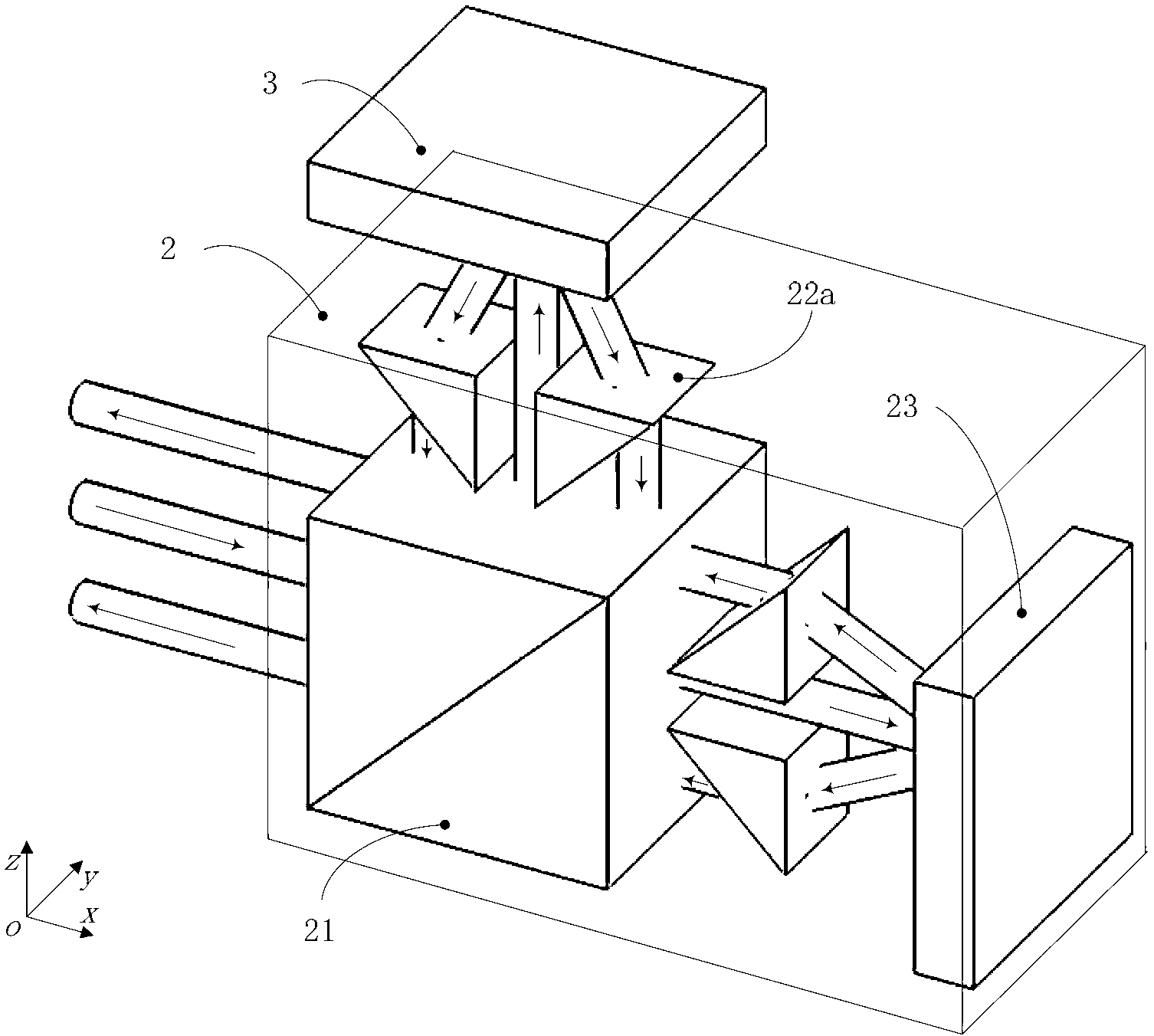

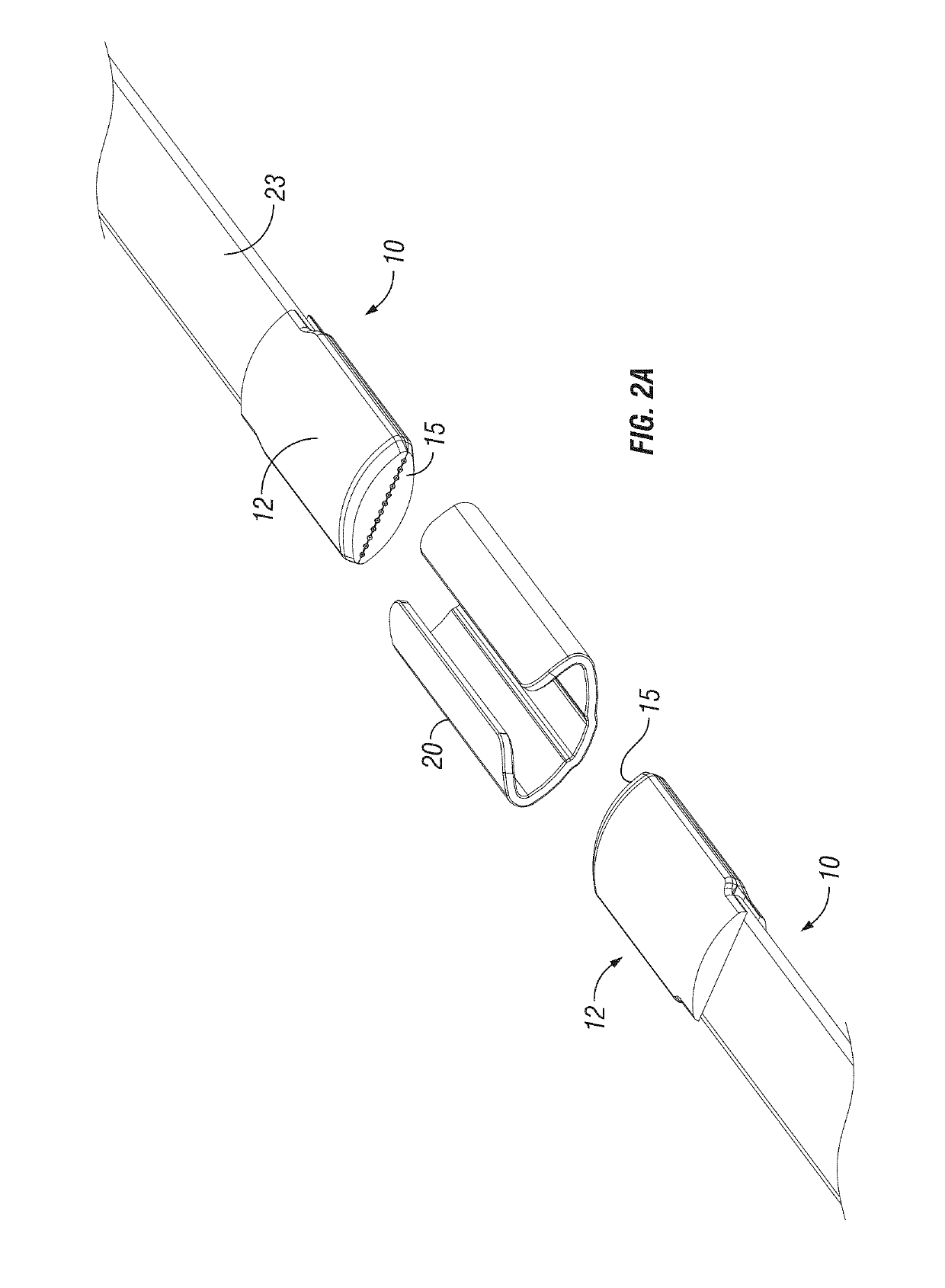

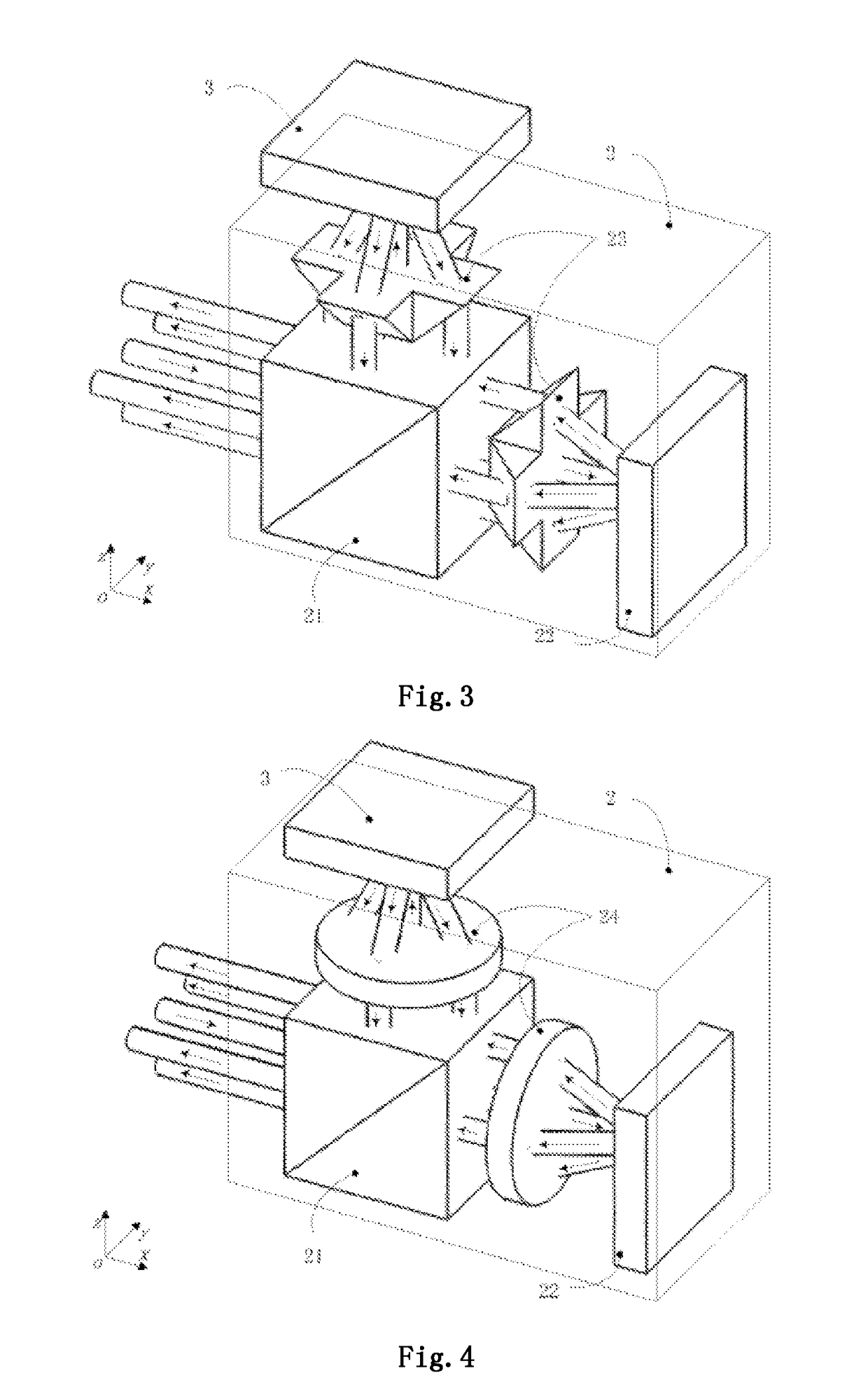

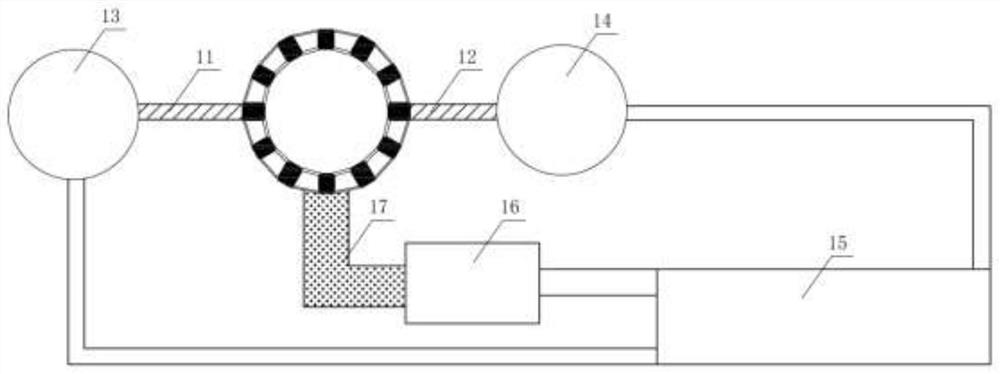

Three-DOF heterodyne grating interferometer displacement measurement system

ActiveUS9903704B2Low environmental sensitivitySimple structureInterferometersUsing optical meansBeam splitterGrating

A three-DOF (Degree of Freedom) heterodyne grating interferometer displacement measurement system comprises a dual-frequency laser, a grating interferometer, a measurement grating, receivers and an electronic signal processing component; the grating interferometer comprises a polarizing beam splitter, a reference grating and dioptric elements; the measurement system realizes displacement measurement on the basis of grating diffraction, the optical Doppler Effect and the optical beat frequency principle. Three linear displacements can be output by the system when the grating interferometer and the measurement grating perform a three-DOF linear relative motion. The measurement system can reach sub-nanometer and higher resolution and precision, and can simultaneously measure three linear displacements. The measurement system has the advantages of being environmentally insensitive, high in measurement precision, small in size, light in weight, and is capable of improving the overall performances of an ultra-precision stage of a lithography machine as a position measurement system for this stage.

Owner:TSINGHUA UNIV

Two-degree-of-freedom heterodyne grating interferometry measurement system

ActiveUS11307018B2Inhibition strengthSmall volumeInterferometersUsing optical meansLight beamEngineering

A two-degree-of-freedom heterodyne grating interferometry measurement system, comprising: a single-frequency laser device for emitting a single-frequency laser, and the single-frequency laser can be split into a beam of reference light and a beam of measurement light; an interferometer mirror group and a measurement grating for forming a reference interference signal and a measurement interference signal from the reference light and the measurement light; and a receiving optical fiber for receiving the reference interference signal and the measurement interference signal, wherein a core diameter of the receiving optical fiber is smaller than a width of an interference fringe of the reference interference signal and the measurement interference signal, so that the receiving optical fiber receives a part of the reference interference signal and the measurement interference signal. The measurement system has advantages of insensitivity to grating rotation angle error, small volume, light weight, and a facilitating arrangement.

Owner:TSINGHUA UNIV +1

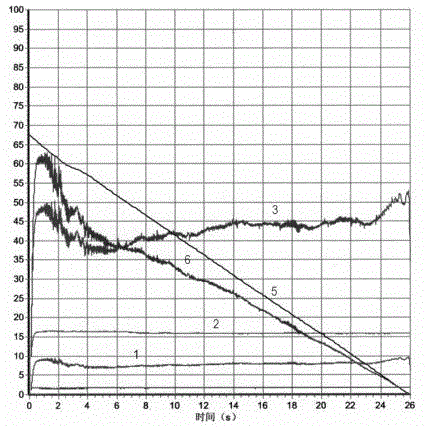

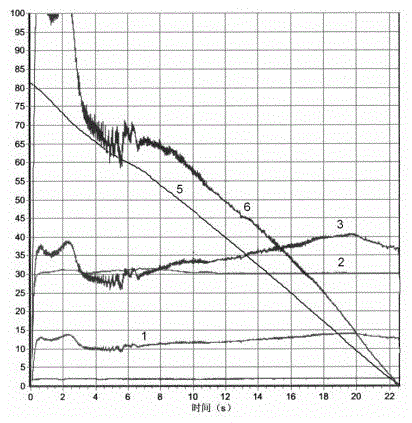

Metal-based powder metallurgy brake pad for high-speed train and preparation method thereof

InactiveCN103244586BConsistent braking performance throughout lifeStable coefficient of frictionFriction liningFiberBoron carbide

The invention provides a metal-based powder metallurgy brake pad for a high-speed train and a manufacturing method thereof. The brake pad is made of the following raw materials: matrix components: 30-60% by weight of copper powder and 20-40% by weight of ferrous powder; lubrication components: 8-20% by weight of graphite powder and 1-5% by weight of molybdenum disulfide; friction components: 1-3% by weight of tungsten, 1-3% by weight of corundum, 1-3% by weight of silica sand and 1-3% by weight of boron carbide; friction stable components: 1-4% by weight of 80-400-mesh carbon fiber powder; and a binding material: resin occupying 1-5% of the sum of the weight of the components. The invention further comprises a manufacturing method of the metal-based powder metallurgy brake pad for the high-speed train. A friction system formed by the brake pad and machine wheels is high and stable in friction coefficient, friction coefficient fluctuation is small during braking, and reliability is high.

Owner:HUNAN DINGMAO TECH CO LTD

Three-dof heterodyne grating interferometer displacement measurement system

ActiveUS20160153764A1Low environmental sensitivitySimple structureInterferometersUsing optical meansGratingRelative motion

A three-DOF (Degree of Freedom) heterodyne grating interferometer displacement measurement system comprises a dual-frequency laser, a grating interferometer, a measurement grating, receivers and an electronic signal processing component; the grating interferometer comprises a polarizing spectroscope, a reference grating and dioptric elements; the measurement system realizes displacement measurement on the basis of grating diffraction, the optical Doppler Effect and the optical beat frequency principle. Three linear displacements can be output by the system when the grating interferometer and the measurement grating perform a three-DOF linear relative motion. The measurement system can reach sub-nanometer and even higher resolution and precision, and can simultaneously measure three linear displacements. The measurement system has the advantages of being environmentally insensitive, high in measurement precision, small in size, light in weight, etc., and is capable of improving the overall performances of an ultra-precision stage of a lithography machine as a position measurement system for this stage.

Owner:TSINGHUA UNIV

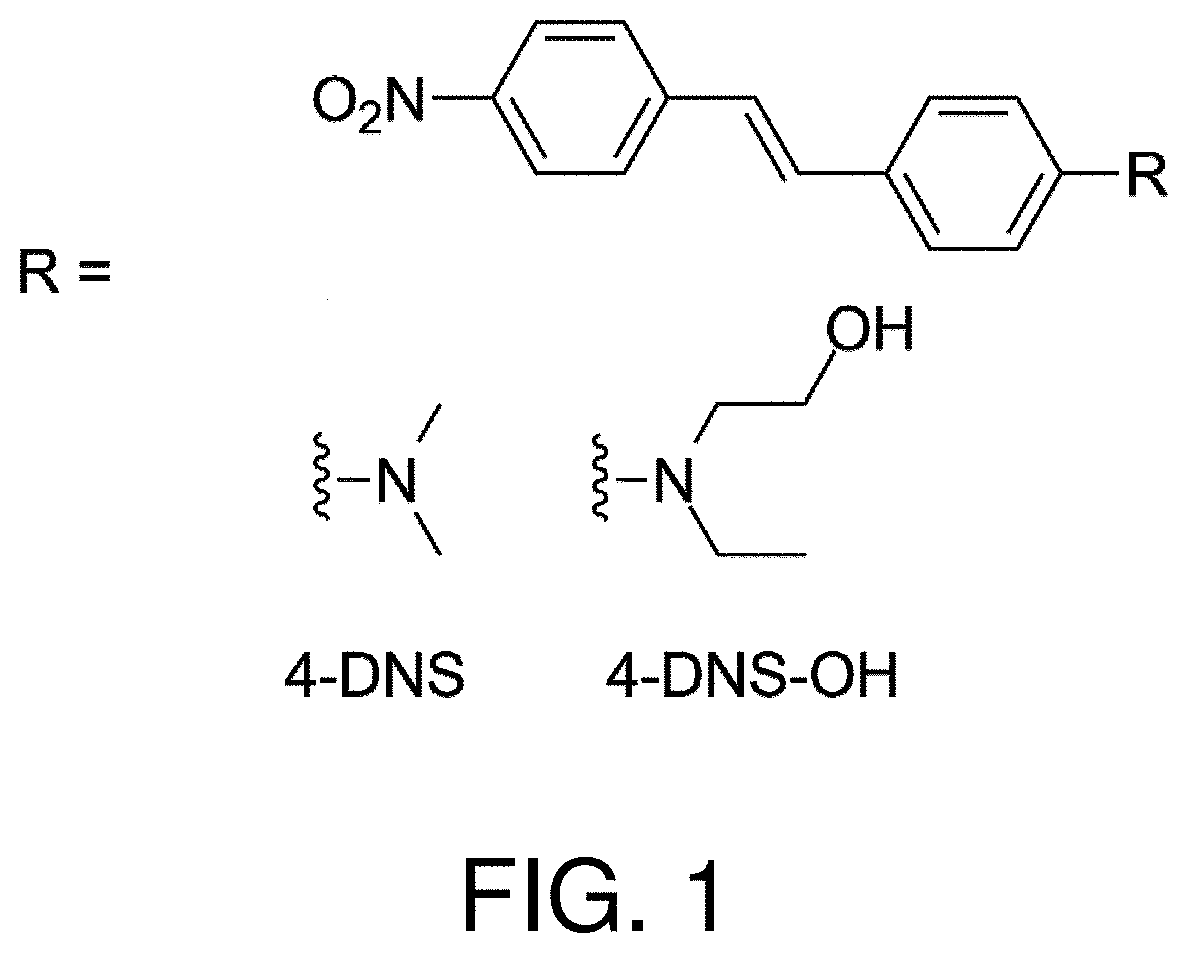

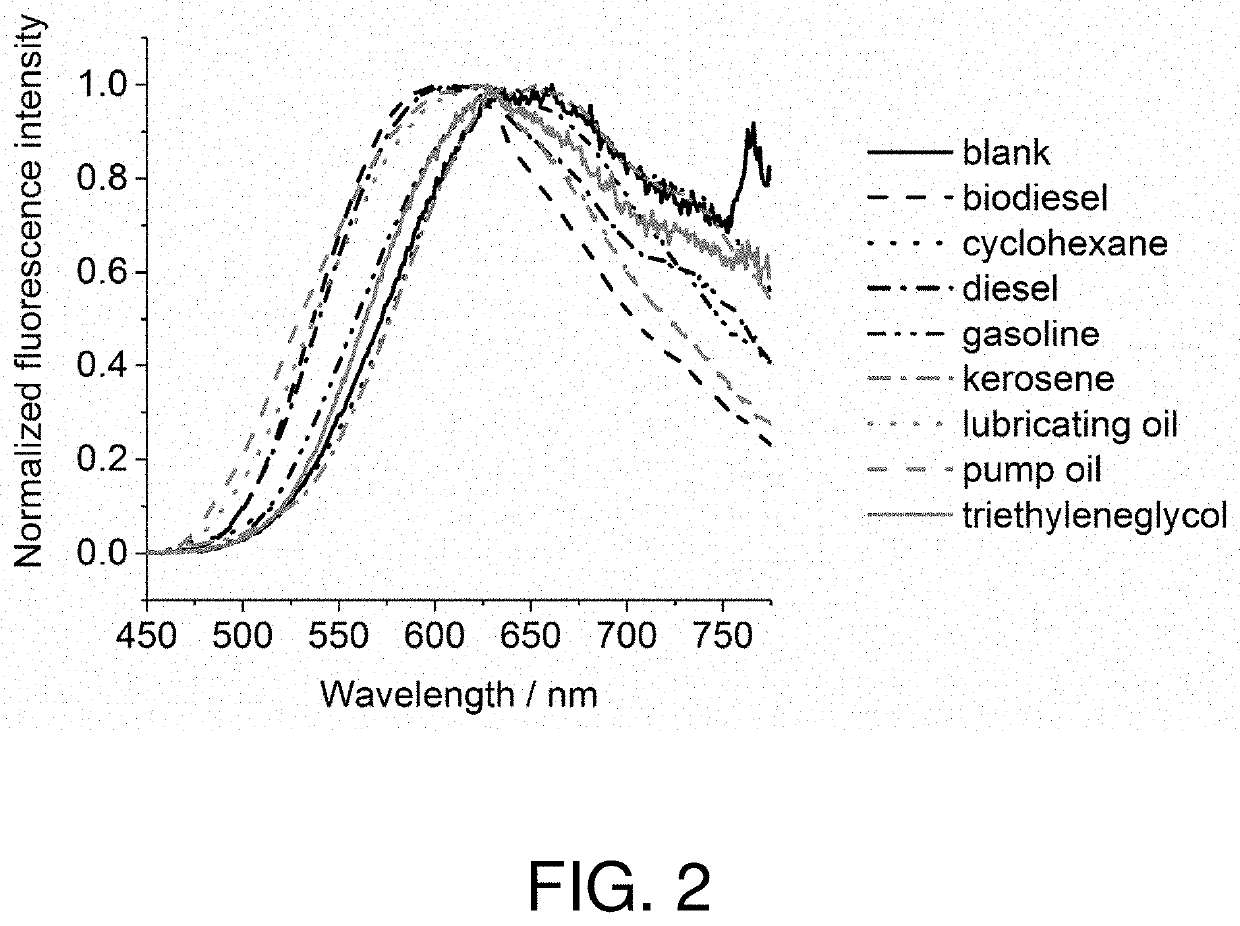

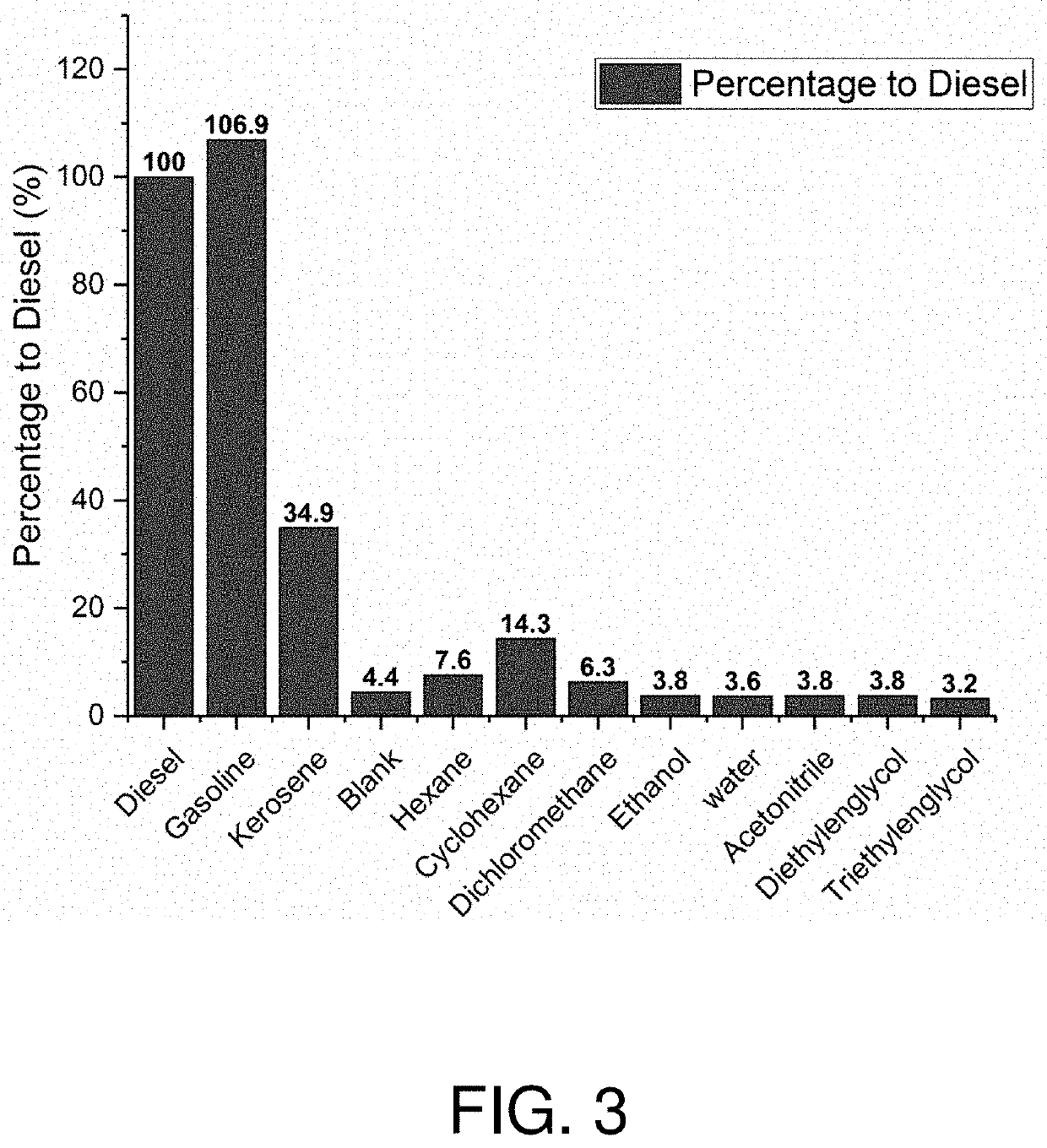

Detection of hydrocarbon contamination in soil and water

ActiveUS20200232918A1Low environmental sensitivityThe effect is accurateAnalysis using chemical indicatorsChemiluminescene/bioluminescenceSoil scienceHydrocarbon contamination

A method for the detection of hydrocarbon contamination in a sample is disclosed. The method includes contacting a sample with a molecular probe. The molecular probe has a photoluminescence which is environmentally sensitive. The photoluminescence from the molecular probe is collected. The method includes determining whether the photoluminescence is indicative of a hydrocarbon contaminated sample. A test strip for the detection of hydrocarbon contamination in a sample is also disclosed. The test strip includes a molecular probe embedded in a substrate and / or immobilized to the substrate, the molecular probe having a photoluminescence which is environmentally sensitive to hydrocarbon contaminated sample.

Owner:BUNDESREPUBLIK DEUT VERTRETEN DURCH DEN BUNDESMINIST FUR WIRTSCHAFT & ENERGIE DIESER VERTRETEN DURCH DEN PRASIDENTEN DER BUNDESANSTALT FUR MATERIALFORSCHUNG UND PRUFUNG BAM

Coaxial three-layer high-activity electrospun nanofiber membrane embedded with biological enzymes and its preparation method

InactiveCN103668485BHigh catalytic efficiencyGood repeatabilityFilament/thread formingNon-woven fabricsSpinningMass transfer resistance

The invention discloses a coaxial three-layer high-activity bio-enzyme-embedded electrostatic spinning nano-fiber membrane and a preparation method thereof. The coaxial three-way electrostatic spinning technology is used to allow bio-enzyme to be embedded into the sandwich layer of slow release activating agent and porous polymer so as to form the porous nano-fiber membrane. The nano-fiber membrane of a sandwich structure sequentially comprises a slow release activating agent layer (1), an immobilized bio-enzyme layer (2) and a porous polymer layer (3) from inside to outside. By building the structure with communicating ducts, immobilization amount of enzyme is increased, sufficient contact of the enzyme and a substrate is promoted, mass transfer resistance between the enzyme and the substrate is lowered, catalytic efficiency and reusability of the enzyme are increased effectively, environmental sensitivity of the bio-enzyme is lowered, and lasting stability of the bio-enzyme when being applied in complex environments is increased.

Owner:DALIAN OCEAN UNIV +1

Wear mitigation method of linear ultrasonic motor and linear ultrasonic motor

InactiveCN102403924BHigh outputIncrease output powerPiezoelectric/electrostriction/magnetostriction machinesMicro structureEngineering

The invention discloses a wear mitigation method of a linear ultrasonic motor, which belongs to the technical field of ultrasonic motors. In the wear mitigation method of the linear ultrasonic motor, the surface modified technology is used for the linear ultrasonic motor, and a pit-type surface micro-structure is prepared on the friction end face of a stator or a rotator, therefore, wear due to three-body friction is reduced, and the output force, the output power and the service life of the motor are effectively improved. The three-body friction is further reduced by optimizing structural parameters of the pit-type surface micro-structure, and the environmental sensitivity of surface friction is reduced by covering a wear resisting layer on the friction end face of the stator and / or the stator. The invention also discloses the linear ultrasonic motor, and the pit-type surface micro-structure is prepared on the friction end face of the stator or the stator.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

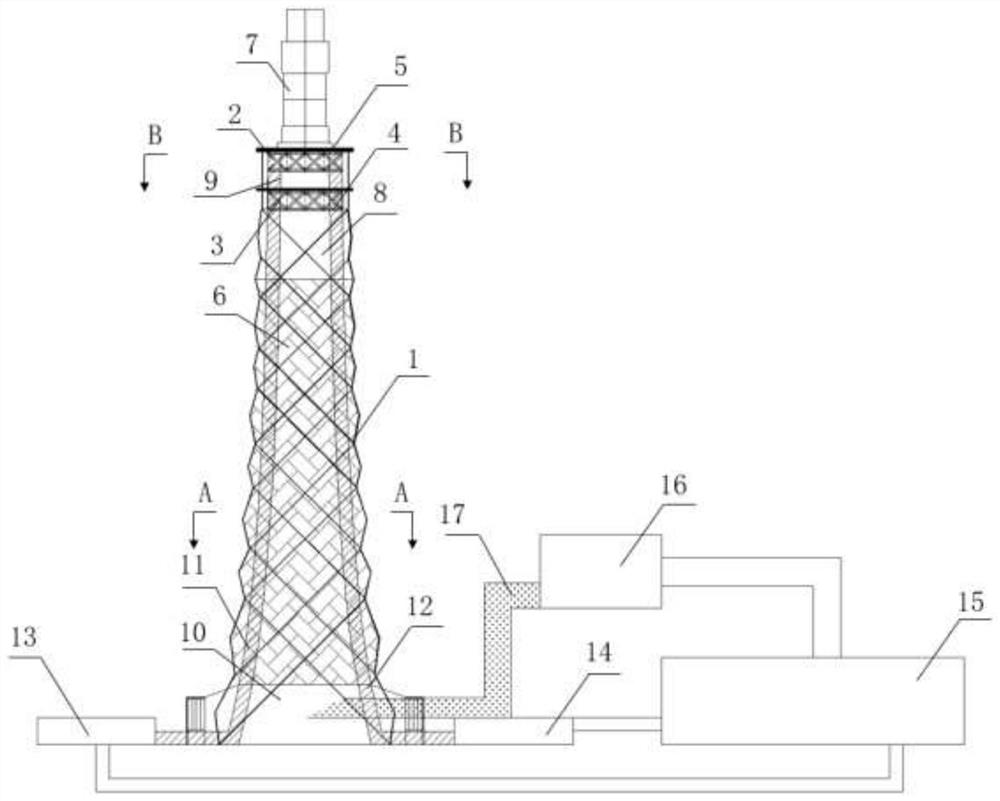

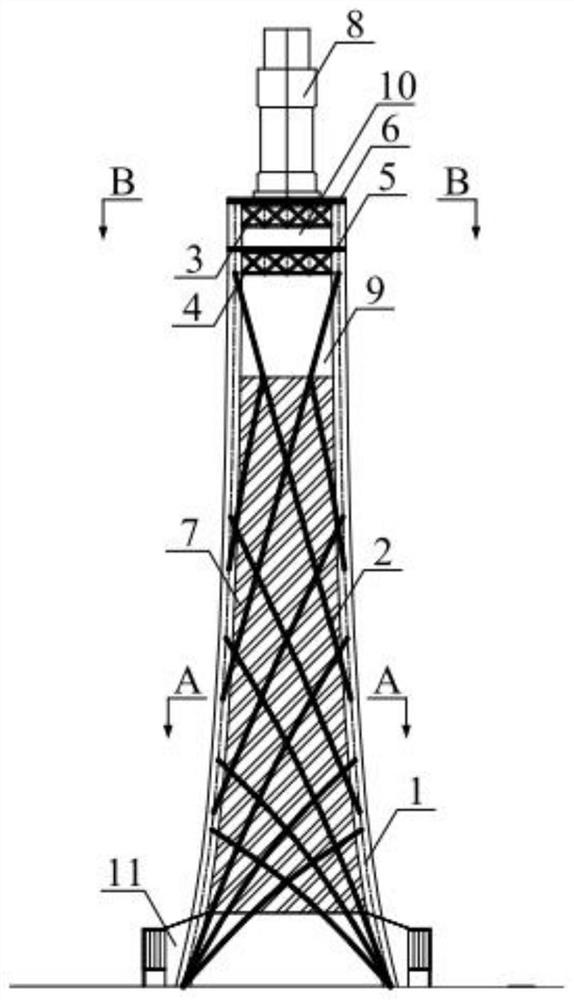

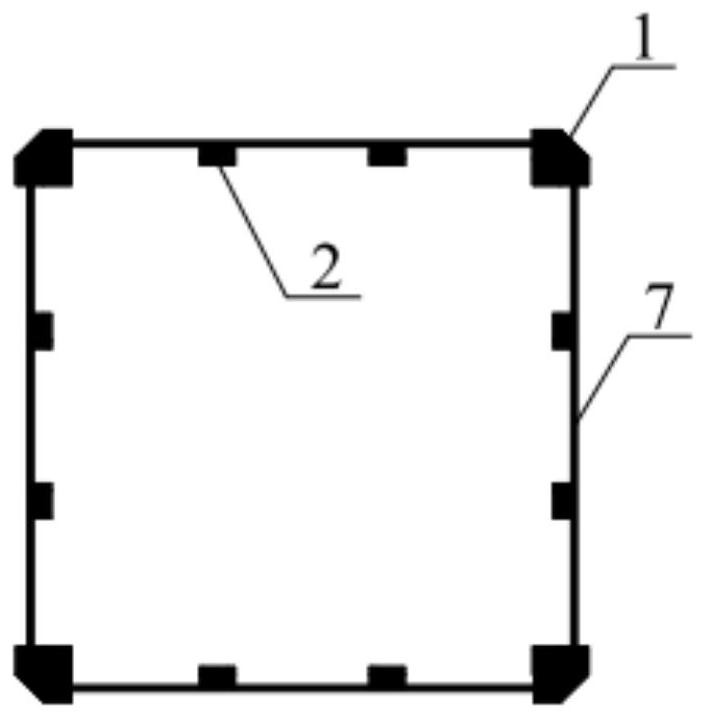

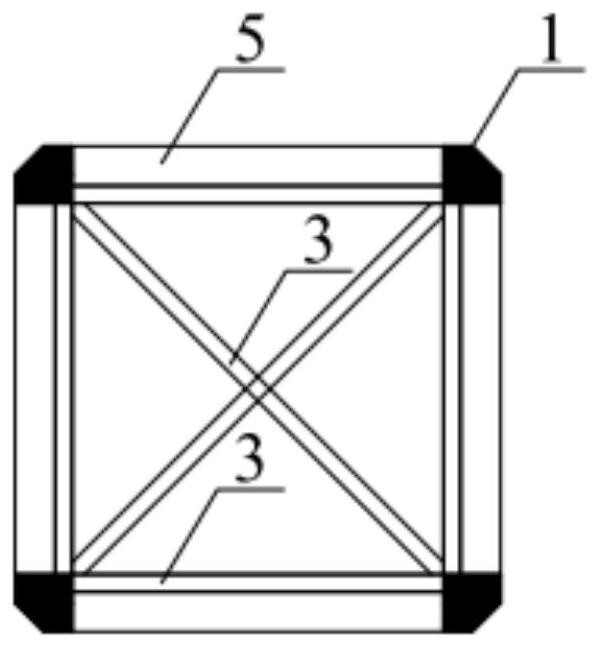

Photo-thermal power generation system comprising diagrid industrial structure

PendingCN113931814AAvoid the impact of production efficiencyLow costFrom solar energySteam engine plantsMolten saltAir cooling system

The invention discloses a photo-thermal power generation system comprising a diagrid industrial structure. The system comprises a photo-thermal tower, a steam generator, a steam turbine, a hot fused salt tank, a cold fused salt tank, a connecting pipeline and the like. A fused salt heat absorber is supported at the top of the photo-thermal tower, is connected with cold and hot fused salt pipelines in a structure and is connected with the cold fused salt tank, the hot fused salt tank and the steam generator outside the structure, power generation is conducted through acting of the steam turbine, and the photo-thermal tower is provided with an air inlet and outlet layer which is connected with a surface radiator inside the structure, a heat return system outside the structure, a circulating water pump and the like to form a surface type indirect air cooling system. In conclusion, a high-efficiency photo-thermal power generation system is formed, the system has photo-thermal power generation and heat dissipation and indirect cooling functions, the problems that a traditional direct cooling system is large in power consumption, and an indirect cooling system is large in occupied area, long in construction period, high in initial investment and the like are solved, environmental protection performance and corrosion resistance of a project are improved, and anti-wind and anti-seismic safety performance is excellent.

Owner:TONGJI UNIV

A kind of high grain boundary strength nickel base alloy and preparation method thereof

The invention relates to a nickel-based alloy with high grain-boundary strength and a preparation method thereof. The nickel-based alloy consists of the chemical components in percentage by weight; 20-25 percent of chromium, 0.2-0.7 percent of copper, 0.01-0.2 percent of carbon, 8.0-10.0 percent of molybdenum, 10-15 percent of cobalt, 0.5-1.5 percent of aluminum, 0.2-0.6 percent of titanium, 0.01-0.02 percent of boron, 0.01-0.03 percent of tungsten, 0.01-0.3 percent of tantalum, 0.02-0.06 percent of rare earth and the balance of nickel and other unavoidable trace impurity elements. The preparation method for the nickel-based alloy with high grain-boundary strength comprises the following steps of (1) preparing raw materials: preparing a proper amount of Incone1617 main material and a small amount of Re, B, Ta and W for component adjustment; and (2) feeding the materials for smelting: putting the materials Cr, Mo, Ta and W which have high smelting points to the bottom of a crucible, then adding the Incone1617 furnace material, sequentially adding the rest of the raw materials, covering the materials with a slag removal agent, and smelting the materials in a vacuum smelting furnace. By the adding of B, Ta and the rare earth elements, the nickel-based alloy is low in environment sensitivity and can achieve effects of purifying the grain boundary and effectively improving the grain-boundary bonding strength.

Owner:CHANGZHOU UNIV

Multifunctional giant frame inclined grid industrial structure

PendingCN113446740ASolution areaSolve the problem of high initial investmentSolar heating energySolar heat storageThermodynamicsEngineering

The invention discloses a multifunctional giant frame inclined grid industrial structure. The structure comprises a giant frame column, an inclined grid, an upper truss beam, a lower truss beam, a combined bottom plate, a combined top plate and a surface skin. A fused salt heat absorber is supported at the top of the structure and is connected to a fused salt pipeline, a cold fused salt tank, a hot fused salt tank and a steam generator in the structure to jointly form a heat absorption system; and the structure is provided with an air inlet and outlet layer, and the air inlet and outlet layer is connected to a surface radiator inside the structure, a regenerative system outside the structure, a circulating water pump and the like to jointly form a surface type indirect air cooling system. According to the multifunctional giant frame inclined grid industrial structure, a multifunctional industrial structure scheme is achieved; the problems that a traditional direct cooling system is large in power consumption, an indirect cooling system is large in occupied area, long in construction period, high in initial investment and the like are solved; meanwhile, the structure is large in overall rigidity and good in stability performance, and the limit value of tower top sunlight gathering on structure displacement is easily met. The multifunctional giant frame inclined grid industrial structure can be widely applied to tower-type photo-thermal power generation areas with different wind loads and seismic intensities.

Owner:NORTHWEST ELECTRIC POWER DESIGN INST OF CHINA POWER ENG CONSULTING GROUP

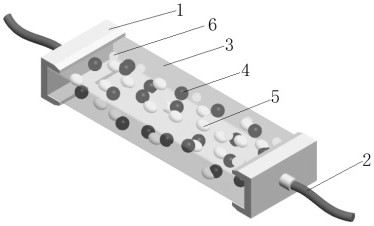

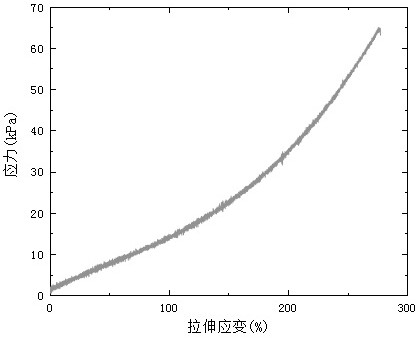

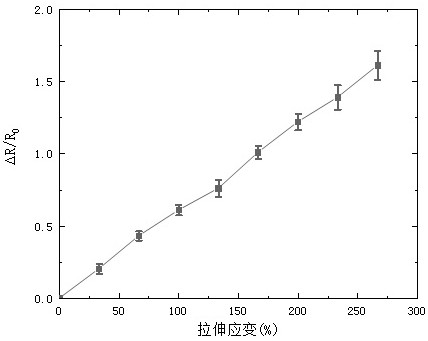

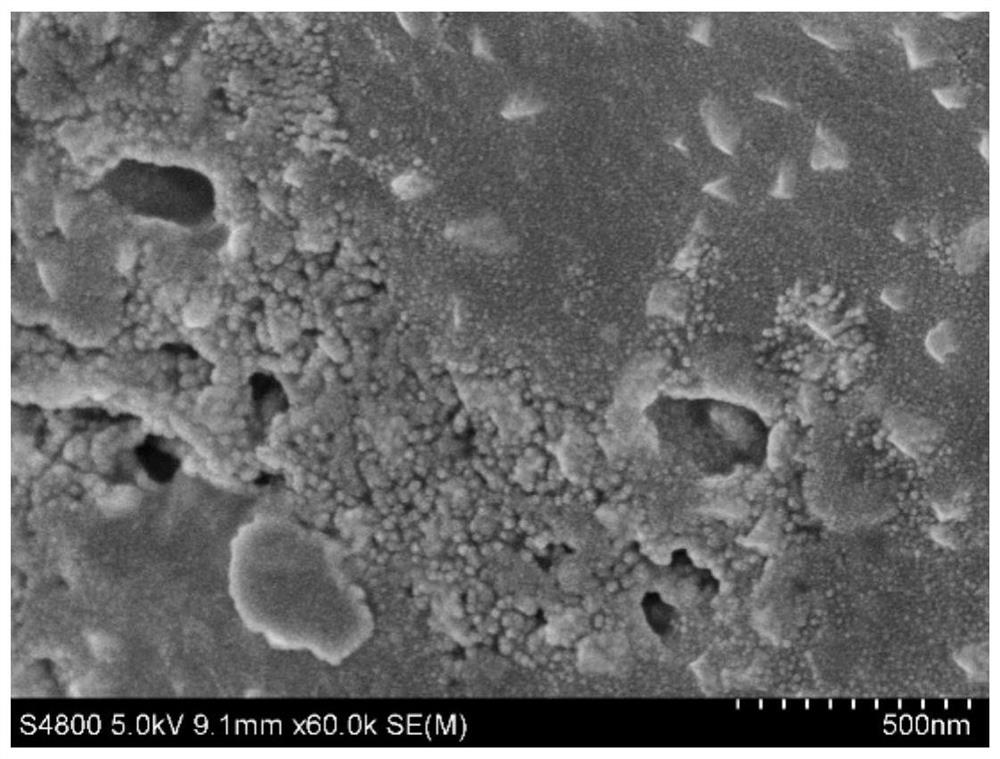

A flexible sensing element of polyvinyl chloride ion gel and its preparation method

ActiveCN112629399BImprove environmental adaptabilityGood stretchabilityElectrical/magnetic solid deformation measurementPolyvinyl chlorideHemt circuits

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

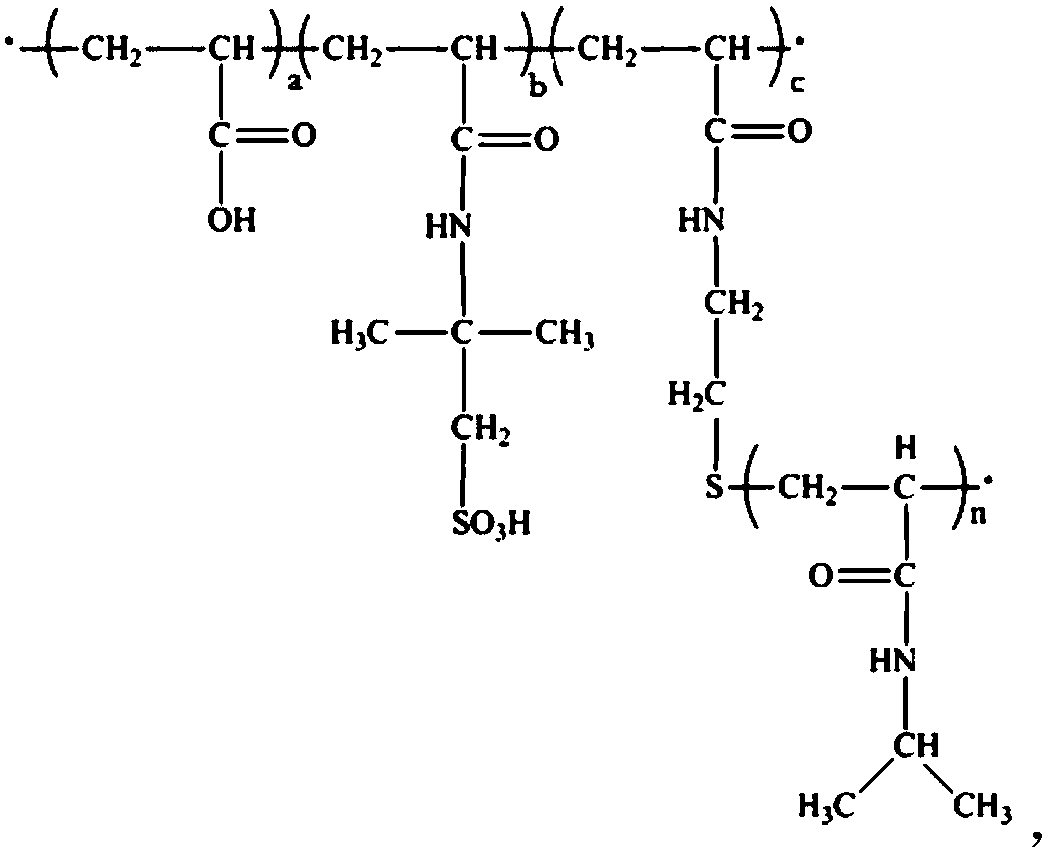

Organic-inorganic composite oil displacement agent, organic-inorganic composite oil displacement system, preparation method and application thereof

ActiveCN108841368BIncrease plastic viscosityLow environmental sensitivityDrilling compositionNanoparticleInorganic compound

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com