A flexible sensing element of polyvinyl chloride ion gel and its preparation method

A technology of polyvinyl chloride and ion gel, applied in the direction of electromagnetic measuring device, electric/magnetic solid deformation measurement, etc., can solve the limitation of polyvinyl chloride gel sensing characteristics, polyvinyl chloride ion gel unmanned and electrical conductivity changes, to achieve good environmental adaptability, reduce environmental sensitivity, and increase the maximum tensile strain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

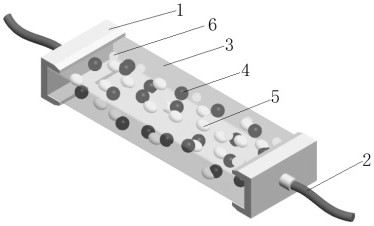

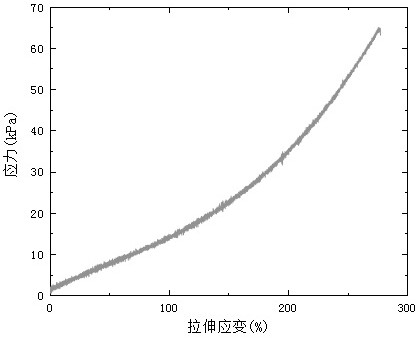

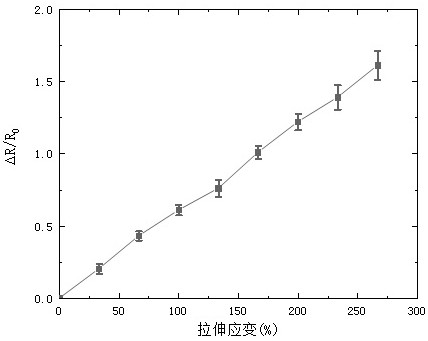

[0038] Preparation and performance test of flexible sensing element of active polyvinyl chloride ion gel

[0039] Preparation Process:

[0040] Step 1) Polymer Mixing:

[0041]Take a clean conical flask, add 2.4137 g dibutyl adipate, 5.1723 g tetrahydrofuran and 0.4868 g ionic liquid 1-ethyl-3-methylimidazolium thiocyanate (EMImSCN) to the conical flask in sequence At room temperature, stir with a magnetic stirrer at a speed of 1500 r / min for 10 min to allow the three liquids to initially mix to obtain a preliminary mixture; then, slowly add 0.3448 g of polyvinyl chloride powder to the above preliminary mixture through a funnel and continue stirring The mixture was placed in a 200W ultrasonic cleaner for 10 minutes, and then the mixture was ultrasonically treated for 30 minutes until the polyvinyl chloride powder was evenly dispersed in the mixture for further dissolution; finally, the mixture was stirred at room temperature with a magnetic stirrer at 1500 r / min Stir at a hi...

Embodiment 2

[0056] Example 2 Preparation and Performance Testing of Flexible Sensing Elements of Passive Polyvinyl Chloride Iongel

[0057] Preparation Process:

[0058] Step 1) Polymer mixing: take a clean conical flask, add 1.568 g dibutyl adipate, 3.36 g tetrahydrofuran and 0.316 g ionic liquid 1-ethyl-3-methylimidazole to the conical flask in sequence Thiocyanate (EMImSCN), stirred with a magnetic stirrer at a speed of 1500 r / min for 10 min at room temperature to allow the three liquids to initially mix; then, slowly add 0.224 g of polyvinyl chloride powder into the above mixture through a funnel, Continue to stir the mixture for 10 min, then place the mixture in a 200W ultrasonic cleaner for 30 min, until the polyvinyl chloride powder is evenly dispersed in the mixture for further dissolution; finally, the mixture is heated at room temperature with a magnetic stirrer at 1500 r Stir at a speed of 24 h until the polyvinyl chloride is completely dissolved;

[0059] Step 2) Ionic gel c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| rate of change | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com