Non-contact real-time online vibration measurement method based on images

A vibration measurement and non-contact technology, which is applied in measuring devices, measuring ultrasonic/sonic/infrasonic waves, image analysis, etc., can solve problems such as troublesome, inability to meet the real-time requirements of the measurement site, heavy calculation of image processing and analysis, etc., to achieve Reduced costs, less preparation work, faster processing results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

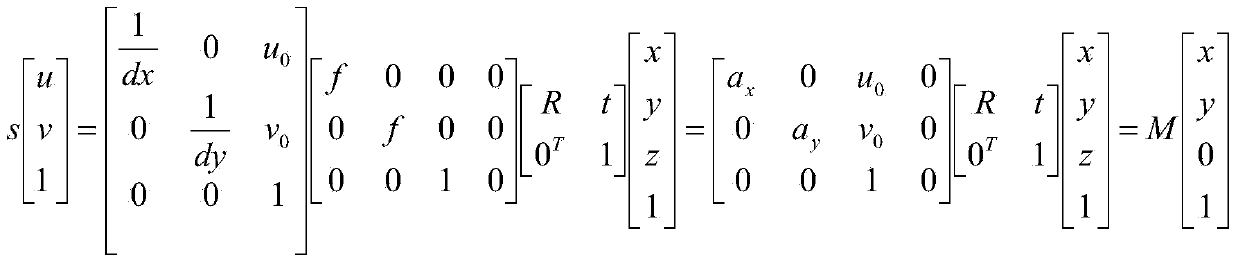

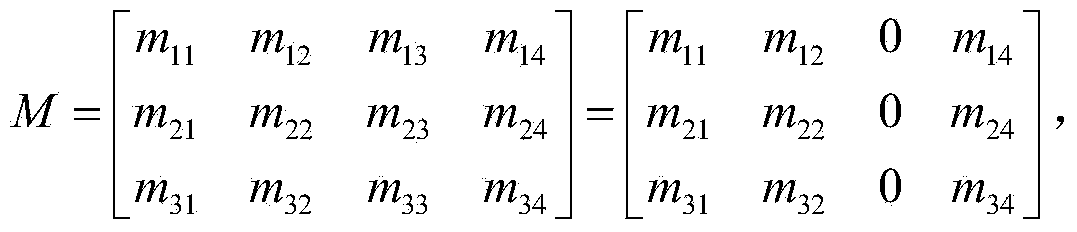

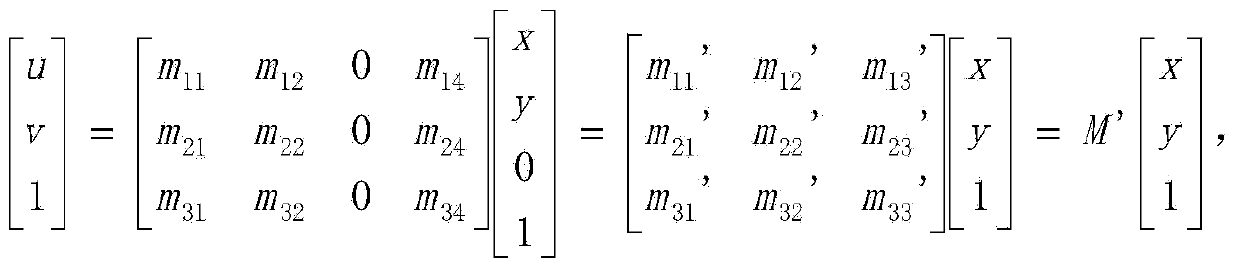

Method used

Image

Examples

Embodiment 1

[0047] A non-contact image-based real-time online vibration measurement method of the present invention involves a device consisting of six parts, namely a high-speed camera, a lens, a bracket, a computer, a display and a power supply module. Specifically in this embodiment, what the high-speed camera adopts is an industrial high-speed CMOS camera, the sampling frequency can reach 6000fps, the lens adopts a fixed-focus lens with a magnification of x5, the high-speed data transmission interface adopts USB3. Industrial computer with high-speed and large-capacity memory, the display adopts resistive touch screen, and the computer and display are connected through VGA and USB2.0. The lens makes the measured target object image on the focal plane of the high-speed camera. The high-speed camera collects the vibration image of the target object at a certain sampling speed, and transmits the image to the computer in real time through the high-speed data transmission interface. The buil...

Embodiment 2

[0075] The steps used in the method in this embodiment and the basic structure of the device on which the method depends are the same as those in Embodiment 1, except that the high-speed camera is a CCD high-speed camera.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com