Patents

Literature

113results about How to "Promote full access" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

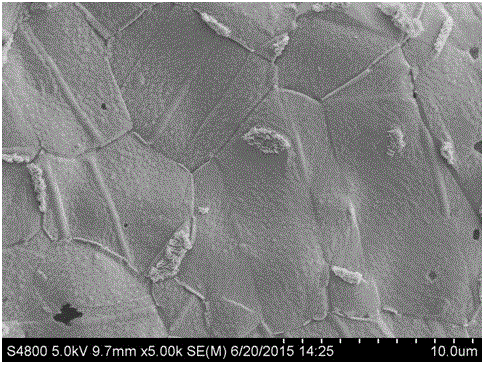

Preparation method of high-purity AlON transparent ceramic powder

InactiveCN105622104AInhibition of agglomerationThe original microscopic shape is maintainedWater basedMetallurgy

The invention belongs to the technical field of synthesis and preparation of ceramic material powder, and in particular, relates to preparation of a high-purity gamma-AlON transparent ceramic powder. The preparation includes the following steps: (1) weighing raw material; (2) preparing a pre-mixed solution; (3) preparing a slurry; (4) carrying out freeze drying; (5) carrying out low temperature calcination; and (6) carrying out high temperature reaction synthesis, to obtain the gamma-AlON transparent ceramic powder. By using the freeze drying technology, water is sublimated at lower temperature, so that nano powder agglomeration in a water-based system can be effectively inhibited, an initial micro-morphology of the raw material can be maintained, and the mixed powder with fluffy organizational structure is obtained; compared with traditional spray drying, the freeze drying technology can reduce the loss of the raw material powder, can improve the utilization rate of the powder, and reduces the preparation cost.

Owner:TIANJIN JINHANG INST OF TECH PHYSICS

Preparation method of foam ceramics

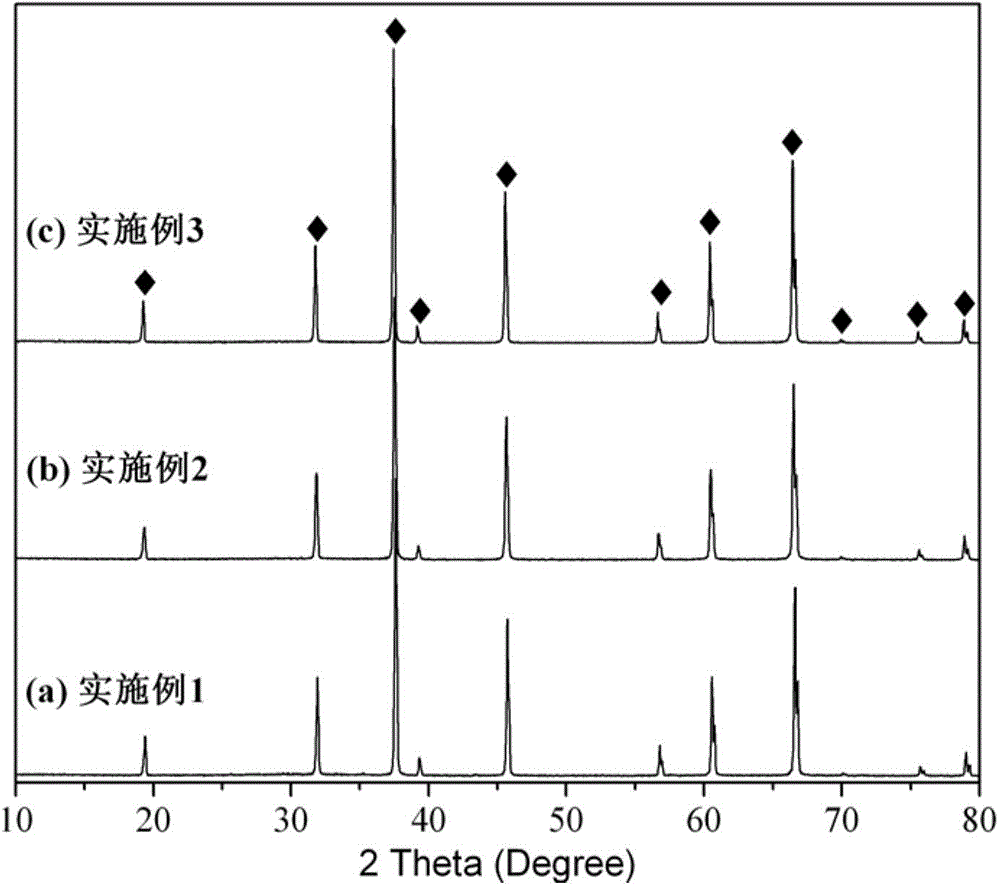

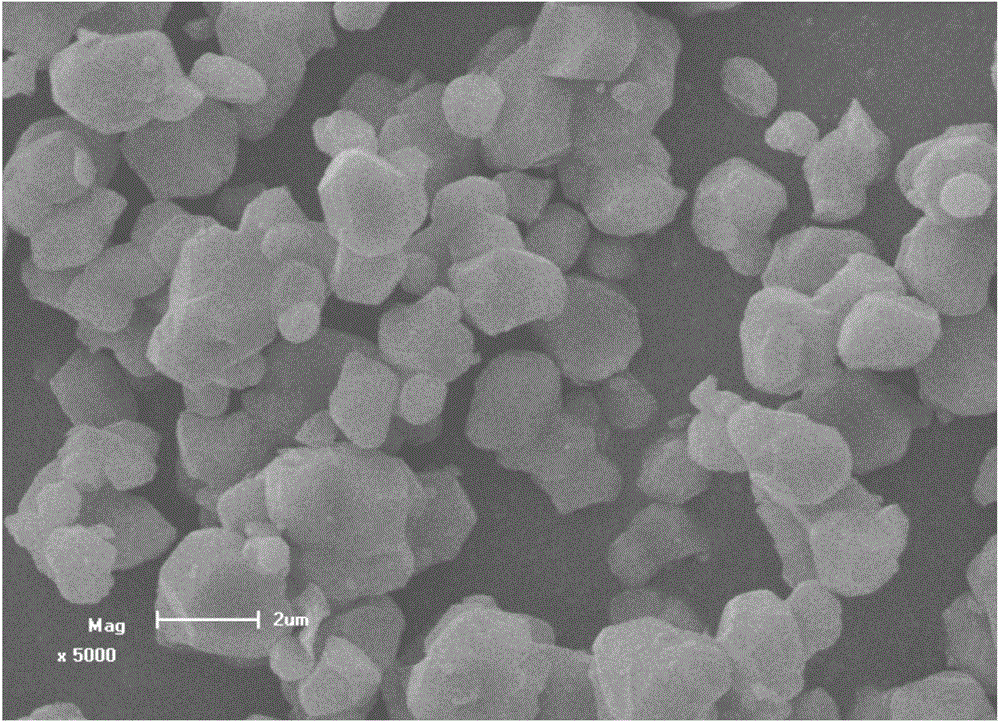

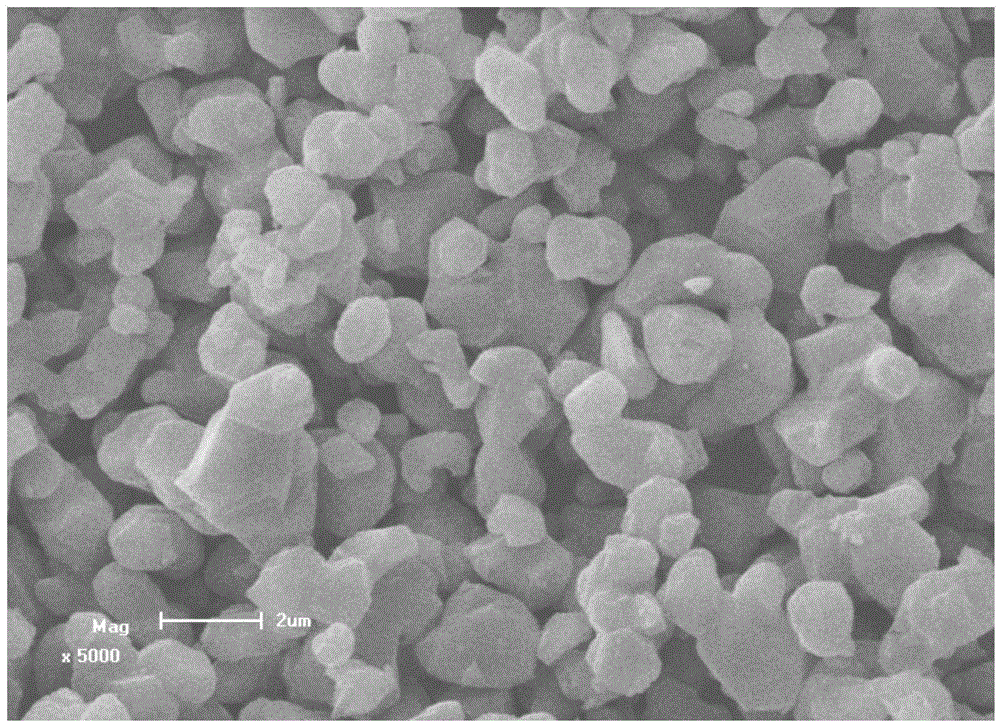

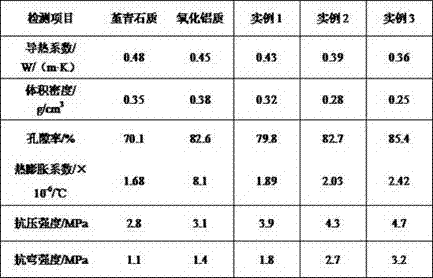

The invention discloses a preparation method of foam ceramics, and belongs to the technical field of porous ceramic material preparation. According to the method, firstly, rice hulls are subjected to high-pressure steaming and boiling; then, crushing and drying are performed to obtain rice hull powder; next, organic matters in the rice hull powder are carbonized at low temperature; through being matched with the catalysis effect of nanometer iron powder and sodium fluoride, silicon carbide crystal whiskers are formed; then, through aerobic calcination, unreacted carbonized organic matters are removed; hydrofluoric acid is used for removing unreacted silicon dioxide, so that the carbide crystal whiskers are uniformly mixed with a polyvinyl alcohol solution, self-made sintering aids, aluminum oxide and the like after being purified; then, through freezing and unfreezing circulation, polyvinyl alcohol realizes the crosslinking curing; finally, after vacuum freeze drying, sintering is performed to obtain the foam ceramics. The foam ceramics have the advantages that the shrinkage is small during the green body firing; collapse cannot easily occur; the mechanical intensity of the product is high; the density is small, and is only 0.25 to 0.32g / cm<3>; the compressive strength reaches 3.9 to 4.7MPa.

Owner:吴刚

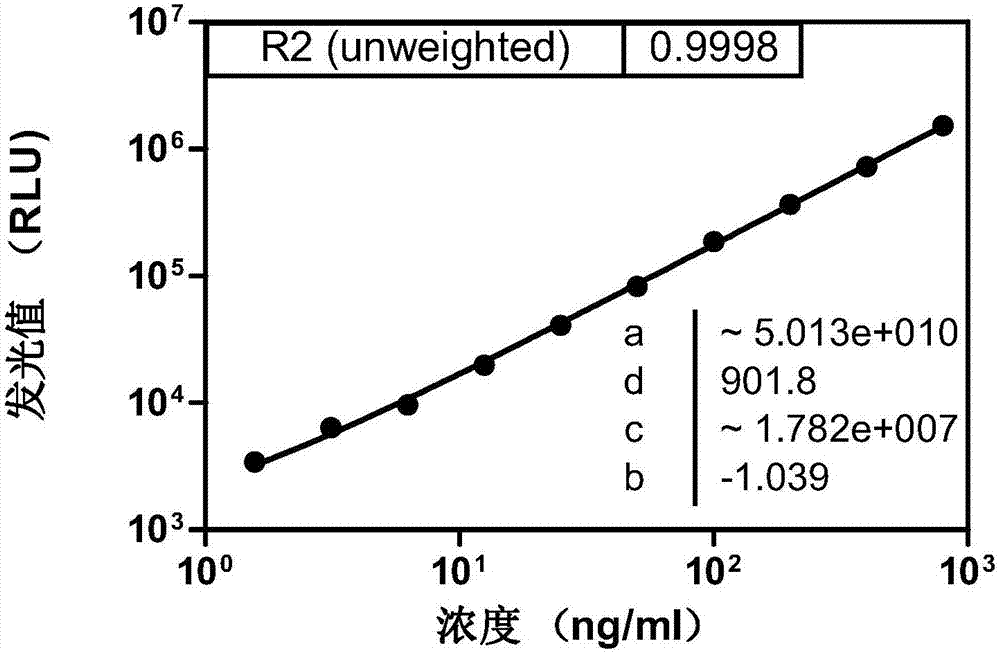

SST2 detection kit based on microparticle chemical luminescence immunity analysis

An sST2 detection kit based on microparticle chemiluminescence immunoassay relates to a chemiluminescence detection kit. The sST2 detection kit is equipped with reaction buffer, magnetic particles coated with sST2 monoclonal antibody, sST2 monoclonal antibody labeled with acridinium ester, luminescent solution, sST2 antigen standard solution, and concentrated washing solution. Prepare reaction buffer; prepare magnetic particles coated with sST2 antibody; prepare acridinium ester-labeled sST2 antibody; prepare sST2 antigen standard solution; prepare luminescent solution; prepare washing solution. It adopts microparticle chemiluminescence immunoassay technology, which has higher sensitivity and better stability than ELISA, filling the gap in the domestic production of microparticle chemiluminescence diagnostic reagents for human serum sST2 detection. It has the advantages of simple operation, high sensitivity, wide linear range, stable results, good safety, and easy automation. It has broad application prospects in clinical testing and other aspects.

Owner:ZHONGSHAN HOSPITAL XIAMEN UNIV

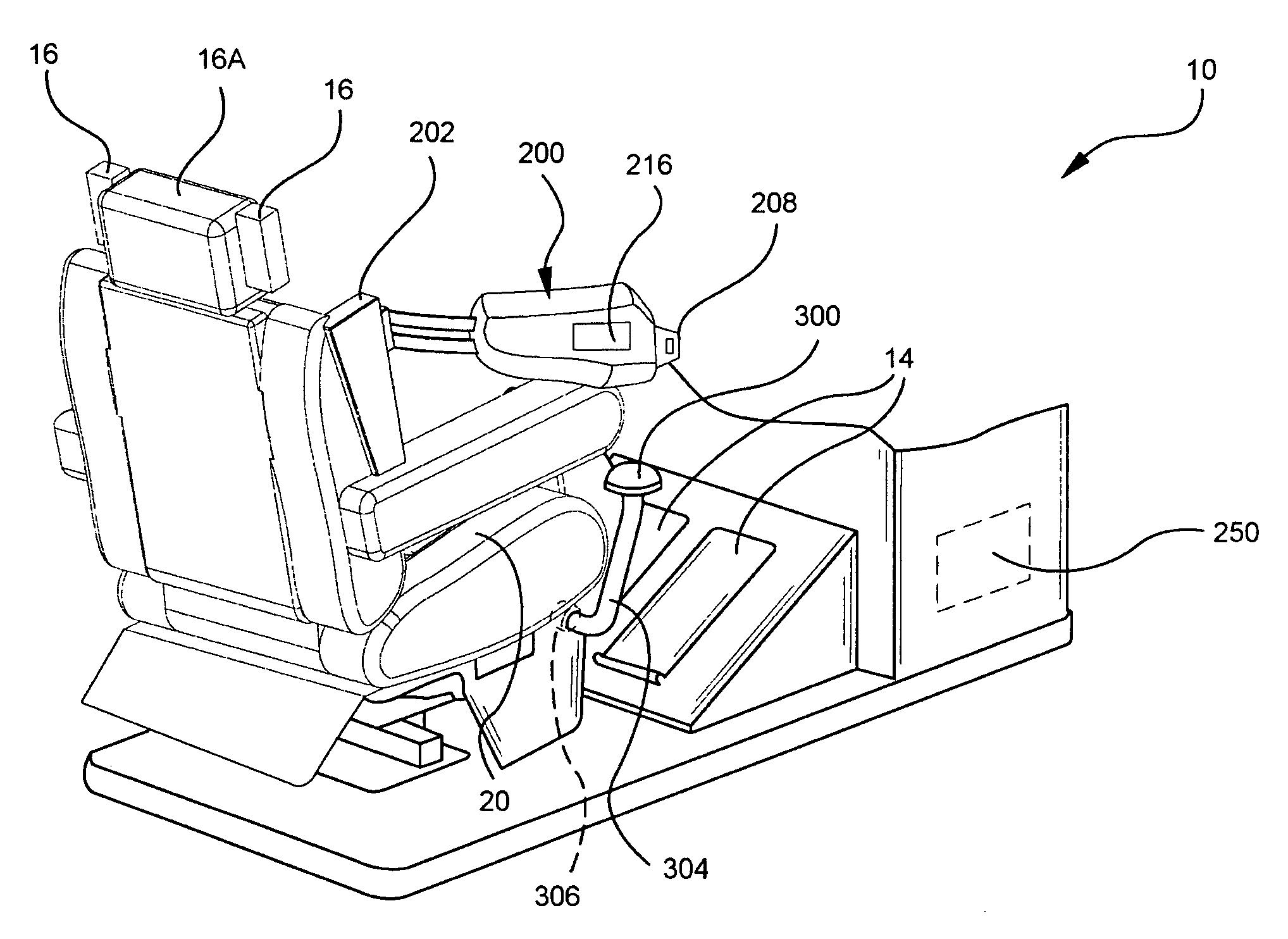

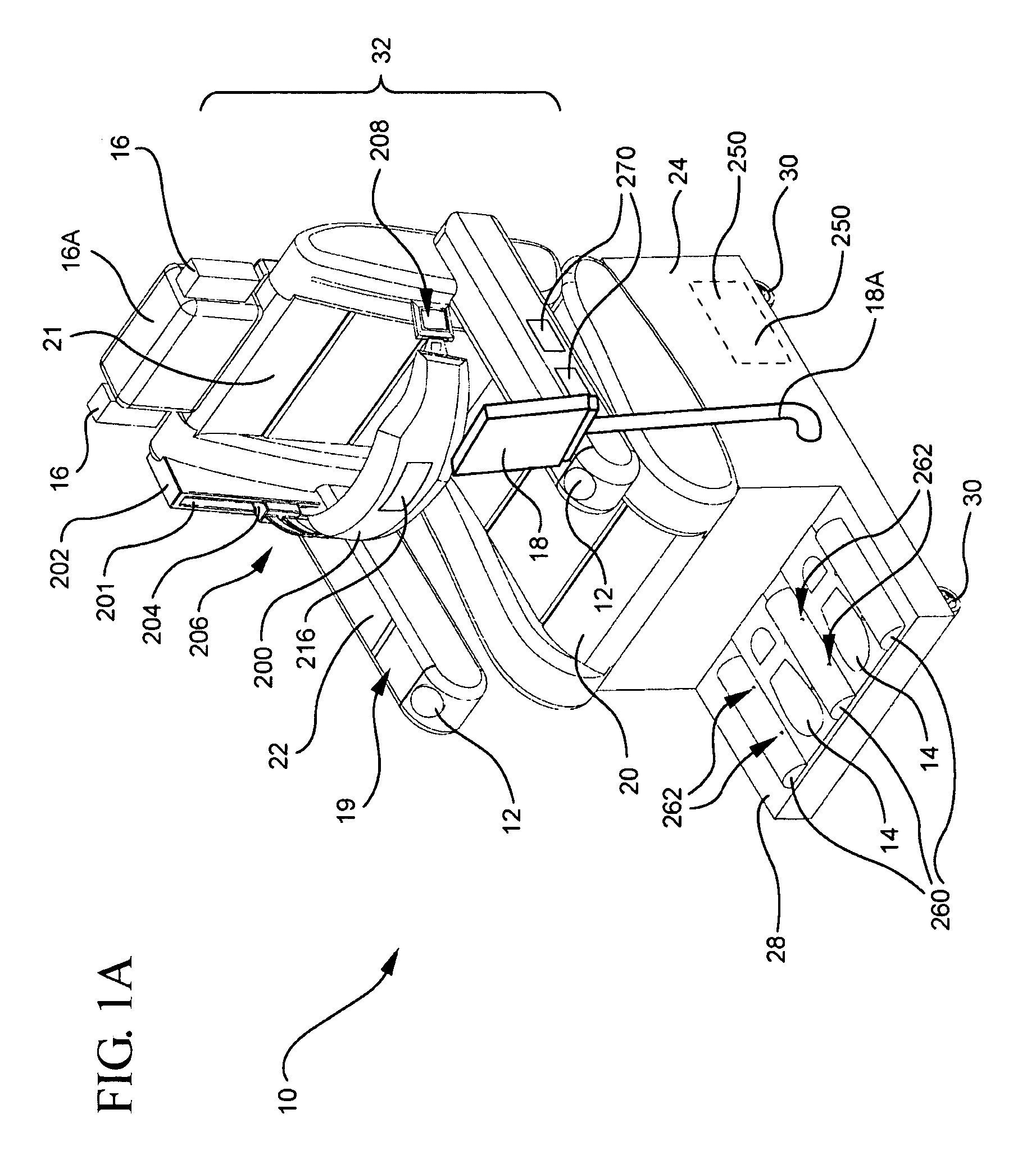

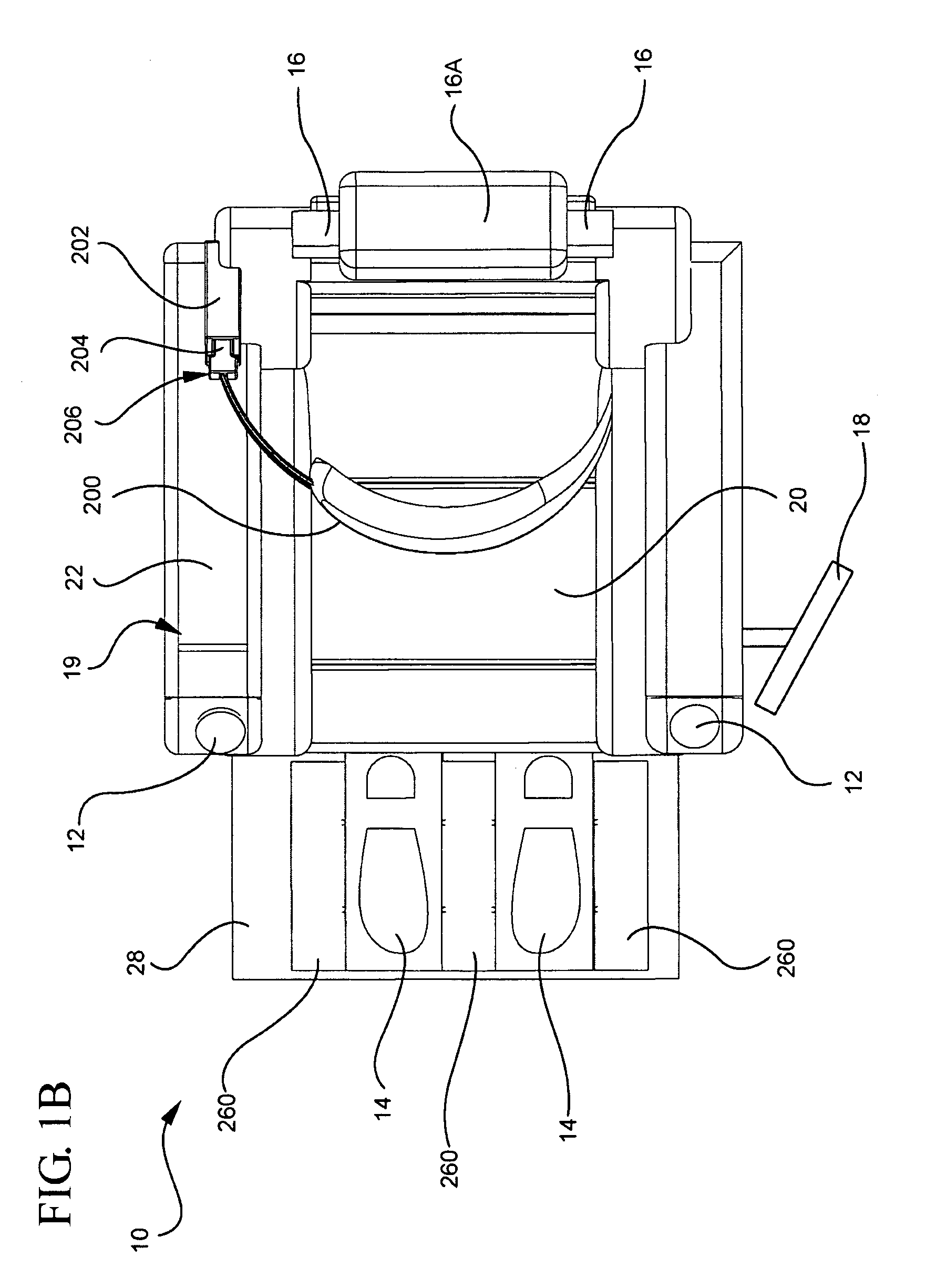

Apparatus for measuring, recording and transmitting electrocardiogram measurements

InactiveUS8219184B2Promote full accessEasy vertical movementElectrocardiographyData processing applicationsGraphicsVASCULAR FUNCTIONS

Embodiments of the present invention include a monitoring device and method for measuring, recording and transmitting a pre-determined set of electrocardiogram measurements. The device provides for an unassisted six or twelve channel measurements of heart and vascular functions using a visual graphical output. Results of the measurements are charted and can be reviewed and analyzed by an authorized health care provider.

Owner:ZIEHM IMAGING

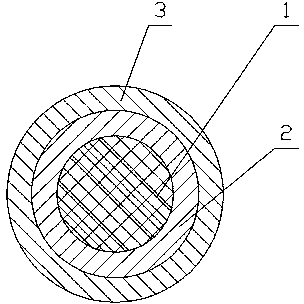

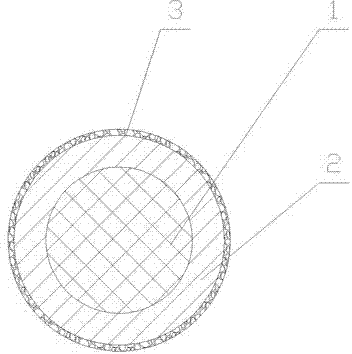

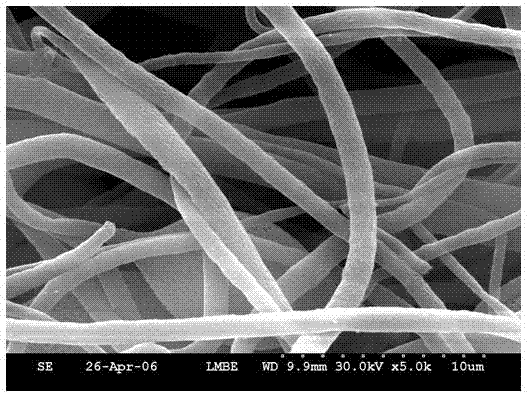

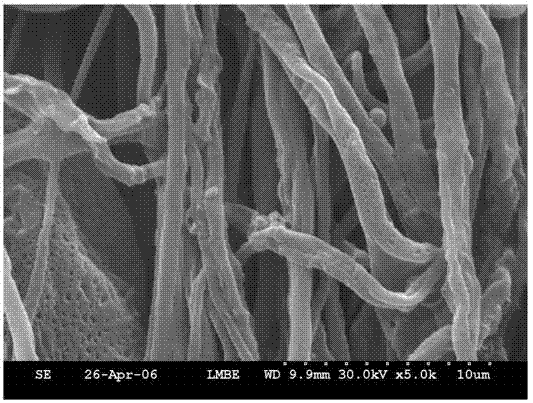

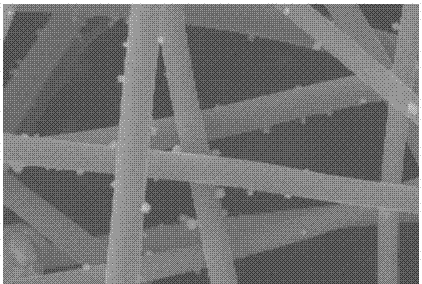

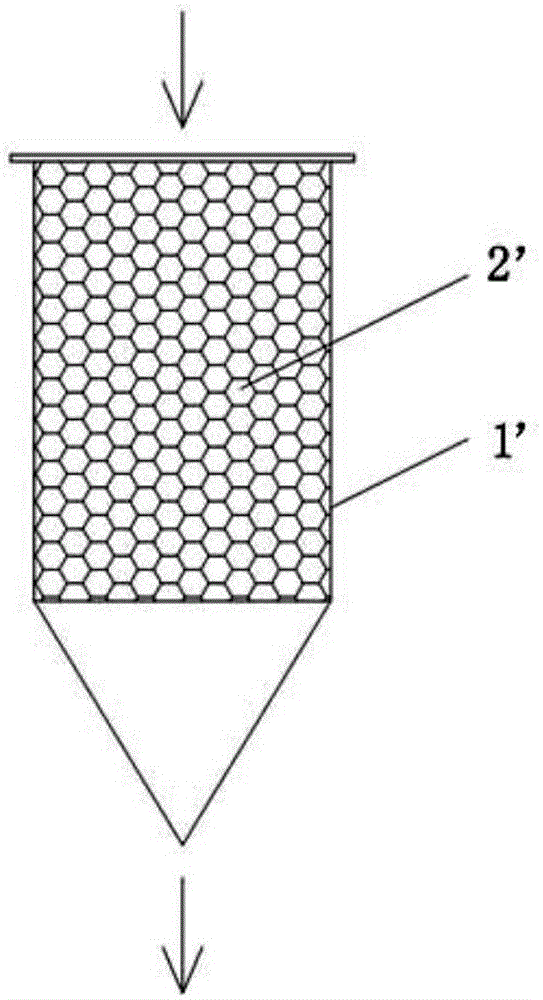

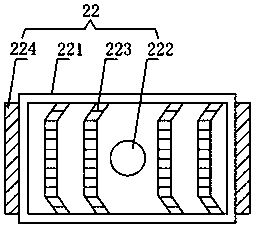

Coaxial three-layer high-activity bio-enzyme-embedded electrostatic spinning nano-fiber membrane and preparation method thereof

InactiveCN103668485AIncrease the amount of enzyme immobilizedPromote full accessFilament/thread formingNon-woven fabricsMembrane configurationReusability

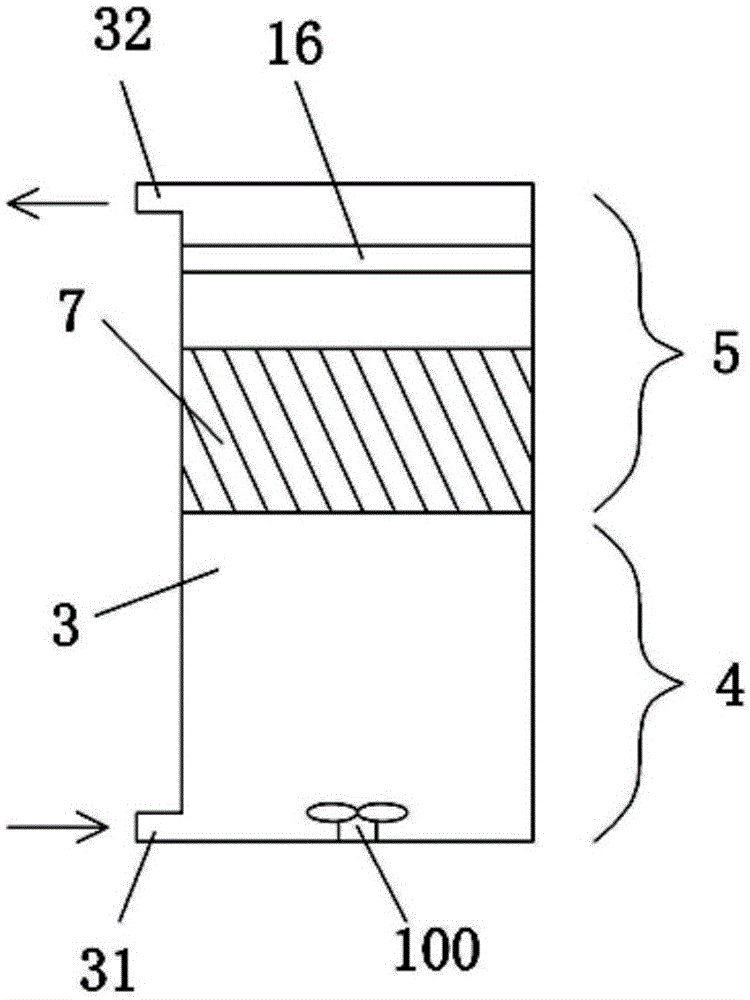

The invention discloses a coaxial three-layer high-activity bio-enzyme-embedded electrostatic spinning nano-fiber membrane and a preparation method thereof. The coaxial three-way electrostatic spinning technology is used to allow bio-enzyme to be embedded into the sandwich layer of slow release activating agent and porous polymer so as to form the porous nano-fiber membrane. The nano-fiber membrane of a sandwich structure sequentially comprises a slow release activating agent layer (1), an immobilized bio-enzyme layer (2) and a porous polymer layer (3) from inside to outside. By building the structure with communicating ducts, immobilization amount of enzyme is increased, sufficient contact of the enzyme and a substrate is promoted, mass transfer resistance between the enzyme and the substrate is lowered, catalytic efficiency and reusability of the enzyme are increased effectively, environmental sensitivity of the bio-enzyme is lowered, and lasting stability of the bio-enzyme when being applied in complex environments is increased.

Owner:DALIAN OCEAN UNIV +1

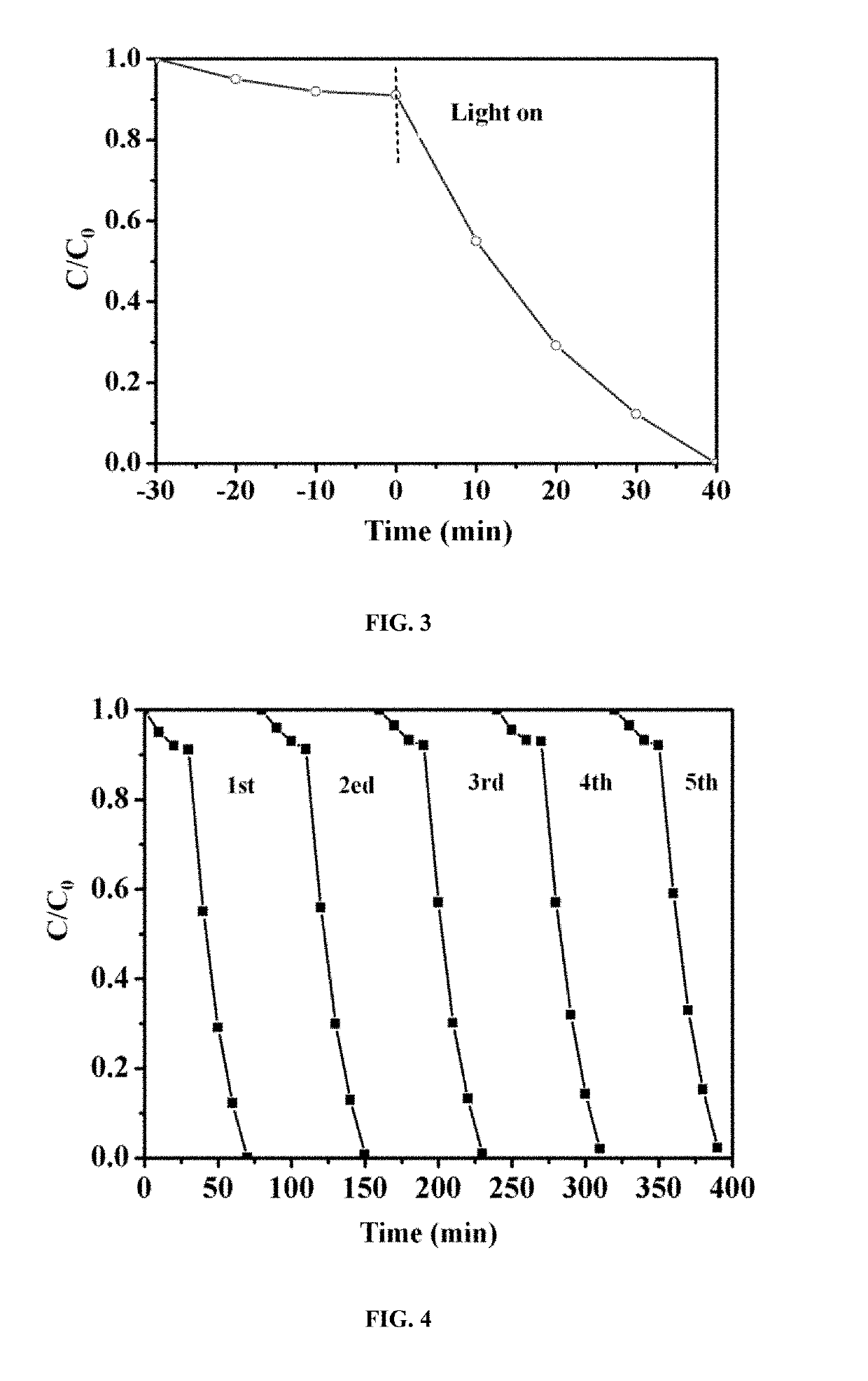

Loaded multifunctional catalysis composite material, preparation method thereof and application of composite material to catalytic removal of water pollutants

ActiveUS20190329236A1Promote full accessReduce recombination rateMaterial nanotechnologyWater/sewage treatment by irradiationPhoto catalysisNickel

The invention discloses a loaded multifunctional catalysis composite material, a preparation method thereof and an application of the composite material to catalytic removal of water pollutants. The preparation method includes the steps: preparing a zinc oxide nano-sheet loaded nickel foam (Ni@ZnO) composite material by an electro-deposition method; compounding molybdenum disulfide micro-nano particles on ZnO porous nano-sheets by an electro-deposition method to obtain Ni@ZnO / MoS2. The composite material Ni@ZnO / MoS2 combines the advantages of components such as nickel foam, the zinc oxide nano-sheets and molybdenum disulfide from the point of material performances, high catalytic degradation activity and recycled performances are achieved, photo-catalysis and electro-catalysis are combined from the point of material application, and the catalytic activity of the composite material is improved by the aid of synergistic effects of photo-catalysis and electro-catalysis.

Owner:SUZHOU UNIV

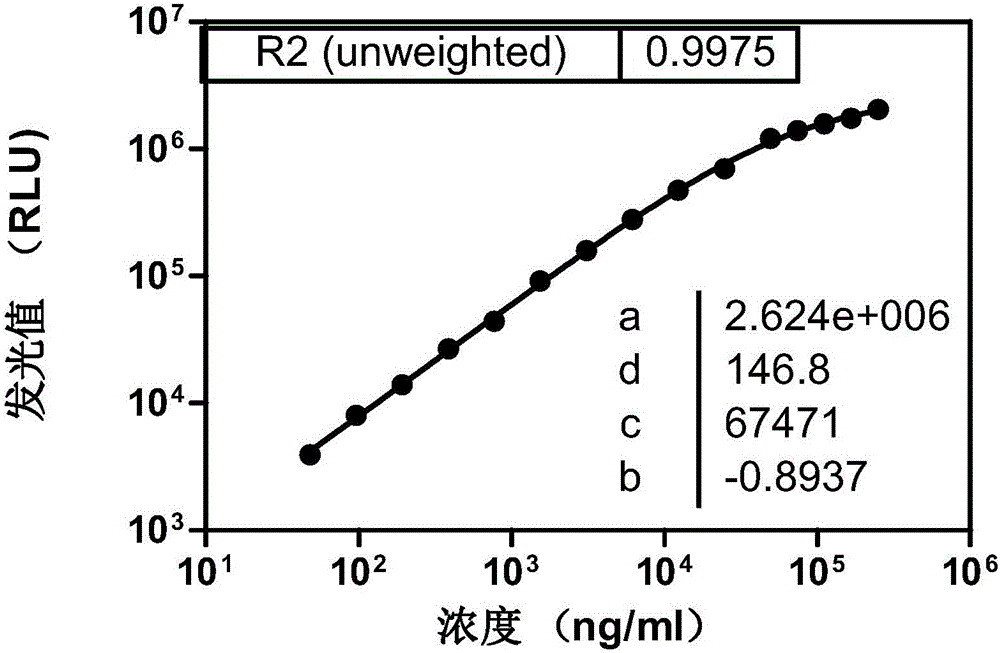

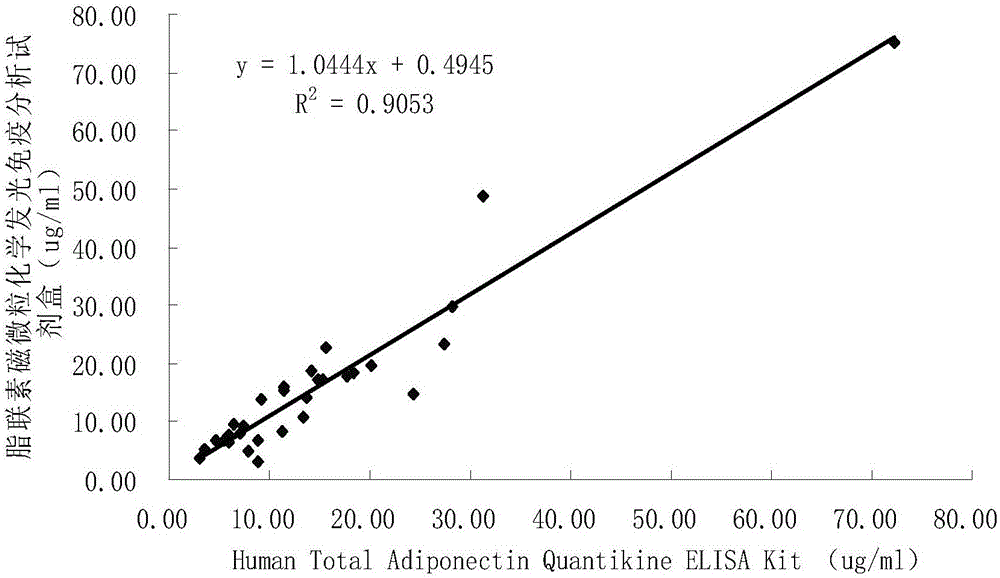

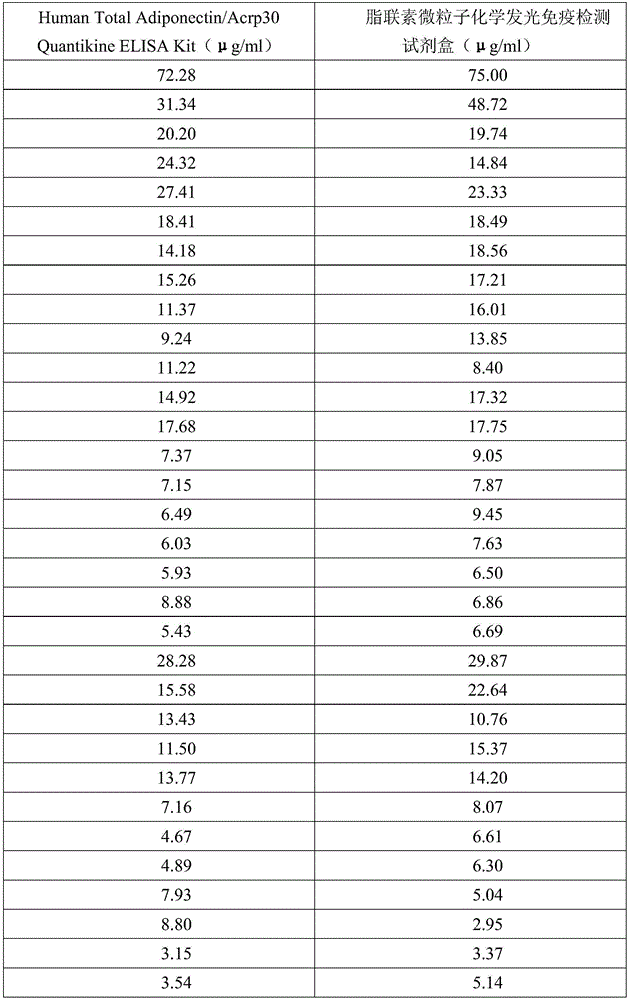

Human serum adiponectin detection kit based on micro-particle chemiluminescence immune assay

ActiveCN105759061APromote full accessShort reaction timeDisease diagnosisBiological testingAntigenSerum adiponectin

The invention discloses a human serum adiponectin detection kit based on micro-particle chemiluminescence immune assay, and relates to the chemiluminescence detection kits. The human serum adiponectin detection kit comprises reaction buffer liquor, magnetic micro-particles coated with an adiponectin monoclonal antibody, the adiponectin monoclonal antibody marked with acridinium ester, luminescence liquor A, luminescence liquor B, an adiponectin antigen standard substance solution and concentrated scrubbing solution. A preparation method for the human serum adiponectin detection kit comprises the following steps: preparing the reaction buffer liquor; preparing the magnetic micro-particles coated with the adiponectin monoclonal antibody; preparing the adiponectin monoclonal antibody marked with acridinium ester; preparing the luminescence liquor; and preparing the scrubbing solution. According to the human serum adiponectin detection kit, the magnetic micro particles are coupled with the monoclonal antibody, and the micro particles can be suspended in a sample solution, so that the antibodies on the surfaces of the micro particles are sufficiently in contact with a to-be-detected object, and the reaction time is shortened; and the acridinium ester is used as the marker, so that a stable and high-strength signal can be obtained. The human serum adiponectin detection kit is simple to operate, is high in sensitivity, is wide in linearity range, is stable in result, is good in safety and is convenient for automation.

Owner:ZHONGSHAN HOSPITAL XIAMEN UNIV +1

Instant macroelement water-soluble fertilizer capable of increasing soil organic matter content

InactiveCN105646083AImprove physical and chemical conditionsImprove biological characteristicsAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersDipotassium phosphateDrip irrigation

The invention relates to fertilizer, in particular to instant macroelement water-soluble fertilizer capable of increasing the soil organic matter content. The instant macroelement water-soluble fertilizer capable of increasing the soil organic matter content is prepared form components in parts by weight as follows: 100-200 parts of concentrated molasses yeast powder, 8-15 parts of poly potassium aspartate, 50-80 parts of citric acid, 3-10 parts of chitin, 30-50 parts of potassium carbonate, 10-30 parts of boric acid, 150-300 parts of urea, 200-400 parts of anhydrous dipotassium phosphate and 180-280 parts of ammonium polyphosphate. The fertilizer can be quickly dissolved, is fully water-soluble, can be applied to facility agriculture such as sprinkling and drip irrigation and the like and realizes integration of water and fertilizer and the efficiency of saving water, fertilizer and labor. The fertilizer can provide organic matters and various macroelement nutrients for soil and crops after usage.

Owner:王越

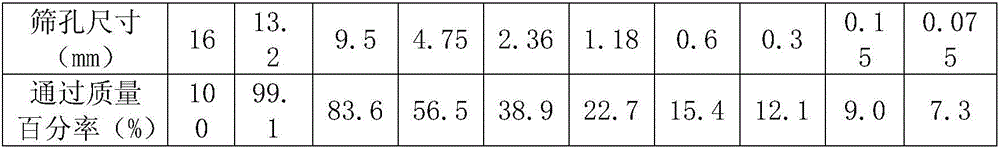

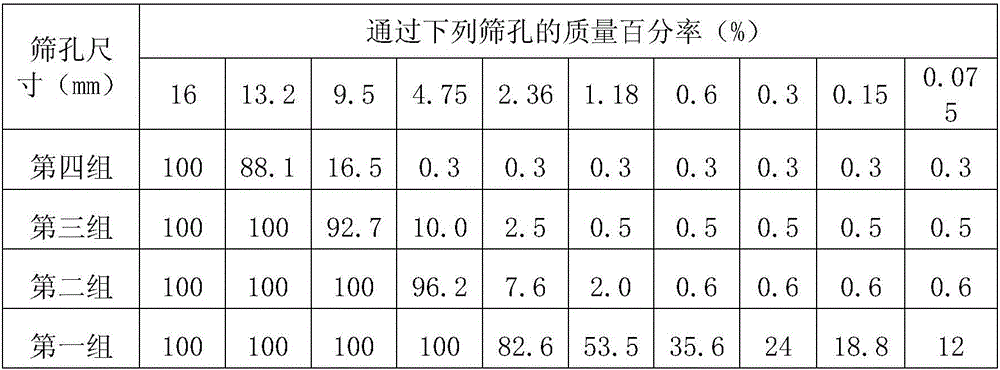

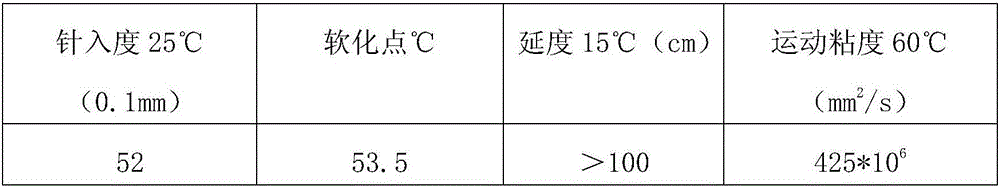

Preparation method of separated plant-mixed warm-hot regenerated asphalt mixed material

InactiveCN106746926AReduce effective utilizationPromote full accessSolid waste managementPavement engineeringBituminous materials

The invention relates to an asphalt material for pavement engineering and in particular to a preparation method of a separated plant-mixed warm-hot regenerated asphalt mixed material. The preparation method comprises the following steps: (1) detecting the asphalt content of a recovered asphalt pavement material, ageing the asphalt performance and mineral aggregate gradation; (2) determining the content of the recovered asphalt pavement material, a novel aggregate, limestone mineral powder, novel asphalt and a regenerator; (3) adding the mixture into a mixing pot for prestirring; (4) adding the regenerator; (5) discharging the obtained product out of a pot and developing at 40-150 DEG C; (6) adding the heated novel aggregate into the stirring pot, adding the developed product in the step (5) and stirring; and (7) adding the novel asphalt and limestone mineral powder into the product obtained in the step (6) and stirring, and then discharging and forming. The asphalt material provided by the invention is simple in process, good in regenerating effect, high in utilization ratio of the regenerator, relatively low in cost and good in comprehensive pavement performance of the product.

Owner:JIANGSU TIANNUO ROAD MATERIAL TECH

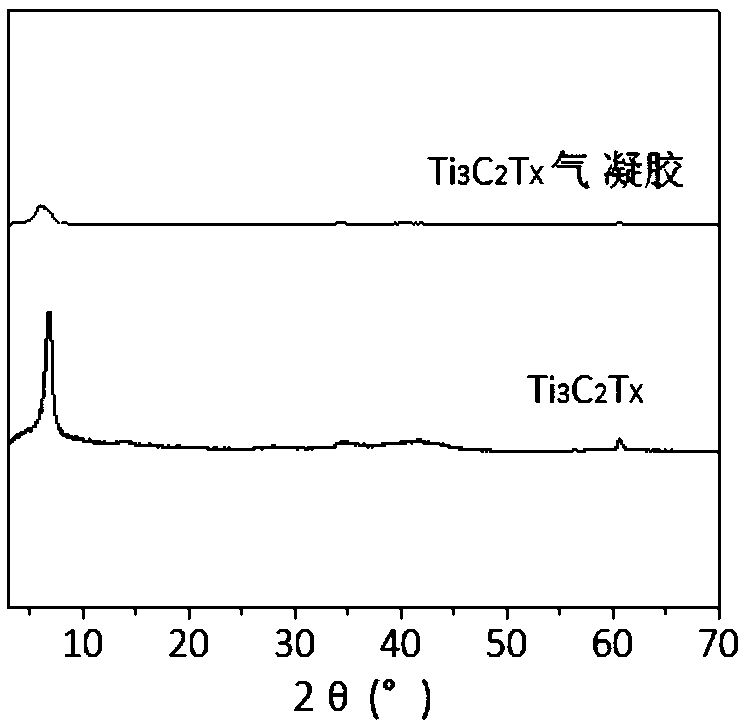

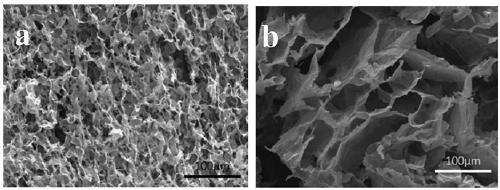

Two-dimensional transition metal carbide (nitride) aerogel as well as preparation method and application thereof

ActiveCN109437202APromote full accessEasy to operateOther chemical processesWater contaminantsTransition metal carbidesFreeze-drying

The invention discloses a two-dimensional transition metal carbide (nitride) aerogel as well as a preparation method thereof and application thereof. A HCl (Hydrochloric acid)+LiF (LithiumFluoride) solution is adopted to corrode a ternary layered carbide (nitride) MAX powder, and stable colloidal-state suspension liquid of two-dimensional transition metal carbide (nitride) nano sheets is obtainedby washing and stripping. A hydrochloric acid solution is added to break electrostatic equilibrium between the two-dimensional transitionp metal carbide (nitride) nano sheets, and the two-dimensionaltransition metal carbide (nitride) nano sheets are guided to be self-assembled to form hydrogel, and finally, vacuum freeze-drying is performed to obtain the two-dimensional transition metal carbide (nitride) aerogel. The prepared aerogel has a high specific surface area and developed holes, has adsorption capacity of 246 mg / g to lead ions, has adsorption capacity of 17 g / g to methylbenzene, and is an ideal adsorption material. The preparation method disclosed by the invention is simple and safe, is easy to control, and is suitable for large-scale industrial production; and the prepared two-dimensional transition metal carbide (nitride) aerogel has a good application prospect in the field of adsorption.

Owner:NANJING UNIV OF TECH

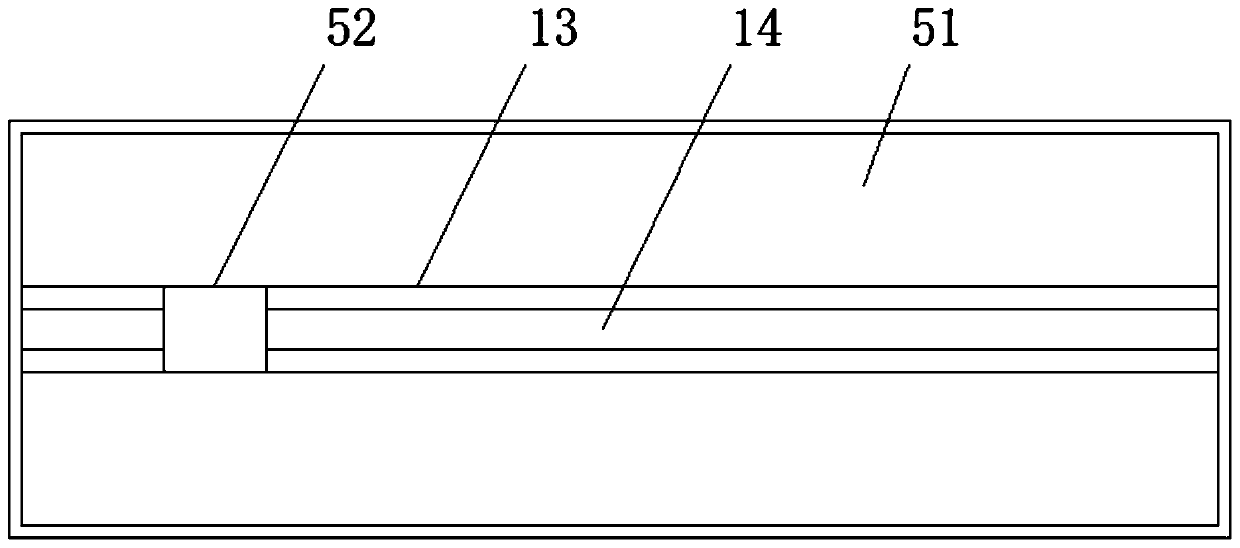

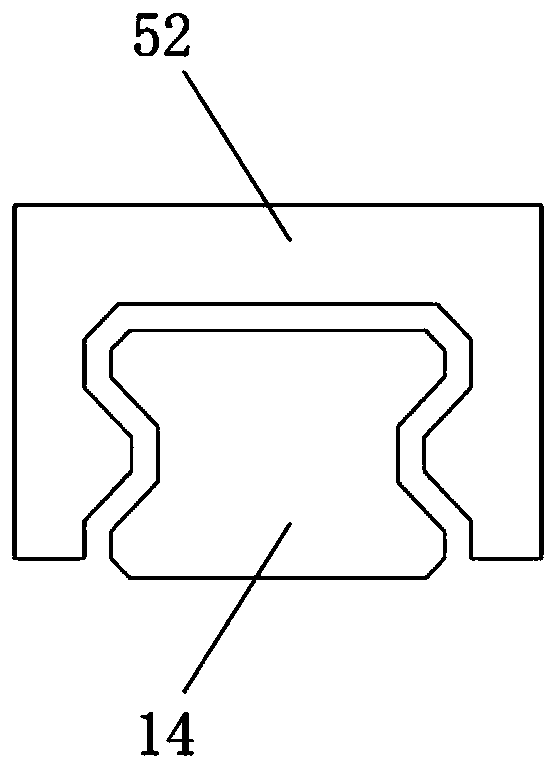

Preparation method of electrode sheet including PTC coating layer and lithium ion battery

ActiveCN110137426AImprove compatibilityGood processing performanceElectrode thermal treatmentFinal product manufactureSolventIon

The invention provides a preparation method of an electrode sheet including a PTC coating layer and a lithium ion battery including the electrode sheet, and belongs to the technical field of lithium ion batteries. The preparation method comprises the following steps: step 1: according to the number of parts by weight, 400-1000 parts of solvent, 50-100 parts of high-molecular polymer and 0. 5-3 parts of conductive agent are uniformly stirred and then 0. 1-5 parts of mixed reagent of high-voltage-resistant crosslink agent and initiator are added, wherein the mass fraction of the initiator in thehigh-voltage-resistant crosslinking agent is 0. 1-2%, and the mixture is stirred for 2-8 hours so as to obtain a coating slurry; step 2: the coating slurry is coated on a current collector and driedat 80-120 DEG C for 2-6h so as to obtain the current collector coated with the PTC coating layer; and step 3, the electrode sheet slurry is uniformly coated on the current collector and dried, rolledand pressed and sliced so as to obtain the lithium ion battery electrode sheet including the PTC coating layer. The molecular design method is used and the high-voltage-resistant crosslink structure system is introduced so as to effectively improve the compatibility and the processing performance of the PTC coating layer and the electrode sheet.

Owner:ZHUHAI COSMX BATTERY CO LTD

Floating type light self-cleaning microorganism immobilization membrane for removing oil contamination polluting water and preparation method of membrane

InactiveCN103641243APromote full accessReduce mass transfer resistanceBiological water/sewage treatmentChemistryPetroleum

The invention discloses a floating type light self-cleaning microorganism immobilization membrane for removing oil contamination polluting water and a preparation method of the membrane. Microorganisms are embedded into an inner layer of a porous polymer by using a coaxial electrostatic spinning technology to form a porous nanofiber membrane with a core-shell structure nanofiber, so that an oil absorbent felt floated on the water surface is formed, thus full contact between the microorganisms and greasy dirt is facilitated, the mass transfer resistance of the microorganisms and the greasy dirt is reduced and the catalytic activity of petroleum degradation microorganisms is effectively improved; a nanometer photocatalyst having the photocatalytic effect is immobilized on the surface of the core-shell structure nanofiber surface, so that the greasy dirty remaining on the surface of the fiber is decomposed under the action of the solar energy; moreover, the floating type light self-cleaning microorganism immobilization membrane has a light self-cleaning function, so that the repeating utilization rate of the oil absorbent felt is increased, and the greasy contamination treatment cost of the water is reduced.

Owner:DALIAN OCEAN UNIV +1

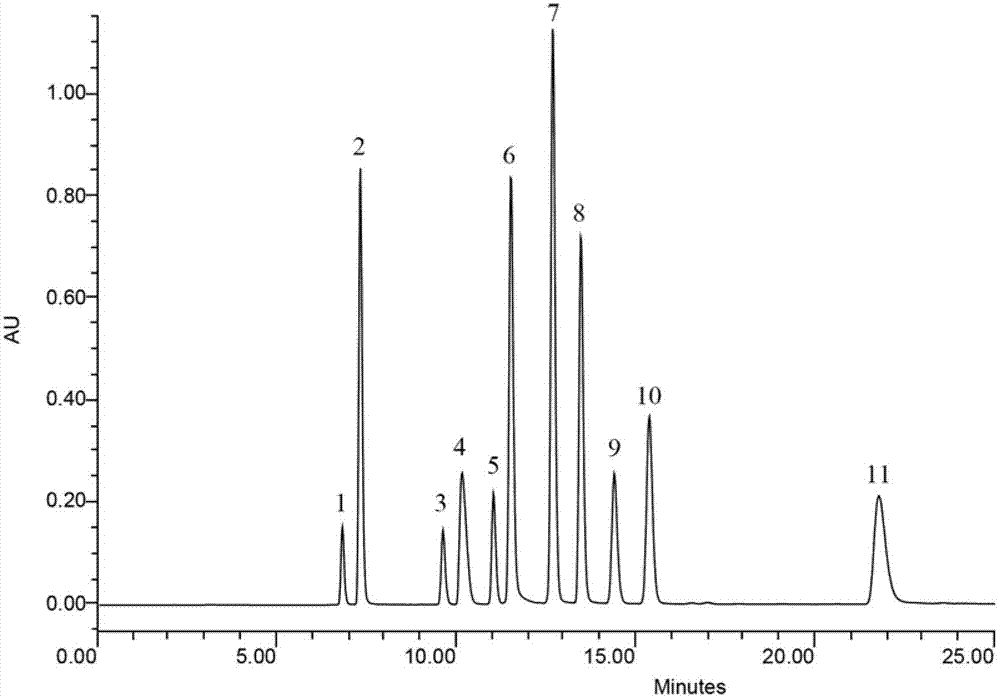

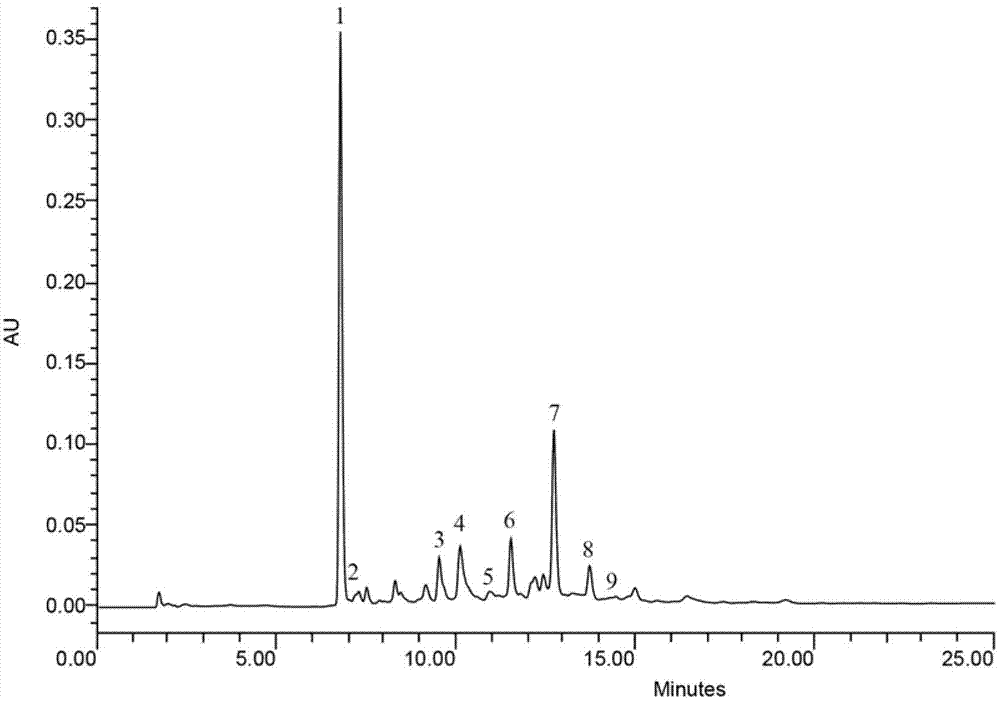

Pear polyphenols extraction method

InactiveCN102727609AHigh extraction rateAvoid oxidation reactionsDigestive systemAntinoxious agentsWater bathsPEAR

The invention relates to a pear polyphenols extraction method, falling into the field of extraction and processing of plant active substances. The method comprises the steps of peeling and stoning young pear fruits, dicing into pieces smaller than 1 cubic centimeter, grinding into powder with liquid nitrogen, soaking with 30-90% ethanol solution at sample / solution mass volume ratio of 1:(20-30), extracting on a constant temperature shaking bed in dark at 50-70 DEG C and uniform speed of 100-170 rpm for 2-6 h, and centrifuging to collect supernatant as pear polyphenols extractive solution. The extraction method adopts liquid nitrogen grinding to enable extraction process under low temperature state, to avoid oxidation reaction of pear polyphenols during grinding process and improve polyphenols activity. Through extraction with the constant temperature shaking bed under uniform speed, sufficient contact between sample and extraction solvent is facilitated to improve extraction rate by 5-17% compared with constant temperature water bath extraction.

Owner:NANJING AGRICULTURAL UNIVERSITY

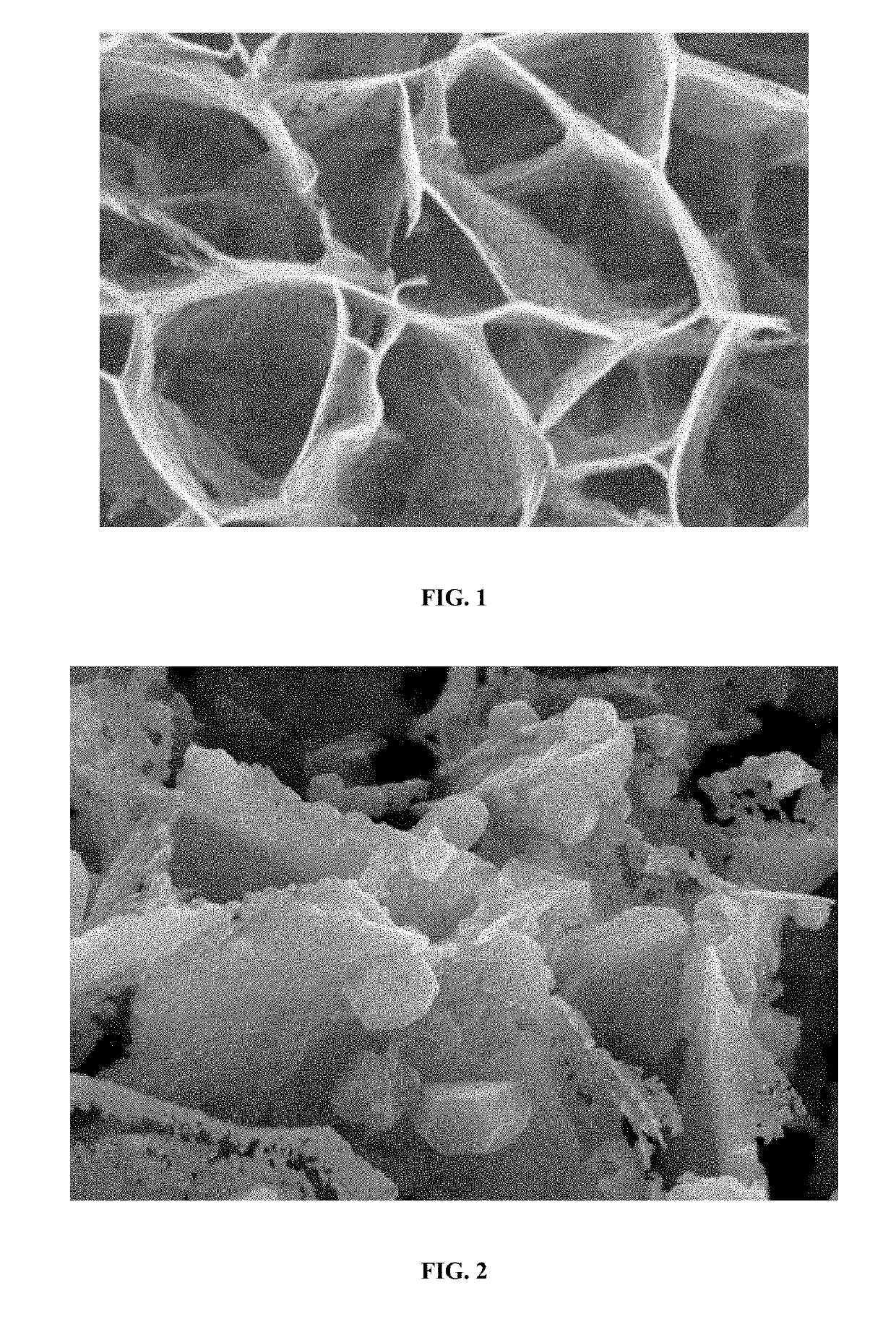

Preparation method for inorganic nanoparticle/graphene three-dimensional porous composite material

InactiveCN105932258APore Size ControlImprove conductivityMaterial nanotechnologyCell electrodesHigh energyMicrosphere

The invention provides a preparation method for an inorganic nanoparticle / graphene three-dimensional porous composite material. According to the preparation method, the inorganic nanoparticle / graphene three-dimensional porous composite material is prepared by the steps of uniformly mixing polystyrene microspheres pre-loaded with inorganic nanoparticles with a graphene oxide solution, then removing a solvent, and packaging and compounding the mixture; and next, removing a polystyrene template through thermal treatment, carrying out thermal reduction on graphene, and keeping the inorganic nanoparticles. The preparation method has the beneficial effects as follows: the polystyrene microspheres are taken as the carrier of the inorganic nanoparticles, so that agglomeration of the inorganic nanomaterial and the graphene lamination can be effectively avoided in the regulation and control process of the porous structure; when the porous composite material is used as the negative electrode of a lithium battery, the inorganic nanoparticles with high theoretical specific capacity supplies possibility for implementation of the high energy density of the material; the three-dimensional conductive network formed by graphene supplies possibility for implementation of the high power density; and in addition, due to the three-dimensional porous structure, the volume change caused by lithium intercalation / deintercalation of the active particles can be effectively relieved, so that the cyclic stability of the material is improved.

Owner:TIANJIN POLYTECHNIC UNIV

Method for preparing cobaltous selenide super-capacitor material through chemical vapor deposition method

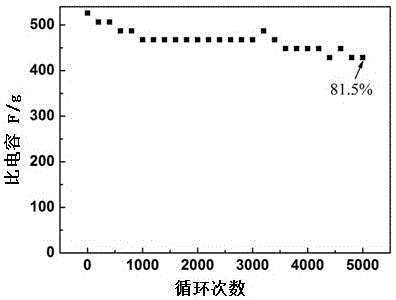

InactiveCN105957723ALarge specific surface areaIncrease contact spaceHybrid capacitor electrodesChemical vapor deposition coatingCapacitanceCobalt

The invention discloses a method for preparing a Co0.85Se super-capacitor material through a chemical vapor deposition method, wherein the Co0.85Se super-capacitor material is a nano film-shaped structure covering a nickel mesh. The specific growth process comprises the following steps: 1), grinding and mixing selenium powder and cobalt powder, putting the mixture of selenium powder and cobalt powder into a quartz boat, and putting the quartz boat into a chemical vapor deposition reacting furnace quartz tube; 2), enabling a foamed nickel mesh to be placed at a position, close to the mouth of the quartz tube, of a downstream side of an air flow; 3), letting in argon gas, exhausting the air in the furnace, stopping the supply of the gas, carrying out heating for some time, and then letting a certain amount of argon gas in the quartz tube for heat preservation, and finally cooling the furnace to the room temperature naturally; 4), taking out foamed nickel, repeatedly washing the foamed nickel through deionized water and ethyl alcohol, drying the foamed nickel, and obtaining the material. The method is simple in operation and does not need complex equipment, and the Co0.85Se uniformly covers the nickel mesh. The material can be prepared in a large area. A composite Co0.85Se nano material electrode is tested in a three-electrode system, presents a high specific capacity of 4462F / g under the current density of 1A / g, and still can maintain 80% or more of the specific capacitance value after 5000-time circulating charging and discharging under a high current of 20A / g, wherein the charge transfer impedance is 0.82 ohm / cm<2>.

Owner:ZHEJIANG UNIV

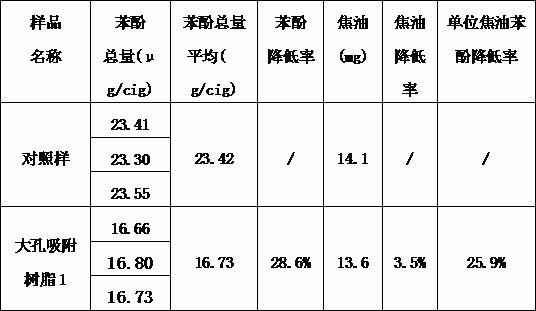

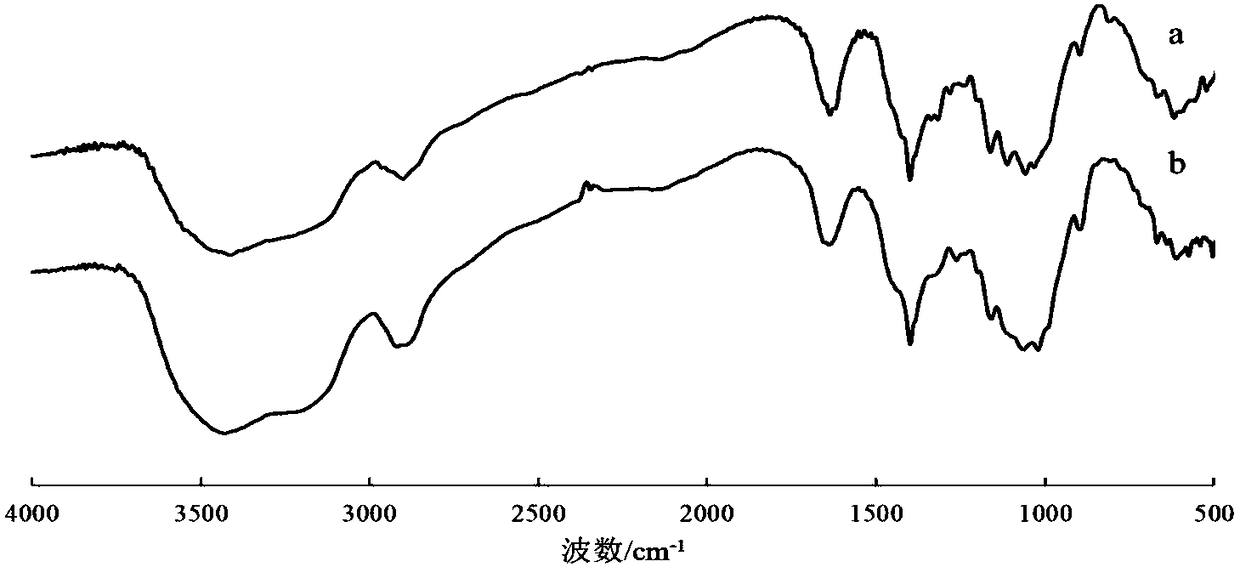

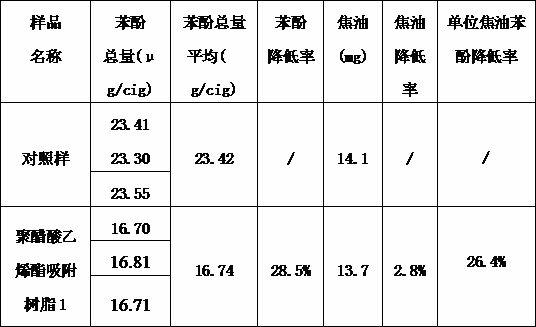

Application of macroporous adsorption resin to cigarettes

InactiveCN102599654APromote full accessLarge specific surface areaTobacco smoke filtersInorganic saltsPolymer science

The invention relates to application of macroporous adsorption resin to cigarettes, which is characterized in that adding the macroporous adsorption resin to a filter of each cigarette can selectively reduce phenol release in mainstream smoke of the cigarette by more than 25%, 10-30mg of the macroporous adsorption resin is added per filter, and the macroporous adsorption resin obtained by suspension polymerization comprises divinyl benzene, styrene, pore-forming agent, initiator, water, inorganic salt and dispersant. The macroporous adsorption resin is capable of effectively adsorbing harmful phenol in smoke while tar release is substantially unchanged or slightly lowered, and has no adverse effect on smoking quality of the cigarettes, and accordingly the phenol release in the smoke of the cigarettes is selectively reduced.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

Preparation method of flexible carbon fiber with superamphiphobic property

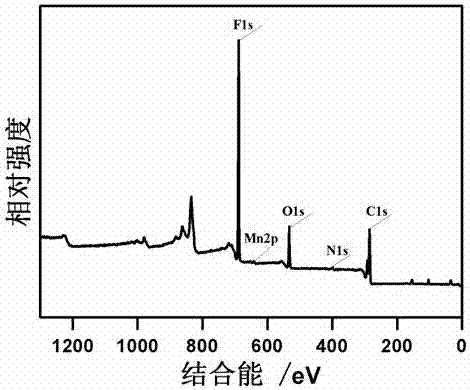

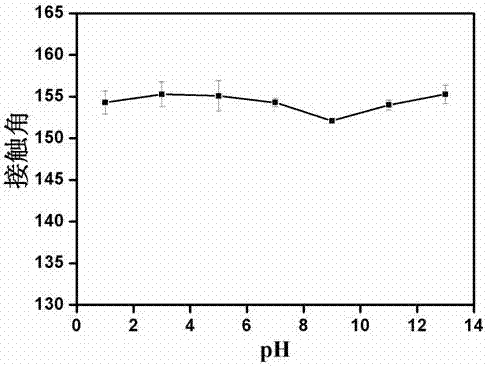

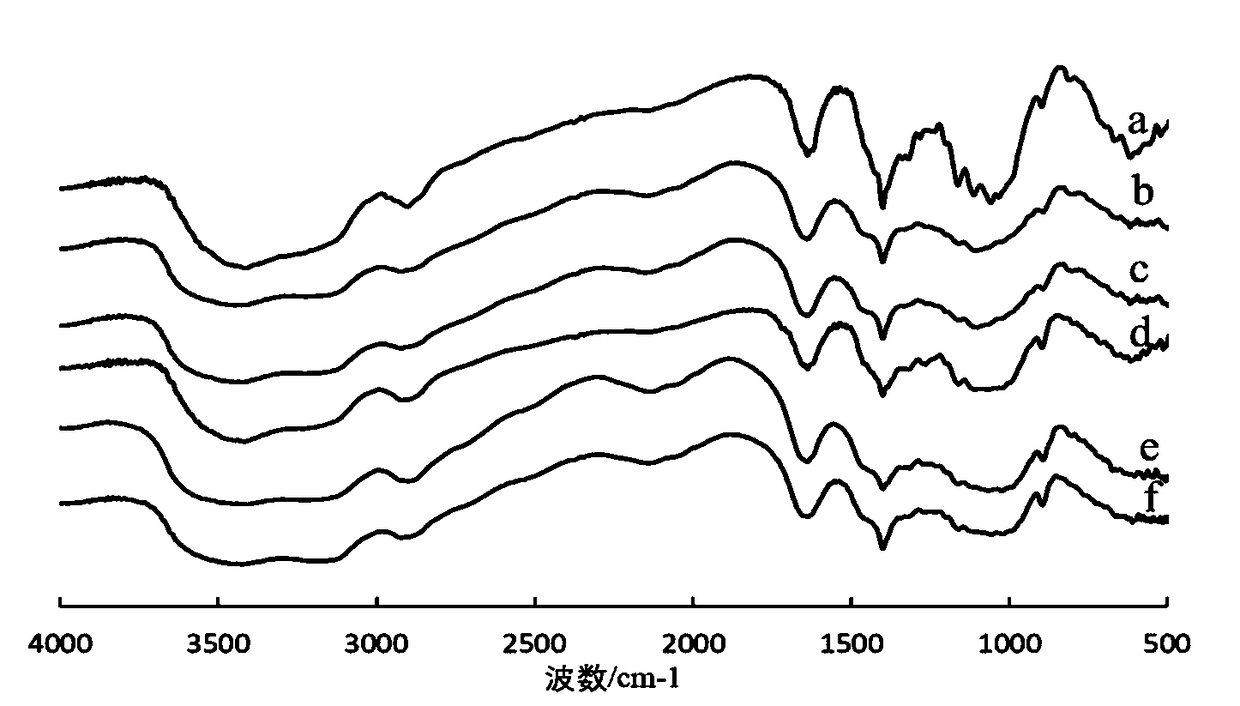

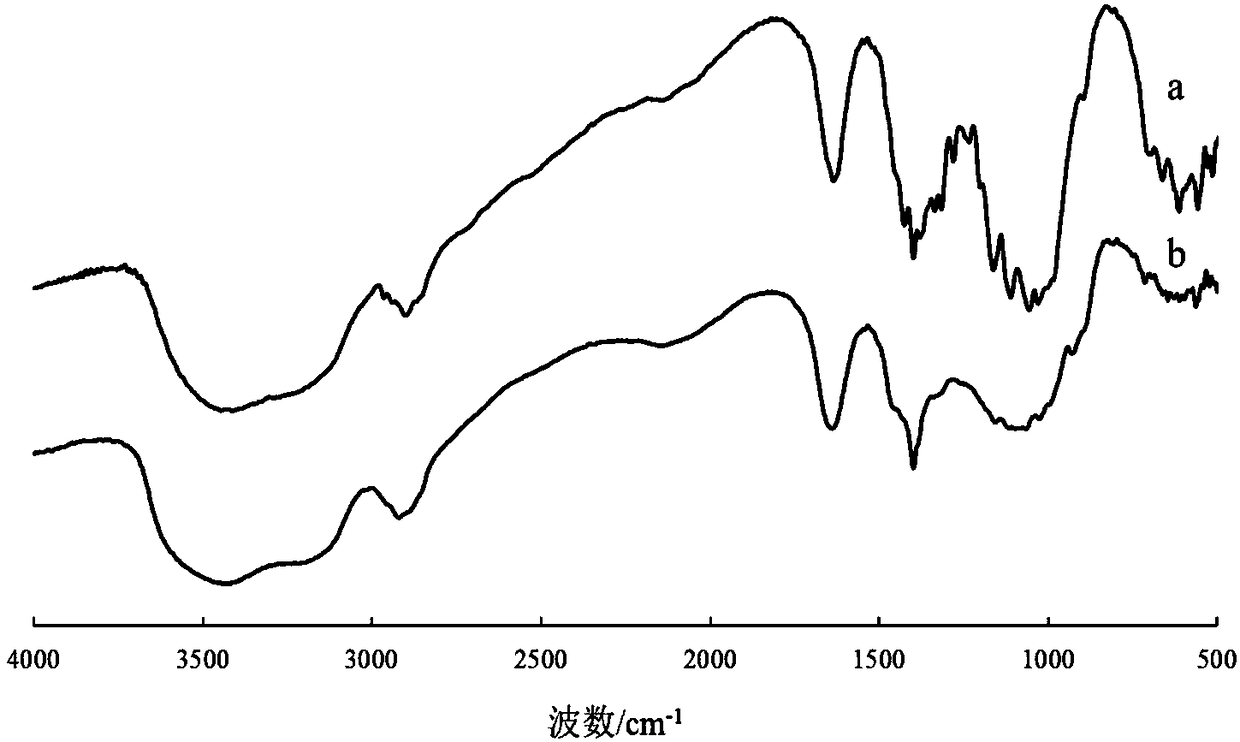

ActiveCN107237128ASuperamphiphobicShape adjustableCarbon fibresArtifical filament manufactureCarbon fibersN dimethylformamide

The invention relates to a preparation method of flexible carbon fiber with superamphiphobic property, and belongs to the technical field of production of superamphiphobic materials. The preparation method comprises the following steps of dissolving polyacrylonitrile and manganeseacetylacetonate into N,N-dimethylformamide, forming a uniform electrostatic spinning solution, and adopting an electrostatic spinning technique, so as to obtain nanometer spinning fibers; pre-oxidizing the nanometer spinning fibers, placing under the nitrogen atmosphere, and carbonizing at high temperature, so as to obtain manganese-doped nanometer carbon fiber; soaking the manganese-doped nanometer carbon fiber into an ethyl alcohol solution of POTS (1H,1H,2H,2H-perfluorooctyltriethoxysilanes), so as to obtain the flexible carbon material with superamphiphobic property. The preparation method has the advantages that the technology is simple, the shape of the spinning fiber can be adjusted, and the green and environment-friendly effects are realized; the average size of the spinning carbon fiber is 300 to 450nm. The prepared carbon fiber with the superamphiphobic property has the advantages that the contact angle is about 155 degrees at different pH (potential of hydrogen) values, the rolling angle is about 4 degrees, and the contact angles for different types of oil are about 152 DEG C.

Owner:YANGZHOU UNIV

Cellulose solution and preparation method thereof

The invention relates to a cellulose solution and a preparation method thereof. The preparation method comprises the following steps of soaking the raw material of cellulose into water at the temperature of 15 to 30 DEG C, and drying, so as to obtain the swelled cellulose; mixing the cellulose and a polarity organic solvent, so as to obtain a cellulose dispersion liquid; mixing the cellulose dispersion liquid and tera-alkyl quaternary ammonium base at the temperature of 15 to 30 DEG C, so as to obtain the cellulose solution; mixing under the stirring condition, wherein the stirring speed is 200 to 400r / min, and the stirring time is 2 to 6h. The preparation method has the advantages that the cellulose is directly dissolved at the temperature of 15 to 30 DEG C, and the degrading of cellulosedue to high temperature can be effectively inhibited; the yield rate of regenerated cellulose in the cellulose solution is greater than or equal to 80%, so that the cellulose can be dissolved at highefficiency.

Owner:NANJING FORESTRY UNIV

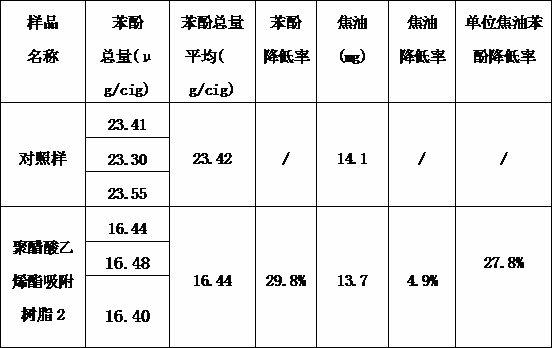

Application of polyvinyl acetate adsorption resin on cigarettes

ActiveCN102613704ALarge specific surface areaHigh adsorption rateTobacco smoke filtersVinyl acetateCigarette filter

The invention relates to application of polyvinyl acetate adsorption resin on cigarettes and is characterized in that the polyvinyl acetate adsorption resin is added to cigarette filters, the release amount of phenol in mainstream smoke in the cigarettes can be selectively reduced by over 25%, and the adding amount of the polyvinyl acetate adsorption resin in each filter is 10-30mg. The polyvinylacetate adsorption resin is prepared by suspension polymerization and is composed of raw materials: divinyl benzene, vinyl acetate, a pore-foaming agent, an initiating agent, water, inorganic salt and a dispersing agent. The polyvinyl acetate adsorption resin material can effectively adsorb the harmful substance phenol in the smoke, the release amount of tar is substantially unchanged or slightlyreduced, negative effects on smoking quality of the cigarettes are avoided simultaneously, and accordingly the aim of selectively reducing the release amount of phenol in the cigarette smoke is achieved.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

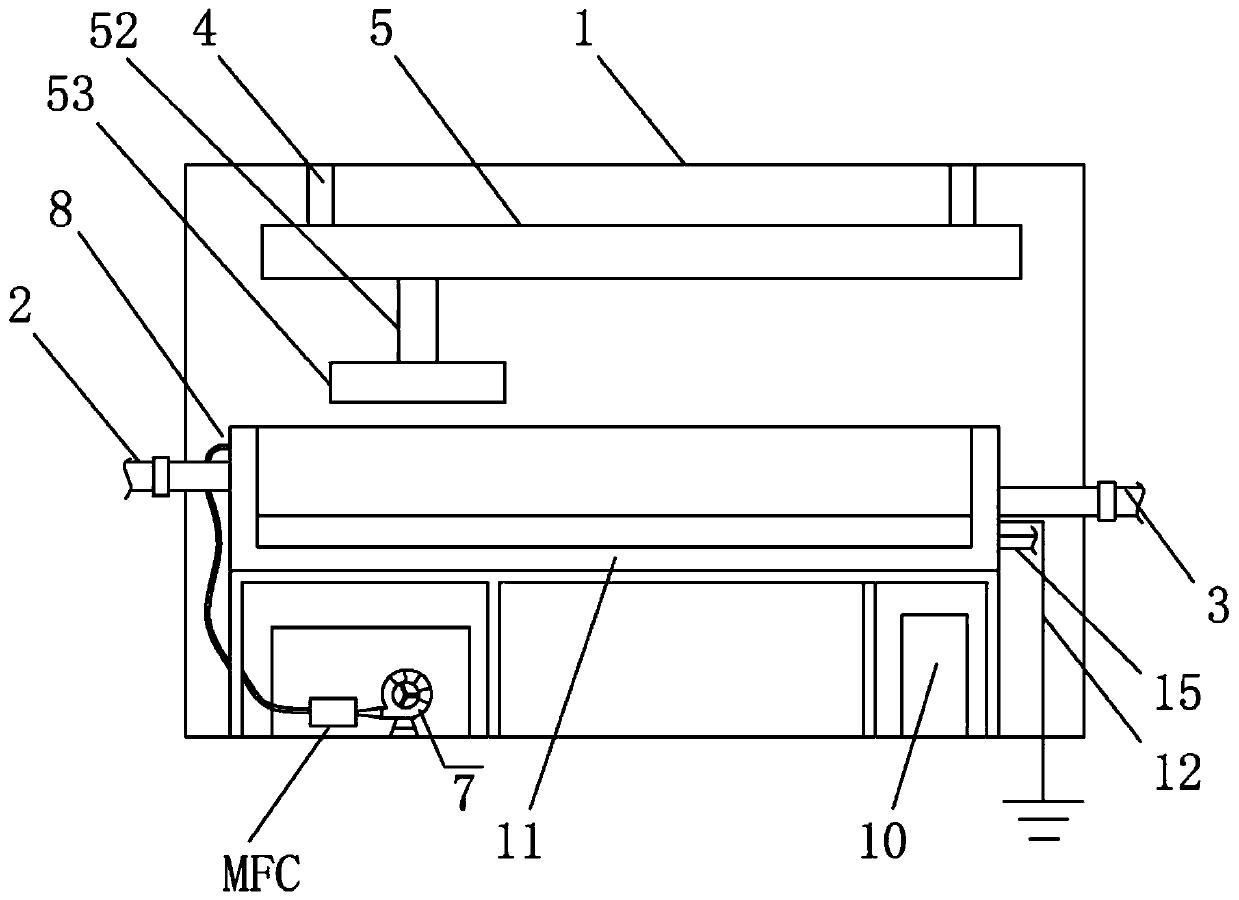

Device for degrading POPs pollutants in soil through low-temperature plasma continuous oxidation bed

PendingCN110883082ARealize double dielectric dischargeStrong oxidizing propertiesContaminated soil reclamationEngineeringEnvironmental engineering

The invention discloses a device for degrading POPs pollutants in soil through a low-temperature plasma continuous oxidation bed. The device comprises a skid-mounted box; a feeding pipe penetrates through one end of the box body; a discharging pipe penetrates through one end, far away from the feeding pipe, of the box body; the top end of the inner wall of the box body is fixedly connected with aconnecting rod; the bottom end of the connecting rod is fixedly connected with a high-voltage discharge electrode; the high-voltage discharge electrode comprises a fixed plate, a movable rod and a high-voltage electrode; the movable rod is movably connected to the lower surface of the fixed plate, the high-voltage electrode is fixedly connected to one end, away from the fixed plate, of the movablerod, a protective shell is fixedly connected to the bottom end of the interior of the box body, and a gas carrying mechanism is fixedly mounted in one end, close to the feeding pipe, of the protective shell. High-activity particles generated by dielectric barrier discharge are used for degrading high-toxicity organic pollutants in soil, and the method has the advantages of continuous system, stable operation, high degradation efficiency and the like.

Owner:上海康恒环境修复有限公司

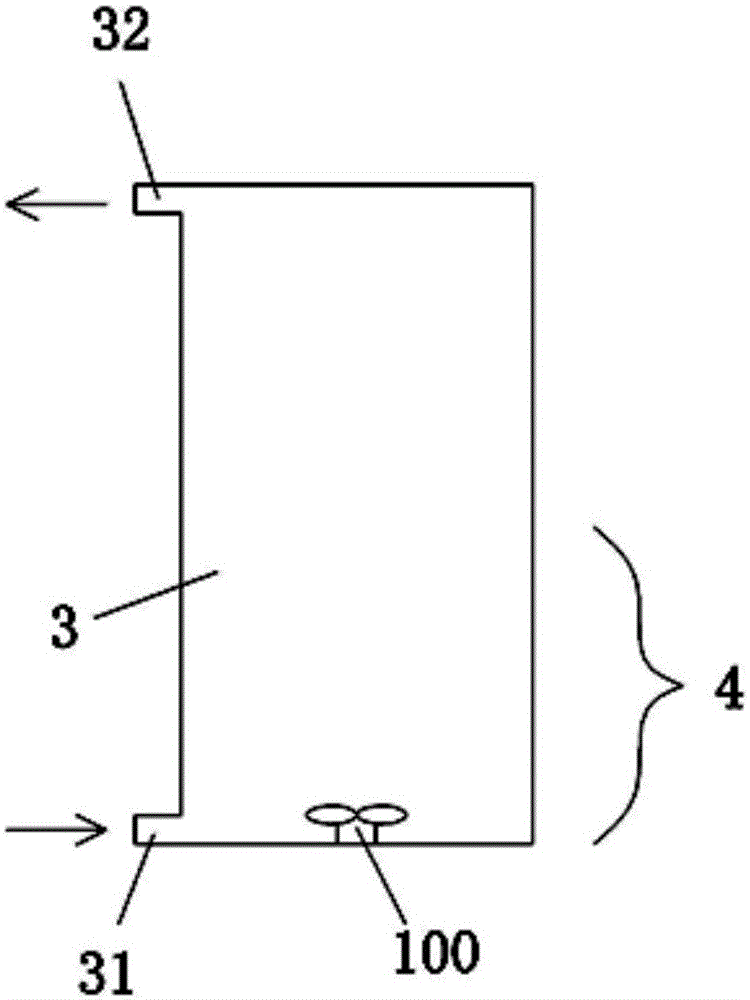

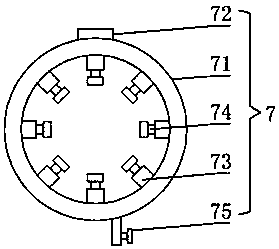

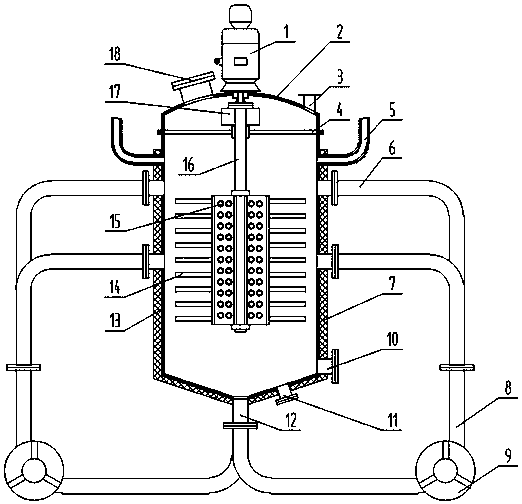

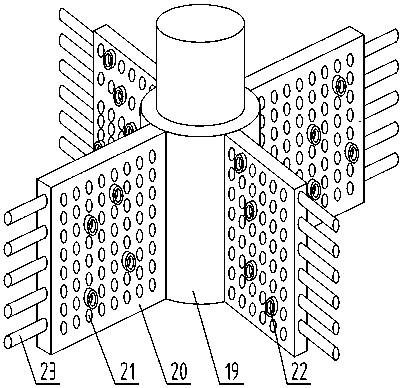

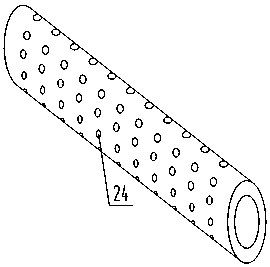

Method and reactor for million kilowatt nuclear power station to process radioactive wastewater

ActiveCN105161156AFast preprocessingPromote full accessRadioactive decontaminationSorbentNuclear power

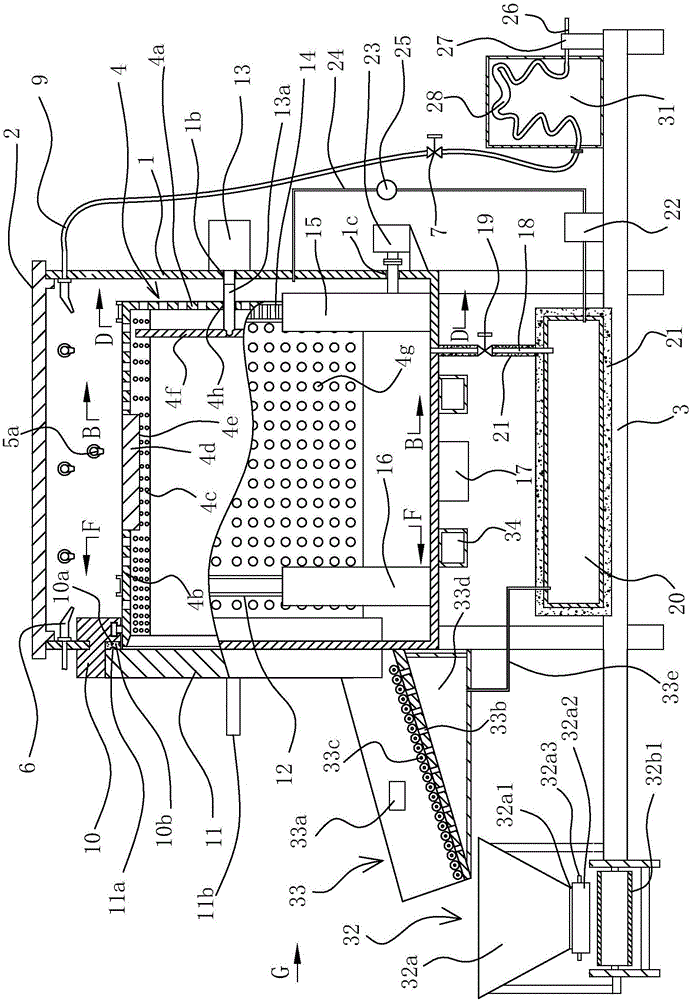

The invention discloses a method and reactor for a million kilowatt nuclear power station to process radioactive wastewater. According to the method, adsorbents with the specific gravity larger than that of the radioactive wastewater is scattered in the radioactive wastewater through stirring, and the adsorbents are used for nuclide ions in the radioactive wastewater. The lower portion of an inner cavity of the reactor is an adsorbing reaction area, and a separating area is arranged on the upper portion of the inner cavity of the reactor. A radioactive wastewater inlet and a stirring device are arranged in the adsorbing reaction area. An intercepting device for keeping the adsorbents stay in the reactor is arranged in the separating area. A water outlet for processed wastewater is formed in the upper portion of the intercepting device. According to the reactor, existing adsorption of a fixed bed is changed into adsorption of a flowing bed, powder or small particle adsorbents can be selected so that the specific surface area can be increased, the adsorbents and the radioactive wastewater can make full contact by stirring the powder or the small particle adsorbents in the radioactive wastewater, and a large amount of radioactive wastewater can be fast preprocessed.

Owner:LINGDONG NUCLEAR POWER +5

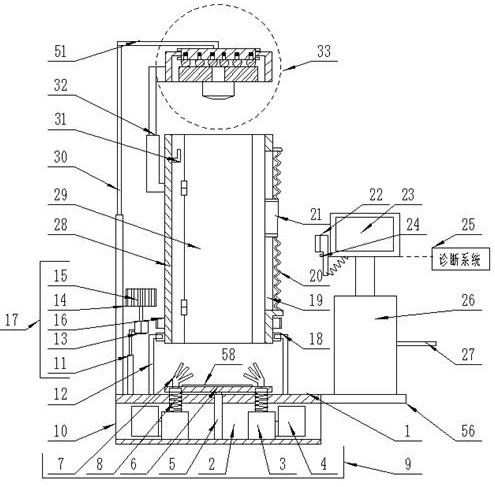

Sleeve-fish steaming device for fishing boat

ActiveCN106418296ARealize automatic nestingImprove work efficiencyMeat/fish preservation by heatingSpray nozzleEngineering

The invention provides a sleeve-fish steaming device for a fishing boat, and belongs to the technical field of food processing equipment. The sleeve-fish steaming device for the fishing boat comprises a steaming box, a steaming cylinder is arranged in the steaming box, a connecting sleeve is mounted on the side wall of the steaming box, an open end of a cylinder body is rotatably connected onto the connecting sleeve, a driving mechanism is arranged between the steaming cylinder and the bottom of the steaming box, stirring vanes are arranged on the inner wall of the cylinder body, a push plate is arrange din the steaming cylinder, a power mechanism is arranged on the steaming box, a sealing door is hinged on the outer wall of the steaming box, a base is arranged on the lower portion of the steaming box, a middle water tank is arranged on the base, communicated with the bottom of the steaming box through a discharge pipe and communicated with the inside of the steaming box through a water return pipe, a plurality of spray nozzles are arranged at the upper end of the steaming box, air outlets of the spray nozzles face the steaming cylinder, a water supply pipe is arranged at the upper end of the steaming box, an exhaust gas heating pipe and a heater are arranged at the bottom of the steaming box, a discharging hopper is arranged on the outer wall of the steaming box, and conveying device for conveying sleeve-fishes is arranged on the base. The sleeve-fish steaming device has the advantages that the sleeve-fish steaming device is high in working efficiency, energy is saved and the like.

Owner:ZHEJIANG OCEAN UNIV

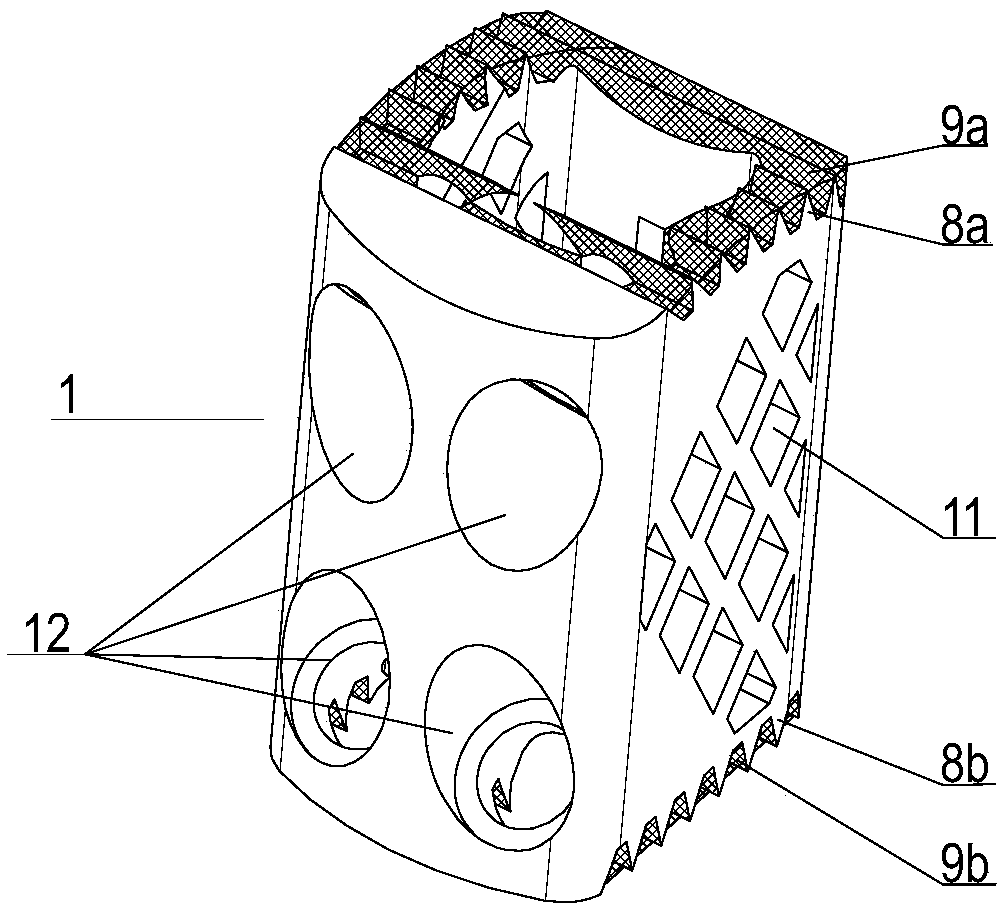

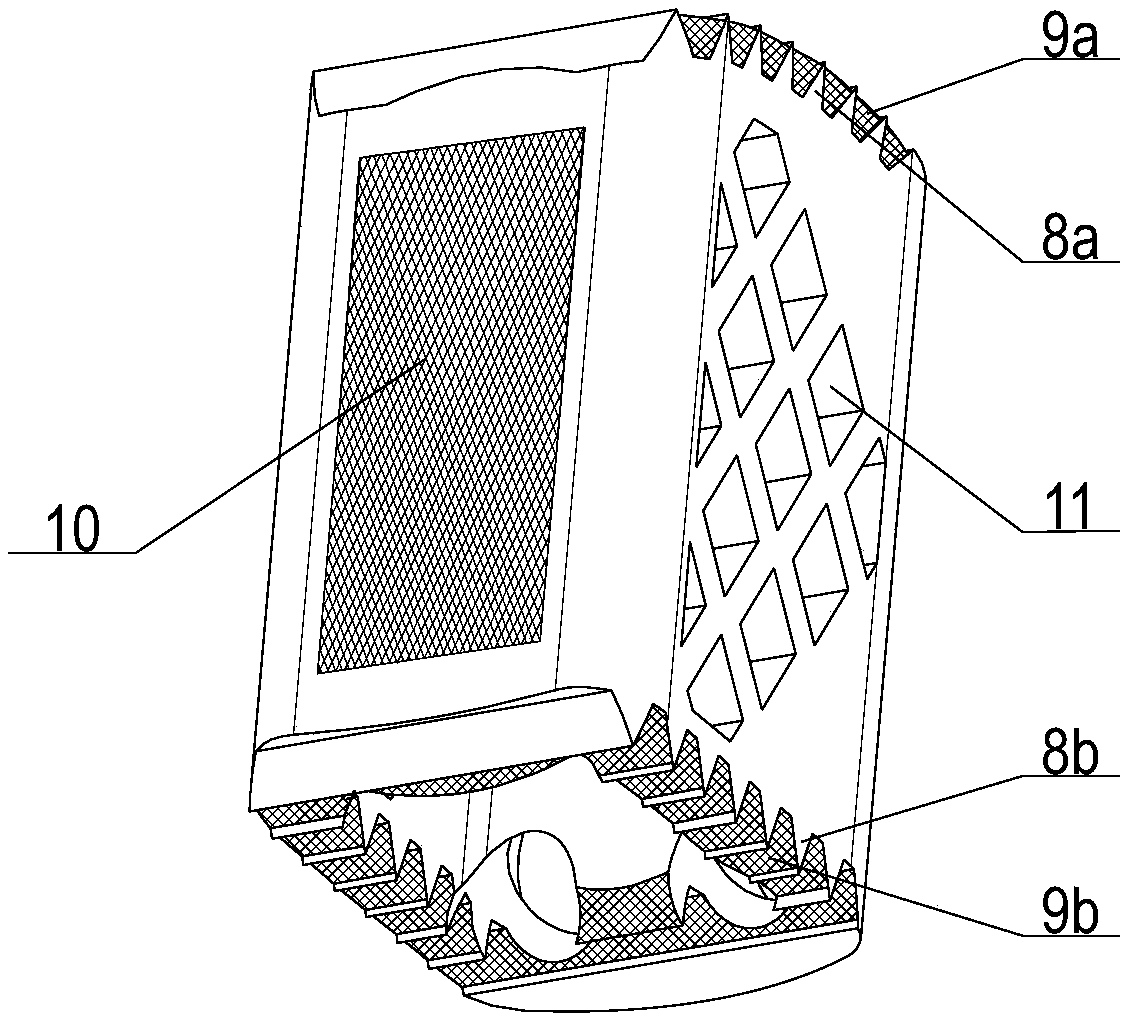

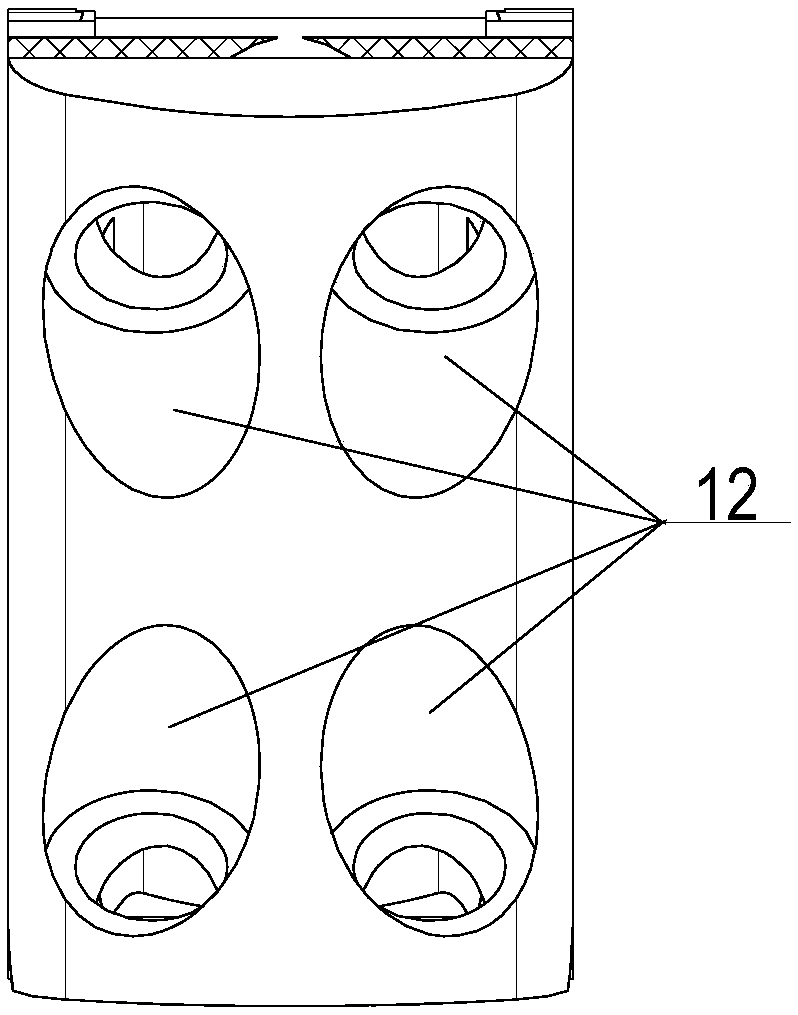

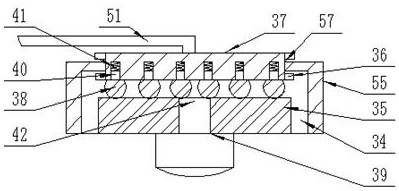

Anterior cervical approach self-fixation artificial centrum

PendingCN109481101AAvoid displacementIncrease frictionSpinal implants3D printingSpinal columnBiomechanics

The invention discloses an anterior cervical approach self-fixation artificial centrum and belongs to the technical field of medical centrum manufacturing. The anterior cervical approach self-fixationartificial centrum is composed of an integrated centrum part and is mainly characterized by comprising an upper-end cambered surface, a lower-end oblique plane, an end face sawtooth structure, an endface micro-hole structure, a side wall rhombus hole, a back wall micro-hole structure, a front wall cambered surface structure, a back wall cambered surface structure and a screw hole structure for front wall self-fixing. A traditional anterior cervical approach titanium plate is removed on the premise that the stability of postoperative spine segments is ensured, the complexity degree of sub-total ectomy fusion of an anterior cervical approach cervical vertebra body is effectively reduced, the surgical time is shortened, the bleeding during surgery is decreased, a biomechanical conduction mode of an anterior cervical approach implantation instrument is optimized, and lots of complications caused by anterior cervical approach steel sheets are avoided. By adopting the above design, the anterior cervical approach self-fixation artificial centrum can effectively decrease lots of complications of a traditional titanium cage and improves prognosis of a patient suffering from the sub-totalectomy fusion of the anterior cervical approach cervical vertebra body.

Owner:SECOND AFFILIATED HOSPITAL OF COLLEGE OF MEDICINEOF XIAN JIAOTONG UNIV

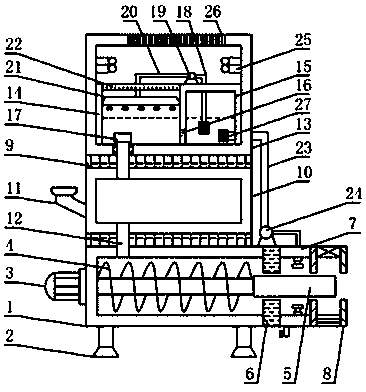

Production equipment and method for composite plastic product

PendingCN110394959AReduce setting timeImprove cooling efficiencyCombination devicesTubular articlesWater pipeWater storage tank

The invention discloses production equipment for a composite plastic product, and belongs to the technical field of composite plastic products. The production equipment for the composite plastic product comprises a tube making machine shell, wherein an opening die matched with a core rod is arranged on the outer wall of the right end of the tube making machine shell; a water cooling device is arranged on the outer wall of the right side of the opening die; a feed inlet is arranged on the outer wall of the left side of a heating box; a filtering water tank and a clear water storage tank are respectively arranged at the left end and the right end of the bottom of an inner cavity of a purification machine shell; a demisting device is arranged at the top of the filtering water tank; and sterilization lamp groups are symmetrically arranged on the tops of the inner walls of the left side and the right side of the purification machine shell. The production equipment for the composite plasticproduct is simple in operation and high in working efficiency; eight fixing pipes are arranged on the inner wall of an annular water collecting pipe, so that clean water is in full contact with the outer wall of a preliminarily formed plastic pipe conveniently, and the cooling efficiency is improved; waste gas is thoroughly purified and treated through four procedures, and damage to the environment caused by the discharge of the unqualified waste gas is effectively avoided; and an air inlet fan and an air exhaust fan are located on the same axis so that residual water drops on the outer wall of the plastic pipe can be conveniently removed.

Owner:苏州盛迪通电子科技有限公司

Method for repairing polluted sites

InactiveCN109759433AEfficient repairPromote full accessContaminated soil reclamationLaboratory cultureActivated carbon

The invention provides a method for repairing polluted sites. The method for repairing the polluted sites comprises the steps that firstly, soil of the polluted sites is selected, a pollutant microorganism culture medium is prepared, microorganism strains capable of effectively treating organic pollutants in the soil can be selected and cultured, separating and purifying are carried out to obtainmixed microorganism bacterium liquid, then water is added to the polluted soil to prepare a slurry soil mixed solution, a pH value is adjusted, finally the mixed microorganism bacterium liquid, a surfactant, potassium ferrate and hydrogen peroxide are added into the mixed solution, and the mixture is placed silently after ultrasonic treatment. According to the method for repairing the polluted sites, combined with biological treatment and chemical oxidation methods, rapid and efficient remediation of soil contaminated by typical organochlorine pesticides such as DDT, HCH and the like can be realized, the surfactant is a mixture of saponin and activated carbon, sufficient contact between potassium ferrate and the organochlorine pesticides can be increased, and the repair cost is reduced.

Owner:湖南新九方科技有限公司

Color ultrasonic diagnostic machine for novel coronavirus patient and diagnostic method thereof

ActiveCN112545558AFacilitates step-by-step comparisonsEasy diagnosisInfrasonic diagnosticsSonic diagnosticsComputer printingVirtual space

The invention discloses a color ultrasonic diagnostic machine for a novel coronavirus patient and a diagnostic method thereof. The machine comprises a supporting base and a diagnostic system. The right side of the supporting base is horizontally and fixedly connected with an expansion plate; a printer is fixedly installed at the upper side of the expansion plate; a paper discharging end is arranged at the right side of the printer in a matched mode; a color ultrasonic diagnostic machine body is fixedly installed at the upper side of the printer; an insertion ring is fixedly connected with theouter wall of the left side of the color ultrasonic diagnostic machine body; and the color ultrasonic diagnostic machine body is provided with an ultrasonic detection probe. According to the color ultrasonic diagnostic machine for the novel coronavirus patient and the diagnostic method thereof, patient ultrasonic images generated through the detection of the ultrasonic detection probe are transmitted into the diagnostic system through an image input module, and then healthy organ ultrasonic images and patient organ ultrasonic images transversely move to penetrate through a comparison virtual space through a transverse moving module, so that block-by-block gradual comparison can be achieved conveniently; and when compared parts are different, a circle marking module marks a difference partthrough a circle, and finally outputs and stores the difference part in a storage module.

Owner:HUNAN KANGRUN PHARMA

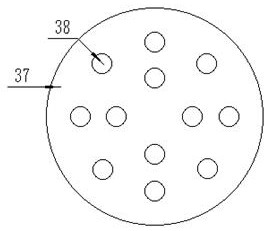

Large-sized built-in ultrasonic alginic acid extractor

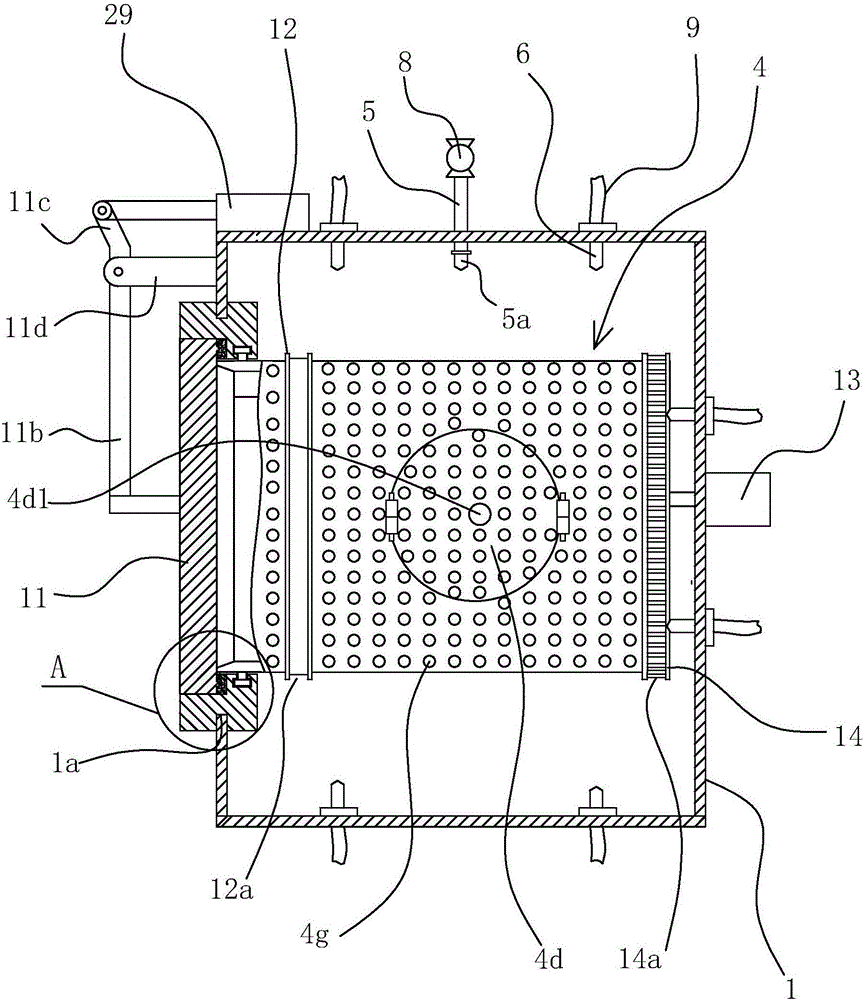

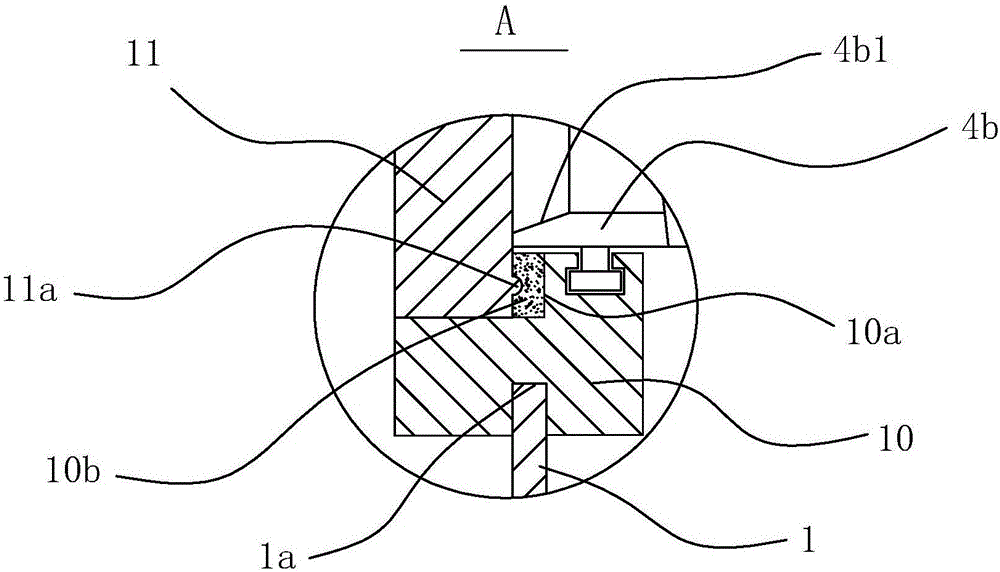

PendingCN107823914AImprove extraction efficiencyPromote full accessEnergy based chemical/physical/physico-chemical processesSolid solvent extractionAlginic acidUltrasonic generator

The invention discloses a large-sized built-in ultrasonic alginic acid extractor, and belongs to the field of extracting equipment. The large-sized built-in ultrasonic alginic acid extractor is used for extracting alginic acid from brown algae, and comprises an extracting tank, wherein a stirring shaft driven by a stirring driving device is mounted inside the extracting tank; stirring blades are mounted on the stirring shaft; stirring holes are formed in the stirring blades; ultrasonic transducers driven by an ultrasonic generator are mounted on the stirring blades respectively; the ultrasonictransducers are connected with ultrasonic amplitude transformers and ultrasonic tool heads respectively. In view of the technical solution, continuous and stable extraction of the alginic acid from the brown algae by large-sized alginic acid extracting equipment can be achieved, the extraction efficiency is improved and the extraction time is shortened.

Owner:YANTAI INST OF COASTAL ZONE RES CHINESE ACAD OF SCI +1

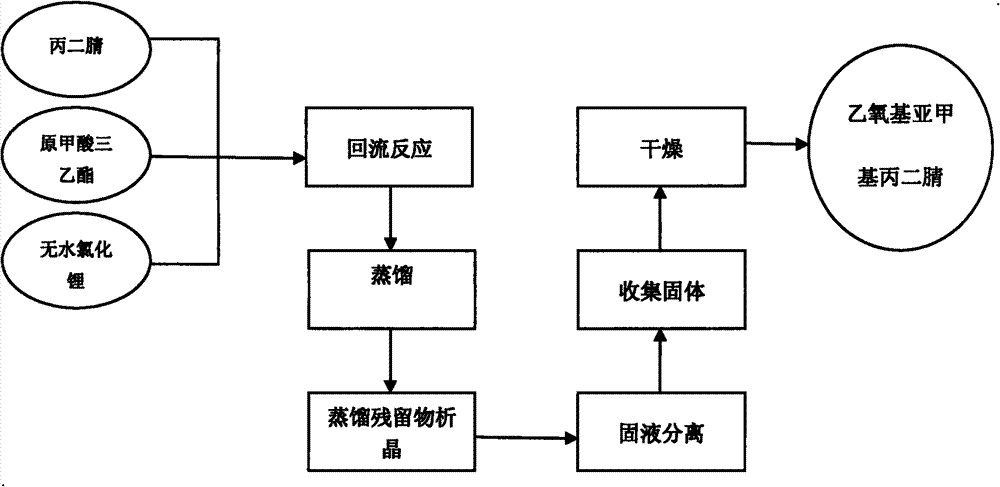

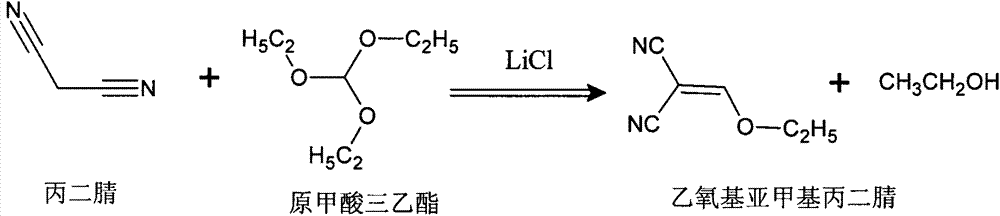

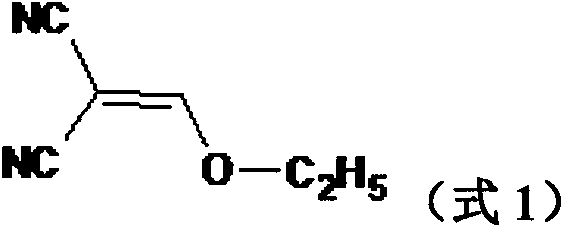

Preparation method and refining method of ethoxymethylenemalononitrile

InactiveCN103664695APromote full accessHigh catalytic efficiencyOrganic compound preparationCarboxylic acid nitrile purification/separationSolventToluene

The invention relates to a preparation method and a refining method of ethoxymethylenemalononitrile. The preparation method comprises the steps as follows: putting malononitrile, triethyl orthoformate and anhydrous lithium chloride in a reaction vessel, stirring the mixture, heating the mixture to the temperature of 78-85 DEG C, after complete reaction, removing ethanol produced in the reaction through distillation, cooling and crystallizing the residual liquid after distillation, and collecting and drying solids to obtain the ethoxymethylenemalononitrile. According to the preparation method, a catalyst is changed into the anhydrous lithium chloride, the full contact of the catalyst with reaction substances is promoted, the ethanol produced in the reaction is directly used as a reaction solvent, and a synthetic reaction is performed at an ethanol backflow temperature, so that the catalytic efficiency, the reaction speed and the reaction efficiency are improved remarkably, the use of a large number of toxic solvents (methylbenzene) is avoided, the environmental protection is facilitated, the reaction operation is simplified, the problem of inconvenience in solvent recovery is solved, the manufacturing cost is reduced remarkably (the cost is reduced by about 40%), and the preparation method is applicable to the industrial production.

Owner:南京易亨制药有限公司

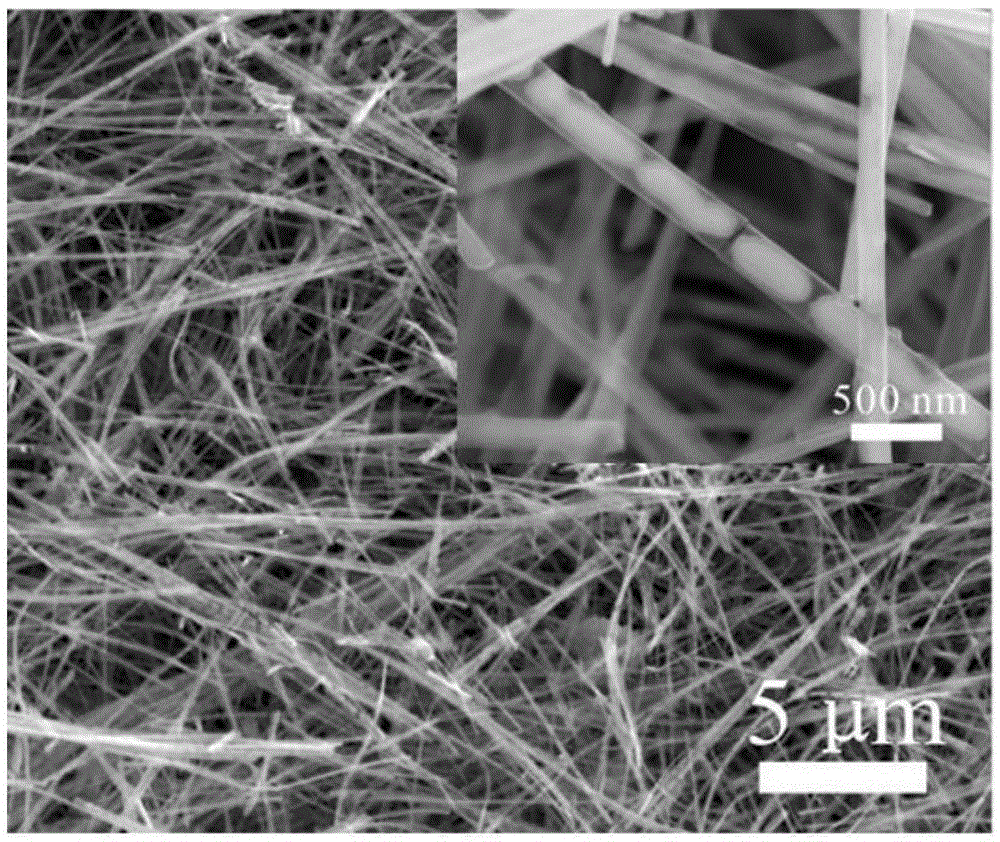

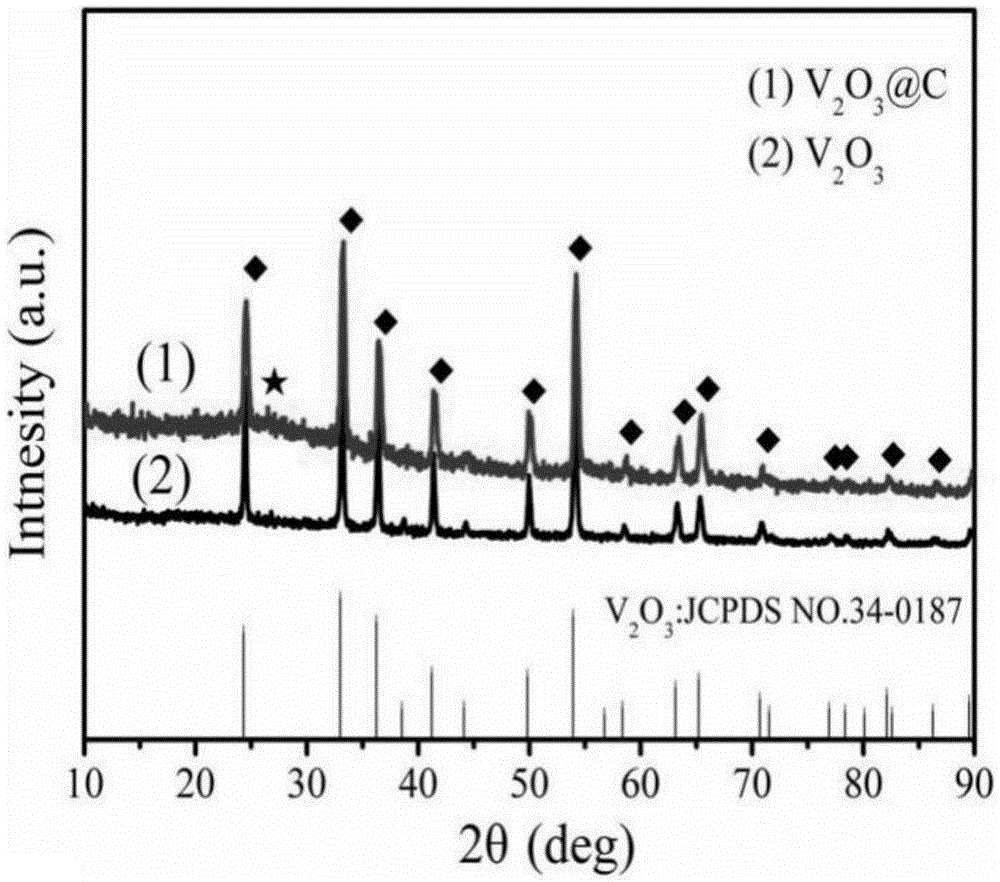

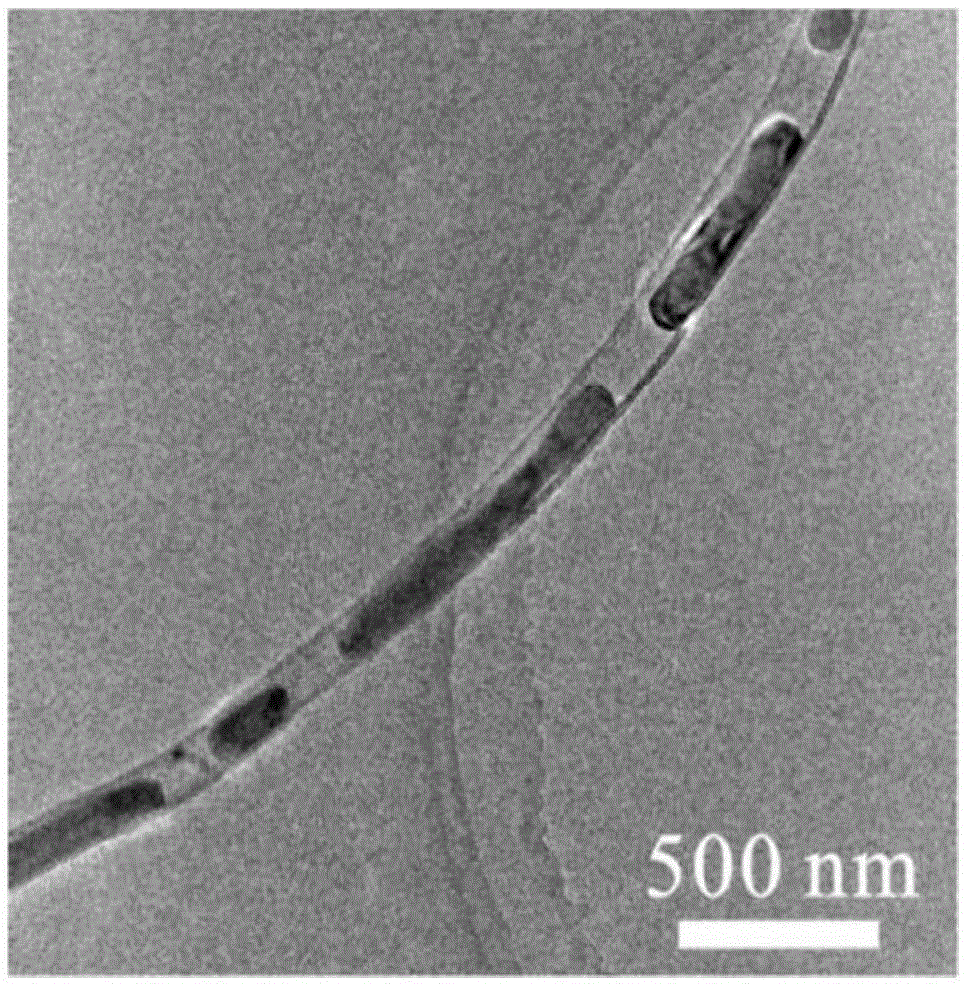

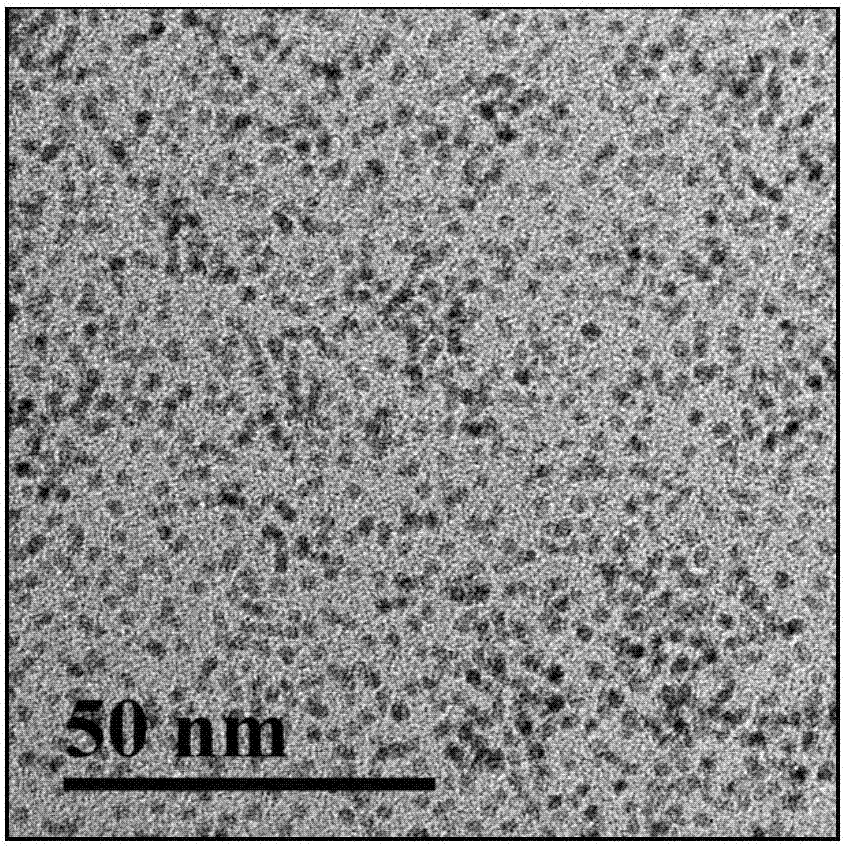

Carbon-coated vanadium trioxide nanowire thin film with pod structure and preparation method of carbon-coated vanadium trioxide nanowire thin film with pod structure

ActiveCN105261743ALarge specific surface areaImprove charge and discharge performanceMaterial nanotechnologyCell electrodesNanowireFiltration

The invention particularly relates to a carbon-coated vanadium trioxide nanowire thin film with a pod structure and a preparation method of the carbon-coated vanadium trioxide nanowire thin film with the pod structure. The method comprises the following steps: (1) preparing a V<3>O<7> nanowire; (2) taking 40ml of homogeneous dispersion liquid, adding 50-500mg of glucose, stirring the dispersion liquid for 10 minutes, mixing the dispersion liquid evenly, finally pouring the evenly mixed solution into a hydrothermal kettle, heating an oven to 180 DEG C, putting the hydrothermal kettle into the oven for heat preservation for 0.5-5 hours, cleaning the sample after a hydrothermal reaction, carrying out vacuum filtration to form a film, and drying the film in a drying oven to obtain the carbon-coated V<3>O<7> nanowire thin film; and (3) putting the dried and formed sample film into a tube furnace for heat treatment, carrying out the heat preservation in an argon condition at 400-1,000 DEG C for 3 hours, naturally cooling the film to a room temperature along with the furnace and obtaining the carbon-coated vanadium trioxide nanowire thin film with the pod structure. The preparation method is reliable in preparation technology, low in energy consumption and high in yield; and the prepared carbon-coated vanadium trioxide nanowire thin film is even in distribution, obvious in pod structure, controllable in length and suitable for the field of electrochemistry.

Owner:WUHAN UNIV OF SCI & TECH

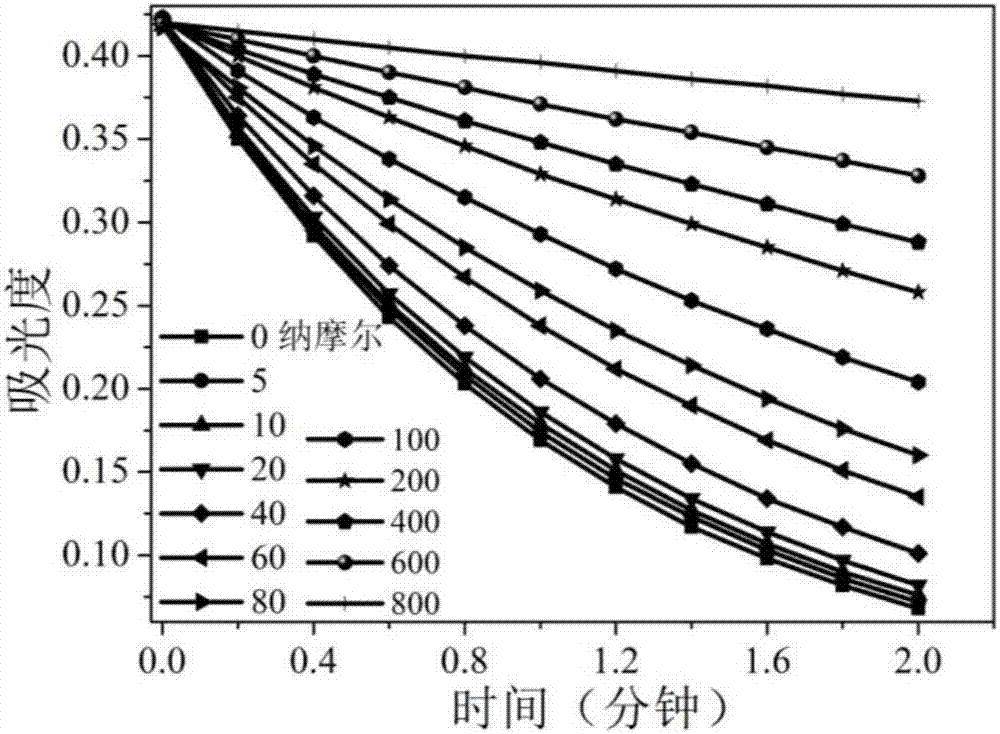

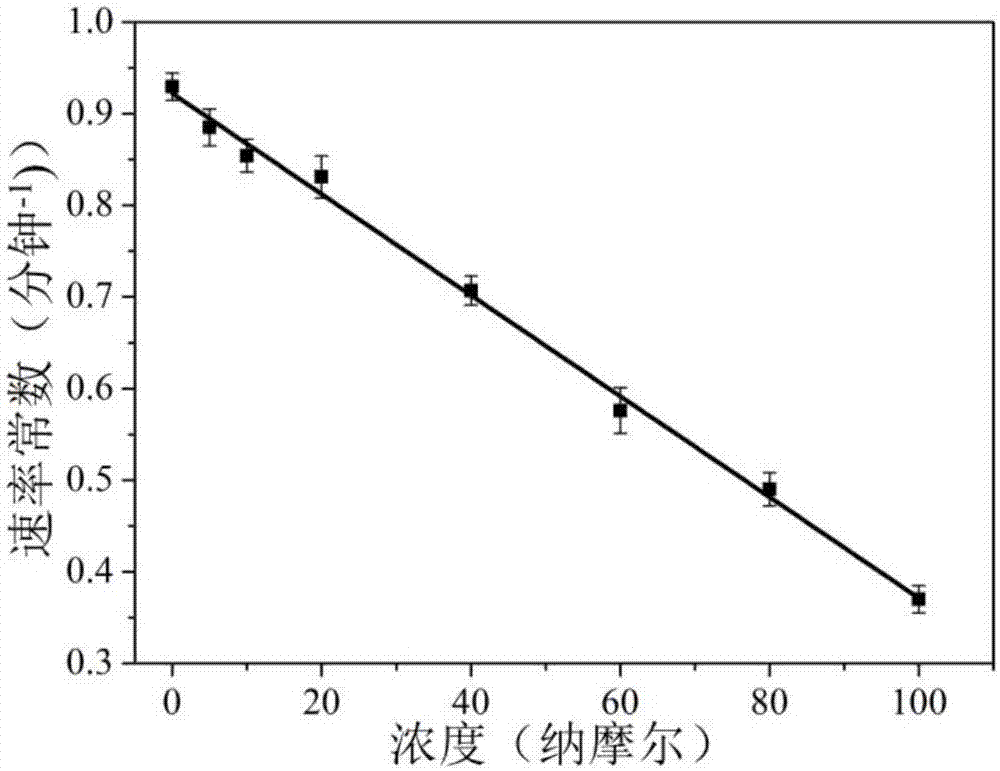

Method for detecting hydrogen sulfide based on ruthenium nanoparticle colorimetric method

ActiveCN107290337APromote full accessHigh detection sensitivityMaterial analysis by observing effect on chemical indicatorColor/spectral properties measurementsNanoparticleHydrazine compound

The invention provides a method for detecting hydrogen sulfide based on a ruthenium nanoparticle colorimetric method. According to the method, ruthenium nanoparticles can enable azo dyes to fade in the presence of hydrazine hydrate, while the hydrogen sulfide can be bound to the ruthenium nanoparticles to form ruthenium sulfur bonds (Ru-S), so that the activities of the ruthenium nanoparticles for degrading the dyes are passivated. When the concentration of the hydrogen sulfide is high, the passivation degree of the ruthenium nanoparticles is deep, and then the azo dyes are difficult to fade. A novel colorimetric method used for detecting the hydrogen sulfide is developed by utilizing hydrogen sulfide induced ruthenium nanoparticle inactivation. By optimizing experimental parameters, the method detects that the hydrogen sulfide shows two good linear relations in the concentration ranges of 0.5-100nM and 100-800nM under the optimal conditions, and the detection limit is 0.6nM. Compared with the colorimetric method in a literature report, the method disclosed by the invention is capable of realizing rapid analysis, extremely high in sensitivity and excellent in selectivity and has important significances when being used for detecting the hydrogen sulfide in actual samples, particularly atmosphere.

Owner:JIANGNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com