Method for preparing cobaltous selenide super-capacitor material through chemical vapor deposition method

A chemical vapor deposition, supercapacitor technology, used in hybrid capacitor electrodes, hybrid/electric double layer capacitor manufacturing, gaseous chemical plating, etc. The problem of high resistivity, to achieve the effect of favorable specific surface area, low cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

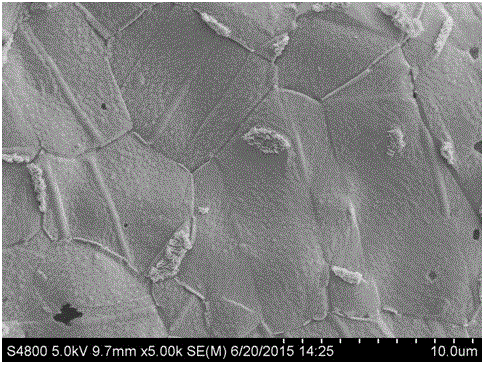

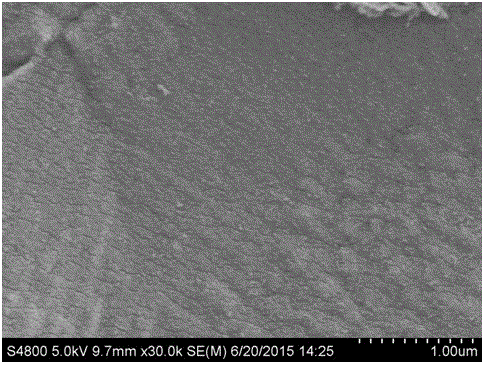

[0029] Use dilute hydrochloric acid, deionized water and ethanol to wash the foamed nickel mesh in turn and dry it: 1mol selenium powder and 1mol cobalt powder are ground and mixed in an agate mortar, then poured into a quartz boat, and then put into a chemical vapor deposition reaction furnace quartz tube middle; place the dry nickel foam net near the mouth of the quartz tube downstream of the air flow; pass in argon gas for 30 minutes to exhaust the air in the furnace, stop ventilation, heat to 950 ° C for 60 minutes, and keep warm at the same time with argon gas at 100 sccm After passing through the quartz tube at a high speed for 60 minutes, stop heating and naturally cool to room temperature; take out the nickel foam, wash it with deionized water and ethanol, and dry it at 60°C for 6 hours to obtain it.

Embodiment 2

[0031] Use dilute hydrochloric acid, deionized water and ethanol to wash the foamed nickel mesh in sequence and then dry it: 2mol selenium powder and 2mol cobalt powder are ground and mixed in an agate mortar, then poured into a quartz boat, and then put into a chemical vapor deposition reaction furnace quartz tube middle; place the dry foamed nickel net near the mouth of the quartz tube downstream of the air flow; pass through the argon gas for 60 minutes to exhaust the air in the furnace, stop the ventilation, heat to 850 ° C for 90 minutes, and keep warm at the same time with argon gas at 50 sccm After passing through the quartz tube at a speed of 90 minutes, stop heating and naturally cool to room temperature; take out the nickel foam, wash it with deionized water and ethanol, and dry it at 60°C for 6 hours to obtain it.

Embodiment 3

[0033] Use dilute hydrochloric acid, deionized water and ethanol to wash the foamed nickel mesh in turn and dry it: 0.5mol selenium powder and 0.5mol cobalt powder are ground and mixed in an agate mortar, then poured into a quartz boat, and then put into a chemical vapor deposition reaction furnace In the quartz tube; place the dry nickel foam net in the downstream of the air flow near the nozzle of the quartz tube; pass in argon gas for 10 minutes to exhaust the air in the furnace, stop the ventilation, heat to 750 ° C for 30 minutes, and keep warm with argon gas at the same time After passing through the quartz tube at a speed of 100 sccm for 30 minutes, stop heating and naturally cool to room temperature; take out the nickel foam, rinse it with deionized water and ethanol, and dry it at 60°C for 6 hours.

[0034] The chemical raw materials selenium powder and cobalt powder used in the above examples are analytically pure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com