Patents

Literature

155results about How to "Excellent specific capacitance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

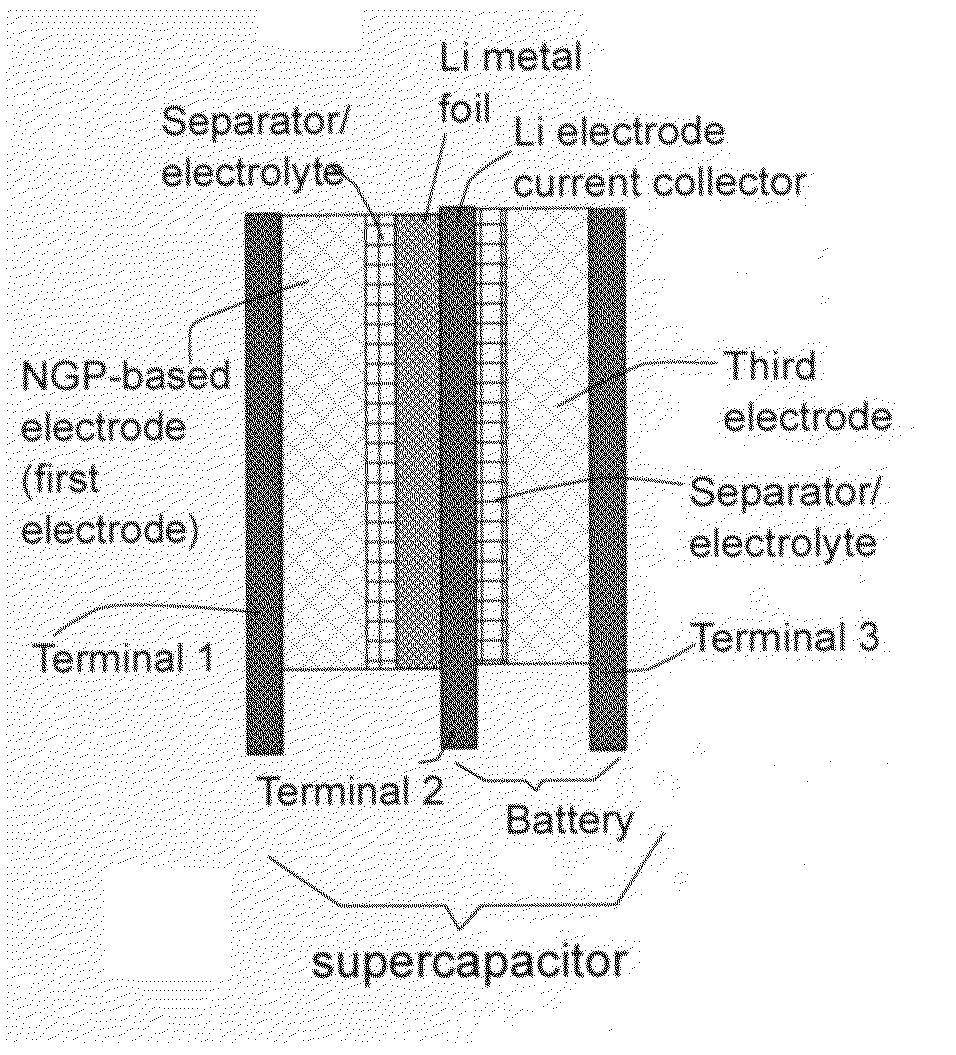

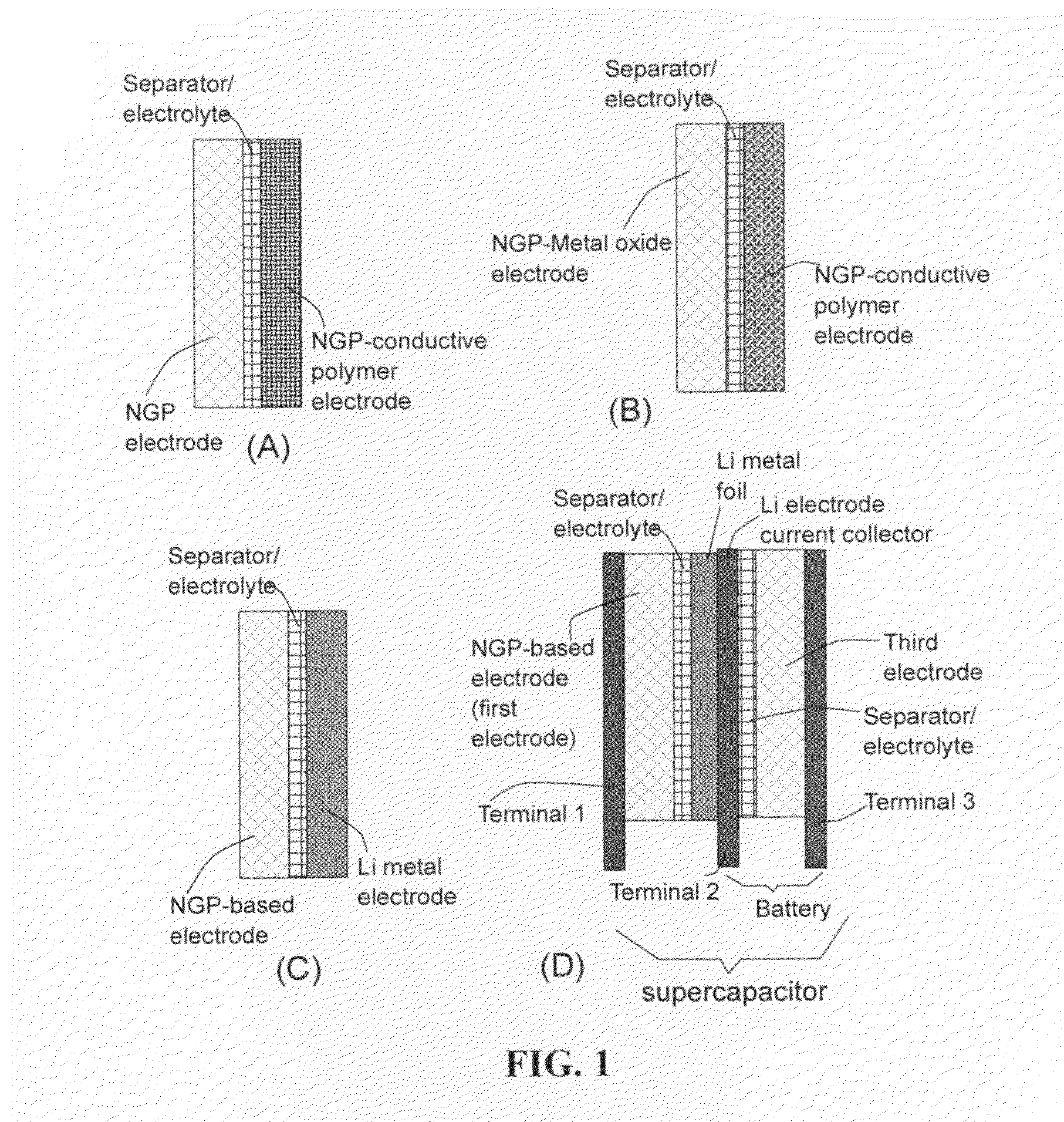

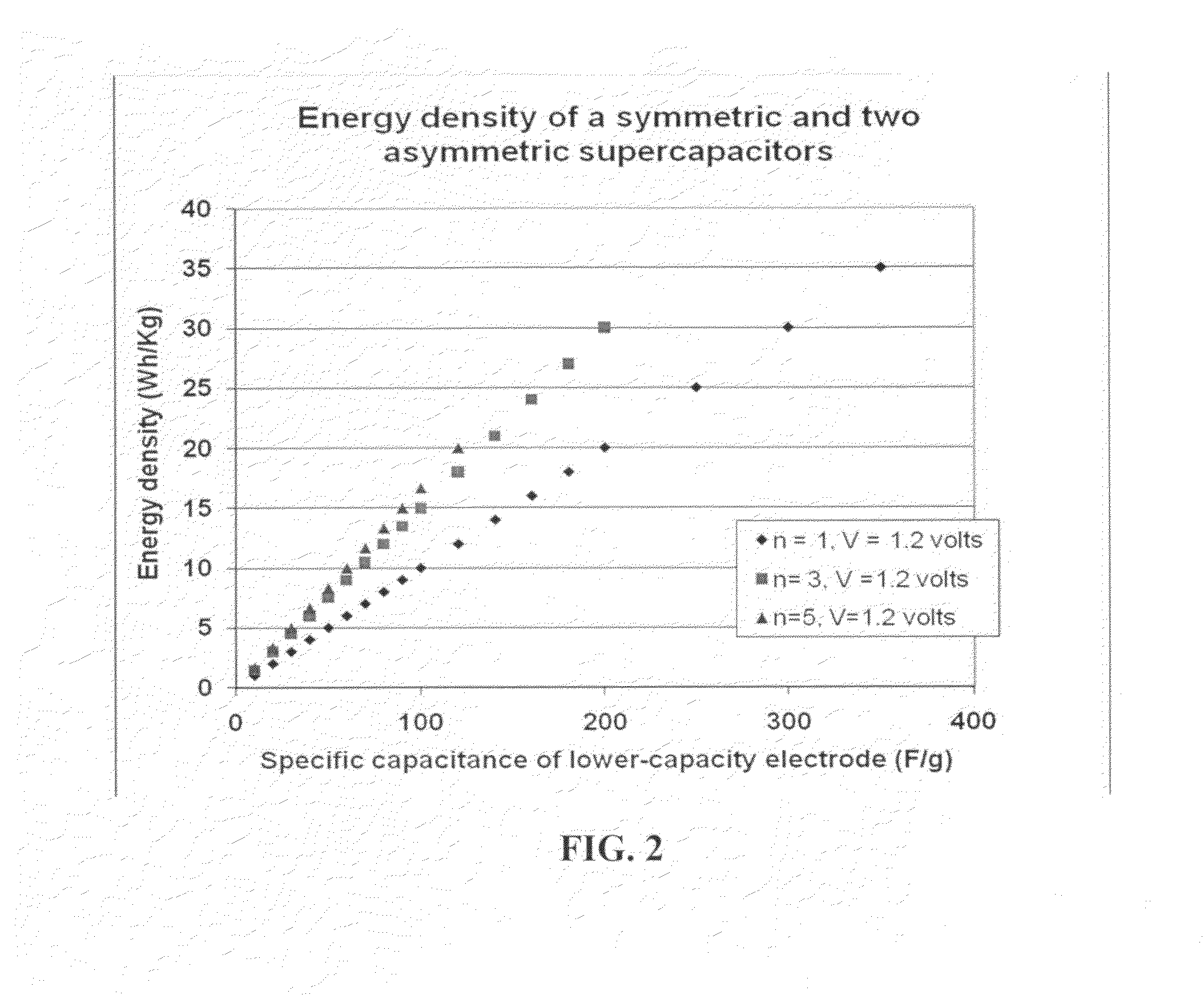

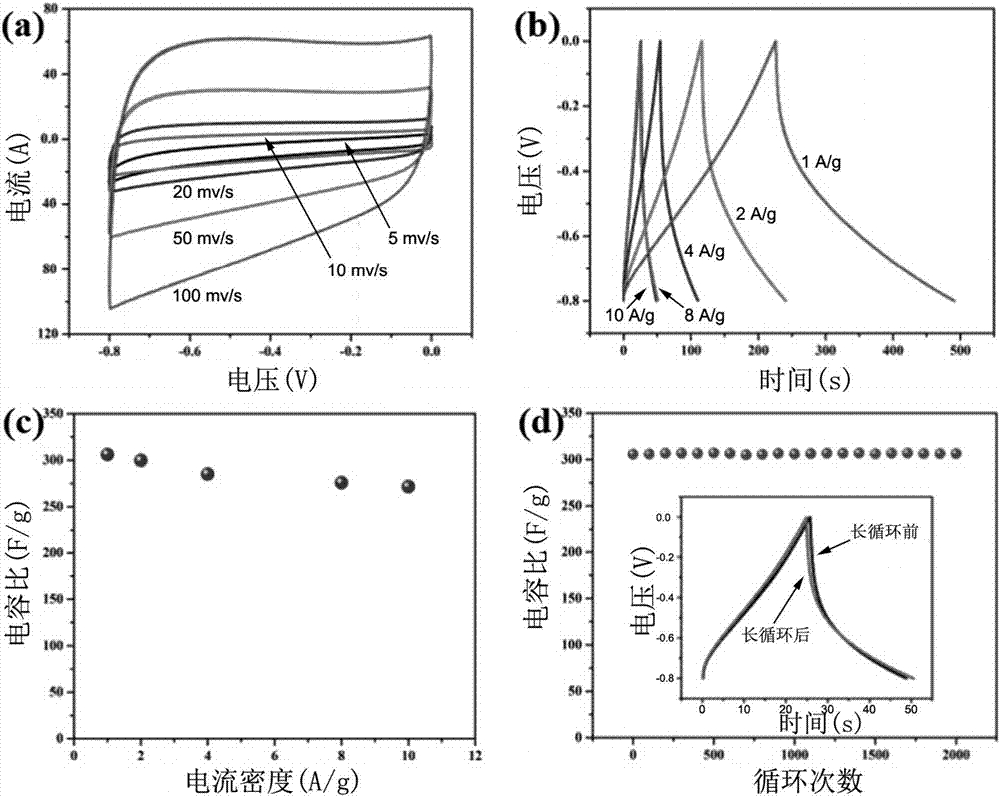

Flexible asymmetric electrochemical cells using nano graphene platelet as an electrode material

InactiveUS20110183180A1Excellent specific capacitanceLarge specific surface areaElectrochemical generatorsHybrid capacitor separatorsPlateletGraphene

A flexible, asymmetric electrochemical cell comprising: (A) A sheet of graphene paper as first electrode comprising nano graphene platelets having a platelet thickness less than 1 nm, wherein the first electrode has electrolyte-accessible pores; (B) A thin-film or paper-like first separator and electrolyte; and (C) A thin-film or paper-like second electrode which is different in composition than the first electrode; wherein the separator is sandwiched between the first and second electrode to form a flexible laminate configuration. The asymmetric supercapacitor cells with different NGP-based electrodes exhibit an exceptionally high capacitance, specific energy, and stable and long cycle life.

Owner:NANOTEK INSTR GRP LLC

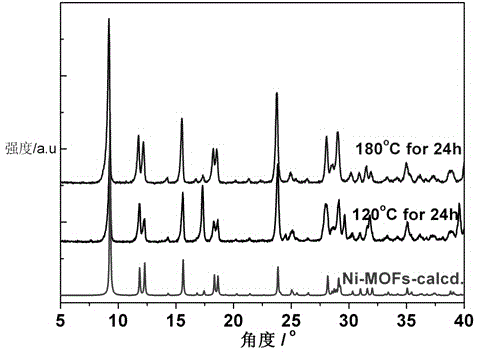

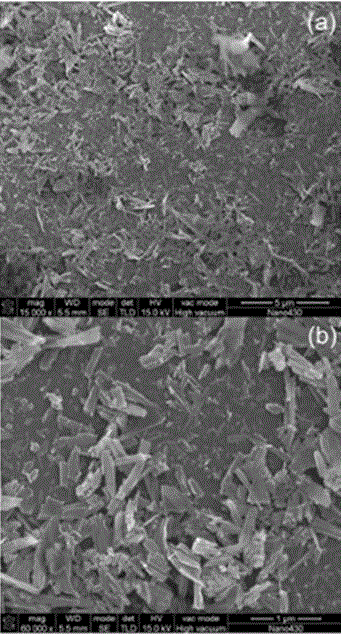

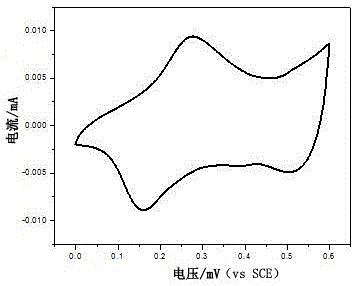

Preparation method of Ni-MOF electrode material

InactiveCN104979104AImprove electrochemical performanceExcellent specific capacitanceHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceAlcohol

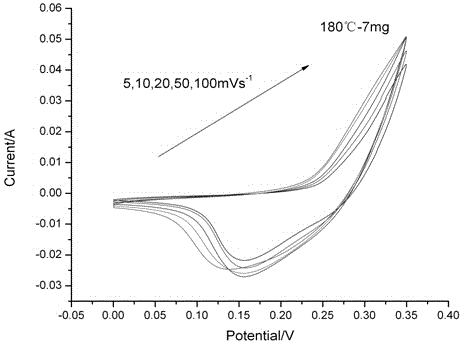

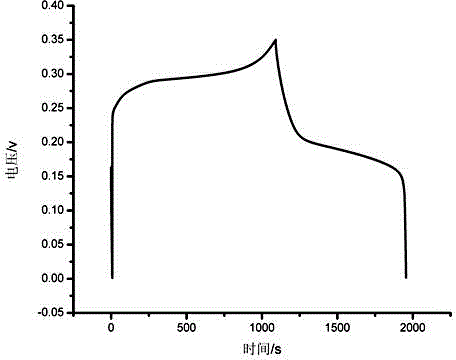

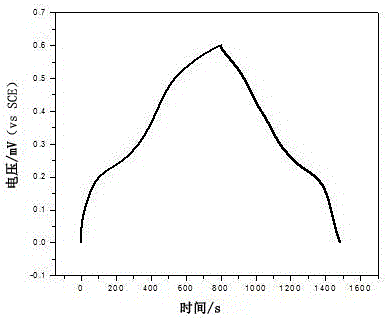

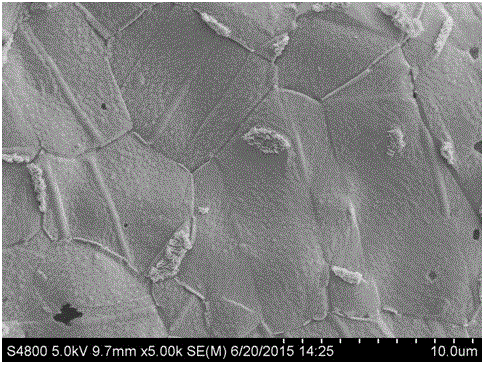

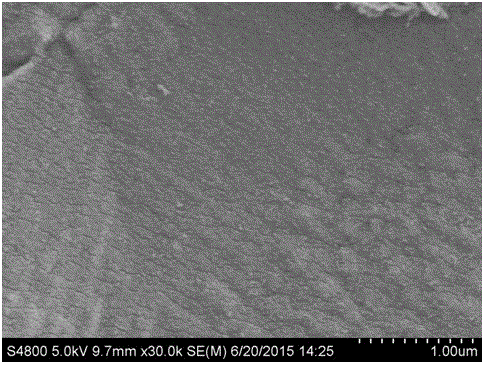

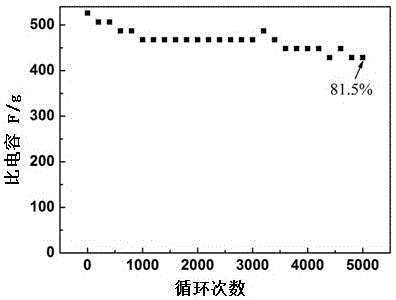

Disclosed in the invention is a preparation method of a Ni-MOF electrode material. A nicdel nitrate aqueous solution with the total concentration of 0.0075 to 0.43mol / l is added into a PTA / DMF solution with the total concentration of 0.005 to 0.03 mol / l, wherein the adding speed is 2 to 5ml / min and the volume ration of the nicdel nitrate aqueous solution to the terephthalic acid solution is 1.5-3 :1; after dissolution stirring of 1 to 2 hours, a precursor solution is obtained; solvothermal reaction is carried out on the precursor solution for 12 to 48 hours in a hydro-thermal kettle with the temperature of 120 to 200 DEG C, centrifugal washing and filtering are carried out on an obtained green precipitate respectively by DMF and absolute ethyl alcohol, and drying is carried out under the temperature of 80 DEG C, thereby obtaining a Ni-MOF electrode material. According to the preparation method, the specific capacitance of the material can be up to 1500F / g; after 3000-times charging and discharging circulation, 90% of specific capacitance still can be kept. The method is simple and can be controlled easily; the conditions are mild; and the production cost is low.

Owner:SHANGHAI INST OF TECH

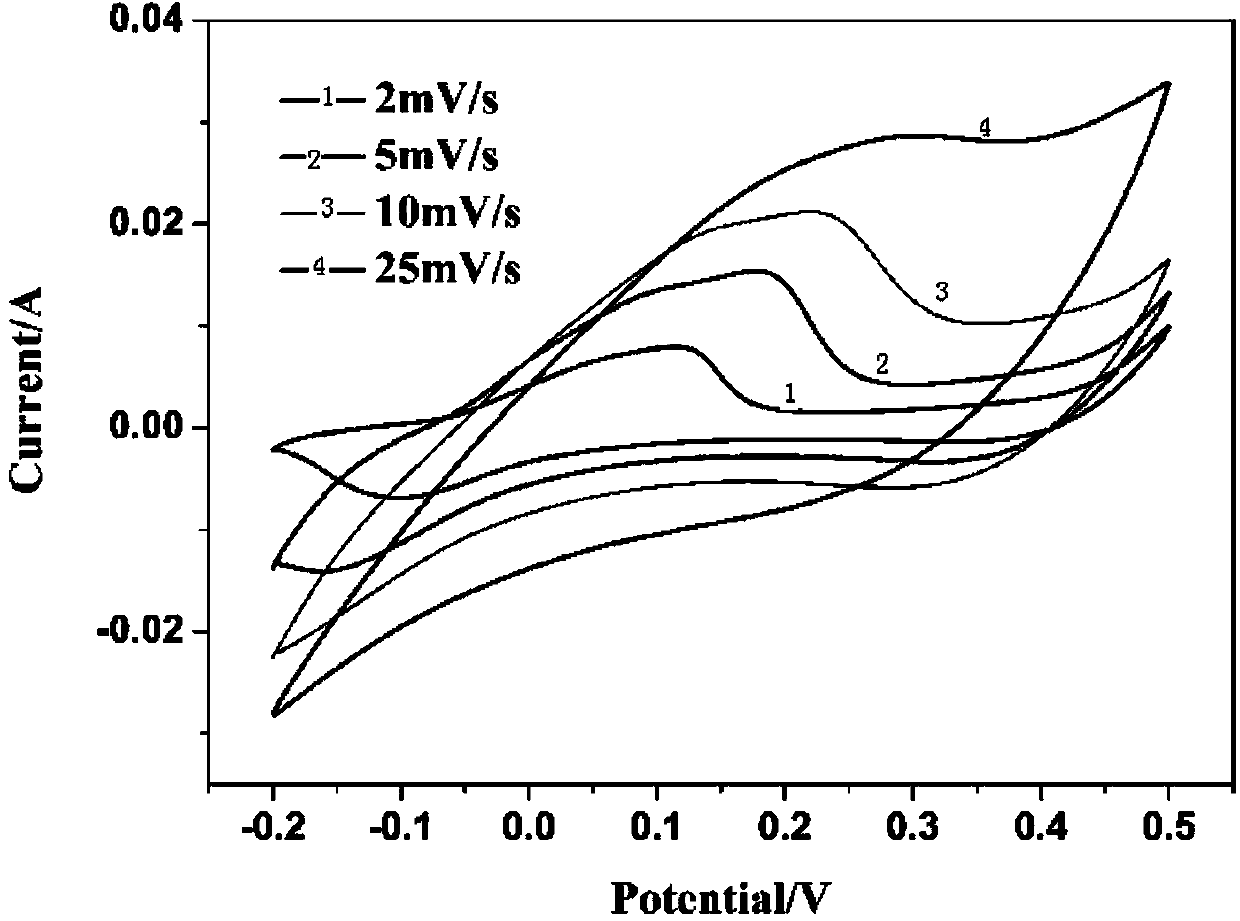

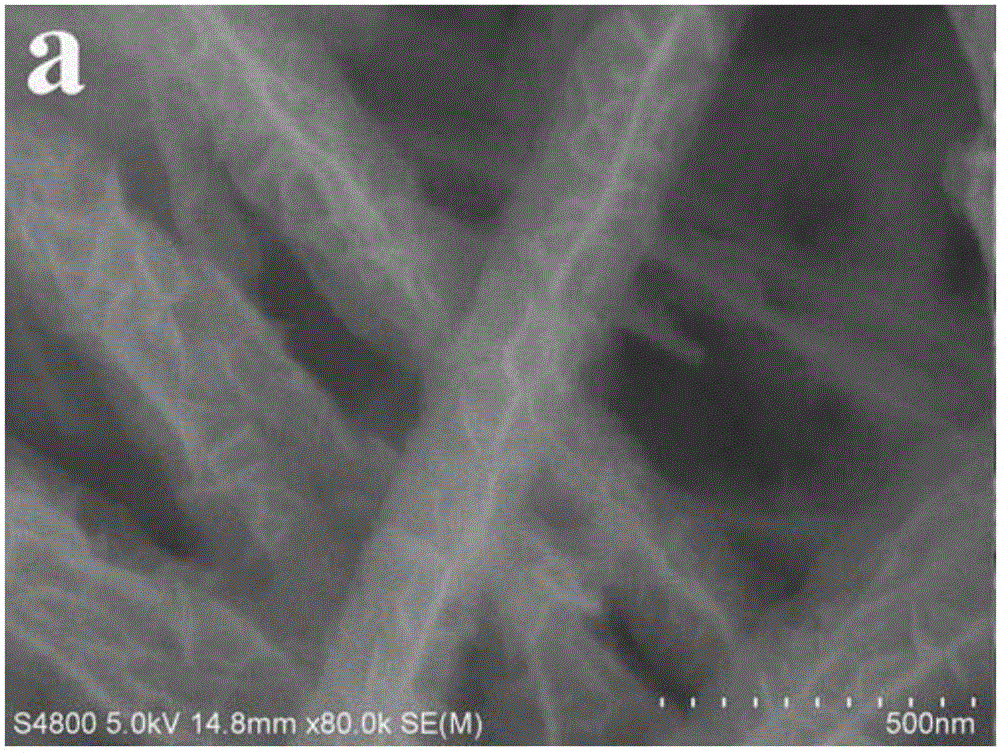

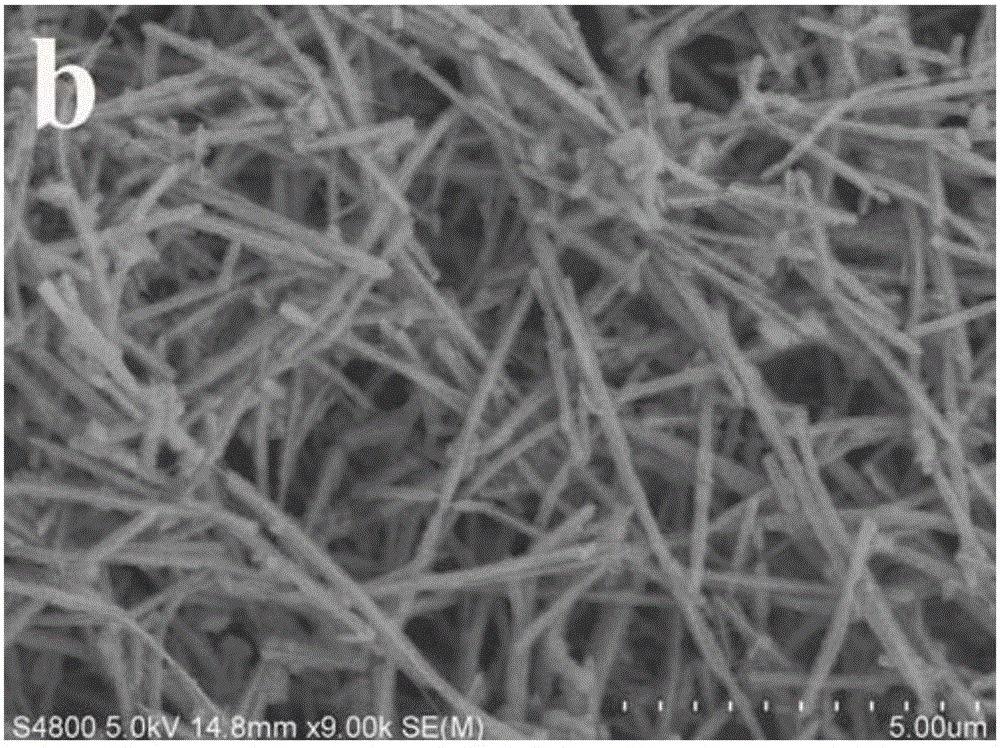

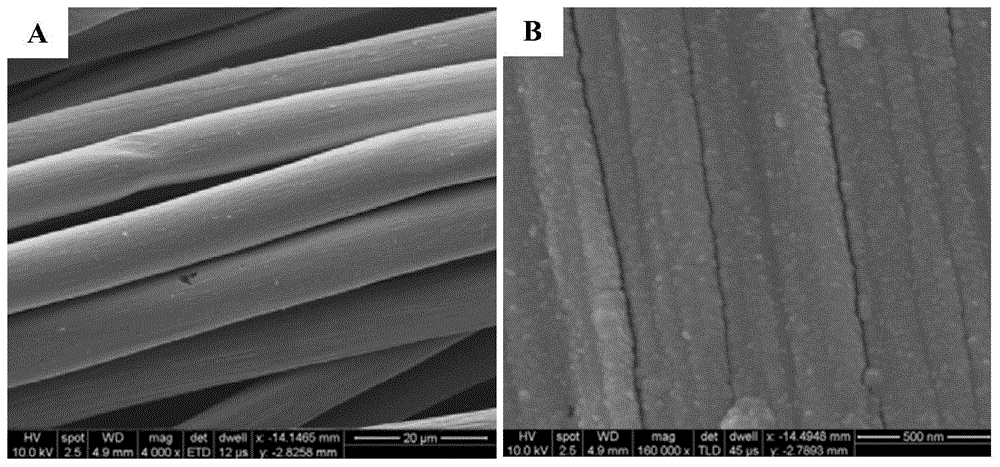

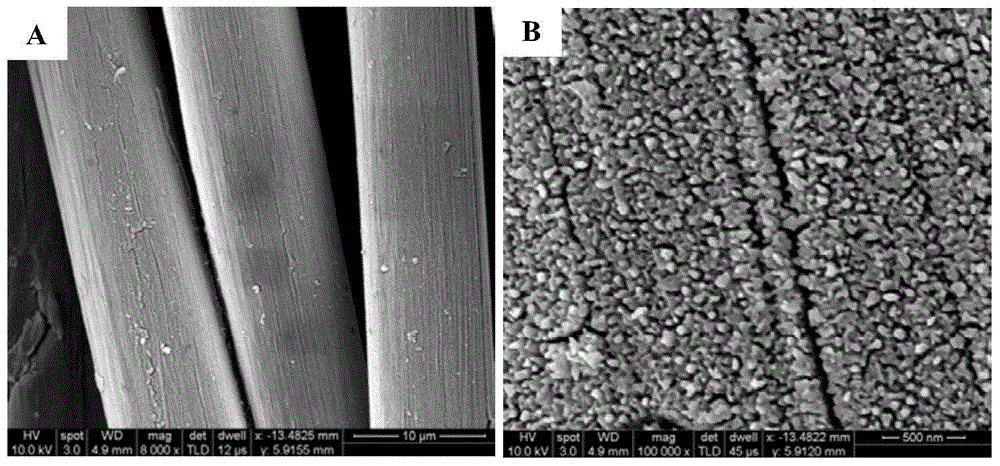

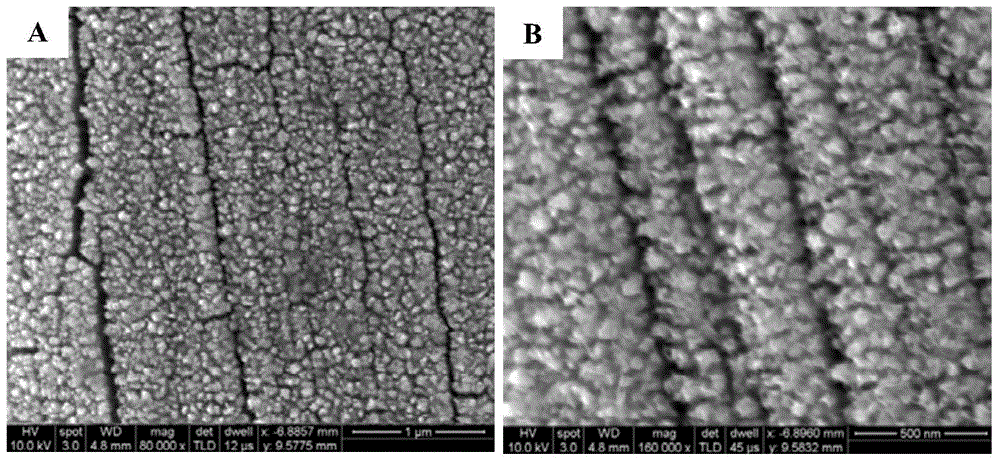

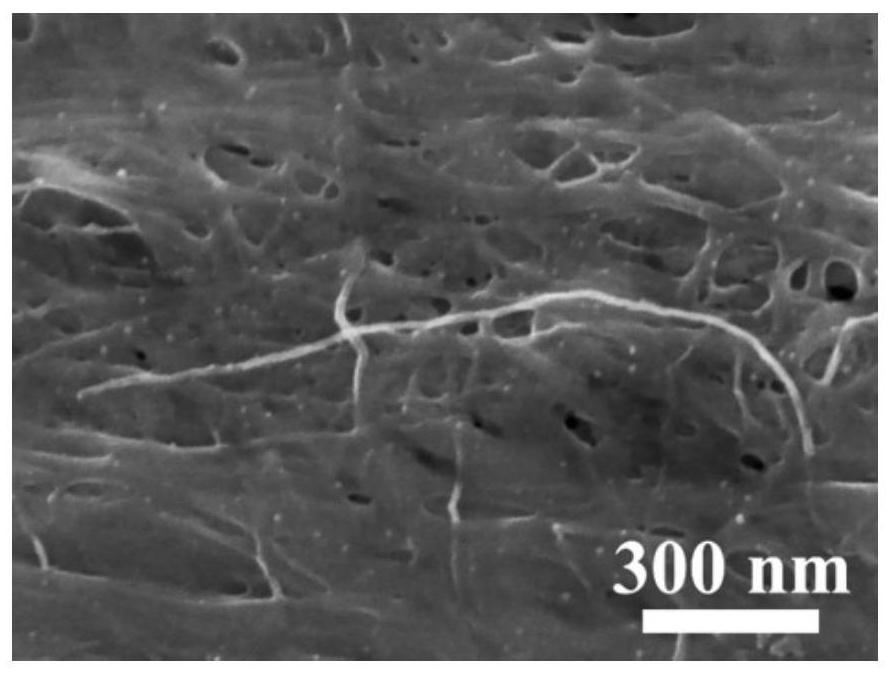

Array carbon nano-tube/carbon fiber-based flexible composite electrode material and preparation method thereof

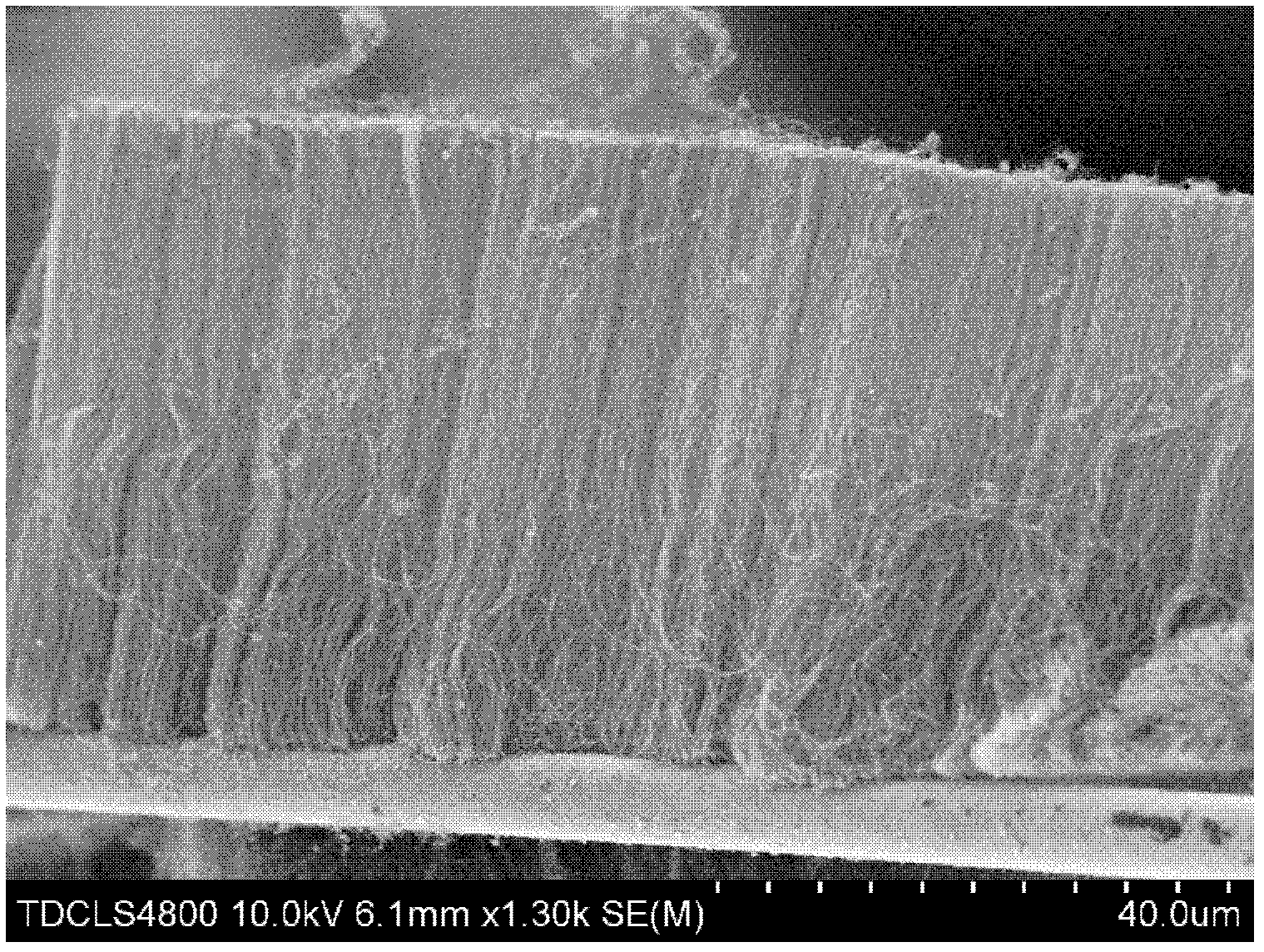

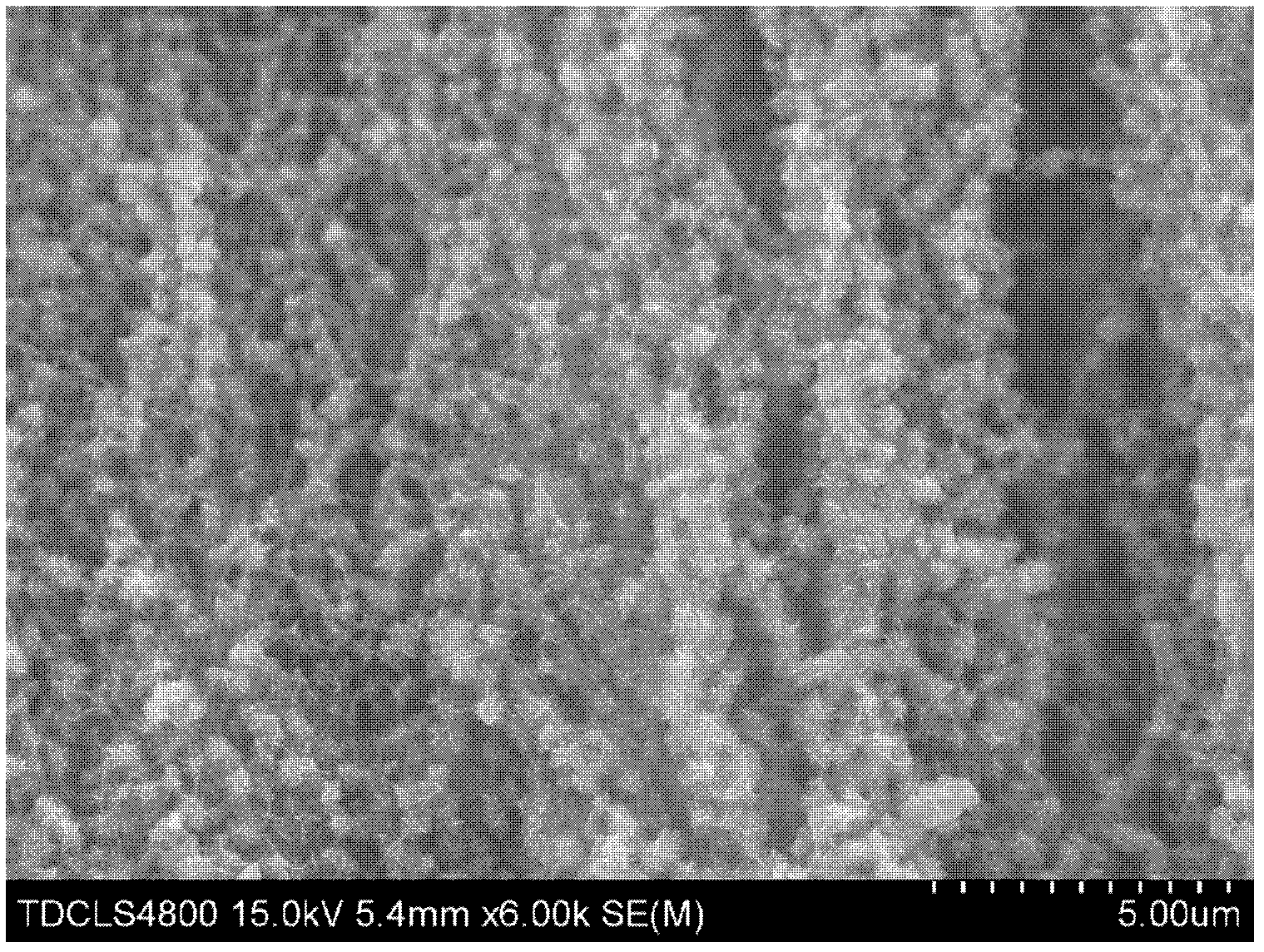

ActiveCN102354612AImprove electrochemical performanceExcellent specific capacitanceCarbon fibresElectrolytic capacitorsSilicon oxideChemical stability

The invention discloses an array carbon nano-tube / carbon fiber-based flexible composite electrode material and a preparation method thereof. The composite material takes a three-dimensional carbon fiber woven body as a substrate, a carbon nano-tube array is grown on the substrate, and nano-scale manganese dioxide particles are deposited on the surface. The preparation process comprises the following steps: performing high-temperature treatment on the three-dimensional carbon fiber woven body under the protection of inert gas; wrapping a layer of nano-scale silicon dioxide on the surface of the carbon fiber; using a chemical vapor deposition method to grow the carbon nano-tube array on the surface of the three-dimensional carbon fiber woven body; and utilizing a constant current electrochemical deposition method to uniformly deposit nano-scale manganese dioxide on an array carbon nano-tube / carbon fiber composite body. The process is simple, and the prepared flexible composite electrode has the advantages of developed conductive network, porous structure, large specific surface area, higher utilization rate of active substances, excellent mechanical strength and excellent chemical stability, thus the composite material provided by the invention is an ideal material for the high-performance large-capacity supercapacitor flexible electrode.

Owner:TIANJIN UNIV

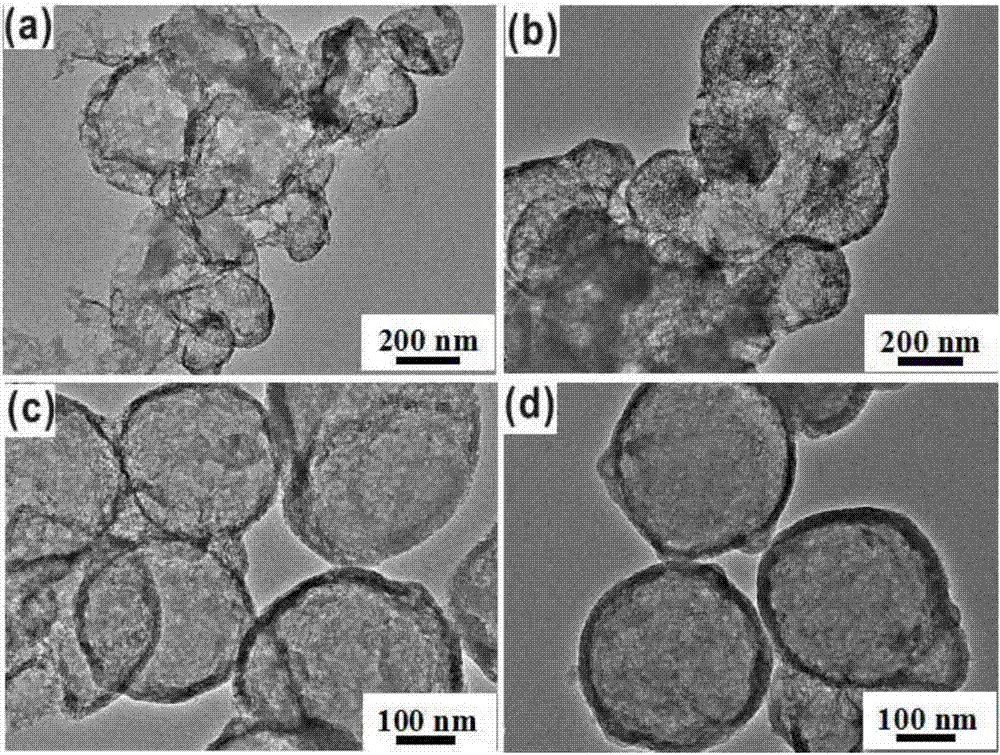

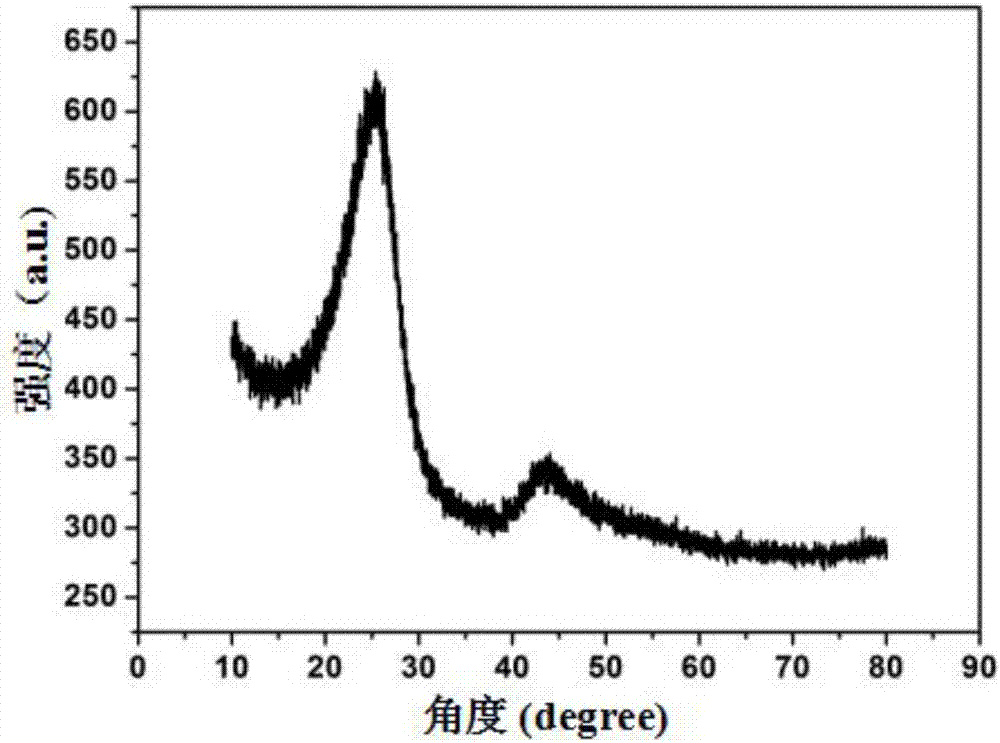

Graphene/carbon ball composite material, and preparation and application thereof

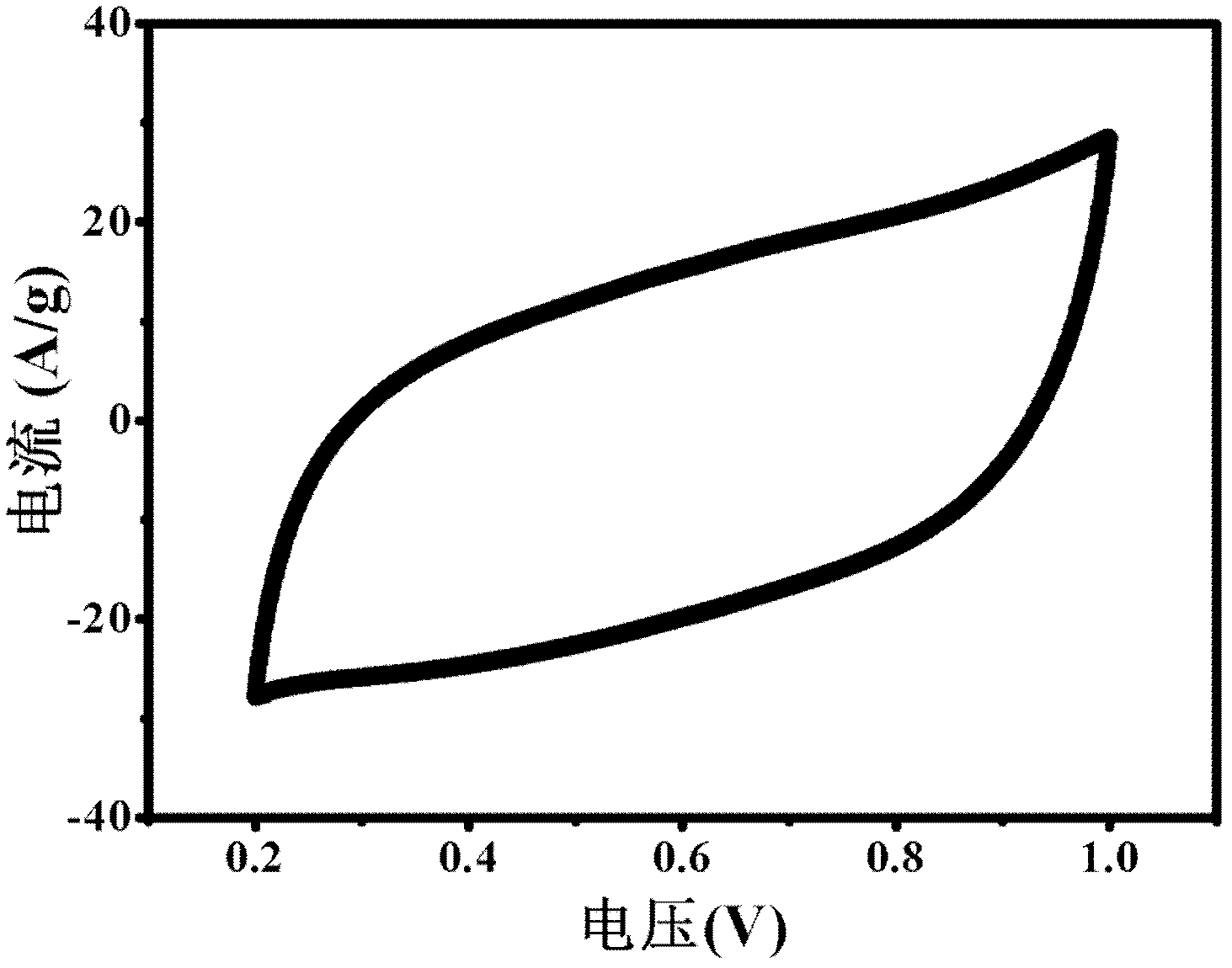

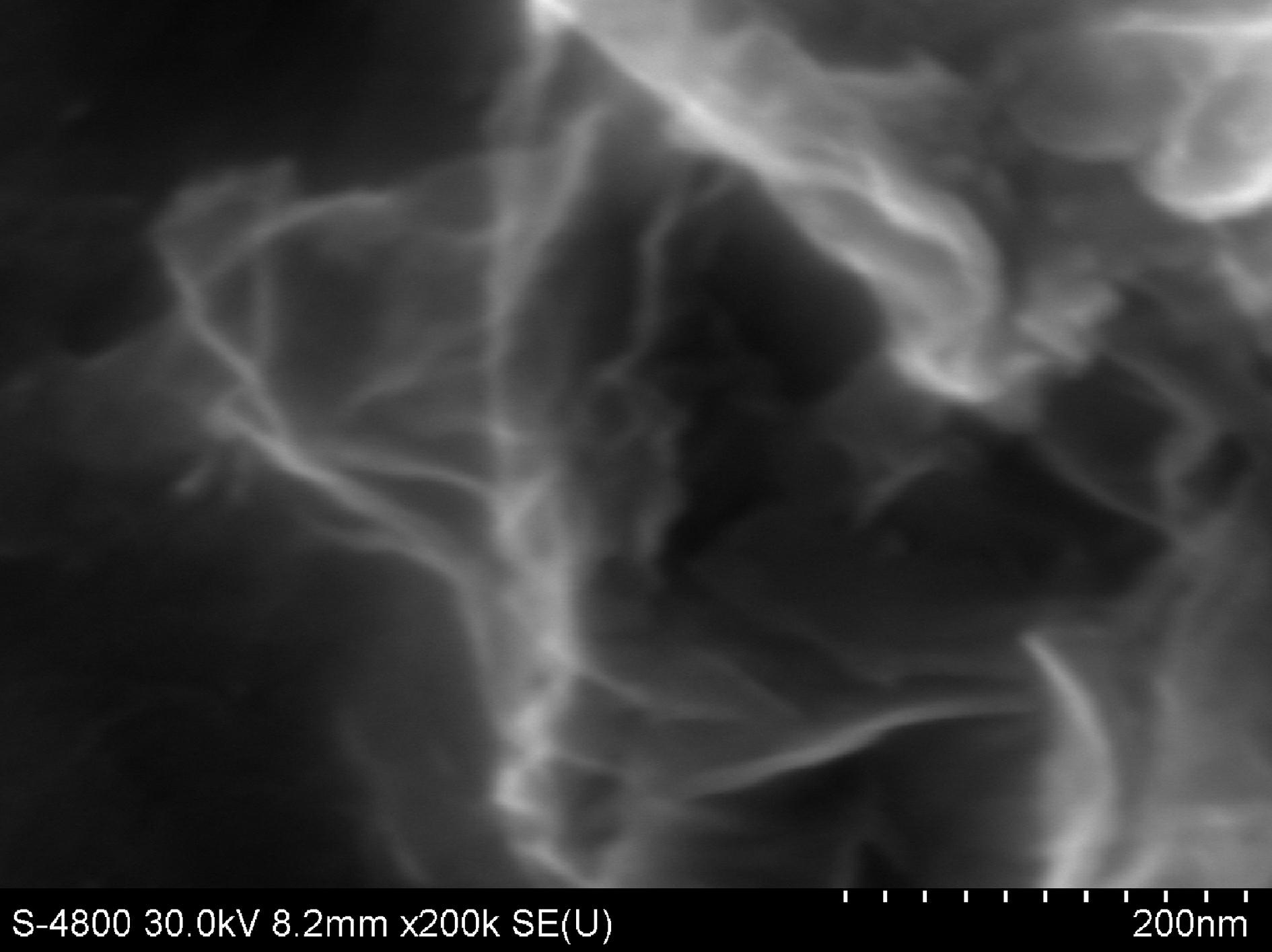

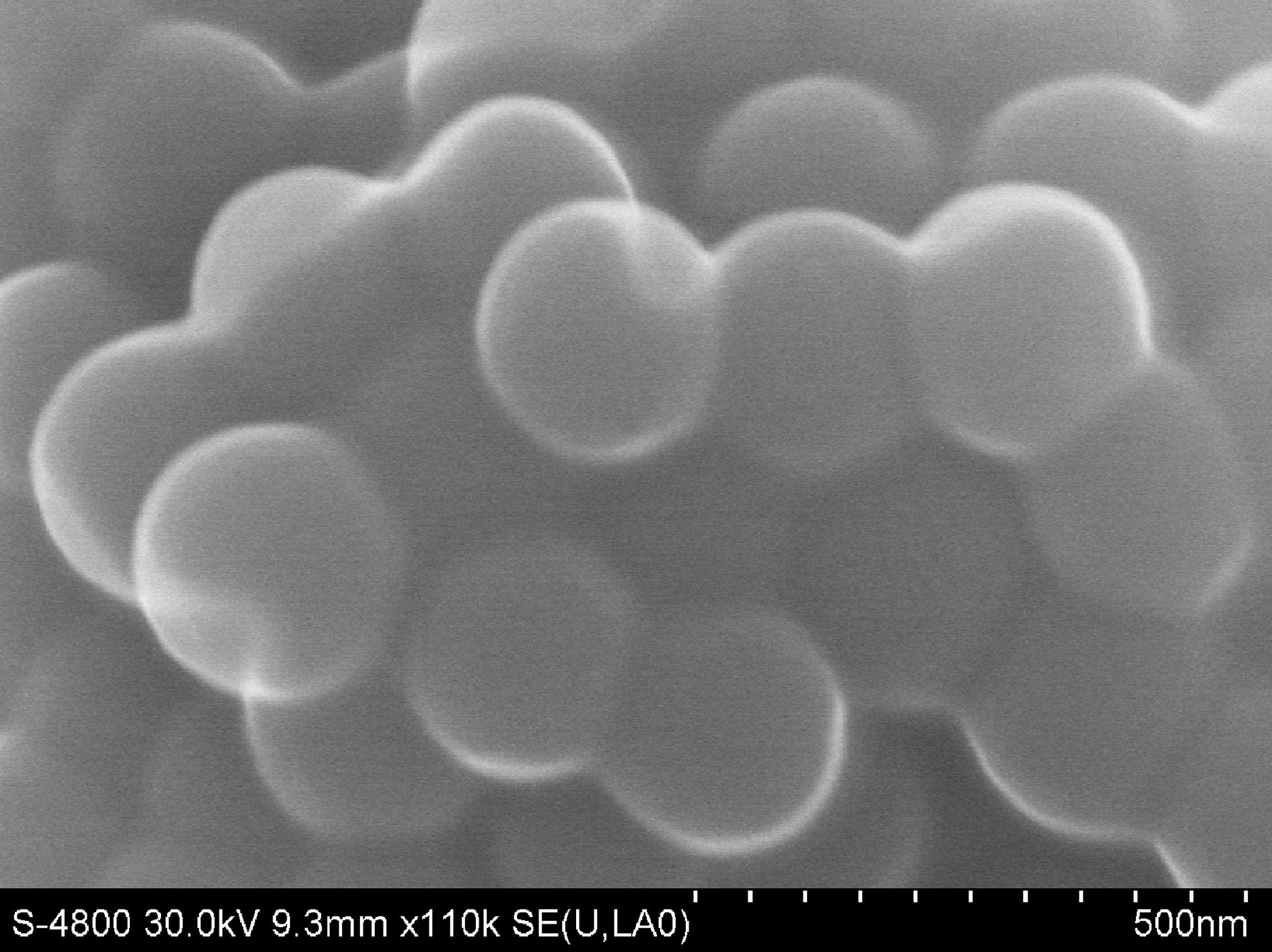

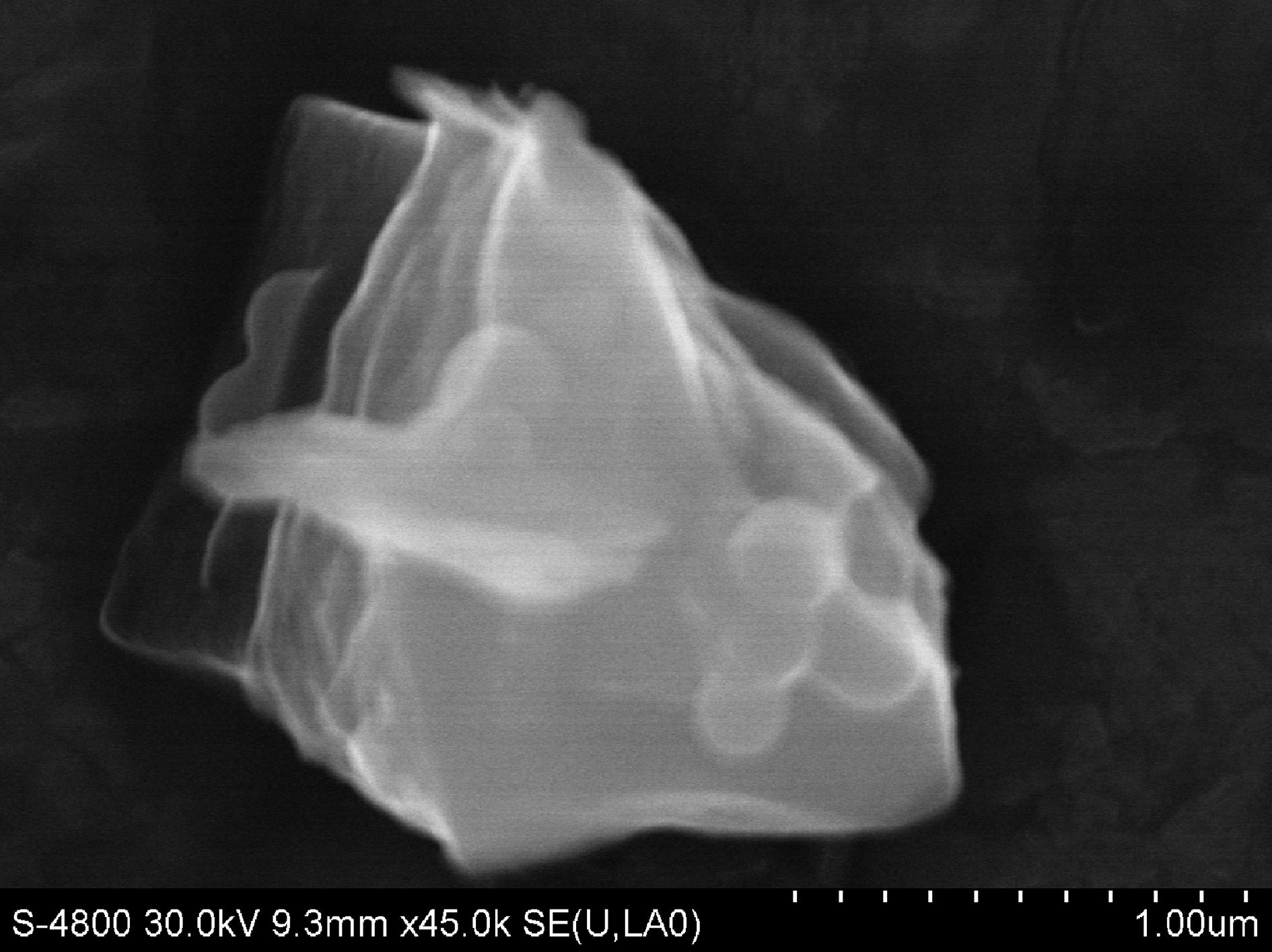

InactiveCN102509643ALow costWide variety of sourcesElectrolytic capacitorsHybrid capacitor electrodesCapacitanceSupercapacitor

The invention provides a preparation method of a graphene / carbon ball composite material, belonging to the technical field of composite materials. The method comprises the following steps of: obtaining a graphene oxide precursor solution in an ultrasonic stripping manner; carrying out hydro-thermal treatment of glucose under a certain temperature to obtain carbon balls; and then self-assembling and reducing graphene oxide and the carbon balls under a certain condition to obtain the graphene / carbon ball composite material. The composite material is used as an electrode material of a super-capacitor. Because graphene agglomeration can be effectively prevented through the carbon balls in the composite material, a graphene electric double layer capacitor can be well displayed, therefore, the composite material shows excellent electrochemical performance.

Owner:NORTHWEST NORMAL UNIVERSITY

Cobaltosic oxide/NiCoAl dual-layer hydroxide composite material and preparation method thereof

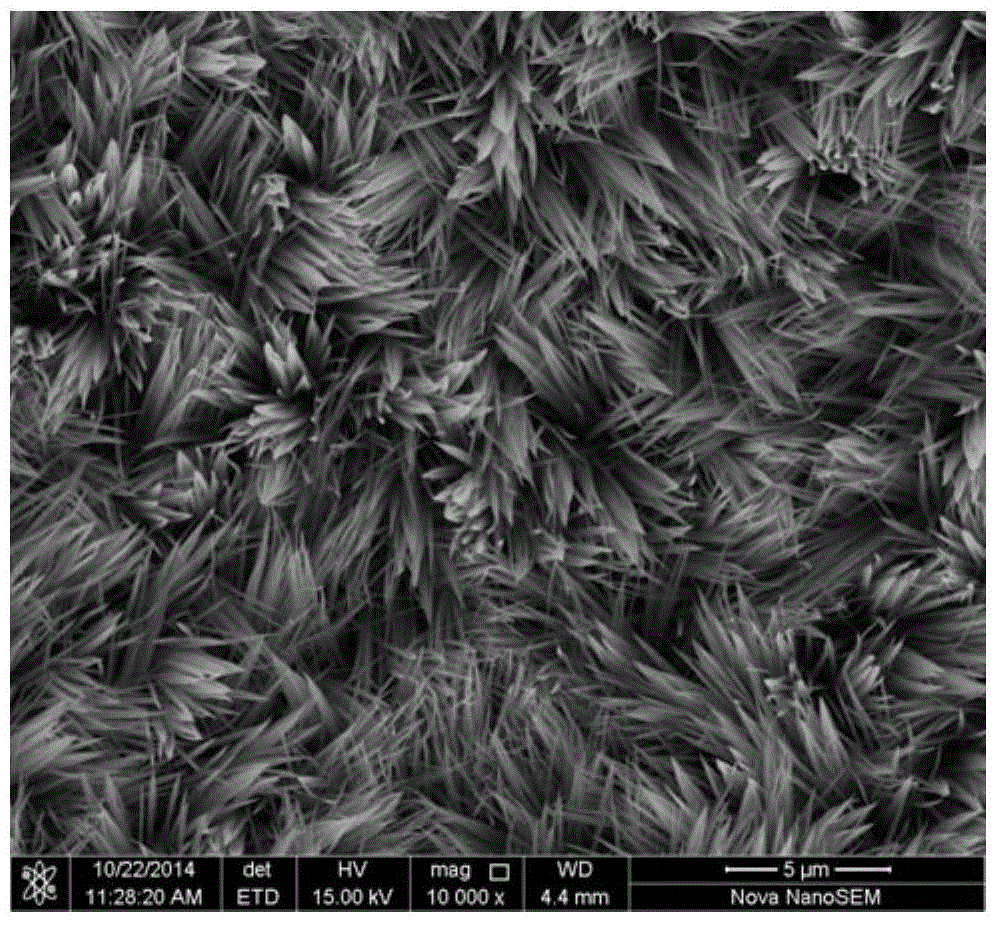

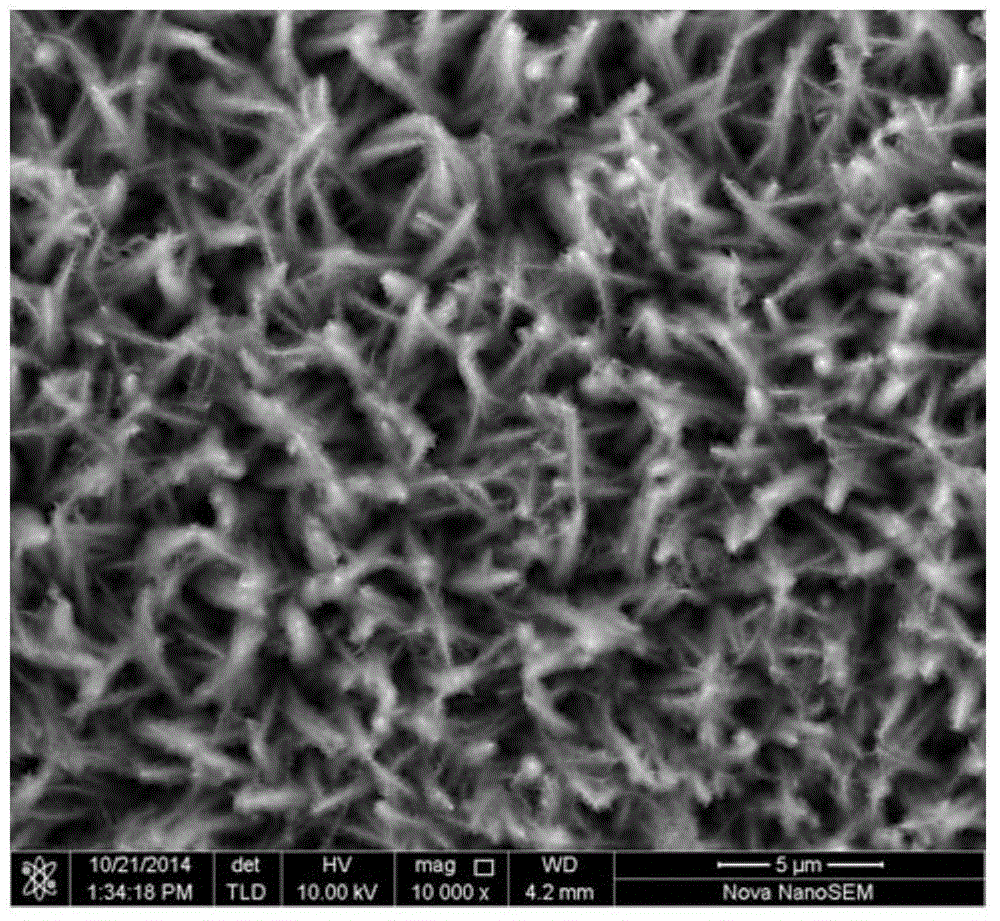

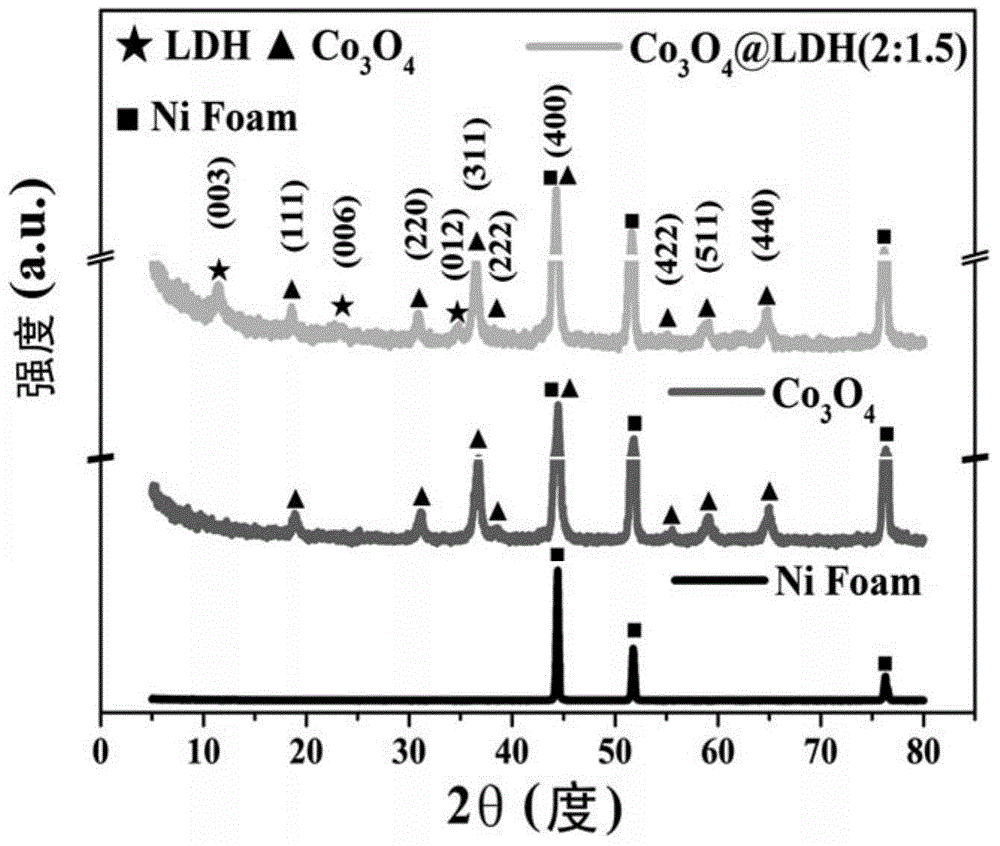

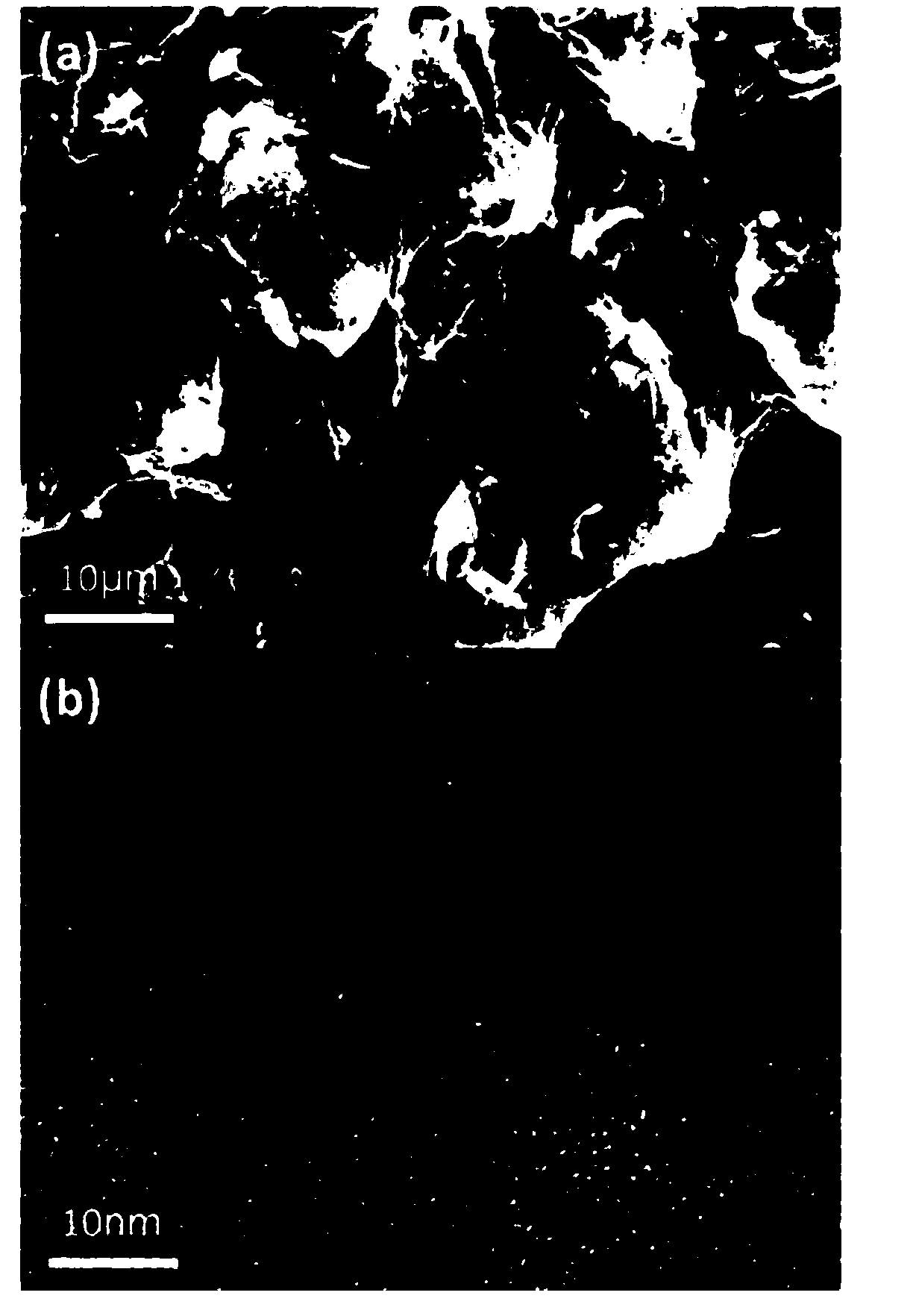

ActiveCN105097299AImprove conductivityImprove cycle stabilityHybrid capacitor electrodesHybrid/EDL manufactureNanowireCobalt(II,III) oxide

The invention discloses a cobaltosic oxide / NiCoAl dual-layer hydroxide composite material and a preparation method thereof. According to the method, a cobaltosic oxide / NiCoAl dual-layer hydroxide compound with a core-shell structure is prepared by a twice hydrothermal method; according to the prepared cobaltosic oxide / NiCoAl dual-layer hydroxide compound with the core-shell structure, a cobaltosic oxide nanowire is taken as a core; NiCoAl dual-layer hydroxide is taken as a shell; and the cobaltosic oxide nanowire and the NiCoAl dual-layer hydroxide generate a synergistic effect to enhance the electrochemical property. Therefore, the technical problems of unstable structure, poor rate capability and the like in the prior art are solved; and the cobaltosic oxide / NiCoAl dual-layer hydroxide composite material is especially suitable for a super capacitor material; the preparation method is simple and fast; and large-scale production can be realized.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

Preparation method for coproduction of high-specific-capacitance active carbon and nano silicon dioxide from rice hull

InactiveCN103408009AExcellent specific capacitanceImprove charge and discharge performanceMaterial nanotechnologySilicaCapacitanceCarbide

The invention discloses a preparation method for coproduction of high-specific-capacitance active carbon and nano silicon dioxide from rice hull, and belongs to the technical field of resource comprehensive utilization and electrochemical supercapacitors. The preparation method comprises the steps of (1) cleaning, drying and grinding rice hull; (2) carbonizing the rice hull ground in the step (1) under a non-oxidizing condition, processing the carbonized rice hull through an acid solution, washing with water and drying to obtain carbide; (3) mixing the carbide obtained from the step (2) with strong base by a certain proportion, adding a certain amount of water, uniformly mixing, drying, controlling a temperature-increasing speed and activating to obtain an activated product; (4) soaking the activated product obtained from the step (3) in hot water, filtering and washing to be neutral, drying and grinding the product to 150-300 meshes to obtain a high-specific capacitance rice hull-based active carbon material; and (5) recovering filtrate obtained from the step (4), adding the acid solution at certain temperature, controlling a speed of dropping acid, regulating pH, aging, filtering and drying to obtain a nano silicon dioxide product.

Owner:JILIN UNIV

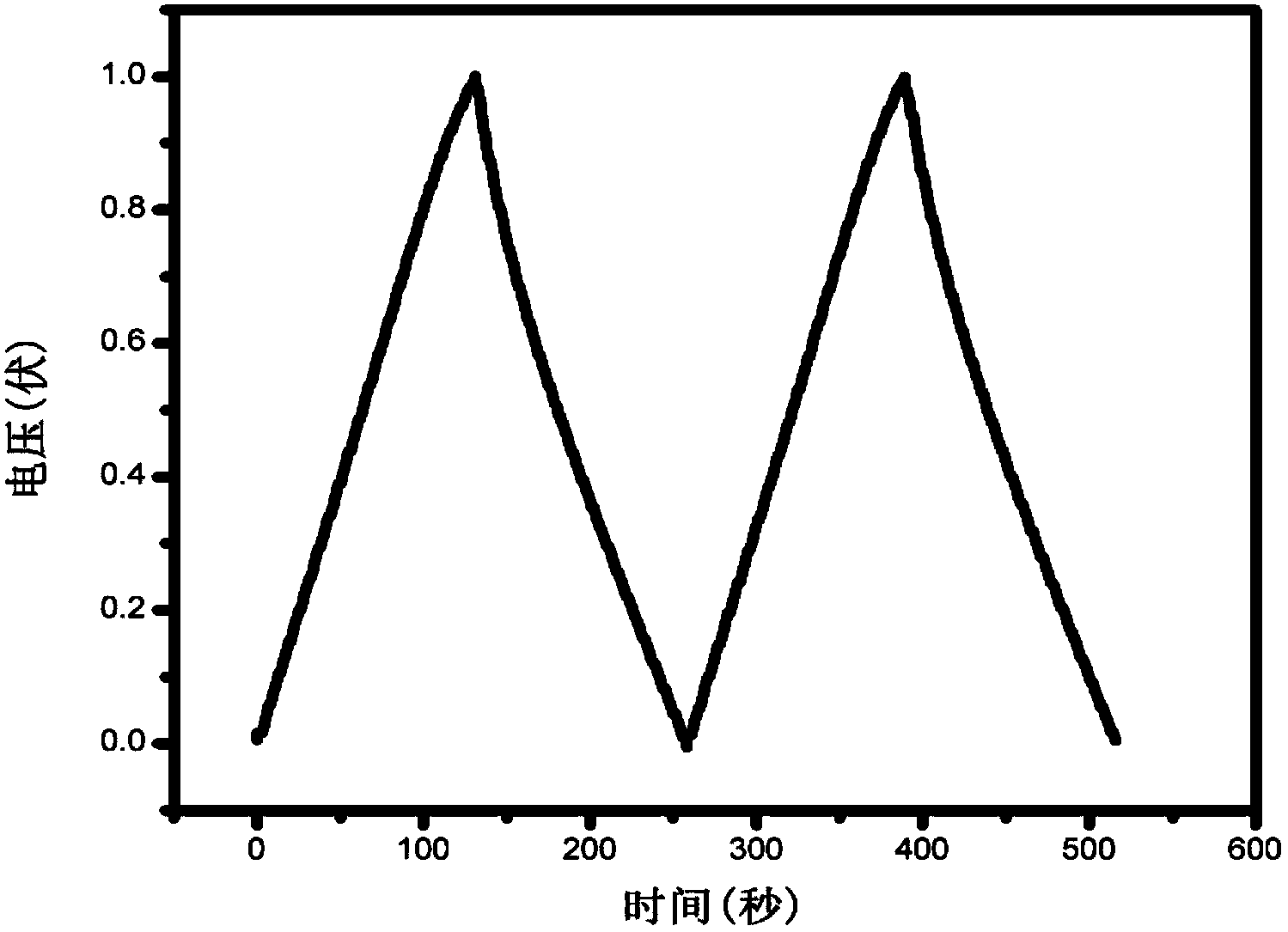

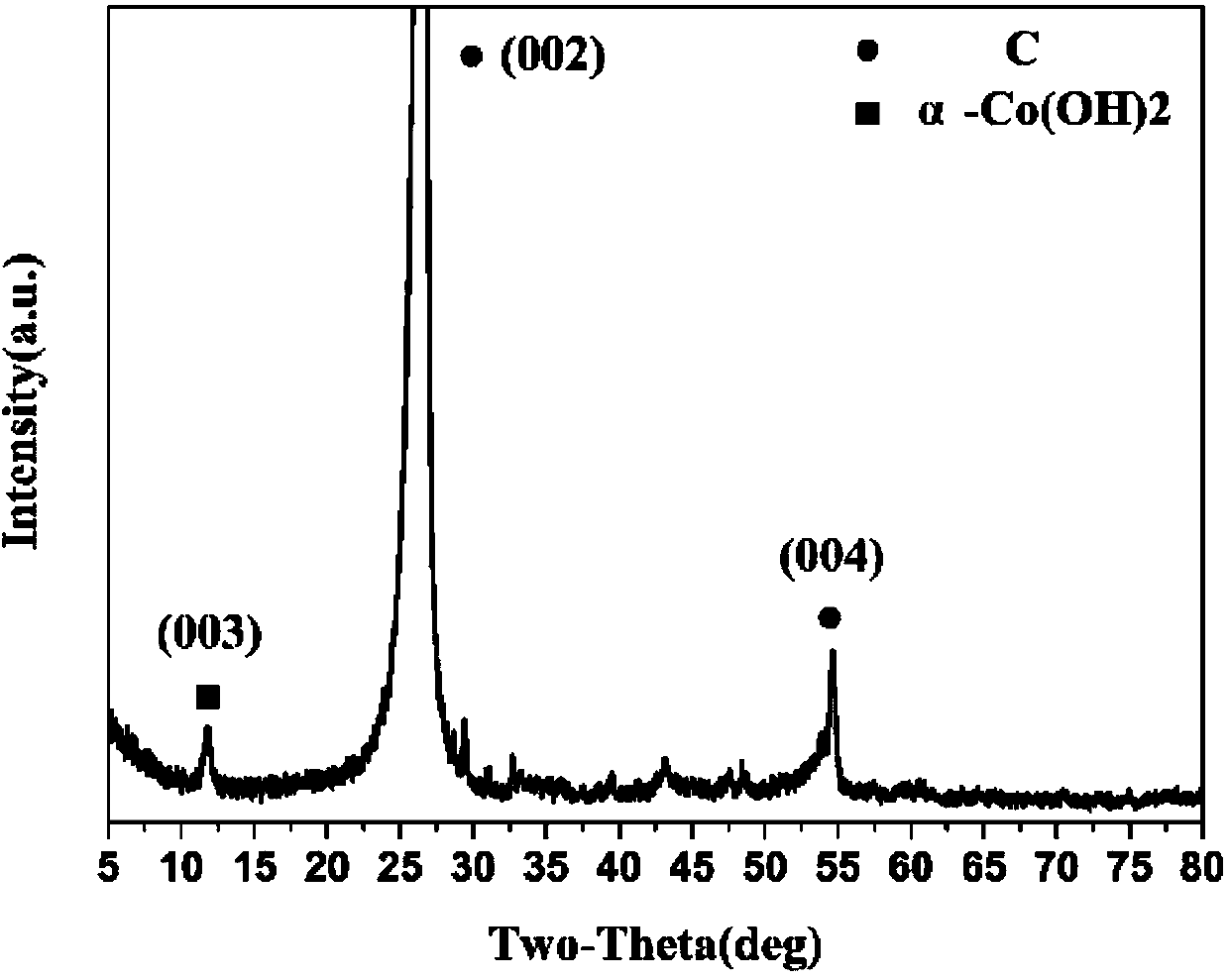

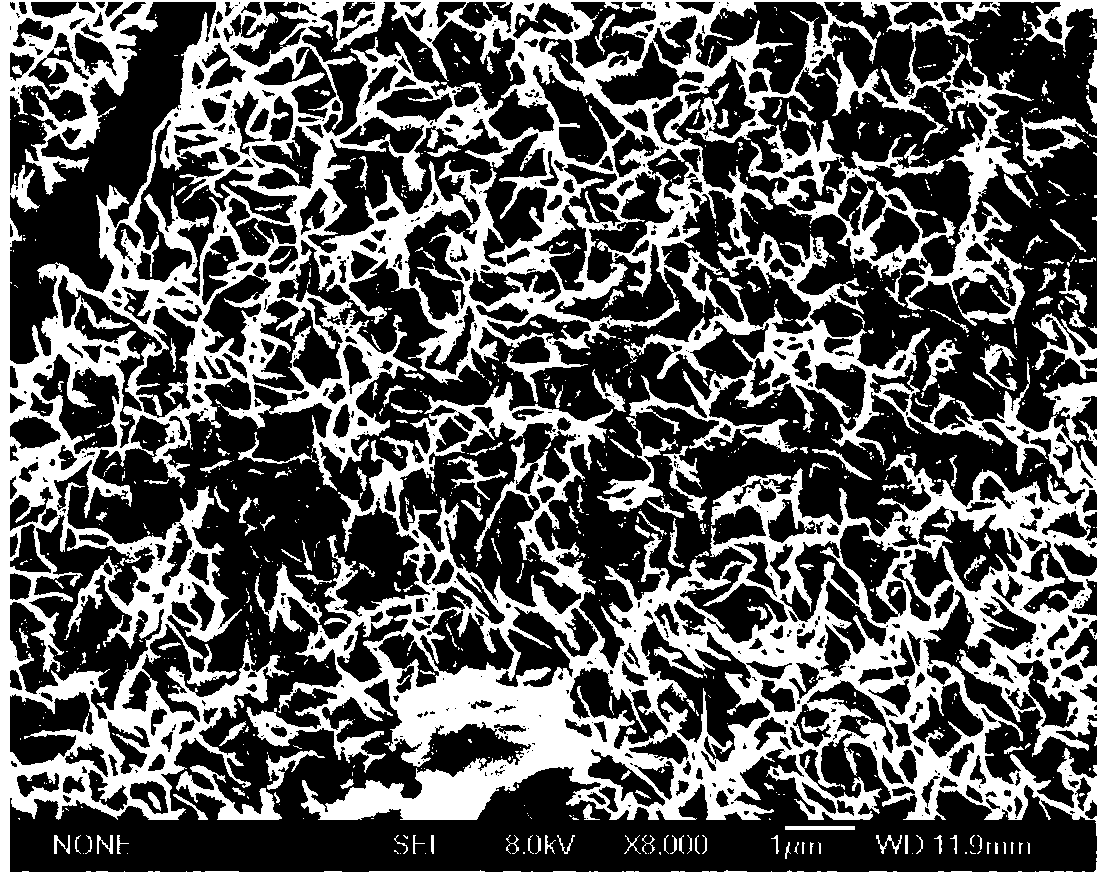

Preparation method for different carbon fibers / cobalt hydroxide electrode and solid-liquid composite electrode system

InactiveCN103426649ALower internal resistanceImprove cycle stabilityHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceFiber

The invention relates to a preparation method for different carbon fibers / a cobalt hydroxide electrode and a solid-liquid composite electrode system. By means of pretreatment and modification of different carbon fibers, the carbon fibers serve as a substrate, composite of metal oxide or hydroxide and the carbon fibers are realized by the electrochemical deposition, and a solid electrode is obtained and has high specific capacitance in the alkaline aqueous solution. Redox substances are added into the alkaline aqueous solution, a composite electrode system that the solid electrode and liquid-phase electrolyte supply the pseudocapacitance jointly is obtained. The composite electrode system has ultra-high specific capacitance, is applied in supercapacitors, and has the advantages of ultra-high energy density, high power density and long service life. The specific capacitance of the composite electrode system can be adjusted by changing the concentration and volume of the redox substances, and the energy density and power density of the supercapacitors can be further changed to meet different using requirements.

Owner:JILIN UNIV

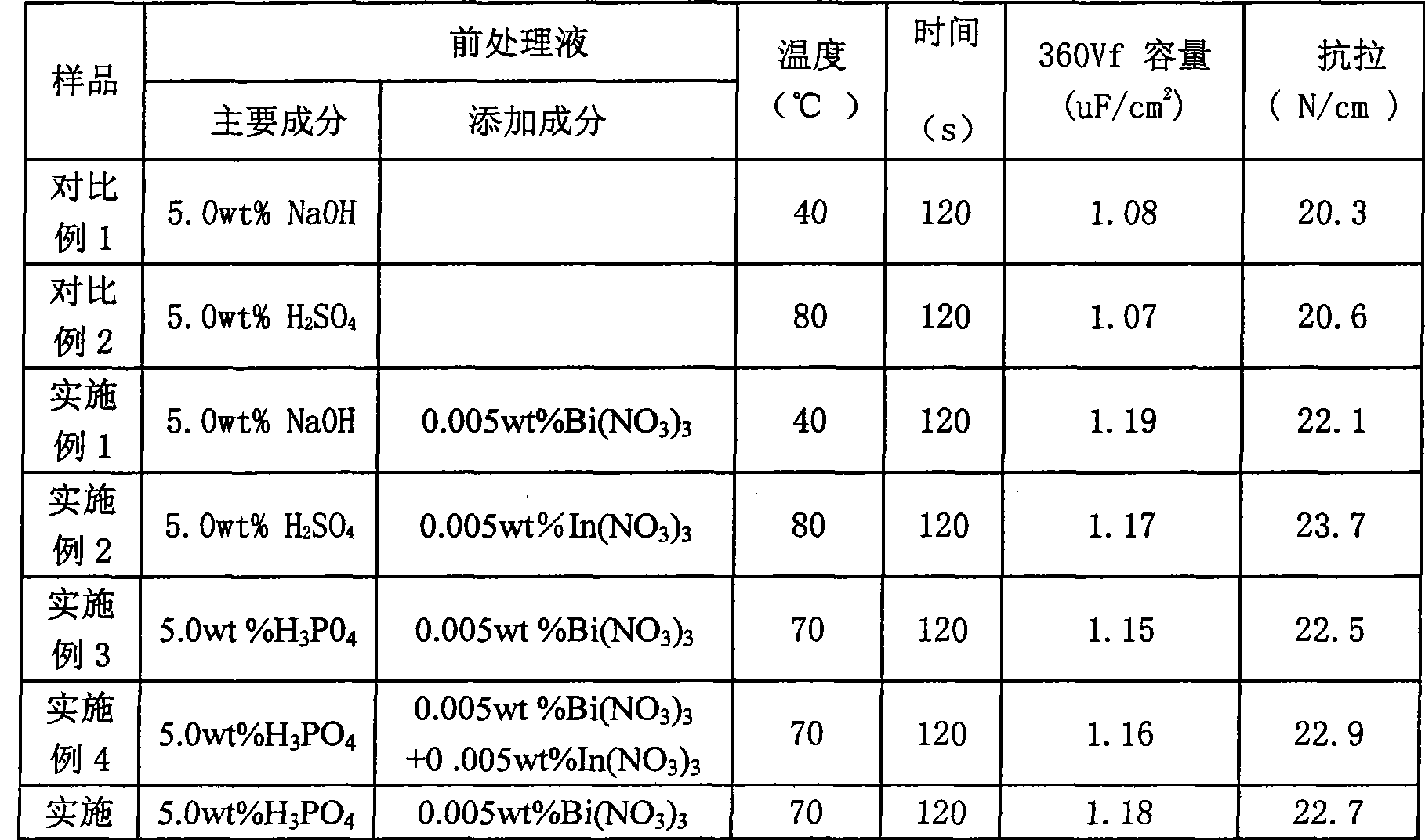

Anode aluminium foil etching process for electrolytic capacitor

InactiveCN1458658AImprove corrosion expansion rateImprove specific capacitanceElectrolytic capacitorsCapacitor manufactureCapacitanceElectrolysis

The etching process of anode aluminum foil for electrolytic capacitor includes one pre-treatment step. The pretreating solution is solution of alkali, acid or their mixture with Zn and / or Pb compound in 0.0001-1.0 wt% added. Aluminum foil is soaked in the pretreating solution for 10-300 sec, and owing to the separation of Zn and / or Pb, the aluminum foil surface becomes more easy in producing homogeneous spot etching in the fore etching process, and this results in raised area expanding rate, specific capacitance and tensile strength of the aluminum foil.

Owner:RUYUAN YAO AUTONOMOUS COUNTY DONGYANGGUANG FORMED FOIL CO LTD

One-dimensional MnO2@NiMoO4 core shell heterojunction composite material and preparation method and application thereof

ActiveCN105914051AEasy post-processingEasy to controlHybrid capacitor electrodesHybrid/EDL manufactureHeterojunctionCapacitance

The invention discloses a one-dimensional MnO2@NiMoO4 core shell heterojunction composite material and a preparation method and an application thereof. The preparation method comprises the steps of: 1) preparing a MnO2 nano-wire monomer; and 2) carrying out contact reaction on urea, soluble nickel salt, soluble molybdate and the MnO2 nano-wire monomer in water so as to prepare the one-dimensional MnO2@NiMoO4 core shell heterojunction composite material. By adopting the method, the MnO2@NiMoO4 composite material with good specific capacitance and circulation stability is obtained, the composite material is capable of serving as an electrode material of an electrochemical capacitor, and the preparation method is simple to operate, low in cost, mild in condition, and green and environmental-friendly.

Owner:ANHUI NORMAL UNIV

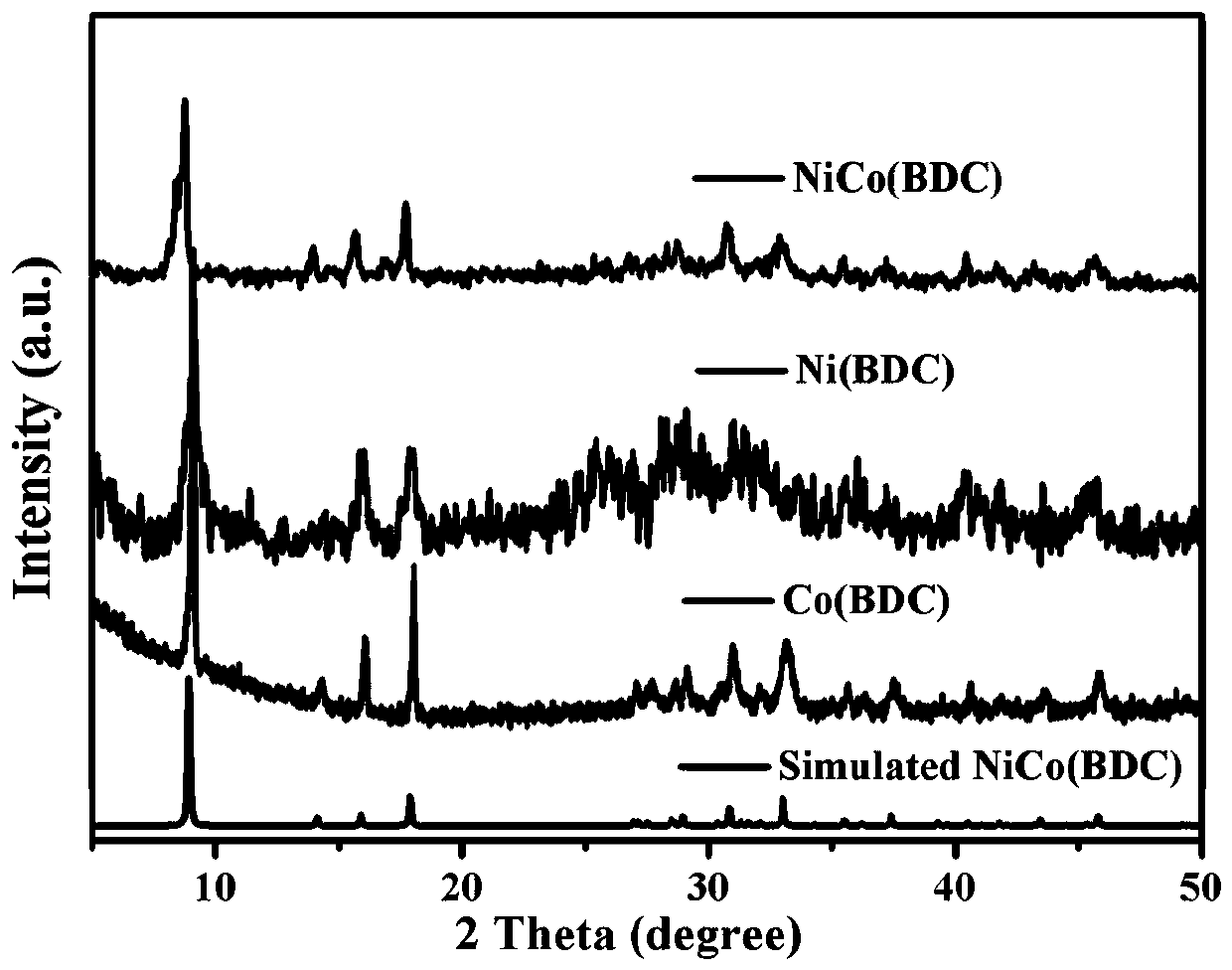

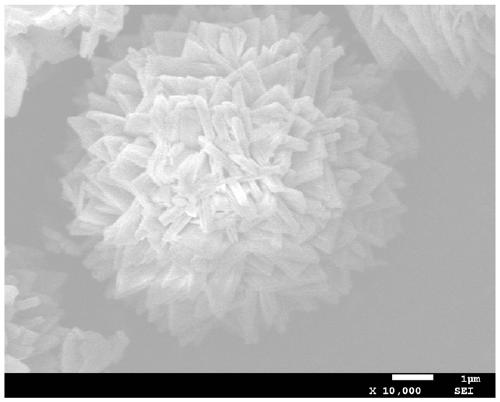

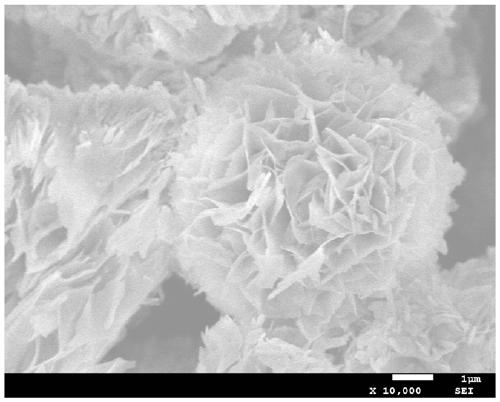

A preparing method and application of a three-dimensional nanoflower metal-organic framework material

ActiveCN109553779AThe synthesis method is simpleLow priceHybrid capacitor electrodesHybrid/EDL manufactureMetal-organic frameworkTerephthalic acid

The invention belongs to a metal-organic framework material, and discloses a composite nanometer metal-organic framework material which has a spherical three-dimensional nanoflower structure and whichis formed by self-assembling of metal ions and an organic component, and application of the material in super-capacitor performance. A one-step synthesis technique is adopted, and self-assembling ofa terephthalic acid organic ligand, cobalt chloride and nickel chloride in a mixture solution consisting of N,N-dimethyl formamide, ethanol and water is utilized to obtain the metal-organic frameworkspherical nanoflower structure with uniform distribution dimension and size and with a diameter of 7-12 [mu]m. Similar nanometer materials can be synthesized by the method. In addition, the metal-organic framework material has a high number of active sites and has good electrical conductivity, so that the metal-organic framework material has good super-capacitor performance.

Owner:CHINA THREE GORGES UNIV

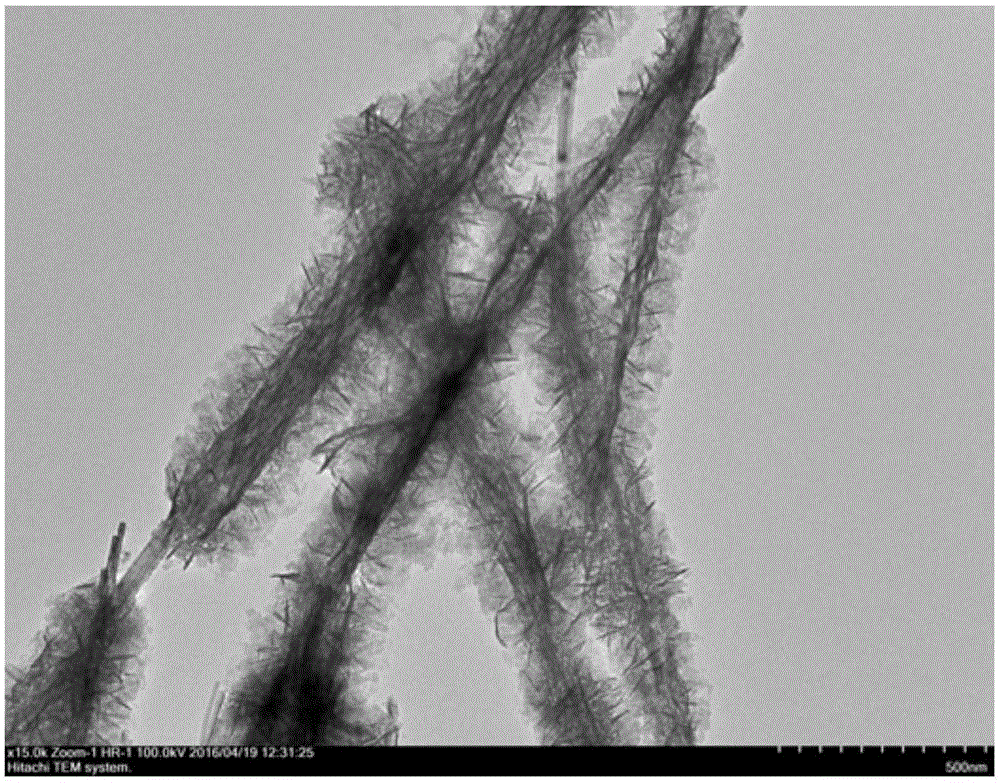

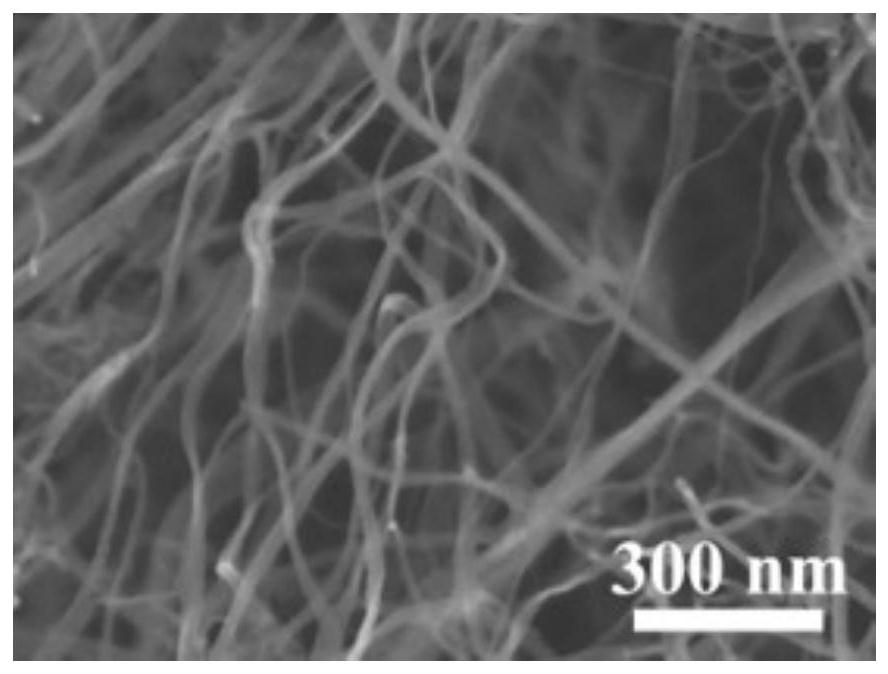

Carbon nanotube/carbon fiber composite material and carbon-base/manganese oxide composite electrode material

InactiveCN105513829AGood flexibilityHigh tensile strengthHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceFiber

The invention relates to a carbon nanotube / carbon fiber composite material and a carbon-base / manganese oxide composite electrode material and belongs to the technical field of electronic functional materials. The carbon nanotube / carbon fiber composite material is a membrane material prepared from carbon nanotubes and conductive carbon fiber by vacuum filtration and has the advantages of good flexibility, good tensile strength, good conductivity, good chemical stability and the like. The above carbon nanotube / carbon fiber composite material is used as a current collector and a reduced graphene oxide / manganese oxide material, a carbon nanotube / manganese oxide composite and a graphene oxide / carbon nanotube / manganese oxide composite material are used as active materials, preparing the carbon-base / manganese oxide composite electrode material. The active materials of the carbon-base / manganese oxide composite electrode material adsorb to the surface of the current collector, giving good strength of flexibility; the advantages such as high specific capacitance and high conductivity are retained, and the defect that a traditional capacitor is poor in flexibility is improved.

Owner:UNIV OF JINAN

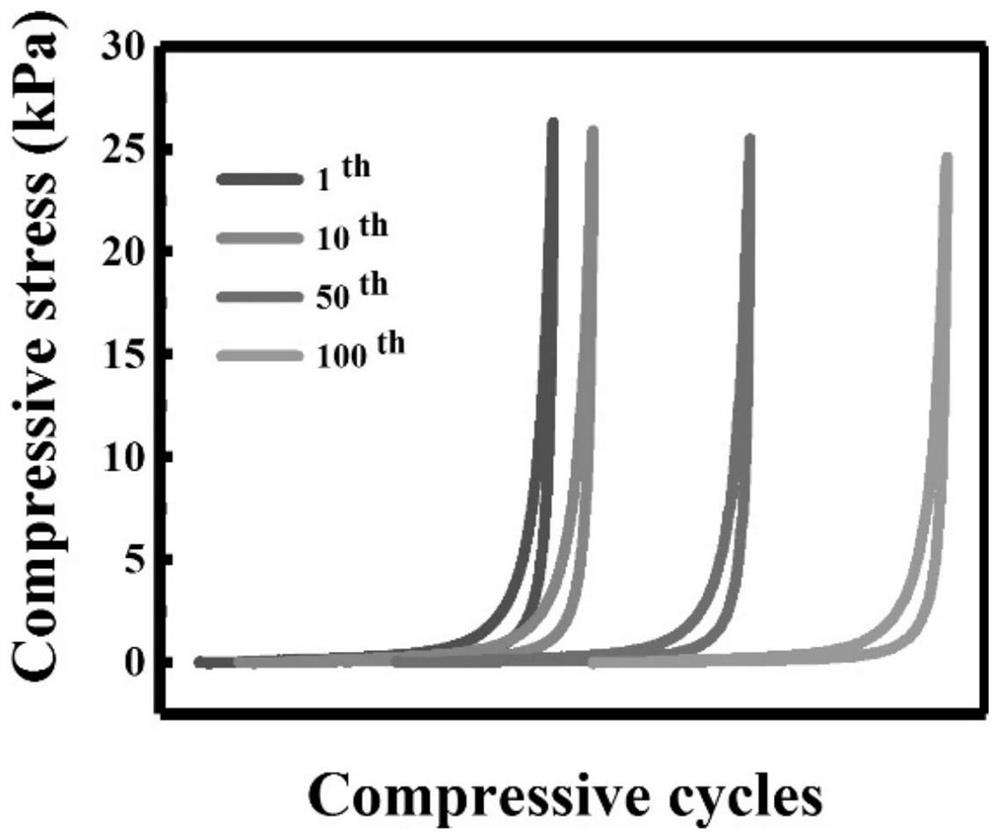

Porous nickel-based carbon fiber composite material and preparation method and purpose thereof

ActiveCN105047420ALarge specific surface areaExcellent specific capacitanceHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceMetal

The invention provides a porous nickel-based carbon fiber material and a preparation method and purpose thereof. The composite material structurally comprises a carbon fiber cloth layer, a porous nano nickel metal film layer and a nickel hydroxide layer from inside to outside successively. A nano nickel metal film is deposited on a carbon fiber cloth substrate, the nano nickel metal film is converted into a porous nano nickel metal film, nickel at the surface layer of the porous nano nickel metal film is oxidized to nickel hydroxide, and thus, the porous nickel-based carbon fiber material is obtained. The material is characterized by being light and flexible and large is the specific surface area, can be used as electrode material of a super capacitor, has obvious characteristic of fake capacitance, is high in capacity and stability, can be applied to the field of energy storage, and is wide in application prospects.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

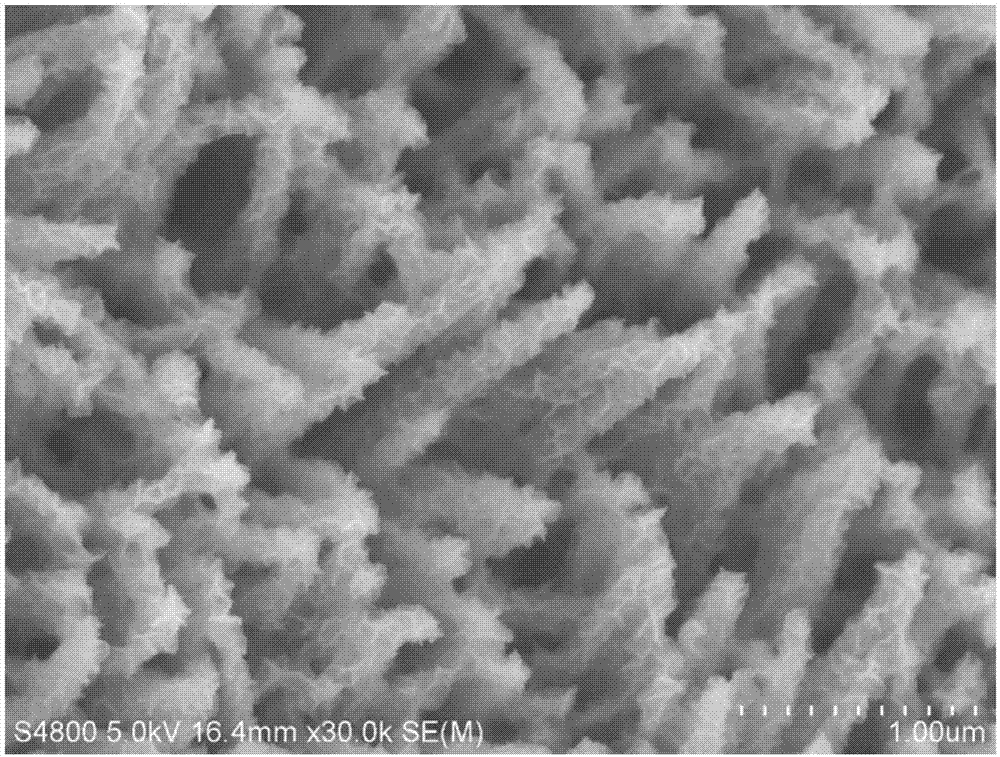

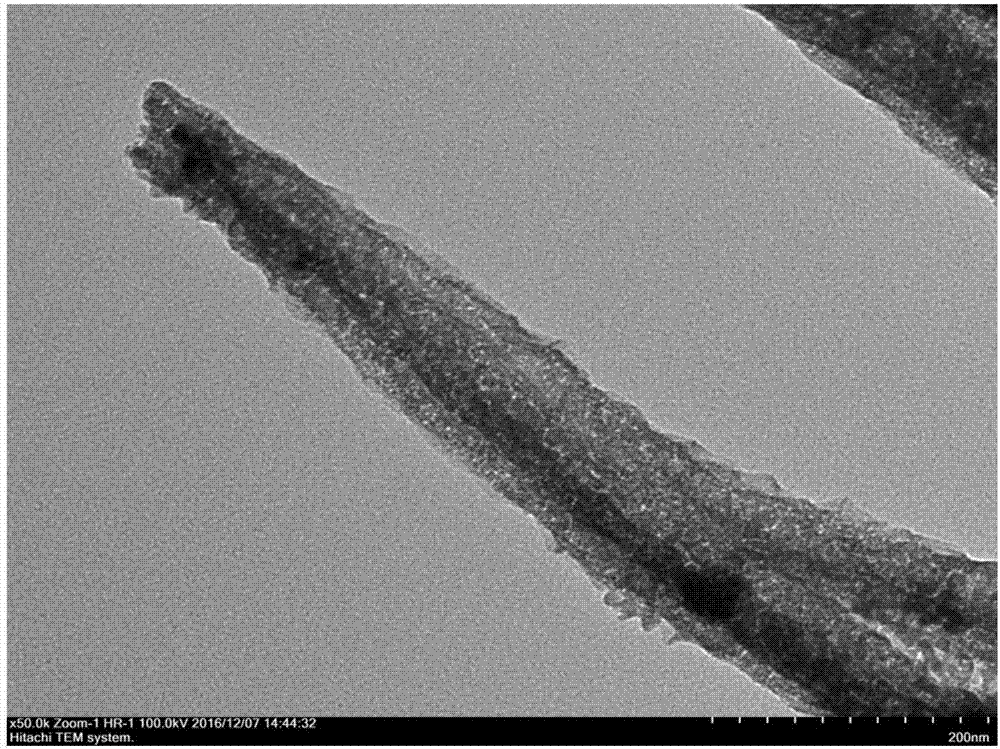

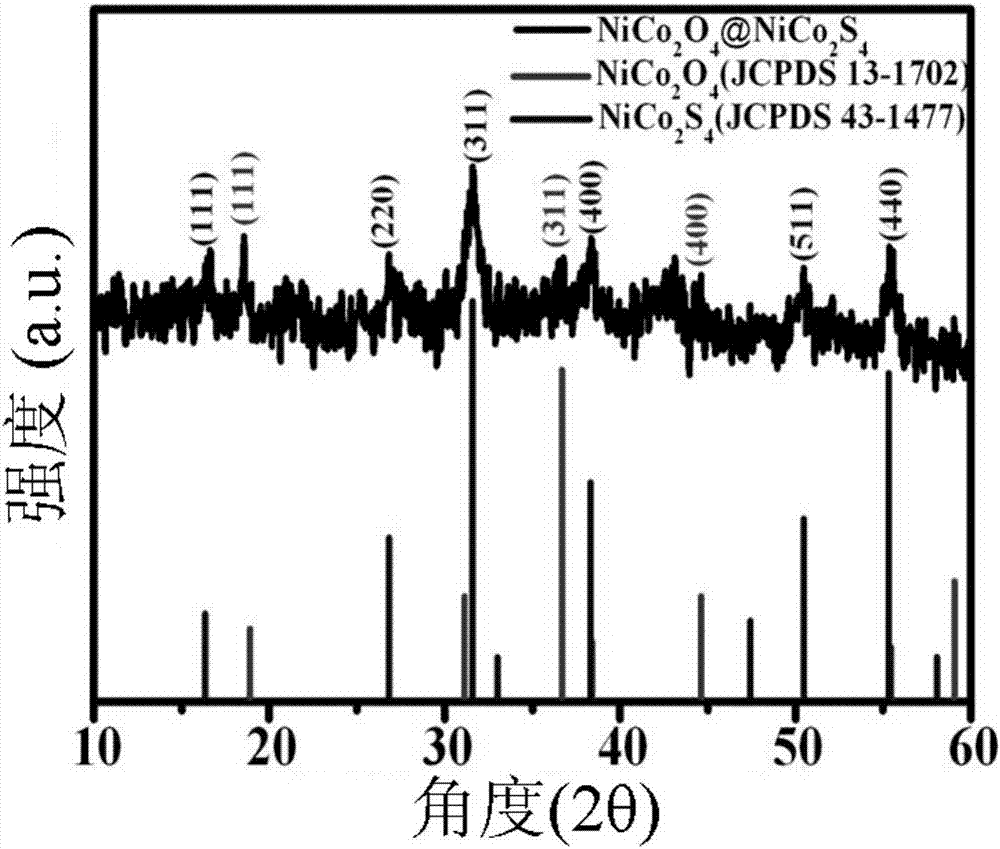

NiCo2O4@NiCo2S4 core-shell nanowire array composite material and preparation method and application thereof

InactiveCN107275123AIncrease capacitanceExcellent specific capacitanceMaterial nanotechnologyHybrid capacitor electrodesCapacitanceNickel salt

The invention discloses a NiCo2O4@NiCo2S4 core-shell nanowire array composite material and a preparation method and application thereof. The preparation method comprises the steps of 1) subjecting a nickel foam to acidification; 2) placing the acidized nickel foam in a closed reaction solution for hydrothermal reaction, conducting washing and drying to obtain a Ni-Co composite precursor, and then washing, drying and calcining the Ni-Co composite precursor to obtain a NiCo2O4 nanowire array material; 3) subjecting the NiCo2O4 nanowire array material, sulfide and water to vulcanization reaction, washing and drying the reaction product to obtain a NiCo2O4@NiCo2S4 core-shell nanowire array composite material, wherein, the reaction solution contains nickel salt, cobalt salt, ammonium salt, urea and water. The NiCo2O4@NiCo2S4 core-shell nanowire array prepared by the method has excellent capacitance, specific capacitance and stability.

Owner:ANHUI NORMAL UNIV

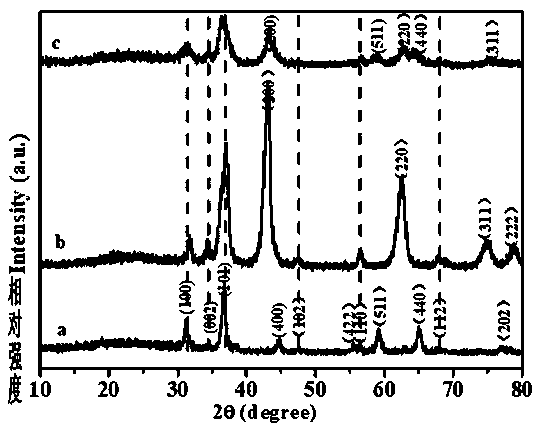

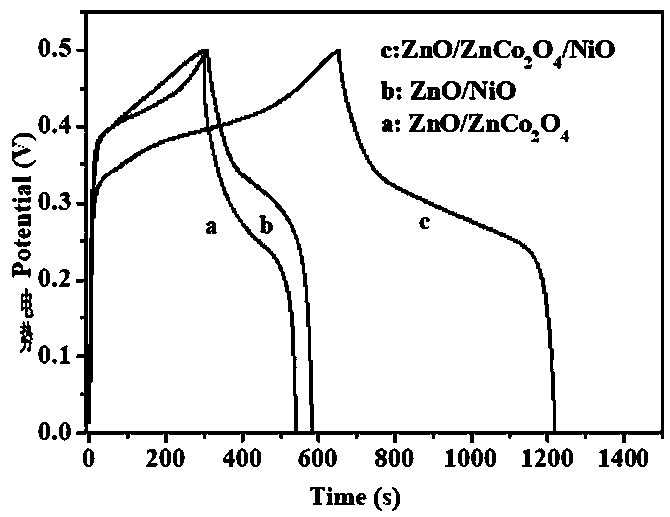

Method for synthesizing ZIF-8-based ternary composite ZnO/ZnCo2O4/NiO by solvothermal process and application of method

ActiveCN108806998AUniform particle distributionGood particle size dispersionHybrid capacitor electrodesSolventChemistry

The invention belongs to the technical field of metal organic framework materials, and relates to a method for preparing a ternary composite material by using zeolitic imidazolate frameworks as a template, in particular to a method for synthesizing a ZIF-8-based ternary composite ZnO / ZnCo2O4 / NiO by a solvothermal process and application of the method. The method disclosed by the invention comprises: dispersing per 290 mg of ZIF-8 polyhedron in 30-90 mL of ethanol containing 0.6-1.4 mmol of nickel nitrate, 0.6-1.4 mmol of cobalt nitrate and 421 mg of hexamethylenetetramine, stirring and mixinguniformly, transferring to a reaction kettle, heating at 100 DEG C to 120 DEG C for 2-4 h, cooling to room temperature, collecting by centrifugation and drying at 60 DEG C to 80 DEG C for 12-24 h to obtain a precursor, and annealing the precursor in the air at 300-350 DEG C by rate of 2 DEG C.min<-1> for 2-3 h, so the ternary composite ZnO / ZnCo2O4 / NiO is obtained. The prepared ZIF-8-based ternarycomposite ZnO / ZnCo2O4 / NiO has uniform particle distribution and good particle size dispersion, and has excellent electrochemical performance and good cycling stability when being used as an electrodematerial of a supercapacitor. The method has the advantages of simple process, low preparation cost and less pollution, and is suitable for industrial production.

Owner:JIANGSU UNIV

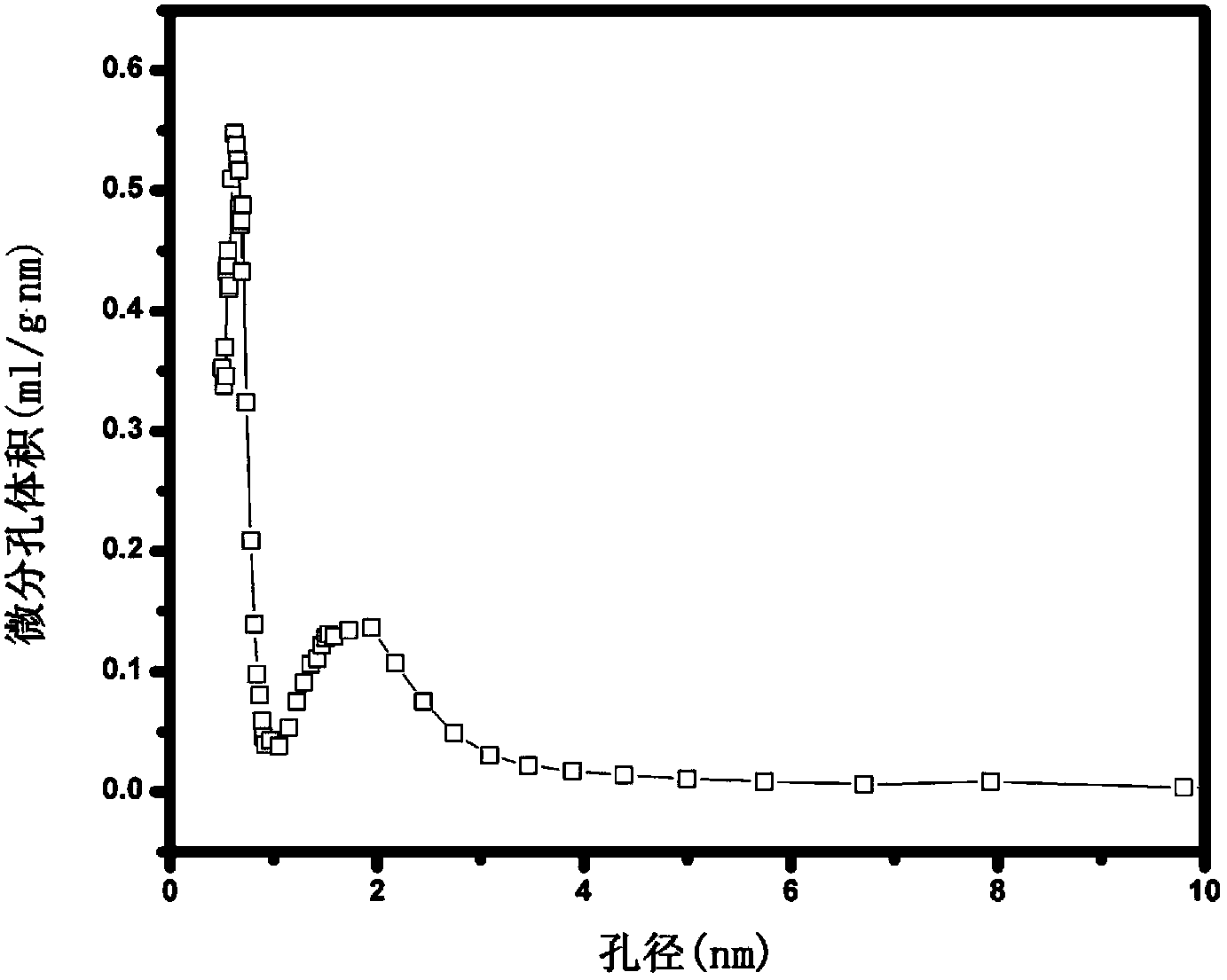

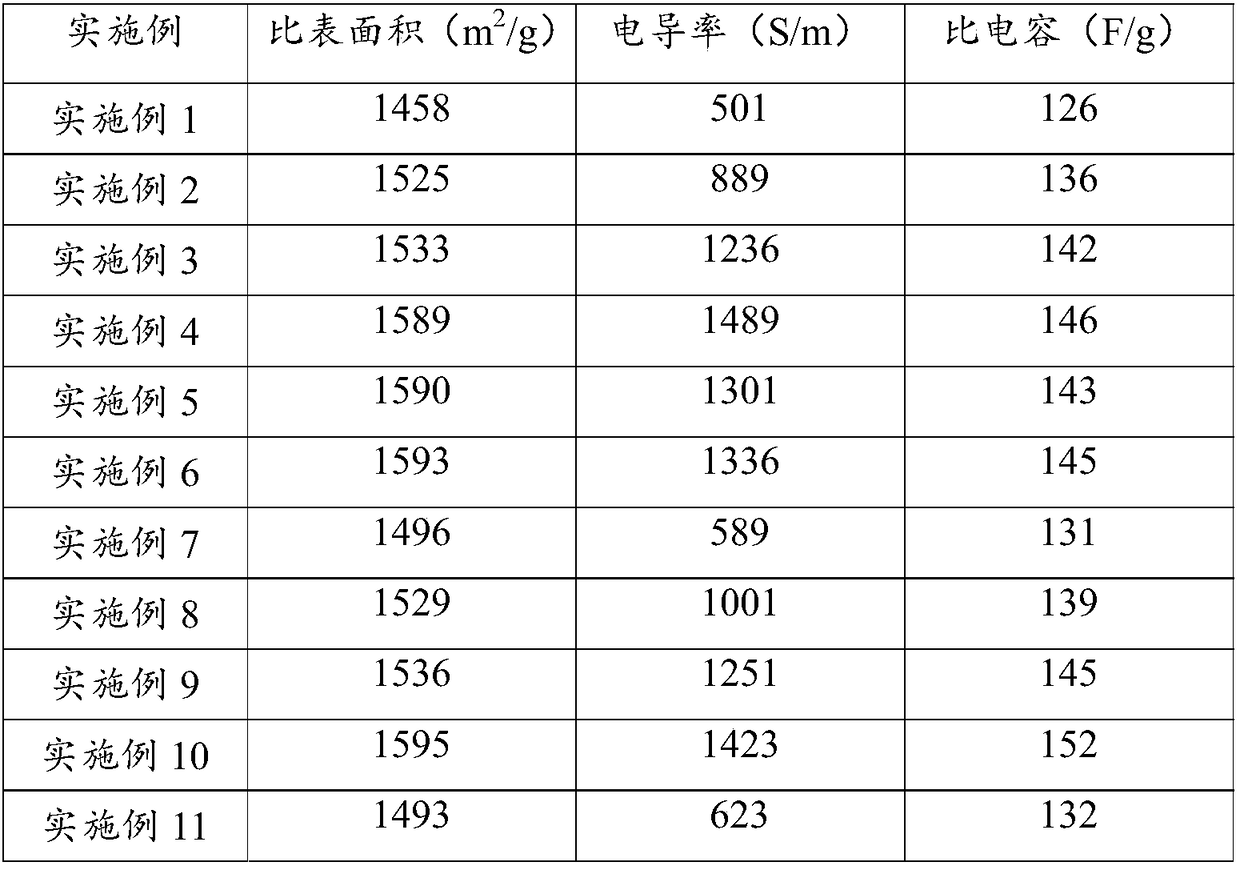

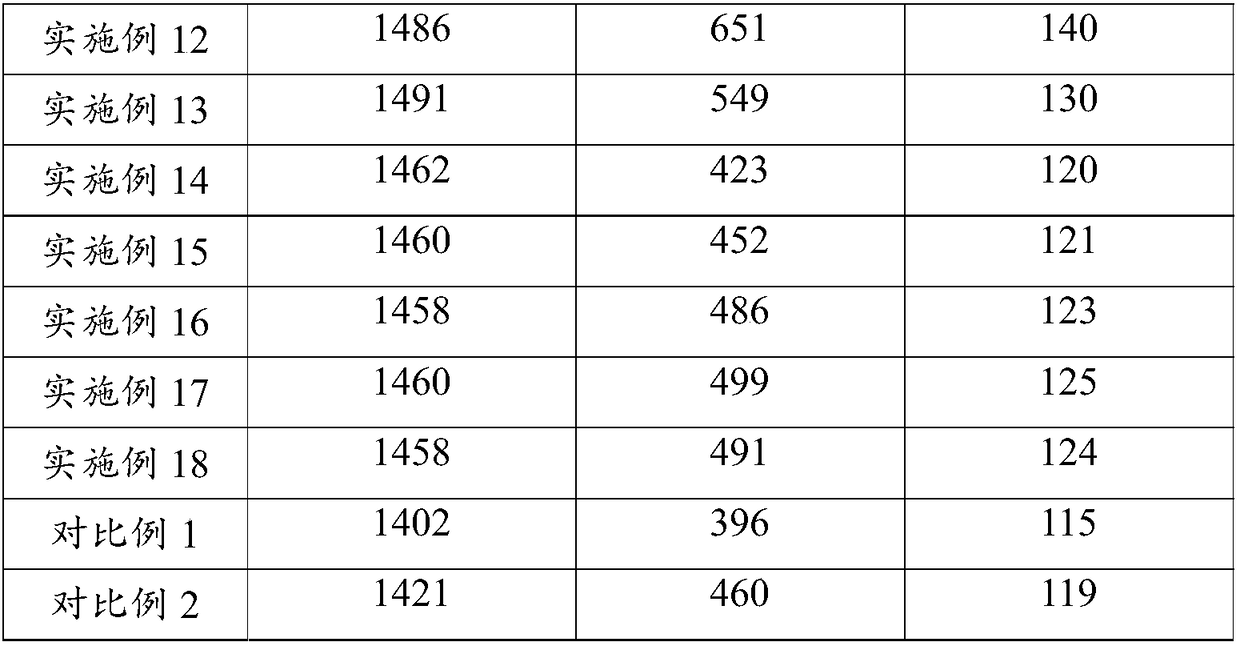

Composite porous carbon material and preparation method and application thereof

InactiveCN108217648AIncrease the amount addedAvoid reunionCell electrodesSingle layer grapheneCvd grapheneCapacitance

The invention provides a composite porous carbon material and a preparation method and application thereof. The preparation method for the composite porous carbon material is characterized in that carbonized materials and graphene materials are adopted as raw materials, a composite carbon material is prepared through hydrothermal reaction, and the composite porous carbon material is obtained through activation and aftertreatment. By use of the method, the additive amount of the graphene materials can be effectively improved, the agglomeration of the graphene materials is avoided, the advantages of the graphene materials are fully performed, the specific surface area, the specific capacitance and the conduction performance of the composite porous carbon material can be effectively improved,and the overall performance of the composite porous carbon material can be improved. In addition, the preparation method for the composite porous carbon material has the advantages of simple technology and light pollution and conforms to the requirement of green development. The composite porous carbon material has the advantages of high specific surface area, high specific capacitance, good conduction performance and excellent overall performance and can be used for preparing electronic elements.

Owner:山东省圣泉生物质石墨烯研究院

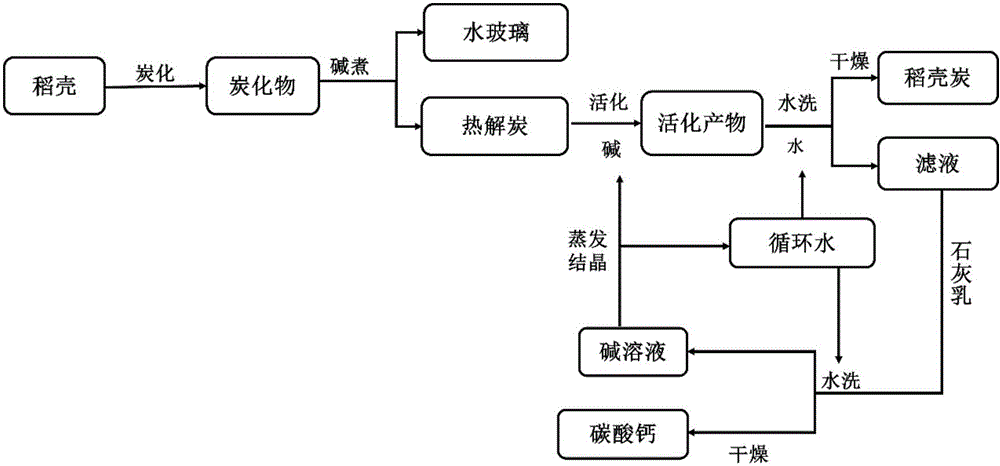

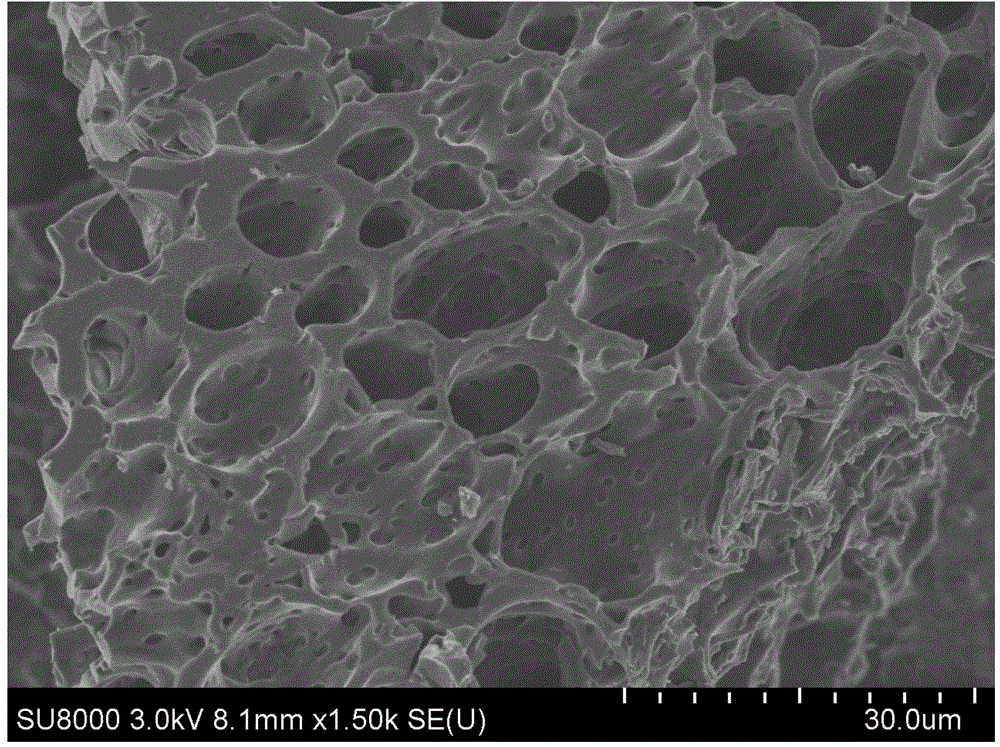

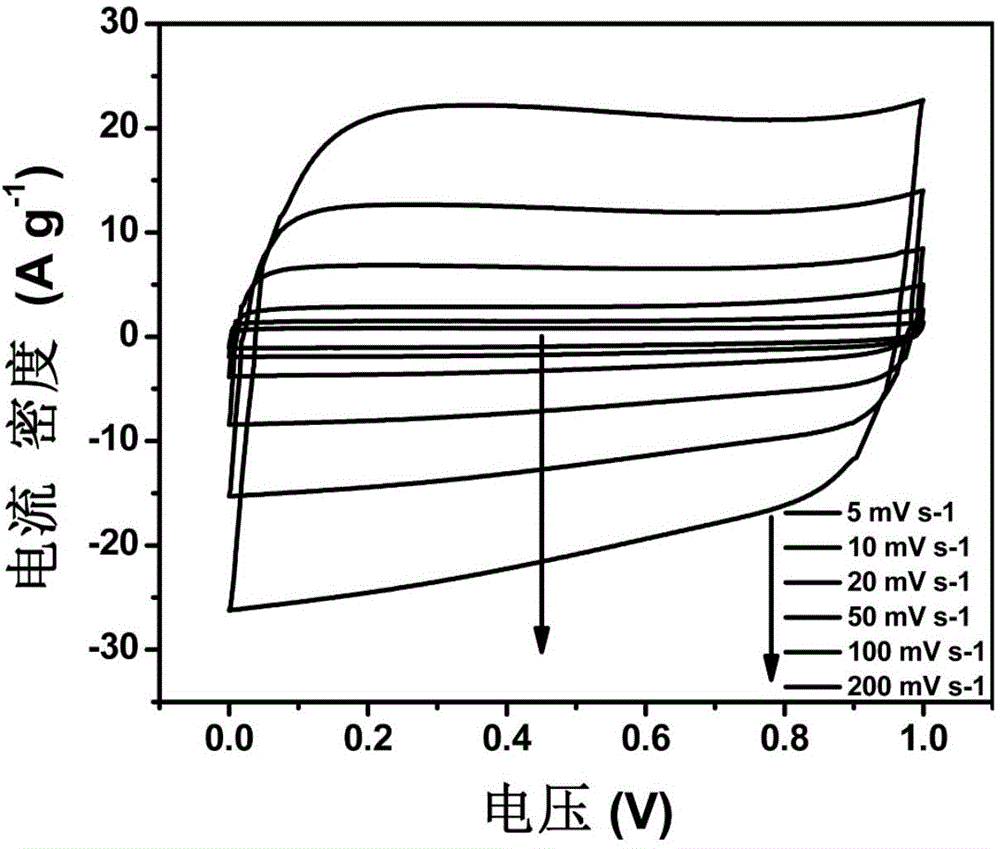

Environment-friendly preparation method for rice-hull-based capacitor carbon material with hierarchical porous structure

The invention aims to provide an environment-friendly preparation method for a rice-hull-based capacitor carbon material with a hierarchical porous structure. The traditional carbonization and activation processes are combined with a template method according to the unique structure of cheap rice hull, the carbon material with the hierarchical porous structure is prepared by taking silica in the rice hull as a template through carbonizing, soda boiling and activating, waste liquid generated in the preparation process is converted into high-modulus water glass and an alkali activating agent, and meanwhile water is recycled. The method has the characteristics of simplicity in operation, low cost, environmental friendliness and the like. By using the method, the problem of environmental pollution caused in the rice hull utilization process is solved, and the production cost is greatly reduced; and the method is beneficial to industrial popularization and application.

Owner:旗禾科技(吉林)有限责任公司

Cobalt selenide nanometer material serving as electrode material of supercapacitor and preparation method of cobalt selenide nanometer material

InactiveCN106098393ALarge specific surface areaImprove space utilizationHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceNanowire

The invention discloses a Co<0.85>Se nanometer material serving as an electrode material of a supercapacitor and a preparation method of the Co<0.85>Se nanometer material. The nanometer material adopts a fibrous nanometer structure. The Co<0.85>Se nanometer material adopts a two-step hydrothermal synthesis method, and the two-step hydrothermal synthesis method comprises the steps of firstly, preparing a precursor Co(OH)(CO<3>)<0.5> nanowire by a hydrothermal reaction method; and secondly, carrying out selenization processing on the precursor by the hydrothermal reaction method to obtain the Co<0.85>Se nanometer material. When placed in a three-electrode system for test, the nanometer electrode material is endowed with high specific capacity of 1,249F / g under current density of 2A / g, the specific volume over 80% still can be maintained after 3,000 cycles of charging and discharging under 100mA current, and the charge transfer impedance is 0.32 ohm / cm<2>. The Co<0.85>Se nanometer electrode material prepared according to the method has the advantages of high specific capacitance, good cycle performance, simplicity in preparation method and low cost.

Owner:ZHEJIANG UNIV

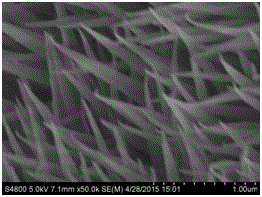

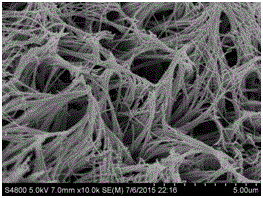

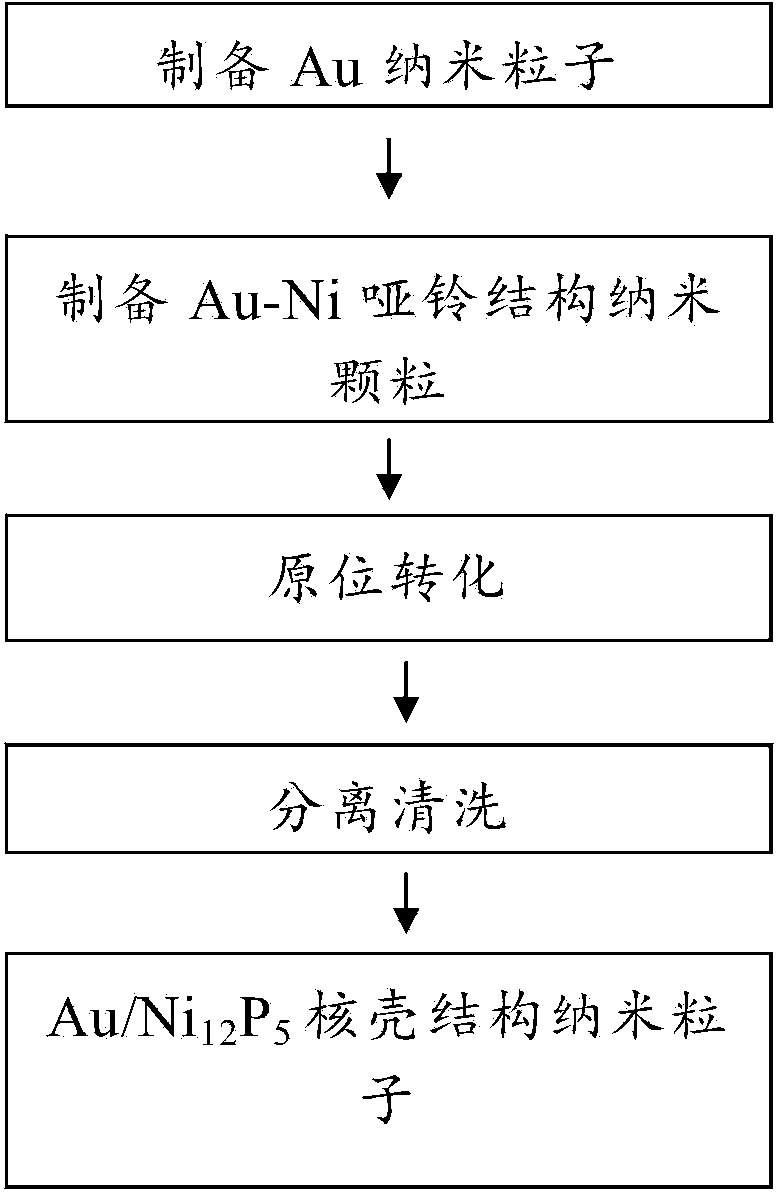

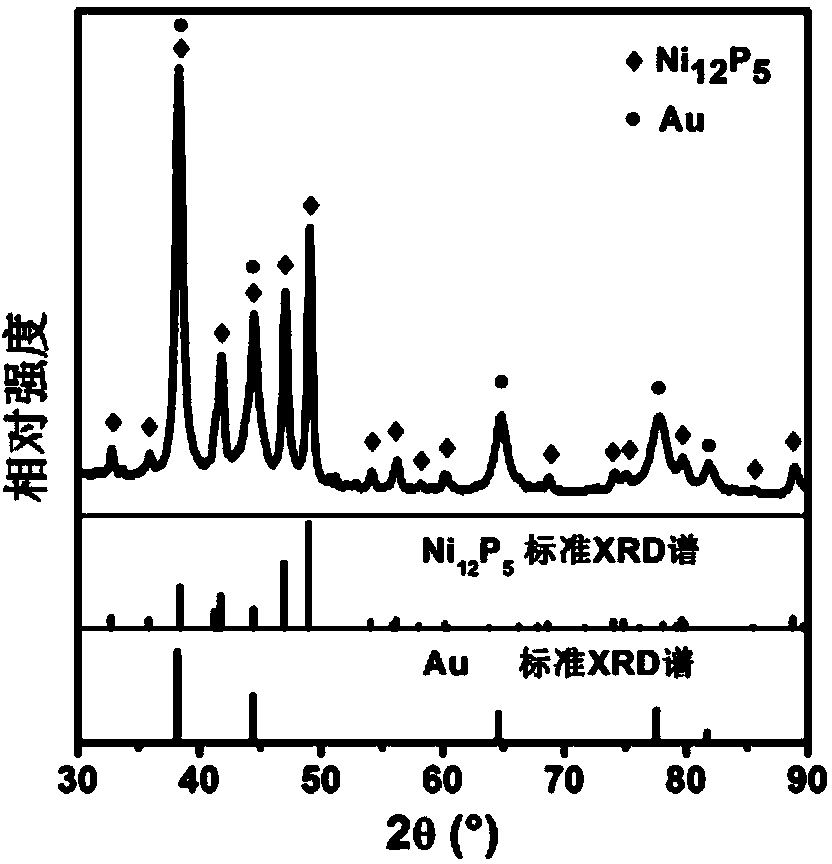

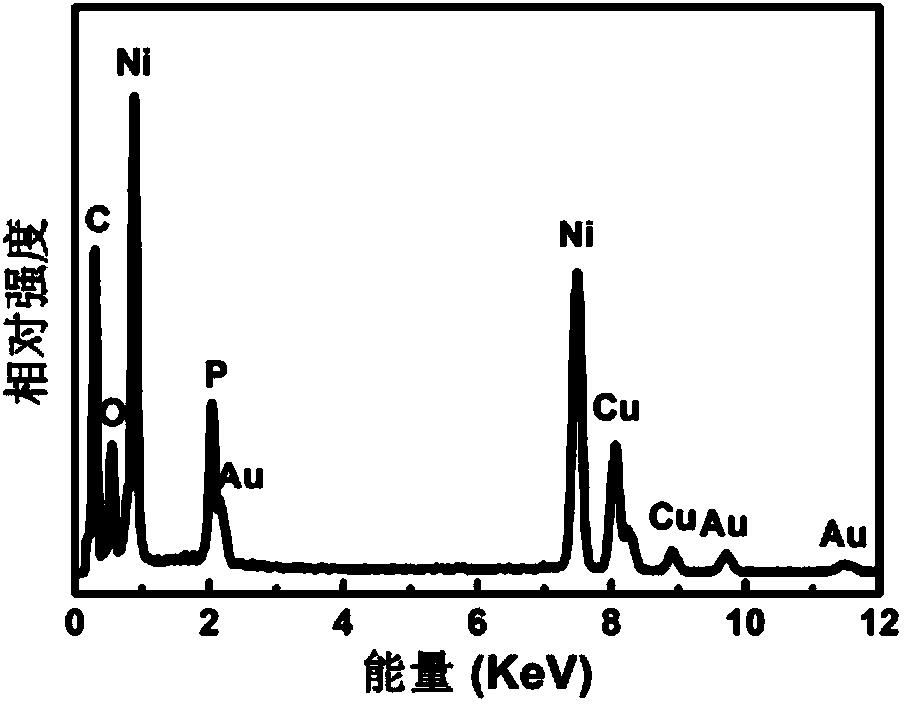

Nano particle of Au/Ni12P5 nuclear shell structure and preparation method thereof

InactiveCN104190921AImprove performanceGood lookingMaterial nanotechnologyHybrid capacitor electrodesCapacitancePtru catalyst

The invention discloses a nano particle of an Au / Ni12P5 nuclear shell structure. The nano particle is composed of a face-centered cubic phase Au shell and a body-centered tetragonal phase Ni12P5 shell layer, and the Ni12P5 shell layer is of a single-crystal structure. A preparation method of the nano particle is a method of in-situ transformation combined with recrystallization and comprises the steps that an Au-Ni dumbbell structure which is synthetized in advance is used as a precursor body, triphenylphosphine is added, and the Au-Ni dumbbell structure is converted into an Au-Ni12P5 nuclear shell structure in an in-situ mode. The method provides a way capable of effectively preparing a novel metal-semiconductor nuclear shell structure nano material with a single crystal semiconductor shell layer, operation is easy, and product homogeneity is good. The obtained nano particle of the Au / Ni12P5 nuclear shell structure has very good stability and physical physicochemical property, the excellent capacitive performance can provide a good foundation in application of electrochemistry energy storage devices with high energy density and high charge and discharge stability, and the nano particle can be widely applied to the fields of supercapacitors, catalysts and the like.

Owner:UNIV OF SCI & TECH BEIJING

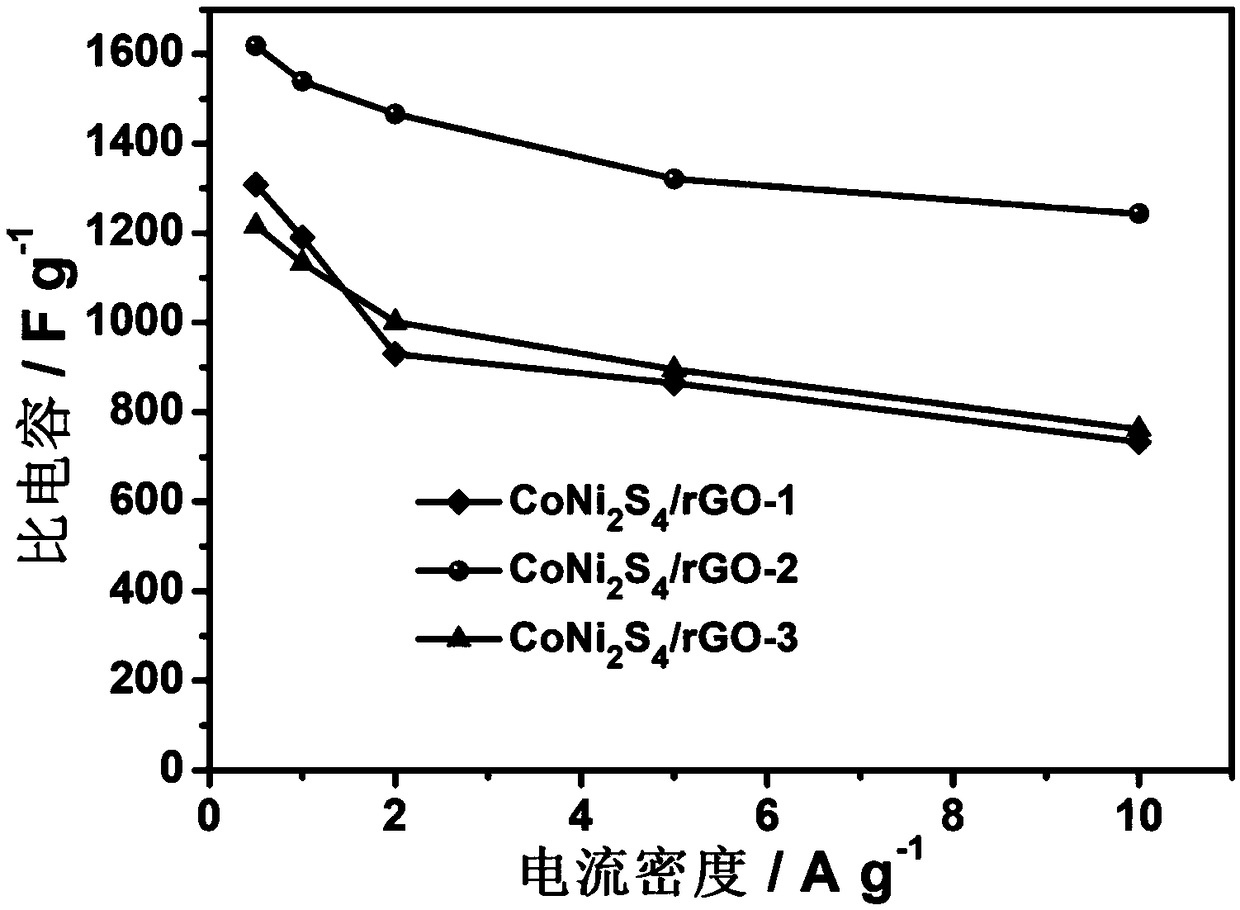

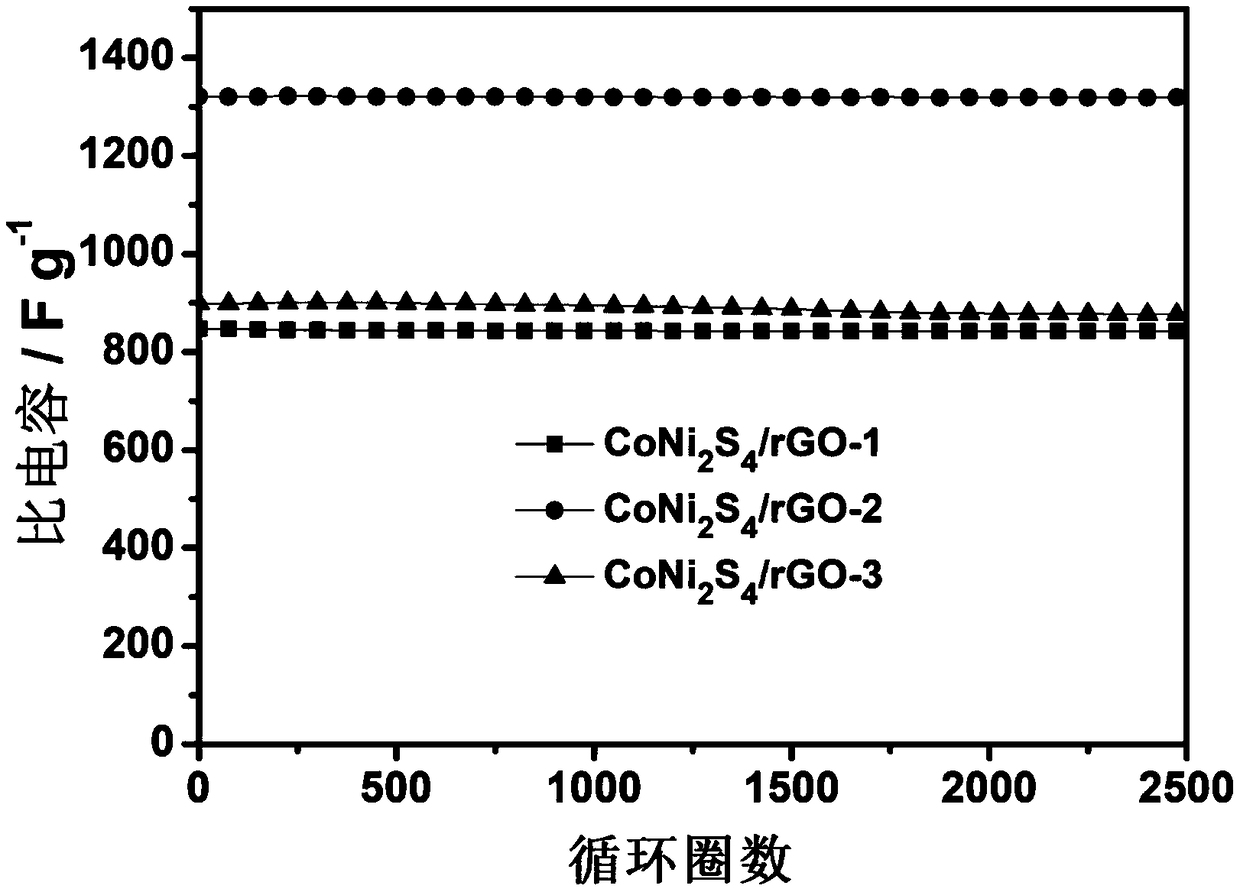

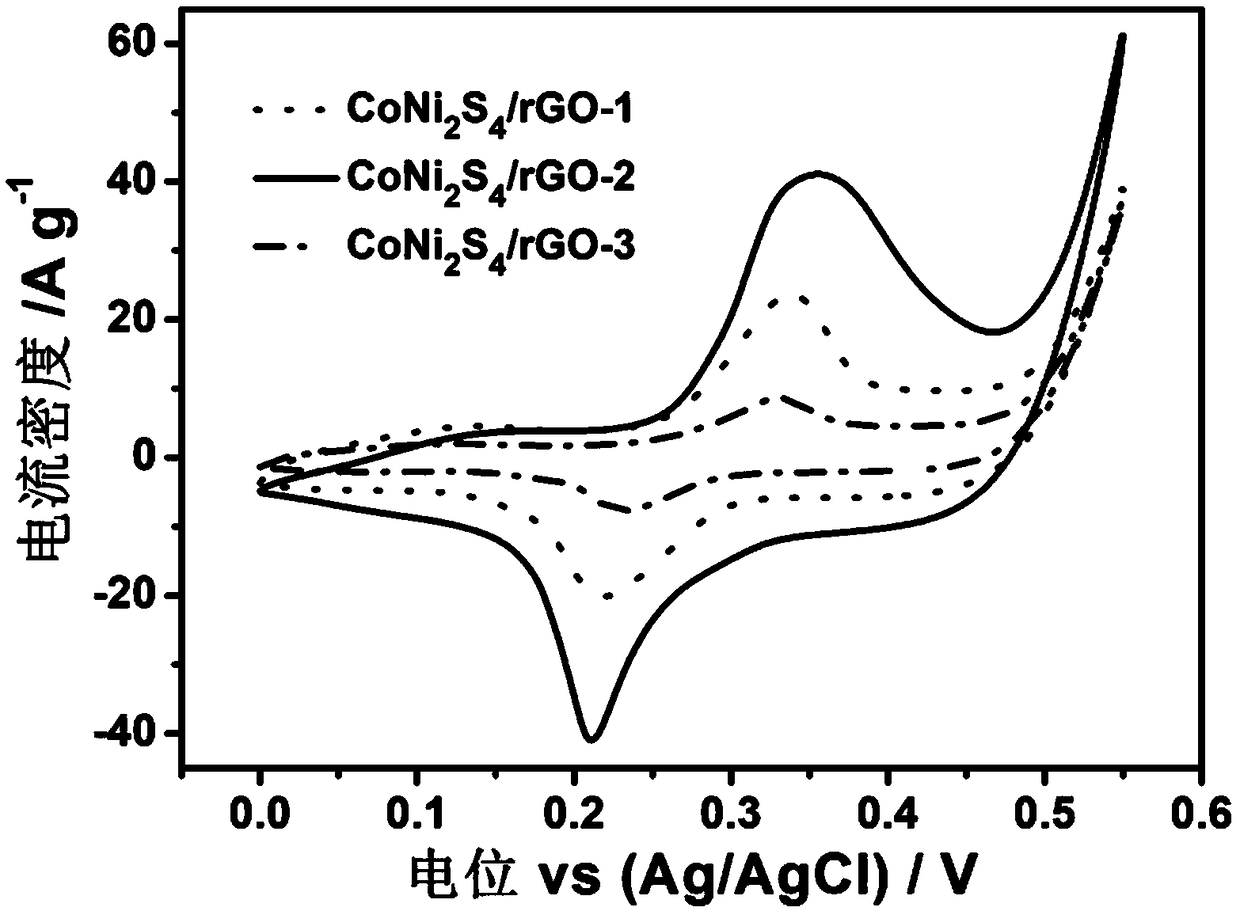

CoNi2S4/graphene composite material for supercapacitor and preparation method thereof

InactiveCN108878167AImprove the phenomenon of easy reunionHigh specific capacitance performanceMaterial nanotechnologyHybrid capacitor electrodesCapacitanceFiltration

The invention discloses a CoNi2S4 / graphene composite material for a supercapacitor and a preparation method thereof. The preparation method comprises the following specific steps that Co(NO3)2.6H2O, Ni(NO3)2.6H2O and thioacetamide CH3CSNH2 are firstly mixed in ethyl alcohol, then graphene oxide GO is added to a ethanol solution for even ultrasonic dispersion, then the ethanol solution is transferred to a hydrothermal reactor for solvothermal reaction, filtration, washing, lyophilization are performed after the reaction is completed, and the CoNi2S4 / graphene composite material for the supercapacitor is obtained. The CoNi2S4 / graphene composite material is good in cycling stability, after circulation is performed for 5000 times, the capacity retention ratio is 87.4%, the maximum high-energy density is 39.56W h.kg<-1>, and the power density is 374.8W h.kg<-1>. By controlling the quality of graphene, the CoNi2S4 / graphene composite material for the supercapacitor and the preparation method thereof can prepare supercapacitor electrode materials, and has advantages of higher capacitance, better cycle performance, environmental protection and the like.

Owner:SHANGHAI INST OF TECH

Preparation method of bacterial cellulose-based carbon aerogel

ActiveCN112110435ASolve the situation of uneven dispersionGood dispersionHybrid capacitor electrodesCarbon preparation/purificationFreeze-dryingSodium hydroxide

The invention belongs to the technical field of biological nano materials, and particularly relates to a preparation method of bacterial cellulose-based carbon aerogel and application of the bacterialcellulose-based carbon aerogel in a supercapacitor. The preparation method of the bacterial cellulose-based carbon aerogel comprises the following steps: (1) dissolving tetramethylpiperidine oxide and sodium bromide in water, and conducting stirring to obtain a mixed solution; (2) adding a bacterial cellulose dispersion liquid into the mixed solution, then adding a sodium hypochlorite aqueous solution and hydrochloric acid for reaction, adding a sodium hydroxide aqueous solution in the reaction process to obtain a reaction product, and cleaning the reaction product with water; (3) adding a mixed solution of water and tert-butyl alcohol, and conducting stirring to form uniform hydrogel; and (4) freeze-drying the hydrogel, and conducting carbonizing to obtain the bacterial cellulose-based carbon aerogel. According to the method disclosed by the invention, the dispersity of the bacterial cellulose can be improved, and the structural stability of the bacterial cellulose is enhanced, so that the carbon aerogel with high mechanical strength and high flexibility is prepared, and an electrode material with excellent electrical properties is provided for a supercapacitor.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

Hollow porous carbon ball electrode material for supercapacitors and method for preparing hollow porous carbon ball electrode material

InactiveCN106986324AExcellent specific capacitanceHigh specific capacitanceMaterial nanotechnologyHybrid capacitor electrodesPolyvinylidene fluorideCurrent collector

The invention discloses a hollow porous carbon ball electrode material for supercapacitors and a method for preparing the hollow porous carbon ball electrode material, and belongs to the technical field of new energy. Hollow MIL-100 (Fe) nanometer materials for the hollow porous carbon ball electrode material are prepared by the aid of layer-by-layer assembly processes, are used as precursors and are subjected to heat treatment and hydrofluoric acid treatment in inert atmosphere to obtain hollow porous carbon balls. The hollow porous carbon ball electrode material, acetylene black and polyvinylidene fluoride are mixed with one another to obtain mixtures when electrodes of the supercapacitors are about to be prepared, and the mixtures are smeared on stainless steel current collectors to obtain working electrodes. The hollow porous carbon ball electrode material and the method have the advantages that the hollow porous carbon ball electrode material for the supercapacitors is high in specific capacitance and electrochemical stability and wide in test electric potential window as compared with single components, is long in service cycle life and is environmentally friendly; the working electrodes are easy to prepare and excellent in electrochemical performance and have broad application prospects.

Owner:江苏海能动力科技有限公司

Preparation method for cobalt sulfide/carbon composite material and product and application therefor

ActiveCN105719846AOvercome conductivityOvercoming the low specific capacitanceHybrid capacitor electrodesHybrid/EDL manufactureCarbon compositesReaction temperature

The invention provides a preparation method for a cobalt sulfide / carbon composite material and a product and an application therefor. The preparation method comprises the following steps of: S1, enabling a soluble cobalt salt to be mixed with carbon disulfide (CS<2>) to obtain a uniform solution, wherein the ratio of the amount of substance of the soluble cobalt salt to carbon disulfide (CS<2>) is 1:1-1.5; S2, moving the solution obtained in the step S1 to a reaction kettle to be subjected to a solvothermal reaction, wherein the conditions of the solvothermal reaction are as follows: the reaction temperature is 180-220 DEG C and the reaction time is 20-24h; and S3, separating the mixture obtained in the step S2, collecting a solid product, and washing and drying the solid product to obtain the cobalt sulfide / carbon composite material. According to the preparation method, carbon disulfide is skillfully taken as the raw material; the carbon disulfide can be used as the solvent, the sulfur source and the carbon source in the solvothermal reaction; the preparation method is simple, easy to operate and low in equipment requirement; and in addition, the cobalt sulfide / carbon composite material has relatively high specific capacitance and cycling stability and low capacitance degradation.

Owner:LINGNAN NORMAL UNIV

Method for preparing cobaltous selenide super-capacitor material through chemical vapor deposition method

InactiveCN105957723ALarge specific surface areaIncrease contact spaceHybrid capacitor electrodesChemical vapor deposition coatingCapacitanceCobalt

The invention discloses a method for preparing a Co0.85Se super-capacitor material through a chemical vapor deposition method, wherein the Co0.85Se super-capacitor material is a nano film-shaped structure covering a nickel mesh. The specific growth process comprises the following steps: 1), grinding and mixing selenium powder and cobalt powder, putting the mixture of selenium powder and cobalt powder into a quartz boat, and putting the quartz boat into a chemical vapor deposition reacting furnace quartz tube; 2), enabling a foamed nickel mesh to be placed at a position, close to the mouth of the quartz tube, of a downstream side of an air flow; 3), letting in argon gas, exhausting the air in the furnace, stopping the supply of the gas, carrying out heating for some time, and then letting a certain amount of argon gas in the quartz tube for heat preservation, and finally cooling the furnace to the room temperature naturally; 4), taking out foamed nickel, repeatedly washing the foamed nickel through deionized water and ethyl alcohol, drying the foamed nickel, and obtaining the material. The method is simple in operation and does not need complex equipment, and the Co0.85Se uniformly covers the nickel mesh. The material can be prepared in a large area. A composite Co0.85Se nano material electrode is tested in a three-electrode system, presents a high specific capacity of 4462F / g under the current density of 1A / g, and still can maintain 80% or more of the specific capacitance value after 5000-time circulating charging and discharging under a high current of 20A / g, wherein the charge transfer impedance is 0.82 ohm / cm<2>.

Owner:ZHEJIANG UNIV

CdS @ Ni3S2 core-shell heterostructure composite material, preparation method and application thereof

ActiveCN106449172AIncrease capacitanceExcellent specific capacitanceHybrid capacitor electrodesCell electrodesCapacitanceThiourea

The invention discloses a CdS @ Ni3S2 core-shell heterostructure composite material, a preparation method and an application thereof. The preparation method comprises the following steps of 1) placing foam nickel in an acid solution for acidizing; and 2) placing the acidized foam nickel in a closed reaction solution for a hydrothermal reaction, and then cleaning and drying so as to acquire a CdS @ Ni3S2 core-shell heterostructure composite material, wherein the reaction solution contains water, cadmium sulfide and thiourea. The CdS @ Ni3S2 core-shell heterostructure composite material prepared through the method possesses an excellent capacitance, a specific capacitance and stability and the CdS @ Ni3S2 core-shell heterostructure composite material can be used as an electrode material of a super capacitor or a lithium ion battery. Besides, operation of the preparation method is simple, a raw material is easy to get and cost is low.

Owner:ANHUI NORMAL UNIV

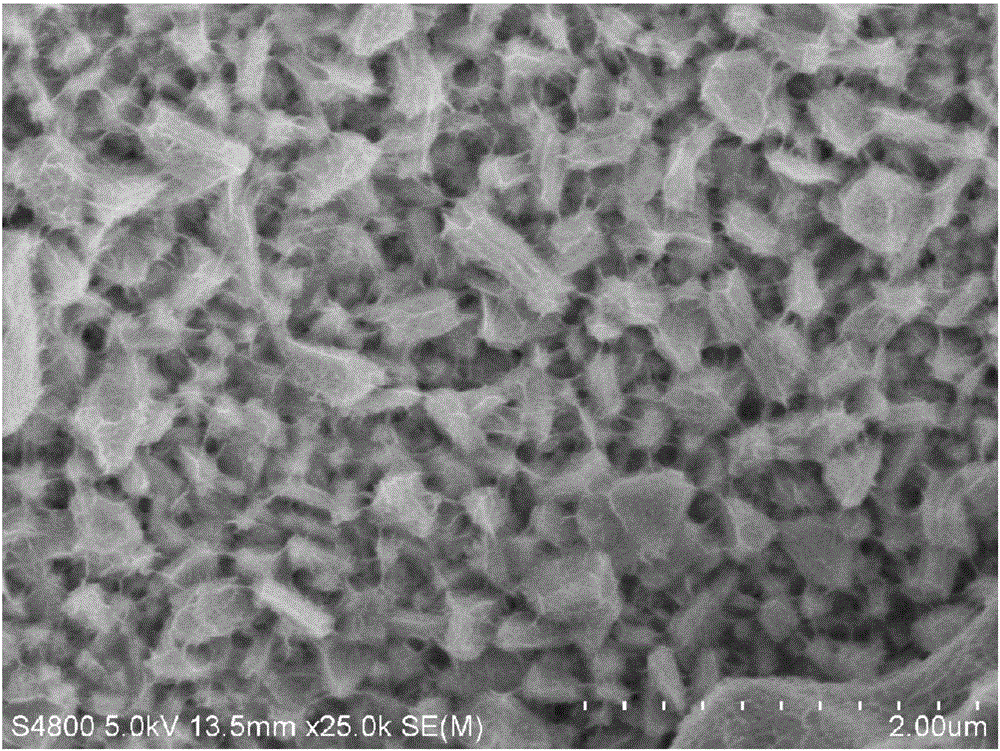

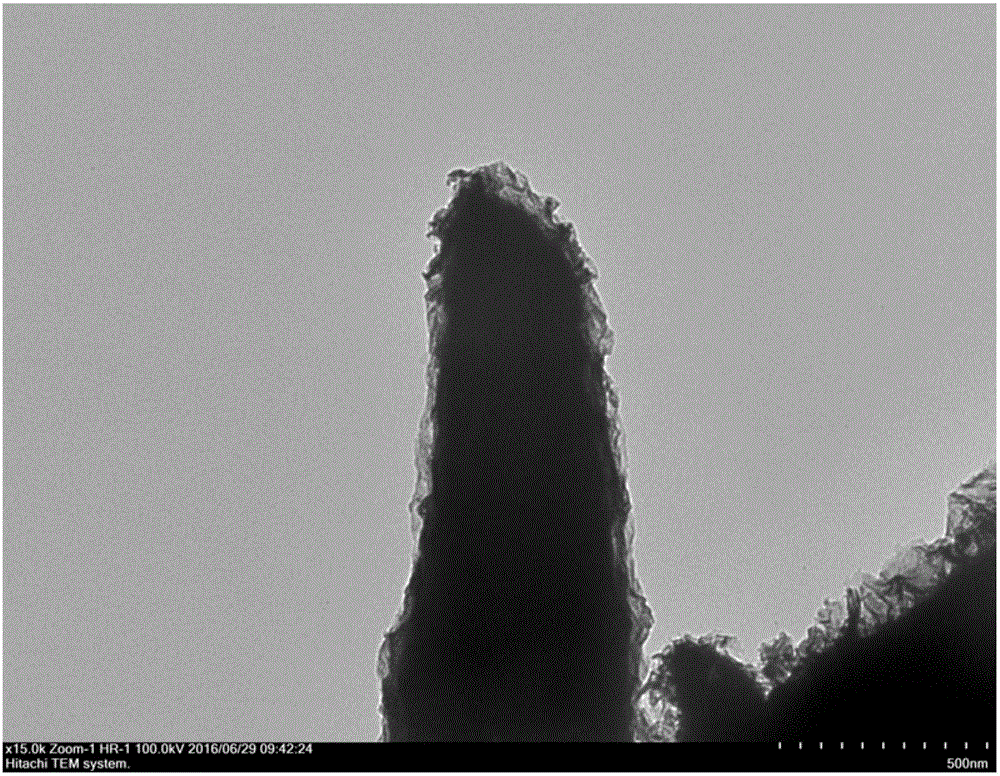

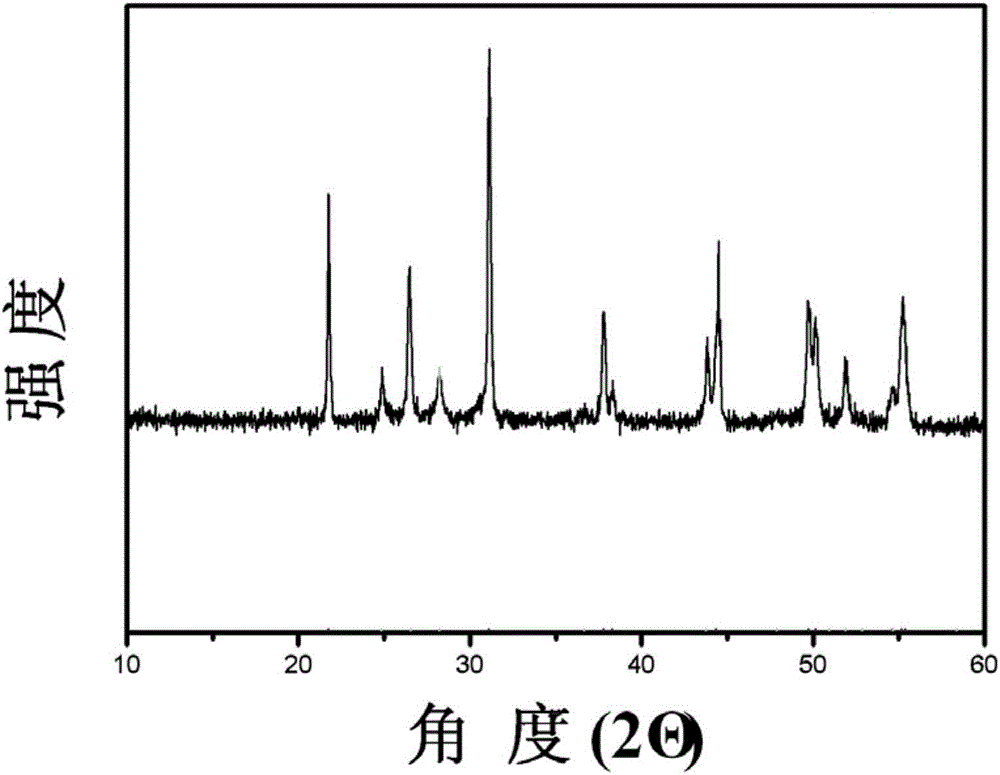

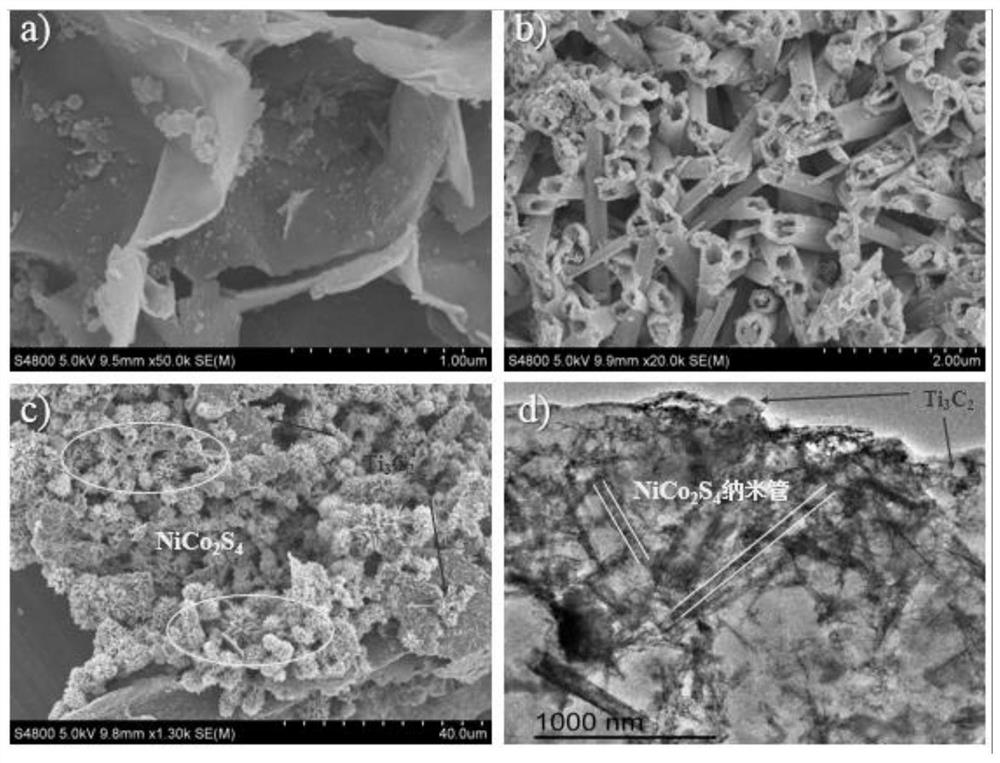

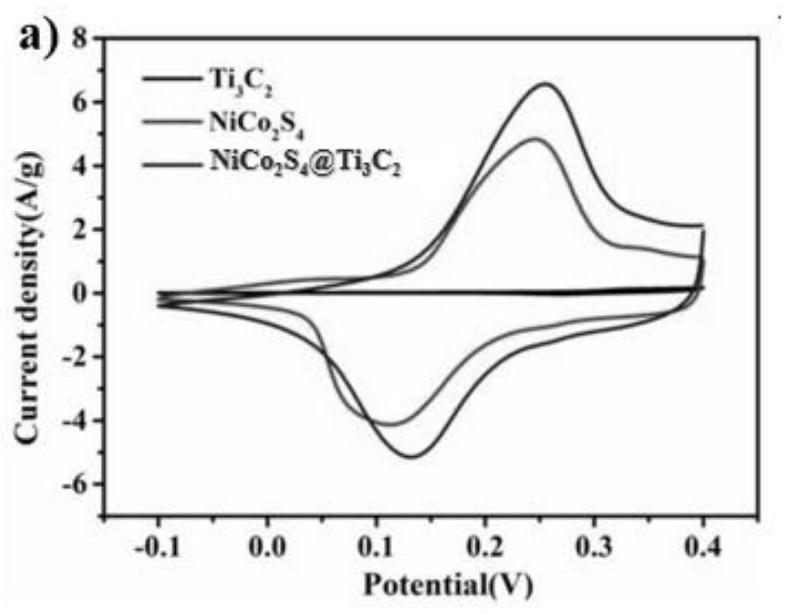

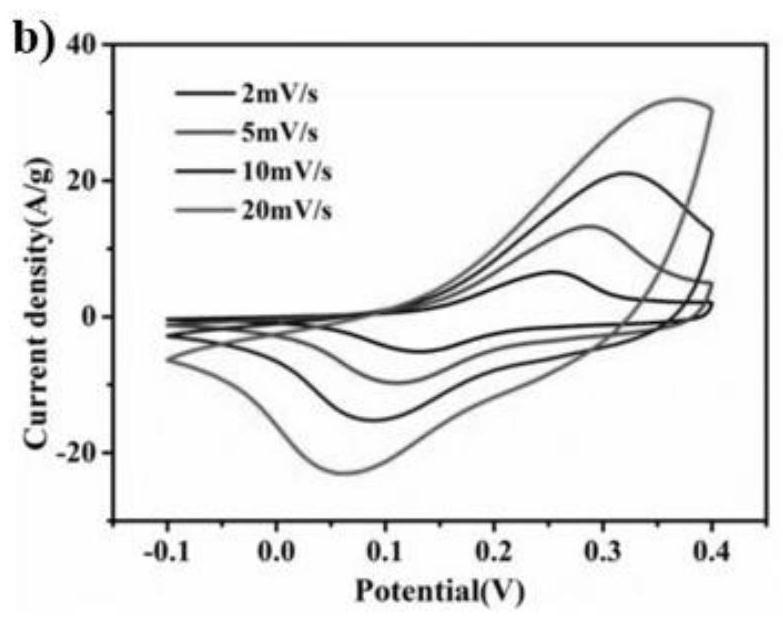

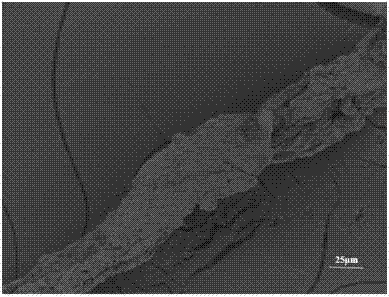

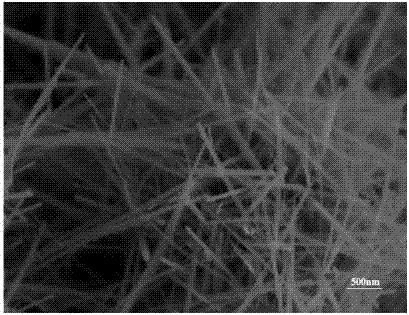

Nanotube NiCo2S4@titanium carbide composite material and preparation method and application thereof

InactiveCN111916288AImprove conductivityHigher theoretical specific capacitanceMaterial nanotechnologyHybrid capacitor electrodesCapacitanceTitanium carbide

The invention discloses a nano tubular NiCo2S4@titanium carbide composite material and a preparation method and application thereof. The nano material takes nickel chloride hexahydrate as a nickel source, takes cobalt chloride hexahydrate as a cobalt source, and employs a two-step hydrothermal method. The method comprises the steps: preparing a nano tubular precursor by a first hydrothermal method, wherein at the moment, the two materials are compounded together by the precursor; vulcanizing the precursor through secondary hydrothermal treatment, wherein the material compounds Ti3C2 of a single sheet layer with hollow tubular NiCo2S4 for the first time to prepare a NiCo2S4@titanium carbide composite material, and the NiCo2S4@titanium carbide composite material is applied to research of electrochemical performance of a supercapacitor, and loading modified Ti3C2 on a NiCo2S4 hollow tube to provide an additional electron transmission path, thereby improving the electron transmission efficiency. Experiments show that compared with a single electrode material, the NiCo2S4 and titanium carbide composite electrode material has more excellent specific capacitance and cycle performance.

Owner:SHAANXI UNIV OF SCI & TECH

Preparation method of MnO2/graphite fiber super capacitor electrode materials

InactiveCN106971860AFacilitated DiffusionPromote migrationHybrid capacitor electrodesHybrid/EDL manufactureMicro structureFiber

The invention discloses a preparation method of MnO2 / graphite fiber super capacitor electrode materials. The method comprises steps of carrying out reduction-oxidation on graphite to obtain graphite fibers; and wrapping and growing MnO2 nano lines on the surfaces of the graphite fibers. The micro-structure of the prepared MnO2 / graphite fiber super capacitor electrode material is MnO2 nano-line wrapped graphite fibers. The MnO2 nano lines are interlaced with each other to form many communicating space hole structures. Thus, a quite big specific surface area is achieved; the specific surface area and the space utilization rate of the electrode are effectively improved; and the specific capacitance, the rate performance and the electrochemical stability of the electrode materials are improved. The specific capacitance value of the prepared electrode material can reach 64.4-105.3F g<-1> in a three-electrode system test. The preparation method is advantaged by simplicity and low cost.

Owner:ZHEJIANG UNIV

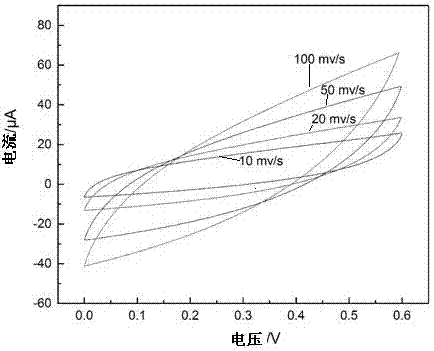

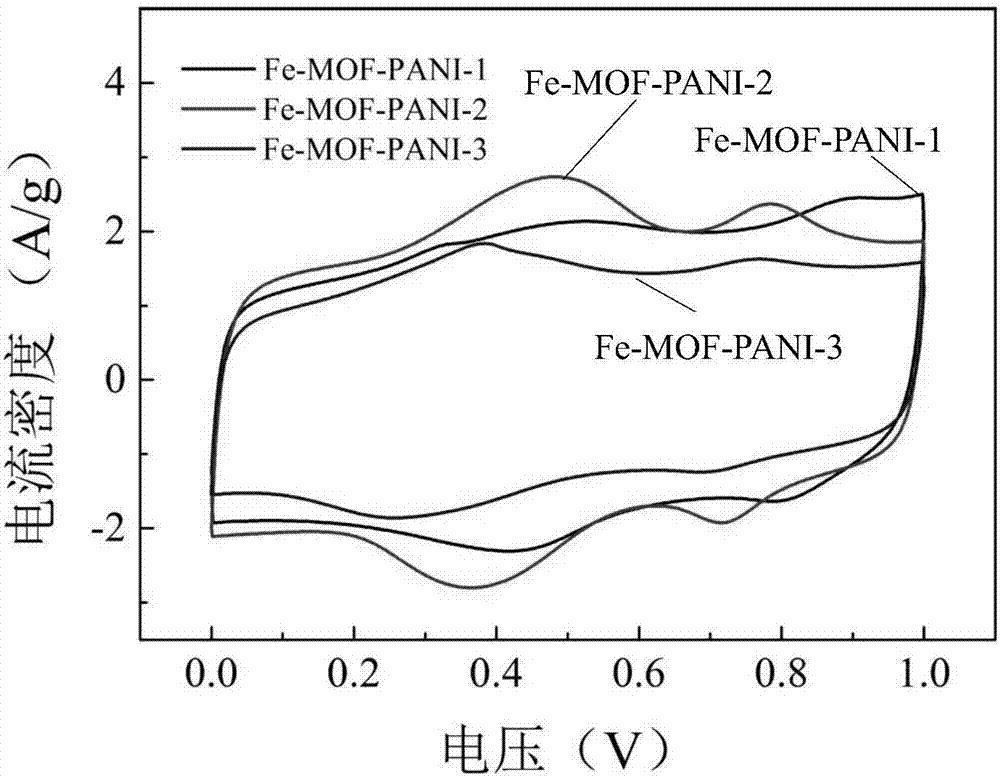

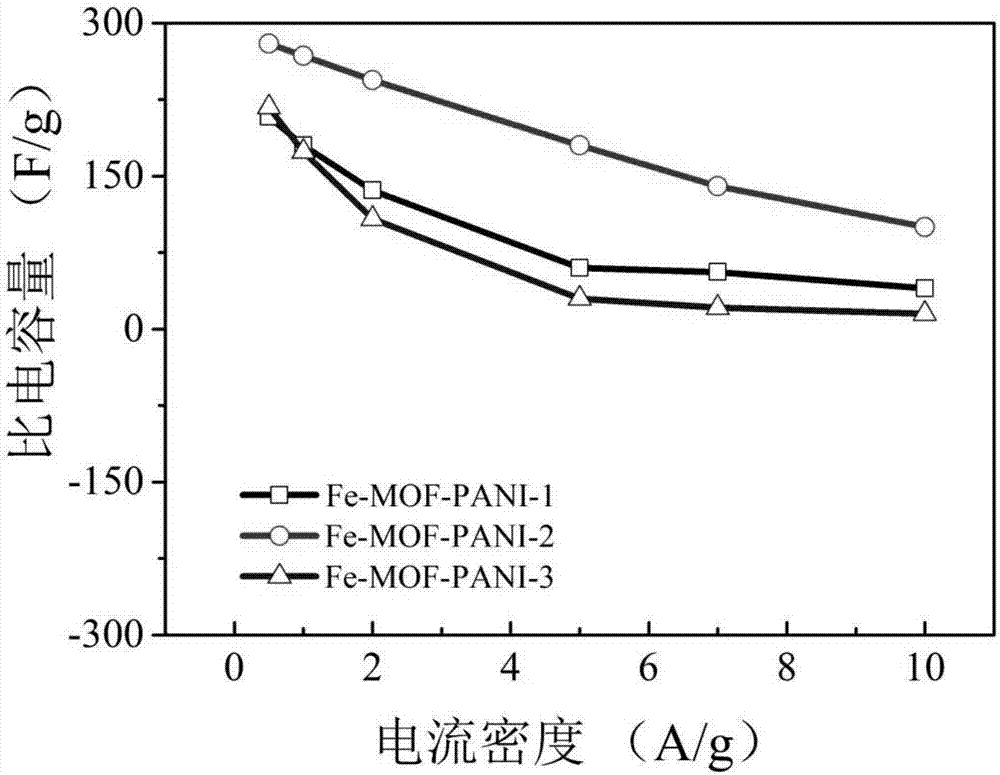

Fe-MOF-polyaniline composite material and preparation method and application thereof

InactiveCN107275110AEasy to prepareEasy to operateHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceAniline

The invention relates to a Fe-MOF-polyaniline composite material which includes a Fe-MOF monomer and an aniline monomer. Fe-MOF is used as a precursor, and aniline is adsorbed inside Fe-MOF. The Fe-MOF-polyaniline composite material is prepared by the steps of synthesizing a Fe-MOF precursor with terephthalic acid and ferric nitrate as raw materials and dissolving the Fe-MOF precursor in aniline solution for low-temperature polymerization reaction. The preparation method of the invention is simple, easy to operate, and environment-friendly. The Fe-MOF-polyaniline composite material prepared has good specific capacitance and rate performance, and is an ideal electrode material for super capacitors.

Owner:DONGHUA UNIV

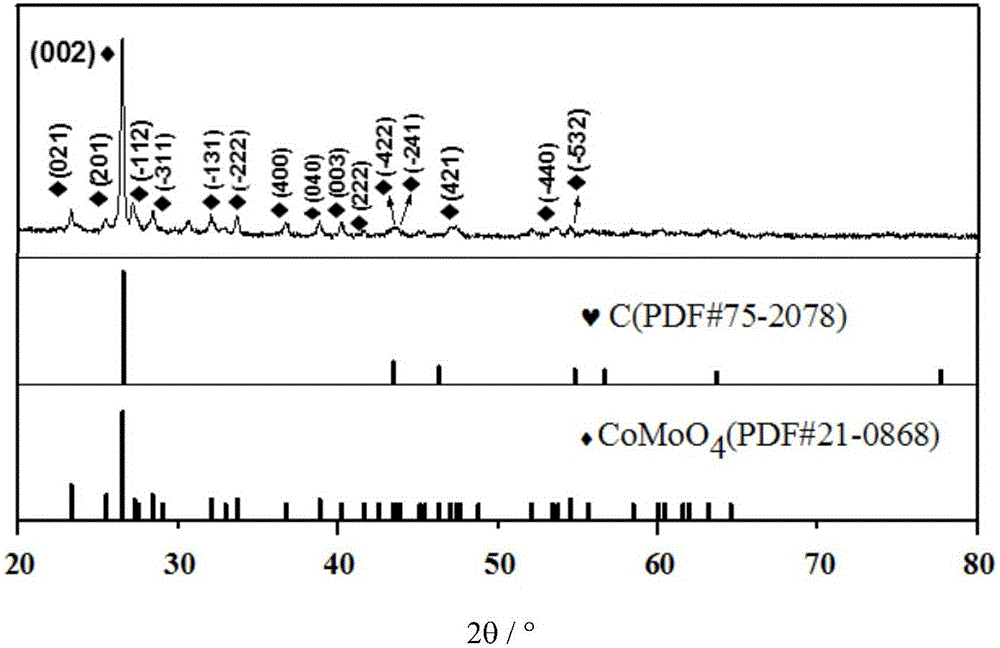

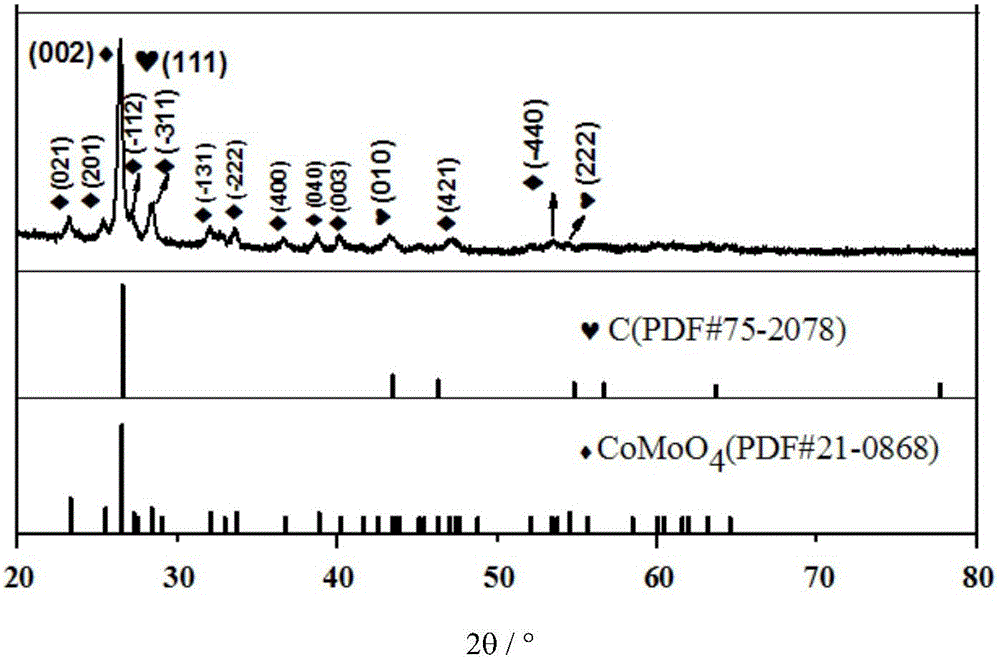

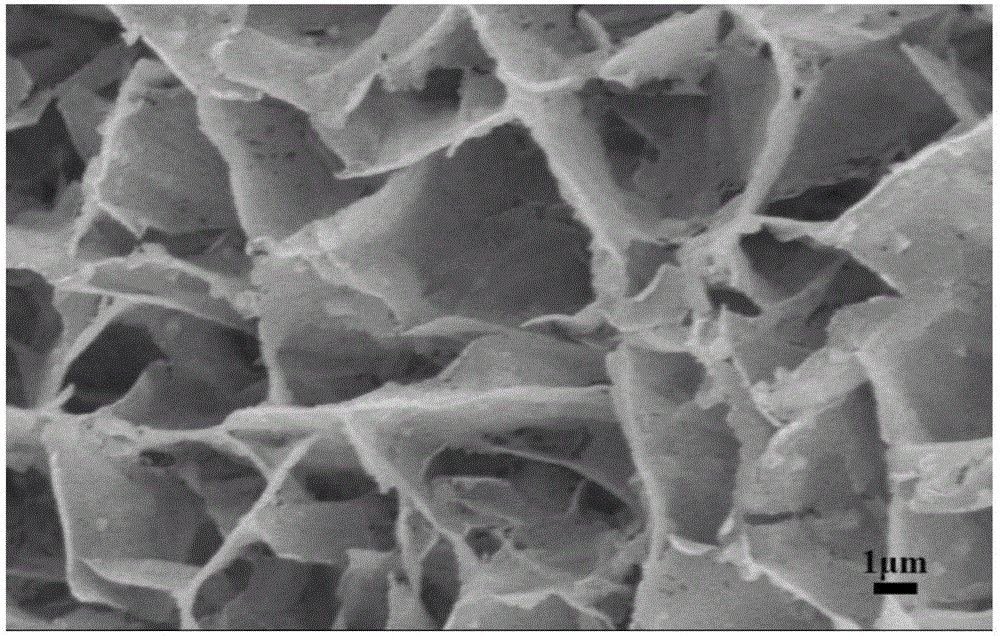

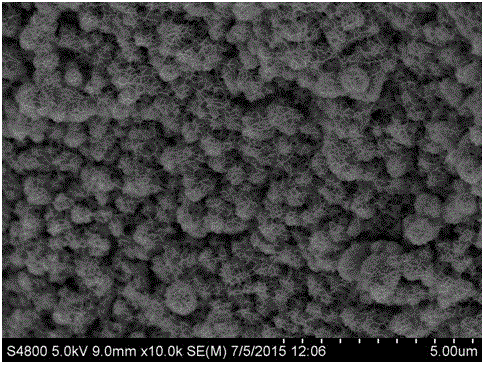

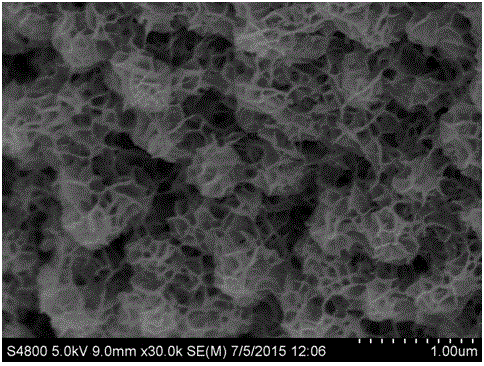

Carbon-coated cobalt molybdate network nanosheet array material, preparation method and application

ActiveCN106449138AImprove mechanical propertiesHigh material utilizationMaterial nanotechnologyHybrid capacitor electrodesCapacitanceCarbon film

The invention discloses a carbon-coated cobalt molybdate network nanosheet array material, which comprises a nano carbon film, cobalt molybdate network nanosheets and nickel foam, wherein the cobalt molybdate network nanosheets vertically grow on the nickel foam in an intersecting manner to form a cobalt molybdate network nanosheet array; and the nano carbon film coats the surface of the cobalt molybdate network nanosheet array. The invention further discloses a preparation method of the carbon-coated cobalt molybdate network nanosheet array material. The prepared carbon-coated cobalt molybdate network nanosheet array material can be used as an electrode material of a super-capacitor, so that the specific capacitance and the cycle performance of the super-capacitor can be significantly improved. The method is simple, short in time, green, environment-friendly, low in cost and suitable for industrialized massive production.

Owner:CHINA JILIANG UNIV

Method for preparing cobalt selenide super-capacitor material by non-template electrodeposition method

ActiveCN106024405ALarge specific surface areaHigh specific capacitanceMaterial nanotechnologyElectrolytic inorganic material coatingCyclic stabilityNickel

The invention discloses a method for preparing a Co0.85Se super-capacitor material by a non-template electrodeposition method. The material is of a nano flower structure; the non-template electrodeposition method is adopted for synthesis of the Co0.85Se nanomaterial; and the method mainly comprises the steps of: (1) preparing an Na2SeO3 solution and a Co(CH3COO)2 solution and then adding a CH3COOLi solution for mixing to obtain a precursor solution; (2) immersing a nickel net into the precursor solution and depositing the Co0.85Se nanomaterial on the surface of the nickel net by an electrochemical deposition method; and (3) washing the product by deionized water and ethanol separately and then drying the product to obtain the Co0.85Se super-capacitor material. The operation and equipment are simple; large-area preparation can be carried out without a template; the formed Co0.85Se nano flower is evenly distributed; a Co0.85Se nanomaterial electrode is tested under a three-electrode system, and has high specific capacity of 1065F / g under the current density of 1A / g; and the charge transfer impedance is 0.43ohm / cm<2>. The prepared Co0.85Se nano electrode material has excellent electrochemical rate capability and cycling stability; and the preparation method and the application field of the electrochemical capacitor material are expanded.

Owner:ZHEJIANG UNIV

Pre-treating process for high-voltage aluminum foil corrosion

InactiveCN101425392AImprove corrosion expansion rateImprove specific capacitanceElectrolytic capacitorsIndiumElectrolysis

The invention relates to the technical field of electrolytic capacitors, in particular to a pretreatment technology of high-voltage anode aluminum foil corrosion, which mainly comprises the following steps: 0.001-0.025 percent bismuth-containing or indium-containing compound or bismuth and indium mixture by weight is added in treatment fluid of alkali, acid, mixed alkali or mixed acid; aluminum foil is placed in pretreatment fluid and soaked for 10-200 seconds under the temperature of 30-80 DEG C; and the even pitting corrosion of the aluminum foil can happen easily when the pitting corrosion happens as the precipitation of the bismuth or the indium from the surface of the aluminum foil, thereby not only the face expansion ratio of the anode aluminum foil is improved, but also the loss of the mechanism strength can not be caused, and the specific volume of the aluminum foil is greatly improved.

Owner:DONGGUAN HEC CONDENSER CO LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com