Porous nickel-based carbon fiber composite material and preparation method and purpose thereof

A composite material and porous nickel technology, applied in the field of porous nickel-based carbon fiber composite materials and their preparation, can solve the problems of complex process and difficult to prepare capacitor electrode materials, etc., and achieve high specific surface area, excellent performance, excellent specific capacitance and cycle performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] In this embodiment, the porous nickel-based carbon fiber composite material is prepared by the following method, which specifically includes the following steps:

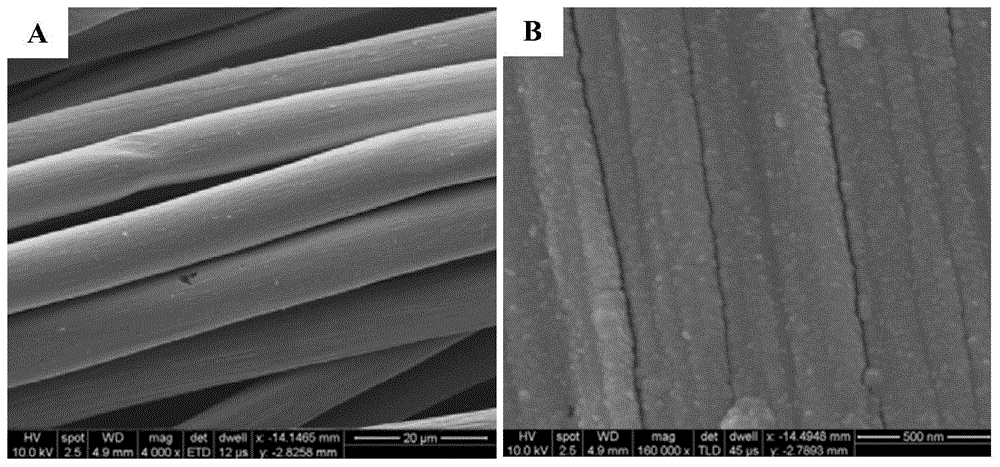

[0061](1) Using carbon fiber cloth as the substrate, the carbon fiber cloth was ultrasonically cleaned in acetone and absolute ethanol for 30 min, then rinsed with deionized water for 5 times, then heated and dried at 120 °C for 12 h, and then put into the sputter deposition chamber , using metallic nickel as the sputtering target material for sputtering deposition, where the parameters of sputtering deposition are: background vacuum degree is 6×10 -5 Pa, the sputtering power is DC 105W, the sputtering pressure is 0.5Pa, the sputtering time is 2h, and the deposition temperature is 25°C;

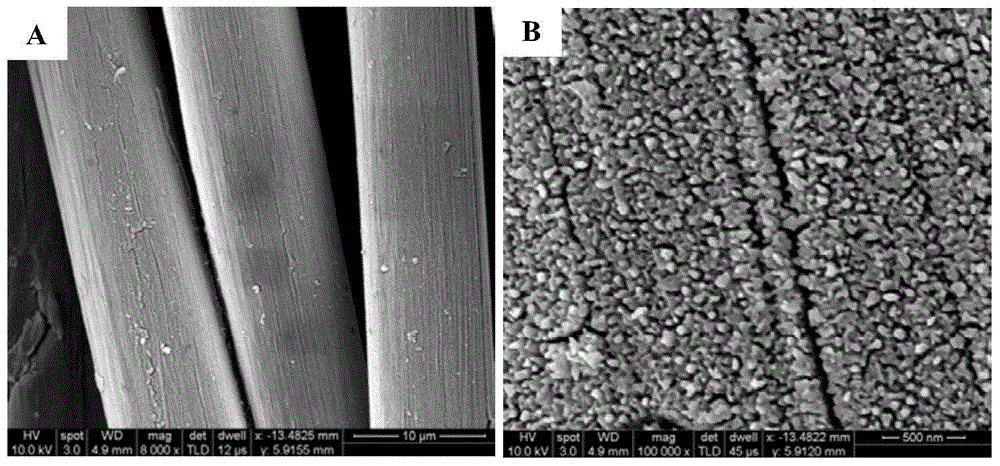

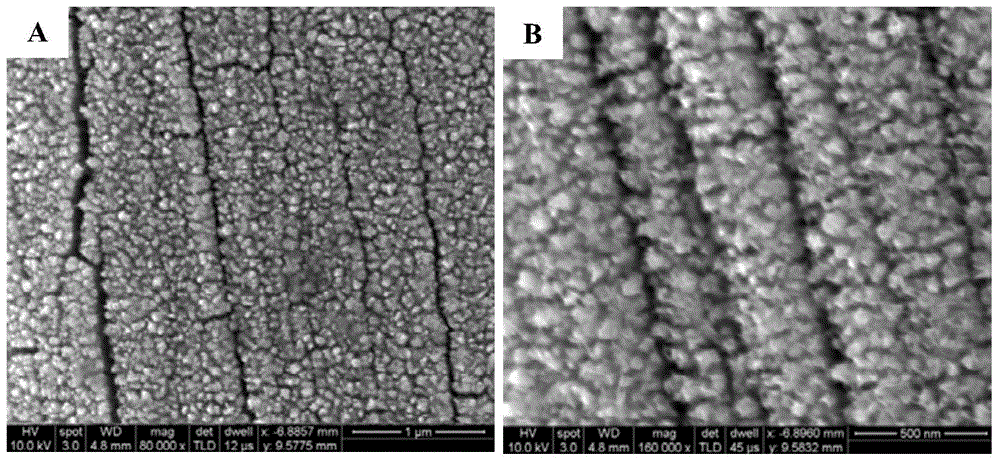

[0062] (2) Immerse the carbon fiber cloth deposited with the metal nickel film obtained in step (1) in a hydrochloric acid solution with a molar concentration of 2.5mol / L, take it out after 270s, wash and remove residual hyd...

Embodiment 2

[0070] In this embodiment, the porous nickel-based carbon fiber composite material is prepared by the following method, which specifically includes the following steps:

[0071] (1) Using carbon fiber cloth as the substrate, the carbon fiber cloth was ultrasonically cleaned in acetone and absolute ethanol for 10 min, then rinsed with deionized water for 10 times, then heated and dried at 110 °C for 24 h, and then put into the sputter deposition chamber , using metallic nickel as the sputtering target material for sputtering deposition, where the parameters of sputtering deposition are: background vacuum degree is 1×10 -5 Pa, the sputtering power is DC 80W, the sputtering pressure is 1Pa, the sputtering time is 3h, and the deposition temperature is 20°C;

[0072] (2) Immerse the carbon fiber cloth deposited with the metal nickel film obtained by step (1) in a hydrochloric acid solution with a molar concentration of 1mol / L, take it out after 200s, clean and remove residual hydro...

Embodiment 3

[0076] In this embodiment, the porous nickel-based carbon fiber composite material is prepared by the following method, which specifically includes the following steps:

[0077] (1) Using carbon fiber cloth as the substrate, the carbon fiber cloth was ultrasonically cleaned in acetone and absolute ethanol for 50 min, then rinsed with deionized water for 3 times, then heated and dried at 130 °C for 20 h, and then put into the sputter deposition chamber , using metallic nickel as the sputtering target material for sputtering deposition, where the parameters of sputtering deposition are: background vacuum degree is 4×10 -5 Pa, the sputtering power is DC 100W, the sputtering pressure is 1.5Pa, the sputtering time is 1h, and the deposition temperature is 30°C;

[0078] (2) the carbon fiber cloth that step (1) is deposited with the metallic nickel thin film is immersed in the sulfuric acid solution that the molar concentration is 4mol / L, takes out after 300s, cleans and removes resi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Area specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com