Patents

Literature

923 results about "Nickel oxide hydroxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nickel oxide hydroxide is the inorganic compound with the chemical formula NiO(OH). It is a black solid that is insoluble in all solvents but attacked by base and acid. It is a component of the nickel-metal hydride battery.

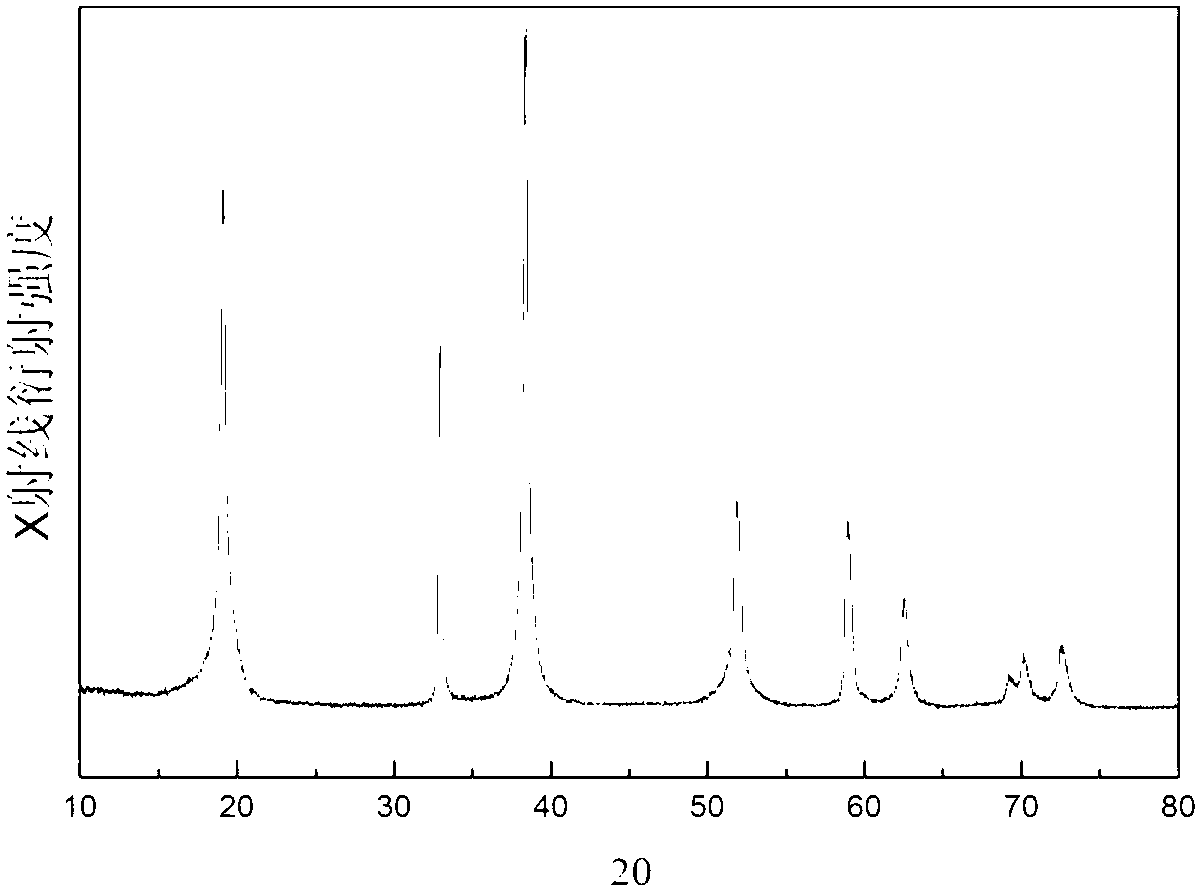

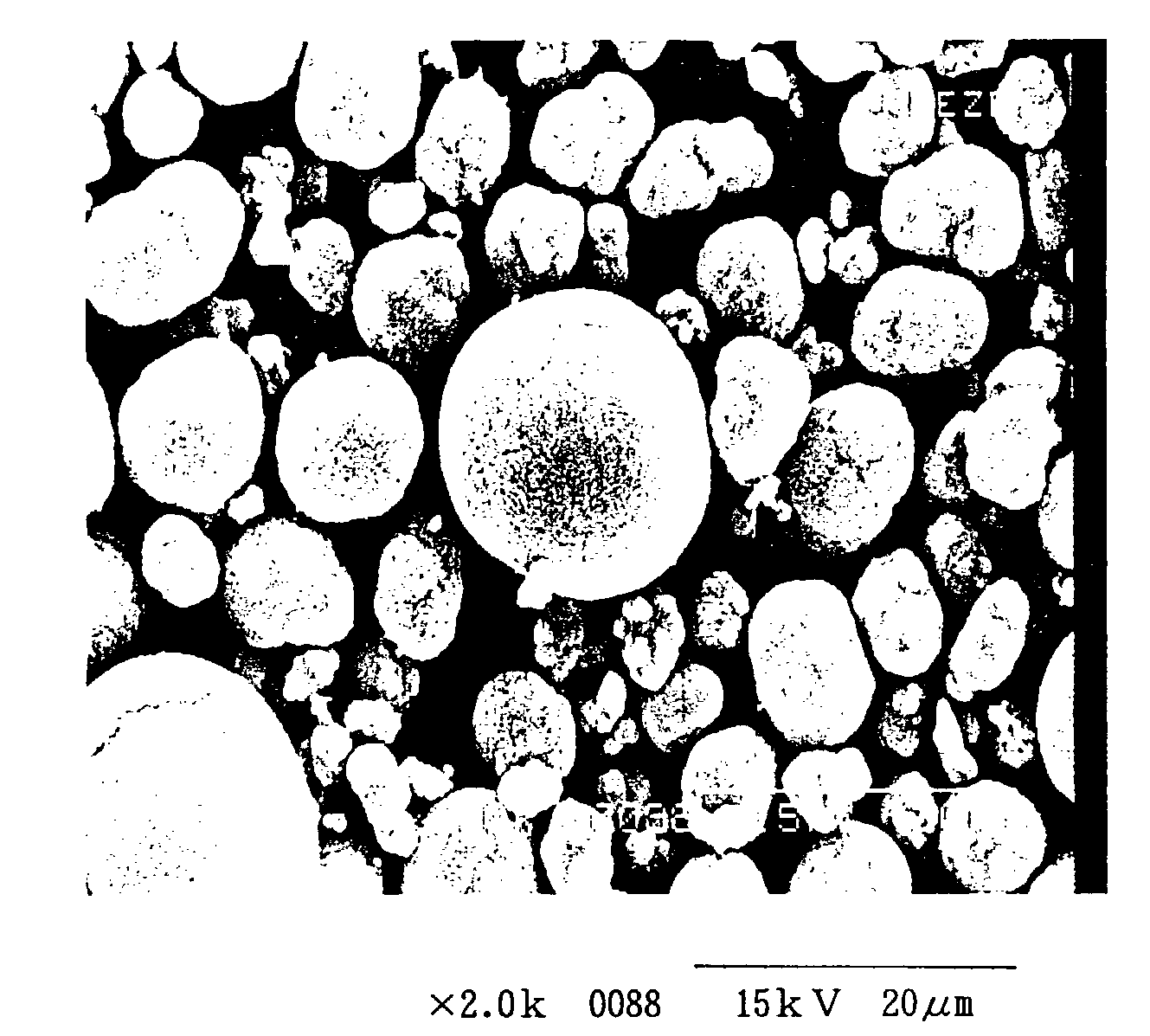

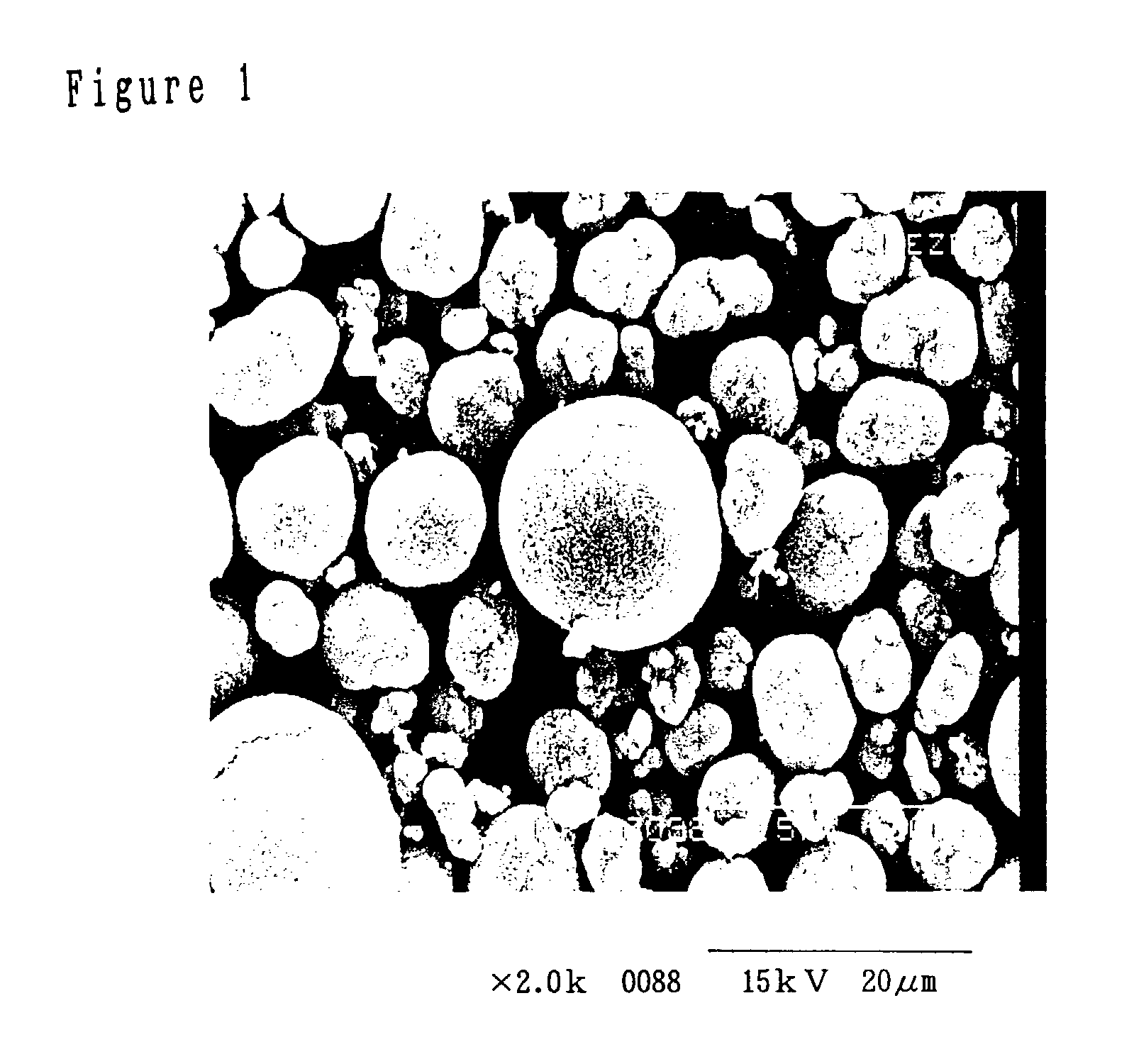

Spherical aluminum-doped nickel cobalt lithium for lithium ion battery and its making method

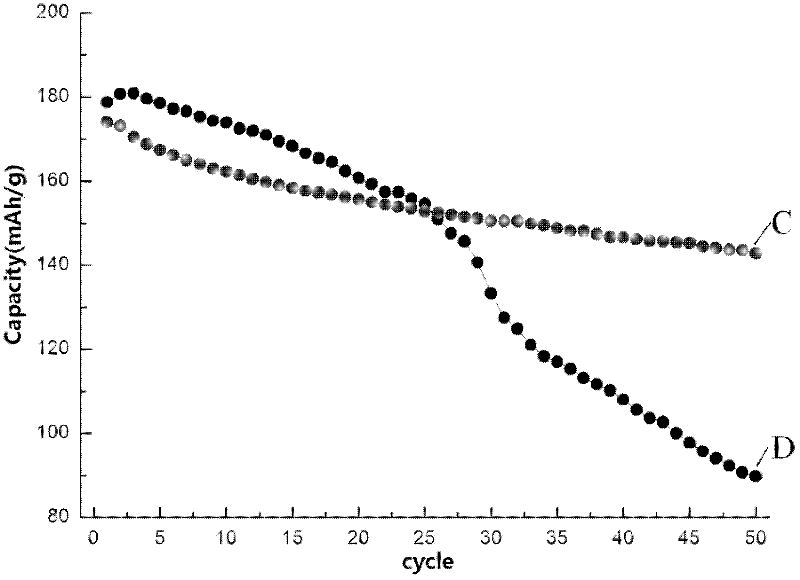

ActiveCN101262061AImprove liquidityImprove charge and discharge cycle stabilityElectrode manufacturing processesLithium compoundsDischarge efficiencyHigh rate

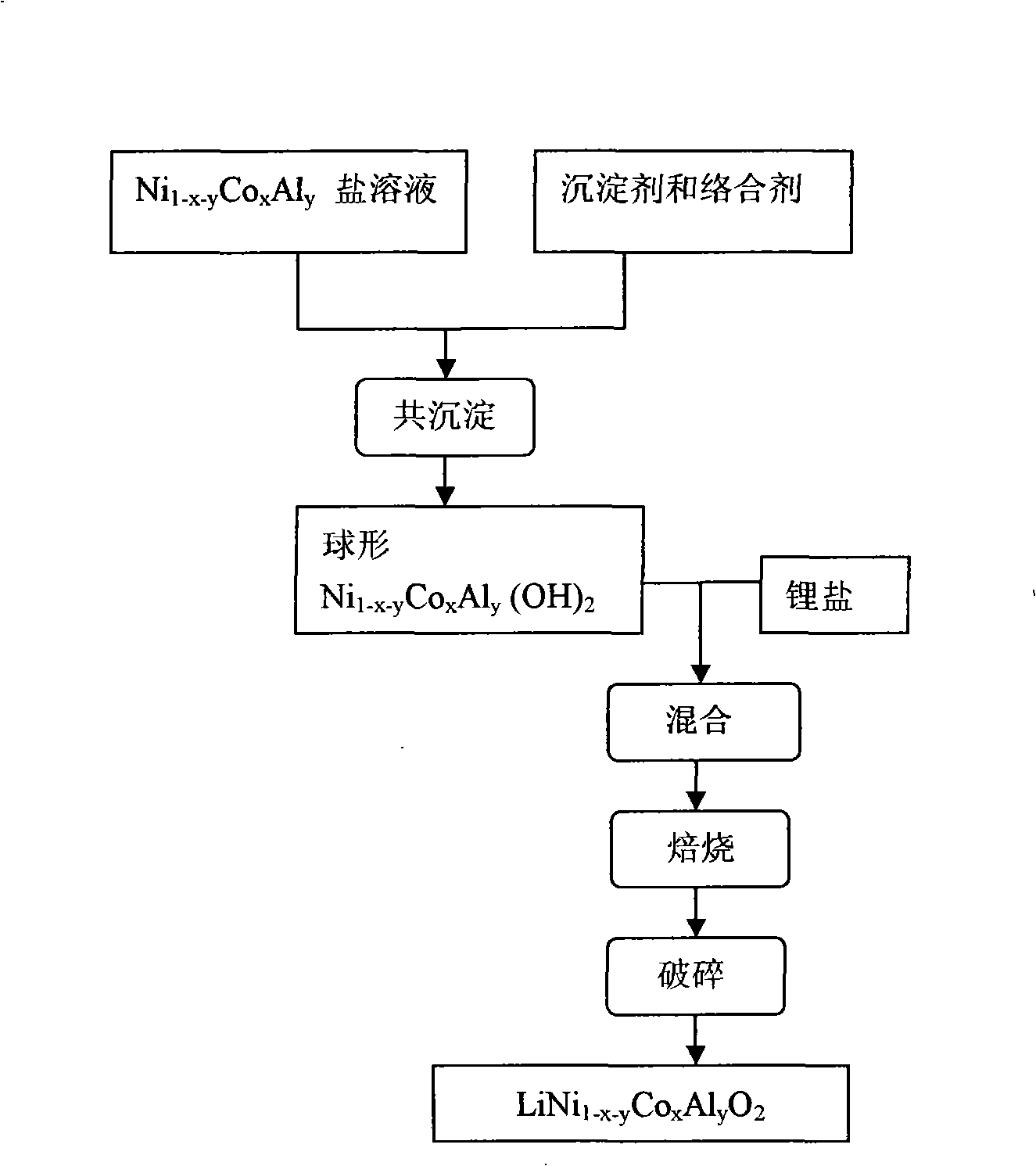

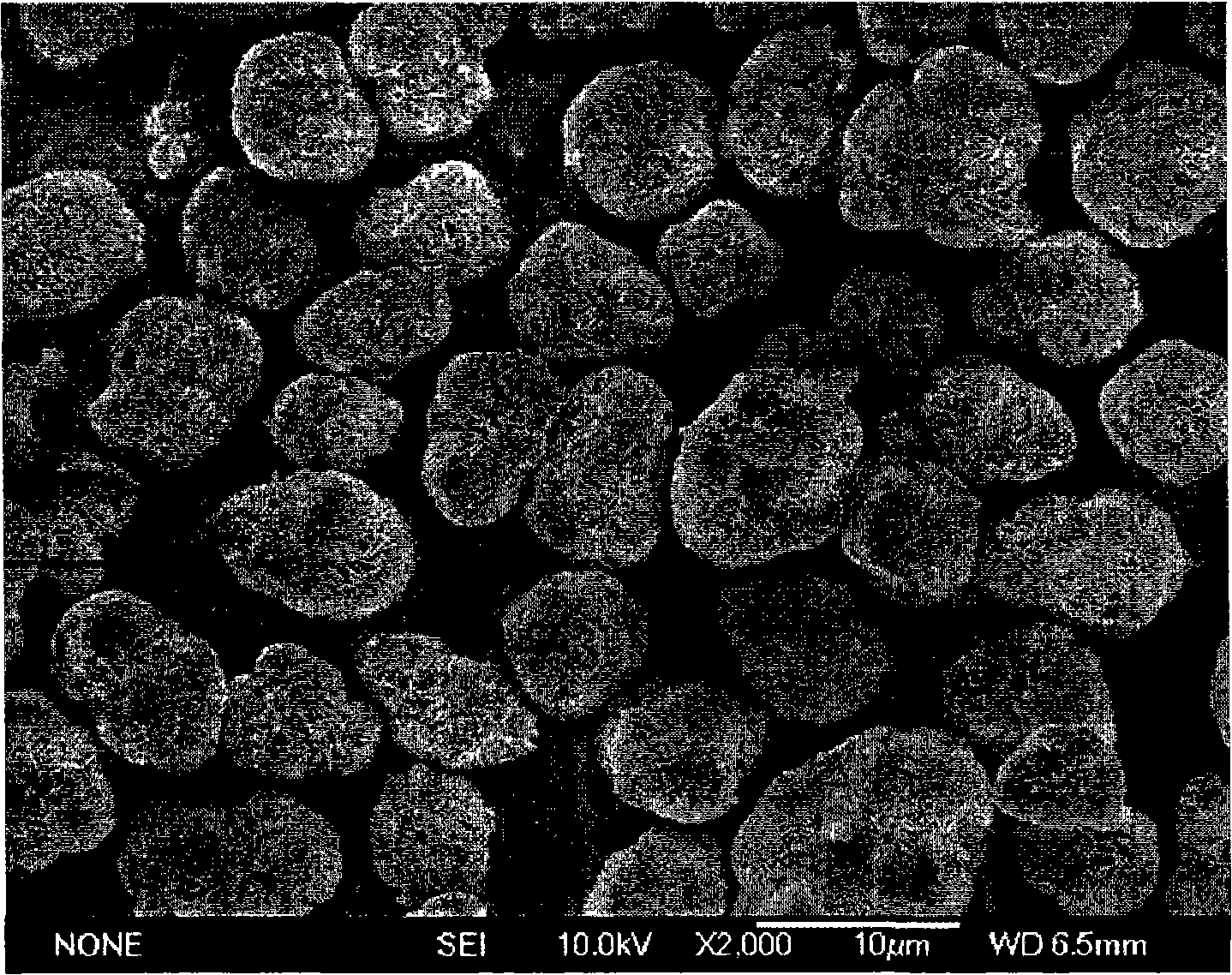

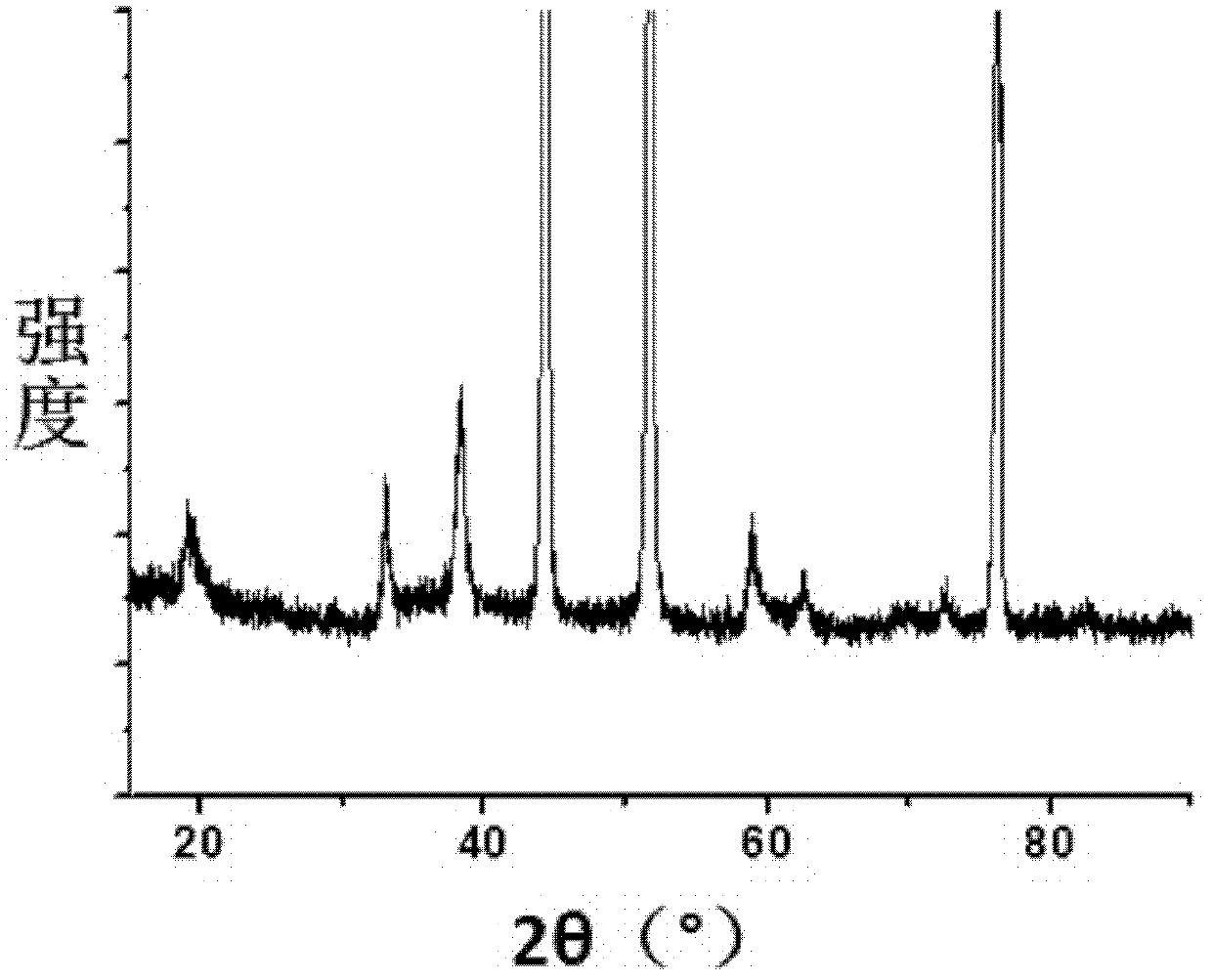

The invention discloses a preparation method of a spherical doped Al-Ni lithium cobalt oxide for lithium-ion battery. The preparation steps are that: first, sulfate, nitrate or chlorate of Al-Ni-Co react with strong alkali that is added with complex agent in liquid phase; the pH value, the temperature and the feeding speed of the reaction solution are controlled so as to produce a spherical precursor of Al-Ni-Co hydroxide; then the spherical precursor of Al-Ni-Co hydroxide is dried and evenly mixed with lithium hydroxide, lithium nitrate or lithium carbonate and dried; the obtained mixture is roasted into a spherical doped Al-Ni lithium cobalt oxide. The spherical doped Al-Ni lithium cobalt oxide has comparatively high tap density and remarkable cycle stability in the process of high-rate charge / discharge cycle, which improves over charge performance of Ni-Co substance and first obviously enhances charge / discharge efficiency; in addition, the preparation method of the spherical doped Al-Ni lithium cobalt oxide has the advantages of being simple, controllable and suitable for industrialized production with low energy consumption, high efficiency, short reaction time and low cost.

Owner:成都巴莫科技有限责任公司

Gradient coated LiNiO2 material and preparation method

InactiveCN103078109AHigh electrochemical capacityInhibit sheddingCell electrodesSource materialManganese

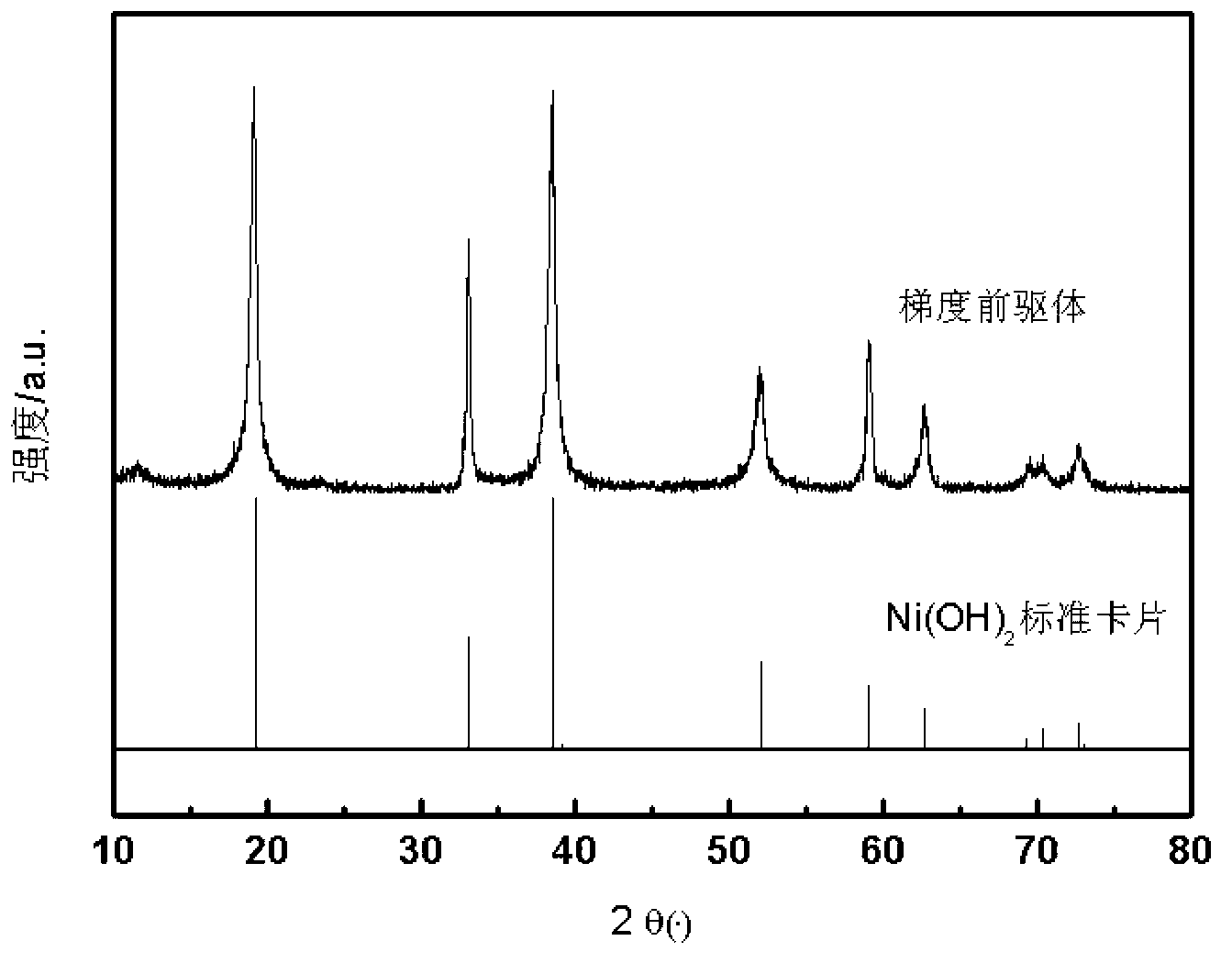

The invention discloses a preparation method for gradient coated LiNiO2 for lithium ion battery positive pole material, so as to solve the problem of bad circulating performance of conventional LiNiO2. The molecular formula of the LiNiO2 is LiNi 1-xMxO2, wherein, the x is less than or equal to 0.3 and greater than 0, the M is adulterated metal ions and is one or more selected from magnesium, nickel, Fe, titanium, zinc, Co, manganese, aluminum, Nb and vanadium, the gradient coat refers to that concentration gradient hydroxide coprecipitate provided with nickel and other metallic elements is coated on the surfaces of spherical nickelous hydroxide material, and then the precursor is mixed with lithium-source material and roasted under high temperature in an oxygen atmosphere furnace, so as to obtain high-performance modified LiNiO2. The gradient coated LiNiO2 obtained in the invention has the characteristics of high specific capacity, excellent circulating performance, excellent high-temperature property and the like, and is suitable for the application field of high- capacity lithium ion batteries.

Owner:CENT SOUTH UNIV

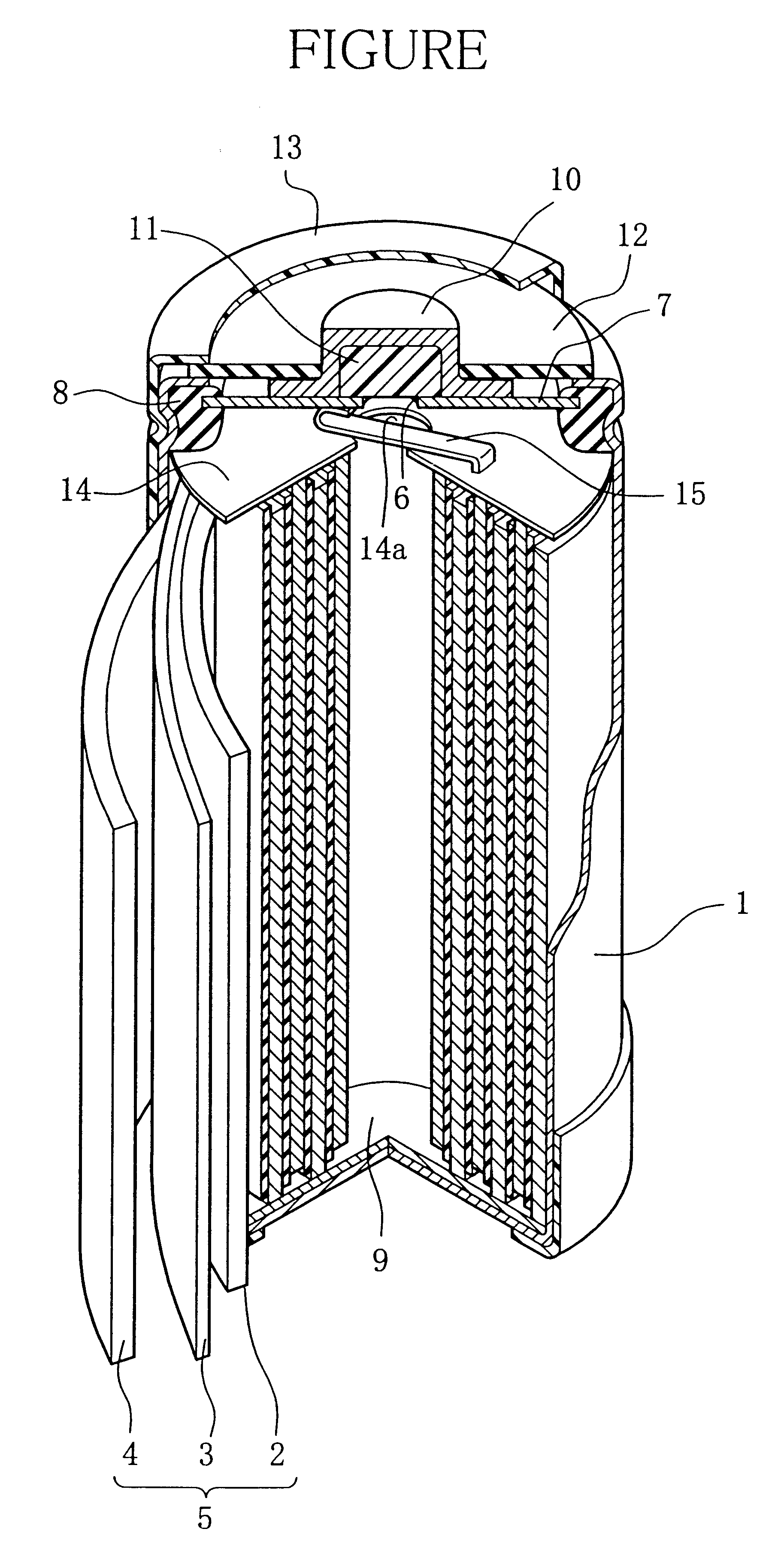

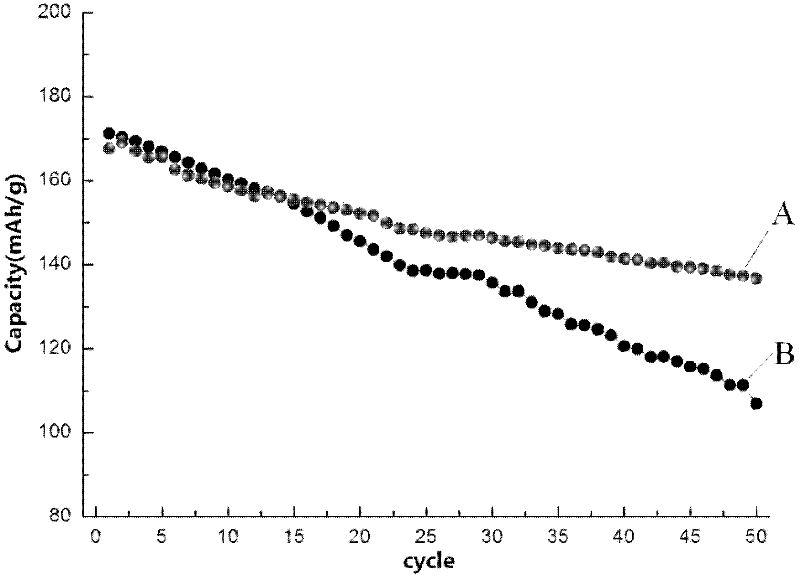

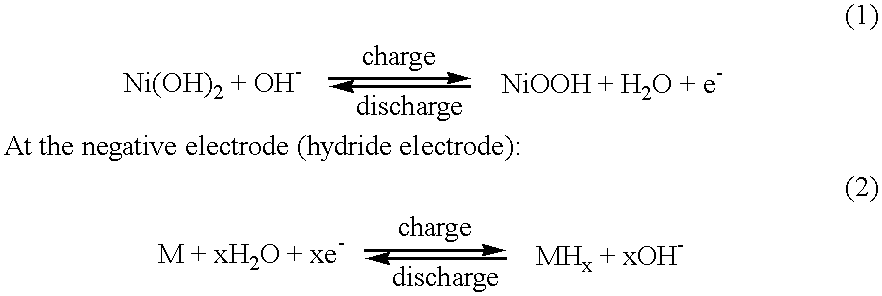

Nickel-metal hydride secondary battery

InactiveUS6399247B1High materialImprove featuresCell seperators/membranes/diaphragms/spacersElectrolytic capacitorsHigh temperature storageNickel oxide hydroxide

A nickel-metal hydride secondary battery comprising electrode group comprising positive electrode comprised mainly of nickel hydroxide, negative electrode comprised mainly of a hydrogen storage alloy, and separator being disposed between the positive electrode and the negative electrode, wherein the electrode group is sealed in battery casing, together with an alkali electrolyte liquid, wherein, in the battery, a W element and an Na element are present simultaneously. The nickel-metal hydride secondary battery of the present invention is advantageous not only in that it exhibits high utilization of the active material and excellent self-discharge characteristics in a high temperature storage as well as high charging efficiency in a high temperature environment, but also in that it has excellent large current discharge characteristics.

Owner:TOSHIBA BATTERY +1

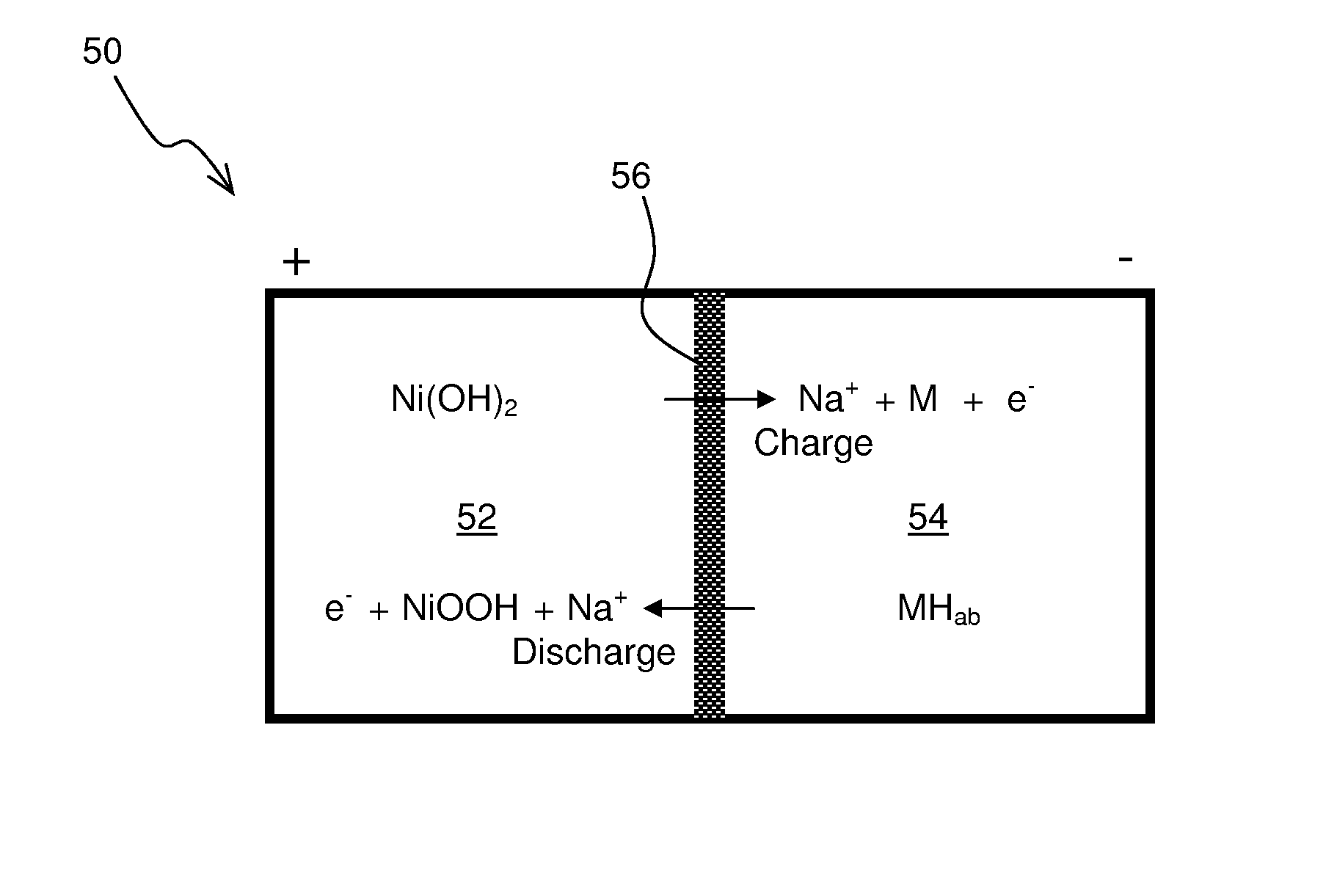

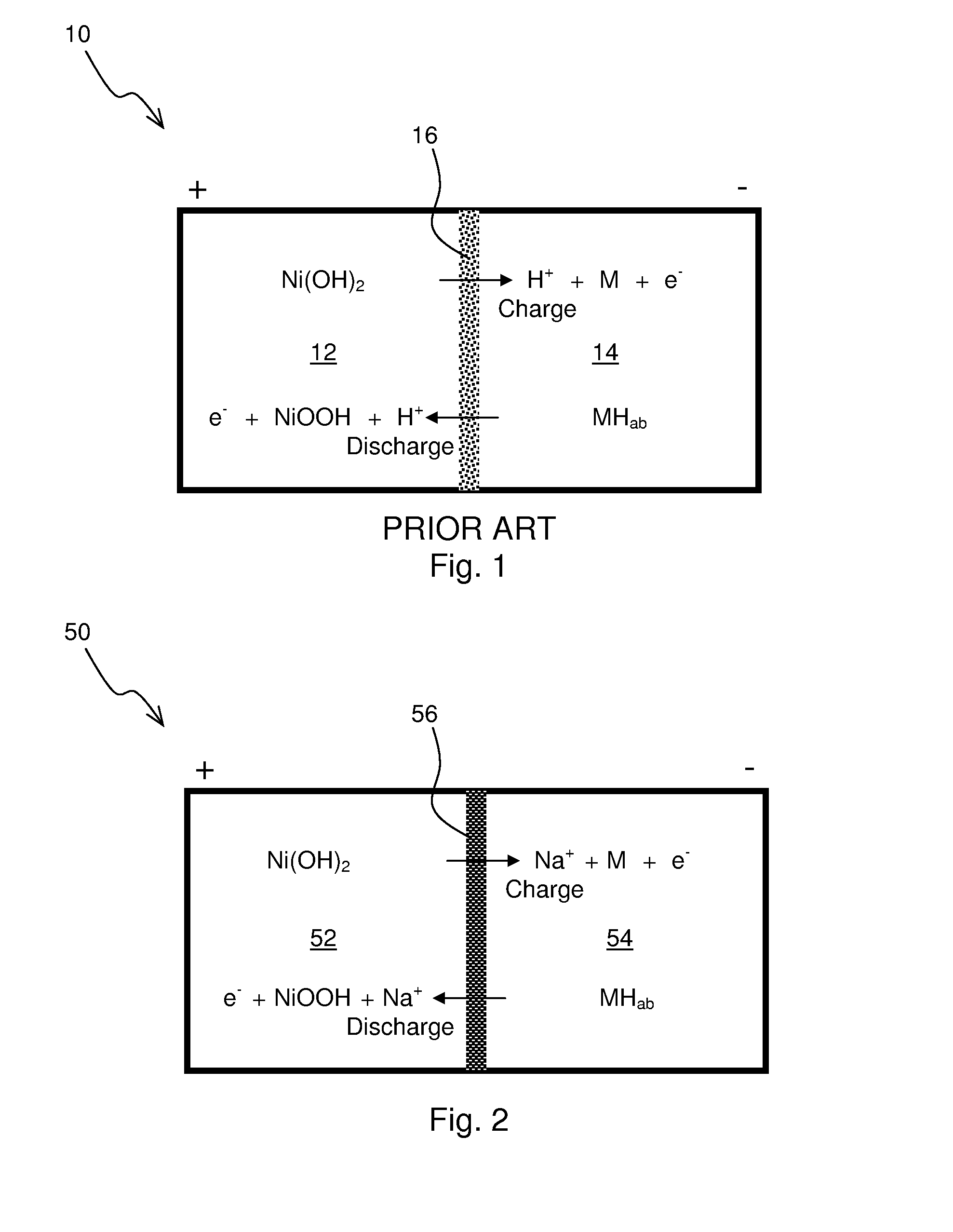

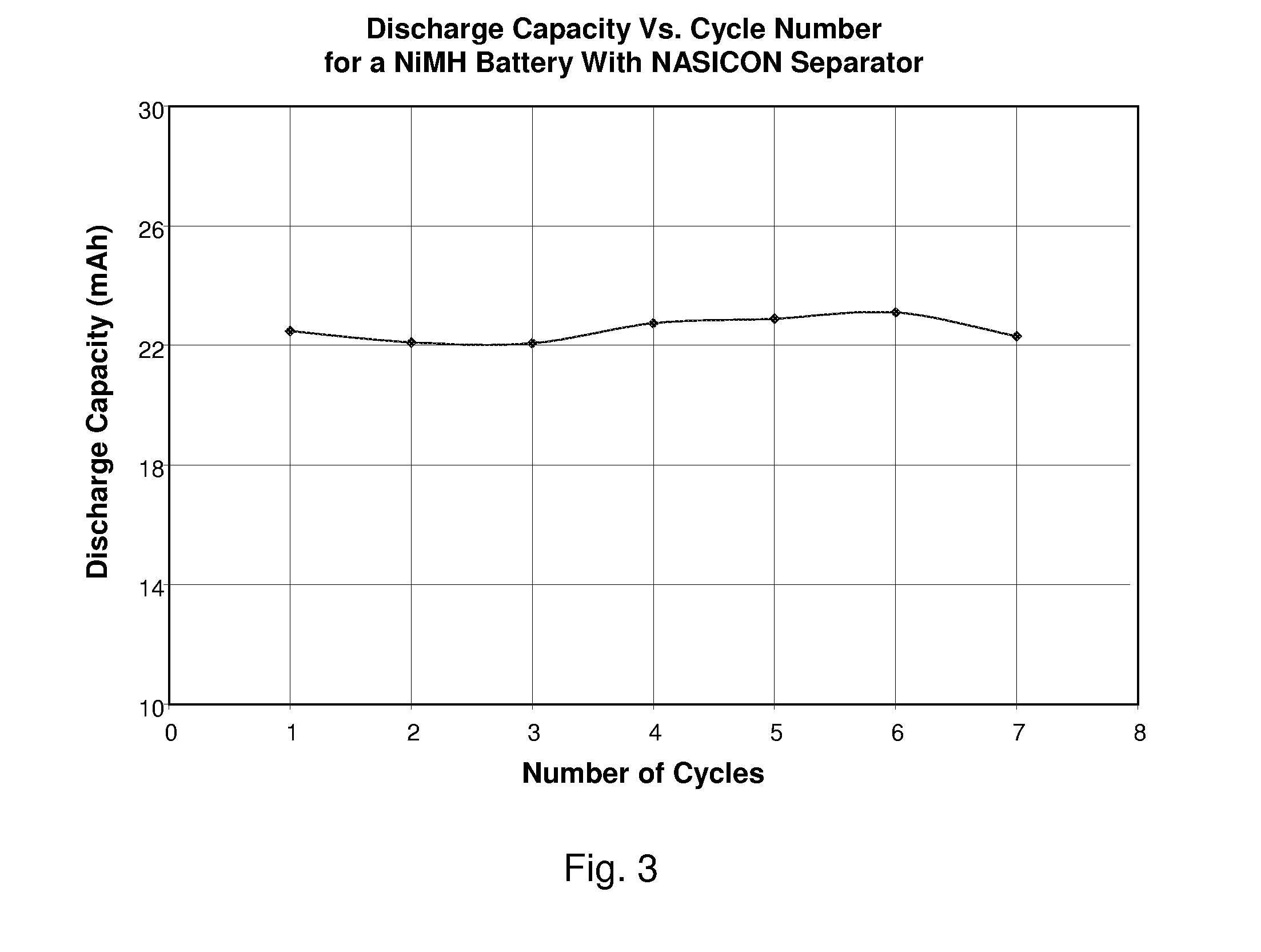

Nickel-Metal Hydride Battery Using Alkali Ion Conducting Separator

ActiveUS20090134842A1Eliminates capacity lossEliminates self dischargeBatteries circuit arrangementsAlkaline accumulatorsAlkali ionsNickel oxide hydroxide

A nickel-metal hydride storage battery comprising a positive electrode containing nickel hydroxide, a negative electrode containing a hydrogen absorbing alloy, an alkaline electrolyte, and an alkali conducting separator provided between the positive electrode and the negative electrode. The alkali conducting separator may be a solid alkali metal ion super ion conducting material, wherein the alkali metal is Na, K, or Li

Owner:FIELD UPGRADING USA INC

Preparation method of lithium-ion battery cathode material coated aluminum

InactiveCN102299299ACoating process conditions are easy to controlImprove high temperature stabilityCell electrodesNickel saltElectrical battery

The invention relates to a method for preparing aluminum-coated anode materials of lithium-ion batteries, which is characterized in that: firstly, soluble nickel salts, cobalt salts, and manganese salts are formulated into salt solutions, and then mixed with ammonia-water-mixed sodium hydroxide or potassium hydroxide solutions React to form precursor particles, wash and dry; add water to the dried precursor particles to prepare a flowable slurry, stir, and add trivalent aluminum salt solution and sodium hydroxide or potassium hydroxide solution dropwise to the slurry at the same time , to obtain the precursor of nickel hydroxide cobalt manganese coated with aluminum; then mix the precursor with lithium source, and then sinter to obtain the positive electrode material of lithium ion battery coated with aluminum. The present invention has the following obvious advantages: raw materials are easy to obtain; coated The process conditions are easy to control, and it is easy to obtain a relatively uniform coating body; the prepared positive electrode material can make the lithium ion battery have superior high temperature stability and better cycle characteristics.

Owner:深圳市天骄科技开发有限公司

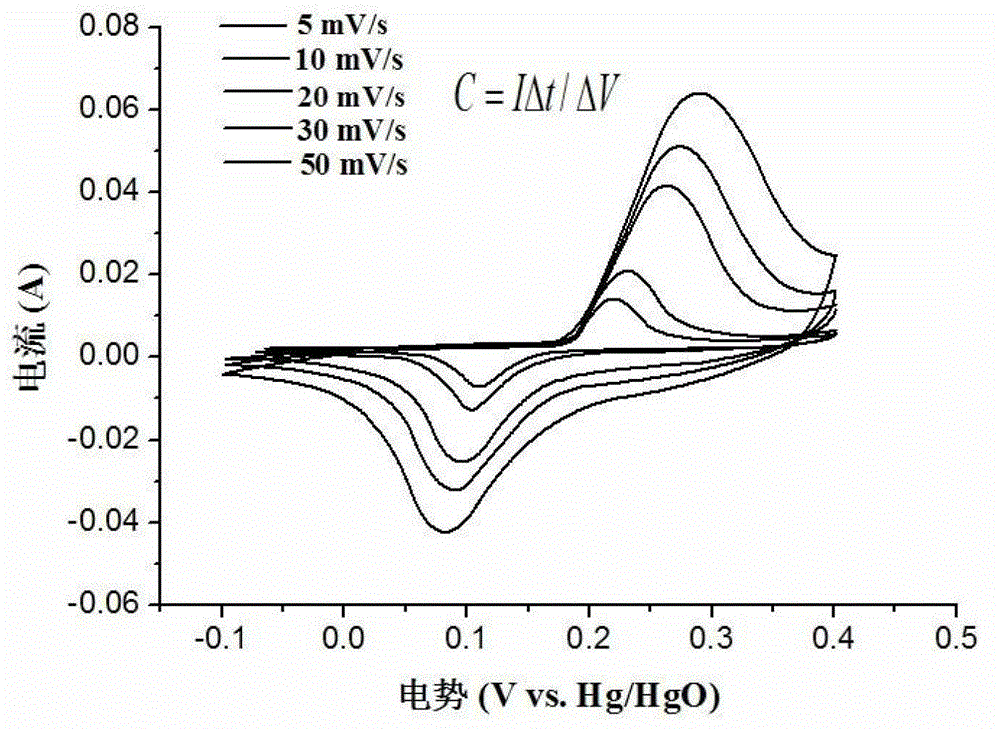

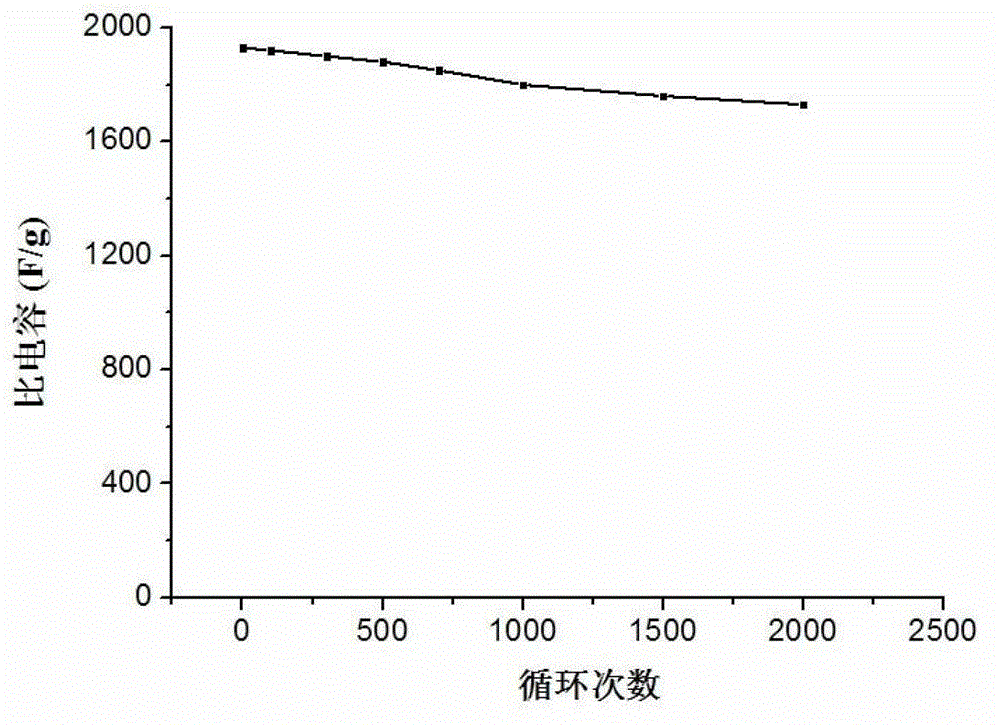

Method for preparing graphene-nickel hydroxide composite electrode material for super capacitor

InactiveCN102354609AHigh specific capacitance valueSimple and efficient in situ preparationElectrolytic capacitorsCapacitanceGas phase

The invention provides a method for preparing a graphene-nickel hydroxide composite electrode material for a super capacitor. The method is characterized by comprising the following steps: preparing a graphene substrate film material through chemical vapor deposition of carbon source gas and hydrogen in plasma enhanced chemical vapor deposition reaction equipment and realizing graphene in-situ growth-nickel hydroxide zero addition compositing through electrochemical deposition of nickel hydroxide. The specific capacitance of the composite electrode material prepared by the method can reach 1918F / g at most and can still maintain more than 80% after hundreds of circulation of high-current charge / discharge. The method is simple and effective; the production cost is reduced; at the same time,the electrode has excellent electrochemical property and is expected to serve as an anode material in the super capacitor for energy storage; the overall property of the electrode material is improved; and the way is widened for development of such fields as hybrid energy power.

Owner:JILIN UNIV

Nickel disulfide carbon nano composite material and preparation method and application thereof

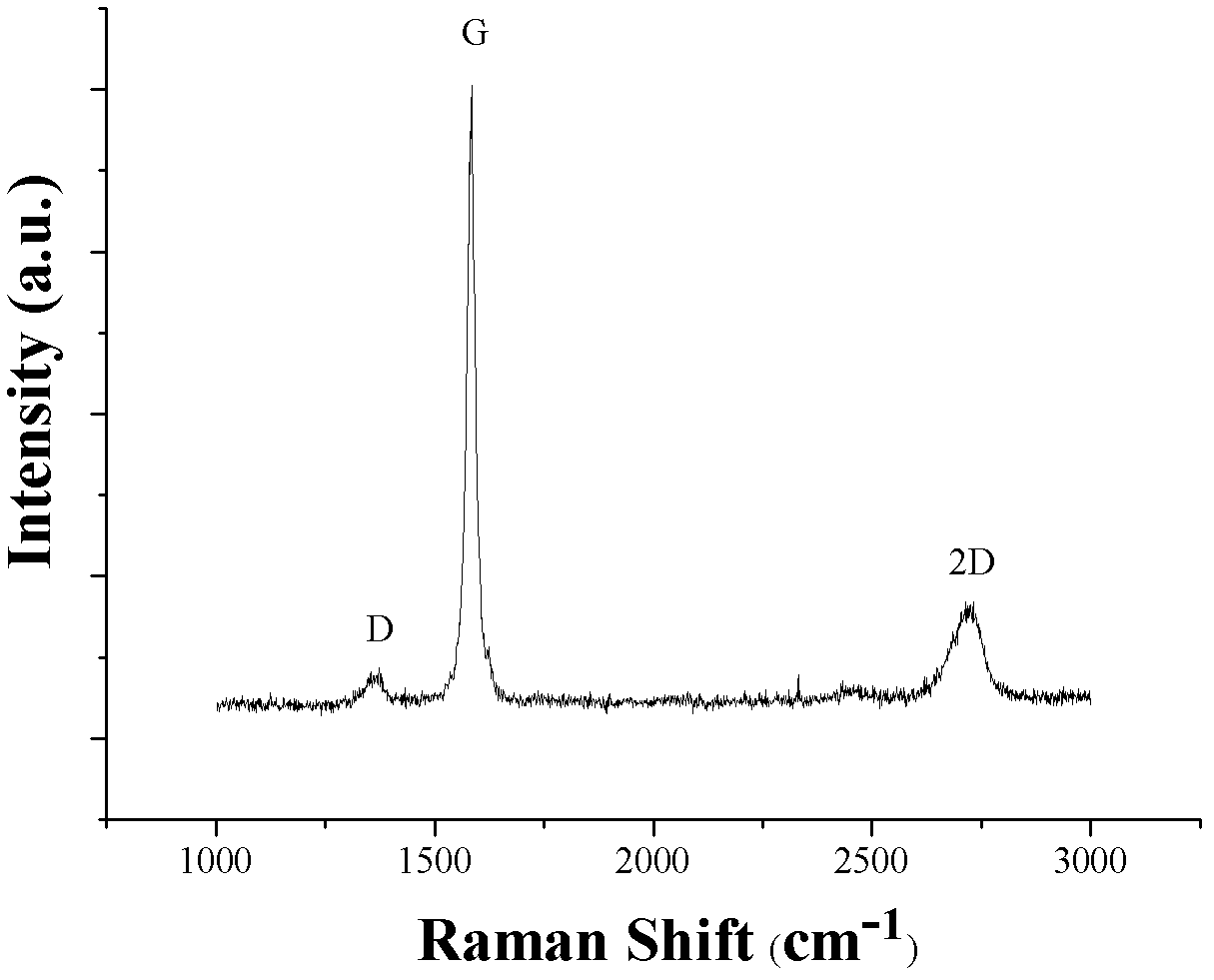

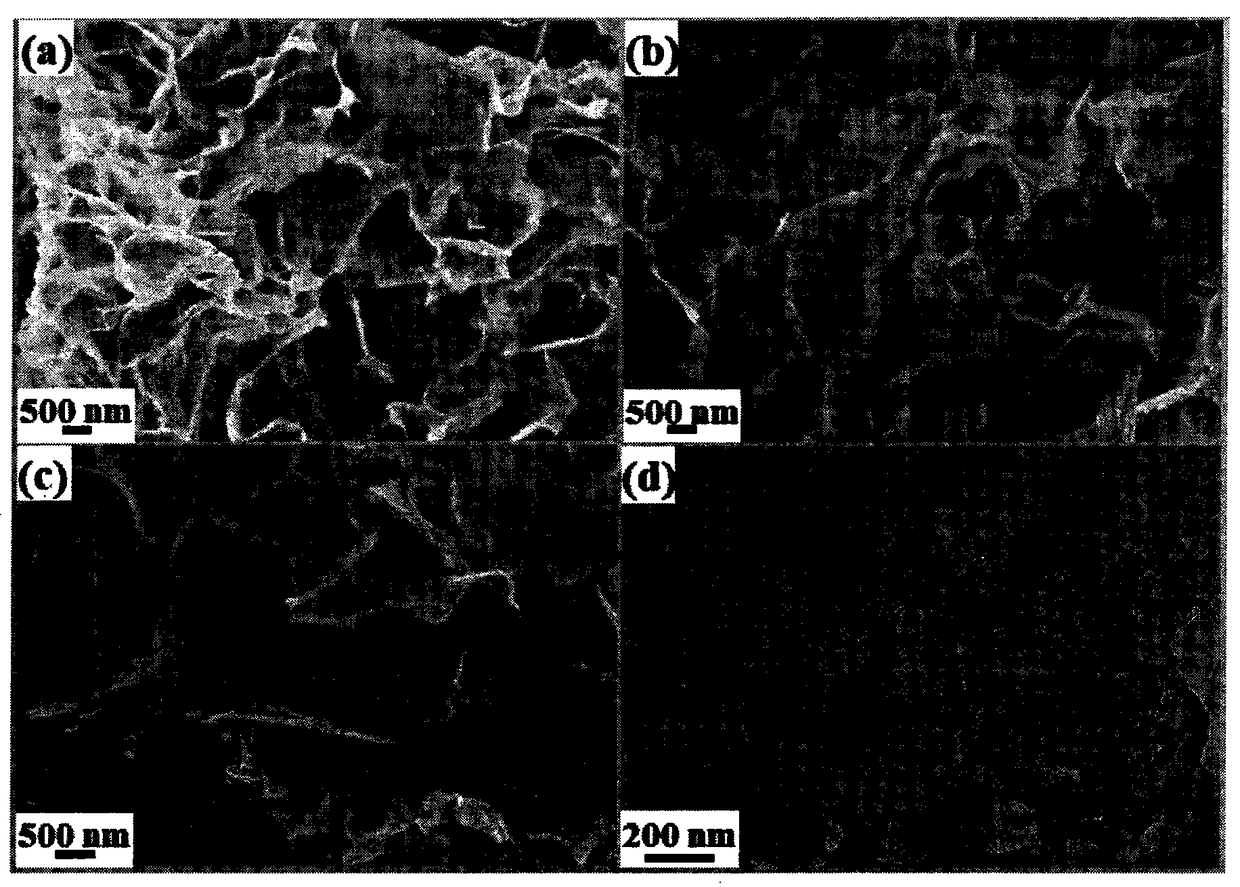

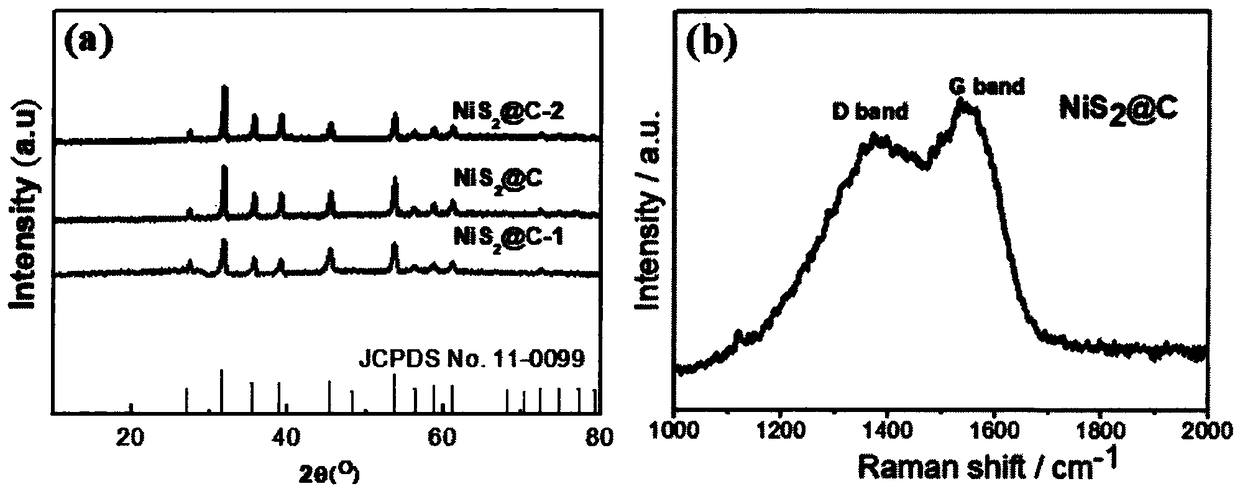

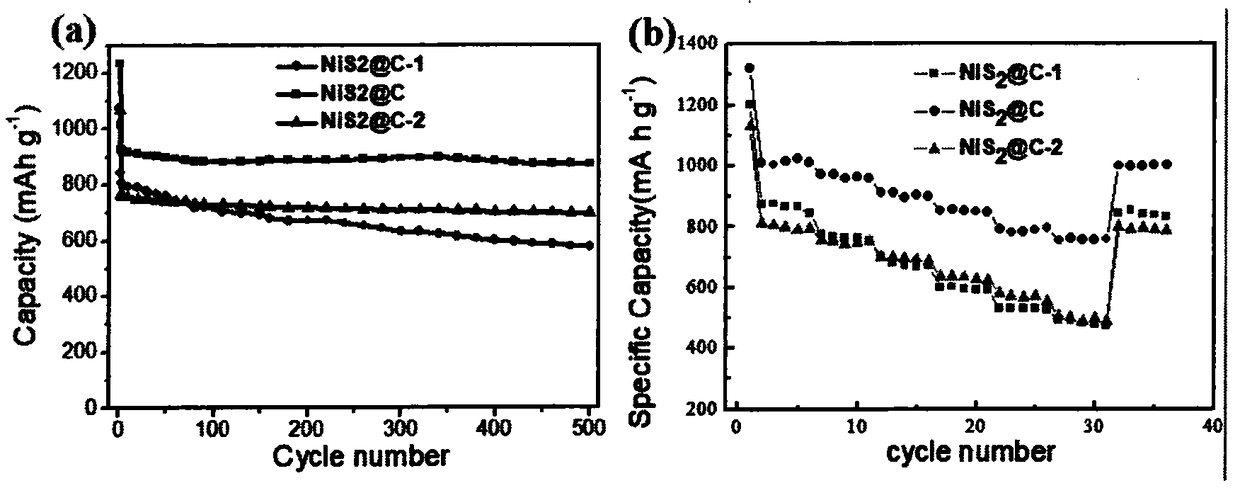

InactiveCN108832097AGood biocompatibilityStrong adhesionMaterial nanotechnologyHybrid capacitor electrodesCarbon compositesCarbon layer

The invention relates to a nickel disulfide carbon nano composite material and a preparation method and an application thereof, wherein the composite material is formed by coating a nickel disulfide nanosheet with a carbon layer. The preparation method comprises the following steps of preparing a nickel hydroxide nanosheet precursor by a hydrothermal method, performing magnetic stirring and dispersing in deionized water to obtain a uniform dispersion liquid of the nickel hydroxide nanosheet precursor, adding a buffering agent tris(hydroxymethyl) aminomethane hydrochloride, and adjusting the pHvalue to be 8.5 by adopting an alkali solution with the pH value of 13, adding dopamine hydrochloride, and magnetically stirring at room temperature for in-situ polymerization, and carrying out washing and centrifugally drying to obtain a nickel hydroxide nanosheet precursor / polydopamine composite material, and carrying out heat treatment and vulcanization with sublimed sulfur powder in a tubularfurnace in nitrogen atmosphere at a certain temperature to obtain the composite material. The preparation process is simple, easy to operate, green and non-toxic and friendly in material preparationprocess; and the prepared nickel disulfide carbon nano composite material is stable in structure, uniform in morphology and high in dispersion. The obtained nickel disulfide carbon nano composite material can be an ideal electrode material of a high-performance lithium ion battery, a supercapacitor and other new energy devices.

Owner:DONGHUA UNIV

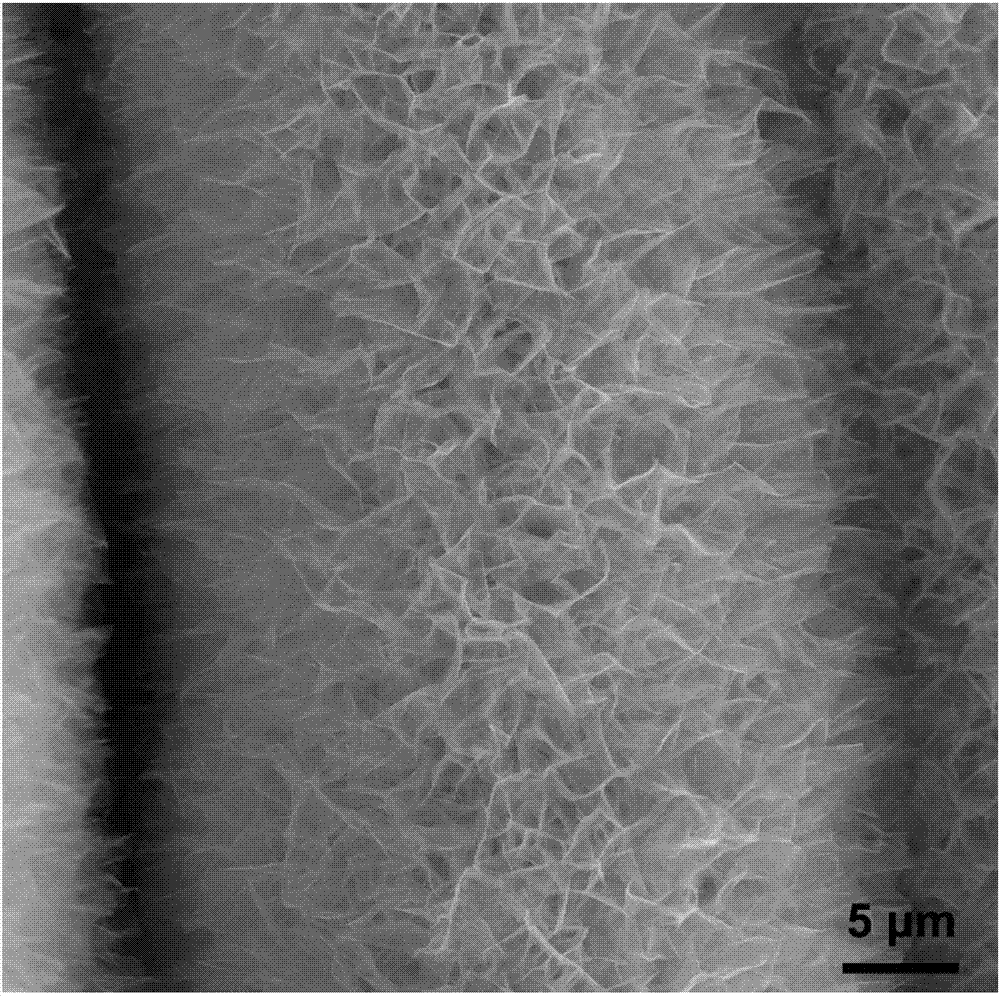

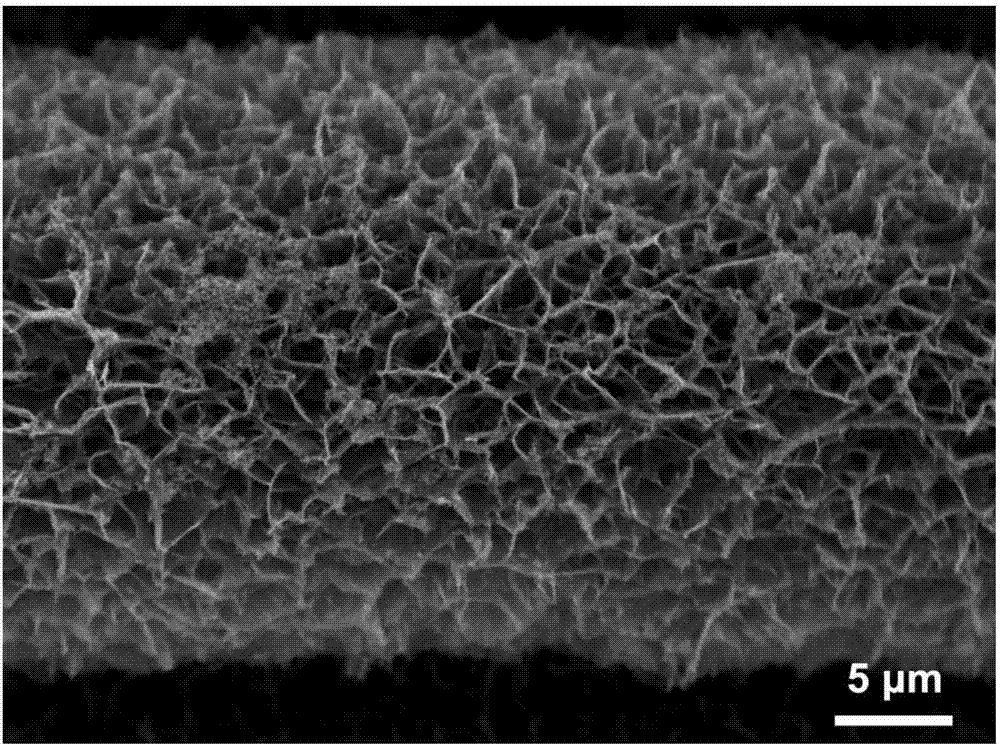

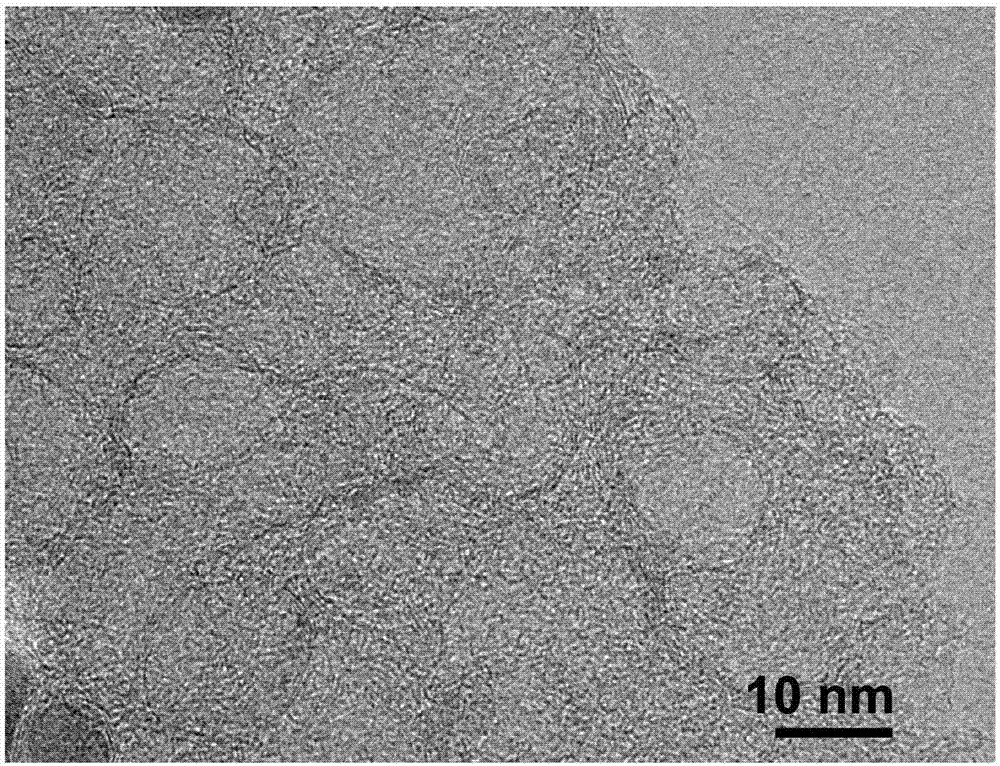

Nitrogen-doped porous vertical graphene nanowall array and preparation method and application thereof

ActiveCN107235472ALarge specific surface areaGrowth active siteMaterial nanotechnologyHybrid capacitor electrodesConductive polymerNitrogen doped

The invention provides a nitrogen-doped porous vertical graphene nanowall array. A compact coating layer is formed by means of nickel hydroxide serving as a template and the self-assembly property of dopamine, then high-temperature carbonization is conducted to prepare a nitrogen-doped vertical graphene nanowall array material, in-situ functional modification is conducted on the basis, the compound functional material loaded with noble metal nanoparticles, noble metal alloy nanoparticles, metal oxides, metal sulfide, metal phosphide, conductive polymers and the like is obtained, and application in the fields of supercapacitors, lithium ion batteries, water decomposition, electrochemical catalysis, enzyme-free biosensors and the like is explored.

Owner:HUAZHONG UNIV OF SCI & TECH

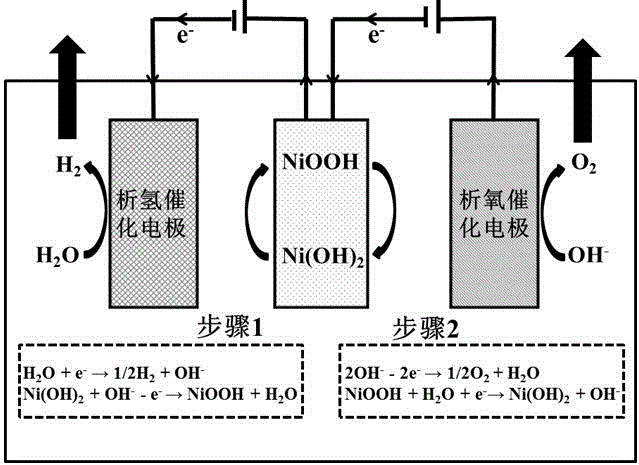

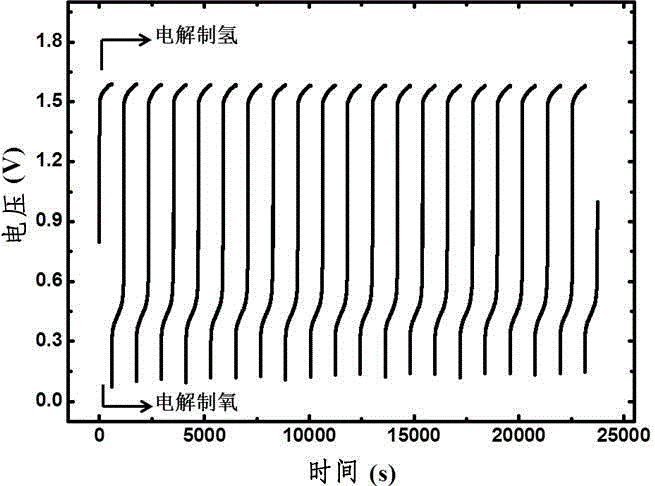

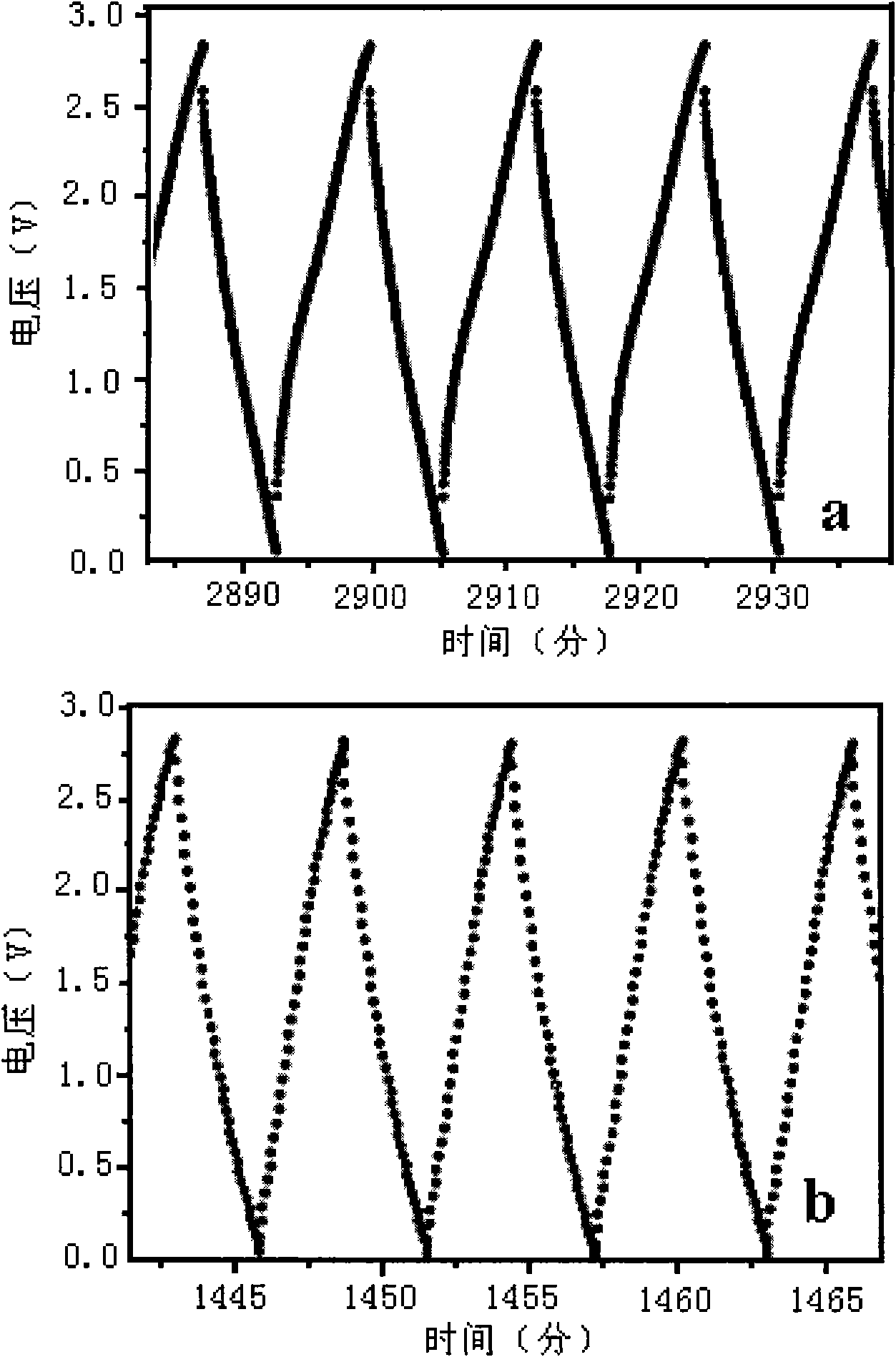

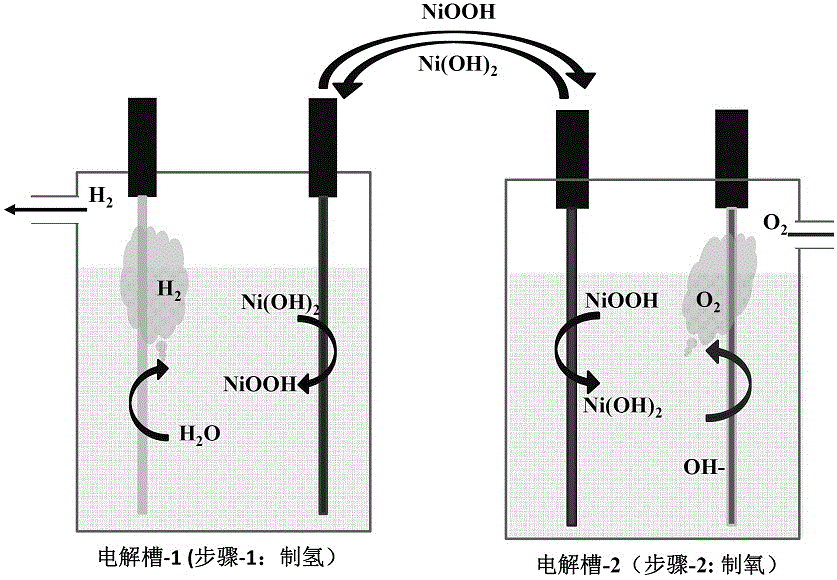

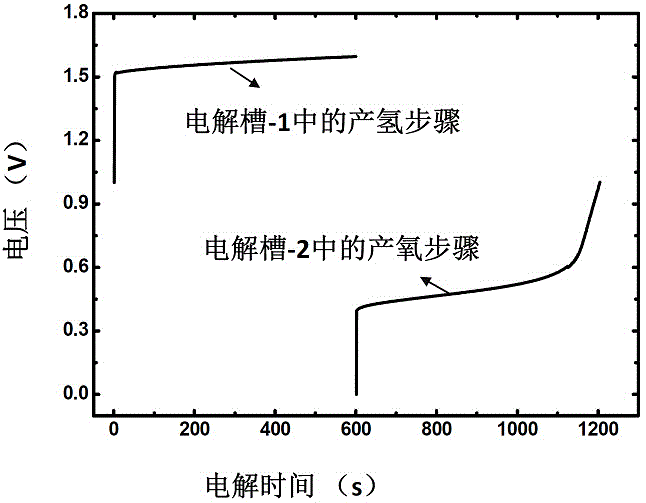

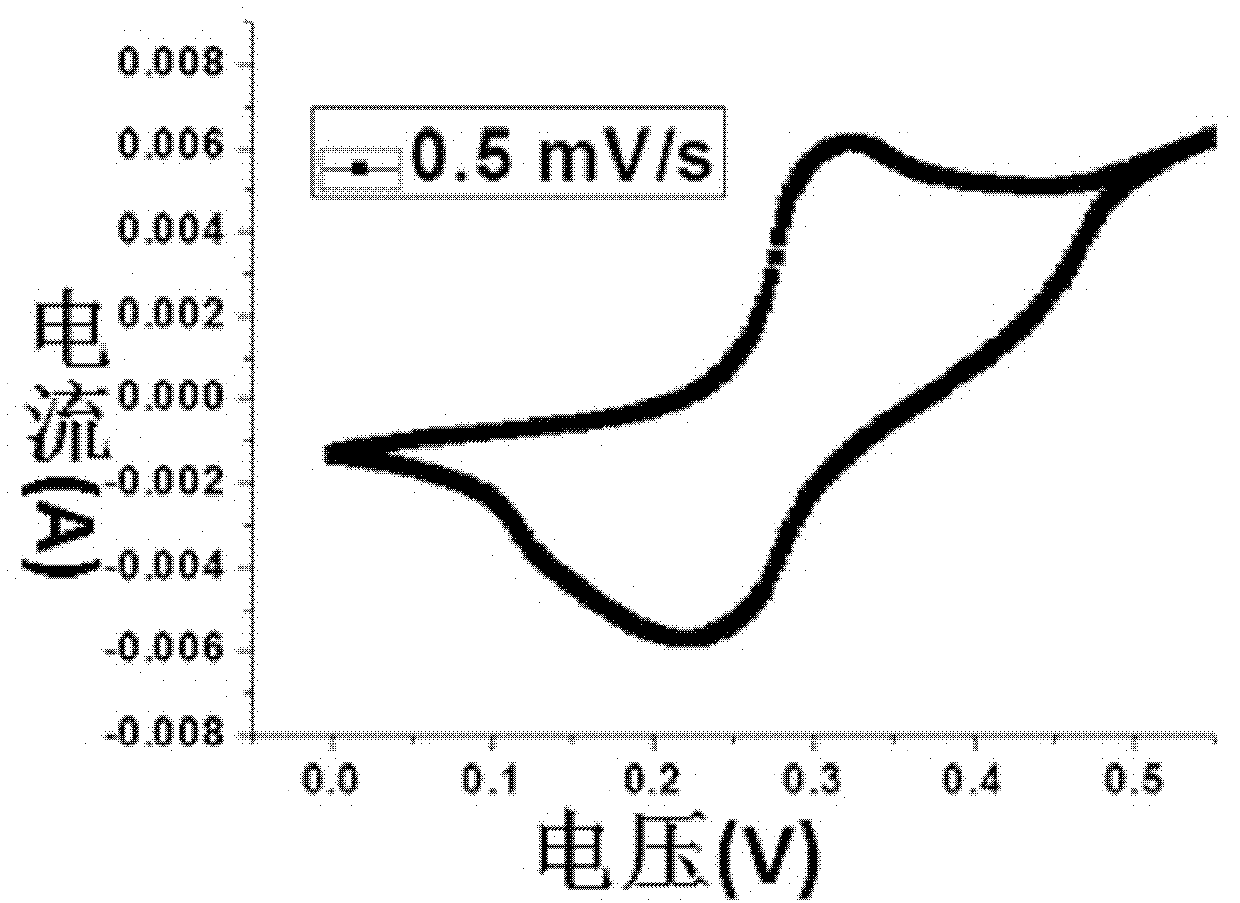

Two-step method and device for producing hydrogen through water electrolysis on basis of three-electrode system

The invention belongs to the technical field of water electrolysis, and particularly relates to a two-step method and device for producing hydrogen through water electrolysis on the basis of a three-electrode system. According to the device, an electrolytic bath comprises a hydrogen evolution catalysis electrode, an oxygen evolution catalysis electrode and a nickel hydroxide electrode. According to the method, water molecules are electrochemically reduced to hydrogen gas on the surface of the hydrogen evolution catalysis electrode, a Ni(OH)2 electrode is electrochemically oxidized to form a NiOOH electrode at the same time, and electrons flow to the hydrogen evolution catalysis electrode from the Ni(OH)2 electrode through an external circuit in the process; the NiOOH electrode is electrochemically reduced to the Ni(OH)2 electrode, hydroxyl ions are electrochemically oxidized to form oxygen gas on the surface of the oxygen evolution catalysis electrode, and the electrons flow to the NiOOH electrode from the oxygen evolution catalysis electrode through the external circuit in the process. According to the device and the method, the hydrogen production step and the oxygen production step which are synchronous in conventional water electrolysis are effectively separated, the high-purity hydrogen gas can be prepared without any diaphragms through the electrolysis device because the hydrogen production step and the oxygen production step are completely separated, and therefore the cost of producing the hydrogen through water electrolysis is lowered further.

Owner:FUDAN UNIV

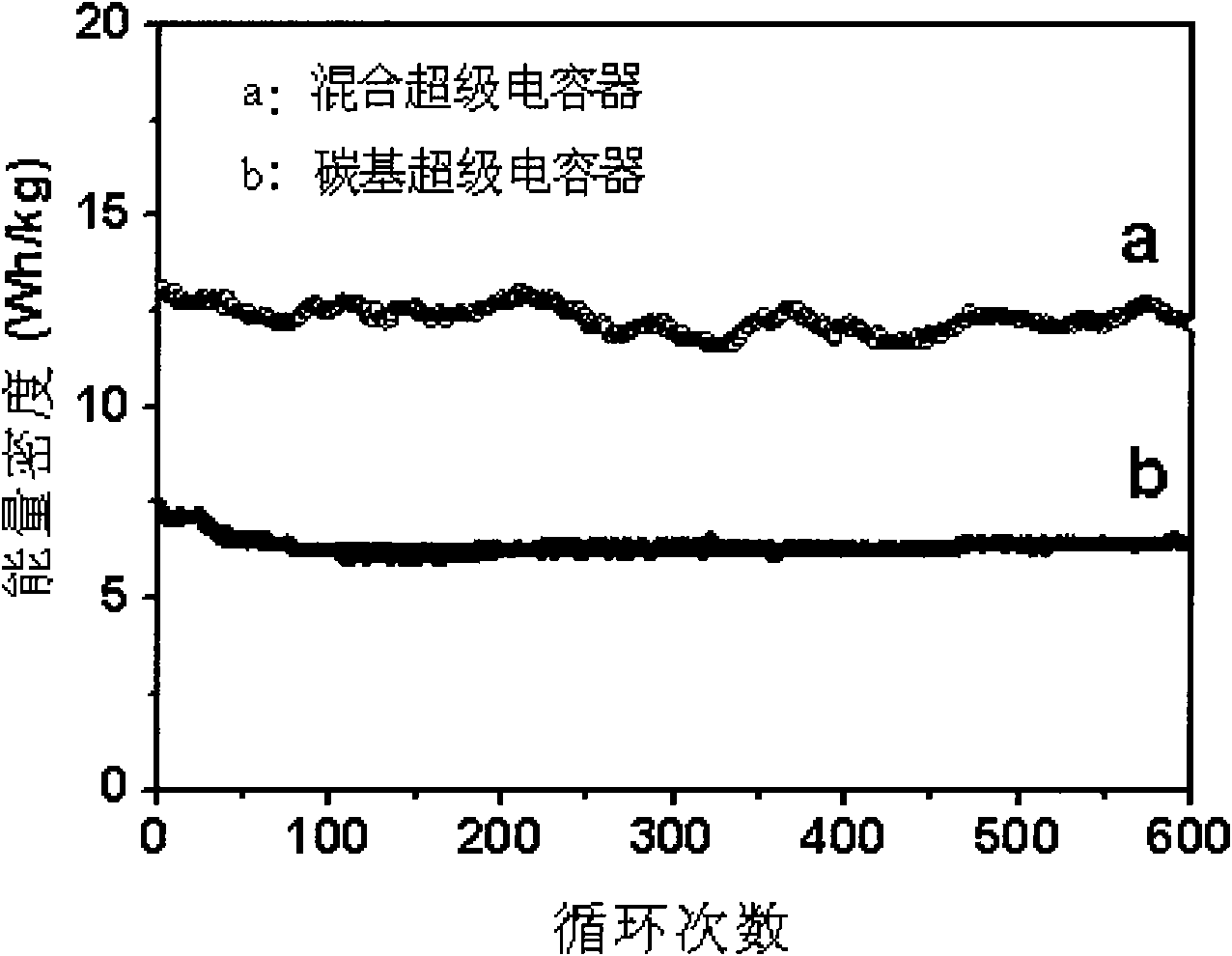

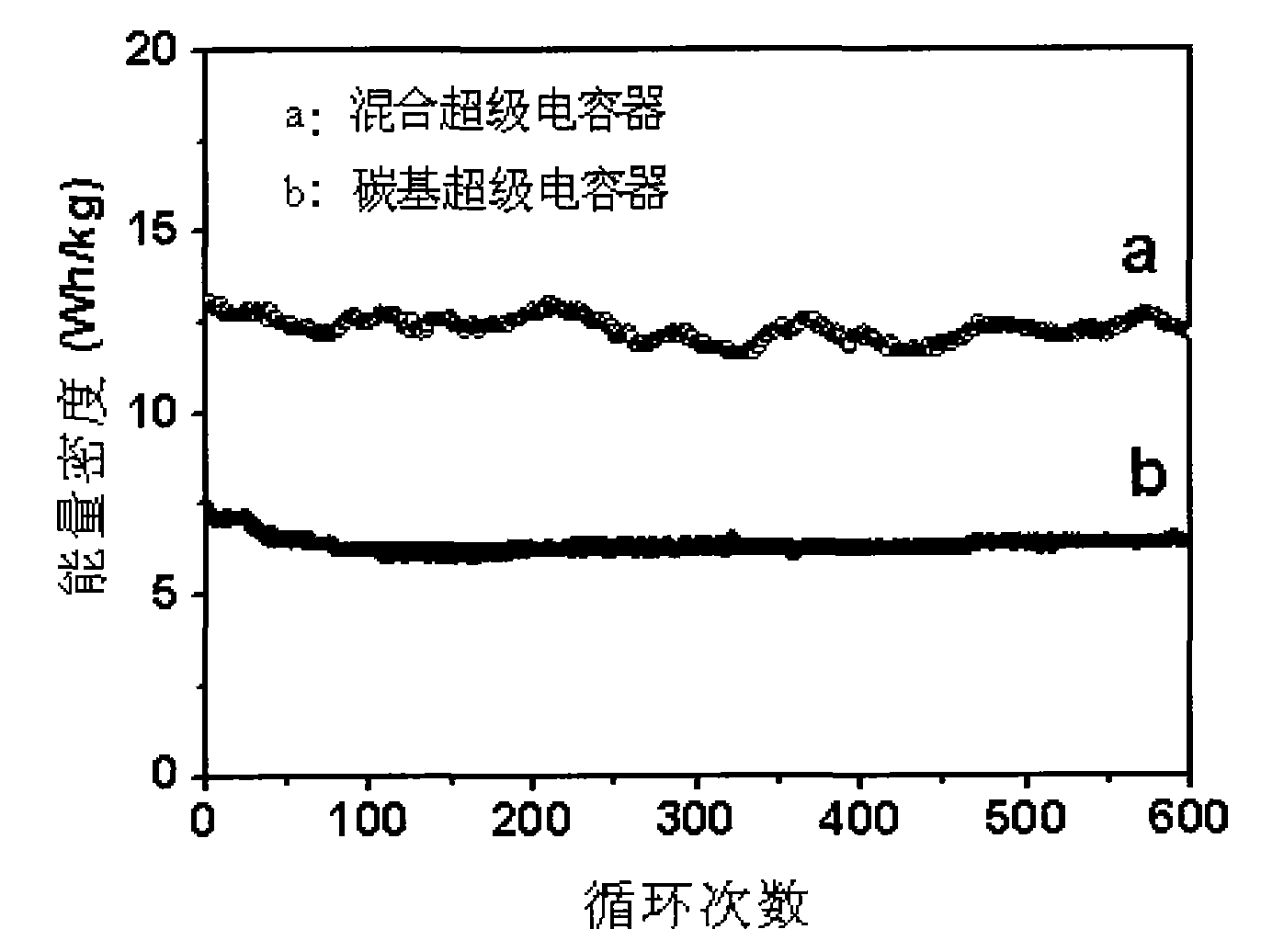

Hybrid super capacitor and manufacture method thereof

InactiveCN101840792AHigh specific capacityLower potentialHybrid capacitorsDouble layer capacitorsFiberManganese

The invention discloses a hybrid super capacitor and a manufacture method thereof, belonging to novel energy storage elements and the technical field of manufacture thereof. A negative active material of the hybrid super capacitor is one or more of polymorphs TiO2-B of nano TiO2 or TiO2, and a positive active material thereof is one or more of carbon nano tube, carbon nano fiber, graphite, conductive carbon black, nickel hydroxide, manganese hydrate or molybdenum hydroxide. The hybrid super capacitor manufactures electrodes by adopting positive and negative active materials, a binder and a conductive agent as raw materials, and assemblies the electrodes into a simulative battery in a glove box so as to manufacture the hybrid super capacitor. The manufacture method provided by the invention has adjustability, simple manufacture process and easy operation, and the assembled hybrid super capacitor has the characteristics of high capacitance, low potential, stable performance, charge and discharge with large current, long cycle life, low cost, easy implementation for mechanized and large-scale production and the like.

Owner:TSINGHUA UNIV

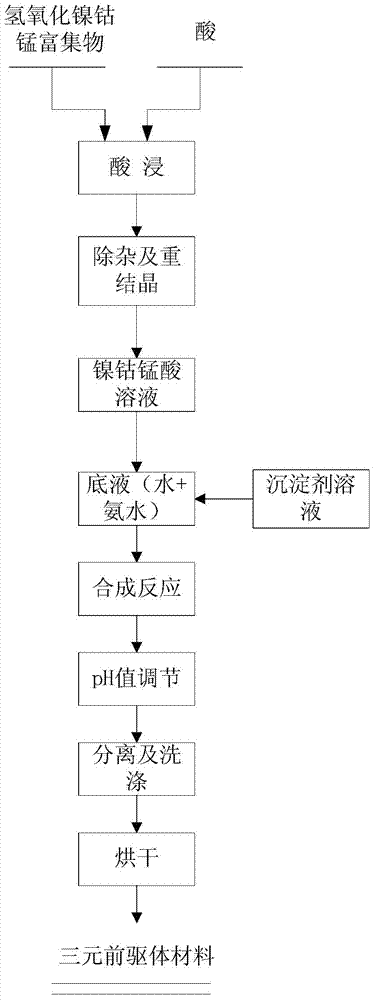

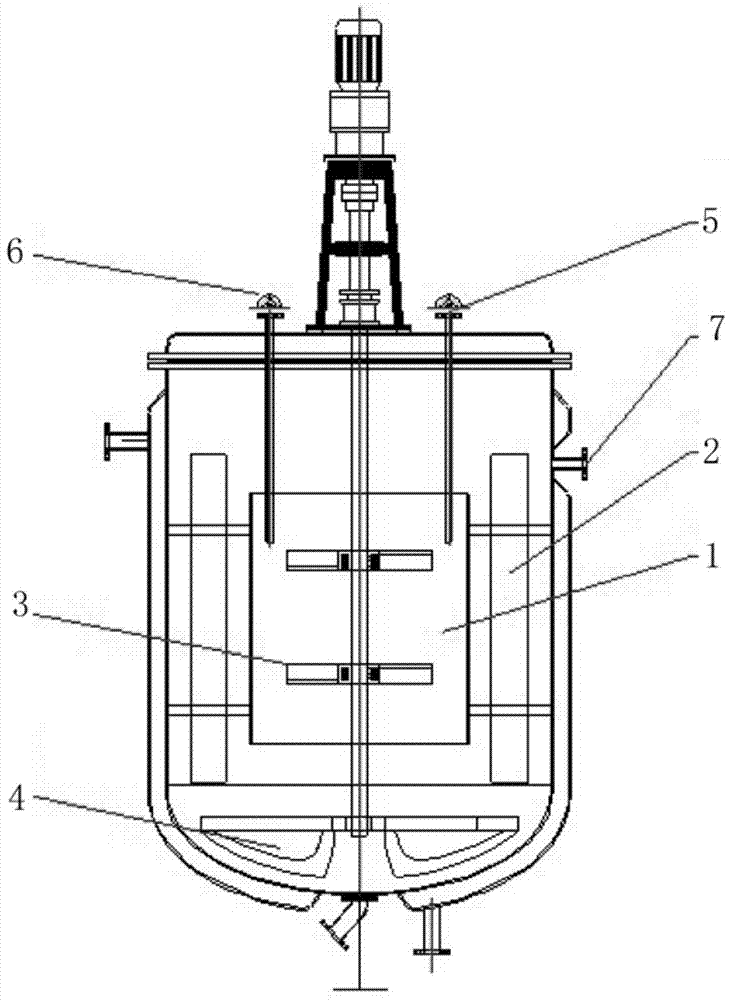

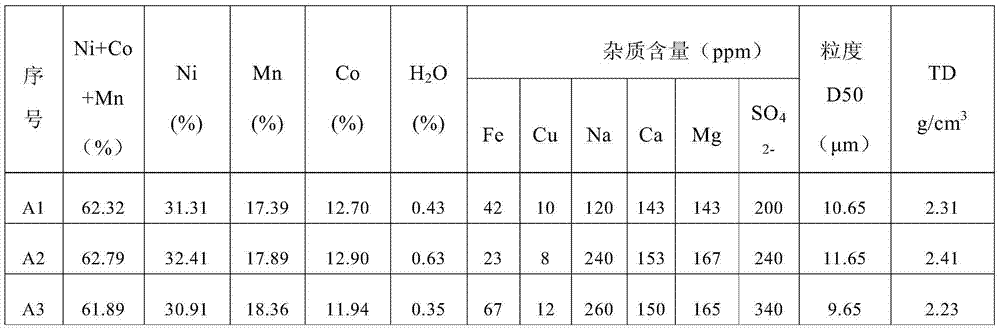

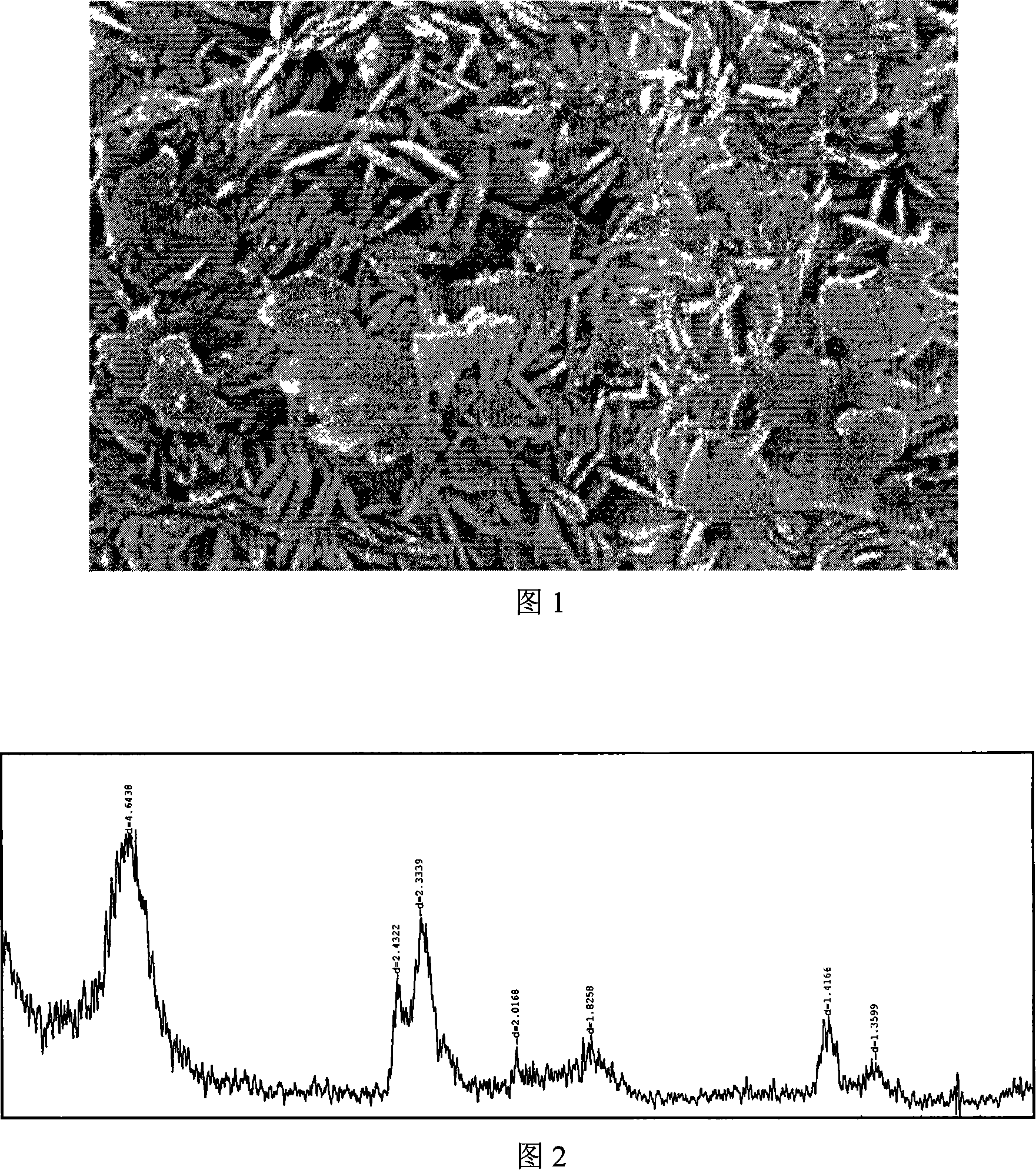

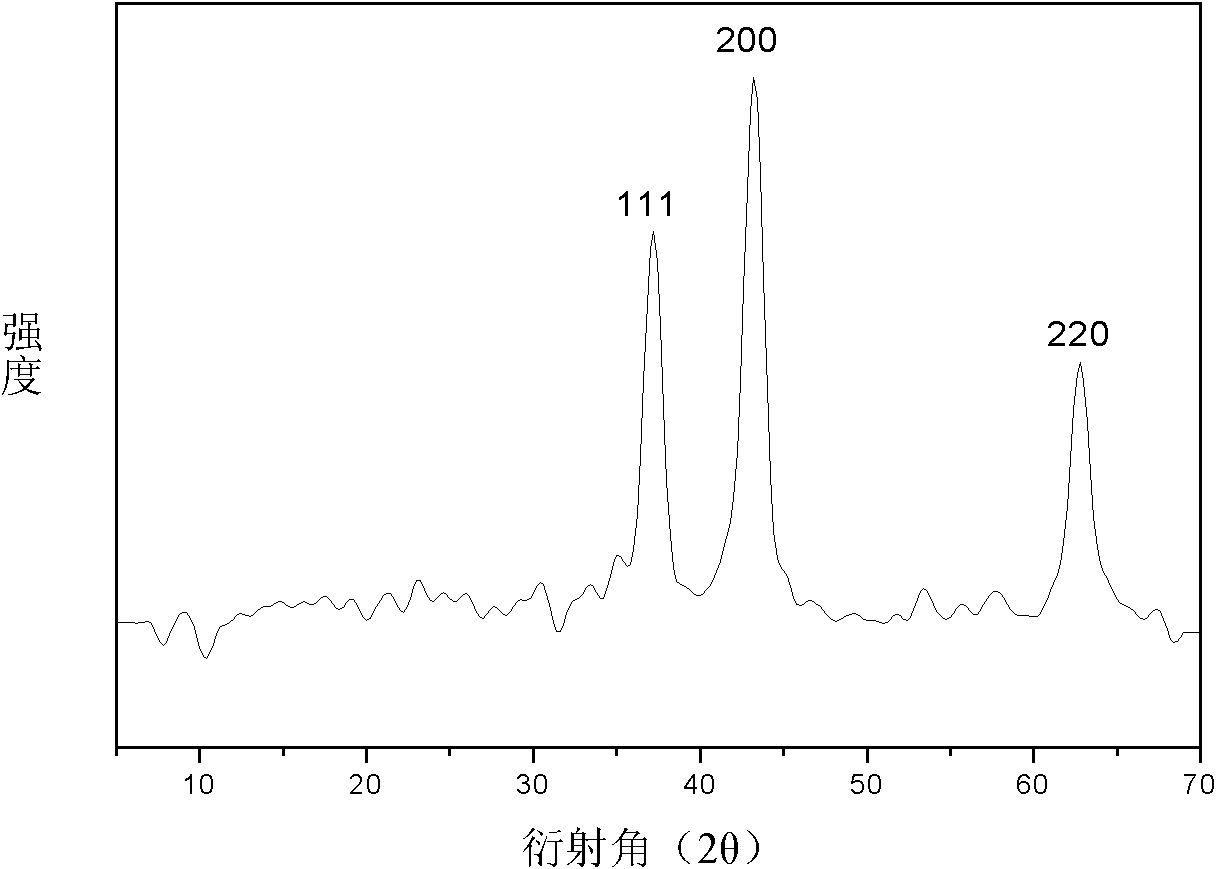

Preparation method of ternary anode material precursor

ActiveCN103545504AReduce manufacturing costLow costCell electrodesSecondary cellsNickel oxide hydroxideManganese

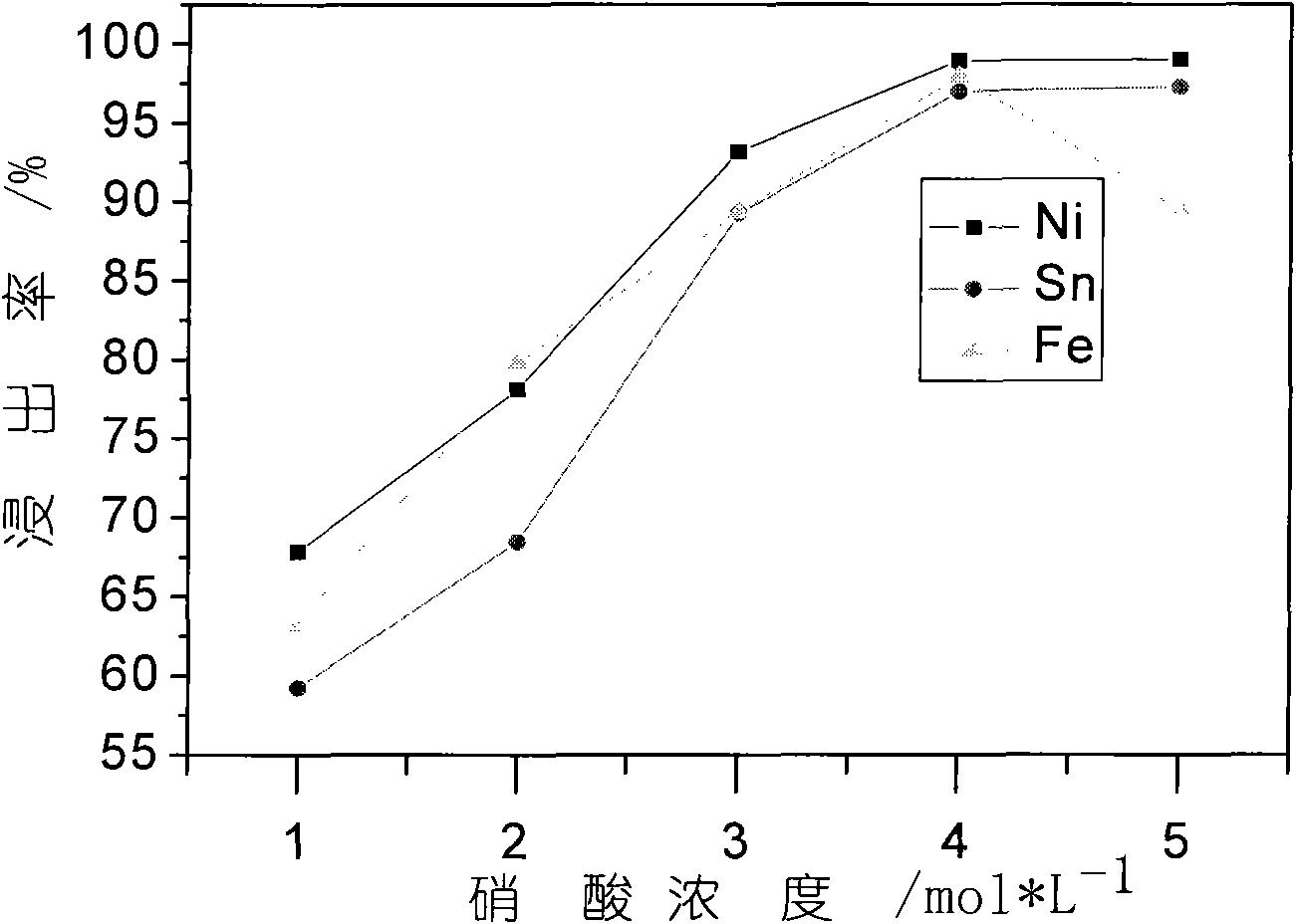

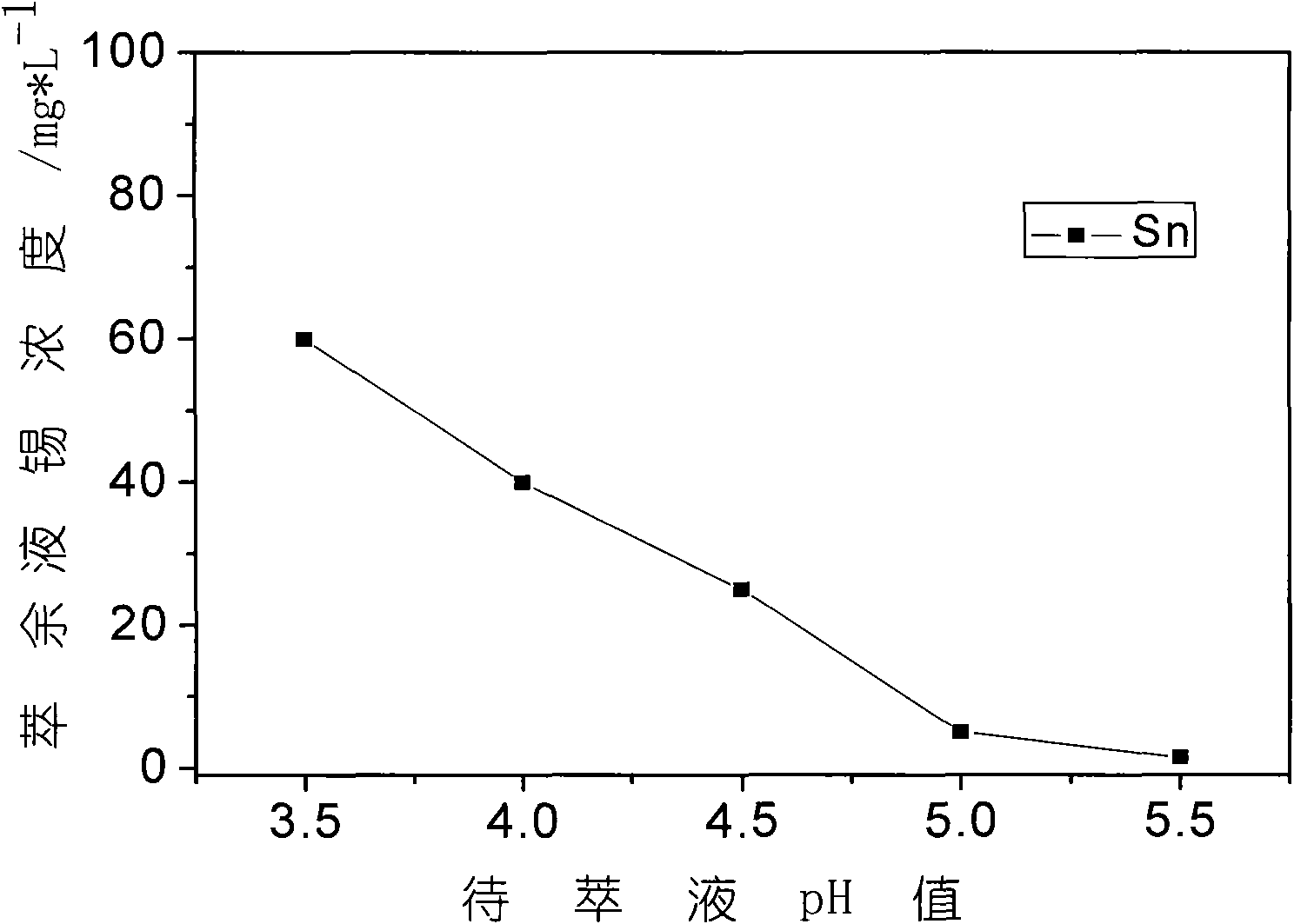

The invention discloses a preparation method of a ternary anode material precursor. According to the preparation method, an intermediate product namely nickel-manganese-cobalt hydroxide concentrate generated by producing electrolytic nickel from laterite, and the preparation process comprises the following process flows: A, acid leaching; B, impurity removal and recrystallization; C, preparation of a mixed salt; D, preparation of a precipitant; E, synthetic reaction; F, adjustment of the pH value; G, separation and washing; H, drying. The ternary anode material precursor prepared by the preparation method disclosed by the invention is uniform in particle size distribution, high in activity, high in density, high in specific capacity and low in cost.

Owner:江西赣锋循环科技有限公司

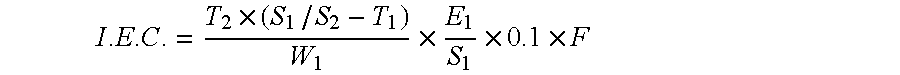

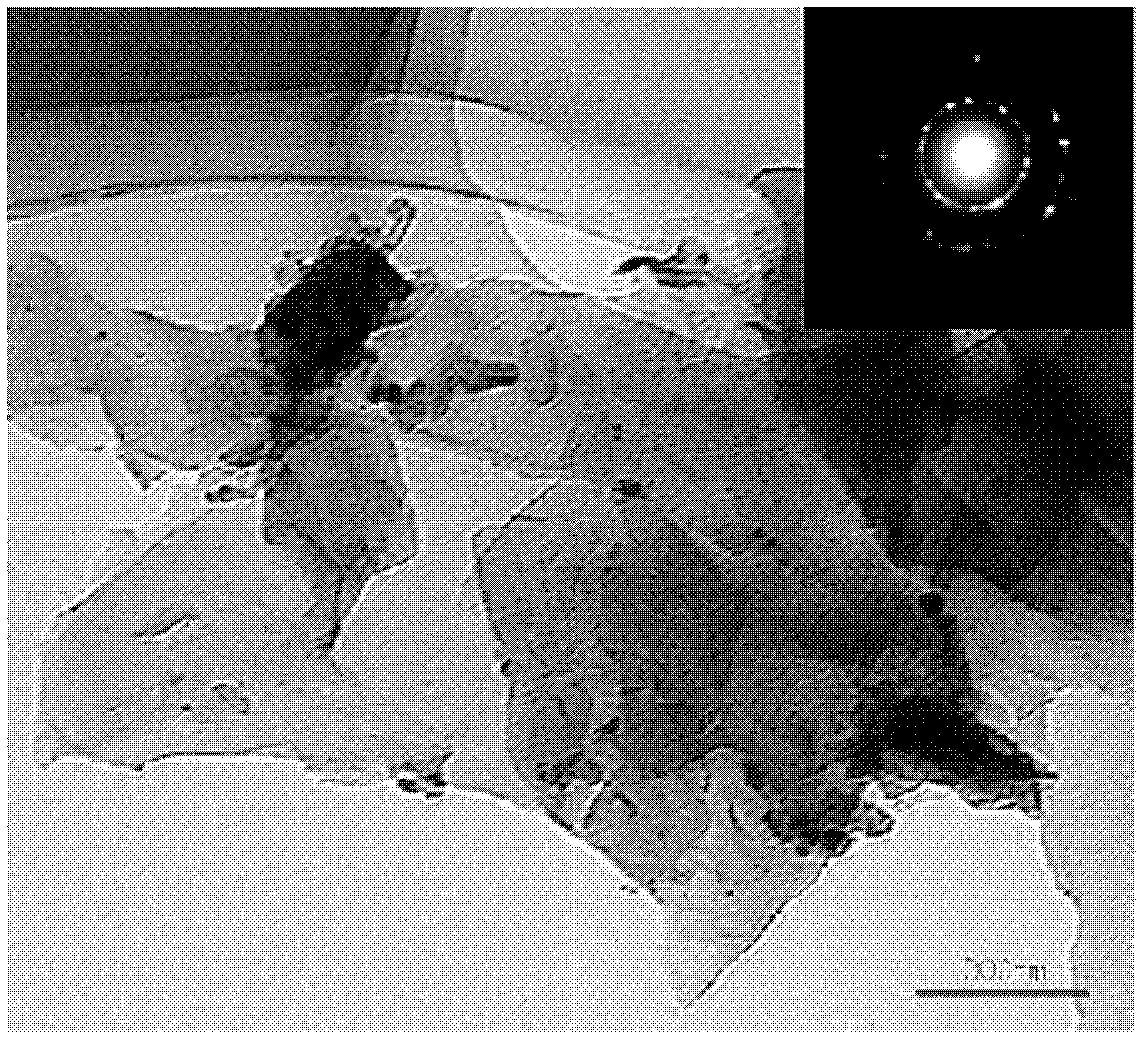

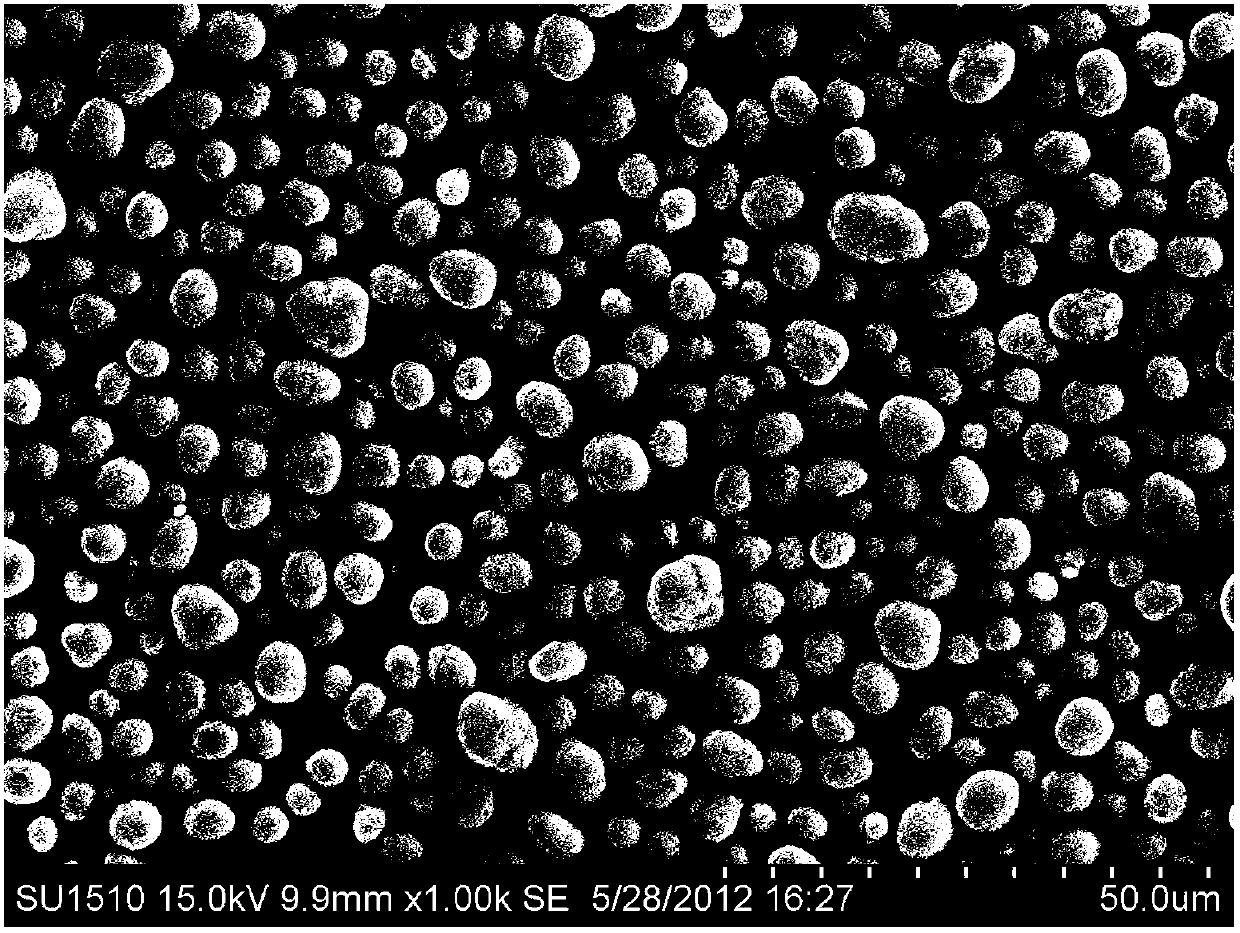

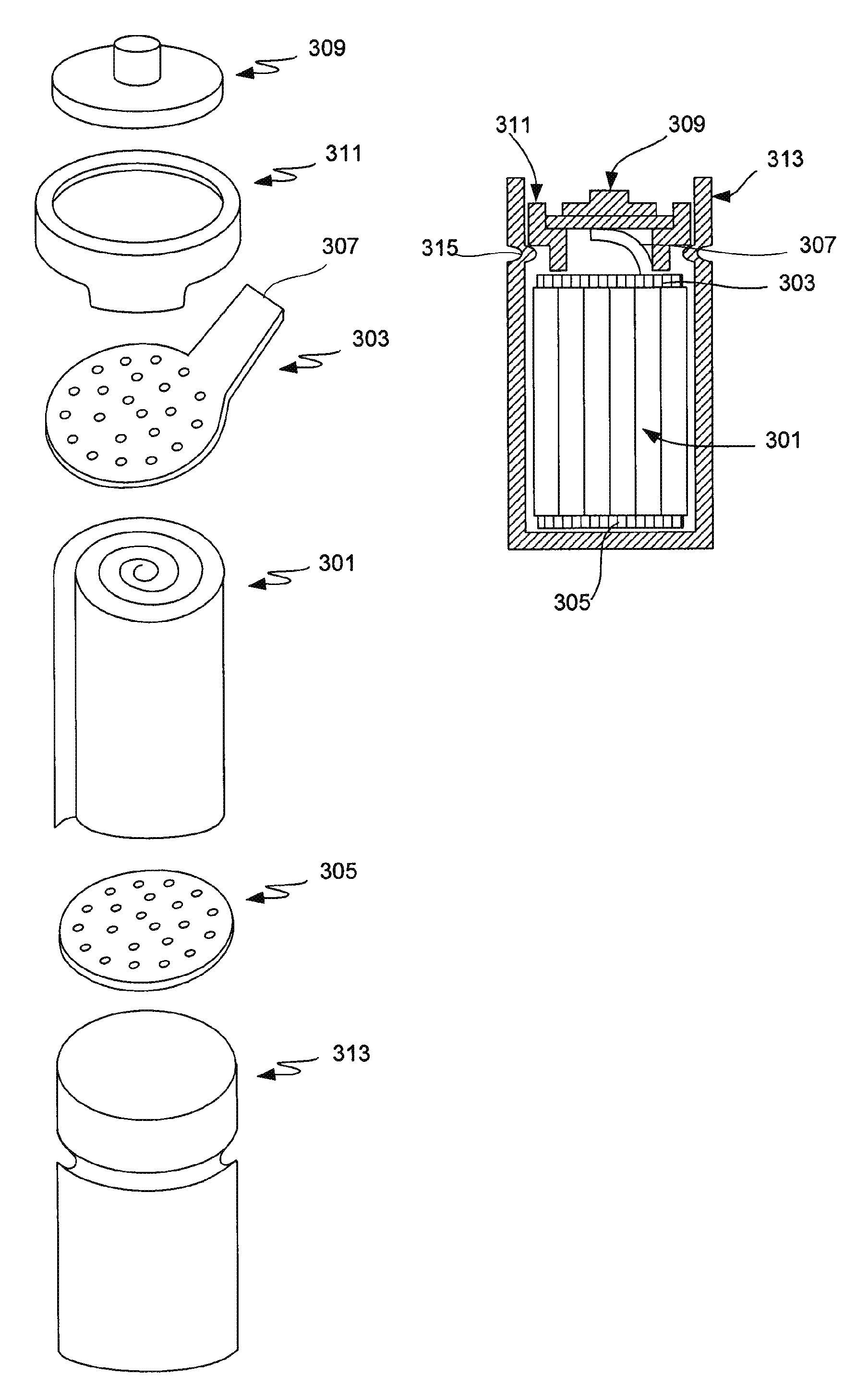

Making method of nickel hydroxide with coated gamma hydroxy cobalt oxide

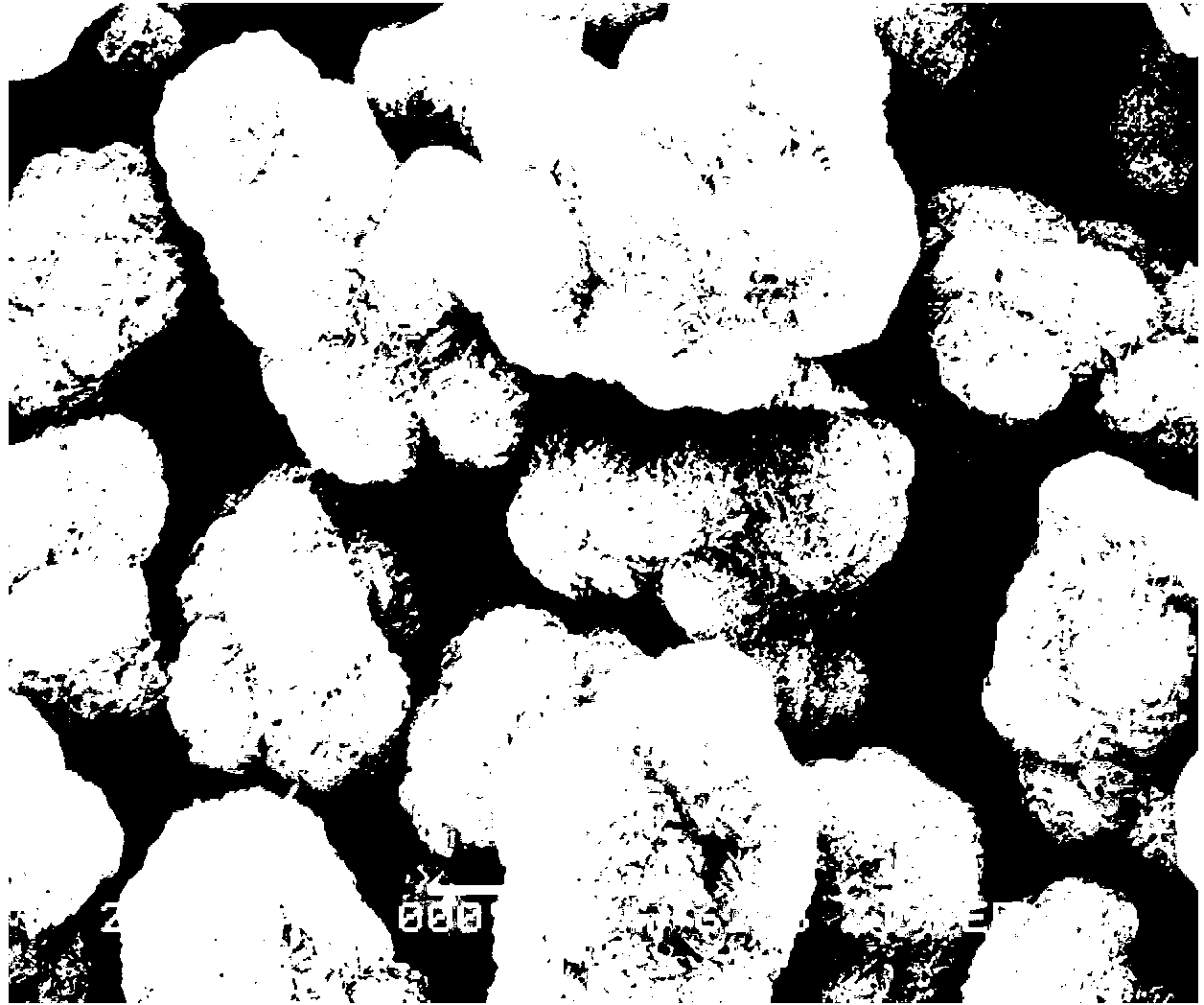

ActiveCN101106193AAlkaline accumulator electrodesNickel oxides/hydroxidesHigh densityNickel oxide hydroxide

The invention relates to a preparation method for nickel hydroxide, which is used as a Ni-H storage battery positive material, coated with gamma hydroxy cobalt oxide. The preparation includes that the sphere surface of nickel hydroxide is coated with a layer of cobalt hydroxide firstly; then, under the conditions of high-density sodium hydroxide and oxygen, the cobalt hydroxide layer coated on the surface is oxidized the gamma hydroxy cobalt oxide, or the treatment of embedding doped metals is exerted on the gamma hydroxy cobalt oxide layer. By controlling the coating layer to be the cobalt hydroxide presenting a shape of flake, the method makes the resulted conducting network coated with the coating layer of gamma hydroxy cobalt oxide more uniform, more integrated and better conductive, and thus attributes the nickel hydroxide positive active material coated with gamma hydroxy cobalt oxide with some characteristics of high recovering rate of over-discharging capacity, good performance of big current discharging, low self-discharging, long lifetime of cycling use and so on.

Owner:JINCHI ENERGY MATERIALS CO LTD

Three-electrode system double-electrolytic bath two-step water-electrolytic hydrogen producing device and method

The invention belongs to the technical field of water electrolysis and particularly relates to a three-electrode system double-electrolytic bath two-step water-electrolytic hydrogen producing device and method. The electrolysis device comprises two independent electrolytic baths 1 and 2, a hydrogen evolution catalyzing electrode, an oxygen evolution catalyzing electrode, a nickel hydroxide electrode and an alkaline electrolyte. According to the electrolysis device, the water electrolysis process is divided into two steps of hydrogen production and oxygen production which are respectively and alternately carried out in the two electrolytic baths 1 and 2. The device has the advantages that the steps of hydrogen production and oxygen production which are simultaneously generated in conventional water electrolysis can be effectively separated and respectively completed in different electrolytic baths, so that high-purity hydrogen can be produced under the condition of adopting no diaphragm and the water-electrolytic hydrogen producing cost is further reduced.

Owner:FUDAN UNIV

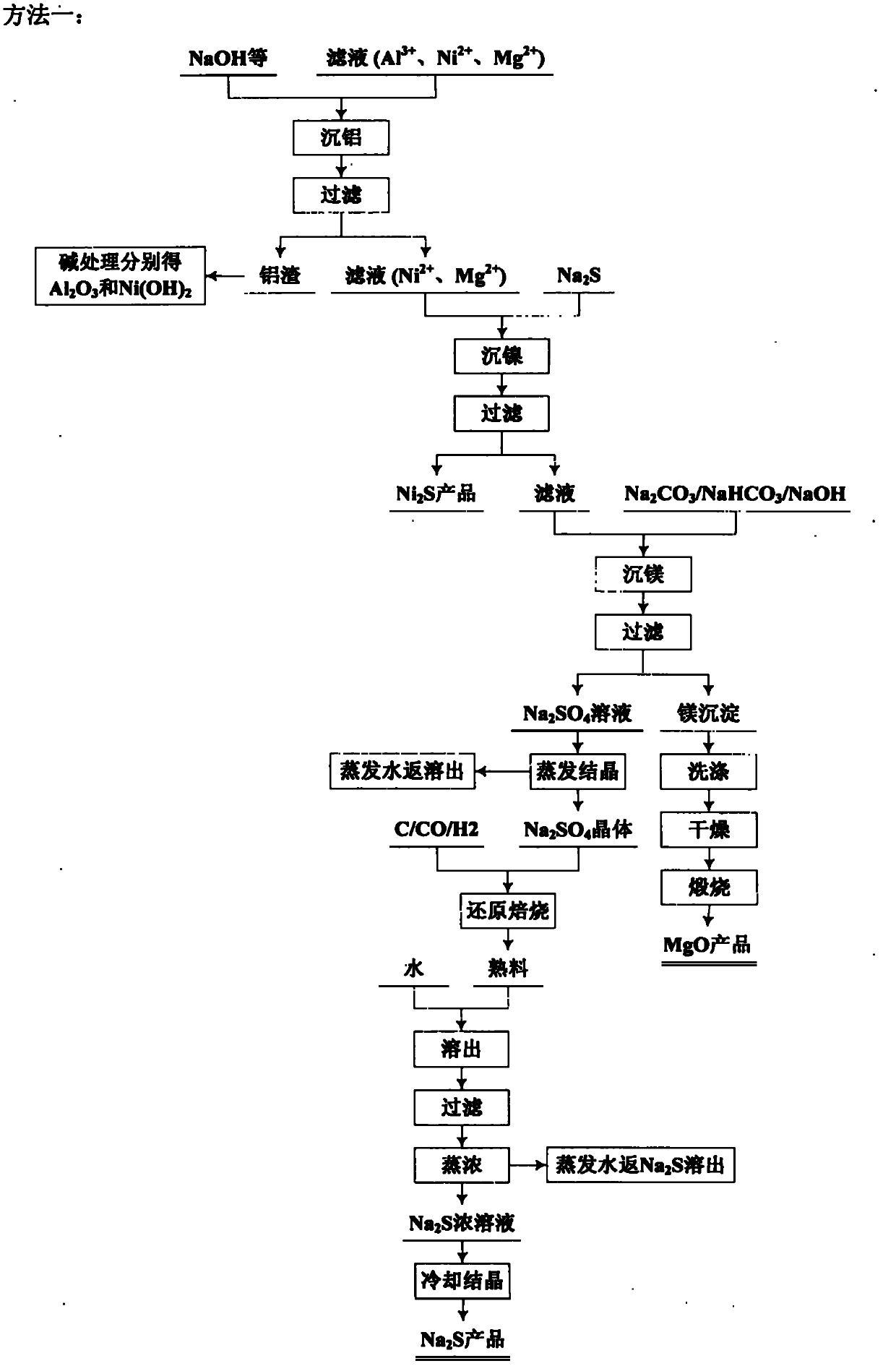

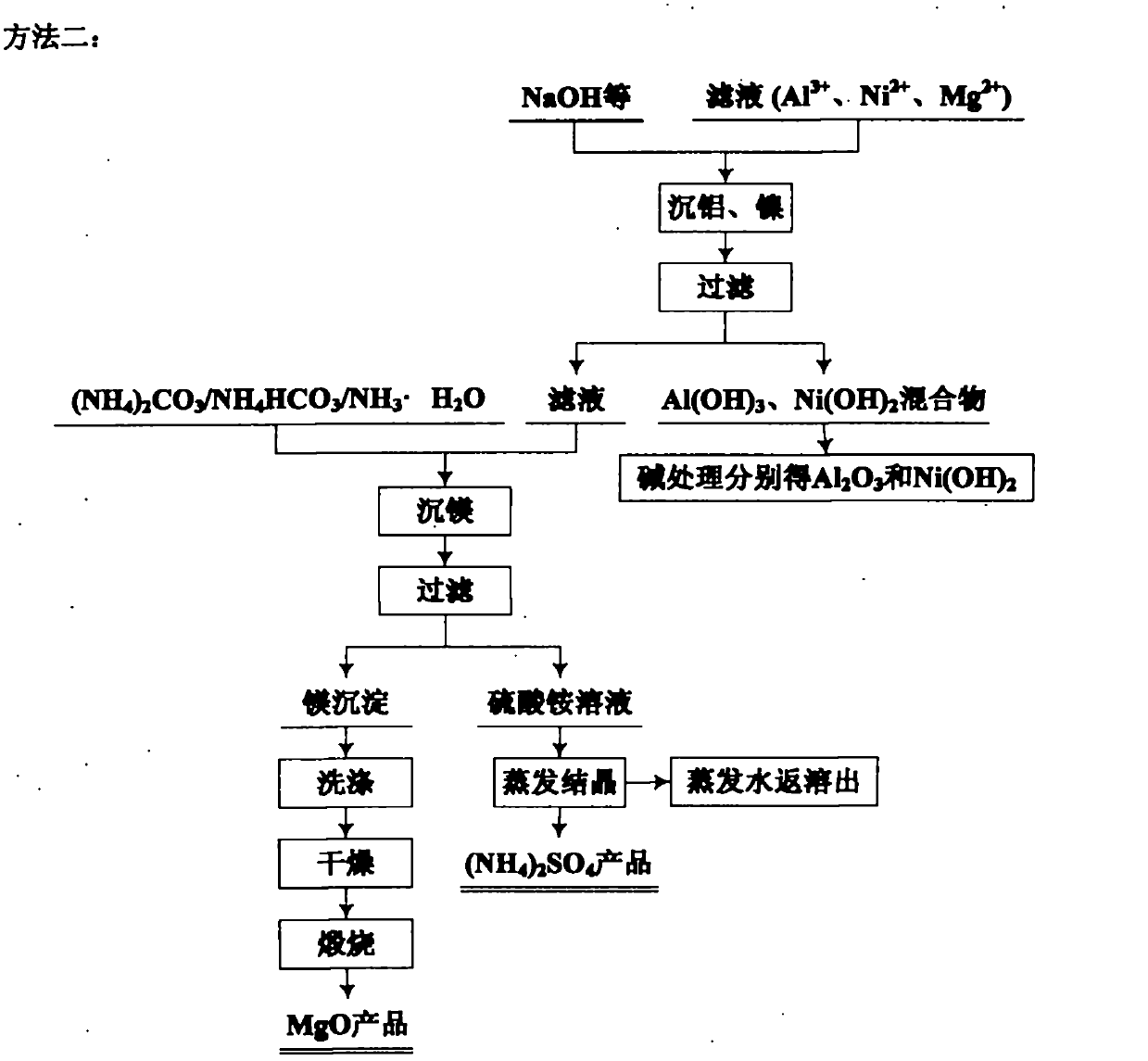

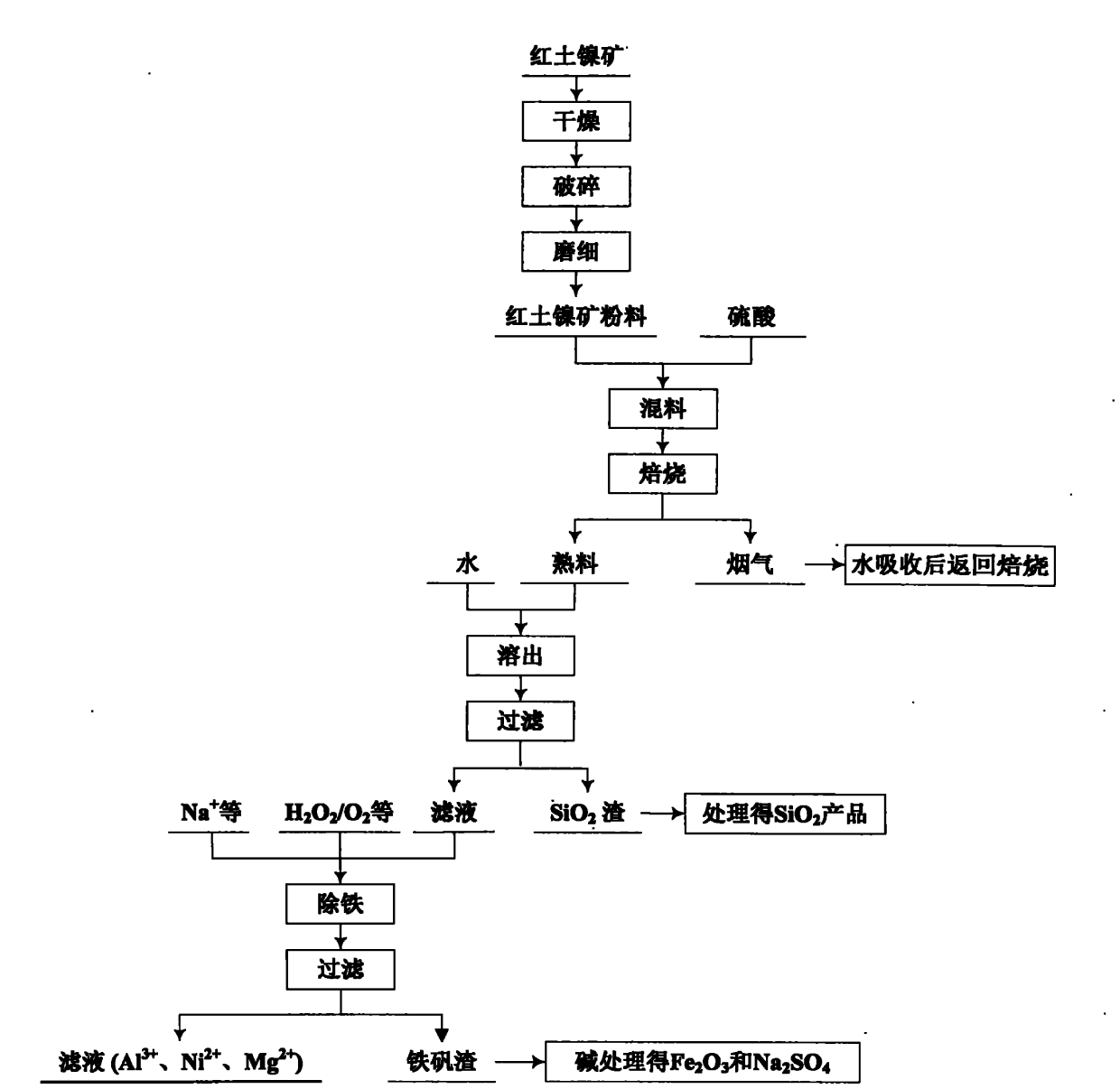

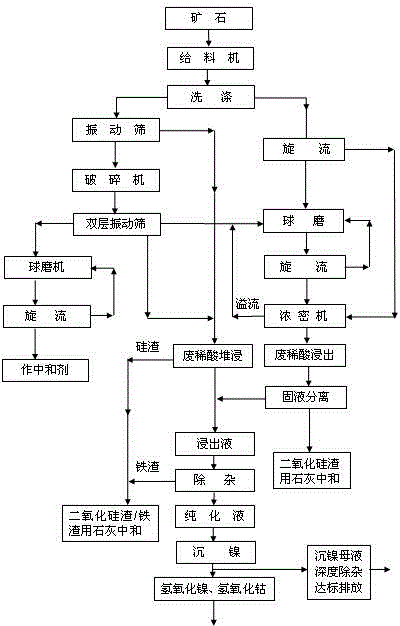

Comprehensive utilization method for laterite-nickel ore

The invention relates to an environmental-friendly comprehensive utilization method for a laterite-nickel ore, which comprises the following steps of: (1) grinding the laterite-nickel ore, mixing with sulfuric acid, roasting, dissolving out roasted clinker and filtering to obtain silicon dioxide and dissolution liquid; (2) deironing the dissolution liquid to obtain liquid No.2 and filter residue (iron compounds), wherein the liquid No.2 comprises aluminum, nickel and magnesium and can be treated by the step (3) or (4); (3) precipitating the aluminum in the liquid No.2 by using alkali, filtering, precipitating the nickel in filtrate by using sodium sulfide, filtering, precipitating the magnesium by using the alkali, and treating filter residue to obtain aluminum oxide, nickel hydroxide, nickel sulfide and magnesium oxide respectively; and (4) precipitating the aluminum and the nickel in the liquid No.2 by using the alkali, treating mixed slag containing the aluminum and the nickel by using the alkali to obtain aluminum hydroxide and nickel hydroxide products, and precipitating the magnesium in filtrate subjected to aluminum and nickel precipitation by using ammonia or ammonium saltto obtain a magnesium oxide product. The method is suitable for treating various laterite-nickel ores, three wastes (waste gas, waste water and waste residue) are not generated, and valuable components magnesium, nickel, iron, aluminum and silicon in the laterite-nickel ore are separated and extracted.

Owner:NORTHEASTERN UNIV

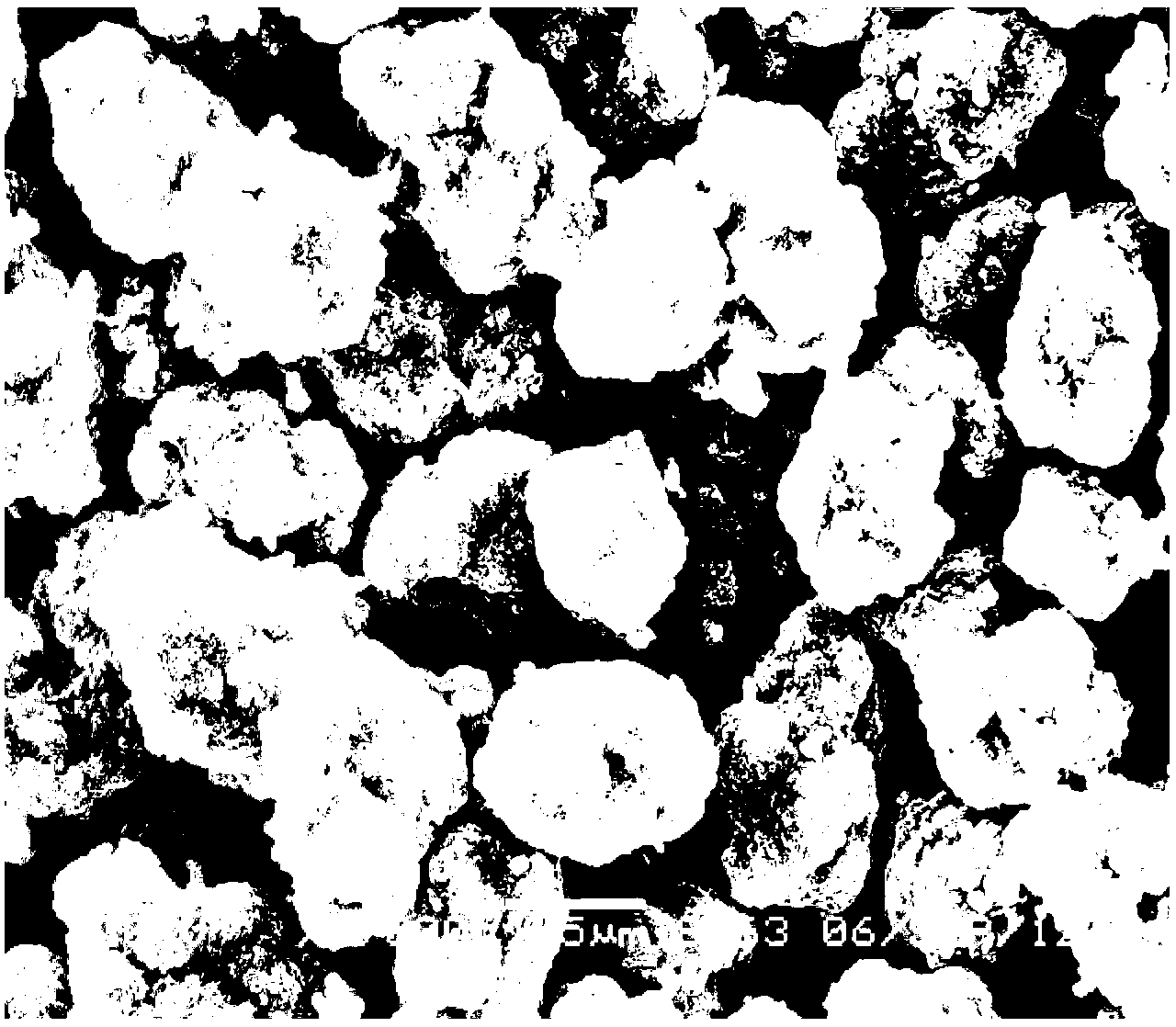

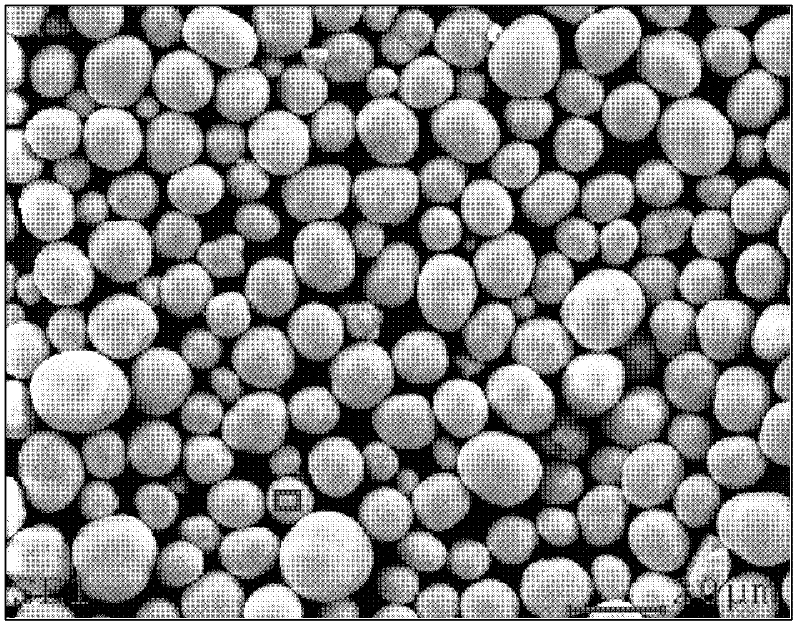

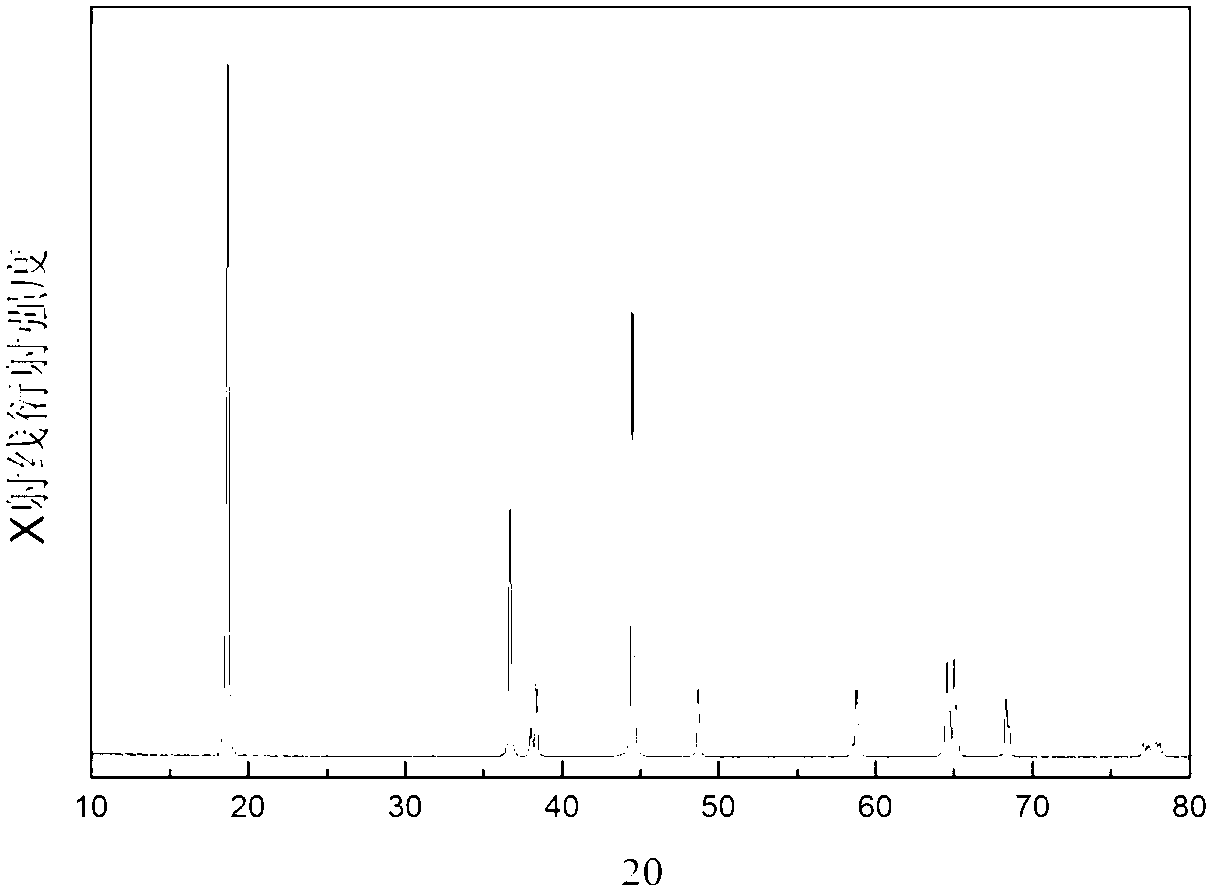

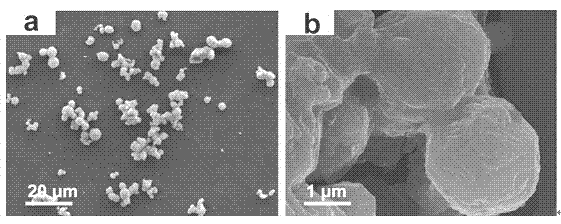

High density cobalt-manganese coprecipitated nickel hydroxide and process for its production

The present invention provides high density cobalt-manganese coprecipitated nickel hydroxide, particularly having a tapping density of 1.5 g / cc or greater, and a process for its production characterized by continuous supply of an aqueous solution of a nickel salt which contains a cobalt salt and a manganese salt, of a complexing agent and of an alkali metal hydroxide, into a reactor either in an inert gas atmosphere or in the presence of a reducing agent, continuous crystal growth and continuous removal.

Owner:TANAKA CHEM

Preparation method of lithium-ion battery positive electrode material spherical nickel-cobalt-lithium aluminate

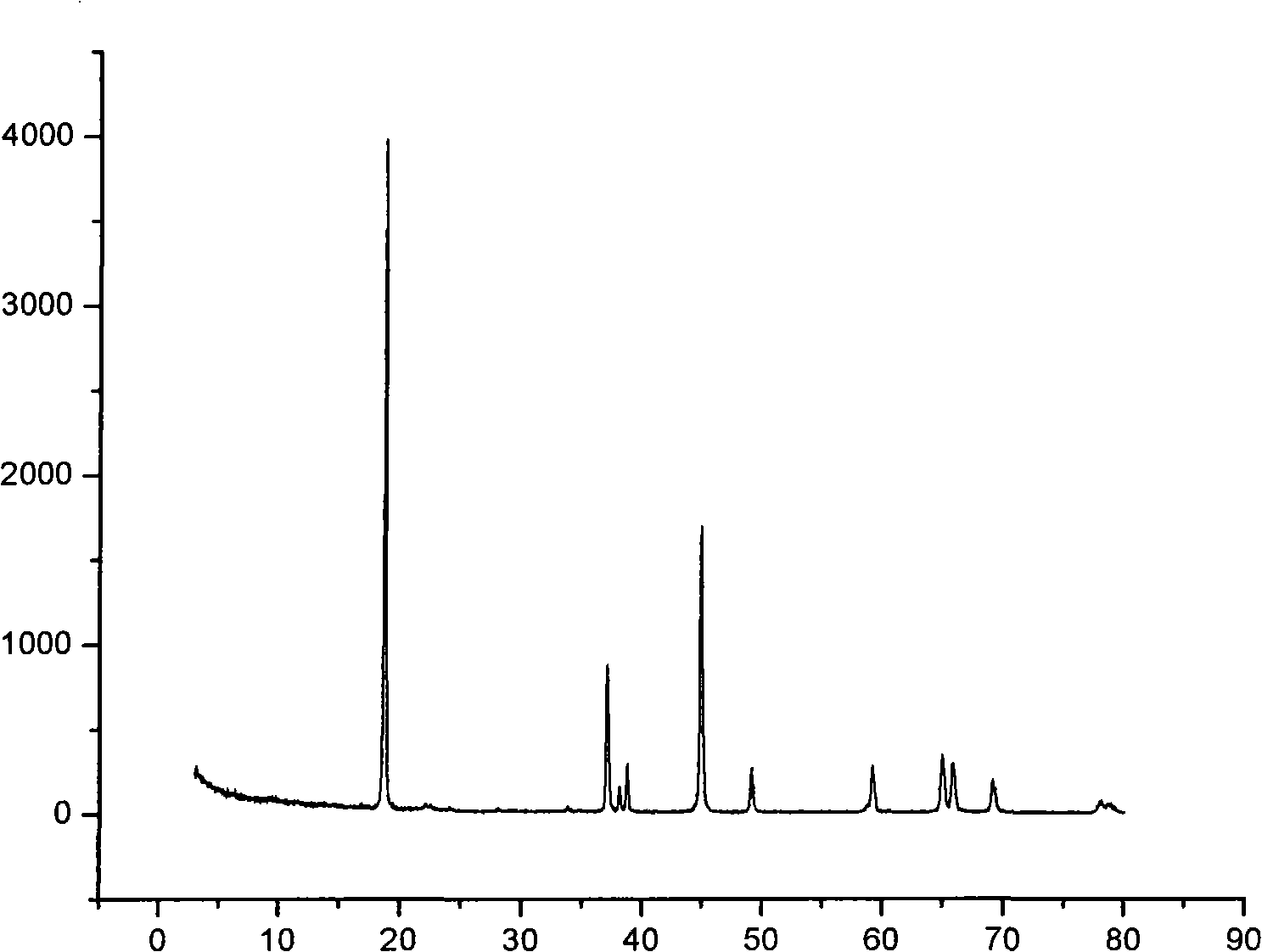

ActiveCN103296263AGuaranteed spherificationHigh tap densityCell electrodesNickel saltReaction temperature

The invention discloses a preparation method of lithium-ion battery positive electrode material spherical nickel-cobalt-lithium aluminate. The preparation method comprises the following steps of: firstly dissolving aluminum salt in deionized water, and preparing AlOOH aluminum sol by adding HNO3 or ammonium hydroxide and nitric acid; preparing nickel salt and cobalt salt into uniform aqueous solution according to a certain ratio; enabling the mixed salt solution to be collectively reacted with the aluminum sol and a mixed alkali solution, adjusting the pH value to be 9 to 12, controlling the reaction temperature, carrying out the solid-liquid separation after 20 to 30h of the reaction, and washing, filtering and drying the reaction product to obtain spherical nickel-cobalt-aluminum hydroxide precursor powder; then mixing the spherical nickel-cobalt-aluminum hydroxide precursor powder with lithium, sintering the mixture, and pulverizing and grading sintered material to obtain the lithium-ion battery positive electrode material spherical nickel-cobalt-lithium aluminate. The prepared spherical nickel-cobalt-lithium aluminate particles are controllable in shape and granularity, high in compacting density, high in specific discharge capacity, good in cycling stability and low in cost.

Owner:山东天骄新能源有限公司

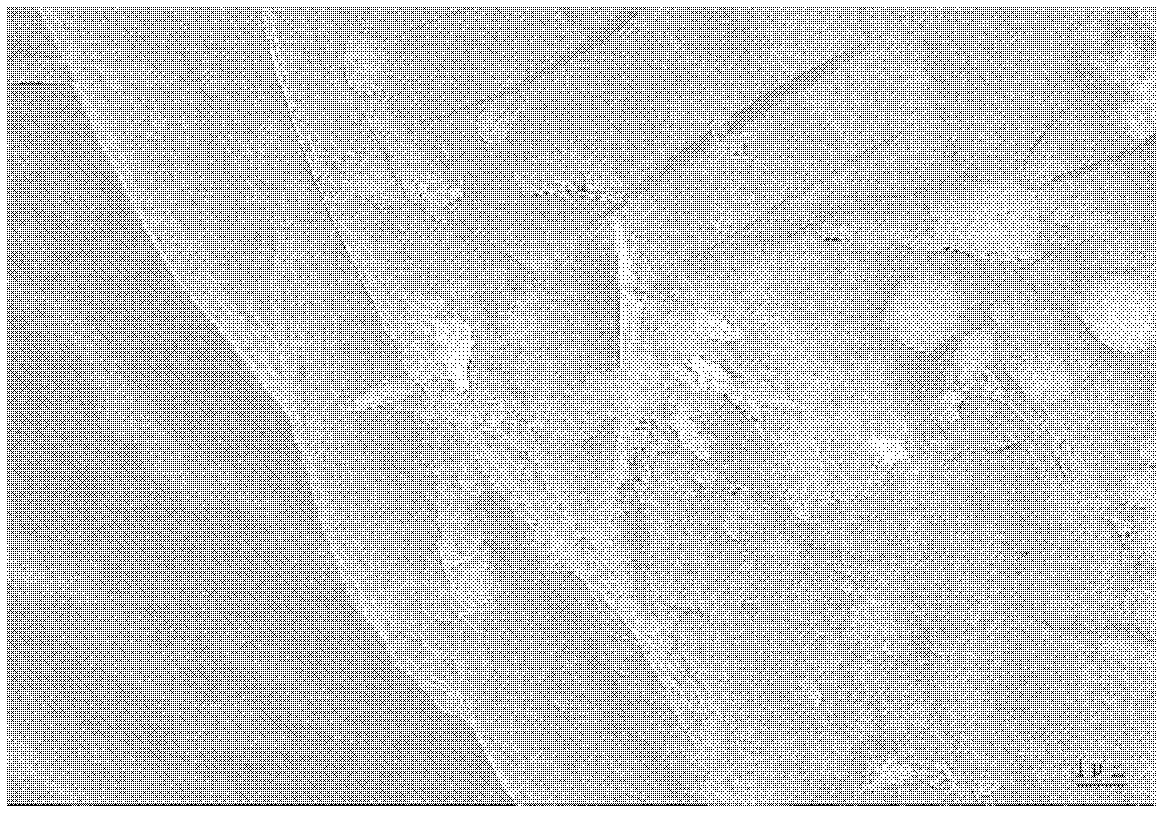

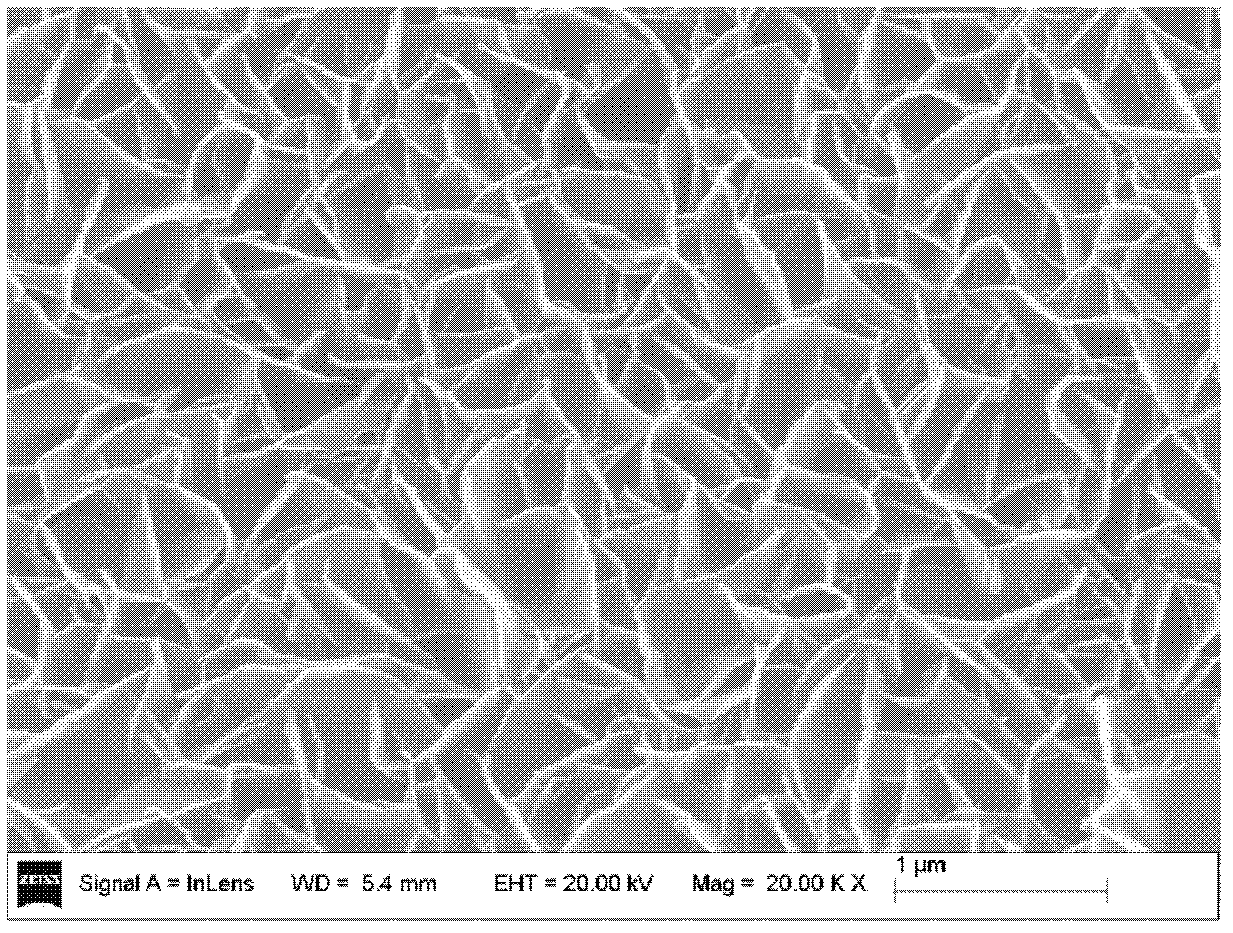

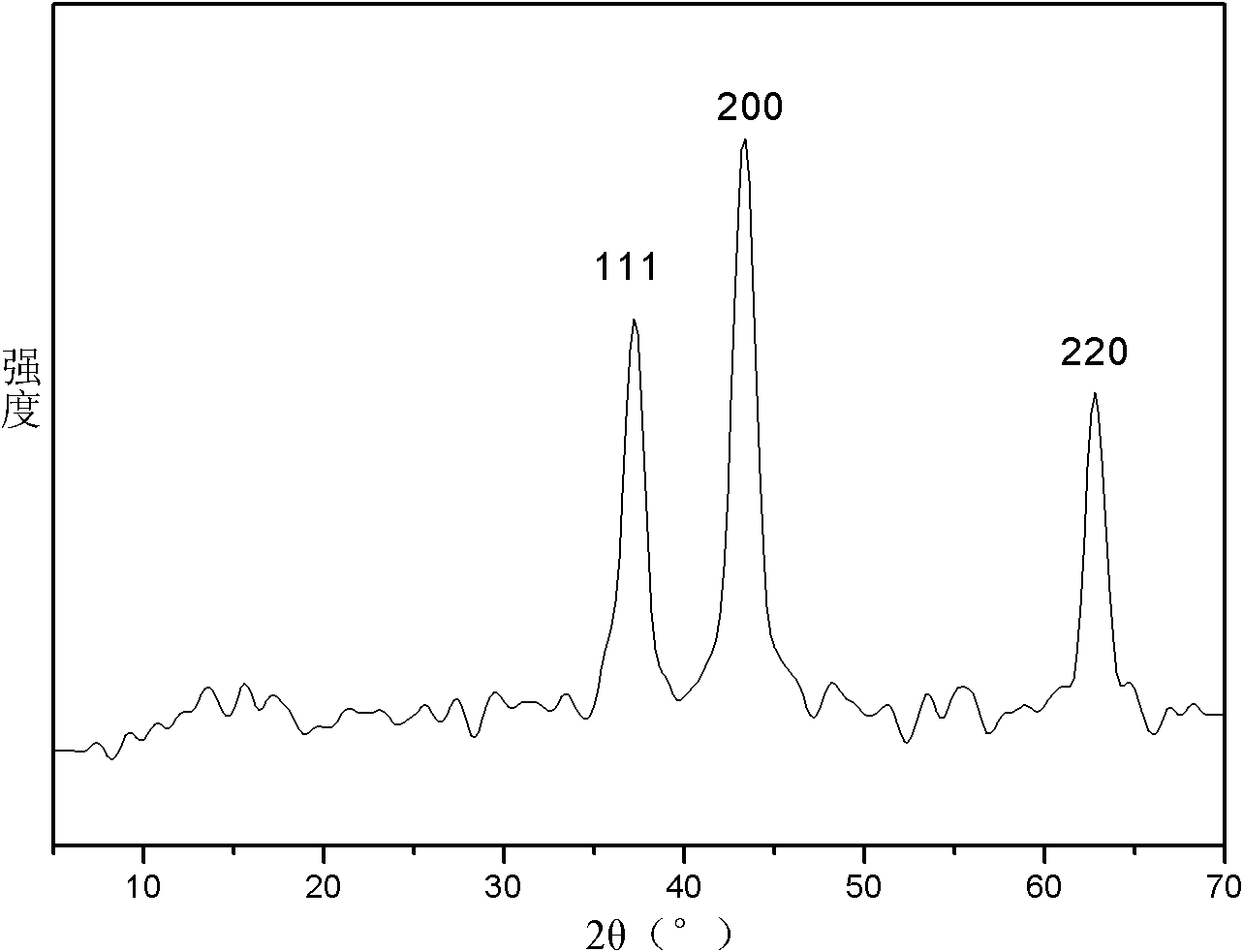

Nickel hydroxide nanosheet thin-film material as well as preparation method and application thereof

InactiveCN102891008AShape is easy to controlSimple methodElectrolytic capacitorsNickel oxides/hydroxidesHigh current densityCapacitance

The invention discloses a nickel hydroxide nanosheet thin-film material as well as a preparation method and application thereof, and belongs to the technical field of nanometer thin-film materials and the technical field of chemical energy storage. Nickel hydroxide nanosheets vertically and sequentially grow on a foam nickel base, wherein the particle size of the nickel hydroxide nanosheets is 0.7-1.5 microns and the thickness is 5-9 nanometers. The preparation method comprises the following steps of: respectively placing foam nickel base sheets in hydrochloric acid, ionized water and ethanol for ultrasonic washing, dissolving soluble nickel salt and hexamine in deionized water to obtain clear solution, obliquely placing the foam nickel sheets in a reaction still, transferring the nickel salt and hexamine solution to the reaction still to carry out hydrothermal reaction, cooling to room temperature by using cooling water after the reaction, taking the foam nickel sheets out from the reaction still for cleaning via water and ethanol, and placing the products in a dryer until the products are dried. The integrated product has large capacitance value (range: 1500-3000F / g or 5-12F / cm<2>), can be well kept under high-current density and has good cycle performance, so that the integrated product is a super capacitor material with huge application prospect.

Owner:BEIJING UNIV OF CHEM TECH

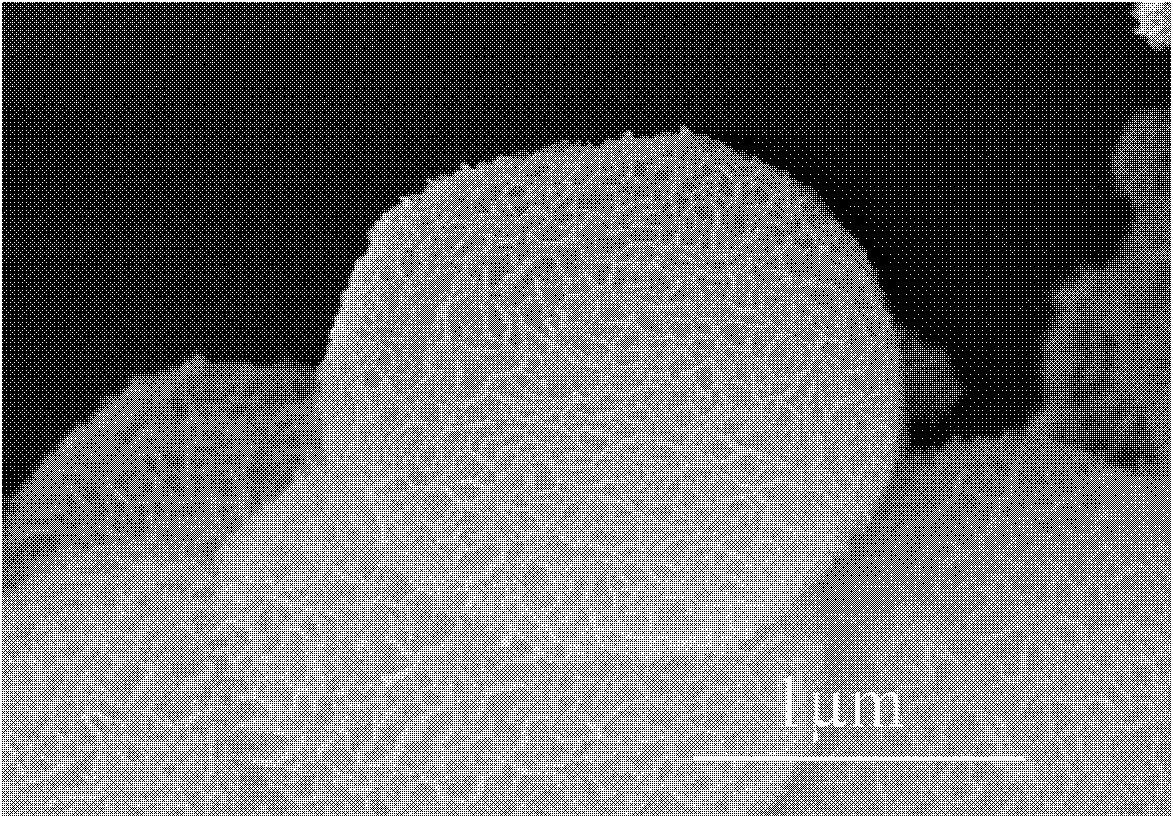

Method for preparing NiO nano flowerlike microspheres with surface topography controllable

InactiveCN102126762AGood for developing performanceGood for developing applicationsNanotechnologyNickel oxides/hydroxidesBenzoic acidNitrate

The invention discloses a method for preparing NiO nano flowerlike microspheres with surface topography controllable, belonging to the technical field of inorganic nano materials. The method is characterized by preparing the microspheres by a solvothermal method and comprises the following steps: dissolving a surfactant into a glycol solvent, respectively dissolving nickel nitrate and benzoic acid into the prepared solution, and later, adding a 2mol / L NaOH solution to form blue-green transparent mixed solution; putting the mixed solution into a stainless steel reactor with polytetrafluoroethylene lining to react; centrifuging the obtained turbid solution and then drying the obtained precipitate in a drying oven to obtain a nickel hydroxide precursor; and calcining the precursor in a muffle furnace to obtain the target products, namely NiO nano flowerlike microspheres. The microspheres prepared by the method have the characteristics of high specific surface area, multiple pore size distribution and high purity; and the preparation process is simple.

Owner:BEIJING UNIV OF CHEM TECH

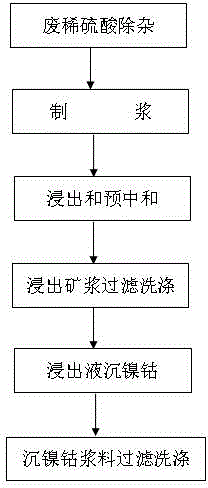

Method for leaching nickel and cobalt form low-iron and high-magnesium and high-iron and low-magnesium laterite-nickel ore by using waste dilute sulphuric acid

The invention provides a method for leaching nickel and cobalt from low-iron and high-magnesium and high-iron and low-magnesium laterite-nickel ore by using waste dilute sulphuric acid. Nickelous hydroxide, cobaltous hydroxide and the like are directly extracted by leaching the laterite-nickel ore with non-concentrated decolored and desalinated waste dilute sulphuric acid. The method specially comprises the steps of: removing impurities out of the waste dilute sulphuric acid, slurrying, leaching and pre-neutralizing, filtering and washing leached ore pulp, settling nickel and cobalt from leachate, filtering and washing nickel and cobalt settled slurry, electrically depositing nickel, and post-treating and recycling iron, magnesium, manganese and the like. The method provided by the invention overcomes the technical difficulty, ensures that a technology of a direct dilute sulphuric acid atmospheric pressure leaching process route operates stably, is greatly lowered in cost, is high in production efficiency, and is high in recycling rate of nickel, cobalt, iron, magnesium, manganese and other metals. The waste dilute sulphuric acid which is an byproduct in industries such as dye industry and is difficult to treat is effectively recycled, the method is environmental-friendly, any harmful gas is not emitted, waste slag is solid materials, trees can be planted on the waste slag for greening, the waste slag can be recycled, and waste water can completely reach the standard for emission.

Owner:杭州蓝普水务有限公司

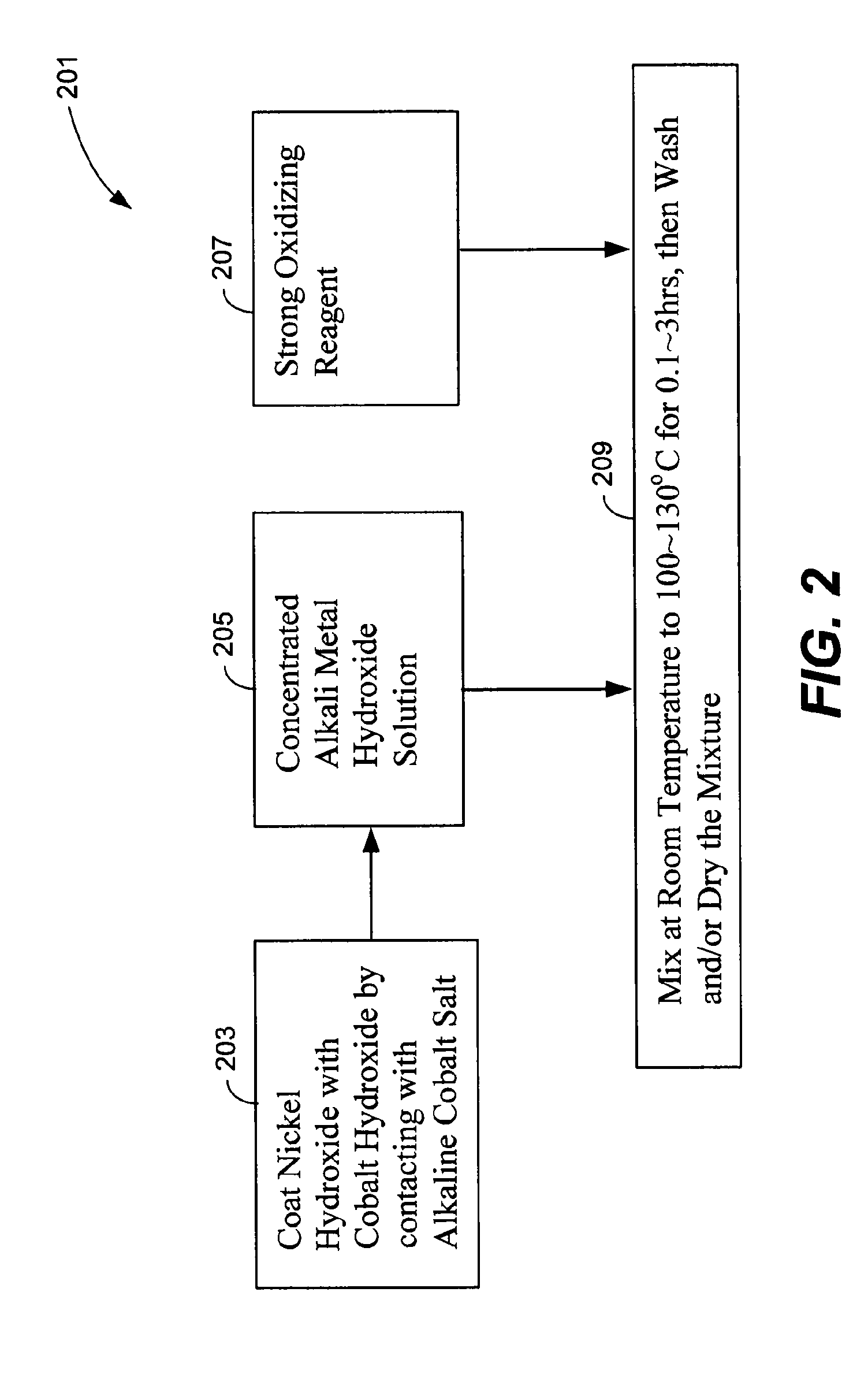

Method to make nickel positive electrodes and batteries using same

InactiveUS20010012586A1Large capacityImprove high temperature performanceElectrode manufacturing processesAlkaline accumulator electrodesAlkaline earth metalConductive polymer

This invention discloses a method to make a positive electrode and the nickel hydride battery using same. The positive electrode at least comprises a nickel hydroxide plus 1-15 wt. % of fine additive powders selected from the group consisting of Co / CoO, Ni, Cu, Zn, ZnO, C, Mg, Al, Mn, silver oxide, hydride, conductive polymer, and combinations thereof. Said positive electrode further comprises one, two or more additives, 0.01-10 wt. %, selected from the group of MgCl2, CaCl2, SrCl2, SrF2, BaCl2, BaF2, MgF2, and other fluorides / chlorides of alkali metals, alkaline earth metals, Al, Y, Sn, Sb, Ag, transition metals, rare earth metals, and composite metal oxide / halide to improve the performance of said positive electrode at high temperature.

Owner:HONG KUOCHIH +1

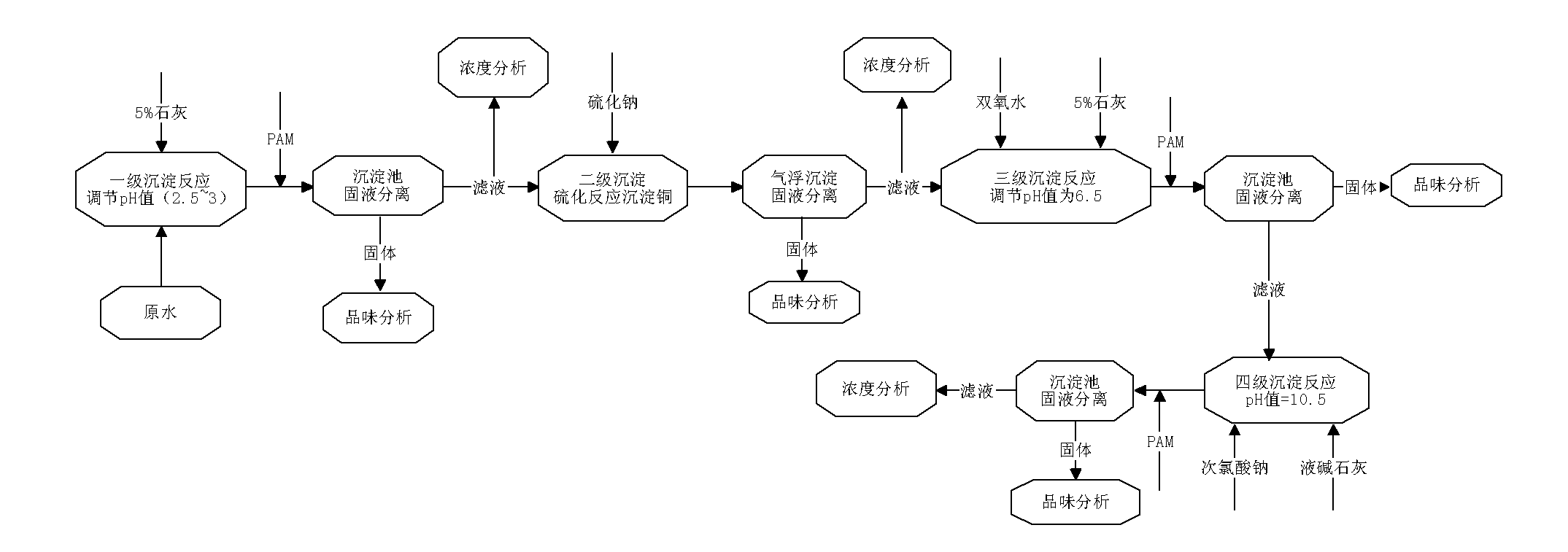

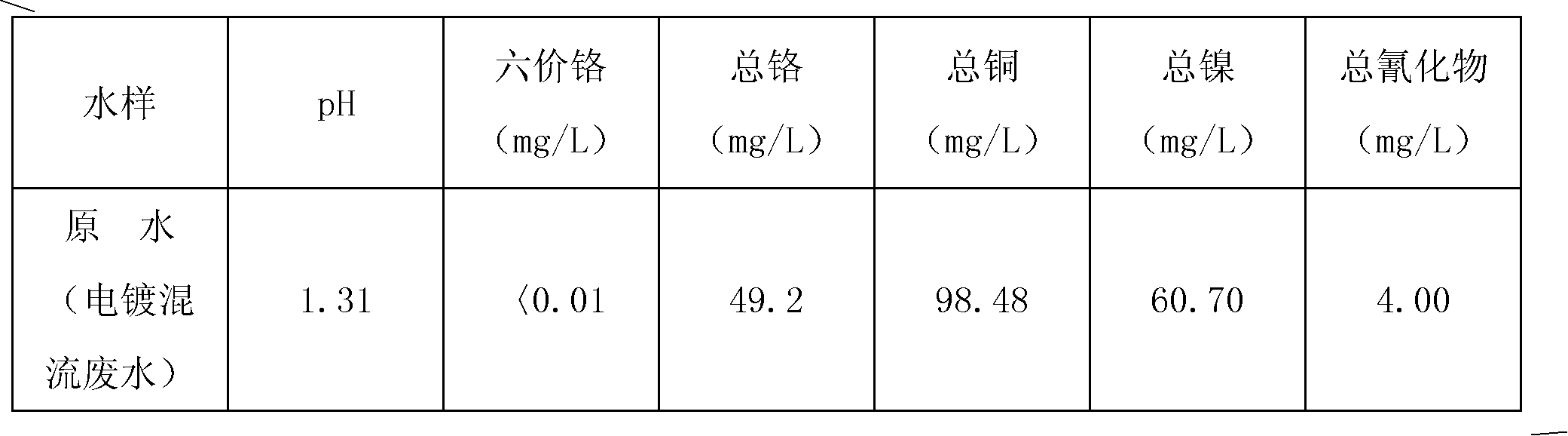

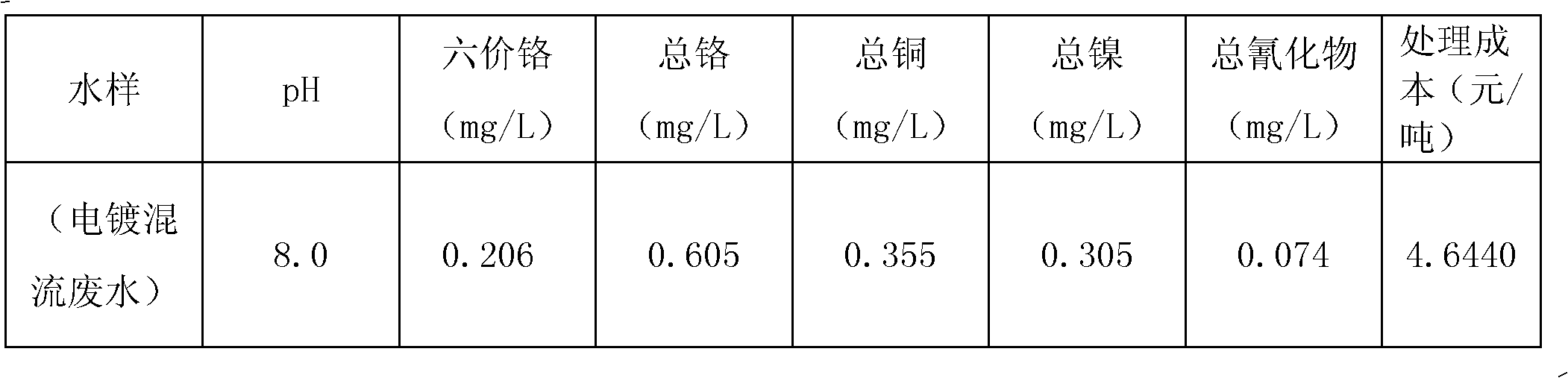

Recovery method of copper-nickel heavy metals in electroplated mixed-flow waste water

ActiveCN102557299AReduce lossesReduce loss rateWaste water treatment from metallurgical processMultistage water/sewage treatmentRecovery methodCopper sulfide

The invention relates to a recovery method of copper-nickel heavy metals in electroplated mixed-flow waste water. The recovery method comprises the following steps of: using lime to adjusting the pH value to be 2.5-3 in the electroplated mixed-flow waste water containing copper and nickel, adding a flocculating agent PAM (polyacrylamide), generating precipitate, and carrying out solid-liquid separation; then adding sodium sulfide, generating copper sulfide precipitate, and carrying out solid-liquid separation; then adding hydrogen peroxide for preventing complexation, using the lime to adjusting the pH value to be 6.5, simultaneously precipitating copper and chromium ions, adding the flocculating agent PAM, and carrying out solid-liquid separation; then using the lime to adjusting the pH value to be 10.5, simultaneously adding sodium hypochlorite for preventing complexation, generating precipitate containing nickel hydroxide, adding the flocculating agent PAM, carrying out solid-liquid separation, and recovering nickel mud; and finally, adjusting the pH value of the discharged water to be 8 by adding sulfuric acid, and realizing standard discharging. The recovery method has the advantages that the process is simple and convenient, the operation is easy, the recovery cost is low and the recovery rate is higher.

Owner:ZHEJIANG HI TECH ENVIRONMENTAL TECH

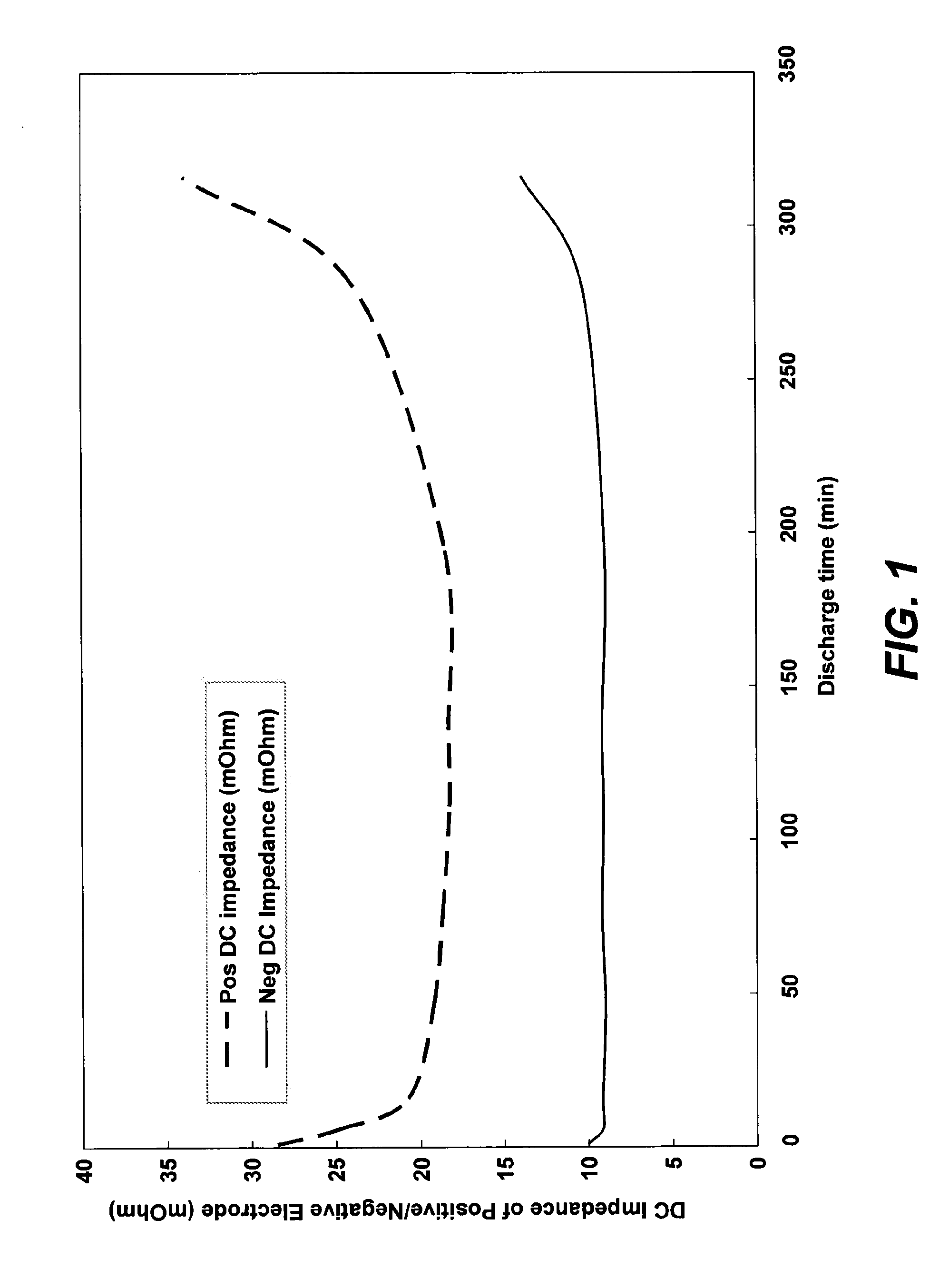

Nickel hydroxide electrode for rechargeable batteries

ActiveUS20090208839A1Facilitate interface reactionImprove reliabilityMaterial nanotechnologyHybrid capacitor electrodesPotassium persulfateNickel oxide hydroxide

The nickel hydroxide particles for a nickel hydroxide electrode may be treated using an alkaline solution of a strong oxidizing agent such as sodium or potassium persulfate to modify the surface nickel hydroxide structure. The resulting modified surface structure has been found to impart various benefits to electrodes formed from the nickel hydroxide. It is believed that the oxidation of cobalt compounds at the surface of the nickel hydroxide particles results in a highly conductive cobalt compound that plays an important role in the high reliability, high stability and high capacity utilization of nickel electrodes as described herein.

Owner:ZINCFIVE POWER INC

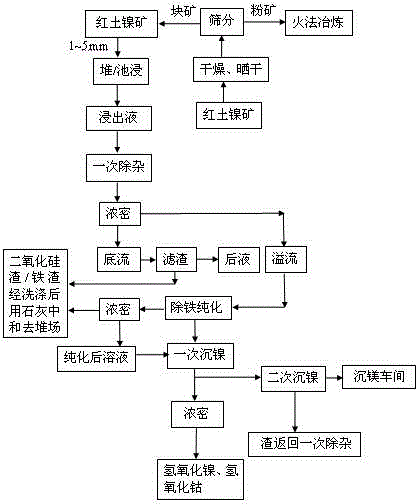

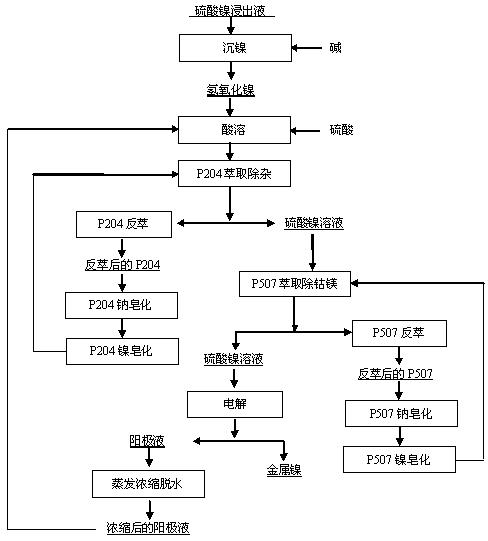

Method for keeping balance of sodium-magnesium-water system in technique for extracting nickel from lateritic nickel ore by wet process

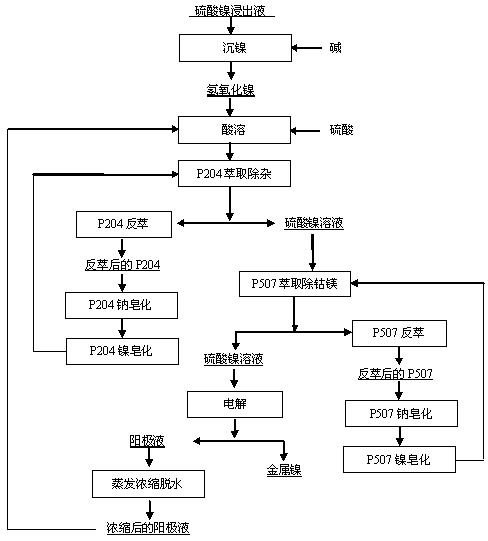

InactiveCN102181665AHigh recovery rateContinuous productionProcess efficiency improvementElectrolysisLaterite

The invention discloses a method for keeping balance of a sodium-magnesium-water system in a technique for extracting nickel from lateritic nickel ore by a wet process, which is characterized by comprising the following steps: (a) dissolving nickelous hydroxide, which is obtained by carrying out alkali nickel precipitation on nickel sulfate leach liquor, in sulfuric acid; (b) extracting the nickel sulfate solution obtained in the step (a) with a P204 extractant to remove impurities, wherein P204 sodium soap is converted into nickel soap before removing the impurities; (c) extracting the nickel sulfate solution obtained in the step (b) with a P507 extractant to remove cobalt and magnesium, wherein P507 sodium soap is converted into nickel soap before removing the cobalt and magnesium; and (d) evaporating the anolyte, which is obtained by electrolyzing the nickel sulfate solution obtained in the step (c), thereby removing part of moisture. By using the method provided by the invention, the sodium, magnesium and water are balanced in the technique for extracting nickel from lateritic nickel ore by a wet process, so that the production can be carried out continuously, thereby increasing the recovery rate of nickel, lowering the treatment cost and having obvious economic efficiency.

Owner:广西银亿新材料有限公司

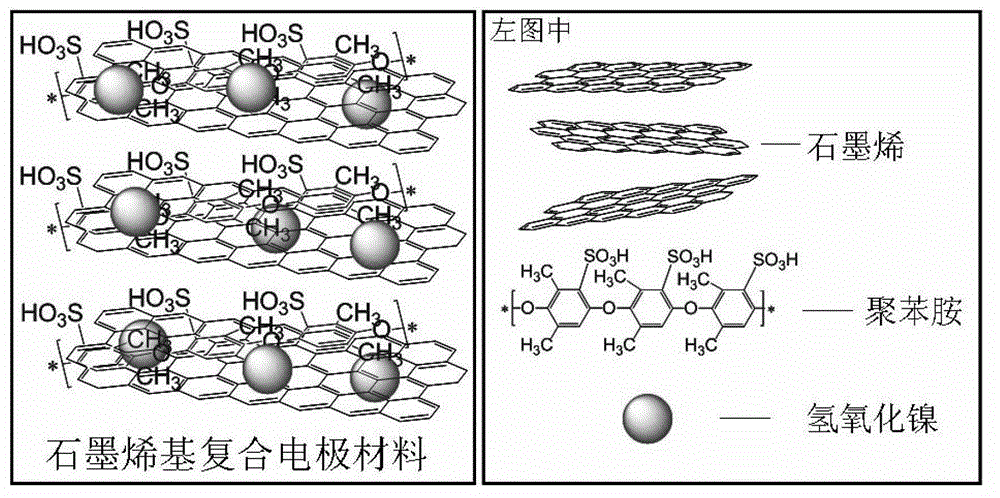

Porous graphene/nickelous hydroxide/polyaniline composite electrode material and preparation method thereof

ActiveCN103151178AConducive to loadLarge specific surface areaHybrid capacitor electrodesHybrid/EDL manufactureCapacitancePorous graphene

The invention discloses a porous graphene / nickelous hydroxide / polyaniline composite electrode material and a preparation method thereof, belonging to the technical field of nano composite materials and electrochemistry. The composite electrode material is composited by porous graphene, nickelous hydroxide and polyaniline, and has a porous structure; the nickelous hydroxide is deposited on the porous graphene by the binding effect of holes; the polyaniline is combined with the surface of the graphene by pi-pi mutual effect and is deposited on the surface of the porous graphene. The particle diameter of the nickelous hydroxide is 20-150nm; the specific surface area of the porous graphene is 350-450m<2> / g, the conductivity is 20-60S.m-1, and the weight loss in the temperature of 900 DEG C is 4-6wt%. The obtained porous graphene / nickelous hydroxide / polyaniline composite electrode material has the advantages that the oxidation and reduction performances are good, the specific capacitance is up to 2480F / g, and after the charging and discharging circulate for 2000 times, the specific capacitance is maintained to be about 90% still.

Owner:JINAN UNIVERSITY

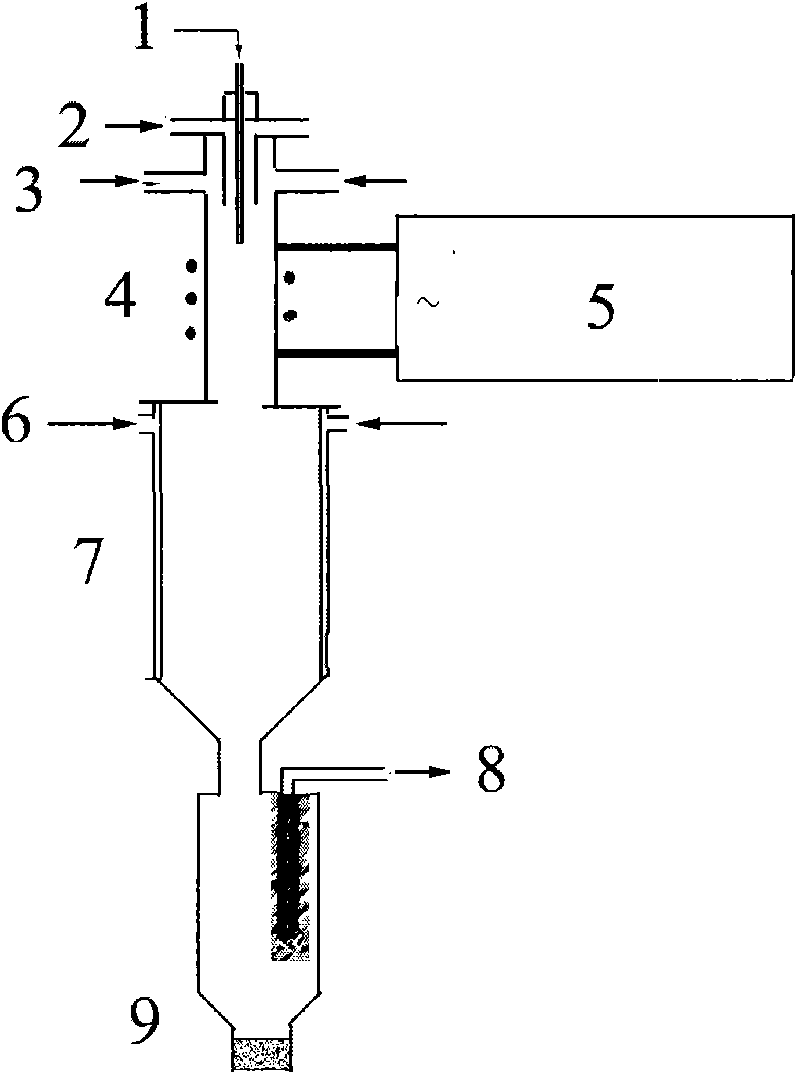

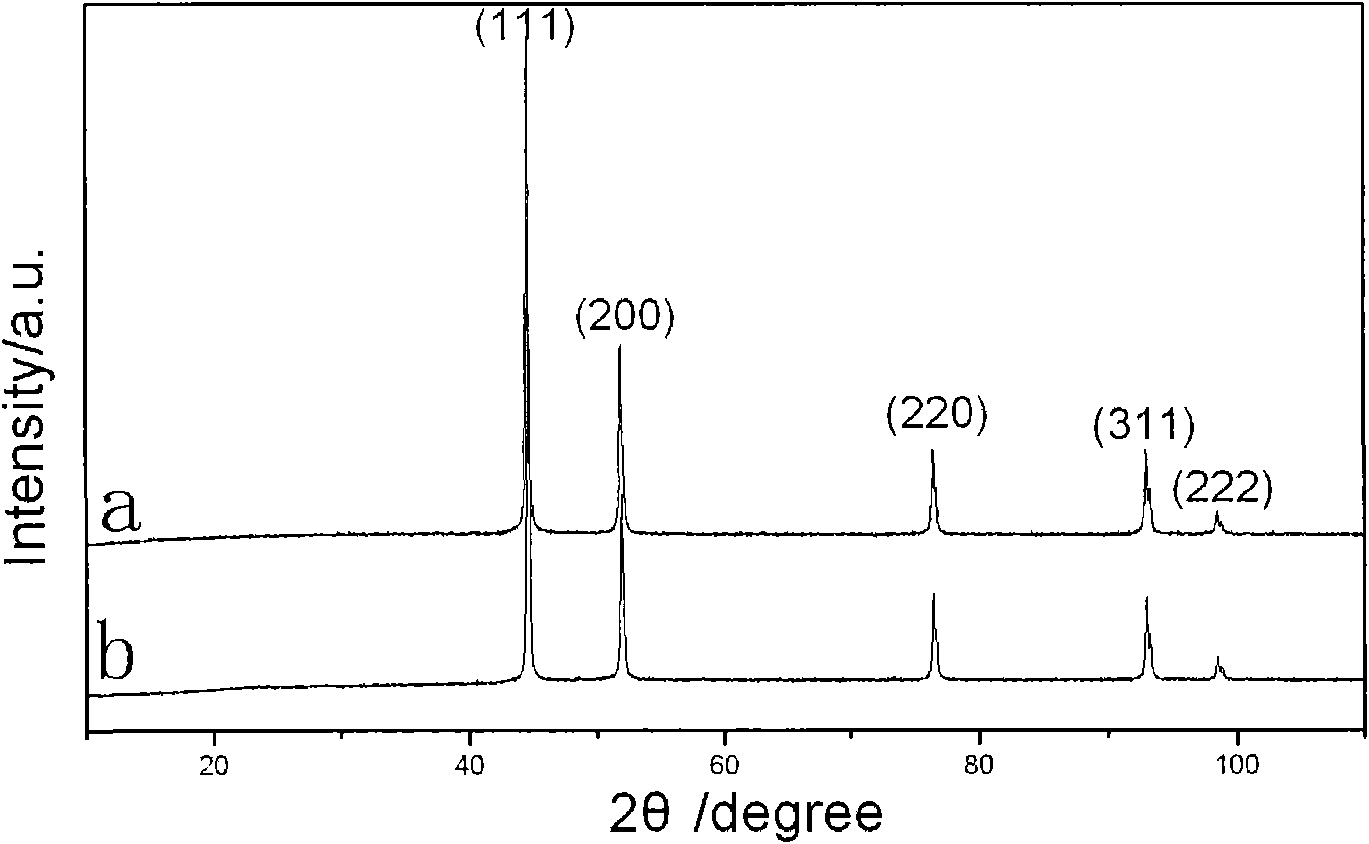

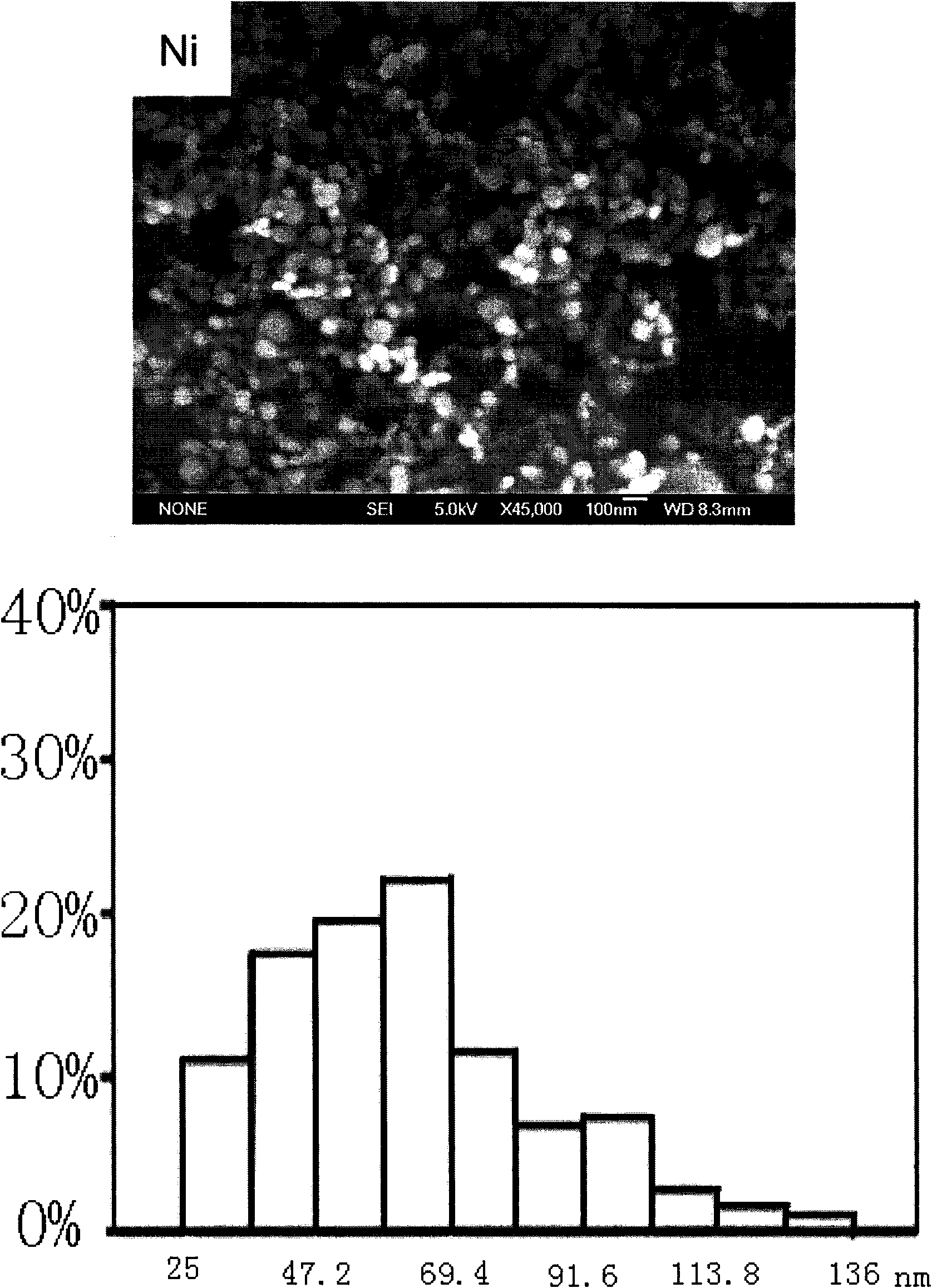

Method preparing superfine metallic nickel powder with high frequency plasma

The invention relates to a method preparing spherical metallic nickel powder with high frequency plasma. The method takes the hydrate of metallic nickel or subcarbonate as raw material and carries out hydrogen reduction through the high frequency plasma technology to prepare the superfine spherical nickel powder. Plasma arc is added to the raw material. The plasma is heated in high temperature through high frequency induction and generates reduction reaction with high-activity hydrogen plasma. The superfine spherical nickel powder can be obtained through a shape controller in the condensation process. The utility model is characterized in that the nickel hydroxide or the subcarbonate are used as the raw material, in the reduction process of the plasma, the particle size and the shape of the nickel powder can be controlled easily, the process flow is short and the production process is environment-friendly.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

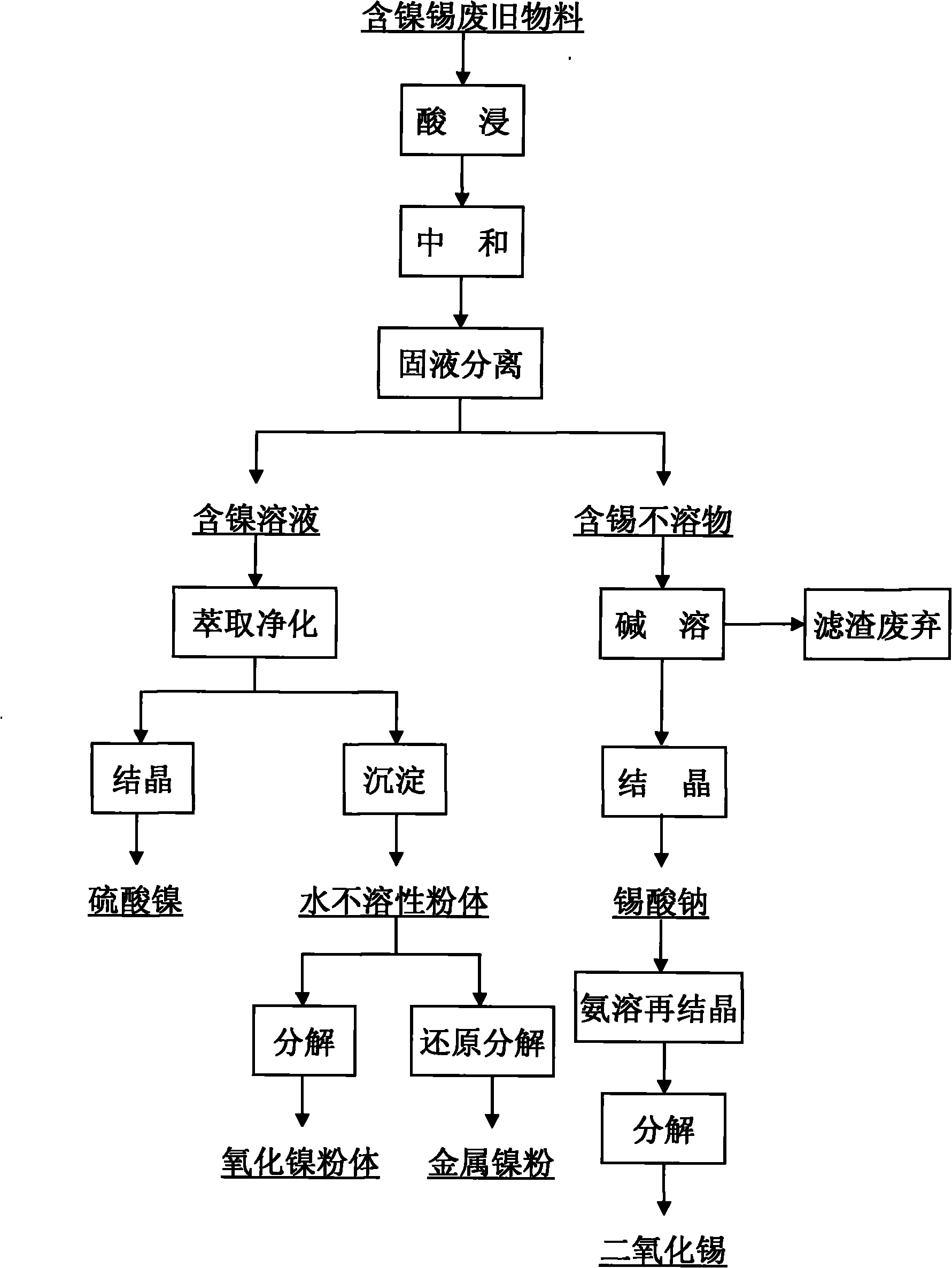

Method for separating and reclaiming metal nickel and tin from waste materials containing nickel and tin

InactiveCN101824540AGood choiceReduce recycling costsProcess efficiency improvementTin dioxideNickel oxide hydroxide

The invention discloses a method for separating and reclaiming metal nickel and tin from waste materials containing nickel and tin. The method is characterized by comprising the following steps of: leaching the waste materials containing the nickel and tin with acid; adjusting pH value of the materials by using an alkali substance to ensure that impurity iron and a valuable component tin are precipitated; filtering the solution to obtain nickel-containing solution and tin-containing precipitate; extracting the nickel-containing solution for impurity removal and purification, wherein purifying fluid can be directly crystallized to prepare nickel sulfate, can be precipitated and degraded to prepare nickel hydroxide, nickel carbonate and nickel oxalate powder materials, and can be further degraded or reduced to prepare nickel oxide powder and metal nickel powder; and adding sodium hydroxide solution into the tin-containing precipitate, dissolving the tin out and allowing the tin to enter the solution, recrystallizing the solution to prepare a sodium stannate product, or further crystallizing and degrading the solution to prepare a tin dioxide powder material. Acid and alkali in low price are consumables in the whole reclaiming process, and product variousness is provided, so the method has significant economic value and market competitiveness.

Owner:GUANGDONG BRUNP RECYCLING TECH

Process for producing nickel oxyhydroxide by electrolytic oxidation

InactiveUS7407521B2Advantages in terms of working environment and costElectrolysis componentsPrimary cellsElectrolysisNickel oxide hydroxide

A process for production of nickel oxyhydroxide by electrolytic oxidation of nickel hydroxide in the presence of an alkali metal halide. The nickel oxyhydroxide is produced by adding nickel hydroxide particles to an aqueous solution of an alkali metal halide and stirring the mixture to prepare a nickel hydroxide slurry, and then converting a portion of the nickel hydroxide to nickel oxyhydroxide by electrolytic oxidation in the presence of the alkali metal halide.

Owner:TANAKA CHEM +1

Lithium silicate-coated Ni-Co lithium aluminate positive electrode material and preparation method thereof

InactiveCN107910539AImprove cycle stabilityImprove high rate discharge performanceCell electrodesSecondary cellsLithium aluminateSilicon dioxide

Owner:CENT SOUTH UNIV

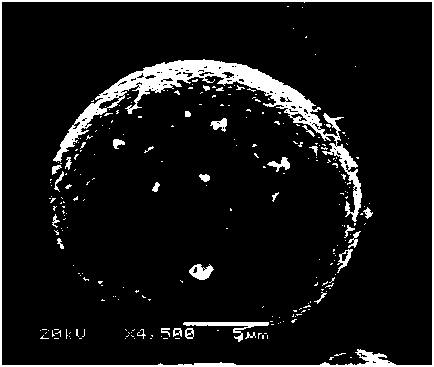

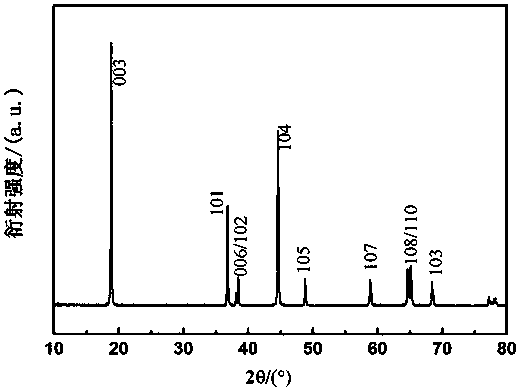

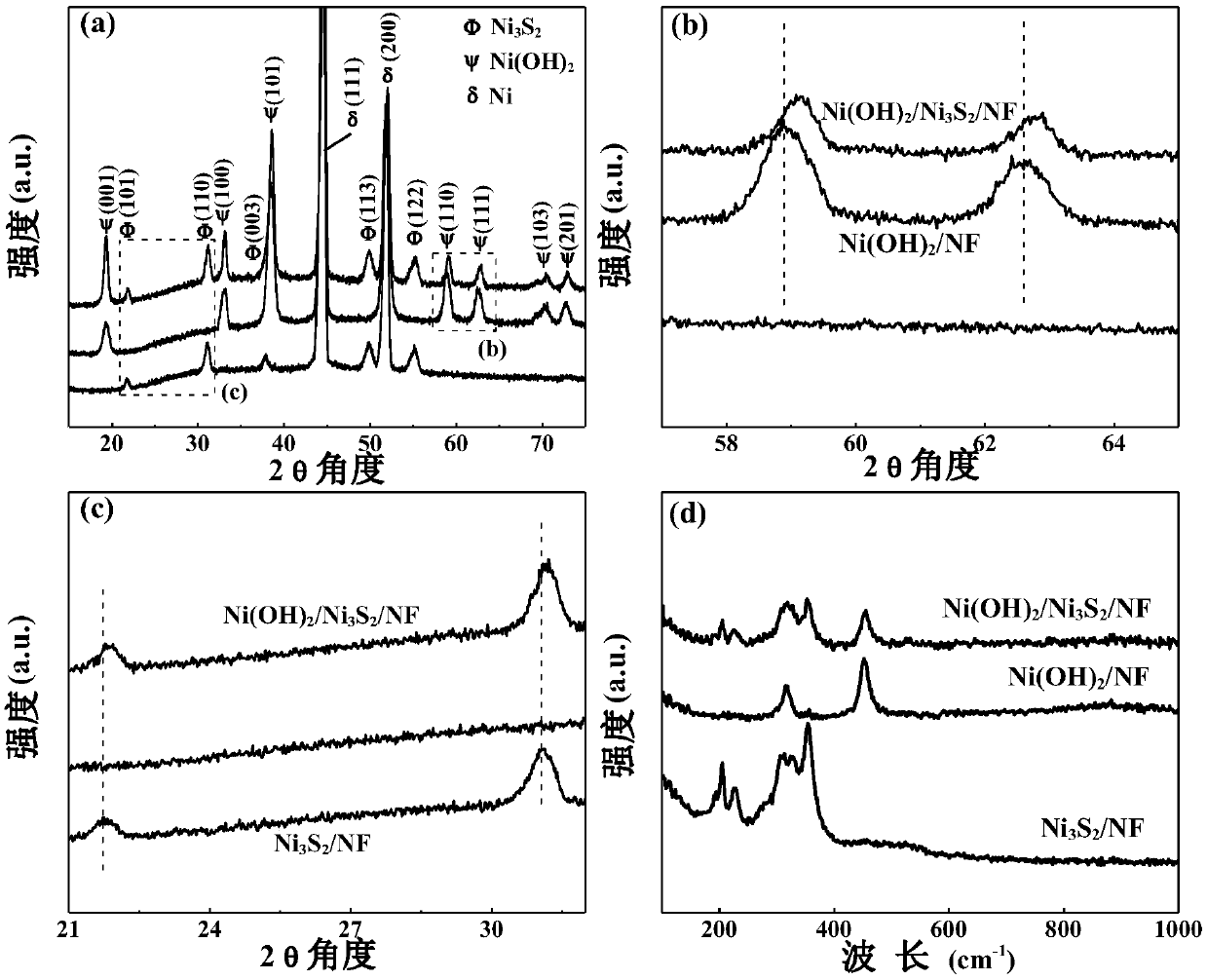

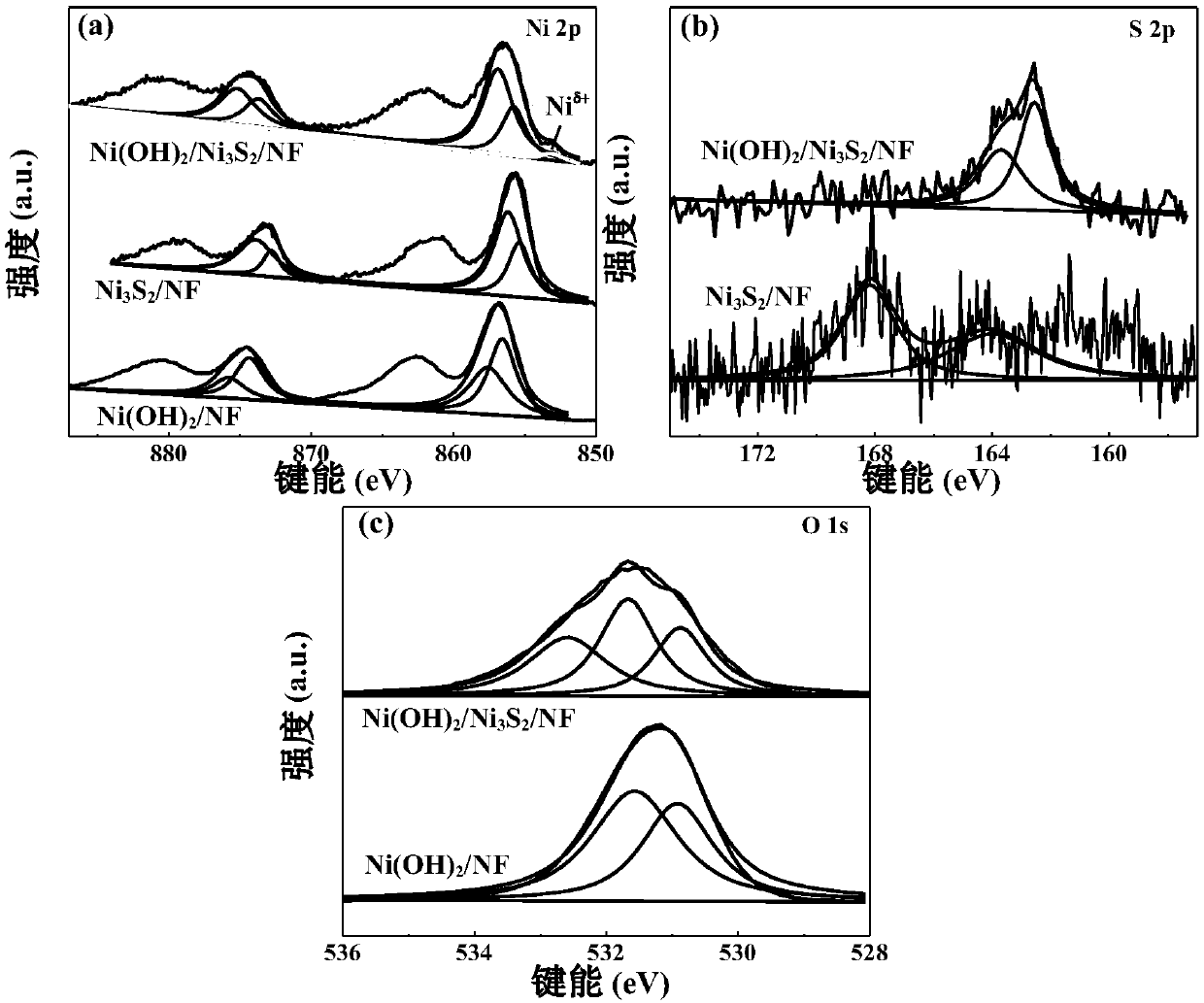

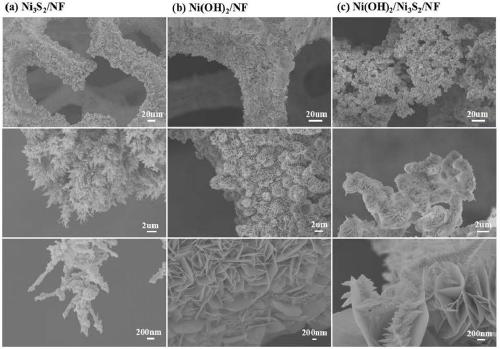

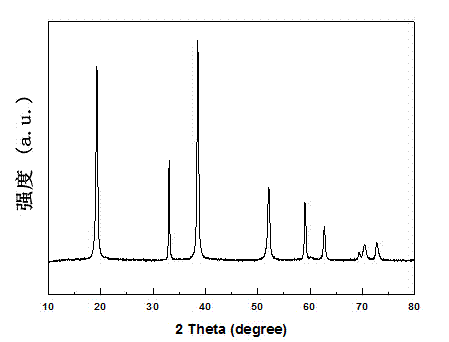

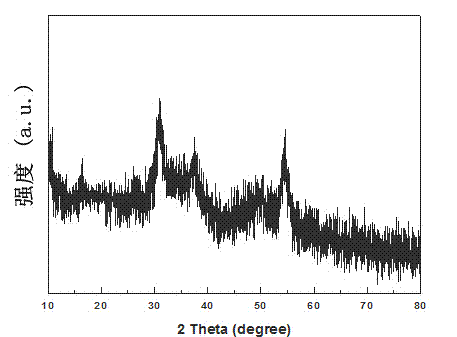

Nickel hydroxide/nickel disulfide/foam nickel composite and preparation method thereof, and application thereof

ActiveCN109659143AAbundant raw materialsLow costMaterial nanotechnologyPhysical/chemical process catalystsElectrolysisSynthesis methods

The invention discloses a nickel hydroxide / nickel disulfide / foam nickel composite and a preparation method thereof, and application thereof. The composite is expressed in the form of Ni(OH)2 / Ni3S2 / NFand can be used as an electrode. In the electrode structure, the nano-stem-like Ni3S2 / NF is a conductive skeleton, and the Ni(OH)2 nanosheet is equivalent to a leaf and grows on the nano-stem-like Ni3S2 / NF skeleton. The heterointerface of Ni(OH)2 and Ni3S2 having a defect structure is the active center. The Ni(OH)2 / Ni3S2 / NF electrode can be used as a bifunctional catalyst, has excellent cathodic catalytic hydrogen evolution and anodic catalytic oxygen evolution reaction performance, and has high current long-term total electrolysis hydrogen production and oxygen production stability. Comparedwith noble metal catalysts such as Pt and RuO2, the catalyst synthesis method is simple, rich in raw materials and low in cost.

Owner:JINAN UNIVERSITY

New method for two-step process preparation of nickel sulfide

InactiveCN104261490ASimple production processReaction conditions are easy to controlNickel sulfidesSODIUM SULFIDE NONAHYDRATEHigh pressure

The invention relates to a new method for two-step process preparation of nickel sulfide. The new method comprises the following steps: transferring a water and urea mixed solution of nickel chloride or a water, ammonia water and ethylene glycol mixed solution of nickel chloride into a high-pressure kettle, performing heating reaction at the temperature of 120-160 DEG C for 8-16h, filtering and washing a generated nickel hydroxide precipitate, and drying to prepare a nickel hydroxide precursor; and then dispersing into ethylene glycol, performing ultrasonic dispersion, adding sodium sulfide nonahydrate, transferring into a reactor, performing reflux reaction at the temperature of 160 DEG C for 12-24h, filtering, washing, and performing vacuum drying for 10-12h to prepare nickel sulfide. The new method provided by the invention has the advantages of simple production process, easiness in control of reaction conditions, no need of using a template agent and a surfactant, environmental friendliness and good consistency of the obtained product, is conductive to production of nickel sulfide, and has important practical significance.

Owner:XUZHOU NORMAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com