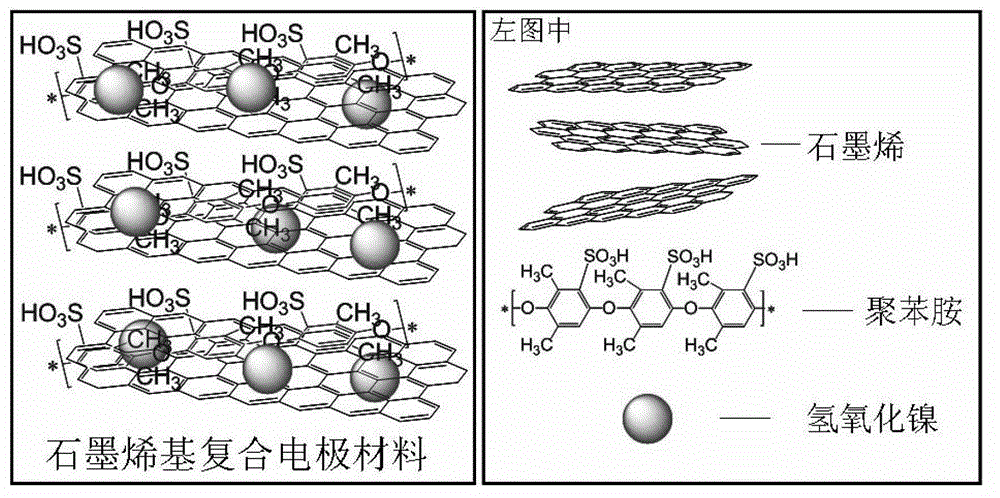

Porous graphene/nickelous hydroxide/polyaniline composite electrode material and preparation method thereof

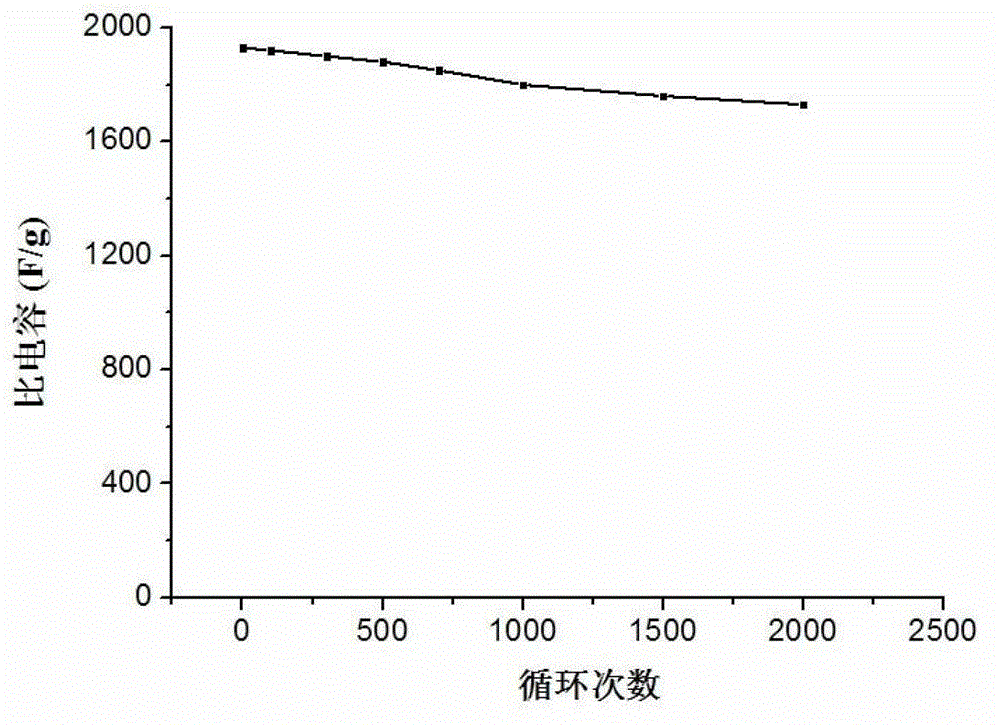

A technology of porous graphene and nickel hydroxide, applied in the fields of nanocomposite materials and electrochemistry, can solve the problems of large capacity attenuation, low specific capacitance and power density of supercapacitors, etc., and achieve reduced grain size and excellent electrochemical performance. , the effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

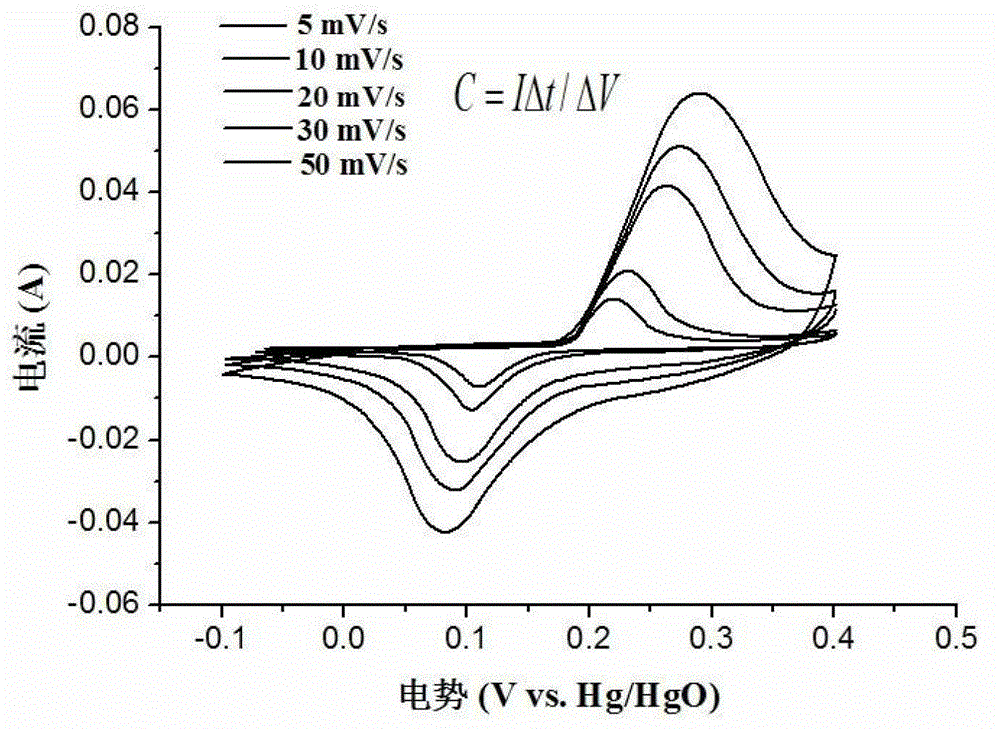

Method used

Image

Examples

Embodiment 1

[0046] (1) Preparation of graphene oxide: Weigh 1g of graphite powder (Tianjin Kemiou Chemical Reagent Co., Ltd.) and add it to 25mL of 98wt% concentrated sulfuric acid, cool to 0°C in an ice-salt bath, add 2.5g of potassium permanganate, and heat to 30 ℃, 60rpm stirring reaction for 2h, add 200mL water, then add 3mL30wt% hydrogen peroxide to react until the solution is bright yellow, centrifuge and wash at 600rpm, put the obtained solid into water, disperse for 1h under ultrasonic power of 300W, frequency of 40Hz, and then , treated at a microwave power of 700W and a frequency of 2KHz for 1h, filtered and dried to obtain graphene oxide.

[0047] (2) Weigh 1g of graphene oxide prepared in step (1), add 3g of sodium hydroxide, and heat in a tube furnace at 760°C under nitrogen protection for 1h to obtain porous graphene; the specific surface area of porous graphene is 350m 2 / g; its conductivity is 60S·m -1 ; The weight loss within 900°C is 4wt%.

[0048] (3) Add 0.5 g of t...

Embodiment 2

[0052] (1) Weigh 1g of graphene oxide prepared in Example 1, add 4g of potassium hydroxide, and heat in a tube furnace at 800°C under nitrogen protection for 1h to obtain porous graphene; the specific surface area of porous graphene is 370m 2 / g; its conductivity is 50S·m -1 ; The weight loss within 900°C is 4.5wt%.

[0053] (2) Add 0.5 g of the porous graphene prepared above and 2.5 g of nickel chloride into 500 mL of water, sonicate for 50 min at a power of 300 W, then add 3 g of potassium hydroxide, and stir at 85 ° C for 7 h. After the reaction, centrifuge to obtain a solid product, wash the solid with deionized water until neutral, and dry to obtain porous graphene / nickel hydroxide, wherein the particle size of nickel hydroxide is 50nm. The porous graphene / nickel hydroxide is a black powder solid, has no special smell, is non-volatile, insoluble in water, and exists thermally stably at 240°C.

[0054] (3) Add 45 mL of 0.30 mol / L aniline solution (1 mol / L hydrochloric ...

Embodiment 3

[0057] (1) Weigh 1g of graphene oxide prepared in Example 1, add 5g of calcium hydroxide, and heat in a tube furnace at 850°C under nitrogen protection for 1.5h to obtain porous graphene; the specific surface area of porous graphene is 390m 2 / g; its conductivity is 40S·m- 1 ; The weight loss within 900°C is 5wt%.

[0058] (2) Add 0.5 g of the porous graphene prepared above and 2.5 g of nickel sulfate into 500 mL of water, sonicate for 60 min at a power of 400 W, then add 3 g of calcium hydroxide, and stir at 80 ° C for 8 h. After the reaction, centrifuge to obtain a solid product, wash the solid with deionized water until neutral, and dry to obtain porous graphene / nickel hydroxide, wherein the particle size of nickel hydroxide is 70nm. The porous graphene / nickel hydroxide is a black powder solid, has no special smell, is non-volatile, insoluble in water, and exists thermally stably at 240°C.

[0059] (3) Add 50mL of 0.25mol / L aniline solution (1mol / L hydrochloric acid as ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com