Patents

Literature

127results about How to "Improve charge and discharge cycle stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Carbon-based composite electrode material and preparation method thereof, and application of the carbon-based composite electrode material to super capacitor

InactiveCN102222565ALarge specific surface areaLower internal resistanceElectrolytic capacitorsCapacitanceNano structuring

The invention relates to a carbon-based composite electrode material and a preparation method thereof, and application of the carbon-based composite electrode material to a super capacitor. The electrode material contains a conductive polymer and a carbon-based material. The conductive polymer is attached to a surface of the carbon-based material in a manner of a nanowire array of a conductive polymer, wherein the arrangement of the nanowire array of the conductive polymer is in a good order; besides, a diameter of the nanowire of the nanowire array of the conductive polymer is 40 to 100 nm and a length of the nanowire is 100 to 1500 nm. The carbon-based composite electrode material provide in the invention has a large specific surface area, so that an active area of a conductive polymer is substantially improved and thus high capacitance can be obtained; besides, the carbon-based composite electrode material provide in the invention has a highly ordered nano structure, so that a transmission path of an electrolyte ion is reduced and an internal resistance of an electrode is also reduced; therefore, the ion in an electrode material can be diffused and transmitted conveniently, and thus high power density can be obtained.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

Flexible supercapacitor and preparation method thereof

InactiveCN102737851ASimple preparation processLow costHybrid capacitor electrodesElectrolytic capacitorsCapacitancePolymer chemistry

The invention provides a flexible supercapacitor. The flexible supercapacitor comprises a housing, two electrodes facing each other and separated with each other, and electrolyte between the two electrodes. The two electrodes facing each other and the electrolyte between the two electrodes are accommodated in the housing. The supercapacitor is characterized in that the electrodes are composed of a conducting polymer and a carbon-based material, and the conducting polymer attaches to a surface of the carbon-based material in a form of a nanowire array of the conducting polymer. The invention also provides a preparation method for the flexible supercapacitor. The flexible supercapacitor prepared by the method has high capacitance, good charge-discharge cycling stability, and is low in cost and simple in preparation technology.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

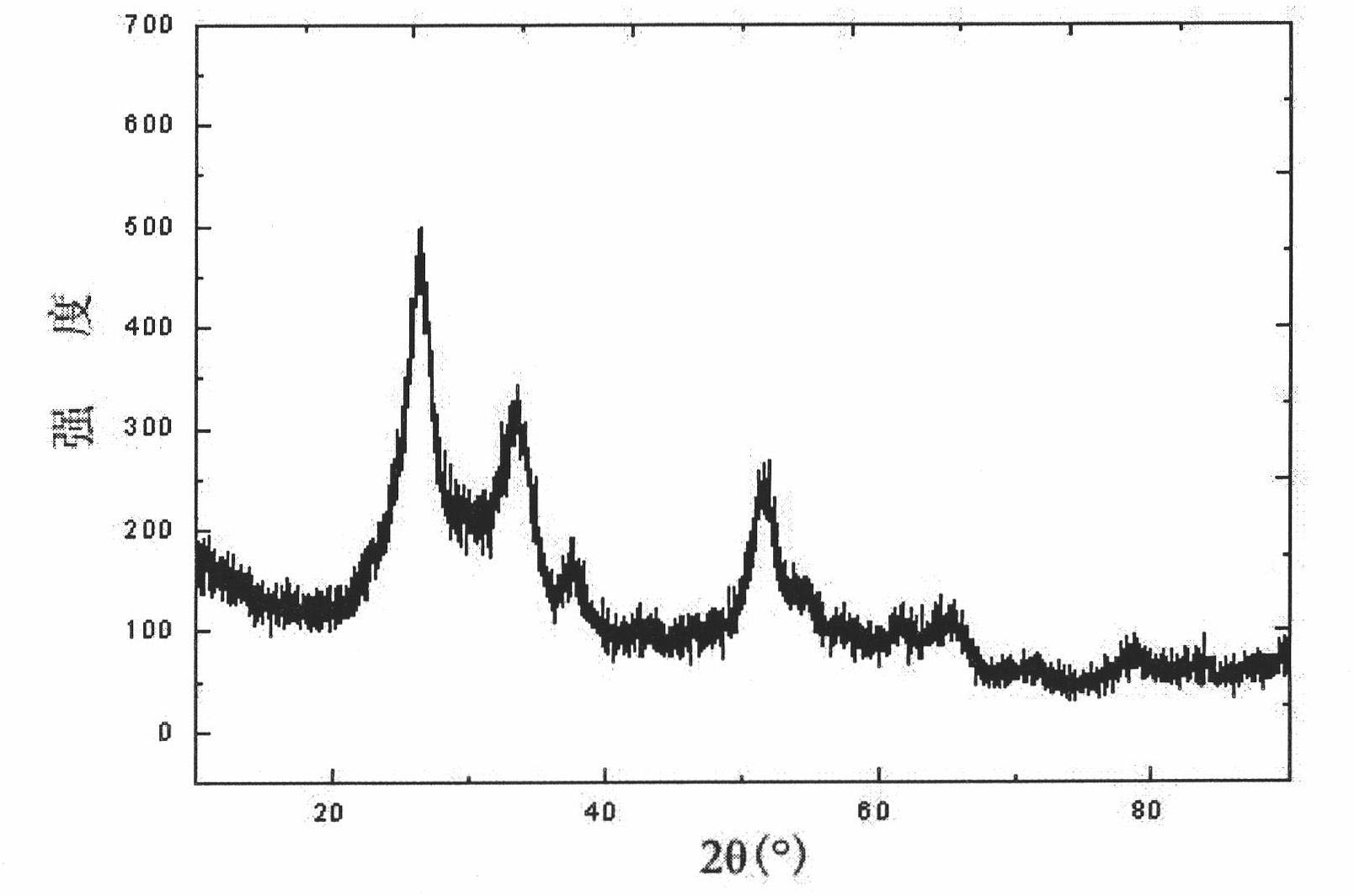

Preparation method of stannic oxide or metallic tin and grapheme lamella composite material

ActiveCN102255072AImprove structural stabilityImprove electrochemical performanceCell electrodesTin dioxideHYDROSOL

The invention provides a preparation method of a stannic oxide and grapheme lamella composite material. The preparation method comprises the following steps of mixing at least one organic solvents, graphene oxide lamella hydrosol and at least one tin salt, heating the mixture at a temperature of 60 to 200 DEG C for 0.5 to 12 hours to obtain a solid substance, and heating the solid substance in the inert gas atmosphere at a temperature of 400 to 700 DEG C for 0.5 to 10 hours. The invention also provides a preparation method of a metallic tin and grapheme lamella composite material. The preparation method comprises the following step of preparing a stannic oxide and grapheme lamella composite material through the preparation method of a stannic oxide and grapheme lamella composite material, and heating the prepared stannic oxide and grapheme lamella composite material in the reducing gas atmosphere at a temperature of 400 to 1000 DEG C for 0.5 to 4 hours. The preparation methods of the invention can improve a structural stability and an electrochemical performance of a material and is beneficial to improve a high-speed charging and discharging performance and a conductivity of a composite material. The preparation methods have the characteristics of cheap and easily available raw materials, simple process, and good applicability for industrial continuous production.

Owner:陕西埃普诺新能源科技有限公司

Preparation method of nitrogen and oxygen in-situ doped porous carbon electrode material and application thereof

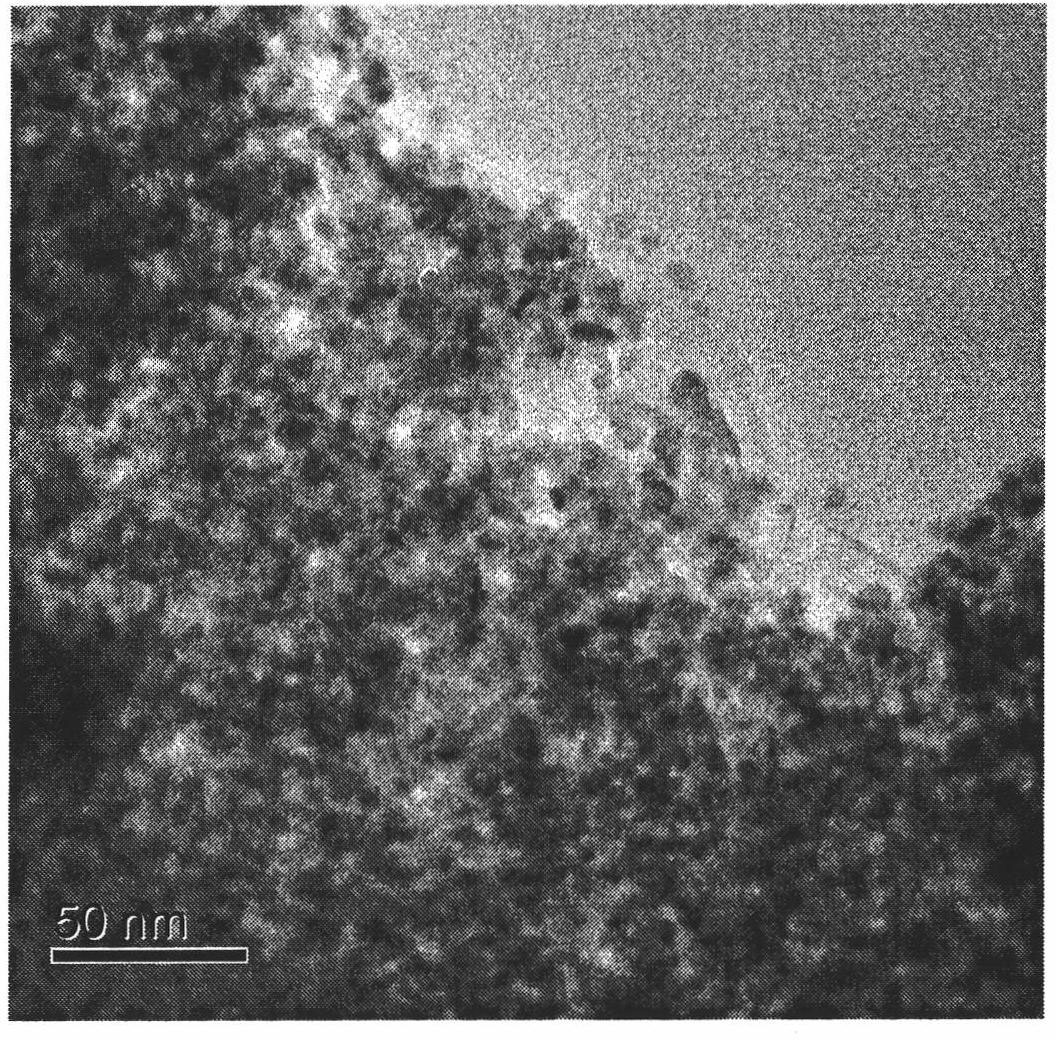

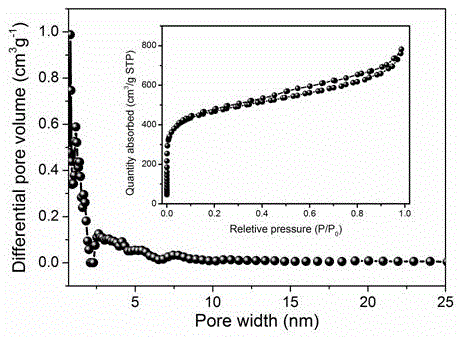

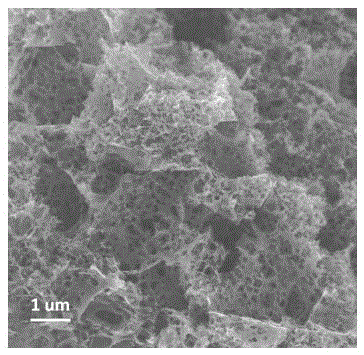

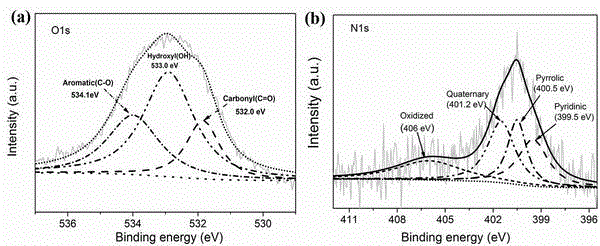

ActiveCN105575673AIncrease surface areaBest charge capacityHybrid capacitor electrodesHybrid/EDL manufacturePorous carbonApatite

The invention relates to a preparation method of nitrogen and oxygen in-situ codoped porous carbon electrode material and an application thereof. The nitrogen and oxygen in-situ codoped porous carbon electrode material is excellent in conductivity, great in chemical stability, three-dimensional and abundant in pore channels. An animal bone, such as an ox bone, a swine bone and a goat bone, is adopted to act as a carbon precursor. The organic component of collagen in the bone acts as a carbon and nitrogen source, and the inorganic component acts as a natural template to act as supporting material in the carbonization process and a pore channel regulating structure for controlling change and size of hydroxyapatite crystals so that the material is prepared. The porous carbon electrode material is abundant and prosperous in pore structures and has micropores, mesopores and macropores with the specific surface of being 1000-3000m<2>g<-1> so that the porous carbon electrode material can be used as supercapacitor electrode material.

Owner:BEIJING UNIV OF CHEM TECH

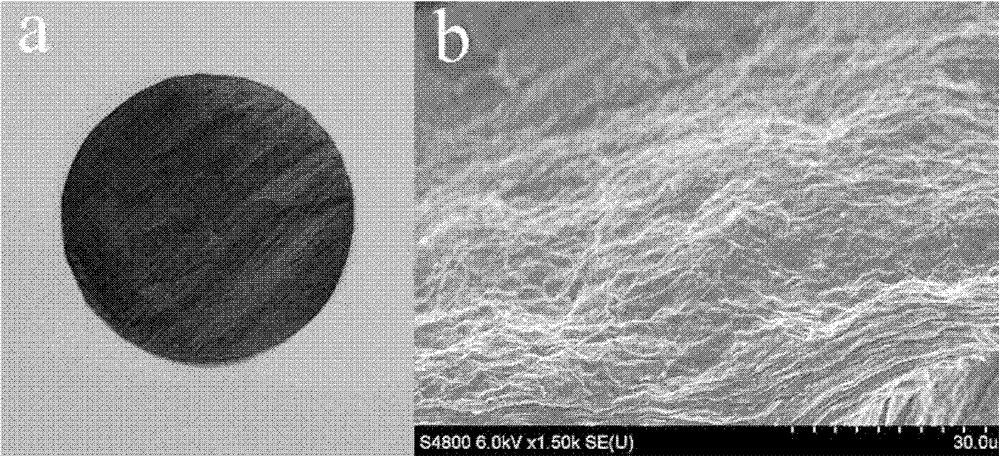

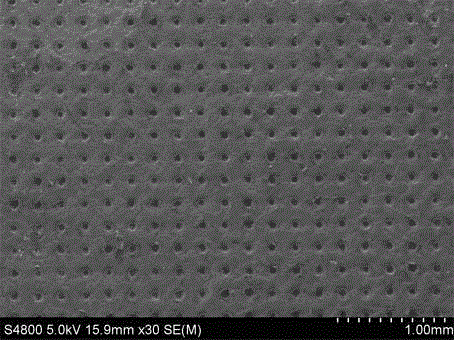

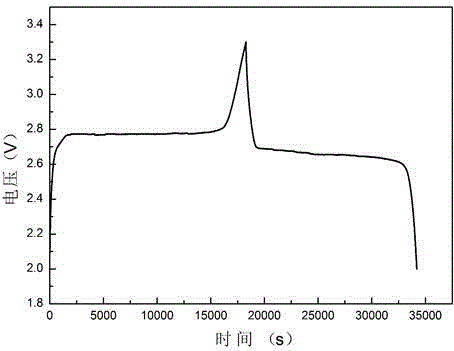

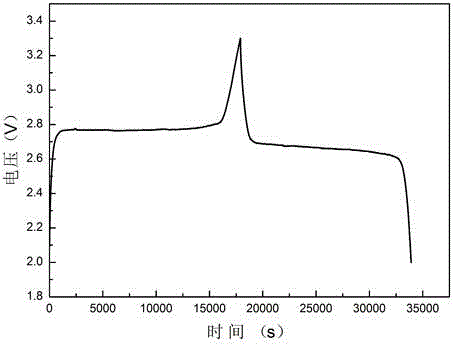

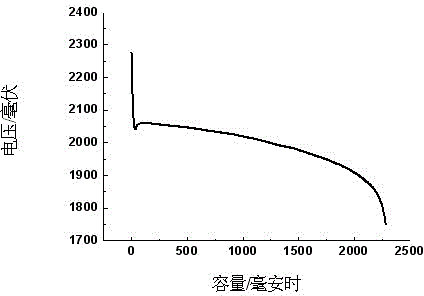

Sodium ion battery negative electrode sheet and sodium ion battery

InactiveCN104966813AEnhanced insertion siteIncrease profitCell electrodesSecondary cellsElectrolytic agentSodium tetrafluoroborate

The present invention discloses a sodium ion battery negative electrode sheet, the negative electrode sheet is a porous graphite film structure, the diameter of the pores is from 2 to 30 microns, the distance between the centers of the circles of the pores is 5 to 50 microns, mass ratio of carbon atoms in the porous graphite film is greater than 99%, the negative electrode sheet may be used directly as the sodium ion battery negative electrode sheet, can avoid the use of a conductive agent, a binder and a metal collector, and has high capacity, corrosion resistance and good conductivity. The present invention also discloses a sodium ion battery using the negative electrode sheet, the sodium ion battery comprises a positive electrode sheet, a negative electrode sheet, a separator and an electrolyte, the sodium ion battery electrolyte solvent is one or more than one of diethanol dimethyl ether, dimethyl ether tetraethanol, and tetrahydrofuran, the electrolyte is one of sodium perchlorate, sodium hexafluorophosphate, sodium tetrafluoroborate and sodium trifluoromethanesulfonate, and the sodium ion battery is simple in production process and good in charging and discharging cycle stability, and has good prospects in the new energy field.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

Lead-acid storage battery negative lead plaster capable of inhibiting hydrogen evolution and preparation method

The invention provides a lead-acid storage battery negative lead plaster capable of inhibiting hydrogen evolution and a preparation method. The technical scheme of the lead-acid storage battery negative lead plaster is as follows: the lead plaster is prepared from the following solid raw materials in parts by weight: 100 parts of lead powder, 1-3 parts of carbon source, 0.15-1.0 part of zinc source, 0.3-2 parts of barium sulfate, 0.1-0.5 part of sodium lignosulfonate and 0.01-0.5 part of fibers. The lead-acid storage battery negative lead plaster provided by the invention is characterized in that a certain quantity of zinc-containing compounds and different types of carbon are added to the negative lead plaster, so that the grain size and the microstructure of the lead negative material are improved, and therefore, the purposes of increasing the capacity of a lead-acid battery, enhancing the ability of the battery to accept charging and improving the charge-discharge cycle stability of the battery are achieved. Tests indicate that the doping of the zinc compound in the negative lead plaster causes the hydrogen evolution potential at the cathode of a lead-acid storage battery to be more negative, so that the hydrogen evolution difficulty is increased, the hydrogen evoluted is reduced, the consumption amount of an electrolyte in the use process is reduced and the service life of the battery can be prolonged; and furthermore, the odds of unsafe accidents such as explosion and the like are reduced to a certain extent.

Owner:FENGFAN

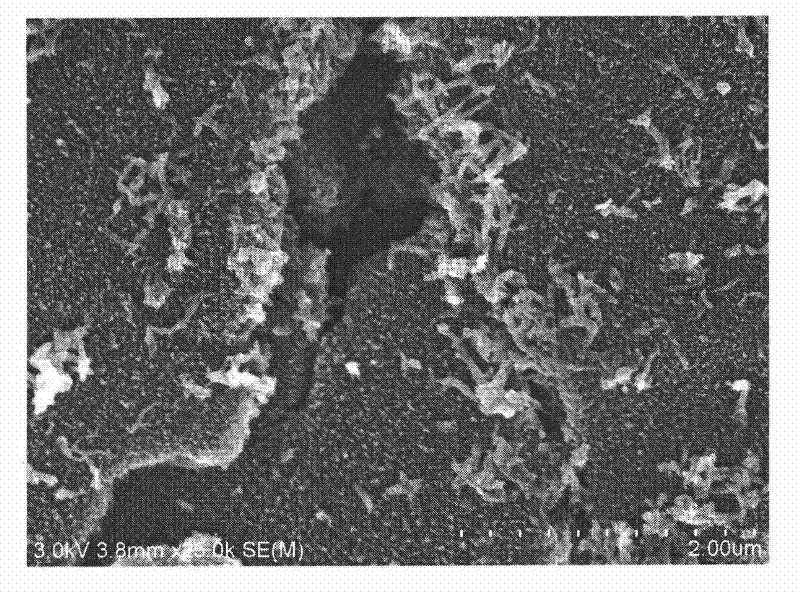

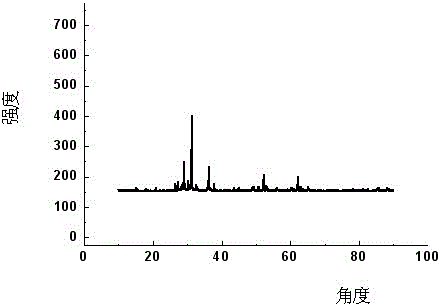

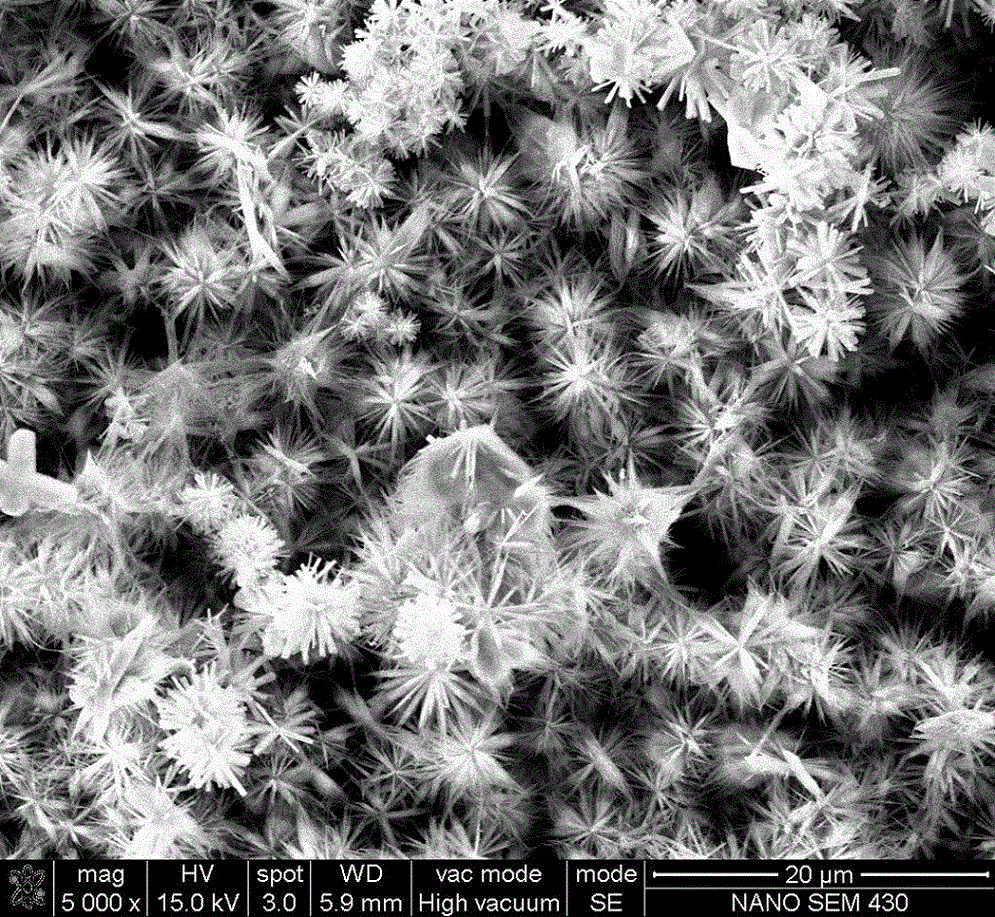

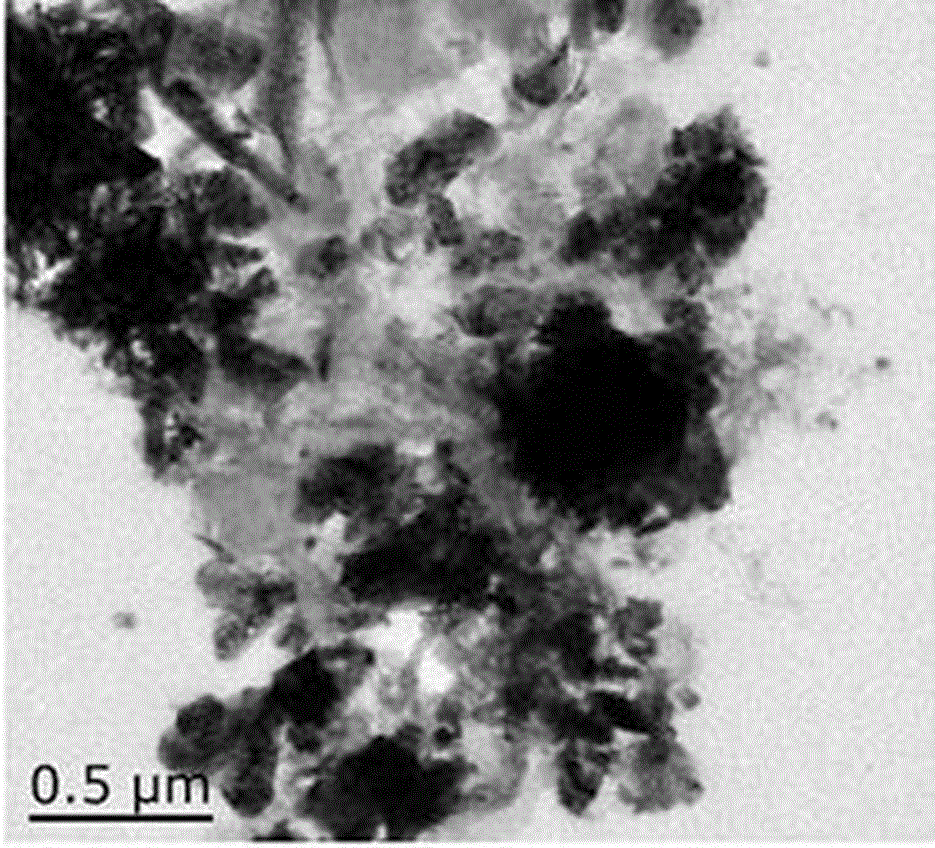

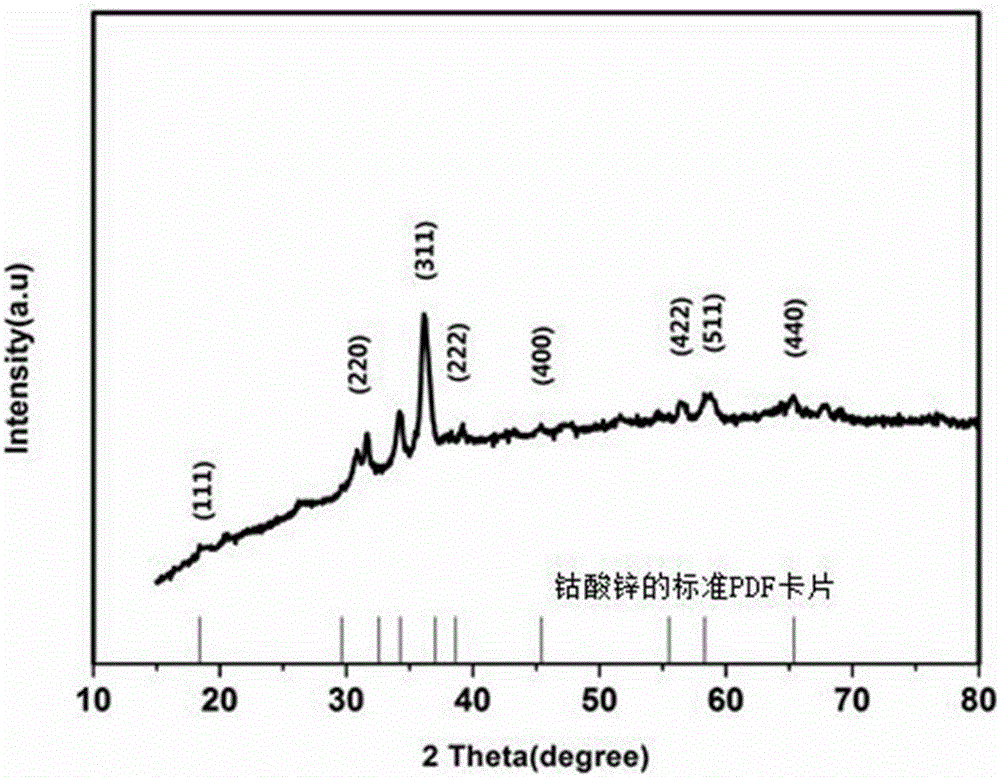

Preparation method and application of nitrogen-doped graphene/nitrogen-doped carbon nanotube/zinc cobaltite composite material

ActiveCN105225844AIncrease contact areaIncrease usageHybrid capacitor electrodesCell electrodesCvd grapheneNitrogen doped carbon nanotube

The invention discloses a preparation method of a nitrogen-doped graphene / nitrogen-doped carbon nanotube / zinc cobaltite composite material. The method comprises the following specific steps: (a) adding potassium permanganate, hydrochloric acid and hydrogen peroxide to graphene oxide, and carrying out a stirring reaction to obtain porous graphene; (b) dialyzing the porous graphene for 8-12 days, carrying out ultrasonic dispersion, then adding a carbon nanotube, carrying out ultrasonic mixing and carrying out suction filtration to form a film; (c) drying the film, and then adding ammonium hydroxide for reaction for 24 hours; (d) adding zinc nitrate, cobalt nitrate, urea, ammonium fluoride, absolute ethyl alcohol and distilled water for reaction for 4 hours; and (e) transferring a mixture to a tube furnace, and sintering the mixture in a nitrogen atmosphere for 2 hours, so as to obtain the composite material. The composite material has relatively good flexibility; the electrochemical properties are barely changed after the composite material is bent into various angles; the specific capacitance value of the composite material can be up to 1802F / g; compared with relatively simple graphene, the carbon nanotube and most of composite materials of the graphene and the carbon nanotube, the composite material provided in the invention are significantly improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Method for producing all-hydrogel stretchable supercapacitor and capacitor

ActiveCN108586664AGood electrochemical propertiesGood stabilityHybrid capacitor electrolytesHybrid capacitor electrodesCarbon nanotubePolyacrylamide

The invention belongs to the field of supercapacitor production and specifically discloses a method for producing an all-hydrogel stretchable supercapacitor and the capacitor. The stretchable supercapacitor is assembled in a traditional sandwich structure by taking sodium alginate / polyacrylamide / carbon nanotube / poly(3,4-ethylendioxythiophene)-polystyrolsulfon acid composite hydrogel with high stretchability as an electrode material and sodium alginate / polyacrylamide / sodium sulfate / redox couple composite hydrogel with high stretchability as electrolyte. Each of the electrode material and electrolyte provided in the method is based on a stretchable hydrogel material, and strong adhesion exists between the electrode material and the electrolyte, so that the constraint that an existing assembling technology needs the help of a stretchable base can be avoided. The all-hydrogel stretchable supercapacitor is suitable for a traditional application field of the supercapacitor and high-end application fields such as wearable electronic equipment, stretchable electronic equipment, electronic skins and portable integrated devices.

Owner:HUAZHONG UNIV OF SCI & TECH

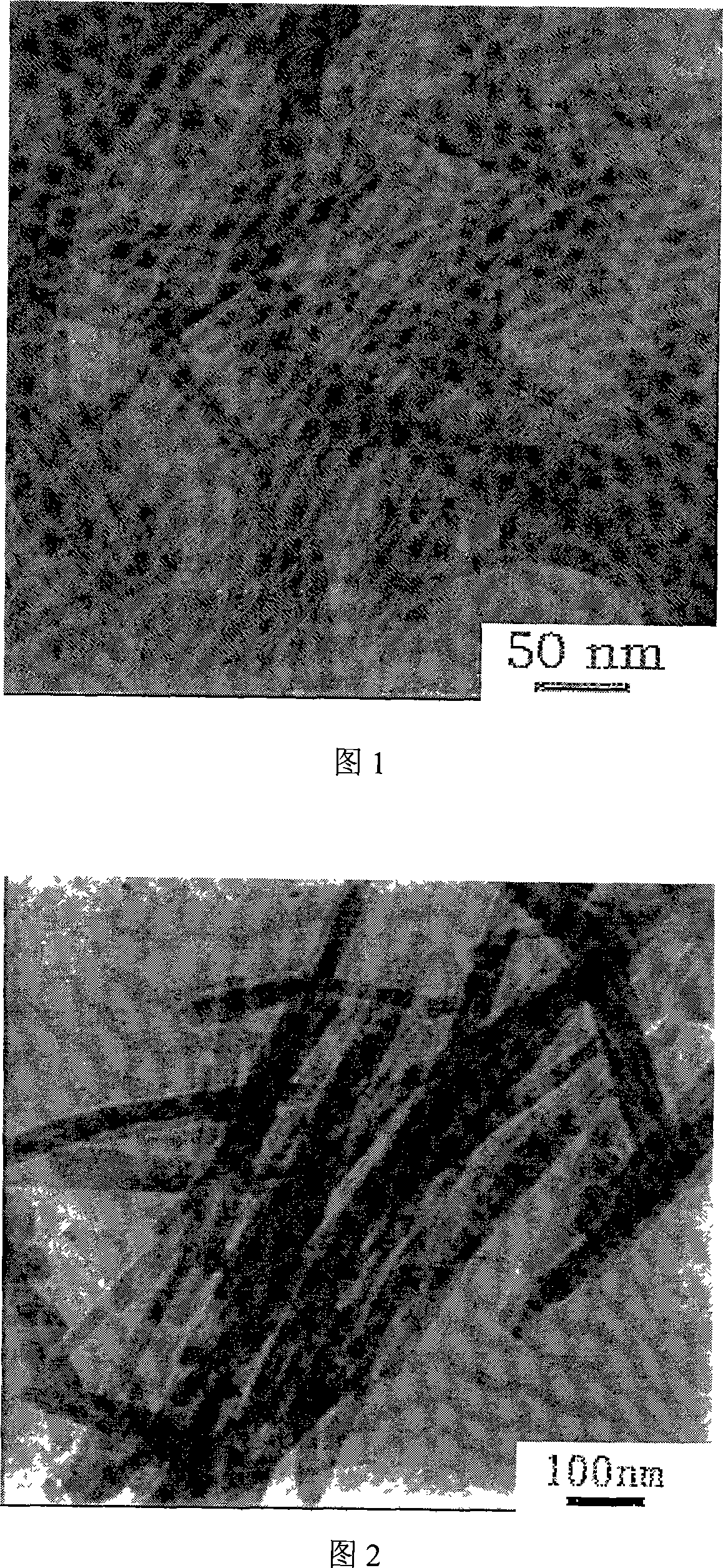

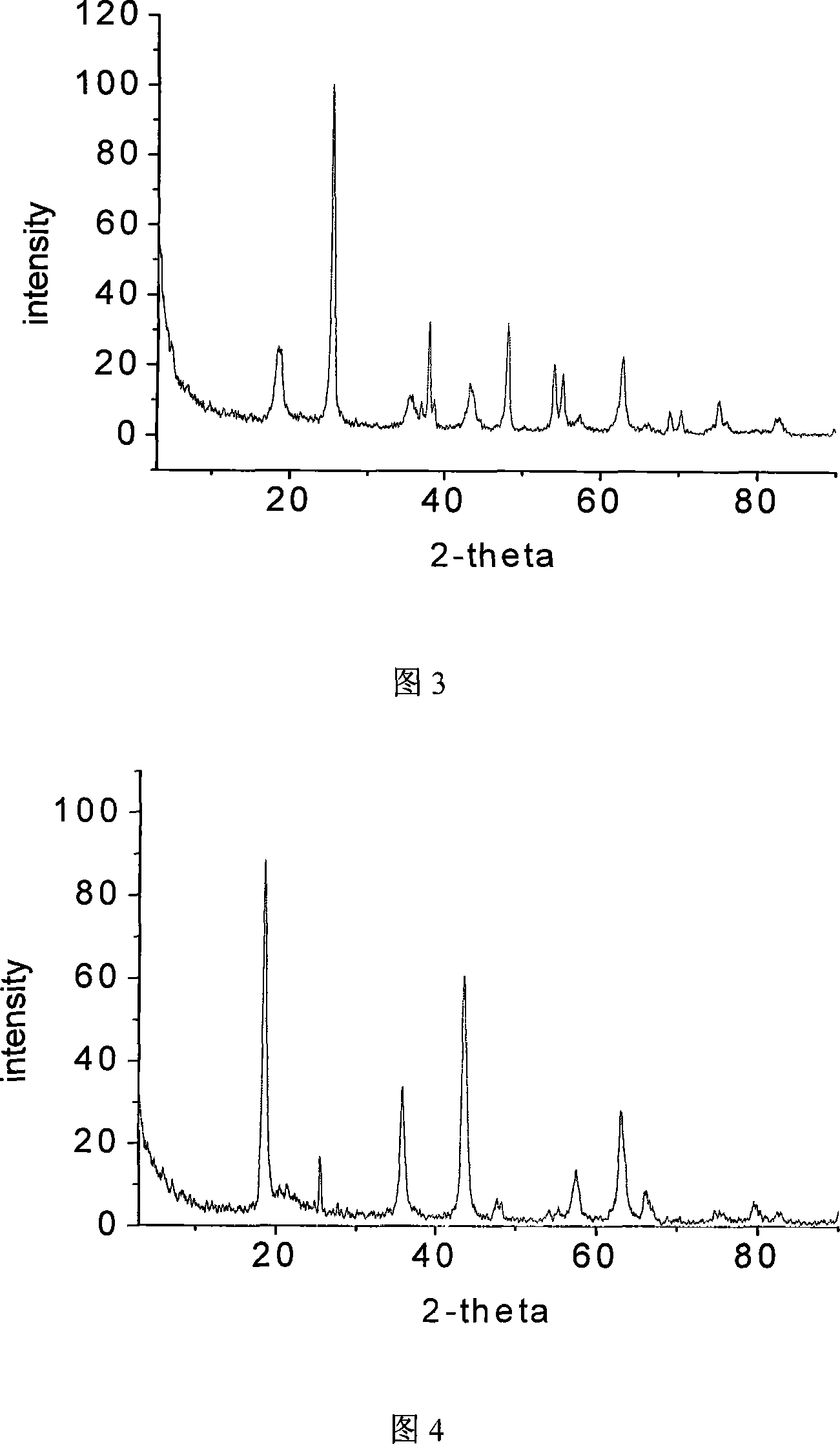

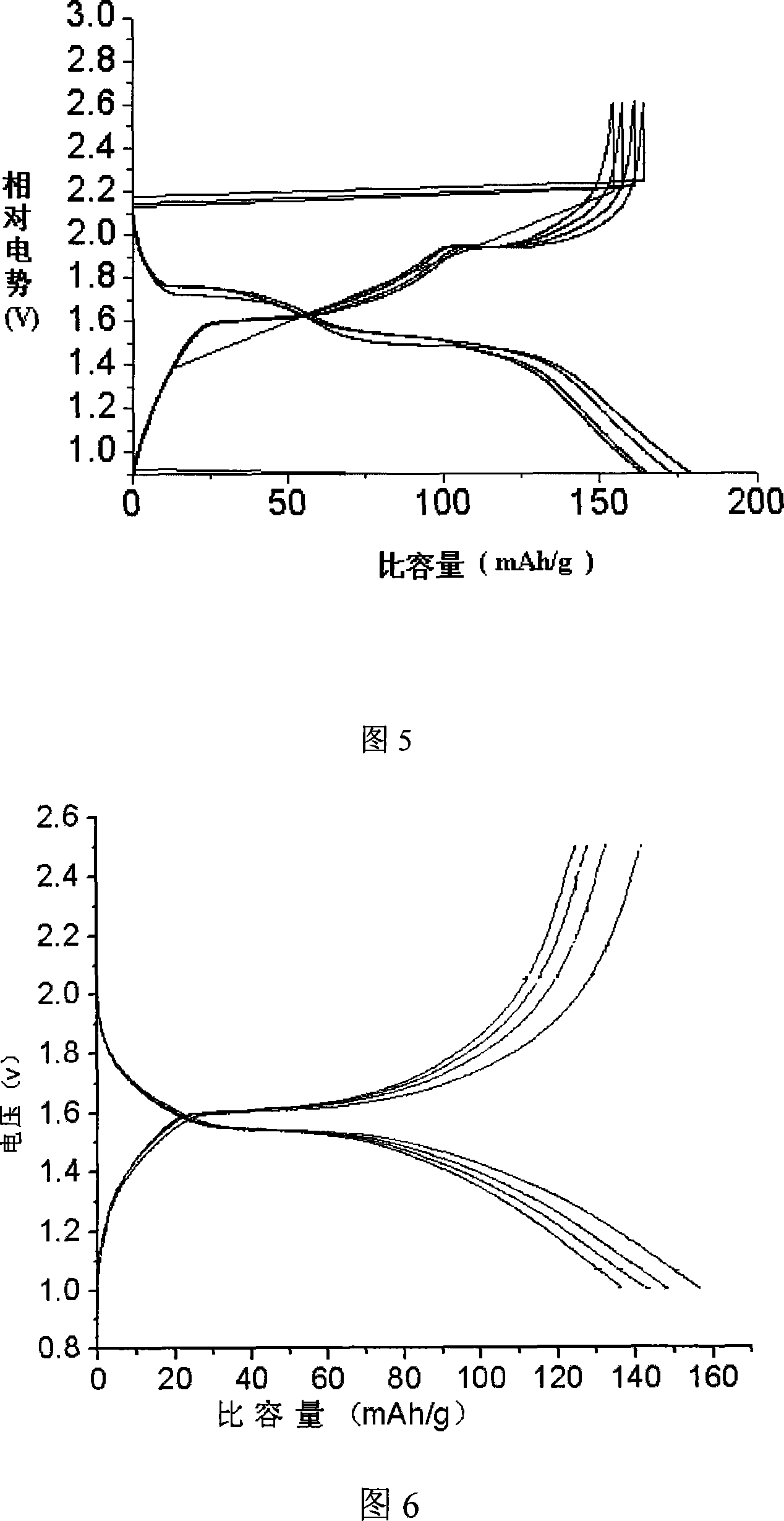

Nano lithium titanate for Negative electrode material of cell or electrochemical vessel, and its and titanium dioxide composite preparing method

ActiveCN101071853AImprove cycle stabilityTheoretical specific capacity is lowElectrode manufacturing processesTitanium dioxidePotassiumSodium hydroxide

This invention discloses nano lithium titanate for cell cathode material and compound with titanium dioxide, its preparation method is that: (1) compound containing titanium and sodium hydroxide (potassium) react by heating, cool, wash by water to different pH value, dry to obtain sodium(potassium) titanate or sodium (potassium) titanate compound; (2) mix the product from step (1) and inorganic lithium salt, heat it up to 451- 1,000 degree C to fuse exchange react for 30minute -48 hours, or mix the product from step (1) and organic or inorganic lithium salt under inert gas and heat it to150-1,000 degree C to fuse exchange react for30 minute - 48 hours, then wash by water and dry to obtain the finished product.

Owner:HENAN UNIVERSITY

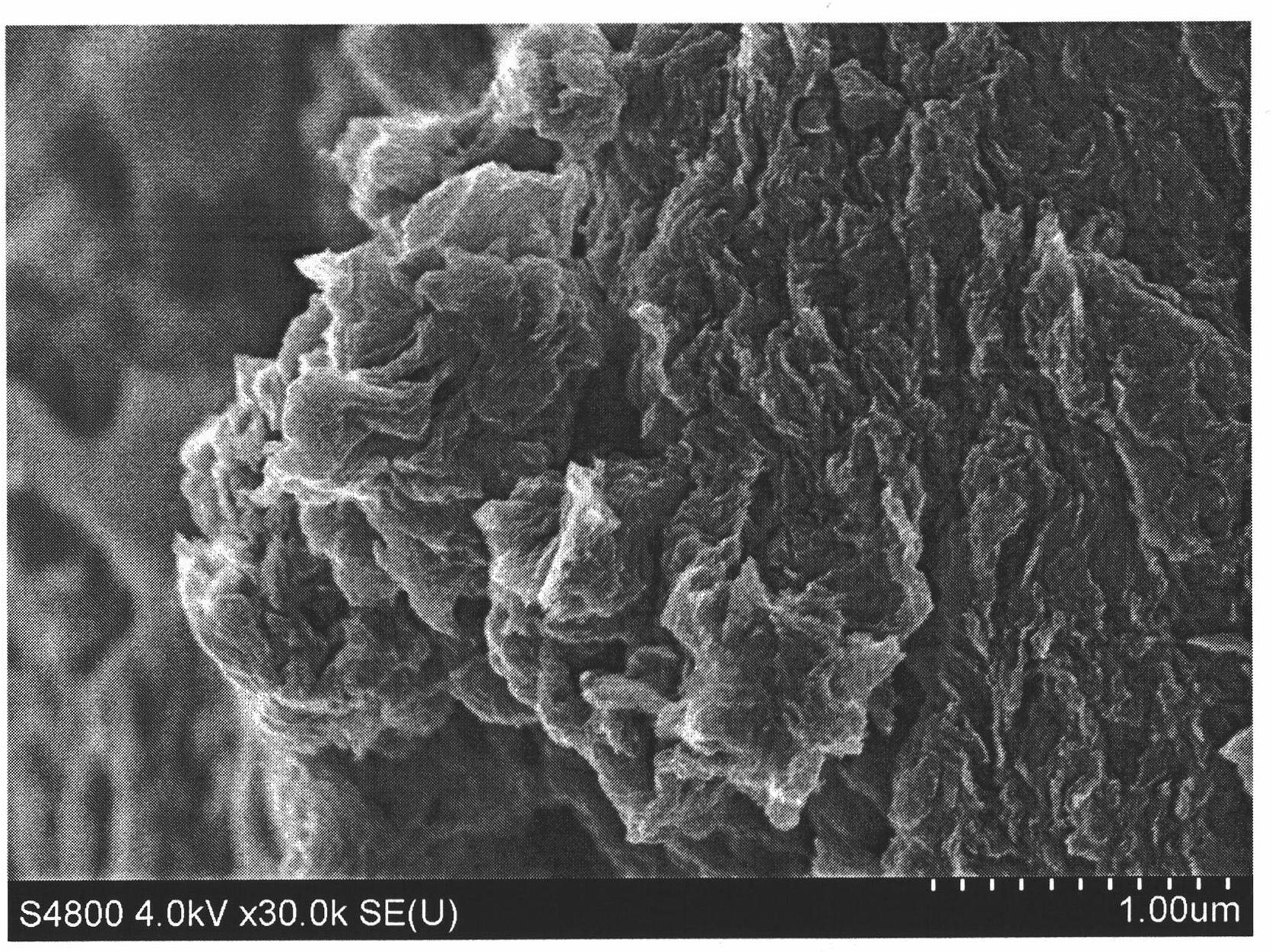

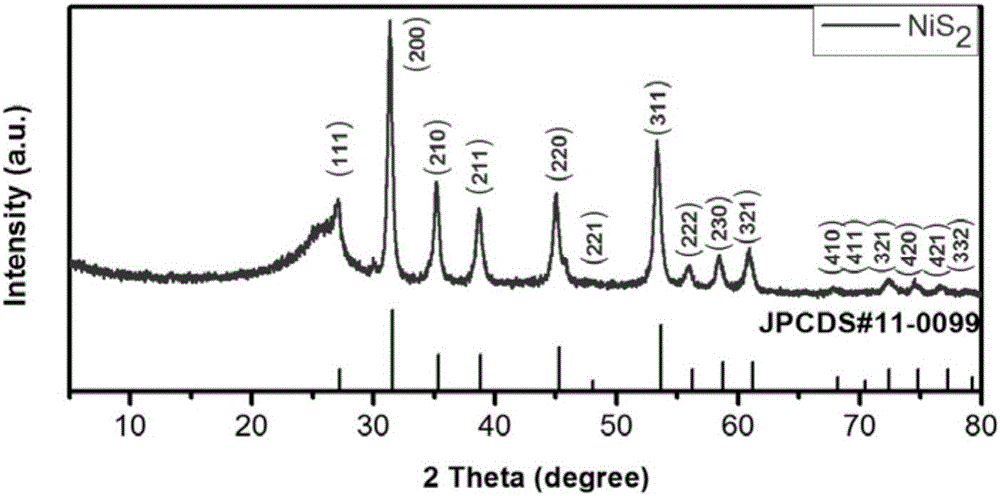

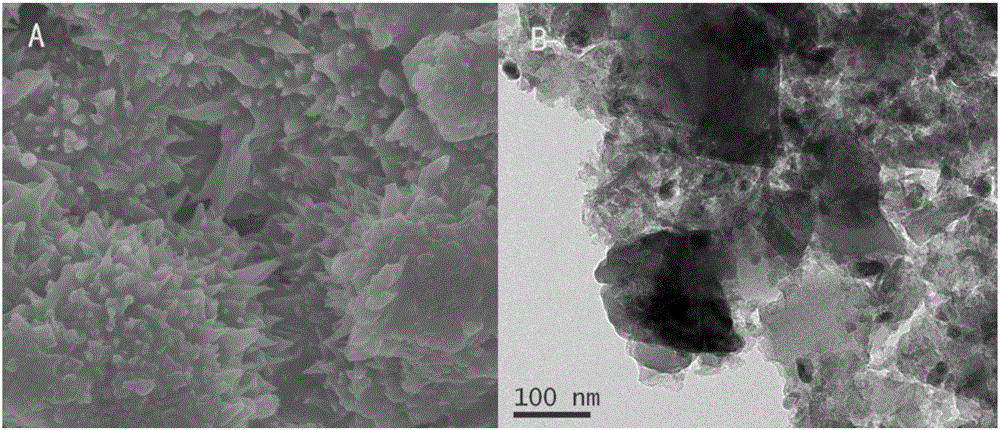

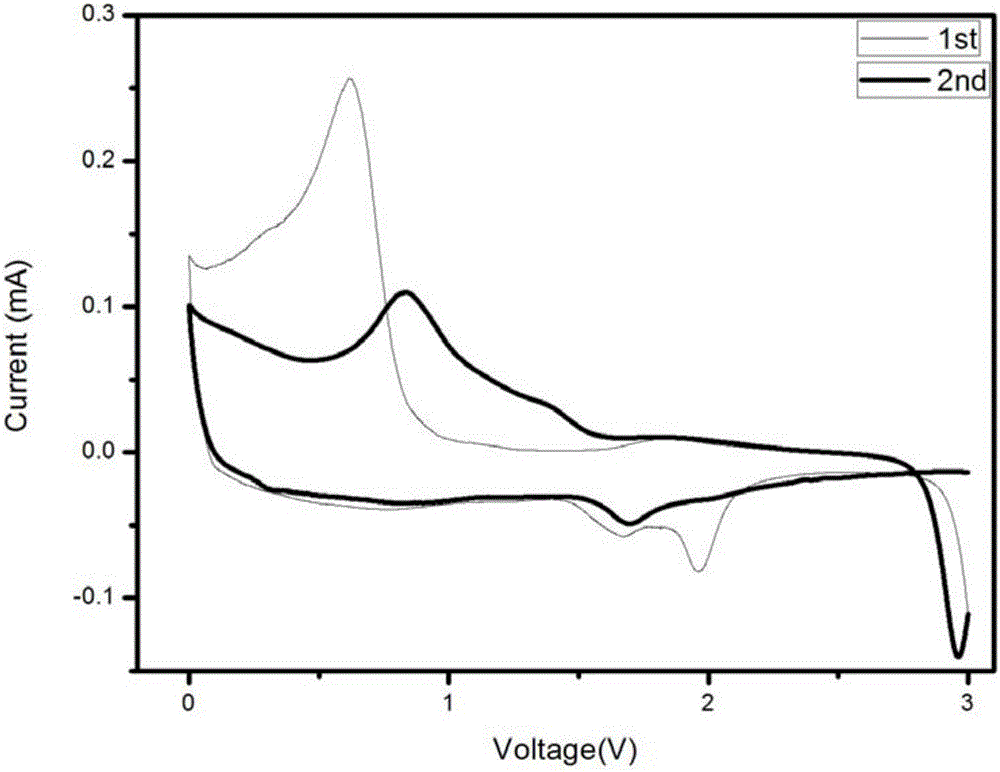

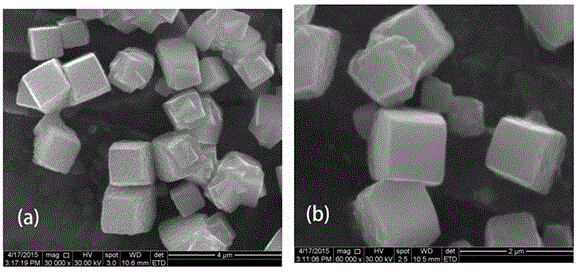

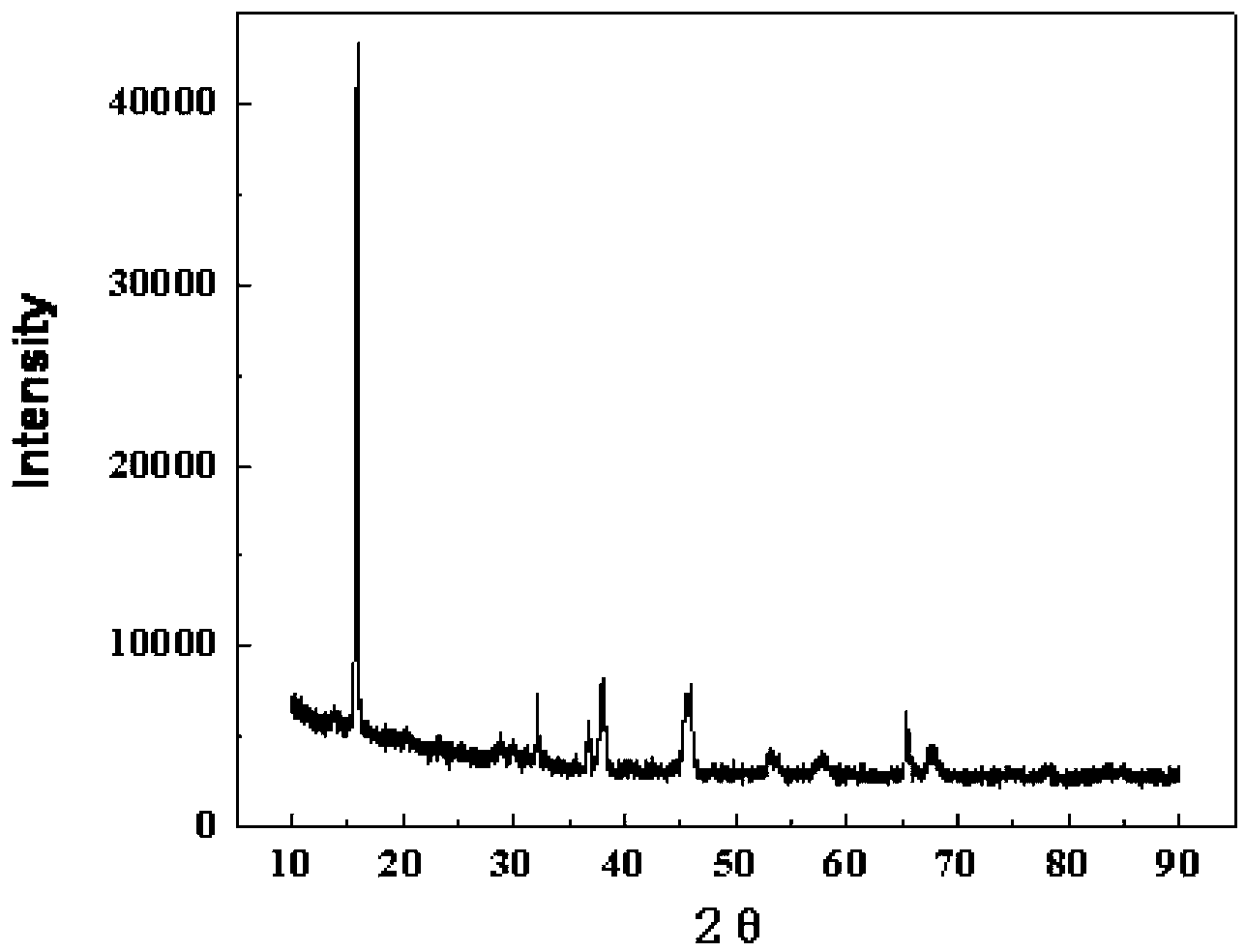

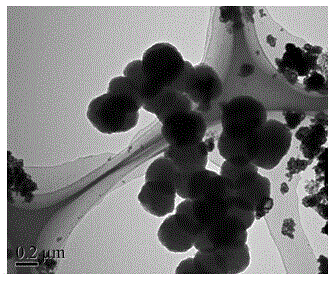

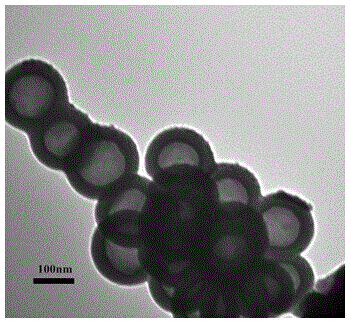

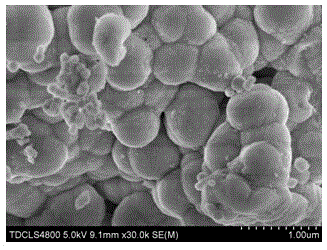

Preparation method of block NiS2 and application of block NiS2 to sodium-ion battery

InactiveCN105883940AIncrease contact areaLower electrode potentialMaterial nanotechnologyCell electrodesNickel saltAlcohol

The invention discloses a preparation method of block NiS2 and an application of the block NiS2 to a sodium-ion battery. According to the method, a 2-methylimidazole alcohol solution is added to a nickel salt alcohol solution, the mixture is evenly mixed, left to stand, subjected to centrifugal separation and dried, and nickel precursors are obtained; the nickel precursors and sulfur powder are ground and mixed, the mixture is placed in a vacuum environment for heat treatment, and a block NiS2 material comprising high-purity NiS2 nano spherical small particles is obtained. The material is used as an anode material to be applied to the sodium-ion battery and shows excellent electrochemical properties such as the high specific capacity, the long cycle life and the like; the preparation method of the block NiS2 material is simple, the cost is low, and industrial production requirements are met.

Owner:CENT SOUTH UNIV

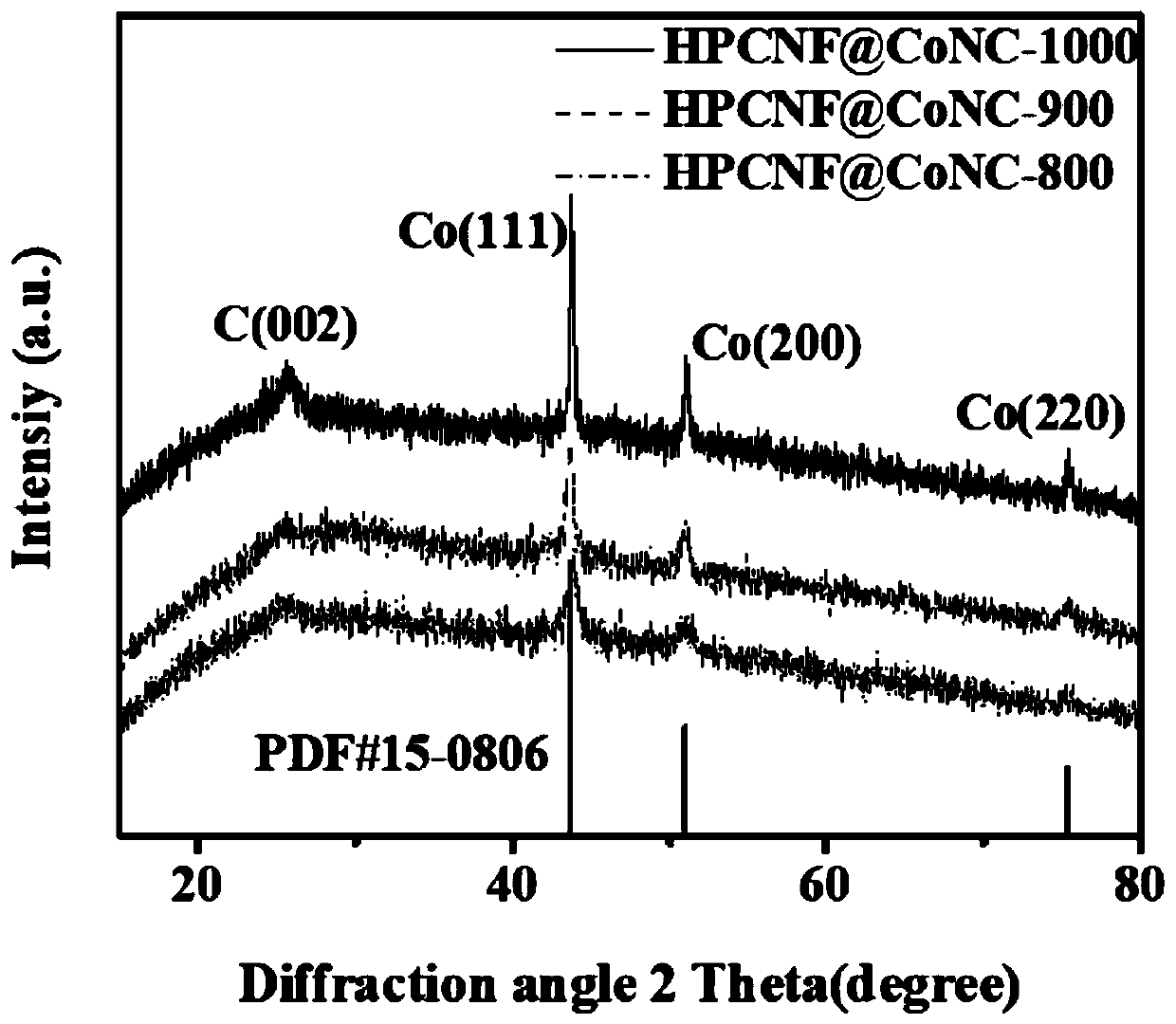

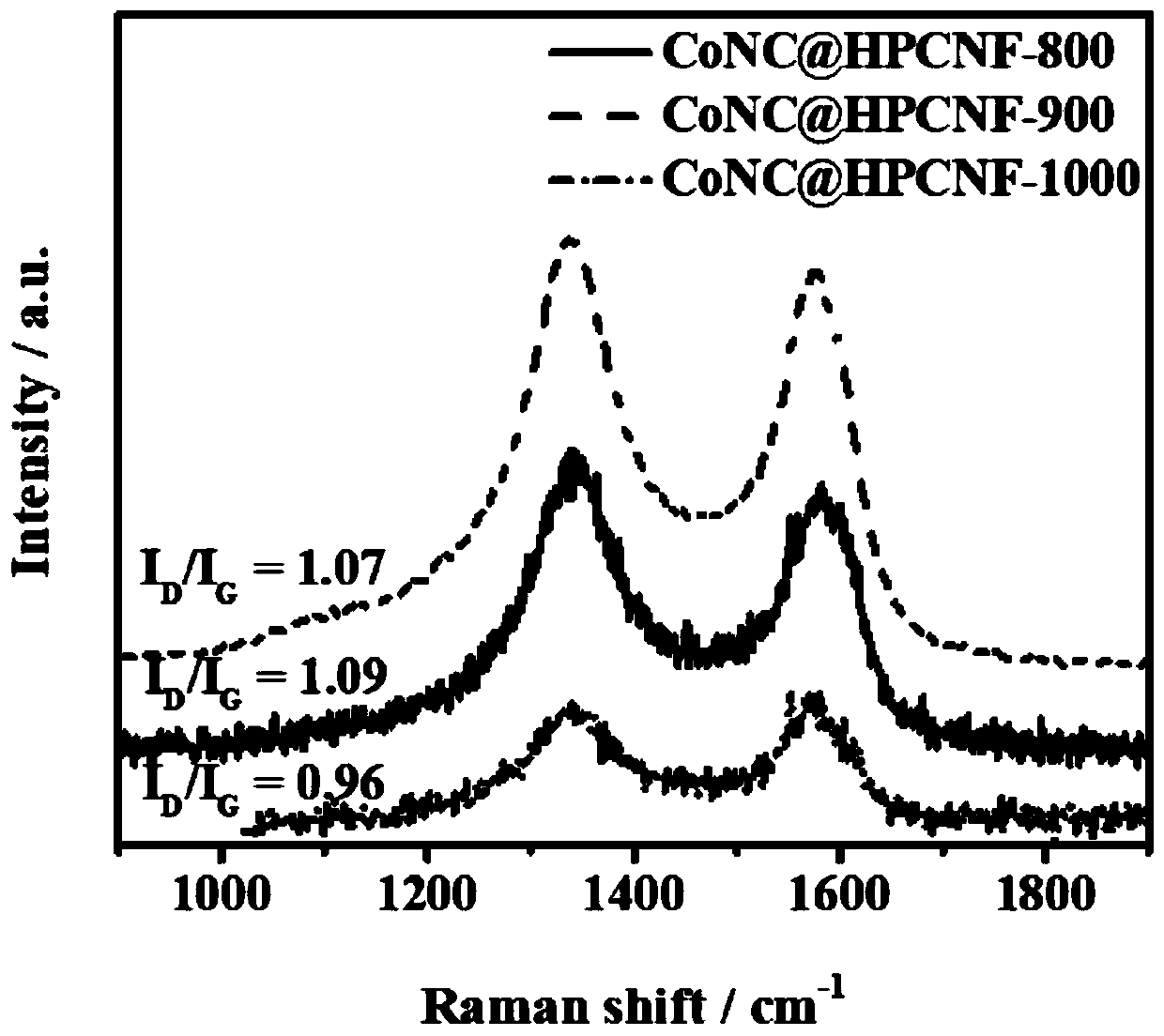

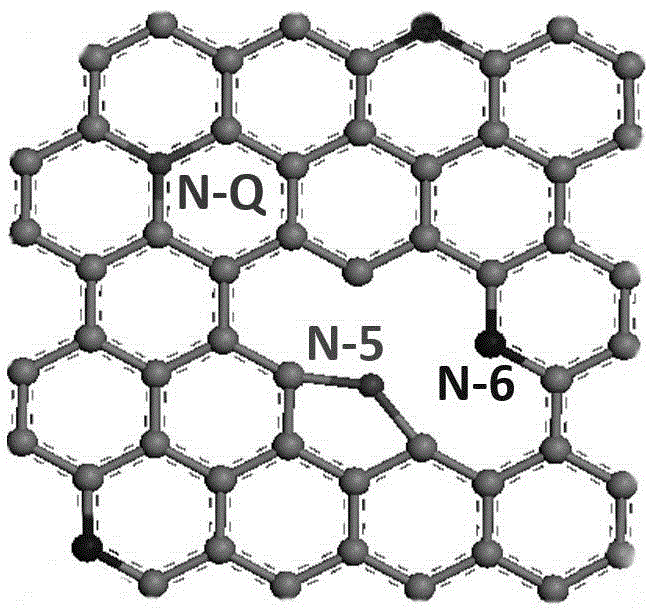

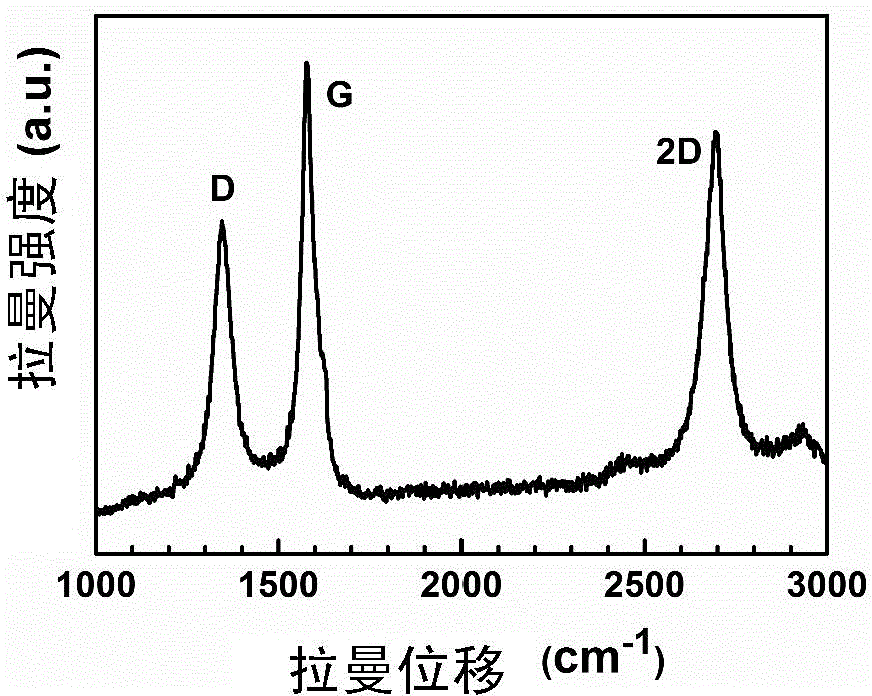

Nitrogen-cobalt-doped hollow carbon nanofiber, preparation method and application thereof and metal-air battery

ActiveCN110336049AGood internal accessImprove conductivityFuel and primary cellsCell electrodesFiberCarbon nanofiber

The invention provides a nitrogen-cobalt-doped hollow carbon nanofiber, a preparation method and application thereof and a metal-air battery. In the nitrogen-cobalt-doped hollow carbon nanofiber provided by the invention, nitrogen and cobalt are dispersed inside and on the surface of hollow carbon nanofiber. The nitrogen-cobalt-doped hollow carbon nanofiber provided by the invention has good ORR and OER performance, and has a half-wave potential of 0.785-0.809V, a limiting current density of 4.58-5.20mA / cm2 at 0.2V, and an overpotential of 473mV to 512mV when the current density is 10mA / cm2. Moreover, the zinc-air battery assembled from the nitrogen-cobalt-doped hollow carbon nanofiber of the invention has good charge-discharge cycle stability, and has no significantly increased voltage gap after 270hours of circulation.

Owner:DONGHUA UNIV

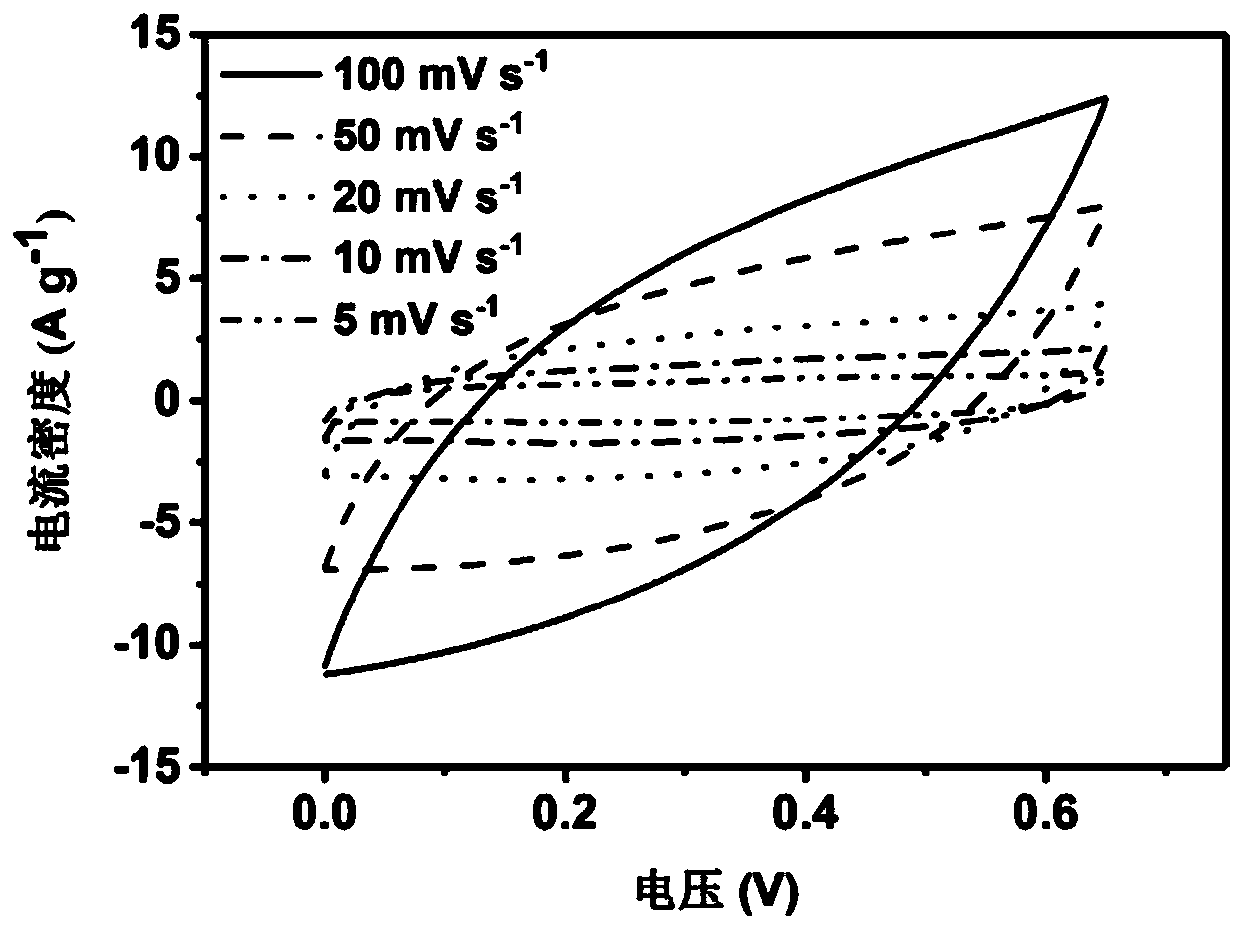

Carbon-based electrode material having super high specific capacitance and combined electrode material thereof

ActiveCN105702473AIncrease capacitance densityIncrease energy densityHybrid capacitor electrodesCapacitanceEnergy density

The invention relates to a carbon-based electrode material having super high specific capacitance and a combined electrode material thereof. Capacitance of the carbon-based electrode material comprises two parts, including double-electric-layer capacitance and Faradaic pseudo capacitance, the double-electric-layer capacitance is 20-60% of the capacitance of the carbon-based electrode material, the specific capacitance of the carbon-based electrode material under the 1A / g current density is more than 400, the volume specific capacitance is more than 300 F / ml, the energy density of a symmetric device of a water-based electrolyte is more than 20 Wh / kg, and the volume energy density is more than 15Wh / kg.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

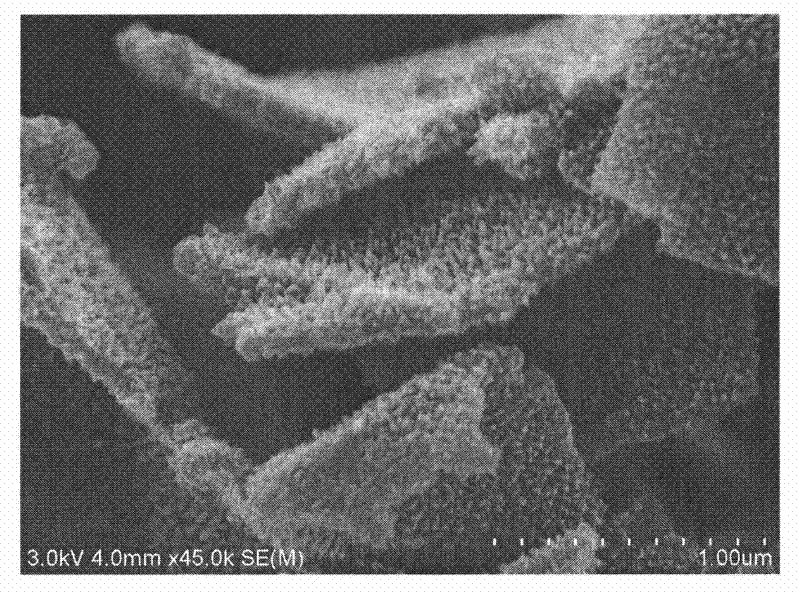

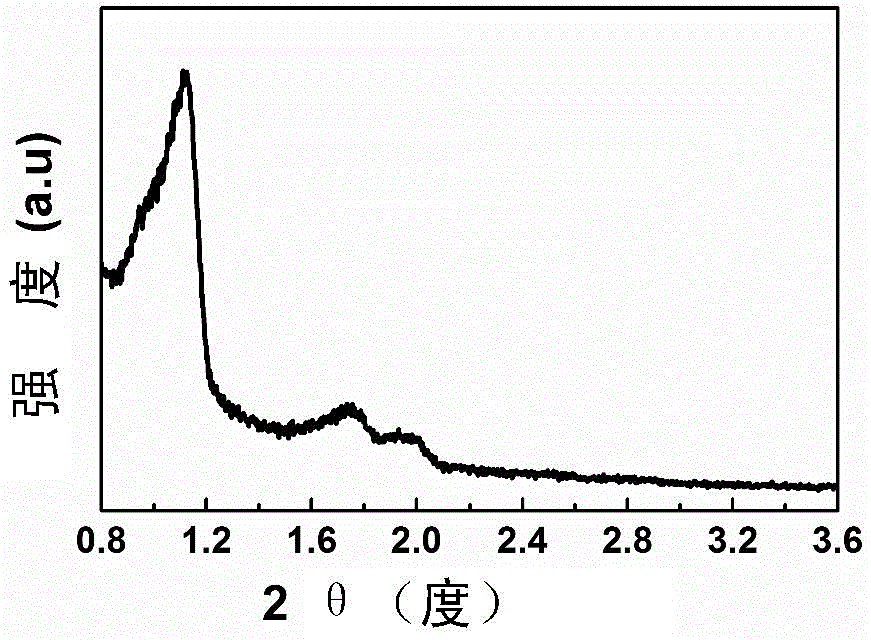

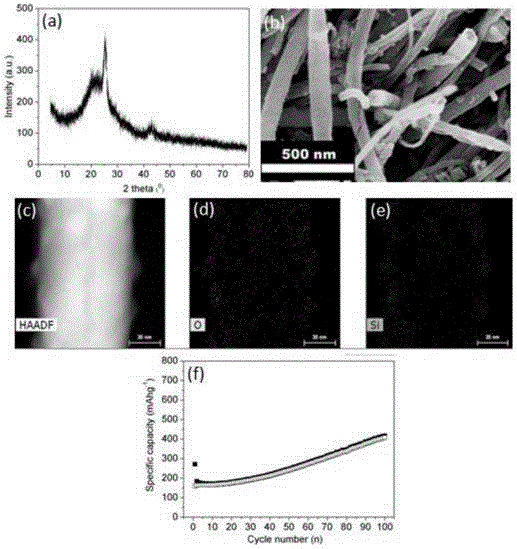

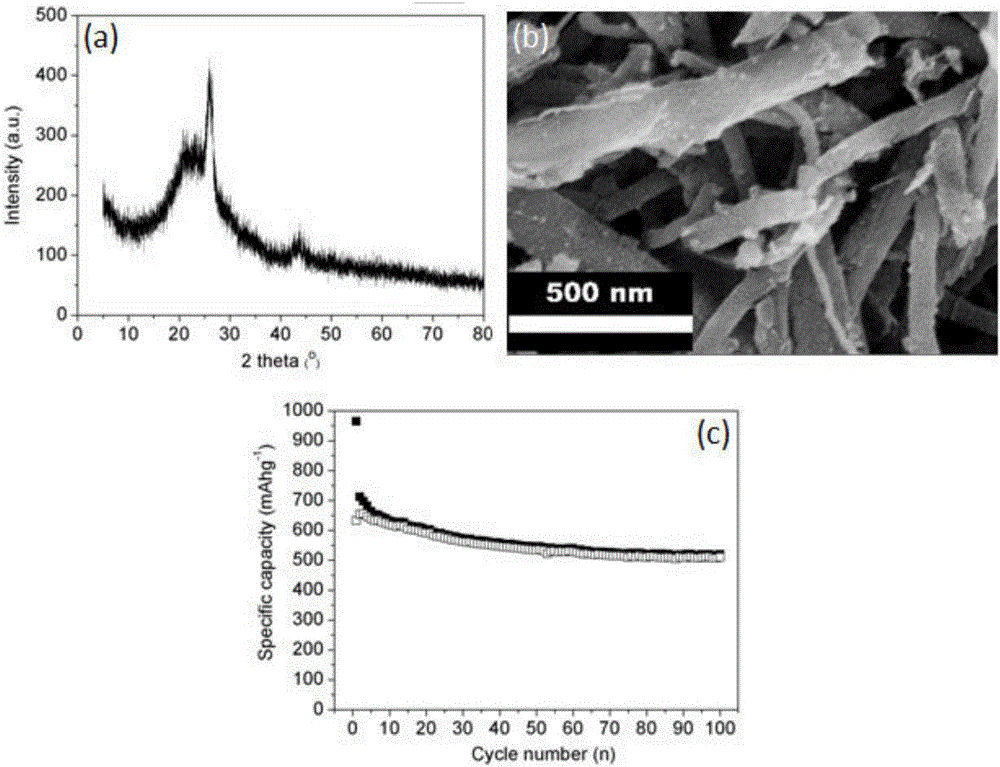

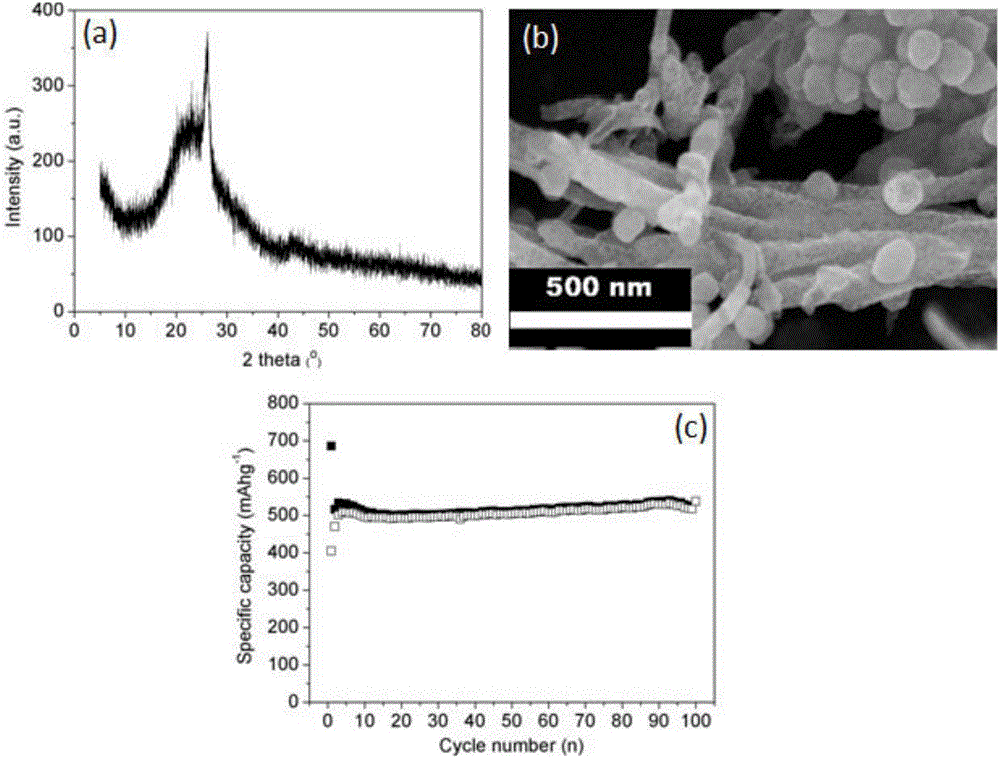

Preparation method of carbon nanotube/silica/carbon composite cathode material

InactiveCN106058179AImprove conductivityImprove performanceCell electrodesSecondary cellsCarbon compositesSucrose

The invention relates to a preparation method of a carbon nanotube / silica / carbon composite cathode material and belongs to the field of electrochemical power sources. The composite cathode material is composed of a carbon nanotube, silica and amorphous carbon. The preparation method: respectively dissolving hexadecyl trimethyl ammonium bromide and lithium hydroxide in an alcohol solution; placing the carbon nanotube in the alcohol solution, dissolving silica with tetraethoxysilane as a raw material in the alcohol solution, and stirring, filtering and drying to obtain carbon nanotube / silica; using sucrose as a carbon source, mixing carbon nanotube / silica with sucrose, dissolving in deionized water, removing water through stirring and drying, sintering for certain time at high temperature under protection of inert gas, and cooling to obtain carbon nanotube / silica / carbon. The composite cathode material has high specific capacity and excellent circulating stability. The preparation method is simple, moderate in preparation condition and low in cost.

Owner:HUNAN UNIV

CoS graded nano-bubble composite sulfur positive electrode material of lithium sulfur battery and preparation method of positive electrode material

ActiveCN108448093AImprove charge and discharge response abilityImprove conductivityMaterial nanotechnologyCell electrodesVulcanizationCharge discharge

The invention discloses a CoS graded nano-bubble composite S positive electrode material of a lithium sulfur battery, and belongs to the technical field of the lithium sulfur battery. The preparationmethod of the CoS graded nano-bubble composite S positive electrode material comprises the steps of firstly, synthesizing TiO2 composite hexadecylamine nanoparticle by hydrolysis of titanium isopropoxide; secondly, coating a surface of the TiO2 composite hexadecylamine nanoparticle with a layer of MOF-loying PVP so that the TiO2 composite nanoparticle can be absorbed during the growth process of ZIF67 and a surface is embedded and an interior are buried onto ZIF-67 to form a Chinese data structure; and finally, performing vulcanization to obtain a CoS graded nano-bubble material with a plurality of CoS hollow spheres sleeving a CoS hollow polyhedron by hydrothermal method of thioacetamide, and injecting S into the CoS graded nano bubbles by a melting method to obtain a final material. TheCoS graded nano-bubble composite S provided by the invention is used as a lithium sulfur battery positive electrode, relatively high charge-discharge performance and stable cycle property are shown, and the important application value in the field of the lithium sulfur battery is achieved.

Owner:CHINA JILIANG UNIV

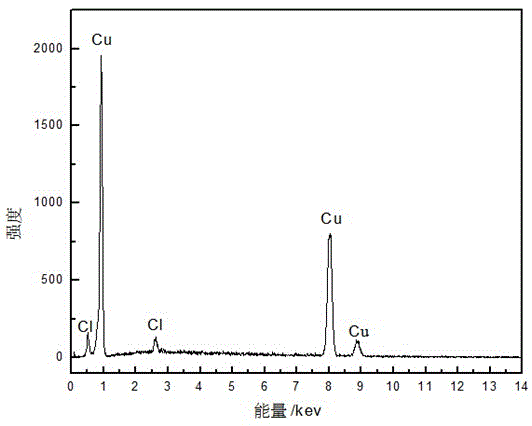

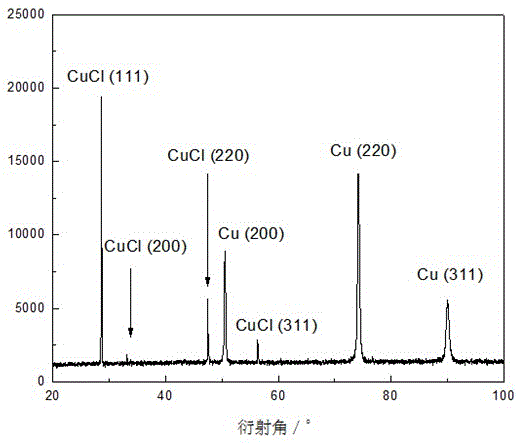

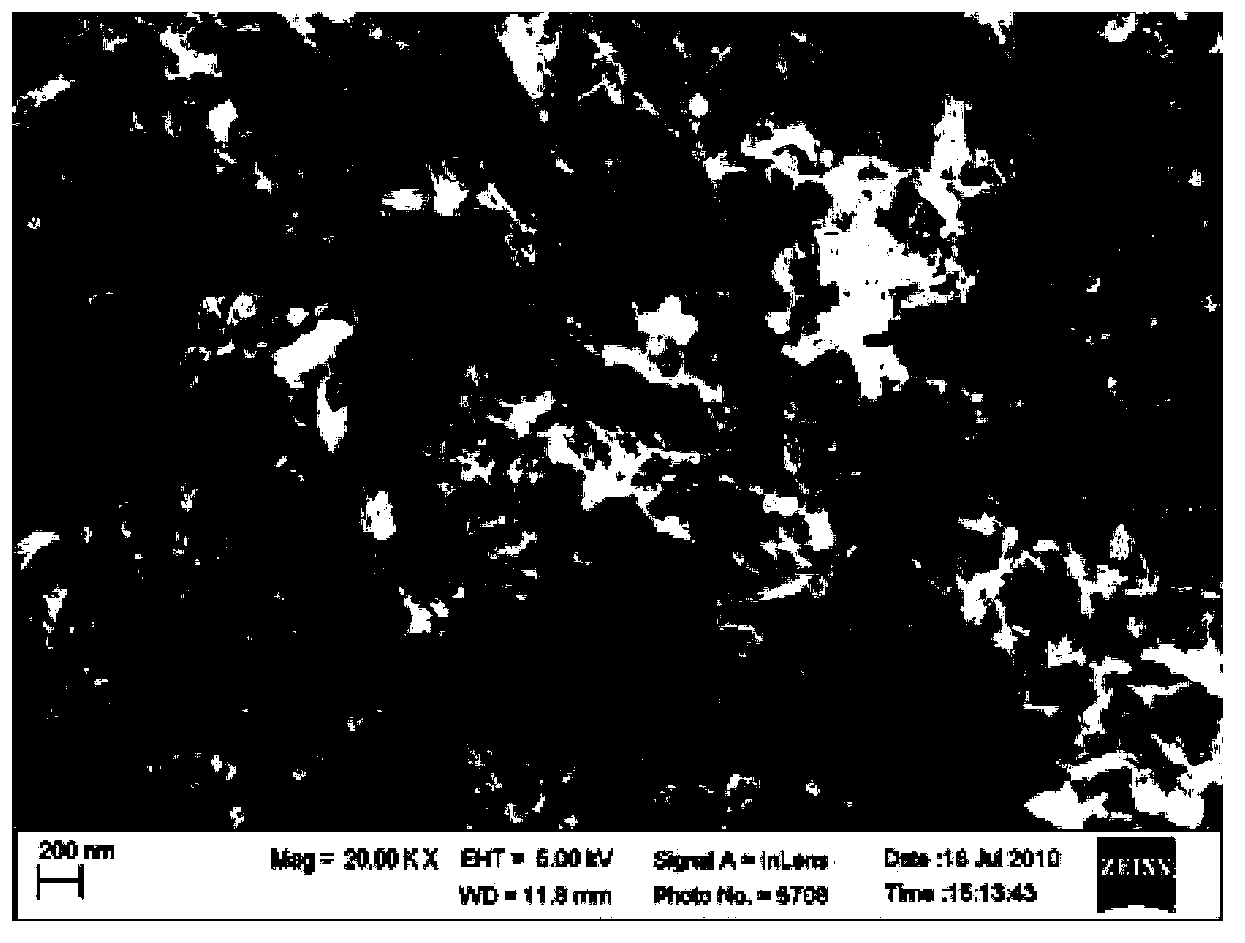

Application of CuCl/Cu composite material

ActiveCN105609761AHigh discharge specific capacityImprove cycle stabilityCell electrodesSecondary cellsWater insolubleNew energy

The invention discloses application of a CuCl / Cu composite material, and belongs to the development and research field of new energy source materials. The CuCl / Cu composite material is substantially obtained through depositing in situ a layer of water-insoluble cubic-crystal phase cuprous chloride active substance on the surface of a metal copper current collector through a one-step anodic oxidation method, and is then assembled with a lithium foil in a glove box filled with high pure argon gas to form a button type simulation lithium ion battery. The homologous substances, i.e. a copper current collector and cuprous chloride, are ingeniously and tightly combined together by an in-situ growth method; the specific surface area of the electrode material is large; the combination with the copper current collector is tight; and the contact resistance is favorably reduced. Compared with the traditional coating type electrode process, the process has the advantages that the operation is simple, environment-friendly and easy for amplification; more importantly, the falling phenomenon of the active substance in the long-period charging / discharging process is favorably relieved; and the rate discharging performance and charging / discharging cycle performance of the lithium ion battery are improved.

Owner:KUNMING UNIV OF SCI & TECH

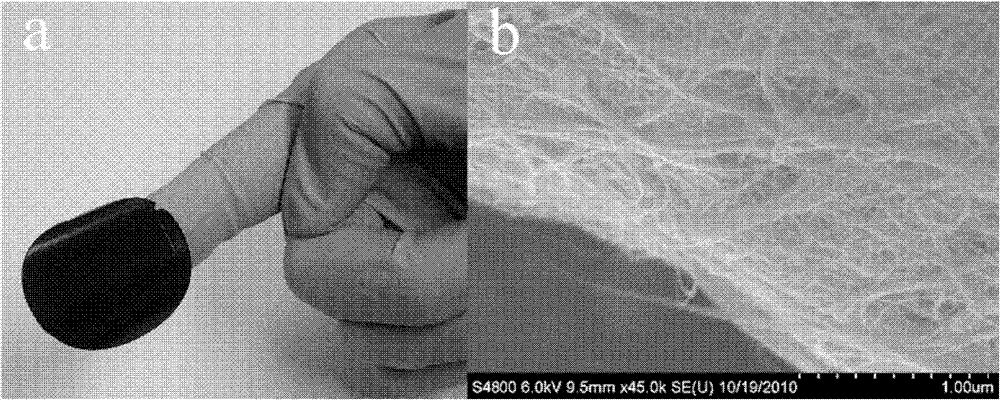

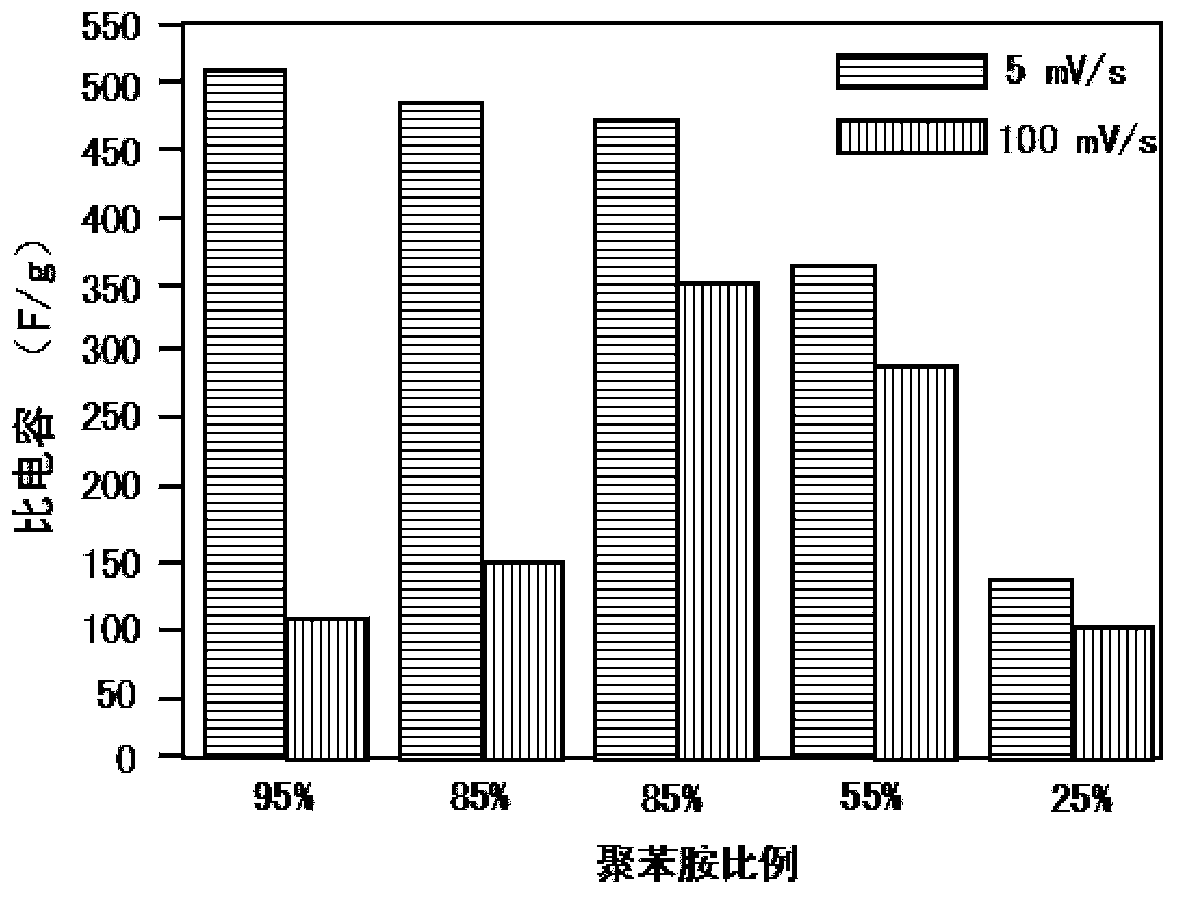

Manufacturing method of multi-wall carbon nanotube and polyaniline nano fiber composite supercapacitor electrode

The invention discloses a manufacturing method of a multi-wall carbon nanotube and polyaniline nano fiber composite supercapacitor electrode. The manufacturing method is characterized by including the following steps that firstly, polystyrolsulfon acid is used for scattering a multi-wall carbon nanotube; secondly, a polyaniline nano fiber is manufactured; finally, the multi-wall carbon nanotube and polyaniline nano fiber composite supercapacitor electrode is manufactured. The electrode of a supercapacitor is manufactured by a compound of the carbon nanotube and the polyaniline nano fiber, and the manufacturing method is simple and suitable for industrial production. In addition, the supercapacitor electrode manufactured with the manufacturing method is high in electrical conductivity, low in equivalent resistance and high in charge-discharge cycle stability.

Owner:HEFEI UNIV OF TECH

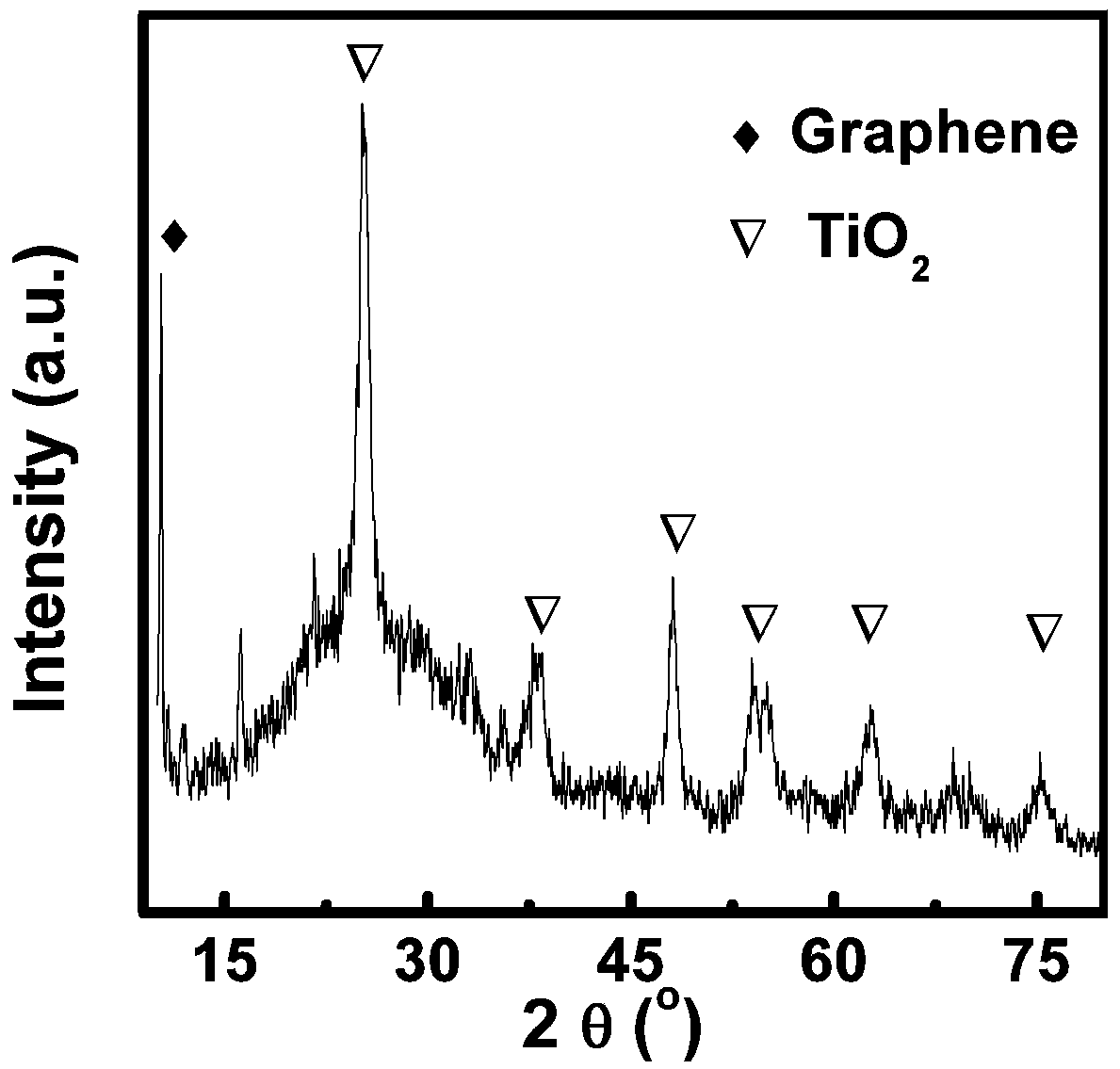

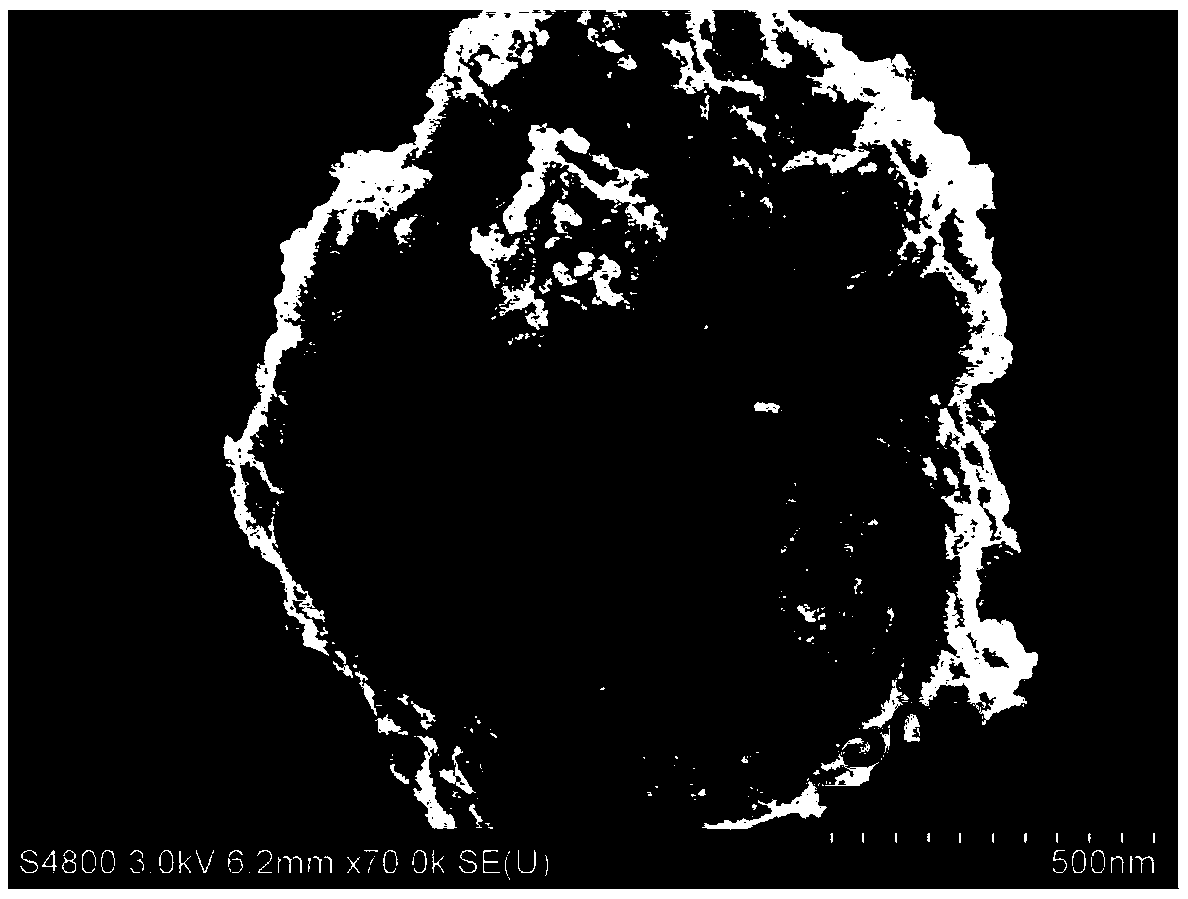

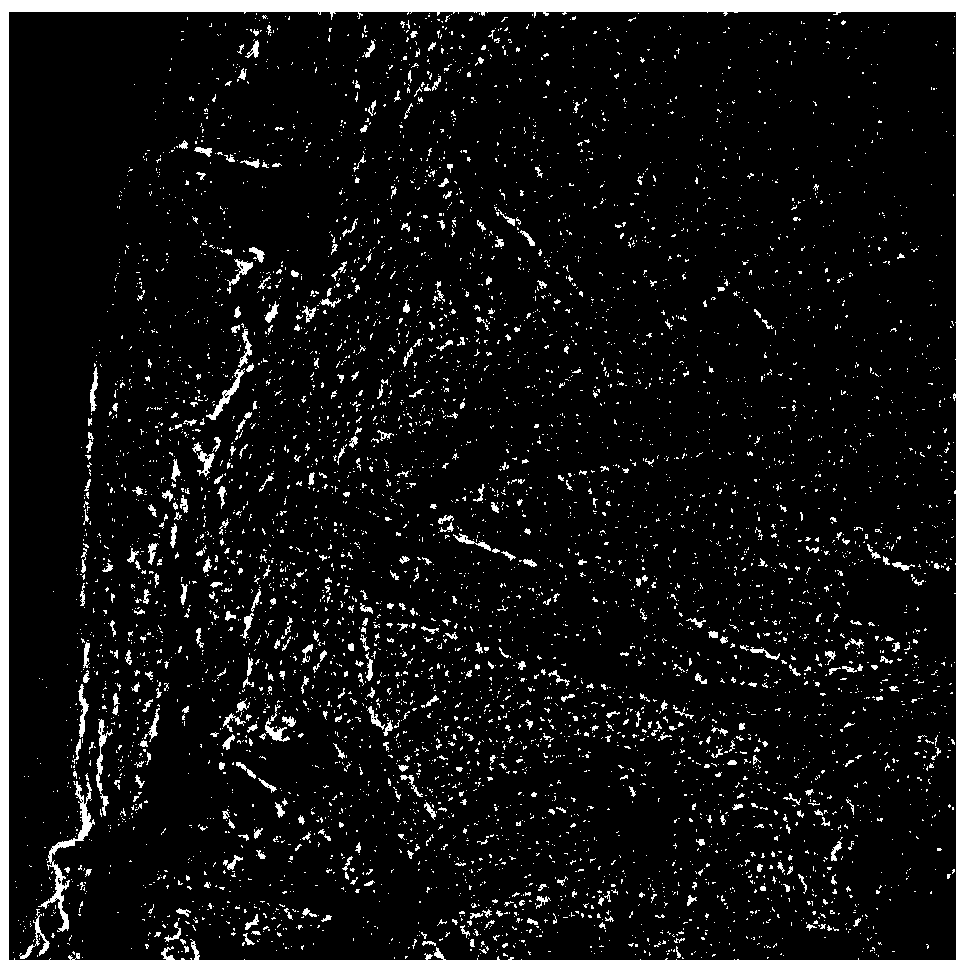

Preparation method for graphene-coated titanium dioxide nanotube

InactiveCN105514436AHigh specific capacityImproved magnification performanceCell electrodesSecondary cellsRefluxHigh rate

A preparation method for a graphene-coated titanium dioxide nanotube comprises the following steps: adding titanium dioxide nano-particles and sodium hydroxide into a hydrothermal reactor for a hydrothermal reaction, and drying at a low temperature to obtain a titanium dioxide nanotube; placing the titanium dioxide nanotube and APTMS into a beaker for reflux, drying at a low temperature to obtain an amino-modified titanium dioxide tube; uniformly mixing the amino-modified titanium dioxide tube with an oxidized graphene solution, filtering, and drying at a low temperature to obtain a titanium dioxide nanotube coated with the oxidized grapheme and provided with an amino; performing calcination processing on the dioxide nanotube coated with the oxidized graphene and provided with the amino at the inert atmosphere to obtain the graphene-coated titanium dioxide nanotube. According to the preparation method, in a functional group grafting process, the surface of the titanium dioxide nanotube is coated with graphene, so that the titanium dioxide nanotube realizes quick charge and discharge with a high rate, improves the specific capacity and the rate capability, and has the characteristics of being simple to operate, high in repeatability and low in cost.

Owner:SHAANXI UNIV OF SCI & TECH

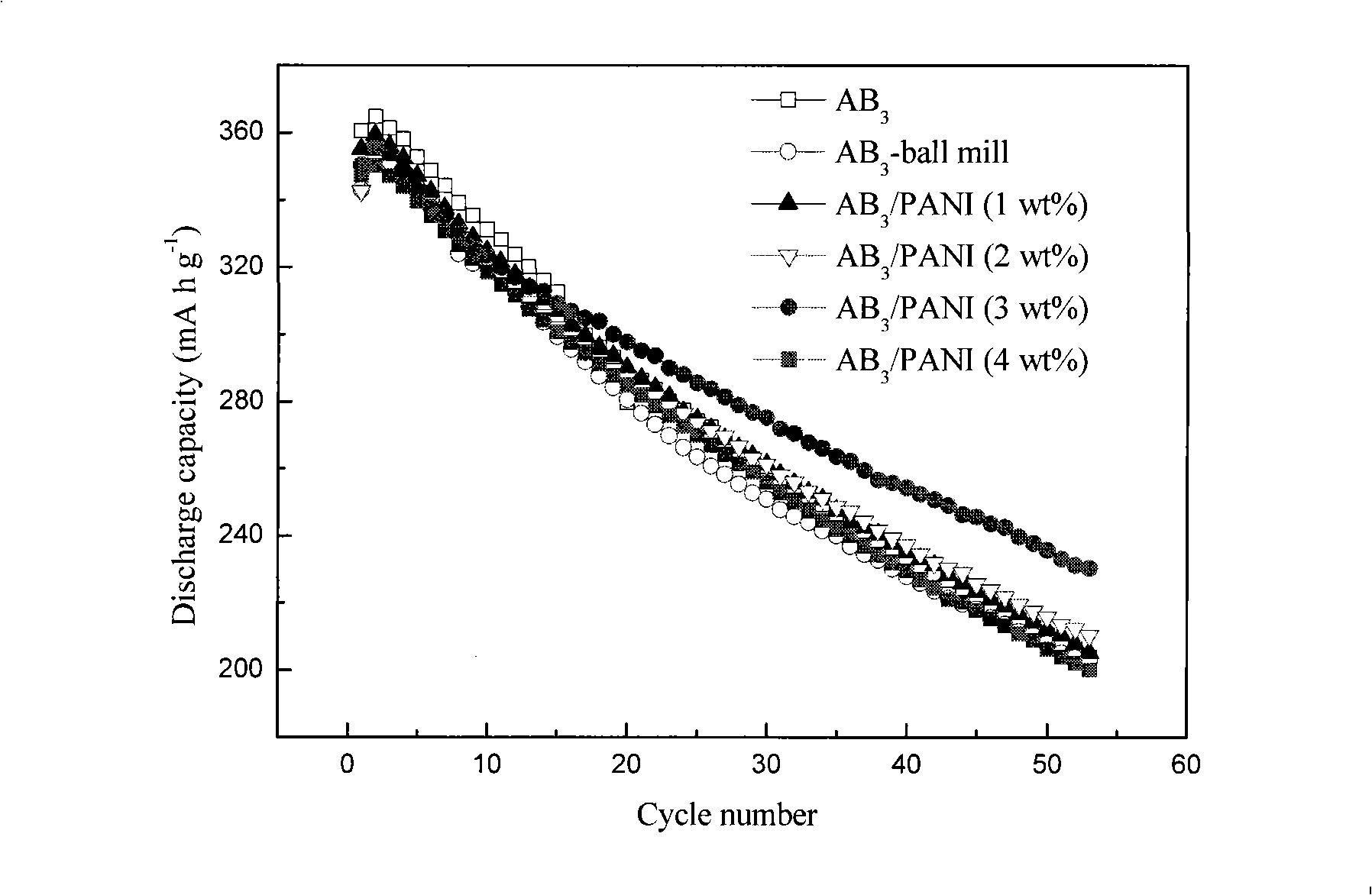

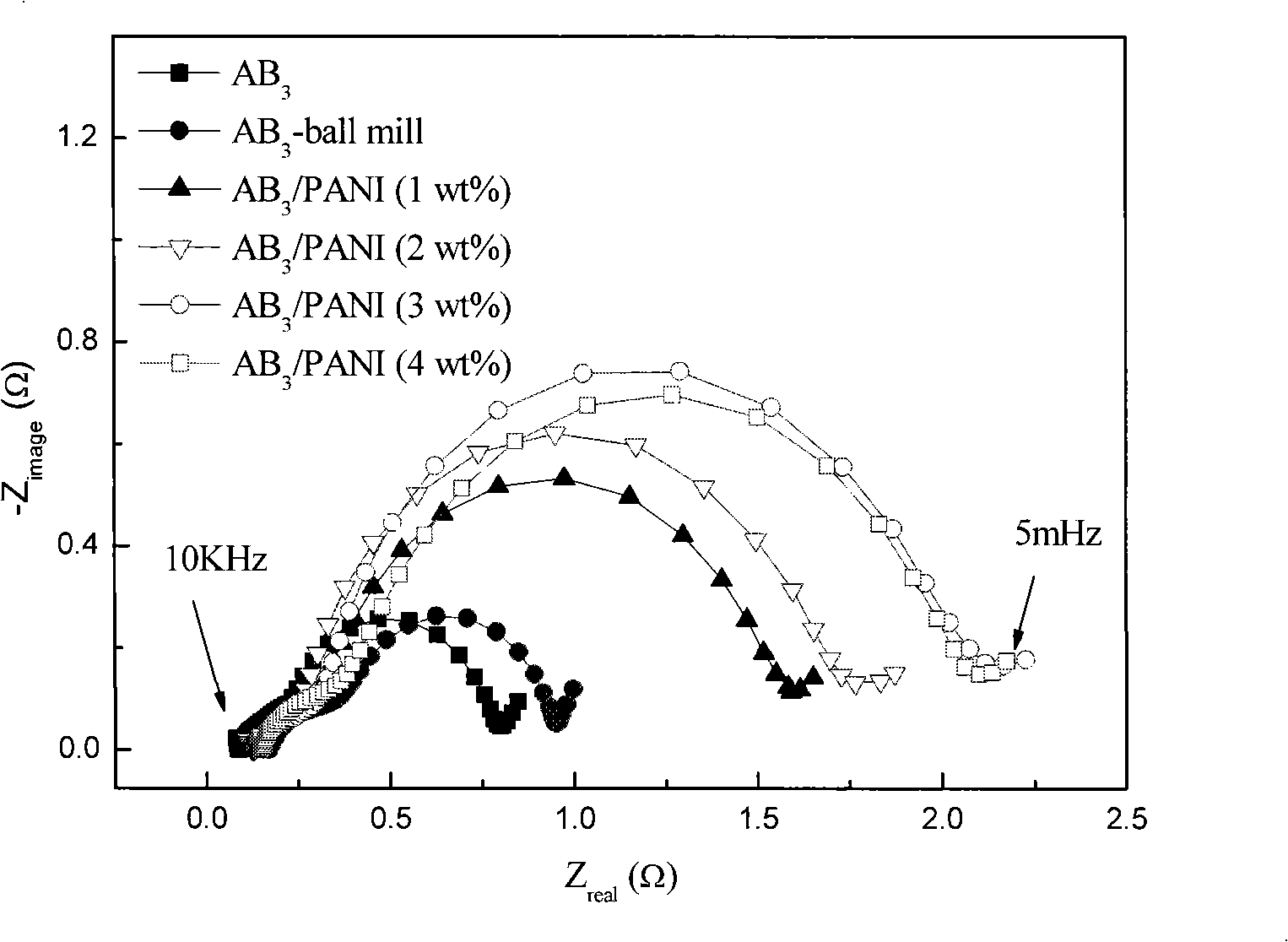

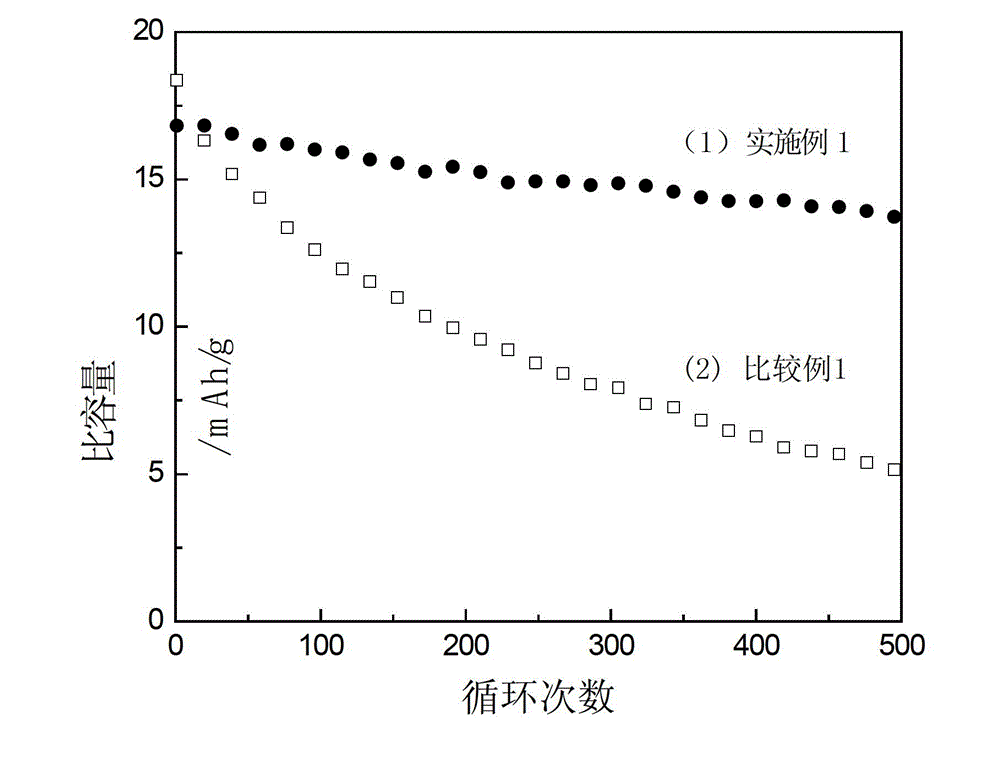

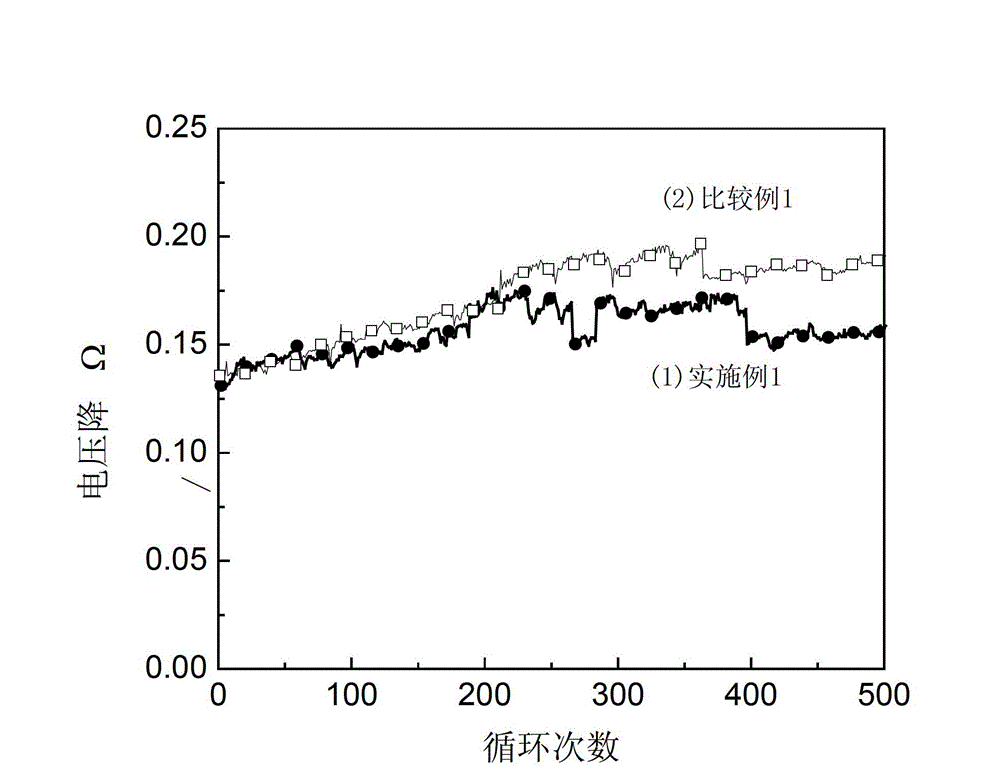

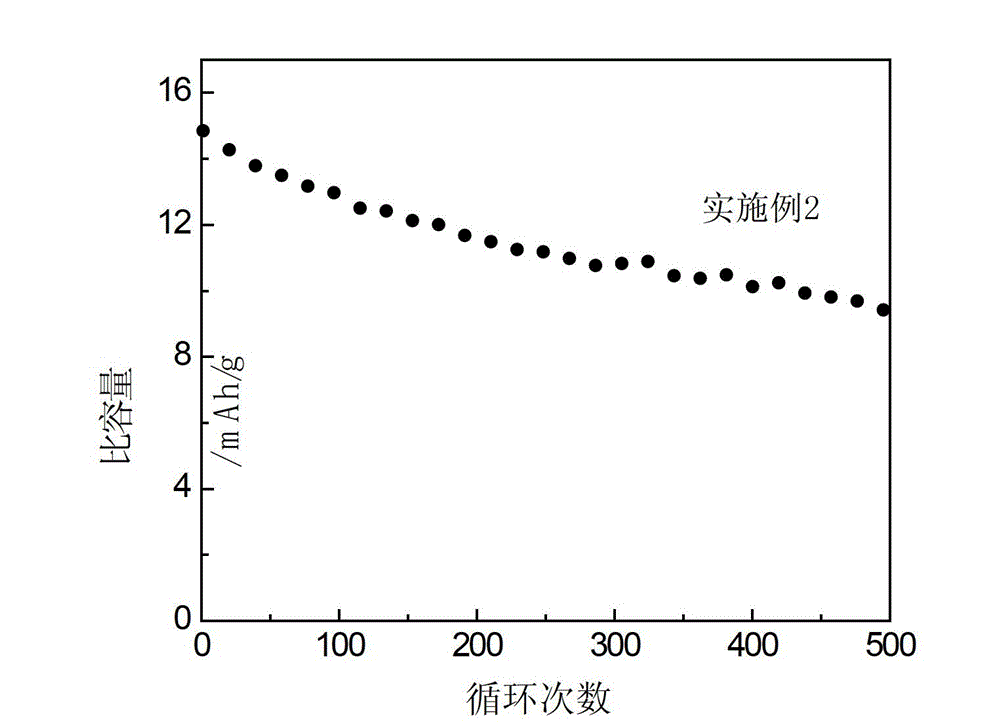

Composite material of conducting high polymers/alloy for nickel-hydrogen battery and preparation thereof

InactiveCN101289576AImprove charge and discharge cycle stabilityPrevent chalkingAlkaline accumulator electrodesNon-conductive material with dispersed conductive materialAlloy compositeBall mill

The invention relates to conductive high molecular polymer / alloy composite material for nickel-hydrogen batteries and a preparation method thereof. The composite material is compositely formed by a metal AB3 alloy and a conductive high molecular polymer, and is a material that the conductive high molecular polymer is coated on the surface of the metal alloy; the mixture ratio of the metal AB3 alloy is La 0.7 Mg 0.3-x Ti x Ni y Co 3.5-y, wherein, x is equal to 0-0.15, and y is equal to 2.0-3.5; and the mass mixture ratio of the metal alloy and the conductive high molecular polymer is 100:1-4. The composite material can be prepared according to the following steps: 1) an organic monomer with conductivity is evoked by acid conditions and oxidant to polymerize to obtain the conductive high molecular polymer; 2) the metal alloy is prepared through a high-temperature smelting furnace, and then undergoes ball milling with the conductive high molecular polymer to obtain the even composite material. The preparation method has simple process and low cost, and can effectively improve the stability of charge / discharge circulation of alloy electrodes by compounding the conductive high molecular polymer and the metal alloy, thereby providing effective protection for alloy electrodes. The material is suitable for applications such as the protection of electrode materials, fuel batteries and so on.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

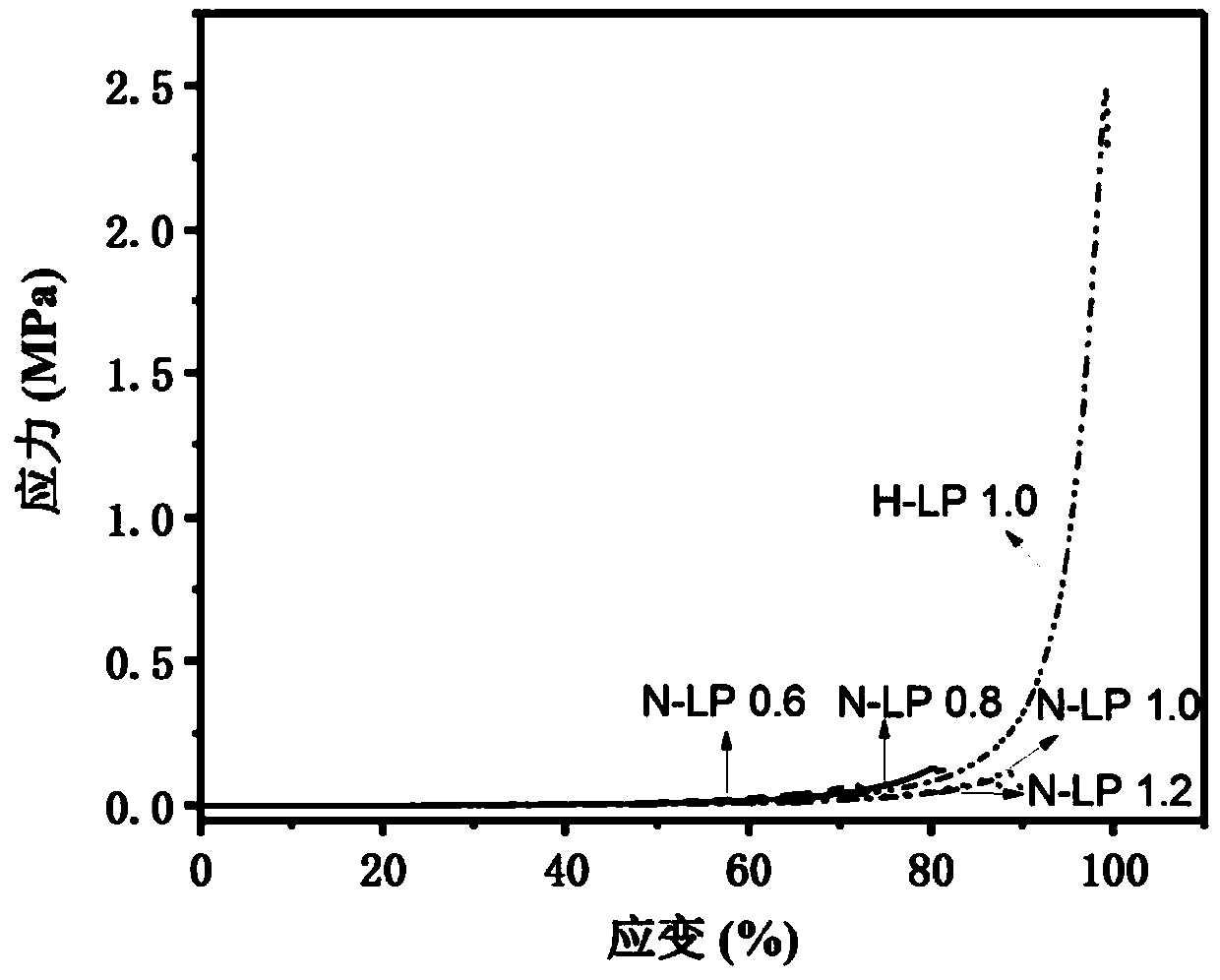

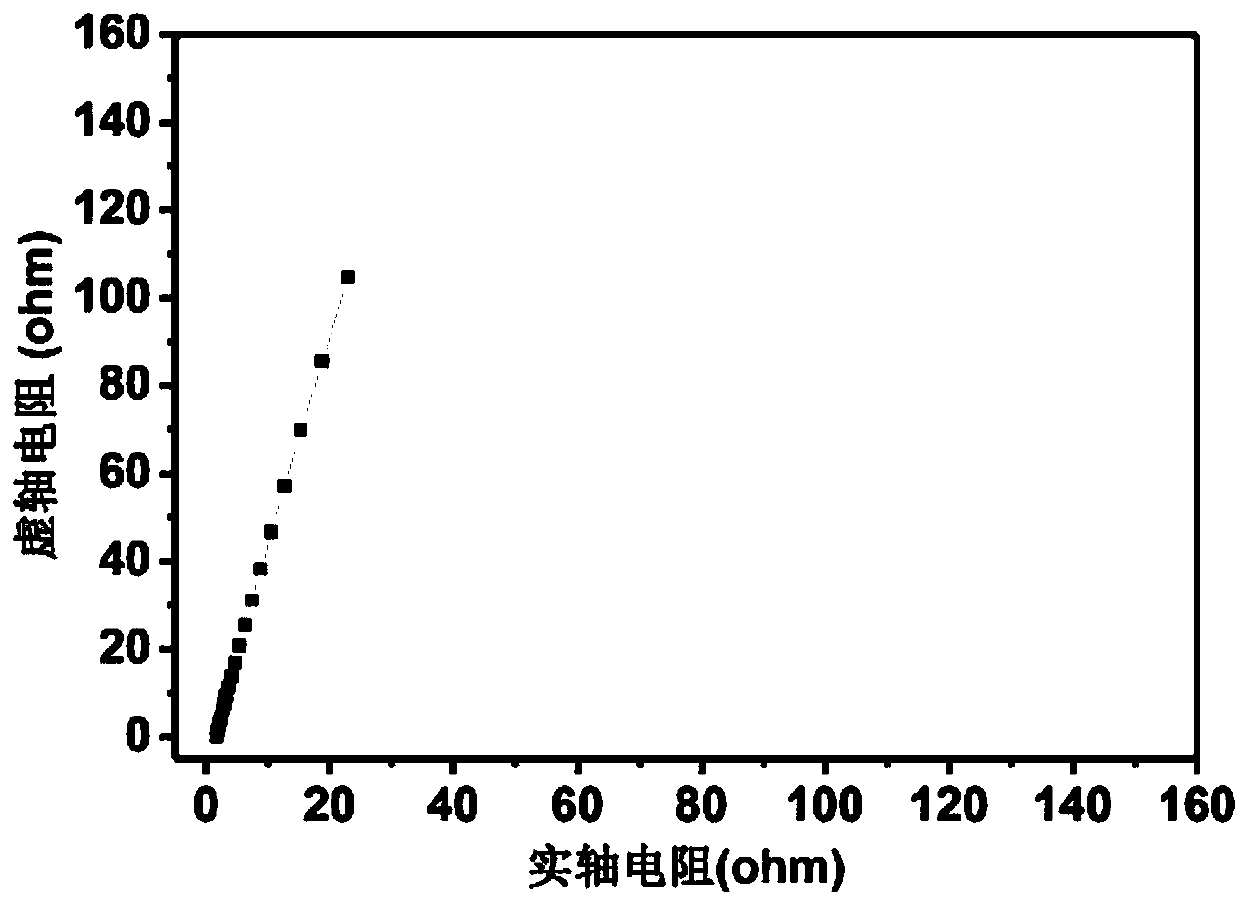

Double-network lignin hydrogel as well as preparation method and application thereof

ActiveCN109517205AEasy to prepareOvercome the disadvantages of poor mechanical propertiesHybrid capacitor electrolytesCapacitanceHydrophobic effect

The invention belongs to the field of lignin-based hydrogel functional materials and discloses double-network lignin hydrogel as well as a preparation method and application thereof. The preparation method disclosed by the invention comprises the following steps: constructing a first network lignin hydrogel system in an alkaline solution by virtue of chemical cross-linking, and soaking the first network lignin hydrogel in an acidic solution, and producing a hydrophobic effect by utilizing lignin in the first network, thereby forming the double-network lignin hydrogel. The double-network ligninhydrogel prepared by the method has high mechanical strength, and the preparation method is simple, low in raw material cost, reproducible, green and environment-friendly. Moreover, the double-network lignin hydrogel has high ionic conductivity, and when the hydrogel serves as electrolyte for assembling a supercapacitor, extra ionic solution soaking is not needed, use of an extra diaphragm is notneeded, and the thickness and weight of the supercapacitor are effectively reduced. The specific capacitance value of the obtained capacitor is higher than the specific capacitance value of a conventional hydrogel electrolyte type flexible supercapacitor. In addition, the double-network lignin hydrogel has excellent charge and discharge cycle stability, compression resistance and bending resistance.

Owner:SOUTH CHINA AGRI UNIV

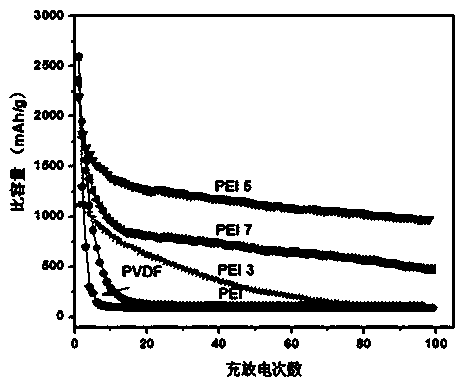

Preparation method of lithium ion battery negative electrode adhesive and method for preparing lithium ion battery negative electrode material

ActiveCN108899548AImproved rheological propertiesImprove charge and discharge cycle stabilityCell electrodesSecondary cellsCross-linkPolyetherimide

The invention provides a preparation method of a lithium ion battery negative electrode adhesive and a method for preparing the lithium ion battery negative electrode material. A cross-linked PEI (Polyetherimide) adhesive prepared according to the invention is water-soluble, low in toxicity, nonflammable, green, environment-friendly and capable of realizing industrial production, the prepared cross-linked PEI adhesive has a hyperbranched network structure, and the structure can form multi-dimensional strong hydrogen bonds with silicon, so that silica nanoparticles are firmly coated. The flexible hyperbranched PEI molecular chain is capable of effectively buffering stress generated by silicon volume expansion, and flows to the damage surface while shrinking the silicon volume to form hydrogen bonds again, and the self-repairing effect is effectively achieved; movement of the silicon can be effectively limited by the network structure, deformation resistance of the electrode is improved,the integrity of the electrode is ensured, and the volume effect problem of the silicon negative electrode can be effectively solved, so that the cycling stability of the silicon negative electrode is greatly improved, the requirements of electric vehicles and other large energy storage devices on high-specific capacity cells are further met, and the development prospects are wide.

Owner:JIAXING UNIV

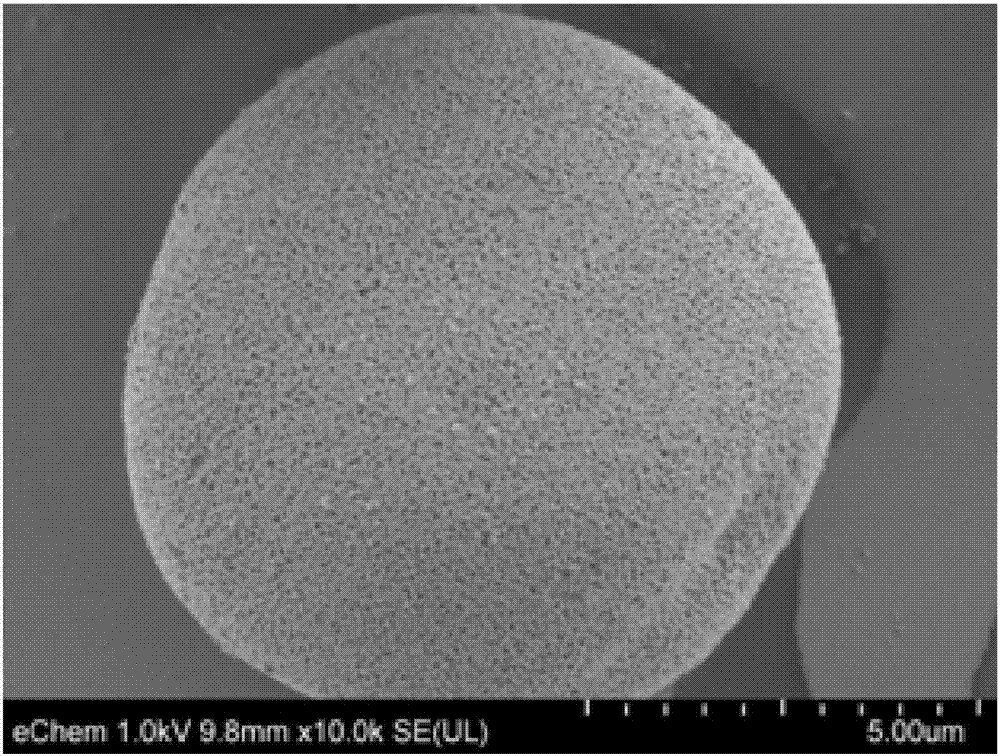

Lithium sodium manganate cathode material and preparation method thereof

ActiveCN103078100AReduce pollutionStable structureCell electrodesManganates/permanganatesDispersed mediaManganate

The invention discloses a lithium sodium manganate cathode material. The lithium sodium manganate cathode material consists of lithium sodium manganate with a layered structure, or sodium manganate with a layered structure, or lithium sodium manganate with a layered structure and a lithium manganate with a spinel structure. A preparation method comprises the following steps: mixing a manganese surface and a sodium surface, or a lithium surface, the manganese surface and the sodium surface and dispersing a mixture in a liquid disperse medium; mixing for 2-8 h through ball milling to obtain a ball-milled material; and putting the ball-milled material in an atmosphere of reducing gas, inert gas or air, roasting the ball-milled material for 6-50 h at 500-1,200DEG C, and cooling the ball-milled material to room temperature to obtain the lithium sodium manganate cathode material. The lithium sodium manganate cathode material is stable in structure, large in specific capacity, stable in cycle capacity, low in cost and environment-friendly; and the preparation method is simple in process, easy to control conditions, low in production cost and low in environment pollution and conducive to large-scale production.

Owner:CENT SOUTH UNIV

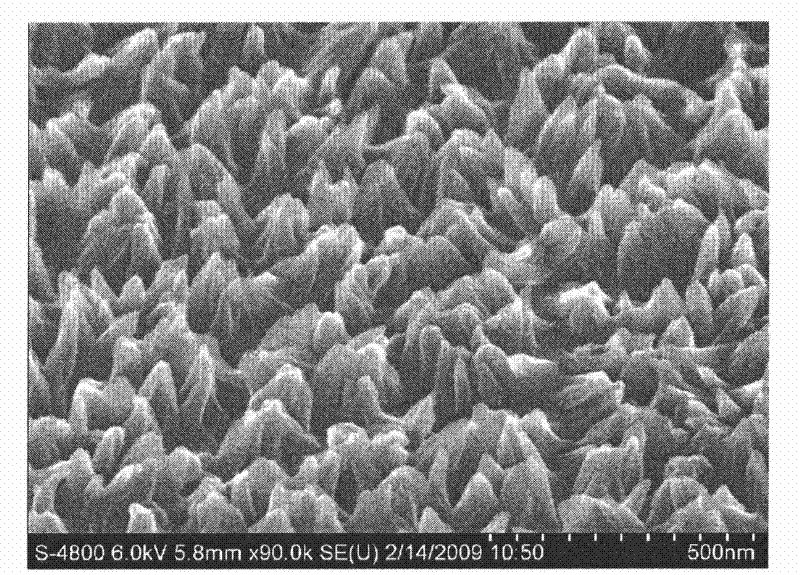

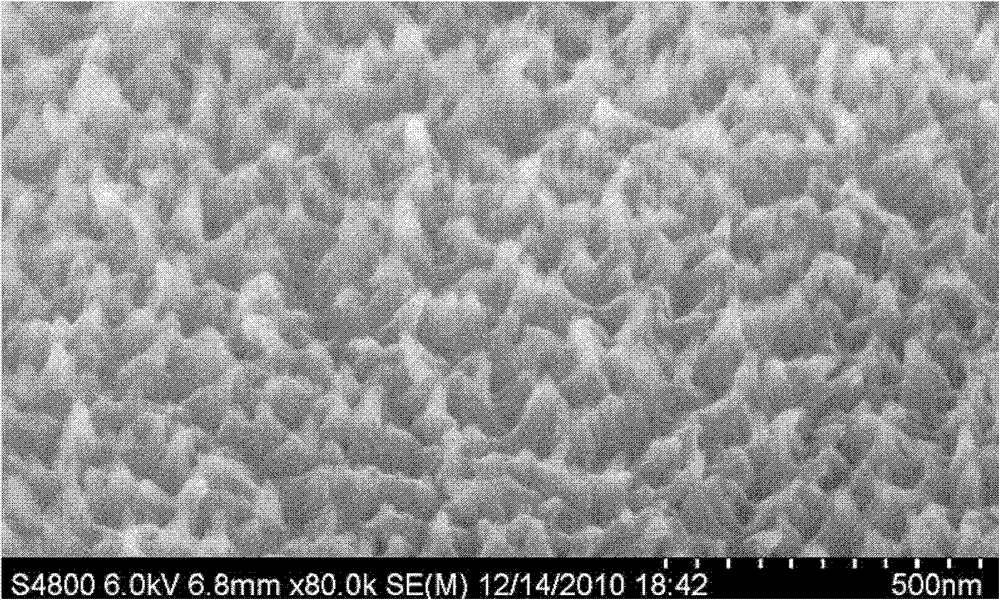

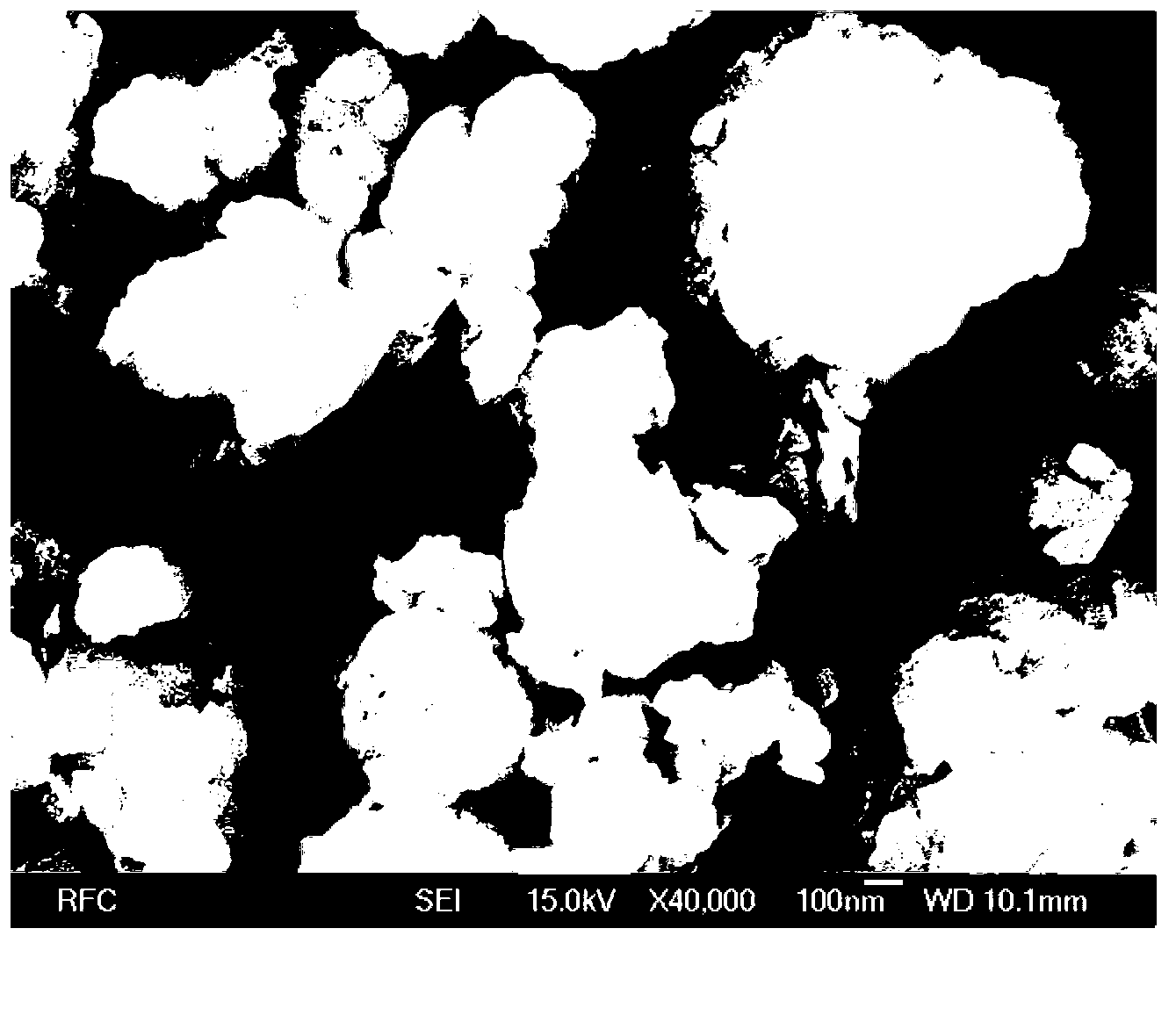

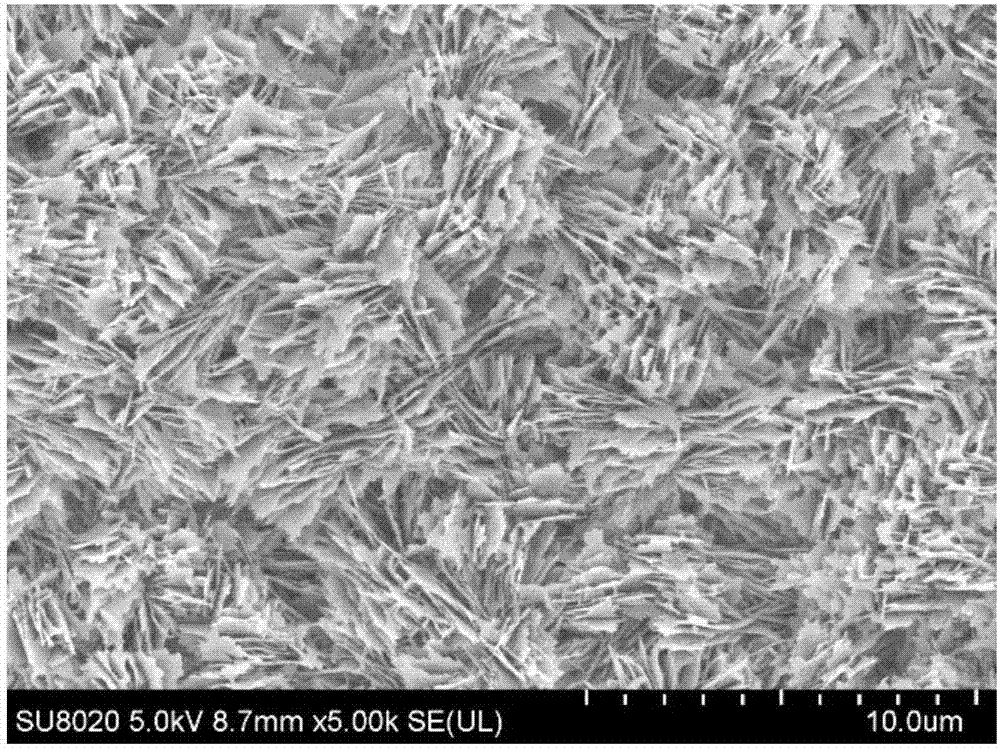

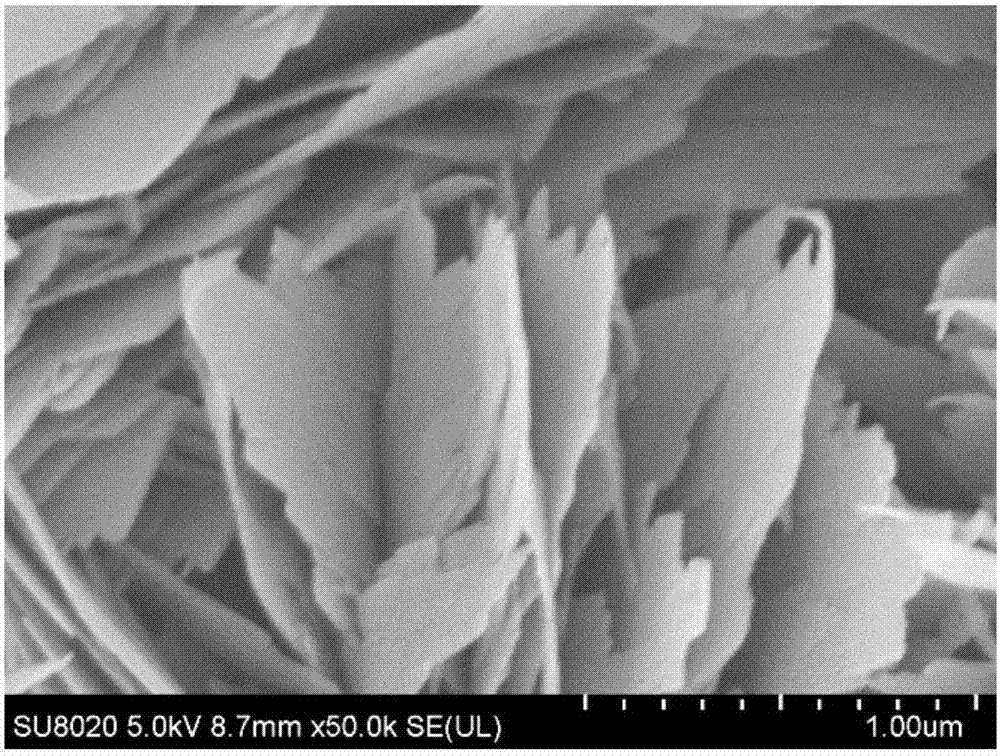

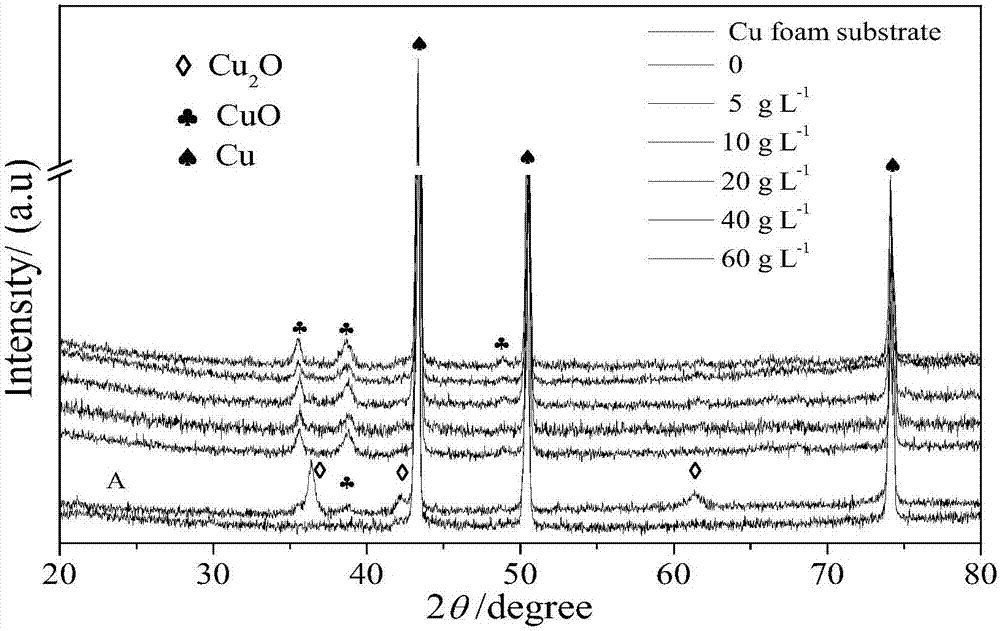

Single-phase CuO nanosheet array film and preparation method thereof

ActiveCN106947995ALarge specific surface areaHigh specific capacitance performanceMaterial nanotechnologyAnodisationCapacitanceCopper oxide

The invention discloses a single-phase CuO nanosheet array film and a preparation method thereof. Copper oxide arrays vertical to a substrate and mutually arranged in a staggered manner grow on the surface of a high-purity copper material through an anodic oxidation process; the single-phase CuO nanosheet array film is obtained through adding (NH4)6Mo7O24.4H2O with a proper concentration in an electrolyte, the thicknesses of CuO nanosheets in the film are 10-30nm, and the lengths of the CuO nanosheets are 300-500nm; and the CuO nanosheets uniformly and compactly grow on the material of the substrate, and are in the shape of a nanoflower and firmly bonded with the material of the substrate. The prepared single-phase CuO nanofilm presents high specific capacitance characteristic and excellent cyclic stability; the preparation steps are simple and controllable; and the single-phase CuO nanofilm is a capacitance electrode material with an actual application value.

Owner:HEFEI UNIV OF TECH

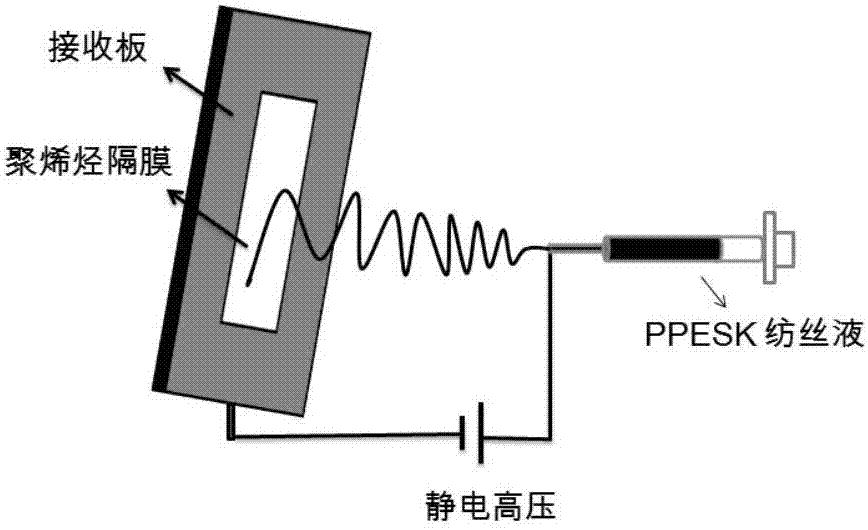

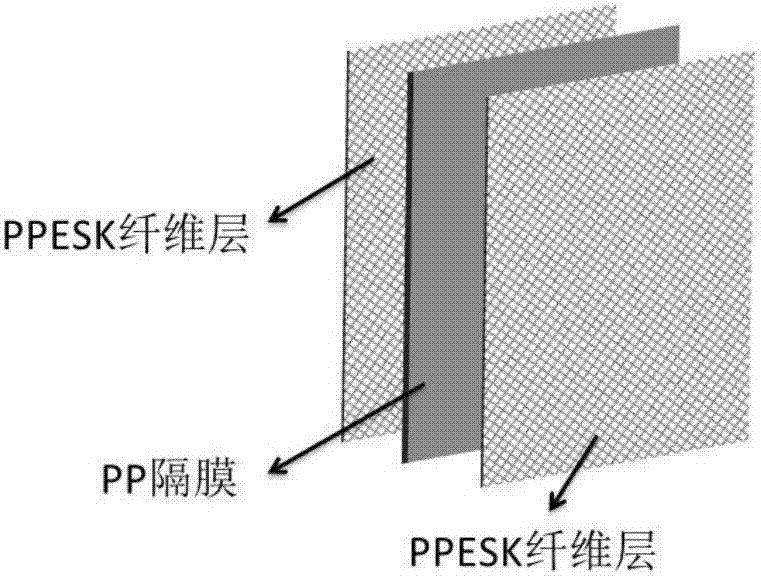

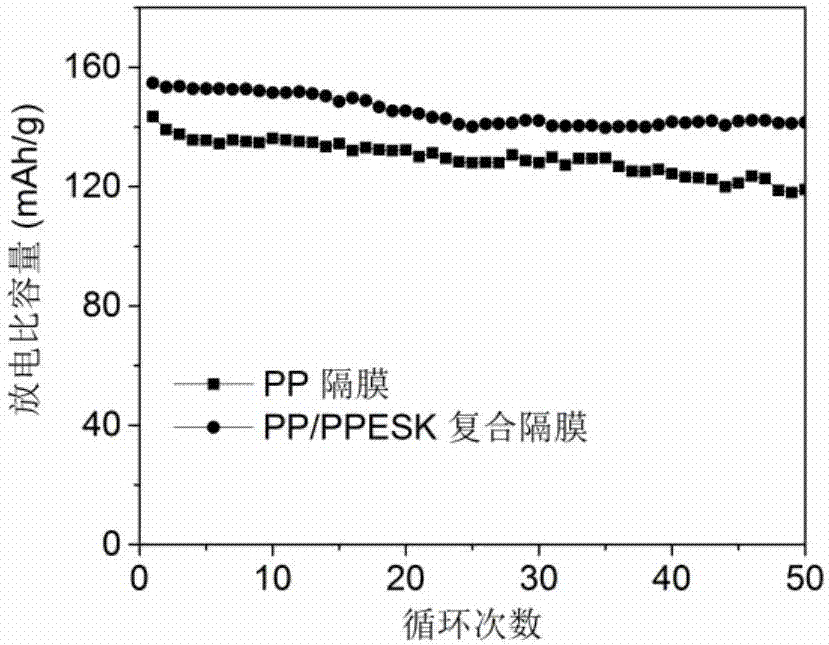

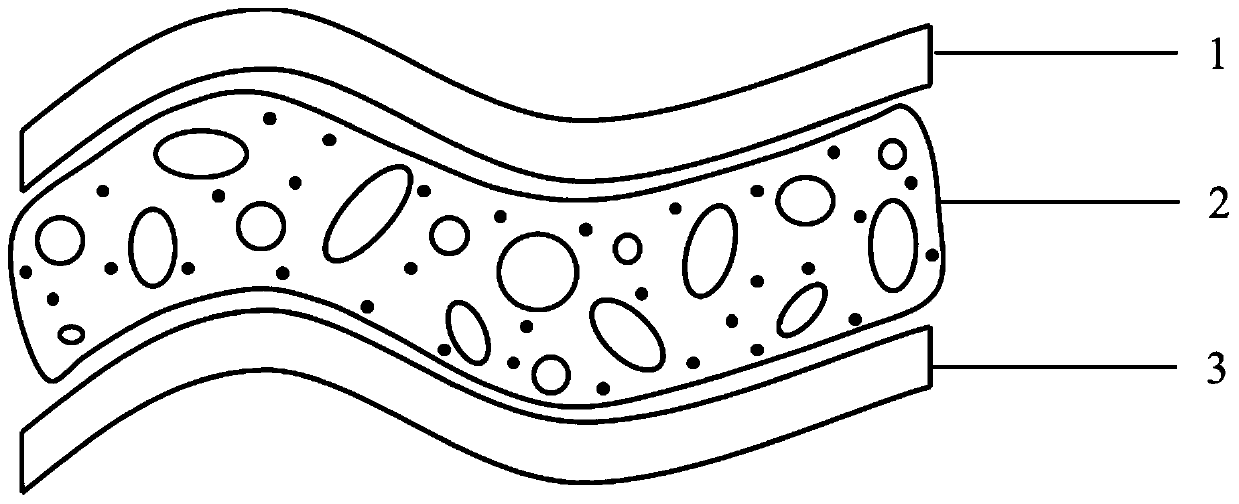

Compound lithium battery diaphragm prepared by spraying electrospun fibers to polyolefin microporous membrane and preparation method thereof

InactiveCN107275554AImprove high temperature resistanceImproved high temperature thermal stabilityElectro-spinningCell component detailsFiberPolymer science

The invention relates to a compound lithium battery diaphragm prepared by spraying electrospun fibers to a polyolefin microporous membrane and a preparation method thereof. The compound lithium battery diaphragm is a three-layered compound membrane by spraying electrospun fibers to the surface of the polyolefin microporous membrane. The intermediate layer of the three-layered compound membrane is formed by a polyolefin microporous diaphragm, the outer layer is formed by a polyaryl ether sulfone ketone nano fiber membrane which is high-temperature-resistant and good in wettability of electrolyte, the compound membrane has relatively high mechanical strength due to the polyolefin diaphragm of the intermediate layer, and the thermal stability and the wettability of electrolyte of the polyolefin diaphragm are effectively improved as a result of the polyaryl ether sulfone ketone nano fibers of the outer layer. Electrochemical testing verifies that the compound diaphragm shows relatively great ionic conductivity and relatively small interface resistance. In addition, the compound diaphragm assembled battery test result shows a stable cycle performance and a good high-rate discharge performance. Therefore, the polyolefin / polyaryl ether sulfone ketone three-layered compound membrane is expected to be a novel high performance lithium battery diaphragm.

Owner:DALIAN UNIV OF TECH

Flexible zinc-air battery based on polymer electrolyte

ActiveCN109921154AImprove ionic conductivityHigh yieldFuel and primary cellsMaterial nanotechnologyHigh concentrationPolymer science

The invention discloses a flexible zinc-air battery based on a polymer electrolyte. The flexible zinc-air battery uses polyvinyl alcohol or polyacrylic acid as a polymer skeleton of a semi-solid electrolyte, uses polyethylene glycol as a pore-forming agent to make the polymer matrix appear in a pore-shaped structure, introduces nano silica into the whole system as a crosslinking agent, a water retaining agent and a plasticizer, and immerses the prepared polymer system in a high concentration potassium hydroxide aqueous solution for a certain period of time to obtain a porous nano silica composite polymer electrolyte. The polymer electrolyte has the characteristics such as high ionic conductivity, high water retention property and excellent flexibility, and the assembled zinc-air battery has the comparative advantages of long cycle stability, high power and energy density and good flexibility by placing the prepared polymer electrolyte between the zinc sheet electrode and the catalyst-coated carbon cloth electrode, which provides theoretical basis and technical support for the practical application of flexible zinc-air batteries.

Owner:TIANJIN UNIV

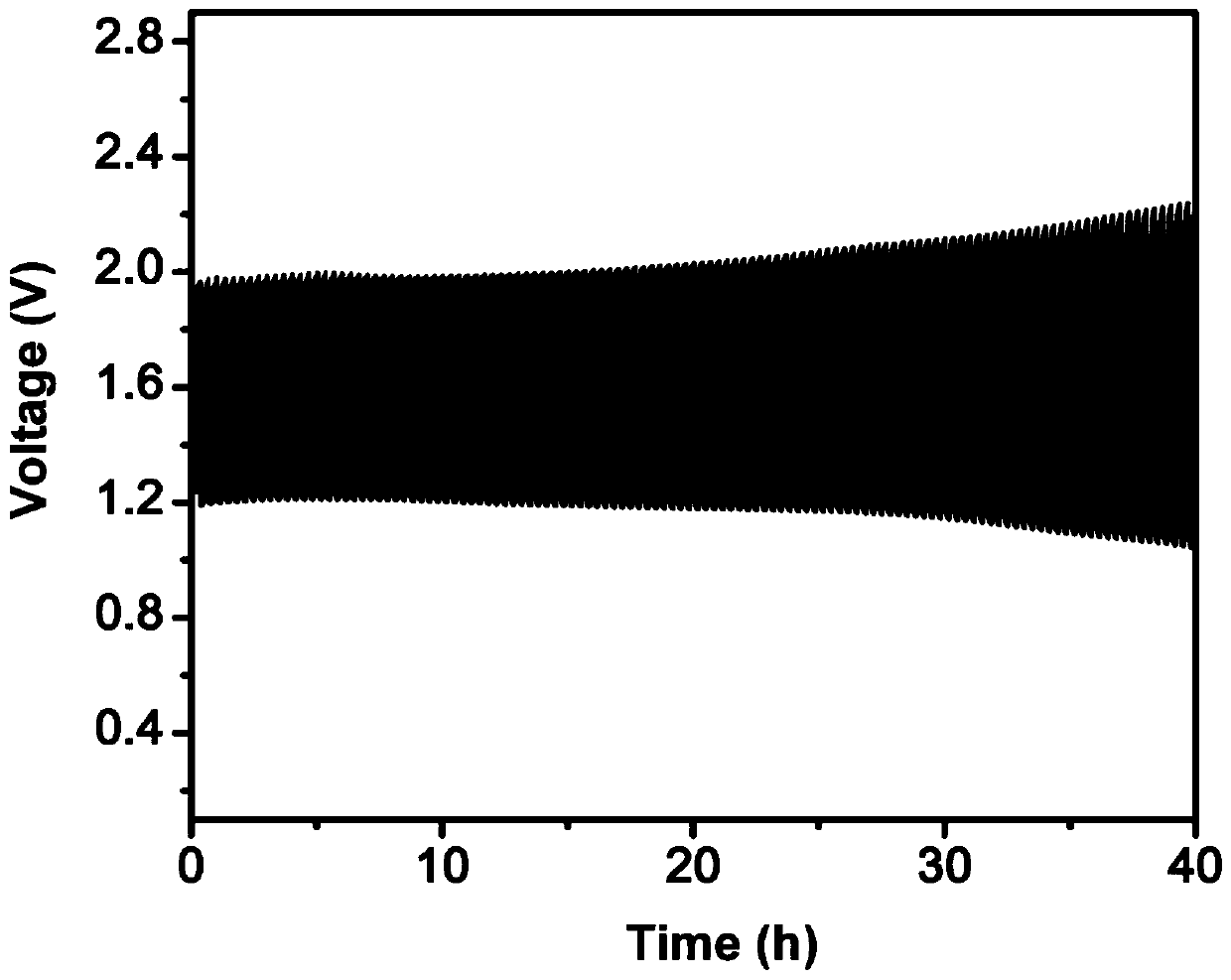

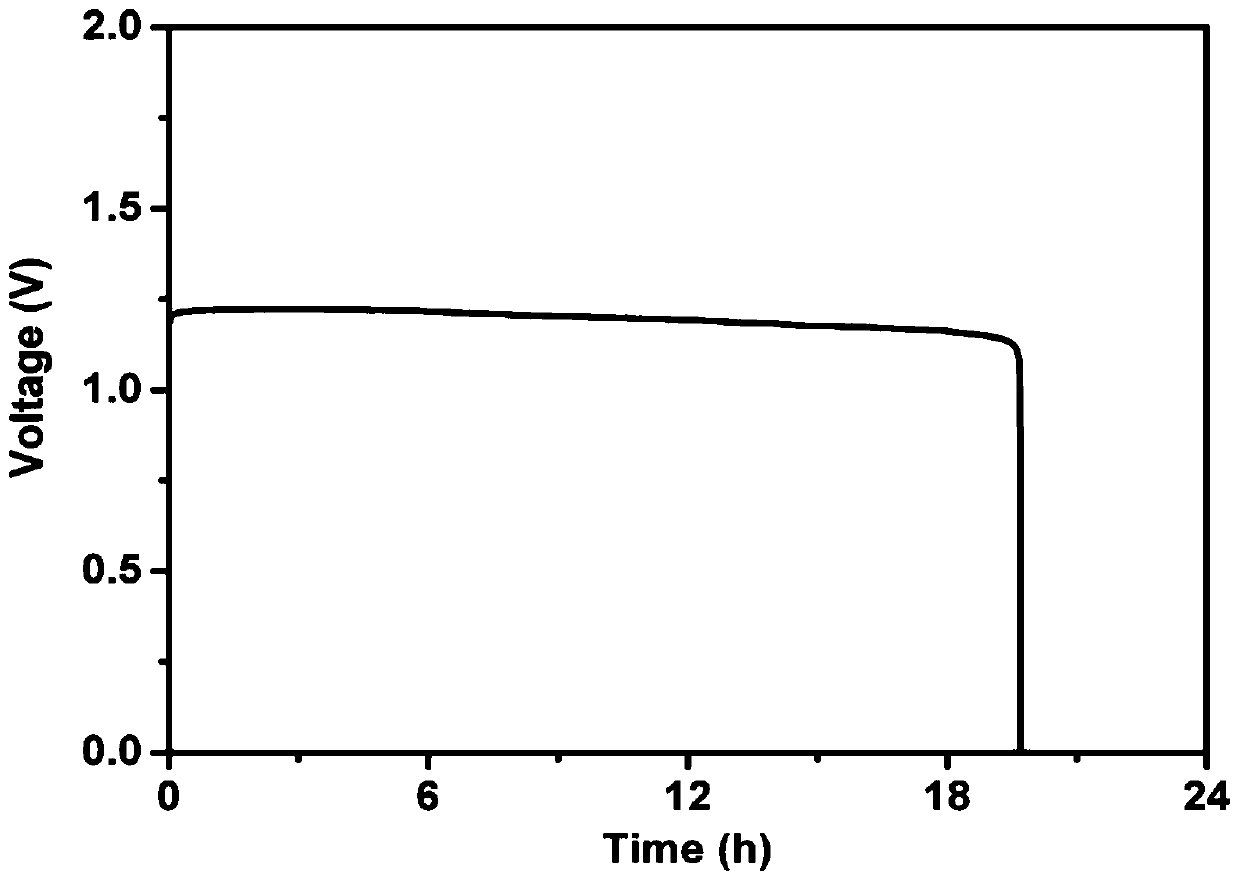

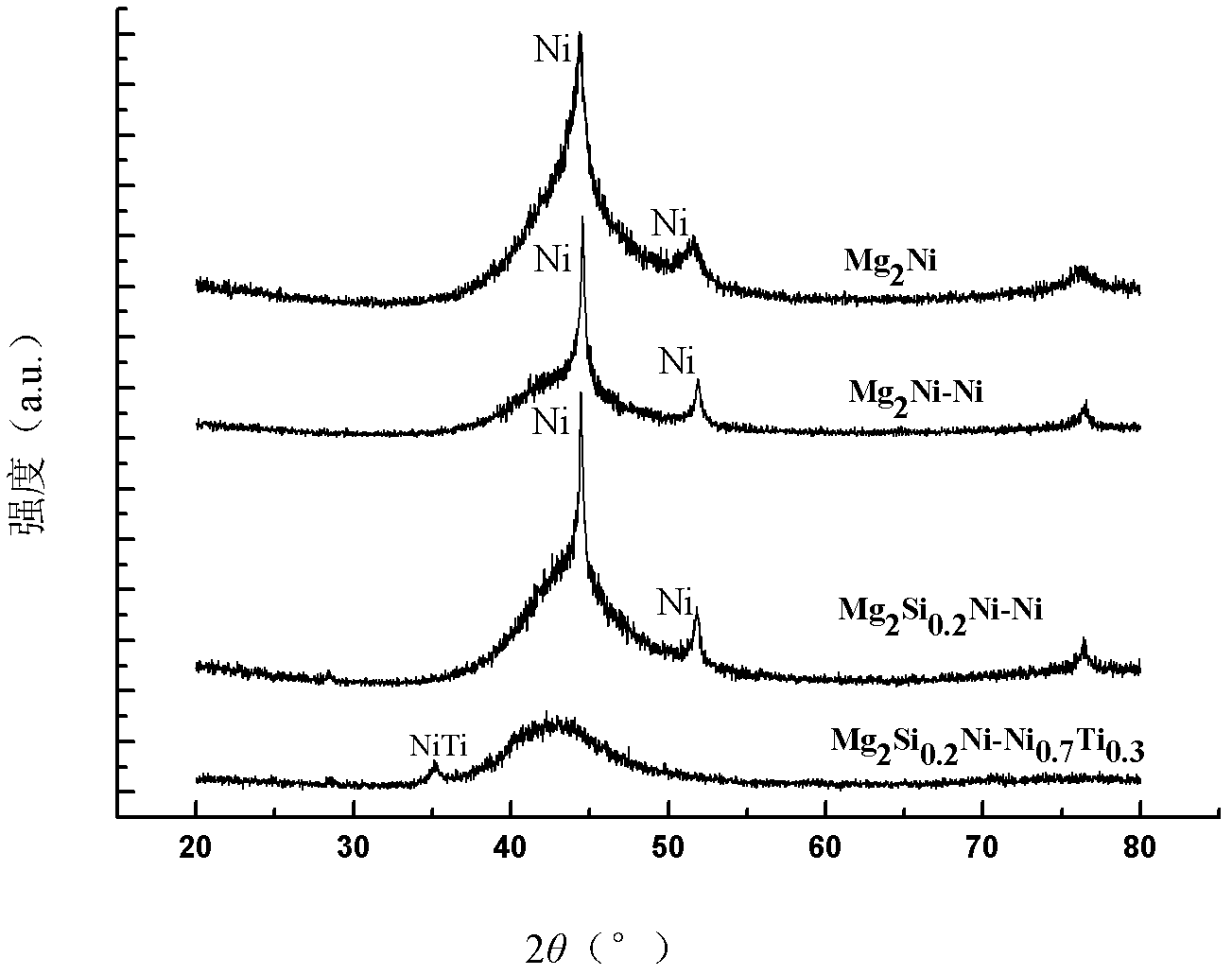

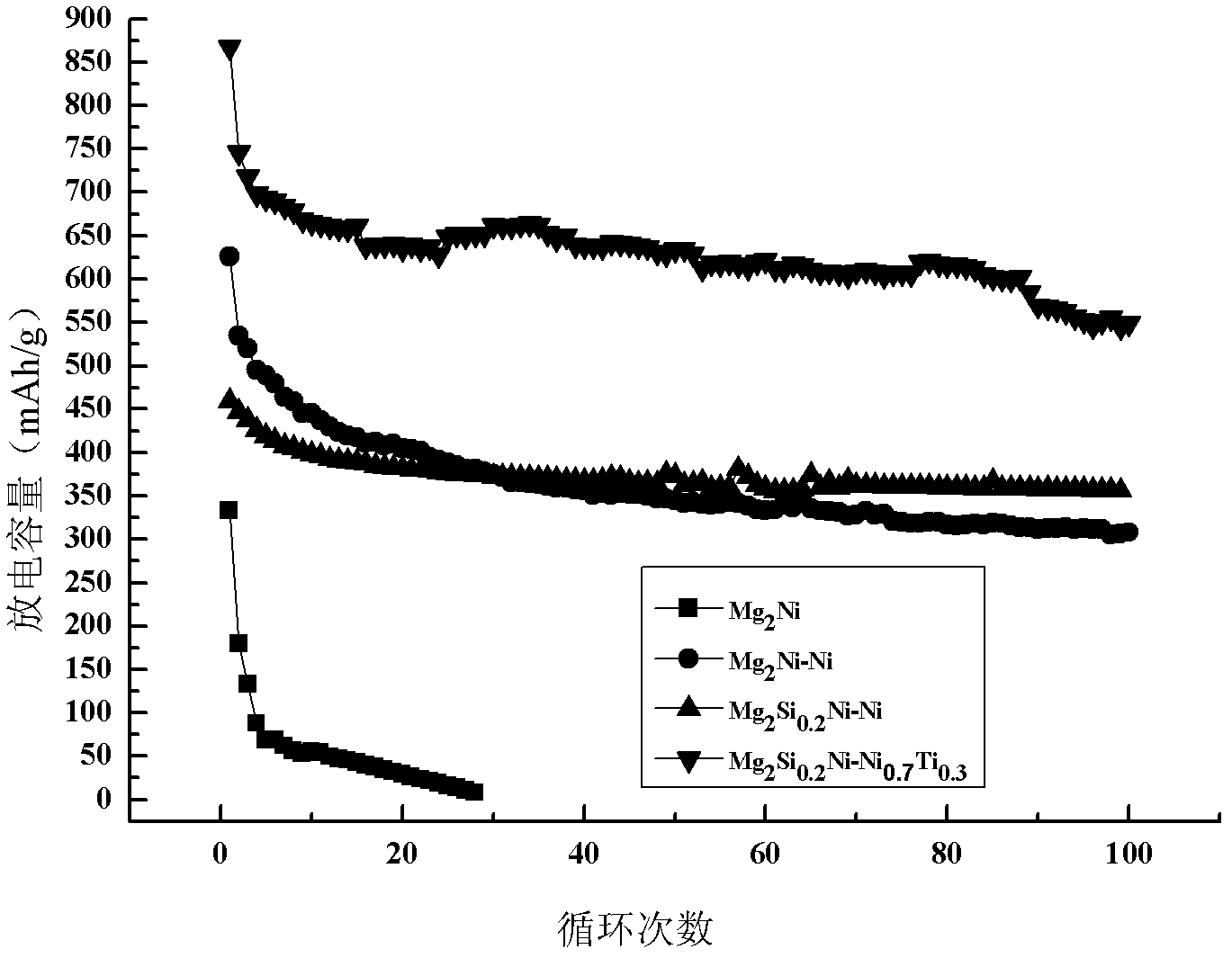

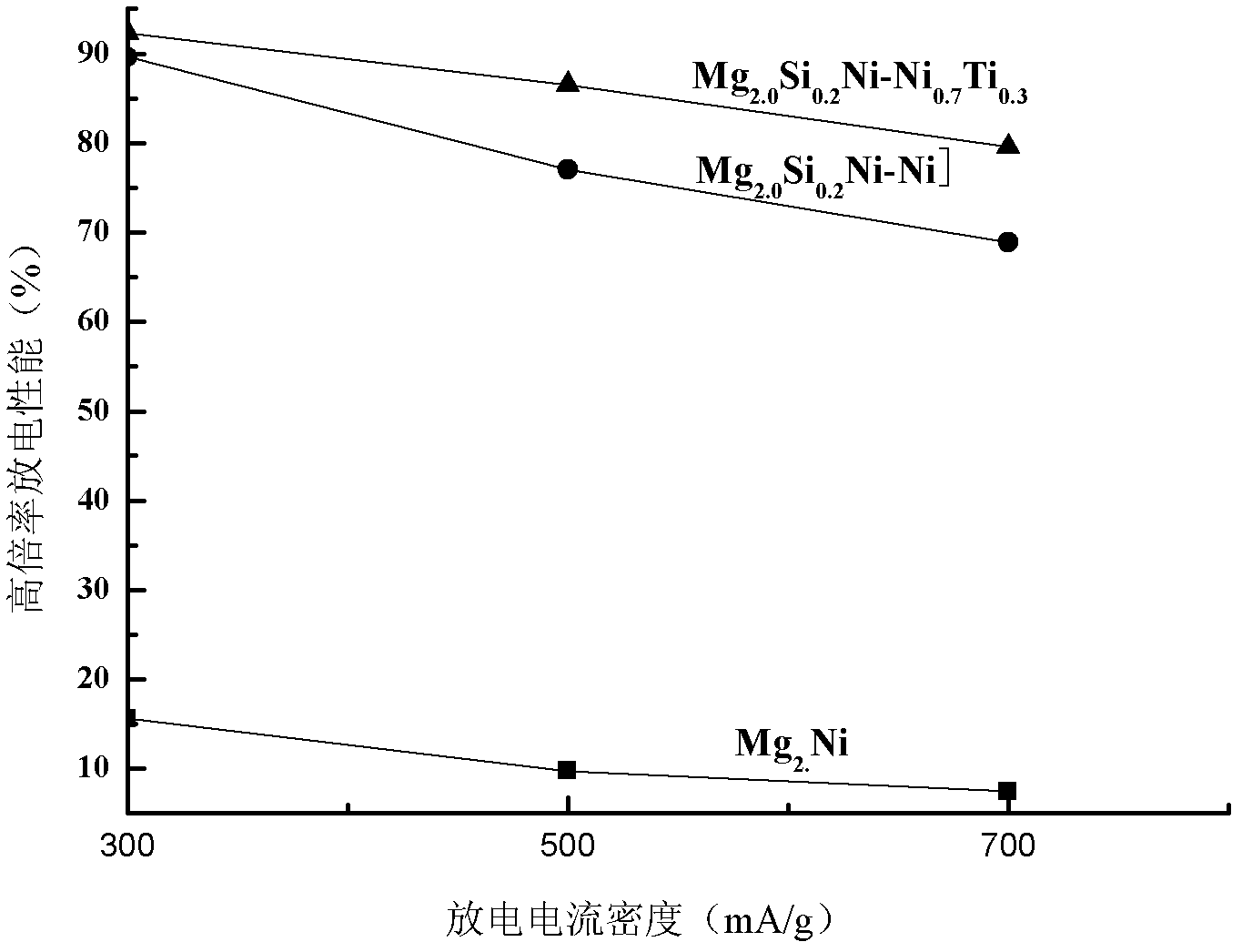

Magnesium-based hydrogen storage alloy material and preparation method thereof

ActiveCN102618761AHigh electrochemical discharge capacityImprove charge and discharge cycle stabilityCyclic stabilityMagnesium

The invention discloses a magnesium-based hydrogen storage alloy material and a preparation method thereof. The chemical general formula of the material is Mgz-xMxNi-Nia-d-eTdAe, Nia-d-eTdAe is coated on the surface of a Mgz-xMxNi amorphous alloy, and the mass ratio of the Mgz-xMxNi amorphous alloy to the Nia-d-eTdAe is 10:1-1:2; M represents one or more elements of which the atomic radius is greater than or equal to Ni and the electro-negativity is greater than Mg and smaller than Ni, z is more than or equal to 1 and less than or equal to 5, x is more than 0 and less than 3, and z is greater than x; T represents one or more elements of which the electro-negativity is greater than Mg and less than or equal to 1.7; and A represents an element of which the electro-negativity is 1.9-2.5, a is more than 0 and less than 3, d is more than 0 and less than 2, e is more than or equal to 0 and less than 1, a is greater than or equal to the sum of d and e, and a-d-e and e are not 0 at the same time. The magnesium-based hydrogen storage alloy material is an amorphous magnesium-based hydrogen storage material with high discharge capacity, good cycling stability and strong over-charge and over-discharge tolerance.

Owner:杨桂玲 +1

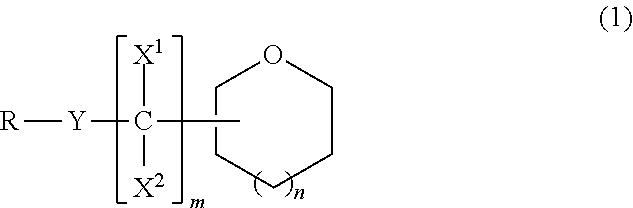

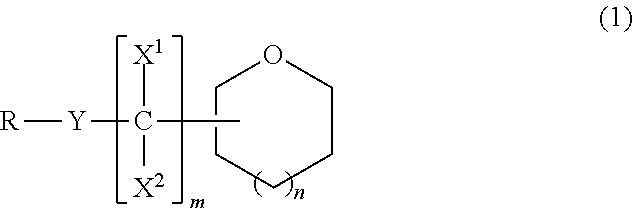

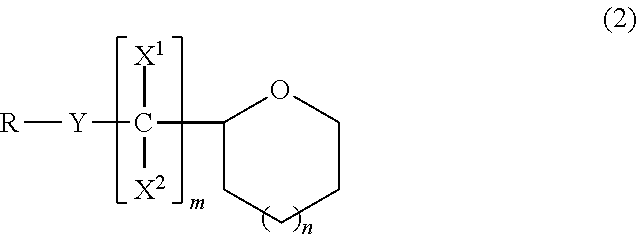

Ether compound, electrolyte composition for non-aqueous battery, binder composition for non-aqueous battery electrode, slurry composition for non-aqueous battery electrode, electrode for non-aqueous battery and non-aqueous battery

InactiveUS20130130102A1High discharge capacityExcellent stabilityOrganic chemistryActive material electrodesEtherBattery electrode

An ether compound represented by the following formula and its use:wherein n represents 0 or 1, m represents an integer of 0 to 2, Y represents —O—, —S—, —C(═O)—O—, and —O—C(═O)—, X1 and X2 represent a hydrogen atom or a fluorine atom, and R represents an aliphatic hydrocarbon group having 1 to 20 carbon atoms and substituted with one or more fluorine atoms, with a proviso that, when m is 0, R has 3 to 20 carbon atoms. R may have in the bond thereof intervening oxygen atom, sulfur atom, and carbonyl group.

Owner:ZEON CORP

Electrolyte of mixed type super capacitor

InactiveCN103943376AGood charge and discharge cycle stabilityImprove charge and discharge cycle stabilityHybrid capacitor electrolytesSolventPropylene carbonate

The invention relates to an electrolyte of a mixed type super capacitor. The electrolyte is prepared by two electrolyte salts and more than two organic solvents, one of the electrolyte salts that are used is lithium salt, and the other is quaternary ammonium salt. One of the solvents is propylene carbonate, and the other solvents are one or more of acetonitrile, propionitrile, ethylene carbonate, dimethyl carbonate, diethyl carbonate, ethyl methyl carbonate, and gamma-butyrolactone. The concentration range of the two electrolyte salts in the electrolyte is 0.1-2 mol / L. A mixed type super capacitor using the electrolyte shows good charge-discharge cycle stability.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

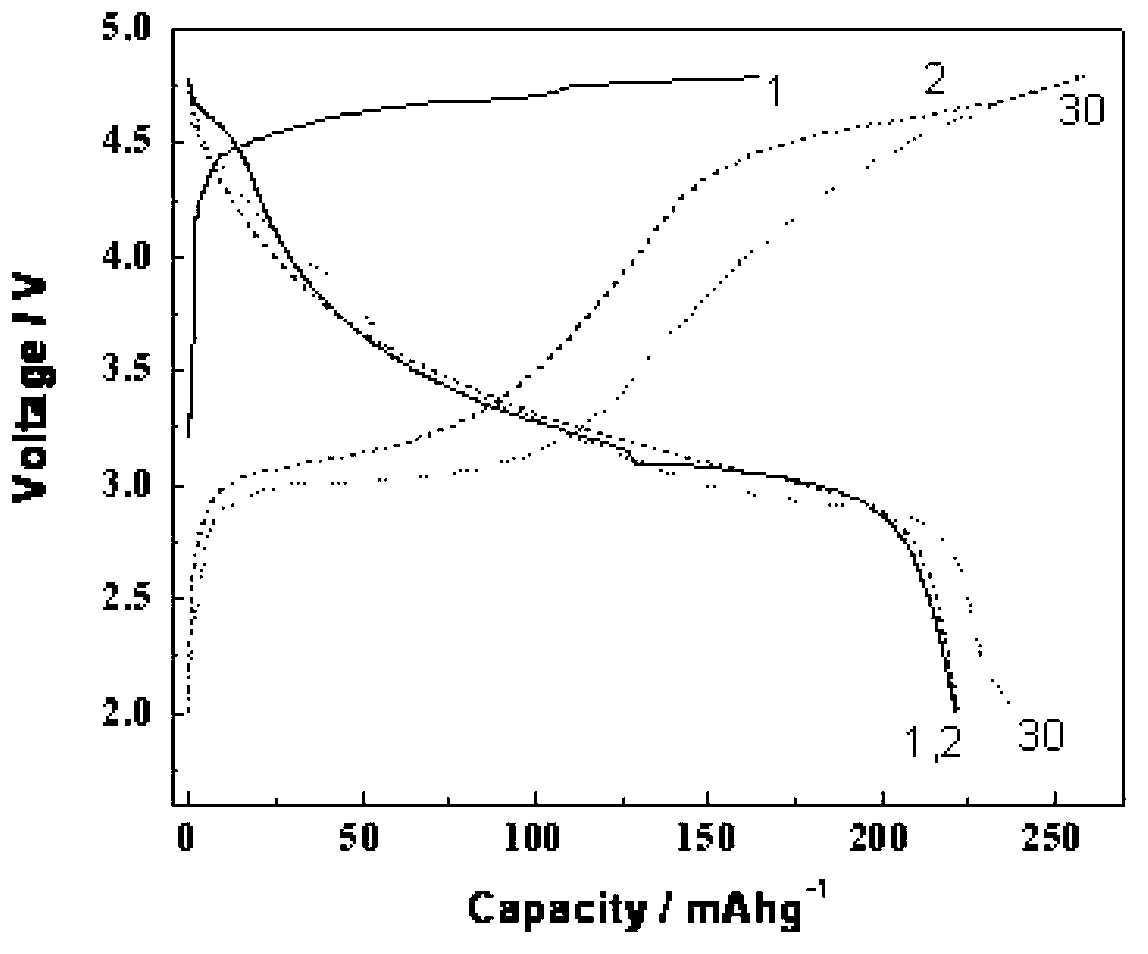

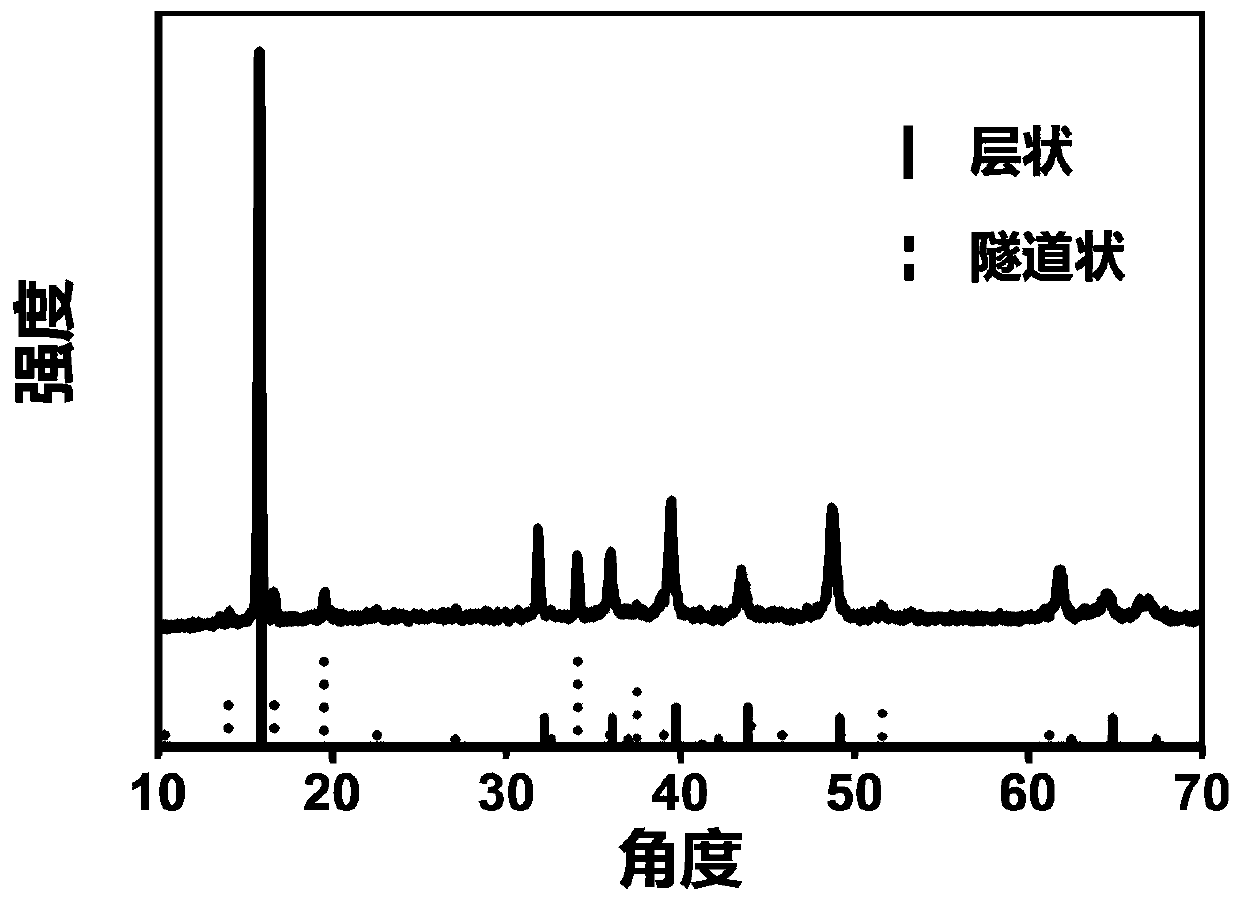

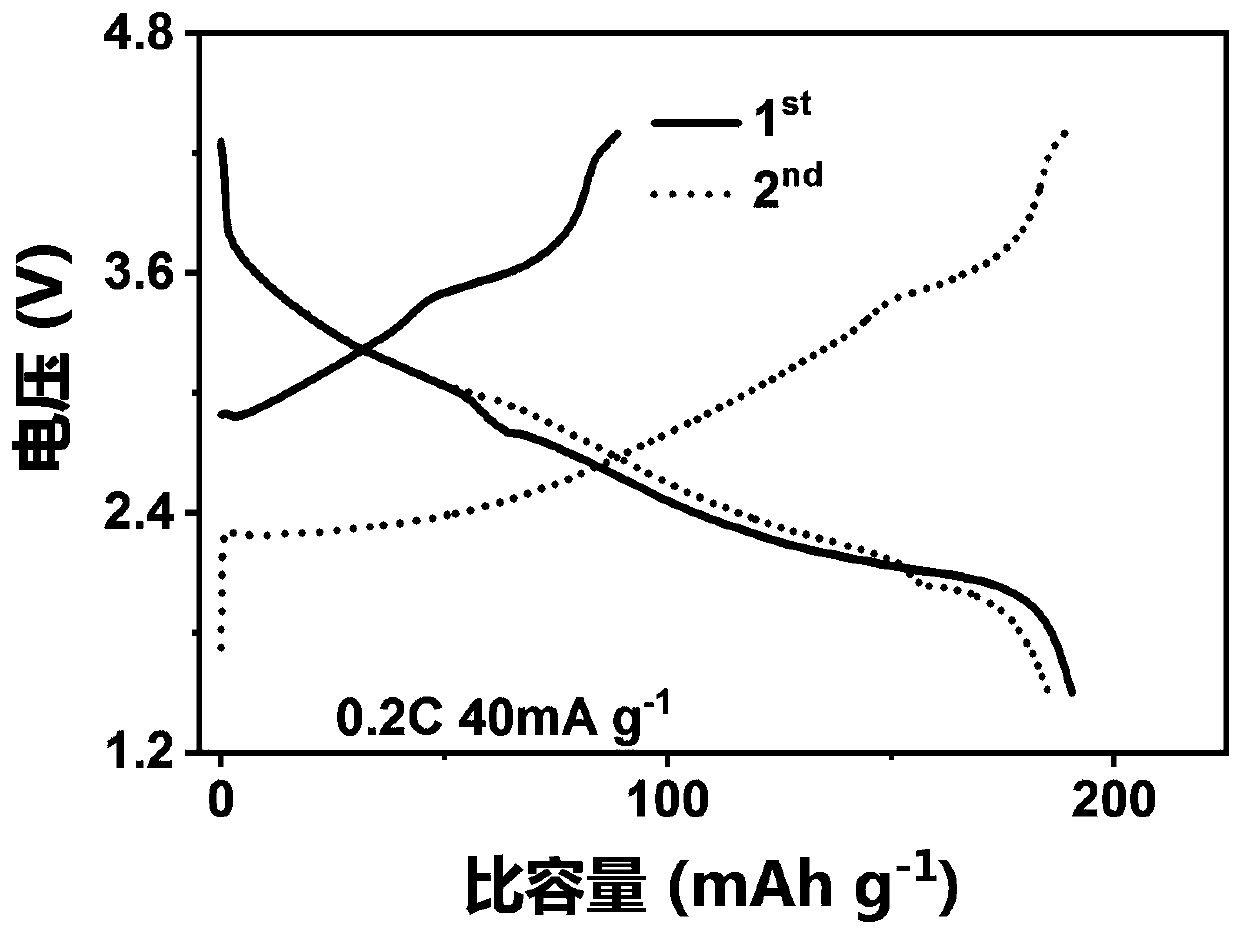

Layered and tunnel-shaped mixed structure sodium ion battery positive electrode material and a preparation method thereof and a sodium ion battery

InactiveCN110729475AEasy to prepareSimple ingredientsFinal product manufactureCell electrodesElectrical batteryCharge and discharge

The invention provides a preparation method of a layered and tunnel-shaped mixed structure sodium ion battery positive electrode material. The preparation method comprises the following steps: mixinga sodium source, an iron source and a manganese source according to a molar ratio and grinding to obtain a mixed powder; calcining the mixed powder for the first time to obtain an intermediate product; and calcining the intermediate product for the second time after grinding so as to obtain the sodium ion battery positive electrode material. The sodium source, the iron source and the manganese source are mixed through a simple solid phase method to be subjected to two times of high-temperature calcination with combination of the specific ratio. The preparation method is simple, the raw materials are easy to obtain and the practical degree is high. The sodium ion battery positive electrode material has higher initial capacity and better charging and discharging cycle stability and has excellent rate performance and 60% capacity in case of 5C (1A g-1). The material has low preparation cost and is easy to produce on a large scale and can meet the application requirements of large-scale sodium ion battery energy storage.

Owner:UNIV OF SCI & TECH OF CHINA

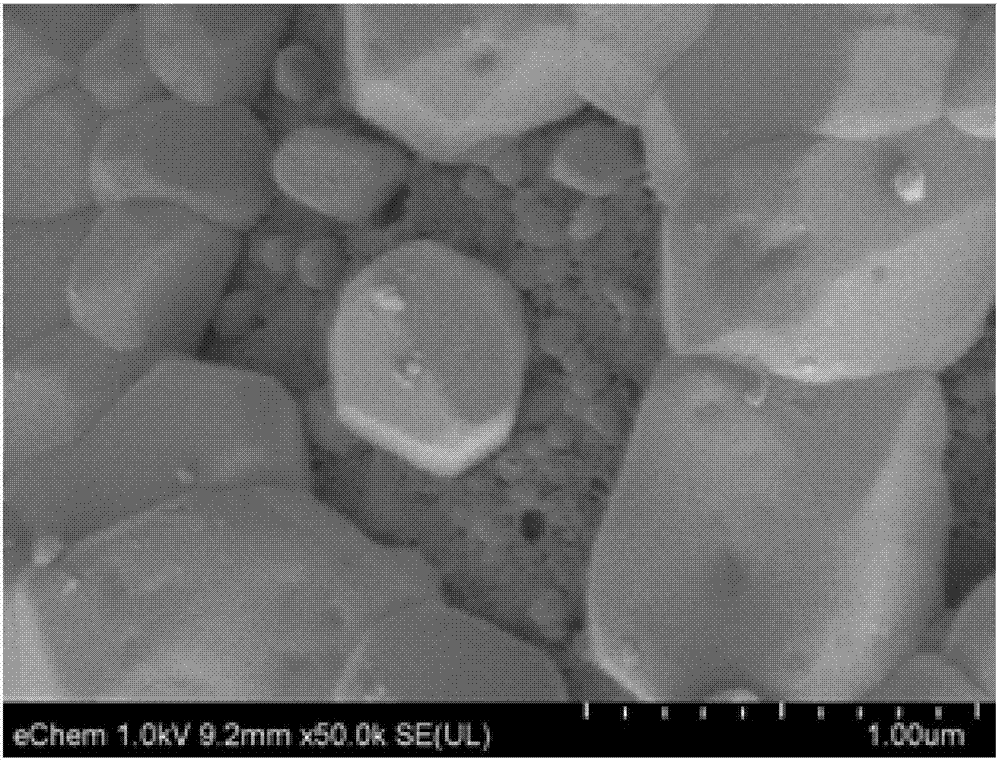

PMMA-coated hollow tin alloy nanoparticles and preparation method and application thereof

InactiveCN104466128AUniform thicknessUniform particle sizeMaterial nanotechnologyCell electrodesCharge dischargeLayer thickness

The invention discloses PMMA-coated hollow tin alloy nanoparticles and a preparation method and application thereof. The preparation method comprises the following steps: preparing nickel nanoparticles with the uniform particle sizes by using a chemical reduction method; by taking the nickel nanoparticles as a template, preparing hollow tin alloy nanoparticles by utilizing a current replacement method, and coating the hollow tin alloy nanoparticles by using an in situ PMMA bulk polymerization method. The PMMA-coated hollow Sn-Ni alloy nanoparticle coating layer disclosed by the invention is controllable in thickness, uniform in particle size and uniform in coating layer thickness. Inactive substances are added into tin metal, and the volume expansion in the tin and lithium alloying process can be relieved by preventing the tin accumulation in the lithium ion embedding and separating process, so that the aim of improving the charge-discharge cycle stability performance of the PMMA-coated hollow tin alloy nanoparticles is achieved, and the volume change of tin serving as a lithium ion battery negative pole material is relieved by utilizing the flexibility of the internal hollow structure and surface polymers. According to PMMA coating, the direct contact among the Sn-Ni alloy nanoparticles can be avoided.

Owner:SHANDONG YUHUANG NEW ENERGY TECH +1

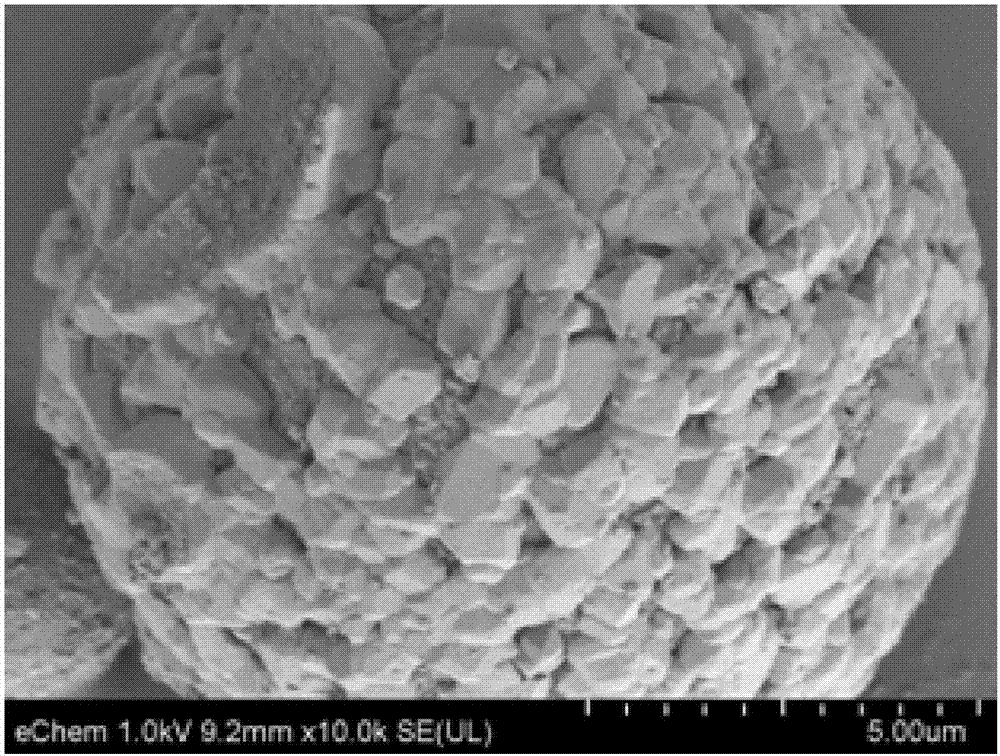

Iron lithium manganese phosphate series particles, and iron lithium manganese phosphate series powder and preparation method therefor

ActiveCN107359342AIncrease energy densityImprove thermal stabilityMaterial nanotechnologyCell electrodesHigh energyCharge discharge

Disclosed is iron lithium manganese phosphate series powder. The iron lithium manganese phosphate series powder comprises multiple iron lithium manganese phosphate series particles; each iron lithium manganese phosphate series particle comprises a core part and a shell part; the core part comprises multiple first iron lithium manganese phosphate series nanoparticles which are combined together and have first average grain diameters; and the shell part comprises multiple second iron lithium manganese phosphate series nanoparticles which are combined together and have second average grain diameters, wherein the second average grain diameters are greater than the first average grain diameters. The iron lithium manganese phosphate series powder can be prepared by steps of sequentially performing primary sintering treatment in the temperature range of 300 DEG C-450 DEG C, performing middle sintering treatment in the temperature range of greater than 450 DEG C-600 DEG C and performing final sintering treatment in the temperature range of greater than 600 DEG C-800 DEG C. By taking the iron lithium manganese phosphate series powder as the negative electrode material of the lithium battery, the lithium battery can obtain high energy density and good high-temperature charge-discharge cycling stability and thermal stability.

Owner:HCM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com