Patents

Literature

77results about How to "Fast charge and discharge performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of transition metal oxide/carbon-based laminated composite material

InactiveCN104733712ALengthy process routeLong process routeHybrid capacitor electrodesCell electrodesNew energyConductive materials

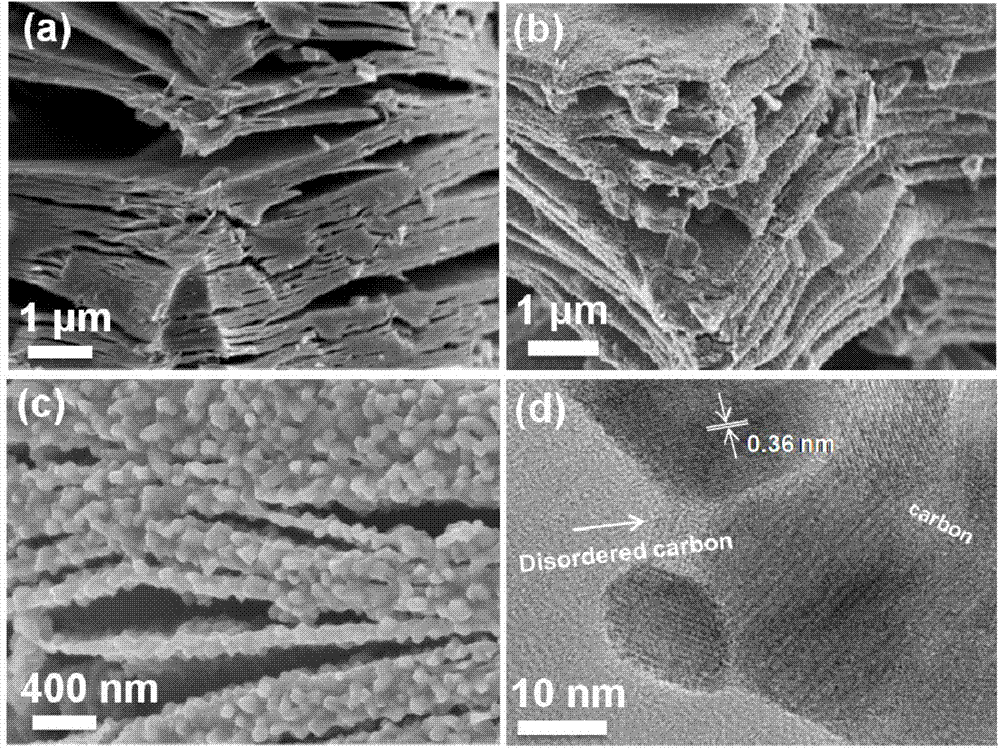

The invention relates to a preparation method of a transition metal oxide / carbon-based laminated composite material. According to the preparation method, a conducting material such as metal carbide, metal nitride or metal carbonitride with a two-dimensional laminated structure is taken as a precursor, a gas containing oxygen elements is taken as an oxidant, and the two-dimensional conducting material is converted into the transition metal oxide / carbon-based laminated composite material by in-situ oxidation under the condition of controlling the oxidation temperature at 300-1000 DEG C and controlling the oxidation time at 1-300 min. The method disclosed by the invention has the advantages of simplicity and easiness in operation, controllable structure and morphology, controllable crystal form and electrochemical properties of metal oxides, and the like; the preparation method is environment-friendly, and nuisanceless, has no by-product, can be used for reducing the economic costs of traditional preparation methods, and can be popularized; and the transition metal oxide / carbon-based laminated composite material not only can be used as a key electrode material of a new energy storage device, but also can be used as a denitration catalyst, so that the material can be applied to the fields of environmental remediation, and the like.

Owner:EAST CHINA UNIV OF SCI & TECH +1

Preparation method of stannic oxide or metallic tin and grapheme lamella composite material

ActiveCN102255072AImprove structural stabilityImprove electrochemical performanceCell electrodesTin dioxideHYDROSOL

The invention provides a preparation method of a stannic oxide and grapheme lamella composite material. The preparation method comprises the following steps of mixing at least one organic solvents, graphene oxide lamella hydrosol and at least one tin salt, heating the mixture at a temperature of 60 to 200 DEG C for 0.5 to 12 hours to obtain a solid substance, and heating the solid substance in the inert gas atmosphere at a temperature of 400 to 700 DEG C for 0.5 to 10 hours. The invention also provides a preparation method of a metallic tin and grapheme lamella composite material. The preparation method comprises the following step of preparing a stannic oxide and grapheme lamella composite material through the preparation method of a stannic oxide and grapheme lamella composite material, and heating the prepared stannic oxide and grapheme lamella composite material in the reducing gas atmosphere at a temperature of 400 to 1000 DEG C for 0.5 to 4 hours. The preparation methods of the invention can improve a structural stability and an electrochemical performance of a material and is beneficial to improve a high-speed charging and discharging performance and a conductivity of a composite material. The preparation methods have the characteristics of cheap and easily available raw materials, simple process, and good applicability for industrial continuous production.

Owner:陕西埃普诺新能源科技有限公司

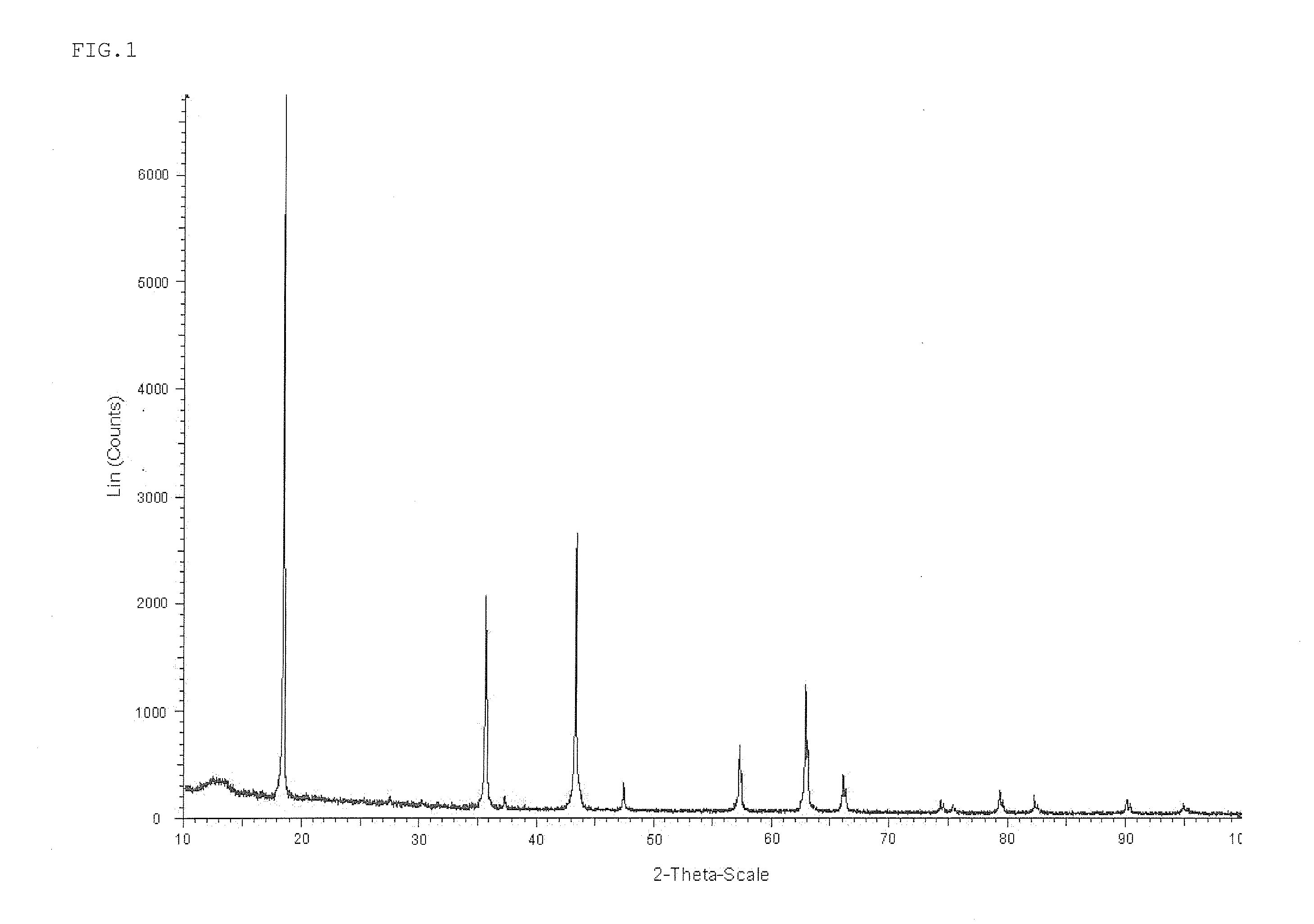

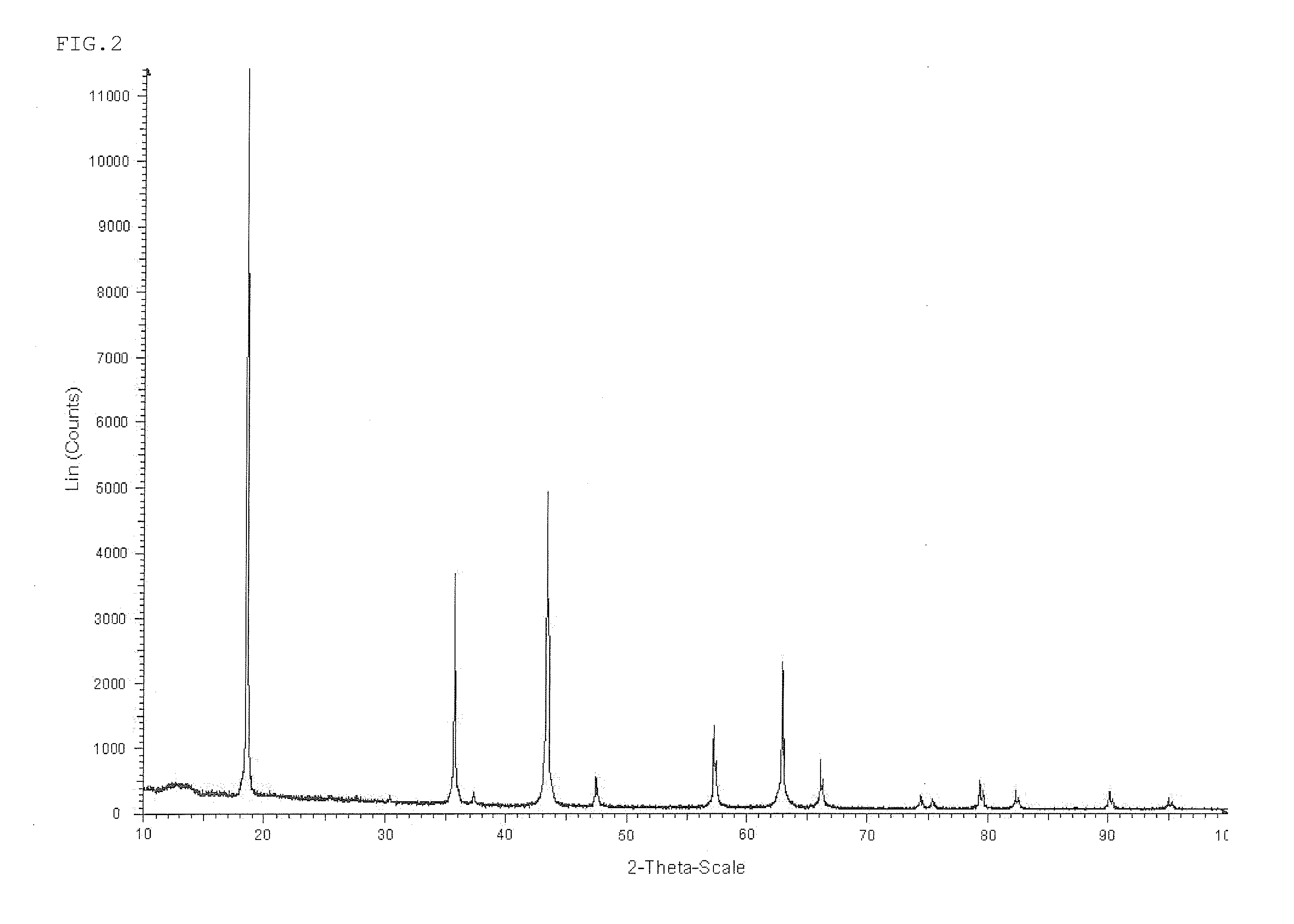

Anode active material for lithium secondary battery and method for preparing the same

InactiveUS20120021292A1Improve high temperature storage performanceExcellent rapid chargingNon-aqueous electrolyte accumulator electrodesLithiumPhysical chemistry

Owner:NIPPON CHECMICAL IND CO LTD

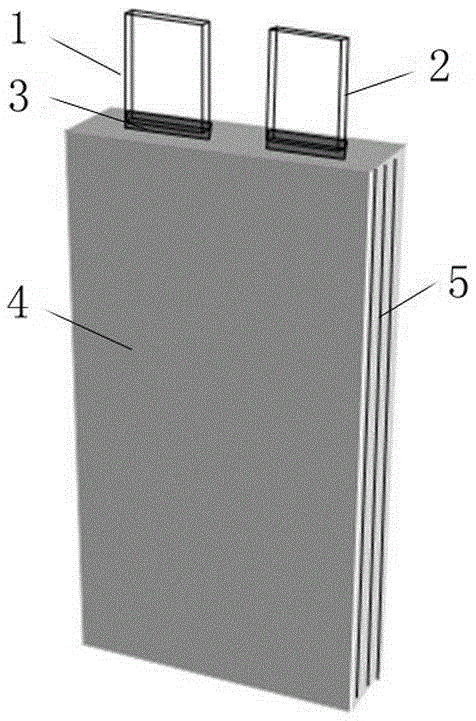

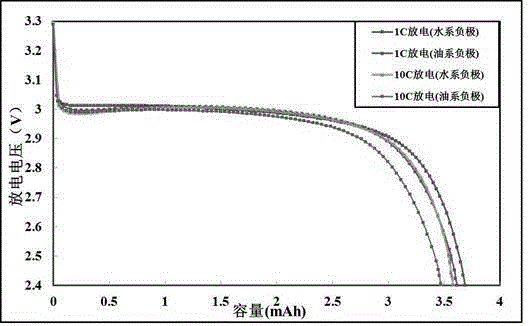

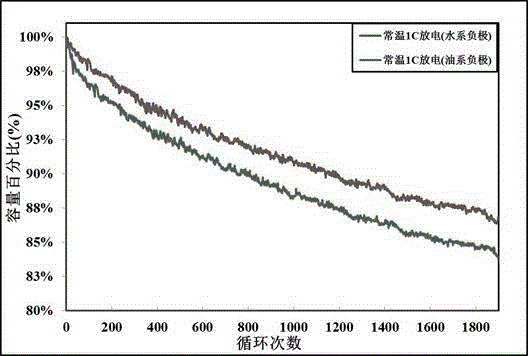

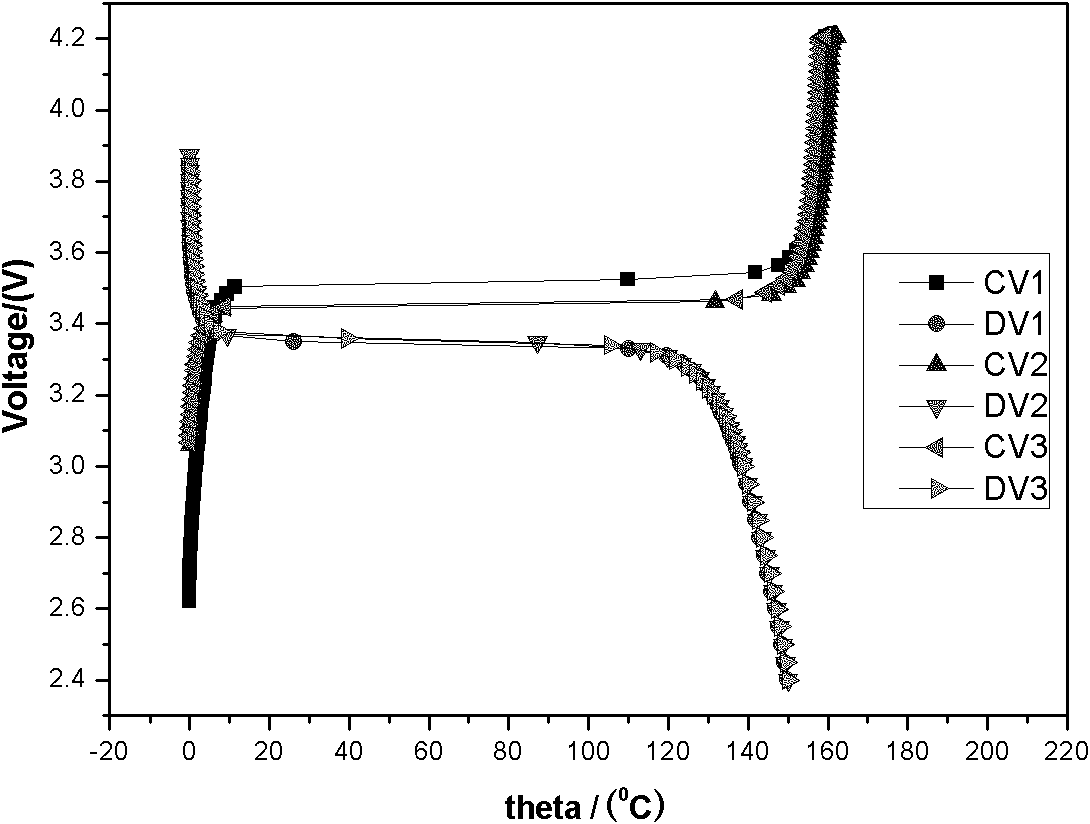

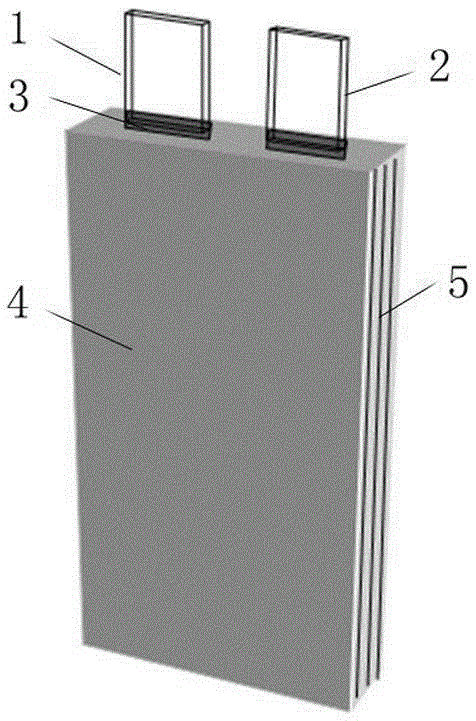

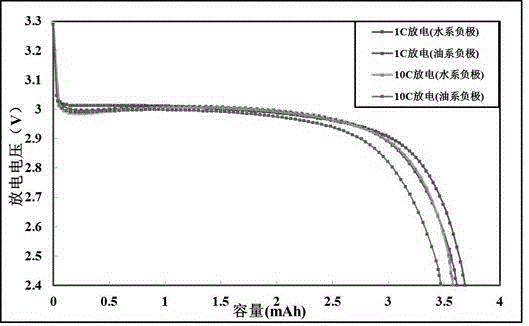

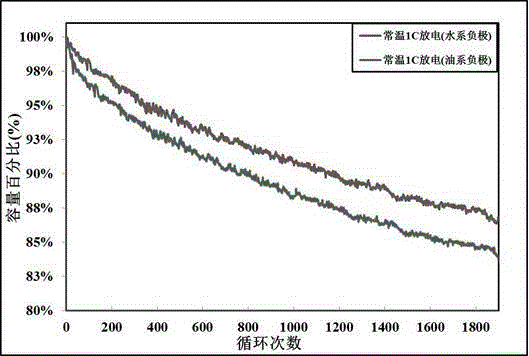

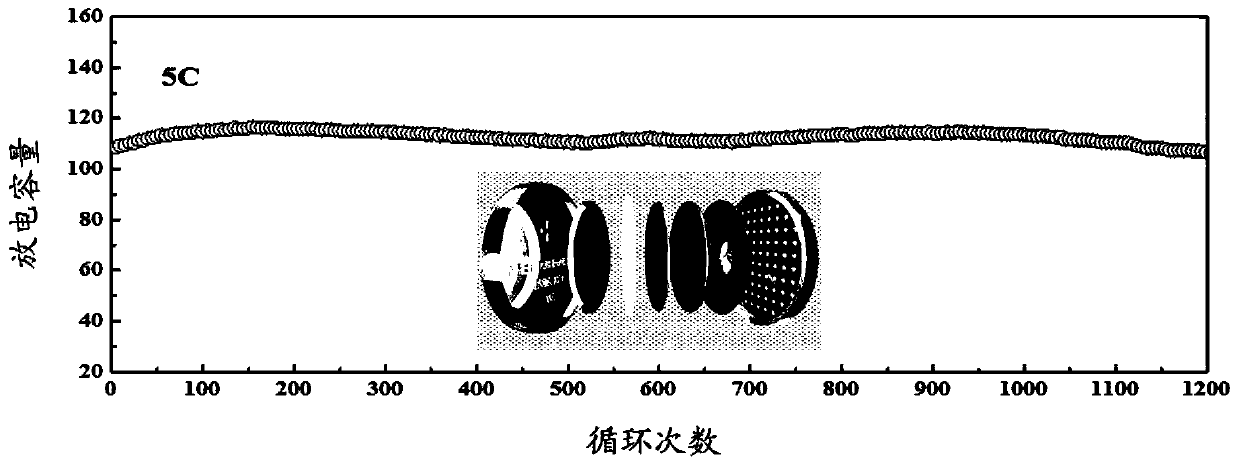

Lithium battery formed on basis of lithium nickel manganese oxide and lithium titanate and preparation method of lithium battery

InactiveCN105336943ALong cycle lifeFast cycle lifeFinal product manufactureCell electrodesElectrolytic agentElectrical battery

The invention discloses a lithium battery formed on the basis of lithium nickel manganese oxide and lithium titanate and a preparation method of the lithium battery. The lithium battery comprises an aluminum-plastic film casing, an anode lug, a cathode lug and a tab film, wherein the aluminum-plastic film casing contains a battery cell and electrolyte; the battery cell comprises an anode piece, a diaphragm and a cathode piece; materials of the anode piece comprise an anode slurry coating consisting of a positive active material, a binding agent, a conductive agent and a solvent and an anode current collector; the positive active material adopts an Al2O3 coating of lithium nickel manganese oxide; the binding agent adopts one or two of polyvinylidene fluoride and polytetrafluoroethylene; the conductive agent adopts one or more of conductive carbon black, conductive graphite and carbon nanotubes; the solvent adopts N-methyl-2-pyrrolidinone; the anode current collector adopts an aluminum foil; the cathode piece adopts an aqueous cathode or an oil-based cathode. According to the designed lithium battery, the purposes of improvement of the reversible specific capacity, the energy density and the rapid charge-discharge capability, the cycle performance and the safety performance of the battery are achieved while the production cost is reduced.

Owner:四川省有色冶金研究院有限公司

Preparation method of zinc oxide nanometer fiber cathode material for lithium ion battery

A zinc oxide nanometer fiber cathode material for lithium ion battery and a preparation method thereof belong to the technical fields of high polymer material and chemical power source. The zinc oxide nanometer fiber material for lithium ion battery provided by the invention has large specific surface area. The method first prepares composite nanometer fiber by electrospinning, and then the nanometer fiber is subjected to high-temperature calcination to obtain the zinc oxide nanometer fiber. The preparation process provided by the invention is simple and easy to control, and has low production cost. The cathode electrode material for lithium ion battery provided by the invention overcomes the disadvantages of zinc oxide nanorod prepared by other methods as cathode material for lithium ion battery, such as low first cycling efficiency, weak cycle stability and high-rate discharge ability. The invention provides a zinc oxide nanometer fiber cathode material for lithium ion battery and the preparation method thereof. The material has high initial discharge capacity and cycling stability, improves high power characteristic and high-rate discharge capacity of cathode material, and is suitable for development requirements of lithium ion power battery for electric vehicles.

Owner:JIANGNAN UNIV

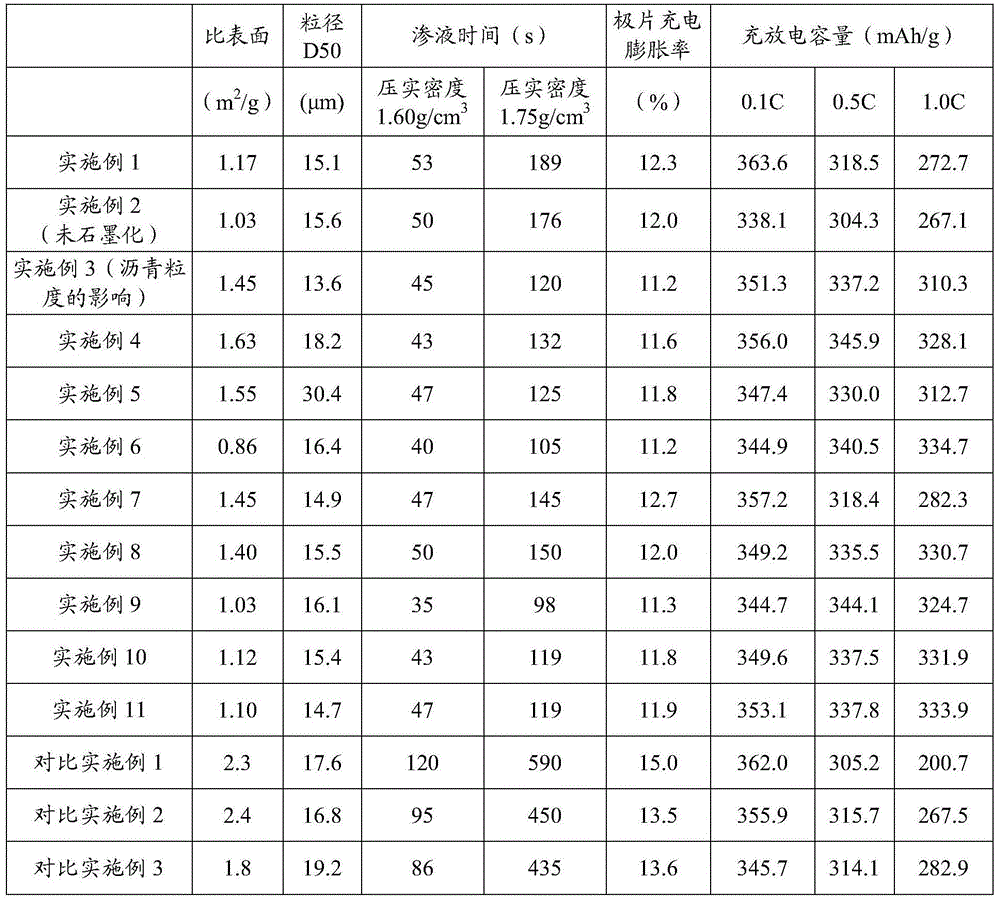

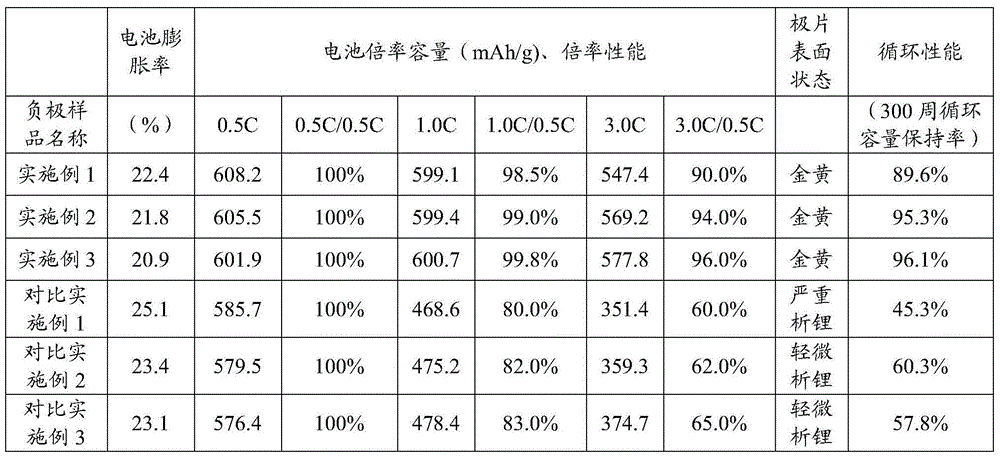

Cell anode material and preparation method thereof

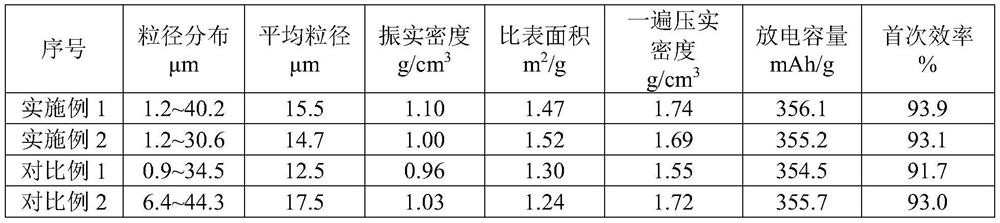

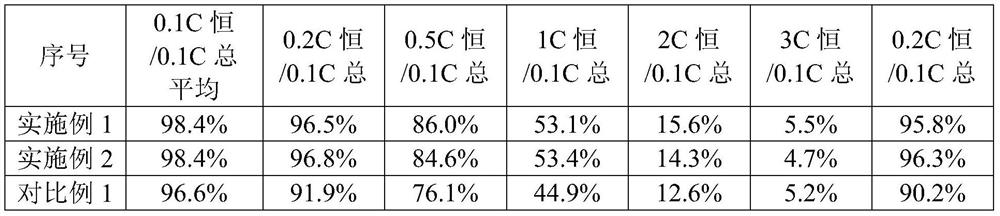

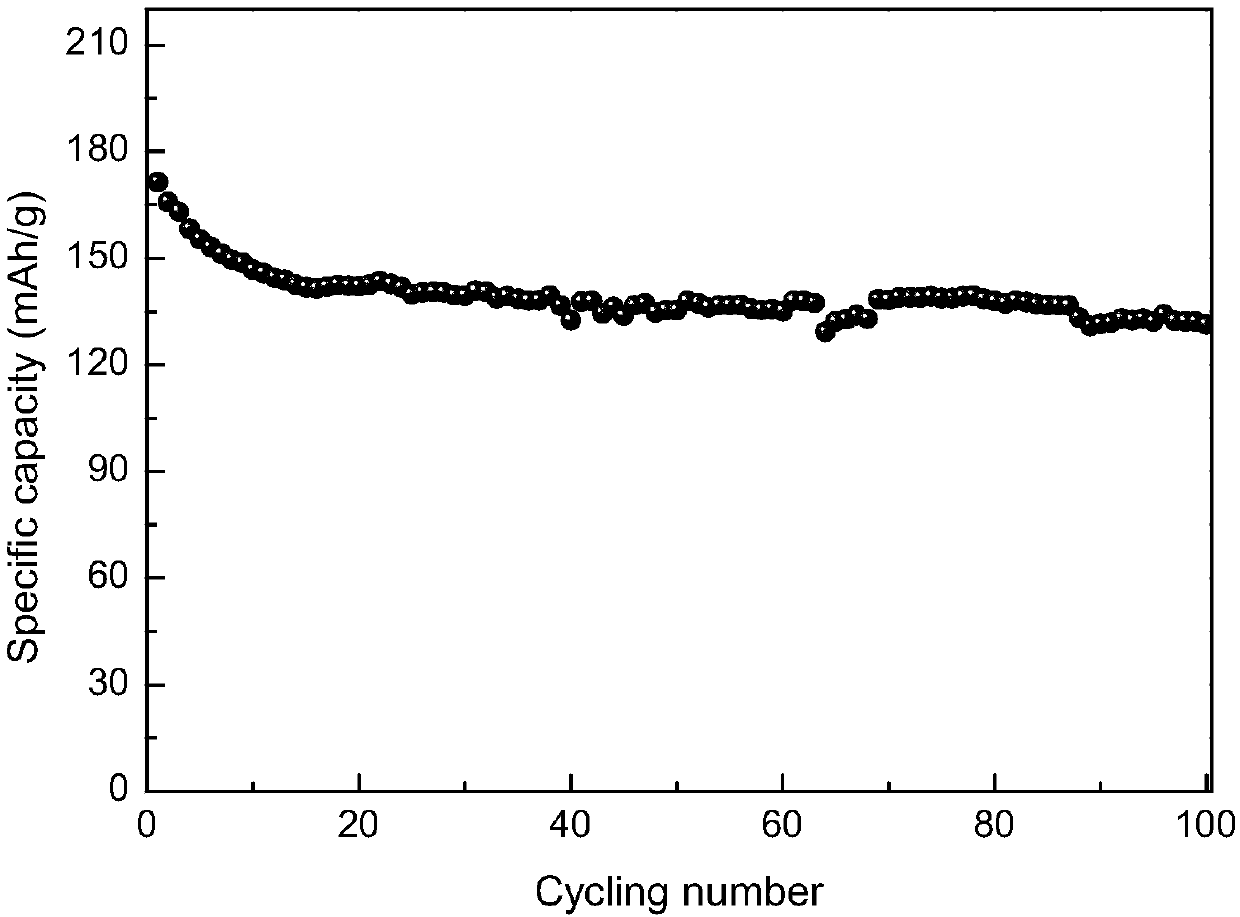

ActiveCN104810508AImprove performanceImprove cycle lifeCell electrodesSecondary cellsCharge dischargeMass content

The invention relates to a cell anode material and a preparation method thereof. The cell anode material comprises primary particles and secondary particles formed through clustering of the primary particles, wherein the primary particles are natural graphite micro powder, and / or artificial graphite micro powder, and / or carbonized or graphitized coke micro powder; the mass content of the secondary particles is 20 to 100 percent; the particle sizes of the cell anode material range from 6 to 60 microns; the average grain diameter D50 is 10 to 25 microns; the specific surface is smaller than 2.5m<2> / g. The anode material prepared according to the method is relatively high in compaction density, relatively low in expansion ratio, and relatively excellent in rate charge-discharge performance.

Owner:四川金泰能新材料有限公司 +1

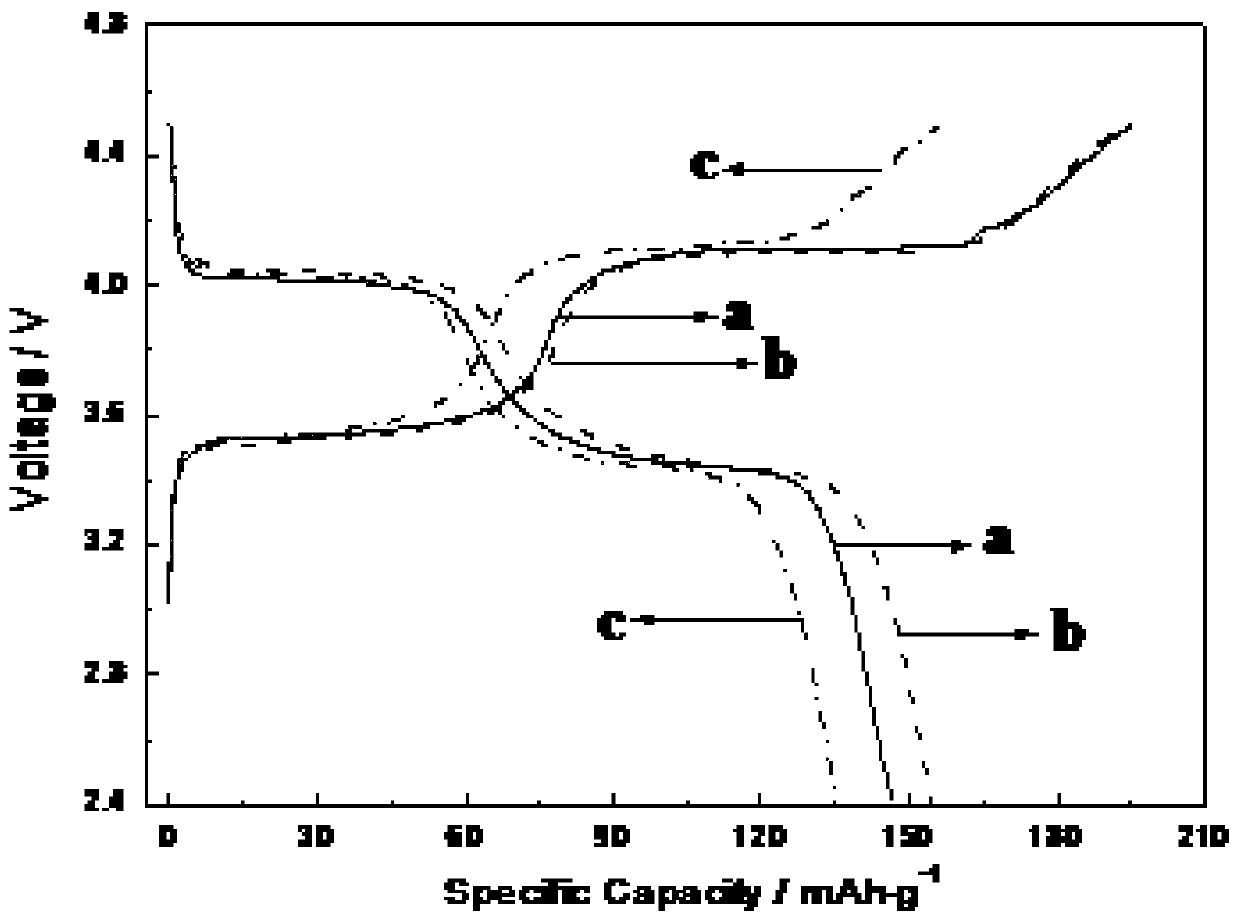

Lithium iron phosphate composite material, its preparation method and application

ActiveCN102437311AImprove conductivityFast charge and dischargeNon-aqueous electrolyte accumulator electrodesChemical compositionLithium iron phosphate

The invention is suitable for the technical field of batteries, and provides a lithium iron phosphate composite material, its preparation method and an application. The lithium iron phosphate composite material has a nanoparticle structure with lithium iron phosphate nanocrystals as the core. The external surface of the nanoparticle structure is covered with a nano-carbon particle coating, the external surface of which is covered with grapheme. The chemical composition of the lithium iron phosphate nanocrystals is LiFe1-xMxPO4, wherein M is metal ions and x is being less than 1 and greater than or equal to 0.001. By cladding the nano-carbon particles with the lithium iron phosphate crystals, adding grapheme and adding metal ions in the lithium iron phosphate crystals, conductivity of the lithium iron phosphate composite material in the embodiment of the invention is greatly improved. Simultaneously, the nano particle size of the lithium iron phosphate crystals guarantees rapid charge and discharge of the lithium iron phosphate crystals in the embodiment of the invention.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

Nitrogen-doped carbon coating germanium composite lithium battery negative electrode material and preparation method and application thereof

InactiveCN106169572ASimple preparation processSave raw materialsCell electrodesSecondary cellsCharge dischargeCarbon coated

The invention belongs to the field of lithium battery technologies, and in particular relates to a nitrogen-doped carbon coating germanium composite lithium battery negative electrode material, and a preparation method and an application thereof. The preparation method of the invention comprises the steps of preparing a germanium nano particle solution; polymerizing germanium nano particles with a nitrogenous organic matter precursor, thus obtaining a germanium / nitrogenous organic polymer; and carbonizing the germanium / nitrogenous organic polymer under protection of inert gas, and thus obtaining a nitrogen-doped carbon coating germanium composite material. The nitrogen-doped carbon coating germanium composite material can be used as the negative electrode active material of a lithium battery for preparing a negative electrode of the lithium battery, and is stable in structure, high in charge-discharge specific capacity, stable in high-magnification circulating charge and discharge, simple in production technology and free of pollution on environment.

Owner:FUDAN UNIV

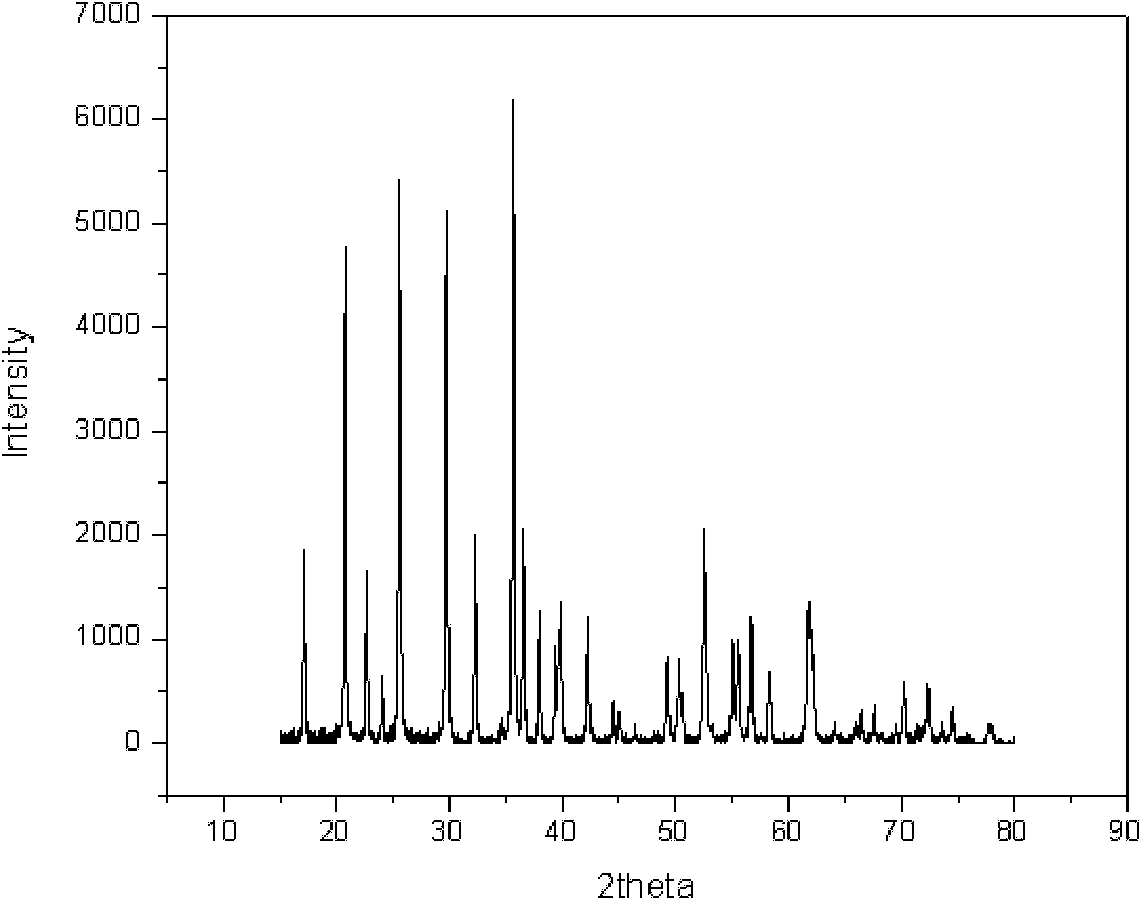

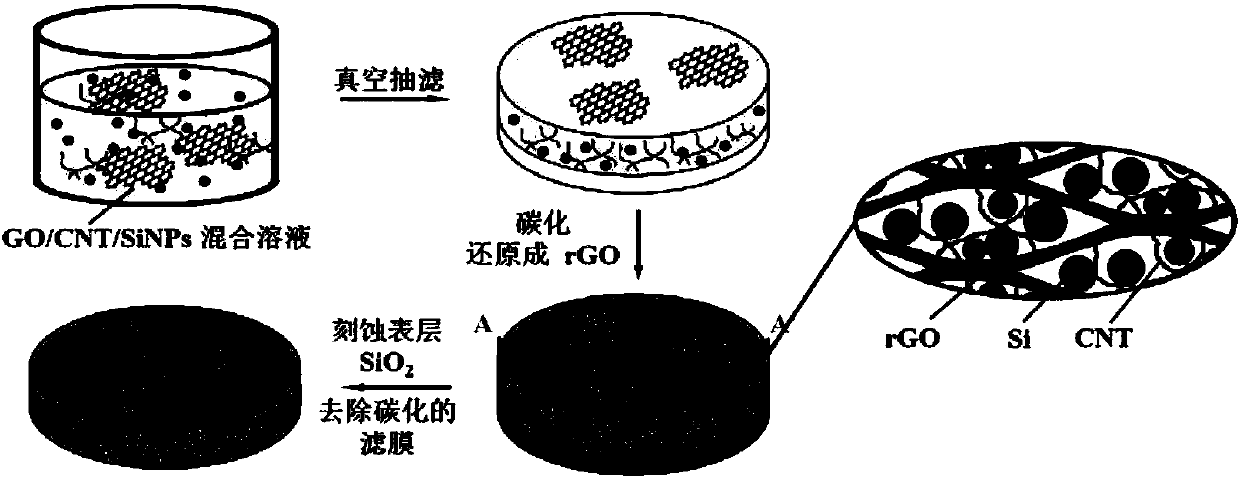

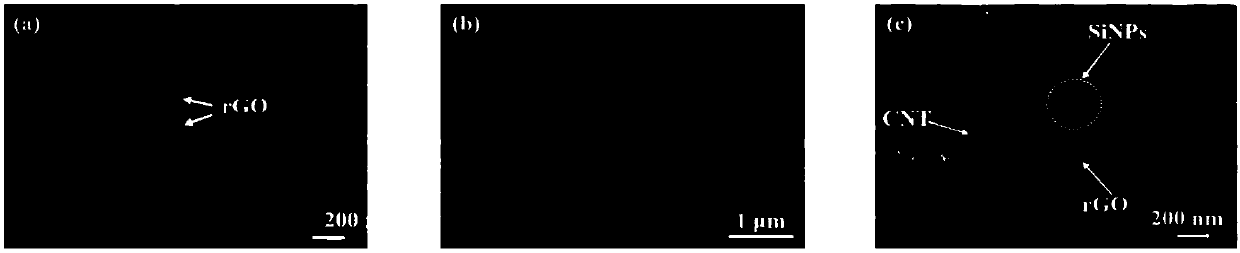

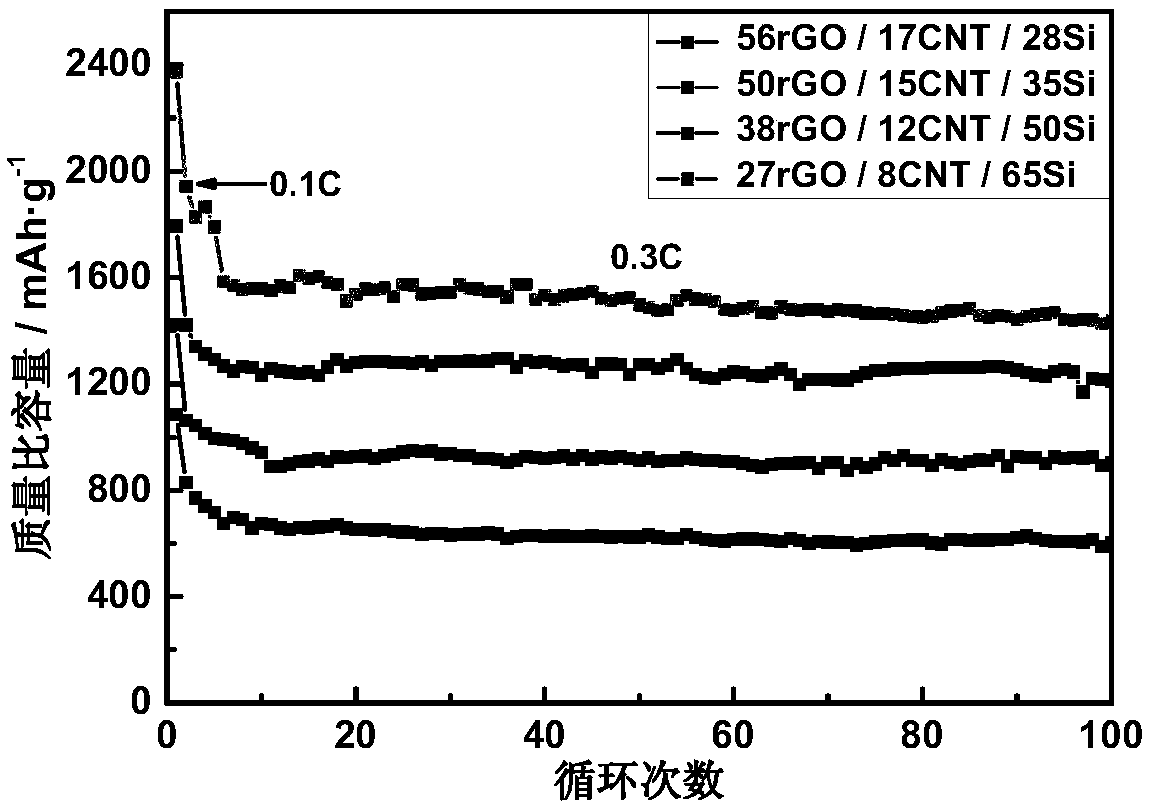

Composite silicon-carbon electrode material with shelly structure

InactiveCN107946570AIncrease capacityImprove cycle performanceCell electrodesSecondary cellsSpatial partitionCarbon nanotube

The invention provides a composite silicon-carbon electrode material with a shelly structure. The composite silicon-carbon electrode material is composed of reduced graphene oxide, silicon nanoparticles and carbon nanotubes, wherein the silicon nanoparticles are dispersed among multiple layers of the reduced graphene oxide; gaps are left between the silicon nanoparticles and the reduced graphene oxide; and the carbon nanotubes prop open the reduced graphene oxide and allow the reduced graphene oxide to include the silicon nanoparticles like shells. The invention also provides preparation and application of the composite silicon-carbon electrode material with the shelly structure. According to the invention, the shelly structure is formed among the layers of the reduced graphene oxide, thecarbon nanotubes provides support among the layers of the reduced graphene oxide and spatial partition for the silicon nanoparticles, so reserved space is left for the volume expansion of silicon during charging and discharging of a battery, and the structural integrity of an active material of a negative electrode can be better maintained; and thus, the battery is allowed to have high capacity which is hard to attenuate, good cyclicity and long service life.

Owner:TSINGHUA UNIV

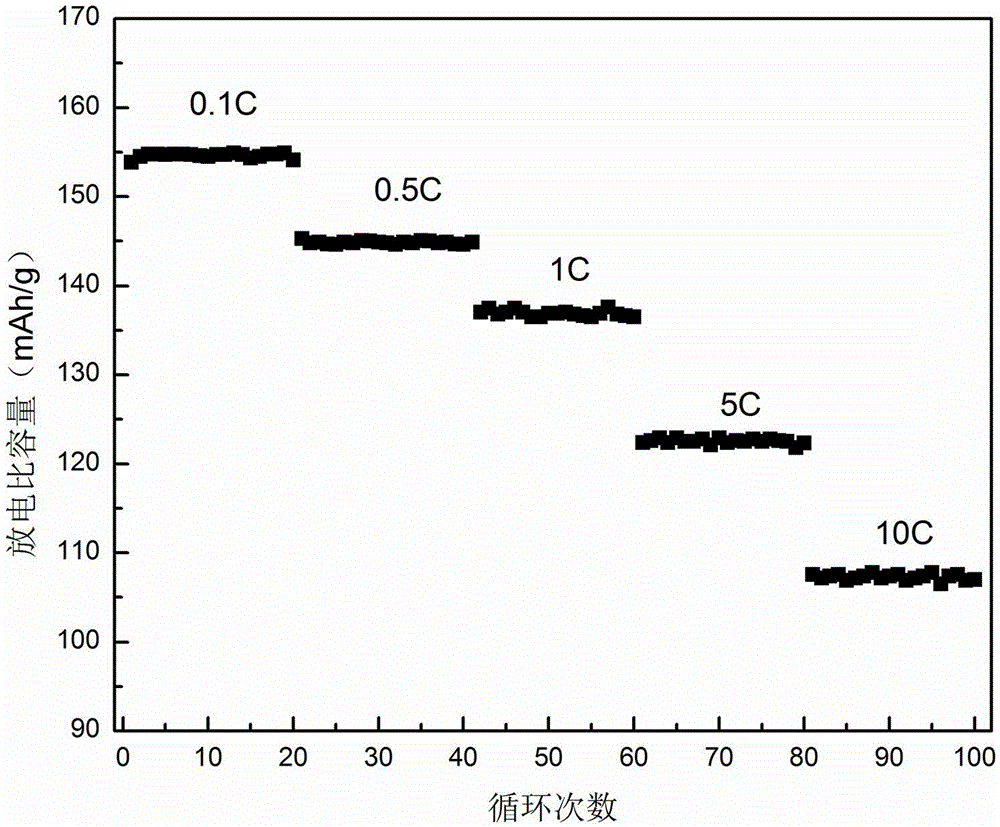

Nickel lithium manganate-based positive electrode material of lithium ion battery and preparation method thereof

InactiveCN105355903AHigh reversible specific capacityFast charge and dischargeCell electrodesSecondary cellsSlurry coatingCarbon nanotube

The invention discloses a nickel lithium manganate-based positive electrode material of a lithium ion battery and a preparation method thereof. A material used for a positive plate comprises a positive electrode current collector and a positive electrode slurry coating which is composed of a positive electrode active substance, a binder, a conductive agent and a solvent, wherein the positive electrode active substance is an Al2O3 coating of nickel lithium manganate, the binder is one or more selected from the group consisting of polyvinylidene fluoride and polytetrafluoroethylene, the conductive agent is one or more selected from the group consisting of conductive carbon black, conductive graphite and a carbon nanotube, the solvent is N-methylpyrrolidone, and the positive electrode current collector employs an aluminum foil. The lithium ion battery designed in the invention has reduced cost, and the purposes of improving reversible specific capacity, energy density, rapid charging and discharging capability, cycle performance and safety performance are achieved.

Owner:四川省有色冶金研究院有限公司

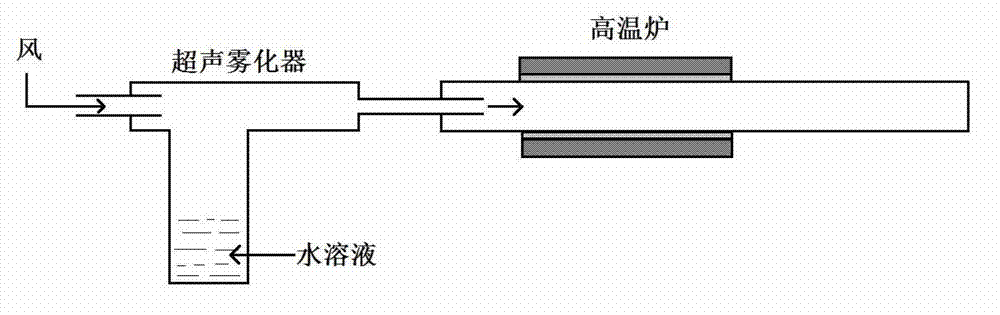

LiFePO4 precursor hollow sphere and preparation method thereof

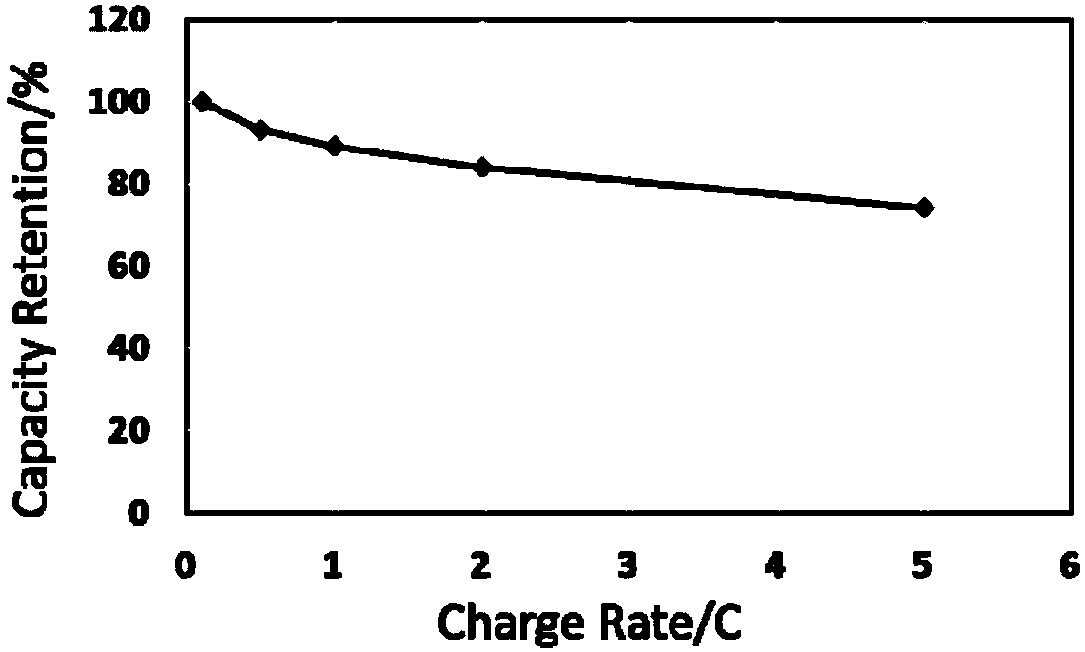

ActiveCN102969505AImprove charge and discharge performanceFast charge and discharge performanceCell electrodesElectrolytic agentPhysical chemistry

The invention relates to a LiFePO4 precursor hollow sphere and a preparation method thereof. The outer diameter of a precursor hollow sphere which is used as a LiFePO4 anode material of a lithium ion secondary battery is 10 nm-100 mu m and the wall thickness is 1 nm-10 mu m. A LiFePO4 anode material precursor with a hollow spherical structure is obtained through carrying out ultrasonic atomization drying on a solution prepared from a lithium compound, an iron compound, a phosphorus compound, a complexing agent and a carbon source. According to the LiFePO4 precursor hollow sphere and the preparation method thereof, a foundation of preparing the LiFePO4 anode material precursor with the hollow spherical structure is laid; and the structure is good for sufficiently contacting the LiFePO4 anode material with electrolyte, reducing a dispersion route of lithium ions and improving the rapid charging / discharging performance of the LiFePO4 anode material.

Owner:NANJING UNIV

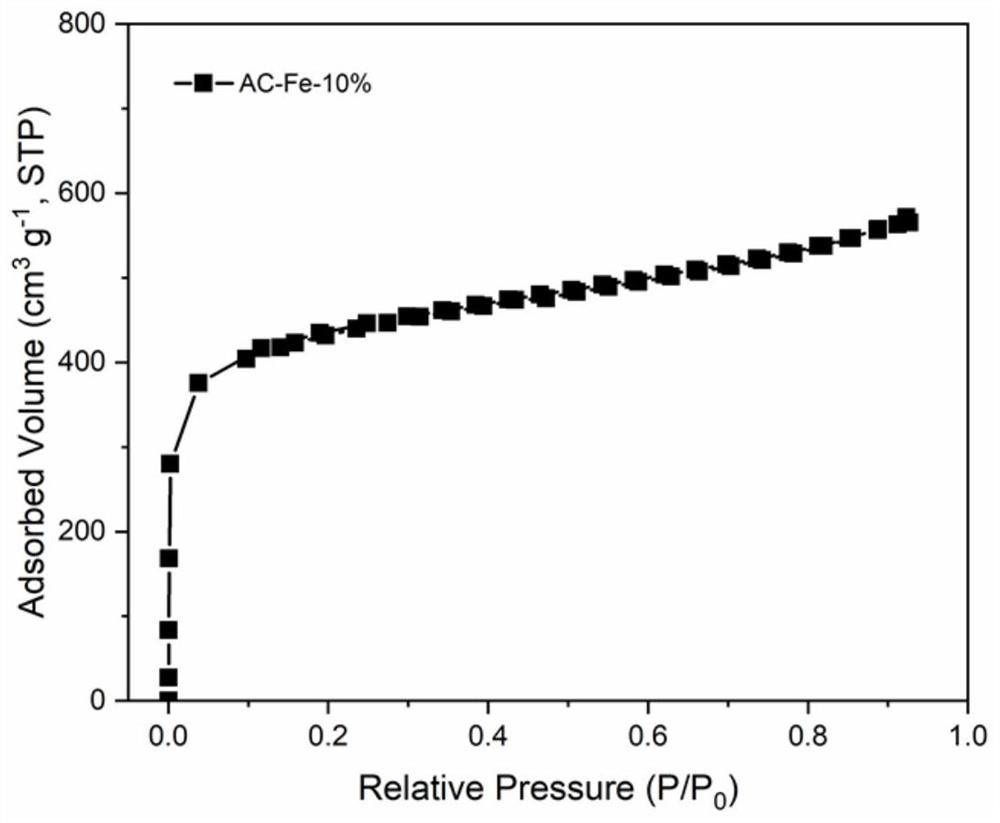

Preparation method and application method of nitrogen-doped porous carbon based on straw hydrothermal carbonization

PendingCN111017927AOvercome temperatureOvercome energy consumptionCarbon compoundsHybrid capacitor electrodesPorous carbonFiltration

The invention provides a preparation method and an application method of nitrogen-doped porous carbon based on straw hydrothermal carbonization. The preparation method comprises the following steps: 1, crushing a biomass raw material rice straw, screening, and drying in a 105 DEG C blast drying oven for 12 hours; 2, carrying out hydrothermal treatment on the crushed rice straw, naturally cooling to room temperature after the reaction is finished, carrying out suction filtration, washing with absolute ethyl alcohol and ultrapure water to remove impurities, and drying to obtain brownish black straw hydrothermal carbon; 3, mixing the straw hydrothermal carbon, an activating agent and melamine according to a certain mass ratio, and fully grinding in a mortar; and 4, putting the ground mixtureinto a tubular furnace, carrying out high-temperature activation in an inert gas atmosphere, naturally cooling to room temperature, and carrying out acid washing, water washing and drying on the obtained material to obtain the nitrogen-doped straw hydrothermal carbon-based porous carbon for the supercapacitor. The method comprises the following steps: A, a working electrode preparation method; andB, a supercapacitor preparation method.

Owner:ZHEJIANG UNIV

Nanometer carbon-lead super capacitor battery

ActiveCN103219162AHigh energy storageImprove power densityLead-acid accumulatorsHybrid capacitor electrodesHigh power densityCapacitance

The invention discloses a nanometer carbon-lead super capacitor battery, which comprises electrodes, wherein the electrodes are made of a carbon nanomaterial and a foam lead composite material; the carbon nanomaterial and the foam lead composite material are prepared by adopting an electrolytic deposition method; and the electrolytic deposition method comprises the following steps: preparing an electrolytic deposition solution; adding a carbon nanomaterial into the electrolytic deposition solution prepared in the step (1); and performing electrolytic deposition to obtain the carbon nanomaterial and the foam lead composite material. According to the nanometer carbon-lead super capacitor battery disclosed by the invention, a lead-acid battery is combined with a super capacitor, so that high energy storage density and high power density are realized simultaneously; high charging and discharging performances are achieved, and the charging speed of the battery is the same as the discharging speed in an unsaturated charging running mode; a carbon material can be used for preventing the phenomenon of sulfation on the cathode, so that a past failure factor of the battery is improved, and the service life of the battery is prolonged; and the nanometer carbon-lead super capacitor battery has very high safety performance, and is an environment-friendly safe battery.

Owner:JIANGSU HUAFU STORAGE NEW TECH DEV

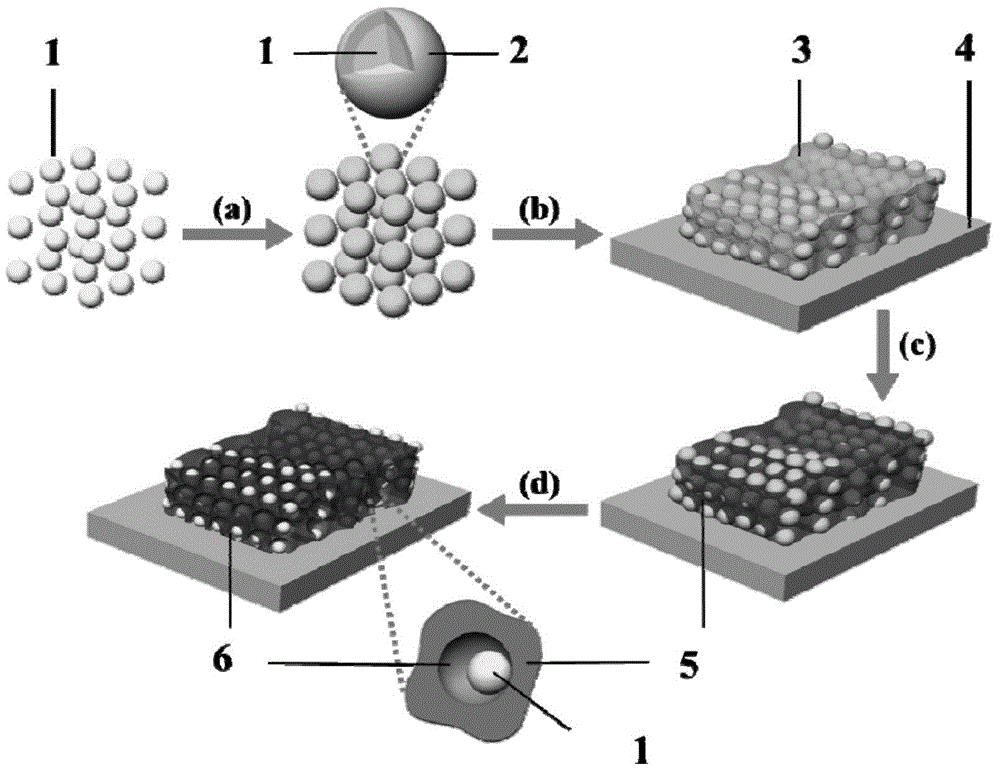

Three-dimensional connected curved graphene and preparation method thereof as well as electrode, capacitor and lithium battery

ActiveCN103833031AGood flexibilityBuffer volume expansionMaterial nanotechnologyGrapheneCapacitanceMicro nano

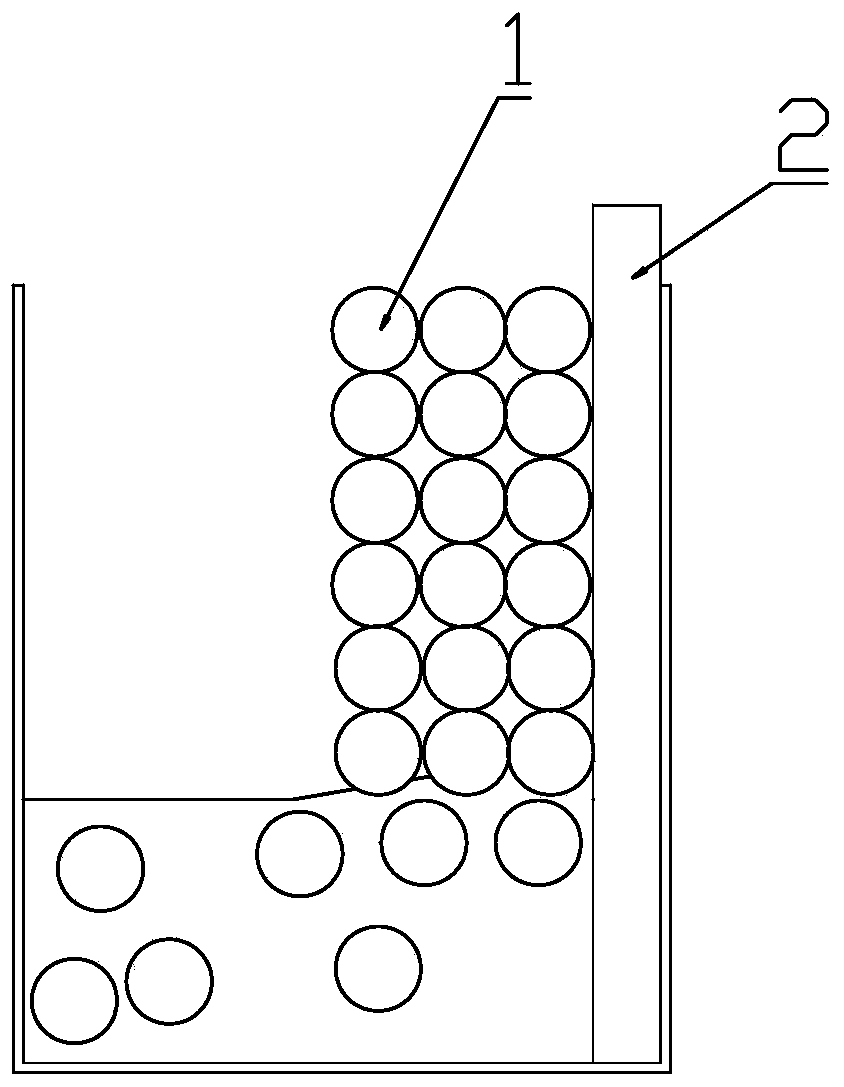

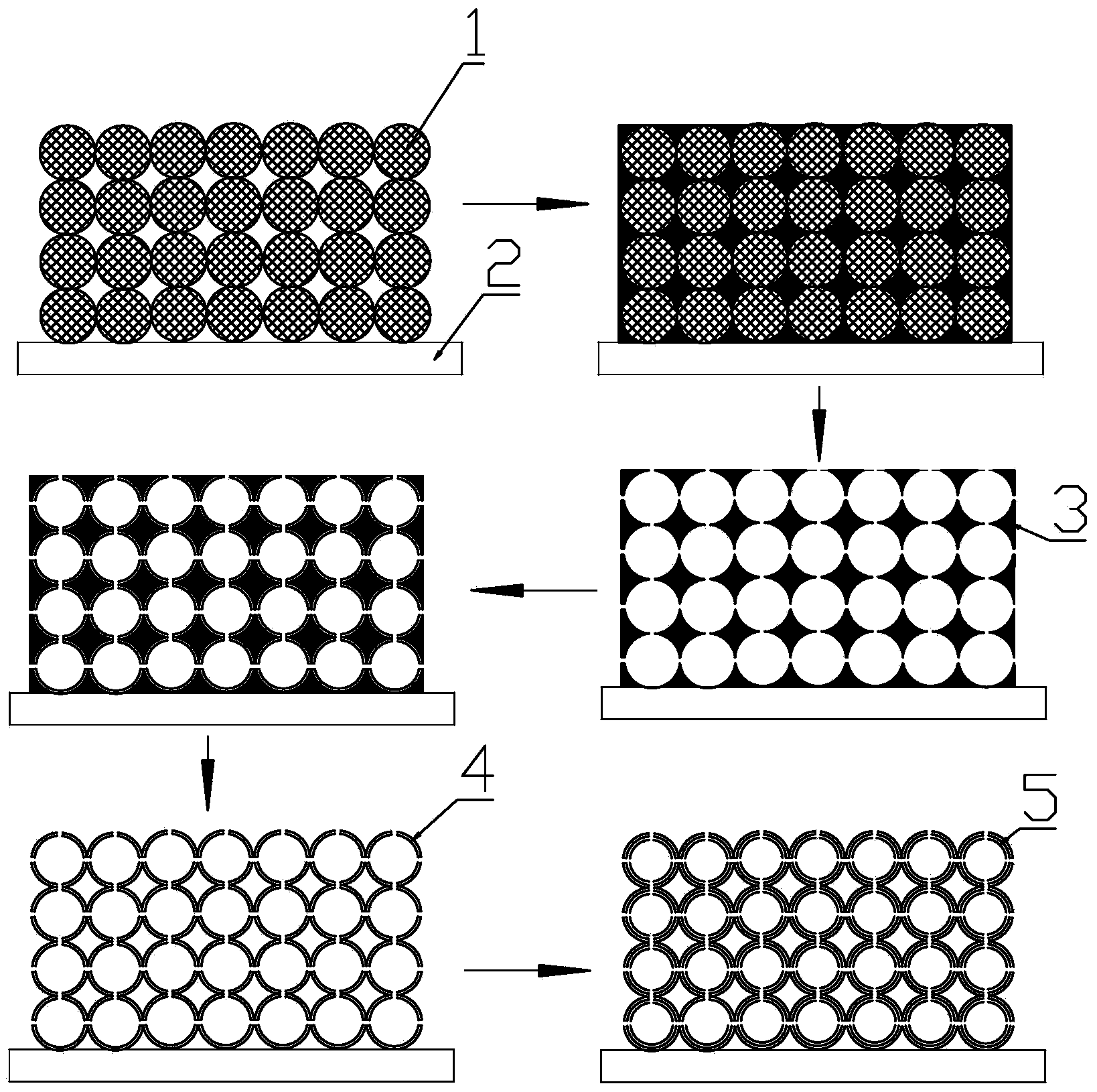

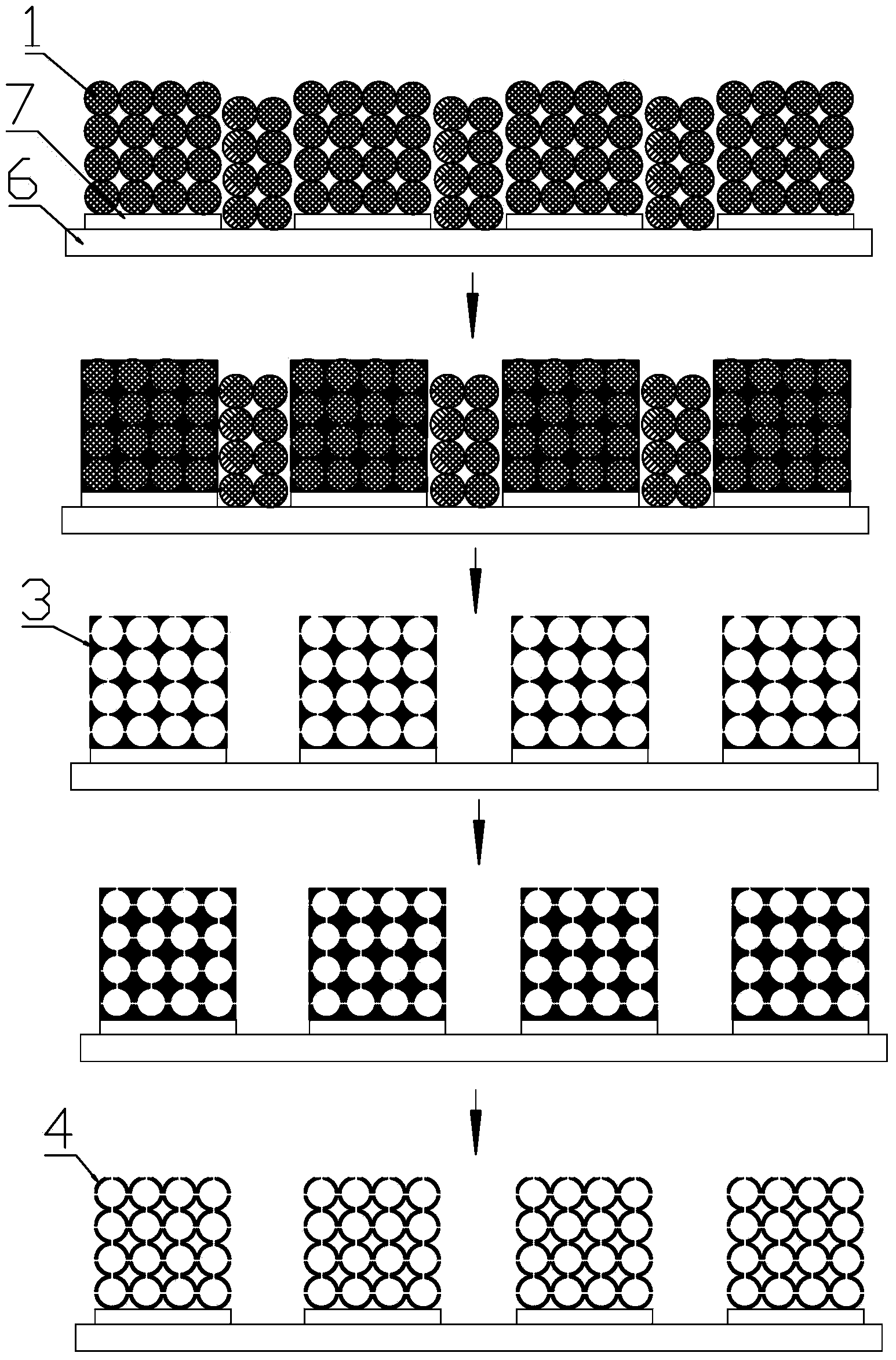

The invention relates to a three-dimensional connected curved graphene and preparation method thereof as well as an electrode, a capacitor and a lithium battery. The three-dimensional connected curved graphene is prepared by firstly forming a polystyrene micro-nanosphere array on a conducting substrate through a self-assembling stacking method, and then depositing metal through an electrochemical deposition method to remove the polystyrene micro-nanosphere, and preparing the graphene on the surface of the three-dimensional connected metal micro-nanosphere cavity structure through the graphene chemical vapor deposition method from the conducting substrate, or self-assembling on the substrate through the self-assembling stacking method to form stacked micro nano-particles array for covering metal element or metal oin, and then preparing the graphene on the surface of the micro nano-particles through the graphene chemical vapor deposition method. The prepared three-dimensional connected curved graphene can be used for manufacturing the electrode for the capacitor and the lithium battery. The three-dimensional connected curved graphene is good in flexibility, excellent in conducting performance, large in specific capacity, and capable of protecting the electrode material and preventing electrode material from peeling off.

Owner:仁恒智研新材料科技(广东)有限公司

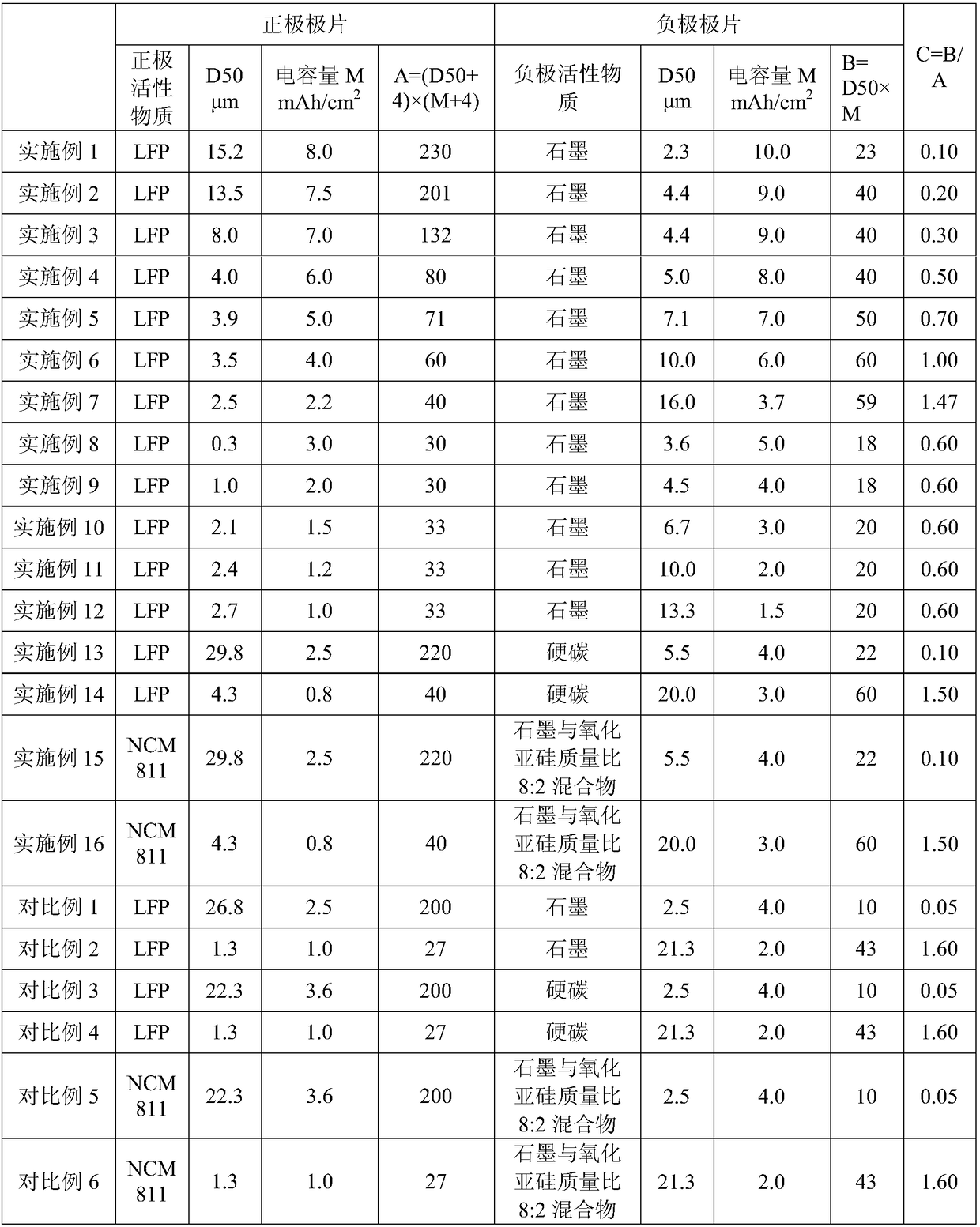

Secondary battery

ActiveCN109509909AImprove cycle lifeIncrease energy densityFinal product manufactureNon-aqueous electrolyte accumulator electrodesHigh energyPole piece

The invention provides a secondary battery. The secondary battery comprises a positive pole piece, a negative pole piece, electrolyte and an isolating membrane, wherein the positive pole piece comprises a positive current collector and a positive diaphragm which is arranged on at least one surface of the positive current collector and comprises an positive active material; the negative pole piececomprises a negative current collector and a negative diaphragm which is arranged on at least one surface of the negative current collector and comprises a negative active material. The secondary battery also meets the following condition that a ratio of the product of D50 negative electrode and M negative electrode to the product of D50 positive electrode plus 4 and M negative electrode plus 4 isgreater than or equal to 0.1 and is smaller than or equal to 1.5. The secondary battery with the advantages of long cycle life, high energy density and quick charge and discharge capacity, provided by the invention, is obtained by reasonably matching a relationship between particle sizes of the positive and negative active materials and capacities of the positive and negative diaphragms.

Owner:CONTEMPORARY AMPEREX TECH CO

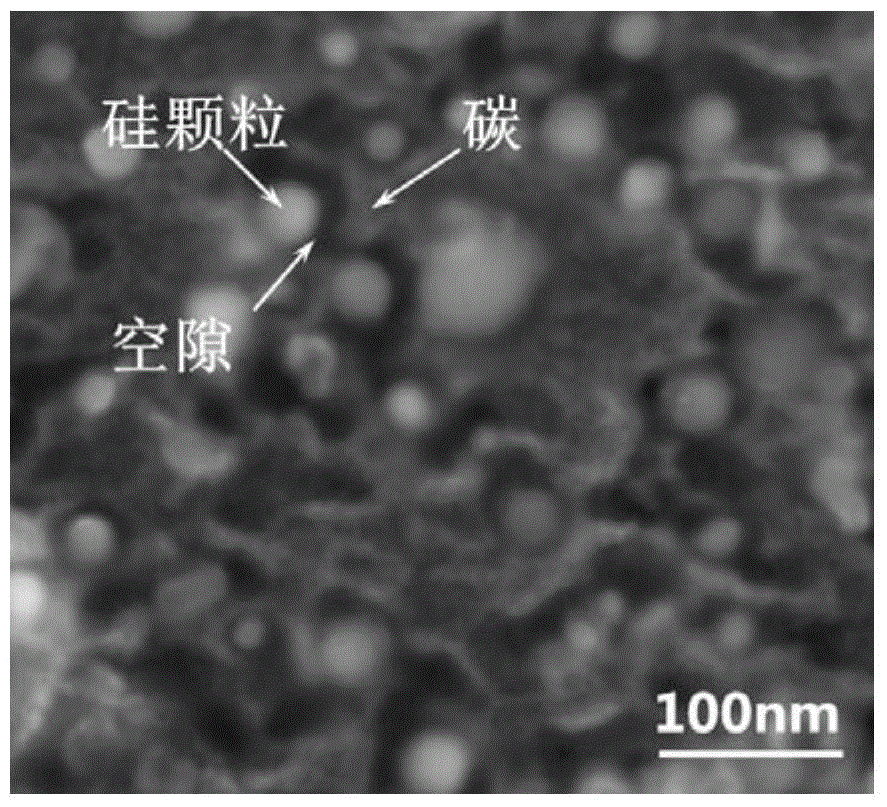

Negative active material and preparation method and application thereof

InactiveCN105047877AIncrease capacityImprove cycle performanceFinal product manufactureCell electrodesSilica nanoparticlesNanotechnology

The invention discloses a negative active material and a preparation method and application thereof. The negative active material comprises silica nanoparticles and a carbon-based material layer, wherein the carbon-based material layer is formed on at least part of outer surfaces of the silica nanoparticles, and gaps exist between at least one part of the carbon-based material layer and the outer surfaces of the silica nanoparticles. A battery prepared from the negative active material is high in capacity, good in circularity and long in service life, and is difficult to attenuate.

Owner:TSINGHUA UNIV

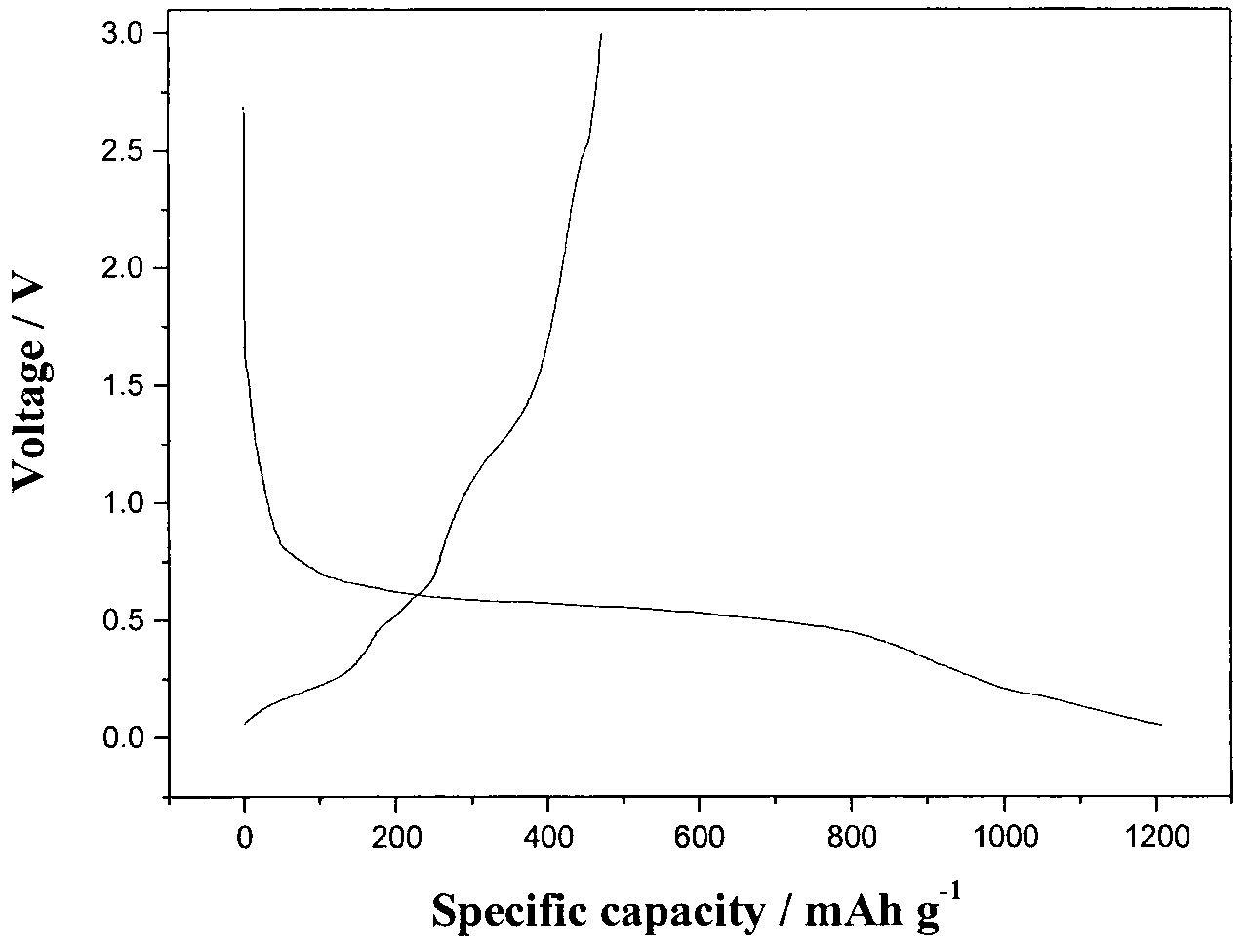

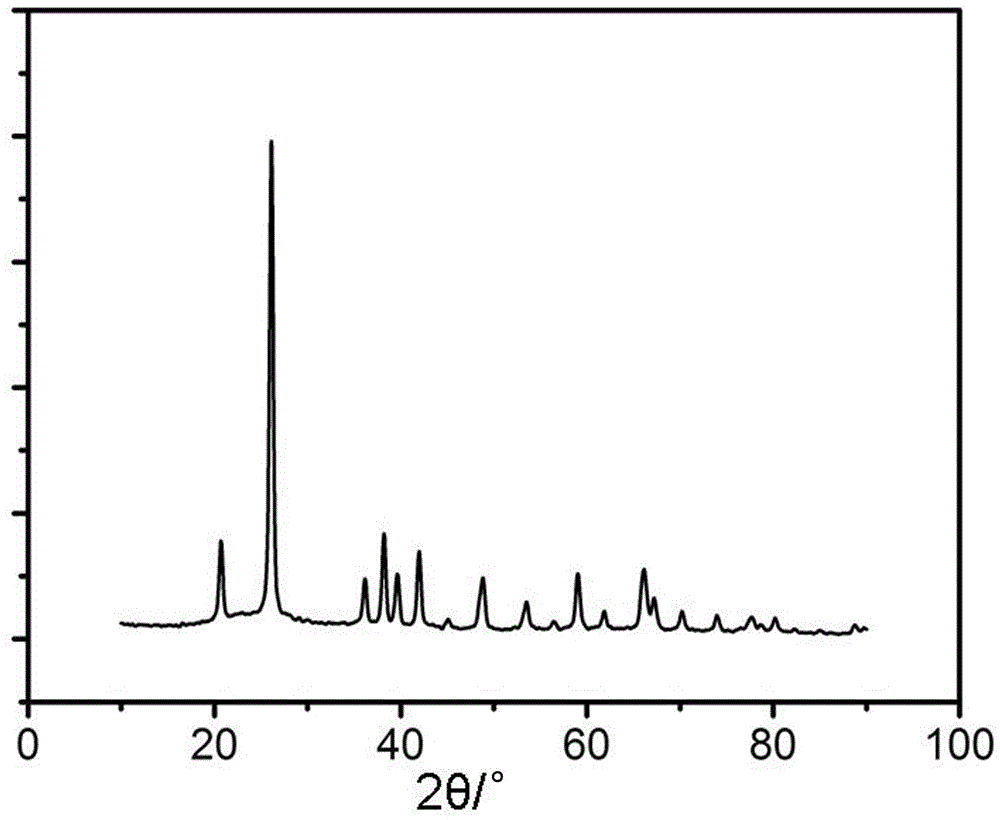

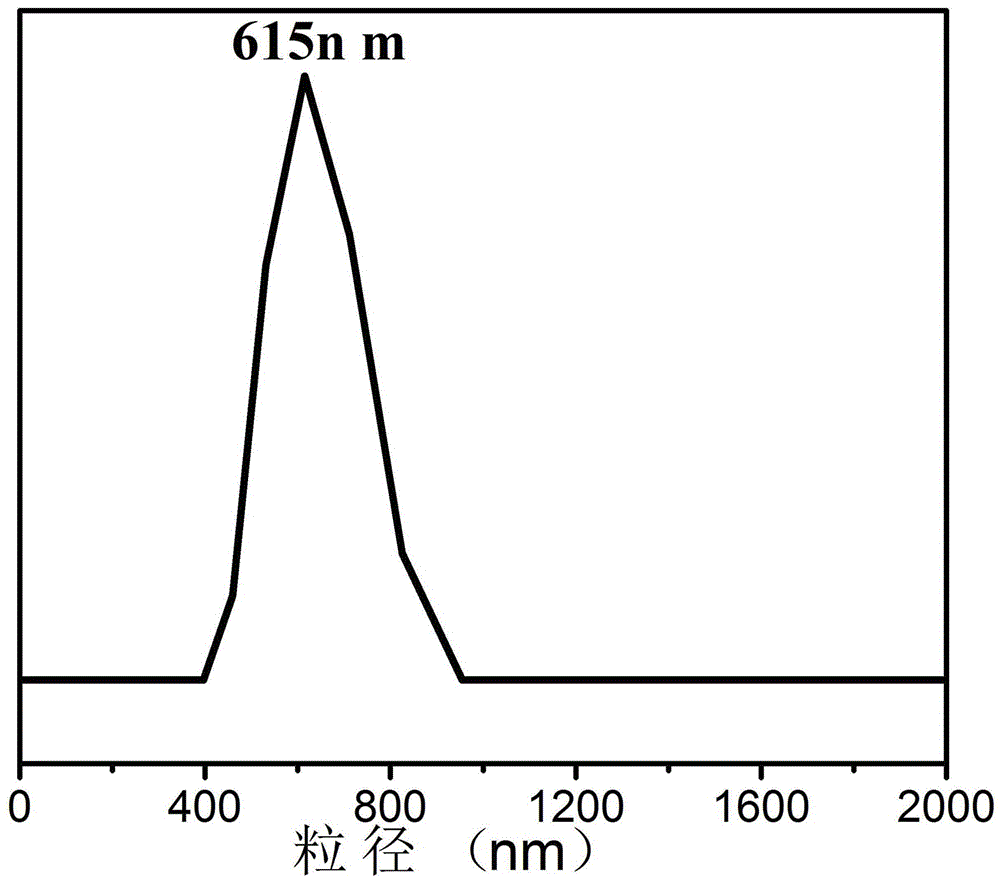

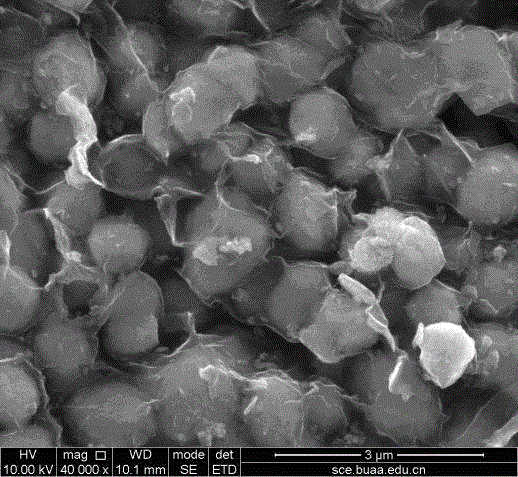

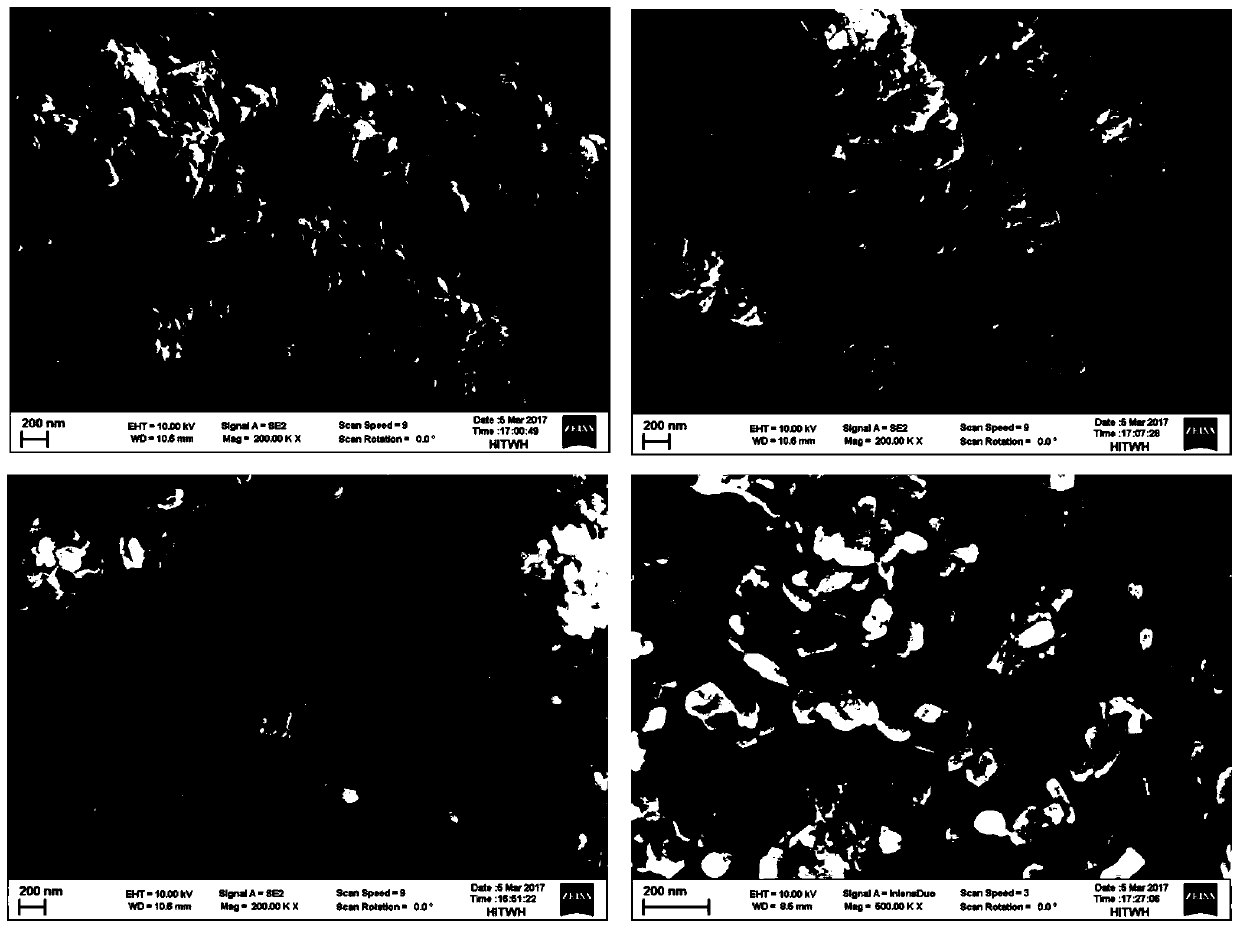

Germanium dioxide/graphene composite and preparation method thereof

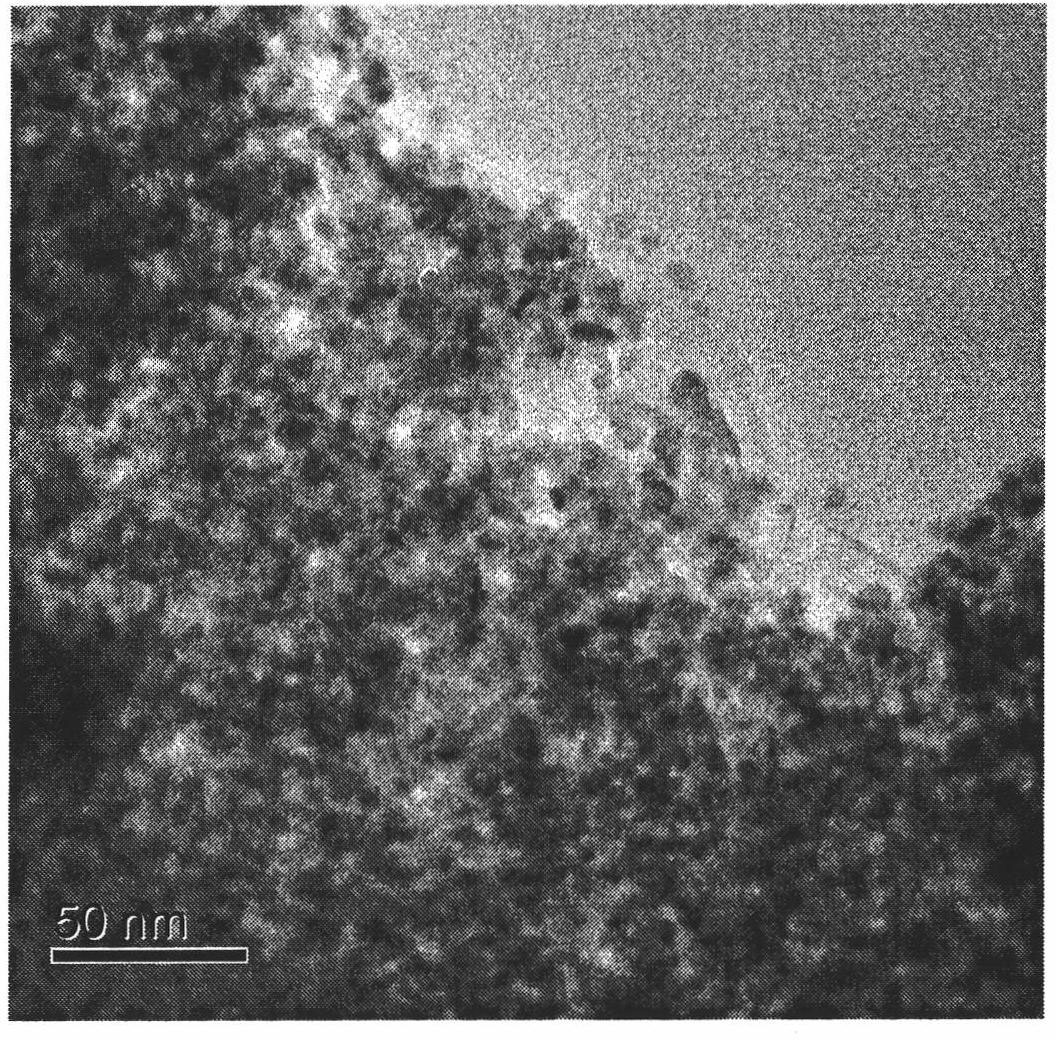

ActiveCN106099066ANo pollution in the processSimple and fast operationCell electrodesSecondary cellsAir atmosphereEvaporation

The invention relates to the technical field of lithium ion battery anode materials, in particular to a germanium dioxide / graphene composite. The composite is formed by wrapping germanium dioxide submicron particles by graphene nanosheets, and the diameter of the germanium dioxide submicron particles ranges from 400 nm to 900 nm. Germanium dioxide powder and graphene oxide are dissolved in distilled water together, then water is completely evaporated at the temperature of 25 DEG C to 45 DEG C, the powder obtained after evaporation is calcined in an air atmosphere for 1-3 h at the temperature of 200 DEG C to 300 DEG C, and the composite is obtained. The prepared germanium dioxide / graphene composite is used as a lithium ion battery anode material and has high charge and discharge specific capacity, good circulating stability and fast charge and discharge performance, the preparation method is simple, pollution is avoided, the reaction temperature is low, the obtained product is high in purity, and no by-product is generated.

Owner:SHANGQIU NORMAL UNIVERSITY

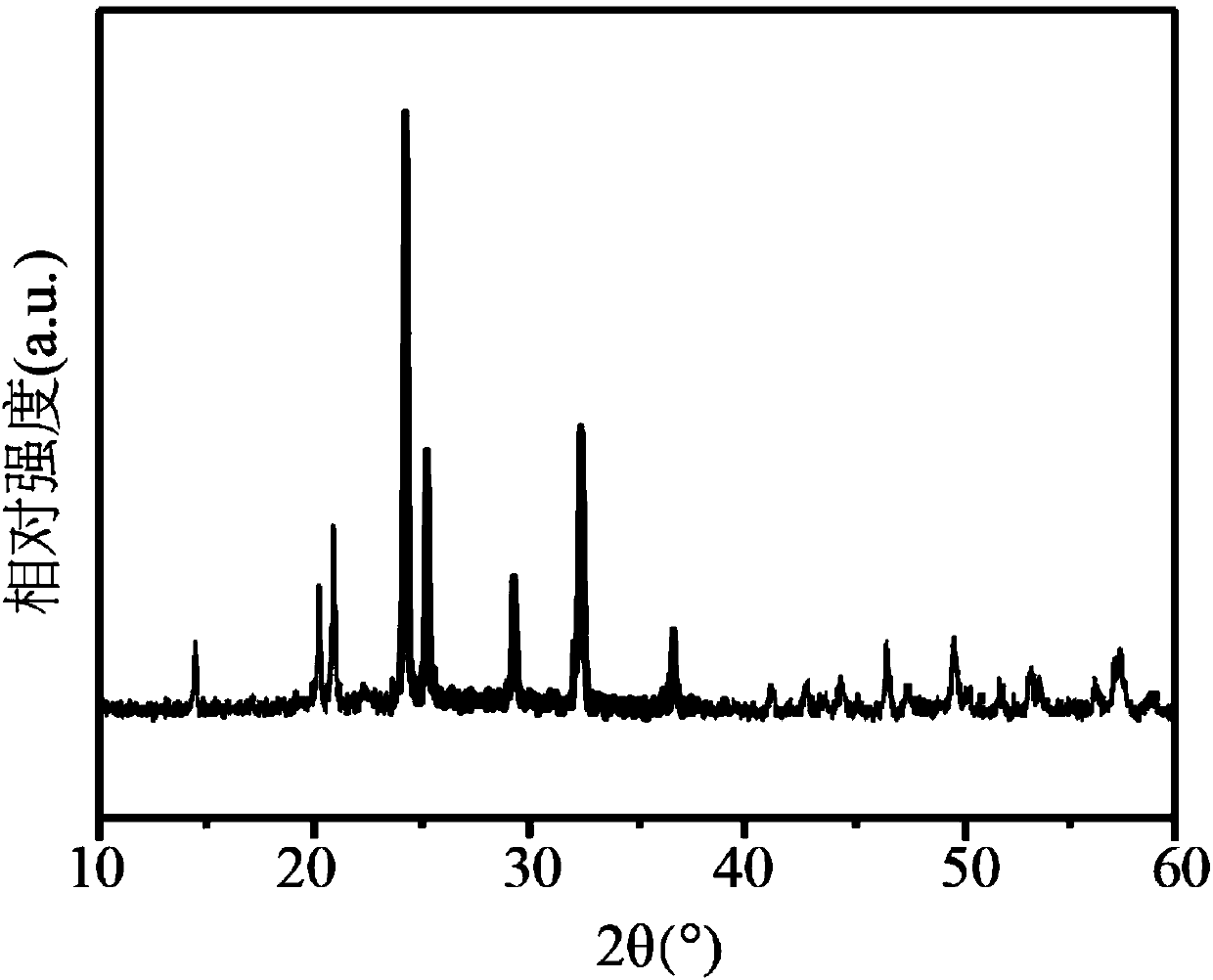

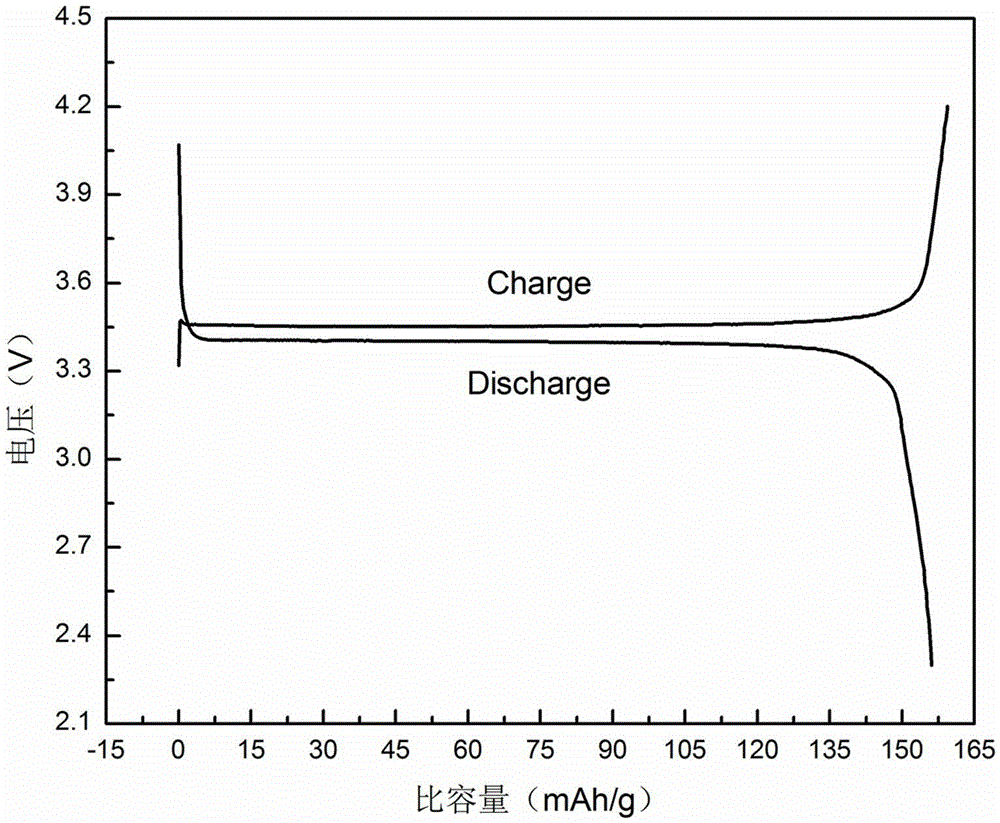

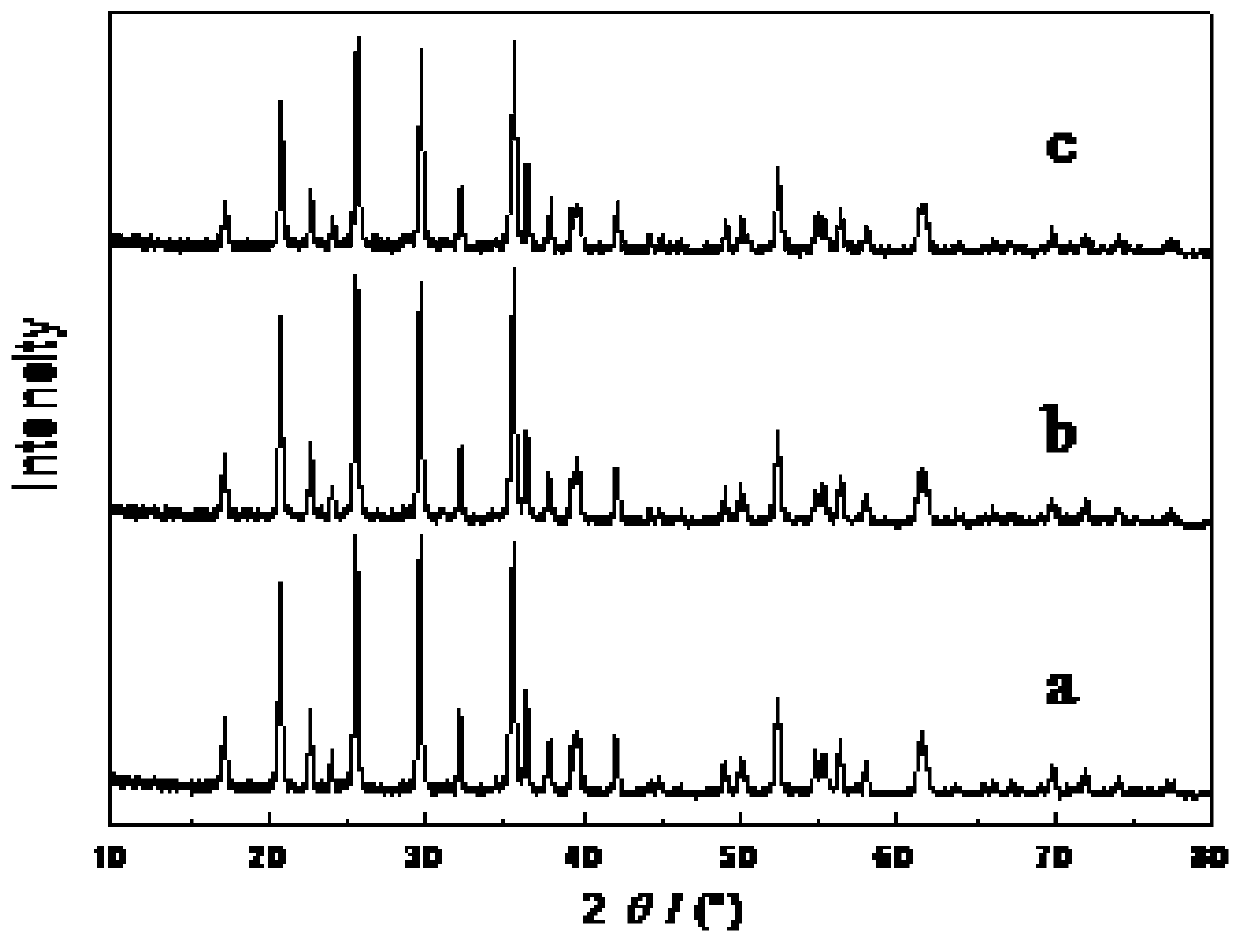

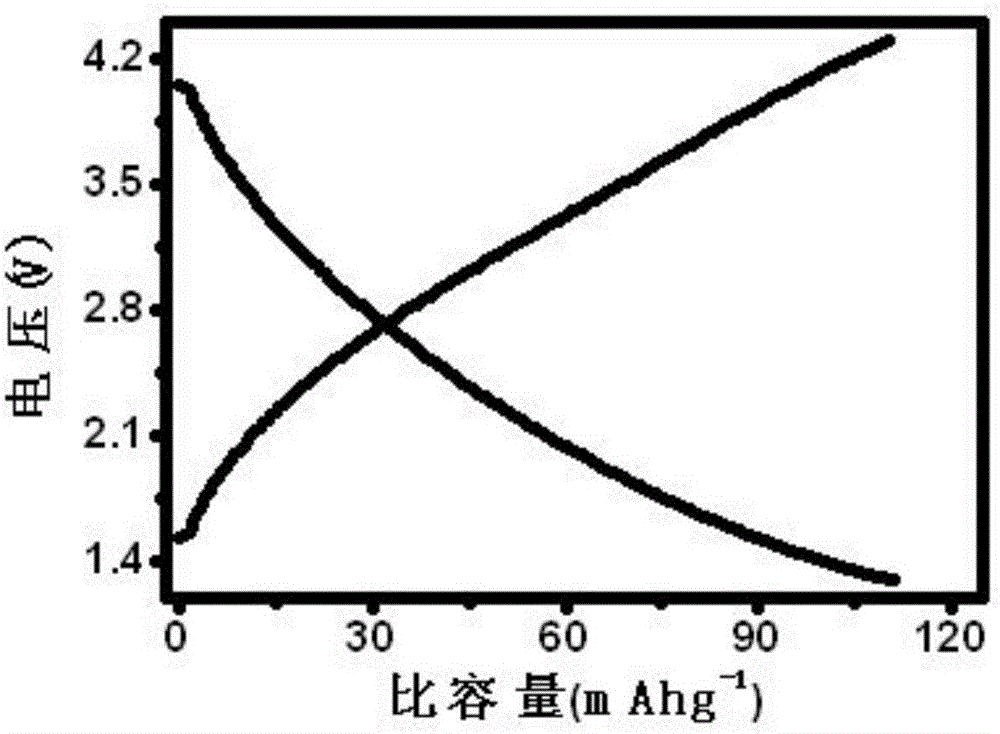

Carbon-coated titanium sodium phosphate composite material and prepared sodium ion battery

InactiveCN110311098AImprove stabilityImprove battery rate performanceCell electrodesSecondary cellsCarbon layerSynthesis methods

The invention discloses a NaTi2(PO4)3 / C composite material and a preparation method thereof. The composite material is composed of carbon layer-coated NaTi2(PO4)3. In the synthesis method, a titaniumsource, a sodium source and a phosphorus source are used as raw materials and are mixed with a carbon source, a carbon-coated NaTi2(PO4)3 electrode material having excellent properties is synthesizedthrough a solid phase method. The preparation method is uniform in coating, simple in process, high in yield and low in cost. Through the preparation method, the conductivity of NaTi2(PO4)3 is remarkably increased, and as a sodium ion battery, high energy density and good cycle stability are exhibited.

Owner:北京金羽新能科技有限公司

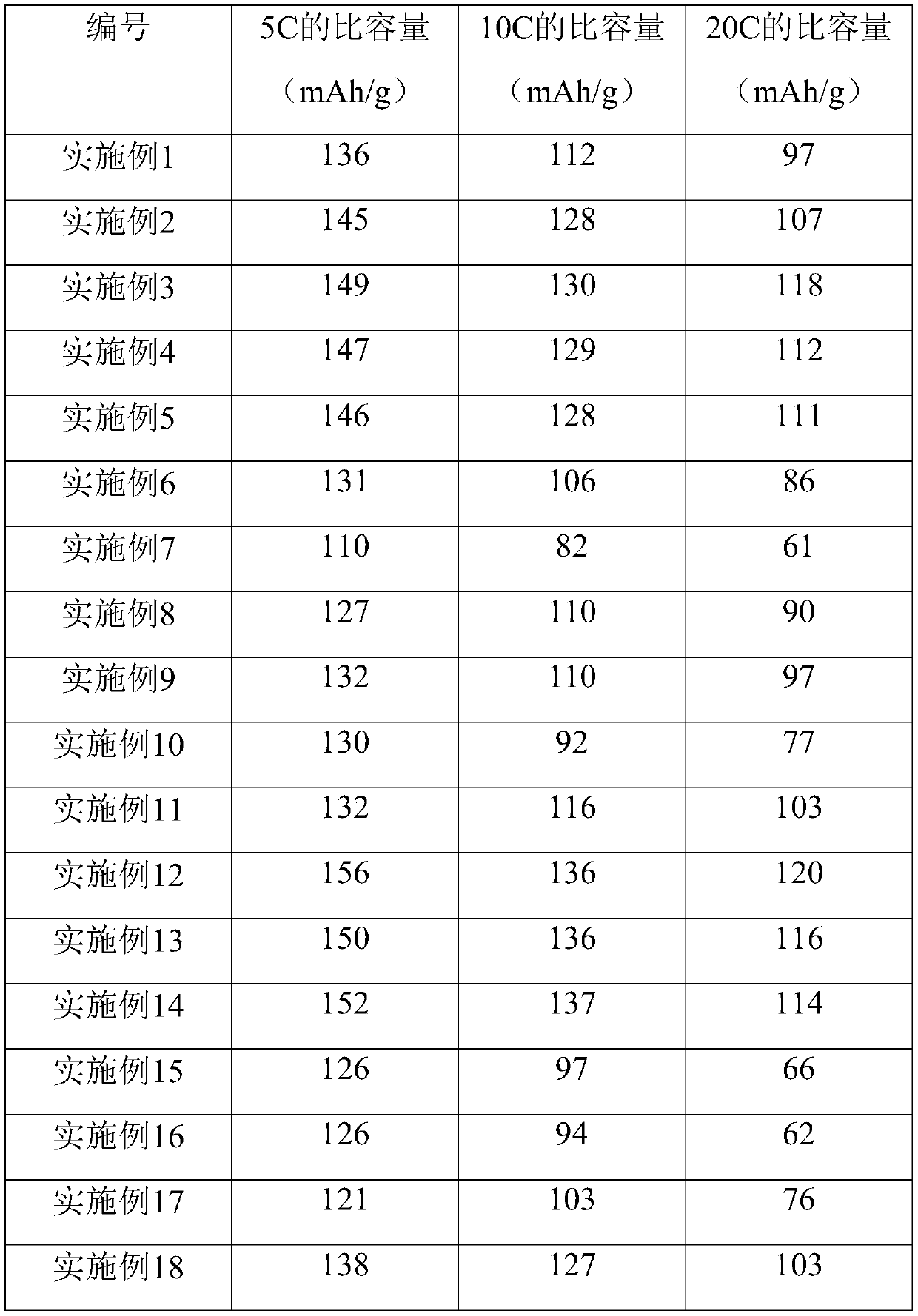

A preparation method of ternary cathode material for coated lithium ion battery

ActiveCN109037644AReduce side effectsImprove migration efficiencyCell electrodesSecondary cellsSolubilityCoprecipitation

A method for preparing ternary cathode material of coated lithium ion battery includes such steps as sequentially adding solution with different ion solubility to carry out coprecipitation reaction, adding polyacrylamide during coprecipitation reaction, pre-sintering and removing polyacrylamide to obtain porous spherical ternary material precursor; Then the precursor of porous spherical ternary material was coated with Al2O3, and sodium dodecyl benzene sulfonate was added into the coated solution. Finally, the cathode active material of lithium ion battery was obtained by sintering. A method for preparing a ternary cathode material of a coated lithium ion battery according to that present embodiment greatly improve the capacity, rate performance and cycle stability of the ternary cathode material of the lithium ion battery.

Owner:QINGYUAN JIAZHI NEW MATERIAL RES INST CO LTD +1

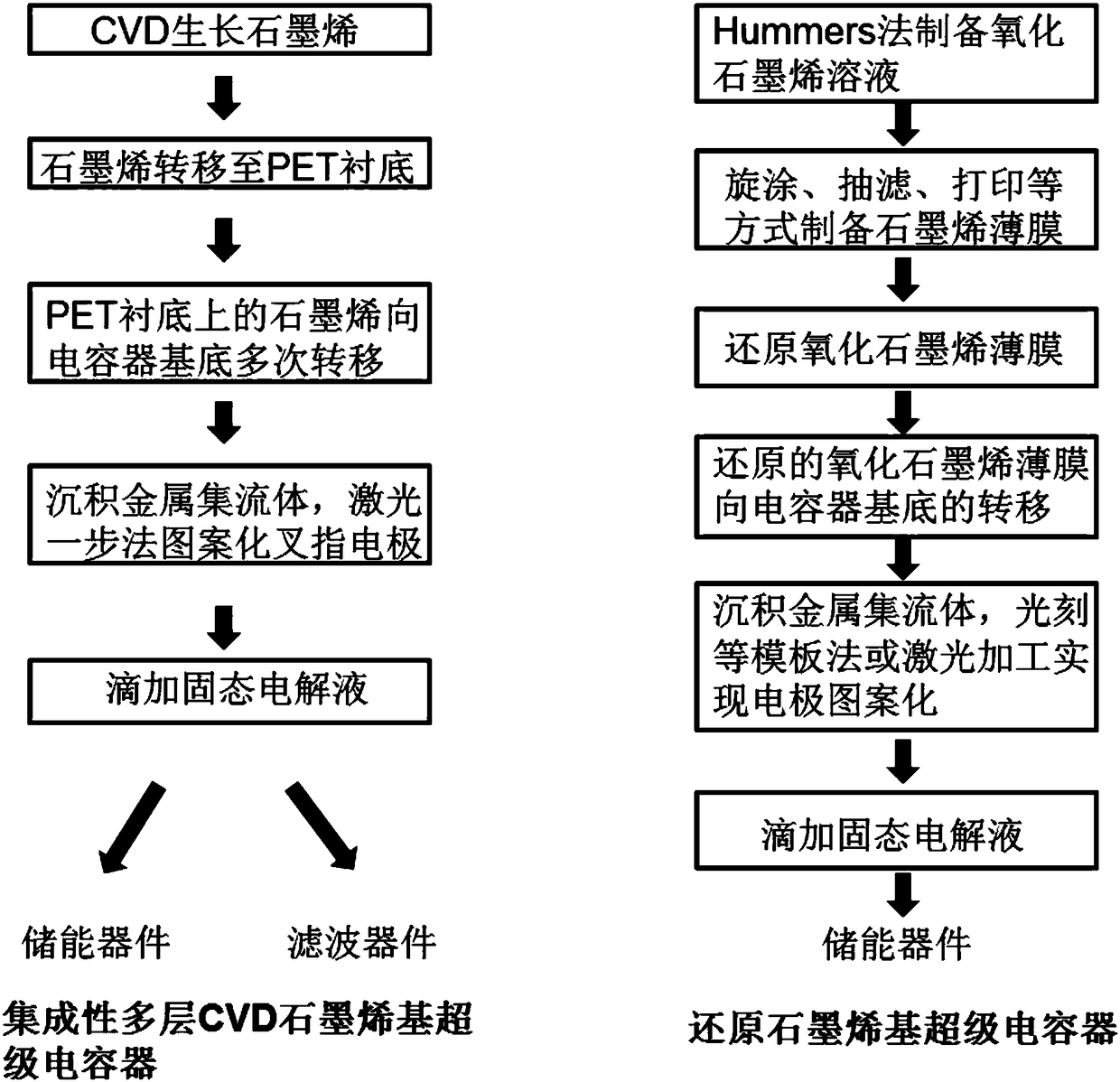

Graphene thin film electrode, preparation method thereof, graphene composite thin film interdigital electrode with conductive line formed on surface and capacitor

ActiveCN108565130APreserve integrityIncrease energy densityHybrid capacitor electrodesMultiple hybrid/EDL capacitorsSingle layer grapheneCvd graphene

The present invention provides a graphene thin film electrode. The graphene thin film electrode comprises an electrode substrate, a graphene thin film composited on the electrode substrate, and a metal thin film composited on the graphene thin film; the graphene thin film is a single-layer graphene sheet or a multi-layer graphene sheet; and single-layer graphene sheets are stacked so as to form the multi-layer graphene sheet. The invention also provides a preparation method of the graphene thin film electrode. According to the graphene thin film electrode and the preparation method thereof ofthe invention, the single-layer graphene sheets are stacked so as to form the multi-layer graphene sheet, so that the multi-layer graphene sheet can be used for preparing the graphene thin film electrode. A flexible graphene conductive electrode can be also prepared; the integrity of a two-dimensional planar structure can be reserved, and the conductivity of graphene can be retained; and the flexible graphene conductive electrode can be directly used for the extremely thin electrode material of a flexible or non-flexible supercapacitor. The interdigital patterning of the electrode is realizedby means of laser carving, so that a light and ultra-thin all-solid supercapacitor can be prepared; the energy density and power density of the device can be improved; and excellent alternating-current filtering performance of the device can be realized.

Owner:UNIV OF SCI & TECH OF CHINA

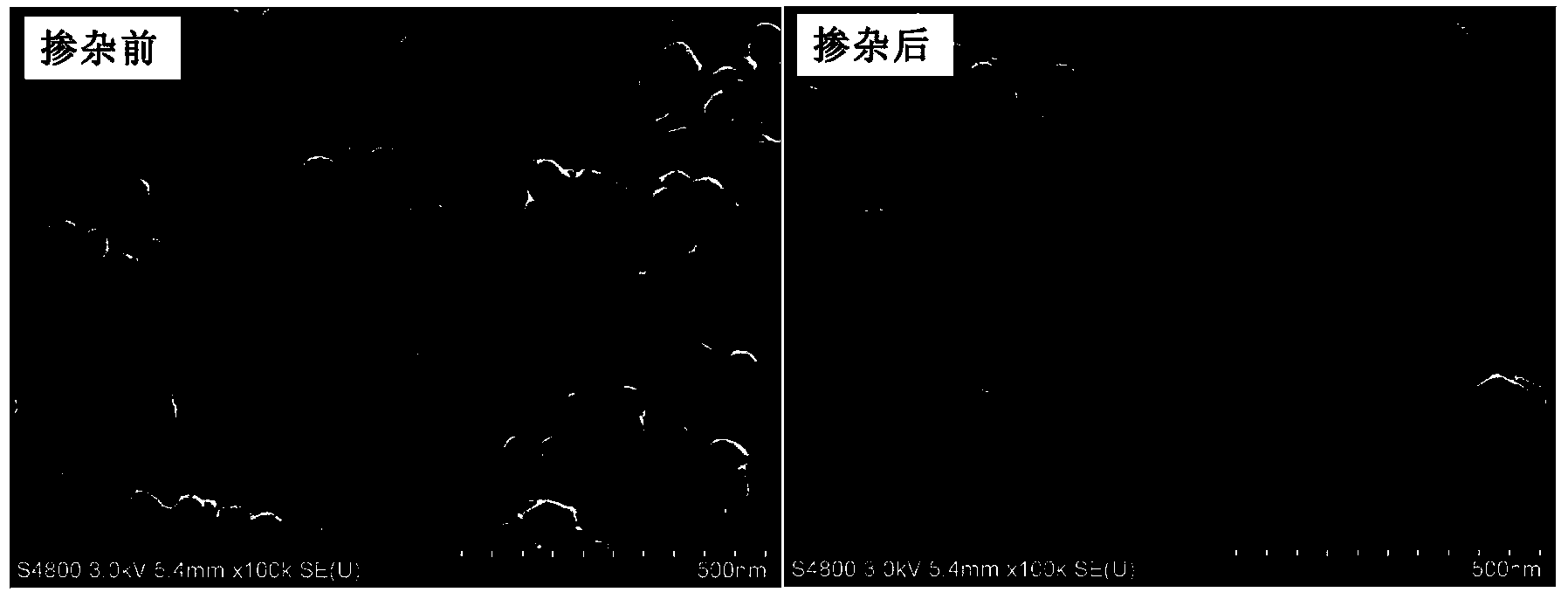

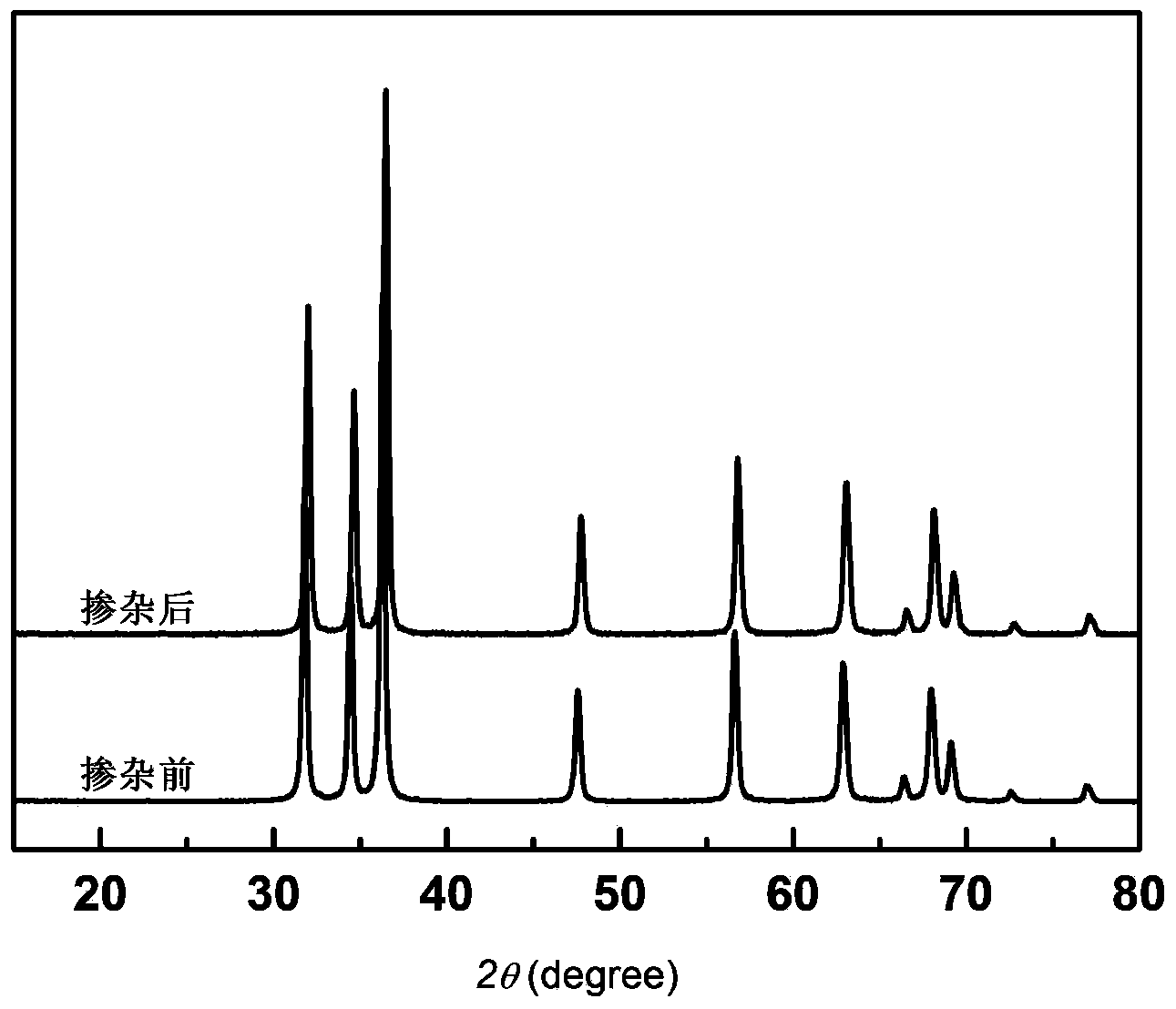

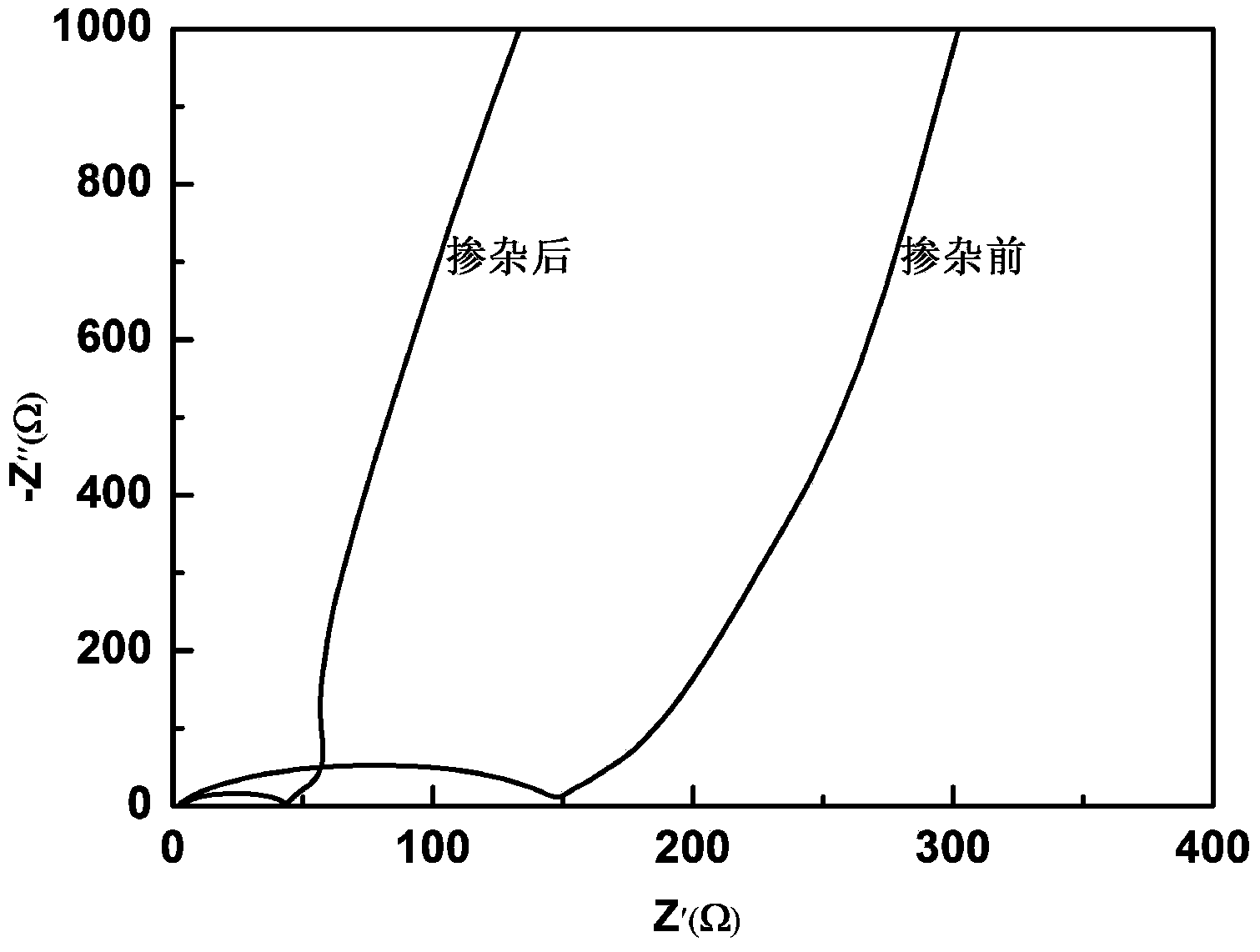

Method for improving conductivity of zinc oxide negative electrode material applicable to lithium ion battery

InactiveCN103972488AImprove conductivityImprove power characteristicsCell electrodesSecondary cellsAluminium-ion batterySodium-ion battery

The invention discloses a method for improving conductivity of a zinc oxide negative electrode material applicable to a lithium ion battery. The method comprises the following steps: dissolving metal zinc salt and doped metal salt in a solvent, stirring the solvent, then transferring the solvent to a hydrothermal kettle for carrying out hydrothermal reaction, ending the reaction, then naturally cooling to room temperature, respectively washing by water and ethyl alcohol alternatively, then draying in vacuum to obtain metal M ion doped zinc oxide negative electrode material. Through the method, the defect of forming negative electricity in a lattice structure of the zinc oxide is avoided and the number of free electrons is increased, thereby improving the conductivity of the zinc oxide. Meanwhile, the doped metal ion is capable of distorting the lattices of the zinc oxide, thereby increasing the gap between the lattices, improving the motion capability of the lithium ions in the crystals, and further overcoming the defects of poor high power characteristic and poor quick charging and discharging capacity caused by poor conductivity of the zinc oxide material; the zinc oxide negative electrode material has the characteristics of high quick charging and discharging capacities, high efficiency and high capability; furthermore, the zinc oxide negative electrode material is stable, efficient, clean, pollution-free and low in cost.

Owner:SHAANXI UNIV OF SCI & TECH

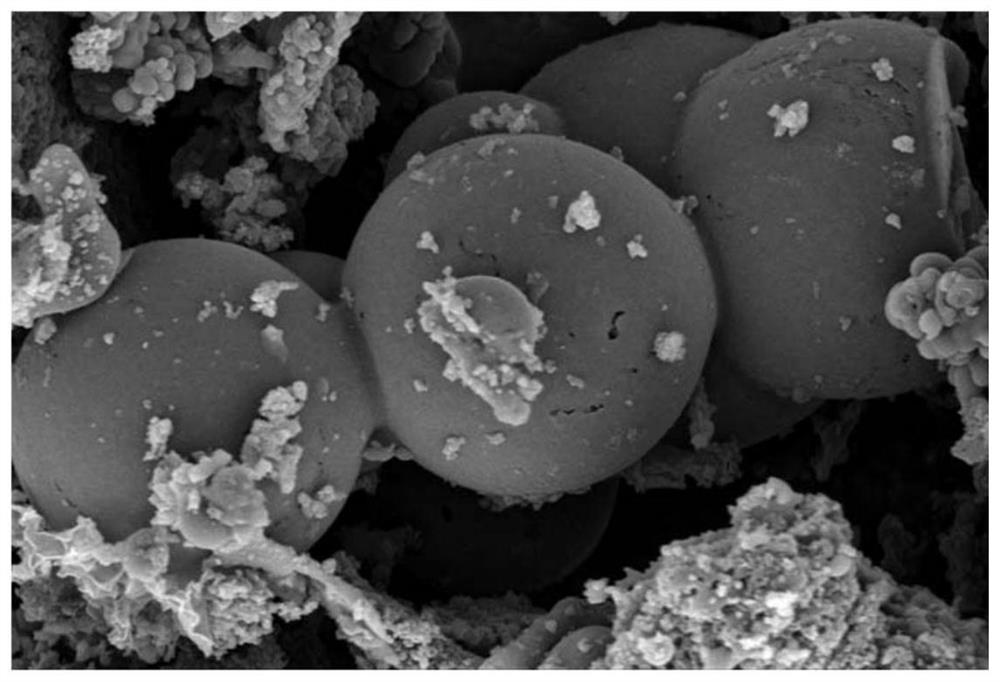

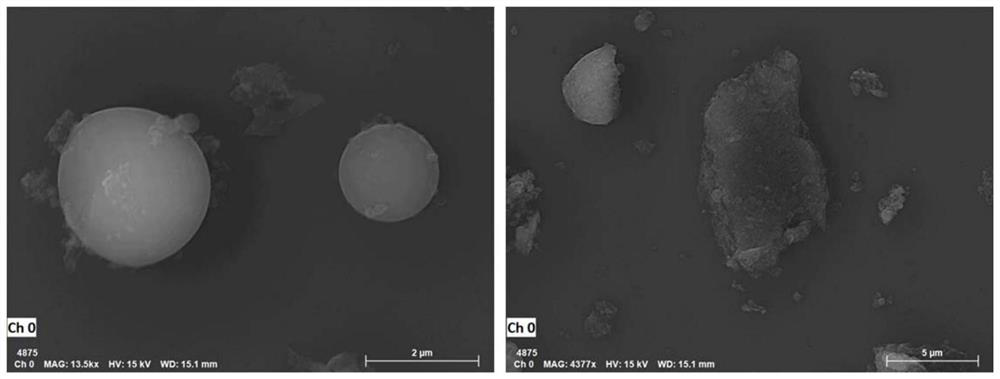

Preparation method and application of iron-modified carbon microsphere/carbon nanosheet composite porous carbon based on hydrothermal carbonization of moso bamboos

ActiveCN112194132AOvercome temperatureOvercome energy consumptionCarbon compoundsHybrid capacitor electrodesIron sulfatePorous carbon

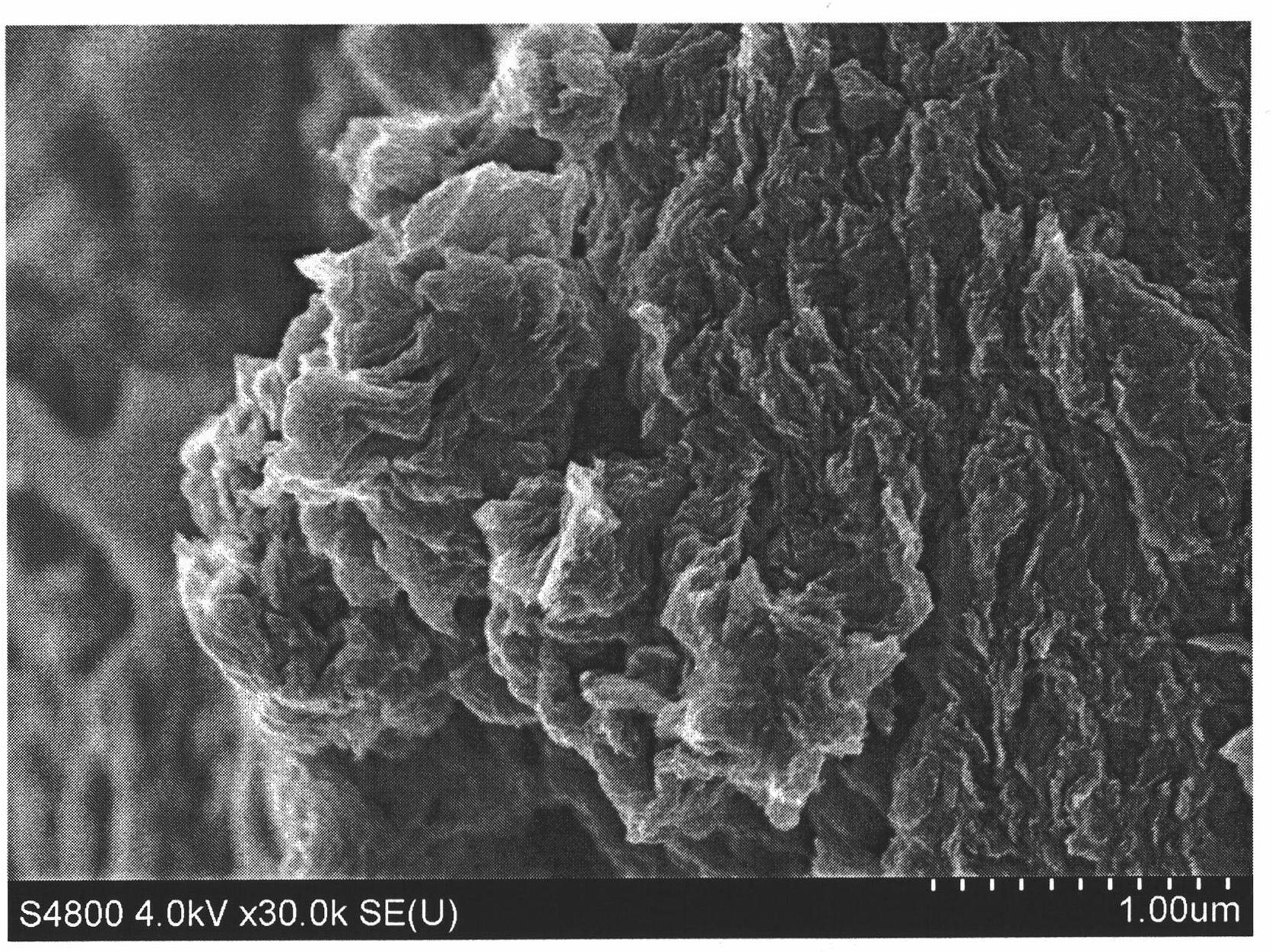

The invention discloses a preparation method of iron-modified carbon microsphere / carbon nanosheet composite porous carbon based on hydrothermal carbonization of moso bamboos. The preparation method comprises the following steps: firstly, crushing biomass raw material moso bamboos into powder, and carrying out screening and drying; secondly, uniformly mixing the crushed moso bamboo raw material, ferric sulfate and ultrapure water, carrying out hydrothermal treatment, naturally cooling to room temperature after the reaction is finished, carrying out suction filtration, washing with absolute ethyl alcohol and ultrapure water to remove impurities, and drying to obtain the iron-modified carbon microsphere / carbon nanosheet composite hydrothermal carbon; and mixing the composite hydrothermal carbon with an activating agent, fully grinding the mixture in a mortar, putting the powder into a tubular furnace, performing high-temperature activation in an inert gas atmosphere, naturally cooling toroom temperature, and performing acid washing, water washing and drying on the obtained material to obtain the iron-modified carbon microsphere / carbon nanosheet composite porous carbon for the supercapacitor. The iron-modified carbon microsphere / carbon nanosheet composite porous carbon prepared by the method has unique morphology, and has a wide application prospect in the fields of porous materials and supercapacitors.

Owner:ZHEJIANG UNIV

Lithium iron phosphate/graphene composite lithium battery positive electrode material with porous structure

InactiveCN107845792AImprove conductivityImproved magnification performanceCell electrodesSecondary cellsLithium iron phosphateFast charging

The invention belongs to the technical field of a lithium battery, and particularly relates to a lithium iron phosphate / graphene composite lithium battery positive electrode material with a porous structure. The positive electrode material has a core-shell structure, wherein the core structure is made of lithium iron phosphate; the shell structure is made of graphene; in addition, hole structuresare formed in the graphene; the hole diameter of the hole structures is 5nm to 100nm; the specific surface area of the positive electrode material is 30 to 300 m<2> / g. Compared with the prior art, thepositive electrode material provided by the invention has the core shell structure, wherein the core structure is made of lithium iron phosphate; the shell structure is made of graphene; in addition,the hole structures are formed in the graphene; through the addition of the graphene, the conductivity of the lithium iron phosphate materials is improved; in the preparation process, ferric ions arereduced into ferrous; partial carbons in graphene sheet layers are used as reducing agents to be consumed, so that holes through which lithium ions can pass are formed in the surface; the rate capability and fast charging and discharging capability of the lithium iron phosphate material are improved.

Owner:深圳市毓丰新材料有限公司

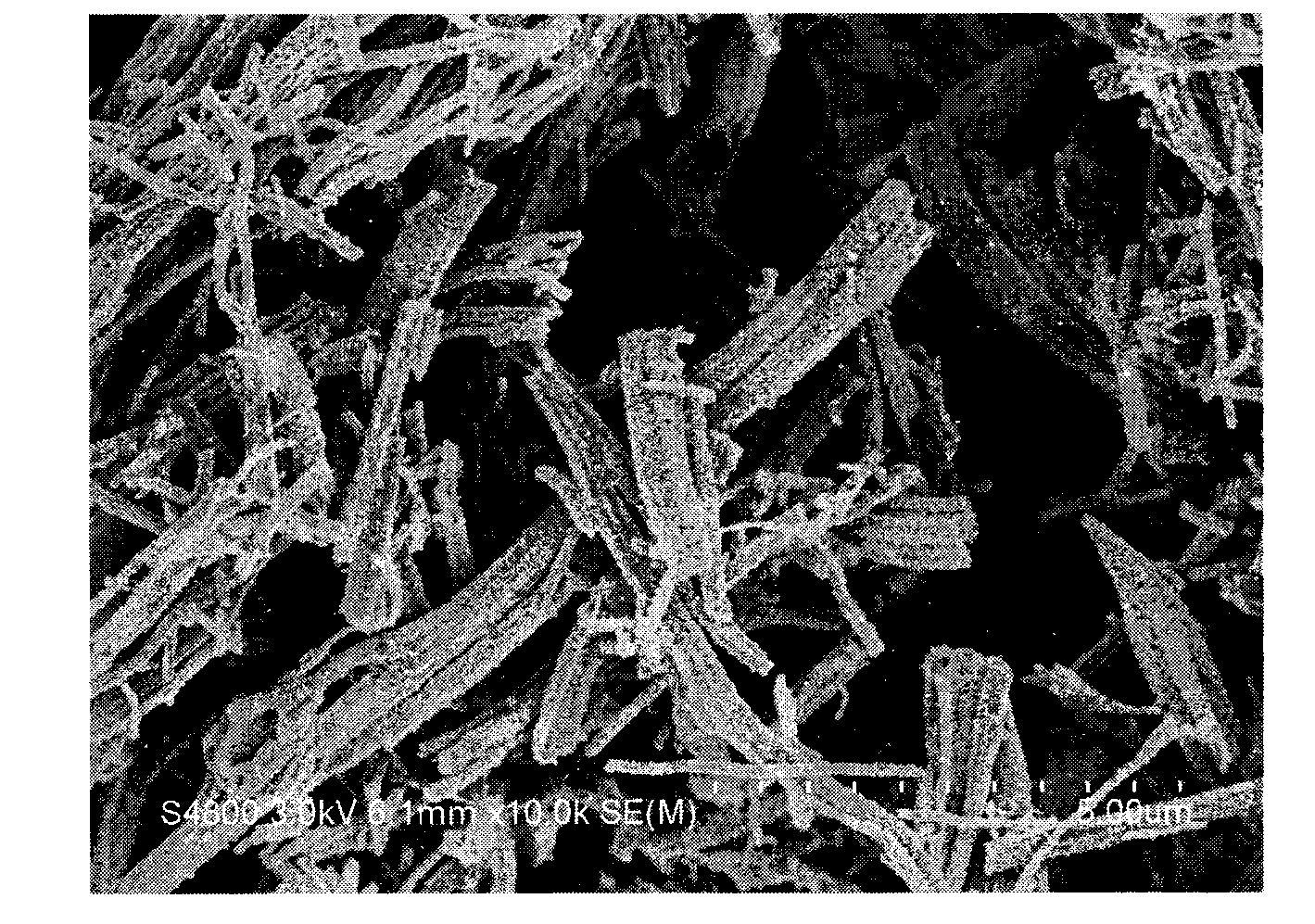

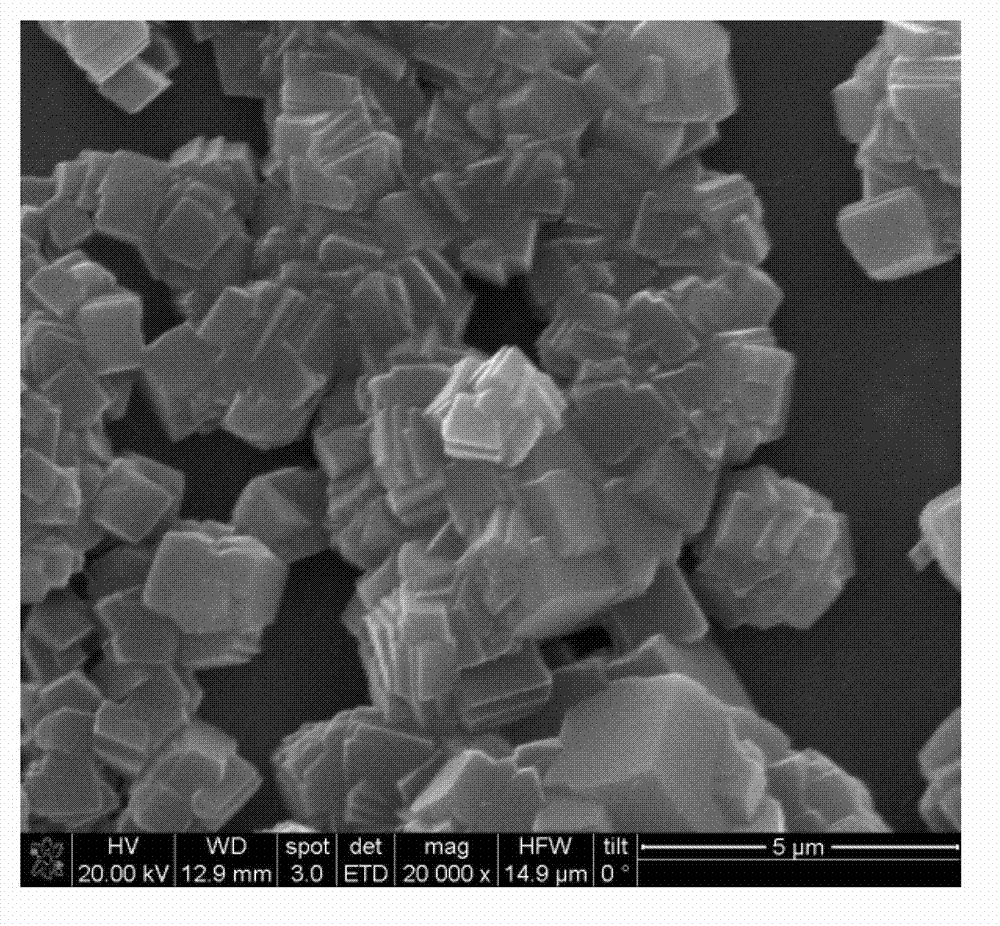

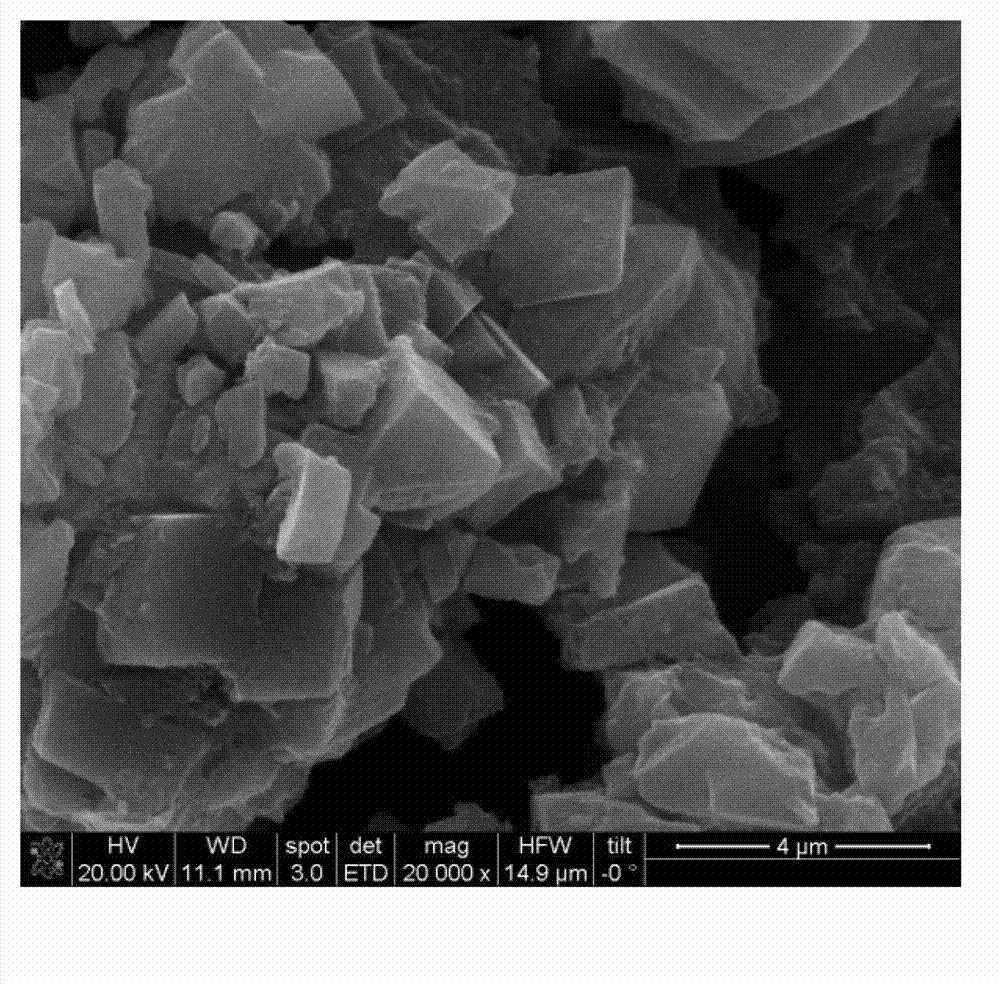

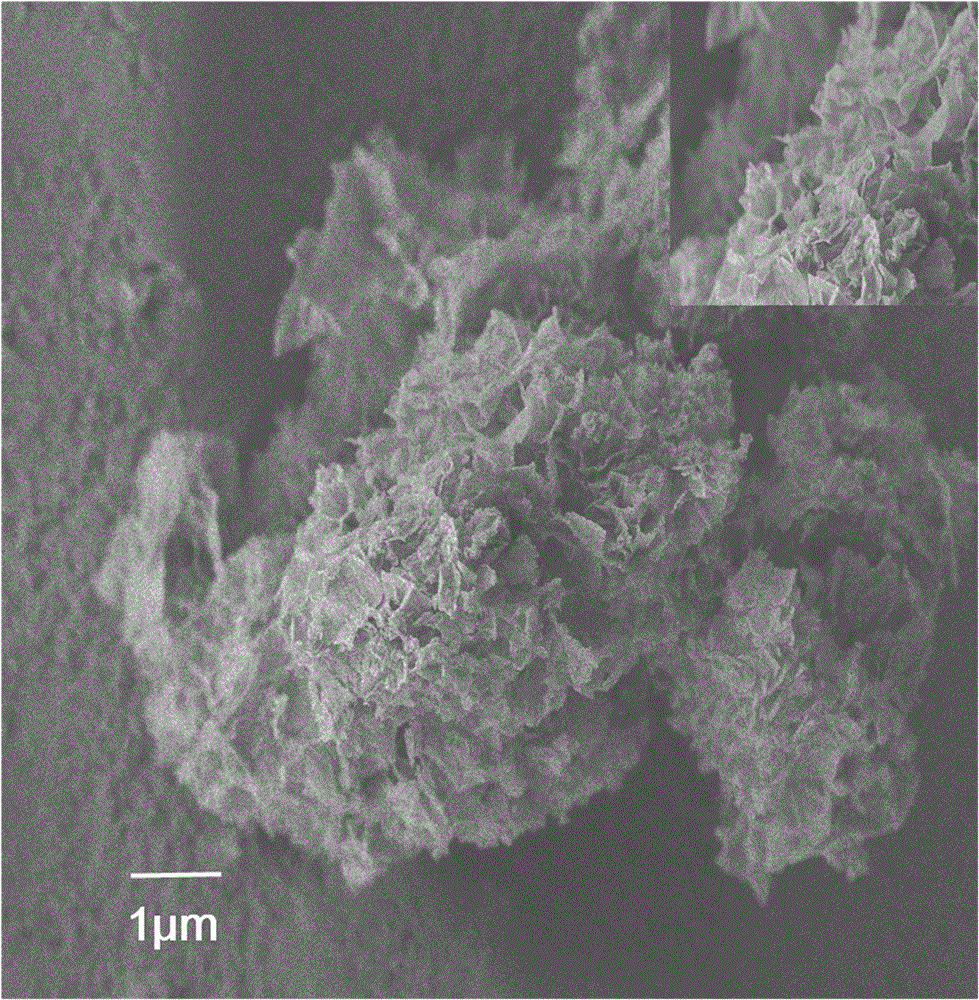

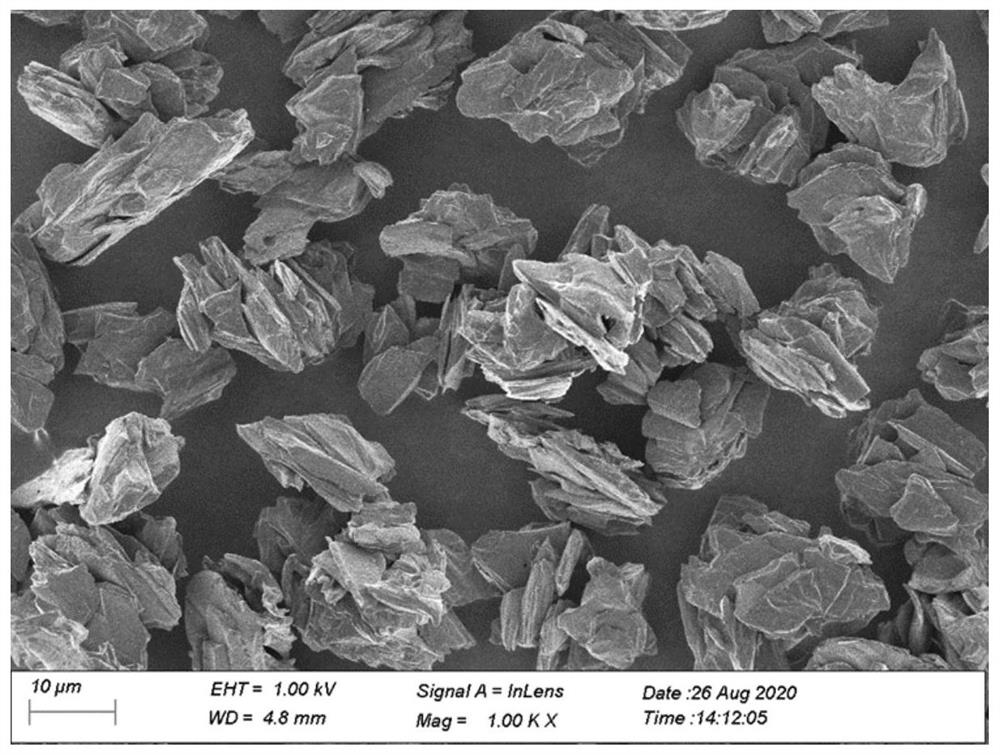

Tremelliform ferric phosphate and preparation method therefor

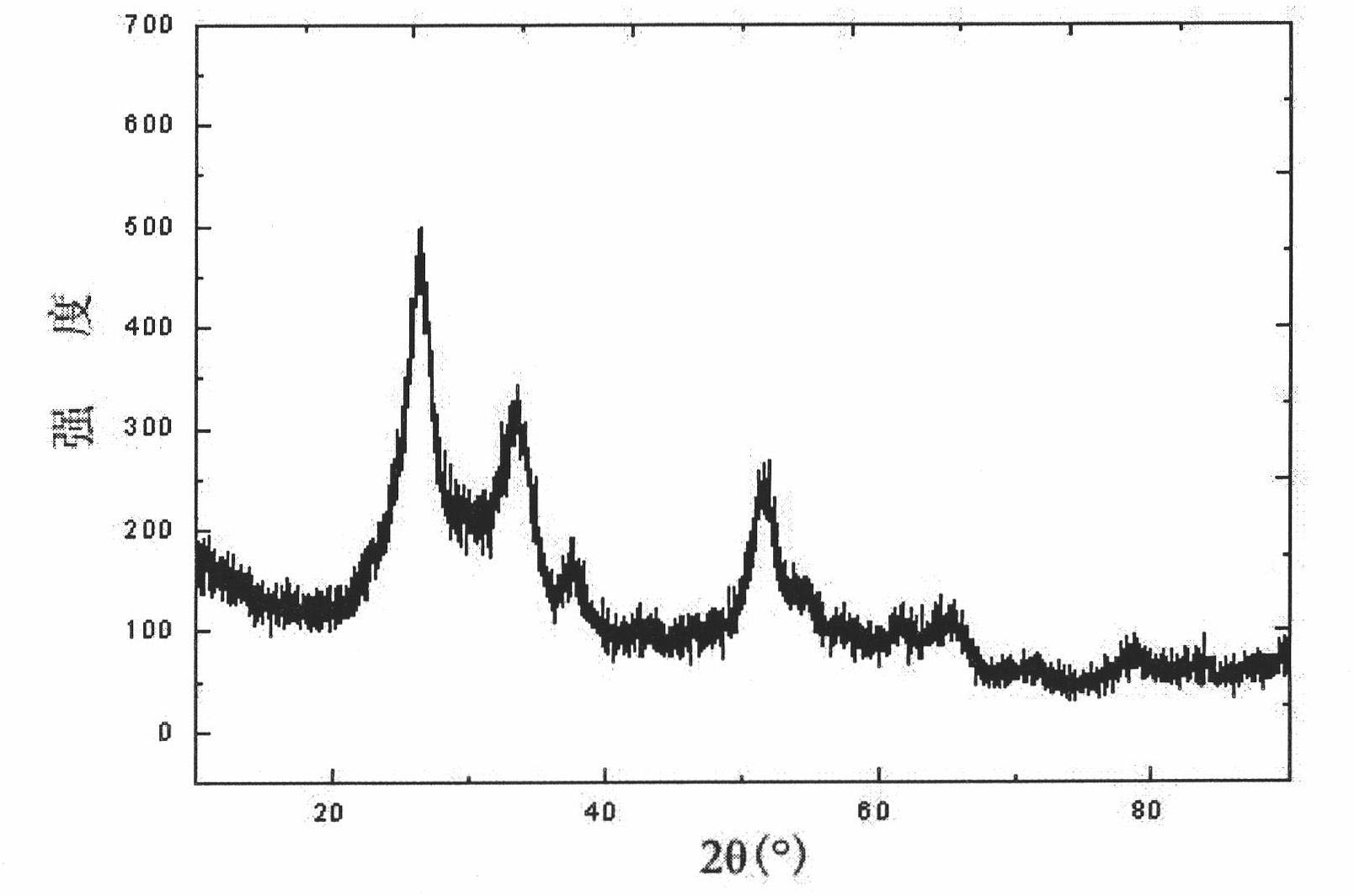

ActiveCN105417517AFast charge and discharge performanceRaise the ratioMaterial nanotechnologyCell electrodesPhosphatePhosphoric acid

The invention relates to tremelliform ferric phosphate and a preparation method therefor. The method comprises the steps: (1) preparing an iron source micellar solution; (2) preparing a metal-ion-free phosphorus source solution; (3) mixing the iron source micellar solution and the metal-ion-free phosphorus source solution; (4) carrying out hydrothermal reaction; and (5) carrying out centrifugal washing and product drying. According to ferric phosphate prepared by the method, nanosheets grow in order so as to form multi-dimensional tremelliform, the cycle and rate capability are excellent, and the low-temperature properties are good. According to the method, impurities such as other cations are not introduced, so that the purity is high, and the stoichiometric ratio is good.

Owner:SHANDONG GOLDENCELL ELECTRONICS TECH

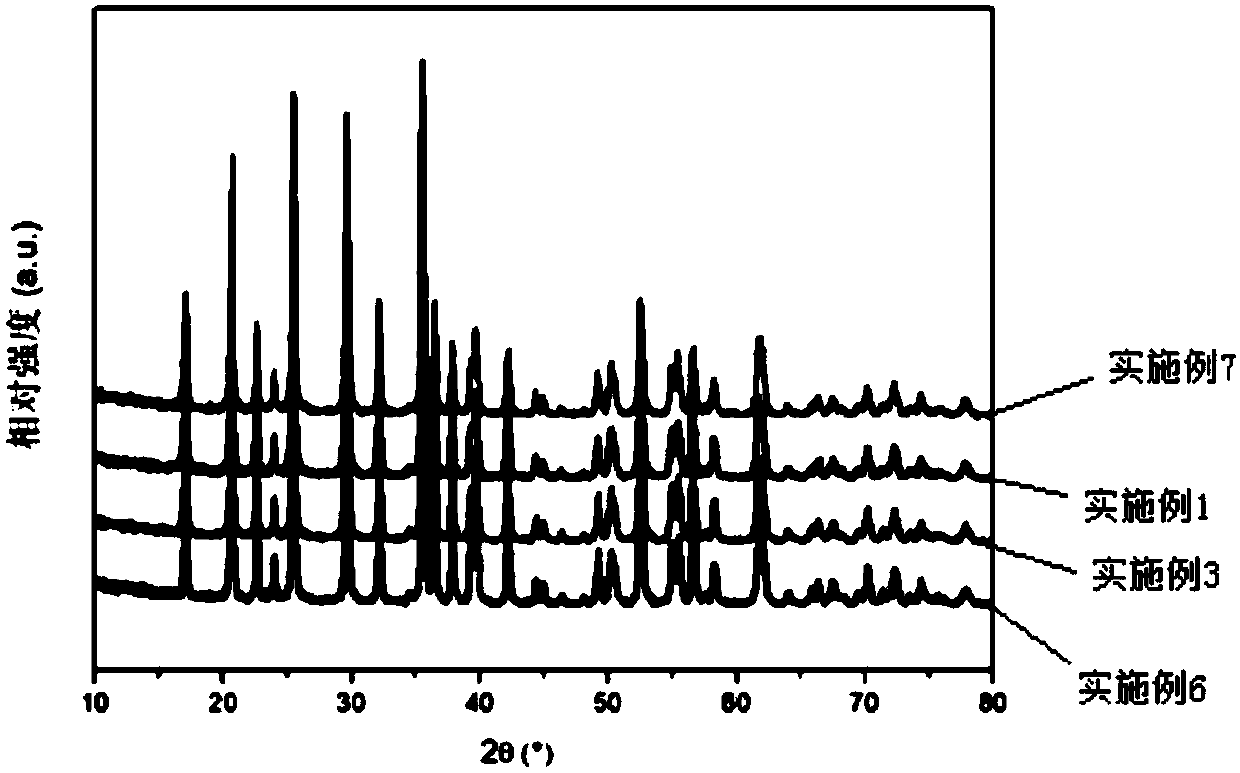

Rare earth doped lithium titanate electrode material and preparation method thereof

ActiveCN109742387AImproved magnification performanceImprove cycle stabilityElectrode manufacturing processesSecondary cellsLithium carbonateRare earth

The invention belongs to the technical field of electrode materials, and particularly relates to a rare earth doped lithium titanate electrode material and a preparation method thereof. The preparation method for the rare earth doped lithium titanate electrode material comprises the following steps that: firstly, mixing titanium dioxide, lithium carbonate, rare earth compound and carbohydrate in solvent to prepare slurry; drying the slurry; under an inert atmosphere, a reduction atmosphere or a vacuum atmosphere, carrying out first-stage calcination; and under an oxidization atmosphere, carrying out second-stage calcination to prepare the rare earth doped lithium titanate electrode material. The rare earth doped lithium titanate electrode material prepared with the preparation method has excellent characteristics, including high multiplying power performance, good cycling stability, quick charging and discharging capability and the like. In addition, the preparation method is simple and can carry out batch preparation.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

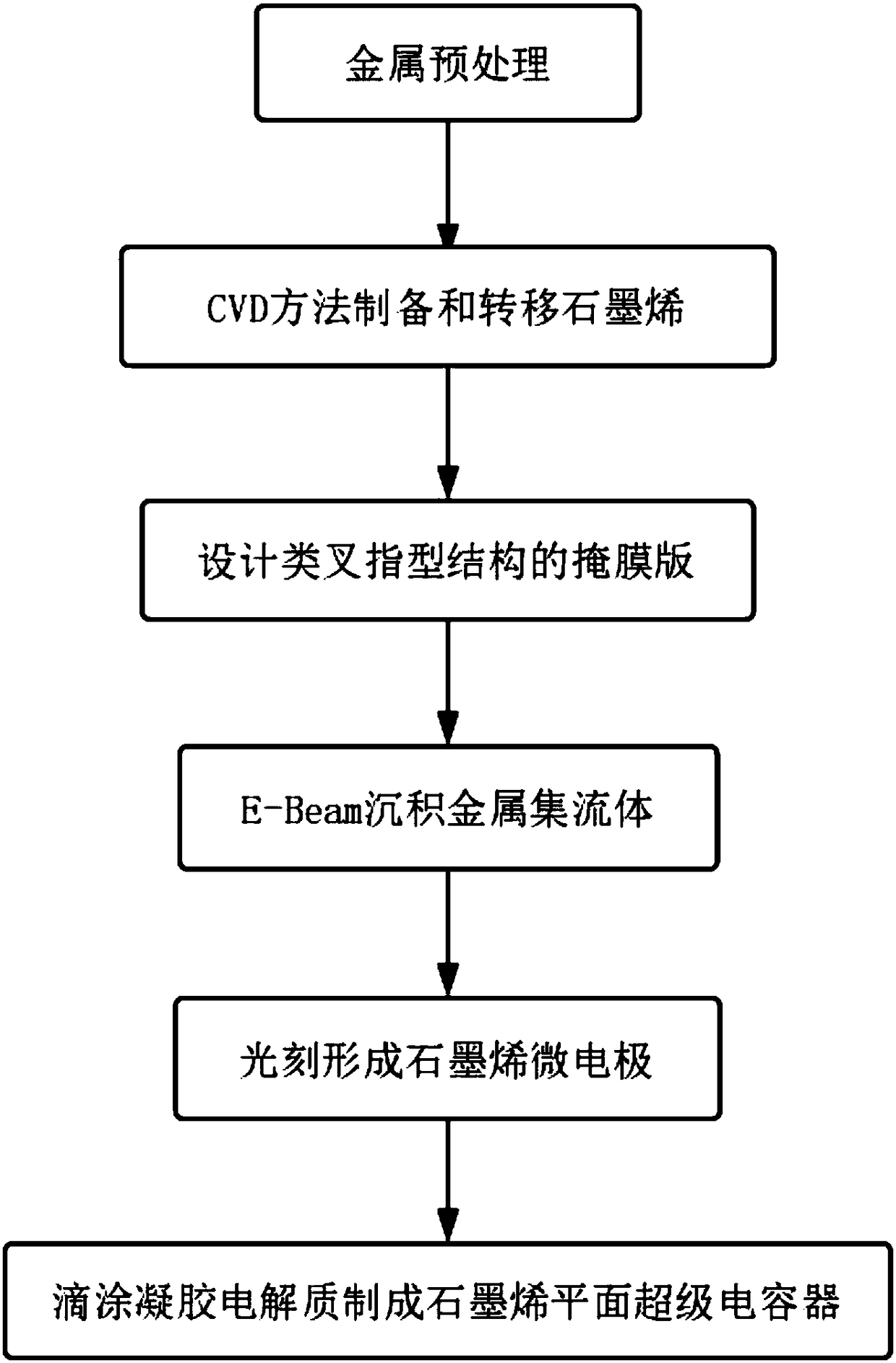

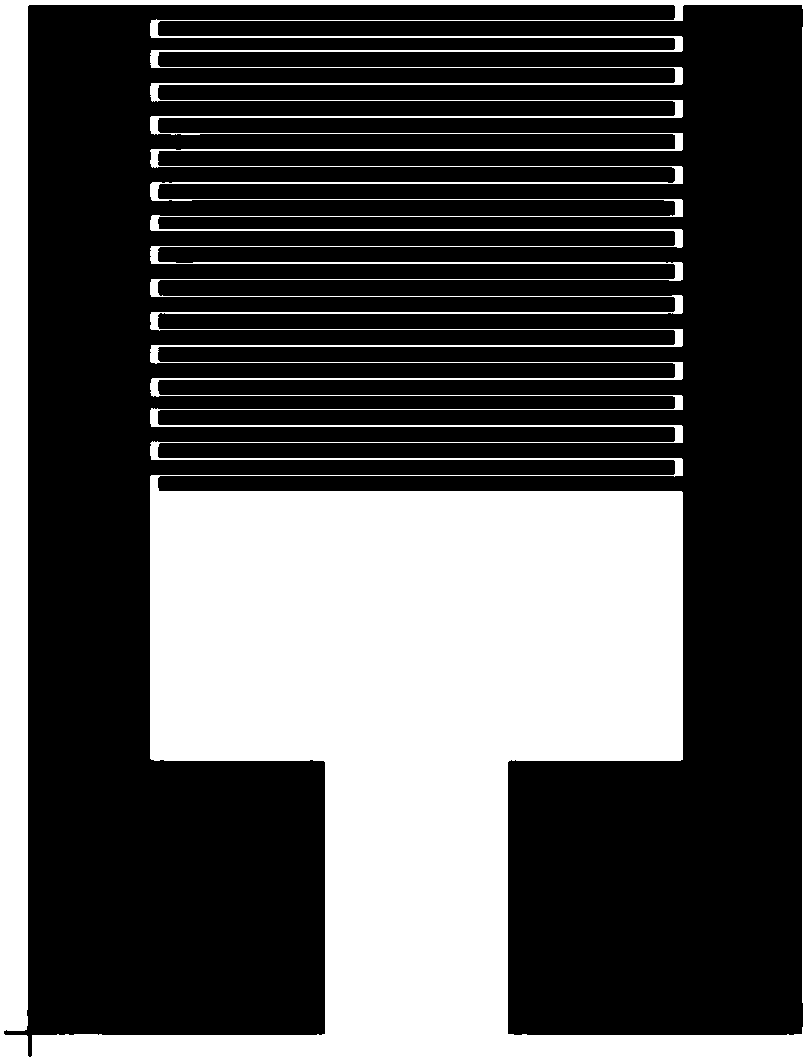

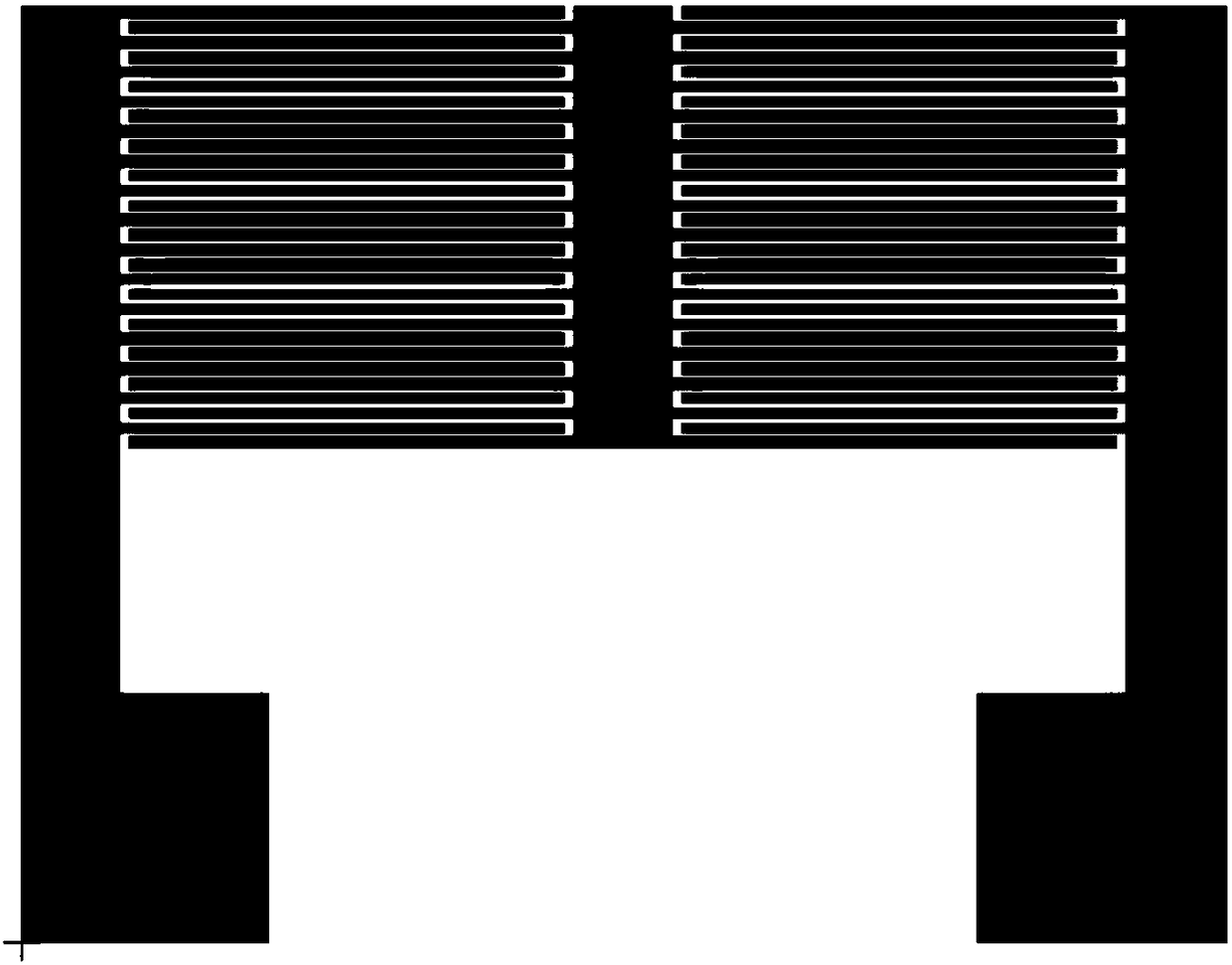

Preparation method of CVD graphene planar miniature supercapacitor

InactiveCN108511207AImprove performanceQuick contactHybrid capacitor electrodesHybrid/EDL manufacturePolymethyl methacrylateCatalytic metal

The invention discloses a preparation method of a CVD graphene planar miniature supercapacitor, for mainly solving the problem that the traditional supercapacitor is large in size, small in effectivecontact area between electrolyte and electrode and blocked in charge transmission. The implementation scheme of the preparation method comprises the steps of preprocessing catalytic metal; growing graphene on the preprocessed metal by using a CVD method, and using polymethyl methacrylate to transfer the graphene on a target substrate; designing a quasi-interdigital photoetching mask; using E-Beamequipment to deposit a metal current collector; producing a graphene microelectrode by using a photoetching technology; and dripping and coating gel electrolyte on the surface of the graphene microelectrode to produce the graphene planar miniature supercapacitor. The graphene planar miniature supercapacitor prepared by the method provided by the invention is small in size, high in integration andflexibility degree, the transportation distance of the transferring charge is shortened, the utilization area of the electrode material is improved, the blockage of the transferring charge in transportation is reduced, the frequency response is increased, and the graphene planar miniature supercapacitor can be applied to wearable equipment.

Owner:XIDIAN UNIV

Lithium manganese phosphate composite material as well as preparation method and application thereof

InactiveCN109742340AUniform particle sizeStable structureMaterial nanotechnologyCell electrodesPhosphateLithium hydroxide

The invention discloses a preparation method of a lithium manganese phosphate composite material; the preparation method comprises the following steps of dissolving manganese sulfate monohydrate and ferrous sulfate heptahydrate into deionized water, then adding ethylene glycol to stir to obtain a mixed solution; dropwise adding an ethylene glycol phosphate solution into a lithium hydroxide ethylene glycol solution for stirring, then dropwise adding the mixed solution, stirring, and carrying out hydrothermal reaction, and drying to obtain a LiMn0.5Fe0.5PO4 precursor; sequentially dissolving lithium hydroxide, tetrabutyl titanate and lanthanum nitrate into absolute ethyl alcohol for stirring, then adding deionized water, and then adding the LiMn0.5Fe0.5PO4 precursor for stirring, carrying out hydrothermal reaction and drying to obtain a Li0.3La0.56TiO3-LiMn0.5Fe0.5PO4 precursor; and enabling the Li0.3La0.56TiO3-LiMn0.5Fe0.5PO4 precursor to be mixed with glucose, and performing ball milling, calcining, cooling and sieving to obtain the lithium manganese phosphate composite material. The lithium manganese iron phosphate composite material is relatively small in particle size, uniform in particle size distribution, and high in degree of crystallinity, so that the electrochemical performance of the material is improved while the material preparation cost is lowered.

Owner:NANJING GUOXUAN BATTERY CO LTD

Graphene-based quasi-solid battery based on printing technology

InactiveCN106532110AWide choiceEasy to manufactureElectrode manufacturing processesSecondary cellsSolid-state batteryCurrent collector

The invention relates to a graphene-based quasi-solid battery based on a printing technology, and belongs to the technical field of a chemical power supply. The graphene-based quasi-solid battery based on the printing technology is characterized in that positive electrode ink is prepared from a functional graphene material, a positive electrode is obtained through printing on a positive electrode current collector by an ink printing method, a solid electrolyte film is obtained by a coating method, a negative electrode material is pressed on a negative electrode current collector to obtain a negative electrode, a surface of the positive electrode is coated with a liquid-state electrolyte, and the quasi-solid battery is obtained by combining the solid electrolyte film and the negative electrode. On the basis of high safety, the battery has rapid charge-discharge performance; moreover, patterned battery fabrication can be performed by a printing mode, the graphene-based quasi-solid battery has the advantages of high thickness controllability, low material waste and the like, and patterning preparation can be achieved.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST

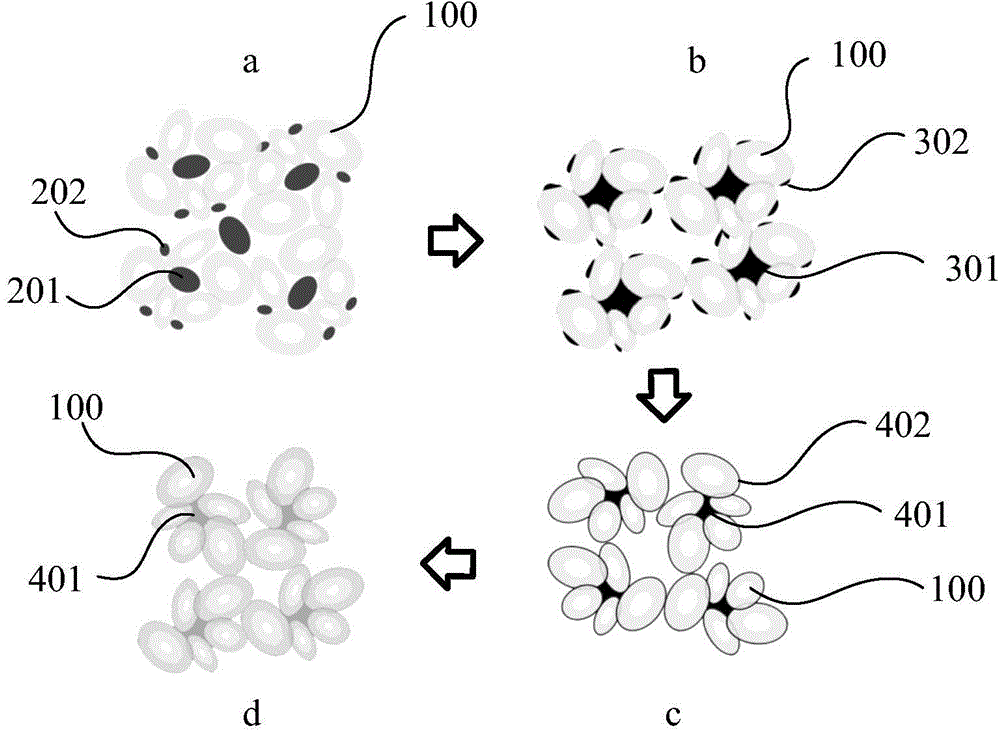

Composite graphite negative electrode material, preparation method and application thereof, and lithium ion battery

ActiveCN112661148AFast charge and discharge performanceVibration highGraphiteCell electrodesGraphiteLithium-ion battery

The invention discloses a composite graphite negative electrode material, a preparation method and application thereof, and a lithium ion battery. The method comprises the following steps: (1) carrying out graphitization treatment, asphalt coating treatment and carbonization treatment on needle coke kiln front powder to obtain first particles; (2) performing asphalt coating treatment, crushing de-polymerization treatment and graphitization treatment on petroleum coke to obtain second particles; and (3) blending the first particles and the second particles; wherein the mass ratio of the first particles to the second particles is 1: (1-4); and the step (1) and the step (2) are not performed in sequence. The composite graphite negative electrode material prepared by the invention comprises two particle structures, has the characteristics of high-rate quick charge-discharge capacity and high tap density of the first particle structure, also has the characteristic of high capacity of the second particle structure, and can be applied to a power lithium battery of a passenger vehicle. Furthermore, the adopted needle coke kiln front powder and coal pitch are low in price, so that the production cost is saved.

Owner:NINGBO SHANSHAN NEW MATERIAL TECH

Preparation method of multilevel structure titanate negative electrode material for lithium ion battery

ActiveCN107749471AStable structureEvenly dispersedMaterial nanotechnologyCell electrodesMuffle furnaceCarbon nanotube

The invention discloses a preparation method of a multilevel structure titanate negative electrode material for a lithium ion battery, and belongs to the technical field of lithium ion batteries. Themethod concretely comprises the following steps: dispersing a sodium source and a titanium source in a glycol and anhydrous ethanol mixed solution to form a solution A; dissolving a barium source in an aqueous solution of anhydrous ethanol to form a solution B; mixing and stirring the solution A and the solution B, heating the obtained solution until evaporative drying is achieved, placing the obtained precursor in a muffle furnace, and carrying out pre-calcining, ball milling and calcining to obtain a BaNa2Ti6O14 material; dispersing the material in an acetone solution, adding carbon nano-tubes, and stirring and heating the obtained solution until the solution is completely volatilized in order to obtain BaNa2Ti6O14-CNT; and carrying out mixing and ball-milling on the BaNa2Ti6O14-CNT andcarbon fibers, and sintering the obtained mixture in nitrogen to obtain the target product. The titanate negative electrode material obtained in the invention has a stable multilevel composite structure, so the titanate negative electrode material has the advantages of considerable wide potential window reversible capacity, excellent rate performances and stable cycle life.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com