Negative active material and preparation method and application thereof

A negative electrode active material and carbon-based material technology, applied in the field of electrochemistry, can solve the problems of limiting the capacity and power performance of lithium-ion batteries, low volume specific capacity, and low tap density, and achieve battery capacity that is not easily attenuated and has high battery capacity , long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

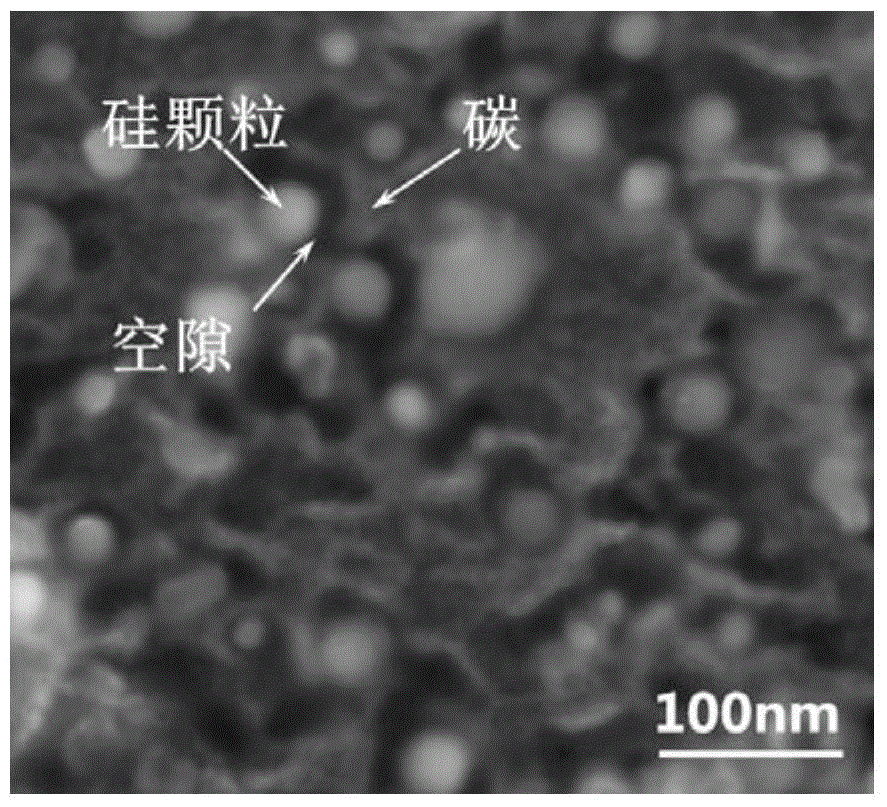

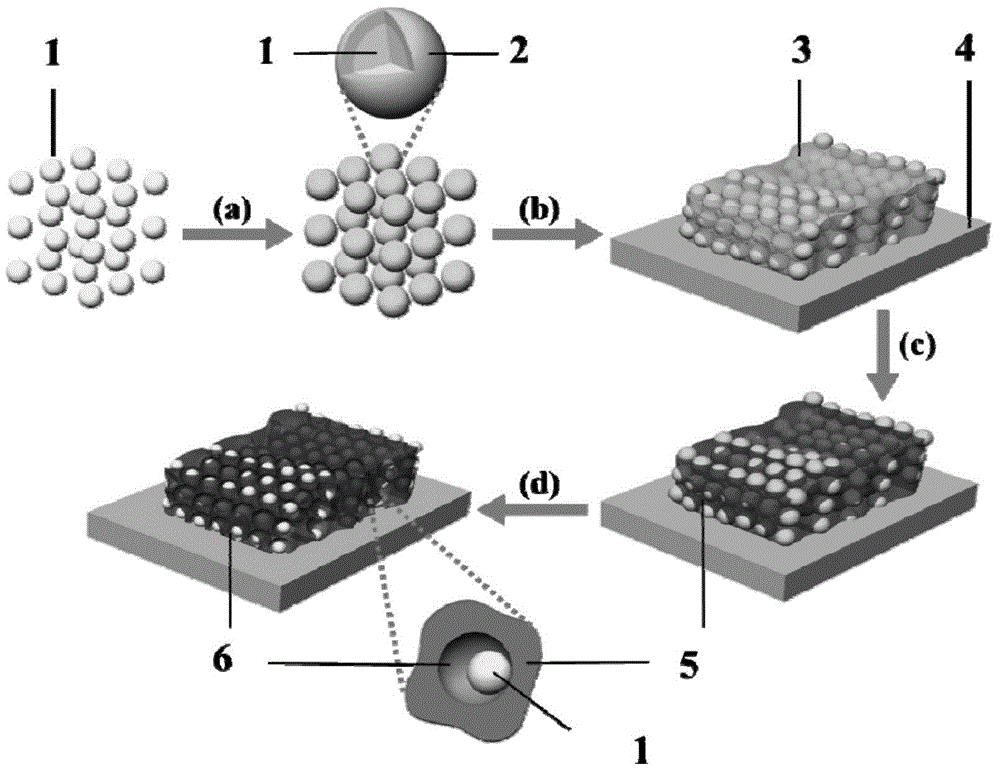

[0056] The process of preparing negative electrode active materials by template method, such as figure 2 As mentioned, the specific method is as follows:

[0057] (a) Ultrasonically disperse 1.5g of silicon particles with an average particle size of 30-50nm in a system of 200mL of ethanol and 50mL of water, then add 10mL of 28%-30% ammonia water, and add 13.5g of tetraethyl orthosilicate (TEOS) dropwise , continuously stirred for 12 hours, hydrolyzed and oxidized on the surface of silicon particles to generate SiO 2 Layer, centrifuged and washed repeatedly to obtain composite particles;

[0058] (b) Mix the above-mentioned composite particles with 13.5g SU-8 photoresist evenly, and spin-coat on the silicon wafer;

[0059] (c) at 900°C, N 2 Carry out high-temperature carbonization of the material in the environment, and the SU-8 photoresist becomes a self-supporting porous carbon skeleton;

[0060] (d) The obtained material is immersed in 4wt% HF, 46wt% water, 50wt% ethano...

Embodiment 2

[0066] Utilize the negative electrode active material prepared in embodiment 1 to prepare button type half battery, concrete processing method is as follows:

[0067] (1) Get the negative electrode active material of silicon content 35% that the embodiment 1 of 4g prepares as active material, 0.5gSuperP is as conductive agent, 0.5g carboxymethyl cellulose (CMC) is as binding agent, is coated on after being dispersed uniformly placed on a copper foil and dried overnight in a vacuum oven at 80°C.

[0068] (2) the product that step (1) obtains at 100kg / cm 2 Down punched into pieces.

[0069] (3) The products stamped into sheets in step (2) are assembled in the glove box as image 3 The shown CR2025 button battery 1, wherein the above-mentioned material is used as the negative electrode, the lithium disc is used as the positive electrode, and the Celgard film is used as the diaphragm, 1mol / LLiPF 6 Mix solution with EC:DEC:DMC (volume ratio 1:1:1) as electrolyte.

[0070] Accor...

Embodiment 3

[0072] The CR2025 button battery obtained in Example 2 was electrochemically tested on a lithium battery charging and discharging system.

[0073] 1. Charge and discharge experiment

[0074] The button battery 1 with a silicon content of 35% obtained in Example 2 is subjected to a charge and discharge test, as follows:

[0075] (1) Test method

[0076] At room temperature, the button battery 1 was tested on a battery testing system (Newwell, CT-3008W).

[0077] Before the test, the battery needs to be aged for 24 hours to allow the electrolyte to fully infiltrate the electrode material.

[0078] The charge cut-off voltage is set to 1.2V, and the discharge cut-off voltage is set to 0.01V.

[0079] The first three cycles are charged and discharged with a small 0.1C rate (current 0.2mA), and the current is increased by 3 times in the subsequent cycle, and the charge and discharge are performed at a rate of 0.3C, that is, a current of 0.6mA. A total of 30 charge and discharge c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com