Preparation method of stannic oxide or metallic tin and grapheme lamella composite material

A technology of graphene sheets and composite materials, which is applied in the direction of electrical components, battery electrodes, circuits, etc., can solve the problems of metal tin particle coating structure, difficult to control product morphology, and low charge and discharge performance of composite materials, and achieve enhanced Conductivity and fast charge-discharge performance, improve structural stability and electrochemical performance, and improve the effect of charge-discharge cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

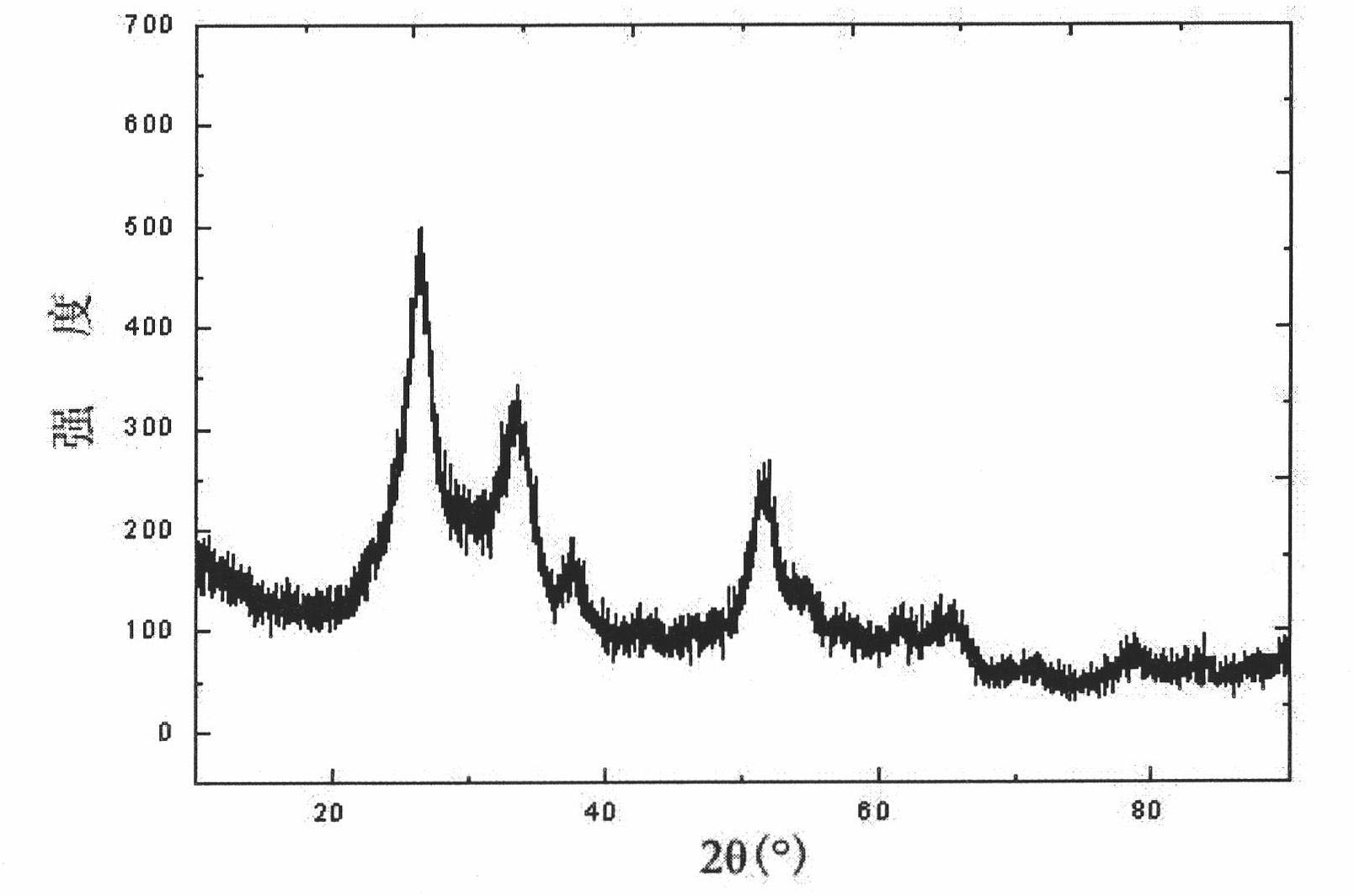

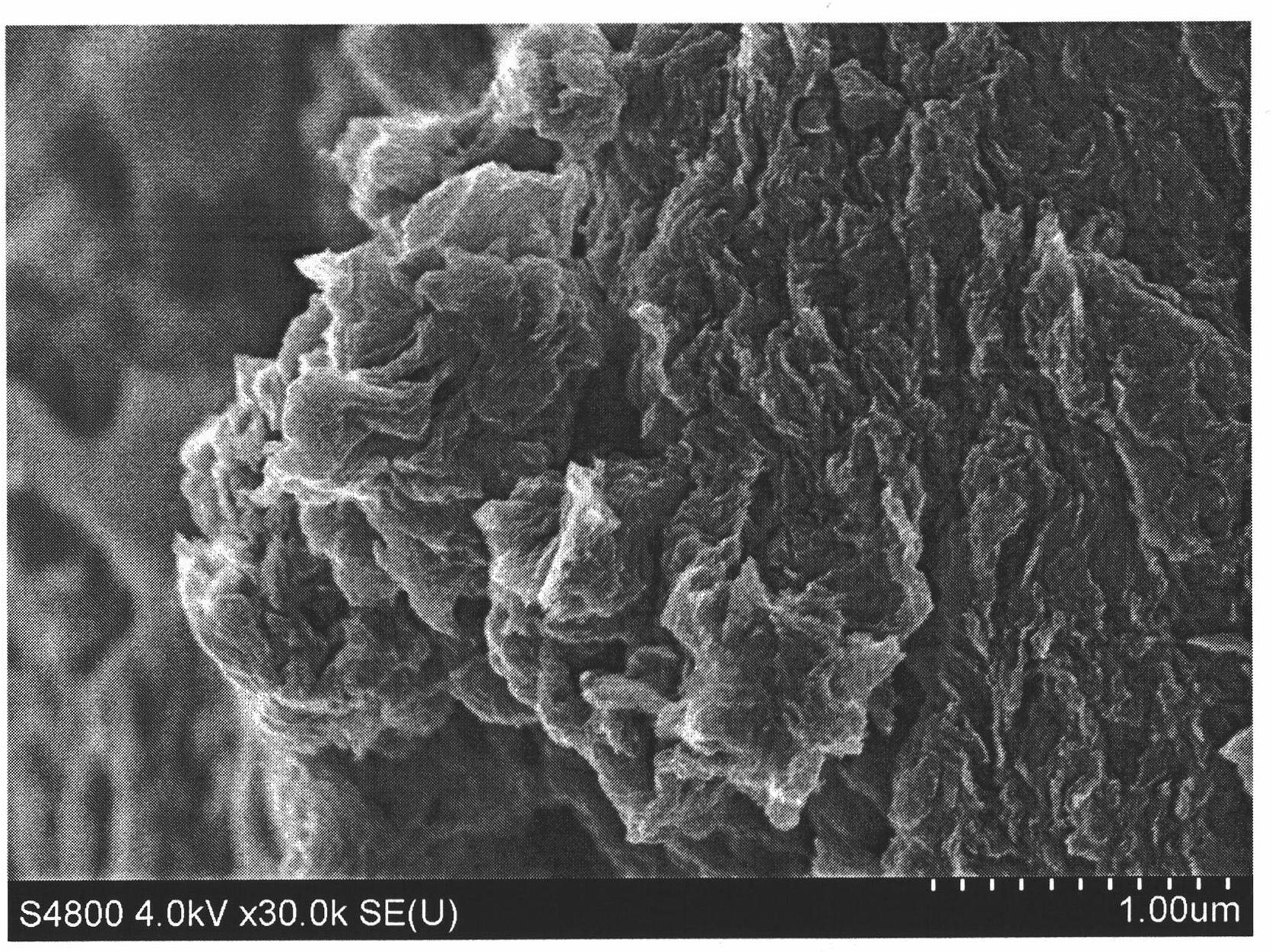

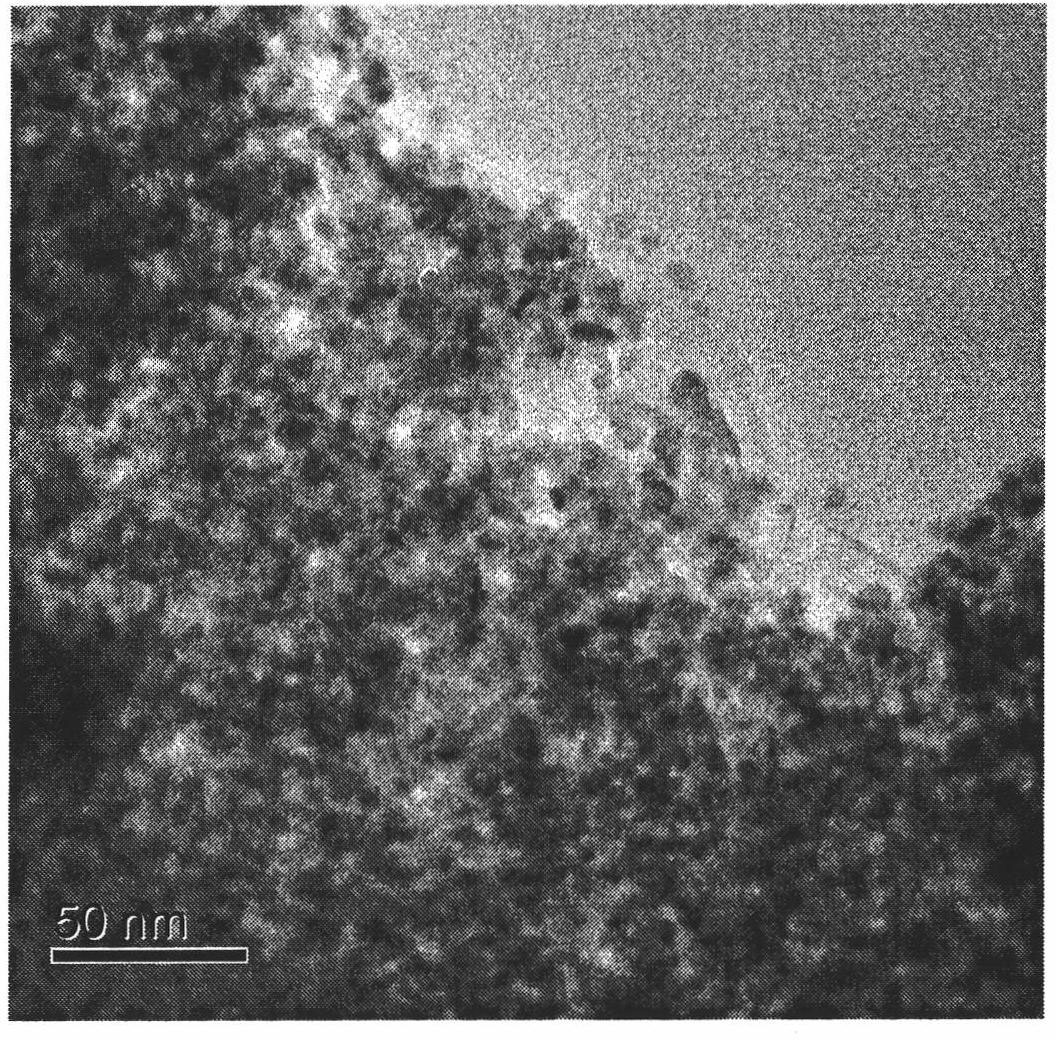

[0030] The invention provides a preparation method of a composite material of tin dioxide and graphene sheet. The method comprises: after mixing organic solvent, graphene oxide sheet hydrosol and tin salt, heating at 60-200°C for 0.5- After 12 hours, a solid substance was obtained; the obtained solid substance was heated at a temperature of 400-700° C. for 0.5-10 hours under the protection of an inert gas. Preferably, after mixing the organic solvent, graphene oxide lamellar hydrosol and tin salt, heat at 120-150°C for 0.5-3h to obtain a solid substance; ℃ temperature heating 0.5-2h.

[0031] According to the preparation method of a tin dioxide and graphene sheet composite material provided by the present invention, the volume ratio of the graphene oxide sheet hydrosol to the organic solvent is 1: 10-50, and the pH of the reaction is 2-6 ; The content of graphene oxide sheet in the graphene oxide sheet hydrosol is 5-20% by weight, and the content of water is 80-95% by weight,...

Embodiment 1

[0042] This embodiment is used to illustrate the preparation method of the tin dioxide and graphene sheet composite material provided by the present invention.

[0043] (1) Preparation of graphene oxide: adding 5.0 g of natural flaky graphite (particle size is 10-100 μm), 4.0 g of sodium nitrate and 20.0 g of permanganate in the concentrated sulfuric acid of 98% by weight to the concentration of 300 g Potassium, the resulting mixture was stirred under 0°C ice bath conditions (that is, the temperature of the mixture was 0°C by means of an ice bath) was stirred for 2h, and then stirred at 30°C for 5h; then 600ml of water was added to the resulting mixture for dilution, Heat up to 90° C. and stir for 0.5 h; add 10 ml of hydrogen peroxide with a concentration of 30% by weight, stir for 30 min and then filter, then centrifuge and wash the obtained filter cake 5 times with hydrochloric acid with a concentration of 3% by weight at a speed of 5000 r / min , and then use deionized water ...

Embodiment 2

[0051] This embodiment is used to illustrate the preparation method of the tin dioxide and graphene sheet composite material provided by the present invention.

[0052] (1) Preparation of graphene oxide: adding 5.0 g of natural flake graphite (10-100 μm in particle size), 5.0 g of sodium nitrate and 25.0 g of permanganate in the concentrated sulfuric acid of 98% by weight to the concentration of 1500 g Potassium, the resulting mixture was stirred at 0°C in an ice bath (that is, the temperature of the mixture was 0°C through an ice bath) for 5 h, and then stirred at 30°C (30°C) for 10 h; then 500 ml of Diluted with water, then heated up to 70°C and stirred for 2h; then added 6ml of hydrogen peroxide with a concentration of 30% by weight, stirred for 60min and filtered, and then the obtained filter cake was treated with hydrochloric acid with a concentration of 10% by weight at 5000r / min Centrifugal washing 5 times at a rotating speed of 5000r / min, followed by centrifugal washin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com