Patents

Literature

46results about How to "Coulombic efficiency is stable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of stannic oxide or metallic tin and grapheme lamella composite material

ActiveCN102255072AImprove structural stabilityImprove electrochemical performanceCell electrodesTin dioxideHYDROSOL

The invention provides a preparation method of a stannic oxide and grapheme lamella composite material. The preparation method comprises the following steps of mixing at least one organic solvents, graphene oxide lamella hydrosol and at least one tin salt, heating the mixture at a temperature of 60 to 200 DEG C for 0.5 to 12 hours to obtain a solid substance, and heating the solid substance in the inert gas atmosphere at a temperature of 400 to 700 DEG C for 0.5 to 10 hours. The invention also provides a preparation method of a metallic tin and grapheme lamella composite material. The preparation method comprises the following step of preparing a stannic oxide and grapheme lamella composite material through the preparation method of a stannic oxide and grapheme lamella composite material, and heating the prepared stannic oxide and grapheme lamella composite material in the reducing gas atmosphere at a temperature of 400 to 1000 DEG C for 0.5 to 4 hours. The preparation methods of the invention can improve a structural stability and an electrochemical performance of a material and is beneficial to improve a high-speed charging and discharging performance and a conductivity of a composite material. The preparation methods have the characteristics of cheap and easily available raw materials, simple process, and good applicability for industrial continuous production.

Owner:陕西埃普诺新能源科技有限公司

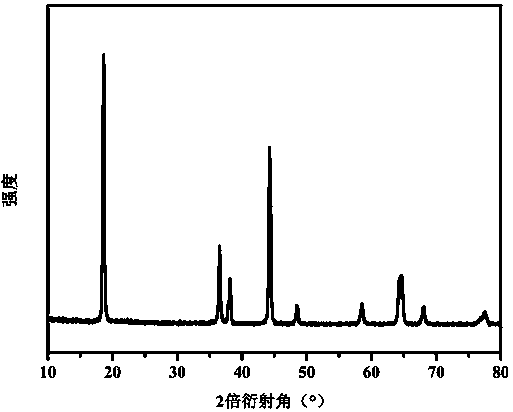

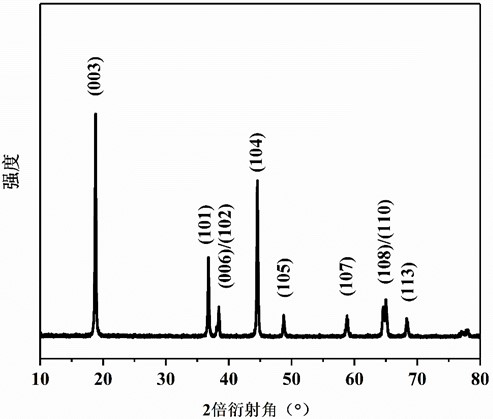

Magnesium ion doped gradient nickel cobalt lithium manganate anode material and preparation method thereof

ActiveCN109686938AUniform size distributionEvenly distributedCell electrodesSecondary cellsManganateReaction temperature

The invention relates to a magnesium ion doped gradient nickel cobalt lithium manganate anode material and a preparation method thereof. The chemical formula of the anode material is LiNixCoyMnzMg (1-x-y-z) O2, wherein x is more than 0.5 and less than 0.9, y is more than 0.05 and less than 0.20, z is more than 0.05 and less than 0.30, and 1-x-y-z is more than 0; the nickel content is gradually reduced from the center to the surface of the anode material particles, the manganese content is gradually increased from the center to the surface of the anode material particles, and the contents of cobalt and magnesium are uniformly distributed in the anode material. The invention also discloses a preparation method of the anode material. The anode material has the advantages that the structure and the cycle performance are stable in the charging and discharging process, the capacity is higher, and the charging and discharging reaction is highly reversible. The method has the advantages of simple process, low reaction temperature and low raw material cost, and is suitable for industrial production.

Owner:CENT SOUTH UNIV

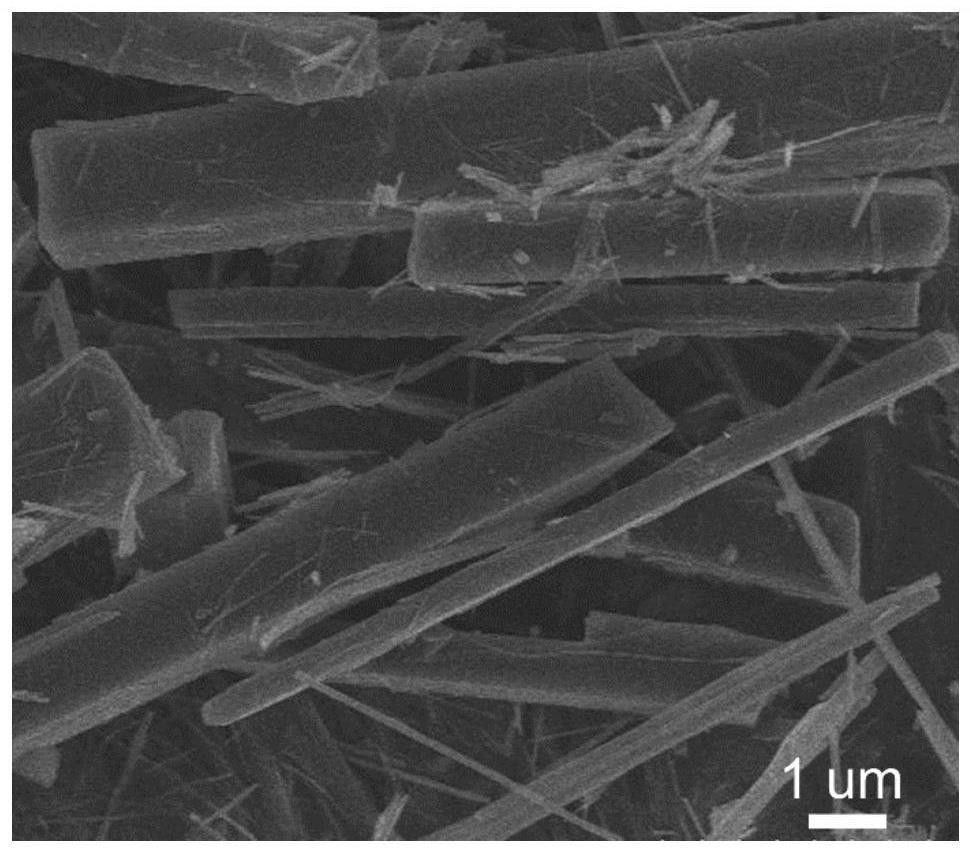

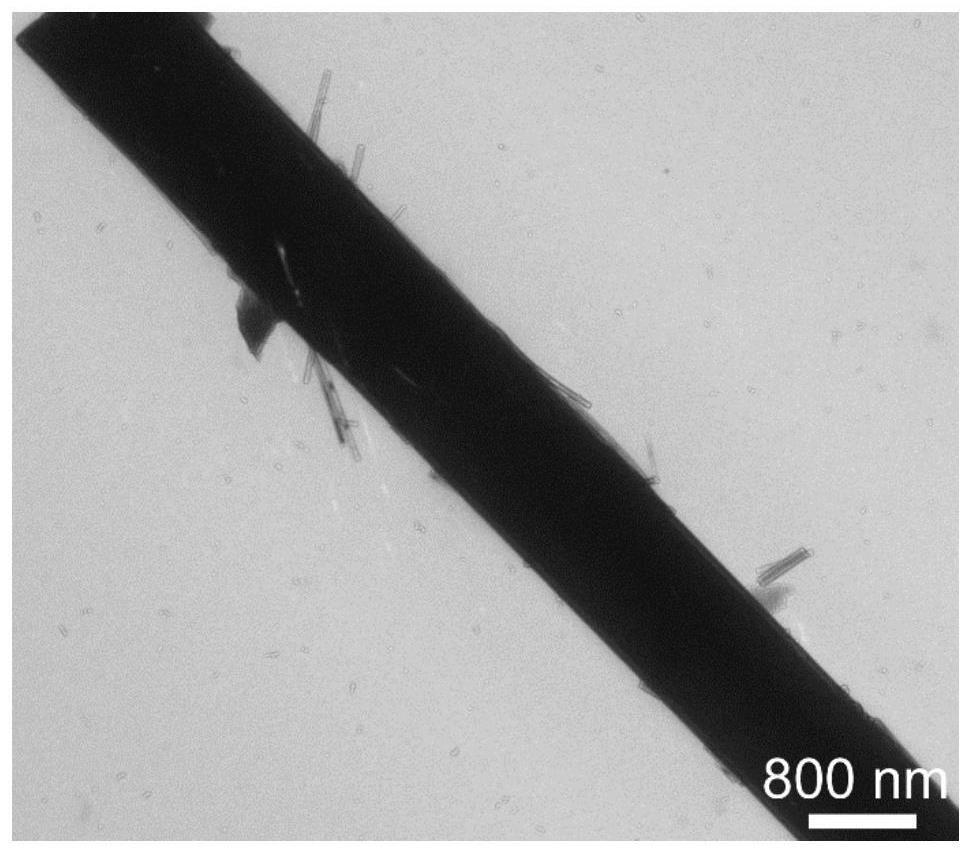

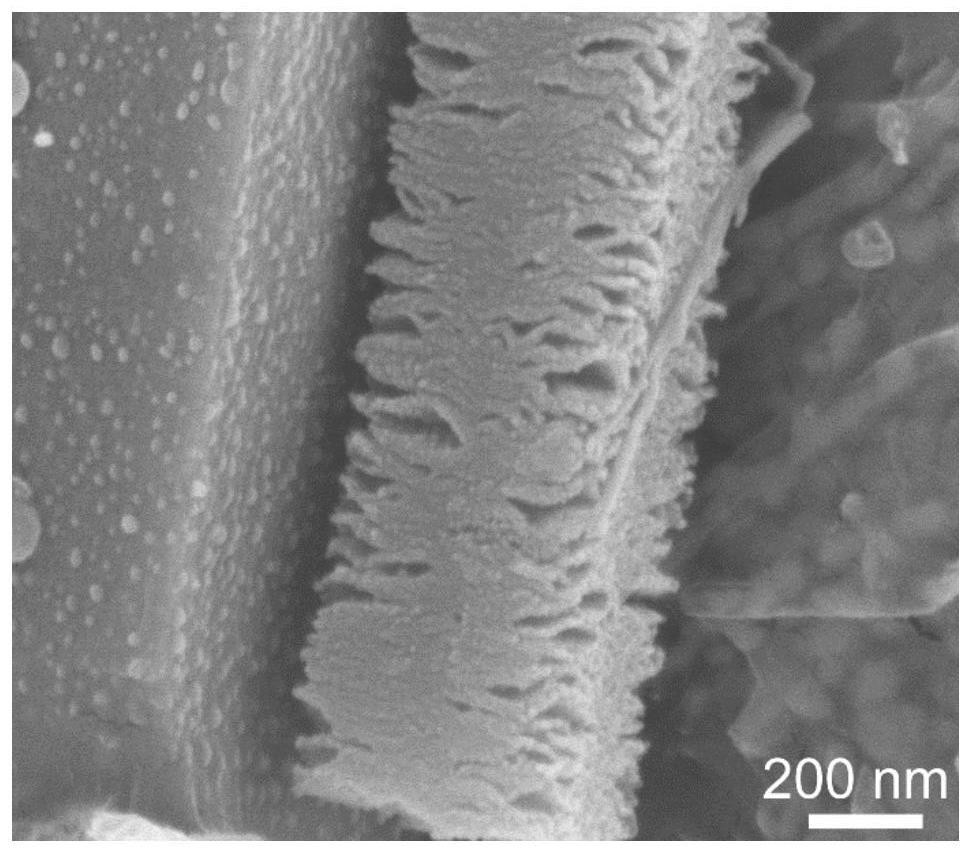

Preparation method of vanadium tetrasulfide/carbon nanotube as negative electrode material for sodium ion battery

InactiveCN109148857AAvoid reunionImprove conductivityNegative electrodesSecondary cellsSulfurCarbon nanotube

A method for preparing a vanadium tetrasulfide / carbon nanotube as a negative electrode material of a sodium ion battery is characterized by comprising the following steps: (1) adding a vanadium sourceinto water, heating and continuously stirring until dissolved, adding a sulfur source, heating and continuously stirring until dissolved to obtain a solution A; 2. Adding multi-wall carbon nanotubesinto water for ultrasonic treatment to obtain a suspension B; 3) adding the solution A into a suspension B, and continuously stirring to obtain a suspension C; 4) heating the suspension C obtained inthe Step 3), carrying out hydrothermal reaction, centrifugal washing and drying to obtain the vanadium tetrasulfide / carbon nanotube as the negative electrode material of a sodium ion battery. The method of the invention is simple in operation and low in cost, and is suitable for industrial production.

Owner:CENT SOUTH UNIV

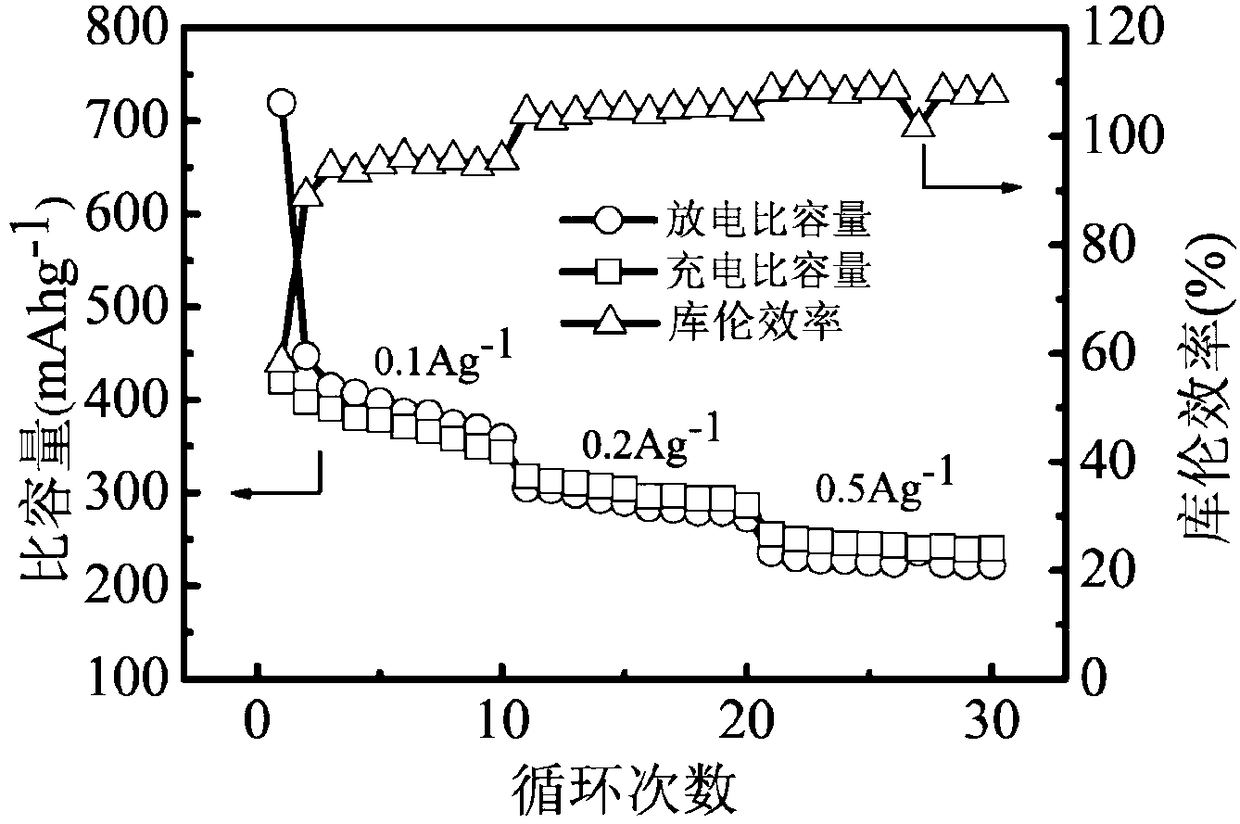

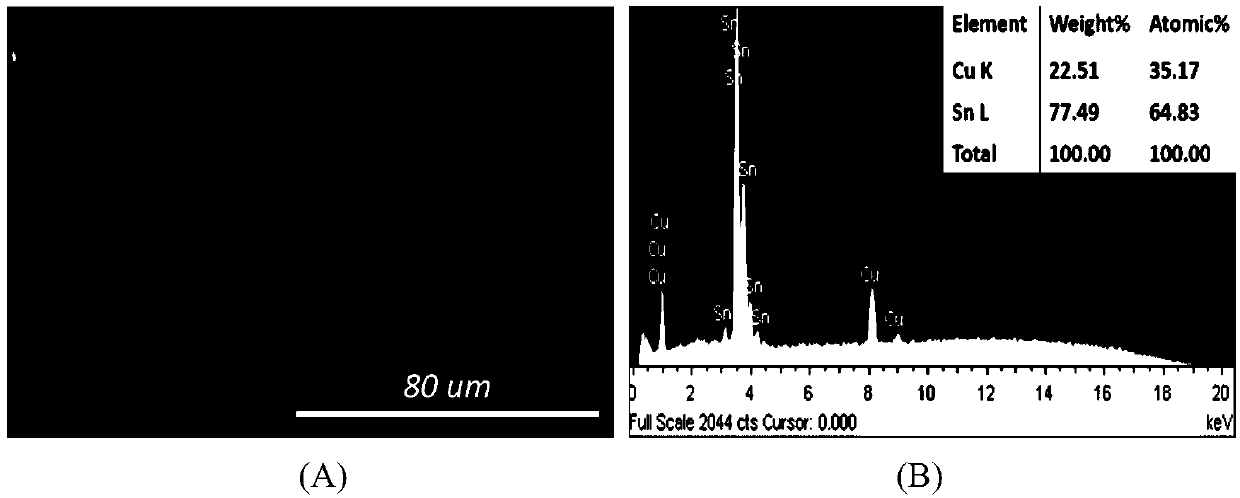

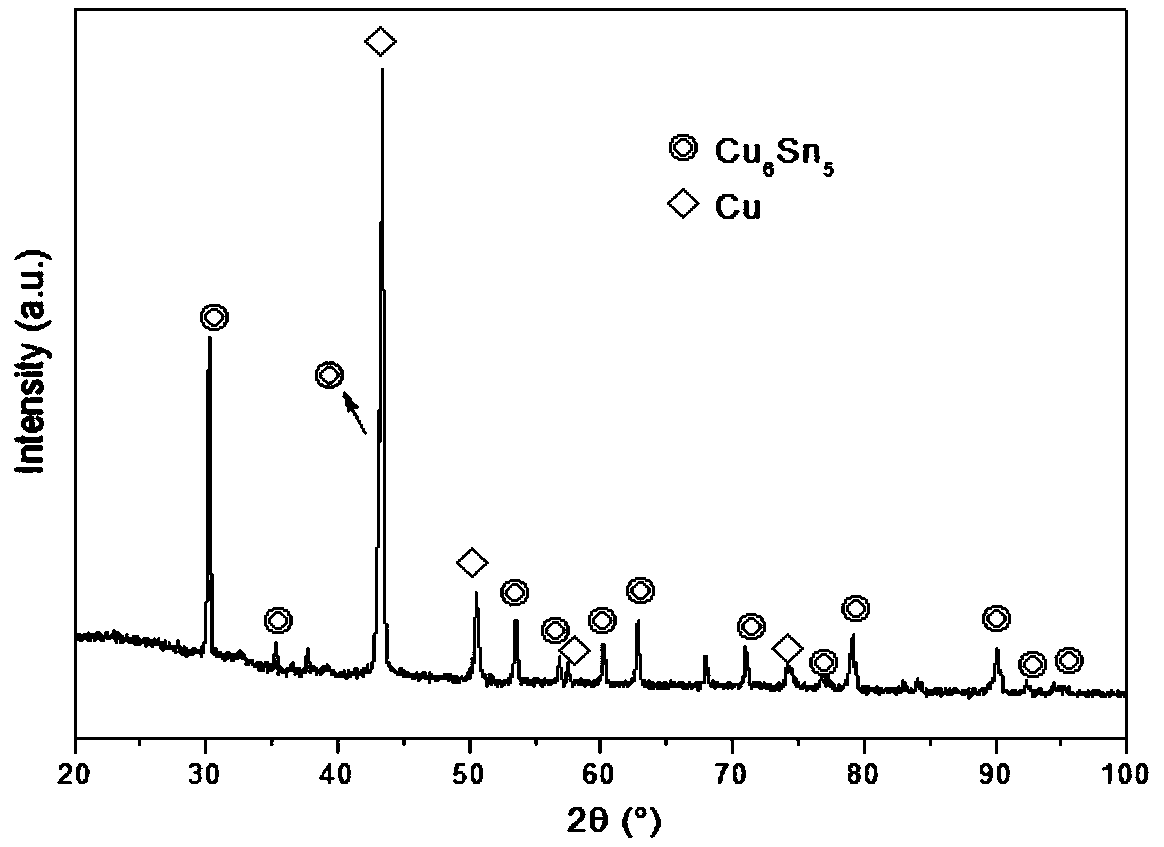

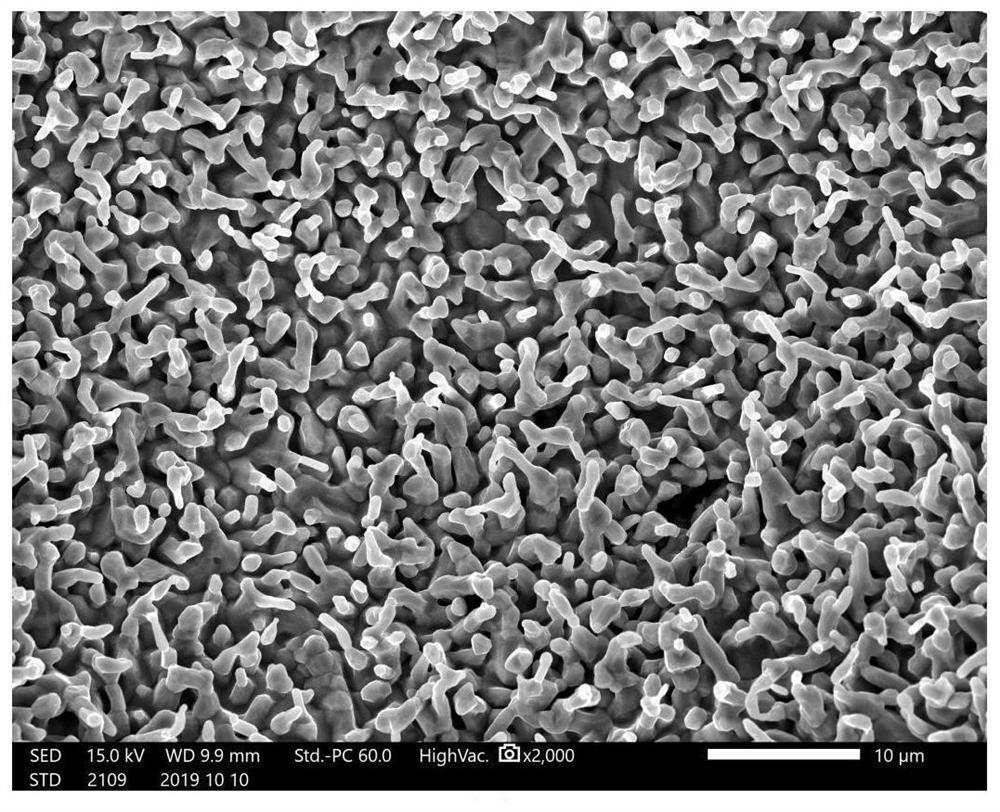

Copper tin alloy-based three-dimensional copper tin compound nanoparticle-microporous copper lithium ion battery cathode and one-step preparation method

ActiveCN109524620ARich nanoporous structureImprove cycle performanceMaterial nanotechnologyNegative electrodesMicro nanoNanoparticle

The invention provides a copper tin alloy-based three-dimensional copper tin compound nanoparticle-microporous copper lithium ion battery cathode and a one-step preparation method. The lithium ion battery cathode is composed of a three-dimensional microporous copper framework with porous walls / pore orientation and copper tin compound nanoparticles. The copper tin compound nanoparticles are Cu6Sn5nanoparticles or mixed particles of Cu6Sn5 nanoparticles and Cu3Sn nanoparticles. The copper tin compound nanoparticles are dispersed and embedded in pore structures of the three-dimensional microporous copper framework with porous walls / pore orientation to form a nanoporous structure so as to finally form a double continuous opened micro-nano graded porous structure. The lithium ion battery cathode provided by the invention can alleviate huge volume change generated in circular lithium embedding and removing processes of the tin cathode material, so that the cyclic performance of the tin cathode is improved.

Owner:SICHUAN UNIV

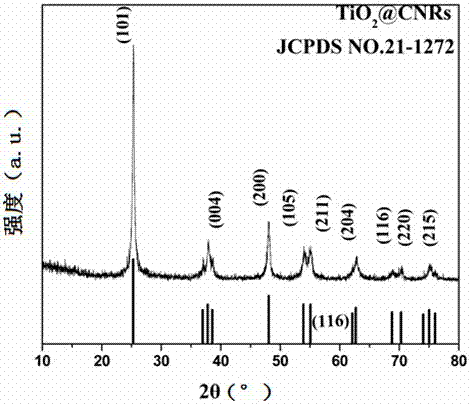

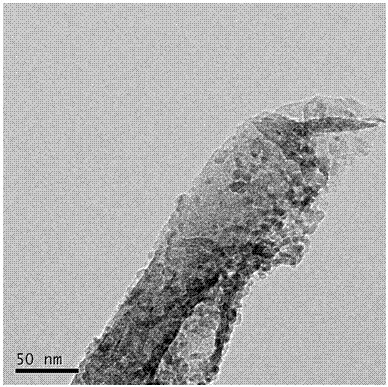

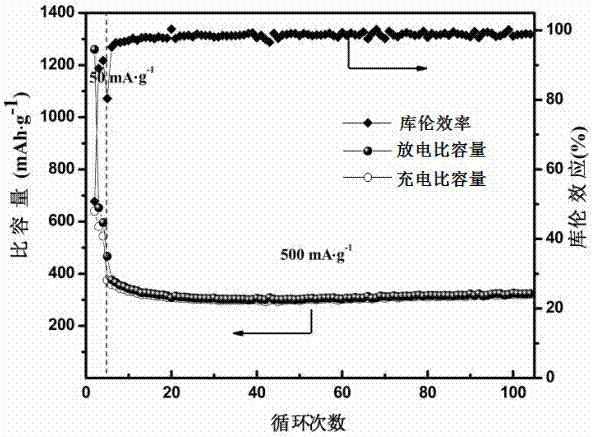

Titanium/graphene nanoribbon composite anode material and preparation method thereof

ActiveCN107482207AExcellent charge and discharge characteristicsImprove cycle lifeMaterial nanotechnologyNegative electrodesQuasi one dimensionalUltrasonic dispersion

The invention discloses a titanium / graphene nanoribbon composite anode material and a preparation method thereof. The anode material is a quasi-one-dimensional nano composite material formed through titanium in a nano-particle shape limited in a graphene nanoribbon. The preparation method comprises the steps that 1, the oxidized graphene nanoribbon is added into an organic solvent, and ultrasonic dispersion is conducted; 2, a titanium source and water are added, centrifugal separation is conducted after heating reflux is conducted, and washing, filtering and drying are conducted on segment; 3, in protective atmosphere, heating treatment and cooling are conducted to obtain the titanium / graphene nanoribbon composite anode material. According to the composite anode material, under 0.01-3.0 V and 500 mA.g-1, the first reversible specific capacity is 375.7 mAh.g-1, after 100 times of circulation, the reversible specific capacity is 320.8 mA.g-1, and under 8000 mA.g-1, the reversible specific capacity can reach 206.7 mAh.g-1, so that the electrohemical performance is good; the method is simple and suitable for industrial production.

Owner:CENT SOUTH UNIV

Carbon-sulfur composite positive electrode for lithium-sulfur battery and preparation method of carbon-sulfur composite positive electrode

ActiveCN112072067AImprove cycle lifeOvercoming the low sulfur content in the cathodePositive electrodesLi-accumulatorsCarbon layerLithium–sulfur battery

The invention discloses a carbon-sulfur composite positive electrode for a lithium-sulfur battery and a preparation method of the carbon-sulfur composite positive electrode, and belongs to the technical field of lithium-sulfur batteries. The carbon-sulfur composite positive electrode consists of a carbon-sulfur composite layer and a conductive carbon layer which are sequentially coated on the current collector; the carbon-sulfur composite layer is composed of a sulfur material, a carbon material I and an aqueous binder, and the conductive carbon layer is composed of a carbon material II and anorganic binder. According to the double-layer carbon-sulfur composite positive electrode prepared by the method, the construction of a high-sulfur-capacity, high-sulfur-content, high-specific-capacity and long-cycle-life high-energy-density lithium-sulfur battery can be realized. The preparation method of the composite positive electrode is simple and convenient to operate, low in cost and easy to amplify, the design and preparation of the positive electrode of the lithium-sulfur battery are effectively promoted, and a new possibility is provided for the practicability of the lithium-sulfur battery with high energy density.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Lithium-sulfur battery anode material and preparation method thereof and lithium-sulfur battery

InactiveCN106340631AUniform sizeLarge specific surface areaCell electrodesLi-accumulatorsChemistryZinc

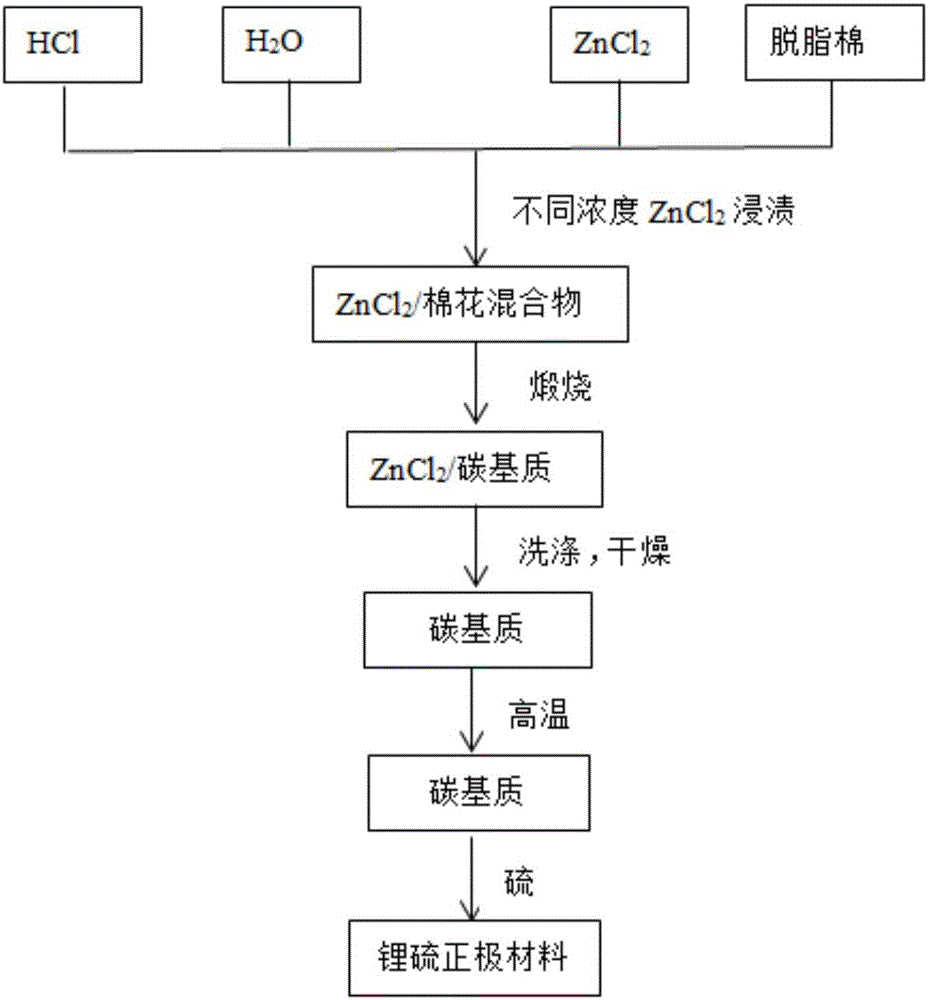

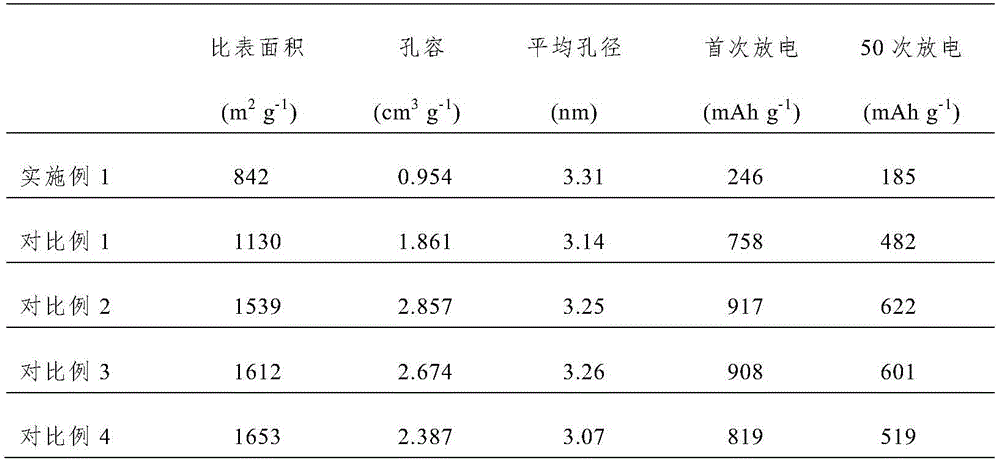

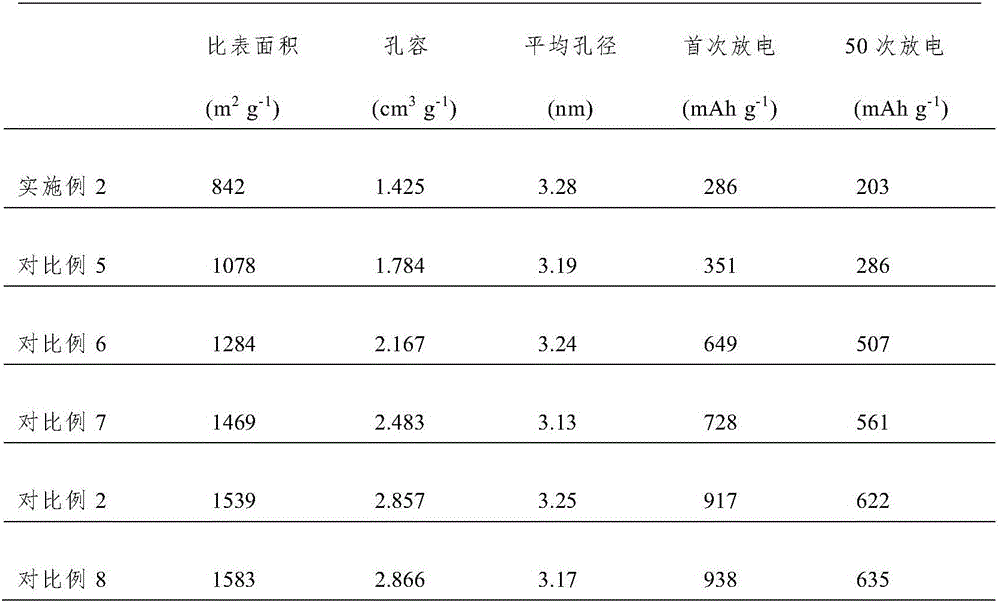

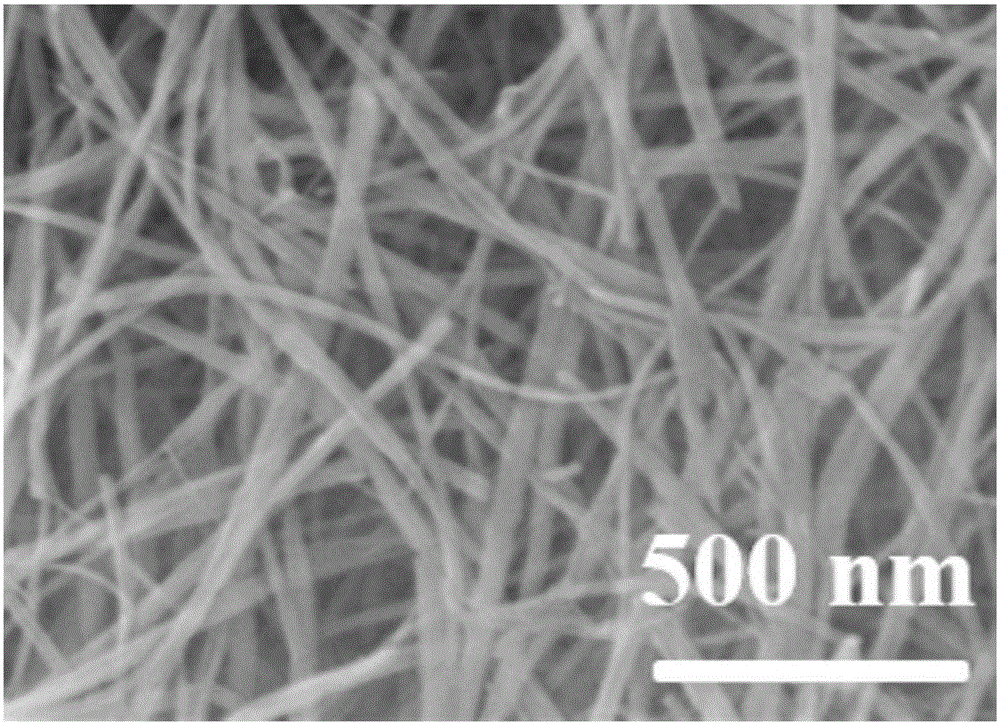

The invention discloses a preparation method of a lithium-sulfur battery anode material, and relates to the technical field of lithium-sulfur batteries. The preparation method comprises the following steps of 1 cotton dipping , wherein cotton is soaked in a hydrochloric acid solution containing zinc chloride for sealed heat preservation, the redundant solution is removed, and a mixture is dried and subjected to heat preservation treatment to obtain gray or brown solids; 2 porous carbon matrix preparing, wherein carbonization treatment and acidification treatment are conducted on the solids in sequence, and then washing, drying and calcining are conducted to obtain a porous carbon matrix; 3 carbon-sulfur composite material preparing, wherein the porous carbon matrix and elemental sulfur are heated together to synthesize the lithium-sulfur battery anode material. The invention further discloses the lithium-sulfur battery anode material prepared through the method and a lithium-sulfur battery. Compared with the prior art, the lithium-sulfur battery anode material obtained through the method has the advantages of being high in sulfur loading amount and capacity, good in cycle performance, simple in process and low in cost.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

Anode material for non-aqueous electrolyte secondary battery, and preparation method and application thereof

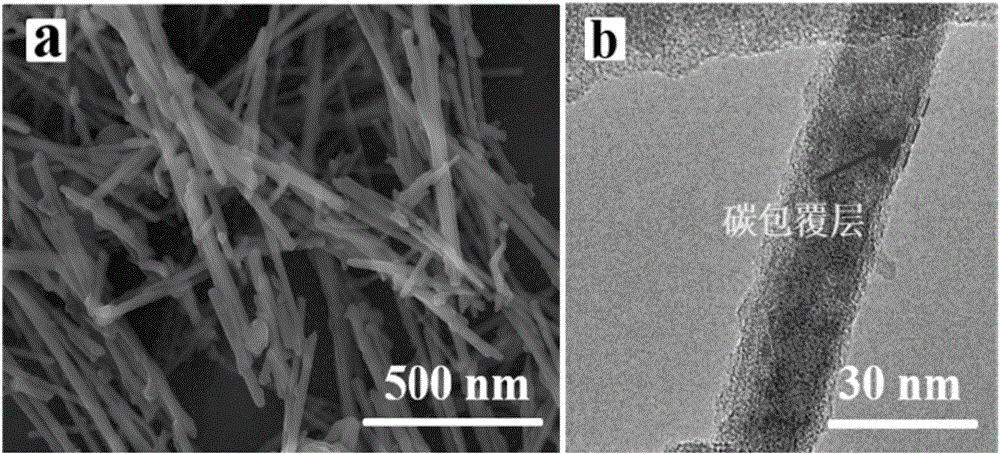

ActiveCN106848282AReduce hardnessImprove conductivityCell electrodesSecondary cellsCarbon compositesSilicon oxide

The invention discloses an anode material for a non-aqueous electrolyte secondary battery, and a preparation method and application thereof. The anode material is prepared from a silicon oxide one-dimensional nano material or a carbon-coated one-dimensional silicon oxide / carbon composite material. The anode material has good electrochemical performance such as higher capacity and good multiplying and circulating performance, and has a good application prospect in the field of energy storage devices such as lithium ion batteries. During a charging / discharging process of the anode material, expansion mainly occurs in the radial direction of the one-dimensional nano material, and the expansion rate of a battery pole piece containing the active material can be reduced to 20 percent or less. According to the one-dimensional nano material provided by the invention, a synthesis technology and a carbon coating technology are simple and practical, the source of raw materials is wide, the device requirements are low, the preparation efficiency is high, and the one-dimensional nano material is suitable for large-scale popularization and application.

Owner:彭宪利

Carbon-based lithium ion battery negative electrode material taking sludge as precursor and preparation of carbon-based lithium ion battery negative electrode material

InactiveCN106920966ASolve problems such as limitationsLarge specific surface areaCell electrodesSecondary cellsResource utilizationSludge

The invention relates to a carbon-based lithium ion battery negative electrode material taking sludge as a precursor and preparation of the carbon-based lithium ion battery negative electrode material. During preparation, the sludge is carbonized and processed in advance, and the carbon-based lithium ion battery negative electrode material is obtained by sequentially performing washing and drying after pickling and alkali activation. Compared with the prior art, the carbon-based lithium ion battery negative electrode material has the advantages of greenness, environmental friendliness, simple preparation process and low production cost, the resource utilization of the sludge can be achieved, and the prepared carbon-based lithium ion battery negative electrode material is high in specific area and specific capacity and good in cycle property and has wide application prospect.

Owner:TONGJI UNIV

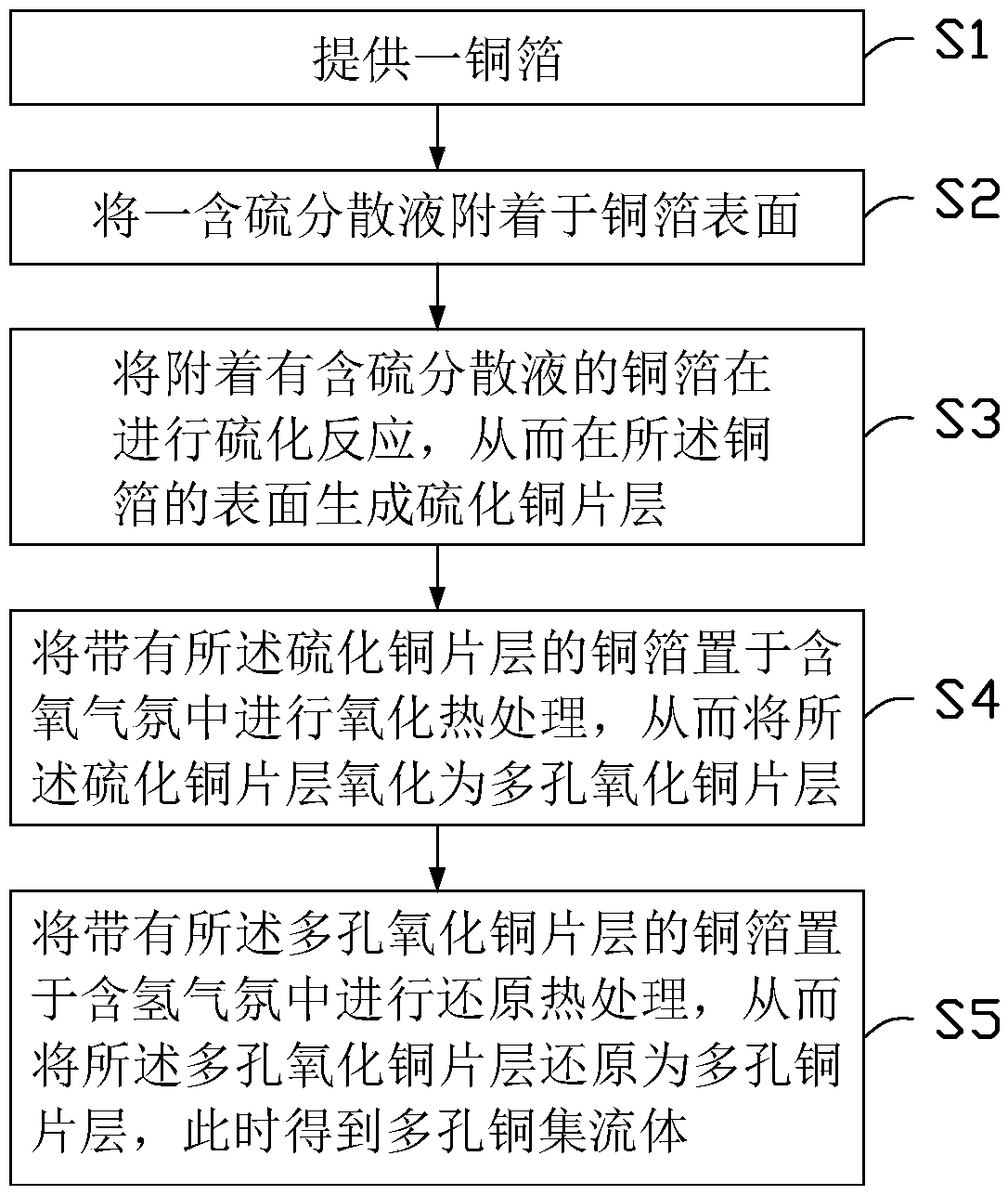

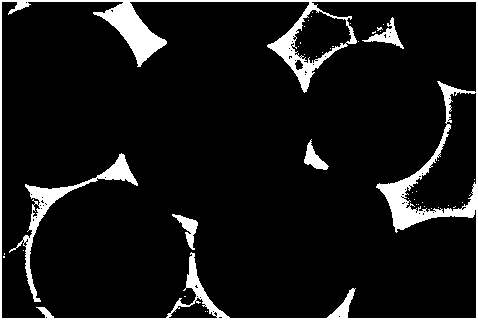

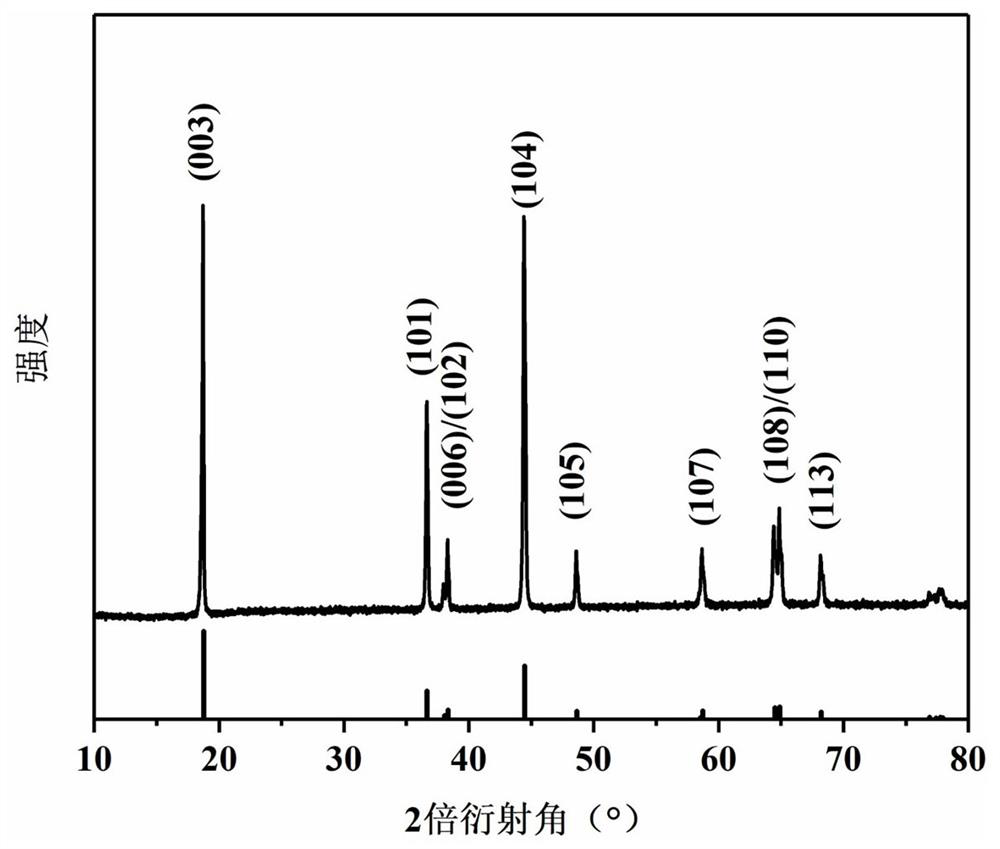

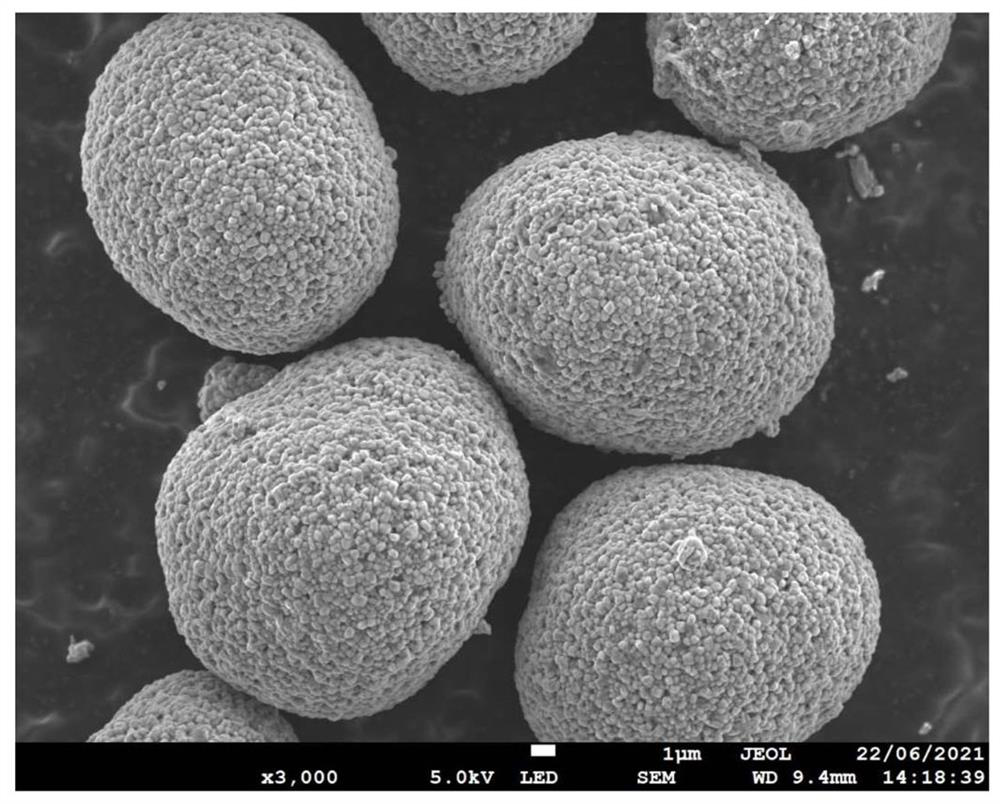

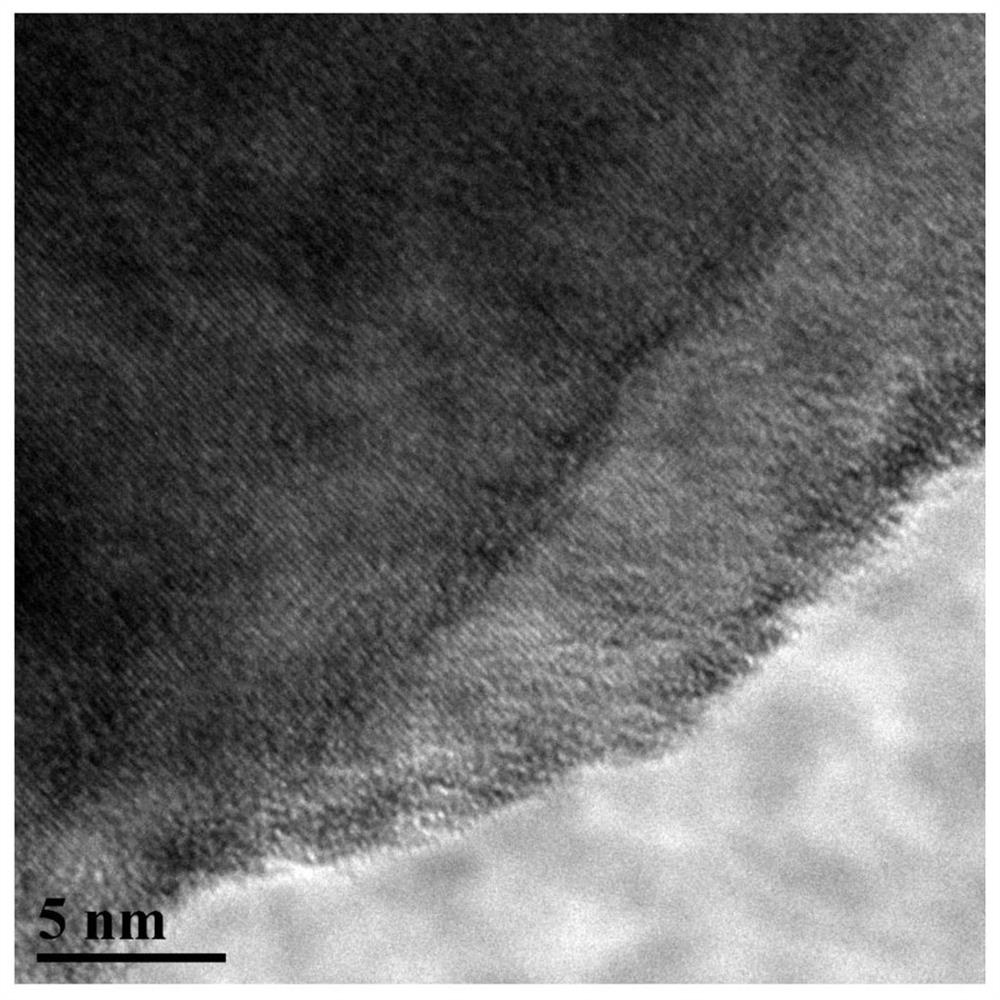

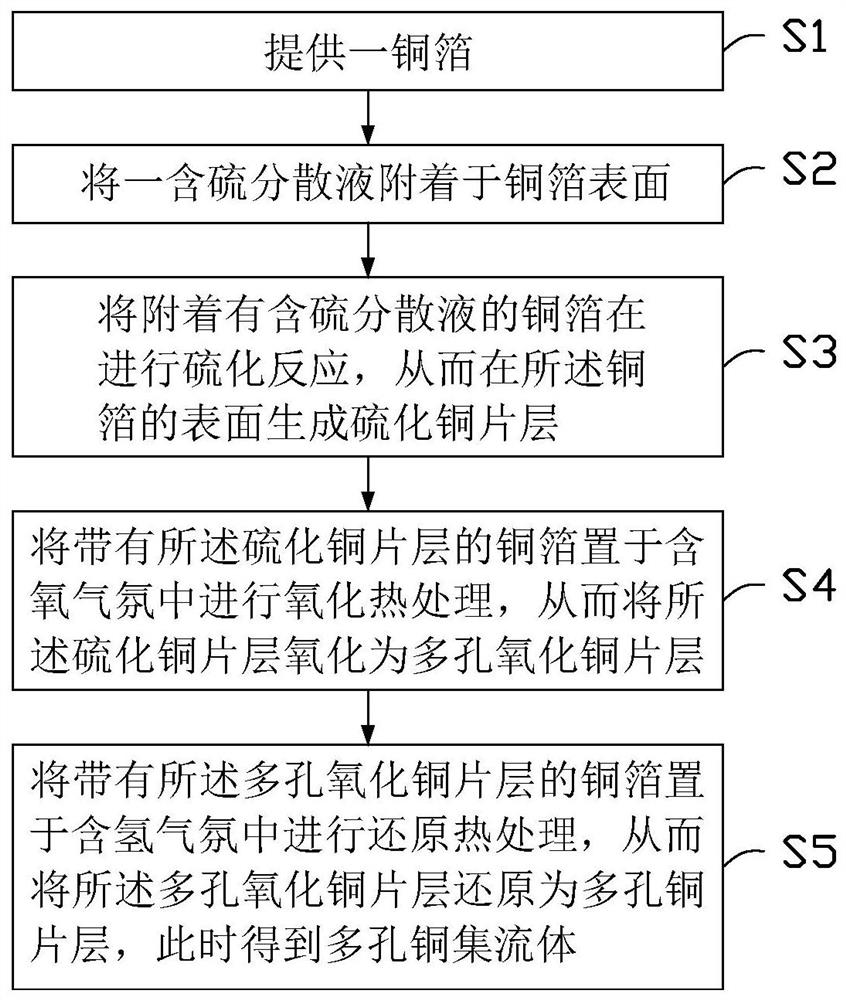

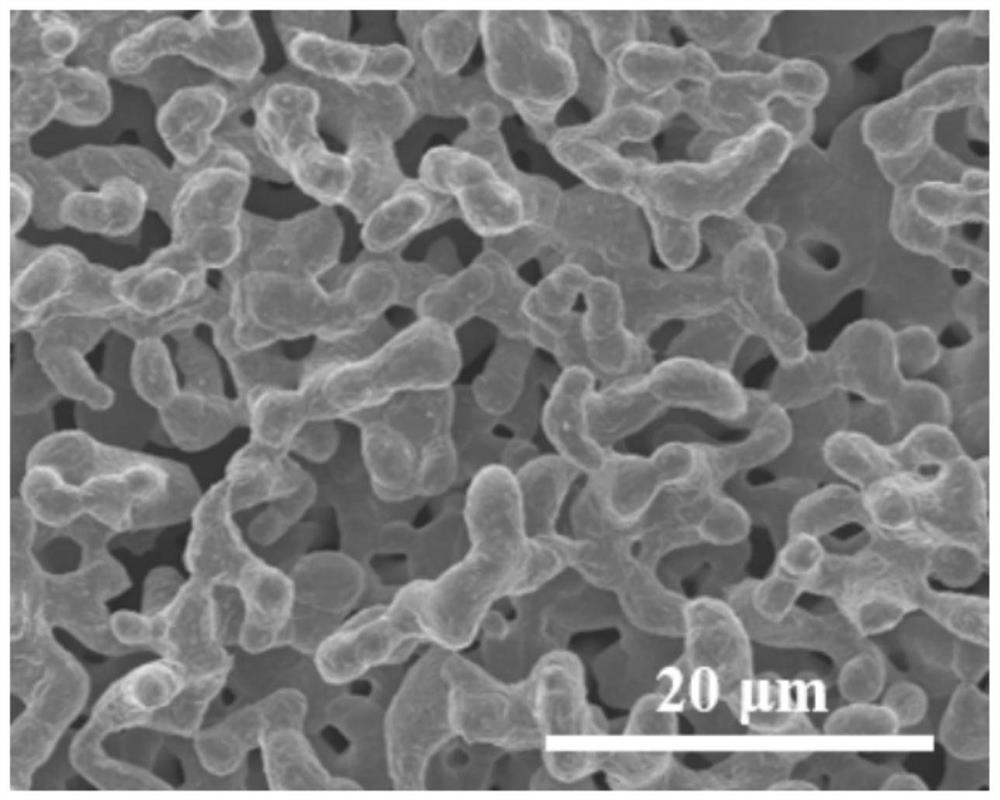

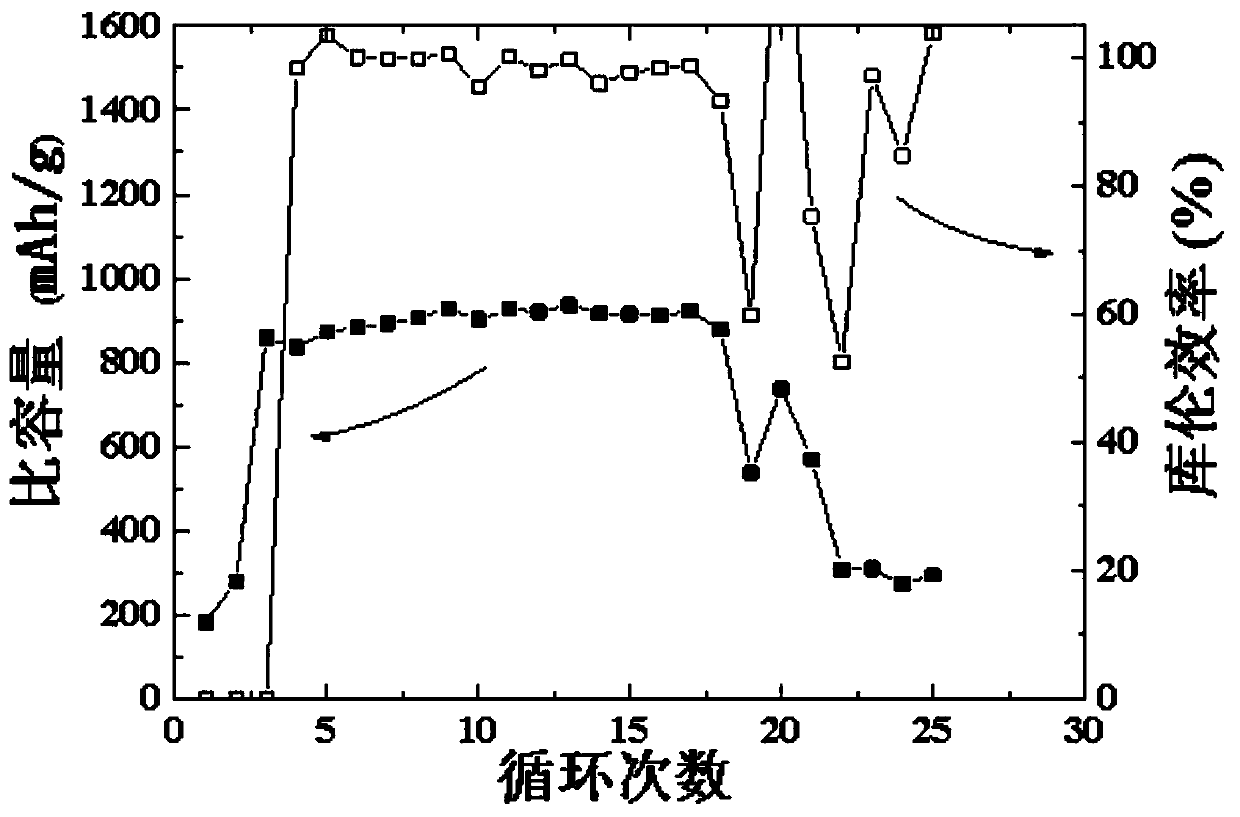

Method for preparing porous copper current collector, porous copper current collector, negative electrode and battery

ActiveCN109546153AModerate pore sizeEvenly distributedElectrode carriers/collectorsHydrogenVulcanization

The invention discloses a method for preparing a porous copper current collector, and the method comprises the following steps: providing copper foil; attaching sulfur-containing dispersion liquid tothe surface of the copper foil; performing the vulcanization reaction on the copper foil to which the sulfur-containing dispersion liquid is attached; and placing the copper foil in an oxygen-containing atmosphere for oxidation thermal treatment after the sulfurization reaction; placing the copper foil in a hydrogen-containing atmosphere for reduction thermal treatment after the oxidation thermaltreatment to obtain the porous copper current collector. The porous copper current collector prepared by the preparation method has a three-dimensional porous structure, and the porous copper currentcollectors having different pore sizes and thicknesses values can be prepared by changing the preparation parameters. The battery which takes the porous copper current collector prepared by the present invention as a negative current collector has higher and more stable coulombic efficiency and a longer cycle life. The three-dimensional porous copper can effectively inhibit the formation and growth of the negative dendritic crystals and can realize deep discharge.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

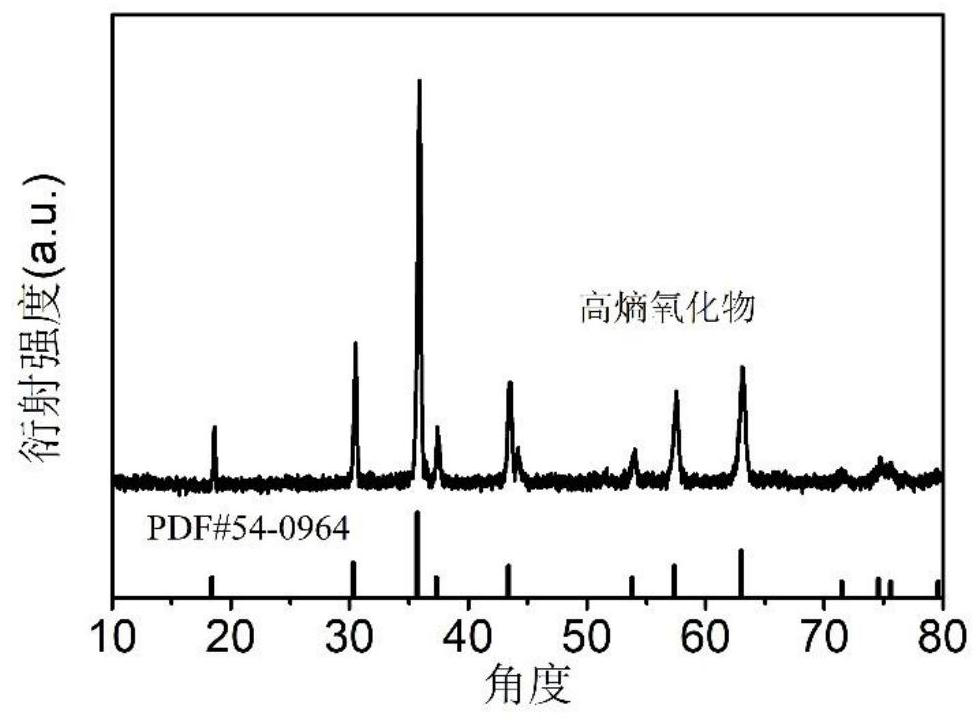

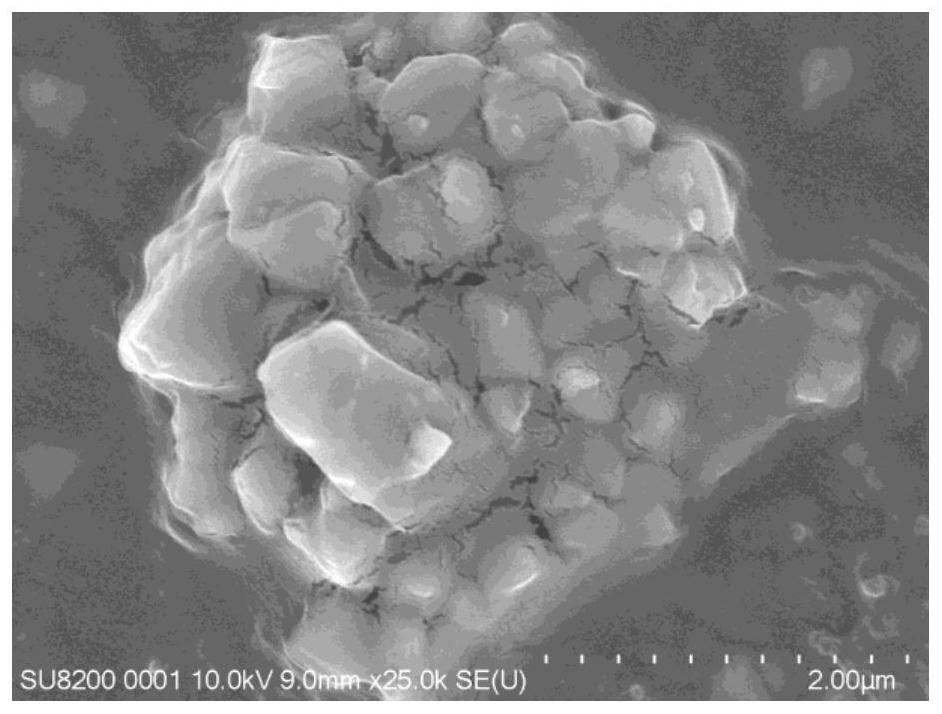

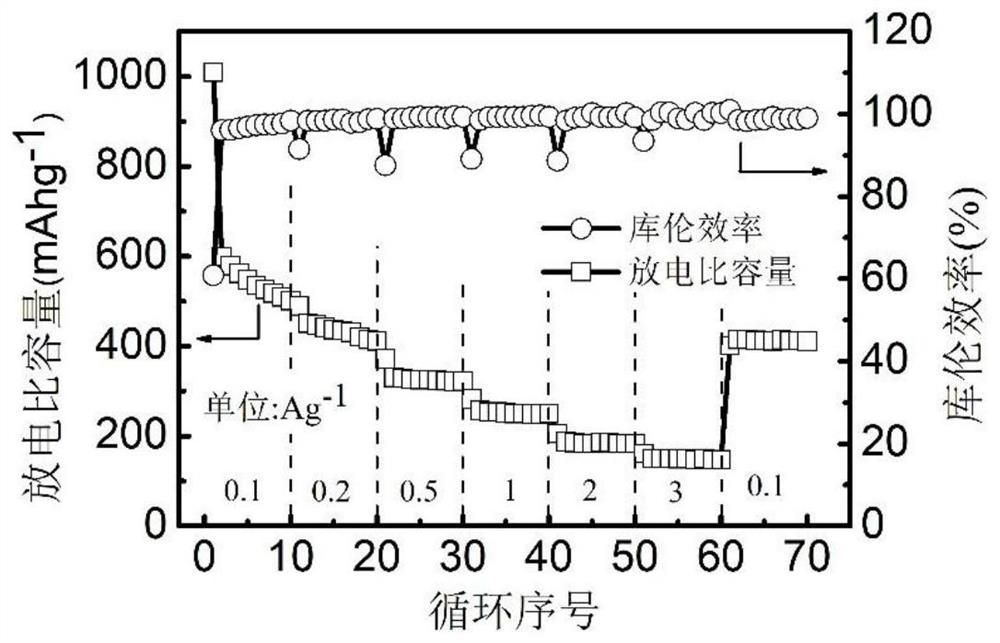

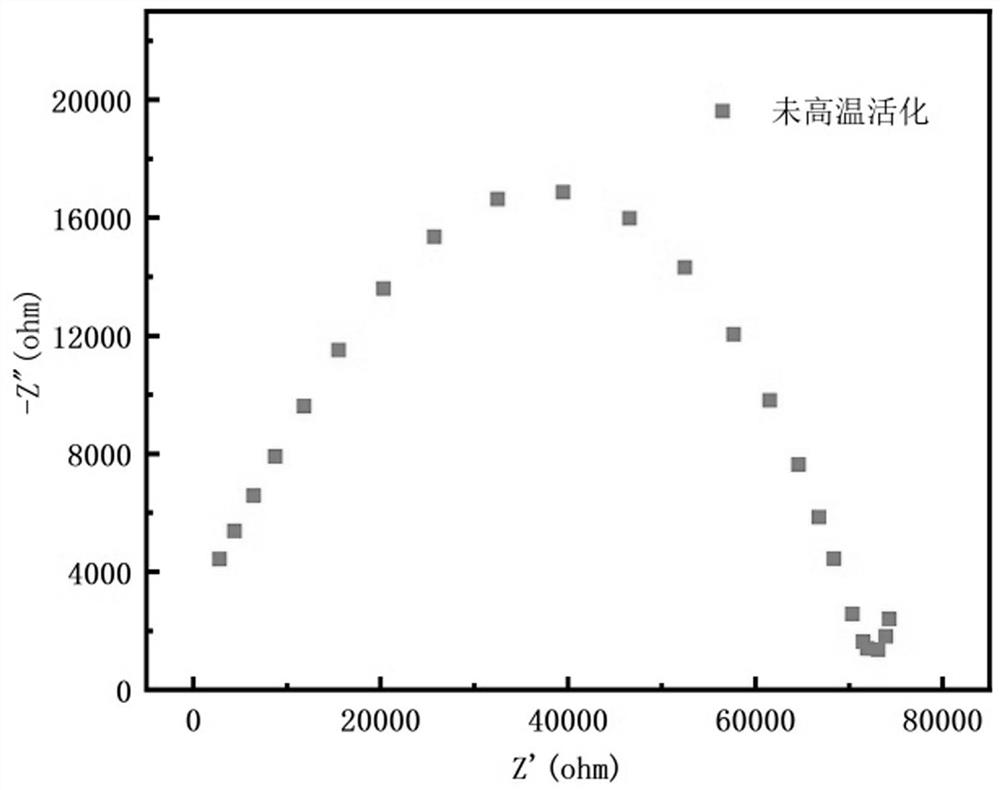

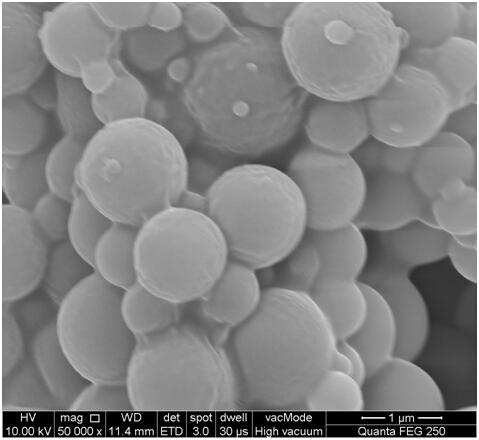

Preparation method of lithium ion battery negative electrode material high-entropy oxide

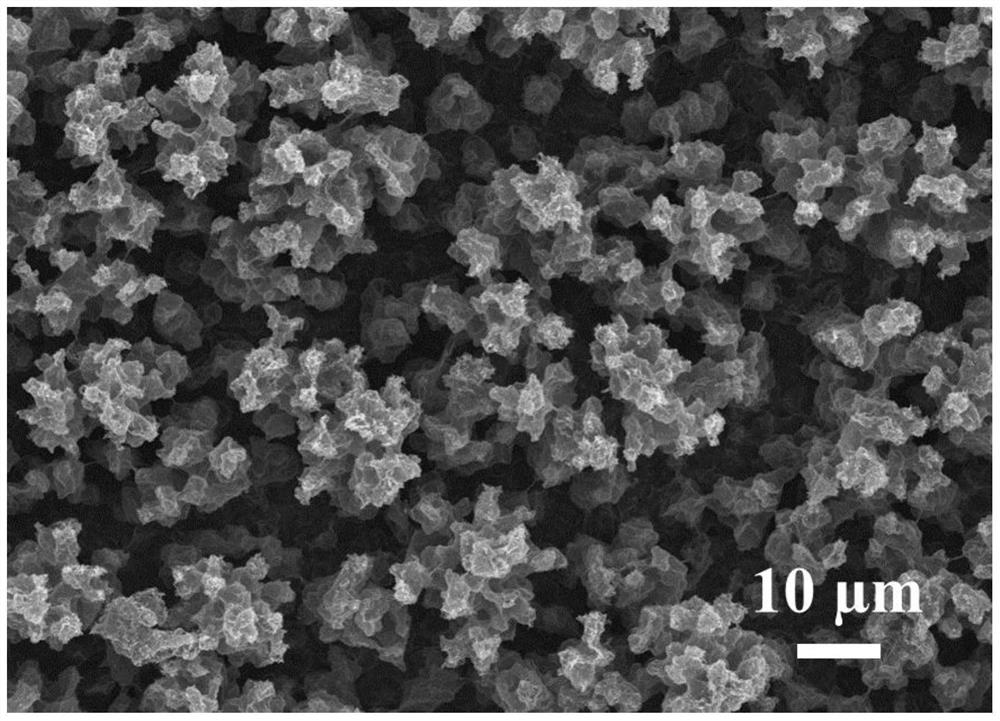

ActiveCN112875764AImprove performanceUniform particle shapeNegative electrodesSecondary cellsPhysical chemistryLithium-ion battery

The invention discloses a preparation method of a lithium ion battery negative electrode material high-entropy oxide. The preparation method comprises the following steps: S1, carrying out oil removal, polishing and rust removal, distilled water washing, alcohol solution secondary washing and vacuum drying on a high-entropy alloy Cr<0.2>Fe<0.2>Mn<0.2>Ni<0.2>Co<0.2> solid; S2, conducting melting, carrying out gas atomization granulation, and conducting cooling and sieving; and S3, taking the high-entropy alloy powder, and conducting oxidation treatment under flowing oxygen, so as to obtain the required (Cr<0.2>Fe<0.2>Mn<0.2>Ni<0.2>Co<0.2>)<3>O<4> high-entropy oxide lithium ion electrode material. The lithium battery negative electrode material (Cr<0.2>Fe<0.2>Mn<0.2>Ni<0.2>Co<0.2>)<3>O<4> high-entropy oxide obtained through the method is a pure phase, the particle morphology is uniform, the particle size is 0.1-2 microns, namely, the material performance is more stable, a battery assembled by the lithium battery negative electrode material high-entropy oxide has very high specific capacity and very good cycle stability and has remarkable economic value, and the method is short in process, easy to operate, low in cost and suitable for industrial production. The method is high in controllability, good in repeatability, wide in applicability and suitable for industrial production.

Owner:CHINA UNIV OF MINING & TECH

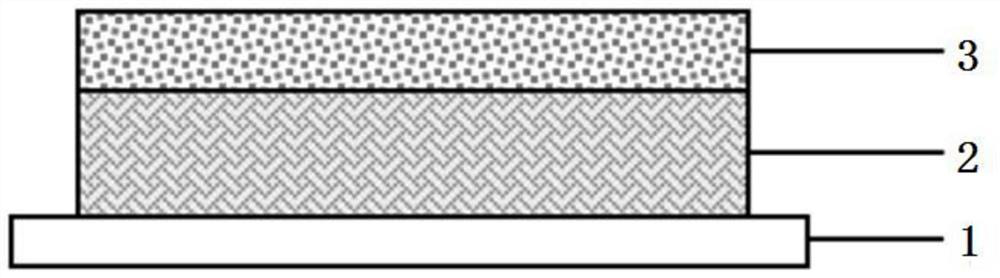

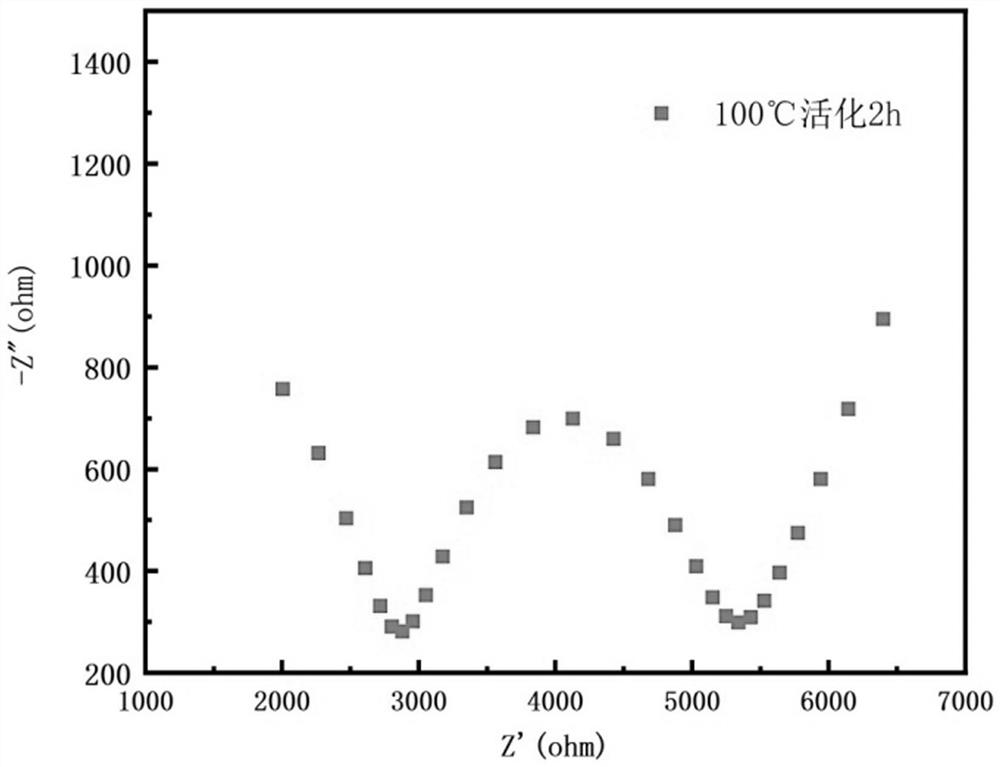

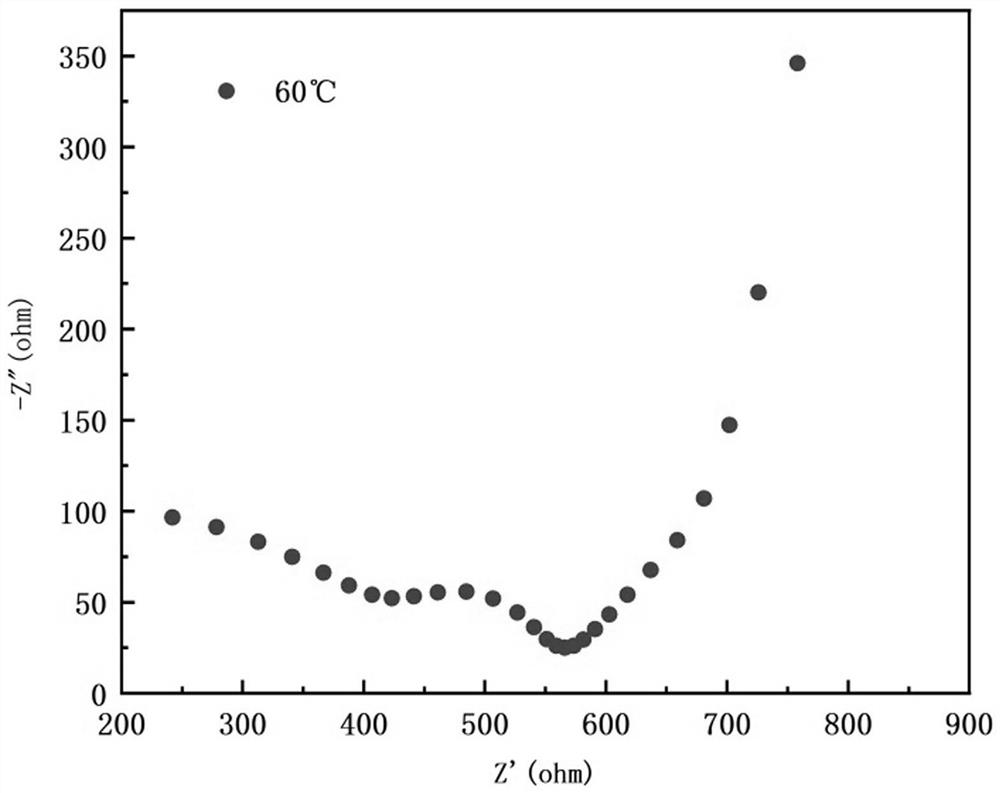

Preparation method of integrated all-solid-state lithium ion battery

InactiveCN112054159AIncreased active contact sitesDeepening of mutual infiltrationSolid electrolytesElectrode thermal treatmentSolid state electrolyteAll solid state

The invention discloses a preparation method of an integrated all-solid-state lithium ion battery. The preparation method comprises the following steps: preparation of a solid-state inorganic electrolyte, preparation of an organic-inorganic hybrid electrolyte and preparation of the all-solid-state lithium ion battery. The method has the advantages that a certain amount of electrolyte is added intothe electrode, and the electrode is artificially infiltrated into the electrolyte, so that the active contact sites of the electrode and the electrolyte are increased, and the mutual infiltration degree of the interface of the electrode and the solid electrolyte of the all-solid-state lithium ion battery after annealing treatment is deepened; more channels are provided for lithium ion conduction,and the interface internal resistance between the prepared all-solid-state lithium ion battery electrode and the electrolyte is reduced.

Owner:LANZHOU UNIVERSITY

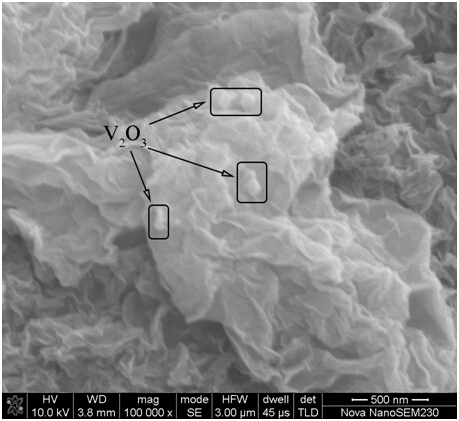

Composite positive electrode material with spring-shaped lamellar structure as well as preparation method and application of composite positive electrode material

PendingCN114050245AImprove structural rigidityImprove conductivityCell electrodesSecondary cellsAluminum IonAluminium-ion battery

The invention provides a composite positive electrode material with a spring-shaped lamellar structure as well as a preparation method and application of the composite positive electrode material. The composite positive electrode material comprises a carbon sheet layer and vanadium trioxide nanoparticles dispersed on the surface of the carbon sheet layer. The invention provides an aluminum ion battery composite positive electrode material with a spring-shaped lamellar structure. The composite positive electrode material adopts a carbon sheet layer as a support skeleton, and is compounded with vanadium trioxide nanoparticles, so the diffusion path of aluminum ions is reduced, and the conductivity of the composite positive electrode material is enhanced; meanwhile, a precursor material is prepared by utilizing a hydrothermal method, and is calcined at high temperature to finally obtain the composite material with the spring-shaped lamellar structure.

Owner:中科南京绿色制造产业创新研究院 +1

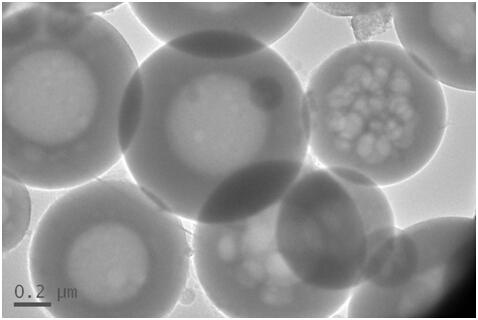

Preparation method of vanadium phosphate/carbon as negative electrode material for hollow spherical lithium ion battery

ActiveCN108281632BUniform particle shapeIncrease capacityCell electrodesSecondary cellsPhysical chemistrySpray dried

The invention discloses a preparation method of hollow spherical negative electrode material vanadium phosphate / carbon for a lithium ion battery. The preparation method comprises the following steps:(1) adding a vanadium source into water, heating and stirring, then adding a high molecular surfactant, heating and stirring to obtain a precursor solution; (2) carrying out spray drying to obtain a precursor of a vanadium phosphate / carbon material; and (3) carrying out heat treatment under an inert atmosphere to obtain the material. In the hollow spherical vanadium phosphate / carbon obtained by the method, vanadium phosphate is a pure phase, the particle morphology is uniform, and the particles are spherical; according to the assembled lithium ion battery, under 0 to 3 V and 100 mA / g, the first discharge gram volume reaches up to 1073.47 mAh / g, and the coulombic efficiency is high; the first reversible specific capacity reaches 551.41 mAh / g, and the capacity retention ratio after 83 timesof circulations is 80.0%; and the method is simple in operation and low in cost, and is applicable to industrial production.

Owner:CENT SOUTH UNIV

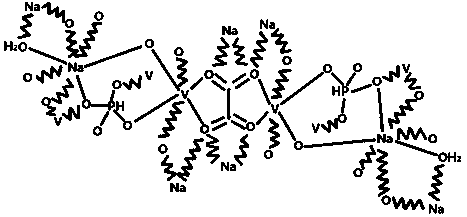

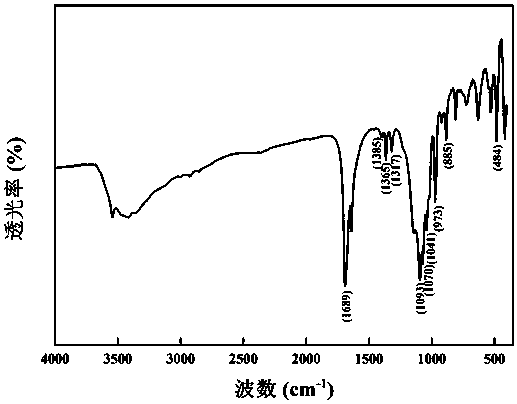

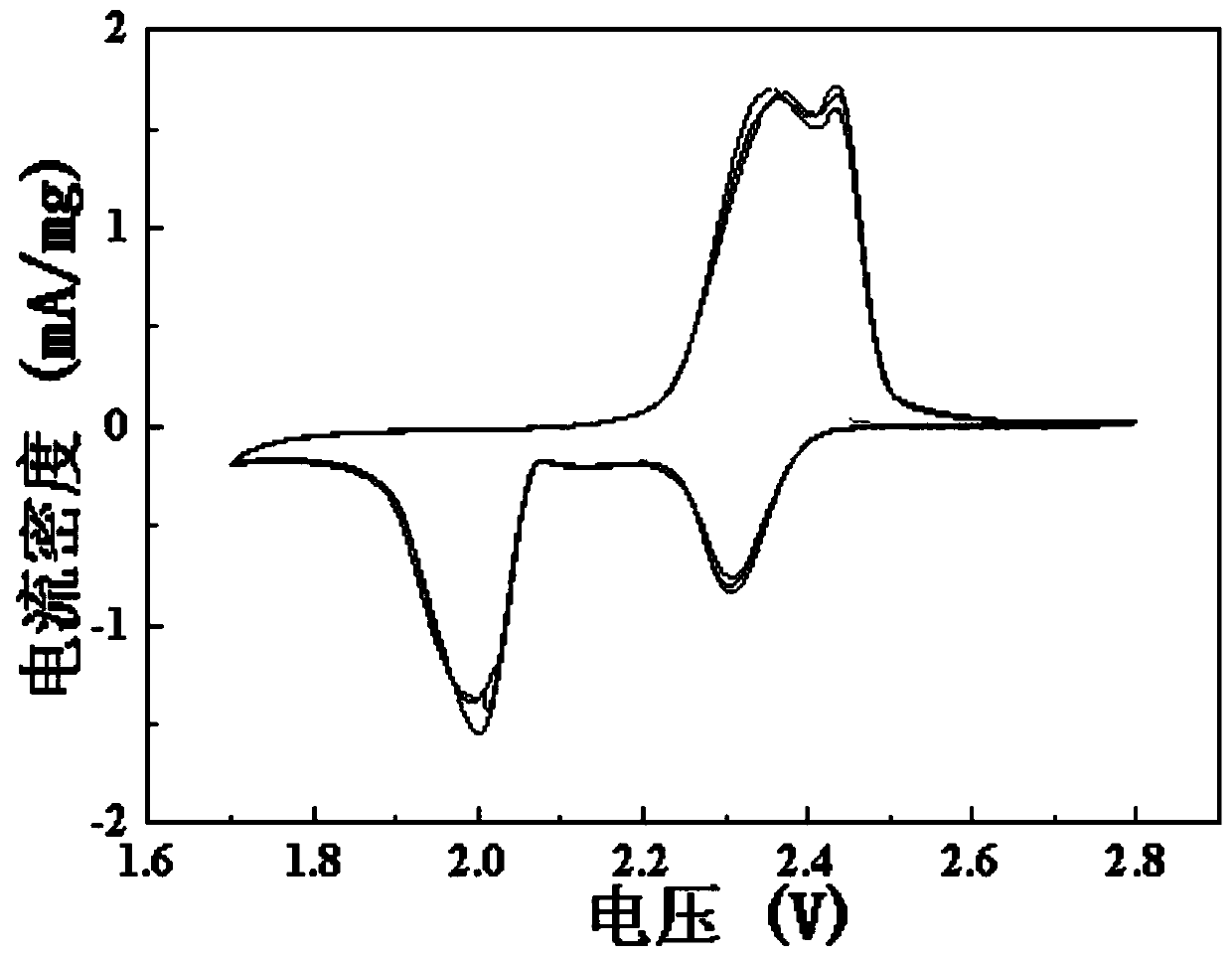

Layered metal organic phosphate frame sodium ion cathode material and preparation method thereof

ActiveCN109546117AImprove discharge capacityImprove cycle stabilityCell electrodesSecondary cellsOXALIC ACID DIHYDRATEPhosphoric acid

The invention provides a layered metal organic phosphate frame sodium ion cathode material and a preparation method thereof. The cathode material is a layered material formed by doping a carbon conductive agent in a metal organic phosphate frame sodium ion cathode material. The single crystal molecular formula of the metal organic phosphate frame sodium ion cathode material is C2H10Na2O16P2V2, andthe molecular structure belongs to a structure of the monoclinic system with the space group being a chiral non-center space group. The method is comprises the following steps: (1) adding a vanadiumsource to water, performing dispersing, adding phosphoric acid, oxalic acid dihydrate, performing stirring, adding a sodium source, and performing dispersing uniformly; (2) performing the hydrothermalreaction, performing filtering, washing and precipitating and drying to obtain an Na-MOF material; (3) mixing the Na-MOF material with a carbon conductive agent, performing grounding to obtain the cathode material. The cathode material of the invention has a large discharge gram volume, is good in rate performance, and is stable in cycle performance and coulombic efficiency. The method of the invention is low in synthesis temperature, is simple in operation, is low in cost, is high in controllability, is good in repeatability, and is suitable for industrial production.

Owner:江西潮实新能源科技有限公司

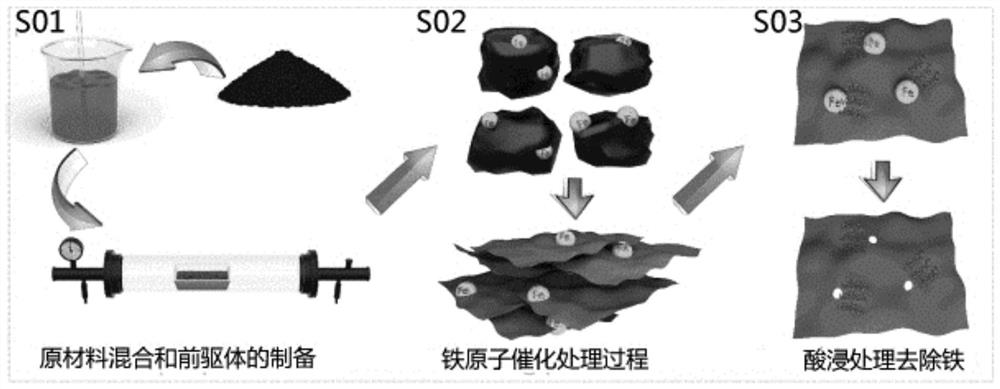

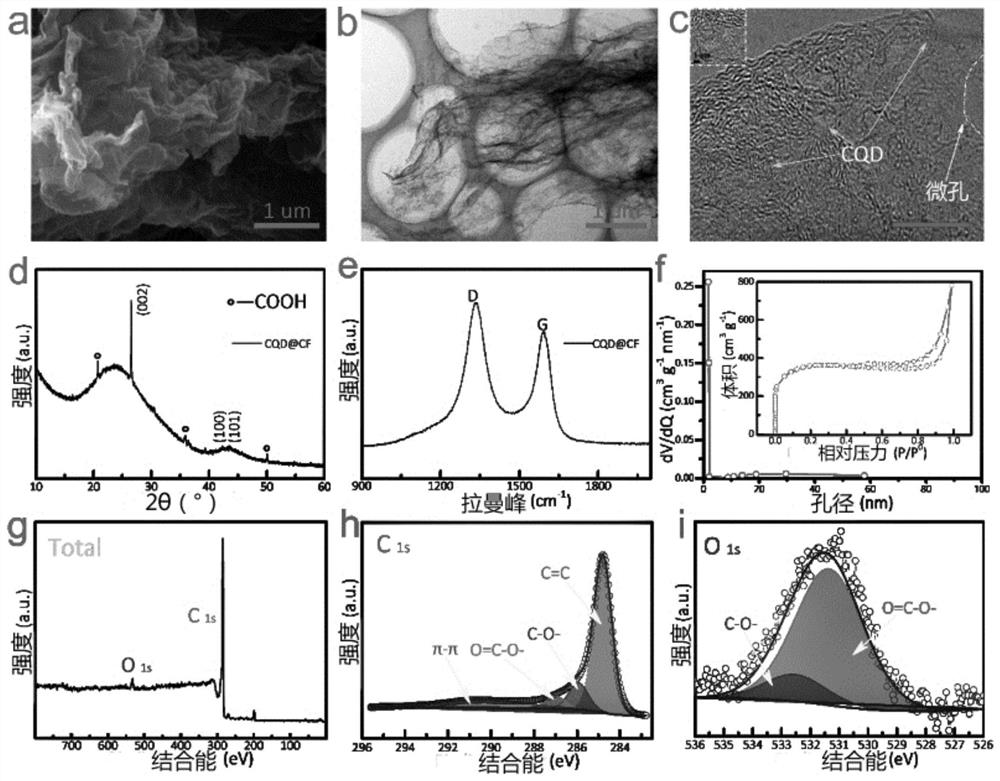

Carbon quantum dot and graphene composite material, and preparation method and application thereof

InactiveCN113471427AIncrease energy densityImprove power densityHybrid capacitor electrodesSecondary cellsElectrolytic agentPtru catalyst

The invention provides a carbon quantum dot and graphene composite material, and a preparation method and an application thereof. The CQD / CF composite material is synthesized by taking anhydrous citric acid as a carbon source and ferric trichloride hexahydrate as a catalyst through a simple and convenient catalytic graphite method; the CQD / CF composite material is composed of a large-specific-surface-area ultrathin graphene-shaped carbon plate and a large number of carbon quantum dots, and porous structures are distributed on the surface of the graphene-shaped carbon plate; the carbon quantum dots are distributed on the graphene-shaped carbon plate; and according to the mixed potassium double-ion capacitor, the carbon quantum dot and graphene composite material is used as a positive electrode, nano-graphite is used as a battery behavior negative electrode, 0.8 M potassium hexafluorophosphate KPF6 is used as an electrolyte, and cellulose paper is used as a diaphragm. The preparation method is simple, and the obtained carbon quantum dot and graphene composite material has excellent an anion storage capacity, excellent structural stability and excellent capacitor performance.

Owner:福建海峡石墨烯产业技术研究院有限公司

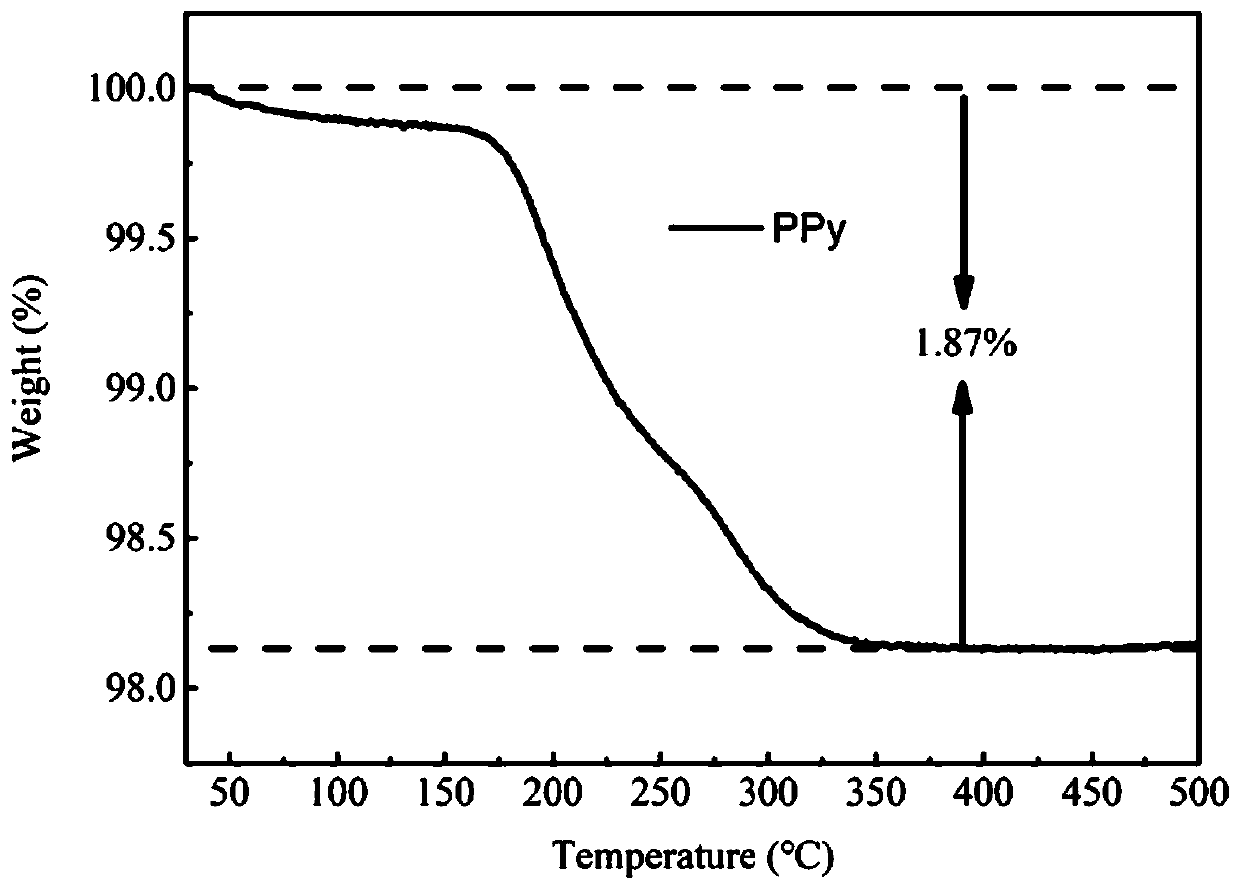

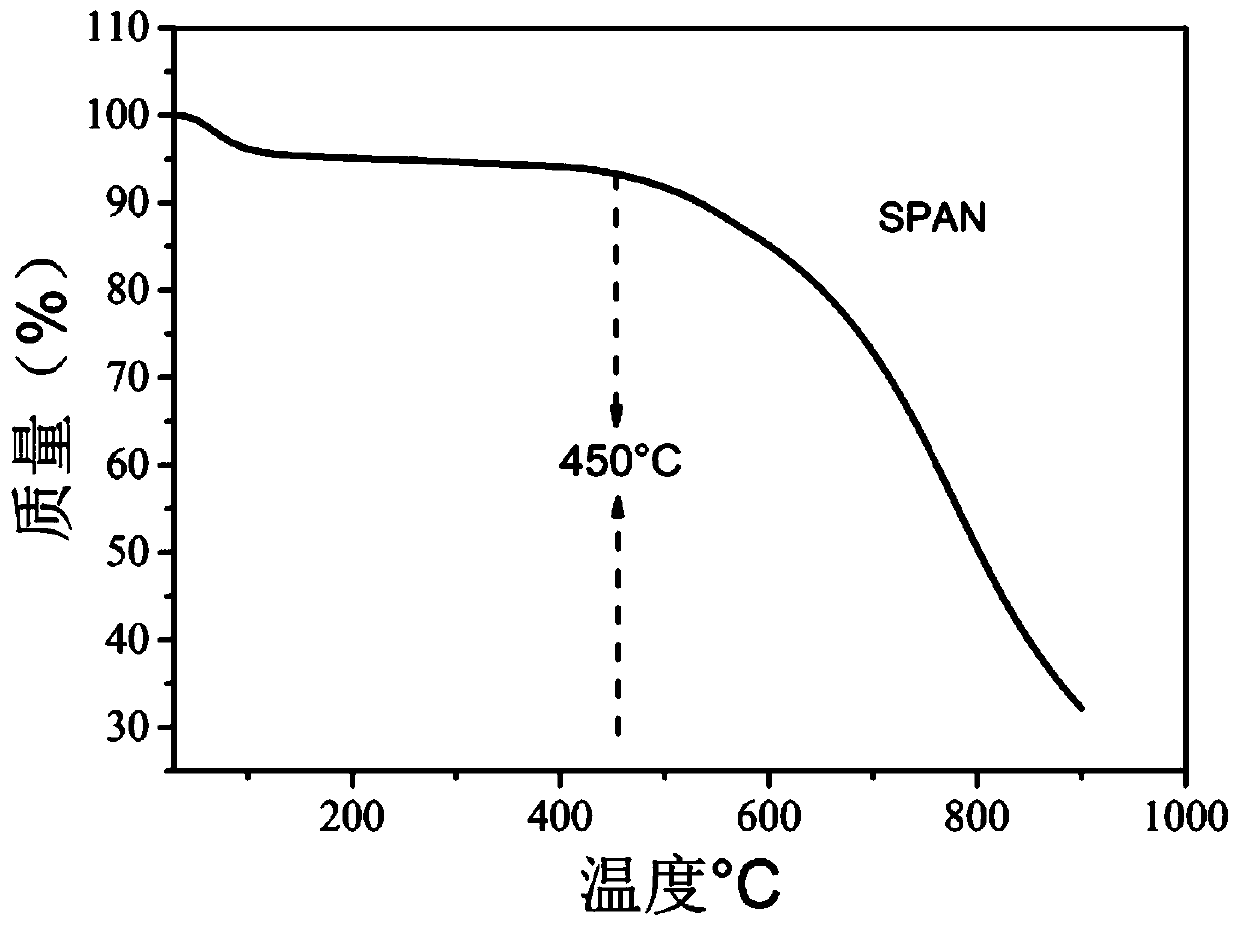

Room temperature sodium-sulfur battery positive electrode material and preparation method and application thereof

PendingCN110098390AAvoid reunionAvoid stickingMaterial nanotechnologySecondary cellsElectrochemical responseChemical reaction

The invention relates to a room temperature sodium-sulfur battery positive electrode material and a preparation method and an application thereof. The preparation method comprises the steps of S1, blending polyacrylonitrile and sulfur powder, ball milling and calcining to obtain a sulfurized polyacrylonitrile precursor material; S2, polymerizing pyrrole monomers on the precursor material in situ to obtain a polypyrrole (PPy) nanolayer; S3, annealing the material obtained in the step S2 to obtain the room temperature sodium-sulfur battery positive electrode material. The surface of sulfurized polyacrylonitrile is coated with an N-doped carbon layer, thereby being capable of well playing a role of protecting and stabilizing the electrode. Meanwhile, the doping of the element N can acceleratethe kinetic process of the electrochemical reaction, reduce the polarization in the electrochemical reaction process, improve the discharge voltage platform of the battery and thus improve the energydensity of the battery. Furthermore, the positive electrode material is carbonized at a low temperature, thereby avoiding the loss of sulfur; and the obtained positive electrode material has excellent cycle performance, stable Coulomb efficiency, high specific capacity and excellent electrochemical performance.

Owner:GUANGDONG UNIV OF TECH

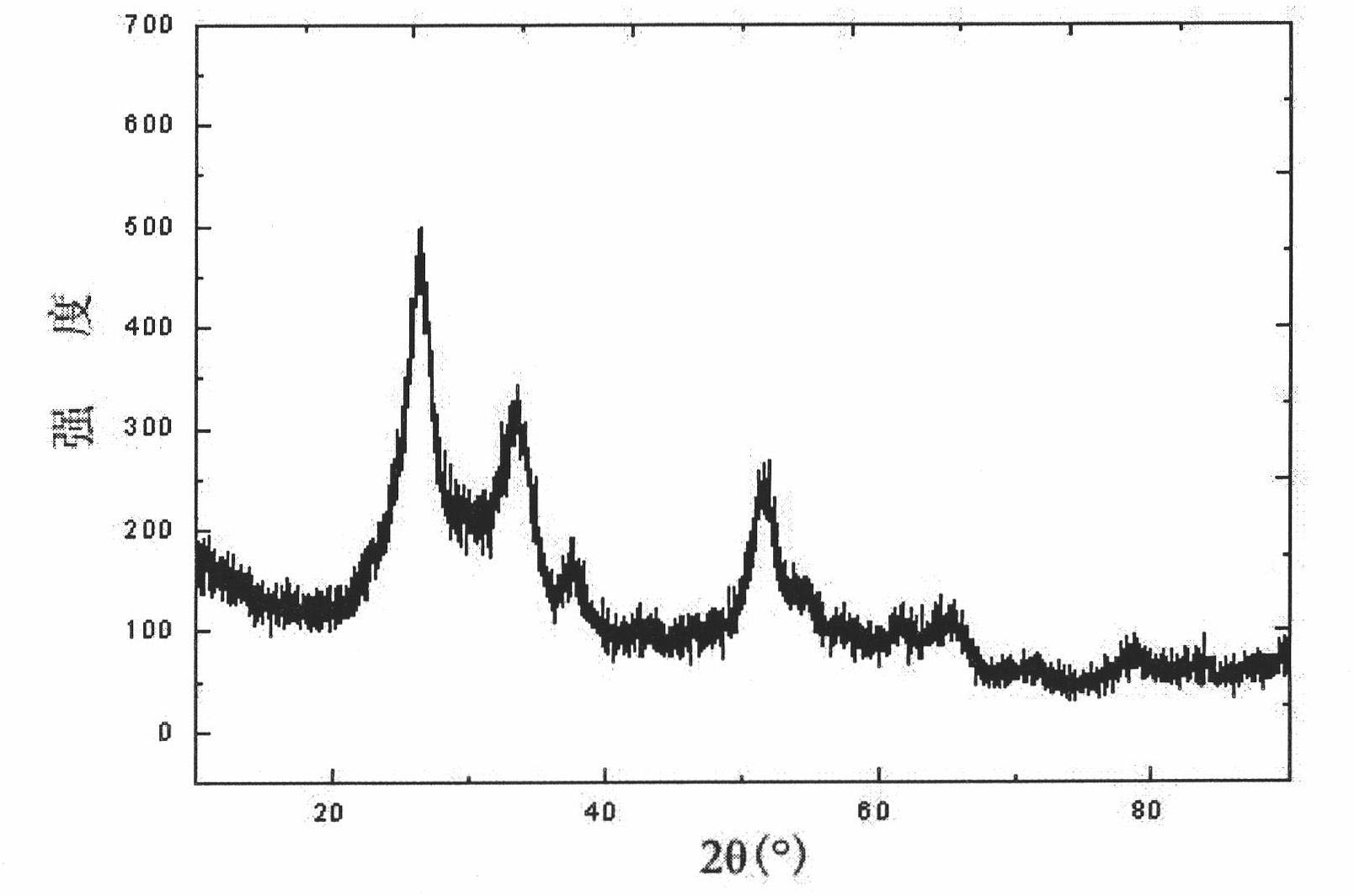

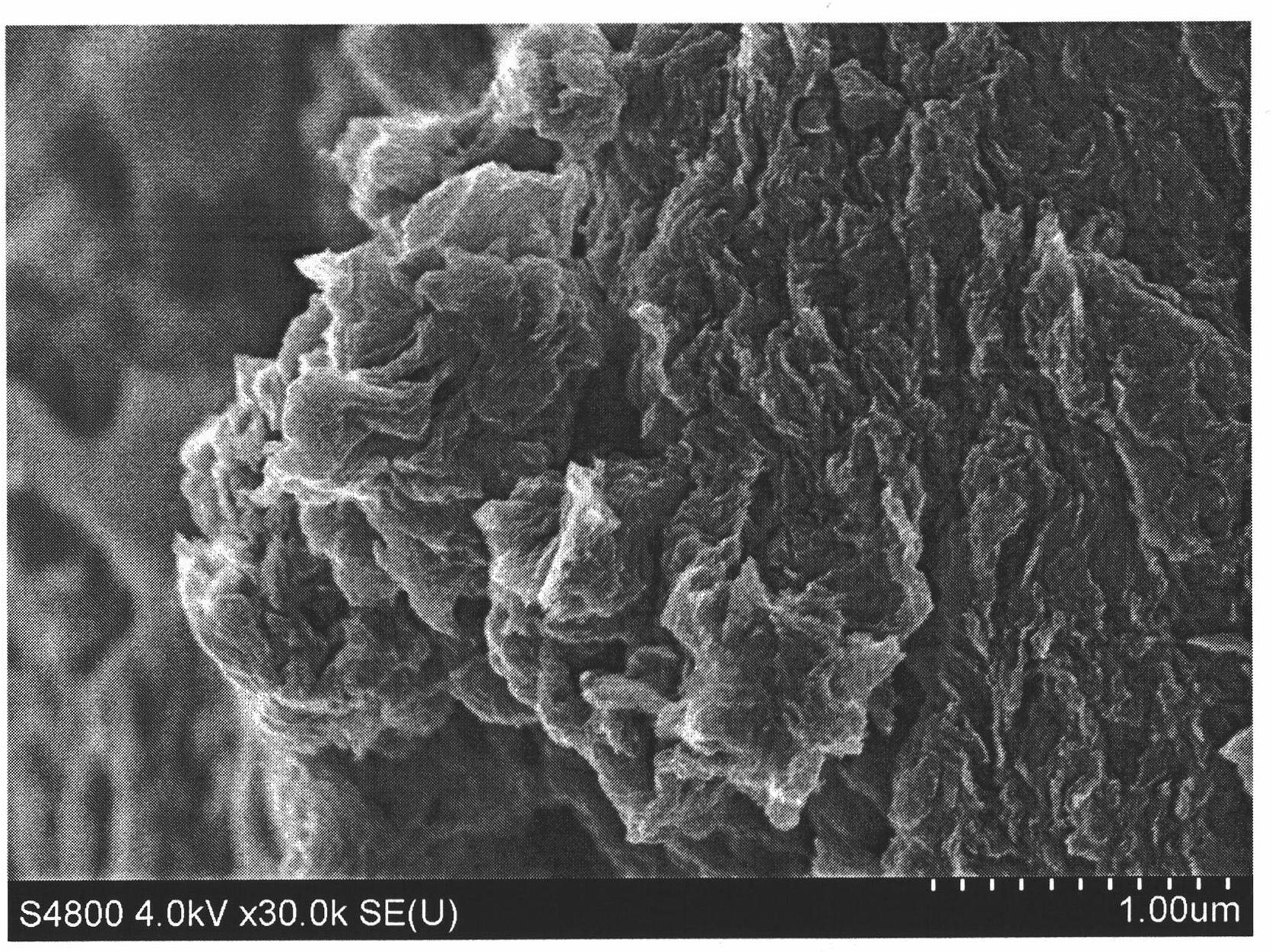

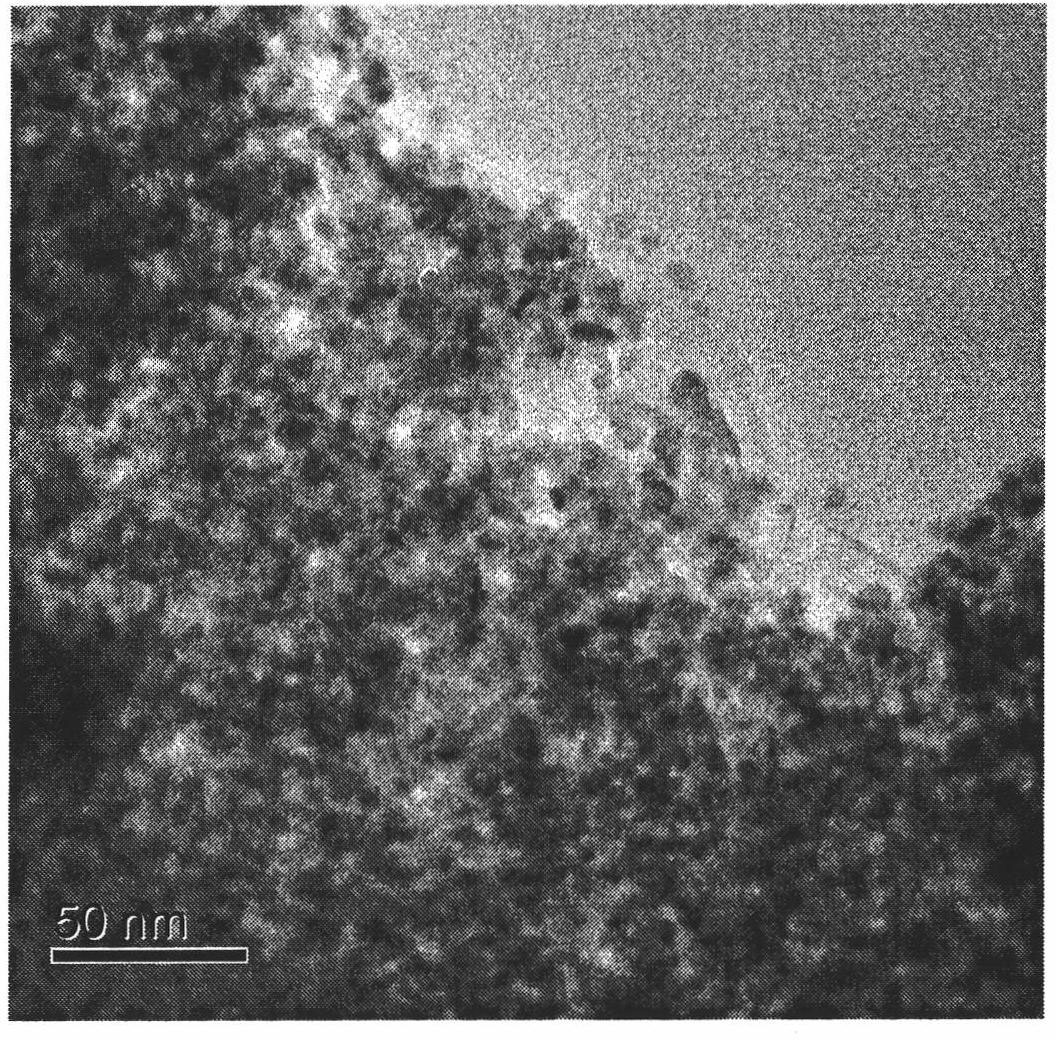

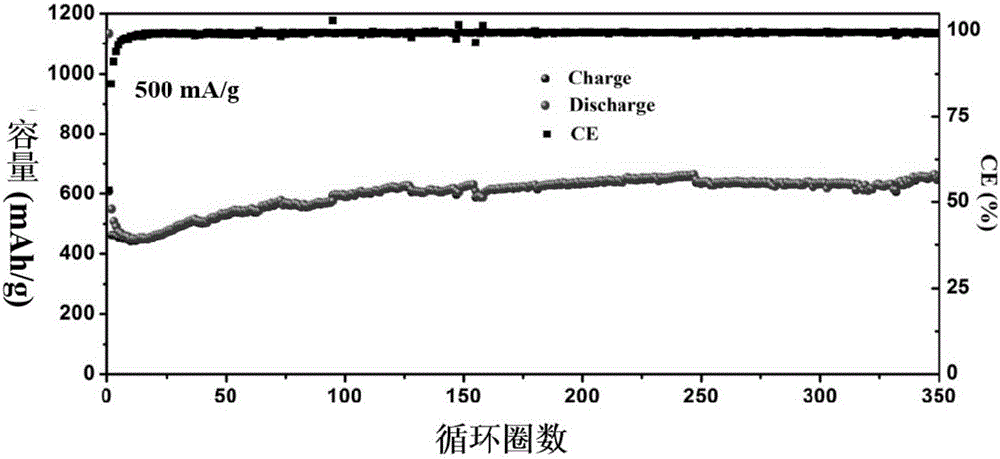

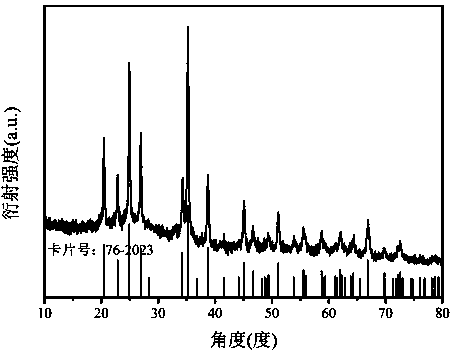

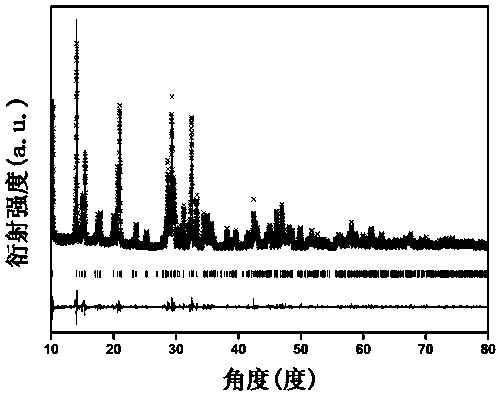

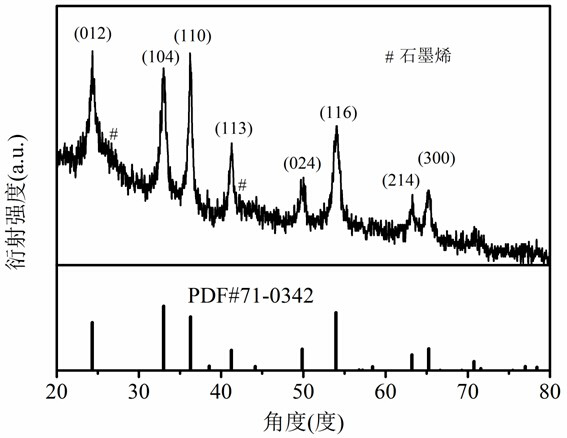

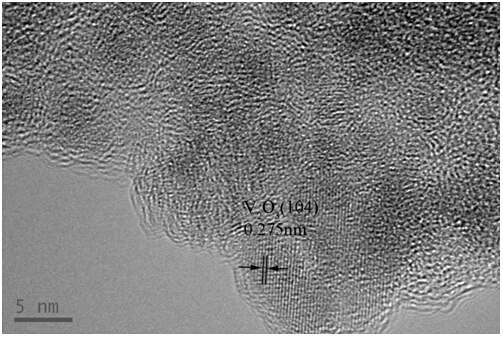

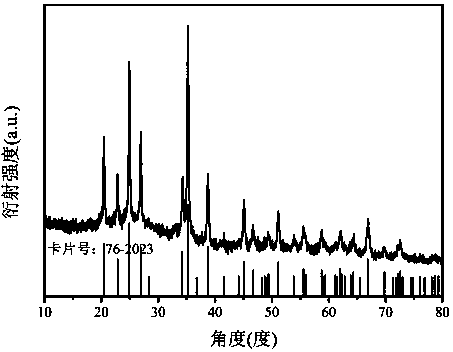

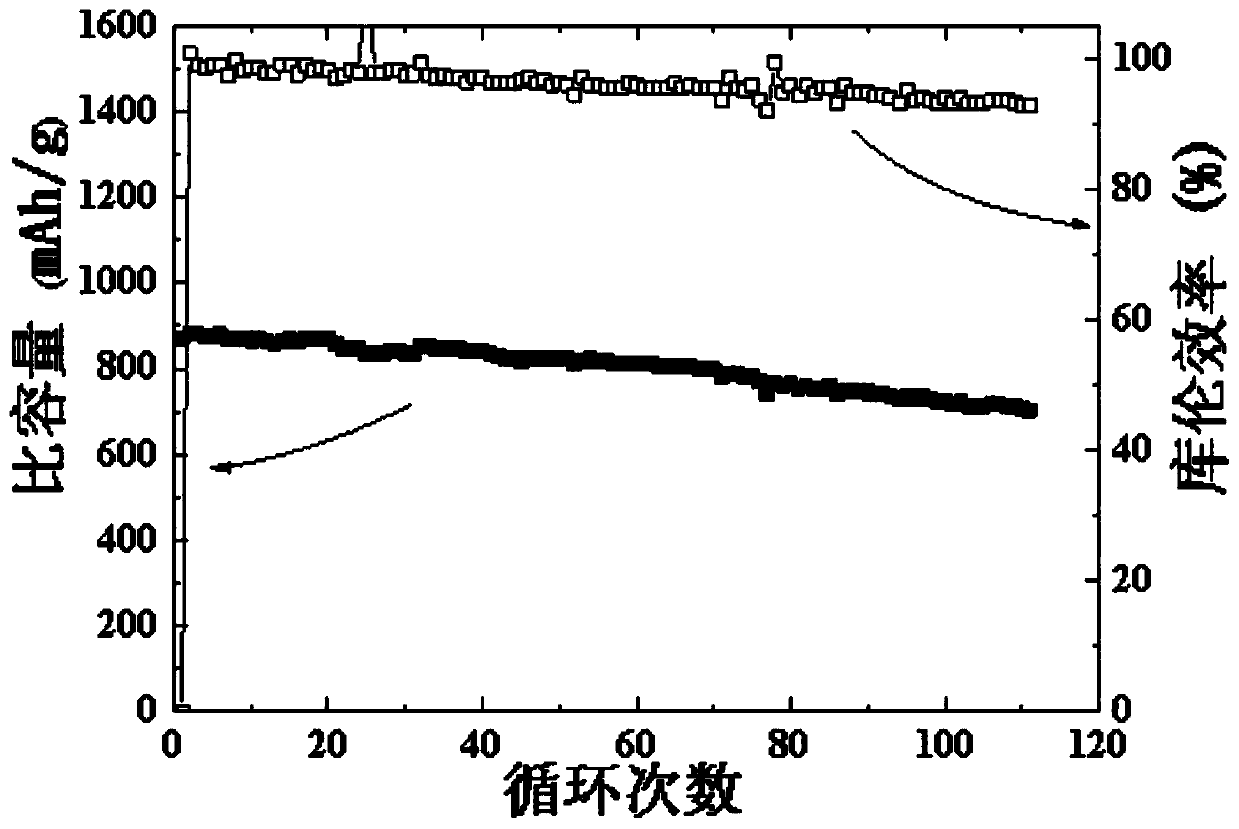

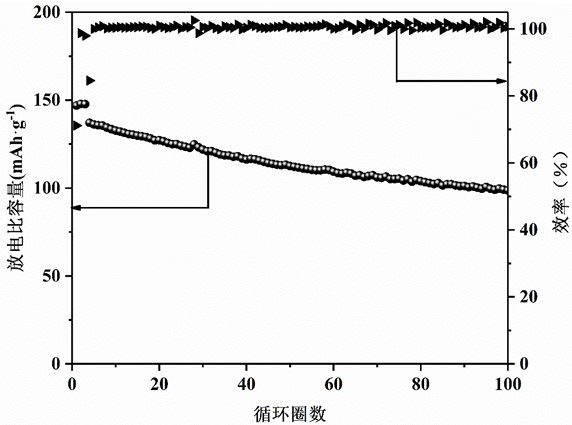

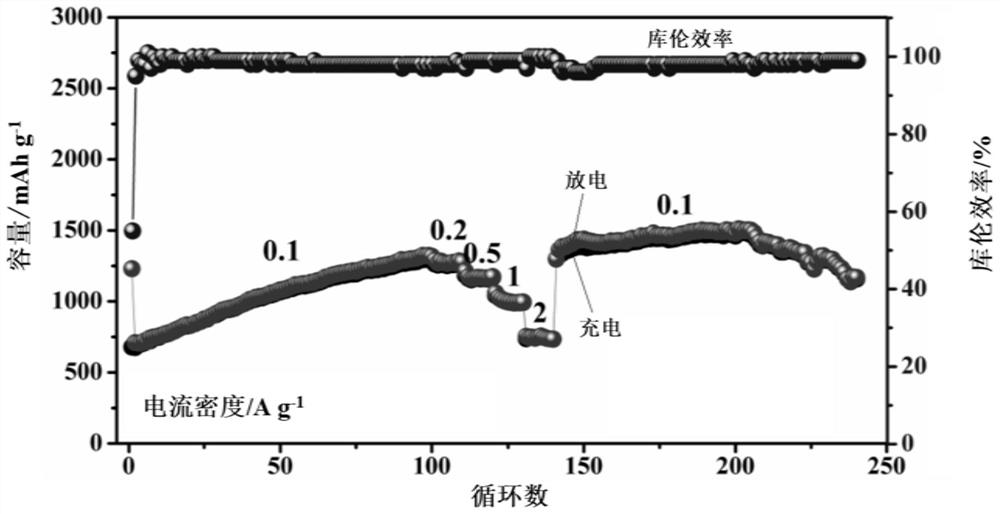

Lithium-ion battery composite negative electrode material vanadium trioxide/graphene and preparation method

ActiveCN108598444BImprove cycle stabilityGood economic valueMaterial nanotechnologyCell electrodesLithium-ion batteryHeat treated

Lithium-ion battery composite negative electrode material vanadium trioxide / graphene and its preparation method. The vanadium trioxide / graphene is made by the following method: (1) adding vanadium source into an oxidation solvent, heating and stirring continuously until dissolved , to obtain solution A; (2) Add graphene oxide into solution A, and then ultrasonically disperse graphene oxide uniformly to obtain liquid B; (3) heat, perform hydrothermal reaction, wash, centrifuge, and dry to obtain a precursor; (4) Carry out heat treatment under reducing atmosphere, and it is ready. In the vanadium trioxide / graphene composite negative electrode material of the lithium ion battery of the present invention, the vanadium trioxide is a nano particle with a particle diameter of 100 to 200 nm anchored on the surface of the graphene, and the vanadium trioxide is a pure phase; the assembled lithium The ion battery has high specific capacity and excellent cycle stability, and has remarkable economic value; the method of the invention is simple in operation, low in cost, strong in controllability and good in repeatability, and is suitable for industrialized production.

Owner:CENT SOUTH UNIV

Preparation method of hollow spherical negative electrode material vanadium phosphate/carbon for lithium ion battery

ActiveCN108281632AIncrease capacityImprove cycle stabilityCell electrodesSecondary cellsSodium-ion batteryRetention ratio

The invention discloses a preparation method of hollow spherical negative electrode material vanadium phosphate / carbon for a lithium ion battery. The preparation method comprises the following steps:(1) adding a vanadium source into water, heating and stirring, then adding a high molecular surfactant, heating and stirring to obtain a precursor solution; (2) carrying out spray drying to obtain a precursor of a vanadium phosphate / carbon material; and (3) carrying out heat treatment under an inert atmosphere to obtain the material. In the hollow spherical vanadium phosphate / carbon obtained by the method, vanadium phosphate is a pure phase, the particle morphology is uniform, and the particles are spherical; according to the assembled lithium ion battery, under 0 to 3 V and 100 mA / g, the first discharge gram volume reaches up to 1073.47 mAh / g, and the coulombic efficiency is high; the first reversible specific capacity reaches 551.41 mAh / g, and the capacity retention ratio after 83 timesof circulations is 80.0%; and the method is simple in operation and low in cost, and is applicable to industrial production.

Owner:CENT SOUTH UNIV

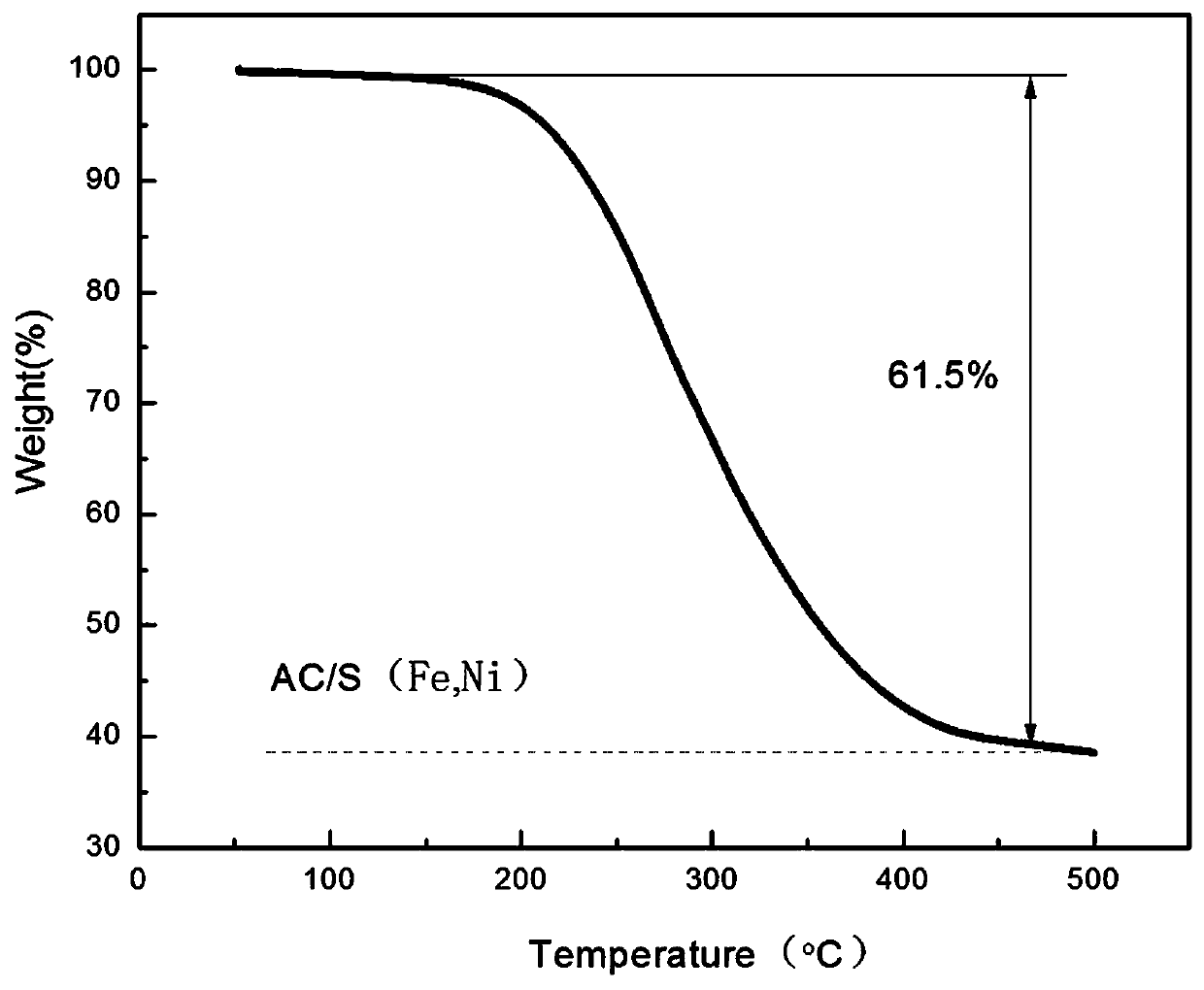

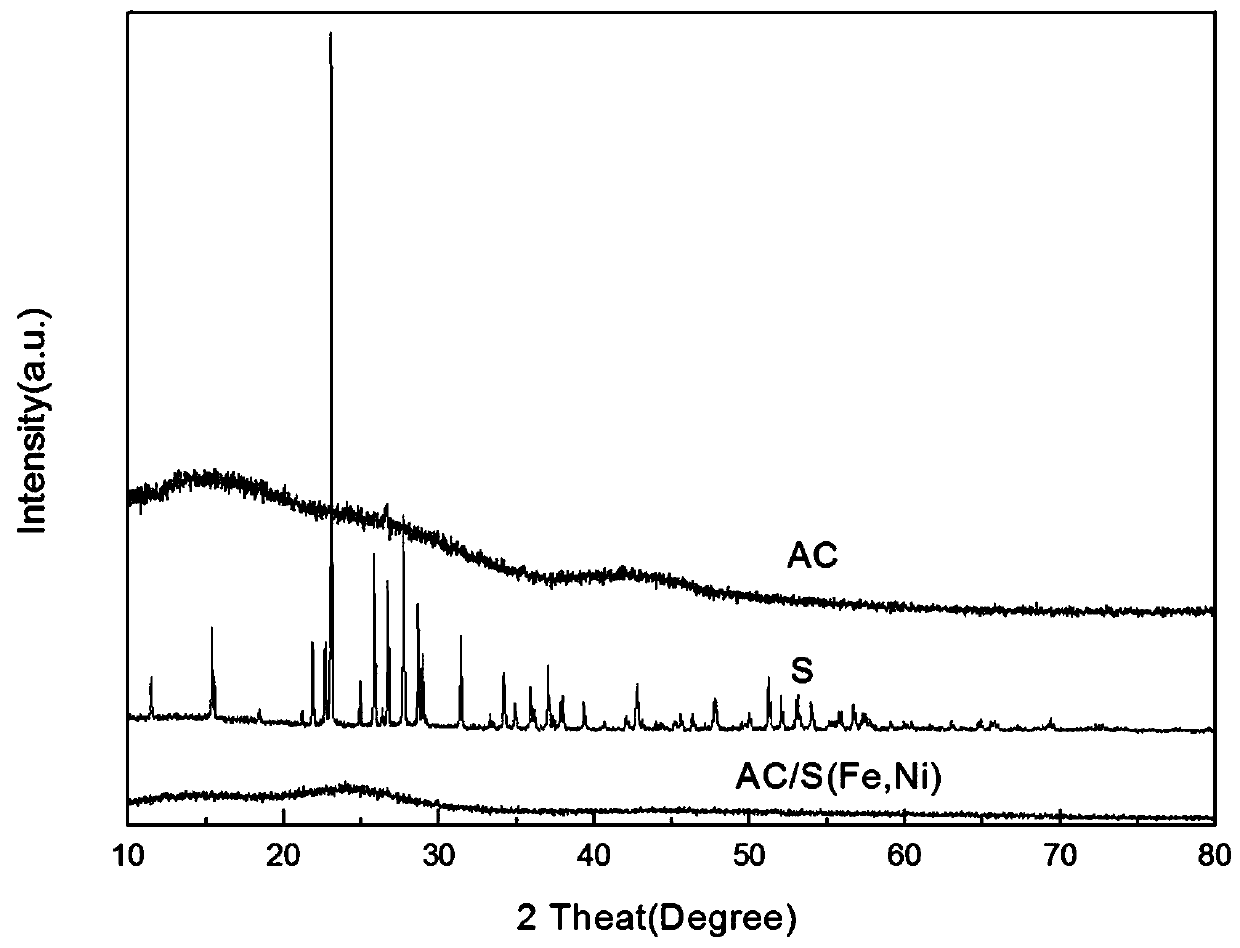

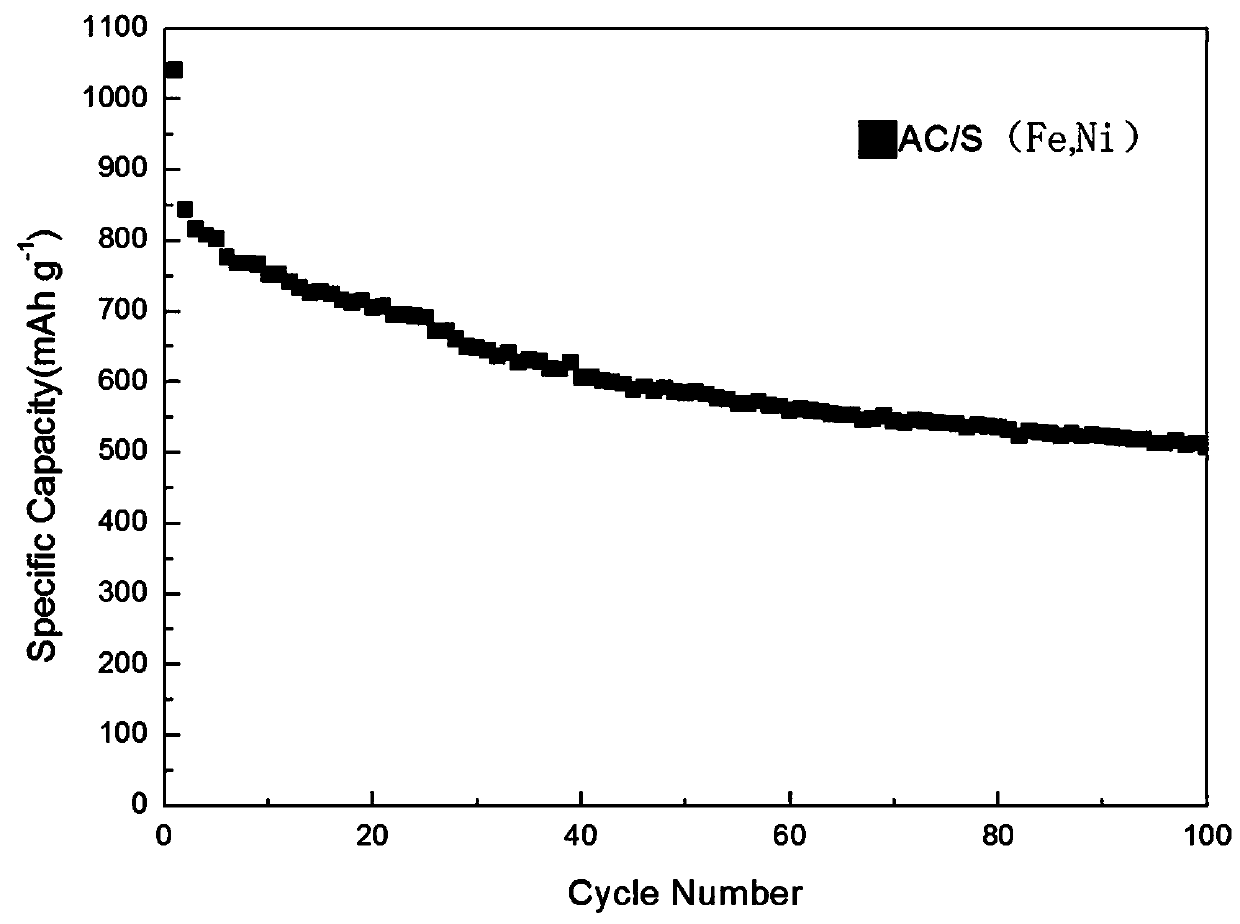

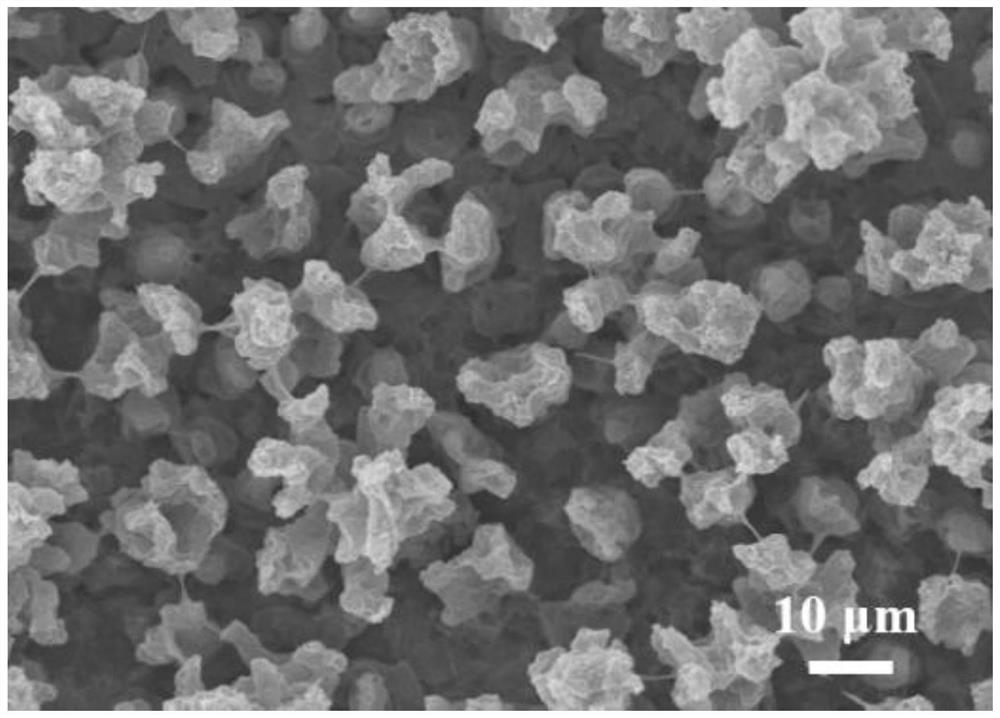

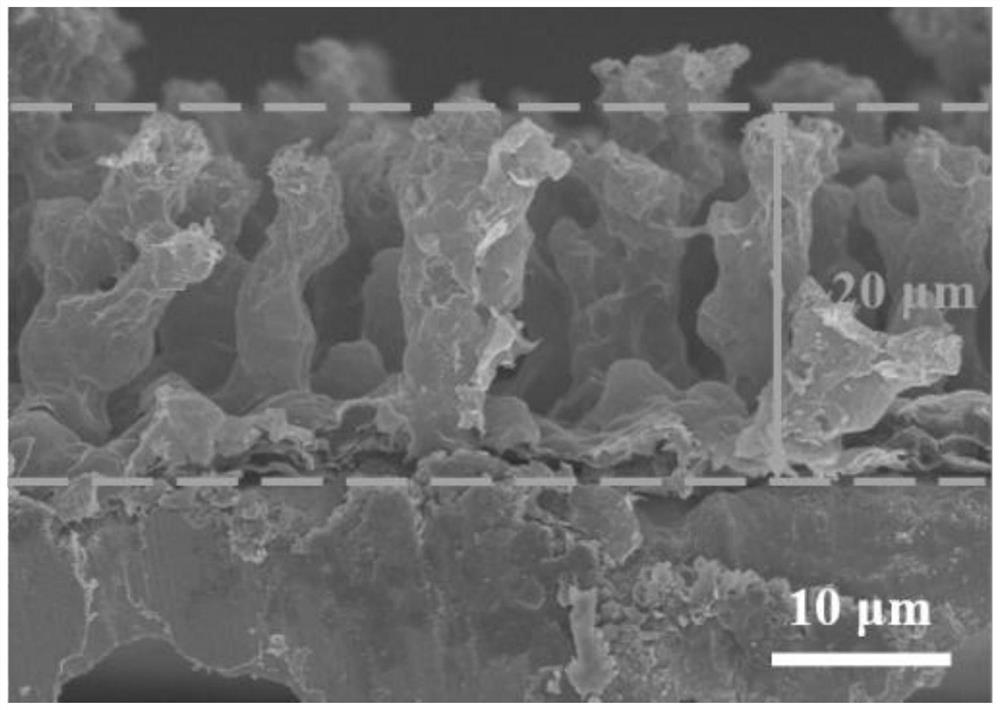

Iron and nickel-doped activated carbon-sulfur material and preparation method and application thereof

InactiveCN107591523AHigh discharge specific capacityImprove cycle performanceCell electrodesLi-accumulatorsActivated carbonSulfur content

The invention discloses an iron and nickel-doped activated carbon-sulfur material. The iron and nickel-doped activated carbon-sulfur material is obtained by activating an inorganic nickel salt, an inorganic iron salt, activated carbon and sulfur as raw materials through a hydrothermal method, a liquid-phase in-situ composite method and a melting method. The preparation method comprises the following steps of (1) preparing iron and nickel-doped activated carbon powder through the hydrothermal method; (2) preparing an unactivated iron and nickel-doped activated carbon-sulfur material through theliquid-phase in-situ composite method; and (3) activating the iron and nickel-doped activated carbon-sulfur material. The iron and nickel-doped activated carbon-sulfur material is used as a positiveelectrode of a lithium-sulfur battery; when the current density is 167.5mA / cm<2>, the initial specific discharge capacity is 1,000-1100mAh / g; and after 100 cycles, the specific capacity is reduced to500-550mAh / g. The iron and nickel-doped activated carbon-sulfur material has the advantages that (1) the sulfur content is greatly improved; (2) dissolution of one part of polysulfide is successfullyinhibited; and (3) component distribution is uniform, negative electrode corrosion and internal resistance increase of the battery caused by the shuttle effect are effectively inhibited, and the effects of providing the specific discharge capacity, reducing the battery capacity attenuation rate and improving the cycle performance are achieved.

Owner:GUILIN UNIV OF ELECTRONIC TECH

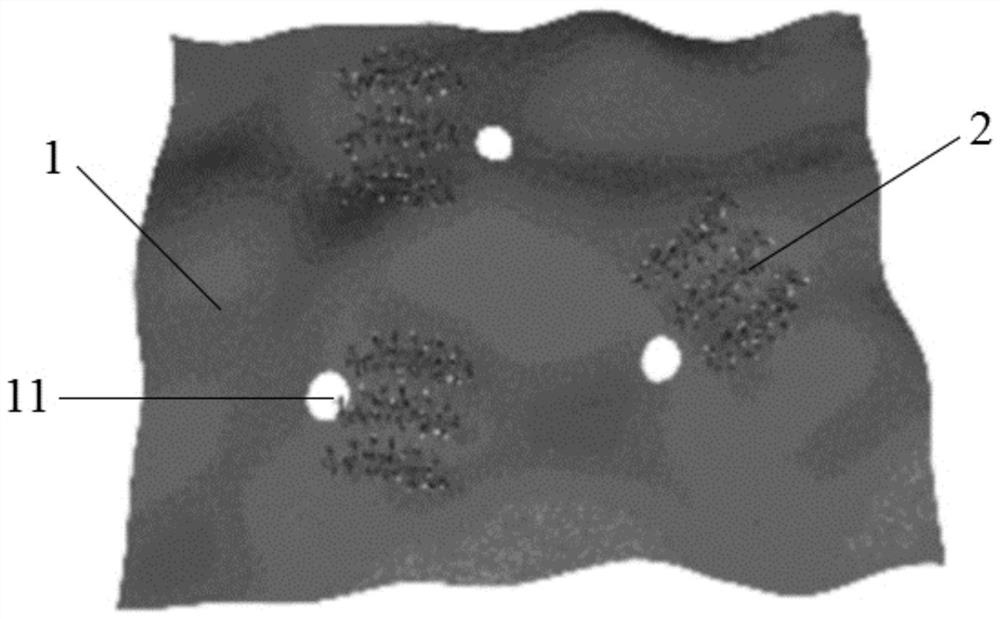

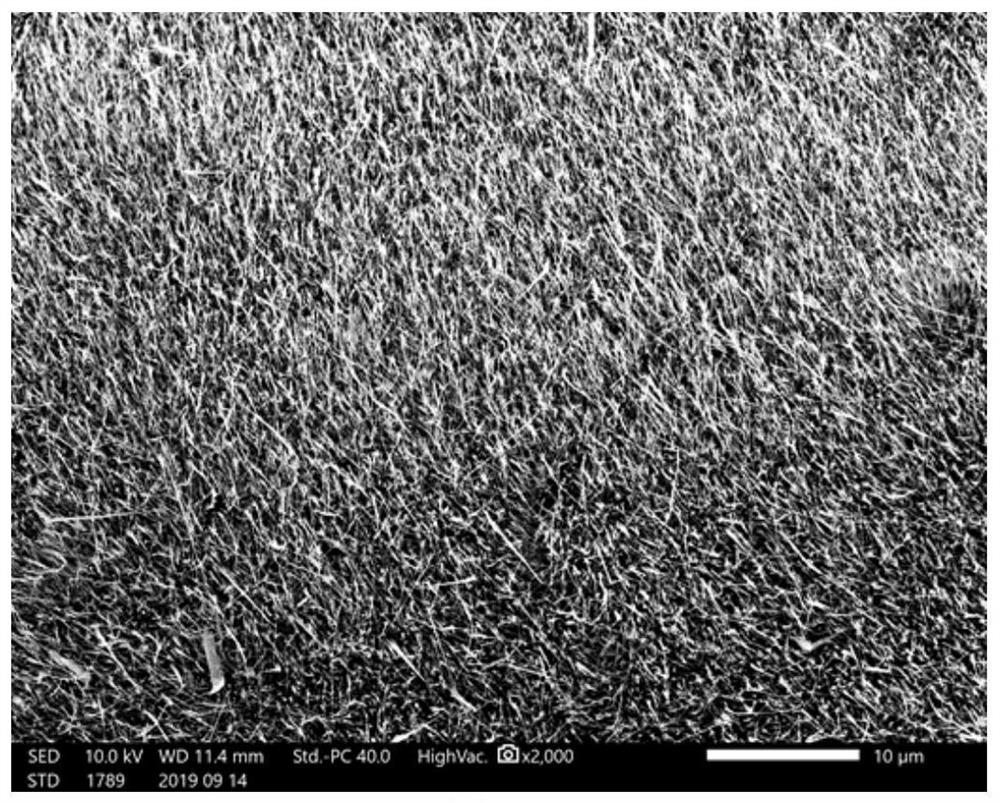

Upright graphene/nano-silver composite material and preparation method and application thereof

ActiveCN113921826ACoulombic efficiency is stableImprove cycle lifeElectrode carriers/collectorsLi-accumulatorsBattery cellSilver Nano

The invention discloses a preparation method of a vertical graphene / nano-silver composite material, and the method comprises the following steps: S1, spraying a graphene oxide solution on a substrate to form a horizontal graphene arrangement layer; S2, spraying a template solution and a graphene oxide solution on the horizontal graphene arrangement layer at the same time to obtain a precursor; S3, performing heat treatment on the precursor material, and then performing cleaning and drying to form an upright graphene array layer to obtain a columnar upright graphene array material; S4, dipping the columnar upright graphene array material in a nano-silver solution, and then performing drying to remove a solvent; S5, carrying out heat treatment on the columnar upright graphene array material impregnated with the nano-silver in an inert atmosphere to obtain the upright graphene / nano-silver composite material. The invention also discloses the upright graphene / nano-silver composite material prepared by the method and application thereof. The application comprises the following two aspects: application as a current collector material and application in preparation of a battery.

Owner:深圳石墨烯创新中心有限公司

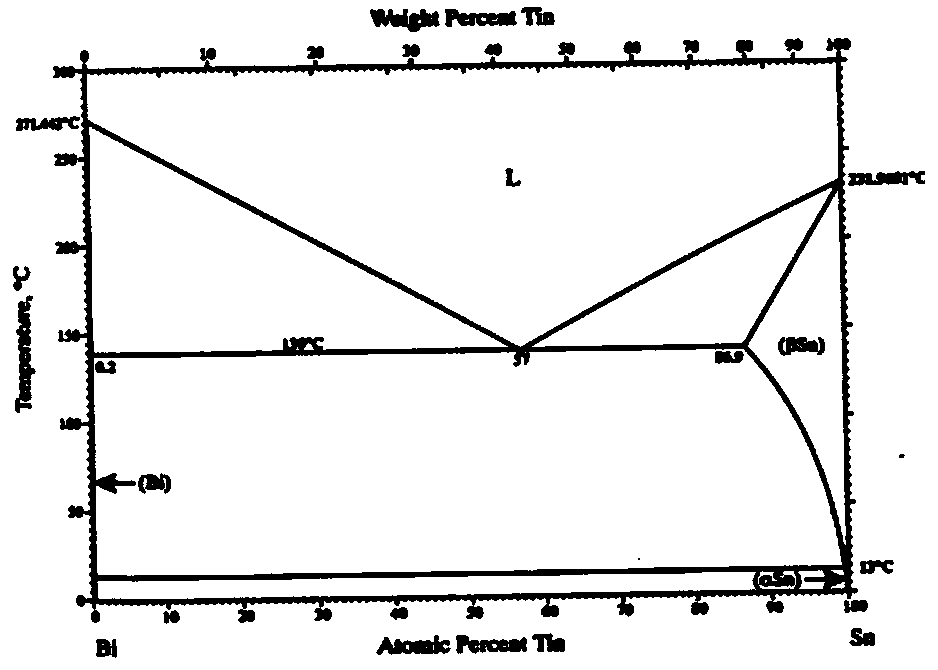

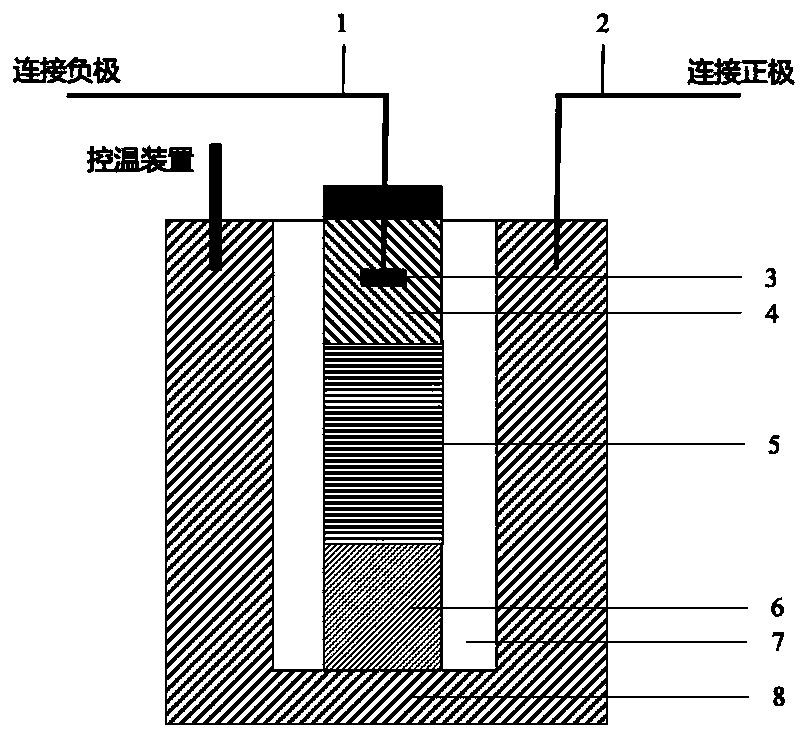

Application of LiI-KI eutectic salt in low-temperature liquid state molten salt lithium battery, and low-temperature liquid state molten salt lithium battery and preparation method thereof

ActiveCN110148779AGood charge and discharge cycleCoulombic efficiency is stableFinal product manufactureLi-accumulatorsElectrolyteMolten salt

The invention provides application of a LiI-KI eutectic salt in a low-temperature liquid state molten salt lithium battery, and a low-temperature liquid state molten salt lithium battery and a preparation method thereof, belonging to the field of lithium batteries. The present invention provides the application of the LiI-KI eutectic salt in the low-temperature liquid state molten salt lithium battery. The eutectic temperature of the LiI-KI eutectic salt taken as an electrolyte is 260-265 DEG C so that it is achieved that the whole liquid state molten salt lithium battery can work at an operation temperature below 300 DEG C. The experiment result shows that: The low-temperature liquid state molten salt lithium battery has good charge-discharge cycles, the open-circuit voltage is 0.76V, thedischarge platform voltage is stabilized at 0.5-0.6V, the discharge platform voltage is 0.8-0.9V, and the coulombic efficiency is basically stabilized at about 97%.

Owner:BEIHANG UNIV

Preparation method of high-voltage positive electrode material with core-shell structure

ActiveCN114094060AMorphological rulesEvenly distributedCell electrodesOrganic solventPhysical chemistry

The invention discloses a preparation method of a high-voltage positive electrode material with a core-shell structure. The preparation method comprises the following steps of (1) ultrasonically dispersing a nickel source, a manganese source and a lithium source in an organic solvent, stirring and dissolving to form a solution containing nickel, manganese and lithium, (2) ultrasonically dispersing the ternary positive electrode material in an organic solvent, then gradually adding the nickel-manganese-lithium-containing solution into the ternary positive electrode material solution, stirring, heating and evaporating to dryness to obtain a powder precursor, (3) drying the powder precursor, heating and sintering in an oxidizing atmosphere, and cooling to obtain a sintered material, and (4) carrying out electric activation treatment on the sintered material to obtain the high-voltage positive electrode material with the core-shell structure. The preparation process is simple and easy to implement, and the prepared high-voltage positive electrode material has the advantages that the structure is stable, the coating layer is not easy to peel off, and the electrochemical performance under high voltage is good.

Owner:CENT SOUTH UNIV

Preparation method of porous copper current collector, porous copper current collector, negative electrode and battery

ActiveCN109546153BModerate pore sizeEvenly distributedElectrode carriers/collectorsElectrical batteryHydrogen atmosphere

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

Lithium-sulfur battery positive electrode active material with self-repairing function and preparation method thereof

ActiveCN110752371AAvoid enteringIncrease loadCell electrodesSulfur compoundsElectrolytic agentElectrical battery

The invention discloses a lithium-sulfur battery positive electrode active material with a self-repairing function and a preparation method thereof, and relates to a lithium-sulfur battery positive electrode material and a preparation method thereof. The invention aims to solve the technical problem of volume change caused by conversion of an active substance of the positive electrode between alpha-S8 and Li2S in the charging and discharging process of the existing lithium-sulfur battery. The lithium-sulfur battery positive electrode active material with the self-repairing function is preparedfrom sulfur and amino silicon oil (chitosan, polyethyleneimine)-terephthalaldehyde (glutaraldehyde and 1,3,5-benzenetricarboxaldehyde). According to the invention, a layer of self-repairing network is adsorbed on the surface of sulfur, the volume change of the positive electrode active material in the charging and discharging process is relieved when sulfur is used as the positive electrode active material of the lithium-sulfur battery, the positive electrode active material is prevented from entering an electrolyte, the shuttle effect of polysulfide is reduced, and the capacity and utilization rate of the positive electrode active material are improved.

Owner:HARBIN INST OF TECH

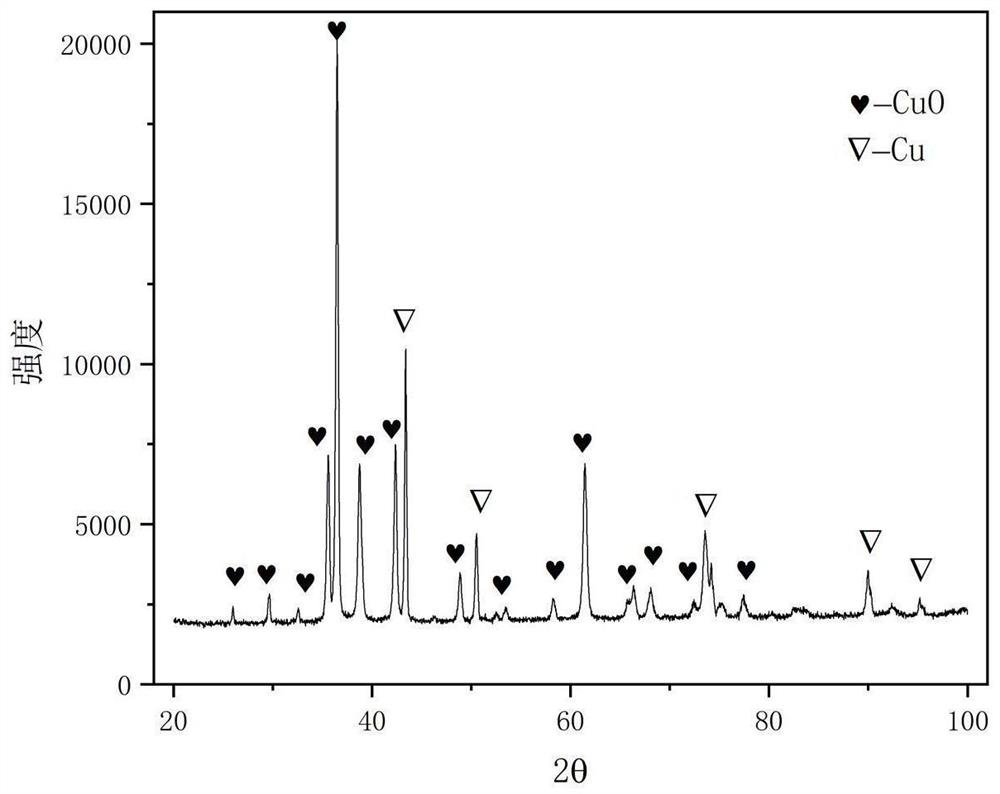

Hollow porous tin dioxide-cuprous oxide-copper or hollow porous tin dioxide-copper integrated lithium battery negative electrode and preparation method thereof

ActiveCN112349876BReduce usageReduce chalkingNegative electrodesLi-accumulatorsNano copperActive particles

Owner:SICHUAN UNIV

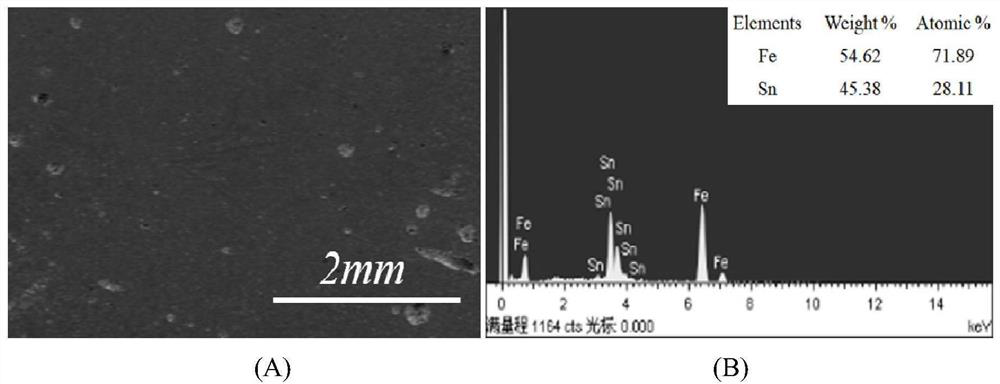

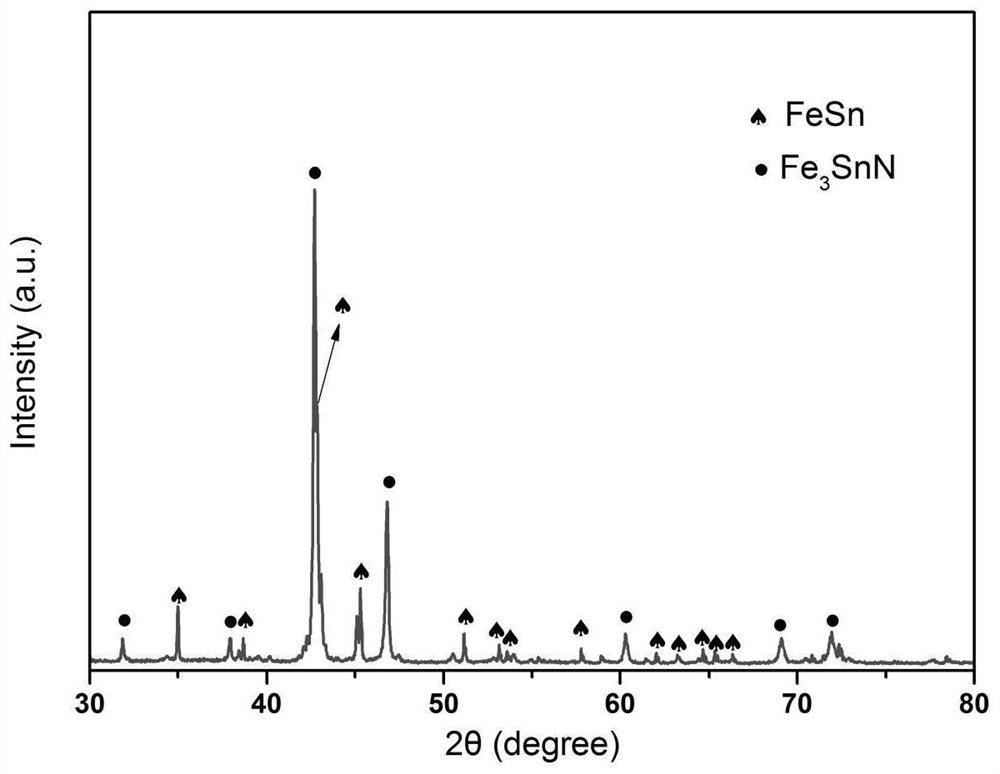

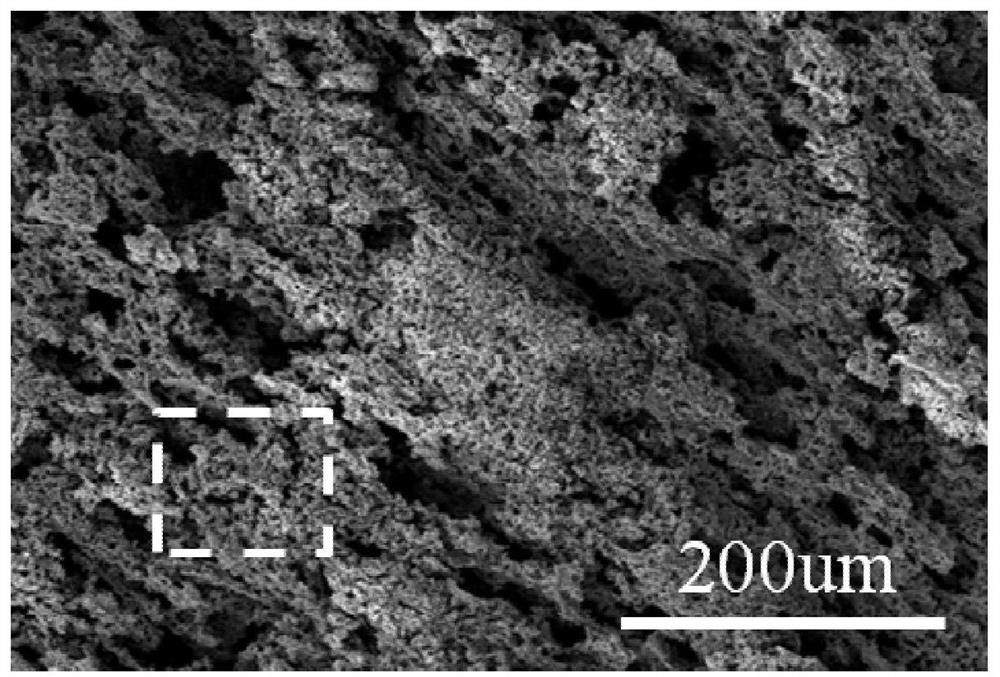

Three-dimensional micro-nano composite porous iron tin-iron tin nitrogen compound integrated lithium ion battery negative electrode and one-step preparation method thereof

ActiveCN112331815ABuffer volume expansionInhibit sheddingSecondary cellsNegative electrodesMicro nanoLithium intercalation

The invention provides a three-dimensional micro-nano composite porous iron-tin-iron-tin-nitrogen compound integrated lithium ion battery negative electrode and a one-step preparation method thereof.The lithium ion battery negative electrode is composed of an iron-tin compound and an iron-tin-nitrogen compound, wherein the iron-tin compound is single FeSn or FeSn / FeSn2, and the iron-tin-nitrogencompound is Fe3SnN; the lithium ion battery negative electrode has a bicontinuous open-pore three-dimensional micron-nano composite hierarchical pore structure, and the nano pore structure is distributed on a three-dimensional micron-porous skeleton formed by an iron-tin compound and an iron-tin-nitrogen compound. According to the invention, the huge volume change of the tin negative electrode material in the cyclic lithium intercalation and deintercalation process can be relieved, and the cycle performance and specific capacity of the tin negative electrode of the lithium ion battery are improved.

Owner:SICHUAN UNIV

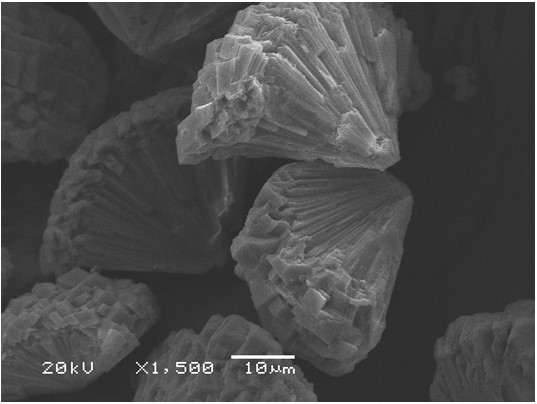

Ternary precursor with radial spherical top cone structure, positive electrode material and preparation method

ActiveCN113258062BMorphological rulesEvenly distributedSecondary cellsPositive electrodesPhysical chemistryCharge and discharge

A ternary precursor with a spherical pyramid-like structure, a positive electrode material, and a preparation method thereof, wherein the cone of the ternary precursor is long strip-shaped primary particles that grow radially, and the top of the sphere is an orderly stacked block-shaped primary particle , and form secondary aggregates; the chemical formula of the ternary precursor is Ni x co y mn (1‑x‑y) (OH) 2 , wherein, 0.3<x<0.9, 0.05<y<0.50, 0.05<1-x-y<0.50. The invention also discloses a preparation method of the ternary precursor with a radial spherical cone-like structure, an anode material and a preparation method. The ternary precursor and the positive electrode material of the present invention have regular morphology and uniform distribution, which is beneficial to the transportation of lithium ions during charge and discharge, and has stable discharge specific capacity, charge and discharge performance and Coulombic efficiency, and good cycle performance. The method of the invention has the advantages of simple process, low reaction temperature and low cost of raw materials, and is suitable for industrialized production.

Owner:CENT SOUTH UNIV

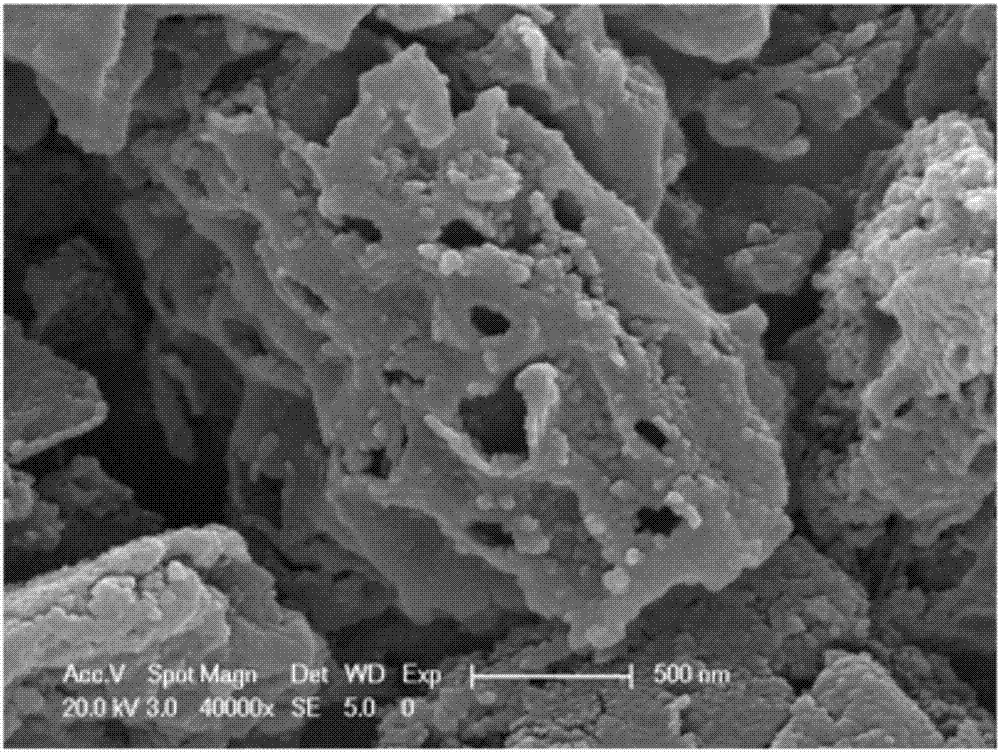

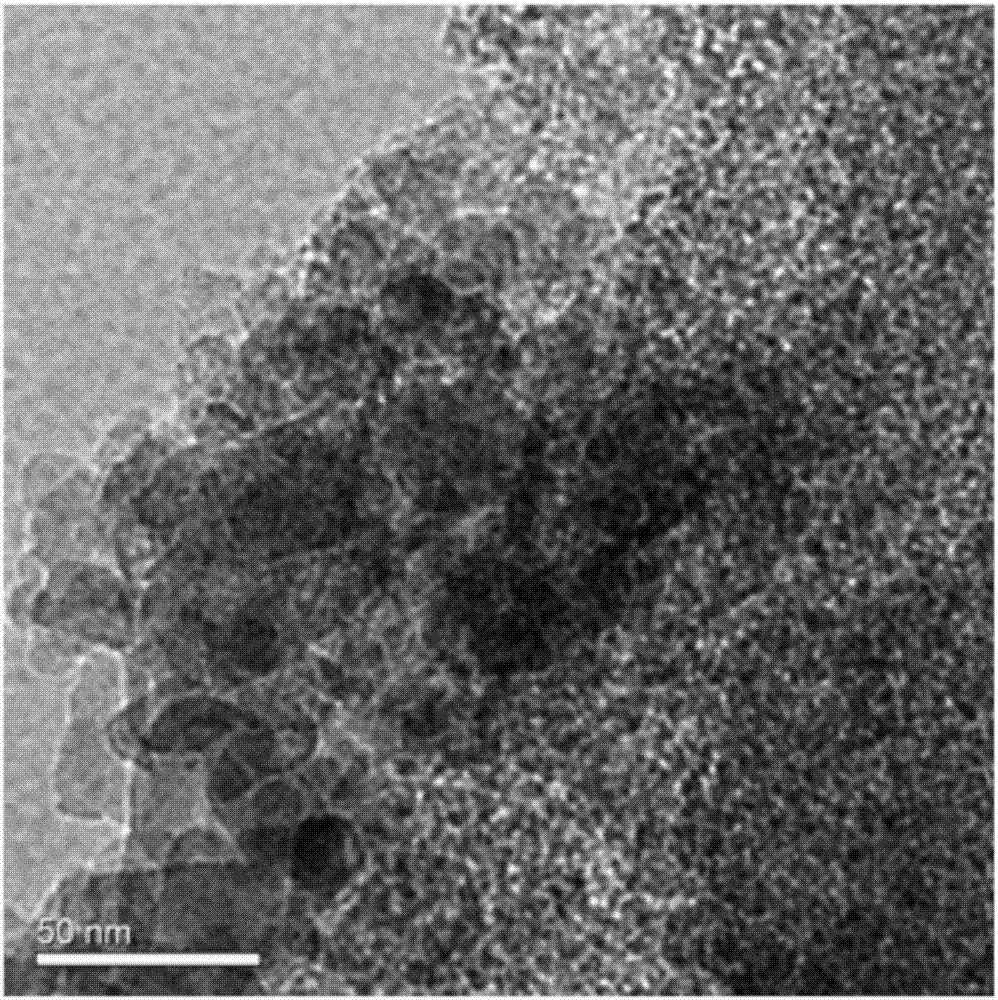

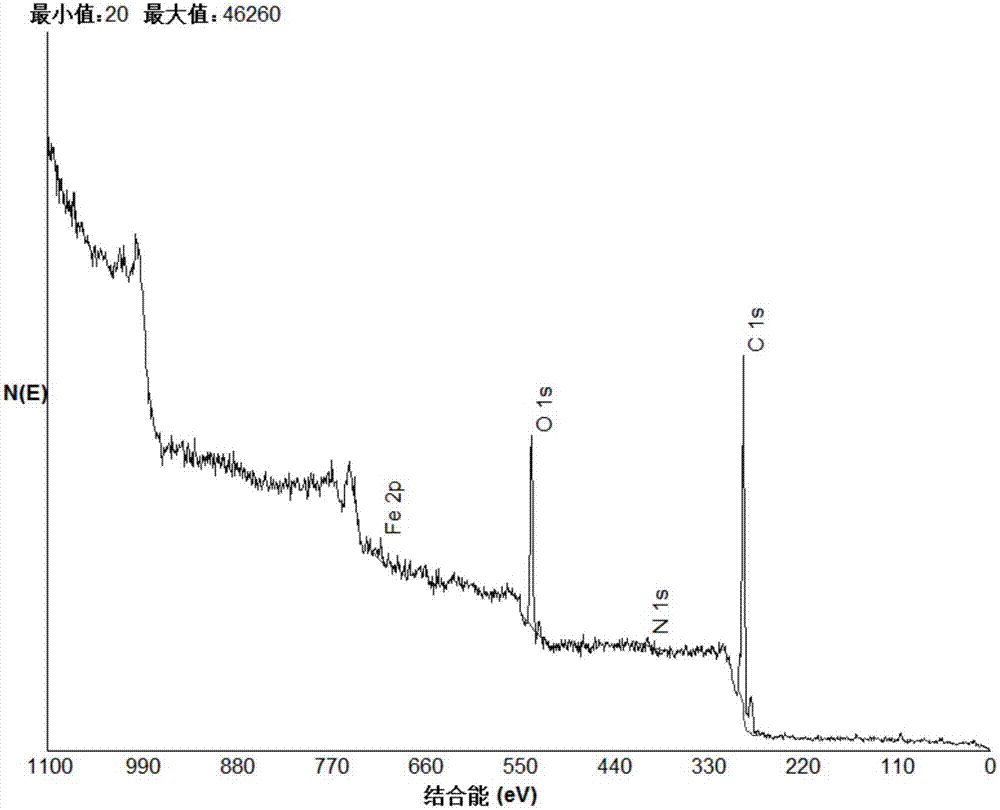

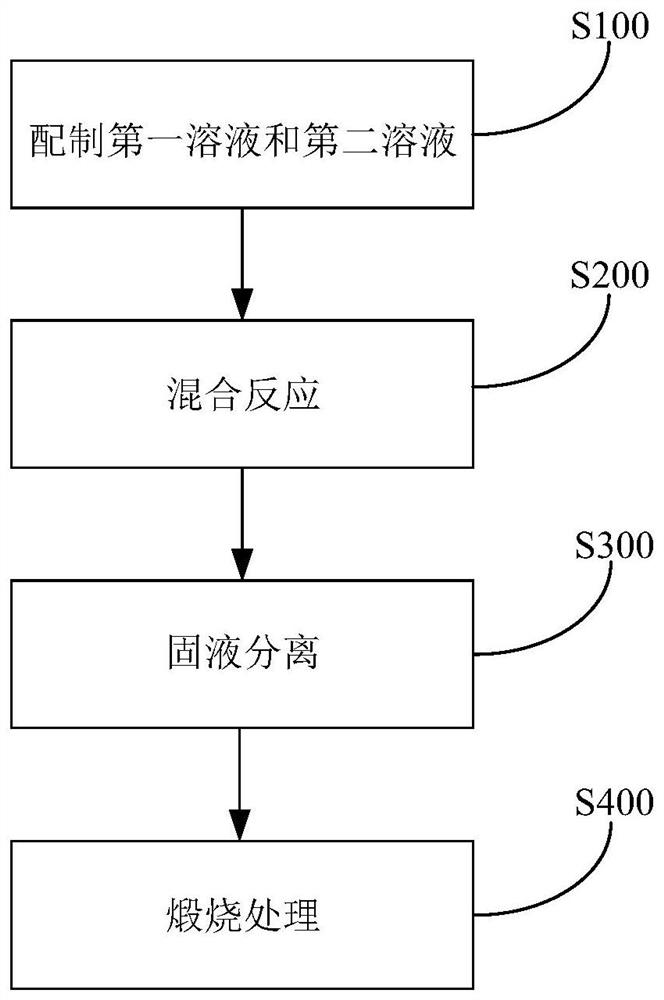

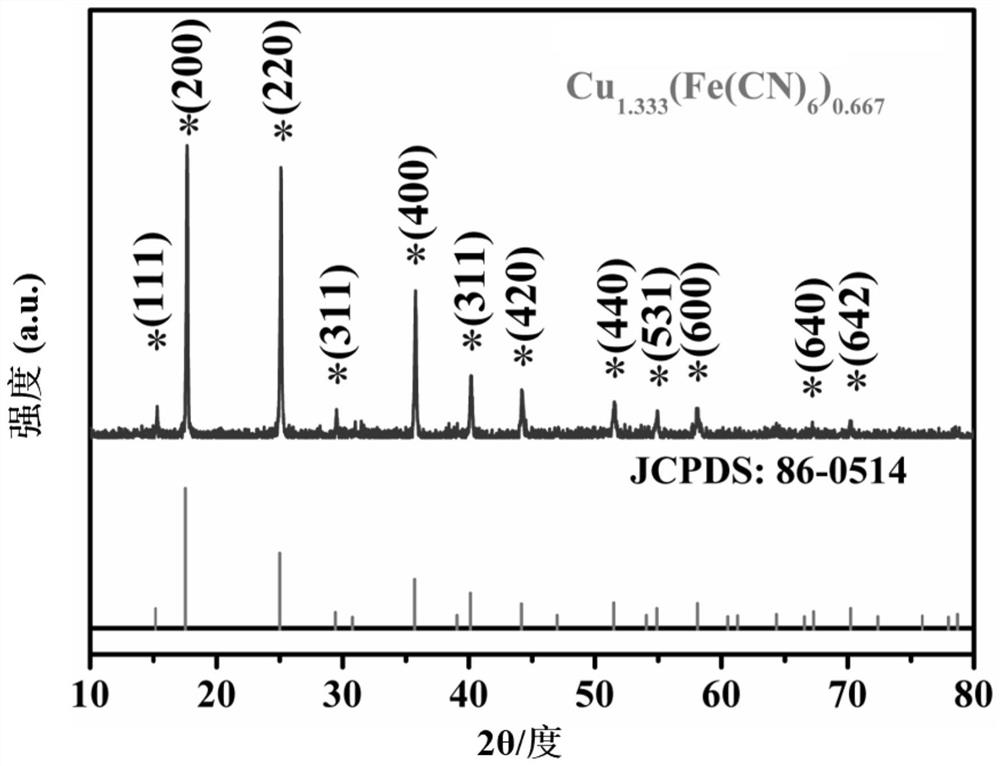

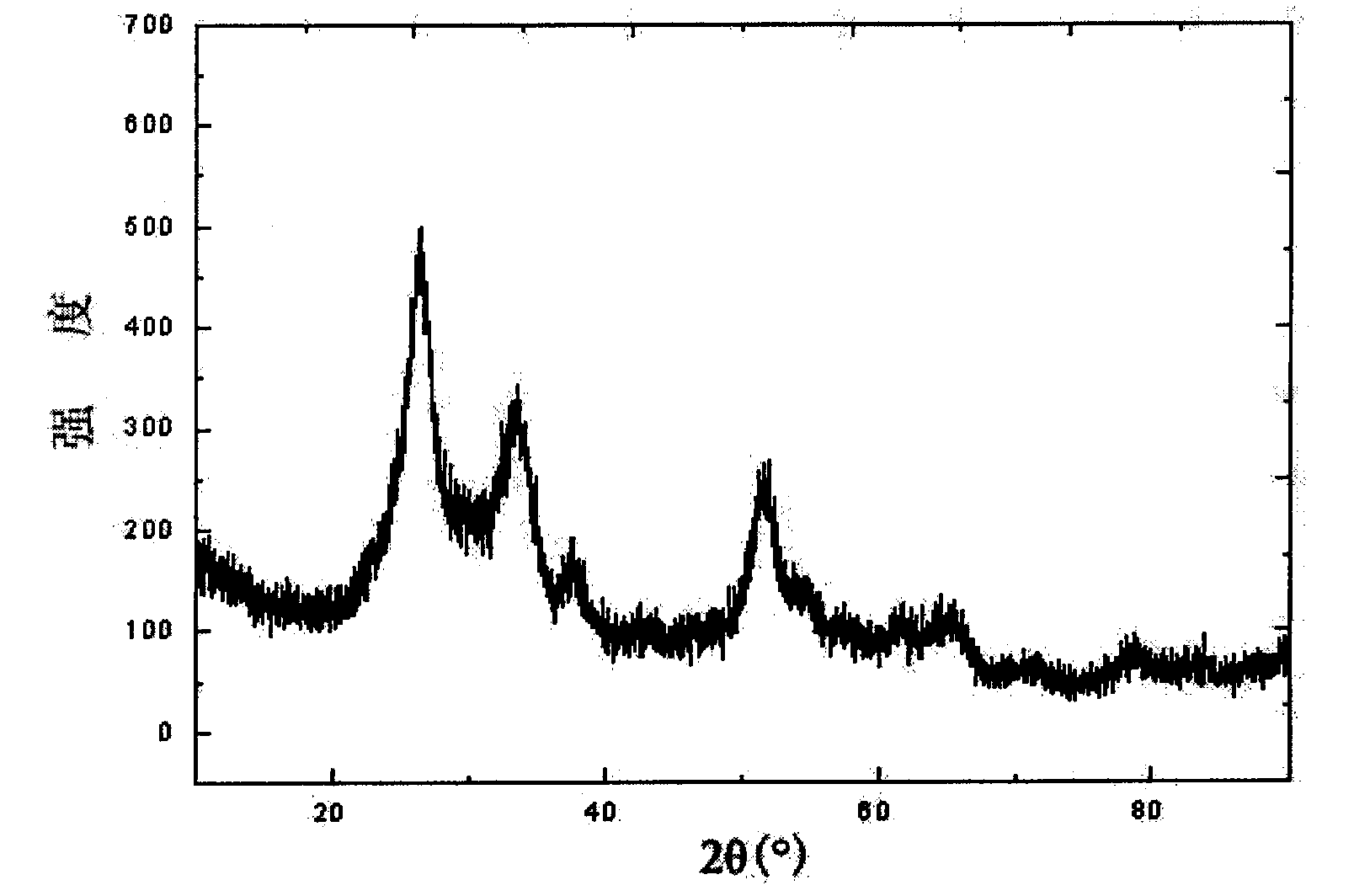

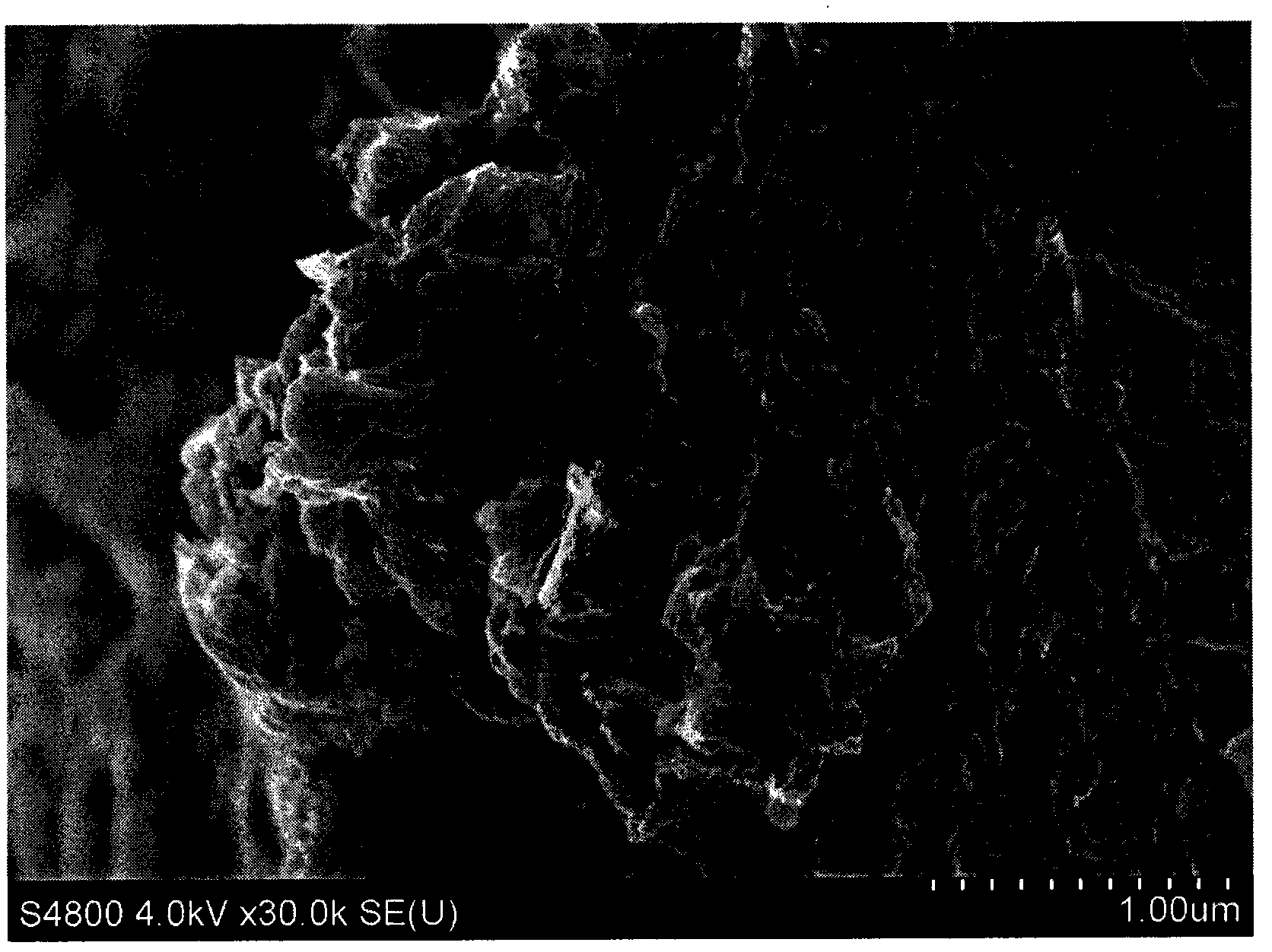

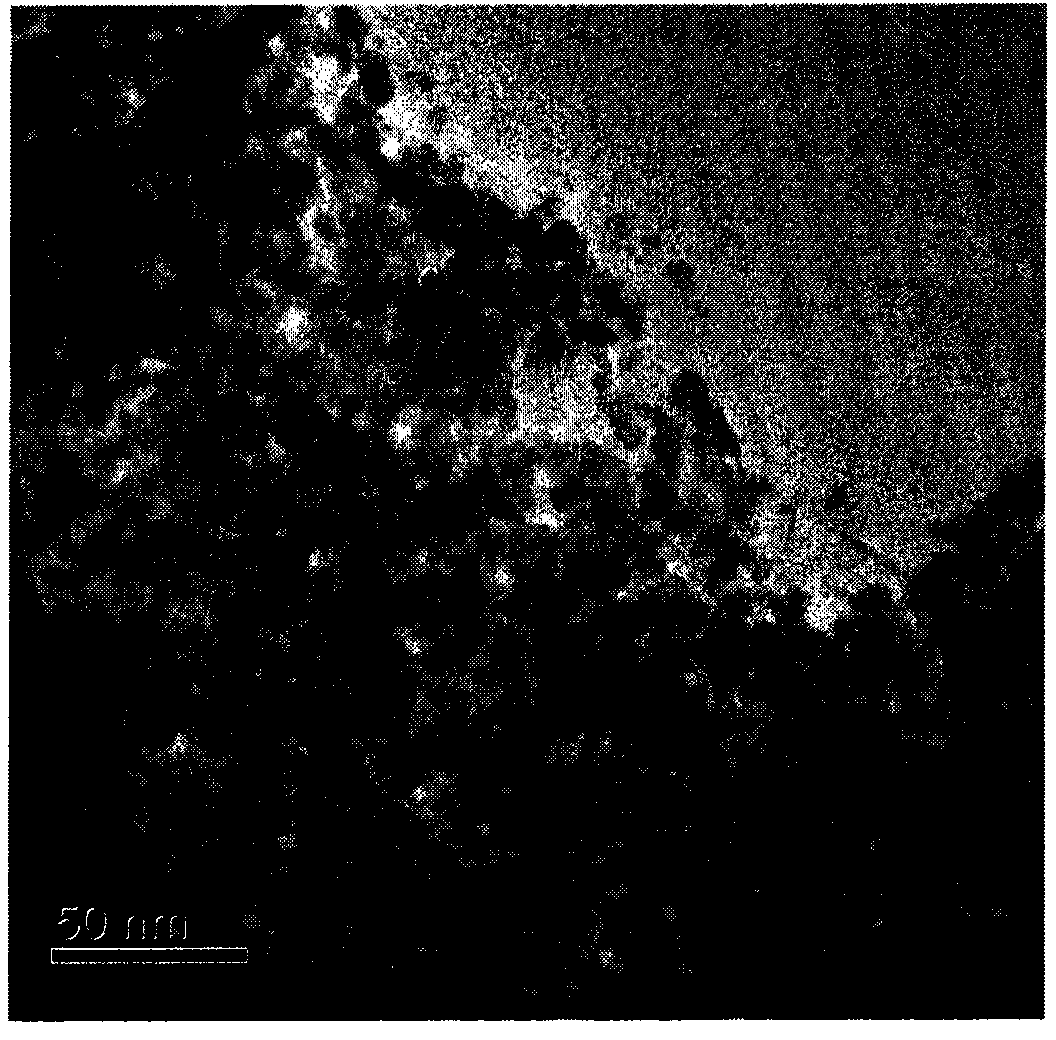

Cu-Fe bimetallic oxide material as well as preparation method and application thereof

InactiveCN112054179ACoulombic efficiency is stableStable Cycle CharacteristicsNegative electrodesSecondary cellsCopper saltBimetal

The invention discloses a Cu-Fe bimetallic oxide material as well as a preparation method and application thereof. The method for preparing the CuFe bimetallic oxide material comprises the following steps: (1) mixing ferricyanate with a solvent to obtain a first solution, mixing copper salt, a complexing agent, a stabilizer and a solvent to obtain a second solution; (2) adding the second solutioninto the first solution and reacting to obtain a reaction product; (3) carrying out solid-liquid separation on the reaction product, and collecting a solid product; and (4) calcining the solid productto obtain the Cu-Fe bimetallic oxide material. The Cu-Fe bimetallic oxide material has a porous structure and a large number of mesopores which are connected with one another and a large specific surface area, and has stable coulombic efficiency, high theoretical capacity and stable cycle characteristics.

Owner:KUNSHAN BAOTRON NEW ENERGY TECH CO LTD

Preparation method of stannic oxide or metallic tin and grapheme lamella composite material

ActiveCN102255072BImprove structural stabilityImprove electrochemical performanceCell electrodesTin dioxideHYDROSOL

The invention provides a preparation method of a stannic oxide and grapheme lamella composite material. The preparation method comprises the following steps of mixing at least one organic solvents, graphene oxide lamella hydrosol and at least one tin salt, heating the mixture at a temperature of 60 to 200 DEG C for 0.5 to 12 hours to obtain a solid substance, and heating the solid substance in the inert gas atmosphere at a temperature of 400 to 700 DEG C for 0.5 to 10 hours. The invention also provides a preparation method of a metallic tin and grapheme lamella composite material. The preparation method comprises the following step of preparing a stannic oxide and grapheme lamella composite material through the preparation method of a stannic oxide and grapheme lamella composite material, and heating the prepared stannic oxide and grapheme lamella composite material in the reducing gas atmosphere at a temperature of 400 to 1000 DEG C for 0.5 to 4 hours. The preparation methods of the invention can improve a structural stability and an electrochemical performance of a material and is beneficial to improve a high-speed charging and discharging performance and a conductivity of a composite material. The preparation methods have the characteristics of cheap and easily available raw materials, simple process, and good applicability for industrial continuous production.

Owner:SHAANXI EPUNO NEW ENERGY TECH CO LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com