Room temperature sodium-sulfur battery positive electrode material and preparation method and application thereof

A sodium-sulfur battery and cathode material technology, applied in battery electrodes, nanotechnology for materials and surface science, positive electrodes, etc., can solve low Coulombic efficiency, slow reaction kinetics volume expansion effect, poor cycle life, etc. problem, to achieve the effect of increasing energy density, increasing discharge voltage platform, and improving conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

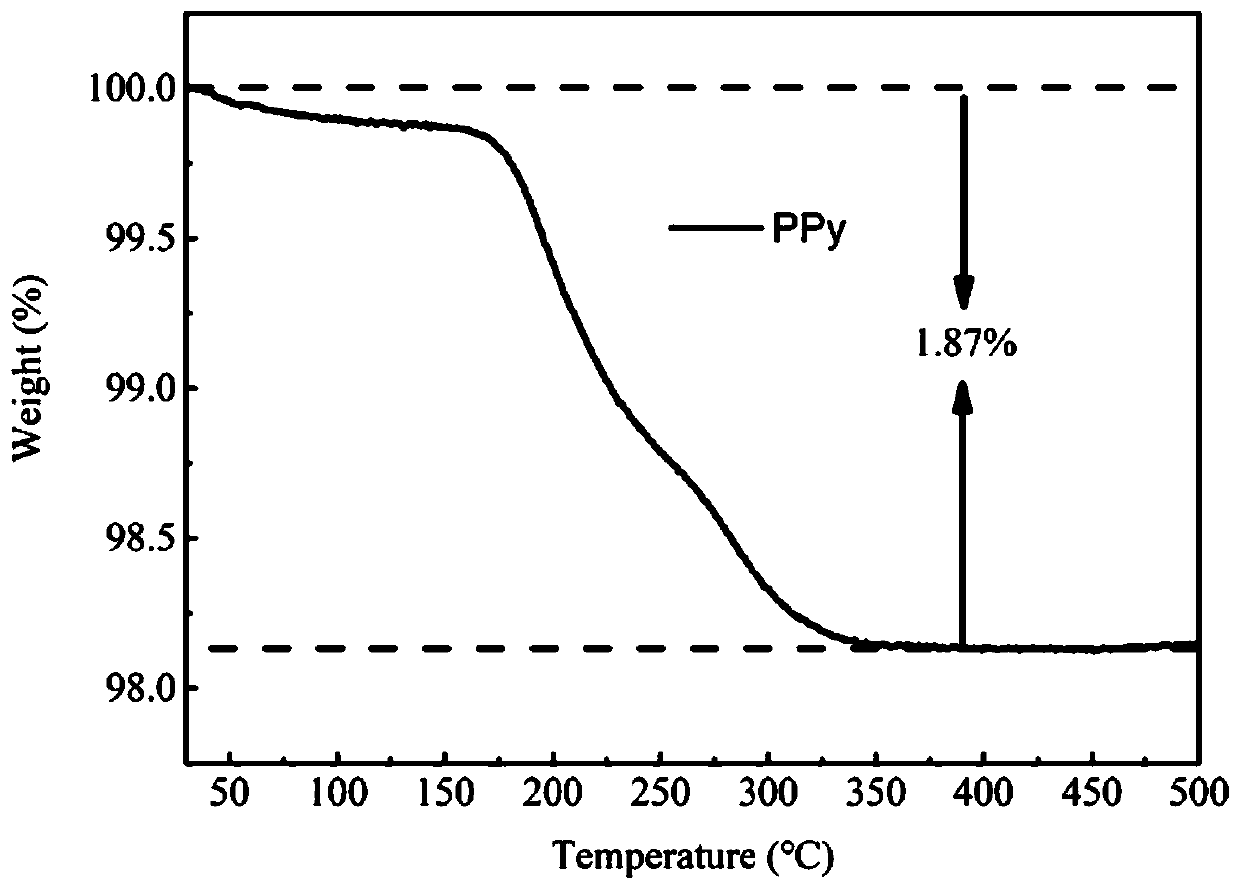

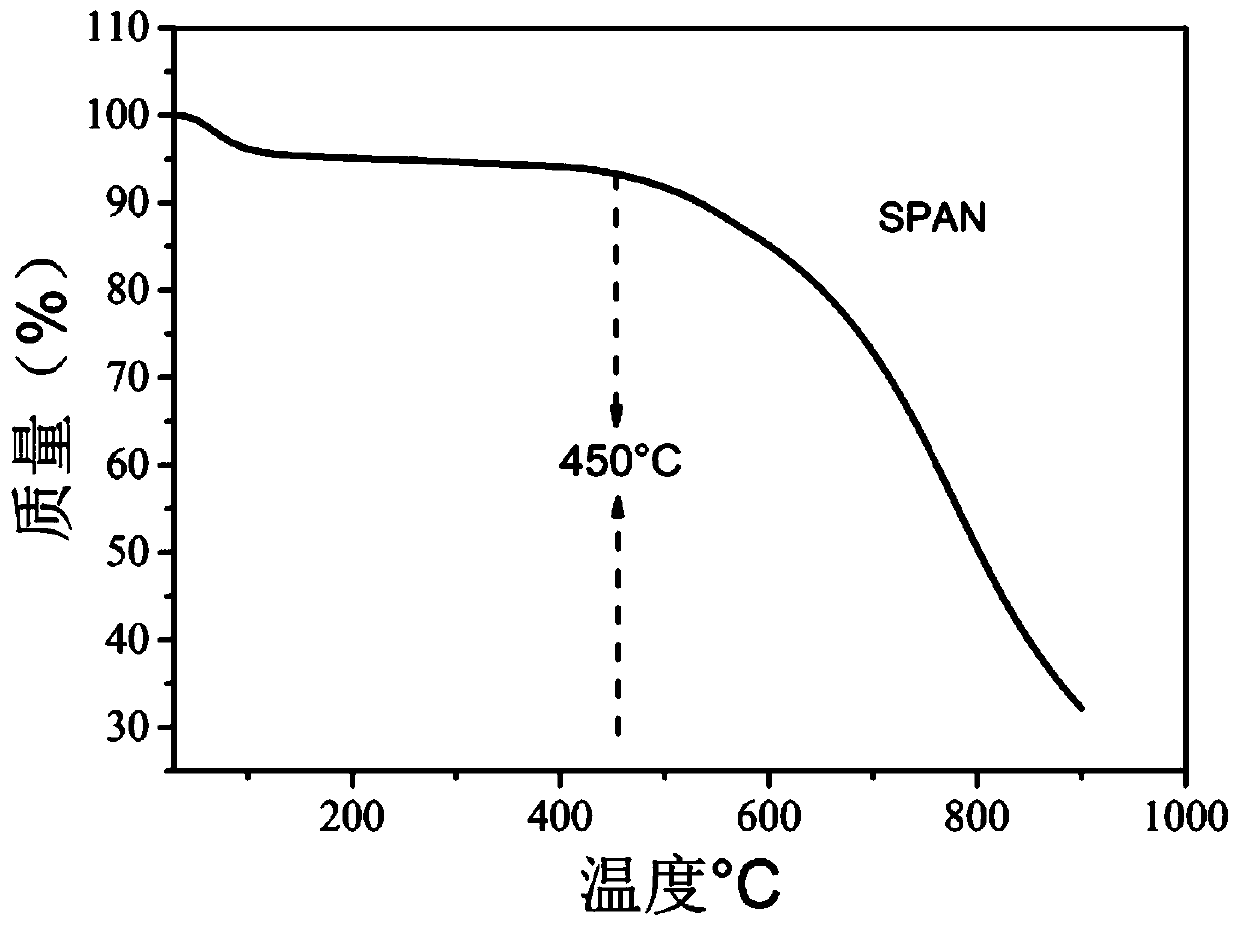

[0060] This embodiment provides a room-temperature sodium-sulfur battery positive electrode material, which is made of a nitrogen-doped nano-carbon layer coated with a vulcanized polyacrylonitrile material compounded by carbonization of PPy, and the particle size of the material is about 200 nm. The coating amount of the nitrogen-doped nano-carbon layer is 3%, the coating thickness is 5nm, and the mass fraction of sulfur in the final positive electrode material is 41%. Concrete preparation process is as follows:

[0061] S1. Mix 1g of polyacrylonitrile (Mw=150000) and 3g of commercial sulfur powder S 8 Blending was carried out in 200mL absolute ethanol solution, followed by high-energy ball milling for 6h at a rotation speed of 400rpm.

[0062] S2. Put the ball-milled sample into a tube furnace under the protection of argon for calcination at a temperature of 300° C. for 5 hours to obtain a vulcanized polyacrylonitrile precursor material.

[0063] S3. Weigh 30 μL of pyrrole ...

Embodiment 2

[0070] This embodiment provides a room-temperature sodium-sulfur battery positive electrode material, which is made of a nitrogen-doped nano-carbon layer coated with a vulcanized polyacrylonitrile material compounded by carbonization of PPy, and the particle size of the material is about 200 nm. The coating amount of the nitrogen-doped nano-carbon layer is 1%, the coating thickness is 3nm, and the mass fraction of sulfur in the final positive electrode material is 39%. Concrete preparation process is as follows:

[0071] S1. Mix 1g of polyacrylonitrile (Mw=150000) and 3g of commercial sulfur powder S 8 Blending was carried out in 200mL absolute ethanol solution, followed by high-energy ball milling for 6h at a rotation speed of 400rpm.

[0072] S2. Put the ball-milled sample into a tube furnace under the protection of argon for calcination at a temperature of 350° C. for 5 hours to obtain a vulcanized polyacrylonitrile precursor material.

[0073] S3. Weigh 10 μL of pyrrole ...

Embodiment 3

[0080] This embodiment provides a room-temperature sodium-sulfur battery positive electrode material, which is made of a nitrogen-doped nano-carbon layer coated with a vulcanized polyacrylonitrile material compounded by carbonization of PPy, and the particle size of the material is about 200 nm. The coating amount of the nitrogen-doped nano-carbon layer is 3%, the coating thickness is 5nm, and the mass fraction of sulfur in the final positive electrode material is 31%. Concrete preparation process is as follows:

[0081] S1. Mix 1g of polyacrylonitrile (Mw=150000) and 3g of commercial sulfur powder S 8 Blending was carried out in 200mL absolute ethanol solution, followed by high-energy ball milling for 6h at a rotation speed of 400rpm.

[0082] S2. Put the ball-milled sample into a tube furnace under the protection of argon for calcination at a temperature of 390° C. for 7 hours to obtain a vulcanized polyacrylonitrile precursor material.

[0083] S3. Weigh 30 μL of pyrrole ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com