Patents

Literature

412 results about "Sodium–sulfur battery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A sodium–sulfur battery is a type of molten-salt battery constructed from liquid sodium (Na) and sulfur (S). This type of battery has a high energy density, high efficiency of charge/discharge and long cycle life, and is fabricated from inexpensive materials. The operating temperatures of 300 to 350 °C and the highly corrosive nature of the sodium polysulfides, primarily make them suitable for stationary energy storage applications. The cell becomes more economical with increasing size.

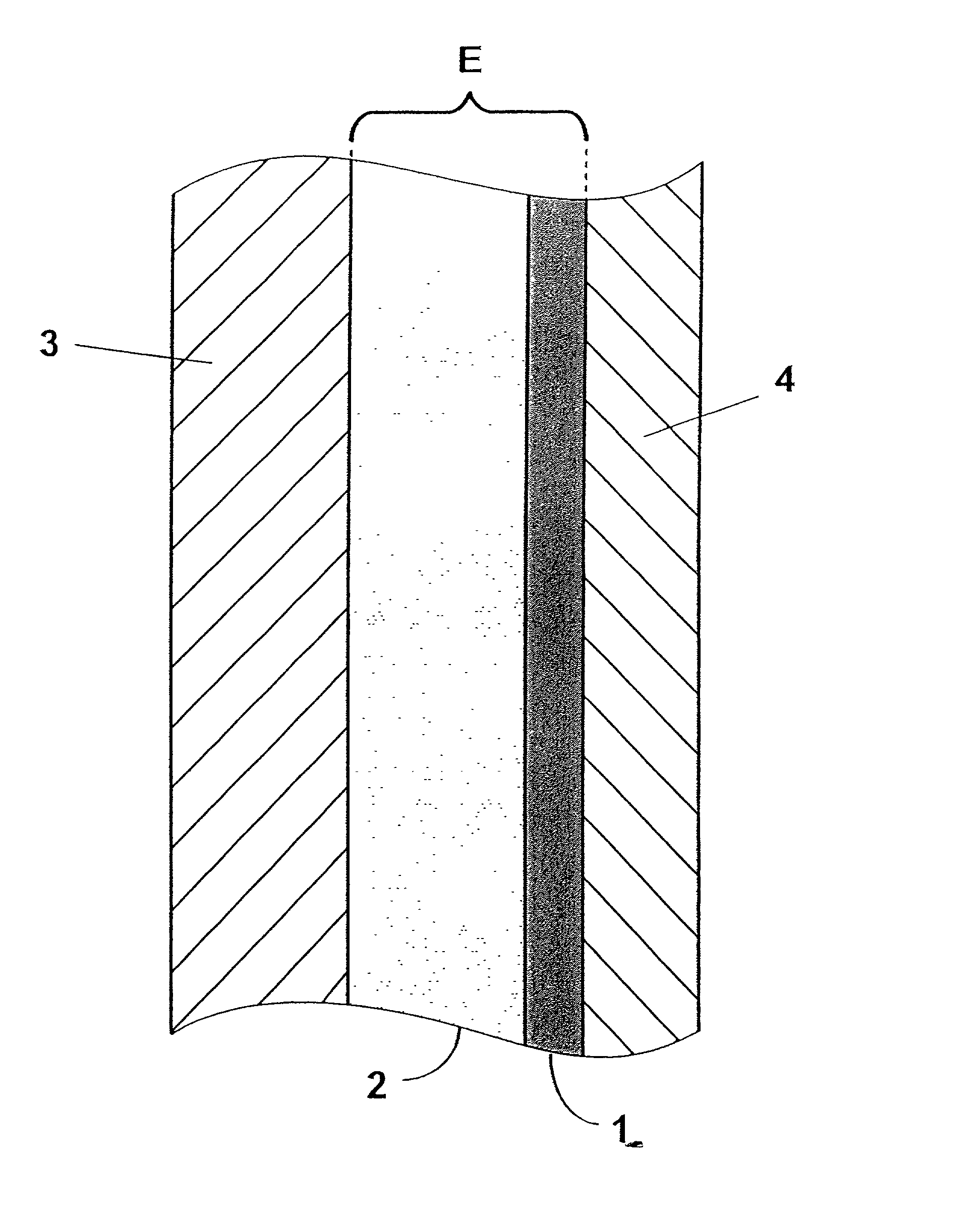

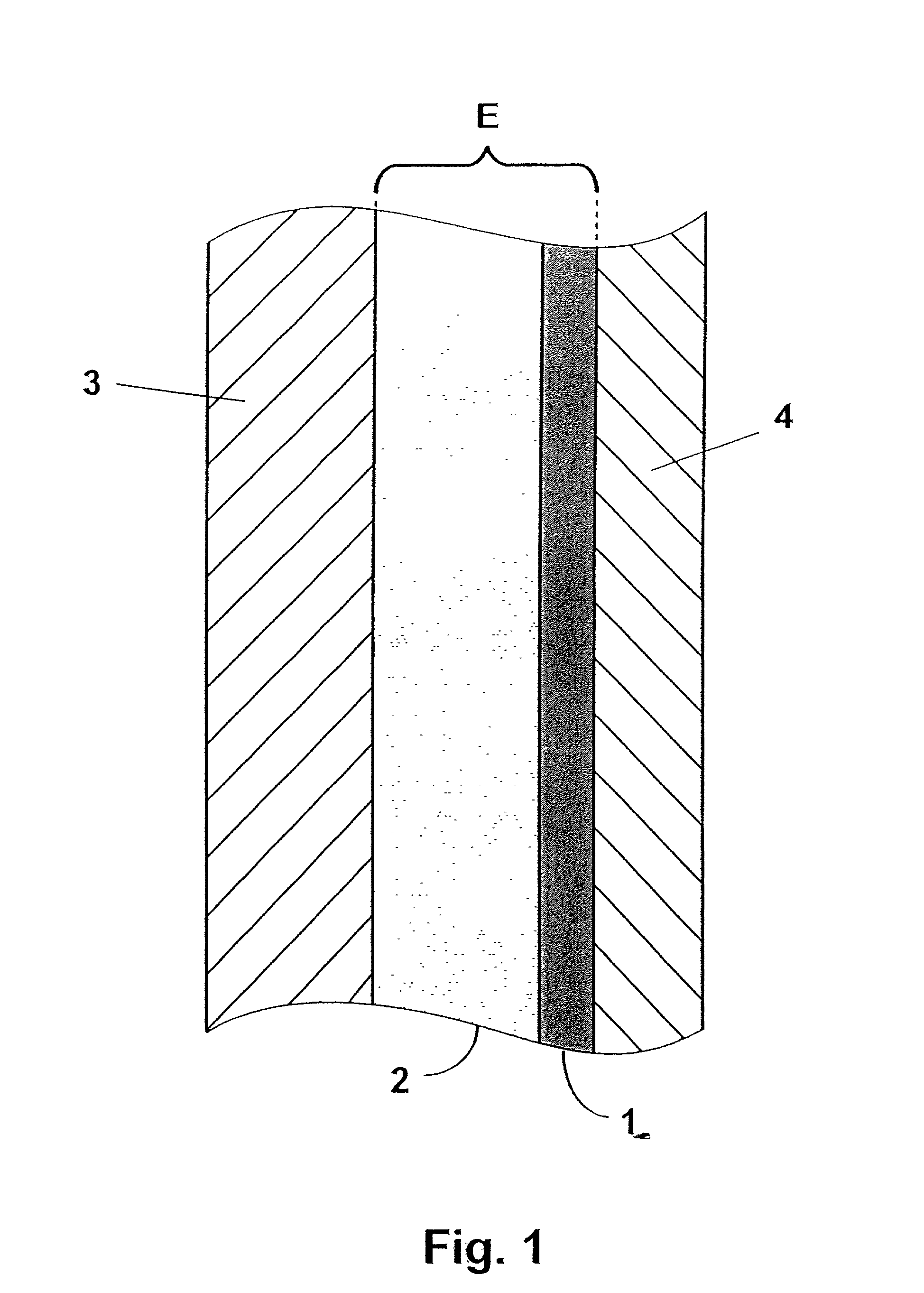

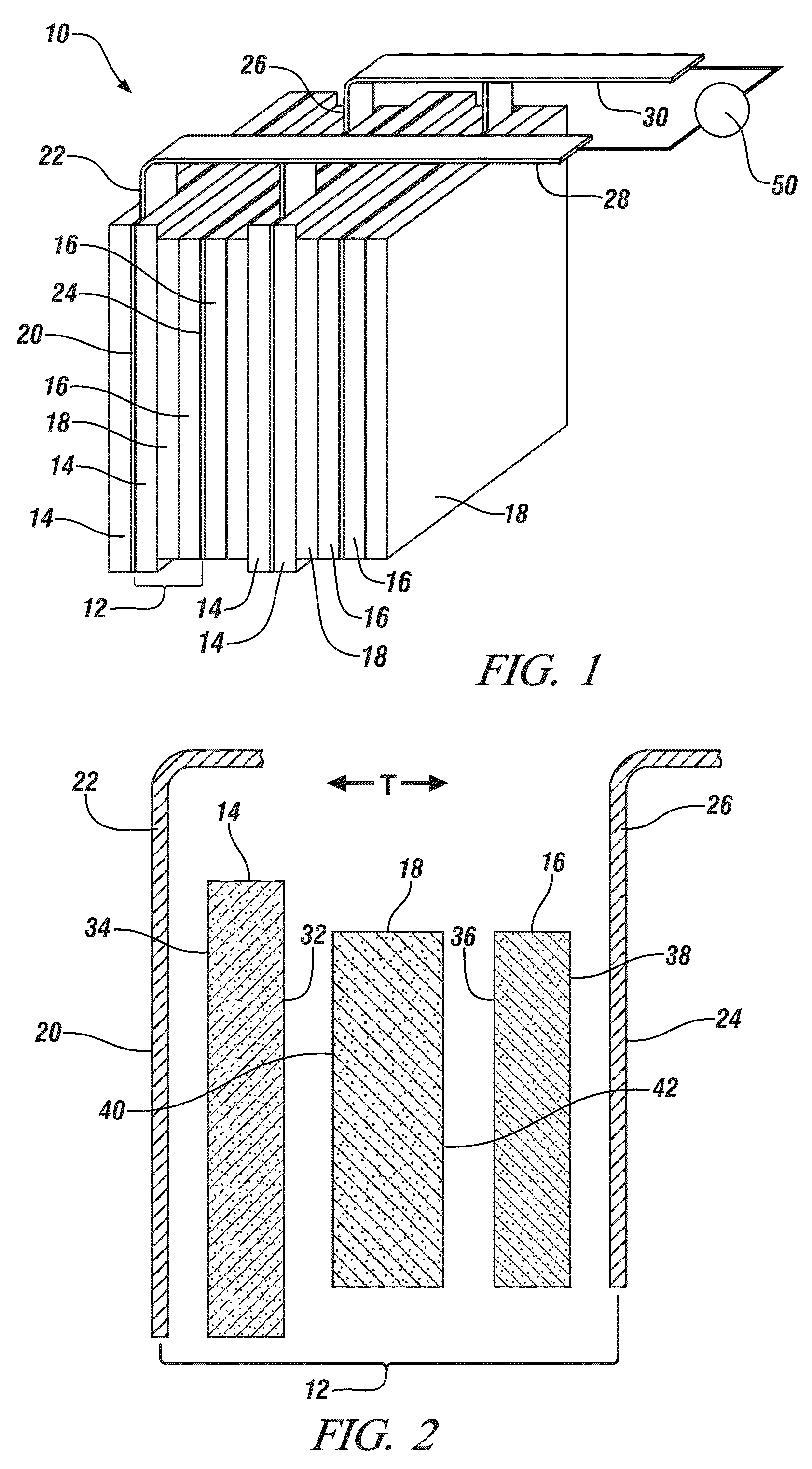

Thin film composite electrolytes, sodium-sulfur cells including same, processes of making same, and vehicles including same

InactiveUS20020172871A1Secondary cellsSolid electrolyte cellsComposite electrolyteElectrical battery

Thin film composite electrolyte structures are disclosed that are preferably ionically conductive but not electronically conductive and are therefore suitable for use in electrochemical cells, such as secondary batteries based on sodium and sulfur. Vehicles including the electrochemical cells are also disclosed.

Owner:TRANS IONICS CORP

Gel electrolyte and preparation method thereof and corresponding anode and lithium sulfur battery

ActiveCN102208680AImprove ionic conductivityImprove conductivityCell electrodesLi-accumulatorsDissolutionSolvent

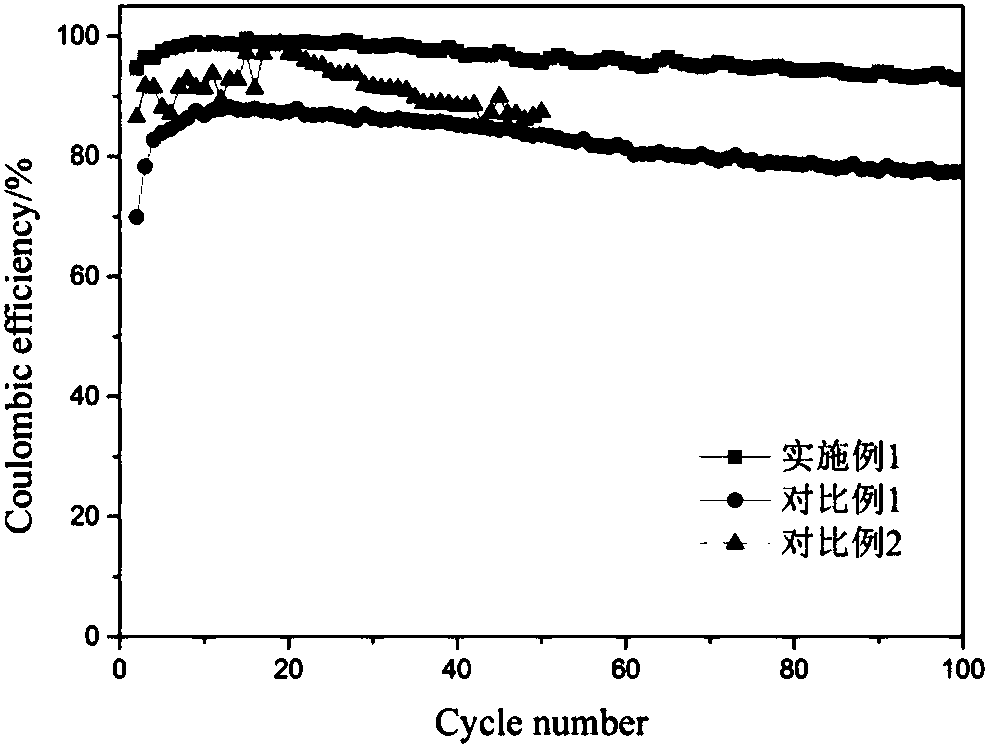

The invention discloses gel electrolyte, which comprises a polymer matrix material, a non-aqueous solvent and an inorganic filler in a mass ratio of 1:5:0.1-1:20:1 and also comprises electrolyte containing 0.5 to 2.0 mol / L of electrolyte lithium salt. The invention also discloses a preparation method of the gel electrolyte. The preparation method comprises the following steps of: mixing the polymer matrix material, the non-aqueous solvent, the inorganic filler and the electrolyte containing the electrolyte lithium salt in an inert atmosphere, and stirring the mixed solution till dissolving at the temperature of between 40 and 90 DEG C. The invention also discloses an anode and a lithium sulfur battery prepared by using the gel electrolyte. The gel electrolyte provided by the invention has high ionic conductivity, and can avoid the dissolution of the sulfur anode and the reactants; the lithium sulfur battery containing the gel electrolyte has good cycle performance; and the method is simple, does not need a large amount of extracting agent, is safe and environment-friendly, and is favorable for large-scale industrialized production.

Owner:DONGFANG ELECTRIC CORP LTD

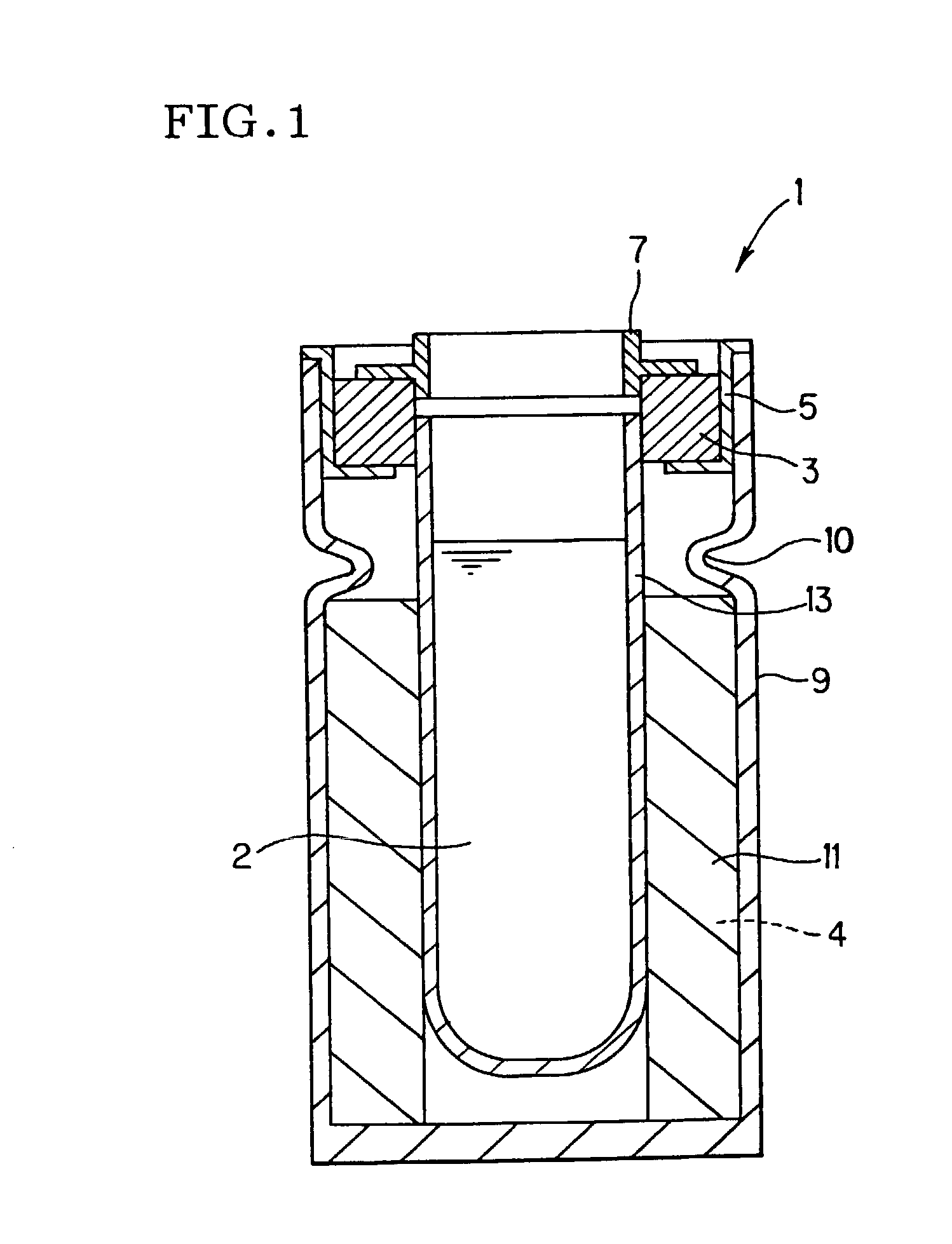

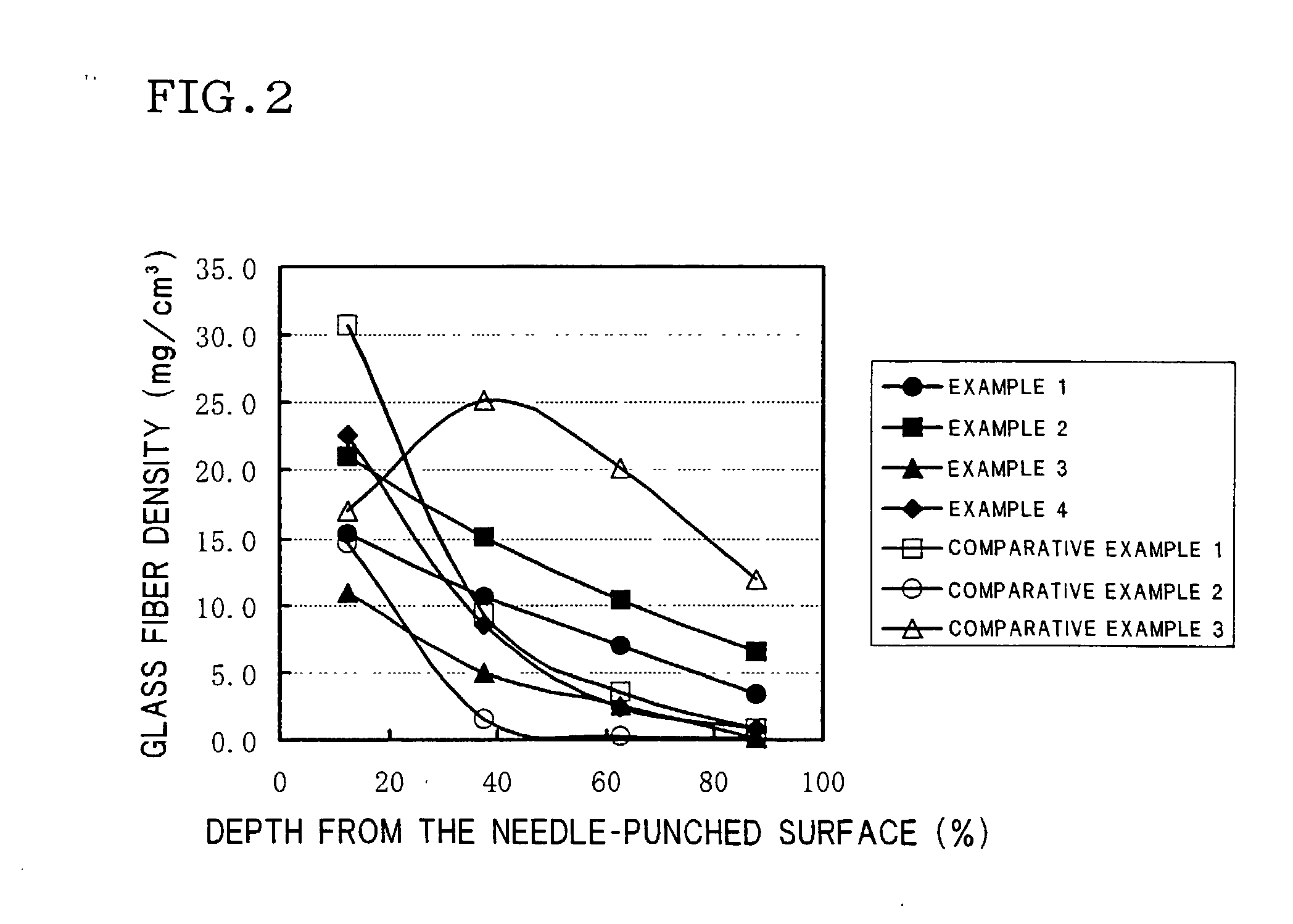

Current collector of positive electrode and sodium-sulfur battery using the same

InactiveUS20030054255A1Electrode carriers/collectorsSolid electrolyte cellsHigh resistanceGlass fiber

A current collector of positive electrode enabling a NaS battery to be excellent in the charge recovery characteristic and low in internal resistance is provided, which collector has a high resistance layer formed by needle-punching glass fibers with 5 to 15 mum fiber diameters into a felt substrate made of carbon fibers or graphite fibers by needle-punching from the one surface of the substrate. The density of the glass fibers needle-punched into the substrate is gradually decreased in the direction from the above mentioned surface to the other surface of the substrate, and the deepest portions of the needle-punched glass fibers reach the depths of 85 to 100% of the substrate thickness.

Owner:NGK INSULATORS LTD

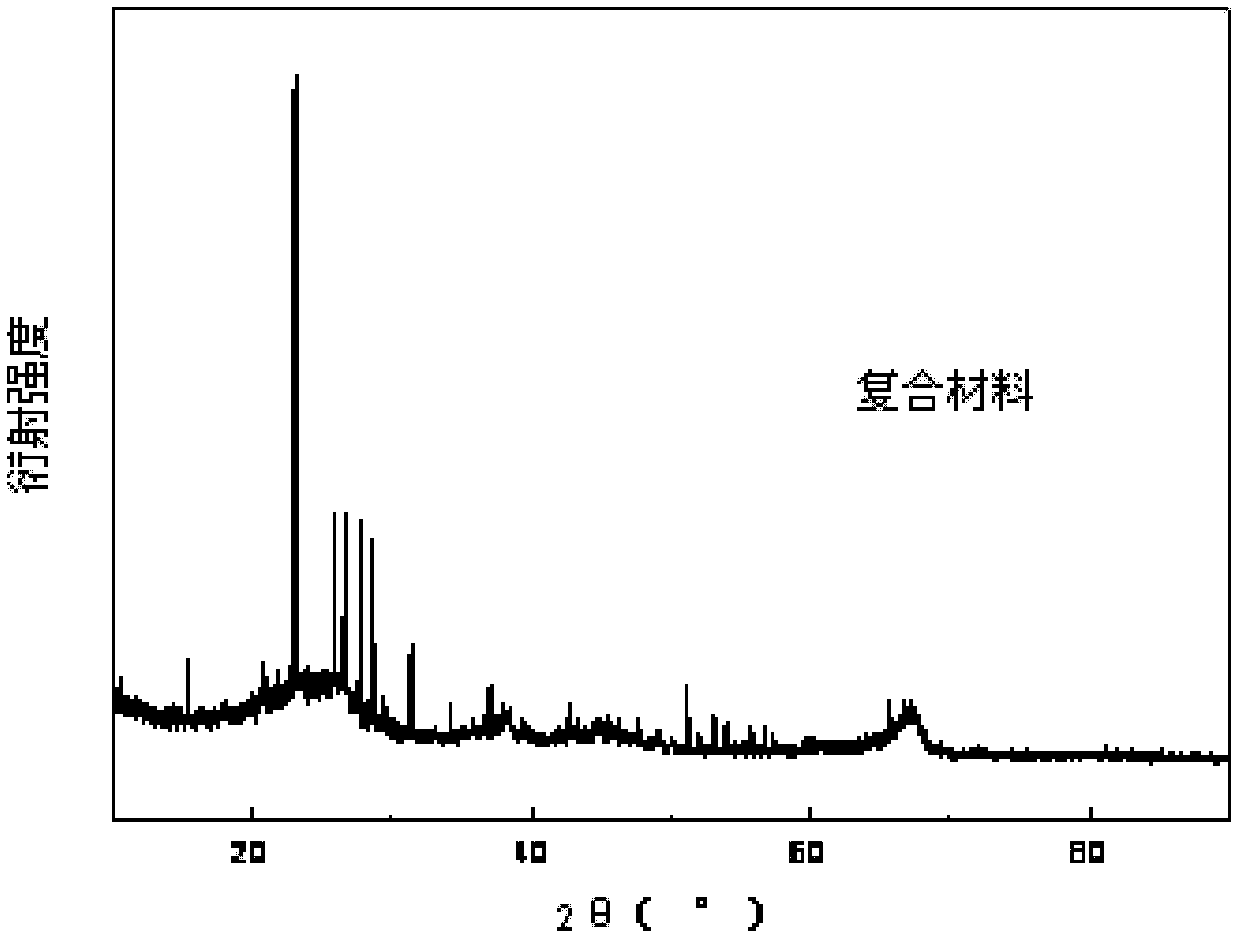

Preparation method of S/TiO2 composite material for anode of sodium-sulfur battery

ActiveCN103840143AImprove conductivityIncrease profitElectrode carriers/collectorsLi-accumulatorsSulfur electrodeHYDROSOL

The invention provides a preparation method of an S / TiO2 composite material for an anode of a sodium-sulfur battery. The preparation method comprises the following steps: dissolving butyl titanate, a template agent and a hydrolysis inhibitor into absolute ethyl alcohol; adding a mixed solution of de-ionized water and the absolute ethyl alcohol to form semi-transparent sol; transferring the sol into a high-pressure reaction kettle to react; calcining a solid product in air to remove the template agent to obtain meso-porous titanium dioxide; dispersing the meso-porous titanium dioxide into a sodium thiosulfate solution dissolved with a surfactant; adding hydrochloric acid to react; washing the solid product by a lot of the de-ionized water and drying; and eating under the protection of an inert atmosphere to obtain the S / TiO2 composite material. The meso-porous titanium dioxide prepared by the preparation method is large in specific surface area, high in porosity and strong in adsorption capability; the electrical conductivity of sulfur can be improved and a lot of nano sulfur and polysulfide can be contained; the polysulfide can be effectively prevented from being dissolved and diffused in electrolyte, and the utilization rate of the sulfur is improved; meanwhile, the structure of the meso-porous titanium dioxide is stable and a pore channel cannot be easily damaged, so as to have buffering effects on volume expansion and retraction in a charging / discharging process of a sulfur electrode.

Owner:CENT SOUTH UNIV

Insulation can special for sodium-sulphur battery

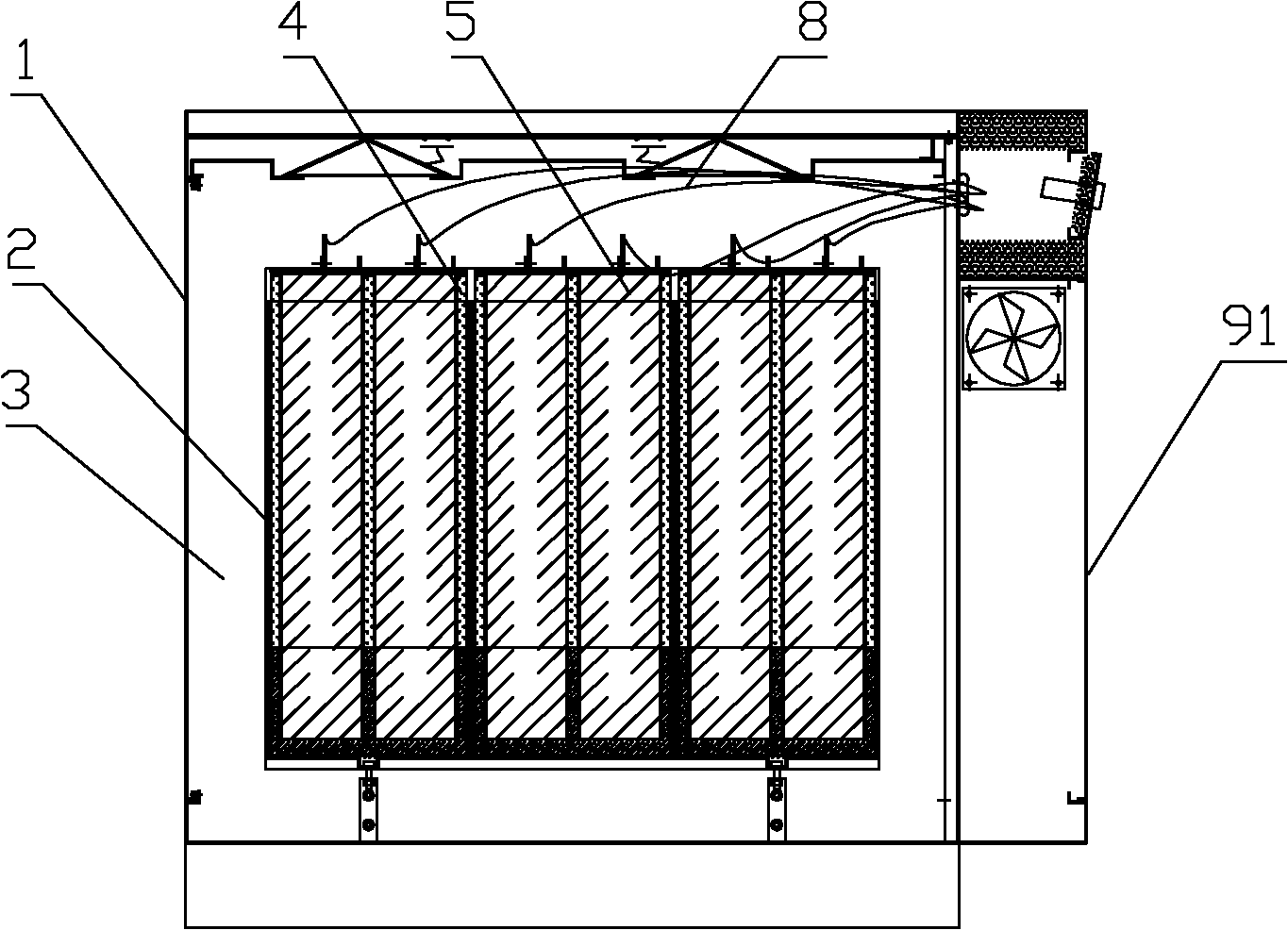

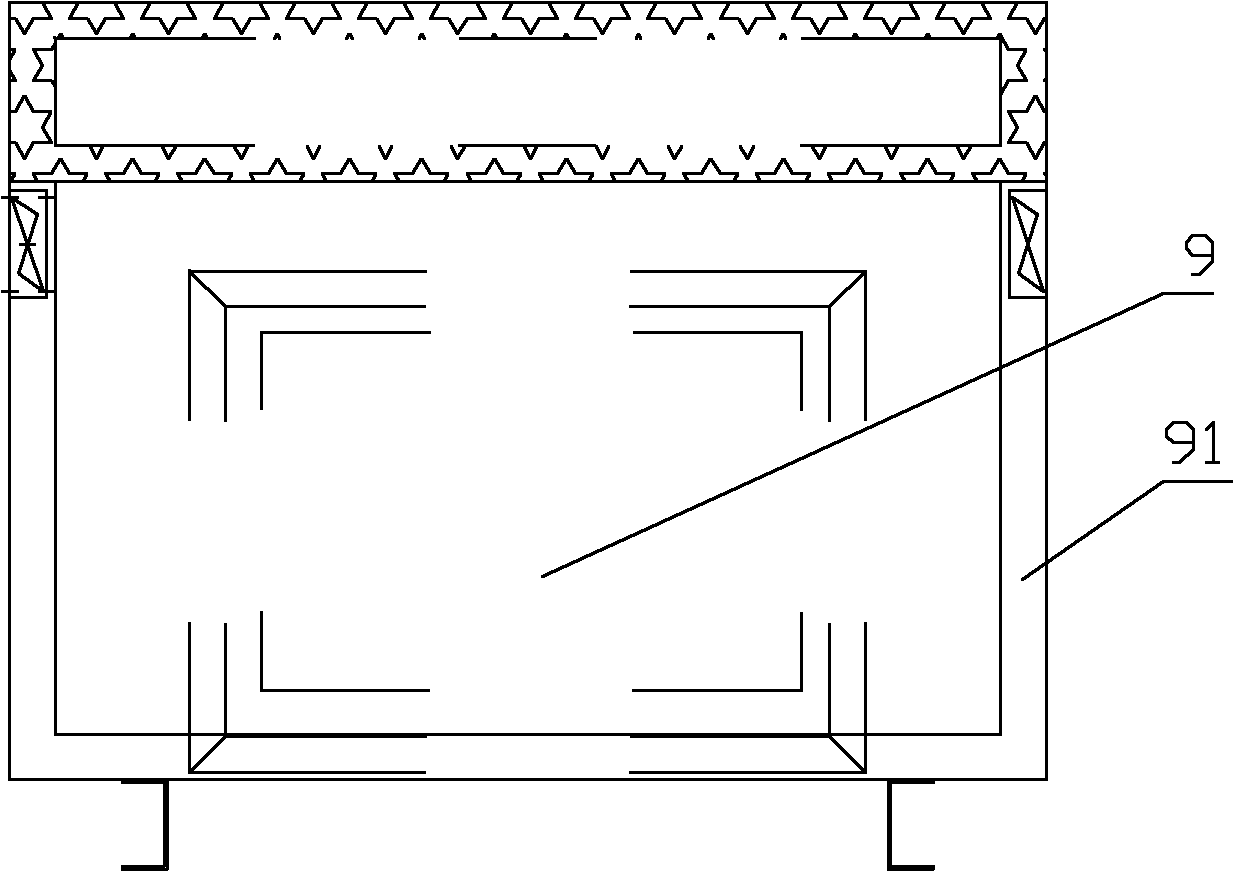

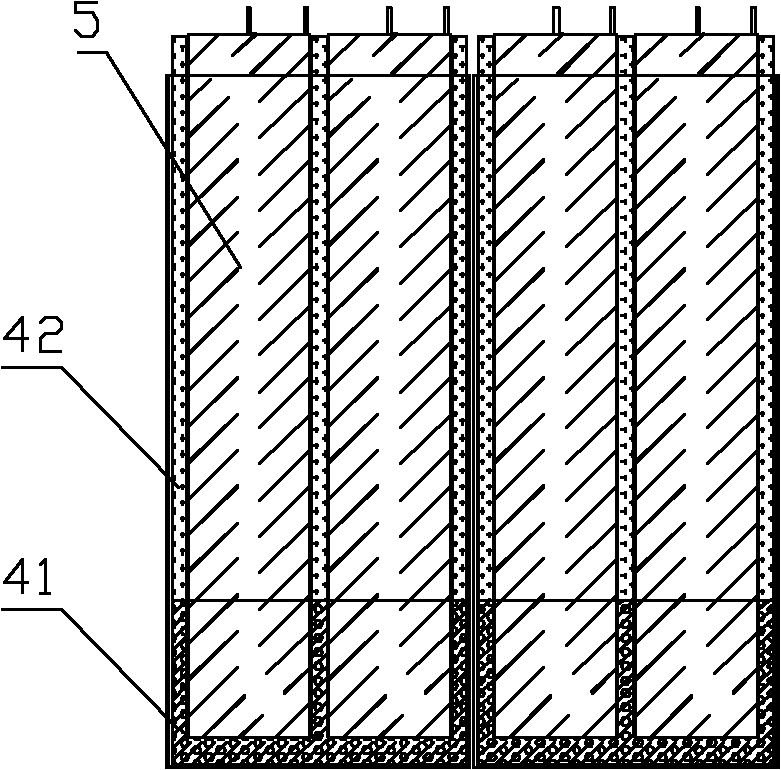

InactiveCN102054952AUniform temperatureEvenly heatedSecondary cellsCell component detailsControl systemElectrical battery

The invention discloses an insulation can special for a sodium-sulphur battery, comprising an outer shell and a liner. A heat-insulating layer is filled between the outer shell and the liner, the liner comprises a plurality of battery mounting brackets, each battery mounting bracket is provided with a battery mounting chamber for mounting batteries, the liner also comprises a plurality of baffleswhich uniformly partition the battery mounting brackets, a temperature detector and a heater are arranged in the same position in each partition, and a battery pack, the temperature detector and the heater are connected with a battery management system outside the insulation can through special cables to form a closed-ring heating control system. In the invention, small units are formed by a plurality of single batteries, the heater and the temperature detector and are partitioned by the baffles so as to uniformly heat each heated body (battery), and a full-closed ring and an answering-type control method of a heating point and a heated point are adopted to keep uniform temperature in an insulating state and realize high efficiency and low energy consumption.

Owner:徐荣辉

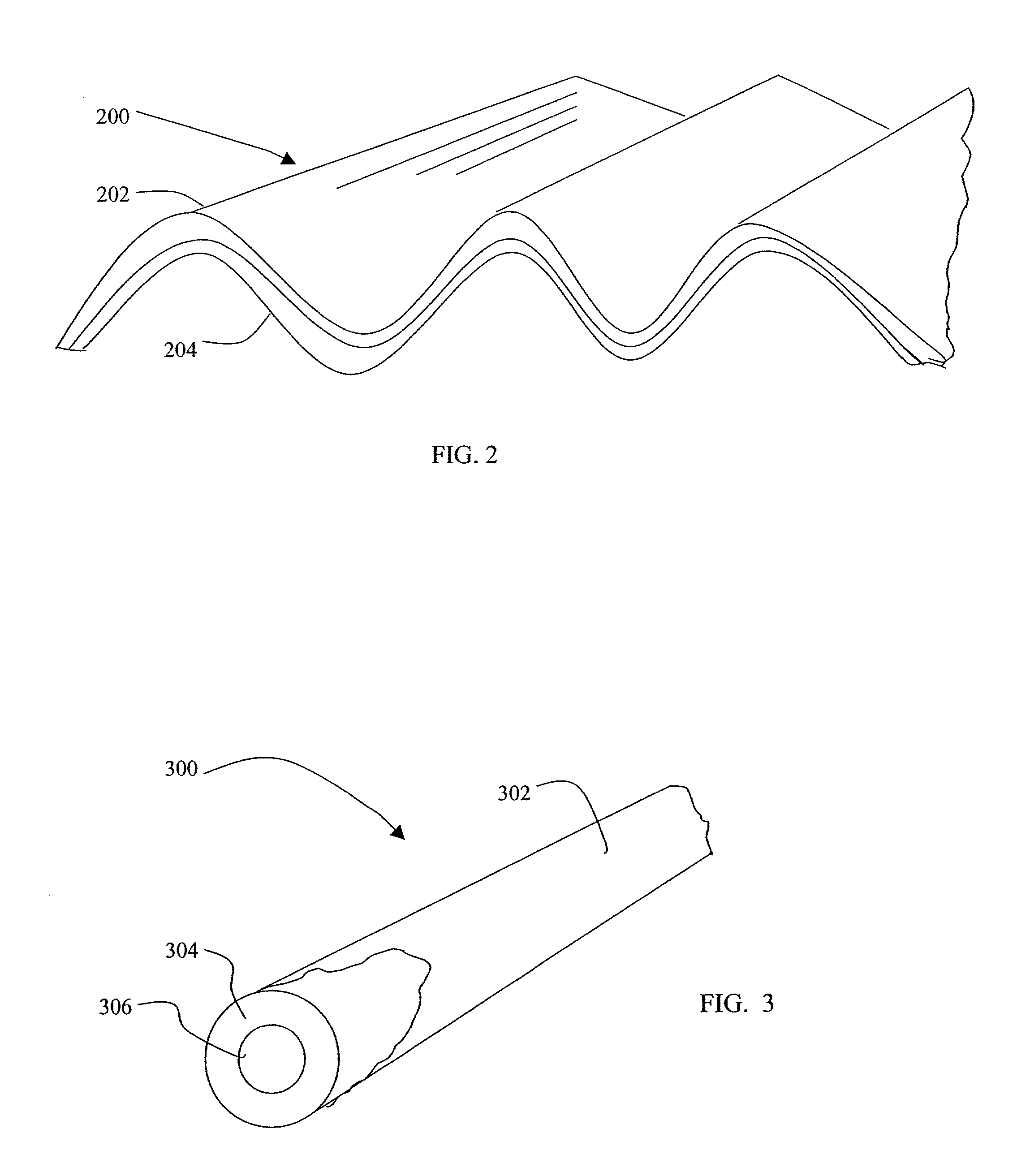

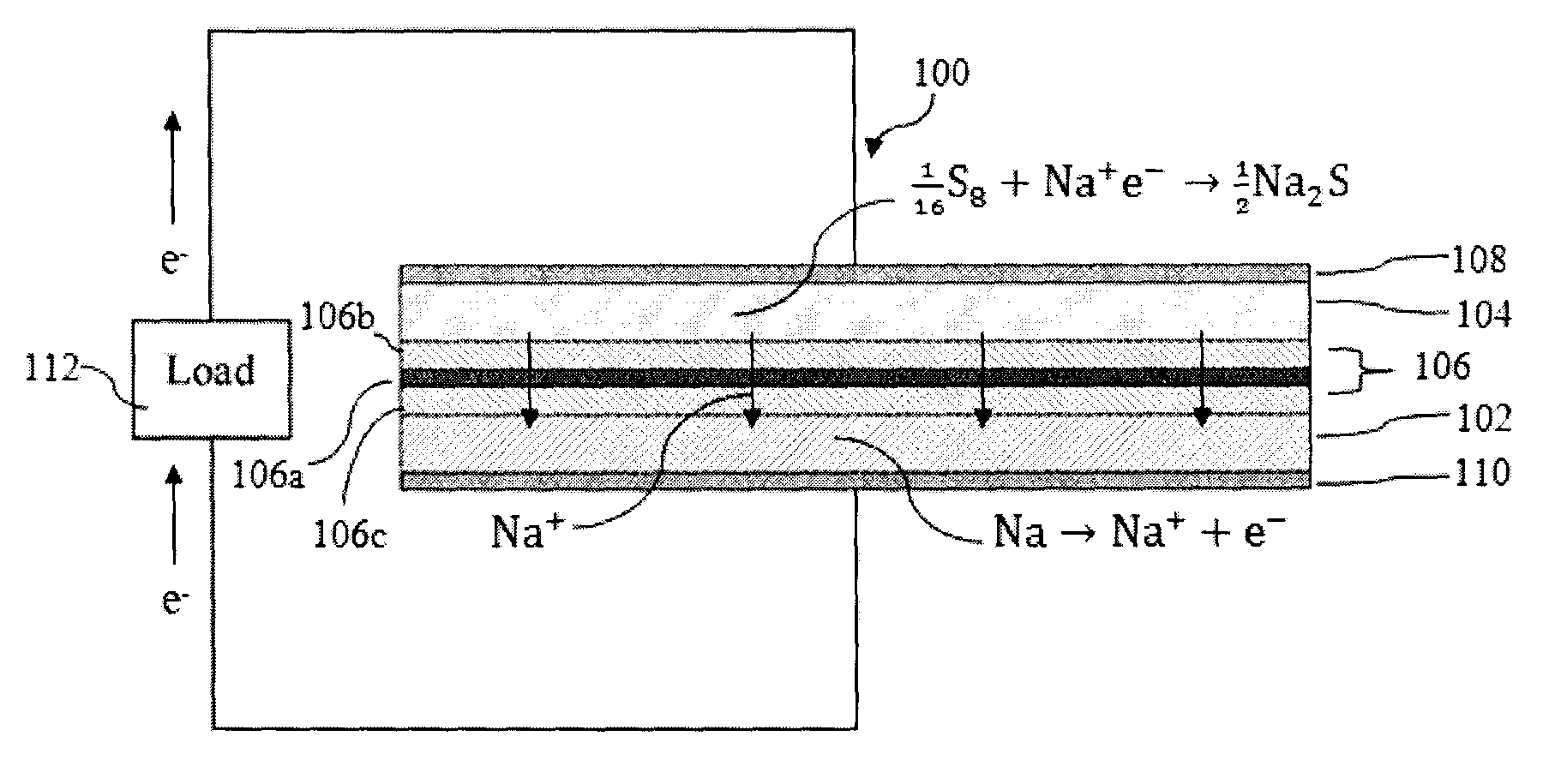

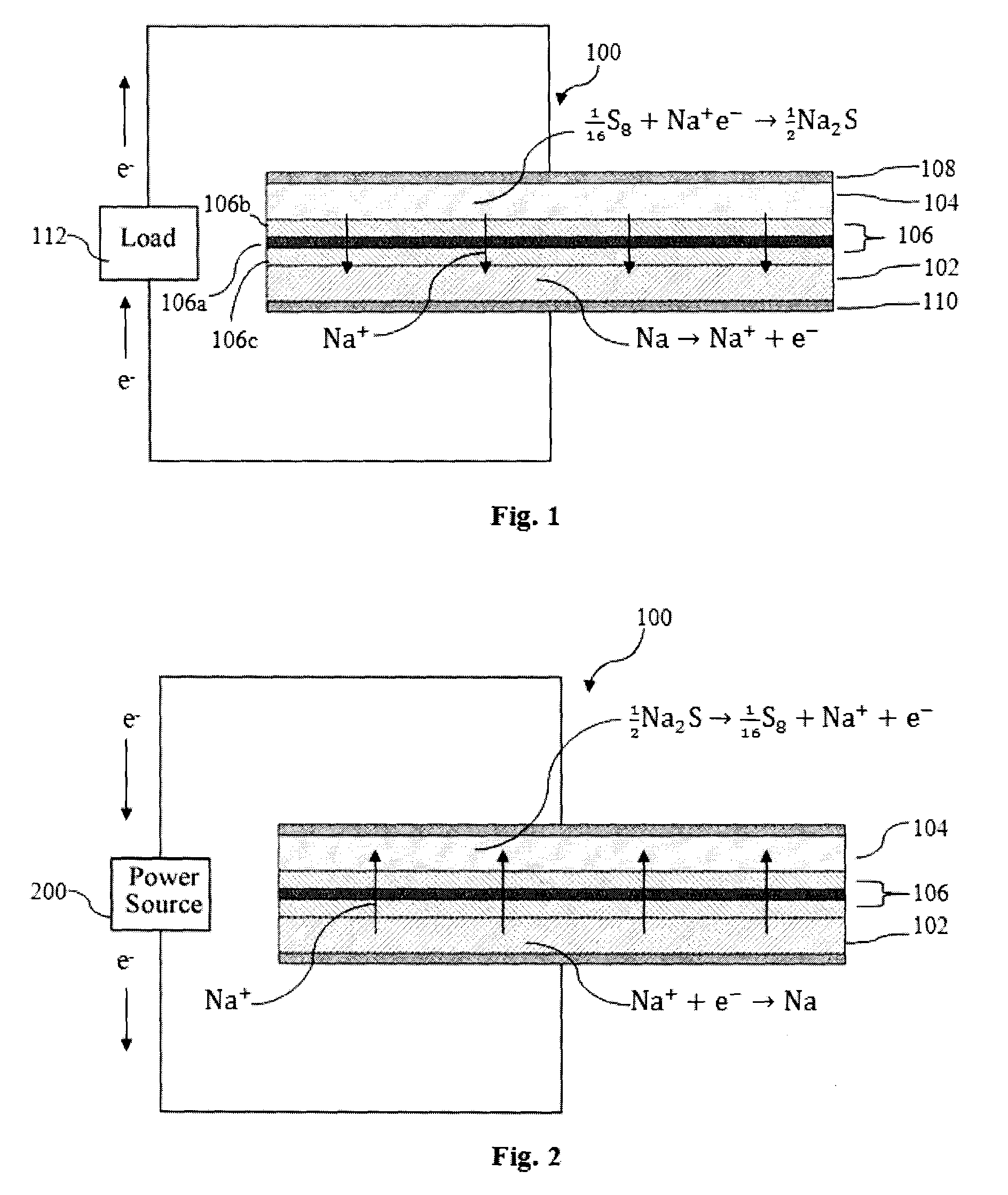

Sodium-sulfur battery with a substantially non-porous membrane and enhanced cathode utilization

InactiveUS20100239893A1Avoid reactionCell seperators/membranes/diaphragms/spacersActive material electrodesSulfurPorous membrane

A sodium-sulfur battery is disclosed in one embodiment of the invention as including an anode containing sodium and a cathode comprising elemental sulfur. The cathode may include at least one solvent selected to at least partially dissolve the elemental sulfur and Na2Sx. A substantially non-porous sodium-ion-conductive membrane is provided between the anode and the cathode to keep sulfur or other reactive species from migrating therebetween. In certain embodiments, the sodium-sulfur battery may include a separator between the anode and the non-porous sodium-ion-conductive membrane. This separator may prevent the sodium in the anode from reacting with the non-porous sodium-ion-conductive membrane. In certain embodiments, the separator is a porous separator infiltrated with a sodium-ion-conductive electrolyte.

Owner:CERAMTEC

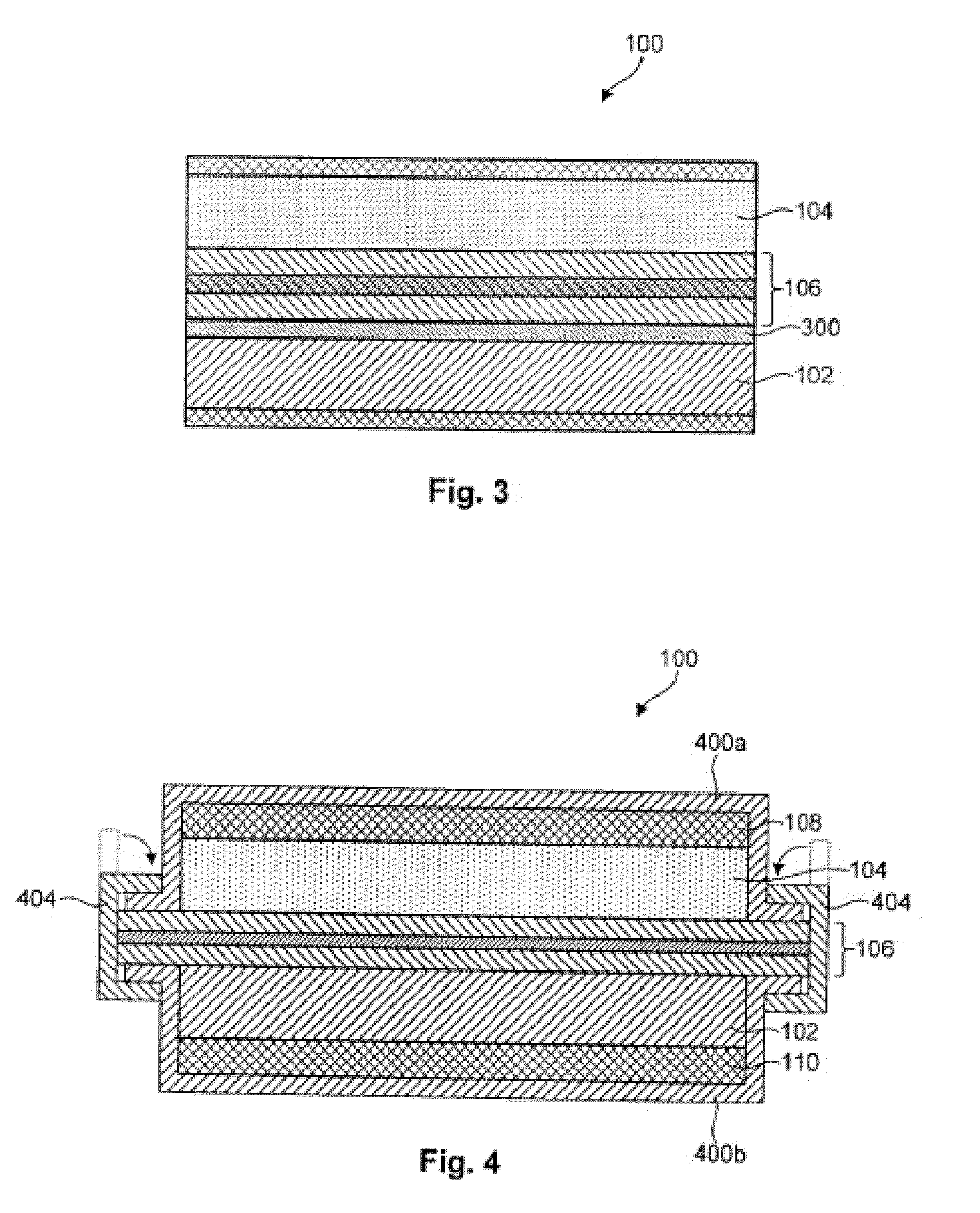

Cathode material for a lithium-sulfur battery

InactiveUS20130292613A1Increase contactImprove distributionElectrode melt handlingConductive materialSulfurGalvanic cell

A method for producing a cathode material for a cathode of a galvanic cell, such as a lithium or natrium sulfur cell. In order to improve the electric and ionic conductivity, the sulfur accessibility and utilization, elemental sulfur, at least one electrically conductive component and a solvent or a solvent mixture are mixed in method step a), the elemental sulfur being completely dissolved in the solvent or in the solvent mixture, and the solvent or solvent mixture is removed in a method step b).

Owner:ROBERT BOSCH GMBH

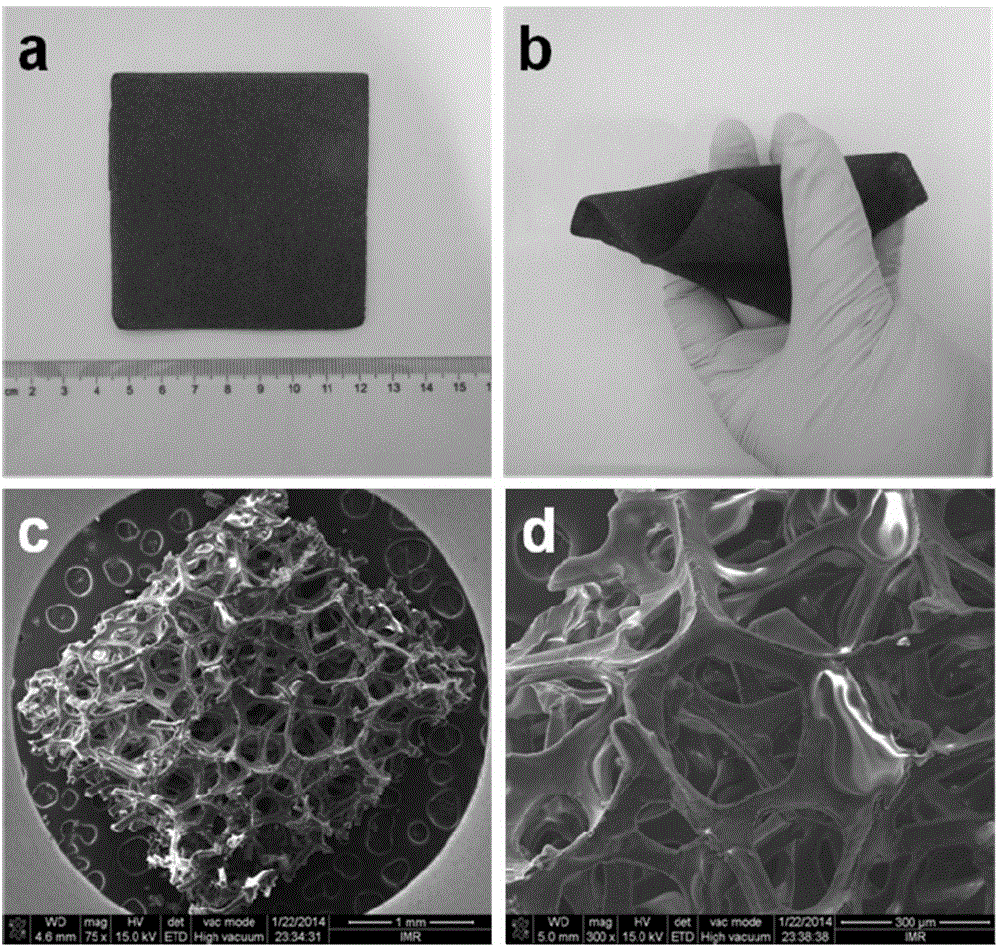

Flexible high-sulfur load self-repairing cathode structure for lithium-sulfur battery and preparation method of flexible high-sulfur load self-repairing cathode structure

ActiveCN105098143AEasy to makeThe preparation process is simple and controllableNon-aqueous electrolyte accumulator electrodesSulfurLithium–sulfur battery

The invention discloses a flexible high-sulfur load self-repairing cathode structure for a lithium-sulfur battery and a preparation method of the flexible high-sulfur load self-repairing cathode structure, and belongs to the field of electrochemical batteries. The lithium-sulfur battery cathode structure disclosed by the invention is composed of graphene / high-molecular polymer flexible foam and a carbon / sulfur active material layer, wherein the active material is sulfur; and the graphene / high-molecular polymer flexible foam provides strength and a self-repairing function. The flexible high-sulfur load self-repairing cathode structure has the characteristics that a multicomponent integrated design of the lithium-sulfur battery is realized; the electrochemical property is ensured; meanwhile, the content of sulfur is increased; high active material surface density of the battery is realized; the obtained lithium-sulfur battery has the advantages of high specific capacity and high specific energy density, and simultaneously has flexibility and self-healing characteristics; the preparation process of the flexible high-sulfur load self-repairing cathode structure is simple and easy to control; large-scale and low-cost preparation can be realized; and the application value is wide.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Electrolyte solution for lithium-sulfur battery

ActiveCN107681197AAvoid negative effectsIncrease capacityLi-accumulatorsSecondary cells servicing/maintenanceSolubilityNon solvent

The invention discloses an electrolyte solution for a lithium-sulfur battery. The electrolyte solution comprises an electrolyte lithium salt, an ionic liquid, a non-solvent liquid and an additive, wherein the viscosity of the non-solvent liquid is lower than that of the used ionic liquid; the solubility of the lithium salt and polysulfide lithium formed in charge and discharge processes in the non-solvent liquid is much lower than the corresponding solubility in the ionic liquid; the additive is another lithium salt with a film-forming function, which is different from the electrolyte lithiumsalt; and fluorinated ether can be selected as the non-solvent liquid. The electrolyte solution mainly aims at developing a complementary synergistic effect of the ionic liquid and the non-solvent liquid; and through assist of the film-forming lithium salt, on one hand, the viscosity of an ionic liquid-based electrolyte solution is reduced and the ionic conductivity of the electrolyte solution isimproved, and on the other hand, the capacity of the electrolyte solution for inhibiting dissolving and shuttling of the polysulfide lithium is strengthened. By adopting the electrolyte solution disclosed by the invention, various negative effects, caused by the polysulfide lithium, to the lithium-sulfur battery are greatly avoided, and the properties, such as the capacity, the cycle performance and the rate capability of the battery are improved as a whole.

Owner:XIAN UNIV OF SCI & TECH

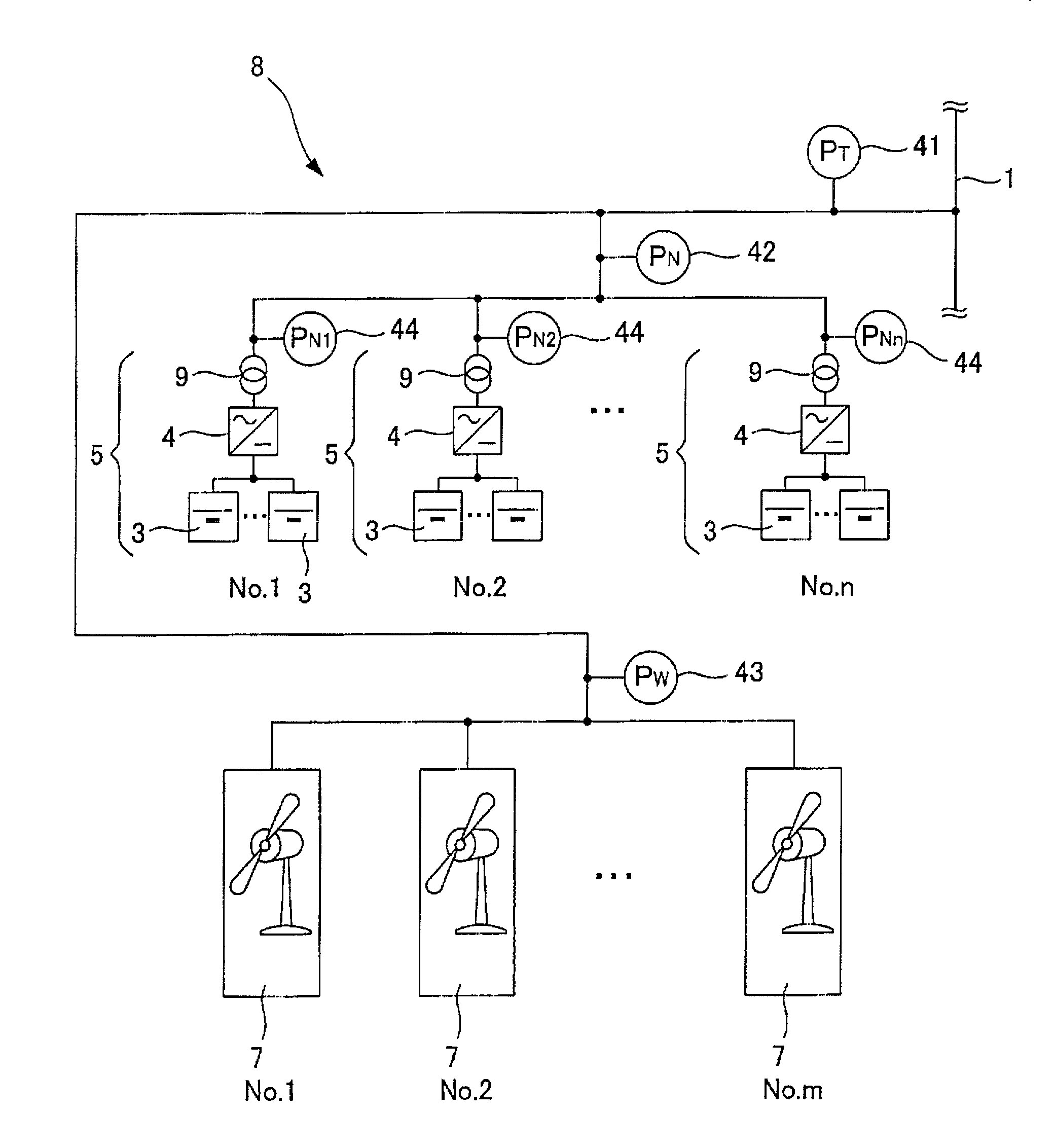

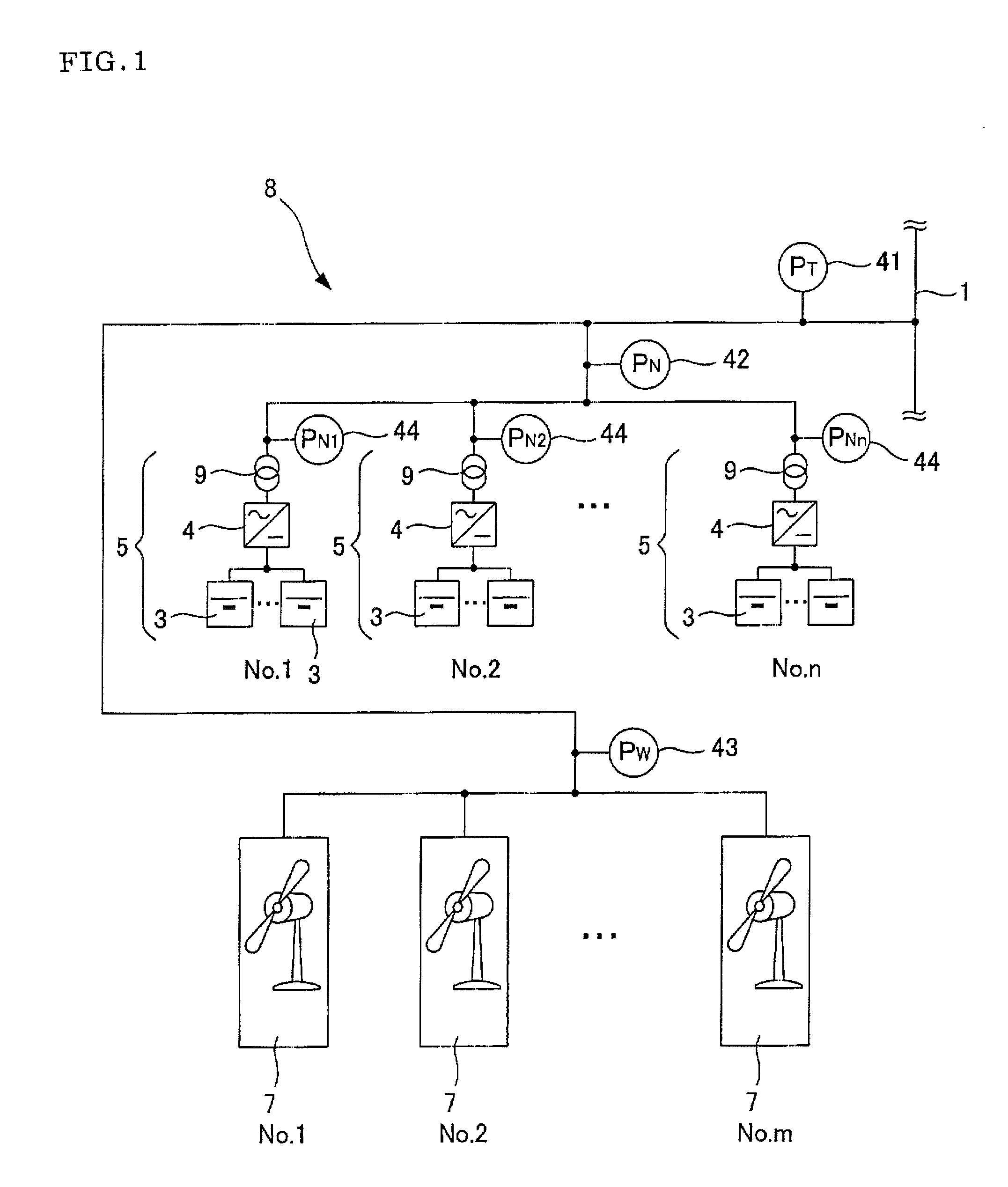

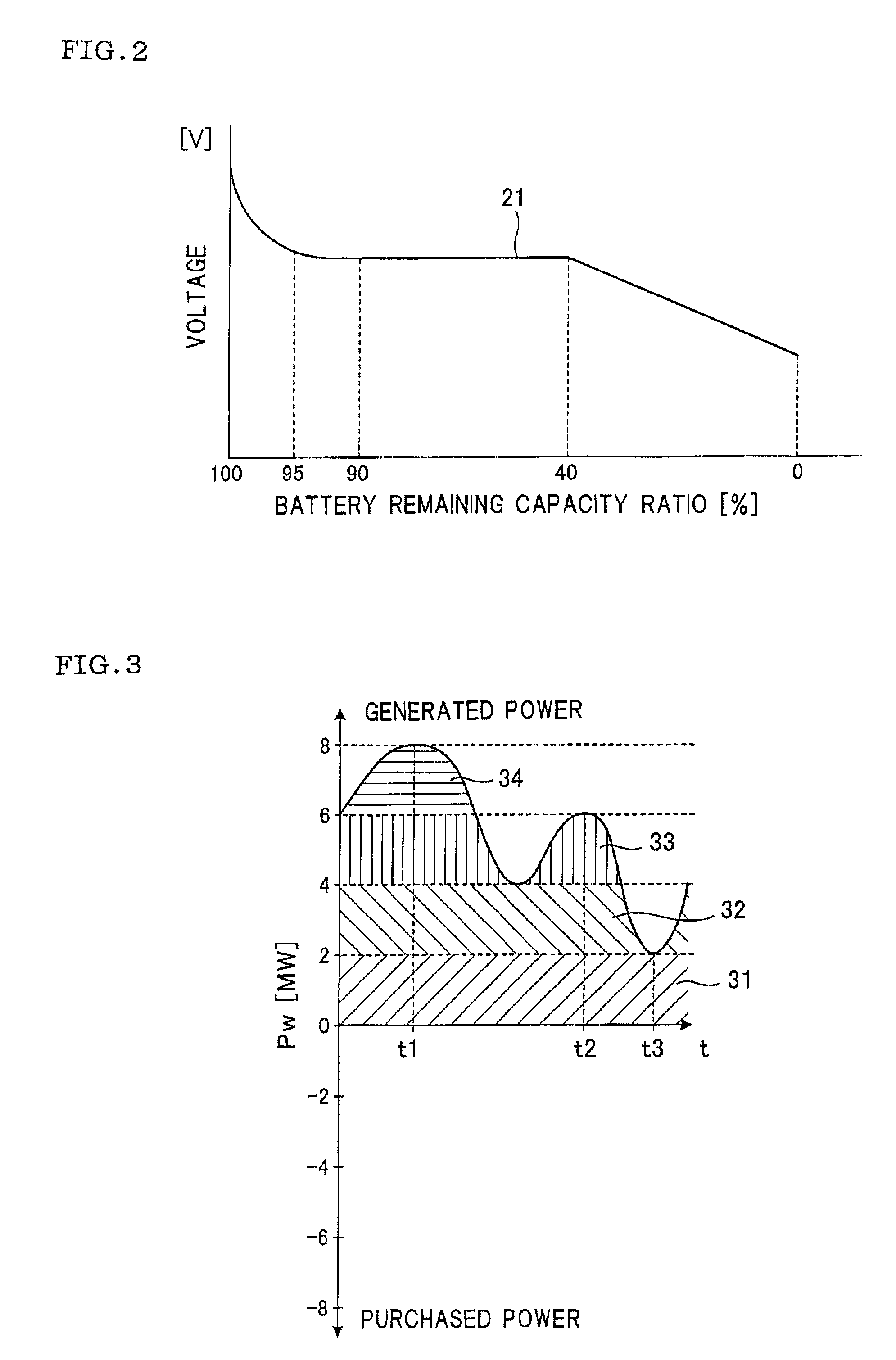

Control method of sodium-sulfur battery

InactiveUS20080076010A1Guaranteed uptimeImprove reliabilityCharge equalisation circuitCharging managementSulfurEngineering

There is disclosed a method of precisely controlling a discharge capacity of a sodium-sulfur battery in an interconnection system where a power generation device in which an output fluctuates is combined with a power storage compensation device including a plurality of sodium-sulfur batteries. The sodium-sulfur battery in which a discharge capacity control value is to be corrected or reset is specified among the plurality of sodium-sulfur batteries, the discharge capacity control value of the specified sodium-sulfur battery is corrected, and all of the plurality of sodium-sulfur batteries is successively specified to repeatedly correct or reset the discharge capacity control value.

Owner:NGK INSULATORS LTD

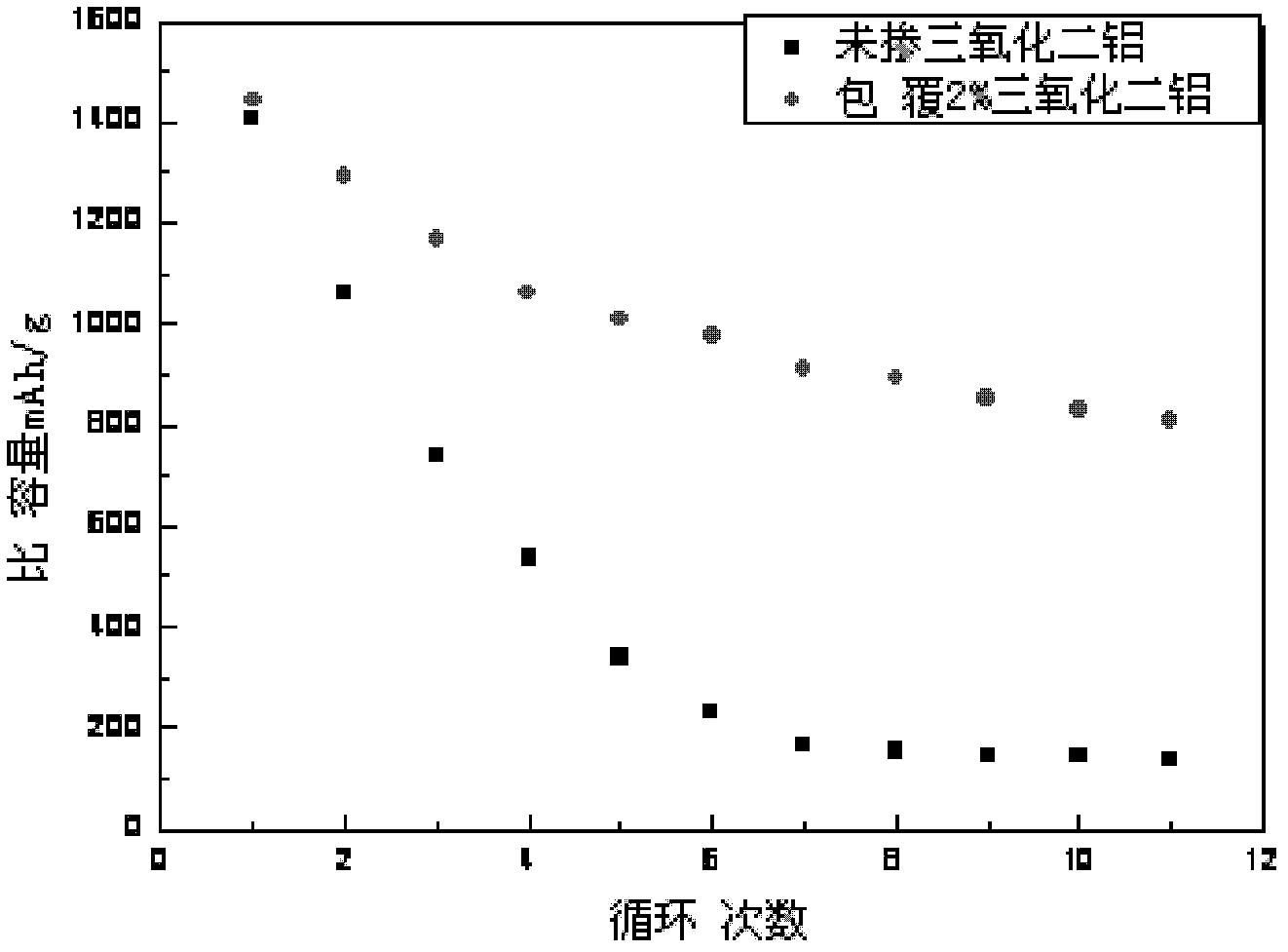

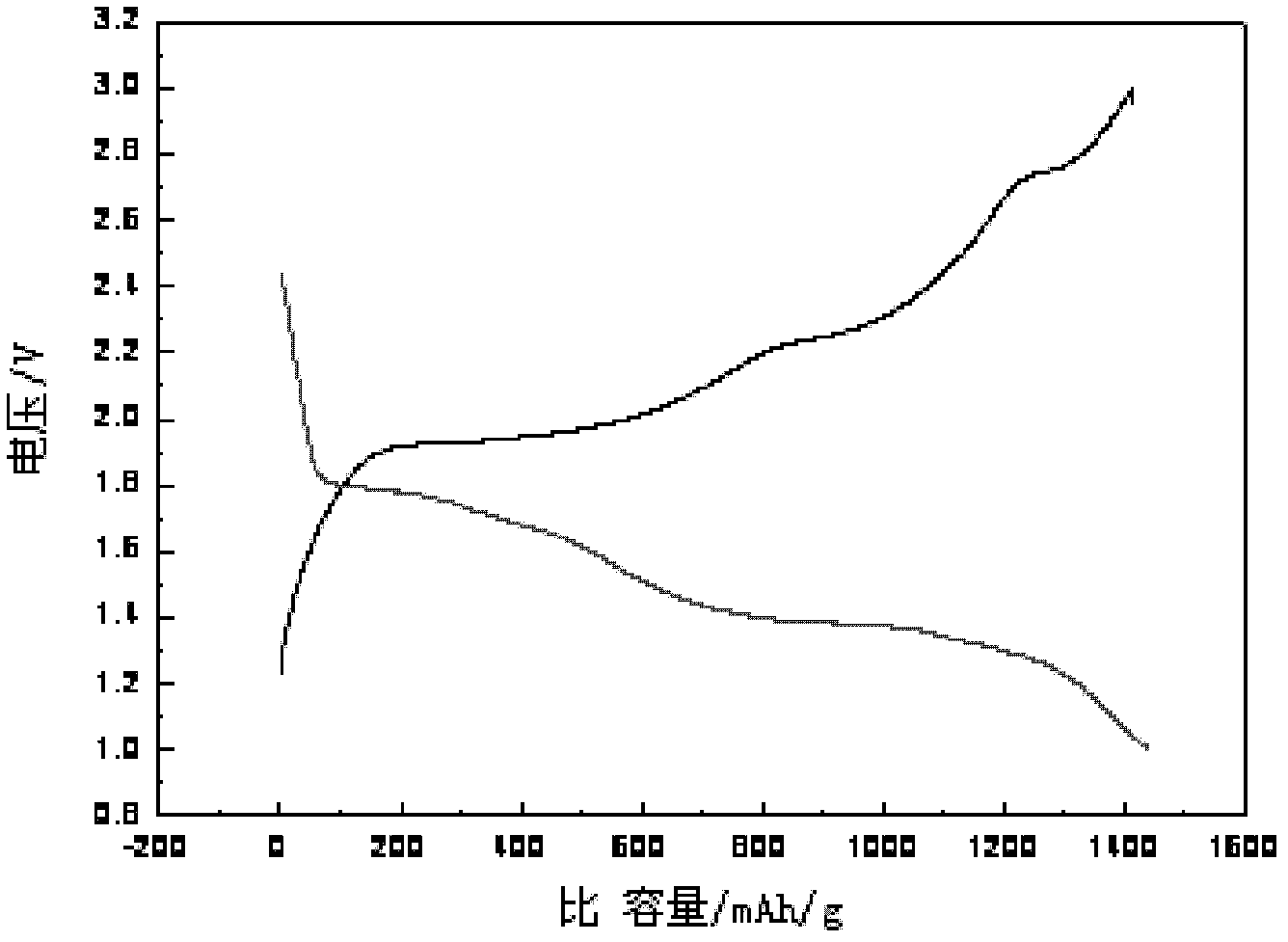

A kind of preparation method of sulfur positive electrode of lithium-sulfur battery

InactiveCN102280614AImprove electrochemical performanceHigh initial discharge specific capacityCell electrodesSodium bicarbonateMass ratio

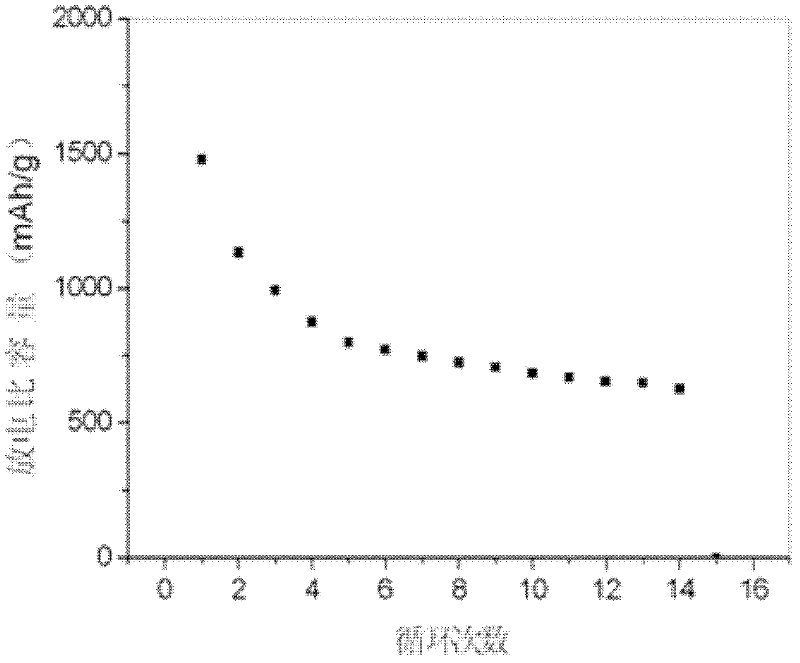

The invention provides a preparation method of a sulfur positive electrode of a lithium sulfur battery. The preparation method comprises the following steps: a) preparing a mixed slurry according to the condition that the mass ratio of a sublimed sulfur to an active carbon is (4-9):2; b) drying and grinding the mixed slurry; c) dispersing the mixture in a sodium bicarbonate or ammonia solution, and performing the ultrasonic oscillation; d) adding an aluminum sulfate, aluminum chloride or aluminum potassium sulfate solution according to the condition that the mol ratio of a sulfur carbon mixture to an aluminum element in aluminum salt is 100:(0.5-3) so as to prepare a composite material covered by the aluminum hydroxide; e) filtering and drying the composite material, warming to 140-300 DEG C within 6-11 hours under the protection of inert gas, and grinding to obtain the sulfur carbon positive electrode material covered by the aluminum oxide for the lithium sulfur battery; and f) preparing the positive electrode of the lithium sulfur battery, assembling and testing the performance of the battery. The initial discharging specific capacity of the sulfur positive electrode composite material for the lithium sulfur battery prepared by the invention can achieve 1441.7.8 mAh / g, the battery discharging specific capacity is still maintained at 808.1mAh / g at room temperature after ten times of circulation, and the capacity retention rate can achieve 56.52%.

Owner:TIANJIN UNIV +1

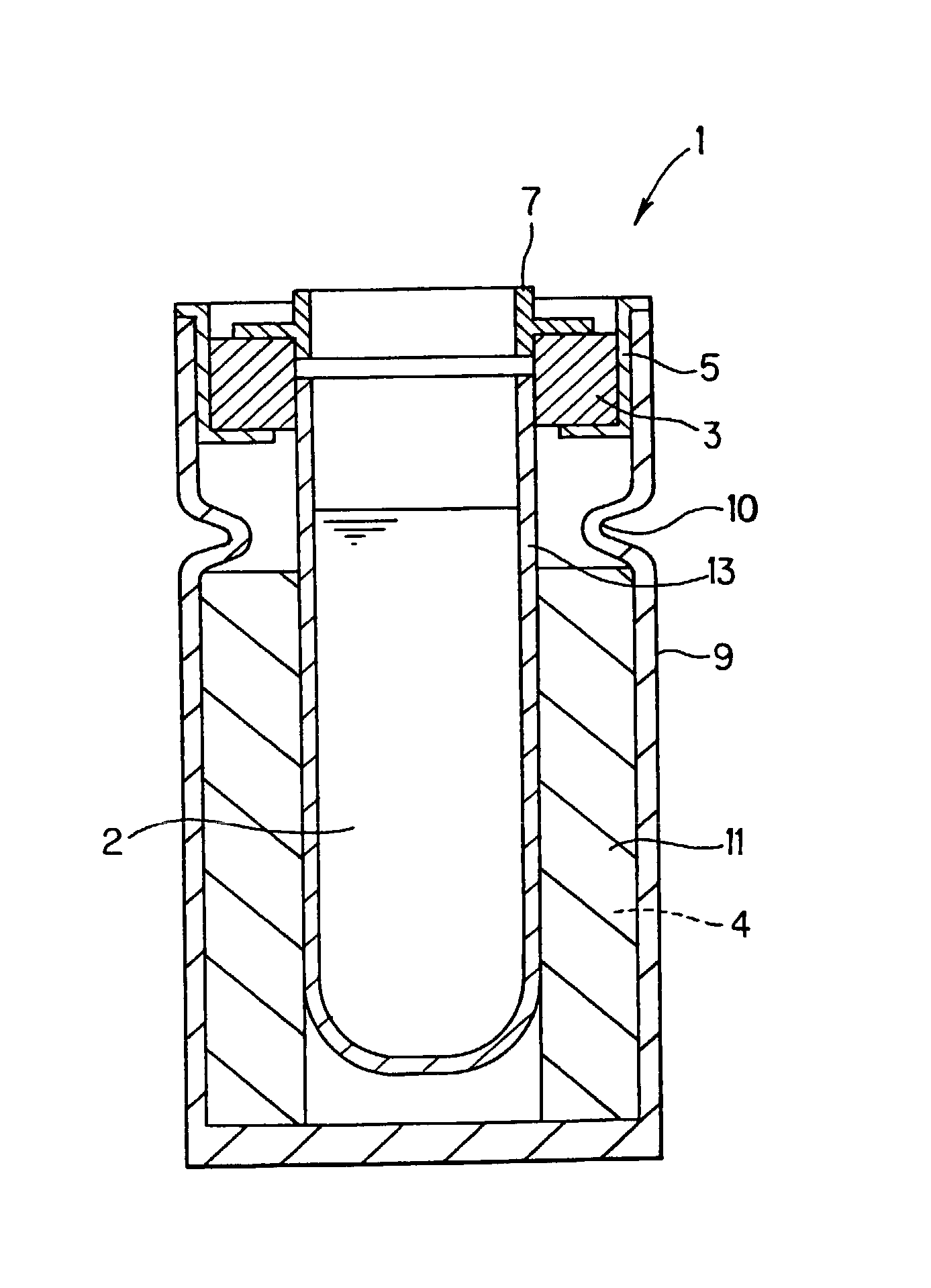

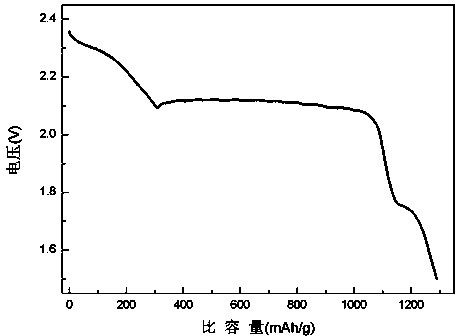

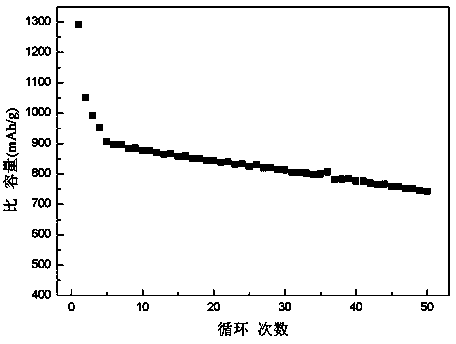

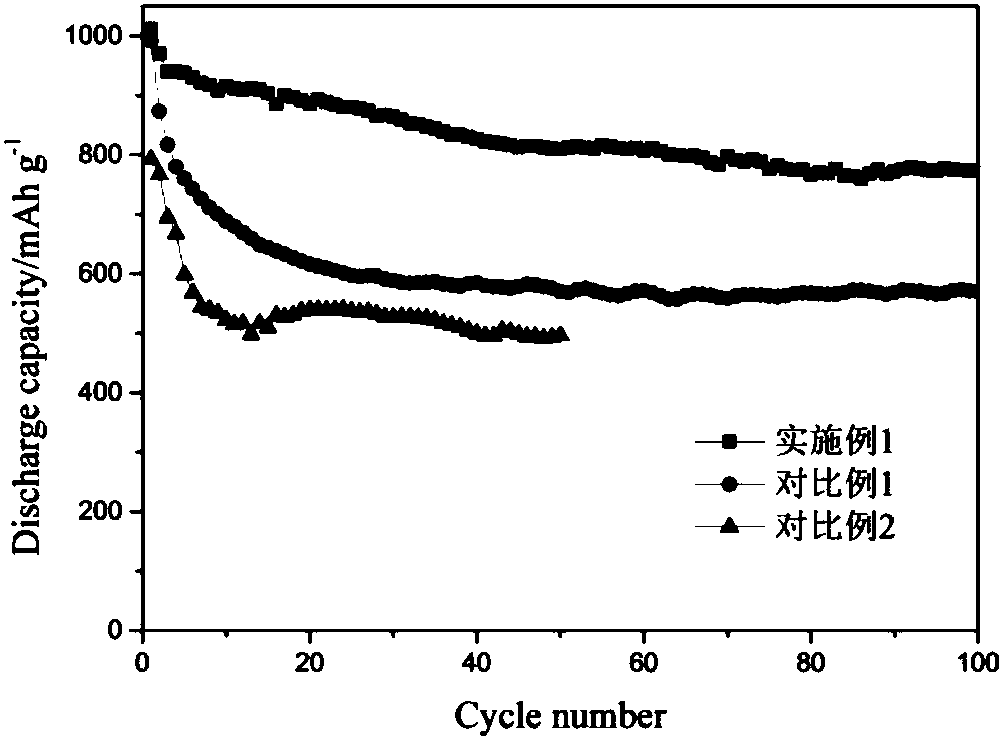

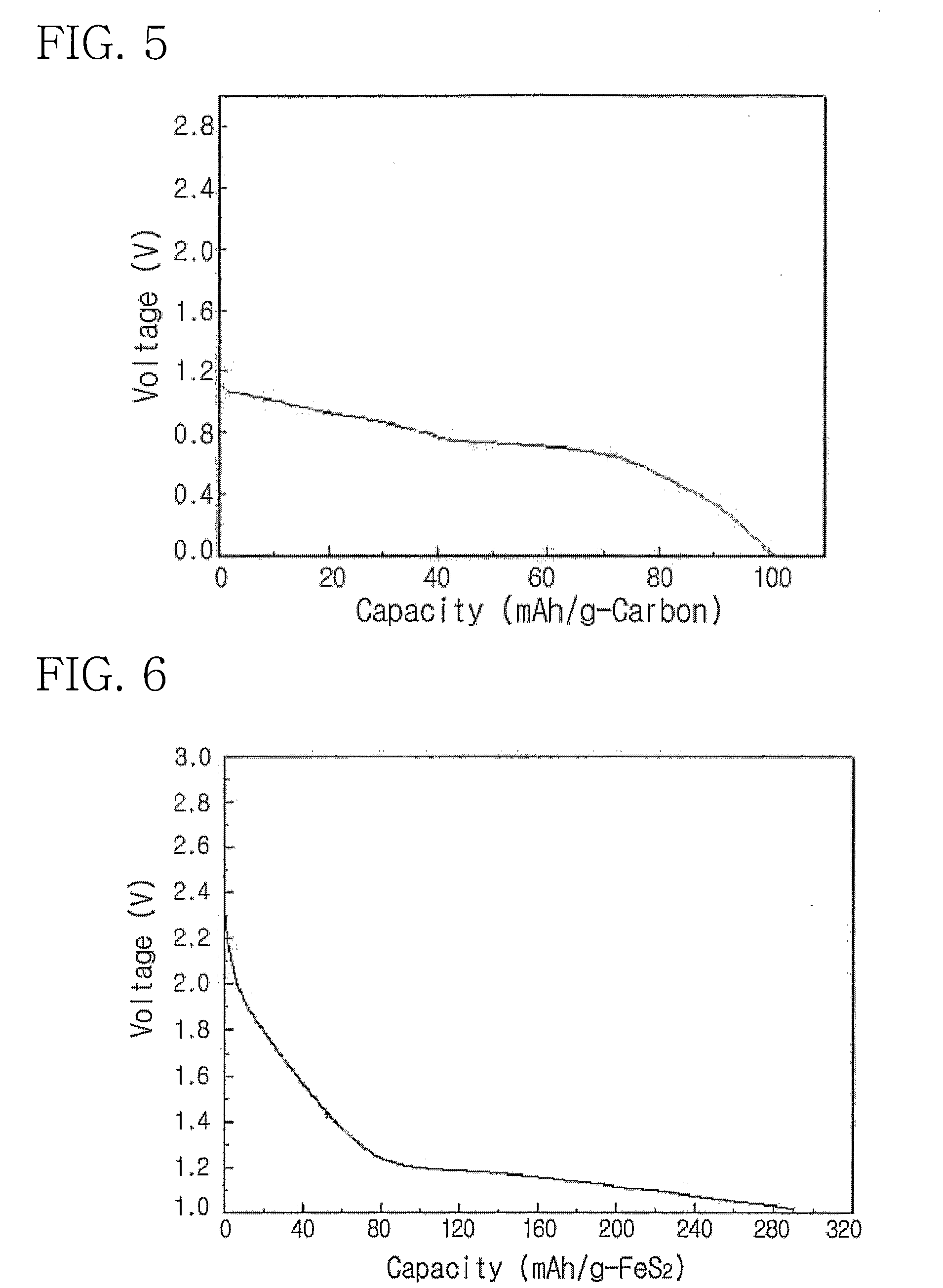

Sodium-sulfur battery and manufacture method thereof

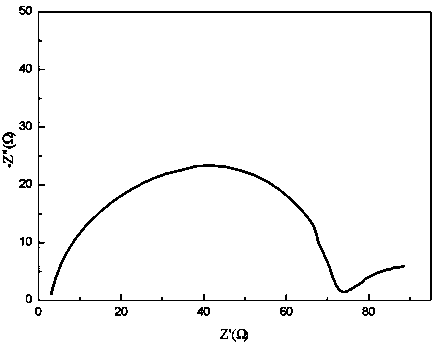

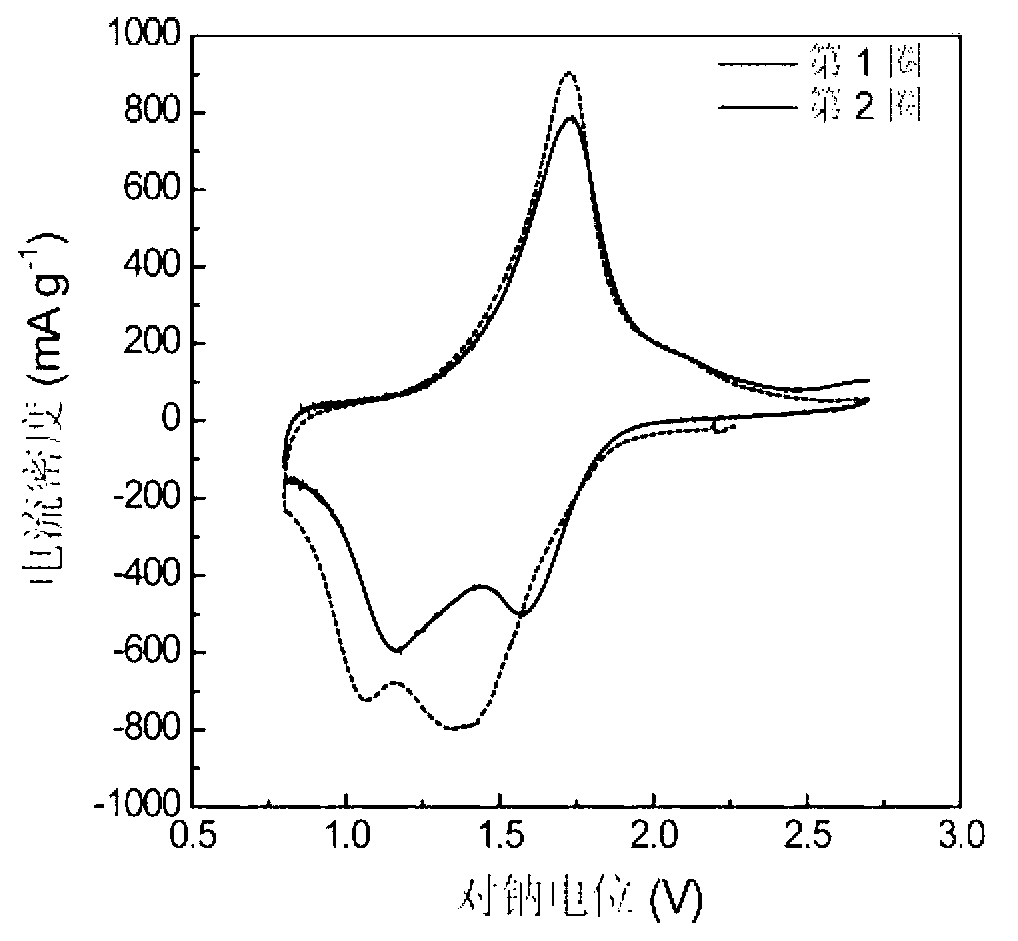

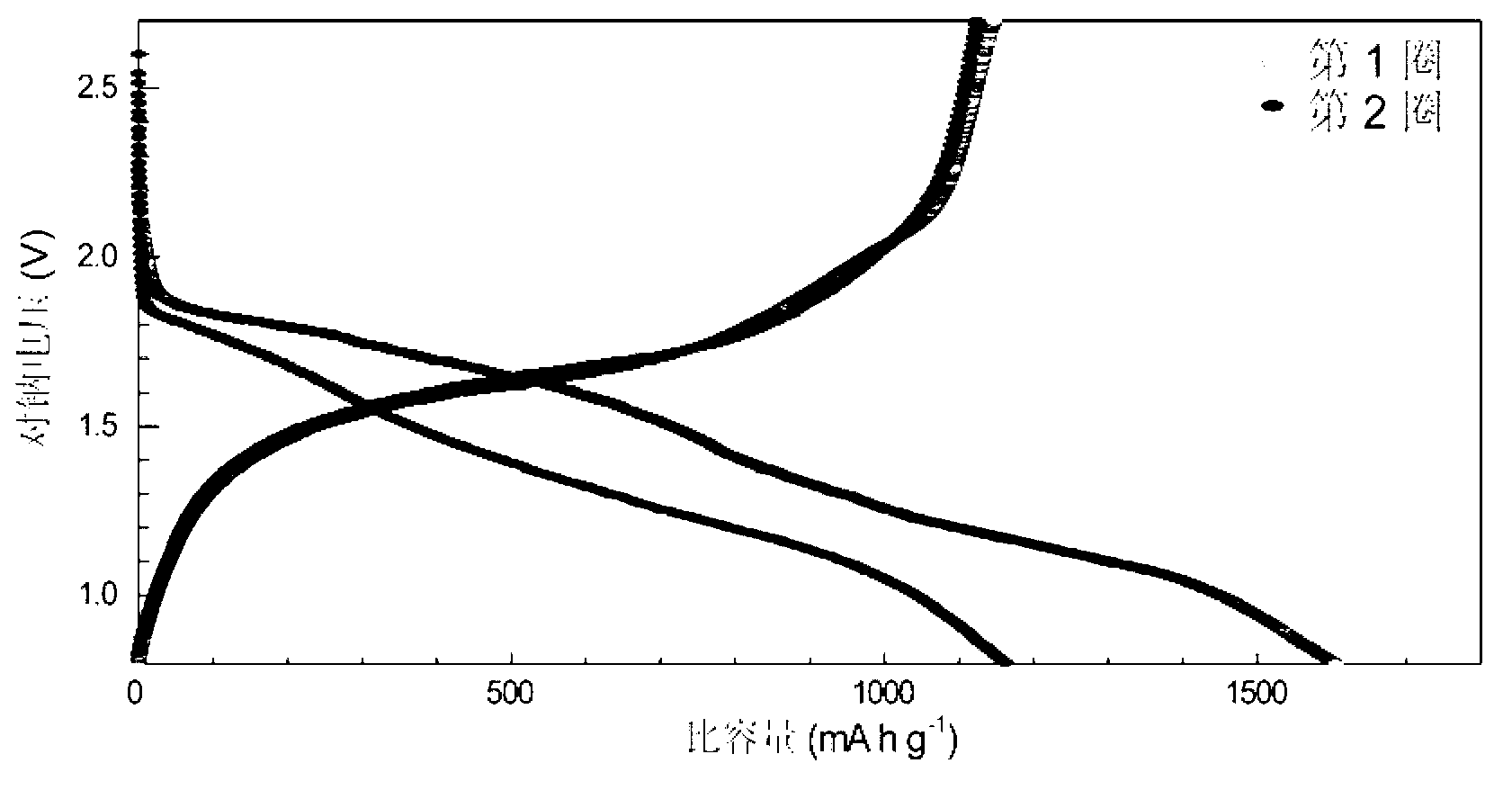

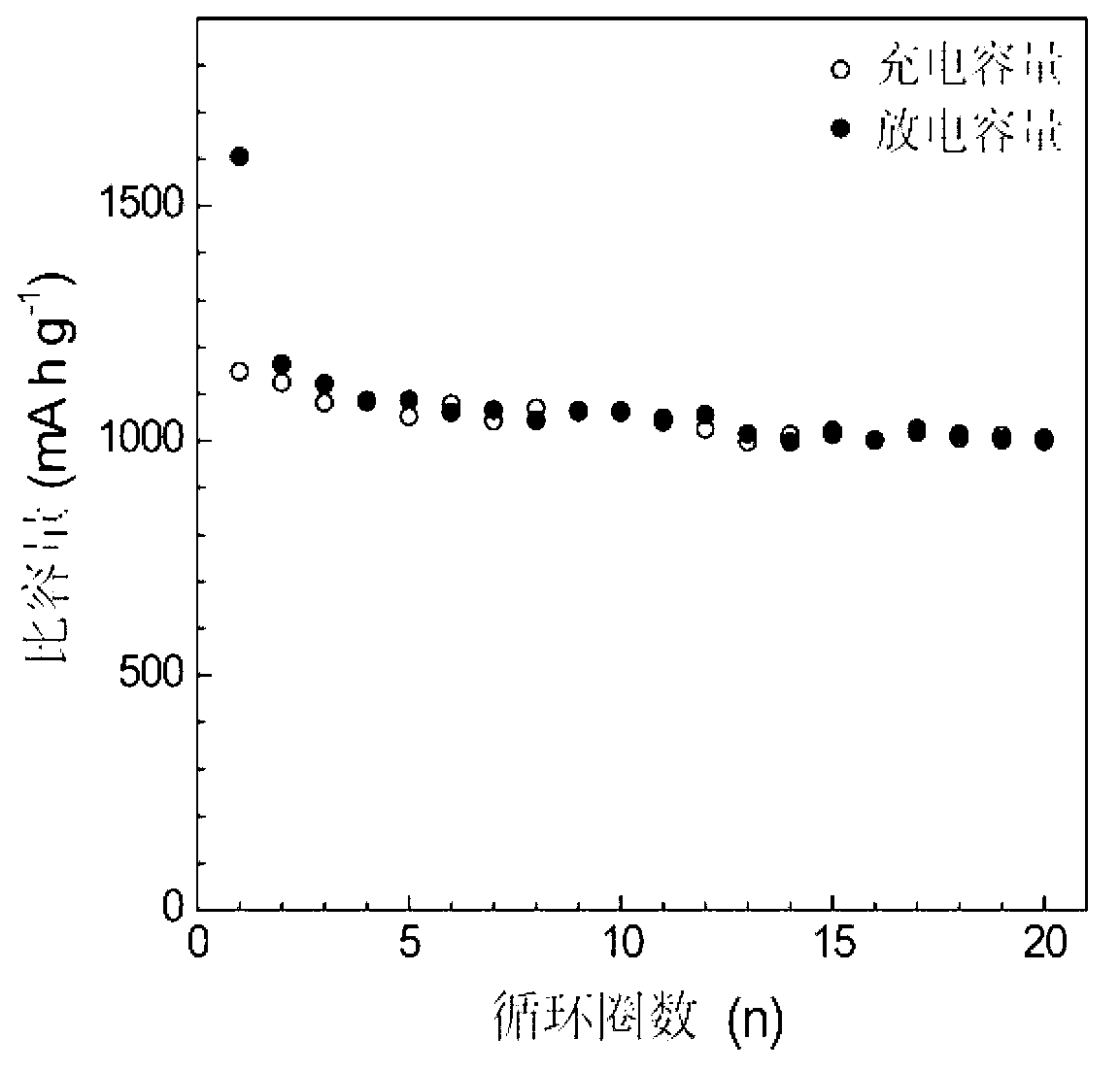

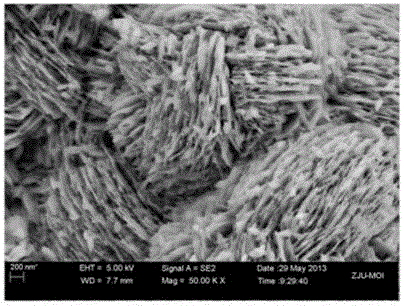

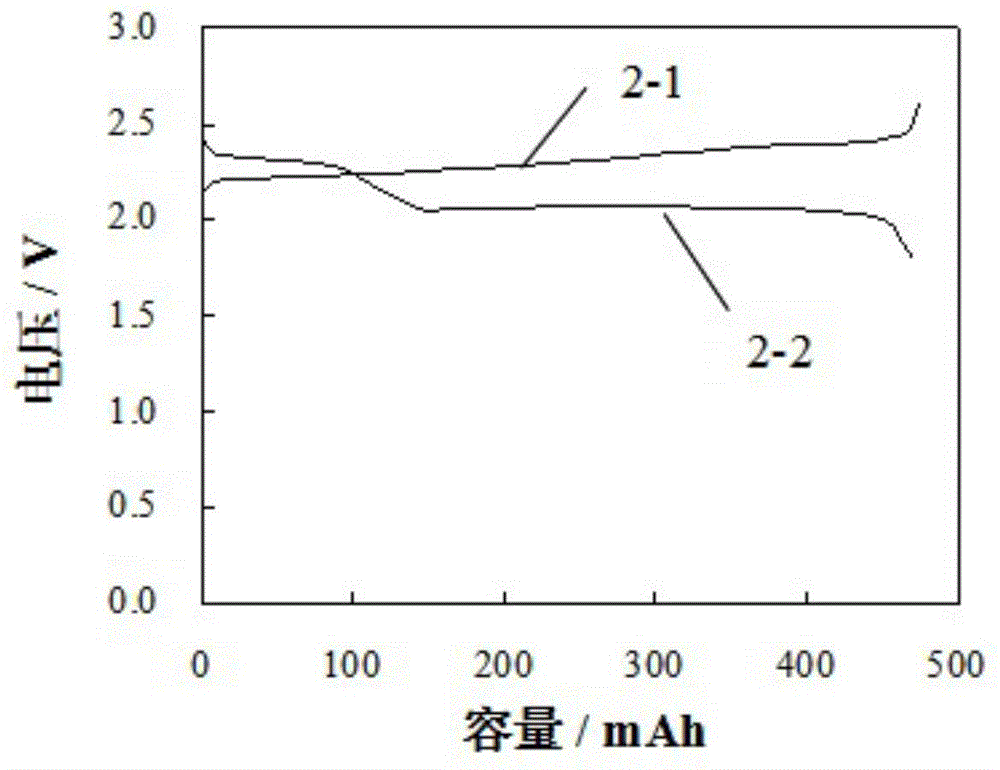

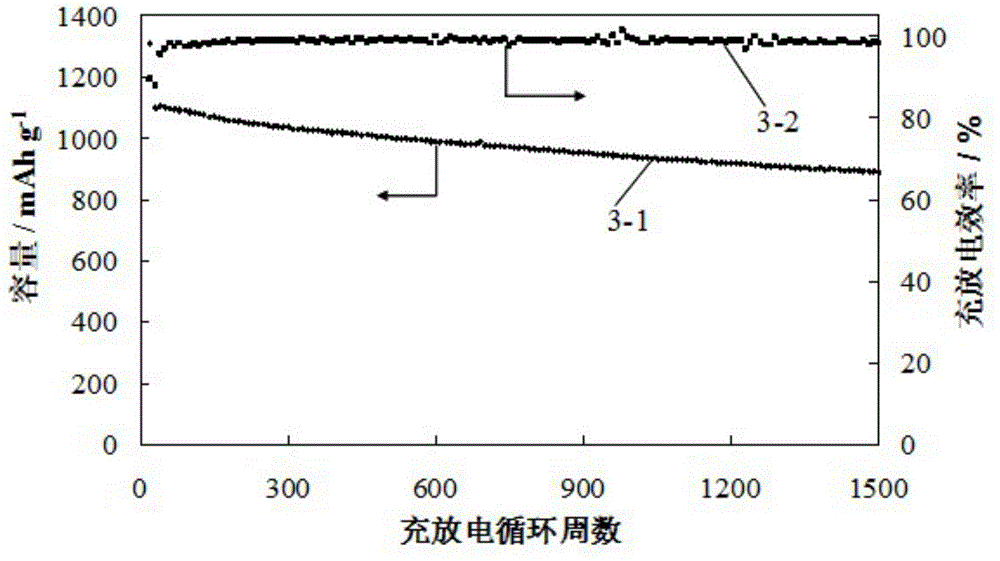

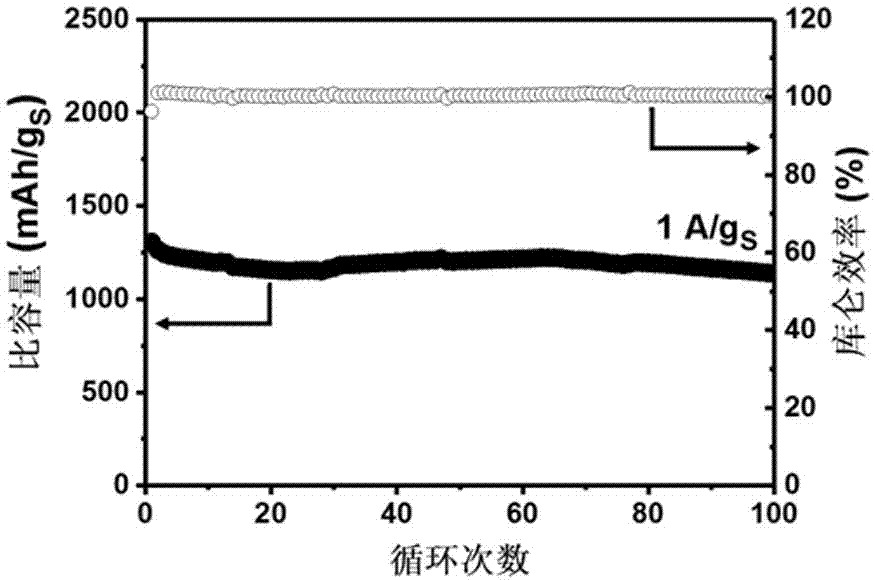

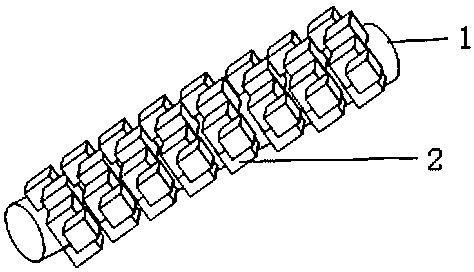

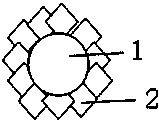

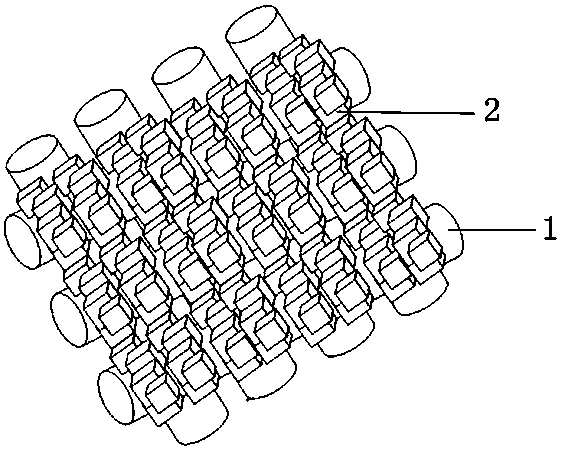

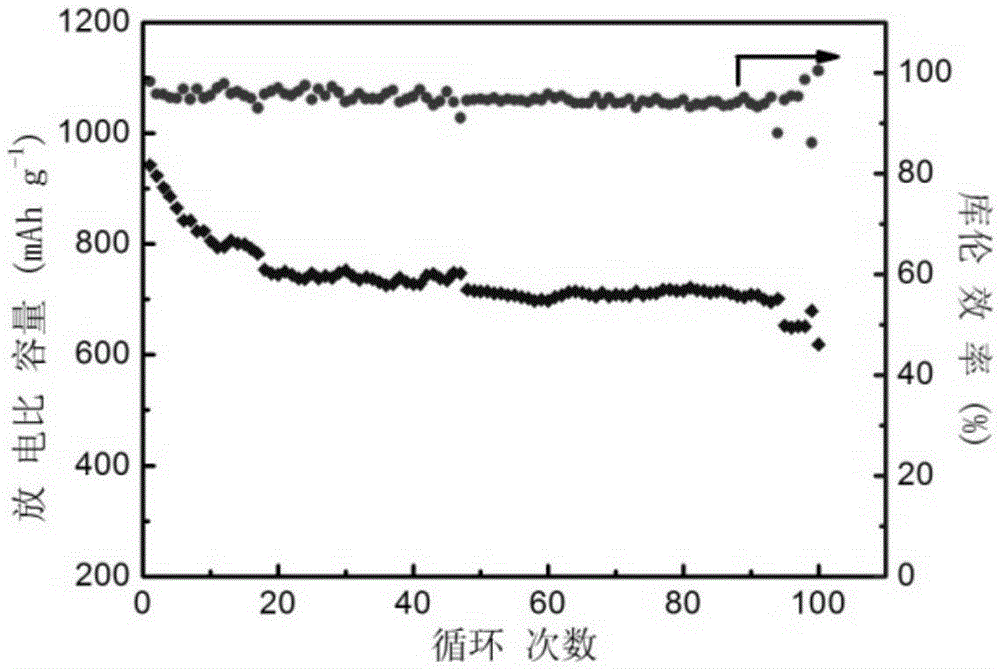

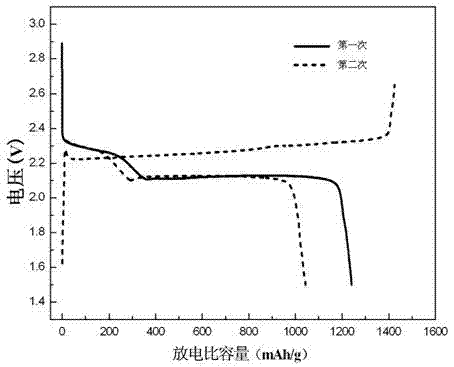

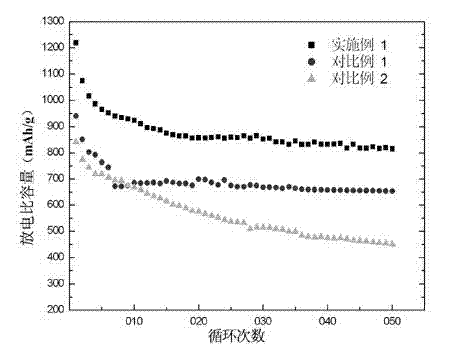

ActiveCN102938475AHigh cycle capacityImprove cycle stabilityCell electrodesSecondary cellsSulfurRoom temperature

The invention discloses a sodium-sulfur battery and a manufacture method thereof. The sodium-sulfur battery comprises a metal sodium cathode, a sulfur-micropore carrier compound anode and organic electrolyte. The sulfur-micropore carrier compound anode is formed by mixing and heating sulfur and a micropore carrier according to a certain ratio, and the sulfur is evenly dispersed in micropore channels of the micropore carrier in short chain sulfur molecule mode. The micropore carrier comprises a carbon micropore carrier, a non-carbon micropore carrier and a composition of the carbon micropore carrier and the non-carbon micropore carrier. The sodium-sulfur battery can keep high circulation capacity, excellent stable circulation performance and good high magnification performance (large-current density charging and discharging) in large temperature range including room temperature. The main composition part sulfur-micropore carrier compound anode is simple in preparation method and suitable for large scale production and has high practicability. Raw materials are easy to obtain.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Positive electrode sulfur-carrying material of lithium-sulfur battery and preparation method of lithium-sulfur battery

InactiveCN104577083APromote diffuse distributionImprove efficiencyCell electrodesFinal product manufactureThioureaCarbonization

The invention relates to the field of batteries, and aims at providing a positive electrode sulfur-carrying material of a lithium-sulfur battery and a preparation method of the lithium-sulfur battery. The preparation method comprises the following steps: adding thiourea and water-soluble monosaccharide or polysaccharide into ionized water to prepare a solution, and performing polymerization to prepare thiourea-glucoresin; further adding hydrophilic nano calcium carbonate and nano lithium cobalt oxide, and uniformly stirring to prepare a turbid liquid; and performing spray-drying, heating at 200 DEG C and 700 DEG C with flow N2, sequentially washing a carbonization product with hydrochloric acid and deionized water, and drying at constant temperature, thereby obtaining lithium cobalt oxide modified sulfur-containing macropore carbon. According to preparation method, sulfur in the sulfur-containing macropore carbon has special affinity with Co, the dispersion distribution of the nano lithium cobalt oxide can be intensified, the use efficiency of the lithium cobalt oxide can be improved, the conductivity of the macropore carbon is also improved due to doping the sulfur, a certain sulfion accumulation function can be also achieved, and the speed capacity and the property stability of the lithium-sulfur battery are greatly improved.

Owner:ZHEJIANG UNIV

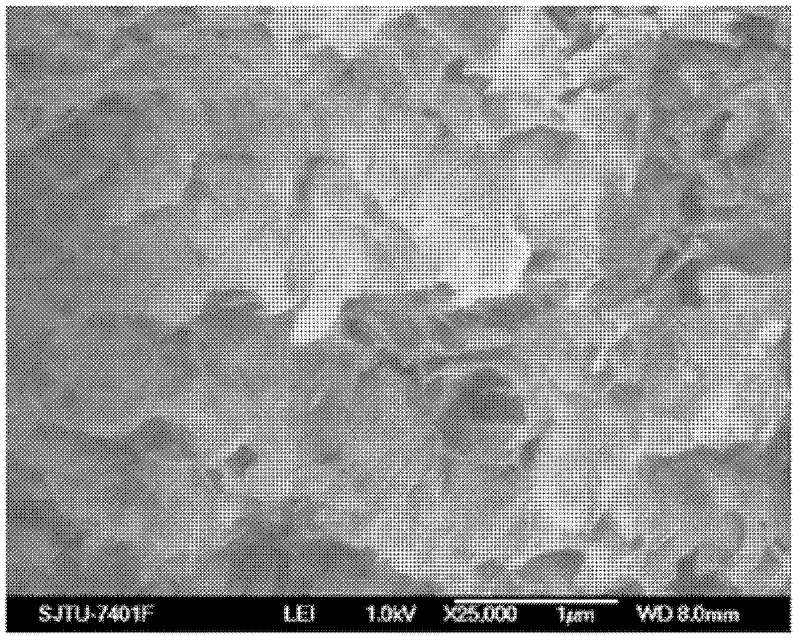

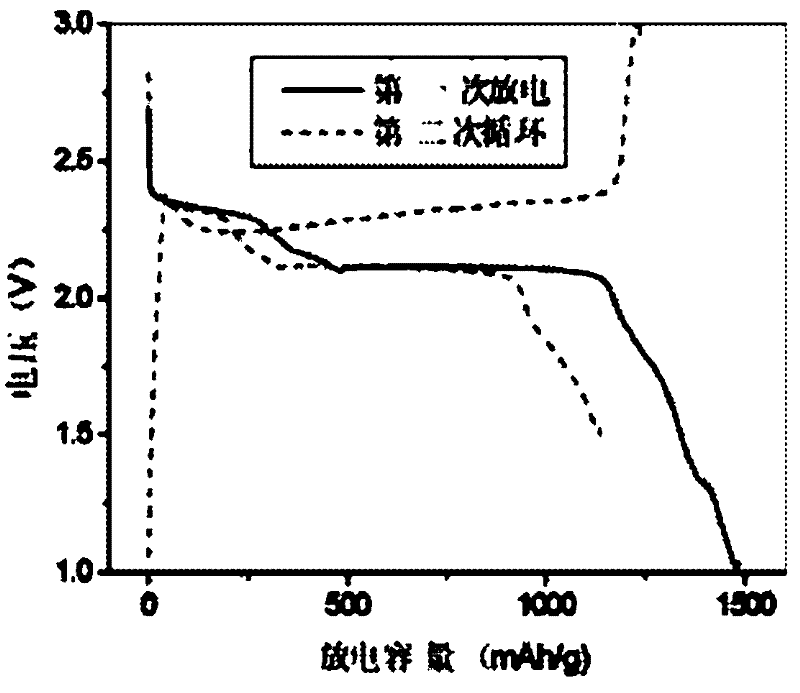

Elemental sulfur composite material containing graphene and preparation method thereof

InactiveCN102522542AIncrease profitIncrease energy densityCell electrodesLithium sulfurSodium–sulfur battery

The invention provides an elemental sulfur composite material containing graphene and a preparation method of the composite material. The composite material is a binary material AxBy, wherein A is grapheme, and B is elemental sulfur, x is more than or equal to 1 percent and less than or equal to 90 percent while y is more than or equal to 10 percent and less than or equal to 99, and x plus y equals to 100 percent, and B is dispersed on the surface of A in a nanometer state. The preparation method comprises the steps of carrying out hydro-thermal treatment on the elemental sulfur and the graphene oxide between 50 and 500 degrees; and reducing the graphene oxide into the graphene by the elemental sulfur, and obtaining the elemental sulfur composite material containing grapheme of which nano-sulfur is uniformly dispersed on the surface of the grapheme at the same time. Lithium sulfur batteries or sodium sulfur batteries are prepared by using the composite material as an anode and a metal lithium or metal sodium as a cathode; moreover, the lithium sulfur batteries can be charged or discharged under the room temperature, and the reversibility specific capacity of the sulfur-based composite material containing grapheme is up to 1480mAh / g.

Owner:SHANGHAI JIAO TONG UNIV

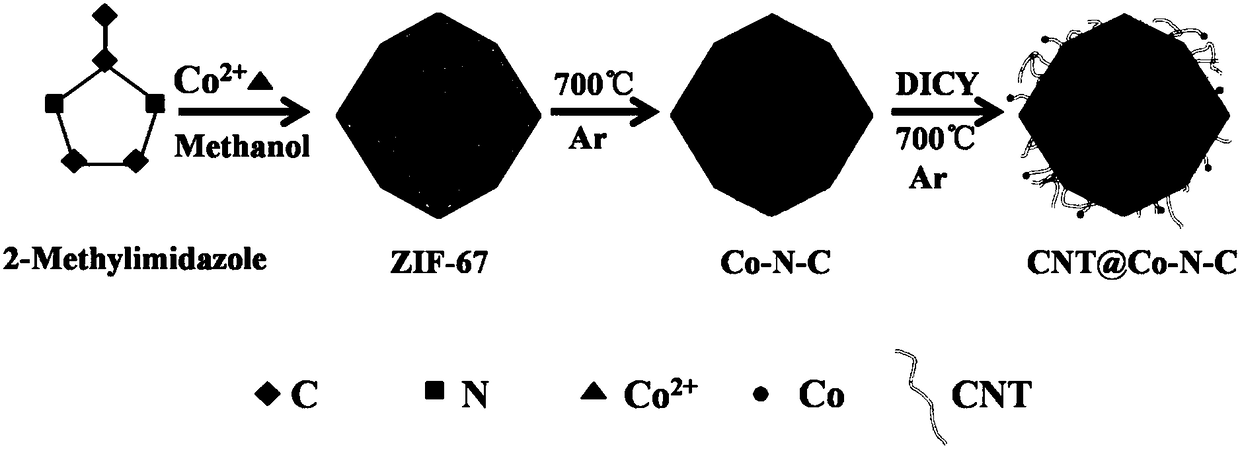

Preparation method of positive electrode material of lithium-sulfur battery, and lithium-sulfur battery

ActiveCN108598390AInhibition of the shuttle effectIncrease the areaMaterial nanotechnologyCell electrodesMetal-organic frameworkCarbonization

The invention relates to a preparation method of a positive electrode material of a lithium-sulfur battery. The preparation method comprises the following steps of enabling cobalt nitrate and 2-methylimidazole to be dissolved into a solvent and performing standing, centrifuging and drying to obtain ZIF-67; performing carbonization on ZIF-67 in inert atmosphere and performing cooling to the room temperature to obtain Co-N-C; and performing carbonization on Co-N-C and dicyandiamide in the inert atmosphere, and performing cooling to the room temperature to obtain CNT@ Co-N-C. The lithium-sulfur battery comprises the positive electrode material used for the lithium-sulfur battery. Beneficial effects are achieved as follows: compared with the single metal organic framework compound-based composite material, the specific surface area and the conductivity of the positive electrode material disclosed in the invention are enlarged and improved, and sulfur load can be realized more effectively;in addition, a shuttle effect of polysulfide in the battery reaction process can be suppressed more effectively; and a constant-current discharge test on the assembled battery proves that the electrochemical performance of the composite material with the carbon nanotubes in an in-situ growth manner is more excellent.

Owner:武汉新能源研究院有限公司

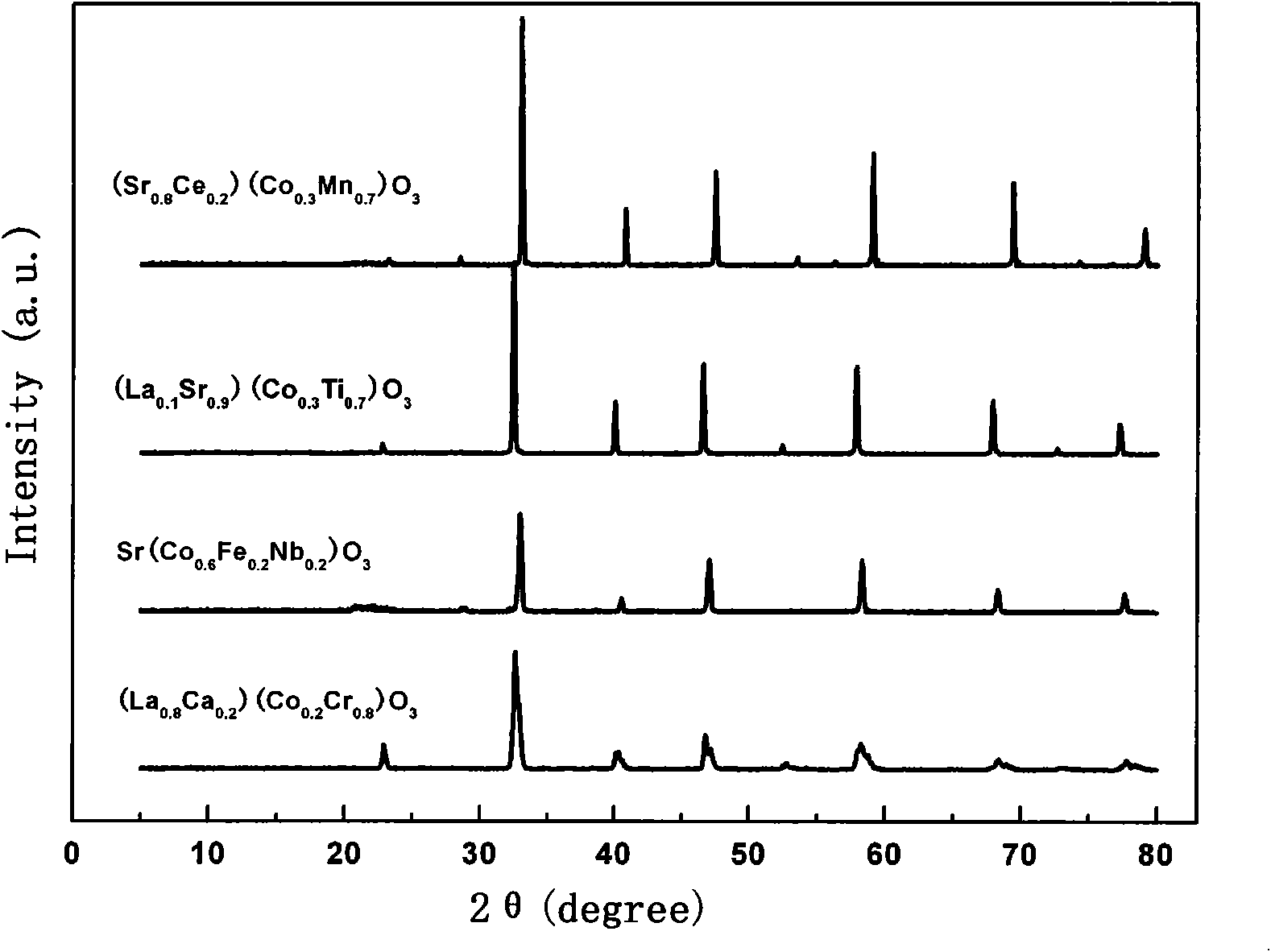

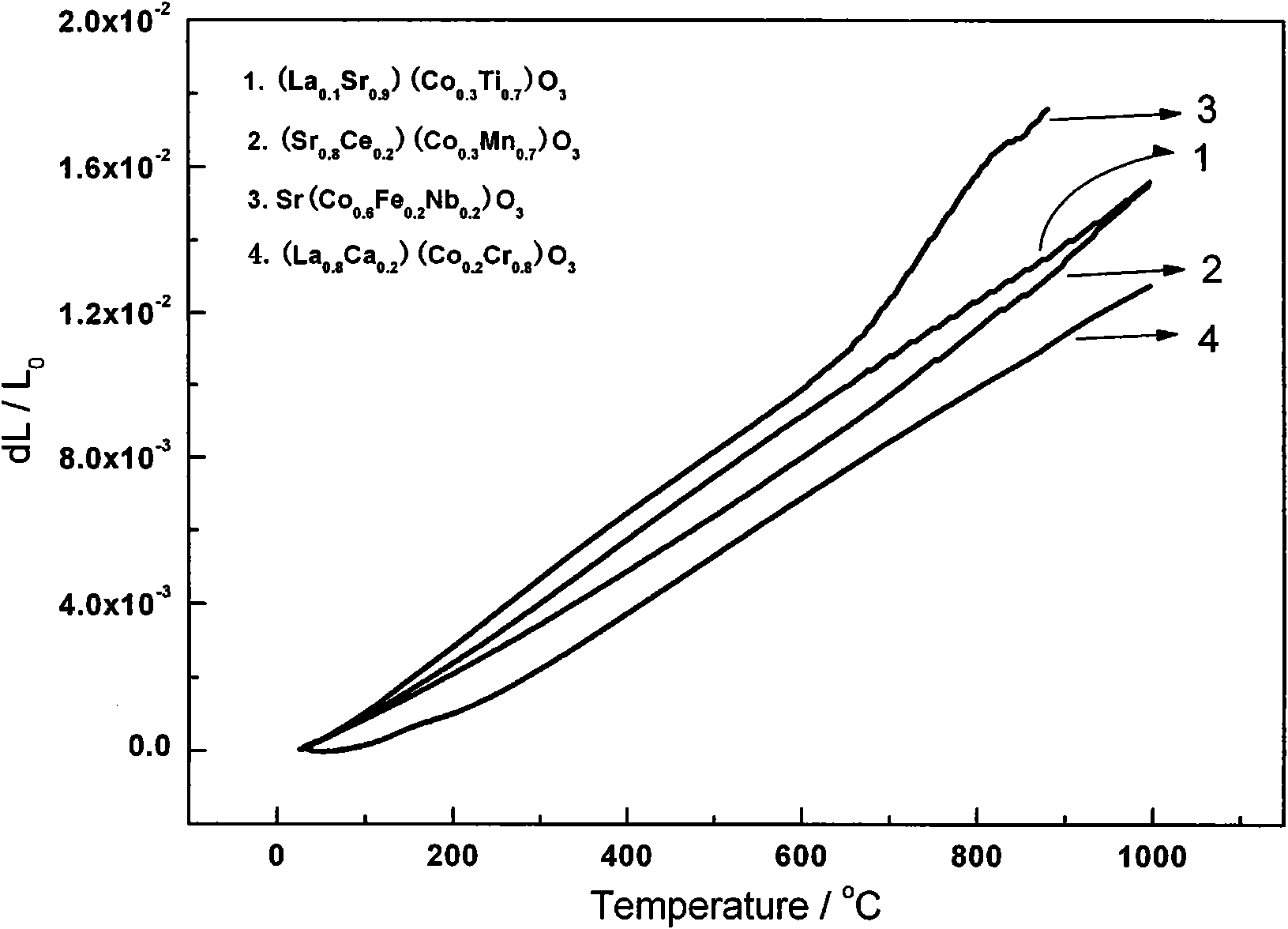

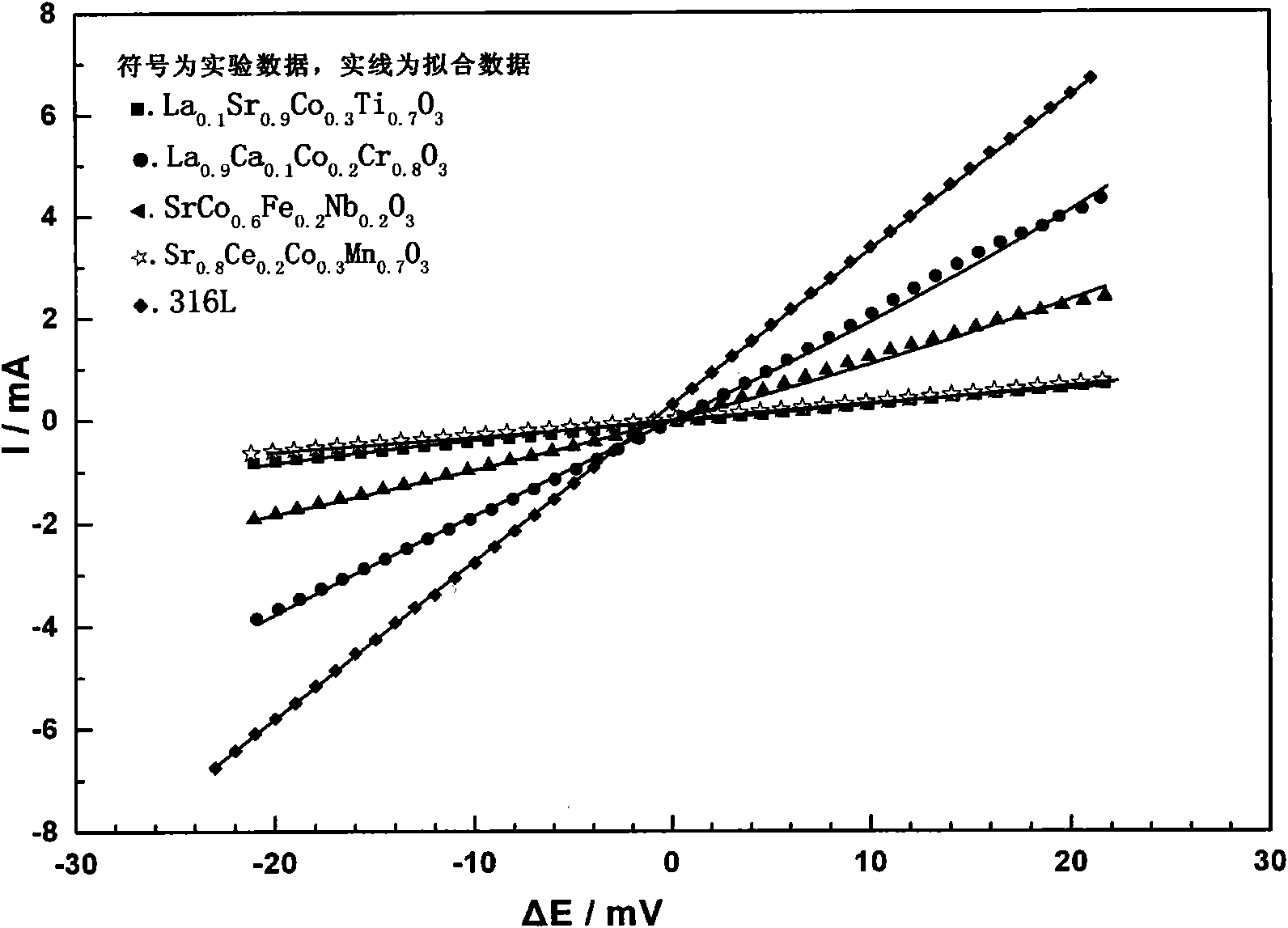

Perovskite structure material and preparation method thereof

InactiveCN101792304AImprove conductivityImprove stabilityCell component detailsRare-earth elementMischmetal

The invention relates to a conductive corrosion-resistant perovskite structure material which is characterized in that the chemical formula of the material can be represented by ABO3, wherein A is a rare earth element or an alkaline earth metal element, or the combination of a rare earth metal element and the alkaline earth metal element, and B is one or more transition metal elements. The conductive corrosion-resistant perovskite structure material has great electronic conductivity and excellent stability and corrosion resistance, in particular to the corrosion resistance against the molten salt environments. The material can be applied in the corrosion resistance of housings of sodium sulfur batteries and the corrosion resistance of devices in other molten salt environments.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

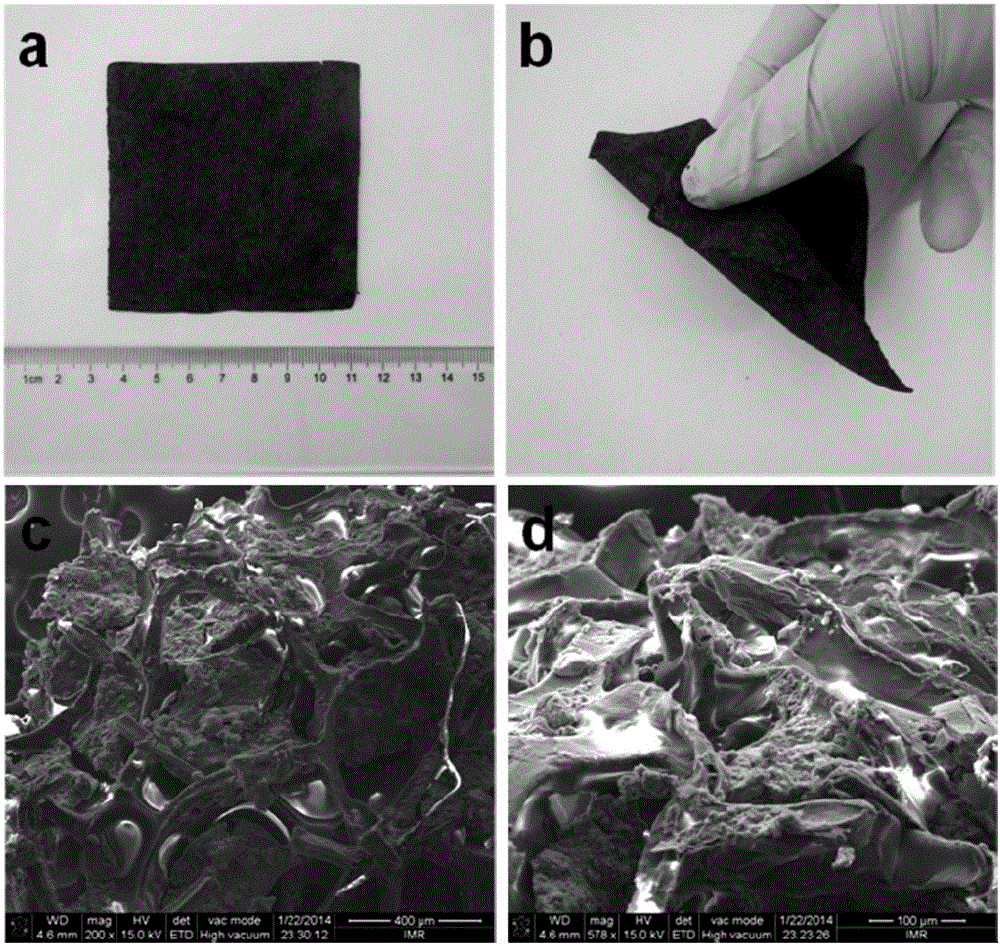

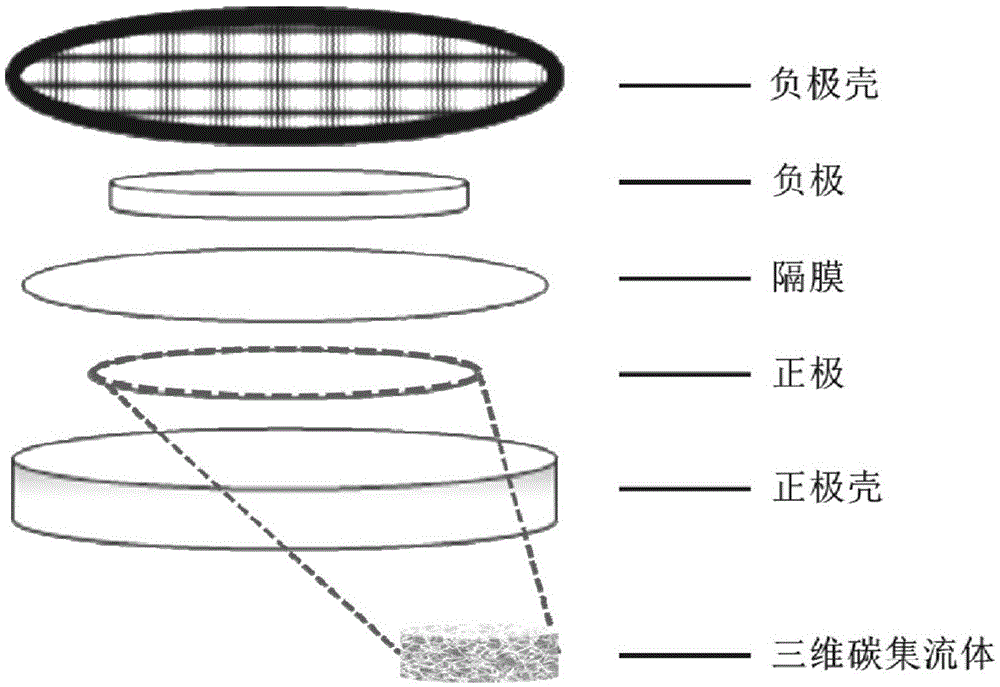

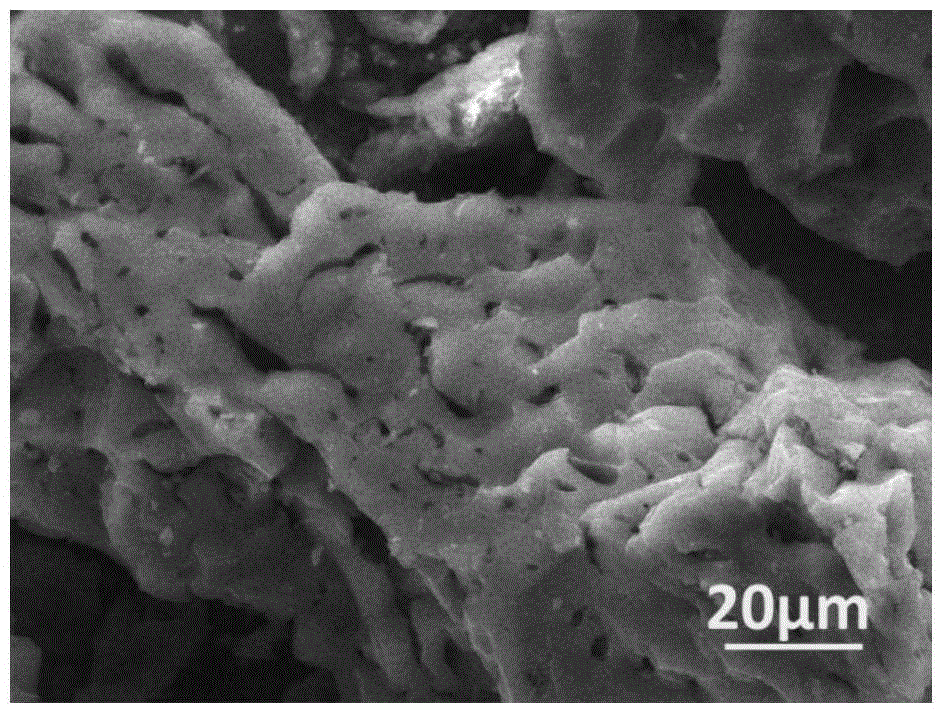

Preparation method and application of lithium-sulfur battery three-dimensional carbon current collector

ActiveCN105489901AImprove cycle stabilityCounteract volume expansionFinal product manufactureElectrode carriers/collectorsCarbonizationSodium–sulfur battery

The invention relates to the field of electrochemical batteries, in particular to a preparation method of a lithium-sulfur battery three-dimensional carbon current collector and application of the lithium-sulfur battery three-dimensional carbon current collector in a lithium-sulfur battery. The preparation method of the lithium-sulfur battery three-dimensional carbon current collector disclosed by the invention comprises the following steps: soaking an organic foam material with an organic solvent for 2-6 h, washing, drying, and preserving the temperature for 2-6 h at the temperature of 700-900 DEG C under the protection of an inert gas so as to obtain the lithium-sulfur battery three-dimensional carbon current collector, wherein the organic foam material is any one of polyurethane foam and melamine foam; and the organic solvent is any one of ethyl alcohol, ethylene glycol, isopropyl alcohol and acetone. According to the preparation method of the lithium-sulfur battery three-dimensional carbon current collector disclosed by the invention, the current collector is prepared through carbonization under a high temperature by adopting the organic foam material, the three-dimensional structure of the current collector can improve the surface sulfur carrying capacity of the current collector and has certain elasticity, and the volume expansion of sulfur in the charging and discharging process can be accommodated.

Owner:HENAN NORMAL UNIV

Metal-sulfur battery based on sulfur-rich transition metal sulfide and preparation method thereof

ActiveCN106898750AIncrease energy densityAchieve long lifeFinal product manufactureCell electrodesNiobiumLithium sulfur

The invention discloses a metal-sulfur battery based on sulfur-rich transition metal sulfide and a preparation method thereof. The metal-sulfur battery comprises a cathode, an anode and an electrolyte; the anode is metal; the cathode comprises transition metal sulfide; a chemical formula of the transition metal sulfide is MSx, wherein x is more than or equal to 3; M is one or more of vanadium, niobium, titanium, molybdenum, tungsten, iron, cobalt and nickel; the metal is lithium, sodium, potassium, magnesium, aluminum, zinc or iron; the electrolyte is an ester-based electrolyte or an ether-based electrolyte. The metal-sulfur battery based on the sulfur-rich transition metal sulfide and the preparation method thereof, disclosed by the invention, have the benefits that transition metal polysulfide is adopted as a cathode material equivalent to sulfur so as to realize the novel metal-sulfur battery such as a lithium sulfur and sodium sulfur battery system, and further the application potential of the metal-sulfur battery is further improved.

Owner:SUZHOU UNIV

ZIF-9-based porous carbon/carbon fiber composite material and preparation method thereof

ActiveCN109192985AHigh porosityLarge specific surface areaMaterial nanotechnologyElectrode carriers/collectorsFiberPorous carbon

A ZIF-9-based porou carbon / carbon fiber composite material and preparation method thereof belongs to the technical field of a preparation method of a metal nanoparticle doped porous carbon / carbon fiber conductive composite material, can solve the problems of poor conductivity and poor stability of the existing composite carbon material, wherein the carbon fiber of a carbon fiber fabric is taken asa growth substrate, and high-density arranged ZIF is grown on the growth substrate; 9, carbonize at high temperature in an inert gas atmosphere to generate porous carbon / carbon fib composite material, and that invention realizes a ZIF-9-based porous carbon and conductive substrate integrated conductive network structure, lithium sulfide batteries, sodium sulfide batteries, lithium-air batteries and fuel cells, electrocatalysis and other fields have a wide range of applications.

Owner:清创人和生态工程技术有限公司

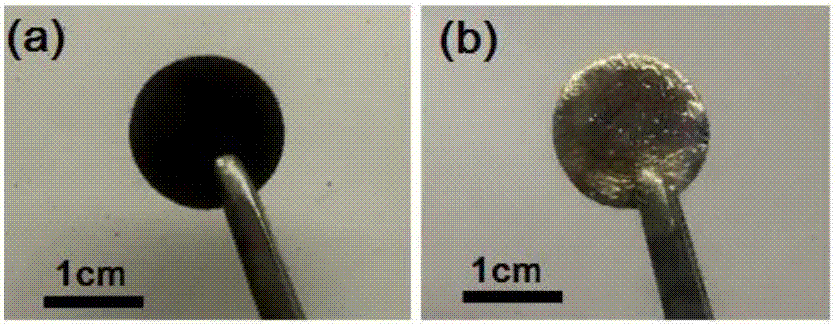

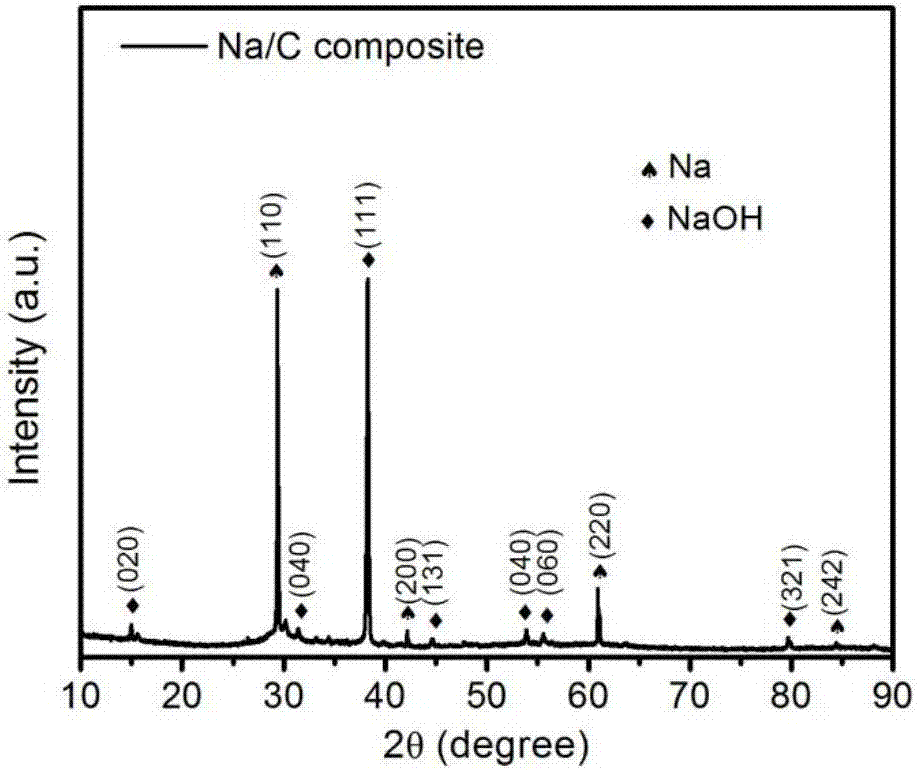

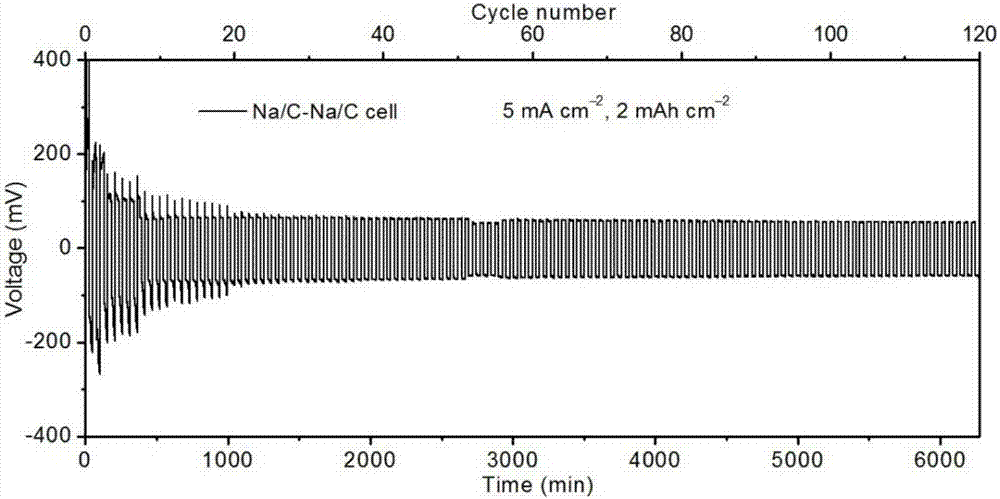

Method for preparing composite sodium negative electrode for sodium-ion battery

InactiveCN107221640AImprove stabilityGrowth inhibitionElectrode melt handlingSecondary cellsHigh current densityNew energy

The invention discloses a method for preparing a composite sodium negative electrode for a sodium-ion battery and belongs to the field of new energy materials. According to the method disclosed by the invention, metal sodium is deposited in gaps of a three-dimensional carbon material or a foamed porous material and other carriers through a hot infusion melting method or an electrodeposition method, so that the composite sodium negative electrode is prepared, wherein the three-dimensional carbon material is applied to providing a sufficient space for pre-stored sodium in the preparation process and providing a carrier for receiving the metal sodium in the battery cycle process. The composite sodium negative electrode can be widely applied to the sodium-ion battery, a sodium air battery, a sodium-sulfur cell and other sodium metal batteries, is assembled into a sodium-ion symmetric cell to still keep a stable voltage platform under high current density, is capable of inhibiting sodium dendritic growth and stabilizing volume change of the sodium electrode in the battery cycle process, and has the advantages of good cycling stability, long service life and the like. The method disclosed by the invention is rich and cheap in carrier materials, controllable in preparation process, low in production cost and capable of realizing batch production.

Owner:UNIV OF SCI & TECH BEIJING

Sealing material for sodium-sulfur cell and preparation thereof

The invention relates to a sealing material for a sodium-sulfur cell and a preparation method thereof, in particular to a beta-Al2O3 ceramic and alpha-Al2O3 ceramic sealing material and a preparation method thereof. The invention belongs to the field of energy source material. The sealing material for the sodium-sulfur cell is characterized in that the sealing material is glass powder which comprises the following components: 20 to 90 weight percent of SiO2, 5 to 40 weight percent of B2O3, 0 to 10 weight percent of Al2O3 and the balance being R2O; R2O can be one or more of Na2O, K2O and Li2O; the sealing material also comprises the following components counted by the weight of all the oxides: 0.5 to 6 weight percent of TiO2 and 0 to 6 weight percent of Y2O3 or CeO2 or La2O3; all raw materials are smelted for 30 to 360 minutes at the high temperature of 1,400 to 1,600 DEG C; and the glass powder is obtained after water quenching and crushing. The sealing material solves the problem of the imperfect heat matching between the borosilicate sealing glass for the sodium-sulfur cell and the beta-Al2O3 ceramics and alpha-Al2O3 ceramics. The sealing body has good resistance to thermal shocks; and after 50 thermal shocks, the sealing body can still not be broken off by hands and can not be fractured and have no micro-cracks when the sealing body is freely dropped onto the cement floor from a 2-meter high position.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Sulfur-carbon composite positive electrode material for lithium-sulfur battery and preparation method of sulfur-carbon composite positive electrode material

ActiveCN104600247AIncrease contentImprove cycle stabilityNon-aqueous electrolyte accumulator electrodesLi-accumulatorsHigh concentrationCarbon composites

The invention particularly relates to a preparation method of a sulfur-carbon composite positive electrode material for a lithium-sulfur battery. Sodium polysulfide is taken as the raw material, and the nano-scale sulfur particles generated by use of a chemical reaction are promoted to be melted by virtue of high-speed ball milling and go into carbon pores of conductive carbon black, and finally, the sulfur-carbon composite positive electrode material is prepared. The high-performance sulfur-carbon composite material is prepared by use of an in-situ wet ball milling method. According to the preparation method, the operation is simple and easy, the energy consumption is low, the cost is low, an environment-friendly effect is achieved, and the industrial production is easy. The thorough dispersion and fixation of sulfur on a conductive substrate are realized; besides, a high-concentration lithium salt electrolyte is adopted to inhibit the solution of polysulfide, and therefore, the cyclic stability and the active substance utilization rate of the material are improved. As a result, the sulfur-carbon composite material prepared by use of the in-situ wet ball milling method is a positive electrode material which is high in specific capacity, long in cycle life and high in rate performance and can be applied to the field of lithium secondary batteries.

Owner:SHANDONG YUHUANG NEW ENERGY TECH +1

Preparation method of gel electrolyte for lithium-sulfur battery

InactiveCN105789694AInhibition of dissolutionImprove cycle performanceSecondary cellsCross-linkPolymer science

The invention relates to a preparation method of a gel electrolyte for a lithium-sulfur battery. The method comprises the following steps: 1, preparing an electrolyte lithium salt and an organic solvent into a basic electrolyte; 2, adding a mixed liquid of a polymeric monomer, a cross-linking agent and a solvent into the basic electrolyte to prepare a cross-linking polymeric liquid; 3, adding an initiator into the cross-linking polymeric liquid, performing initiated polymerization at a temperature of 15-45 DEG C for 2-6 hours to finish a preparation process of the gel electrolyte for the lithium-sulfur battery, and injecting the gel electrolyte into the lithium-sulfur battery which is being assembled. According to the preparation method, the gel electrolyte formed after initiated polymerization is put into the lithium-sulfur battery in an assembling process, and the battery has a relatively high capacity retention ratio no matter the battery is under a high temperature condition or a low temperature condition, so that high and low temperature adaptability of the lithium-sulfur battery is improved effectively; a manufacturing process of the battery is improved; and the manufacturing cost of the battery is lowered. The preparation method is suitable for large-scale commercial production of the lithium-sulfur battery.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST

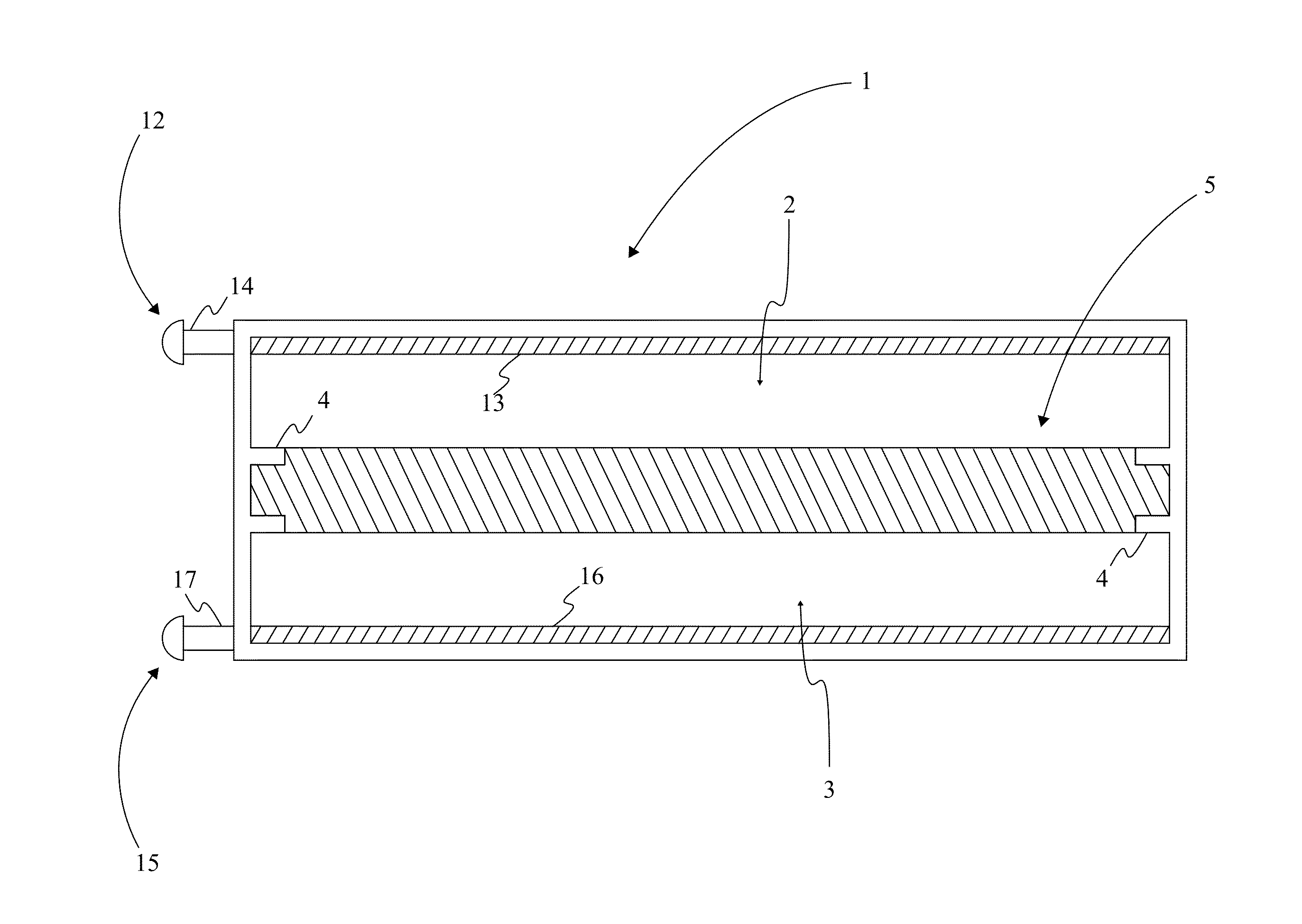

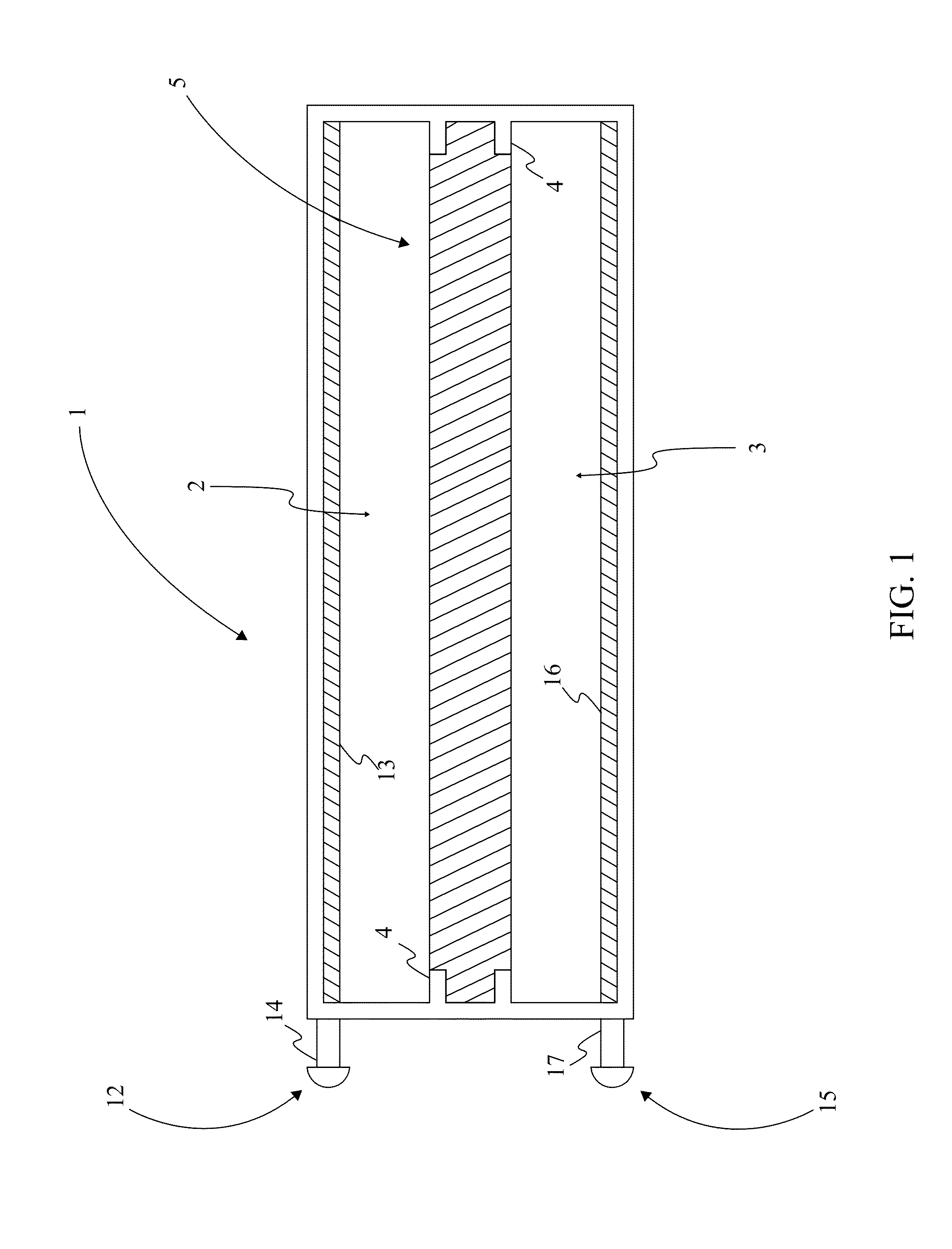

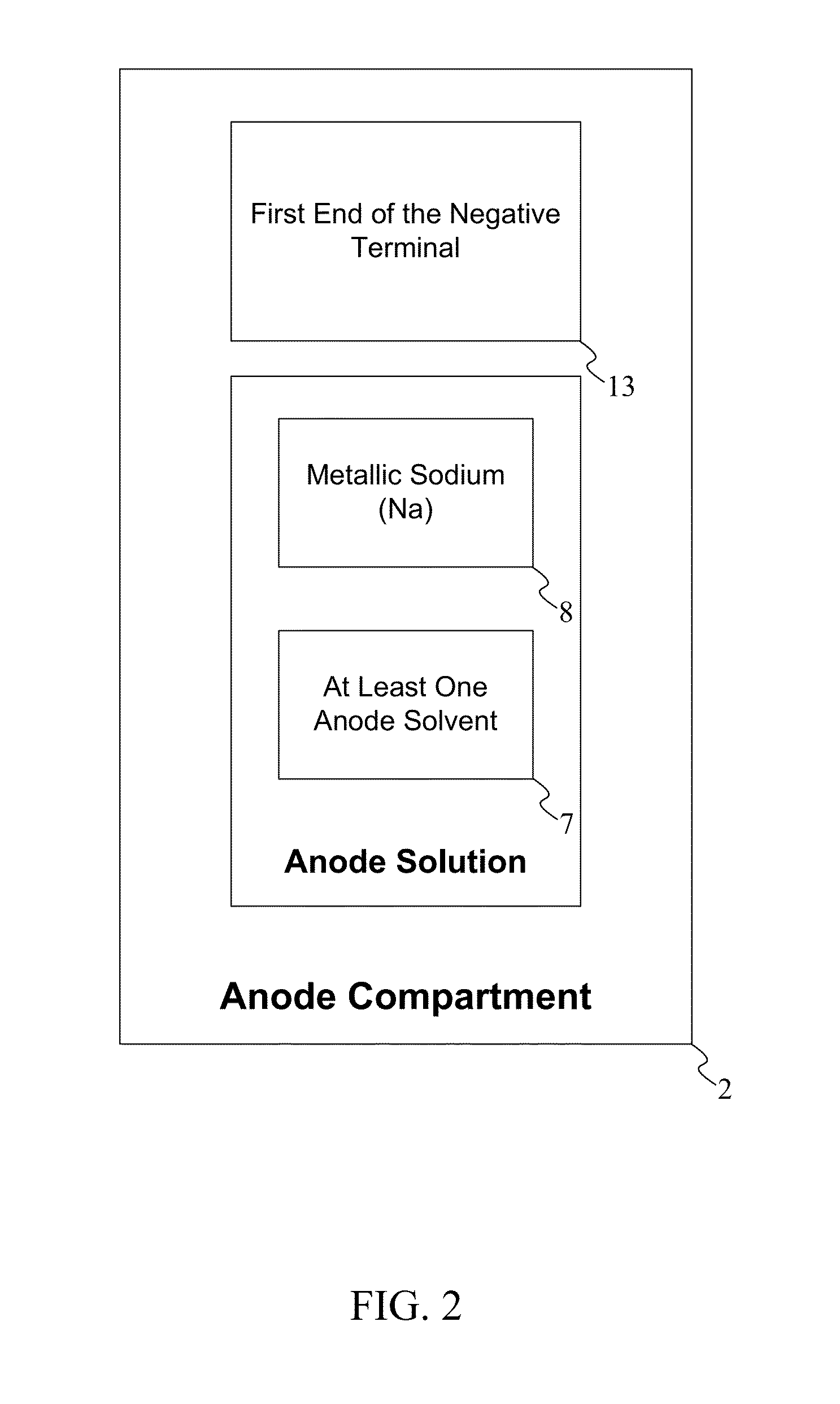

Sodium-Sulfur Battery

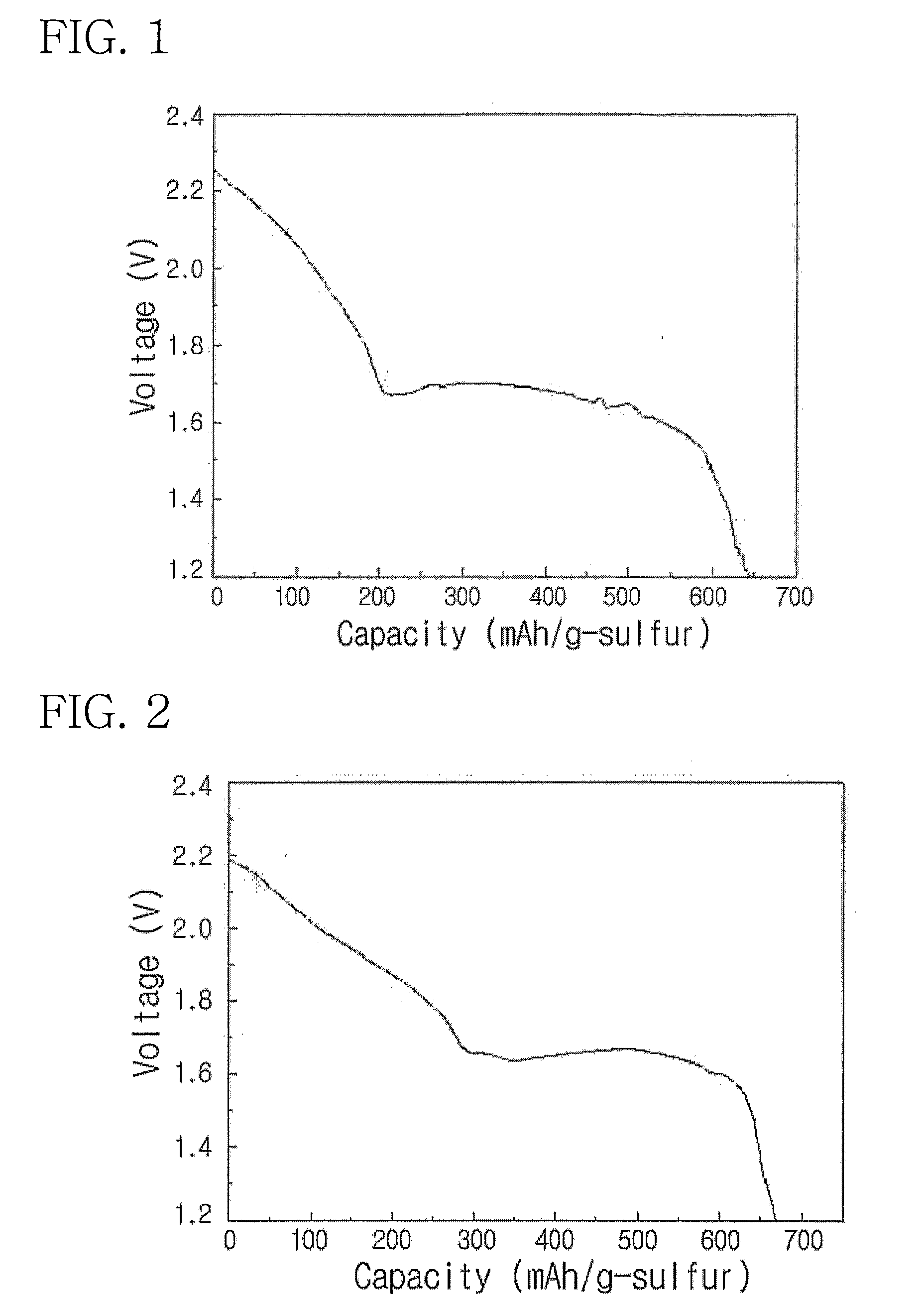

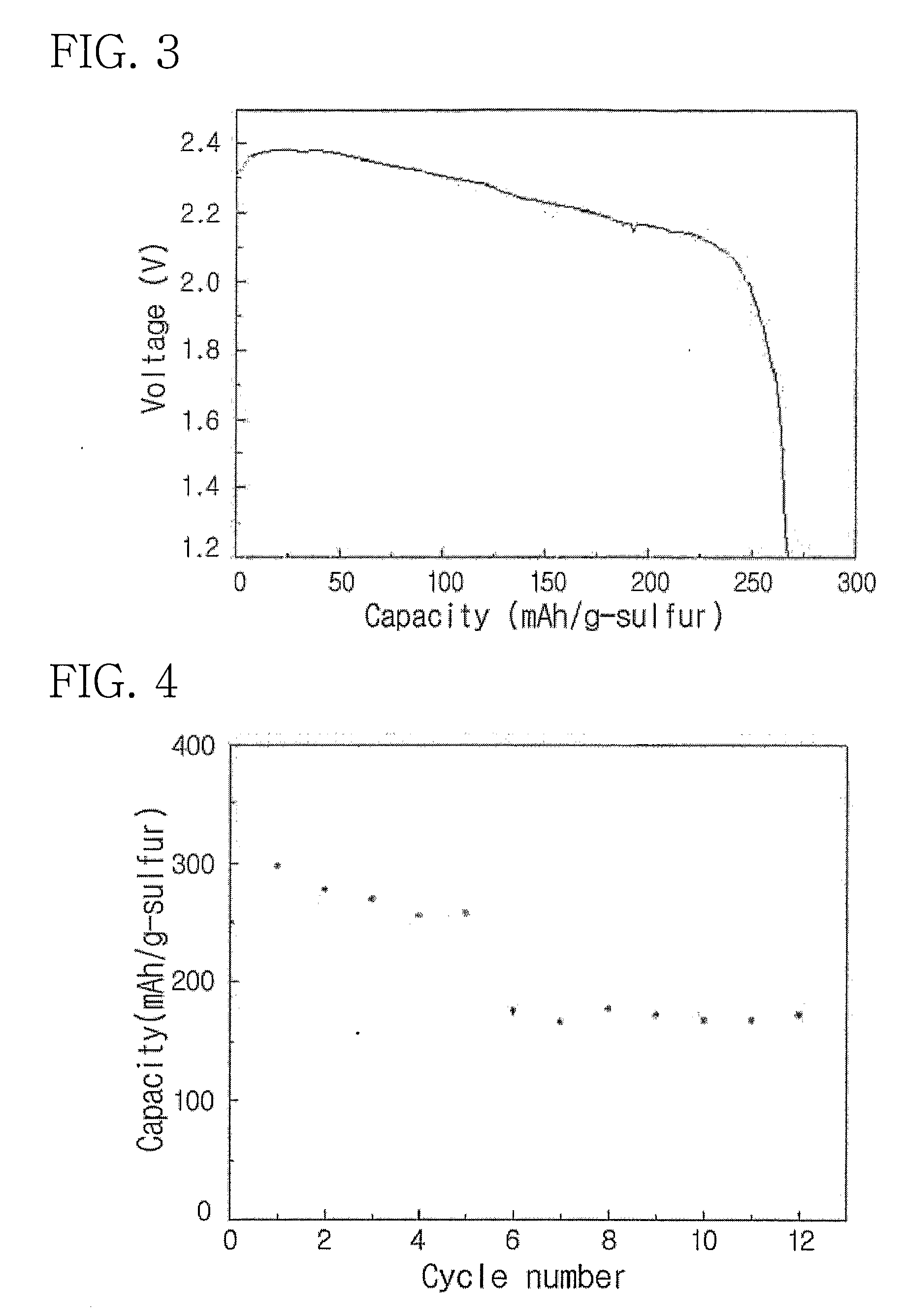

InactiveUS20130288153A1High operating cell potentialReduce the temperatureRegenerative fuel cellsSecondary cellsElectrode potentialNanowire

A sodium sulfur secondary battery is a battery that operates at a comparatively lower temperature, while maintaining a high operating cell potential comparable to existing sodium sulfur battery configurations. The apparatus accomplishes this through the arrangement of component materials selected based on experimentation results demonstrating favorable performance in a secondary battery configuration. The sodium sulfur battery comprises a housing, containing an anode solution, a cathode solution, and a sodium ion conductive electrolyte membrane. The anode solution contains metallic sodium and anode solvent. The cathode solution contains elemental sulfur and a cathode solvent. The sodium ion conductive electrolyte membrane is a Sodium Titanate Nano-membrane formed from long TiO2-nanowires. The electrolyte membrane is positioned between the anode solution and the cathode solution. The electrolyte membrane is able to selectively transports of sodium ion between the anode solution and the cathode solution at temperatures below 75° C. generating an electrode potential.

Owner:MORIS TECH CENT

Nas battery using liquid electrolyte

InactiveUS20070154814A1Additional drawbackLimiting operation temperatureNon-aqueous electrolyte accumulatorsSolid electrolyte cellsOrganic solventIron sulfide

The present invention relates to a sodium-sulfur battery consisted of solid sodium for the negative electrode (comprising carbon, sodium metal oxide and the like comprising sodium compound, sodium ion); solid sulfur for the positive electrode (comprising sulfur, sulfur compound such as iron sulfide, nickel sulfide); and liquid electrolyte which sodium salt and organic solvent such as grymids or carbonates are soaked in cell guard, thereby improving a drawback of prior art for conventional battery.

Owner:GYEONGSANG NAT UNIV

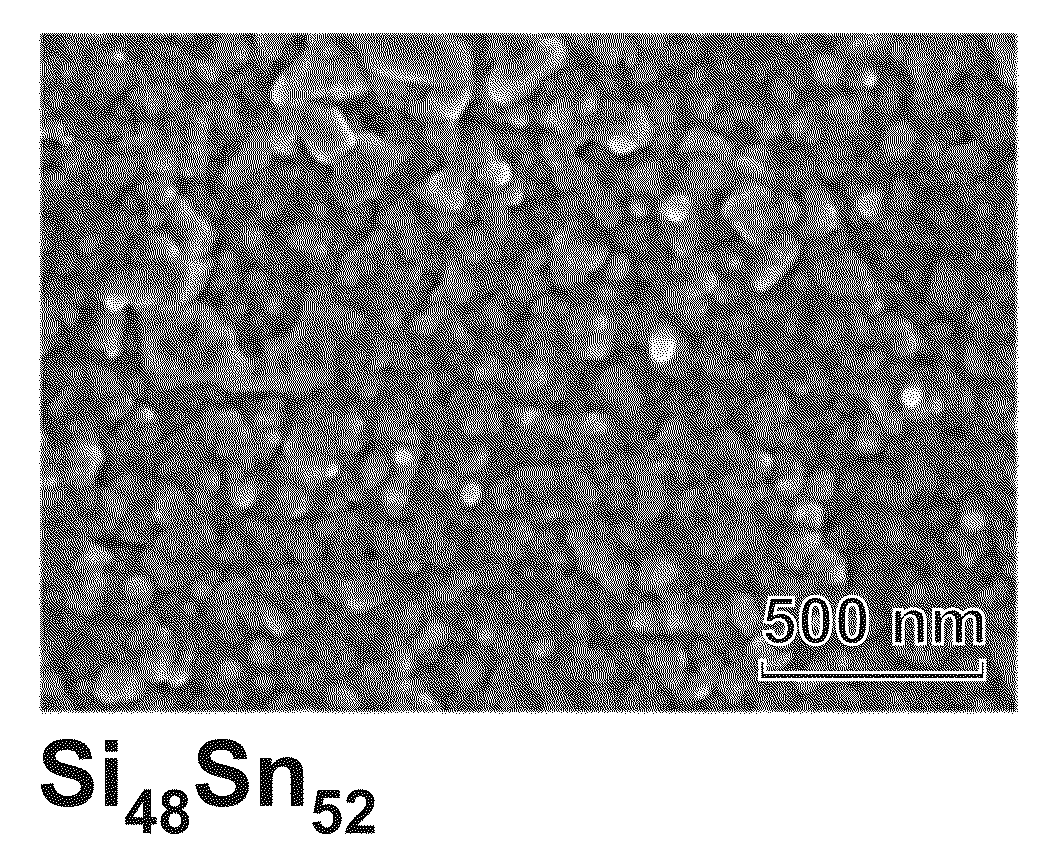

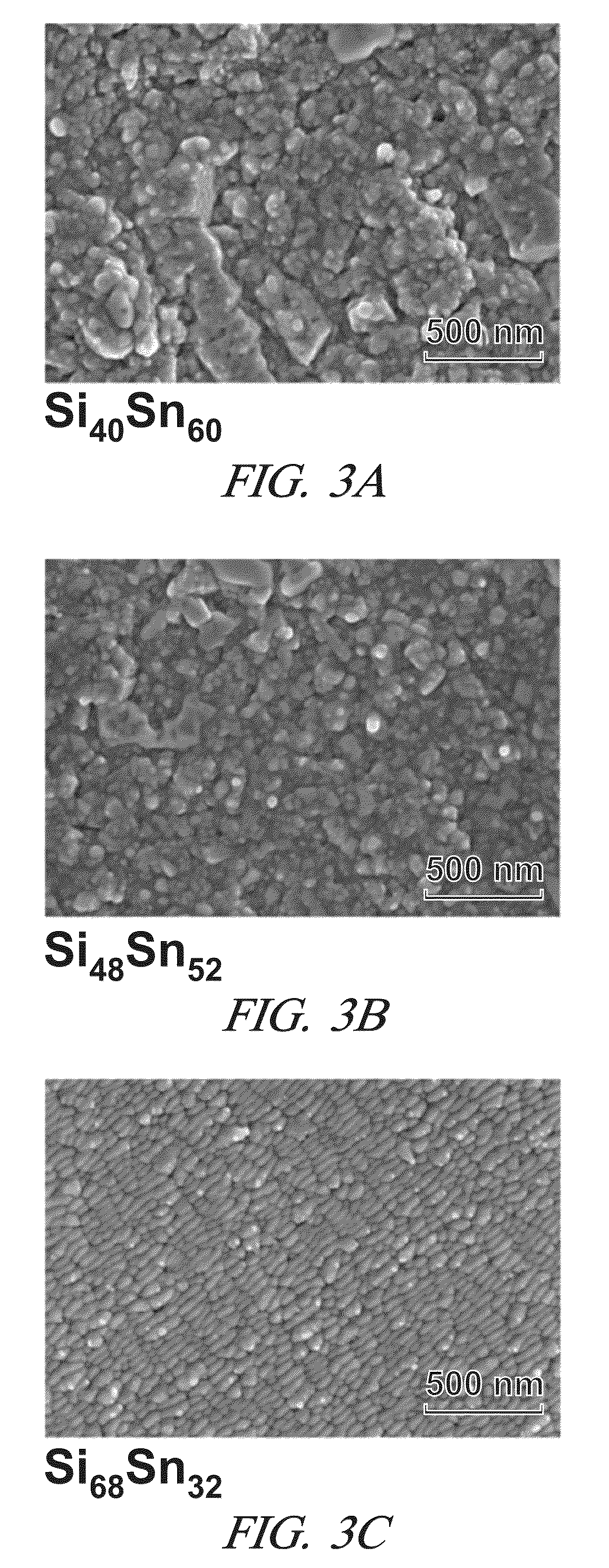

Phase separated silicon—tin composite as negative electrode material for lithium-ion and lithium sulfur batteries

ActiveUS9005811B2Reduce stressMitigate the fracture of the larger composite particlesMaterial nanotechnologyElectrode melt handlingElectrical batteryLithium sulfur

A composite of silicon and tin is prepared as a negative electrode composition with increased lithium insertion capacity and durability for use with a metal current collector in cells of a lithium-ion battery or a lithium-sulfur battery. This negative electrode material is formed such that the silicon is present as a distinct amorphous phase in a matrix phase of crystalline tin. While the tin phase provides electron conductivity, both phases accommodate the insertion and extraction of lithium in the operation of the cell and both phases interact in minimizing mechanical damage to the material as the cell experiences repeated charge and discharge cycles. In general, roughly equal atomic proportions of the tin and silicon are used in forming the phase separated composite electrode material.

Owner:GM GLOBAL TECH OPERATIONS LLC

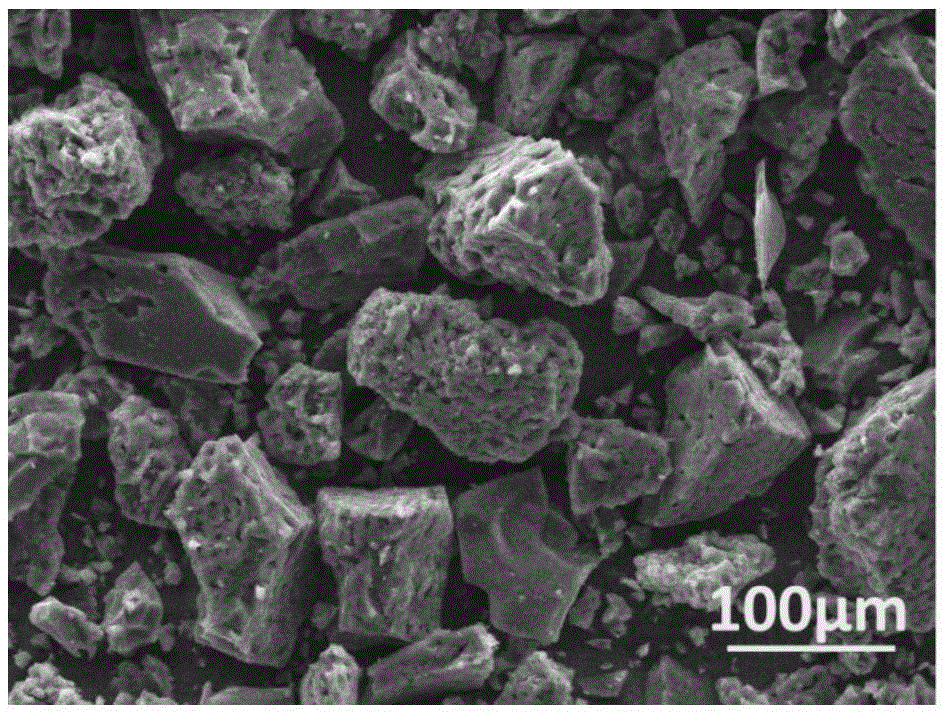

Method for preparing biomass activated carbon and application of biomass activated carbon to lithium sulfur batteries

InactiveCN105417540AWell-developed poresAbundant specific surface areaCell electrodesSecondary cellsLithium sulfurSodium–sulfur battery

The invention discloses a method for preparing biomass activated carbon and application of the biomass activated carbon to lithium sulfur batteries. The method includes crushing natural plant materials, soaking the natural plant materials in zinc chloride solution and then freezing the natural plant materials until the natural plant materials are in solid states; carbonizing solid at high temperatures to obtain the biomass activated carbon with rich pores, large specific surface areas and flat, narrow and long macroporous structures. The method and the application have the advantages that the biomass activated carbon and sulfur can be combined with each other to obtain biomass activated carbon / sulfur composite anode materials, anodes further can be manufactured, and the lithium sulfur batteries are high in sulfur active substance utilization rate, specific discharge capacity and coulomb efficiency and good in circulation stability when the biomass activated carbon is applied to the lithium sulfur batteries.

Owner:XIANGTAN UNIV

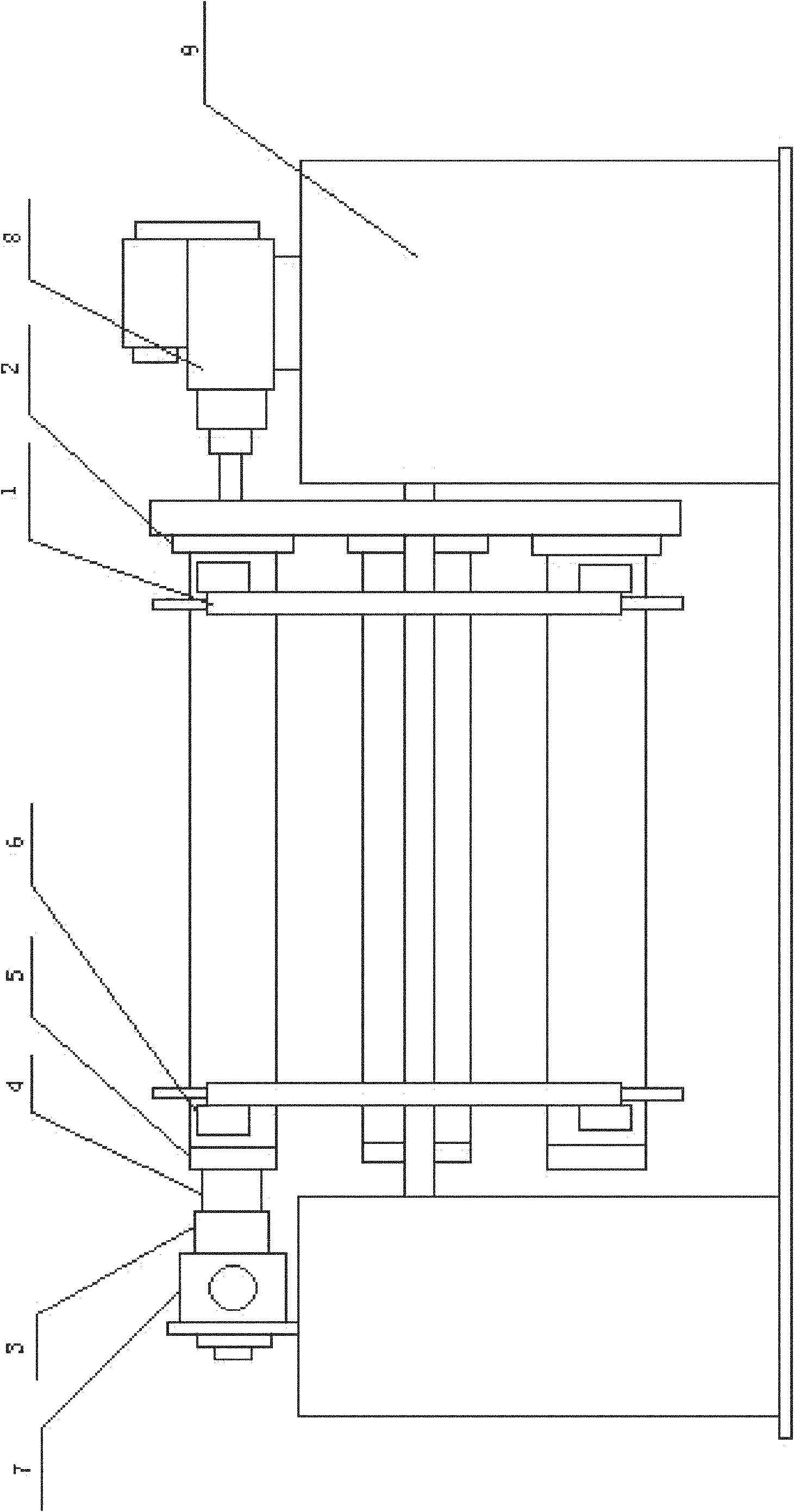

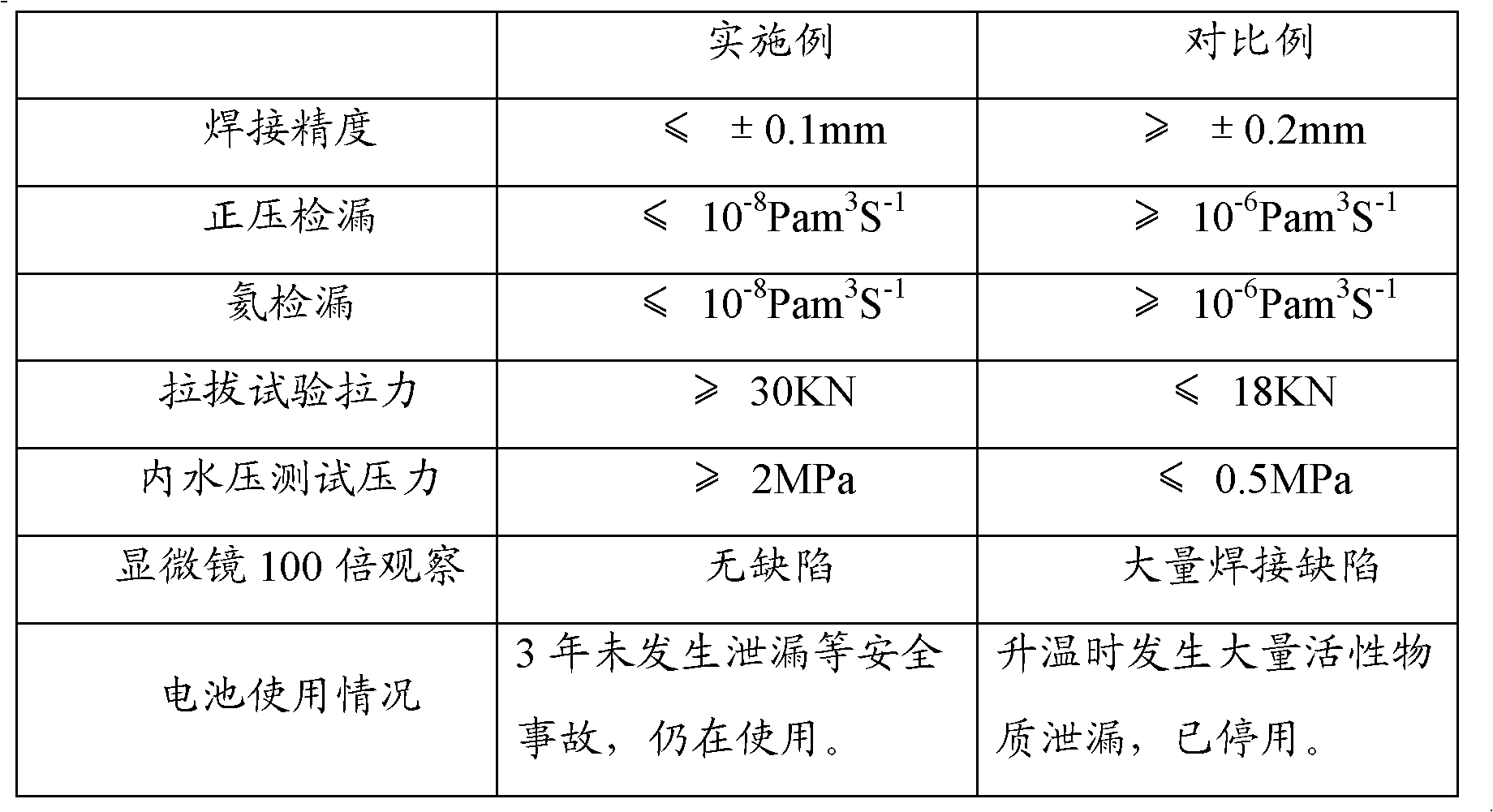

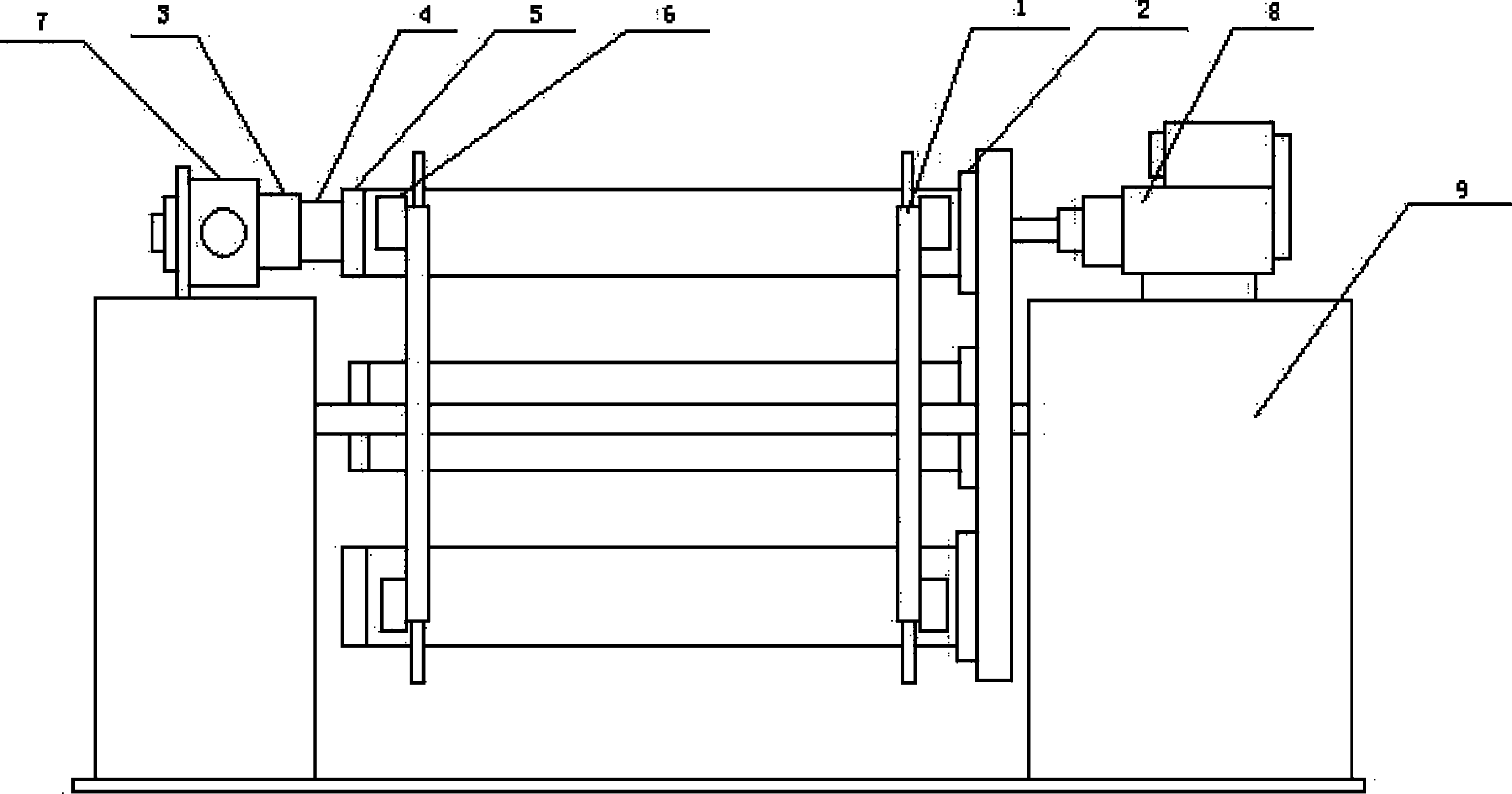

Precision control device of vacuum laser welding machine for preparing sodium-sulfur batteries

ActiveCN102601524AGuaranteed welding accuracyEasy to unloadLaser beam welding apparatusSulfurElectrical battery

The invention discloses a precision control device of a vacuum laser welding machine for preparing sodium-sulfur batteries. The sealing performance of the sodium-sulfur batteries welded by the device can be improved, safety of the batteries is ensured, and safety use of the sodium-sulfur batteries is guaranteed. The technical scheme includes that the device comprises a rotary bracket, a positioning sleeve, a coupling transmission mechanism, a rotating block, a fixing sleeve, a hinge locking mechanism, a slewing mechanism, an ejector mechanism and a control transmission mechanism, a plurality of batteries are sequentially placed into a battery cavity in a vacuum box, the rotating block of the coupling transmission mechanism is inserted into a fixing sleeve matching groove for the batteries in an aligned manner through motors of the slewing mechanism and the control transmission mechanism so that the batteries are completely coupled with an end cap, the slewing mechanism drives the batteries to rotate at a uniform speed, the end cap is fixed by the positioning sleeve, and a battery housing is pushed at a position at which the battery housing is matched with the end cap to be welded with the end cap so that a welding track position is fixed.

Owner:上海电气企业发展有限公司

Positive electrode material of lithium sulfur battery and preparation method and application of material

The invention relates to a positive electrode material of a lithium sulfur battery and a preparation method and application of the material and in particular discloses a nanometer material. The material has the following characteristics: (i) the material refers to Fe2O3 nano-particles; (ii) the nano-particles are in a cube shape and have the size of 300-500nm; (iii) the material is in a porous structure, and the pore size distribution of the particles is in the range of 1-10nm. According to the nanometer material, polysulfide produced by the sulfur positive electrode material in a discharging process can be effectively stored, loss caused by dissolution of the polysulfide is avoided, and the capacity and cycling stability of the battery are obviously improved. In addition, the invention also discloses a preparation method and application of the nanometer material.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Elemental sulfur anode of secondary lithium-sulfur battery and preparation method of elemental sulfur anode

ActiveCN103500813ASmall particlesEvenly dispersedNon-aqueous electrolyte accumulator electrodesLi-accumulatorsSlurryVacuum drying

The invention provides an elemental sulfur anode of a secondary lithium-sulfur battery and a preparation method of the elemental sulfur anode. The method comprises the following steps: step 1, dissolving sublimed sulfur in a volatile solvent to prepare a sulfur solution; step 2, dispersing a composite conductive agent into an NMP (Nuclear Matrix Protein) solution of a binder PVDF (Polyvinylidene Fluoride) and stirring to prepare a finely-dispersed previous slurry; step 3, dropwise adding the sulfur solution into the previous slurry, and continuing to stir; step 4, opening a closed container, and continuing to stir for 0.5-1 hour to obtain slurry with uniformly-dispersed sulfur and carbon; step 5, coating the slurry onto a current collector; step 6, punching after vacuum drying, wherein the dosage rate of the sublimed sulfur, the conductive agent and the binder is (40-80):(50-10):10. The method uses functionalized aluminum foil as the current collector, the slurry with uniformly-dispersed and closely-connected sulfur and carbon prepared with a one-pot method is used as a coating layer, and therefore an electrode piece which has large possibility of caking and has large surface density is obtained. The preparation method has the advantages of simplicity, uniform dispersion of sulfur and carbon, high carrying capacity and high utilization rate of elemental sulfur.

Owner:SHANGHAI INST OF SPACE POWER SOURCES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com