Metal-sulfur battery based on sulfur-rich transition metal sulfide and preparation method thereof

A transition metal and sulfur battery technology, applied in the field of energy storage, can solve the problems of high pollution, slow kinetic de-intercalation, low specific capacity, etc., and achieve the effects of improving electrical conductivity, superior battery performance, and preventing agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

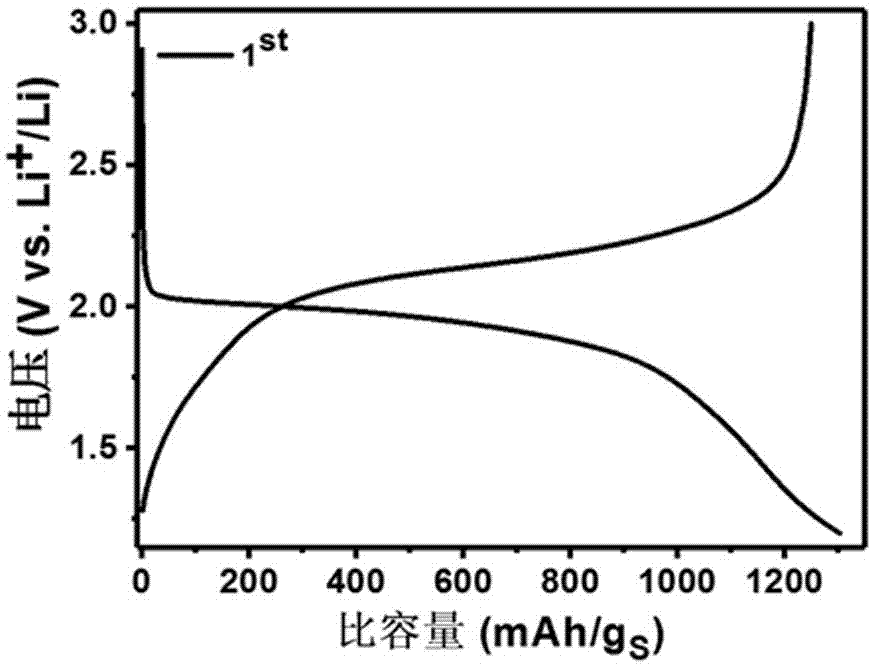

[0037] Example 1 MoS 3 / Preparation of CNT cathode material (acid hydrolysis method)

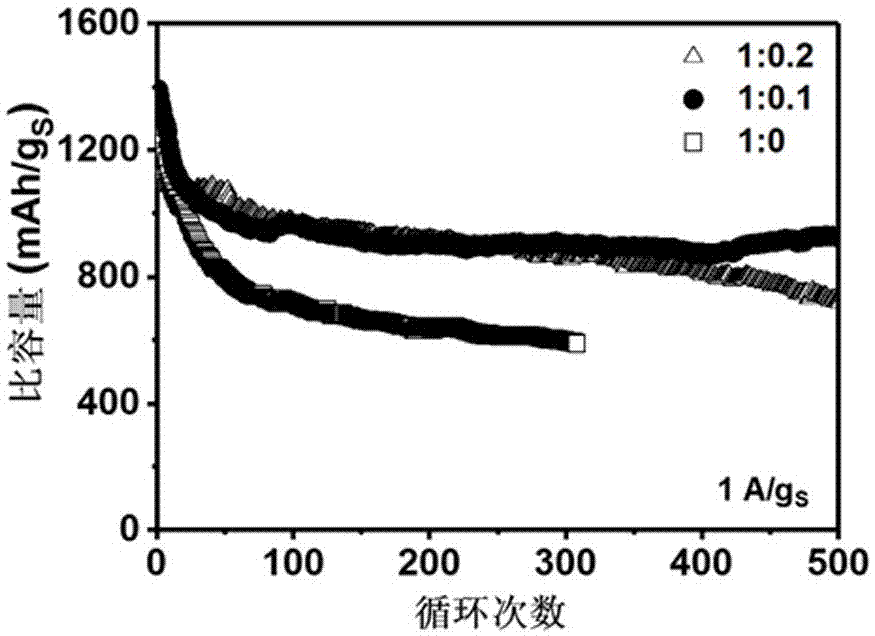

[0038] Material synthesis: Add 40 mL of an aqueous solution containing 1 mmol of ammonium tetrathiomolybdate to a 250 mL round-bottomed flask, and mix well under magnetic stirring; then add 40 mL of an aqueous solution containing 12 mg of dispersed carbon nanotubes, Thoroughly stirred for 20 min and supplemented with ultrasound for 10 min to form a uniform mixed solution. Under the condition of magnetic stirring, 1 mol / L dilute HCl was slowly added to the obtained mixed solution until the final pH value of the mixed solution was around 3. After continuing to fully react for two hours, transfer to a 50 mL centrifuge tube for centrifugation, wash with deionized water three times, and freeze-dry in liquid nitrogen for freeze-drying. The final black powder was annealed at 200°C for 2 h under the protection of Ar to form the final product. The mass ratio of transition metal sulfides and carbon...

Embodiment 2

[0045] Example 2 TiS 4 / Preparation of CNT cathode material (solid phase ball milling method)

[0046] Mix 0.176 g of carbon nanotubes, 0.48 g of titanium metal powder and 1.28 g of sulfur powder according to the set stoichiometric ratio, transfer them to a ball mill tank for evacuation for 2 h, and then place them in an Ar gas glove box for 12 h; After being assembled in the glove box, it was transferred to a ball mill for 80 h at a speed of 500 rpm. The final product TiS 4 / CNT, the mass ratio of transition metal sulfides and carbon-based materials is about 1:0.1.

[0047] Wherein, the preparation of the electrode and the assembly of the battery are the same as in Example 1, and the test interval is 1.5-3.0 V; the test results are shown in Image 6 . Depend on Image 6 It can be concluded that TiS 4 The / CNT electrode exhibits a working voltage of ~2.1 V and a specific capacity of ~860 mAh / g, demonstrating the excellent battery capacity of the disclosed metal-sulfur b...

Embodiment 3

[0048] Embodiment 3 CoS 5 / Preparation of CNT cathode material (liquid phase synthesis method)

[0049] Disperse 22 mg of carbon nanotubes uniformly in the aqueous solution, disperse uniformly with the aid of ultrasound, then add an aqueous solution containing 0.8 mmol cobalt sulfate, stir well, and then slowly add 1 mmol Na 2 S 4 Aqueous solution; After fully reacting for twelve hours, the final product CoS 5 / CNT, the mass ratio of transition metal sulfides and carbon-based materials is about 1:0.11.

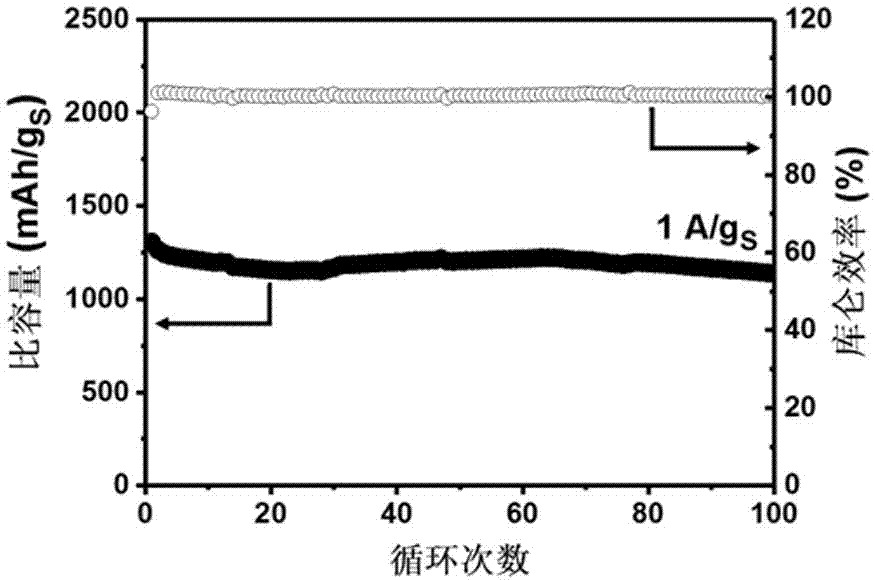

[0050] Wherein, the preparation of the electrode and the assembly of the battery are the same as in Example 1, and the test range is 1.7-3.0 V. For the test results, see Figure 7 ,Depend on Figure 7 It can be concluded that CoS 5 The / CNT electrode exhibits a working voltage of ~1.9 V and a specific capacity of ~1100 mAh / g, demonstrating the excellent battery capacity of the metal-sulfur battery disclosed in this invention.

[0051] Figure 8 For the MoS synthesized und...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com