A kind of preparation method of sulfur positive electrode of lithium-sulfur battery

A technology of lithium-sulfur batteries and sulfur cathodes, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of poor cycle performance, low electrochemical activity, and poor reversibility of cathode materials, and achieve good electrochemical performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Configure 10g of the mixture according to sublimated sulfur: activated carbon=4:2 (mass ratio), add 100g of absolute ethanol, mix evenly in a ball mill, filter the obtained mixed slurry into a glass vessel, and place in a vacuum oven to dry Dry, after drying, move it into a mortar and grind it evenly for later use. The resulting mixture was evenly dispersed in sodium bicarbonate solution, and ultrasonically oscillated to make it evenly mixed.

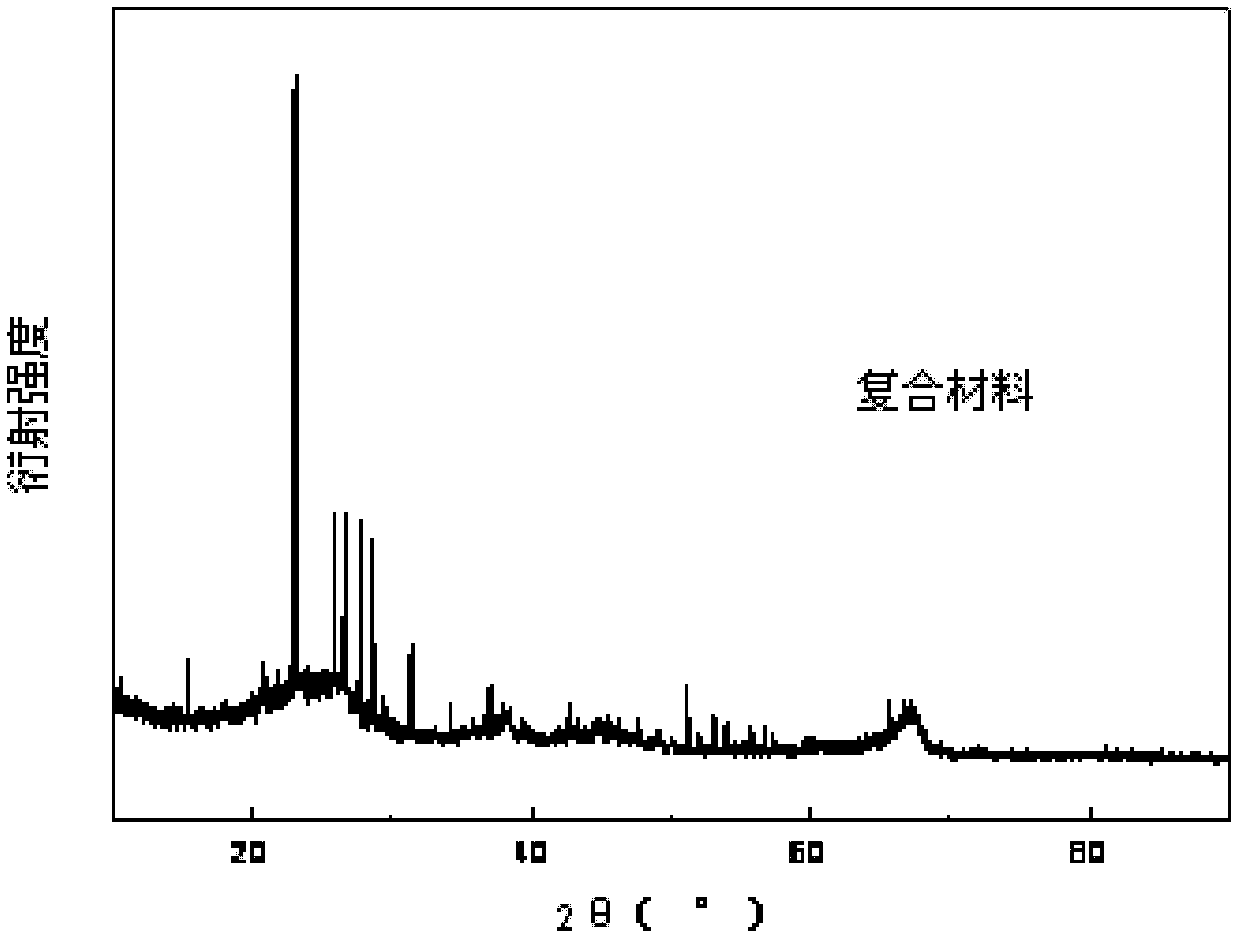

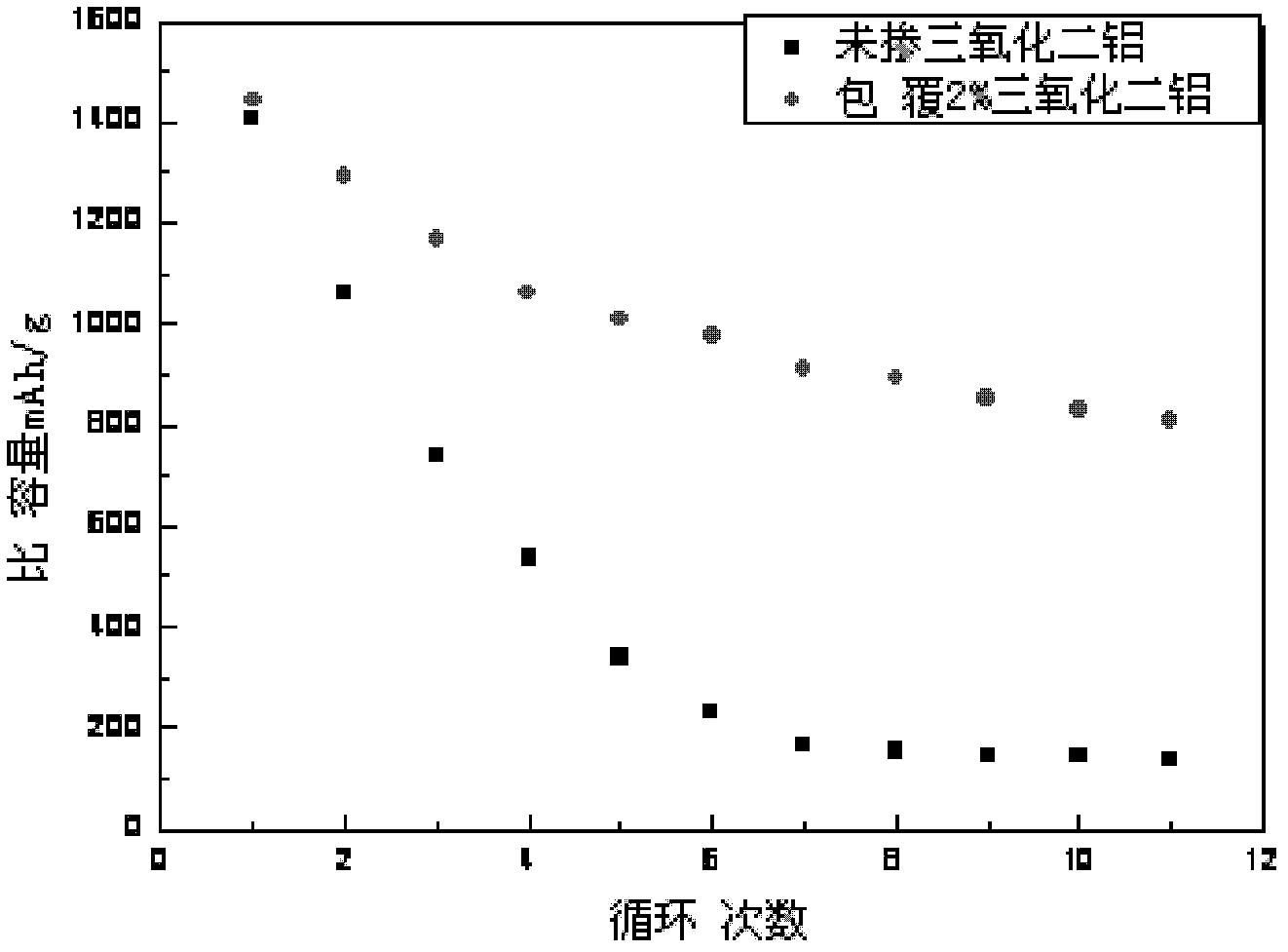

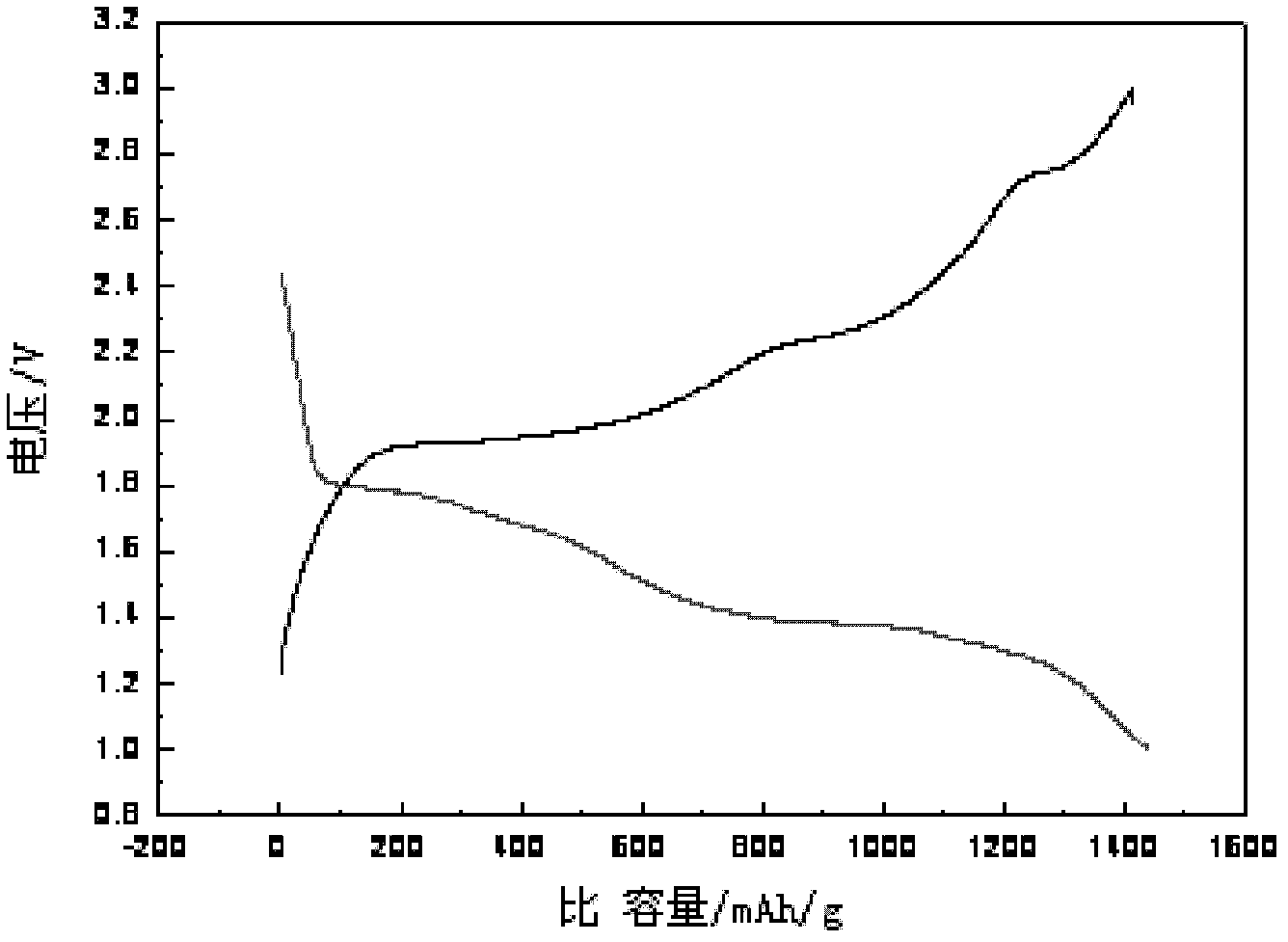

[0036] According to sulfur-carbon mixture: aluminum element in aluminum sulfate = 100:0.5 (molar ratio), add aluminum sulfate solution under mechanical stirring, filter after fully reacting, wash with distilled water, put it in a vacuum drying oven and dry it fully, then put it into a tube type furnace, under the protection of nitrogen, the temperature was gradually raised to 140°C within 11 hours. After the mixture is cooled down to normal temperature, the composite material obtained above is taken out from the tube furnace and...

Embodiment 2

[0039] Configure 10g of the mixture according to sublimated sulfur: activated carbon=9:2 (mass ratio), add 100g of absolute ethanol, mix evenly in a ball mill, filter the obtained mixed slurry into a glass vessel, and place in a vacuum oven to dry Dry, after drying, move it into a mortar and grind it evenly for later use. The resulting mixture was evenly dispersed in ammonia solution, and ultrasonically oscillated to make it evenly mixed.

[0040] According to sulfur-carbon mixture: aluminum element in aluminum nitrate = 100:1.0 (molar ratio), add aluminum nitrate solution under mechanical stirring, filter after fully reacting, wash with distilled water, put it in a vacuum drying oven and dry it fully, put it into a tube type The furnace was gradually heated to 300°C within 6 hours under the protection of nitrogen. After the mixture is cooled down to normal temperature, the composite material obtained above is taken out from the tube furnace and ground evenly to obtain a sulf...

Embodiment 3

[0043]Configure 10g of the mixture according to sublimated sulfur: activated carbon=6:2 (mass ratio), add 100g of absolute ethanol, mix evenly in a ball mill, filter the obtained mixed slurry into a glass vessel, and place in a vacuum oven to dry Dry, after drying, move it into a mortar and grind it evenly for later use. The resulting mixture was evenly dispersed in sodium bicarbonate solution, and ultrasonically oscillated to make it evenly mixed.

[0044] According to sulfur carbon mixture: aluminum element in aluminum chloride = 100: 1.5 (molar ratio), add aluminum chloride solution under mechanical stirring, filter after fully reacting, wash with distilled water, put it in a vacuum drying oven and dry it fully, put In a tube furnace, the temperature was gradually raised to 280°C within 8 hours under the protection of argon. After the mixture is cooled down to normal temperature, the composite material obtained above is taken out from the tube furnace and ground evenly to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com