Patents

Literature

511 results about "ALUMINUM POTASSIUM SULFATE" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

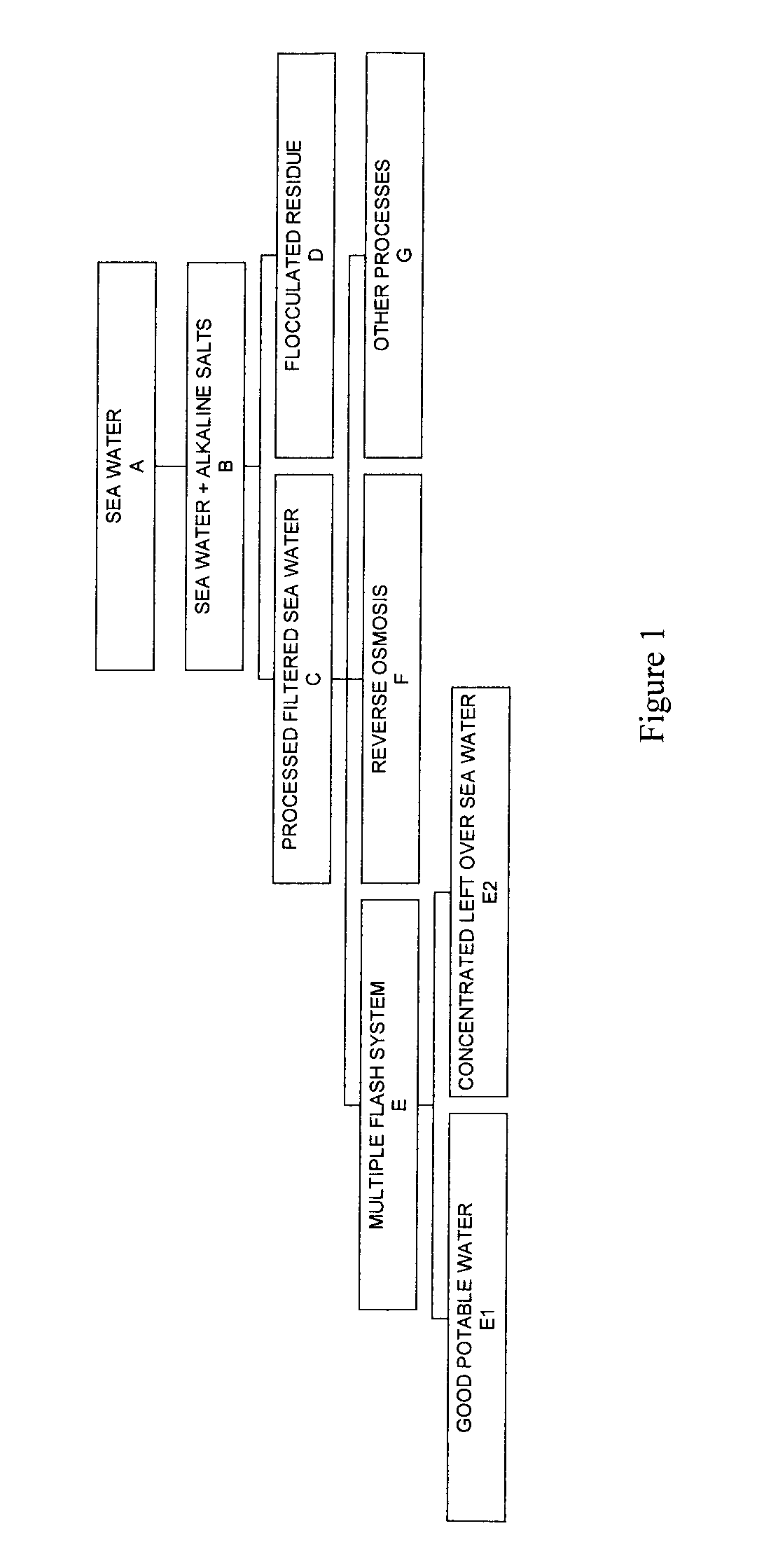

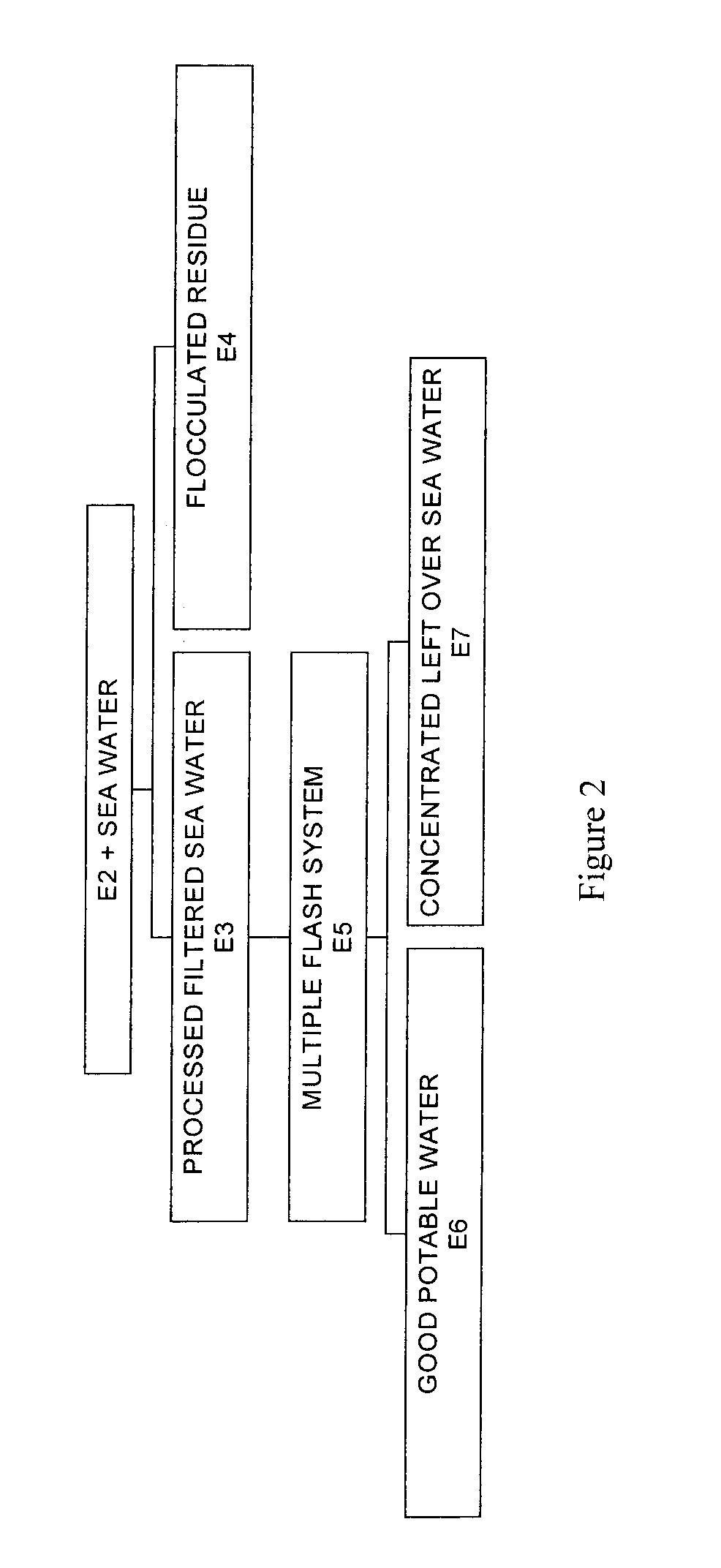

Process for pre-treating and desalinating sea water

ActiveUS20050098499A1Reduce maintenanceExtend equipment lifeGeneral water supply conservationSeawater treatmentCalcium bicarbonatePotassium hydroxide

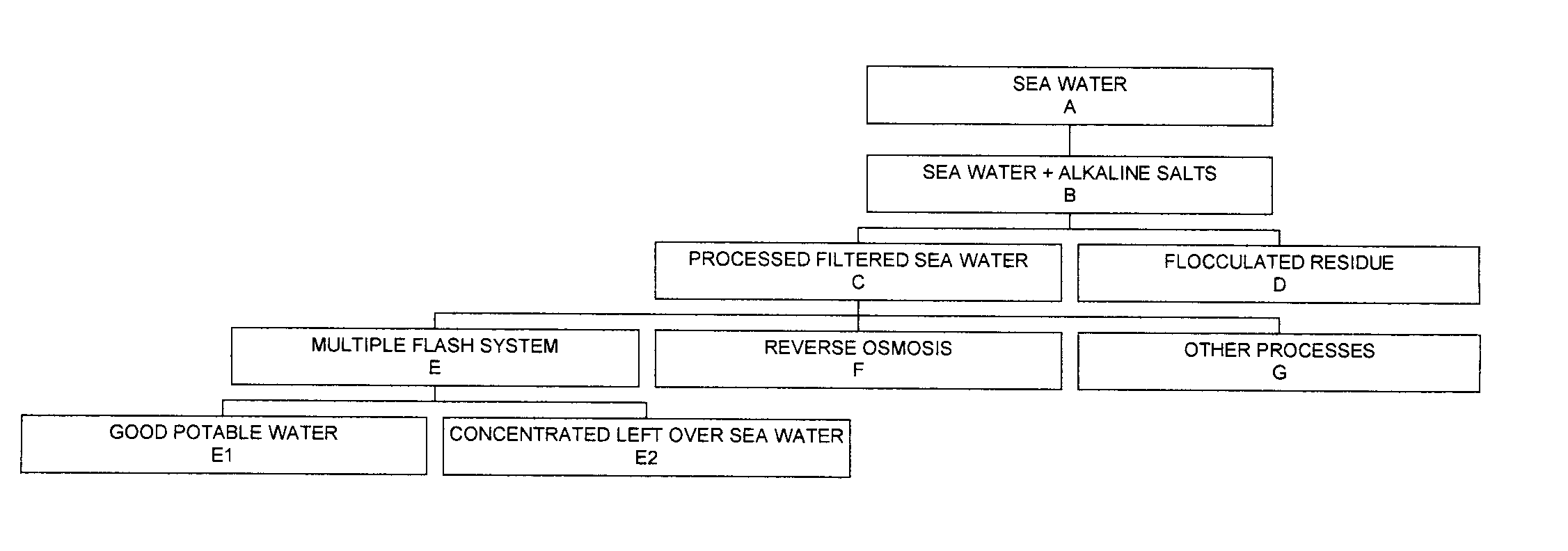

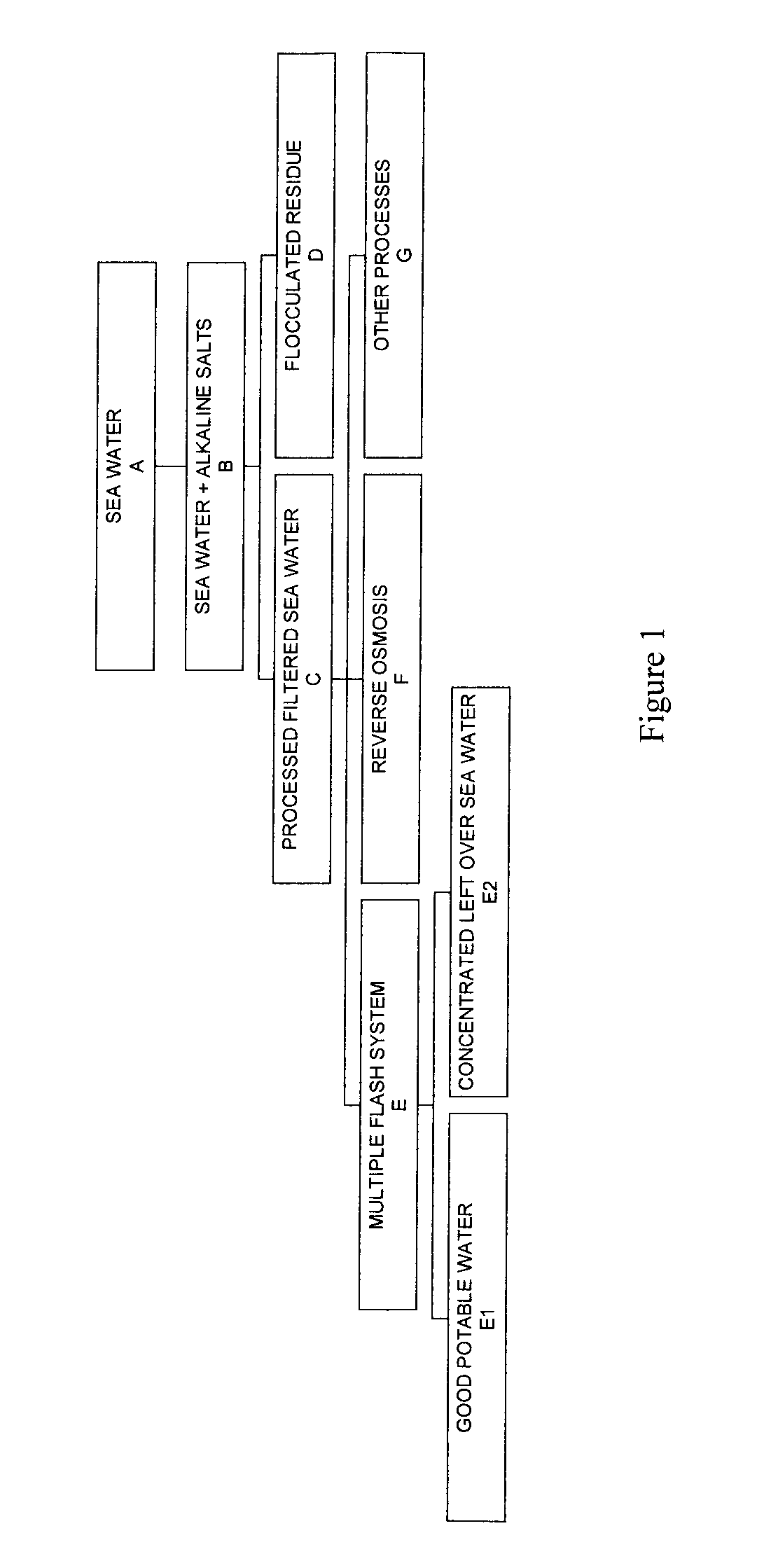

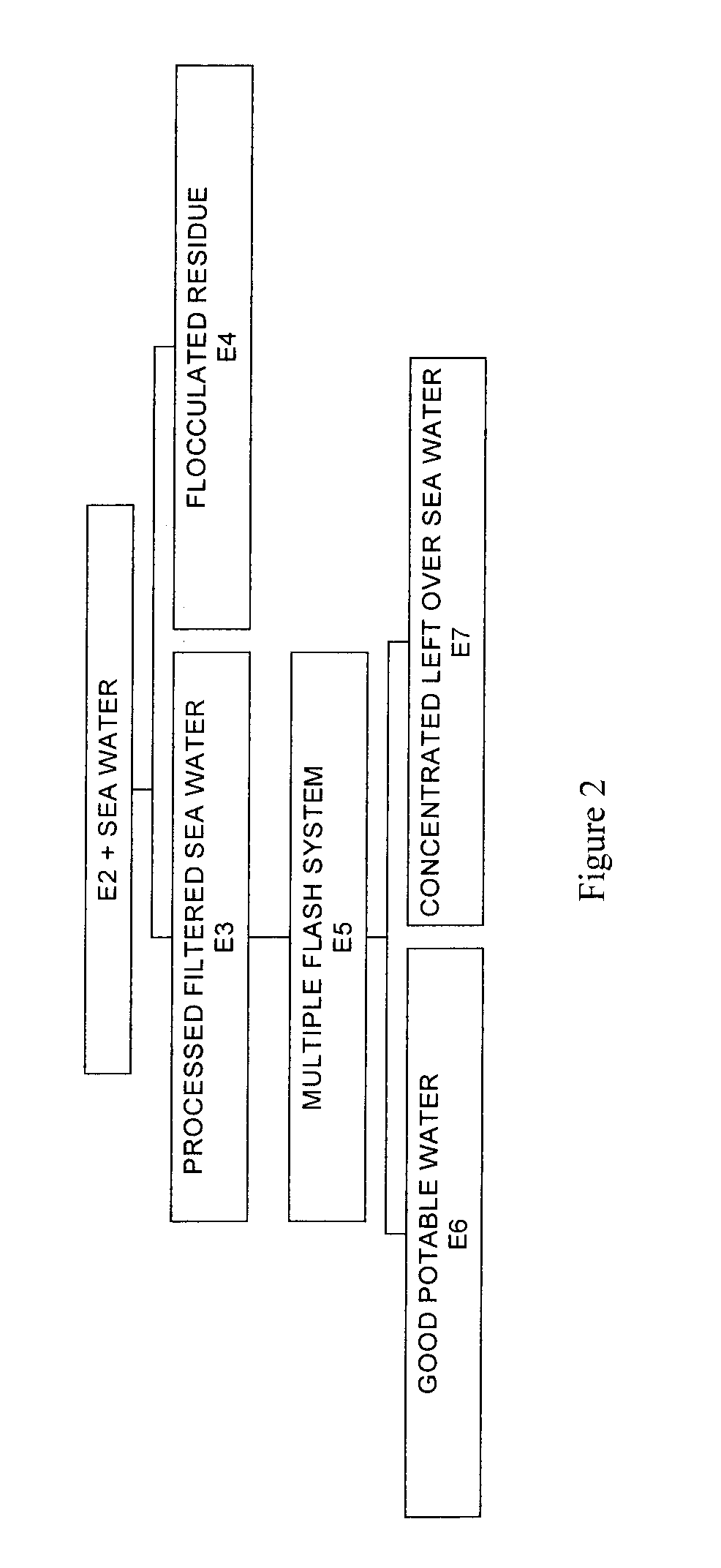

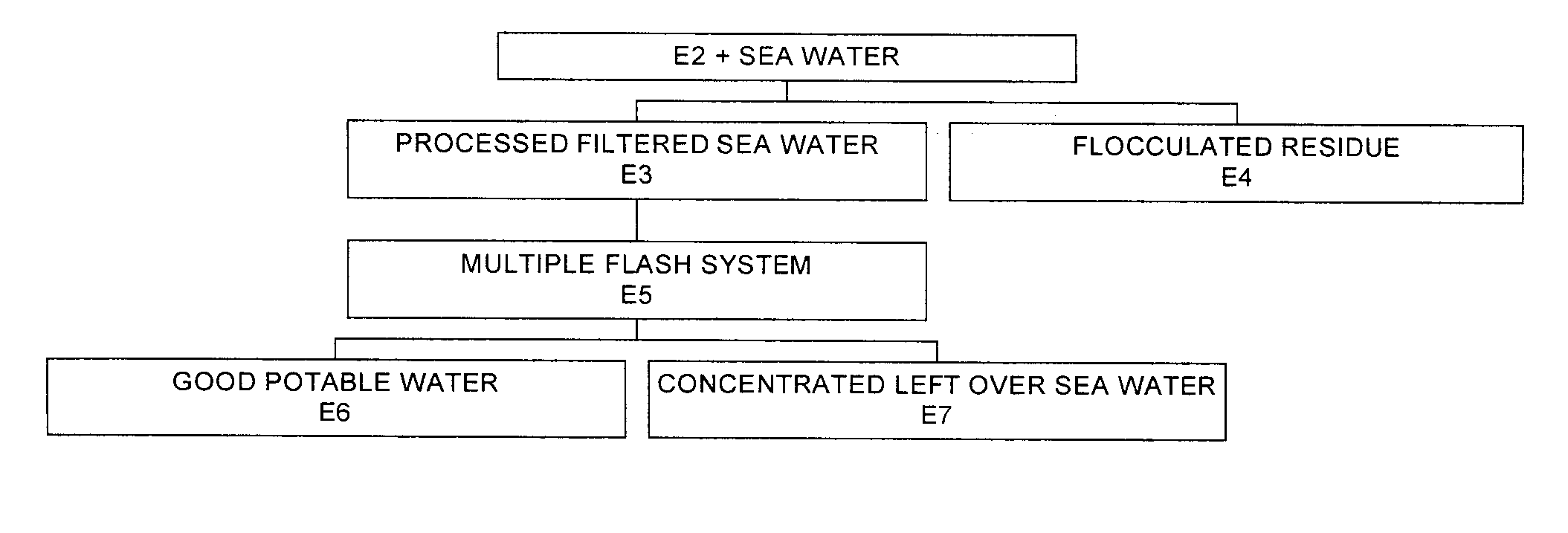

Water containing dissolved salts, such as calcium sulfate, calcium chloride, magnesium sulfate, magnesium chloride, sodium carbonate, sodium chloride, sodium sulfate, calcium bicarbonate, and mixtures thereof, is treated to reduce the concentration of those salts. About 0.1 to about 60 g / L of sodium hydroxide, sodium carbonate, potassium hydroxide, potassium carbonate, calcium hydroxide, calcium carbonate, aluminum hydroxide, aluminum sulfate, aluminum potassium sulfate, and mixtures thereof is added to the water, whereby a precipitate forms in the water. The precipitate is separated from said water and the water is desalinated using reverse osmosis, flash evaporation, or another method. The process is preferably performed by first adding calcium oxide or calcium hydroxide, separating the precipitate that forms, then adding sodium hydroxide and sodium carbonate to form a second precipitate.

Owner:HUSSAIN MOHAMMED AZAM

Process for pre-treating and desalinating sea water

ActiveUS7198722B2Extend equipment lifeReduce maintenanceGeneral water supply conservationSeawater treatmentCalcium bicarbonateReverse osmosis

Owner:HUSSAIN MOHAMMED AZAM

Cementitious capillary crystalline waterproofing agent

InactiveCN101759414AImprove impermeabilityPromotes self-healingSolid waste managementSelf-healingSodium Bentonite

The invention discloses a cementitious capillary crystalline waterproofing agent, which contains the following raw materials in parts by weight: 50 parts of Portland cement; 25 parts of quartz sand; 9 parts of siliceous dust; 3 parts of calcium hydroxide; 2 parts of sodium bentonite; 1 part of kieselguhr; 3.9 parts of instant sodium silicate; 2.5 parts of aluminum potassium sulfate; 0.3 parts of zinc fluosilicate; 0.20 parts of sodium polyacrylate; 0.2 parts of hydroxypropyl methyl cellulose; 2 parts of zinc stearate; 0.5 parts of naphthalene water reducer; 0.2 parts of sugar lime; 0.1 parts of citric acid; and 0.1 parts of antifoaming agent. After the raw materials are weighed according to the proportions, the raw materials are ground into particles with grain size more than or equal to 200-mesh sieve in a ball mill to obtain the finished product. The invention has the advantages that the cost is low, the anti-permeability is good, the self-healing performance is good, the bonding power is strong, the steel bar corrosion is prevented, no toxicity and no harmfulness are caused and the construction is easy.

Owner:河南奥思达新材料有限公司

Lightening gypsum suspended ceiling

The invention discloses a light-quality plaster ceiling in the architectural decorative material domain, which comprises the following parts: 50-70% architectural plaster, 8-15% light filler, 0.5-1.5% modifier, 1-2% waterproofing agent and 5-10% polyvinyl alcohol solution, wherein the lightweight fill is one or two or three of light calcium carbonate or lightweight magnesium carbonate or white carbon black according to random rate; the modifier is composed of 100g water, 15-20g silicasol, 5-7g sodium fluoride, 4-6g aluminum potassium sulfate, 7-9g potassium bichromate and 0.5-1g tributyl phosphate; the waterproofing agent is organic silicon waterproofing agent of sodium silanol methyl or potassium silanol methyl; the glass fiber is low-alkaline or non-alkaline glass fiber.

Owner:云南天之豪装饰材料有限公司

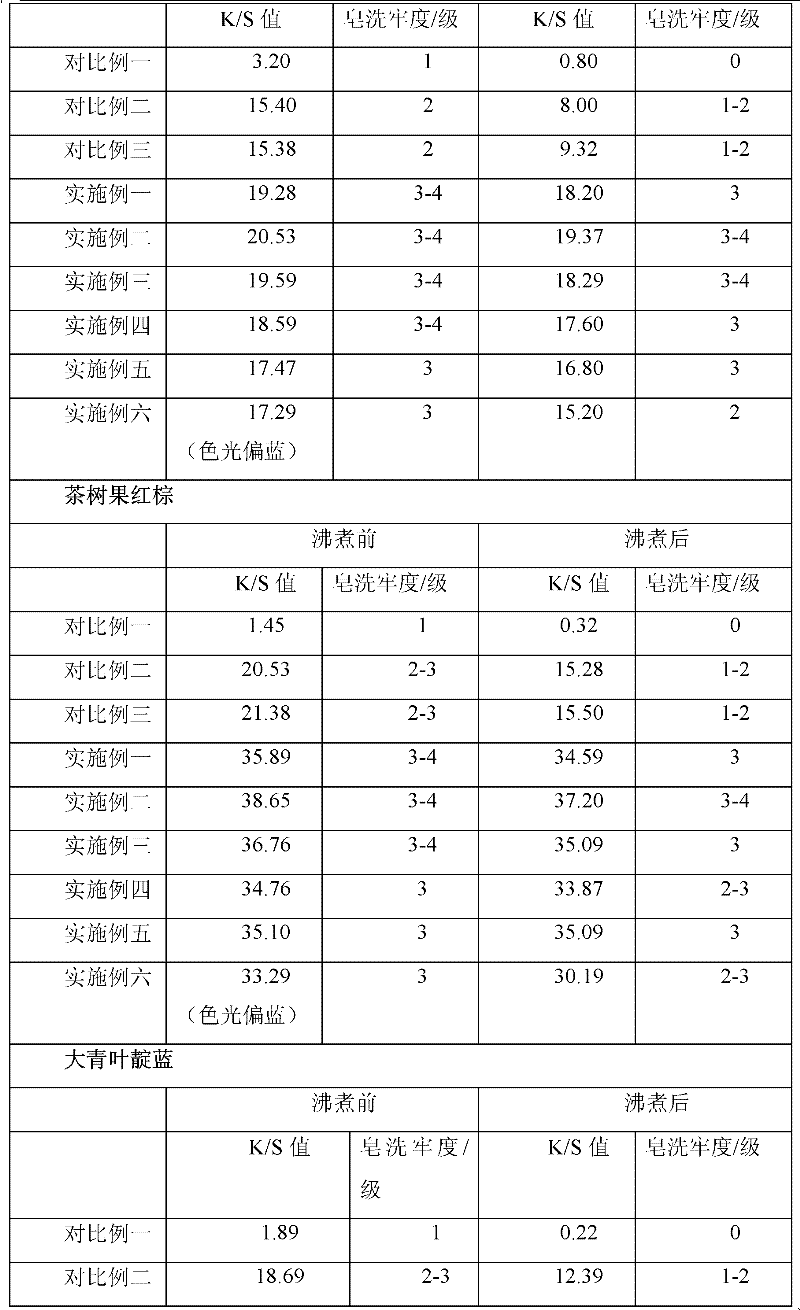

Method for dyeing cotton fibers by using natural dye

The invention relates to a method for dyeing cotton fibers by using a natural dye, comprising the following steps of: 1) boiling the cotton fibers and drying the cotton fibers for later use; 2) modifying the cotton fibers; 3) dyeing the cotton fibers; and 4) fixing the color of the cotton fibers, wherein the dosage of a color fixing agent is 1-5% of the mass of the cotton fibers, the temperature of color fixation is 50-85 DEG C, the color fixing agent is added to the cotton fibers obtained in step 3), the time of color fixation is 20-50 min, drying is performed after water washing, and the color fixing agent can be one or two of sodium chloride, sodium sulfite, citric acid and aluminum potassium sulfate dodecahydrate. The food-grade fixing agent is selected in the method; therefore, the troubles caused by synthetic dyes and heavy metals for the health of human are solved, and the fastness of the cotton fibers can be enhanced; as a result, the dyed cotton fibers are natural and soft in color and have no harm to the human body and the environment.

Owner:CHANGZHOU MYSUN BIOLOGICAL MATERIALS

Modified petroleum coke granule composite profile control water blocking agent and multi-round bidirectional blocking control technology

InactiveCN103013480AExpand the affected volumeEnhanced ultimate recoveryFluid removalDrilling compositionMeth-Thiourea

The invention discloses a modified petroleum coke granule composite profile control water blocking agent and a multi-round bidirectional blocking control technology. The water blocking agent comprises agents A, B and C, the agent A comprises the ingredients: polyacrylamide solution with the concentration of 0.1-0.3% (by weight), sodium silicate, aluminum potassium sulfate, hydrochloric acid with the concentration of 30% ( by weight), and calcium chloride, the agent B comprises polyacrylamide solution with the concentration of 0.1-0.3% (by weight), modified petroleum coke granules of 20-800mum and surfactant, and the agent C comprises the ingredients: polyacrylamide solution with the concentration of 0.3-0.7% (by weight), N-N' methylene bisacrylamide, organic chromium crosslinking agent, and thiocarbamide; and the multi-round bidirectional blocking control technology is of a multi-round bidirectional blocking control measure developed according to geologic features, state and oil producing conditions of different regions of oil fields; and the water blocking agent is matched with the blocking control technology, so that the problems that the conventional profile control water blocking agent is low in strength, and bad in anti-erosion property and shearing resistance property can be solved, further digging of remaining petroleum is conducted, the water content ratio of an oil well can be reduced, the effect of displacement in flooding can be improved, and the production demand of the oil field can be met.

Owner:DAQING ZHONGYOU TAIKE PETROLEUM TECH SERVICE

White finishing mortar composition

The invention provides a white surface mortar compound which comprises the following components of parts by weight: 400 to 600pbw of white cement, 50 to 100pbw of semi-water gypsum, 50 to 100pbw of calcium hydroxide, 200 to 400pbw of modified fiber light calcium, 30 to 50pbw of latex powder which can be dispersed again, 2 to 4pbw of cellulose ether, 1 to 3pbw calcium chloride, 1 to 3pbw of calcium formate, 1 to 3pbw of aluminum potassium sulfate, 1 to 5pbw of polypropylene fiber and 250pbw of water. The surface mortar compound of the invention can be hydrated with cement and other components to form fine, dense and good finish surface to be applied for painting a wall body with different color surfaces, and the cost is reduced while the construction efficiency is enhanced. The compound is particularly applicable to an insulation system of the external wall of a civil building and an office building, which is economic and can be used as the surface mortar and internal dope of other wall bodies.

Owner:SHANGHAI DONGSHENG NEW MATERIALS

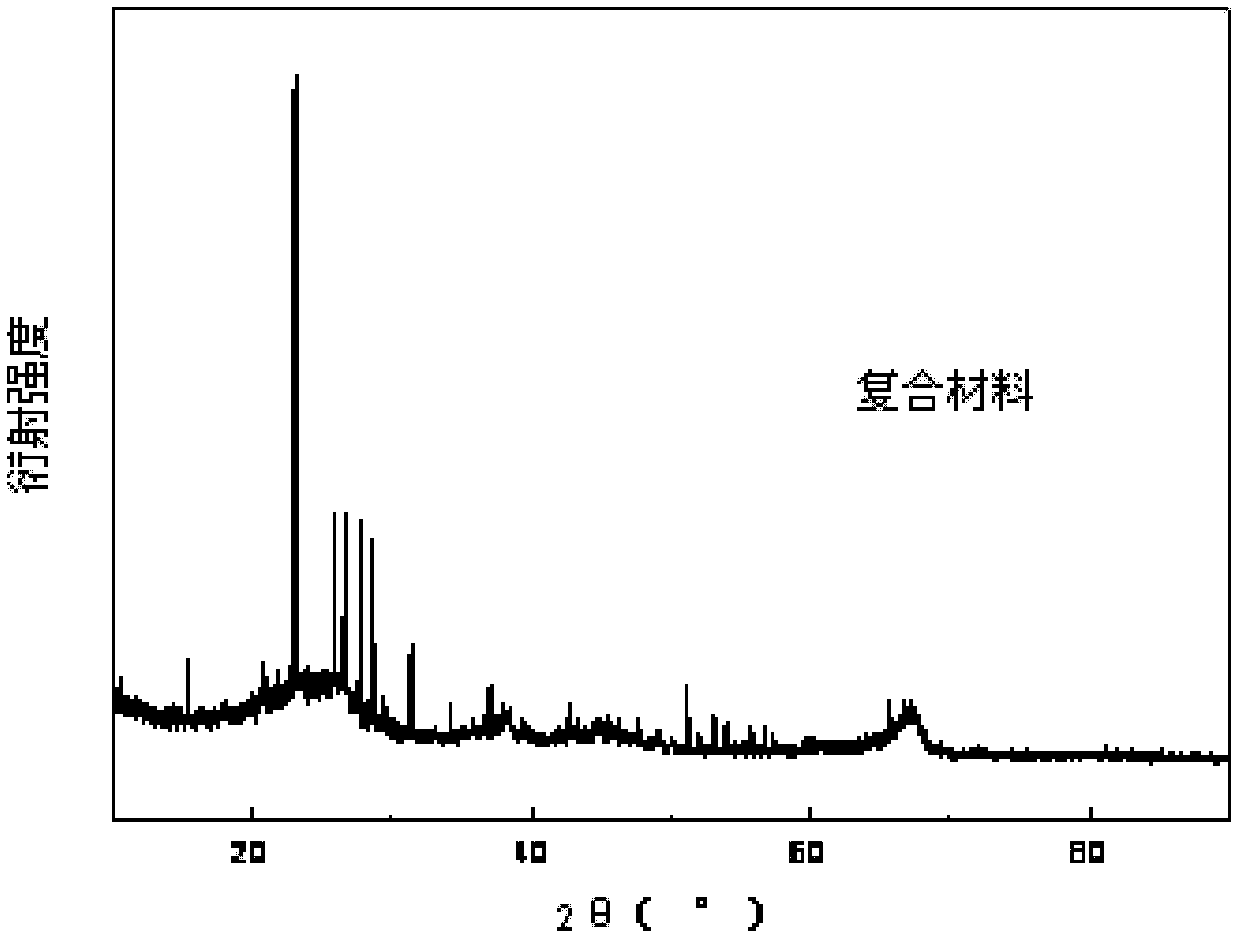

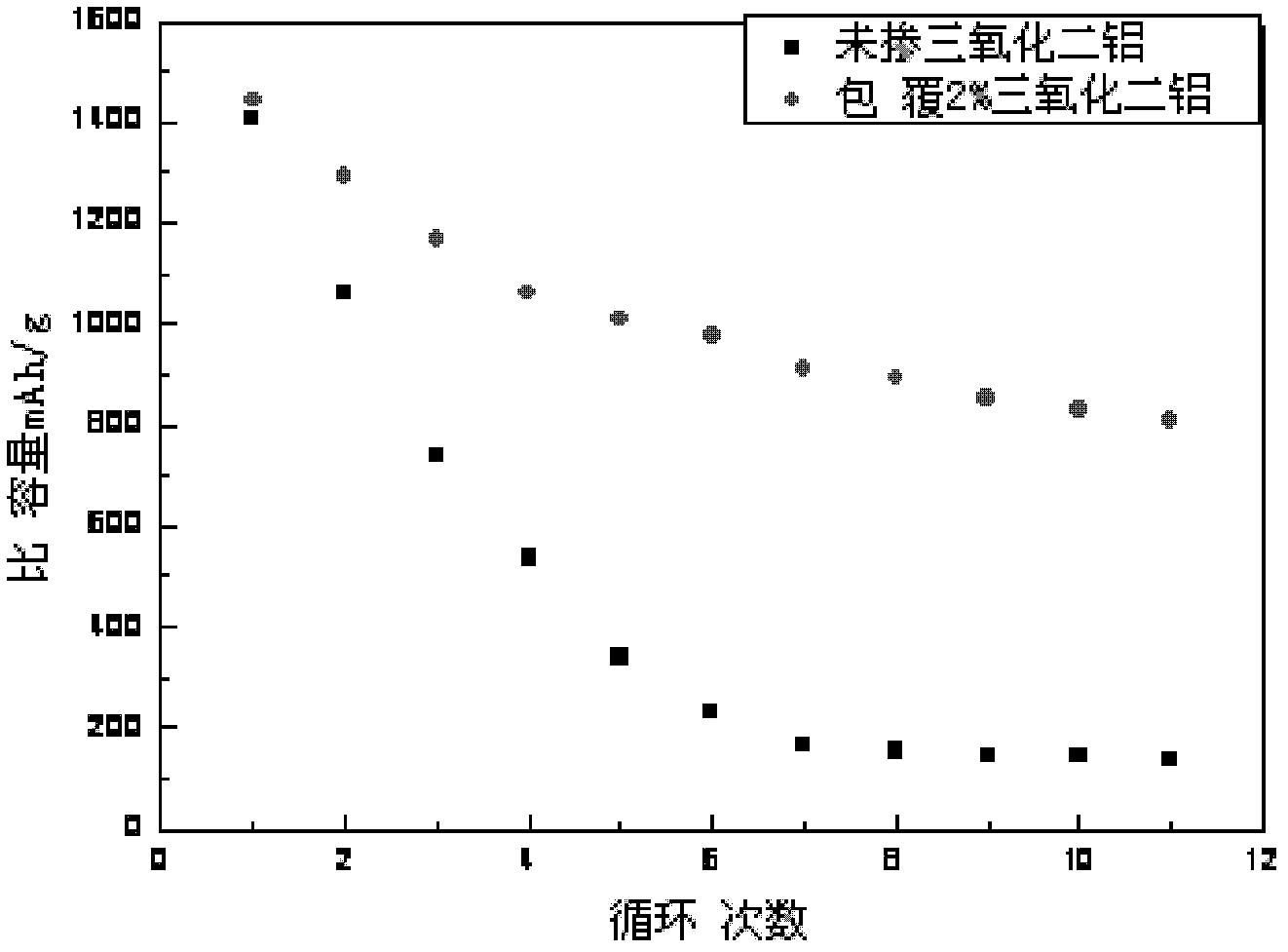

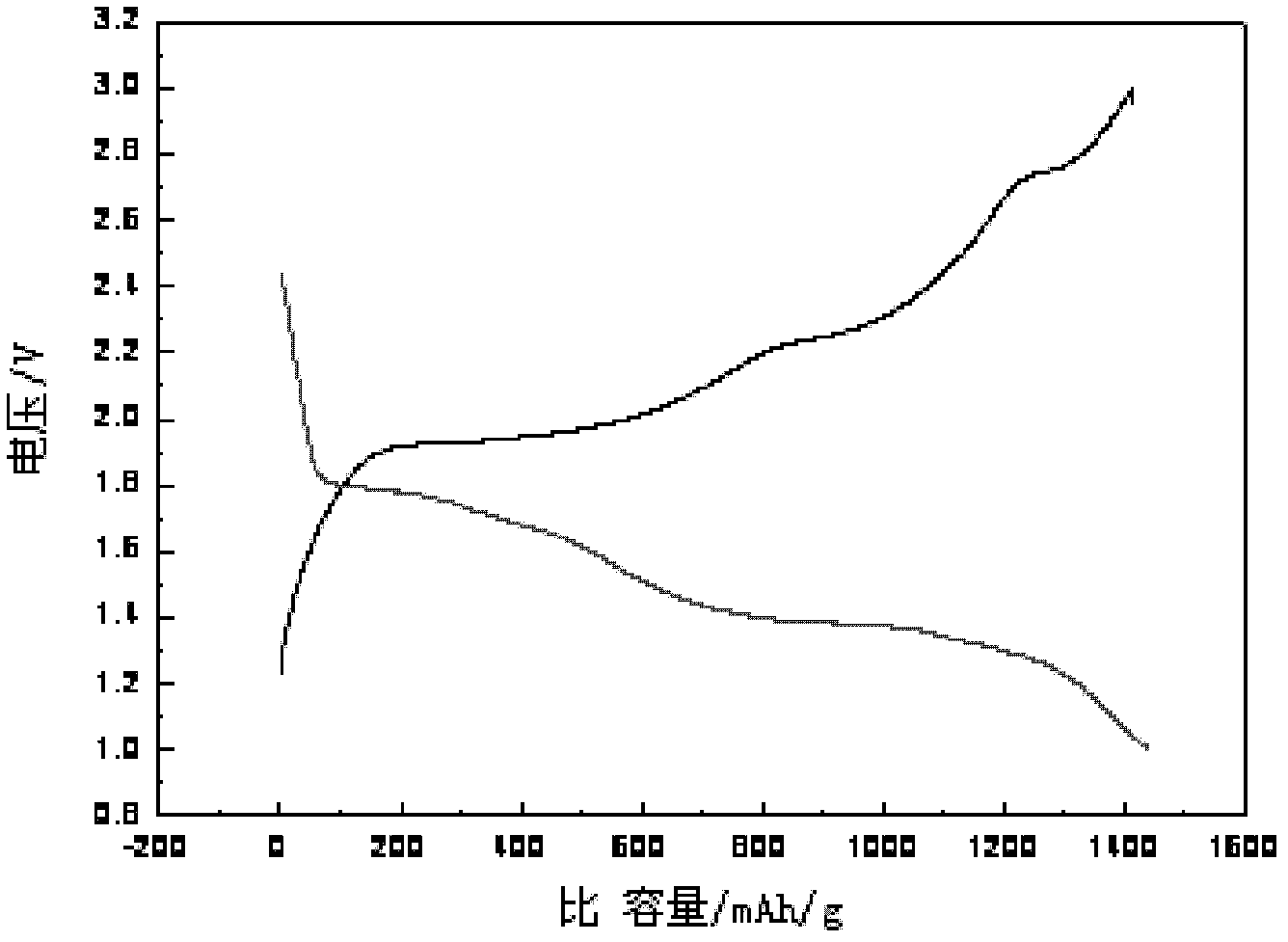

A kind of preparation method of sulfur positive electrode of lithium-sulfur battery

InactiveCN102280614AImprove electrochemical performanceHigh initial discharge specific capacityCell electrodesSodium bicarbonateMass ratio

The invention provides a preparation method of a sulfur positive electrode of a lithium sulfur battery. The preparation method comprises the following steps: a) preparing a mixed slurry according to the condition that the mass ratio of a sublimed sulfur to an active carbon is (4-9):2; b) drying and grinding the mixed slurry; c) dispersing the mixture in a sodium bicarbonate or ammonia solution, and performing the ultrasonic oscillation; d) adding an aluminum sulfate, aluminum chloride or aluminum potassium sulfate solution according to the condition that the mol ratio of a sulfur carbon mixture to an aluminum element in aluminum salt is 100:(0.5-3) so as to prepare a composite material covered by the aluminum hydroxide; e) filtering and drying the composite material, warming to 140-300 DEG C within 6-11 hours under the protection of inert gas, and grinding to obtain the sulfur carbon positive electrode material covered by the aluminum oxide for the lithium sulfur battery; and f) preparing the positive electrode of the lithium sulfur battery, assembling and testing the performance of the battery. The initial discharging specific capacity of the sulfur positive electrode composite material for the lithium sulfur battery prepared by the invention can achieve 1441.7.8 mAh / g, the battery discharging specific capacity is still maintained at 808.1mAh / g at room temperature after ten times of circulation, and the capacity retention rate can achieve 56.52%.

Owner:TIANJIN UNIV +1

Fireproof heat insulation wet felt and production process thereof

The invention relates to a fireproof heat insulation wet felt, which comprises an inorganic fiber blanket and an inorganic adhesive, wherein the weight ratio of the inorganic fiber blanket to the inorganic adhesive is 1:3-6. The inorganic fiber blanket is one or mixture of more of 1260 ceramic fiber blanket, high-aluminum ceramic fiber blanket, zirconium-containing ceramic fiber blanket, chromium-containing ceramic fiber blanket, polycrystalline mullite fiber blanket, glass fiber blanket and high-silica fiber blanket; and the inorganic adhesive is one or composite solution of more of water glass, silicon sol, aluminum sol, aluminum phosphate, aluminum sulfate and aluminum potassium sulfate. The wet felt can be randomly folded and bent in any direction, is wrapped, wound and stick togetherwith the shapes of equipment and parts during construction, and particularly can remarkably improve the construction efficiency during construction of a special-shaped part or a pipeline part or the like. The wet felt is formed by soaking the inorganic fiber blanket into the inorganic adhesive, so the wet felt is very easily bent, has good wet strength, and can be cut into various shapes and sizes or subjected to compression molding.

Owner:上海伊索热能技术股份有限公司

Compound powdery deodorant bacterial poison eliminating agent and preparation method thereof

InactiveCN101755838ASolve technical problems that cannot coexist stablyProcessing speedBiocideDisinfectantsCarcinogenRadioactive agent

The invention discloses a compound powdery deodorant bacterial poison removing agent and a preparation method thereof. The compound powdery deodorant bacterial poison eliminating agent contains the following components in parts by weight: 10-55 parts of sodium carbonate, 20-40 parts of copper sulfate, 10-20 parts of aluminum potassium sulfate, 10-20 parts of ferrous sulphate, 10-20 parts of calcium carbonate, 10-20 parts of malic acid, 10-20 parts of calcium oxide and 1-10 parts of polyacrylamide. The invention can remove heavy metal ions, radioactive substances, carcinogen, blue-green algae, SS, COD, BOD and polluted and harmful substances which are difficult to be treated by the traditional common sterilization treatment agent in a broad spectrum way at high efficiency and has the remarkable effects of decolorization, deodorization, dehydration, deoiling, sterilization and the like as well as the advantages of less consumption, rapid treatment, quick response, low operation cost and strong adaptability to high dirty degree on pollutants, wide pH value range and wide range of sewage temperature change.

Owner:章云

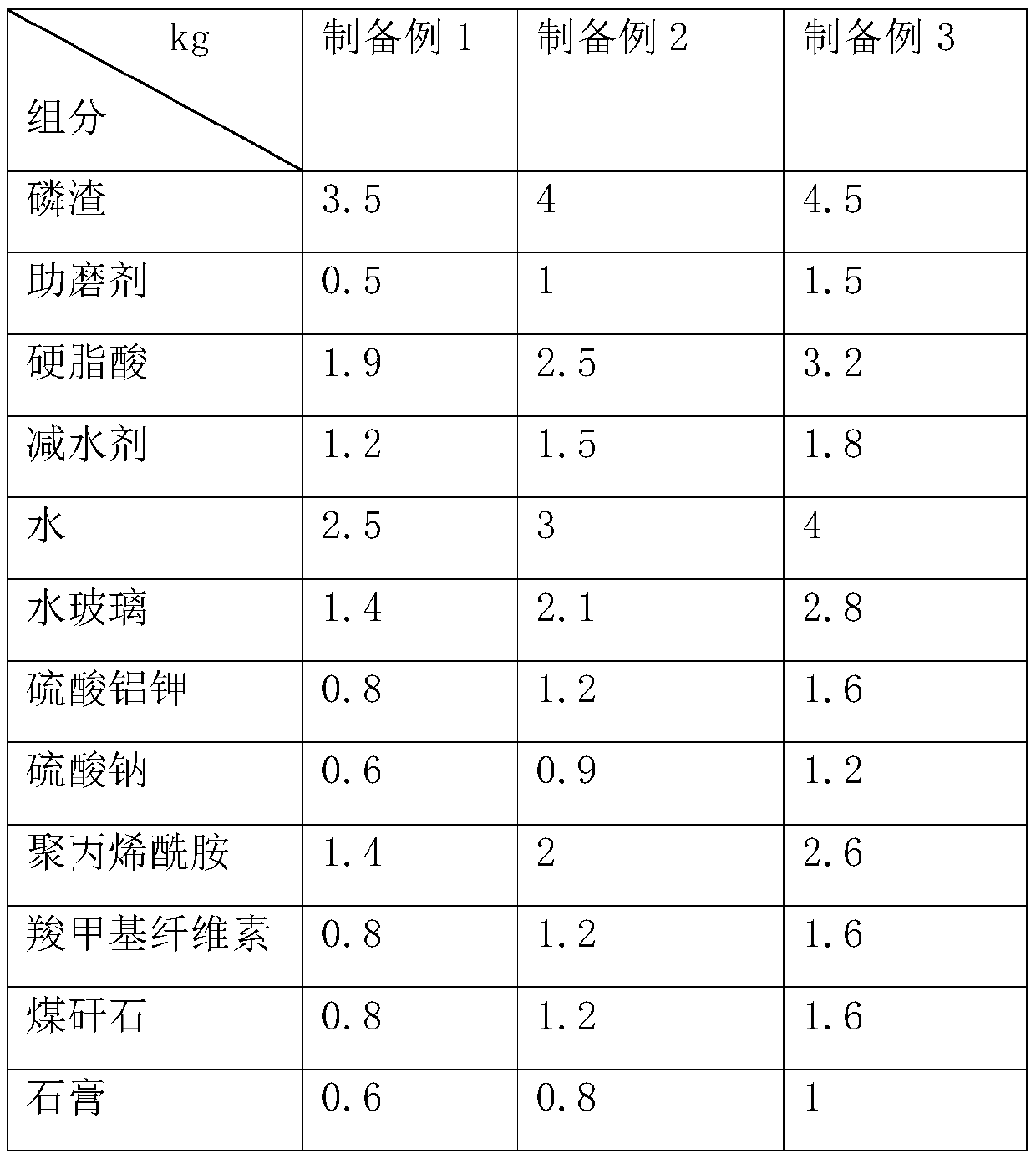

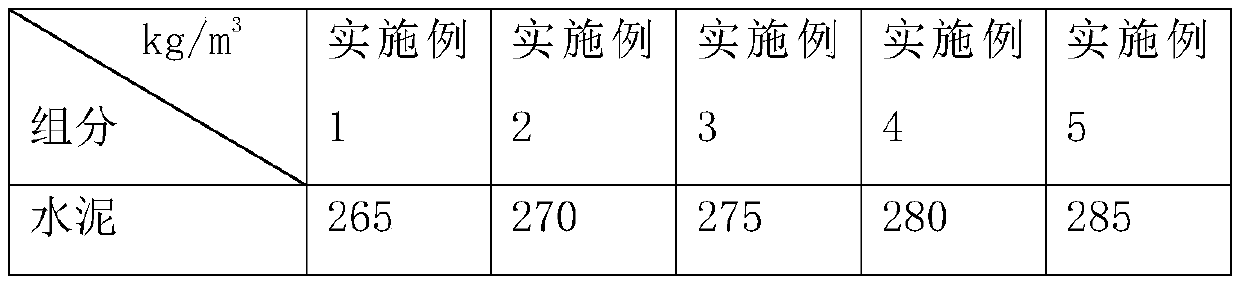

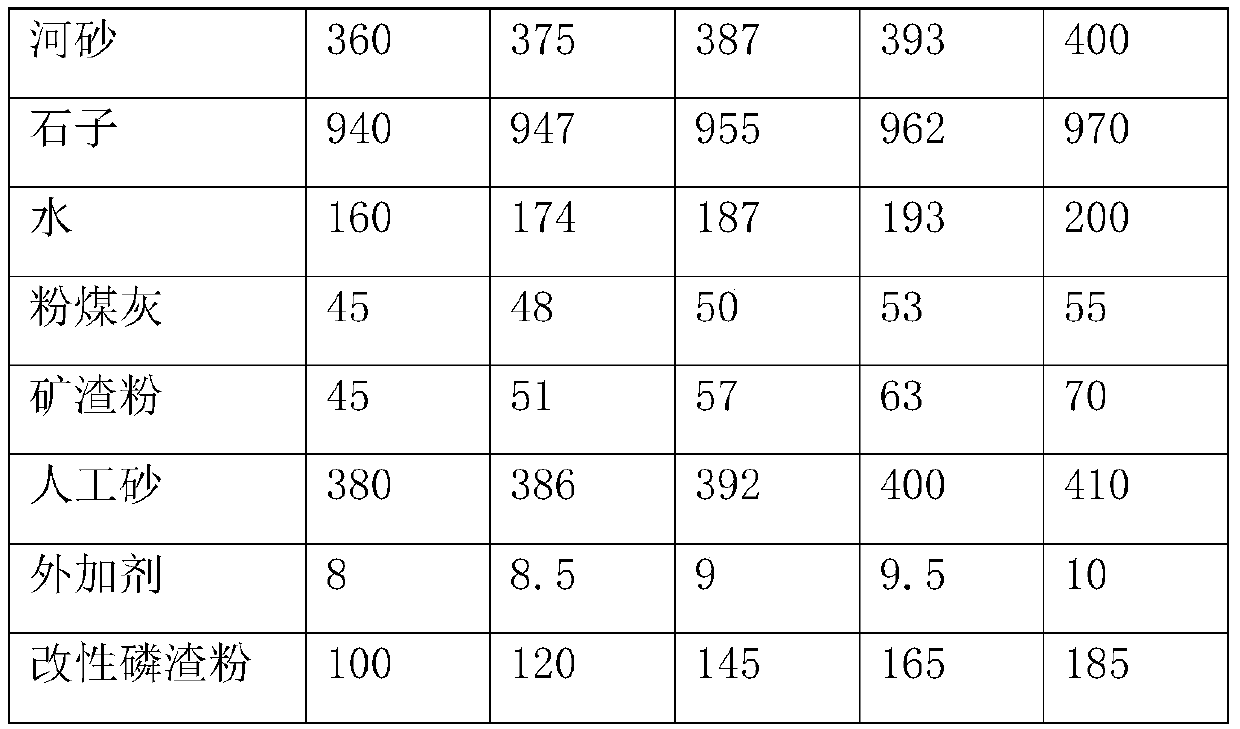

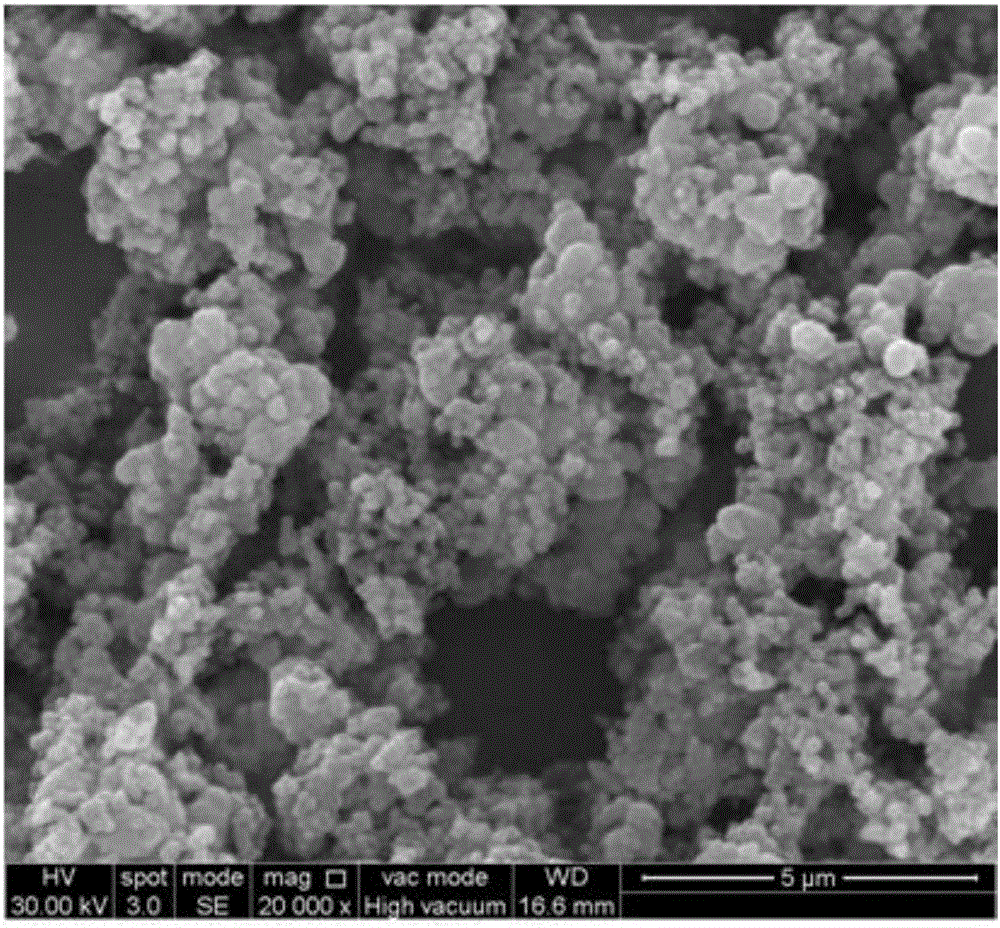

Concrete taking industrial waste residues as admixture and preparation method thereof

The invention discloses concrete taking industrial waste residues as an admixture and a preparation method thereof. The concrete taking industrial waste residues as an admixture is prepared from the following raw materials in parts by weight: 265-285 parts of cement, 360-400 parts of river sand, 940-970 parts of stones, 160-200 parts of water, 45-55 parts of fly ash, 45-70 parts of slag powder, 380-410 parts of artificial sand, 8-10 parts of an additive and 100-185 parts of modified phosphorus slag powder. The modified phosphorus slag powder comprises the following components: phosphorus slag,a grinding aid, stearic acid, a water reducing agent, water, water glass, aluminum potassium sulfate, sodium sulfate, polyacrylamide, carboxymethyl cellulose, coal gangue and gypsum. The concrete taking industrial waste residues as an admixture has the advantages that the setting time is short, the early strength is high, nitric oxide in automobile exhaust can be adsorbed and degraded, industrialsolid waste is utilized, environmental protection is facilitated, and waste is turned into wealth.

Owner:青岛康力商砼工程有限公司

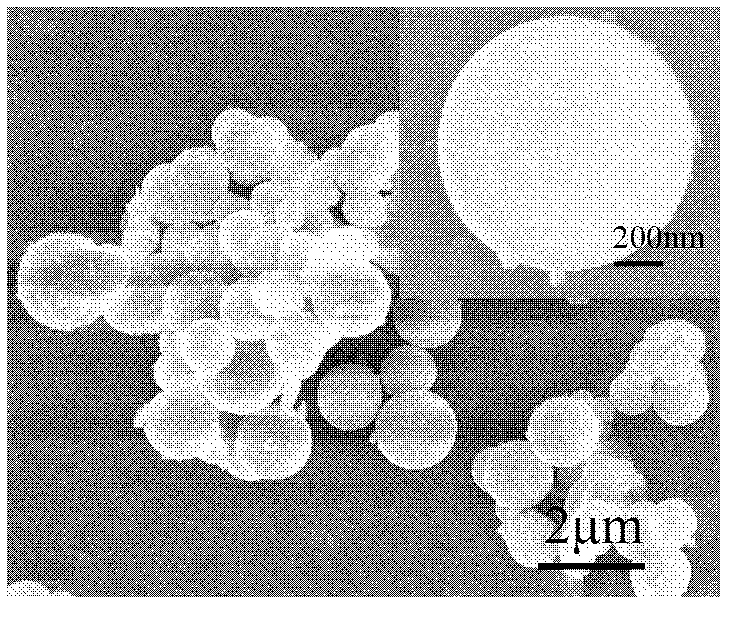

Inorganic hydrated salt phase change energy storage microcapsule and preparation method thereof

InactiveCN106244117AIncrease coverageSimple processHeat-exchange elementsCalcium Chloride HexahydratePotassium fluoride

Belonging to preparation methods of energy storage microcapsule materials, the invention provides an inorganic hydrated salt phase change energy storage microcapsule and a preparation method thereof. The energy storage microcapsule includes an inorganic hydrated salt serving as the core material and an inorganic material serving as the wall material. The core material is one or more of potassium fluoride dehydrate, sodium acetate trihydrate, sodium thiosulfate pentahydrate, calcium chloride hexahydrate, magnesium sulfate heptahydrate, barium hydroxide octahydrate, sodium sulfate decahydrate, sodium sulfate decahydrate, disodium hydrogen phosphate dodecahydrate, ammonium aluminium sulfate dodecahydrate, aluminum potassium sulfate dodecahydrate, and aluminum sulphate ocatadecahydrate. The wall material is one or more of silicon dioxide, calcium carbonate, alumina and titanium dioxide. The core material accounts for 30%-80% of the mass of the microcapsule composite material, and the wall material accounts for 20%-70% of the mass of the microcapsule energy storage material. The prepared phase change energy storage microcapsule material has a phase transition temperature of 25-100DEG C and a diameter of 0.1-50 micrometers. The phase change energy storage microcapsule has the advantages of high encapsulation rate, good sealing performance, large phase change potential heat value, and simple preparation method, and has great industrial application prospect.

Owner:CHINA UNIV OF MINING & TECH

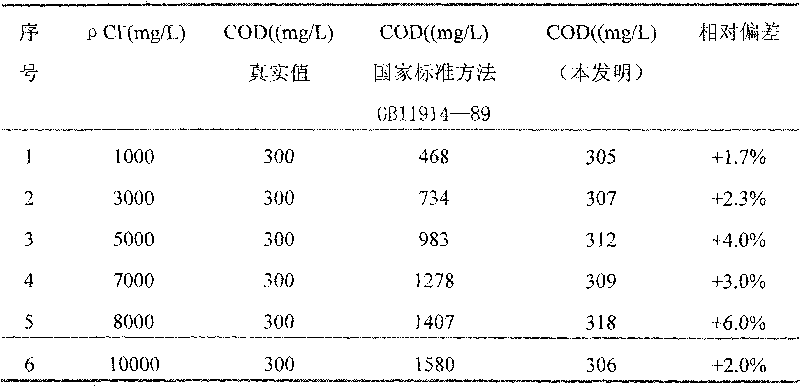

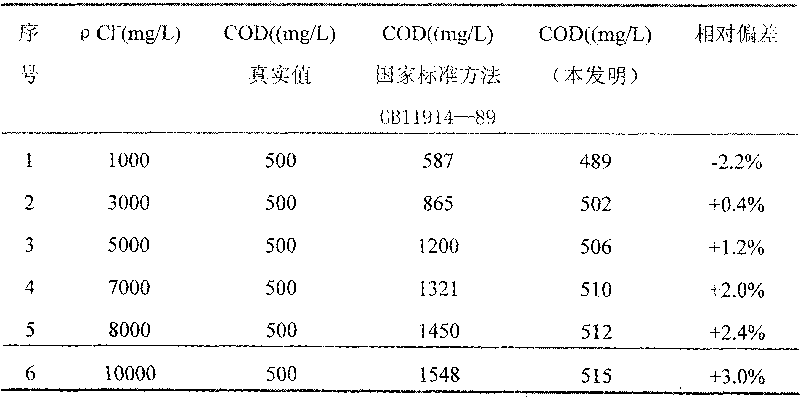

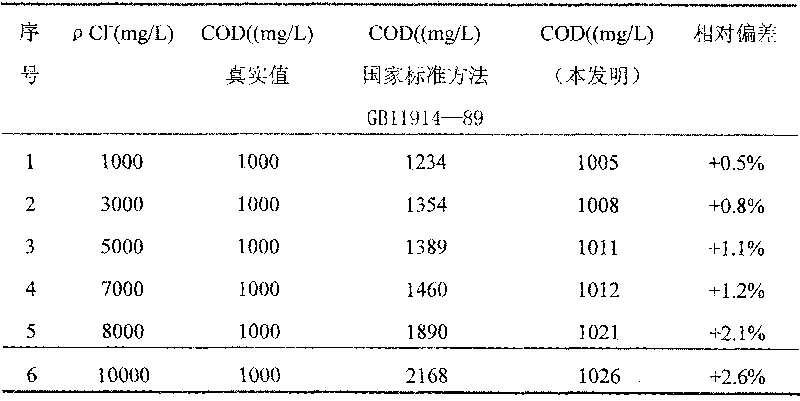

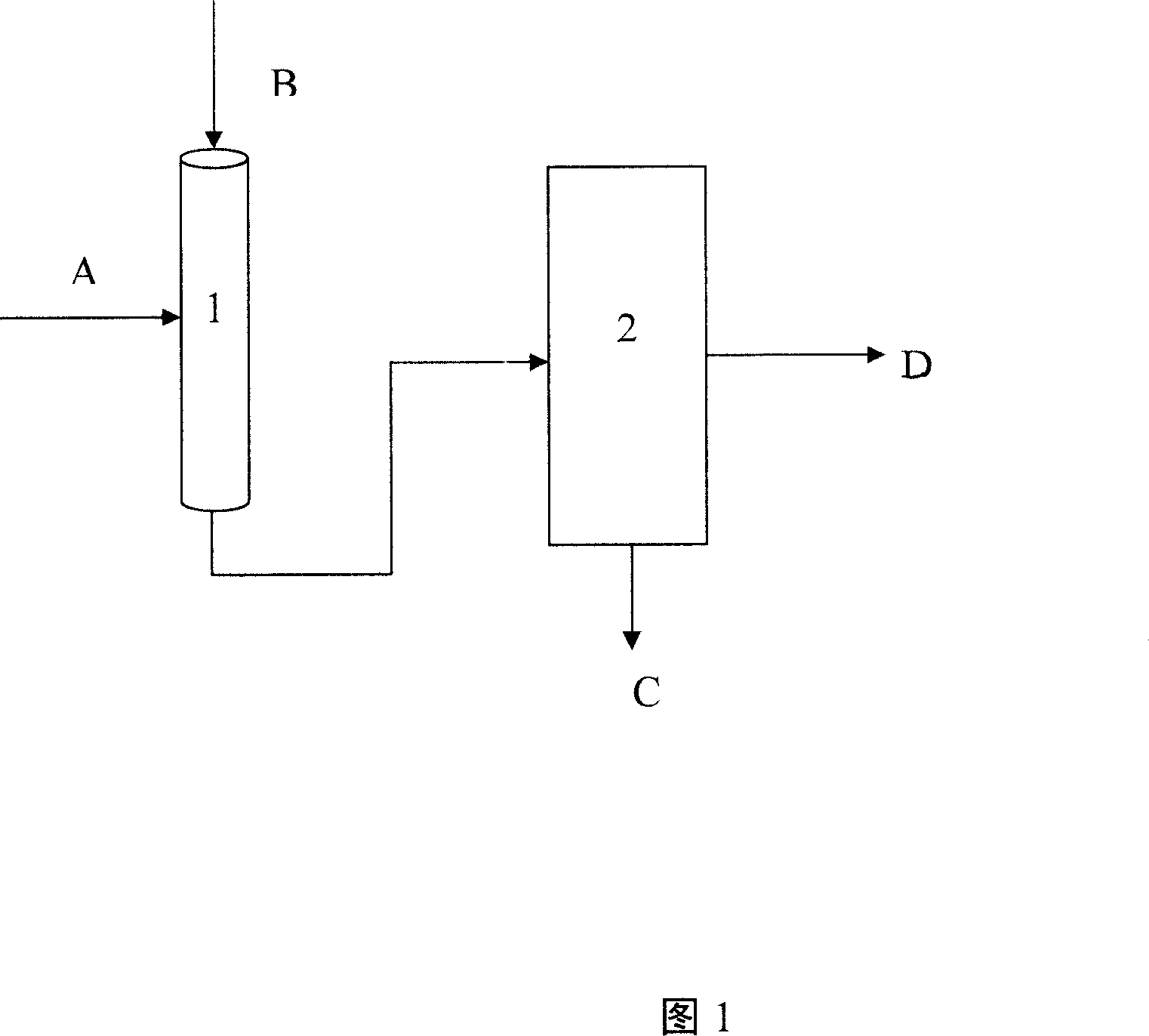

Reagent and method for determining chemical oxygen demand of high-chloride wastewater

InactiveCN101713739AShort measurement timeShort analysis timeMaterial analysis by observing effect on chemical indicatorColor/spectral properties measurementsDigestionChromium

The invention discloses a reagent and a method for determining the chemical oxygen demand of high-chloride wastewater. The reagent consists of a reagent A and a reagent B, wherein the reagent A comprises 20 to 40 mass percent of potassium dichromate, 20 to 50 mass percent of aluminum potassium sulfate, and 10 to 60 mass percent of ammonium molybdate; and the reagent B comprises 20 to 40 mass percent of silver sulfate, 10 to 20 mass percent of bismuth nitrate, 10 to 20 mass percent of chromium potassium sulfate, and 20 to 60 mass percent of mercury sulfate. The method comprises the steps of: during the determination, sequentially adding the reagent A and the reagent B into a water sample, placing the obtained solution into a digestion device for digestion, cooling the obtained product, and then performing colorimetric determination. The reagent and the method are suitable for wastewater with the chloride ion concentration of between 1,000 and 10,000mg / L; and the reagent has the characteristics of accurate formula proportion, accurate and reliable determined data, short determination time, simple determination steps, convenient operation and the like; and the method can perform batch determination.

Owner:JIANGSU POLYTECHNIC UNIVERSITY +1

Preprocessing method for coking wax oil used as hydrocracking raw material

ActiveCN101144031ATo achieve the processing effectReduce the temperatureRefining with acid-containing liquidsHydrocarbon oil crackingPhosphorous acidPretreatment method

The invention relates to a pretreatment method for hydrocracking raw material to improve the processing property of coker gas oil to be equivalent with straight-run refining wax oil through remove polar impurities, such as coke powder, colloid, heterocyclic benzenoid, and basic nitrogen compound, from coker gas oil, which includes the following steps: the pretreatment agent and the coker gas oil are mixed under 20-120 DEG C according to 0.1-10 percent by weight proportion; the pretreatment agent includes 49-89 percent of active components, such as hydrochloric acid, nitric acid, perchloric acid, sulfuric acid, phosphorous acid or phosphorous anhydride; 10-50 percent of cosolvents, such as ferric chloride, glycerol, ethylene glycol or DMF; and 0.1-10 percent one or more of polyacrylamide, polyaluminium chloride, polymeric aluminum ferric chloride, sodium meta-aluminate, sodium sulfate, sulfuric acidaluminum, aluminum potassium sulfate, and sodium silicate; the mixed materials are gravity settled in a settling tank, the sedimentation temperature is 60-150 DEG C, and the time is 30-120min, refined coker gas oil can be directly blended into hydrocracking device to decrease the initial temperature of hydrocracking prerefining section by more than 10 DEG C or improve the device processing capacity by more than 30 percent.

Owner:PETROCHINA CO LTD +1

Cold press composite pellet binder

The invention relates to a novel caking agent for preparing a pellet used for smelting by using a cold pressing method, in particular to a caking agent which needs to be added when using the cold pressing method to prepare a composite pellet comprising manganese powder. The invention is characterized in that the caking agent is formed by mixing the following two matters: (1) cornstarch and potato starch are used as the main materials, potassium permanganate and sodium hydroxide are added and mixed; and (2) solid sodium silicate is used as a main component, aluminum potassium sulfate and sodium fluosilicate are added. The first types of matters mainly obtain the wet pellet intensity and meet the intensity demand of the strap transmission on the pellet between a pellet press and a drying kiln. The second types of matters mainly obtain the dry pellet intensity, meet the intensity demand of transmission and autoimmunization pellet matching on the pellet and maintain the pellet to not crack at high temperature. Compared with the traditional sintering technique, the cold-pressing composite pellet caking agent saves the energies and reduces pollution. The technique can also be applied to produce carbon pellets, realizes using coal for replacing coke, reduces the cost of the reducer and promotes the comprehensive utilization of the resources.

Owner:云南文山斗南锰业股份有限公司 +2

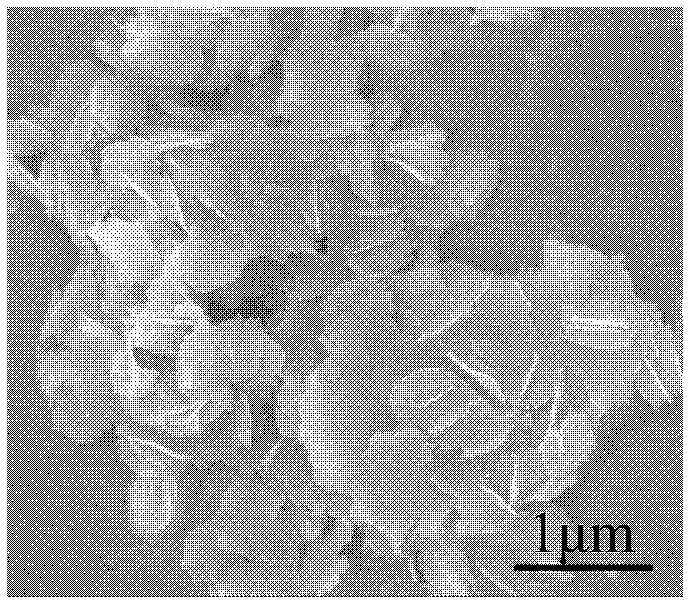

Preparation and application of adsorbing agent of pseudo-boehmite and gamma-Al*O* hollow microspheres

InactiveCN101618312AReduce concentrationControllable grain sizeOther chemical processesMicroballoon preparationCongo redOrganic dye

The invention discloses a preparation method and an application of an adsorbing agent of pseudo-boehmite and gamma-Al2O3 (nuclear shell) hollow microspheres. The method comprises the following steps: dissolving aluminum sulfate, ammonium alum and aluminum potassium sulfate or a mixture thereof in an arbitrary proportion in distilled water; then respectively adding a certain quantity of urea and sodium tartrate; after the mixture is stirred uniformly, transferring the mixture into a hydrothermal kettle to carry out hydrothermal processing; and respectively obtaining the pseudo-boehmite and the gamma-Al2O3 (nuclear shell) hollow microsphere products after hydrothermal products are naturally cooled, filtered, washed, dried in vacuum and roasted. The method has simple process, moderate condition and good ruggedness of the (nuclear shell) hollow microsphere structure. The prepared pseudo-boehmite / gamma-Al2O3 hollow microspheres have excellent adsorption performance, particularly have good adsorption and purification effects on organic dye such as Congo red in waste water, and the like and hard degraded organic matters such as phenol, and the like and can be regenerated and recycled for many times, and regenerated products have the performance of adsorbing organic pollutants.

Owner:WUHAN UNIV OF TECH

Dipped anti-oxidation fluid capable of improving high temperature anti-oxidation performance of graphite products and application method thereof

ActiveCN102775991ASolve problems that reduce impregnation efficiencySimple processGraphiteChemical inhibitorsOxidation resistantGraphite

The invention relates to a dipped anti-oxidation fluid capable of improving high temperature anti-oxidation performance of graphite products and an application method thereof, and aims to improve inoxidizability of graphite products at a temperature of more than 1000 DEG C. Dipping of graphite with dipping liquid I and dipping liquid II is carried out under a normal pressure or a pressure of 0.1 to 0.6 MPa; the solute of dipping liquid I is composed of 50 to 80% of sodium hexametaphosphate and 20 to 50% of aluminum potassium sulfate, and the solute of dipping liquid II comprises 30 to 70% of sodium silicate and 30 to 70% of sodium tetraborate, and the weight of compositional components of the two solutes respectively sums to 100%; during utilization, a weight ratio of the solute of dipping liquid I to water is 1: 0.1-0.125, and a weight ratio of the solute of dipping liquid II to water is 1: 3.3-5.0. The graphite products obtained after two-step dipping have obviously improved high temperature antioxidation performance during the process of high temperature heat treatment.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

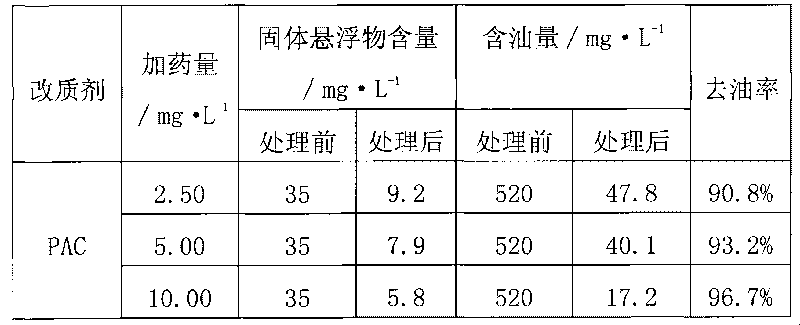

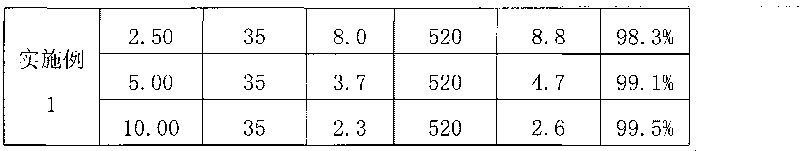

Efficient composite powdery soil modifier and preparation method thereof

InactiveCN102443399AFunction increaseImprove processing efficiencyAgriculture tools and machinesFatty/oily/floating substances removal devicesRadioactive agentHazardous substance

The invention discloses an efficient composite powdery soil modifier and a preparation method thereof. The efficient composite powdery soil modifier contains the following substances, such as malic acid, medical stone, calcium sulfate, copper sulfate, calcium carbonate, aluminum potassium sulfate, calcium oxide and polyacrylamide. Compared with the prior art, the efficient composite powdery soil modifier can remove polluted and harmful substances, such as heavy metal ions, radioactive substances, cancerogenic substances, blue algae, SS (Suspended Solids), COD (Chemical Oxygen Demand), BOD (Biochemical Oxygen Demand), and the like which are difficult to treat by the current common soil sewage treating agent in a broad-spectrum and efficient way, has various effects of obvious decoloration, deodorization, dehydration, deoiling, bacterium removal, and the like, has the advantages of less dosage, high treatment speed, obvious effect, low running cost and strong adaptability on high dirty concentration, wide pH value range and wide sewage temperature change of soil sewage and is suitable for different soil water quality conditions and treatment process and equipment condition adjustment production with different treatment requirements so as to achieve an optical treatment effect.

Owner:章云

Method for preparing water-based penetration type concrete protective agent

The invention relates to a method for preparing a water-based penetration type concrete protective agent. The concrete protective agent is prepared from the following raw materials: aluminum potassium sulfate dodecahydrate, sodium hydroxide, citric acid, a silane coupling agent, a sodium silicate aqueous solution and deionized water. The method comprises the following operation steps of: adding the aluminum potassium sulfate dodecahydrate into the deionized water, and stirring; adding sodium hydroxide, and stirring; adding the citric acid, and stirring; sequentially adding the sodium silicate aqueous solution and the silane coupling agent, stirring, and obtaining a mixed solution; and standing to obtain the water-based penetration type concrete protective agent. The concrete protective agent penetrates into the concrete to react with the concrete so as to form a whole protective layer, the penetration of moisture, salt and the like on the concrete can be reduced to the greatest degree, and freeze thawing, carbonization, erosion, alkali-aggregate reaction, crack and other damages and corrosions are reduced; and the protective agent is good in waterproof effect, simple in construction process, long in product storage period and wide in application range.

Owner:ANHUI TRANSPORT CONSULTING & DESIGN INST +1

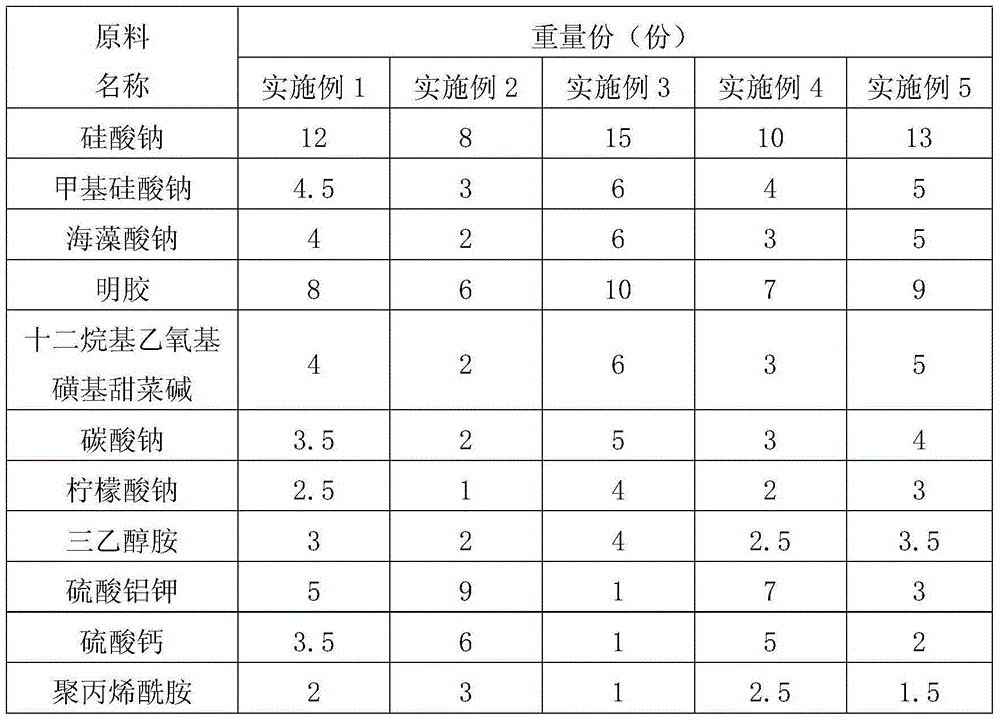

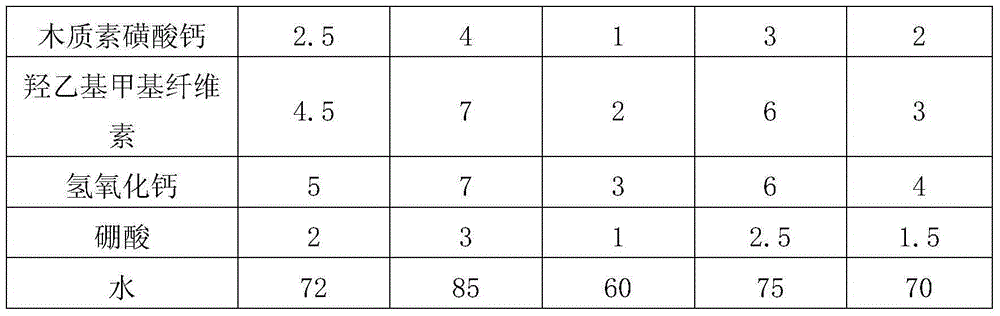

Inorganic-organic composite permeable crystallization type waterproof agent

The invention discloses an inorganic-organic composite permeable crystallization type waterproof agent. The waterproof agent is prepared from, by weight, 8-15 parts of sodium silicate, 3-6 parts of methyl sodium silicate, 2-6 parts of sodium alginate, 6-10 parts of gelatin, 2-6 parts of dodecyl ethoxy sulpho betaine, 2-5 parts of sodium carbonate, 1-4 parts of sodium citrate, 2-4 parts of triethanolamine, 1-9 parts of aluminum potassium sulfate, 1-6 parts of calcium sulfate, 1-3 parts of polyacrylamide, 1-4 parts of calcium lignosulphonate, 2-7 parts of hydroxyethyl methyl cellulose, 3-7 parts of calcium hydroxide, 1-3 parts of boric acid and 60-85 parts of water. The inorganic-organic composite permeable crystallization type waterproof agent has good waterproofness, endurance performance and self-curing performance and is low in cost and capable of being applied to waterproofing of house faces, basements, restrooms and the like.

Owner:GUILIN HEXIN WATERPROOF DECORATION MATERIAL

Sewage flocculant

InactiveCN104843841APromote degradationLow ecotoxicityWater/sewage treatment by flocculation/precipitationSludgeMolybdenum chloride

The invention relates to the technical field of sewage treatment, in particular to a sewage flocculant. The flocculant consists of the following components in parts by weight: 12-25 parts of poly-aluminum calcium chloride, 5-15 parts of ferric chloride, 2-10 parts of aluminum potassium sulfate, 2-8 parts of sodium carboxymethylcellulose, 1-6 parts of sodium hypochlorite, 10-30 parts of poly-molybdenum chloride, 10-20 parts of diatomite, 10-20 parts of zeolite and 0.01-0.05 part of additives. The sewage flocculant has the beneficial effects that the obtained flocculant is good in degradability, low in ecotoxicity, free of stimulation on human bodies, obvious in flocculation effect on the treatment of various complex sewage and high in cost performance for dehydration of sludge; the sewage flocculant has the characteristics of no toxicity and residue for human bodies, good flocculation effect and wide application range.

Owner:ZHANGJIAGANG SHANMU NEW MATERIAL TECH DEV

Wormcast organic solid fertilizer and preparation method thereof

InactiveCN104030769AHigh in trace elementsIncrease profitFertilizer mixturesPotassium persulfateLivestock manure

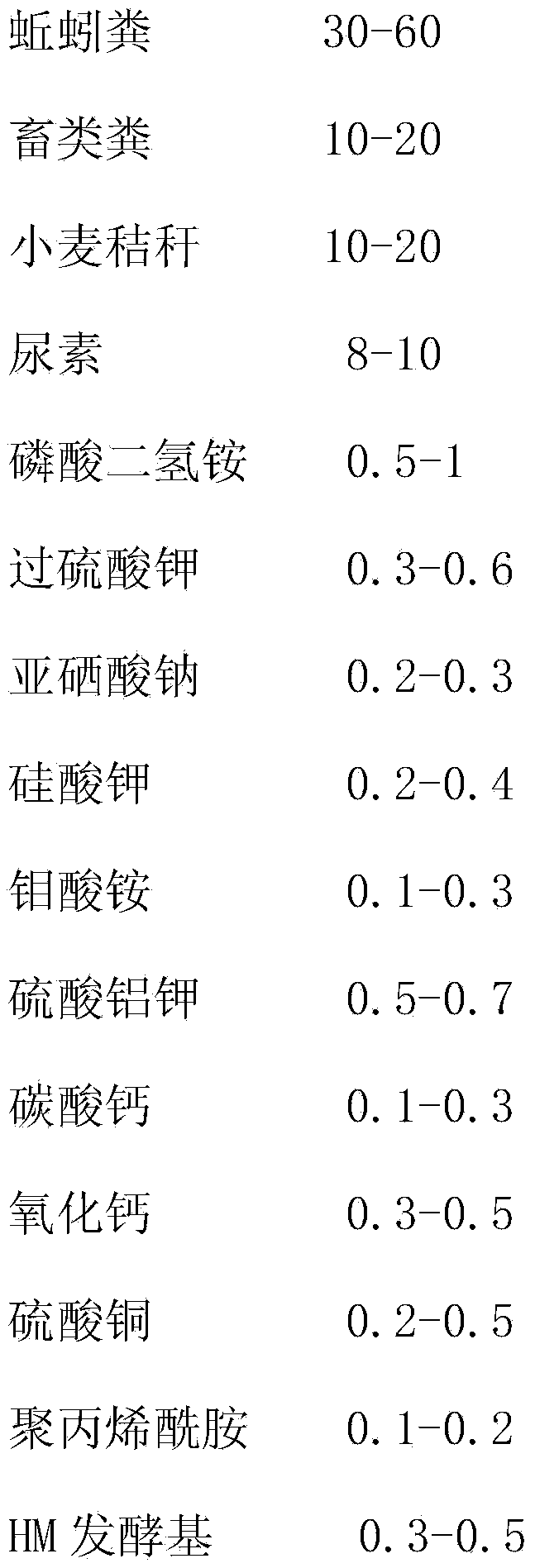

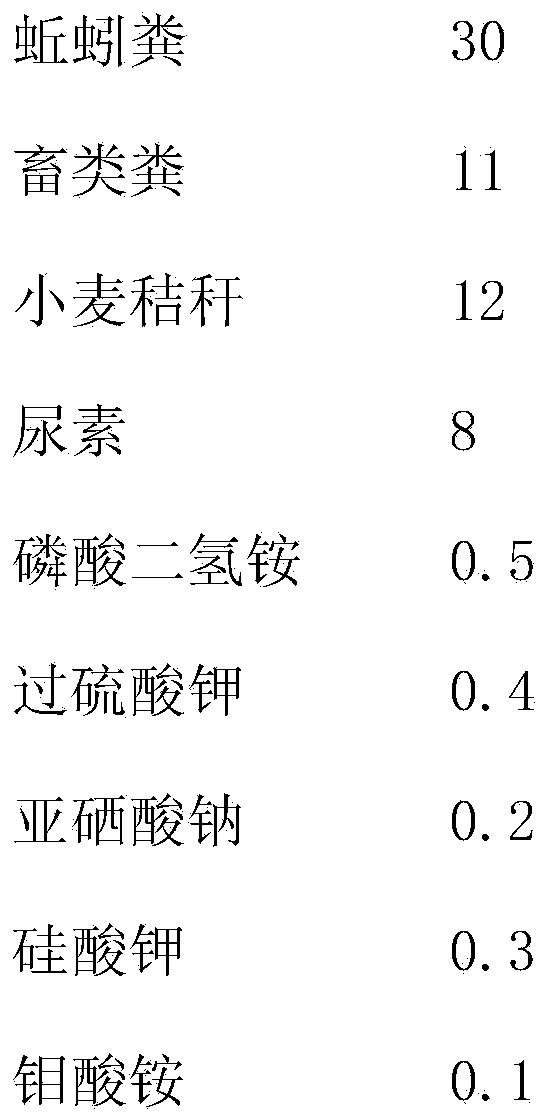

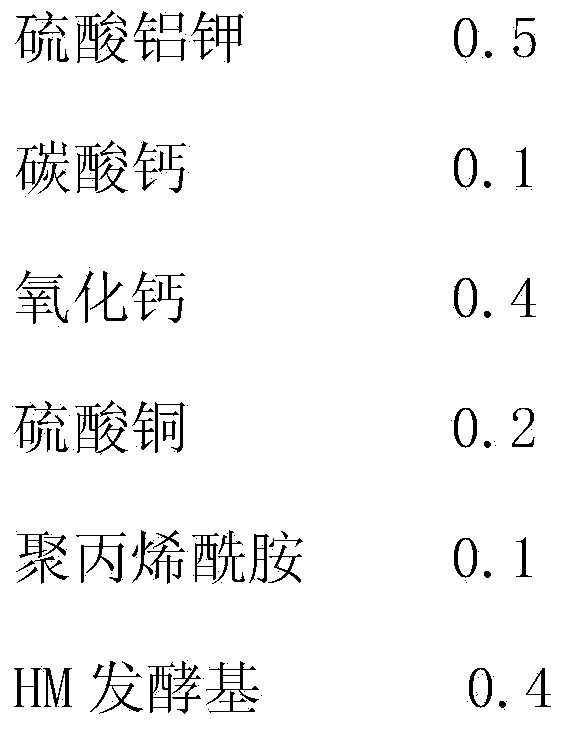

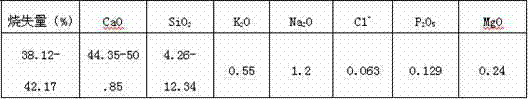

The invention discloses a wormcast organic solid fertilizer and a preparation method of the wormcast organic solid fertilizer. The wormcast organic solid fertilizer comprises, by weight, 30-60 parts of wormcast, 10-20 parts of livestock manure, 10-20 parts of wheat straw, 8-10 parts of urea, 0.5-1 part of ammonium dihydrogen phosphate, 0.3-0.6 parts of potassium persulfate, 0.2-0.3 part of sodium selenite, 0.2-0.4 part of potassium silicate , 0.1-0.3 part of ammonium molybdate, 0.5-0.7 part of aluminum potassium sulfate, 0.1-0.3 part of calcium carbonate, 0.3-0.5 part of calcium oxide, 0.2-0.5 part of copper sulfate, 0.1-0.2 part of polyacrylamide and 0.3-0.5 part of HM fermentation bases. After the raw materials are mixed and fermented, the prepared organic fertilizer contains rich microelements needed by plants, growth of the plants is facilitated, soil quality can be conveniently improved, soil is looser and is not hardened, and the fertilizer can be efficiently absorbed into soil.

Owner:安徽利海新城镇开发有限公司

Method for producing walling material by using papermaking white mud

The invention discloses a method for producing a walling material by using papermaking white mud. The method is characterized by comprising steps of: taking 40-60 percentage (by weight) of papermaking white mud, 20-45 percentage (by weight) of lithium slag, 10-20 percentage (by weight) of cement and 1-6 percentage (by weight) of active excitant, and adding into a mixer for mixing, wherein the active excitant is made of a mixture of polyacrylic acid, polycarboxylic acid water-reducing agent and aluminum potassium sulfate; dispensing the mixture into a group of molds, and placing on a vibratingtable of a block molding machine for molding by vibration; placing the molds filled with the mixed materials into a curing case with temperature of 15-25 DEG C and humidity more than 90% to cure for 20-30 hours and then demolding; and further putting into a curing case with temperature of 60-80 DEG C to cure for 20-30 hours by steaming, thereby obtaining the walling material. The method for producing the walling material by using the papermaking white mud has the advantages of good product performance, reducing pollution to environment caused by industrial refuse, reducing manufacturing cost of the walling material, saving a large number of building materials, reducing energy consumption, and being both economical and environmental-friendly.

Owner:绵阳西南科大瑞方科技有限公司

Printing and dyeing wastewater purification powder and preparation method thereof

ActiveCN105347455AEfficient purification abilityWater contaminantsWater/sewage treatmentCross-linkDyeing wastewater

The invention discloses a printing and dyeing wastewater purification powder and a preparation method thereof. The powder includes the following raw materials by weight: 10-15 parts of modified starch, 15-20 parts of active Chinese medical stone powder, 20-30 parts of acrylic polyether sodium sulfonate, 20-30 parts of polyacrylamide, 10-15 parts of aluminum potassium sulfate dodecahydrate, 5-10 parts of alumina, 3-5 parts of aluminium polychlorid, 15-20 parts of aluminum sulfate, 15-19 parts of fly ash, 15-20 parts of iron oxide, 18-23 parts of polysilicate ferrite, 20-25 parts of polyvinyl acetate, 15-20 parts of sodium carbonate, 5-10 parts of sodium chlorate, 12-15 parts of sodium silicate, 15-22 parts of calcium hydroxide, 18-23 parts of sodium hydroxide, 8-12 parts of diatomite, 5-20 parts of cross-linked rectorite, 5-8 parts of a chitosan-graphene composite material and 80-100 parts of water. The printing and dyeing wastewater purification powder not only has efficient purifying capability but also can remove a plurality of pollutants.

Owner:浙江彩虹庄印染有限公司

Broad-spectrum cut flower antistaling agent

InactiveCN104542579AExtended shelf lifeImprove universalityDead plant preservationVitamin CCut flowers

The invention discloses a broad spectrum cut flower antistaling agent. The antistaling agent comprises water, cane sugar, 8-hydroxyquinoline, ammonia oxygen vinyl glycine, gibberellin, aluminum potassium sulfate, calcium nitrate, a citric acid, a boric acid and a vitamin C. Through pretreatment, the antistaling agent is used as insertion liquid or used for spraying; the antistaling agent is effective to various cut flowers such as chrysanthemums, Chinese roses, sword lilies and carnations, the universality is good, the quality guarantee period of the cut flowers can be prolonged by 5-10 days, and the longest quality guarantee period of the cut flowers can reach more than 15 days.

Owner:詹银表

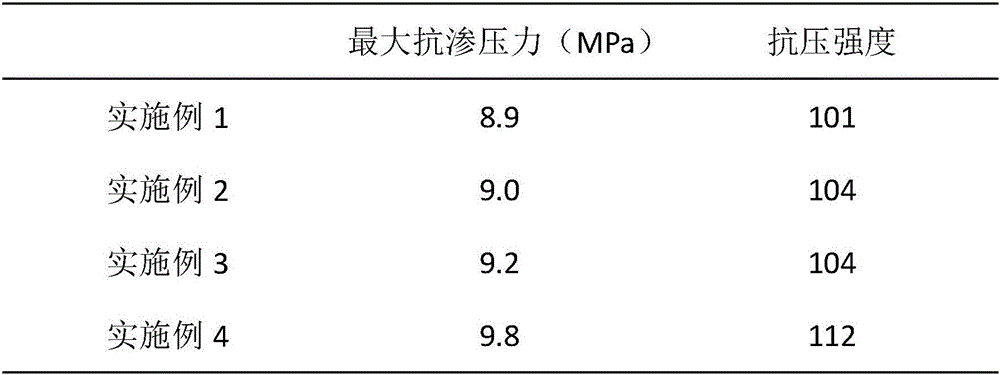

High-strength waterproof concrete

The invention provides a high-strength waterproof concrete. The concrete comprises the following components in parts by weight: 100-120 parts of cement, 80-85 parts of coarse aggregate, 90-100 parts of fine aggregate, 20-25 parts of bentonite, 20-25 parts of asphalt powder, 2-5 parts of alkyl sodium sulfonate, 2-3 parts of copper sulfate, 10-12 parts of basalt fiber, 5-8 parts of polypropylene fiber, 2-3 parts of Grace fiber, 0.2-0.5 part of sodium perfluorooctylsulfonate, 0.1-0.2 part of coconut oil diethanolamide, 0.5-1 part of bisphenol A epoxy resin, 0.1-0.2 part of styrylphenol polyoxyethylene ether, 3-5 parts of iron chloride, 0.2-0.5 part of phenyl salicylate, 2-5 parts of aluminum potassium sulfate, 0.1-0.2 part of 1,6-hexamethylene diisocyanate and a right amount of water. The invention also discloses a method for preparing the concrete. According to the invention, the concrete has favorable impermeability, and the maximum impermeability pressure can be up to 9.8 MPa; and the obtained concrete has high compression strength, and the maximum compression strength can be up to 112 MPa.

Owner:SICHUAN UNIV

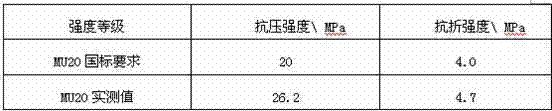

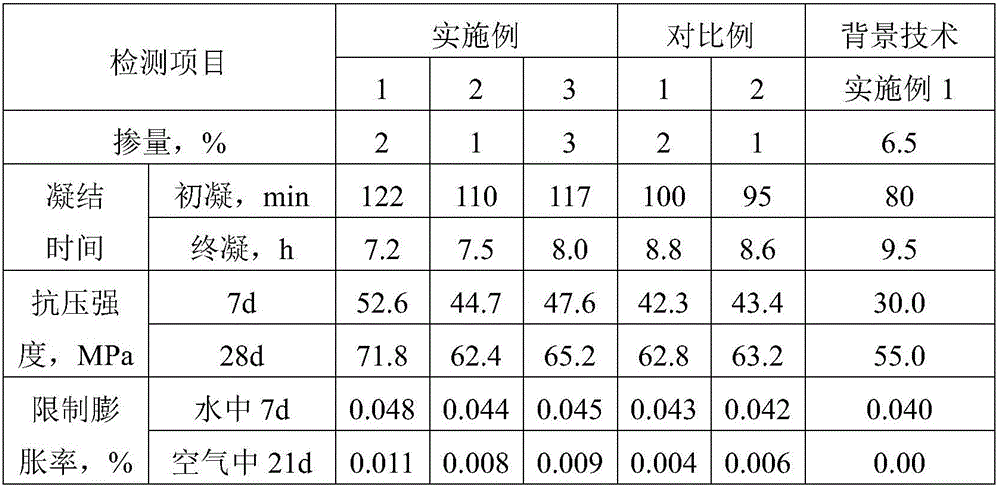

Expansive agent for building concrete

The invention discloses an expansive agent for building concrete. The expansive agent comprises, by weight, 10-20 parts of calcium silicoaluminate, 20-25 parts of calcium sulfoaluminate, 20-30 parts of sulfur fixation residues, 15-25 parts of red mud, 10-15 parts of magnesium slag, 4-8 parts of modified calcium oxide, 4-7 parts of magnesium oxide, 3-8 parts of methanesiliconic acid sodium salt, 3-5 parts of triisopropanolamine, 5-8 parts of aluminum potassium sulfate, 0.1-0.3 part of azodicarbonamide, 0.5-0.8 part of sodium citrate, 2-4 parts of sodium dodecyl benzene sulfonate, 0.4-0.6 part of ethylene-vinyl acetate copolymers and 1-3 parts of polycarboxylic acid water reducing agents. The expansive agent has the advantages that the expansive agent is high in strength and excellent in compensation capacity and calcium oxide regulation and control reaction and is a concrete admixture with a great prospect, and the like.

Owner:GUILIN HUAYUE ENVIRONMENTAL PROTECTION TECH CO LTD

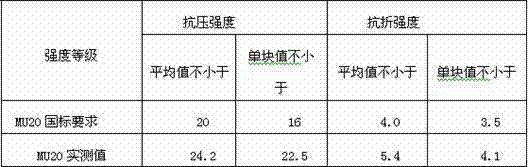

Baking-free brick made by the Yellow River mud and production method thereof

The invention relates to a burn-free brick and a production method thereof, particularly to a burn-free brick produced with the Yellow River silt and a production method thereof. The burn-free brick is produced by the extrusion of press machines after mixing the raw materials at a weight ratio as follows: 50-70% Yellow River silt; 20-30% fluoride gypsum powder; 5-10% cement; 3-5% aluminum potassium sulfate and 2-5% construction-used acrylic rubber powder. The invention makes full use of waste fluoride gypsum and a large number of Yellow River silt and is energy-saving and emission reducing and can prevent environmental pollution to meet ecological environmental protection requirements. The burn-free bricks have the advantages of low cost, high strength and good comprehensive performance and each performance are much higher than the relevant national standards of bricks for construction. The production method of has advantages of simple process and convenient production.

Owner:李浩

SBR modified asphalt and preparation method thereof

ActiveCN110003672AWith low temperature performanceWith scalabilityBuilding insulationsAntioxidantPotassium

The invention discloses an SBR (styrene-butadiene rubber) modified asphalt and a preparation method thereof, and belong to the technical field of asphalt modification. Raw materials of the SBR modified asphalt comprise, by mass, 80-84.5% of matrix asphalt, 12-15% of aromatic oil and 3.5-5% of an SBR asphalt modifier, wherein raw materials of the SBR asphalt modifier comprise, by weight, 100 partsof a modified SBR emulsion (by dry rubber), 0.1-1 part of an antioxidant, 5-10 parts of an isolating agent, 3-6 parts of a dicyandiamide-formaldehyde condensate and 2-6 parts of potassium aluminum sulfate. The preparation method comprises the following steps: heating the matrix asphalt until melting, adding the aromatic oil and the SBR asphalt modifier, and shearing and swelling the obtained mixture to obtain the SBR modified asphalt. The SBR modified asphalt has good low temperature performances, ductility and bonding property, and has greatly improved viscosity, high temperature performancesand anti-aging property.

Owner:山东海方橡胶科技有限公司

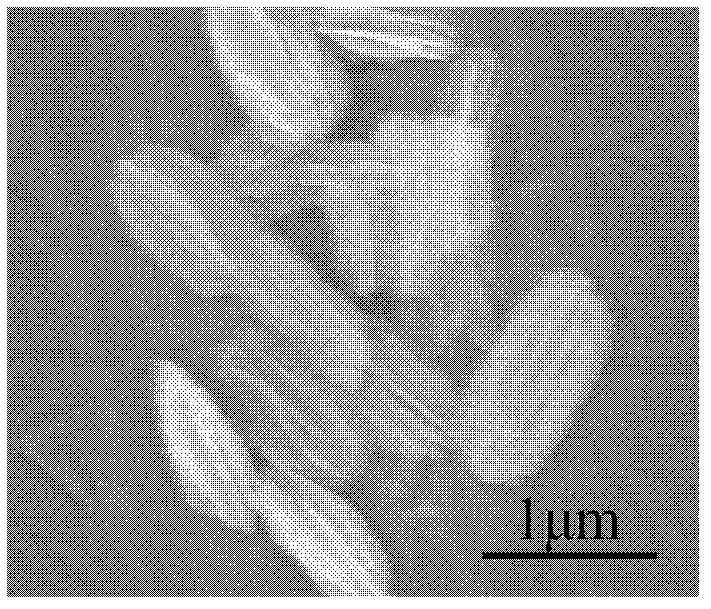

Preparation and application of hierarchical mesoporous γ-al2o3 nanostructured adsorbent

InactiveCN102294220AShape is easy to controlImprove adsorption capacityOther chemical processesDispersed particle separationAluminium chlorideThiourea

The invention discloses a preparation method and application of a graded mesoporous γ-Al2O3 nanostructure adsorbent. The method is as follows: first, one of aluminum sulfate, aluminum chloride, aluminum nitrate, aluminum potassium sulfate and aluminum ammonium thiourea species, or a mixture thereof in any proportion is dissolved in distilled water, and then a certain amount of thiourea is added respectively, stirred evenly and then transferred to a hydrothermal kettle for hydrothermal treatment, and the product is naturally cooled, filtered, washed, vacuum-dried and roasted, A series of graded mesoporous γ-Al2O3 nanostructured adsorbent products in the form of microspheres, sheets, sea urchins and spindles were obtained. This method has the advantages of simple process, mild conditions, and various hierarchical nanostructures. The prepared hierarchical mesoporous alumina nanostructure material has excellent adsorption and purification effects on the refractory organic matter phenol in water, and has excellent adsorption and purification effects on the most important greenhouse gas CO2 Also has good adsorption capacity.

Owner:WUHAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com